Harmless treatment method for drilling wastes of oil and gas fields

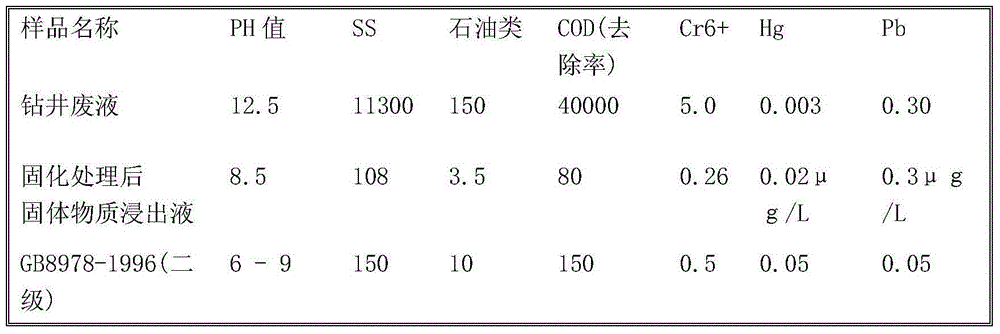

A technology for harmless treatment of drilling waste, applied in the field of waste treatment, can solve the problems of polluting animal and plant life, growing soil and water sources, surface water pollution, disconnection, etc., to reduce the concentration of heavy metal ions and reduce the content of petroleum , reduce the effect of COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The harmless treatment methods of oil and gas field drilling waste include: solid-liquid separation of drilling waste fluid, adding water treatment agent during solid-liquid separation, mechanical strengthening of solid-liquid separation, liquid water is directly returned to oil and gas field drilling mud for reuse; The equipment collects solid waste such as rock cuttings and waste mud sludge; put the collected solid waste into the mixer, and add the solidification enhancement treatment agent to the mixer, so that the solidification enhancement treatment agent and the solid containing a certain amount of water The waste is fully and evenly mixed, and the stirring time is 3-5 minutes;

[0033] The curing enhancement treatment agent includes RDH-1 curing agent and RDH-2 curing agent, the RDH-1 curing agent is added by 3% of the solid waste weight, and the RDH-2 curing agent is added by 3% of the solid waste weight 25% by weight added, where,

[0034] The composition of d...

Embodiment 2

[0037] The harmless treatment methods of oil and gas field drilling waste include: solid-liquid separation of drilling waste fluid, adding water treatment agent during solid-liquid separation, mechanical strengthening of solid-liquid separation, liquid water is directly returned to oil and gas field drilling mud for reuse; The equipment collects solid waste such as rock cuttings and waste mud sludge; put the collected solid waste into the mixer, and add the solidification enhancement treatment agent to the mixer, so that the solidification enhancement treatment agent and the solid containing a certain amount of water The waste is fully and evenly mixed, and the stirring time is 3-5 minutes;

[0038] Described curing enhancement treatment agent comprises RDH-1 curing agent and RDH-2 curing agent, and described RDH-1 curing agent is added by 5% of solid waste weight, and described RDH-2 curing agent is added by solid waste weight 20% by weight added, where,

[0039] The composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com