Production process of plant fiber nonwoven filter cloth for wet air puncture drainage reinforcement

A plant fiber and production process technology, applied in non-woven fabrics, textiles and papermaking, water resources protection and other directions, can solve the problems of short process flow, fiber web strength not meeting the quality requirements of non-woven geotextiles, low gram weight, etc. , to achieve the effects of rich raw material sources, good market prospects and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The basic steps of the production process of the special plant fiber nonwoven filter cloth for wet air puncture type drainage reinforcement in this embodiment are as follows:

[0043] The first step, the plant fiber raw material is first cut into short fibers, then opened into single fibers, and then the plant fibers are made into a suspension slurry, which contains plant-derived adhesives (no chemical adhesives are used here, which can avoid polluted environment);

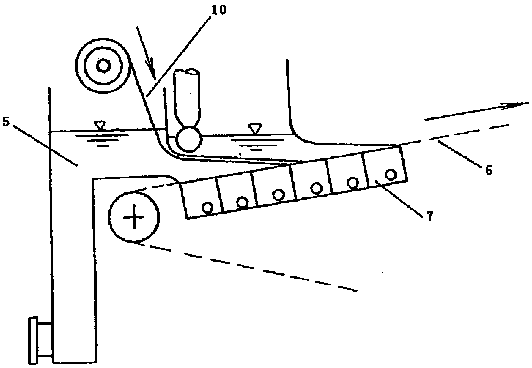

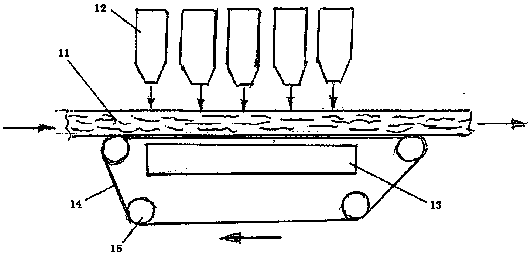

[0044] The second step is to put the plant fiber suspension slurry into the wet-laid equipment to make a plant fiber web, or put the plant fiber suspension slurry and the plant fiber yarn net into the wet-laid equipment at the same time to make a web with yarn Vegetable webs of nets;

[0045] The third step is to puncture the plant fiber net with jet air, so that the fibers in the plant fiber net are entangled with adjacent fibers or yarns, and form a mechanical combination, and finally the plant fiber net...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com