Carbon fiber woven belt for reinforcing composite aerial material and production method of belt

A composite material and carbon fiber technology, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problem that carbon fiber cloth or felt is not suitable for use, and achieve the effect of high flexibility, high tensile strength and strong integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

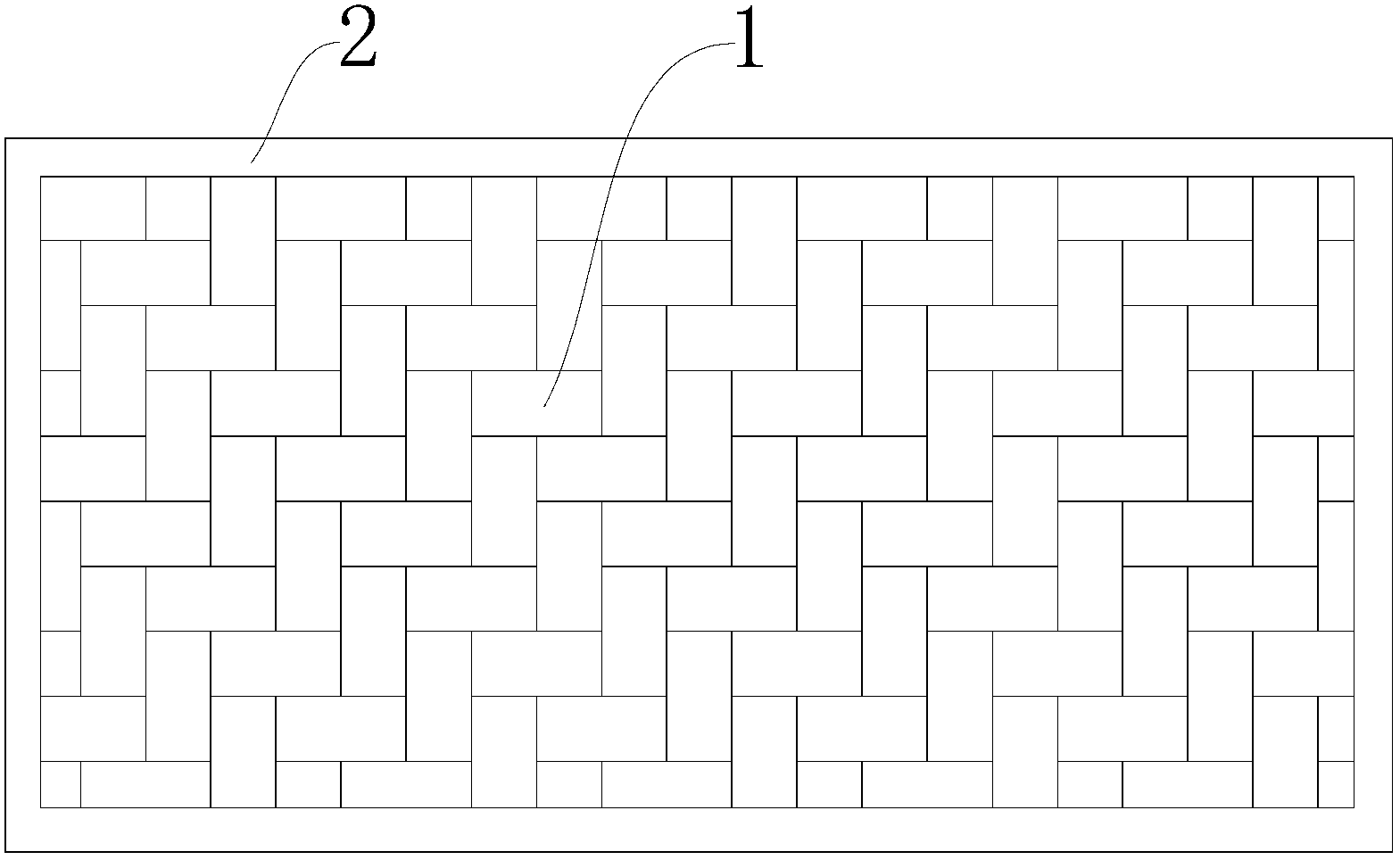

[0012] Such as figure 1 As shown, the carbon fiber webbing for aviation composite material reinforcement described in this embodiment is mainly composed of carbon fiber bundles 1, and the carbon fiber bundles 1 are divided into warp direction carbon fiber bundles and weft direction carbon fiber bundles. The warp and weft weaving of carbon fiber yarn bundles in the weft direction is woven into a webbing, and an overlock line 2 is provided at its edge.

[0013] The warp-direction carbon fiber bundles and weft-direction carbon fiber bundles are uniformly composed of 3000 yarns, 6000 yarns or 12000 yarns.

[0014] The overlock thread 2 is high-strength polyester yarn.

[0015] The production method of carbon fiber webbing for aviation composite material reinforcement, after the warp-oriented carbon fiber yarn is exported through the creel, it first passes through a tension control device, and then passes through the eyelet of the creel to form a neat carbon fiber yarn bundle 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com