After-water-injection vibrating and compacting construction method of desert photovoltaic bracket pile foundation

A photovoltaic support and construction method technology, applied in the field of foundation, can solve problems such as poor economy, high cost, and difficult quality assurance, and achieve the effects of improving bearing capacity and anti-overturning ability, saving building materials, and improving engineering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

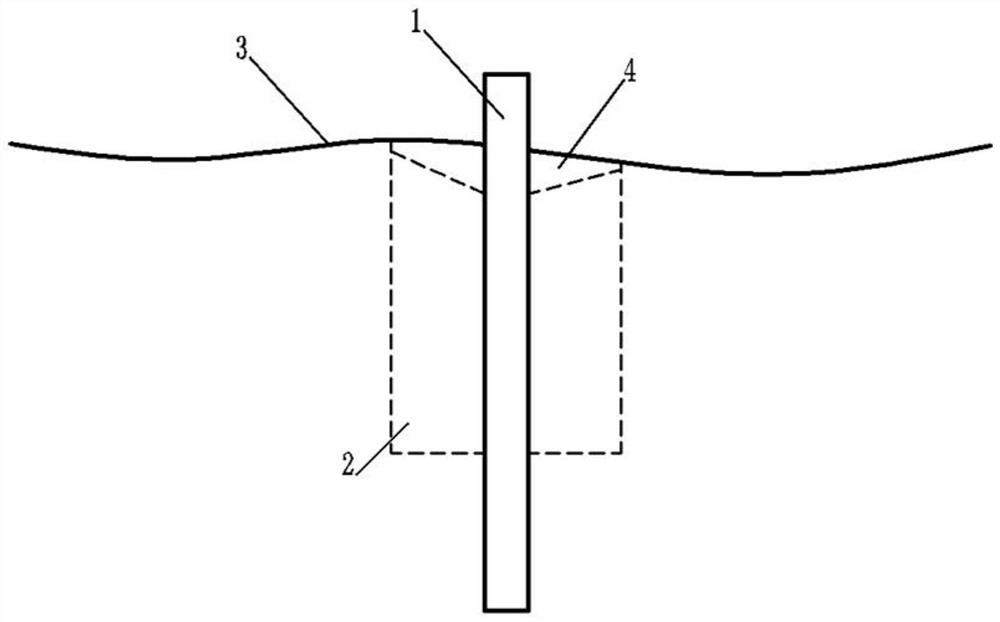

[0034] according to Figure 1-Figure 2 A post-injection vibration-dense construction method for desert photovoltaic support pile foundation shown, including the following steps

[0035] Step 1: Site leveling;

[0036] Step 2: Measure and locate

[0037] After step 1 is completed, mark the center position of the foundation pile 1 of the photovoltaic support foundation on the ground according to the design drawing, measure and set out the position of the foundation pile 1 of the photovoltaic support foundation and mark it;

[0038] Step 3: Piling into piles;

[0039] Step 4: Strengthen the sand layer around the pile;

[0040] Step 5: Surface 3 treatment of the sand layer around the pile.

[0041] In actual use, the pile foundation site is first leveled and properly compacted with bulldozer equipment. Then mark the center position of the photovoltaic support foundation pile 1 on the ground according to the design drawings, and use measuring tools and instruments to measure, ...

Embodiment 2

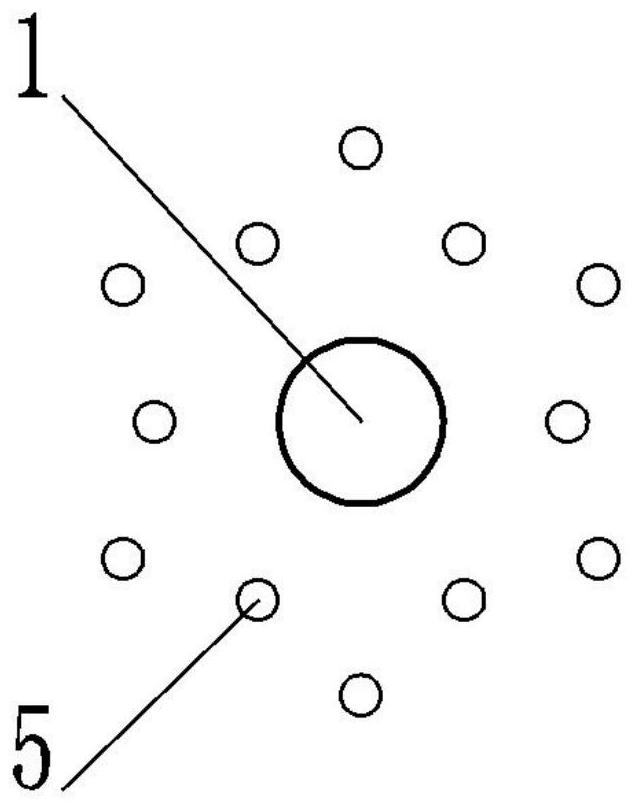

[0047] according to Figure 1-2The post-injection vibration-dense construction method of a desert photovoltaic support pile foundation shown is different from Example 1 in that the specific method for strengthening the sand layer around the pile in the fourth step is: for the photovoltaic support foundation pile 1, steel bars For concrete pouring piles, after the concrete reaches the preset strength, if the foundation pile 1 of the photovoltaic support is a reinforced concrete prefabricated pile or steel pile, after the pile driving is completed, sand around the pile shall be carried out within the preset sand layer reinforcement range 2 layer reinforcement; during reinforcement, insert a metal water pipe with a diameter of 20-40 mm into the sand layer around the pile to a predetermined depth, and evenly arrange water injection and vibration positions 5 around the foundation pile 1 of the photovoltaic support, and inject water into the water injection and vibration positions 5....

Embodiment 3

[0055] according to Figure 1-2 The post-injection vibration-dense construction method of a desert photovoltaic support pile foundation shown is different from the first embodiment in that: when the sand layer around the pile is reinforced in the fourth step, that is, the sand layer of the photovoltaic support foundation pile 1 is reinforced The sand layer compaction coefficient in range 2 is not less than 0.94.

[0056] In actual use, the adoption of this technical solution can ensure the stability of the photovoltaic support foundation pile 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com