Preparation method of soybean-fiber composite fuse

A soybean fiber and fuse technology, applied in textiles, papermaking, yarn, etc., can solve problems such as application limitations, achieve low cost, low dependence, and expand application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

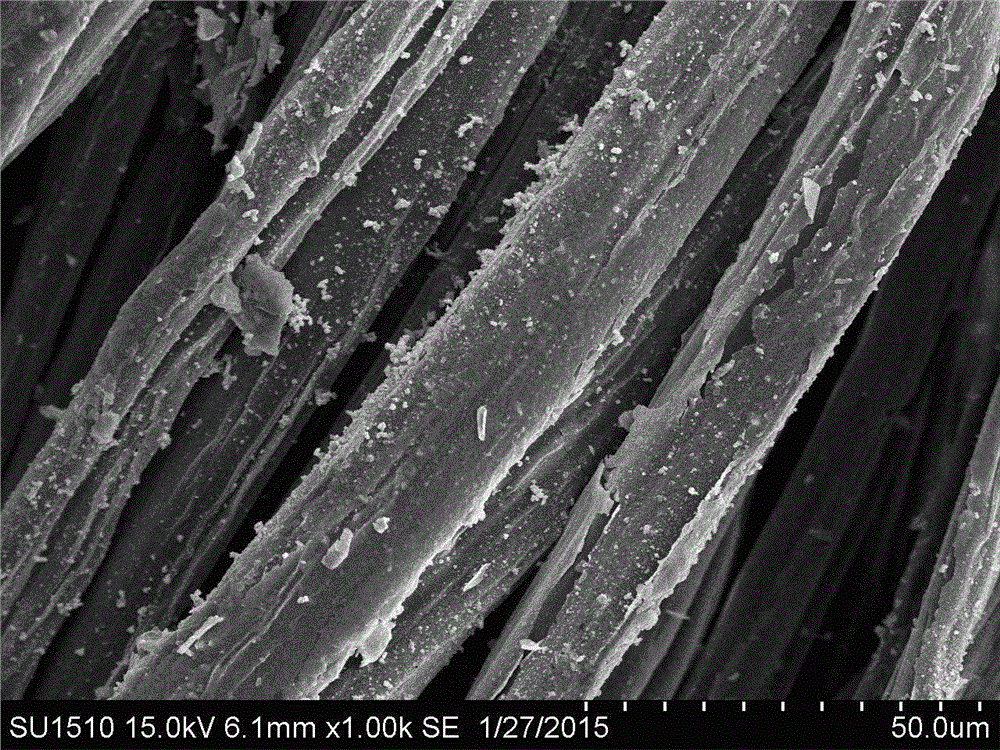

Image

Examples

Embodiment 1

[0018] Rinse the soybean fiber with deionized water, dry it, place it in a solution of 3-aminopropyltrimethoxysilane acetone with a concentration of 0.1%, soak it for 5 minutes, take it out, and dry it to obtain the surface-modified soybean fiber .

[0019] Dissolve 1 g of chloroauric acid, 5 g of trisodium citrate, 10 g of sodium chloride, and 2 g of sodium borohydride in 500 mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1 L to obtain a gold nanosol solution.

[0020] The modified soybean fiber is placed in the above solution for 4 hours, taken out and washed to obtain surface-activated soybean fiber.

[0021] Dissolve 5g of copper chloride, 20g of tartaric acid, 5g of potassium hydroxide, 1g of potassium carbonate, 1g of copper sulfate, and 5g of formaldehyde in 500mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1L to obtain an electroless cop...

Embodiment 2

[0024] Rinse the soybean fiber with deionized water, dry it, place it in a solution of 3-aminopropyltrimethoxysilane acetone with a concentration of 1%, soak it for 10 minutes, take it out, and dry it to obtain the surface-modified soybean fiber .

[0025] Dissolve 2 g of chloroauric acid, 10 g of trisodium citrate, 20 g of sodium chloride, and 4 g of sodium borohydride in 500 mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1 L to obtain a gold nanosol solution.

[0026] The modified soybean fiber is placed in the above solution for 12 hours, taken out and washed to obtain surface-activated soybean fiber.

[0027] Dissolve 10g of copper chloride, 30g of tartaric acid, 10g of potassium hydroxide, 2g of potassium carbonate, 2g of copper sulfate, and 10g of formaldehyde in 500mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1L to obtain an electroless...

Embodiment 3

[0030] Rinse the soybean fiber with deionized water, dry it, place it in a solution of 3-aminopropyltrimethoxysilane acetone with a concentration of 0.5%, soak it for 8 minutes, take it out, and dry it to obtain the surface-modified soybean fiber .

[0031] Dissolve 1.5 g of chloroauric acid, 8 g of trisodium citrate, 15 g of sodium chloride, and 3 g of sodium borohydride in 500 mL of deionized water. After the dissolution is complete, add deionized water until the volume of the solution is 1 L to obtain a gold nanosol solution.

[0032] Put the modified soybean fiber in the above solution for 9 hours, take it out, and wash it to obtain surface-activated soybean fiber.

[0033] Dissolve 8g of copper chloride, 25g of tartaric acid, 7g of potassium hydroxide, 1.5g of potassium carbonate, 1.5g of copper sulfate, and 7g of formaldehyde in 500mL of deionized water. After the dissolution is completed, add deionized water until the volume of the solution is 1L to obtain an electroles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com