Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201 results about "Fusible alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A fusible alloy is a metal alloy capable of being easily fused, i.e. easily meltable, at relatively low temperatures. Fusible alloys are commonly, but not necessarily, eutectic alloys. Sometimes the term "fusible alloy" is used to describe alloys with a melting point below 183 °C (361 °F; 456 K). Fusible alloys in this sense are used for solder.

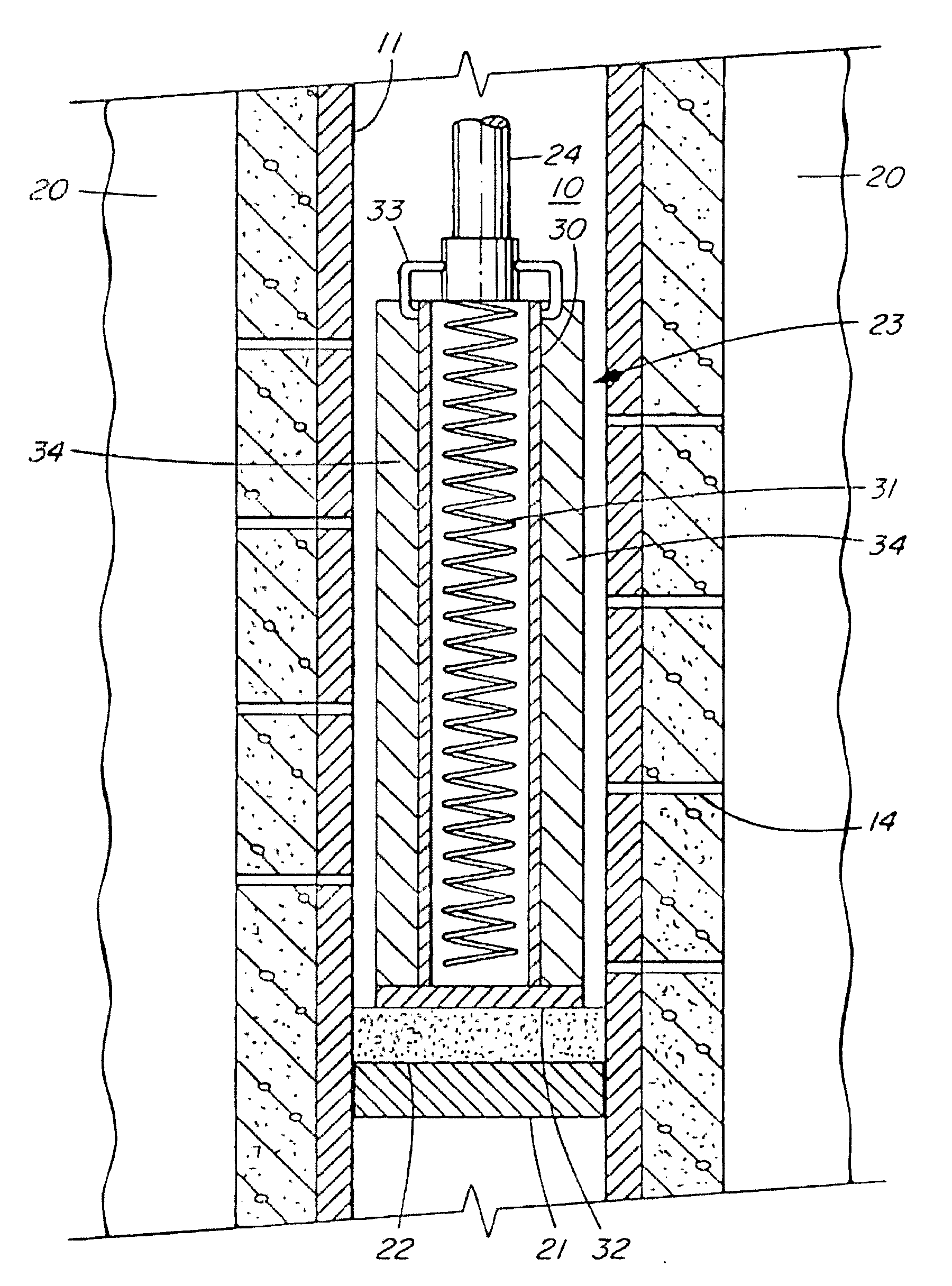

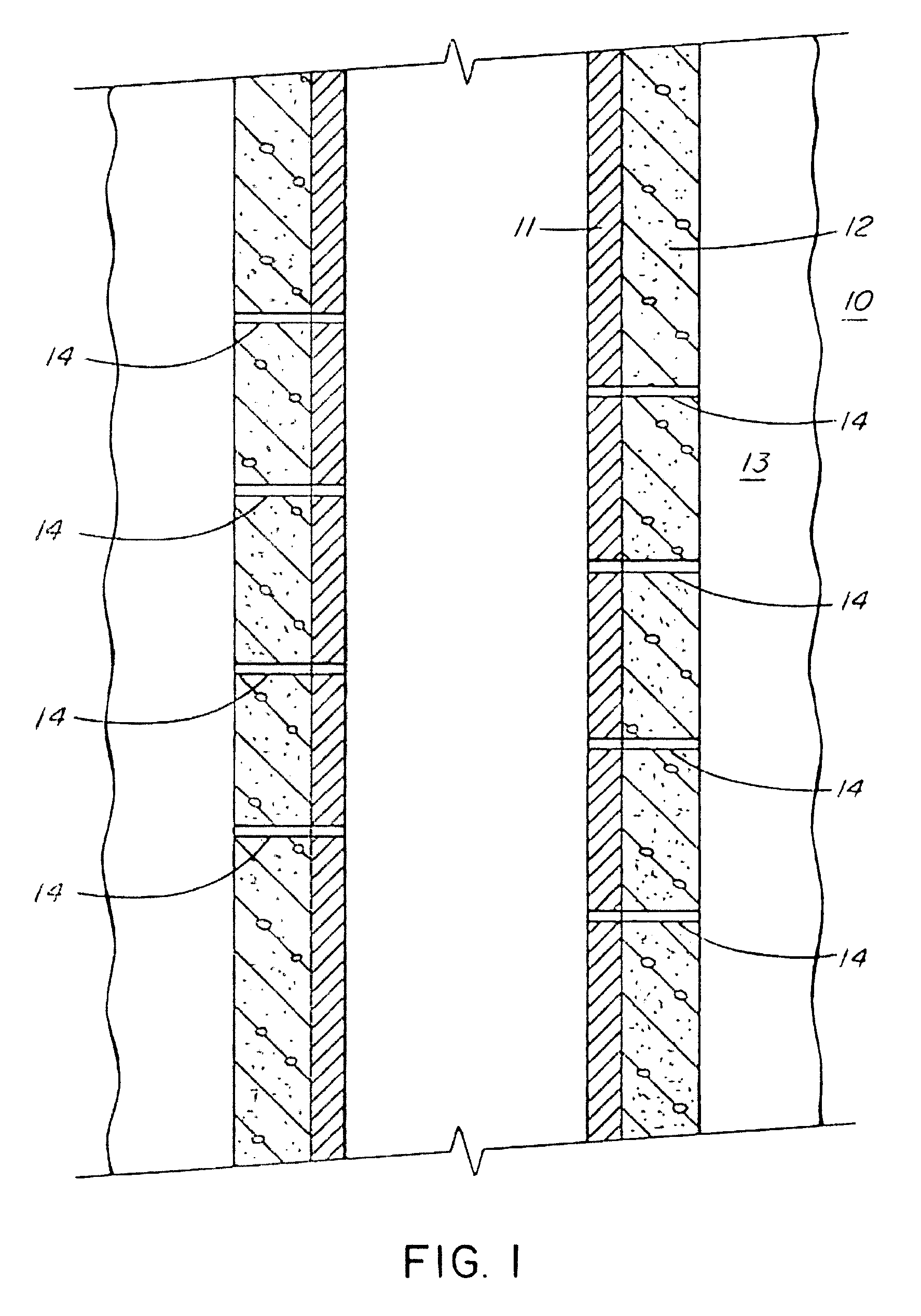

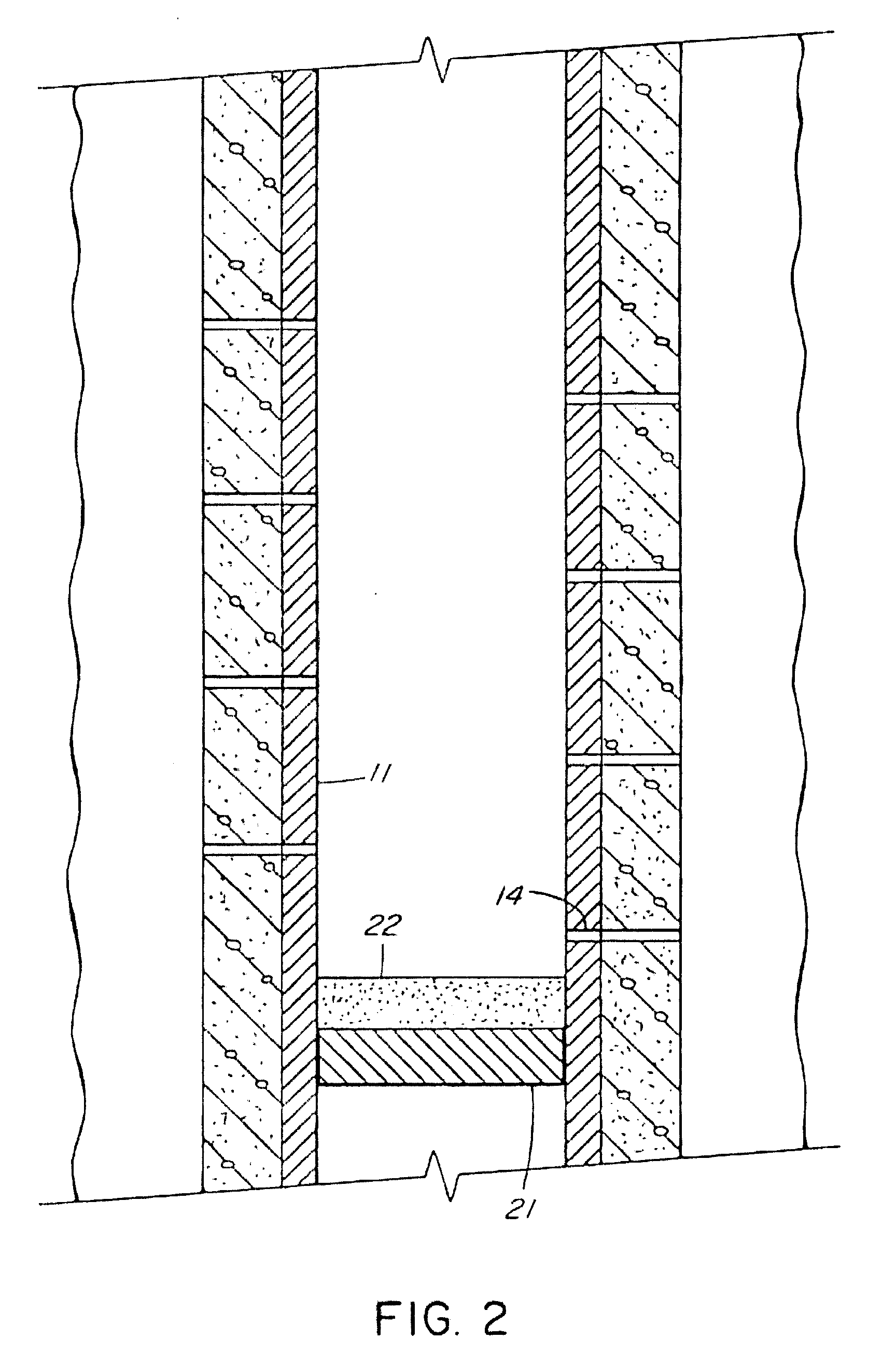

Method and apparatus for plugging perforations

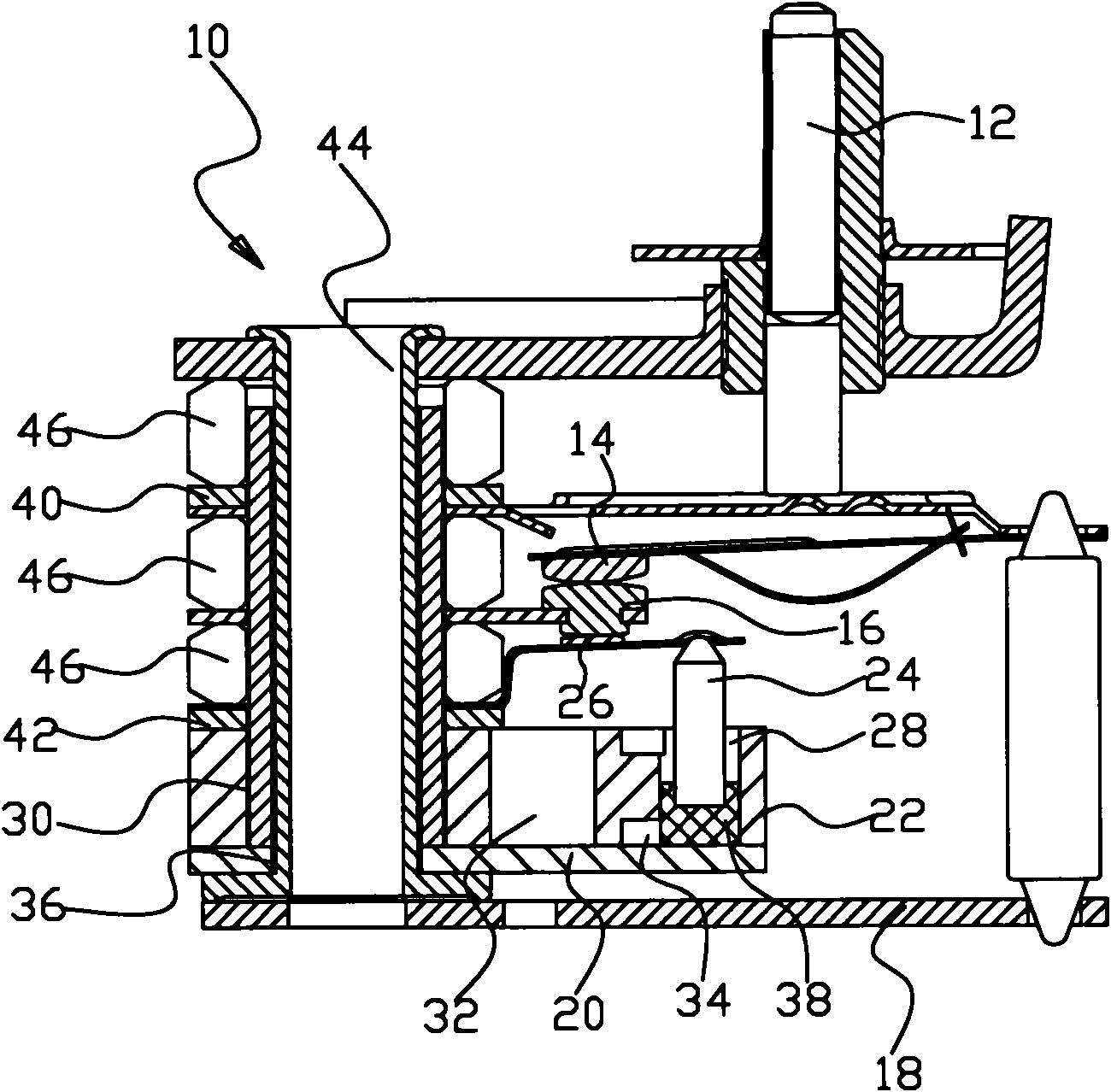

Apparatus and method for plugging perforations in an oil or gas well. A bridge plug is formed in the casing below the perforations. A heating tool and a fusible alloy adjacent the heating tool is lowered into the well to a position above the bridge plug and adjacent the perforations. Heat is applied to melt the fusible alloy and pressure is applied to the molten material to force it through the perforations. The heating operation is terminated to allow the molten material to solidify and plug the perforations.

Owner:SPENCER HOMER L

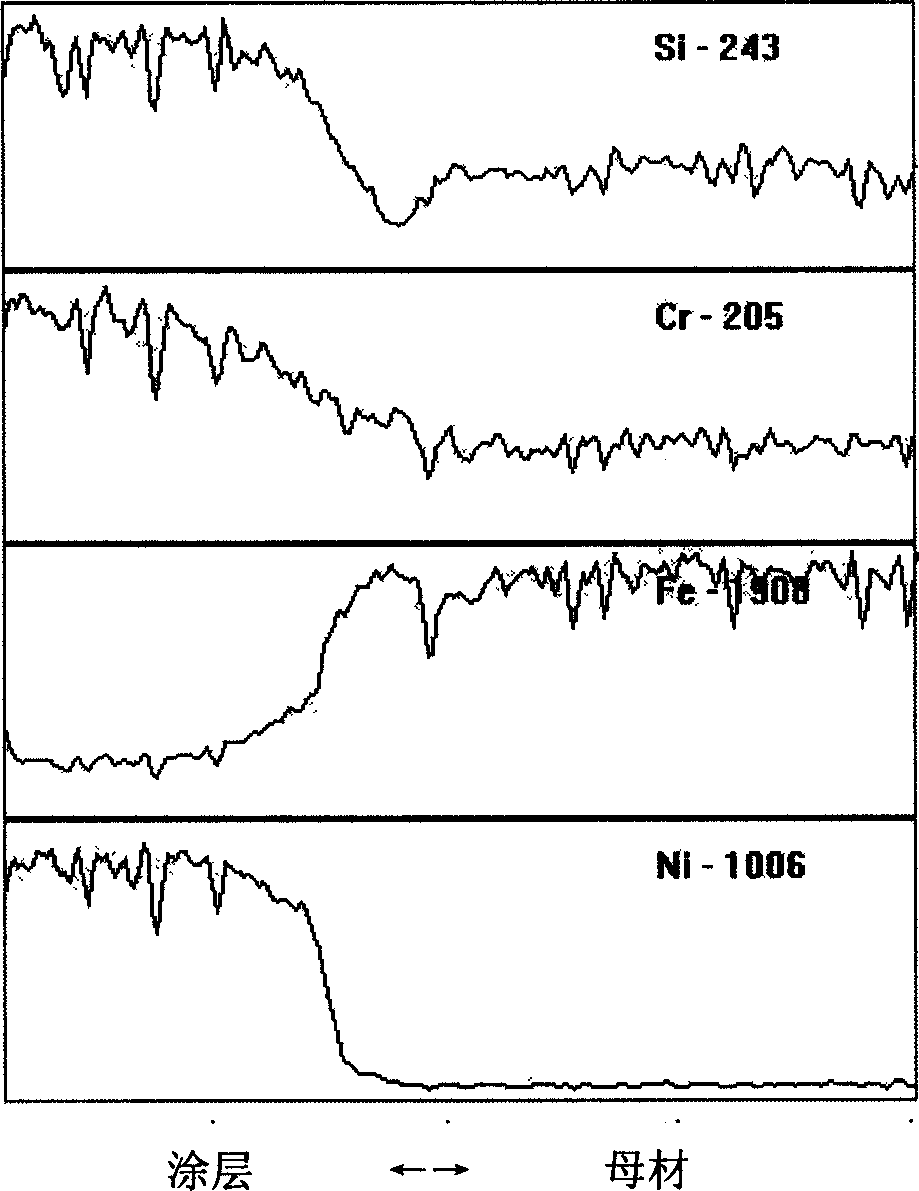

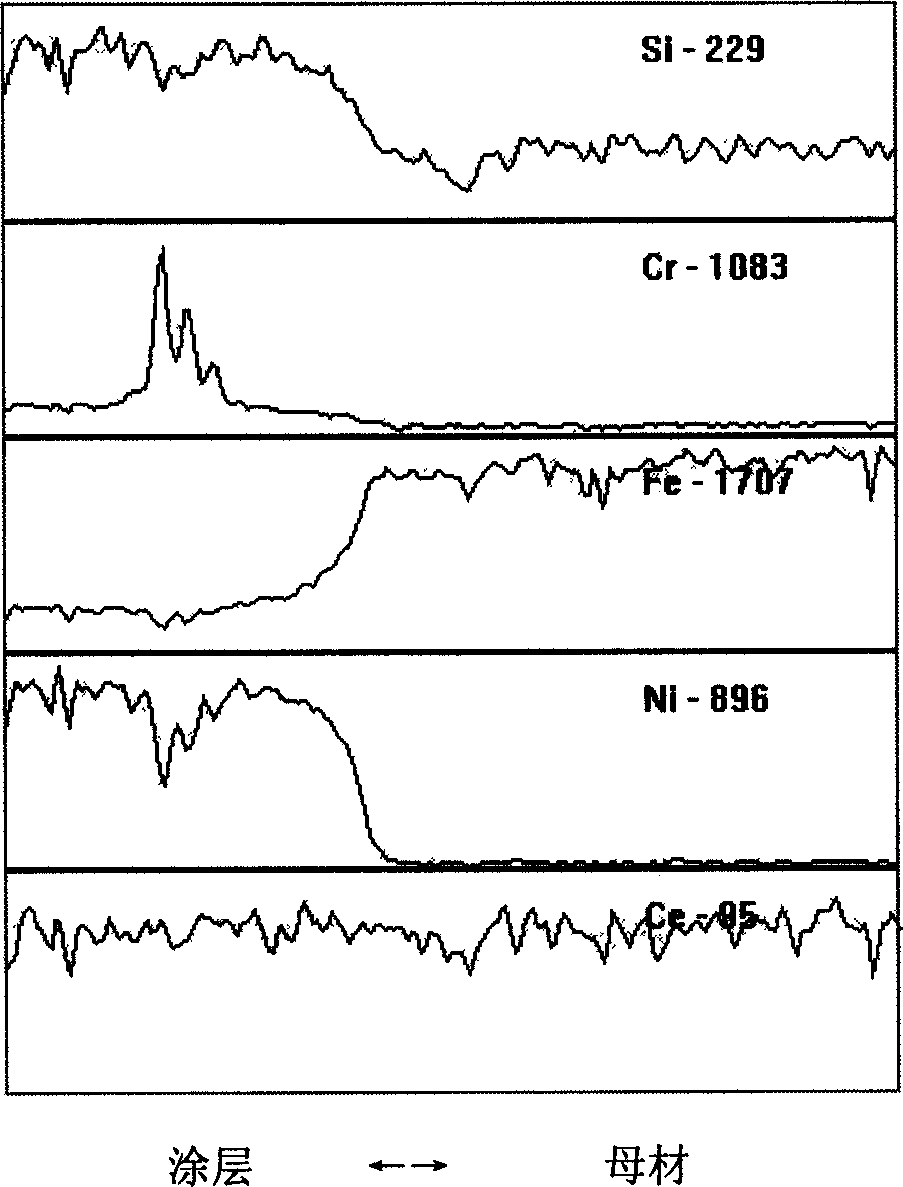

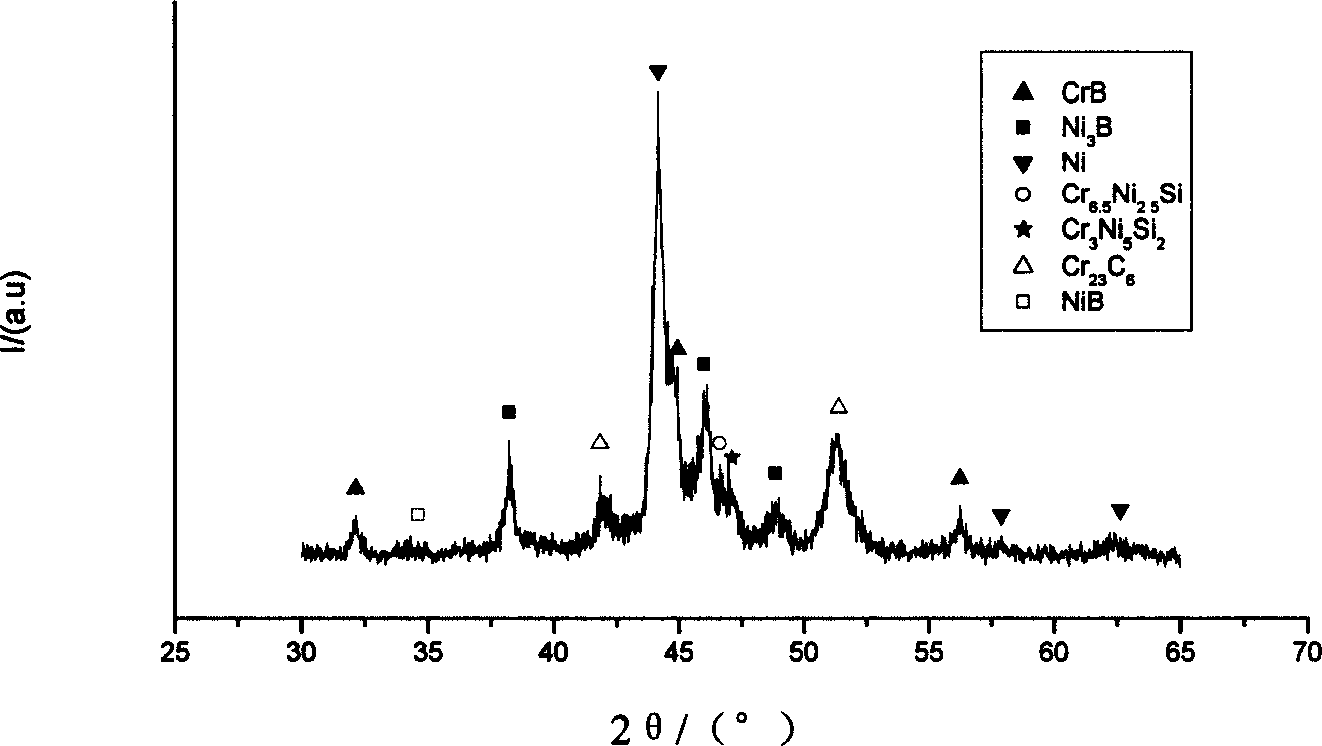

Nickel base self-fusible alloy-rare earth composite coating material and its preparing method

InactiveCN1580324AEasy to modifyImprove performanceMetallic material coating processesParticulatesSilanes

The invention is a nano-particulate demulsifying agent used in demulsification of trinary oil recovery produced fluid. The application of new technique of trinary oil recovery enhances the crude oil recovery, where the polymer injection oil-recovery technique increases the oil, obviously, but also causes the difficulty in demulsifying the produced fluid at the same time. Its character lies in that: the nano-particulate demulsifying agent is composed of particle nucleating material which processes the surface of nano silicon oxide material by silane coupler and fluorine compound and reacting solvent containing arenes as dimethylbenzene, as well as polyether demulsifying agent as multicomponent polyether, amine polyether and resin polyether. It effectively solve the problem about the demulsification of trinary oil recovery polymer injection produced fluid, field used quantity little, demulsifying speed rapid, dehydrating efficiency high and oil-water interface regular.

Owner:HEFEI UNIV OF TECH +1

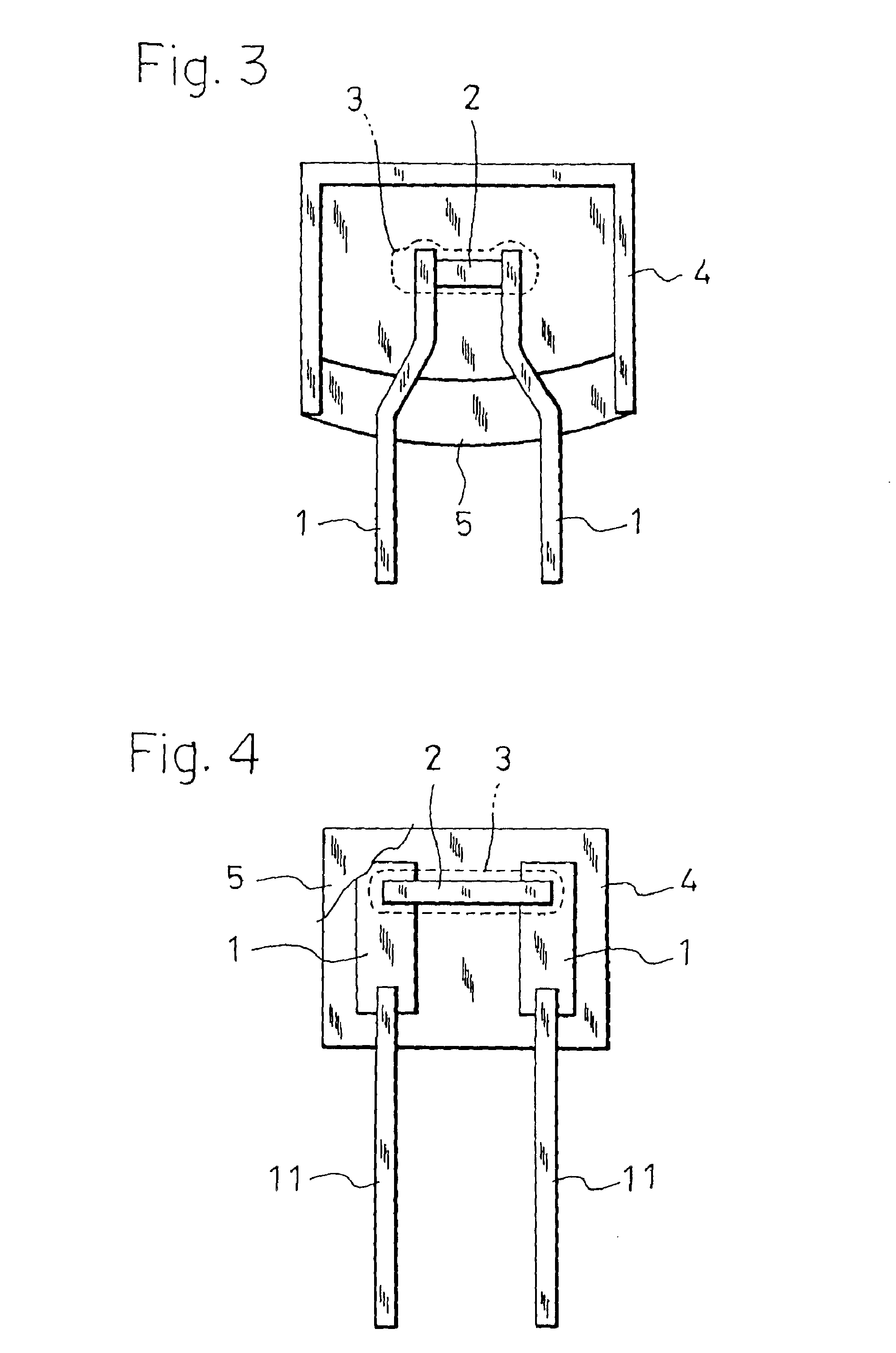

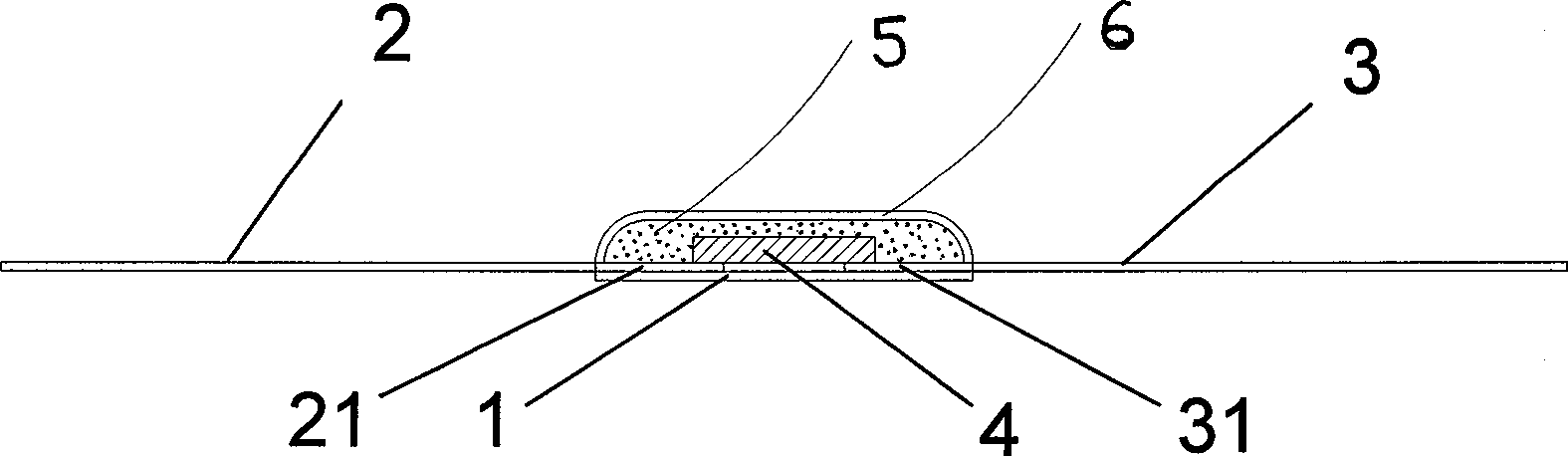

Thermal fuse

InactiveUS6838971B2Inspection is accurateEasy to distinguishFuse device manufactureHeating/cooling contact switchesGardner color scaleImaging processing

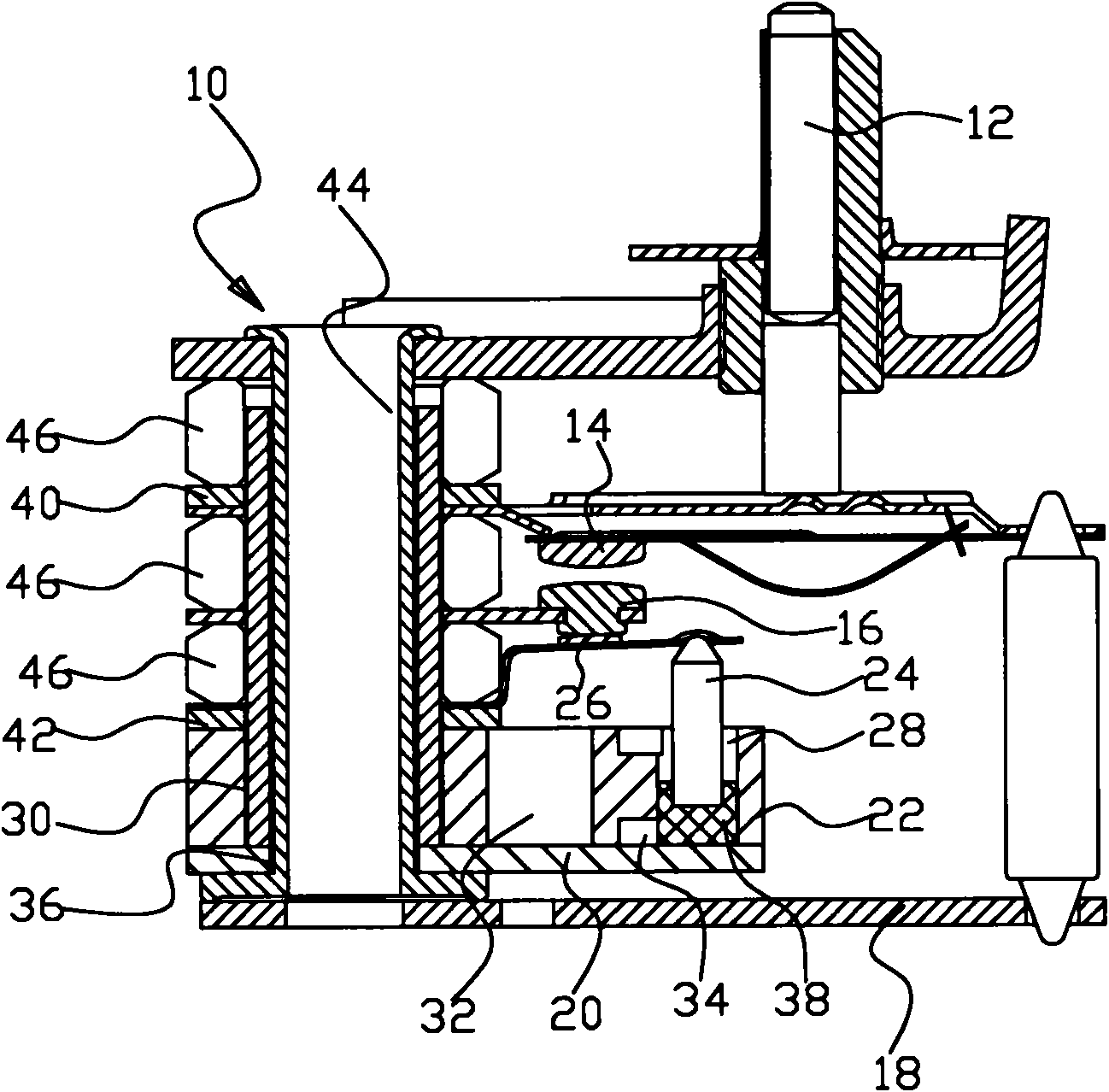

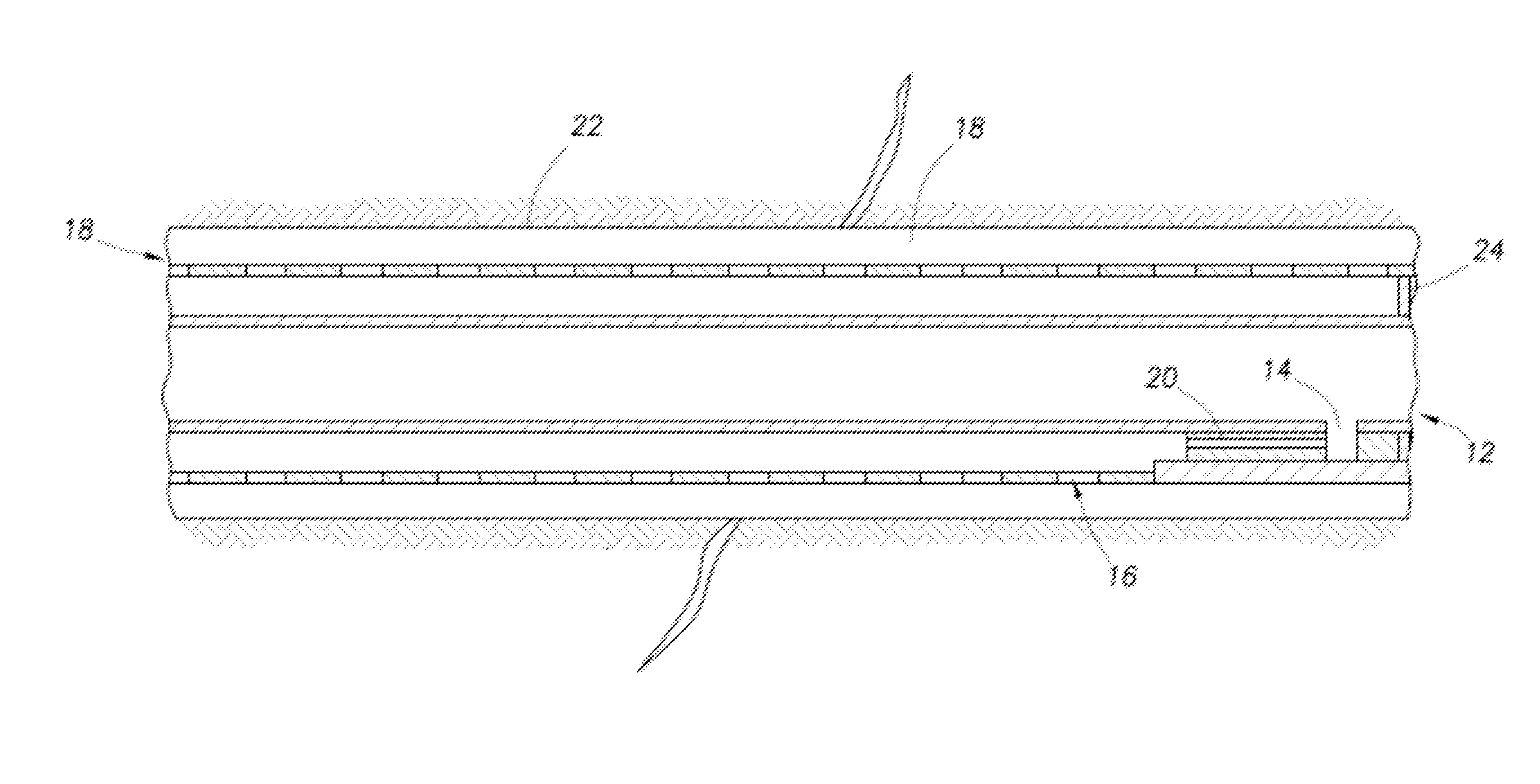

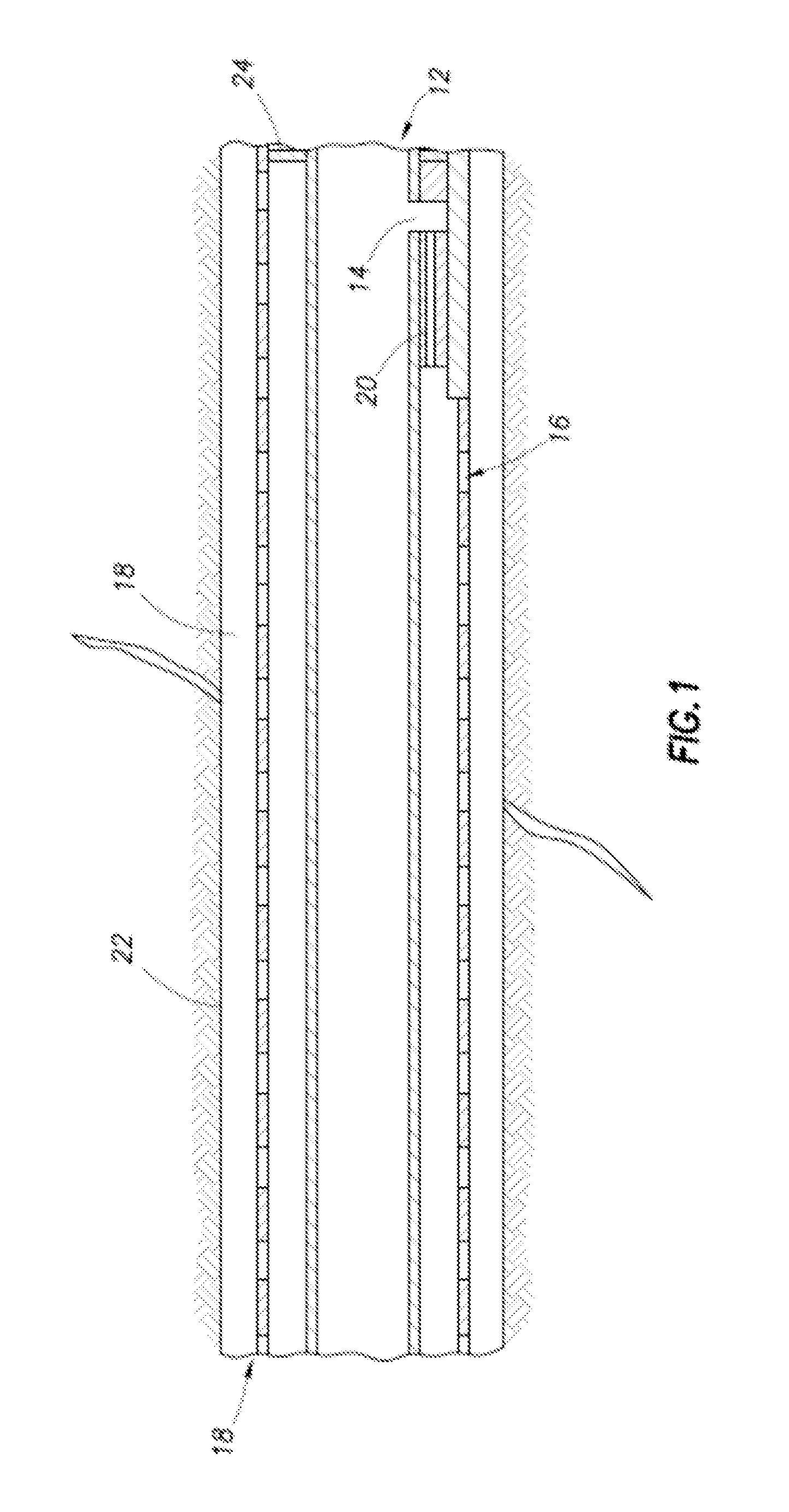

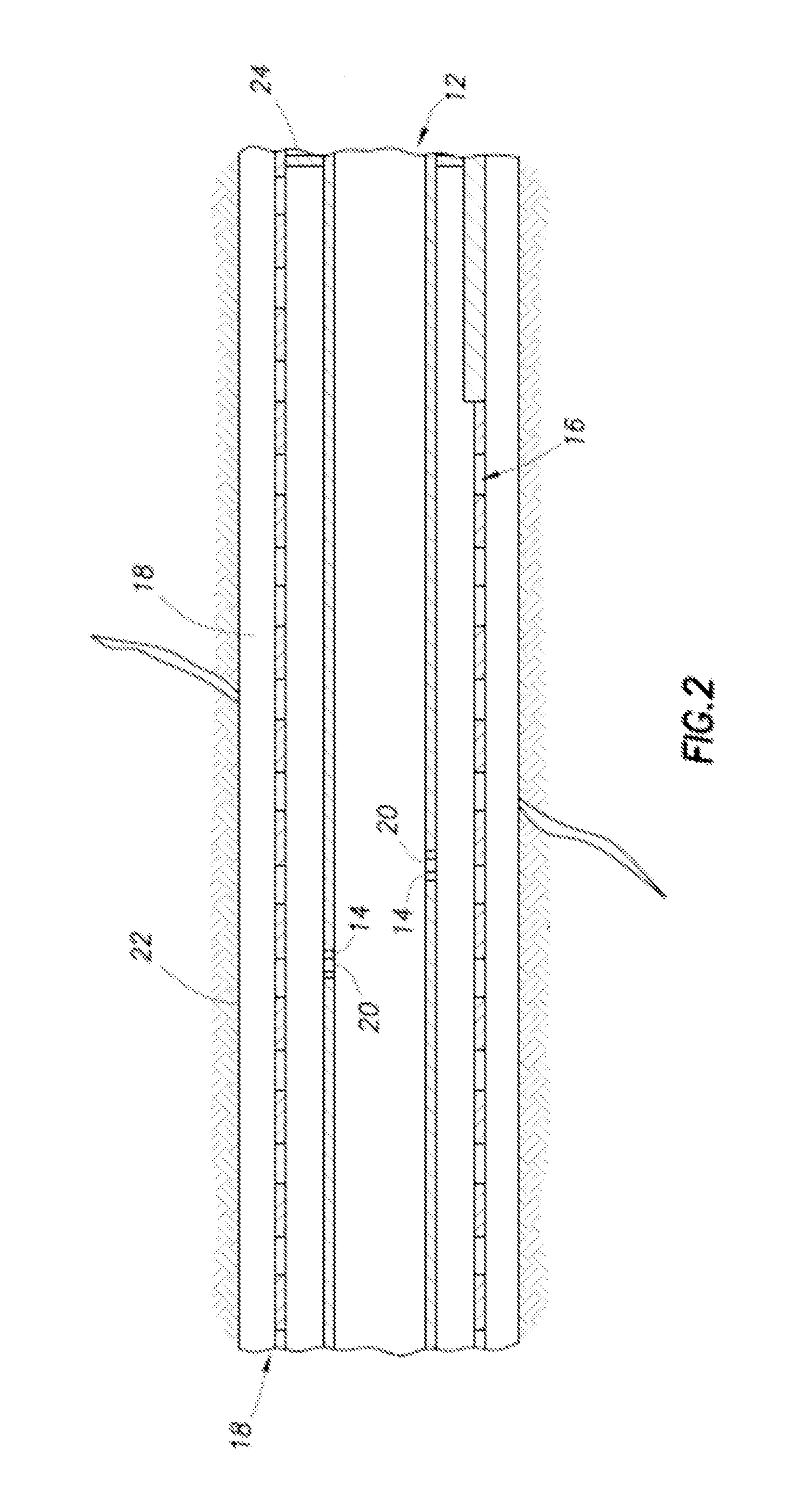

Quantity of flux coated on fusible alloy of a thermal fuse disclosed can be inspected accurately by an image processing method. The thermal fuse comprises:(a) first insulation film 11 coupled with a pair of metal terminals 12; (b) fusible alloy 13 coupled between ends of the metal terminals 12, being placed above first insulation film 11; (c) flux 14 coated on fusible alloy 13; and(d) second insulation film 15 disposed on first insulation film 11 so that an internal space is formed, being placed above fusible alloy 13, wherein at least either of first insulation film 11 or second insulation film 15 is transparent or translucent, and flux 14 has the Gardner color scale from 4 to 16.

Owner:PANASONIC CORP

Sample preparation mold for fractured rock mass model sample

The invention relates to a sample preparation mold for a fractured rock mass model sample. The sample preparation mold comprises a base and an outer frame structure, wherein an inner cavity of the outer frame structure is used for forming the fractured rock mass model sample, and the outer frame structure is positioned on the base. The sample preparation mold further comprises a plug board and a fracture position regulating structure, wherein the plug board is made of a fusible alloy material, the fusible alloy material is formed in a solid state at the normal temperature and can melt after being heated to a melting point temperature; the fracture position regulating structure is positioned in the outer frame structure and is connected with the plug board. The sample preparation mold provided by the invention can conveniently and quickly make the rock mass model sample with a complicated three-dimensional fracture, strictly control the size and the direction of the fracture, simultaneously consider the situation whether the fracture is filled or not filled or not, satisfy the requirements for repeated sample preparation and be combined and assembled according to different sample sizes, so that the practicability of the sample preparation mold is improved.

Owner:SHAOXING UNIVERSITY

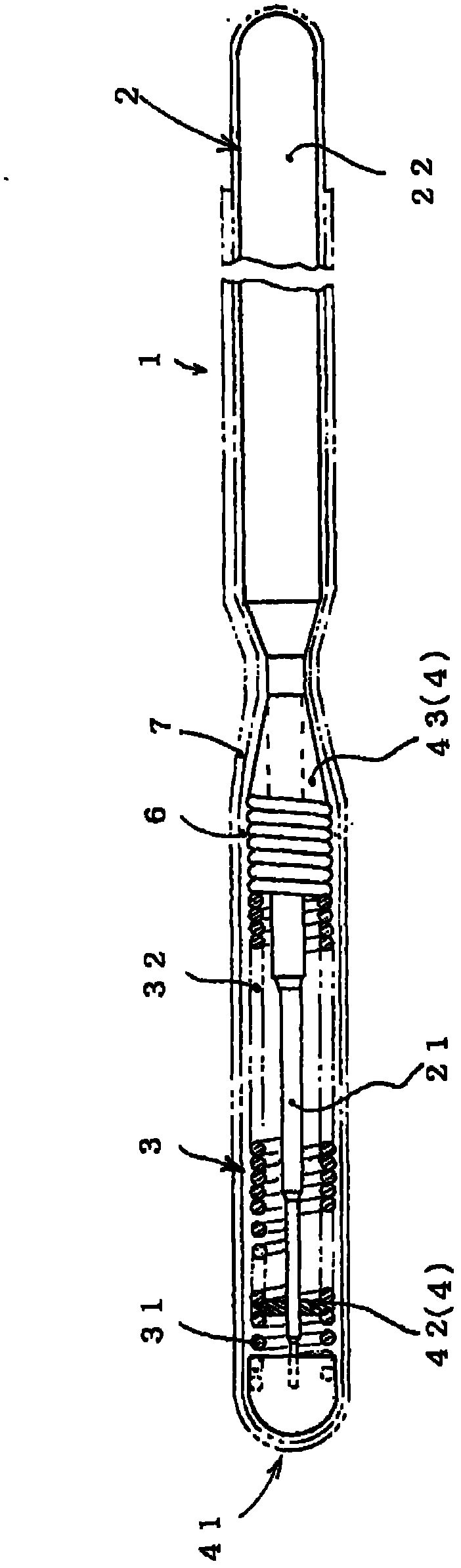

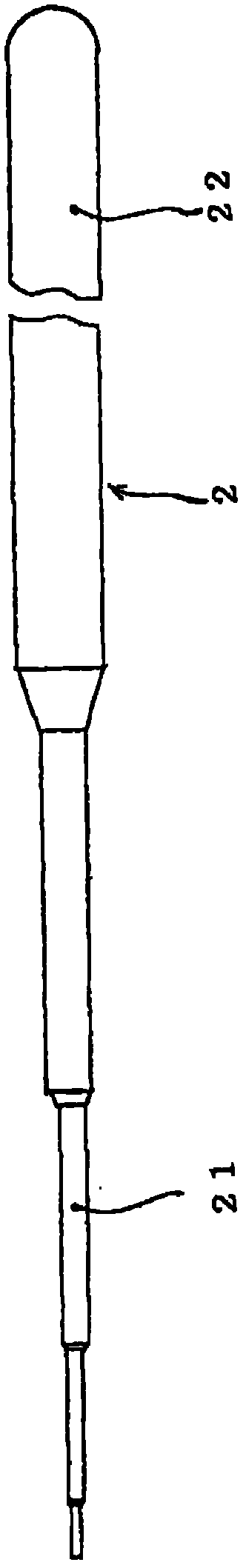

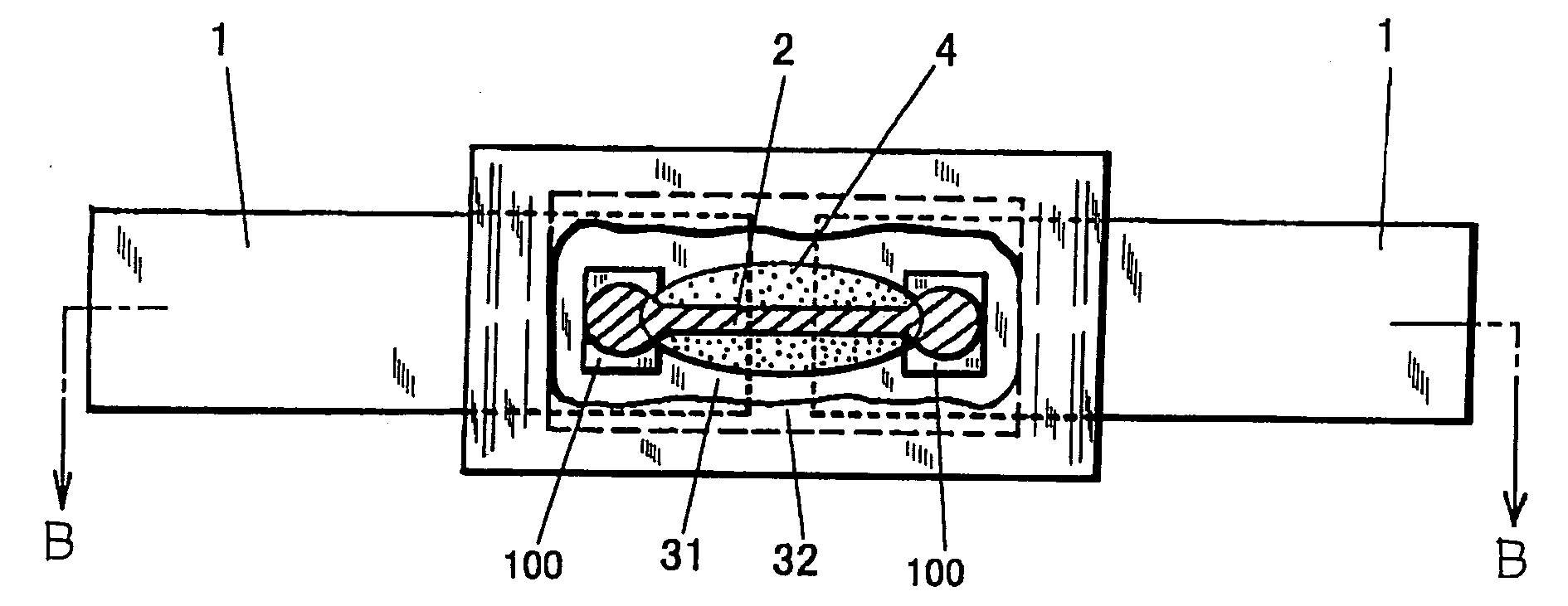

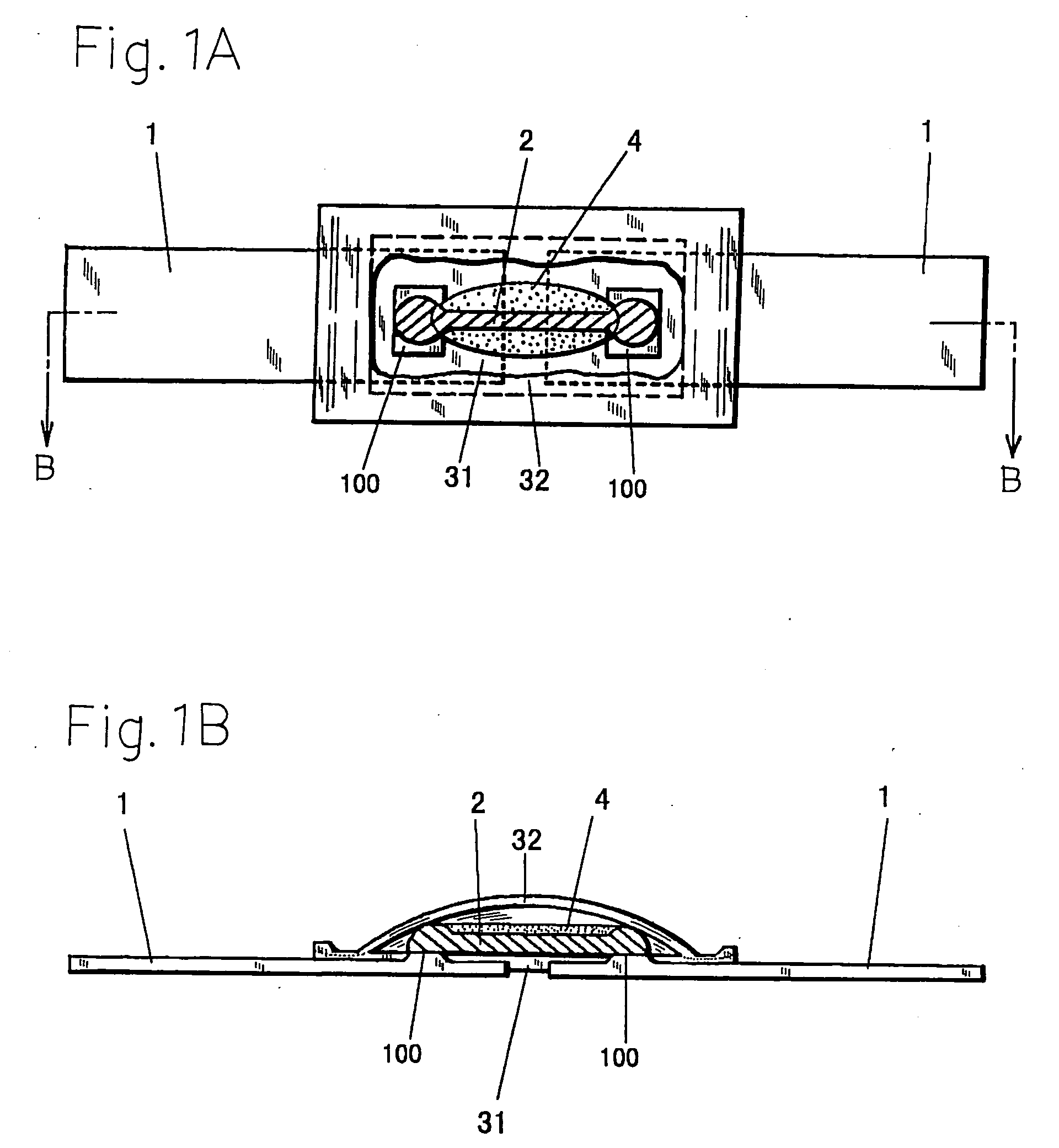

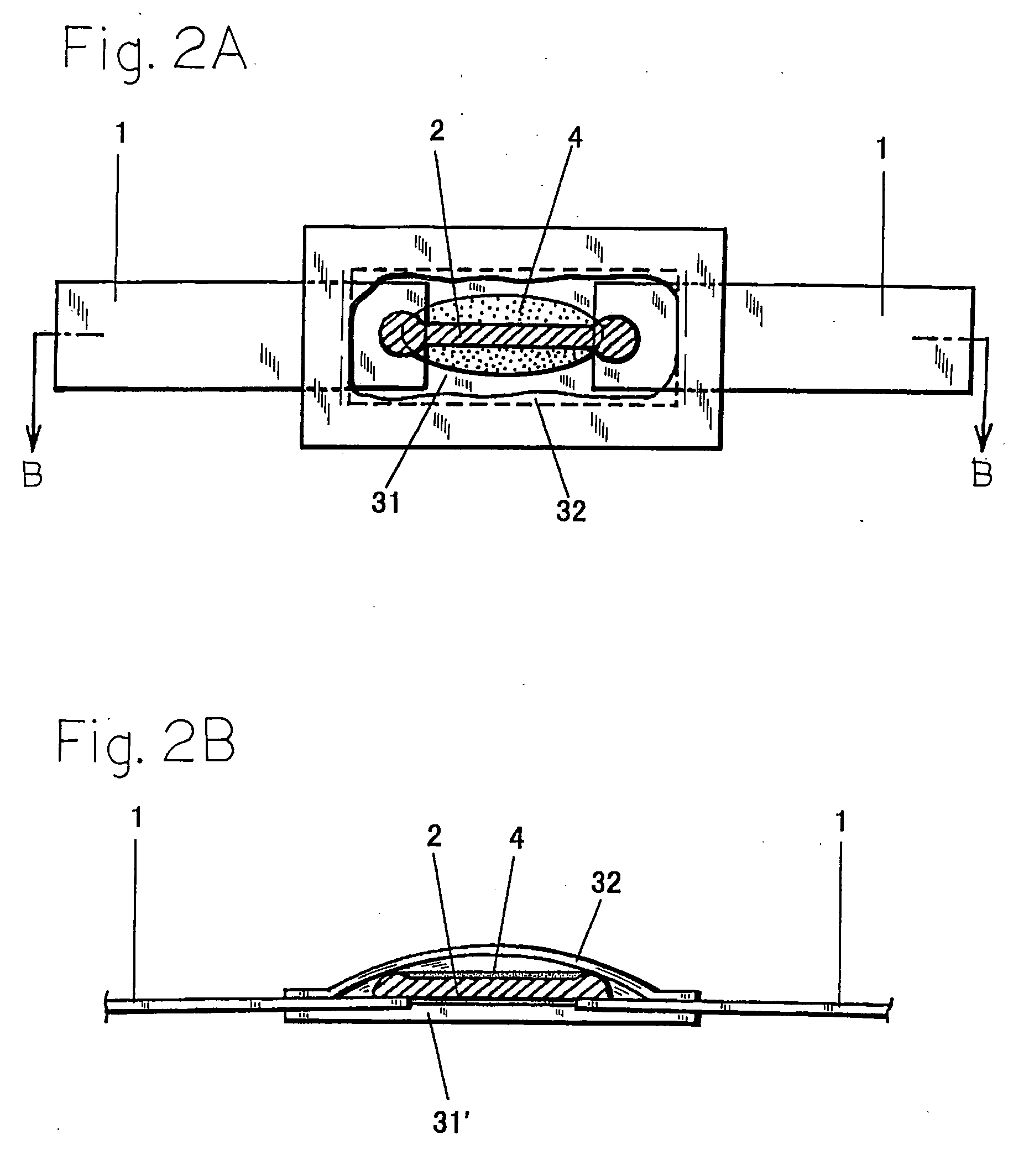

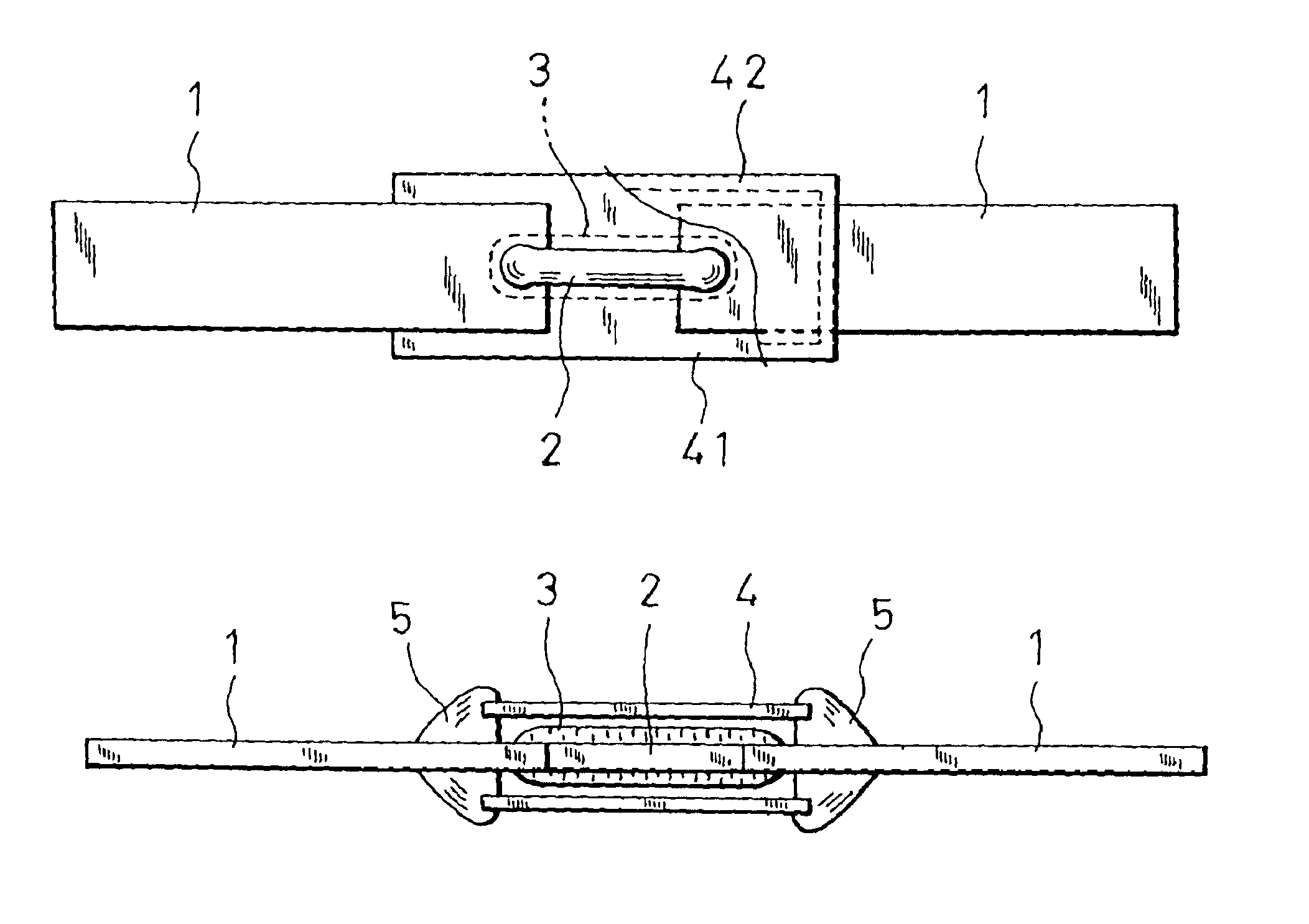

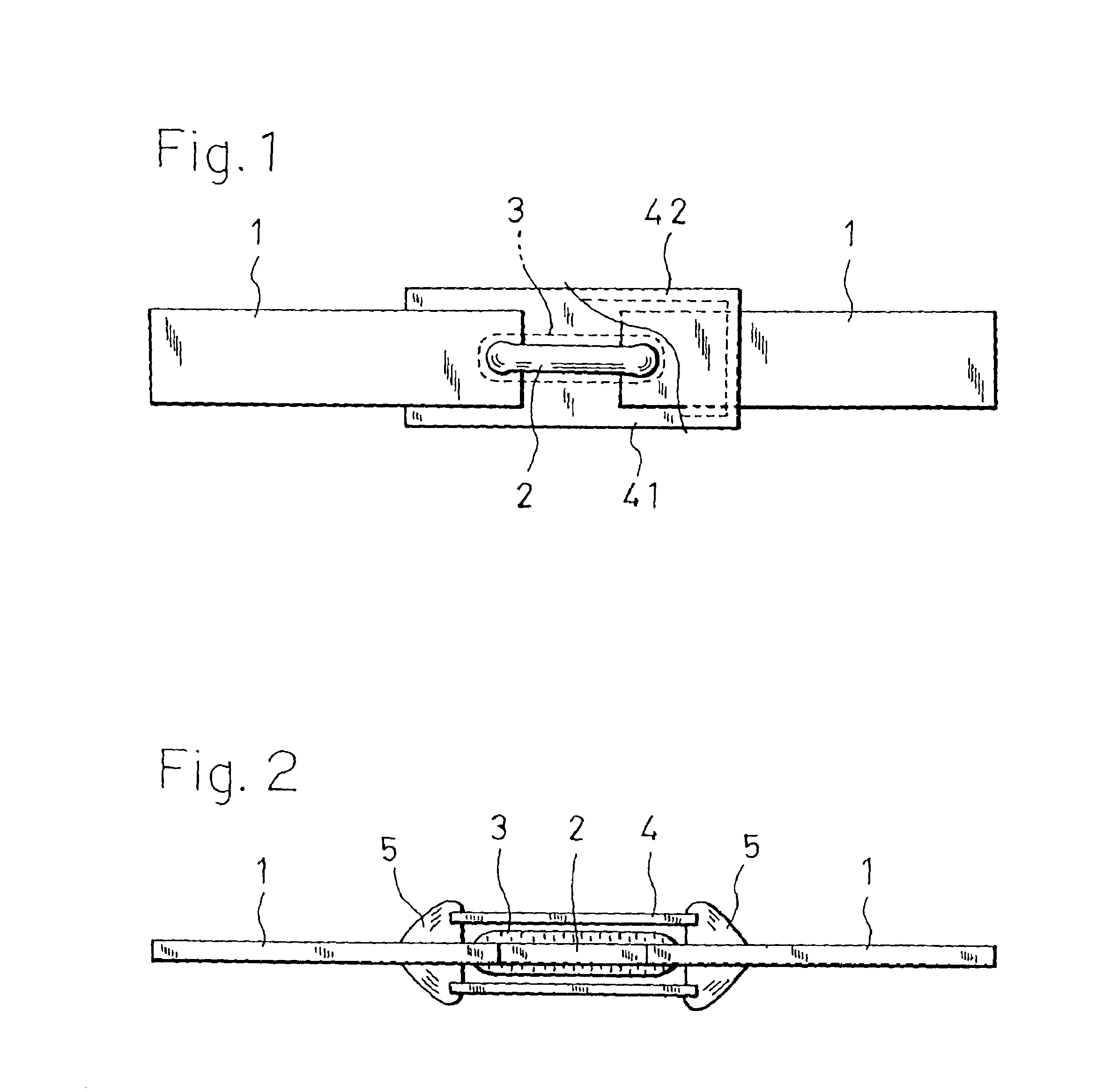

A medical guide wire, a method of making the same, an assembly of microcatheter and guiding catheter combined with the medical guide wire

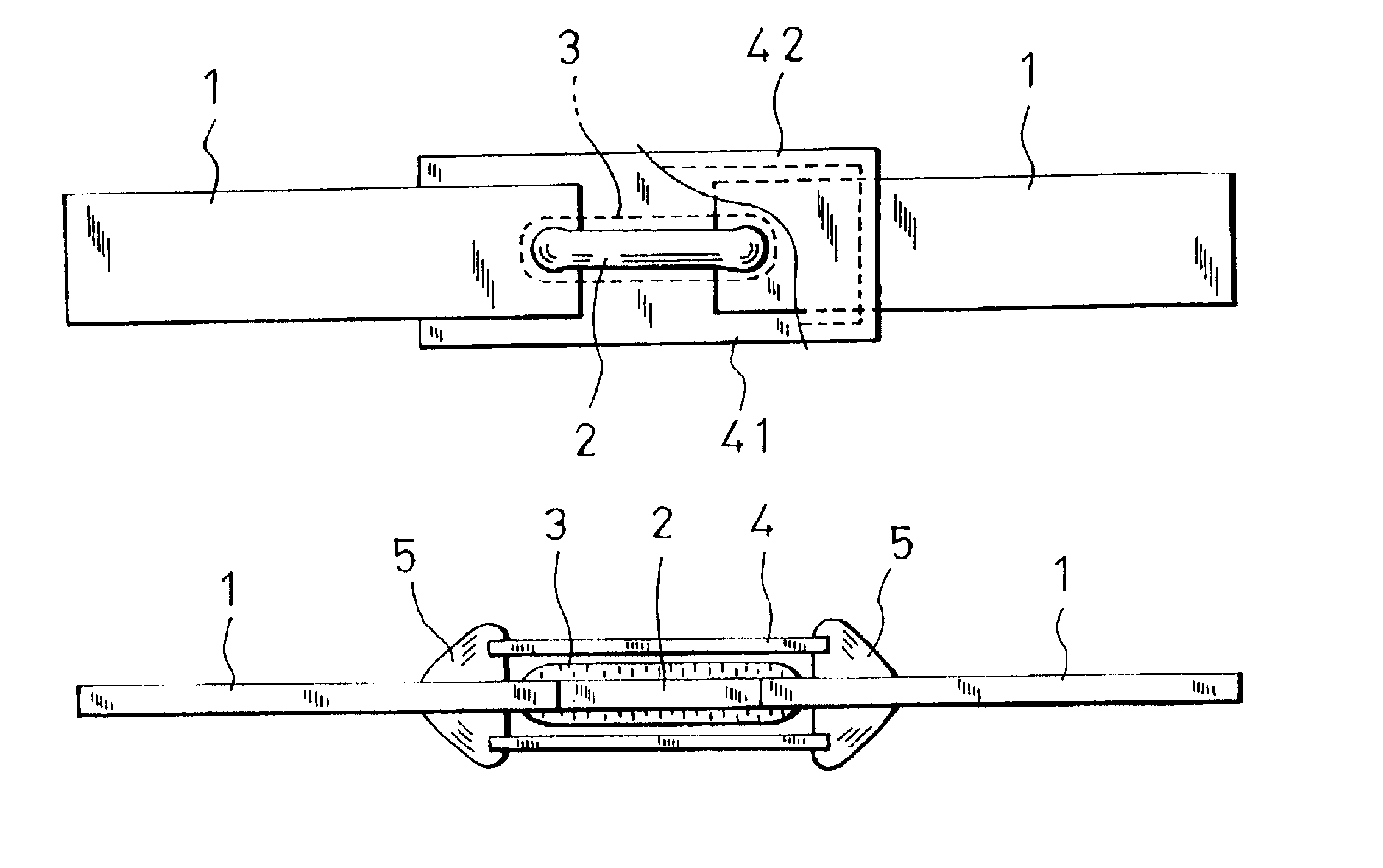

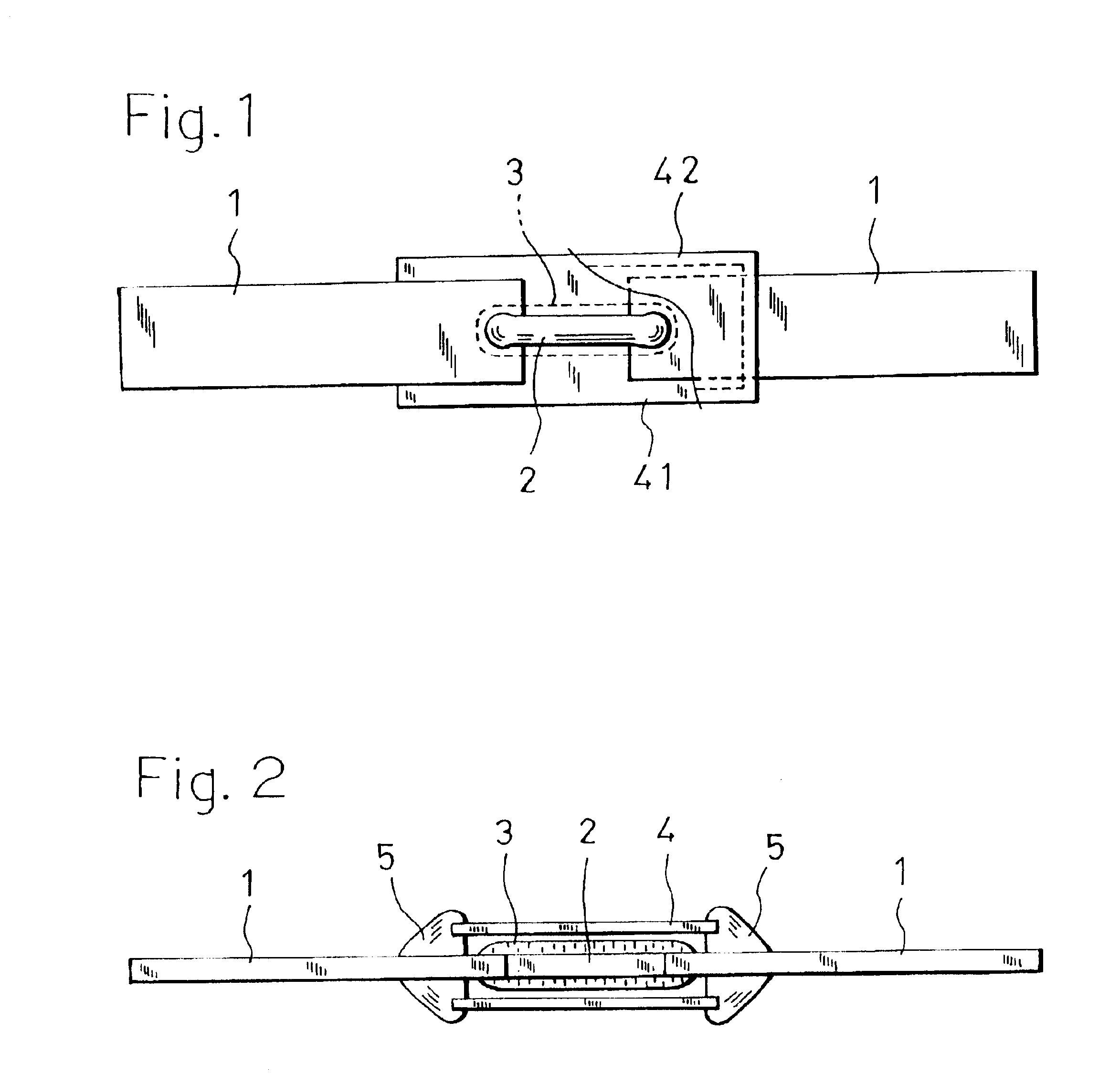

In a medical guide wire (1), a flexible core wire (2) is made of austenitic stainless steel wire treated with a solid solution procedure, and tightly drawn with a whole cross sectional reduction ratio as 90%-99%. Upon forming a head plug (41) at a distal end by welding a distal end tip of the core wire (2) to a distal end tip of a helical spring body (3), a eutectic alloy is used as a welding member (4). The eutectic alloy has a predetermined melting temperature point so as to reduce a thermal influence against the core wire (2), thereby improving a mechanical strength property of the core wire (2) so as to lengthwisely reduce and diametrically minimize the head plug (41).

Owner:ASAHI INTECC CO LTD

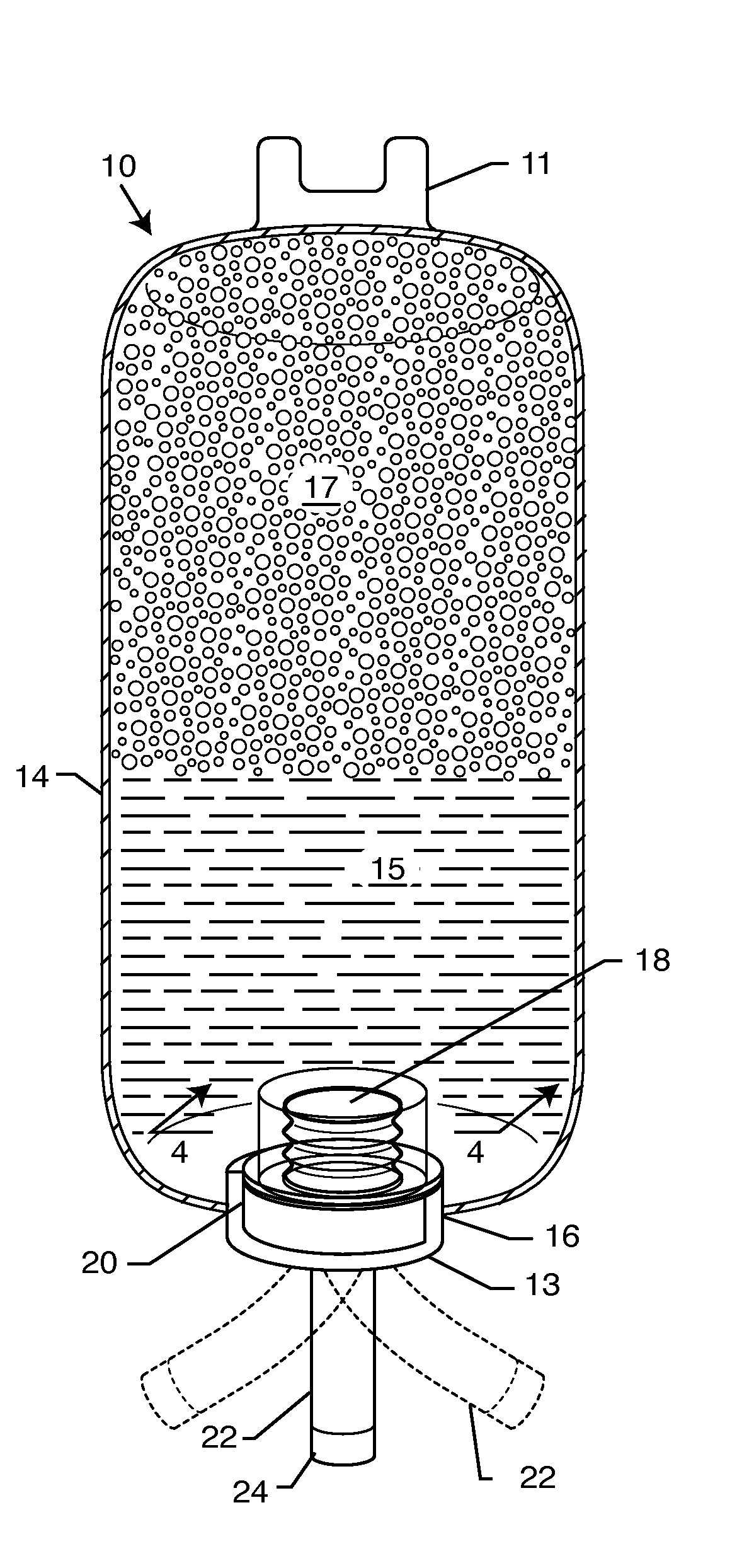

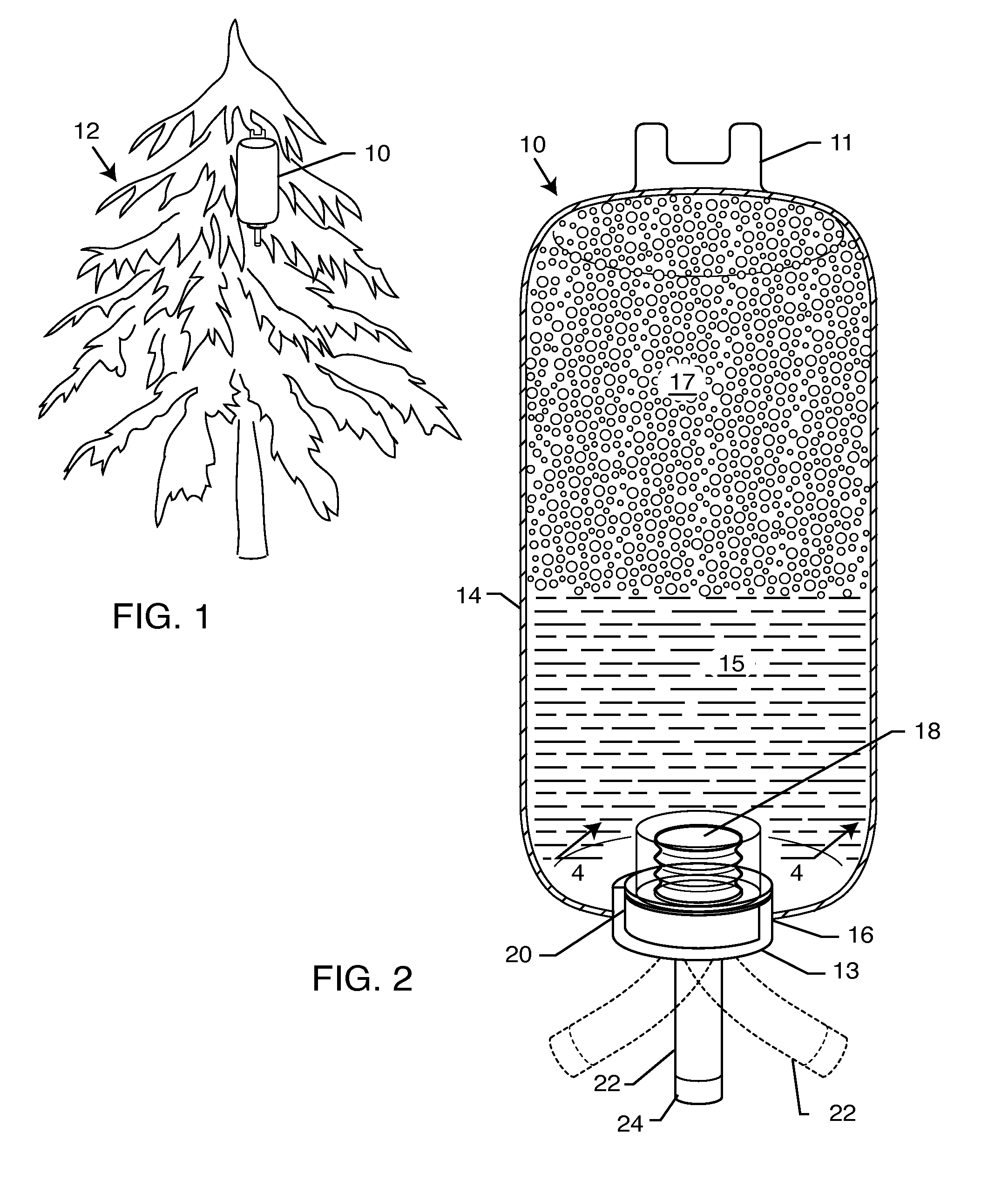

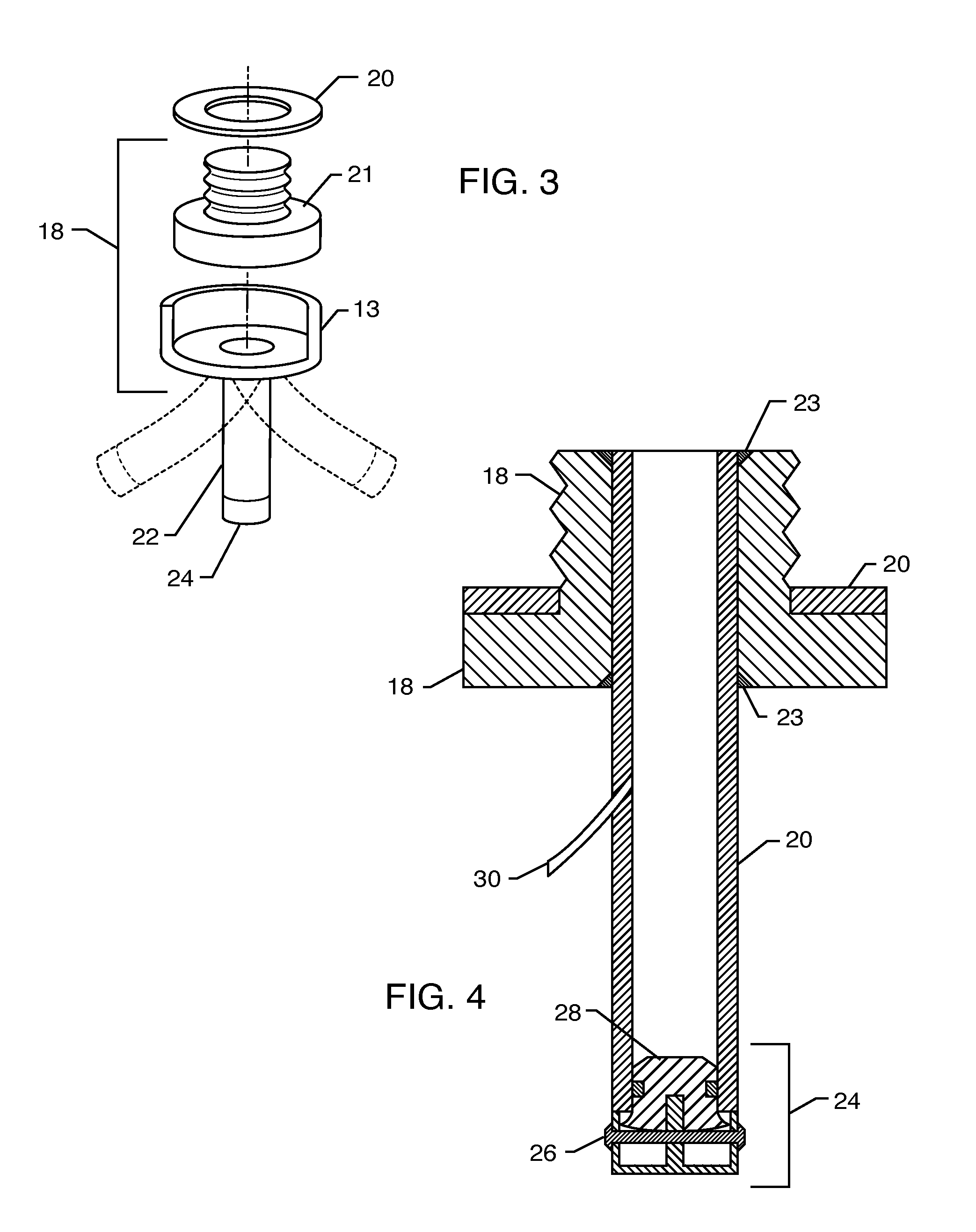

Self-activated fire extinguisher

An automatic fire extinguisher that is self-activated in the presence of specified temperature. The fire extinguisher includes a sealed pressure vessel having a fitting and a tube permitting access to the contents of the pressure vessel. A valve in the end of the tube includes a fusible alloy temperature sensor designed to melt or soften in the presence of heat and / or flame. Once the temperature sensor softens or melts, the contents of the pressure vessel are released through the valve thereby extinguishing the fire. A capillary tube is provided to charge the pressure vessel with fire suppressant agent and a pressurized gas.

Owner:AMERON GLOBAL

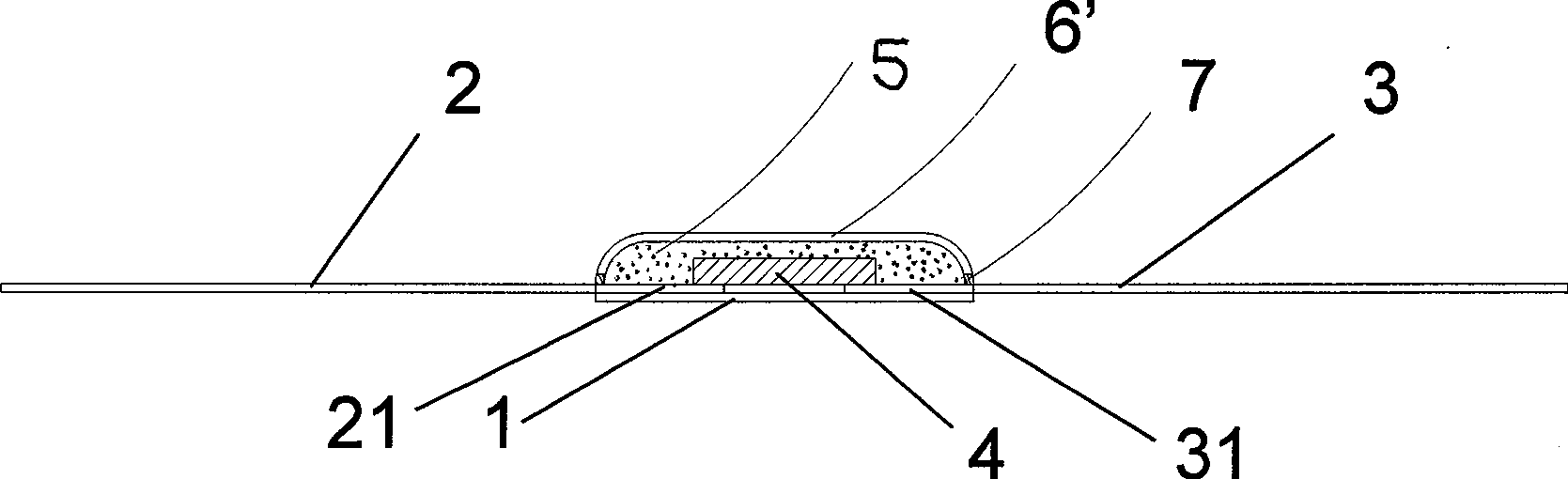

Temperature fuse element, temperature fuse and battery using the same

InactiveUS20070024407A1Damage suppressionPrimary cell maintainance/servicingHeating/cooling contact switchesAlloyMaterials science

A thermal fuse comprises: a first insulating film to which a pair of metal terminals are attached; a fusible alloy located above the first insulating film and connected between the leading end portions of the pair of metal terminals; and a second insulating film located above the fusible alloy and attached to the first insulating film so as to define a space with the first insulating film. The fusible alloy includes an Sn—Bi—In—Zn alloy containing 0.5 to 15 weight % of Bi, 45 to 55 weight % of In and 0.5 to 5 weight % of Zn with the balance being Sn.

Owner:PANASONIC CORP

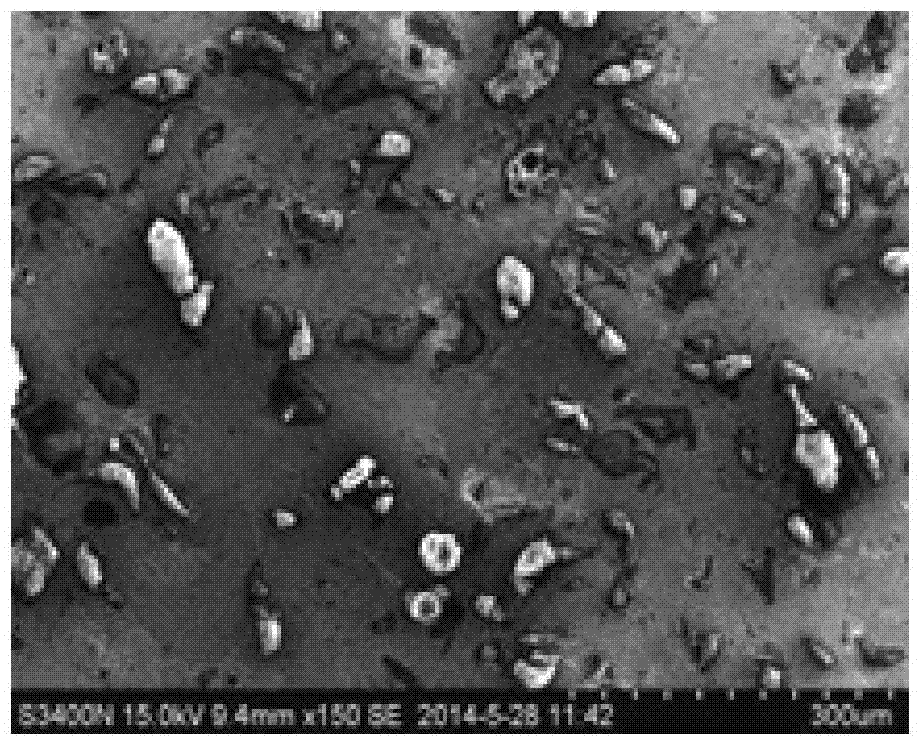

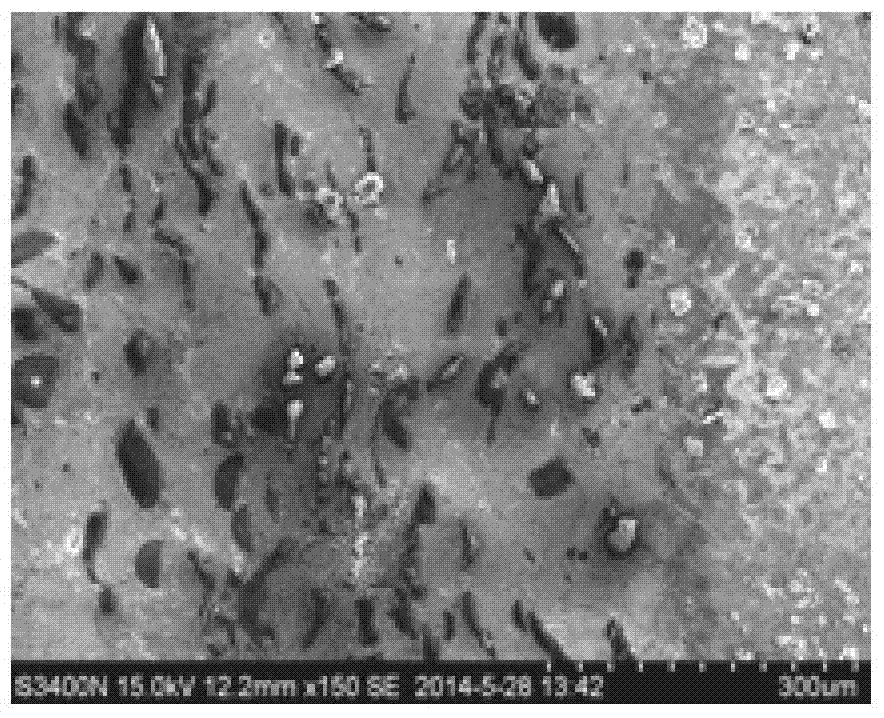

Preparation method for wear-resistant thermally-sprayed composite copper-aluminum alloy coating and coating material

The invention discloses a preparation method for a wear-resistant thermally-sprayed composite copper-aluminum alloy coating and a coating material. The preparation method sequentially comprises the following steps: (1) uniformly mixing copper-aluminum alloy powder and self-fusible alloy powder to prepare thermal spraying mixed powder, wherein the mixed powder comprises the following elements in percentage by weight: 80-85% of copper, 9-14% of aluminum, 3.8-4.3% of nickel, 0.5-1.5% of chromium, 0.5-1.5% of iron, 0-2% of boron, 0-2% of silicon and 0-2% of carbon; (2) treating the surface of a workpiece; (3) preheating the workpiece at 250-300 DEG C; (4) thermally spraying a priming coat on the surface of the workpiece; (5) thermally spraying the thermal spraying mixed powder obtained in the step (1) on the surface of the priming coat; (6) remelting, cooling, preserving heat at 350-550 DEG C for 1-2 hours, and cooling to obtain the coating. The coating has relatively high wear resistance and hardness.

Owner:GUANGDONG AURICAN HARDWARE TECH CO LTD +1

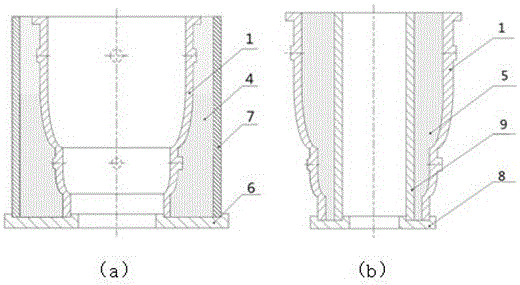

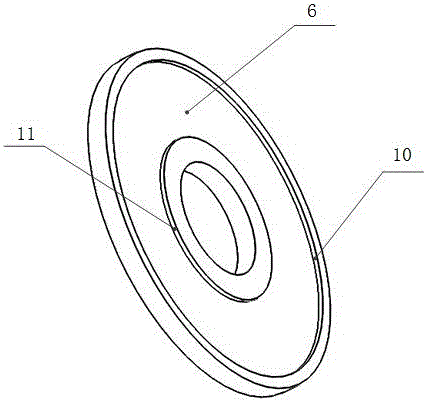

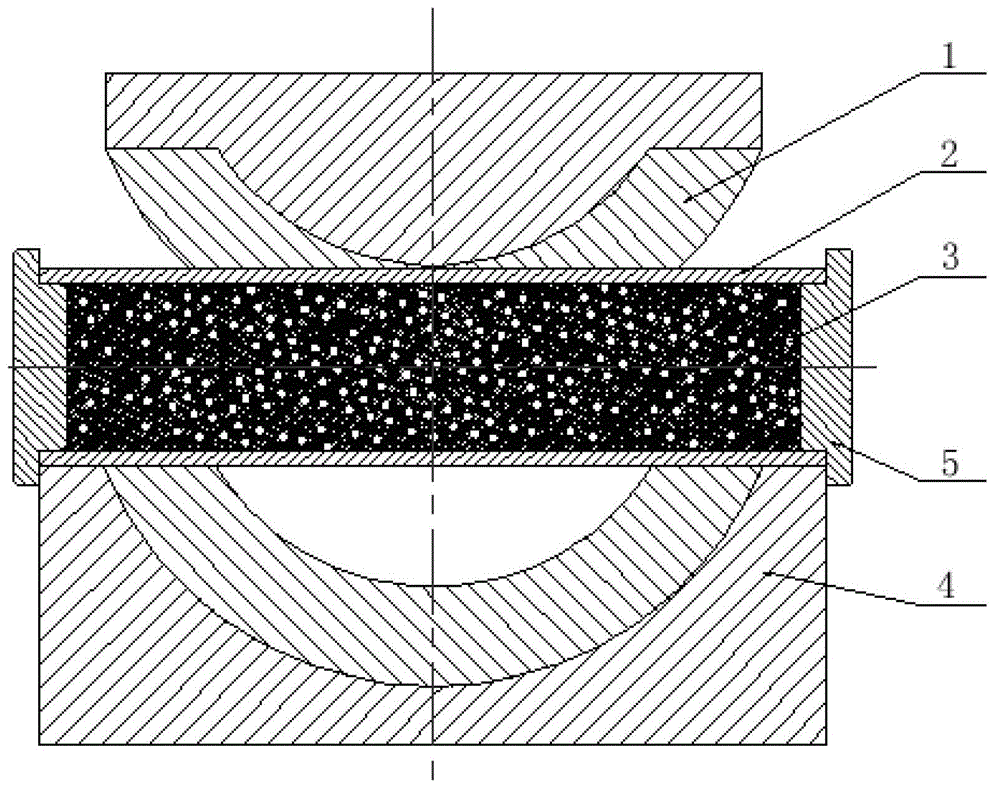

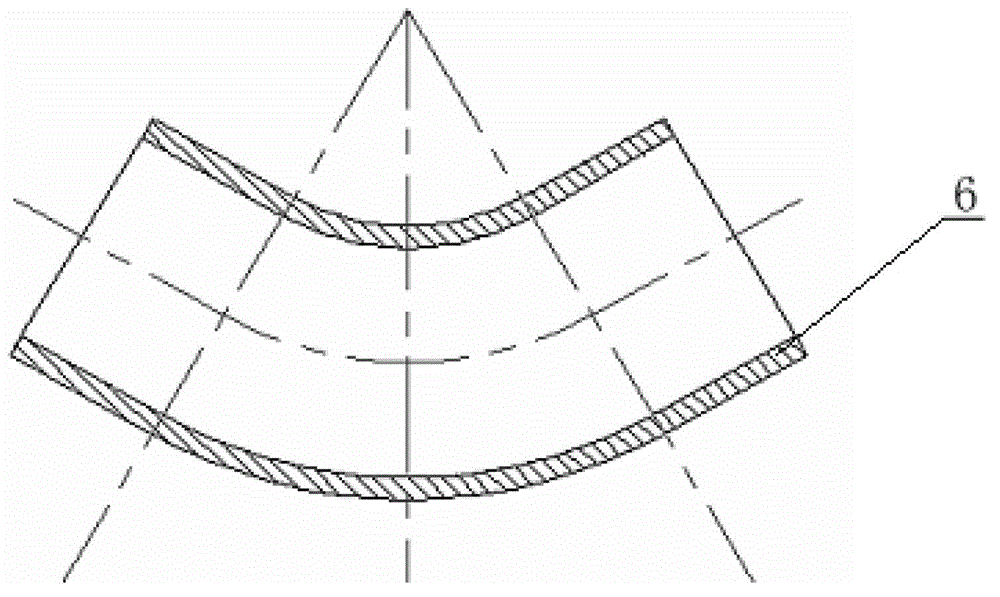

Finish machining die and method for titanium alloy thin-walled shell casting blank

The invention provides a finish machining die and method for a titanium alloy thin-walled shell casting blank. The finish machining die is characterized in that the titanium alloy thin-walled shell casting blank is externally coated with an external casting mold and internally contains an internal casting mold. A fusible alloy is externally cast on the outer surface of the titanium alloy thin-walled shell casting blank, so that the outer surface of a titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the inner surface. Similarly, the fusible alloy is internally cast on the inner surface of the titanium alloy thin-walled shell casting blank, so that the inner surface of the titanium alloy thin-walled shell is thickened, and the thin wall cannot deform during cutting of the outer surface. By adoption of the finish machining die and method, the rigidity and the strength of parts can be effectively improved, the working procedures are reasonably arranged, the working efficiency is high, the machining cost is low, and not only can the problem of machining deformation of titanium alloy thin-walled shell parts be solved, but also the machining precision and the surface quality of the parts are greatly improved.

Owner:XIJING UNIV

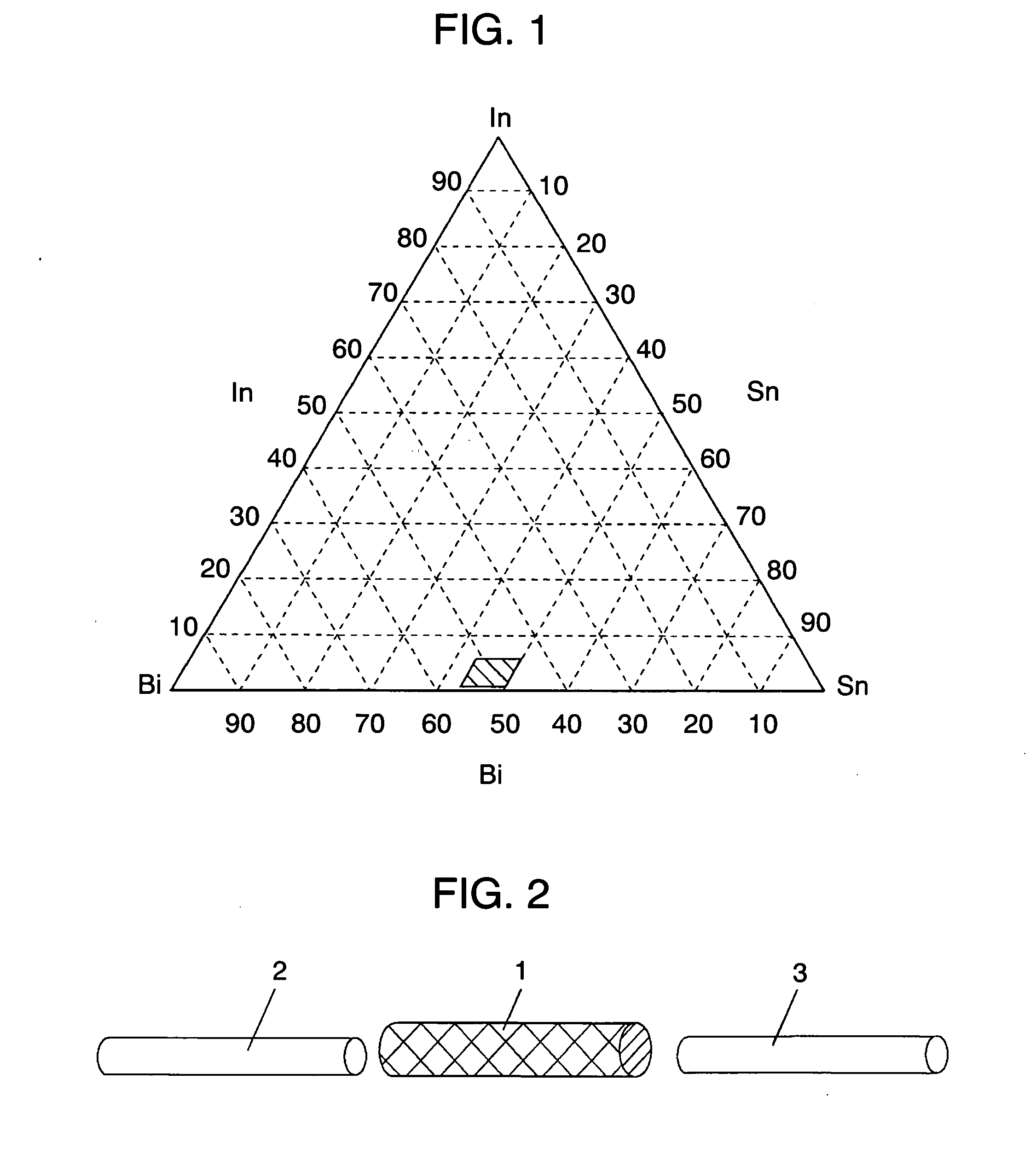

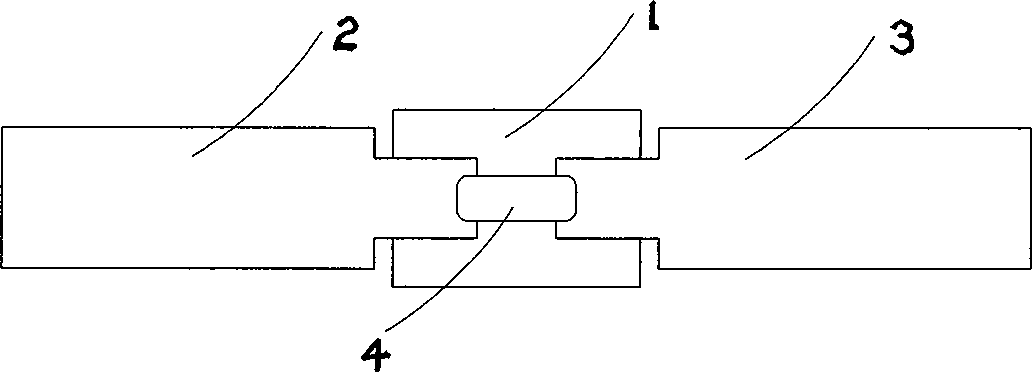

Element for thermal fuse, thermal fuse and battery including the same

InactiveUS20050083166A1Primary cell maintainance/servicingHeating/cooling contact switchesIndiumAlloy

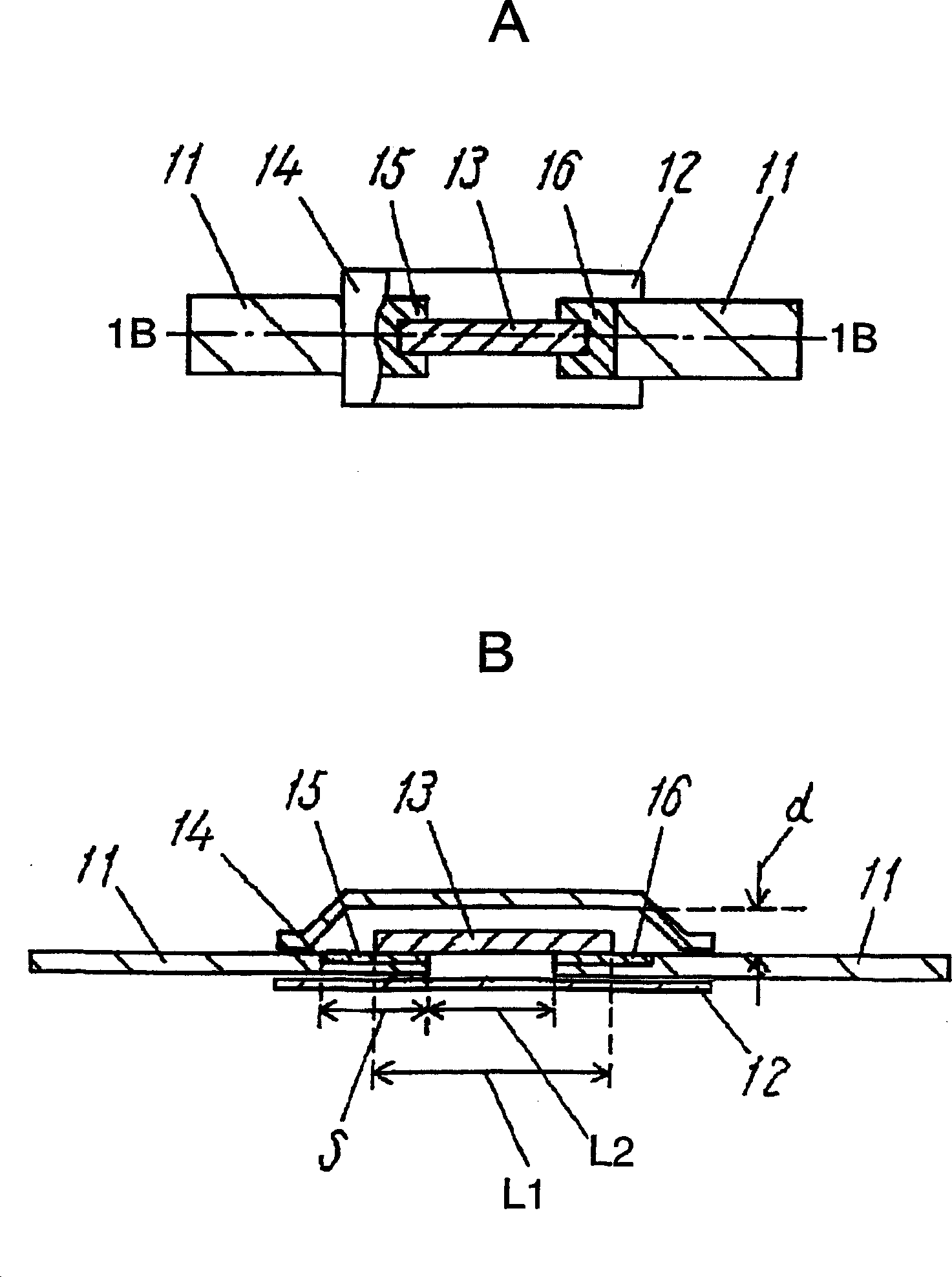

A thermal fuse includes a first insulation film having a pair of metal terminals mounted thereto, a fusible alloy located over the first insulation film and connected between respective ends of the metal terminals, a second insulation film provided over the fusible alloy and bonded to the first insulation film as to provide a space between the first and second insulation films. The fusible alloy includes an Sn—Bi—In alloy containing 20 to 39.5 wt. % of tin, 11.5 to 31 wt. % of bismuth, and 49 to 68.5 wt. % of indium. The fusible alloy does not release lead or cadmium even after being disposed of since it contains no lead and no cadmium.

Owner:PANASONIC CORP

Fusible alloy and thermal fuse

InactiveUS20050007234A1Accurate separationHeating/cooling contact switchesEmergency protective devicesAlloyOperating temperature

The thermal fuse of the present invention contains a fuse element 1 that is formed of a fusible alloy having a composition of 43.5-50 wt % Sn, 0.1-5 wt % In, and balance being Bi and inevitable impurities, or a fusible alloy having a composition of 5-33 wt % In, 4.7-15.5 wt % Zn, and balance being Sn and inevitable impurities; a pair of electric terminals 2, 3 connected to the fuse element; and case 8 for accommodating at least the fuse element 1. The opening end of case 8 has a predetermined shape. By employing the structure above, a thermal fuse having an operating temperature as high as 130-190° C. can be easily obtained.

Owner:PANASONIC CORP

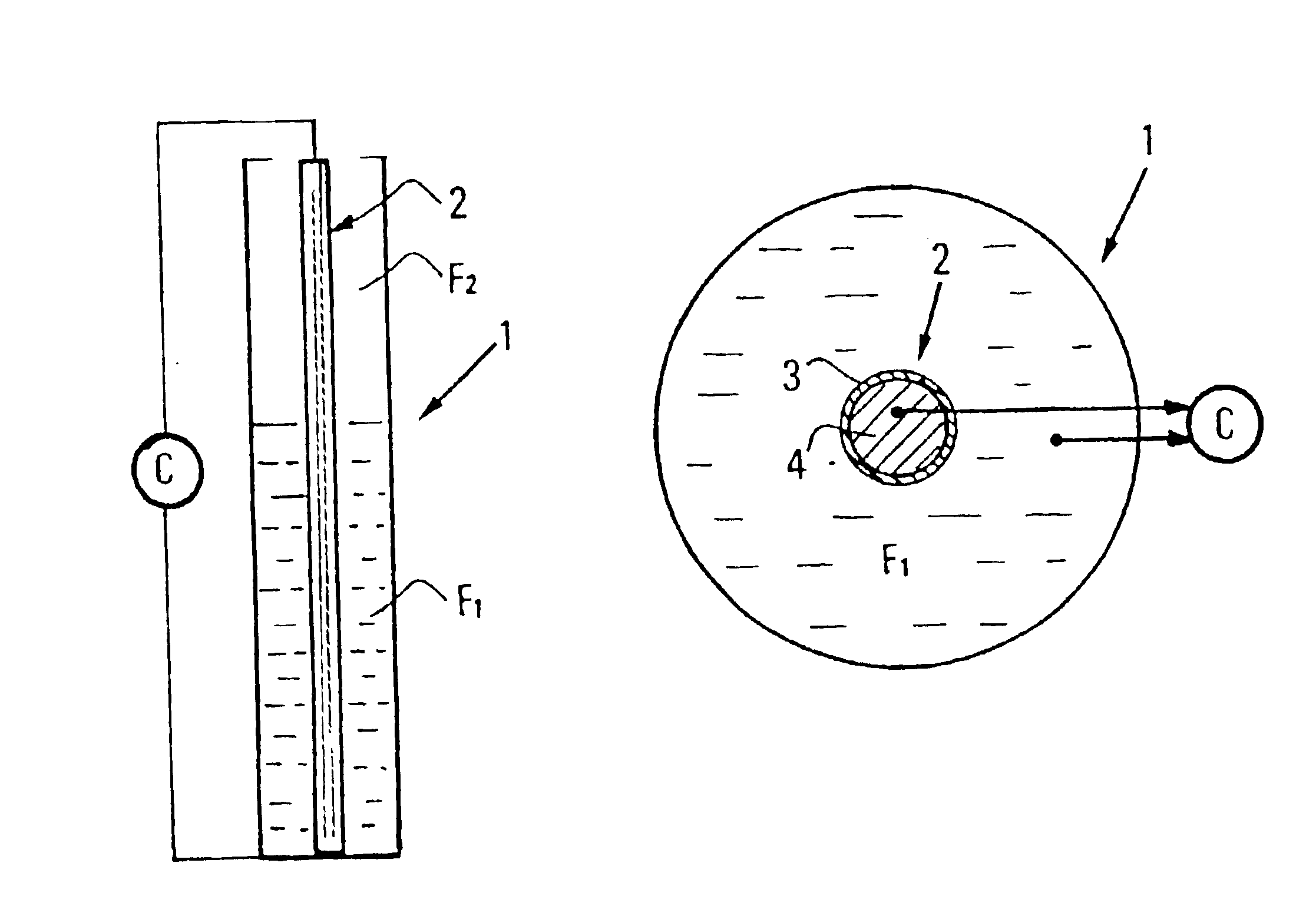

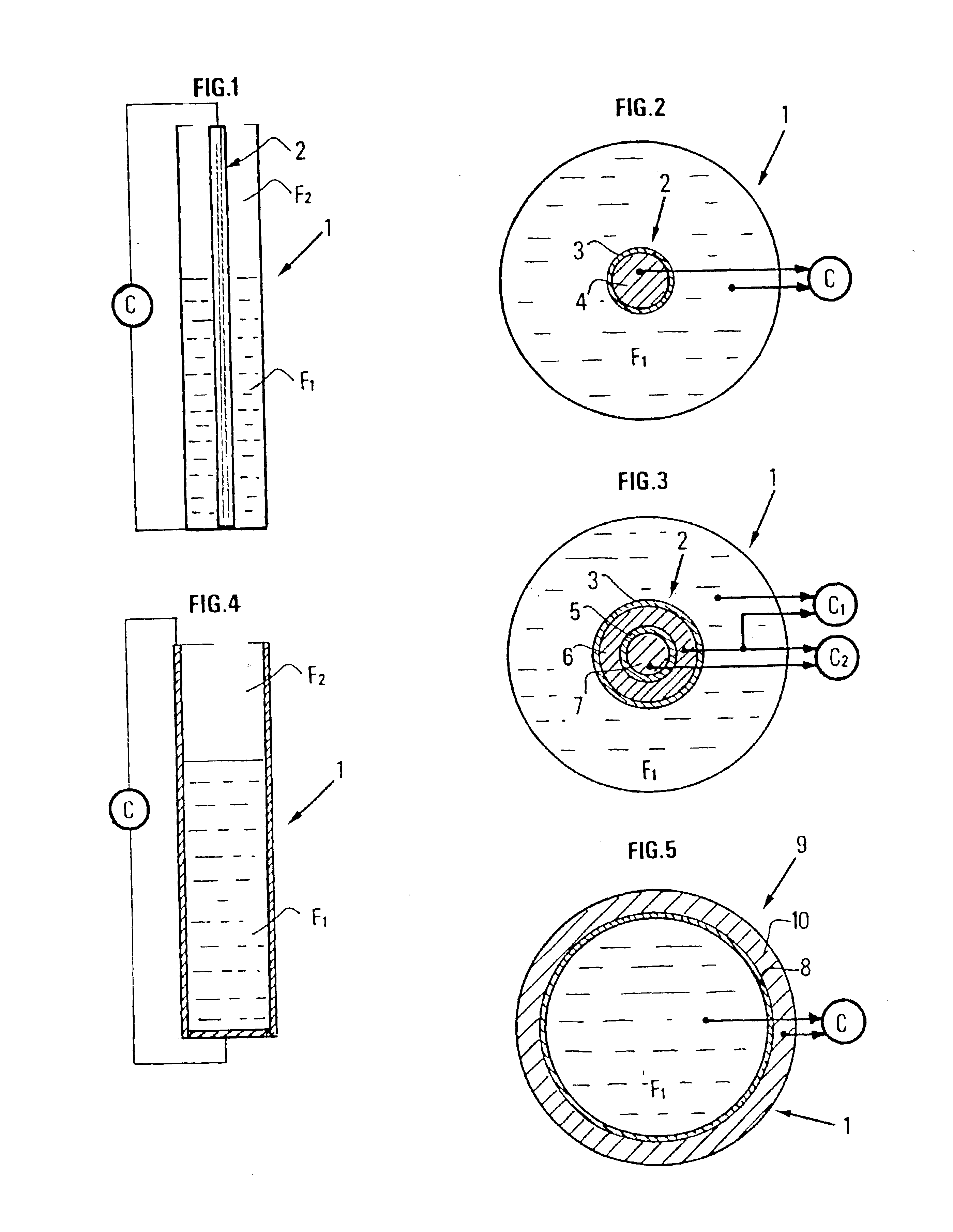

Capacitive probe for measuring the level of an electricity-conducting liquid in a vessel and method of manufacturing such a probe

InactiveUS6844743B2Good precisionTime stableResistance/reactance/impedenceMachines/enginesCapacitanceHigh pressure

Capacitive probe measuring the level, in a vessel and with high precision, of the interface between a conducting fluid (F1) and a non-conducting fluid (a gas or oil for example), suited to work under high pressure and high temperature conditions. The probe comprises a preferably tubular insulating layer (3) made of a dielectric heat-resisting material (a metal oxide such as zirconia or alumina) baked at a high temperature, with a first face in contact with conducting fluid (Fl) and an opposite face in contact with a second electrode (4), consisting for example of a coating or of a layer made of a fusible alloy deposited on the opposite face of insulant (3), selected according to the temperature range within which the capacitive probe is intended to work, or possibly of an added tube. Alloys based on zinc, tin, copper, etc, can for example be used. A second capacitor of the same type used for temperature compensation of the first one can be placed within the tubular insulating layer. Its capacitance is for example of the order of 1 nF. The probe can be applied in laboratory apparatuses working under high pressure and high temperature conditions, notably in petrophysical test cells.

Owner:INST FR DU PETROLE

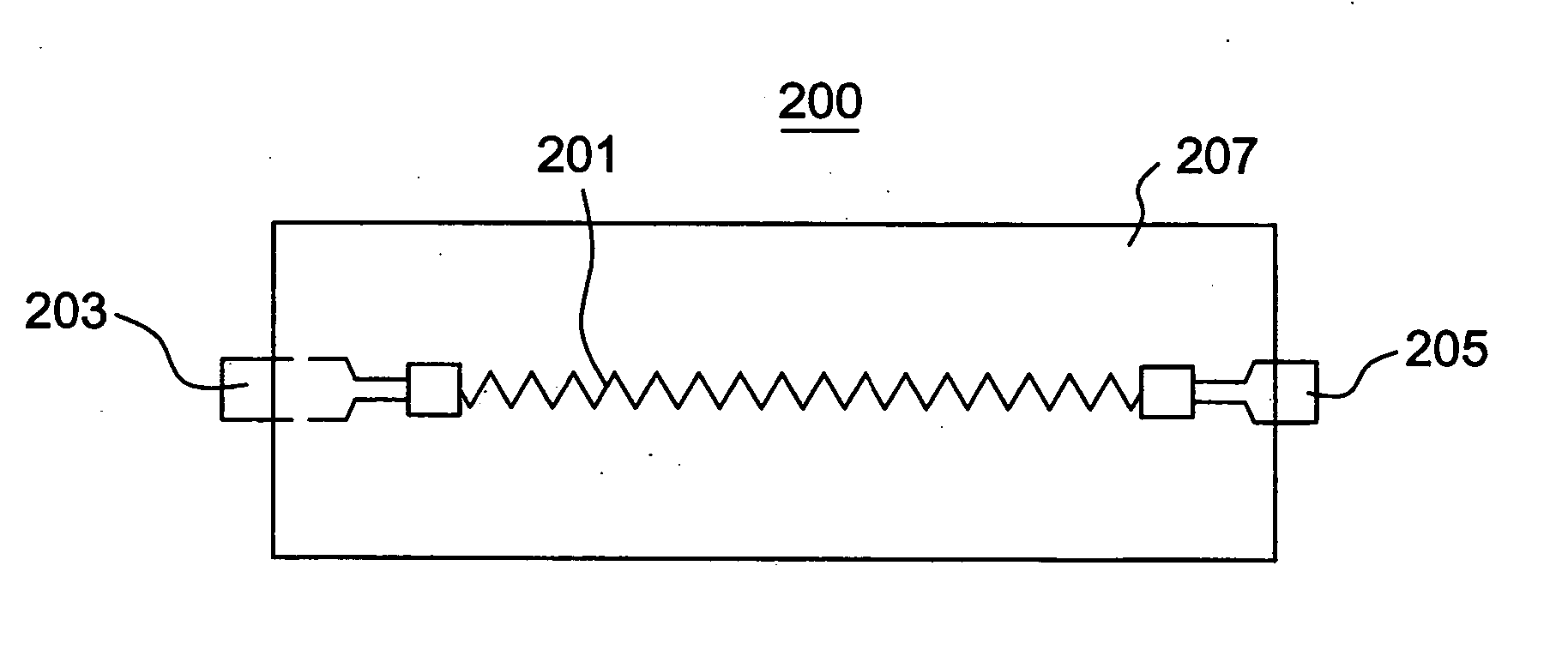

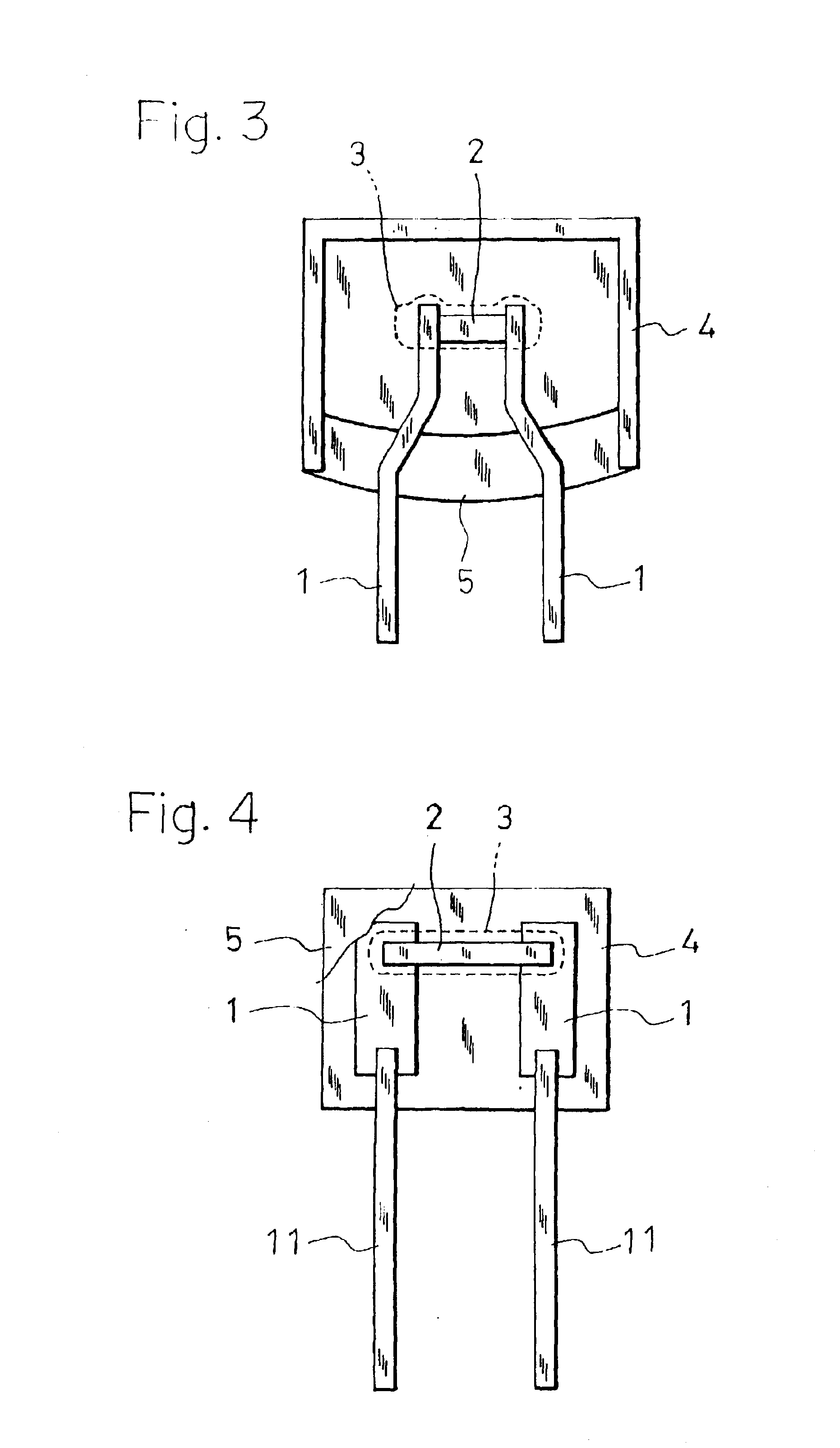

Thermal fuse having a function of a current fuse

InactiveUS20040196133A1Protective switch detailsElectrothermal relaysElectrical resistance and conductanceHot melt

A thin thermal fuse is provided with a rush current resistance performance so as to be usable also as a current fuse. In a thermal fuse in which a low-melting fusible alloy piece 2 having an alloy composition containing 40 to 70% Bi is connected between a pair of flat lead conductors 1, 1, a flux 4 is applied to the low-melting fusible alloy piece 2, and the piece is sandwiched between a resin base film 31 and a resin cover film 32 to provide insulation, the resistance of the low-melting fusible alloy piece 2 is set so as to enable the low-melting fusible alloy piece 2 to be fused off also by Joule heat due to an allowable maximum current of a secondary battery.

Owner:UCHIHASHI ESTEC

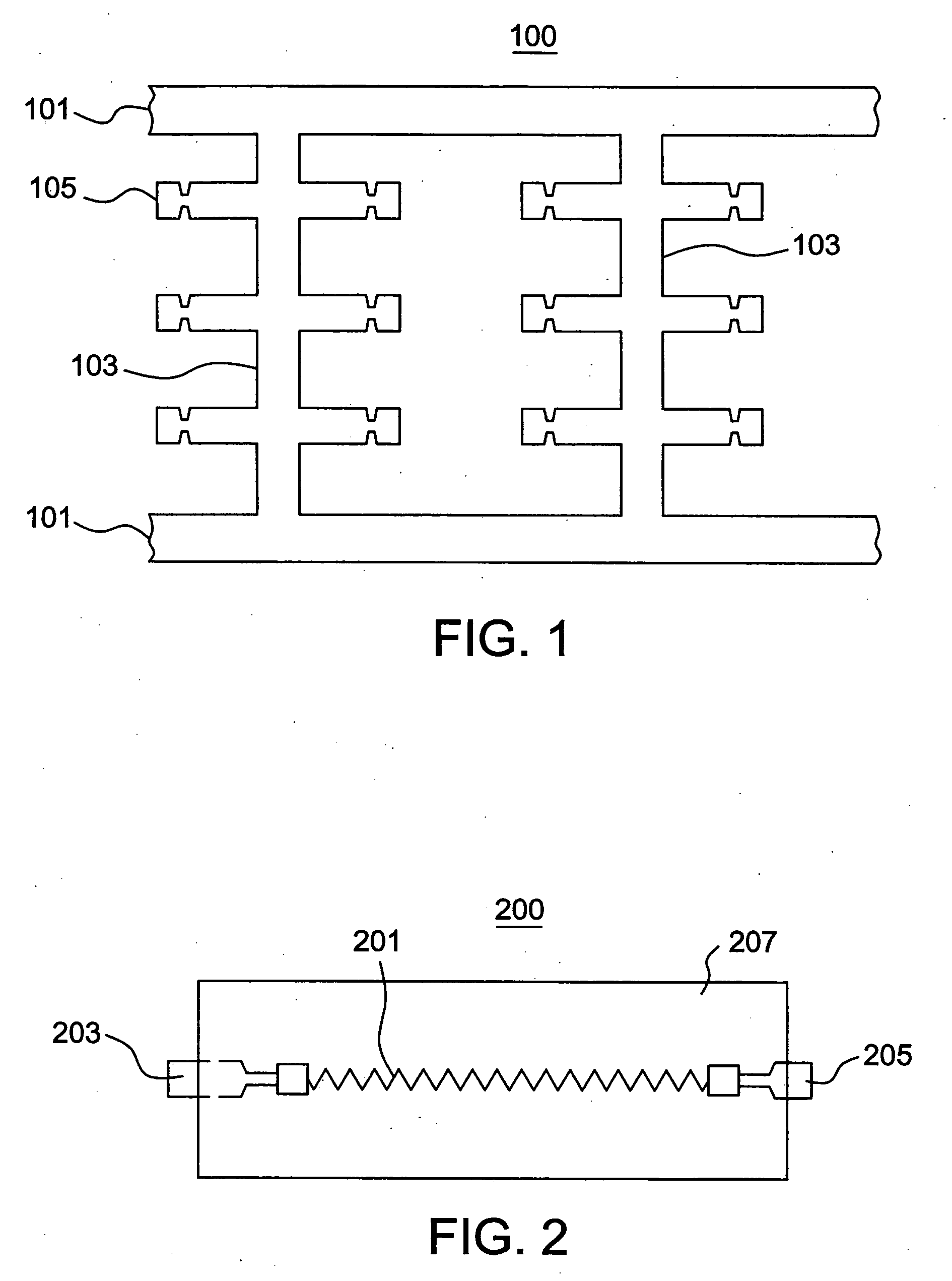

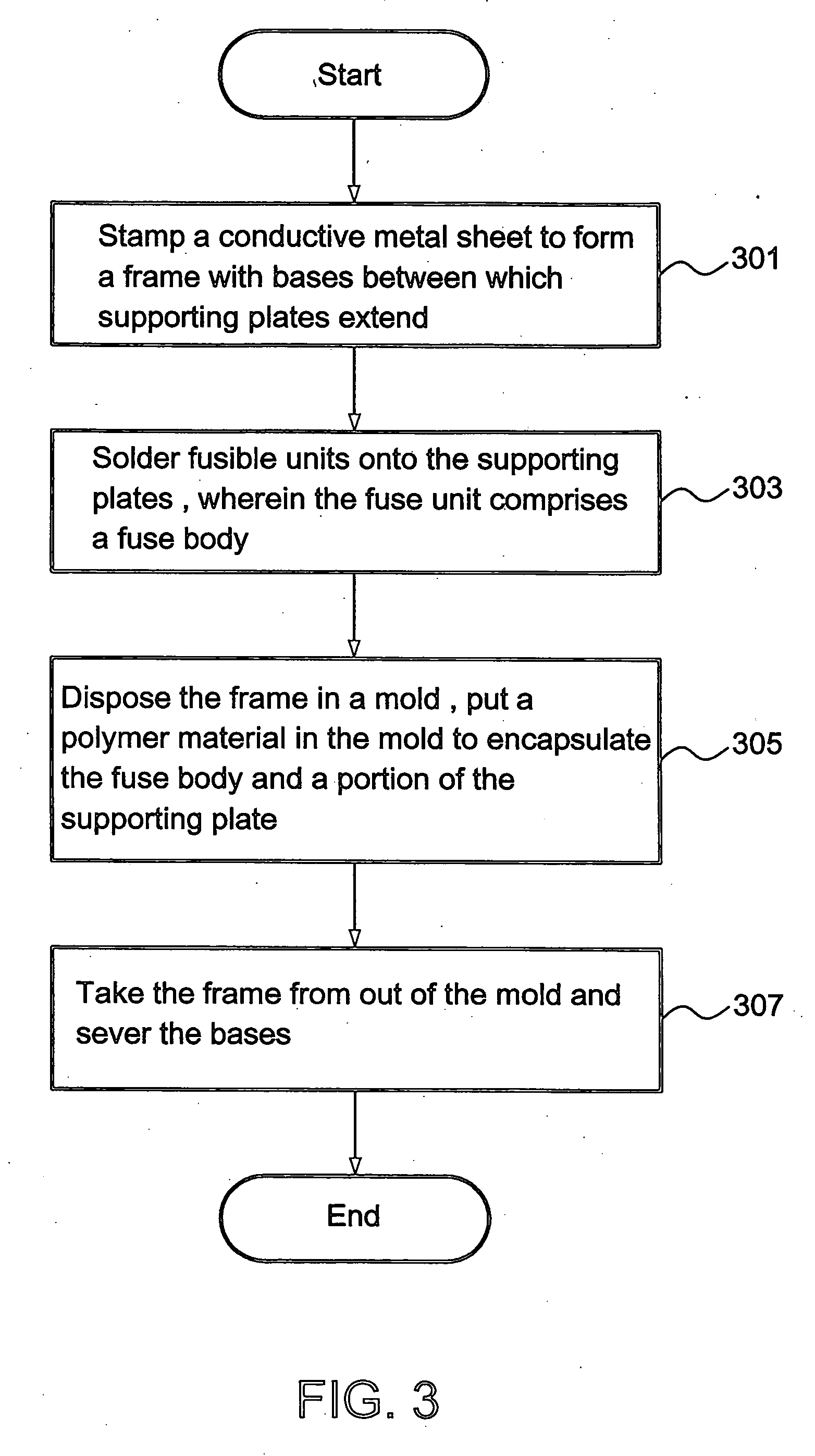

Over-current protector

InactiveUS20070159292A1Simple manufacturing methodLow costFuse device manufactureMetal sheetEngineering

An over-current protective device is characterized by comprising: a fuse cover, a fusible body disposed therein, and a first electrode and a second electrode respectively extending from the two ends of the fusible body. A method for fabricating the over-current protective device comprises the following steps: stamping a conductive metal sheet to form a frame with a base having two ends respectively extending as a supporting plate, and soldering a fusible unit containing the fusible body between the supporting plates; disposing the frame having the soldered fusible unit into a mold, putting a polymeric material into the mold for covering the fusible body and the supporting plates, and molding the fusible body into a required shape; taking out the frame covered by the polymeric material and cutting the base off so as to obtain an over-current protective device having two electrode plates extending from two ends thereof.

Owner:INPAQ TECH

Alloy type thermal fuse and fuse element thereof

InactiveUS6819215B2Heating/cooling contact switchesEmergency protective devicesTO-18Self-heating can

The invention provides a thermal fuse and a fuse element of the low-melting fusible alloy type in which the fuse element has an alloy composition of 37 to 43% In, 10 to 18% Sn, and the balance Bi. As a result, the operating temperature is in the range of 65 to 75° C., requests for environment conservation can be satisfied, the diameter of the fuse element can be made very thin or reduced to about 300 mumphi, self-heating can be suppressed, and the thermal stability can be satisfactorily guaranteed.

Owner:UCHIHASHI ESTEC

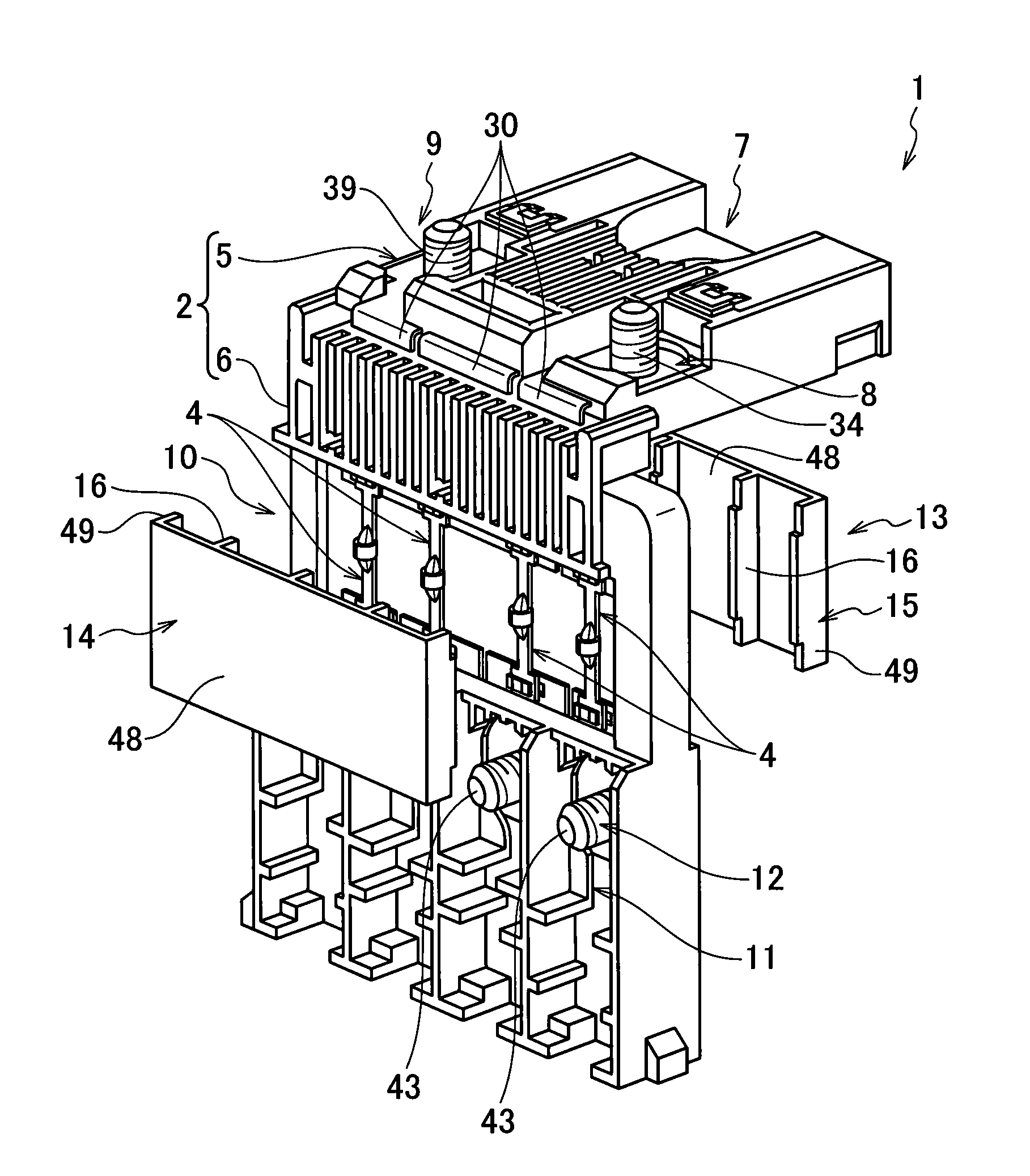

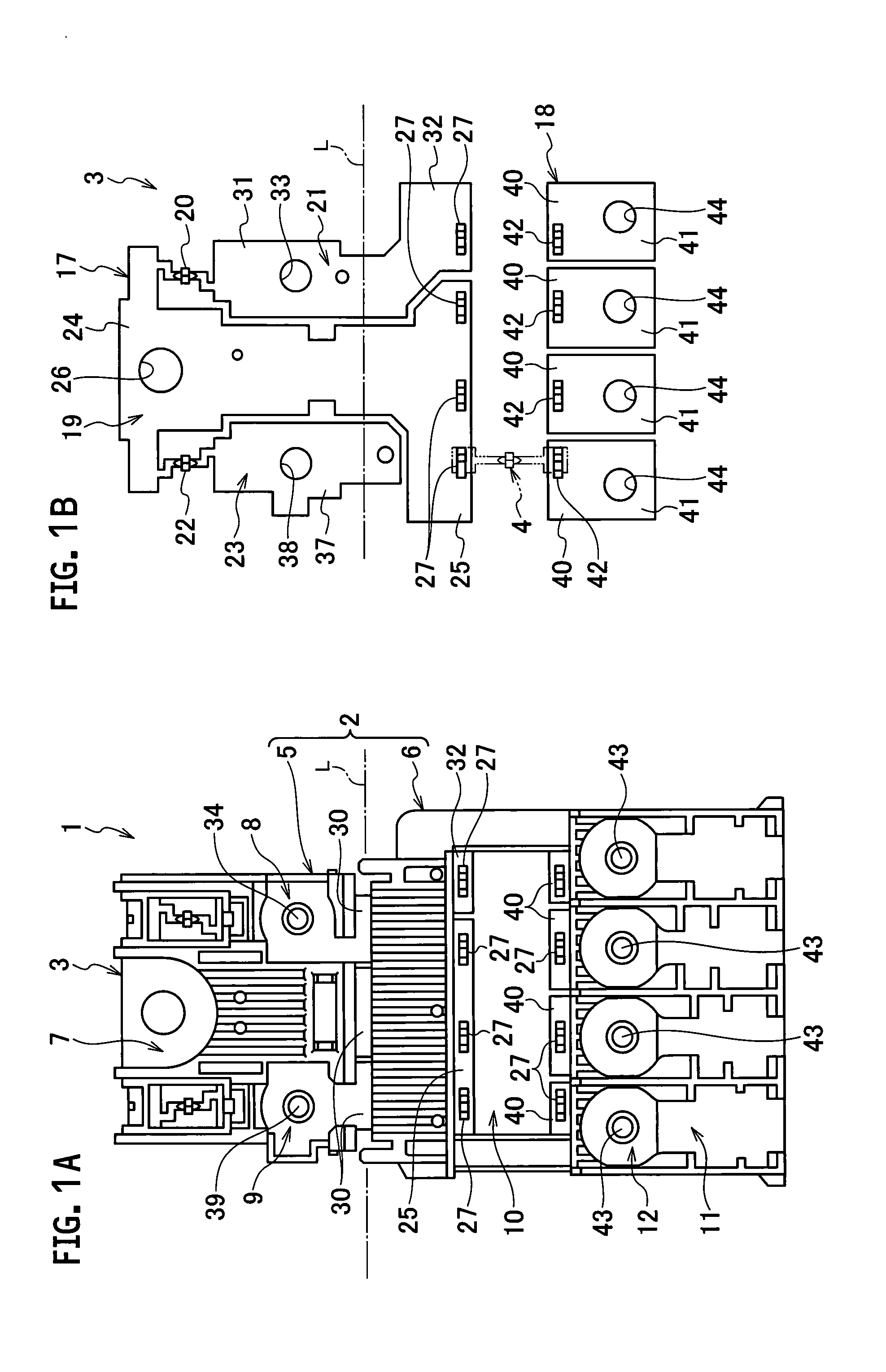

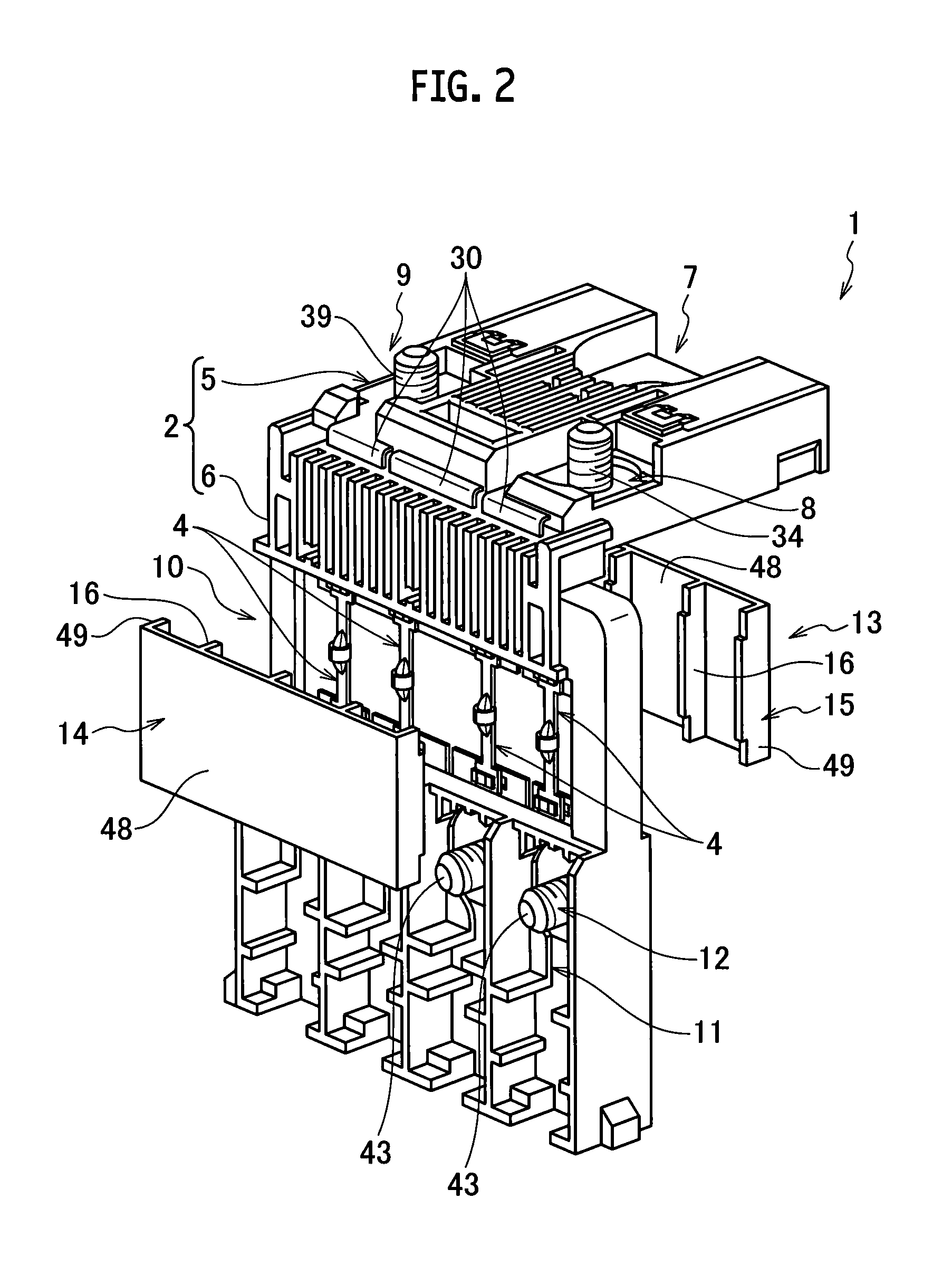

Fuse unit

ActiveUS20150130584A1Easy to mergeEasy to manufactureElectrothermal relaysRelay bases/casings/coversElectrical conductorFuse cutout

A fuse unit comprising a resin housing formed by insulator, a circuit body formed by conductor, molded integrally with the resin housing and branching and transferring electricity from a power source side to a load side, and a fusible body provided on the circuit body and fusing at overcurrent to the load side; the circuit body is formed by a block side circuit body connected to the power source side, and a block side terminal body connected to the load side, a block side first connection end to which one side of the fusible body is detachably connected is formed on the block side circuit body, and a block side second connection end to which the other side of the fusible body is detachably connected is formed on the block side terminal body.

Owner:YAZAKI CORP

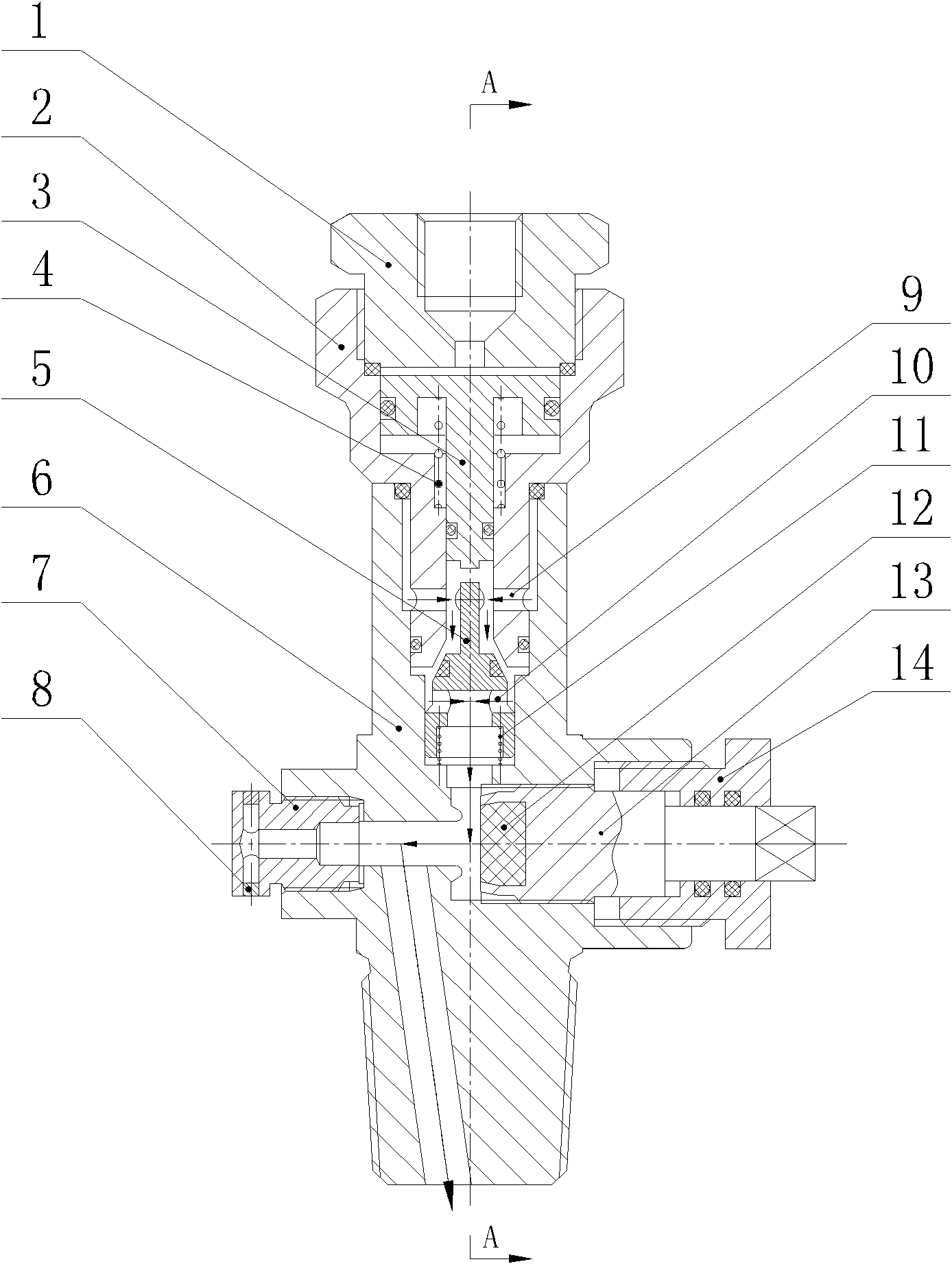

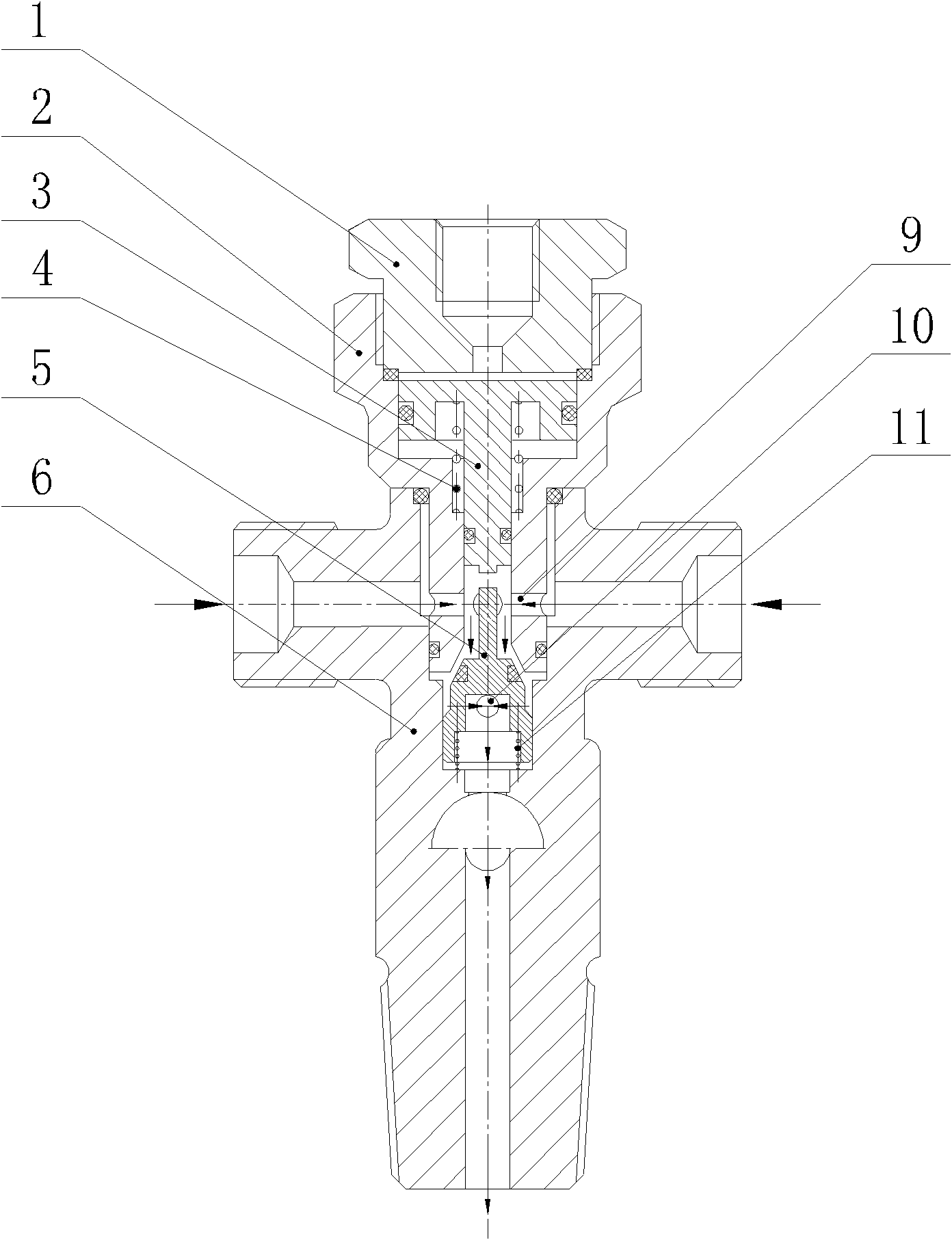

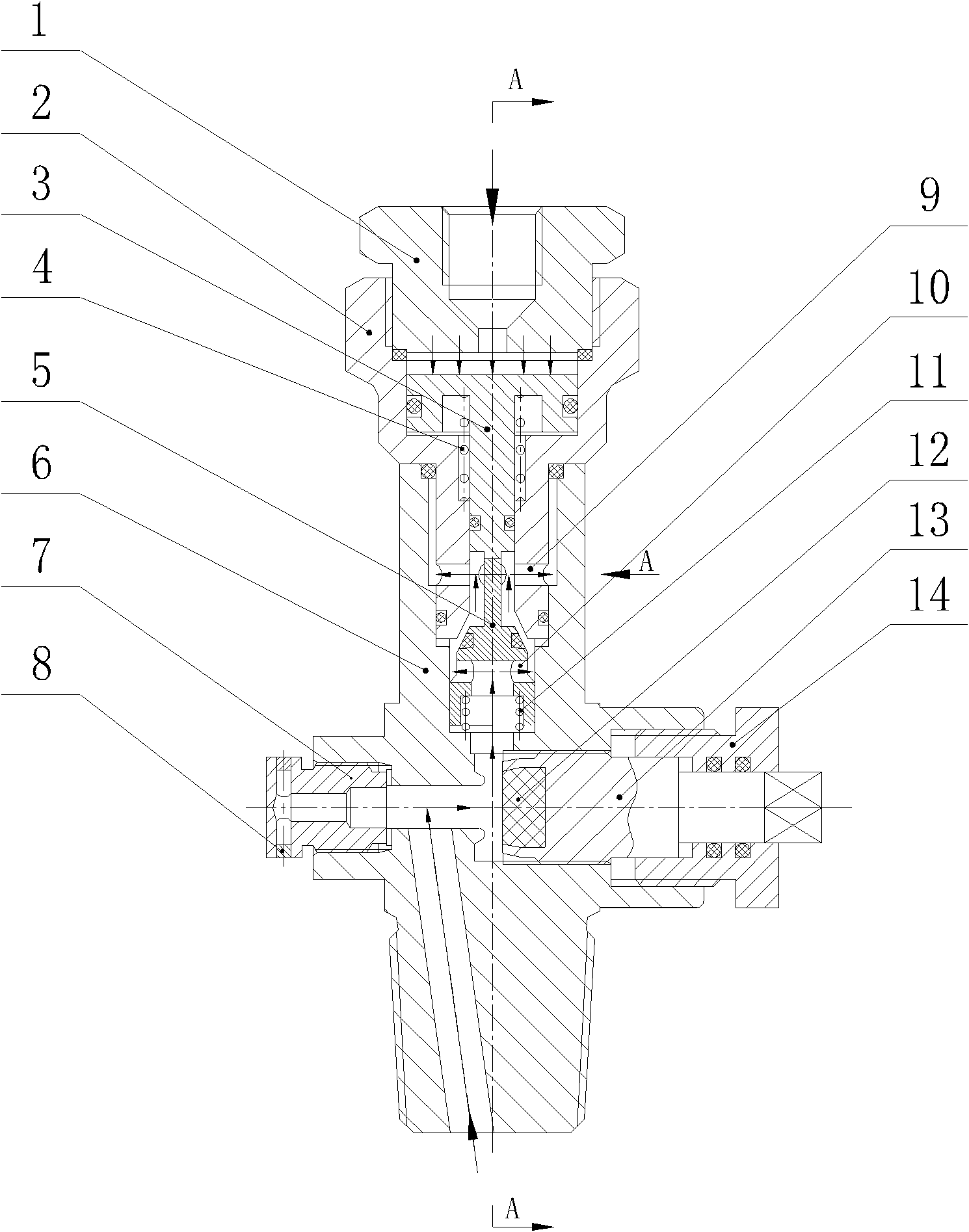

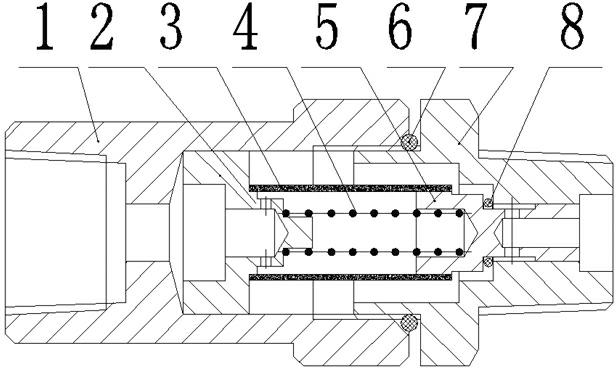

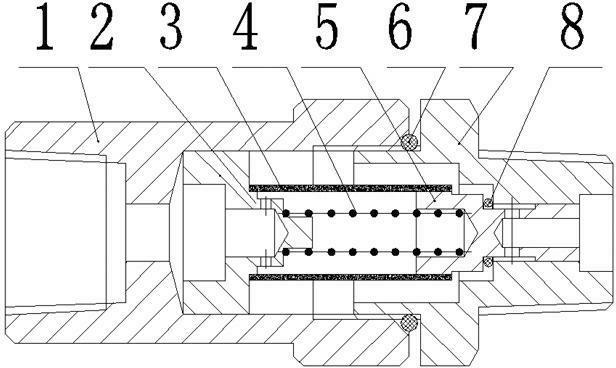

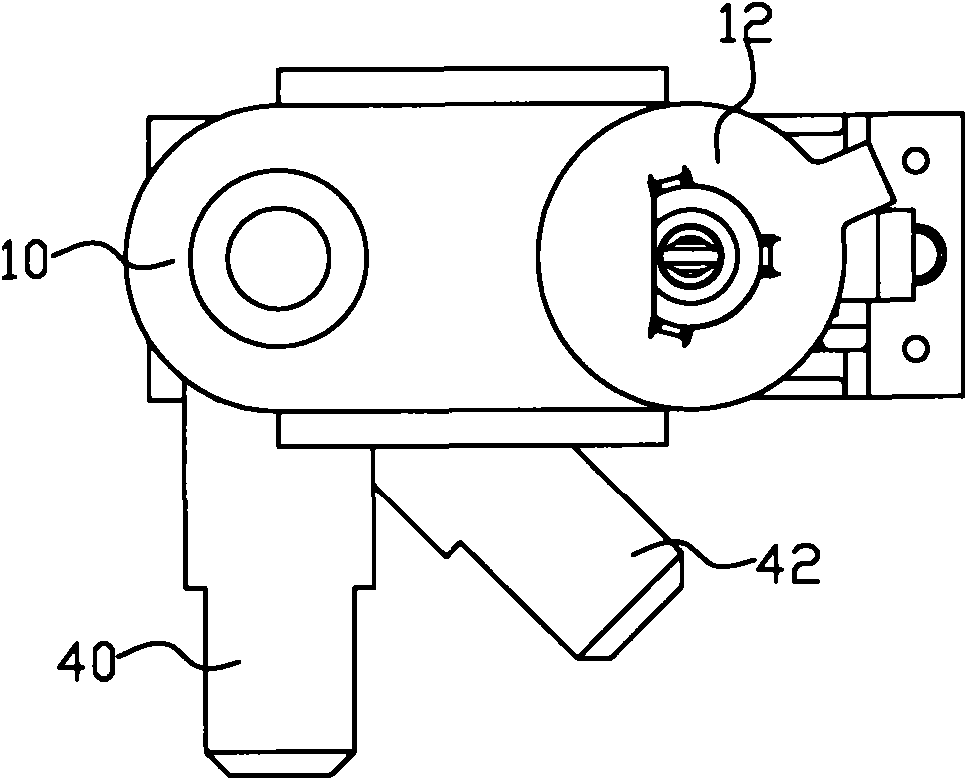

Valve for compressed gas collecting bottle and concentrating pneumatic control method thereof

InactiveCN101915359AImprove deflation work efficiencyOvercome the shortcomings of high cost and poor securityOperating means/releasing devices for valvesContainer filling methodsDischarge efficiencyEngineering

The invention relates to a valve for compressed gas collecting bottle and a concentrating pneumatic control method thereof. The valve comprises an end cover 1, a connecting sleeve 2, a piston 3, a pressure spring 4, a conical valve core 5, a valve main body 6, a safety screw plug 7, a reset spring 11 and an emergent manual switch component, wherein the reset spring 11, conical valve core 5, the connecting sleeve 2, the pressure spring 4, the piston 3, and the end cover 1 are orderly assembled in the upright cavity of the valve main body 6, from up to down. The safety screw plug 7 of a fusing alloy plug 8 in a side hole is assembled in a left inner hole of the valve main body 6. The emergent manual switch component which comprises a cushion 12, a screw rod 13 and a screw sleeve is assembled in a right inner hole of the valve main body 6 through the screw sleeve 14. The invention can increase the charging / discharging efficiency, relives the labor intensity and is reliable to use. The valve is reasonably designed, the structure is simple and compact, the pneumatic control is utilized, the abrasion is small and the service life is long.

Owner:湖南江南银箭新能源装备有限公司

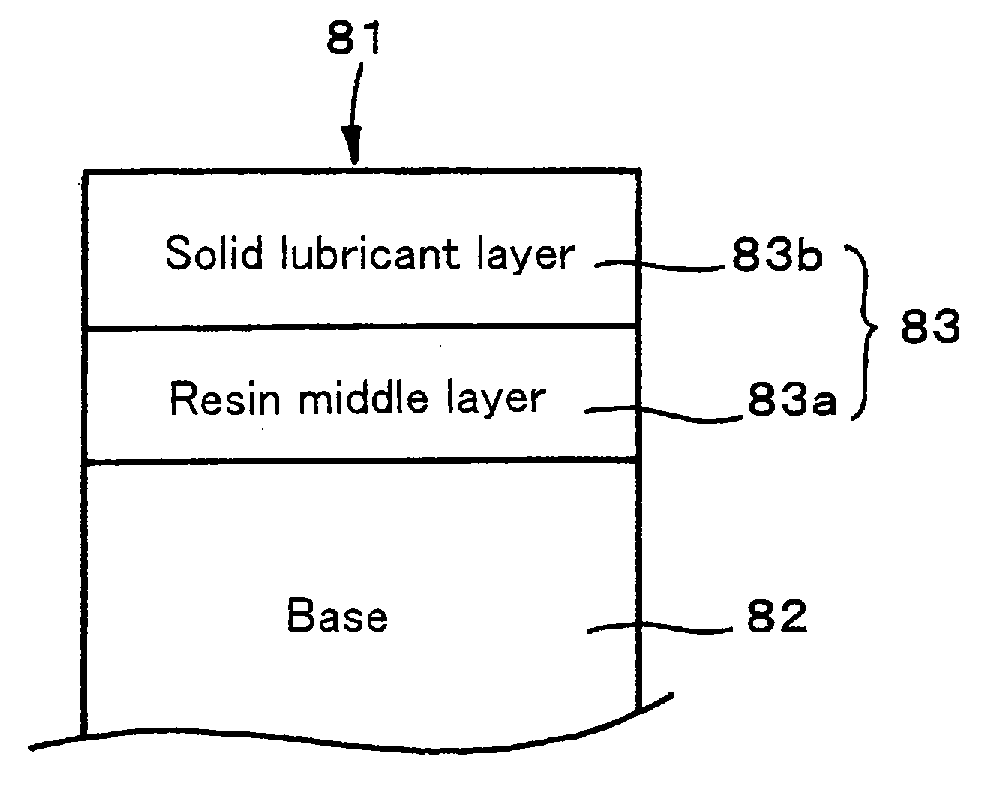

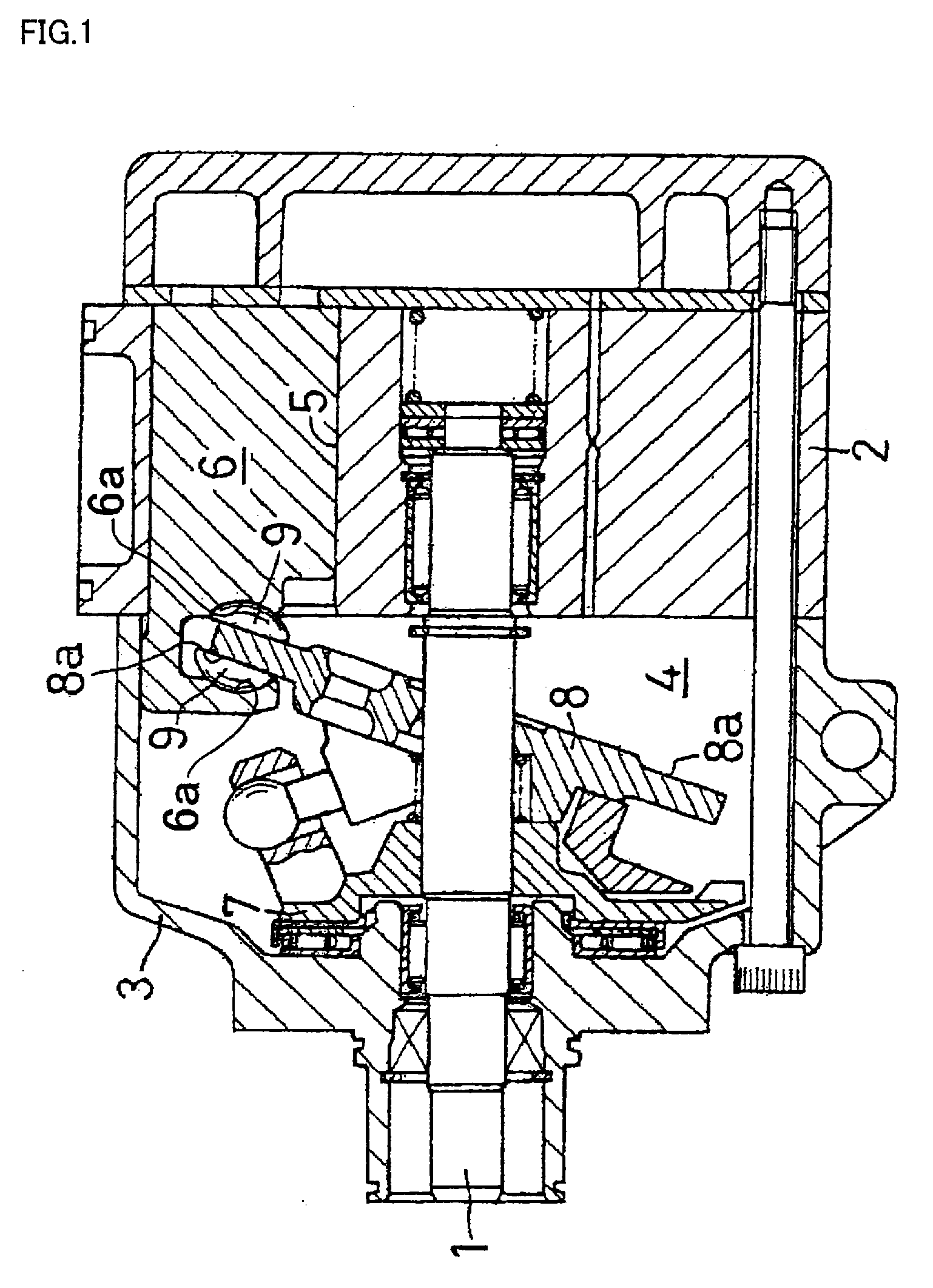

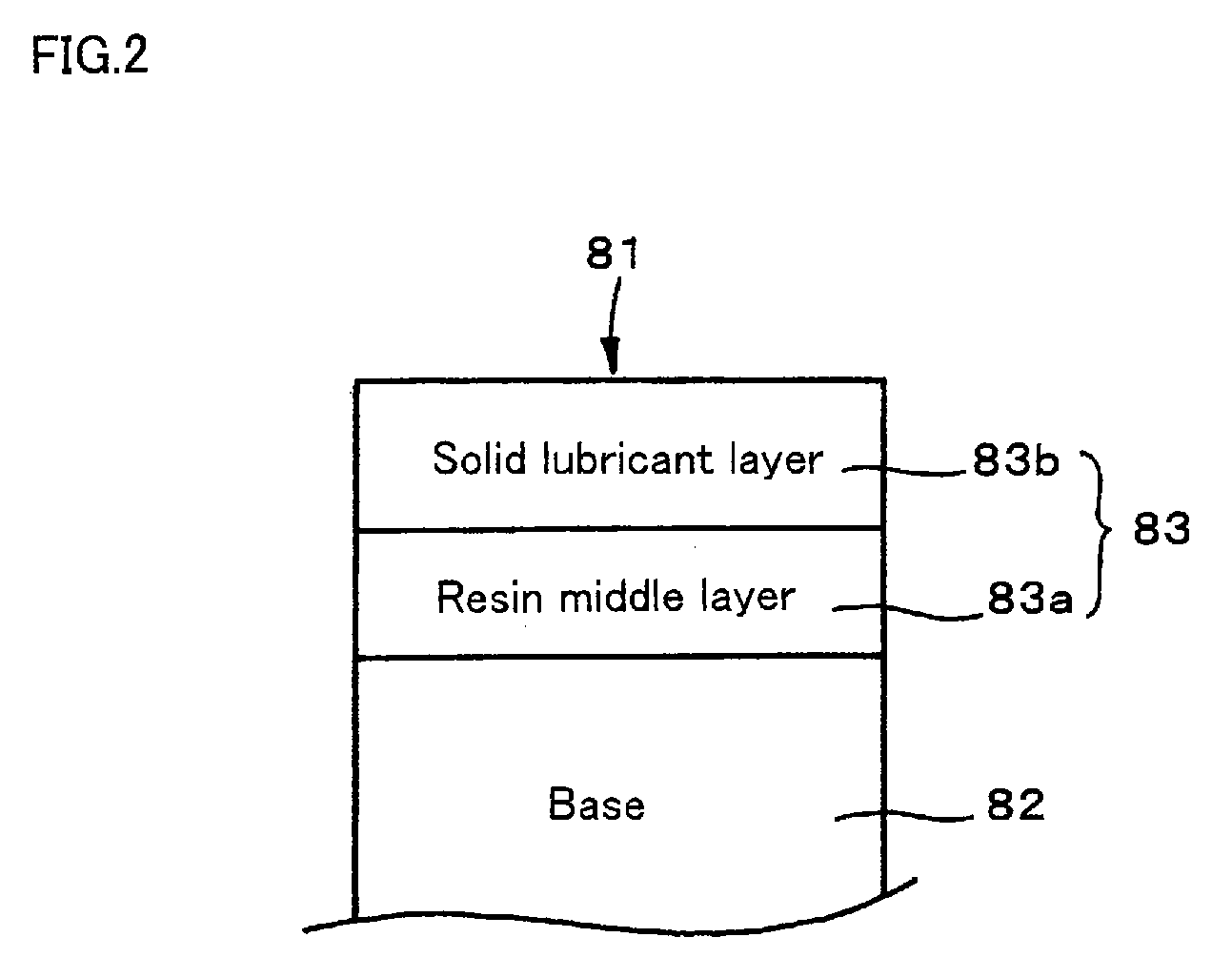

Slide member

InactiveUS20090136747A1Excellent wear resistance and sticking resistanceSynthetic resin layered productsAdditivesSurface layerInter layer

[Object of the Invention] An object of the present invention is to provide a slide member having a protective coat with good sticking resistance and wear resistance.[Disclosure of the Invention] A slide member comprises a base and a protective coat formed on the sliding surface side end surface of the base. The protective coat comprises a resin middle layer made of a mixture of fusible alloy, thermal conductive filler and heat resisting resin for middle layer, and a solid lubricant surface layer formed on the resin middle layer and made of a mixture of solid lubricant and heat resisting resin for surface layer.

Owner:SANDEN CORP

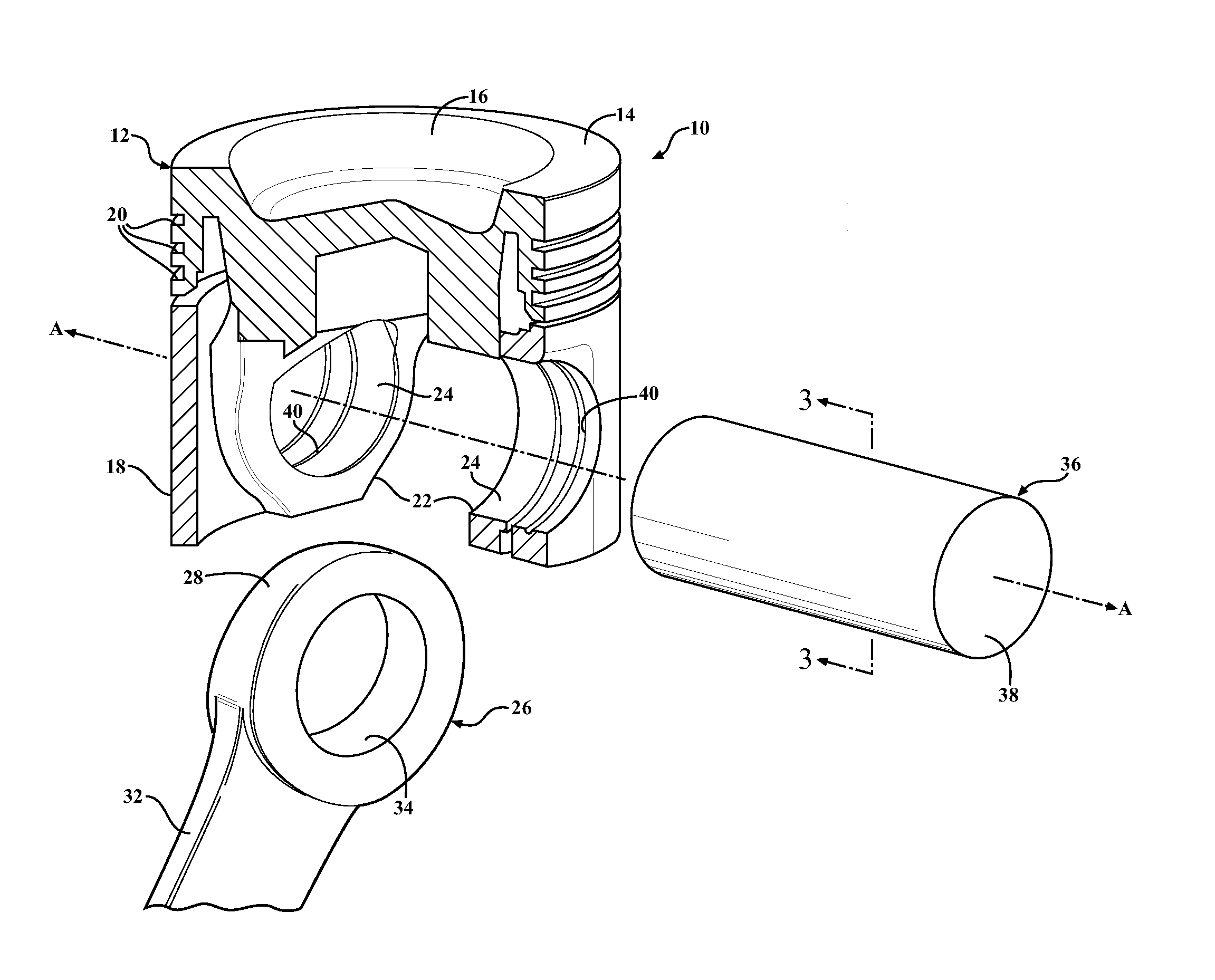

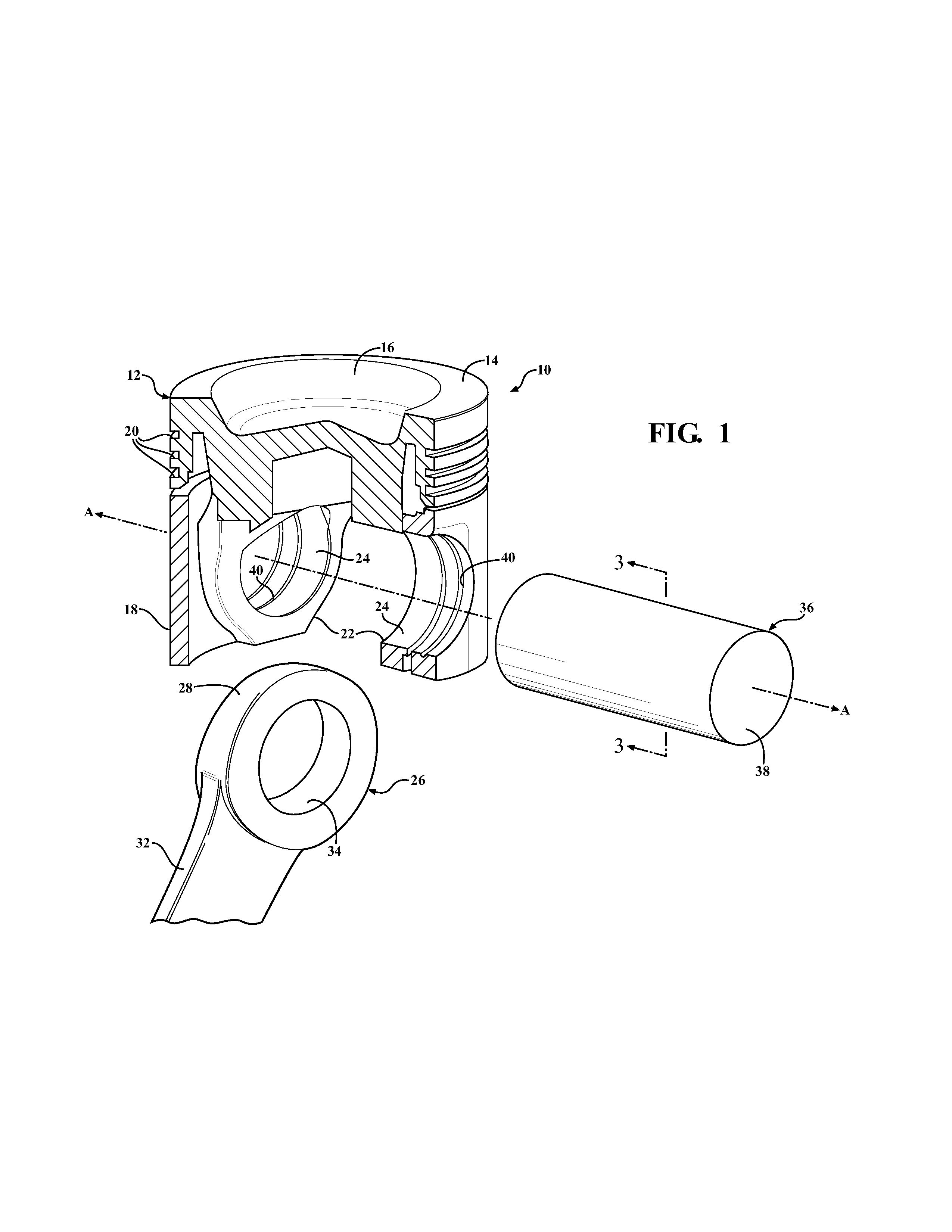

Piston pin for heat dissipation

A piston assembly including a piston body pivotally connected to a connecting rod by a wrist pin. The wrist pin includes a sealed cavity therein partially filled with a heat transfer medium. The heat transfer medium may be composed of a fusible alloy. The sealed cavity may be comprised of discrete compartments. The wrist pin may be integrated with the connecting rod and share a conjoined sealed cavity therewith so that heat transfer medium can draw heat effectively away from the piston body.

Owner:TENNECO INC

Fluxing agent as well as preparation method and application thereof

ActiveCN101764002AIn line with the development trend of safety and environmental protectionAchieves the effect of using fluxes containing halogensFuse device manufactureOrganic acidAlloy

The invention discloses a fluxing agent as well as a preparation method and application thereof. The fluxing agent comprises the following components in percentage by weight: 60-80 percent of rosin, 2-20 percent of organic acid and 10-30 percent of octadecanamide. The fluxing agent can be applied to temperature fuse elements to promote the fusing of a fusible ally wire. Compared with the prior art, the fluxing agent does not contain halogen and accords with the development tendency of environment protection. When applied to temperature fuse, the fluxing agent can achieve the effect of using a fluxing agent containing halogen.

Owner:上海神沃电子有限公司

High-voltage direct-current thermal fuse

ActiveUS20170004947A1Simple internal structureUse directlyHeating/cooling contact switchesThermal switch detailsHigh-voltage direct currentAlloy

A high-voltage direct-current thermal fuse comprising a high-voltage low-current thermal fuse connected to a high-voltage direct-current circuit. The high-voltage low-current thermal fuse comprises a casing, fusible alloy wires, wherein the fusible alloy wires are connected between the two leads. One of the leads is sequentially sleeved with an arc extinguishing sleeve and a spring. One end of the arc extinguishing sleeve is in contact with the fusible alloy wires; and the other end of the arc extinguishing sleeve is in contact with the spring. One end of the spring is connected to the inner end face of the casing; and the spring is in a compressed state. The high-voltage direct-current thermal fuse further comprises a conventional thermal fuse; or further comprises a current. The high-voltage direct-current thermal fuse solves the problem of timely arc cutting-off and can be directly applied to a high-voltage direct-current circuit.

Owner:XIAMEN SET ELECTRONICS

Power-free type automatic closing device for normally-open fireproof door

ActiveCN106869659ASimple structureScientific and reasonable designWing openersWing closersGlass ballTemperature control

The invention discloses a power-free type automatic closing device for a normally-open fireproof door. The power-free type automatic closing device solves the problem that in the prior art, a door cannot be automatically closed during fires due to manual damage or circuit faults or other reasons. The power-free type automatic closing device comprises an outer cover shell installed on the wall, an automatic closing executing mechanism arranged in the outer cover shell, and a door installation seat installed on the fireproof door and matched with the automatic closing executing mechanism. The automatic closing executing mechanism comprises a piston cylinder body provided with a fixed piston rod and a constantly-moving piston rod, a lever supporting seat, a compression spring, a temperature control glass ball or a fusible alloy and a movable lever, wherein the lever supporting seat, the compression spring and the temperature control glass ball or the fusible alloy are fixed to the top of the piston cylinder body correspondingly, and the temperature control glass ball or the fusible alloy is provided with a temperature sensor and can be automatically exploded and cracked when the temperature detected by the temperature sensor reaches the preset value. The power-free type automatic closing device is simple in structure, scientific and reasonable in design, not likely to be damaged, long in service life and capable of saving cost and is hardly affected by external interference factors.

Owner:应急管理部四川消防研究所

Alloy type thermal fuse and fuse element thereof

InactiveUS6774761B2Heating/cooling contact switchesEmergency protective devicesSelf-heating canThermal stability

Owner:UCHIHASHI ESTEC

Temperature fuse and method of manufacturing the same

The invention relates to a thermal fuse for electronic circuit protection, in particular to a thermal fuse for lithium-ion battery protection, and a manufacturing method thereof. The thermal fuse comprises a plastic backing film; a pair of metal electrodes are arranged above the backing film; the metal electrodes are relatively linearly arranged and are provided with space among the end parts; the metal electrodes are welded through fusible alloy; wherein, the surface of the fusible alloy is covered with cosolvent which is coated by a layer of adhesive; the adhesive and the backing film form a closed space; the end parts of the metal electrodes, the fusible alloy and the cosolvent are sealed in the closed space; or, the surface of the fusible alloy is covered with cosolvent, and the backing film at the external side of the cosolvent is provided with an annular upper cover piece; the cosolvent is coated with a layer of adhesive; the adhesive, the upper cover piece and the backing film form a closed space; and the end parts of the metal electrodes, the fusible alloy and the cosolvent are sealed in the closed space.

Owner:SHANGHAI CHANGYUAN WAYON CIRCUIT PROTECTION CO LTD

Novel self-lubricating iron-based coatings coupling preparation process

InactiveCN101113661AIncrease costSimple and fast operationMolten spray coatingDrilling rodsCouplingAtmospheric pressure

The invention relates to a preparation technique of a novel self-lubricating iron-based coating coupling. The preparation technique consists of the following steps: 1. the preparation of the iron-based spraying and welding coating adopts iron-based self-fusible alloy powder as the material, and an iron-based alloy coating is prepared on a general coupling surface via the spraying and re-fusion techniques; 2. the sprayed and welded coupling surface is polished to make sure that the width of the coating surface ranges from 0.25mm- 0.60mm and the roughness is no more than Ra0.8Mum; 3. sulfurization of low temperature ion on the surface: the ion undertakes the spraying and coupling process in a low temperature ion sulfurization oven with a voltage of 800-1000 volt, an atmospheric pressure of 20-50Pa and a temperature of about 300 DEG C for about eight hours. A protective layer of the butter is smeared on the coupling surface to prevent the oxidation of the surface. The preparation technique is characterized by low cost and easy operation. And the self-lubricating iron-based alloy spraying and welding oil-sucker rod coupling acquired from the preparation technique has better wear resistance and self-lubrication quality, with a long service life.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Branch fuel gas fire arrestor for inflammable gas collecting bag

The invention relates to a branch fuel gas fire arrestor for an inflammable gas collecting bag. The branch fuel gas fire arrestor mainly comprises a shell, a spring seat, a spring, a fusible alloy micro-pore sleeve, a sealing ring and a connector, and is characterized in that: the spring is connected with a one way valve. The branch fuel gas fire arrestor has the advantages that: during tempering of the internal one-way device, a pressure is increased momentarily and gas supply is cut off automatically, so that accidents can be prevented to the maximum extent, and the safety of human bodies and equipment is ensured.

Owner:江苏亚洲气体设备有限公司

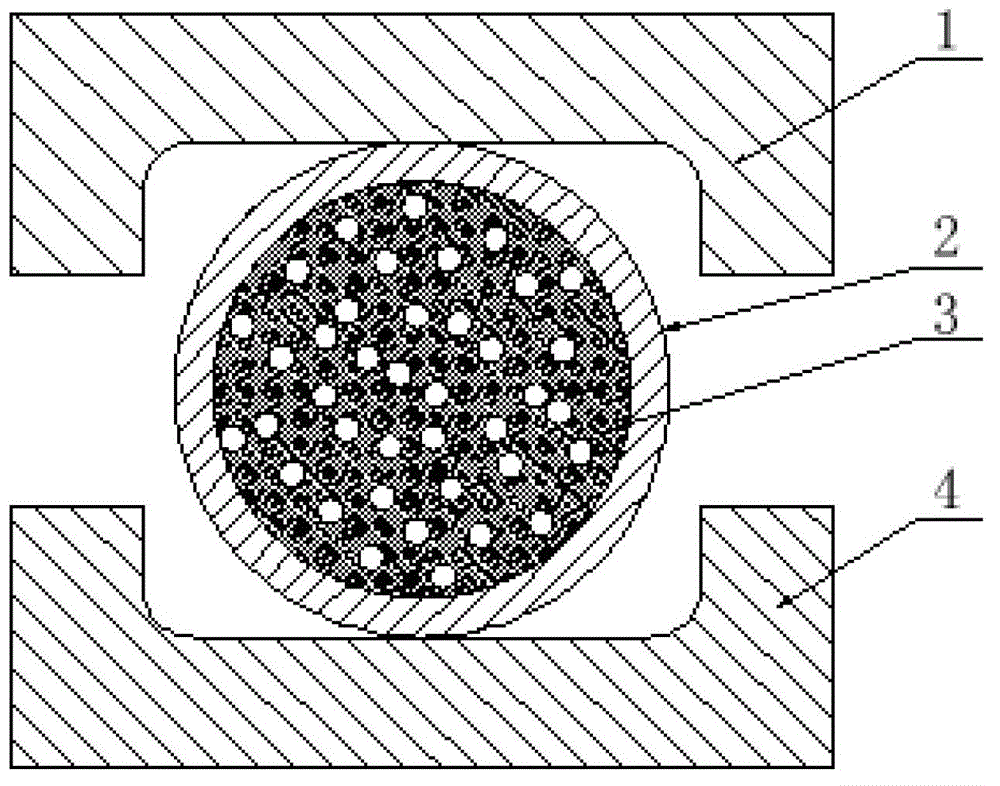

Medium forming method for improving forming property of thick-wall metal pipe fittings

The invention relates to a medium forming method for improving the forming property of thick-wall metal pipe fittings. The method comprises the following steps: S1, preparing composite medium, namely, granular medium is uniformly mixed with fusible alloy under molten state, wherein the melting point of the fusible alloy is lower than the melting temperatures of a tube blank and the granular medium; S2, filling composite medium, namely, a fluid-shaped composite medium is filled in a hollow tube blank and then cooled until the composite medium is solidified; S3, forming pipe fittings; and S4, taking out the granular medium, namely, the solidified fusible alloy in a pipe is converted into molten fusible alloy, so that the molten fusible alloy drives the granular medium to be separated from the pipe fittings. The invention overcomes the defects that when the traditional rigid mould method is used for thick-wall metal pipe fitting forming, good forming quality is hard to achieve, avoids multi-step molding of metal pipe fittings, greatly saves the die cost, shortens the production period, and achieves the purpose of environmental-friendly and rapid production.

Owner:WUHAN UNIV OF TECH

Temperature controller

ActiveCN101562090AAvoid failureSimple processHeating/cooling contact switchesThermal switch detailsElectrical and Electronics engineeringHeat transfer

The invention discloses a temperature controller which comprises an insulating system, a contact switch and a safety switch. The insulating system comprises a plurality of insulators. The contact switch is connected with the insulating system, and comprises a movable contact piece and a fixed contact piece, wherein the movable contact piece can be conductively contacted with the fixed contact piece. The safety switch comprises a heat transfer piece, an insulating seat, a fusible body, a control rod and a movable safety piece. The heat transfer piece is arranged on the insulating seat which is provided with a containing via hole and is arranged against on the heat transfer piece to form a containing cavity body with an upward opening. The fusible body is arranged in the containing cavity body. The control rod is inserted into the containing via hole from top to bottom, and the lower end of the control rod supports against on the fusible body. The movable safety piece is connected with the insulating system, is supported against by the control rod, and is in normally closed connection with the fixed contact piece.

Owner:厦门升明电子有限公司

Thermal fuse

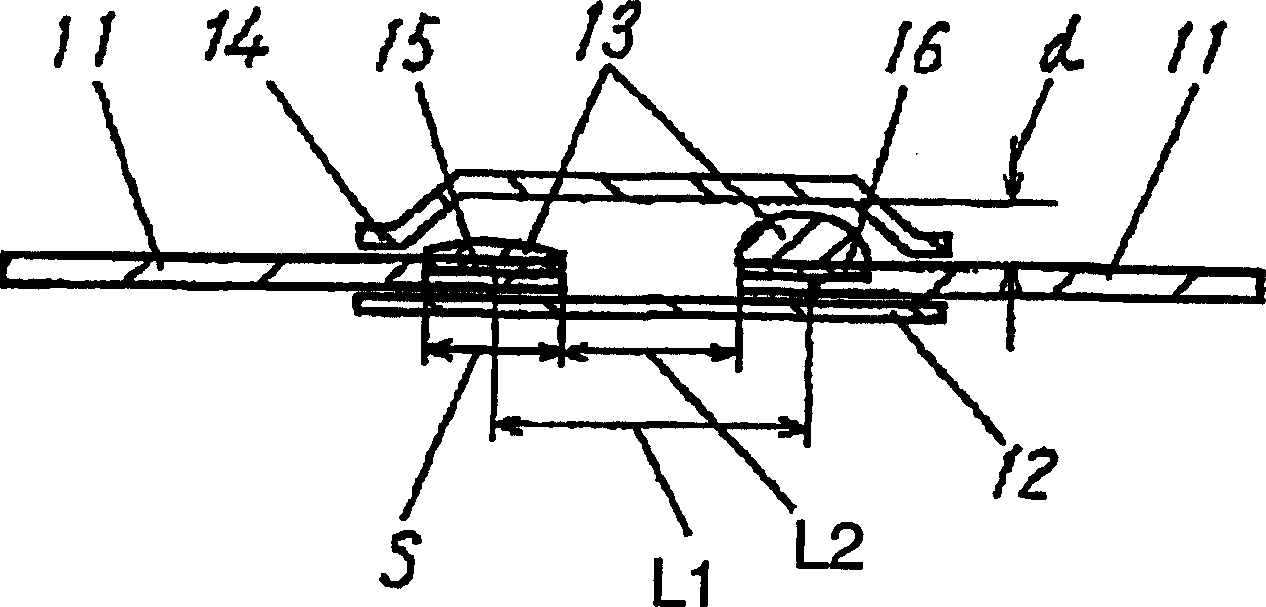

A thermal fuse having a quick melting property is provided. In the thermal fuse, metal layers 15, 16 connected to a fusible alloy 13 are provided at respective leading ends of a pair of metal terminals 11. The metal layers 15, 16 have larger wettability to a fusible alloy 13 than wettability of metal terminals 11 and first insulating film 12. The area (S) of the metal layers 15, 16, the length (L1) and the volume (V) of the fusible alloy 13, the distance (L2) between the leading ends of the metal terminals 11, and the distance (d) from the bottom face of the second insulating film 14 to the top face of the metal layers 15,16 satisfy the relation of Sd>V(L1+L2) / 2L1.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com