Medium forming method for improving forming property of thick-wall metal pipe fittings

A technology for metal pipe fittings and formability, which is applied in the field of medium forming to improve the formability of thick-walled metal pipe fittings. It can solve the problems of poor working environment, complicated filling process, and long production cycle, and achieve low production costs, no depressions on the pipe wall, and Make simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

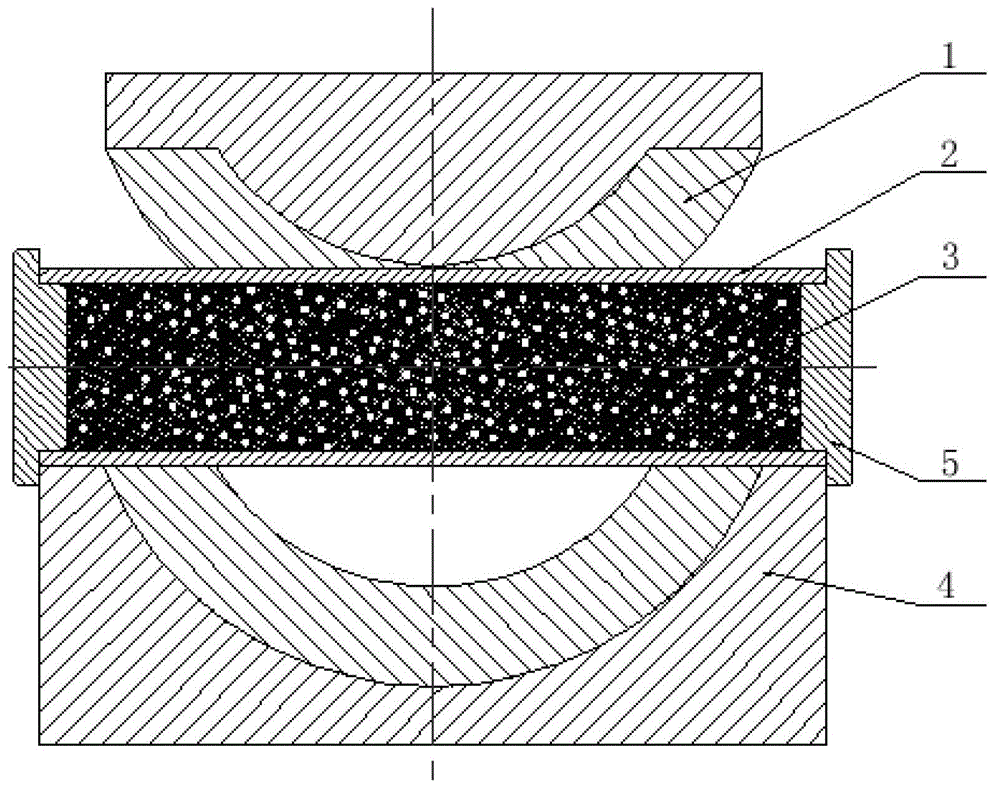

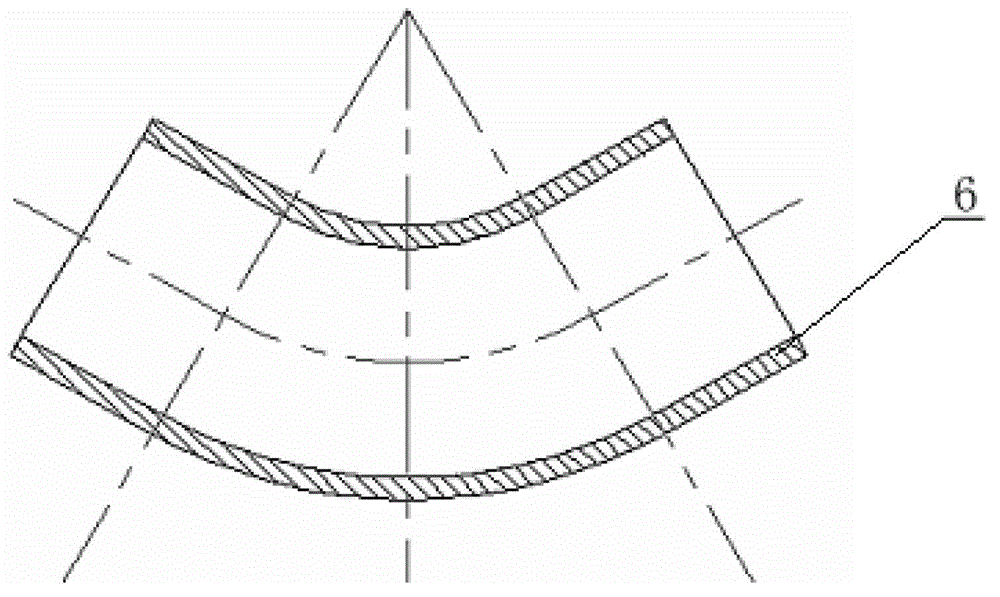

[0041] Combine below figure 1 and figure 2 This embodiment will be specifically described. This embodiment is to figure 1 The shown straight tube blank 2 is pressed and formed as figure 2 As shown in the bent pipe fitting 6, the straight pipe blank 2 in this embodiment is an aluminum alloy 6061-T651 with a yield strength of 275MPa, a melting point range of 580-650°C, a diameter of the pipe blank 2 of 76mm, and a wall thickness of 6mm.

[0042] For thick-walled metal pipes such as aluminum alloys and magnesium alloys with low strength, the requirements for the compression resistance of the composite medium 3 filled in the pipes are not high, and bismuth-based or tin-based low-melting point alloys can be used as fusible alloys. The bismuth-based low melting point alloy includes 50.6% Bi, 26.9% Pb, 12.5% Sn, and 10% Cd, with a strength of 42.1MPa and a melting point of 70°C. The tin-based low melting point alloy includes 85.4% Sn, 14.6% Bi, its strength is 85MPa, and its ...

Embodiment approach 2

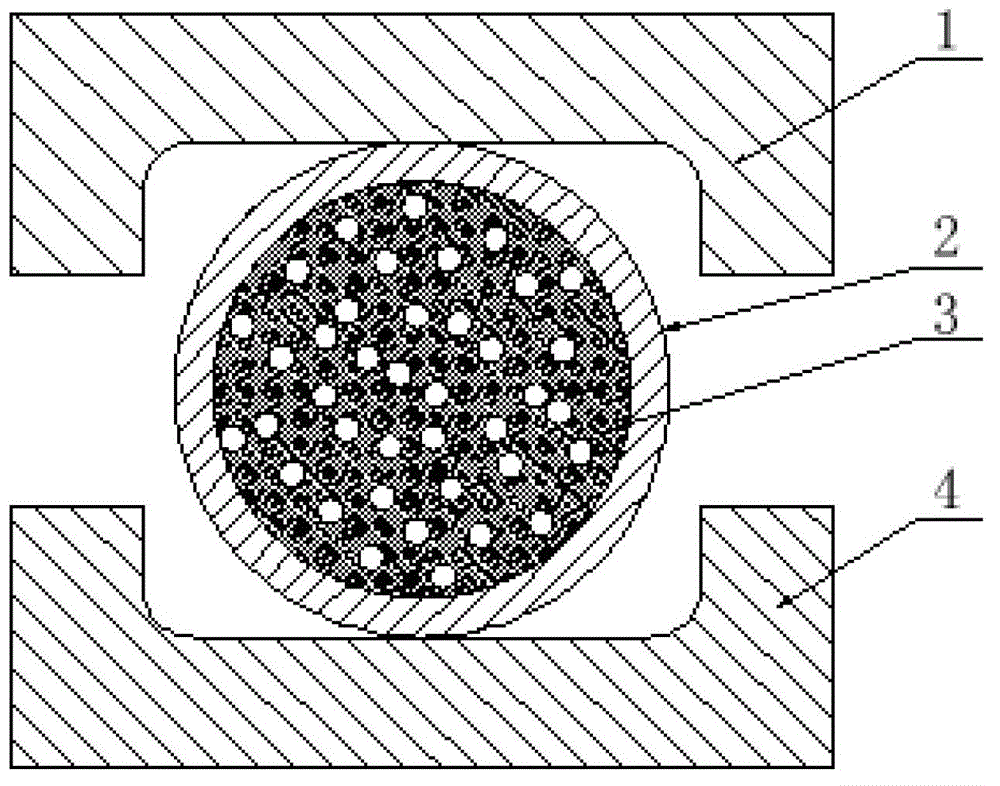

[0052] Combine below image 3 and Figure 4 This embodiment will be specifically described. In this embodiment, the 35# carbon steel pipe with high strength is used, the yield strength is 315MPa, the diameter-thickness ratio is 12.8, and the steel pipe with the diameter-thickness ratio less than 20 is called a thick-walled pipe, which requires a composite medium that can withstand relatively high pressure. .

[0053] In this embodiment, steel balls with a diameter of 4 mm are solidified with a zinc-based low-melting point alloy, and the two are uniformly mixed at a ratio of 1:1. The zinc-based low melting point alloy includes 92.4%Zn, 4%Al, 3.5%Cu, 0.1%Mg, with a strength of 194MPa and a melting point of 380°C.

[0054] This embodiment is to image 3 The shown straight tube billet 2 is pressed and formed as Figure 4 As shown in the square pipe fitting 6 , the forming device includes an upper mold cavity 1 , a lower mold cavity 4 , a tube blank 2 and a composite medium 3 ...

Embodiment approach 3

[0061] Combine below Figure 5 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 and Embodiment 2 is that the processing steps of the parts are reduced, that is, two bendings and partial flattening are completed at one time, and the manufactured pipe fitting 6 is a special-shaped cross-section pipe, and the cross-sectional shape includes: Round, square and oval. The method of the present invention is applicable to any pipe 6 whose cross-section is a closed curve profile shape. In this embodiment, the properties of the material of the tube blank 2 and the composite medium 3 filled therein are the same as those in the first embodiment. refer to Figure 5 , The forming device includes a tube blank 2, an upper mold cavity 1, a lower mold cavity 4, a composite medium 3 and a sealing plug 5.

[0062] The forming steps are as follows:

[0063] S1, uniformly mixing fusible alloy and steel ball at a ratio of 1:1 to form composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com