Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Eliminate springback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

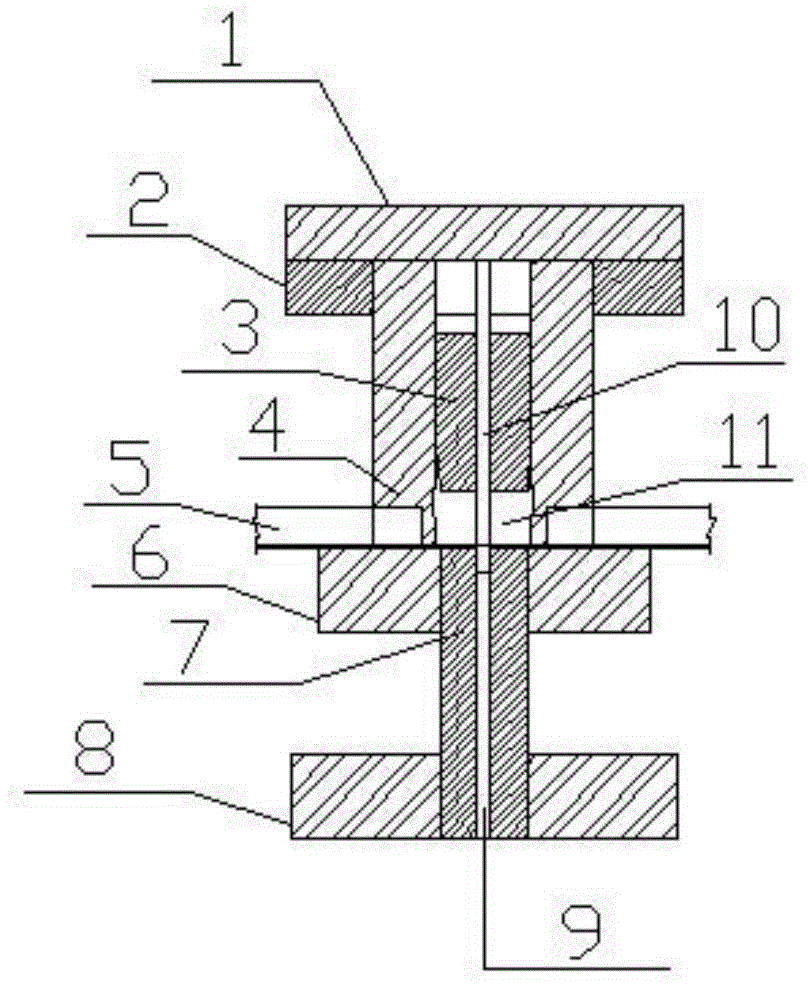

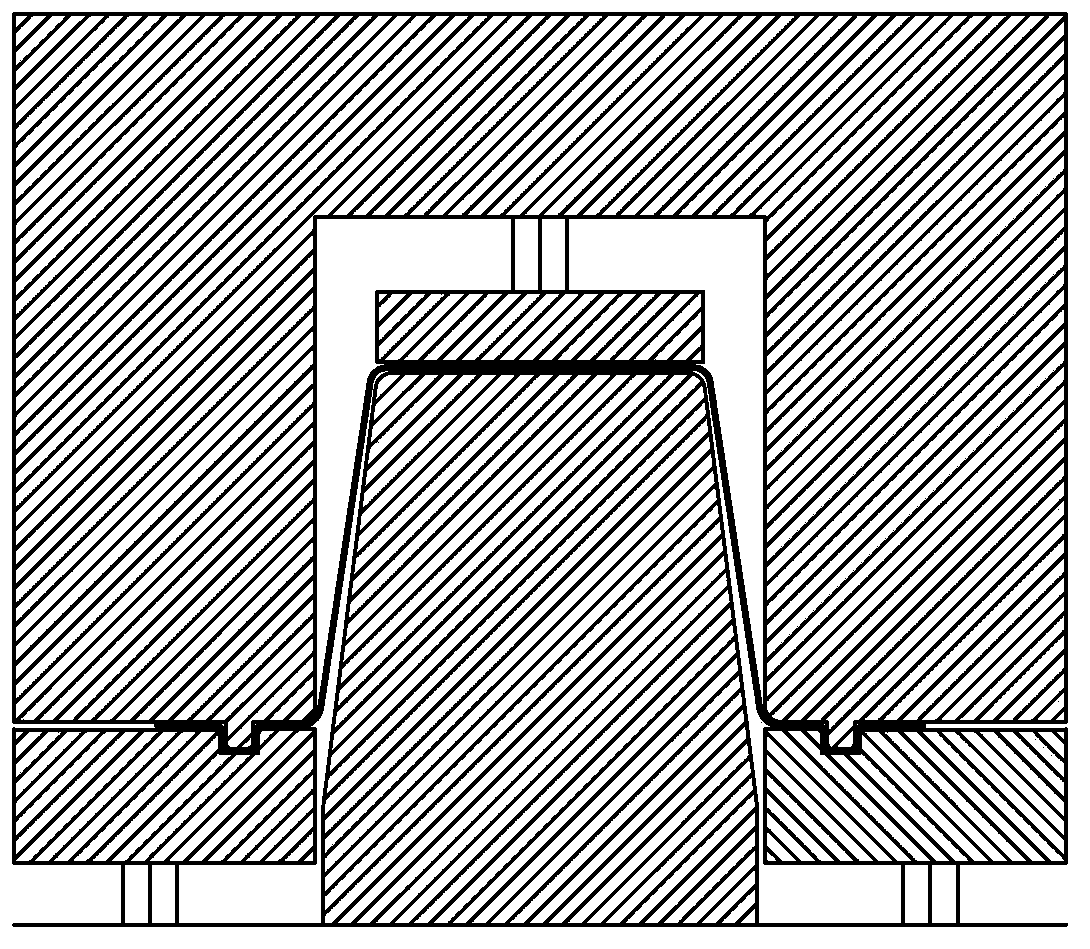

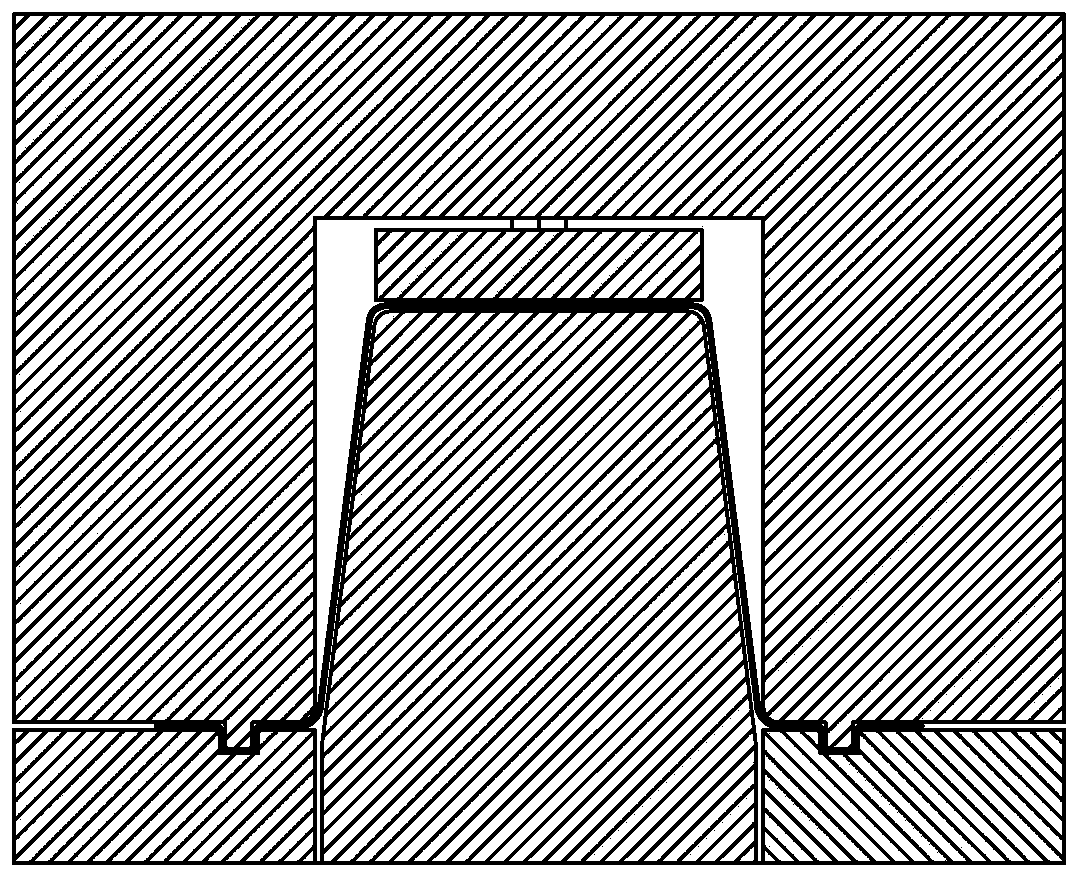

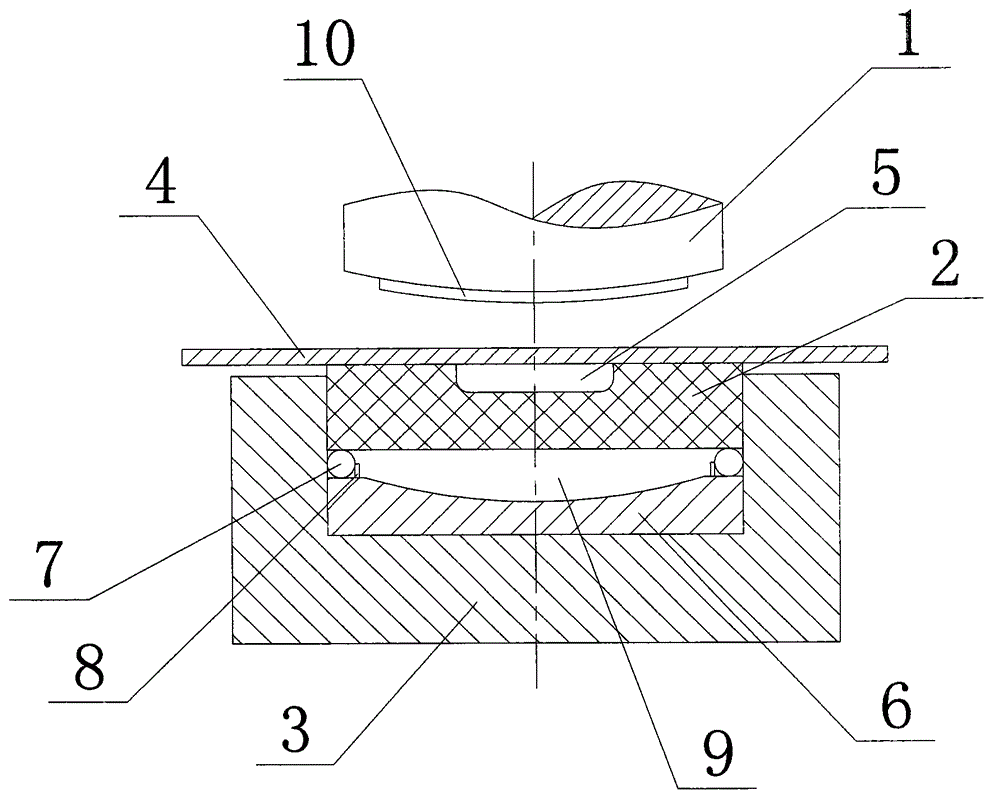

Thermal punch forming technique and forming mold for super-strength steel

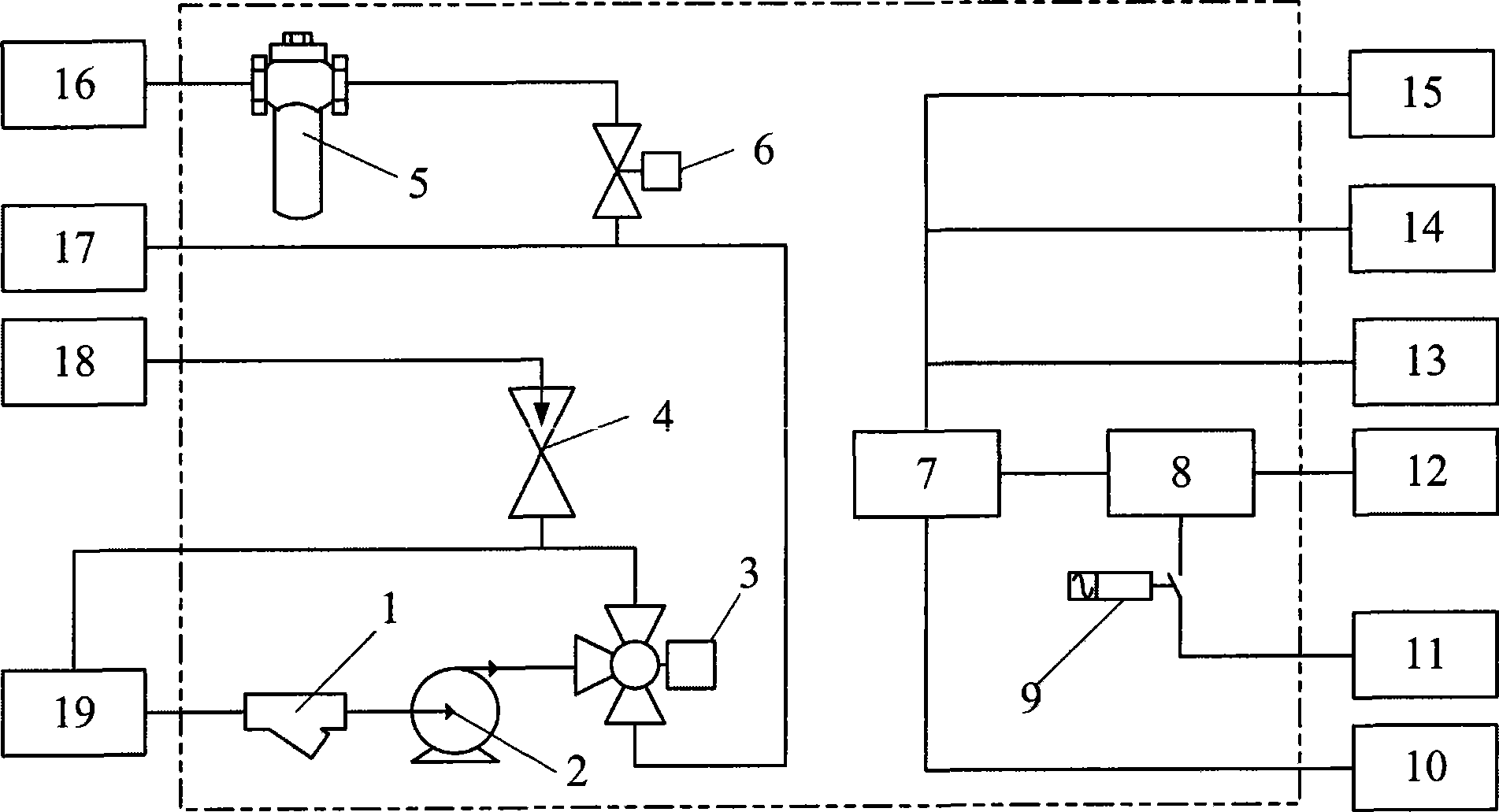

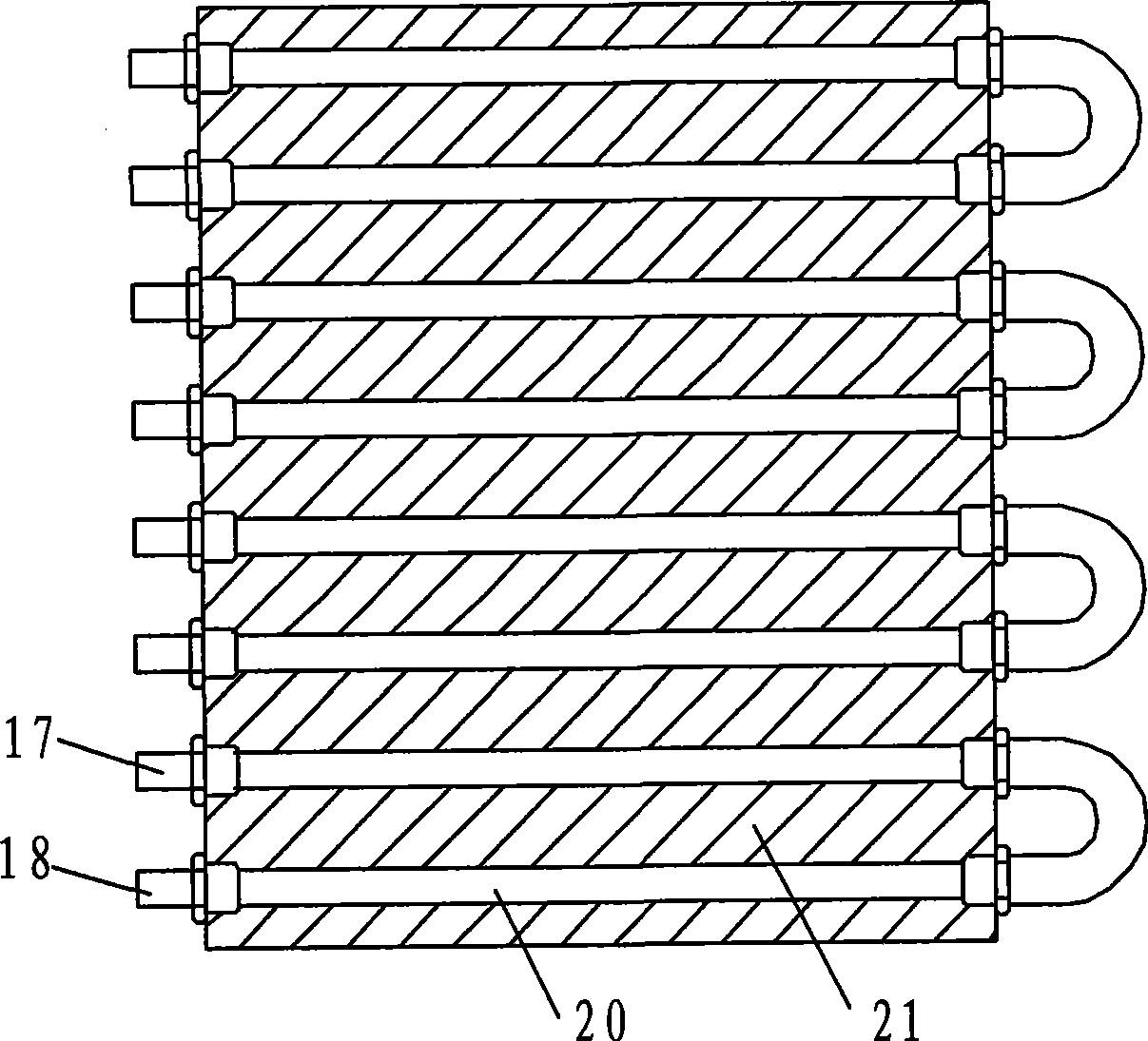

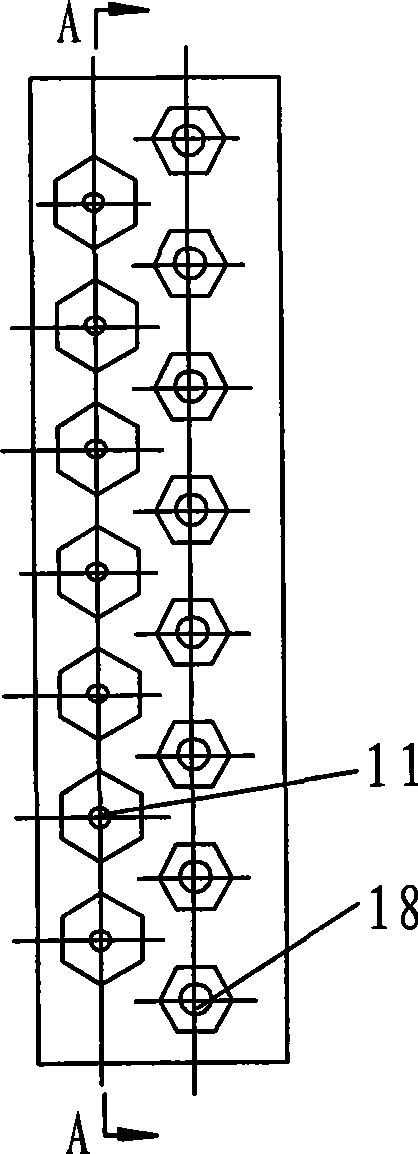

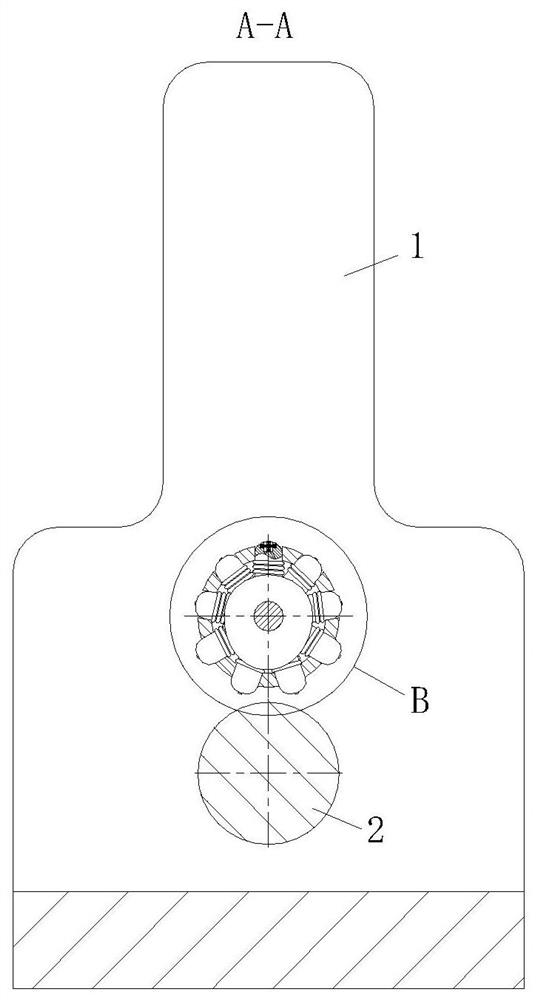

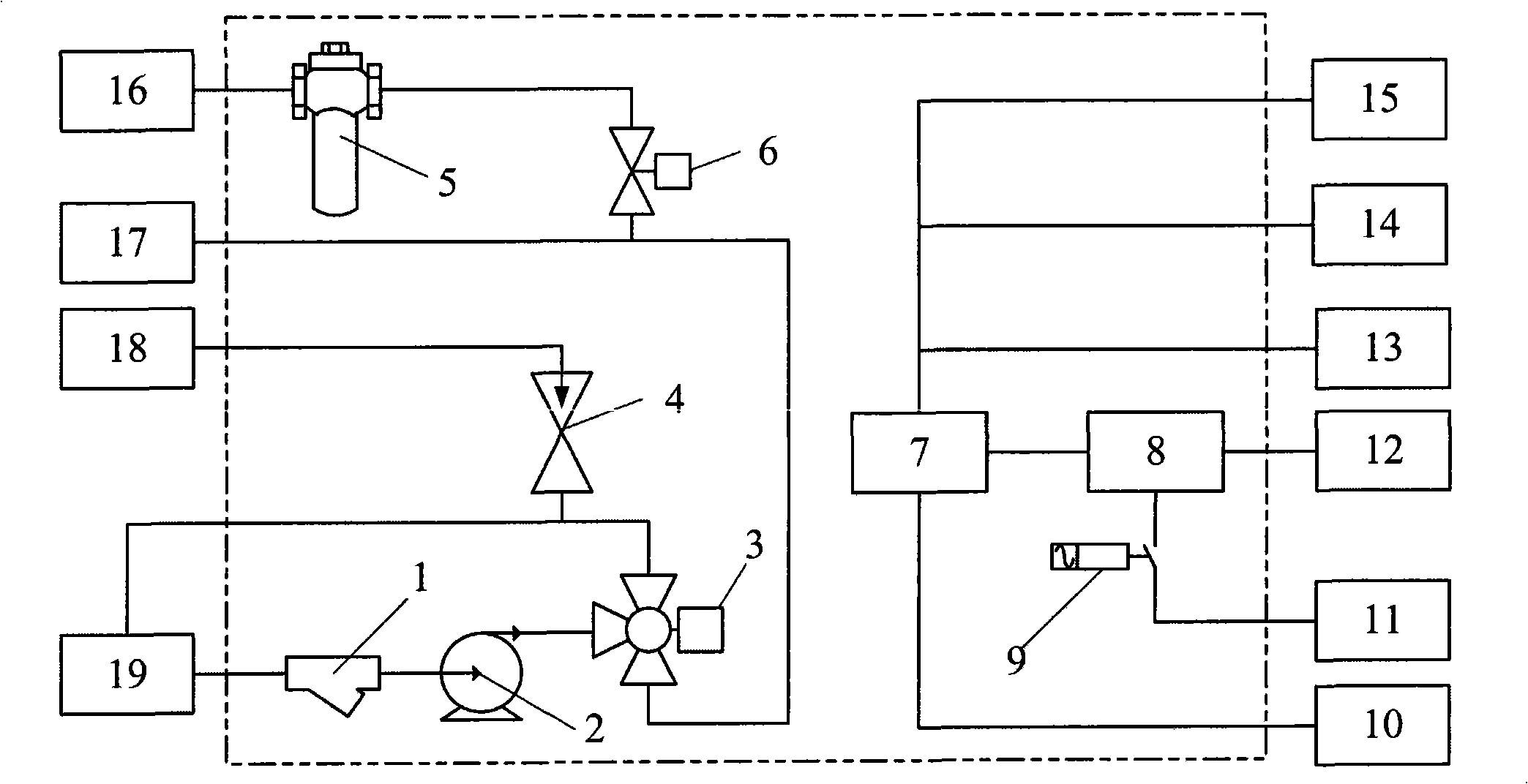

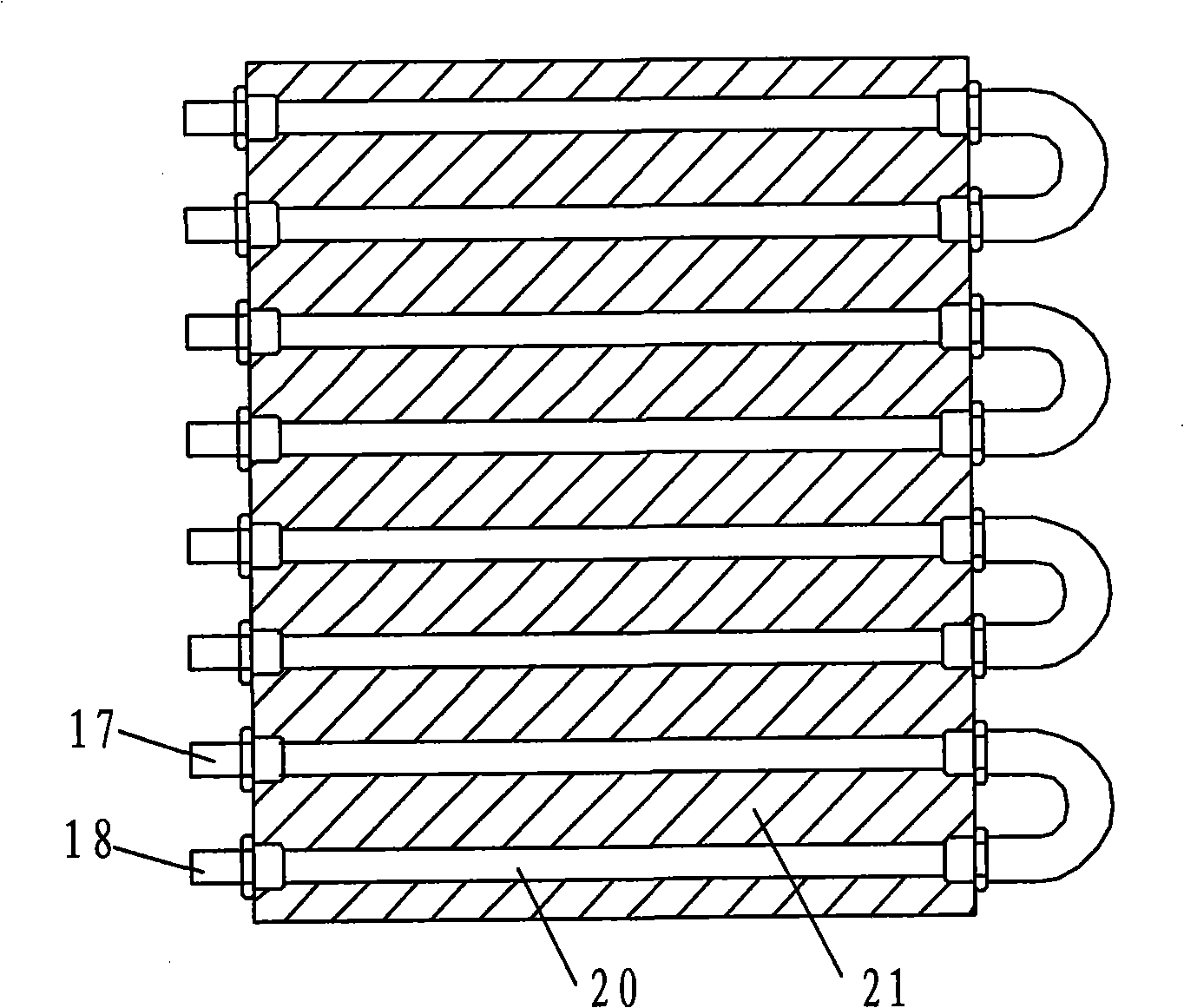

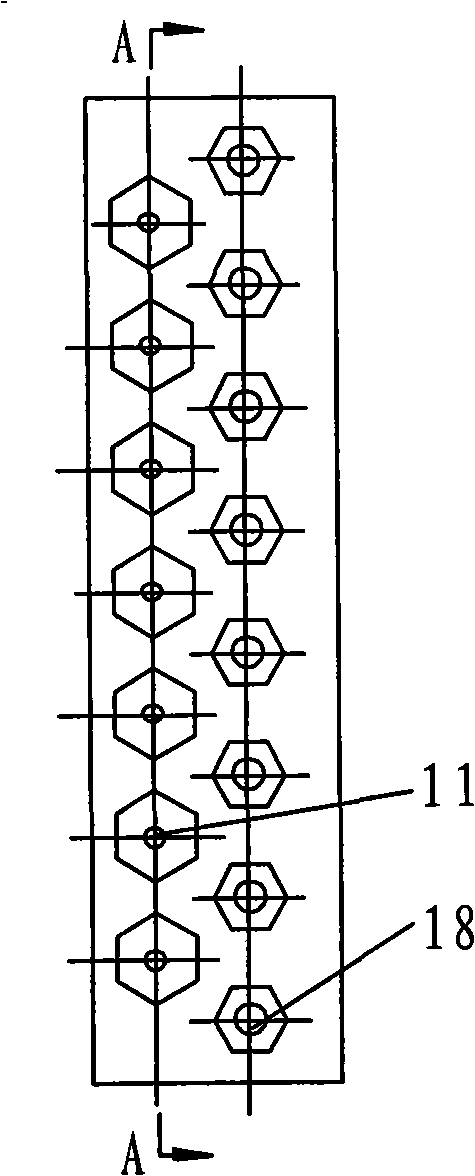

The invention provides an ultra-high strength steel thermal punching molding process and a molding die thereof. Before the thermal punching molding of ultra-high strength steel sheet, the thermal punching molding process is used for heating parts which are in contact with the ultra-high strength steel sheet in a die and need to be punched, so as to lead the surface temperature of the parts to reach or exceed martensite temperature of the ultra-high strength steel. Then, the ultra-high strength steel sheet which is heated to be totally austenitized is put in the die to be punched and molded. When closed, the thermal punching die is cooled. The die parts which are in contact with the molded parts are utilized for quenching the molded parts. The thermal punching molding die comprises a convex die, a concave die and a control unit. An electrothermal element and a cooling water channel are arranged in the convex die and the concave die. A temperature sensor is arranged in the convex die and the concave die. A reset switch and a pressure plate are respectively arranged on lateral sides of the concave die and the convex die. The ultra-high strength steel thermal punching molding process and the molding die thereof avoid cracks on surfaces and at the inner parts of the molded parts, eliminate the part molding resilience and ensure the precision and the quality of products.

Owner:SHANDONG UNIV

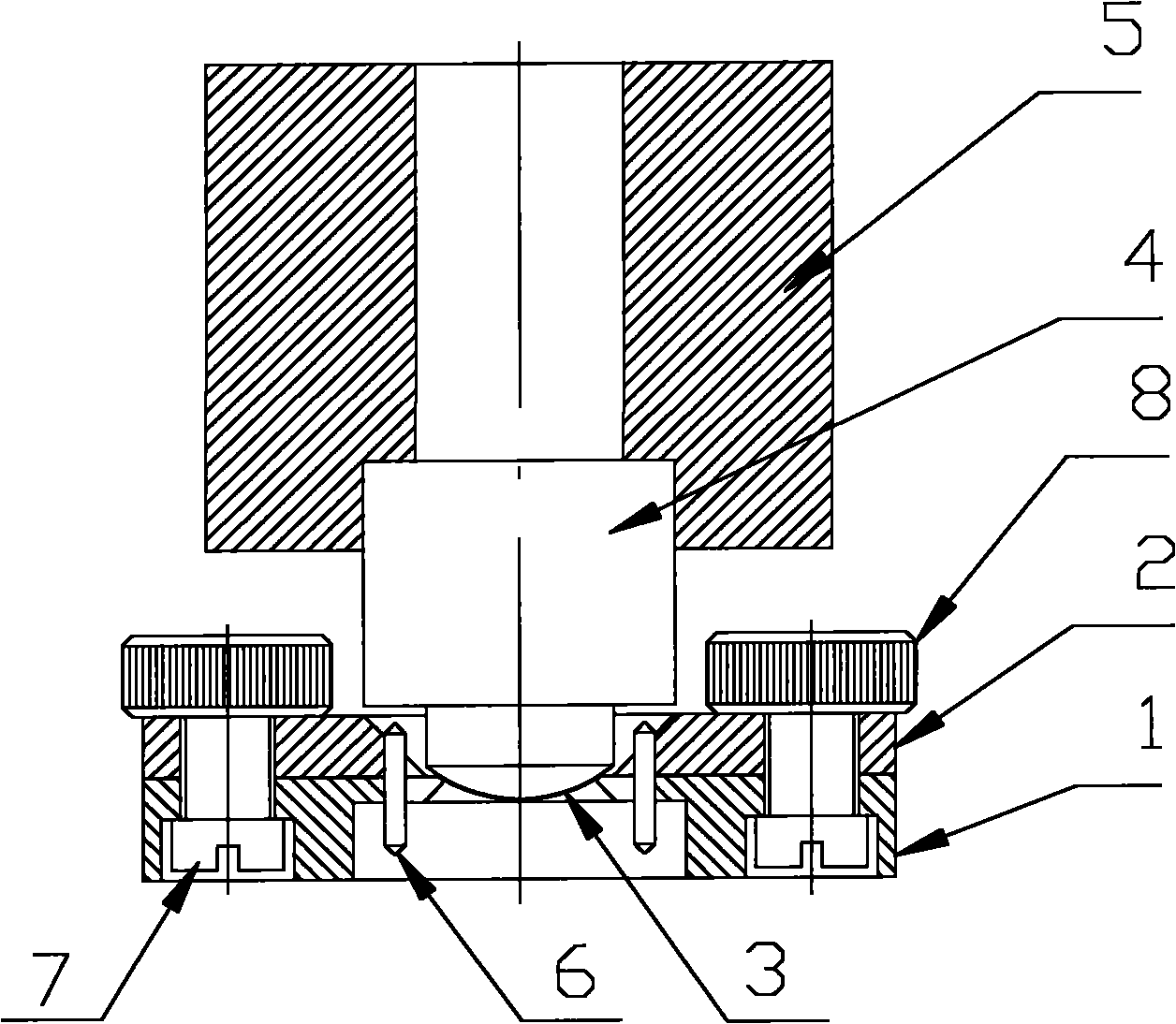

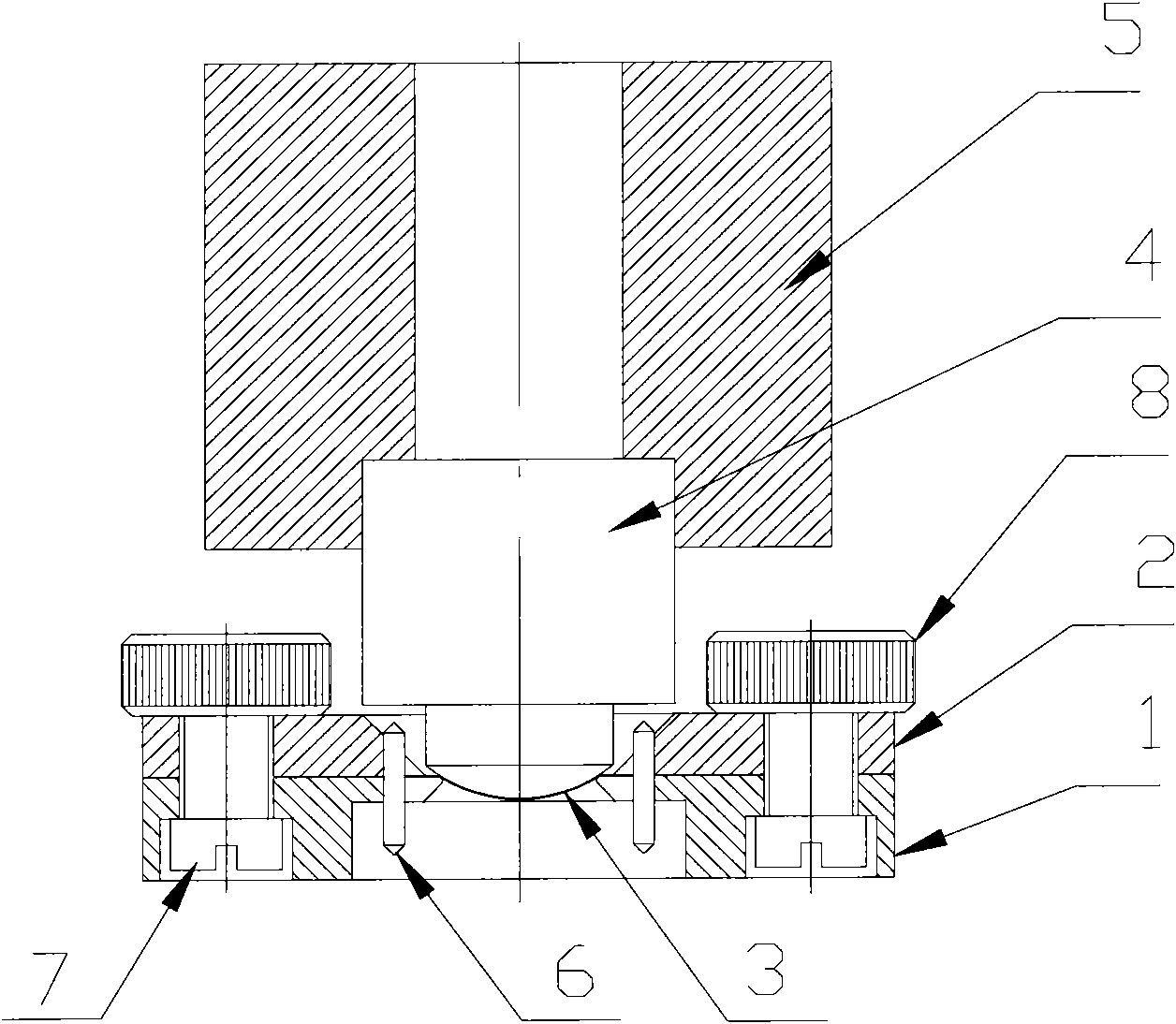

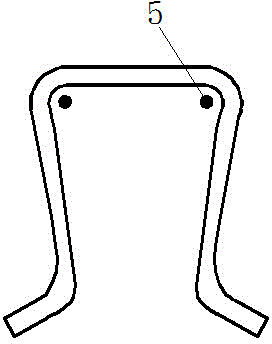

Novel online precise bending forming device

ActiveCN104985029AOvercome the problem that the size cannot meet the drawing requirementsEliminate springbackEngineering

The invention discloses a novel online precise bending forming device. The novel online precise bending forming device comprises a cut-off upper cutter and a bending lower cutter. A fixed top plate is arranged on the top of the cut-off upper cutter. Material pressing plates are arranged on the left side and the right side of the cut-off upper cutter in parallel. Positioning plates are arranged on the outer sides of the material pressing plates. A pressing springback cutter is arranged between the material pressing plates. A cutter groove is formed in the middle of the pressing springback cutter. The cut-off upper cutter penetrates the cutter groove. An upper cutter hole is formed in the middle of the bending lower cutter. The novel online precise bending forming device has the beneficial effects that the pressing springback cutter is arranged between the left material pressing plate and the right material pressing plate, and an inclined face is machined at the lower end of the pressing springback cutter; the pressing springback cutter is pressed downwards by a certain distance after the bending lower cutter finishes bending and returns; and a metal workpiece is pressed till the bending angle is smaller than 90 degrees, and therefore springback of materials is eliminated. The press-down amount of the pressing springback cutter can be regulated according to the springback condition of the materials, and therefore the bending angle can be accurately controlled, the angle can meet the requirement of drawings after bending springback is conducted, and the production efficiency is improved by 30% compared with the efficiency of an original production method.

Owner:FOSHAN XINHONG MACHINERY CO LTD

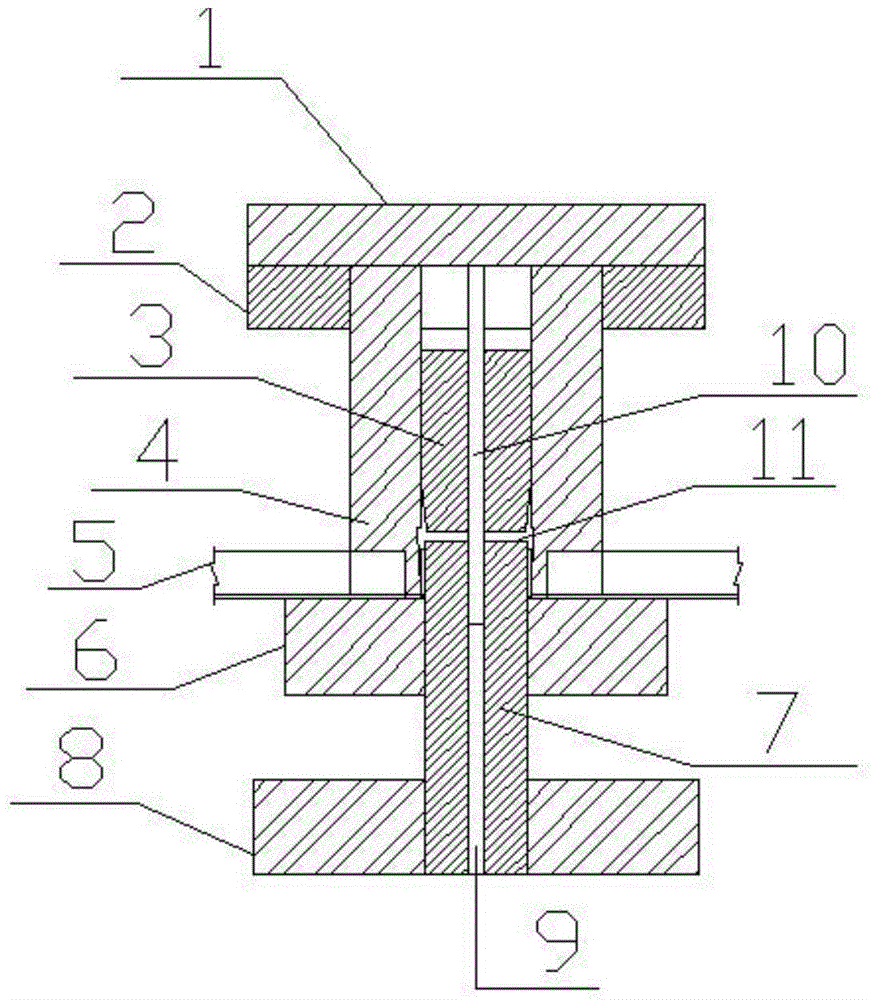

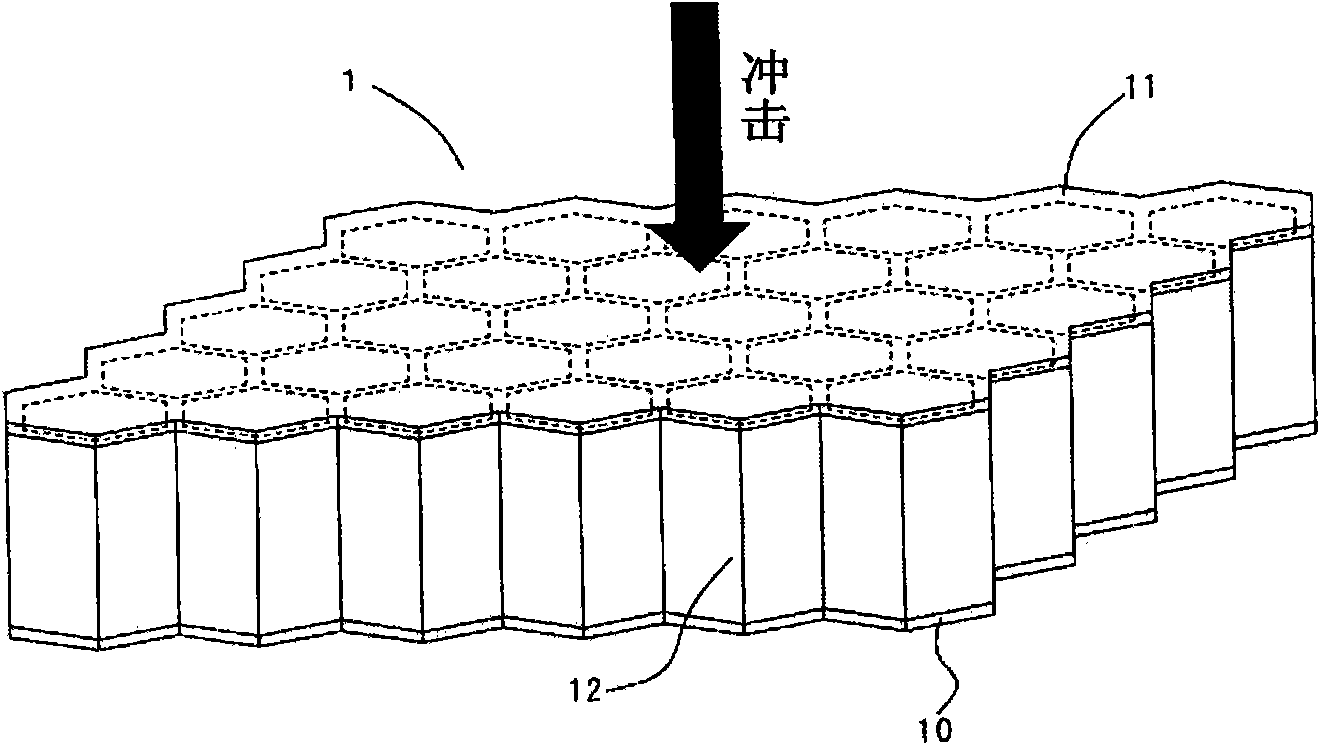

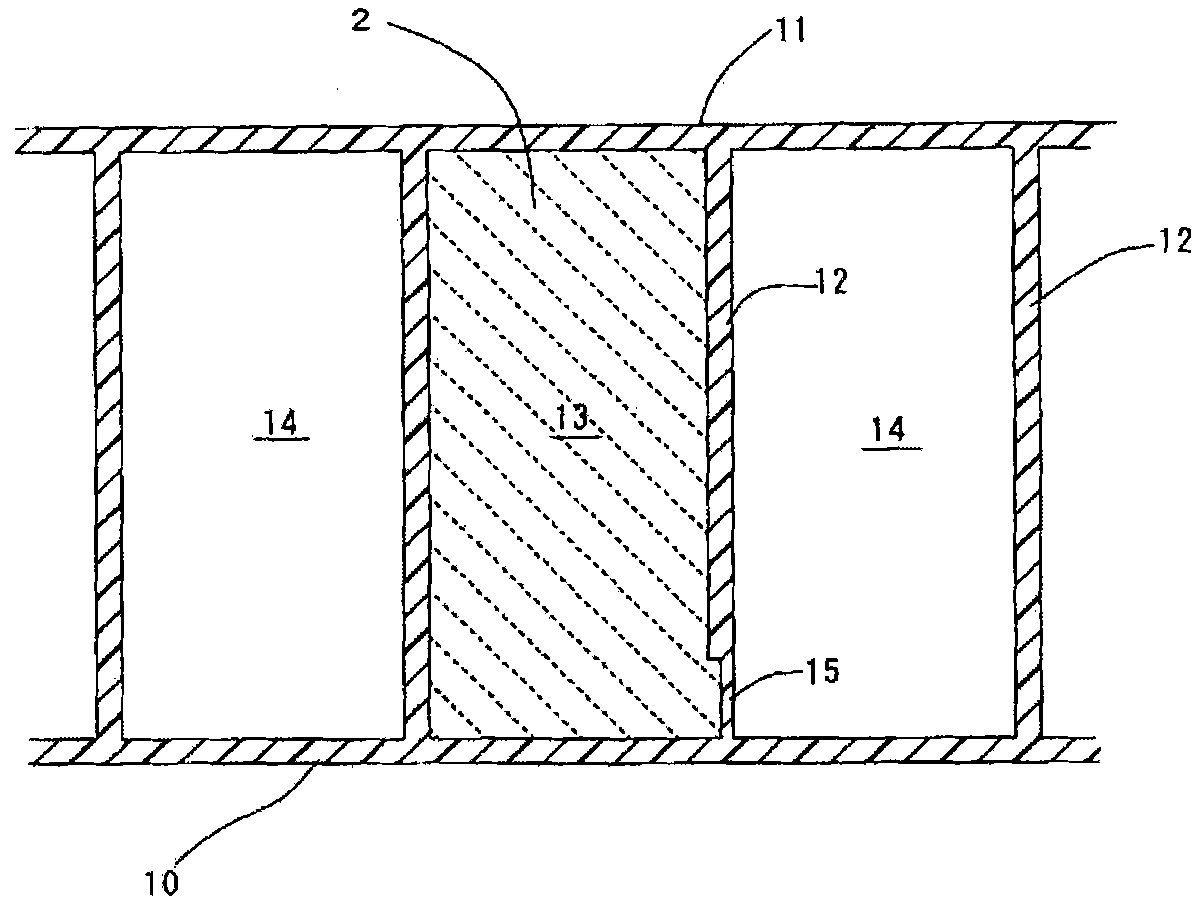

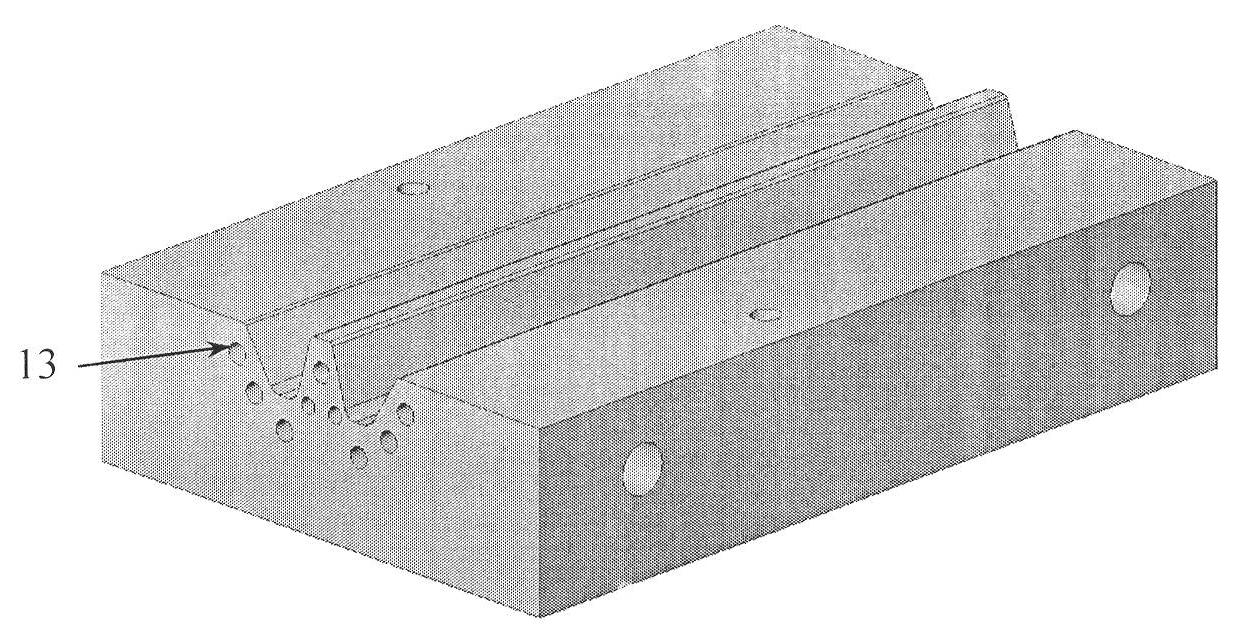

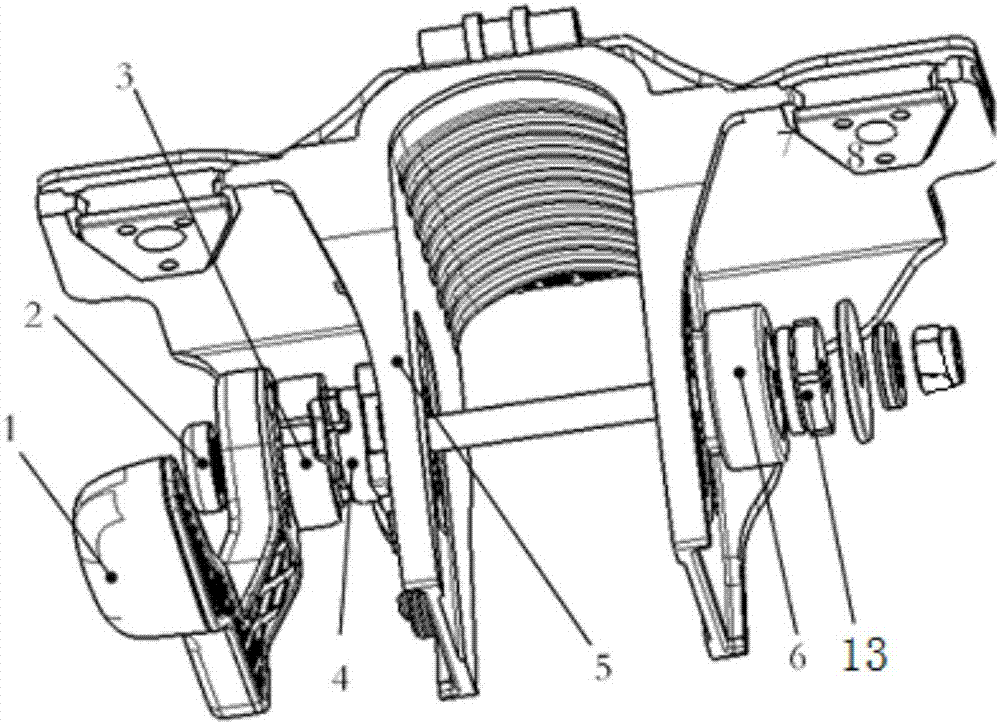

Shock absorbing apparatus

InactiveCN101939558AEliminate springbackEffective absorptionPedestrian/occupant safety arrangementSuperstructure subunitsAtmospheric airMolecular physics

Disclosed is a collapsible device comprising charged cells (13) charged with a filling medium (2) composed mainly of a liquid, and vacant cells (14) charged with atmospheric air. At least one vacant cell (14) is adjacent to the charged cell (13), and at least one of ribs (12) defining the charged cells (13) and the adjacent vacant cells (14) has a fragile portion (15) formed therein. After the fragile portion (15) is broken, more impact energy can be absorbed by the flow resistance of the filling medium (2) which flows from the charged cells (13) to the vacant cells (14).

Owner:TOYODA GOSEI CO LTD

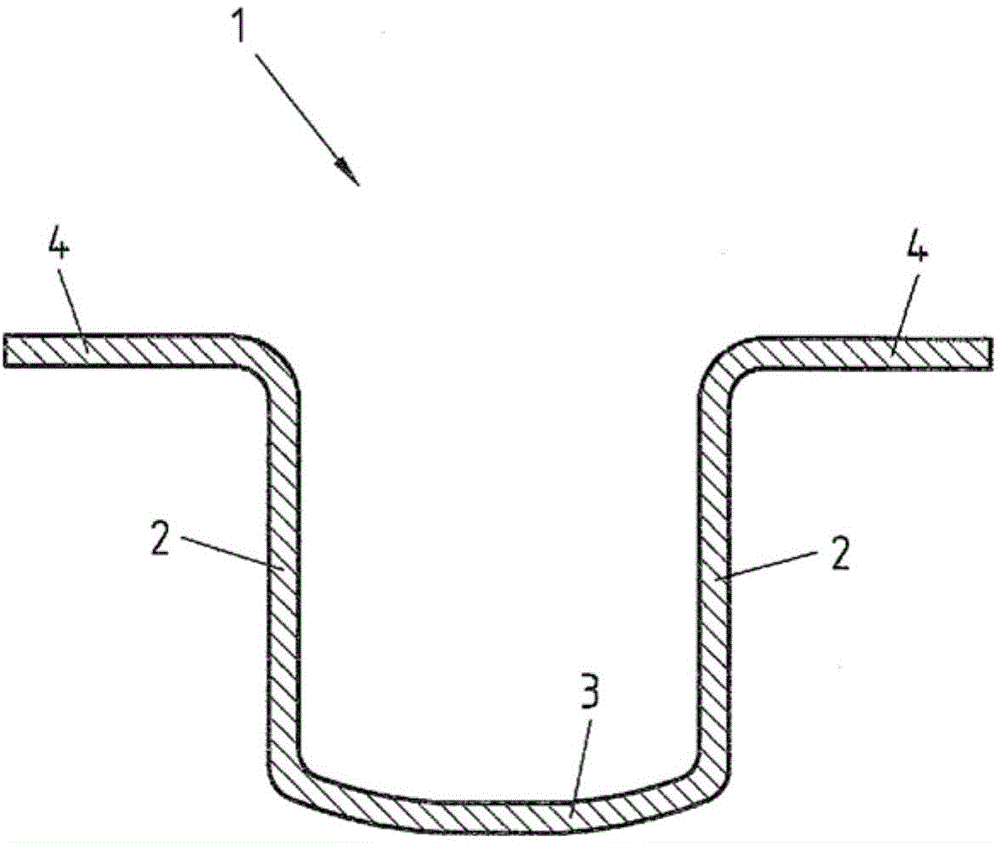

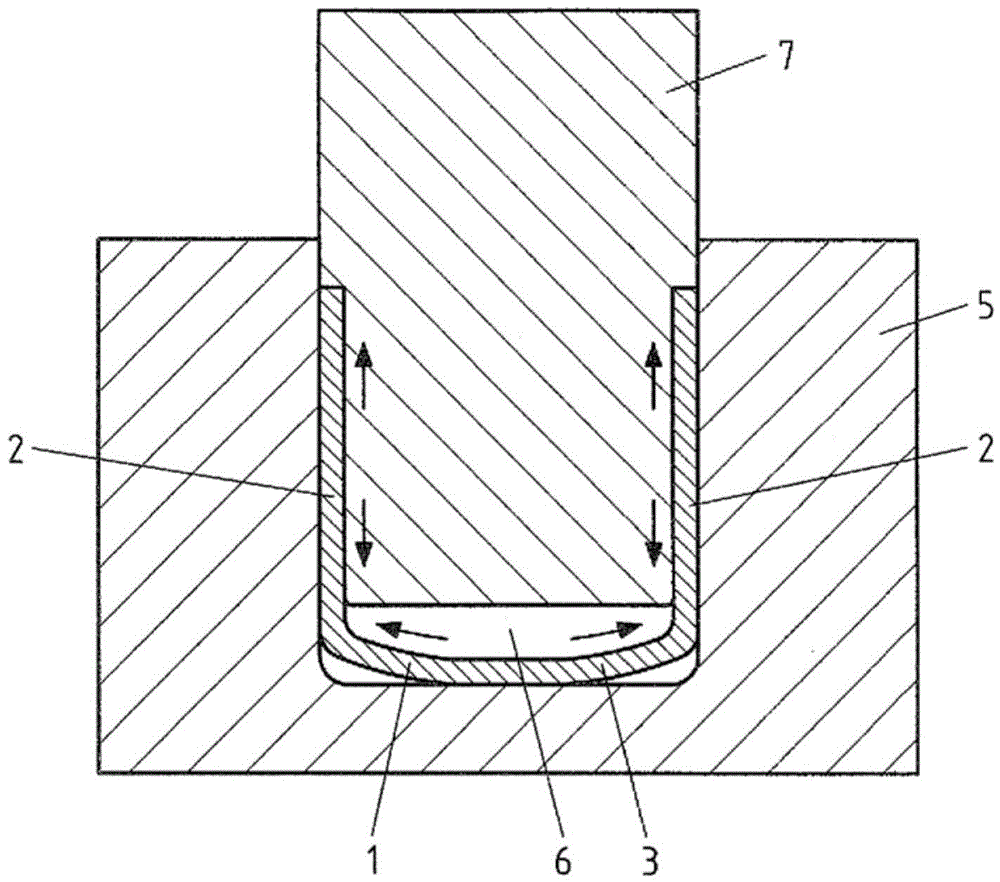

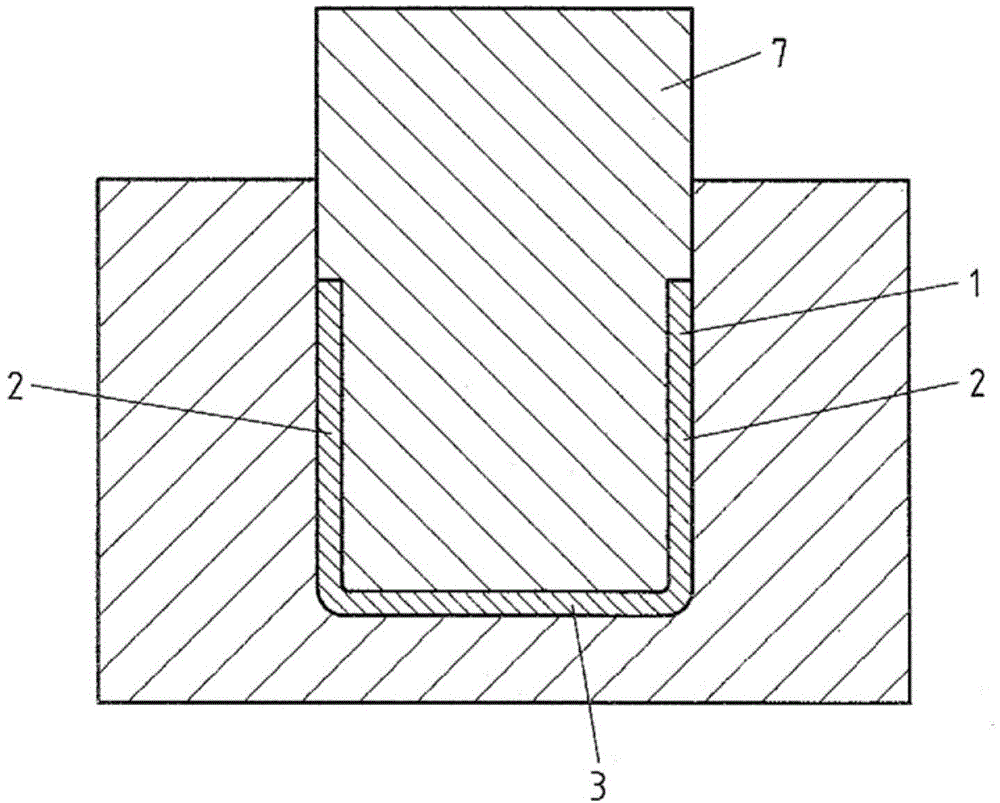

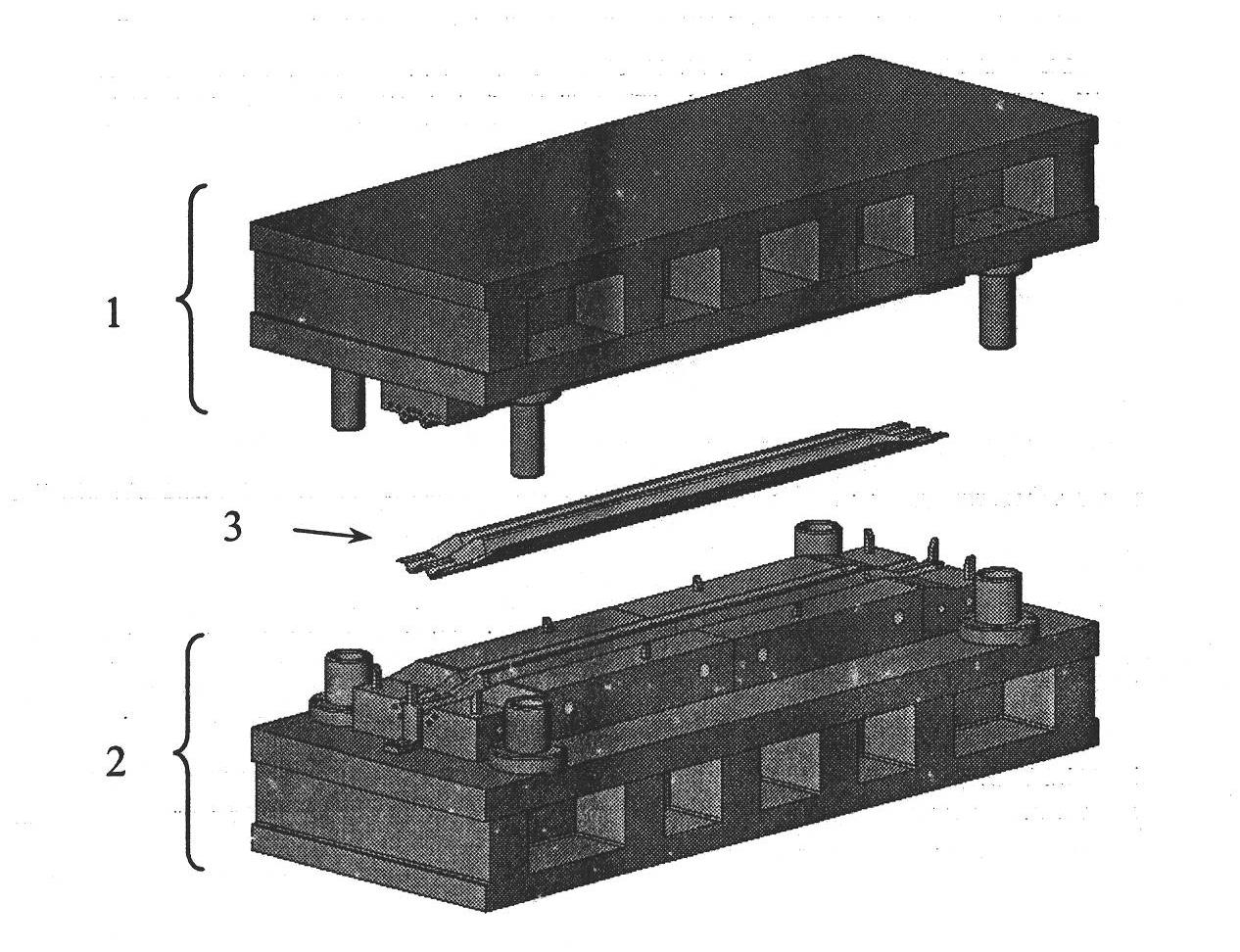

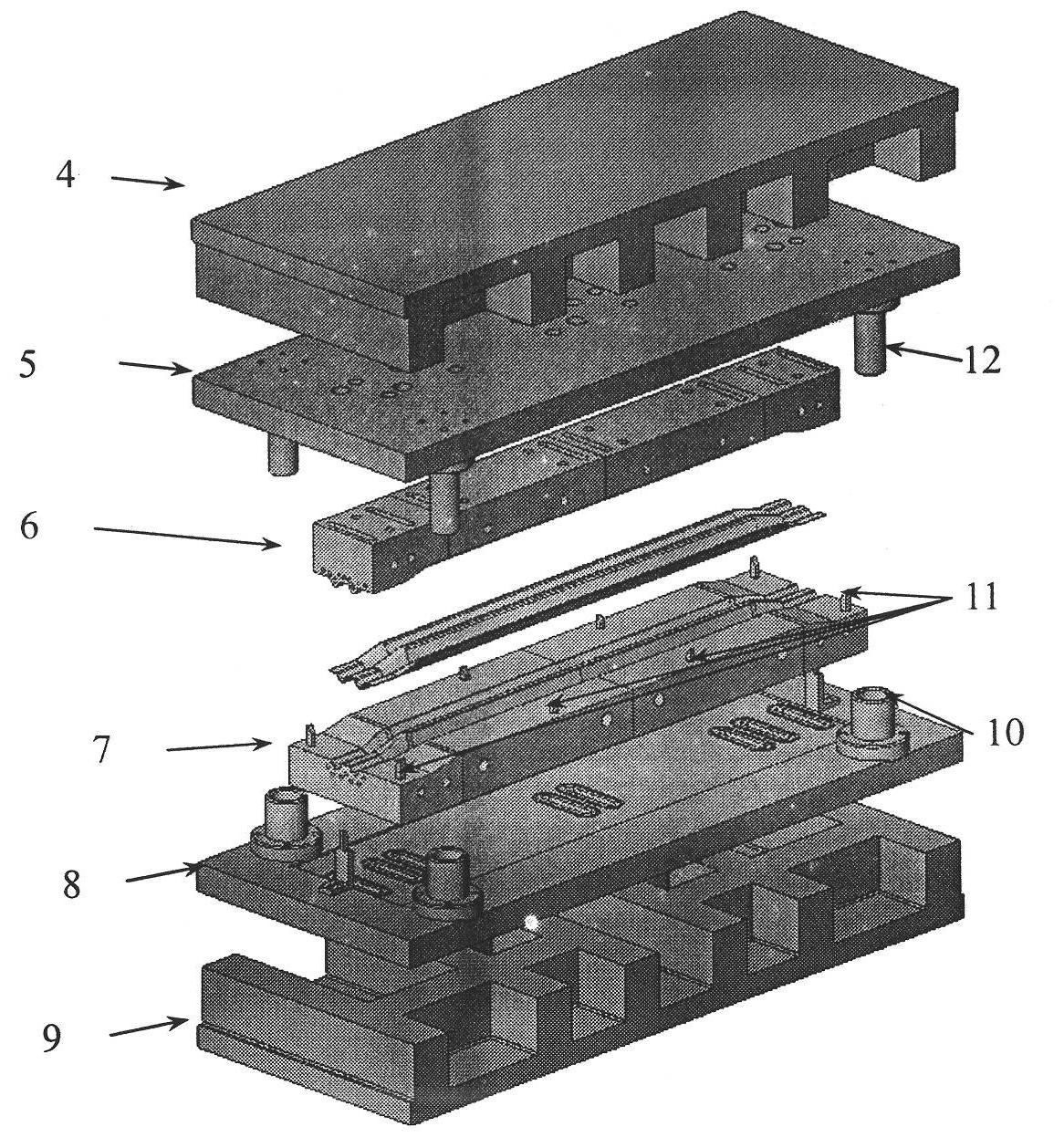

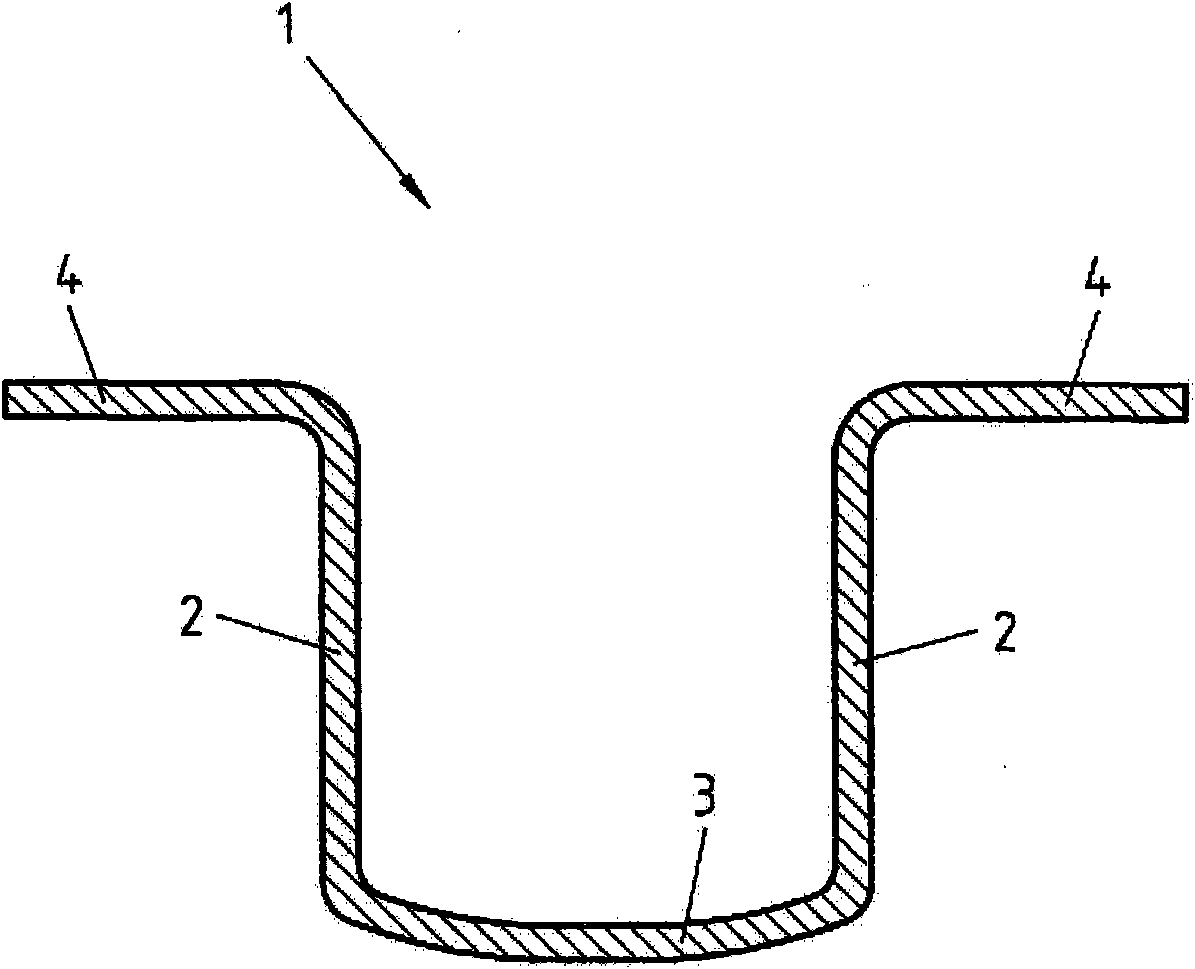

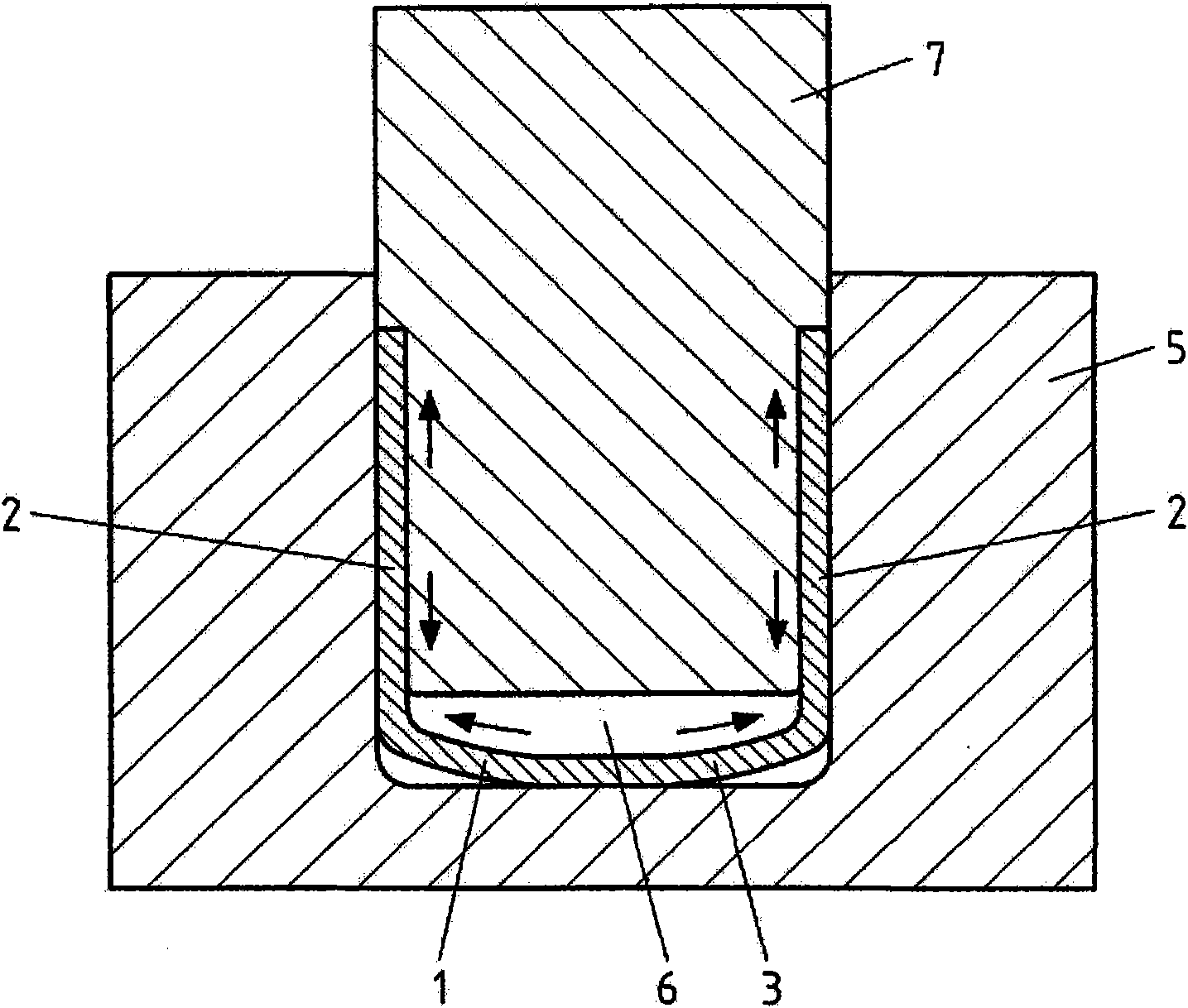

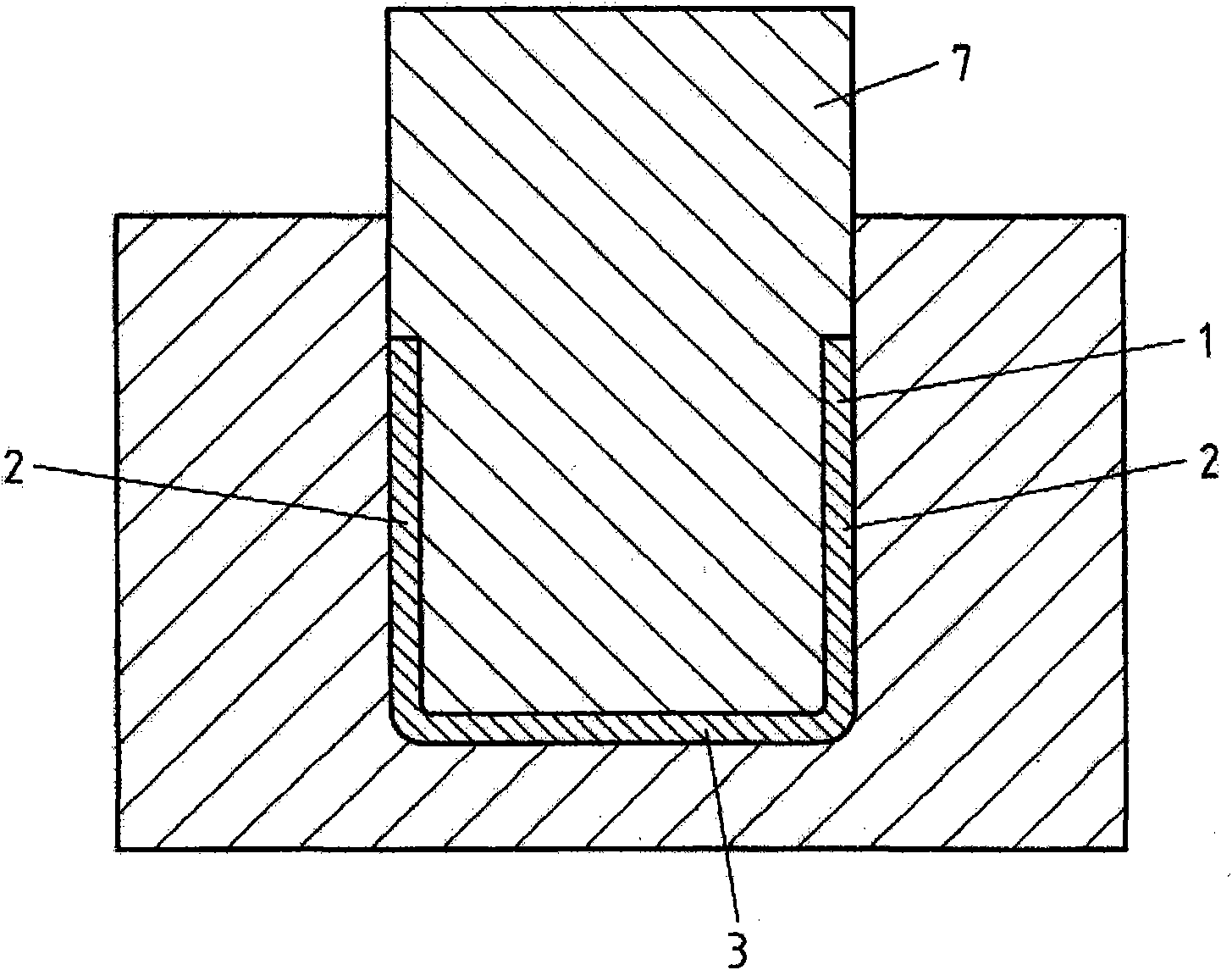

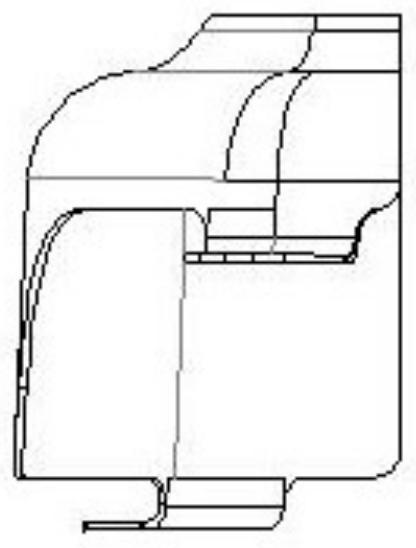

Production method of highly dimensionally accurate half shells

InactiveCN104959442AEliminate springbackSmall toleranceShaping toolsEngineeringBiomedical engineering

Owner:THYSSENKRUPP STEEL EURO AG

Springback compensation method of thin-wall stamped part with large relative bending radius

InactiveCN104307939AEliminate theoretical reboundShorten the development cycleShaping toolsThin walledEngineering

The invention relates to a springback compensation method of a thin-wall stamped part with large relative bending radius. The springback compensation method comprises the following steps: analyzing the springback of the stamped part by adopting finite element software to obtain a first springback compensation; correcting a mould, and carrying out springback analysis to obtain a second springback compensation; correcting the mould again, and carrying out springback analysis to obtain a third springback compensation; carrying out comparison analysis and judging whether the size precision requirement is met or not; and if not meeting the size precision requirement, continuing the process till the size precision requirement is met. According to the springback compensation method disclosed by the invention, the size of the part subjected to springback is finally close to the size required by the part in theory by means of circulation proceeding of springback analysis, springback compensation and springback analysis, simulation mould repair and gradual approach, and then, the practical springback is reduced through experiments, so that the purpose of less mold repair, even no mold repair is achieved; the development period of a product is shortened, and the development cost is lowered. The springback compensation method belongs to the field of sheet metal working and is applicable to forming the thin-wall stamped part with relatively large relative bending radius.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

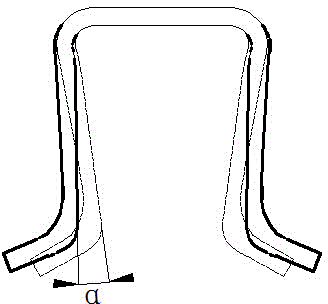

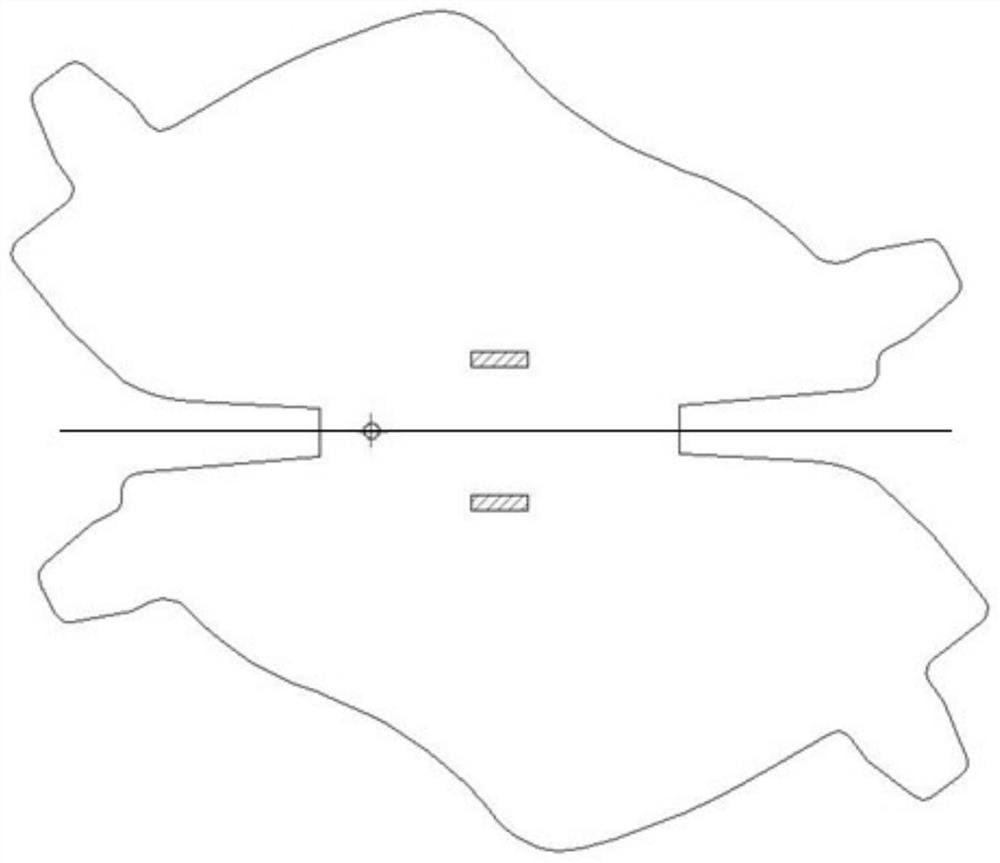

Device for eliminating warping rebound of side wall of stamped component and edge pressing technology

InactiveCN103357736AEliminate warp springbackEliminate springbackStamping processDistribution characteristic

The invention discloses a device for eliminating warping rebound of a side wall of a stamped component. The device comprises a concave mould and a convex mould matched with the concave mould, and is characterized in that a pressing plate connected with a pressing plate nitrogen cylinder is arranged inside the concave mould; a positioning heave is arranged on a contact surface of the concave mould and a metal sheet; an edge pressing ring connected with an edge pressing ring nitrogen cylinder is arranged on the outer side of the convex mould; a positioning groove matched with the positioning heave is arranged on a contact surface of the edge pressing ring and the metal sheet; the distance from an initial position of the edge pressing ring before working to a base is Lmm. The invention further provides an edge pressing technology using the device. In the edge pressing technology, based on distribution characteristics of an internal stress in the metal sheet stamping process and a warping rebound forming principle, the warping rebound of the side wall of the stamped component is effectively eliminated by controlling the stroke of the edge pressing ring and the flow of a material on the metal sheet; in particular for stamped components of a high-strength steel plate and an aluminum plate, the edge pressing technology has the advantage that the rebound can be effectively eliminated without relatively high deformation.

Owner:DALIAN UNIV OF TECH

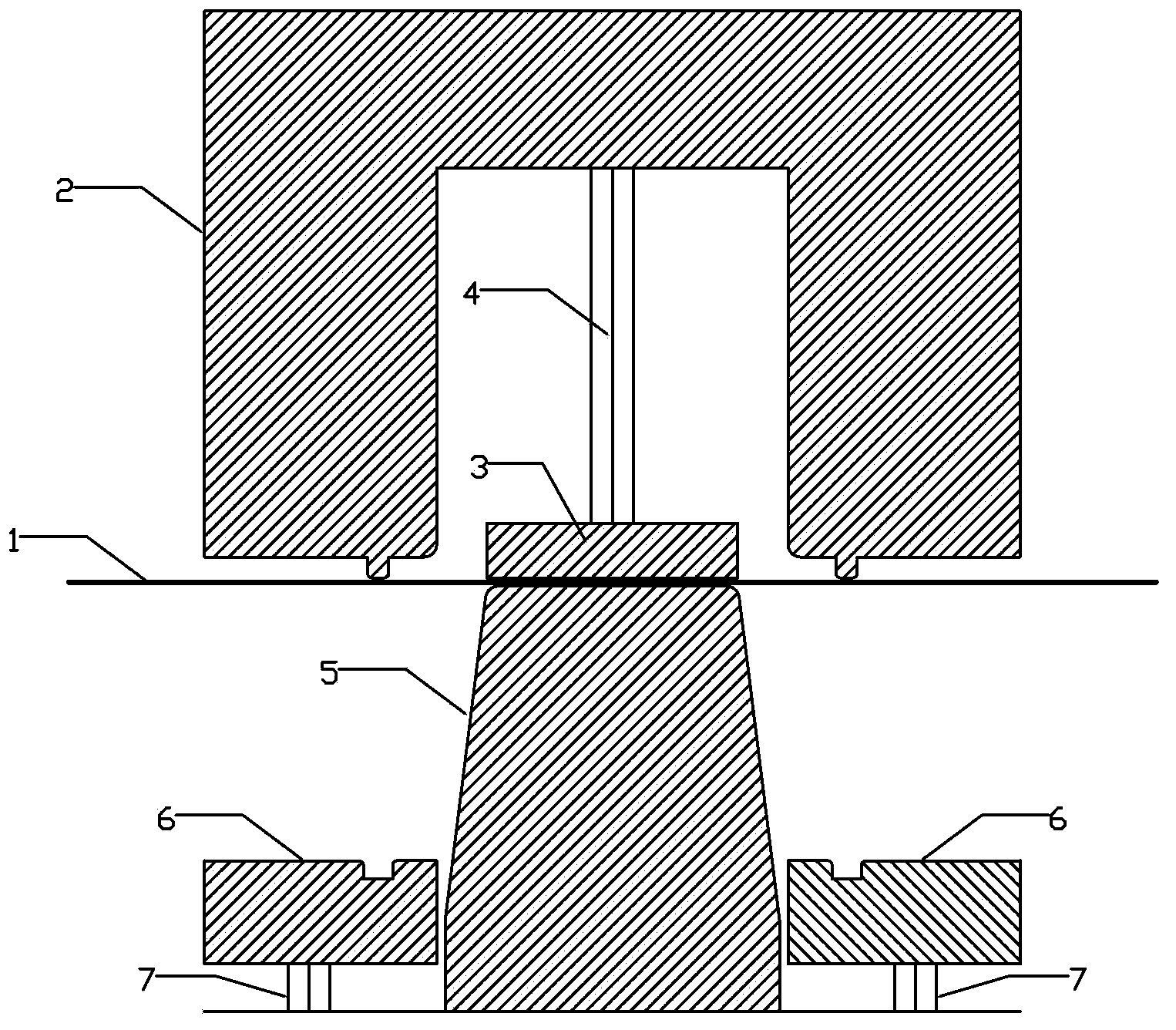

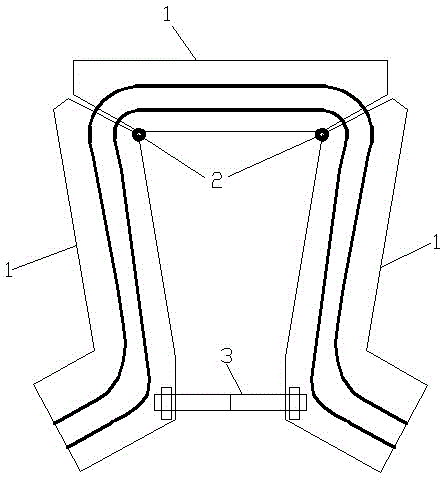

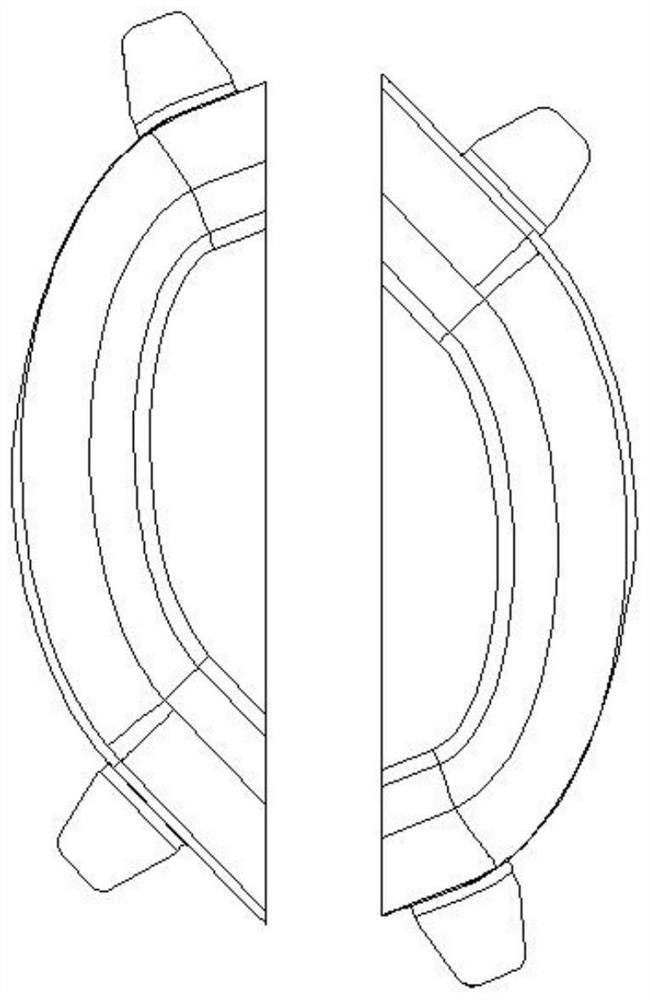

Ultra-high strength steel hot-stamping die for car door anticollision beam

InactiveCN101972814AHigh strengthReduce weightShaping toolsLoad-supporting pillarsHot stampingEngineering

The invention provides a hot-stamping die for an anticollision beam, comprising an upper die and a lower die, wherein the upper and lower dies mainly comprise combined convex / concave dies, cooling systems and a cooling seal ring. The blocks of the combined convex / concave dies avoid the corners and are staggered relatively. The cooling systems adopt drill holes, wherein the diameter of the holes is 8-30mm and the peaks of the holes are 3-10mm distant from the profiles; the two ends of the holes are sealed after hole drilling; runway type water troughs are processed near the places where the block dies are 10-50mm distant from the two end faces; the cooling water enters from one water trough and flows out of the other water trough; and seal grooves are arranged on the cooling water troughs and the cooling water troughs are provided with the seal ring and are externally connected with cooling water pipes.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Production method of highly dimensionally accurate half shells

InactiveCN101888908AGood deformabilityLow investment costMetal-working apparatusBiomedical engineering

Owner:THYSSENKRUPP STEEL EURO AG

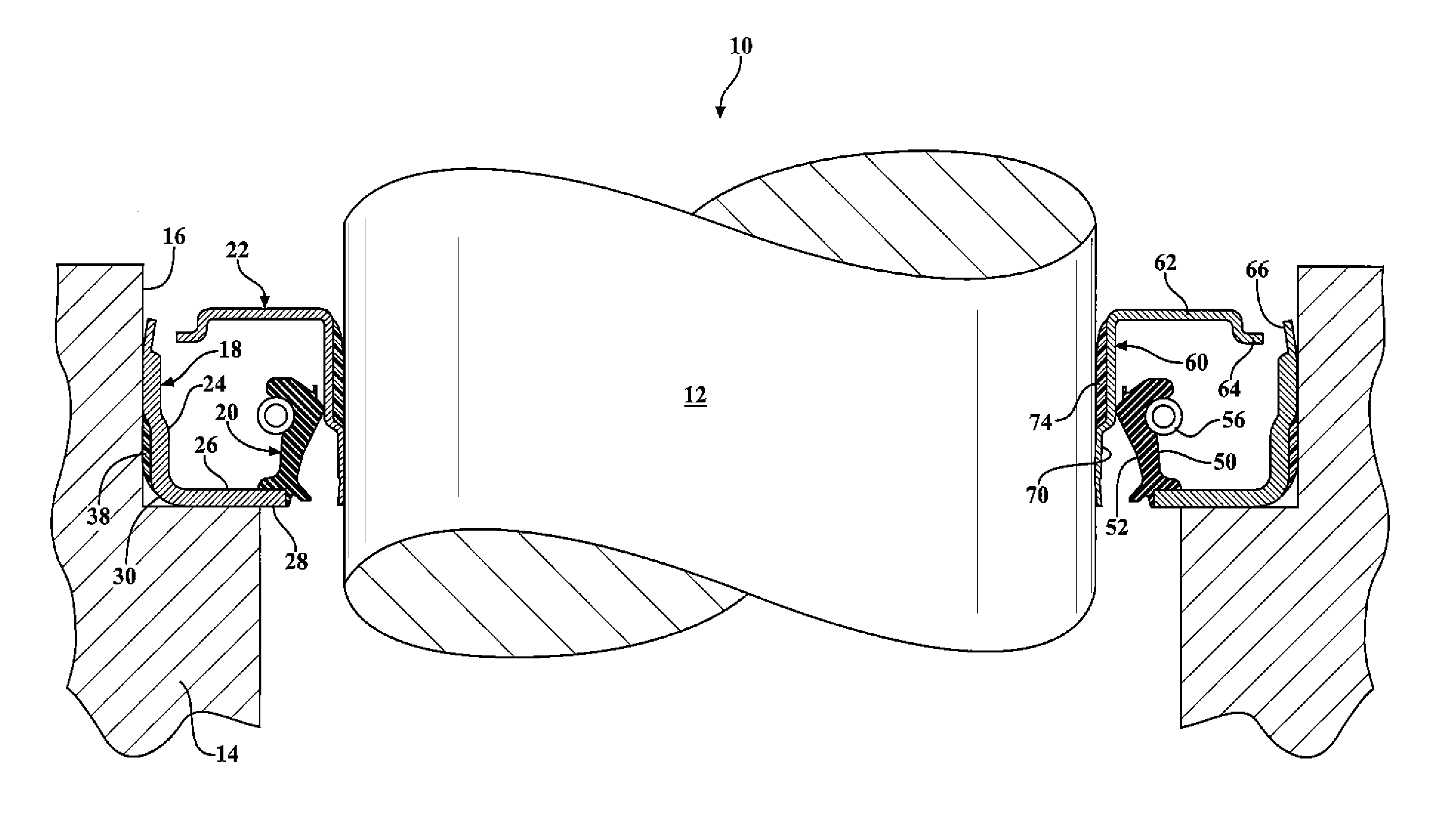

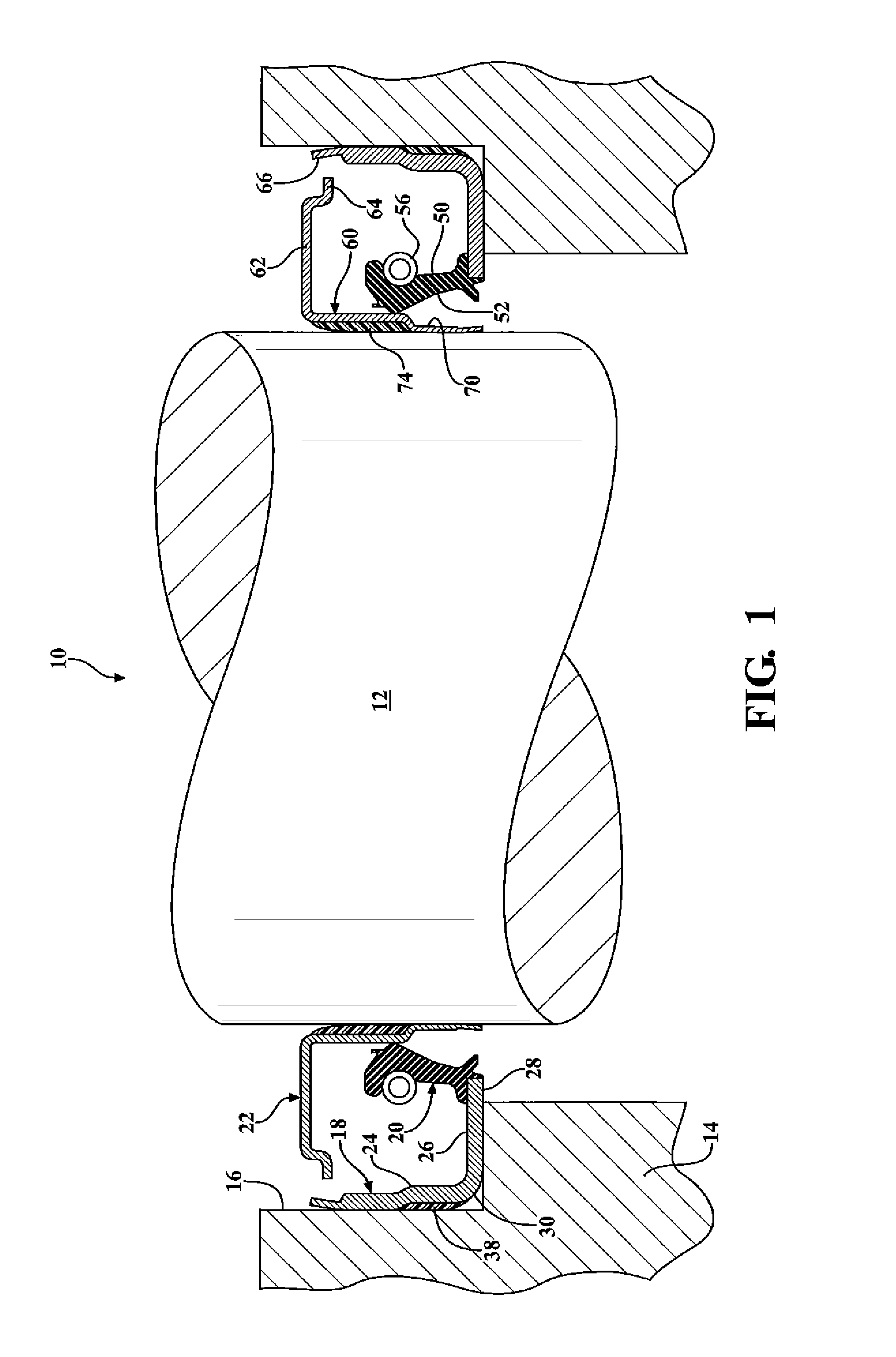

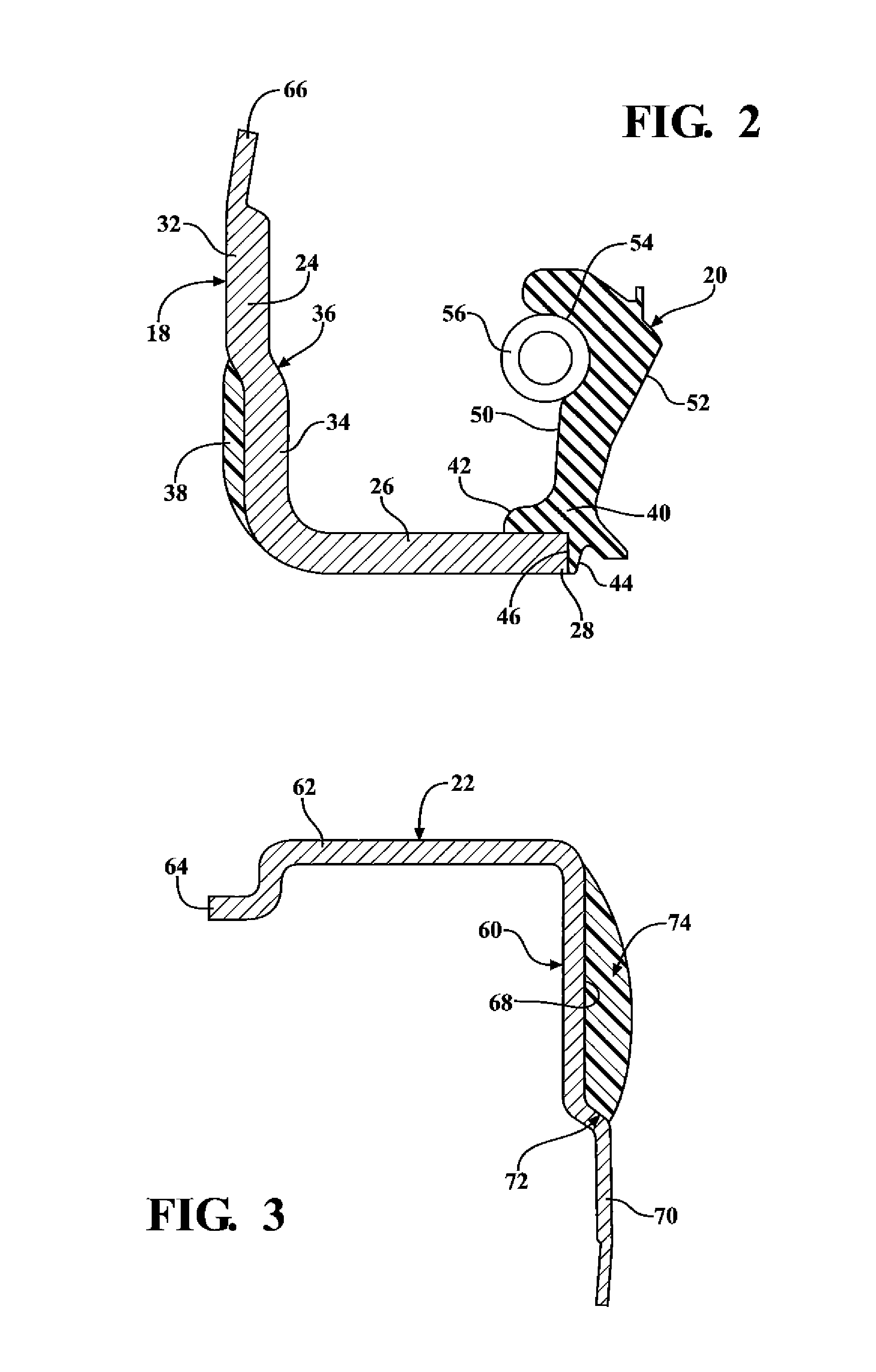

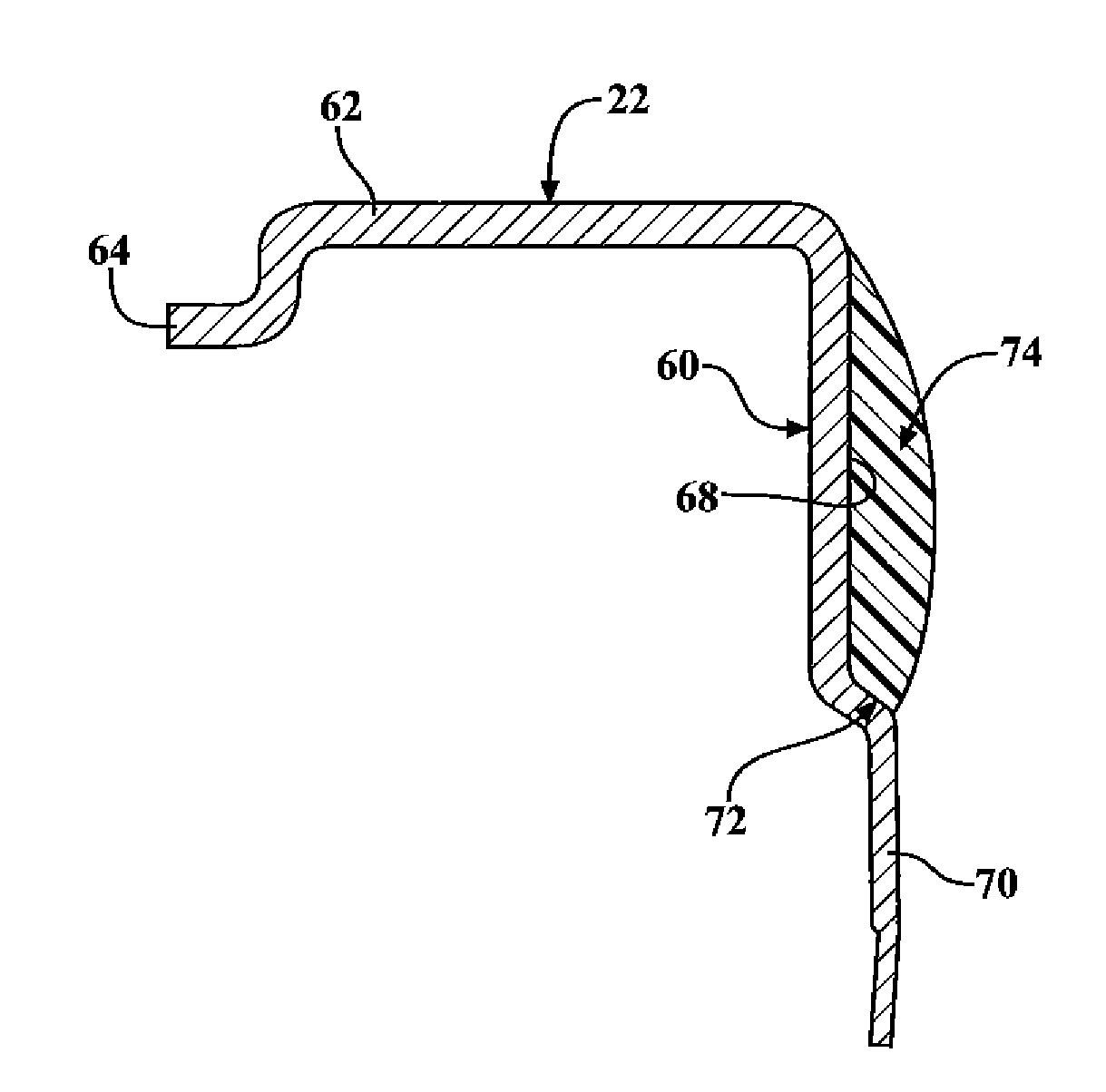

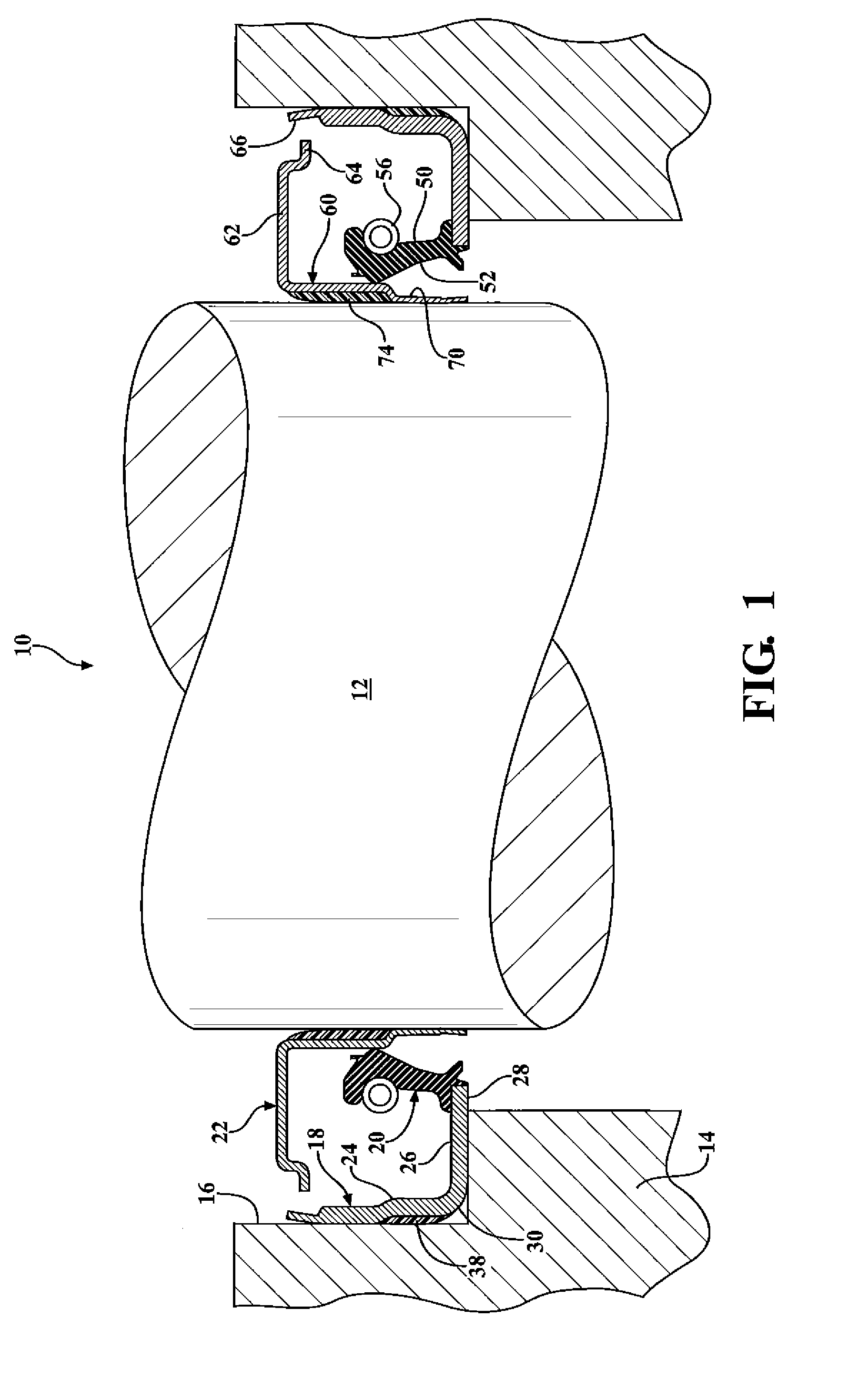

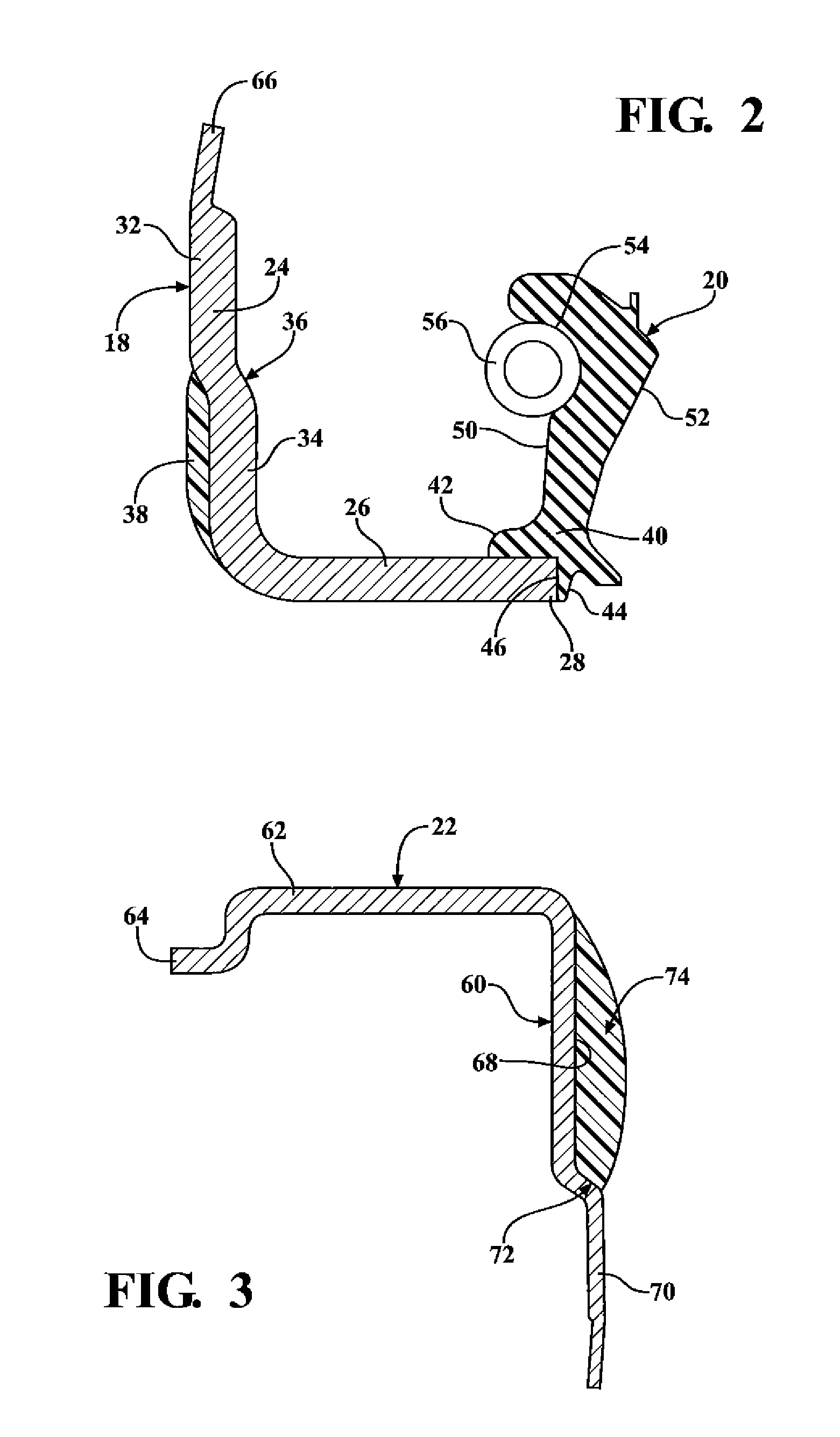

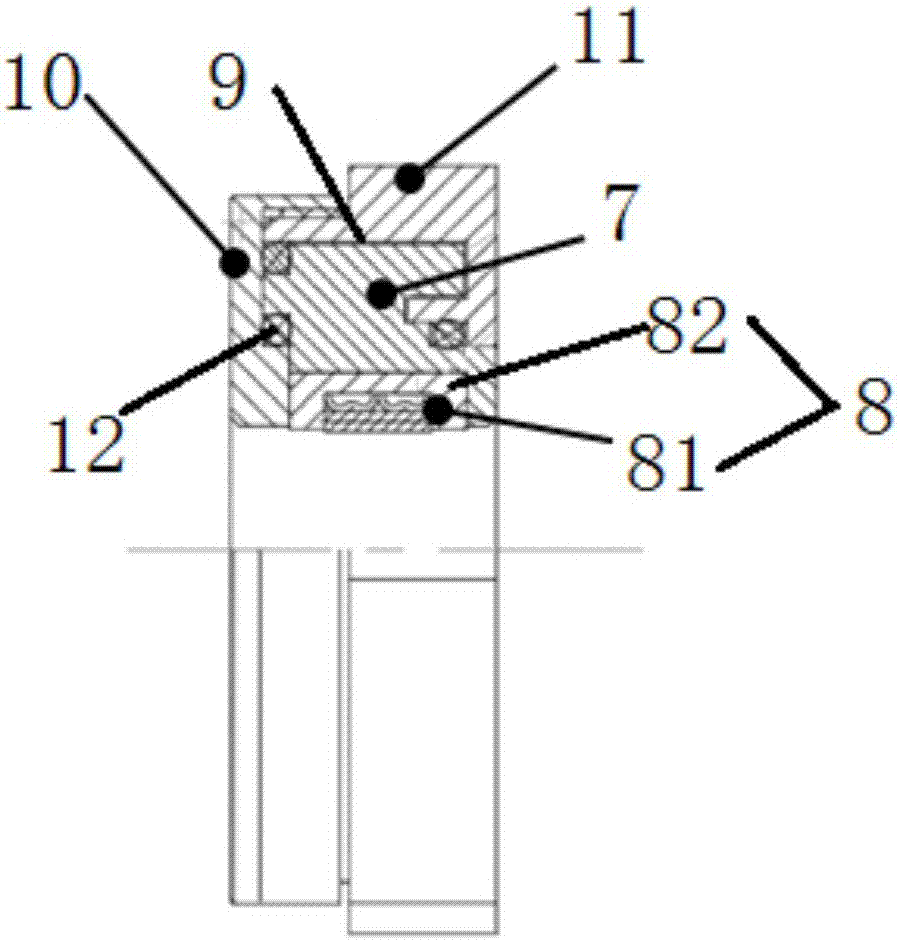

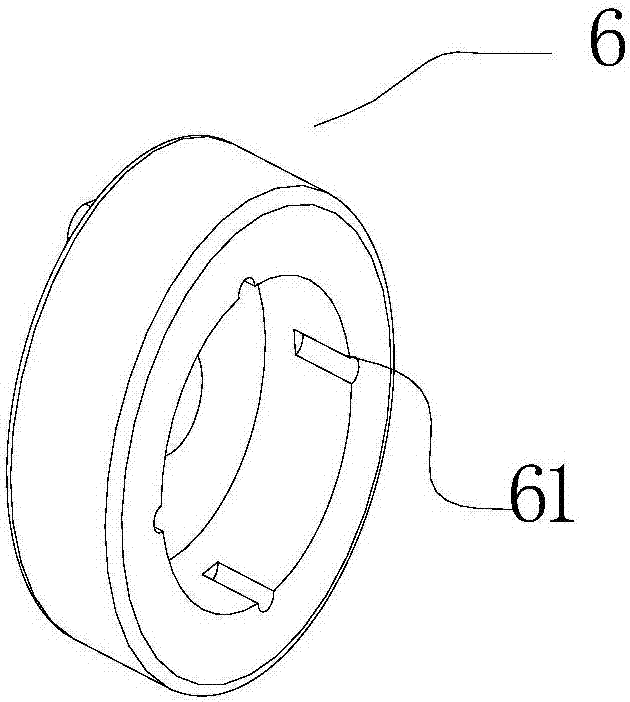

Fluid Seal Assembly

InactiveUS20120153573A1Improved seal assemblyEliminate the problemEngine sealsThermal expansionCylinder block

A fluid seal assembly (the assembly) of the present invention is disposed between an outer surface, i.e. engine block or any other part that requires application of the assembly and a rotatable member, such as, for example a shaft, wherein the assembly circumscribes the shaft and lubricated the shaft and the same rotates around the axis. The assembly includes a primary seal and a wear sleeve. The primary seal includes a casing and a seal element that contacts a sealing surface on the wear sleeve. The casing includes an outer diameter and an outer seal formed onto the outer diameter. The wear sleeve has a cylindrical portion defining an inner diameter and an inner seal formed into the inner diameter of the wear sleeve. The outer and inner seals of the present invention provide improved retention in metal bores during thermal expansion and eliminate spring back effect of the assembly after installation.

Owner:WADE ALFRED ROBERT +2

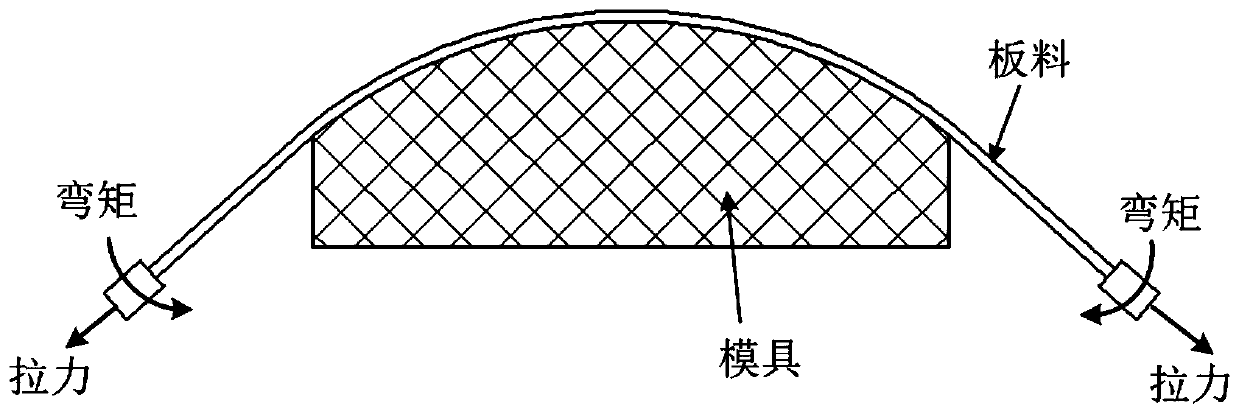

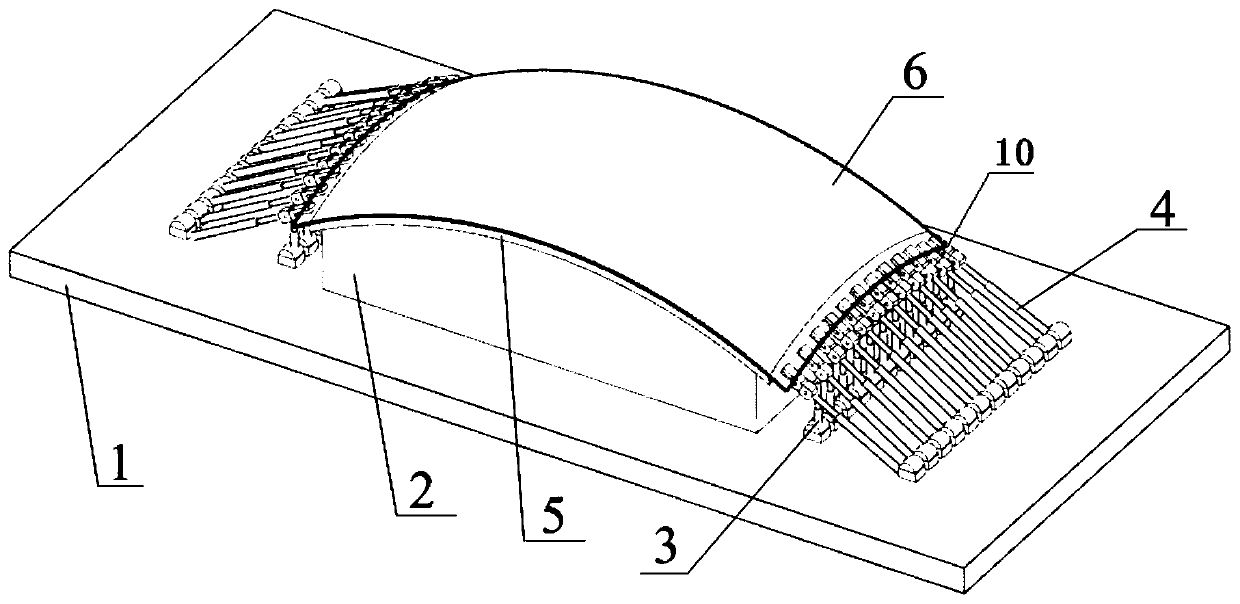

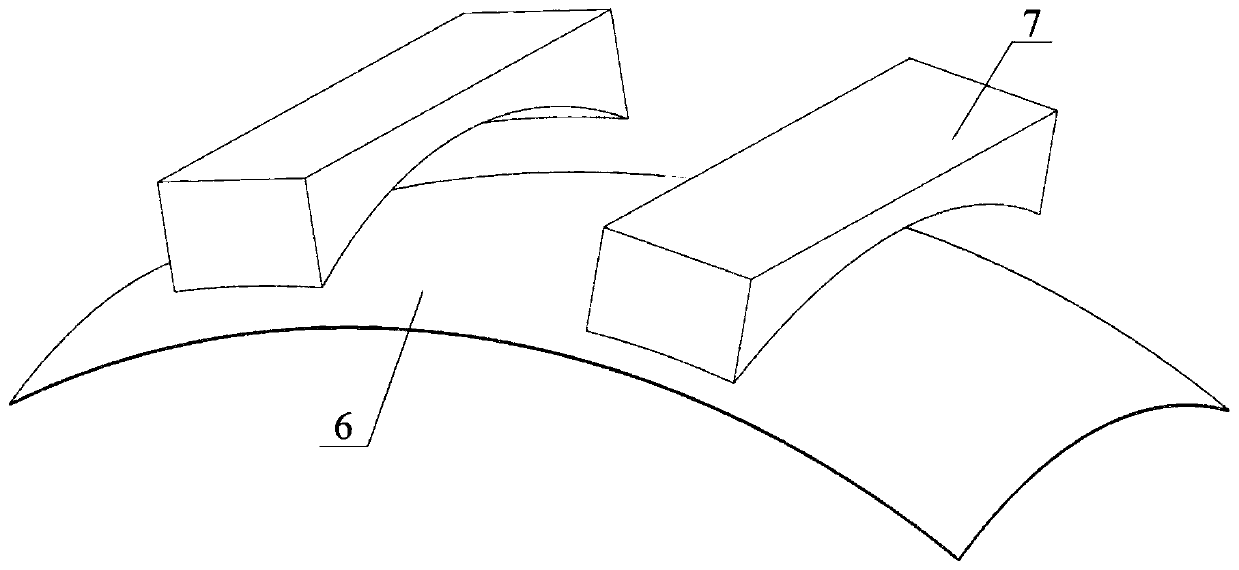

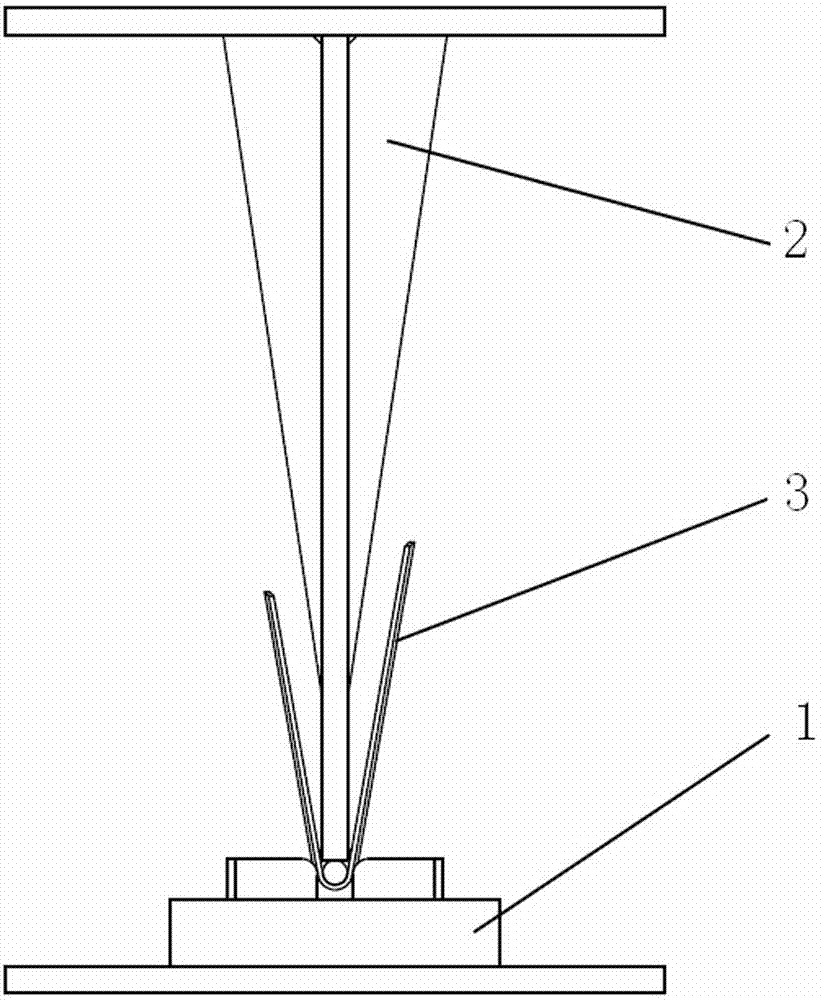

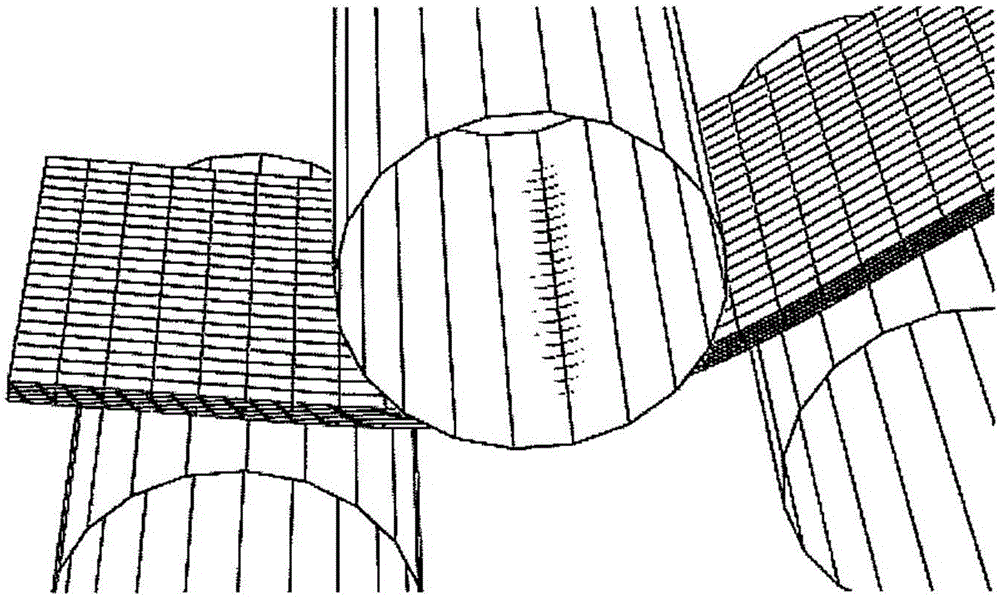

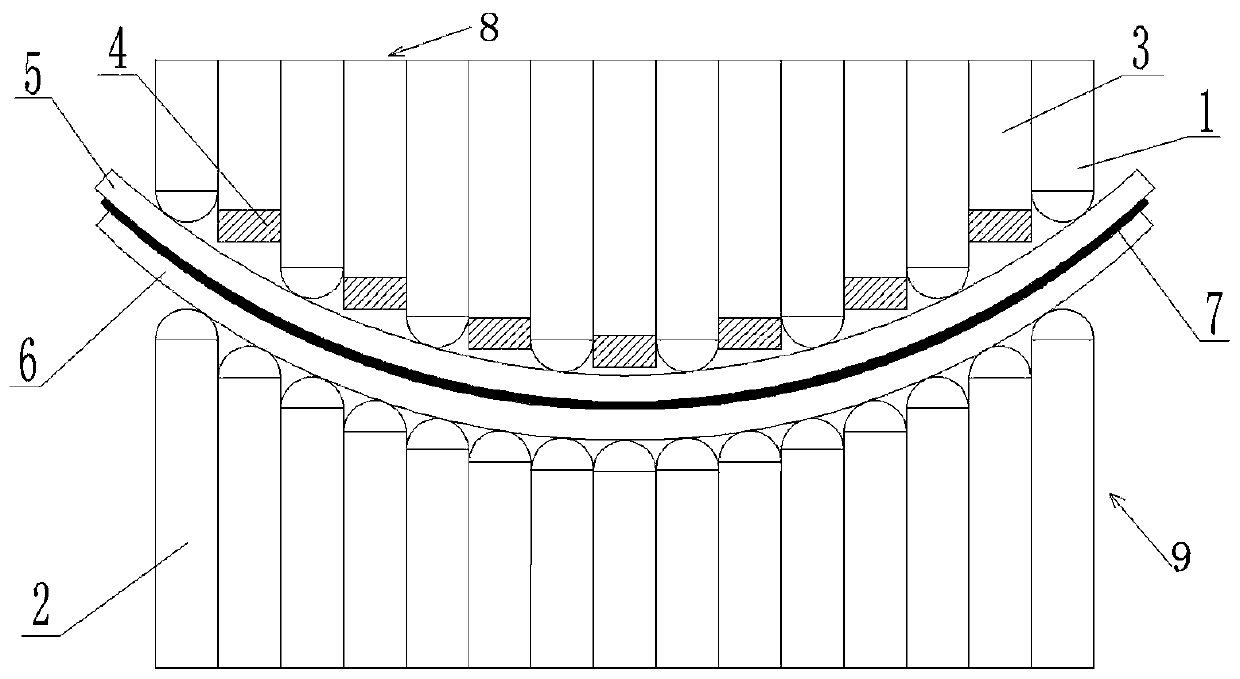

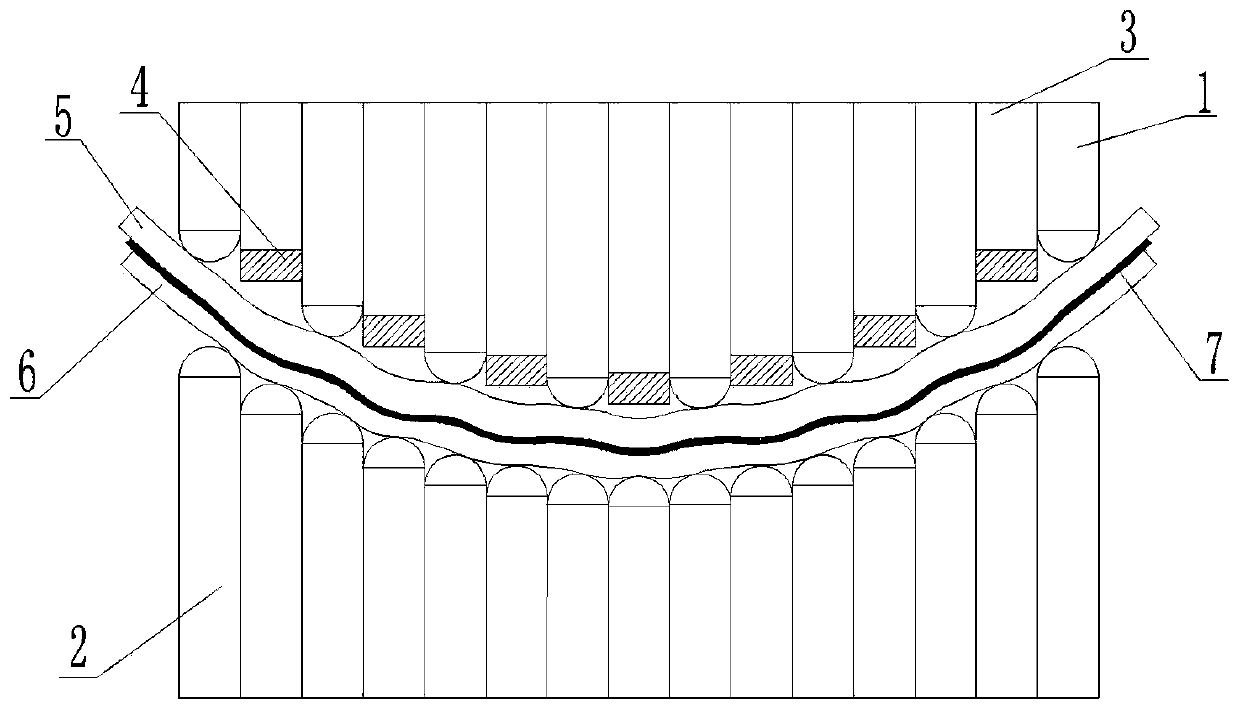

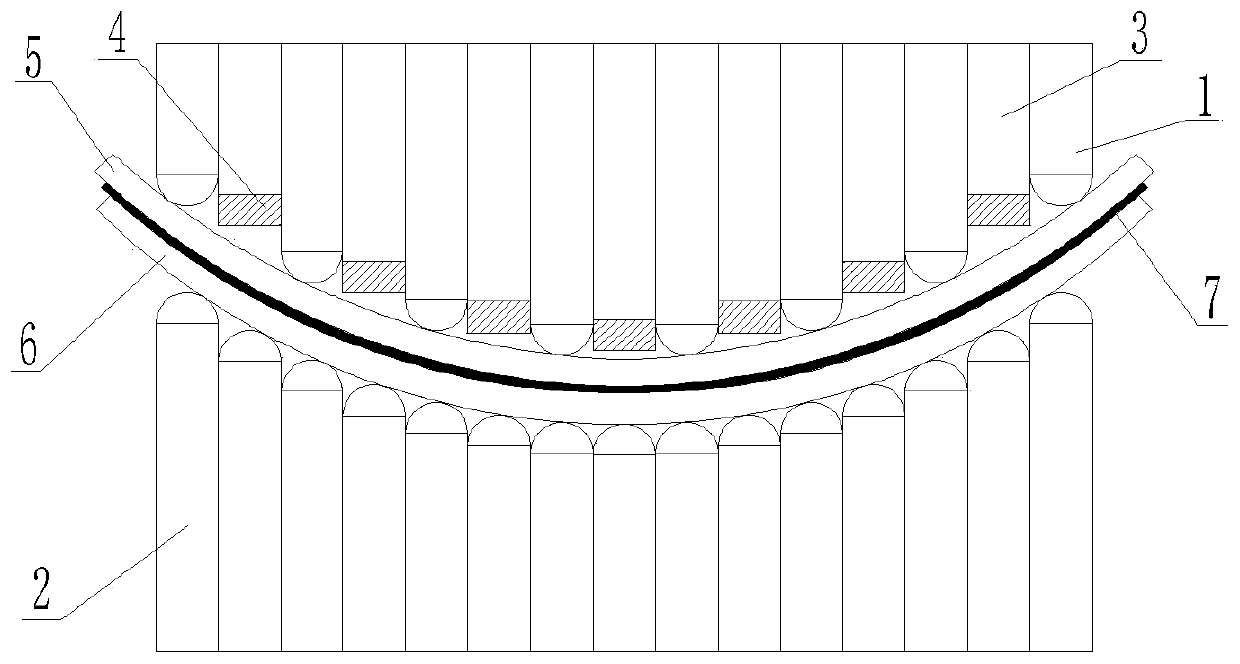

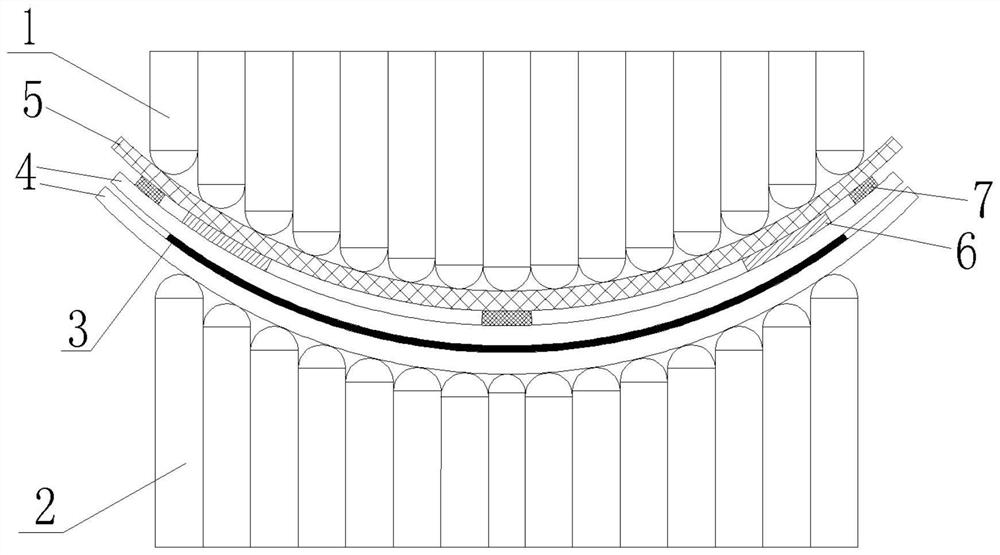

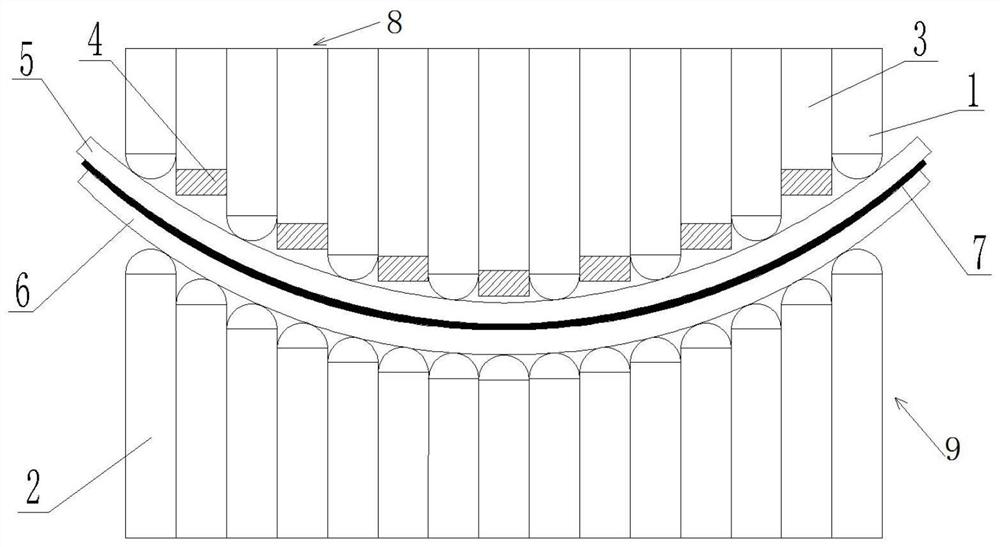

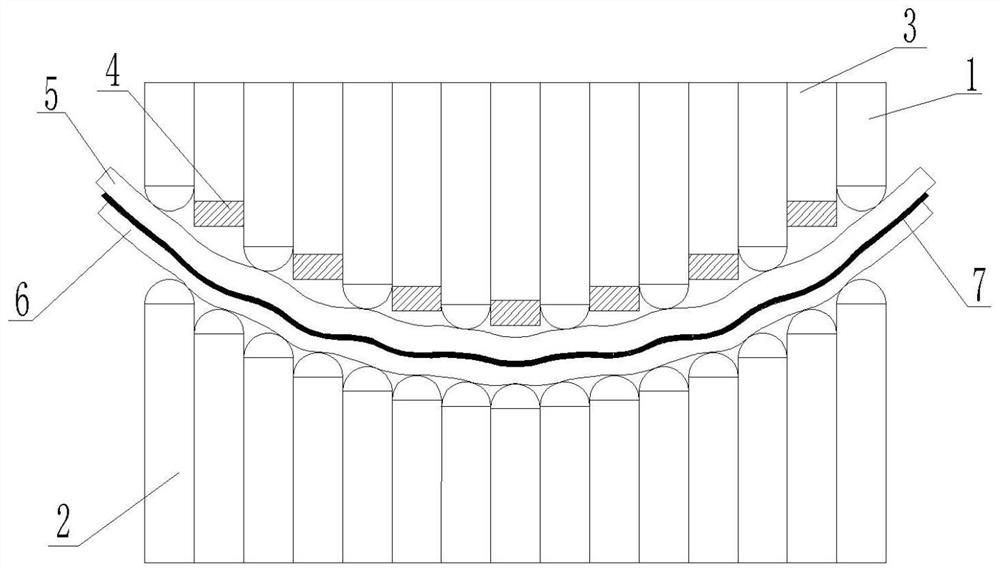

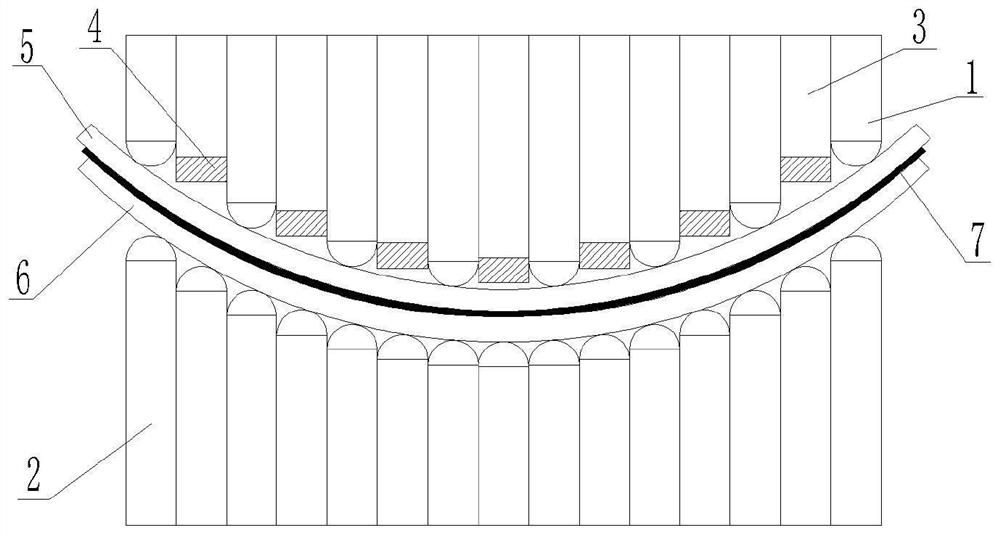

Stretch forming-electromagnetism composite forming device and method for multi-curvature skin piece

ActiveCN111167919ARaise the forming limitIncrease the tensile stressShaping toolsEngineeringElectromagnetic forming

The invention discloses a stretch forming-electromagnetism composite forming device and method for a multi-curvature skin piece. The stretch forming-electromagnetism composite forming device comprisesa bottom plate, a mold and an electromagnetic coil used for forming a plate on the mold, the mold is mounted on the bottom plate, and the electromagnetic coil is arranged above the mold. The stretchforming-electromagnetism composite forming device is characterized in that the stretch forming-electromagnetism composite forming device further comprises a vertical oil cylinder, a tangential oil cylinder, and a chuck used for clamping the edge of the plate, one end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the bottom plate, and the other end of the tangential oil cylinder used for tangentially stretching the plate is hinged to the chuck. A stretch forming and discharging composite process is adopted, stretch forming is conducted to solve a certainspringback problem, then remaining springback is eliminated through electromagnetic force, in this way, the thickness reduction of the plate can meet the design requirement, and meanwhile the requirement for electromagnetic forming energy can also be greatly lowered.

Owner:CENT SOUTH UNIV

Method for forming steel blade in one-time pressing mode

The invention provides a method for forming a steel blade in a one-time pressing mode. The method for forming the steel blade in the one-time pressing mode solves the problem that an existing blade consumes time and labor, cracks easily and affects operation efficiency when being formed in a welding mode. The method for forming the steel blade in the one-time pressing mode comprises the steps that (a) a steel plate is discharged and a positioning datum line is drawn on the steel plate; (b) the central line of a bent lower mould and the positioning datum line of the steel plate are aligned, an upper mould is bent and pressed downwards, and the steel plate is prebent to 17-23 degrees; (c) the bent steel plate is heated; (d) the heated bent steel plate is put into a forming lower mould, and an inner core is put into the bent steel plate; (e) a front forming upper mould and a rear forming upper mould are pressed downwards together until the blade is formed; (f) the front forming upper mould and the rear forming upper mould are moved upwards by a certain amount of displacement, together pressed rear ends of the blade are separated due to elasticity, and the inner core is taken out; (g) the front forming upper mould and the rear forming upper mould are downwards pressed again, and then after the rear forming upper mould is rotated upwards, the rear ends of the blade are welded to obtained the formed blade. The method for forming the steel blade in the one-time pressing mode has the advantages of being low in cost, simple in structure and convenient to machine.

Owner:山西渝煤科安运风机有限公司

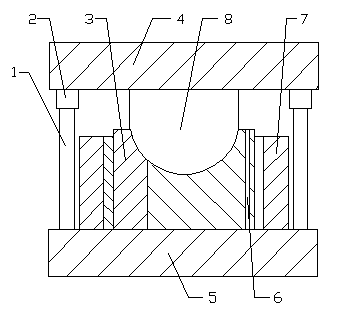

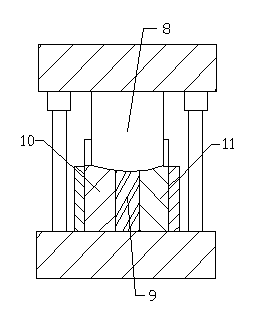

Automobile brake shoe wing plate bending die

The invention discloses an automobile brake shoe wing plate bending die which comprises an upper die and a lower die. The lower die mainly comprises a guide pillar, a positioning plate, a lower die plate, a positioning pin, a fixing plate, a female die ejector block, a female die left part and a female die right part; and the upper die mainly comprises a guide sleeve, an upper die plate and a male die. The bending die adopts design of an upper and lower die structure; a U-shaped section is formed by the female die left part, the female die right part and the female die ejector block; in the forming process, a workpiece is clamped; the workpiece is prevented from running in the pressure forming process; and a correcting force generated by the die is acted on the turned position of the bent part, so that the effect of eliminating rebound is achieved.

Owner:CHENGDU KEZHIHAO MACHINERY EQUIP TECH SERVICE

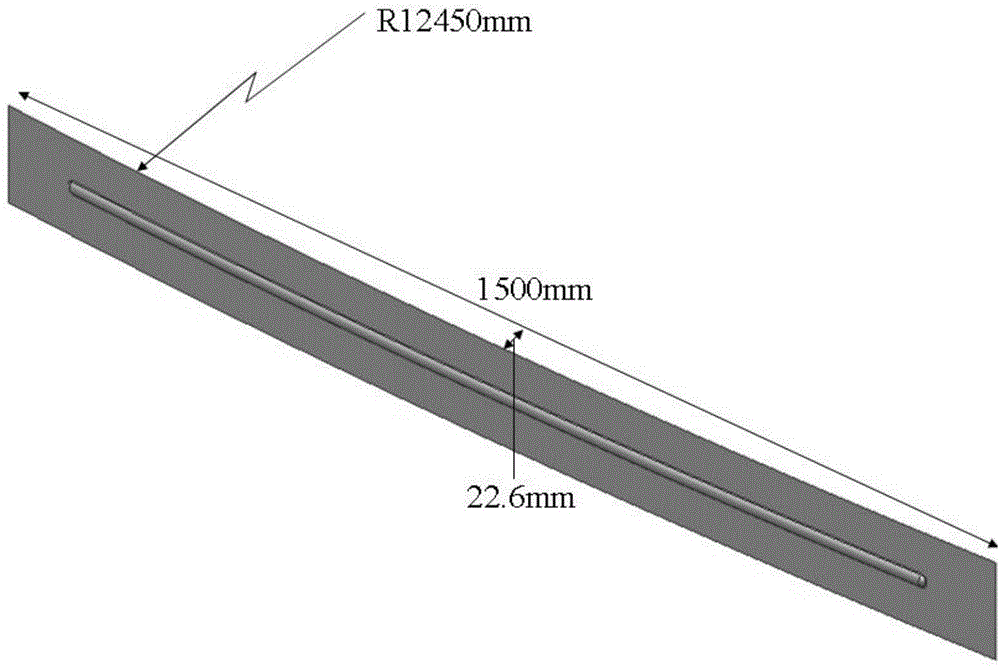

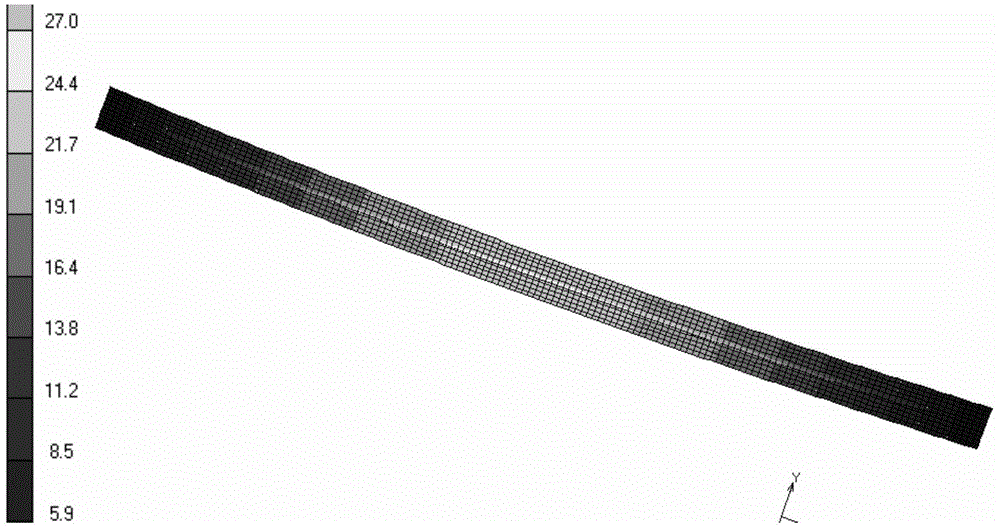

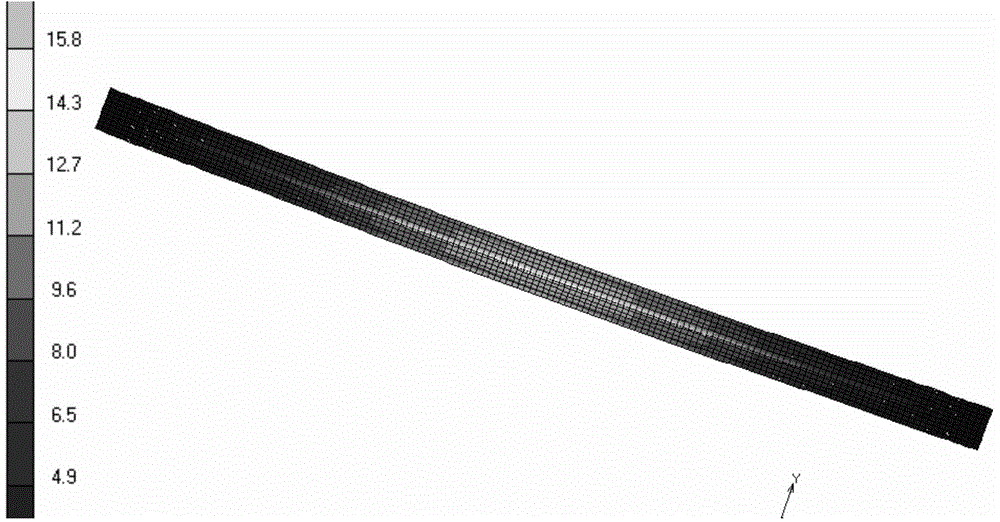

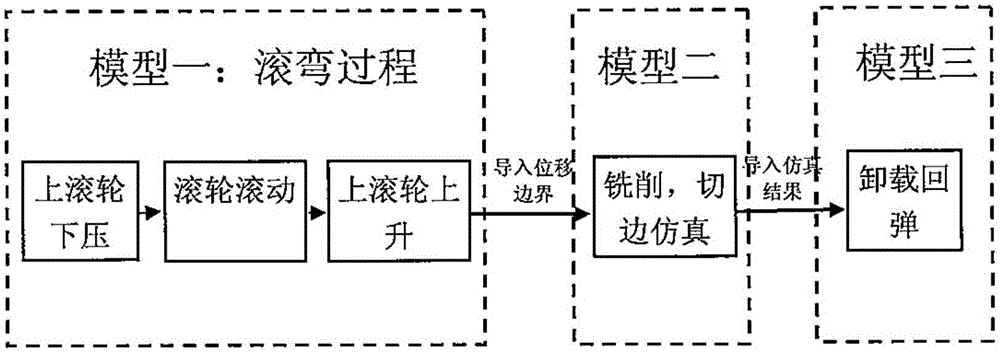

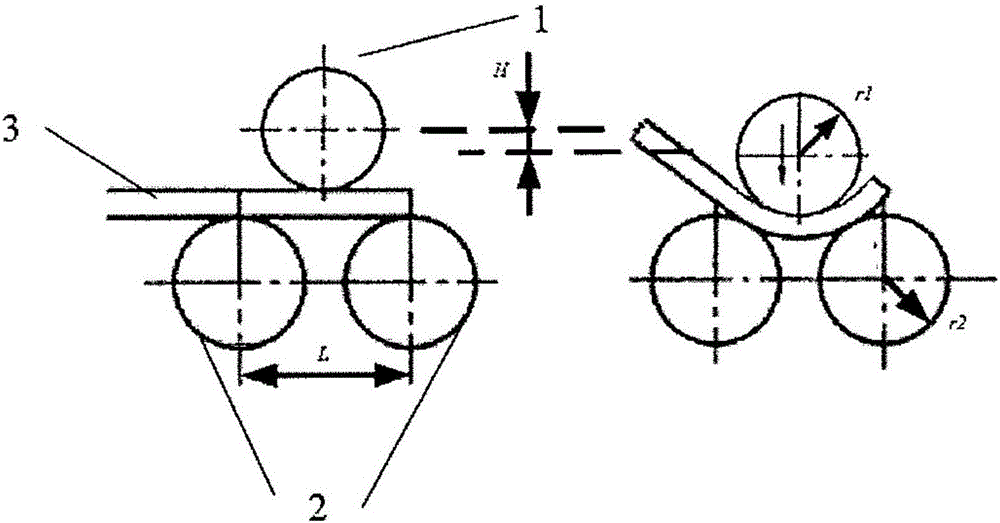

Finite element simulation method for roll bending-milling process of large-scale stepped thin-walled workpiece

ActiveCN106709148AAvoid performance-degrading bugsEliminate springbackGeometric CADDesign optimisation/simulationEngineeringElastic plastic

The invention discloses a finite element simulation method for a roll bending-milling process of a large-scale stepped thin-walled workpiece. The method comprises the following steps of: establishing a roll bending model of a plate material which is an elastic plastic body, and carrying out grid generation by adoption of shell units so as to simulate a roll bending process of the plate material; simulating a side scraping process through a sub-model technology, segmenting a to-be-milled area of the plate material according to a part structure of the large-scale stepped thin-walled workpiece, and modifying thickness values of shell units in different areas of the plate material so as to simulate a milling process of the large-scale stepped thin-walled workpiece; and simulating a spring-back process. According to the finite element simulation method for the roll bending-milling process of the large-scale stepped thin-walled workpiece, the roll bending-milling process of the large-scale stepped thin-walled workpiece can be accurately controlled, and the spring-back in the machining process can be controlled and even eliminated, so that the defect that the material performance is reduced due to the usually adopted means such as later shape correction, repeated roll bending and the like is avoided.

Owner:COMAC +1

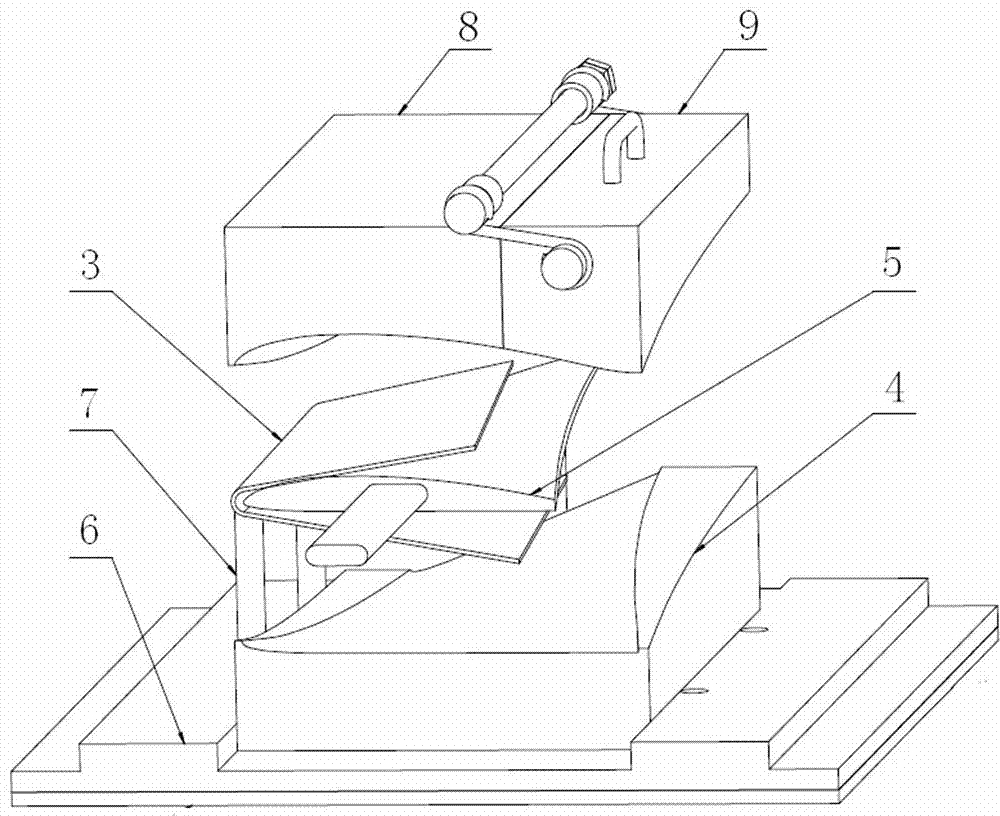

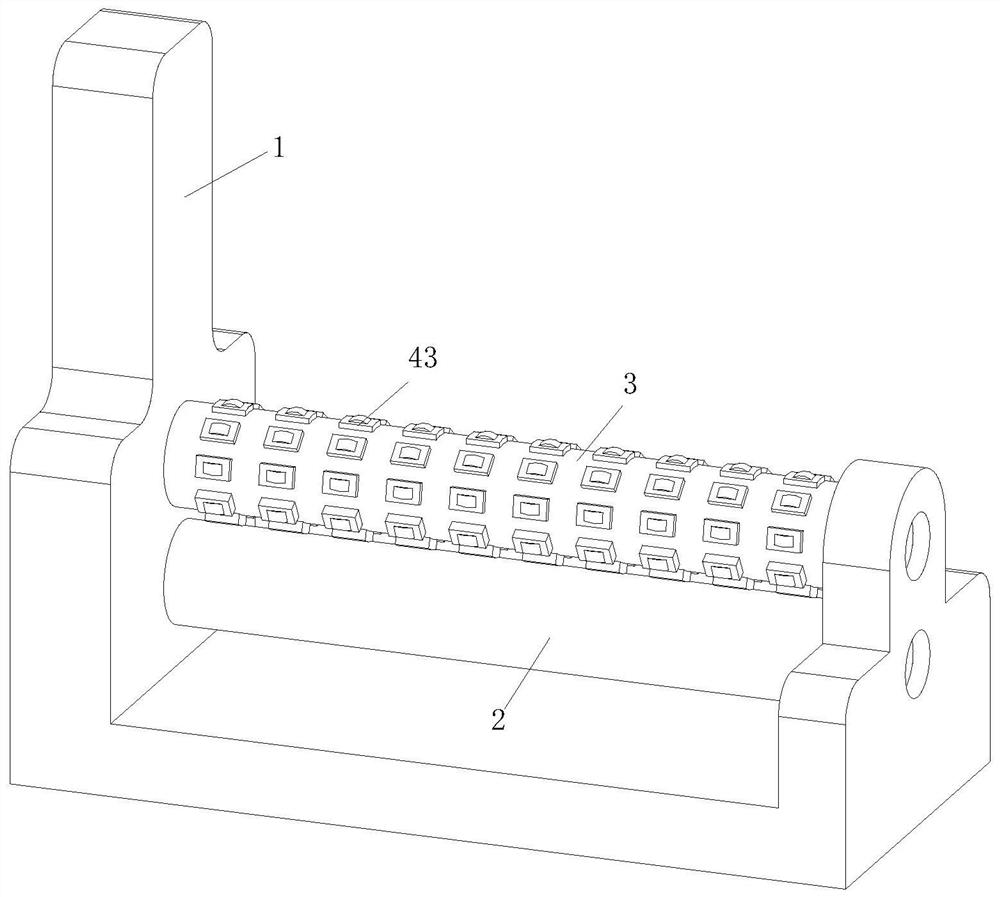

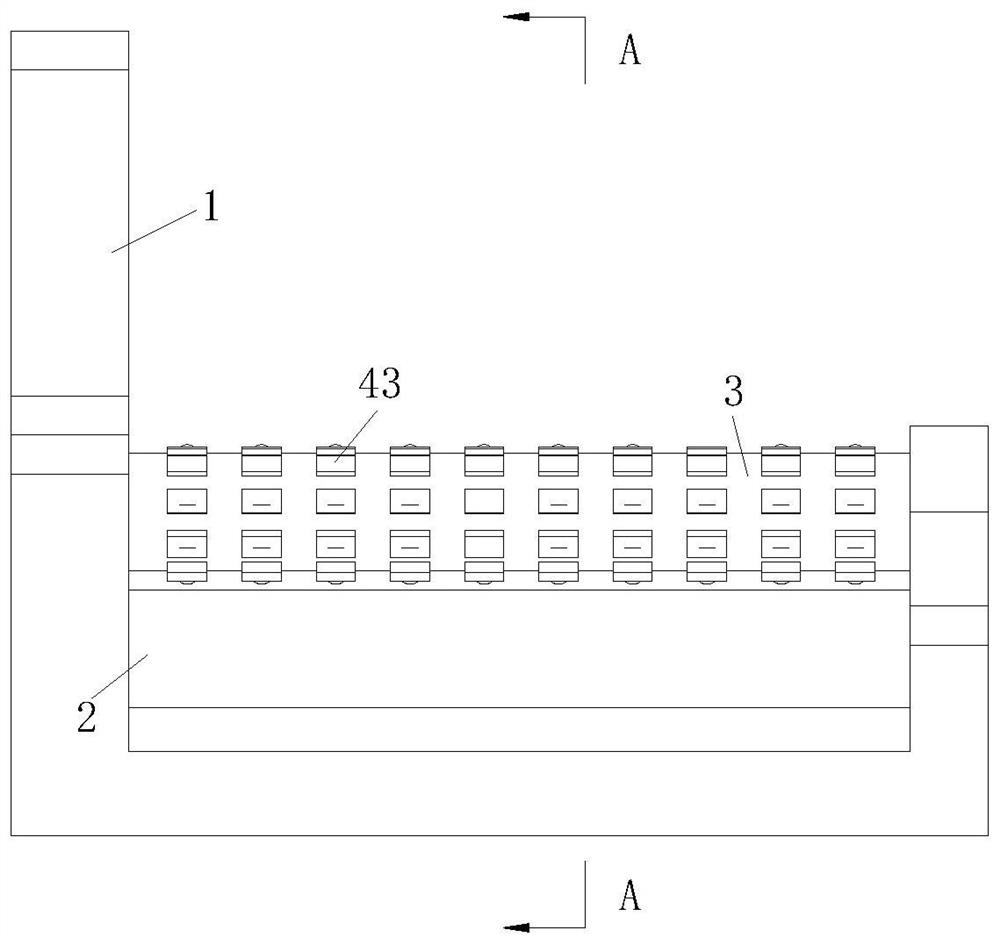

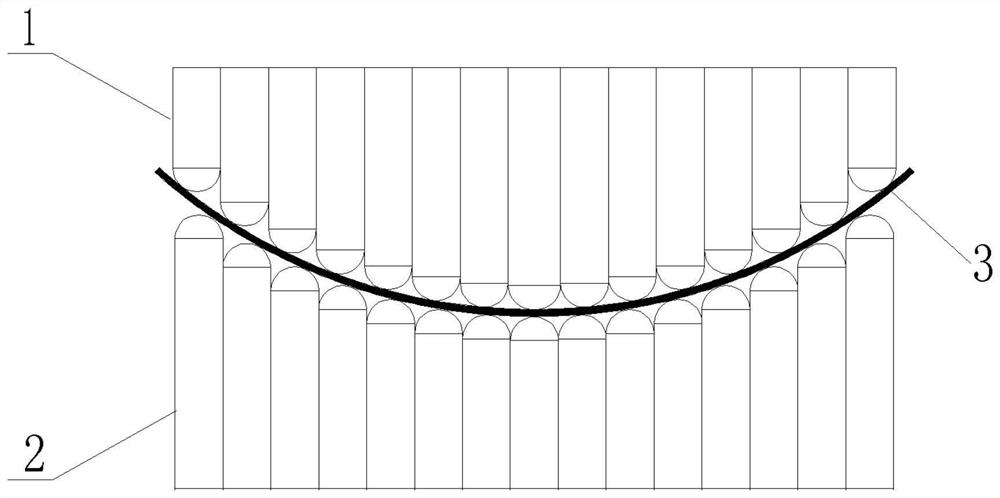

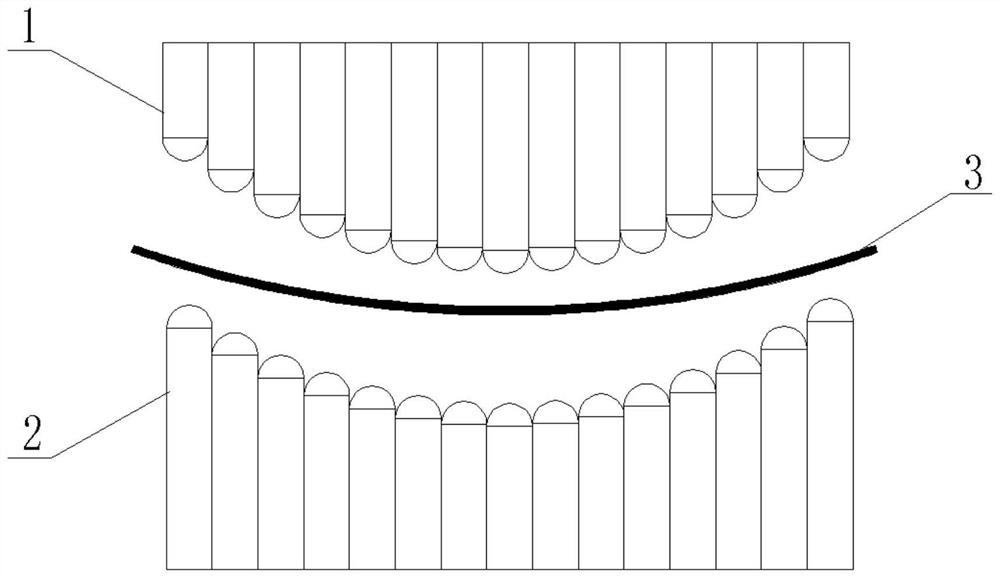

Electromagnetic-multipoint composite forming device and forming method for sheet material

The invention discloses an electromagnetic-multipoint composite forming device for a sheet material. The device comprises upper punching heads and lower punching heads; a plurality of the upper punching heads are arrayed to form a male die; a plurality of the lower punching heads are arrayed to form a female die; a coil supporting rod which can be displaced up and down is arranged in the male dieand / or the female die; and an electromagnetic coil which can form the sheet material is arranged at one end, close to the sheet material, of the coil supporting device. According to the electromagnetic-multipoint composite forming device for the sheet material, on one hand, different shapes of sheet materials can be rapidly formed by forming a shape changeable flexible die by controlling the positions of the upper punching heads and the lower punching heads by a computer; and on the other hand, the rebounding of the sheet material is greatly reduced or even completely eliminated through electromagnetic forming, so that the sheet material forming quality is improved.

Owner:CENT SOUTH UNIV

Polyurethane rubber bending die

The invention relates to a polyurethane rubber bending die which comprises a male die body, rubber and a female die body. A rubber pad is arranged on the rubber. A pressure reduction groove is formed in the middle on the top of the rubber downwards. A steel cushion plate is arranged in a pit bottom of the female die body. The upper surface of the steel cushion plate is a curved surface. Steel bars are arranged in the two sides of the steel cushion plate in a cushioned mode. The steel bars are tangent to the top ends of the female die body, a baffle and the rubber. A cavity is formed between the rubber and the steel cushion plate. The curvature radius of the upper surface of the steel cushion plate is equal to the sum of the curvature radius of a rubber forming part and the thickness of the rubber cushion. Due to the fact that the cavity is formed between the rubber and the steel cushion plate, rubber pressure formed during bending forming can be reduced; due to the fact that the steel cushion plate is additionally arranged, and the upper surface of the steel cushion plate is the curved surface, it can be ensured that forming force on the whole curved surface is uniform; due to the fact that the pressure reduction groove is formed in the top of the rubber, side pressure formed during forming can be increased, springback can be eliminated, and the workpiece quality and dimensional accuracy are improved.

Owner:ANHUI YUHUI ELECTRONICS TECH

Numerically-controlled machine tool enclosing plate machining process

The invention discloses a numerically-controlled machine tool enclosing plate machining process, and aims at solving the problem of same-direction bending of edges of an enclosing plate. According tothe technical scheme, the machining process is characterized in that the steps of material selecting, side edge bending, two-end bending, trimming forming and excess material cutting are sequentiallyconducted, and the enclosing plate which has the decoration effect is formed by an enclosing plate profile through the steps of one-time side edge bending, first-time two-end bending and second-time two-end bending. According to the numerically-controlled machine tool enclosing plate machining process, the four sides of the enclosing plate profile can be bent towards the same direction.

Owner:浙江克拿德电子有限公司

Resilience-proof device for bending die

Owner:HEFEI LANGJIA MECHANICAL & ELECTRICAL EQUIPCO

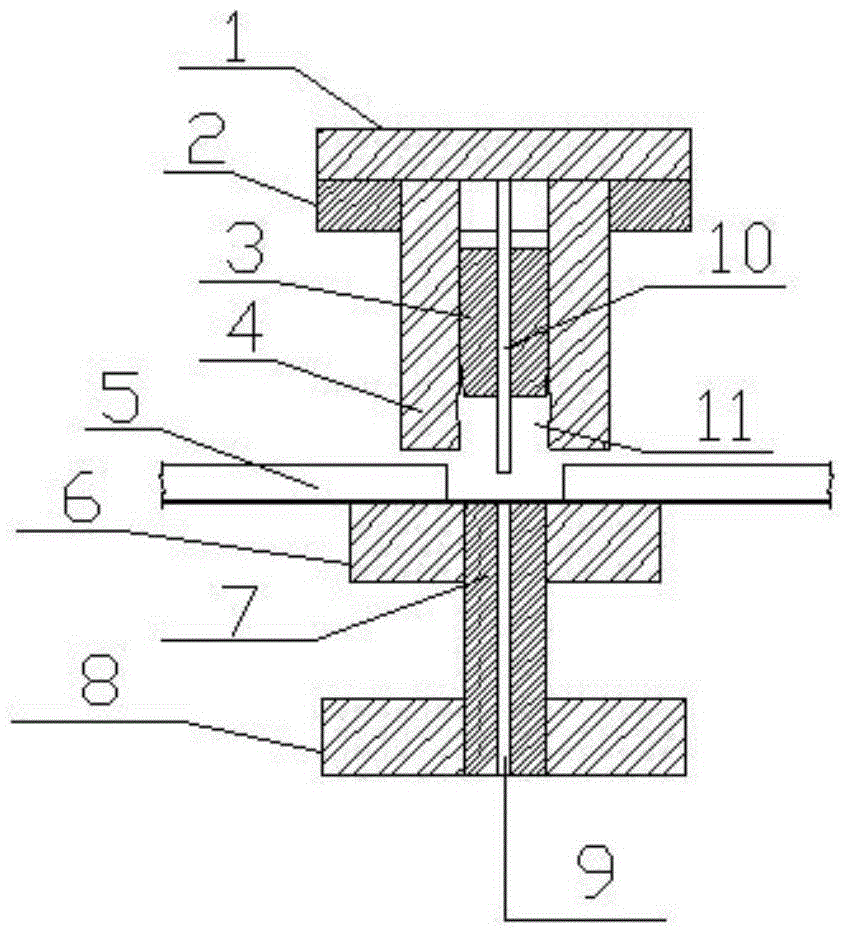

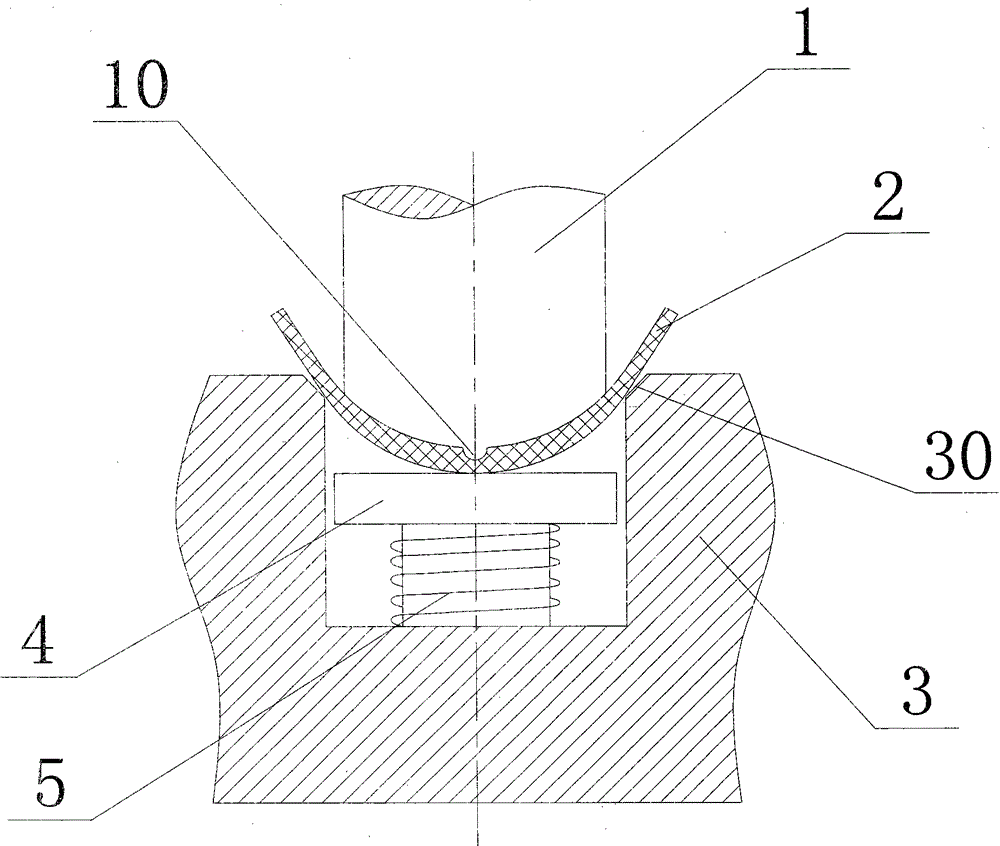

Orthopedic clamp for microwave tube grid and orthopedic method thereof

ActiveCN101814410AEliminate internal stressEliminate springbackNon-emitting electrodes manufactureMicrowave tubeHydrogen

The invention discloses an orthopedic clamp for a microwave tube grid and an orthopedic method thereof. The orthopedic clamp comprises a base and a pressure plate positioned above the base; a male die is provided with a spherical surface and matched with the base through the spherical surface, and the surface of the male die contacted with the base is a smooth spherical surface; the pressure plate is provided with a hollow part matched with the spherical surface; one end, opposite to the spherical surface, of the male die, is matched with a pressure block; and the base and the pressure plate are provided with coaxial positioning pin holes and positioned and fixed through the positioning pin holes. The orthopedic clamp with the structure and the orthopedic method thereof are characterized in that the molded grid is arranged on the grid orthopedic clamp and orthopedic heat treatment is performed in a hydrogen furnace so as to eliminate internal stress generated during pressing and molding the grid, size the grid according to the designed curved surface radius, eliminate resilience during molding the grid, make the curved surface radius of the orthopedic annealed grid meet the designrequirement and ensure the quality of the grid.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Hydraulic hollow tube springback control method and device

The invention relates to the field of tube part manufacturing, in particular to a tubular hydraulic forming part machining method and device. The hydraulic hollow tube springback control method comprises the steps that the initial bent angle of a mold is set according to the preforming target angle of a part; the part is placed into the mold to be preformed; and the part is taken out of a mold cavity after being preformed, the actual bent angle of the part is measured, the bent angle of the mold is adjusted, and the new bent angle of the mold is the bent angle of the mold during final part machining. The hydraulic hollow tube springback control device is formed by combining a plurality of independent mold cavity sections. The axes of rotating shafts are rotation centers corresponding to the bent positions of the machined part. Each mold cavity section is provided with a springback adjusting mechanism. According to the tubular hydraulic forming part machining method and device, springback in the tube part forming process can be eliminated, the part springback amount does not need to be pre-calculated, and springback can be directly and flexibly adjusted through the device, so that the part development cycle in the early period is shortened, the hydraulic forming mold abrasion is reduced, and the size precision of the hydraulic forming part is improved.

Owner:SHANGHAI BAOSTEEL NEW TECH PARTS

Fluid seal assembly

InactiveUS20140250688A1Eliminate the problemHigh retention rateEngine sealsMetal-working apparatusThermal expansionEngineering

A fluid seal assembly (the assembly) of the present invention is disposed between an outer surface, i.e. engine block or any other part that requires application of the assembly and a rotatable member, such as, for example a shaft, wherein the assembly circumscribes the shaft and lubricated the shaft and the same rotates around the axis. The assembly includes a primary seal and a wear sleeve. The primary seal includes a casing and a seal element that contacts a sealing surface on the wear sleeve. The casing includes an outer diameter and an outer seal molded onto the outer diameter. The wear sleeve has a cylindrical portion defining an inner diameter and an inner seal molded into the inner diameter of the wear sleeve. The outer and inner seals of the present invention provide improved retention in metal bores during thermal expansion and eliminate spring back effect of the assembly after installation.

Owner:AB SKF

Metal plate leveling machine

The invention belongs to the technical field of leveling machines, and particularly relates to a metal plate leveling machine. The metal plate leveling machine comprises a rack, a fixed roller, a working roller and a controller, wherein the two ends of the fixed roller and the two ends of the working roller are rotatably arranged on the rack, and the working roller is arranged above the fixed roller; and a first cavity is arranged in the working roller, a set of first holes are uniformly arranged in the working roller at equal intervals, the set of first holes are communicated with the first cavity, and an anti-rebound mechanism is arranged in the first cavity and comprises a motor, a first shaft, a cam and an anti-rebound protruding block. Through the arrangement of the anti-rebound mechanism, anti-rebound treatment is carried out in real time in the metal plate leveling process, rebounding possibly occurring after metal plate leveling is eliminated, meanwhile, the stress balance state of materials in the metal plate is changed through the anti-rebound mechanism, rebounding is eliminated, and the metal plate leveling quality is further improved.

Owner:李学海

Thermal punch forming mold for super-strength steel

The invention provides an ultra-high strength steel thermal punching molding process and a molding die thereof. Before the thermal punching molding of ultra-high strength steel sheet, the thermal punching molding process is used for heating parts which are in contact with the ultra-high strength steel sheet in a die and need to be punched, so as to lead the surface temperature of the parts to reach or exceed martensite temperature of the ultra-high strength steel. Then, the ultra-high strength steel sheet which is heated to be totally austenitized is put in the die to be punched and molded. When closed, the thermal punching die is cooled. The die parts which are in contact with the molded parts are utilized for quenching the molded parts. The thermal punching molding die comprises a convex die, a concave die and a control unit. An electrothermal element and a cooling water channel are arranged in the convex die and the concave die. A temperature sensor is arranged in the convex die and the concave die. A reset switch and a pressure plate are respectively arranged on lateral sides of the concave die and the convex die. The ultra-high strength steel thermal punching molding process and the molding die thereof avoid cracks on surfaces and at the inner parts of the molded parts, eliminate the part molding resilience and ensure the precision and the quality of products.

Owner:SHANDONG UNIV

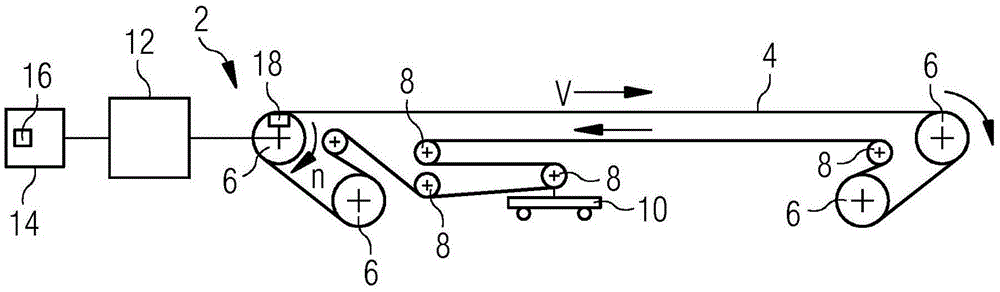

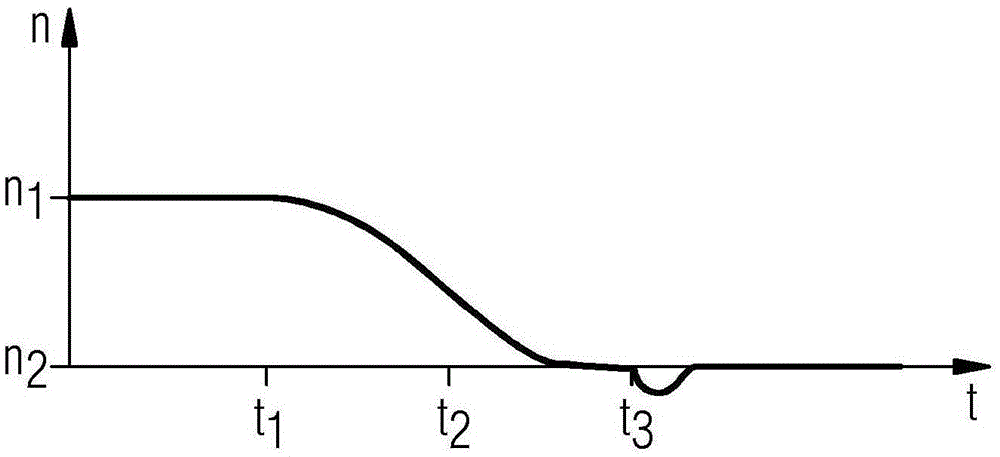

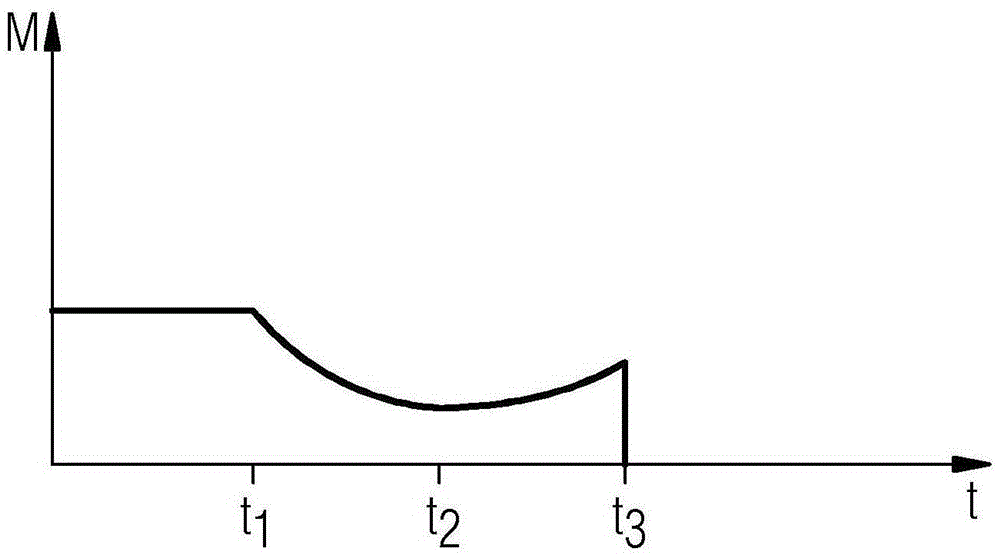

How the transmission device works

ActiveCN104066662BAvoid strainEliminate springbackConveyorsControl devices for conveyorsTransmission beltControl theory

Owner:SIEMENS AG

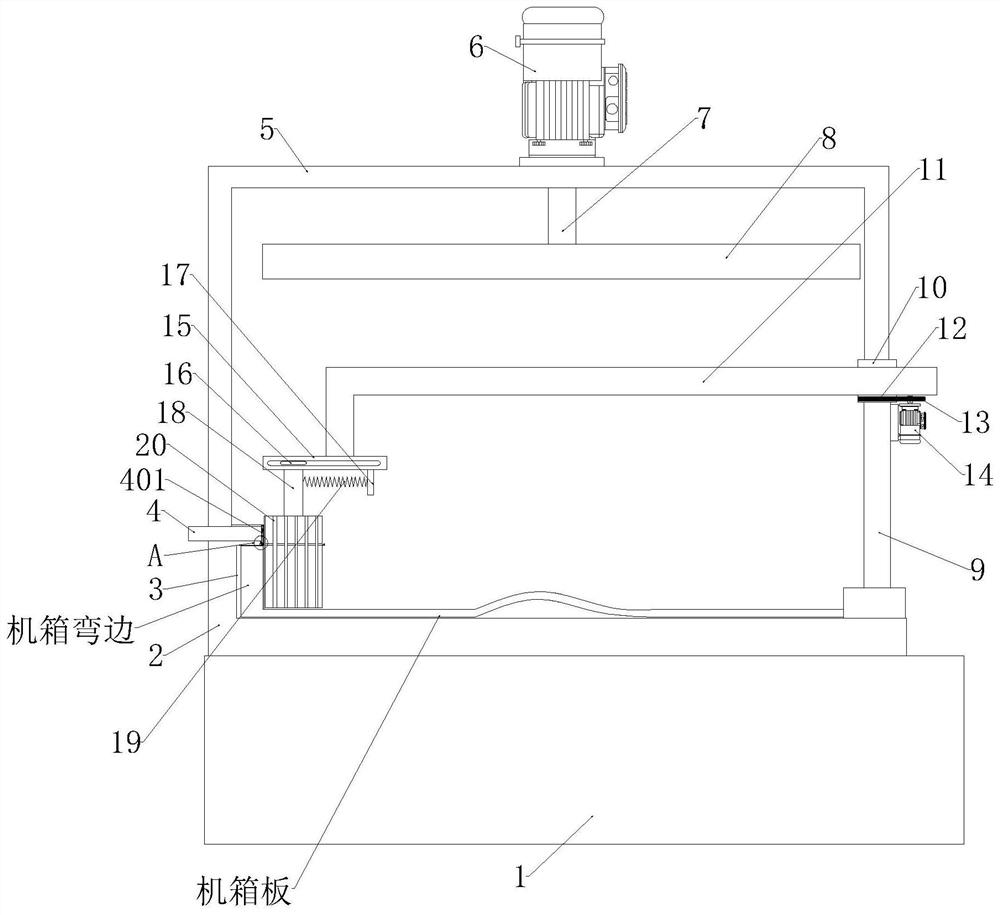

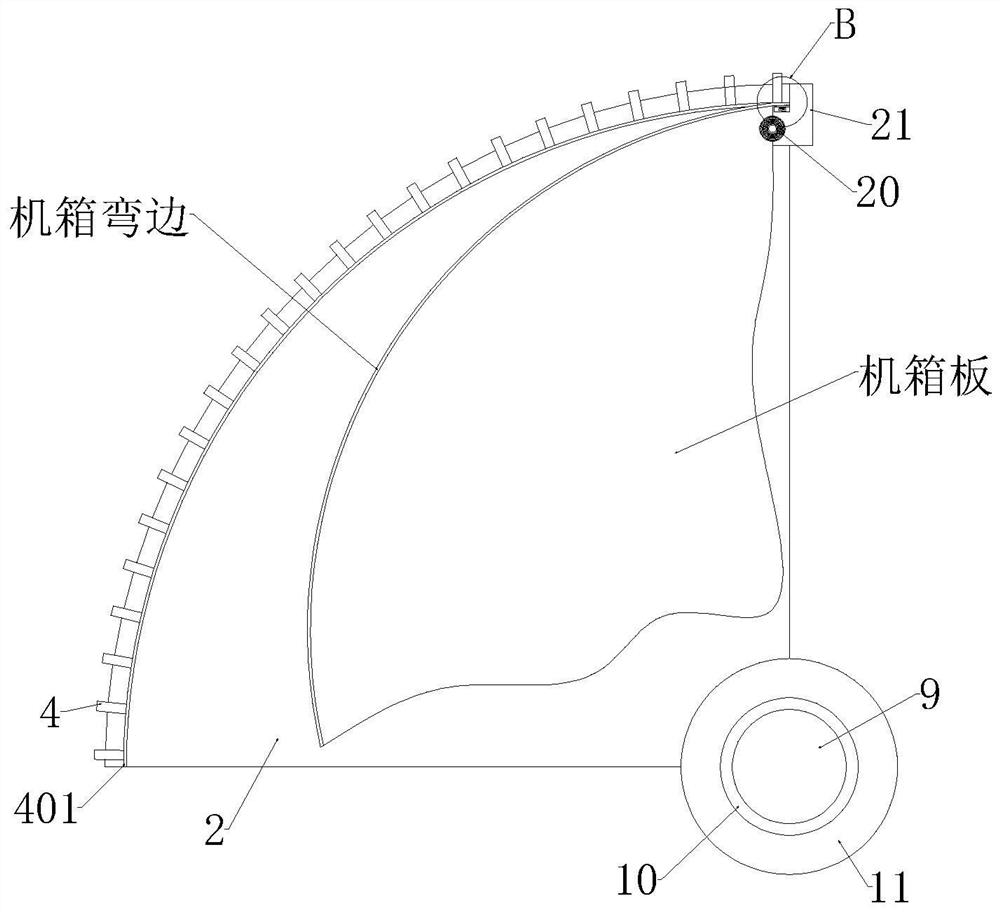

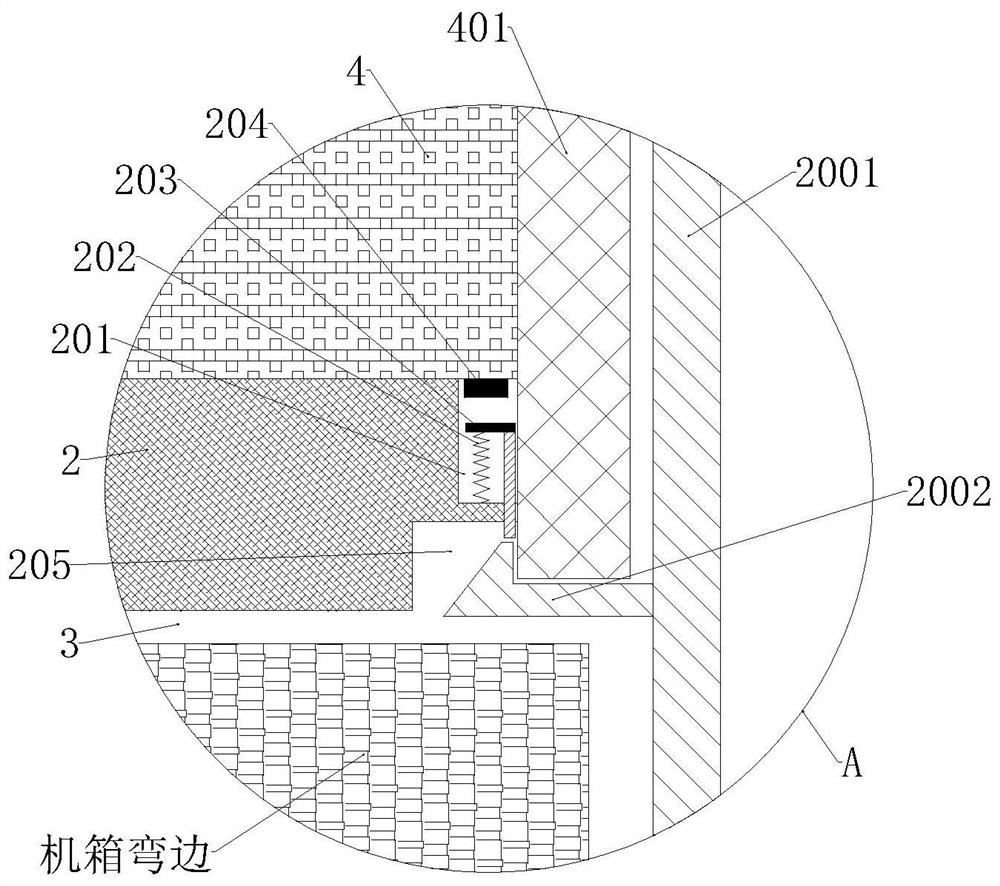

Intelligent control case surface shaping treatment equipment

The invention provides intelligent control case surface shaping treatment equipment, and relates to the technical field of case shaping. The intelligent control case surface shaping treatment equipment comprises a bottom supporting box, the bottom supporting box is of a square block structure, a bottom supporting tray is fixedly mounted at the top end of the bottom supporting box, and the bottom supporting tray is of a fan-shaped tray structure. According to a winding pressing sheet, a plurality of pressing steel bars are flexibly connected and wound into a structure similar to a tape measure, so that the pressing steel bars are orderly stretched during rotation, and each pressing steel bar is correspondingly connected with an iron block on each electromagnetic relay in an adsorption and fitting manner; and a locking clamping hook is fixedly arranged in the middle of the outer circle face of each pressing steel bar, and a clamping hook of each locking clamping hook faces upwards, so that the locking clamping hooks stretch into clamping grooves while the pressing steel bars are attracted to the iron blocks on the electromagnetic relays, locking connection is carried out when the pressing steel bars and the iron blocks are attracted, and therefore, the plurality of pressing steel bars can be effectively improved to press and fix the shaped bent edge of a case.

Owner:HANGZHOU YUHANG ASSOC FENG YU INSTR

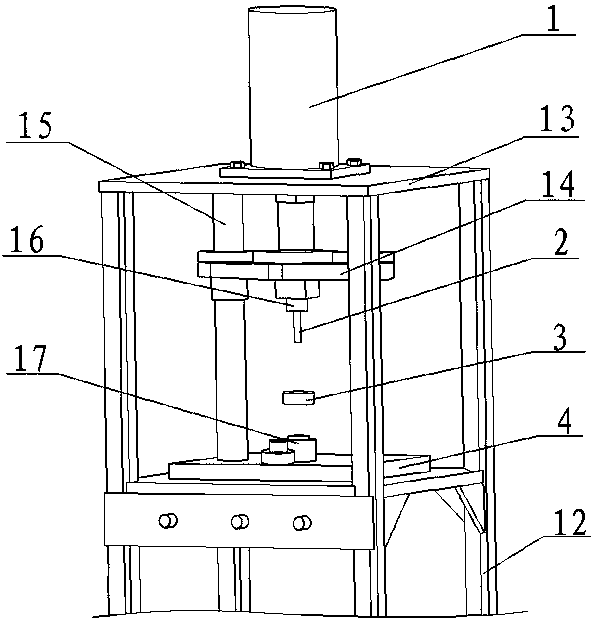

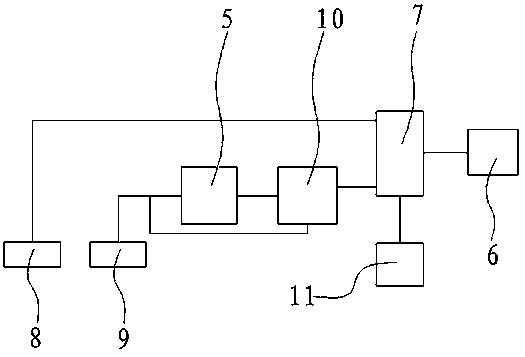

A rubber sleeve press-fitting device equipped with an automatic pressure-holding system and a press-fitting method

ActiveCN110227924BEliminate springbackReduce work intensityMetal working apparatusCouplingEngineering

The invention relates to a rubber sleeve press fitting facility with an automatic pressure keeping system and a press fitting method. The rubber sleeve press fitting facility comprises a driving device, a press head, guide sleeves, an operation platform frame, a starting switch and a time relay. The operation platform frame is used for allowing couplings to be placed. The output end of the drivingdevice is fixedly connected with the press head and used for driving the press head to move towards the operation platform frame. The press head is used for fixing rubber sleeves, pressing the rubbersleeves into the guide sleeves in sequence, enabling the rubber sleeves to penetrate through the guide sleeves arranged on the movement path of the press head, and then pressing the rubber sleeves into the couplings. The starting switch is electrically connected with the time relay and the driving device through wires, and used for controlling the start and stop of the driving device and controlling the driving device to drive the press head to keep the state of pressing the rubber sleeves in the couplings in the set time period. By the adoption of the rubber sleeve press fitting facility with the automatic pressure keeping system and the press fitting method, the purpose that after the rubber sleeves are pressed and installed, the pressure keeping time is accurately controlled is achieved, the phenomenon that due to the fact that a conventional press machine does not have the pressure keeping process, the rubber sleeves conduct springback movement is eliminated, the potential qualityhazard that due to the springback movement of the rubber sleeves, the press fitting sizes of the rubber sleeves cannot be controlled is eliminated, and the potential quality hazard which exists due to the fact that the pressure keeping time is excessively short is fundamentally eliminated.

Owner:LOVOL HEAVY IND CO LTD

Forming process of a straddle mower dust cover

Owner:NANTONG FULEHUA MACHINERY CO LTD

A multi-point-electromagnetic gasification composite forming device and forming method for plates

The invention discloses a multi-point-electromagnetic gasification compound forming device and forming method for plates, including an upper punch and a lower punch that can move up and down, a plurality of upper punch arrays form an upper punch group, and multiple A lower punch array forms a lower punch group, which is characterized in that an elastic clamping assembly, a first elastic pad and an electrified metal sheet are arranged between the upper punch group and the lower punch group, and the metal sheet is arranged on the elastic Between the clamping assembly and the first elastic pad, the elastic clamping assembly includes a second elastic pad for clamping on the upper and lower sides of the plate. On the one hand, the present invention can control the position of the upper punch and the lower punch by the computer to form a "flexible mold" with variable shape, so as to realize the rapid forming of plates of different shapes; The amplitude is reduced or even completely eliminated, which improves the quality of sheet forming.

Owner:CENT SOUTH UNIV

Handle adjusting mechanism for steering pipe column and vehicle

ActiveCN107487354AReduce rotation speedEliminate springbackSteering controlsLocking mechanismEngineering

The invention discloses a handle adjusting mechanism for a steering pipe column and a vehicle. The handle adjusting mechanism comprises a clamping support and a connecting shaft, wherein the clamping support is used for clamping the pipe column, and the connecting shaft is used for fixedly penetrating through the pipe column and penetrating through the clamping support in a mode of being capable of radially moving. A locking mechanism and a fastening mechanism which are located on the two sides of the clamping support correspondingly are arranged on the connecting shaft in the axial direction. The locking mechanism comprises an adjusting handle connected to the connecting shaft. The adjusting handle rotates the connecting shaft towards the first direction to enable the connecting shaft to be locked on the clamping support, and the adjusting handle rotates the connecting shaft towards the second direction opposite to the first direction so that the connecting shaft can be unlocked from the clamping support. The adjusting mechanism further comprises a buffer piece. The buffer piece can apply buffer force towards the first direction to the connecting shaft when the connecting shaft is rotated towards the second direction, so that the springback phenomenon which occurs when the adjusting handle is loosened instantly to the limiting position is eliminated, and the rotating speed of the adjusting handle is buffered.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

An electromagnetic-multi-point composite forming device and forming method for sheet materials

The invention discloses an electromagnetic-multi-point composite forming device for sheet materials, which includes an upper punch and a lower punch, a plurality of the upper punch arrays form the punch, and a plurality of the lower punch arrays form the punch. The concave mold, the convex mold and / or the concave mold are provided with a coil support rod capable of moving up and down, and an electromagnetic coil capable of shaping the sheet material is provided at the end of the coil support rod close to the sheet material. On the one hand, the present invention can control the position of the upper punch and the lower punch by the computer to form a "flexible mold" with variable shape, so as to realize the rapid forming of plates of different shapes; The amplitude is reduced or even completely eliminated, which improves the quality of sheet forming.

Owner:CENT SOUTH UNIV

A Machining Technology of Numerical Control Machine Tool Coaming

ActiveCN107695141BRealize bending in the same directionEliminate springbackNumerical controlStructural engineering

The invention discloses a numerically-controlled machine tool enclosing plate machining process, and aims at solving the problem of same-direction bending of edges of an enclosing plate. According tothe technical scheme, the machining process is characterized in that the steps of material selecting, side edge bending, two-end bending, trimming forming and excess material cutting are sequentiallyconducted, and the enclosing plate which has the decoration effect is formed by an enclosing plate profile through the steps of one-time side edge bending, first-time two-end bending and second-time two-end bending. According to the numerically-controlled machine tool enclosing plate machining process, the four sides of the enclosing plate profile can be bent towards the same direction.

Owner:浙江克拿德电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com