Device for eliminating warping rebound of side wall of stamped component and edge pressing technology

A technology for stamping parts and warpage, which is applied in the field of devices for eliminating warping and springback of the side wall of stamping parts and its edge-holding process. Improved safety, elimination of warping and springback, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

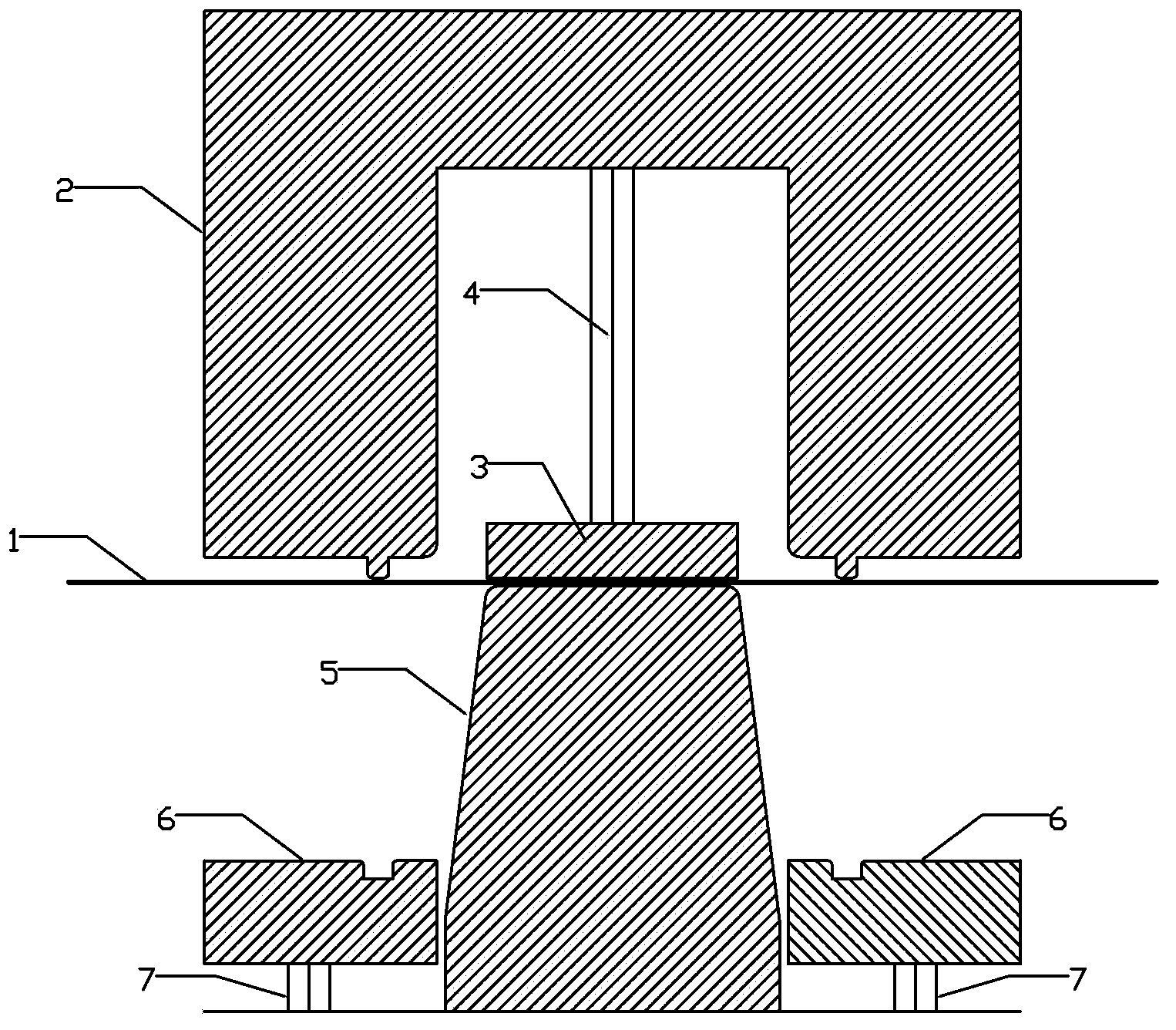

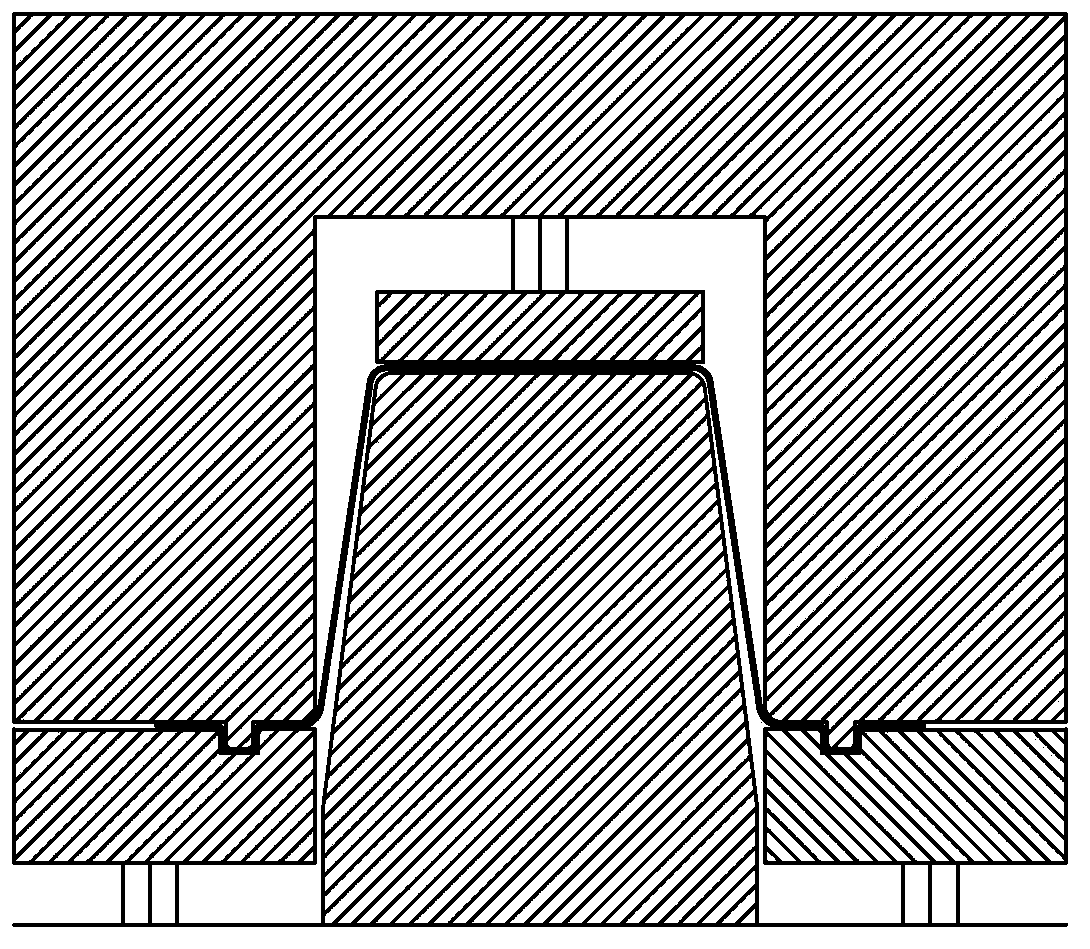

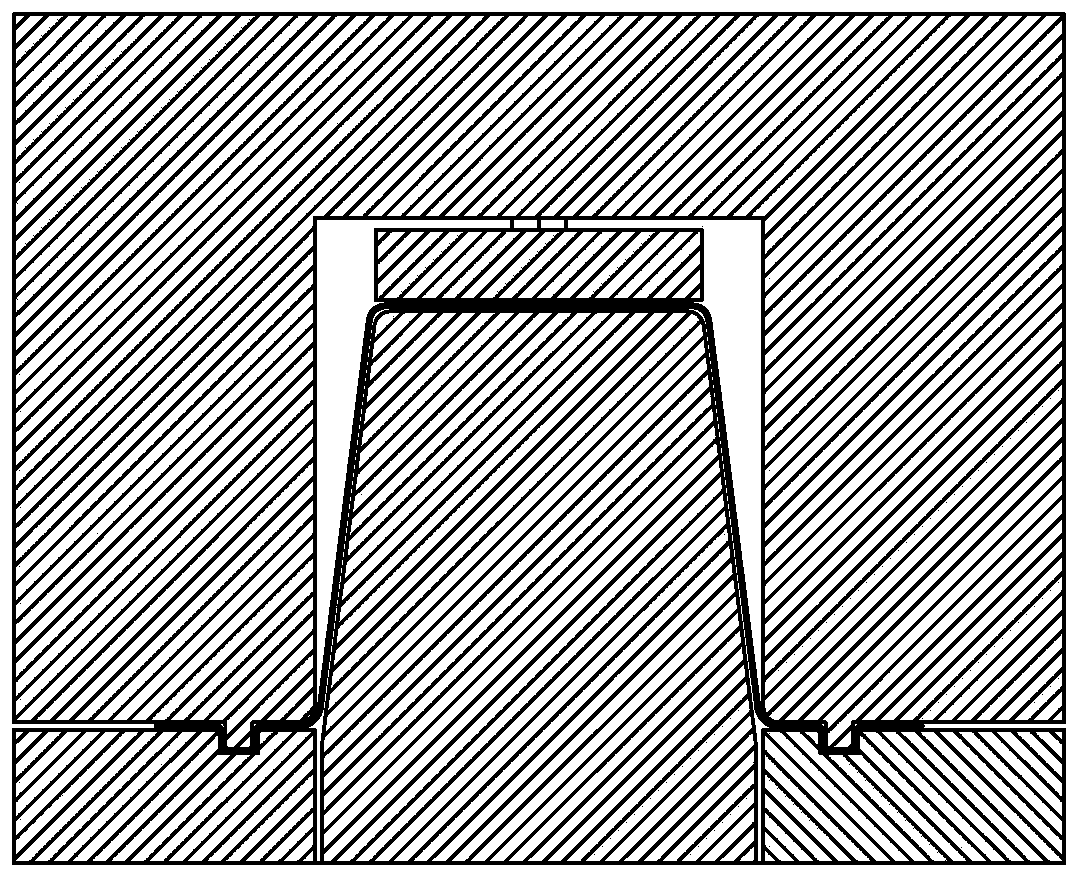

[0021] Such as figure 1 As shown, a device for eliminating the warping and springback of the side wall of stamping parts includes a die 2 and a punch 5 matching the die 2. The die 2 is provided with a nitrogen cylinder 4 connected to the pressing plate. Pressing plate 3, positioning protrusions are provided on the surface of the concave die 2 in contact with the metal sheet 1; the outer side of the punch 5 is provided with a blank holder 6 connected to the blank holder nitrogen cylinder 7, and the blank holder The surface of the ring 6 in contact with the metal sheet 1 is provided with a positioning groove that matches the positioning protrusion. According to factors such as the thickness of the metal sheet 1, the depth of the positioning groove is generally selected between 6-8mm. The distance between the initial position of the blank holder 6 and the base before it works is L mm, and L is usually between 5-10mm; the die 2 and the Rounded corners are provided at the intersec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com