Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

486results about How to "Small tolerance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

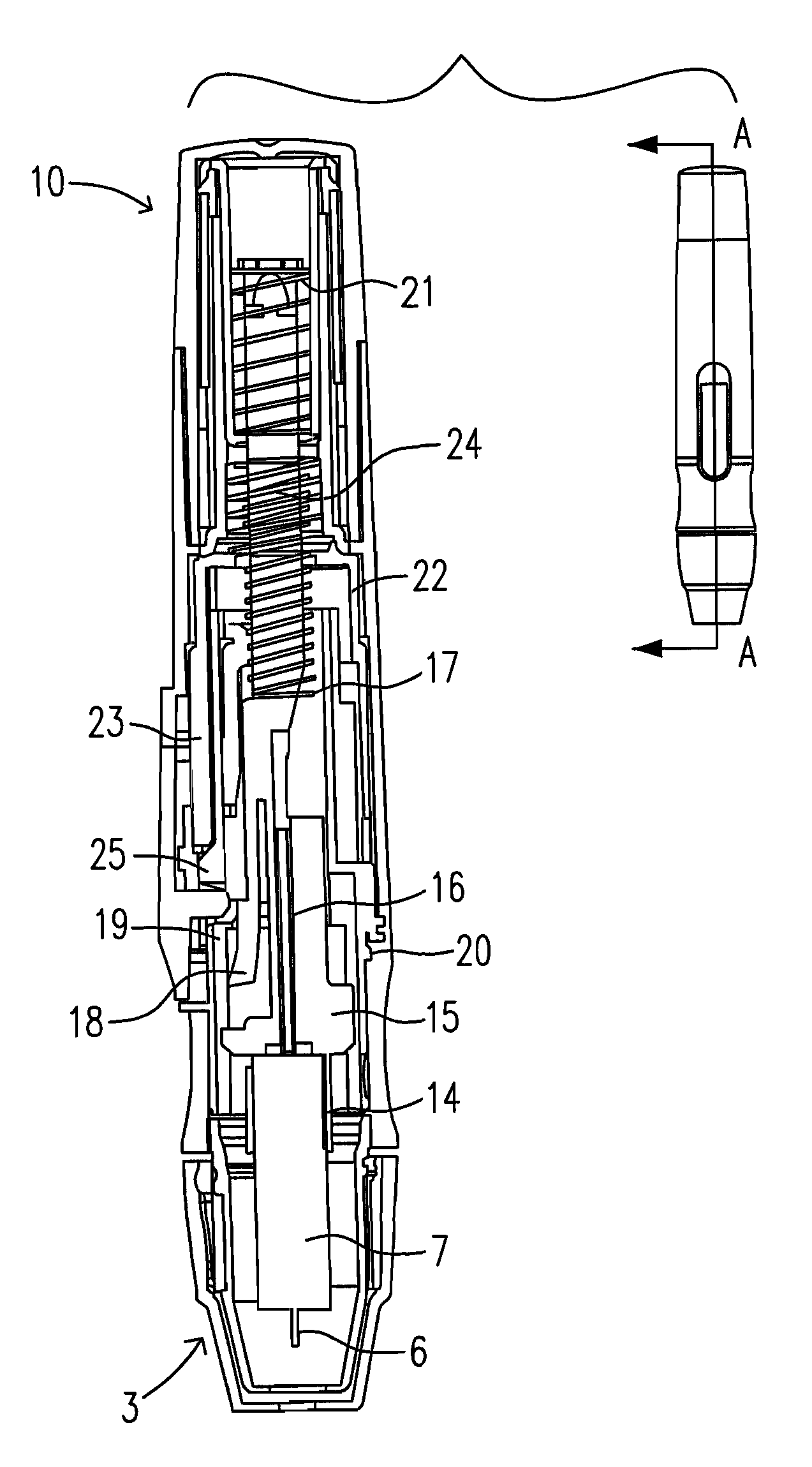

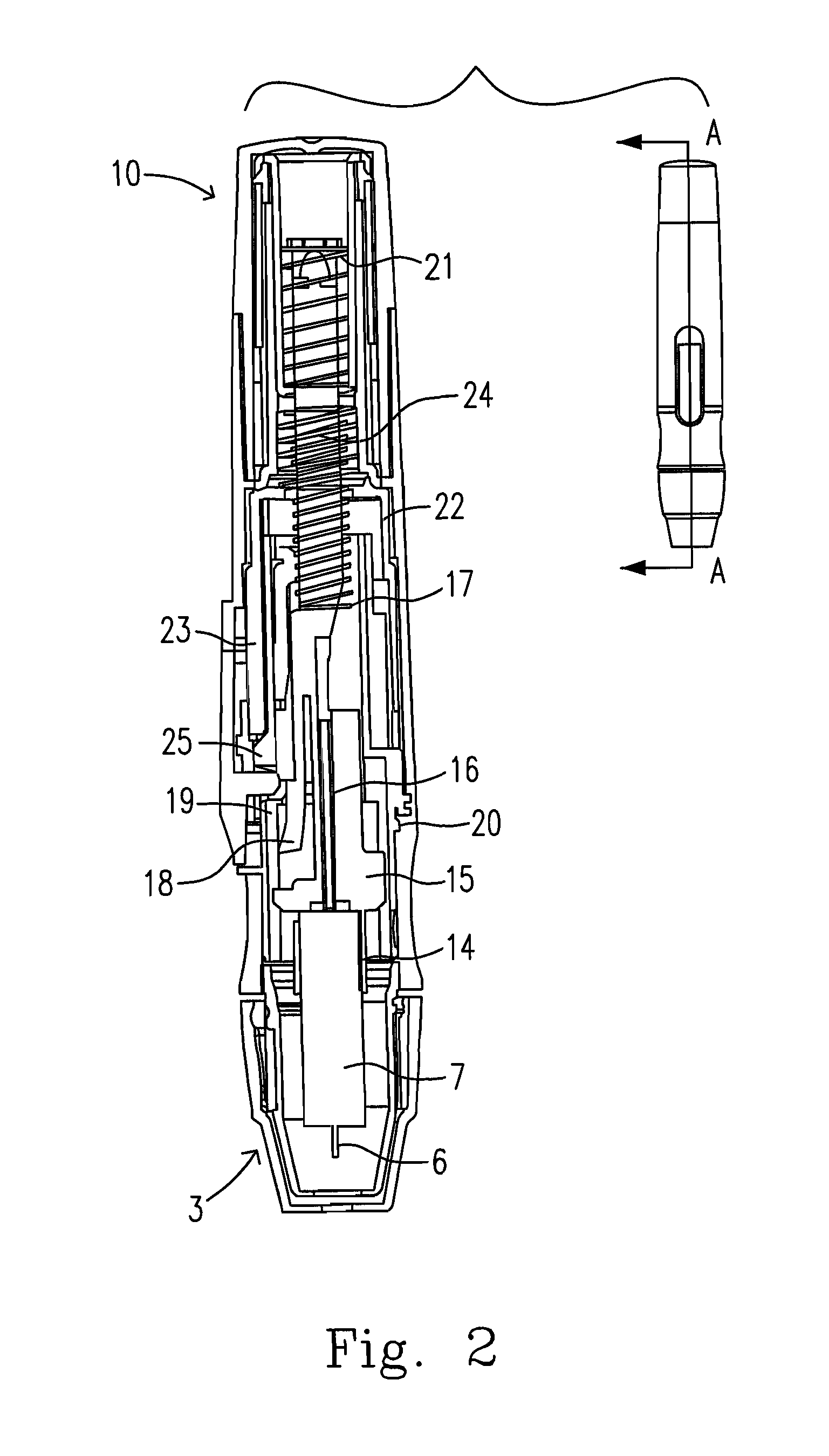

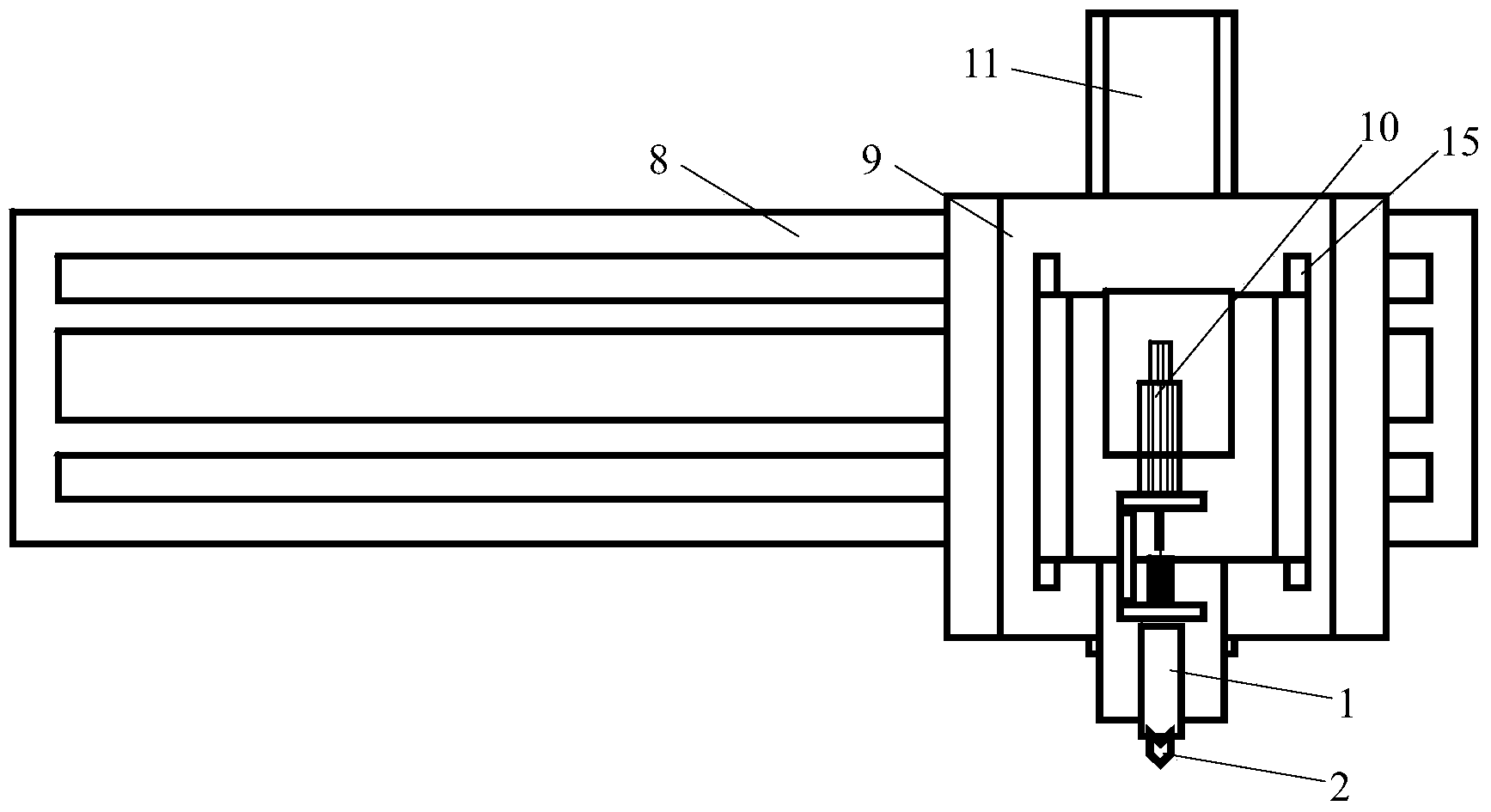

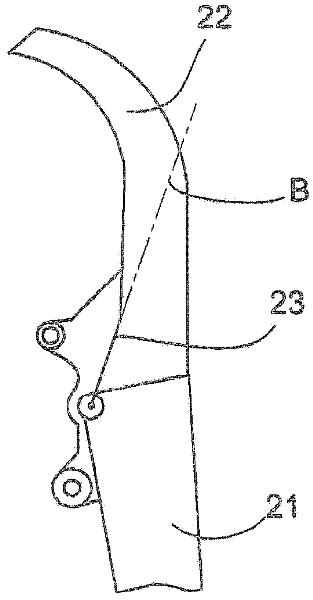

Lancing device

ActiveUS20100094324A1Increase speedRelieve painCatheterDiagnostic recording/measuringElectrical and Electronics engineeringLance device

Owner:BIONIME

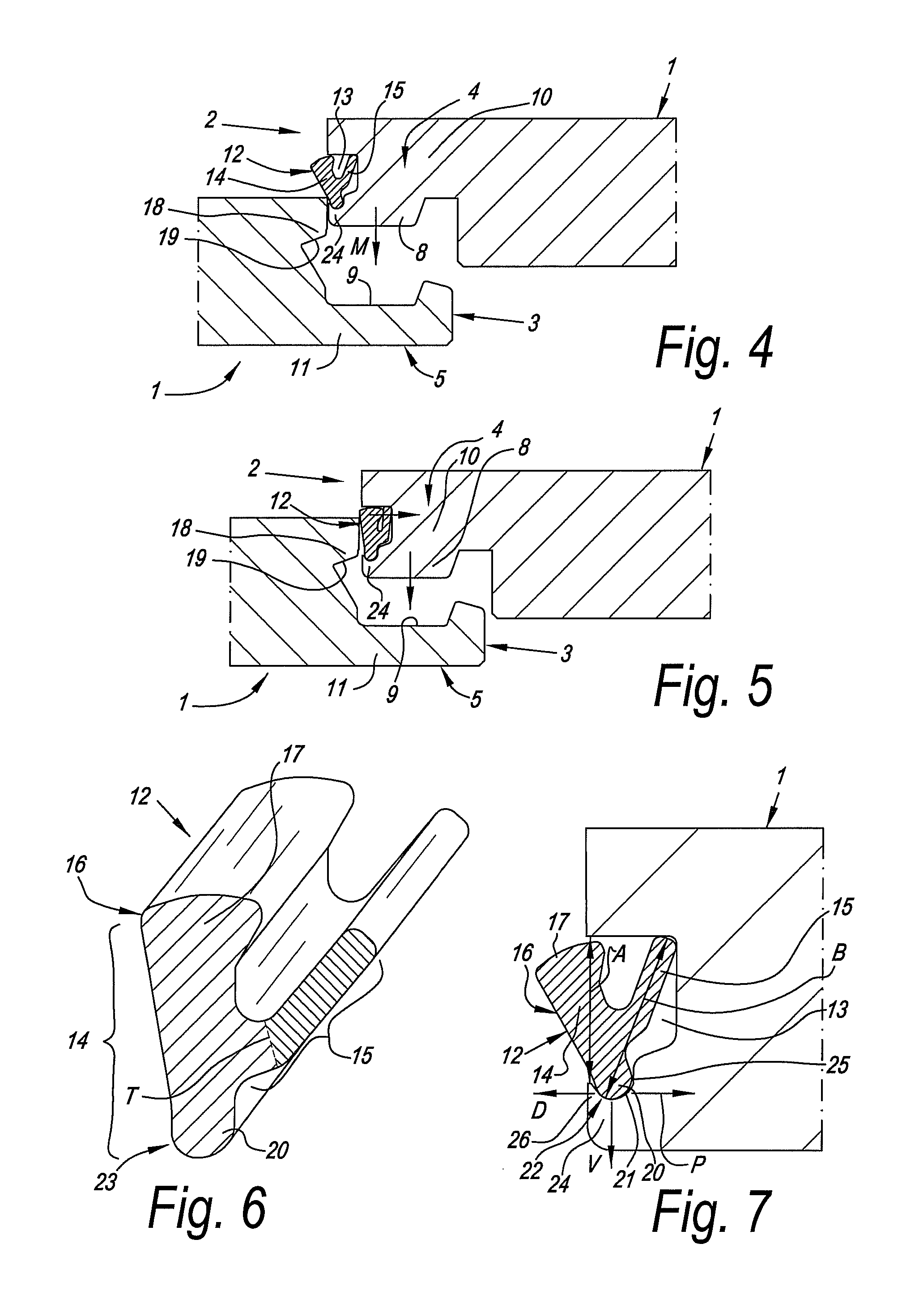

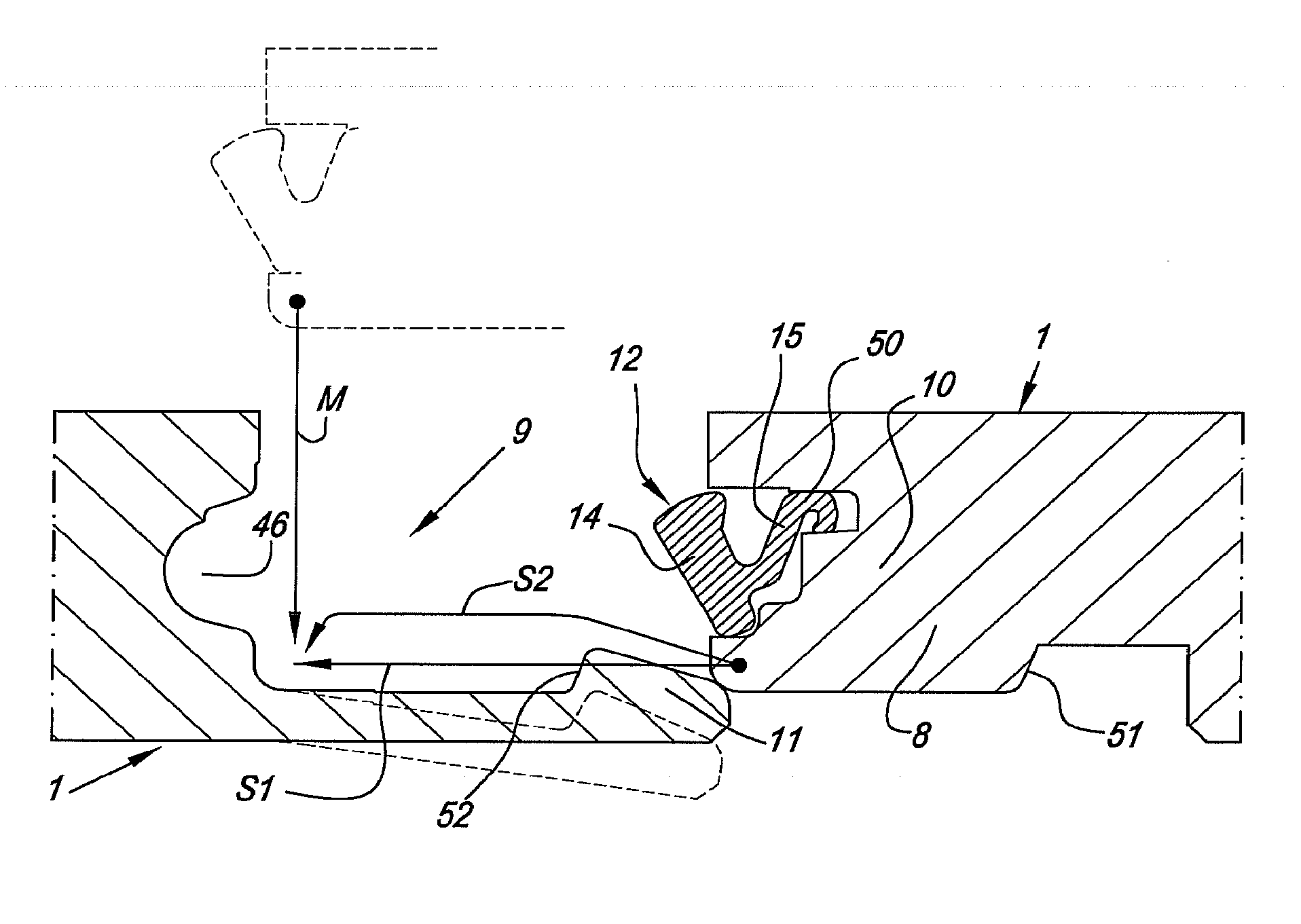

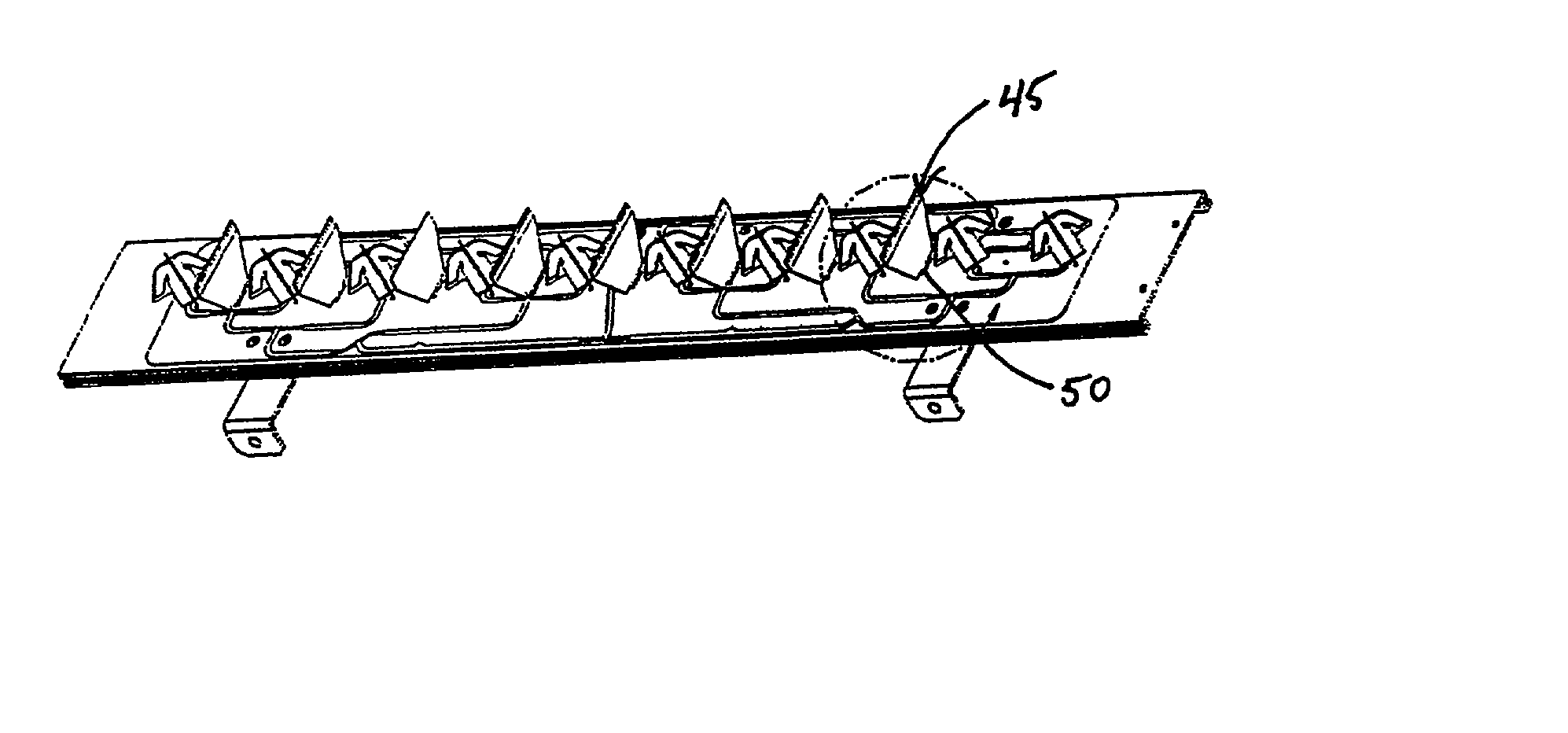

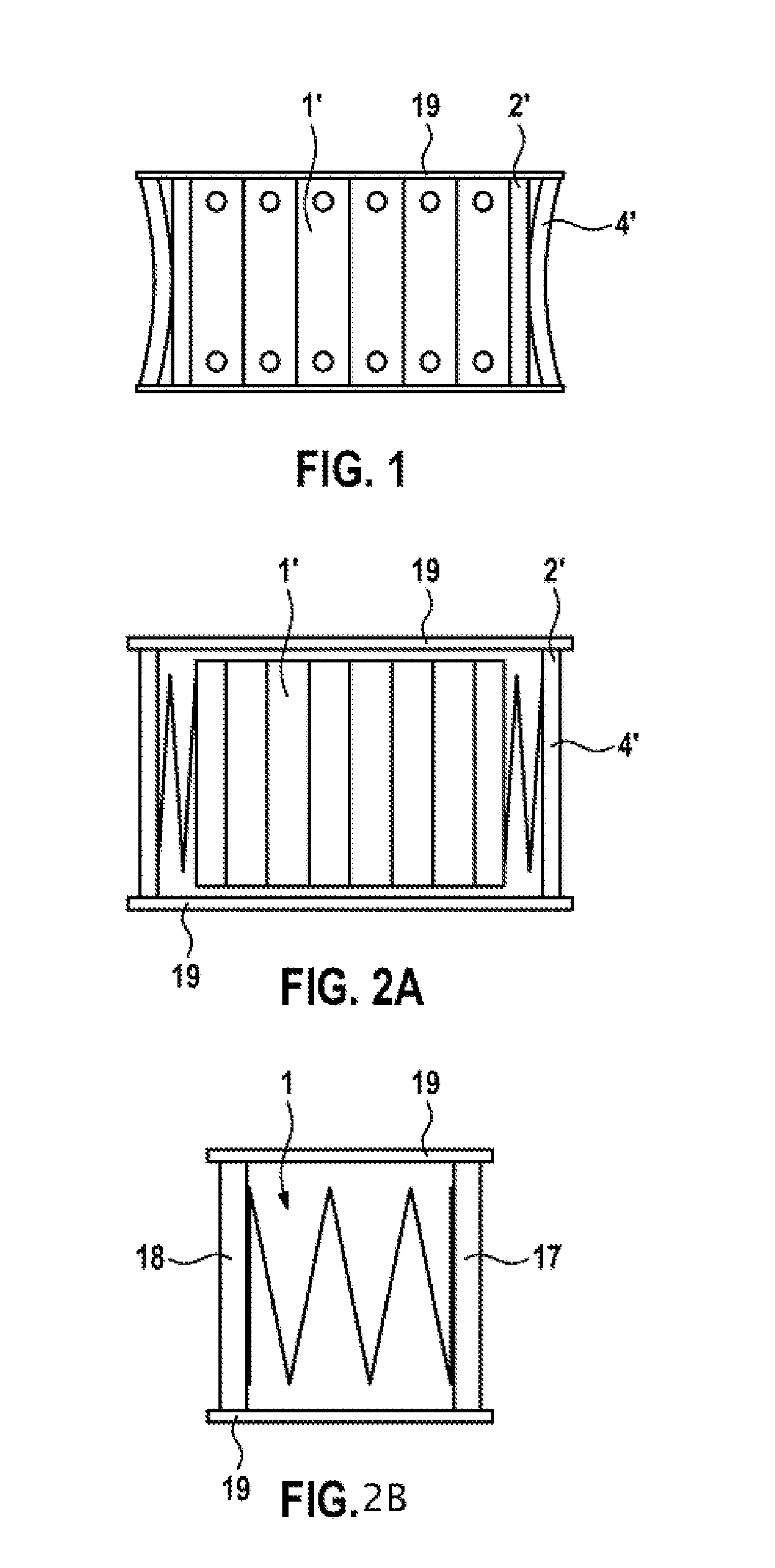

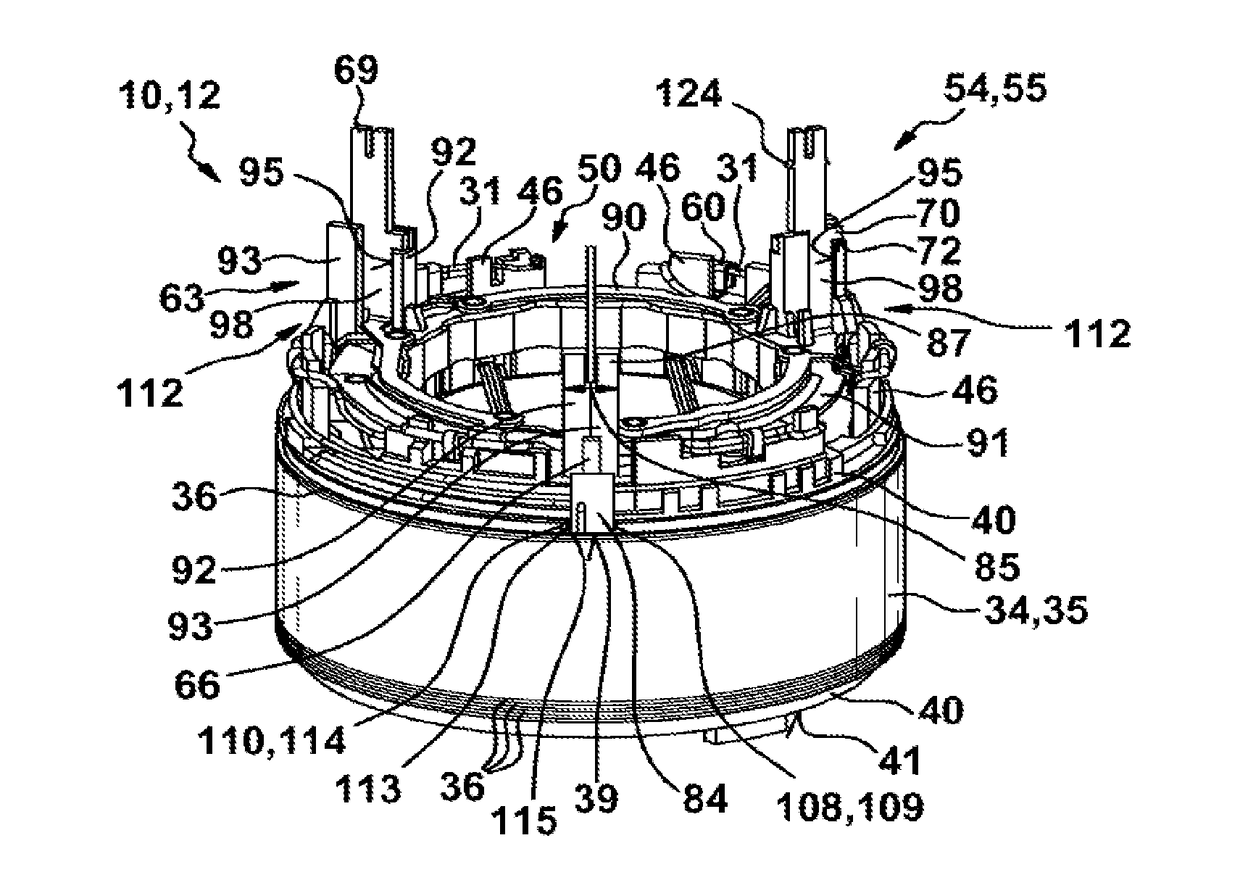

Floor panel

Floor panel, with a horizontally and vertically active locking system allowing that two of such floor panels can be connected to each other at said sides by providing one of these floor panels, by means of a downward movement, in the other floor panel; wherein the vertically active locking system includes a locking element in the form of an insert; wherein this locking element includes at least a pivotable lock-up body. The pivotable lock-up body includes a support portion which is rotatable against a support surface pertaining to the floor panel concerned, and more particularly in a seat.

Owner:FLOORING IND LTD

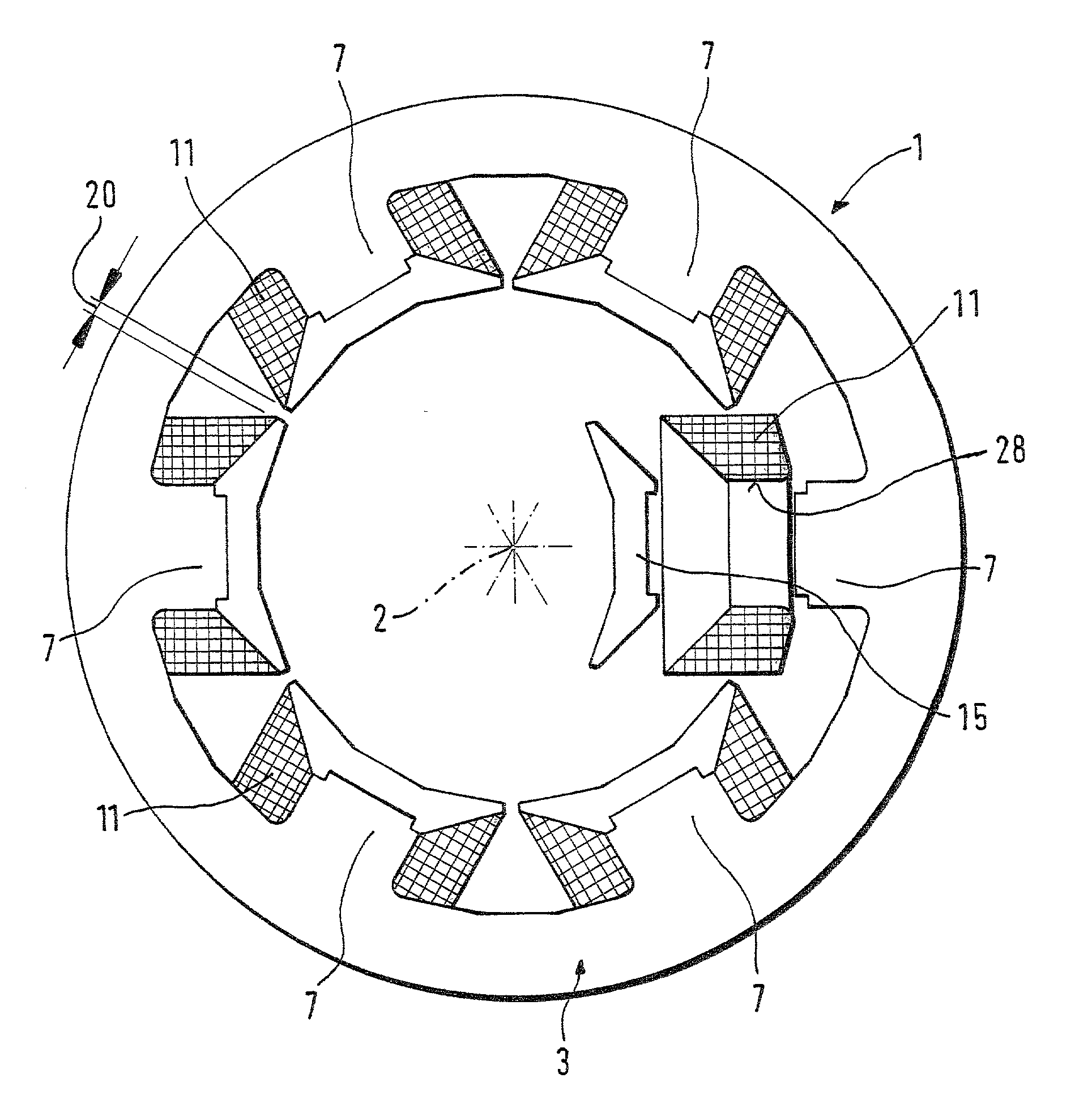

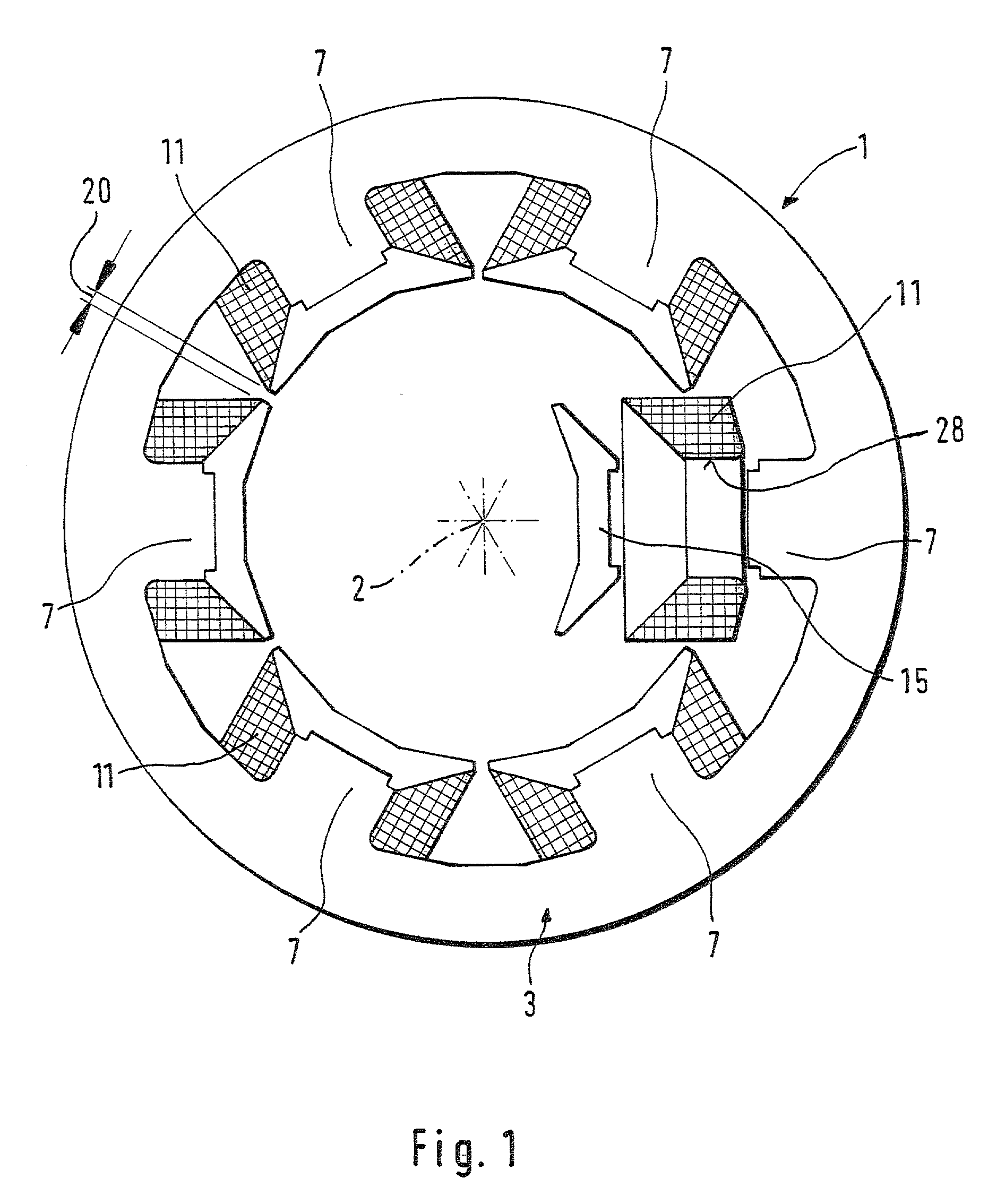

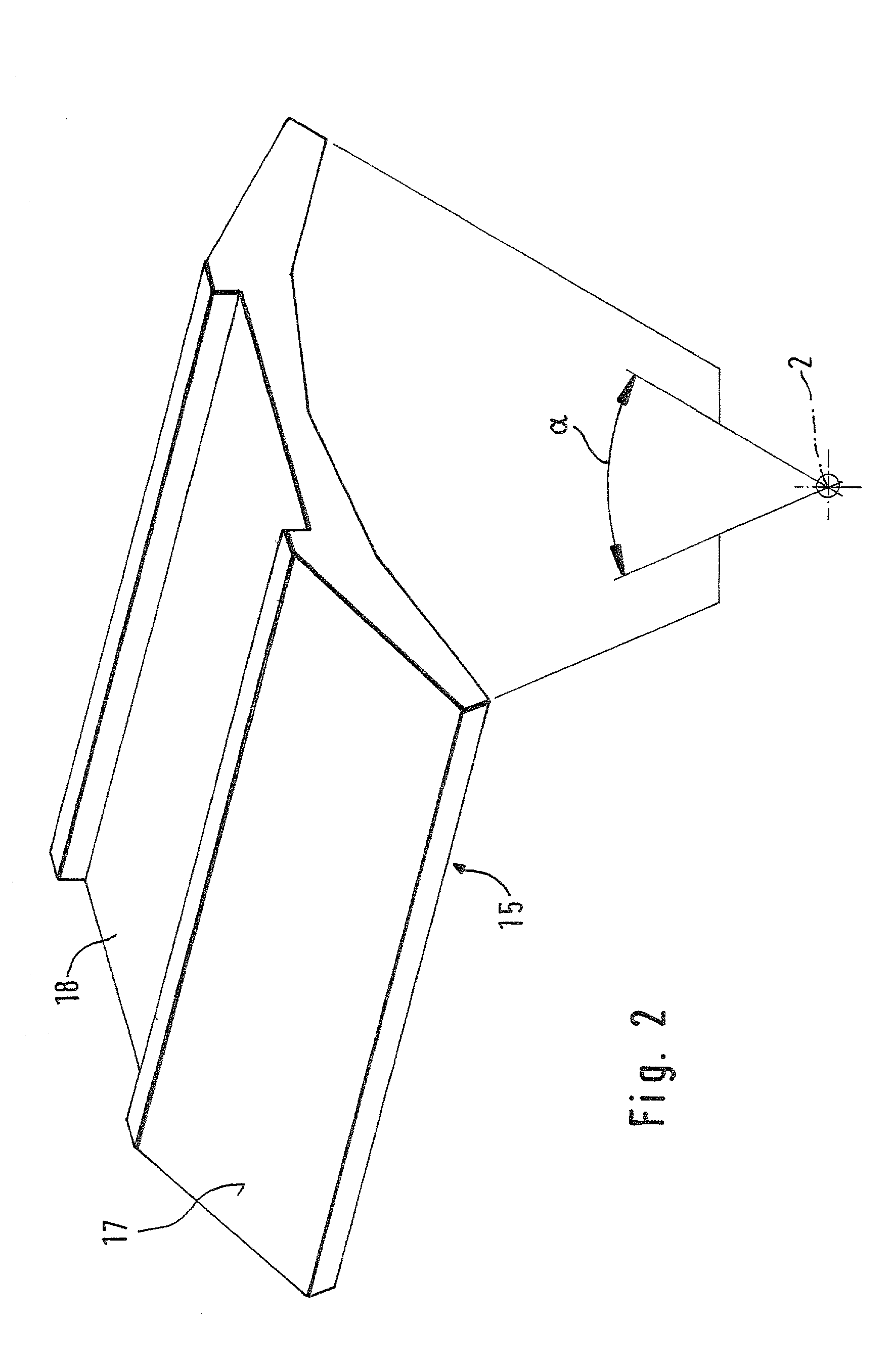

Stator

InactiveUS20020149282A1Small toleranceImproved performance dataWindingsMagnetic circuit stationary partsPole pieceConductor Coil

A stator according to the related art comprises preassembled coils that are slid onto stator pole teeth and secured to the respective stator pole tooth by means of a single part. This has the disadvantage, however, that a magnetic flux in the winding head of the exciting coil cannot be directed in defined fashion. A stator according to the invention comprises at least one pole shoe (15) that secures a coil (11) on a stator pole tooth (7).

Owner:ROBERT BOSCH GMBH

Floor panel

Floor panel, with a horizontally and vertically active locking system allowing that two of such floor panels can be connected to each other at said sides by providing one of these floor panels, by means of a downward movement, in the other floor panel; wherein the vertically active locking system comprises a locking element in the form of an insert; wherein this locking element comprises at least a pivotable lock-up body; characterized in that the pivotable lock-up body comprises a support portion which is rotatable against a support surface pertaining to the floor panel concerned, and more particularly in a seat.

Owner:FLOORING IND LTD

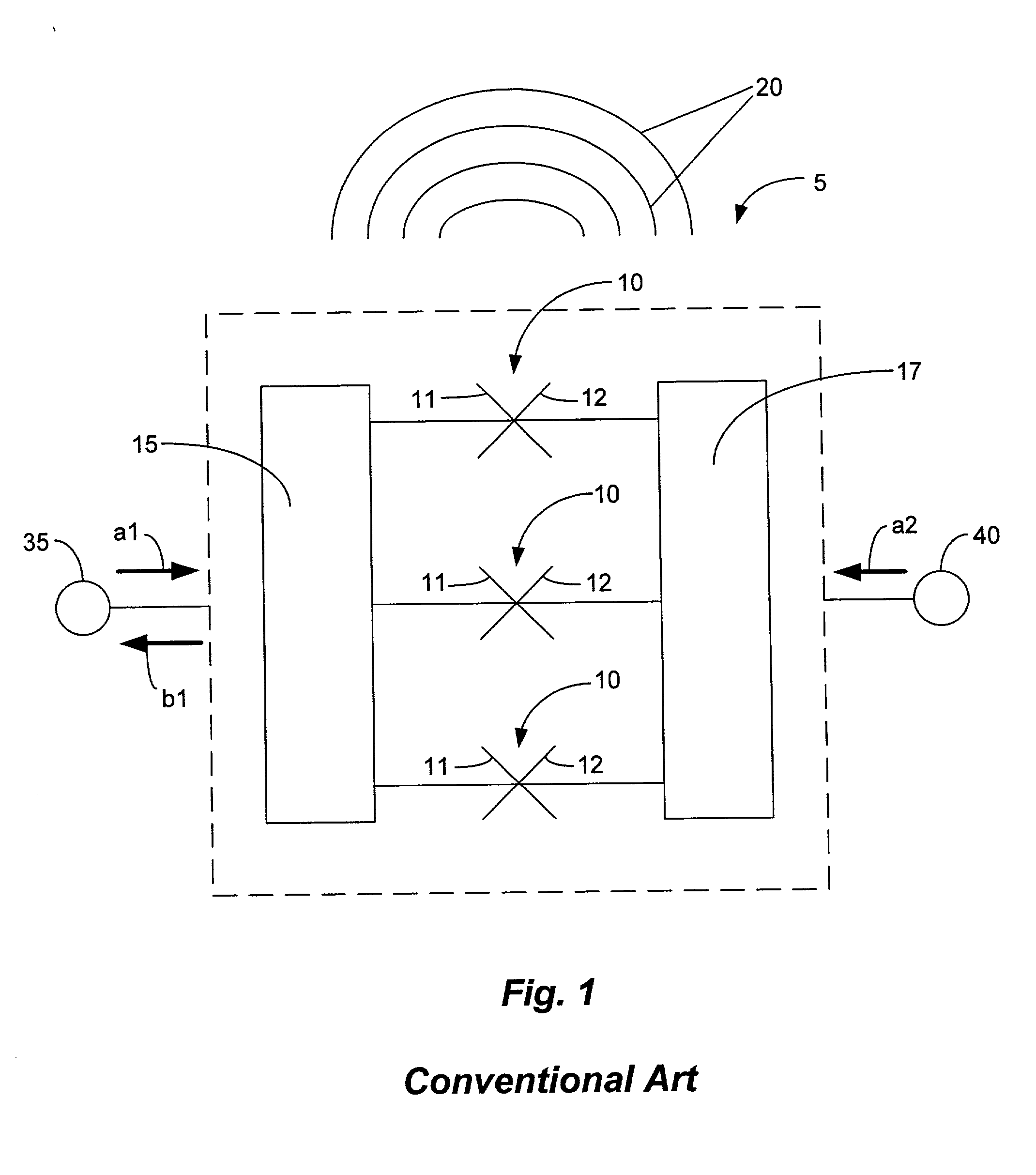

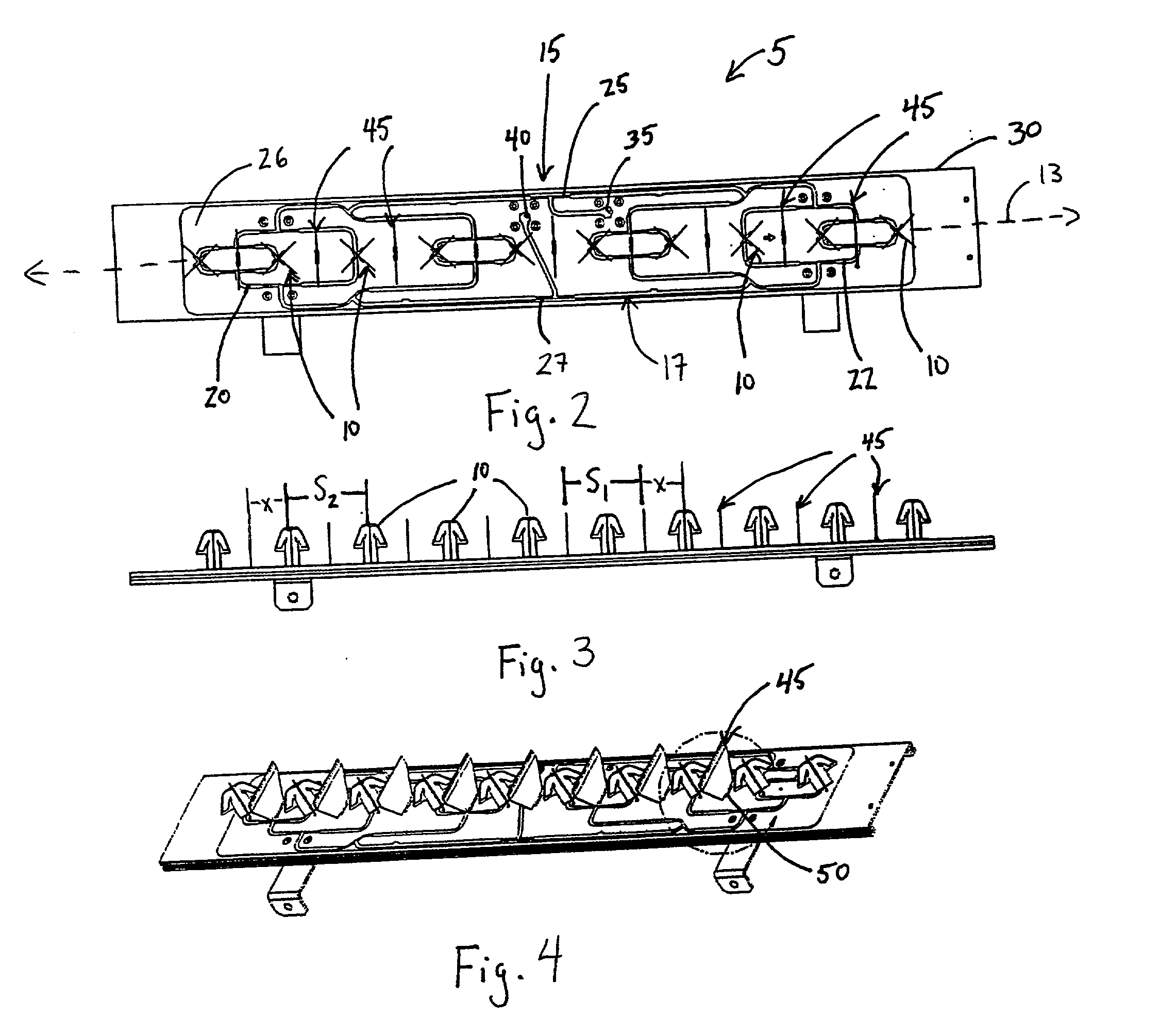

Radio frequency isolation card

InactiveUS20020101388A1Improve antenna performanceHigh sensitivityAntenna supports/mountingsIndividually energised antenna arraysDielectricEngineering

One or more feedback elements generate a feedback signal in response to a transmitted signal outputted by each radiator of the antenna system. This feedback signal is received by each radiator, also described as a radiating element, and combined with any leakage signal present at the port of the antenna. Because the feedback signal and the leakage signal are set to the same frequency and are approximately 180 degrees out of phase, this signal summing operation serves to cancel both signals at the output port, thereby improving the port-to-port isolation characteristic of the antenna. Each feedback element can include a photo-etched planar metal strip supported by a planar dielectric card made from printed circuit board material. Such feedback elements can provide a high degree of repeatability and reliability in that the manufacturing of such feedback elements can be precisely controlled.

Owner:COMMSCOPE TECH LLC

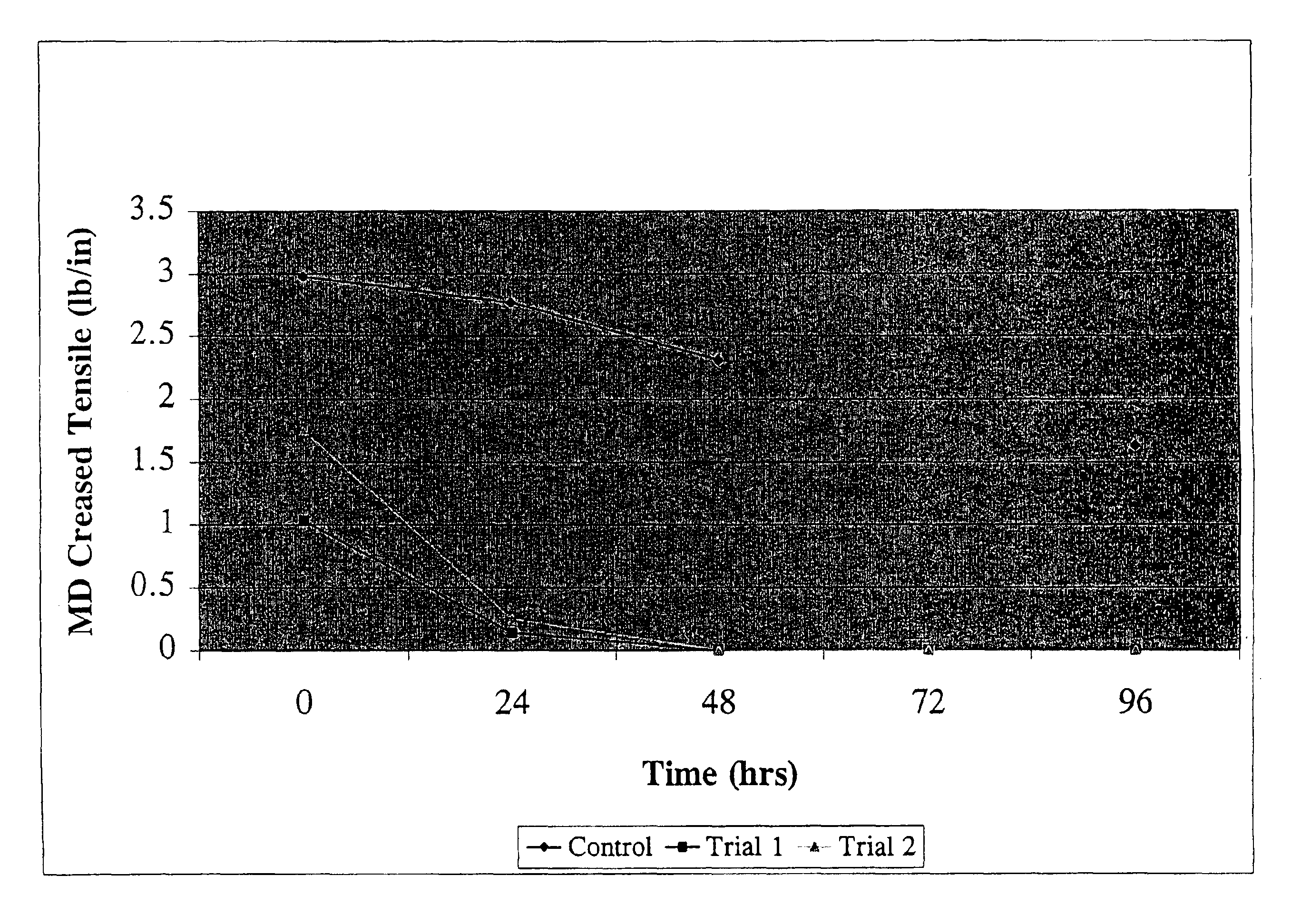

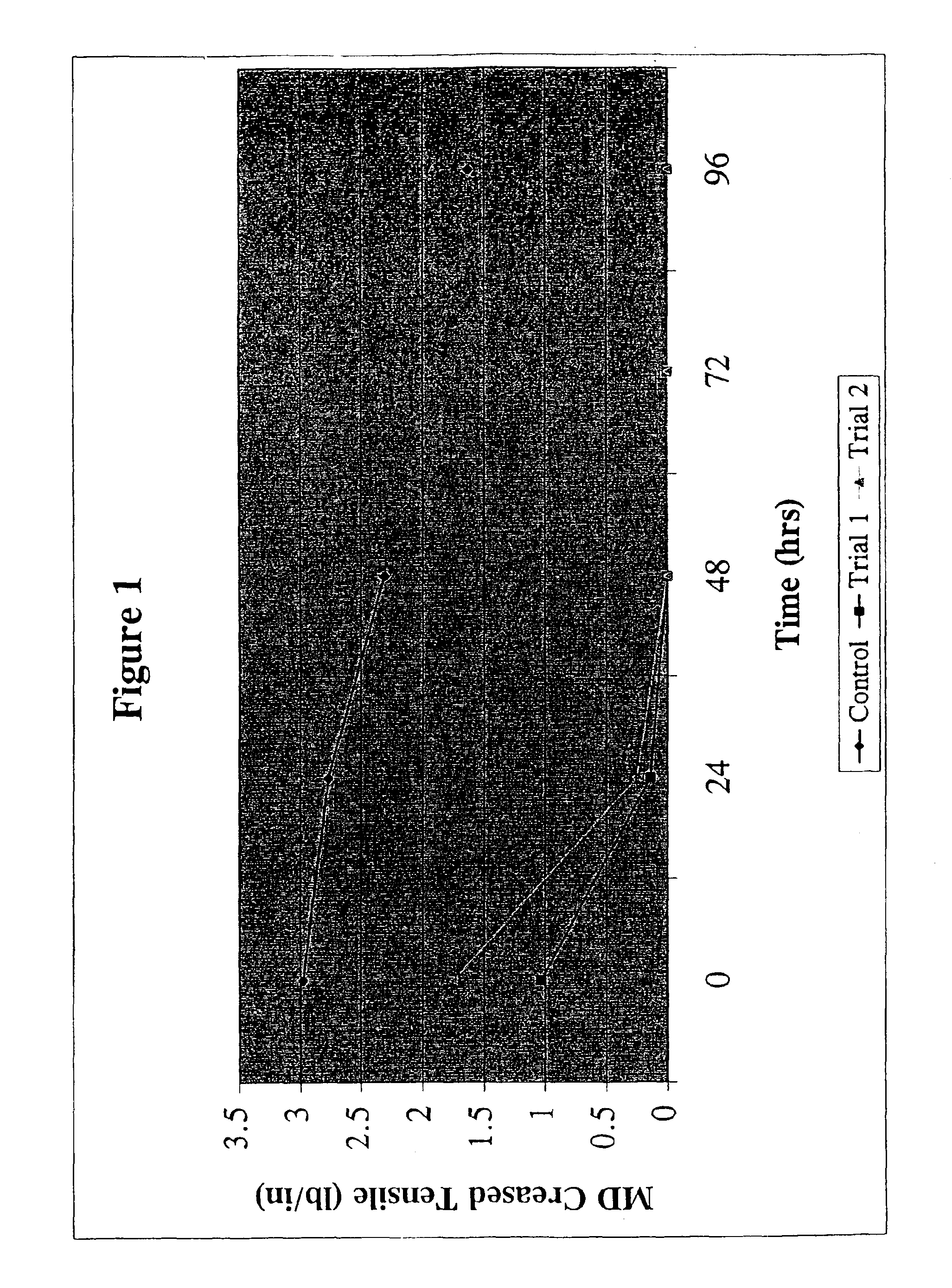

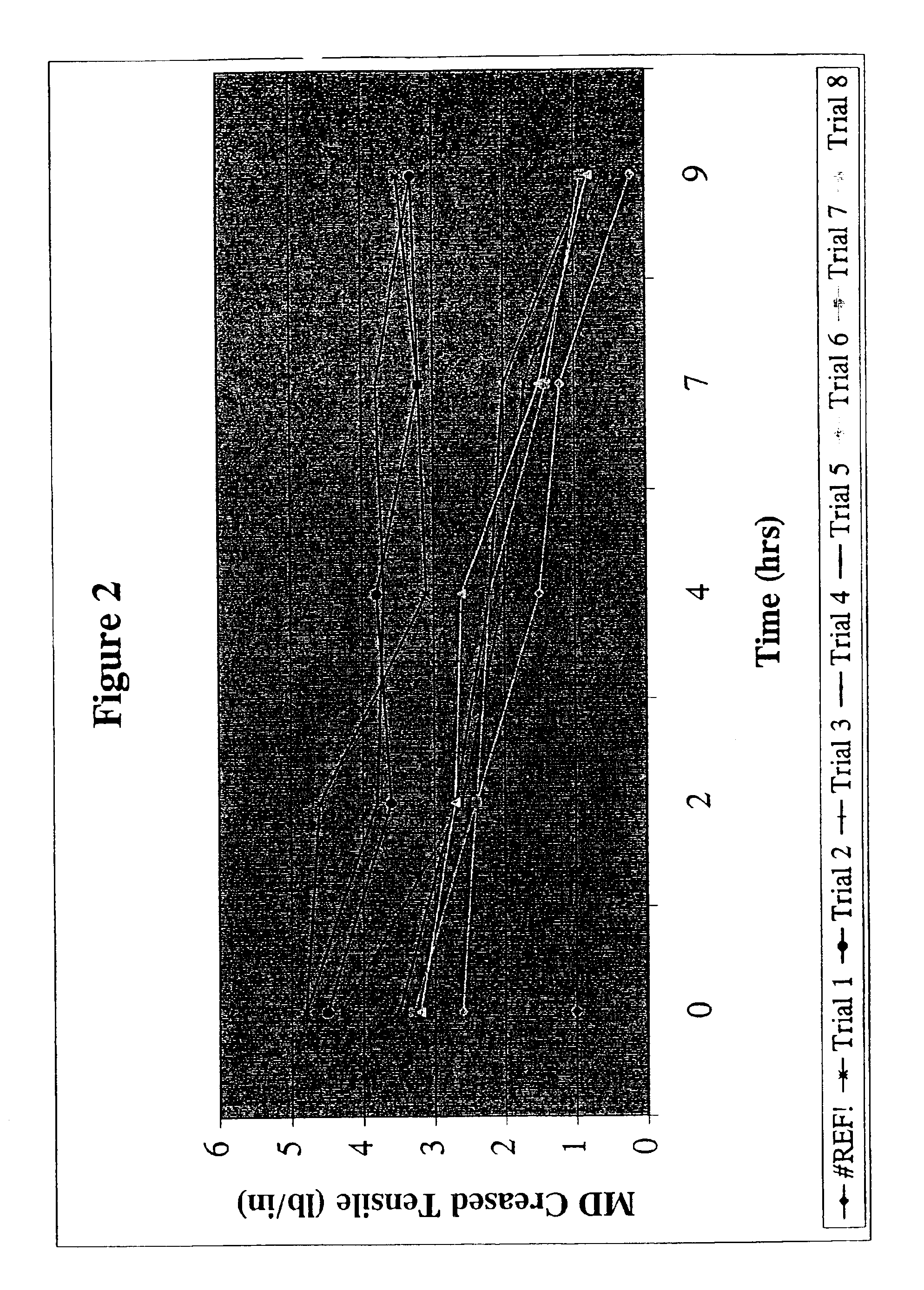

Low boron containing microfiberglass filtration media

InactiveUS6933252B2Enhanced filtration performance characteristicSmall toleranceFibre treatmentSynthetic resin layered productsAir filtrationFiber

The present invention provides nonwoven glass composites formed from an essentially boron free glass wool and an essentially boron free chopped glass fiber, used as a reinforcing material. The nonwoven glass composites are suitable for air filtration apparatus and can be used in the semiconductor industry where the elimination of boron from clean rooms is of importance.

Owner:HOLLINGSWORTH VOSE

Radio frequency isolation card

InactiveUS6515633B2Improve antenna performanceIncreasing port-to-port isolation characteristicAntenna supports/mountingsIndividually energised antenna arraysDielectricEngineering

One or more feedback elements generate a feedback signal in response to a transmitted signal outputted by each radiator of the antenna system. This feedback signal is received by each radiator, also described as a radiating element, and combined with any leakage signal present at the port of the antenna. Because the feedback signal and the leakage signal are set to the same frequency and are approximately 180 degrees out of phase, this signal summing operation serves to cancel both signals at the output port, thereby improving the port-to-port isolation characteristic of the antenna. Each feedback element can include a photo-etched planar metal strip supported by a planar dielectric card made from printed circuit board material. Such feedback elements can provide a high degree of repeatability and reliability in that the manufacturing of such feedback elements can be precisely controlled.

Owner:COMMSCOPE TECH LLC

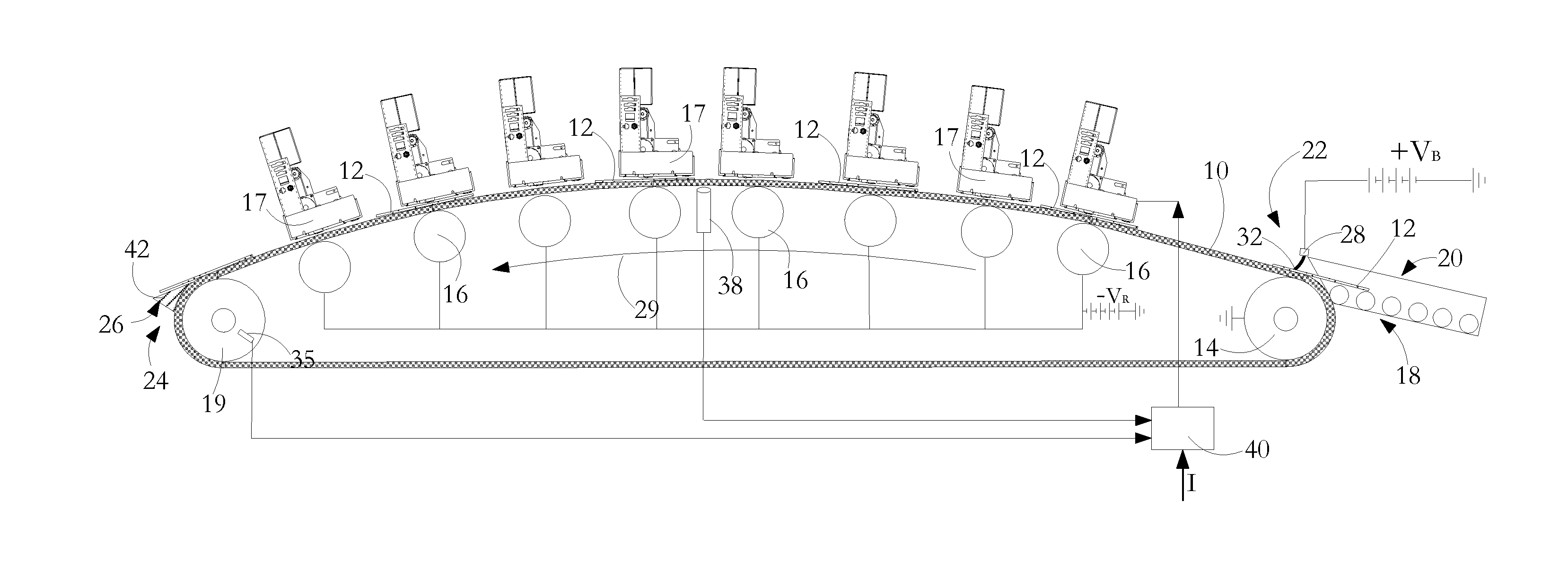

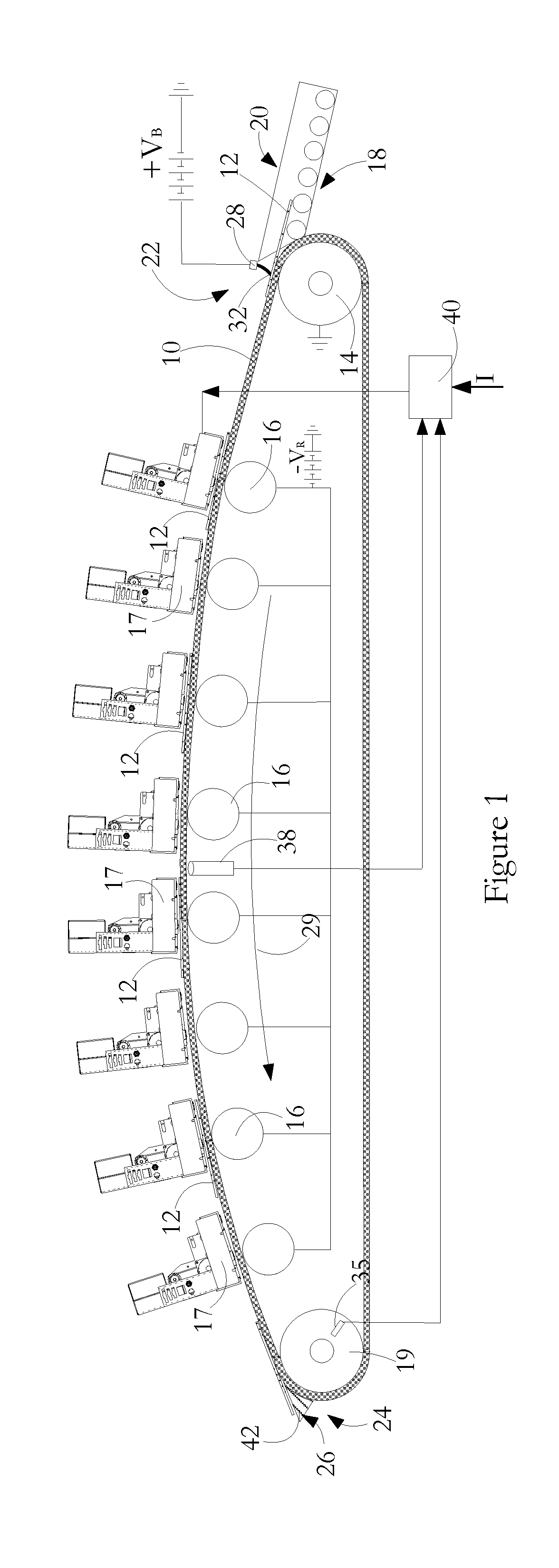

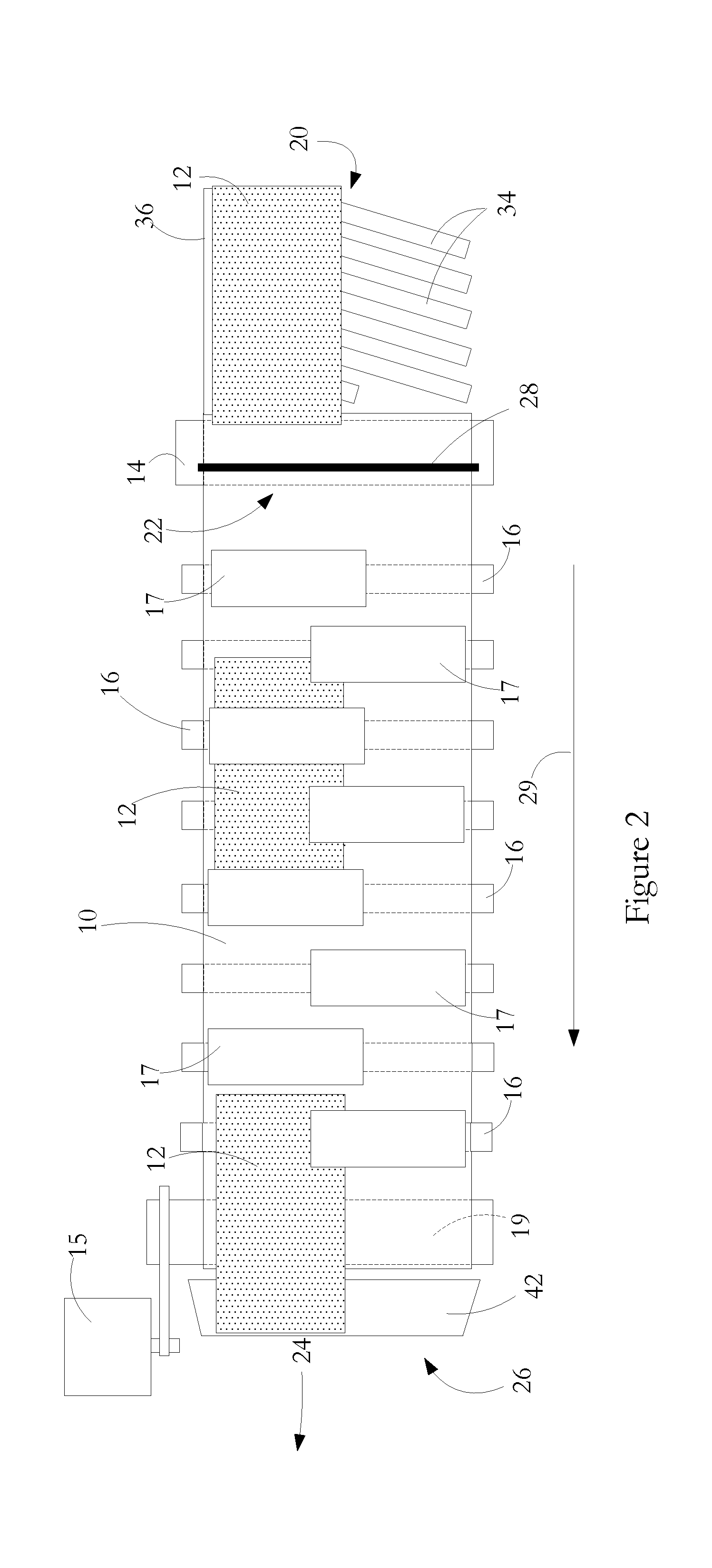

Multiple print head printing apparatus and method of operation

ActiveUS20130201237A1Precise positioningSmall toleranceTypewritersOther printing apparatusEngineeringMotor coordination

A printing apparatus has a series of inkjet print heads spaced from one another in a transport direction. A continuous belt driven around a roller system is used to feed sheet media successively to the print heads so that a partial image printed by one print head is overprinted at a subsequent print head with registration of the partial images. A sheet medium is caused to become electrostatically tacked to the belt by passing the sheet past a charging device. Movement of the belt is tracked by a tracking sub-system and operation of the print heads is coordinated with the tracked belt movement to achieve precise registration of the partial images.

Owner:DELPHAX TECH

Sensor

ActiveUS20110153277A1Small tolerance limitSmall toleranceMeasurement apparatus componentsError detection/correctionElectrical and Electronics engineering

A sensor for measuring any desired variable, with the sensor having a sensor housing with a specimen feed and with at least two measured value pick-ups and at least two processing units being arranged redundantly respectively pairwise with respect to one another and / or diversely in the sensor housing.

Owner:LIEBHERR WERK EHINGEN

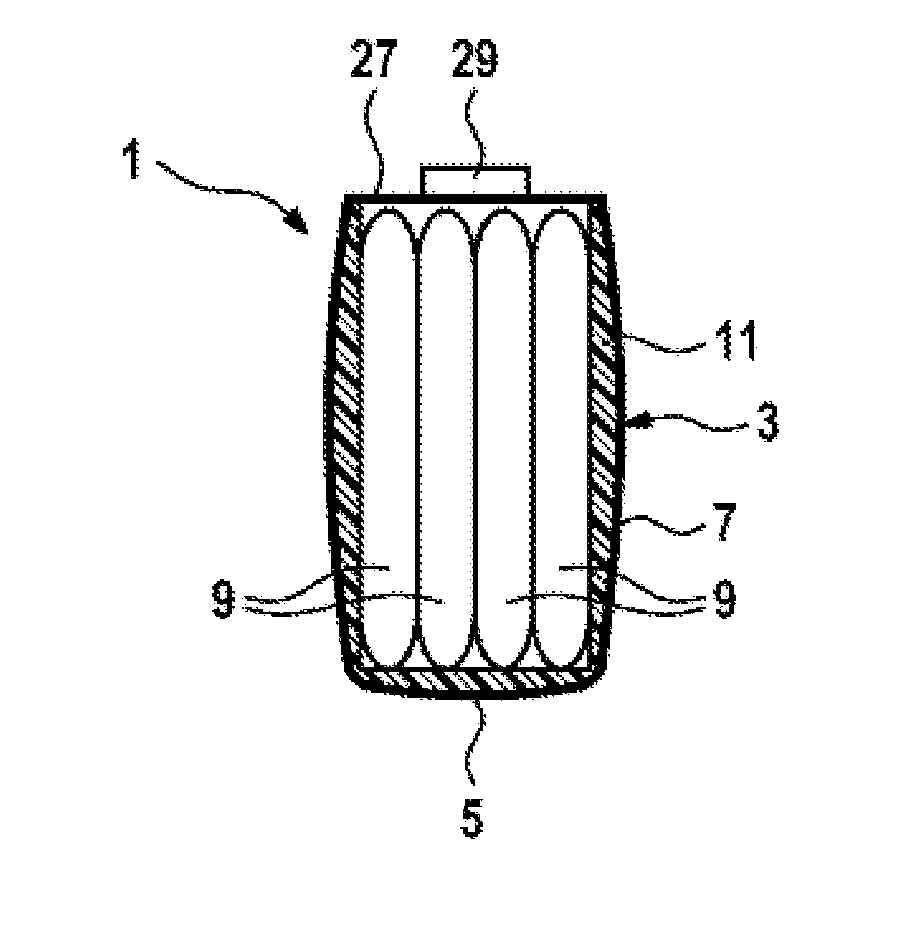

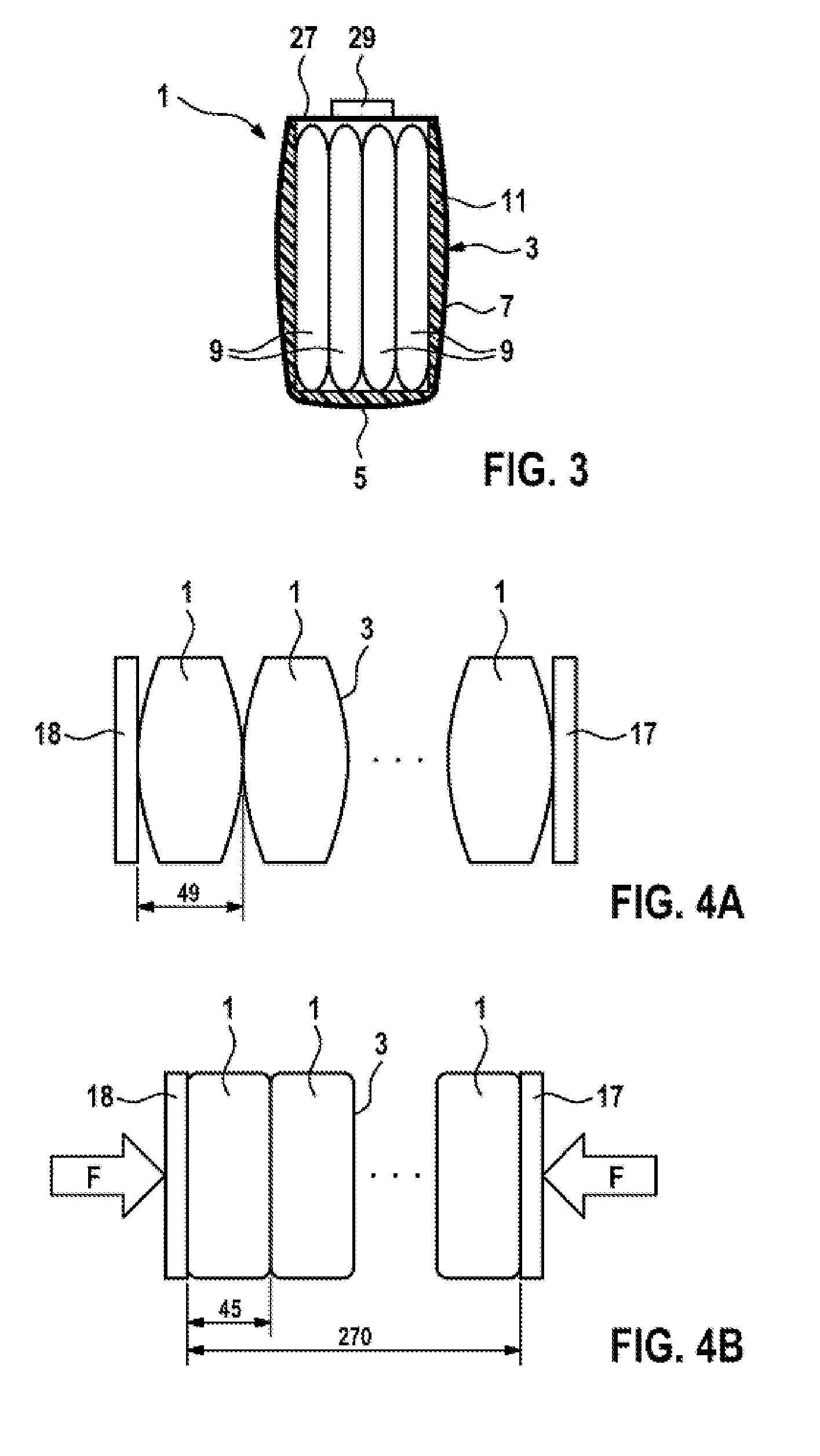

Restraining of battery cells by way of a cambered design of the battery housing

ActiveUS20150214570A1Avoid damageReduce weightCell seperators/membranes/diaphragms/spacersFinal product manufacturePre stressPre stressing

The invention relates to a battery cell (1) for pre-stressed battery modules (13). The invention further relates to corresponding pre-stressed battery modules (13) and corresponding production methods. The battery cell (1) has a cell housing (3) and a chemicals carrier (9). The chemicals carrier (9) is arranged in the cell housing (3). The cell housing (3) has a bulging design.

Owner:ROBERT BOSCH GMBH

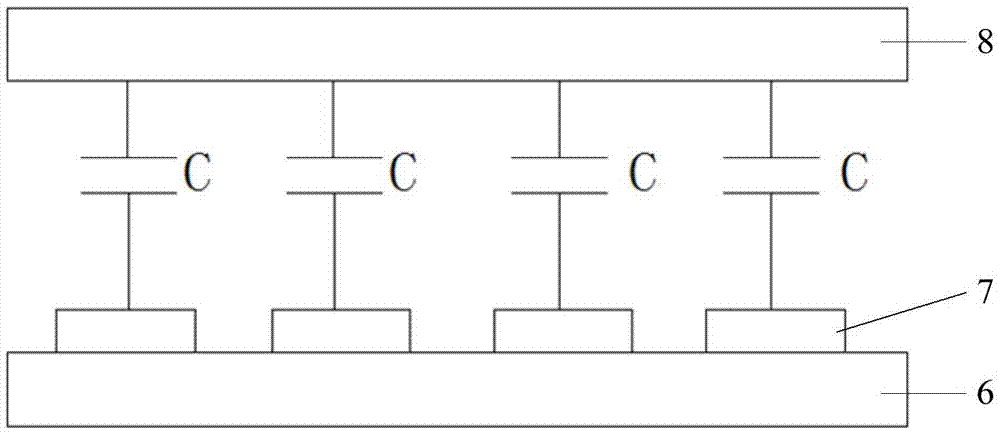

Pressure detection structure and touch device

ActiveCN105446538ASmall toleranceAvoid compromising consistencyDigital data processing detailsForce measurementCapacitanceDisplay device

Owner:SHENZHEN GOODIX TECH CO LTD

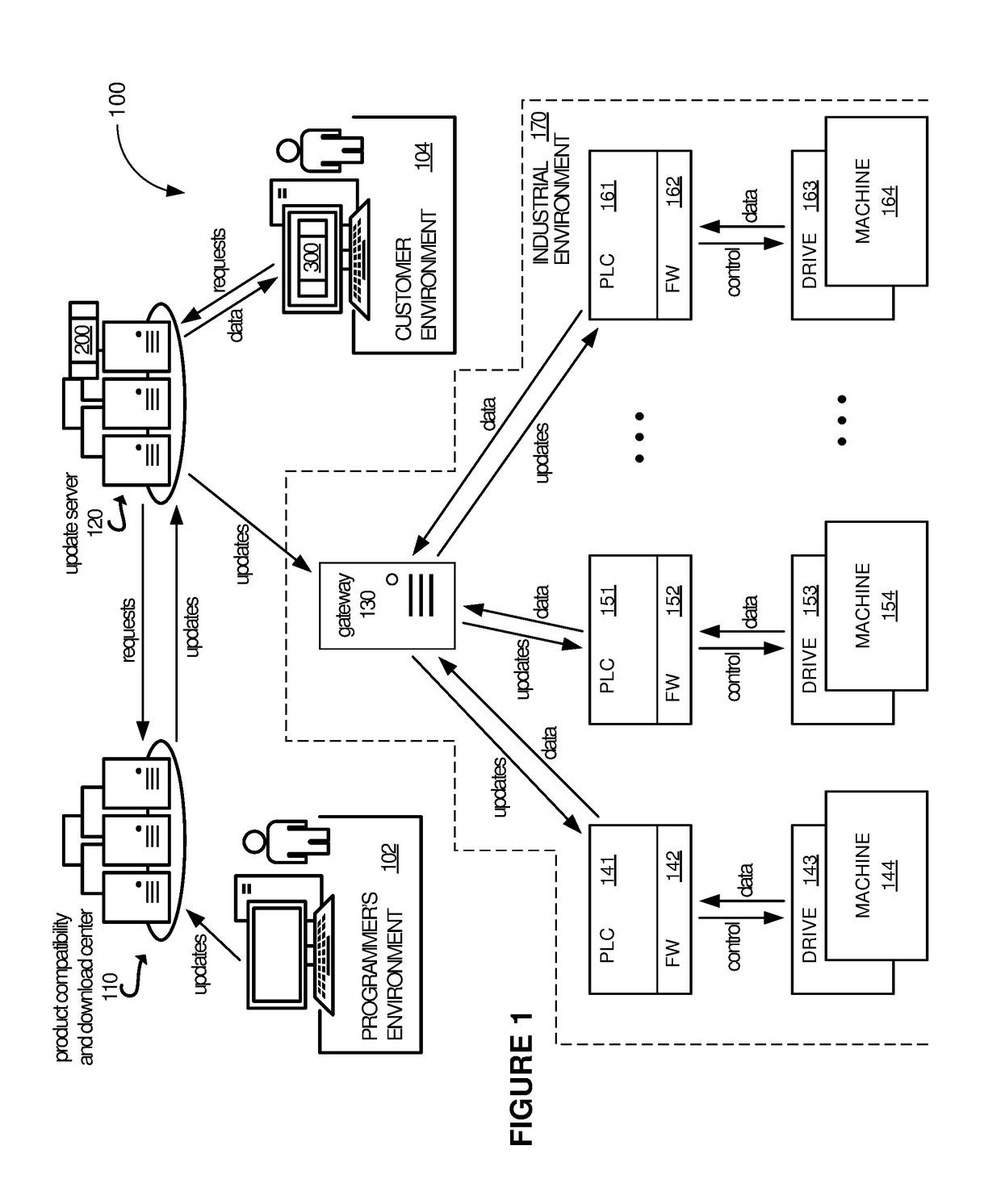

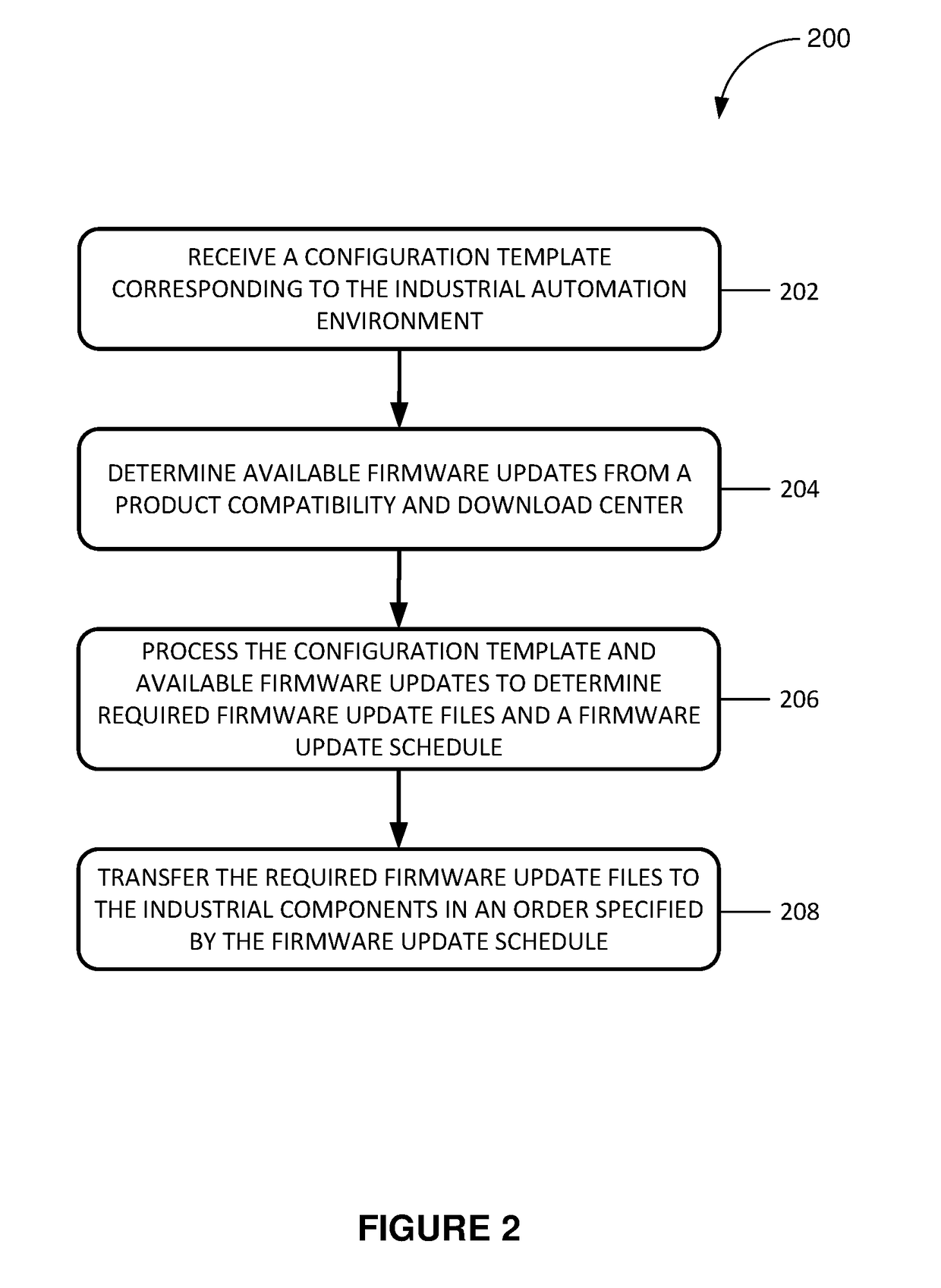

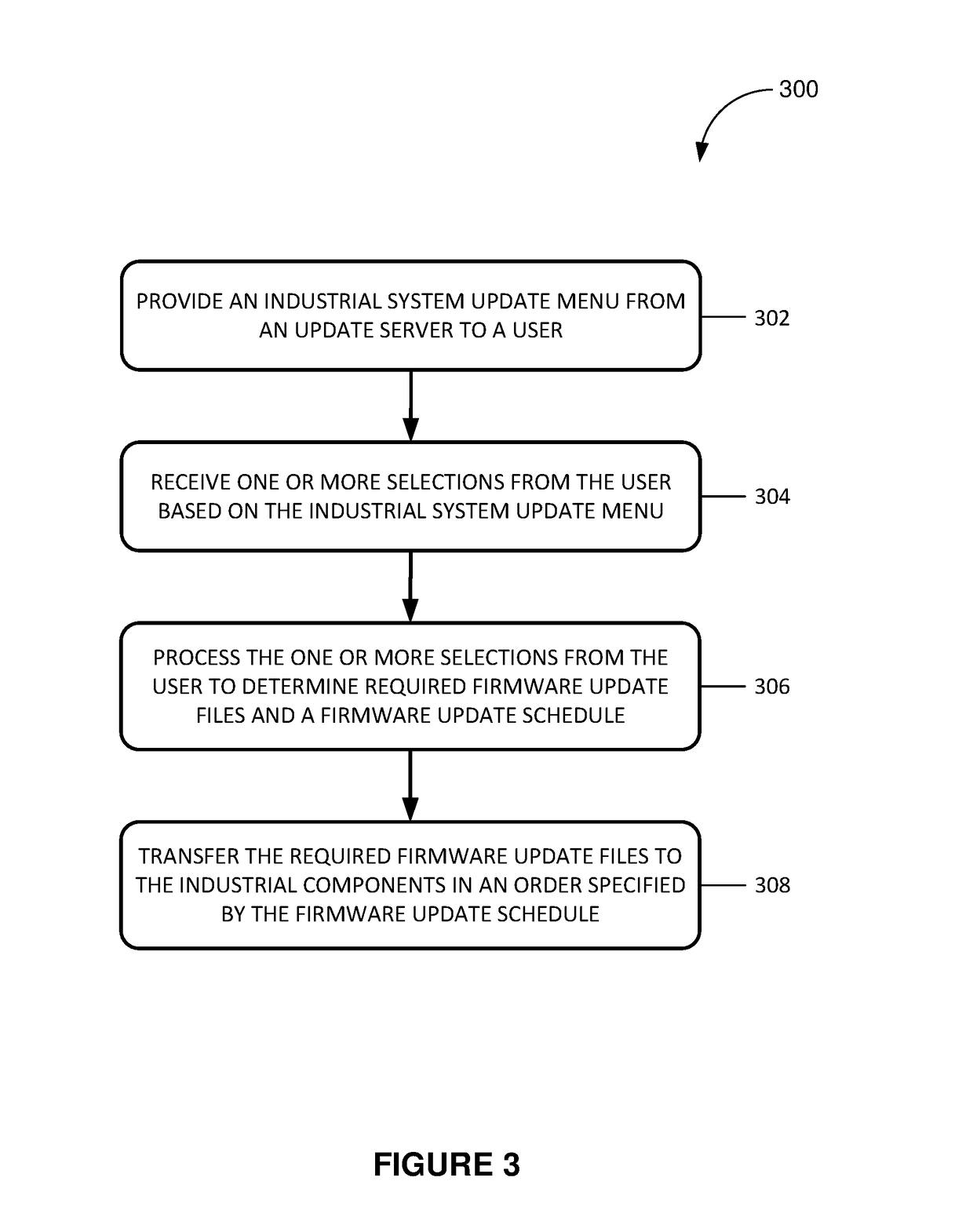

Launch multiple devices firmware update operation from another application with device list context

ActiveUS20180359144A1Small toleranceQuality improvementProgramme controlProgram loading/initiatingIndustrial systemsApplication software

A method for updating firmware within an industrial automation environment comprising a plurality of industrial components is provided. The method includes providing an industrial system firmware update menu from an update server to a user through a web interface within an application running on a user device, and receiving one or more selections of the industrial system firmware update menu from the user through the web interface. The method also includes processing the one or more selections of the industrial system firmware update menu to determine required firmware update files and a firmware update schedule, and transferring the required firmware update files to the industrial components in an order specified by the firmware update schedule.

Owner:ROCKWELL AUTOMATION TECH

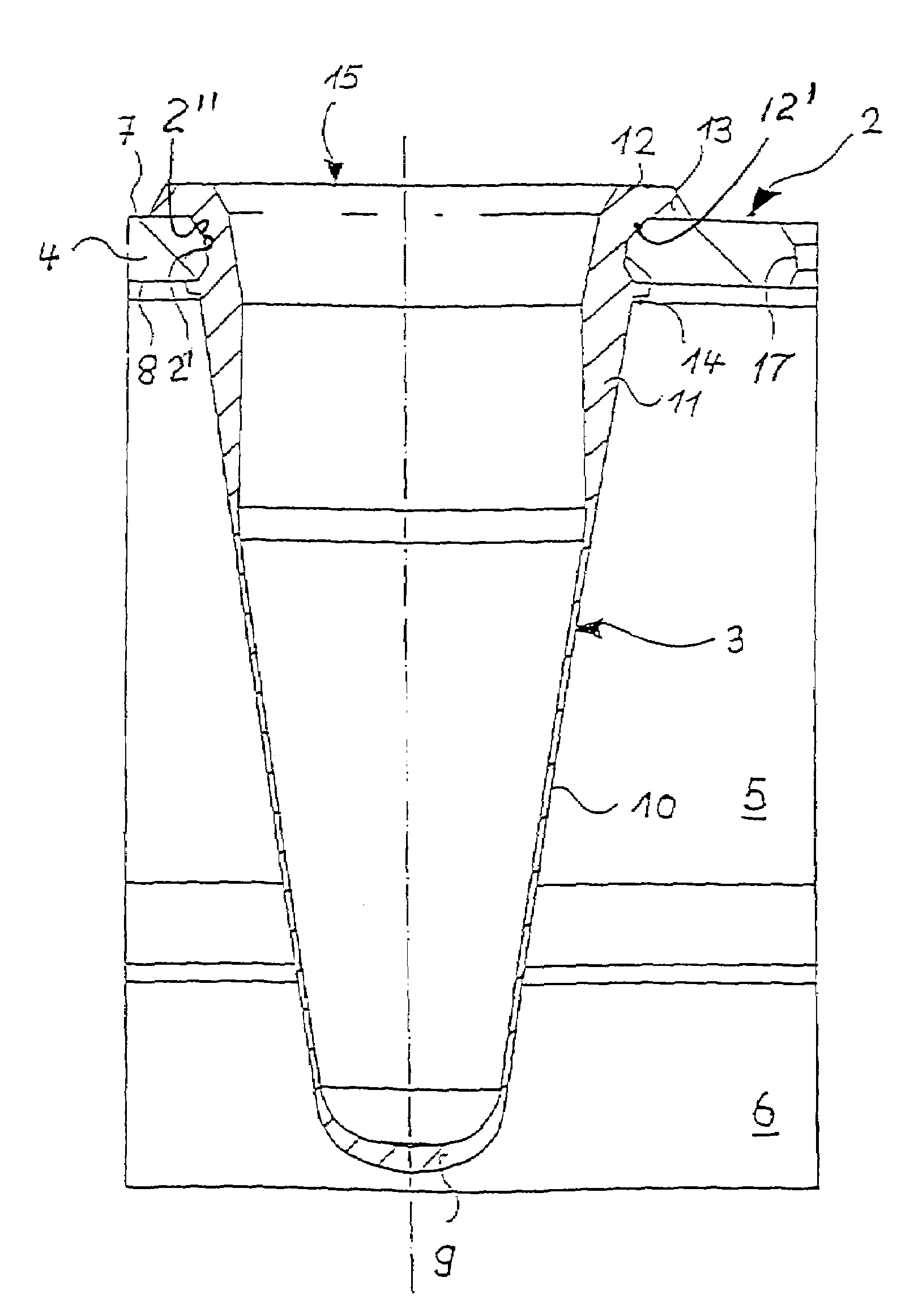

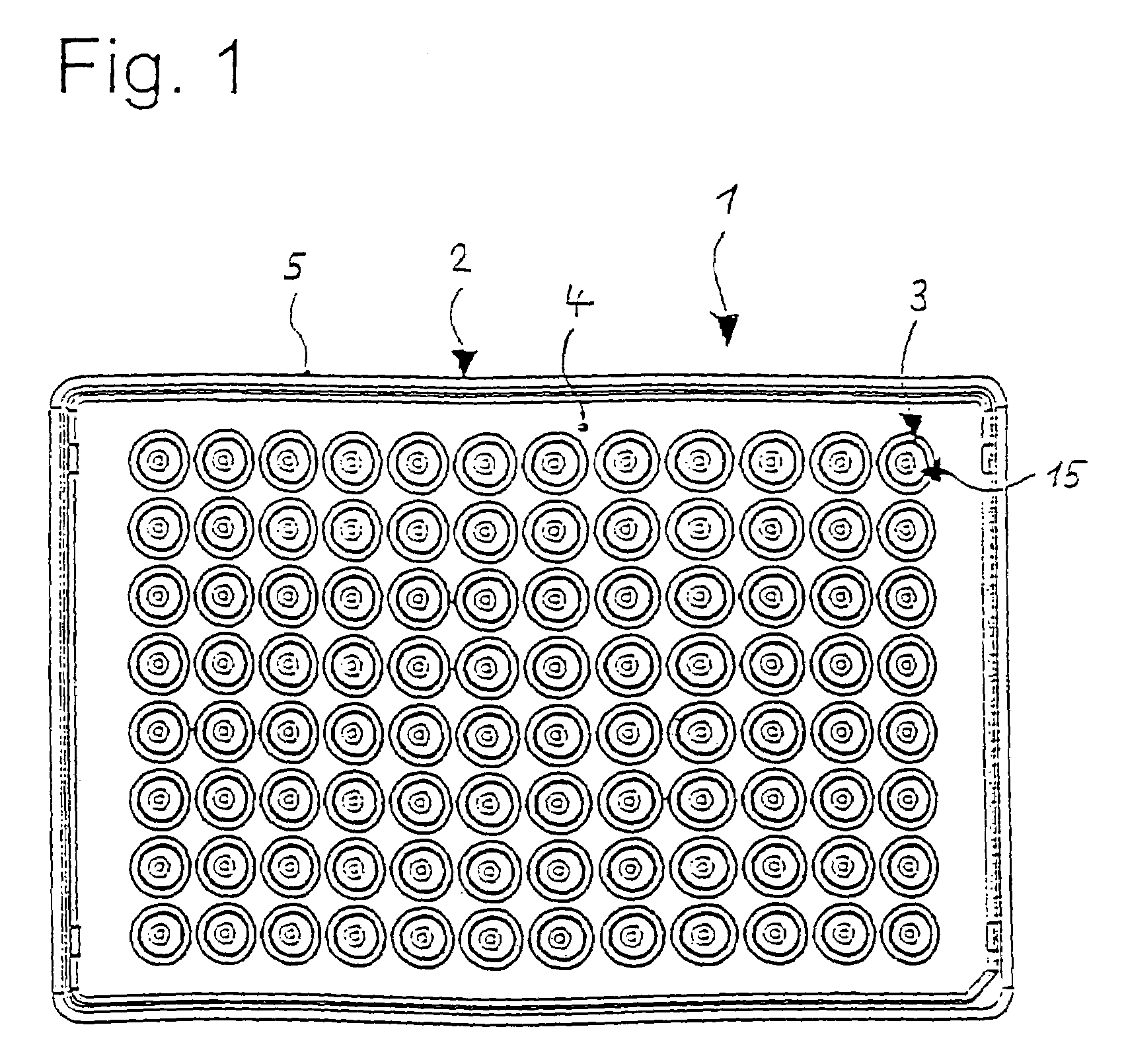

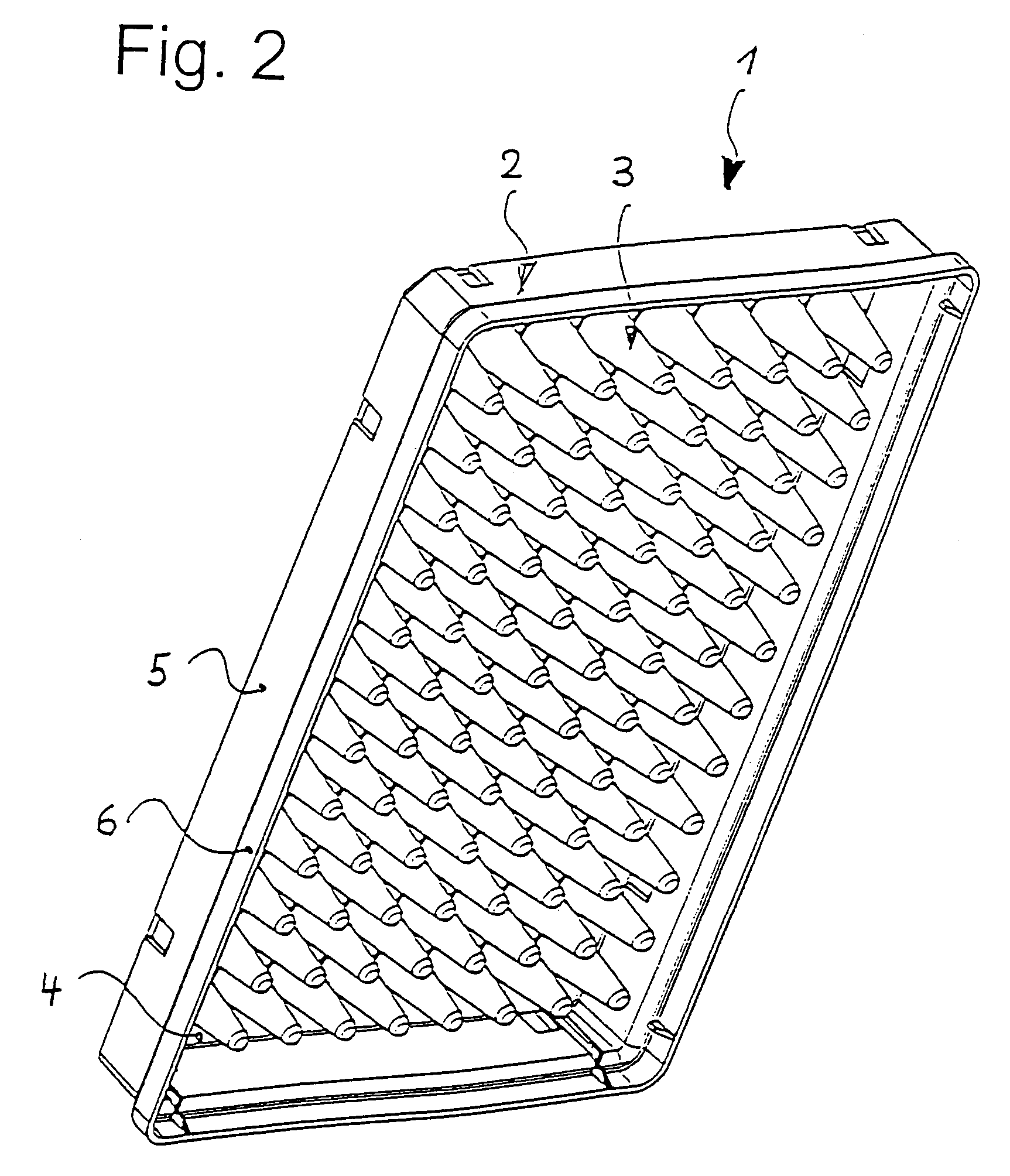

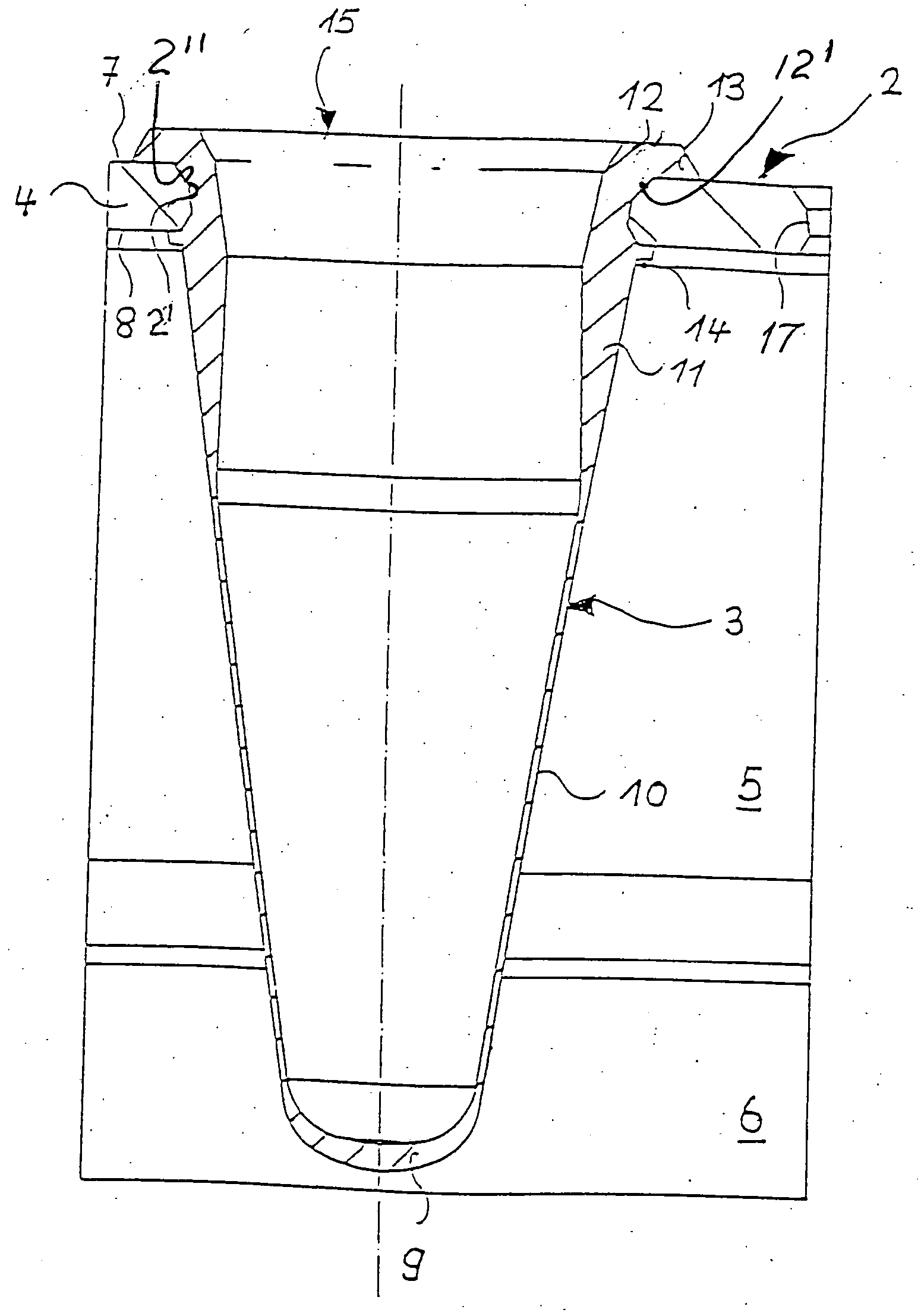

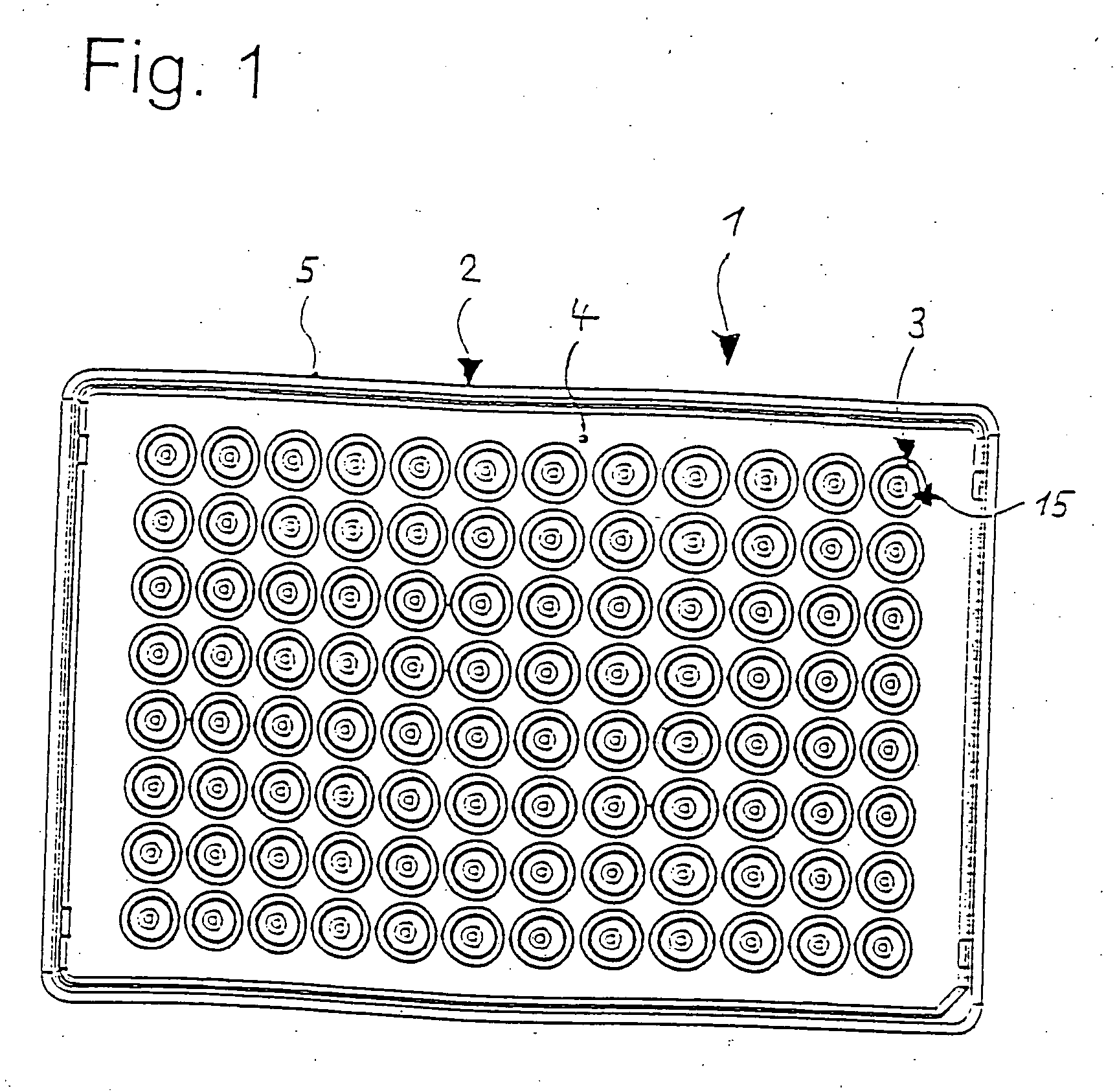

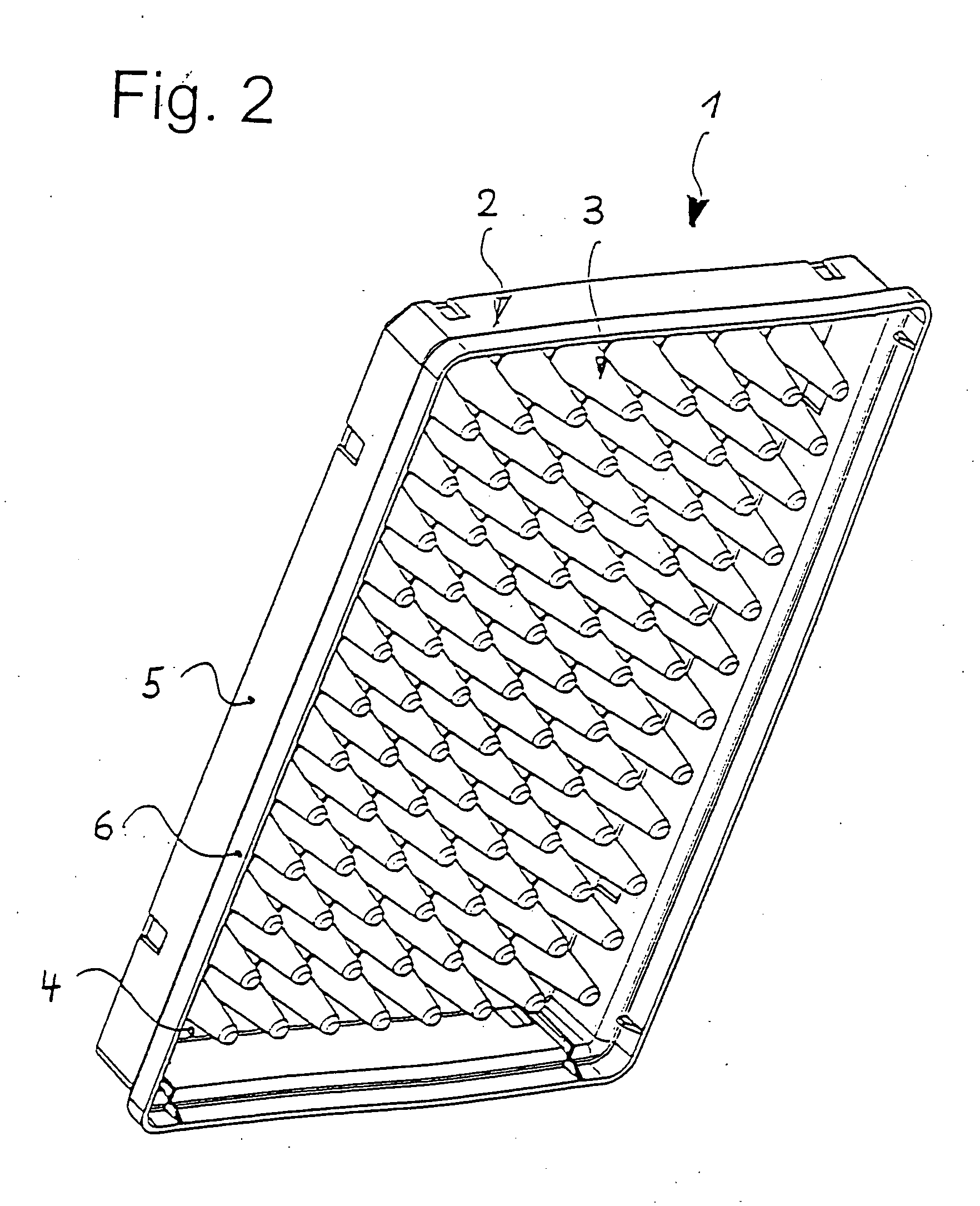

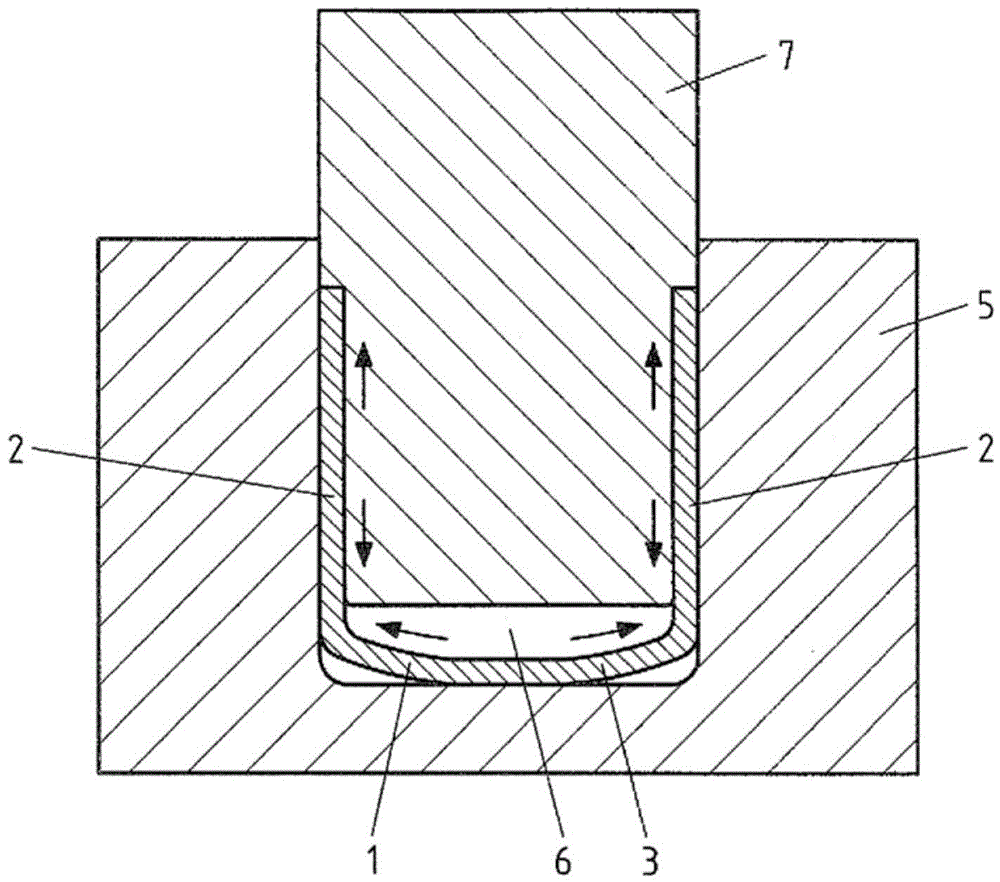

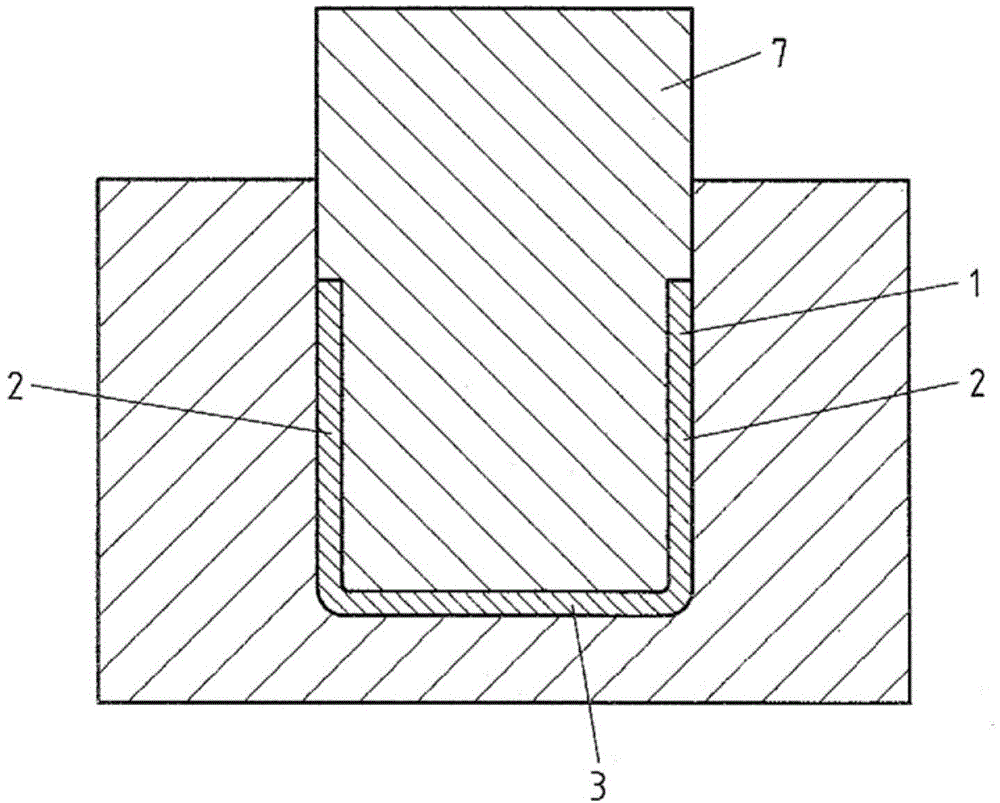

Microtitration plate

InactiveUS7347977B2Improve stabilityReduce distortion problemsBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOxygen

A microtitration plate has a frame (2) made of a first stiff plastic and having a plate (4) with multiplicity of holes (2′), and a multiplicity of vessels (3) made of a second plastic suited for the PCR and / or exhibiting permeability to oxygen, which are fixedly connected to the plate (4) by directly molding them to the holes (6), which have a receiving portion (9, 10, 11) protruding from an underside (8) of the plate (4), and which are accessible from an upper surface (7) of the plate through apertures (15).

Owner:EPPENDORF AG

Device for forming a bore to facilitate insertion of an arcuate nail into a bone

InactiveUS20100292722A1Small toleranceIncreased torsional stiffnessFastenersEngineeringCircular segment

Owner:KLAUE KAJ

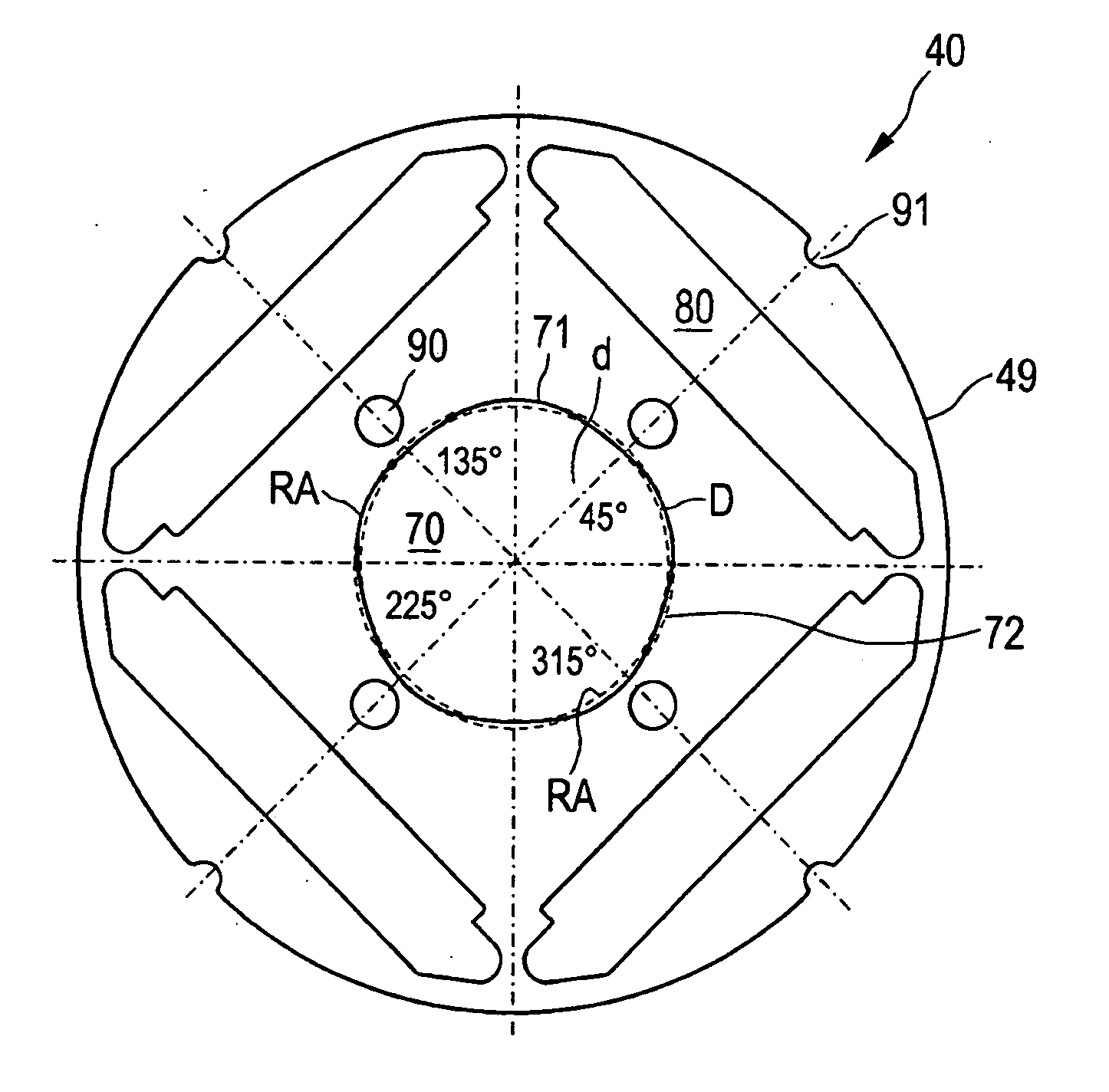

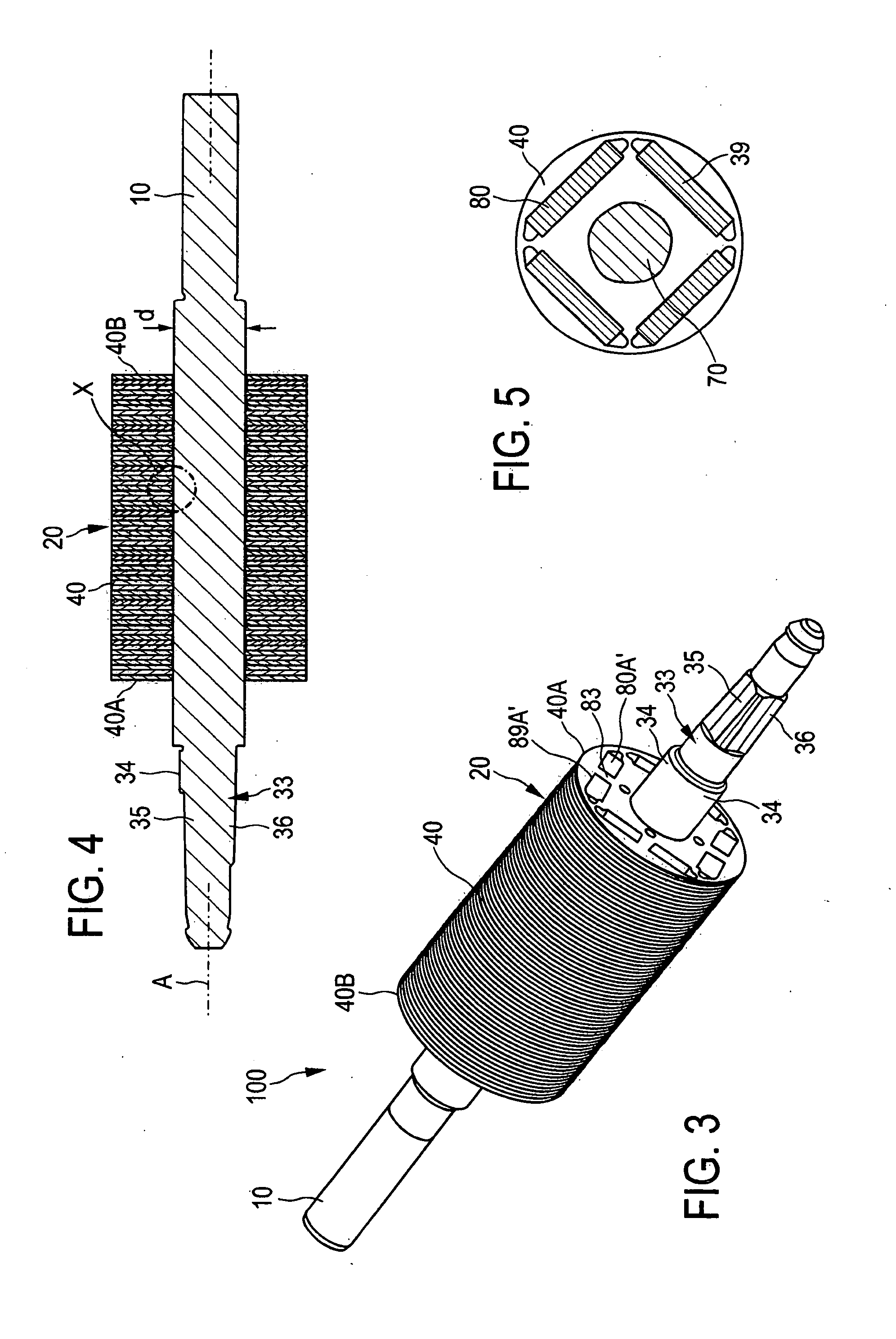

Rotor for an electric motor, an electric motor and a production process for an electric motor

ActiveUS20120014823A1Increase spaceSmall toleranceMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringElectric motor

A rotor (100) for an electric motor (1000). The rotor (100) has a rotor shaft (10) and a rotor core (20) attached onto the rotor shaft (10). The rotor core has a plurality of core laminations (40, 140) arranged along an axis (A) of the rotor core (20), and has a plurality of poles of at least one pole pair, the core lamination (40, 140) having: a central recess (70, 170) through which the rotor shaft (10) passes and which has a contour (71, 171) as well as adjacent areas (AF), and a plurality of receiving structures arranged at peripheral angular positions in order to each form a receiving element for a pole-forming element on the rotor core (20). In this context, it is provided according to the invention that the rotor core has a surface (OF) facing the rotor shaft (10) that is formed together with the adjacent areas (AF) of the central recess (70, 170) of the plurality of core laminations (40, 140), and that has uneven areas crosswise to the axis (A) of the rotor core (20) that are formed by the contours (71, 171) of the central recesses (70) of the plurality of core laminations (40, 140). The contours (71, 171) of the central recesses (70, 170) of at least a first core lamination and a second core lamination of the plurality of core laminations (40, 140) are arranged so as not to be congruent with each other.

Owner:HILTI AG

Precision die forging and shaping technical method for automobile steering knuckle rough type parts

InactiveCN102672096ALow forming speedNo crack phenomenonRailway componentsMetal-working apparatusEngineeringMaterial distribution

The invention provides a precision die forging and shaping technical method for automobile steering knuckle rough type parts. The precision die forging and shaping technical method mainly comprises the process steps of blanking, heating, extruding and drawing out a rod part, pre-forging, upsetting, performing material distribution and performing multi-way precision die forging and shaping and is specifically as follows: blanking through a cutting device, and heating to the temperature of 1080 DEG C-1180 DEG C in a medium-frequency induction furnace; placing a round bar which is well heated into a female die of an extruding and drawing-out die to form a stock comprising a cylindrical surface and a steering knuckle rough rod part; placing the stock after upsetting and material distribution into a multi-way die forging die, firstly enabling an upper male die and an upper die seat in the vertical direction to move downwards, and closing the upper male die and a lower female die for forging; and then using male dies on the symmetrical left side and right side in the horizontal direction to perform extrusion precision forging and shaping. According to the method provided by the invention, as the die forging is performed on a multi-way die forging hydraulic machine, the shaping speed is much lower than that of die forging on a hammer, thus the occurrence of the phenomenon of forming cracks on the surface due to strong speed sensitivity caused by too-high speed can be avoided; and the contact friction resistance between a forged piece and the surface of a die cavity during the processes of die forging, shaping and ejection of the forced piece can be greatly reduced, the surface quality of the forged piece is further improved, and the utilization rate of the material of the forged piece is improved.

Owner:CHONGQING UNIV OF TECH

Microtitration plate

InactiveUS20050058578A1Low toleranceIncrease wall thicknessBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringOxygen

A microtitration plate has a frame (2) made of a first stiff plastic and having a plate (4) with multiplicity of holes (2′), and a multiplicity of vessels (3) made of a second plastic suited for the PCR and / or exhibiting permeability to oxygen, which are fixedly connected to the plate (4) by directly molding them to the holes (6), which have a receiving portion (9, 10, 11) protruding from an underside (8) of the plate (4), and which are accessible from an upper surface (7) of the plate through apertures (15).

Owner:EPPENDORF AG

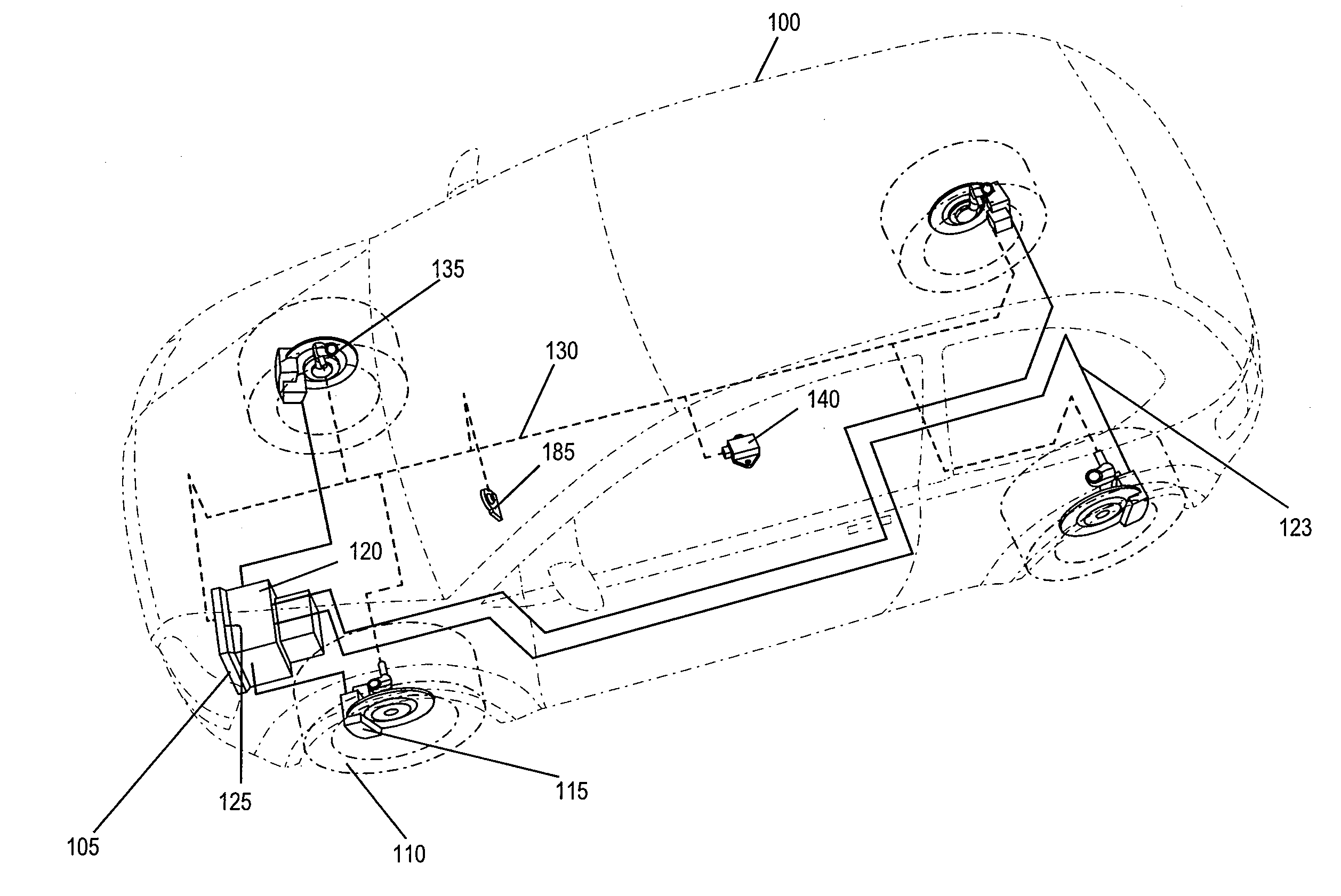

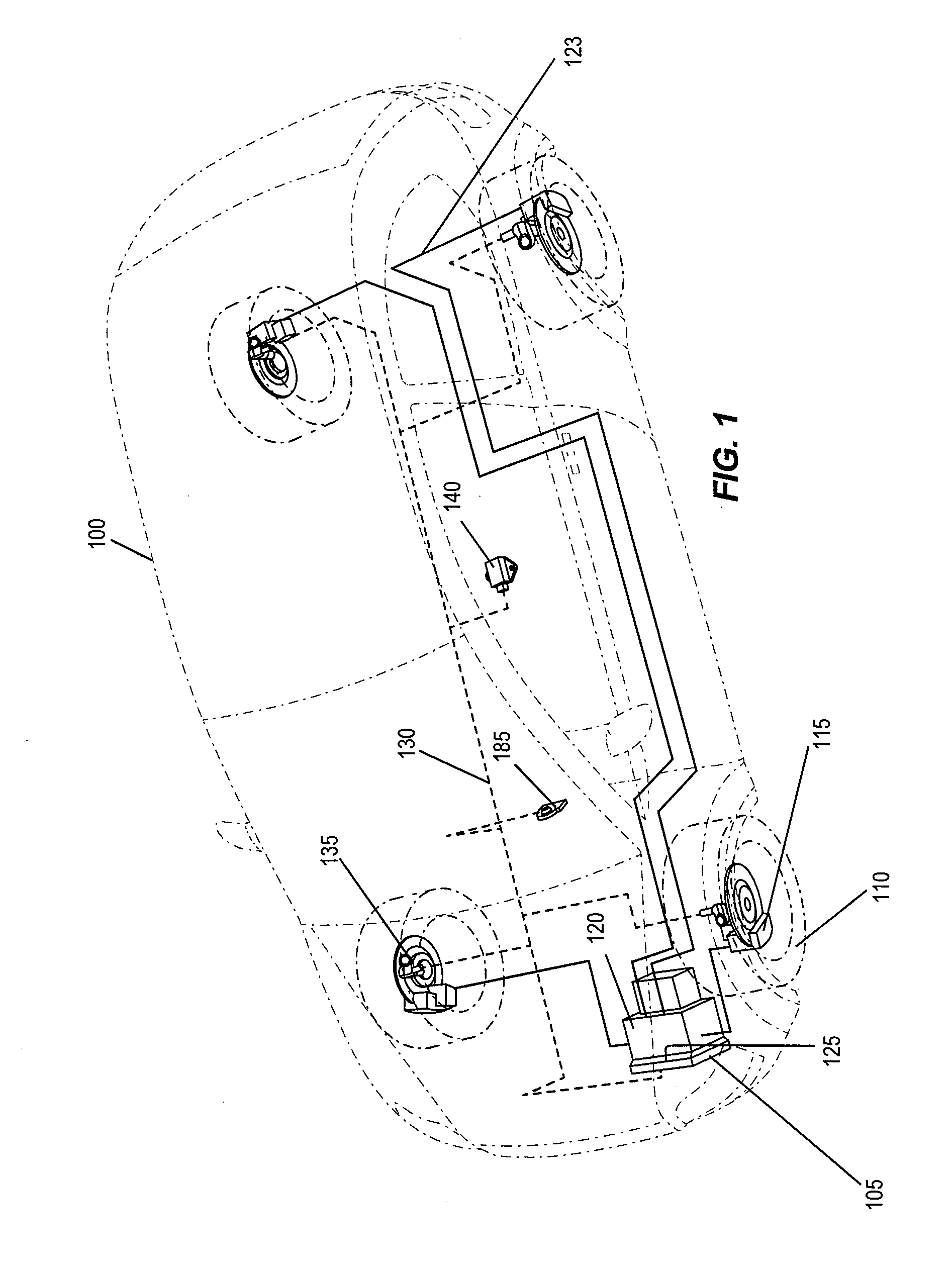

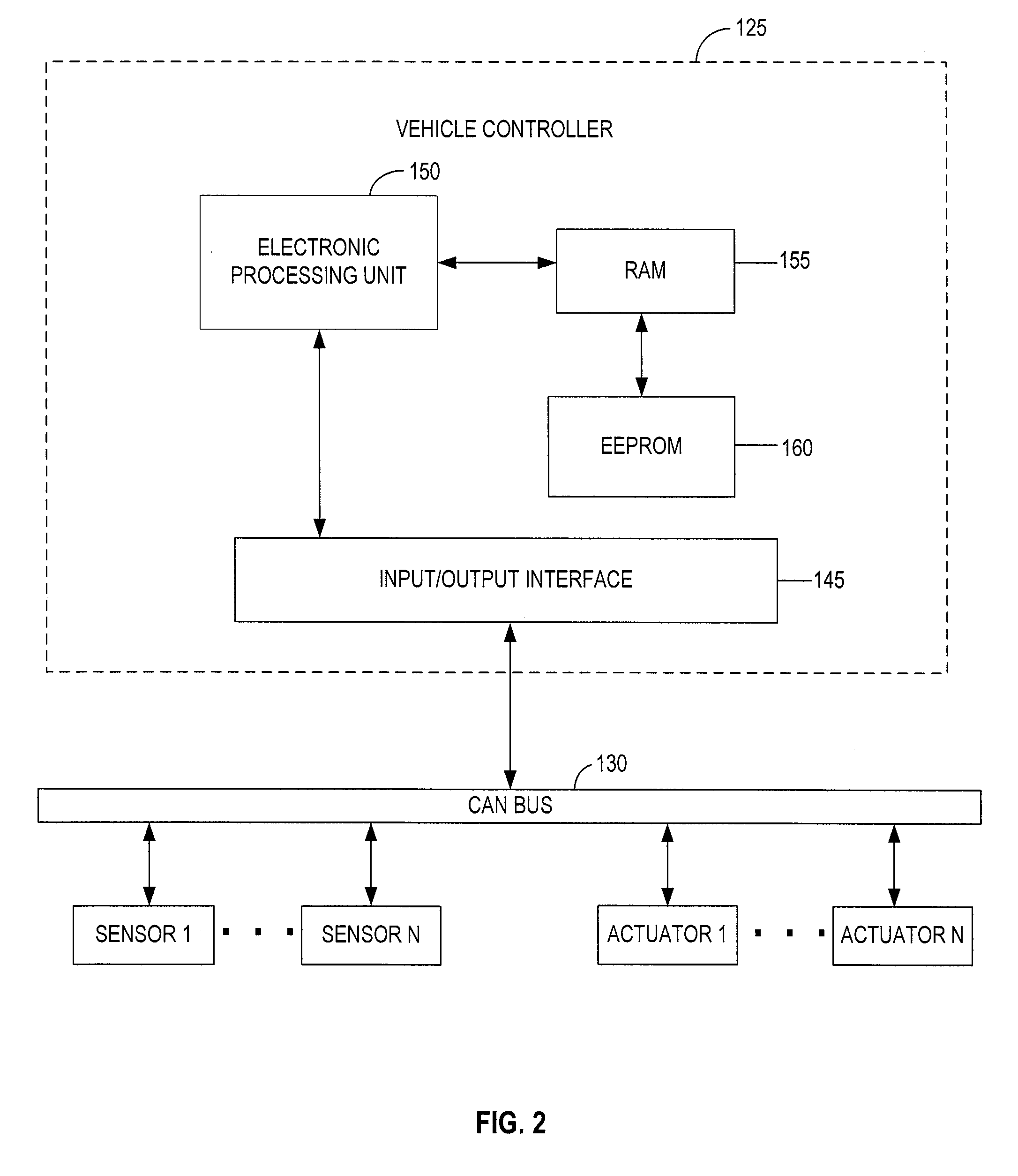

Good checking for vehicle longitudinal acceleration sensor

ActiveUS20110066320A1Small toleranceFew conditionVehicle testingRegistering/indicating working of vehiclesEmbedded systemSignal function

A controller for indicating whether a previously-detected, acceleration-sensor malfunction no longer exists. The controller includes an electronic memory and an electronic processing unit connected to the electronic memory. The electronic processing module includes a malfunction monitoring module, a failure handling module, and a signal checking module. The signal checking module performs a signal check after the malfunction monitoring module generates the fault signal. The signal check includes executing a signal check function with a longitudinal acceleration signal. Also disclosed is a vehicle including the controller, and a method executed by the controller.

Owner:ROBERT BOSCH GMBH +1

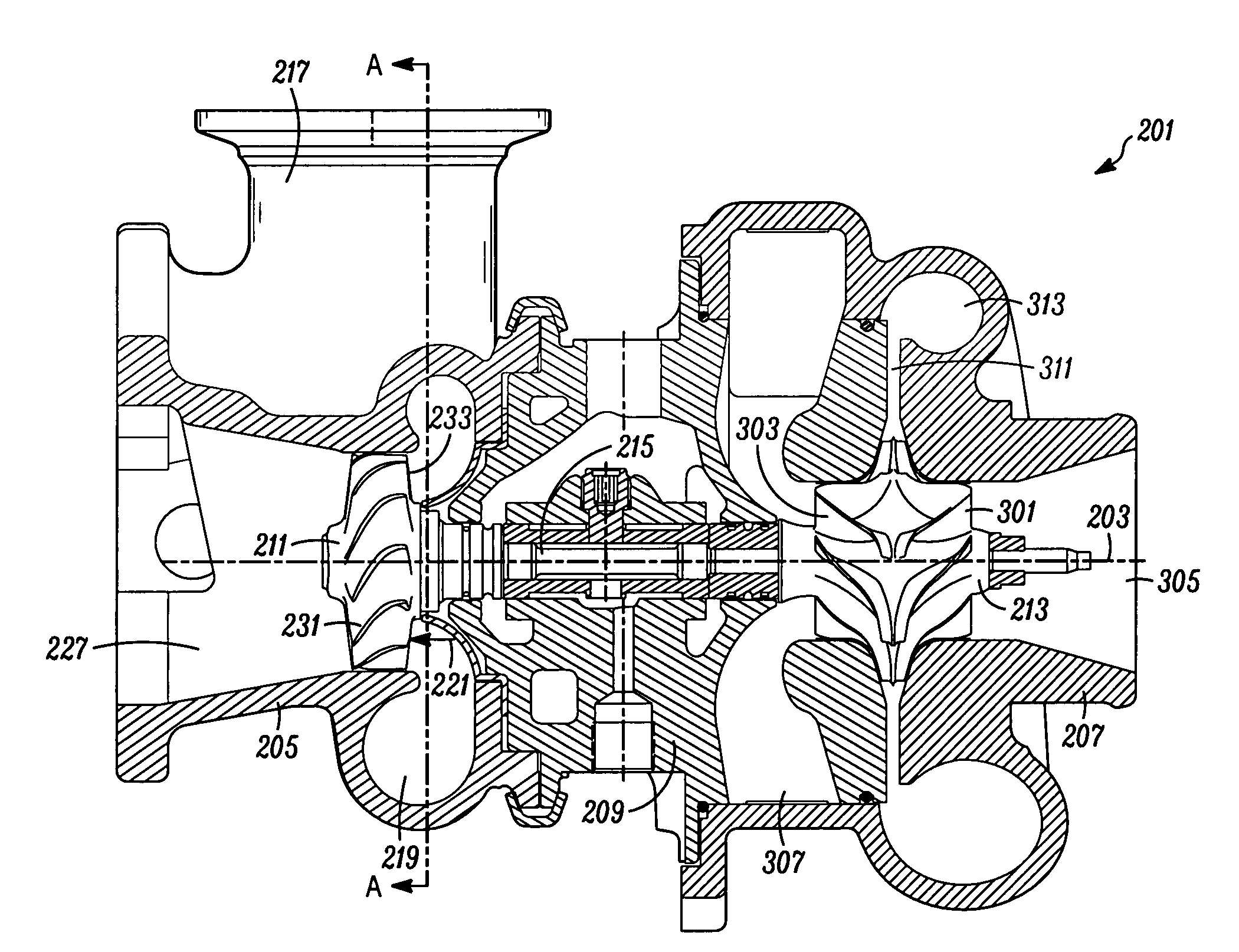

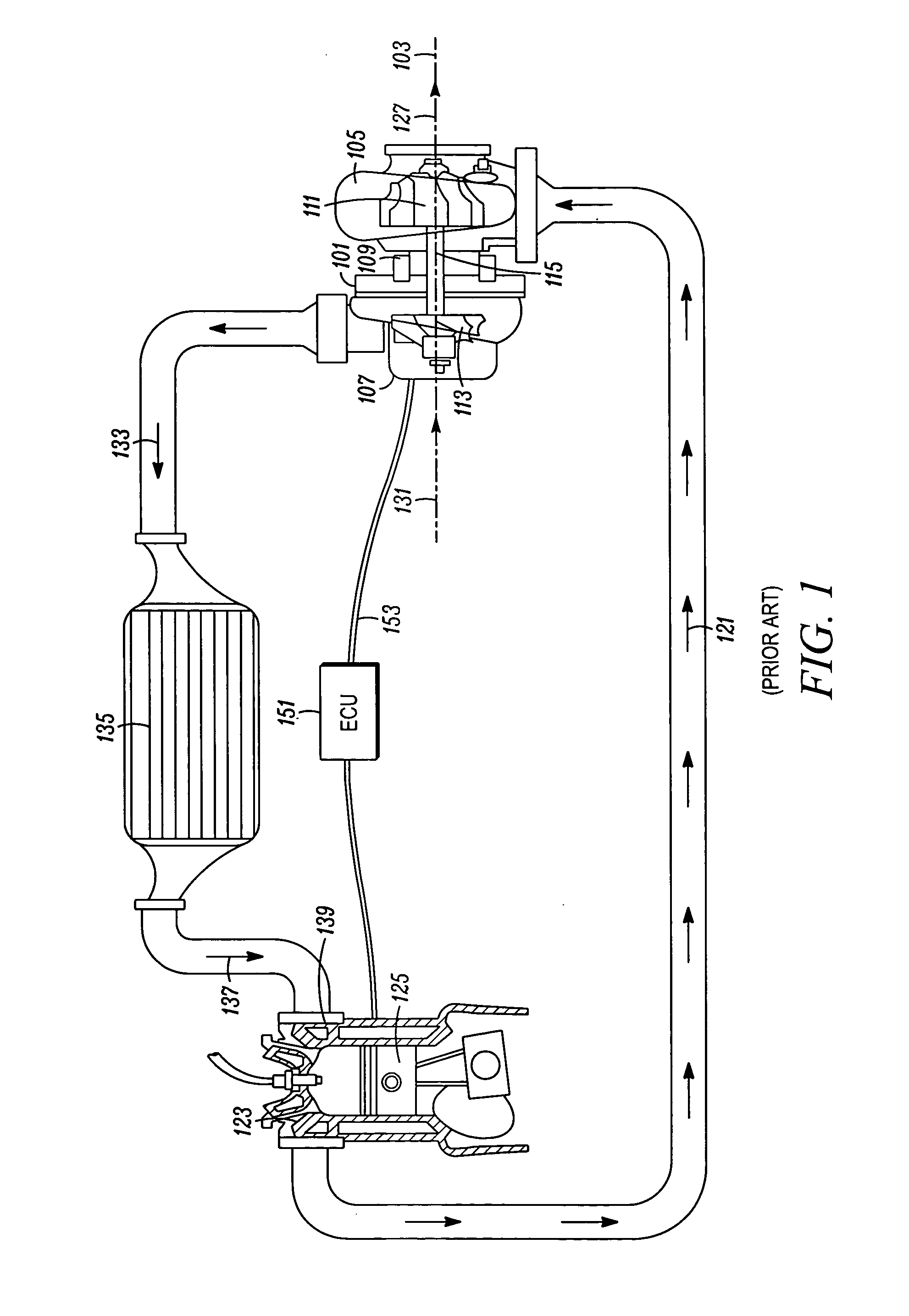

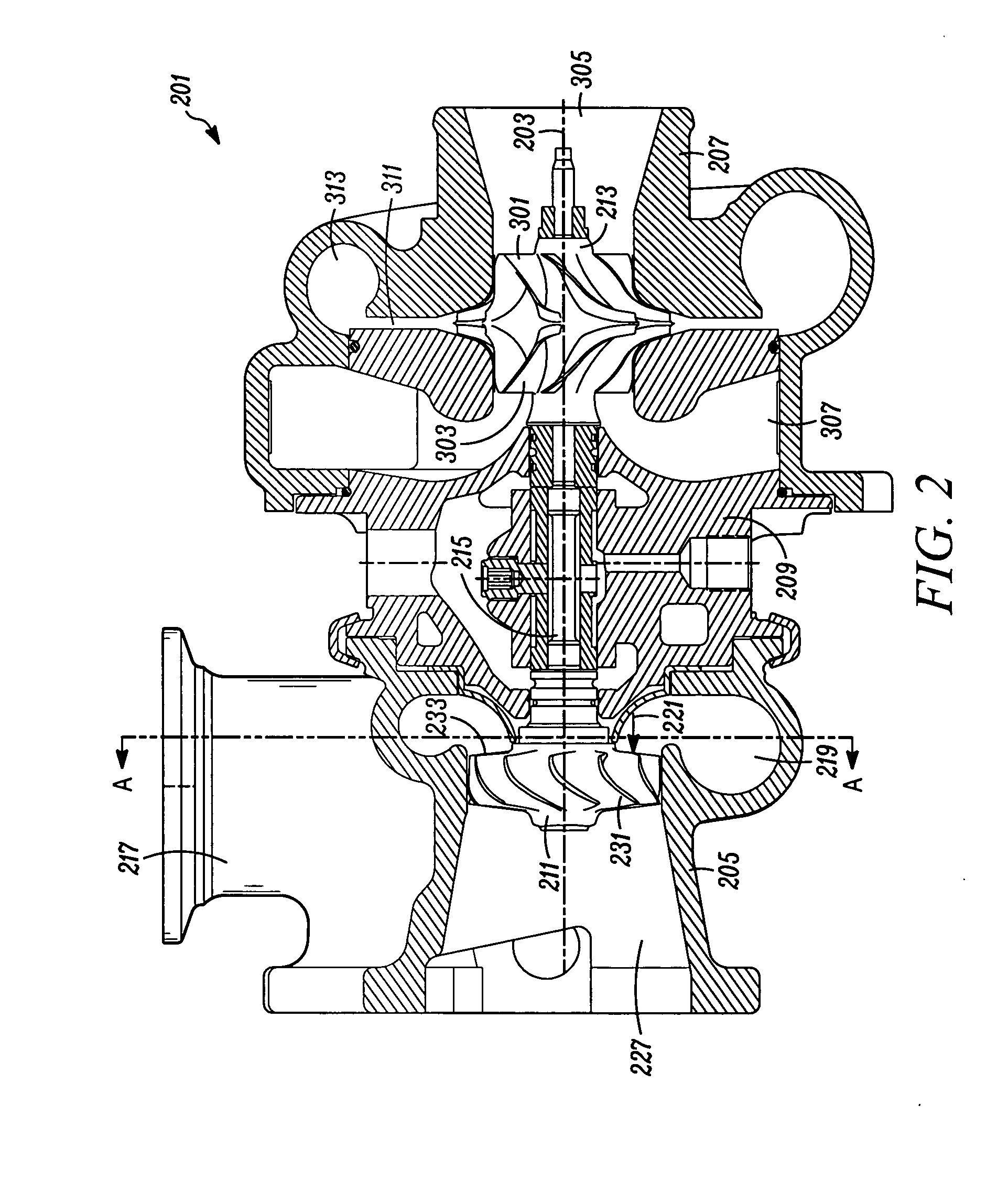

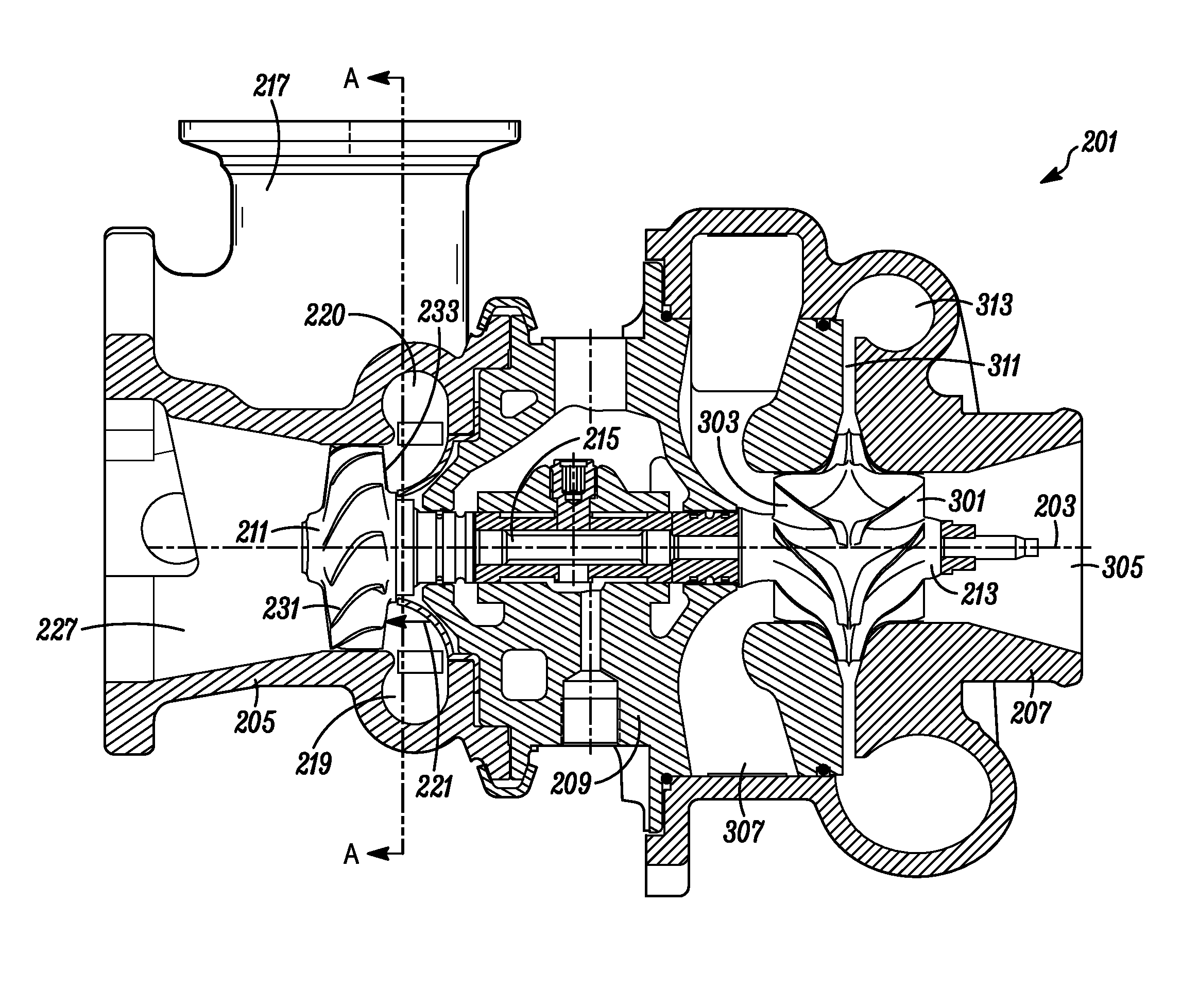

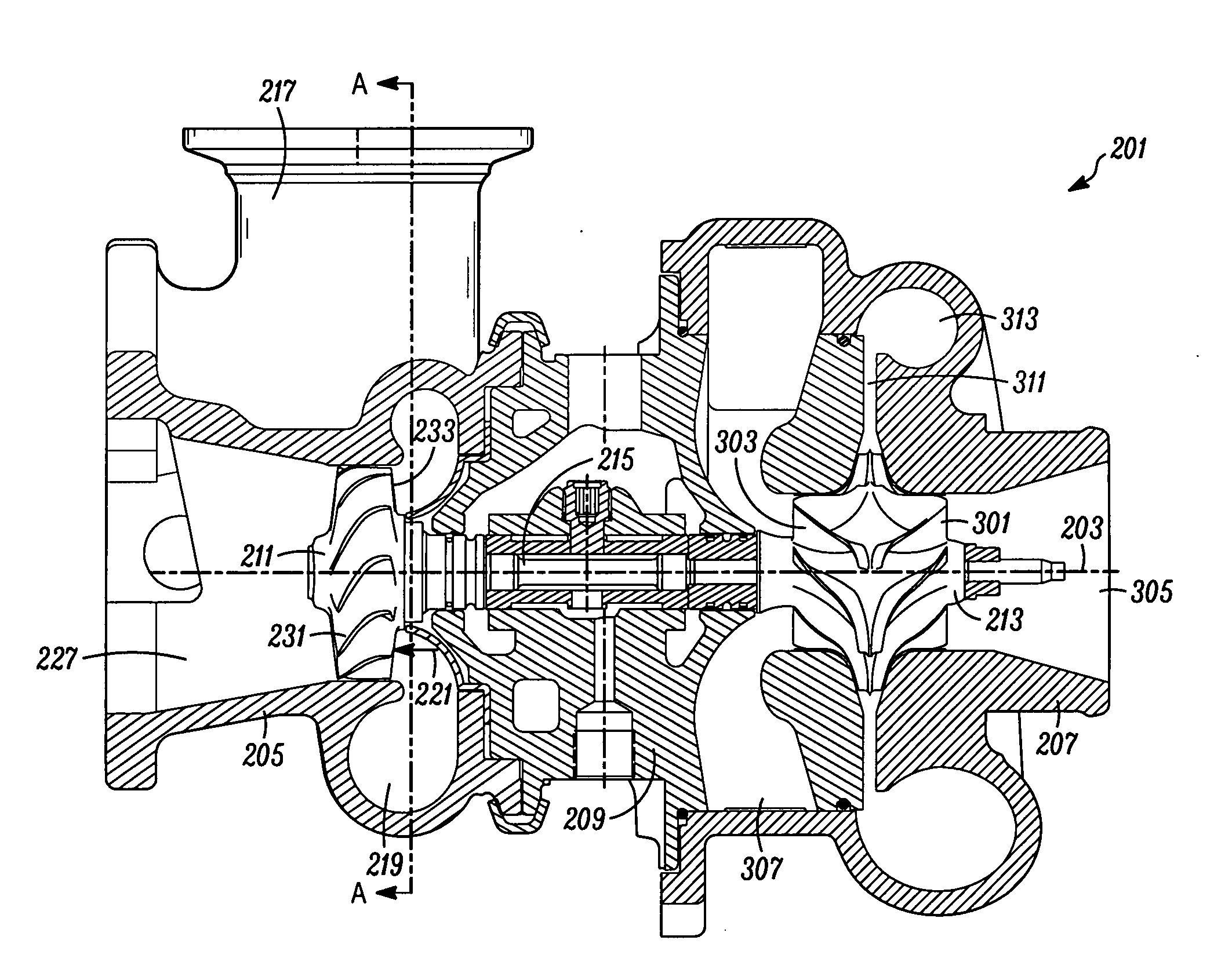

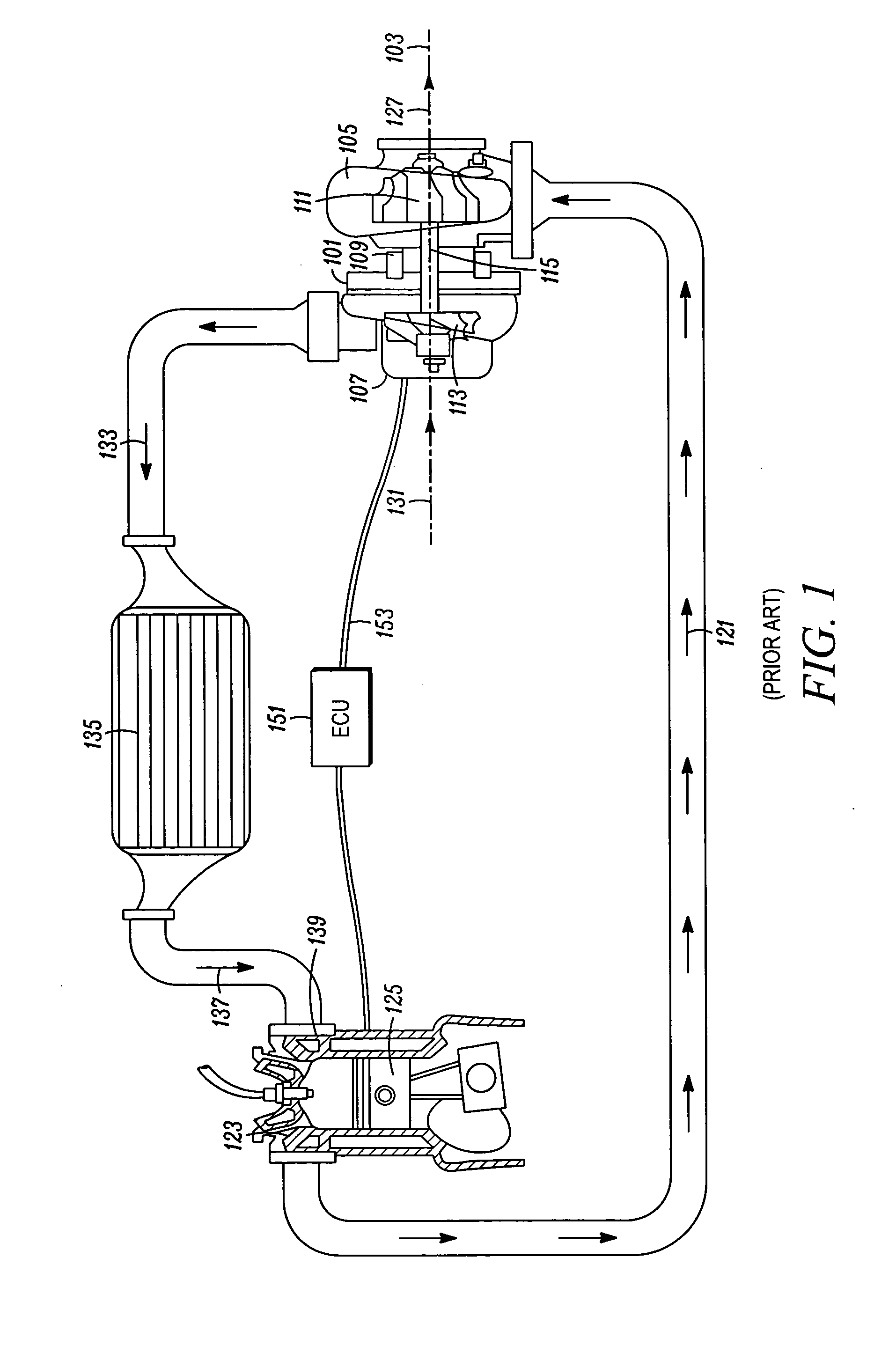

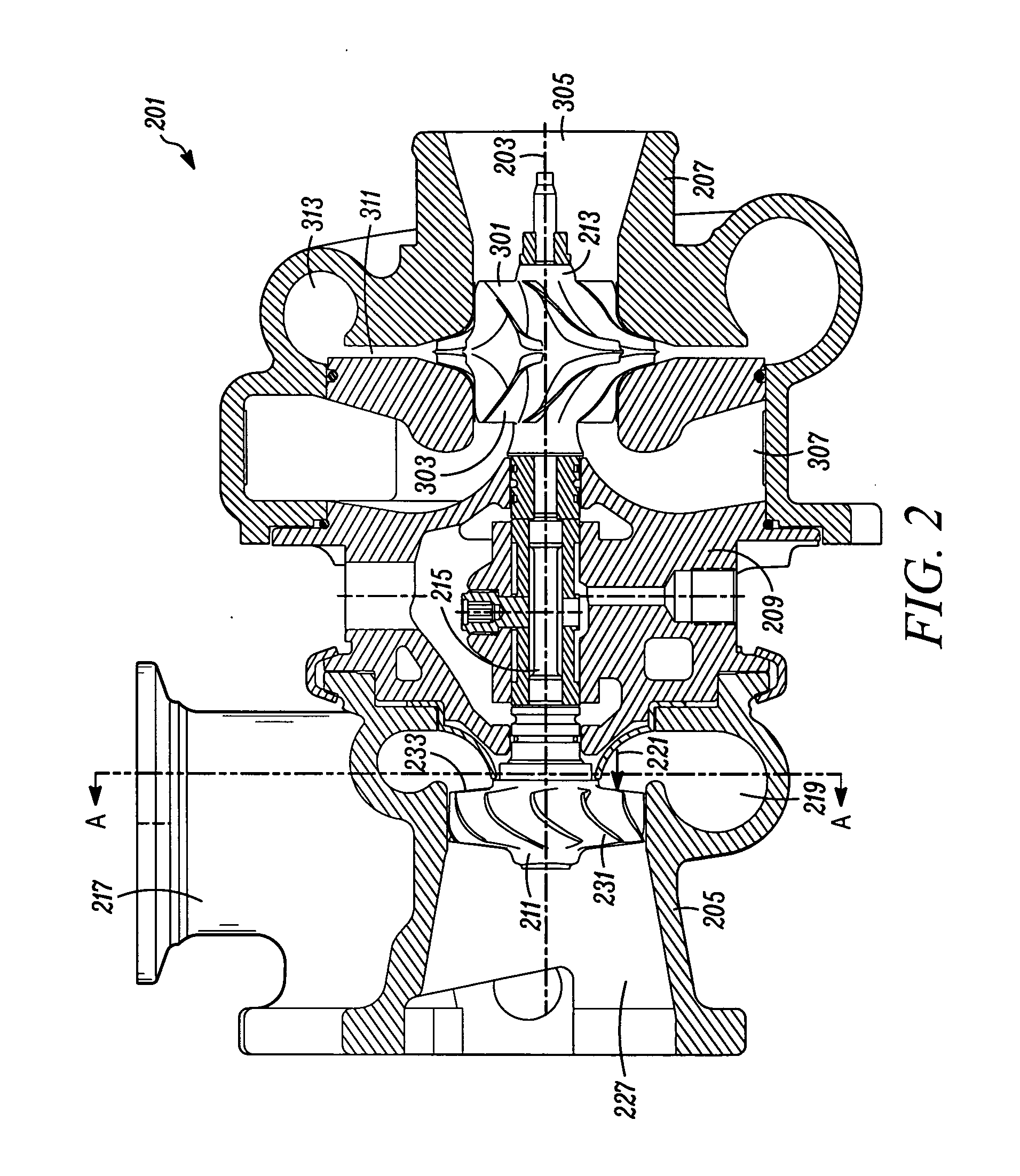

Axial Turbine

InactiveUS20110252790A1Low moment of inertiaSmall sizeInternal combustion piston enginesPump componentsImpellerTurbine wheel

A turbocharger including a turbine wheel having a hub-to-tip ratio of no more than 60% and blades with a high turning angle, a turbine housing forming an inwardly spiraling primary-scroll passageway that significantly converges to produce highly accelerated airflow into the turbine at high circumferential angles, and a two-sided parallel compressor. The compressor and turbine each produce substantially no axial force, allowing the use of minimal axial thrust bearings.

Owner:GARRETT TRANSPORATION I INC

Net point punching device for die core

InactiveCN103878227APrecise Control of UniformitySmall toleranceMetal working apparatusPunchingMeasuring instrument

The invention relates to the technical field of displaying and discloses a net point punching device for a die core. The net point punching device comprises a punching mechanism, a laser distance measuring instrument, a displacement calculation controller and an upper computer. The punching mechanism and the laser distance measuring instrument are installed on an installation support, the installation base is installed on a first horizontal guide rail and can horizontally move along the first horizontal guide rail. A first driver is installed on the first horizontal guide rail and connected with the installation base through a first transmission mechanism. The displacement calculation controller is respectively and electrically connected with the laser distance measuring instrument and the upper computer. The upper computer is electrically connected with the punching mechanism and the first driver. The laser distance measuring instrument is adopted for accurately measuring the depth and bore diameter of net points, the flatness of the die core surface and the distance between the net points in real time. In the punching process, net point punching force and the moving position of the punching mechanism can be adjusted in real time, so that the bore diameter, the depth and evenness are accurately controlled, and then the depth and bore diameter tolerance of the net points is reduced.

Owner:BOE TECH GRP CO LTD +1

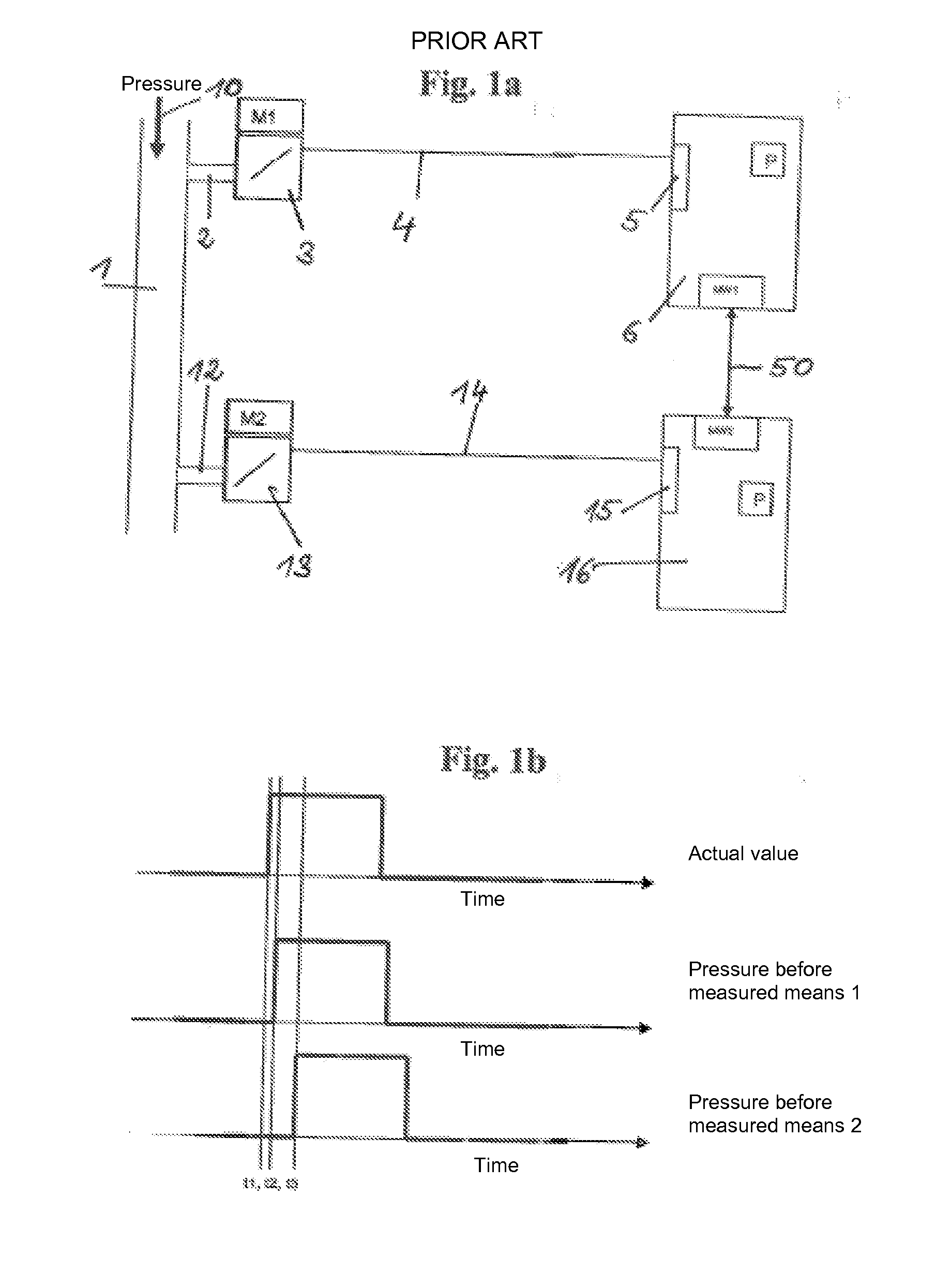

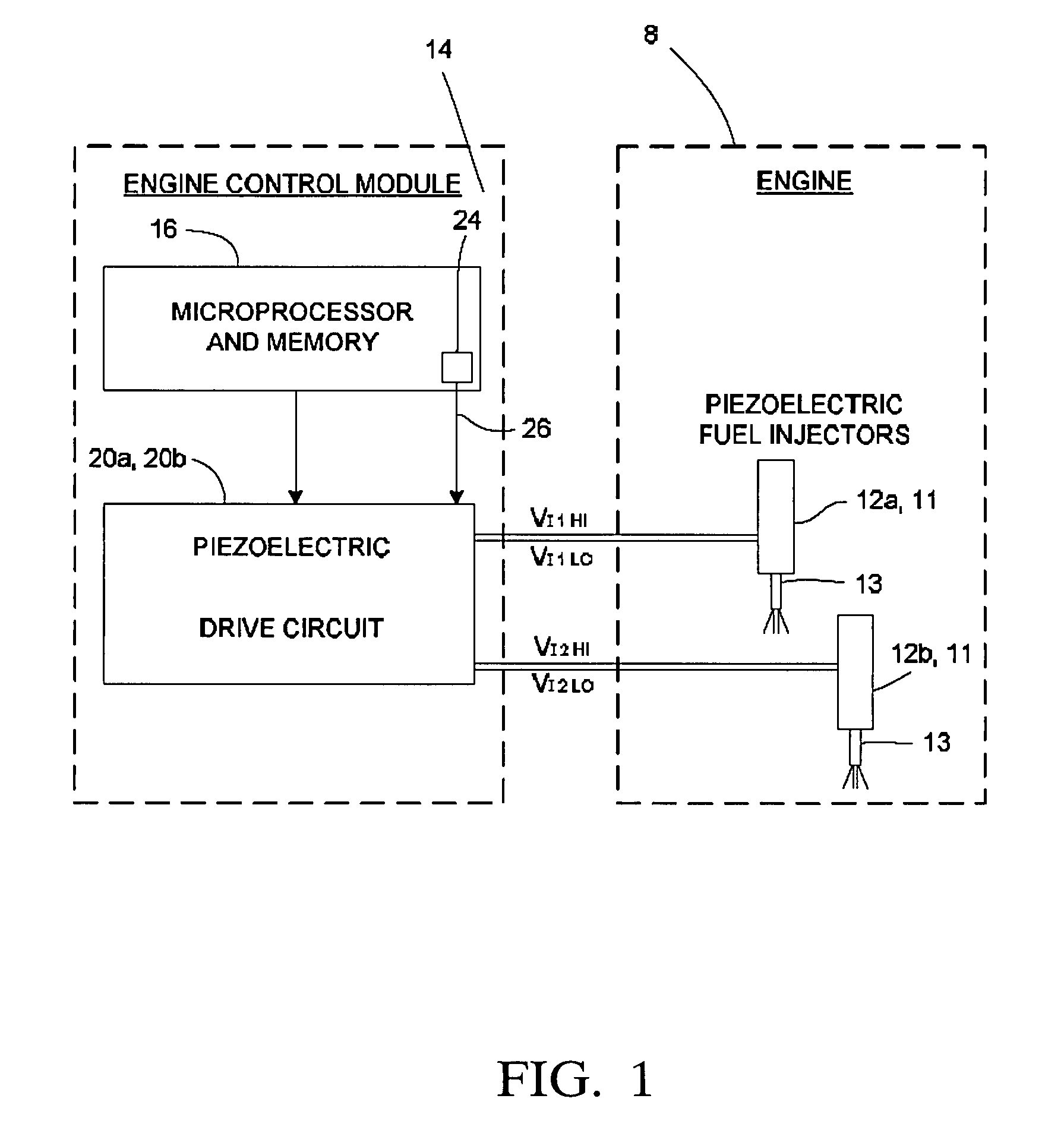

Drive circuit for an injector arrangement and a diagnostic method

InactiveUS7497204B2Small toleranceEnabling detectionAnalogue computers for vehiclesElectrical controlDriver circuitCapacitance

The invention relates to a drive circuit for an injector arrangement comprising a first fuel injector in parallel with a capacitive component. The drive circuit comprises: a selector means (SQ1, SQ2) and diagnostic means. The selector means (SQ1, SQ2) is operable to select the first fuel injector and / or the capacitive component into the drive circuit and to deselect the first fuel injector and / or the capacitive component from the drive circuit. When the capacitive component is selected and the first fuel injector is deselected, the diagnostic means is operable to sense a current (Isense) through the first fuel injector. When the sensed current (Isense) is at variance from a first threshold current (Ilimit) the diagnostic means is operable to provide a first signal on detection of a stack terminal short circuit fault associated with the first fuel injector. The capacitive component may be a second fuel injector.

Owner:DELPHI TECH HLDG S A R L

Axial turbine wheel

InactiveUS20110252792A1Low moment of inertiaSmall sizeBlade accessoriesCombustion enginesImpellerTurbine wheel

A turbocharger including a turbine wheel having a hub-to-tip ratio of no more than 60% and blades with a high turning angle, a turbine housing forming an inwardly spiraling primary-scroll passageway that significantly converges to produce highly accelerated airflow into the turbine at high circumferential angles, and a two-sided parallel compressor. The compressor and turbine each produce substantially no axial force, allowing the use of minimal axial thrust bearings.

Owner:GARRETT TRANSPORATION I INC

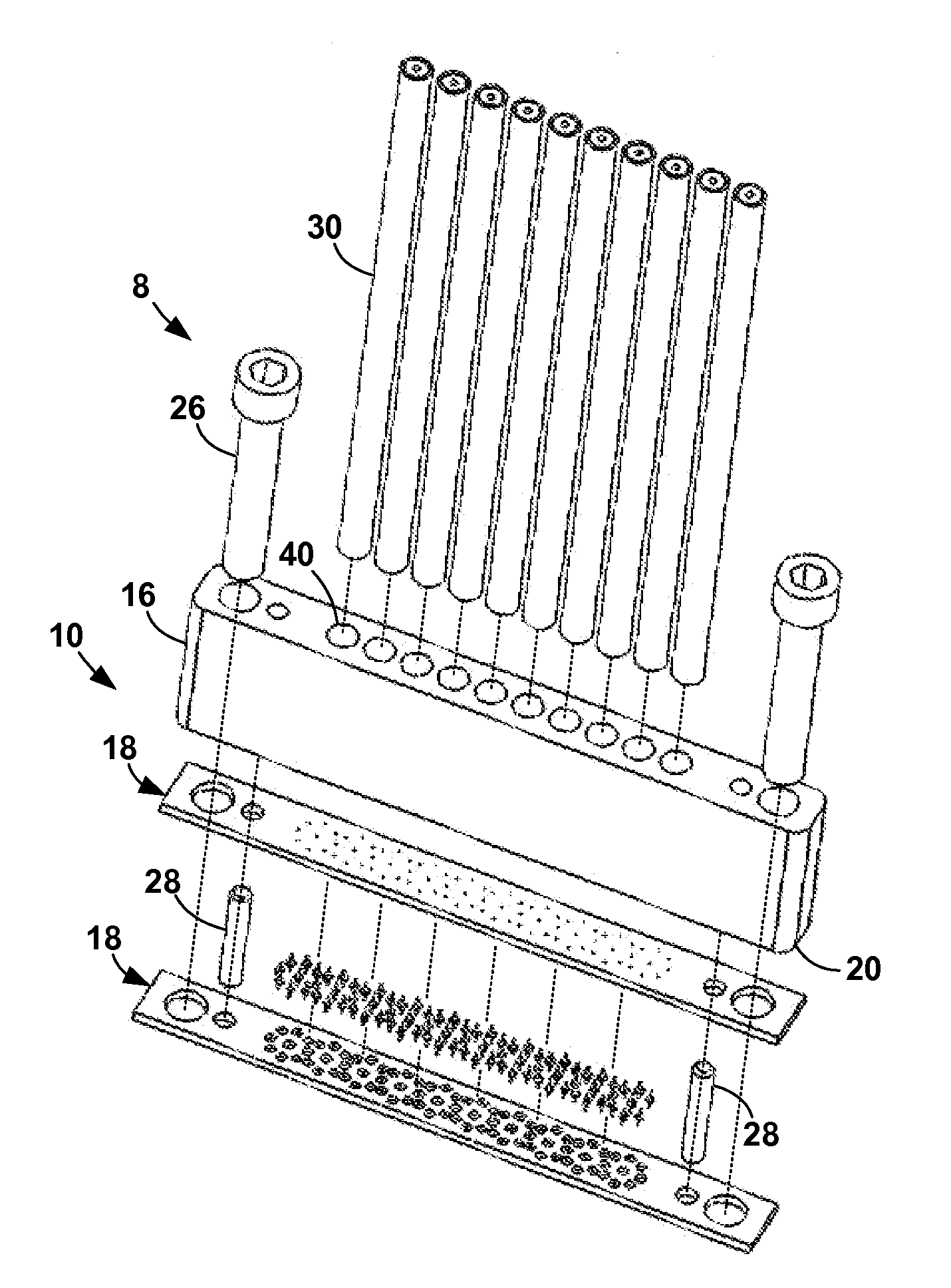

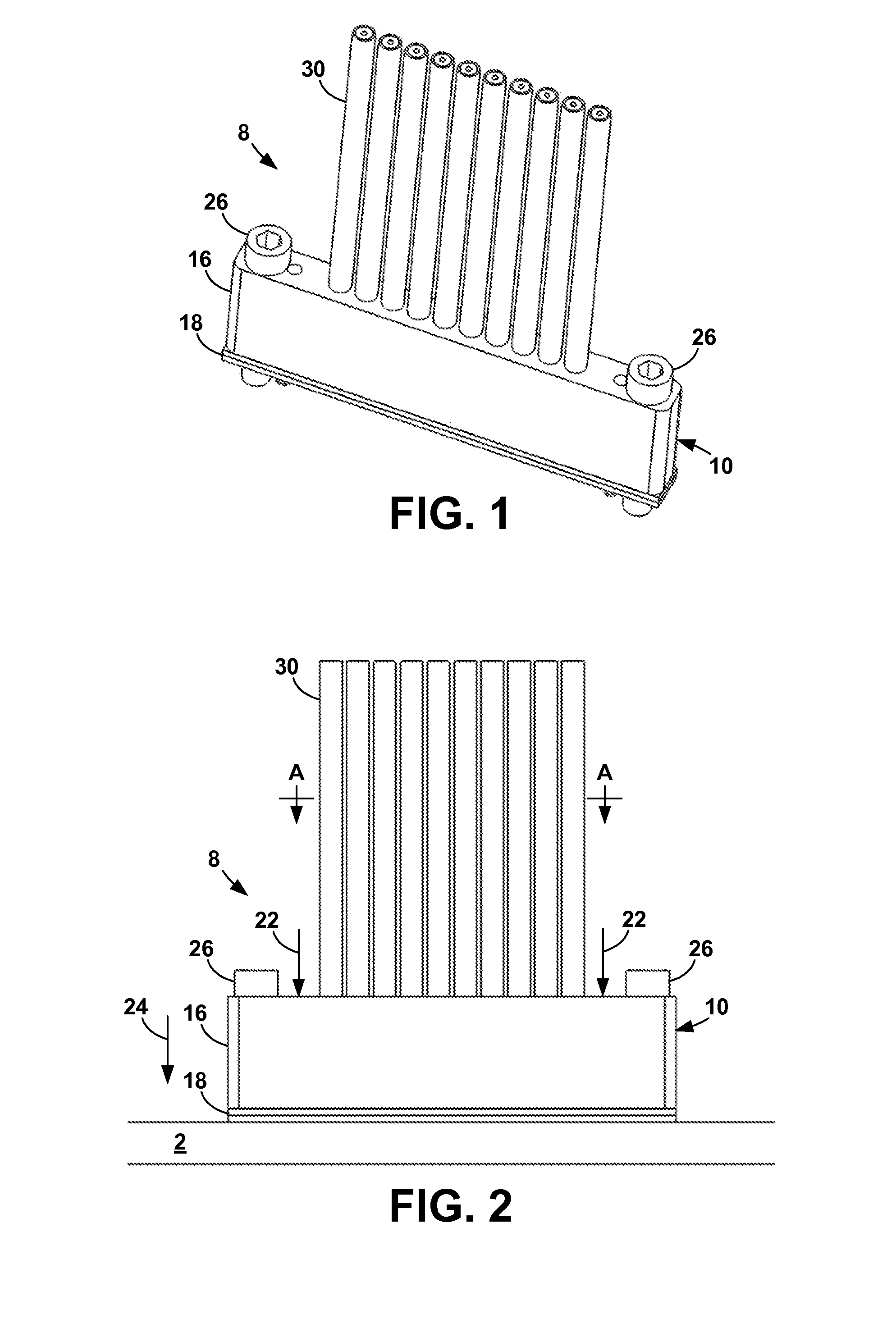

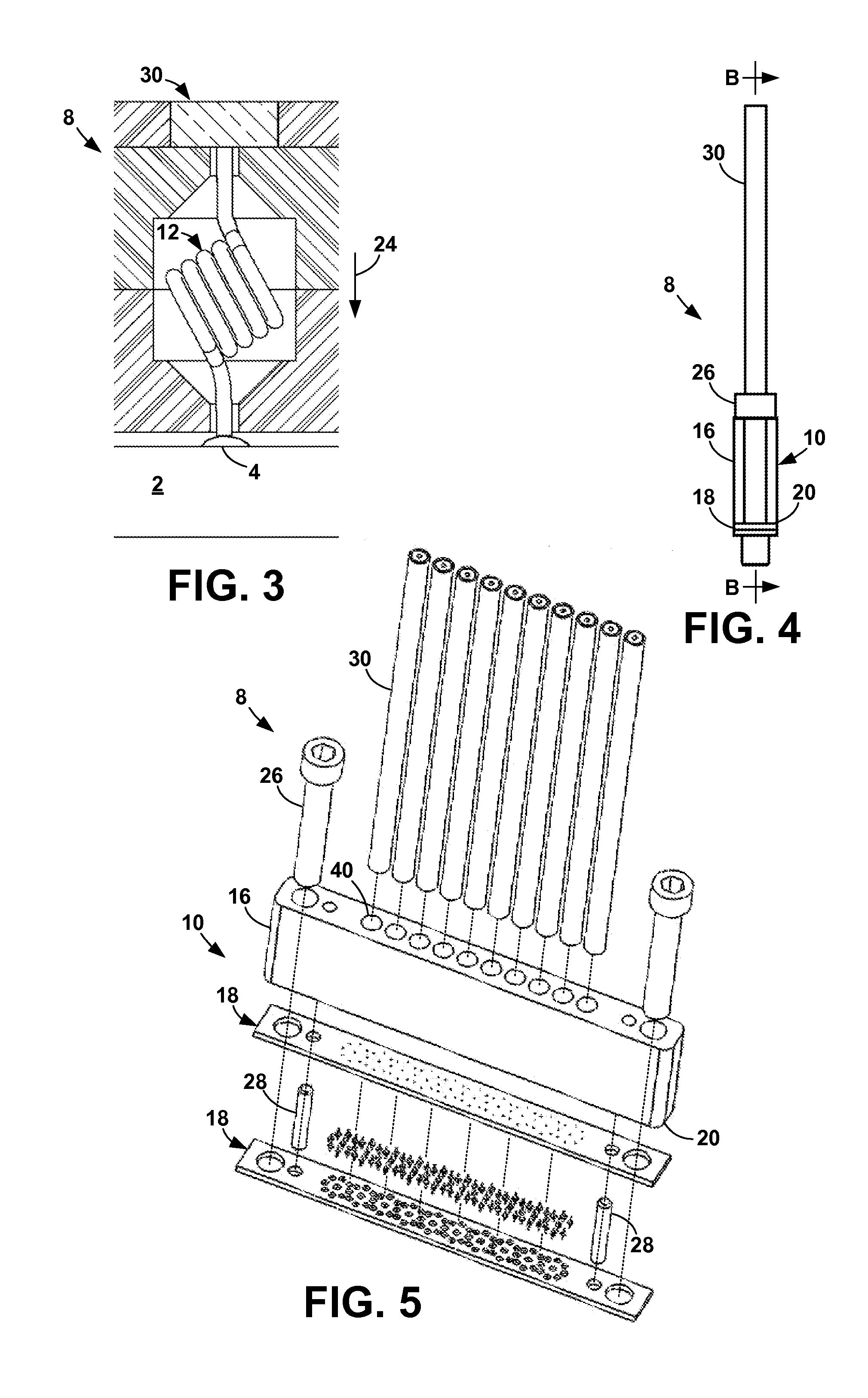

Controlled-Impedence Cable Termination Using Compliant Interconnect Elements

ActiveUS20140199885A1Minimizes detrimental electrical effect of terminationIncrease contact areaLine/current collector detailsElectrically conductive connectionsConductive coatingGround plane

An apparatus for terminating a controlled-impedance cable using compliant electrical contacts to provide an interface to another device. The terminator includes a conductive ground block for securing the cable by its ground shield and providing a common ground. Once the cable is anchored in the ground block, the block face and cable ends are dressed to make a reliable electrical contact with the compliant signal contact that electrically connects the cable center conductor to the device. An insulating or conductive plate mounted to the ground block holds the signal contact and optional ground contacts that electrically connect the ground block to the ground plane of the device. The ground contacts surround the signal contact in a pattern that closely mimics the impedance environment of the cable. When using a conductive plate, the signal contact is insulated from the plate by an insulating centering plug or a non-conductive coating.

Owner:ARDENT CONCEPTS INC

Workstation of a textile machine for creating cross-wound spools

The invention relates to a workstation of a textile machine for creating cross-wound spools, comprising a thread receiving mechanism disposed within an unwinding region of a feeding spool, thread monitoring and treatment mechanisms mounted within a thread passageway region and a winding device for creating a cross-wound spool. According to the invention, the workstation (1) has a thread guidance channel (6) that encloses a thread passageway, is composed of multiple portions and has receptacle housings (18, 21) or receiving portions (31, 32, 33) for various thread monitoring and treatment mechanisms. The thread guidance channel (6) is extended between a feeding spool (2) at an unwinding position (AS) and a winding device (4) and can be locally applied with negative pressure according to the need, so that the negative pressure flow is present in the thread guidance channel (6) and the flow direction can be determined as desired.

Owner:SAURER GERMANY GMBH & CO KG

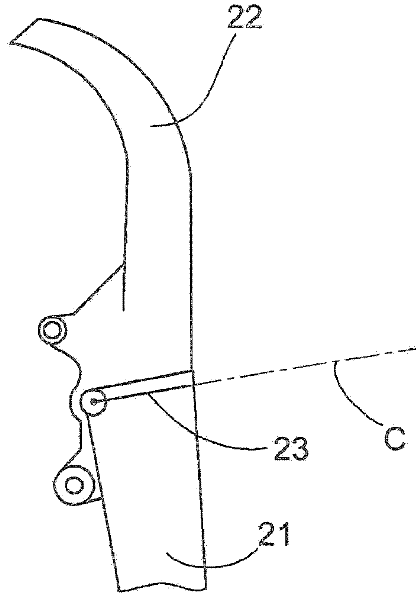

Stator for an electric machine, and method for producing such a stator

ActiveUS20170366060A1Small toleranceEasy to fixWindings insulation shape/form/constructionManufacturing dynamo-electric machinesElectrical conductorElectric machine

The invention relates to a stator (10) and to a method for producing a stator (10) for an electric machine (12), comprising a stator body (34) which has radial stator teeth (14) for receiving sub-coils (17) of an electric winding (16). An insulating plate (40) with guide elements (44) for connection wires (30, 31) is arranged between the sub-coils (17) on an end face (39) of the stator body (34), and a separately produced wiring plate (52) is arranged axially over the insulating plate (40), said wiring plate having conductor elements (63) for electrically contacting the connection wires (30, 31) with customer-specific connection plugs (56) of a controller. The wiring plate (52) is supported directly on the end face (39) of the stator body (34) by means of spacers (84).

Owner:ROBERT BOSCH GMBH

Production method of highly dimensionally accurate half shells

InactiveCN104959442AEliminate springbackSmall toleranceShaping toolsEngineeringBiomedical engineering

Owner:THYSSENKRUPP STEEL EURO AG

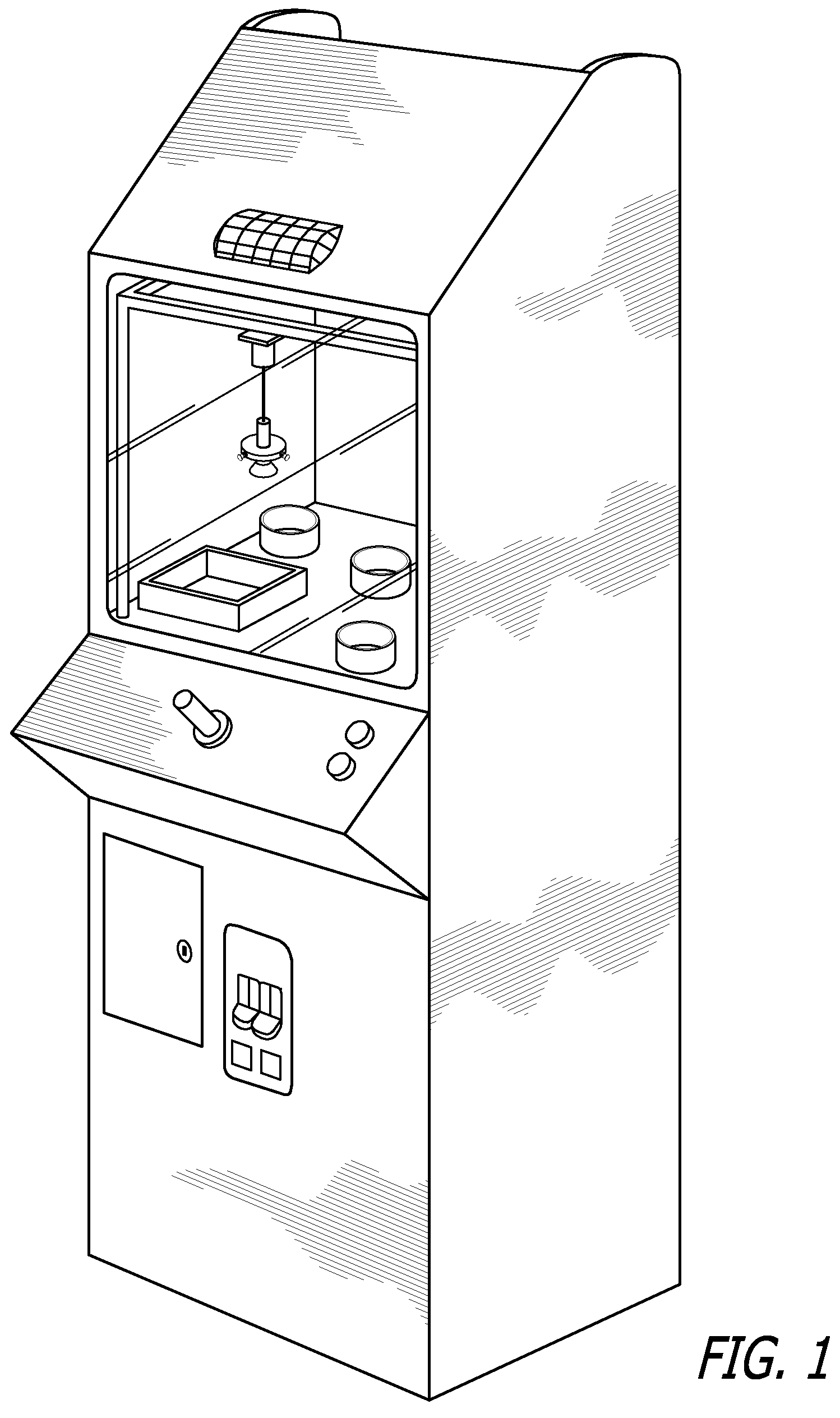

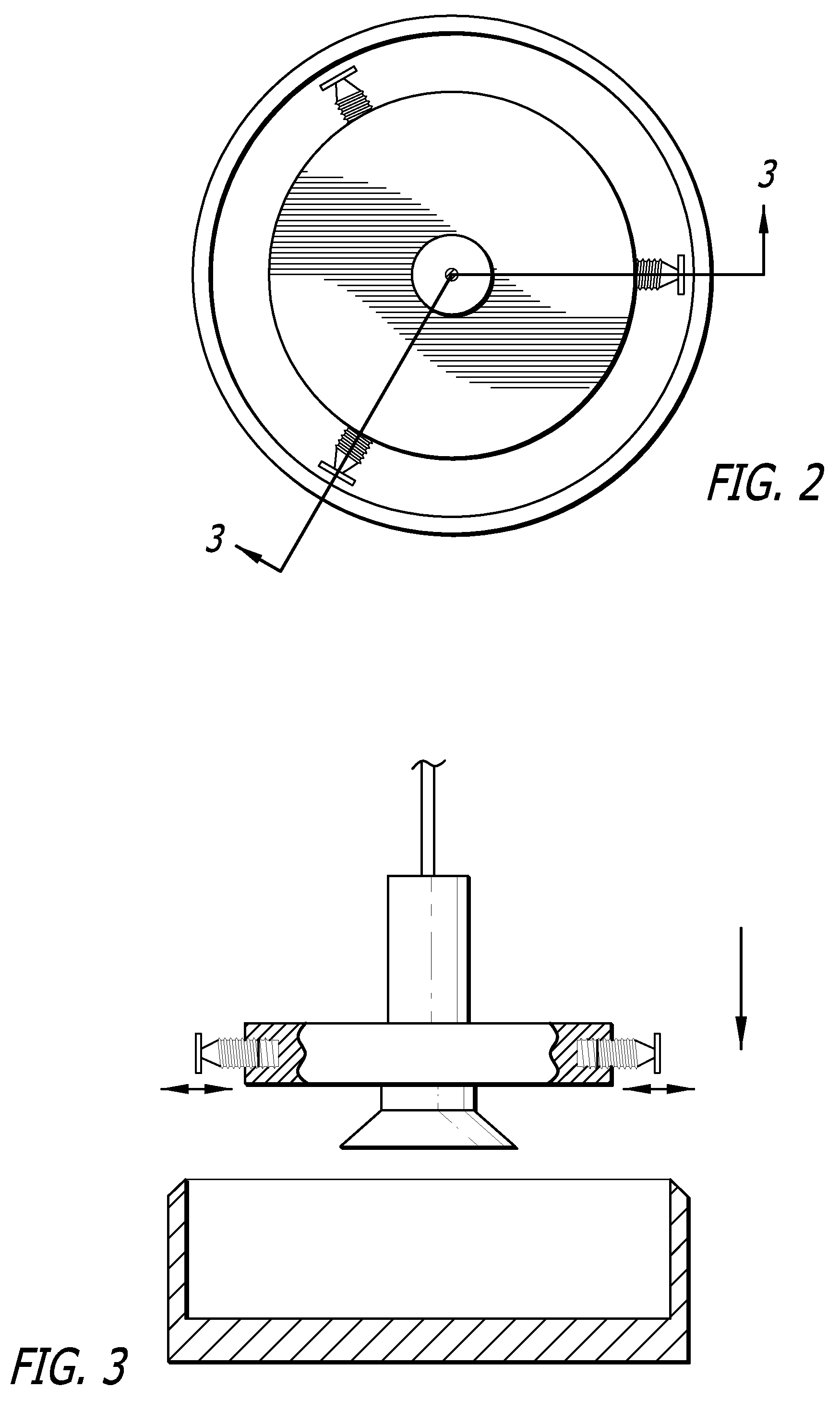

Vacuum crane pick-up device

ActiveUS8070167B1Increase and decrease toleranceSmall toleranceIndoor gamesApparatus for meter-controlled dispensingHollow coreEngineering

An arcade game pick-up device for use with hollow cylindrical targets that can be picked-up by applying a suction force to the bottom of the target, the pick-up device having a suction means and a control for reducing the tolerance between an impeding structure and the upper wall of the target to control the win percentage.

Owner:STEPHEN P SHOEMAKER TRUST

Axial turbine with radial vnt vanes

A turbocharger including a turbine wheel having a hub-to-tip ratio of no more than 60% and blades with a high turning angle, a turbine housing forming an inwardly spiraling primary-scroll passageway that significantly converges to produce highly accelerated airflow into the turbine at high circumferential angles, and a two-sided parallel compressor. The compressor and turbine each produce substantially no axial force, allowing the use of minimal axial thrust bearings.

Owner:HONEYWELL INT INC

Axial turbine with parallel flow compressor

InactiveUS20110252791A1Increasing efficiency of turbochargerReduce load levelPump componentsCombustion enginesImpellerTurbine wheel

A turbocharger including a turbine wheel having a hub-to-tip ratio of no more than 60% and blades with a high turning angle, a turbine housing forming an inwardly spiraling primary-scroll passageway that significantly converges to produce highly accelerated airflow into the turbine at high circumferential angles, and a two-sided parallel compressor. The compressor and turbine each produce substantially no axial force, allowing the use of minimal axial thrust bearings.

Owner:GARRETT TRANSPORATION I INC

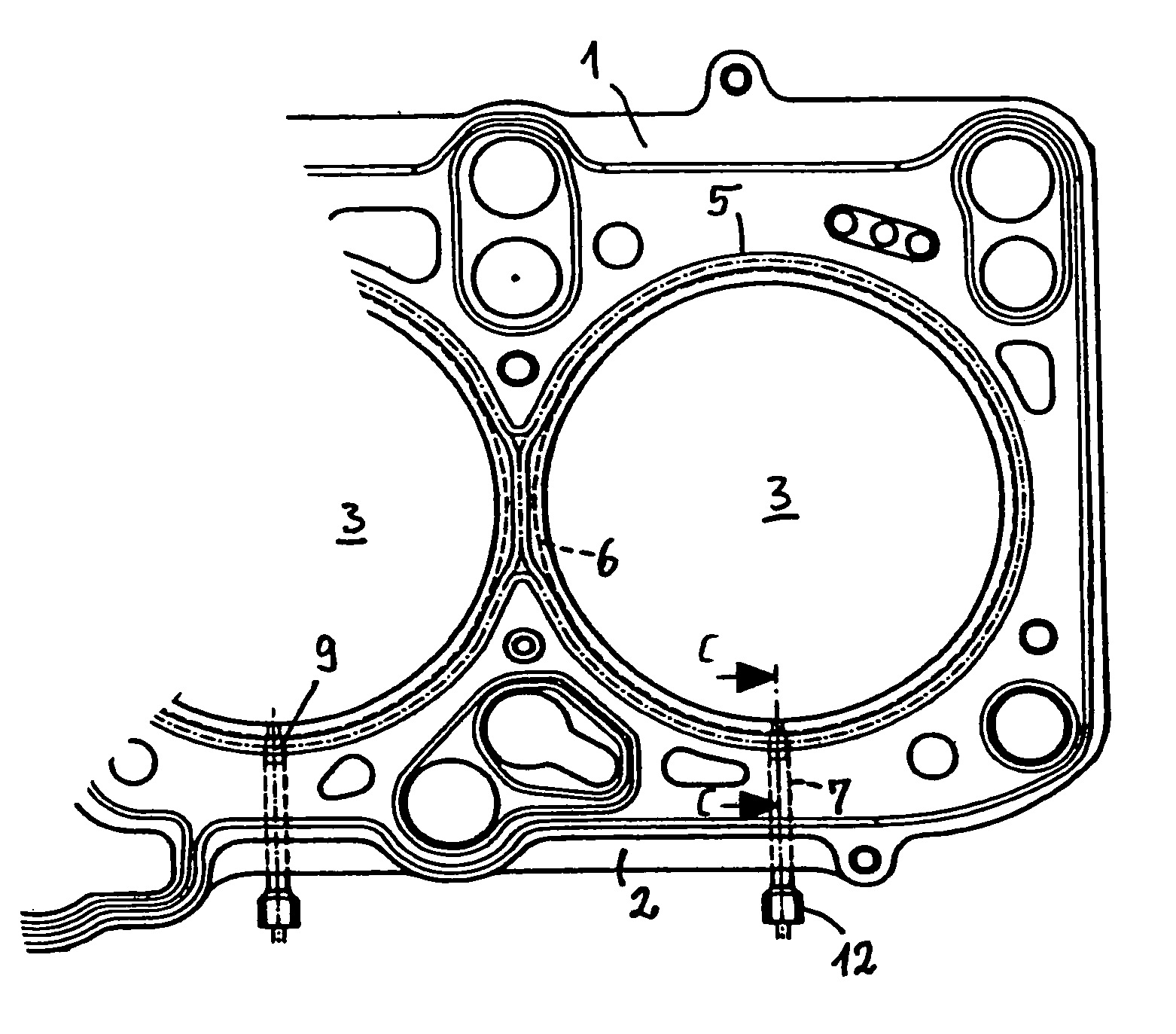

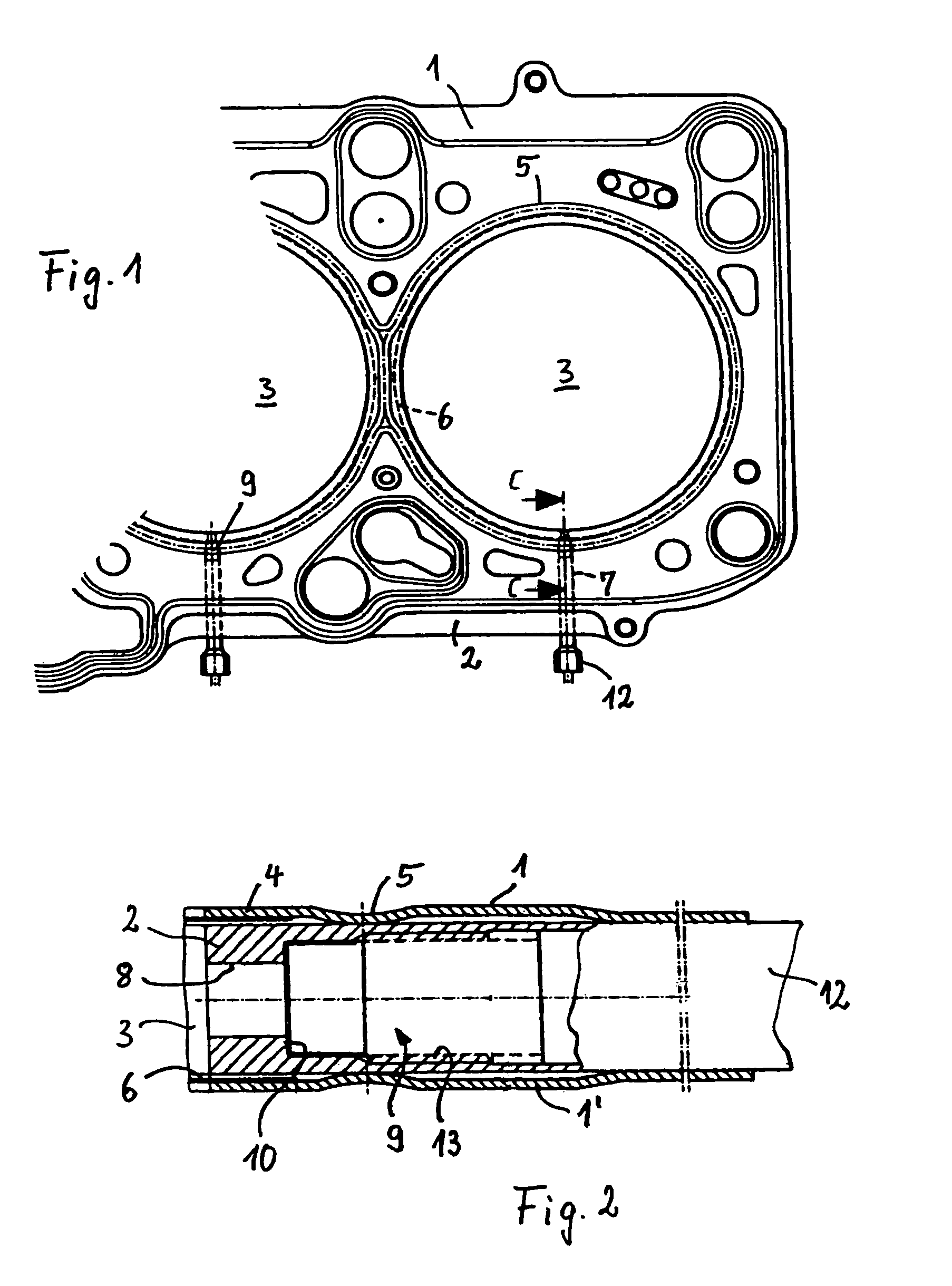

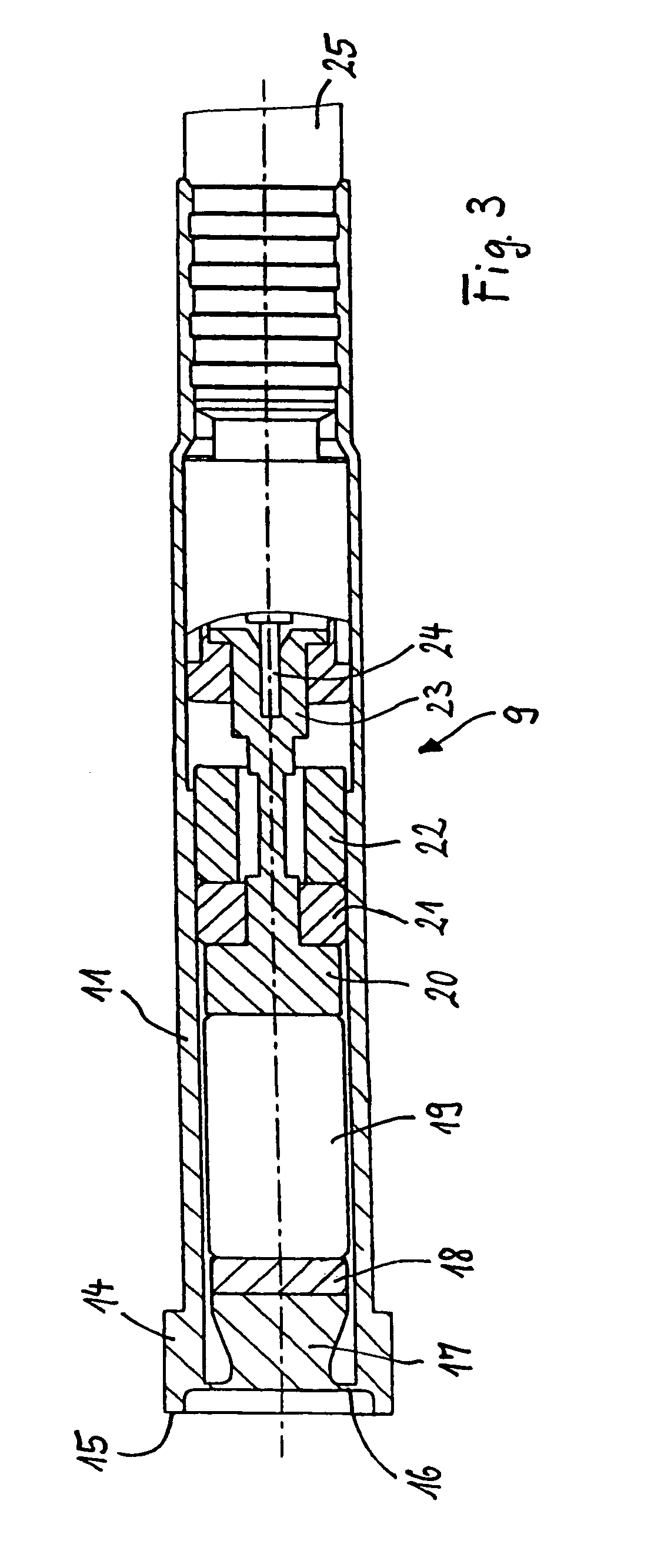

Cylinder head gasket

A metallic cylinder head gasket for an internal combustion engine having at least one combustion chamber. The gasket includes at least one sheet-metal layer having at least one opening corresponding to the at least one combustion chamber of the internal combustion engine and at least one bore extending from the outer edge to the edge of the opening. A membrane, closing the bore at the combustion-chamber side is exposed to the gas pressure of the combustion chamber. A pressure sensor disposed in the sheet-metal layer is pressurized axially relative to the bore by movement of the membrane by the gas pressure of the combustion chamber.

Owner:ELRINGKLINGER AG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com