Net point punching device for die core

A punching device and mesh point technology, applied in the punching field, can solve the problems of difficult adjustment of impact force, large variation of mesh aperture and depth tolerance, etc., and achieve the effects of improving punching accuracy, yield and controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

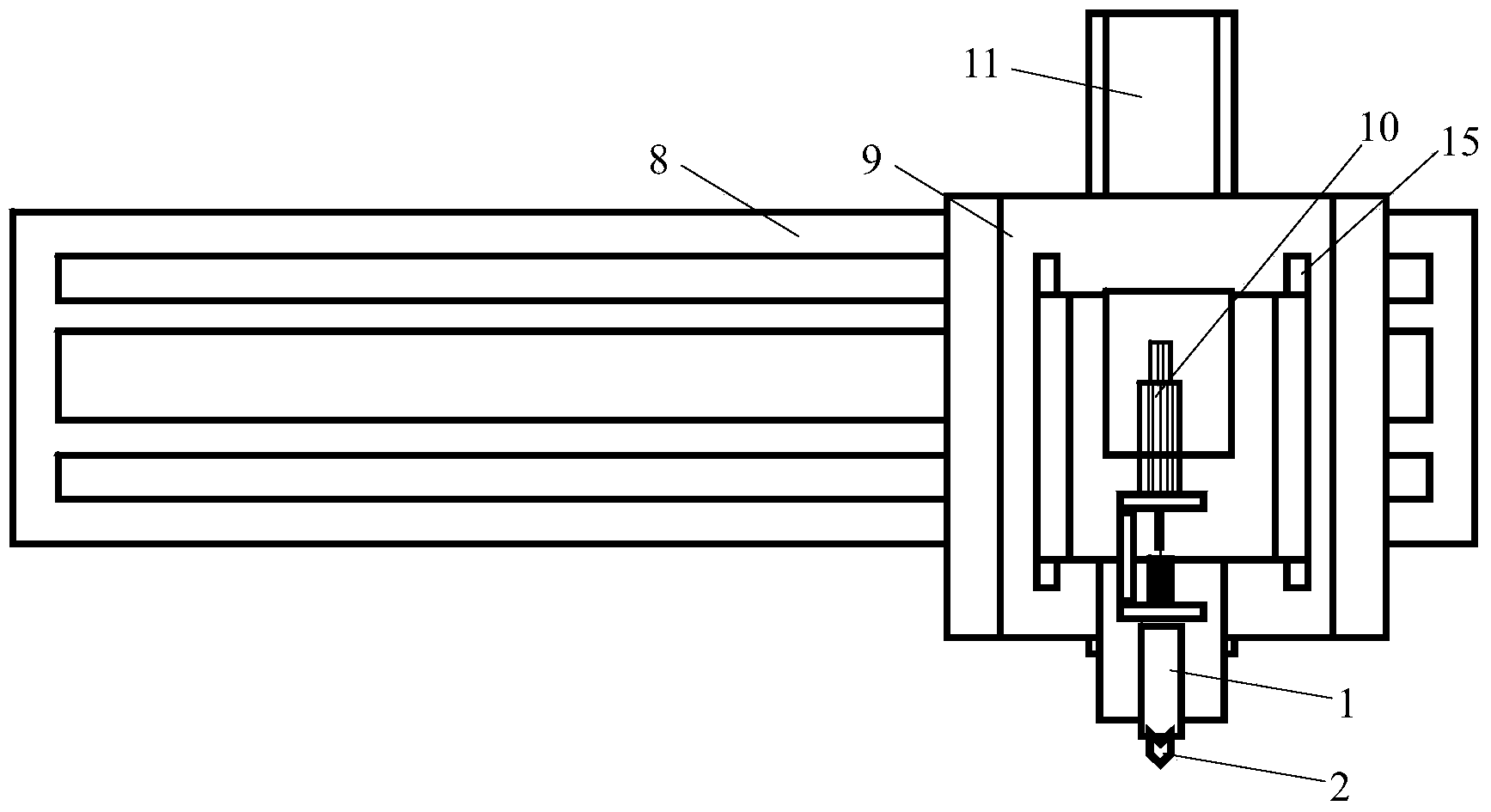

[0029] Such as figure 1 with image 3 As shown, a die core dot stamping device according to an embodiment of the present invention includes a stamping mechanism, a mounting base 9, a first driver, a first horizontal guide rail 8, a laser rangefinder 11, a displacement calculation controller, a host computer and working platform12. Wherein, the working platform 12 is positioned under the cutter head 2; the stamping mechanism and the laser range finder 11 are all fixed on the mounting support 9, and the mounting support 9 is installed on the first horizontal guide rail 8 and can move along the first horizontal guide rail. 8 do horizontal movement, the direction of movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com