Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65results about How to "Precise dose control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

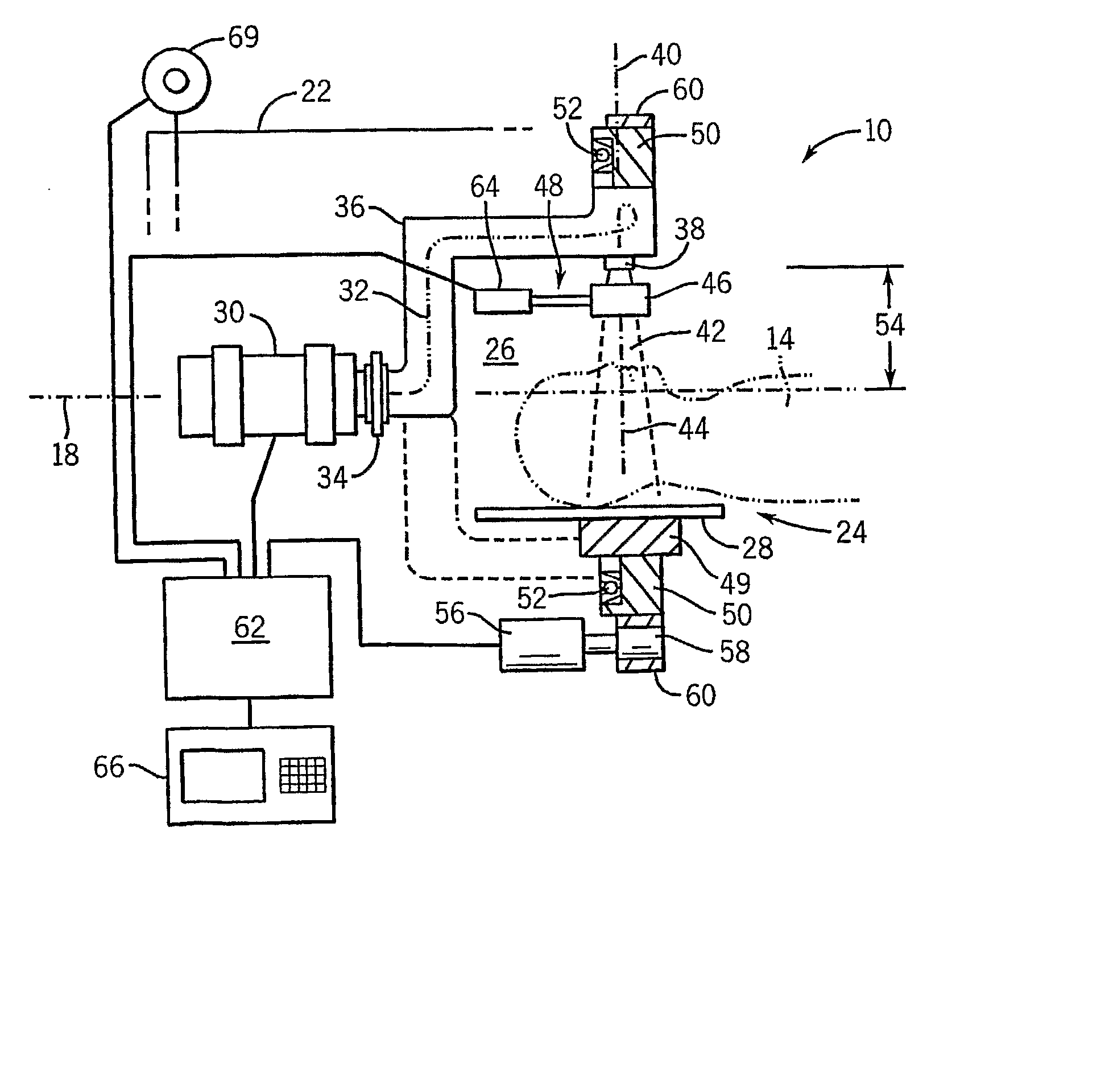

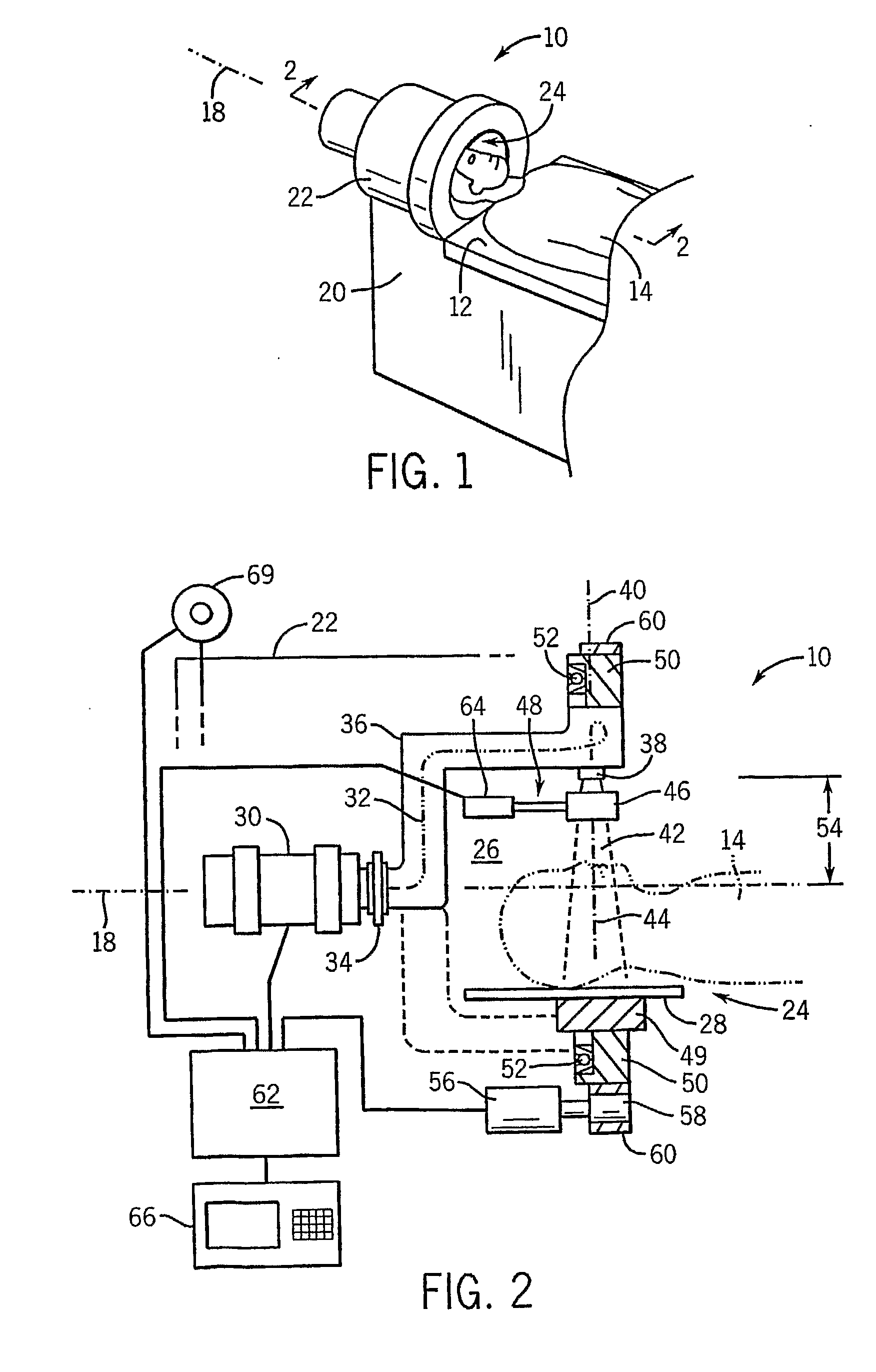

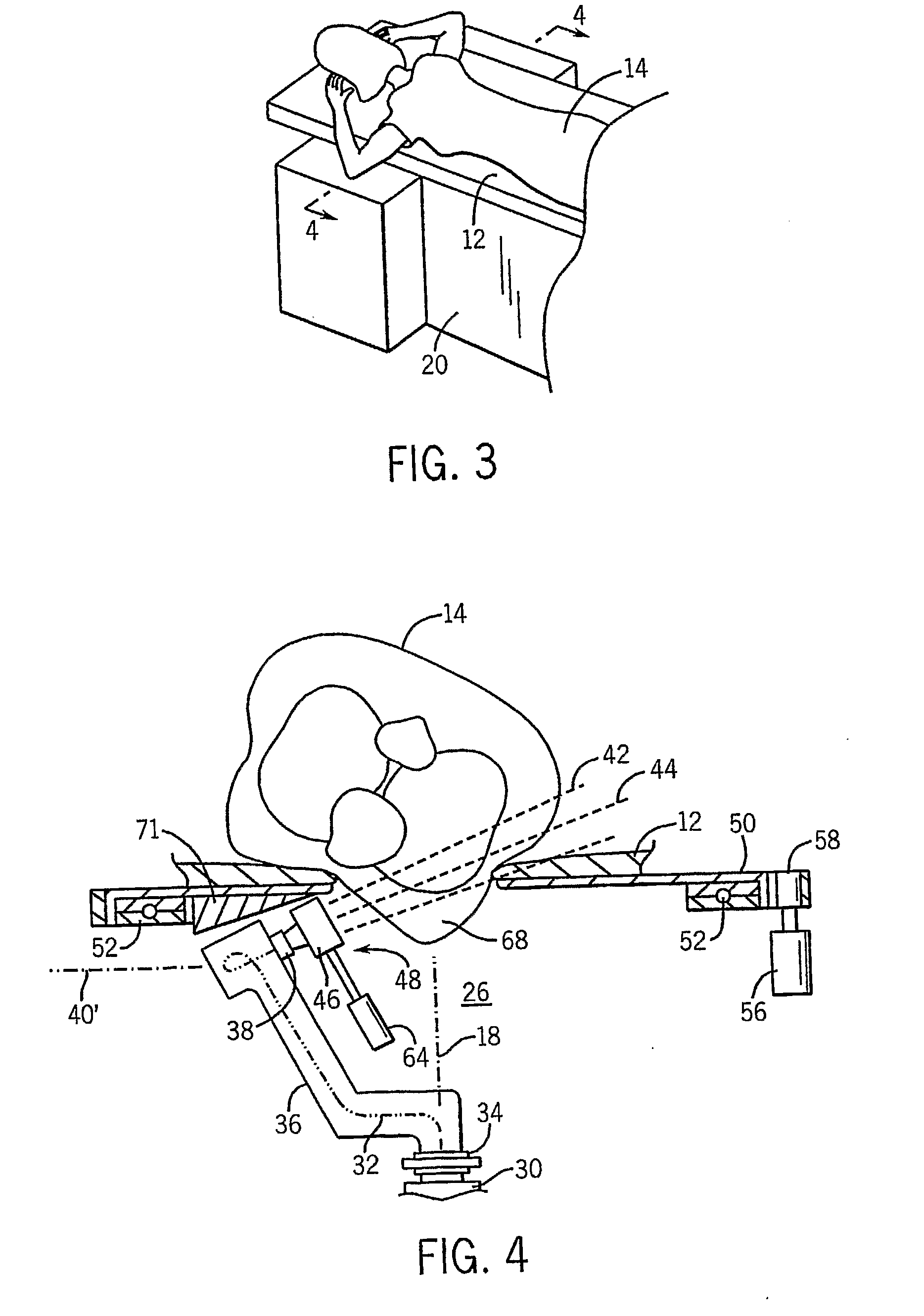

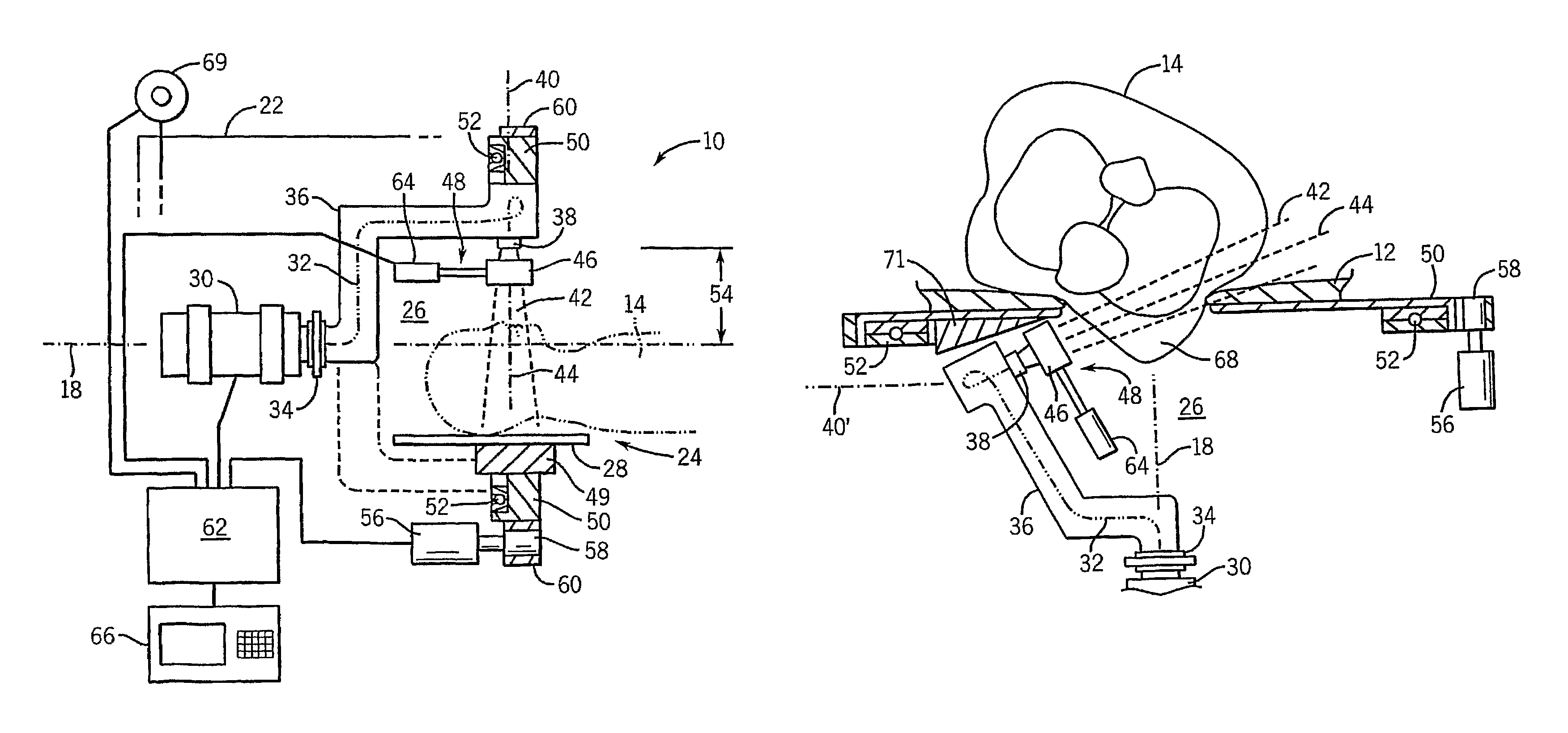

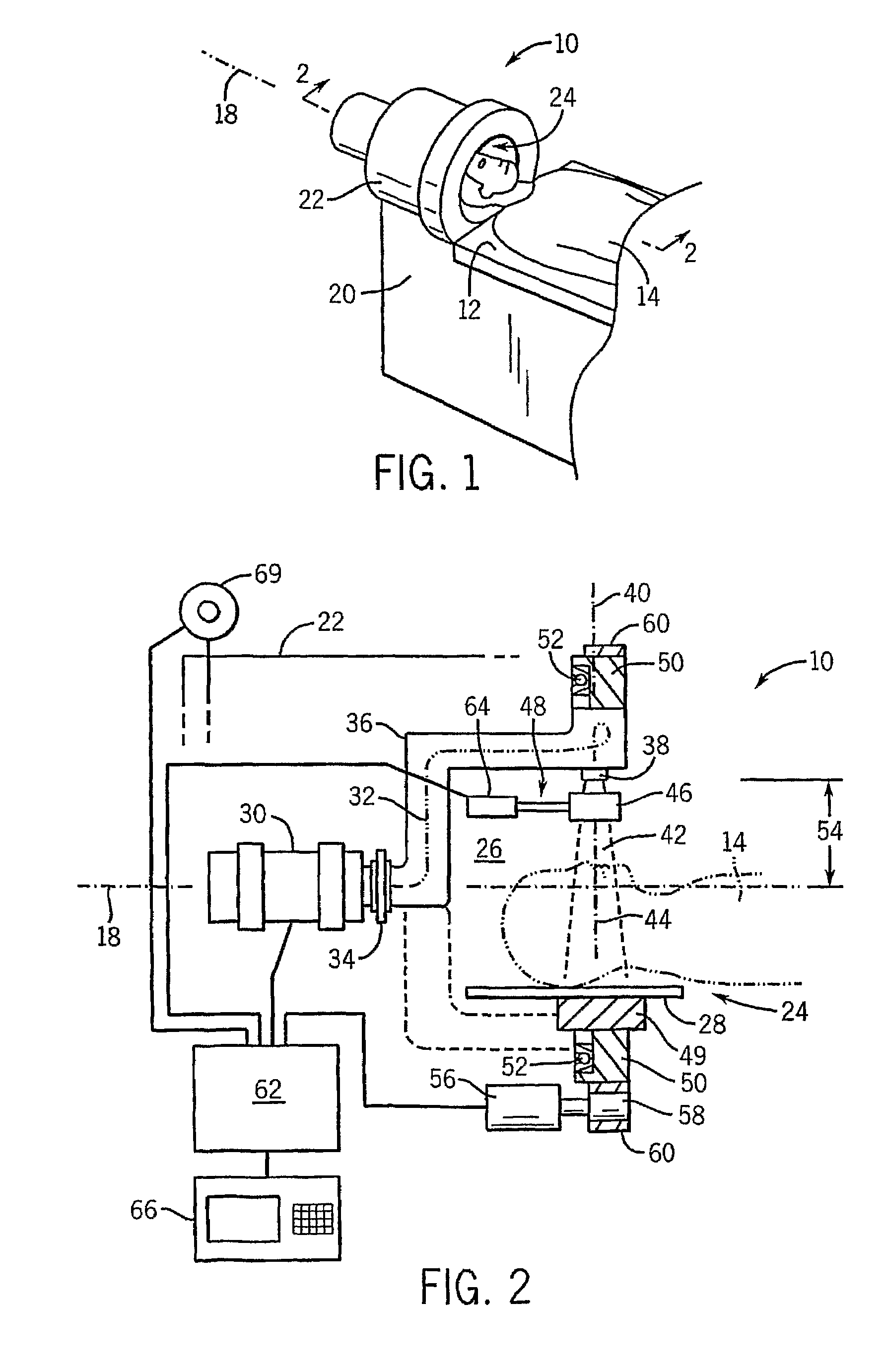

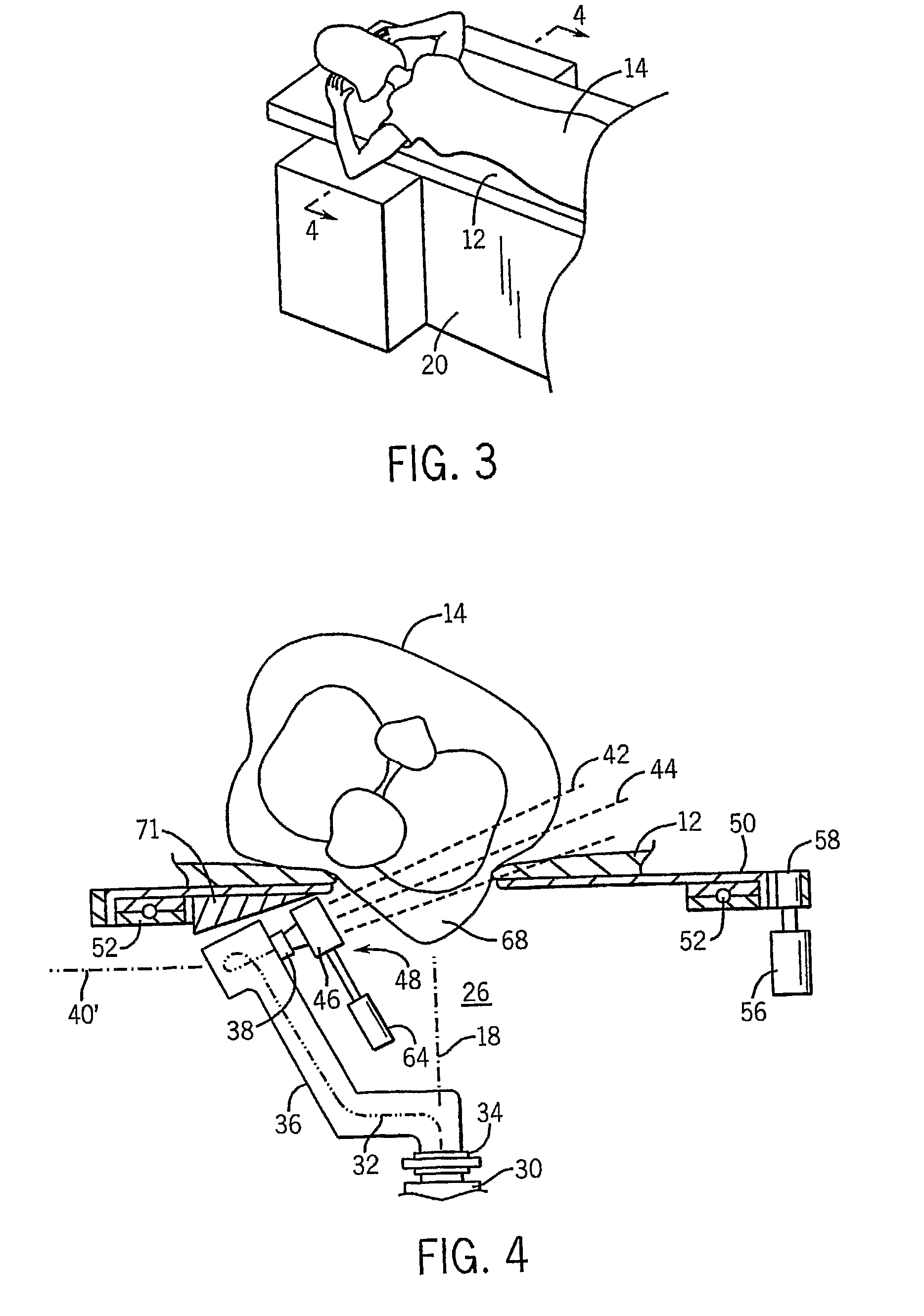

Small Field Intensity Modulated Radiation Therapy Machine

ActiveUS20070242801A1Easy to controlShorten the axial distancePatient positioning for diagnosticsX-ray/gamma-ray/particle-irradiation therapyHuman bodyRadiation therapy

A small field radiation therapy machine having an aperture diameter of 30 cm or less provides improved ray definition for specialized treatment of portions of the human body such as head a breast.

Owner:WISCONSIN ALUMNI RES FOUND

Small field intensity modulated radiation therapy machine

ActiveUS7519149B2Easy to controlShorten the axial distancePatient positioning for diagnosticsX-ray/gamma-ray/particle-irradiation therapyHuman bodyIntensity-modulated radiation therapy

A small field radiation therapy machine having an aperture diameter of 30 cm or less provides improved ray definition for specialized treatment of portions of the human body such as head a breast.

Owner:WISCONSIN ALUMNI RES FOUND

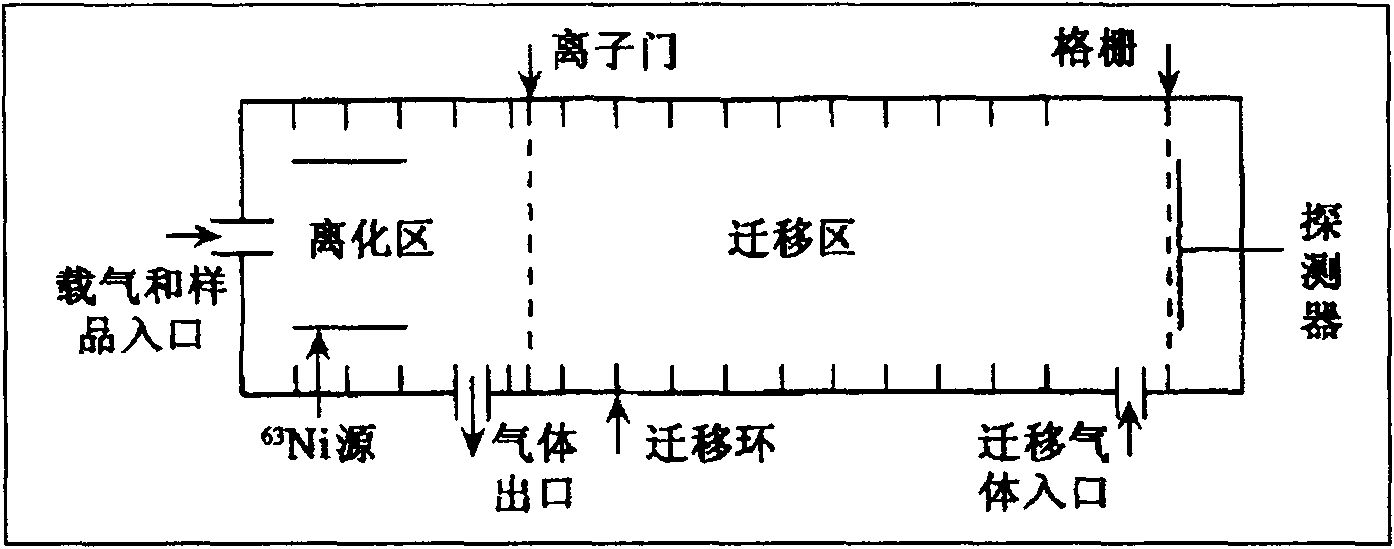

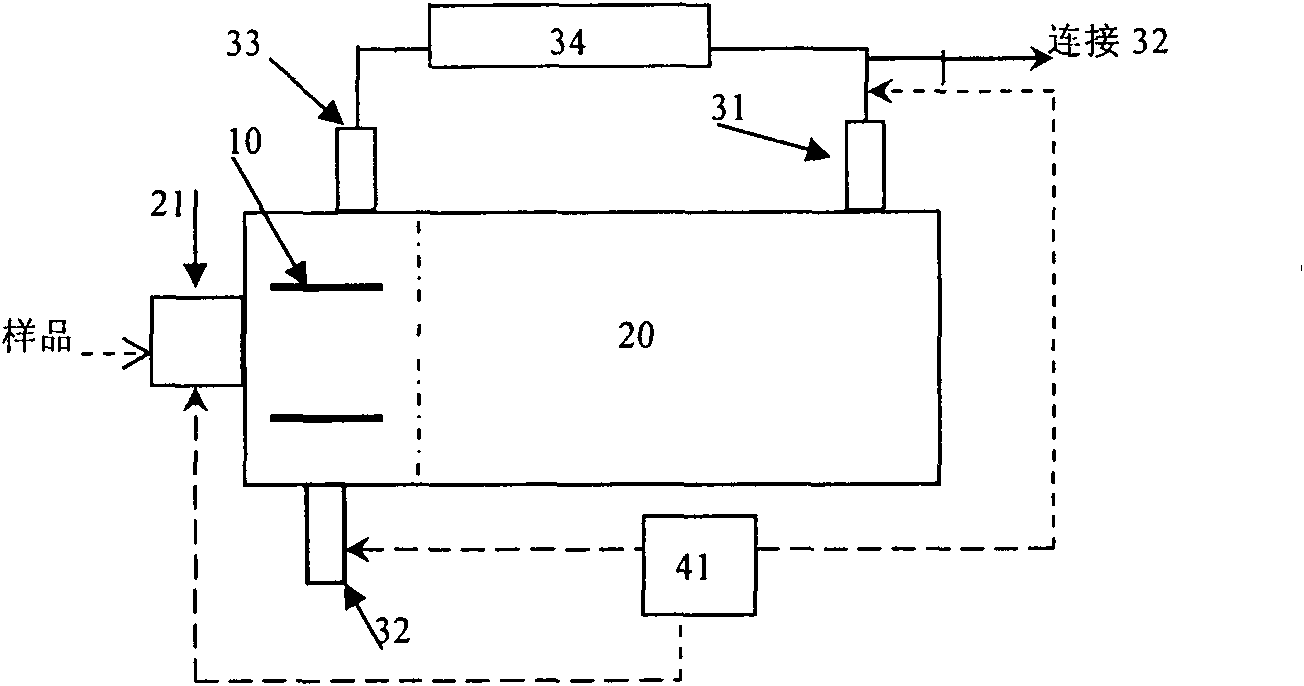

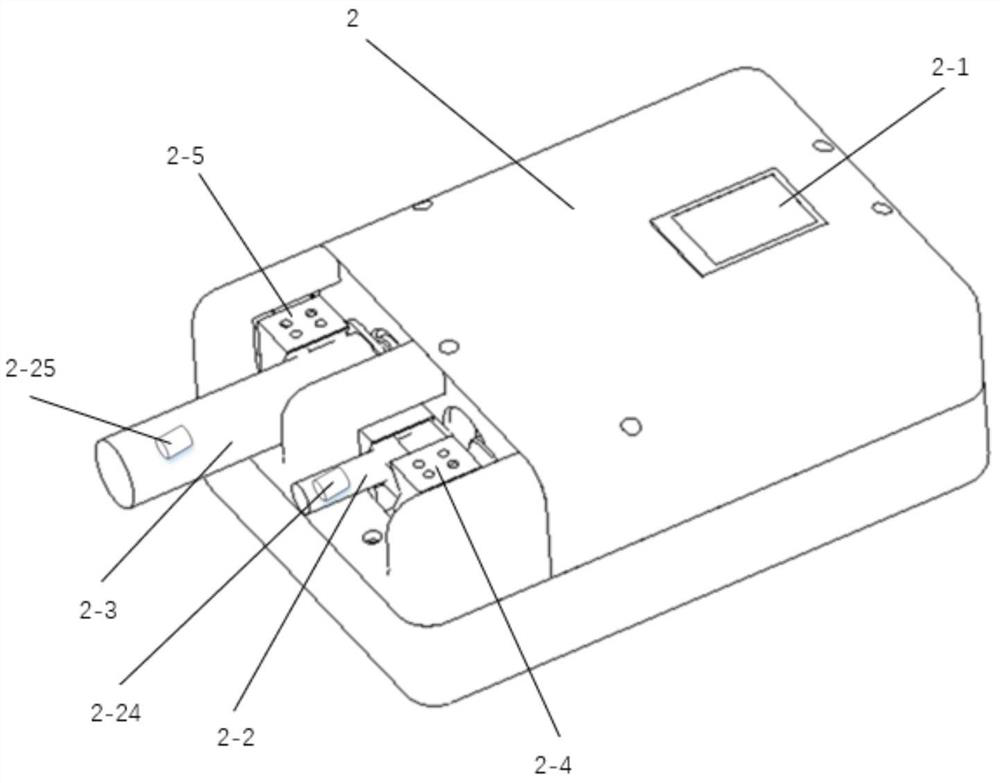

Detecting system of ion migration spectrometer (IMS) using doping agent and detecting method thereof

ActiveCN102033100ASimple structurePrecise dose controlMaterial analysis by electric/magnetic meansDopantInjection port

The invention discloses a detecting method of an ion migration spectrometer (IMS) using a doping agent. The ion migration spectrometer comprises a sample injection device, a migration pipe and a gas path system connected with the sample injection device and the migration pipe, wherein the gas path system comprises a pump, a filter device, a gas inlet and a gas outlet; and the gas inlet and the gas outlet are arranged on the migration pipe so as to provide clean gas used as migrating gas flow and sample carrying gas. The detecting method comprises the following steps: providing a sample collecting carrier for collecting samples; combining the doping agent and the sample collecting carrier; using the sample collecting carrier combined with the doping agent to collect samples; and guiding the sample collecting carrier after the samples are collected into the sample injection port of the ion migration spectrometer so as to implement detection of an ion migration spectrum. In the method, an independent gas path for the doping agent is not needed, so the implementation is simpler; and simultaneously, the quantity of the doping agent can be controlled and detected more easily and more accurately.

Owner:NUCTECH CO LTD

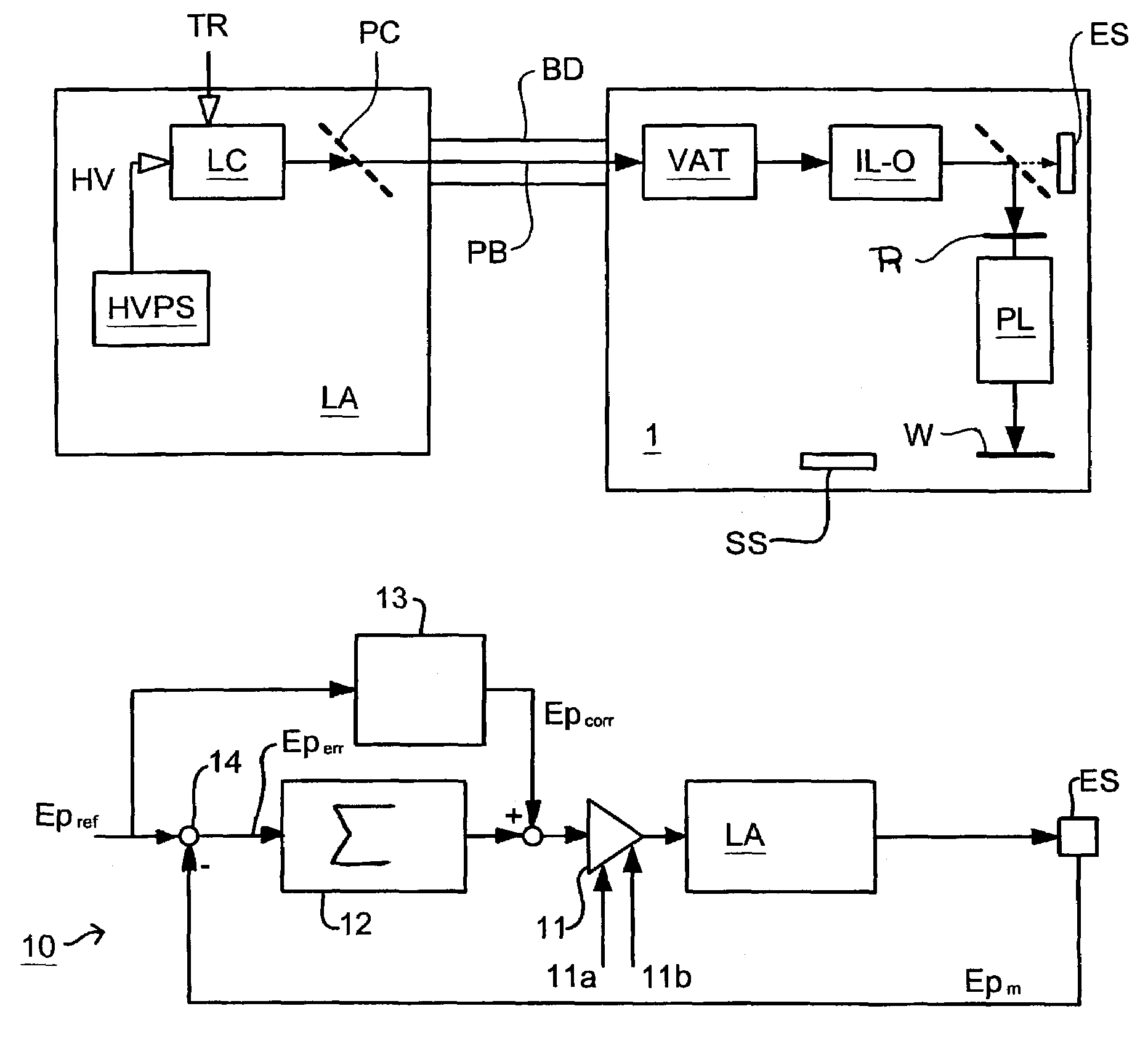

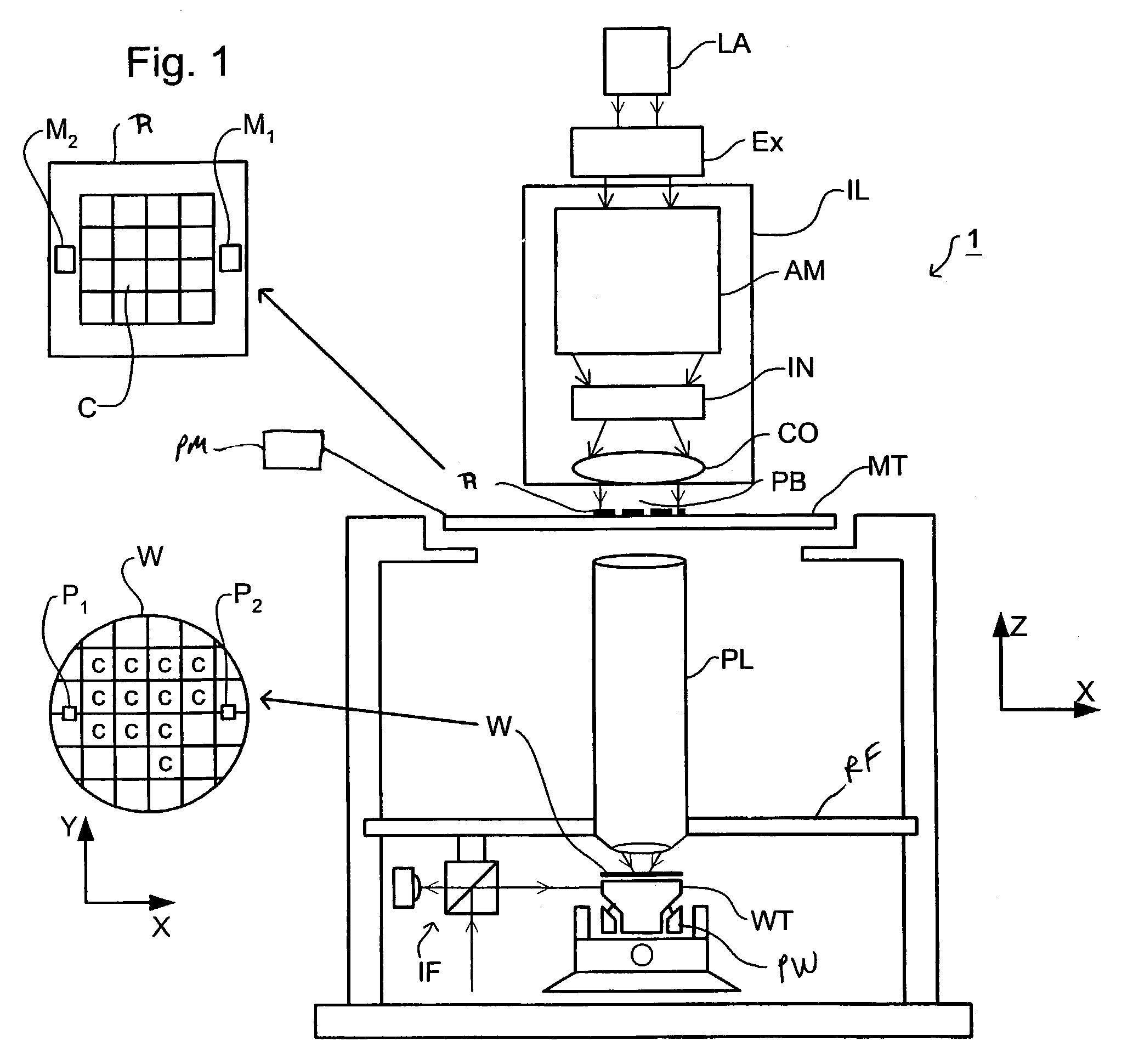

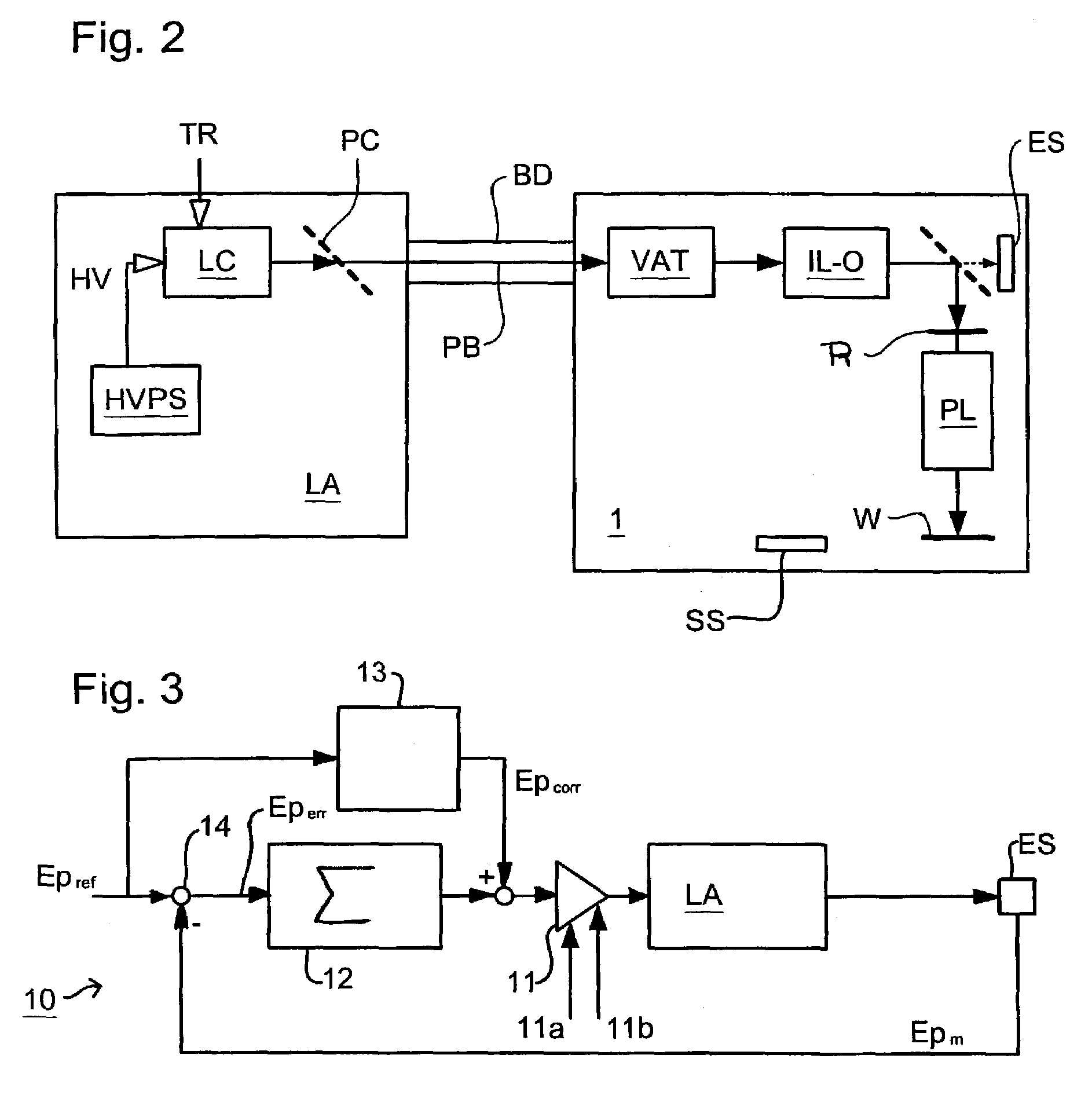

Lithographic apparatus, device manufacturing method, performance measuring method, calibration method and computer program

ActiveUS7057705B2Precise dose controlLaser detailsSemiconductor/solid-state device manufacturingMoving averageClosed loop

A controller for a pulsed radiation source is a closed-loop controller of minimum order, preferably first, to effect dead beat control. Performance indicators for a pulsed radiation source in a lithographic apparatus are based on moving averages (MA) and moving standard deviations (MSD) of the error between target and actual pulse energies. The normalized indicators are given by:MAE,n(xk)=1∑i=k-(Nslit-e-1)kEpref(i)·∑i=k-(Nslit-e-1)kEperr(i)(k=Nslit-e…Nscan),wherein Epref(i) and Eperr(i) indicate reference energy per pulse and energy error per pulse for point i andMSDE,n(xk)=1Nslit-e-1∑i=k-(Nslit-e-1)k[Eperr(i)Epref(i)-MAE,n(xk)]2(k=Nslit-e…Nscan).

Owner:ASML NETHERLANDS BV

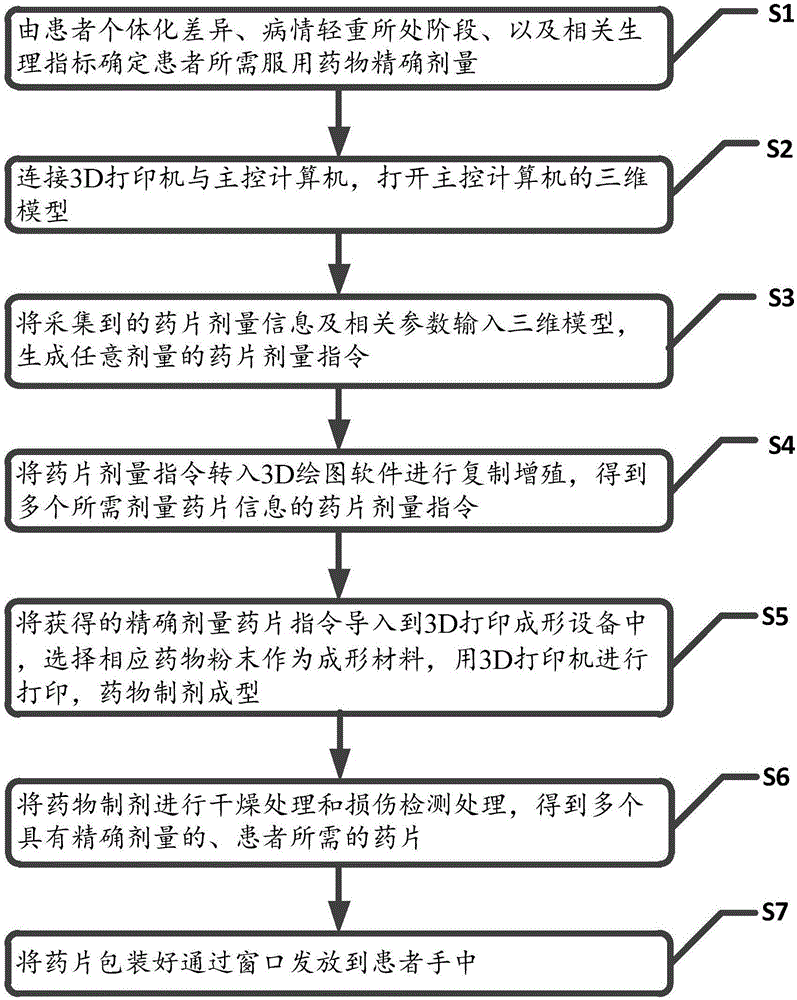

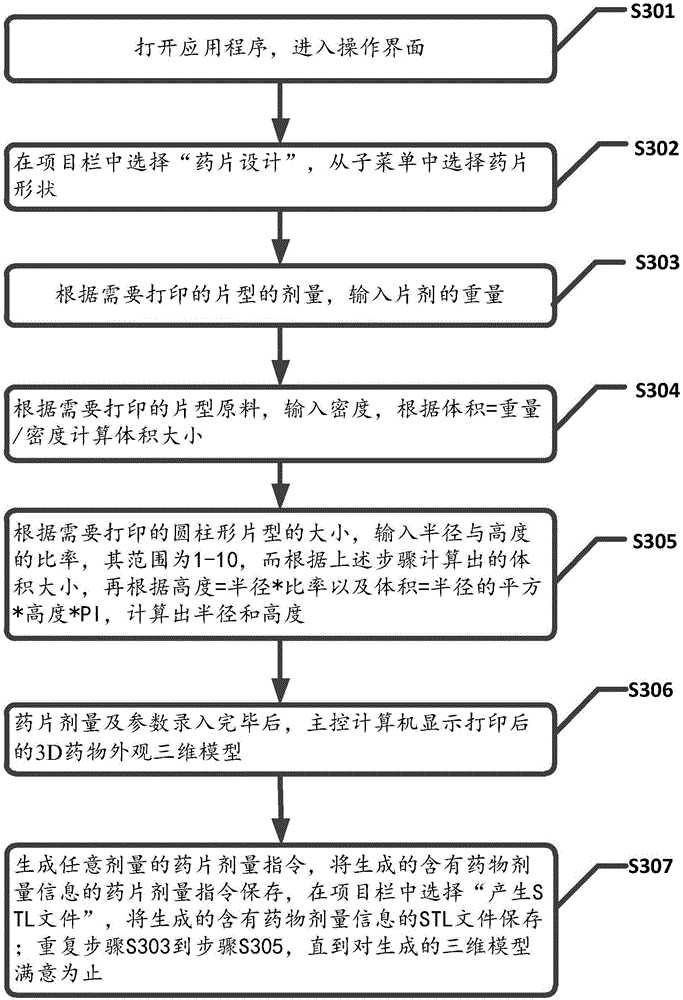

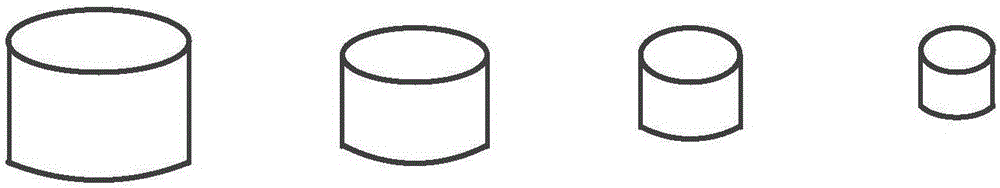

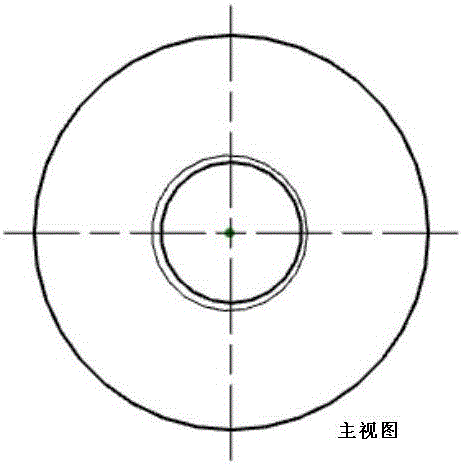

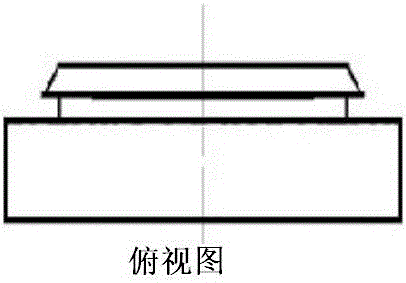

Method for preparing tablet with any dose based on 3D printing

InactiveCN106821755AImprove securityThe operation interface is simple and clearAdditive manufacturing apparatusPharmaceutical product form changeDrugPhases of clinical research

The invention discloses a method for preparing a tablet with any dose based on 3D (three-dimensional) printing. A 3D printing technology is combined with preparation of medicinal tablets, three-dimensional modeling is started on a computer for controlling the printing process of a 3D printer, the medicine dose required by a patient is input after the density of a medicine preparation and the ratio of the radius to the height of the tablet are set, a 3D model can develop the appearance of the tablet which is to be printed, and the tablet with precise dose can be printed after pharmaceutical personnel confirm. The medicine with precision dose, which is required to be taken by the patient and is determined by a doctor according to the individual difference of the patients, the stage of the disease according to the disease degree as well as related physiological index can be prepared into tablets by the 3D printer, so the medicine safety is greatly improved, and customized design and personalized treatment are realized.

Owner:GUANGDONG PHARMA UNIV

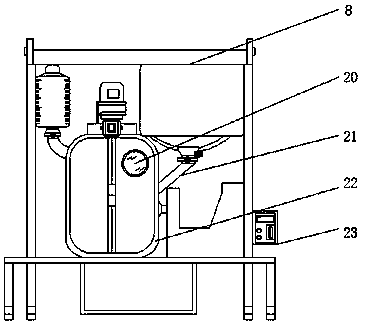

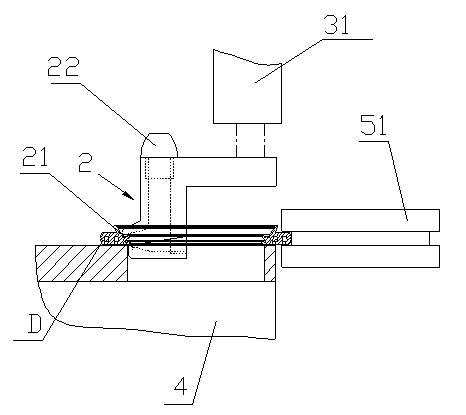

Microneedle array device for minimally invasive precision subcutaneous administration

InactiveCN106178245APrecise control of injection speedPrecise dose controlMicroneedlesMedical devicesMotor drivePropeller

The invention discloses a microneedle array device for minimally invasive precision subcutaneous administration. The device comprises an injection pump, a hose and a five-needle-head microneedle. The injection pump comprises a lead screw, a clamp, an injection syringe, a base, a lead screw, a nut propeller, a screw rod and a stepping motor. One end of the lead screw and one end of the screw rod are connected with the stepping motor, the other end of the lead screw penetrates through the nut propeller to be fixed to the base through a support, the other end of the screw rod is directly fixed to the nut propeller, the injection syringe is fixed into a V-shaped guiding groove of the base through the clamp, a piston of the injection syringe is connected with the nut propeller, the stepping motor drives the screw rod to rotate, the screw rod rotates to drive a nut meshed with the screw rod to move linearly, the nut pushes the nut propeller to move in the guiding direction of the lead screw, and therefore the injection syringe is pushed to move rightwards, and medicine liquid in the injection syringe enters the five-needle-head microneedle through the hose. The depth of the microneedle into skin can be precisely controlled by controlling the rotating angle of the microneedle nut relative to a needle cap.

Owner:HANGZHOU DIANZI UNIV

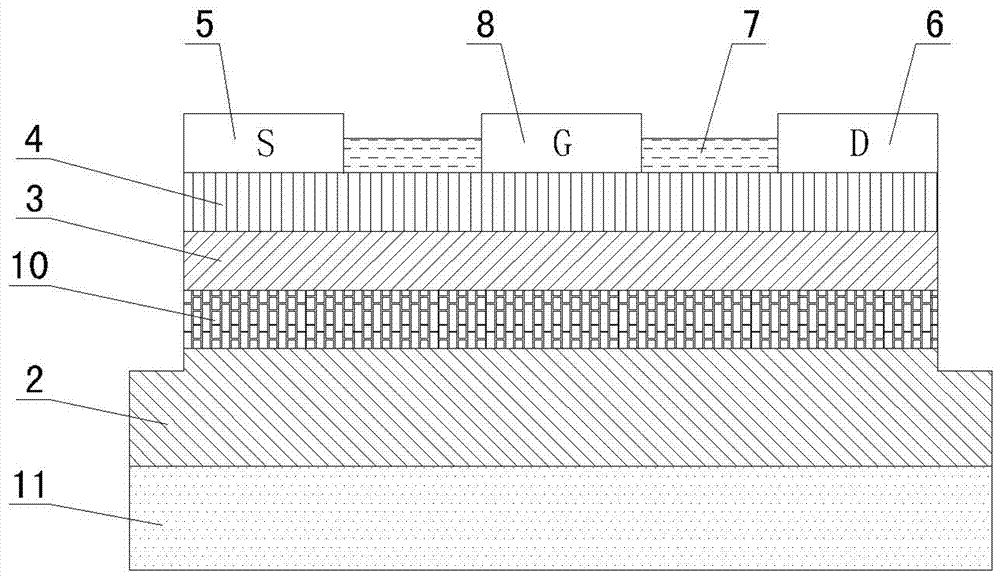

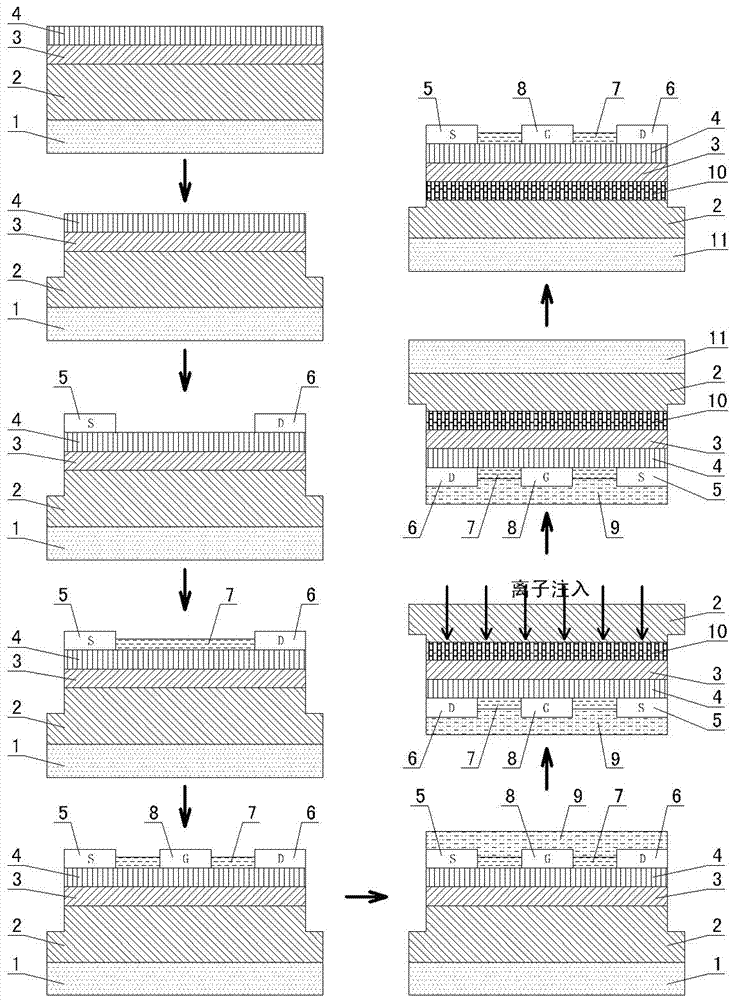

GaN power device based on ion implantation and manufacturing method thereof

PendingCN107170671ASuppress leakage currentImprove breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesOhmic contactEngineering

The invention discloses a GaN power device based on ion implantation and a manufacturing method thereof. The GaN power device includes a GaN buffering layer, a GaN channel layer and an AiGaN barrier layer which are successively arranged from bottom to top. The A1GaN barrier layer is provided with an active electrode, a gate electrode and a drain electrode thereon, wherein the active electrode and the drain electrode are both ohmic contacts, the gate electrode is a Schottky contact, and all electrodes are covered with a passivation layer therebetween. The passivation layer is connected to the A1Gan barrier layer. The A1Gan barrier layer and the Gan channel layer are heterostructures and the interface between the A1Gan barrier layer and the Gan channel layer forms a 2D electron gas which acts as a transverse working conductive channel of the GaN power device due to polarization effects. An ion isolation region is formed by performing ion implantation on the bottom surface of the GaN buffering layer. The ion isolation region is disposed in the upper part of the GaN buffering layer and is connected to the GaN channel layer, and the GaN buffering layer is provided with an ion isolation region therein and then the bottom surface of the GaN buffering layer is bonded to a high heat conductive substrate. According to the invention, since an ion isolation region is formed by performing ion implantation, the GaN channel and the GaN buffering layer are isolated, such that current leakage is reduced and breakdown voltage is increased.

Owner:GUANGDONG INST OF SEMICON IND TECH

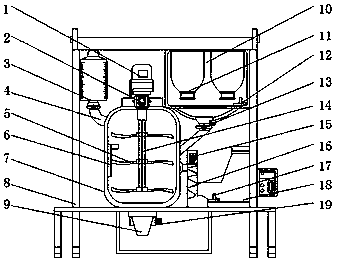

Efficient concrete stirring equipment

InactiveCN107775806ASave human resourcesImprove the effect of the finished productMixing operation control apparatusCement mixing apparatusPressure sensorBiochemical engineering

The invention discloses a high-efficiency concrete mixing device, which comprises a water tank and a bearing frame. A water tank is installed on one side of the inner top of the bearing frame, and a stone quantitative chamber is installed on the other side of the inner top of the bearing frame. The stone quantitative chamber Stone tanks are installed on both sides of the inner top, and a first pressure sensor is installed at the bottom of the stone quantitative chamber. The main body of the mixing tank is installed on the carrier below the stone quantitative chamber. A powder quantitative chamber is arranged on one side of the stone quantitative chamber, and a second pressure sensor is installed at the bottom of the powder quantitative chamber, and a control panel is installed on the side of the carrier near the powder quantitative chamber. The invention can accurately control the amount of each proportion of concrete and improve the overall quality of concrete.

Owner:苏州市瑞川尔自动化设备有限公司

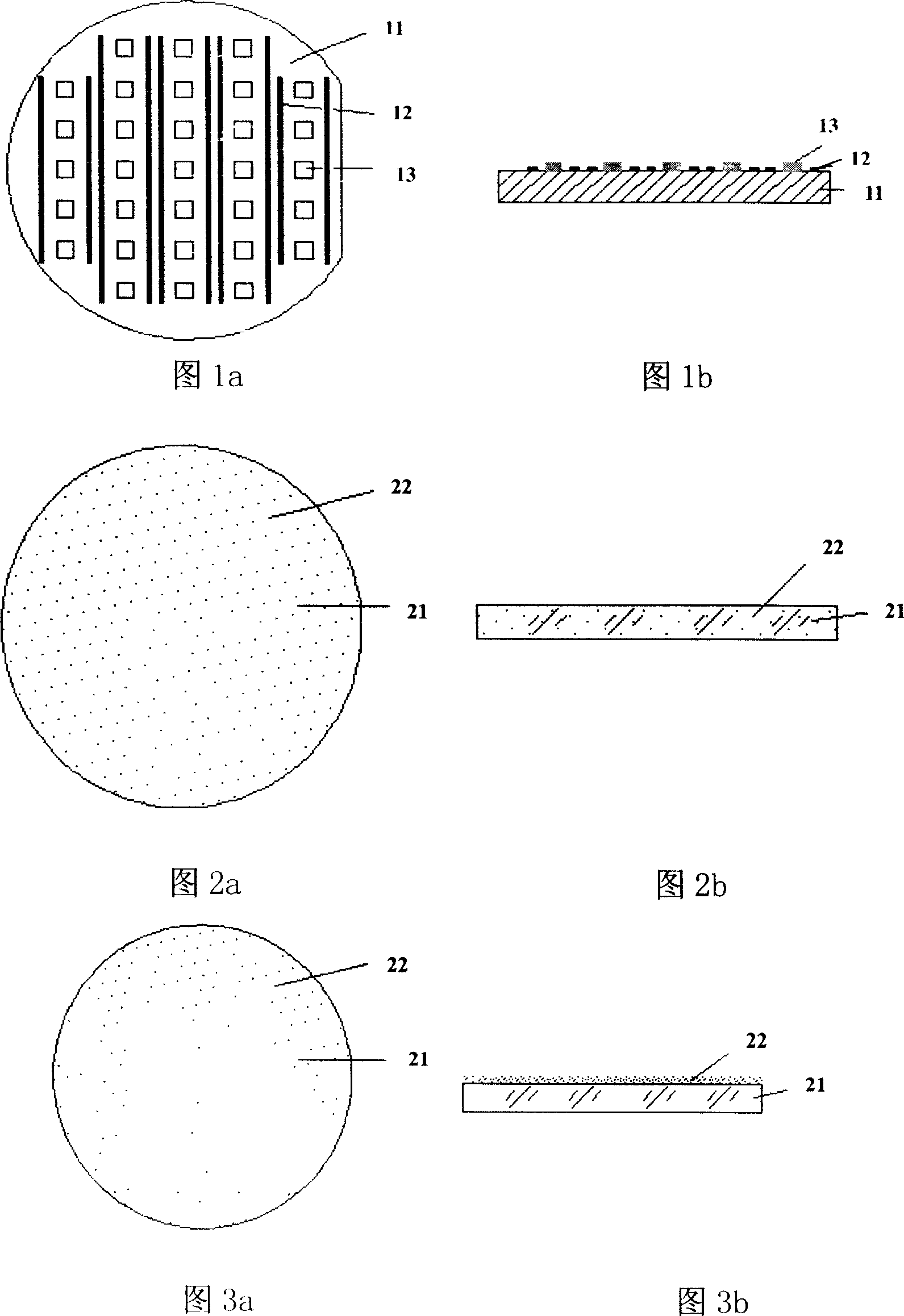

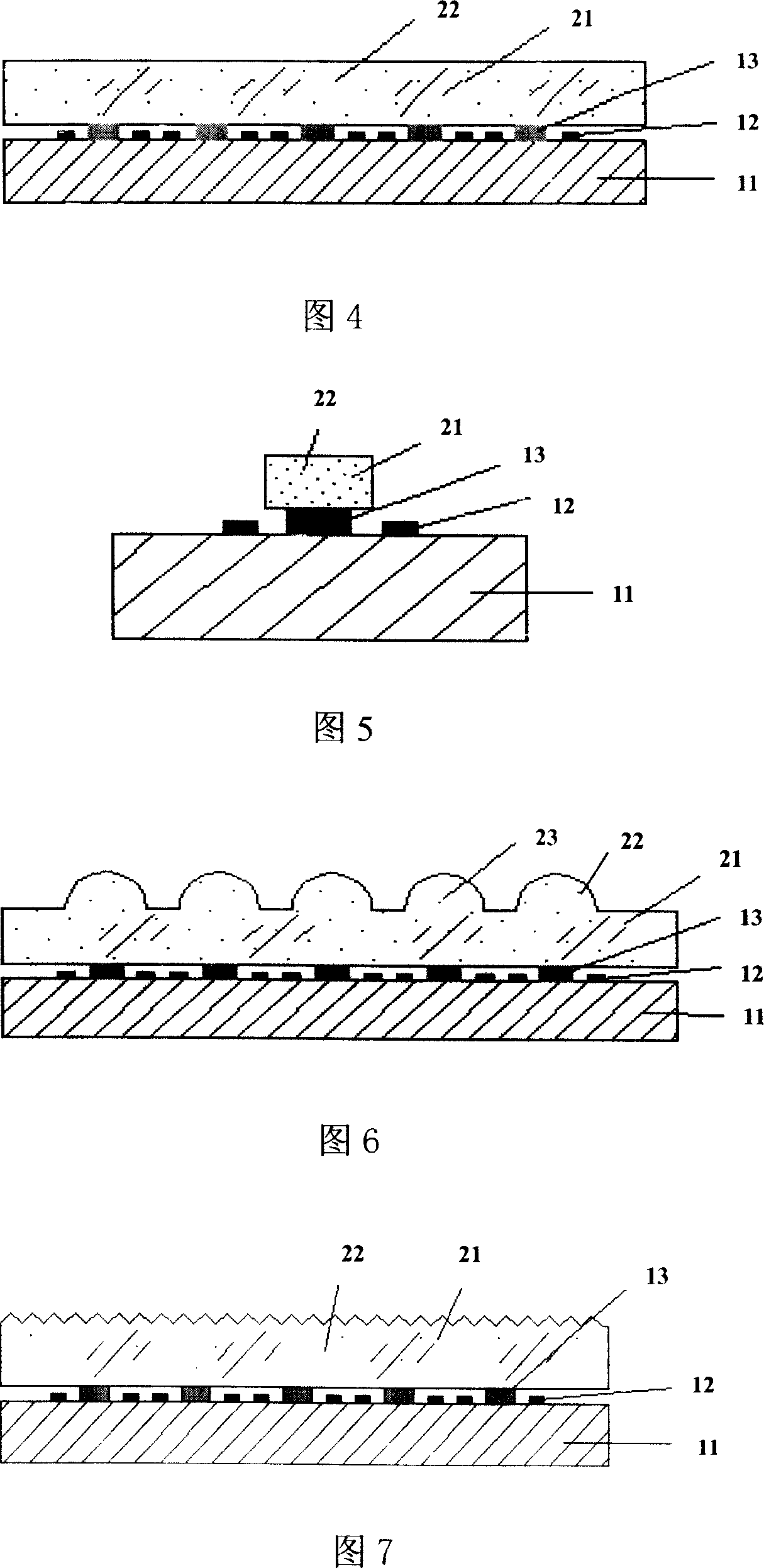

A making method for white LED chip

ActiveCN101150152AIncrease productivityImprove product reliabilitySemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringWafer bonding

This invention relates to a preparing method for white LED chips with a monochromatic light-emitting chip, a lead, a base chip with fluorescent powder and a wafer base board characterizing that a wafer bonded technology is applied to the chip with fluorescent powder and the wafer base board to bond them to be cut to get LED chip generating white light, and the bonded technology includes an anode bonding, adhesive bonding and low temperature surface activated bonding.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

Suspension dispersible tablets and preparation method

ActiveCN102475689AImprove bioavailabilityPatient compliance is goodOrganic active ingredientsDrageesAdhesiveActive component

The invention relates to dosage forms of medicines, and discloses suspension dispersible tablets which at least comprise (1) an effective active component, (2) an excipient mixture at least comprising a disintegrating agent, and (3) suspension particles comprising a filling agent, a suspending agent and an adhesive. The suspension dispersible tablets have advantages as suspensions, such as wide distribution in gastrointestinal tracts and high bioavailability, and have advantages as tablets, such as appropriate hardness, easy transportation, easy carrying, and accurate dosage controlling.

Owner:HAINAN PULIN PHARMA +1

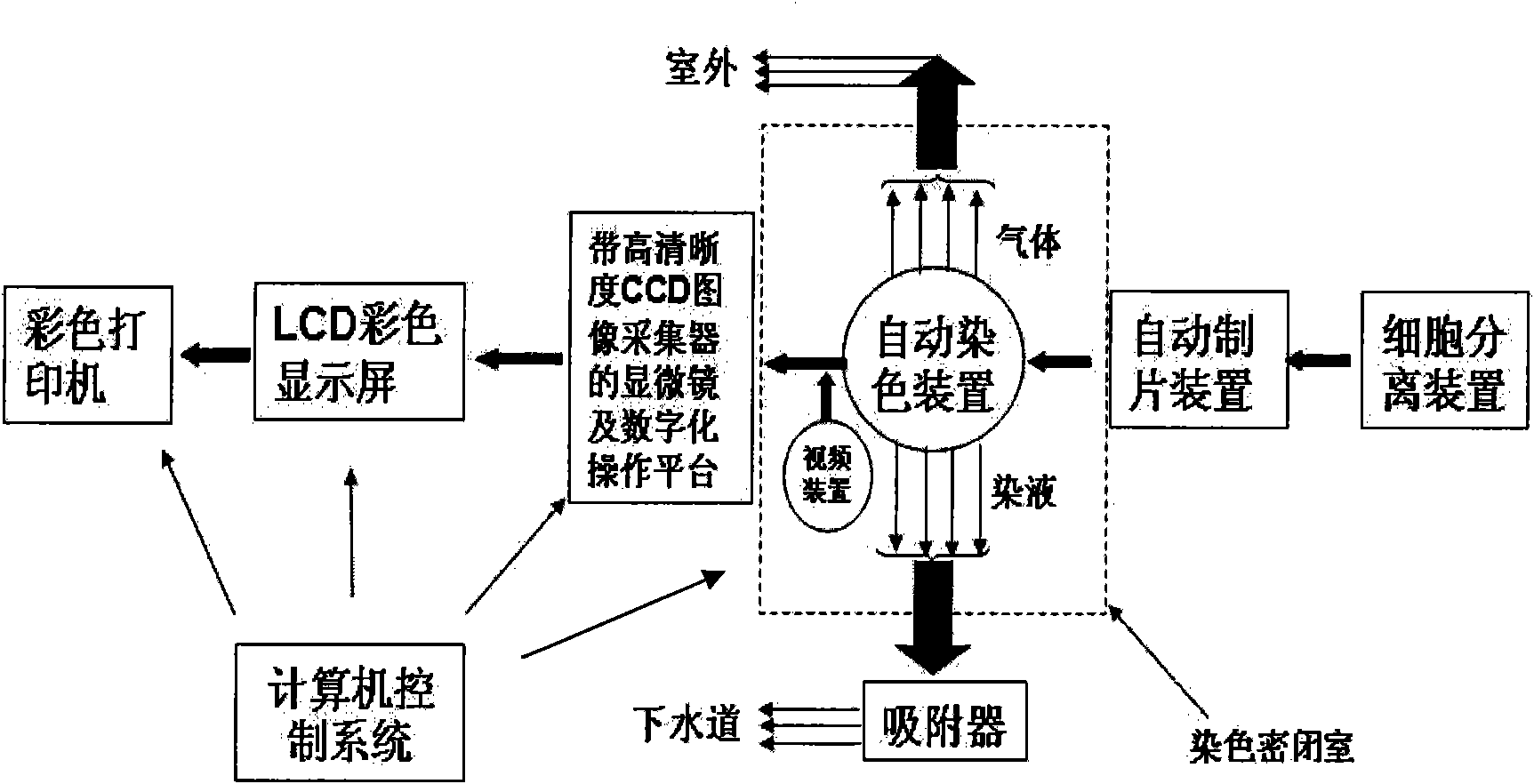

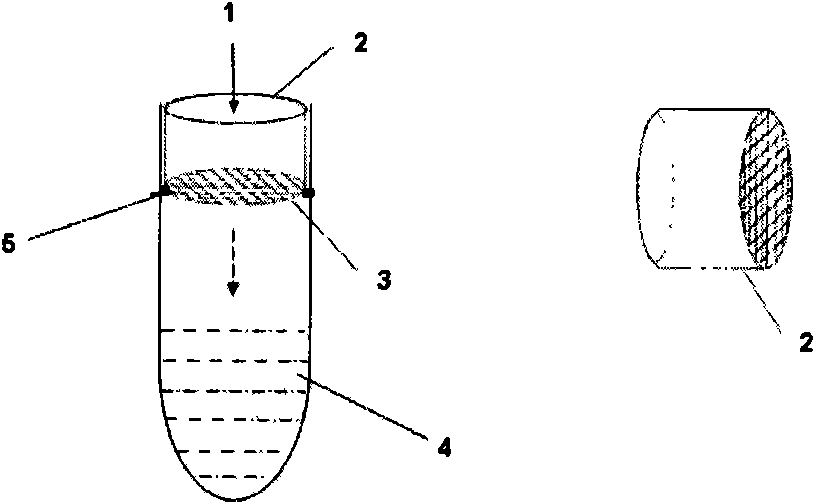

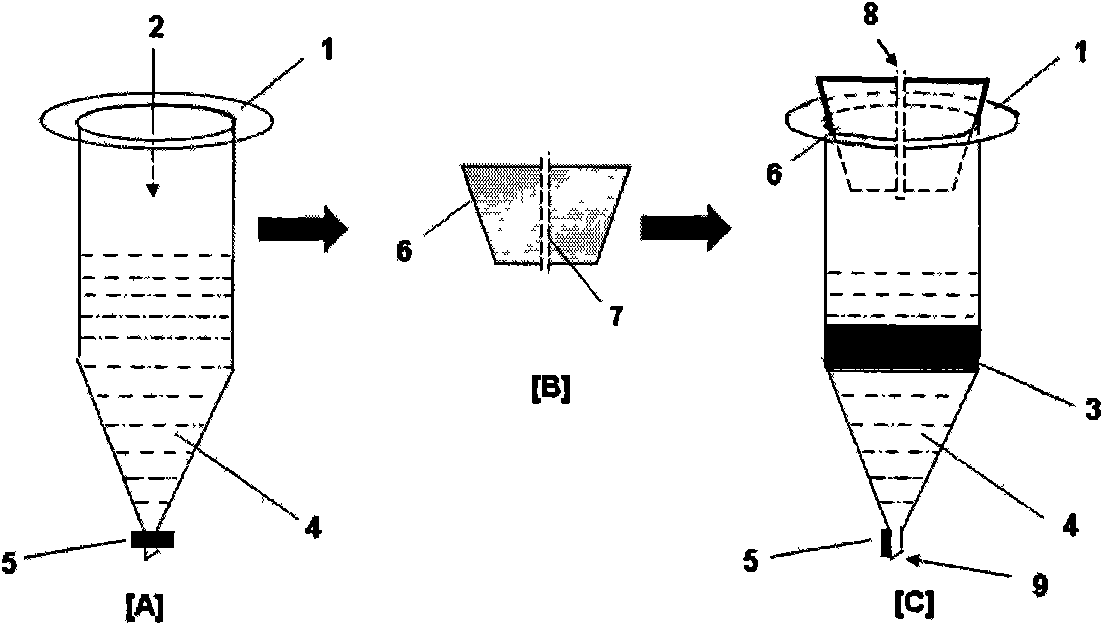

Urinary cell micro staining analysis method

ActiveCN101629946AAccurate control of dyeing typesPrecise dose controlPreparing sample for investigationStaining techniqueAutomatic control

The invention belongs to the field of medical tests, and relates to a urinary cell micro staining analysis system, in particular to a urinary cell micro staining analysis method and an involved analyzing device. Combining with a computer automatic control and recognition technique, the invention provides a urinary cell micro staining quantitative system which can achieve cell separation, extraction and thin layer flaking of arena, support a single-flow micro staining technique, and aim at clinical large samples and rapid analysis. The system overcomes the defects of the prior art, and the results of urine sample clinical medical inspection practices show that the urinary cells are stained clearly, are distributed evenly and are easy to recognize and quantitate. The method can prevent sample cross contaminations and can perform precise quantitative analysis without staining solution environmental pollution. The method is in accordance with the requirements on arena examination standardization established by the inspection branches of International (NCCL) and Chinese Medical Association.

Owner:彭艾 +2

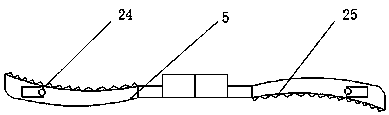

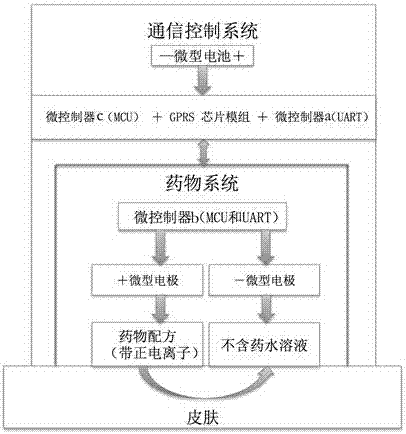

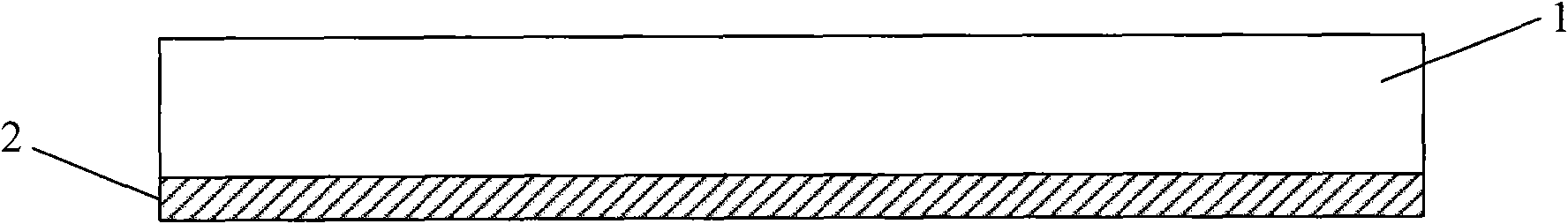

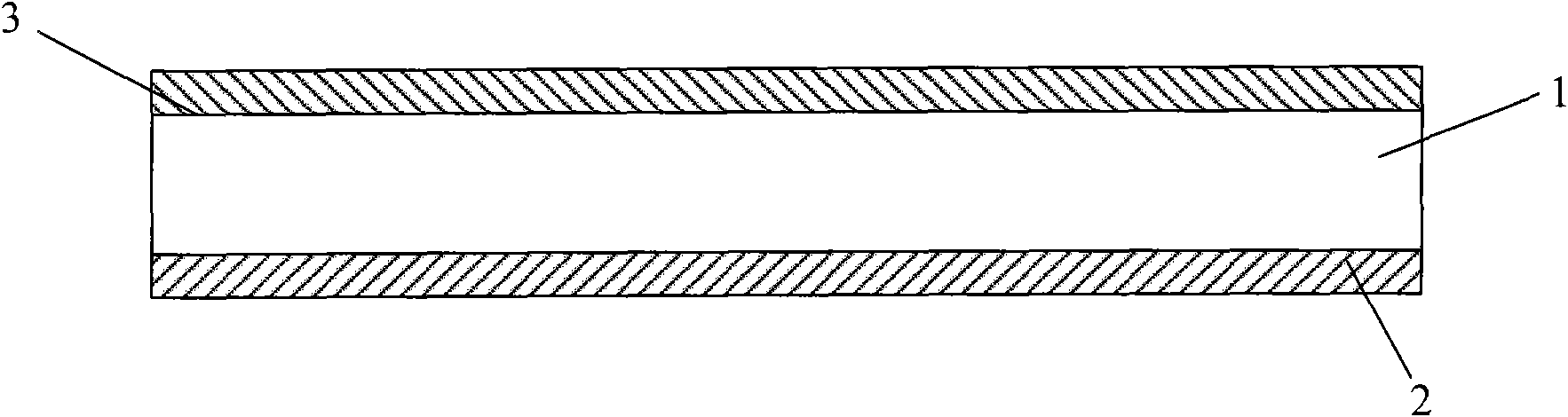

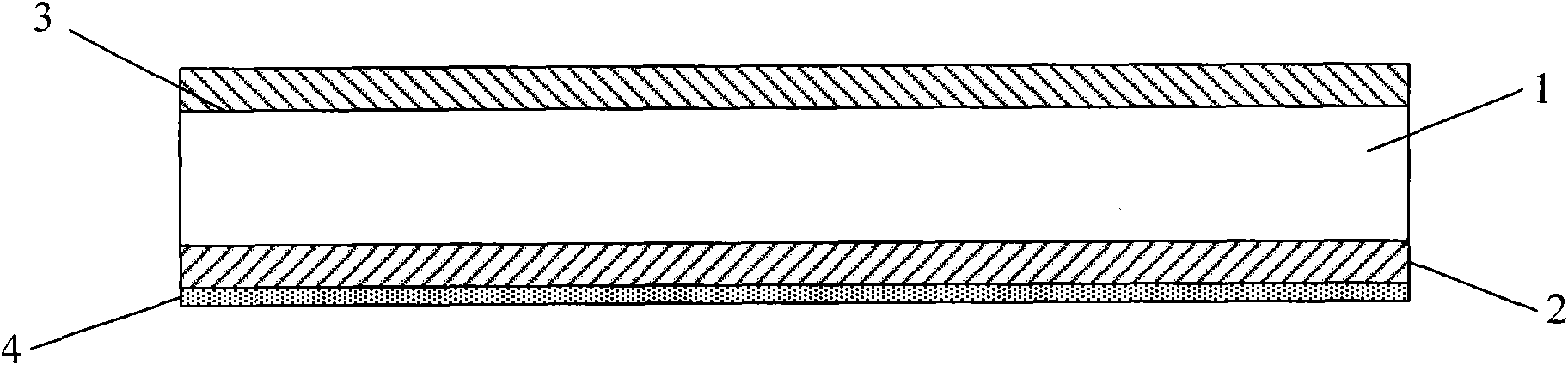

Convenient-type transdermal administration patch apparatus and preparation method thereof

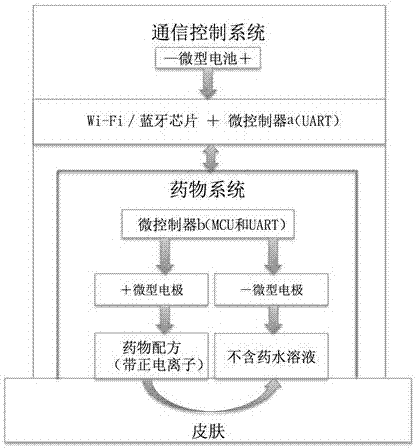

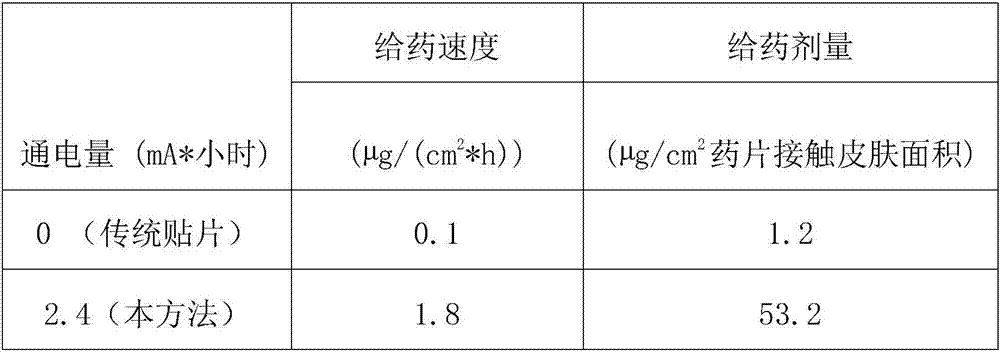

ActiveCN107029343AMedication convenienceShorten the timeOrganic active ingredientsElectrotherapyMicrocontrollerWireless control

Owner:CHANGZHOU HUAJIA MEDICAL DEVICE LTD +1

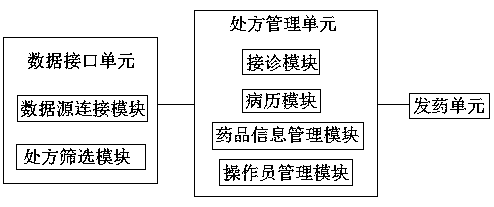

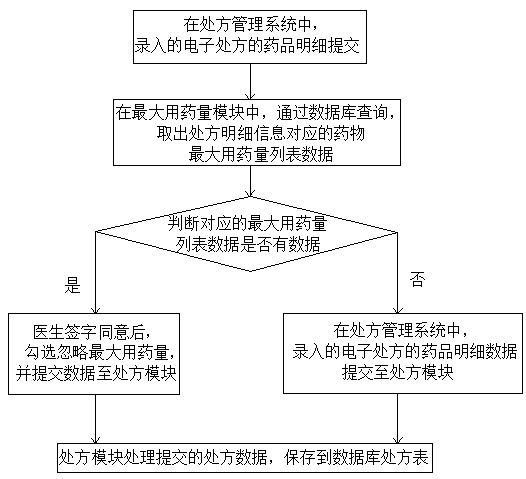

Intelligent traditional Chinese medicine pharmacy system

PendingCN108766523AStructural specificationCompact structureDrug and medicationsHealthcare resources and facilitiesContraindicationData interface

The invention discloses an intelligent traditional Chinese medicine pharmacy system, and belongs to the technical field of medicine. The intelligent traditional Chinese medicine pharmacy system is characterized by comprising a data interface unit, a prescription management unit and a medicine dispensing unit, which are connected electrically; the data interface unit sends a queried and obtained prescription data signal to the prescription management unit; the prescription management unit sends the reviewed prescription data signal to the medicine dispensing unit; and the medicine dispensing unit receives the prescription data signal and then sends medicines through an intelligent medicine dispensing machine. According to the invention, the safety of the medication is ensured by the arrangement of contraindication compatibility; detailed information of a prescription can be accurately checked before the medicines are dispensed, and subsequent inspection is not required; the entire electronic prescription is standardized in procedure and strong in effectiveness from the treatment to the completion of the medicine dispensing, thereby greatly improving the accuracy of medicine dispensing and the efficiency of medicine dispensing, and saving the time for taking medicines for patients; the medicine dispensing machine is compact in structure, small in space occupation and simple to operate; and the system is controlled by a mechanical automatic program, the prescription is simply written and the medicine packing speed is high.

Owner:CHENGDU YH INTELLIGENT EQUIP TECH CO LTD

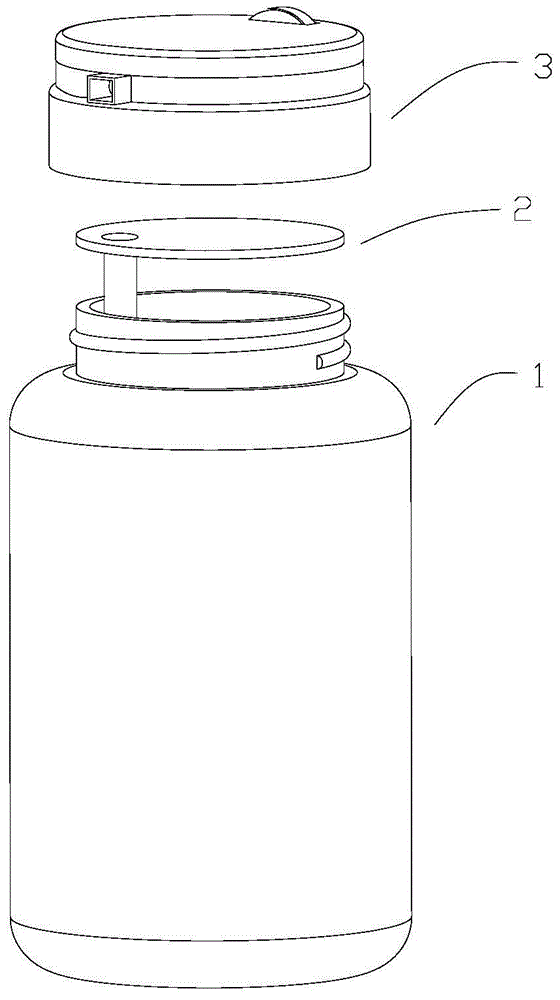

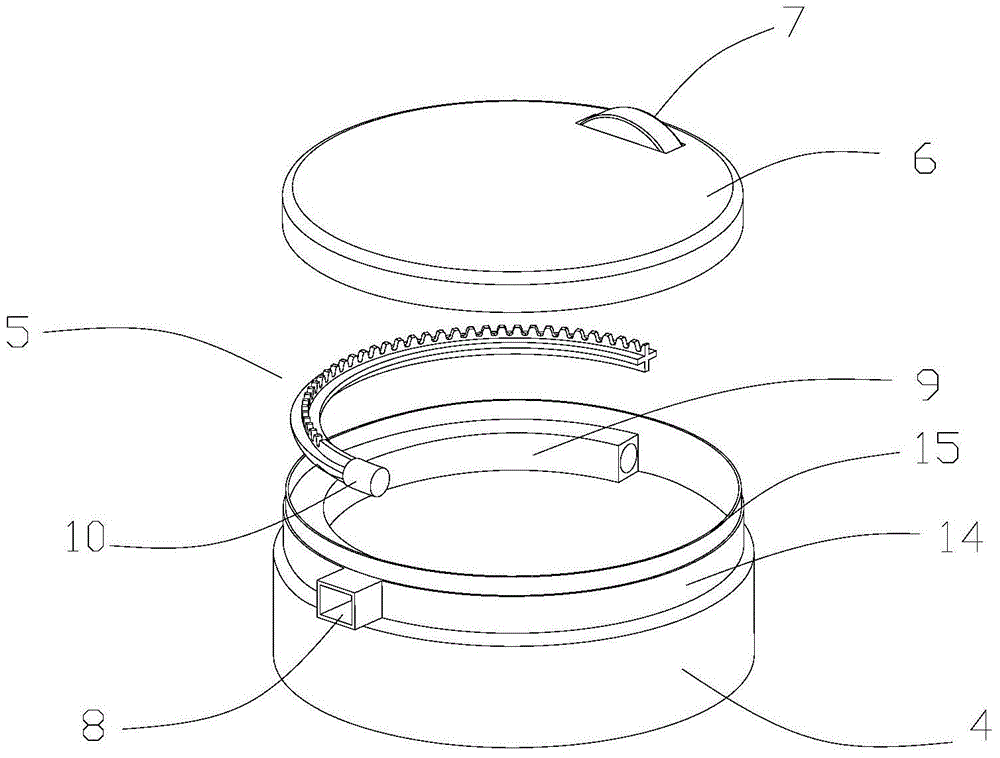

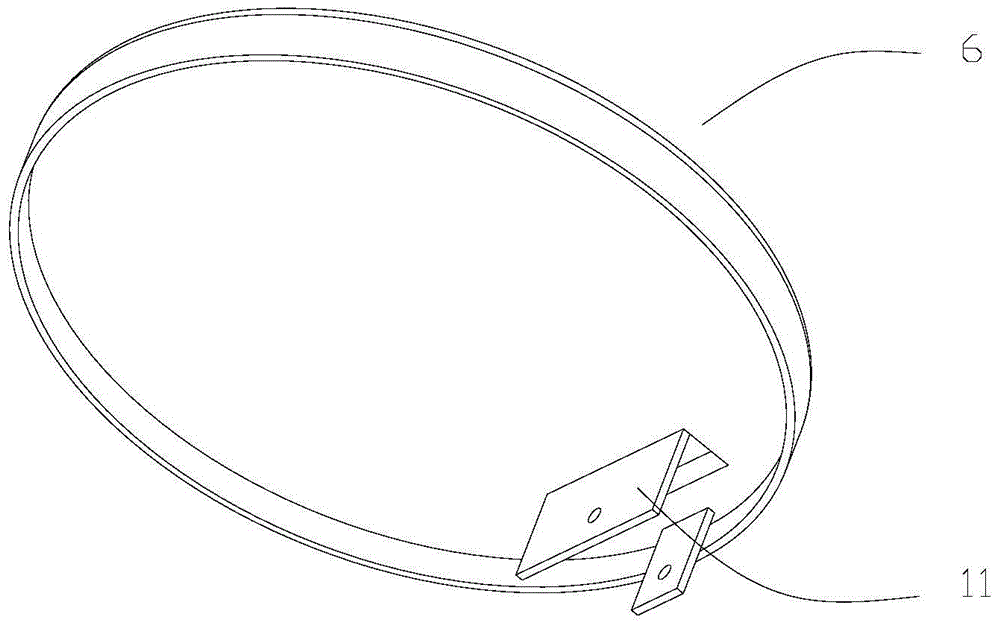

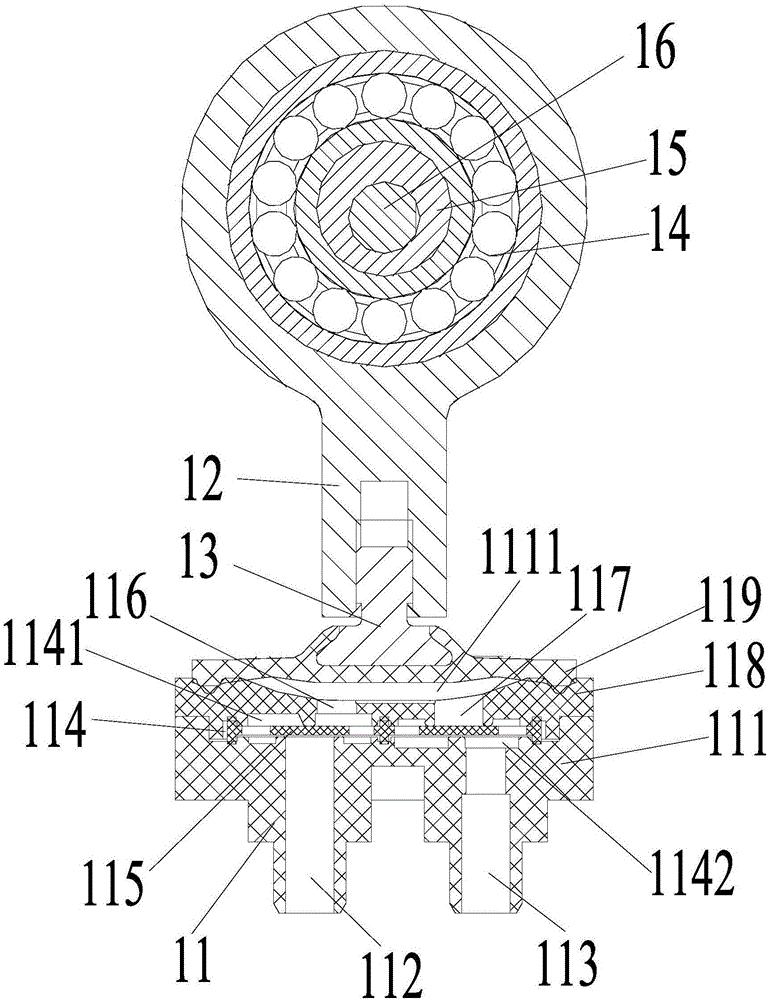

Hand wheel pumping bottle

The invention provides a hand wheel pumping bottle which comprises a bottle body, a suction tube and a sorption pump cover, wherein a bottle opening is formed in the upper end of the bottle body; an outer thread is formed in the bottle opening; the suction tube is made of a flexible material and extends to the bottom of the bottle body from the bottle opening; a sealing part is arranged at the top end of the suction tube; the external diameter of the sealing part is equal to that of the bottle opening; a first one-way valve capable of upward breakover in the unidirectional manner is arranged at the top end of the suction tube; the sorption pump cover is arranged above the sealing part of the suction tube and is connected with the thread of the bottle opening; the water inlet of the sorption pump cover directly faces the first one-way valve. The hand wheel pumping bottle can conveniently guide soup in the bottle out and can easily control the poured dosage of the soup.

Owner:杨培基

Benazepril pharmaceutical compsn. and process for its prepn.

InactiveCN101032491ASolve the problem of low dissolution rateAvoid degradationPowder deliveryPill deliveryProcess equipmentMedicine

The present invention provides one kind of medicine composition of benazepril and its preparation process. The present invention solves the problem of benazepril with low dissolution and the problems of the preparation process in medicine sticking and medicine degradation. The preparation process combines solid dispersing technology and traditional tablet preparation, and is simple, accurate in dosage control and high in production efficiency.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

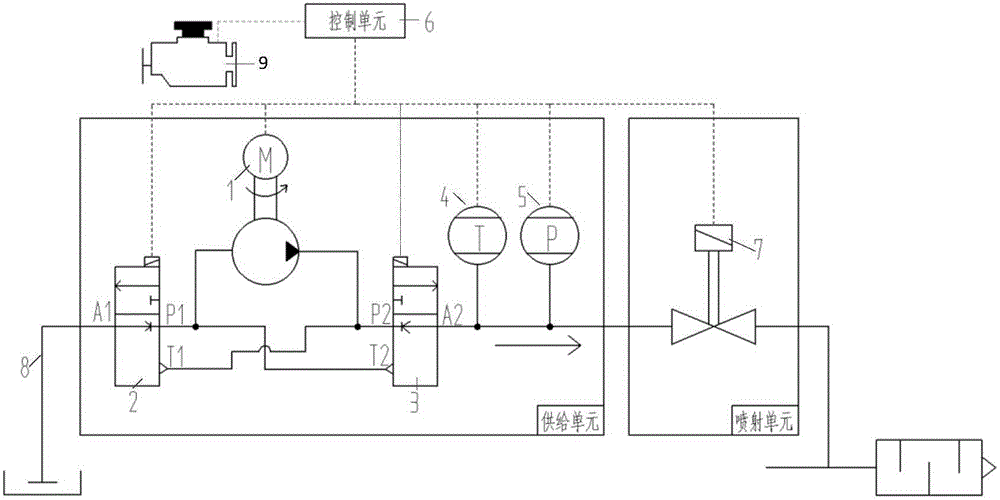

Urea solution supply system and method used for SCR (selective catalytic reduction) system anti-crystallization and pump suction unit

InactiveCN106762048AReduced risk of cloggingPrevent crystallizationInternal combustion piston enginesExhaust apparatusHydraulic structureEngineering

The invention provides a pump suction unit which is composed of an upper one-way valve body and a lower one-way valve body. A first liquid inlet hole and a first liquid outlet hole which are communicated with the outside world are arranged on one end of the lower one-way valve body and away from the upper one-way valve body, and a hydraulic structure is arranged at one end on the upper one-way valve body and away from the lower one-way valve body; a one-way valve membrane is arranged between the upper one-way valve body and the lower one-way valve body, the one-way valve membrane is contacted with the upper one-way valve body to form a gap enabling the first liquid inlet hole and second liquid inlet hole to be communicated and contacted with the lower one-way valve body to form a gap enabling the first liquid outlet hole and second liquid outlet hole to be communicated, and the pump suction unit has the advantage of accurate control of dosage. The invention further provides a urea solution supply system and method used for SCR (selective catalytic reduction) system anti-crystallization. Since a reversing unit is arranged, a urea solution absorbed exceedingly by a pipeline can be sucked back through the pipeline, the situation that extra urea solutions are remained in the pipeline and a dosing module to produce crystallization is avoided, and risk in pipeline clogging is reduced.

Owner:重庆凯瑞伟柯斯环保科技有限公司

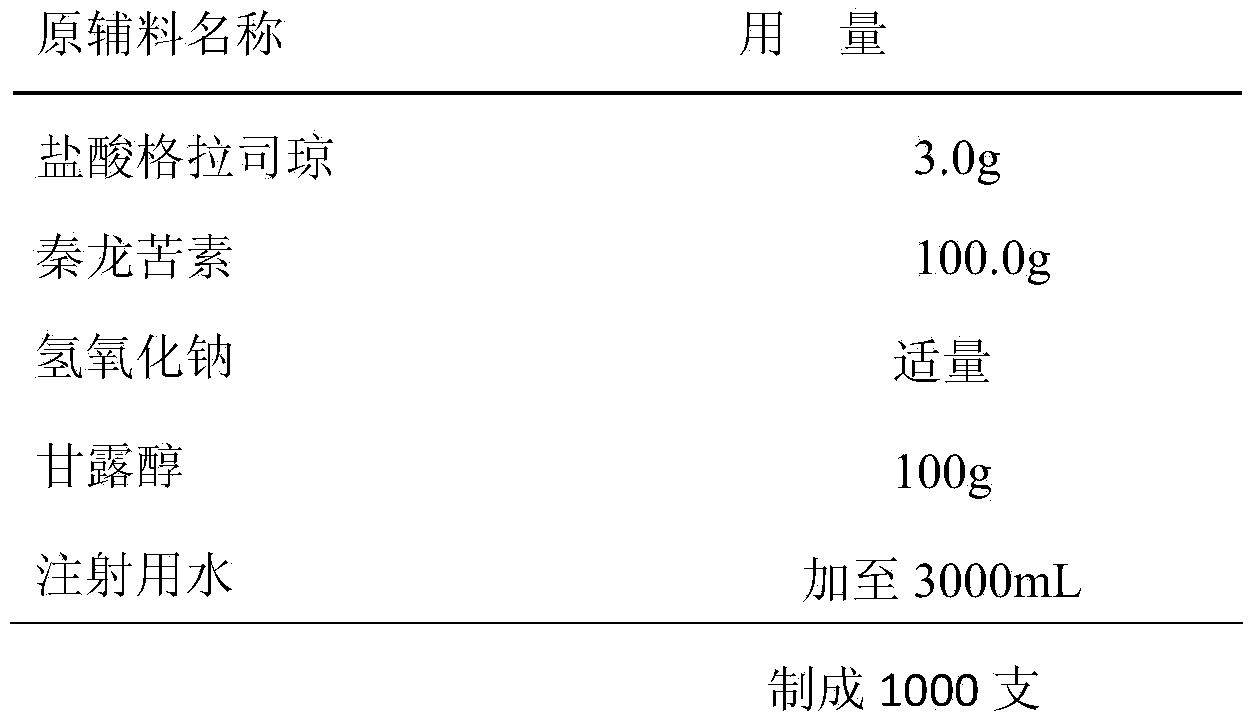

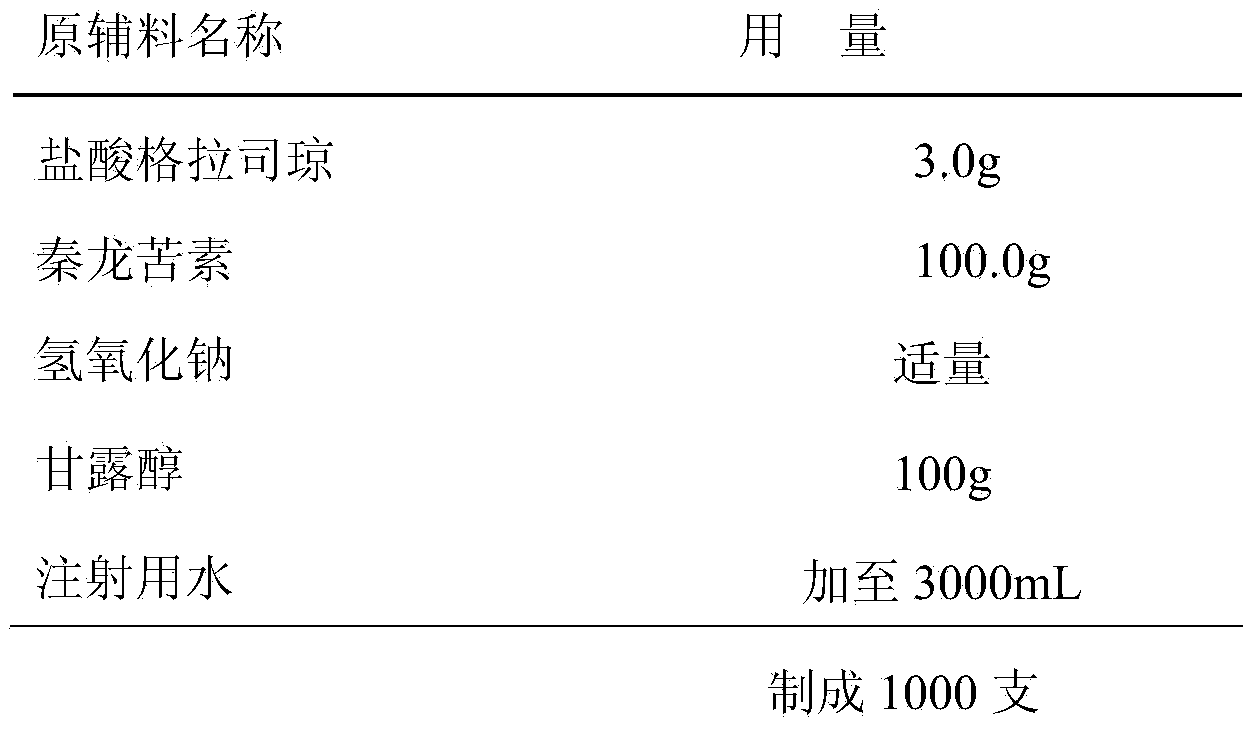

Pharmaceutical composition containing granisetron hydrochloride and preparation thereof

ActiveCN104095870ASignificant synergistic therapeutic effectAvoid damageOrganic active ingredientsDigestive systemFreeze-dryingTherapeutic effect

The invention particularly relates to a pharmaceutical composition containing granisetron hydrochloride and a freeze-dried powder injection thereof and belongs to the field of medicine. The granisetron hydrochloride enables the liver transaminase content to be increased during nausea and vomiting in the treatment, radiotherapy and chemotherapy process and accordingly influences the treatment effect on nausea and vomiting. For overcoming the technical shortcomings, the invention provides a pharmaceutical composition containing the granisetron hydrochloride. An applicant prepares the pharmaceutical composition into the freeze-dried powder injection through reasonable compatibility and finds that the pharmaceutical composition has good treatment effect on nausea and vomiting in the treatment, radiotherapy and chemotherapy process when applying the freeze-dried powder injection to vomiting-stopping treatment, the adverse medicine effect can be remarkably reduced, and the pharmaceutical composition especially has remarkable protection effect on the liver and therefore is suitable for development of clinic treatment medicine.

Owner:CHINA NAT MEDICINES GUORUI PHARMA

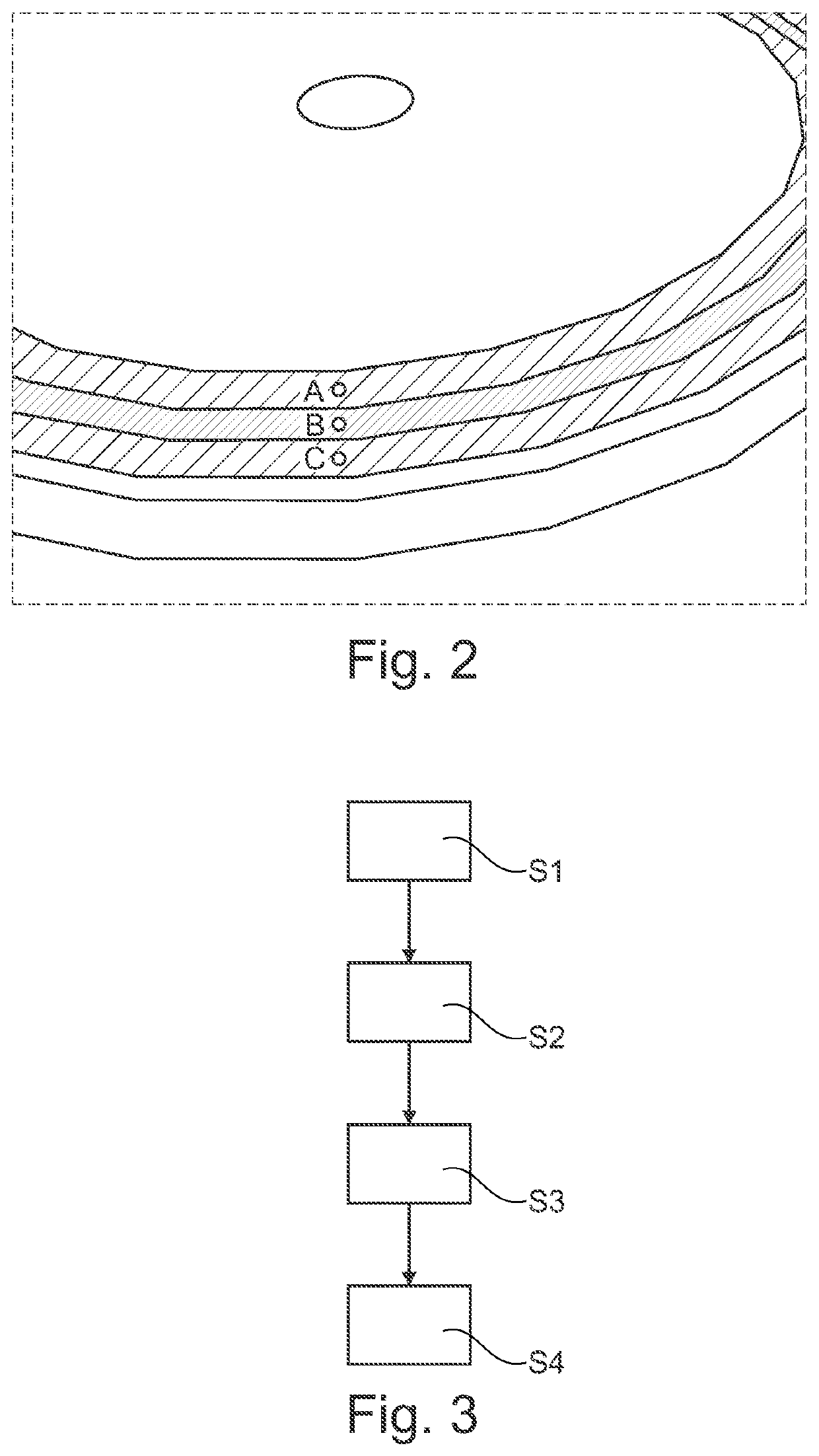

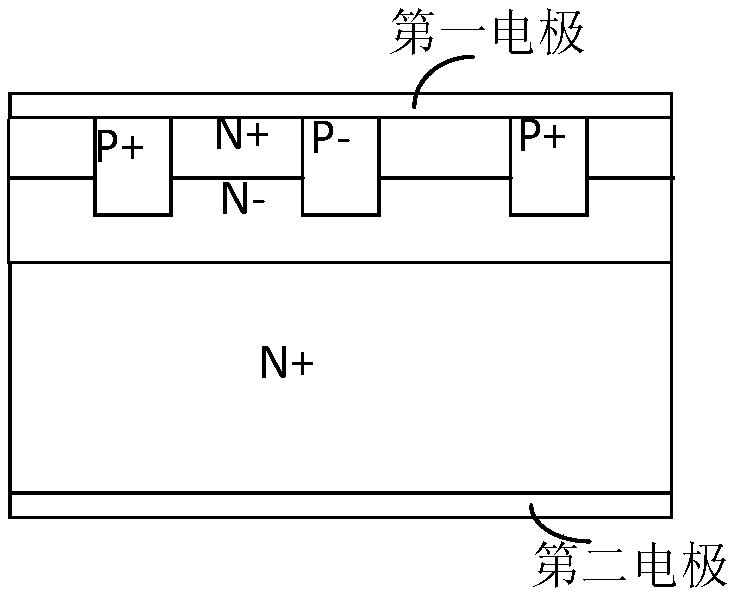

Preparation method for solar wafer

InactiveCN102339893AIncrease the open circuit voltageIncrease short circuit currentFinal product manufactureSemiconductor devicesSolar cellMetal electrodes

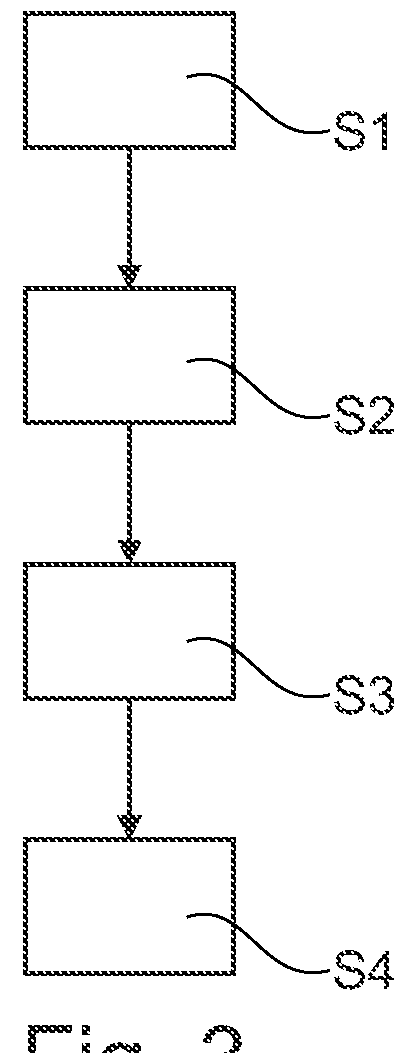

The invention discloses a preparation method for a solar wafer, which comprises the following steps of: S1) implanting P-type ions into the backside of a P-type substrate wafer through an ion implantation method to form a P+ doped layer; S2) forming an N-type doped layer on the surface of the P-type substrate wafer; S3) plating a silicon nitride film on the surface of the P-type substrate wafer; S4) making a metal electrode on the surface of the P-type substrate wafer and sintering to form a surface electrode; and S5) making a metal electrode on the backside of the P-type substrate wafer and sintering to form a backside electrode, wherein when a P type is replaced by an N type, the N type is replaced by the P type at the same time. By adopting the ion implantation method, the doped layers can be enabled to be even, the doping dose can be accurately controlled and therefore the conversion efficiency of a solar cell can be enabled to be closer to a theoretic design value.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

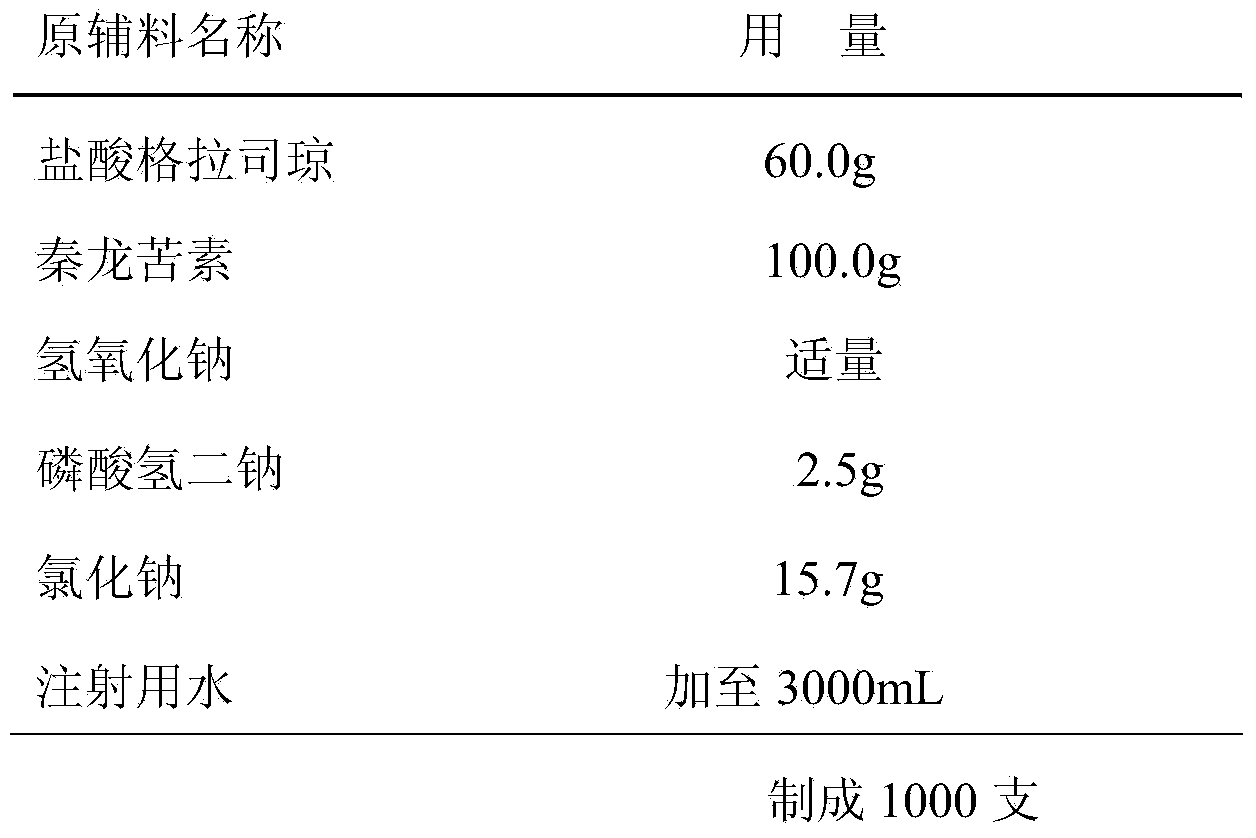

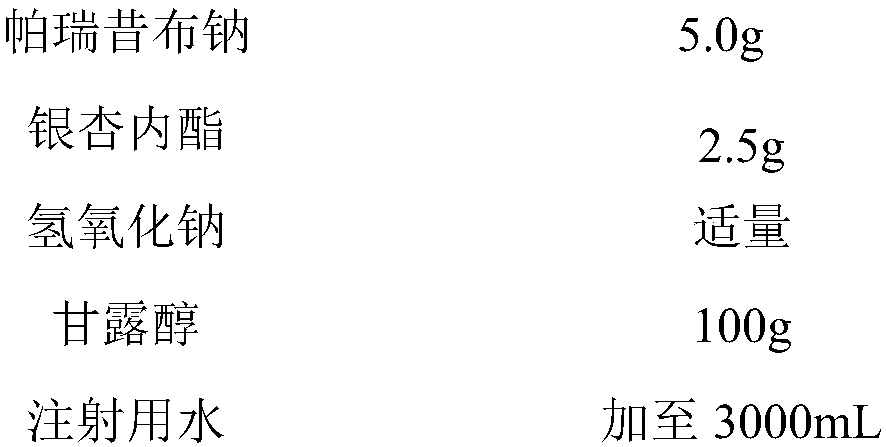

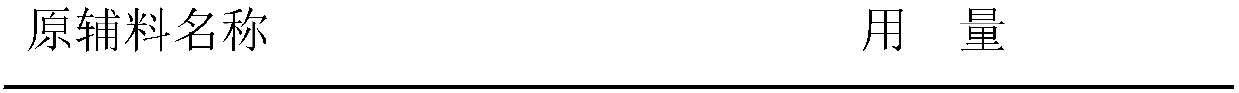

Pharmaceutical composition containing parecoxib sodium

The invention relates to a pharmaceutical composition containing parecoxib sodium, and belongs to the field of medicine. The side effects of parecoxib sodium are increased along with the increase of dosage and exposure duration in the analgesic treatment process, the rise of liver transaminase will occur if parecoxib sodium is taken for a long time, and consequently the clinical application rangeof the drug is affected. In order to overcome the technical defect of large adverse reactions in the analgesic treatment process in the prior art, the pharmaceutical composition for analgesia is provided; parecoxib sodium and ginkgolide serve as active pharmaceutical ingredients of the pharmaceutical composition, and when the pharmaceutical composition is used for analgesic treatment, the two active ingredients have a significant synergistic effects in analgesia, can significantly reduce adverse reactions caused by drugs and show a significant protective effect on liver especially, so that thepharmaceutical composition is suitable for being developed into clinical treatment drugs.

Owner:YANGTZE RIVER PHARM GRP GUANGZHOU HAIRUI PHARM CO LTD +1

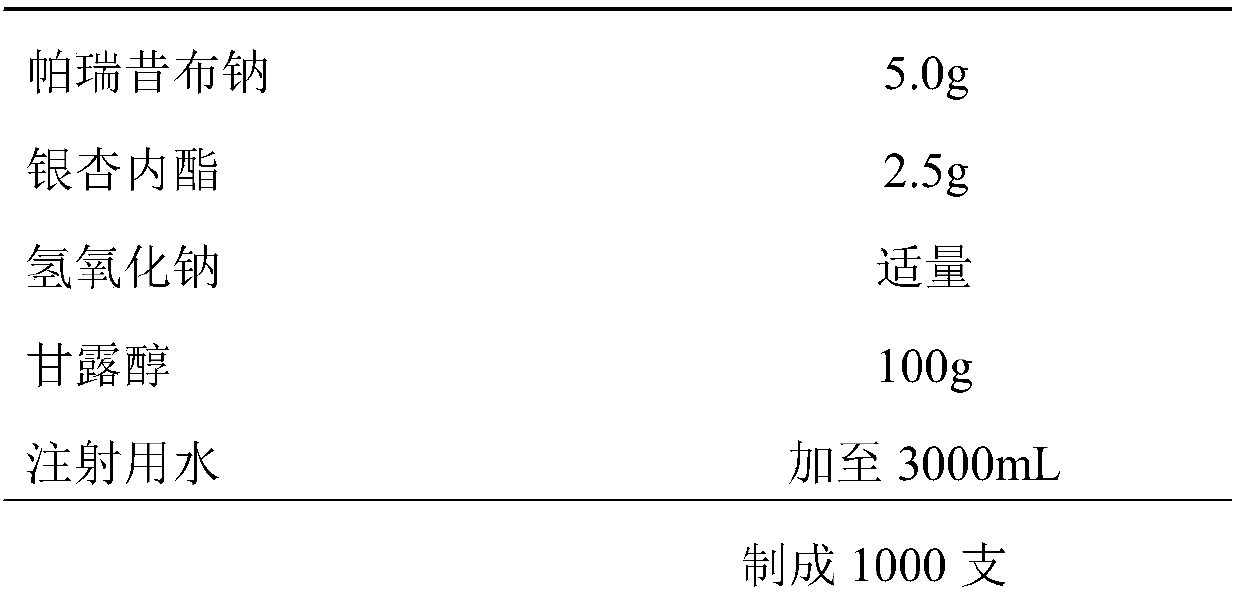

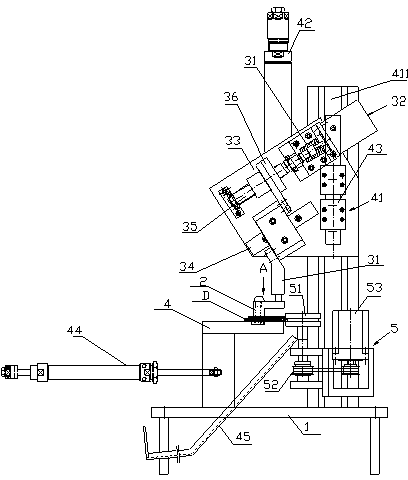

Lubricant spraying system for gasket

ActiveCN103212503AImprove lubrication qualityPrecise dose controlSpraying apparatusRolling resistanceFriction force

The invention relates to a lubricant spraying system for a gasket. The lubricant spraying system for the gasket comprises a gasket platform used for placing the gasket to be sprayed, a spraying nozzle capable of obliquely moving to the inner side of the gasket, and a friction wheel capable of being arranged at one side of the gasket platform in a rotary mode, wherein at least two rotation rollers are symmetrically arranged on the gasket platform, and the gasket is in contacting connection with the rotation rollers and the friction wheel and rotates under the driving of rolling frictional force of the friction wheel. The lubricant spraying system for the gasket is capable of automatically spraying lubricant to the inner side of the gasket, accurately controls the dosage and uniformity of the lubricant on each gasket, and improves the lubricating quality of the gasket.

Owner:镇江泛沃新能汽车技术股份有限公司

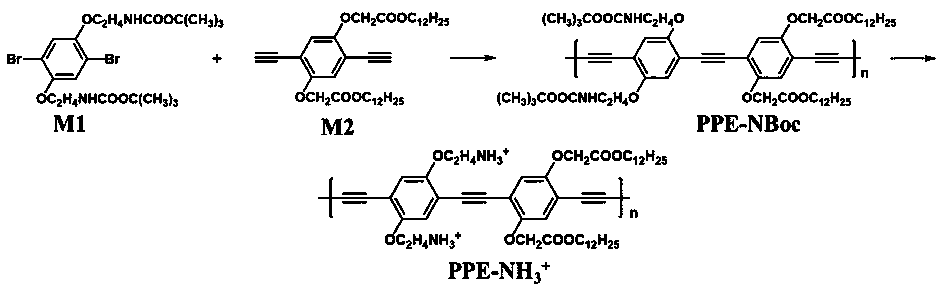

Occult blood fingerprint appearing agent, occult blood fingerprintappearing cotton piece and application ofoccult blood fingerprintappearing cotton piece

ActiveCN110698650ALower protein contentThe effect is clearDiagnostic recording/measuringSensorsSide chainTert-Butyloxycarbonyl protecting group

The invention discloses an occult blood fingerprint appearing agent, an occult blood fingerprintappearing cotton piece and application oftheoccult blood fingerprint appearing cotton piece. A polyphenylene ethynylene type conjugated polymer with amino on the side chain protected by t-butyloxycarboryl is synthesized through an Sonogashira coupling reaction, theprotecting group is removed through trifluoroacetic acid, and an aminated polyphenylene ethynylene fluorescence conjugated polymer is obtained and is dissolved in a solvent, so that the occult blood fingerprint appearing agent is obtained.A non-woven fabric is adopted as a basematerial and is soaked through the fingerprint appearing agent, so that the occult blood fingerprint appearing cotton piece is obtained; the cotton piece coversan object loaded with an occult blood fingerprint; and after uncovering the cotton piece, bright fingerprint lines can be observed under ultraviolet light of 415nm. According to the technical scheme,the occult blood fingerprint appearing agent provided by the invention is simple and convenient to operate, short in developing time, good in developing effect, and suitable for occult blood fingerprint developing on different objects; and particularly, by adopting the appearing cotton piece, the appearing cotton piece is portable, reusable, capable of realizing industrial production, and suitablefor occult blood fingerprint appearing of objects in various dimensions on sites with different situations.

Owner:SUZHOU UNIV

Surface hardening method for martensite stainless steel

InactiveCN102168254AProcessing speedSimple processVacuum evaporation coatingSputtering coatingCase hardeningMartensitic stainless steel

The invention relates to a surface hardening method for martensite stainless steel. In the technical scheme, the surface hardening method comprises the following steps of: putting a processed martensite stainless steel workpiece on a workbench of a vacuum chamber of an ion implanter, vacuumizing until the pressure is between 2.0*10<-3> and 3.0*10<-3>Pa, and removing a passivation layer on the surface of the workpiece by using an ion cleaning source; and implanting nitrogen ions to the martensite stainless steel workpiece of which the surface passivation layer is removed under the conditions that: the vacuum degree is between 5.0*10<-4> and 5.0*10<-2>Pa, the accelerating voltage of the ion source is between 10 and 100 kV, and the implantation dose is between 5.0*10<15> and 5.0*10<19> ions / centimeter<2> to obtain the surface-hardened martensite stainless steel, wherein the operating conditions of the cleaning source include: filament current is between 6 and 10 A, arc voltage is between 40 and 70 V, extraction voltage is between 0.6 and 1.5 kV, and extraction current is between 40 and 70 mA. The surface hardening method has the characteristics of simple process and no pollution in the processing process; and the abrasion performance and hardness of the surface of the product processed by the method are improved substantially, the combination between a hardening layer and a stainless steel substrate is firm, and the service life is long.

Owner:WUHAN UNIV OF SCI & TECH

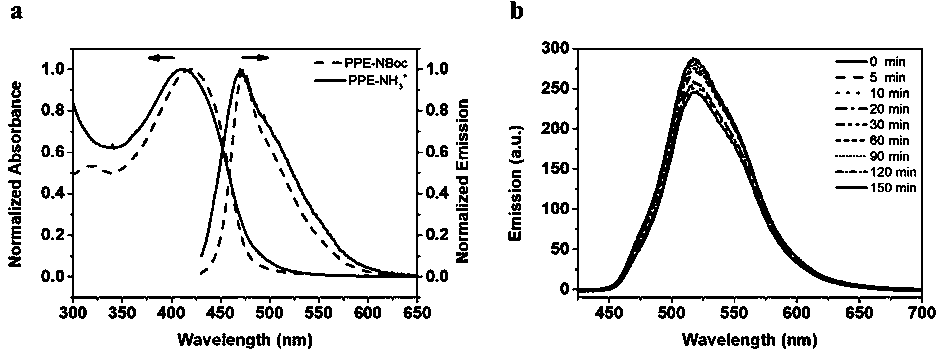

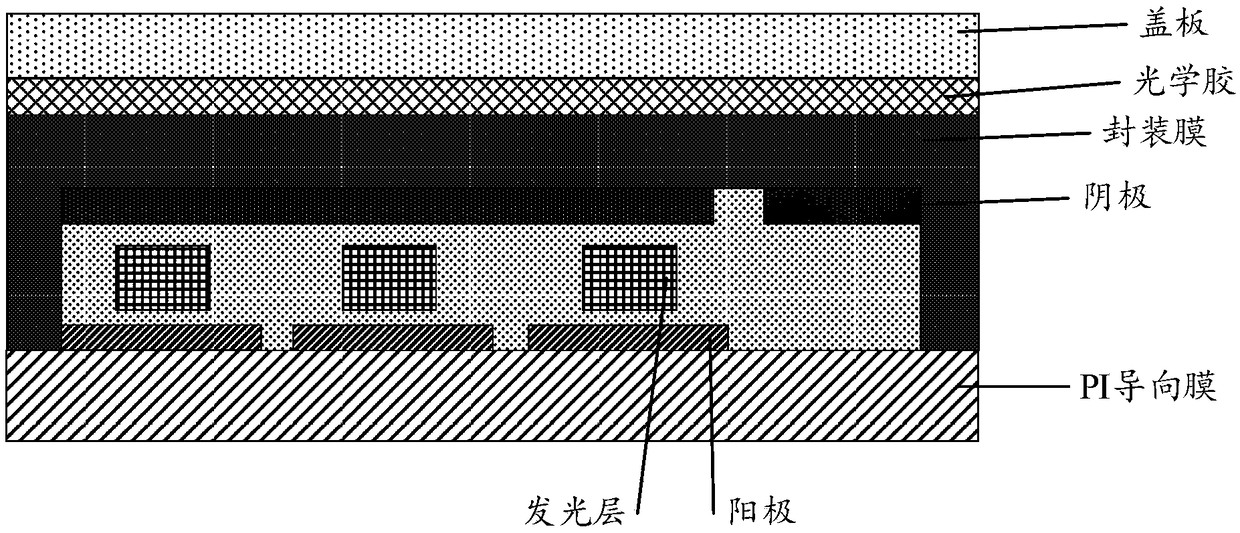

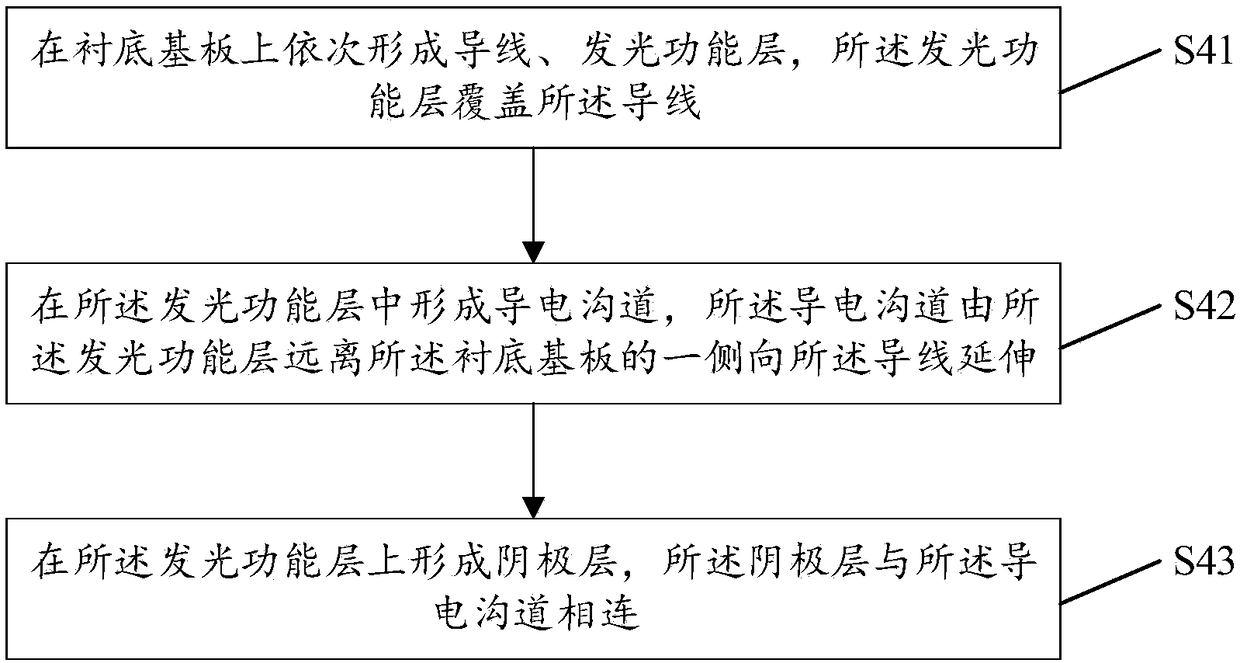

Display panel and production method thereof as well as display device

ActiveCN108231673AAvoid touch blind spotsAchieve connectionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to the technical field of display and particularly relates to a display panel and a production method thereof. The production method of the display panel comprises the followingsteps: successively forming lead wires and a light-emitting function layer on a substrate, wherein the light-emitting function layer covers the lead wires; forming conducting channels in the light-emitting function layer, wherein the conducting channels extend from one side away from the substrate of the light-emitting function layer to the lead wires; forming a cathode layer on the light-emittingfunction layer, wherein the cathode layer is connected with the conducting channels. According to the scheme, conducting particles are poured into the light-emitting function layer to form the conducting channels, so that the cathode is connected with the lead wires; the wiring length between the cathode and the lead wires is reduced; the touch control blind area on the display panel caused by the oversized wiring area is avoided.

Owner:BOE TECH GRP CO LTD

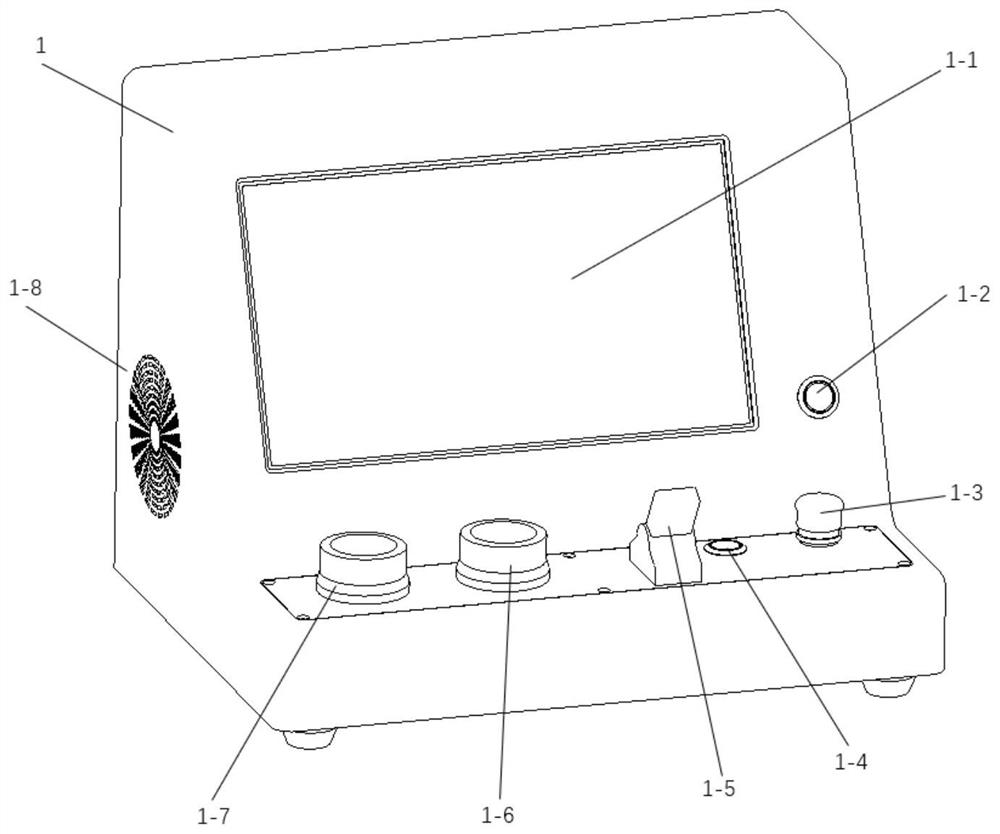

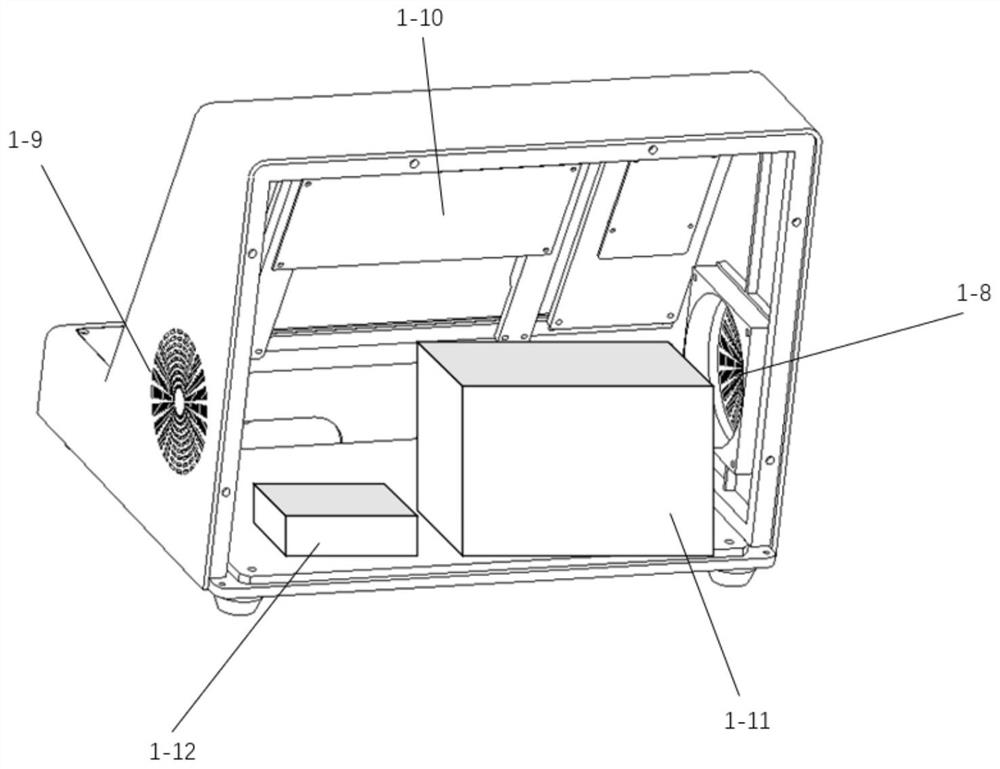

Medicine and embolism particle mixed injection device capable of being remotely controlled

ActiveCN112494093APrecise control of injection speedPrecise dose controlOcculdersFlow monitorsPharmaceutical drugAnalog signal

The invention discloses a medicine and embolism particle mixed injection device capable of being remotely controlled. The medicine and embolism particle mixed injection device comprises a console andan execution structure, wherein the execution structure comprises a first injector, a second injector, an injector fixing device, an injector pushing device, an injector stroke limiting device, a controller II and a serial port display screen; the console comprises a controller I; and the controller I is connected with the controller II, a touch display screen, a power-on button, a safety mechanism button, a real-time speed control rocker, a maximum pressure control knob, a maximum speed control knob, an analog signal collector and a heat dissipation module. The medicine and embolism particlemixed injection device is simple and reliable to operate, and can realize remote non-contact sterile medicine and embolism material mixed injection operation, vibrator mixing of medicines and granularembolism materials, accurate injection speed and dosage control and real-time monitoring of injection flow and pressure, so that the accurate embolism curative effect is achieved, the exposure time for interventional physicians to inject the medicines in an operation is greatly shortened, and the work intensity of the physicians is reduced.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

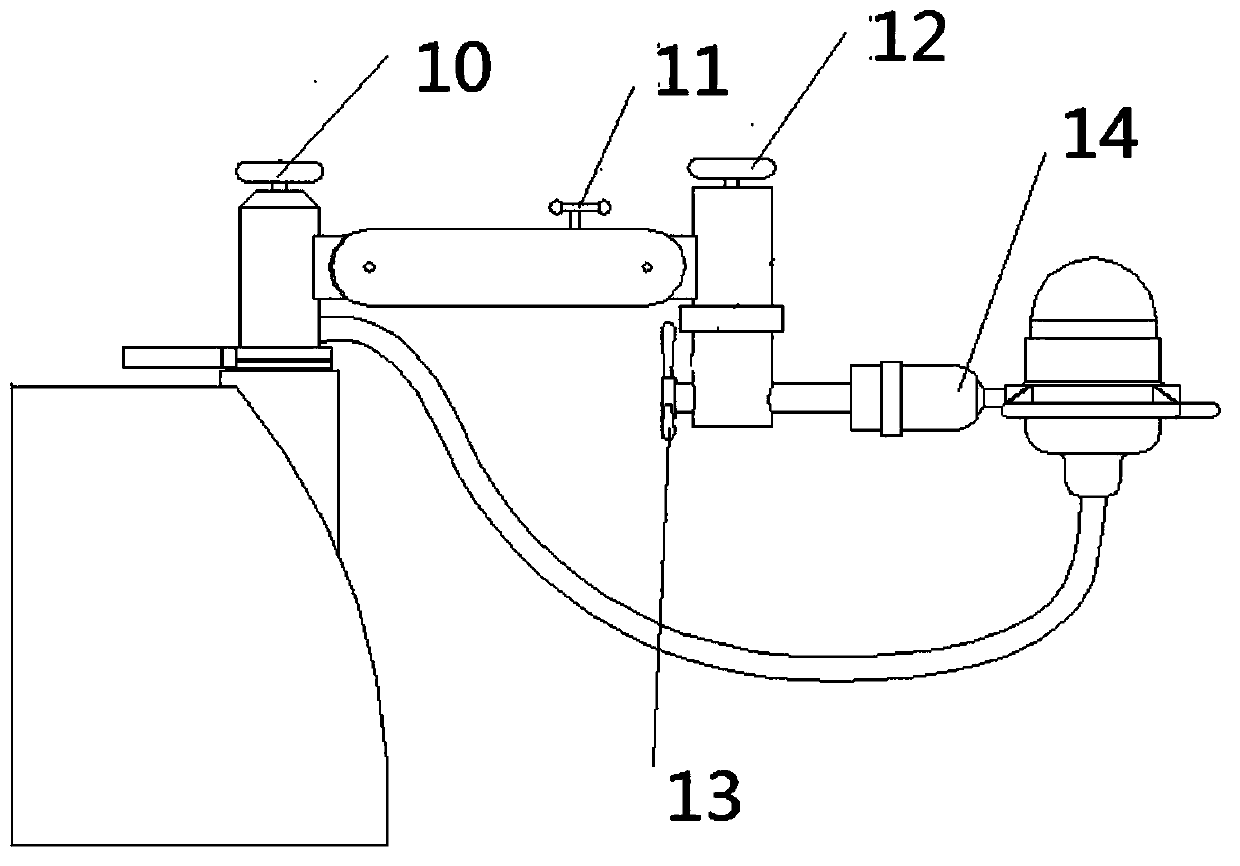

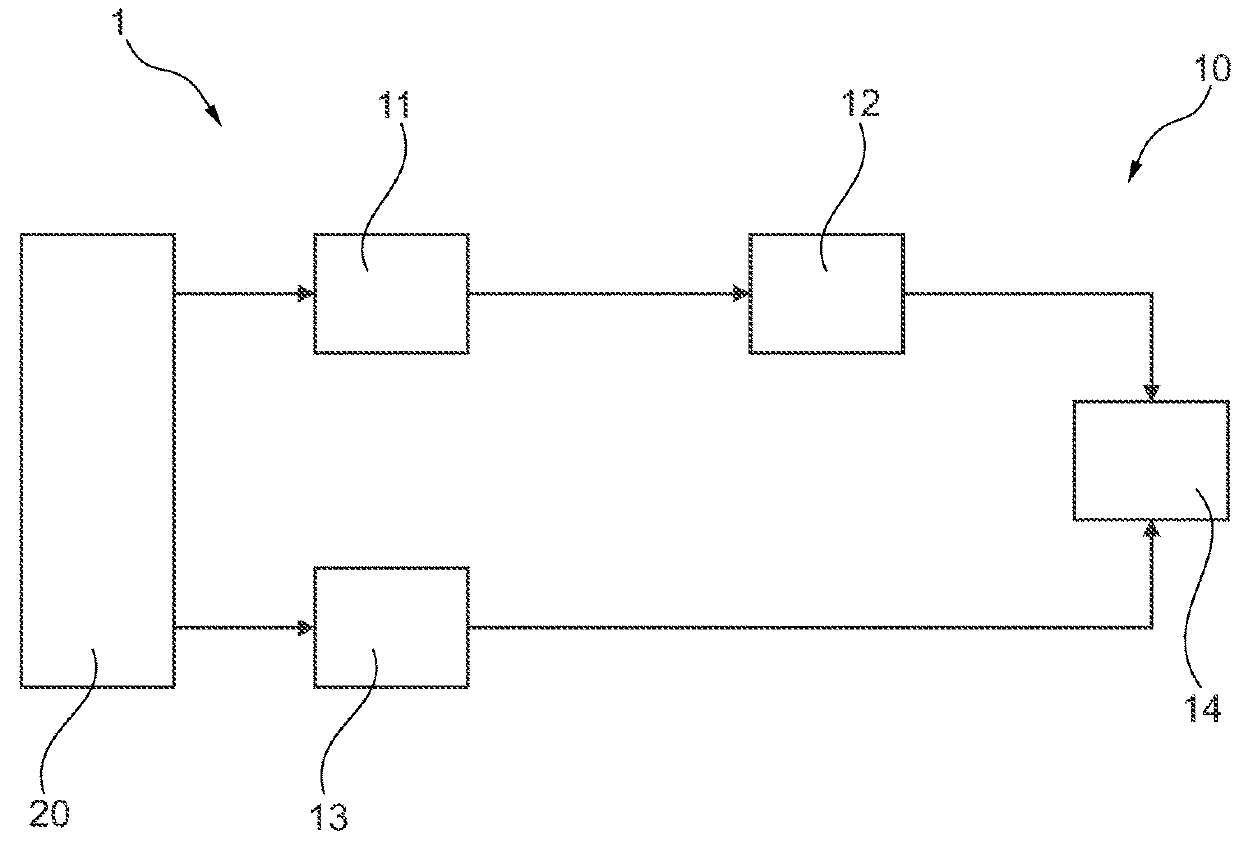

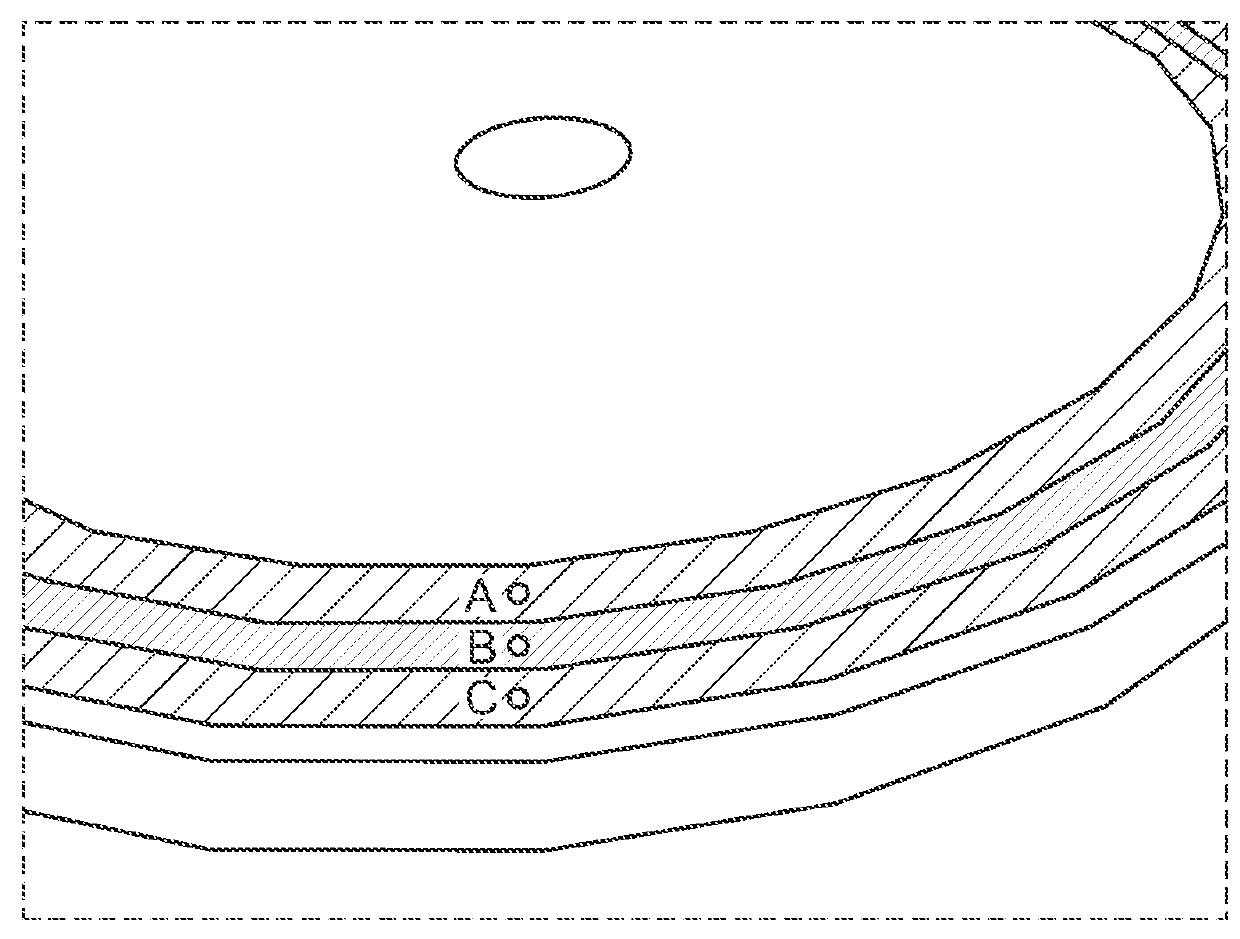

Device for determining spatially dependent x-ray flux degradation and photon spectral change

ActiveUS10757795B2Precise dose controlProvide informationX-ray spectral distribution measurementComputerised tomographsEngineeringComputational physics

The invention relates to a device (10) for determining spatially dependent x-ray flux degradation and photon spectral change, a system (1) for determining spatially dependent x-ray flux degradation and photon spectral change for an x-ray tube (20), a method for spatially dependent x-ray flux degradation and photon spectral change for an x-ray tube (20), a computer program element for controlling such device (10) or system (1) for performing such method and a computer readable medium having stored such computer program element. The device (10) for determining spatially dependent x-ray flux degradation and photon spectral change comprises an acquisition unit (11), a processing unit (12), a calculation unit (13), and a combination unit (14). The acquisition unit (11) is configured to acquire x-ray flux degradation data for the x-ray tube (20). The processing unit (12) is configured to process the x-ray flux degradation data into spatially dependent flux degradation data. The calculation unit (13) is configured to calculate at least a photon spectral change of the x-ray tube (20) and to convert the photon spectral change into a spatially dependent spectrum. The combination unit (14) is configured to combine the spatially dependent flux degradation data and the spatially dependent spectrum.

Owner:KONINKLJIJKE PHILIPS NV

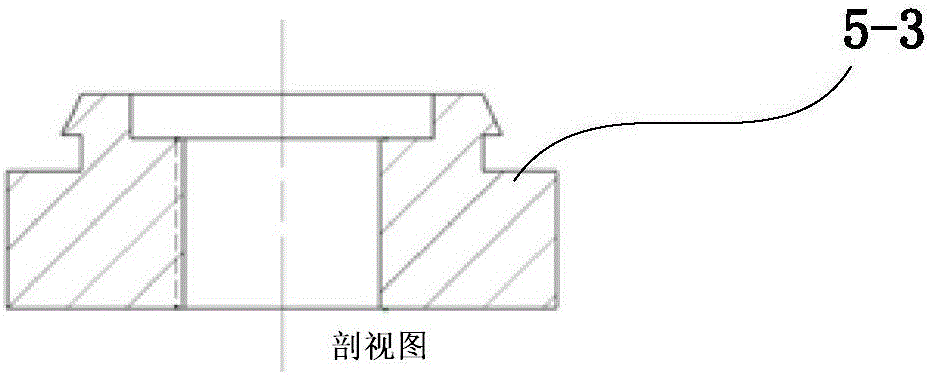

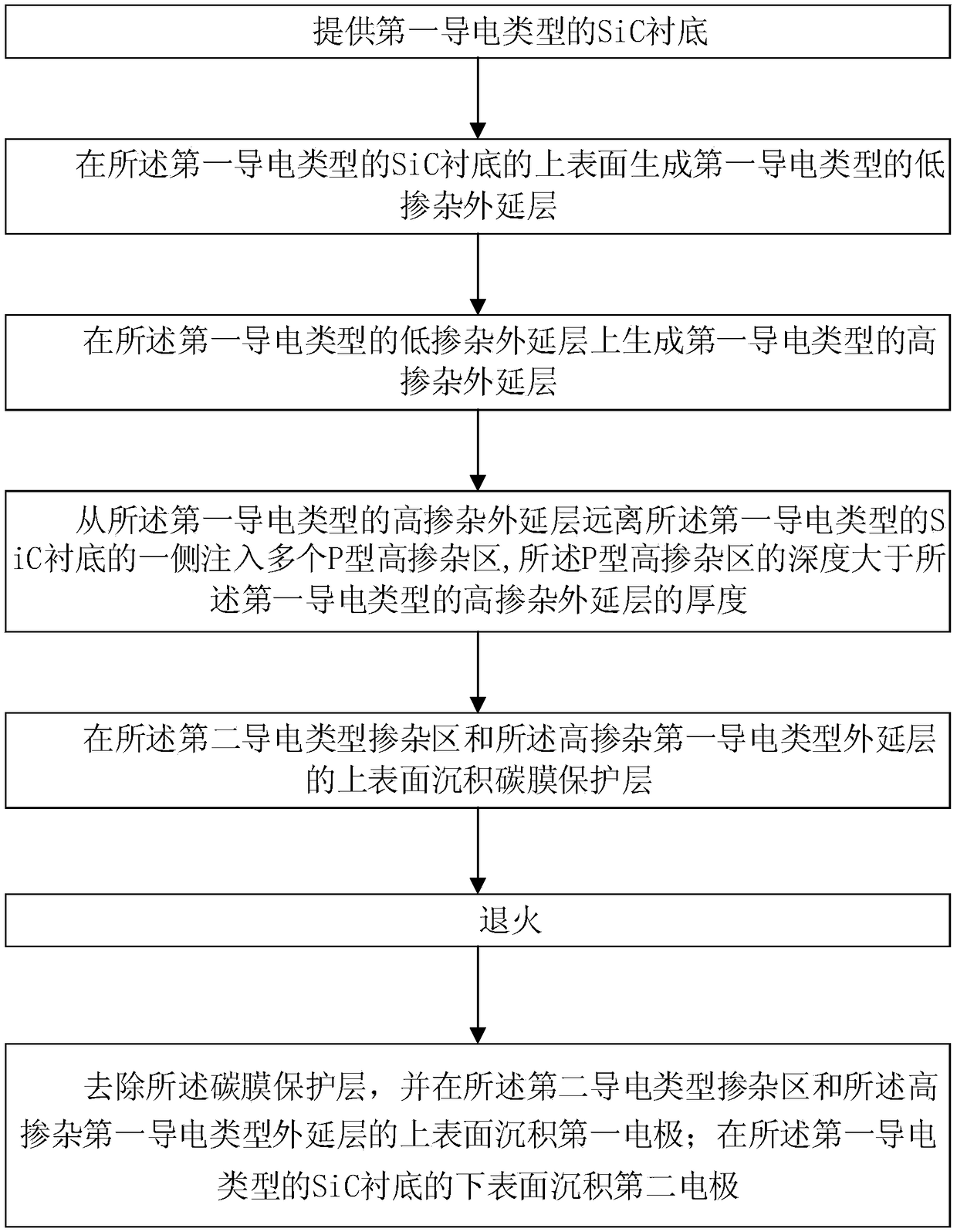

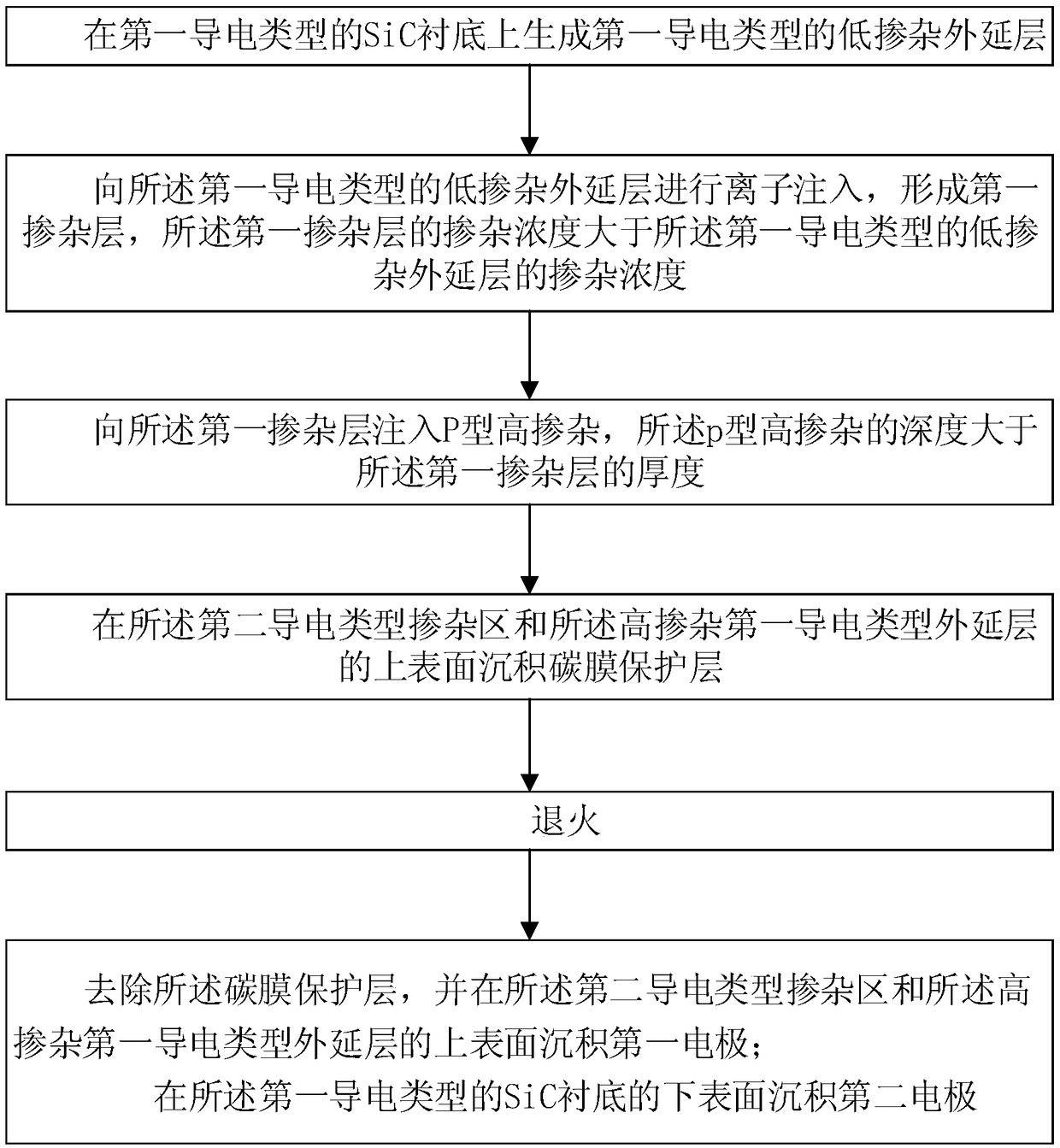

SiC knot barrier Schottky diode and manufacturing method thereof

InactiveCN109461768AAccurately change the effective barrier heightLower Schottky BarrierSemiconductor/solid-state device manufacturingSemiconductor devicesPower flowSchottky diode

The invention relates to a SiC knot barrier Schottky diode and a manufacturing method thereof. The SiC knot barrier Schottky diode comprises a first conductive type SiC substrate layer, a low-doped first conductive type epitaxial layer, a high-doped first conductive type epitaxial layer, and multiple second conductive type doping areas; the depth of the second conductive type doping area is greater than the thickness of the high-doped first conductive type epitaxial layer, a first electrode and a second electrode. By adjusting the surface doping concentration, the barrier width is reduced, sothat the barrier of the diode is reduced, the effective barrier height of the contact of the metal-semiconductor is changed through different doping concentrations, the barrier width is reduced, and the electron with small free path can penetrate the barrier, the forward tunneling current is increased, the on-state resistance is equivalently reduced, and the diode breakover can be realized throughsmall voltage.

Owner:QINHUANGDAO JINGHE SCI & TECH RES INST CO LTD

Latent fingerprint developing cotton sheet and application

InactiveCN110710980ASurvey EasyReduce pollutionPreparing sample for investigationDiagnostic recording/measuringLatent fingerprintProcess engineering

The invention discloses a latent fingerprint developing cotton sheet and application. A non-woven fabric is used as a base material and immersed in a fingerprint developing agent, the base material isin a wet state after being adsorbed and loaded with the fingerprint developing agent, and the latent fingerprint developing cotton sheet is obtained. The cotton sheet is immersed in the developing agent to prepare the developing cotton sheet, and by controlling the amount of the developing agent, the developing cotton sheet which does not contaminate a latent fingerprint object can be obtained; and the developing cotton sheet covers an object containing the latent fingerprint, after the cotton sheet is torn off, the object is naturally dried, fingerprint lines can be observed under a light source matched with the developing agent, and the fingerprint lines are suitable for photographing and recording. According to the method for developing the latent fingerprint by the cotton sheet, the development effect is good, portability is achieved, operation is simple, and the development time is short; the application range is wide, and cotton sheets of different sizes carrying different developing agents can be prepared; and the cotton sheets can be reused and suitable for criminal investigation on-site operation and industrial production.

Owner:SUZHOU UNIV

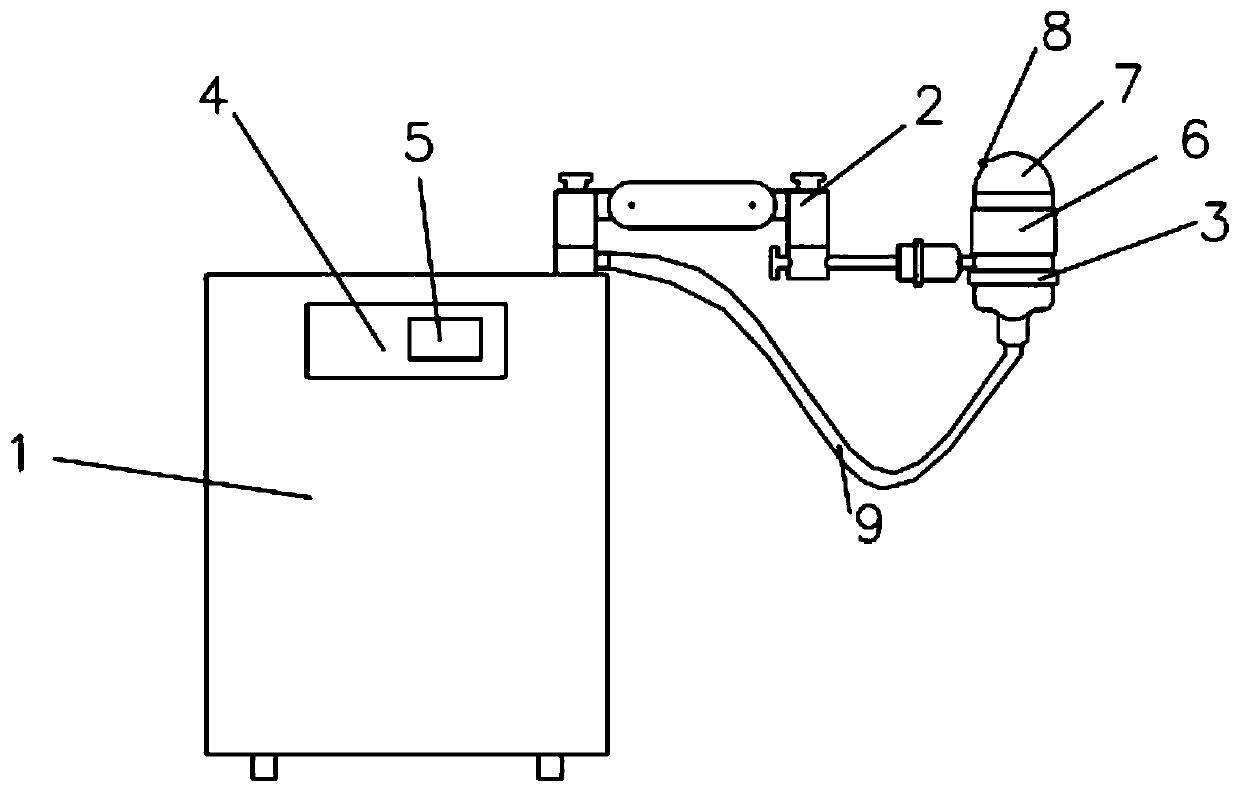

Shock wave therapeutic instrument

PendingCN110772416APrecise dose controlImprove the treatment experienceVibration massageShock waveEngineering

The present invention discloses a shock wave therapeutic instrument. The shock wave therapeutic instrument comprises a main engine, a movable arm and a shock wave source, the main engine is provided with a control end, the control end is connected with the shock wave source through an electric wire, a water inlet pipe is also connected between the main engine and the shock wave source, the shock wave source is arranged at an outer end of the movable arm, the movable arm is a two-section arm, and the shock wave source realizes three modes of movements of moving up and down, and left and right and rotating through linkage of the movable arm. An intelligent control module is arranged in the control end and stores parameter information so as to control frequency and intensity of shock waves generated by the shock wave source. An electromagnetic shock wave generating device is arranged in the shock wave source, a water bag is arranged at an output end of the shock wave source, and the waterbag contacts with an electromagnetic shock wave generating device to conduct the shock waves to act on a disease focus of a patient. The shock wave therapeutic instrument has remarkable advantages ofeasiness in mastering, safety, flexibility, convenience, light side effect, etc.

Owner:徐州康良电子科技有限公司

Device for determining spatially dependent x-ray flux degradation and photon spectral change

ActiveUS20180279457A1Precise dose controlProvide informationX-ray spectral distribution measurementTomographyFrequency spectrumX-ray

The invention relates to a device (10) for determining spatially dependent x-ray flux degradation and photon spectral change, a system (1) for determining spatially dependent x-ray flux degradation and photon spectral change for an x-ray tube (20), a method for spatially dependent x-ray flux degradation and photon spectral change for an x-ray tube (20), a computer program element for controlling such device (10) or system (1) for performing such method and a computer readable medium having stored such computer program element. The device (10) for determining spatially dependent x-ray flux degradation and photon spectral change comprises an acquisition unit (11), a processing unit (12), a calculation unit (13), and a combination unit (14). The acquisition unit (11) is configured to acquire x-ray flux degradation data for the x-ray tube (20). The processing unit (12) is configured to process the x-ray flux degradation data into spatially dependent flux degradation data. The calculation unit (13) is configured to calculate at least a photon spectral change of the x-ray tube (20) and to convert the photon spectral change into a spatially dependent spectrum. The combination unit (14) is configured to combine the spatially dependent flux degradation data and the spatially dependent spectrum.

Owner:KONINKLJIJKE PHILIPS NV

Psoriasis treating liquid medicine for external use

InactiveCN106110177ARegulate endocrineRegulate immune functionInanimate material medical ingredientsPharmaceutical delivery mechanismCuticleParapsoriasis

A psoriasis treating liquid medicine for external use is prepared by mixing extracts of fresh rhizoma curcumae longae, fomes japonica and radix angelicae dahuricae with mineral fulvic acid. During treatment, the skin of an aural acupuncture point-the ear center is lacerated by a stone needle knife, and then the psoriasis treating liquid medicine is used to infiltrate the acupuncture point with pressing. As long as patients with psoriasis insist on using the psoriasis treating liquid medicine without violating taboos, the psoriasis can be cured.

Owner:雷大鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com