Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve the effect of the finished product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

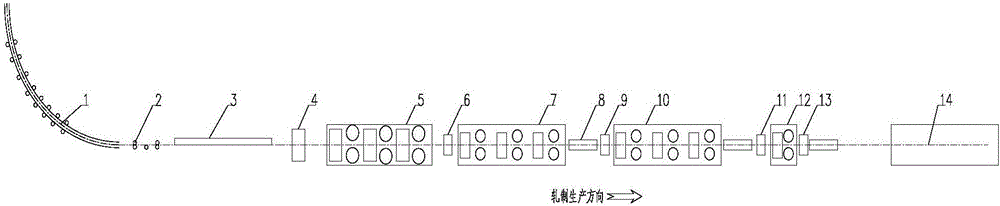

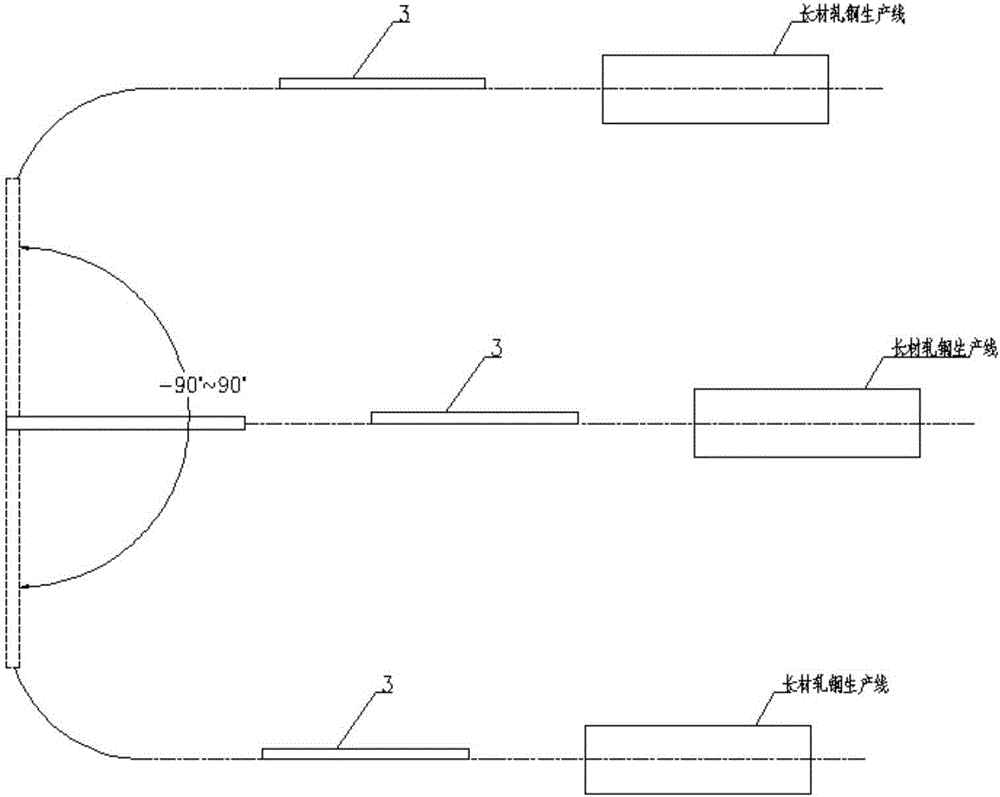

Long-bar rolling production line and production technology thereof

InactiveCN106269868AAvoid lostAvoid losses and achieve endless rollingMetal rolling arrangementsFailure rateProduction line

The invention discloses a long-bar rolling production line and a production technology thereof, and belongs to the technical field of bar rolling. The production line comprises a continuous casting machine, a withdrawal and straightening machine, a pre-rolling emergency shear, a roughing mill unit, a head cutting flying shear, an intermediate mill unit, a finishing mill unit, a reducing and sizing unit and a cooling bed which are connected by roller beds in sequence, wherein the continuous casting machine is a single-machine uniflow continuous casting machine; and the roller bed between the continuous casting machine and the roughing mill unit is a heat preservation roller bed. The production technology comprises the steps of: carrying out single-machine uniflow continuous casting, carrying out heat preservation by using the conveying roller bed, straightening by using the withdrawal and straightening machine, rolling by using the roughing mill unit, rolling by using the intermediate mill unit, rolling by using the finishing mill unit, rolling by using the reducing and sizing unit, cooling and collecting. The long-bar rolling production line and the production technology have the beneficial effects that round billets are directly rolled after the round billets are cast by using the single-machine uniflow continuous casting machine, thereby reducing middle working procedures and heat loss, realizing endless rolling, meanwhile omitting a heating surface and reducing a failure rate in a production process.

Owner:CISDI ENG CO LTD

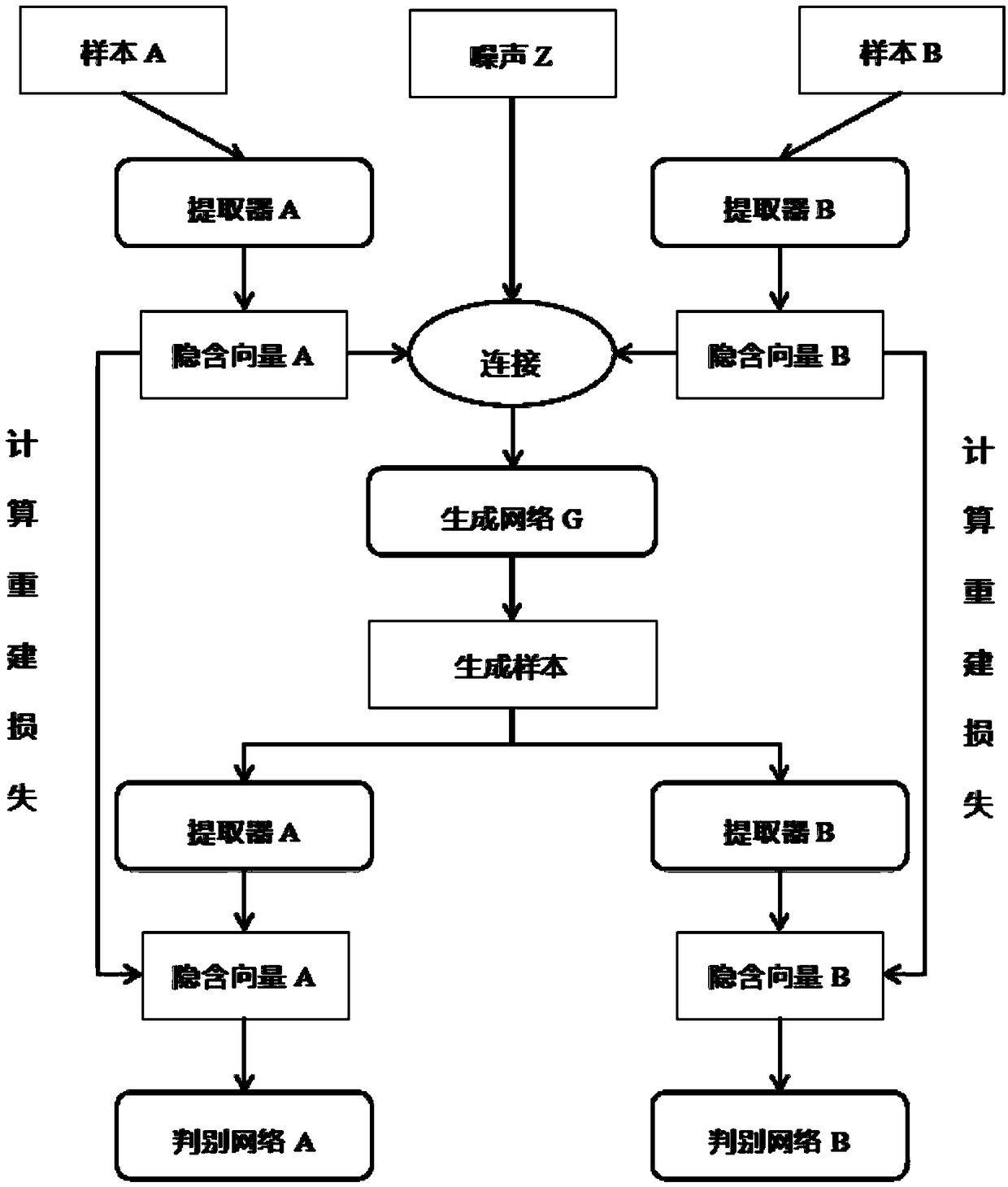

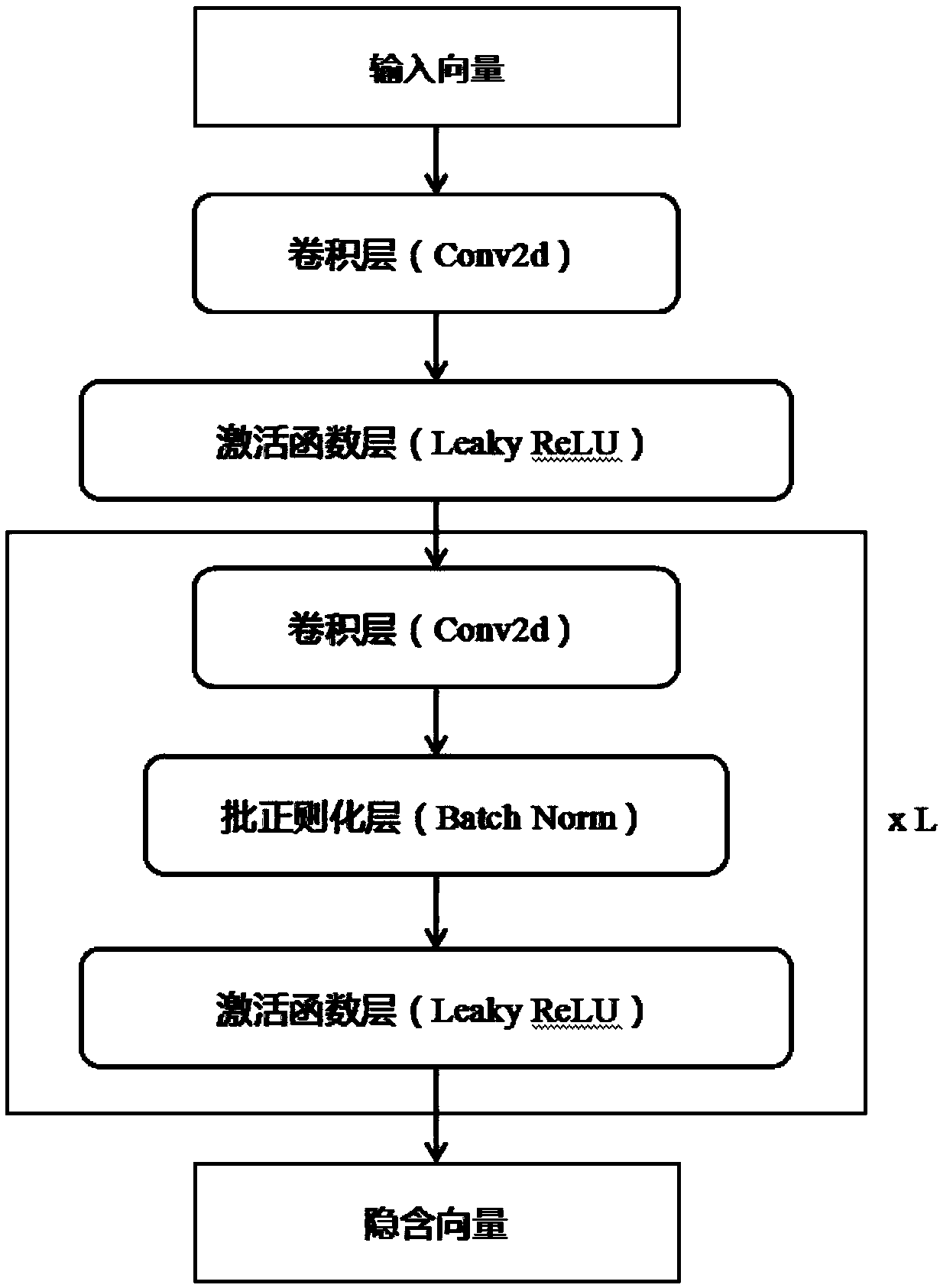

A picture synthesis method based on a generative adversarial network

PendingCN109447906ASimplify operation stepsImprove production efficiency and finished product effectGeometric image transformationNeural learning methodsGenerative adversarial networkGroup of pictures

The invention relates to a picture synthesis method based on a generative adversarial network, which is used for carrying out feature extraction and fusion on pictures in different domains to generatea new picture, and comprises the following steps of firstly collecting and sorting picture samples, and grouping the picture samples to ensure that each group of pictures has the same feature; then constructing and training an adversarial network, and initializing network parameters; then selecting an appropriate loss function and an optimization method; then transmitting the samples into the generative adversarial network to start training; and finally properly adjusting the network parameters according to the training result, so that a better result is expected to be obtained. According tothe invention, the image content is synthesized, a new image is generated, manual operation is simplified, and the working efficiency is improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

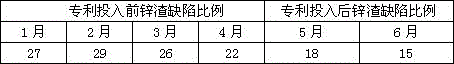

Treatment method for purifying zinc pot in hot galvanizing production

The invention discloses a treatment method for purifying a zinc pot in hot galvanizing production. A purification treatment process comprises the steps that hot galvanizing production is carried out while aluminium content of molten zinc is maintained to be 0.025-0.030wt% and scummings in the zinc pot are cleaned in a hot galvanizing production process. The treatment method for purifying the zinc pot in the hot galvanizing production has the advantages that generation of iron in the zinc pot is inhibited by increasing the aluminium content in the molten zinc from 0.18-0.20% at ordinary times to 0.025-0.030%, so as to improve zinc layer adhesiveness and glossiness of a galvanized plate, and quality of the galvanized plate is effectively improved; iron content in the zinc pot after being purified by adopting the treatment method is obviously reduced, and thus a foundation is laid for follow-up generation.

Owner:HEBEI IRON AND STEEL

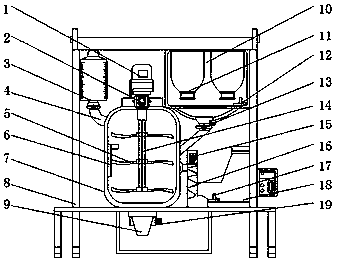

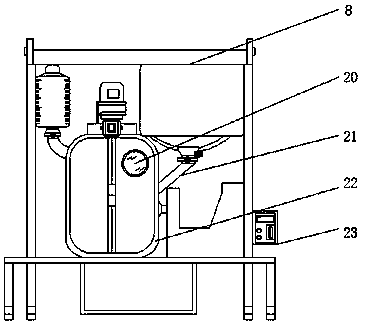

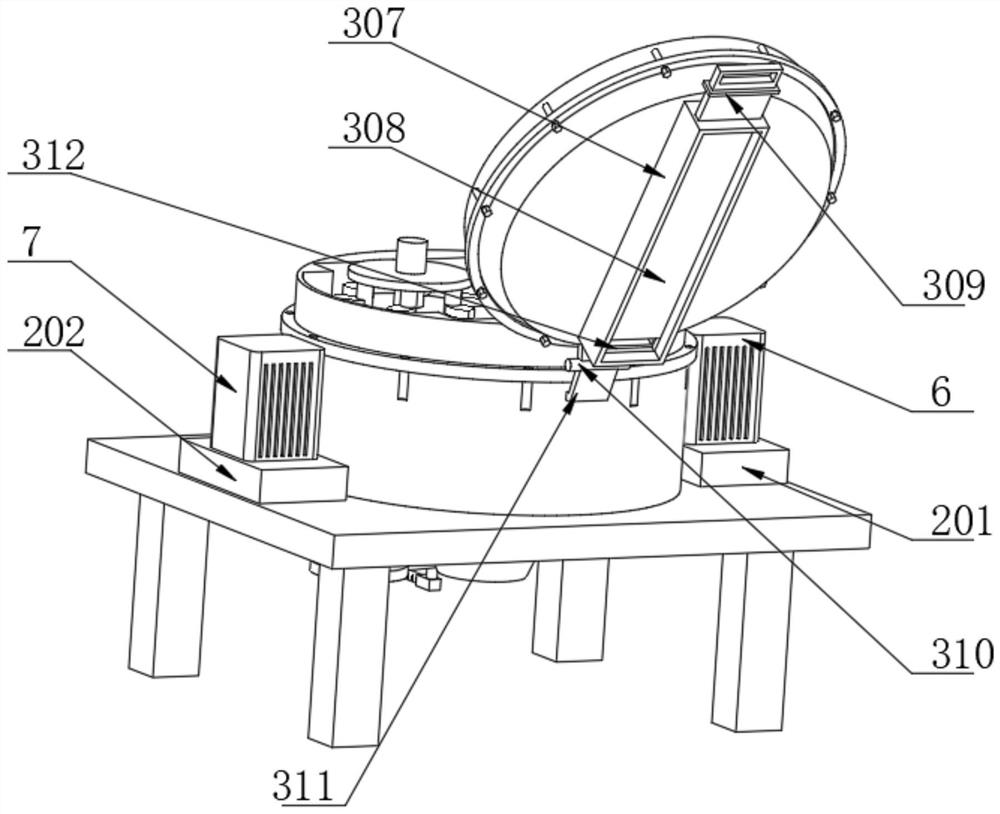

Efficient concrete stirring equipment

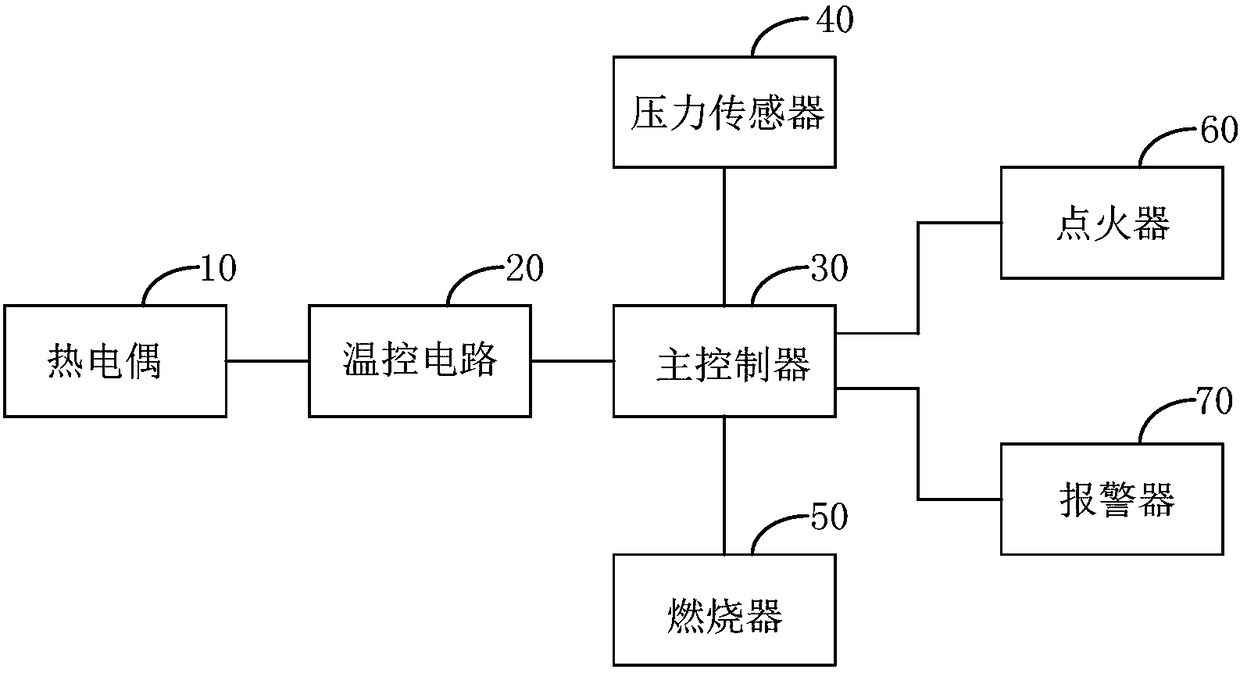

InactiveCN107775806ASave human resourcesImprove the effect of the finished productMixing operation control apparatusCement mixing apparatusPressure sensorBiochemical engineering

The invention discloses a high-efficiency concrete mixing device, which comprises a water tank and a bearing frame. A water tank is installed on one side of the inner top of the bearing frame, and a stone quantitative chamber is installed on the other side of the inner top of the bearing frame. The stone quantitative chamber Stone tanks are installed on both sides of the inner top, and a first pressure sensor is installed at the bottom of the stone quantitative chamber. The main body of the mixing tank is installed on the carrier below the stone quantitative chamber. A powder quantitative chamber is arranged on one side of the stone quantitative chamber, and a second pressure sensor is installed at the bottom of the powder quantitative chamber, and a control panel is installed on the side of the carrier near the powder quantitative chamber. The invention can accurately control the amount of each proportion of concrete and improve the overall quality of concrete.

Owner:苏州市瑞川尔自动化设备有限公司

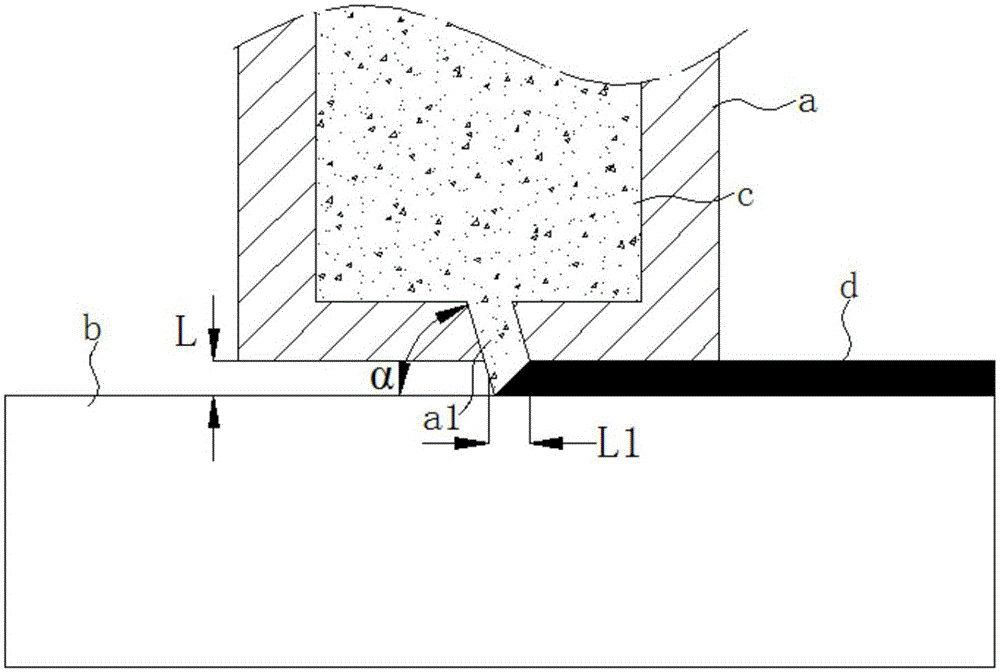

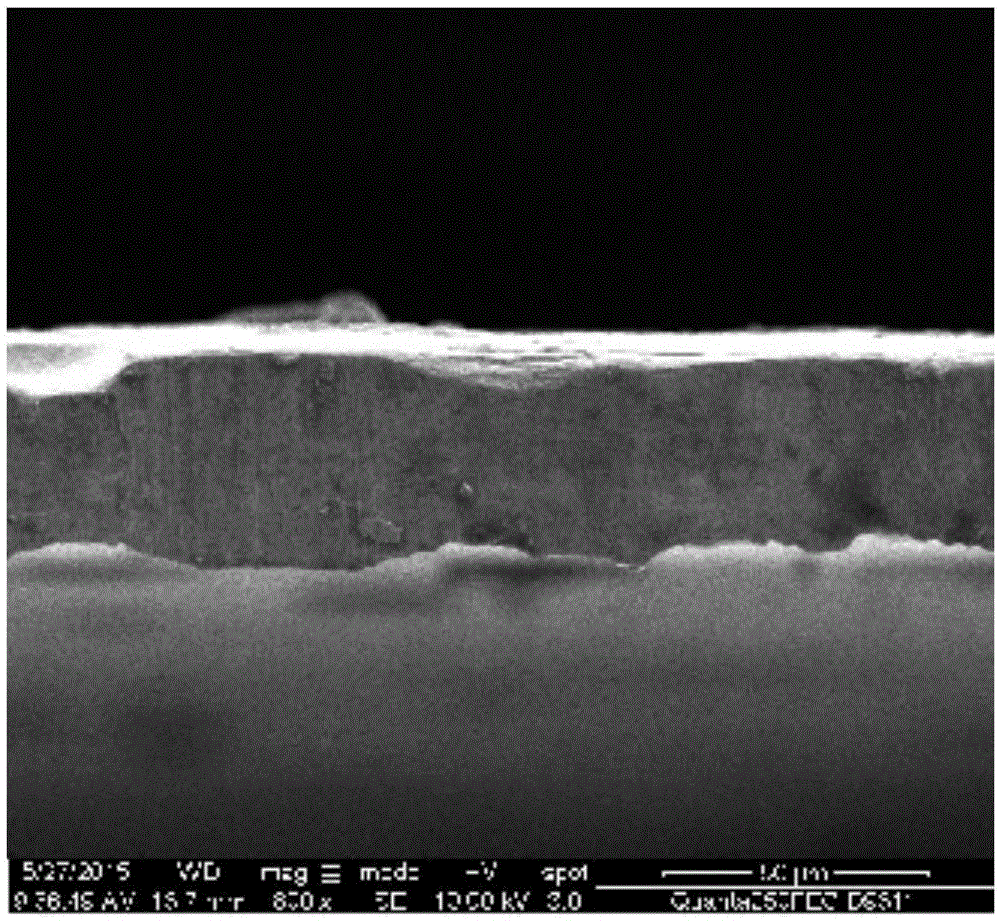

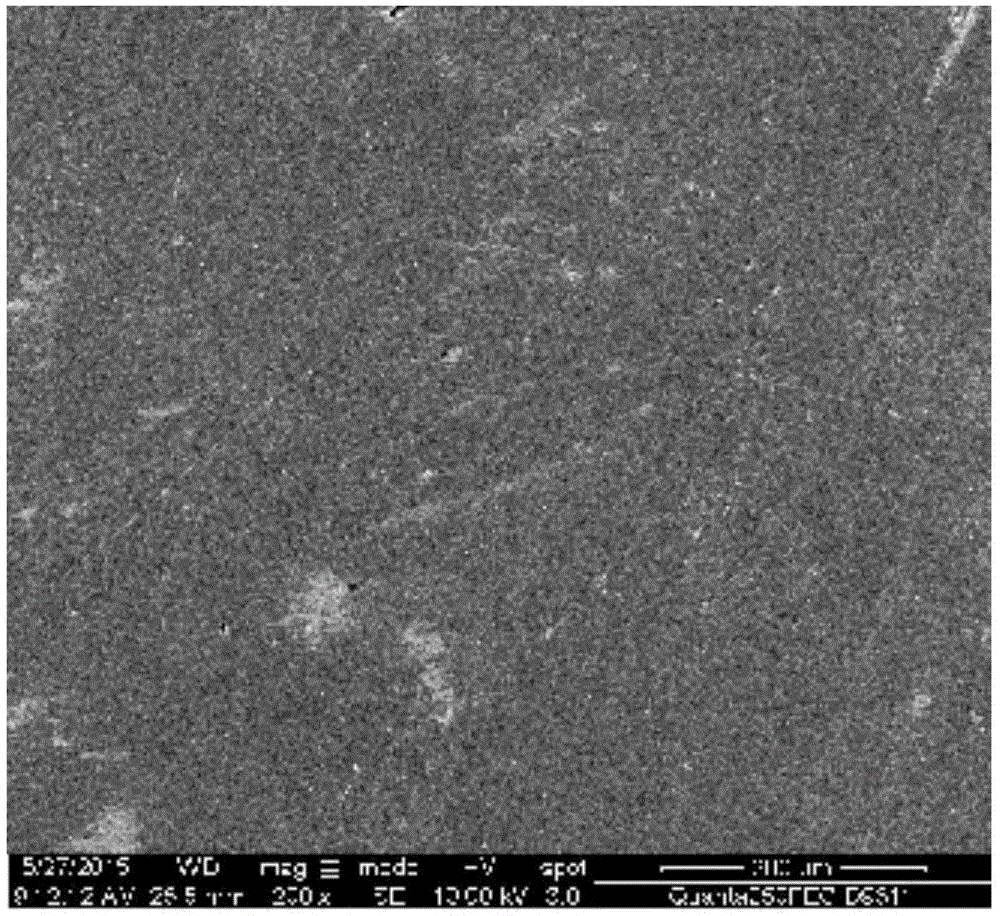

Preparing method of ultrathin amorphous alloy strip

The invention relates to a preparing method of an ultrathin amorphous alloy strip. Molten steel obliquely sprays the surface of a cooling body, and the spraying direction of the molten steel is opposite to the rotating direction of the cooling body. Meanwhile, the distance between the lower end face of a nozzle and the cooling body is reduced, and therefore the scraping pressing and correcting functions on molten steel laminar flow from the lower end face of the nozzle are improved, and the prepared amorphous alloy strip is thin and even. Meanwhile, the smoothness and density of the free surface of the amorphous alloy strip are improved. The acute angle formed between a nozzle runner and the surface of the cooling body is set in the range of 15-85 degrees, the transverse disturbance of the amorphous alloy strip to the laminar flow molten liquid is small in cooperation with the scraping pressing and correcting functions of the lower end face of the nozzle, and therefore the surface stress of the strip is reduced, and the transverse radian of the strip is reduced; and the quality and the finished product performance of the amorphous alloy strip are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

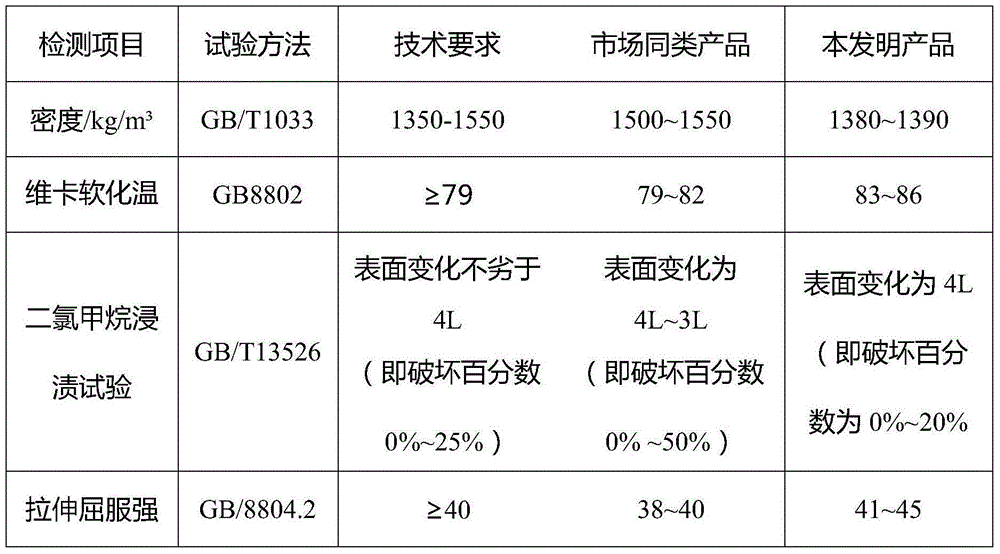

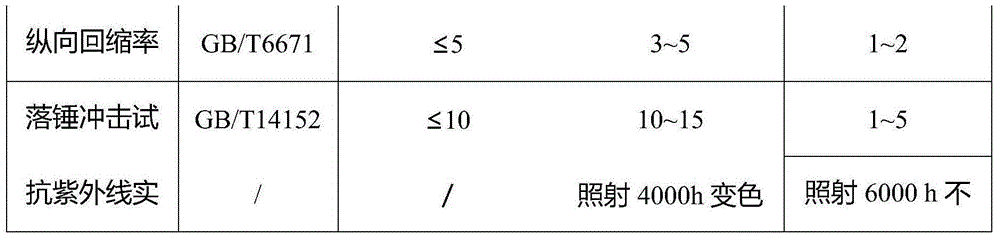

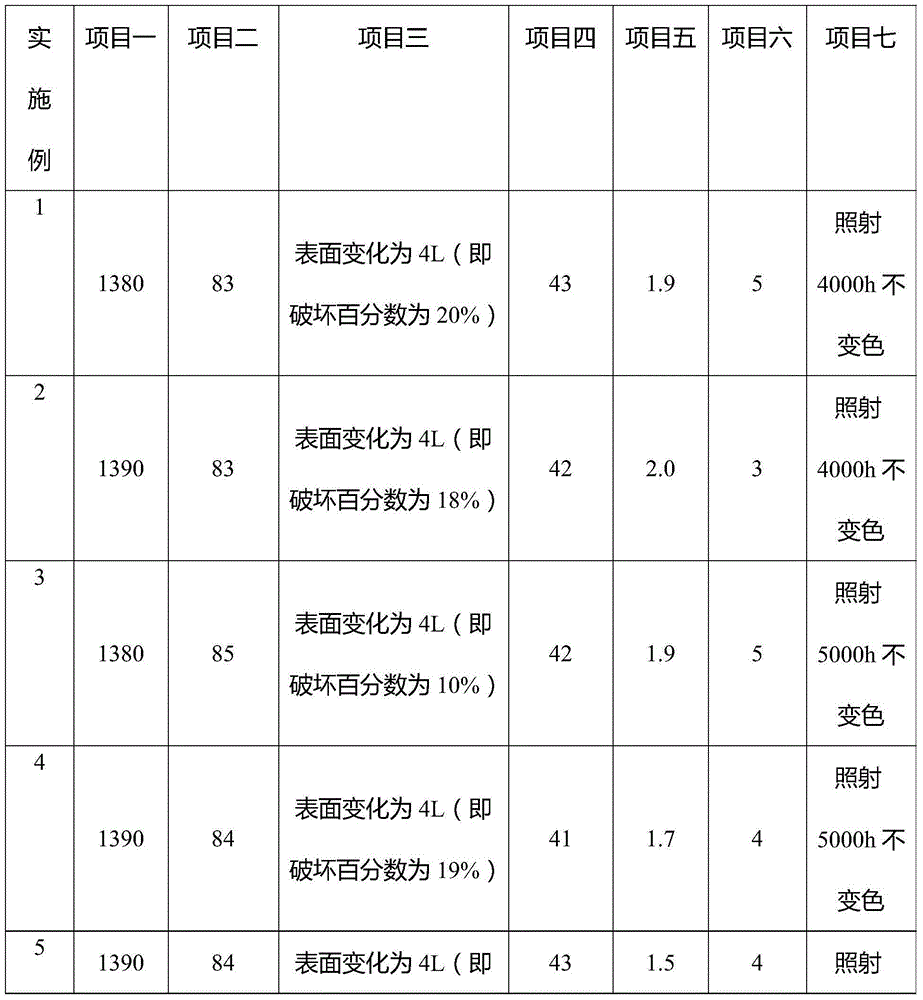

PVC (polyvinyl chloride) composite water drainage tube

InactiveCN104987625AImprove the effect of the finished productExtended service lifeSynthetic resin layered productsTubular articlesPolyvinyl chlorideDrainage tubes

The invention discloses a PVC (polyvinyl chloride) composite water drainage tube, relates to the field of water drainage tubes for building water supply and drainage, and aims to solve the problem that performances such as strength, corrosion resistance and the like are not ideal. The tube wall of the PVC composite water drainage tube is a composite structure consisting of an inner layer, a middle layer and an outer layer, wherein the thickness of the middle layer is greater than or equal 5 / 8 of the total thickness of the tube wall but less than or equal to 3 / 4 of the total thickness of the tube wall; each of the inner layer and the outer layer is prepared from the following raw materials comprising the following components in parts by weight: 80-120 parts of PVC, 30-45 part of activate calcium carbonate, 0.7-1 part of PE (polyethylene) wax, 0.6-0.9 part of stearic acid and 4-6 parts of a stabilizer; and the middle layer is prepared from the following raw materials comprising the following components in parts by weight: 45-120 parts of ASA (acrylonitrile styrene acrylate) reclaimed materials, 0.4-1 part of PE wax, 0.3-1 part of stearic acid and 2-4.8 parts of a stabilzier. The tube has extremely good performances such as corrosion resistance, ageing resistance and the like, and the manufacturing cost is reduced by at least 50% in comparison with that of similar products.

Owner:杨纪超 +1

Ethylene propylene diene monomer rubber and a preparation method thereof

The invention discloses ethylene propylene diene monomer rubber (EPDM) and a preparation method thereof. The ethylene propylene diene monomer rubber is prepared through one-stage mixing and two-stagemixing of 100-140 parts of ethylene propylene diene monomer, 3-7 parts of zinc oxide, 2-5 parts of stearic acid, 1-3 parts of a flow dispersant RL-20, 1-3 parts of a flow venting agent PW, 30-70 partsof nano-calcium carbonate, 20-50 parts of white carbon black, 2-5 parts of silicon 69, 30-50 parts of paraffin oil, 30-60 parts of carbon black N774, 0.7-1.5 parts of sulfur and 2-7 parts of a totalaccelerator EG-5. The EPDM rubber with low hardness, high tensile strength and elongation at break, excellent high-temperature resistance and ozone aging resistance is prepared through optimization ofthe types of filler, product formulas and the production process, the product has excellent appearance, no blueing and blooming phenomena, the high quality requirements of high performance automobiles and civilian rubber products are met; and meanwhile, the dispersibility and venting properties of the filler in the production process are improved, the weighing efficiency of the accelerator is improved, and risks of error weighing and leakage weighing in the traditional weighing process of multiple accelerators are reduced, so that the quality and stability of the product are ensured.

Owner:四川宏亿复合材料工程技术有限公司

High-strength anti-corrosion collecting pipe material and manufacturing method thereof

InactiveCN108754193AHigh strengthHigh strength after weldingTemperature control deviceMetal rolling arrangementsChemical compositionMetallurgy

The invention discloses a high-strength anti-corrosion collecting pipe material which comprises a core material and a skin material. The skin material is composited on the surface of the core material. The core material comprises the following chemical components of, by mass, 0.05-0.15% of Si, 0.15-0.35% of Fe, 0.4-0.5% of Cu, 1.0-1.5% of Mn, 0.15-0.25% of Mg, 0.05% or the less of Zn, 0.05-0.12% of Ti and the balance Al and inevitable impurities. The skin material comprises the following chemical components of, by mass, 6.8-8.2% of Si, 0.3% or the less of Fe, 0.3% or the less of Cu, 0.1% or the less of Mn, 0.05% or the less of Mg, 0.1% or the less of Zn, 0.05% or the less of Ti and the balance Al and inevitable impurities.

Owner:DALISHEN ALUMINUM

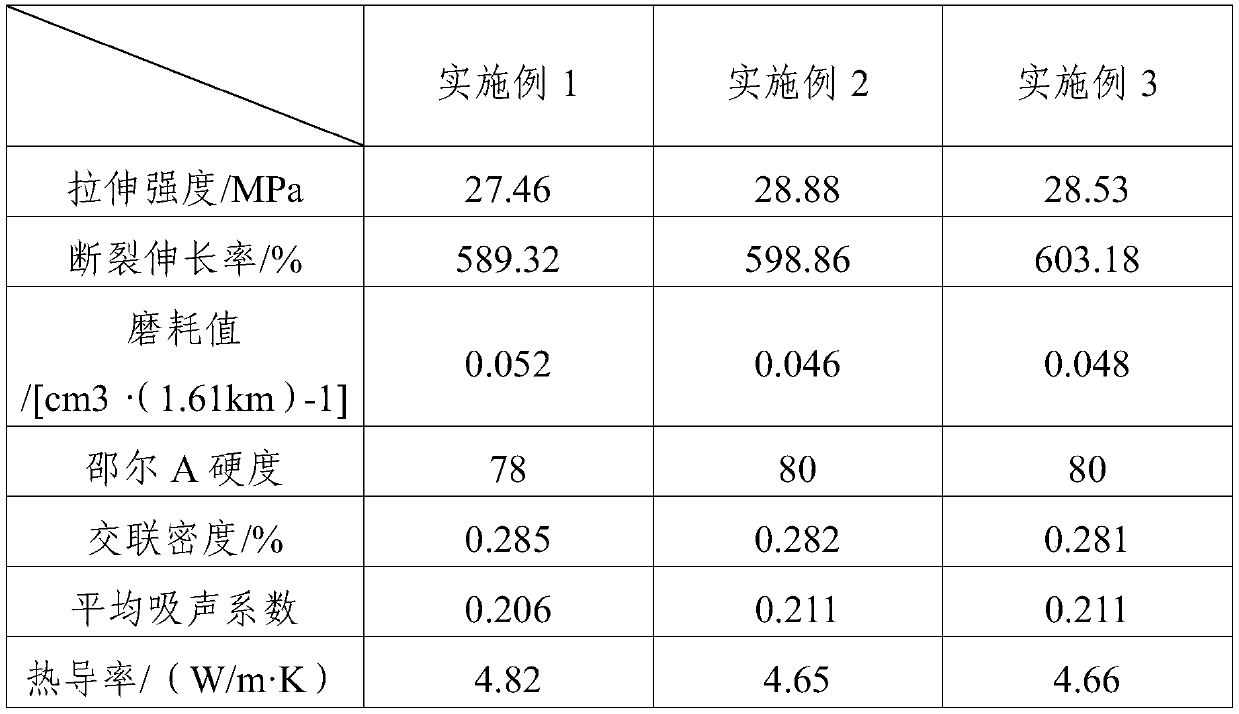

Automobile tire rubber material with excellent sound absorption performance and preparation method thereof

The invention provides an automobile tire rubber material with excellent sound absorption performance and a preparation method thereof, and relates to the field of rubber materials. The composition isprepared from the following components in parts by weight: 30-50 parts of natural rubber, 60-80 parts of epoxidized solution polymerized styrene-butadiene rubber, 40-60 parts of butadiene rubber, 20-30 parts of high-strength methyl vinyl silicone rubber, 5-15 parts of eucommia ulmoides gum grafted butyl methacrylate, 4-8 parts of polyisoprene, 5-10 parts of zinc oxide whisker, 5-10 parts of porous carbon nanotubes, 5-10 parts of aluminum oxide, 10-15 parts of nano attapulgite, 30-40 parts of carbon black, 20-30 parts of organic modified white carbon black, 20-30 parts of nano calcium carbonate, 5-10 parts of microcrystalline wax, 5-10 parts of stearic acid, 1-3 parts of sulfur, 1-3 parts of a homogenizing agent A78, 0.1-5 parts of an accelerant and 1-5 parts of an anti-aging agent. The automobile tire rubber material provided by the invention has excellent mechanical properties, excellent sound absorption and heat conduction properties, and great market application prospects, and canbe widely popularized to reduce noise brought by automobile tires on the road surface.

Owner:安徽品罗科技有限公司

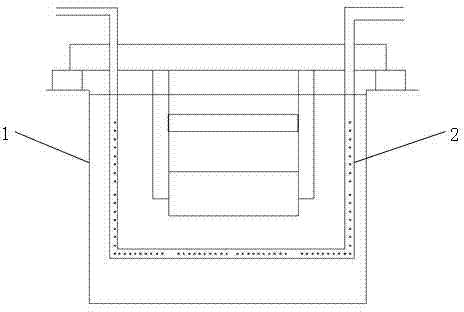

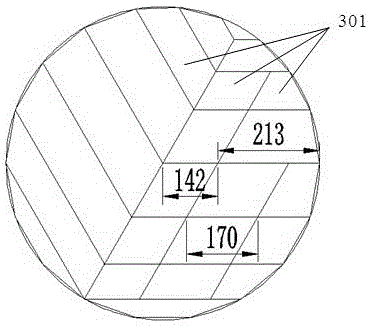

Three-dimensional reel iron core of amorphous alloy transformer

ActiveCN105161259AIncrease design capacityImprove the effect of the finished productTransformers/inductances magnetic coresDistribution transformerAlloy

The invention discloses a three-dimensional reel iron core of an amorphous alloy transformer. A core column in the iron core of the transformer is composed of a plurality of amorphous alloy bands, the core column with any diameter size can be obtained, the phenomenon that the diameter of the core column is limited by the bandwidth size of bands in the past is avoided, the design capacity of the transformer is increased, and the finished product performance of the iron core of the transformer is improved. The three-dimensional reel iron core can be widely applied to large-capacity amorphous alloy distribution transformers, large-capacity amorphous alloy dry type transformers and amorphous alloy main transformers.

Owner:SHANGHAI ZHIXIN ELECTRIC AMORPHOUS +3

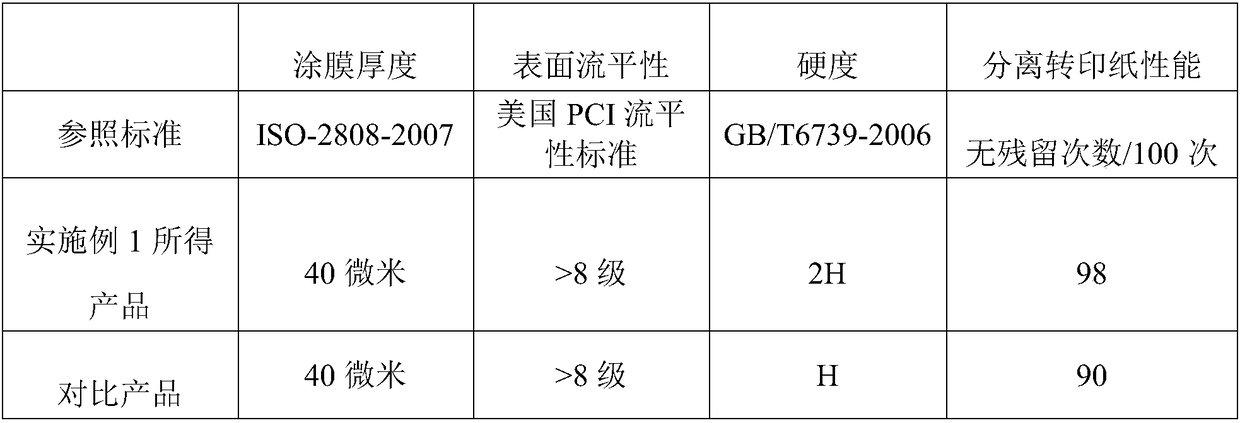

Powder coating for surface treatment of thermal transfer printing metal substrate and preparation method thereof

InactiveCN108822703AImprove curing rateImprove curing hardnessPowdery paintsPolyester coatingsPolyester resinHardness

The invention discloses a powder coating for surface treatment of a thermal transfer printing metal substrate and a preparation method thereof. The powder coating comprises 52 to 60 parts by weight ofa polyester resin, 5.3 to 7.7 parts by weight of an auxiliary agent, 5 to 10 parts by weight of a pigment, and 20 to 32 parts by weight of a filling material, wherein the auxiliary agent comprises 4.5 to 5.3 parts by weight of a curing agent, 0.8 to 1.2 parts by weight of a leveling agent, 0 .3 to 0.8 part by weight of a transfer printing agent and 0.2 to 0.4 part by weight of a degassing agent.The powder coating obtained by using the preparation method provided by the invention has the following advantages: the rate of curing is high; the curing hardness of a coating film formed from the powder coating is high and can achieve 2H; the process of separating transfer printing paper in the process of transfer printing can be easily implemented; the rate of separation is up to 98%; the construction speed and finished product effects of a thermal transfer printing process are improved; and problems like difficult tearing of paper in the process of paper tearing in the prior art are overcome.

Owner:廊坊市开元盛琳粉末涂料有限公司

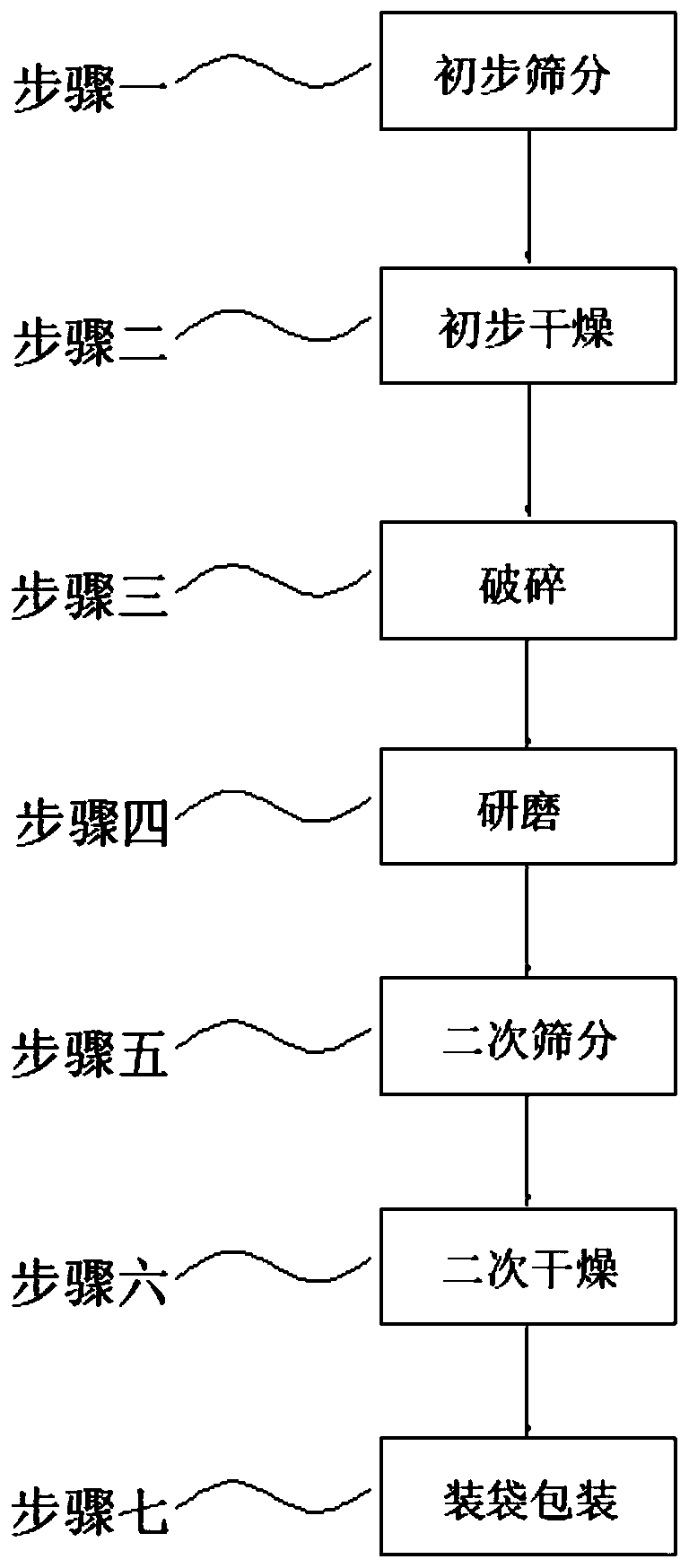

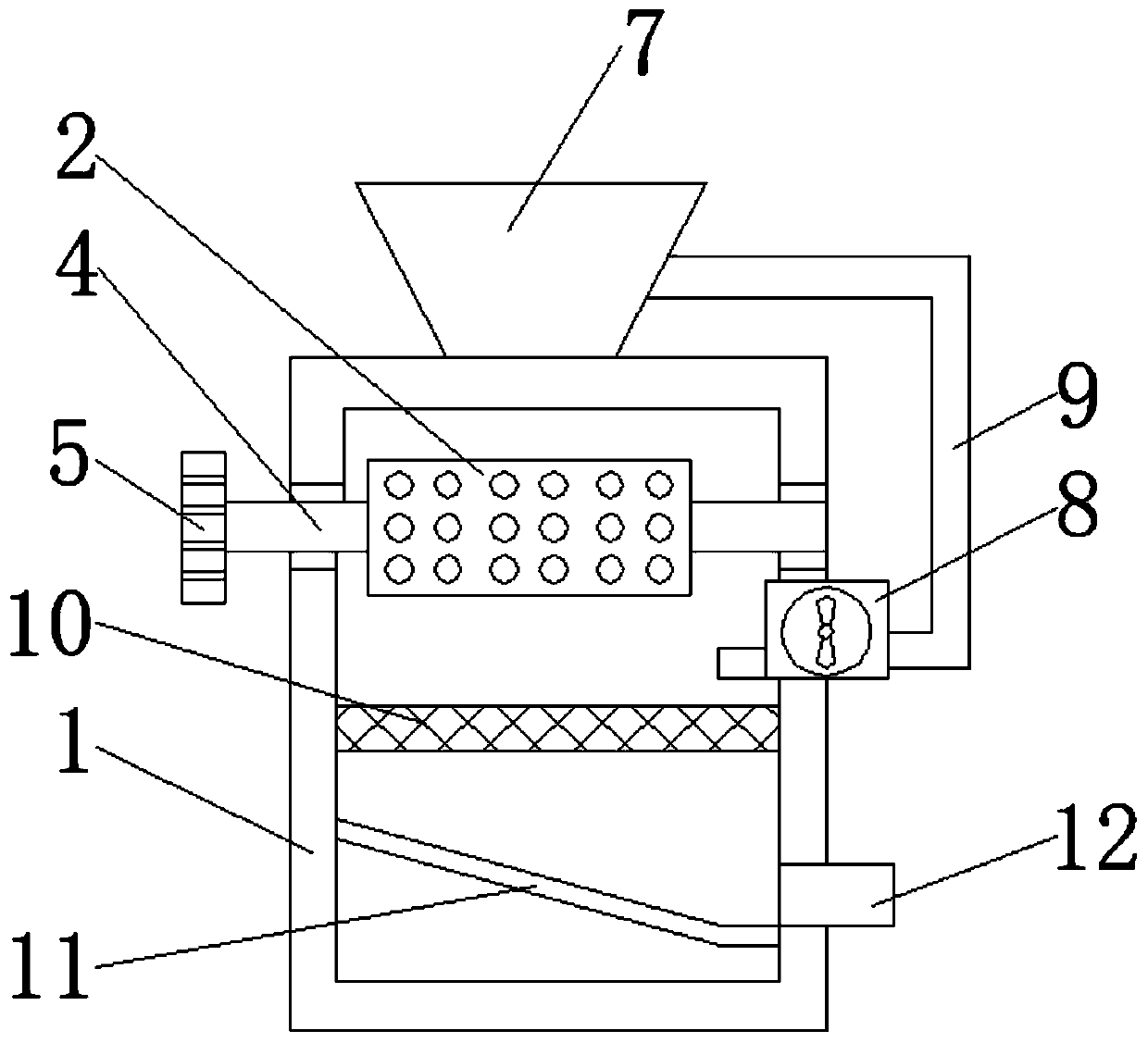

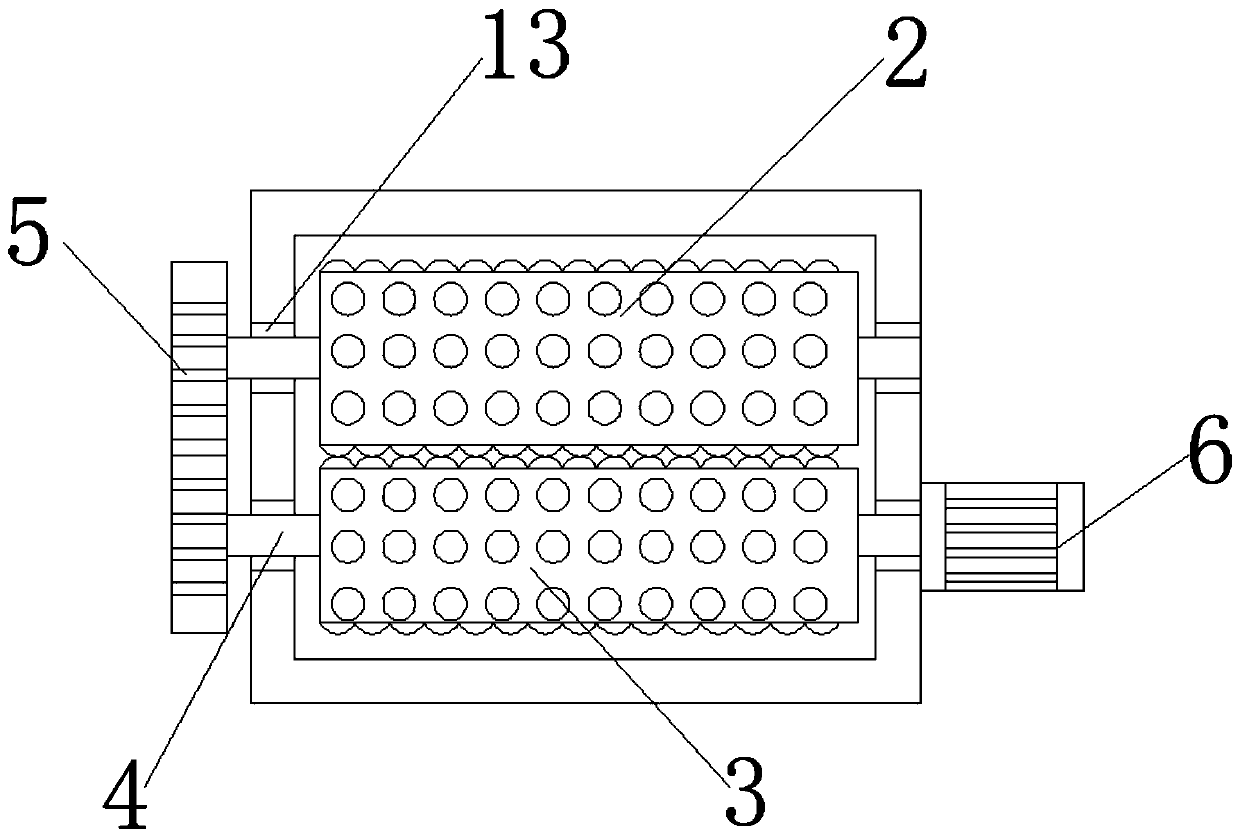

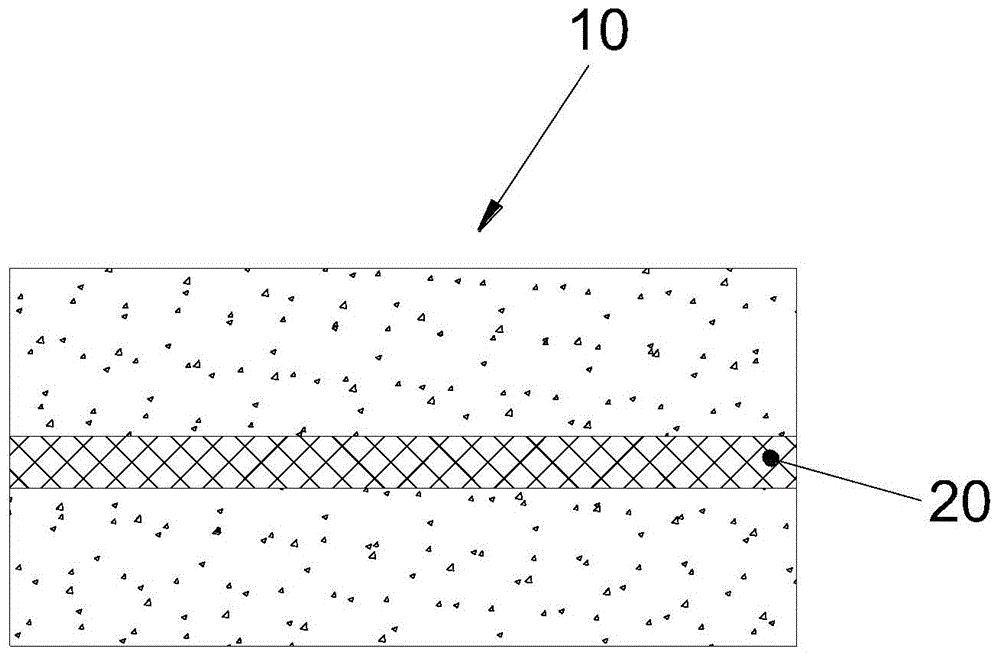

Processing technology of blast furnace slag powder

ActiveCN110152855AAvoid the phenomenon of resurgenceGuarantee the quality of finished productsGrain treatmentsSlagMoisture regain

The invention discloses a processing technology of blast furnace slag powder. The processing technology comprises the following steps of firstly, preliminary screening, secondly, preliminary drying, thirdly, crushing, fourthly, grinding, fifthly, secondary screening, sixthly, secondary drying and seventhly, bagging packaging. In the above first step, a worker shovels out ore slag in a blast furnace, the ore slag is subjected to vibration screening through a mining vibration screen, non-burnt-up ore or large-particle ore slag in the ore slag is filtered to be left above a screen plate, and filtering screening is achieved. In the above second step, the ore slag in the first step is put into an ore slag dryer. By means of the processing technology of the ore slag powder, the ore slag is preliminarily screened before being crushed, non-burnt-up ore existing in the ore slag is recycled, two times of drying treatment are carried out in the early stage and the later stage of the technology, the phenomenon of moisture regain is avoided before production bagging of the ore slag powder, and the finished product quality of the ore slag powder is guaranteed.

Owner:贵州日恒资源利用有限公司

High-performance quartzite board and production method

InactiveCN104929338AImprove crack resistanceImprove stress resistanceCovering/liningsCeramic shaping apparatusEngineeringQuartz

The invention provides a high-performance quartzite board. The high-performance quartzite board comprises a quartzite board body and support cloth which are integrally formed, wherein the support cloth is clamped inside the quartzite board body. The high-performance quartzite board has the advantages that the problem that an existing quartzite board is prone to cracking and poor in pressure resistance is solved; the crack and pressure resistance of the formed quartzite board are increased by the support cloth inside the quartzite board body, the performance of the finished quartzite board is increased evidently, product service life is prolonged, and product use cost is lowered.

Owner:南京上登工贸有限公司

Temperature control system and method of combustion equipment

InactiveCN108167861AImprove the effect of the finished productGuaranteed continuityDrying gas arrangementsCombustion regulationEngineeringThermocouple

Owner:江苏旭润机电科技有限公司

Method for preparing graphene glass

InactiveCN108751702AImprove the lubrication effectImprove uniformityGlass furnace apparatusGlass shaping apparatusSlurryGraphene

The invention discloses a method for preparing graphene glass and relates to the field of glass. The method comprises the following steps: (1) grinding solids; (2) mixing materials; (3) heating and melting; (4) injecting graphene slurry; (5) processing and molding. According to the method disclosed by the invention, the graphene is prepared into slurry to be added into the material melt in a sprayform, the lubricating property and uniformity between the materials are enhanced, and the prepared glass is stable, excellent in brittle resistance and excellent in wear resistance.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

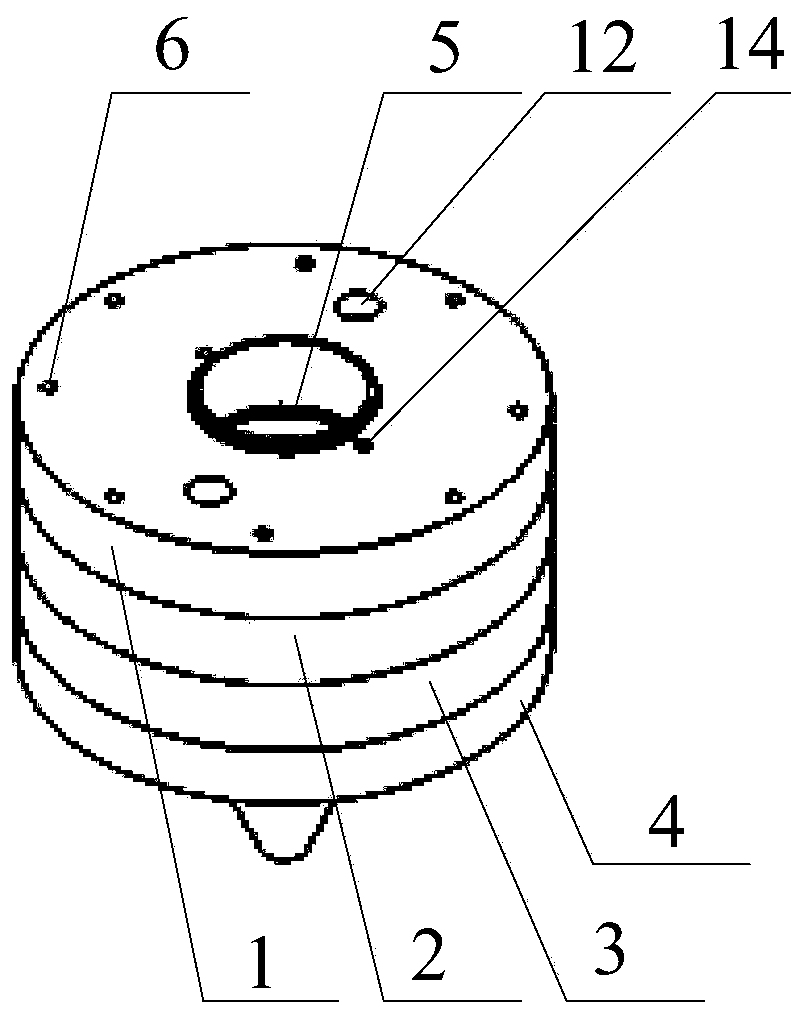

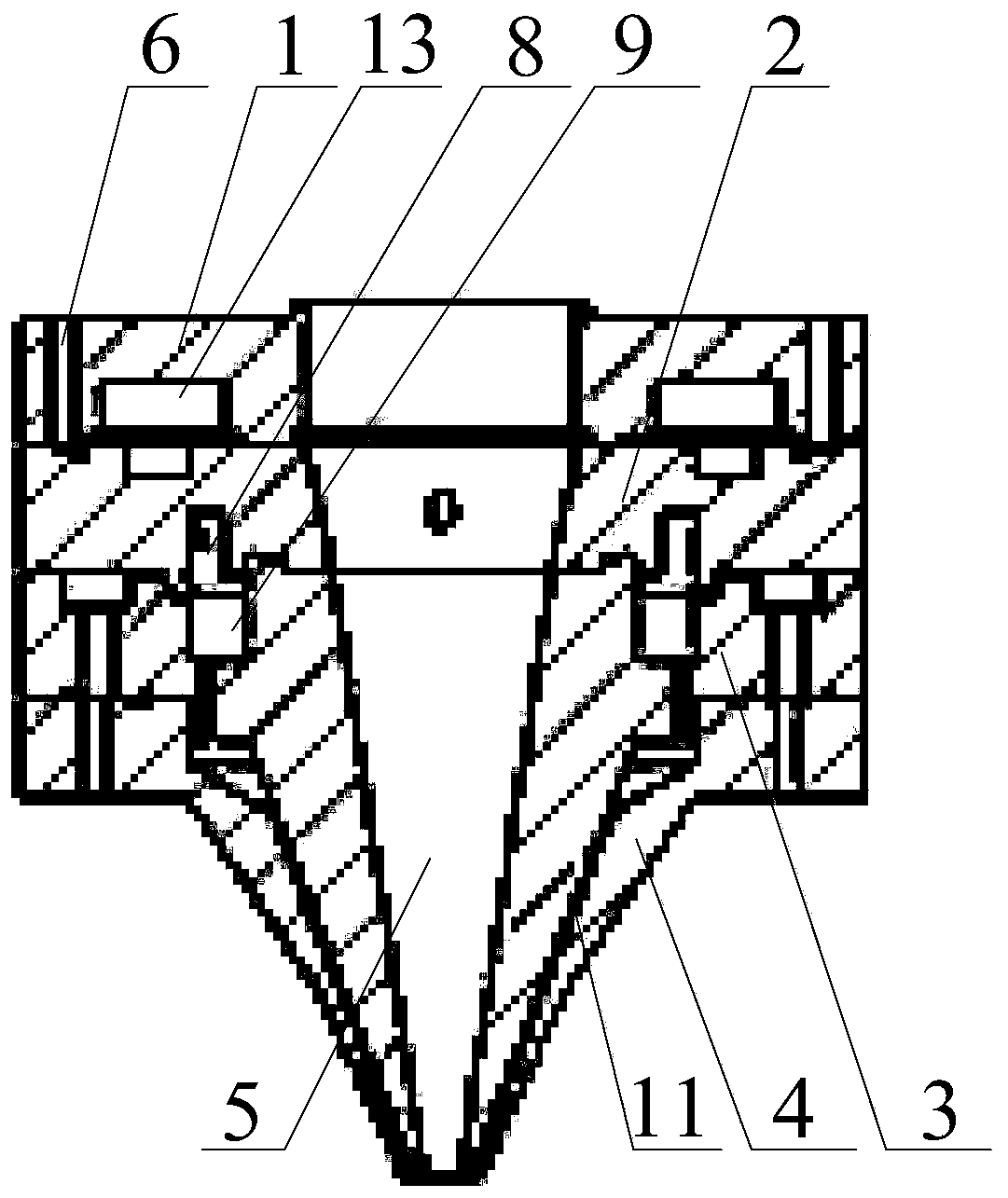

Powder feeding head for underwater laser additive manufacturing and cladding layer preparation

ActiveCN110090957AIncrease profitSlow down the flowAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleHeating effect

The invention provides a powder feeding head for underwater laser additive manufacturing and cladding layer preparation. The powder feeding head comprises a first component, a second component, and athird component and a fourth component which are sequentially connected from top to bottom; the first component, the second component and an axis opening of the third component are communicated to form a laser cavity, and the axis opening of the first component is connected with a coaxial laser. According to the embodiment of the powder feeding head, a flow path of powder is distributed, so that metal powder enters from powder feeding screw holes, and sequentially pass through a powder flow passage, and a powder mixing chamber and a powder collision platform; the flowing speed of the metal powder is greatly reduced when the powder nozzle is reached by the metal powder, so that the time of laser acting between the metal powder and the laser cavity can be greatly prolonged, and the powder utilization rate is improved, so that the powder feeding head is suitable for underwater low-temperature long-time additive manufacturing, and the metal powder transmitted by the powder feeding head isbetter in heating effect, and the finished product effect of the laser additive manufacturing and the cladding layer preparation can be improved.

Owner:XI AN JIAOTONG UNIV

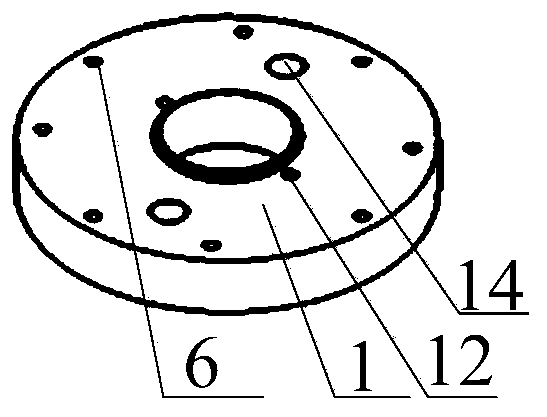

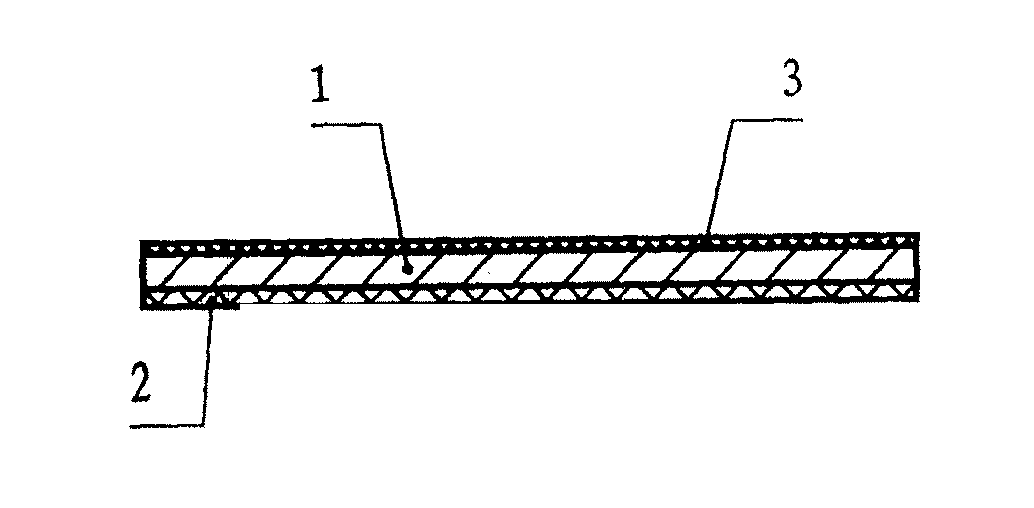

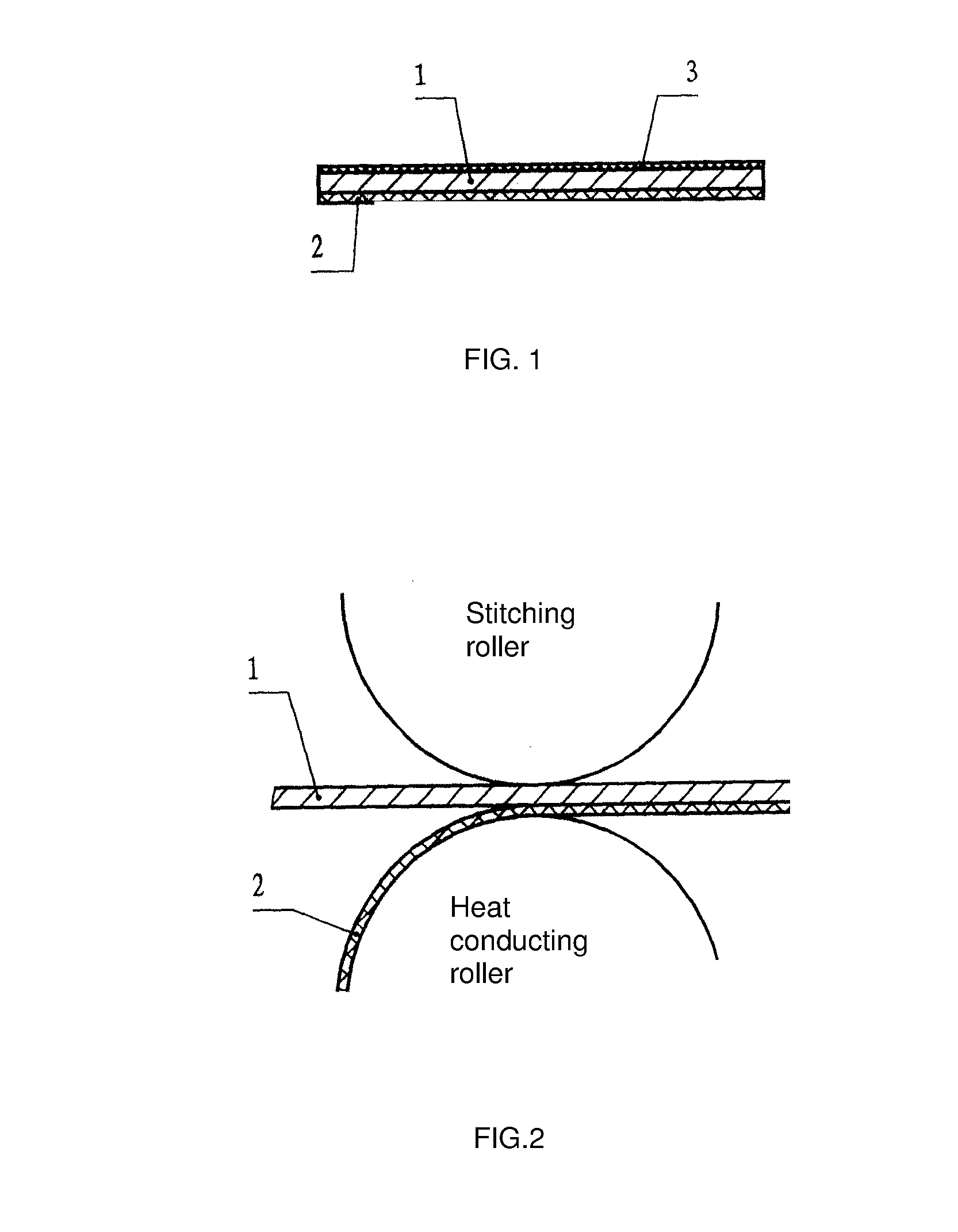

Offset PS Plate with Compound Support and Its Manufacturing Process

InactiveUS20080107895A1Save aluminumImprove performanceSynthetic resin layered productsRecord information storageVolumetric Mass DensityAluminum substrate

This invention involves with a kind of offset PS plate with compound support and its manufacturing process. PS plate has sensitization imaging layer set up on the front side of its aluminum substrate, and has a membrane of polymer materials covered on the back side of the substrate, which form the structure of compound support. The manufacturing process firstly deoils and cleans the aluminum substrate, and covers a membrane of polymer materials on the back side of plate substrate; then conducts electrochemical corrosion and roughening, generates oxidation layer through the oxidization of anode, carries out sealing or hydrophilic treatment for the oxidation layer, and coats sensitization liquid onto this oxidation layer; finally, dries and cuts the plates into finished products. This invention may use relatively thin aluminum materials to keep relatively high quality, greatly reduce the consumption of aluminum, and decrease the cost. The mentioned membrane is featured by strong toughness; after compounding, the substrate enjoys great tensile strength, so the plate is not easy to break during printing; and also, the substrate has lower density, which could lighten the weight of finished plates. Polymer membranes have extremely smooth surface, so multiple sheets of PS plates overlapped won't scratch the sensitization layer, and will require no interleaving paper. What's more, the manufacturing process of PS plate with compound support is basically accordant with the original one, and the compounding of membrane is simple and quick.

Owner:WENZHOU KONITA PRINTING EQUIP

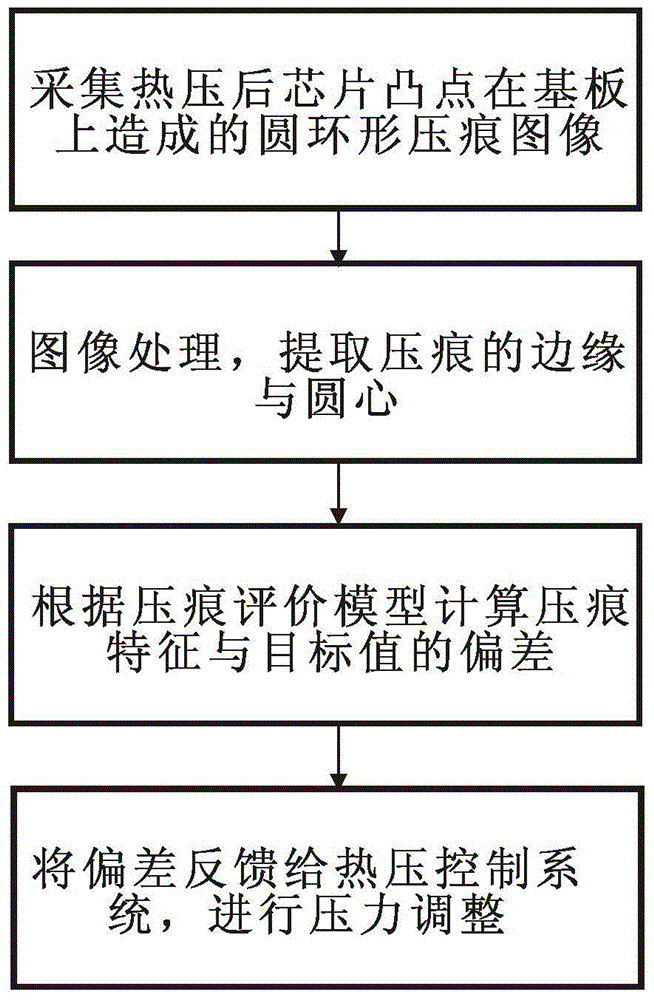

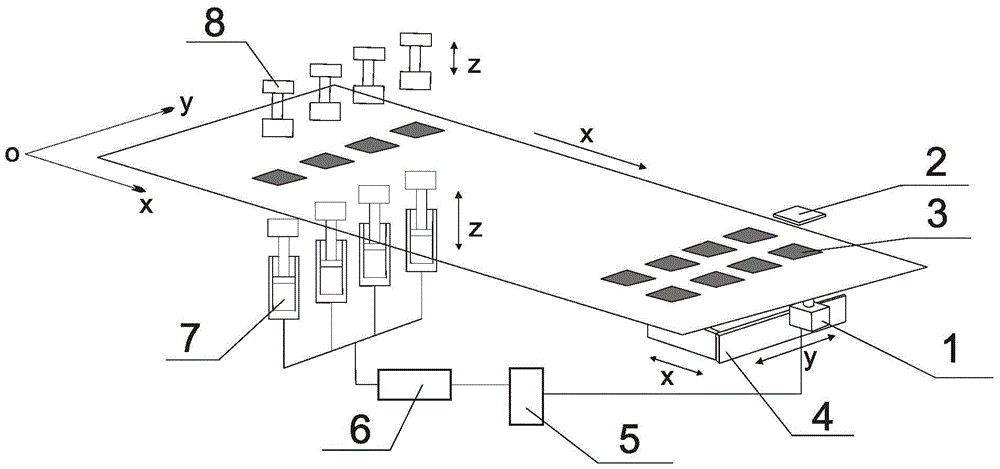

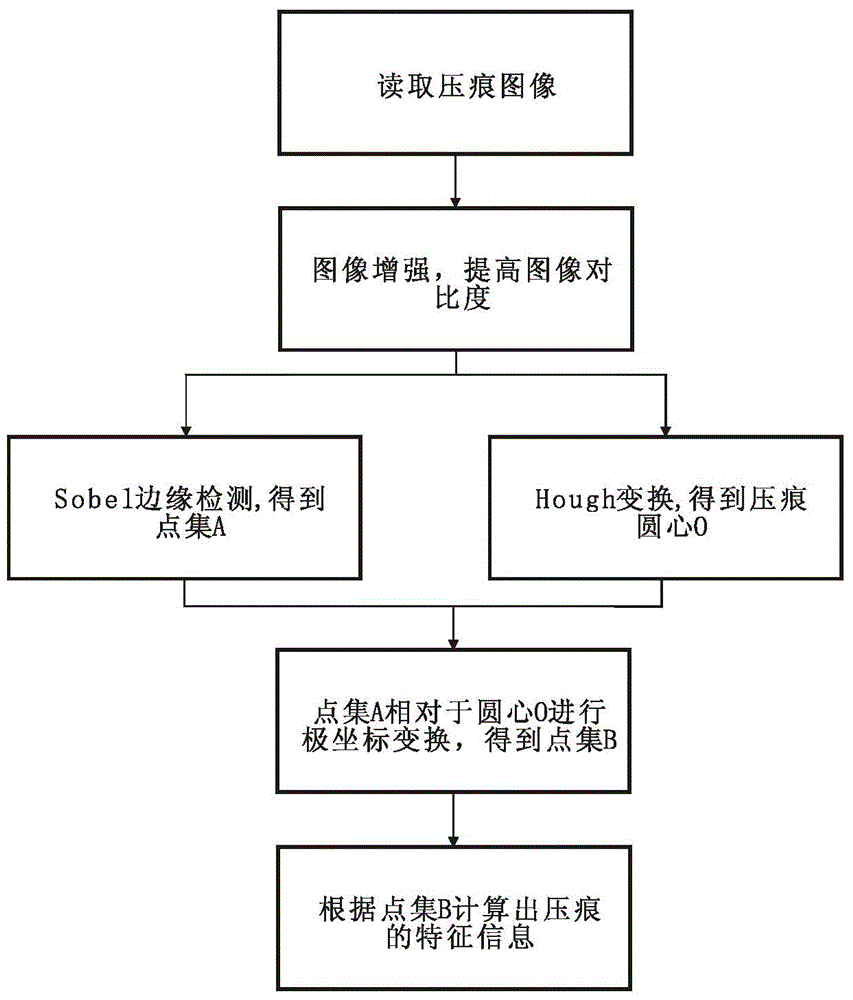

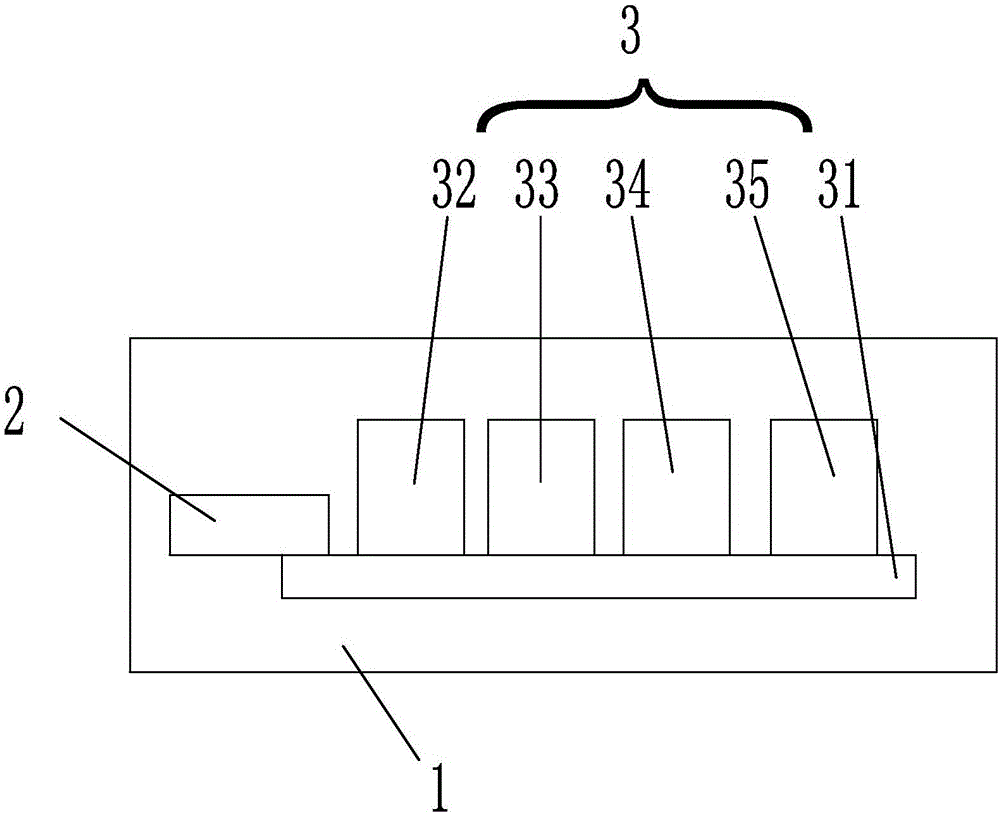

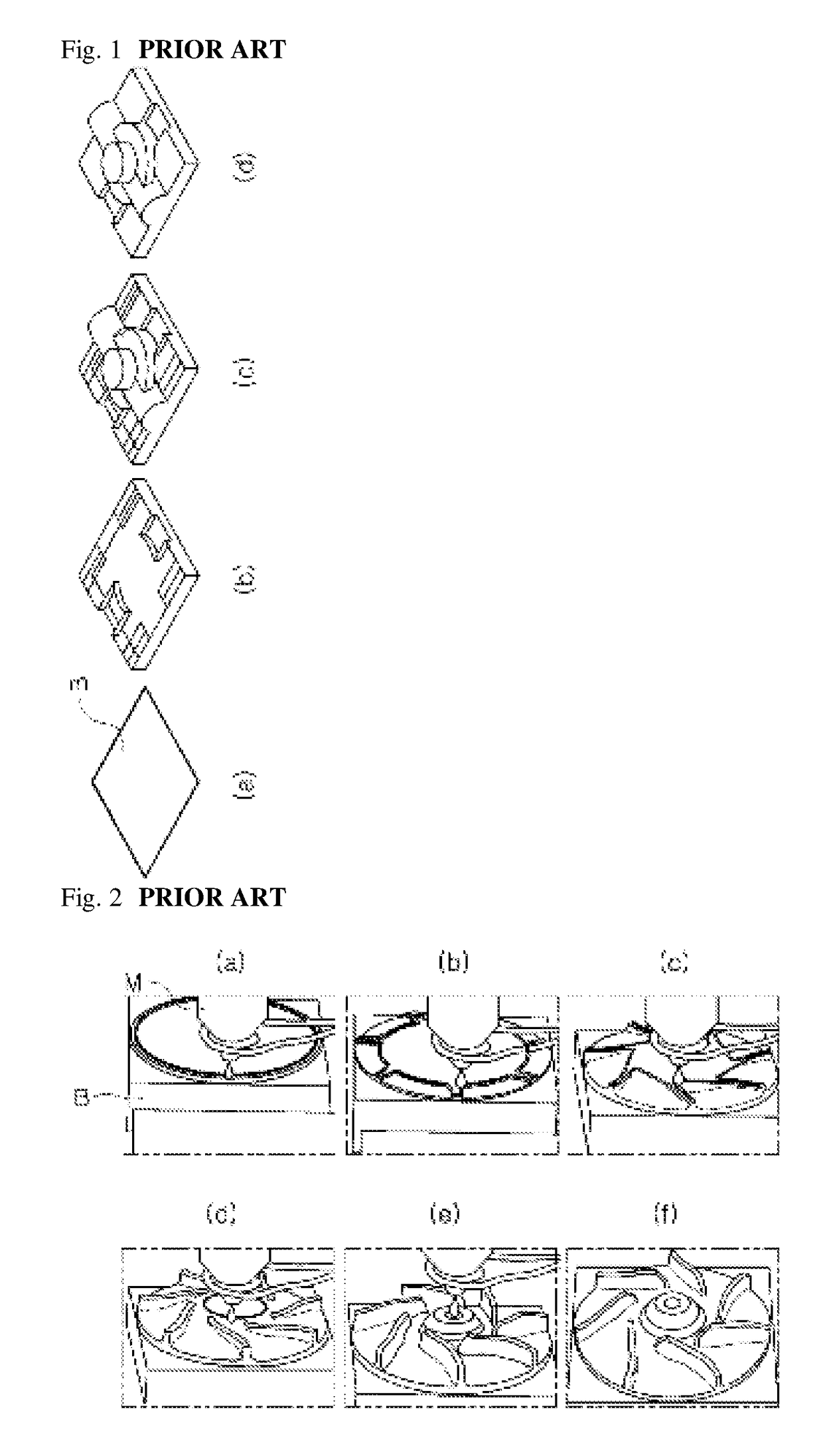

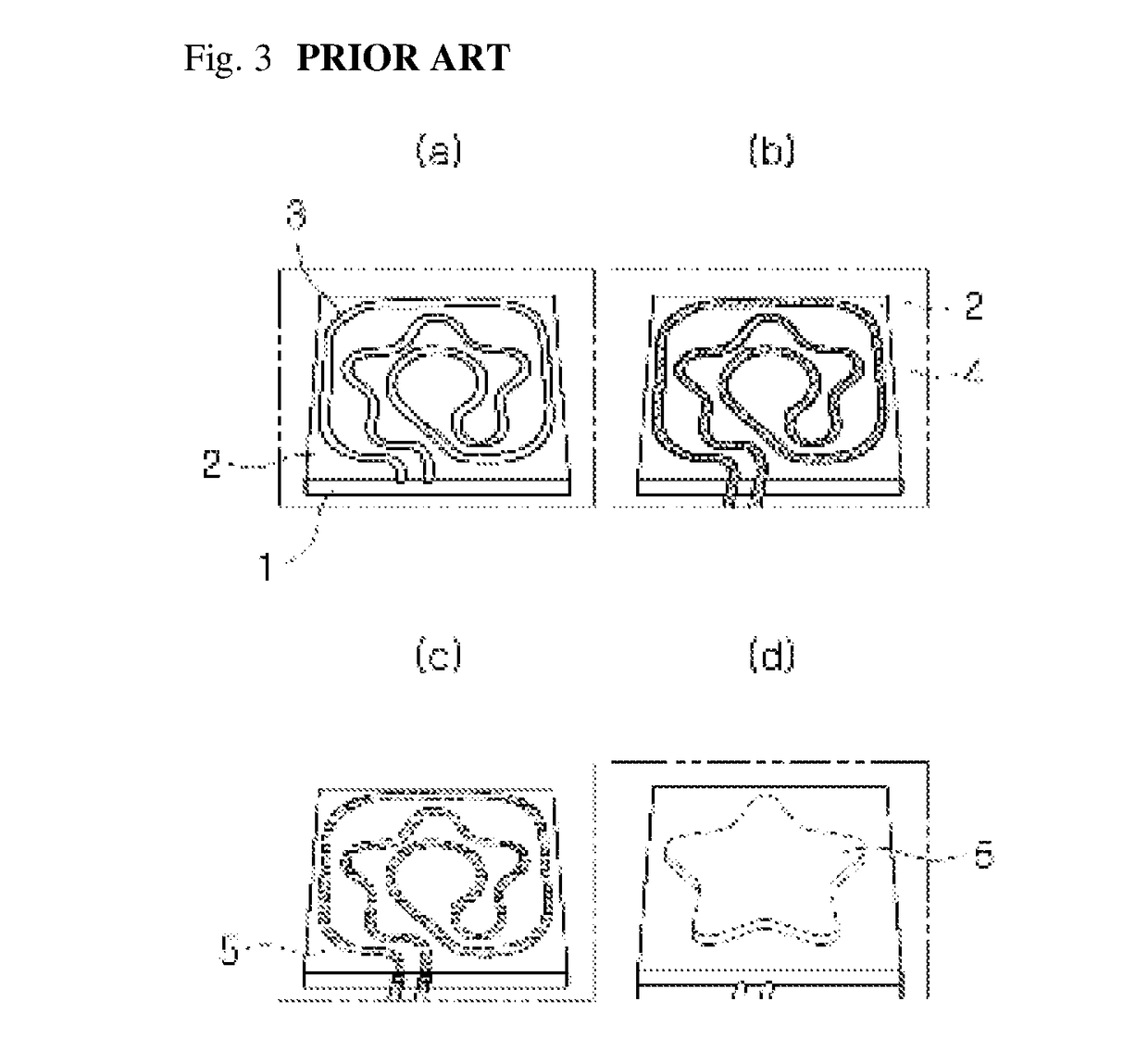

Chip thermal pressure detection method and system and chip hot-pressing packaging control system

ActiveCN104795341ALow costEasy to operateSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl systemAtmospheric pressure

The invention discloses a chip thermal pressure detection method. The method includes the steps of 1, a circular impression image made by a circular bump of a hot-pressed chip on an antenna; 2, extracting an outline and a center of circle from the circular impression image; 3, equally dividing the outline along the periphery into multiple arc segments; 4, acquiring width of each arc segment; 5, weighting and adding the widths of the arc segments to obtain impression width. The invention further provides a thermal pressure detection system and a chip hot-pressing packaging control system both based on the method; according a difference between the detected impression width and target impression width, a corresponding pressure control command is generated to adjust hot pressure of a hot-pressing head unit upon the chip. The pressure is indicated by the impression width, the magnitude of the pressure is adjusted according to the difference of the impression widths, and thus pressure uniformity is ensured and hot-pressing precision and product performance are improved.

Owner:WUHAN HUAWEIKE INTELLIGENT TECH

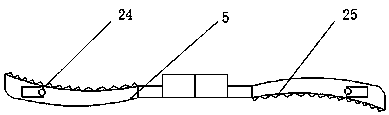

Full-automatic data-line-cutting tin pick-up machine

InactiveCN106112183AShorten gap timeIncrease productivitySolder feeding devicesSoldering auxillary devicesProduction effectEngineering

The invention discloses a full-automatic data-line-cutting tin pick-up machine. The full-automatic data-line-cutting tin pick-up machine comprises a machine frame, a conveying device, a processing device and a control device. The conveying device and the processing device are arranged on the machine frame. The processing device is provided with a clamp guide rail. The conveying device is connected with the clamp guide rail in the processing device and is used for conveying a clamp clamping a data line. The clamp guide rail pushes the clamp to move in the conveying direction through a first drive device. The processing device is sequentially provided with a line cutting mechanism, a first soldering flux pick-up mechanism, a second soldering flux pick-up mechanism, a tin pick-up mechanism and a trimming mechanism on one side of the clamp guide rail in the conveying direction of the clamp. According to the full-automatic data-line-cutting tin pick-up machine, the data line is clamped through the clamp, the four procedures including line cutting, soldering flux pick-up, tin pick-up and trimming are sequentially completed on the clamp guide rail, and each procedure is independently completed through drive of drive devices; and meanwhile, transportation is conducted between the procedures through the guide rail, the interval time is shortened, the production efficiency and the finished production effect are improved, and the production cost is also saved.

Owner:JIB ENTERPRISE GRP CO LTD

Technology for processing blank painted enamel jewelry

PendingCN109770492AImprove the effect of the finished productImprove processing efficiencyJewelleryAssembly lineMachining process

The invention discloses a technology for processing blank painted enamel jewelry. The technology comprises the following steps of a, blank manufacturing; b, blank grinding; c, blank cleaning; d, enamel raw material manufacturing; e, delineating; f, enamel contour firing; g, primary enamel painting; h, primary enamel firing; i, secondary enamel painting; j, secondary enamel firing; k, polishing. The technology has the advantages that pre-delineating and firing are carried out in the processing process of the blank painted enamel jewelry to obtain a green body, then painting and firing are carried out on the basis of delineating to obtain a finished product, the operation difficulty of enamel painting can be reduced, and the effect of the finished product of the enamel jewelry is improved. Delineating and drawing are sequentially carried out step by step, assembly line work can be carried out, and the processing efficiency of the blank painted enamel jewelry can be improved.

Owner:SHENZHEN ZHONGBAOYING JEWELRY TECH CO LTD

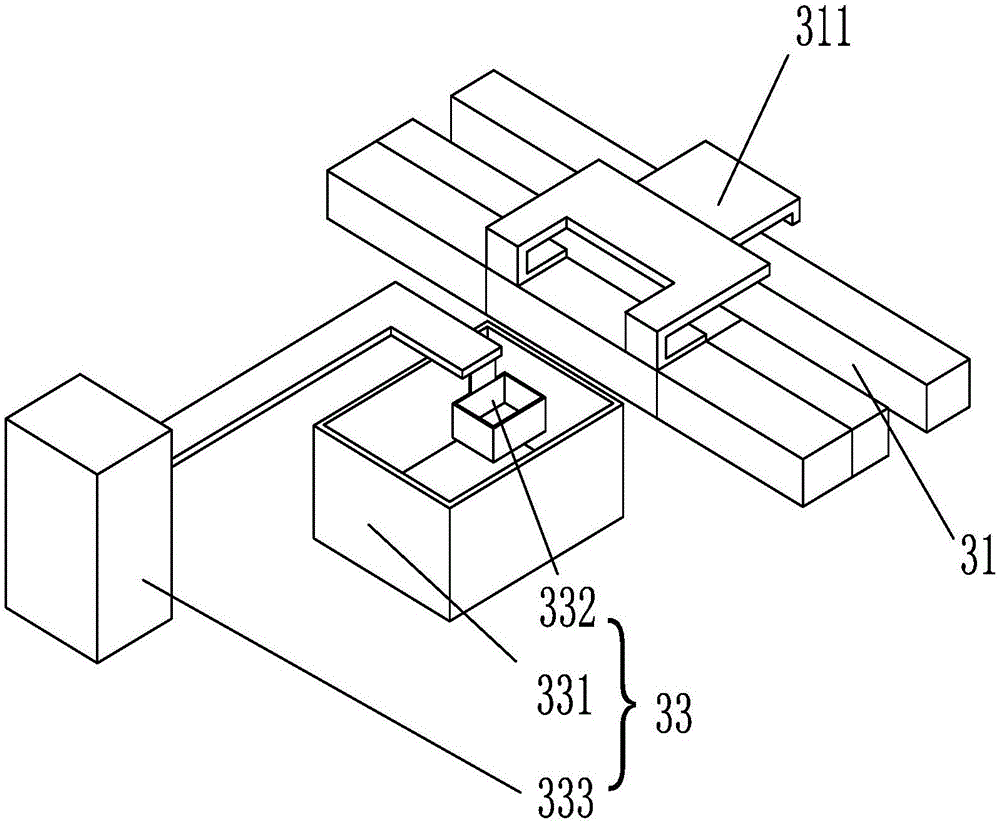

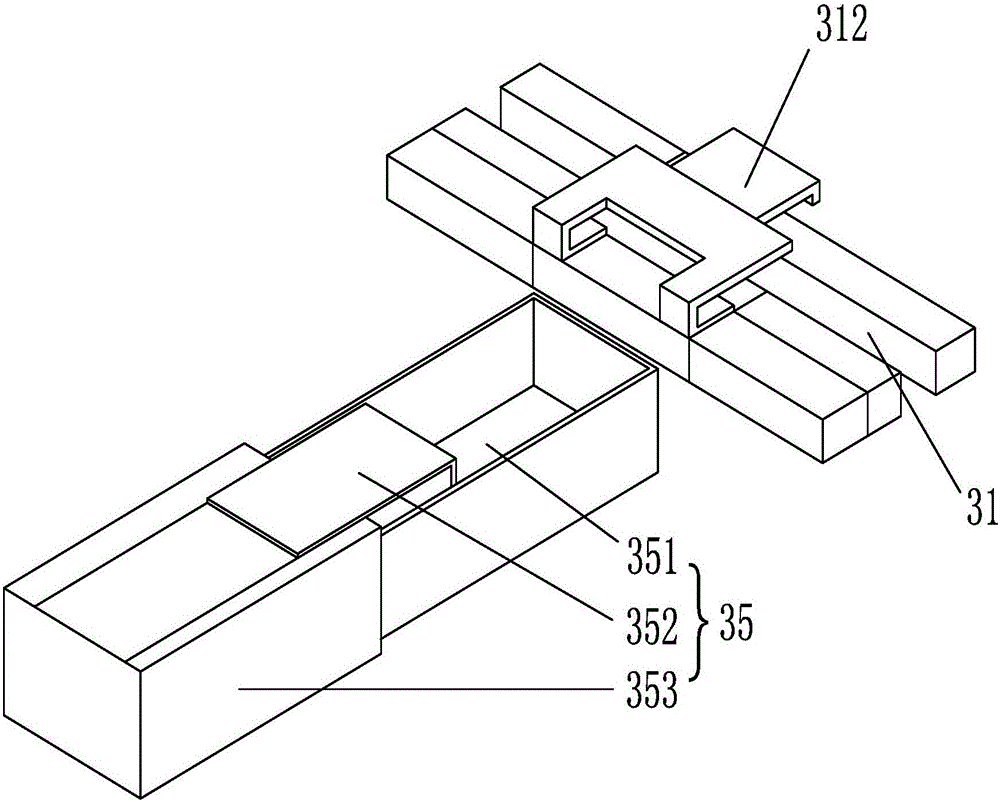

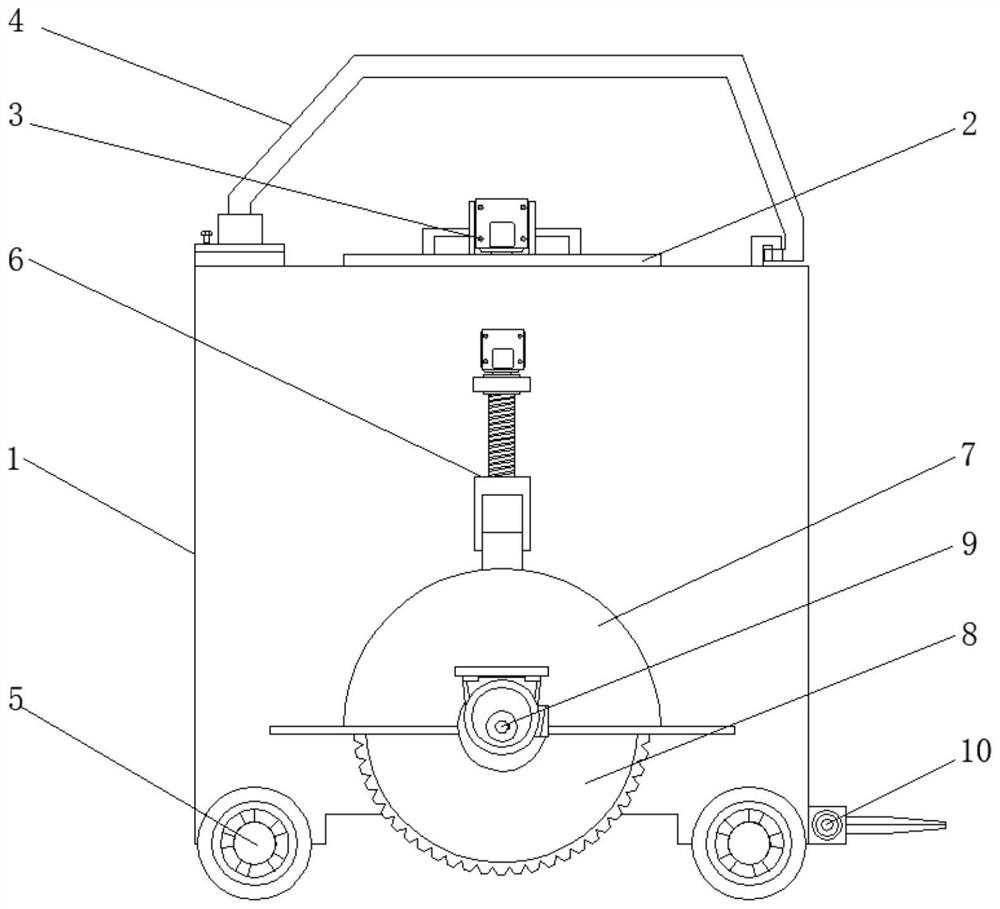

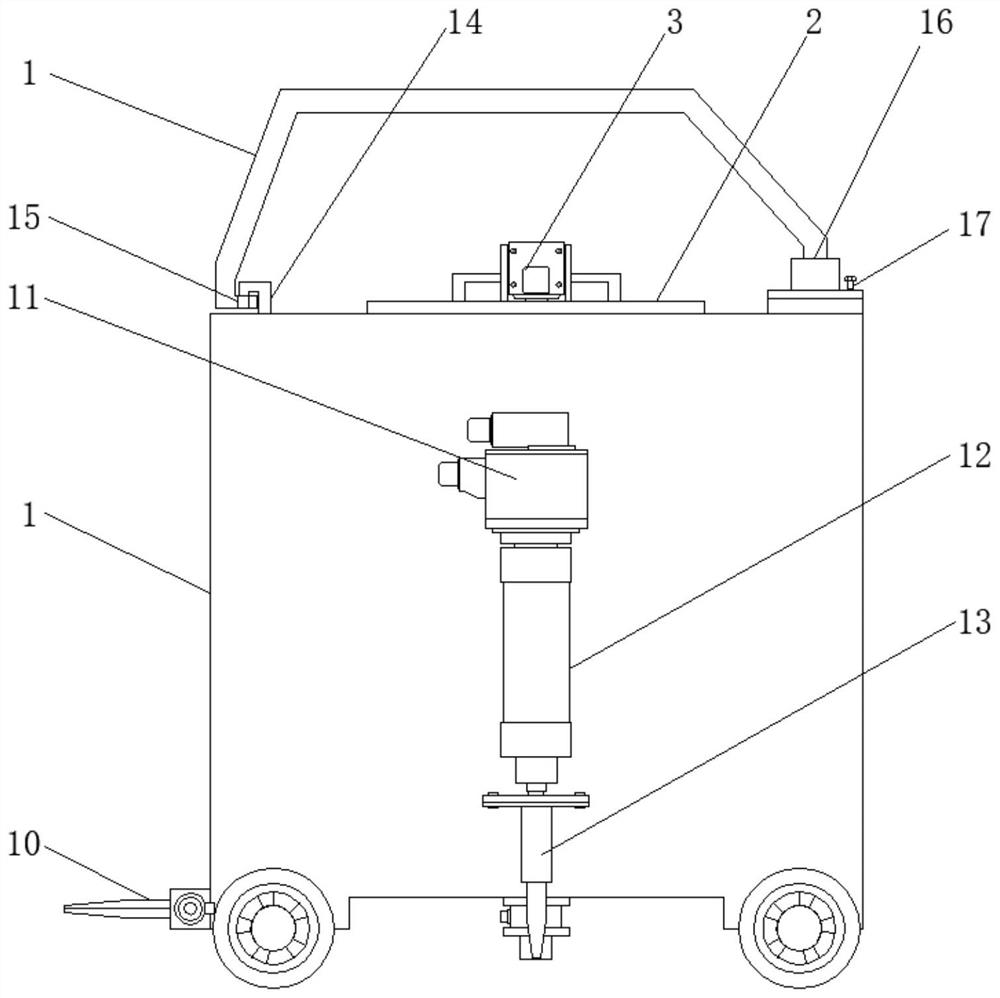

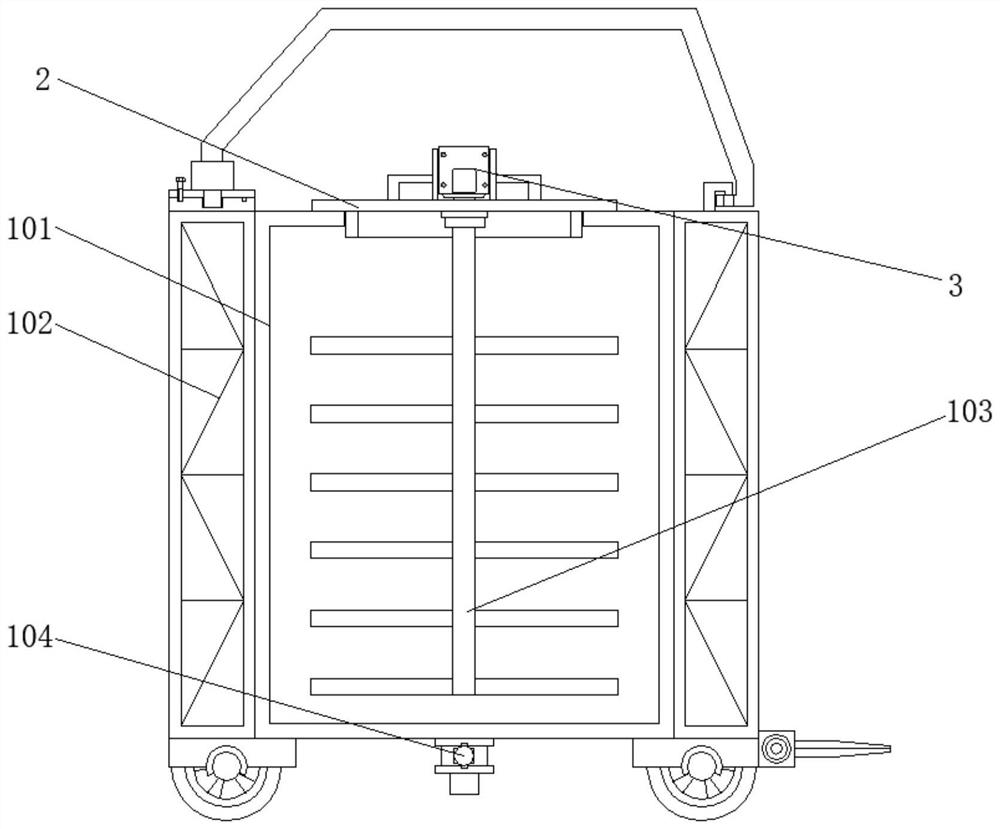

Portable repairing equipment integrating municipal traffic and pavement cutting and filling

InactiveCN112176840AReduce the burden onSolve the trouble of moving three different devices for use at the same timeRoads maintainenceArchitectural engineeringAir pump

The invention discloses portable repairing equipment integrating municipal traffic and pavement cutting and filling. The portable repairing equipment comprises a main body box, a lifting assembly anda scraping assembly, a gland is installed at an opening in the upper end of the main body box, a first motor is fixed above the gland, a push rod is installed above the first motor, and the push rod is connected with the lifting assembly. Idler wheels are arranged on the left side and the right side of the bottom of the main body box, the lifting assembly is installed on the outer wall of the front face of the main body box, a protective shell is arranged on the front face of the lifting assembly, a cutting wheel is installed in the protective shell, a second motor is installed in the middle of the cutting wheel, and the scraping assembly is installed at the lower right corner of the main body box. And an air pump is fixed to the back face of the main box, an air cylinder is connected to the lower portion of the air pump, and a punching head is installed below the air cylinder. The whole device integrates the functions of road surface cutting, road surface crushing and road surface filling, and the trouble that in the prior art, three kinds of different equipment need to be carried at the same time for use is effectively solved.

Owner:彭丽辉

Metal product having internal space formed therein and method of manufacturing thereof

ActiveUS9636790B2Low costShorten the timeShaping toolsAdditive manufacturing apparatusCooling channelCooling efficiency

There are provided a metal product having an internal space formed therein, allowing for improvements in the flow of a coolant in the internal space, such as a cooling channel and an increase in cooling efficiency, and a method of manufacturing thereof. The metal product includes a body part having a first space formed therein; a space formation member having a second space formed therein, mounted on the body part to be communicated with the first space; and a finishing part forming an exterior by covering the space formation member in a state in which the space formation member is mounted on the body part.

Owner:INSSTEK

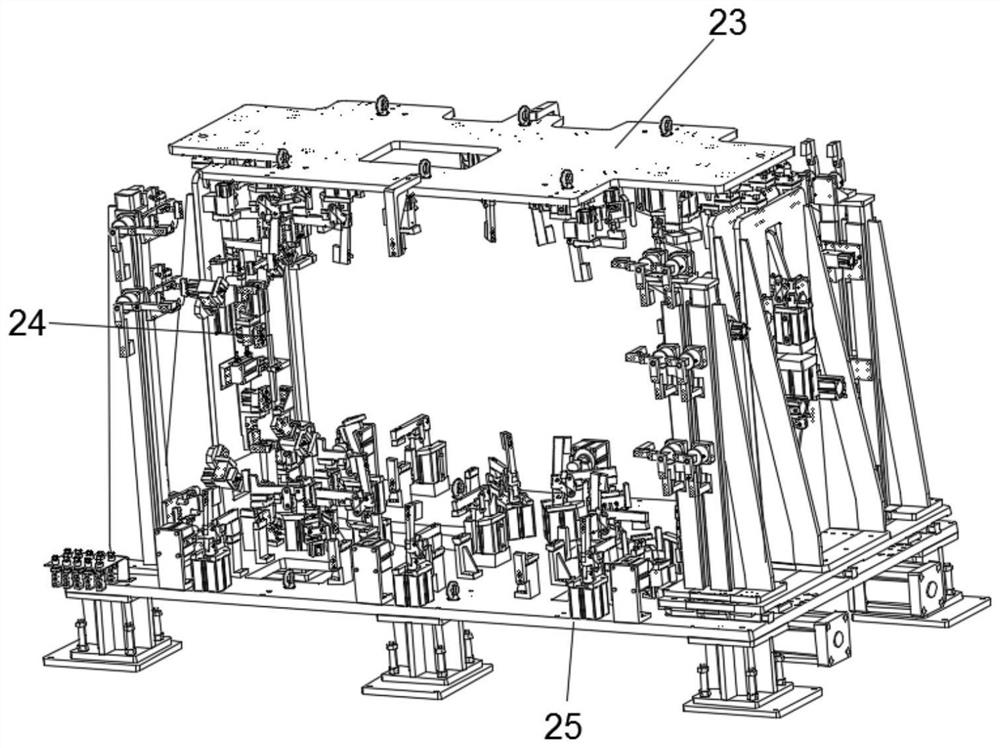

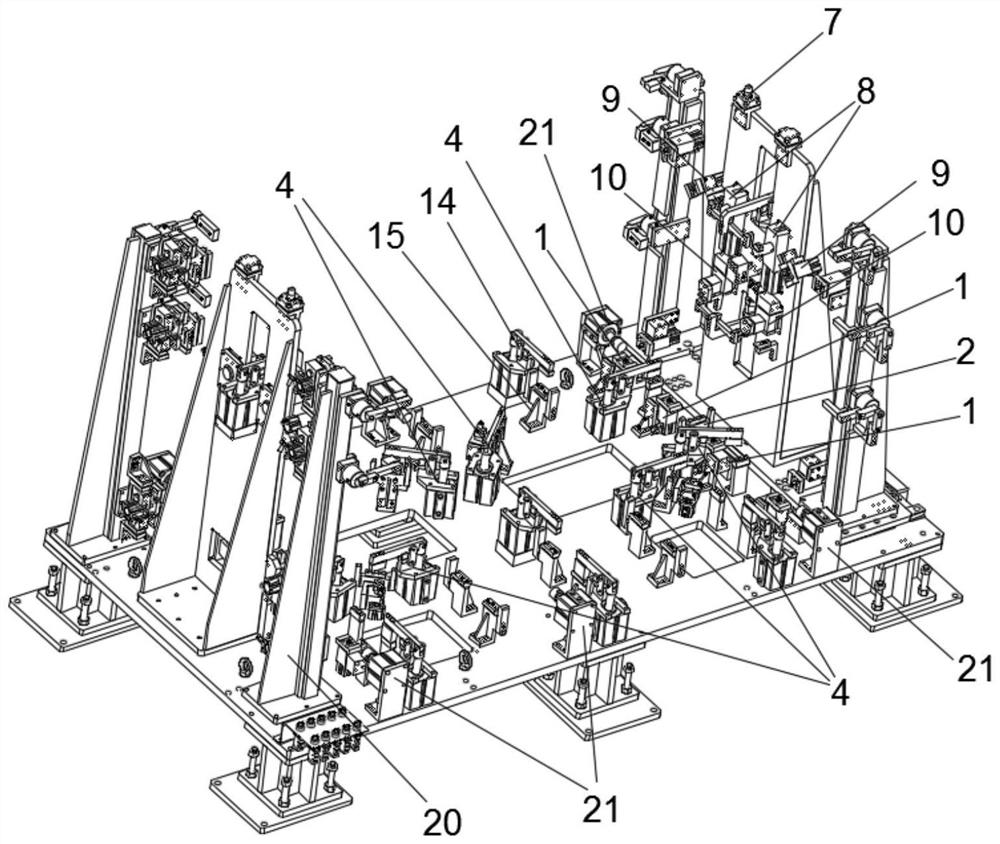

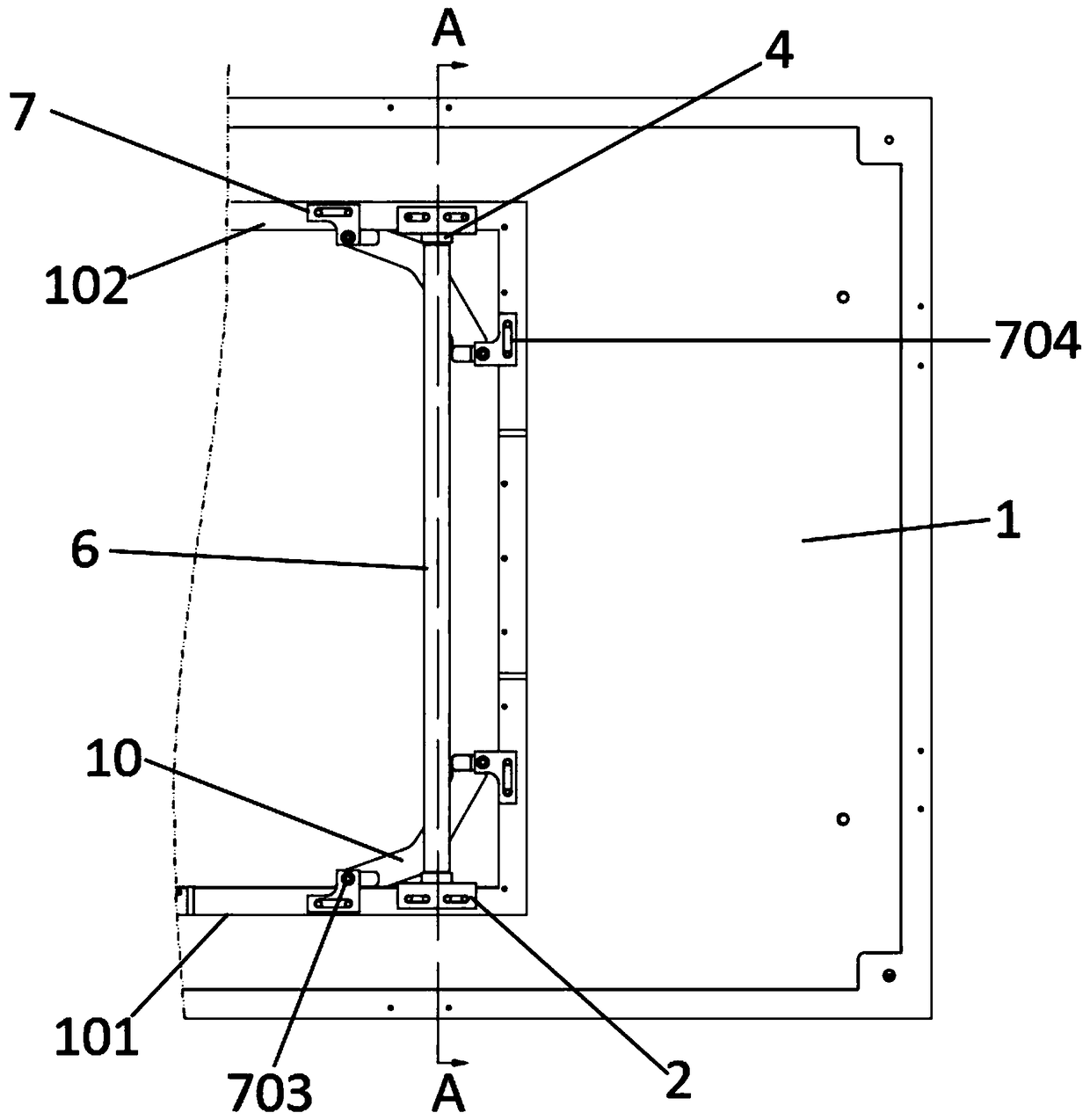

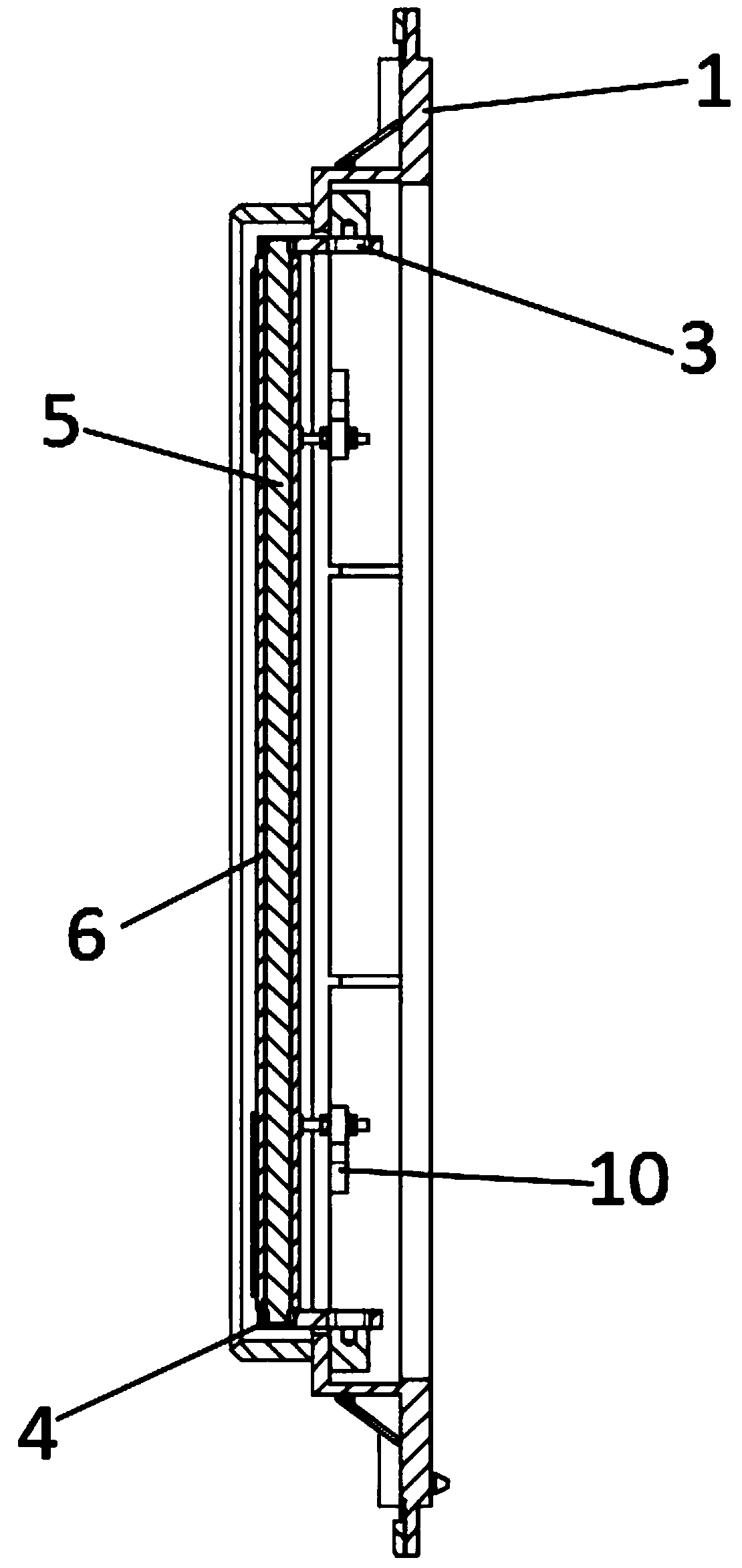

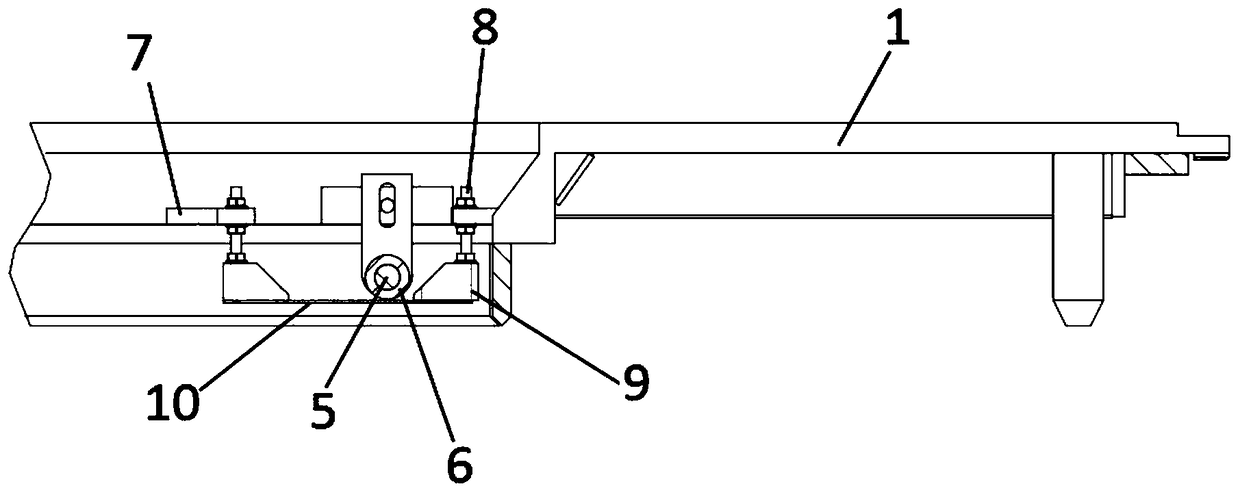

Efficient full-automatic welding tool for energy storage cabinet

PendingCN114043141APrecise positioningEasy feedingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringIndustrial engineering

Disclosed is an efficient full-automatic welding tool for the energy storage cabinet comprising a bottom plate and is characterized in that a plurality of bases are fixedly arranged on the lower wall of the bottom plate, and two first corner cylinders are fixedly arranged on one side of the upper wall of the bottom plate; the two first corner cylinders are fixedly arranged on one side of the upper wall of the bottom plate, two second corner cylinders corresponding to the first corner cylinders are fixedly arranged on the other side of the upper wall of the bottom plate, first corner positioning pins are arranged on the two first corner cylinders, second corner positioning pins are arranged on the two second corner cylinders, and two long-opening grooves and two short-opening grooves are formed in the bottom plate. A front frame assembly positioning device is arranged on the bottom plate, and three placing tables are fixedly arranged on the bottom plate. The invention has the advantages that parts and assemblies can be automatically limited, fool-proof and mistake-proof effects can be realized, workpieces can be prevented from deviating, multi-angle and multi-station linkage welding requirements of electric cabinets can be met by the aid of the overturning tables, unnecessary labor intensity of operators can be reduced by the aid of robot automation, and more time and energy can be saved to guarantee the efficiency and the quality of products.

Owner:FUJIAN JUNPENG COMM TECH

Auxiliary forming process for thin-walled product and tool structure thereof

PendingCN109228264AFlexible adjustment of spacingImprove stretch forming effectDomestic articlesEngineeringRejection rate

The invention discloses an auxiliary forming process for a thin-walled product and a tool structure thereof and relates to the field of manufacturing of refrigerator liners. The process comprises thefollowing steps: S1, heating and softening liner ABS and HIPS plates; S2, bubbling the softened ABS and HIPS plates; S3, performing contact with a straight edge rolling auxiliary mold when the liner ABS and HIPS plates are bubbled to drive the auxiliary mold to rotate; S4, stretching the ABS and HIPS plates to a coating main body by means of a non-blocking baffle plate; S5, adjusting smoothness offour corners of the panels by means of a corner auxiliary mold assembly; S6, carrying out vacuum adsorption after leveling the stretching movement; and S7, carrying out cooling forming and demoldingto obtain a plastic-rubber part of an inner cavity of the refrigerator. The auxiliary forming tool is designed according to a novel forming process, is easy to mount and can move freely along the X, Yand Z axes, the distance between the tool and a plastic uptake mold core is adjusted flexibly, and the material flow thickness of the softened ABS and HIPS panels are uniform and smooth, so that thestretching forming effect of a liner product is enhanced and the rejection rate is reduced.

Owner:CHANGHONG MEILING CO LTD

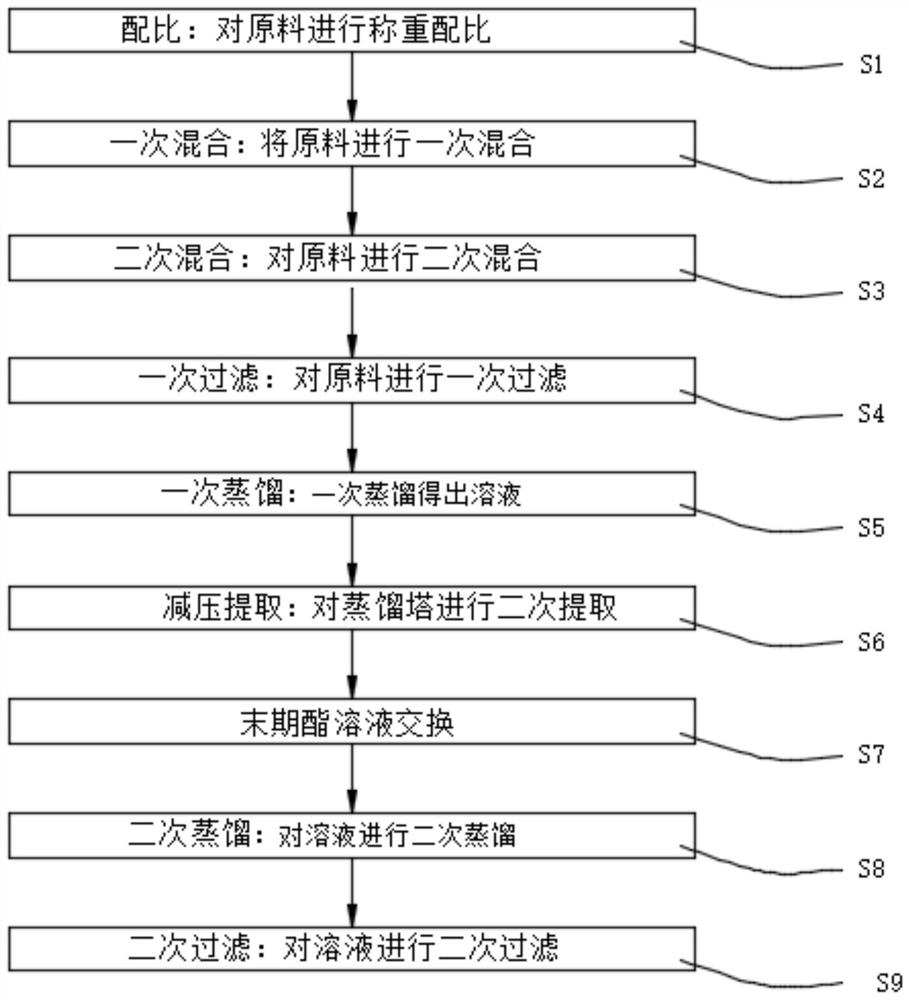

Synthesis method of chemical reagent auxiliary agent containing acetate

PendingCN112225663AAvoid problemsImprove qualityPreparation by ester-hydroxy reactionOrganic compound preparationAcetic acidDistillation

The invention discloses a synthesis method of a chemical reagent auxiliary agent containing acetate. The synthesis method comprises the following steps of: S1, proportioning; S2, primary mixing; S3, secondary mixing; S4, primary filtration; S5, primary distillation; S6, extraction under reduced pressure; S7, final-stage ester solution exchange; S8, secondary distillation; S9, secondary filtration.During use, a user can fully mix chemicals such as acetate, acetic acid, ethylene glycol and the like through primary mixing and secondary mixing, so that more impurities in a solution are avoided, meanwhile, the solution is desalted through micro-jet extraction and high-pressure distillation after secondary mixing, the quality of the chemical auxiliary agent is improved; meanwhile, secondary pressurization is carried out on the auxiliary agent through secondary distillation to remove the solvent, moisture in the solution is removed through the final-stage ester solution exchange after secondary pressurization, so that the purity of the solution is improved; secondary filtration and screening are carried out on the solution through secondary filtration, and therefore the finished producteffect of the chemical reagent auxiliary agent containing acetate is improved again.

Owner:锦州怡嘉科技有限公司

A powder feeding head for underwater laser additive manufacturing and cladding layer preparation

ActiveCN110090957BIncrease profitSlow down the flowAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringErbium lasers

The present invention provides a powder delivery head for underwater laser additive manufacturing and melting layer preparation, including: first parts, second parts, third components and fourth components connected from top to bottom,The first part of the first component, the second component, and the axis of the third component consisting of the laser chamber, wherein the first component is connected to the coaxial laser;The path of the metal powder enters from the pollination snail hole, and then passes through the powder runway, powder mixed chamber, and the powder collision platform to reach the powder nozzle.The time for laser effects from the room, improve the powder utilization rate, so that the powder delivery head is suitable for low temperature for underwater and long -term increase in materials, and the effect of metal powder transmitted by this powder delivery head is better, which can improve laser additive materialsThe effect of manufacturing and melting layer prepared.

Owner:XI AN JIAOTONG UNIV

High strength corrugated pipe

InactiveCN103421229AImprove performanceSuitable for occasions with harsh environment and high bearing strengthProcedure AgentsChlorinated polyvinyl chloride

The invention discloses a high strength corrugated pipe, which is mainly formed by PE resin raw materials, and is characterized by further comprising 4-5 percent of compound stabilizer, 5-6 percent of chlorinated polyvinyl chloride, 2-3 percent of processing agent ACR, 2-3 percent of metal powder and 1-2 percent of color master. The compound stabilizer, chlorinated polyvinyl chloride, processing agent ACR, metal powder and color master are added in the PE resin raw materials as per a certain proportion, so that a series of properties of a product are improved, and the requirements for poor environment and occasions of load bearing strength can be satisfied. In addition, calcium carbonate and stearic acid are added into the raw materials, so that the product is enabled to be shaped easily, and the scratch resistance of the surface of the product is realized.

Owner:ANHUI ZHONGHONG PIPE IND TECH

Purification treatment method of zinc pot in hot-dip galvanizing production

ActiveCN103572190BHigh aluminum contentGood adhesionHot-dipping/immersion processesAfter treatmentPresent method

The invention discloses a method for purifying zinc pots in hot-dip galvanizing production. The purifying process is to carry out hot-dip galvanizing production under the condition that the aluminum content of the zinc liquid in the zinc pot is maintained at 0.025-0.030 wt%. Clean up the scum in the zinc pot during the galvanizing production process. This purification treatment method increases the aluminum content in the zinc liquid in the zinc pot from the usual 0.18-0.20% to 0.025-0.030%, thereby inhibiting the formation of iron in the zinc pot and improving the adhesion and gloss of the zinc layer of the galvanized sheet , Effectively improve the quality of galvanized sheet. The iron content in the zinc pot treated by the purification treatment method is obviously reduced, thereby laying a foundation for the subsequent generation.

Owner:HEBEI IRON AND STEEL

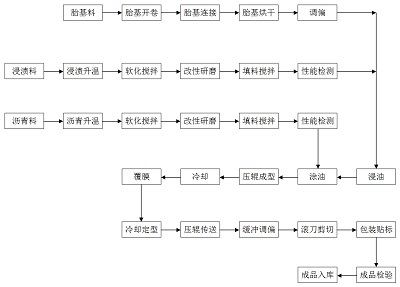

A kind of polymer waterproof membrane and its forming method

ActiveCN112695957BImprove the effect of the finished productSolid waste managementRoof covering using flexible materialsPolymer scienceEngineering

The invention relates to a polymer waterproofing membrane and a forming method thereof. The waterproofing membrane comprises the following components in parts by mass: 0.50-0.55% of petroleum asphalt, 0.05-0.10% of high-activity rubber powder, and 0.10-0.10% of aromatic oil. 0.15%, styrene SBS 0.10-0.15%, styrene-butadiene rubber SBR 0.05-0.10%, and stone powder 0.05-0.10%; a thickness detection device connected to the thickness controller is also provided on both sides of the tire base, and the thickness detection The device detects the oil thickness on both sides of the tire base in real time. When the detected oil thickness on both sides of the tire base exceeds the preset threshold range, the thickness detection device sends the detection result to the thickness controller, and the thickness controller immediately controls the two sides of the scraper to make the spacing Adjustment, so as to ensure that the most suitable thickness of oiling can further improve the effect of the finished product, further improve the yield of the finished product, and save raw materials while ensuring the stability of product performance and effect.

Owner:江苏佳创纳米科技有限公司

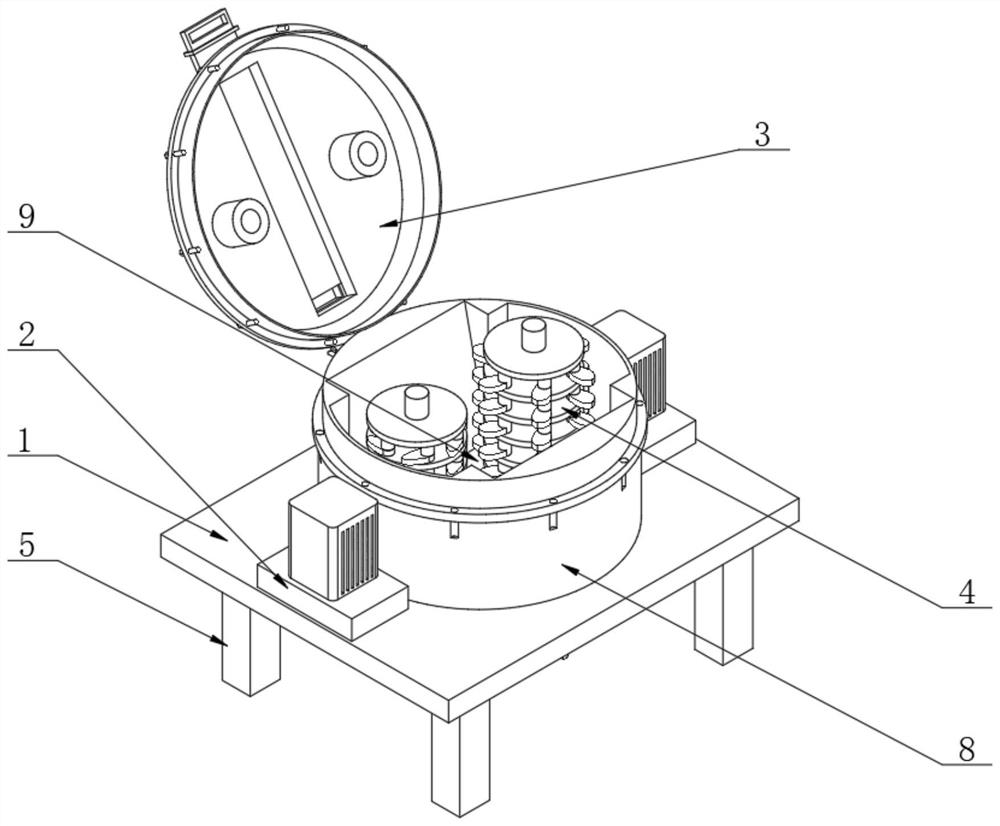

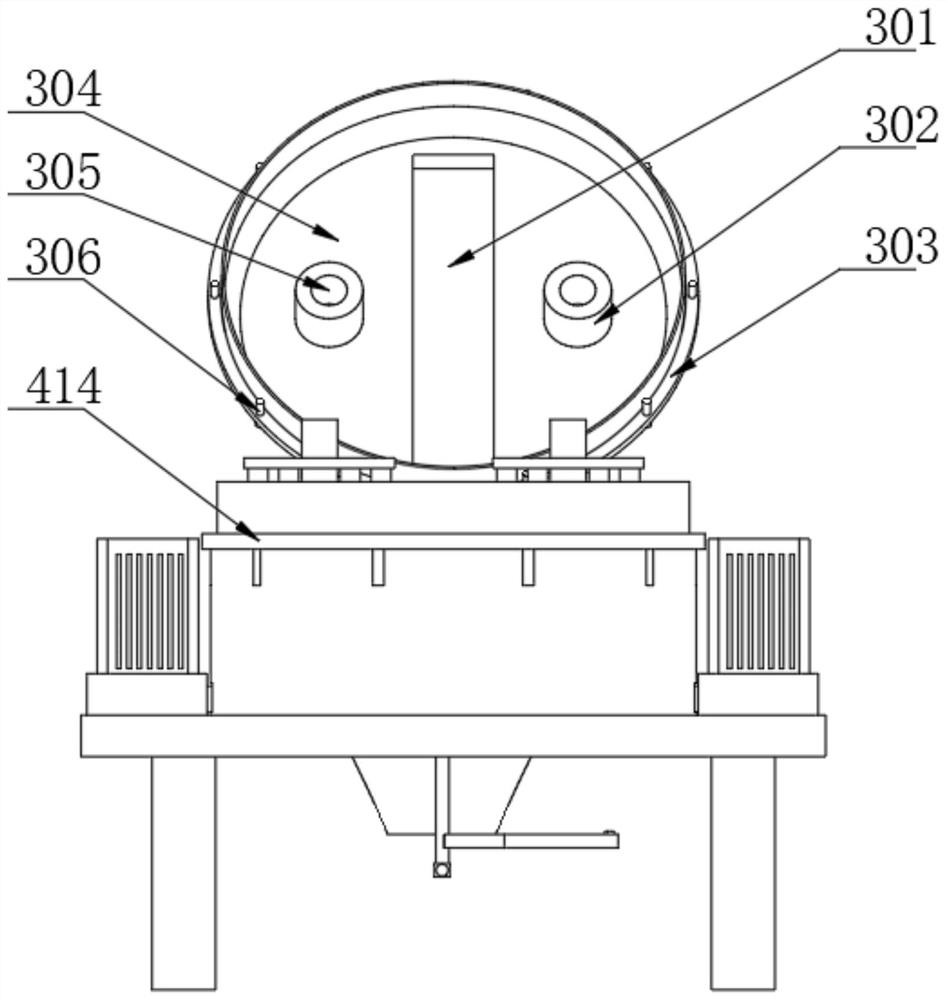

Vertical shaft type sand making crusher and using method thereof

InactiveCN113499829AImprove breakage operationsConvenient post-productionGrain treatmentsElectric machineStructural engineering

The invention relates to the technical field of sand making crushers, in particular to a vertical shaft type sand making crusher and a using method thereof. The vertical shaft type sand making crusher comprises a transmission assembly, the interior of the transmission assembly comprises a first motor mounting plate and a second motor mounting plate, the first motor mounting plate and the second motor mounting plate are fixedly mounted on the left side and the right side of the upper surface of a mounting table correspondingly, and two supporting columns are fixedly mounted on each of the left side and the right side of the lower end of the mounting table. Power transmission can be carried out on sand making of a double-rotor hammer head through the transmission assembly, it is ensured that operation of the double-rotor hammer head can be normally carried out, and therefore the situation that the double-rotor hammer head cannot be driven to make sand due to insufficient power is avoided, sand making of the double-rotor hammer head is achieved, and damage operation of the double-rotor hammer head to materials is effectively improved; and through an upper cover assembly, stability between the upper cover assembly and a crushing assembly in the crushing process can be achieved, and therefore equipment is effectively prevented from breaking down during working, and production is guaranteed.

Owner:重庆新酢坊建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com