Three-dimensional reel iron core of amorphous alloy transformer

A technology of three-dimensional wound iron core and amorphous alloy, which is applied in the direction of transformer/inductor magnetic core, etc., can solve the problems of transformer capacity limitation, inability to use large-capacity transformer, and transformer design capacity limitation, etc., so as to improve the performance of finished products and improve The effect of design capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] based on the following Figure 1 ~ Figure 3 , specifically explain the preferred embodiment of the present invention.

[0015] Such as figure 1 As shown, the present invention provides a three-dimensional wound iron core of an amorphous alloy transformer, comprising: a core leg assembly, an upper iron yoke 1 arranged at the upper end of the core leg assembly, and a lower iron yoke 2 arranged at the lower end of the core leg assembly.

[0016] Such as figure 1 As shown, the stem combination includes three stems 3, the stems 3 are cylindrical, and the positions of the stems 3 are randomly distributed.

[0017] Such as figure 2 As shown, in one embodiment of the present invention, the three stems are distributed on the three vertices of an isosceles triangle, the width of the entire stem combination is W, and the center-to-center distance between two stems is MO, The diameter of each stem is Φ.

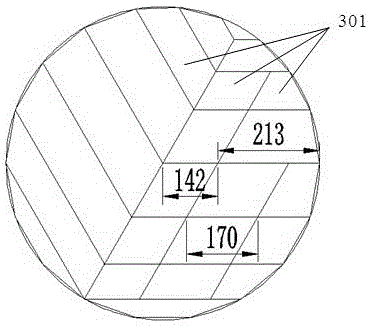

[0018] Such as image 3 As shown, each core column 3 includes several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com