Temperature control system and method of combustion equipment

A temperature control system, temperature control method technology, applied in the control of combustion, lighting and heating equipment, dryers, etc., to solve problems such as unstable flame, extinguishment or loss, and inability to ensure safe and continuous operation of the burner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

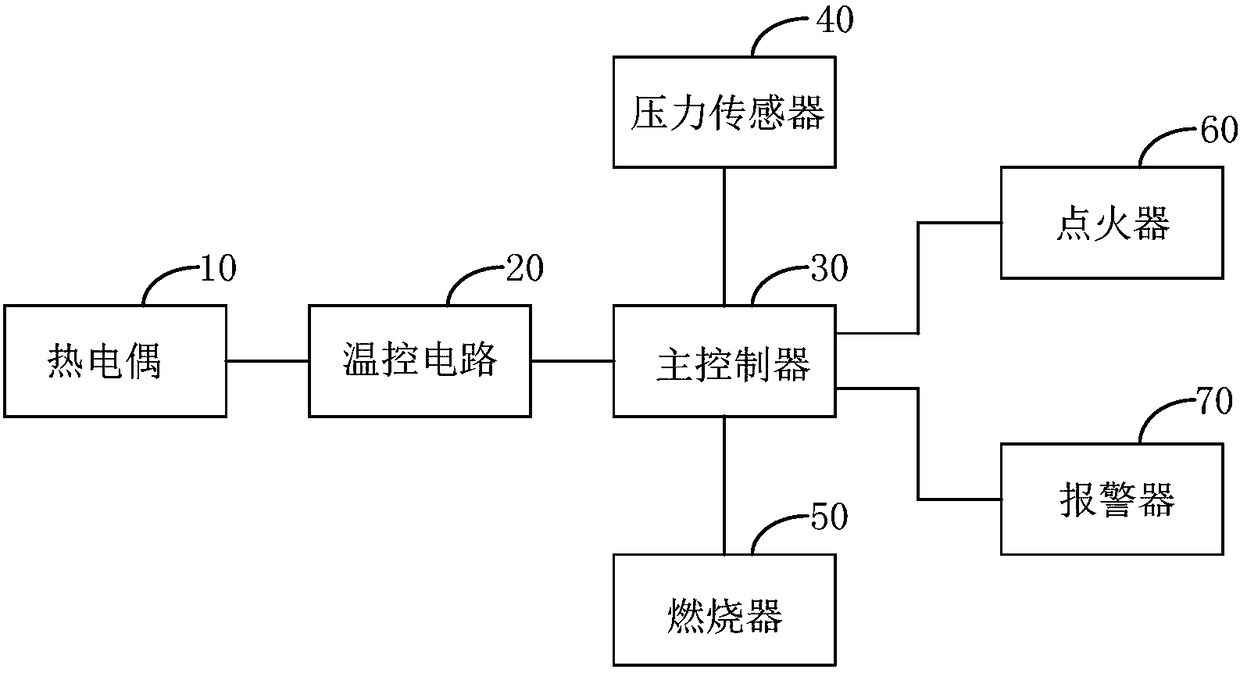

[0042] figure 1 It is a schematic diagram of the temperature control system of the combustion equipment provided by Embodiment 1 of the present invention.

[0043] refer to figure 1 , the system includes: thermocouple, temperature control circuit, main controller, pressure sensor and burner. respectively connected with the main controller;

[0044] Thermocouple, used to detect the current temperature in the drying room, and send the current temperature to the temperature control circuit;

[0045] The temperature control circuit is used to receive the current temperature sent by the thermocouple and send the current temperature to the main controller;

[0046] The pressure sensor is used to detect the current pressure signal of the burner and send the pressure signal of the burner to the main controller;

[0047]The main controller is used to receive the current pressure signal sent by the pressure sensor and the current temperature sent by the temperature control circuit, ...

Embodiment 2

[0062] image 3 The flow chart of the temperature control method of the combustion equipment provided by the second embodiment of the present invention.

[0063] refer to image 3 , the method includes the following steps:

[0064] Step S101, detecting the current temperature in the drying room.

[0065] Step S102, detecting the current pressure signal of the burner.

[0066] Step S103, comparing the current pressure signal with the preset pressure signal to obtain a flame signal.

[0067] Step S104, judge the flame state according to the flame signal, if the flame state is that the flame exists, then execute step S105; if the flame state is that the flame does not exist, execute step S106;

[0068] Step S105, compare the current temperature with the preset temperature, and control the heating of the burner according to the comparison result.

[0069] Step S106, receiving the ignition command information sent by the main controller, and providing an ignition source for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com