Powder coating for surface treatment of thermal transfer printing metal substrate and preparation method thereof

A technology for powder coatings and metal substrates, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of difficult paper tearing and high hardness of coating films, and achieve the effects of improving curing rate, high hardness, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the powder coating for the surface treatment of thermal transfer metal substrates, the steps include:

[0033] (1) 57 parts by weight of polyester resin SJ4E, 5.0 parts by weight of triglycidyl isocyanurate, 1.0 parts by weight of acrylate copolymer, 0.6 parts by weight of polytetrafluorowax, 0.4 parts by weight of benzoin, and 8 parts by weight of titanium dioxide 25 parts by weight of high-gloss barium sulfate were mixed with a mixer for 8 minutes; wherein, the oil absorption of high-gloss barium sulfate was 17g / 100g; polyester resin SJ4E was added in 3 times, adding 20 parts by weight for the first time and adding 20 parts by weight for the second time , adding 17 parts by weight for the third time;

[0034] (2) A twin-screw extruder is used for melt extrusion, wherein the temperature in zone I of the extruder is 110° C., and the temperature in zone II of the extruder is 115° C.;

[0035] (3) cooling and compressing, crushing to obtain the ...

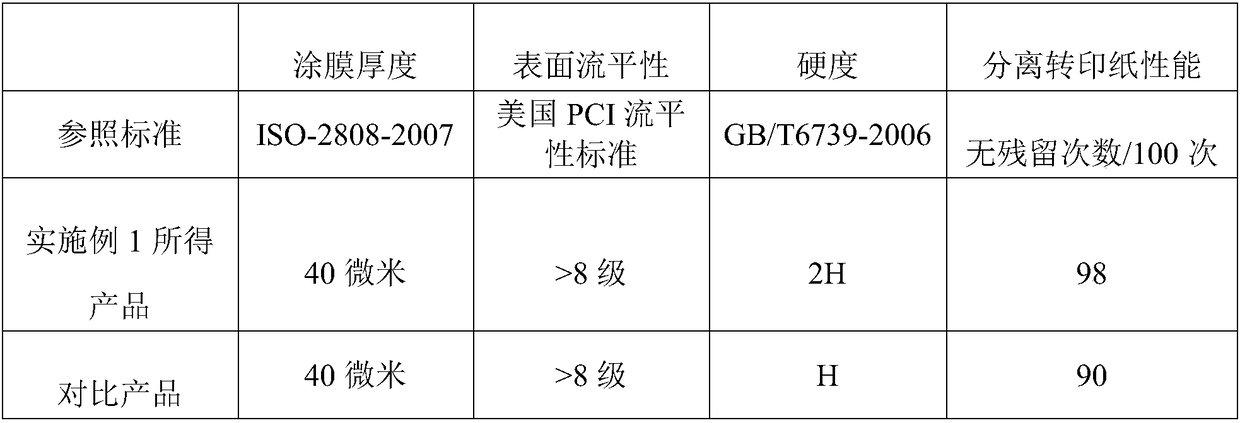

experiment example

[0041] The powder coating product obtained in Example 1 above is sprayed, and the spraying step includes: using a high-voltage electrostatic spraying method to spray the powder coating product obtained in Example 1 on the surface of an aluminum profile to obtain a workpiece; placing the workpiece at 210° C. for 10 minutes and baking it to make The workpiece is completely solidified; after the workpiece is cooled, apply thermal transfer glue evenly on the workpiece, then cover the wood grain transfer paper and wipe it flat; put the processed workpiece into the baking condition of 170°C Bake for 15 minutes; after cooling, tear off the transfer paper to obtain a coating film of wood grain powder coating.

[0042] Compared with the product preparation method, the steps include:

[0043] (1) 50 parts by weight of polyester resin SJ4E, 7.0 parts by weight of triglycidyl isocyanurate, 3.0 parts by weight of acrylate copolymer, 0.5 parts by weight of polytetrafluorowax and 0.3 parts b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com