Composition for packaging optoelectronic device, packaging structure and optoelectronic device

A technology of optoelectronic devices and packaging structures, which is applied in the direction of electric solid state devices, photovoltaic power generation, electrical components, etc., to achieve the effects of high light transmittance, high curing rate, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: Preparation of Encapsulation Composition 1

[0077] The components used are described below:

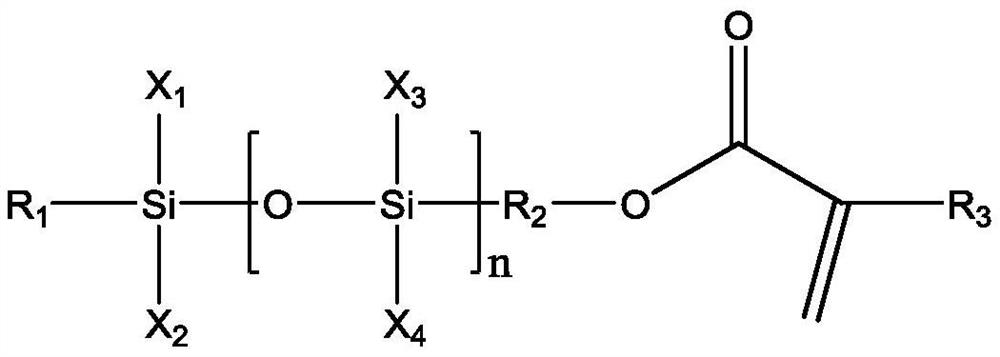

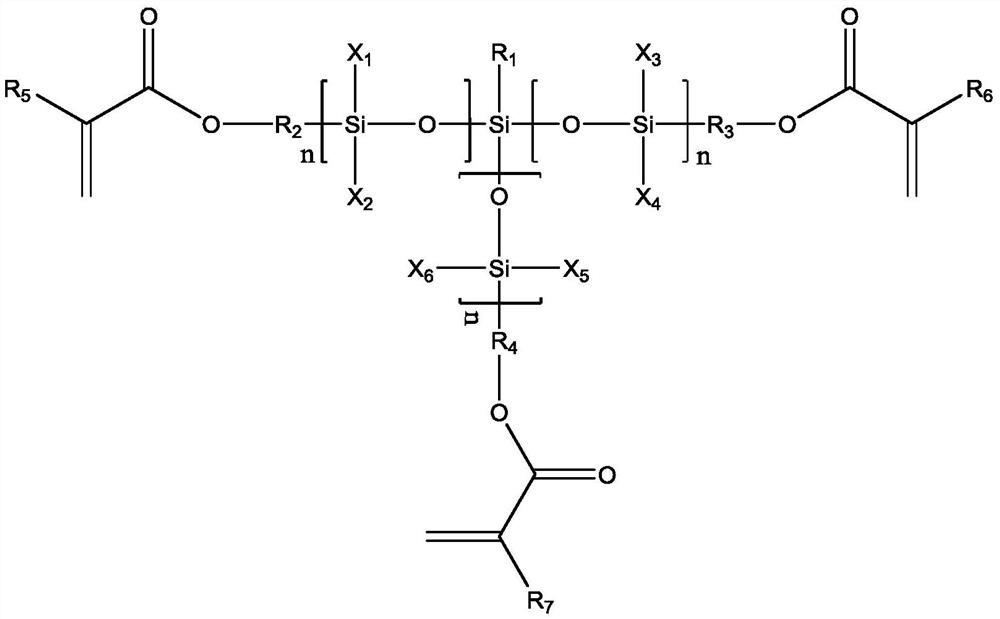

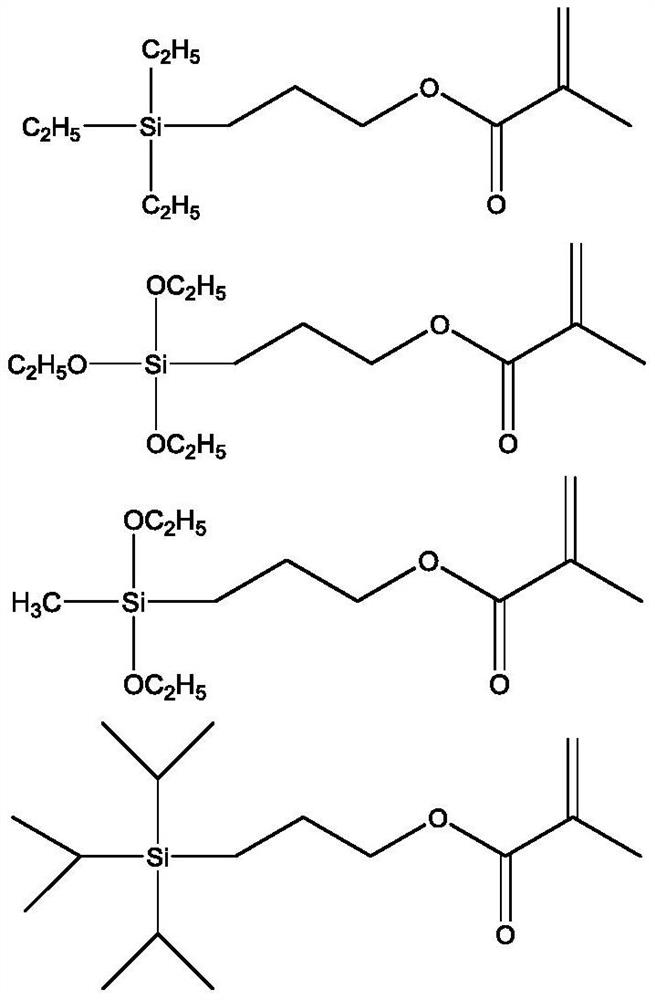

[0078] (A) silicon-containing monomer: (A1) monomer of formula 5; (A2) monomer of formula 9;

[0079] (B) Photocurable monomers: (B1) 2-phenylethyl (meth)acrylate, (B2) glycerol diacrylate;

[0080] (C) Initiator: benzyl(diphenyl)phosphine oxide.

[0081] In a brown glass bottle, add 10% (A1), 40% (B1), 45% (B2) and 5% (C) of the total mass, shake and mix at room temperature for 2 hours, and then filter to obtain the composition for packaging 1; Then apply the composition on the surface of the ITO substrate by inkjet printing to form a sample with an area size of 10cm×10cm×10um (length×width×thickness), and then pass 100mW / cm 2 The UV curing equipment cures the packaging composition by ultraviolet curing for 10 to 30 seconds, and finally forms a packaging protective film.

[0082] The performance evaluation of the encapsulant is as follows:

[0083] Photocur...

Embodiment 2

[0091] Embodiment 2: Preparation of encapsulation composition 2

[0092] A detailed description of the components used in Example 2 follows:

[0093] (A) silicon-containing monomer: (A1) monomer of formula 5; (A2) monomer of formula 9;

[0094] (B) Photocurable monomers: (B1) 2-phenylethyl (meth)acrylate, (B2) glycerol diacrylate;

[0095] (C) Initiator: benzyl(diphenyl)phosphine oxide.

[0096] In a brown glass bottle, add 10% (A2), 40% (B1), 20% (B2) and 5% (C) of the total mass, shake and mix at room temperature for 2 hours, and then filter to obtain the composition for packaging 2; Then apply the composition on the surface of the ITO substrate by inkjet printing to form a sample with an area size of 10cm×10cm×10um (length×width×thickness), and then pass 100mW / cm 2The UV curing equipment cures the packaging composition by ultraviolet curing for 10 to 30 seconds, and finally forms a packaging protective film.

Embodiment 3

[0097] Embodiment 3: Preparation of encapsulation composition 3

[0098] The components used in Example 3 are described in detail as follows:

[0099] (A) silicon-containing monomer: (A1) monomer of formula 5; (A2) monomer of formula 9;

[0100] (B) Photocurable monomers: (B1) 2-phenylethyl (meth)acrylate, (B2) glycerol diacrylate;

[0101] (C) Initiator: benzyl(diphenyl)phosphine oxide.

[0102] In a brown glass bottle, add 70% (A1), 5% (B1), 25% (B2) and 5% (C) of the total mass, shake and mix at room temperature for 2 hours, and then filter to obtain the composition for packaging 3; Then apply the composition on the surface of the ITO substrate by inkjet printing to form a sample with an area size of 10cm×10cm×10um (length×width×thickness), and then pass 100mW / cm 2 The UV curing equipment cures the packaging composition by ultraviolet curing for 10 to 30 seconds, and finally forms a packaging protective film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com