Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

387results about How to "Guarantee the quality of finished products" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gold and silver hollow bracelet processing technology

ActiveCN103416925AReduce processing technologyGuaranteed purity and colorJewelleryNanotechnologySheet material

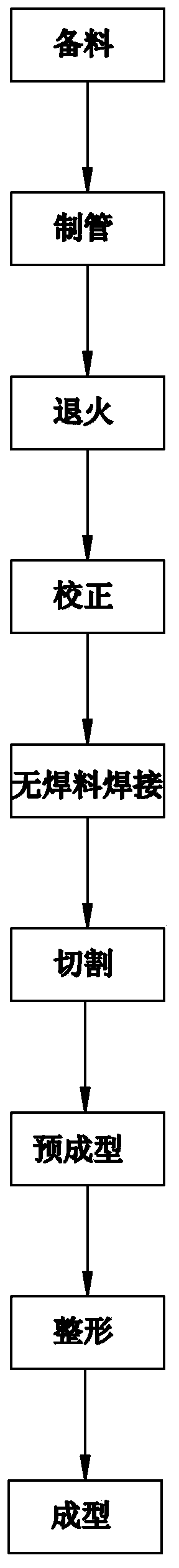

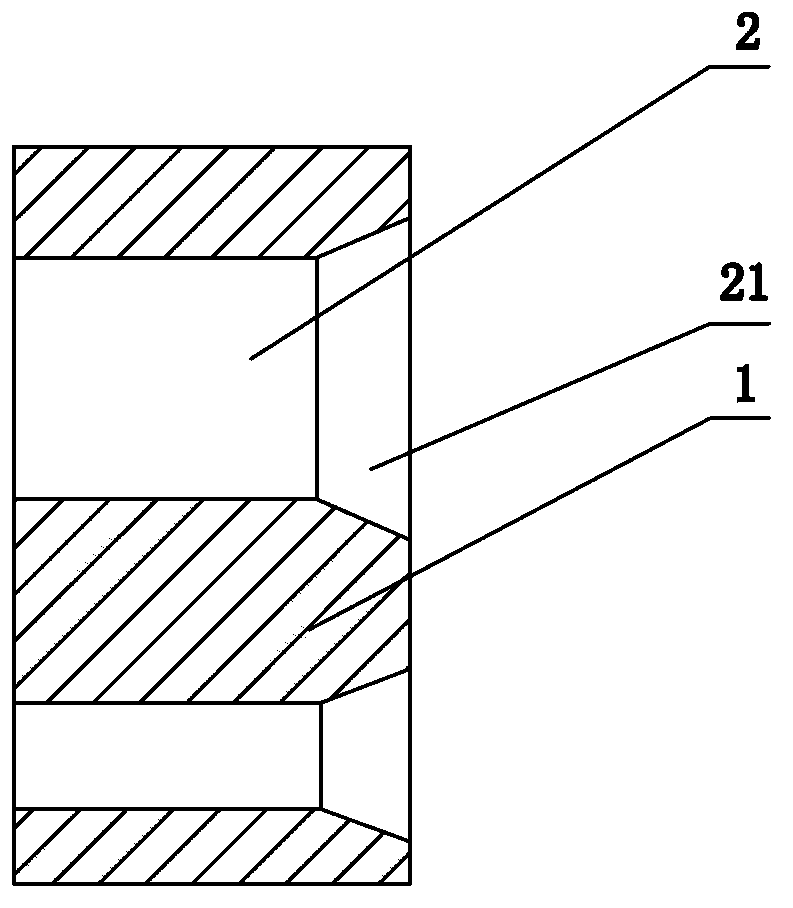

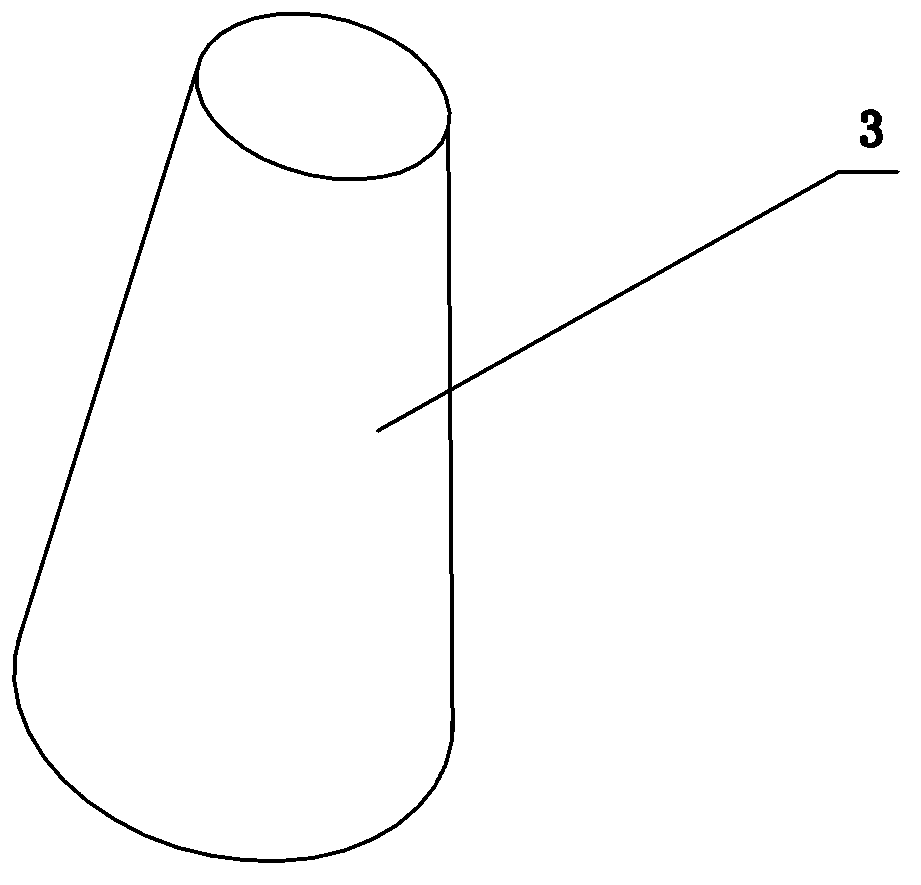

The invention discloses a gold and silver hollow bracelet processing technology and belongs to the technical field of jewelry processing technologies. The processing technology comprises the following steps: preparing material: according to the specifications for processing gold and silver hollow bracelets, preparing sheet material with corresponding specifications; manufacturing a pipe: processing the sheet material into a round pipe with a gap and straightening the round pipe; annealing; calibrating: straightening the gap; welding without welding material: eliminating gap through high-temperature heating to form a gapless round pipe; cutting: cutting the gapless round pipe according to the finished size of a gold and silver hollow bracelet, and polishing two ends of the gapless round pip; pre-forming: processing the gapless round pipe into an open type circular ring, and forming a closed circular ring by performing high-temperature heating on the open type circular ring; shaping: shaping the shape of the closed circular ring until specified requirements are met; forming: processing the closed circular ring into a hollow bracelet with elliptic sections. Through the processing steps, since a only a piece of sheet material is needed, the hollow bracelet can be manufactured, the processing technology is reduced, the processing efficiency is improved, the forming effect is good, and meanwhile, the gap is closed automatically through high temperature, so that welding without welding material is achieved, and the purity and fineness are guaranteed.

Owner:SHENZHEN SUNFEEL JEWELRY CO LTD +1

Method for repairing damage of external shield of medium and high voltage cable

InactiveCN102361271ATightly boundGuaranteed shielding effectApparatus for repairing insulation/armouring cablesPolyesterSurface finishing

The invention discloses a method for repairing the damage of an external shield of a medium and high voltage cable, belongs to the technical field of wires and cables, and is used for cleanly processing the damaged external shield and the surface of an insulator. The method comprises the following steps of: completely wrapping a damage part by using a pressing sheet of an external semi-conductive material; tightly winding the exterior of the damage part by using a polyester belt or a polytetrafluoroethylene belt; putting the repaired damage part into a heating device which is pre-heated to a constant temperature of 118 to 122 DEG C; heating for 4 to 6 minutes under the pressure of 1.1 MPa to 1.3 MPa; and cooling, and then cutting a thicker part to make the appearance smooth. The method has the advantages that: the appearance of the repaired part is almost the same as that of the unrepaired part; the thickness of the external shield can be guaranteed; any influence of the external shield is avoided; the shielding effect of the external shield and the quality of finished cable products are guaranteed; and economical cost is low.

Owner:圣安电缆有限公司

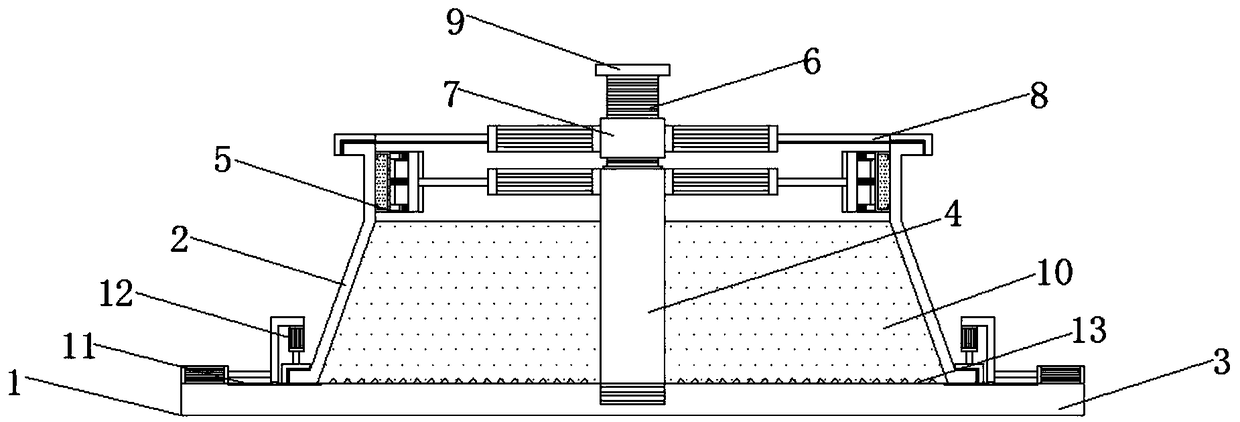

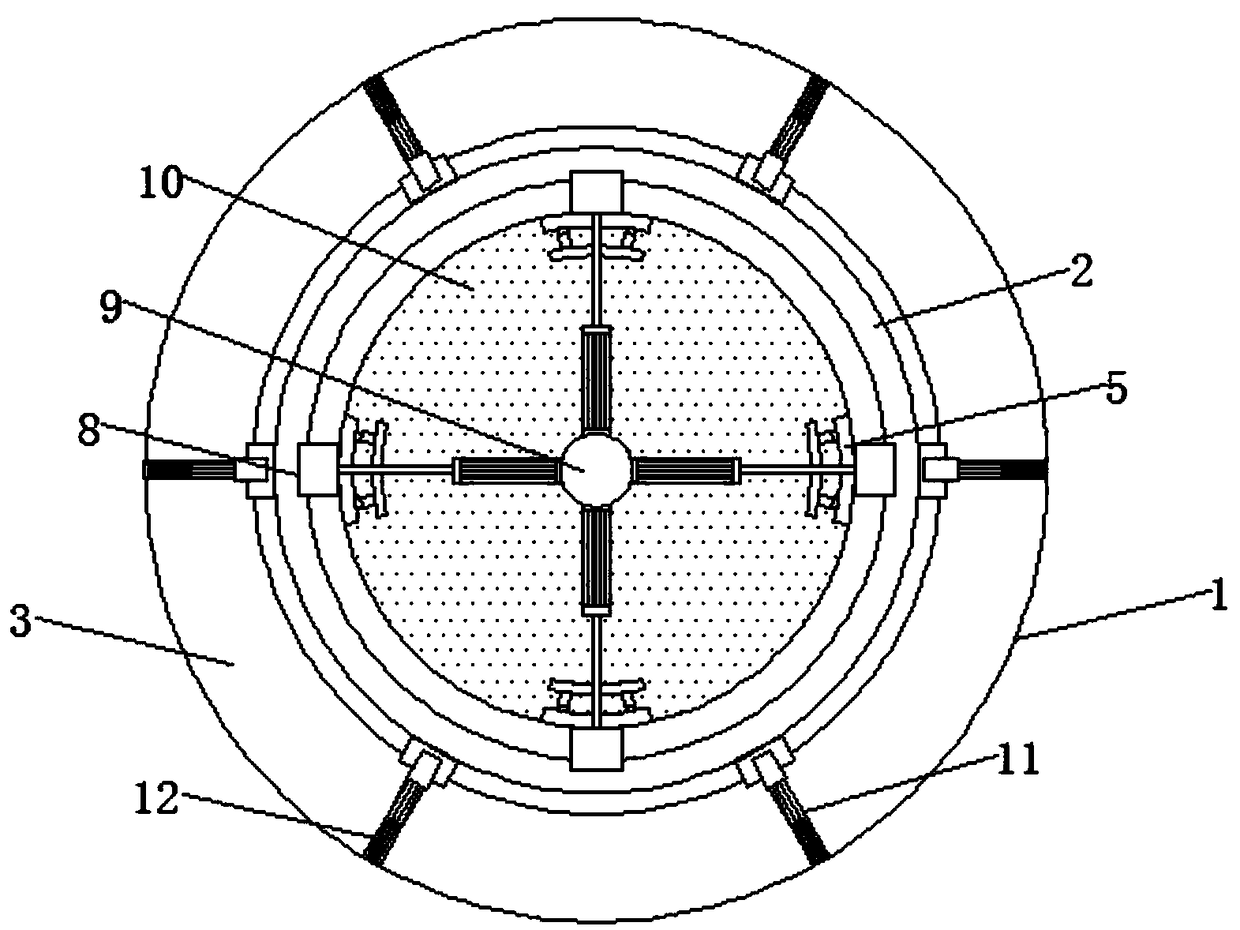

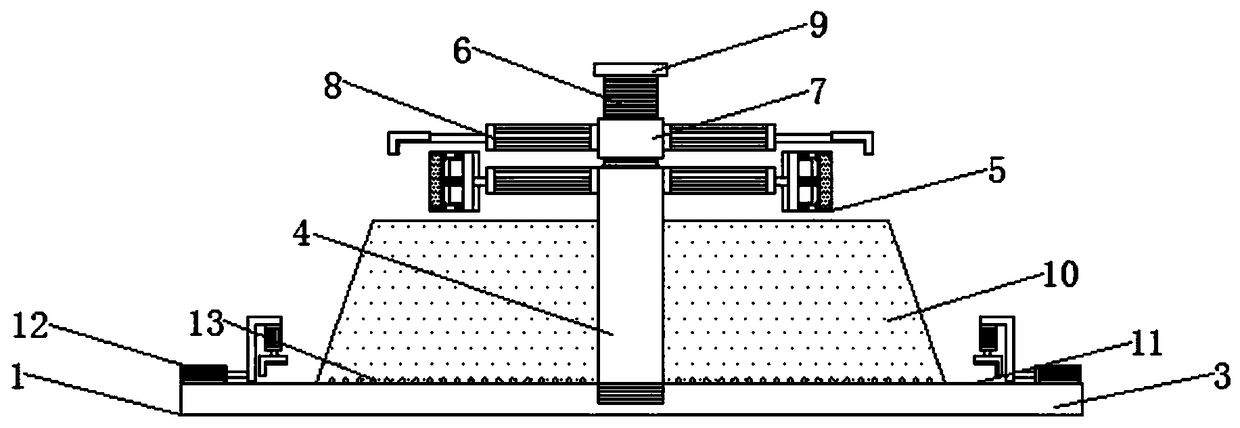

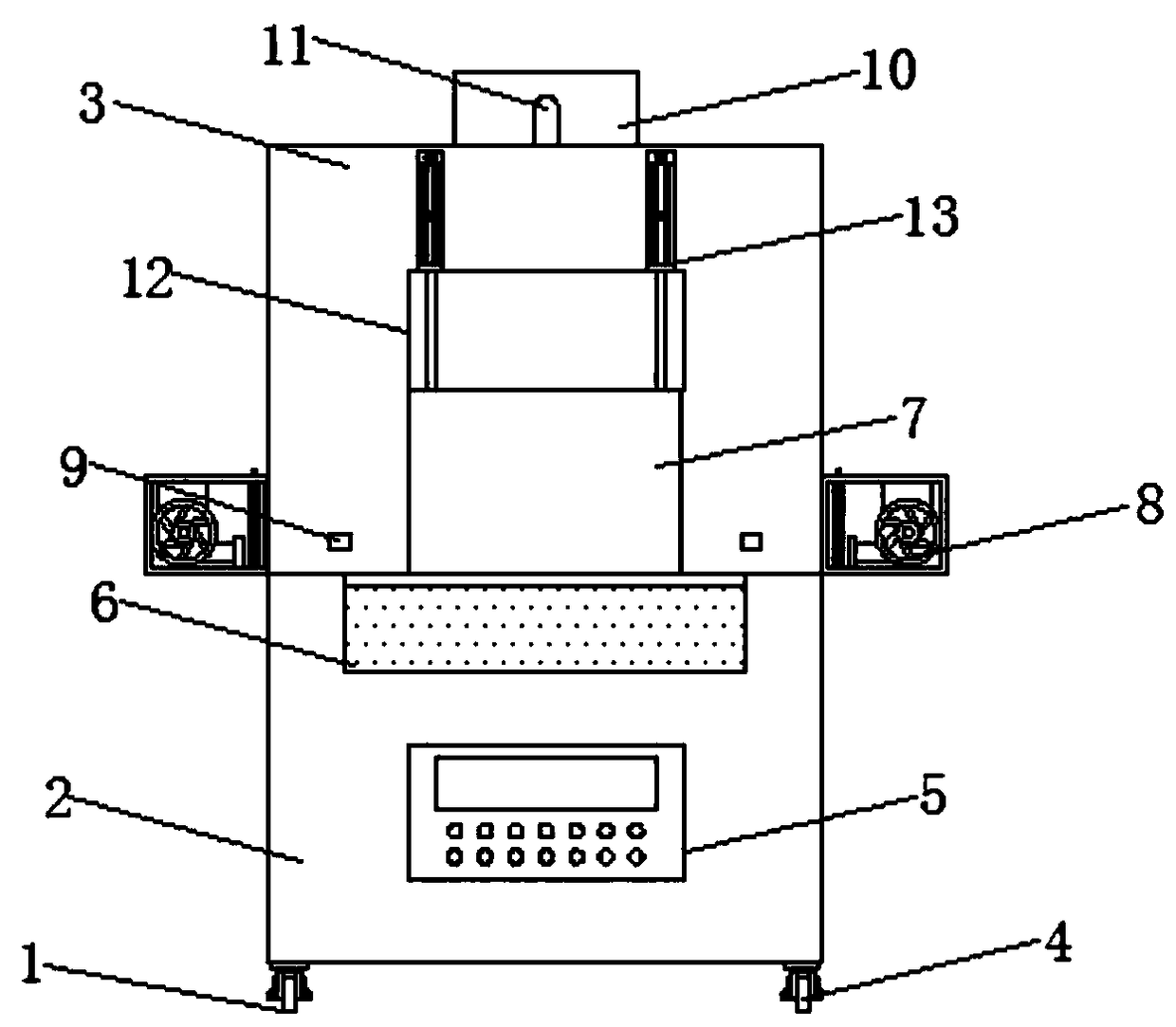

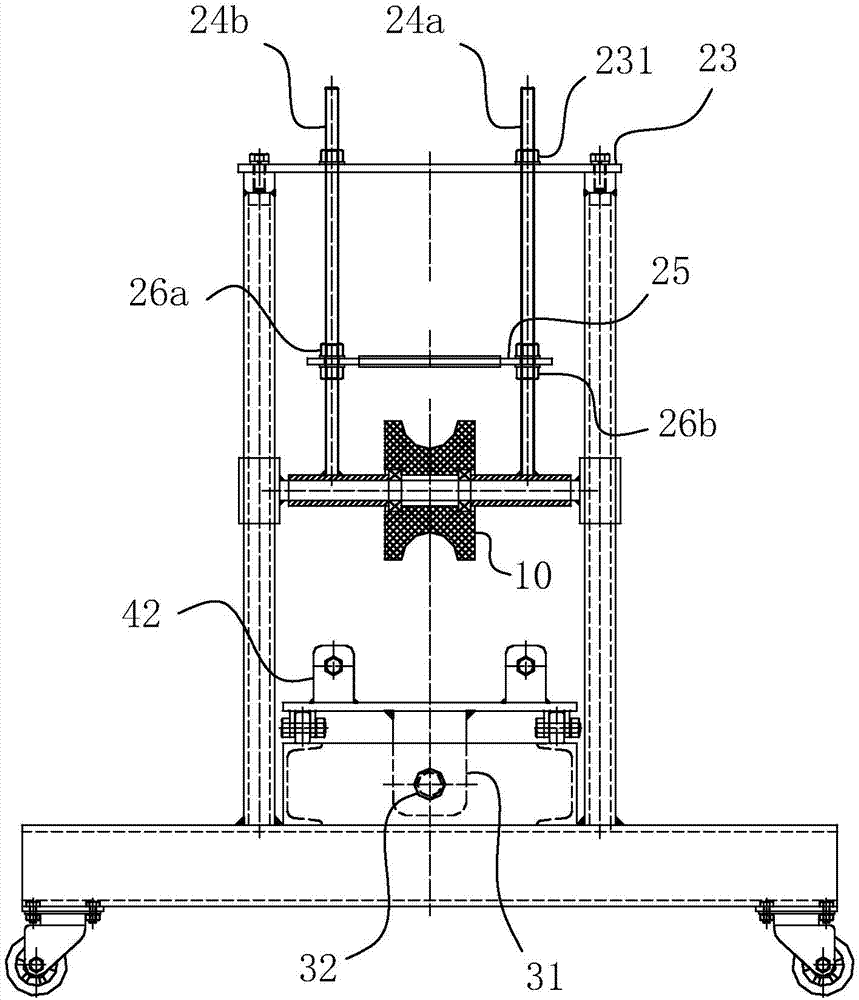

Precision hole processing equipment for thin-wall casing type part

ActiveCN109128904AAchieve fixationAvoid fixationPositioning apparatusMetal-working holdersEngineeringInternal Fixators

The invention discloses precision hole processing equipment for a thin-wall casing type part. An equipment body is installed on the outer side of the casing type part, a base is arranged on the bottomof the equipment body, a vertical rod is installed on the middle of the base, internal fixators are installed on the circumference of the top end of the vertical rod, a screw rod is installed on thetop of the vertical rod, and a convex edge is arranged at the top end of the screw rod. A sliding sleeve is arranged on the outer side of the screw rod in a sleeving mode, top fixators are installed on the circumference of the sliding sleeve, and bottom fixators are installed on the outer side of the base. According to the precision hole processing equipment for the thin-wall casing type part, thescrew rod and the sliding sleeve are cooperatively used, the sliding sleeve can drive the top fixators to move up and down on the screw rod, the top end of the casing part is fixed and prevented frommoving in the vertical direction, meanwhile, flexible adjustment can be carried out according to parts with different heights, simplification and practicality are achieved, and the application rangeof the equipment body is expanded.

Owner:贵州欣宇泰科精密科技有限公司

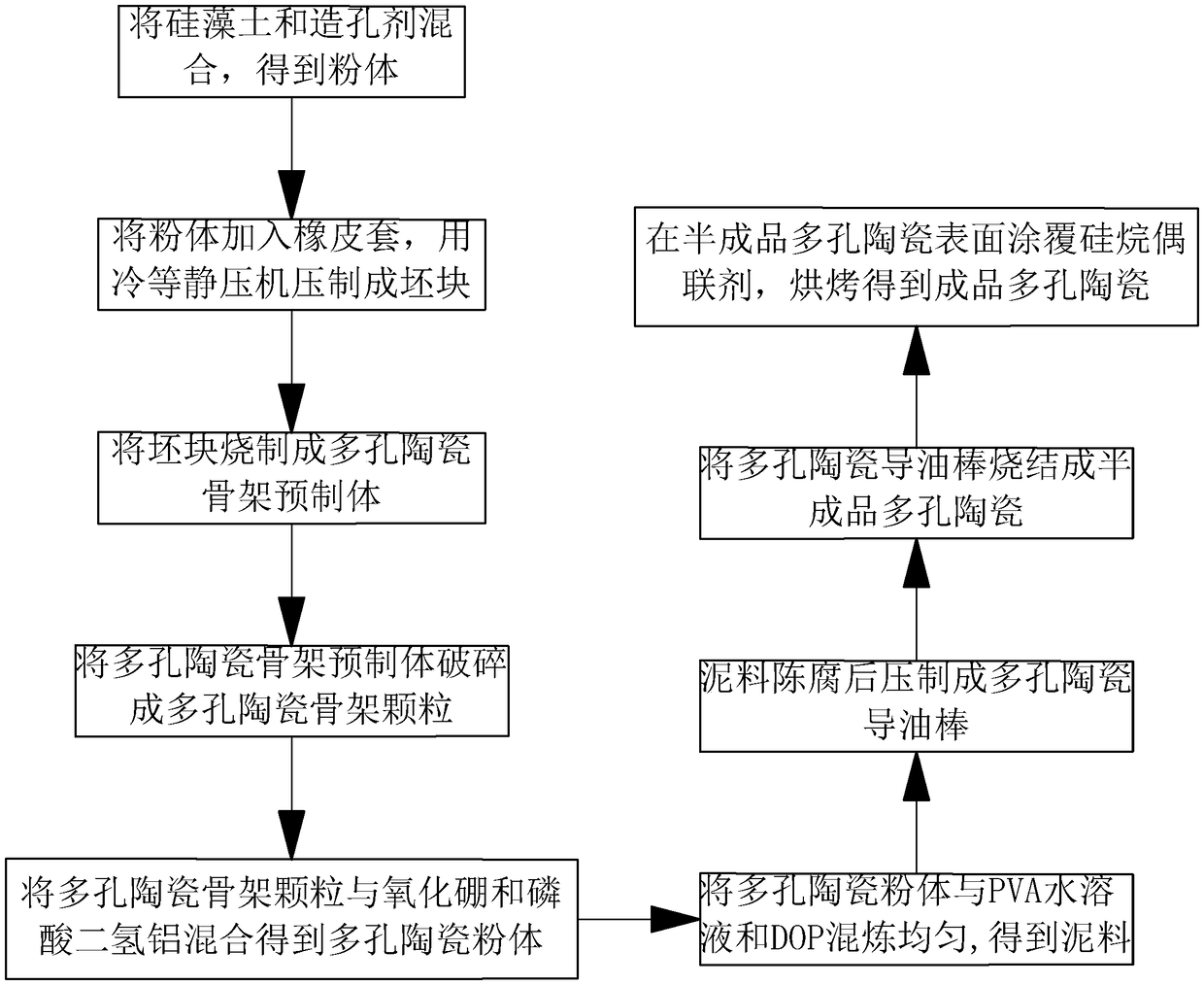

Electronic cigarette atomizer porous ceramic, preparation method thereof, and electronic cigarettes provided with electronic cigarette atomizer porous ceramic

ActiveCN109180171AHigh strengthImprove oil locking abilityTobacco devicesCeramicwarePhosphateElectronic cigarette

The invention discloses an electronic cigarette atomizer porous ceramic, a preparation method thereof, and electronic cigarette provided with the electronic cigarette atomizer porous ceramic, and belongs to the field of electronic cigarette. The electronic cigarette atomizer porous ceramic comprises, by mass, 50 to 80 parts of diatomite, 5.35 to 12.2 parts of boron oxide, and 2.15 to 9.8 parts ofaluminium dihydrogen phosphate. According to the preparation method, adding of boron oxide and aluminium dihydrogen phosphate is capable of increasing porous ceramic compressive strength. The preparation method comprises following steps: diatomite and a pore forming agent are mixed; blank material blocks are prepared; a porous ceramic skeleton prefabricated body is prepared through sintering; theporous ceramic skeleton prefabricated body is crushed; a porous ceramic powder is prepared; a pug is prepared; moulding of porous ceramic oil guide rods is carried out; semi-finished porous ceramic sintering is carried out; and the surface of semi-finished porous ceramic is coated with a silane coupling agent so as to obtain a finished product. The preparation method is capable of realizing uniform distribution of pores in the porous ceramic, and improving oil absorption and oil locking capacity; and the electronic cigarette provided with the electronic cigarette atomizer porous ceramic are capable of providing consumers with good experience feeling.

Owner:NINGBO TOPTEK ADVANCED CERAMICS CO LTD

Processing technology of dried vegetable-tapioca flour noodle

InactiveCN101632423AGuarantee the quality of finished productsIncrease varietyFood preparationPreservativeTableting

The invention relates to a processing technology of dried vegetable-tapioca flour noodle, which comprises the steps of (1) the preparation of vegetable particle flour, (2) the preparation of tapioca particle flour, (3) the preparation of materials for the dried vegetable-tapioca flour noodle, (4) the preparation of vegetable-tapioca flour dough, (5) the curing and the tablet forming of the vegetable-tapioca flour dough and (6) the slicing, drying and cutting-off of the formed tablets. The producing process of the invention is completed without adding any preservative or artificial pigment, has no pollution to the produced products, ensures the quality of finished noodles, diversifies the variety of dried noodles, enriches the nutrition, and improves the cooking quality and the mouthfeel of dries noodles.

Owner:陆昌盛

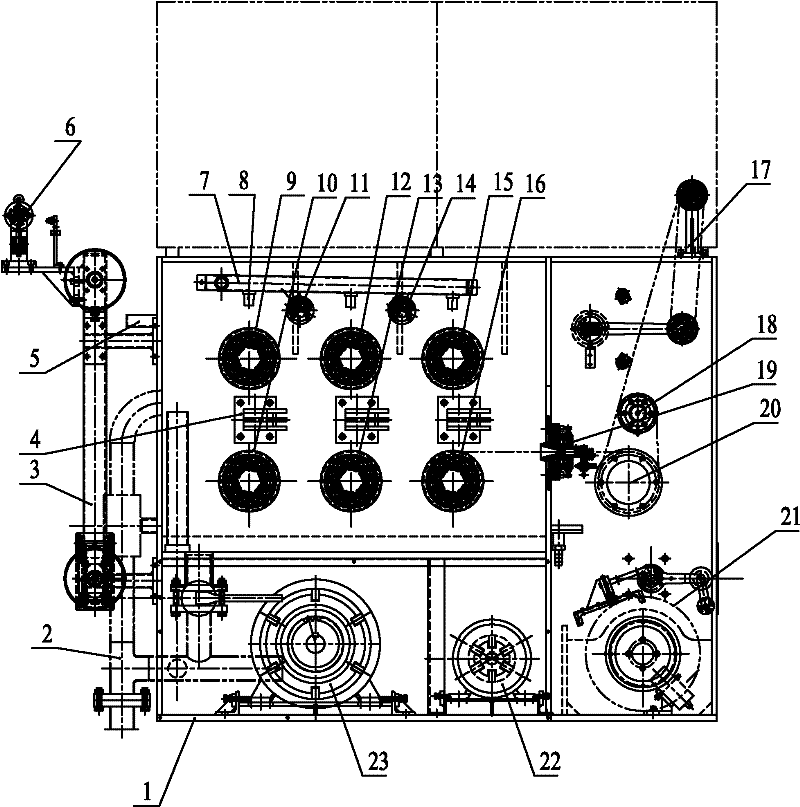

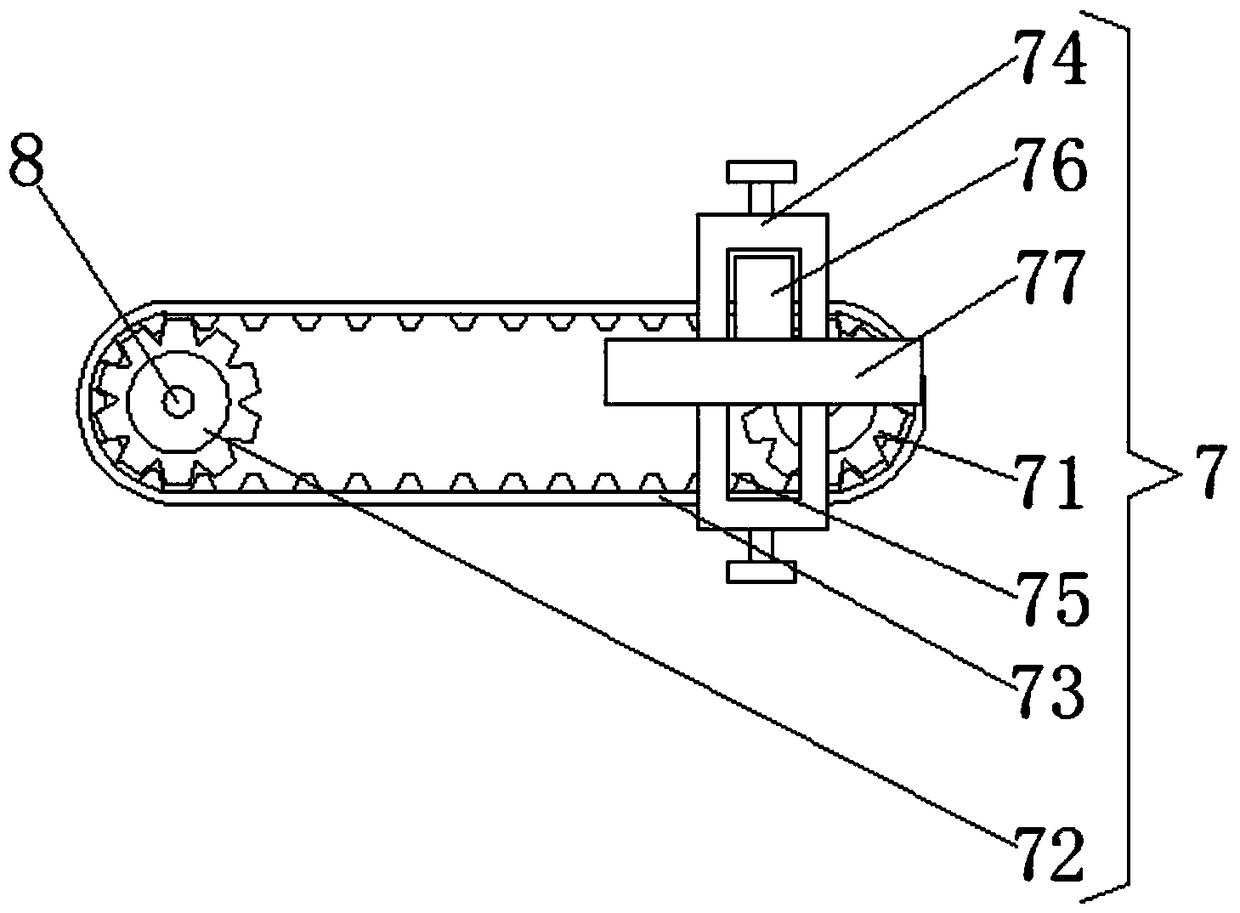

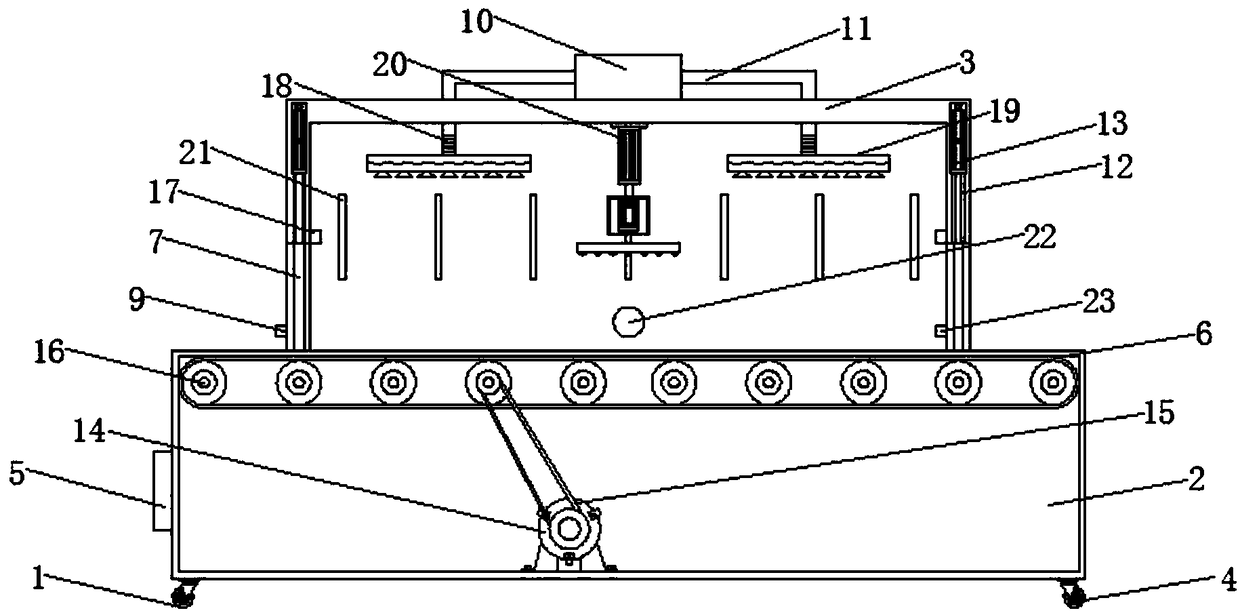

Water tank wire drawing machine

ActiveCN102327909AGuarantee the quality of finished productsIngenious structureSmall footprintEngineering

The invention relates to a water tank wire drawing machine. The water tank wire drawing machine comprises a wire drawing main machine and a take-up device, and is characterized in that the wire drawing main machine comprises a box body, wherein a tension mechanism is mounted on the left side wall of the box body; a wire inlet box is mounted on the left side wall of the box body, and a steel wire penetrates into the box body via the wire inlet box; a main motor is mounted at the lower part of the box body, the box body is divided into two parts, namely a transmission box and a water tank, a transmission device is mounted in the transmission box, and the transmission device is driven by relying on the main motor; a wire outlet die box is mounted on the right side wall of the water tank; anda wire guide shaft and a traction and orientation mechanism are mounted on the box body, the back end of the wire guide shaft extends into the transmission box and is linked with the transmission device, a wire guide wheel is mounted at the front end of the wire guide shaft, and the steel wire which penetrates out of the wire outlet die box is firstly wound on the wire guide wheel for one circle,then wound on the traction and orientation mechanism for multiple circles and further led to the take-up device. The water tank wire drawing machine is ingenious, compact and reasonable in structure,small in floor area, and uniform and stable in drawing speed, and can ensure the quality of a steel wire finished product.

Owner:WUXI CHANGXIN TECH

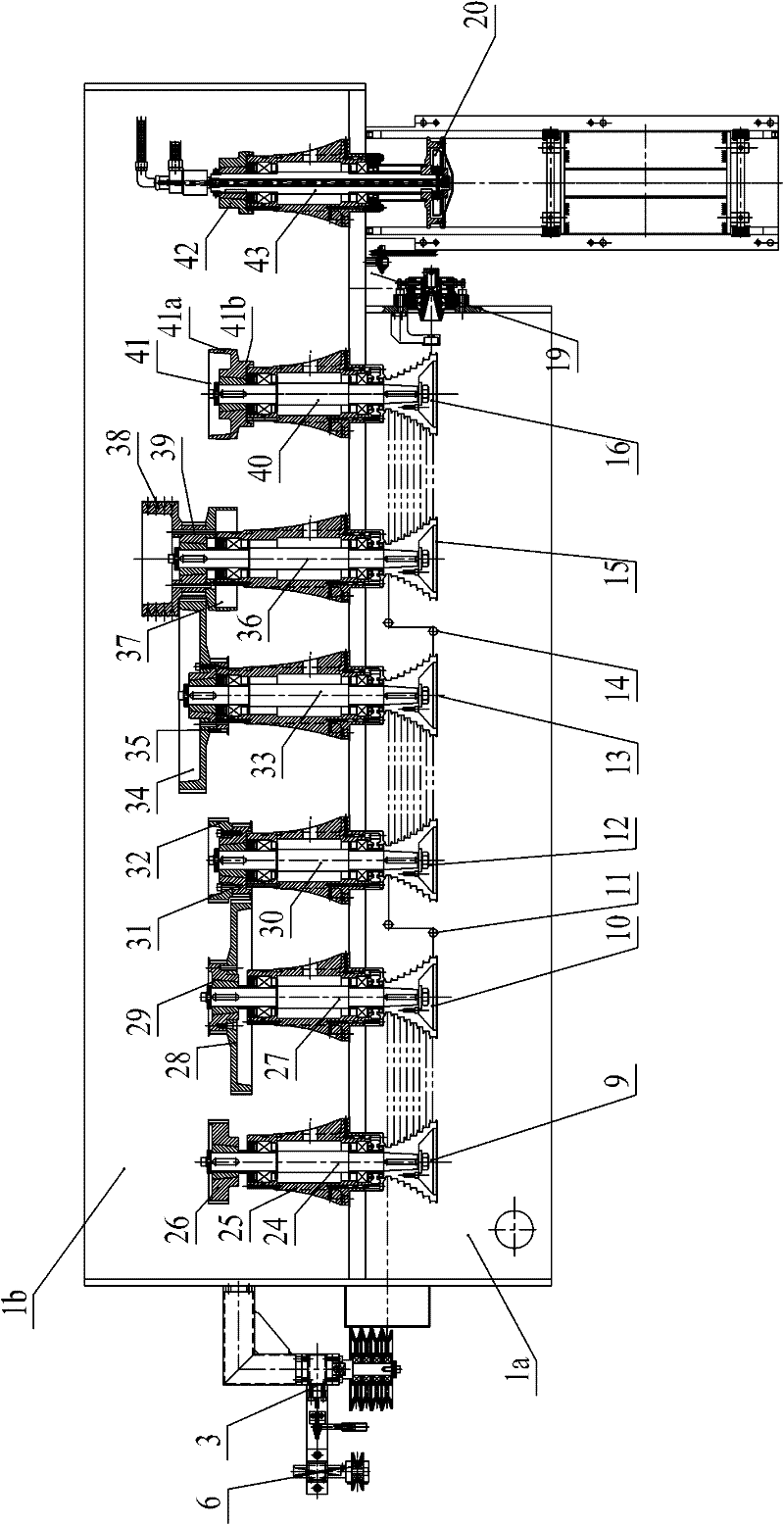

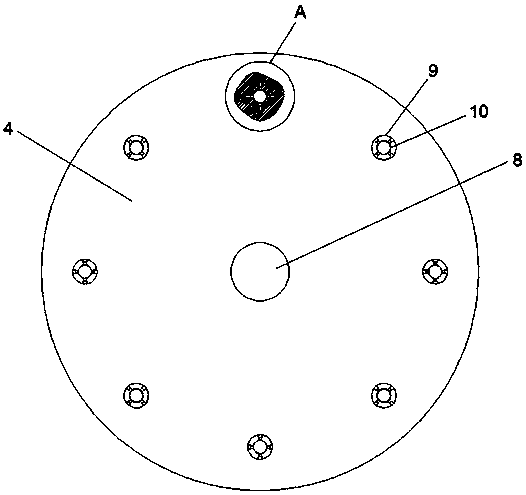

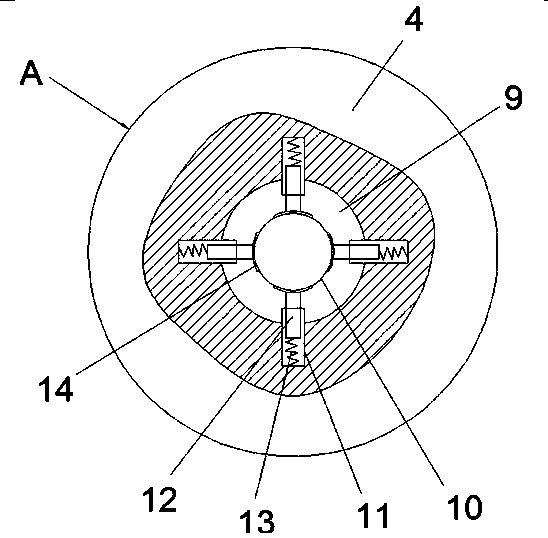

Cable stranding machine with multistage stranding structure

InactiveCN108172341AExtended service lifeGuarantee the quality of finished productsCable/conductor manufactureMultiple stagesPolygonal line

The invention discloses a cable stranding machine with a multistage stranding structure, comprising a vertical disc. The disc is provided with a plurality of winding wheels uniformly distributed on the circumference. The winding wheels are connected with the disc through rotating shafts. A first-stage winch, a second-stage winch and a third-stage winch are arranged in turn on one side of the disc.A line die holder is arranged on one side of the third-stage winch away from the disc. The cable stranding machine is reasonable in design. Because of the setting of the multiple stages of winches, the broken lines of cables from the winding wheels to the line die holder are smooth, and large friction caused by large break angles of the cables is prevented. The cables apply pressure to lantern rings in multiple directions when shaking. The friction between the cables and the lantern rings is reduced as the pressure is absorbed in the compression and elongation process of springs, and therefore, the wear between the lantern rings and the winches is reduced. In conclusion, the wear between the cables and the winches is reduced, the wear of the through holes of the winches is reduced, the service life of the winches is prolonged, and the quality of finished cables is ensured.

Owner:江阴市华伟机械制造有限公司

Recyclable temporary road subgrade block

InactiveCN103194947ALow costEasy to makeSingle unit pavingsTemporary pavingsArchitectural engineeringSubgrade

The invention provides a recyclable temporary road subgrade block, aiming at overcoming the defects of the existing cast-in-place concrete way used for temporary roads in a construction site. The temporary road subgrade block comprises a base block, a long-side connection faucet piece, a short-side connection faucet piece, hook pieces, limited blocks and limited angle steel components. The temporary road subgrade block has the beneficial effects that the subgrade block can meet the use requirement of a temporary road of a site, and meanwhile does not require any other materials, is simple to manufacture and convenient to assemble, can be recycled for multiple times, is applicable to all temporary roads in constructional engineering sites, is simple in structure, safe, reliable, and flexible in arrangement, can save a large amount of concrete material cost and measure expense, and can shorten the construction period.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

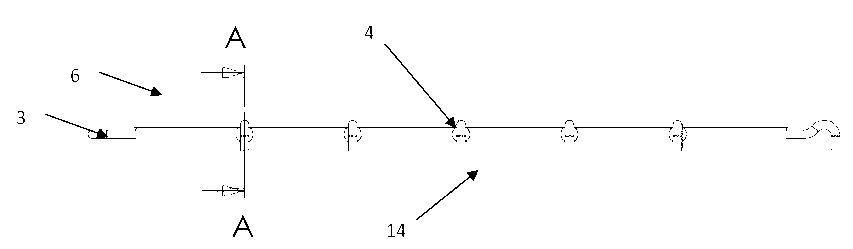

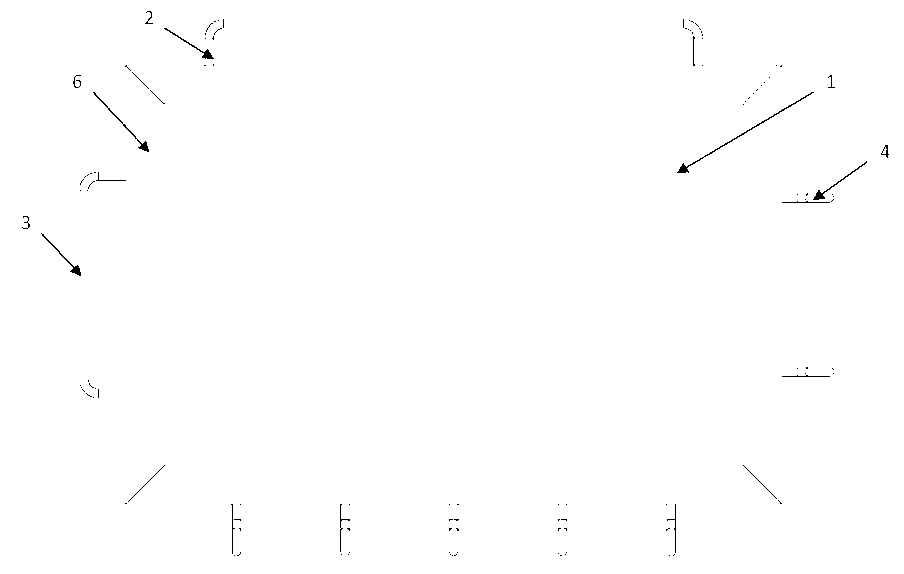

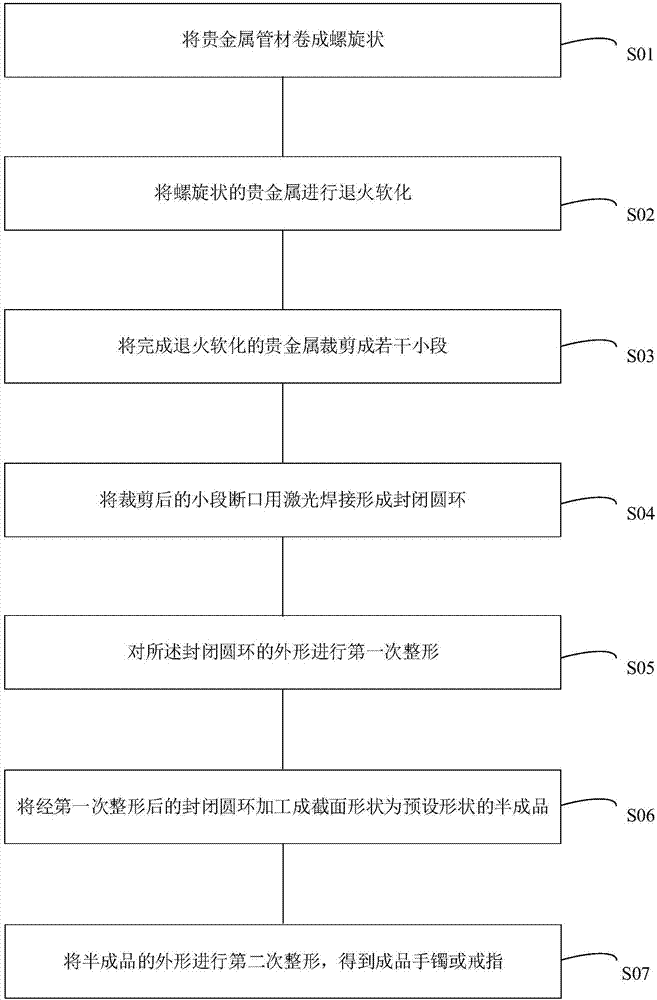

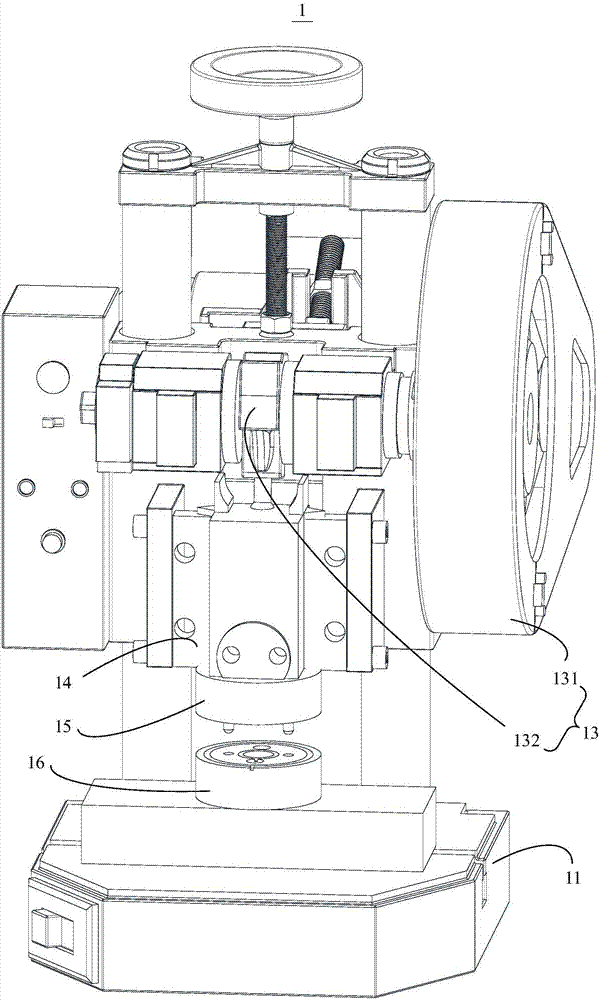

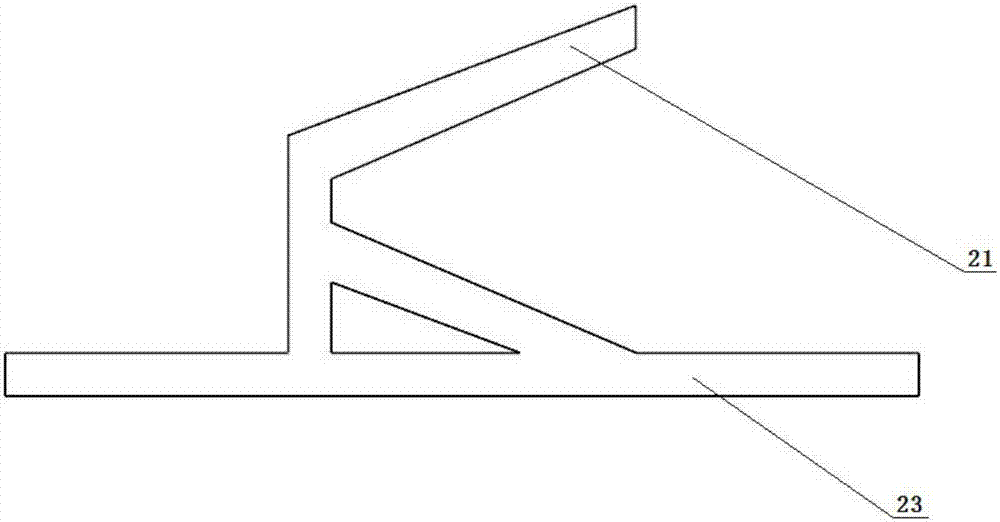

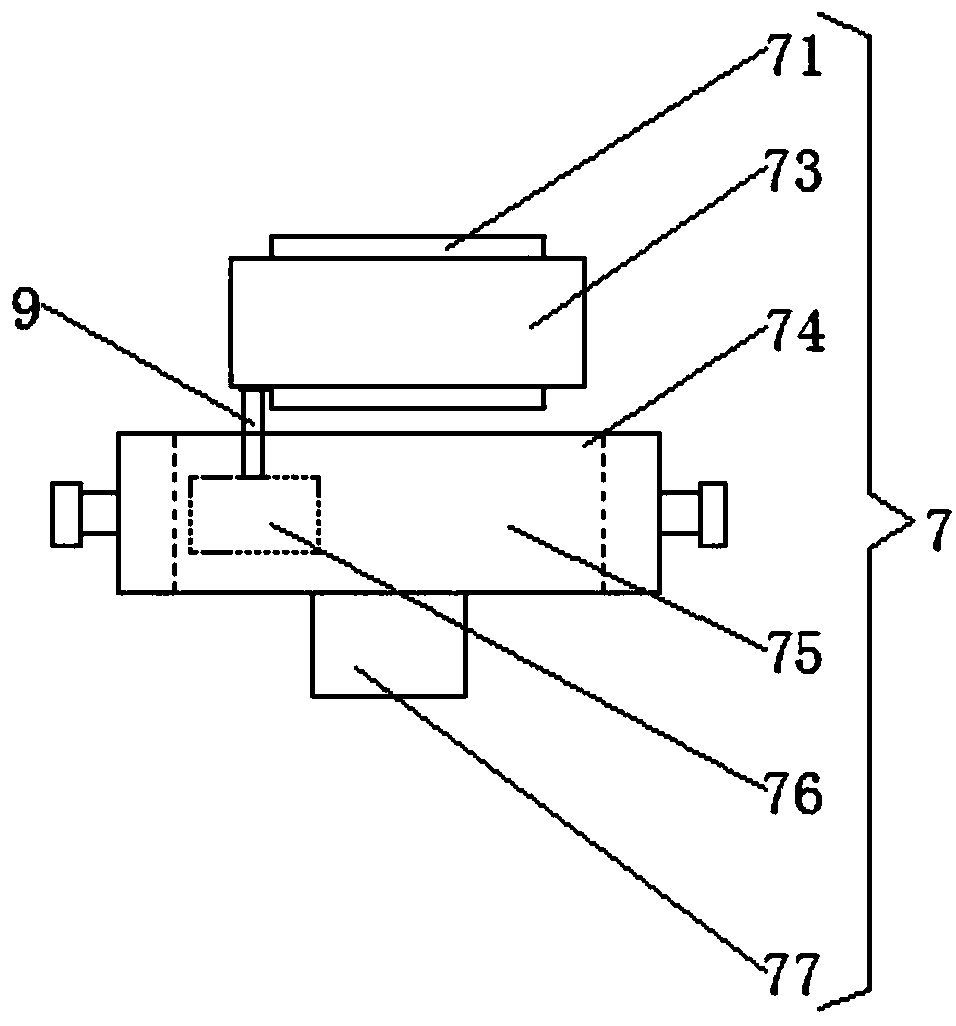

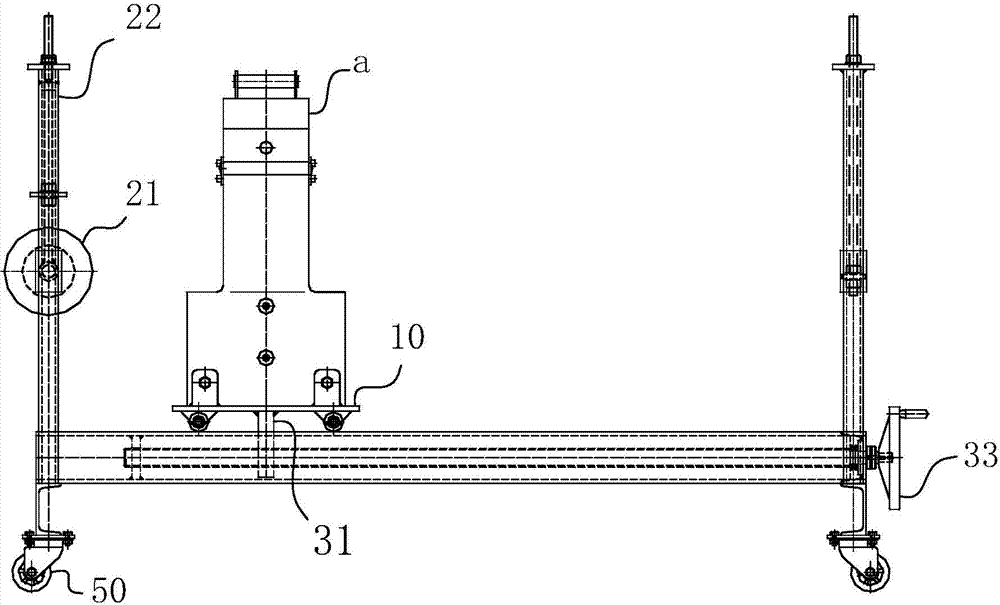

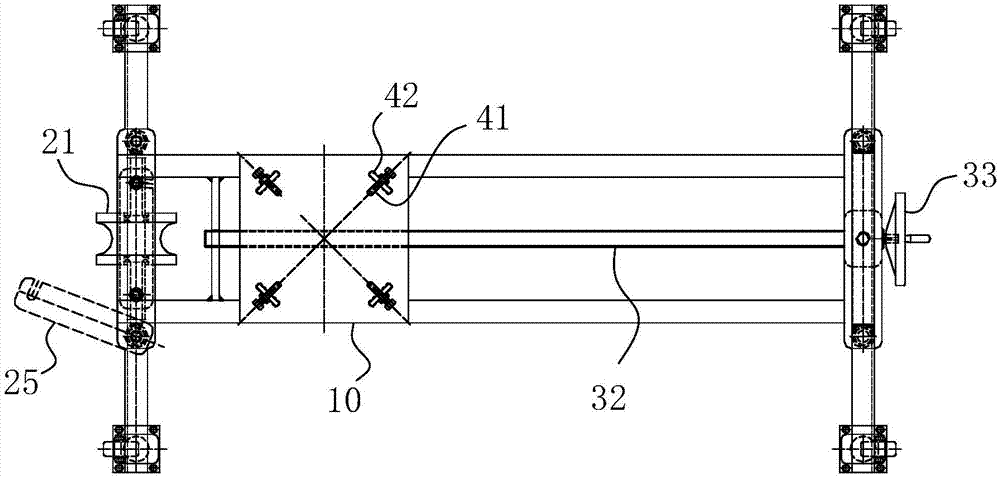

Processing technology for precious metal bracelet or ring, rounding equipment and arcing equipment

InactiveCN106862875AImprove machining accuracyWon't hurtBraceletsWrist-watch strapsMetallurgyWork in process

The invention discloses a processing technology for a precious metal bracelet or ring, rounding equipment and arcing equipment. The processing technology includes the following steps that a precious metal tubular product is rolled to be of a spiral shape; spiral-shaped precious metal is subjected to annealing softening; the precious metal subjected to annealing softening is cut into a plurality of small sections; the small sections of cut fractures are subjected to laser welding so that an enclosed circular ring can be formed; the appearance of the enclosed circular ring is subjected to primary shaping; the enclosed circular ring subjected to primary shaping is processed into a semi-finished product with the cross-section shape being a preset shape; and the appearance of the semi-finished product is subjected to secondary shaping, and accordingly a finished bracelet or ring product can be obtained. The processing technology aims to solve the problems that the precious metal bracelet or ring in the prior art is low in processing efficiency and poor in forming effect in the course of processing and the purity and precision cannot meet the requirements easily.

Owner:深圳市金银世界珠宝首饰有限公司

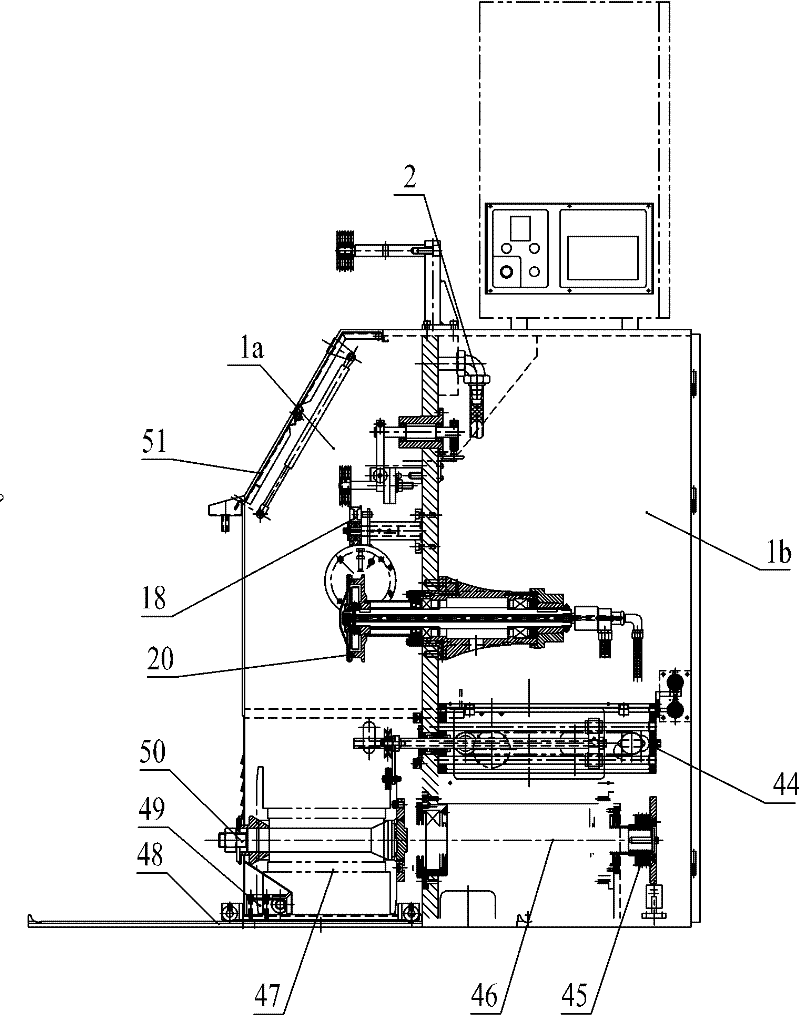

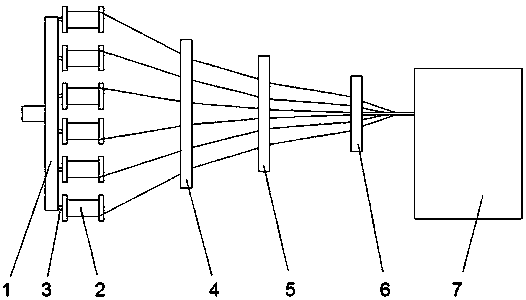

Mobile smelting furnace amorphous thin ribbon production overall machine system structure and control method thereof

The invention discloses a mobile smelting furnace amorphous thin ribbon production overall machine system structure and a control method thereof. The mobile smelting furnace amorphous thin ribbon production overall machine system structure comprises a railway frame; a railway is arranged on the railway frame; a tundish bracket and a furnace vehicle frame are arranged on the railway; a smelting furnace is mounted on the furnace vehicle frame; a tundish is arranged on the tundish bracket; a ribbon spraying ladle is arranged below the tundish bracket; a thin ribbon cooling copper roller is arranged below the ribbon spraying ladle; a thin ribbon winding machine is arranged in the ribbon outlet direction of the thin ribbon cooling copper roller; amorphous thin ribbons which are arranged in coils are prepared by smelting, molten liquid transferring, ribbon spraying, cooling and sizing, and winding; according to the system, a discontinuous production mode is changed into a continuous production mode, so that the production efficiency is greatly improved, and meanwhile, the stability of the product is also greatly improved.

Owner:JIANGSU GUONENG ALLOY TECH CO LTD

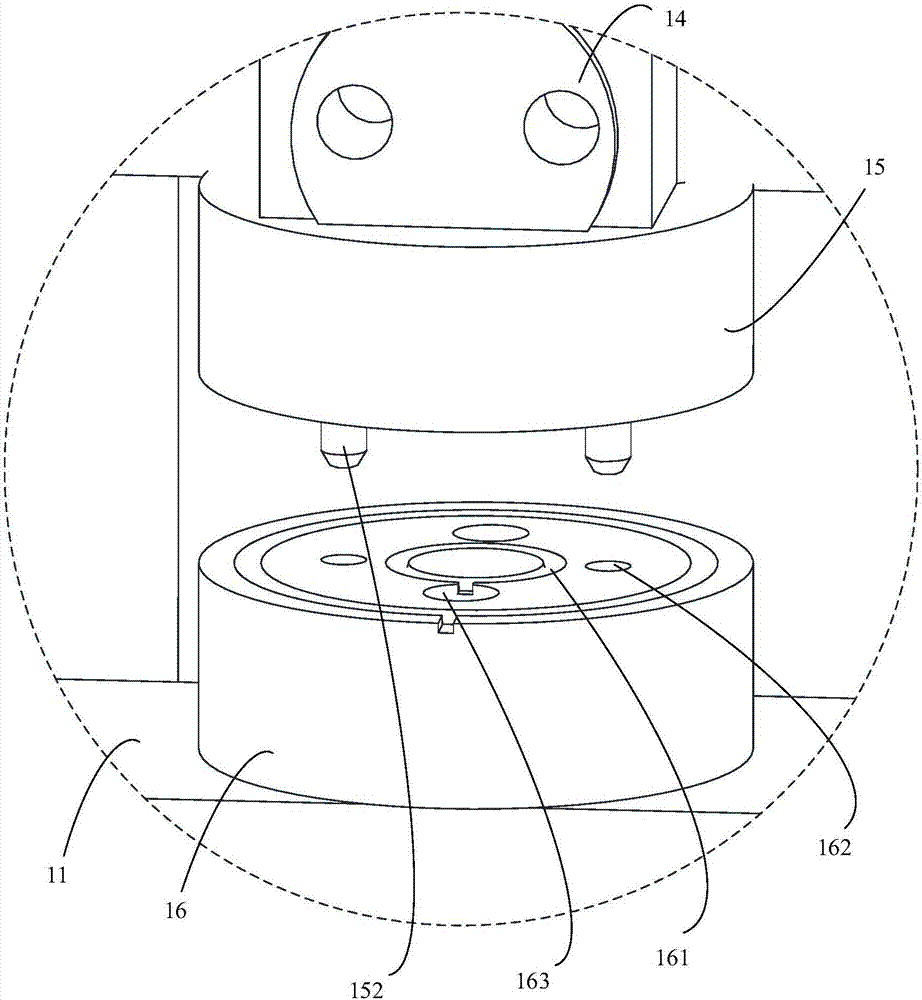

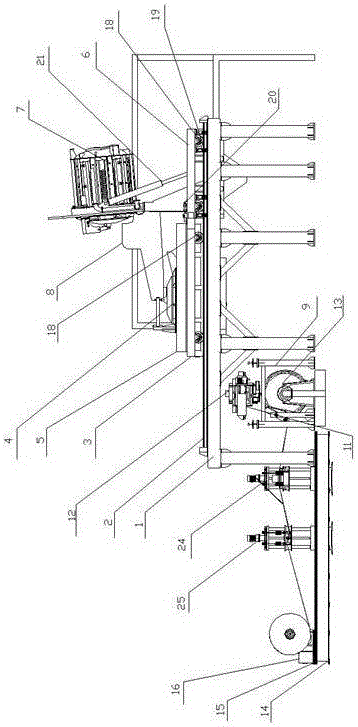

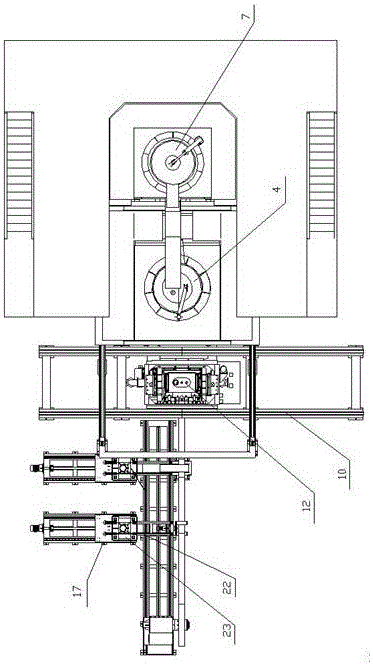

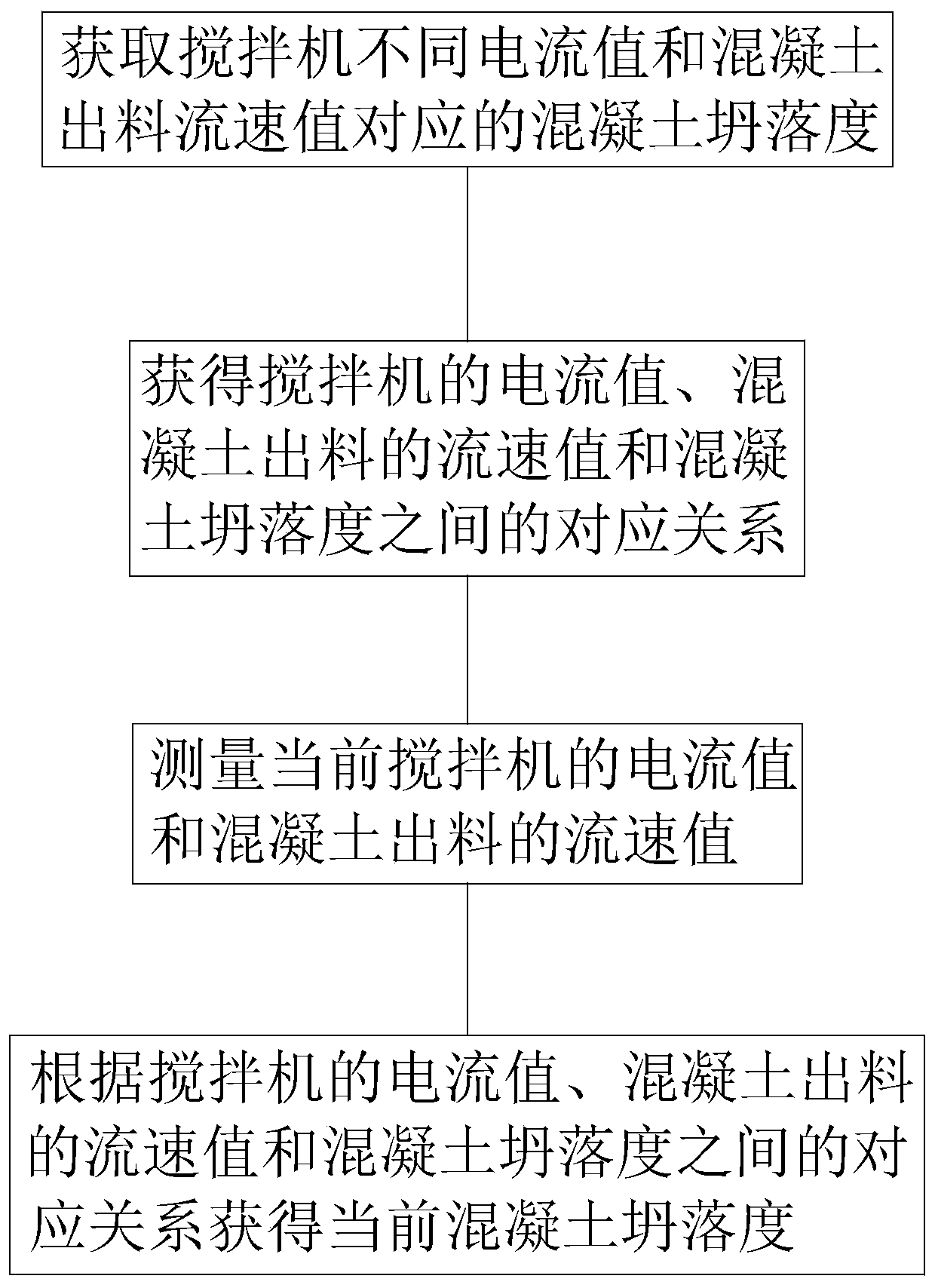

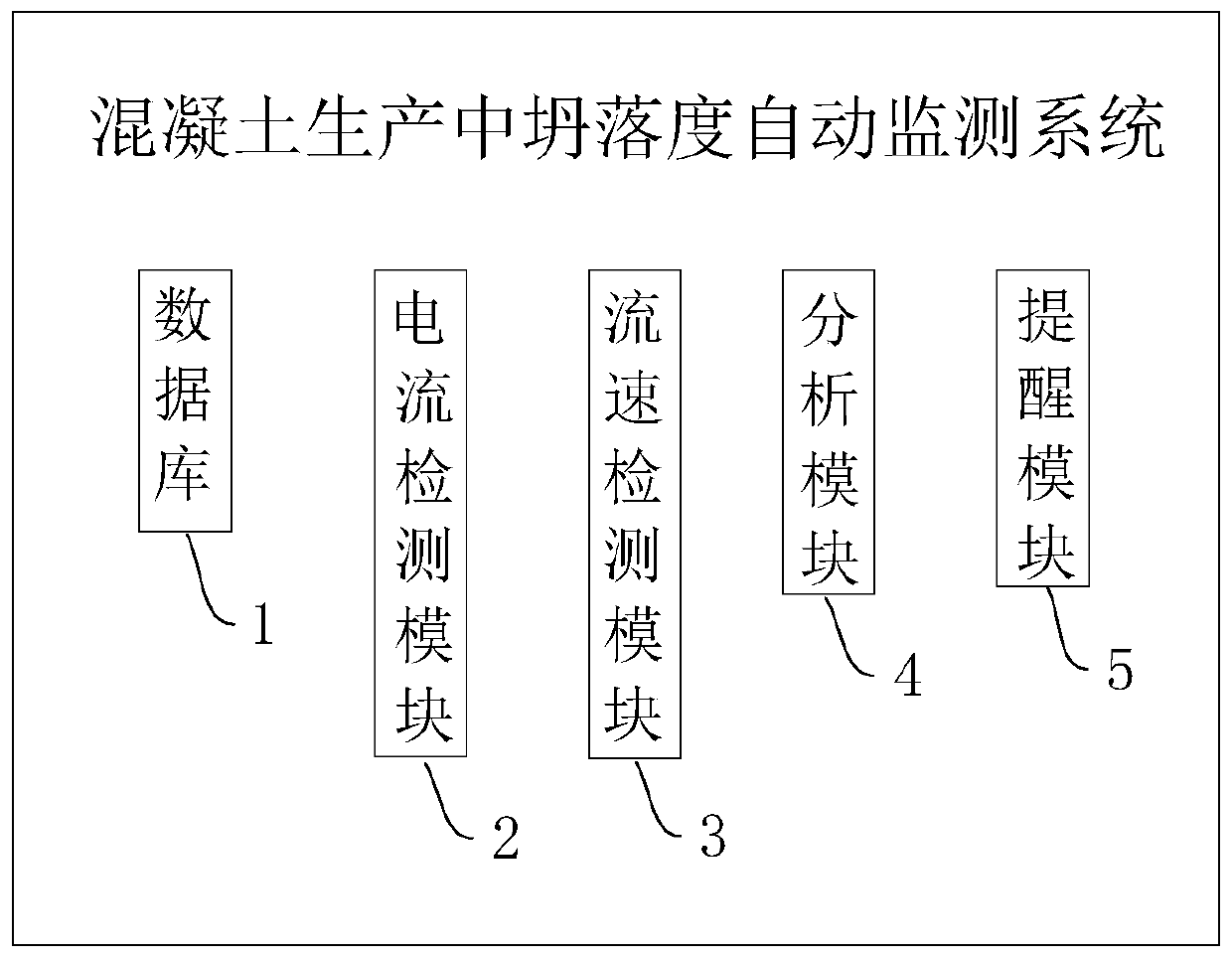

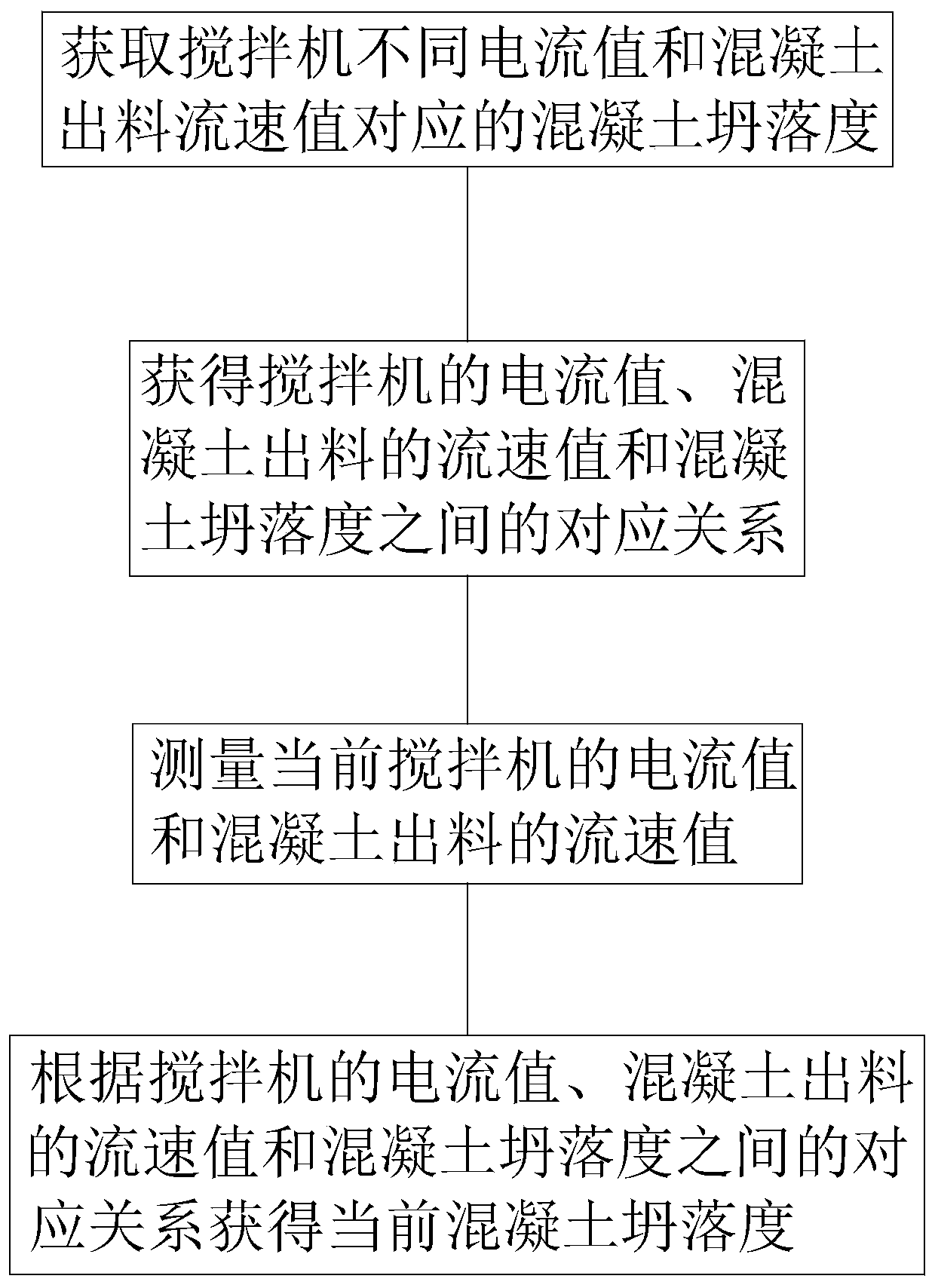

Automatic monitoring method and system for slumps in concrete production

InactiveCN109975529AQuality improvementGuarantee the quality of finished productsMaterial testing goodsMonitoring systemStructural engineering

The invention relates to the field of concrete production, in particular to an automatic monitoring method and an automatic monitoring system for slumps in concrete production. The automatic monitoring method comprises the steps of: acquiring concrete slumps corresponding to different current values and concrete discharging flow velocity values of a stirring machine; acquiring a corresponding relation among the current values of the stirring machine, the concrete discharging flow velocity values and the concrete slumps; measuring the current value and the concrete discharging flow velocity value of the stirring machine at present; and acquiring a current concrete slump according to the corresponding relation among the current values of the stirring machine, the concrete discharging flow velocity values and the concrete slumps. By adopting the automatic monitoring method and the automatic monitoring system, the staff can determine the quality of the concrete according to the slump of the currently discharged concrete, improve the detection efficiency of the concrete slump, ensure the quality of the finished product of the concrete, provide a reference for the improvement of the nextproduction, and improve the quality of concrete production.

Owner:上海申昆混凝土集团有限公司

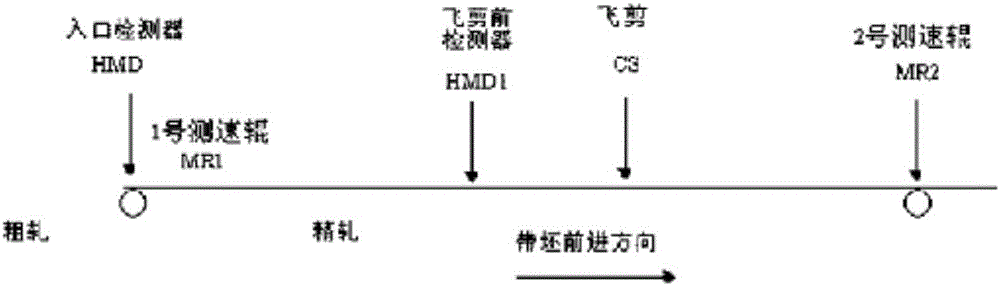

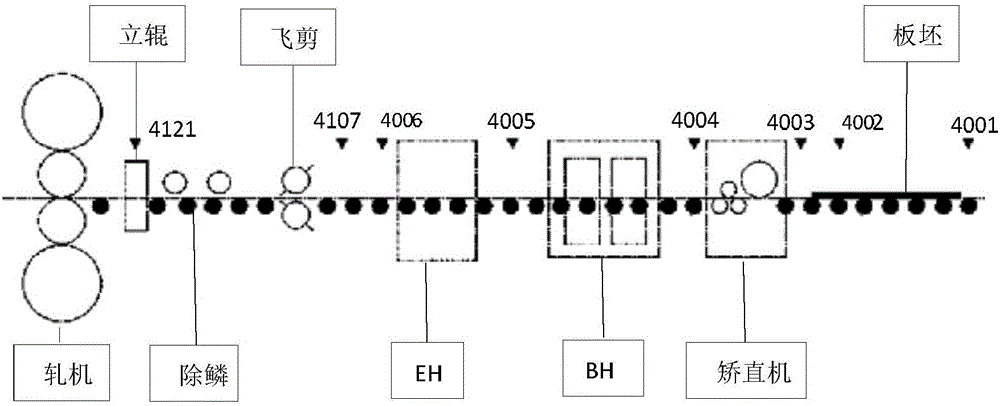

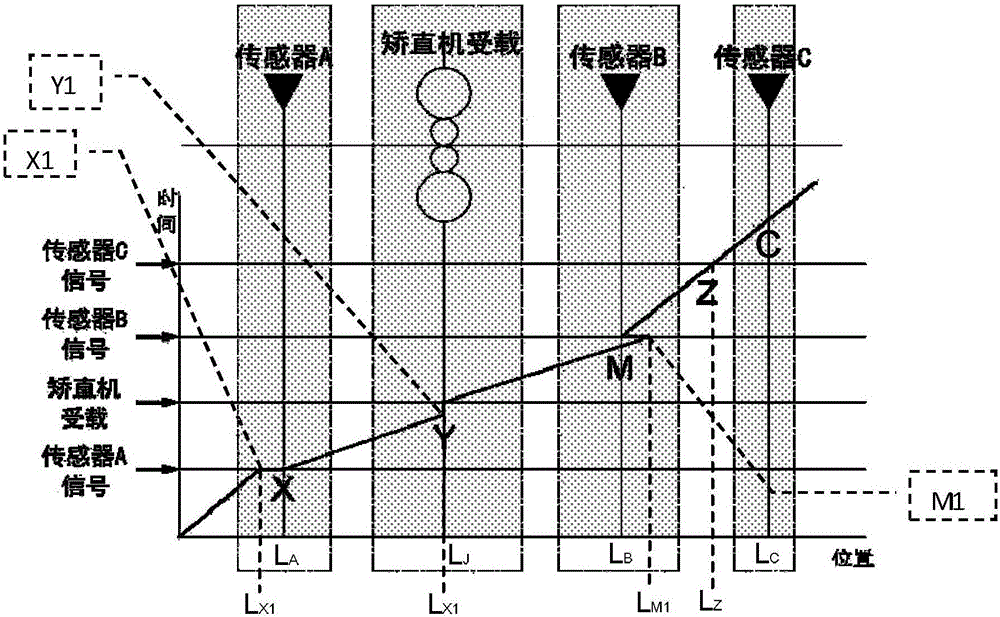

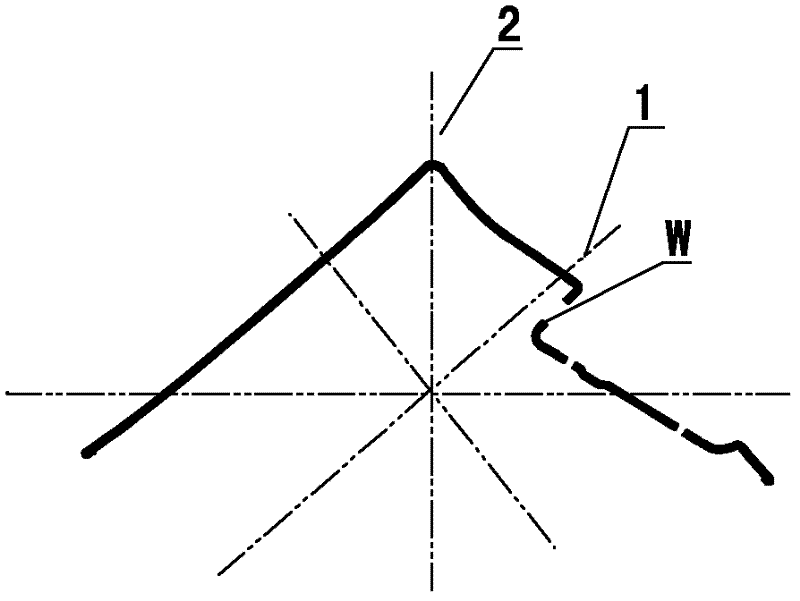

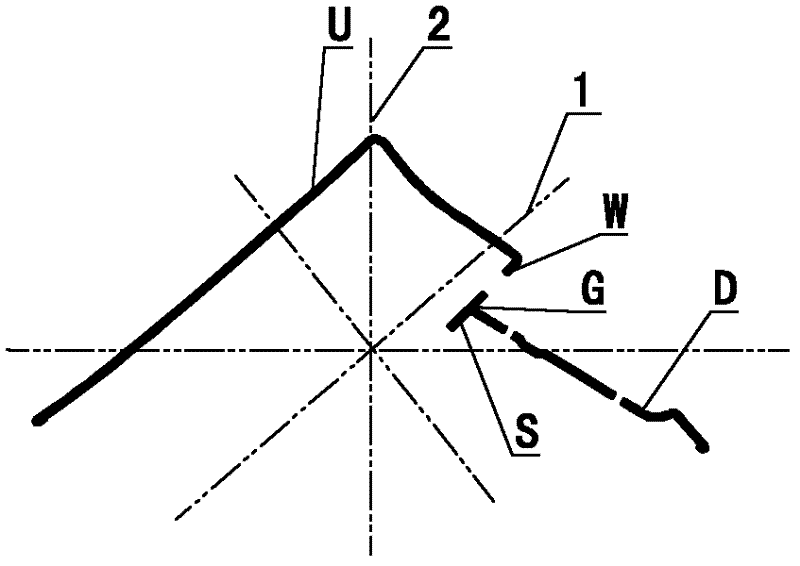

Hot-rolled flying shear head and tail initial shearing position dynamic control method

ActiveCN107433287ARealize dynamic controlAccuracy requirements metRare end control deviceMetal rolling arrangementsProduction lineSite location

The invention relates to control over a steel billet flying shear of a hot rolling machine, in particular to an initial shearing position dynamic control method applicable to a hot rolling machine flying shear. The method comprises the following steps of determining a position tracking detection range; determining dynamic detection points; calculating the distance from each dynamic detection point to a flying shear start point; determining the width of a tracking travel window; determining the practical running position of a strip steel; determining the calculated shearing length of the strip steel; comparing the calculated shearing length of the strip steel with a strip steel shearing length set value; and starting the flying shear to shear the strip steel. The detection areas of the head and tail positions of the strip steel are controlled through a finish rolling inlet of a hot continuous rolling production line; through combination with arrangement of the strip steel head and tail position tracking travel window and correction of the basic displacement of the strip steel, position tracking integrated initial points are switched dynamically, and dynamic control over strip steel initial shearing position control points is realized. Position tracking data are more aligned with the requirement for the practical site location precision.

Owner:BAOSHAN IRON & STEEL CO LTD

Processing method for dehydrated mulberry leaves

ActiveCN103609661AReduce crude fiber contentGood palatabilityFruits/vegetable preservation by heatingFruits/vegetable preservation by dehydrationNutritionBlanching

The invention discloses a processing method for dehydrated mulberry leaves. The processing method comprises the following steps: (1) blanching and cooling, namely cleaning fresh mulberry leaves at 1 to 8 leaf positions, immersing the cleaned fresh mulberry leaves in alkaline liquid, performing ultra-low-temperature blanching processing, fishing out the processed mulberry leaves, and cooling the processed mulberry leaves quickly by using cold water; (2) dehydrating and drying, namely drying the cooled mulberry leaves in a dehydrator, and drying the dried mulberry leaves in hot air drying equipment until the water content is 30 to 50 percent; (3) permeating and drying, namely immersing the dried mulberry leaves in compound sugar liquid for permeation treatment, drying the mulberry leaves in a heat pump drying equipment again until the water content is below 10 percent. According to the processing method, an alkali liquid ultra-low-temperature blanching technology is adopted, so that the damage to nutritional active ingredients caused by the high temperature is avoided and the effect on removing the grass flavor is good compared with that in a conventional blanching mode.

Owner:GUANGDONG XINDA CHRYSALIS SILK

Four-edge board cutting machine for cutting carpentry veneer and four-edge cutting method of carpentry veneer

InactiveCN103009439AImprove finished product qualityNo gapsProfiling/shaping machinesEngineeringEnergy consumption

The invention relates to a four-edge board cutting machine for cutting a carpentry veneer, and a four-edge cutting method of the carpentry veneer. The four-edge board cutting machine comprises a rack, a rectangular bearing platform used for supporting the carpentry veneer, a rectangular bottom press bench used for implementing a flatting action on the supported carpentry veneer, a movable knife rest encircling the outside of the bottom press bench, cutting knifes fixedly mounted on an inner side wall at the periphery of the movable knife rest, a roller oppositely-grinding type veneer conveying mechanism used for conveying the carpentry veneer, a bottom press bench lifting control mechanism, a movable knife rest lifting control mechanism and a veneer feeding mechanism. According to the four-edge board cutting machine, a full frame of the carpentry veneer is compressed and flatted firstly, and then the four edges of the carpentry veneer are cut at the same time, so that joint opening or lamination of butting edges of the four cutting edges of the carpentry veneer are avoided in subsequent links such as assembling and prepressing, and the production efficiency of a core-board or a plywood is improved; the energy consumption is reduced; and the quality of a finished product is ensured.

Owner:河北北方绿野居住环境发展有限公司

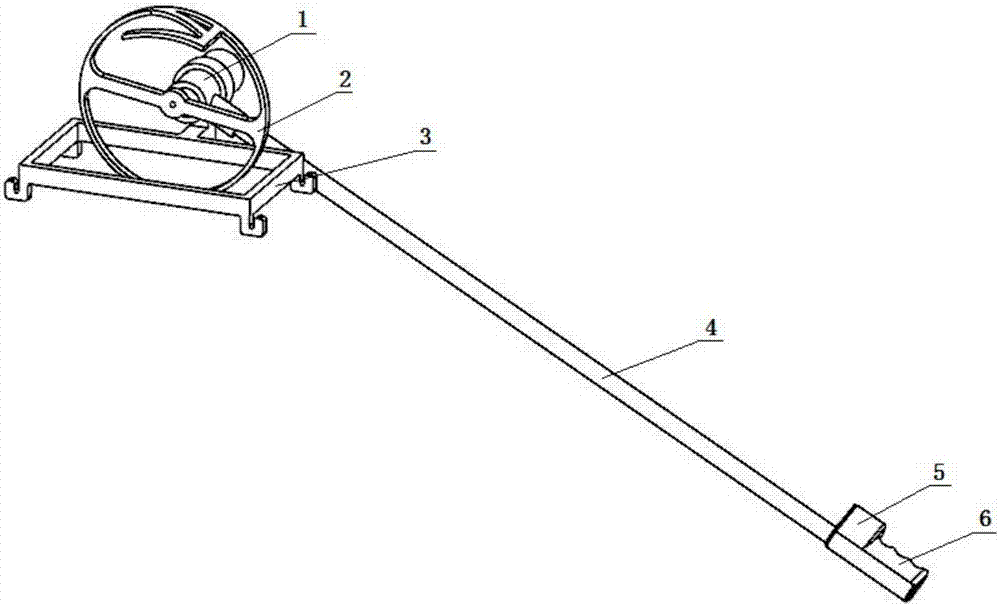

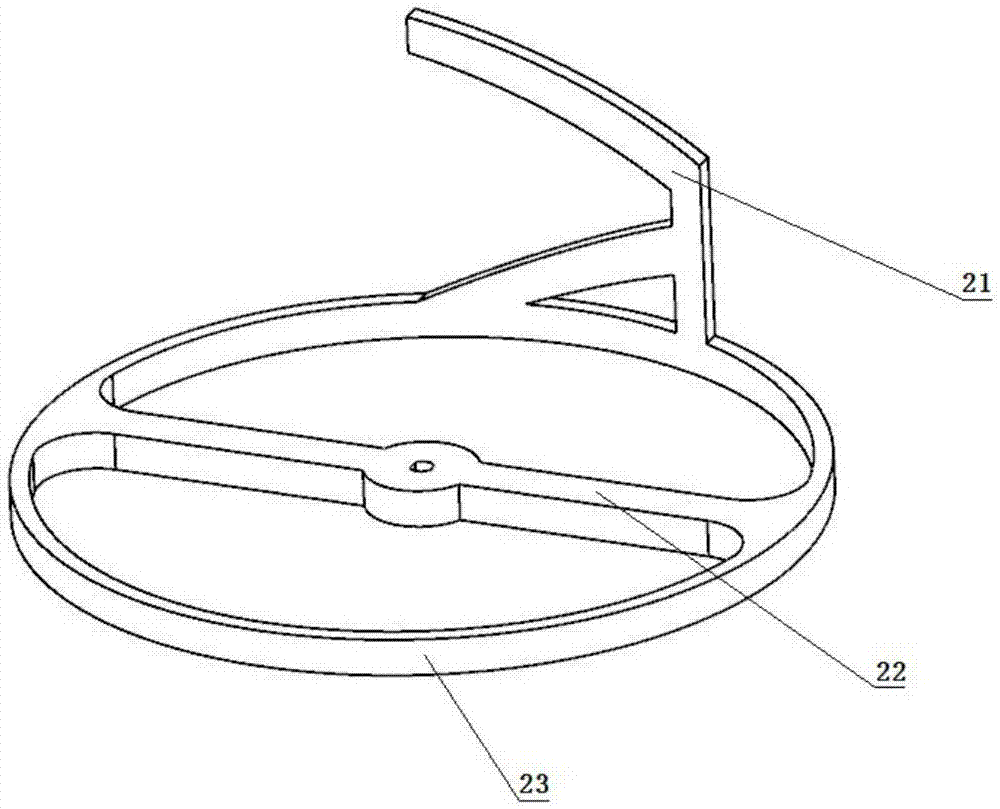

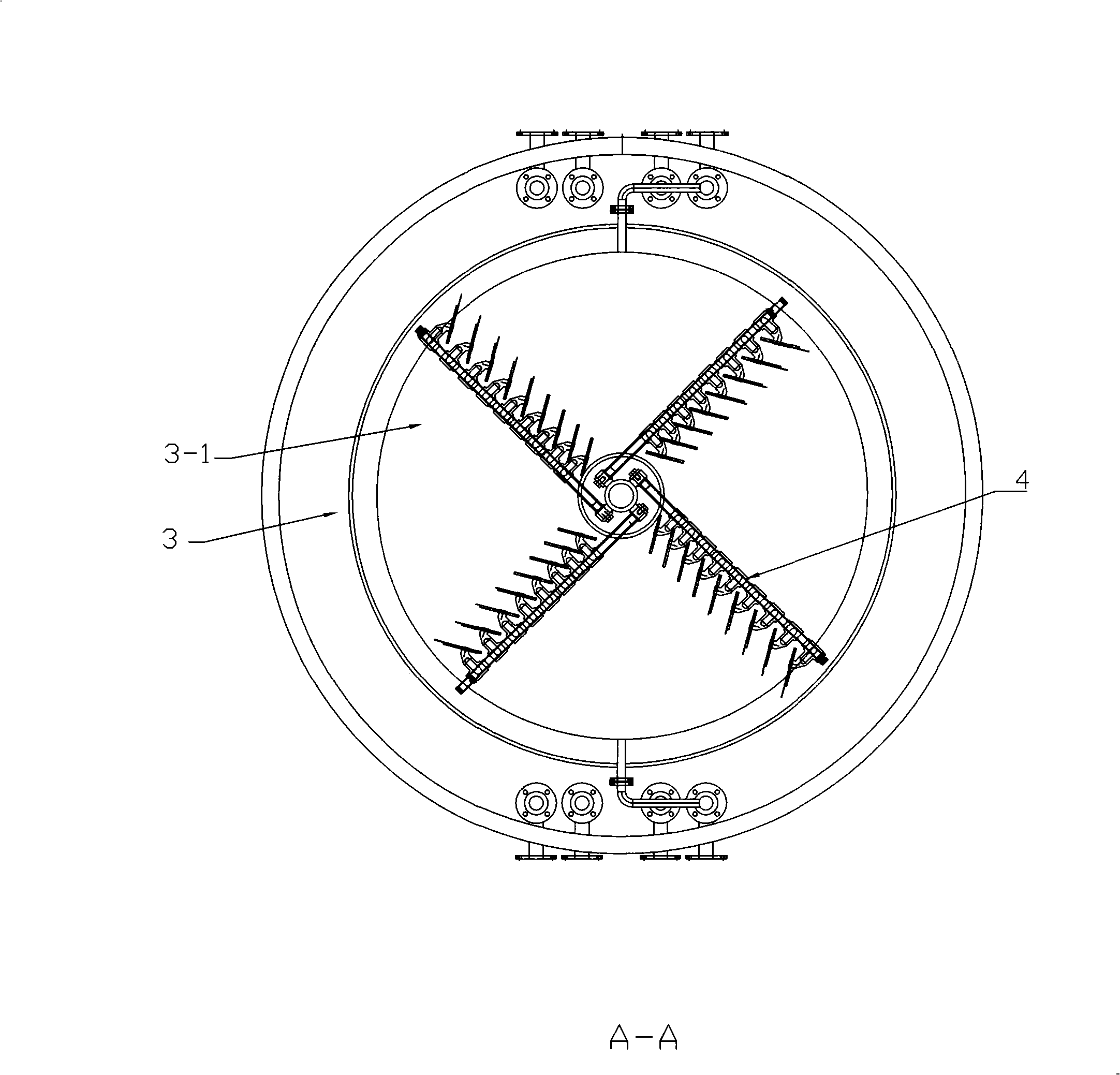

Rotary fruit picker

ActiveCN107371608ASimple and flexible operationReduce labor intensityPicking devicesMechanical engineeringFruit rot

Owner:NORTHEASTERN UNIV

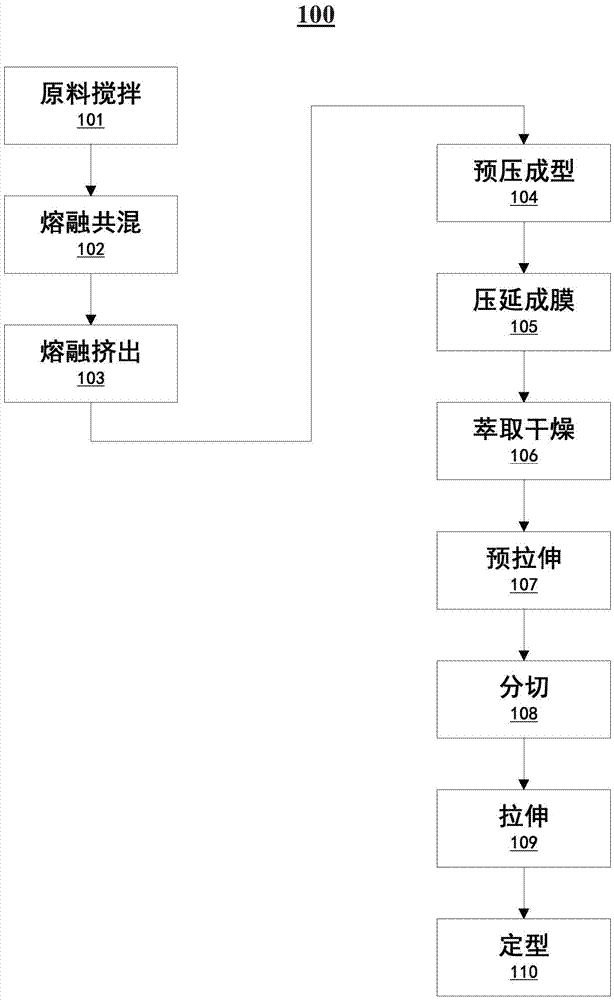

Method of manufacturing ultrahigh molecular weight polyethylene fiber

InactiveCN106978637AQuality assuranceImprove continuityArtificial filament heat treatmentStretch-spinning methodsFiberMolten state

The invention discloses a method for manufacturing ultra-high molecular weight polyethylene fibers. The method comprises the following steps: stirring ultra-high molecular weight polyethylene powder and a solvent to form a resin; heating the resin, and blending the ultra-high molecular weight polyethylene powder and the solvent in the resin in a molten state to form a melt; extruding the melt while maintaining the molten state; pre-pressing the melt into a base film; calendering the base film into a film; extracting the solvent to form a dry film; pre-stretching the dry film to form a pre-drawn slitting the pre-stretched film to form a slit film; stretching the slit film to form a stretched film; heating the stretched film to set the stretched film. The method of the invention can continuously produce ultra-high molecular weight polyethylene fibers with stable quality.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

Flexible OLEM and AMOLEM ultrathin glass cover plate thinning process

The invention discloses a flexible OLEM and AMOLEM ultrathin glass cover plate thinning process which is high in rate of finished products and stable in quality. The process includes steps: step one,pre-cleaning; step two, primary etching, to be specific, chemically etching each glass plate to realize once integral strengthening, and making the product thickness in a range of 200+ / -10micron through chemical strengthening etching; after etching is finished, subjecting products to thickness section classification, and classifying at section intervals of 5micron to facilitate subsequent secondary etching operation; step three, glass plate deep thinning pretreatment, to be specific, attaching two to-be-etched products in a same section to upper and lower surfaces of a supporting plate; sealing two short sides and long sides with half sides of acid-proof tapes until three layers of plate materials of fitting sides are completely protected by the tapes; step four, secondary etching, to be specific, performing thickness measurement at a fixing position of three layers of laminated plates until target thickness is achieved, wherein the target thickness is equal to a value obtained by subtracting thinning thickness from the sum of the thickness of the two to-be-etched glass plates and thickness of the supporting plate; step five, product separation; step six, wiping; step seven, finalinspection of appearance.

Owner:惠晶显示科技(苏州)有限公司

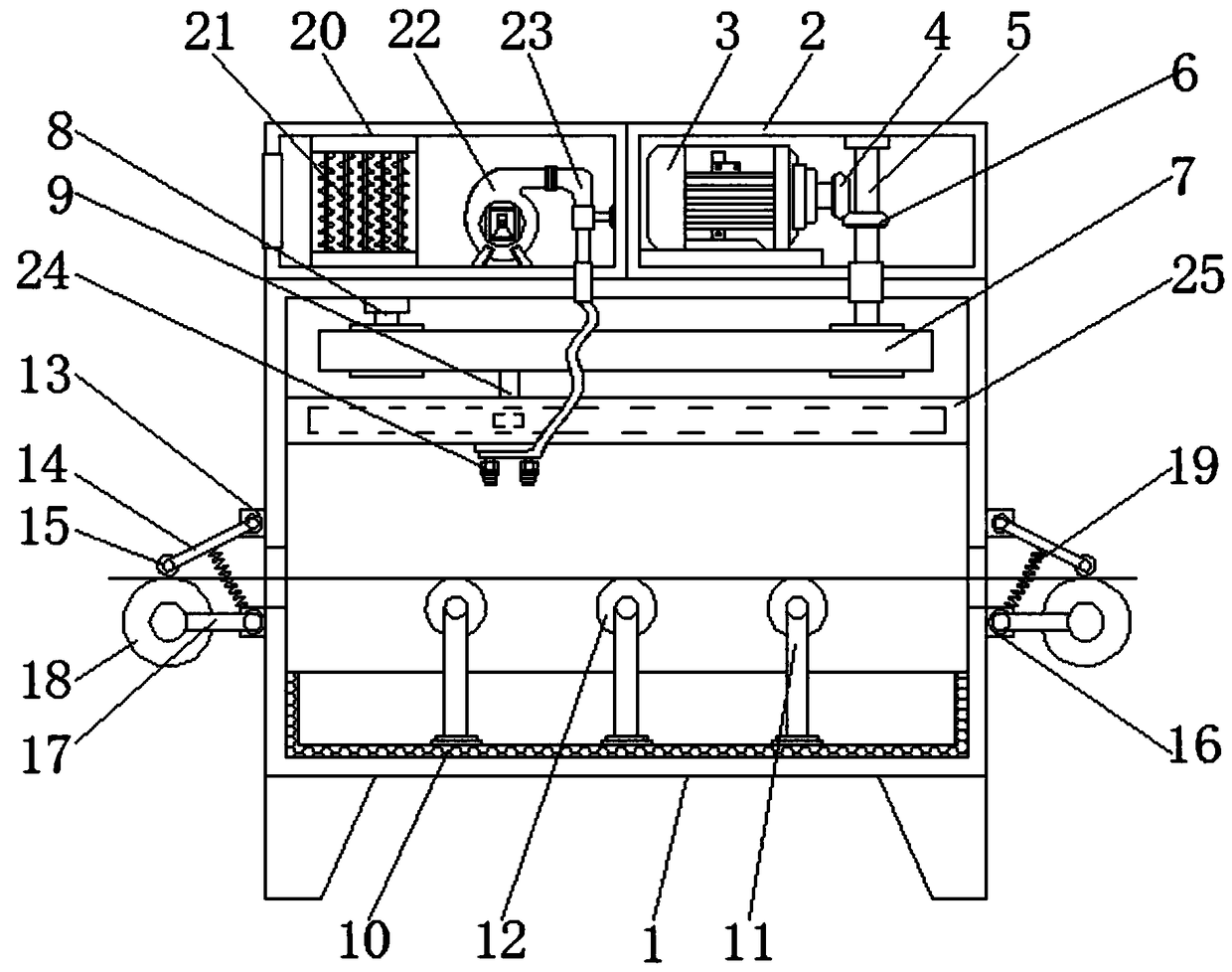

Rapid and uniform drying device for textile fabric

InactiveCN108106379AAchieve the purpose of dryingFail to meet production requirementsDrying gas arrangementsDrying machines with progressive movementsEngineeringDrying time

The invention discloses a rapid and uniform drying device for textile fabric, and relates to the technical field of textile machinery equipment. The rapid and uniform drying device comprises a box body, a motor box is fixedly connected to the right side of the top of the box body, and a motor is fixedly connected to the bottom of the inner wall of the motor box; a first bevel gear sleeves the surface of an output shaft of the motor, a first rotating rod is rotationally connected to the top of the inner wall of the motor box, a second bevel gear sleeves the surface of the first rotating rod, and the surface of the second bevel gear is meshed with the surface of the first bevel gear; and the bottom end of the first rotating rod sequentially penetrates through the motor box and the box body to extend into the interior of the box body, and a reciprocating device is fixedly connected to the surface of the part, extending into the interior of the box body, of the first rotating rod. According to the rapid and uniform drying device for the textile fabric, the problem that the textile fabric can not meet the production requirement due to incomplete drying is solved, the drying efficiency of the textile fabric is improved, the drying time of the textile fabric is saved, and the efficiency of the whole processing program is improved.

Owner:宁波市鄞州智伴信息科技有限公司

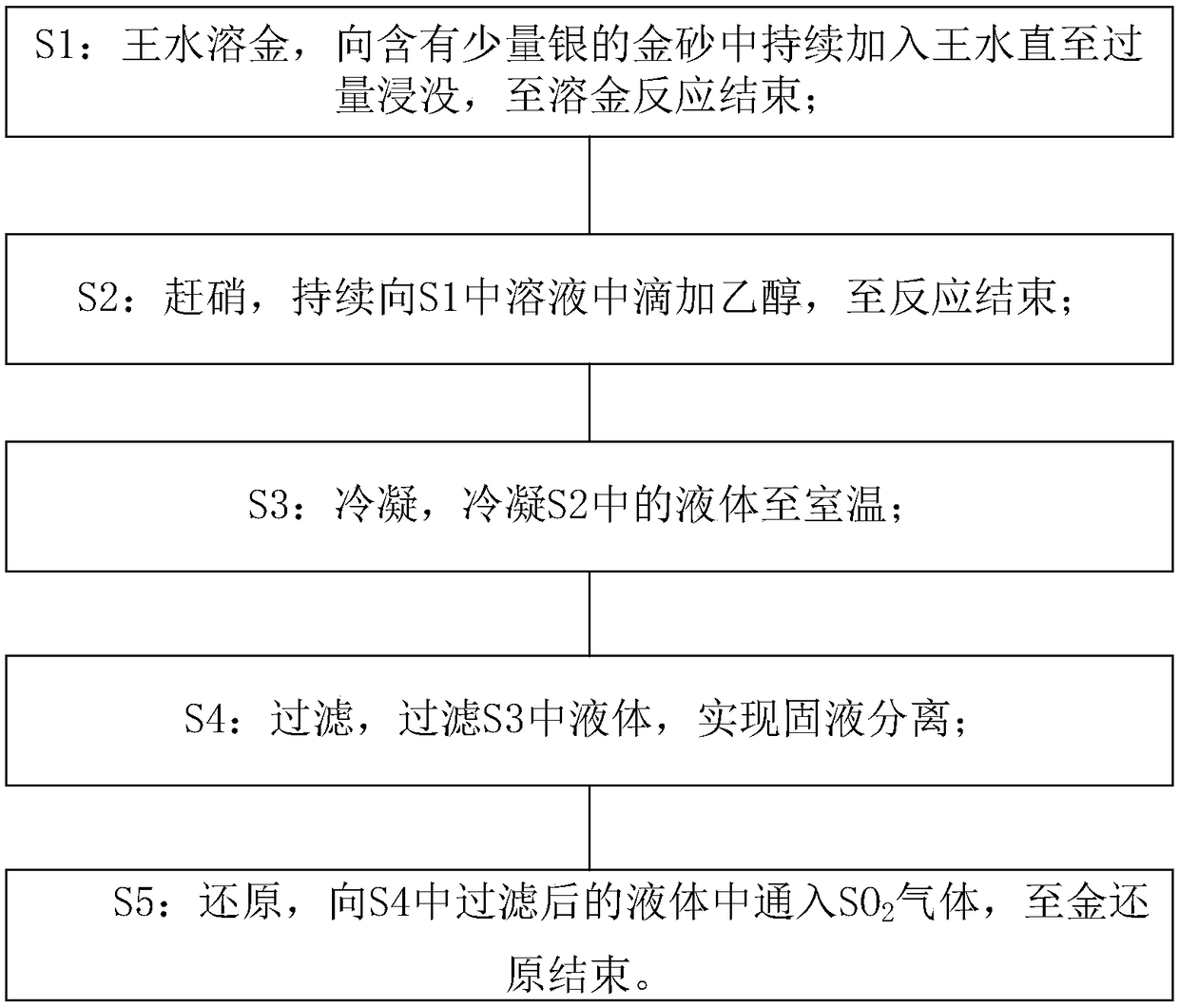

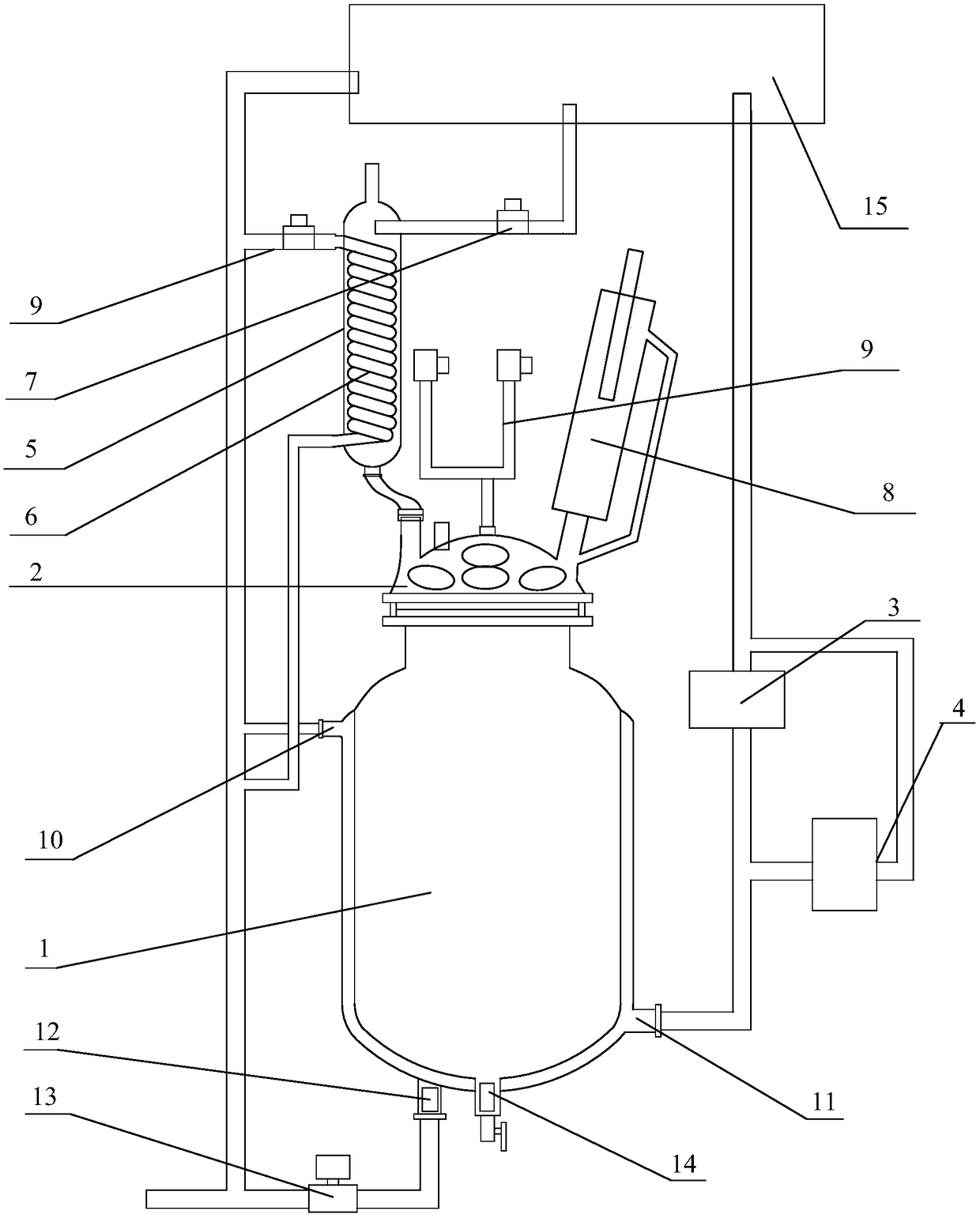

Method and device used for gold purification

PendingCN108642301AHigh precisionGuarantee the quality of finished productsProcess efficiency improvementAlcoholRoom temperature

The invention belongs to the technical field of gold purification, and particularly discloses a method and device used for gold purification. The method used for gold purification comprises the stepsof S1, aqua regia gold dissolving, wherein aqua regia is continuously added into gold sand containing a small amount of silver until excessive immersion is achieved, and the gold dissolving reaction is finished; S2, nitric acid esterification, wherein ethyl alcohol is continuously and dropwise added into the solution in the S1 until the reaction is finished; S3, condensation, liquid in the S2 is condensed to the room temperature; S4, filtering, liquid in the S3 is filtered, and solid-solution separation is achieved; S5, reduction, SO2 gas is led into the liquid filtered in the S4 until gold reduction is finished. Through the above step, the gold purification precision is greatly improved, high-purity gold can be extracted from the low-purity gold at a time, and meanwhile, the finished product quality of the high-purity gold is ensured.

Owner:SHANDONG MOKINGRAN JEWELRY +1

Method for processing tube number winding pipe

InactiveCN101468367ASimple working processReduce processing timeOther chemical processesEngineeringConductor Coil

The invention relates to a method for processing a syphon, and belongs to the field of the method for manufacturing brass instruments. The processing method comprises: filling a mixture of sand and water in a straight pipe; cooling the straight pipe till the mixture of the sand and the water is condensed to a solid; processing the straight pipe of which the inside is filled with the mixture of the sand and the water into the syphon; and unfreezing the processed syphon till the water in the syphon thaws and flows out from the syphon. The method can simplify processing flow, reduce processing time, improve production efficiency and yield, reduce the manufacturing cost of a product, and ensure the quality of a finished product in order to achieve good performing effect in performance.

Owner:TIANJIN JINBAO MUSICAL INSTR

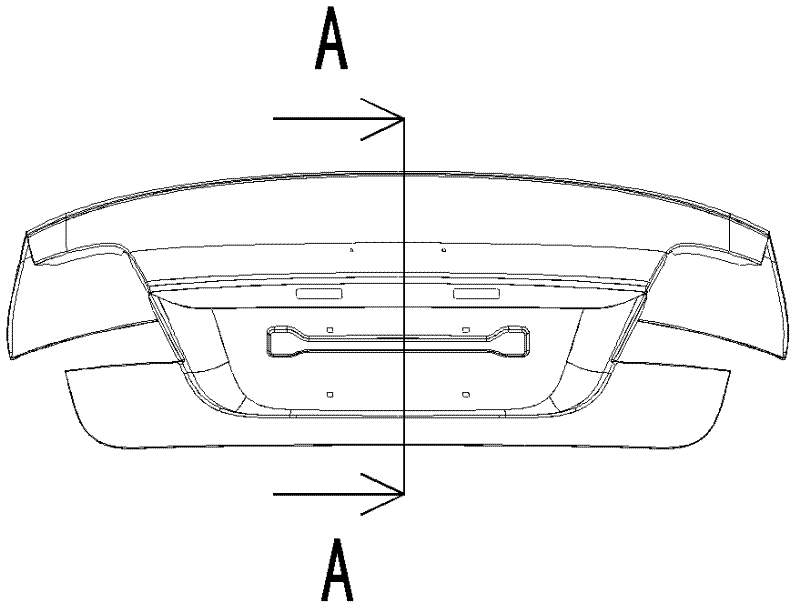

Trunk outer plate and punching process thereof

ActiveCN102310887AGuarantee the quality of finished productsEasy to processSuperstructure subunitsOptical signallingBody in whiteEngineering

The invention discloses a trunk outer plate and a punching process thereof, which belong to the field of automobile body-in-white part design and manufacture. The trunk outer plate disclosed by the embodiment of the invention comprises a license plate lamp installing sectional surface which is parallel to the X axis of an automobile body, a part is divided into two parts by the trunk outer plate through making a crossing line parallel to the XY plane of the automobile body along the license plate installing sectional surface, the upper part is positioned above the crossing line, the lower part is positioned under the crossing line, the upper part comprises the license plate lamp installing sectional surface, and the upper part and the lower part are connected through laser brazing. In theembodiment of the invention, the trunk outer place is divided into the upper part and the lower part, in addition, the laser brazing connection mode is adopted, and the problem of forming incapability caused by punching negative angle occurrence of the part when a license plate is arranged on a trunk cover is solved, through the structural design of the trunk outer plate, the quality of finished products is ensured, and simultaneously, the trunk outer plate is easy to process and manufacture.

Owner:CHERY AUTOMOBILE CO LTD

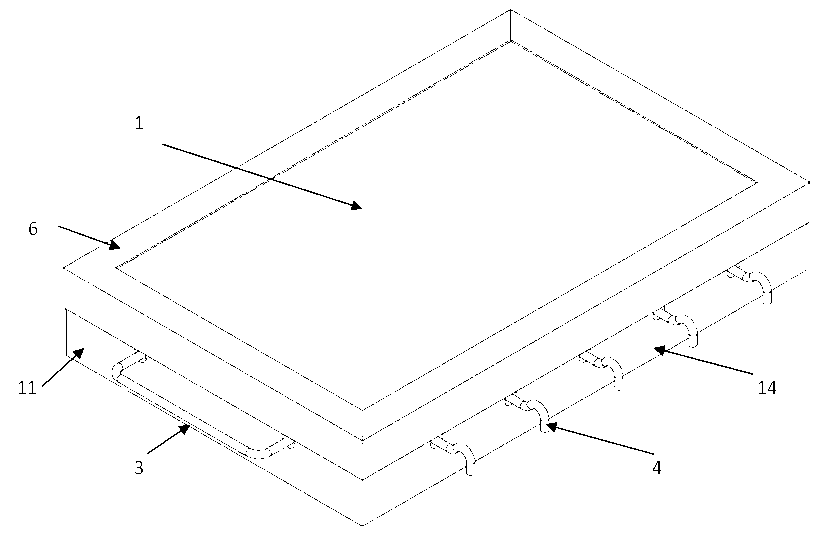

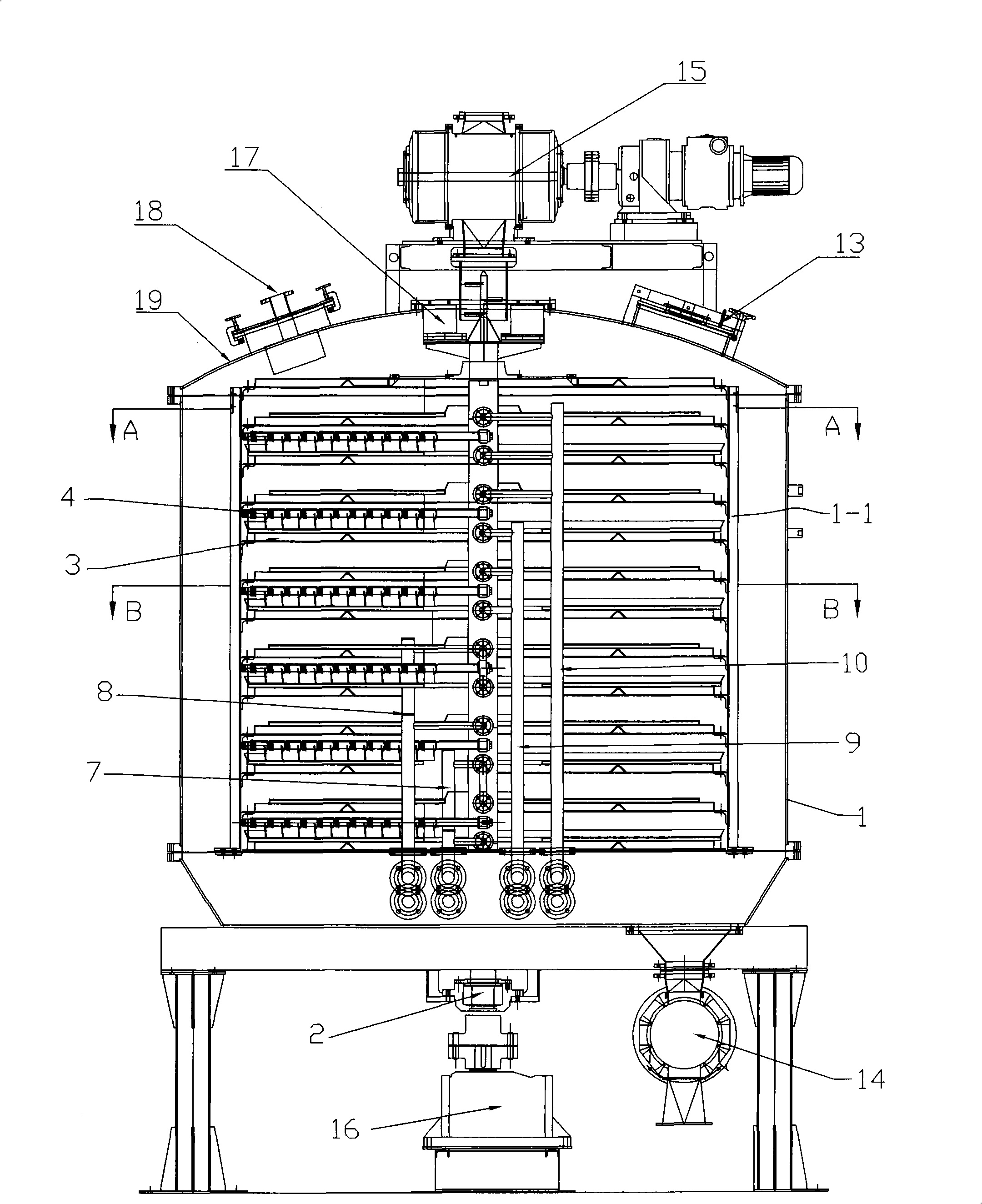

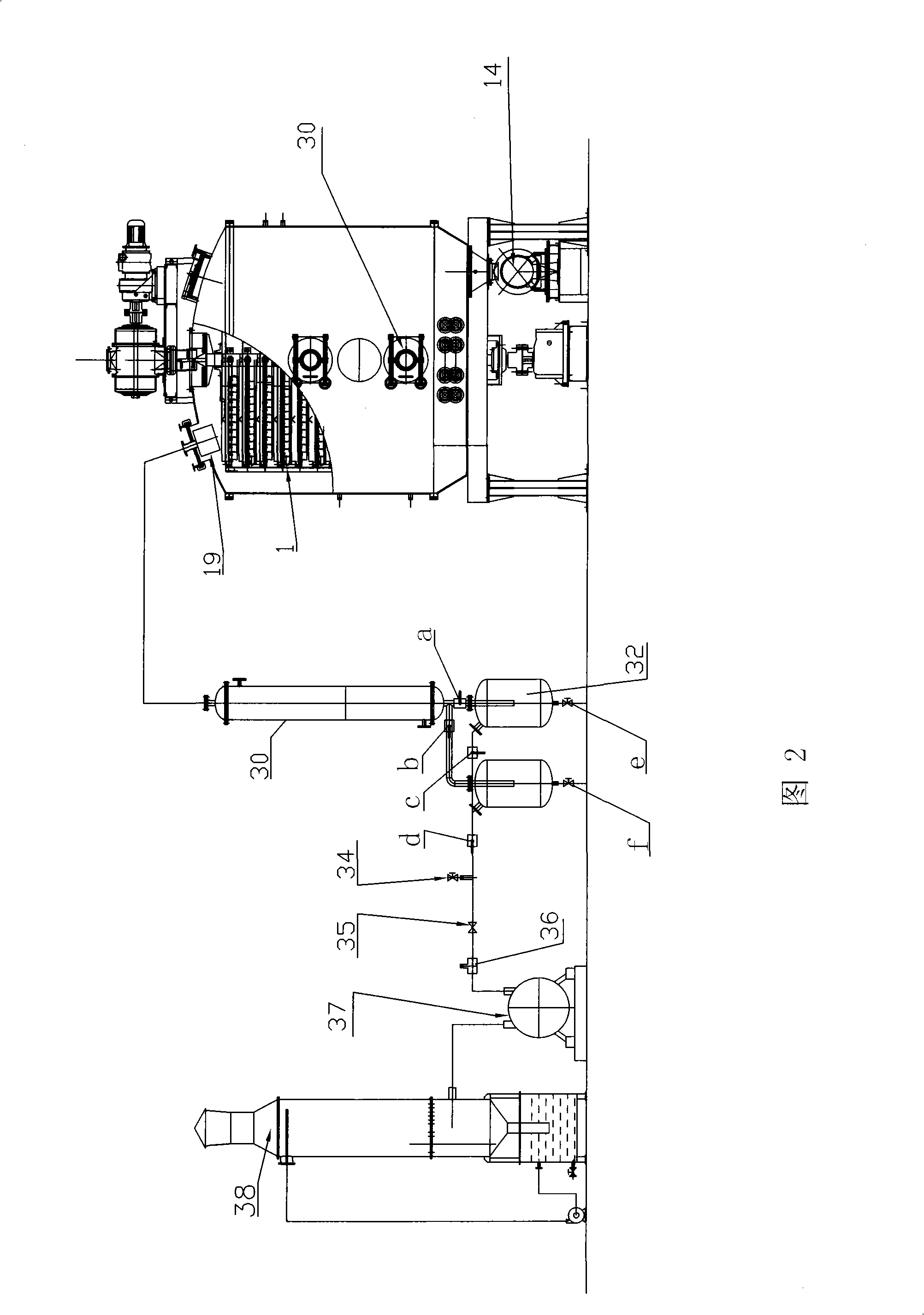

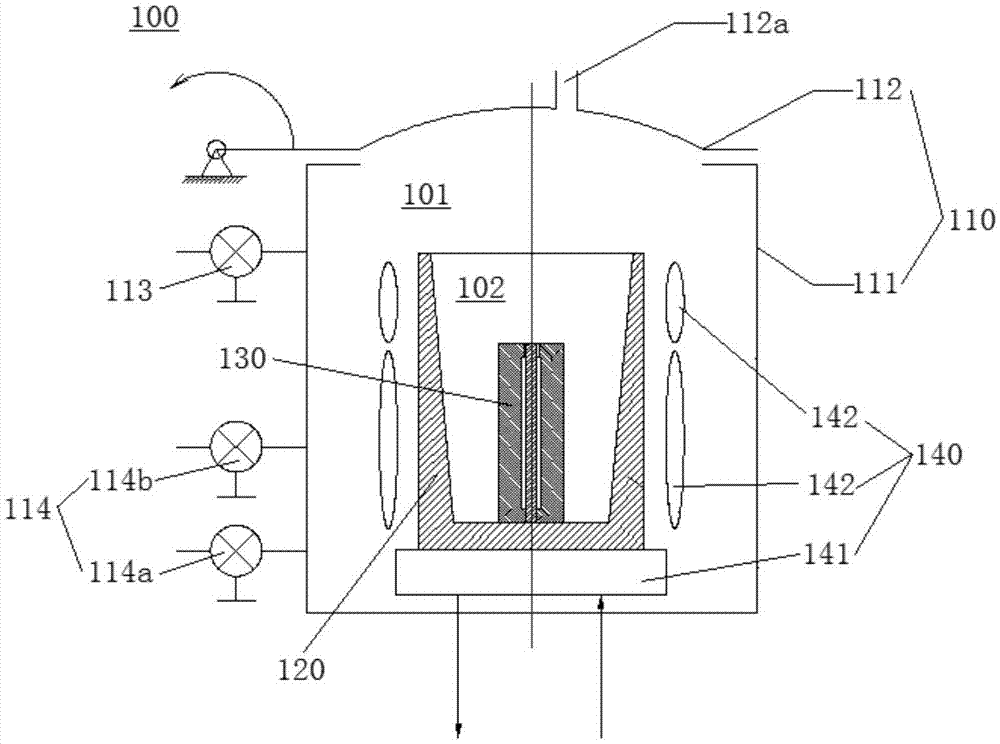

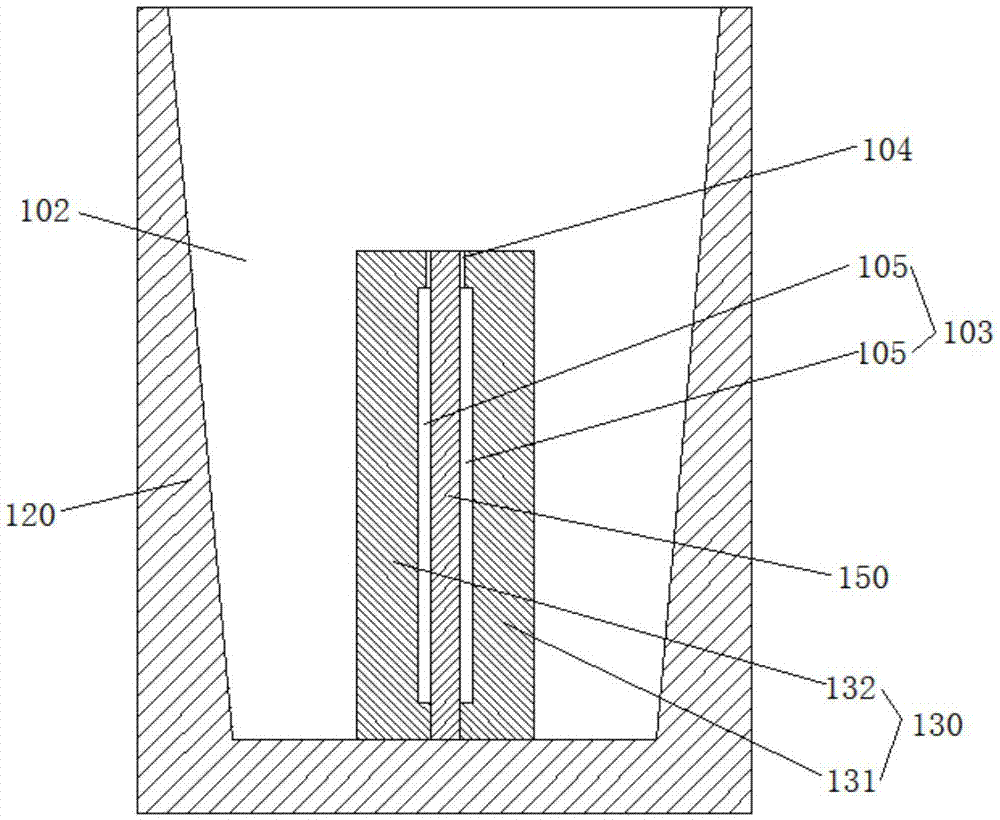

Hot plate type continuous vacuum drying system

InactiveCN101408371AGuarantee the quality of finished productsReduce the feeding and discharging speedDrying using combination processesDrying solid materials with heatHeat conductingEngineering

The invention relates to a hot-plate type continuous vacuum drying system, comprising a main machine and a cylinder of the main machine; a main shaft is arranged inside the cylinder of the main machine; a bed bracket is arranged on the inner wall of the cylinder; a plurality of layers of plate-style jacket heating devices are arranged on the bed bracket; the main shaft passes through central apertures of each plate-style jacket heating device and is arranged between the top and the bottom of the cylinder; the upper end faces of the plate-style jacket heating devices are material-bearing faces; the main shaft is provided with a plurality of branch arms and material turning plates are arranged on the lower end faces of the branch arms; and the plate-style jacket heating device is a plate jacket casing inside which a heat conducting pipeline is arranged; the plurality of layers of plate-style jacket heating devices can be at least divided into a high-temperature layer group, an intermediate-temperature layer group, a low-temperature layer group and a cooling layer group from top to bottom. The hot-plate constant vacuum drying system adopts the combined heating system adopting both drying and cooling so as to reduce the processes and largely enhance the manufacturing efficiency and the productivity; and simultaneously the drying system can realize the constant vacuum feeding and discharging, solvent recycling and disposal of harmful gas.

Owner:查晓峰

Infiltration device and infiltration system comprising same

The invention discloses an infiltration device and an infiltration system comprising the same. The infiltration device comprises a first container, a second container, a forming mold and a temperature field control device, wherein a first cavity is defined out through the first container; the second container is arranged in the first cavity, and a second cavity for containing infiltration liquid is defined out through the second container; the forming mold is provided with a third cavity and a communication structure for communicating with the second cavity and the third cavity, and through the communication structure, at least part of the infiltration liquid in the second container can enter the second cavity through the communication structure based on gravity; and the temperature field control device is arranged to be used for controlling the temperature of the infiltration liquid. According to the infiltration device, control is easy, production is safe, moreover, the product yield is high, and the defects that no shrinkage cavity exists or shrinkage is poor are overcome.

Owner:BYD CO LTD

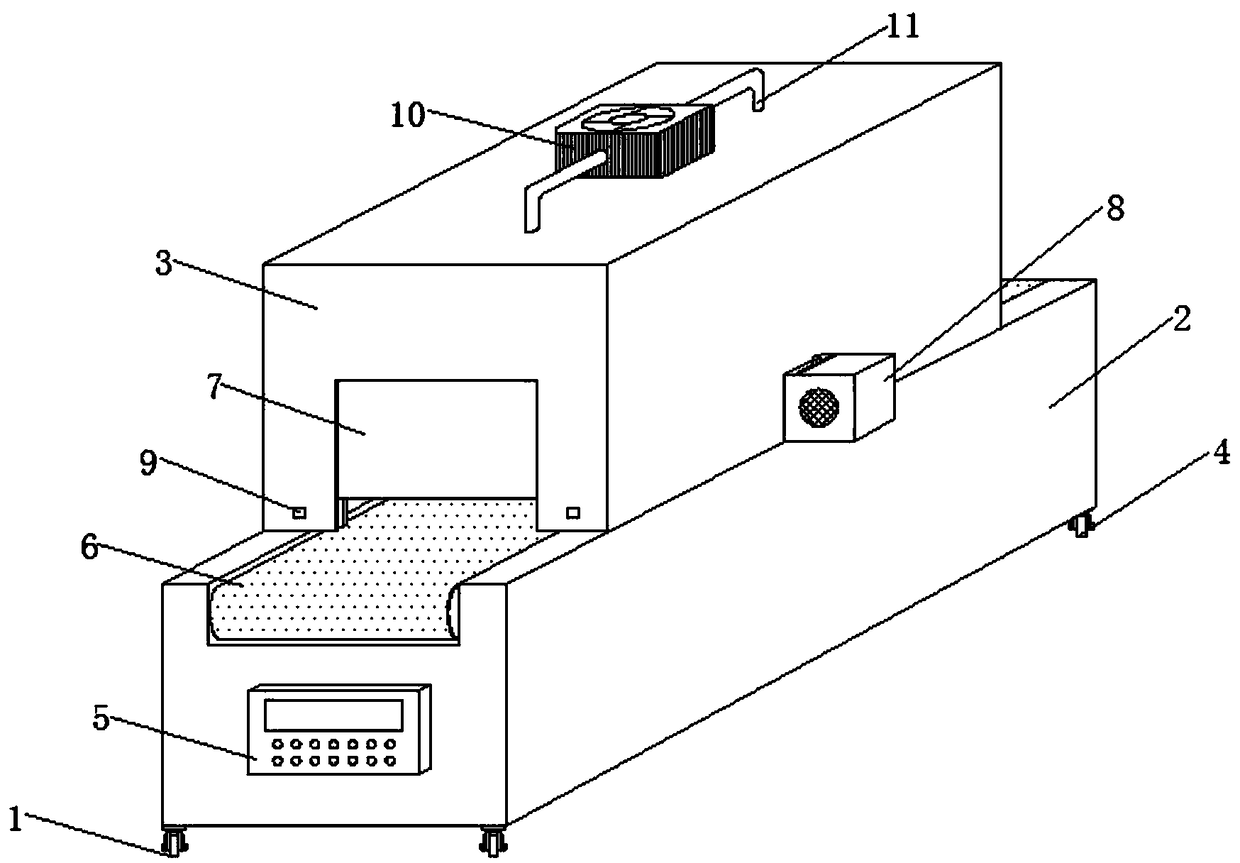

Paint baking device for electronic product processing

InactiveCN108838043AImprove continuityImprove work efficiencyPretreated surfacesCoatingsCooking & bakingEngineering

The invention discloses a paint baking device for electronic product processing. A base is arranged at the bottom of a device body, an Y355 motor is installed at the bottom in the base, and a belt isinstalled at one end of the Y355 motor. Conveyor rollers are installed at one end of the belt, a conveyor belt is laid on the outer side of the conveyor rollers, a baking box is installed at the top of the base, and a fan is installed on the middle portion of the top of the baking box. Wind supply pipes are installed on two sides of the fan, telescopic pipes are fixedly connected to the bottom ends of the wind supply pipes, wind distributing plates are installed at the bottoms of the telescopic pipes, and a roaster is installed at the top end of the middle portion in the baking box. Electric heating pipes are installed on middle portions of two sides in the baking box, wind outlets are formed in bottom ends of two sides in the baking box, and wind exhaust boxes are installed on the outer sides of the wind outlets. The wind supply pipes are connected with the wind distributing plates through the telescopic pipes, the telescopic pipes can drive the wind distributing plates to stretch andretract back and forth when wind blows, the paint baking device is flexible and fast, the blowing range of draught of the wind distributing plates is expanded, and the work efficiency of the device body is improved.

Owner:芜湖通全电子电器科技创业有限公司

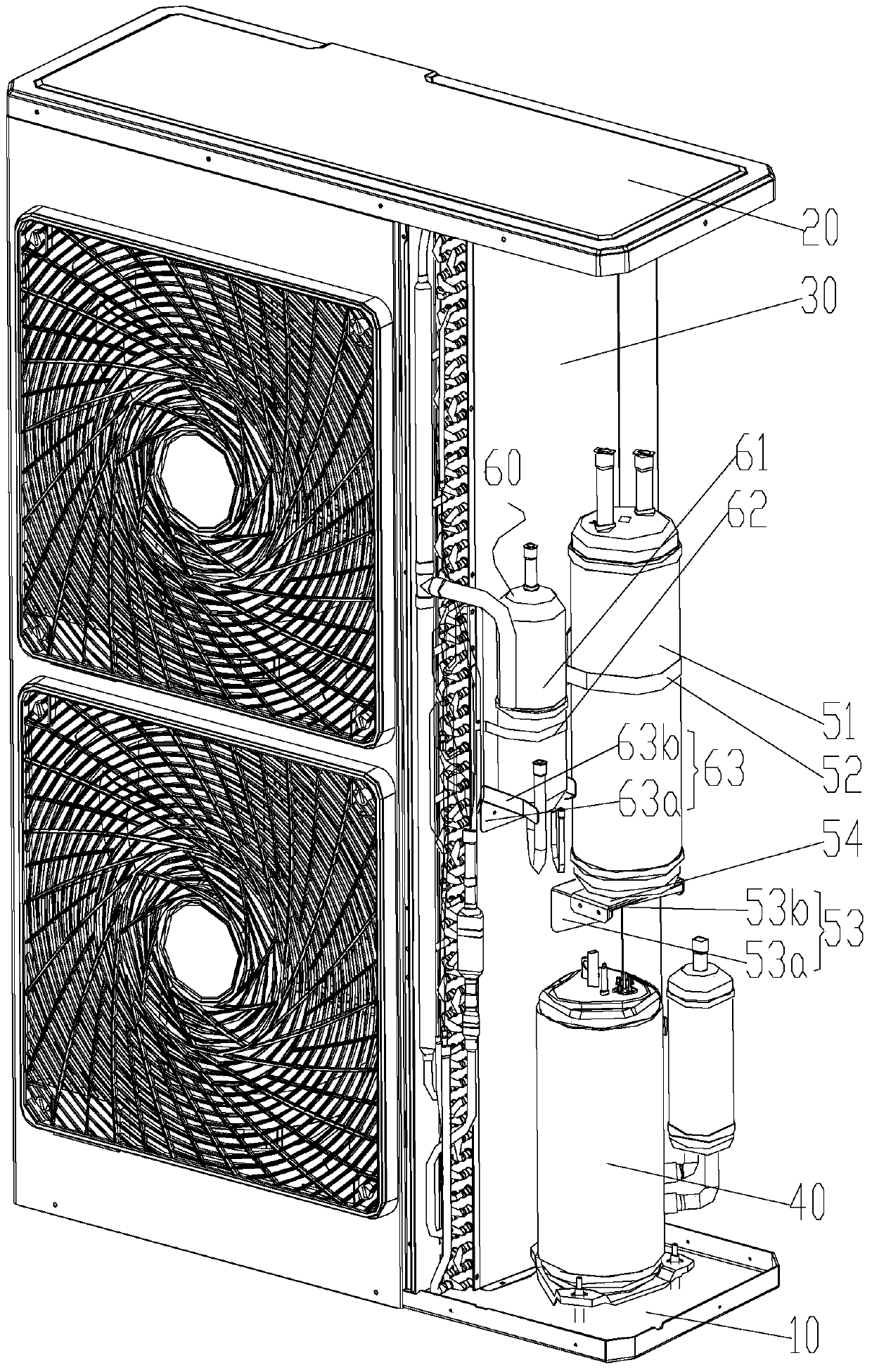

Outdoor unit of air conditioner

ActiveCN104197430ABig spaceReduce vibration and noiseLighting and heating apparatusAir conditioning systemsVibration amplitudeVapor–liquid separator

The invention provides an outdoor unit of an air conditioner. The outdoor unit comprises a base plate, a top cover, a partition, a compressor and a gas-liquid separator. The partition is disposed between the base plate and the top cover. The compressor is disposed on the base plate. The gas-liquid separator is disposed on the partition. The bottom of the gas-liquid separator is higher than the top of the compressor. The distance between the bottom of the gas-liquid separator and the base plate is smaller than two thirds of the height of the partition. Due to the fact that the gas-liquid separator is disposed on the partition, the gas-liquid separator and the compressor are disposed at different positions, mutual vibration transmission of the gas-liquid separator and the compressor is avoided, and vibration frequency and vibration amplitude are lowered. Due the fact that the distance between the compressor and the gas-liquid separator is increased, that is to the peripheral space of the compressor is increased, vibration, caused by the compressor, to peripheral air is dissipated easily, vibration noise of the compressor is reduced effectively, performance of the outdoor unit is increased, user experience is increased, and the service life of the outdoor unit is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

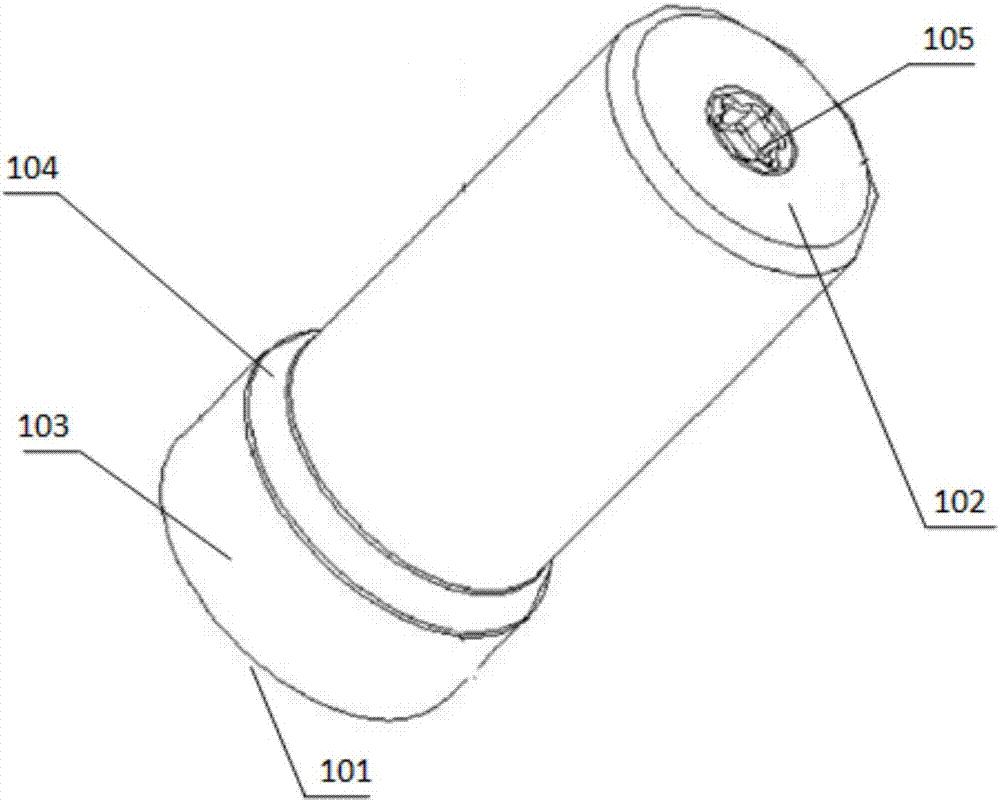

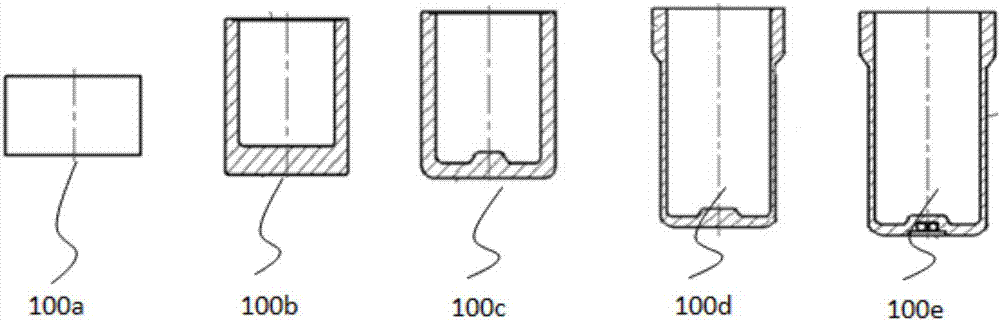

Cold-forging forming process for energy accumulator tank forging and reverse extrusion die

ActiveCN106881366AGuarantee the quality of finished productsReduce manufacturing costExtrusion diesEngineeringForging

The invention provides a cold-forging forming process for an energy accumulator tank forging. The cold-forging forming process comprises the steps of blanking, specifically, a rod-like blank is prepared; first reverse extrusion, specifically, the rod-like blank is placed into a first reverse extrusion die in a first predetermined shape to carry out first reverse extrusion to obtain a cup-shaped blank provided with a boss on the outer surface of the bottom; second extrusion, specifically, the cup-shaped blank is placed into a second reverse extrusion die with a second predetermined shape to carry out second reverse extrusion to obtain a cup-shaped blank provided with a boss on the inner surface of the bottom; third reverse extrusion, specifically, the cup-shaped blank is placed into a third reverse extrusion die with a third predetermined shape to carry out third reverse extrusion to obtain a cup-shaped blank provided with a step part; and fourth reverse extrusion, specifically, the cup-shaped blank is placed into a fourth reverse extrusion die with a fourth predetermined shape to carry out fourth reverse extrusion to obtain a finished product with an energy accumulator tank provided with a blind hole in the outer surface of the bottom. In the second reverse extrusion process of the cold-forging forming process for the energy accumulator tank forging, provided by the invention, the longitudinal pressure borne by the upper end surface of the cup-shaped blank is relatively small, so that the cup-shaped blank cannot be excessively upset, and the quality of the finished product of the energy accumulator tank forging is guaranteed.

Owner:JIANGSU CHUANGYI PRECISION FORGING

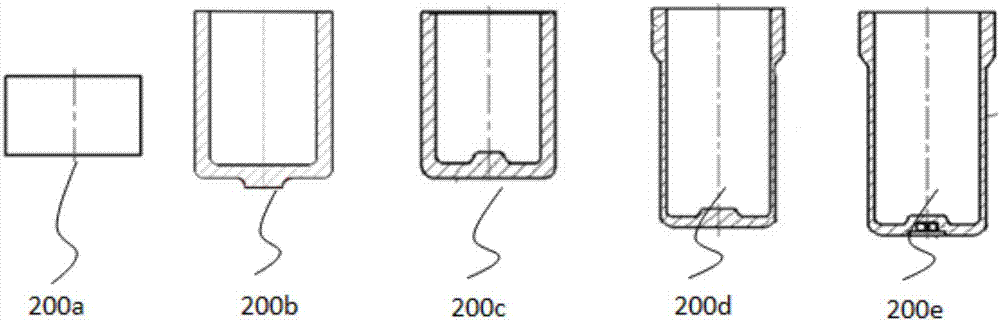

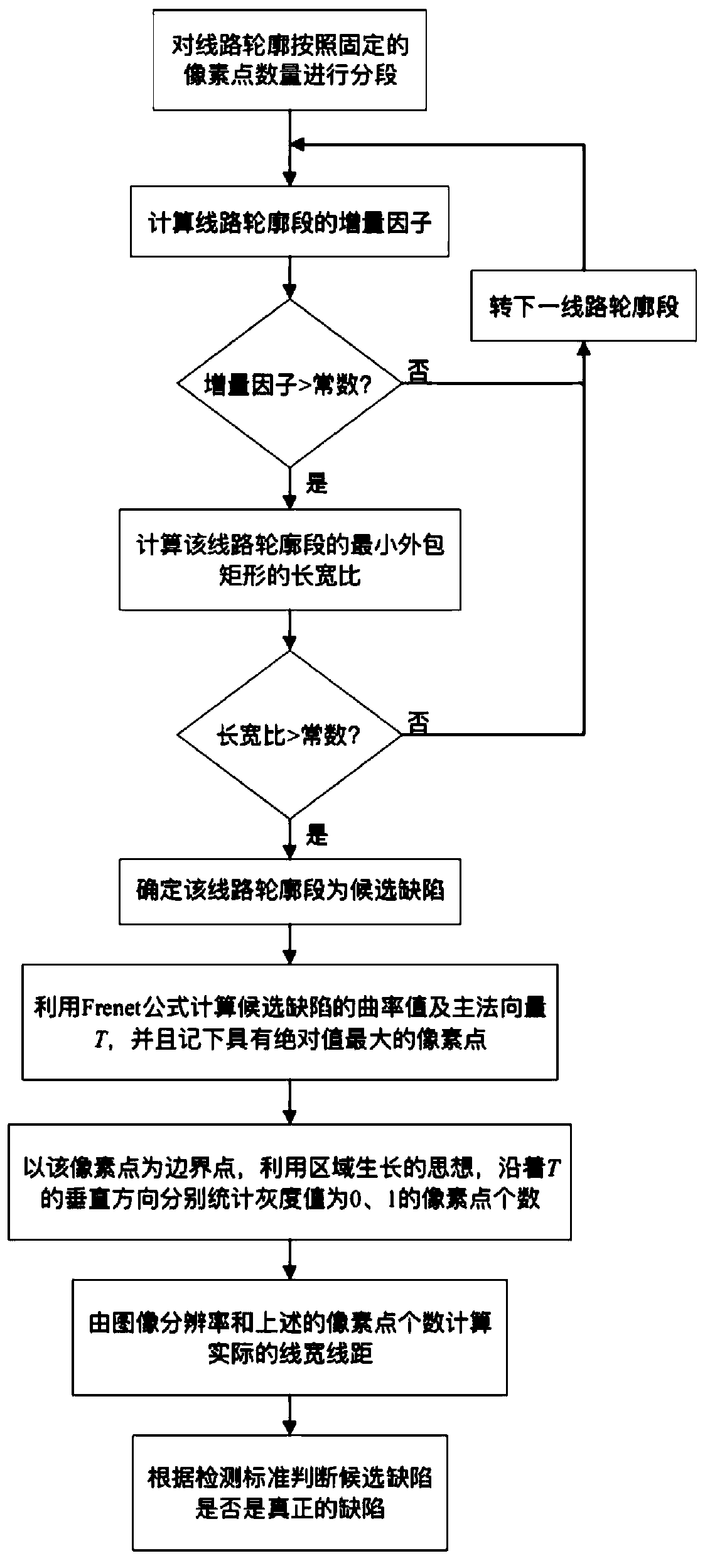

Geometric positioning-based flexible circuit board line defect identification method

ActiveCN110544238AAchieve sagAchieving identifiabilityImage enhancementImage analysisMinimum bounding rectangleSize measurement

The invention discloses a geometric positioning-based flexible circuit board line defect identification method. The geometric positioning-based flexible circuit board line defect identification methodcomprises the following steps: S1, segmenting a line contour according to a preset number of pixel points; S2, calculating an increment factor of each contour section in the X direction or the Y direction, and roughly positioning candidate defect positions; S3, determining a minimum bounding rectangle of the contour section according to the increment factor; S4, determining candidate line defectpositions according to the length-width ratio of the minimum bounding rectangle; S5, measuring the defect positions of the candidate lines on the basis of a Frenet frame; and S6, judging the defect type according to the measurement result. According to the invention, the defects of the recesses and the projections of the FPC circuit part are identified and the sizes of the recesses and the projections are measured, so that the quality of finished products in FPC actual production is guaranteed.

Owner:SOUTH CHINA UNIV OF TECH

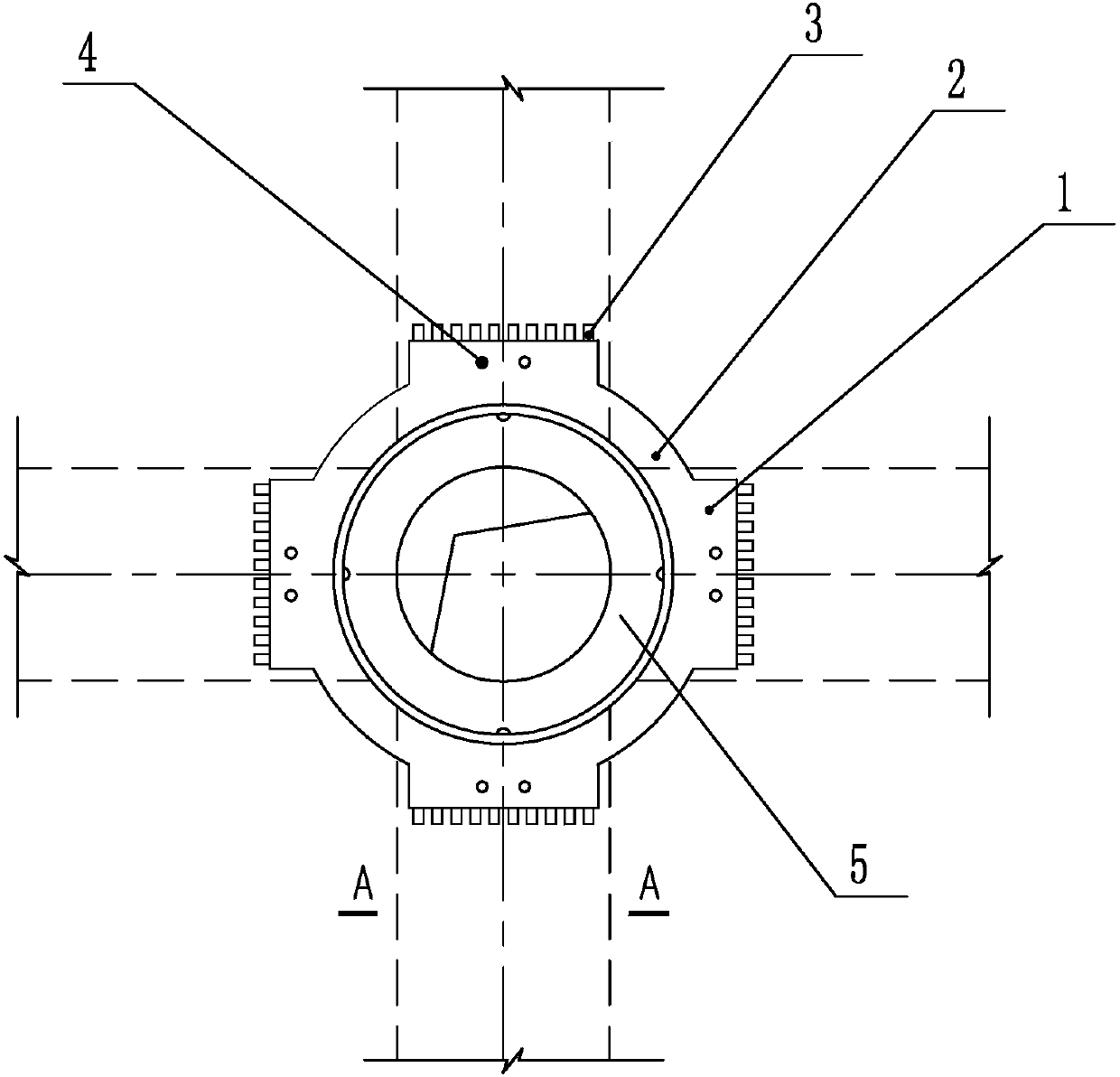

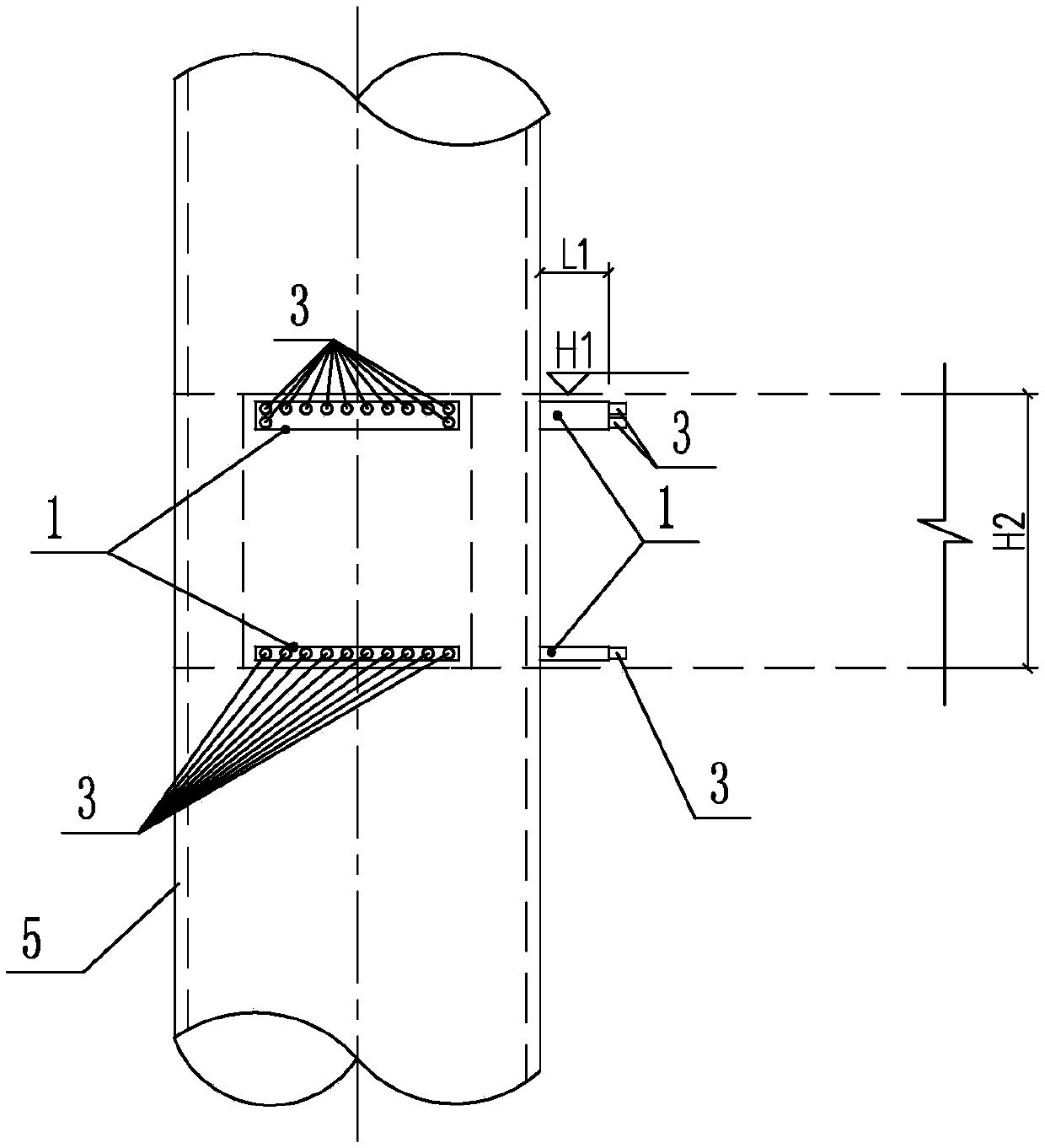

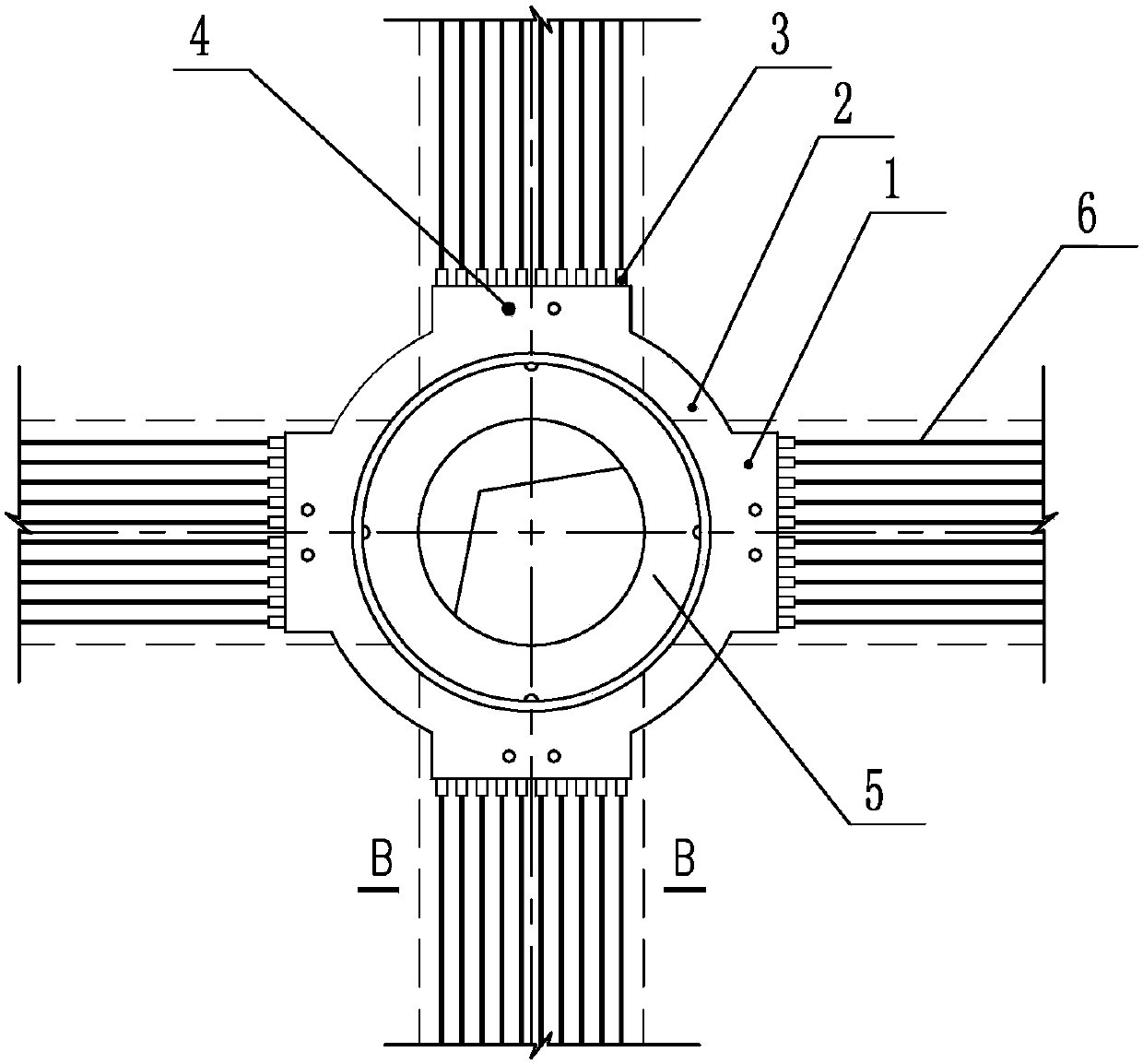

Steel pipe concrete column and beam main bar connecting node and construction method thereof

PendingCN107938837ALow shape change impactGuarantee the quality of finished productsBuilding constructionsPorosityThick plate

The invention relates to a steel pipe concrete column and beam main bar connecting node, which comprises a steel pipe column, thick plate steel corbels and straight threaded sleeves, wherein one end of each thick plate steel corbel is welded with the steel pipe column; the other end of each thick plate steel corbel is welded with the end surface of the corresponding straight threaded sleeve; and two concrete ventilated holes are also formed in each thick plate steel corbel. The connecting node provided by the invention effectively solves the difficult problems that beam bars, column bars, corbels, stiffening plates and the like in the node position are staggered and converged, and the construction space for node steel bar binding welding, concrete casting and the like is narrow, so that the steel bar anchoring quality and the concrete pouring compactness are difficult to control. Through the design of the thick plate steel corbels, the straight threaded sleeves are welded on the thickplate steel corbels; beam longitudinal bars are connected by using the straight threaded sleeves; and the phenomena of zero aperture ratio, zero node steel bar welding in a construction site and zeronode steel bar crossed penetration on the steel pipe column can be realized.

Owner:广西建工第五建筑工程集团有限公司

Seaweed puree dried noodles and processing method thereof

InactiveCN101982100AImprove immunityGuarantee the quality of finished productsFood preparationRaw materialNutrient content

The invention discloses seaweed puree dried noodles and a processing method thereof. the seaweed puree dried noodles are prepared from the following raw materials in parts by weight: 200-250 parts of flour, 0.5-1.25 parts of salt, 0.16-0.3 part of alkali and 100-125 parts of seaweed puree. Seaweed puree and flour are adopted to prepare the seaweed puree dried noodles. The seaweed puree dried noodles are characterized in that the noodles have rich nutrients, the nutrient components can be easily absorbed after the noodles are eaten, and the noodles are convenient to store, carry and eat.

Owner:FUZHOU CHANGSHENG FOOD

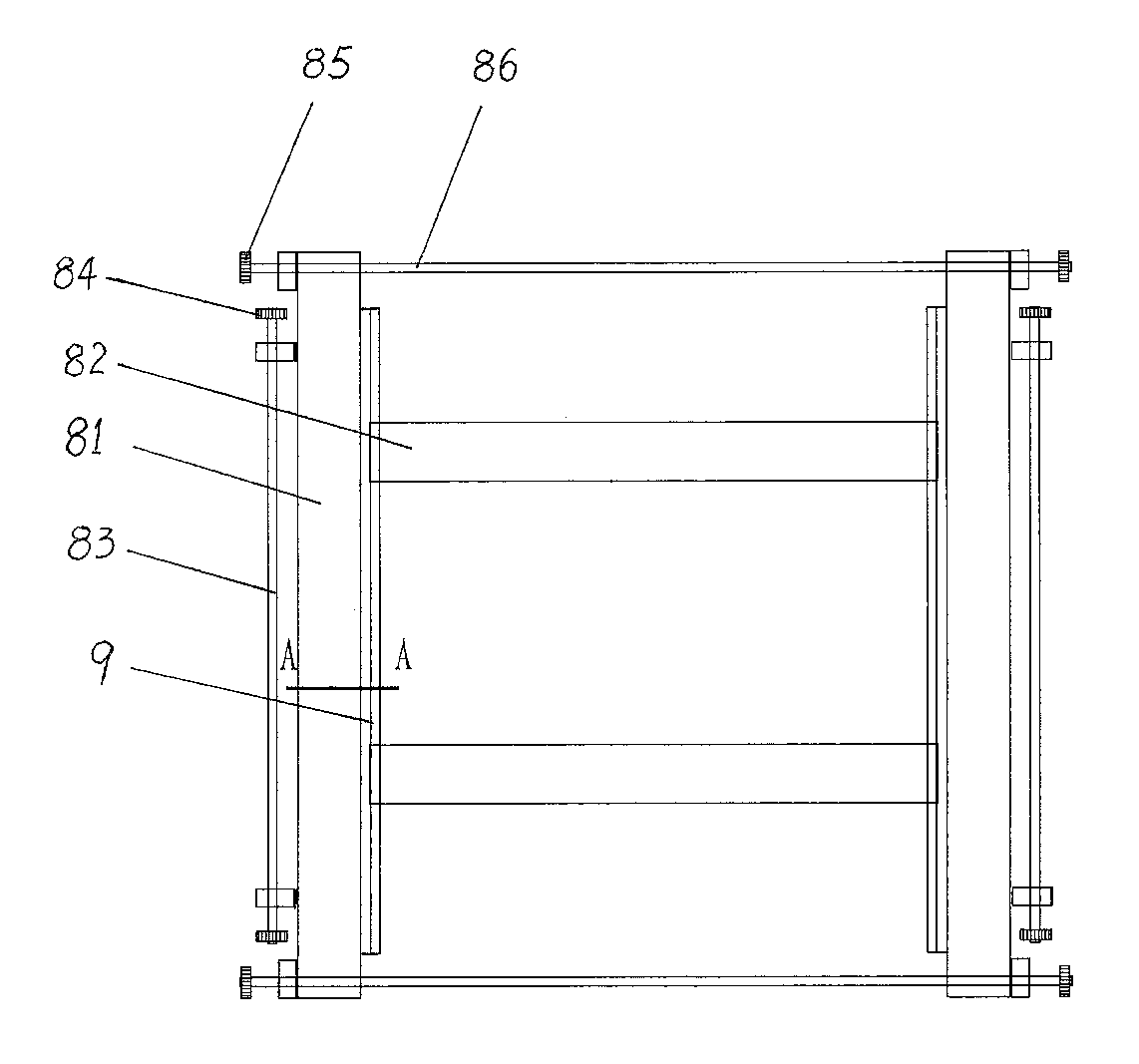

Wire compression jointing work platform

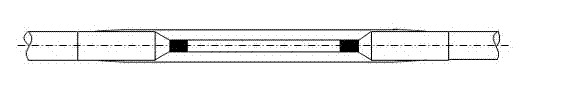

ActiveCN103594903AAvoid centeringAvoid errorsLine/current collector detailsProcess qualityFixed frame

The invention belongs to the field of electric power construction project large-section wire compression jointing manufacturing, and particularly relates to a wire compression jointing work platform used for large-section wire compression jointing. The wire compression jointing work platform comprises a fixing frame serving as a base body, a platform part fixedly connected with a compression jointing top is arranged on the fixing frame, a supporting unit used for supporting and limiting the spatial position of a wire to be in compression jointing is further arranged on the side, next to the platform part, of the fixing frame, and a supporting path of the supporting unit and a wire penetrating path of the compression jointing top are located in the same straight line. The wire compression jointing work platform is overall easy and convenient to operate, meanwhile, staff organizations are simplified, the compression jointing time is saved, and the wire compression jointing work platform has the advantages that the compression jointing process is improved, compression jointing workers are reduced, and the compression jointing time is shortened; the process quality is improved, and meanwhile the construction work efficiency is greatly improved.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com