Water tank wire drawing machine

A water tank wire drawing machine and wire drawing technology, which is applied in the field of metal product production, can solve the problems of long assembly line, frequent shutdown, and large floor space, and achieve uniform and stable drawing speed, ensure the quality of finished products, and occupy a small floor area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings and embodiments.

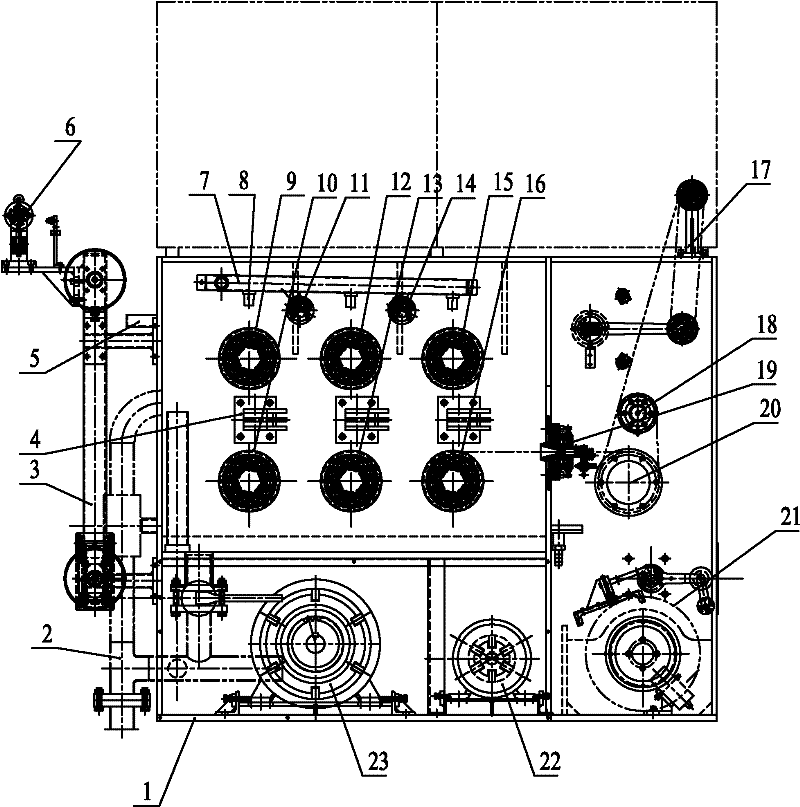

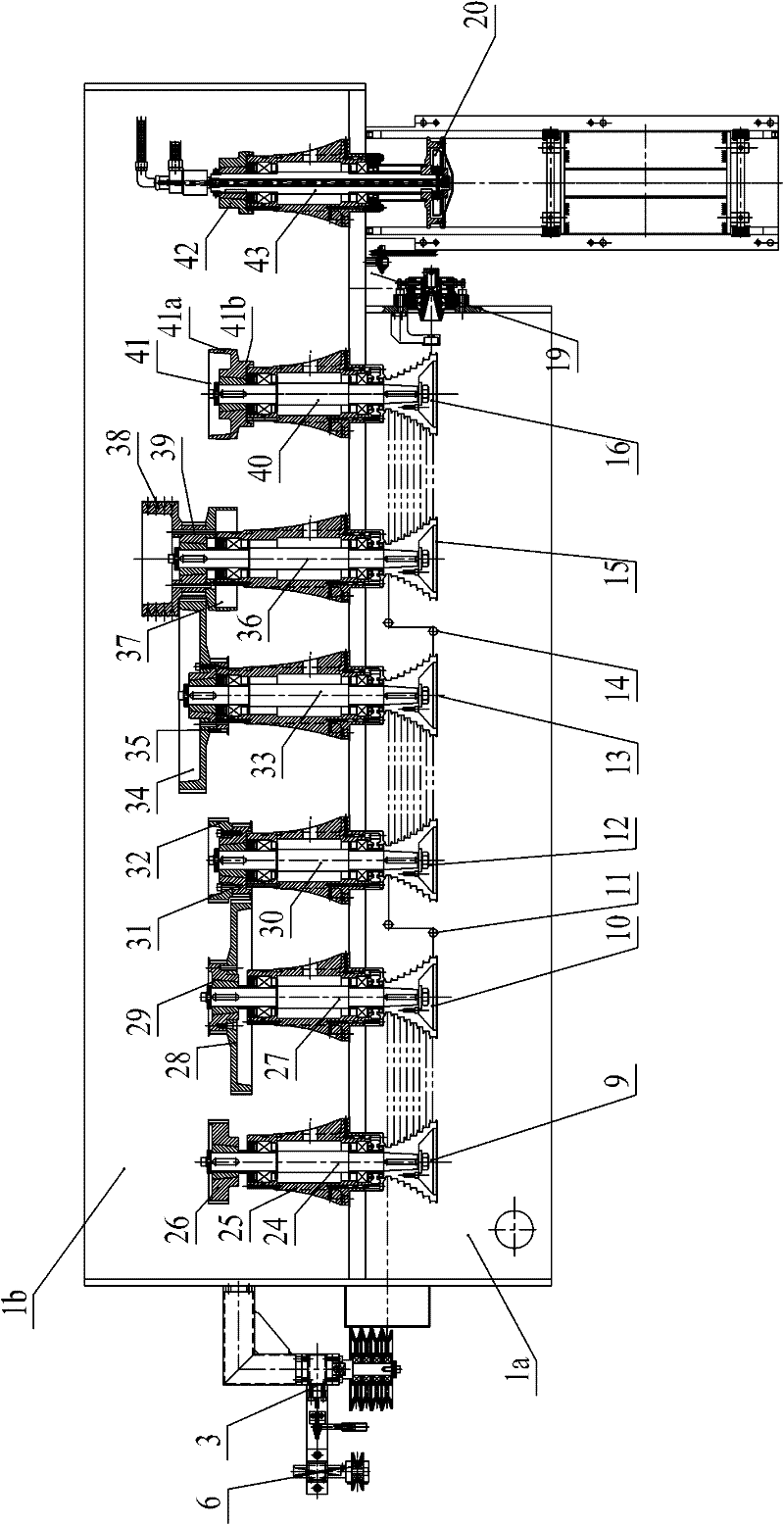

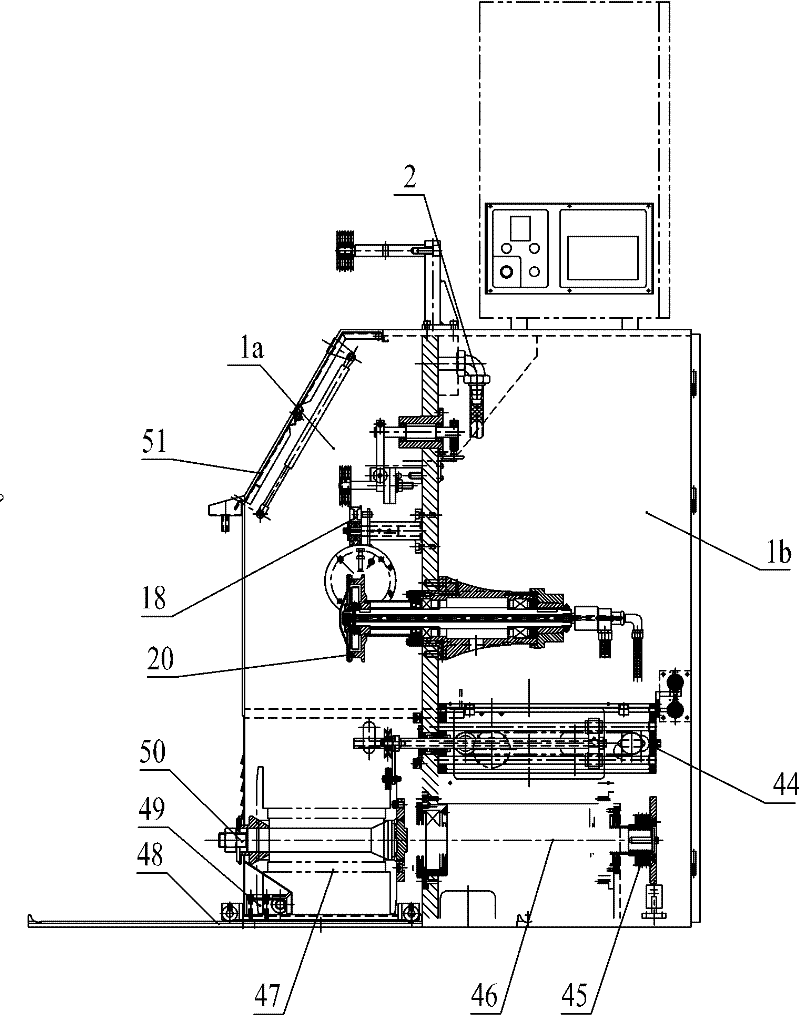

[0031] The wire drawing machine is mainly composed of a wire drawing host and a wire take-up device 21 .

[0032] Such as Figure 1~Figure 3 As shown, the wire drawing host includes a box body 1, and a tension mechanism 3 is installed on the left side wall of the box body 1, and the tension mechanism 3 is used to maintain a stable tension force on the steel wire before starting wire drawing. A guide roller 6 for introducing steel wires is installed; a wire feeding box 5 is installed on the left side wall of the casing 1 , and the steel wire after the tension mechanism 3 adjusts tension passes through the wire feeding box 5 into the casing 1 .

[0033] The structure of the tension mechanism 3 is specifically as in 5.1~ Figure 5.4 As shown, it is mainly made up of support 3.9, column 3.8, lower fixed plate 3.7, lower wheel axle 3.2, upper fixed plate 3.10 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com