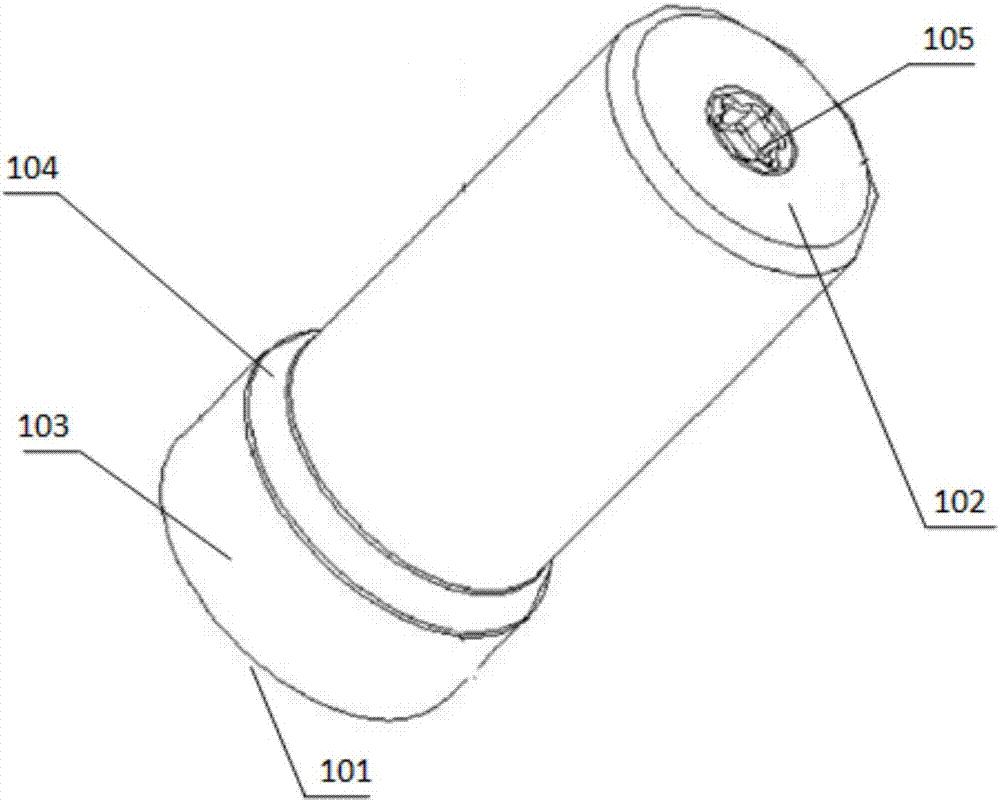

Cold-forging forming process for energy accumulator tank forging and reverse extrusion die

A forming process and accumulator technology, applied in the direction of metal extrusion dies, etc., can solve the problems of frequent replacement, upsetting, affecting product quality, etc., and achieve the effect of ensuring the quality of finished products and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

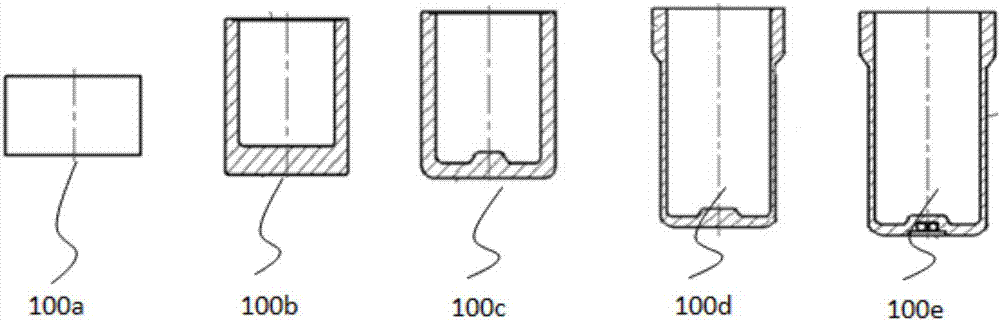

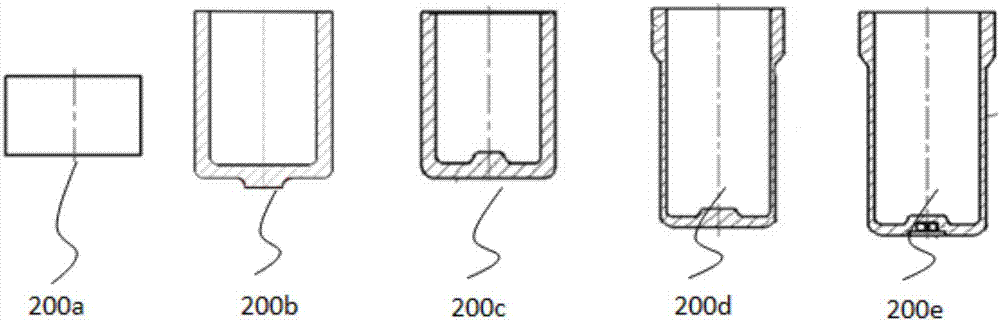

[0044] Please refer to image 3 , in a specific embodiment, the accumulator tank forging cold forging process provided by the present invention includes the following steps:

[0045] 1. Blanking: Take 20CrMnTi round steel and saw and cut it to form a rod-shaped blank 200a.

[0046] 2. The first spheroidizing annealing: use the annealing furnace to heat the rod-shaped billet 200a to a certain temperature for spheroidizing annealing, so as to reduce the hardness of the billet, achieve the purpose of softening the billet, and facilitate subsequent processes.

[0047] 3. Machining blanks: using a lathe to remove scale, micro-cracks and rust on the surface of the softened rod-shaped blank 200a to obtain a high-quality rod-shaped blank 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com