Wire compression jointing work platform

A work platform and wire crimping technology, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve problems such as inability to align, high labor intensity, and troubles for on-site workers, so as to reduce labor intensity and The effect of labor cost, improvement of construction work efficiency, and saving of crimping operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

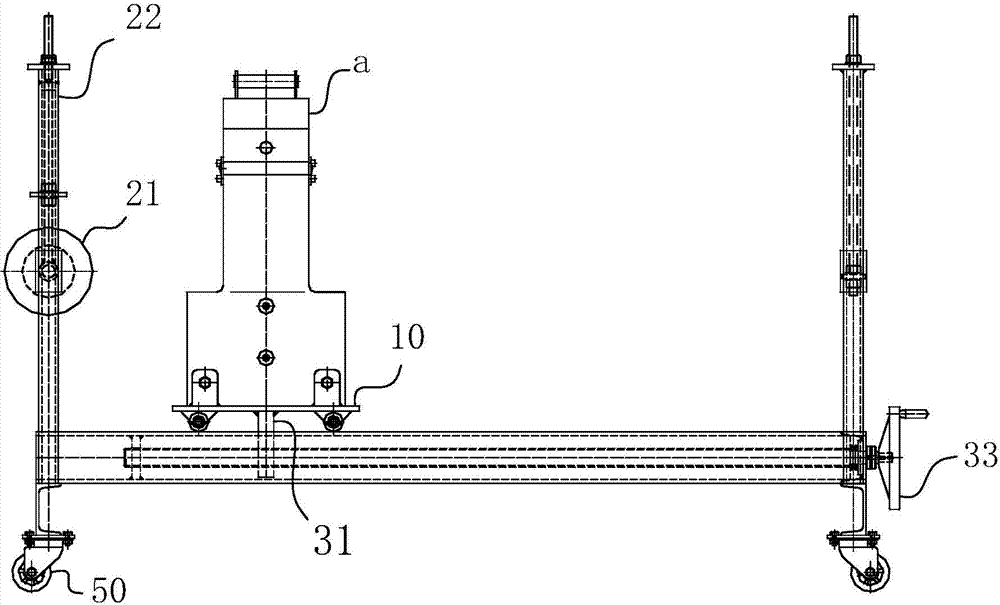

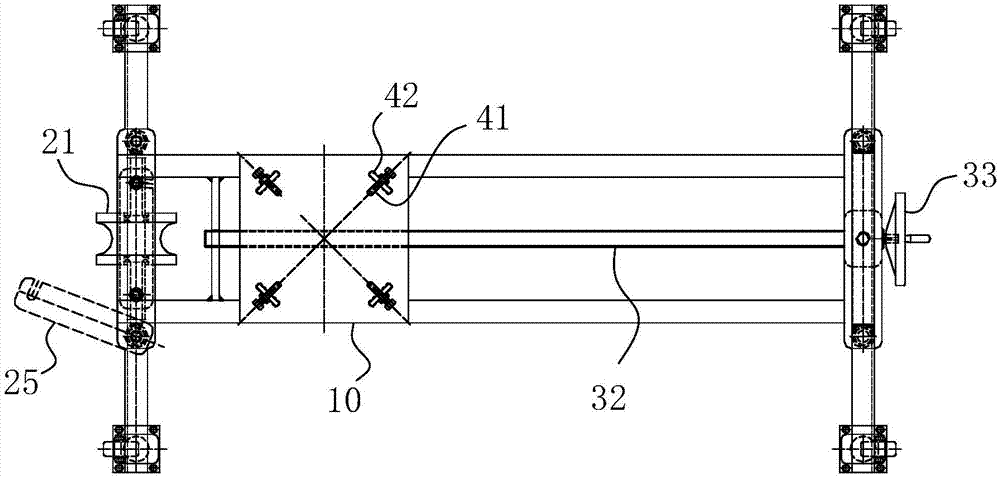

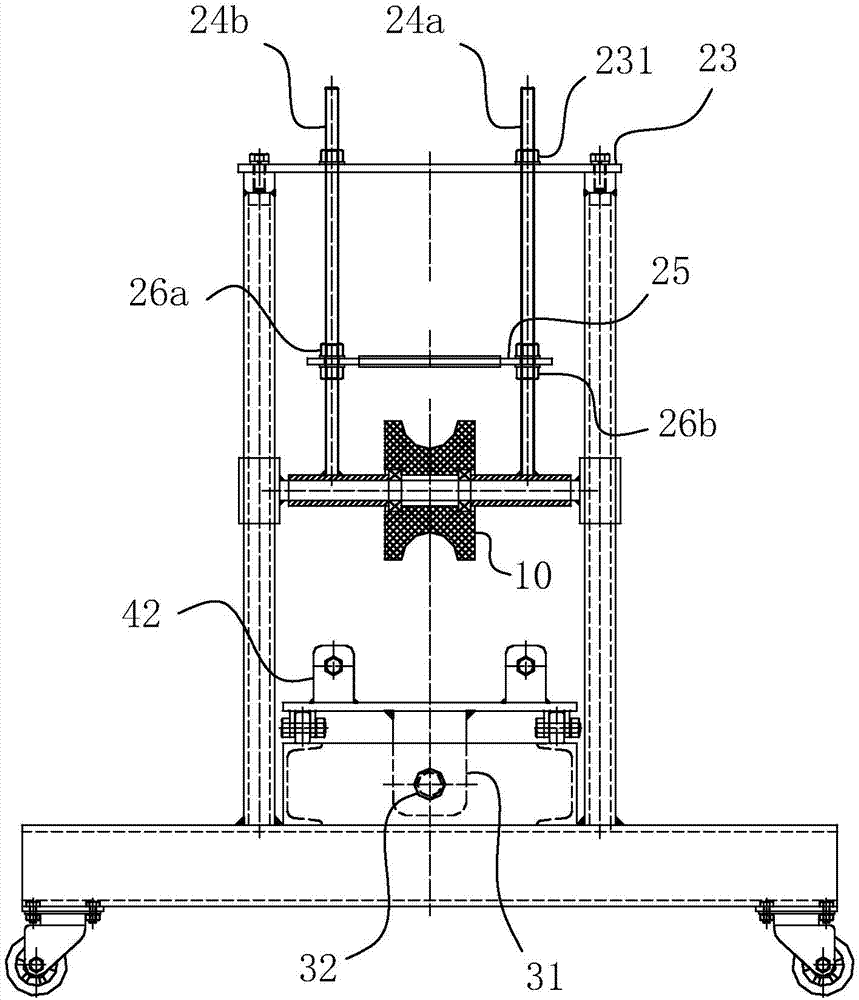

[0030] For ease of understanding, the specific composition structure and corresponding work flow of the present invention are described as follows in conjunction with the accompanying drawings:

[0031] The present invention in practical application, such as Figure 1-4 As shown, it consists of a hydraulic jack for wire crimping (that is, a crimping jack a with hydraulic power as its power source), a platform part 10 for fixing the hydraulic jack, and a support unit located on the side of the platform part 10; The supporting wheel 21 realizes the supporting effect of the wire to be crimped, and it has the adjustable performance in the vertical direction; the platform part 10 realizes the final crimping operation of the wire to be crimped, and itself has a horizontal displacement along the wire passing direction Effect. The wire to be crimped is guided and supported by the supporting wheel 21. The wire is placed on the wheel groove of the supporting wheel 21, and the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com