Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

488 results about "Body in white" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Body in white (BIW) refers to the stage in the automobile manufacturing in which a car body's components have been joined together, using one or a combination of different techniques: welding (spot, MIG/MAG), riveting, clinching, bonding, laser brazing etc. BIW is termed before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, seats, upholstery, electronics, etc.) have been assembled in the frame structure.

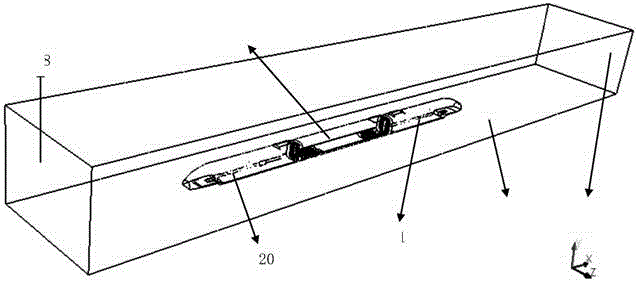

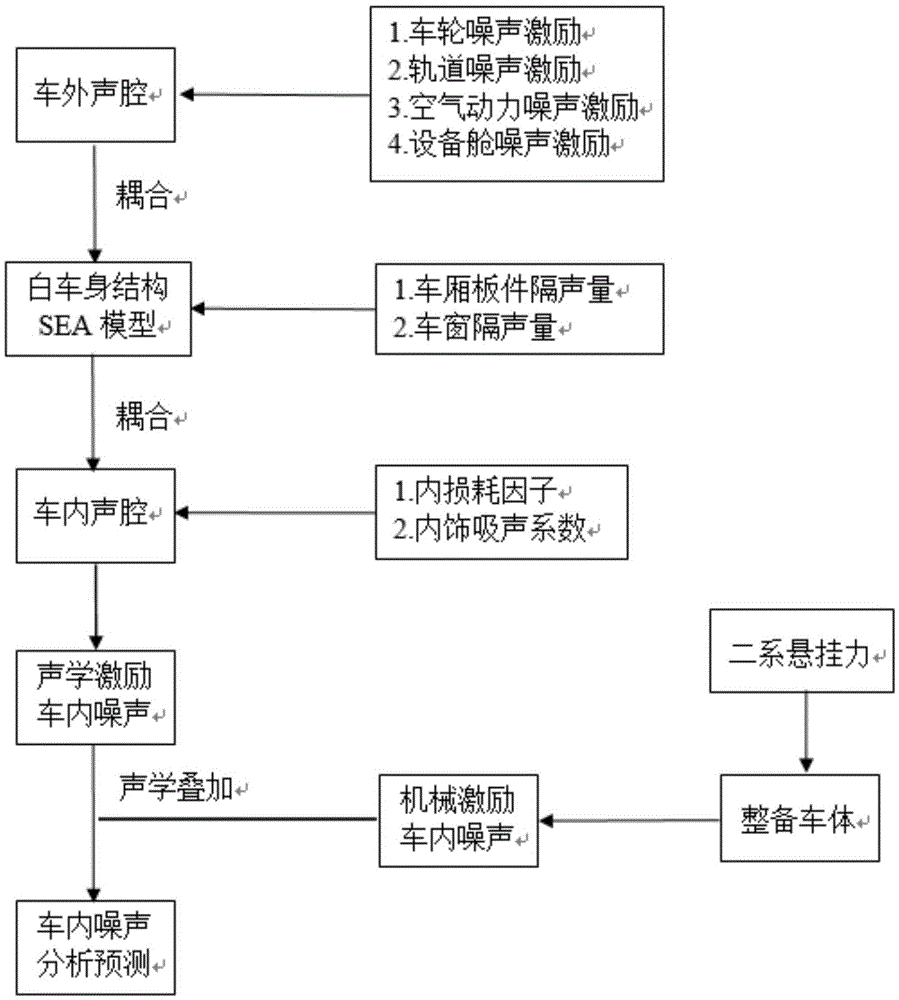

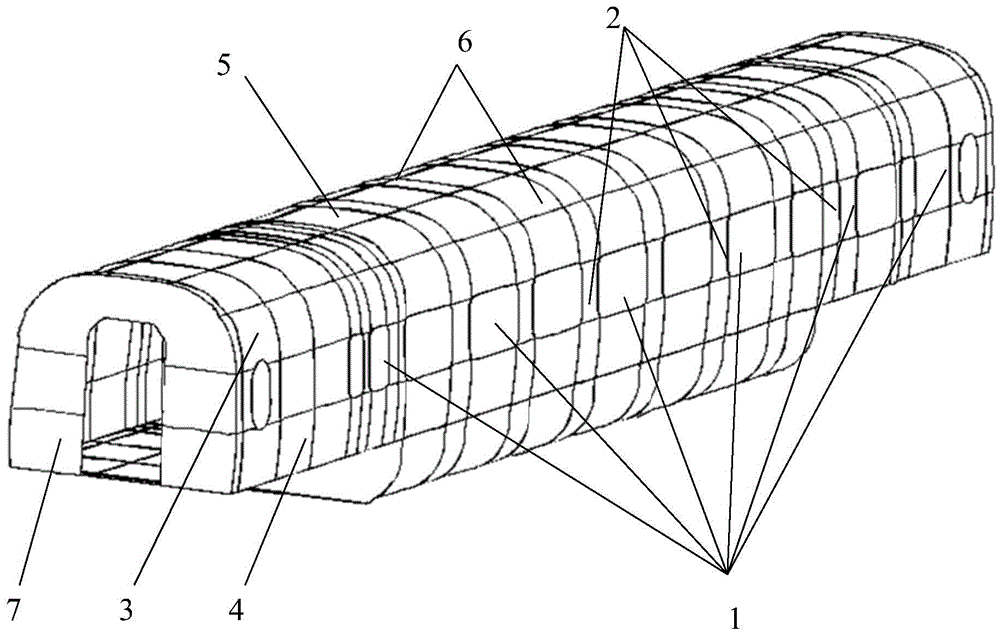

Interior noise analysis and prediction method of high speed train

InactiveCN105590003AShorten the development cycleAccuracy impactGeometric CADSustainable transportationEngineeringInterior noise

The invention discloses an interior noise analysis and prediction method of a high speed train. The method comprises the following steps: establishing a train reconditioning train body model, a statistical energy analysis model of a body in white structure and an interior and exterior vocal cavity statistical energy analysis model, and carrying out simplification and subsystem division; obtaining the statistical energy analysis parameters of the train body structure and an interior vocal cavity model, and loading the statistical energy analysis parameters onto a train body structure model plate subsystem and a vocal cavity model subsystem; and obtaining exterior vocal excitation source energy borne on the train body, applying the exterior vocal excitation source energy onto the exterior vocal cavity statistical energy analysis model, causing the exterior vocal excitation source energy to reach an interior vocal cavity after the exterior vocal excitation source energy is attenuated by the sound insulation property of a structural plate in a body in white structure model so as to obtain structural noise energy radiated into the train by the reconditioning train body under the function of the two-line suspension force of a compartment, and then, carrying out interior noise analysis and prediction. The problem that the interior noise of the train is difficult in prediction and the problems of the upper limit boundedness of a frequency domain, complex calculation flow, incomplete motivation consideration in the traditional method are overcome, calculation efficiency and prediction accuracy are improved, and development and test cost is lowered.

Owner:ZHEJIANG UNIV

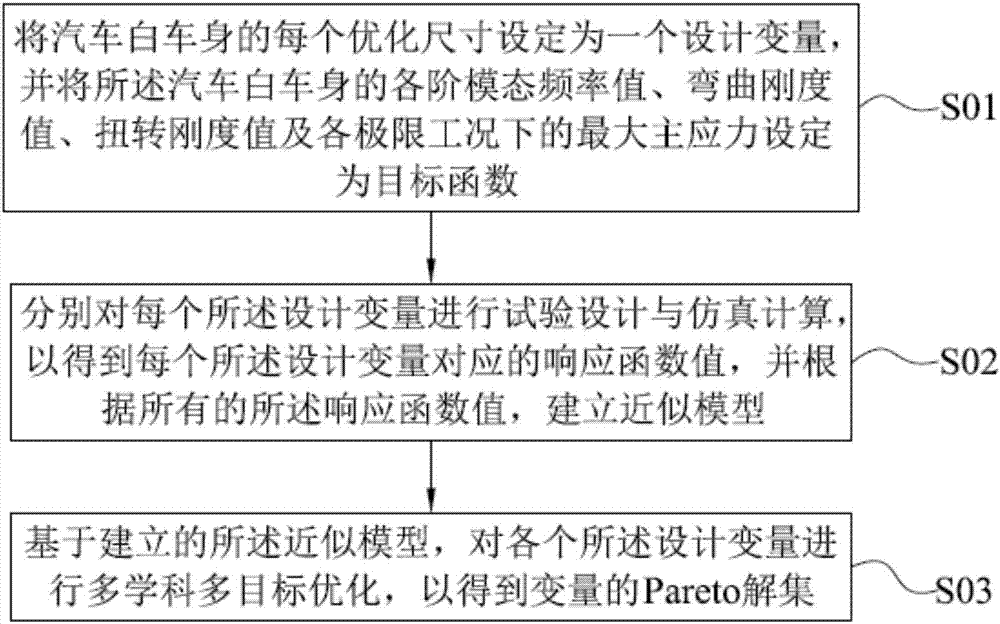

Automobile body-in-white light weighting analysis method

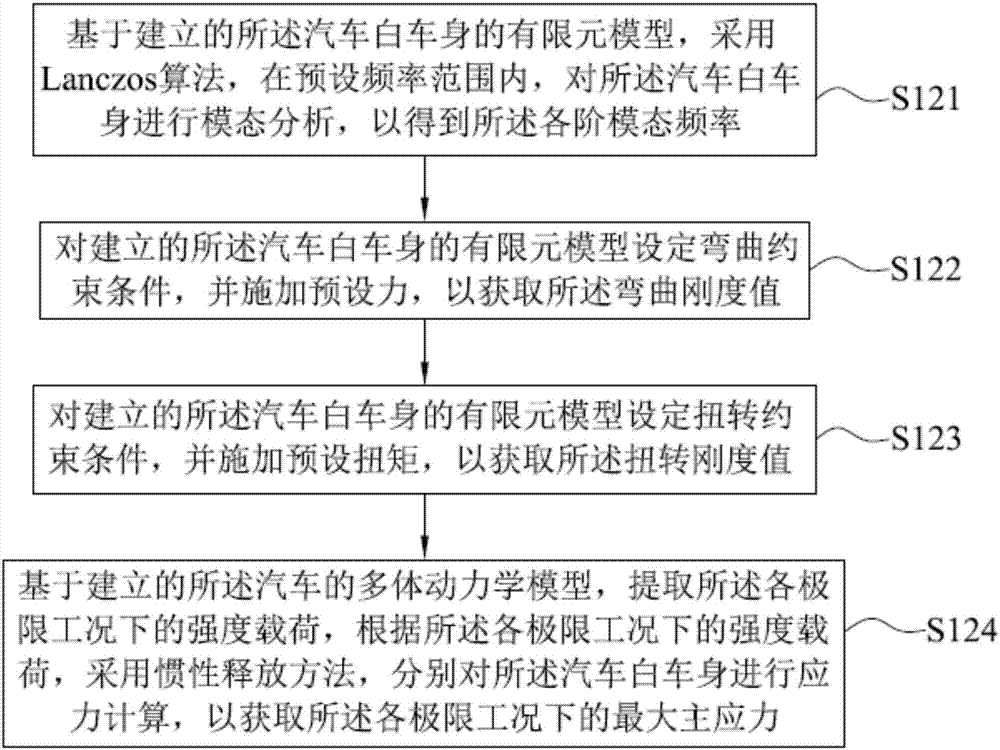

The invention provides an automobile body-in-white light weighting analysis method. The method comprises following steps: setting each optimization size of automobile body-in-white as a design variable and setting the modal frequency value of each stage, bending rigidity value, torsional rigidity value and maximum principal stress at all extreme work conditions of the automobile body-in-white as target functions; performing experiment design and simulation calculation on each design variables to obtain response function values corresponding to each design variable and according to the response function values, establishing a simulation model; based on the simulation model, performing multiple discipline and multi-target optimization on the design variables to obtain Pareto solution set of the variables. According to the automobile body-in-white light weighting analysis method of the invention, through selecting proper design variables, analysis methods and technical routes, the light weighting of automobile body-in-white is realized and at the same time, on the basis of satisfying multiple discipline and multi-target, the optimized size parameters of the automobile body-in-white among all performances can be found.

Owner:JIANGLING MOTORS

Car body sound vibration roughness NVH design method based on low frequency acoustic sensitiveness inside vehicle

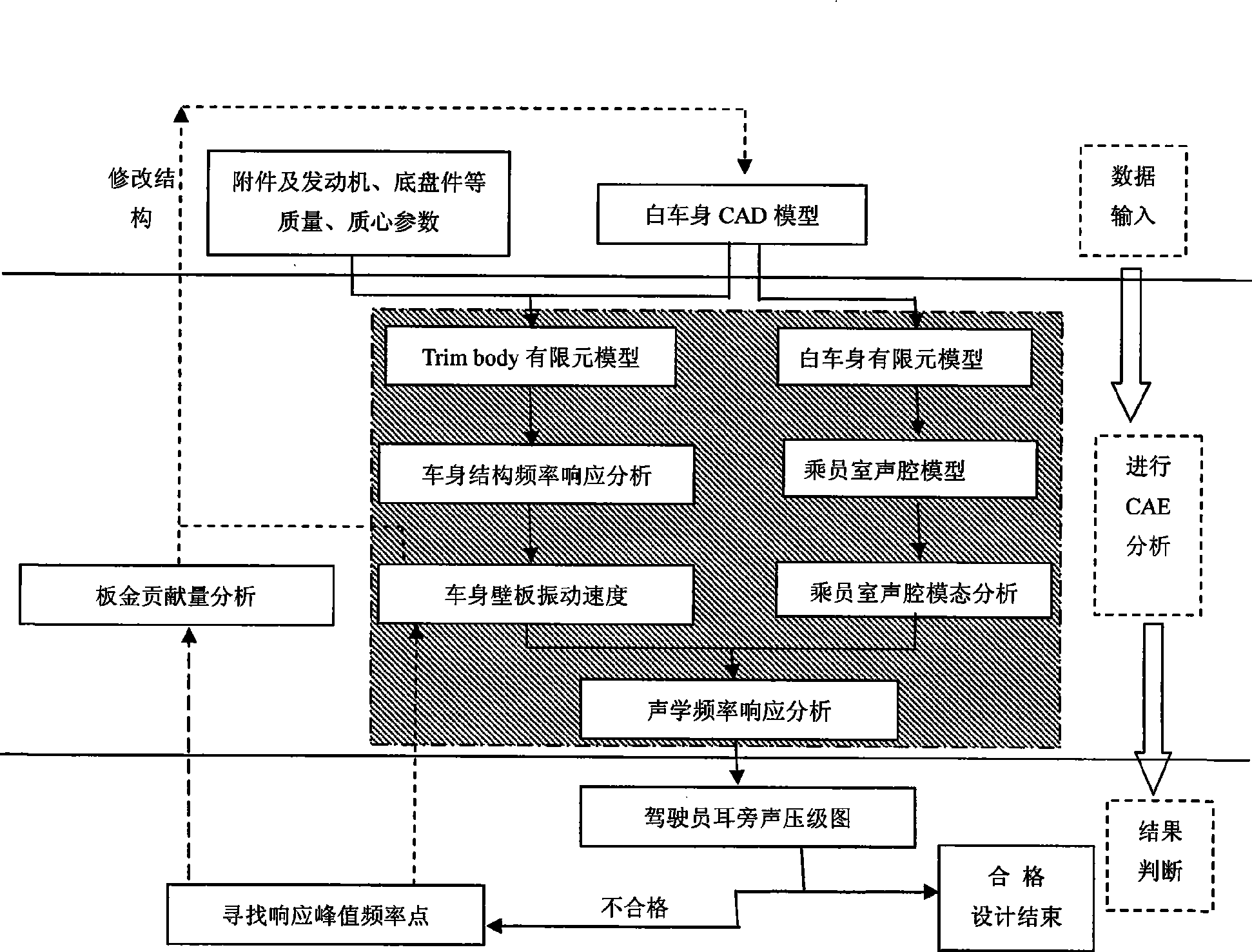

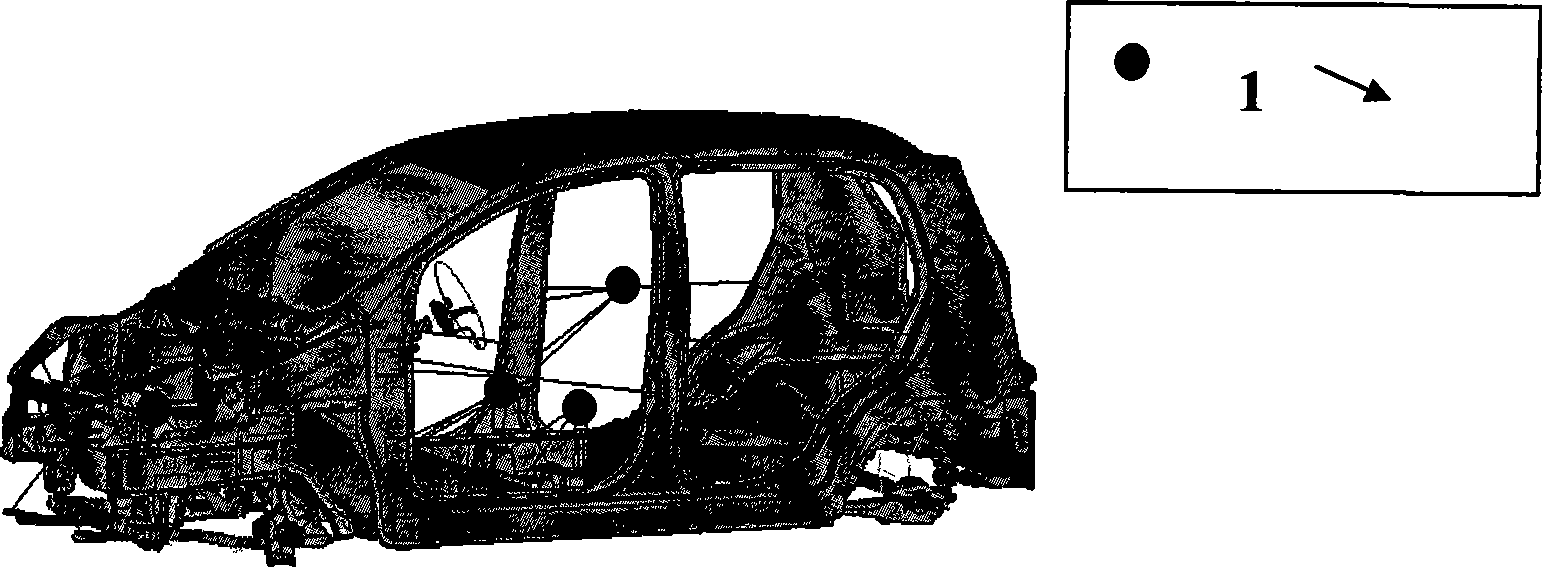

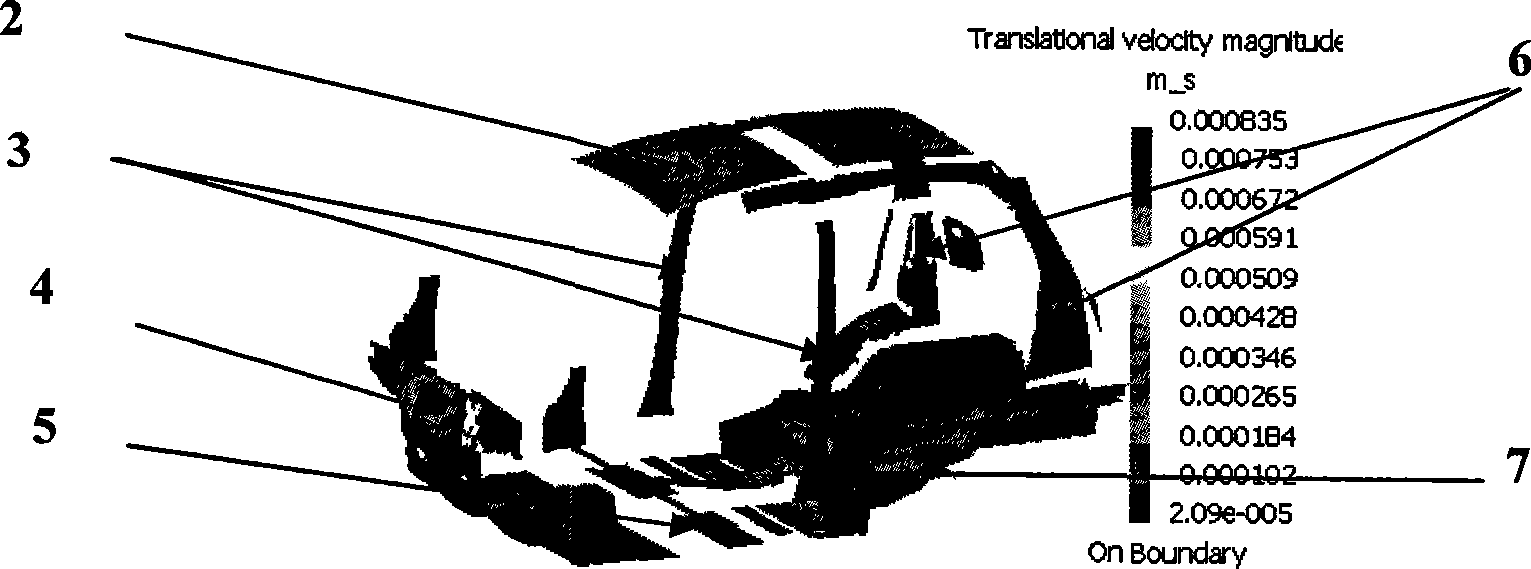

The invention relates to a method for designing the automobile body acoustic vibration unevenness NVH based on a low frequency automobile acoustic sensitivity. The method comprises the following steps: firstly, establishing a body-in-white finite element modeling, and establishing an acoustic finite element modeling for a cab on the basis of the body finite element modeling; secondly, carrying the frequency response analysis on the positions of a suspending point of an engine on the automobile body, a suspension mounting point, an exhaust hanging point, and the like; thirdly, taking the vibration speed of a body wall plate obtained by the frequency response analysis as a boundary condition, and the sound pressure level beside ears of a driver by solving the acoustic response of the cab; further, the influence level of larger sheet metal parts and mounting points which have great influence on the sound pressure level are acquired by checking the vibration situation of the body wall plate displayed by the frequency response analysis result at higher sound pressure response frequency points, and analyzing the sheet metal contribution; and finally, amending the design proposal of the sheet metal parts and the design proposal of the local rigidity of the mounting points.

Owner:CHERY AUTOMOBILE CO LTD

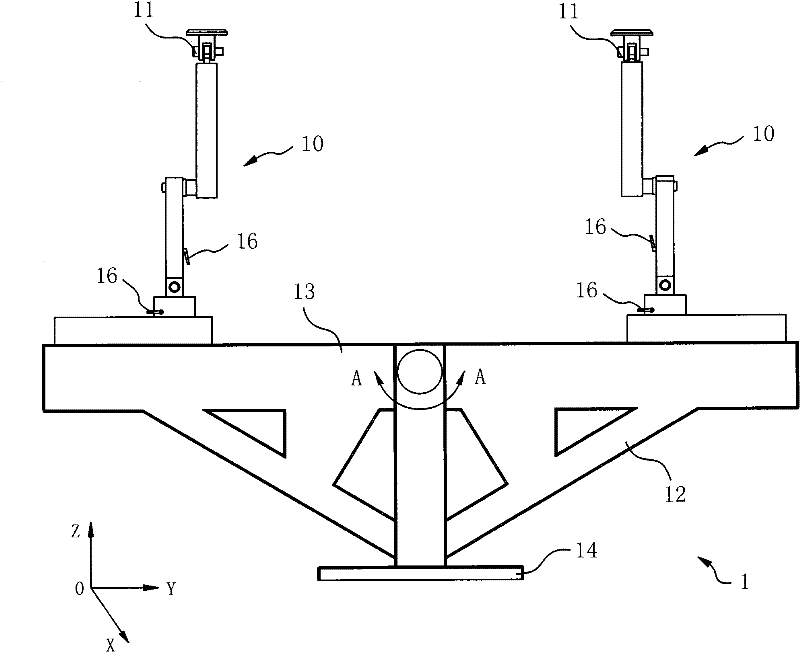

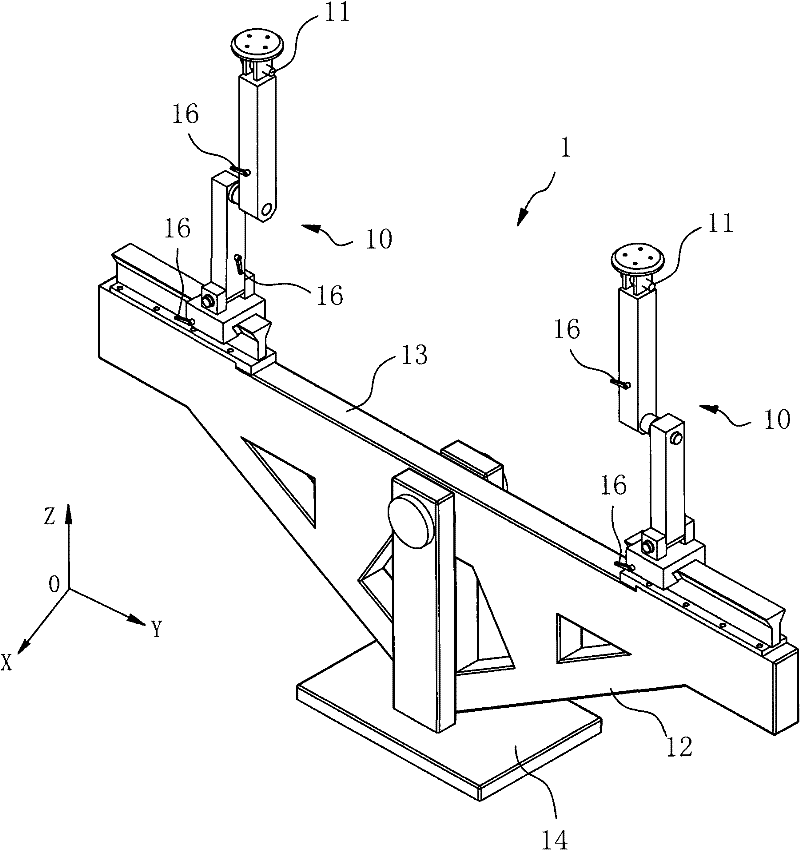

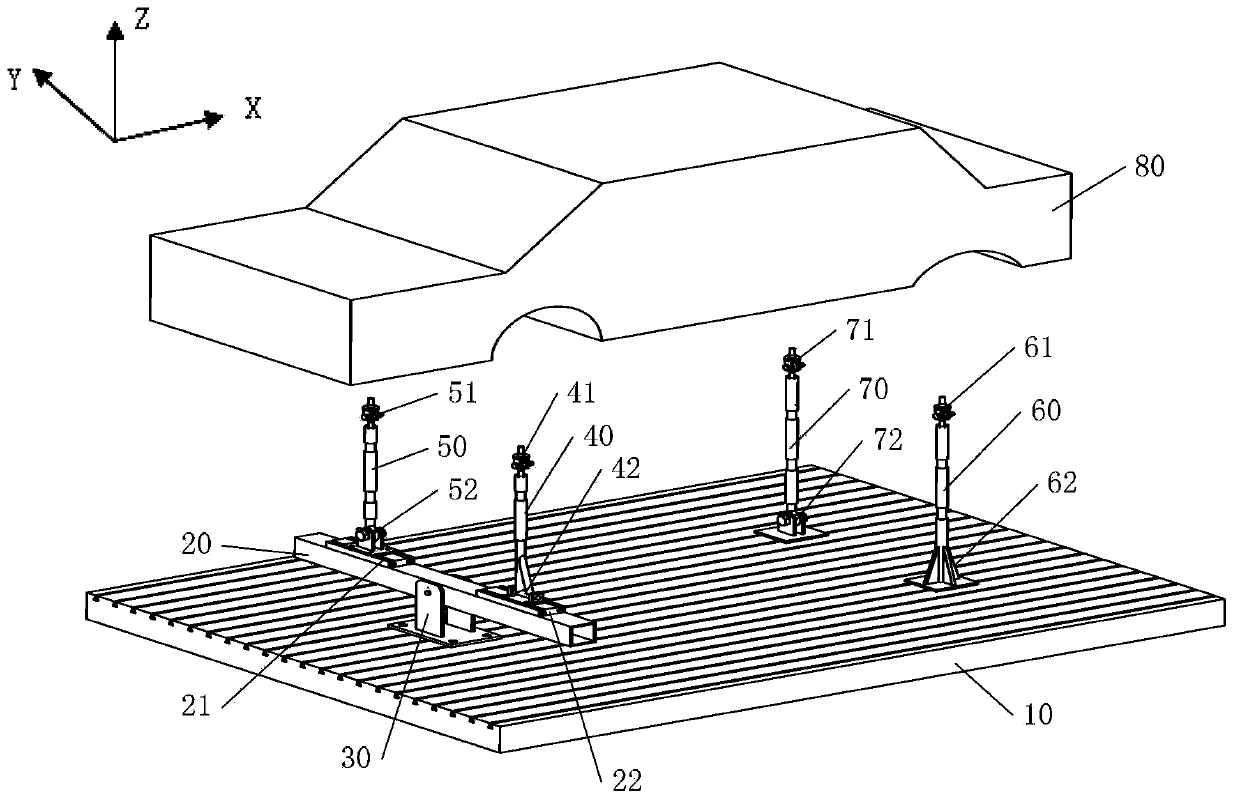

Automotive body in white torsion rigidity test system and method thereof

The invention discloses an automotive body in white torsion rigidity test system. The system comprises: a constraint subsystem and a loading subsystem. The constraint subsystem comprises: a front suspension rack and a rear suspension rack. The loading subsystem comprises at least two power take-offs and a loading device. Through using an innovative improved design, the test system can carry out adaptive adjusting during a test process so that generation of stress can be reduced, versatility is good and test needs of different kinds of vehicle types can be satisfied. The invention also discloses a method for carrying out an automotive body in white torsion rigidity test by using the above test system. By using the method, the automotive body in white can be easily and rapidly leveled and ideal test data can be acquired. The test method of the automotive body in white torsion rigidity can be substantially improved. Compared to the other current test method, innovation improvements are realized in many aspects, such as the constraint processing, a position and a mode of load applying, collection of the test data and determination and the like.

Owner:SAIC MOTOR

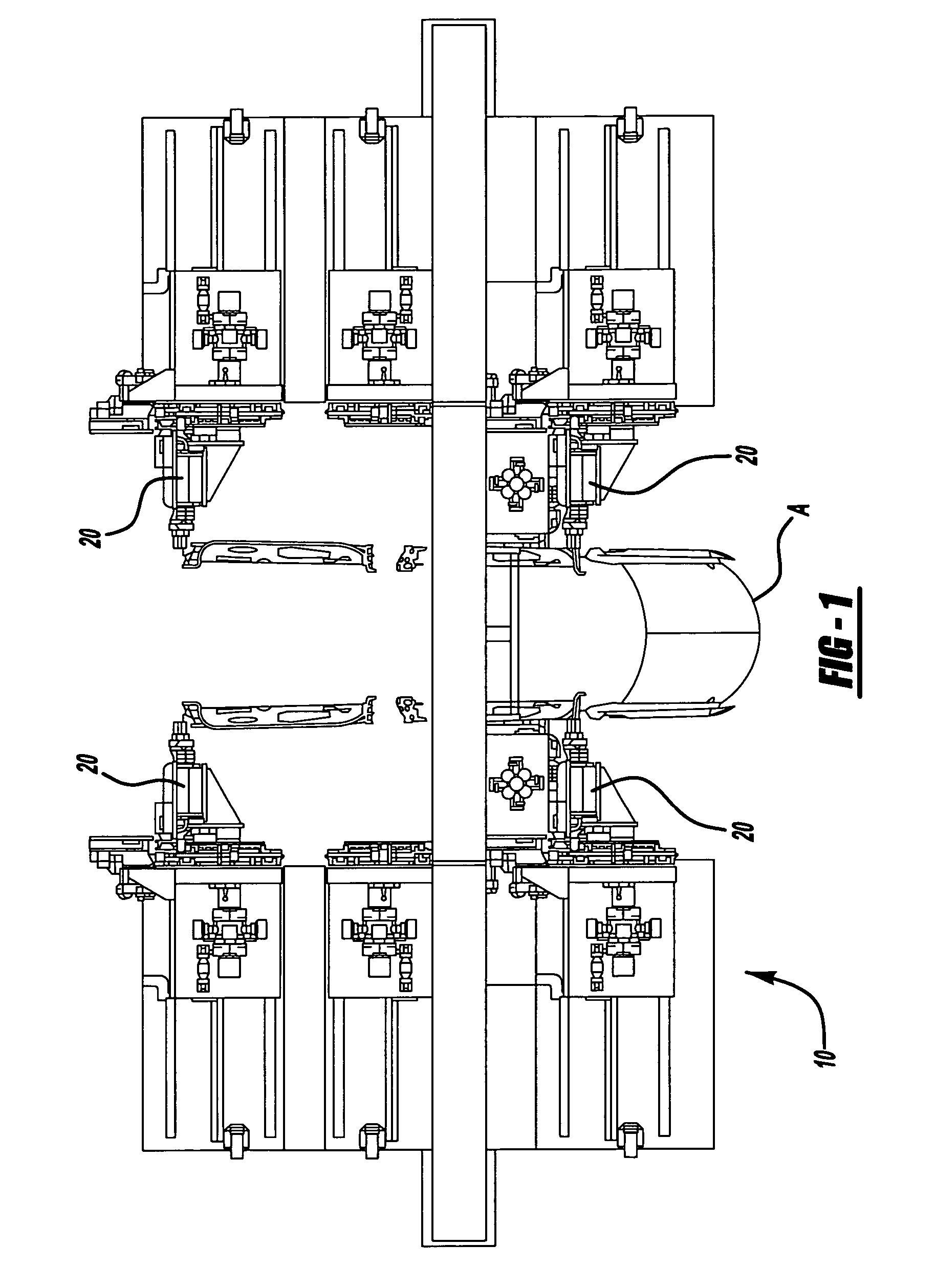

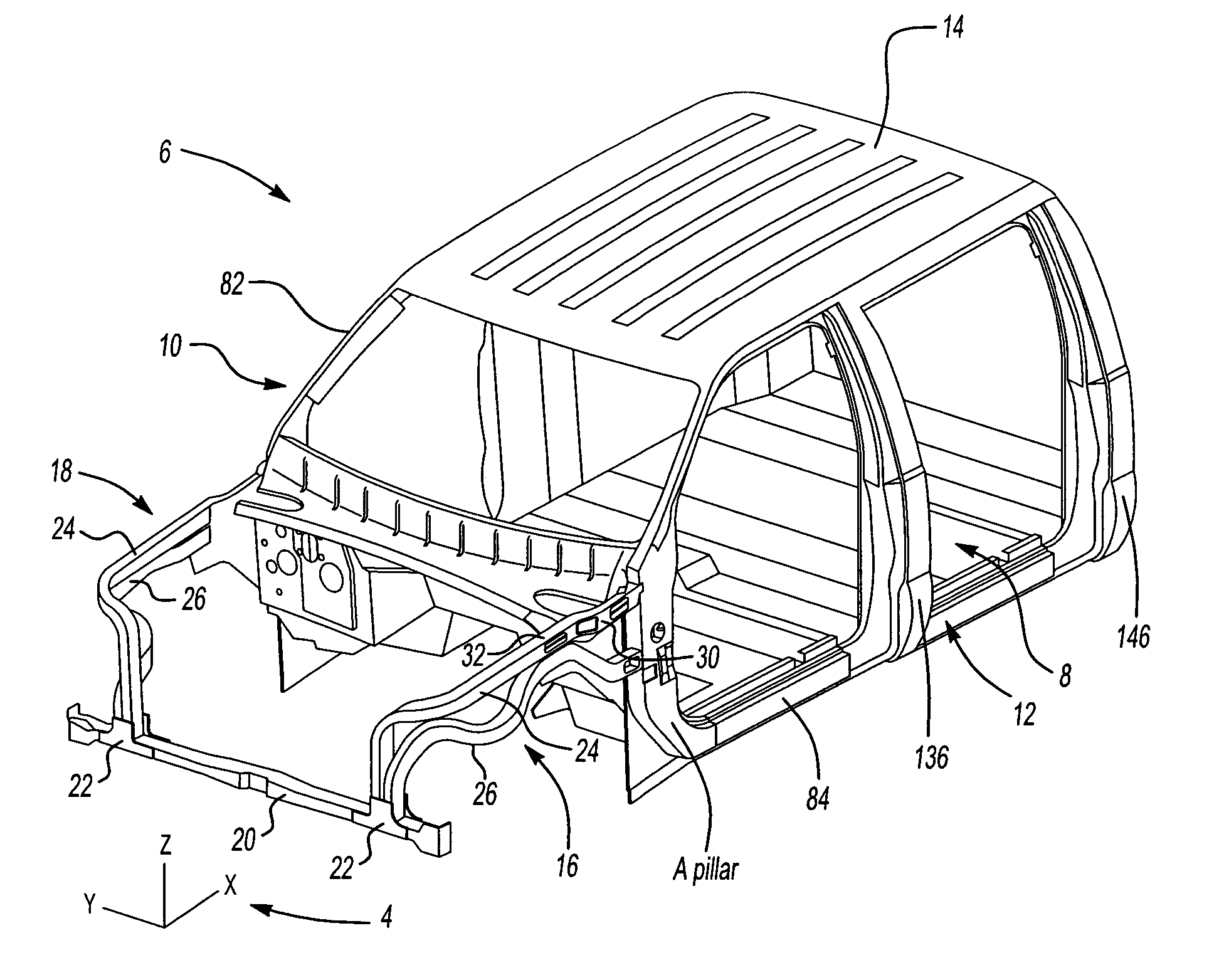

Method and apparatus for assembling exterior automotive vehicle body components onto an automotive vehicle body

InactiveUS7143494B2Assembly precisionMeet specificationsAutomatic control devicesAssembly machinesMobile vehicleEngineering

The present invention generally relates to a method and programmable apparatus for the assembly of body components to an automotive body that has undergone a progressive series of framing and welding steps so as to produce a structurally rigid body frame, termed a body-in-white. More specifically, this invention relates to creating a new net locating scheme (X-Y and Z Cartesian coordinate system) for a body-in-white to direct associated tooling to create net attachment features on a rigid body frame with respect to a new net locating scheme so that components may be attached to an automotive body at a net location eliminating the need for any slip plane attachment techniques.

Owner:KUKA SYST NORTH AMERICA LLC

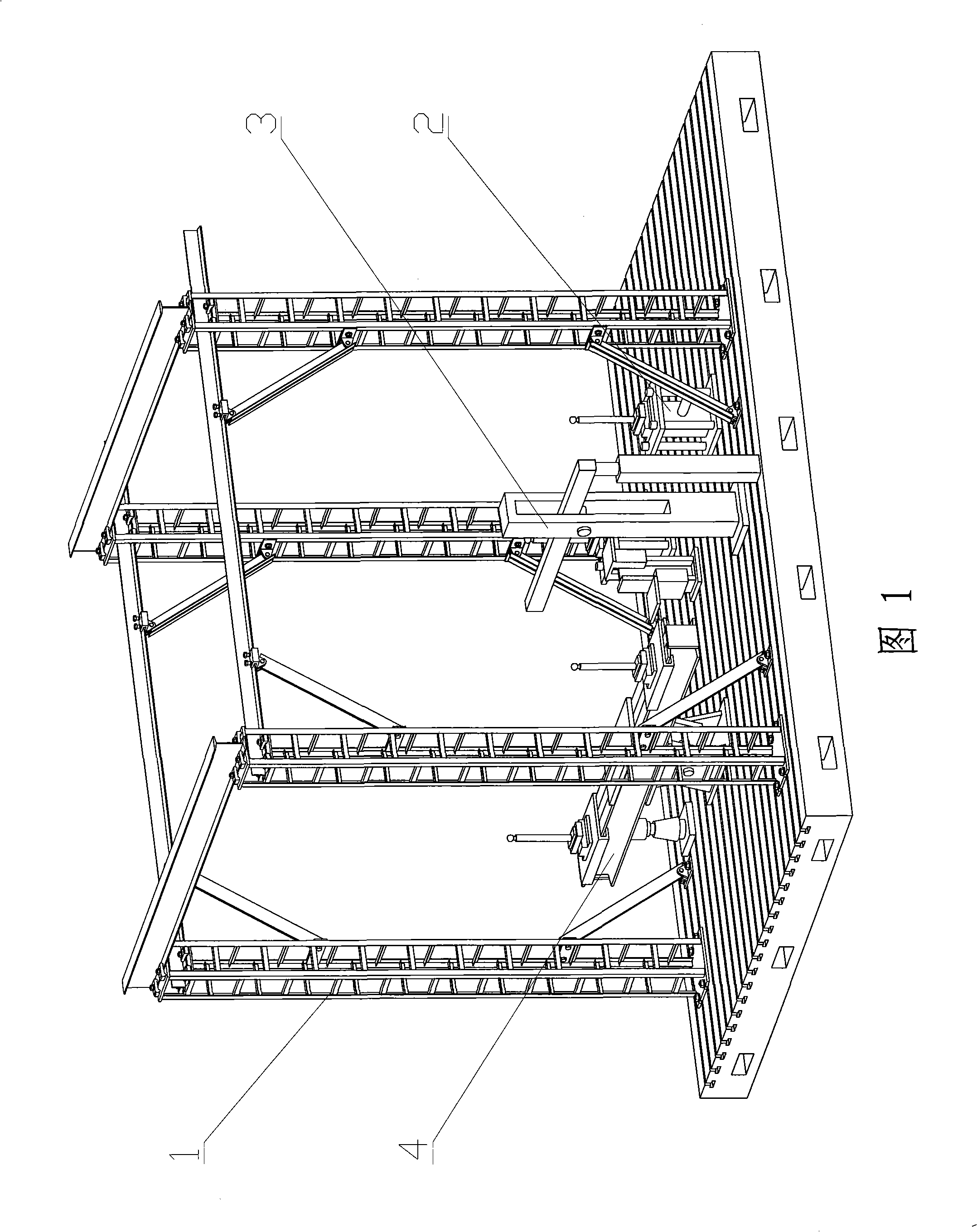

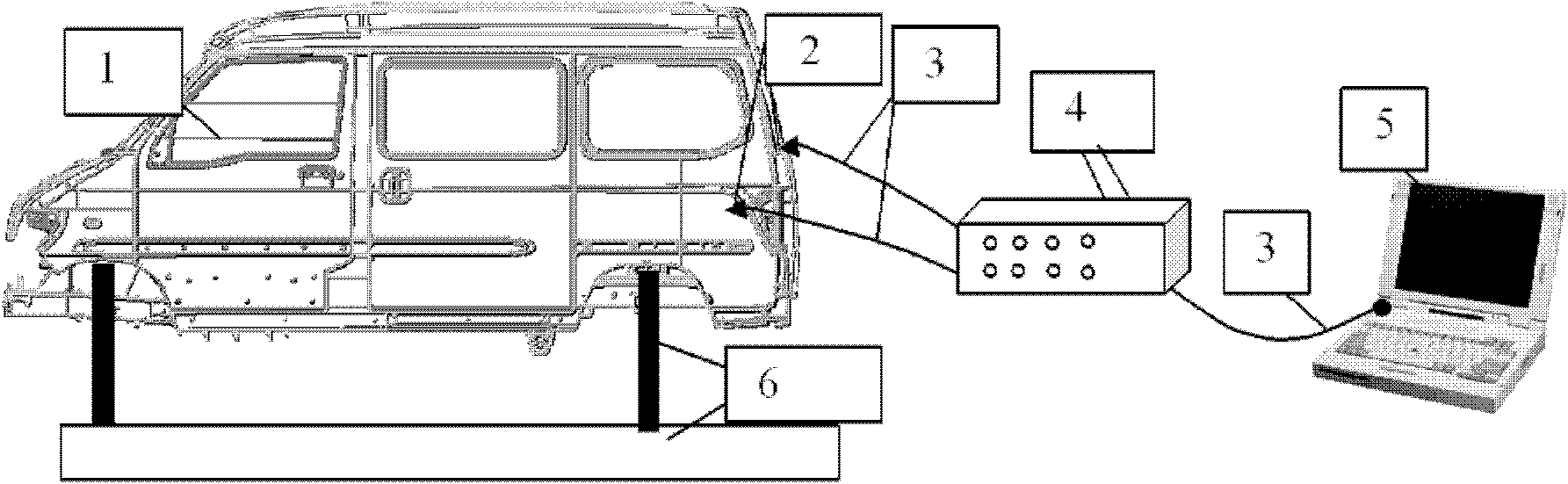

Combined type automobile white body dynamic and static state performance flexible integrated test system

InactiveCN101408470ACompact structureReasonable layoutVehicle testingElasticity measurementCombined testStatic performance

A flexible integrated test system of dynamic and static properties of a combination automotive body-in-white comprises a portal frame, a support restraint device, an adjustable concentrated force loading device, a torsion pendulum frame loading device and a measuring appliance assembly. The support restraint device for supporting the automotive body-in-white to be tested is fixed on the portal frame, the measuring appliance assembly is fixed on the portal frame by a support or directly fixed on the portal frame, the adjustable concentrated force loading device and the torsion pendulum frame loading device which loads stress on the automotive body-in-white to be tested are fixed on the portal frame or arranged on the peripheral side of the portal frame. The flexible integrated test system of dynamic and static properties of the combination automotive body-in-white has the advantages of simple and compact structure, reasonable layout, convenient operation, comprehensive function, wide application and good expansibility.

Owner:HUNAN UNIV

System and method for testing body-in-white bending rigidity of automobile

The invention discloses a system for testing the body-in-white bending rigidity of an automobile. The system comprises a constraining subsystem and a loading subsystem, wherein the constraining subsystem comprises a front suspension rack and a back suspension rack; and the loading subsystem comprises at least two power output devices and a loading device. An innovative improvement design is adopted, and the testing system can undergo self-adaptive adjustment in the testing process, so that the stress is reduced; and moreover, the testing system has extremely high generality, so that the testing requirements of different automobile types are met completely. The invention further discloses a method for testing the body-in-white bending rigidity of the automobile by using the testing device. Due to the adoption of the method, the body-in-white of the automobile can be leveled easily and quickly, and ideal test data are obtained; a testing method for the body-in-white bending rigidity is improved substantially; and compared with other conventional testing methods, the testing method disclosed by the invention has the advantage of very remarkable innovative improvements on the aspects of constraint processing, load application positions and modes, acquisition and judgment of test data, and the like.

Owner:SAIC MOTOR

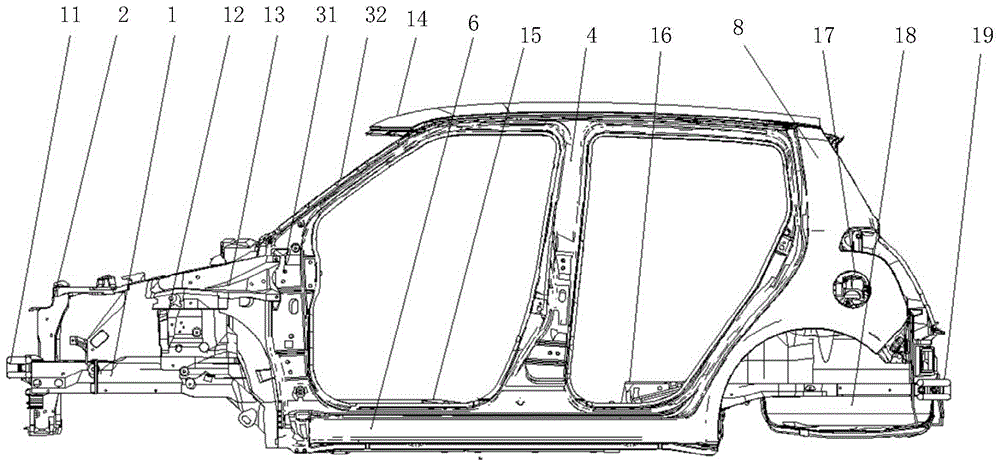

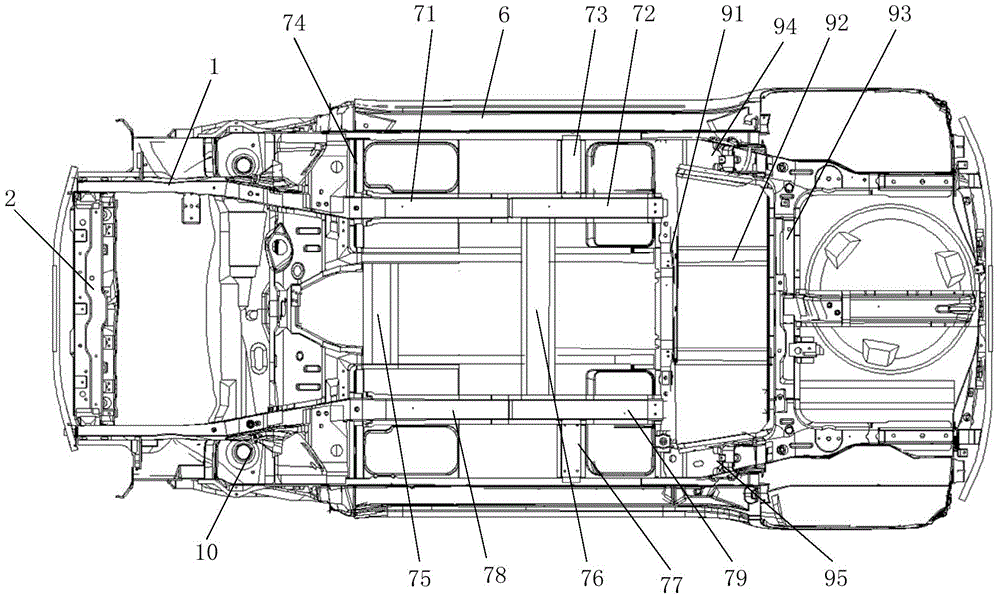

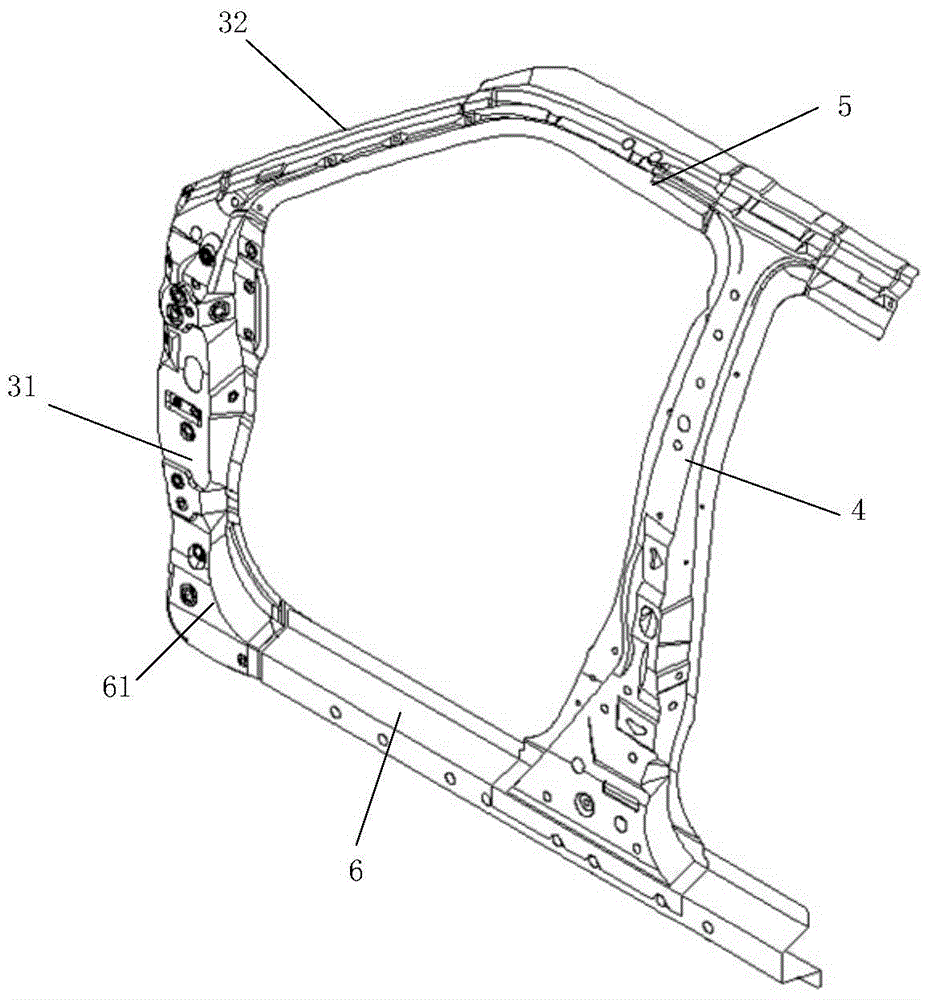

Body in white bend resistance structure and arrangement mode thereof

ActiveCN105015623AIncrease local overlapImprove bending resistanceSuperstructure subunitsMonocoque constructionsStructural engineeringEngineering

The invention provides a body in white bend resistance structure and an arrangement mode thereof. The lower end of a lower vertical plate of a column A is in overlap connection with a sill strip. The upper end of the lower vertical plate of the column A is in overlap connection with an outer plate of the column A. The outer plate of the column A is in overlap connection with an upper beam of a column B. The upper end of an outer plate of the column B is in overlap connection with the upper beam of the column B. The lower end of the outer plate of the column B is in overlap connection with the sill strip. Two to three layers of spot welding connection is formed at each overlap joint to form a closed structure. The bend resistance section of the sill strip, the bend resistance section of the vertical plate of the column A, the bend resistance section of the outer plate of the column A and the bend resistance section of the upper beam of the column B are each in a closed annular shape. Due to the fact that the bend resistance sections form the closed annular shapes and are composed of three or four sheet metal parts, the bend resistance is improved; due to extending sections at the upper and lower ends of the outer plate of the column B, the overlap connection efficiency of the upper beam and the sill strip of the column B and the outer plate of the column B is enhanced, and the bend resistance performance is improved; the transverse and longitudinal staggered closed structure has the effect of enhancing inertia torque, and the bend resistance performance is improved.

Owner:CHINA AUTOMOTIVE ENG RES INST

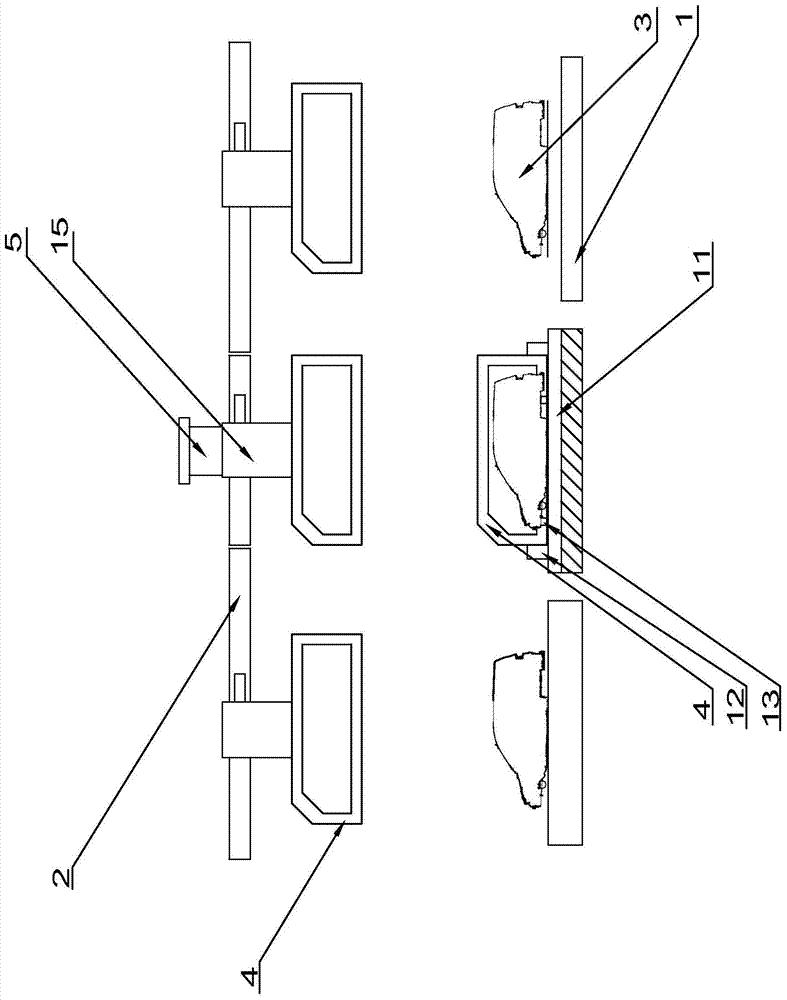

Positioning fixture of rear door of automobile

The invention discloses a positioning fixture of a rear door of an automobile. The positioning fixture comprises a framework, an X-direction limiting oblique block, a first Y-direction limiting block, a second Y-direction limiting block, a first Z-direction limiting block and a second Z-direction limiting block, wherein the first and second Y-direction limiting blocks are fixedly arranged on the right side of the framework and arranged at the front part and the rear part at an interval, and a compactor is respectively correspondingly arranged on the right side of each of the first and second Y-direction limiting blocks; the first Z-direction limiting block is fixedly arranged in front of the first Y-direction limiting block, and the second Z-direction limiting block is fixedly arranged behind the second Y-direction limiting block; and the X-direction limiting oblique block is positioned at the back upper part of the second Z-direction limiting block, a limiting boss is arranged on the left side of the X-direction limiting oblique block, the shape and thickness of the limiting boss tally with those of a gap between the rear door and a body in white, and a fixture positioning pin which can be inserted into the positioning hole of the body in white is fixedly arranged below the framework. Repeated debugging is not required, the fixture can be used for adjusting the rear door to an assembly position once, and the operation is simple, time-saving and labor-saving.

Owner:力帆科技(集团)股份有限公司

Method and apparatus for assembling exterior automotive vehicle boby components onto an automotive vehicle boby

InactiveUS20070039155A1Assembly precisionMeet specificationsAutomatic control devicesAssembly machinesNetwork connectionMotorized vehicle

The present invention generally relates to a method and programmable apparatus for the assembly of body components to an automotive body that has undergone a progressive series of framing and welding steps so as to produce a structurally rigid body frame, termed a body-in-white. More specifically, this invention relates to creating a new net locating scheme (X, Y and Z Cartesian coordinate system) for a body-in-white to direct associated tooling to create net attachment features on a rigid body frame with respect to a new net locating scheme so that components may be attached to a automotive body at a net location eliminating the need for any slip plane attachment techniques.

Owner:KUKA SYST NORTH AMERICA LLC

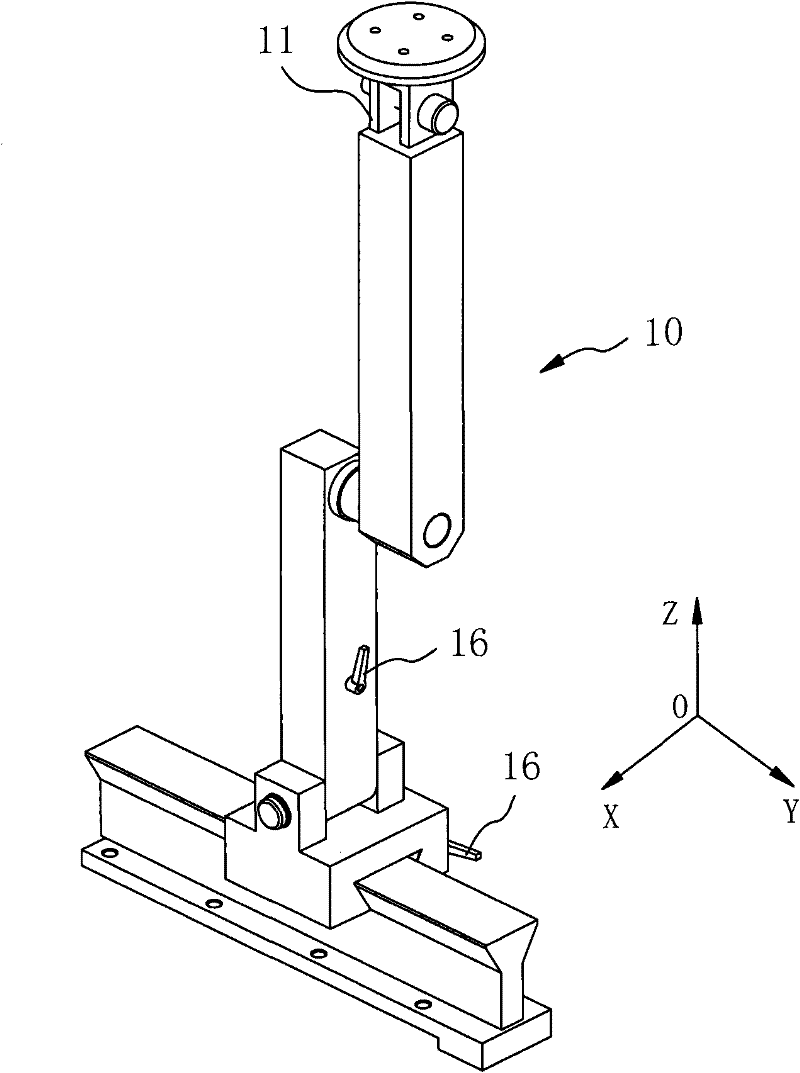

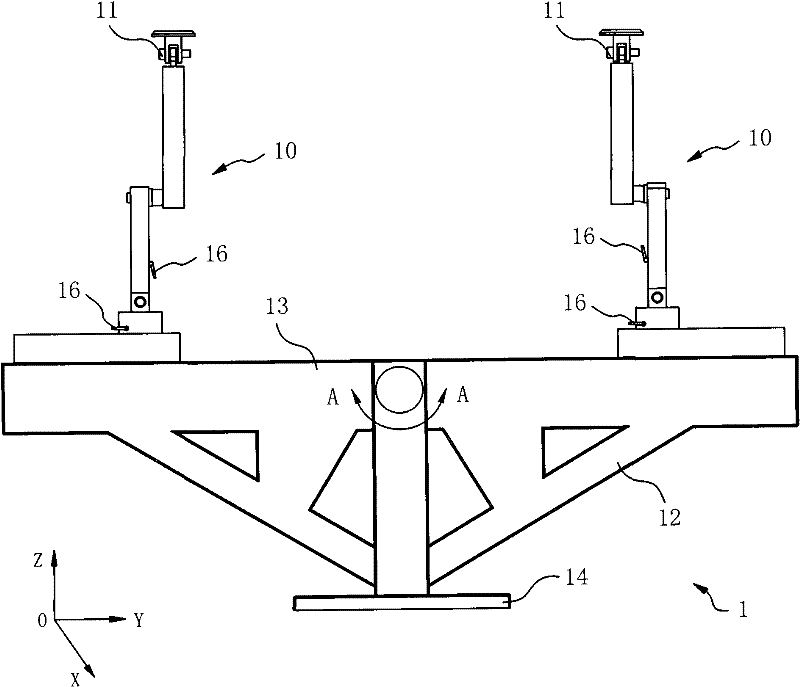

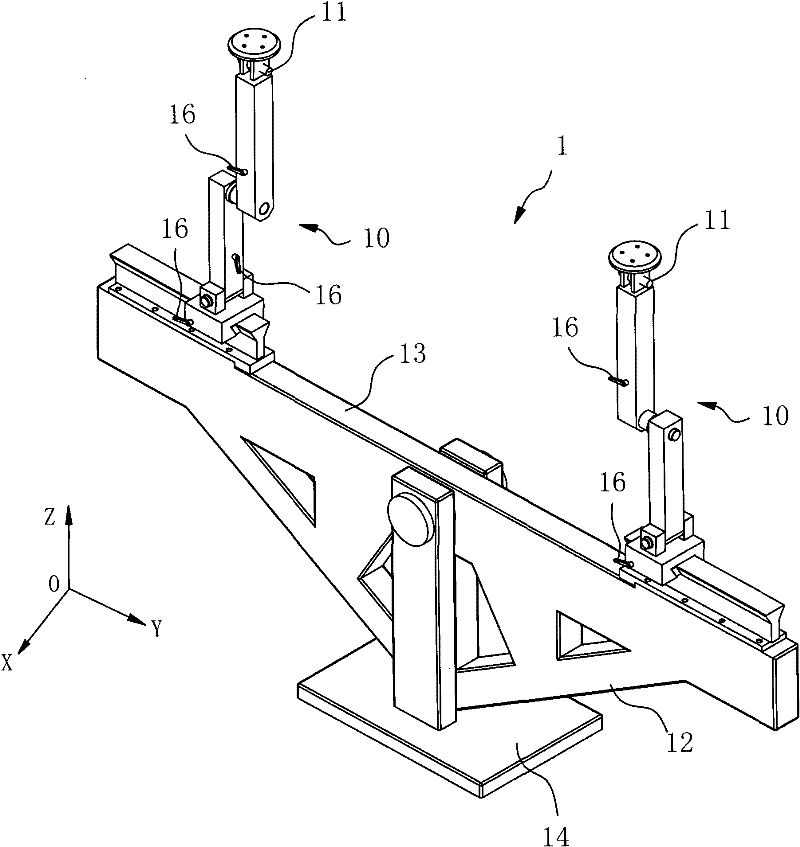

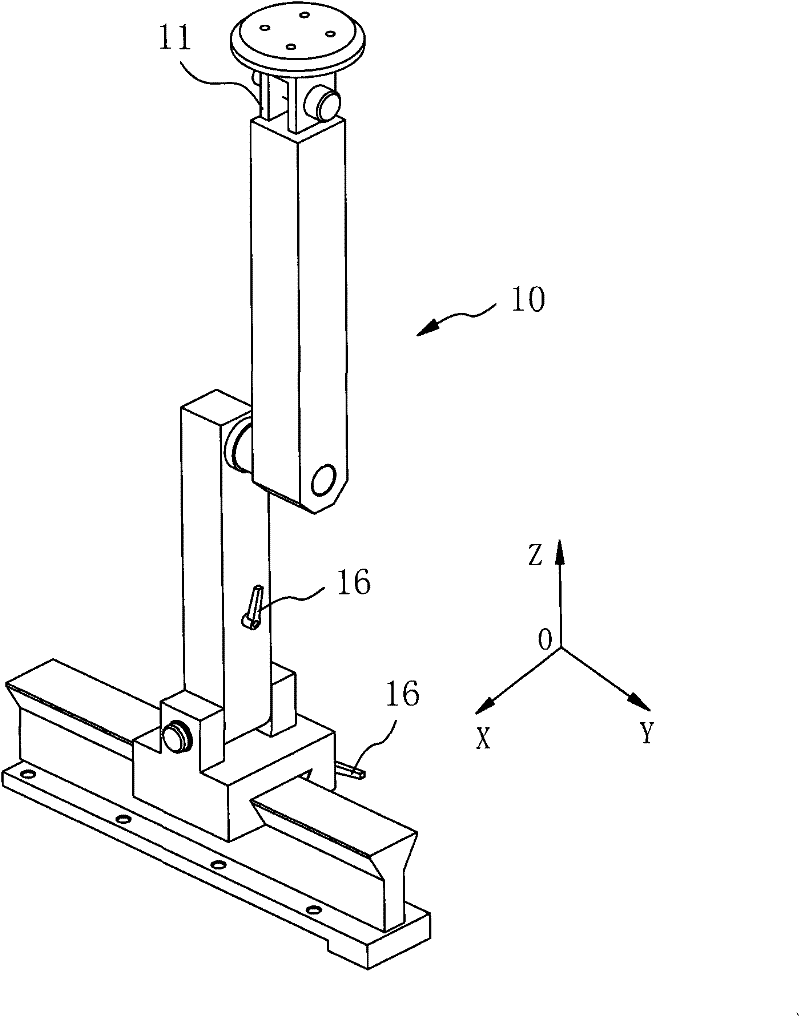

Passenger car body-in-white bending and torsion stiffness test restraint device

The invention provides a passenger car body-in-white bending and torsion stiffness test restraint device which includes a workbench, a torsion crossbeam, a first column, a second column, a third column, and a fourth column. The torsion crossbeam is horizontally arranged on one side of the workbench via a support, and can rotate horizontally around the support. The lower end of the first column and the lower end of the second column are arranged on the two sides of the torsion crossbeam respectively. The lower end of the third column and the lower end of the fourth column are arranged on the other side of the workbench at an interval. The top end of each column is provided with a connecting member which limits three mobile degrees of freedom but does not limit three rotational degrees of freedom. The lower end of the third column or the lower end of the fourth column is fixed on the workbench, and among the connecting members between the lower ends of the remaining three columns and the workbench or the torsion crossbeam, one is a unidirectional rotary hinge, and the other two are connecting members which limit three mobile degrees of freedom but does not limit three rotational degrees of freedom. In such a manner, the six degrees of freedom of the car body space are restrained, the influence of a frame to the car body stiffness is eliminated, and the car body posture can be easily adjusted.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Single set geometry method for assembly of a vehicle

InactiveUS7574801B2Labor intensiveSpace intensiveUnderstructuresMetal working apparatusMobile vehicleEngineering

Owner:FORD GLOBAL TECH LLC

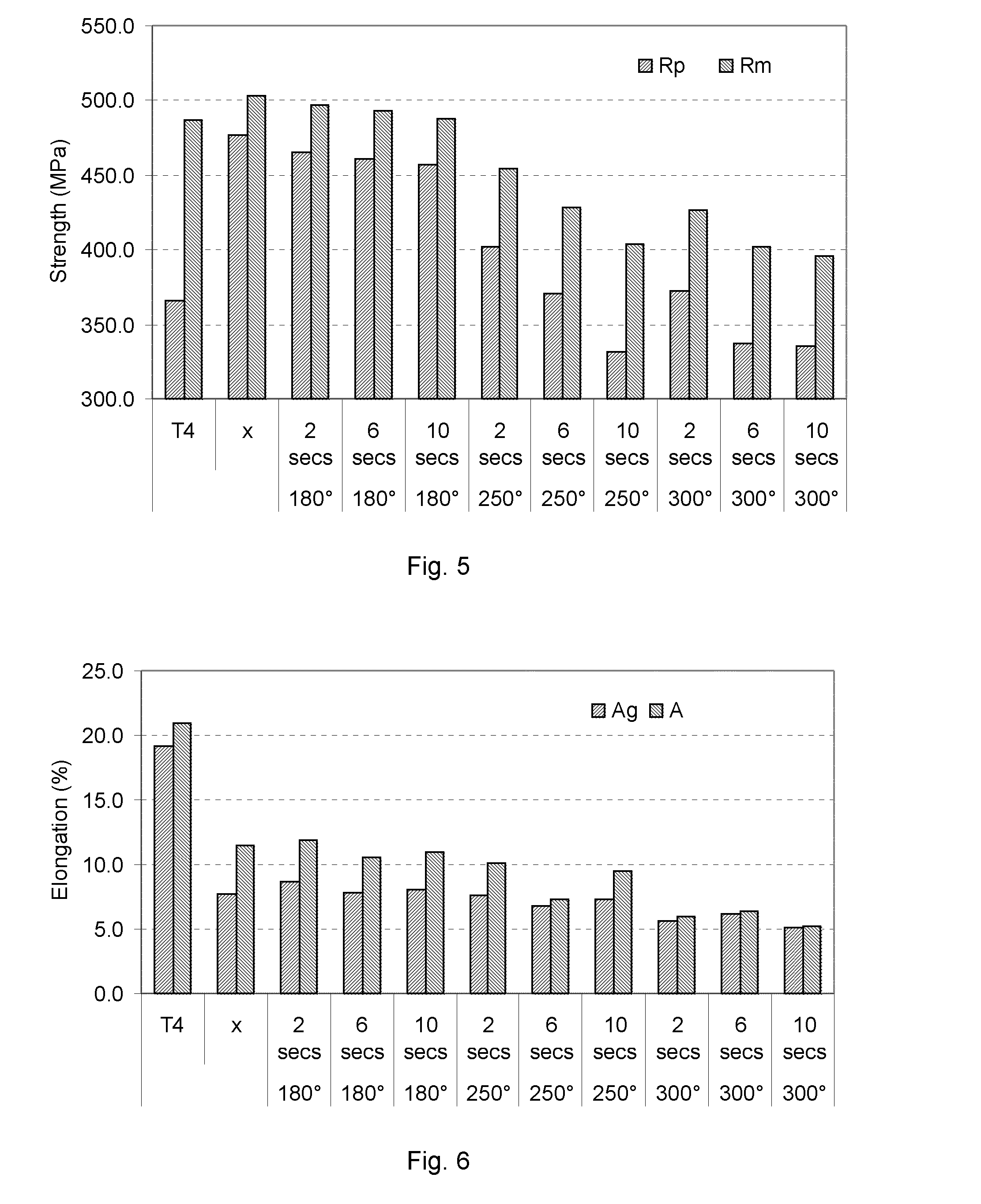

Production of formed automotive structural parts from aa7xxx-series aluminium alloys

InactiveUS20150217813A1Sufficient formabilityThin material handlingMetal layered productsQuenchingHeat treating

A method of manufacturing a formed aluminium alloy automotive structural part or a body-in-white (BIW) part of a motor vehicle, including the steps of: providing a rolled aluminium alloy bare or composite sheet product having a gauge of about 0.5 mm to 4 mm, wherein the sheet product includes at least one layer an AA7xxx-series aluminium alloy, the sheet product having been subjected to solution heat treatment and quenching followed by at least 1 day of natural ageing; subjecting the naturally aged sheet product to reversion annealing treatment, namely a heat treatment at a temperature between 100° C. and 350° C. during 0.1 to 60 seconds; optionally subjecting the heated sheet product to forced cooling operation; within 2 hours, preferably within 30 minutes, from the reversion annealing treatment, forming the sheet product to obtain a three-dimensionally formed automotive structural part or body-in-white (BIW) part.

Owner:ALERIS ALUMINUM DUFFEL

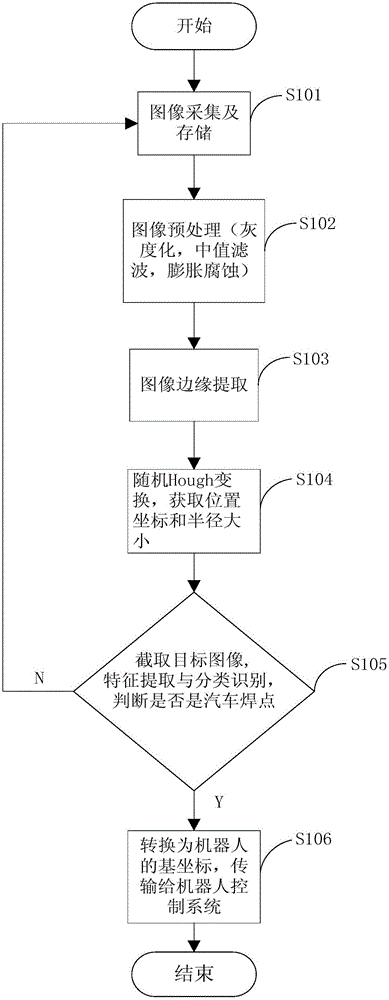

Car body-in-white welding spot positioning method and device based on robot visual servo

ActiveCN104942496AImprove detection efficiencyQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesProduction lineFeature extraction

The invention discloses a car body-in-white welding spot positioning method and device based on robot visual servo. The method comprises the steps that a partial car body image with body-in-white welding spots is collected and stored in a storage unit, and the image is read from the storage unit; the image is preprocessed; edge extraction is performed on the preprocessed image; the position coordinates and radius sizes of the car body-in-white welding spot or circular hole targets in the image are acquired by utilizing random Hough transformation; a target image is intercepted, feature extraction and classification recognition are performed on the target image, and a positioning coordinate is obtained and transmitted to a robot control system. According to the car body-in-white welding spot positioning method and device, quick and automatic recognizing and positioning of a car body-in-white welding spot quality detection robot on the body-in-white welding spots to be detected are achieved, the car body-in-white welding spot quality detection robot can be guided to accurately position the body-in-white welding spots, and the key technical problems are solved for achieving intelligent detection of the car body-in-white welding spot quality detection robot on the welding spot quality on a car industry manufacturing production line.

Owner:HUNAN UNIV

Method for Producing a Body Shell of a Motor Vehicle and Body Shell for a Motor Vehicle

InactiveUS20120280534A1Low costShorten the timeVehicle seatsMetal-working apparatusBody in whiteMotorized vehicle

Owner:DAIMLER AG

Method and apparatus for assembling exterior automotive vehicle body components onto an automotive vehicle body

InactiveUS7913370B2Assembly precisionMeet specificationsAutomatic control devicesAssembly machinesEngineeringMotorized vehicle

The present invention generally relates to a method and programmable apparatus for the assembly of body components to an automotive body that has undergone a progressive series of framing and welding steps so as to produce a structurally rigid body frame, termed a body-in-white. More specifically, this invention relates to creating a new net locating scheme (X, Y and Z Cartesian coordinate system) for a body-in-white to direct associated tooling to create net attachment features on a rigid body frame with respect to a new net locating scheme so that components may be attached to a automotive body at a net location eliminating the need for any slip plane attachment techniques.

Owner:KUKA SYST NORTH AMERICA LLC

Stainless frame construction for motor vehicles

InactiveUS20050146162A1Improve protectionVehicle seatsLiquid surface applicatorsCoated surfaceMotorized vehicle

A motor vehicle having a stainless supporting frame structure or a stainless body-in-white, including a supporting frame structure and flat body components mounted thereon, the supporting frame structure being formed of rust-resistant steels as well as light metal alloys and / or plastics and the flat body components being formed of rust-resistant steels, light metal alloys and / or plastics, the surface of the supporting frame structure or the body-in-white being free of anti-corrosion coating or anti-corrosion painting. In addition, a method for manufacturing a motor vehicle having a corrosion-resistant body-in-white includes the steps of: manufacturing a supporting frame structure by joining and / or welding together rust-resistant steels; and mounting flat body components and / or body panels made of light metals, plastics, or rust-resistant steels, thereby forming the body-in-white. A color-providing surface coating of the body-in-white is directly applied to the uncoated surface of the rust-resistant steels, light metals, or plastics.

Owner:DAIMLER AG

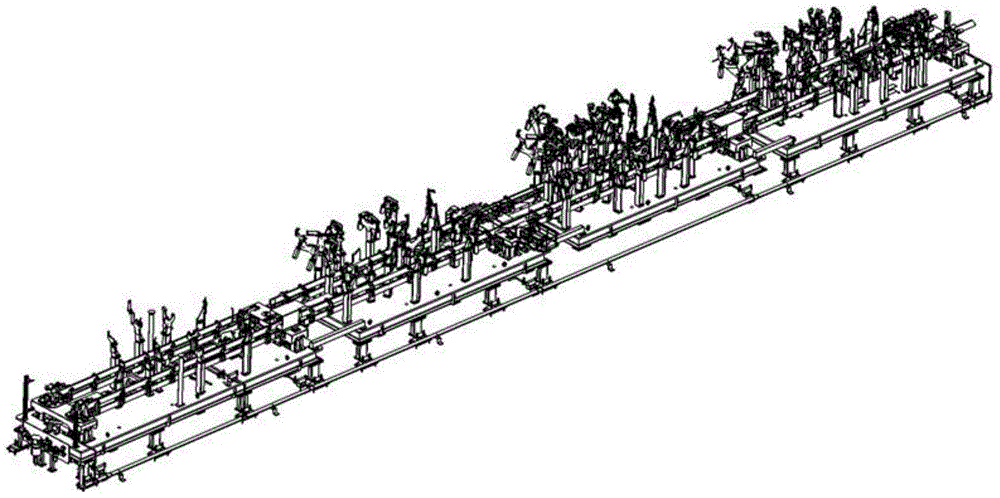

SUV (Sport Utility Vehicle) vehicle automatic welding production line and production method thereof

InactiveCN104801868AHigh degree of automationIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to the mechanical automation technical field, particularly to an SUV (Sport Utility Vehicle) vehicle automatic welding production line and a production method thereof. The unmanned operation on the integral SUV body-in-white automatic welding production line is implemented through the control on coordinative operation of a plurality of robots, the matching of clamping of a particular fixture and the automatic welding of the welding robots. The production method comprises conveying a left side body and a right side body of a vehicle body and a lower vehicle body to an integral assembly workstation through bilateral intelligent air conveying devices and a lower vehicle body conveying roller bed for integral vehicle body assembly respectively and achieving the floor repair welding action through four of the welding robots; continuing to conveying integral welding products of the integral assembly workstation to a first repair welding workstation through the roller bed, performing the repair welding action through four of the welding robots, continuing to conveying the integral welding products to a third workstation and achieving the repair welding action through two of the robots; continuing to conveying the bodies in white conveyed from the third workstation after welding to a storage workstation through the roller bed and placing the bodies in white at the appropriate position of the storage workstation to perform the body-in-white storage. According to the integral body-in-white automatic welding production line, the unmanned operation is implemented, the degree of automation is high, and the production efficiency is high.

Owner:上海澜誉工业自动化设备有限公司

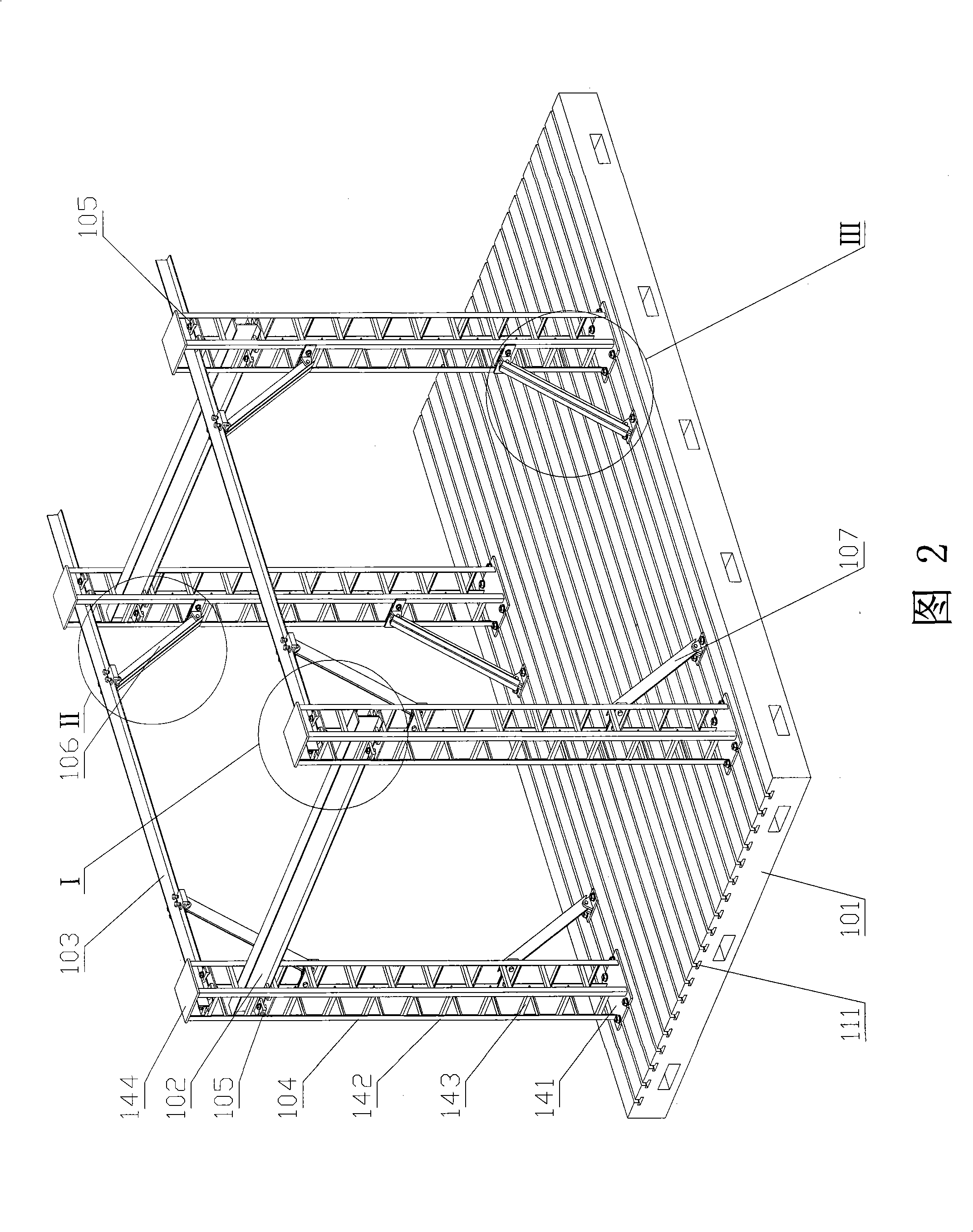

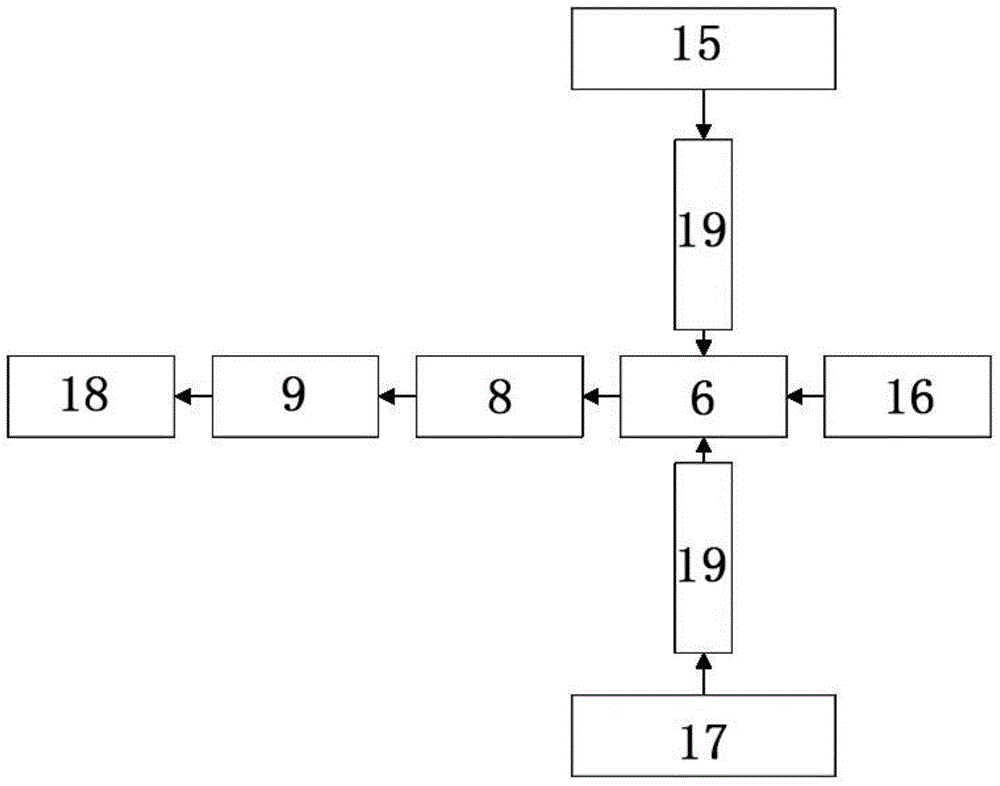

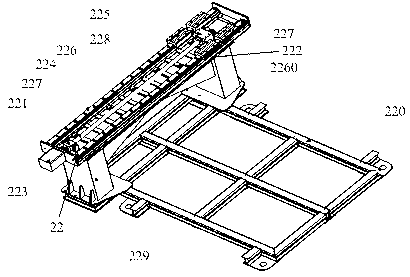

Multi-type vehicle body in white welding main combined fixture

ActiveCN106271318AFixing Shared Targeting IssuesSolve positioning positions with different widthsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a multi-type vehicle body in white welding main combined fixture. The multi-type vehicle body in white welding main combined fixture comprises a positioning device, wherein the positioning device is used for supporting a body in white and comprises a plurality of positioning bases; a side wall clamping device is arranged on two sides of the positioning device, and is moved towards or away from the positioning device through a translation mechanism which is arranged under the side wall clamping device; a rotary mechanism is arranged under the side wall clamping device and is used for adjusting the horizontal position of the side wall clamping device; each positioning base comprises a positioning assembly, a translation device and a height adjusting mechanism, each translation device is used for adjusting the horizontal position of the corresponding positioning assembly, and each height adjusting mechanism is used for adjusting the vertical position of the corresponding positioning assembly. The invention aims at providing the multi-type vehicle body in white welding main combined fixture, so that the multi-type vehicle body in white welding main combined fixture can be applied to multiple vehicle types.

Owner:QINGLING MOTORS GRP

Body-in-white air-tightness detection system and detection method

InactiveCN105738046AGuaranteed manufacturing air tightnessLow costMeasurement of fluid loss/gain rateEngineeringOrganic glass

The invention discloses a body-in-white air-tightness detection system and a detection method. The system comprises at least eight organic glass plates, a pressure sensor, a fog generator, a blower fan and an air input sensor, wherein the organic glass plates are in sealing connection with each glass window on the body-in-white to form a sealed body chamber, the fog generator and the blower fan are respectively in sealing communication with the body chamber, the pressure sensor is arranged in the body chamber, and the air input sensor is arranged between the blower fan and the body chamber. The system has a simple structure, realizes low cost and guarantees that the experiment result is accurate, air-tightness detection and leakage positioning can be effectively realized through repeated body-in-white air-tightness detection in short time, and body-in-white air-tightness can be guaranteed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Welding manipulator

InactiveCN102909471ARealize fully automatic weldingLow costResistance electrode holdersGear transmissionBody in white

The invention relates to a welding manipulator which comprises a feeding device and welding pliers connected with the feeding device. The feeding device comprises a linear module and a rotating module which are connected with the welding pliers; the rotating module comprises a gear bank rotating module connected with the feeding device by a slewing bearing; the welding pliers are fixed on the gear bank rotating module; the welding manipulator replaces a robot to move so as to carry out feeding by the linear module and the rotating module and is low in cost; by the linear motion of the linear module and the rotation motion of the rotating module, the high-accuracy positioning of a random space trace can be implemented in a mechanical stroke; the rotating module adopts the gear bank rotating module to carry out high accuracy rotation; the linear module implements high-accuracy linear transmission; when the linear module is linked with the rotating module in a multi-axis manner, the full-automatic welding of a resistance spot welding point on an automobile body in white can be implemented; the welding pliers are fixed and driven to rotate by a gear of the gear bank rotating module; the structure setting is ingenious; an additional connecting mechanism is simplified; and the high-accuracy feeding is implemented by gear transmission.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Body-in-white torsional fatigue testing system and method thereof

InactiveCN102944431AImproved torsional fatigue performanceQuick testVehicle testingFatigue testingMetal

The invention provides a body-in-white torsional fatigue testing system and a method thereof. The body-in-white torsional fatigue testing system comprises a constraint subsystem and a loading subsystem, wherein the constraint subsystem comprises a front shock absorber bearing rack for supporting a first end of a body-in-white and driving the body-in-white to generate torsion, and a rear shock absorber bearing rack for supporting a second end of the body-in-white; and the loading subsystem is used for loading the front shock absorber bearing rack so as to drive the body-in-white to generate the torsion. According to the body-in-white torsional fatigue testing system and the body-in-white torsional fatigue testing method provided by the invention, the fatigue state of the body-in-white of an automobile under a torsional working condition can be very easily and rapidly tested, including data such as fatigue life of metal plate and cracked welding spots; and the testing method on the torsional fatigue property of the body-in-white is substantially improved.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

Opening, in particular tailgate for an automobile

InactiveUS8622458B2Reduce weightSuperstructure subunitsMonocoque constructionsElectrical and Electronics engineeringFastener

Owner:CO PLASTIC OMNIUM

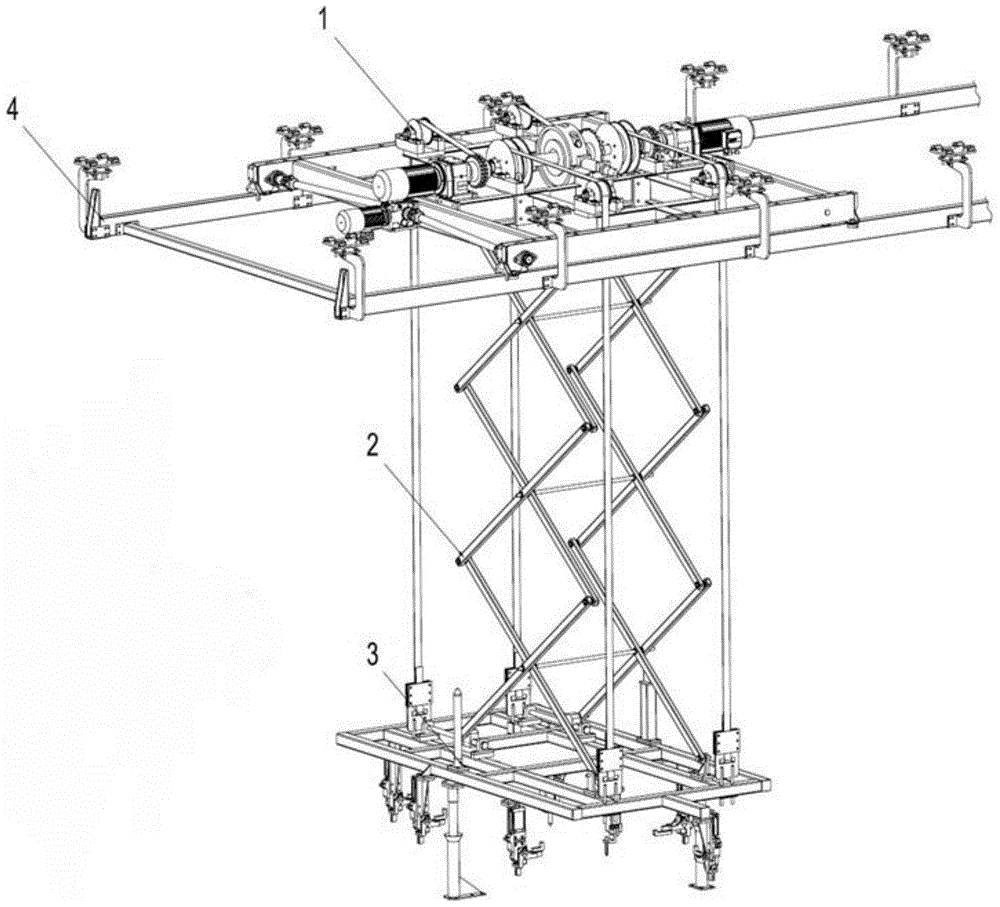

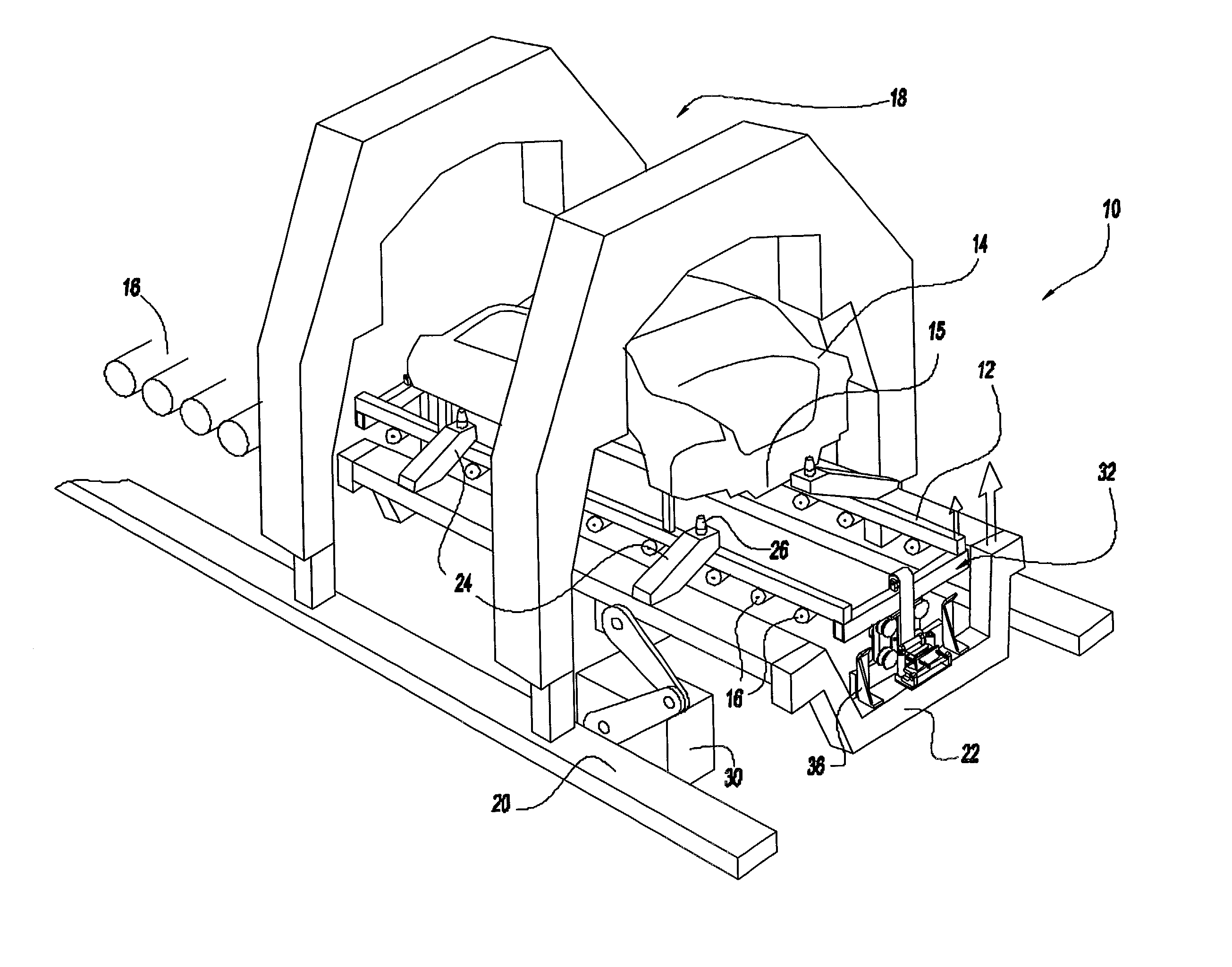

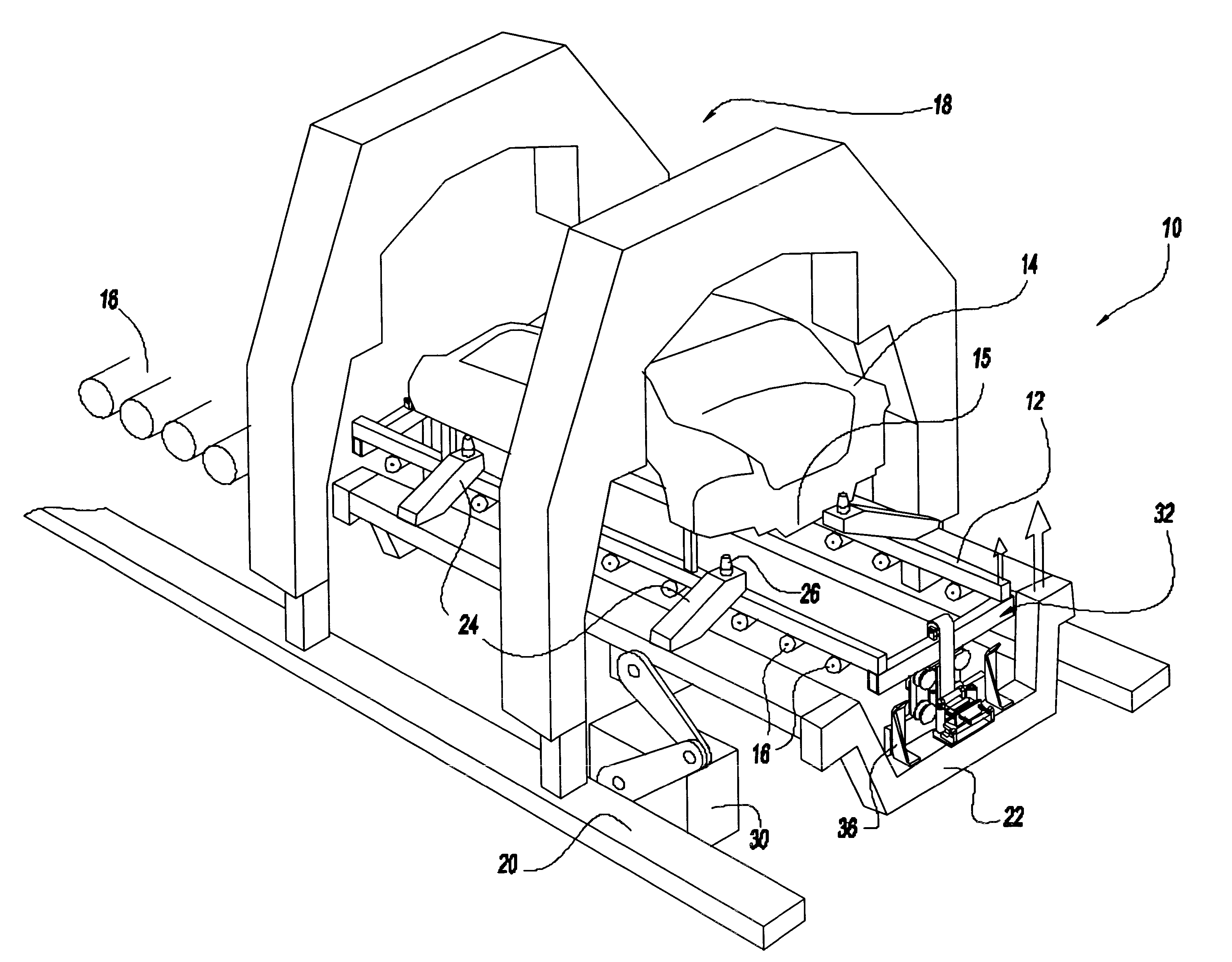

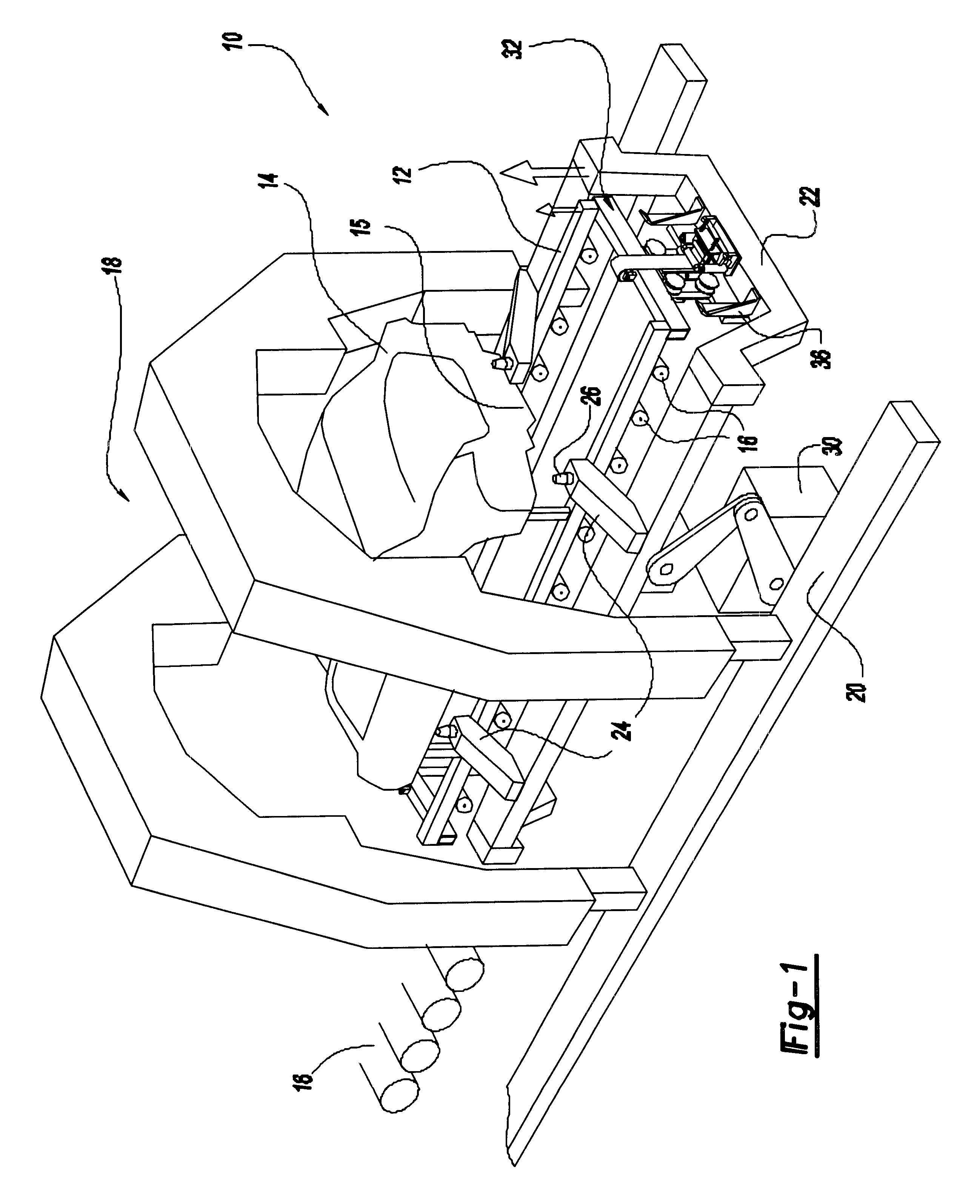

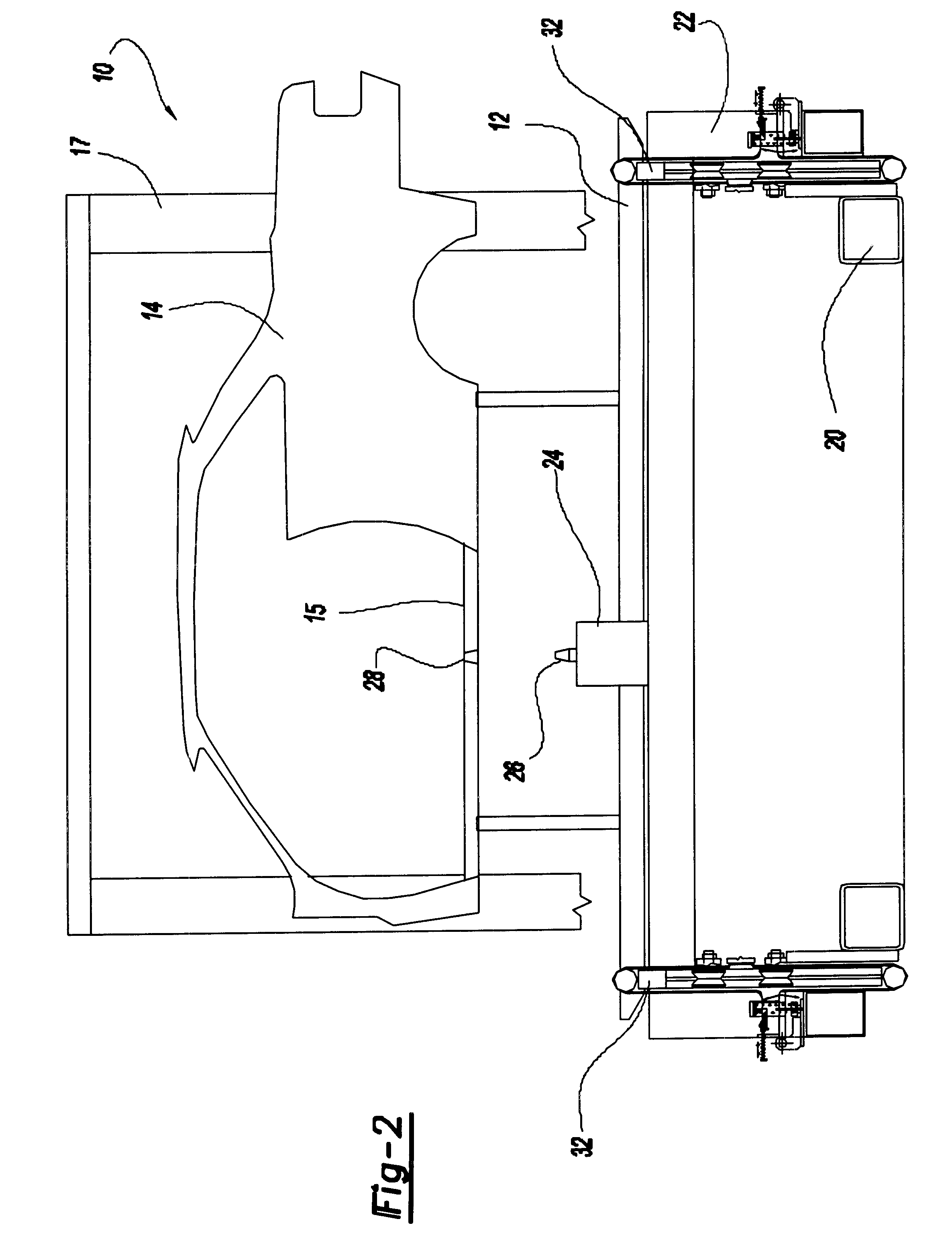

Soft touch lifter

InactiveUS20030000804A1Reduce impact speedEliminate needLifting framesSupporting framesClosed loopEngineering

A "soft touch" lifter for an automotive "Body in White" geometry station like a framing system is disclosed having a unique lifting assembly for elevating both the automotive body and the underbody tooling to a geometry position. The system includes a lift assembly which is vertically slidably mounted to a stationary base and movable between a first position in which the lift frame is positioned beneath a skid positioned at the geometry station and upon which the automotive body is supported, and a second position elevated from the first position. An underbody tooling assembly is mounted to the lift frame, and this tooling assembly includes a plurality of locators which register with position receptors on the automotive underbody when the skid is positioned at the geometry station. A pair of T-shaped lift arms are slidably mounted to the stationary base at opposite ends of the skid, and these lift arms are movable between a lower and an upper position. In their lower position, the lift arms register with the skids so that movement of the lift arms from their lower and to their upper position simultaneously elevates the skid with its supported automotive body to an upper position. A closed loop belt mechanically connects the lift arms to both the stationary base and the lift frame so that the lift arms move from their lower and to their upper position at a speed substantially one-half of the speed of movement of the lift frame from its first and to its second position. Furthermore, as the lift frame approaches its second position and the lift arms simultaneously approach their upper position, the tooling locators fully engage the receptors in the automotive body and slightly elevate the automotive body from the skid to the geometry position to avoid any geometrical impact from the handling system to the part located by the geometry tooling.

Owner:VALIANT CO LTD

Body-in-white welding spot optimization method based on variable density method and fatigue life analysis

PendingCN110287550AReduce the number of solder jointsAchieving Lightweight GoalsGeometric CADInternal combustion piston enginesStress distributionElement model

The invention discloses a body-in-white welding spot optimization method based on a variable density method and the fatigue life analysis, and the method comprises the specific steps of building a finite element model of a whole vehicle, and building a body-in-white welding spot finite element model; partitioning the established body-in-white welding spot model according to the modal influence weight; establishing a welding spot topological optimization calculation model based on the variable density method partition; applying an inertia release method to the body-in-white welding spot model after topology optimization, and taking a load spectrum of virtual iteration as excitation; calculating the stress distribution around a welding spot under excitation, and analyzing the fatigue life of the welding spot to predict the potential risk of the welding spot; and carrying out position and number optimization adjustment on a welding spot area with insufficient fatigue life. According to the method, the number of the body-in-white welding spots is reduced through the topological optimization, the body-in-white light target is achieved, the design variables of the fatigue life analysis are reduced, the calculation efficiency is improved, and the method plays a key role in improving the body-in-white rigidity and the modal performance.

Owner:NANJING UNIV OF SCI & TECH

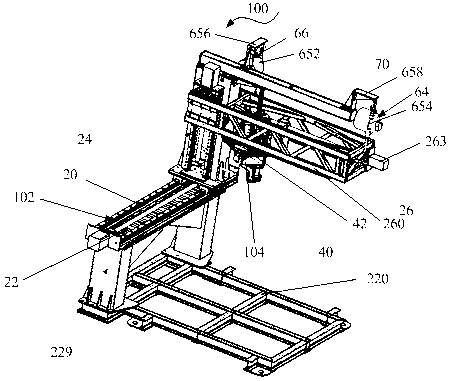

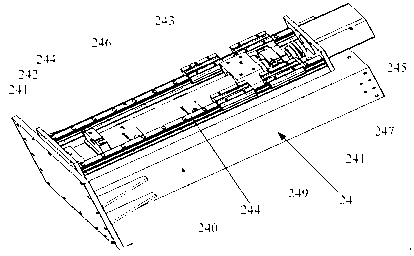

Flexible assembly system for welding

InactiveCN104118497ASmall footprintImprove space utilization efficiencyWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a flexible assembly system for welding. According to the flexible assembly system for welding, assembly clamps corresponding to different vehicle models are conveyed through overhead clamp conveying rails so that bodies in white can be clamped and fixed to welding stations of a high speed roller bed conveying guide rail, after the bodies in white are welded on the welding stations, the assembly clamps are driven by a lift to leave the high speed roller bed conveying guide rail, and the bodies in white are conveyed through the high speed roller bed conveying guide rail. According to the system, different models of bodies in white are fixed through different models of assembly clamps conveyed by the multiple parallel overhead clamp conveying rails, so that occupied area is reduced, the space utilization rate is increased, maintenance and detection are convenient to perform, and the purpose of flexible assembly for flexible welding is achieved. The flexible assembly for welding is used in the field of welding production lines.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD

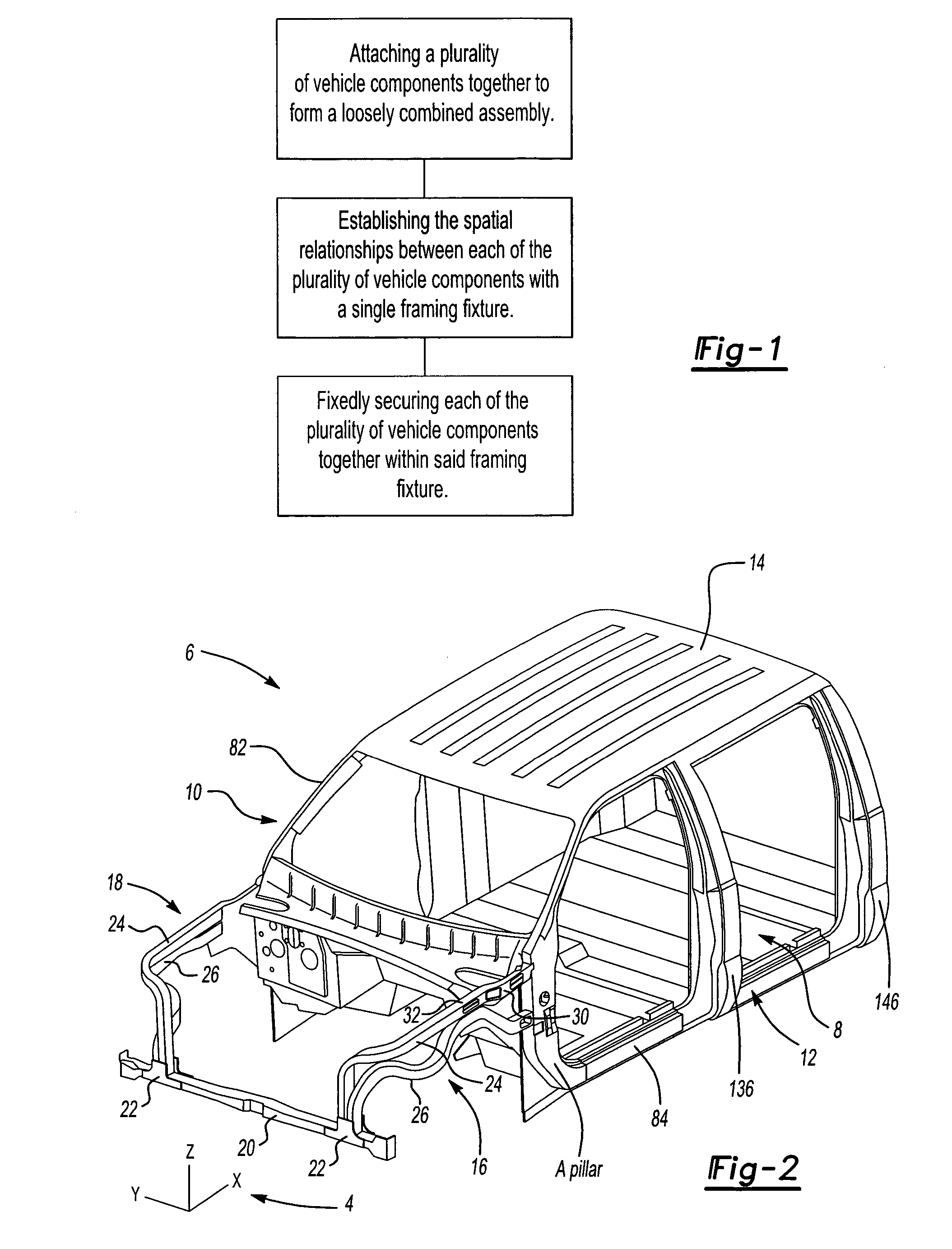

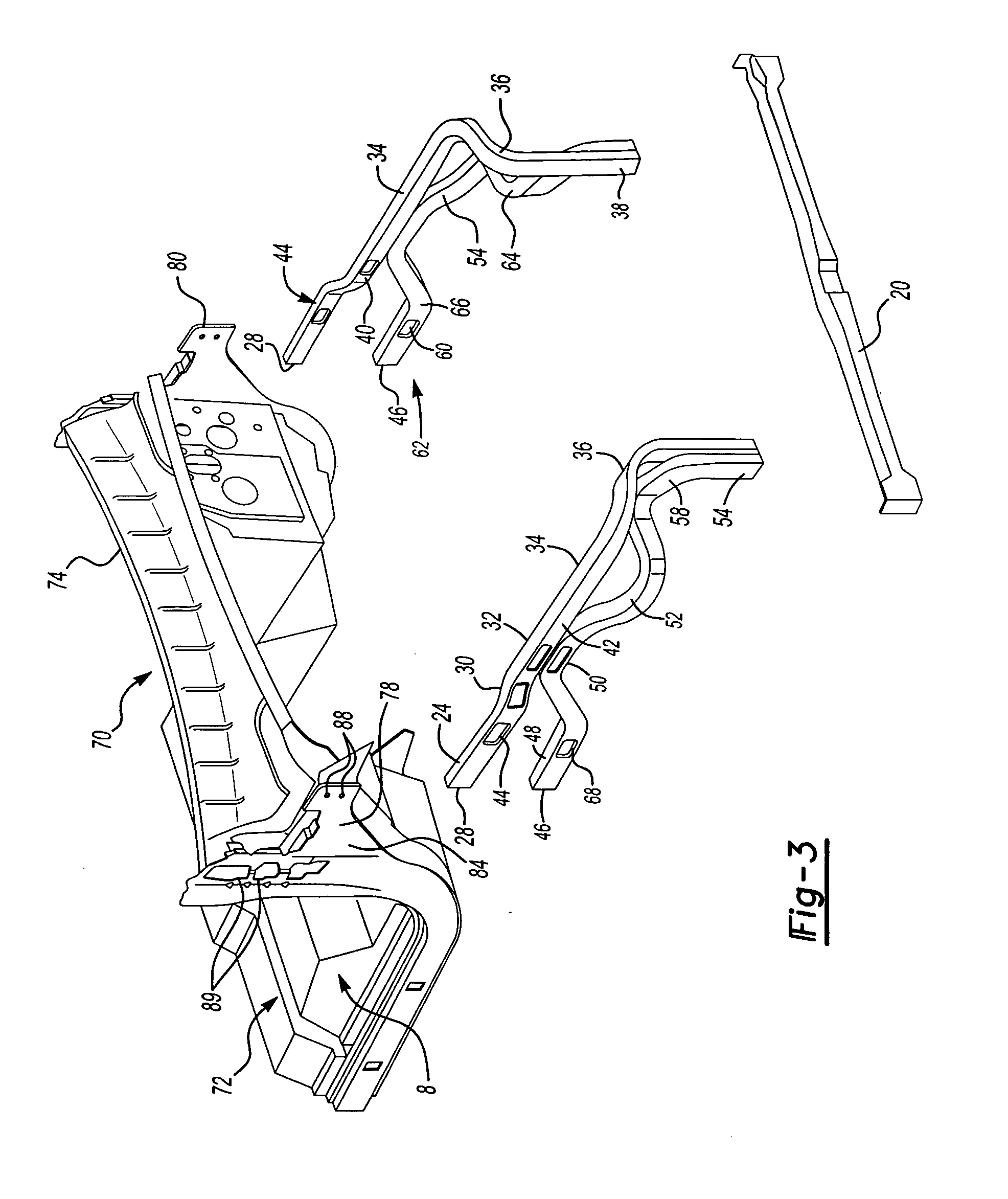

Single set geometry method for assembly of a vehicle

InactiveUS20060283015A1Improved floor space efficiencyFloor space intensiveUnderstructuresMetal working apparatusImproved methodMotorized vehicle

An improved method of manufacturing an assembly comprising at least two components. Assembly components are attached together to form a combined assembly. The combined assembly is engaged by a single framing fixture that establishes the spatial relationships between each of the assembly components. After the spatial relationships are final, the assembly is fixed having securing points that are accessible when engaged by the single framing fixture. The method significantly reduces the load-weld-load sequences used in conventional body-in-white framing processes for motor vehicles.

Owner:FORD GLOBAL TECH LLC

Soft touch lifter

InactiveUS6505726B1Reduce impact speedEliminate needLifting framesConveyor partsEngineeringMechanical engineering

Owner:VALIANT CO LTD

Motor vehicle and rear-end module therefor

The invention relates to a motor vehicle comprising a body (2), which body has at least two rear longitudinal members each forming a primary load path for collision forces, wherein the motor vehicle (1) has a rear-end module (20) that can be pre-assembled as a sub-assembly, which rear-end module can be connected to the body (2) as part of the vehicle assembly after the completion of the body-in-white and has at least a supporting structure (21a, 21b) for fastening chassis components of a rear wheel suspension and a support structure (22a, 22b) extending from the supporting structure (21a, 21b) toward the motor-vehicle rear for absorbing collision forces, wherein the supporting structure (21a, 21b) and the support structure (22a, 22b) form at least one second load path for collision forces.

Owner:AUDI AG

Ultrasonic wave detection device for thinning rate of body in white

ActiveCN102589490AQuick checkEasy to detectAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansProcess systemsMicrocomputer

The invention relates to an ultrasonic wave detection device for a thinning rate of a body in white. The ultrasonic wave detection device comprises ultrasonic wave probes, a data acquisition and management system, a microcomputer, a connecting cable and a clamp system arranged corresponding to the body in white; and software comprise a signal analysis and process system. The body in white is fixed on a rack through a clamp, ultrasonic waves generated by a plurality of ultrasonic wave probes are reflected on the surface of the body in white, the microcomputer receives ultrasonic waves reflected from different detection points, and the data of the different detection points are calculated so as to obtain the thinning rate of parts. The invention provides a whole set of equipment for the design of the parts and the consistency detection in the practical manufacturing process, the thinning rate of the parts can be detected effectively, the body in white, which is thinned excessively, is prevented from entering the next production link, the time needed by the road test is reduced, the development process of a finished automobile is shortened, the product quality of enterprises is improved, and simultaneously, the unqualified automobiles on the market are reduced.

Owner:HUNAN UNIV AISHENG AUTO TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com