Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1956 results about "Fatigue testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

HIGH CYCLE FATIGUE. Historically, high cycle fatigue (LCF) refers to situations that require more than 10 4 cycles to failure where stress is low and deformation is primarily elastic. In high-cycle fatigue situations, materials performance is commonly characterized by an S-N curve, also known as a Wöhler curve .

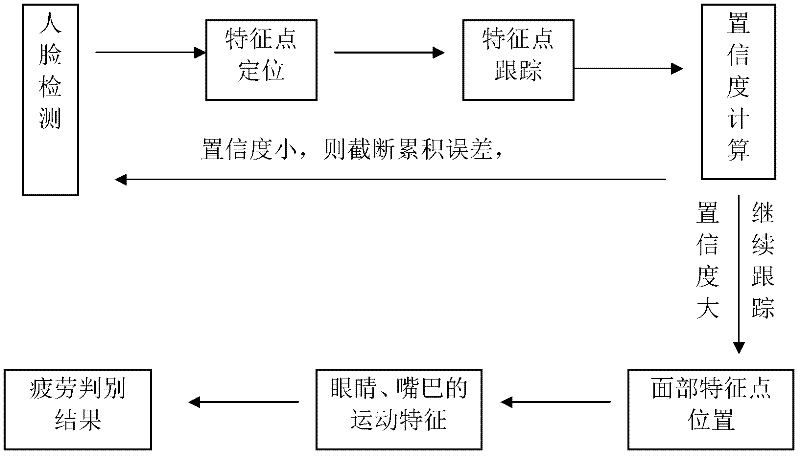

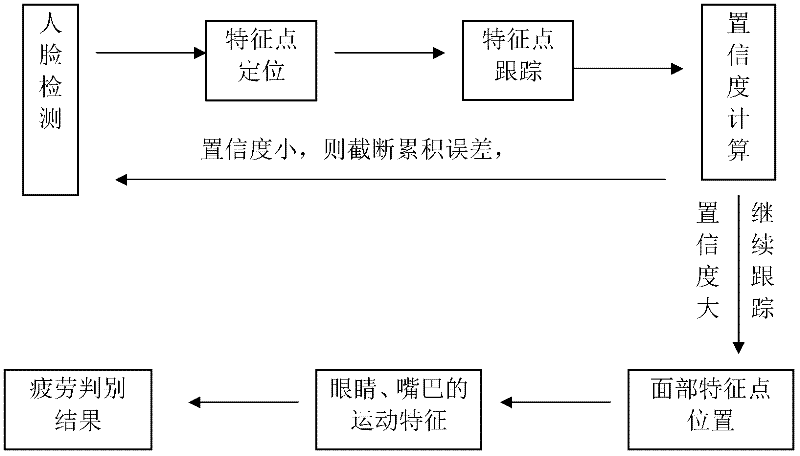

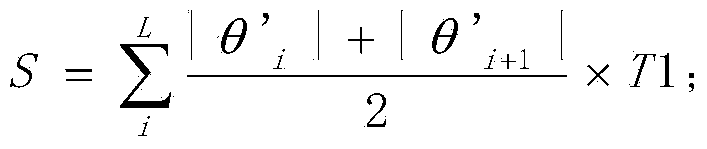

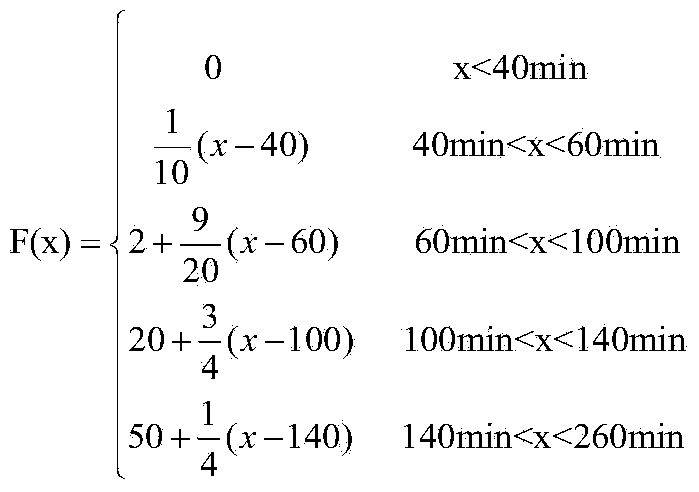

Driver fatigue detection method based on face video analysis

ActiveCN102254151ADetection speedImprove reliabilityCharacter and pattern recognitionActive safetyPattern recognition

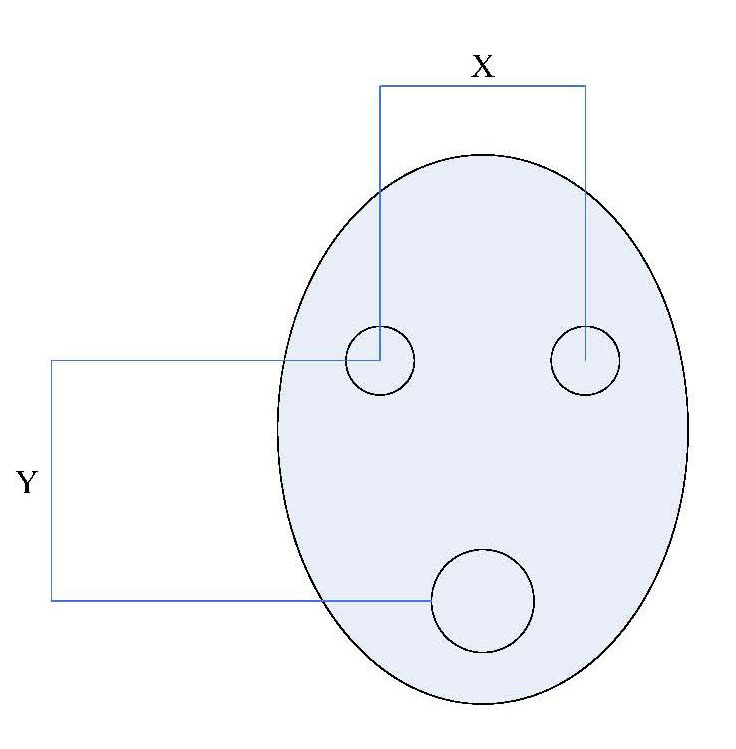

The invention relates to a driver fatigue detection method based on face video analysis, belonging to the field of vehicle active safety and mode recognition. The method comprises the steps of: carrying out face detection on a face image to be detected for primarily positioning local organs, such as eyes, nose and mouth; further obtaining face characteristic points positioned accurately; and finally, on the basis of an accurate positioning result of multiple frames of face characteristic points to be detected, carrying out quantization description on a face motion characteristic, and obtaining the result of fatigue detection on a driver to be detected according to a face motion statistical indicator. The driver fatigue detection method has high reliability, has no special requirements on hardware, does not involve complex operation, and has good instantaneity so as to be applied in real time in practice. The driver fatigue detection method has better robustness on the aspects of eyeglasses wearing, face angles, nonuniform illumination and the like, and can be suitable for various types of vehicles for reminding a driver of being in a fatigue state so that traffic accidents are avoided.

Owner:TSINGHUA UNIV

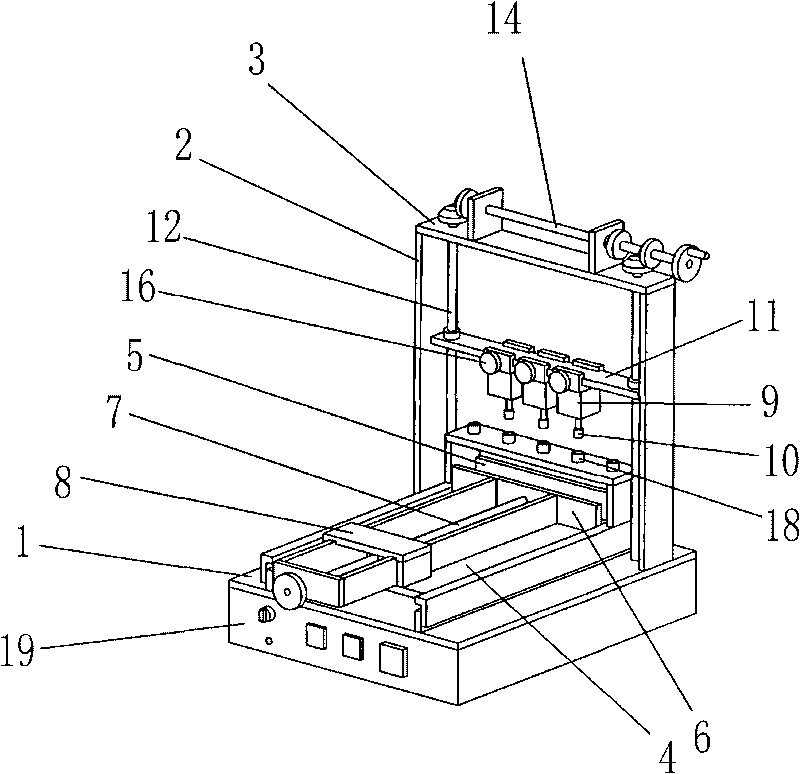

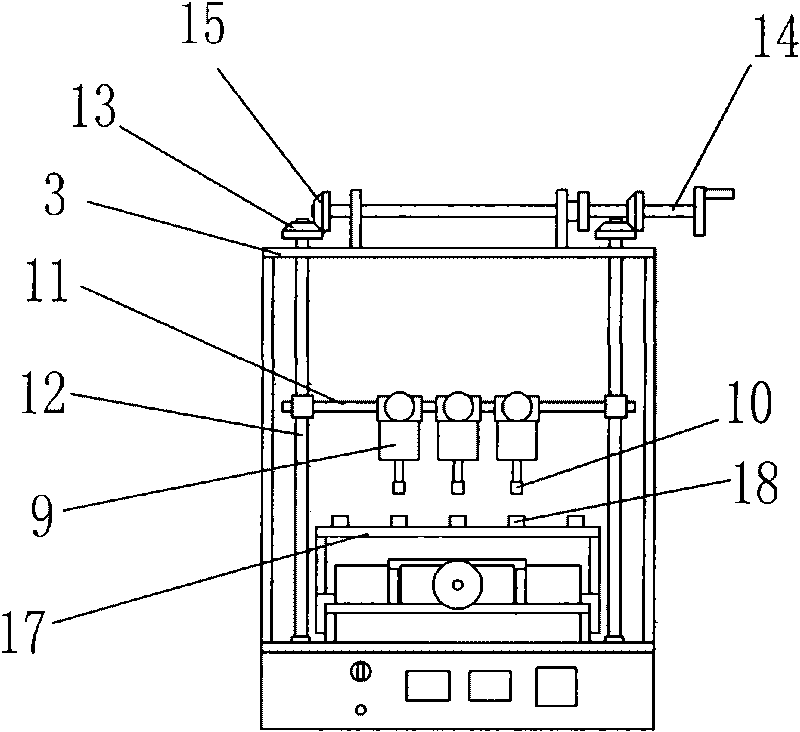

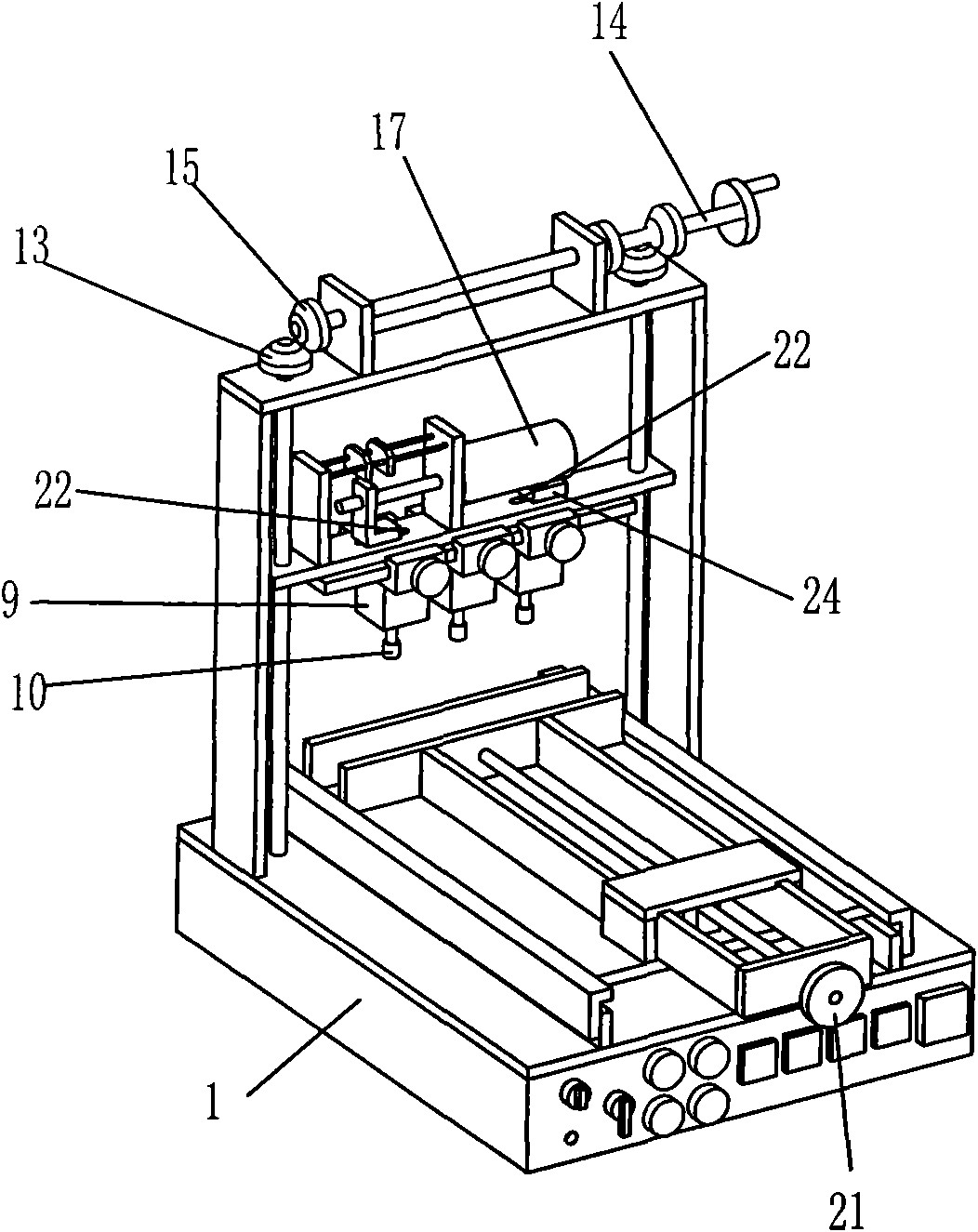

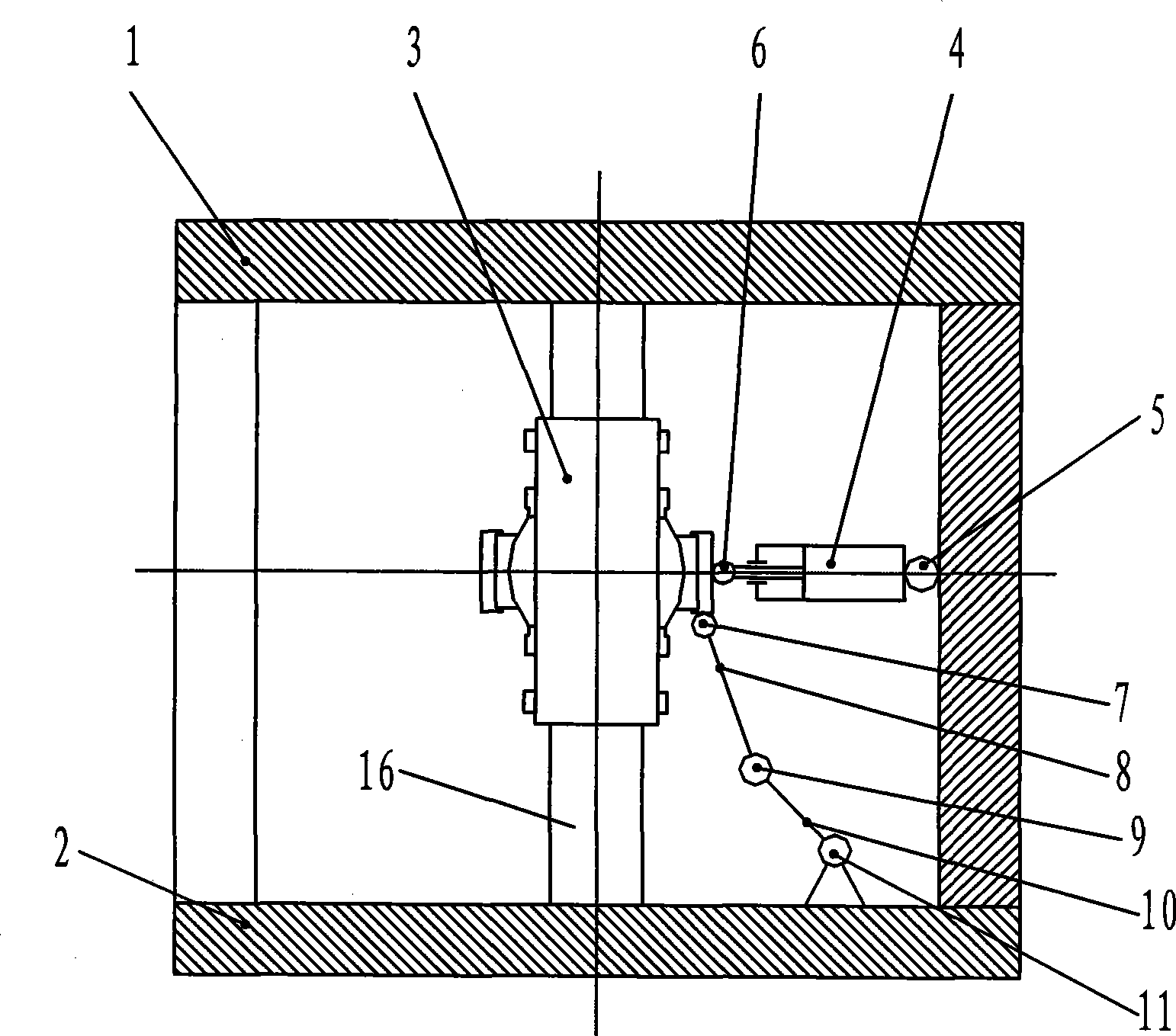

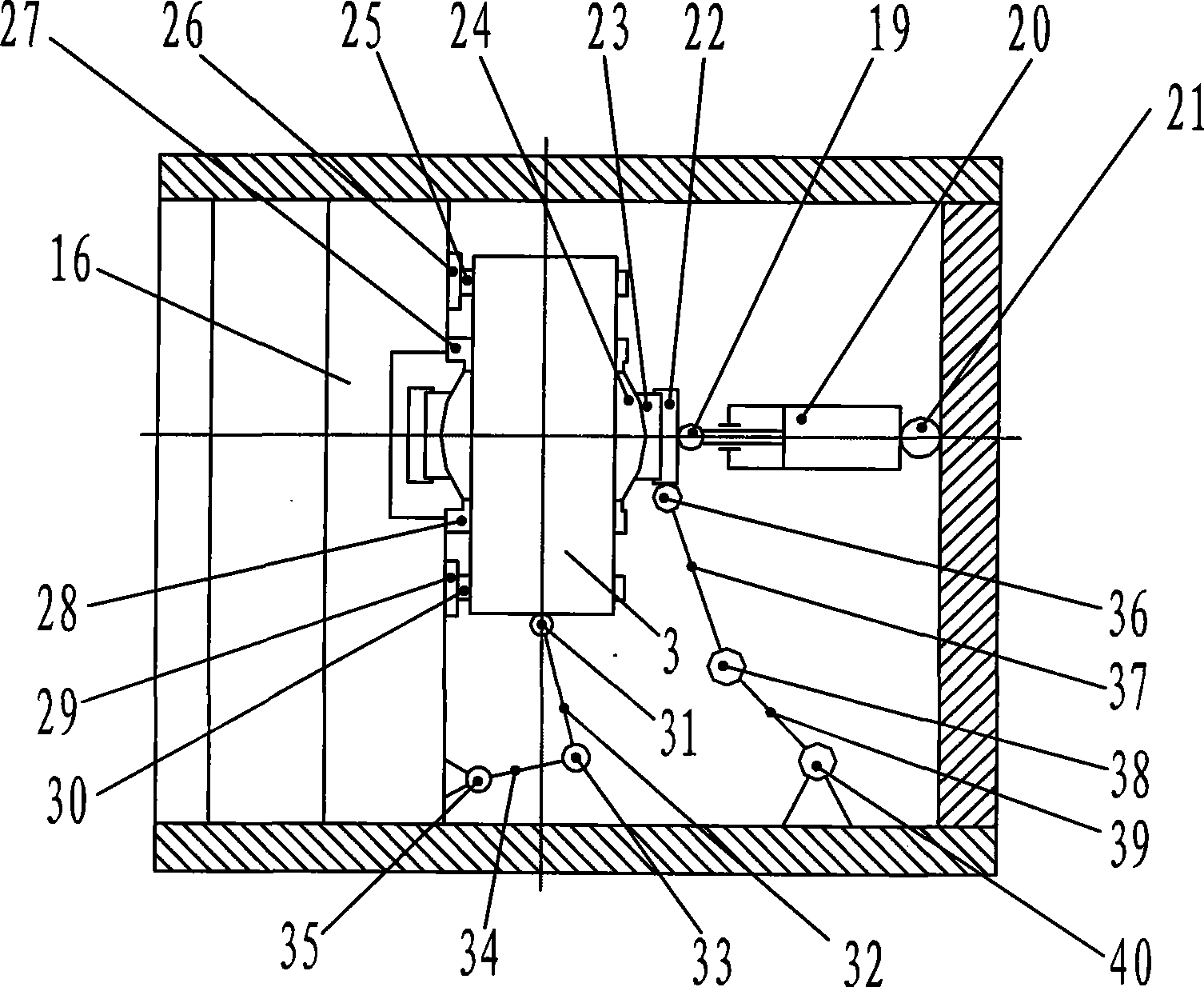

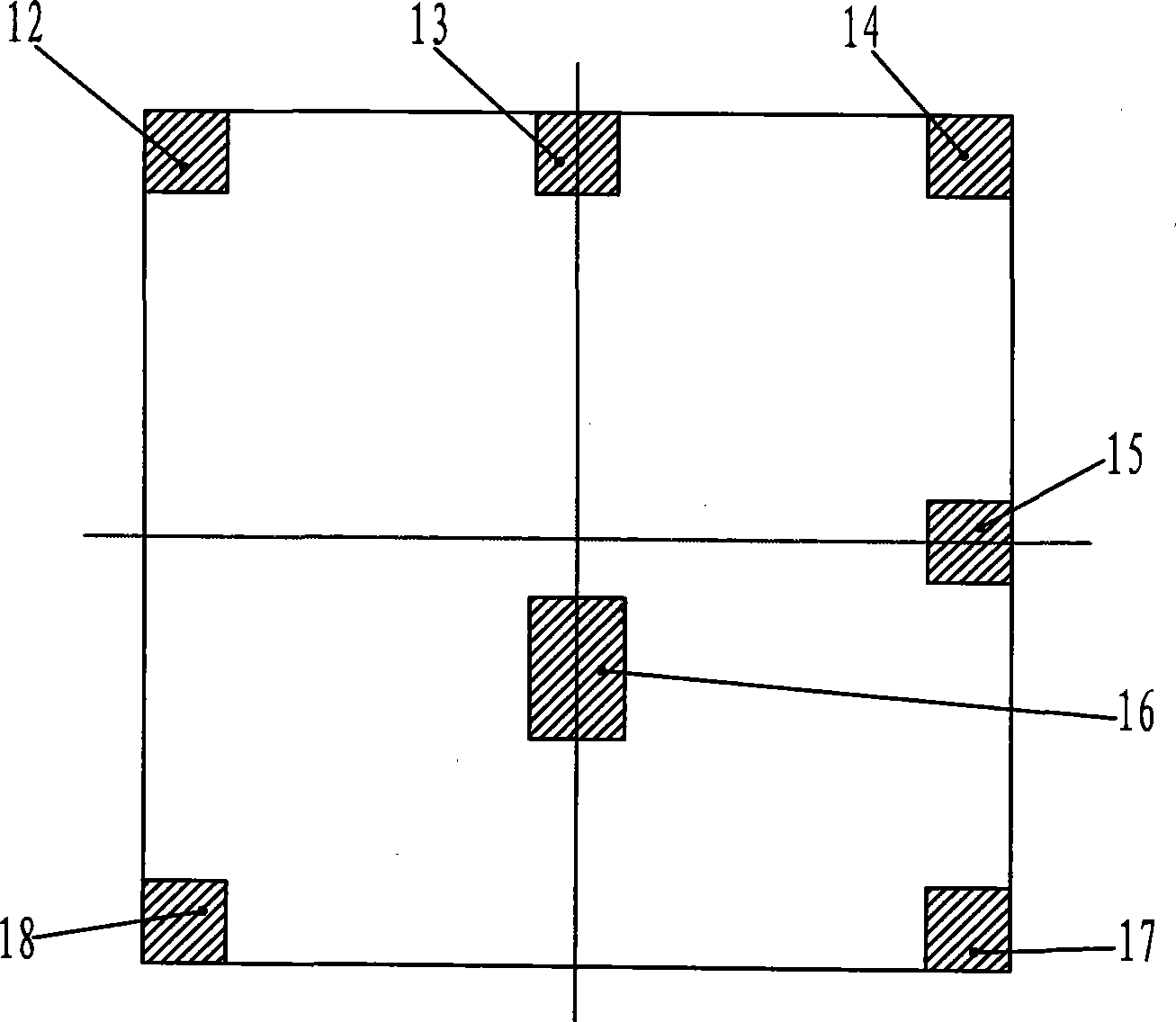

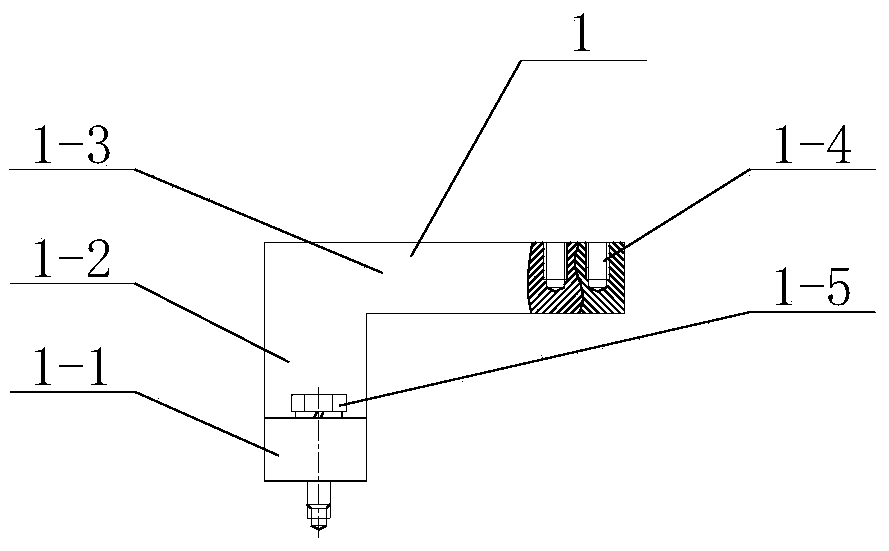

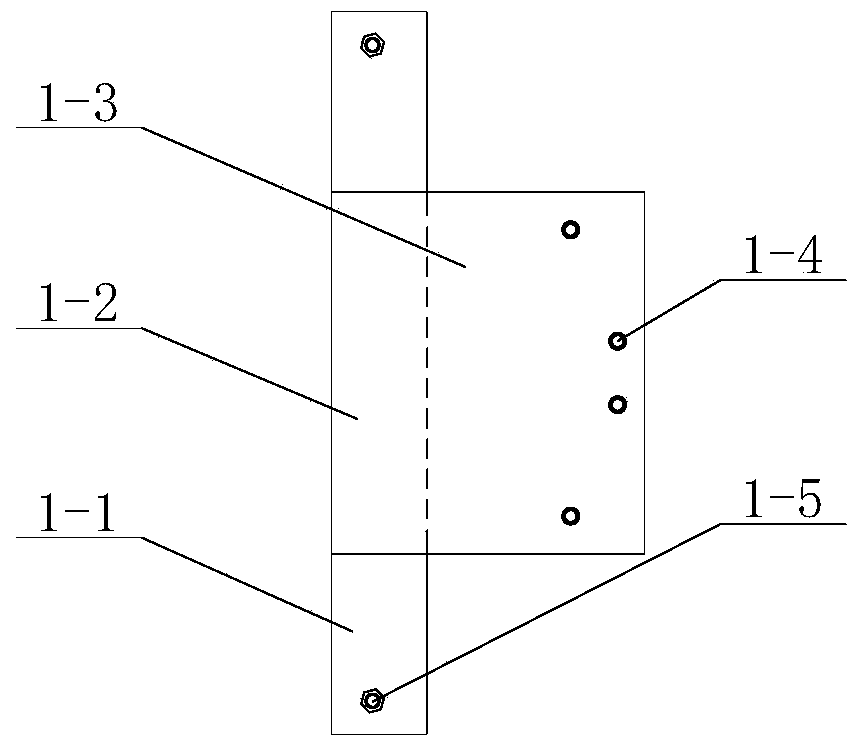

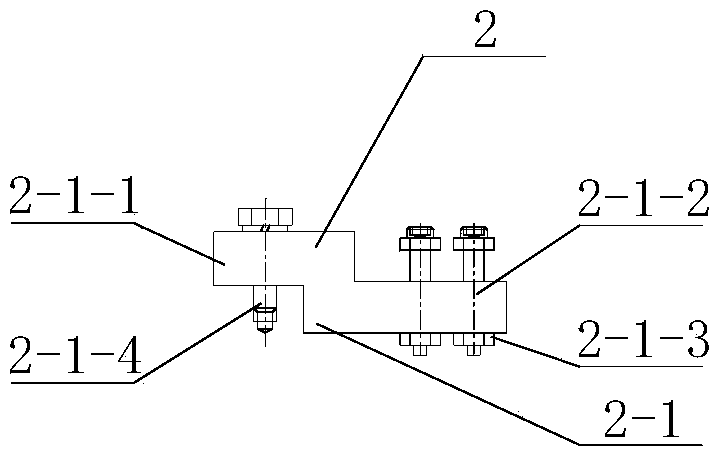

Fatigue testing device of button switch

InactiveCN101750224AIncrease productivityEasy to useStructural/machines measurementPush switchTest fixture

The invention relates to a fatigue testing device of a button switch, comprising a worktable (1) and a bracket (2) fixed on the worktable (1). A holding device for placing the button switch to be tested is arranged on the worktable (1), a cylinder (9) is arranged above the holding device, and the lower end of a piston of the cylinder (9) is connected with a pressing pole (10) for pressing the key of the button switch to be tested. The testing device also comprises a control device which is connected with the cylinder (9), used for controlling the cylinder (9) and setting testing parameters. The fatigue testing device of the button switch has the advantages that the button switch is automatically pressed by utilizing the cylinder, wherein the pressing force and the pressing frequency are kept highly consistent, and the pressing force, the pressing time interval and the pressing times all can be adjusted and set, thereby the invention has the advantages of very convenient use, good testing effect and high efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

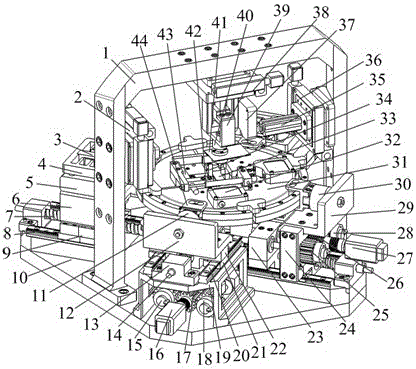

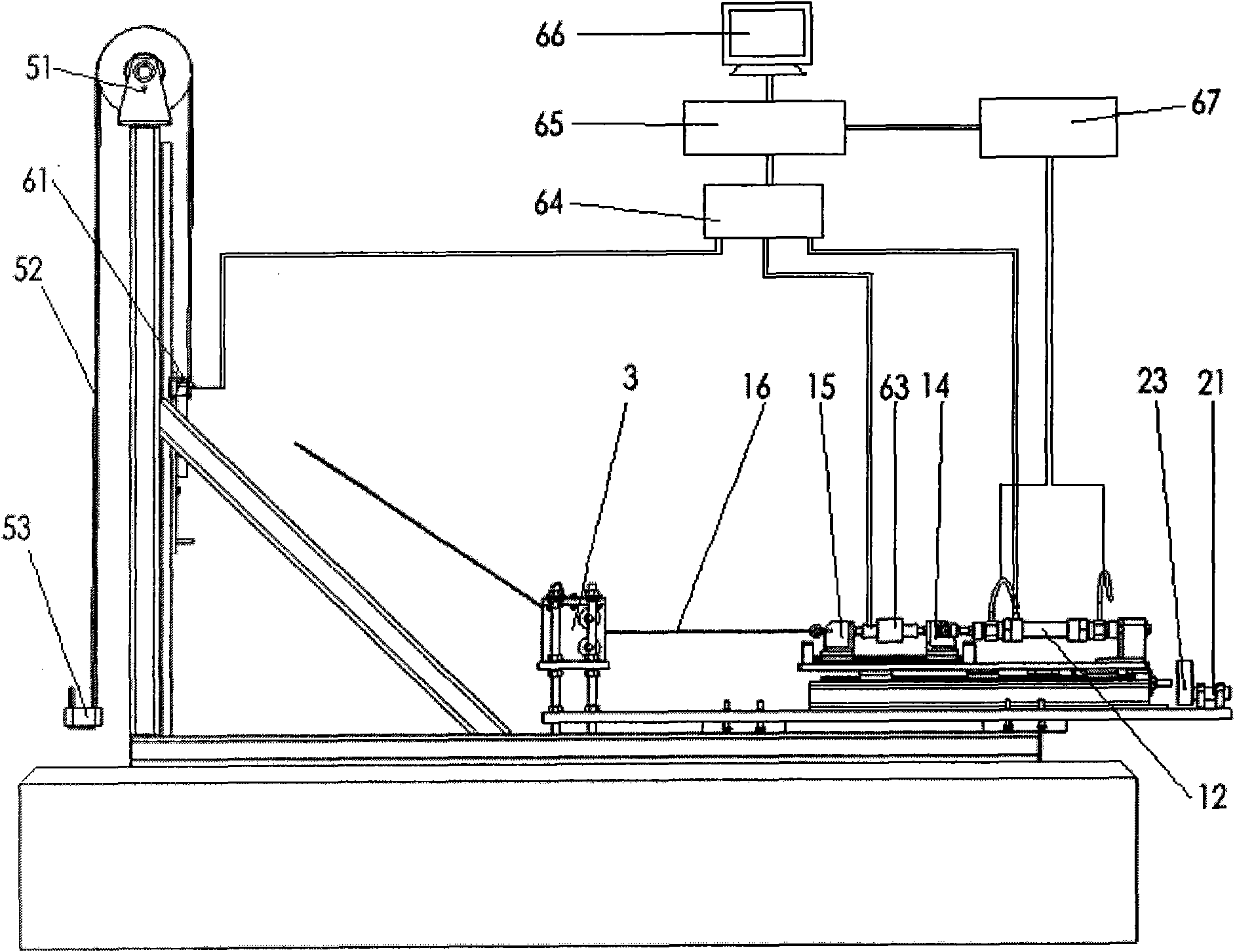

Material mechanical property in-situ testing system and method in dynamic and static load spectrum

ActiveCN106226152AImprove compatibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringMultiple modes

The invention relates to a material mechanical property in-situ testing system and method in a dynamic and static load spectrum, and belongs to the field of mechanical tests. The system integrates the following functions: a static testing function of biaxial drawing and shearing in an orthogonal plane, a shearing static testing function, a double shaft pull-pull mode fatigue testing function, and a static / dynamic press testing function. A complicated static / dynamic load spectrum can be established. Multi-mode composite load mechanical property evaluation can be performed on a film material or a block material, for example: high-cycle fatigue tests based on double-shaft pre-stretching load and impact press tests based on double-shaft stretching-shearing pre-load. At the same time, special defects are pre-fabricated on the central area and cross shaped arm area of a test piece; the analysis functions of a variable-zoom optical imaging system or a digital speckle strain analysis system can be utilized; the provided system and method can also be used to research the deformation behavior and cracking expansion rules of micro defects in a component under a multi-dimensional stress, and an evaluation tool is provided for performance degradation rules of products and optimized preparation method of materials.

Owner:JILIN UNIV

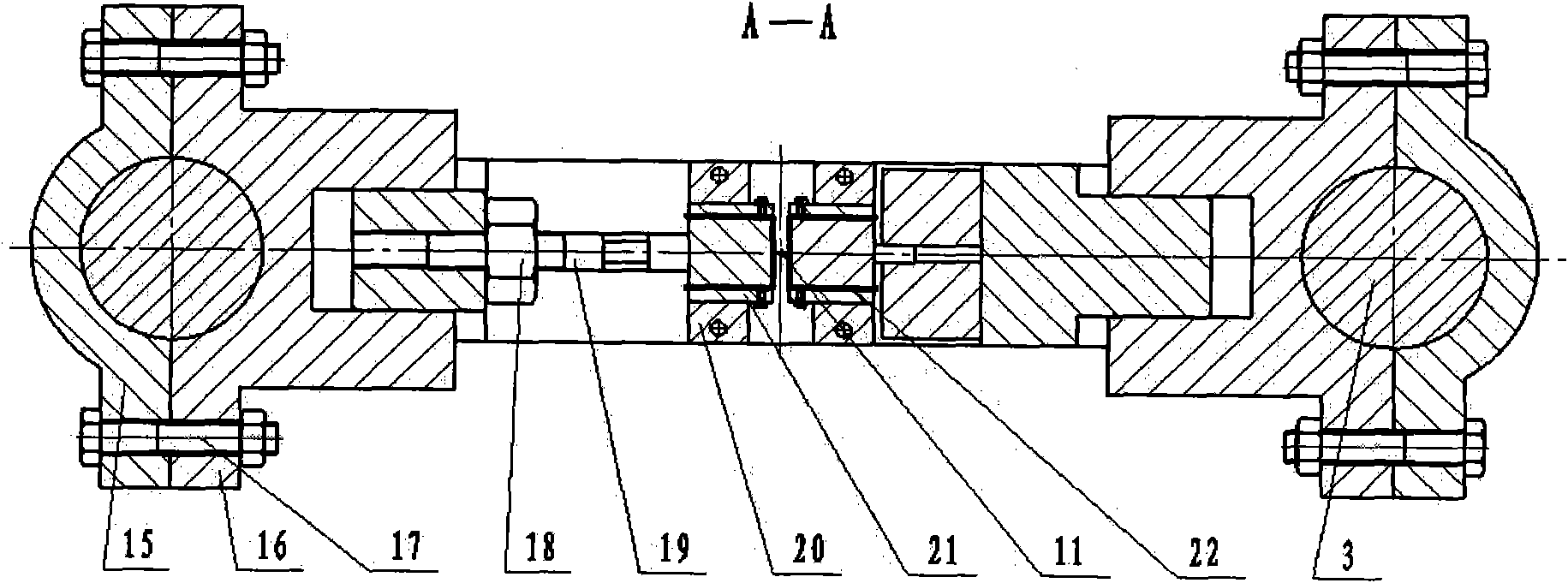

Steel wire fretting fatigue testing machine and method

InactiveCN101598647AEasy to controlEasy to measureMaterial strength using tensile/compressive forcesCompression deviceEngineering

The invention relates to a steel wire fretting fatigue testing machine and a method. The testing machine mainly comprises a horizontal loading device, an axial clamping device and an axial tensile compression device, wherein the horizontal loading device consists of a concave horizontal support saddle, a guiding support saddle, a wedged slide block, a loading steel wire, a pressure sensor, a loading rod and a locking nut; the axial clamping device consists of a spoke-type tensile compression sensor, a threaded rod connected with the spoke-type tensile compression sensor and an upper holding block fixed on the threaded rod; and the axial tensile compression device consists of an oil cylinder, a threaded rod connected with the piston of the oil cylinder and a lower holding block fixed on the threaded rod. The steel wire fretting fatigue testing machine has the advantages that by exerting horizontal set load on an axial steel wire through the horizontal loading device and by acting axial fatigue stress on a steel wire sample through the axial clamping device and the axial tensile compression device, the testing machine realizes fretting fatigue test of the coaction of fretting wear and axial fatigue stress of the steel wire sample; dynamic adjustment of the concave horizontal support saddle ensures that an axial fatigue steel wire does not generate bending stress; moreover, fluctuation ranges of both amplitude and frequency are wide and easy to control and measure by utilizing computer program.

Owner:CHINA UNIV OF MINING & TECH

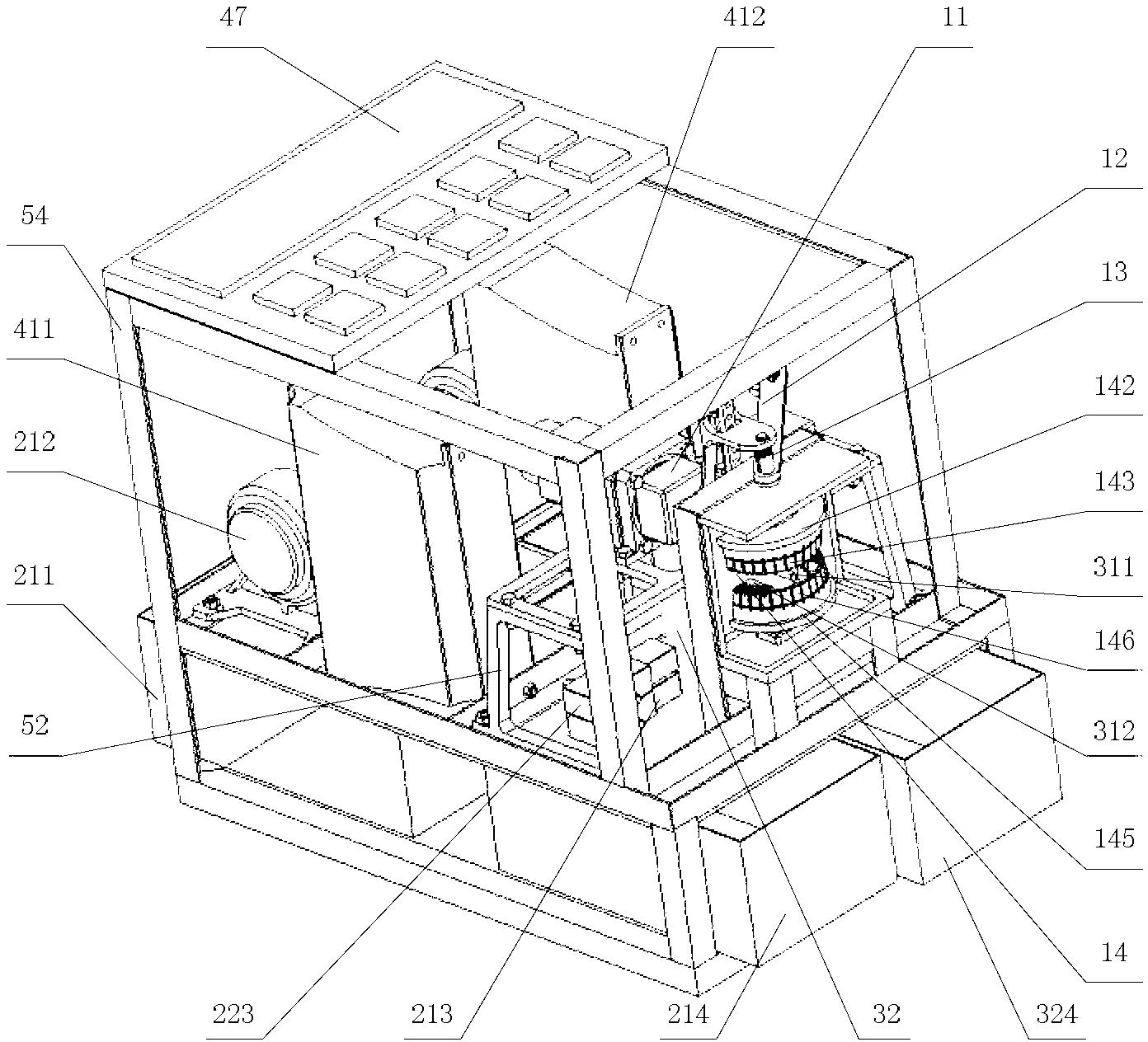

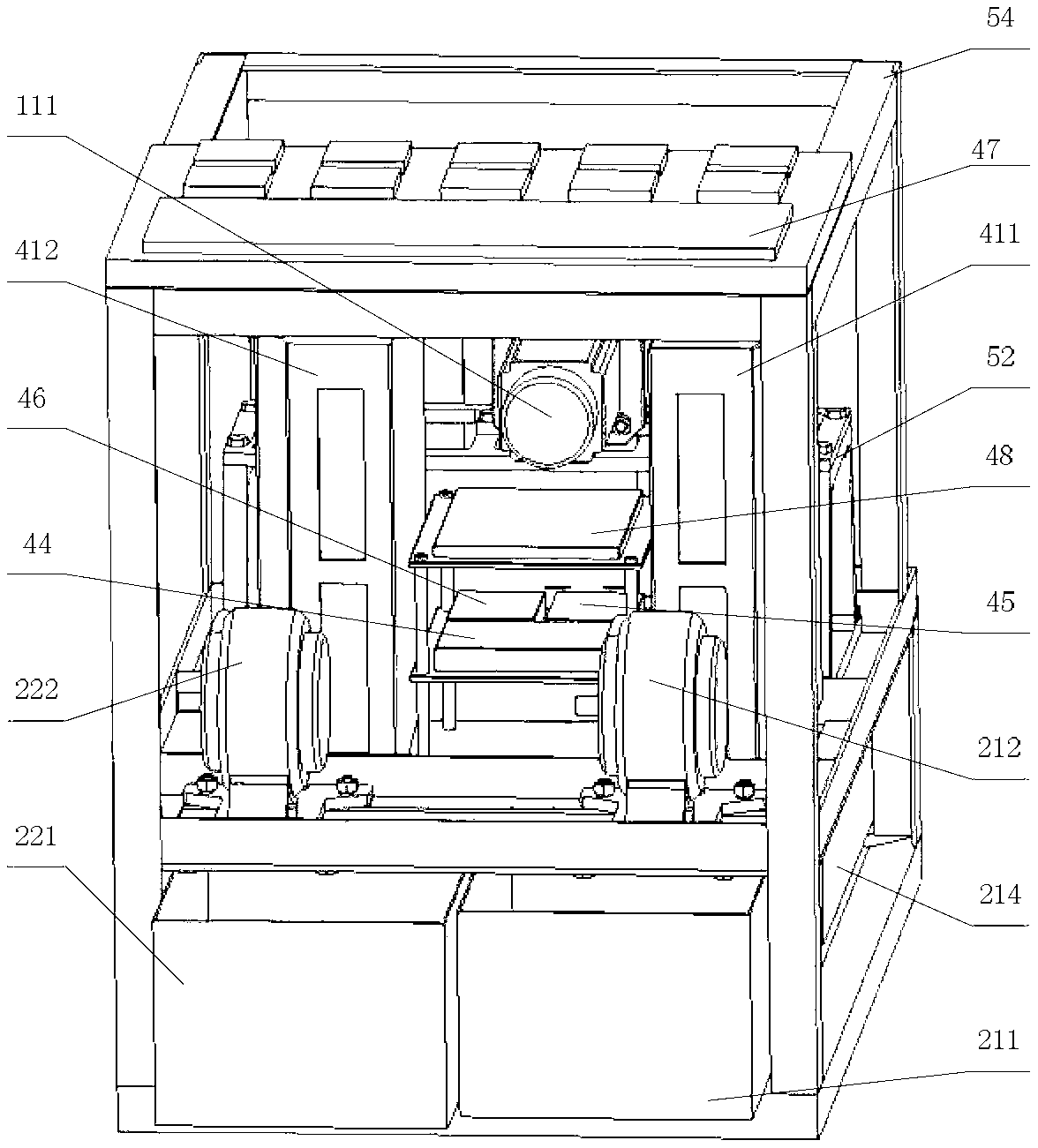

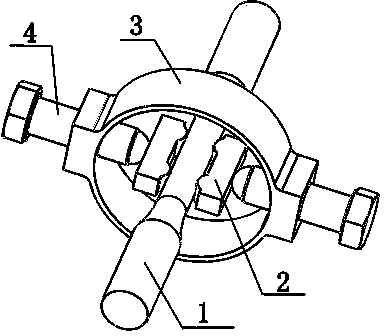

Oral environment simulation test machine

InactiveCN102841028AAvoid complex processHigh degree of automationMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceNatural toothDentures

The invention discloses an oral environment simulation test machine comprising a stomatognathic two-free-degree motion unit, intraoral liquid spouting units, an intraoral temperature adjusting unit and a control unit. The stomatognathic two-free-degree motion unit, the intraoral liquid spouting units and the intraoral temperature adjusting unit are respectively connected with the control unit and arranged in an integral framework of the test machine. The stomatognathic two-free-degree motion unit is arranged at the front end of the integral framework of the test machine for observers to observe simulation states of stomatognathic two-free-degree chewing movements in a window form. The intraoral liquid spouting units are arranged on the rear end and the lower end of the integral framework of the test machine. The intraoral temperature adjusting unit is arranged on the front end of the integral framework of the test machine. The control unit is arranged between the stomatognathic two-free-degree motion unit and the intraoral liquid spouting unit. The oral environment simulation test machine achieves frictional wear and fatigue test between extra-oral dentures and natural teeth, and oral environment simulation of a service life forecast experiment under a simulate real oral environment.

Owner:NANJING UNIV OF SCI & TECH

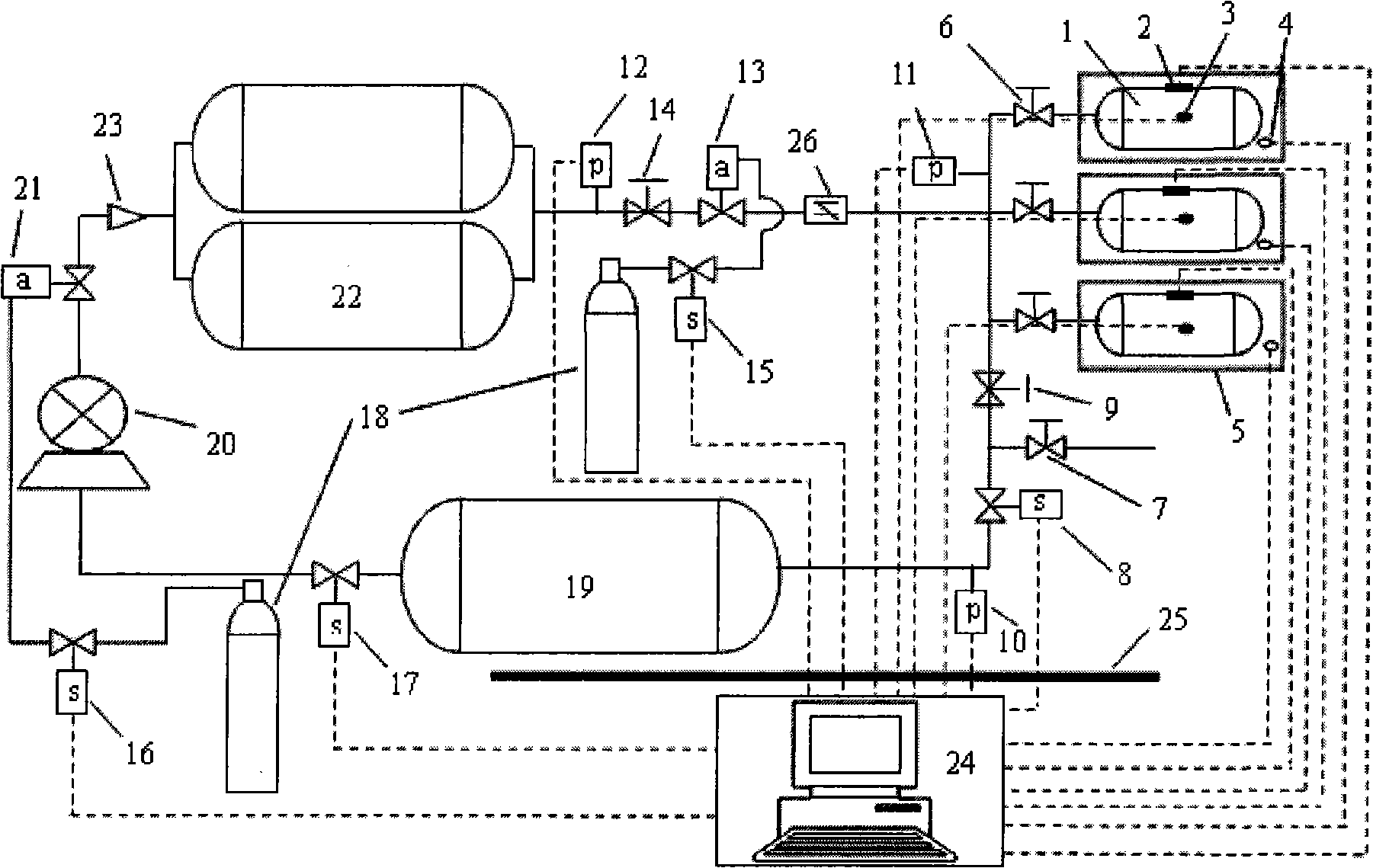

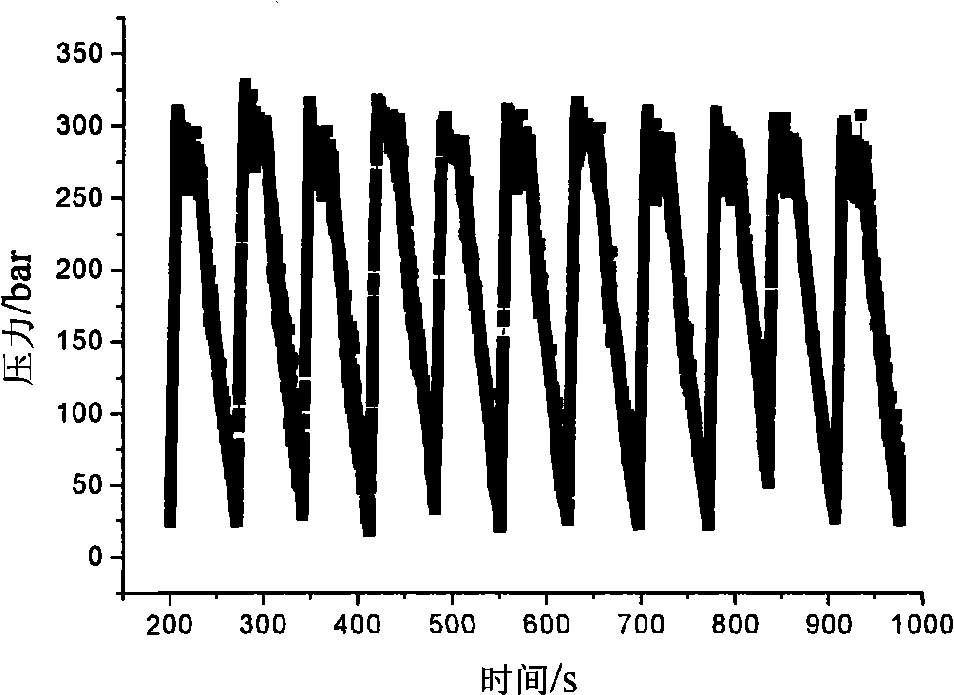

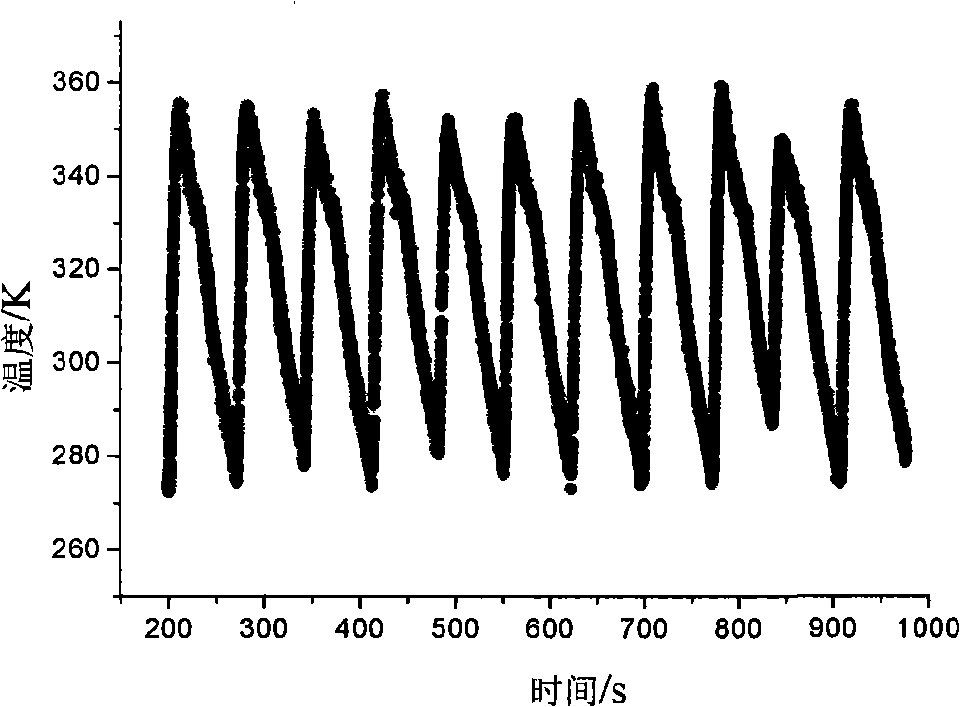

Gas circulation charging/discharging fatigue test system for full-automatic high pressure vessel

InactiveCN101403669ANo wasteNo pollutionMaterial strength using tensile/compressive forcesAutomatic controlSolenoid valve

The invention discloses a full-automatic high-pressure container gas circular charging and discharging fatigue test system which not only can realize the full-automatic control of the high-pressure gas circular charging and discharging fatigue test but also can carry out the on-line automatic detection to the fatigue condition of the high-pressure container. The automatic control of the circular charging and discharging is realized through the dynamic response signals of a temperature sensor arranged inside the tested container, the dynamic response signals of each pressure sensor on the high-pressure pipelines and switching of solenoid valves controlled by the control strategy. The gas medium in the circular charging and discharging process can be recycled after the pressurizing by a pressure-releasing receiving tank and a gas compressor so as to avoid the gas waste and environment contamination. The dynamic fatigue states of the high-pressure container in the circular charging and discharging process are acquired through the changing of response signals of a hydrogen sensor arranged in a sealed bin of the tested container and the response signals of a strain sensor stuck to the surface of the tested container; and when the released hydrogen concentration reaches the set value or the strain of the container material exceeds the set value in the charging and discharging process, the fatigue test system is closed automatically.

Owner:TONGJI UNIV

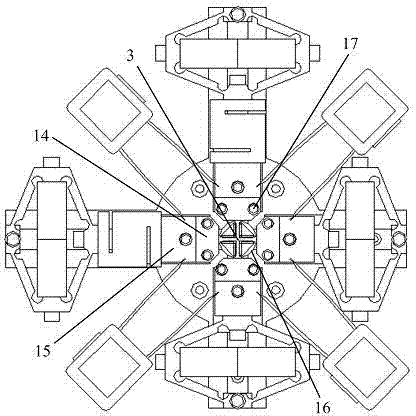

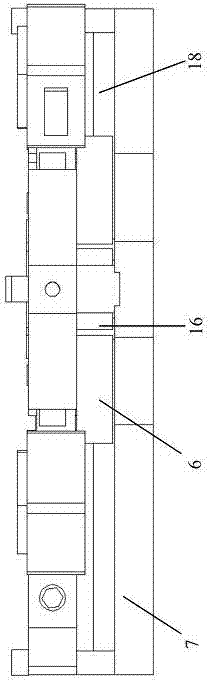

Online material biaxial static-dynamic performance test platform under service temperature

ActiveCN104502202AImprove reliabilityImprove stabilityMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesAlloyEngineering

The invention relates to an online material biaxial static-dynamic performance test platform under service temperature, belonging to the field of precision drive. The large-stroke biaxial synchronous identical-speed or synchronous different-speed displacement output is realized by virtue of four groups of piezoelectric actuators which are orthogonally distributed, and the biaxial static tensile test or dynamic fatigue test for a block-shaped material or a film material with a characteristic size being in a millimeter scale can be carried out under a high / low temperature service condition by combining with an embedded high temperature electrothermal alloy sheet / parr patch. The online material biaxial static-dynamic performance test platform is likely to use in conjunction with a scanning electron microscope with a relatively-large vacuum cavity or other microimaging device with an open-type carrier space, such as an optical microscope, an atomic power microscope and a high speed camera, so that the multimode biaxial static tensile test or the large-frequency-range biaxial dynamic fatigue test can be carried out, and the research for the microstructure evolution behavior and fatigue failure mechanism of various structural materials or functional materials under a complicated service condition such as a high / low temperature condition and a static-dynamic plane stress condition can be facilitated.

Owner:JILIN UNIV

Fretting fatigue testing method allowing contact load to be adjusted in real time and testing machine adopting fretting fatigue testing method

InactiveCN104931366ASolve the problem that the fretting fatigue test that cannot simulate the component subjected to alternating contact loadsGood repeatabilityMachine part testingMaterial strength using repeated/pulsating forcesFatigue damageMotor drive

The invention relates to a fretting fatigue testing method allowing a contact load to be adjusted in real time and a testing machine adopting the fretting fatigue testing method. The testing machine comprises an electronic-hydraulic servo fatigue testing machine, fretting supporting platforms, a fretting device and a computer testing and controlling system, wherein the fretting supporting platforms are fixed on supporting stand columns of the fatigue testing machine; the fretting device is horizontally arranged on the fretting supporting platform; the fatigue testing machine comprises an upper clamp and a lower clamp which are used for fixing a test piece; a contact load sensor, a motor drive signal and a displacement signal of the fretting device are connected with a computer data acquisition control system. Two fretting pad clamps are fixed in middles of two lead screw cross beams, and two opposite fretting pads are mounted at two ends of each fretting pad clamp. A fretting fatigue test with the contact load changing in real time is performed through the fretting fatigue testing machine, influences of the contact load on fretting fatigue damage are researched, meanwhile, fretting fatigue tests at different amplitudes and frequencies can be researched, and an experiment method is provided for deeper understanding of a fretting fatigue damage mechanism.

Owner:TIANJIN UNIV

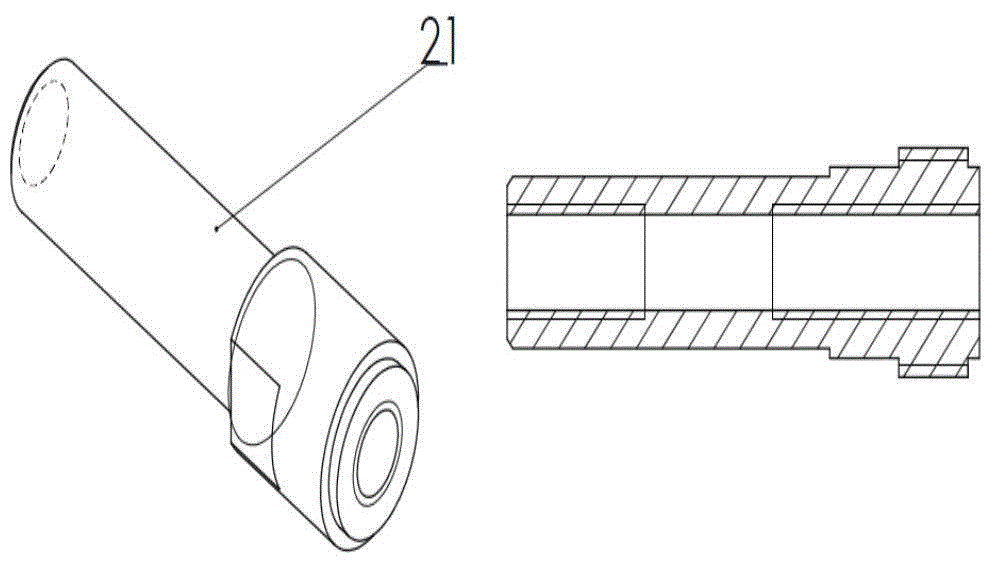

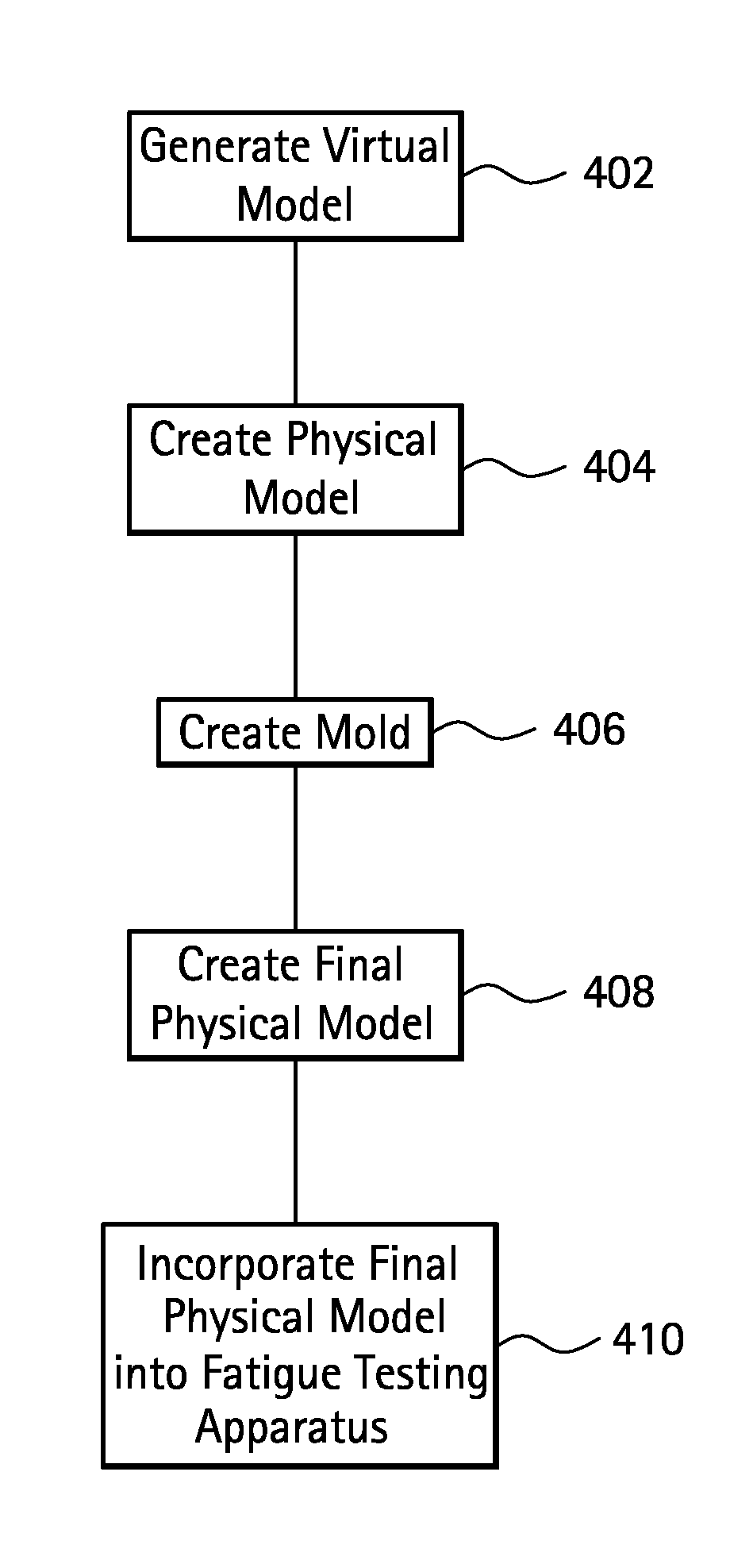

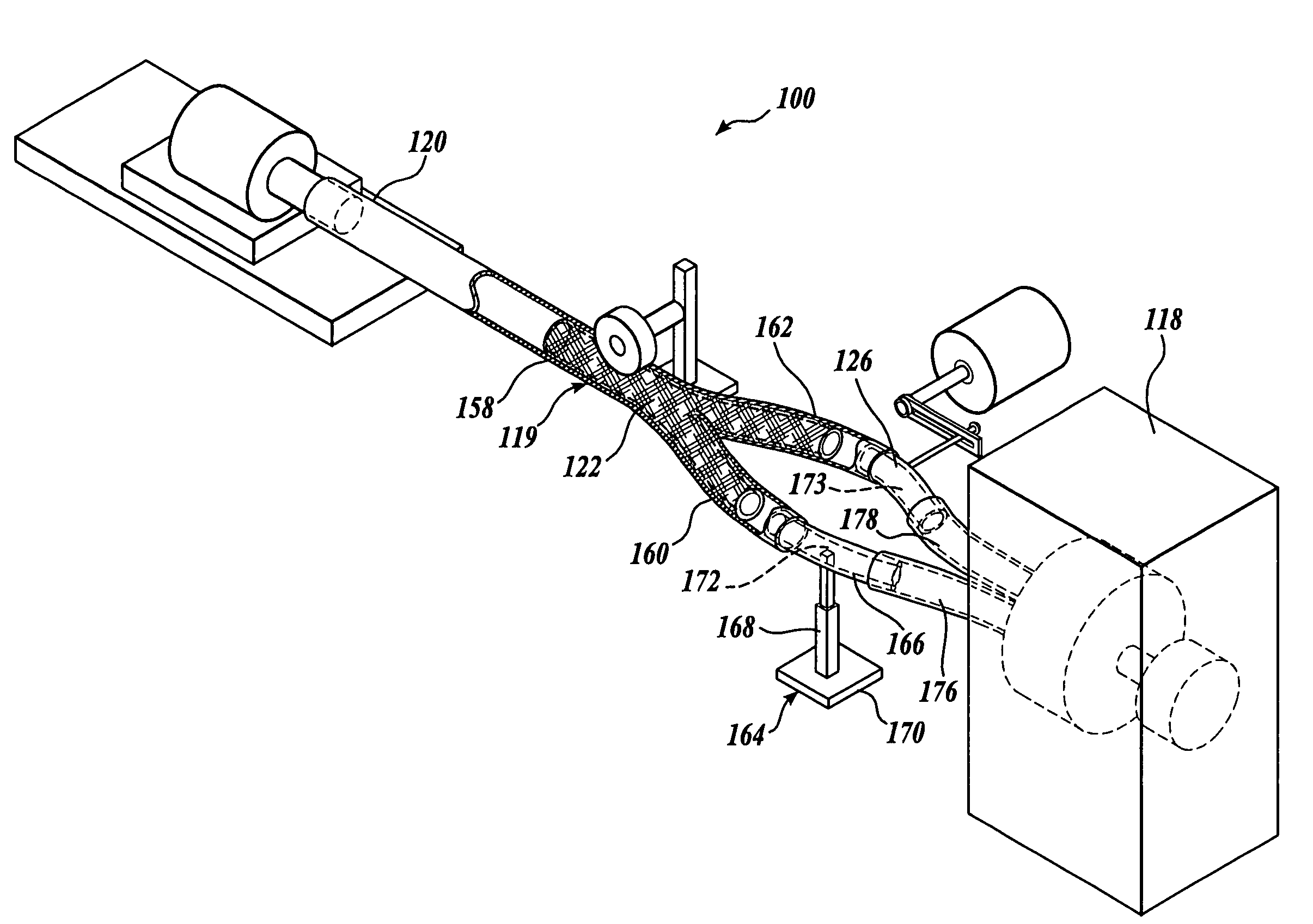

Anatomically compliant aaa model and the method of manufacture for in vitro simulated device testing

InactiveUS20080243284A1Additive manufacturing apparatusStructural/machines measurementEngineeringFatigue testing

The present invention is directed to the fabrication of a test apparatus and the test apparatus itself. The test apparatus is designed to be a component used in a durability / fatigue testing unit.

Owner:CORDIS CORP

Evaluation method for fatigue damage and service life of horizontal axis wind turbine blade

ActiveCN102607831AGet actual lifespanShort cycleMachine part testingStrength propertiesFatigue damageImpeller

The invention discloses a test method for the fatigue damage and the service life of a horizontal axis wind turbine blade, aiming to obtain a more exact blade fatigue performance parameter by adopting a test detection and computational analysis means having low cost and high efficiency so as to meet the requirements of blade design, research and development and detection. The method is characterized in that on the basis of the characteristic that the impeller speed of a horizontal axis wind turbine is lower, and the period change frequency of various fatigue loads is also lower, a series of steps of carrying out static loading testing on the wind turbine blade to obtain a stress / strain amplitude distribution condition under the effect of various fatigue loads and analyzing by combining a material property curve and a cumulative damage theory are adopted to realize the evaluation to the blade fatigue performance. Compared with the traditional horizontal axis wind turbine blade fatigue testing technology, the method has the advantages of short period, low cost, capability of obtaining a final service life parameter of the blade, and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Apparatus and method for fatigue testing

ActiveUS7204152B2Material strength using tensile/compressive forcesUsing mechanical meansEngineeringFatigue testing

Owner:ROLLS ROYCE PLC

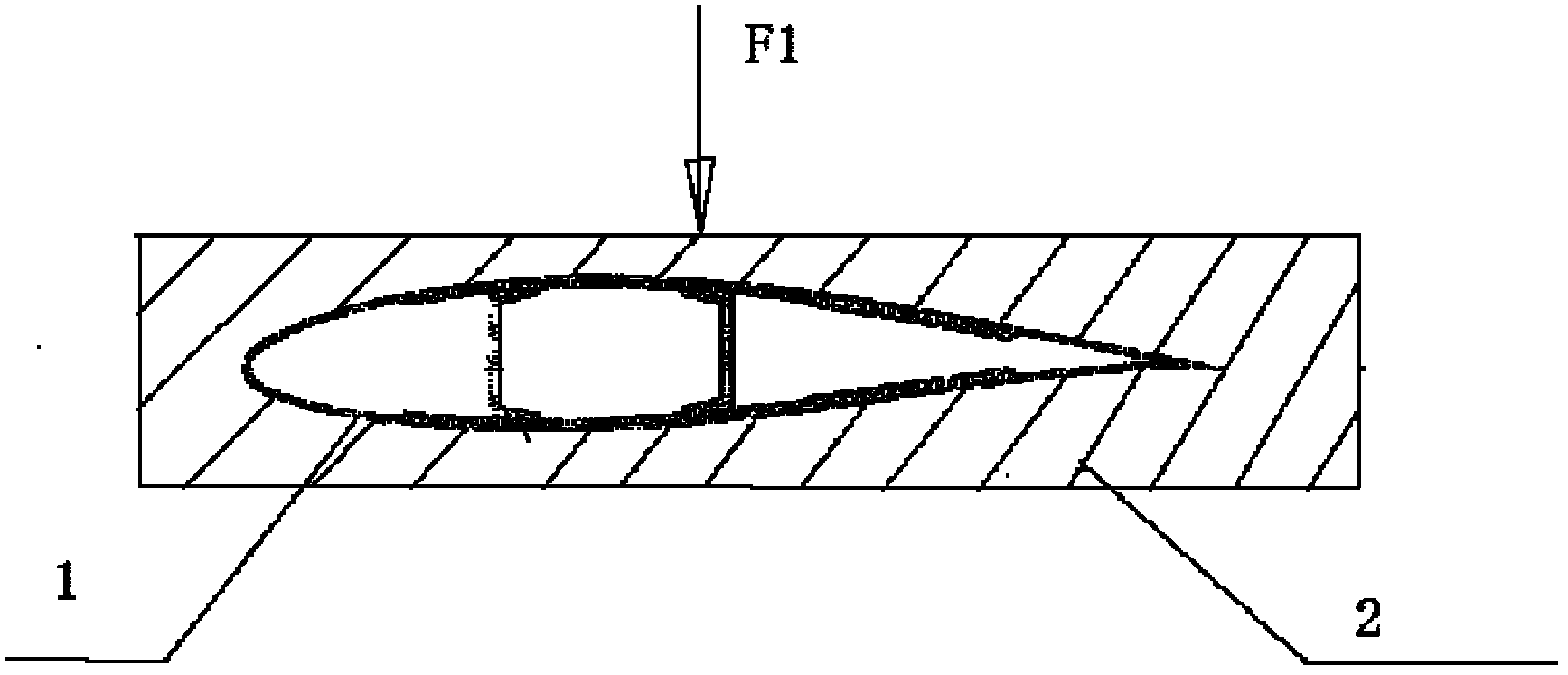

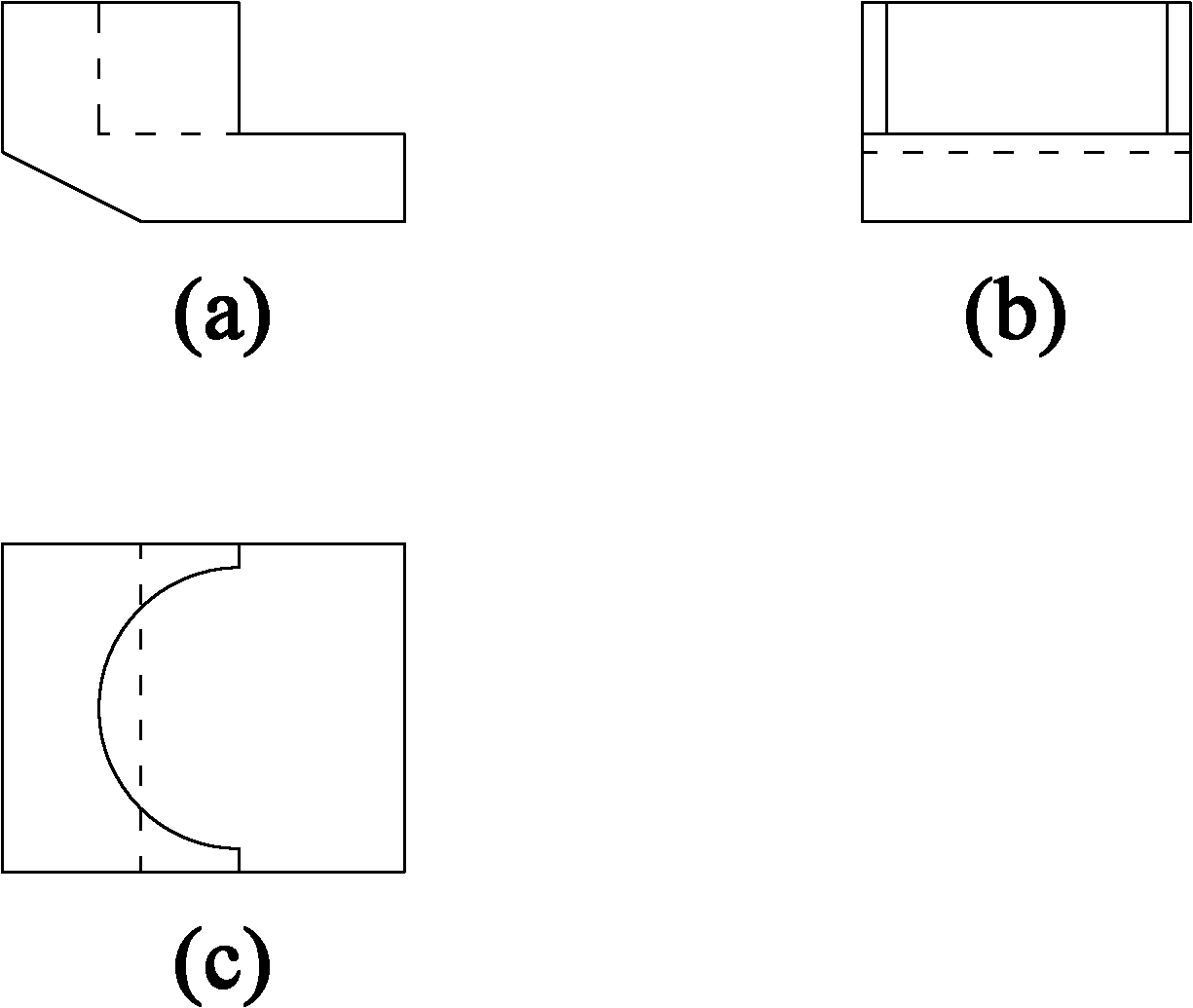

Device for testing composite asphalt pavement interlayer shear fatigue, and method thereof

ActiveCN102519808ASimple structureEasy to operateMaterial strength using steady shearing forcesRoad surfaceEngineering

The invention discloses a device for testing composite asphalt pavement interlayer shear fatigue, and a method thereof. According to the present invention, a skew shearing experiment is adopted to determine the composite asphalt pavement interlayer shear fatigue lives under different temperature conditions. The device comprises a loading bar, a load testing system, a pressing block, a supporting block and a support platform, wherein the pressing block and the supporting block are provided with a concave part, when the loading rod loads, a specimen requiring test is positioned in a space formed by docking of the two concave parts. The testing method is: placing the specimen in the supporting block and the pressing block, loading on the specimen through a testing machine to generate the skew shearing failure to obtain the maximum failure load, and carrying out the shear fatigue experiment under the repeated load effect according to 0.2-0.8 times the maximum failure load. The device and the method are simple and easy to operate, the actual stress state of the composite asphalt pavement can be accurately simulated, and the important significances are provided for the designs and the evaluations of the composite asphalt pavement interlayer shear property and the interlayer structure and material, and the design of the asphalt layer thickness.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

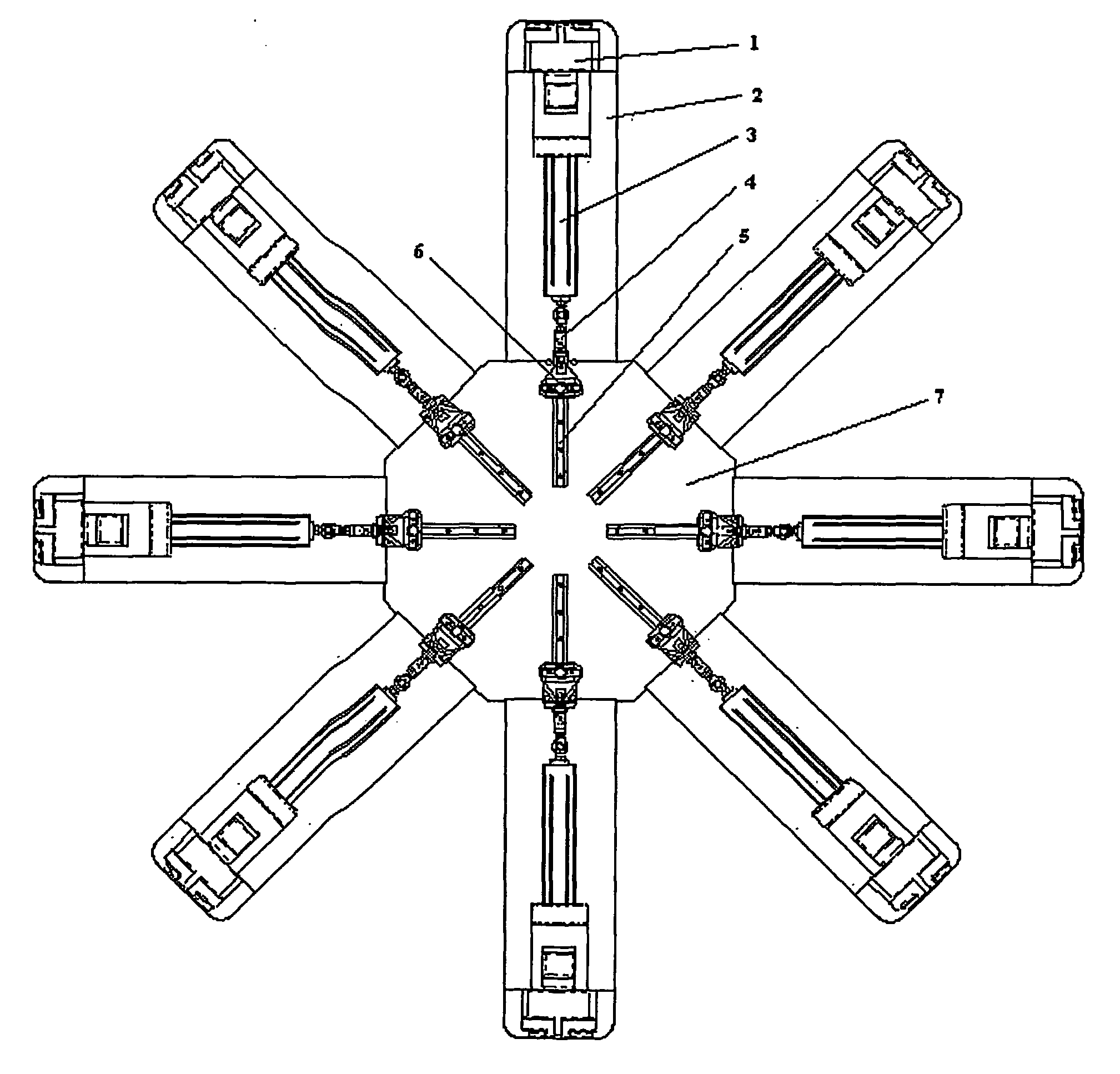

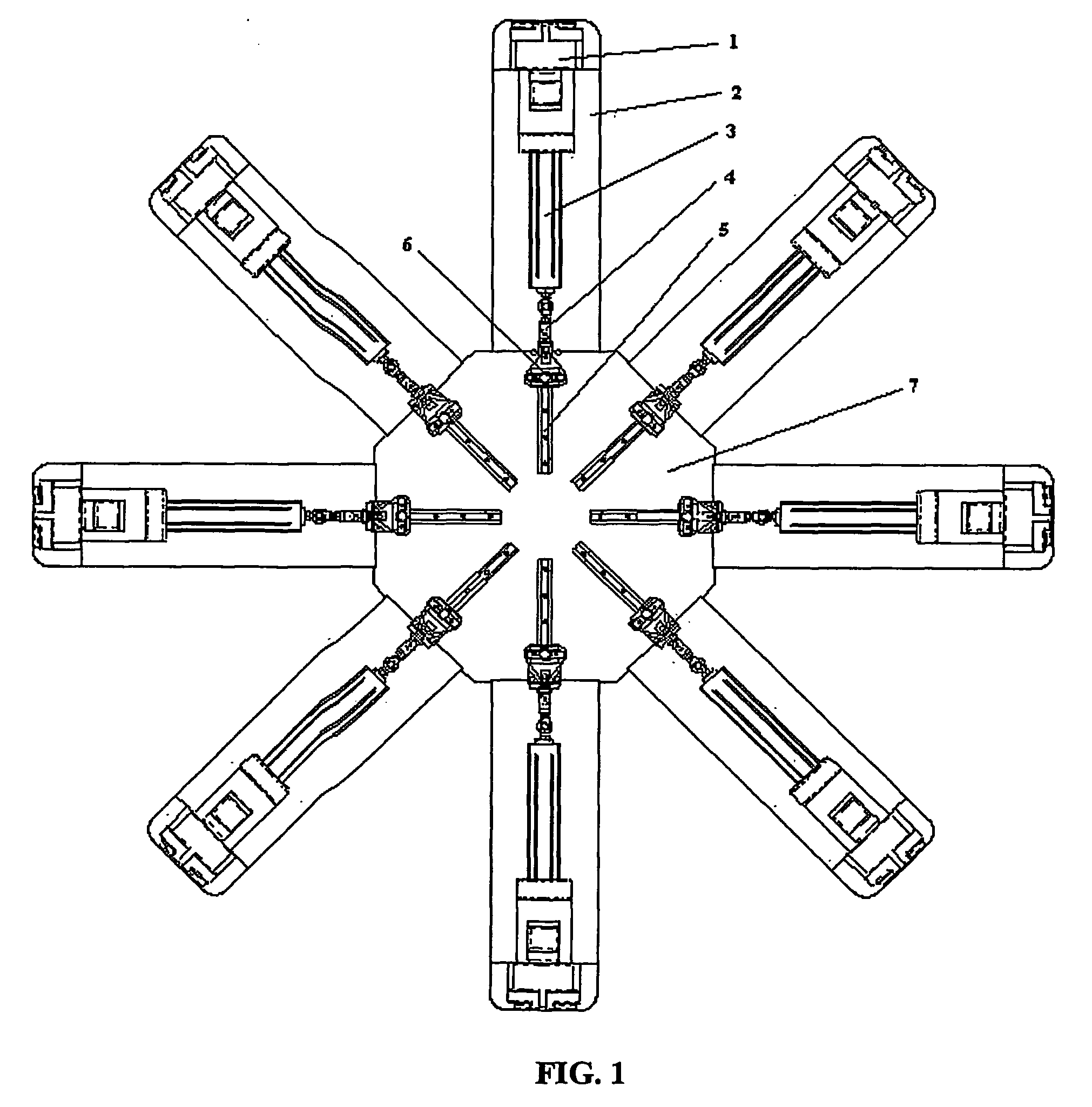

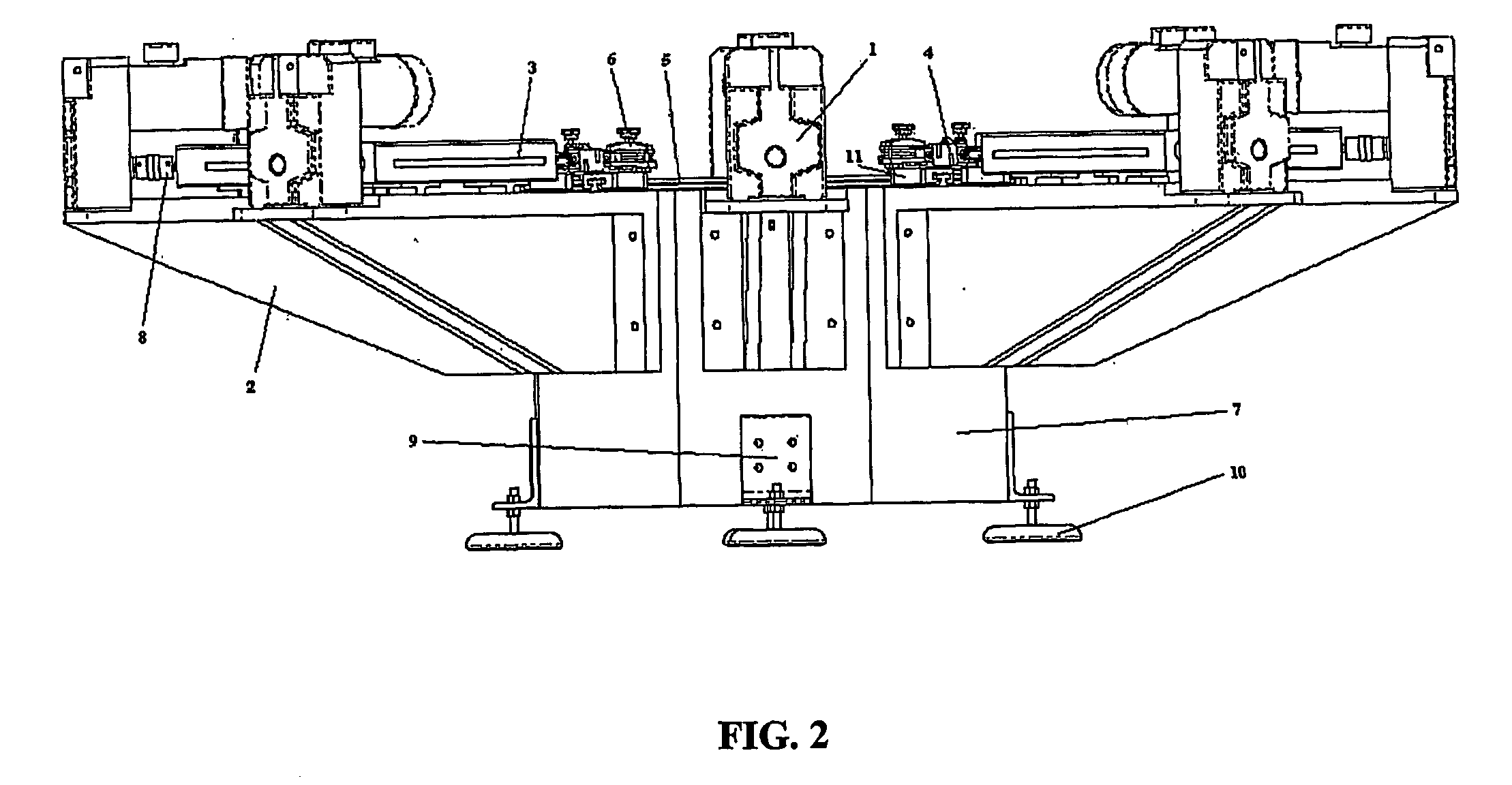

Multiaxial Universal Testing Machine

InactiveUS20080034885A1Reduce speedIncrease torqueMaterial strength using tensile/compressive forcesHorizontal axisElectric machinery

The invention concerns a multiaxial universal testing machine, which allows evaluating the mechanical behaviour and performance of materials with planar structures, such as fabrics, composites and laminates. The machine comprises 4 horizontal axes at 45°, with 8 gripping jaws displaceable along slide rails and moved by the action of 8 independent motors. The connection between a gripping jaw and its respective motor is assured by a linear actuator. The test specimen is fixed by the gripping jaws and can be subject to tensile, compression and fatigue testing, making possible the analysis of the materials behaviour under simultaneous multi-directional loads.

Owner:UNIVERSITY OF MINHO

Fatigue driving detection method

InactiveCN104207791AAccurately judge fatigue statusDiagnostic recording/measuringSensorsSteering wheelDriver/operator

The invention discloses a fatigue driving detection method, belonging to the field of safe driving of automobiles. According to the fatigue driving detection method, a fatigue physiological parameter is obtained as a detection index variable by collecting behavioral indicators (mainly including steering wheel data, driving time and driving speed) of a driver and carrying out information preprocessing, a BP (back-propagation) neural network is trained by using the fatigue index variable to establish a corresponding fatigue detection network model, and the fatigue detection is carried out by using the model. According to the fatigue driving detection method, the fatigue of the driver can be objectively and accurately judged on the premise of not influencing the driving operation of the driver by collecting the vehicle data in real time.

Owner:JIANGNAN UNIV +1

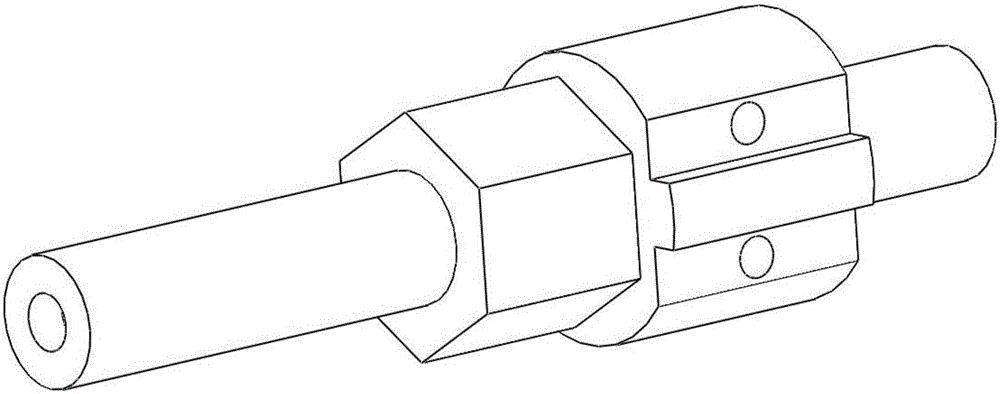

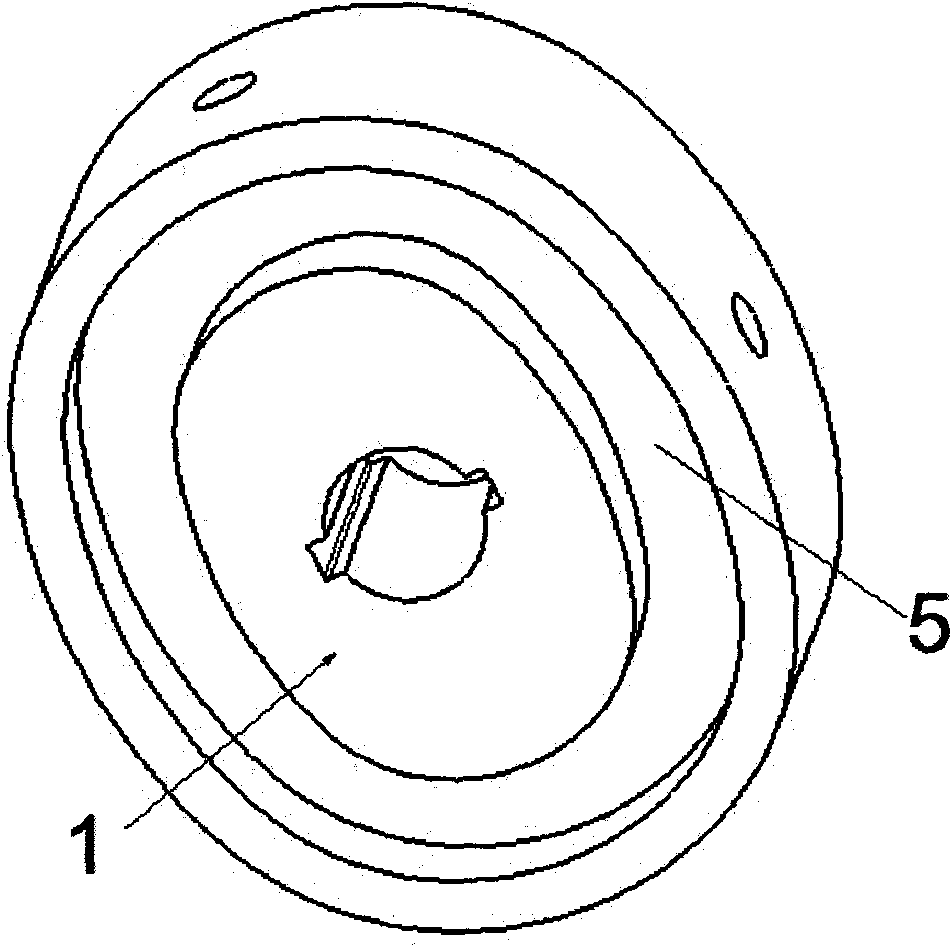

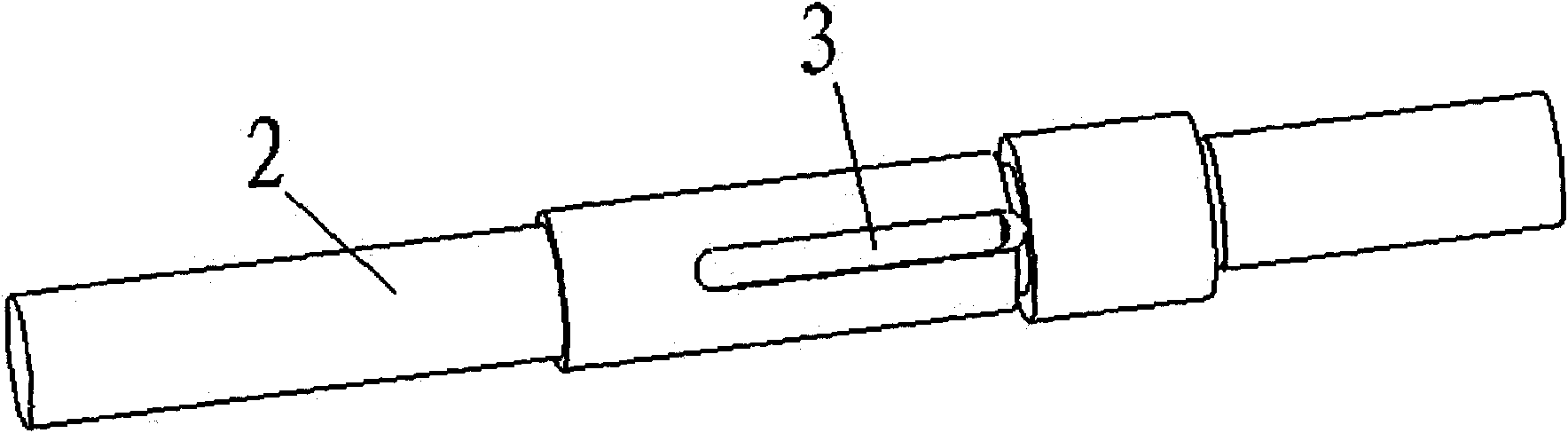

Point contact type fretting fatigue test device and point contact type fretting fatigue test method

The invention discloses a point contact type fretting fatigue test device and a point contact type fretting fatigue test method. The test device comprises a fretting bridge in direct contact with a sample, a loading ring with a ring surface perpendicular to the axial direction of the sample, and a loading bolt which passes through the wall of the loading ring to be in contact with the fretting bridge; the sample passes through the center of the ring surface of the loading ring; the contact surface of the fretting bridge and the sample is provided with a fretting bridge leg in the shape of a convex arc surface; the fretting bridge leg or the loading bolt is provided with a strain foil and is connected with a strain gauge; the point contact between the fretting bridge and the sample is achieved by the direct contact between the fretting bridge leg of the fretting bridge and the sample; the contact surface of the sample can generate slight relative movement and normal pressure is applied to the contact surface of the sample, by means of adjusting the loading bolt to apply pressure to the fretting bridge. Matched with a fatigue testing machine, the test device can be used for performing theoretical research on stretching tension, torsion and tension-torsion composite fretting fatigue modes.

Owner:SOUTHWEST JIAOTONG UNIV

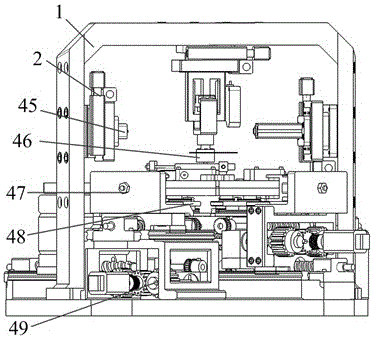

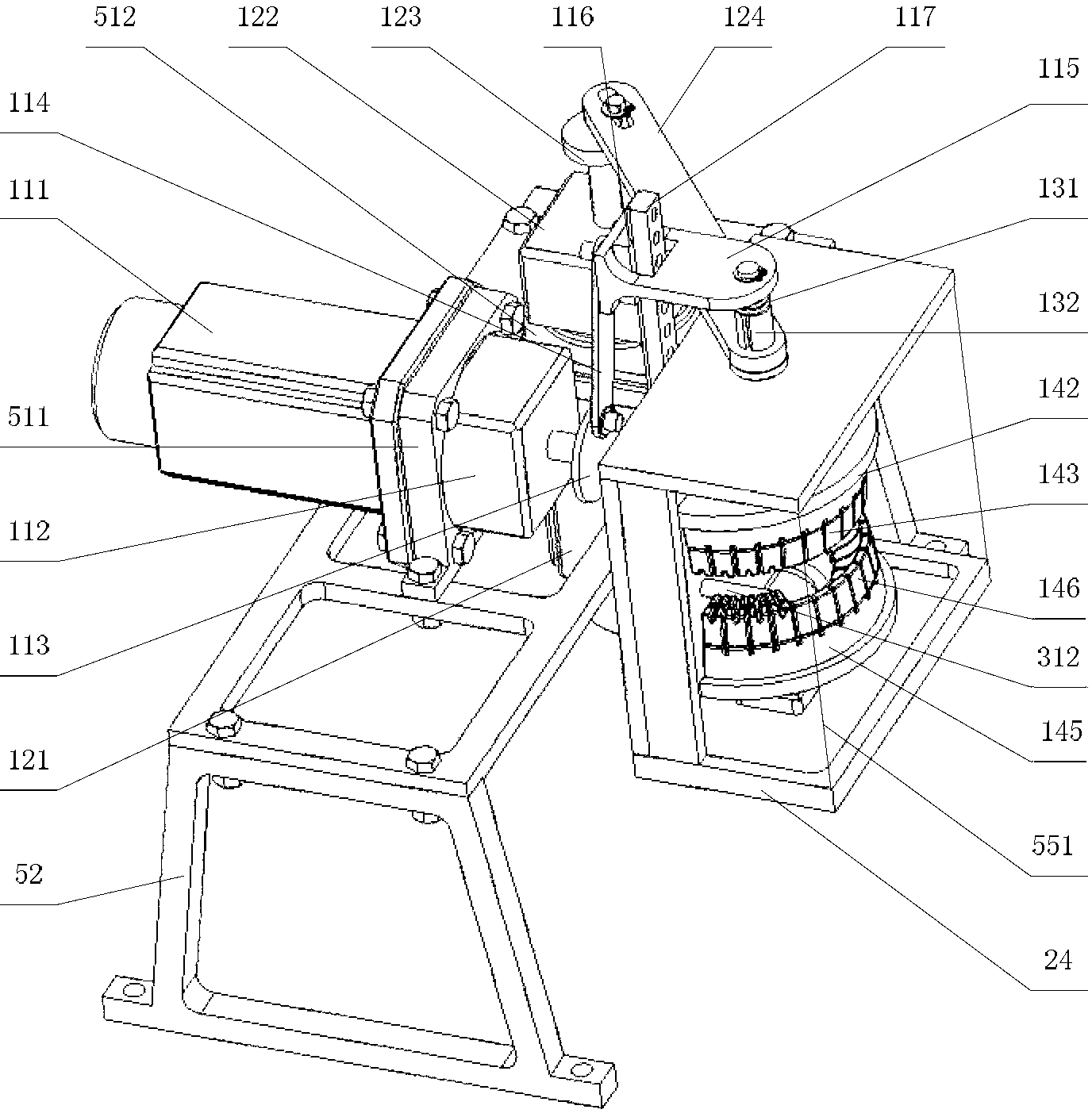

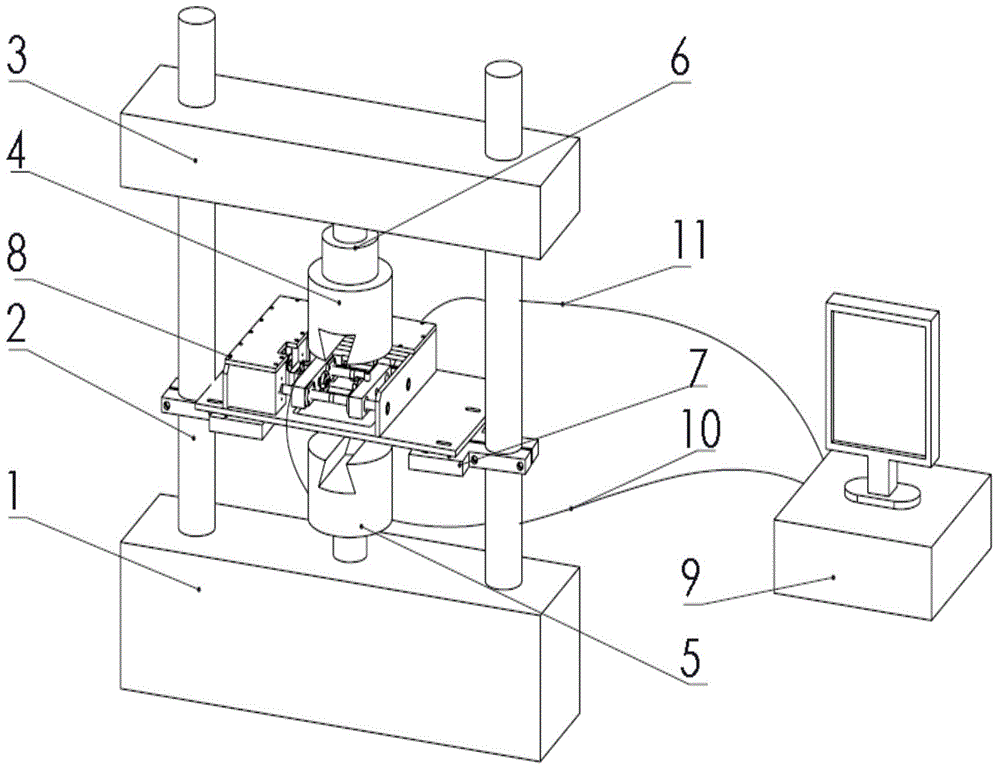

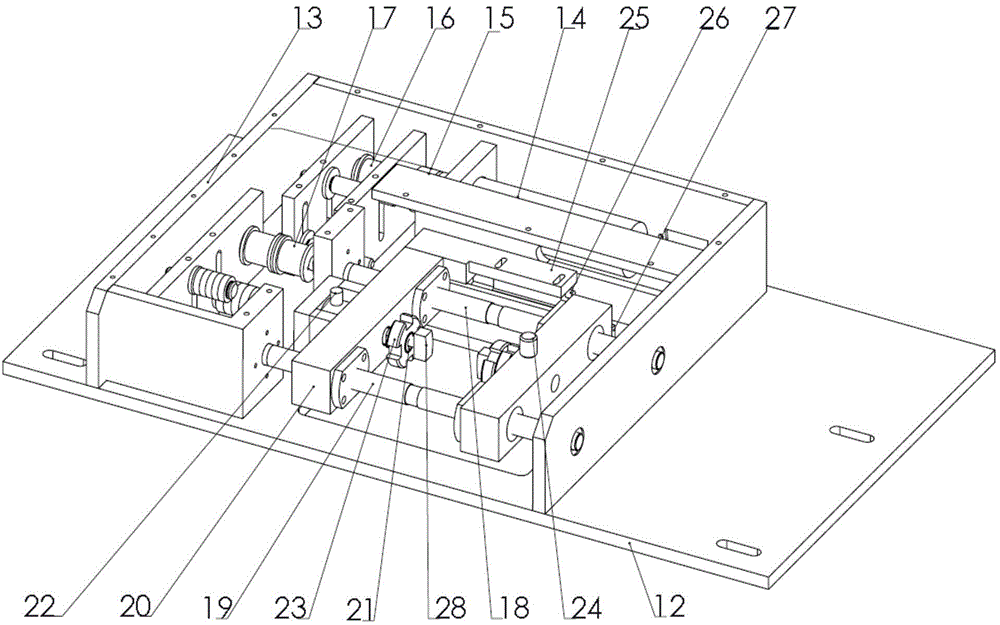

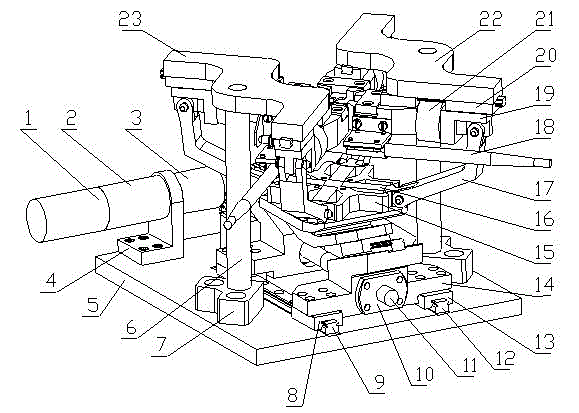

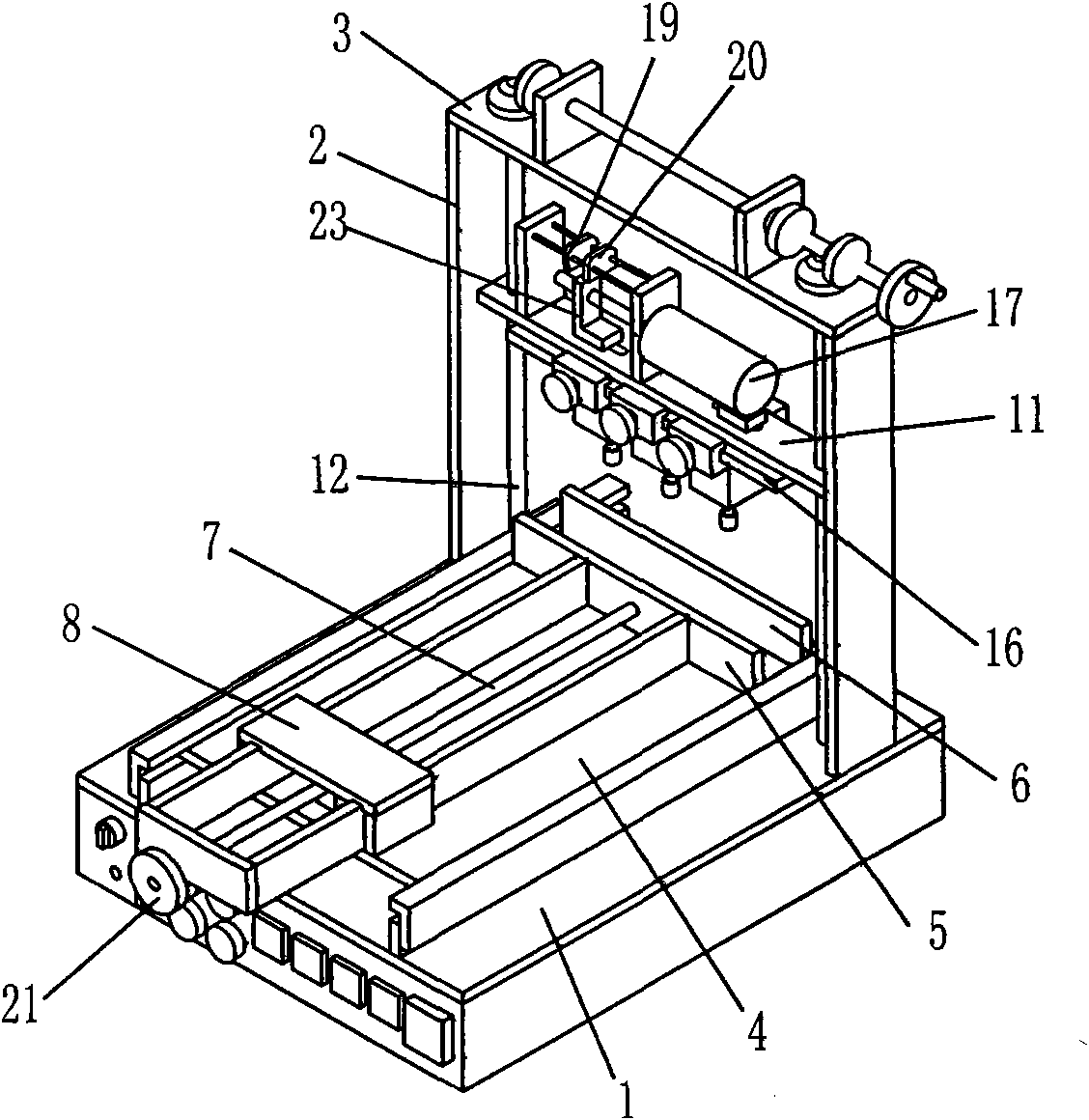

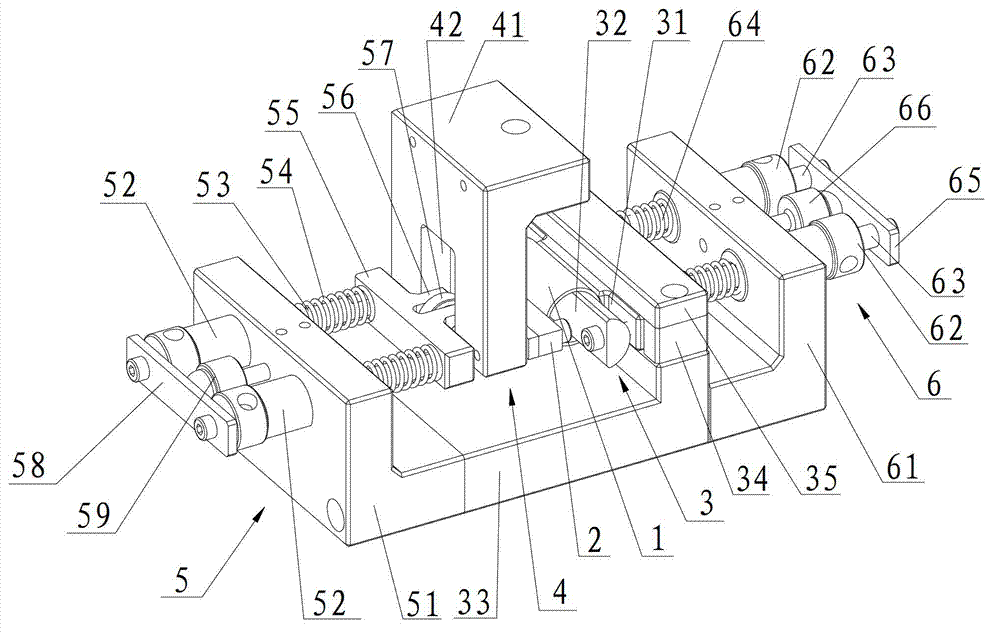

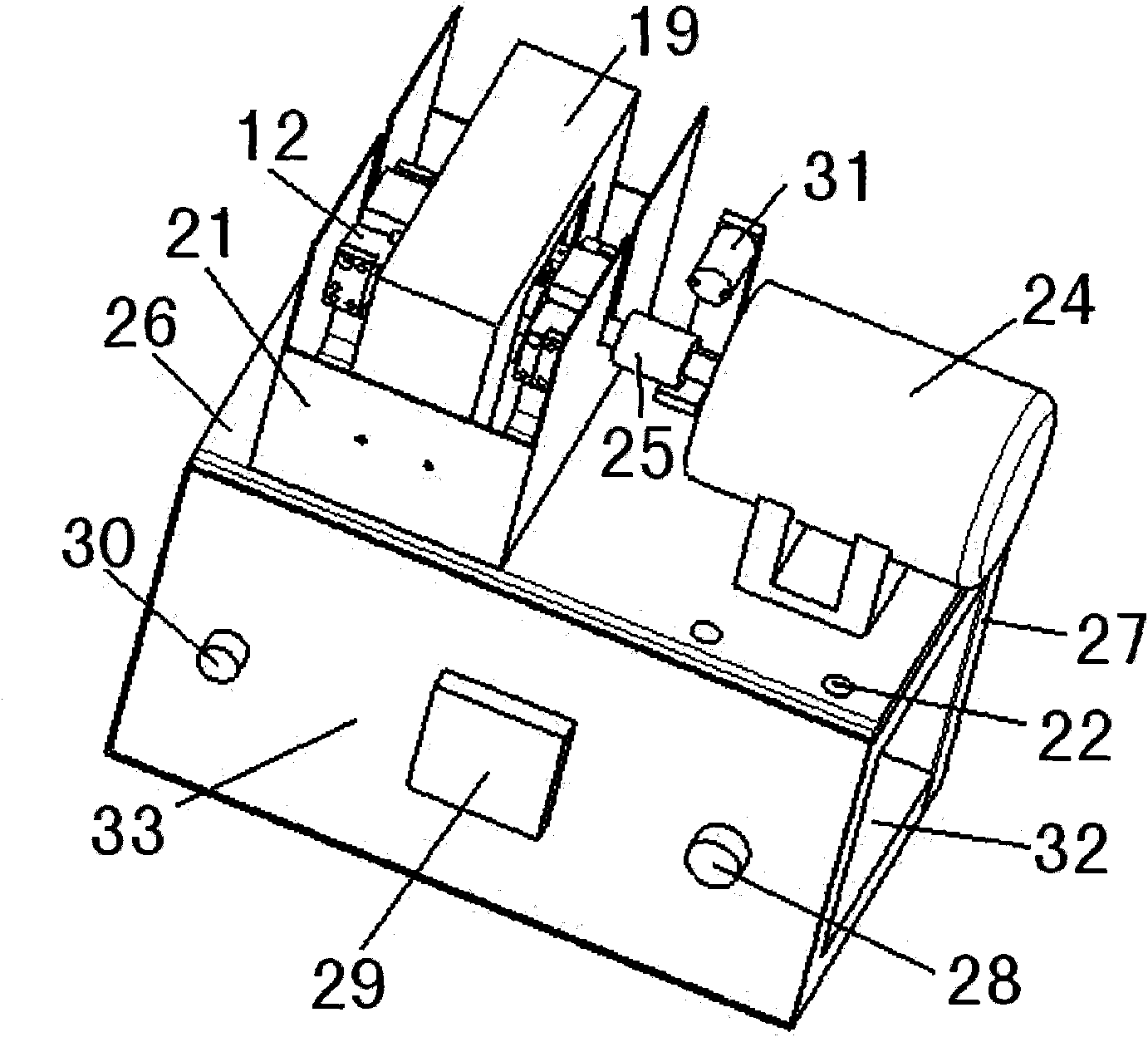

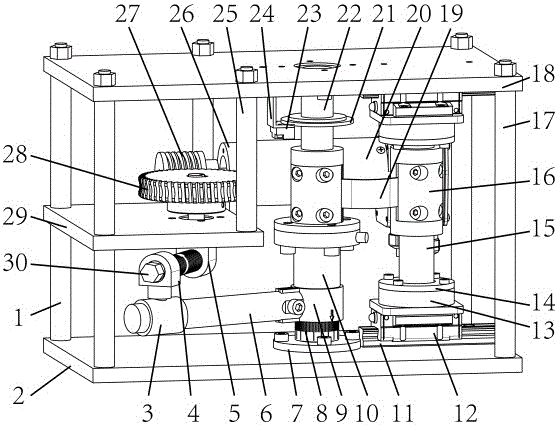

Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

ActiveCN104913974ANovel structureCompact structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesFatigue loadingScientific instrument

The invention relates to a material micro-mechanical property biaxial tension-fatigue test system and a test method thereof, and belongs to the field of precise scientific instruments. The test method is characterized in that orthogonal tensile load is applied to a test piece to make two mutually vertical tensions exist in one plane, and fatigue load can also be applied to the test piece on the basis of the tensile load in order to research the micro-mechanical properties of a material under different load forms and load sizes. The system is composed of a precise loading-transmitting unit, a fatigue unit, a mechanics and deformation signal detection unit, and a test piece clamping unit. The test system has the advantages of novel and compact structure, respective realization of uniaxial tension test, biaxial tension test, uniaxial tension-fatigue test and biaxial tension-fatigue test, good compatibility with an optical microscope, and dynamic research of the relationship between the microstructure of the material and the deformation damage mechanism under tension-fatigue load conditions.

Owner:JILIN UNIV

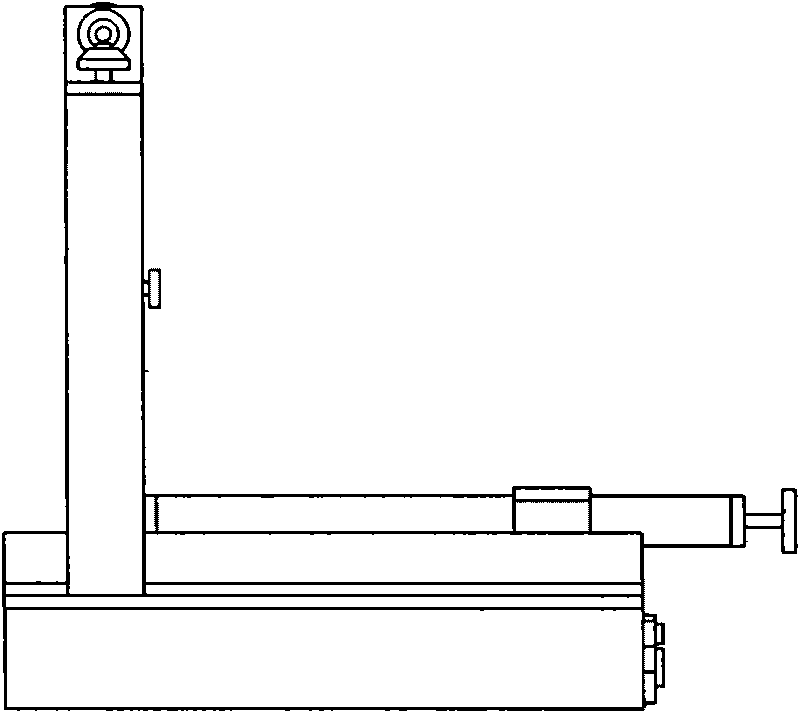

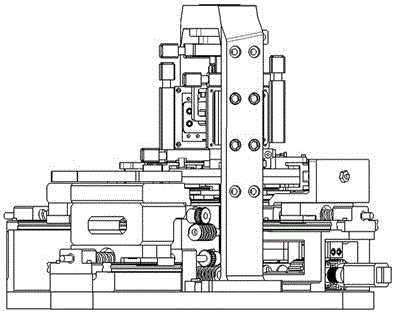

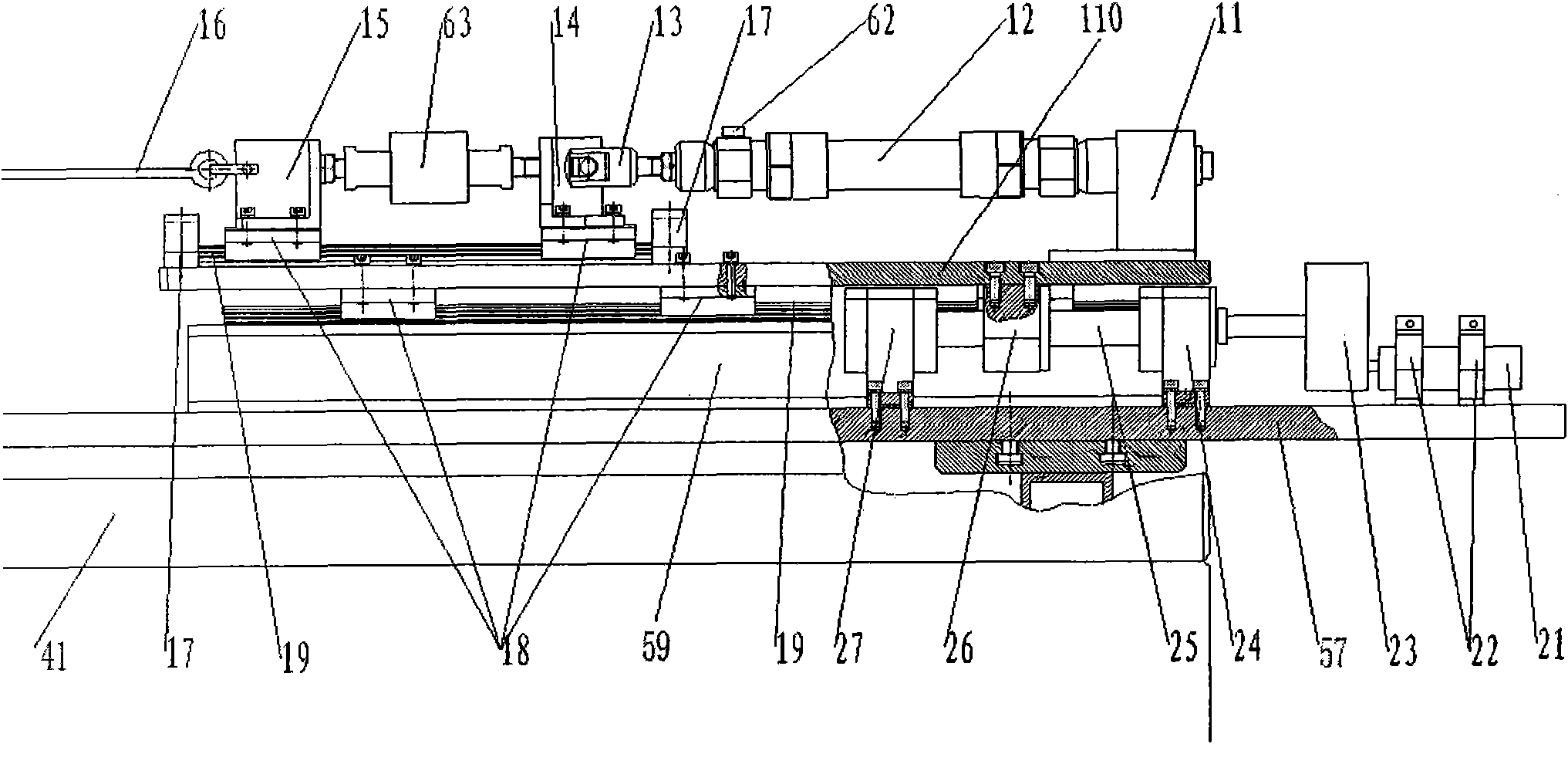

Fatigue testing machine applied to tension test piece and method thereof

InactiveCN101957290AMaximum average displacementMaximum peak displacementMaterial strength using tensile/compressive forcesMechanical componentsPull force

The invention discloses a fatigue testing machine applied to a tension test piece. The fatigue testing machine is mainly used for a tensile test and a tensile fatigue test for mechanical components. The testing machine comprises a fatigue force application mechanism, a pretightening force mechanism, a straightening roller mechanism, a test fixing frame, an auxiliary mechanism and a control system. A power system of the fatigue testing machine comprises the fatigue force application mechanism and the pretightening force mechanism; the tensile force output by the power system is redirected by the straightening roller mechanism and is transmitted to the tension test piece; and the fatigue force application mechanism, the pretightening force mechanism, the straightening roller mechanism and the auxiliary mechanism of the fatigue testing machine are arranged on the test fixing frame. The fatigue testing machine has the advantages of adopting hybrid pneumatic and electric power as the power system of the fatigue testing machine, mastering numerous parameters including the maximum average displacement, the minimum average displacement, peak displacement, the maximum average tension, minimum average tension, minimum fatigue tension, frequency, accumulated test times, accumulated test time and the like, and providing a basis for optimization design of the tension test piece.

Owner:ZHEJIANG UNIV

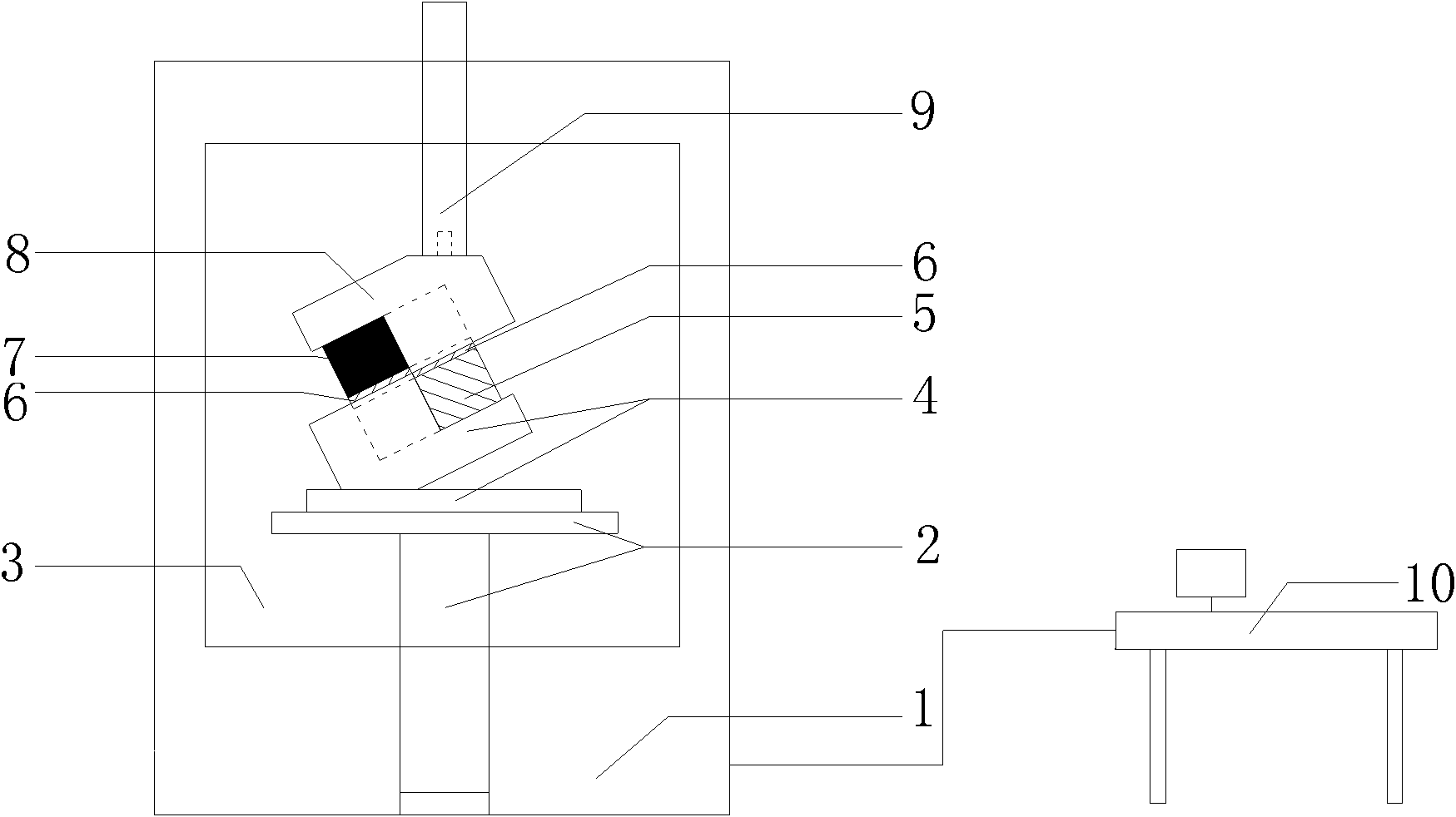

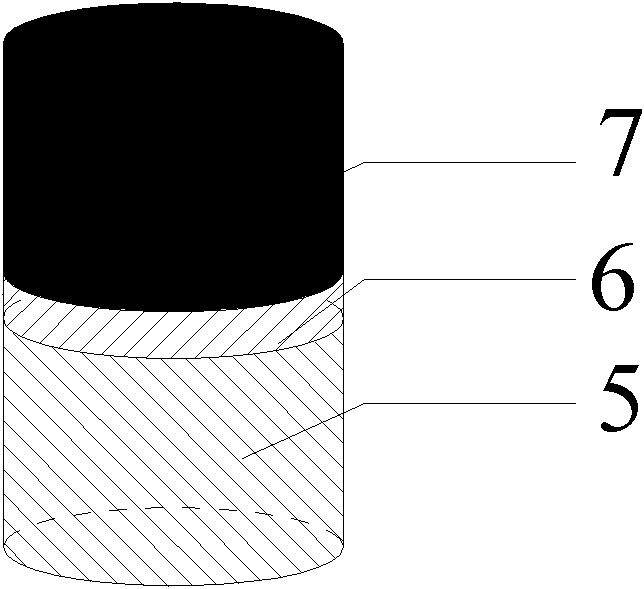

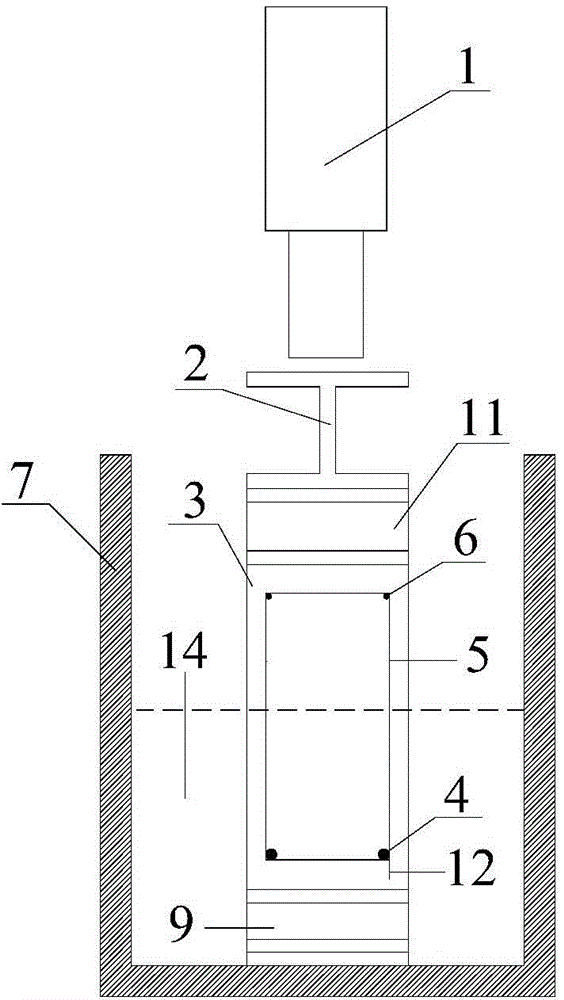

High-temperature creep fatigue test system

InactiveCN105021468AHigh measurement accuracyEasy to operateMaterial strength using tensile/compressive forcesEngineeringFatigue testing

A high-temperature creep fatigue test system, which consists of a fatigue testing machine, specimen holders, a high temperature furnace, a sample, a high temperature extensometer, a cooler and host computer. Upper and lower specimen holders are in threaded connection to ensure the uniform axial loading of the specimen; the specimen holders are connected to the fatigue testing machine; the high-temperature extensometer is connected with the specimen through a jaw; a high temperature furnace mounted on the fatigue testing machine moves to a corresponding position, and wraps the specimen inside; the cooler through inlet and outlet pipes is respectively connected to the upper and lower specimen holders; the fatigue testing machine and the high-temperature extensometer are connected to the host computer; the host computer by reading real-time measurement strain of the high-temperature extensometer controls the fatigue testing machine, so as to conduct strain-controlled high-temperature creep fatigue test. The present invention has the beneficial effects that deformation of the material in high-temperature creep fatigue test can be measured, and has the characteristics of easy operation and high measurement accuracy.

Owner:BEIHANG UNIV

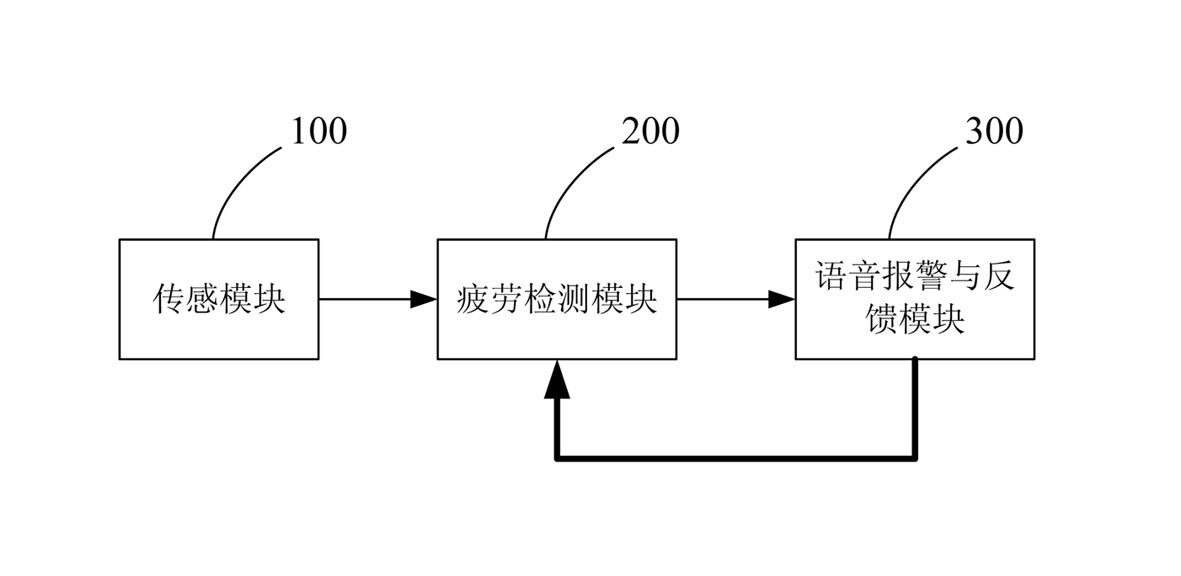

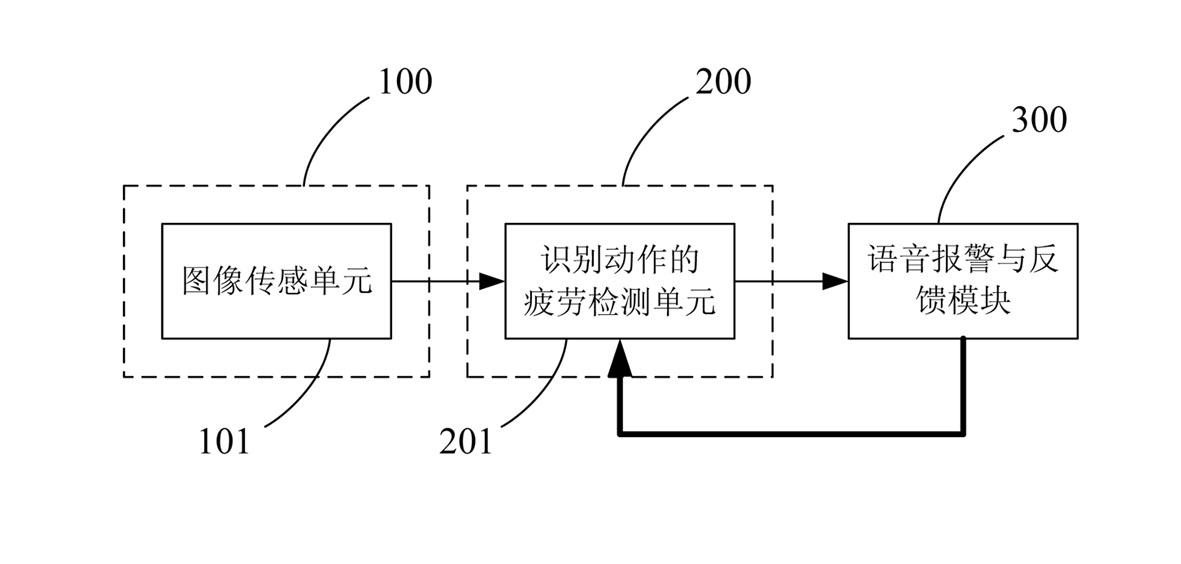

Feedback type fatigue detecting system

The invention provides a feedback type fatigue detecting system which is characterized by comprising a sensing module, a fatigue detecting module and a sound alarm and feedback module, wherein the sensing module is used for collecting an image optical signal and / or a sound signal from a driver; the fatigue detecting module is connected with the sensing module and is used for judging the fatigue state of the driver according to the collected image optical signal and / or the sound signal; and the sound alarm and feedback module is connected with the fatigue detecting module and is used for sending out a sound alarm signal and a sound interactive signal according to the fatigue state of the driver and feeding the related information of the sound interactive signal back to the fatigue detecting module as a reference standard for judging the fatigue state of the driver. The feedback type fatigue detecting system has high accuracy for fatigue detection of the driver and can effectively avoid generating false alarm and leakage alarm.

Owner:庄力可 +3

Fatigue test device for vehicle body thin plate, and test method thereof

ActiveCN102735557AEnsure consistencyAvoid influenceMaterial strength using repeated/pulsating forcesTest efficiencyEngineering

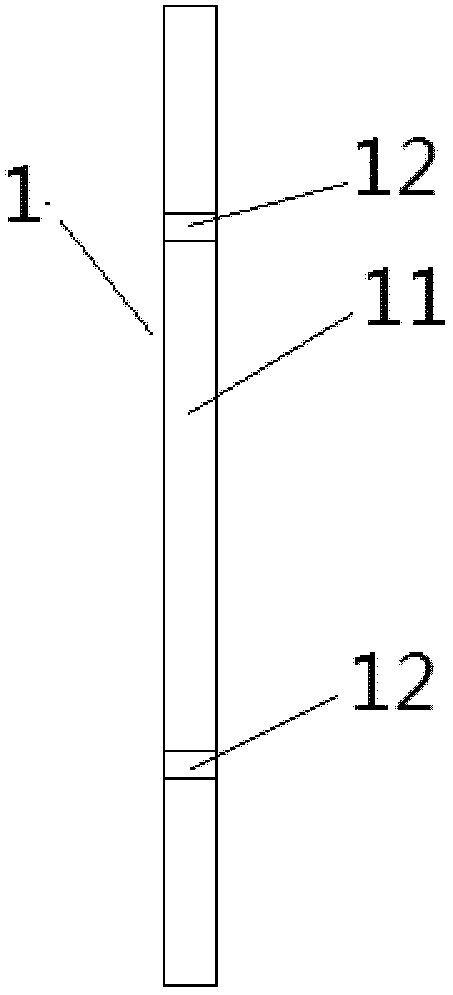

The present invention discloses a fatigue test device for a vehicle body thin plate, and a test method thereof, and belongs to the field of material fatigue test. The test device comprises: a centering apparatus and an anti-bending constraining apparatus. The centering apparatus comprises a vertical column and two centering clamping blocks, wherein the vertical column is provided with a reference plane correspondingly attaching to holding fixtures so as to make a center line of a fatigue specimen parallel to the reference plane, and the two centering clamping blocks are intervally and vertically arranged on the reference plane of the vertical column, such that the fatigue specimen is centered to a center line of test fixtures. The test method comprises: selecting a thin plate fatigue specimen and measuring a static tension curve; carrying out calibration on test force, selecting the initial test force, and setting a condition fatigue limit of the material; adopting the fatigue test device to carry out centering and anti-bending constraining on the fatigue specimen, and adopting a testing machine to carry out a fatigue test on the fatigue specimen. According to the present invention, uniformity of the test process is ensured and influence on the tested result due to additional factors is reduced by the centering apparatus and the anti-bending constraining apparatus, the test efficiency is improved, and the test cost is saved.

Owner:CHERY AUTOMOBILE CO LTD

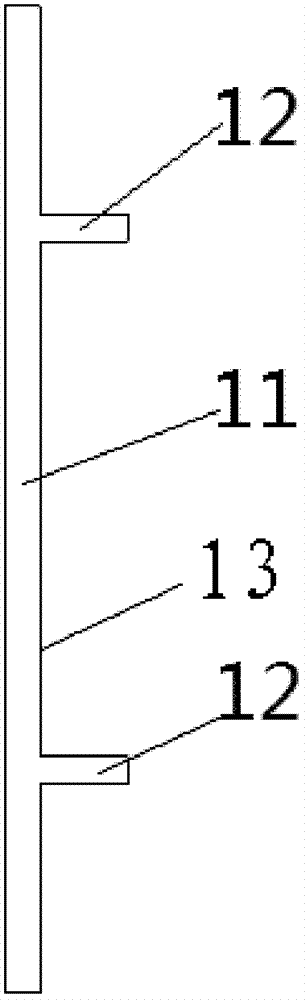

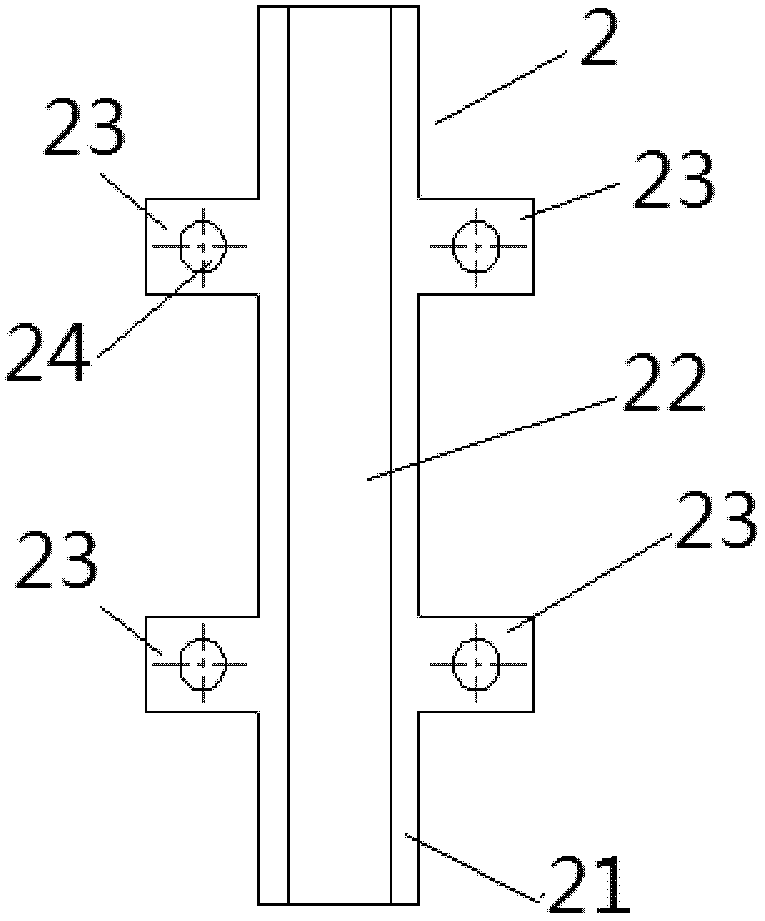

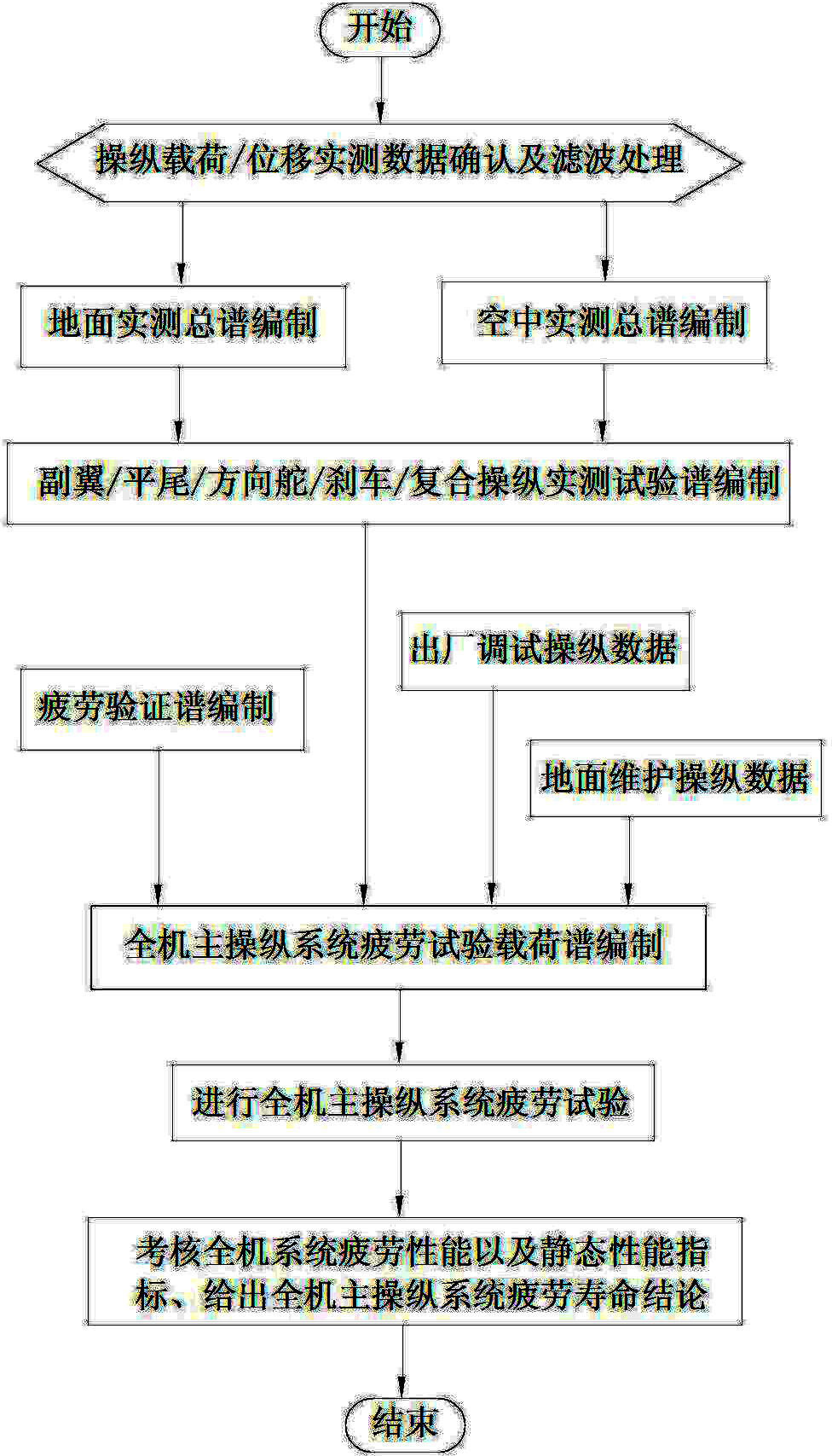

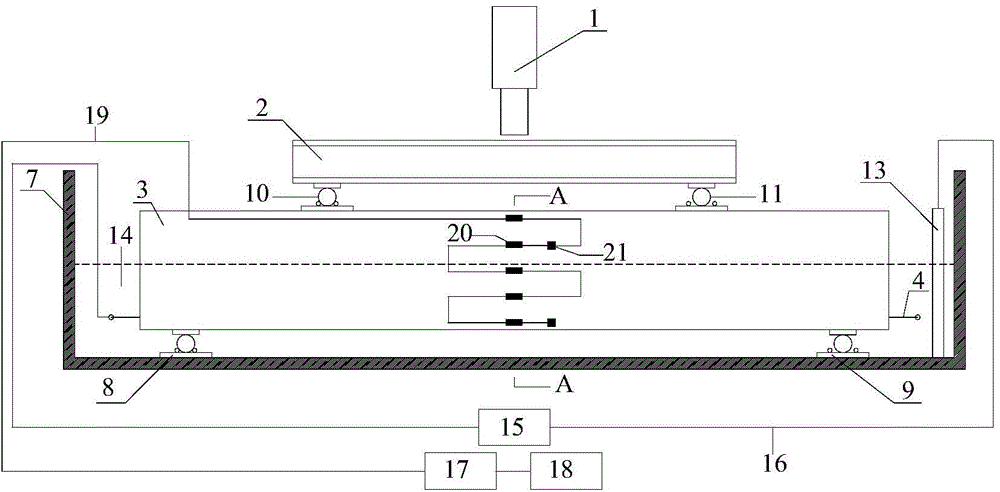

Fatigue test method for full-aircraft main operating system of aircraft

ActiveCN102680221AManifestation of fatigueImprove reliabilityMachine part testingStatic performanceFatigue testing

The invention belongs to a fatigue life determining technology for an operating system of an aircraft and relates to a fatigue test method for a full-aircraft main operating system of the aircraft. According to the fatigue test method, the fatigue coordination loading of an operating load and an operating displacement can be carried out, a fatigue test including the operating load and an operating displacement spectrum on the full-aircraft main operating system of the aircraft can be implemented, and meanwhile, the problem of simultaneous test of aircraft body fatigue on the same fatigue testing machine is taken into account, so that the fatigue properties of components and supporting parts of the full-aircraft main operating system and static performance indicators of the full-aircraft main operating system are all actually assessed; the actual loaded conditions of the main operating system of the aircraft under normal operating and emergency operating conditions are more truly reflected, the fatigue properties of the structure and mechanism of the main operating system of the aircraft are embodied; and the test cost is reduced, and the reliability of a test result is improved.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

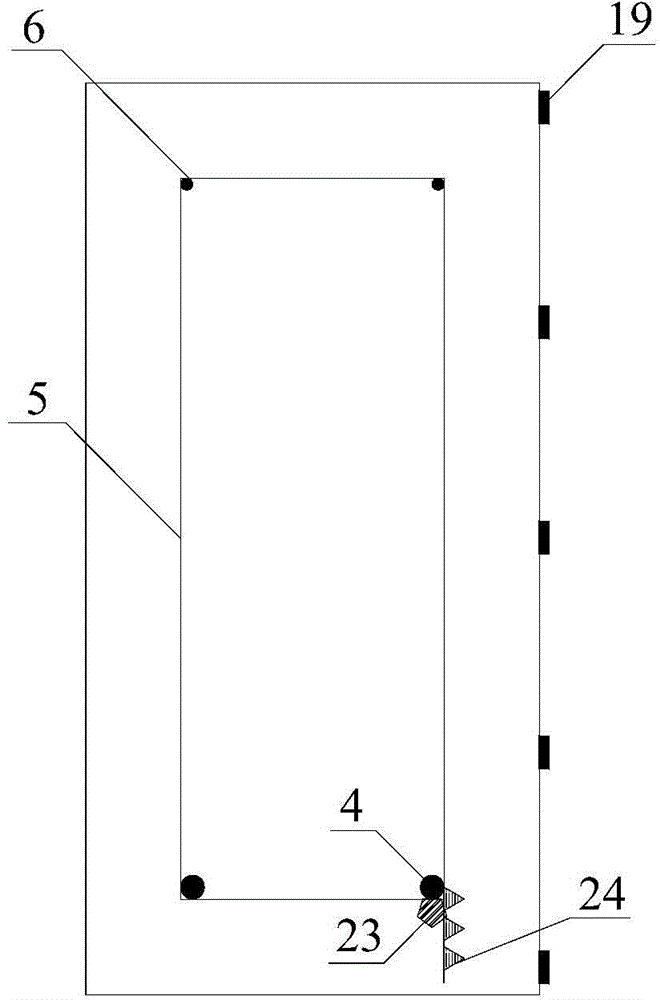

Corrosion-fatigue testing method for reinforced concrete on basis of optical-fiber sensing and device thereof

ActiveCN104483258AThe test data is accurate and reliableRealize real-time synchronous monitoringWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceReinforced concreteRebar

The invention discloses a corrosion-fatigue testing method for reinforced concrete on the basis of optical-fiber sensing and a device thereof. The corrosion-fatigue testing method comprises the following steps: (1) casting a reinforced concrete beam and arranging fiber grating sensors; (2) installing the reinforced concrete beams; (3) connecting with a power supply; (4) injecting electrolyte; and (5) acquiring test data. The device constructed according to the method comprises the reinforced concrete beam to be tested, a load distributing beam, a supporting device, a corrosion groove with an opened upper end, a hydraulic jack, a monitoring device and a direct-current voltage stabilizing power supply. The corrosion-fatigue testing method and the device disclosed by the invention have the advantages that the coupling action of a corrosion medium and alternating stress is fully considered, and the environment is closer to the use environment of the reinforced concrete structure in service, so that the test data is more effective and reliable.

Owner:ZHEJIANG UNIV

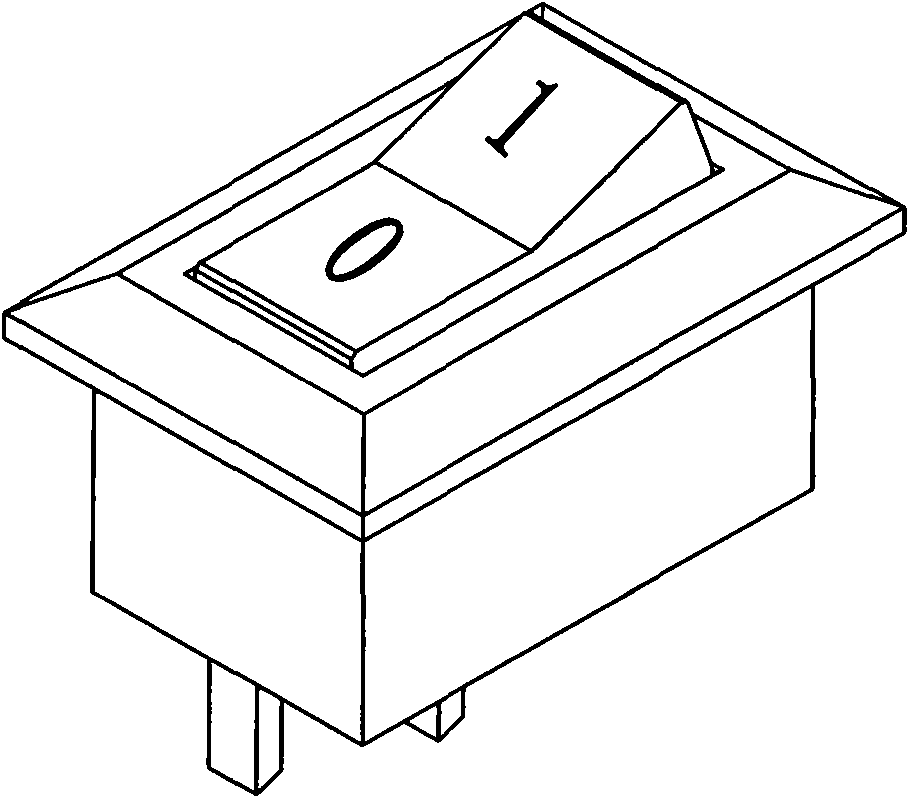

Ship-shaped switch fatigue test device

InactiveCN101660977AImprove test efficiencyConsistent strengthStructural/machines measurementCircuit interrupters testingTest efficiencyFatigue testing

The invention relates to a ship-shaped switch fatigue test device which is used for testing a ship-shaped switch comprising two press ends. The ship-shaped switch fatigue test device comprises a working platform, a bracket, a first drive device and a second drive device, wherein the working platform is used for fixing the ship-shaped switch; the bracket is fixed on the working platform, and a press column for pressing the ship-shaped switch is arranged on the bracket; the first drive device is used for driving the press column to move up and down so as to press the ship-shaped switch; and thesecond drive device is used for driving the press column to horizontally move above the ship-shaped switch. The ship-shaped switch fatigue test device can carry out a fatigue test on a plurality of ship-shaped switches simultaneously and improves the test efficiency, the force and the frequency for pressing the ship-shaped switch each time keep consistent, and the test effect is better.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

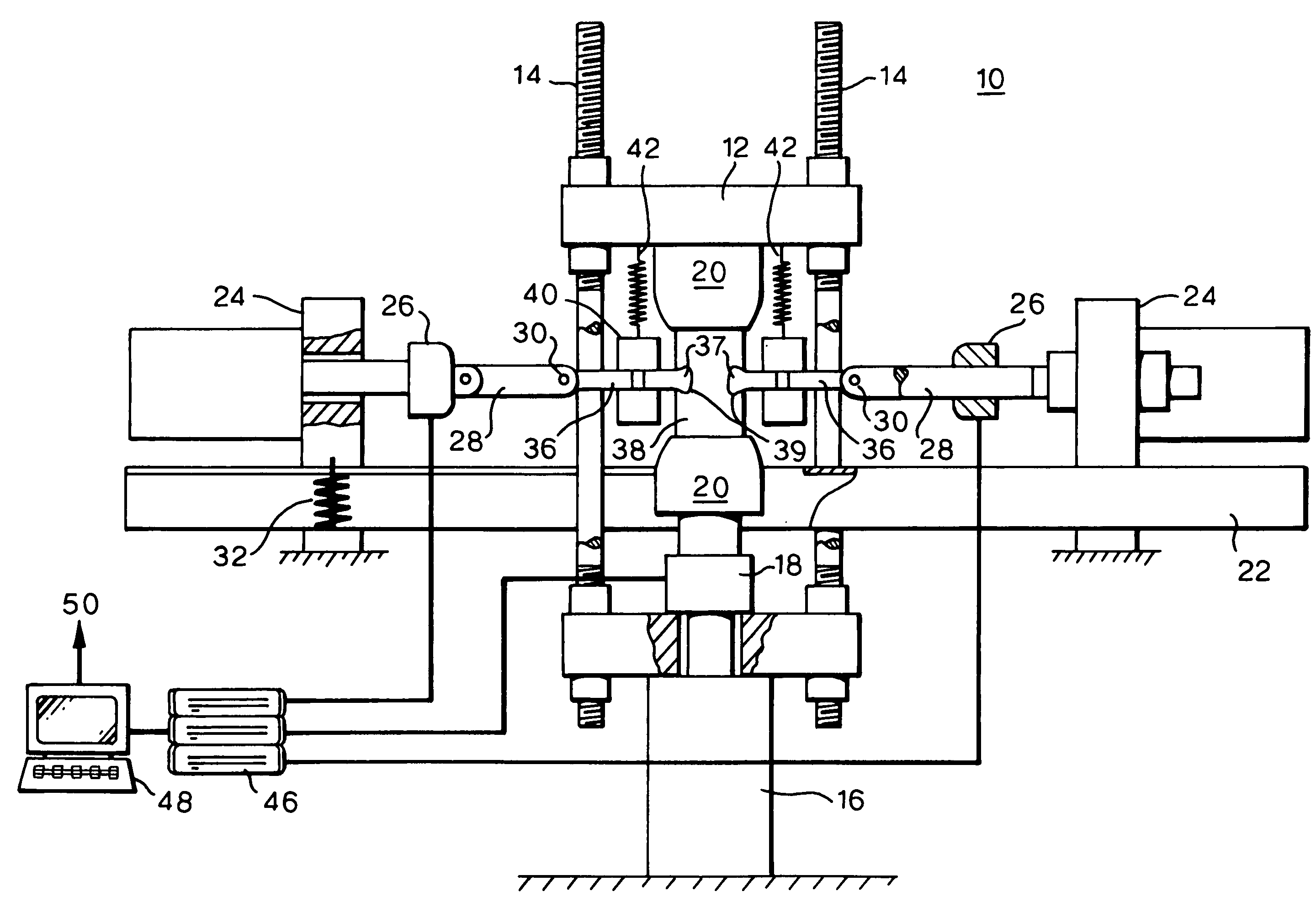

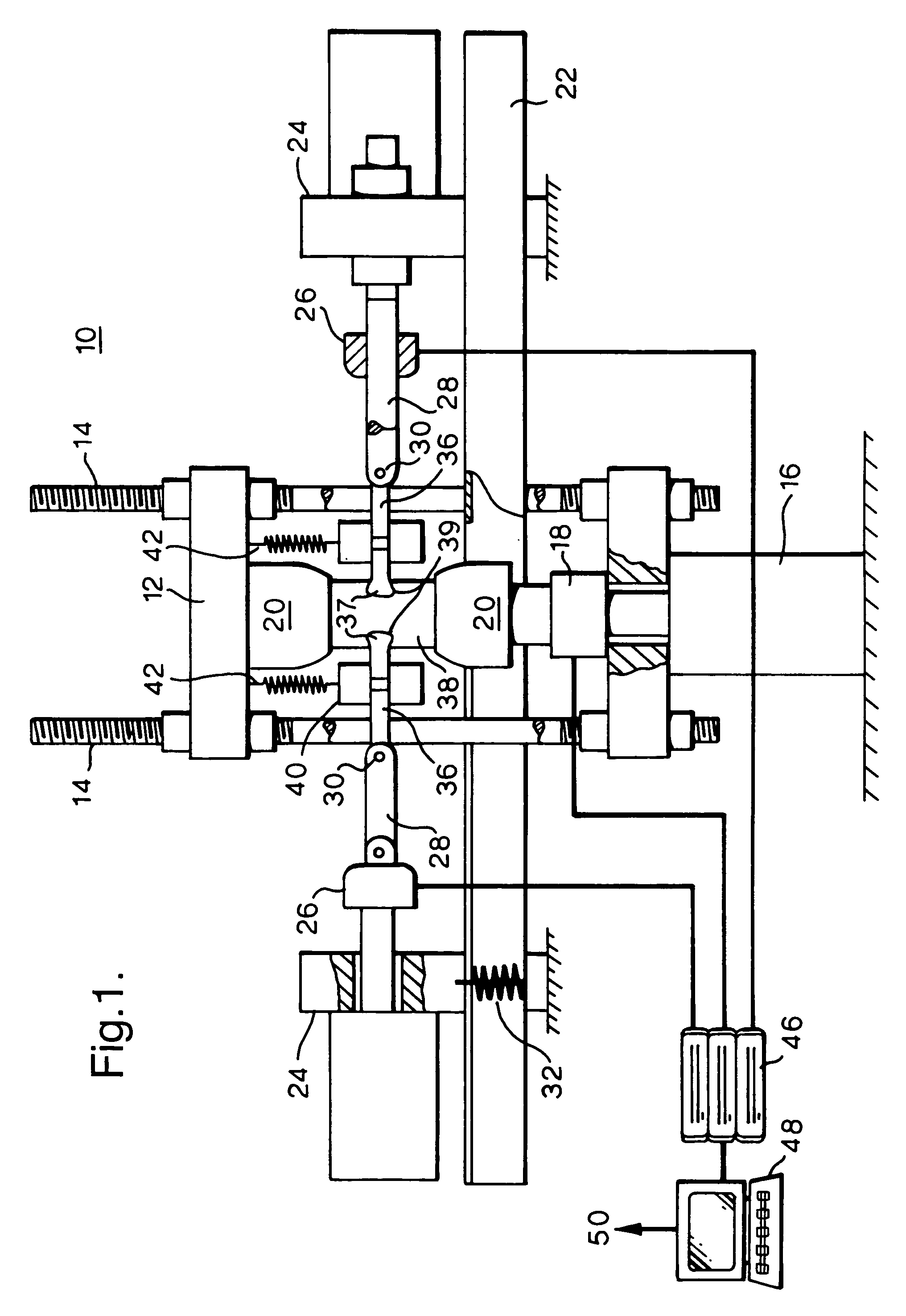

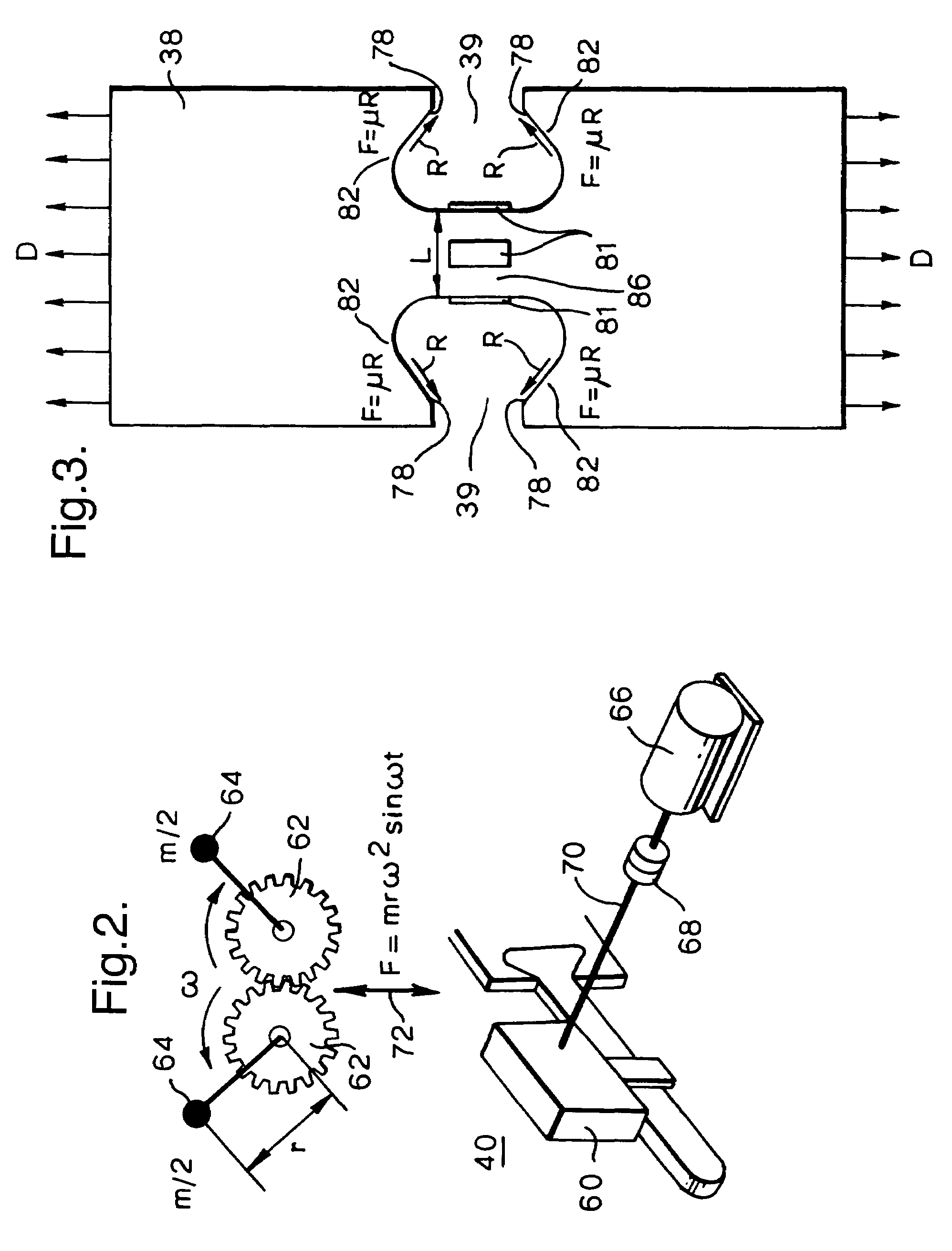

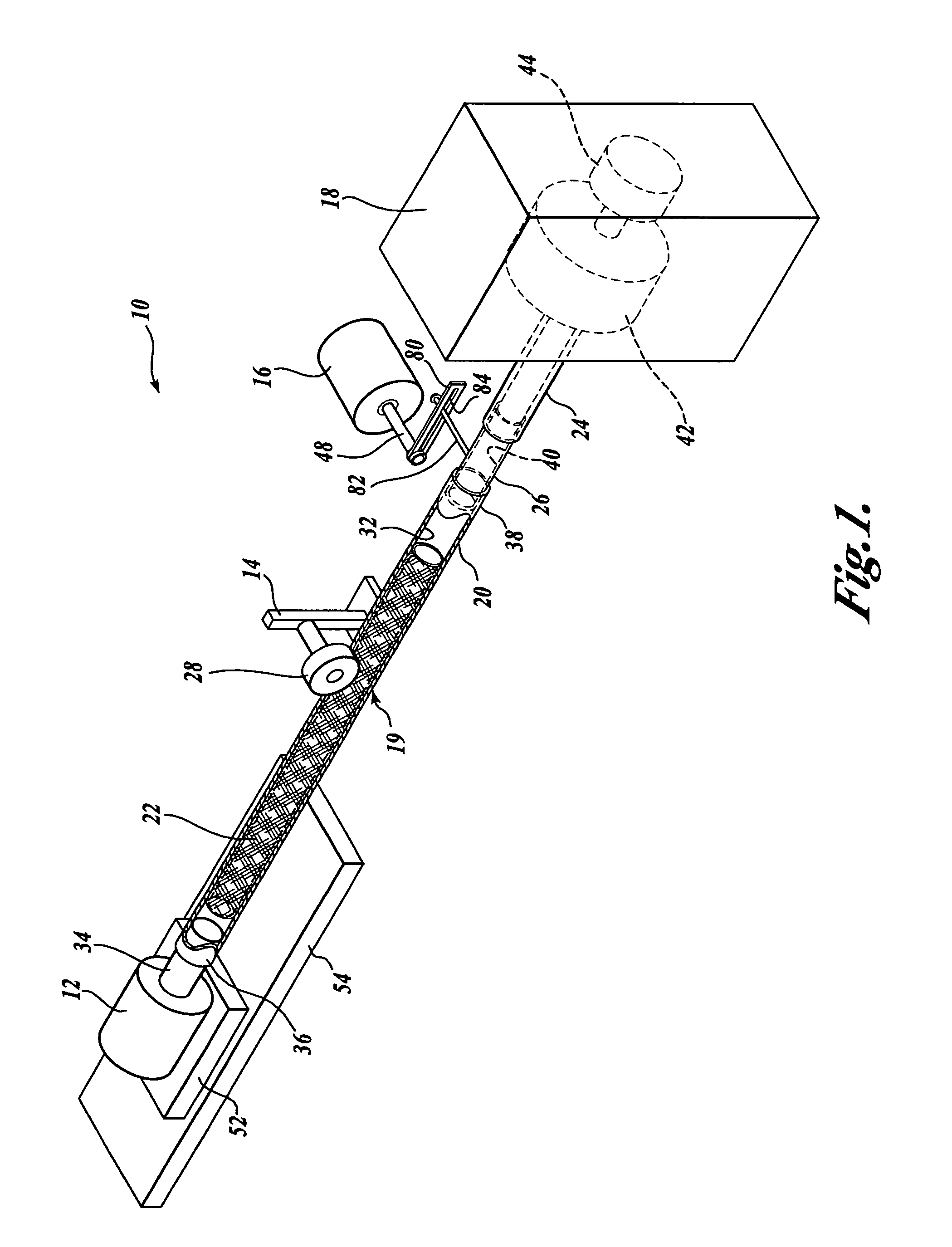

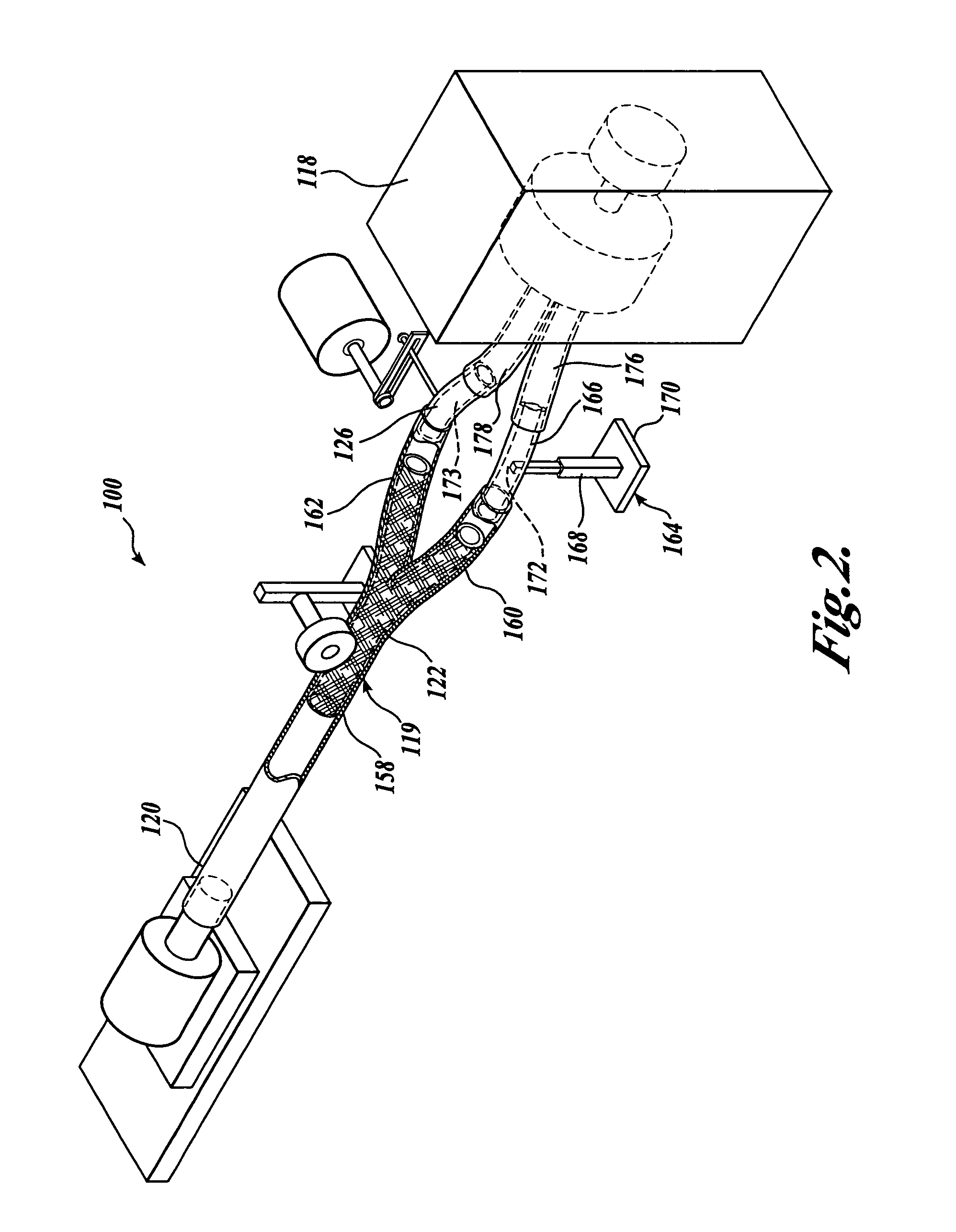

Method and apparatus for vascular durability and fatigue testing

A vascular prosthesis tester (10) for inducing stresses upon a vascular prosthesis (22) having a channel extending through the vascular prosthesis is disclosed. The tester includes a pump (18) adaptable to pressurize a fluid disposed within the channel to induce a radial stress upon the vascular prosthesis. The tester may further include a bend applicator (16) operable to induce a bending stress, a torque applicator (12) operable to induce a torque, a linear force applicator (52) operable to induce a linear force, and / or a stop (28) for inducing a lateral push stress upon the vascular prosthesis. A method of fatigue testing a vascular prosthesis contained within a fluid conduit is also disclosed. The method includes injecting a fluid within the inner channel and inducing a torque, bending stress, linear stress, and / or later push stress upon the vascular prosthesis.

Owner:TA INSTR WATERS LLC

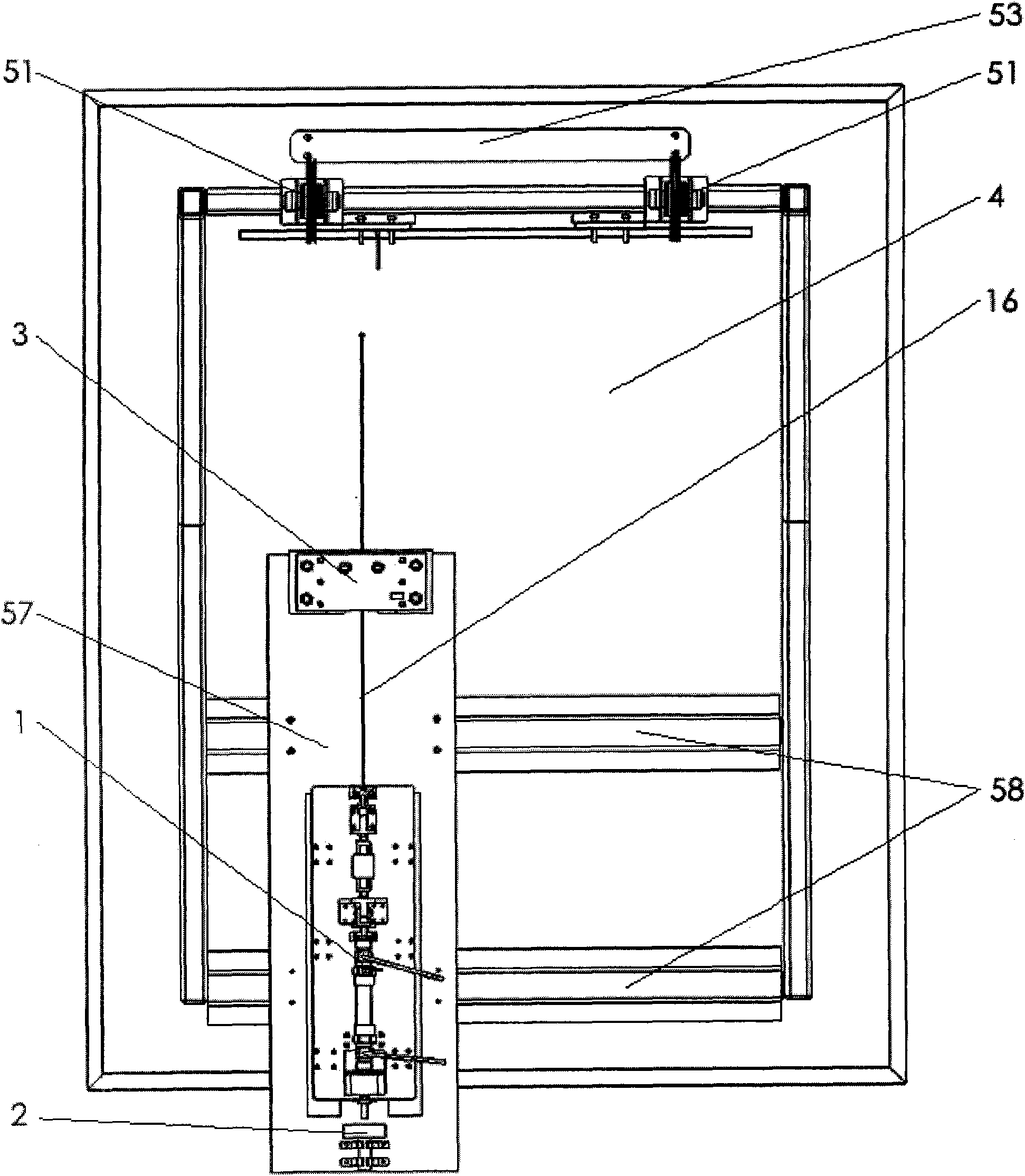

Fatigue-tesing machine for ball socket bearing of helicopter main rotor

The invention discloses a fatigue testing machine of a ball socket bearing of a main rotor of a helicopter. The fatigue testing machine is characterized in that a first rolling guide (26) and a second rolling guide (29) are fixedly connected to a central upright post (16); a first supporting sleeve(25) is fixedly connected on the first rolling guide (26); a second supporting sleeve (30) is fixedly connected to the second rolling guide (29); both the first supporting sleeve (25) and the second supporting sleeve (30) support a main shaft of a rotor wing (3); an inner hole of an inner ring (24) of the ball socket bearing of an auto bank unit of a main rotor is matched with an outer cylindrical surface of the main shaft of the rotor wing(3); the inner ring (24) of the ball socket bearing of the auto bank unit of the main rotor is sheathed with an outer ring thereof to form a spherical pair. The invention can accurately simulate the real working conditions of the ball socket bearing of the auto bank unit of the main rotor, such as the temperature, the load, and the like, and accurately simulate the real movements of the ball socket bearing of the auto bank unit of the main rotor, such as the speed, the acceleration and the like. The invention has the advantages of compact structure, beautiful appearance and convenient operation and maintenance.

Owner:YANSHAN UNIV

Clamping device for pipe-flat plate line contact fretting wear experiments

ActiveCN102866058ASimple structureEasy to operateStrength propertiesMechanical engineeringFatigue testing

The invention discloses a clamping device for pipe-flat plate line contact fretting wear experiments. In the clamping device, a cylindrical pipe clamping assembly and a flat plate clamping assembly are arranged to stably clamp experimental samples i.e., a cylindrical pipe and a flat plate respectively; a cylindrical pipe pressing assembly and a flat plate pressing assembly are arranged to respectively provide pressing forces along horizontal opposite directions for the cylindrical pipe and the flat plate, and therefore, the flat plate and the cylindrical pipe are in line contact and bear stable and uniform normal load and the pipe-flat plate line contact fretting wear experiments can be carried out in cooperation with a uniaxial fatigue testing machine. The clamping device is simple in structure, convenient for operation, capable of carrying out the experiments in cooperation with the conventional uniaxial fatigue testing machine, has no need for introducing a biaxial fretting wear testing machine, thereby reducing the experimental cost.

Owner:SUZHOU NUCLEAR POWER RES INST +1

Combinatorial testing accessory of vibration testing platform and static fatigue testing method

ActiveCN104020038AFunction increaseAchieve diversificationMaterial strength using repeated/pulsating forcesVibration testingTest sampleEngineering

The invention relates to a material and structure testing device and method, and in particular relates to a combinatorial testing accessory of a vibration testing platform and a static fatigue testing method. The combinatorial testing accessory consists of support brackets, a test sample clamp, a vibration transmission device and a bridging bracket. When the accessory is combined, the support bracket is mounted on a vibration testing platform rack, the bridging bracket is mounted on the two support brackets in a spanning manner, the test sample clamp is mounted on the support brackets for clamping a test sample, and the vibration transmission device is mounted on the surface of a vibration testing platform. According to the static fatigue testing method, the combinatorial accessory is mounted on the vibration testing platform and is used for performing 7 types of 13 static fatigue tests on the test sample. The testing device and the testing method expand the function of the vibration testing platform, achieve diversification of load modes, including multiple load modes of pulling, compression, bending, twisting and the like and the combination of the load modes, in the fatigue testing, have a large range of testing frequency, are capable of performing fatigue testing on 5-4500 Hz, and are applicable to high cycle and super high cycle static fatigue testing research on materials and structures.

Owner:SHANDONG UNIV

Spring fatigue testing equipment and testing method thereof

InactiveCN101881693AEfficient detectionRealize unmanned operationMachine part testingMaterial strength using repeated/pulsating forcesDrive shaftElectric machinery

The invention provides spring fatigue testing equipment applied to the field of testing, and also relates to a testing method of the equipment. A bracket (23) of the spring fatigue testing equipment has a reverse T-shaped structure; a cam disk (1) is arranged on a transmission shaft (2); the side face of the cam disk (1) is provided with a slide block type slot (5); a locking block (12) is fixed to a side edge of the bracket (23); a rocker shaft (10) passes through a big hole (34) and a circular hole (36); another rocker shaft (14) passes through a small hole (35); a small end (8) of the rocker shaft is propped against the locking block (12); one end of the rocker shaft (14) opposite to the small end (8) of the rocker shaft is connected with a slide block (20); the slide block (20) is embedded in the slot (5); the transmission shaft (2) is connected with a motor (24); and the motor (24) is connected with a control switch (28). The invention realizes high-efficiency testing of the spring fatigue equipment, greatly reduces the required power output and also realizes unmanned operation.

Owner:JAPHL POWERTRAIN SYST

Rubber diaphragm antifatigue test device

InactiveCN101419147AAdjustable speedImprove test efficiencyMaterial strength using repeated/pulsating forcesRubber membraneElectric machinery

The invention relates to a fatigue resistance testing device for a rubber membrane. A reciprocating transmission mechanism adopts a double-eccenter connecting rod type structure and is positioned on the top of the device; the top end of a reciprocating rod is connected with a counter; the reciprocating transmission mechanism is in driving communication with a motor arranged on the right top of the device; the bottom end of the reciprocating rod is in mechanical connection with a membrane clamping mechanism; the bottom of the center of the clamping mechanism is provided with a balancing spring; the right end of the membrane clamping mechanism is communicated with an air pressure pump through a valve; the middle part of an air inlet pipe is connected in series with an air pressure sensor and an air pressure meter; the middle part of the reciprocating rod is provided with a fixing piece; the upper part and the lower part of the reciprocating rod are provided with a sliding sleeve respectively; and the sliding sleeve restricts the moving direction of the reciprocating rod. The fatigue resistance testing device has the advantages of simple structural principle, large testing range, high efficiency, convenient operation and use, safe and reliable operation and good automation degree.

Owner:QINGDAO UNIV

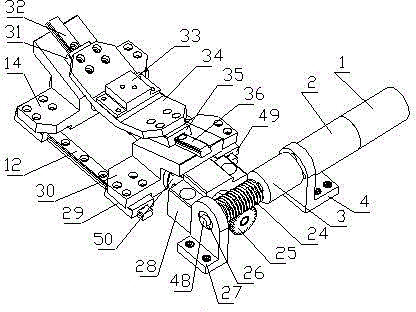

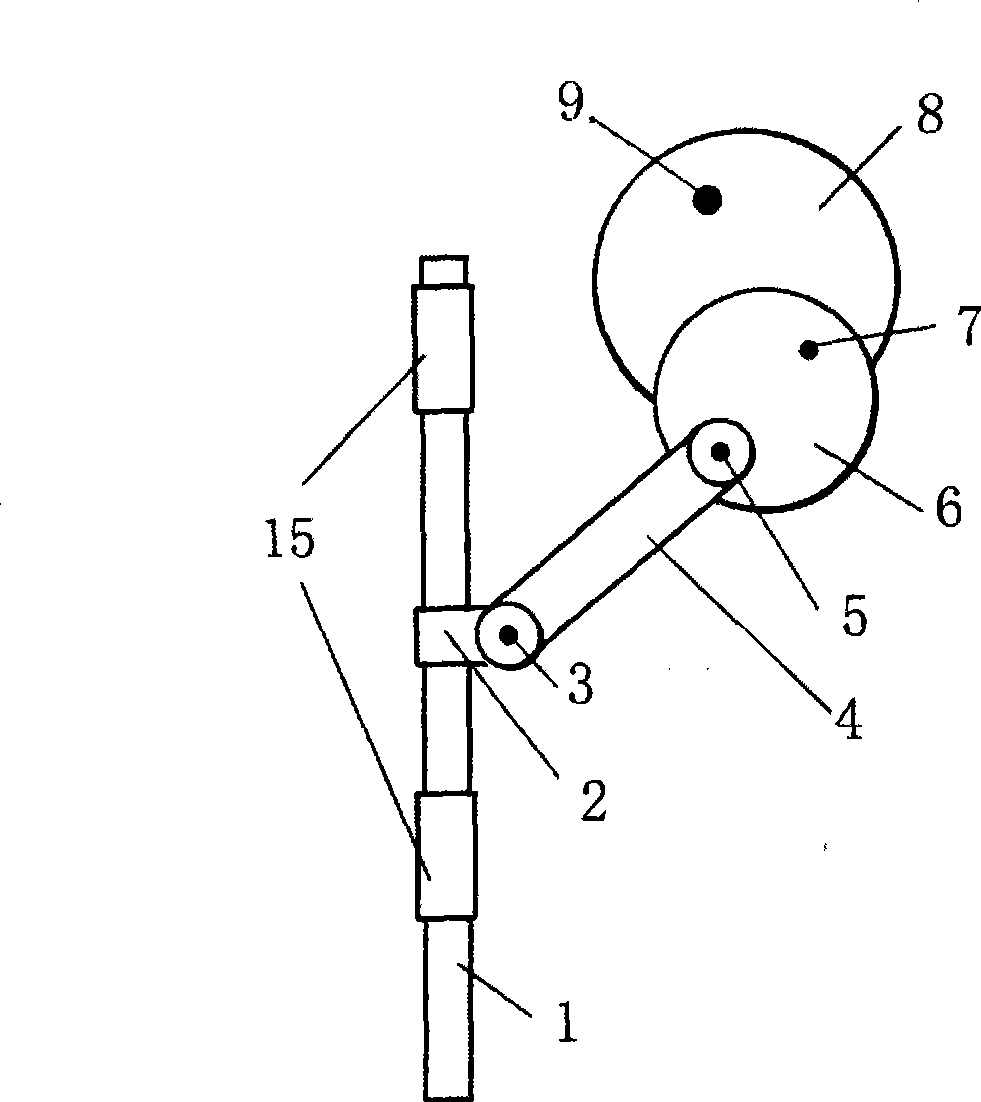

Flexural fatigue mode adjustable tester for testing mechanical properties of materials, and testing method thereof

ActiveCN105758733AAvoid influenceAccurate measurementWork measurementMaterial strength using steady bending forcesAngular degreesEngineering

The invention relates to a flexural fatigue mode adjustable tester for testing mechanical properties of materials, and a testing method thereof, belonging to the field of precision instruments. The tester comprises a flexural fatigue loading unit, a test piece clamping unit, an associated movement unit and a precise detection unit, wherein the flexural fatigue loading unit is powered by a direct current servo motor, a crank and rocker mechanism is driven to realize reciprocating swinging of a rocker by primary worm gear reduction, the rocker drives the clamping unit to realize reciprocating rotation, a bended test sample is repeatedly bent along with the reciprocating rotation of the clamping unit, and the associated movement unit does associated rotation and translation under the driving of the bended test sample. The tester has the advantages that the error of converting bending moment in three-point bending loading is avoided, the influence of the friction force of a support roller on the testing result is avoided, the bending moment and the bending angle can be accurately measured, different fatigue modes can be realized, and fatigue testing with different stress amplitudes and different average stresses can be realized.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com