Gas circulation charging/discharging fatigue test system for full-automatic high pressure vessel

A technology for fatigue testing and high-pressure containers, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of fatigue test systems requiring manual operation, poor heat transfer performance, and inability to accurately control the charging and discharging process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

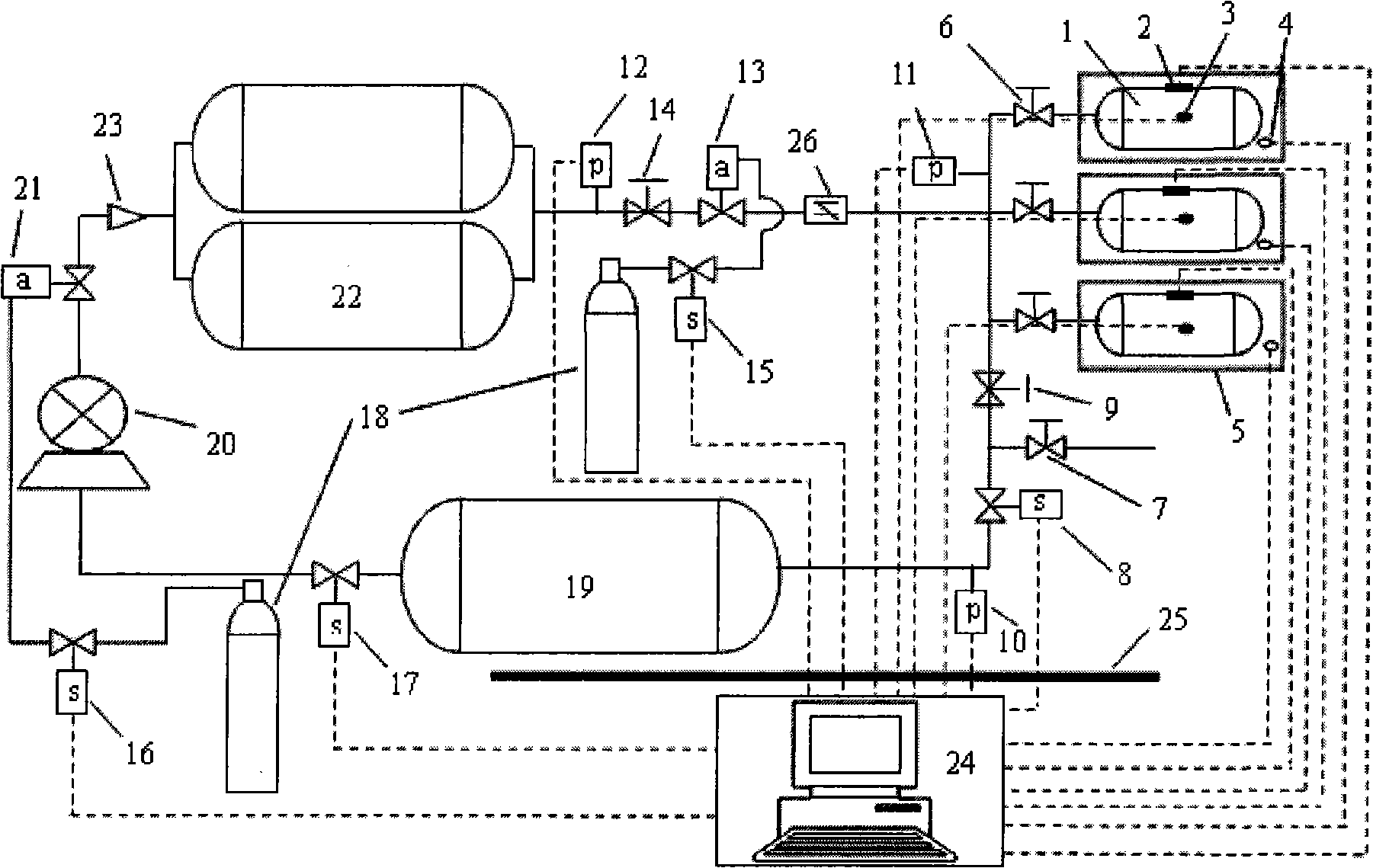

[0020] The system consists of three functional module areas, one is the high-pressure gas cycle filling module, including a high-pressure gas storage container 22, a gas compressor 20, a low-pressure gas storage container 19, a low-pressure nitrogen cylinder 18, a pneumatic valve 13, a solenoid valve 8, One-way valve 23, gas pressure regulator 9, 14, flow regulating valve 26, pressure sensor 12, and pressure-resistant stainless steel pipes and pipe joints and other components; another functional module area is the fatigue test area, including the tested high-pressure vessel 1, cut-off Valve 6, solenoid valve 8, gas pressure sensor 11, temperature sensor 3, gas leakage sensor 4, strain sensor 2, airtight cabin 5, pressure-resistant stainless steel pipes and pipe joints and other components; there is also a functional area for automatic control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com