Material micro-mechanical property biaxial tension-fatigue test system and test method thereof

A technology of micromechanics and biaxial stretching, which is applied in the direction of testing material strength by applying repetitive force/pulsation force and testing material strength by applying stable tension/compression. Novel, guaranteed symmetry and synchronicity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

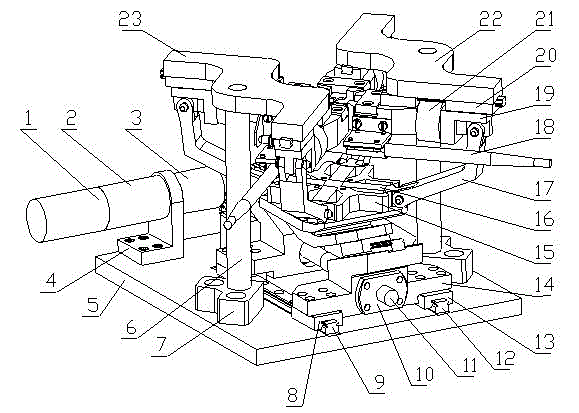

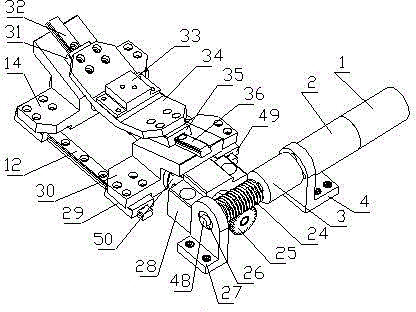

[0038] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0039] see Figure 1 to Figure 7 As shown, the biaxial tension-fatigue testing system for material micromechanical properties of the present invention includes a precision loading-transmission unit, a fatigue unit, a mechanical and deformation signal detection unit, a specimen clamping unit, etc., wherein the precision loading-transmission unit passes Screws are fixed on the bottom plate 5, and the fatigue unit is installed on the precision loading-transmission unit through two symmetrical guide rails Ia32, slider Ia31, guide rail Ib36, and slider Ib35, and the fatigue unit is respectively connected to the specimen through four identical connecting rods 17. The clamping units are connected, and the mechanical and deformation signal detection unit is installed on the specimen clamping unit; the test method utilizes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com