Automotive body in white torsion rigidity test system and method thereof

A technology of torsional stiffness and testing system, which is applied in the field of static stiffness testing of automobile body-in-white, can solve problems such as increasing costs, affecting the testing process, and complicated operation, and achieves the effects of reducing stress, improving testing methods, and excellent versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

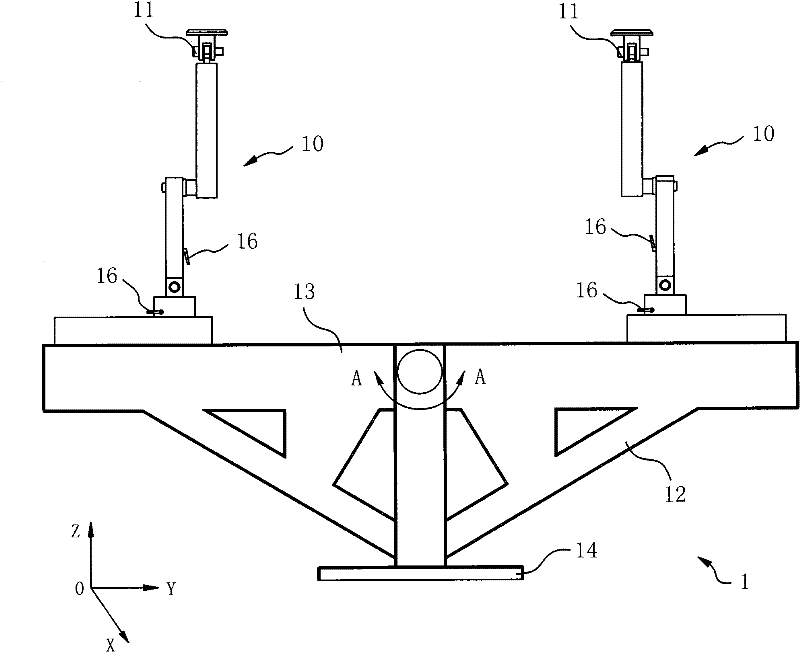

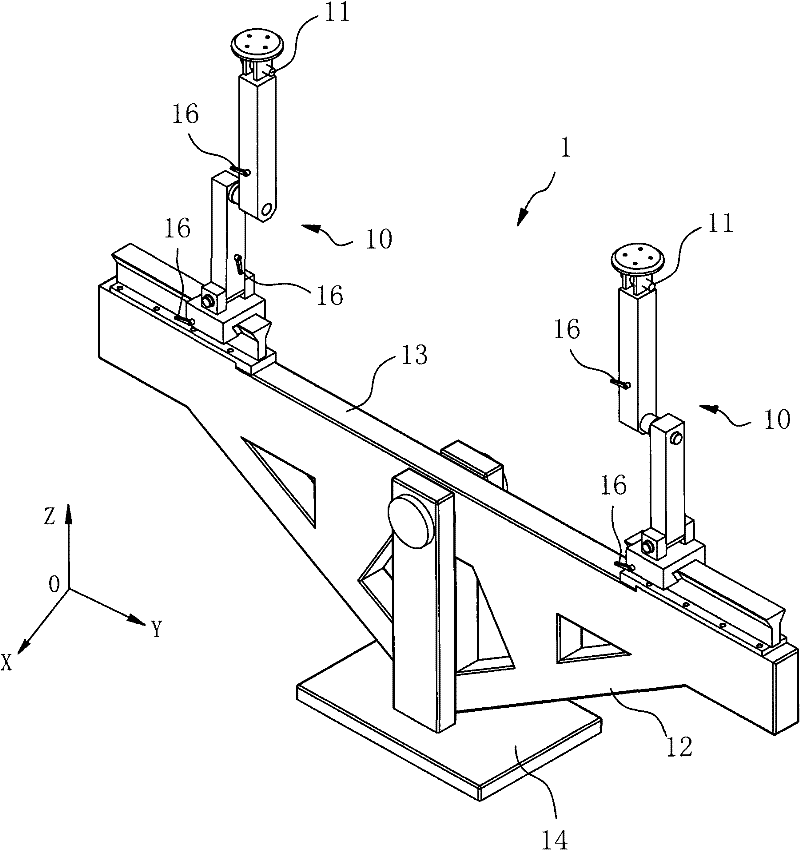

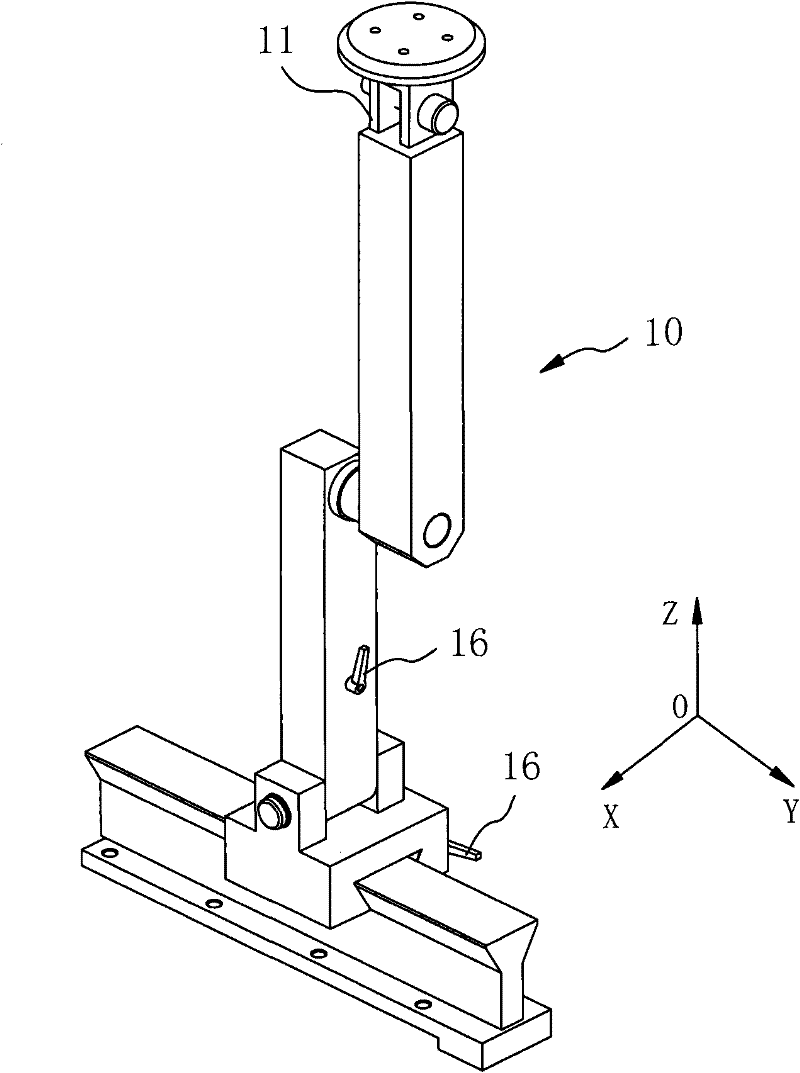

[0076] In a nutshell, in the torsional rigidity test system of the automobile body-in-white of the present invention, it mainly includes two major components, the restraint subsystem and the loading subsystem, so as to realize the functions of constraining the spatial position and applying loads to the body-in-white respectively, and in the attached Figure 1-8 The schematic map shows the basic structural composition of the above-mentioned constraint subsystem in a preferred embodiment of the system of the present invention, and in Figure 10 The overall composition of the loading subsystem is also exemplarily shown in the diagram, and these components and their composition will be described in detail below in conjunction with these drawings.

[0077] Please also see Figure 1 to Figure 5 , in the preferred embodiment above, the constraint subsystem includes a front suspension platform 1 and a rear suspension platform 2 . Such as figure 1 and figure 2 As shown, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com