Automobile tire rubber material with excellent sound absorption performance and preparation method thereof

A technology for automobile tires and rubber materials, applied in the field of automobile tire rubber materials and their preparation, can solve the problems of nervous system damage, long duration, hearing loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

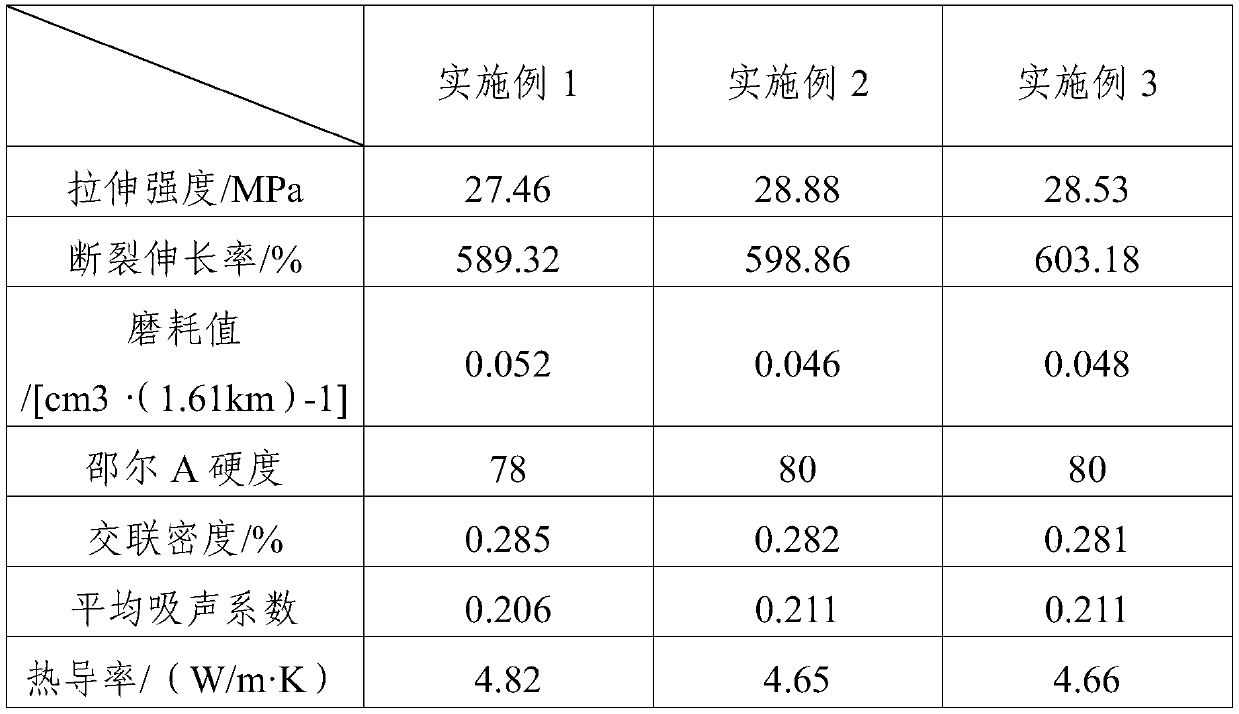

Embodiment 1

[0031] A car tire rubber material with excellent sound-absorbing properties comprises the following components in parts by weight:

[0032] 50 parts of natural rubber, 70 parts of epoxy-solution polystyrene-butadiene rubber, 45 parts of butadiene rubber, 28 parts of high-strength methyl vinyl silicone rubber, 12 parts of eucommia grafted butyl methacrylate, polyisoprene 4 parts, 10 parts of zinc oxide whiskers, 8 parts of porous carbon nanotubes, 10 parts of aluminum oxide, 12 parts of nano-attapulgite, 30 parts of carbon black, 20 parts of organically modified white carbon black, 20 parts of nano-calcium carbonate, 5 parts of microcrystalline paraffin, 5 parts of stearic acid, 1 part of sulfur, 2 parts of leveling agent A78, accelerator CZ, accelerator DPG compounded at a mass ratio of 2:1, 1 part of accelerator, anti-aging agent 264 and anti-aging agent 4020 is 5 parts of anti-aging agent compounded according to the mass ratio of 1:5.

[0033] The preparation method of epox...

Embodiment 2

[0040] A car tire rubber material with excellent sound-absorbing properties comprises the following components in parts by weight:

[0041] 40 parts of natural rubber, 80 parts of epoxy-solution polystyrene-butadiene rubber, 40 parts of butadiene rubber, 25 parts of high-strength methyl vinyl silicone rubber, 10 parts of eucommia grafted butyl methacrylate, polyisoprene 5 parts, 5 parts of zinc oxide whiskers, 10 parts of porous carbon nanotubes, 10 parts of aluminum oxide, 12 parts of nano-attapulgite, 30 parts of carbon black, 20 parts of organically modified white carbon black, 20 parts of nano-calcium carbonate, 6 parts of microcrystalline paraffin, 10 parts of stearic acid, 3 parts of sulfur, 1 part of leveling agent A78, 4 parts of accelerator compounded by accelerator CZ, accelerator DPG at a mass ratio of 2:1, anti-aging agent 264 and anti-aging agent 4020 is 5 parts of anti-aging agent compounded according to the mass ratio of 1:1.

[0042] The preparation method of ...

Embodiment 3

[0049] A car tire rubber material with excellent sound-absorbing properties comprises the following components in parts by weight:

[0050] 30 parts of natural rubber, 60 parts of epoxy-solution polystyrene-butadiene rubber, 40 parts of butadiene rubber, 30 parts of high-strength methyl vinyl silicone rubber, 10 parts of eucommia grafted butyl methacrylate, polyisoprene 5 parts, 5 parts of zinc oxide whiskers, 10 parts of porous carbon nanotubes, 8 parts of aluminum oxide, 10 parts of nano-attapulgite, 40 parts of carbon black, 30 parts of organically modified white carbon black, 20 parts of nano-calcium carbonate, 10 parts of microcrystalline paraffin, 5 parts of stearic acid, 1 part of sulfur, 1 part of leveling agent A78, 2 parts of accelerator compounded by accelerator CZ, accelerator DPG at a mass ratio of 2:1, anti-aging agent 264 and anti-aging agent 4020 is 5 parts of anti-aging agent compounded according to the mass ratio of 1:2.

[0051] The preparation method of ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com