Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126 results about "Filament current" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filament current. in an x-ray machine the strength of the current to the filament is varied by the use of a filament or stepdown transformer.

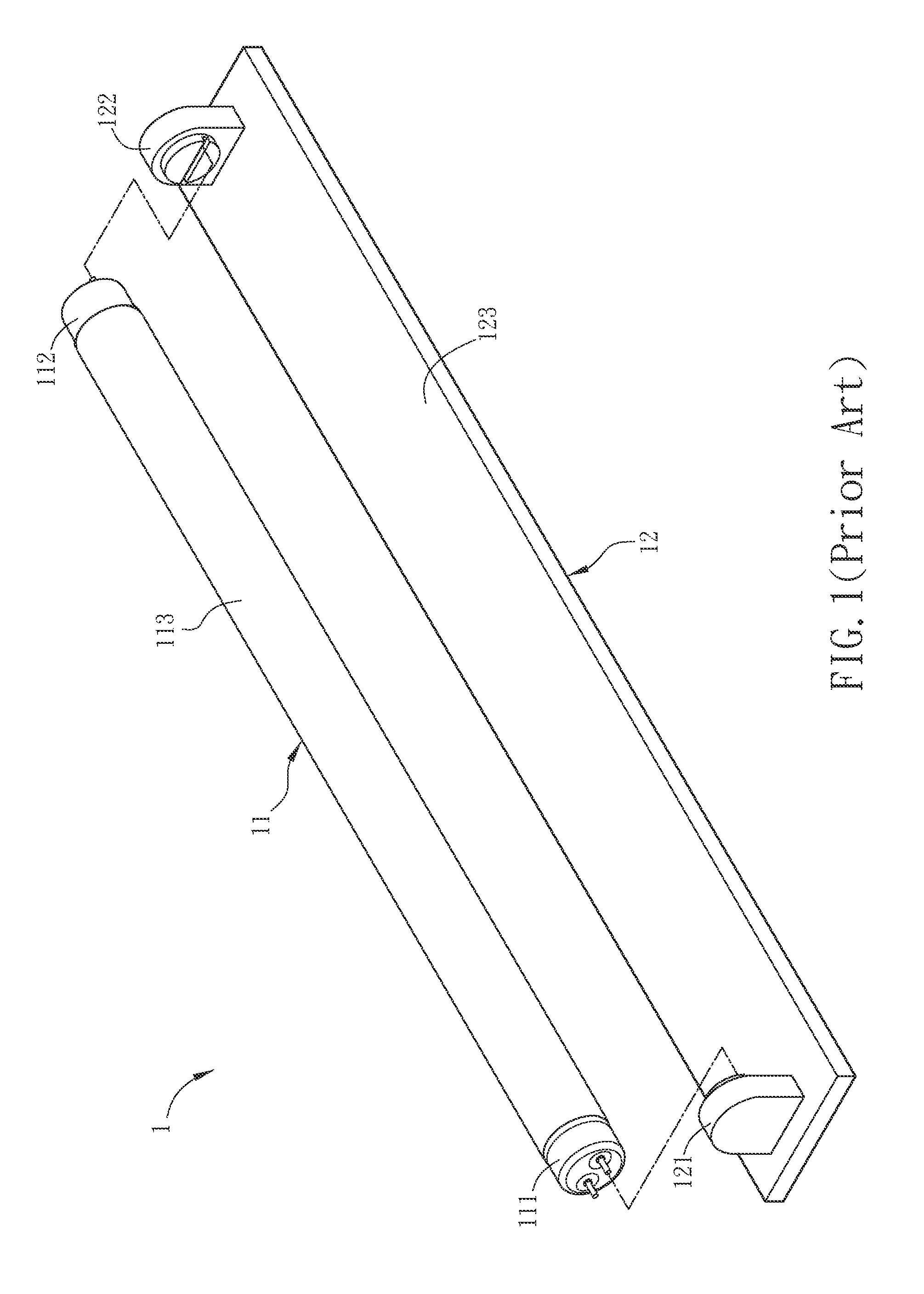

Light Emitting Apparatus

InactiveUS20130147350A1Point-like light sourceElongate light sourcesElectricityElectrical connection

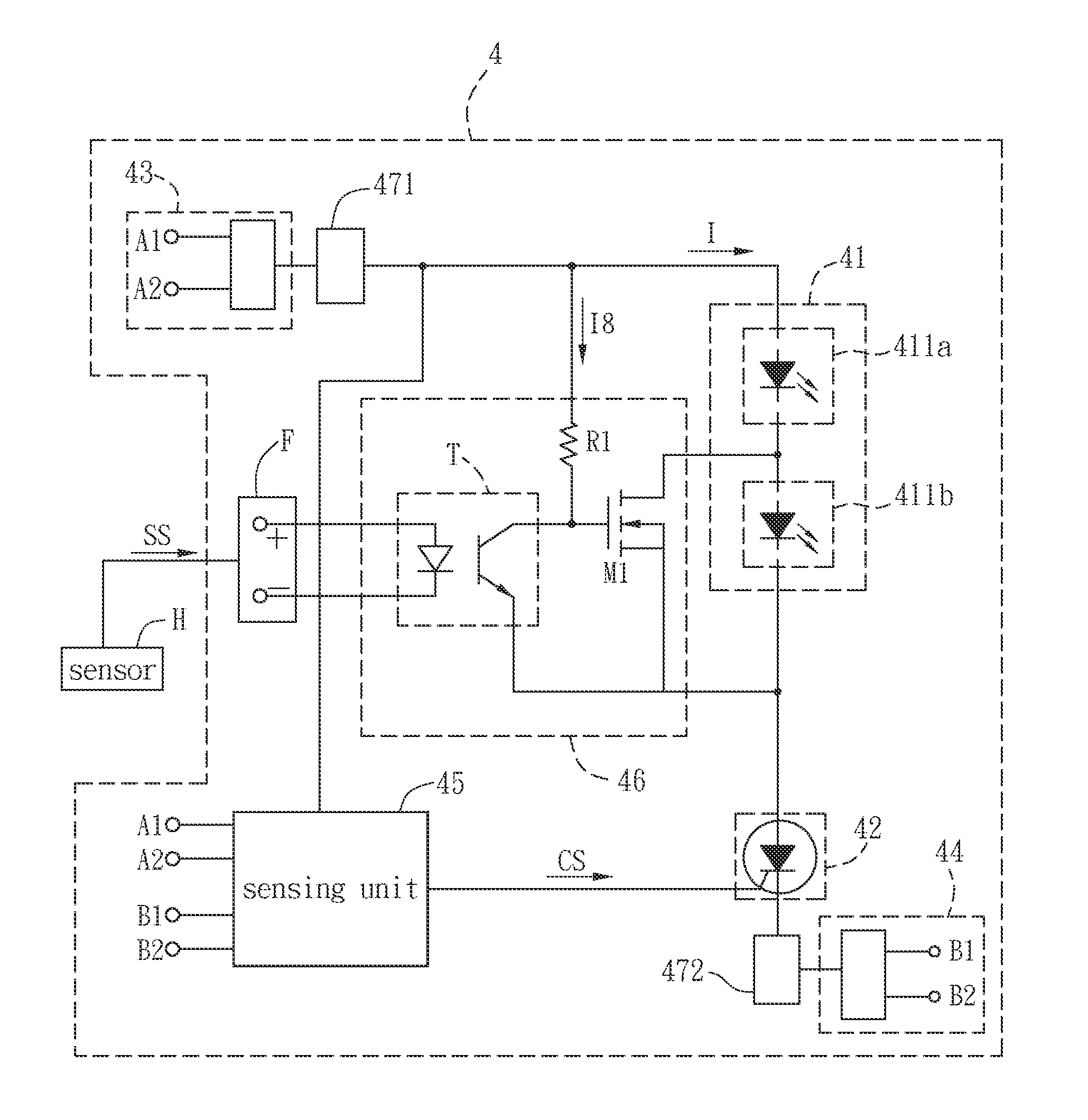

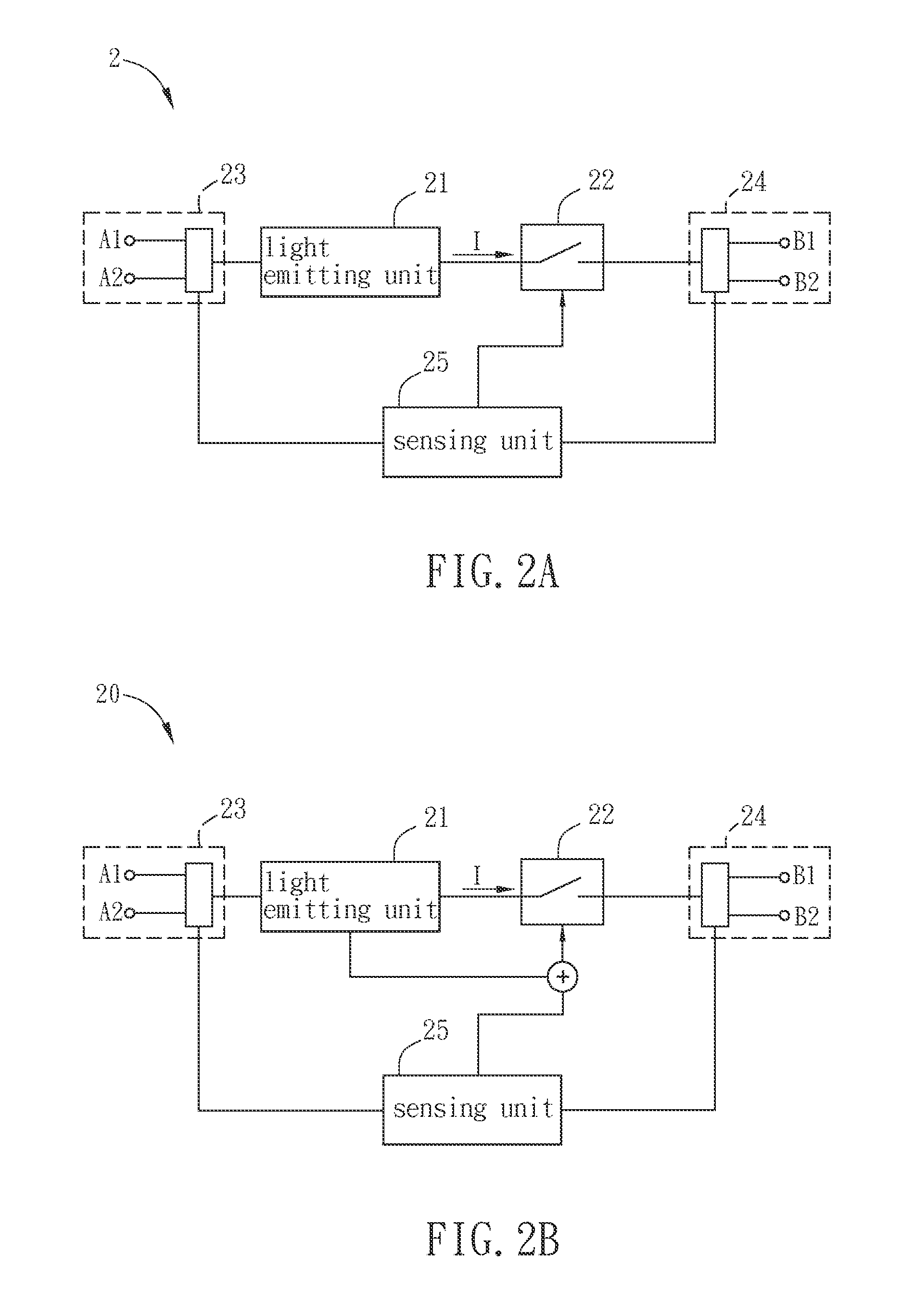

A light emitting apparatus receives an external power. A switching unit is electrically connected with a light emitting unit to form a serial circuit. A first electrical connection element is electrically connected with the external power and the light emitting unit. A second electrical connection element is electrically connected with the external power and the switching unit. A sensing unit is electrically connected with the first electrical connection element, the second electrical connection element and the switching unit. When filament currents flow between two electrical input terminals of the first electrical connection element and between two electrical input terminals of the second electrical connection element, the sensing unit controls the switching unit to turn on to enable the light emitting unit to receive the external power and start to emit light. Thus, users can avoid the risk of electric shock when installing the light emitting apparatus.

Owner:GIO OPTOELECTRONICS CORP

Surface nano tip array and its preparing method

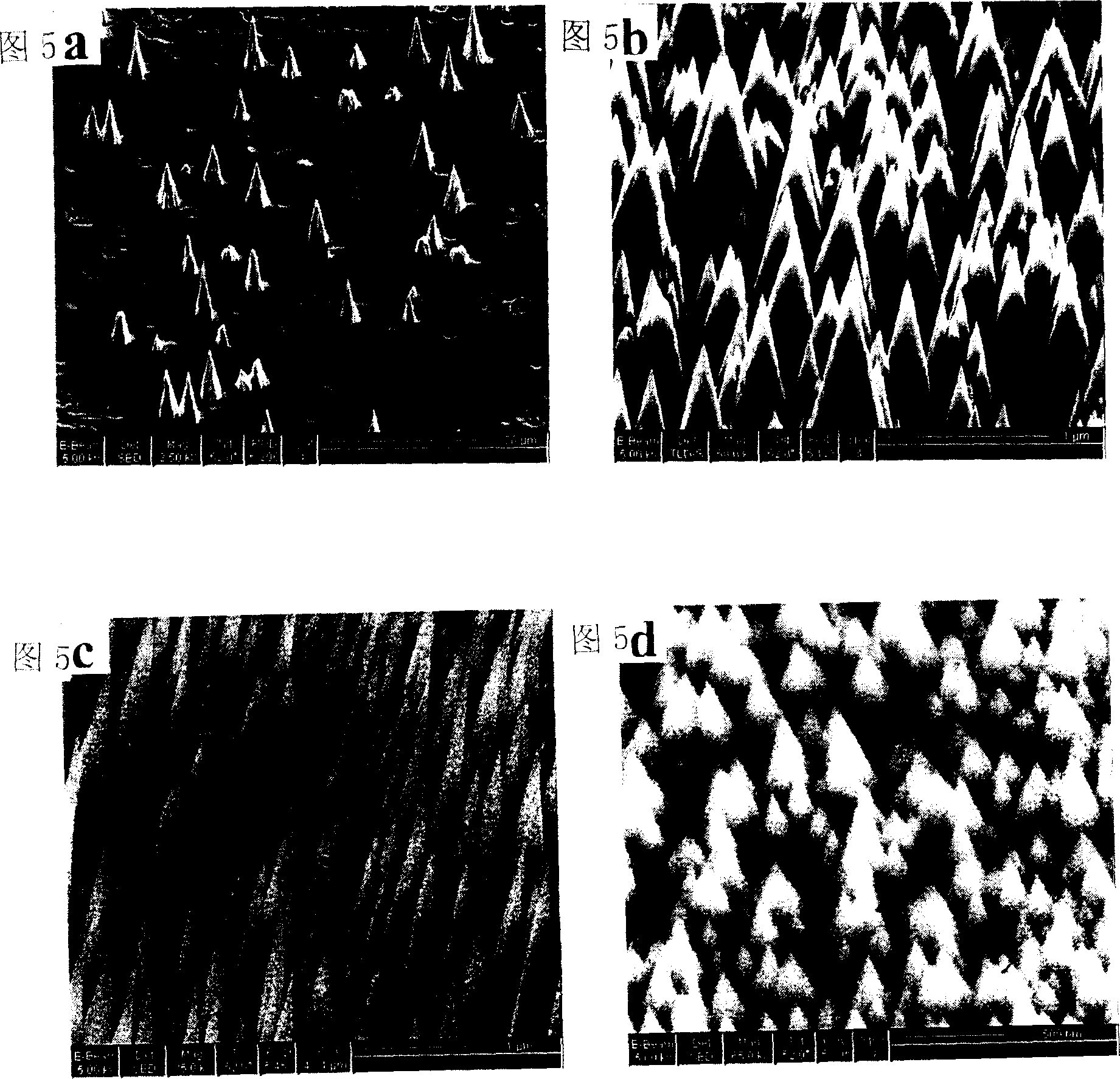

InactiveCN1978310AControllable aspect ratioSmall tip curvature radiusIndividual molecule manipulationGas phaseDiameter ratio

This invention relates to a surface nm cone array and its manufacturing method, in which, said surface nm conical array is formed by applying a plasma etching technology and preparing nm conical array on a substrate with the major diameter ratio between 50-8000, the curvature radius on the tip lower than 5 nm, the bottom diameter of 200-2000 nm, the cone angle of 16-72 deg. and the density of 109 cm2-105 cm2, the preparation method includes: putting it in a CVD device after cleaning the substrate in a biased chemical gas phase deposition device, vacuumizing it to 10-2 Torr, applying plasma pre-etching process, then turning off the bias and filament current then to re-vacuumize it to 10-2 Torr then to etch it to form a surface nm cone array.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

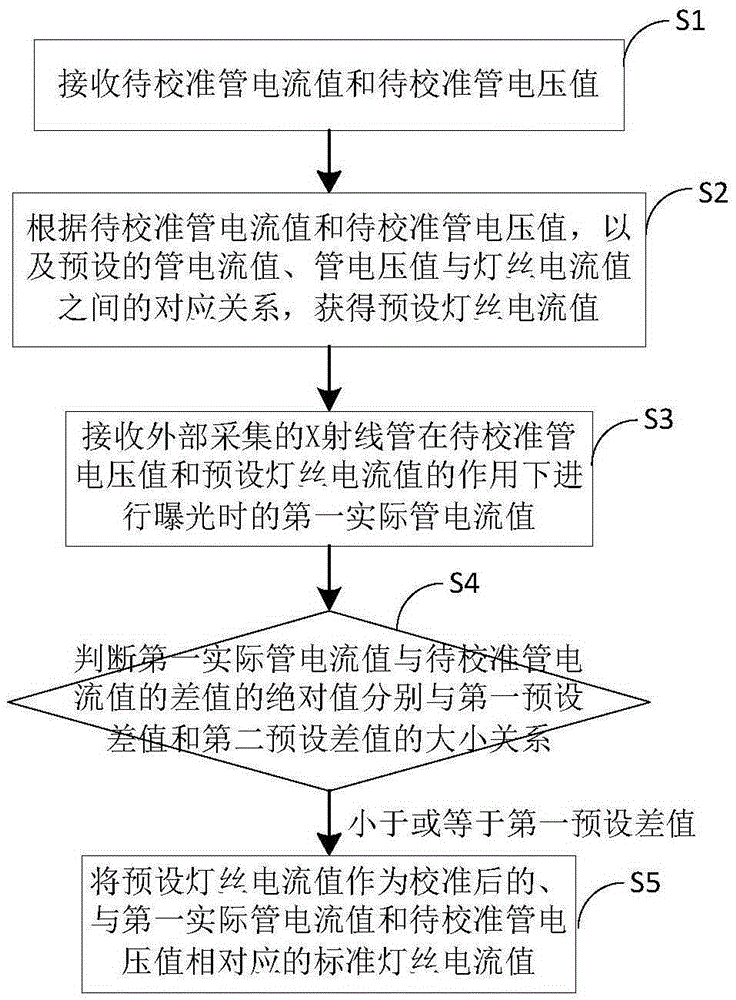

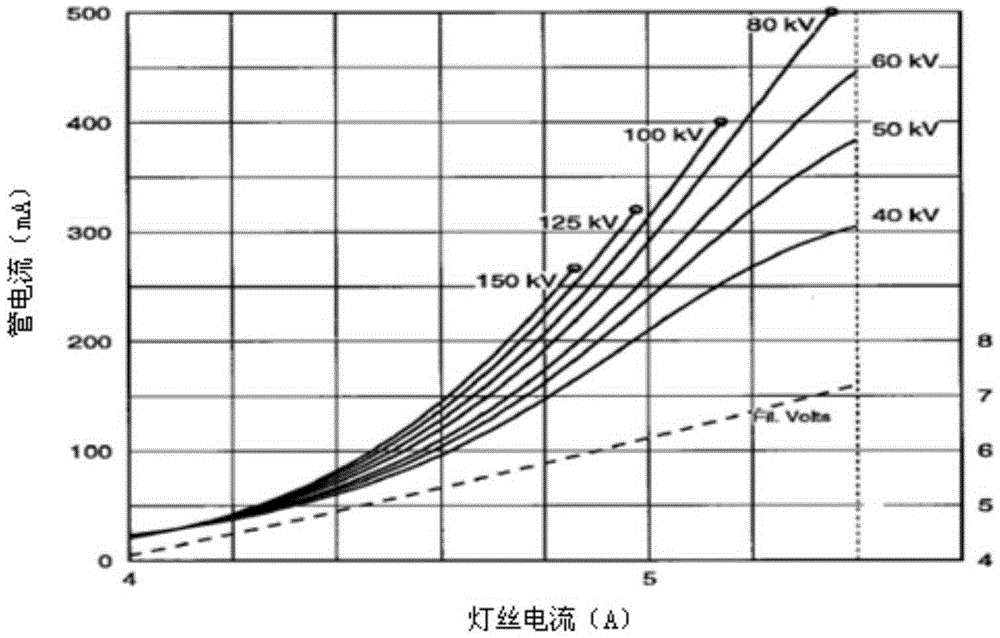

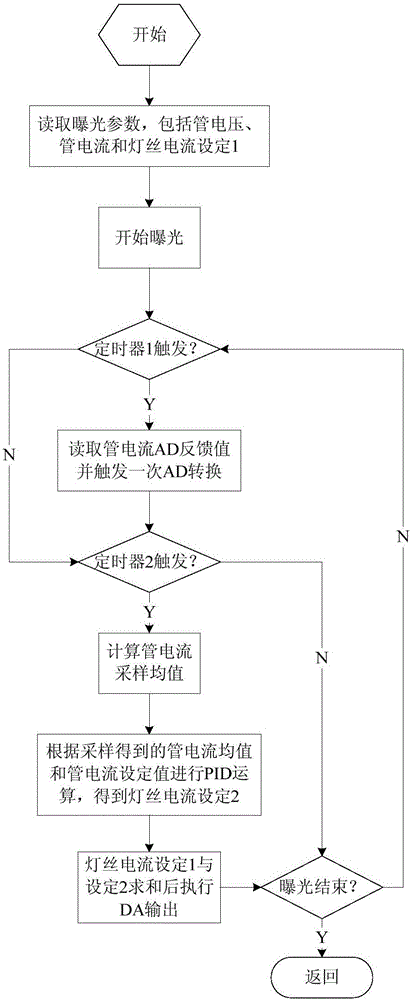

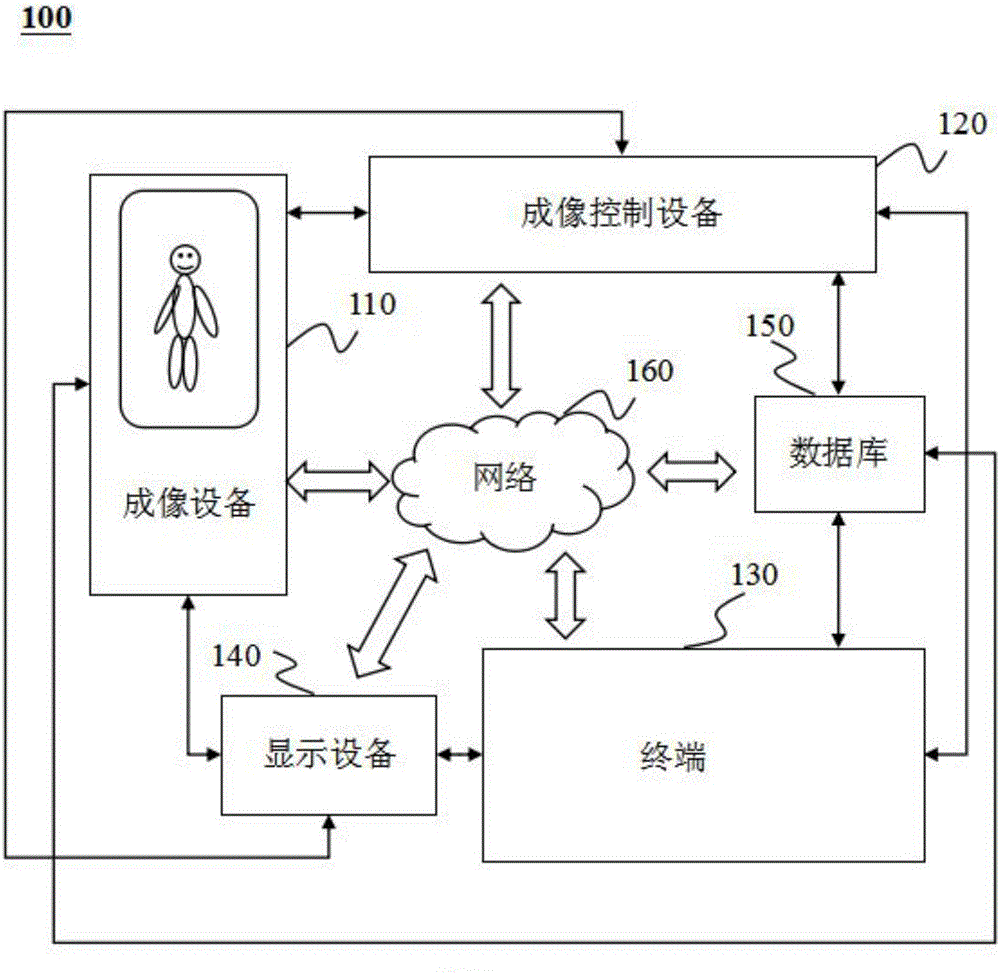

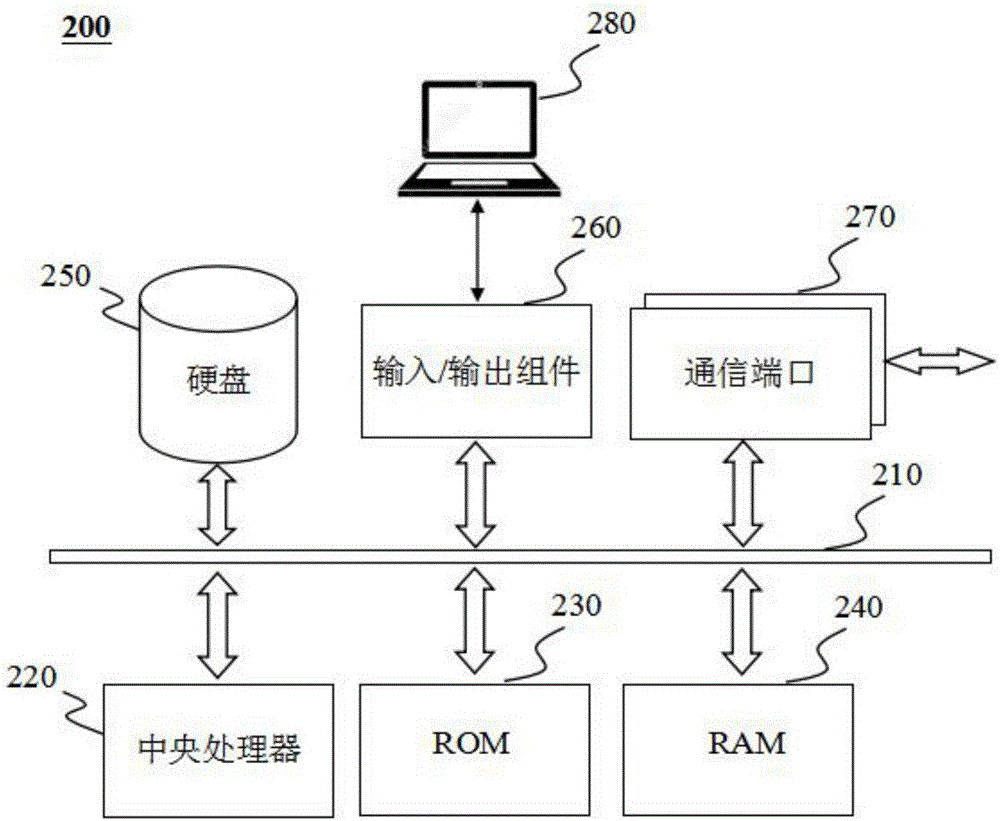

Filament current value calibration method and device for X-ray tube

ActiveCN105430858AReduce exposureDon't waste lifeComputerised tomographsTomographyFilament currentLife length

The invention discloses a filament current value calibration method and device for an X-ray tube, and the method comprises the steps: receiving a few of to-be-calibrated tube current values and to-be-calibrated tube voltage values; obtaining a preset filament current value according to the to-be-calibrated tube current values, the to-be-calibrated tube voltage values, and the relation among a preset tube current value, a preset tube voltage value and the filament current value; receiving a first actual tube current value, collected externally, of the X-ray tube under the action of the to-be-calibrated tube voltage values and the preset filament current value during exposure; judging the size relation between the absolute value of the difference, between a first actual tube current value and the to-be-calibrated tube current value, and a first preset difference value, and the size relation between the absolute value of the difference, between the first actual tube current value and the to-be-calibrated tube current value, and a second preset difference value; and enabling the preset filament current value to serve as a calibrated standard filament current value corresponding to the first actual tube current value and the to-be-calibrated tube voltage value when the absolute value is less than or equal to the first preset difference value. The method is small in number of exposure times, and does not cause the service life of the X-ray tube to be reduced.

Owner:SUZHOU POWERSITE ELECTRIC CO LTD

Random waveform X-ray generating device and generation method

The invention relates to a random waveform X-ray generating device and a generation method. The random waveform X-ray generating device comprises a random signal generator used for generating high-stability random waveform, a grid-control X-ray bulb tube power supply system and a grid-control X-ray bulb tube of a working power supply used for providing grid-control X-ray bulb tube filament current, grid electrode control signals and anode high voltage. The grid-control X-ray bulb tube uses the electric signals generated by the random signal generator to control electron beams in the X-ray bulb tube emitted by filament to the anode so as to achieve generation of X-ray of random waveform. The random waveform X-ray generating device resolves the technical problem that only X-ray with single waveform can be generated in the prior art, is a high-stability random waveform X-ray generating device, aims at achieving generation of high-stability random waveform X-ray and provides an experimental apparatus of simulating an X-ray source for a pulsar navigation ground simulation system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

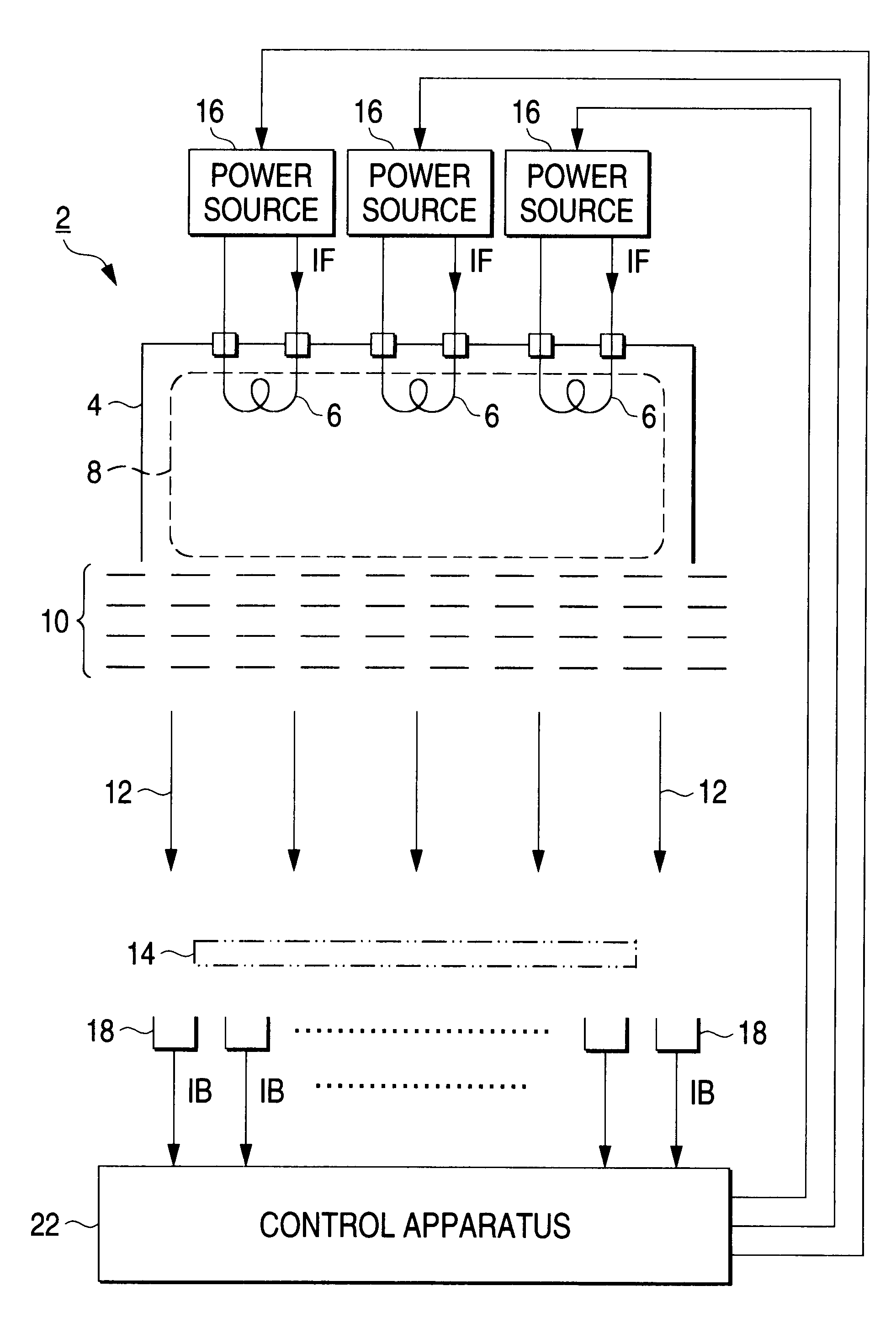

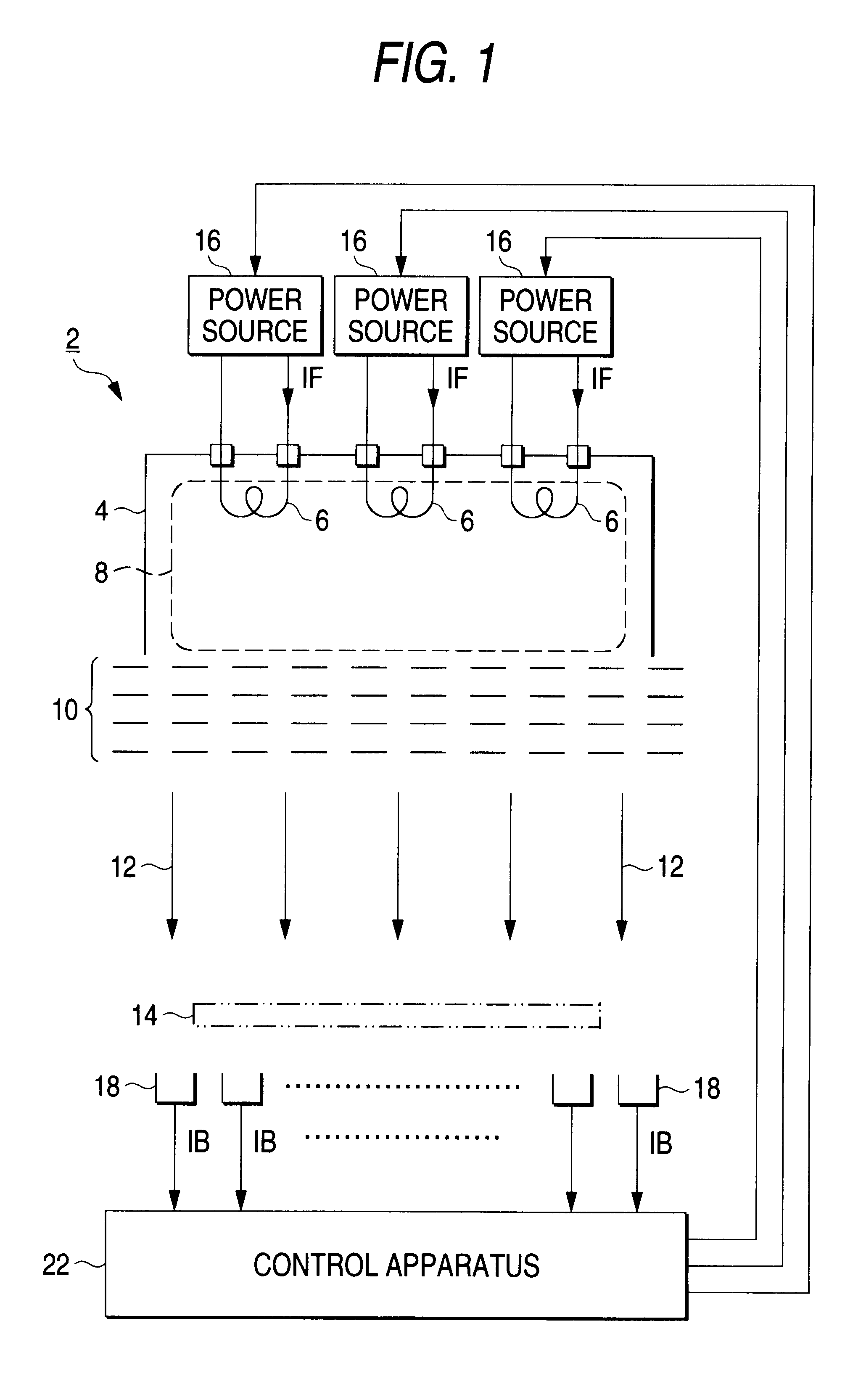

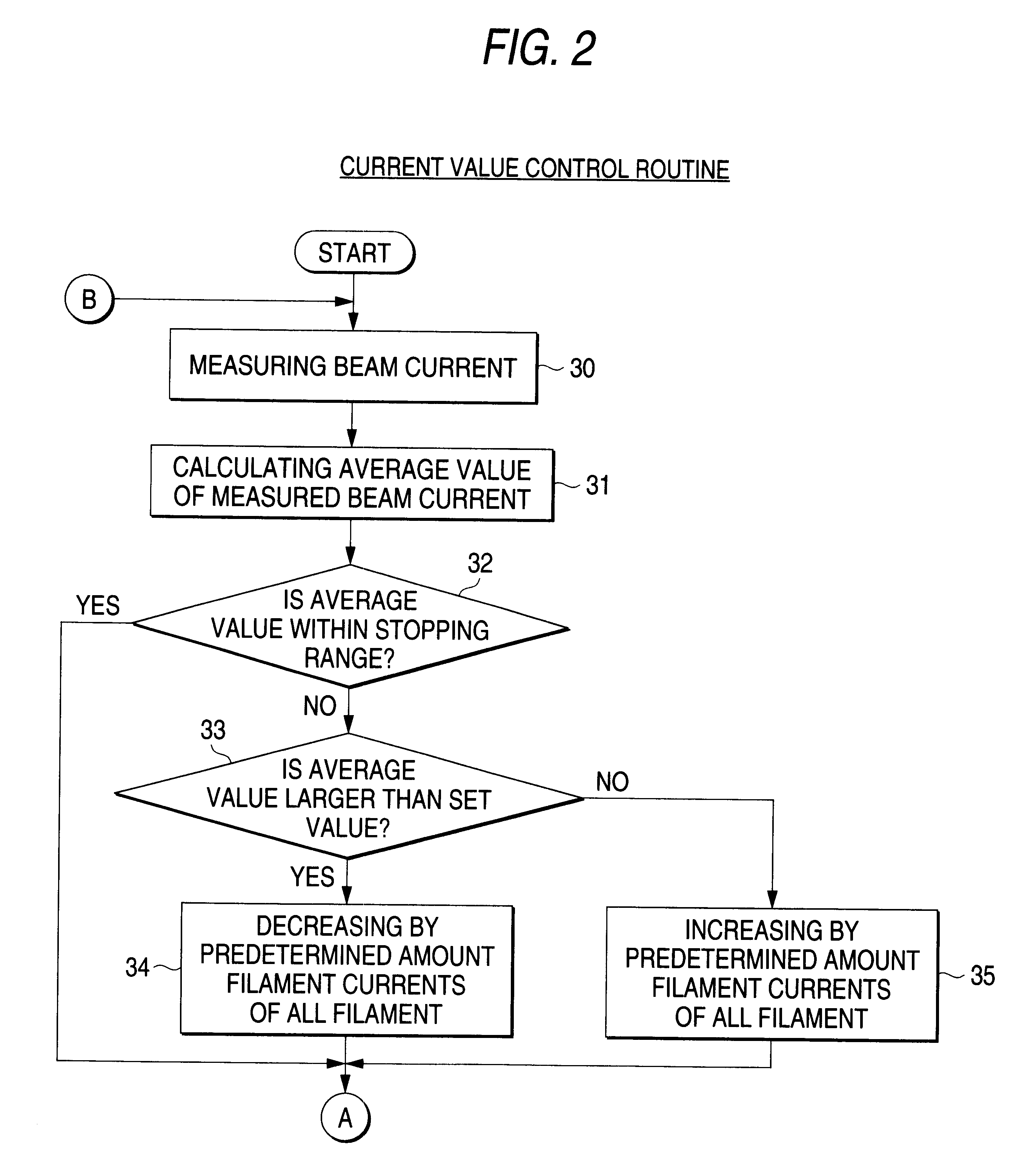

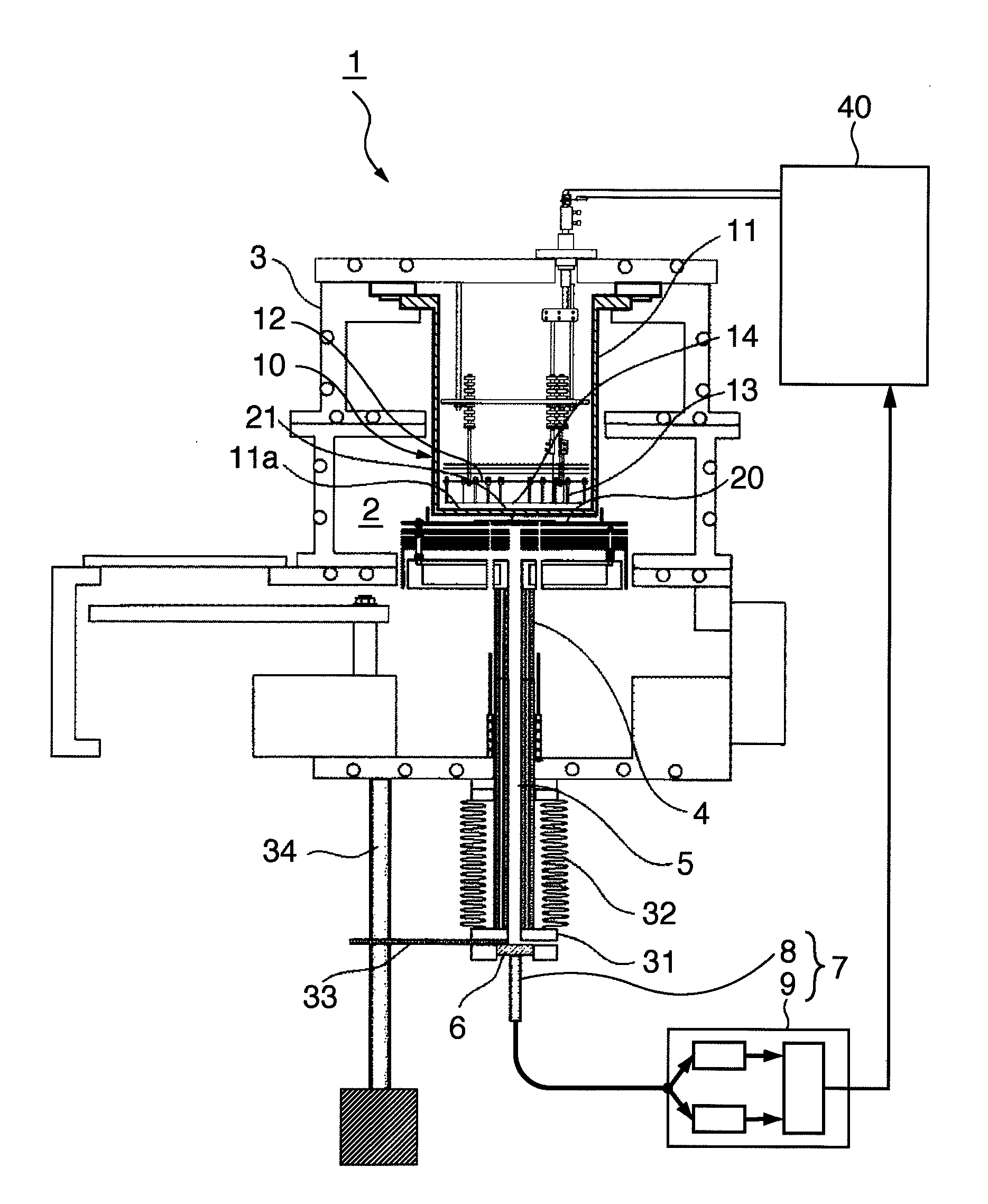

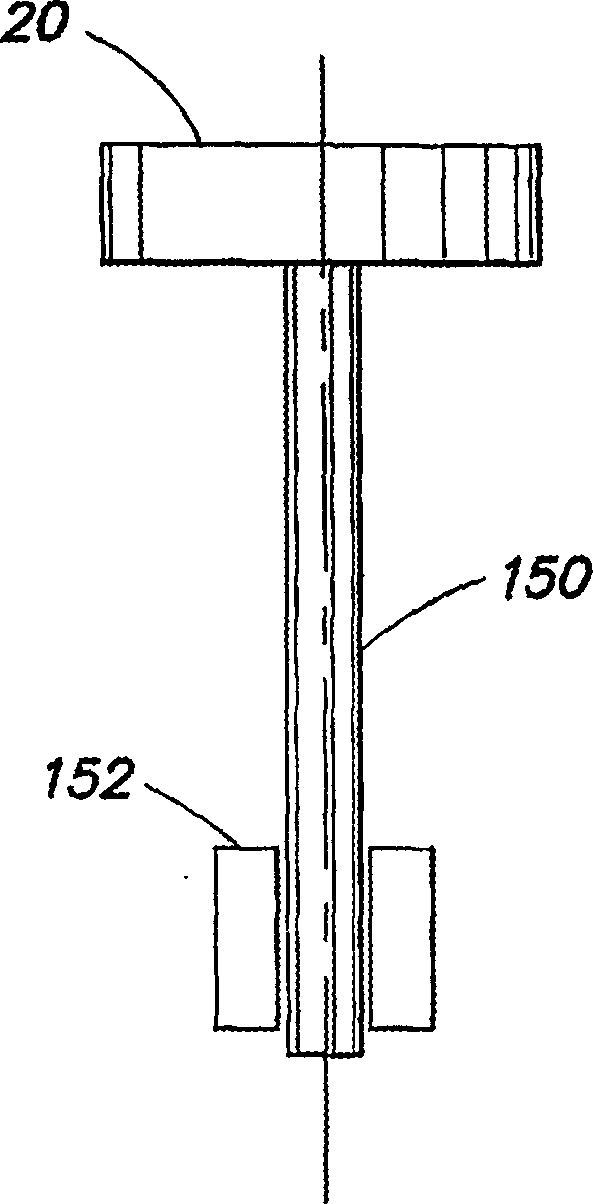

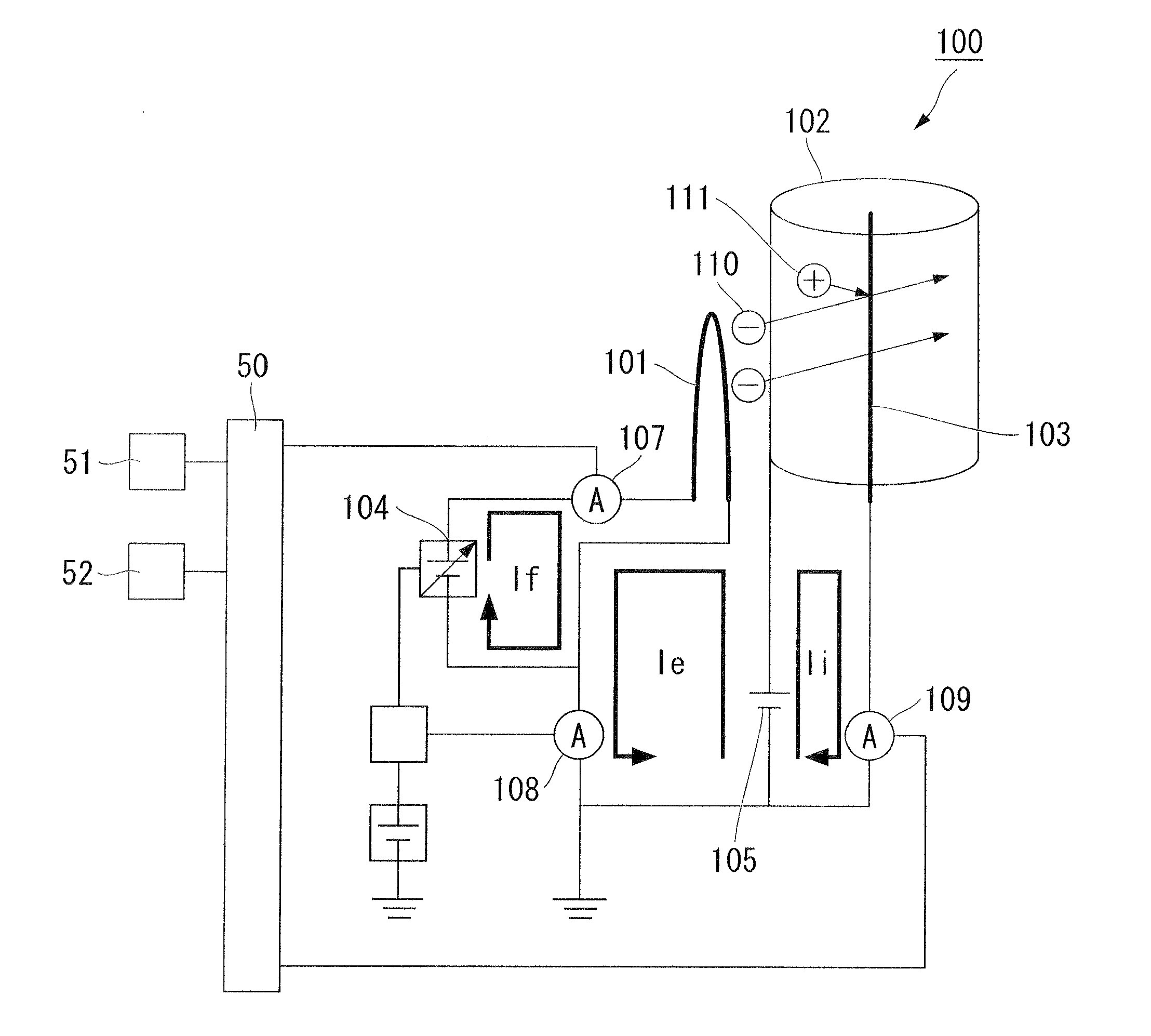

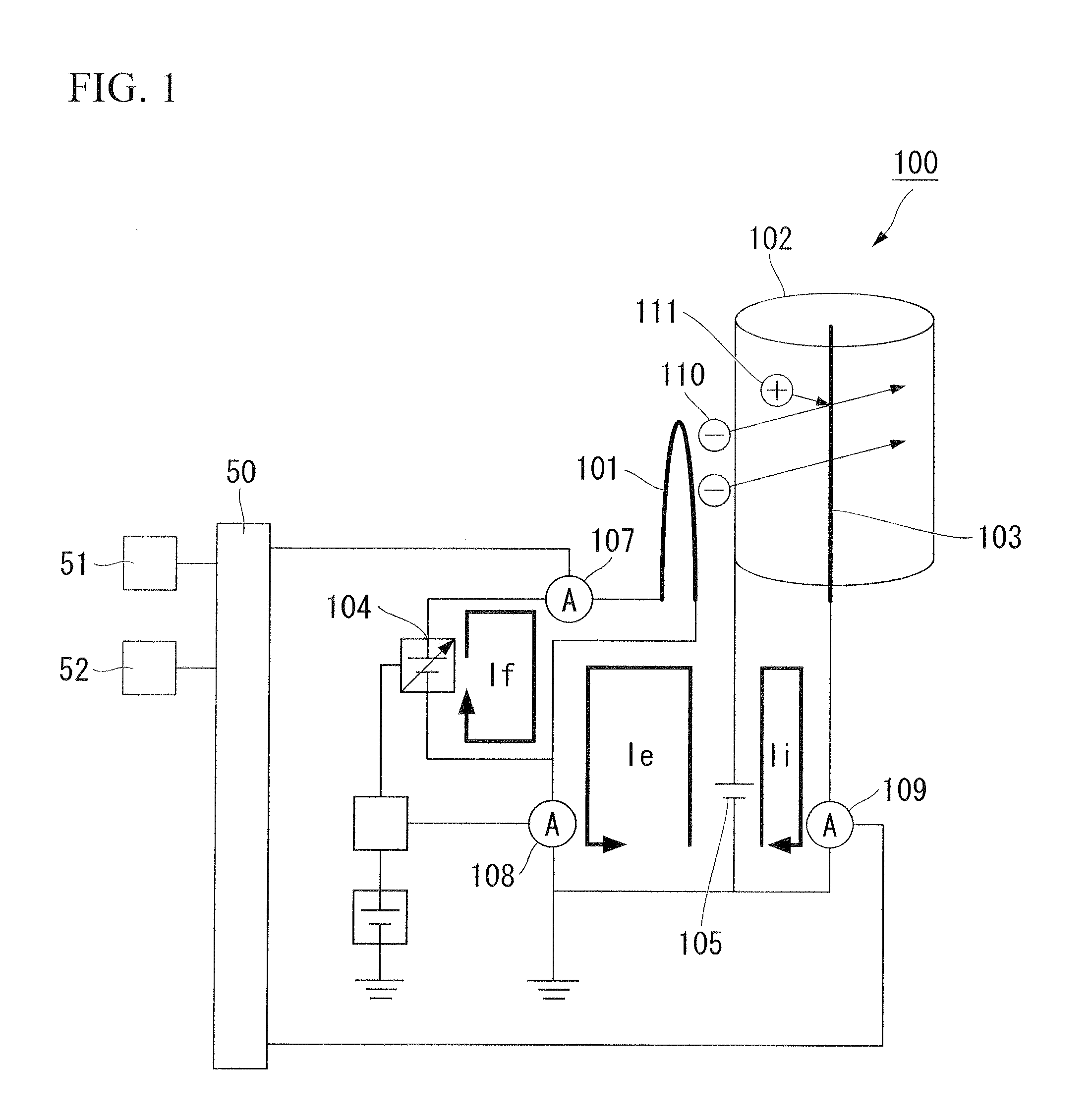

Ion implanting apparatus

An ion implanting apparatus is provided with a control apparatus 22 for controlling the filament current passing to the respective filaments 6 in accordance with the beam current IB measured by a plurality of beam current measuring instruments 18. The control apparatus 22 performs, at least once respectively, {circle around (1 the current value control routine which calculates average values of all beam current measured by the beam current measuring instruments 18, and increases and decreases the respective filament current IF such that the average value comes near to the set value, and {circle around (2 the uniformity control routine which groups the beam current measuring instruments 17 into the number of the filaments, seeks for a maximum value and the minimum value from all the measured values of the beam current IB, decides groups to which the maximum value and the minimum value belong, decreases the filament current IF passing to the filaments 6 corresponding to the maximum value, and increases the filament current IF passing to the filaments 6 corresponding to the minimum value.

Owner:NISSIN ION EQUIP CO LTD

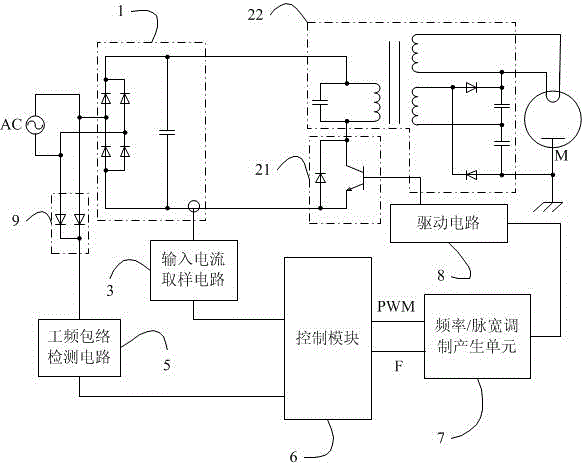

Control method for frequency-conversion power supply circuit starting process of magnetron

InactiveCN104811053AReduce overvoltageReduce overcurrent impactConversion with intermediate conversion to dcInduction heating controlDriver circuitElectricity

The invention provides a control method for the frequency-conversion power supply circuit starting process of a magnetron. The method comprises the steps that s1) after electrification, a switch control signal is sent to a drive circuit in the initial minimal pulse width value and the initial switch frequency value, and at the same time, a sampling signal is output to a control module; s2) the pulse width of the switch control signal is increased gradually till the filament power of the magnetron reaches a preset basic power value for filament heating; s3) whether the anode current of the magnetron is increased and the increase amount are determined, the pulse width of the switch control signal is increased and the frequency of the switch control signal is reduced if the anode current is increased, and the pulse width and the frequency of the switch control signal are maintained if the anode current is not increased; and s4) whether the anode power of the magnetron reaches an oscillation-starting power threshold of the magnetron is determined, if the threshold is not reached, the s3) is returned to, and if the threshold is reached, the starting process is completed. The control method can be used to control the filament current during starting within the specification of the magnetron, and ensure that starting is completed in the standard prescribed time of the product.

Owner:FUZHOU GOLDENCHIP POWER SUPPLY TECH

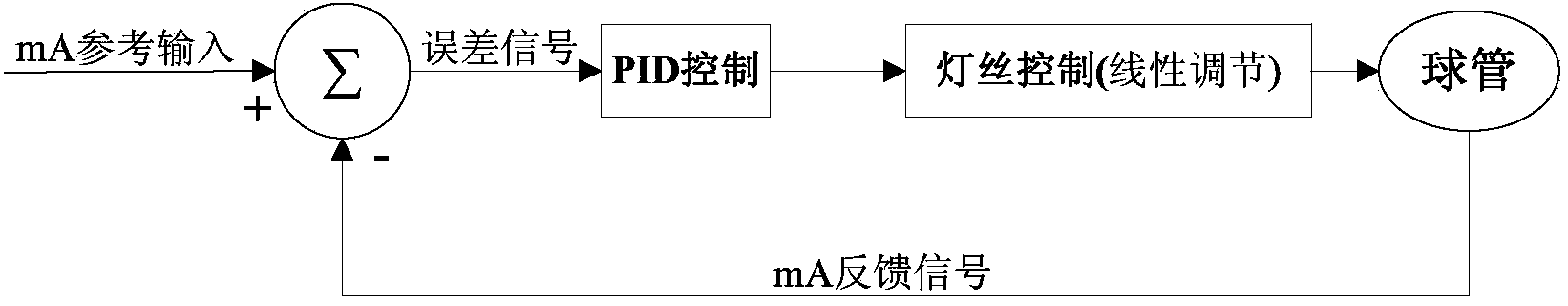

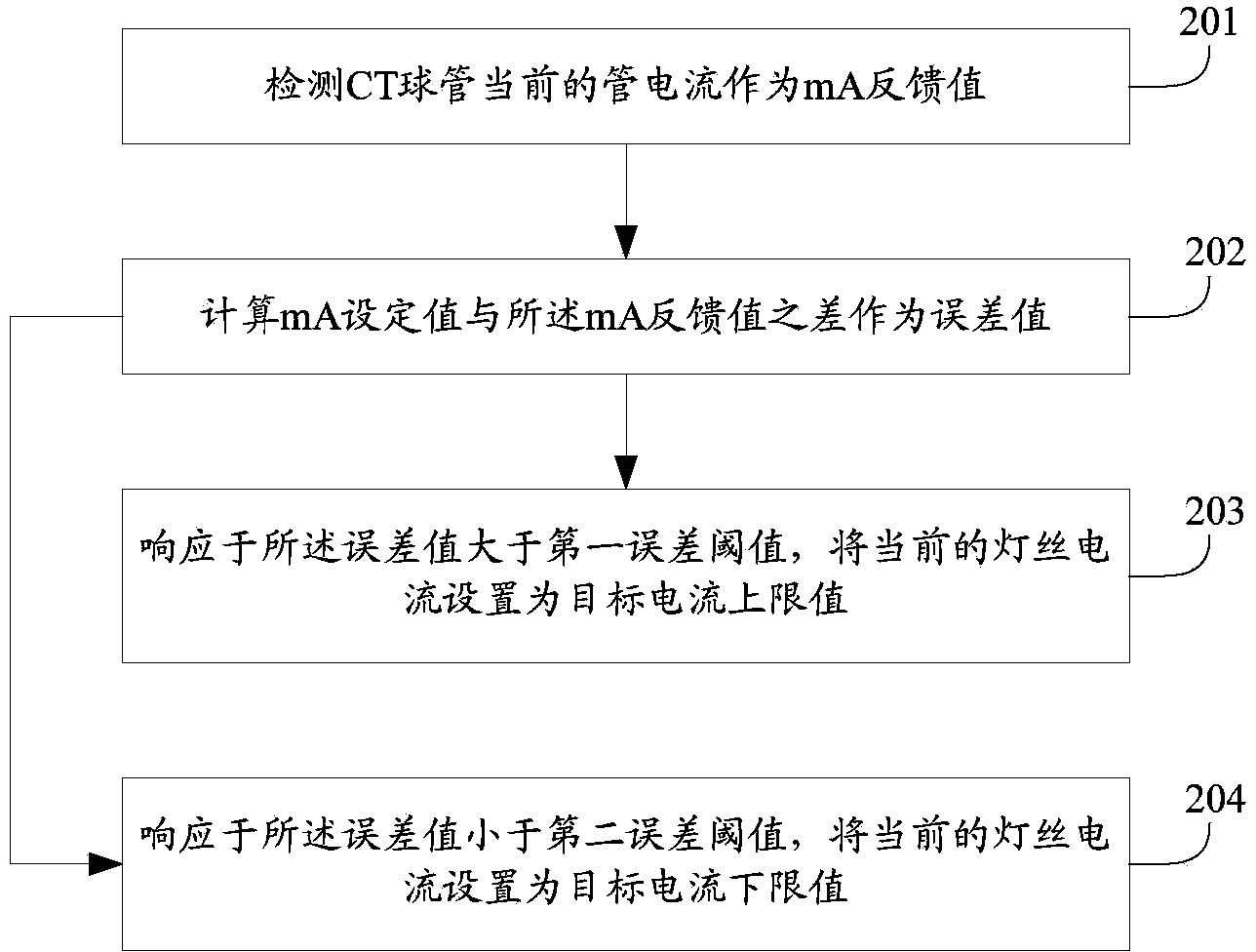

Method and device for controlling filament current in CT bulb tube

The embodiment of the invention discloses a method for controlling filament current in a CT bulb tube. The method comprises the steps of detecting current tube current of the CT bulb tube and using the tube current as an mA feedback value; calculating the difference of an mA set value and the mA feedback value and using the difference as an error value; setting current filament current as a target current upper limit value if the error value is greater than a first error threshold value; setting the current filament current as a target current lower limit value if the error value is smaller than a second error threshold value, wherein the target current upper limit value is greater than the target current lower limit value, the first error threshold value is greater than 0, and the second error threshold value is smaller than 0. By means of the technical scheme, the change speed of actual tube current can rapidly follow the change of the mA set value, and accordingly quick adjustment of radiation dosage is achieved. In addition, the embodiment of the invention further provides a device for controlling the filament current in the CT bulb tube.

Owner:NEUSOFT MEDICAL SYST CO LTD

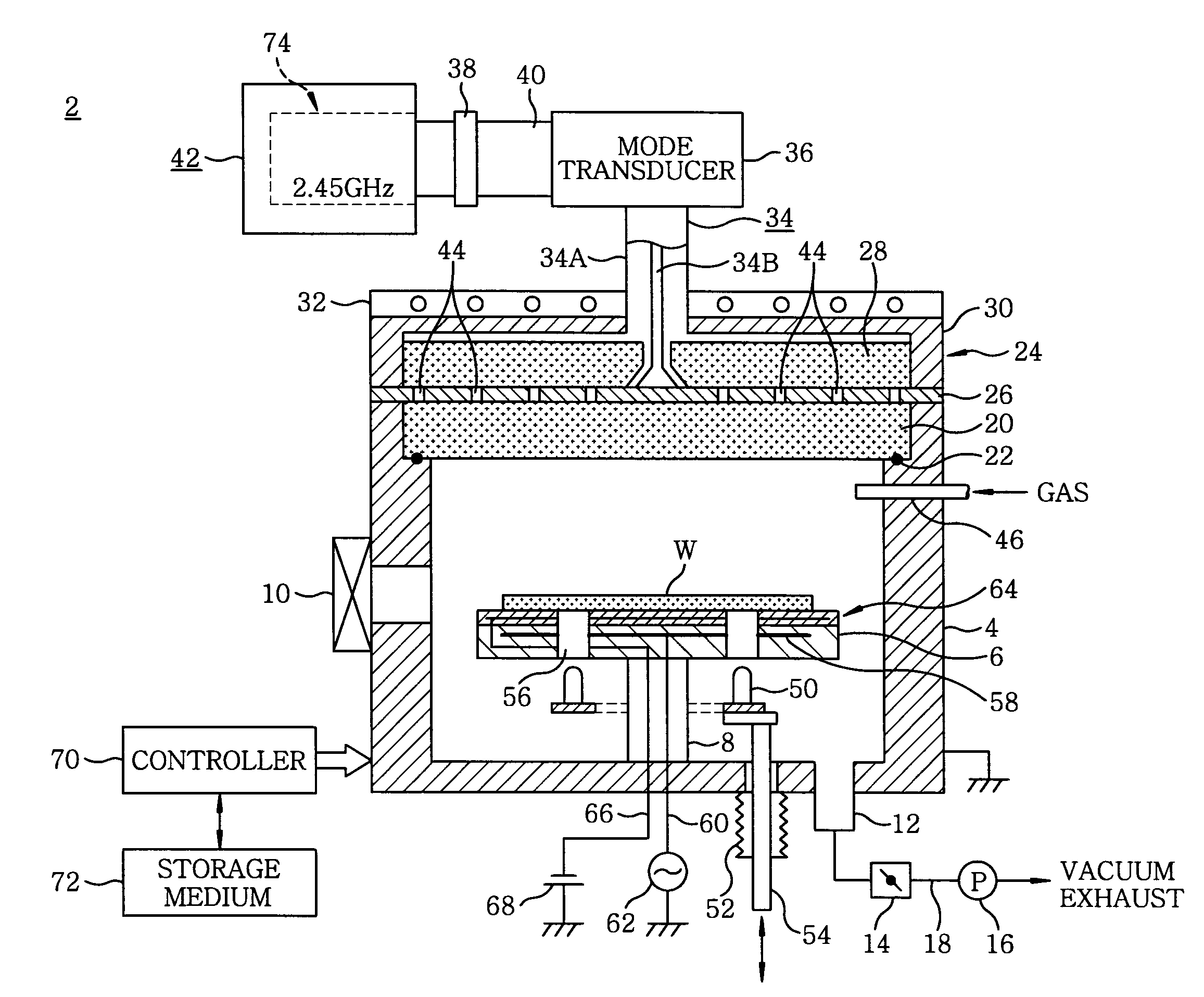

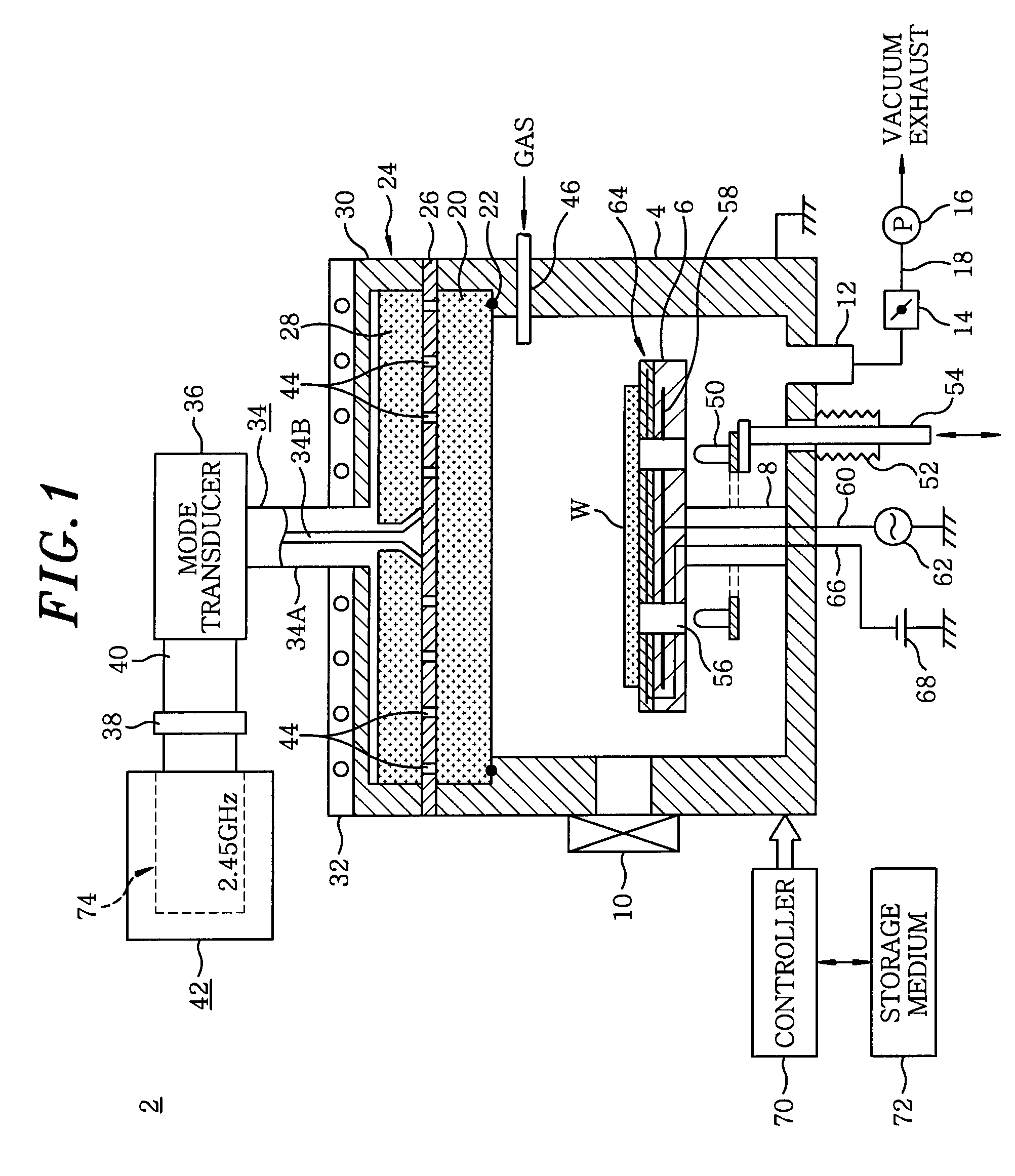

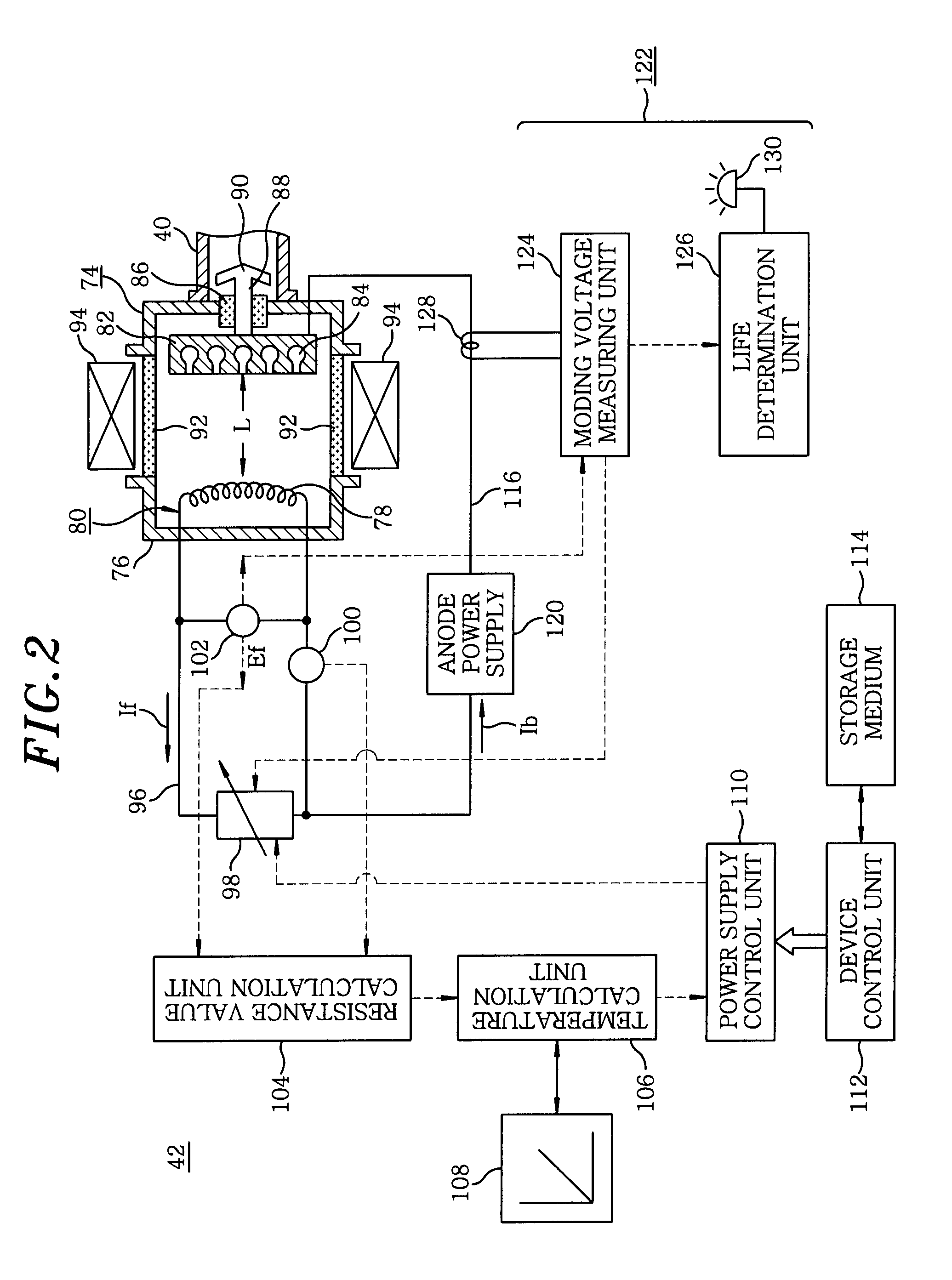

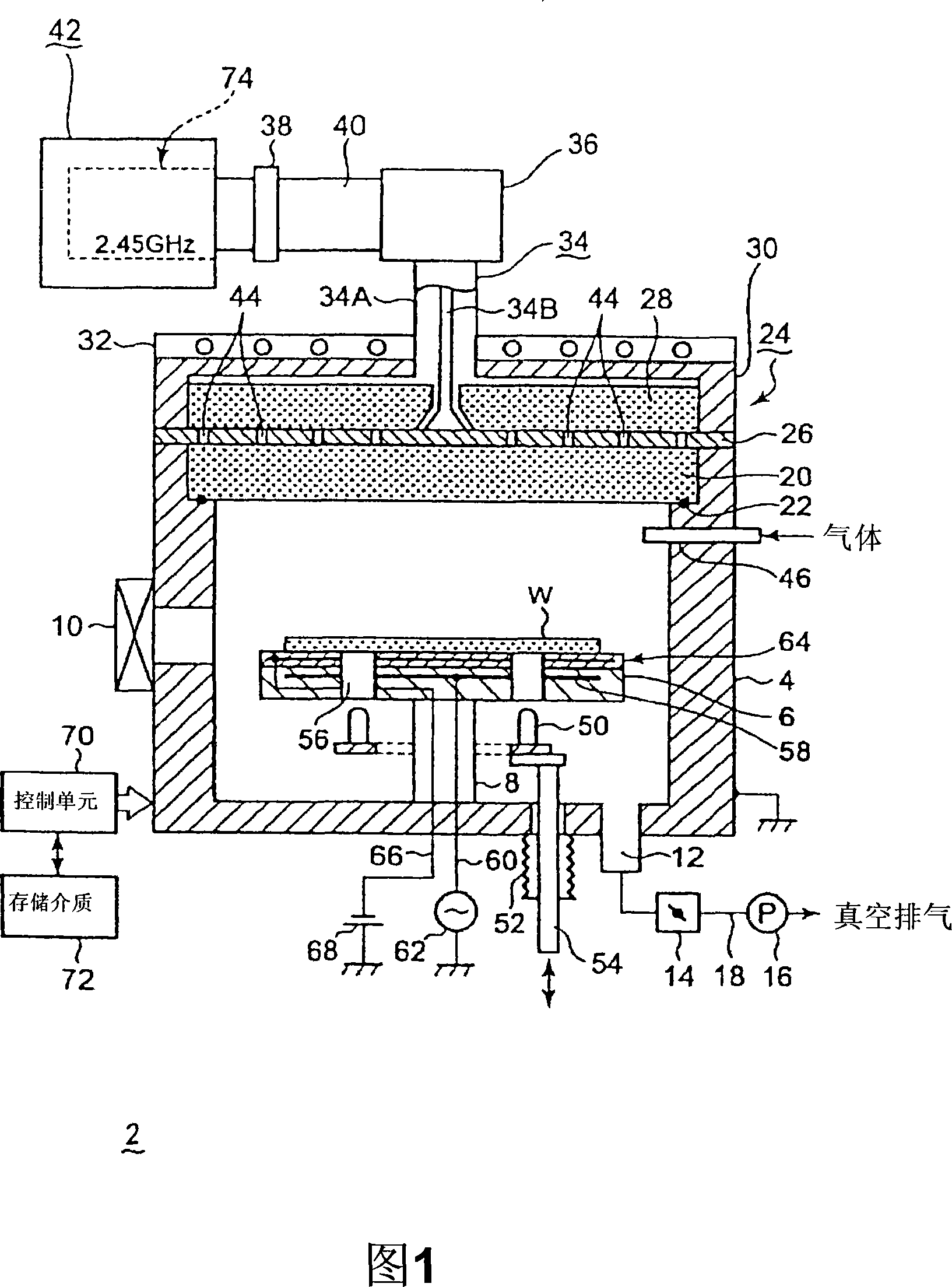

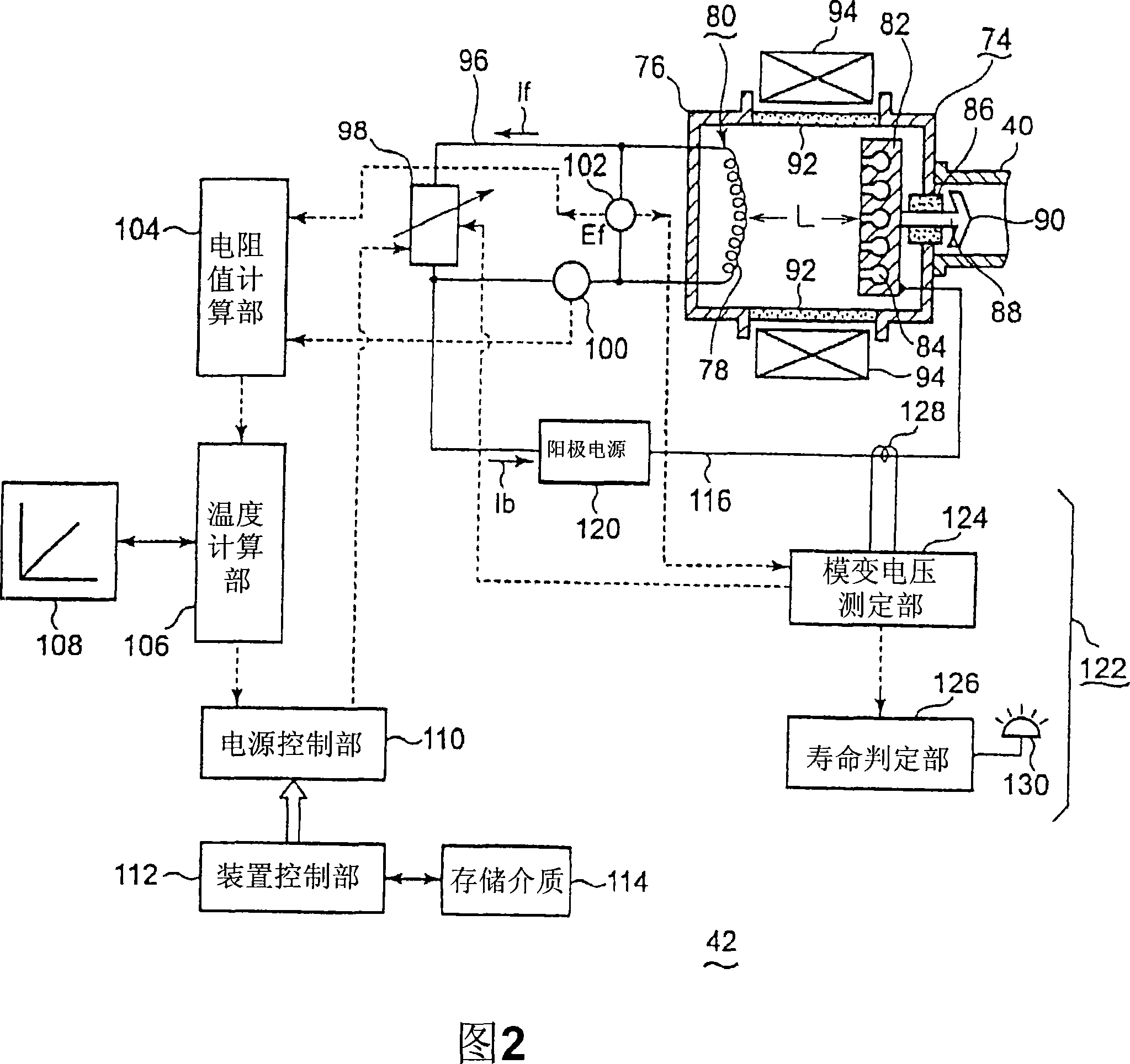

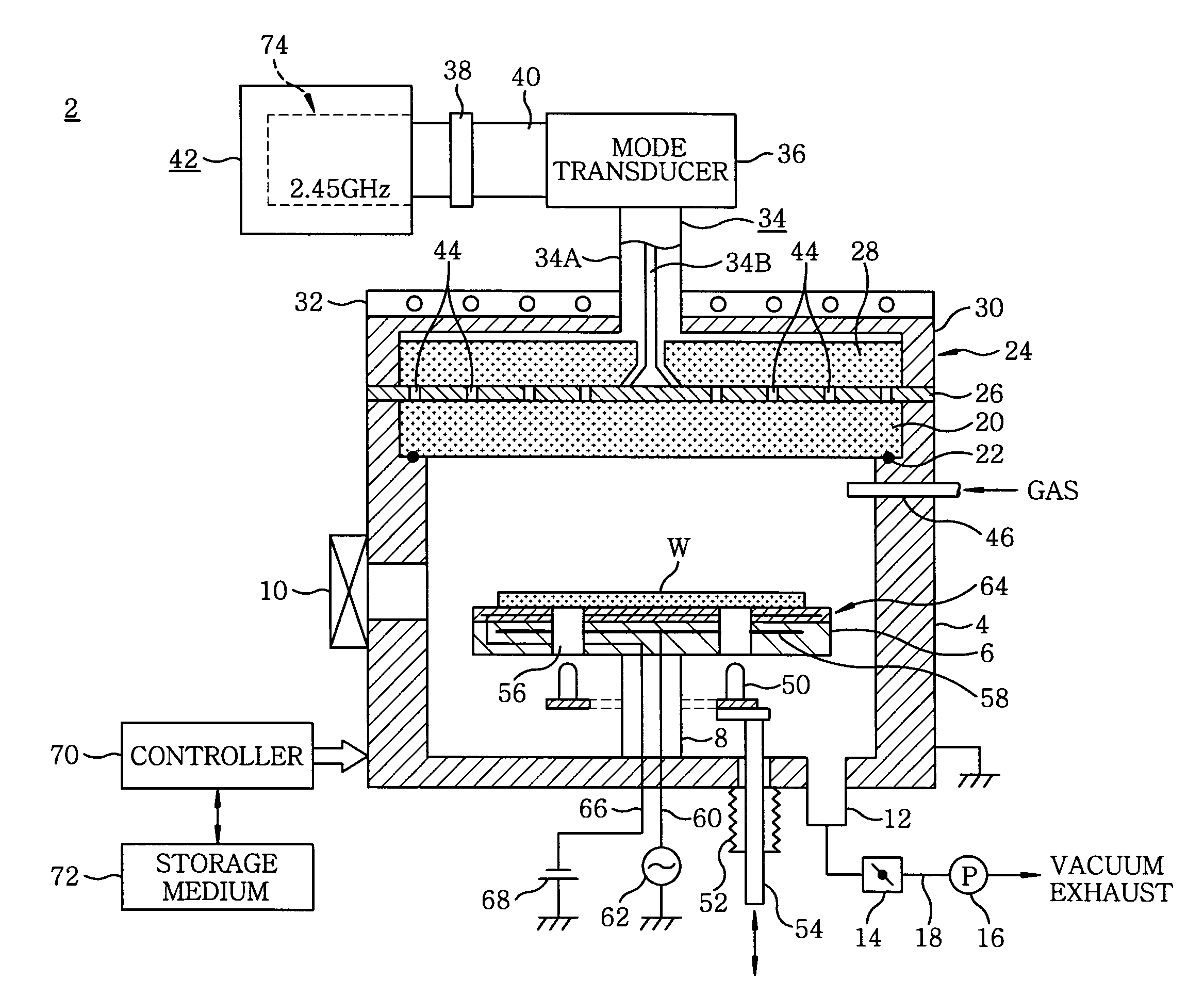

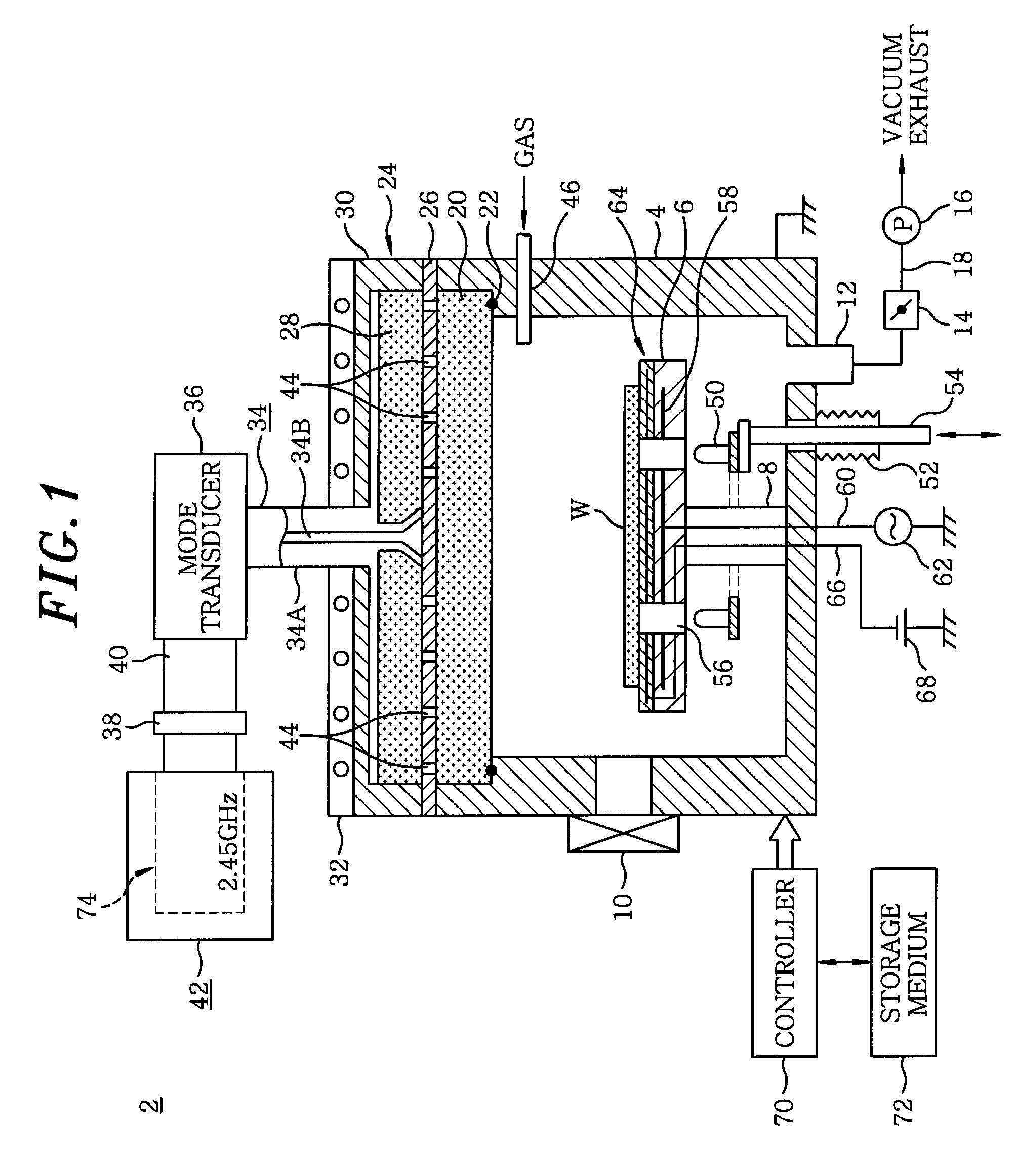

Magnetron control method, magnetron service life judgment method, microwave generation device, magnetron service life judgment device, processing device, computer program, and storage medium

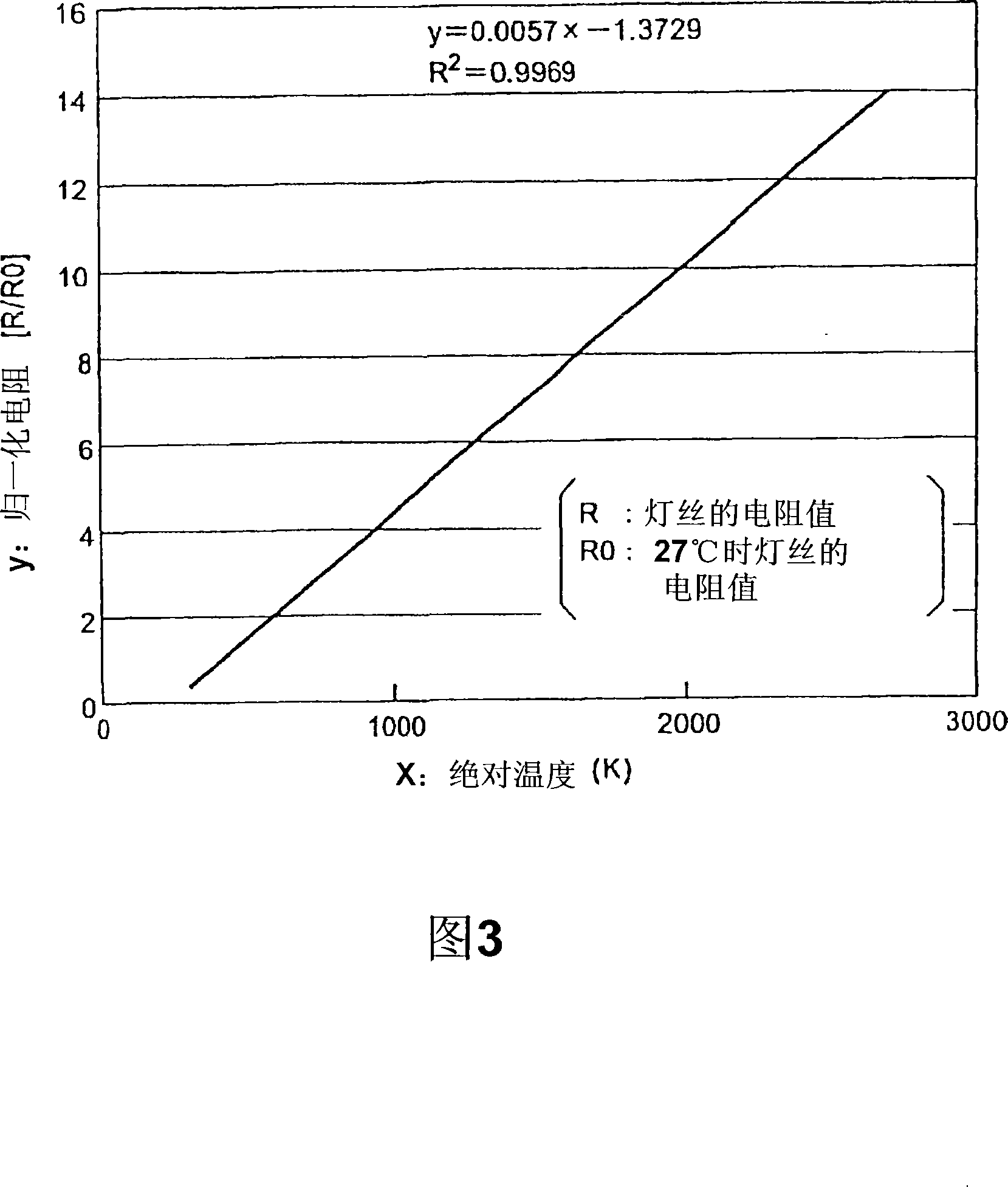

InactiveUS20080309239A1Extended service lifeImprove accuracyMagnetronsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMicrowave

A microwave generation device includes: a magnetron having a cathode containing a filament and an anode containing a hollow resonator arranged to oppose to each other; a filament current measuring unit; and an application voltage measuring unit for measuring voltage applied to the filament. Based on the current and the voltage obtained by the current measuring unit and the voltage measuring unit, a resistance value calculation unit obtains a resistance value of the filament. A temperature calculation unit calculates the filament temperature from the resistance value and the resistance-temperature dependent characteristic. A filament power source is controlled by a power control unit so that the filament temperature is within a predetermined temperature range.

Owner:TOKYO ELECTRON LTD

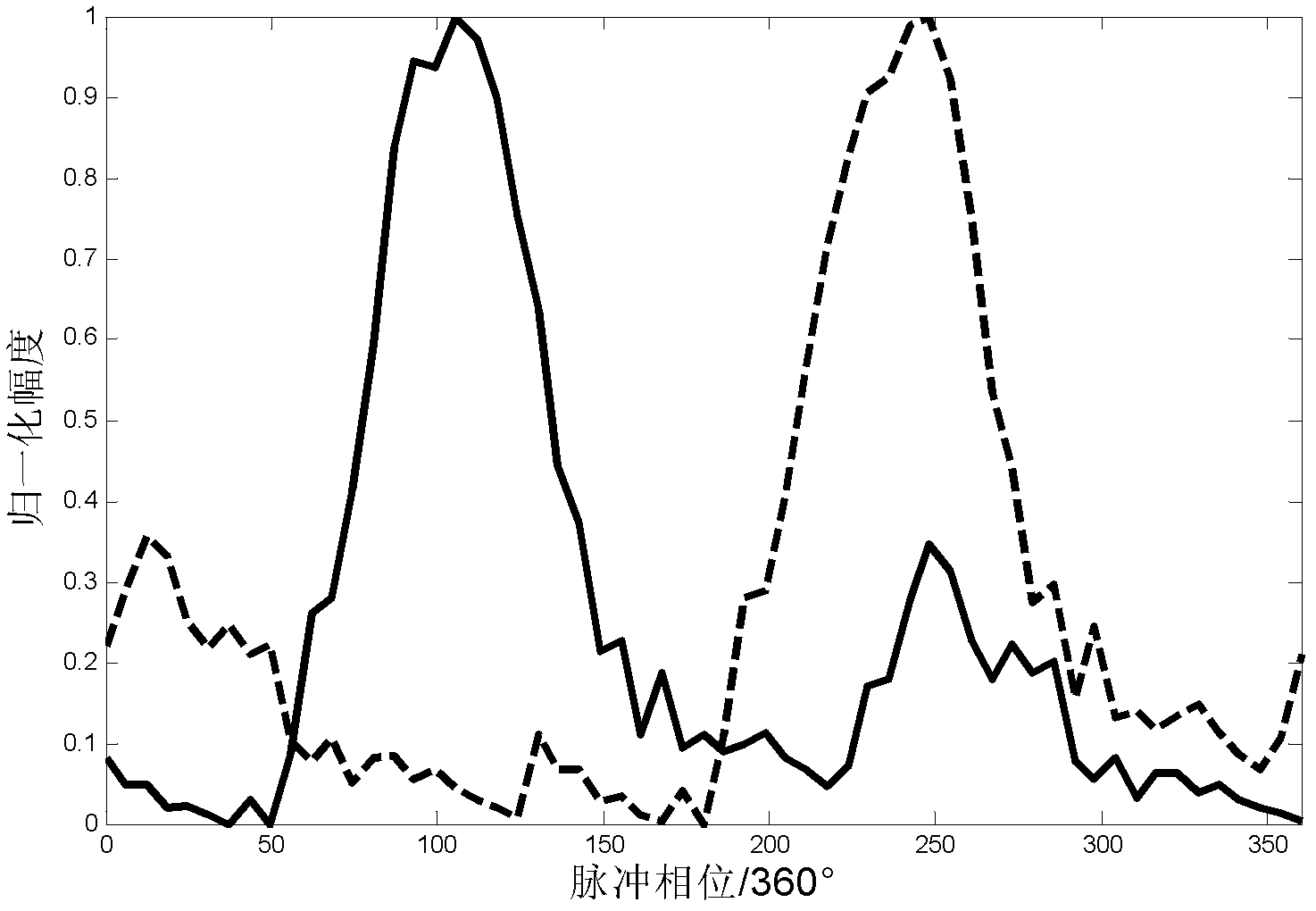

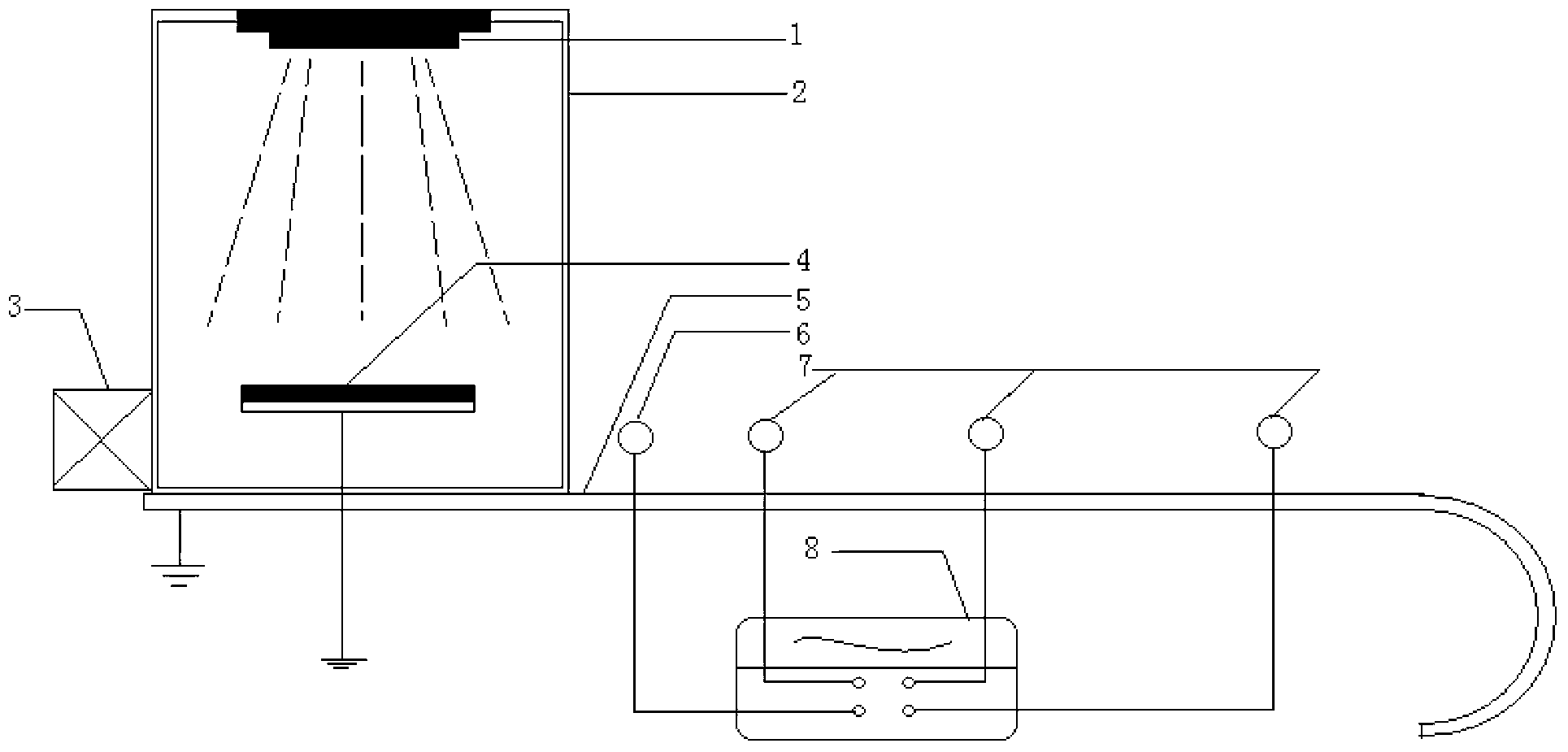

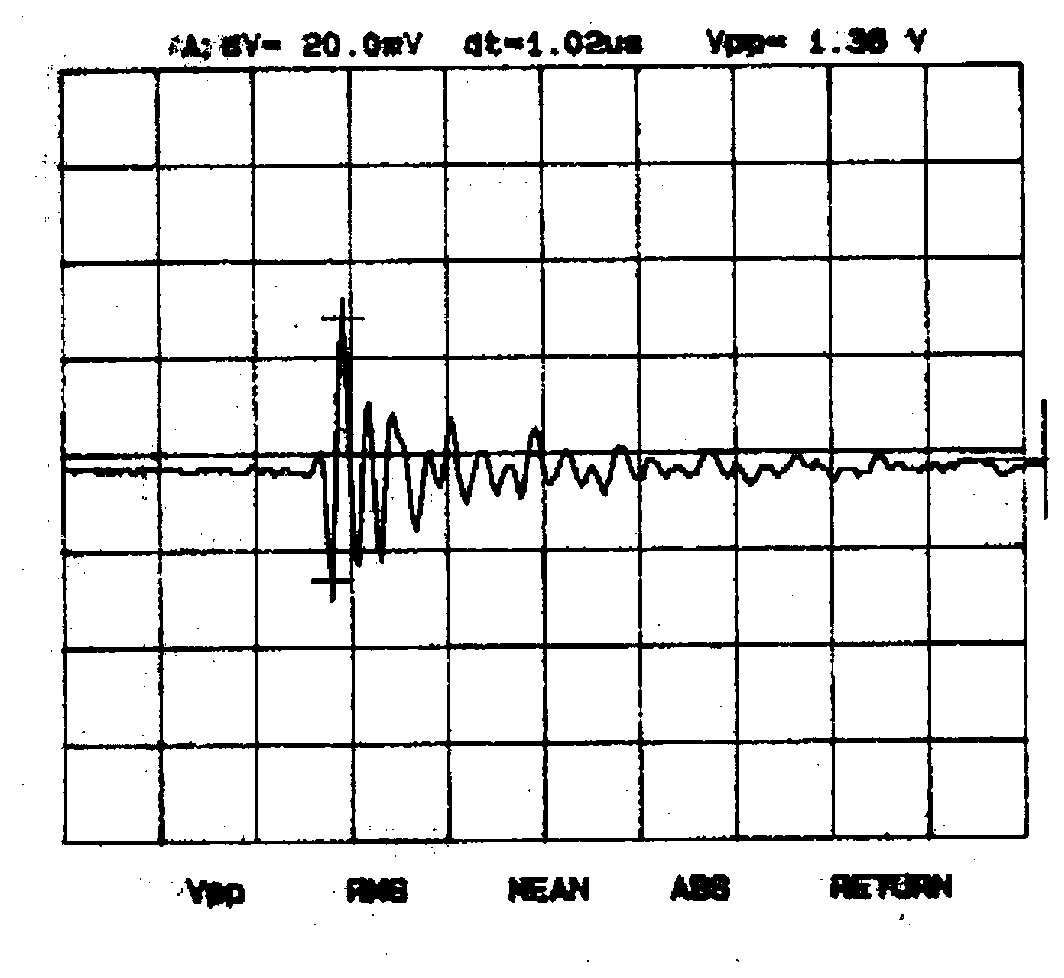

Device and method for measuring satellite material surface electrostatic discharge pulse characteristics

InactiveCN103267903AEliminate Boundary Reflection IssuesAvoid interferenceElectromagentic field characteristicsElectrostatic field measurementsMeasurement devicePulse characteristics

The invention relates to a device and a method for measuring satellite material surface electrostatic discharge pulse characteristics in the space plasma environment, and belongs to the field of measurement. The device comprises an electronic gun, a vacuum chamber, a vacuum pumping system, a grounded metal board, a reference pulse signal receiving antenna, arrayed pulse signal receiving antennas and a spectrometer. The method comprises the steps of placing satellite surface material samples into the vacuum chamber, start the vacuum pumping system, starting the electronic gun, regulating acceleration voltage and filament current of the electronic gun, conducting real-time monitoring on beams of the electronic gun by means of a Faraday cup, starting the spectrometer, respectively measuring frequency domains of discharge signals of the pulse signal receiving antennas of different positions, and conducting real-time monitoring on space distribution of discharge pulse radiation electromagnetic fields in an experiment process. An arc structure at the tail end of the grounded metal board resolves the problem of edge reflection of the radiation fields, and measurement of the space distribution of the radiation fields is conducted through the antennas.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

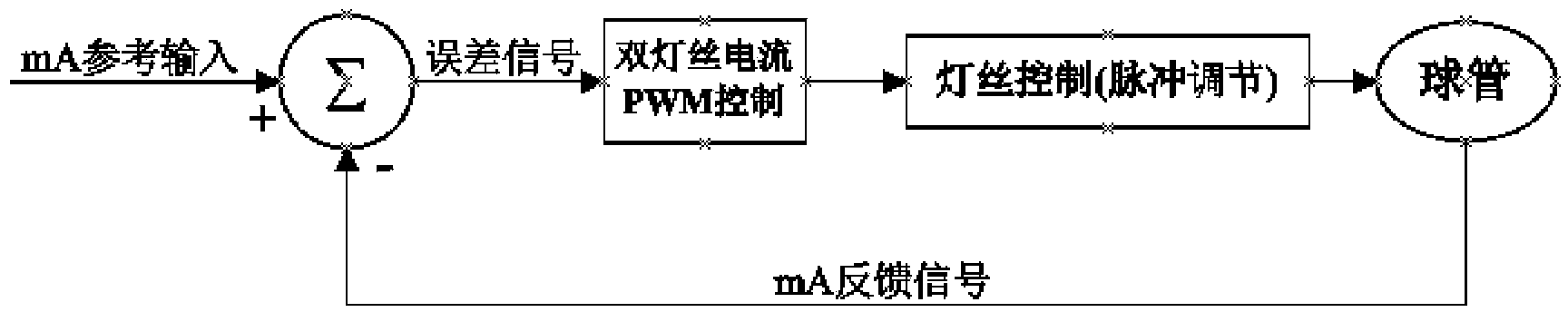

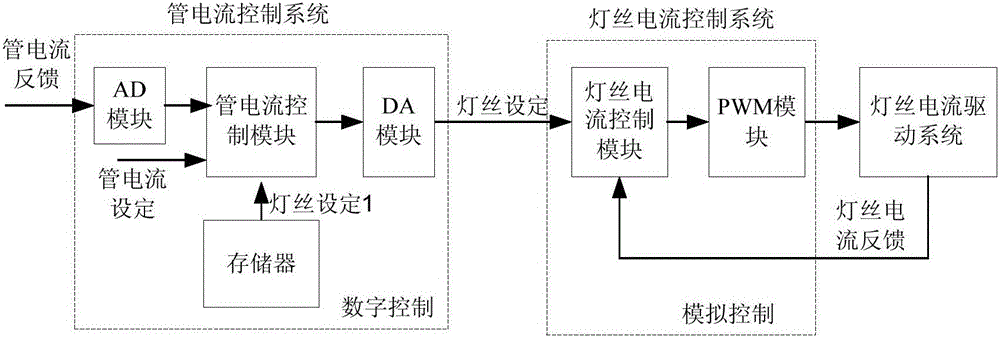

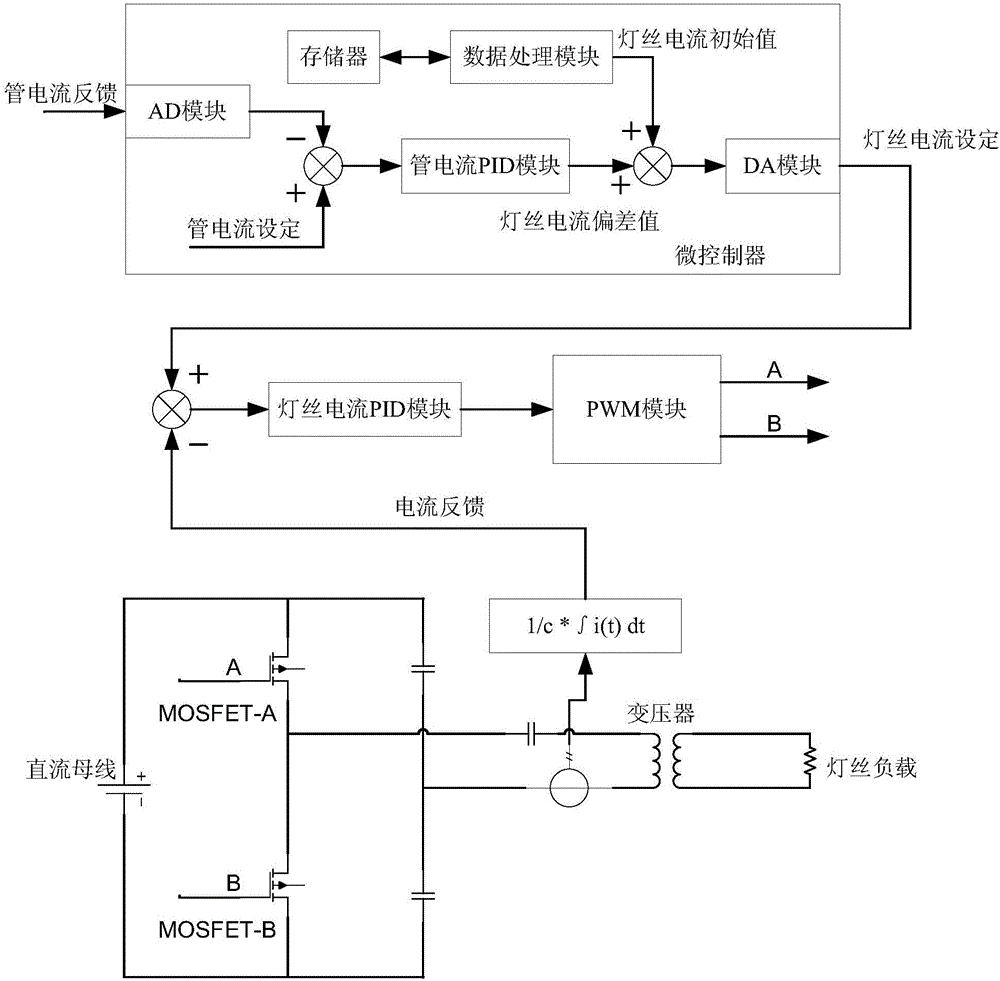

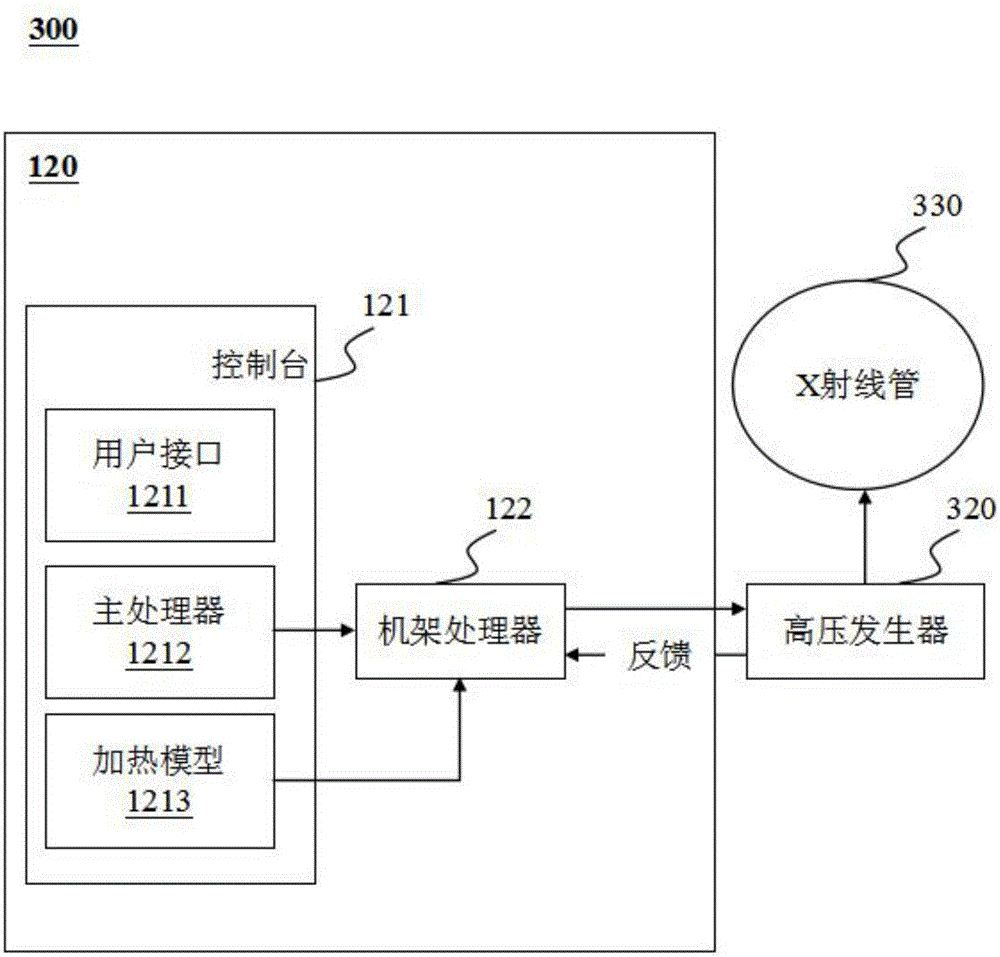

System for controlling tube current in mixed way and control method thereof

The invention relates to a system for controlling tube current in a mixed way. The system comprises a tube current control system and a lamp filament current control system connected with the tube current control system, wherein the lamp filament current control system is connected with a lamp filament through a lamp filament current driving system. A method comprises the following steps that the tube current control system controls the tube current according to the tube current fed back by an X-ray ball tube; the lamp filament current set value is output to the lamp filament current control system; the lamp filament current control system controls the lamp filament current according to the lamp filament current set value and the lamp filament current value fed back by the lamp filament current driving system; a lamp filament current driving signal is output; the lamp filament current is controlled through controlling the lamp filament current driving system. The tube current can be precisely controlled; the accuracy and the stability can be improved; the device aging problem in the simulation technology is solved, so that the design is more flexible; the size is reduced; the cost is reduced; the system consistency is improved.

Owner:LIAONING KAMPO MEDICAL SYST

Magnetron control method, magnetron service life judgment method, microwave generation device, magnetron service life judgment device, processing device, computer program, and storage medium

InactiveCN101107693AGood effect and effectExtend your lifeSemiconductor/solid-state device manufacturingTransit-tube cathodesElectrical resistance and conductanceMicrowave

It is possible to increase the service life of a magnetron. There is provided a magnetron service life judgment method. A microwave generation device includes: a magnetron (74) having a cathode (80) containing a filament (78) and an anode (82) containing a hollow resonator (84) arranged to oppose to each other; a filament current measuring unit (100); and an application voltage measuring unit (102) for measuring voltage applied to the filament. According to the current and the voltage obtained by the current measuring unit (100) and the voltage measuring unit (102), a resistance value calculation unit (104) obtains a resistance value of the filament. A temperature calculating unit (106) calculates the filament temperature from the resistance value according to the resistance-temperature dependent characteristic. A filament power source (98) is controlled by a power control unit (110) so that the filament temperature is within a predetermined temperature range. Moreover, the voltage applied to the filament is successively lowered and the voltage applied to the filament when the moding phenomenon occurs is obtained as the moding voltage and the magnetron service life is judged according to the moding voltage.

Owner:TOKYO ELECTRON LTD

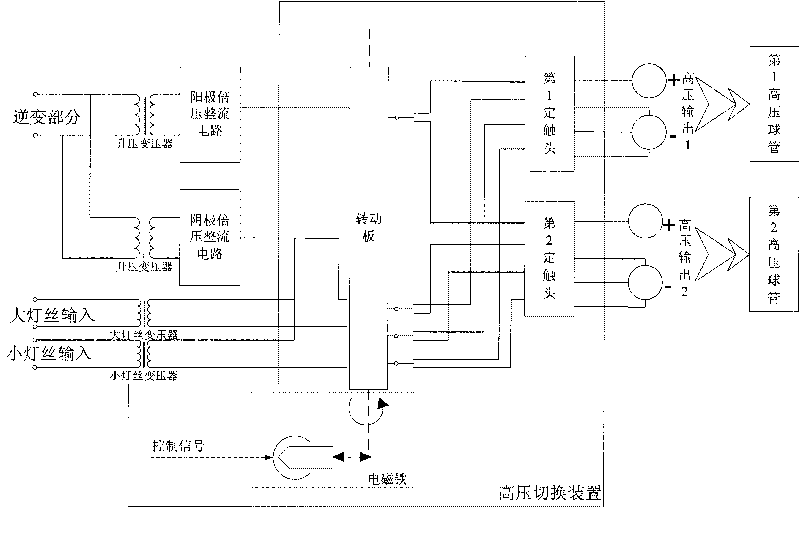

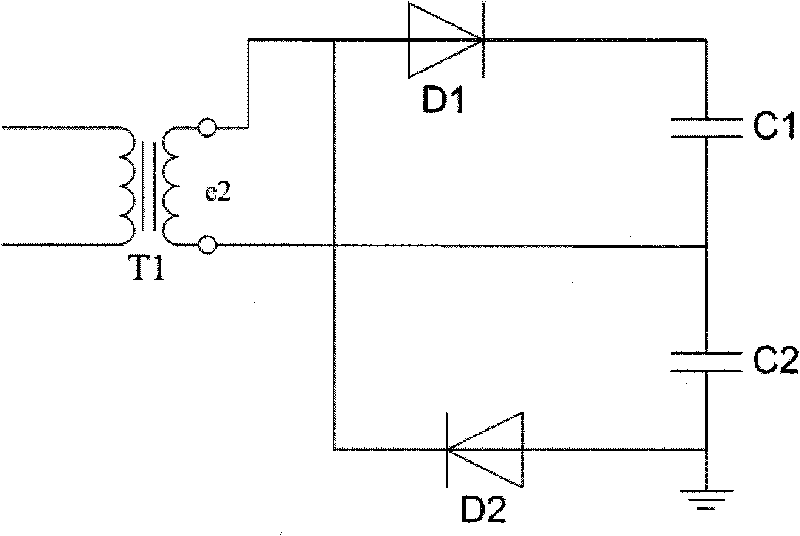

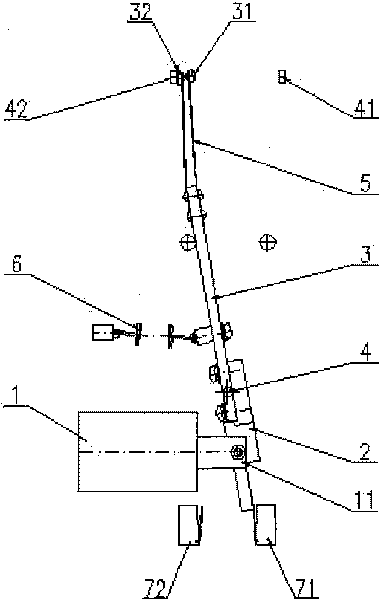

Dual-bulb tube high-voltage oil tank

The invention relates to a dual-bulb tube high-voltage oil tank arranged in an X-ray high-voltage generator. The high-voltage oil tank is provided with a voltage-multiplying rectification circuit, a boosting transformer, a filament transformer and a high-voltage switching device, wherein a primary winding of the boosting transformer is connected with an inversion part of the high-voltage generator; the voltage output by the inversion part is boosted and output to the voltage-multiplying rectification circuit through the primary winding; the high-voltage direct-current voltage output by the voltage-multiplying rectification circuit is transmitted to a first high-voltage bulb tube and a second high-voltage bulb tube through the high-voltage switching device. The invention ensures participation in high-voltage generator resonance, adopts voltage-multiplying rectification circuit, has a high resonance frequency of 80-250kHz and little output high voltage ripple, improves the quality of X ray emitted by the bulb tube, ensures that the filament current frequency output by the dual-bulb tube high-voltage oil tank is 40kHz so as to improve the definition of perspective and exposure images, is small in size to realize effective isolation between strong current and weak current.

Owner:NEUSOFT MEDICAL SYST CO LTD

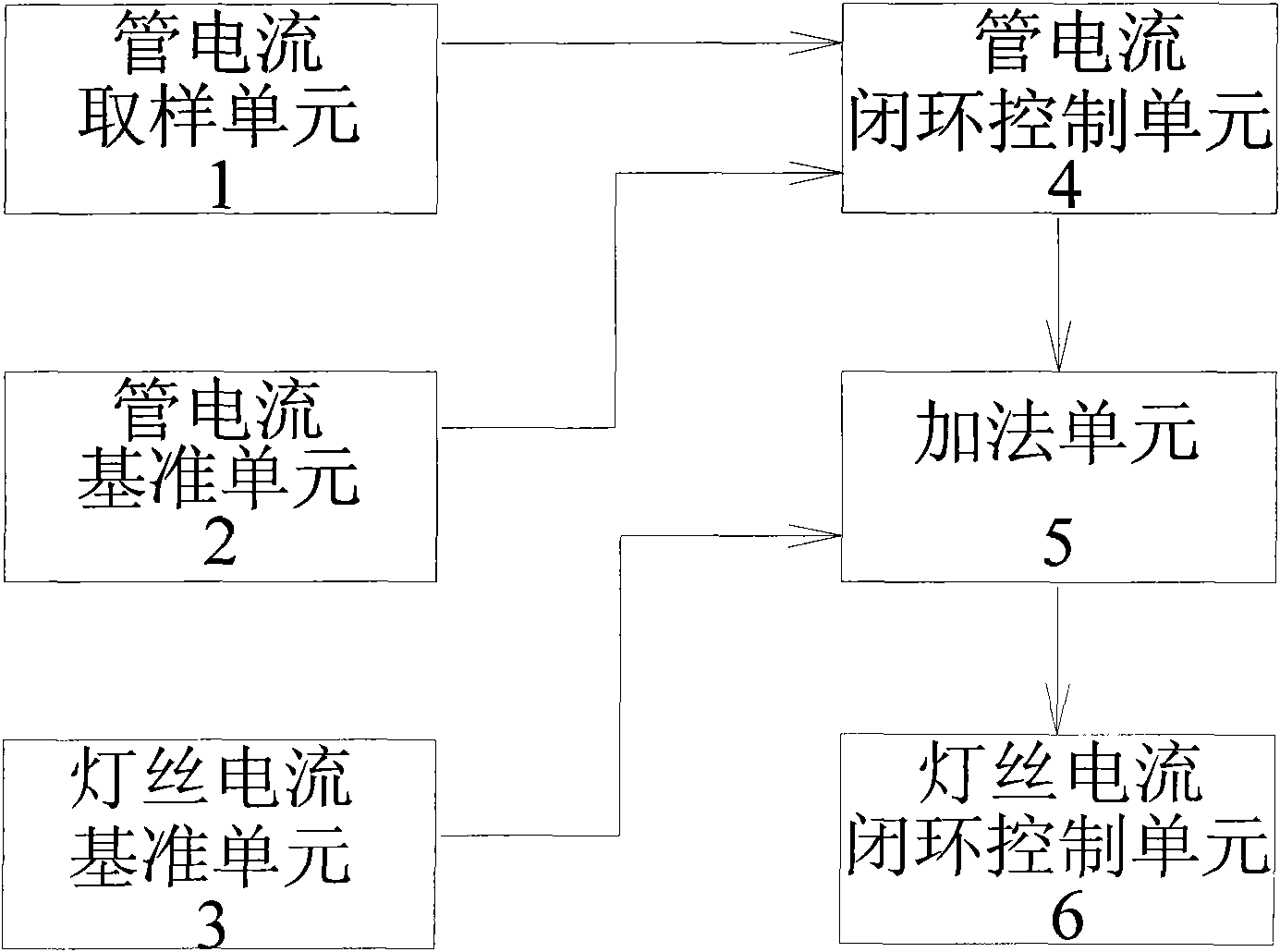

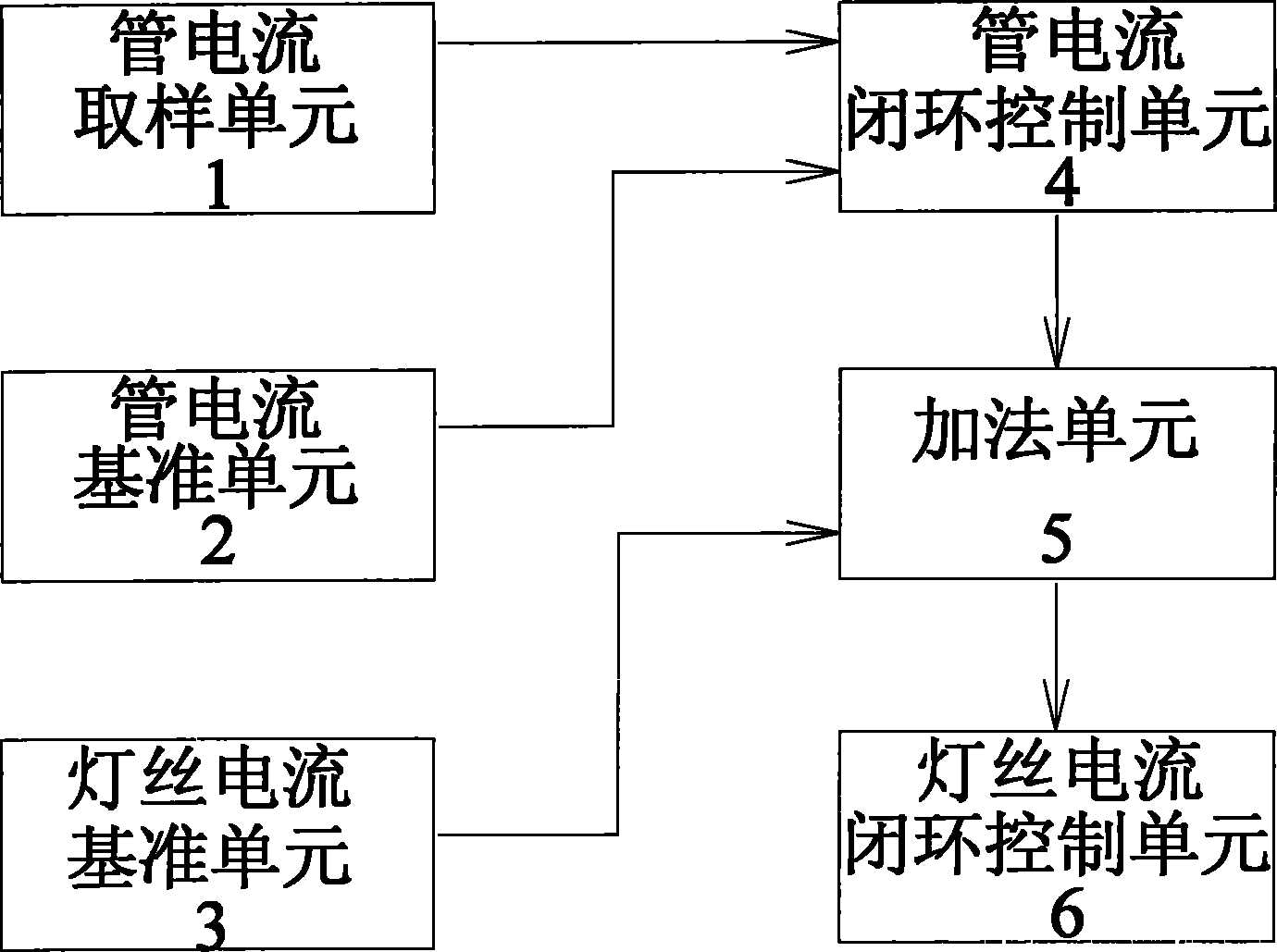

Filament current and tube current dual-closed loop control device for X-ray machine

The invention provides a filament current and tube current dual-closed loop control device for an X-ray machine, belonging to the technical field of medical apparatus and instruments, and structurally consisting of a tube current sampling unit, a tube current reference unit, a filament current reference unit, a tube current closed-loop control unit, an addition unit, and a filament current closed-ring control unit. According to the technical points, a tube current is dynamically adjusted by using the tube current closed-loop control unit, and a filament current reference and tube current dual-closed loop is controlled by the addition unit. The filament current and tube current dual-closed loop control device provided by the invention has the advantages as follows: not only can the tube current stabilize the filament current, but also the filament current is stabilized again through a tube current feedback signal, so that the tube current and the filament current obtain higher precision and stability through dual-path closed ring. Particularly, the filament current and tube current dual-closed loop control device for the X-ray machine has very obvious effects in large-current photograph, continuous fluoroscopy and pulse fluoroscopy.

Owner:NANJING PERLOVE RADIAL VIDEO EQUIP

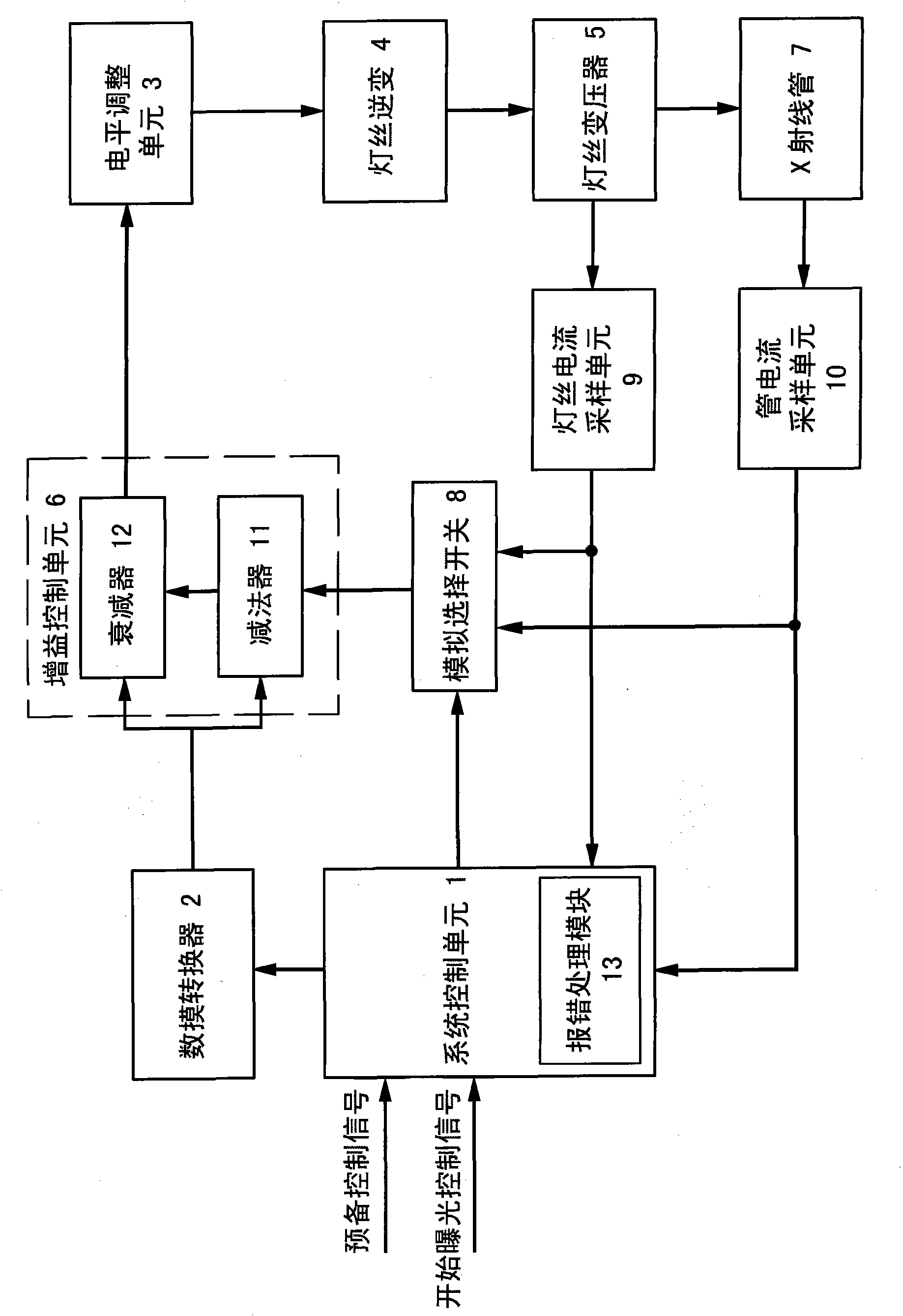

Method and device for controlling currents of X ray tube

ActiveCN102026466APractical and convenientImprove stabilityX-ray apparatusClosed loopFilament current

The invention relates to a method for controlling currents of an X ray tube and a device for controlling the currents of the X ray tube by implementing the control method. In the method and the device, an analog option switch gates a filament current sampling unit or a tube current sampling unit and feeds back to a gain control unit, so that two closed-loop gain control loops are formed. Time-shared control is performed on the two closed-loop gain control loops, namely time-shared gain control is performed on filament currents and tube currents. Therefore, multiple-loop time-shared control can be performed on the currents of the X ray tube, the filament currents can be rapidly improved into currents required by proximity exposure, and more precise tube currents can be obtained after normal work, so that the X ray tube is practical and convenient and has high stability.

Owner:SHANTOU INST OF UITRASONIC INSTR CO LTD

Light emitting apparatus

A light emitting apparatus receives an external power. A switching unit is electrically connected with a light emitting unit to form a serial circuit. A first electrical connection element is electrically connected with the external power and the light emitting unit. A second electrical connection element is electrically connected with the external power and the switching unit. A sensing unit is electrically connected with the first electrical connection element, the second electrical connection element and the switching unit. When filament currents flow between two electrical input terminals of the first electrical connection element and between two electrical input terminals of the second electrical connection element, the sensing unit controls the switching unit to turn on to enable the light emitting unit to receive the external power and start to emit light. Thus, users can avoid the risk of electric shock when installing the light emitting apparatus.

Owner:GIO OPTOELECTRONICS CORP

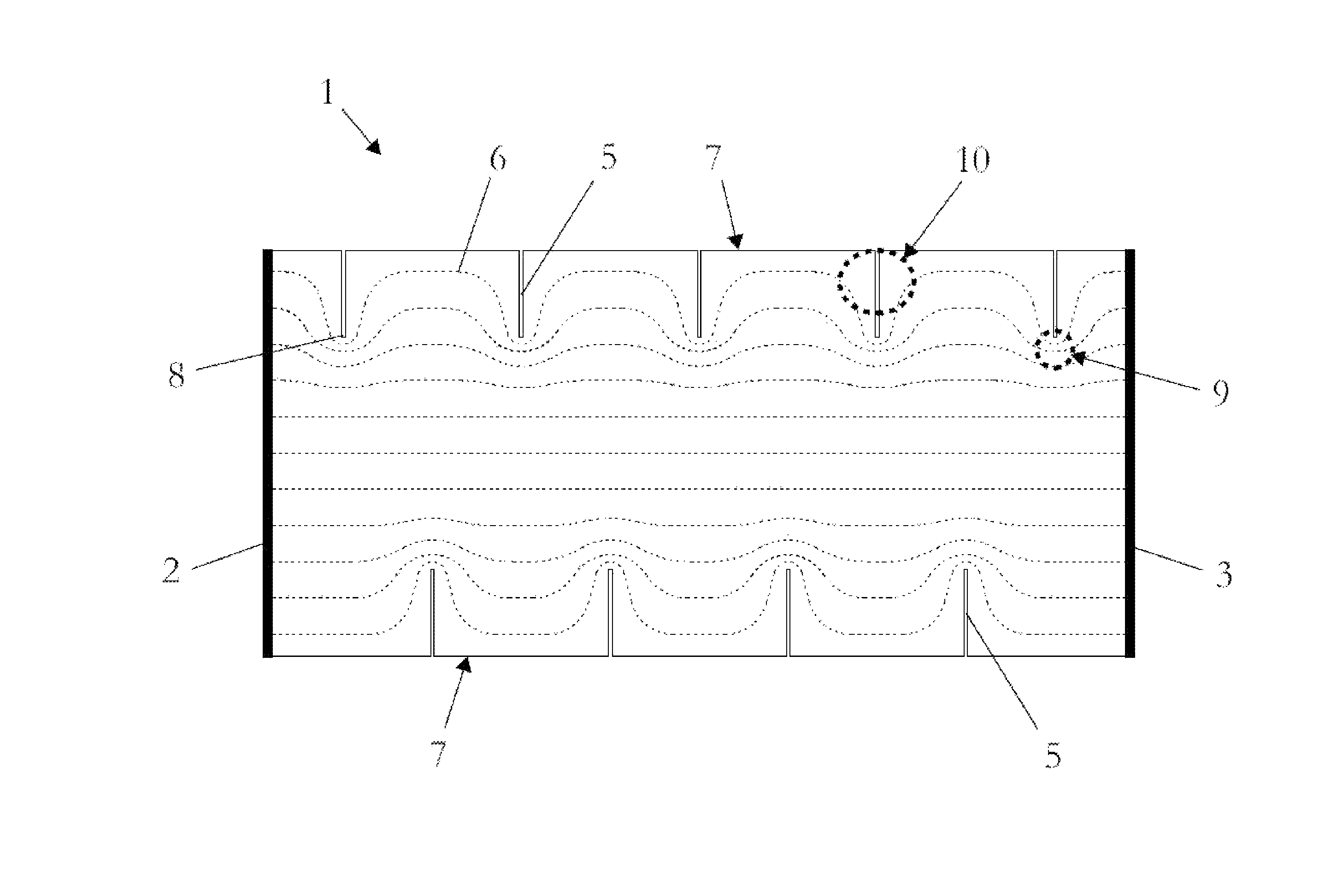

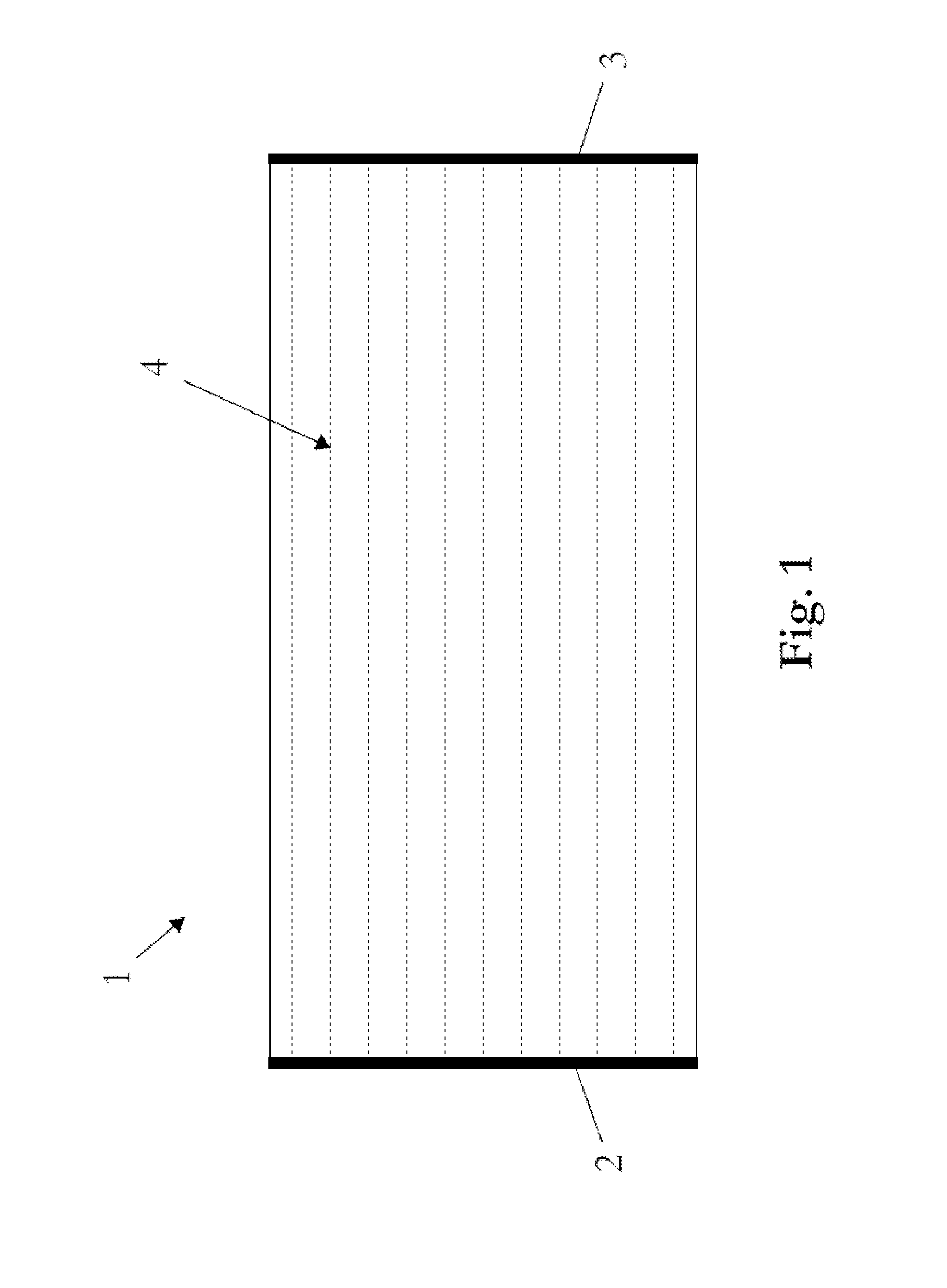

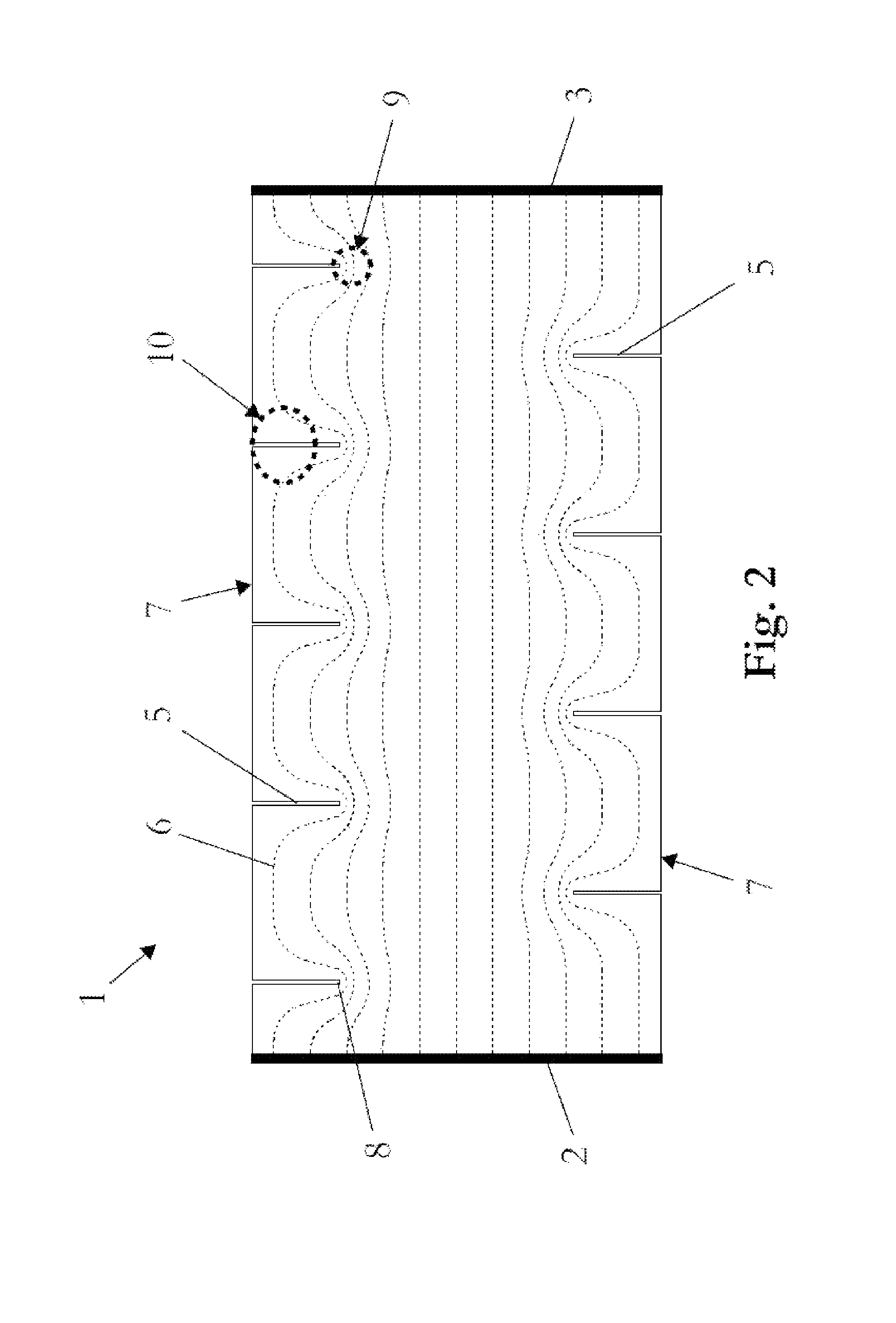

Laminar evaporator

ActiveUS9555199B2High densityMedical devicesTobacco devicesElectricityElectrical resistance and conductance

The disclosure relates to a laminar evaporator, comprising a laminar electrical resistance heating element for pulse heating and evaporation of an inhalationally receivable material distributed or distributable on the heating element surface by means of an electric heating current flowing or flowable in a laminar manner with at least two electrical contacts and / or poles (2, 3) for introducing the filament current into the resistance heating element, where the resistance heating element has at least one slot-shaped recess (5) constricting the lines of flux (4) of the original electric field forming or formable between the poles (2, 3) and is superficially bonded with an open-celled porous structure holding or capable of holding the material.

Owner:NICOVENTURES TRADING LTD

Plasma lighting system

InactiveUS20120161629A1Avoid interferenceExtend your lifeMagnetronsElectric light circuit arrangementSmart lightingWireless lan

A plasma lighting system is disclosed. Interference with an electronic device using the same band as that of the plasma lighting system can be avoided by changing the shape of vanes constituting a magnetron, and a filament current of the magnetron at an initial starting stage and that in a normal state are adjusted to be different, thus avoiding interference with a wireless LAN and attenuating noise, and a resonator has a mash form to increase efficiency. Because a rectangular waveguide is bent substantially at a right angle, and the magnetron and the resonator are disposed at one side on the basis of a waveguide space of the waveguide, thus reducing the size and an installation space of the plasma lighting system.

Owner:LG ELECTRONICS INC

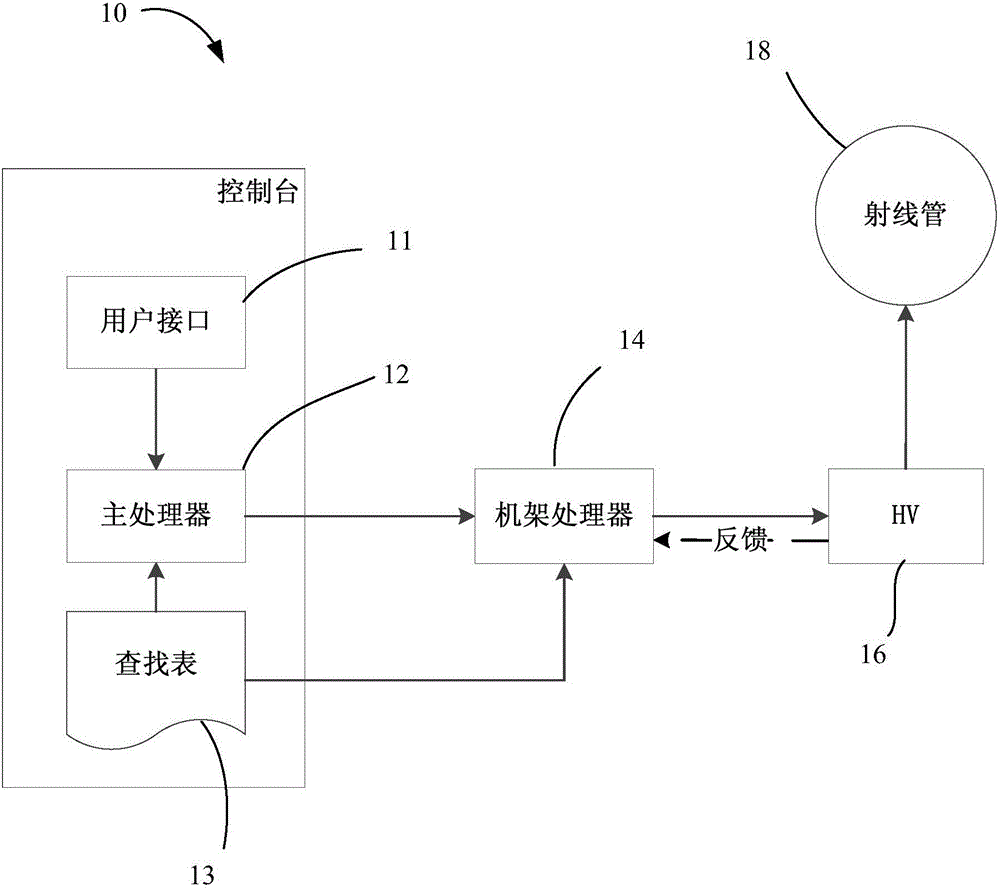

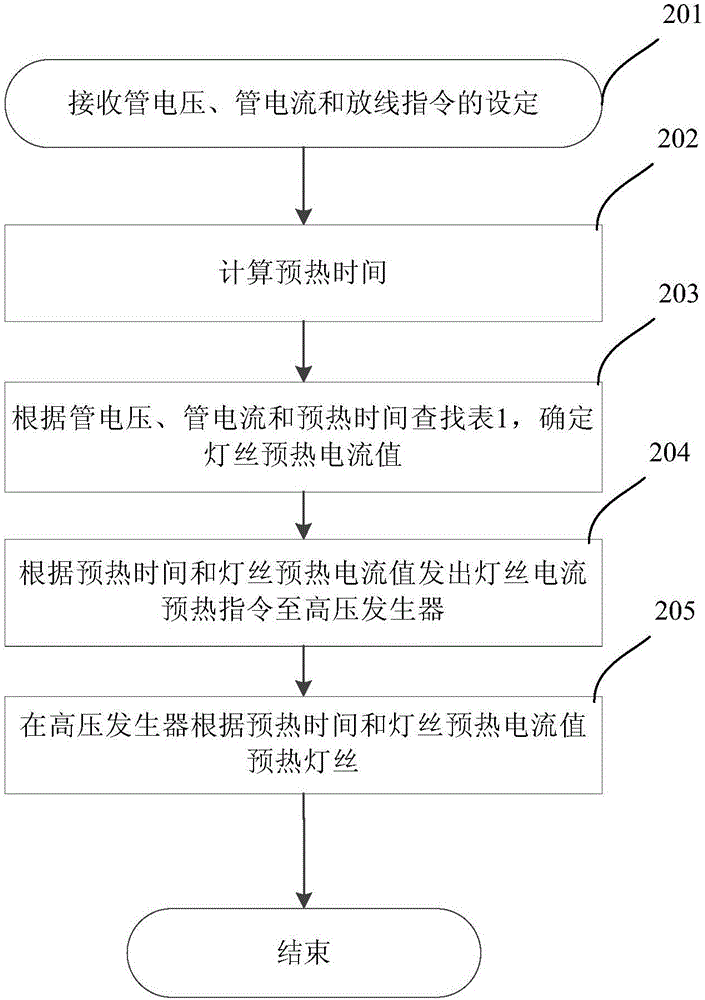

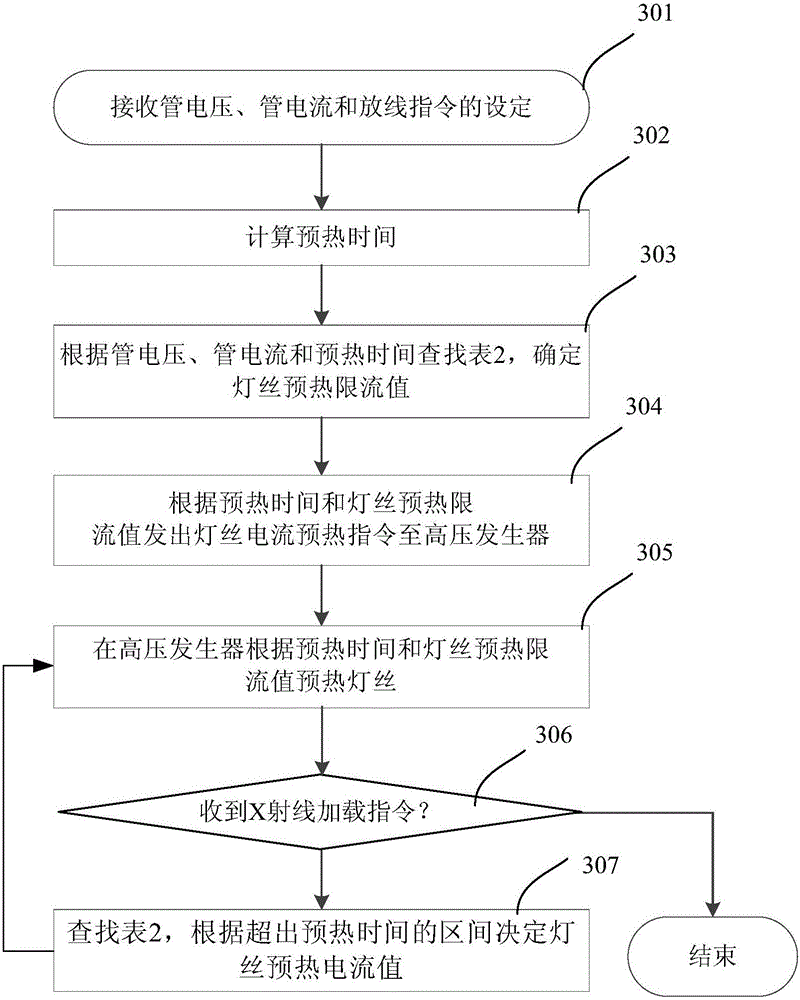

Preheating method and circuit of X-ray tube lamp filament of CT equipment

The invention provides a preheating method and circuit of an X-ray tube lamp filament of CT equipment. The preheating method comprises the following steps that setting of tube voltages, tube currents and a paying-off instruction are received, preheating time is calculated, and a lamp filament preheating current value is determined according to the tube voltages, the tube currents and the preheating time; a lamp filament current preheating instruction is sent to a high voltage generator of an X-ray tube according to the preheating time and the lamp filament preheating current value; the lamp filament is preheated on the high voltage generator according to the preheating time and the lamp filament preheating current value.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

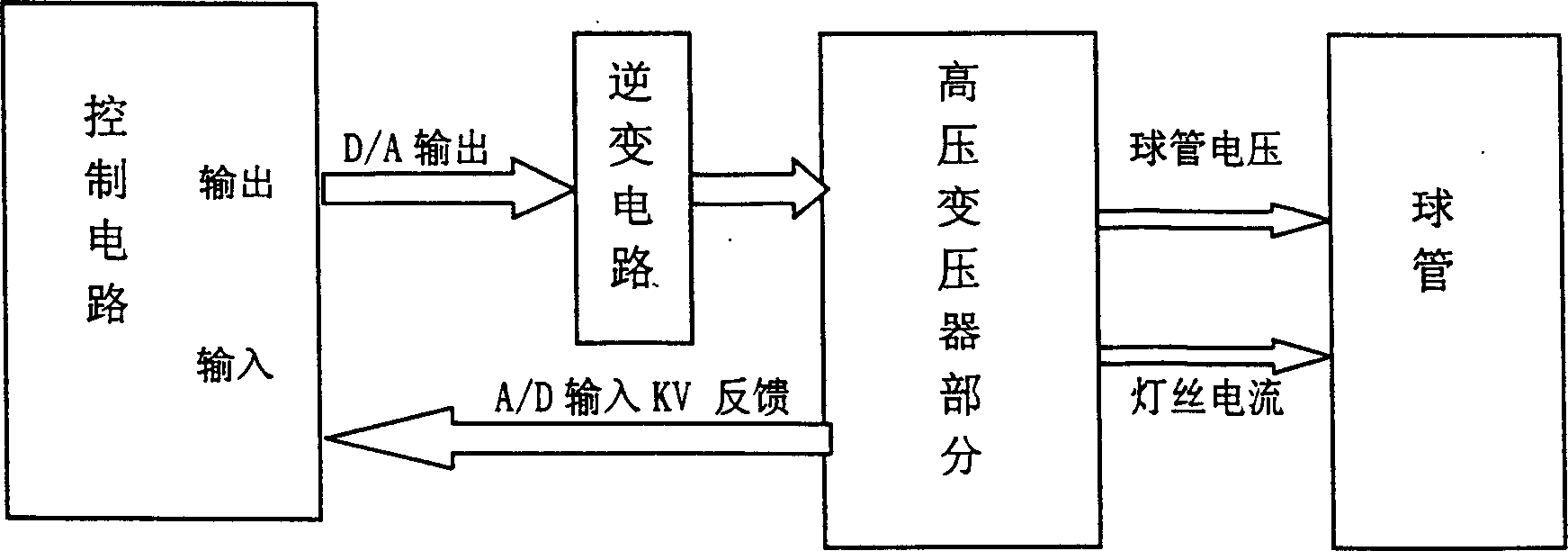

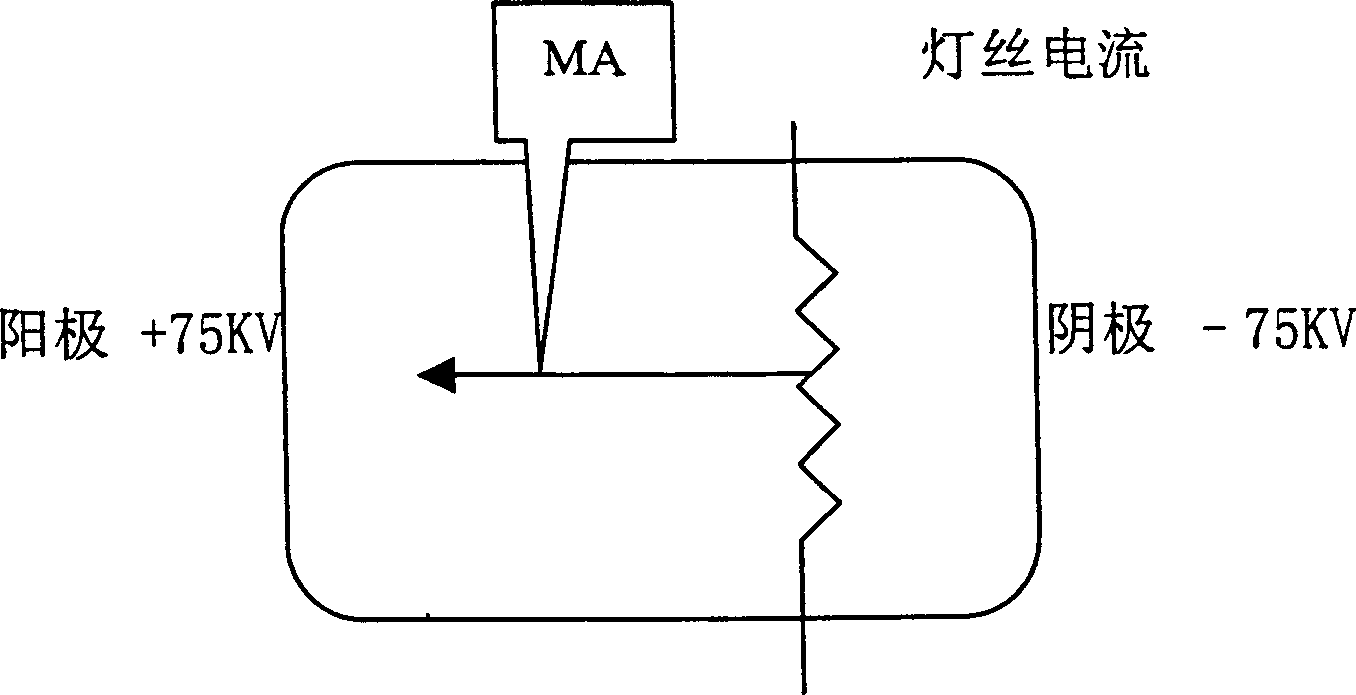

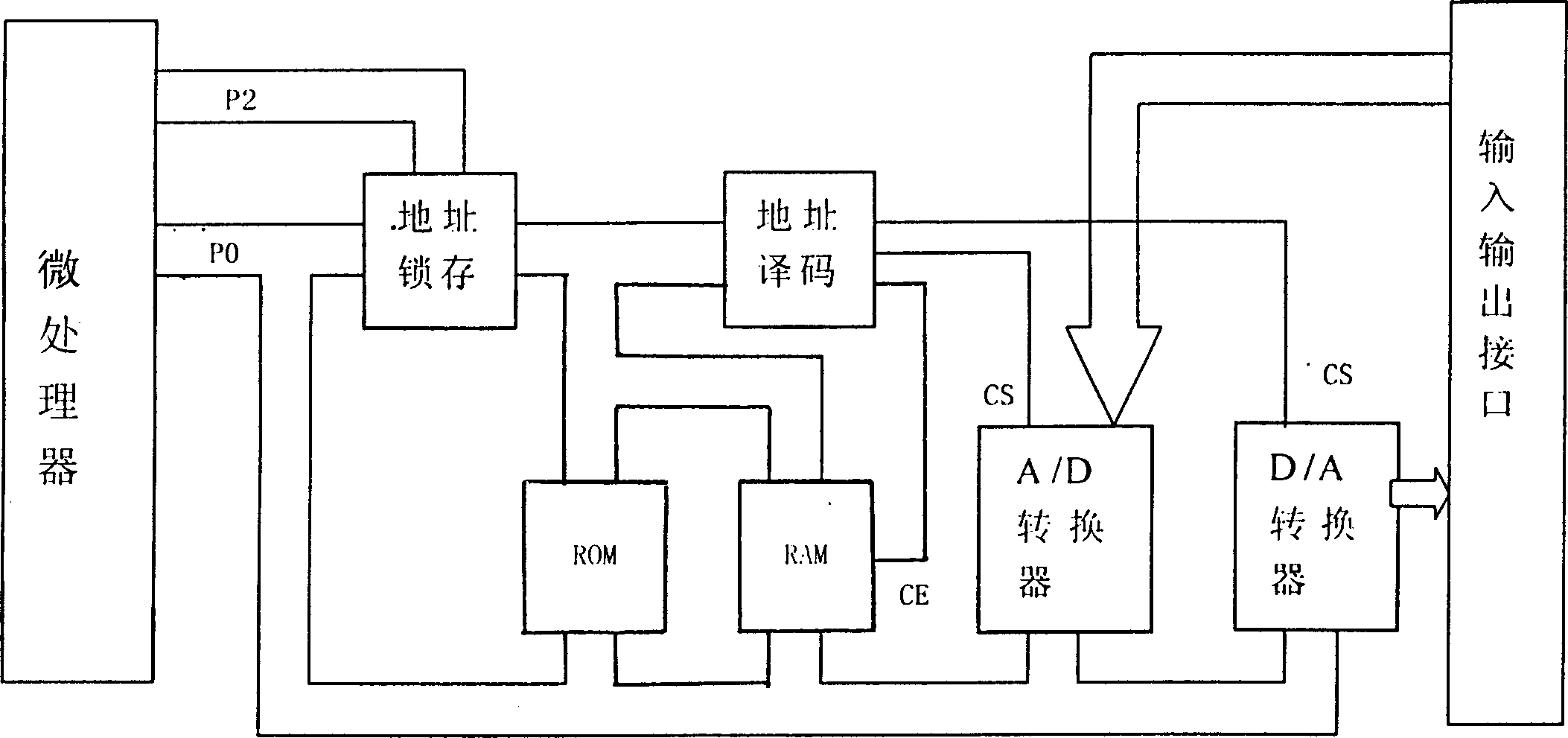

X ray apparatus high voltage generator microcomputer control debugging method

A microcomputer control debugging method for high-voltage generator of x ray machine has its hardware structure composed of control circuit, inverse transformation circuit, high-voltage transformer and ball tube, and their connections are the control circuit output to be connected with the input end of high-voltage transformer through D / A converter, the output of the high-voltage transformer to the connected with the input ends of ball tube varying voltage and lamp filament current, and the output of the high-voltage transformer to be feedback to the input end of the control circuit through A / D converter; and the hardware part uses storage chip (RAM) with lithium cell to store training management data in the storage chip in advance and carries on the debugging for ball tube in the high-voltage generator of X ray machine by utilizing the storage chip.

Owner:PHILIPS & NEUSOFT MEDICAL SYST

Car lamp control method and control circuit

InactiveCN101242693AEliminate spike currentAchieve smooth transitionElectrical apparatusElectric light circuit arrangementEngineeringPeak current

The invention discloses a controlling method of vehicle light and corresponding control circuit of vehicle light, which is capable of eliminating peak current when the vehicle light is started. The invention output PWM signal, namely pulse width modulation signal, by main control chip to vehicle light driving chip; during startup of the vehicle light, duty cycle of the PWM signal is adjusted, thus duty cycle of PWM signal is increased gradually with time, so that voltage upon vehicle light is increased with time, until the voltage upon vehicle light is equal to rated voltage of vehicle light. The provided method of the invention makes voltage of the vehicle light increase gradually from 0V to rated, which realizes smooth transition of filament current, and eliminate peak current when vehicle starts up.

Owner:LIANCHUANG AUTOMOBILE ELECTRONICS

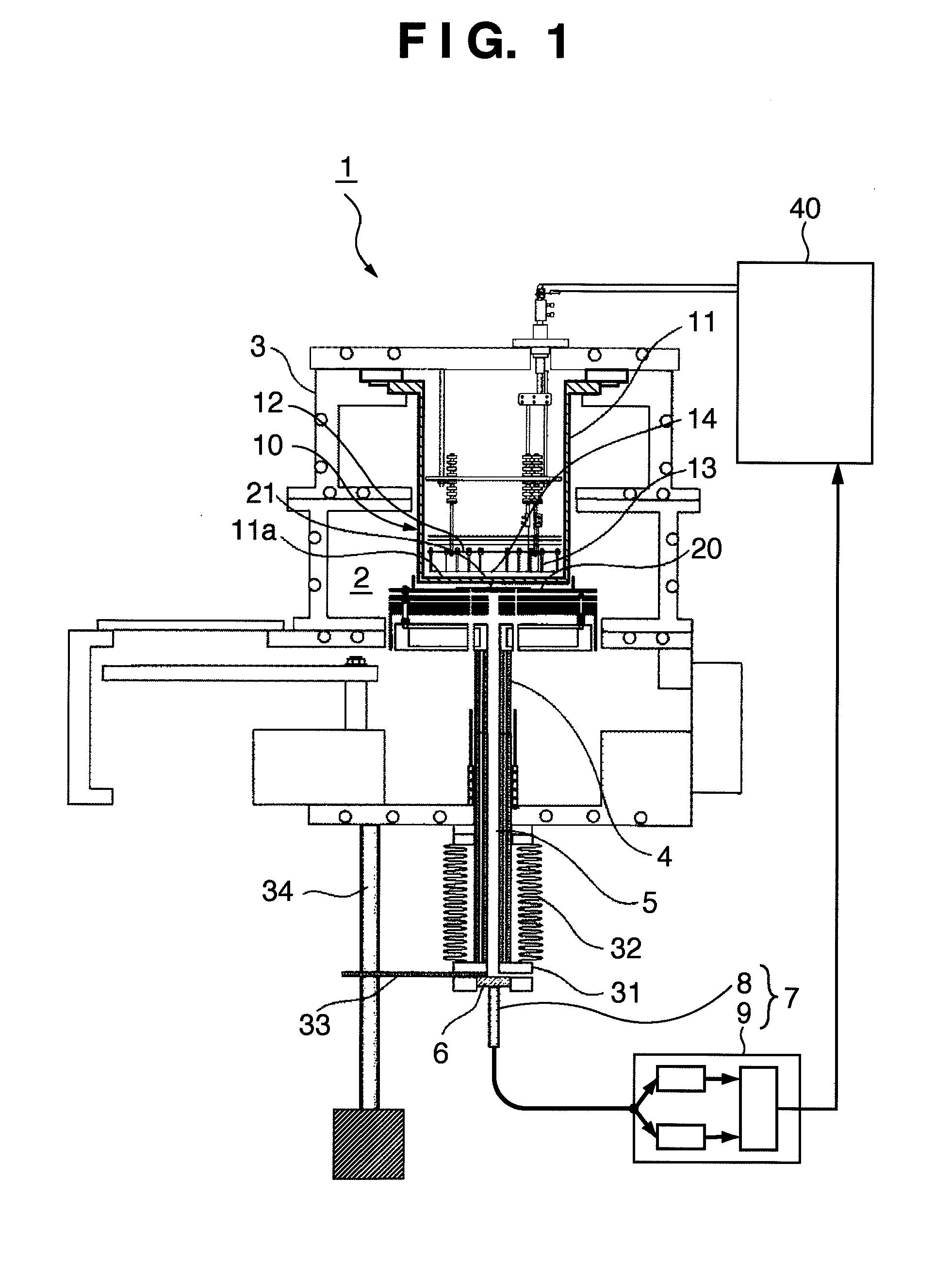

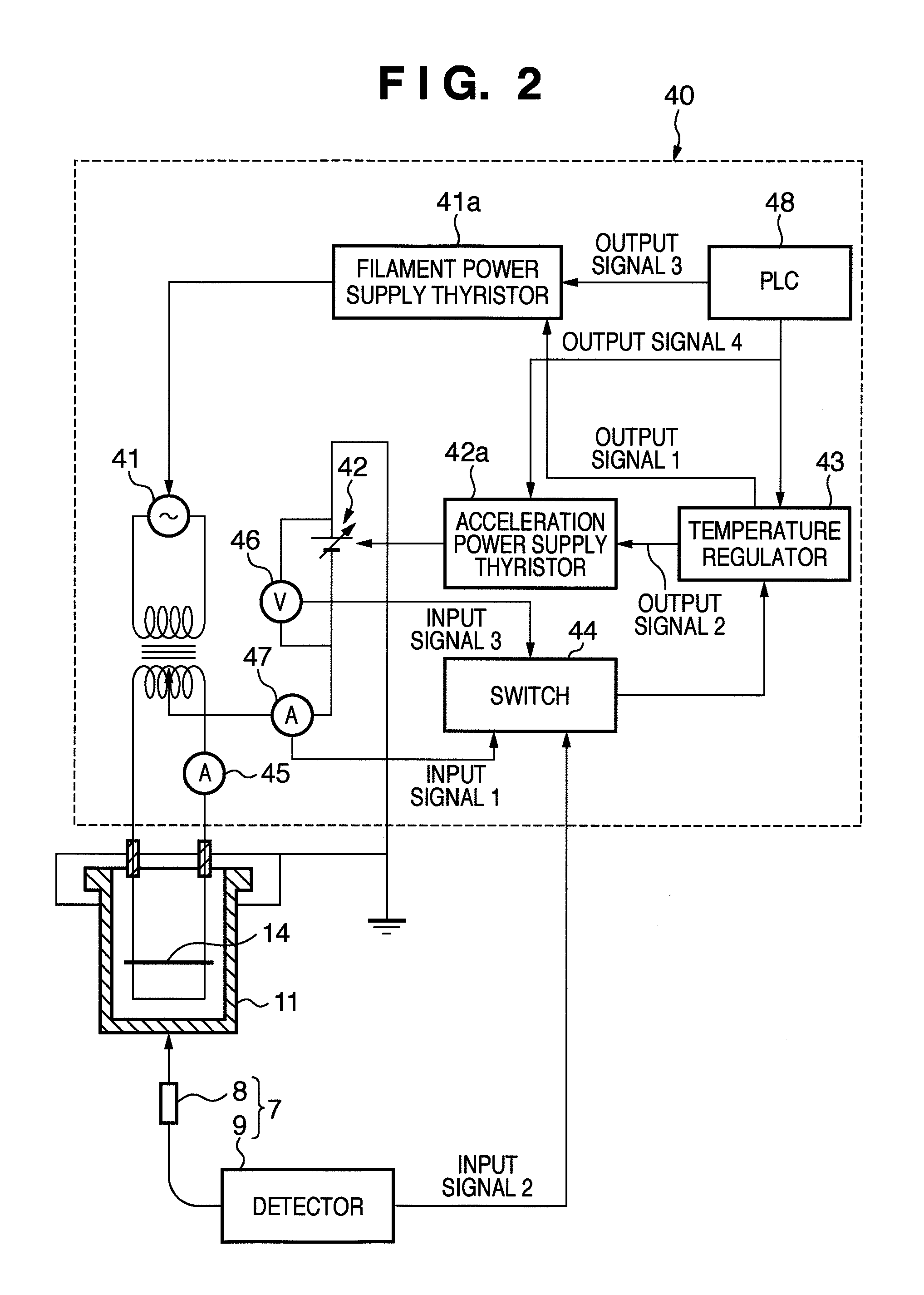

Temperature control method for heating apparatus

InactiveUS20100243618A1Increase temperaturePrevent stateElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlVoltmeter

Owner:CANON ANELVA CORP

X-ray tube filament current data correction method and X-ray tube filament current data correction system

The invention discloses an X-ray tube filament current data correction method and an X-ray tube filament current data correction system. The method comprises the steps of acquiring a first to-be-corrected tube current value and a to-be-corrected filament current value which correspond with a first correction point; performing a first filament laying operation according to the first to-be-corrected tube current value and the to-be-corrected filament current value; determining at least one actual tube current value in the filament laying operation; determining a difference between the actual tube current value and the first to-be-corrected tube current; and correcting the first correction point according to the difference.

Owner:LIANYING GUIZHOU MEDICAL TECH CO LTD

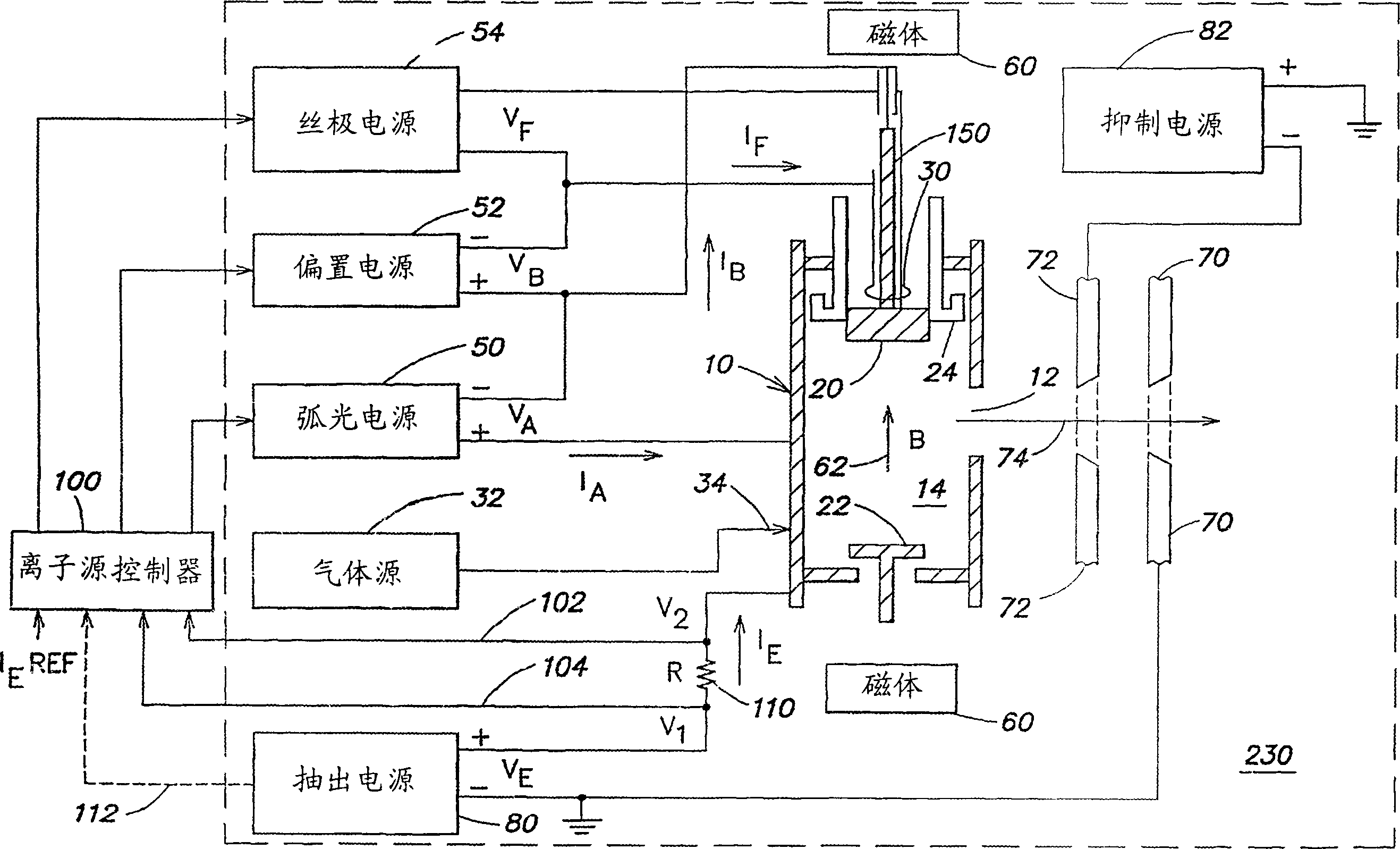

Control system for indirectly heated cathode ion source

An indirectly heated cathode ion source includes an extraction current sensor for sensing ion current extracted from the arc chamber and an ion source controller for controlling the filament power supply, the bias power supply and / or the arc power supply. The ion source controller may compare the sensed extraction current with a reference extraction current and determine an error value based on the difference between the sensed extraction current and the reference extraction current. The power supplies of the indirectly heated cathode ion source are controlled to minimize the error value, thus maintaining a substantially constant extraction current. The ion source controller utilizes a control algorithm, for example a closed feedback loop, to control the power supplies in response to the error value. In a first control algorithm, the bias current IB supplied by the bias power supply is varied so as to control the extraction current IE. Further according to the first control algorithm, the filament current IF and the arc voltage VA are maintained constant. According to a second control algorithm, the filament current IF is varied so as to control the extraction current IE. Further according to the second control algorithm, the bias current IB and the arc voltage VA are maintained constant.

Owner:VARIAN SEMICON EQUIP ASSOC INC

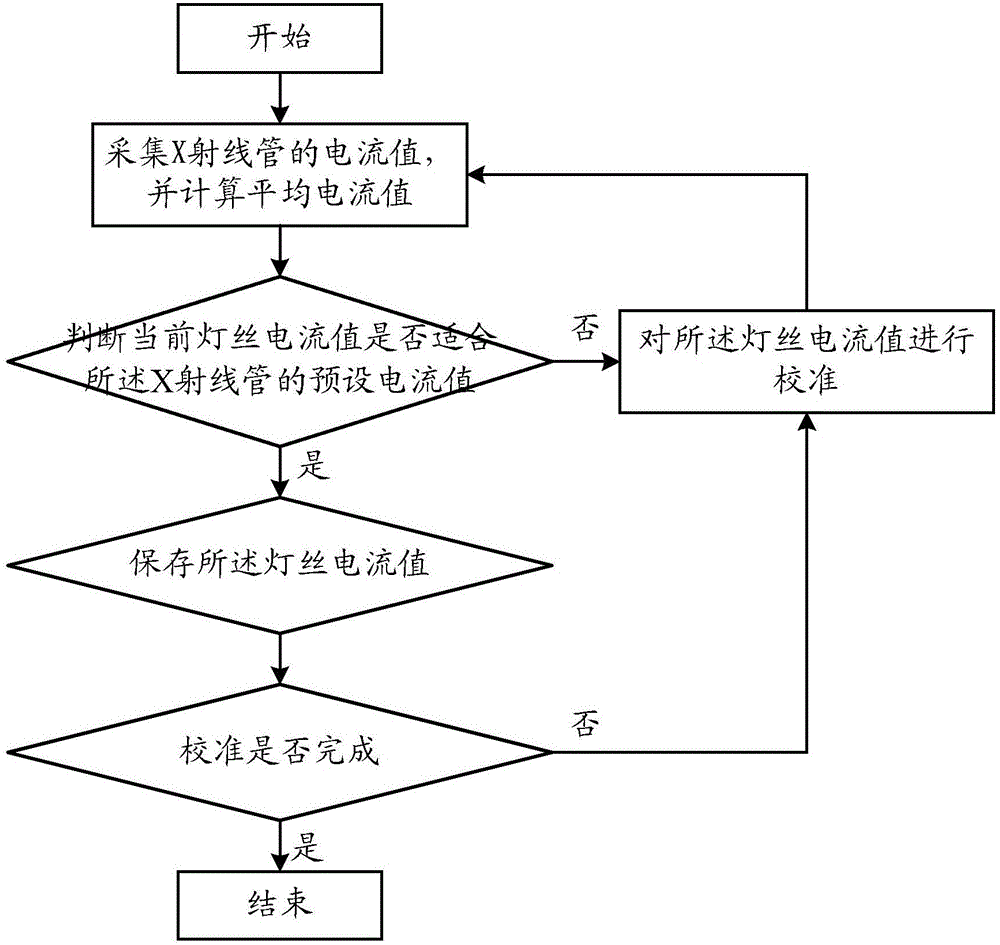

Calibration method and system for filament current of X-ray tube

ActiveCN106645227AReduce exposureShort calibration timeMaterial analysis by transmitting radiationSoft x rayAverage current

The invention is applicable to the field of medical instruments and provides a calibration method for filament current of an X-ray tube. The calibration method comprises the following steps: acquiring current values of the X-ray tube for multiple times, calculating an average current value, judging whether the current filament current value conforms to a preset current value of a current level to be calibrated of the X-ray tube according to the average current value, if the current filament current value does not conform to the preset current value, calibrating the filament current value, carrying out the step of acquiring the current values of the X-ray tube for multiple times and calculating the average current value again, if the current filament current value conforms to the preset current value, saving the filament current value, and ending the calibration. According to the calibration method for the filament current of the X-ray tube, whether the current filament current value conforms to the preset current value of the X-ray tube can be judged only according to the average current value, and a user can know whether the filament current value is proper without a large number of tests; the calibration time is short, and the number of times of anode exposure is reduced; meanwhile, judgment and calibration are carried out according to the average current value obtained by multiple samplings and calculation; the precision of the calibrated current is high.

Owner:深圳市深图医学影像设备有限公司

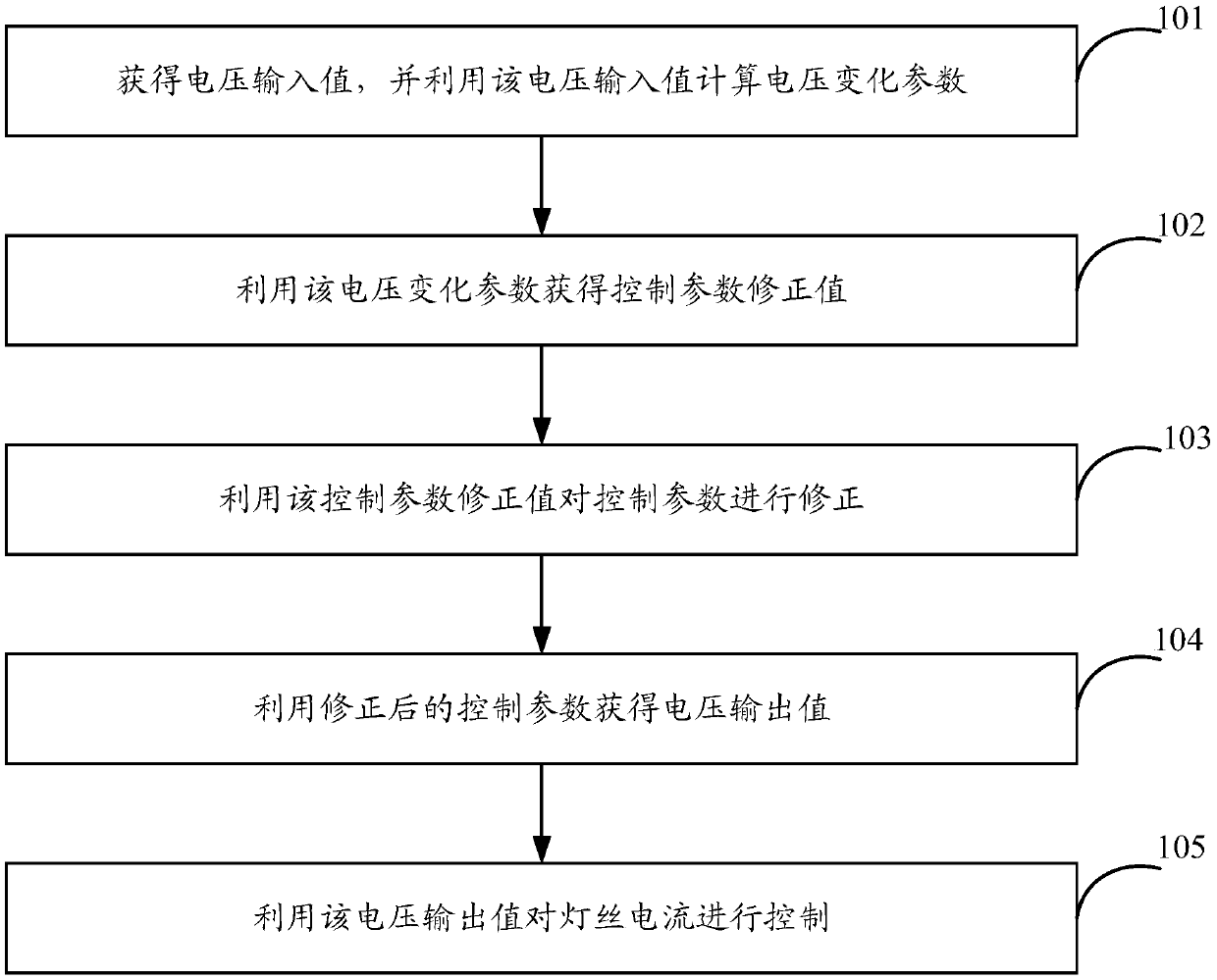

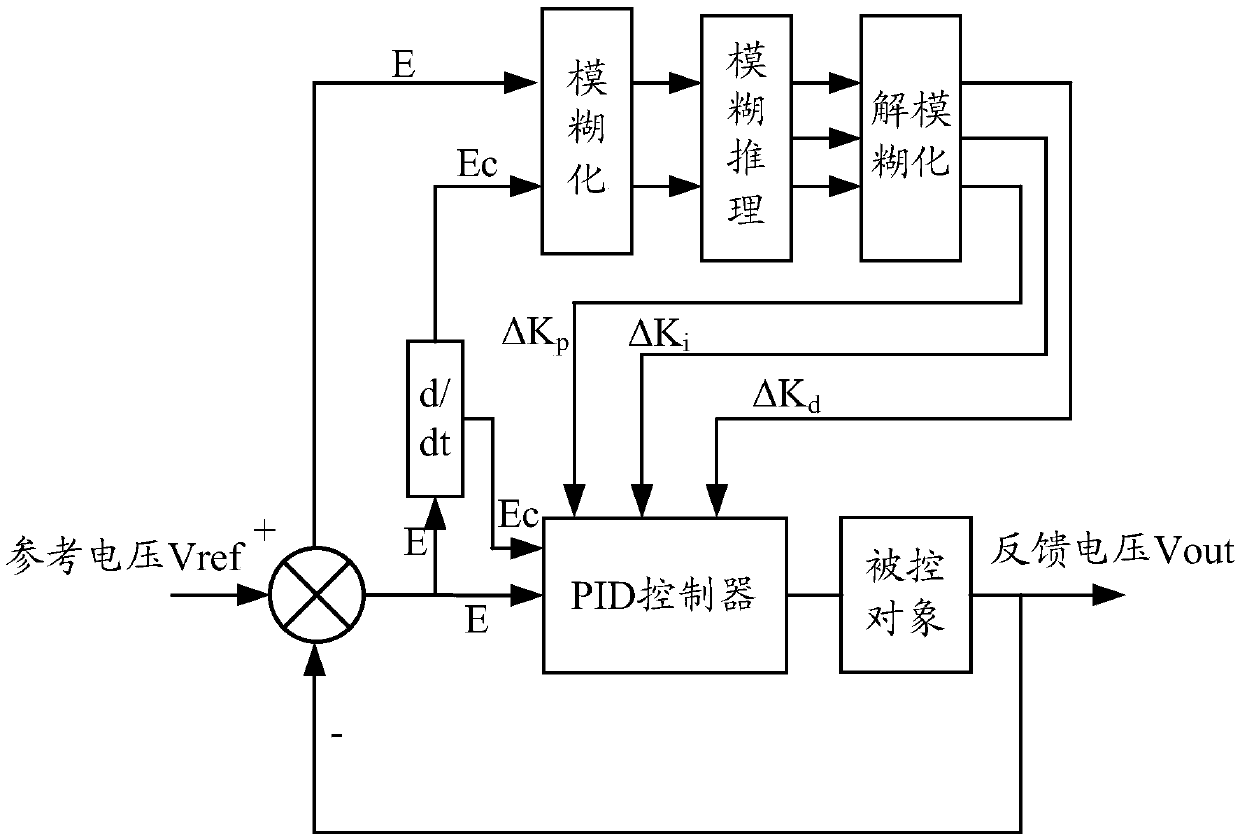

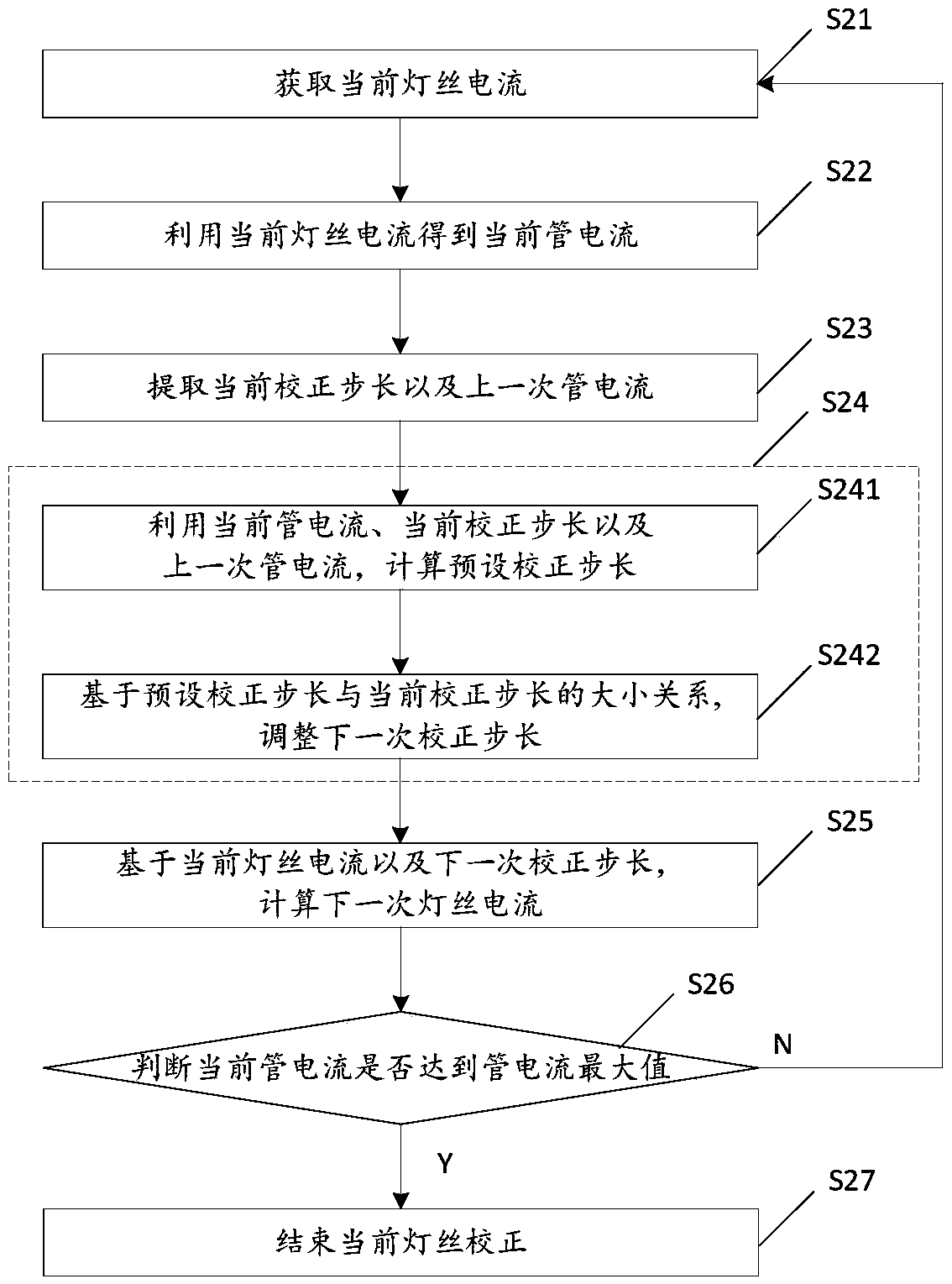

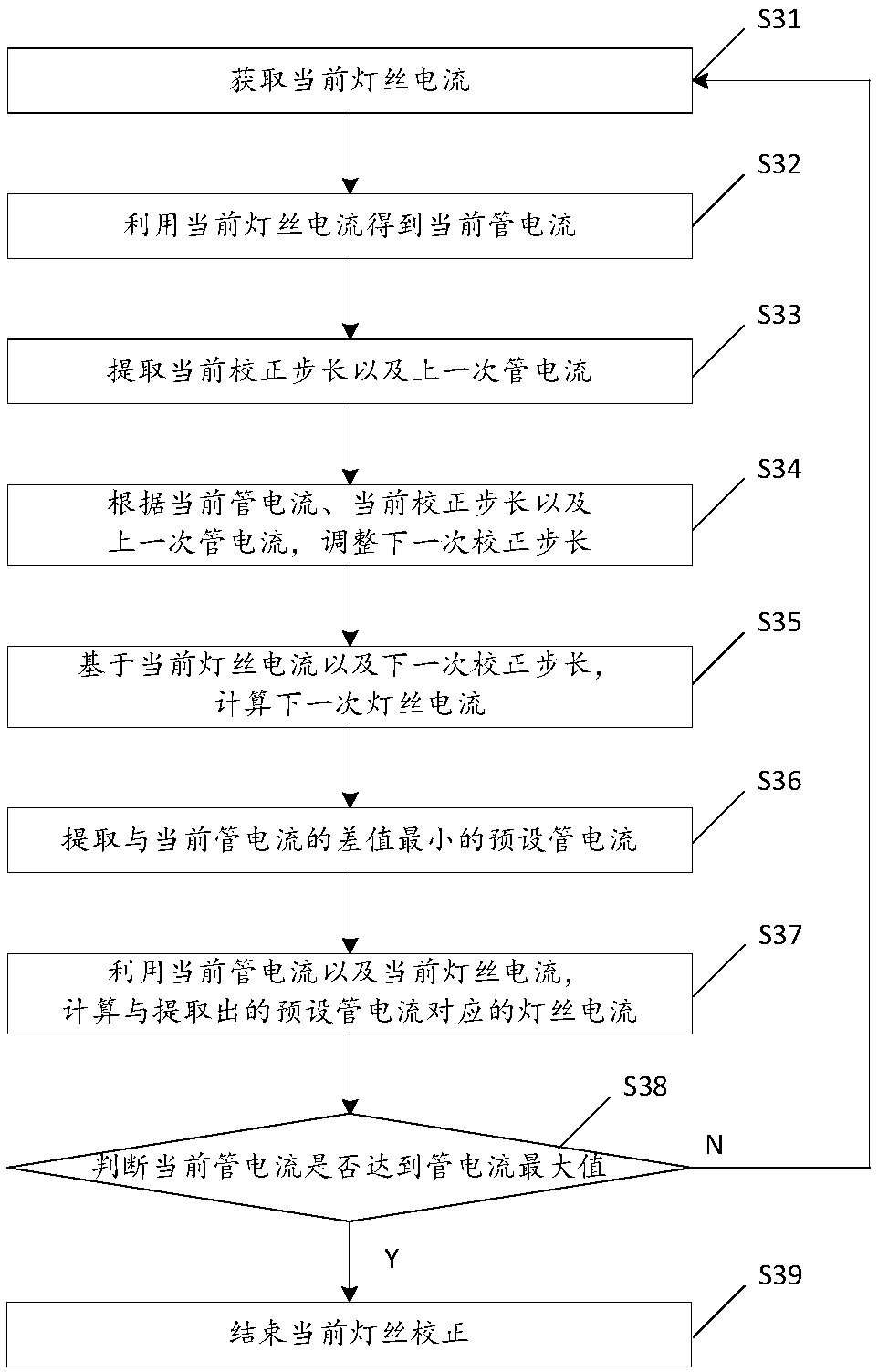

Control method and apparatus of filament currents

ActiveCN105517278AEasy to controlIncrease speedElectrical apparatusElectric light circuit arrangementImaging qualityEngineering

The invention provides a control method and apparatus of filament currents. The method comprises the following steps: obtaining voltage input values, and calculating voltage change parameters by use of the voltage input values; obtaining control parameter correction values by use of the voltage change parameters; correcting control parameters by use of the control parameter correction values; obtaining voltage output values by use of the control parameters after correction; and controlling the filament currents by use of the voltage output values. According to the technical scheme provided by the invention, the corrected control parameters can meet control requirements, a PID controller can better control the filament currents, the filament currents maintain rapid, stable, accurate and reliable at a filament preparation stage and a filament exposure stage, the real-time performance and the anti-interference capability are quite high, the dynamic and static performance is good, static and dynamic performance of tube currents is improved accordingly, and the image quality is improved.

Owner:NEUSOFT MEDICAL SYST CO LTD

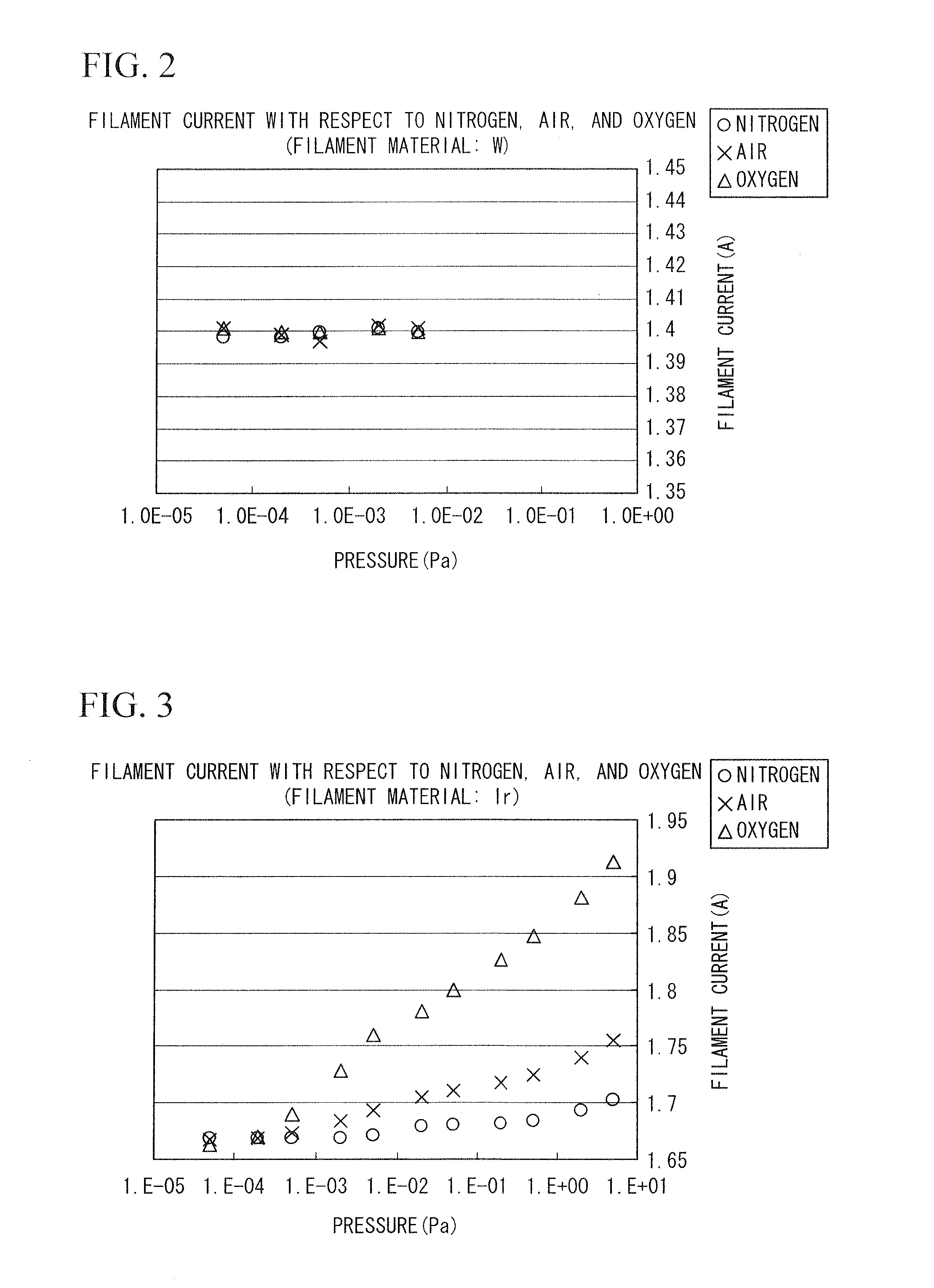

Oxygen detection method, air leakage determination method, gas component detection device, and vacuum processing apparatus

ActiveUS20110315872A1Detection of leakageLow costVacuum gauge using ionisation effectsMaterial analysis by electric/magnetic meansPower flowOxygen

An oxygen detection method, includes: preparing a grid, an ion collector, and a filament in which an oxide are formed on a surface of metal; controlling a filament current flowing to the filament so that an emission current becomes constant; discharging thermionic electrons which are caused by heat generation by applying the filament current, and generating ions by ionizing a gas; capturing the ions with the ion collector; and detecting oxygen being present in a vacuum processing chamber by measuring a filament current value.

Owner:ULVAC INC

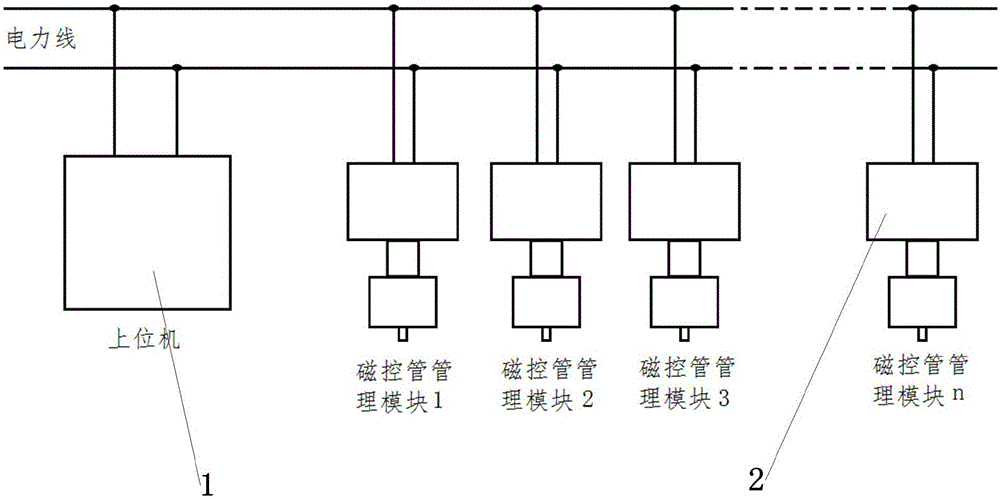

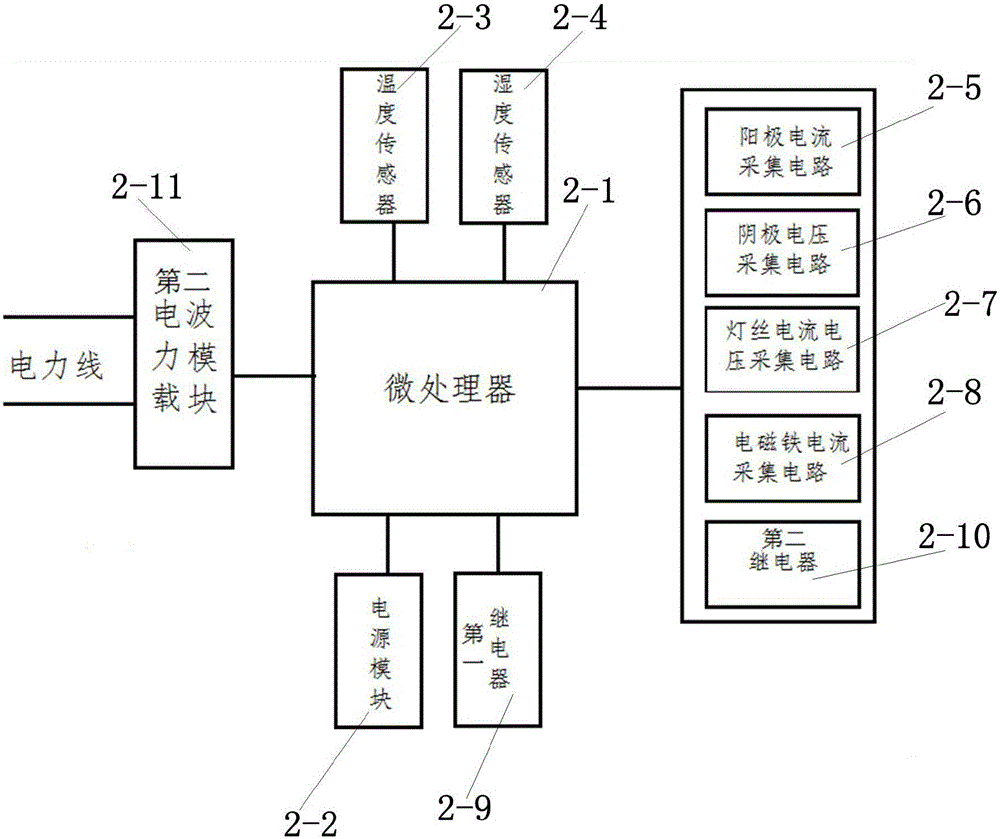

Power line carrier based distributed control system for magnetron power sources

ActiveCN105162247AAvoid low frequency interferenceReliable Data Transfer RateCircuit arrangementsEnergy industryLow voltageCarrier signal

The invention discloses a power line carrier based distributed control system for magnetron power sources. The system includes an upper computer and a magnetron management module, wherein the upper computer is used for monitoring working states of the magnetron power sources and performing remote control; and the magnetron management module is in communication with the upper computer and is used for supervisory control and for collecting temperature, humidity, anode current, cathode current, filament voltage, filament current and electromagnet current of the magnetrons. According to the invention, low-voltage broadband power line carrier technology is utilized and the working frequency range is 1-40 MHz, so that low-frequency interference is avoided effectively and reliable data transmission with a transmission range of 200 to 300 m can be realized. The system can meet power control demands of magnetrons in a single microwave device. No separate wiring is needed and the system has advantages of being easy in execution and adjustment, comparatively small in operation maintenance load, good in data security and large in bandwidth.

Owner:XIAN ENBIENS PHOTOELECTRIC

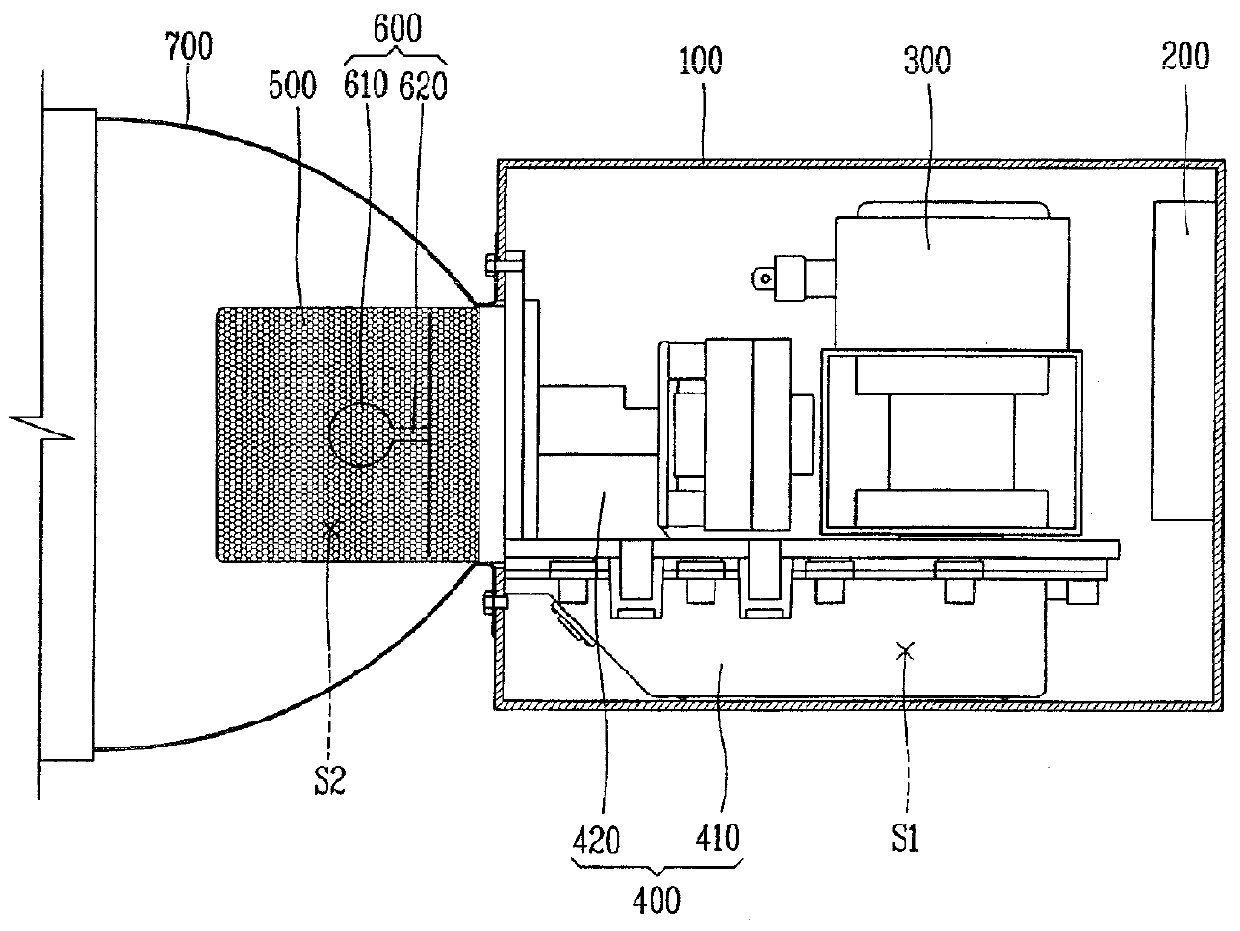

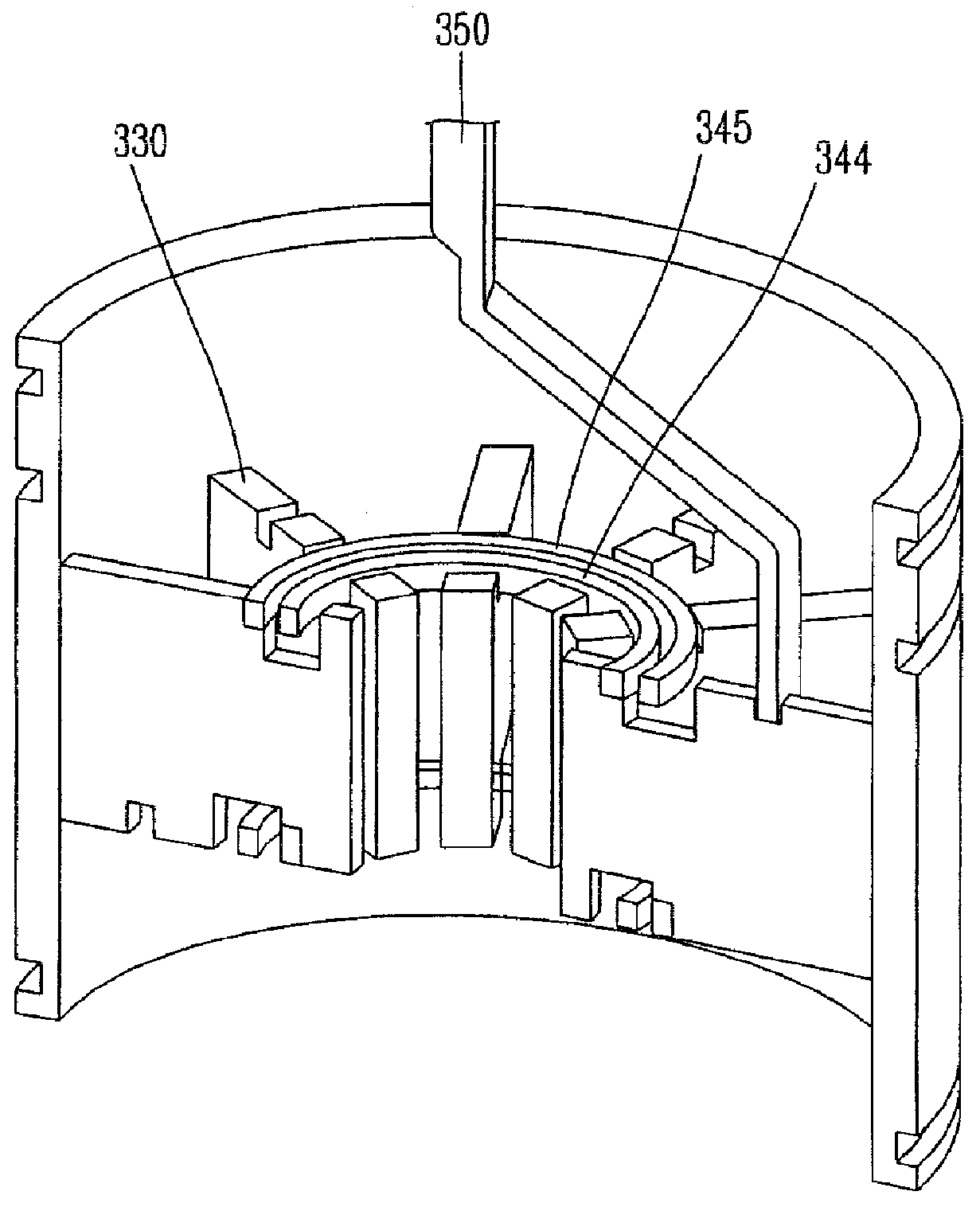

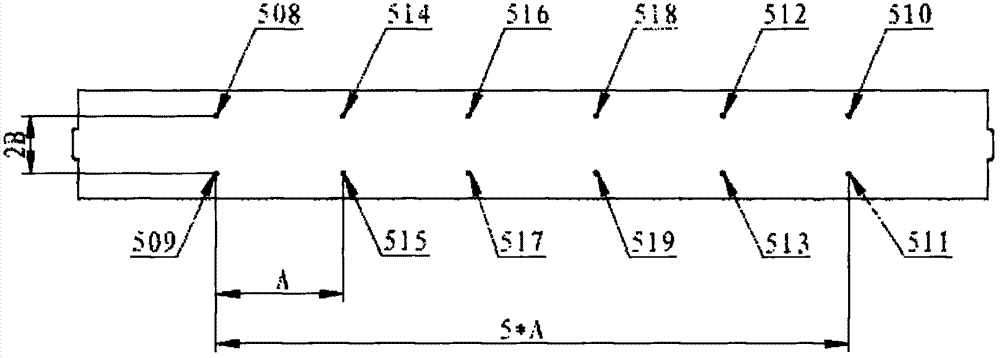

Ion source uniform air supply structure device

The invention discloses an ion source uniform air supply structure device in an ion injection system. The structure device is showed as figure 1. Due to the fact that air supply pipelines (501) to (507) are designed at the bottom of an air supply cover plate to enable the supplied air to flow into an arc chamber cavity uniformly, filaments are installed on two end plates of the arc chamber, when a certain filament current passes through, the filament is heated to emit electrons, at the same time the supplied air and the electrons mutually collide to cause ionization, and at last uniform plasma is formed, so that the arrangement of the air supply cover plate is important to the uniform air supply. The air supply cover plate (5) is made of molybdenum material which is high-temperature-resistant, high-pressure-resistant, high in strength and prominent in conductive characteristics, so that corrosion to the air supply cover plate (5) caused in an air flowing process is reduced. The invention relates to an ion injection device and belongs to the field of semiconductor manufacturing.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

Filament calibration method, device and electronic device

The invention discloses a filament correction method, a device and an electronic device, wherein, the method comprises the steps of obtaining a current filament current; Obtaining the current tube current by using the current filament current; Extracting the current correction step size and the last tube current; Adjusting the next correction step length according to the current tube current, thecurrent correction step length and the last tube current; Calculating a next filament current based on the current filament current and the next correction step. The next calibration step is adjustedaccording to the change of the current. When the change of the current is larger and larger, the calibration step is automatically reduced, and the precision of the current is improved. In addition, the accuracy of the tube current can be ensured with the least number of exposure times by the filament correction method with variable step size, and the service life of the ray tube can be prolonged.

Owner:SUZHOU POWERSITE ELECTRIC CO LTD

Magnetron control method, magnetron service life judgment method, microwave generation device, magnetron service life judgment device, processing device, computer program, and storage medium

InactiveUS7915827B2Extended service lifeImprove accuracyMagnetronsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMicrowave

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com