Filament current value calibration method and device for X-ray tube

A filament current and X-ray tube technology, which is applied to X-ray equipment, electrical components, computer tomography scanners, etc., can solve the problems of the filament current value calibration method with many exposure times, and achieves the benefits of processing, no waste of life, and reduced life. The effect of a small amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

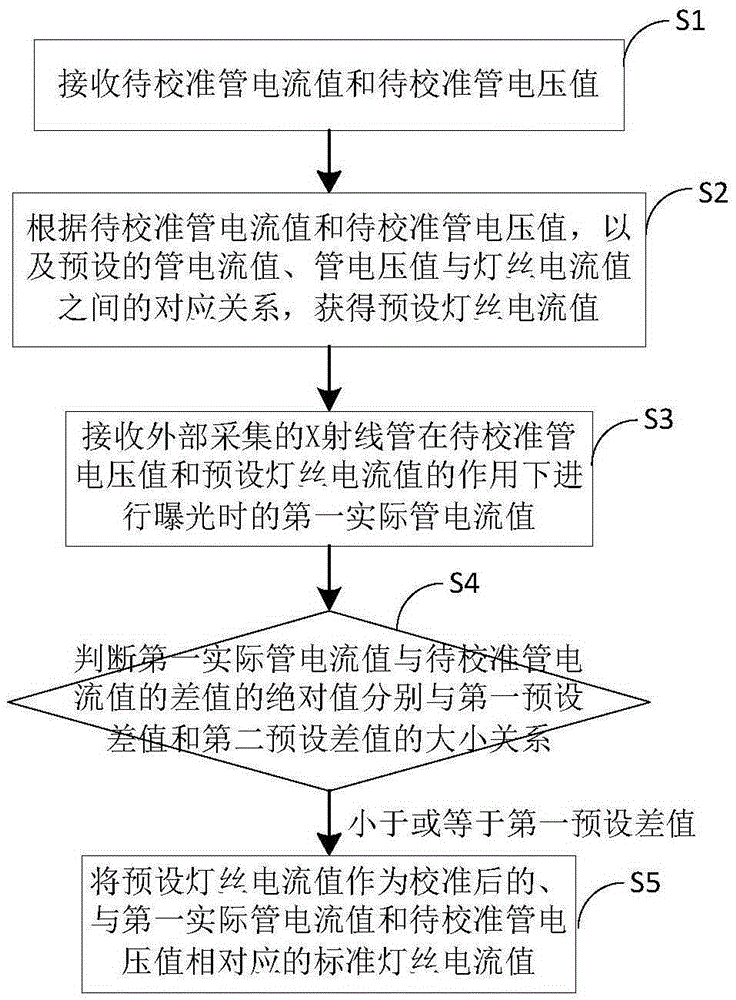

[0067] This embodiment provides a method for calibrating the filament current value of an X-ray tube, such as figure 1 As shown, the method includes the following steps:

[0068] S1. Receive a few tube current values and tube voltage values to be calibrated that need to be calibrated, not all tube current values and tube voltage values to be calibrated that need to be calibrated.

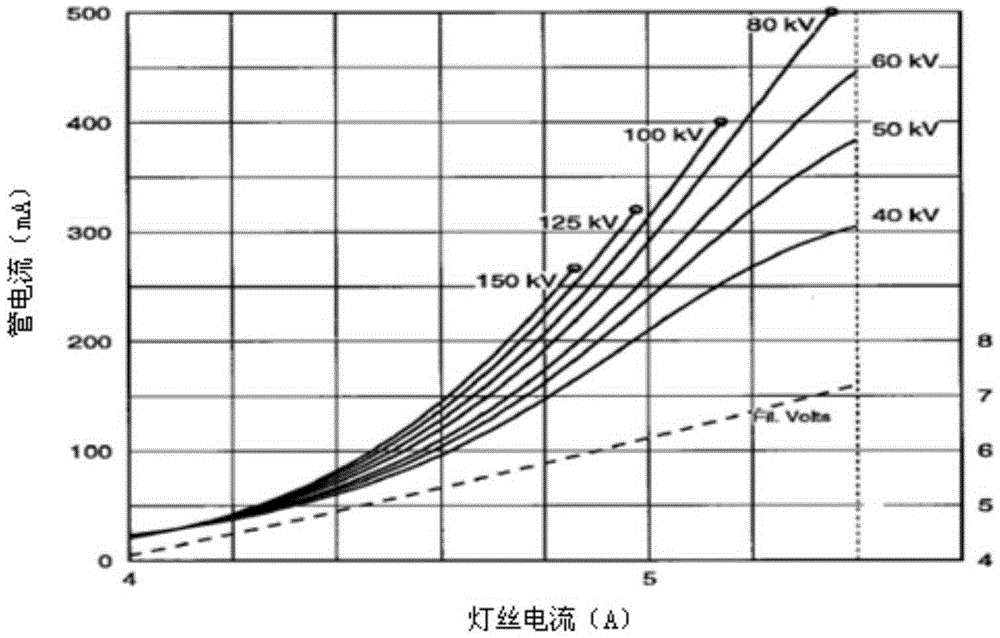

[0069] S2. Obtain a preset filament current value according to the tube current value to be calibrated, the tube voltage value to be calibrated, and the preset corresponding relationship between the tube current value, the tube voltage value, and the filament current value. Preferably, the correspondence between the above preset tube current value, tube voltage value and filament current value can be estimated by using the known tube current value and tube voltage value in the X-ray tube manual to obtain the corresponding filament current value , and stored in the form of a table. For exam...

Embodiment 2

[0106] This embodiment provides a device for calibrating the filament current value of an X-ray tube, such as Figure 4 As shown, the device includes:

[0107] The first receiving unit 1 is used to receive a few tube current values to be calibrated and tube voltage values to be calibrated;

[0108] The first obtaining unit 2 is configured to obtain a preset filament current value according to the tube current value to be calibrated, the tube voltage value to be calibrated, and the preset correspondence between the tube current value, the tube voltage value, and the filament current value;

[0109] The second receiving unit 3 is used to receive the first actual tube current value when the externally collected X-ray tube is exposed under the action of the tube voltage value to be calibrated and the preset filament current value;

[0110] The first judging unit 4 is used to judge the relationship between the absolute value of the difference between the first actual tube curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com