Hydraulic device for the injection of bone cement in percutaneous vertebroplasty

a percutaneous vertebroplasty and hydraulic device technology, applied in the medical field, can solve the problems of reducing the life expectancy, deteriorating the quality, and insufficient manual pressure, so as to reduce the overexposure of the operator to ionizing radiation, reduce the time loss, and slow down the solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

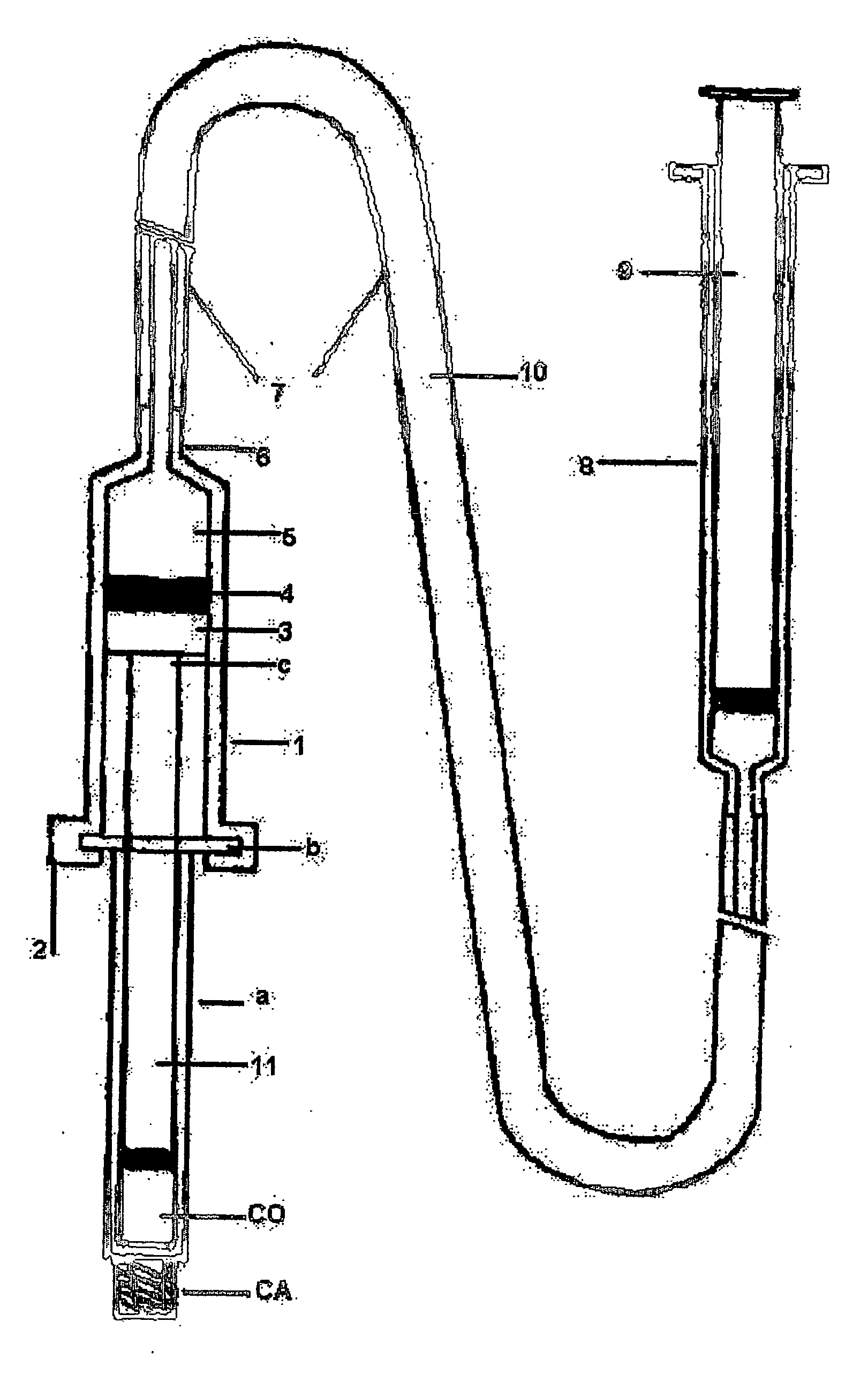

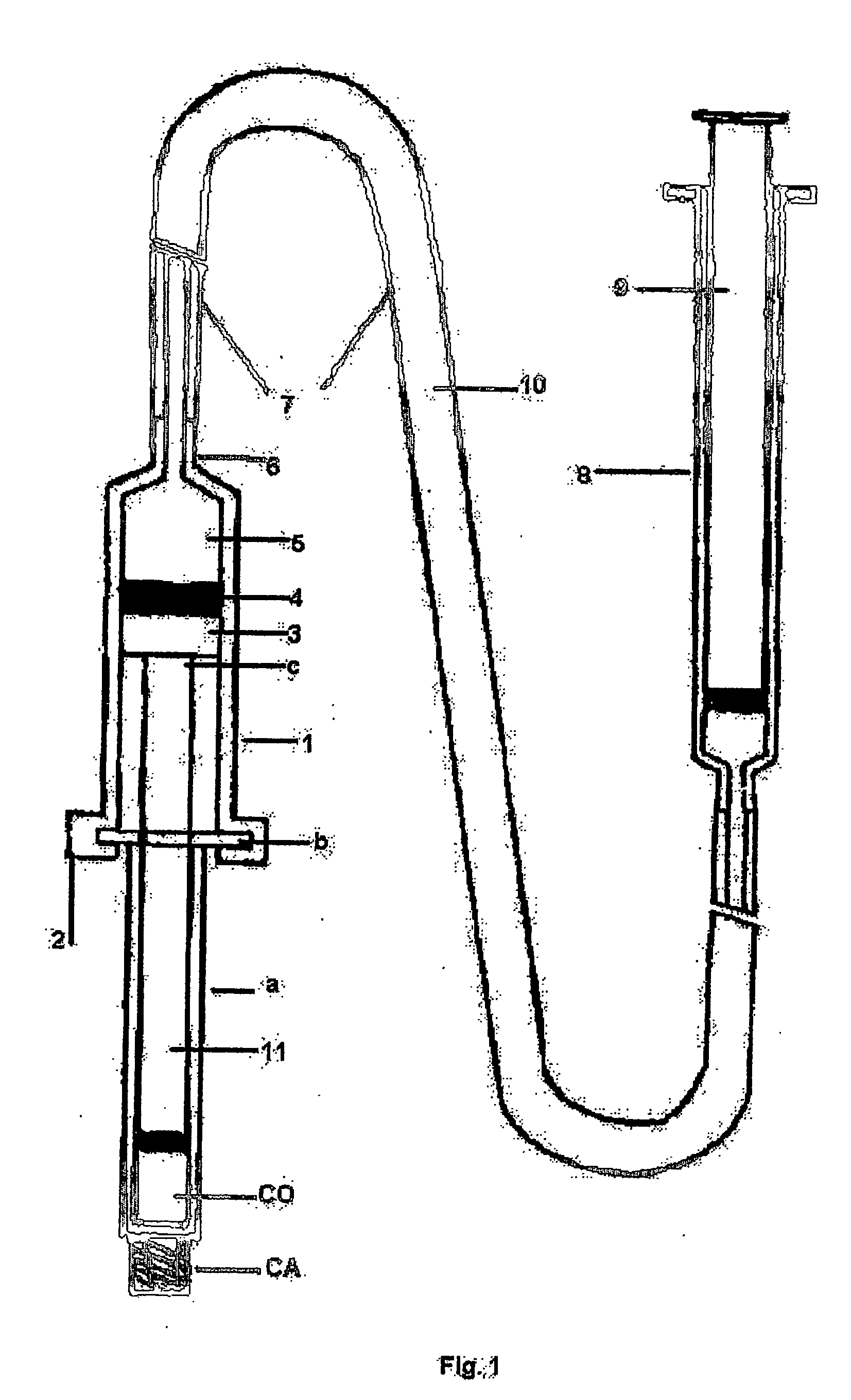

[0040] The present describes a new device and method to treat affections of the bones, specifically, in the treatment of osteoporotic or fractured vertebral bodies.

[0041] These bone structures have different pathological states of diverse ethiology (trauma, osteoporosis, primary bone tumors or metastasys, etc.). An alternative of treatment to stabilize and to consolidate this structures consists on the injection of a bio-materials such polymethylmethacrylate in the interior of the vertebral body for healing purpose.

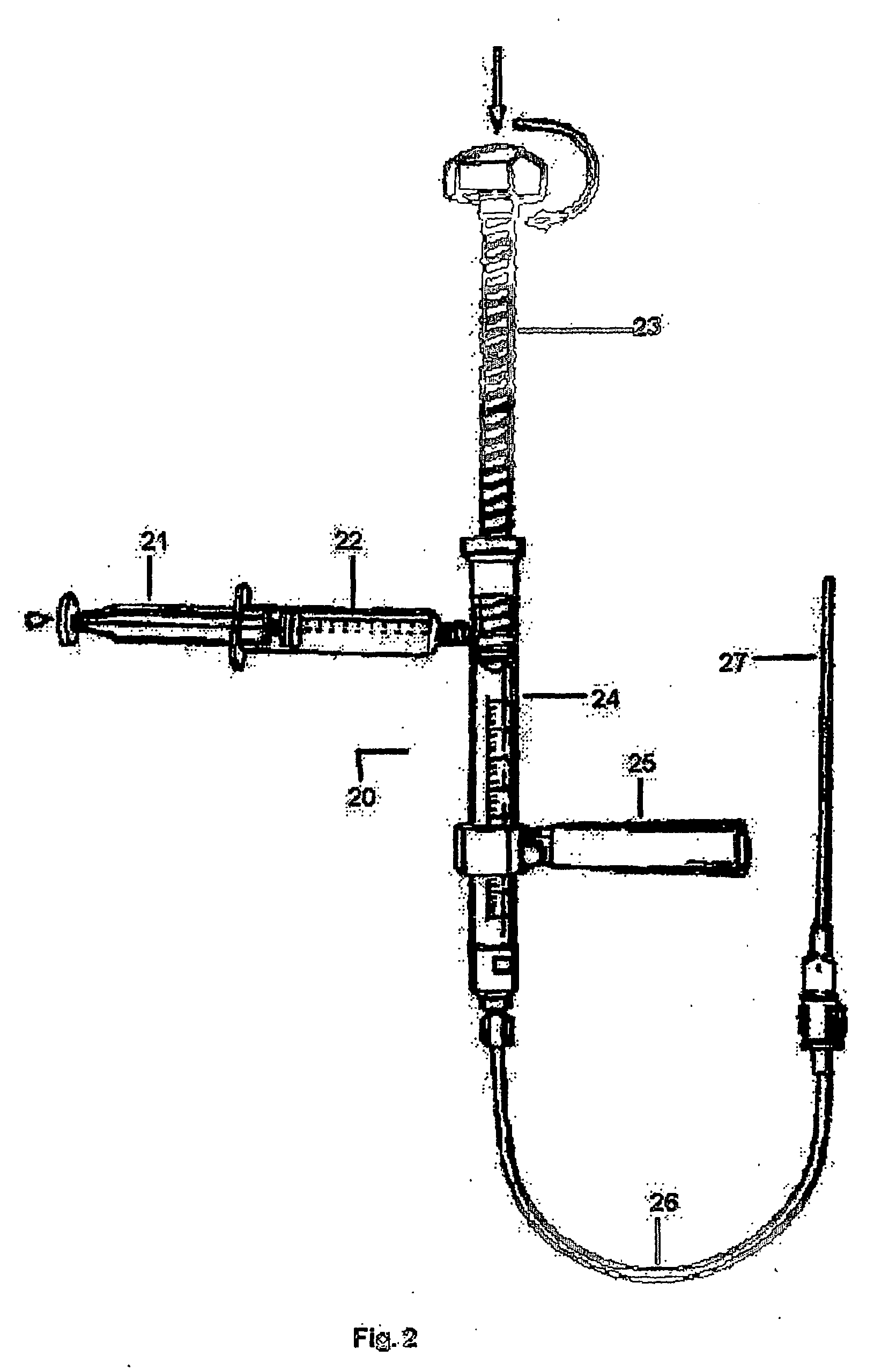

[0042] The injection of biomaterials such as bone cement is carried out by means of a hydraulic device exerting pressure on small caliber conventional syringes connected directly to the needle; since the cement has the property of becoming hard quickly.

[0043] The theoretical basic principle for the operation of the device of the present invention consists on the amplification of the hydraulic pressure generated at distance and transmitted by the hydraulic tube.

[0044] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com