Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

431 results about "Grating pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

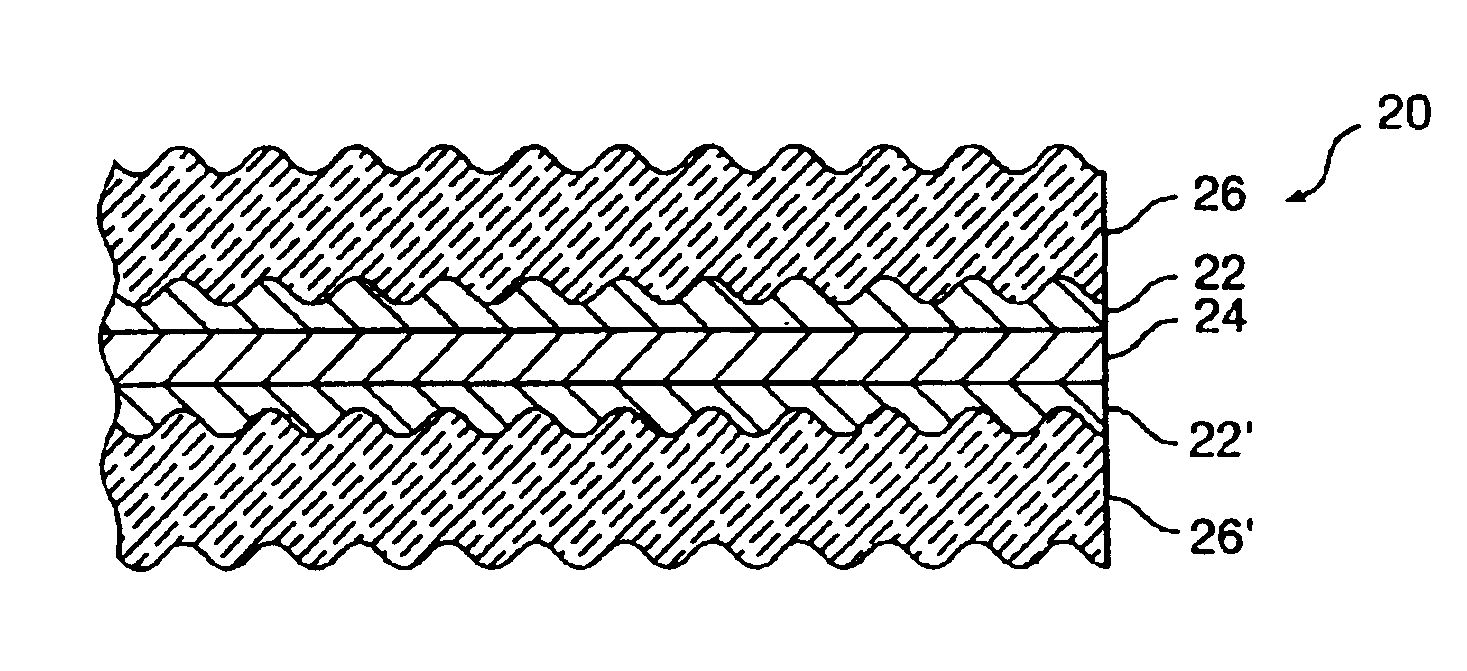

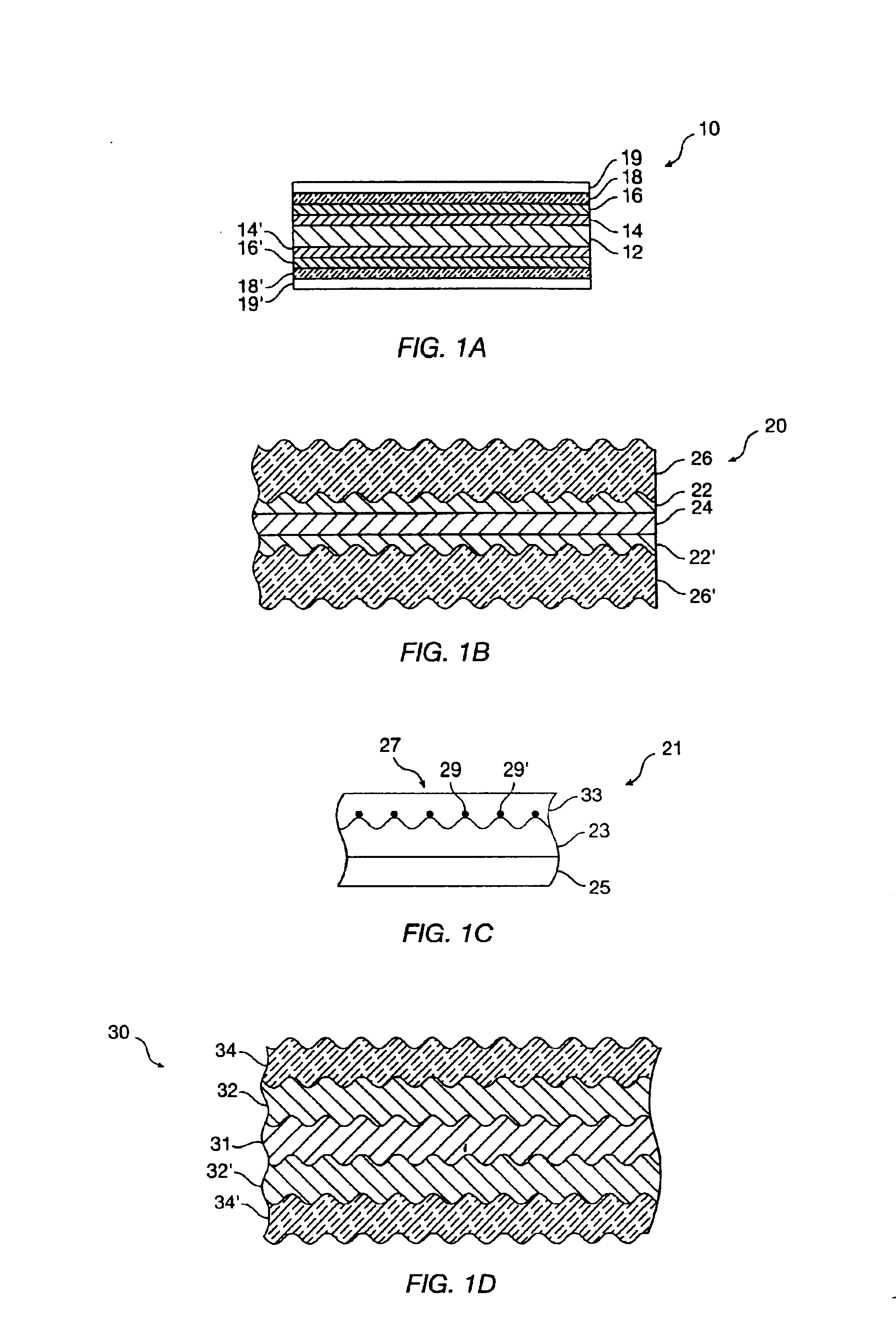

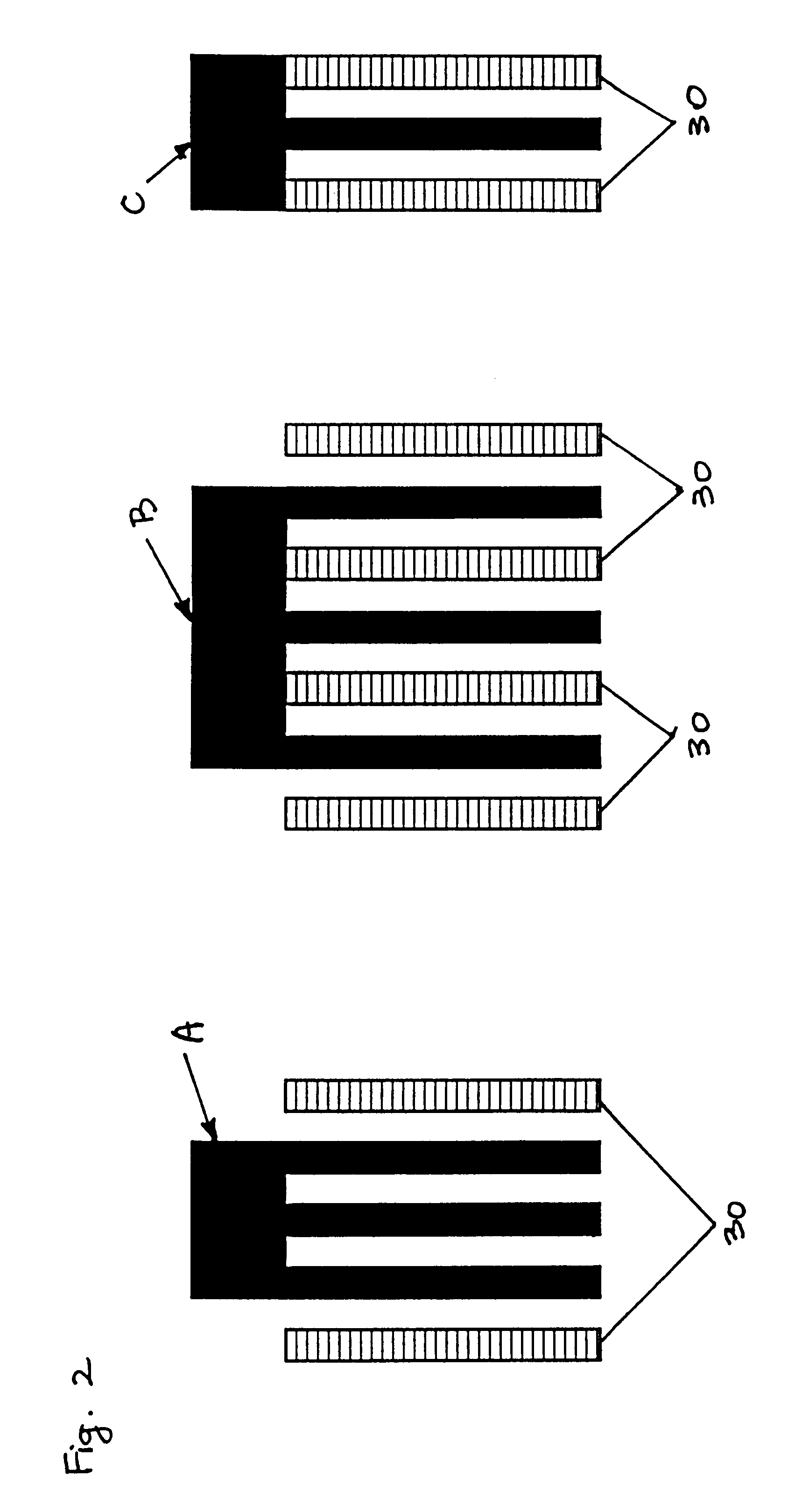

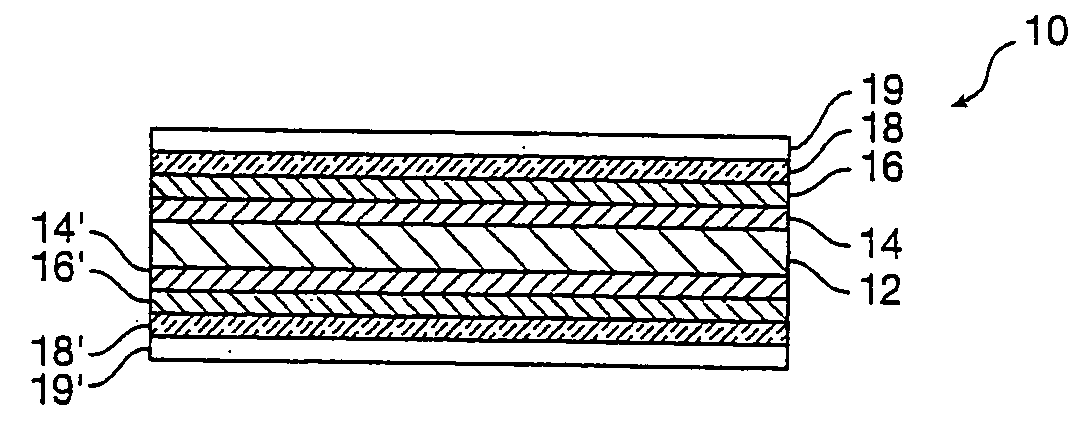

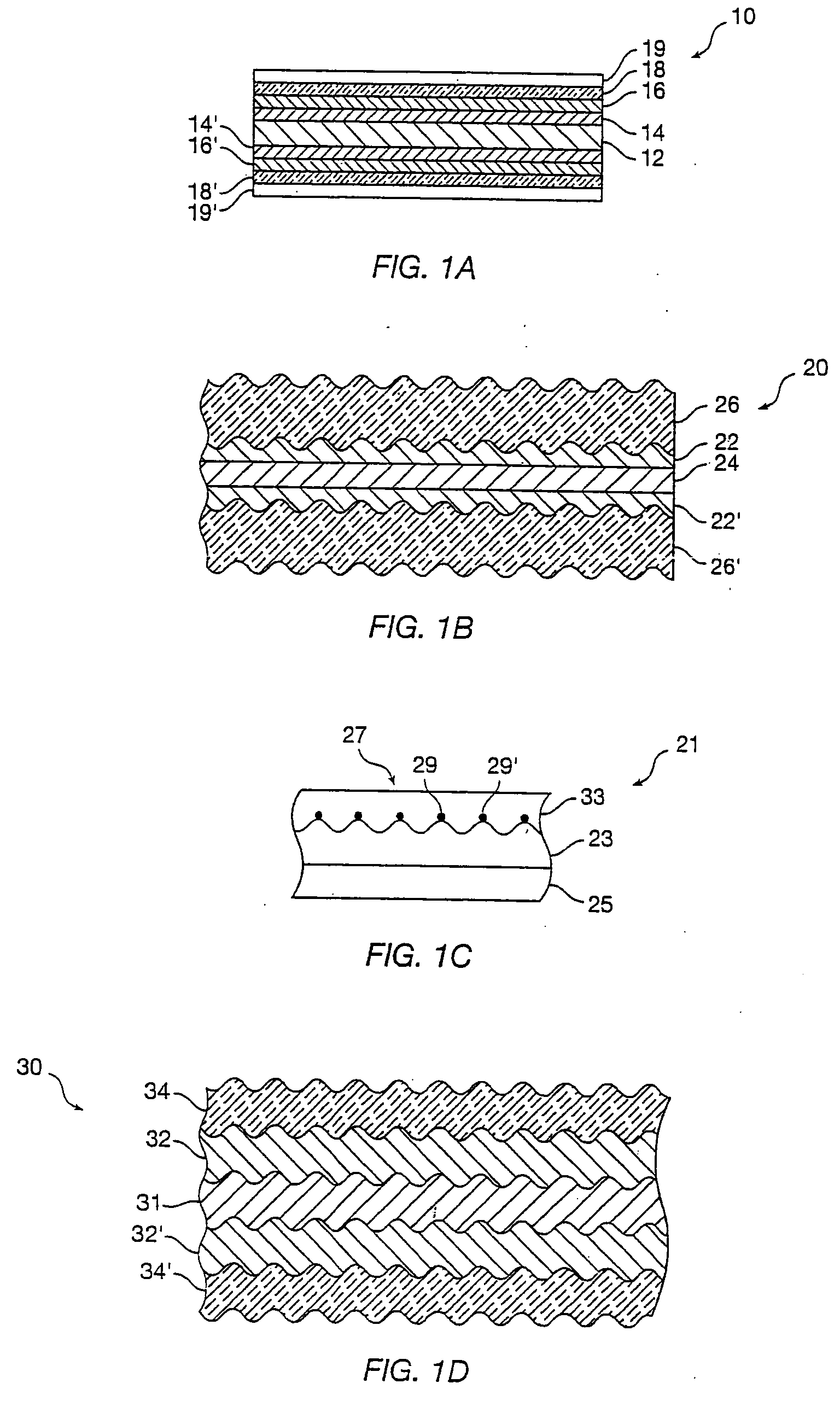

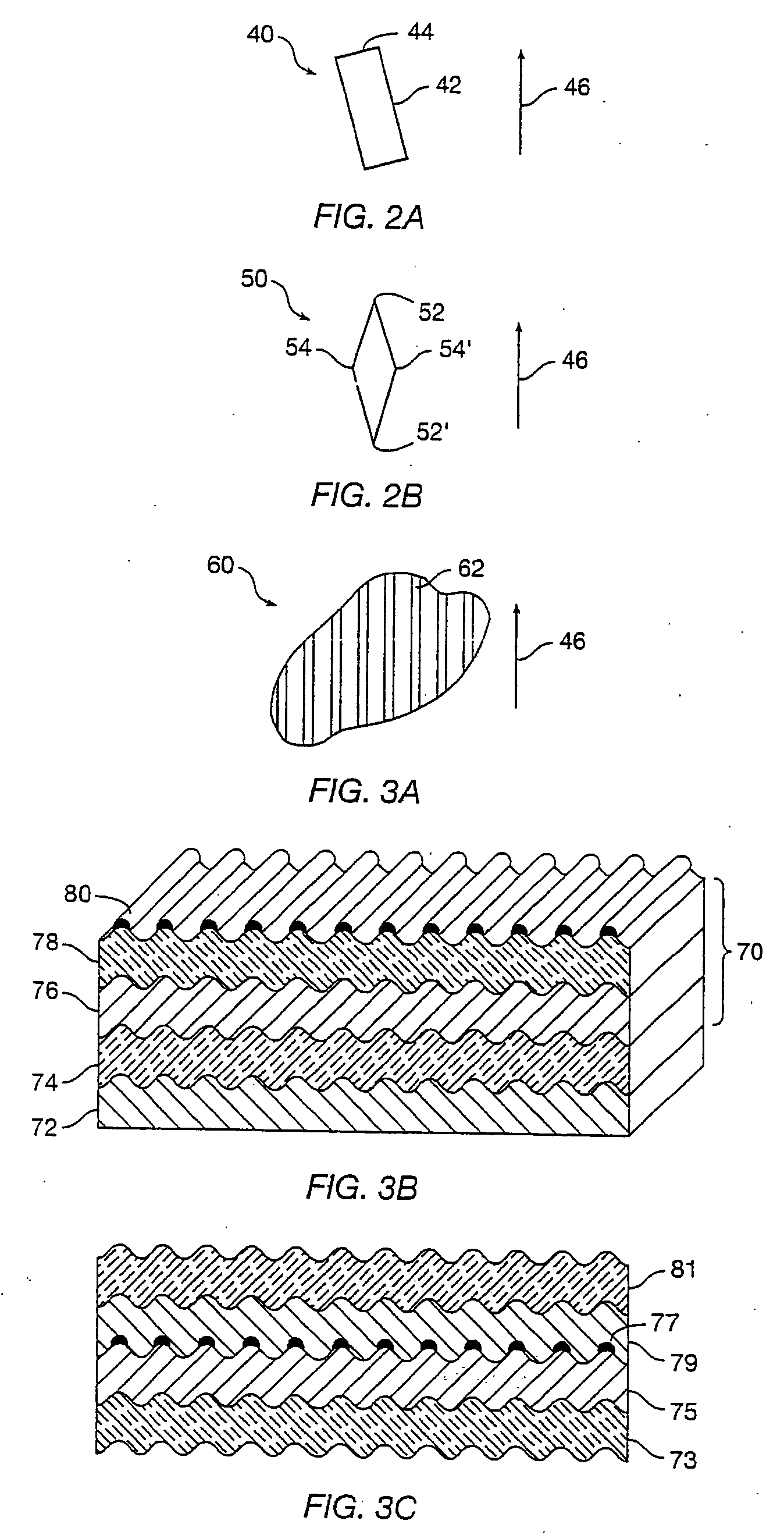

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

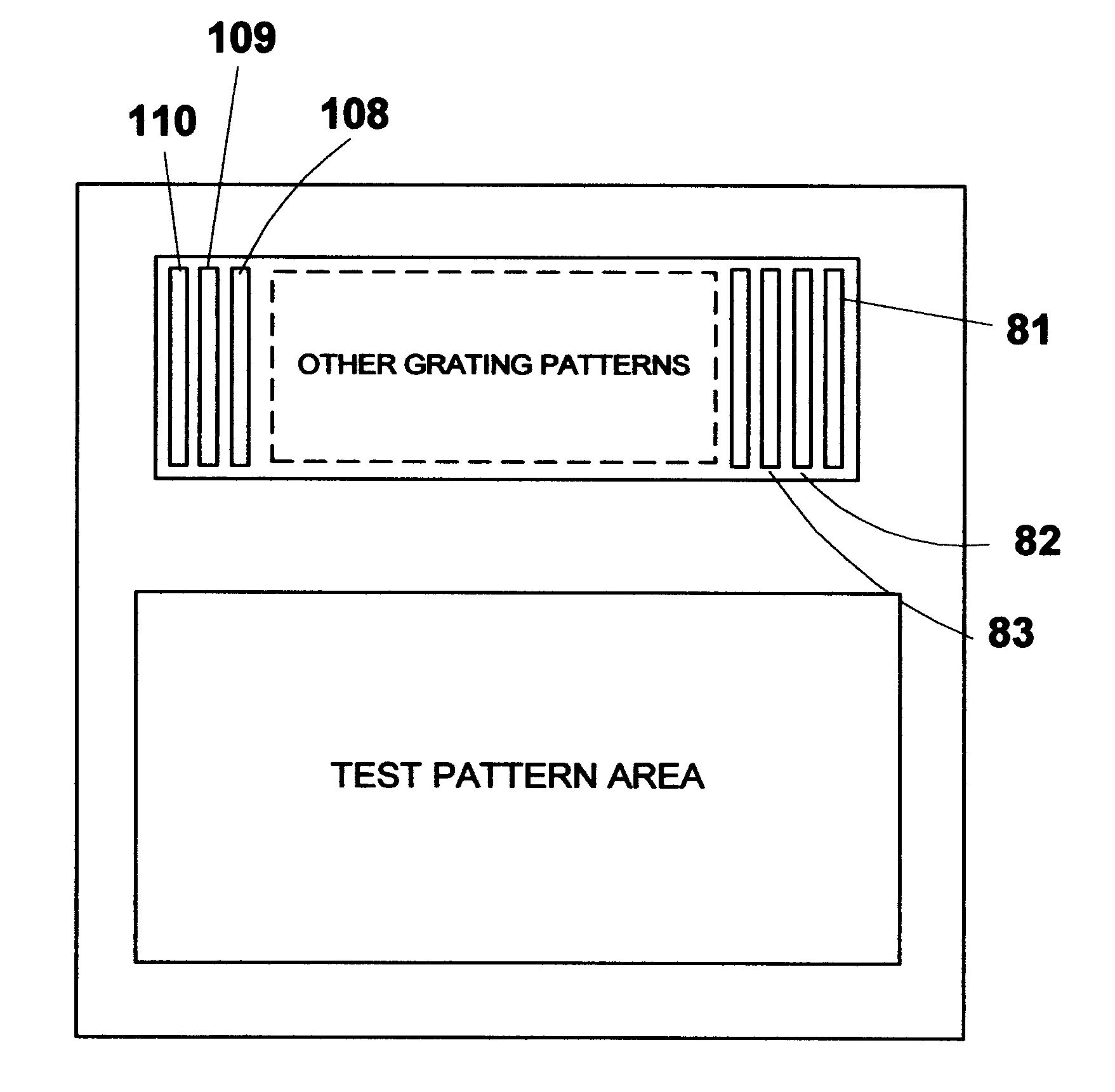

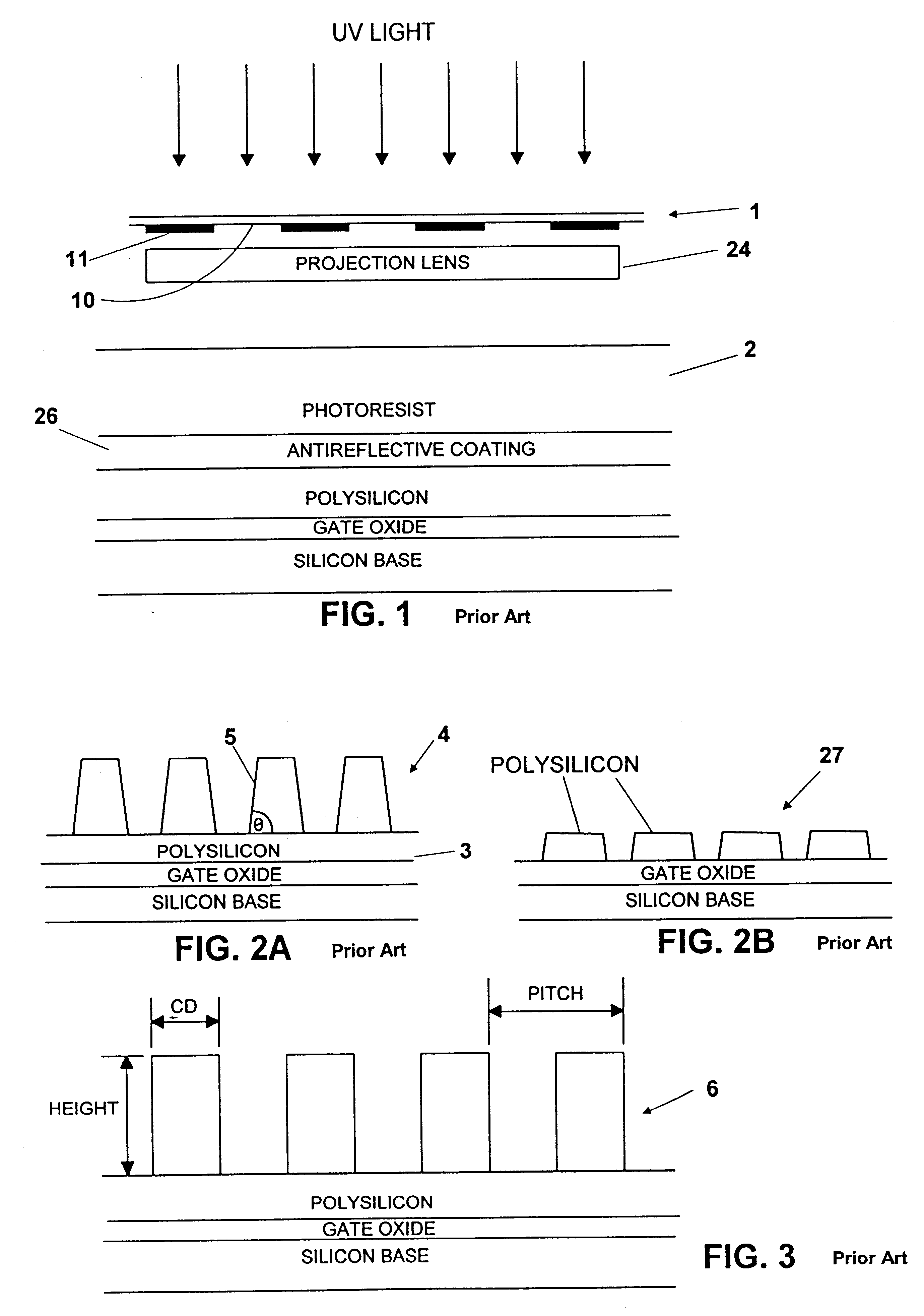

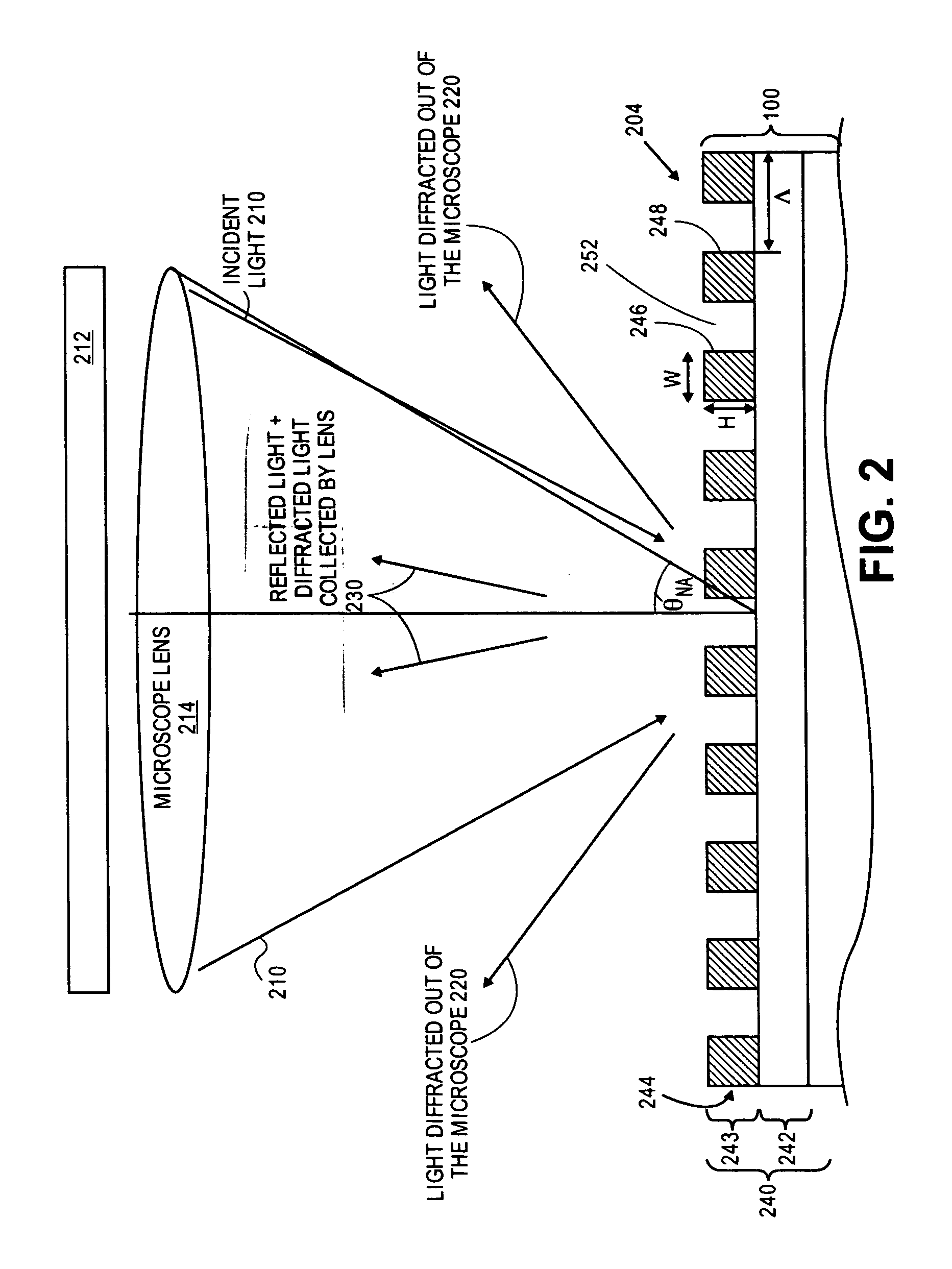

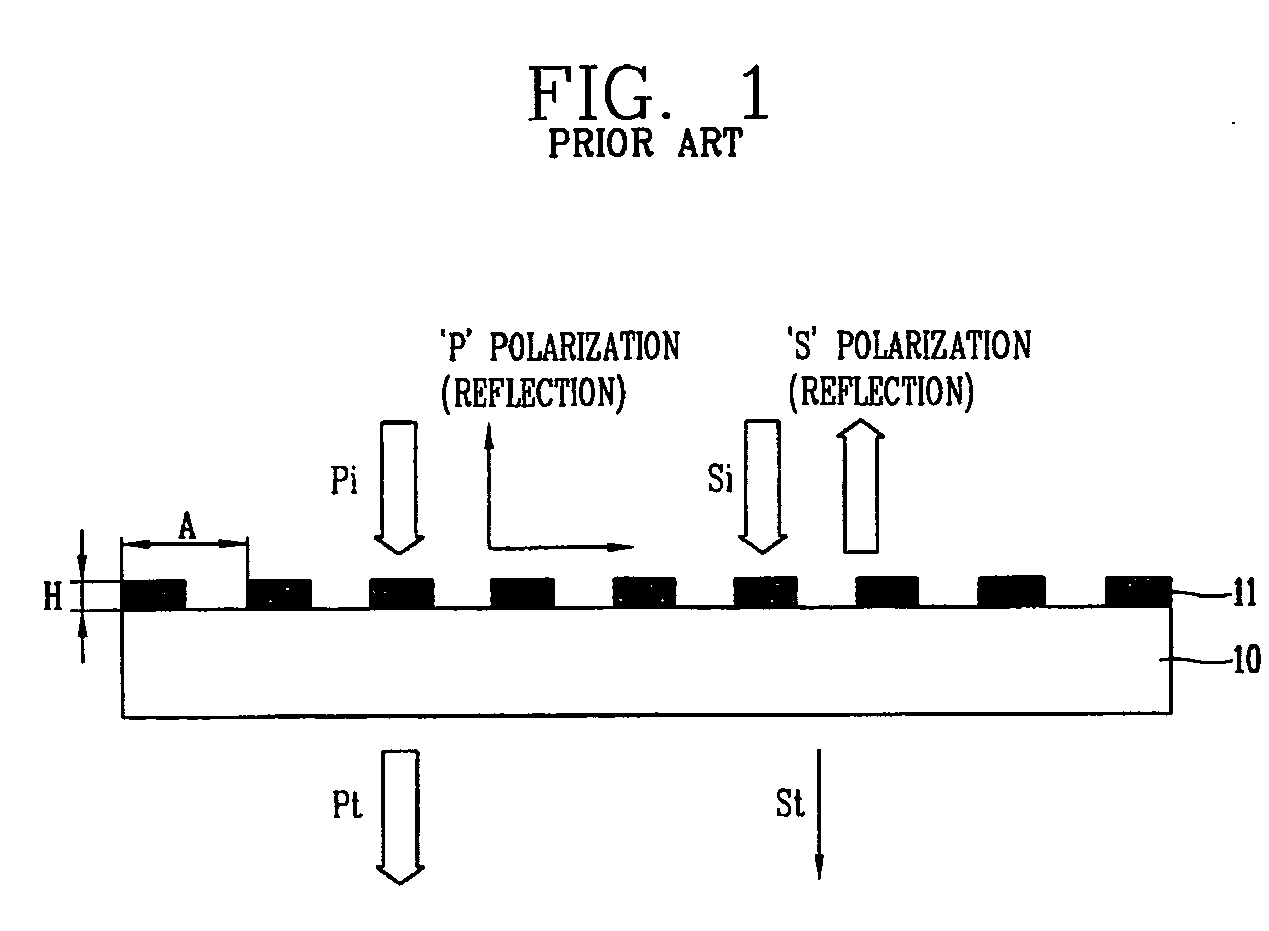

Method and apparatus for the determination of mask rules using scatterometry

InactiveUS6433878B1Polarisation-affecting propertiesSemiconductor/solid-state device manufacturingGrating patternPhotolithography

A method and apparatus for determining optical mask corrections for photolithography. A plurality of grating patterns is printed onto a wafer utilizing a photomask having at least one grating. Each grating pattern within the plurality of grating patterns is associated with known photolithographic settings. Each grating pattern is illuminated independently with a light source, so that light is diffracted off each grating pattern. The diffracted light is measured utilizing scatterometry techniques to determine measured diffracted values. The measured diffracted values are compared to values in a library to determine a profile match. A 2-dimensional profile description is assigned to each grating pattern based on the profile match. A database is compiled of the profile descriptions for the plurality of grating patterns. Photomask design rules are then generated by accessing the database containing the 2-dimensional profile descriptions. In preferred embodiments, the design rules are used to create and correct masks containing OPC corrections, phase-shifting mask corrections and binary masks. In a preferred embodiment the at least one grating is a bi-periodic grating. In a preferred embodiment, the scatterometry technique is optical digital profilometry utilizing a reflectometer or ellipsometer.

Owner:TOKYO ELECTRON US HOLDINGS INC

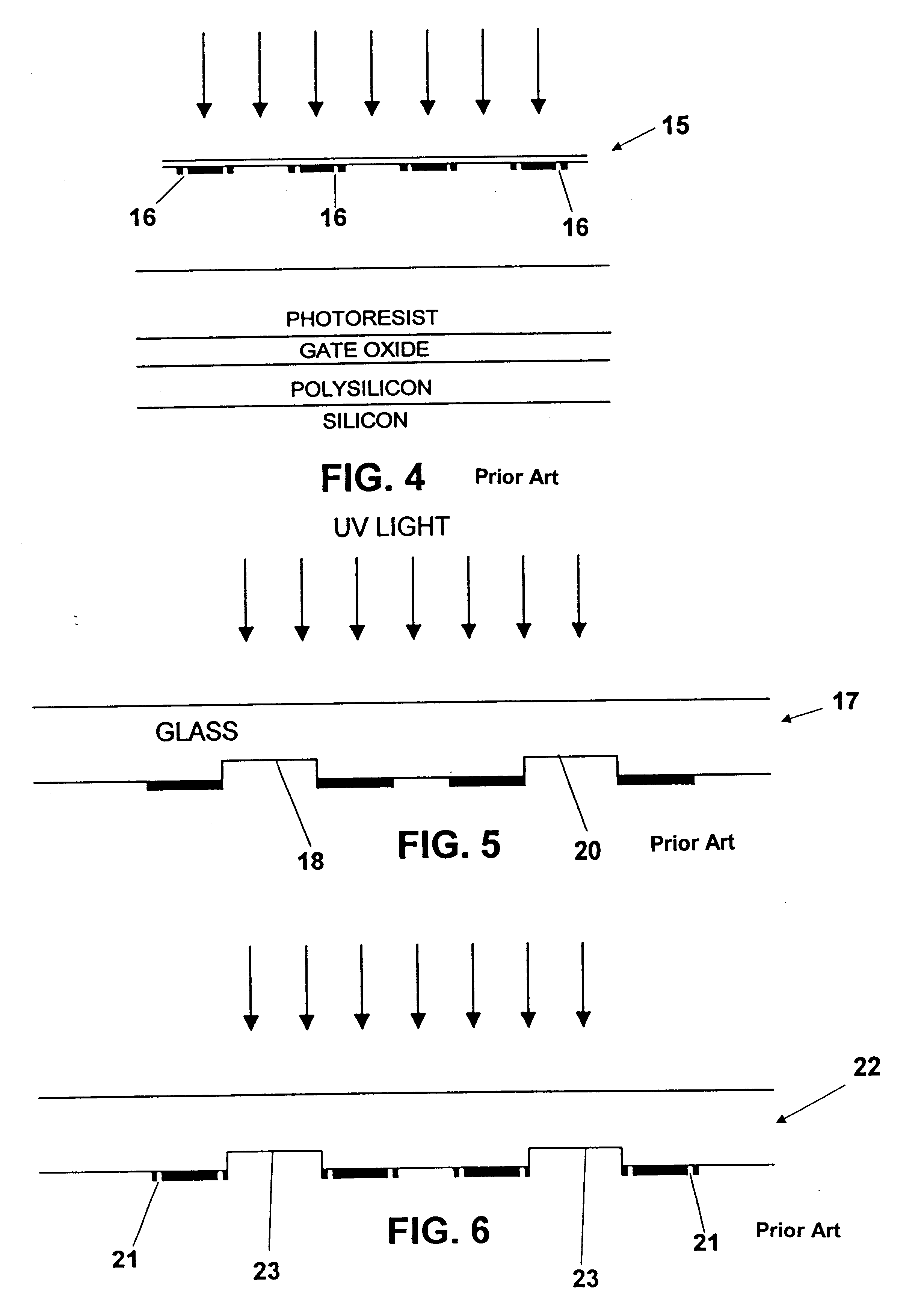

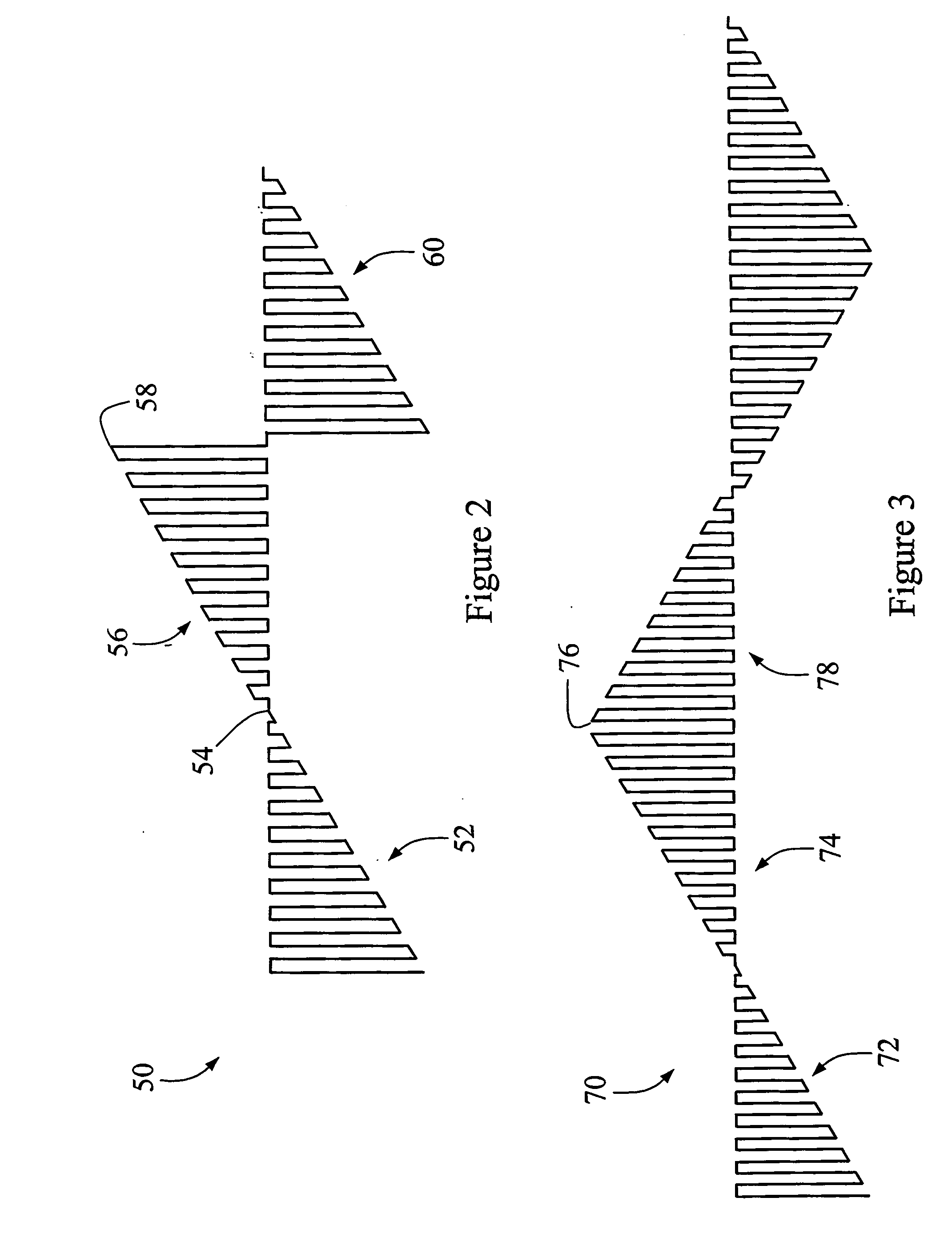

Optimized alternating phase shifted mask design

InactiveUS6338922B1Overcome problemsReduce impactPhotomechanical exposure apparatusMicrolithography exposure apparatusPhase shiftedGrating pattern

A method for reducing lens aberrations sensitivity and proximity effects of alternating phase shifted masks is described. The critical features of a chip design layout are first identified. Multiple, narrow phase regions and auxiliary phase transitions, which provide additional opaque features, are then formed alongside the critical features such that a grating pattern of substantially uniform pitch is printed. Together with a complementary trim mask, the circuit pattern so delineated has reduced sensitivity to lens aberrations and proximity effects.

Owner:IBM CORP

Alignable diffractive pigment flakes

Diffractive pigment flakes are selectively aligned to form an image. In one embodiment, flakes having a magnetic layer are shaped to facilitate alignment in a magnetic field. In another embodiment, the flakes include a magnetically discontinuous layer. In a particular embodiment, deposition of nickel on a diffraction grating pattern produces magnetic needles along the grating pattern that allow magnetic alignment of the resulting diffractive pigment flakes. Color scans of test samples of magnetically aligned flakes show high differentiation between illumination parallel and perpendicular to the direction of alignment of the magnetic diffractive pigment flakes.

Owner:VIAVI SOLUTIONS INC

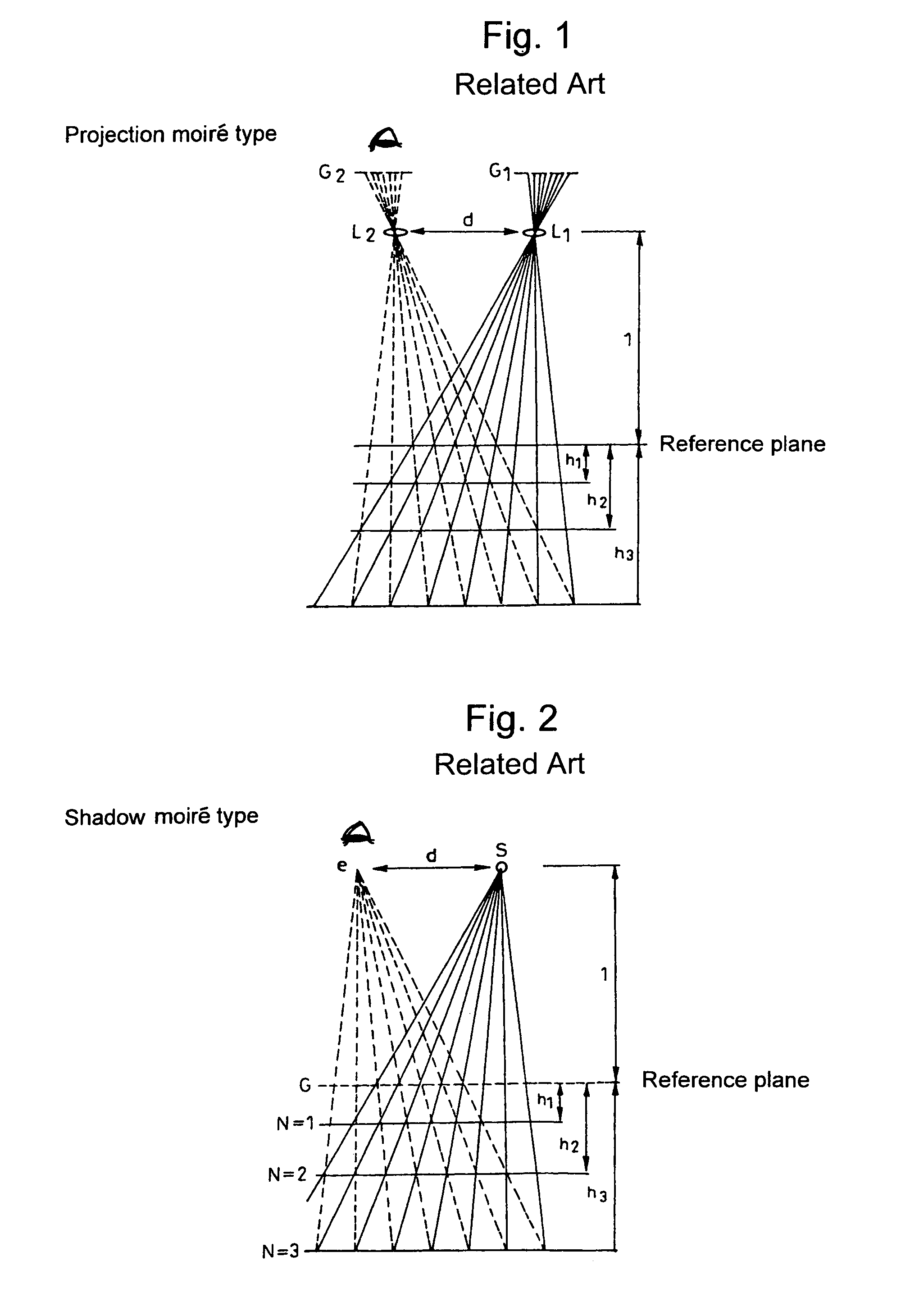

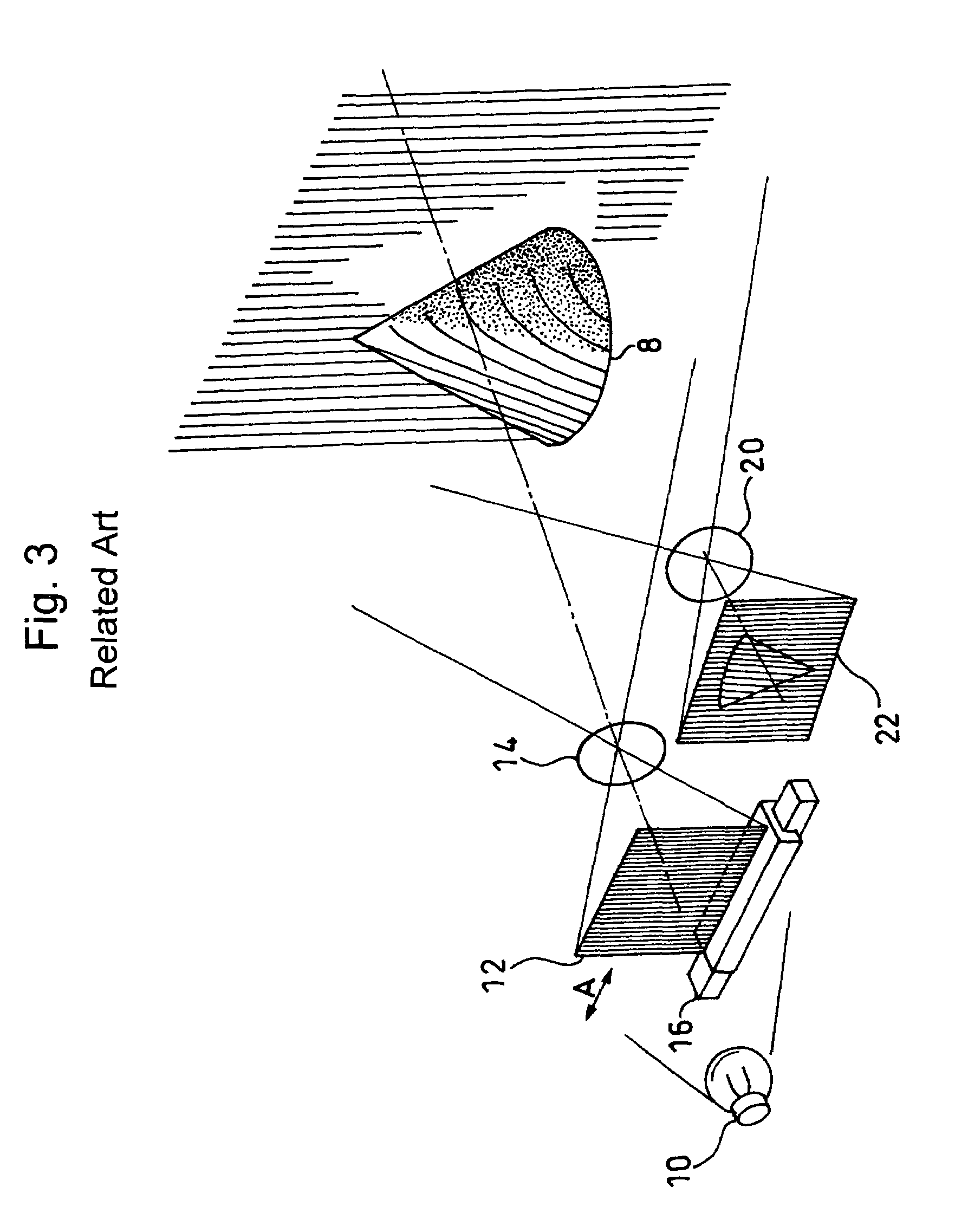

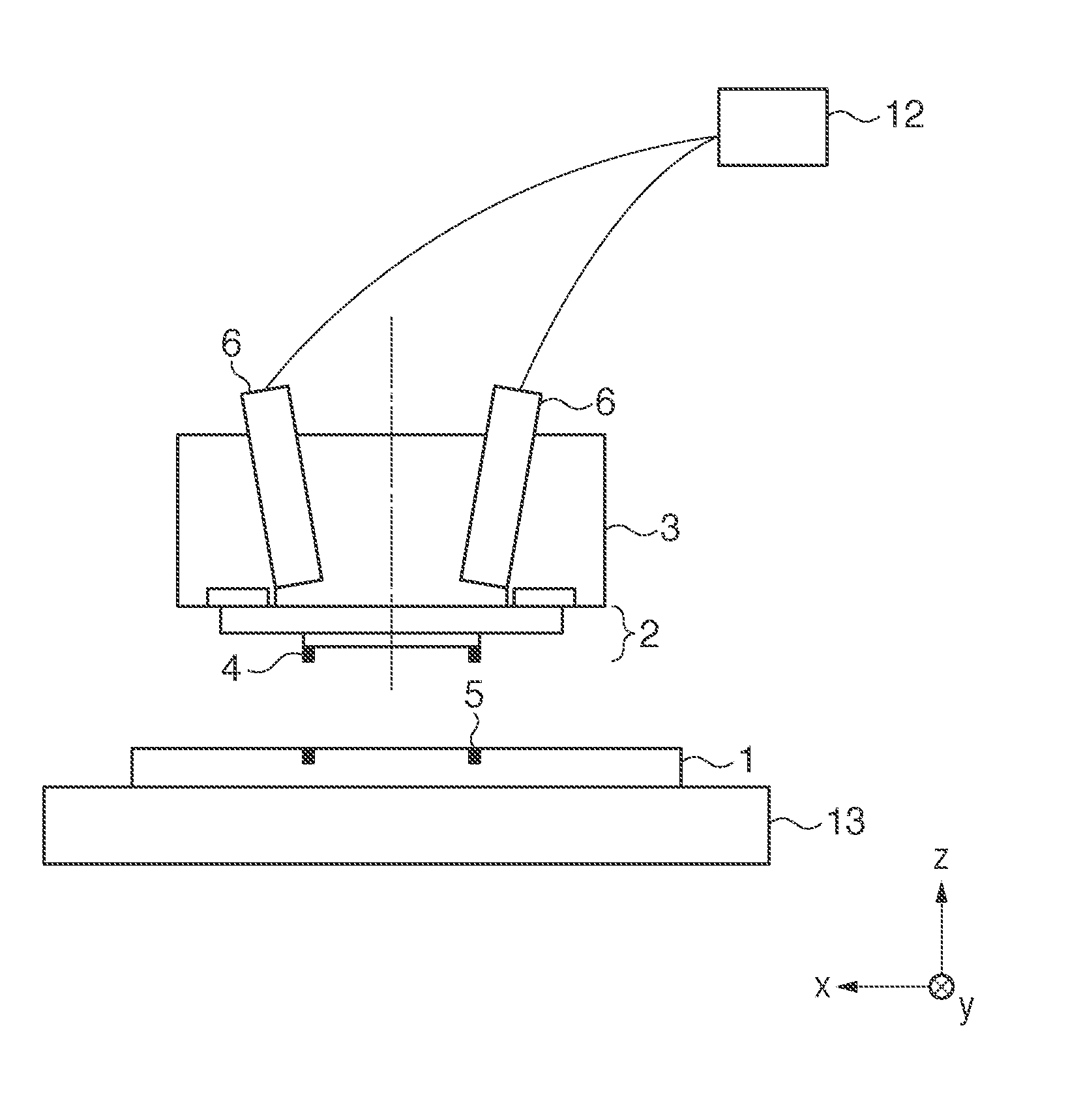

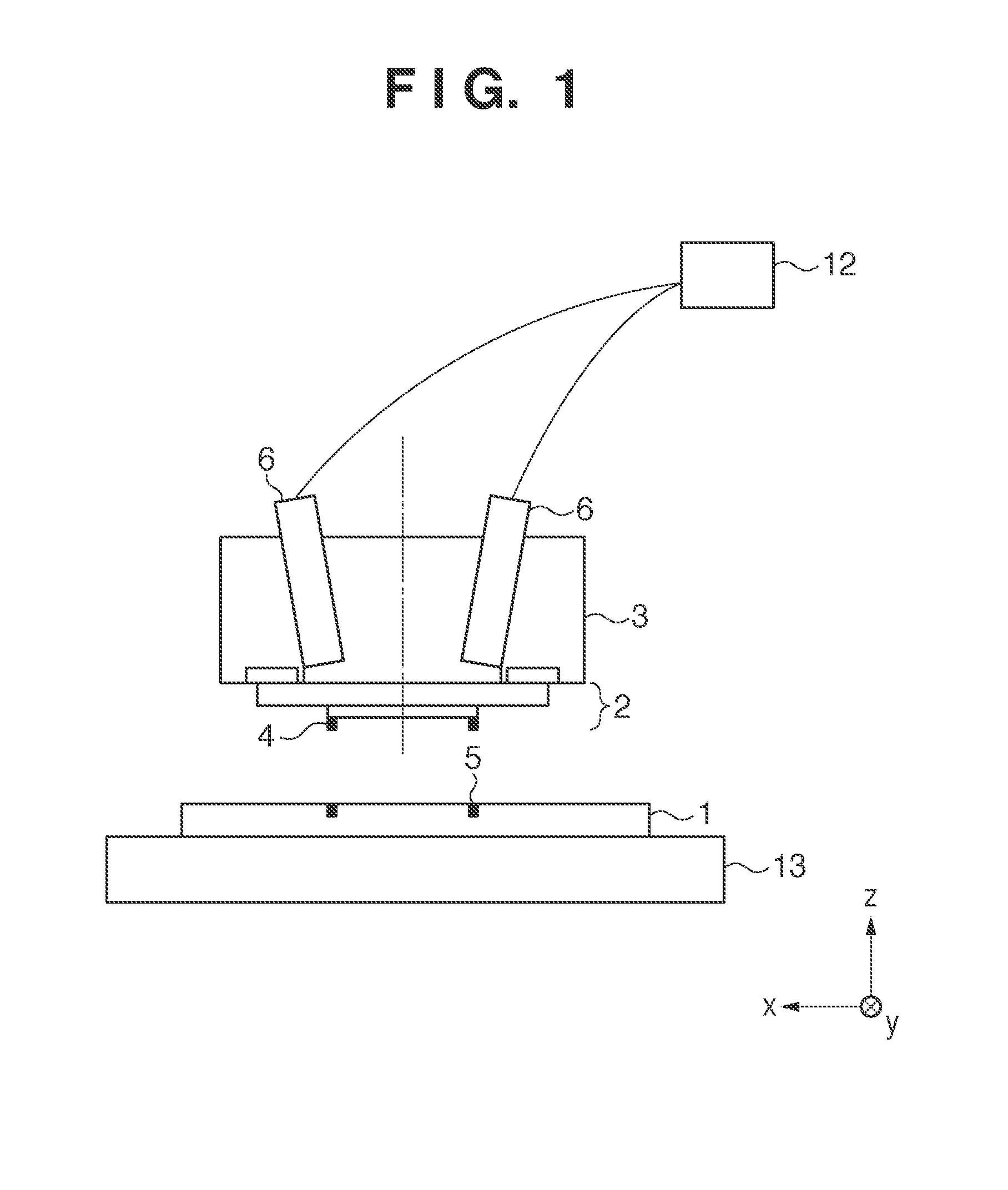

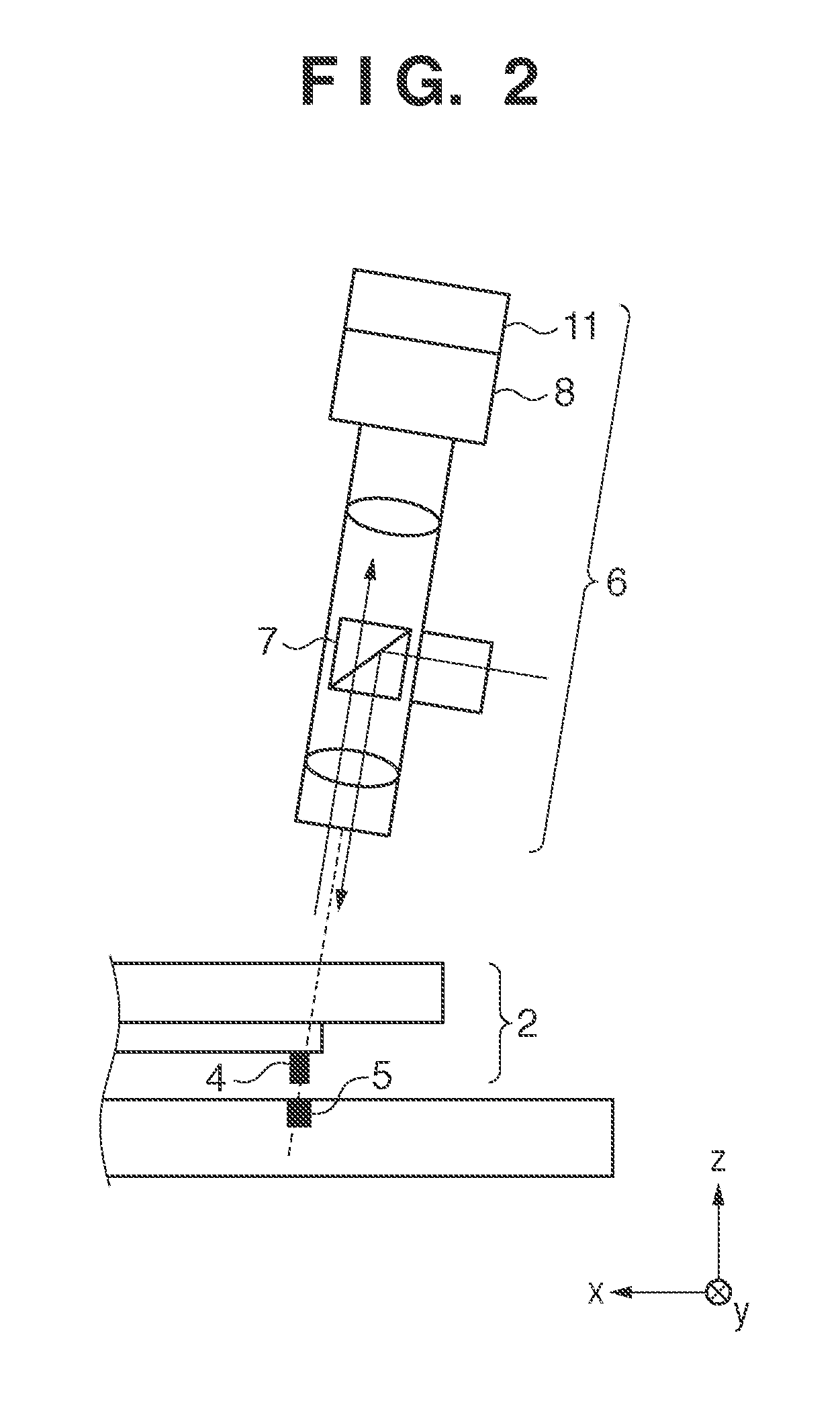

Method and apparatus for non-contact three-dimensional surface measurement

ActiveUS7286246B2Simple configurationSmall sizeInvestigating moving sheetsCharacter and pattern recognitionThree dimensional shapeAcoustics

A non-contact three-dimensional surface measurement method is provided in which a grating pattern projected onto an object being measured, while the phase of the pattern is being shifted, is observed in a different direction from a projection direction to analyze the contrast of a grating image deformed in accordance with the shape of the object and thereby obtain the shape thereof. The method enables measurement of a three-dimensional shape over a large measurement range in a short time in a non-contact manner by successively shifting the focus on the projection and the imaging sides to enlarge the measurement range in the direction of depth.

Owner:MITUTOYO CORP

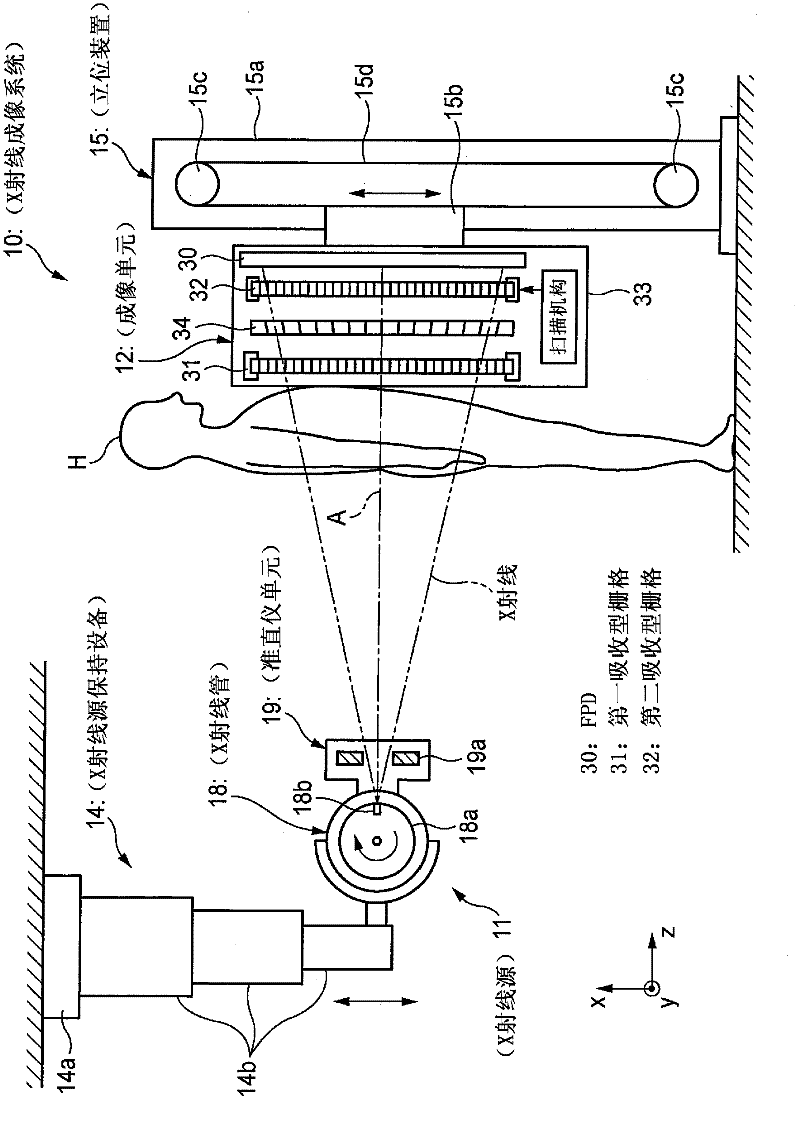

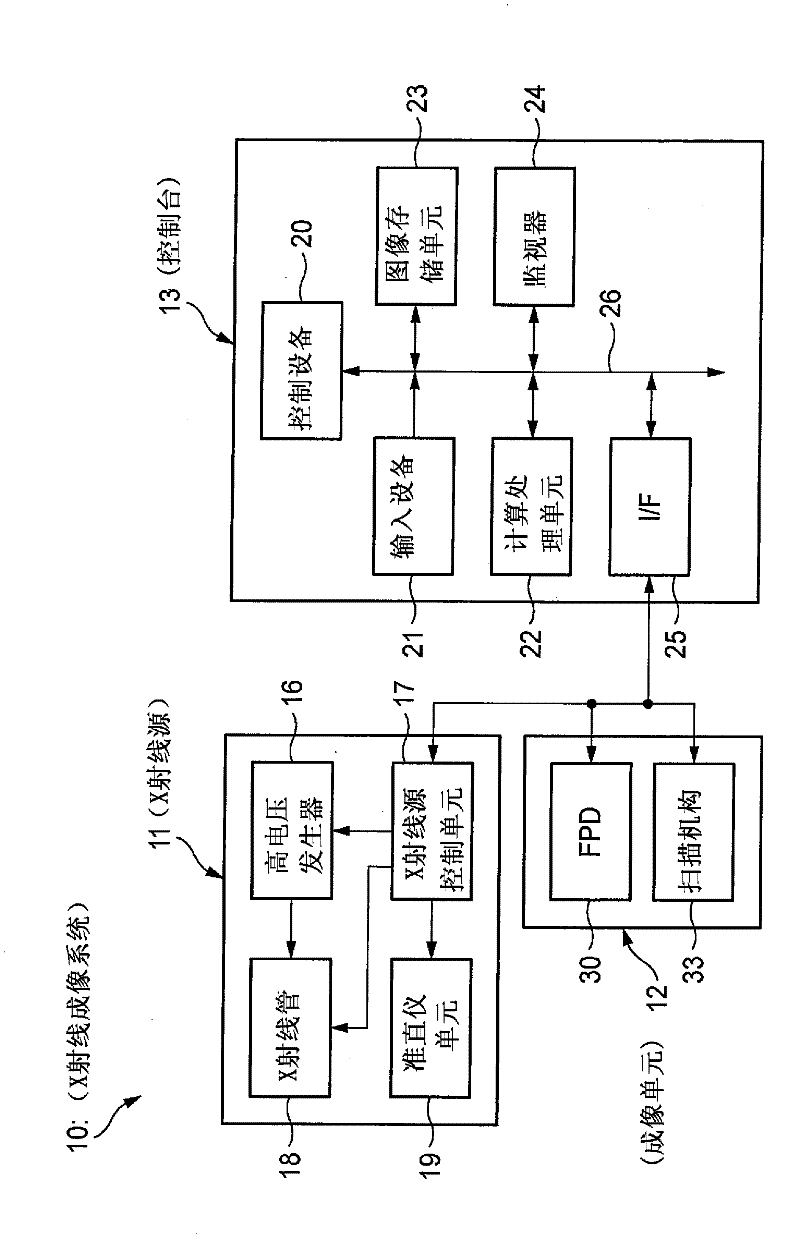

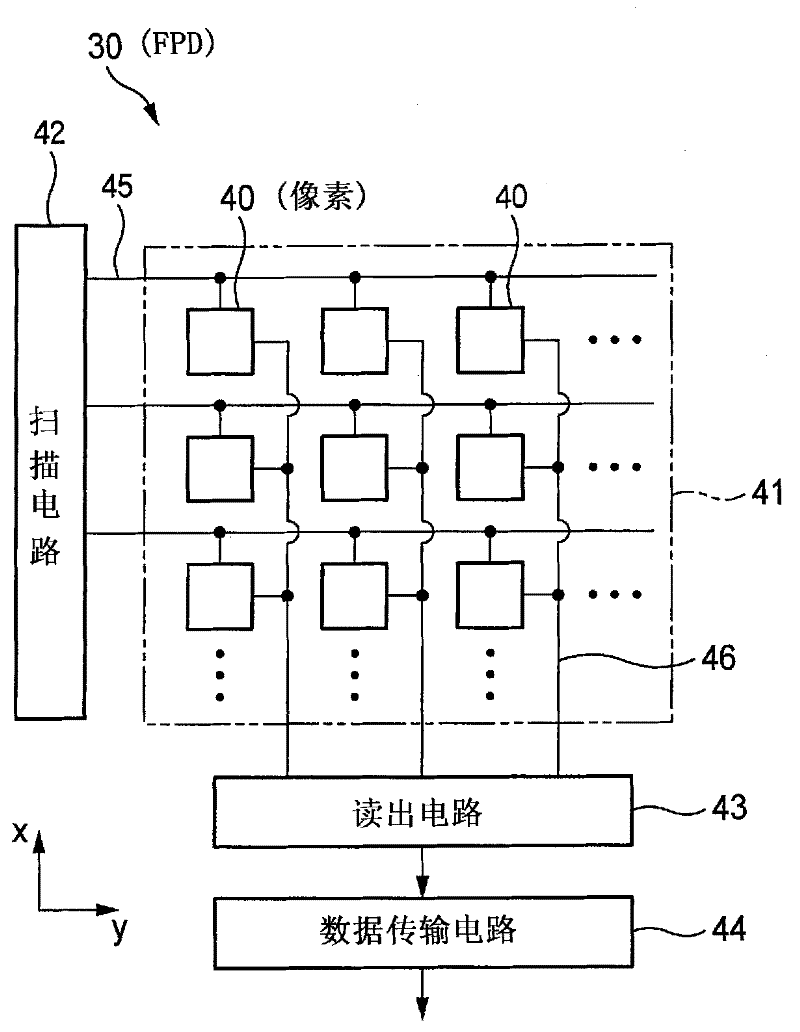

Radiological image detection apparatus, radiographic apparatus and radiographic system

InactiveUS20120163554A1Reduce scattered radiationReduce radiationMusculoskeletal system evaluationRadiation/particle handlingImage detectionGrating pattern

A radiological image detection apparatus includes a first grating unit, a grating pattern unit, a radiological image detector, and an anti-scatter grating. The grating pattern unit has a period that substantially coincides with a pattern period of a radiological image formed by radiation having passed through the first grating unit. The radiological image detector detects the radiological image masked by the grating pattern unit. The anti-scatter grating is arranged on a path of the radiation incident onto the radiological image detector and removes scattered radiation. A smoothing process is performed for at least one of a surface and a backside of the anti-scatter grating intersecting with a traveling direction of the radiation.

Owner:FUJIFILM CORP

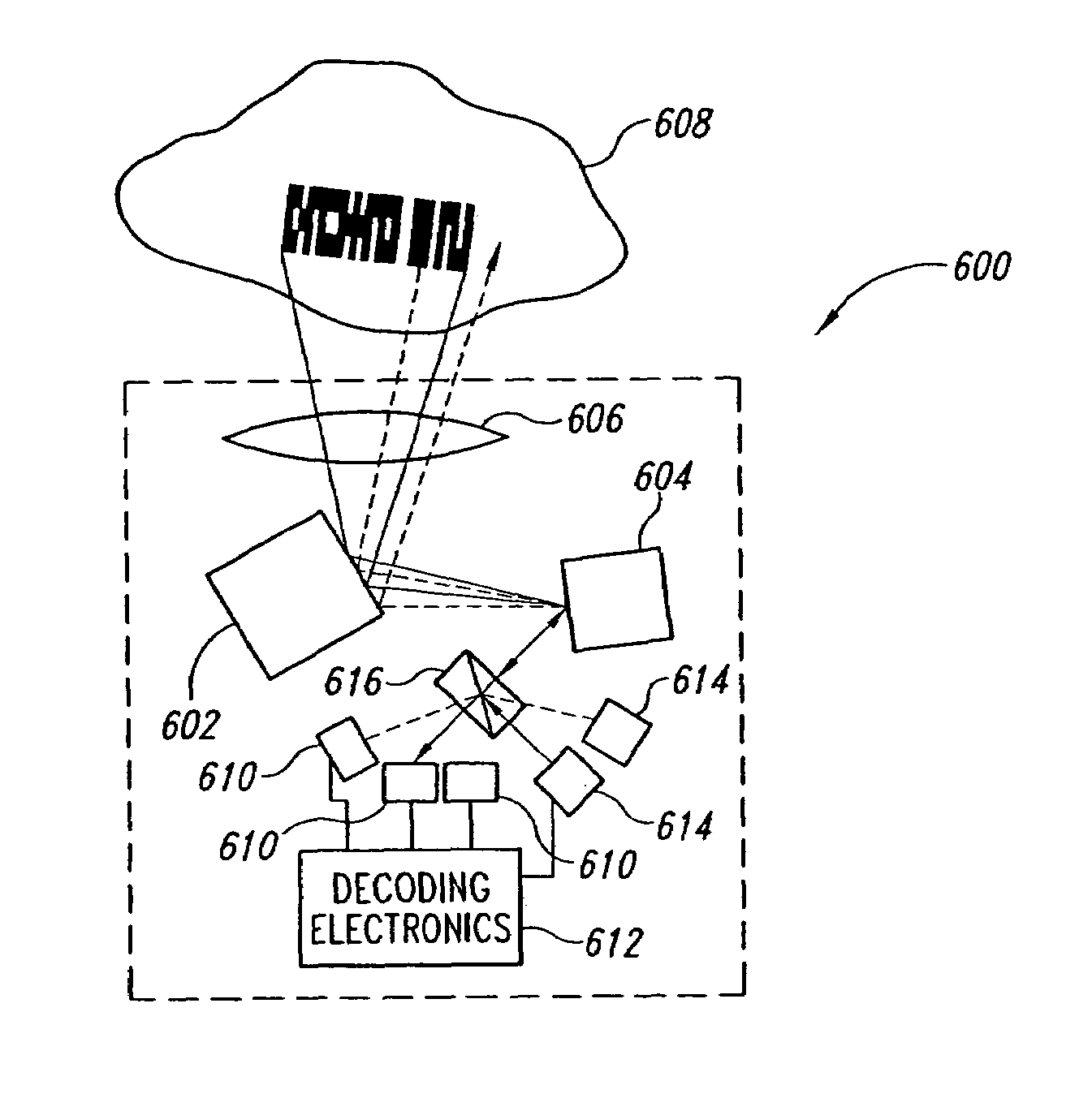

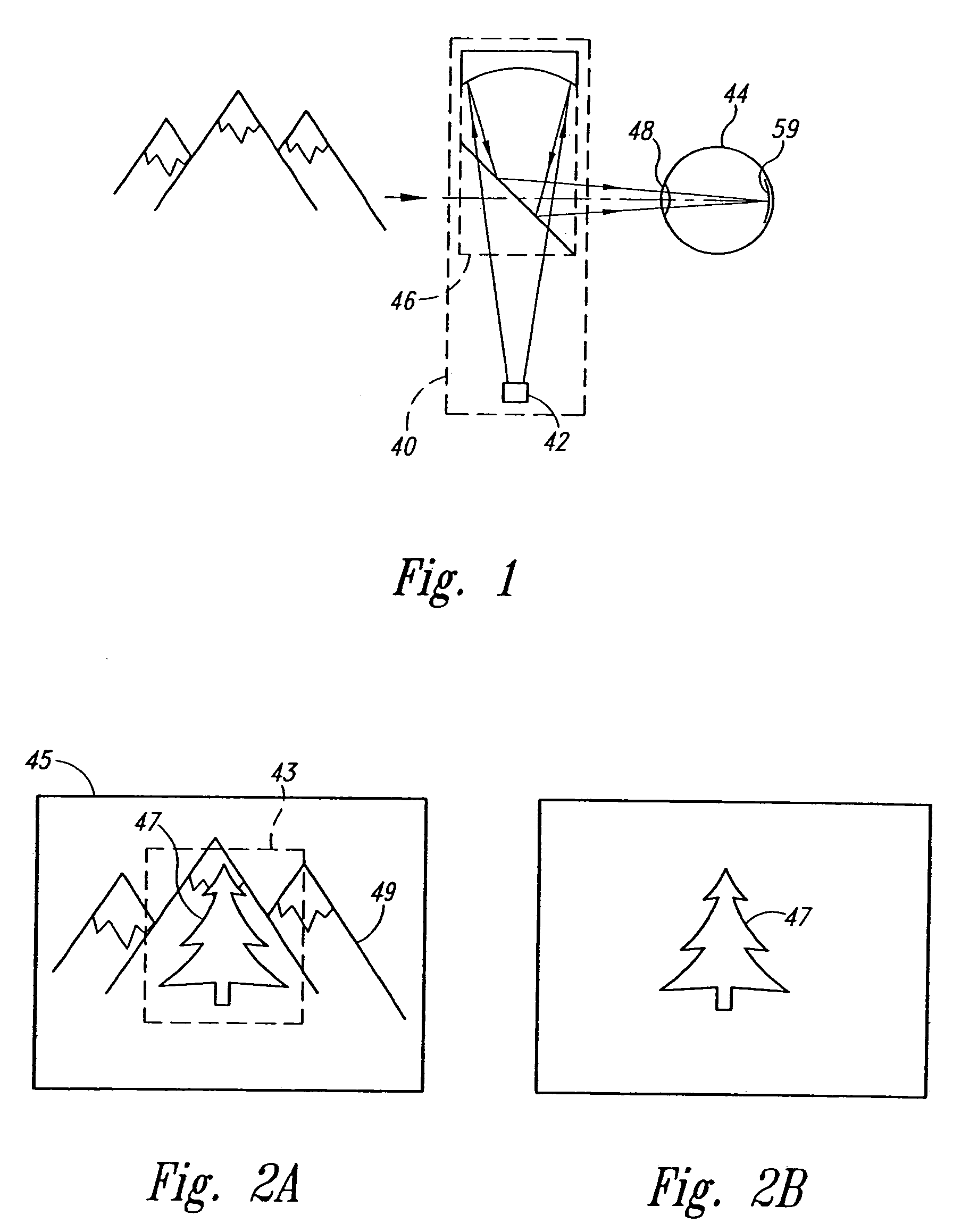

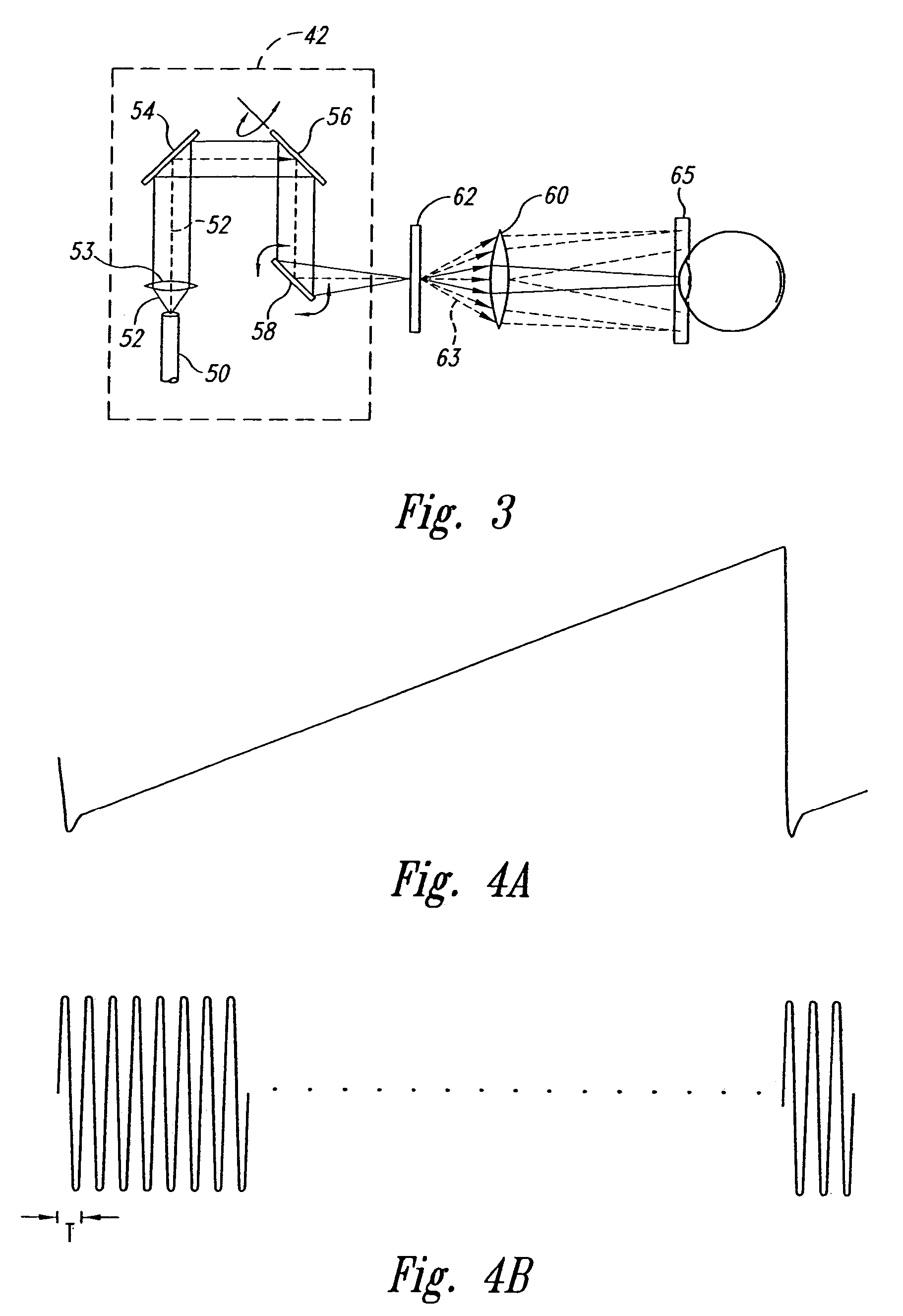

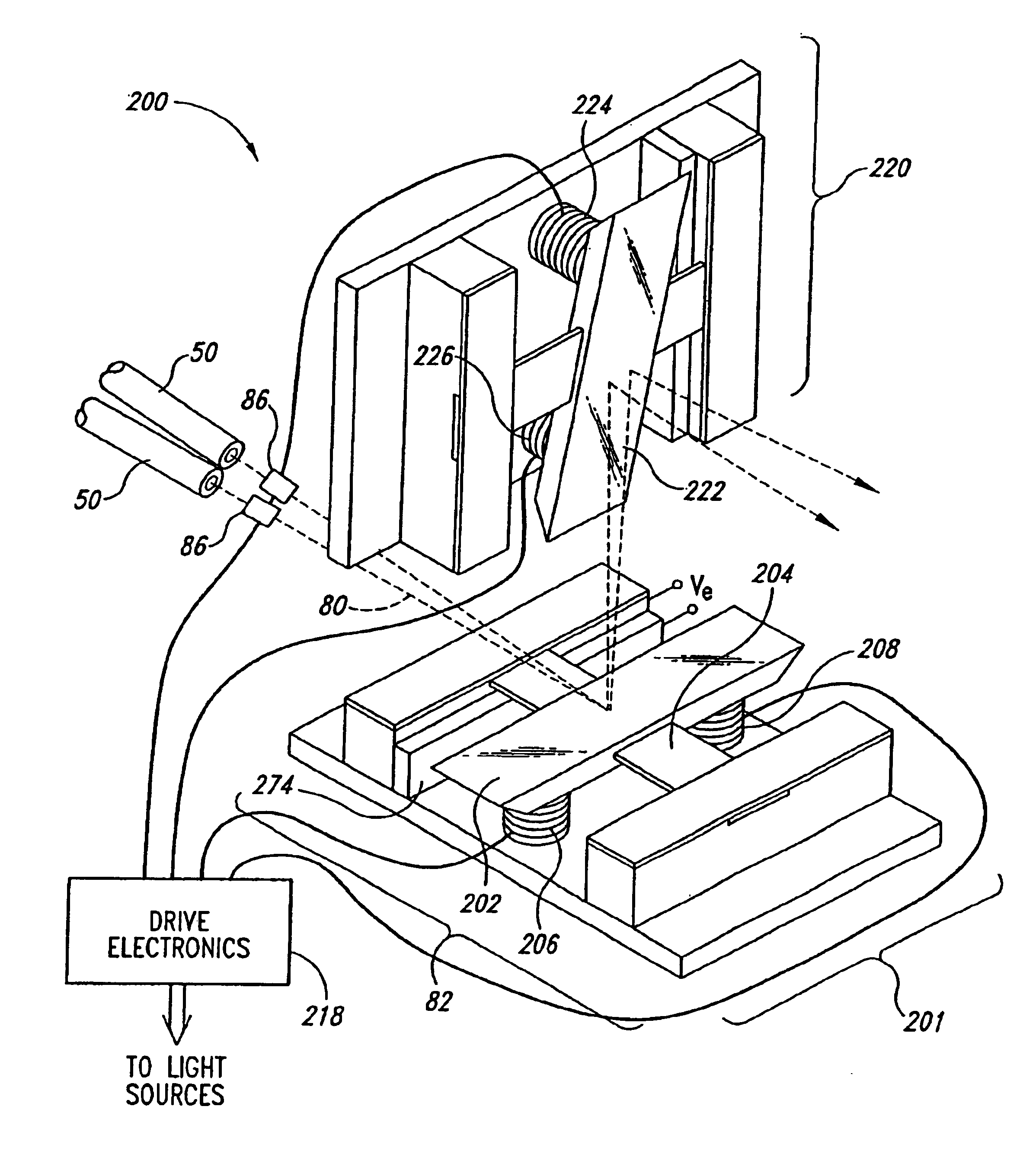

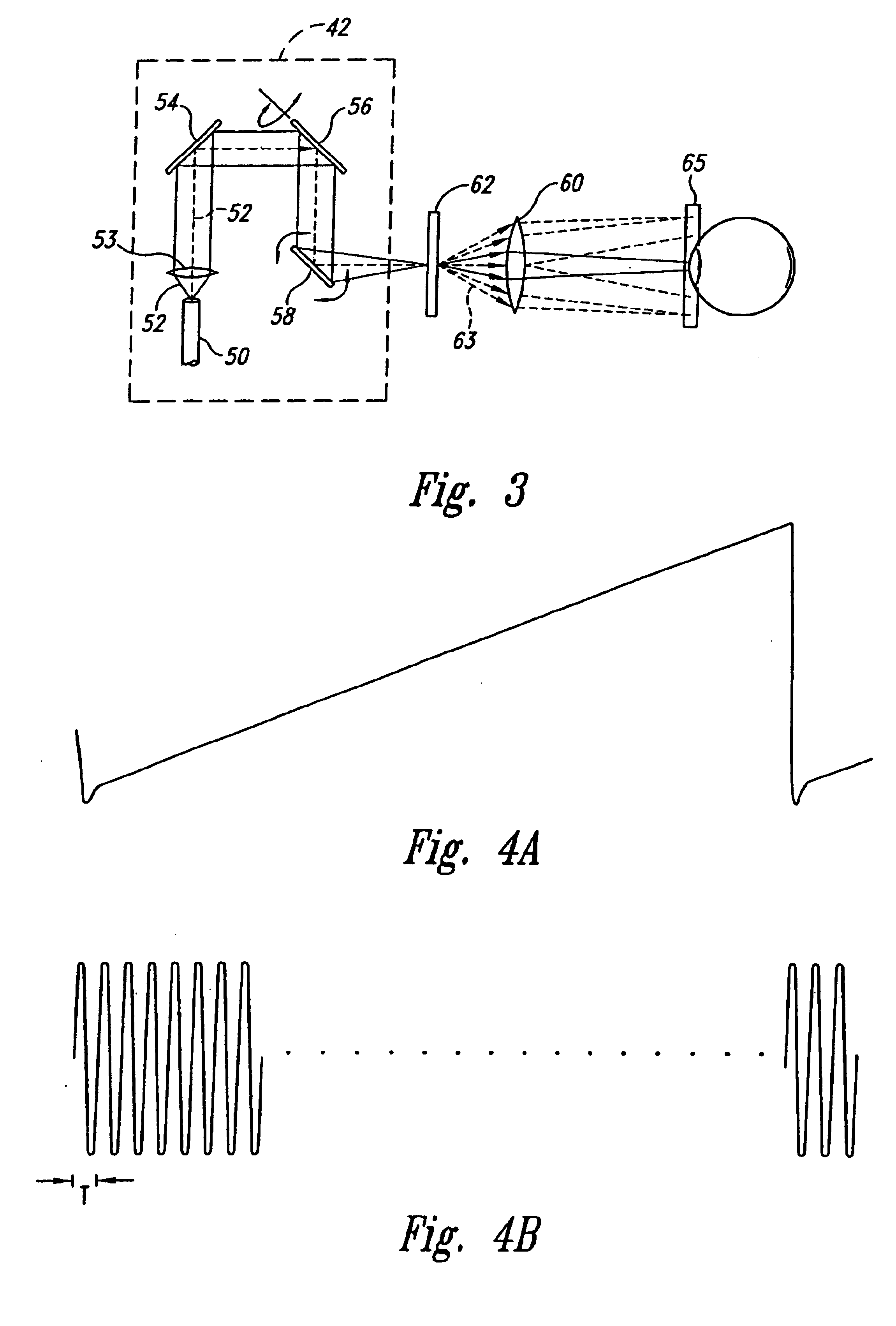

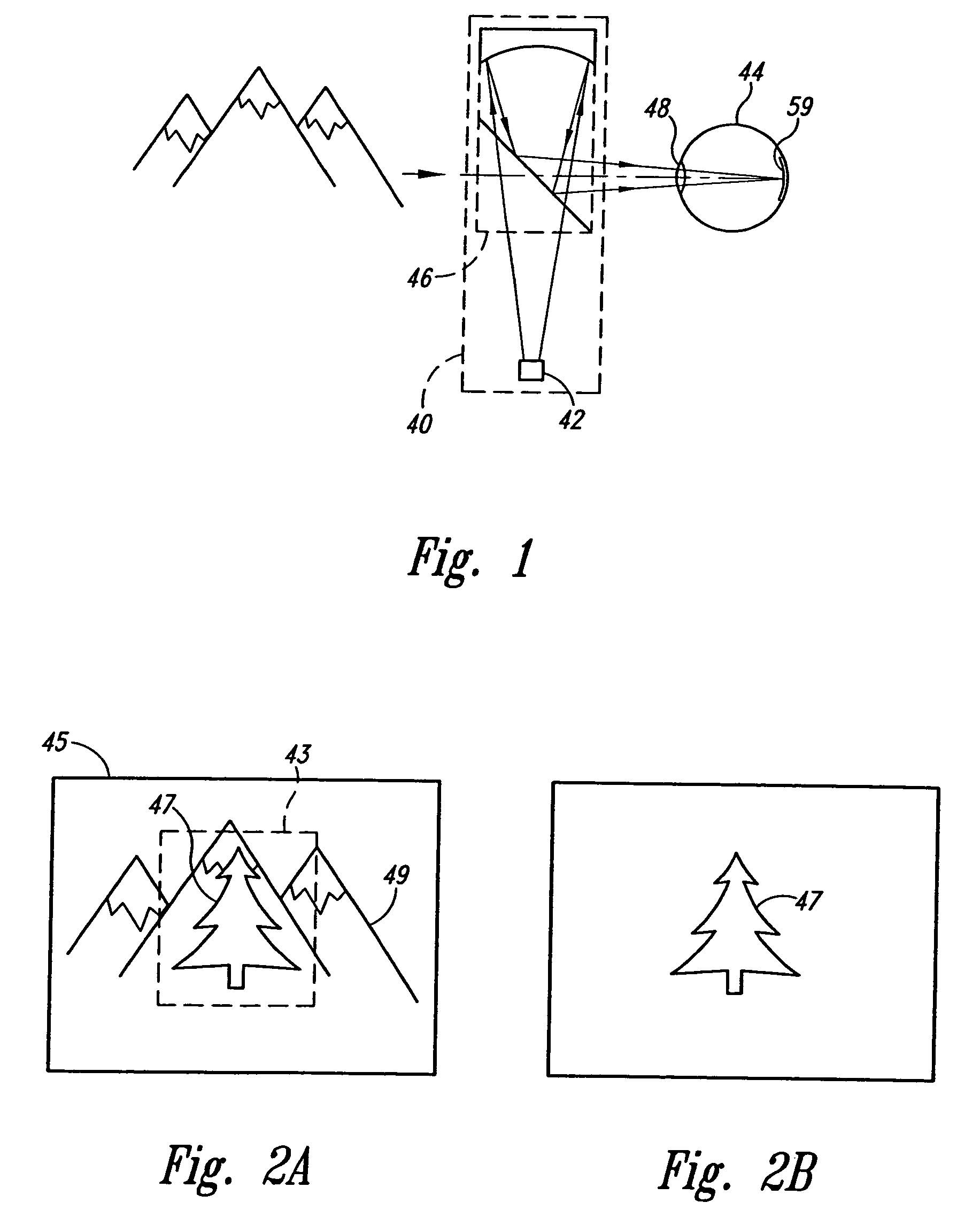

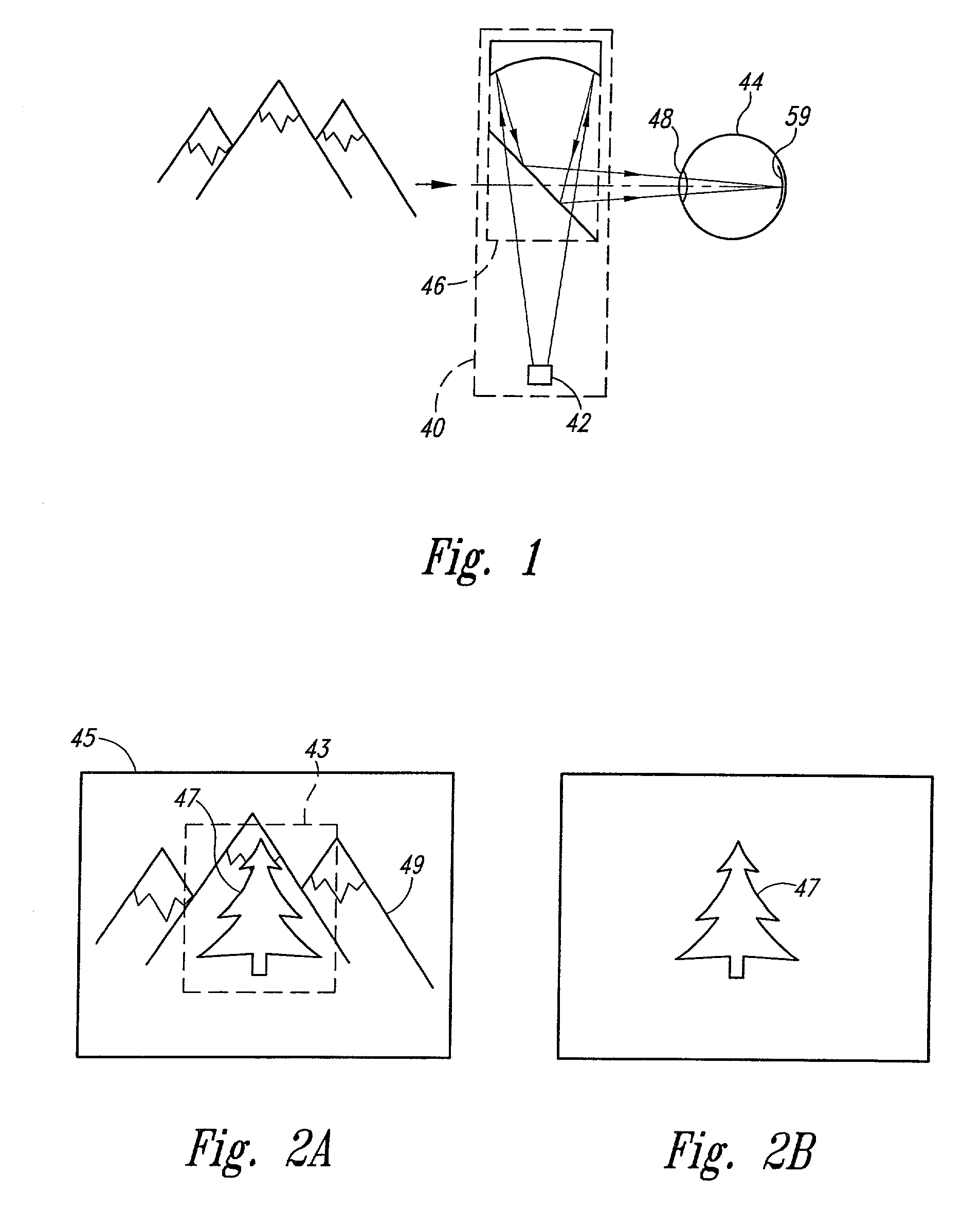

Multiple beam scanning imager

InactiveUS7209271B2Light provideCharacter and pattern recognitionSensing by electromagnetic radiationLight beamGrating pattern

A display apparatus includes a scanning assembly that scans about two or more axes, typically in a raster pattern. A plurality of light sources emit light from spaced apart locations toward the scanning assembly such that the scanning assembly simultaneously scans more than one of the beams. The light sources are positioned such that their beams each illuminate discrete regions of the image field that are substantially non-overlapping with respect to the other discrete regions. The image is thus formed from a set of “tiles”. By activating a first light source during a forward sweep of the mirror and activating a second light source during a reverse sweep of the mirror, two halves a common line can be written during a single sweep of the mirror. Shifting the position of the sources such that the two halves are aligned reduces raster pinch. In alternative embodiments, the same approach is used for imaging. Also, various approaches to controlling the frequency responses of the various scanners are described, including active control of MEMs scanners and passive frequency tuning.

Owner:MICROVISION

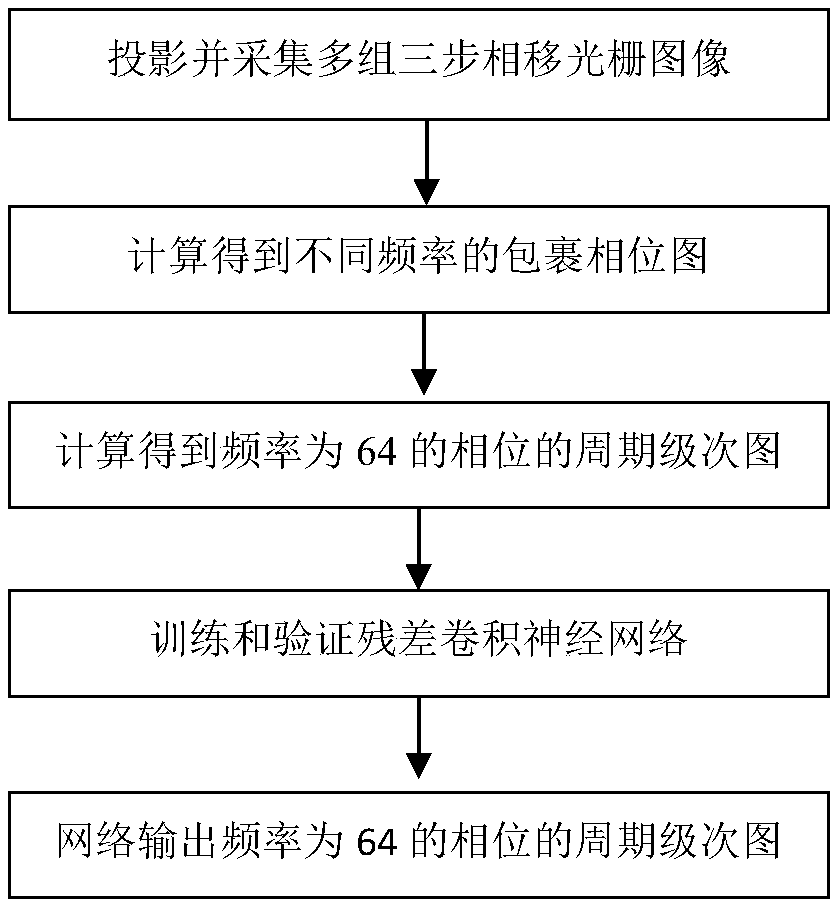

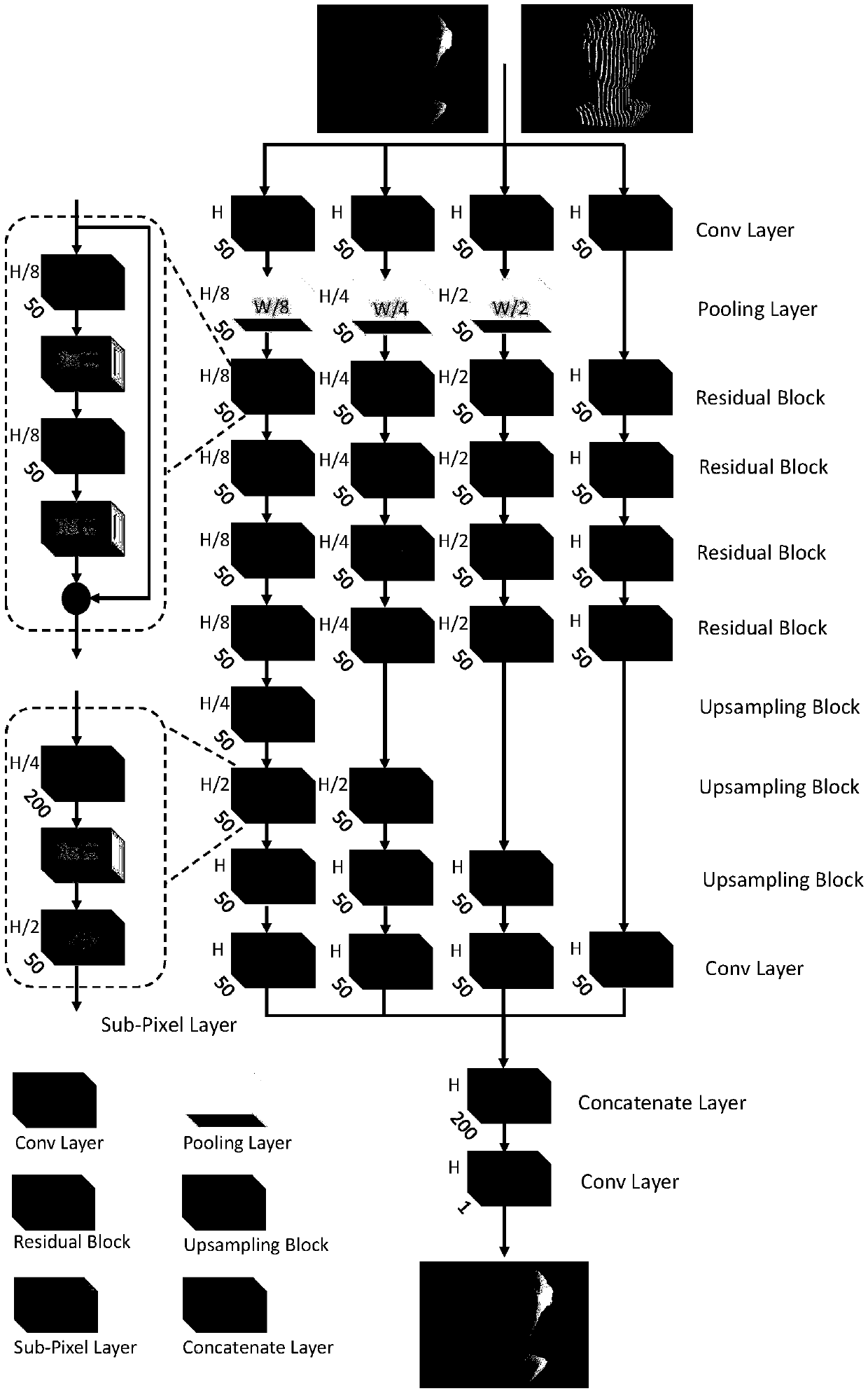

Fringe projection time phase unwrapping method based on deep learning

ActiveCN109253708AImprove accuracyLess mistakesUsing optical meansNeural architecturesPhase shiftedPhase unwrapping

The invention discloses a fringe projection time phase unwrapping method based on deep learning. Firstly, four sets of three-step phase shift grating patterns are projected to a to-be-tested object, the frequencies are 1, 8, 32 and 64 respectively, and a camera collects a raster image and obtains a wrapped phase image by using a three-step phase shift method; then, a multi-frequency algorithm based on time phase unwrapping is used for carrying out phase unwrapping on the wrapped phase image to obtain a periodic level map of a phase with the frequency of 64; a residual convolutional neural network is constructed; the input data is set to be the wrapped phase image with the frequencies of 1 and 64, and the output data is the periodic level map of the phase with the frequency of 64; finally,a training set and a verification set are made to train and verify the network; and the network verifies a test set to output the periodic level map of the phase with the frequency of 64. According tothe fringe projection time phase unwrapping method based on deep learning in the invention, the deep learning method is adopted and the wrapped phase image with the frequency of 1 is used for unwrapping the wrapped phase image with the frequency of 64; and an absolute phase image with less error points and higher accuracy can be obtained.

Owner:NANJING UNIV OF SCI & TECH

Method and apparatus for the determination of mask rules using scatterometry

InactiveUS20020131055A1Polarisation-affecting propertiesSemiconductor/solid-state device manufacturingContour matchingGrating pattern

A method and apparatus for determining optical mask corrections for photolithography. A plurality of grating patterns is printed onto a wafer utilizing a photomask having at least one grating. Each grating pattern within the plurality of grating patterns is associated with known photolithographic settings. Each grating pattern is illuminated independently with a light source, so that light is diffracted off each grating pattern. The diffracted light is measured utilizing scatterometry techniques to determine measured diffracted values. The measured diffracted values are compared to values in a library to determine a profile match. A 2-dimensional profile description is assigned to each grating pattern based on the profile match. A database is compiled of the profile descriptions for the plurality of grating patterns. Photomask design rules are then generated by accessing the database containing the 2-dimensional profile descriptions. In preferred embodiments, the design rules are used to create and correct masks containing OPC corrections, phase-shifting mask corrections and binary masks. In a preferred embodiment the at least one grating is a bi-periodic grating. In a preferred embodiment, the scatterometry technique is optical digital profilometry utilizing a reflectometer or ellipsometer.

Owner:TOKYO ELECTRON US HOLDINGS INC

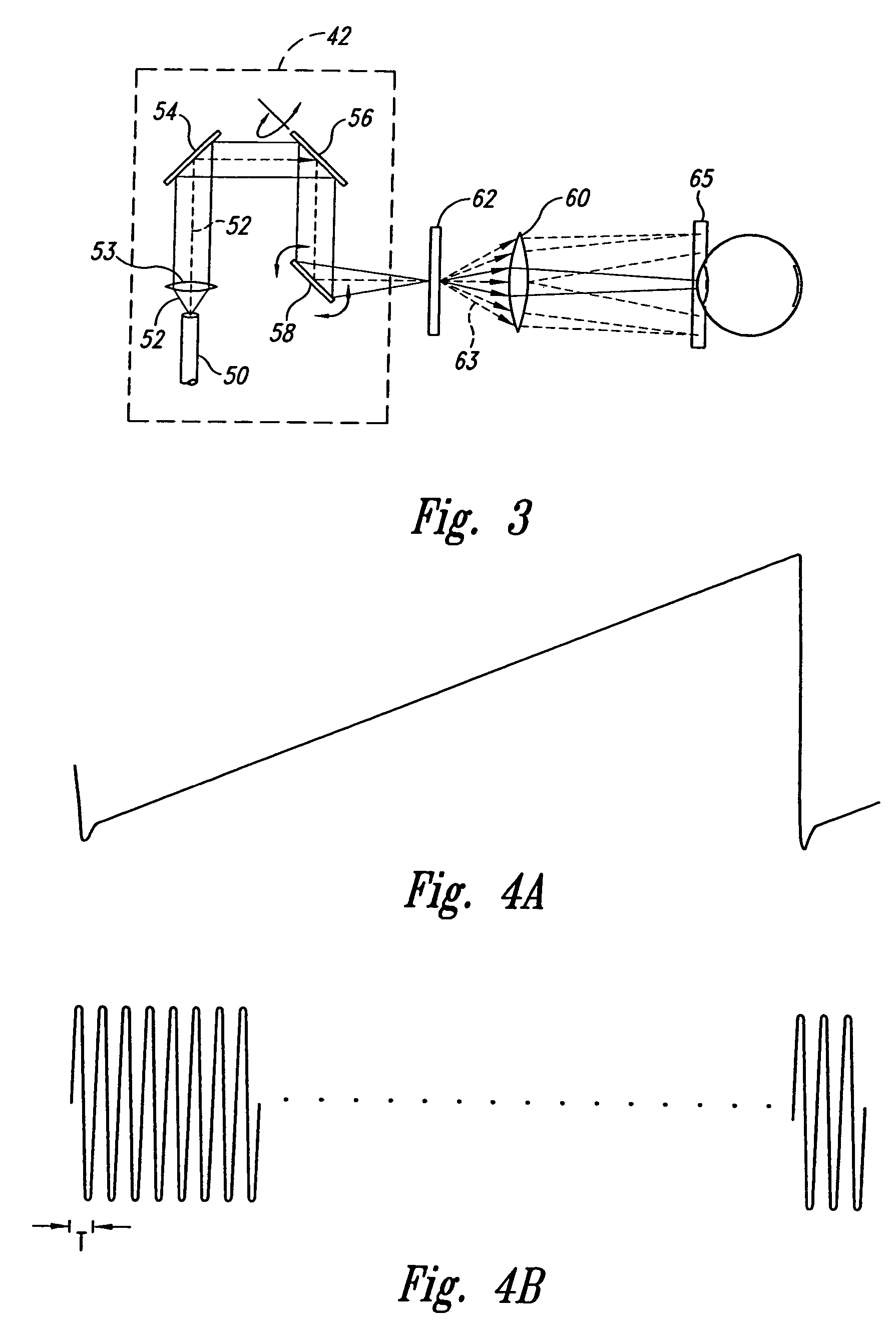

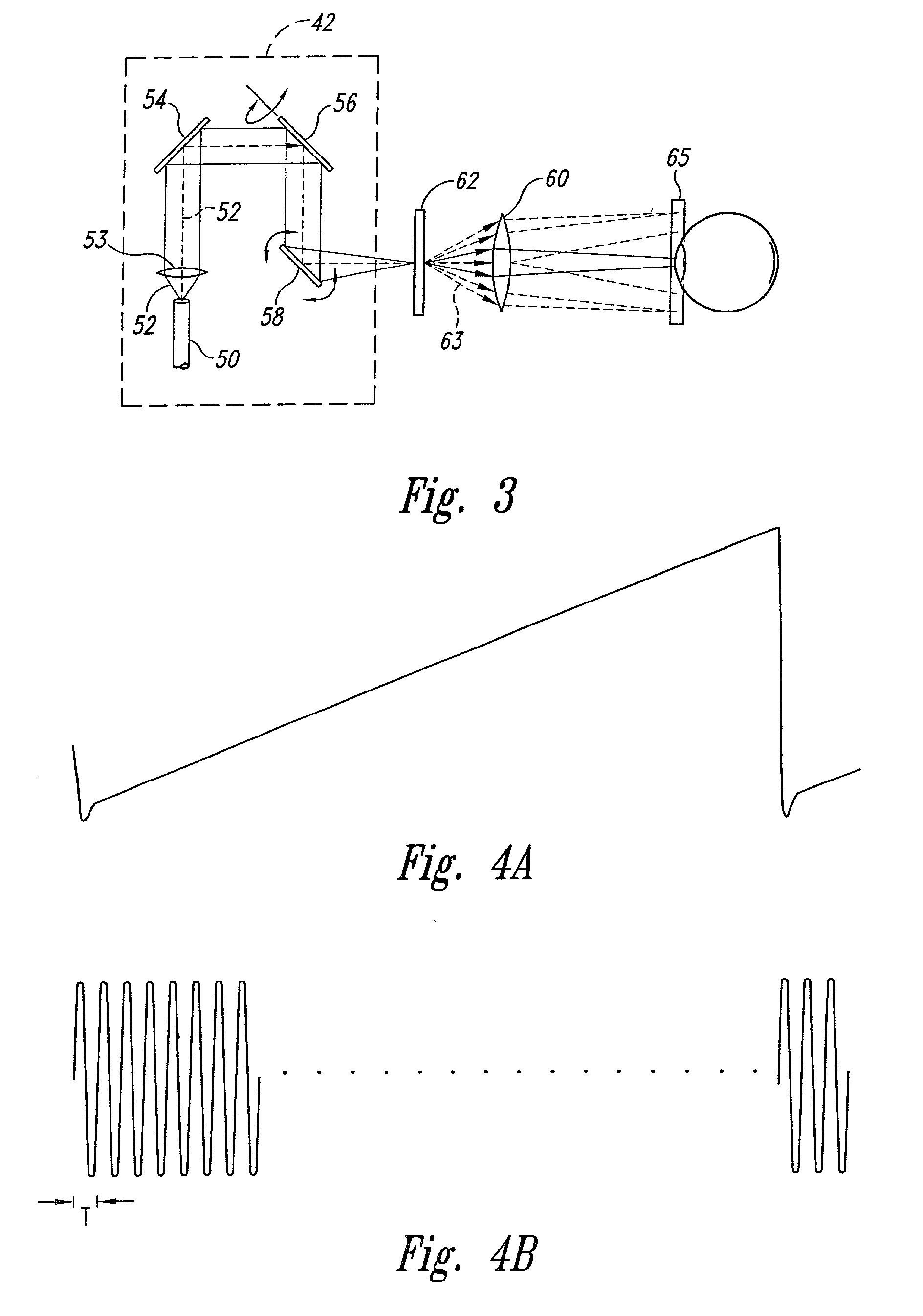

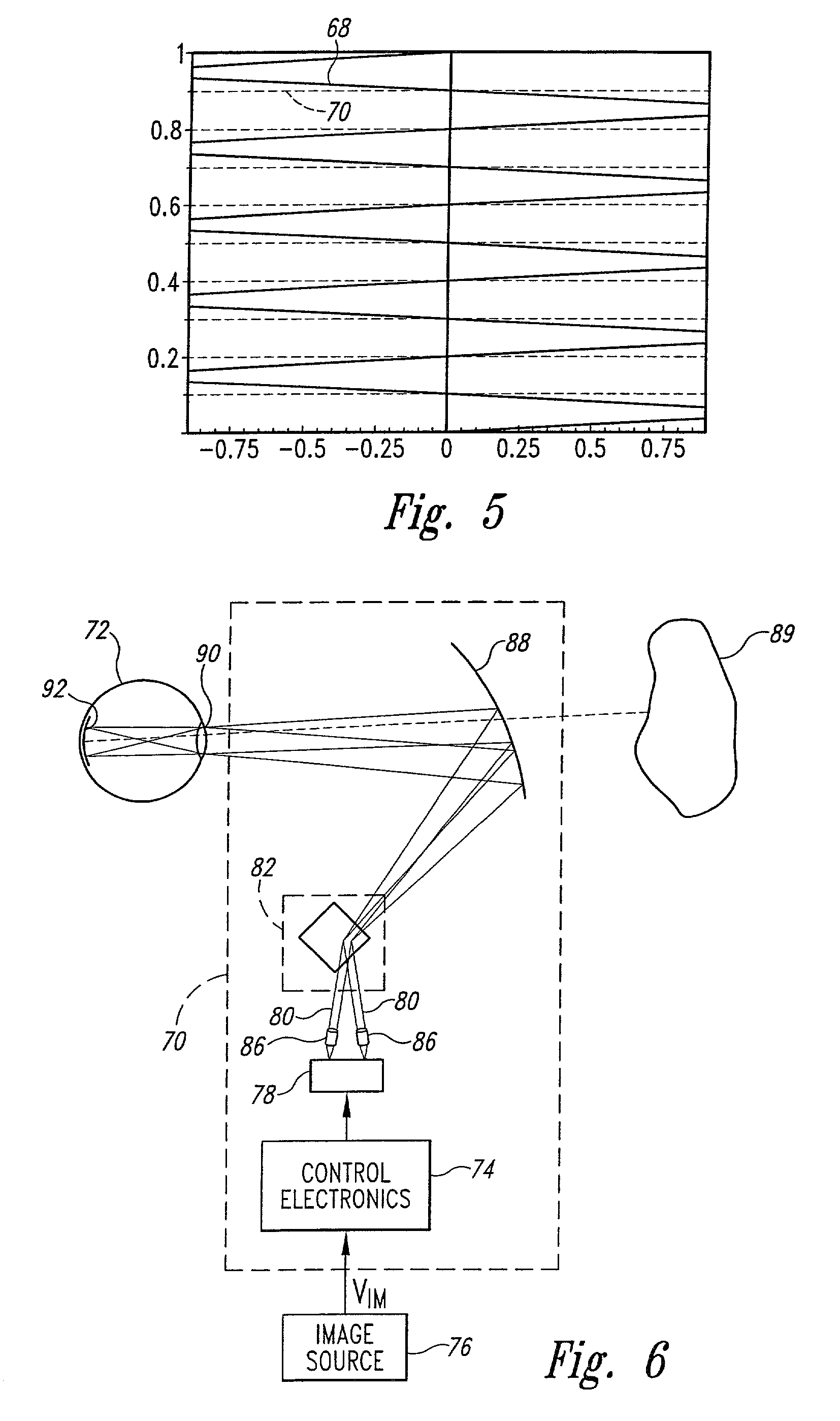

Resonant beam scanner with raster pinch compensation

InactiveUS6924476B2Light provideTelevision system detailsBeam/ray focussing/reflecting arrangementsLight beamBeam scanning

A MEM s scanning device has a variable resonant frequency. In one embodiment, the MEMs device includes a torsion arm that supports an oscillatory body. In one embodiment, an array of removable masses are placed on an exposed portion of the oscillatory body and selectively removed to establish the resonant frequency. The material can be removed by laser ablation, etching, or other processing approaches. In another approach, a migratory material is placed on the torsion arm and selectively stimulated to migrate into the torsion arm, thereby changing the mechanical properties of the torsion arm. The changed mechanical properties in turn changes the resonant frequency of the torsion arm. In another approach, symmetrically distributed masses are removed or added in response to a measured resonant frequency to tune the resonant frequency to a desired resonant frequency. A display apparatus includes the scanning device and the scanning device scans about two or more axes, typically in a raster pattern. Various approaches to controlling the frequency responses of the scanning device are described, including active control of MEMs scanners and passive frequency tuning.

Owner:MICROVISION

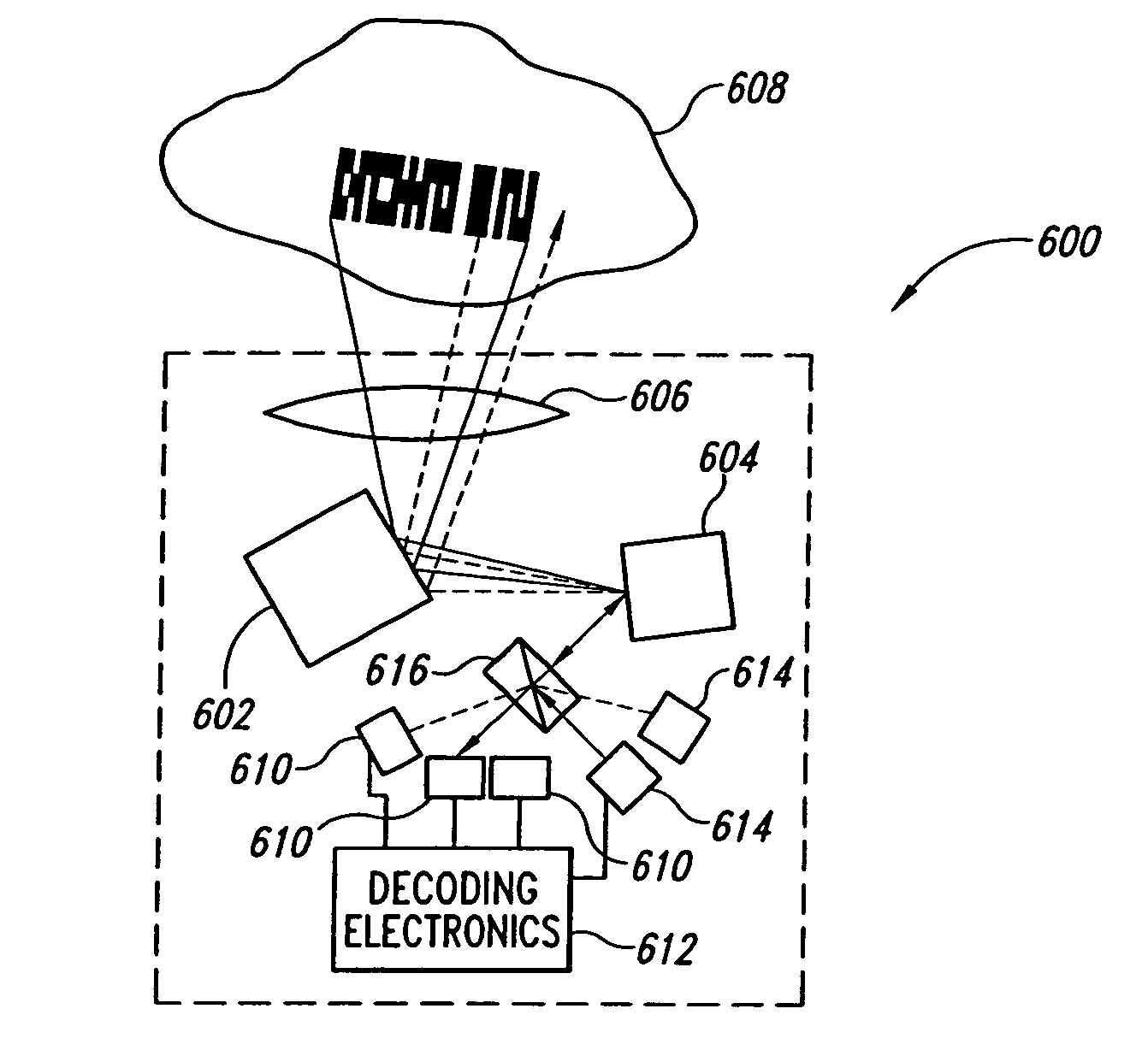

Scanned beam image capture device with a plurality of scan regions

InactiveUS7075687B2Light provideSensing by electromagnetic radiationOptical elementsDisplay deviceGrating pattern

A display apparatus includes a scanning assembly that scans about two or more axes, typically in a raster pattern. A plurality of light sources emit light from spaced apart locations toward the scanning assembly such that the scanning assembly simultaneously scans more than one of the beams. The scanning assembly includes a plurality of mirrors that sweep their respective beams through respective regions of an image field. The regions are immediately adjacent so that an overall image is produced by “tiling” of the regions. Because sweeps of the scanning assembly scan a plurality of tiles simultaneously the resolution and / or field of view of a display for a given scan angle and mirror size is increased relative to a single mirror sweeping a single beam. In alternative embodiments, tiling is used for imaging. Also, various approaches to controlling the frequency responses of the various scanners are described, including active control of MEMs scanners and passive frequency tuning.

Owner:MICROVISION

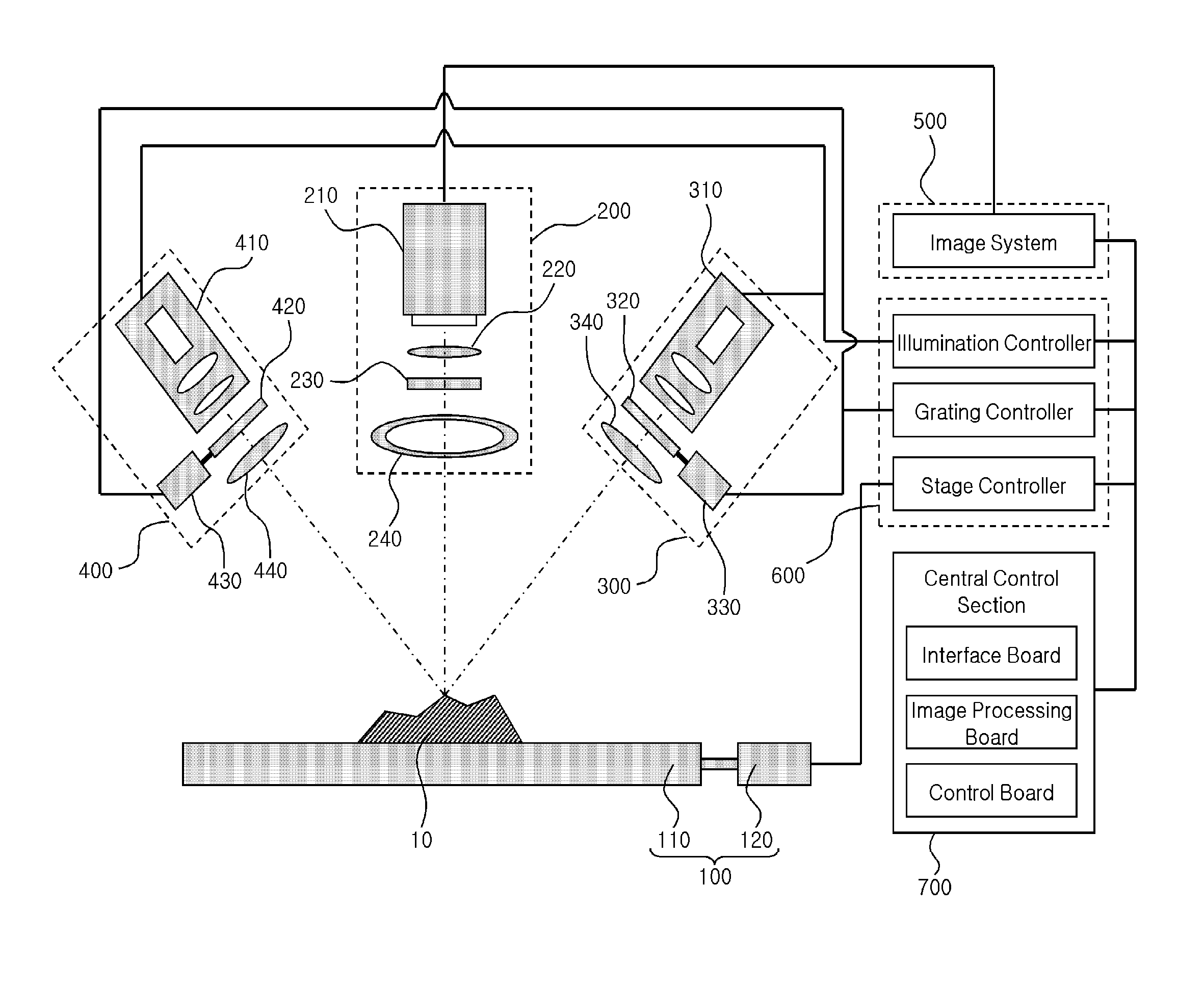

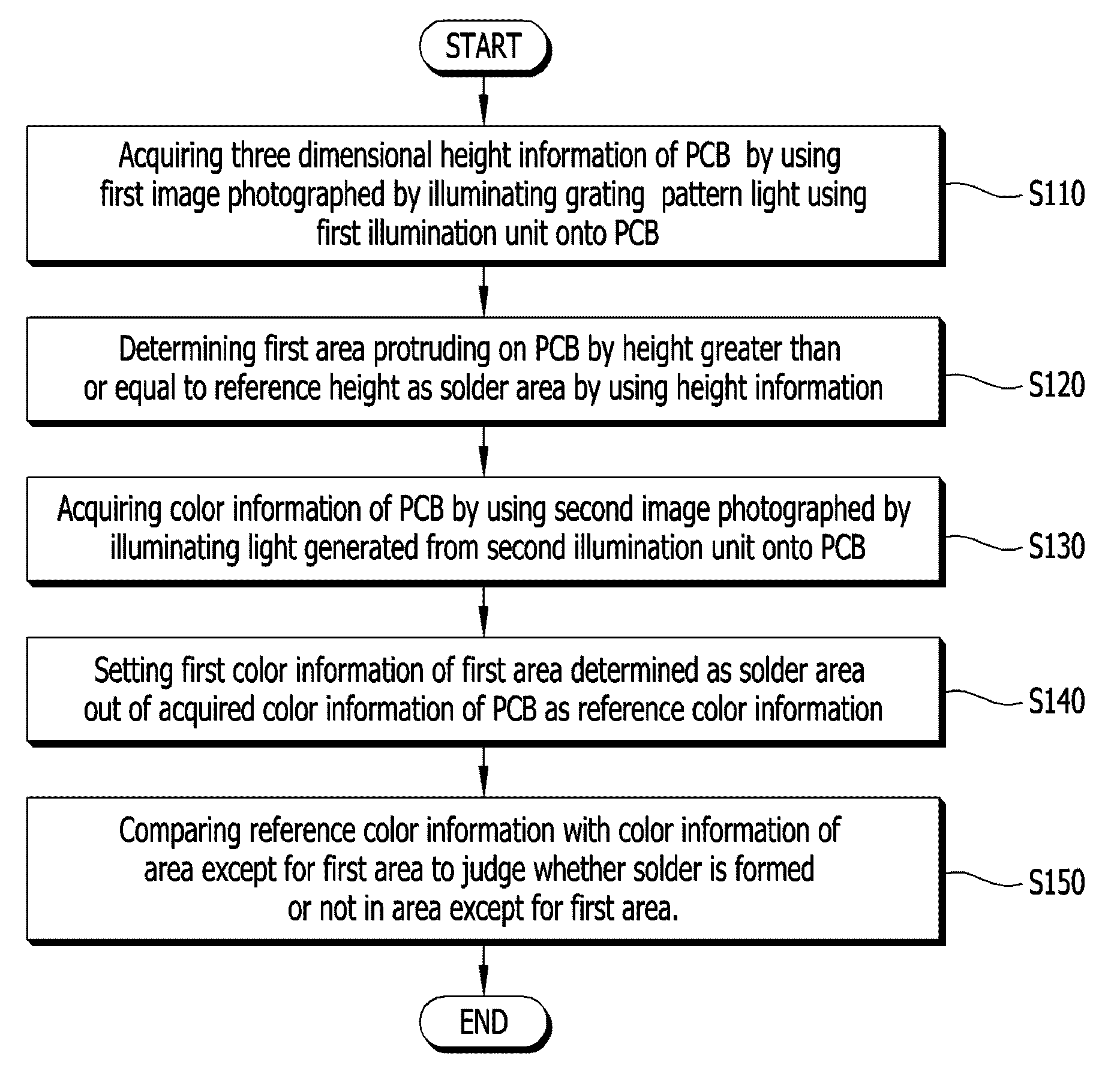

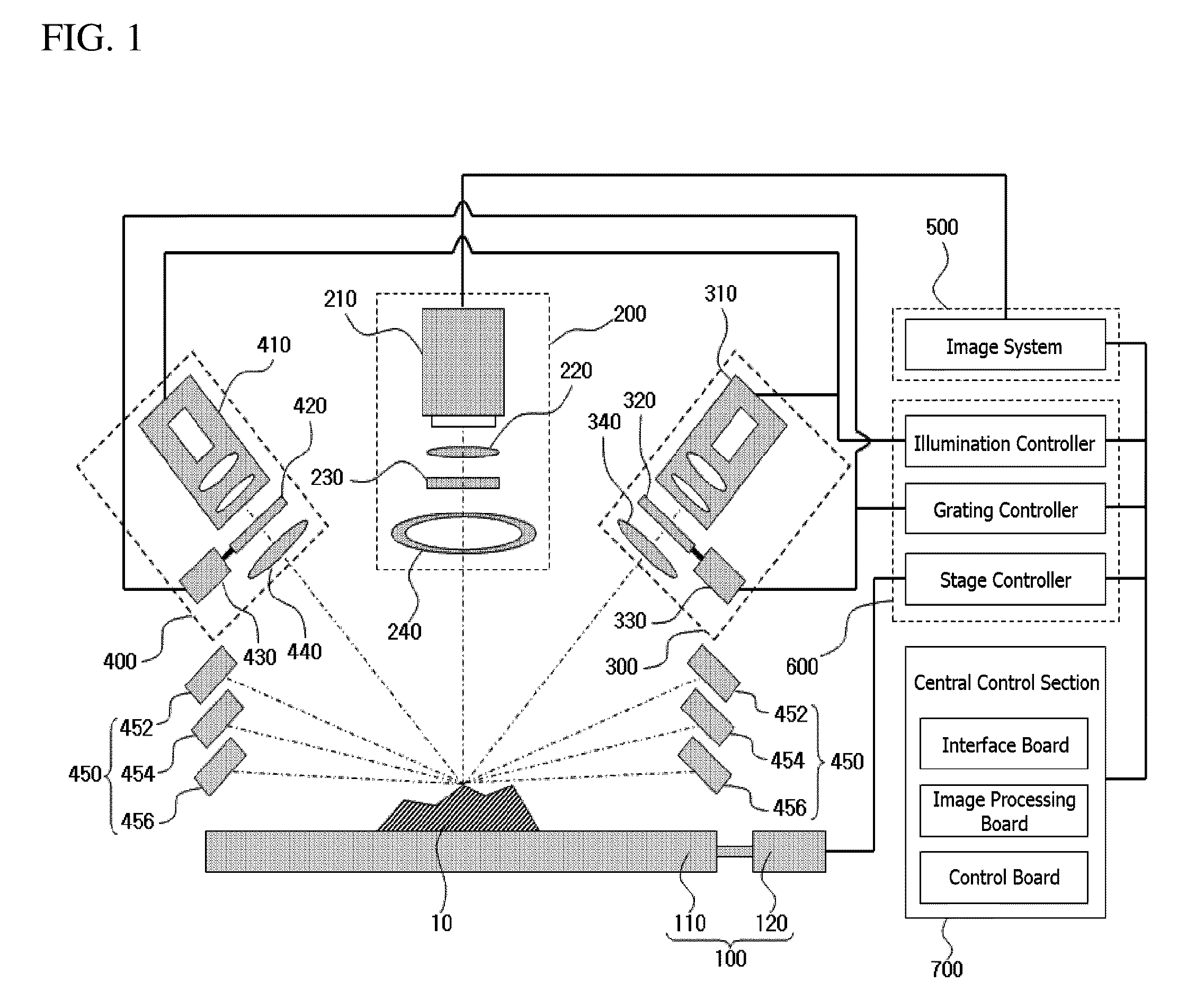

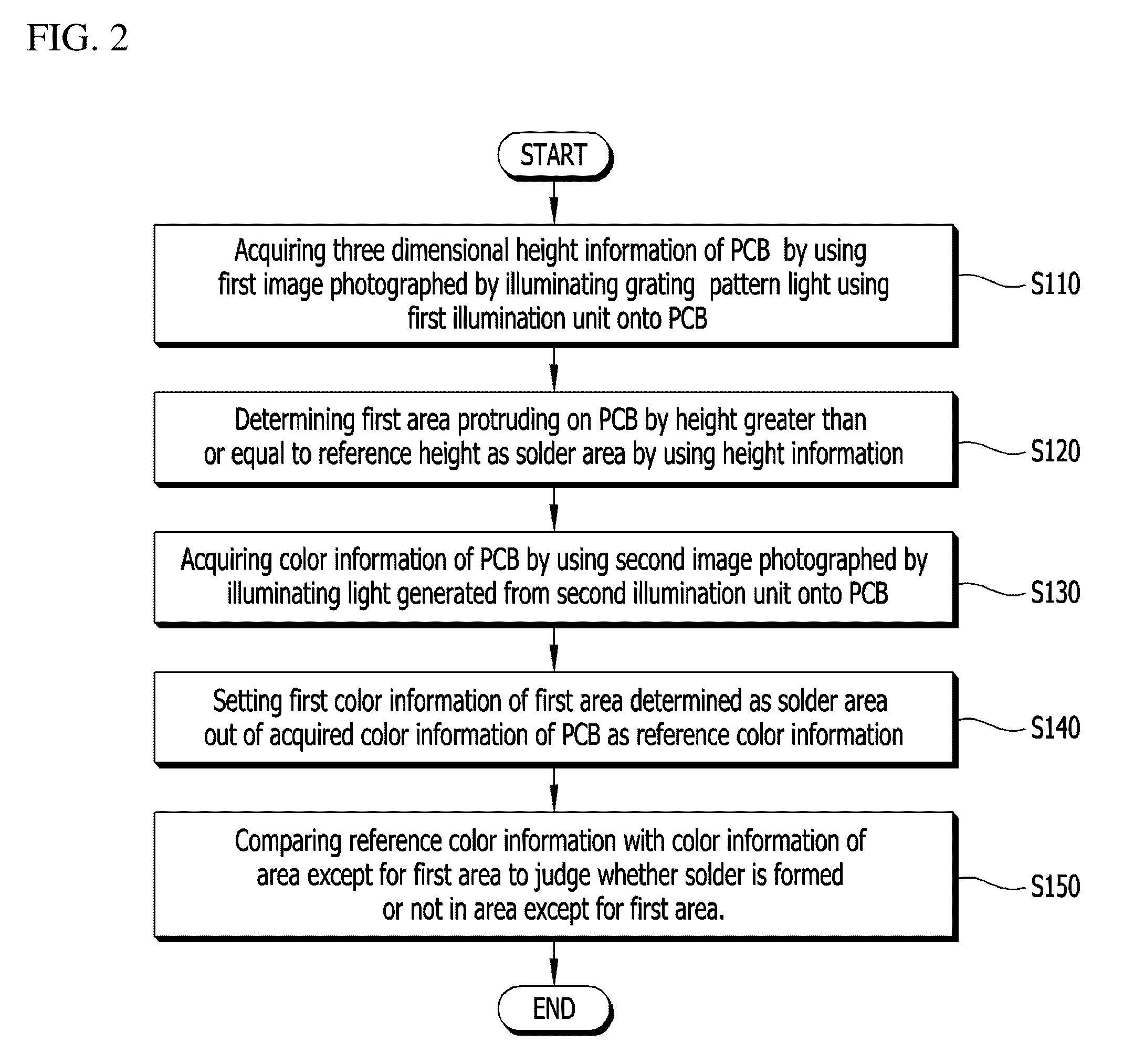

Method for inspecting measurement object

ActiveUS20110002529A1Improve inspection reliabilityNoise minimizationImage analysisCharacter and pattern recognitionGrating patternContrast ratio

Owner:KOHYOUNG TECH

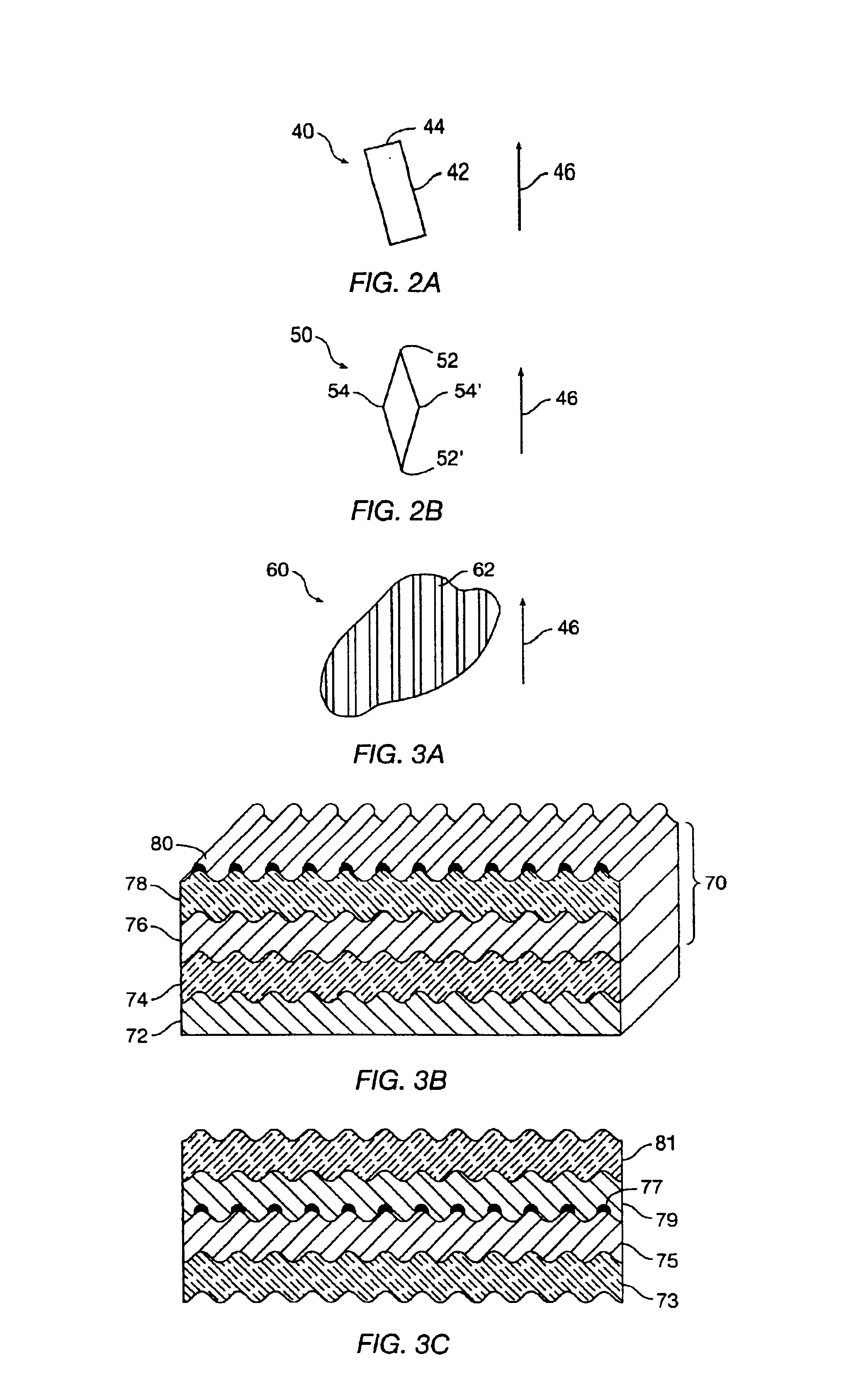

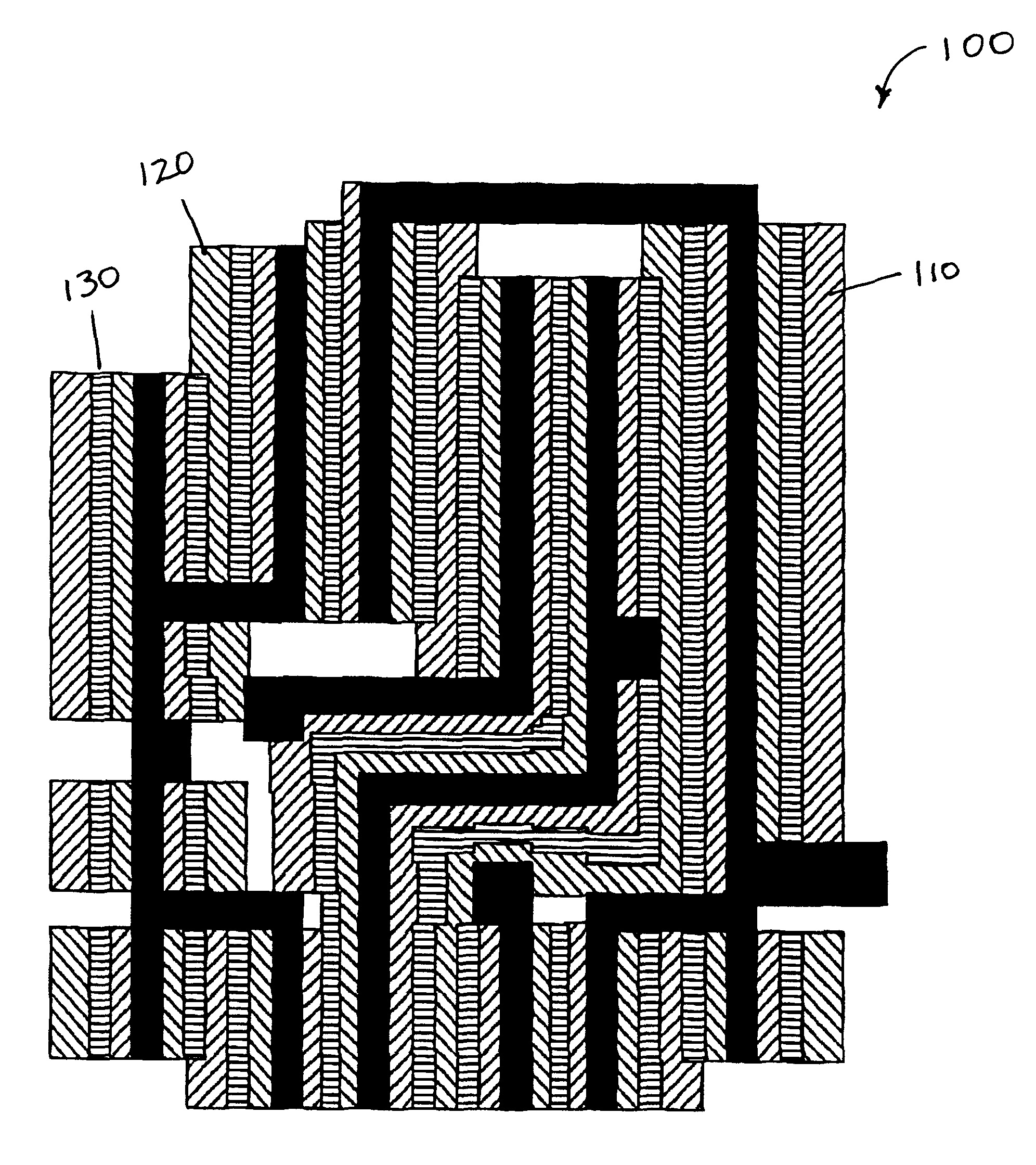

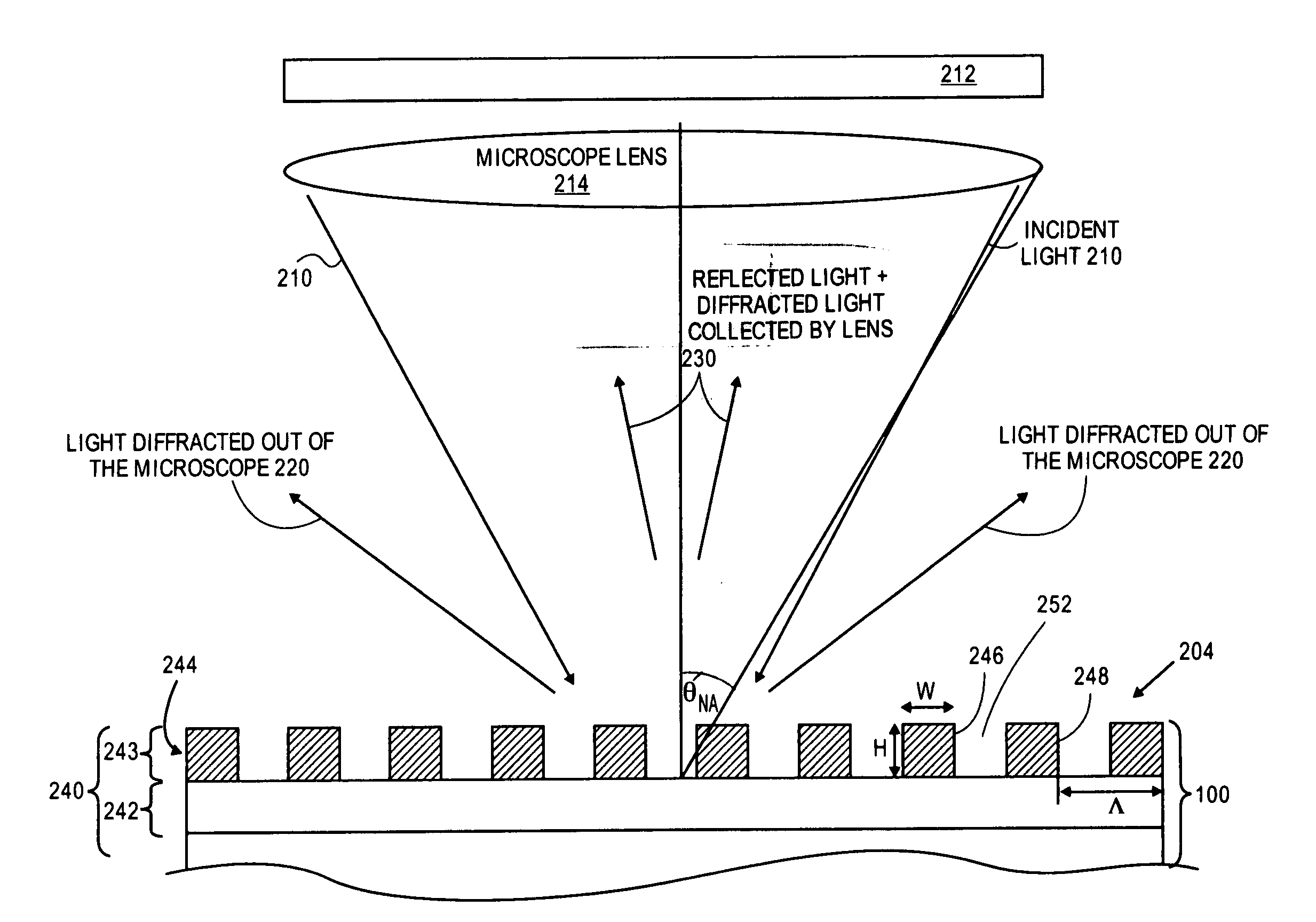

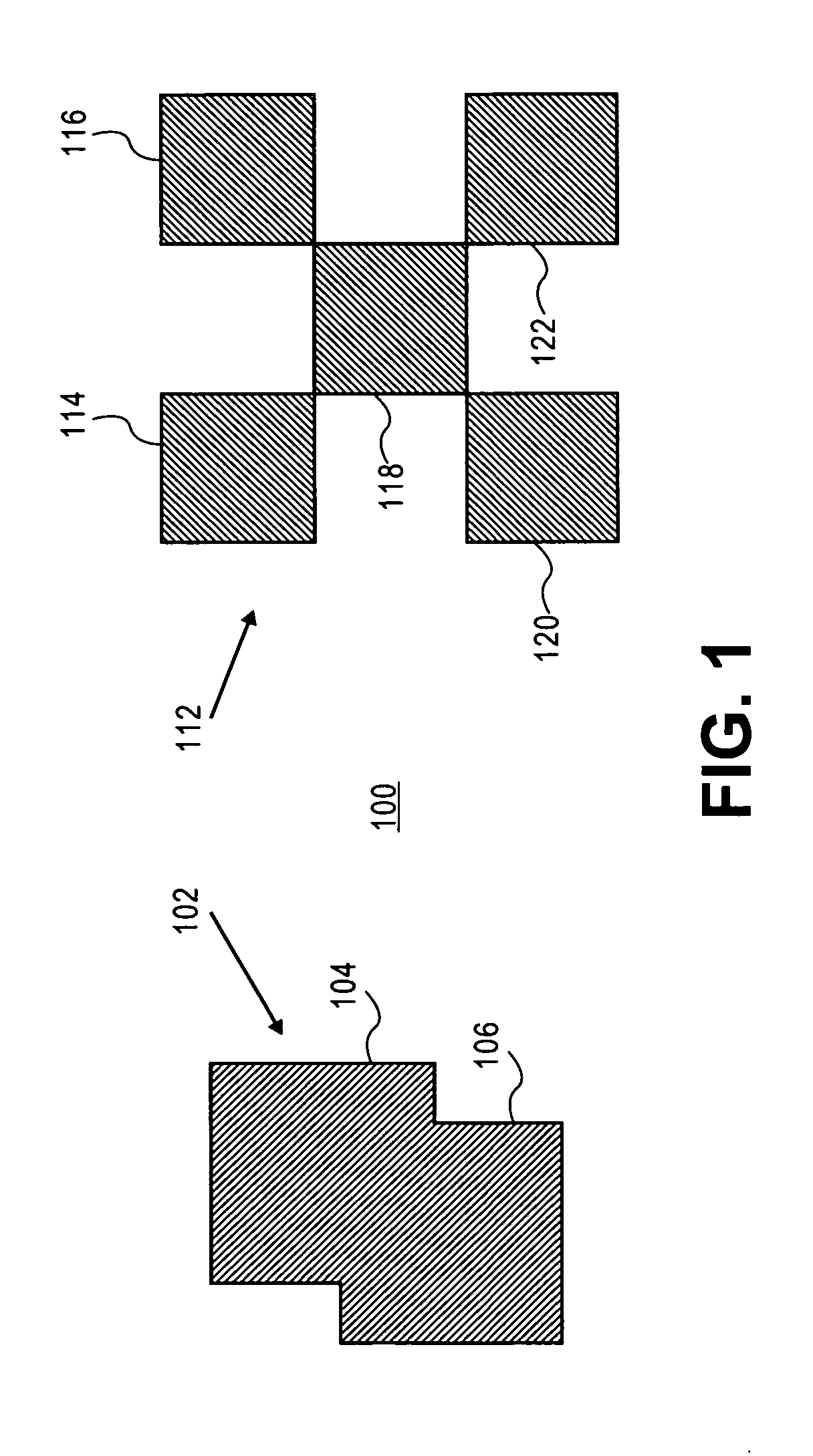

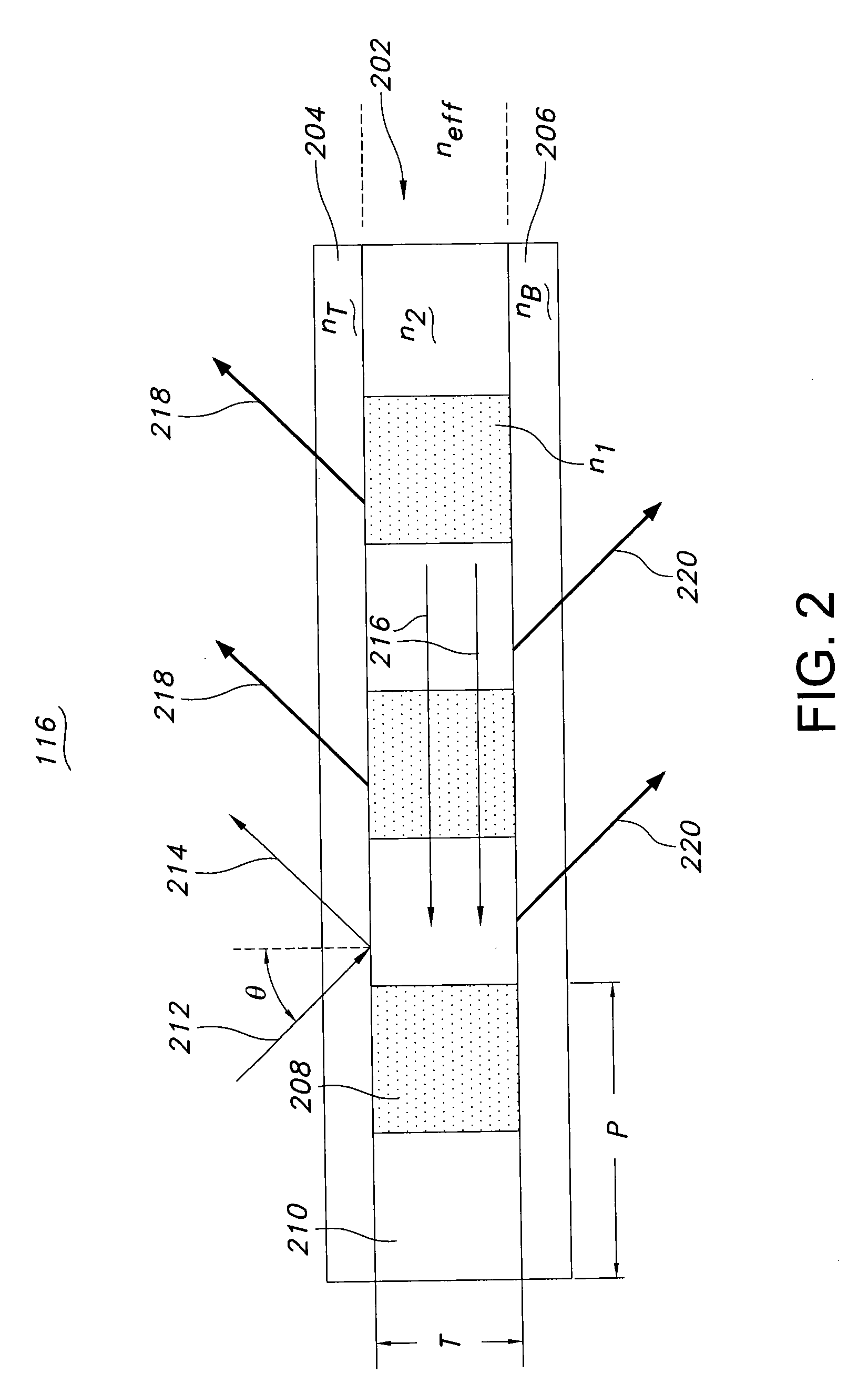

Wafer-based optical pattern recognition targets using regions of gratings

Pattern recognition targets including regions of one or more layers of gratings are used for semiconductor fabrication wafer alignment. Grates of the gratings are below the resolution limit of the alignment microscopes, and have dimensions compatible with design rules applied to actual device circuitry. Targets may be located by the contrast of light 0racted back from the regions and through a numerical aperture of the microscope. Target contrast may be achieved by controlling the diffractive properties of the regions. A grating with a pitch that causes a significant amount light to diffract out of the numerical aperture will appear darker, while a grating with a pitch that produces minimal diffraction with appear much brighter. Moreover, for a darker causing pitch, a region of layers gratings having grates stacked on each other can appear even darker, while a region having layers of grates interleaved can appear even brighter.

Owner:INTEL CORP

Radiological image detection apparatus, radiographic apparatus and radiographic system

InactiveCN102551761AQuality is not affectedReduce scatterMusculoskeletal system evaluationTomographyImage detectionGrating pattern

The invention discloses a radiological image detection apparatus, a radiographic apparatus and a radiographic system. The radiological image detection apparatus includes a first grating unit, a grating pattern unit, a radiological image detector, and an anti-scatter grating. The grating pattern unit has a period that substantially coincides with a pattern period of a radiological image formed by radiation having passed through the first grating unit. The radiological image detector detects the radiological image masked by the grating pattern unit. The anti-scatter grating is arranged on a path of the radiation incident onto the radiological image detector and removes scattered radiation. A smoothing process is performed for at least one of a surface and a backside of the anti-scatter grating intersecting with a traveling direction of the radiation.

Owner:FUJIFILM CORP

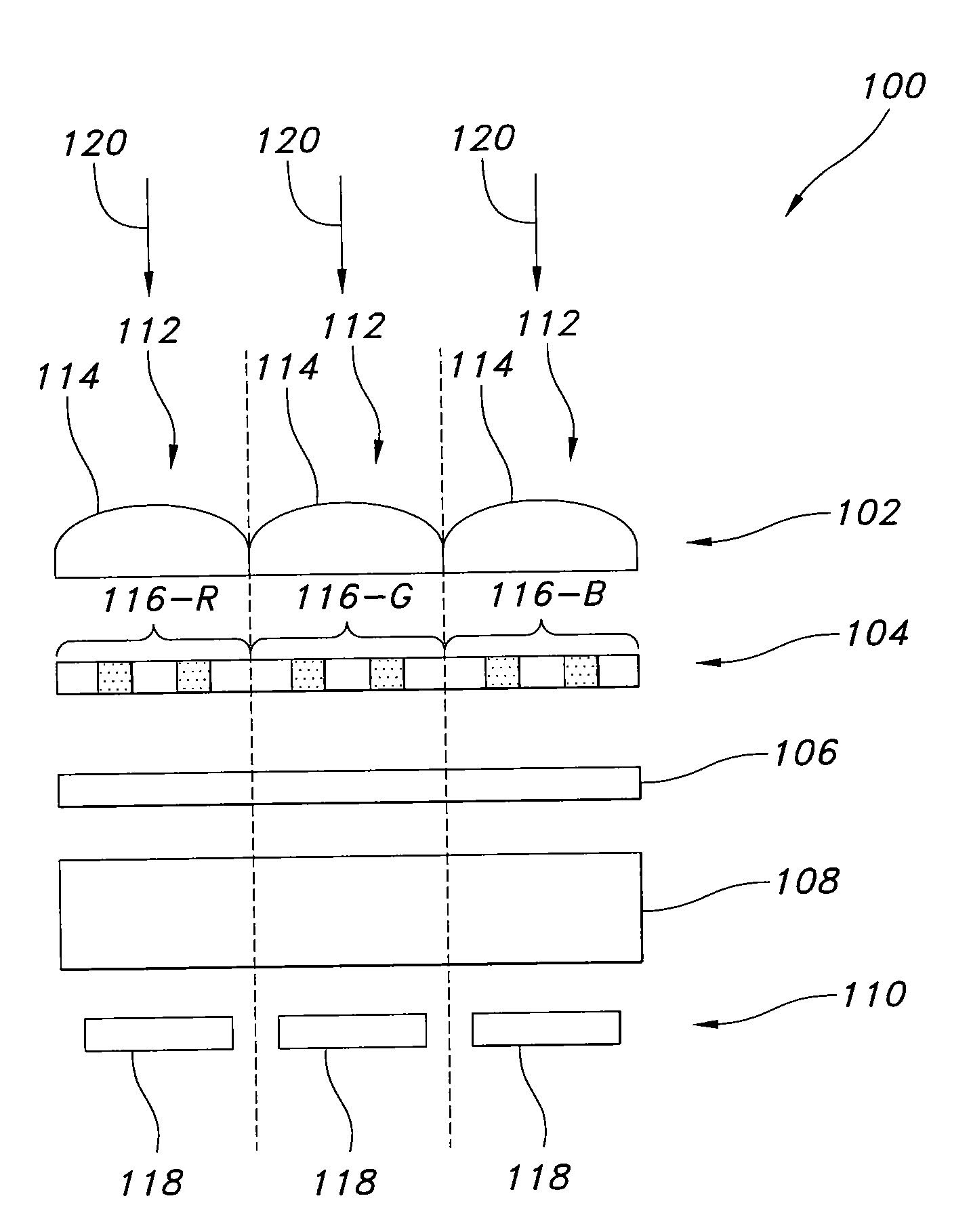

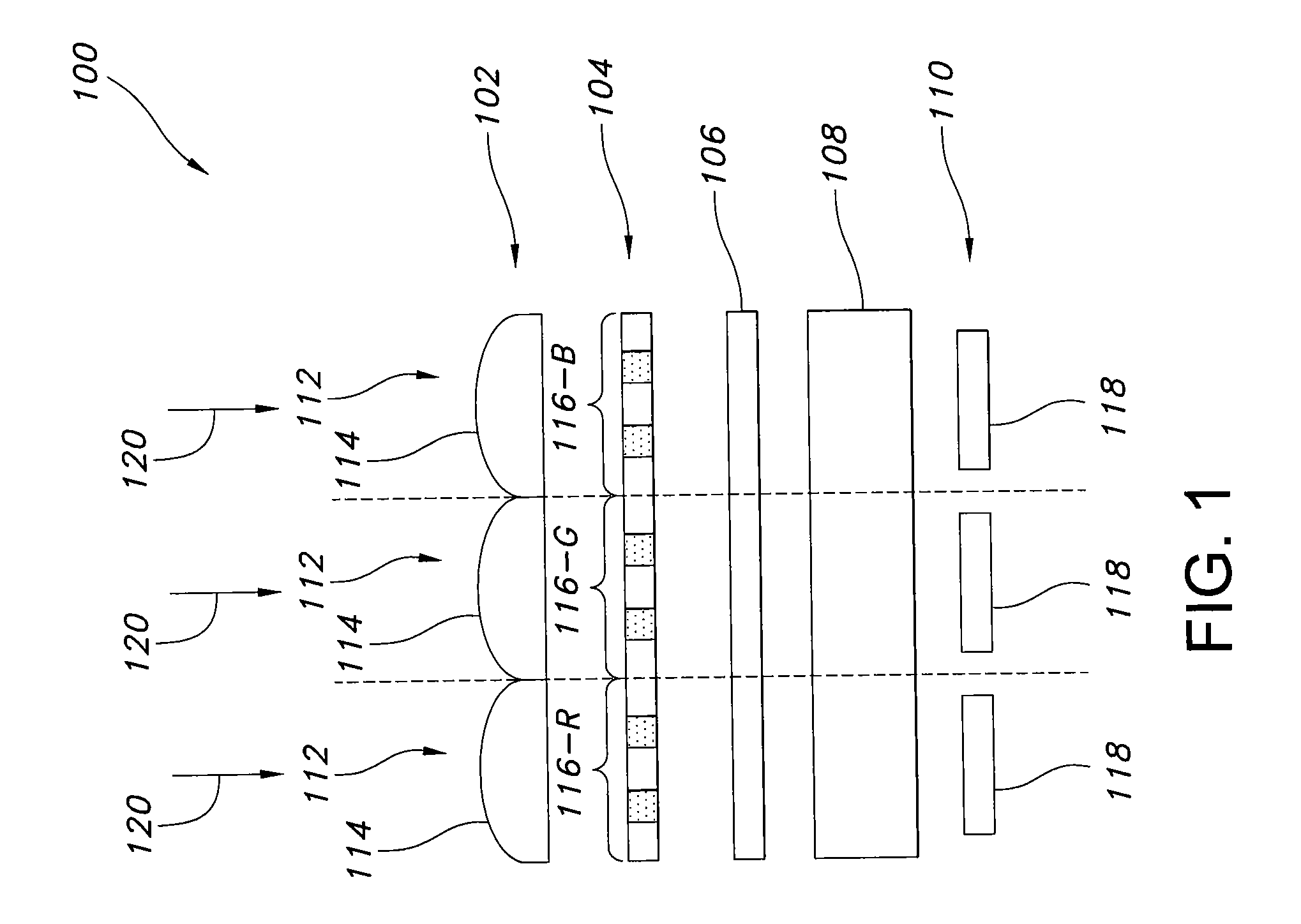

Guided-mode-resonance transmission color filters for color generation in CMOS image sensors

Imager pixel arrays and methods for forming imager pixel arrays. An image sensor pixel includes a photosensor and a waveguide grating resonance filter formed over the photosensor. The waveguide grating resonance filter is configured to pass light to the photosensor in a wavelength band and to block light outside of the wavelength band. The waveguide grating resonance filter includes a grating material having a first refractive index and arranged in a grating pattern with a grating pitch, and has an effective refractive index that is a function of the first refractive index. A combination of the grating pitch and the effective refractive index is selected to correspond to the wavelength band.

Owner:APTINA IMAGING CORP

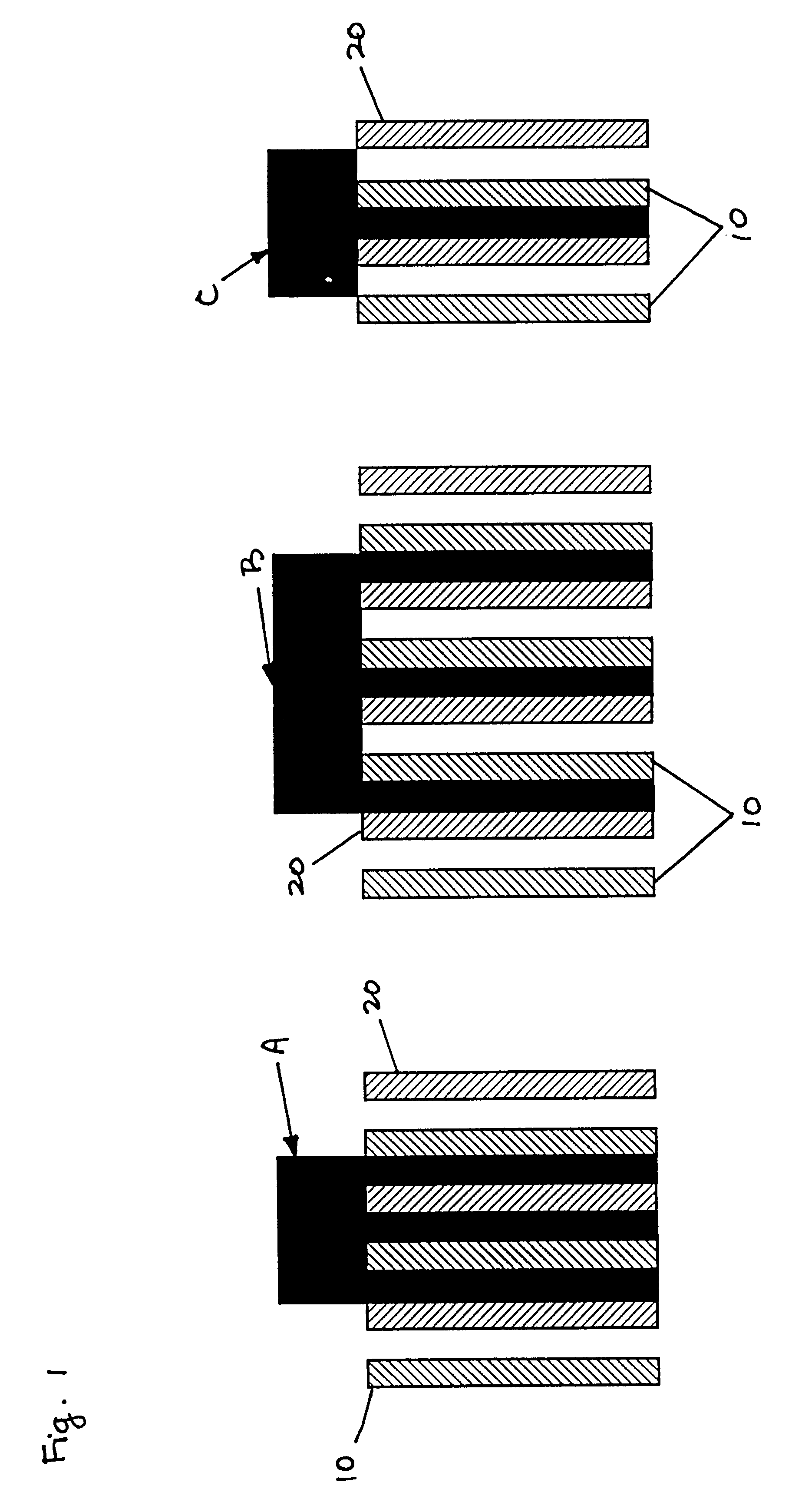

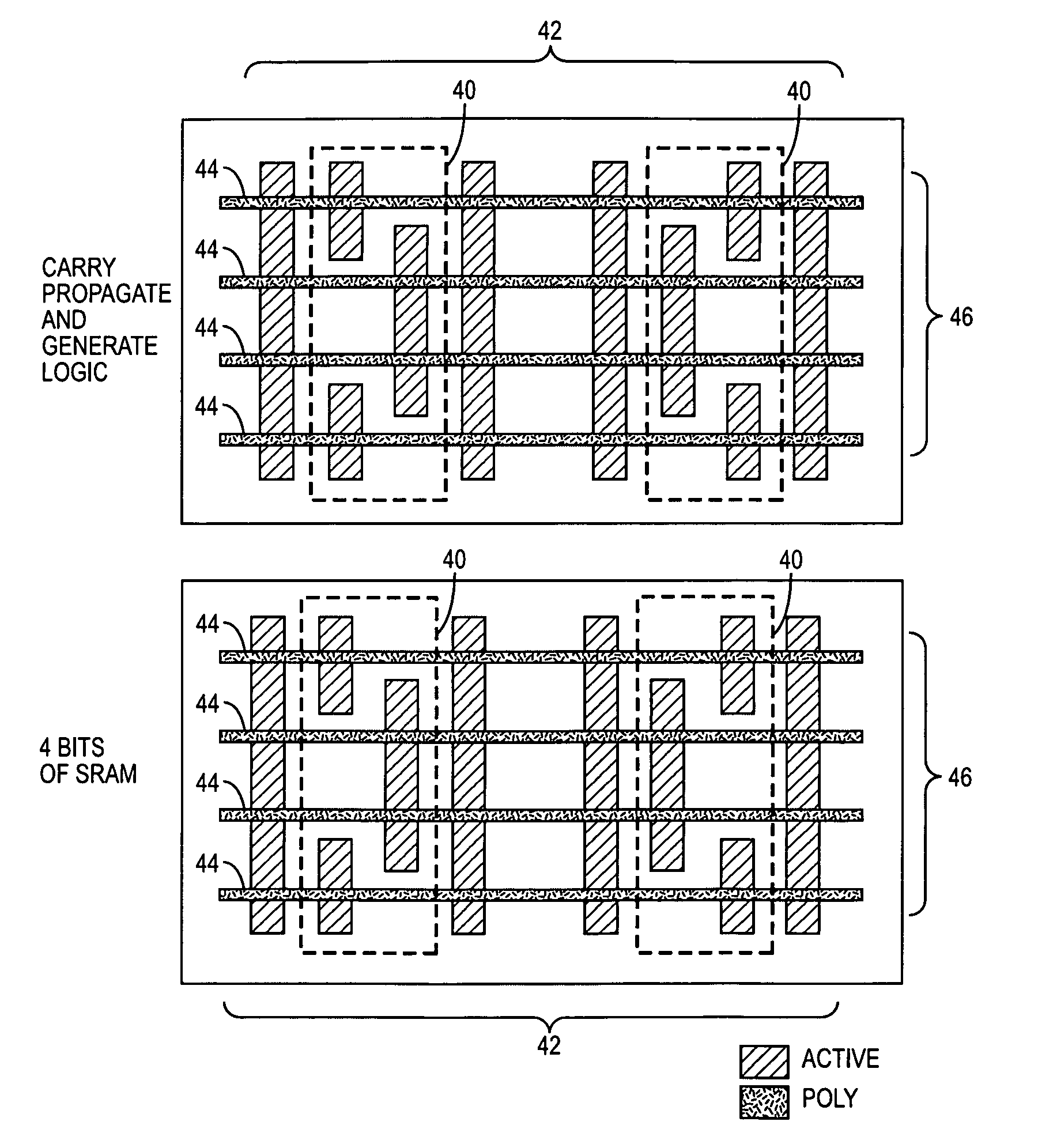

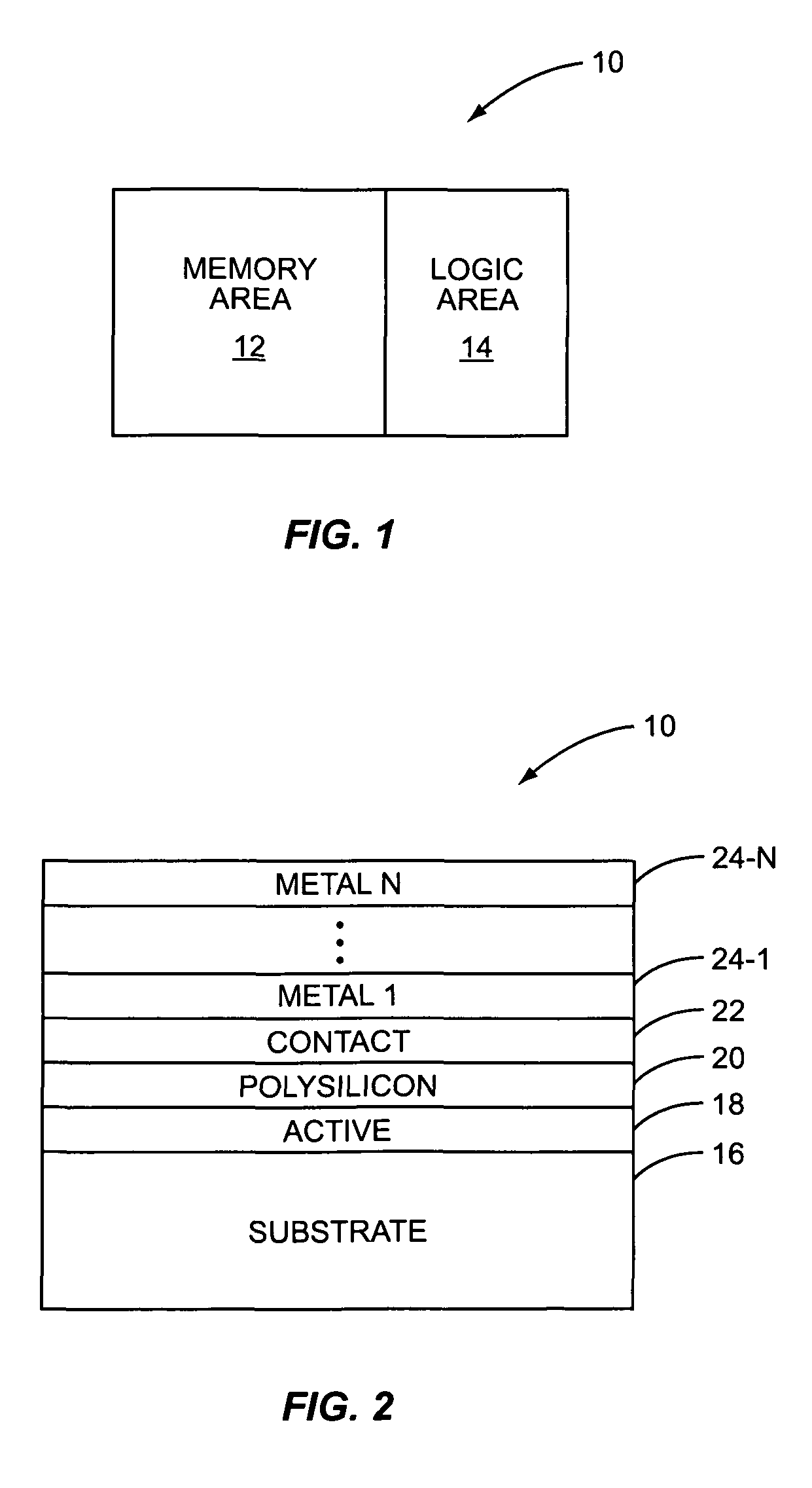

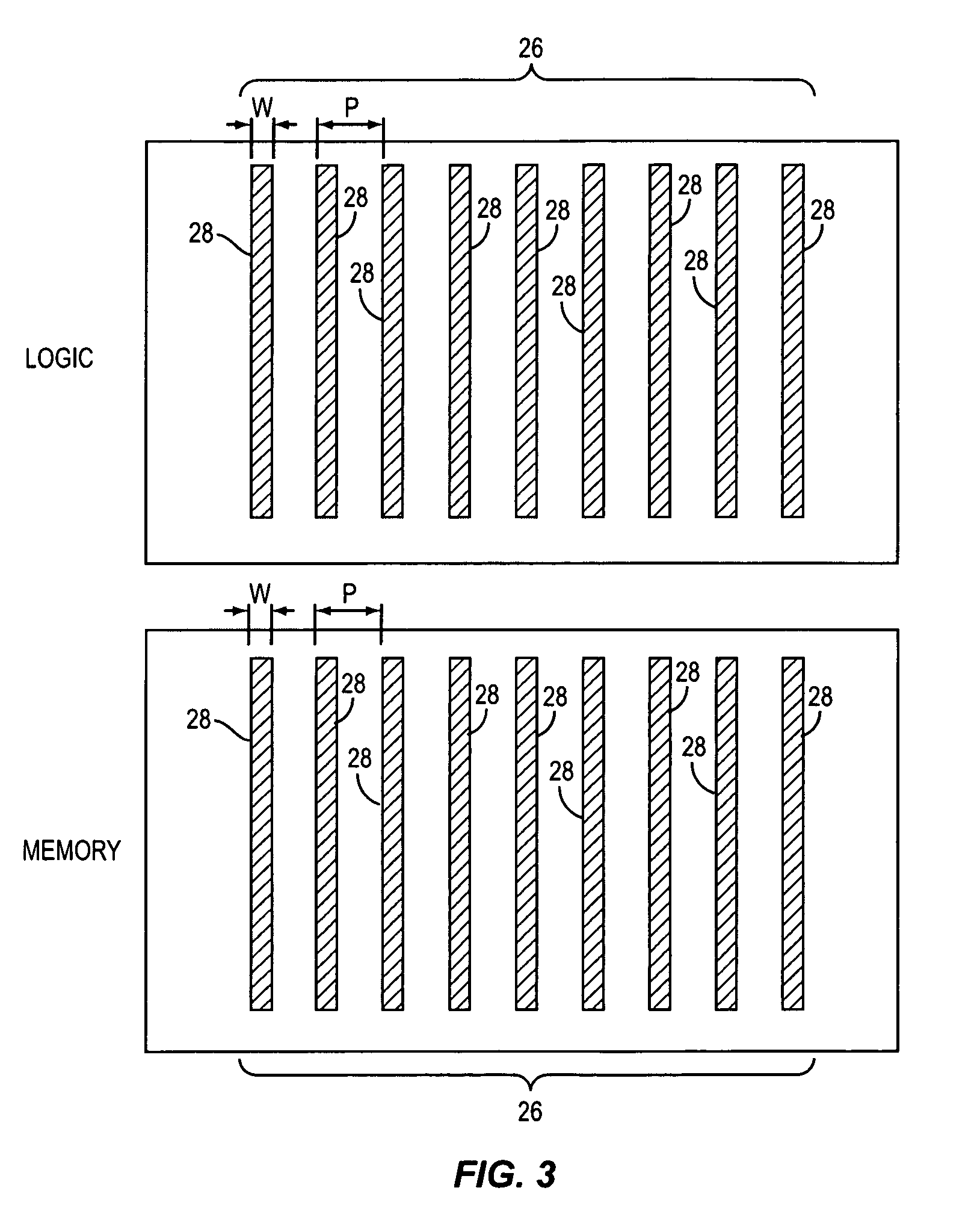

Regular pattern arrays for memory and logic on a semiconductor substrate

InactiveUS8198655B1Reliably and affordably manufacturedSemiconductor/solid-state device detailsSolid-state devicesLithographic artistRegular pattern

An integrated circuit comprising both memory and logic wherein at least one layer of the integrated circuit is fabricated using a common grating pattern for both memory and logic is described. In one embodiment, the integrated circuit comprises a substrate, an active layer, and a gate material layer such as a polysilicon layer, and the active layer, the gate material layer, or both the active layer and the gate material layer are formed using a common grating pattern for both memory and logic. By using a common grating pattern for both memory and logic, a corresponding layer of the integrated circuit can be reliably and affordably manufactured using sub-wavelength lithography.

Owner:CARNEGIE MELLON UNIV

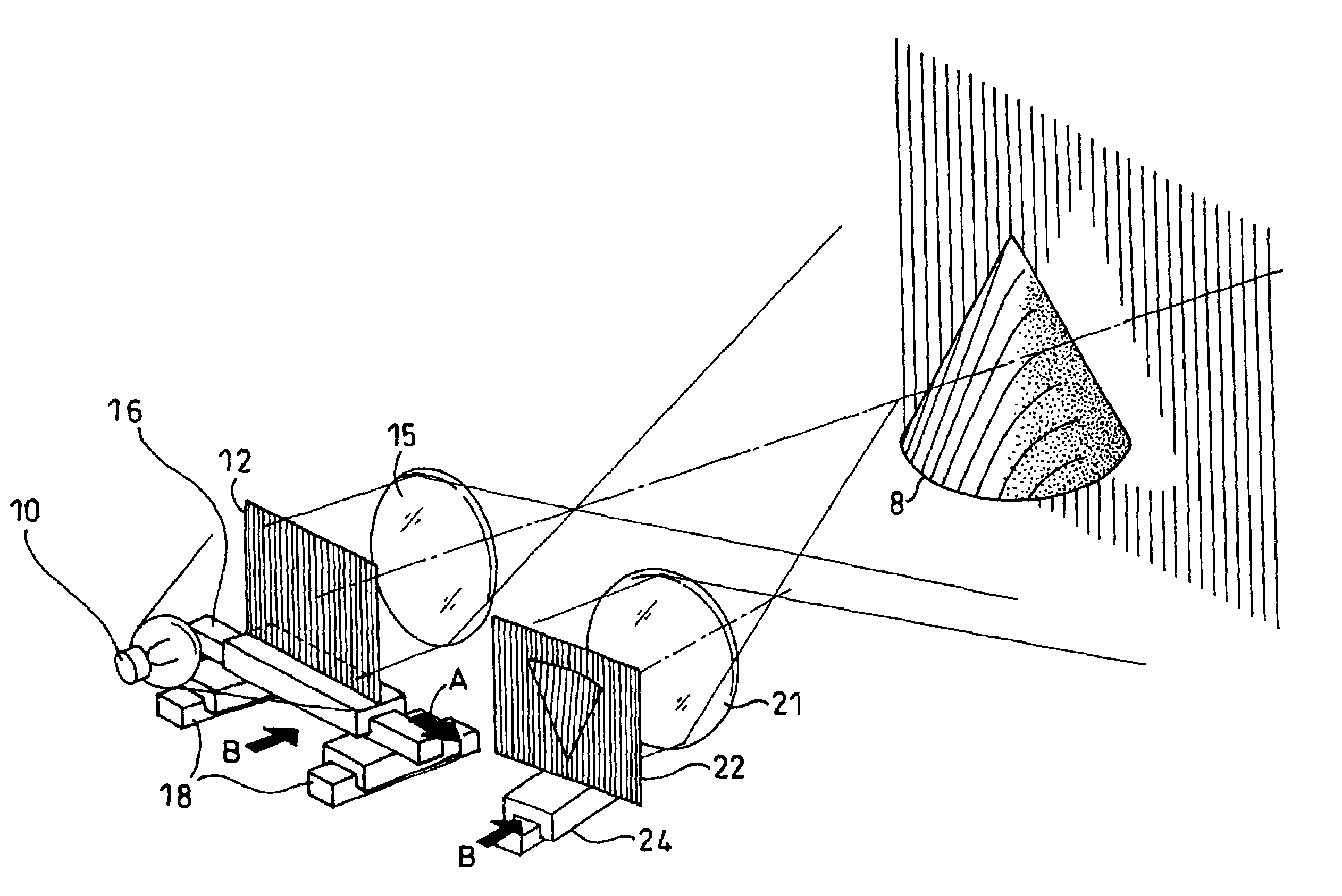

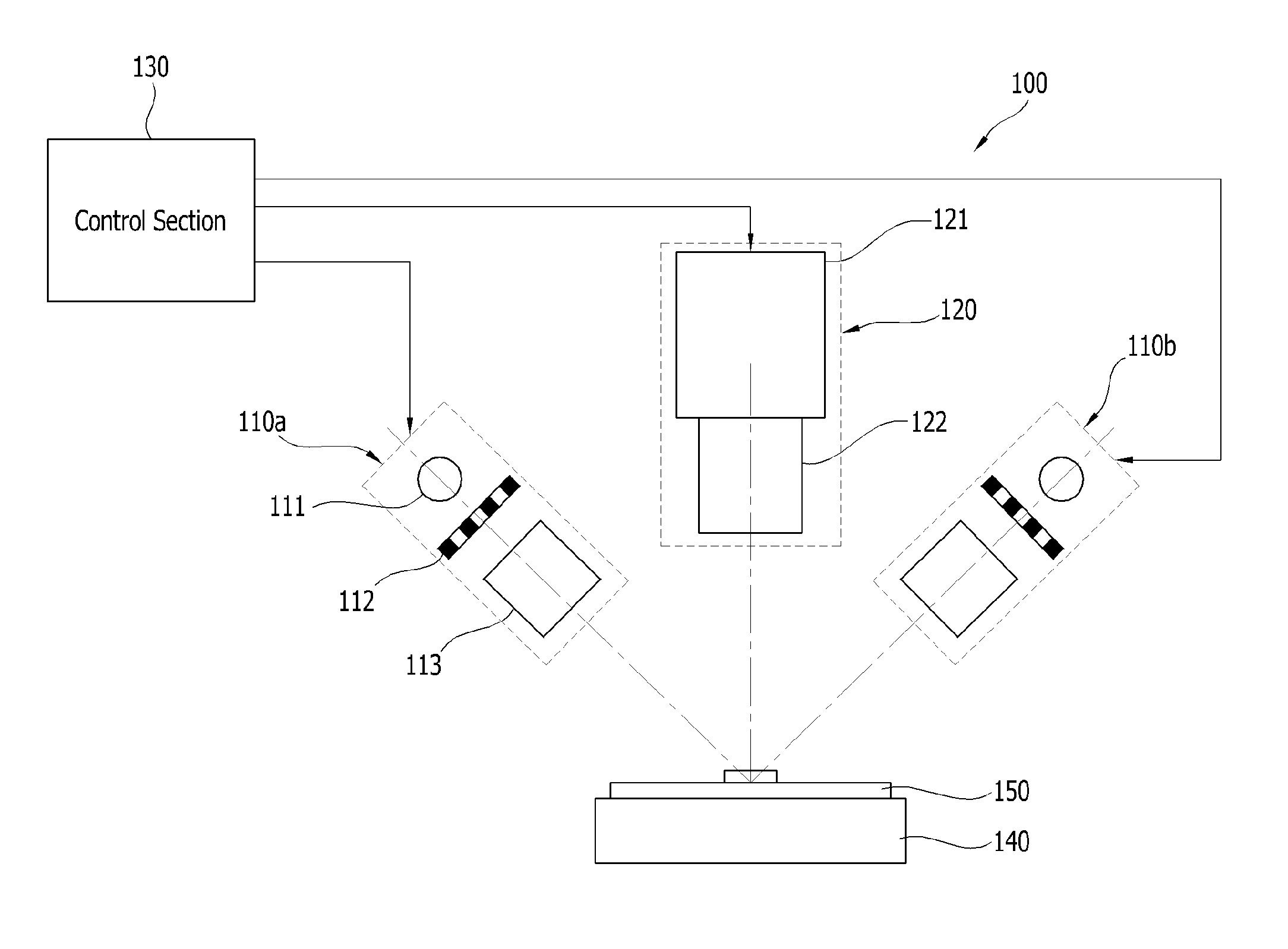

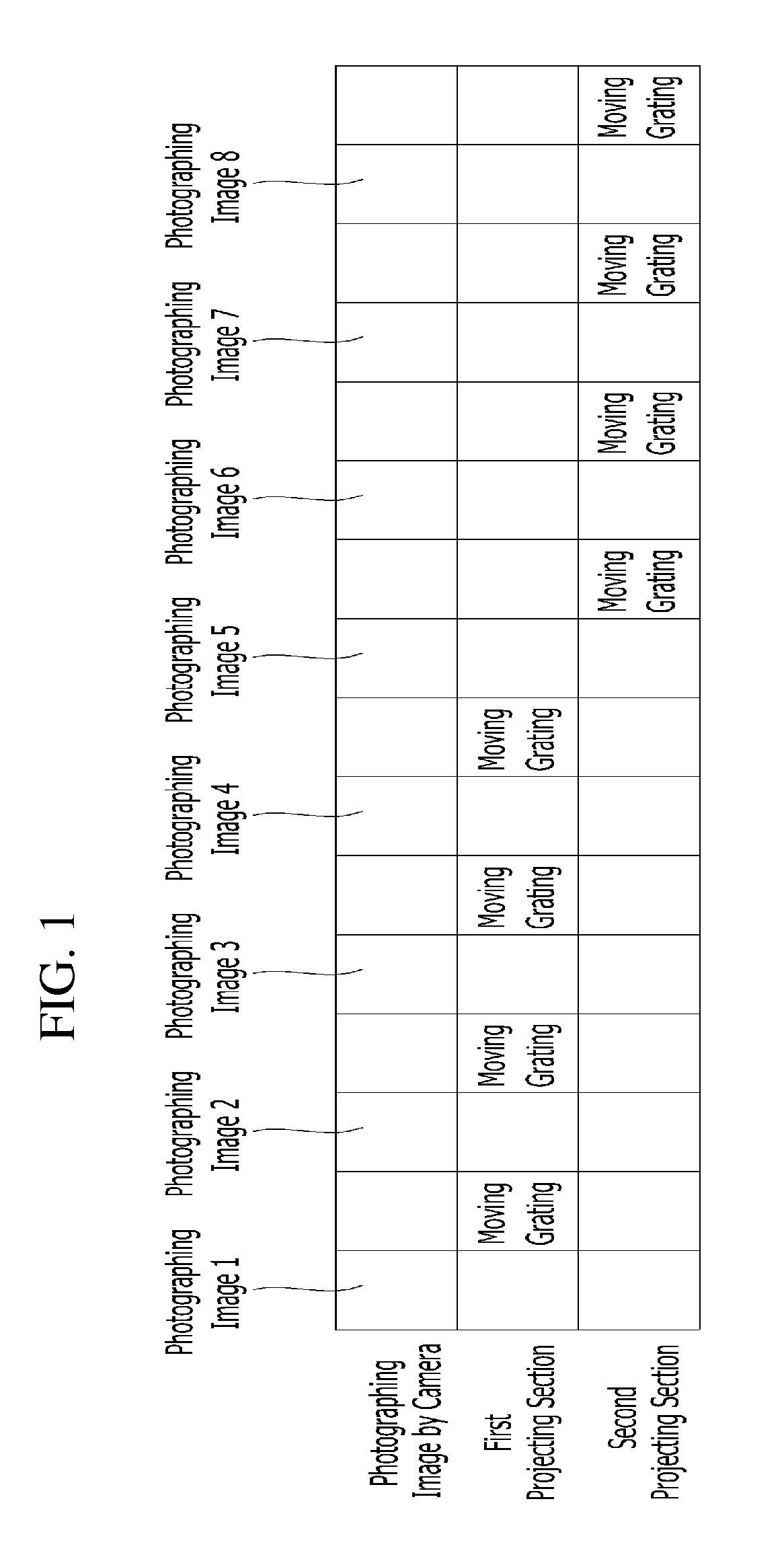

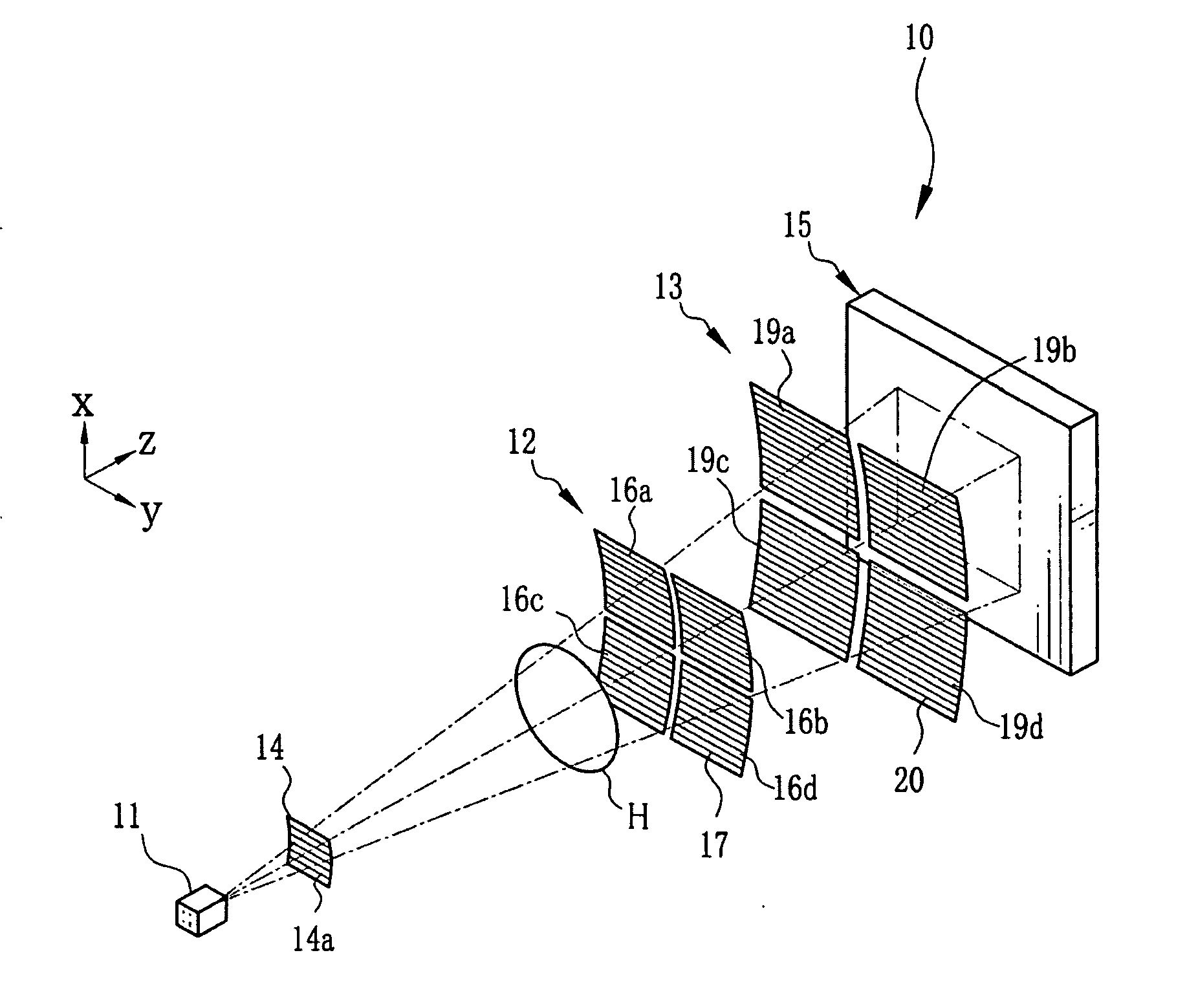

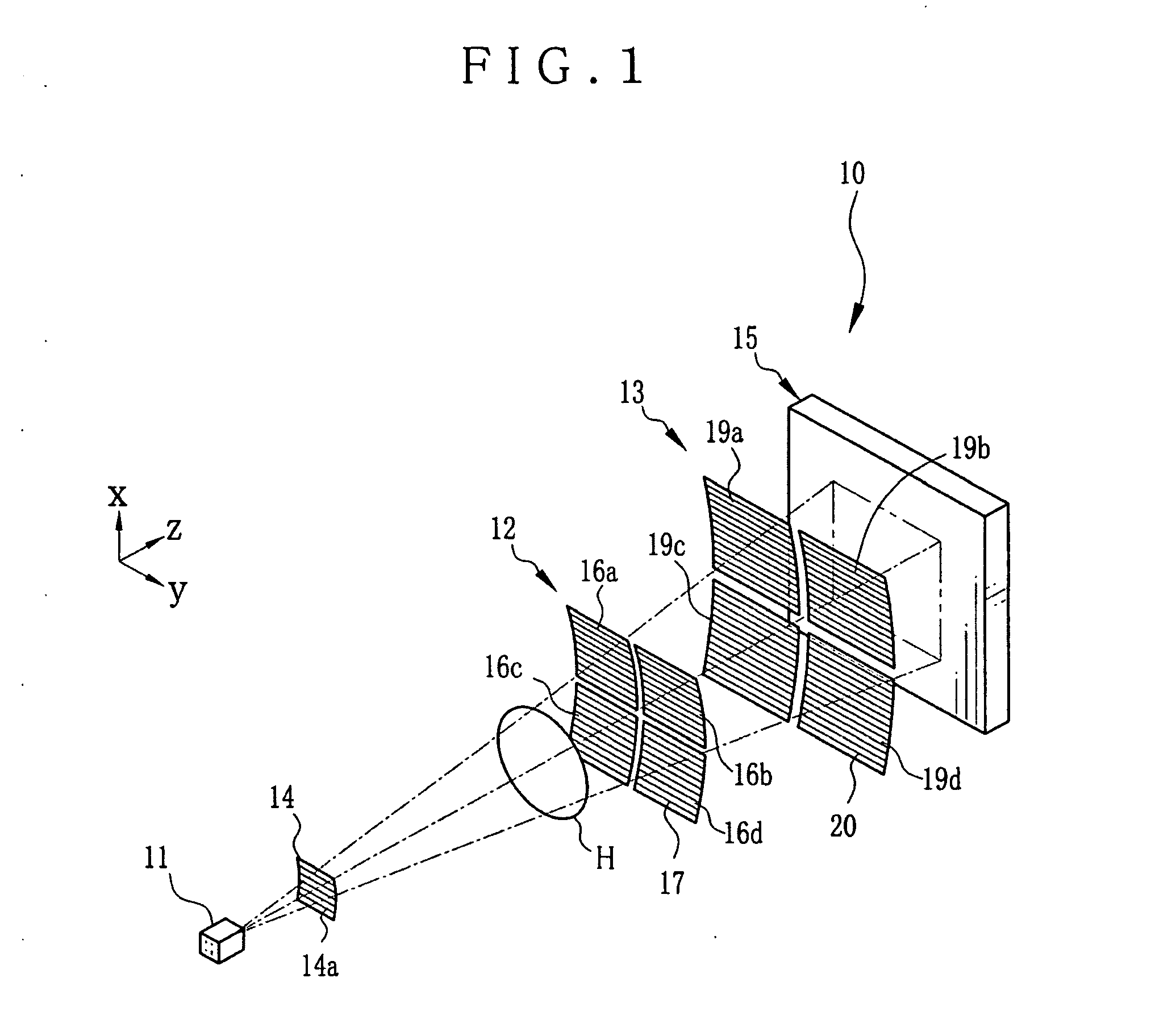

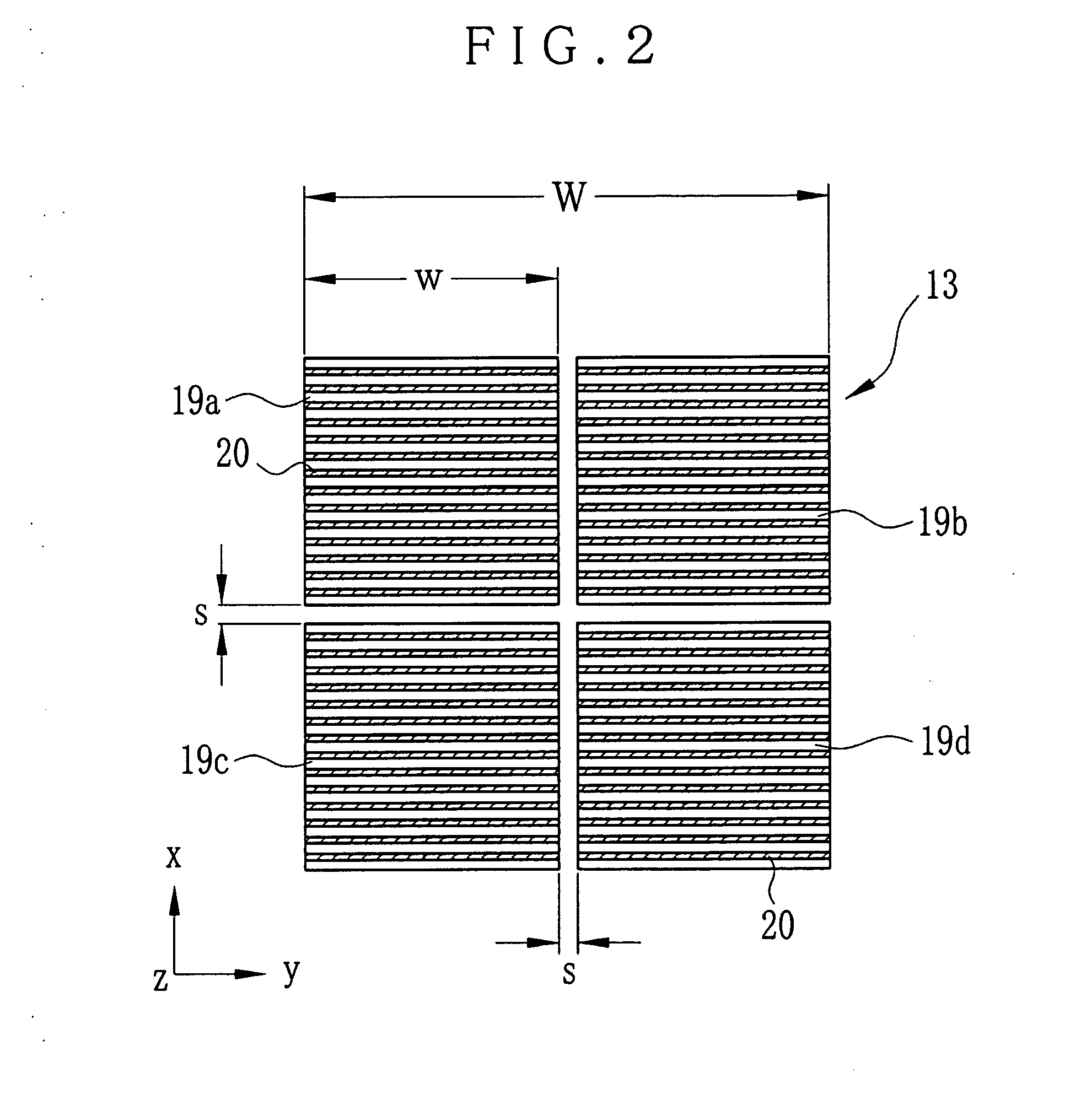

Three dimensional shape measurement apparatus and method

ActiveUS20100302364A1Reduced measurement timeImage analysisCharacter and pattern recognitionThree dimensional shapeGrating pattern

A three dimensional shape measurement apparatus includes m projecting sections, each of which includes a light source and a grating element, and, while moving the grating element by n times, projects a grating pattern light onto a measurement target for each movement, wherein the ‘n’ and the ‘m’ are natural numbers greater than or equal to 2, an imaging section photographing a grating pattern image reflected by the measurement target, and a control section controlling that, while photographing the grating pattern image by using one of the m projecting sections, a grating element of at least another projecting section is moved. Thus, measurement time may be reduced.

Owner:KOHYOUNG TECH

Method of measuring measurement target

ActiveUS20100290696A1Accurate measurementAccurate areaImage enhancementImage analysisGrating patternPhysics

In order to measure a measurement target on a PCB, height information of the PCB is acquired by using a first image photographed by illuminating a grating pattern light onto the PCB. Then, a first area protruding on the PCB by greater than a reference height is determined as the measurement target by using the height information. Thereafter, color information of the PCB is acquired by using a second image photographed by illuminating light onto the PCB. Then, the first color information of the first area determined as the measurement target out of the color information of the PCB is set as reference color information. Thereafter, the reference color information is compared with color information of an area except for the first area to judge whether the measurement target is formed in the area except for the first area. Thus, the measurement target may be accurately measured.

Owner:KOHYOUNG TECH

Grating production method, diffraction grating device, and radiation imaging apparatus

InactiveUS20120002785A1Precise arrangementImaging devicesRadiation/particle handlingRadiation imagingX-ray

An X-ray imaging apparatus includes a diffraction grating device. The diffraction grating device has a composite grating, including small grating plates having radiopaque areas and radio-transparent areas arranged in a grating pattern, and a first support plate being radio-transparent, for receiving the small grating plates secured thereto. A first holding plate being radio-transparent retains the composite grating thereon. The first holding plate includes a concave surface for retaining and curving the composite grating. A second holding plate being radio-transparent is secured to the composite grating, for sandwiching in cooperation with the first holding plate. Also, an opening is formed in each of the holding plates to open in an area of the small grating plates. A clamping cap squeezes the holding plates for sealing. Also, a second support plate being radio-transparent sandwiches the small grating plates with the first support plate.

Owner:FUJIFILM CORP

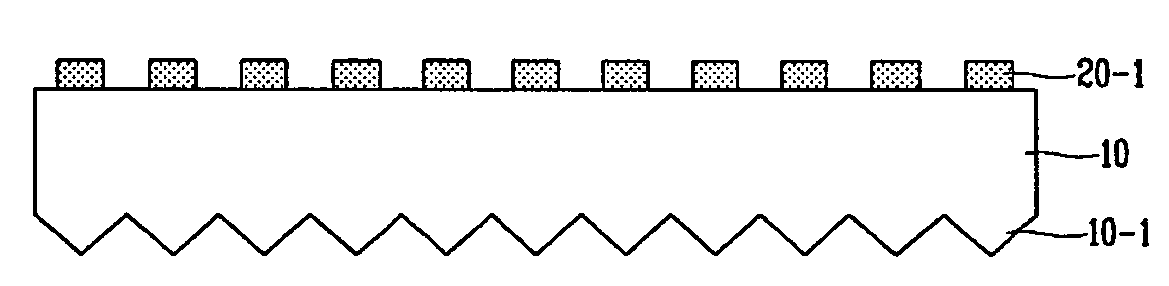

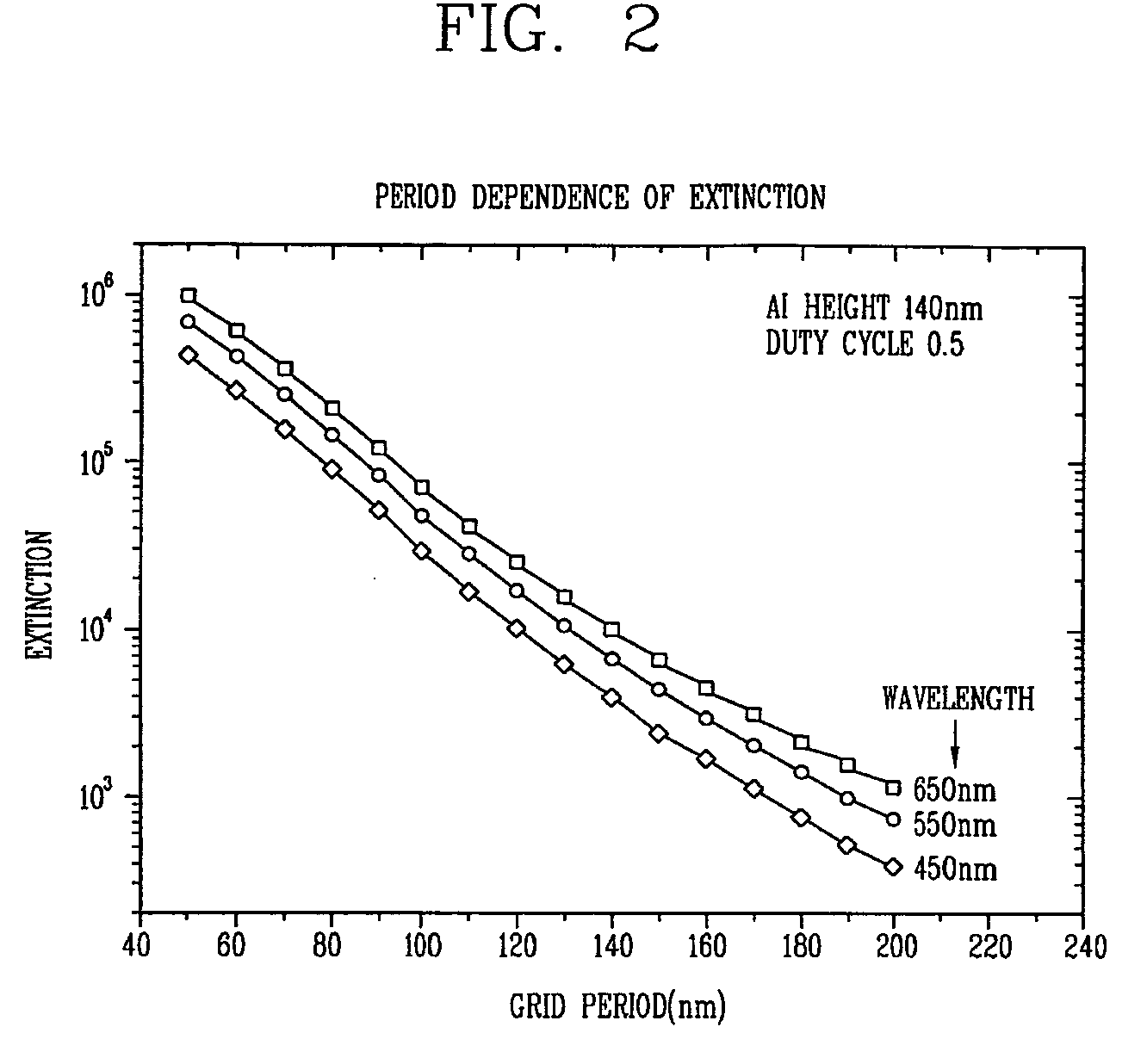

Wire grid polarizer and fabrication method thereof

InactiveUS20060072194A1High visible light transmittanceEasy to makePolarising elementsDiffraction gratingsWire gridTransmittance

A wire grid polarizer capable of increasing a visible light transmittance and a fabrication method thereof. The wire grid polarizer comprises a substrate having a first surface and a second surface, a plurality of metallic wires formed on the first surface, and grating patterns formed on the second surface and having a grating period shorter than a half of a wavelength of an incident light beam.

Owner:LG ELECTRONICS INC

16-step dual-frequency grating phase shift profilometry capable of absolute phase unwrapping

InactiveCN101655360AGuaranteed measurement accuracyGuaranteed Measurement RequirementsUsing optical meansMeasurement studyThree dimensional shape

The invention provides 16-step dual-frequency grating phase shift profilometry capable of absolute phase unwrapping in the three-dimensional sensor technology. The invention is characterized by usingcomputers to design codes to generate 16 dual-frequency grating patterns, using a digital light projector to image the grating patterns on the surface of an object instantaneously in sequence, using apick-up device to record the deforming fringe pattern of the object, subsequently using the functional relationship between the gratings with two frequencies, using the absolute phase unwrapping method to directly realize phase unwrapping of point to point in the whole field range and having no relation with the path for phase unwrapping, effectively inhibiting accumulative error diffusion, usingphase measuring profilometry to process the deforming fringes, accurately restoring the three-dimensional shape of the object and obtaining such digital information as deformation of the object and the like by further analyzing the data processing results. The method can be used for measurement study of the characteristics of the object surface with the characteristic of diffuse reflection. The method has the advantages of high measurement precision and strong adaptability to the surface topography of the object, etc.

Owner:SICHUAN UNIV

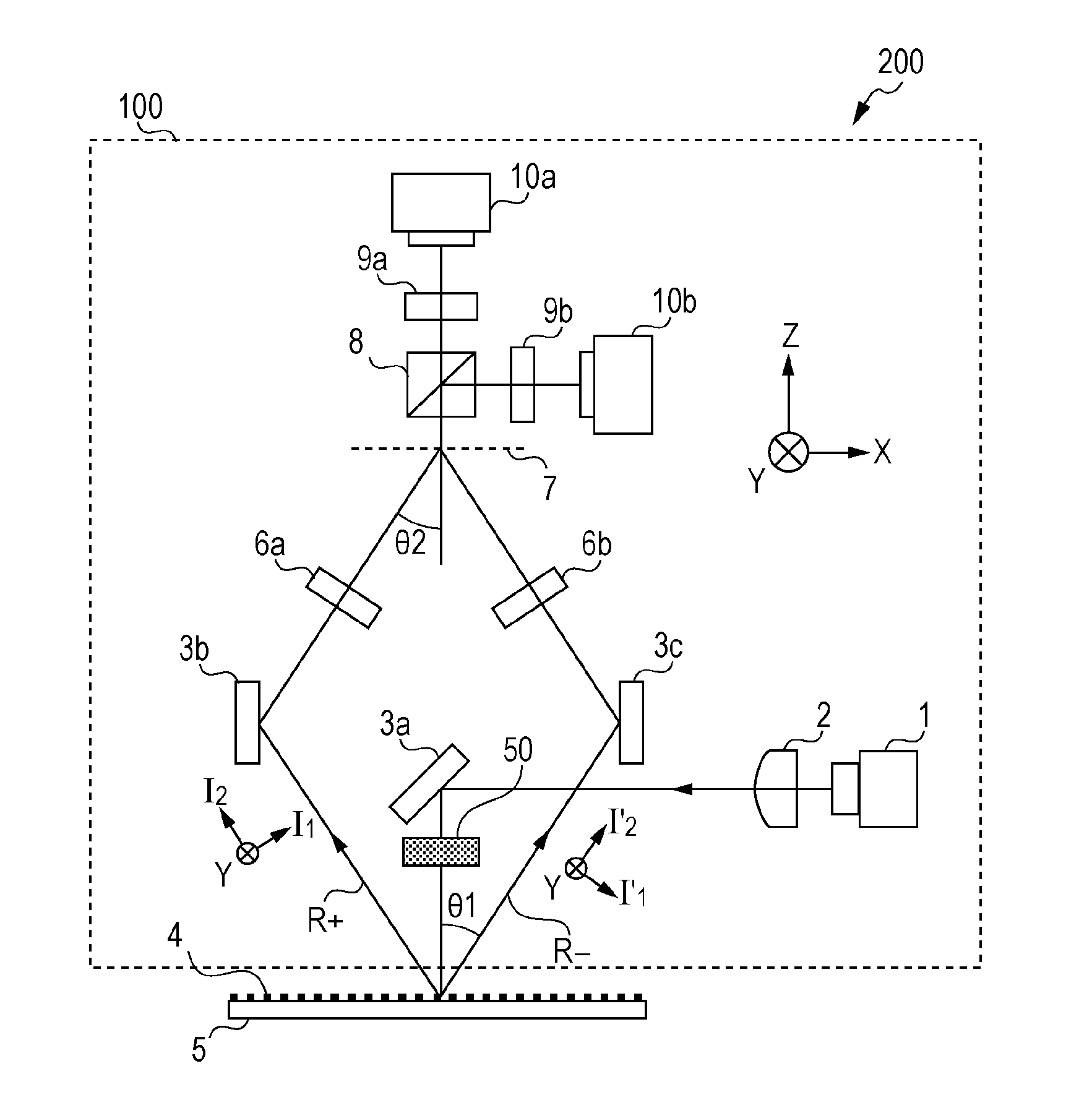

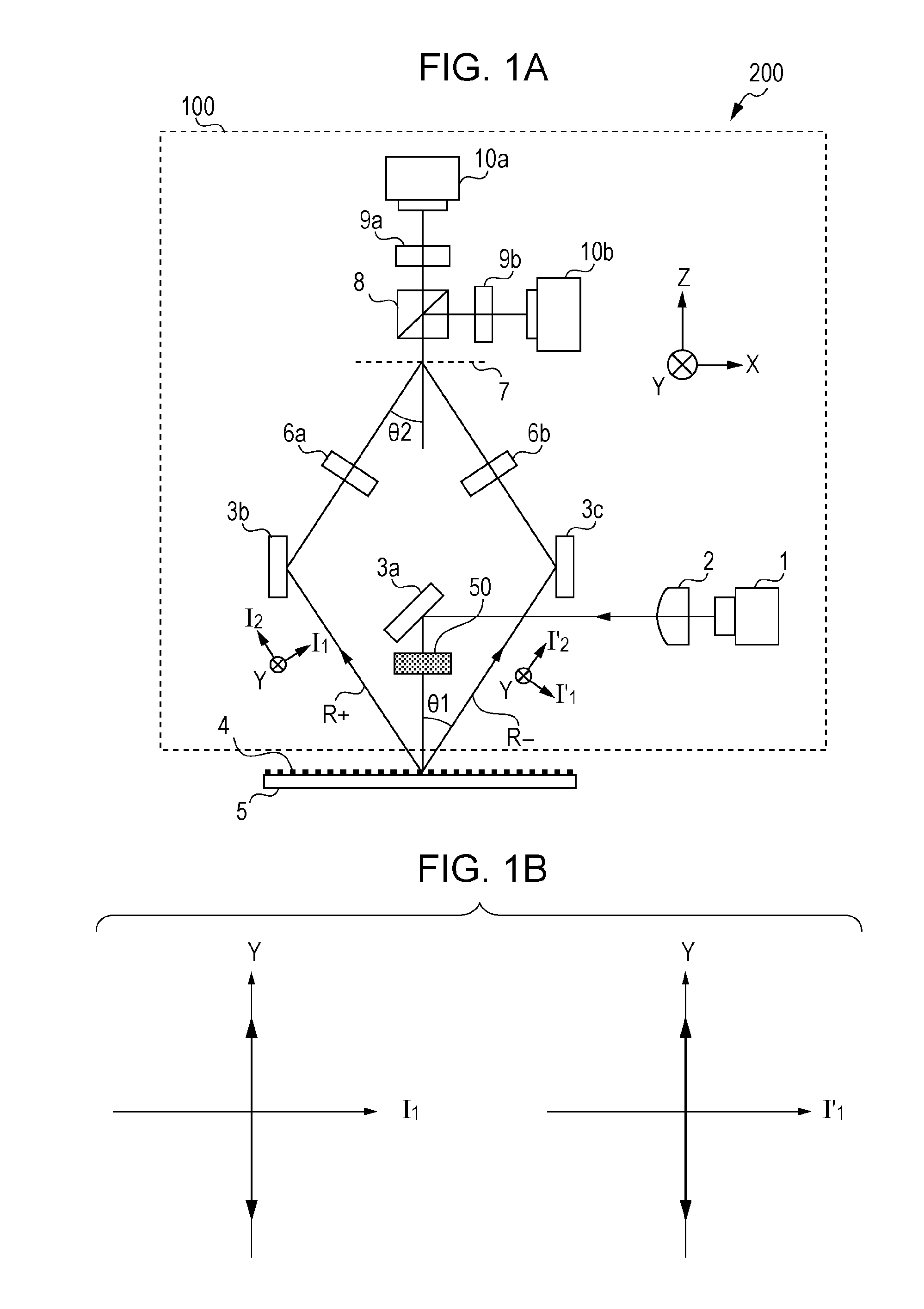

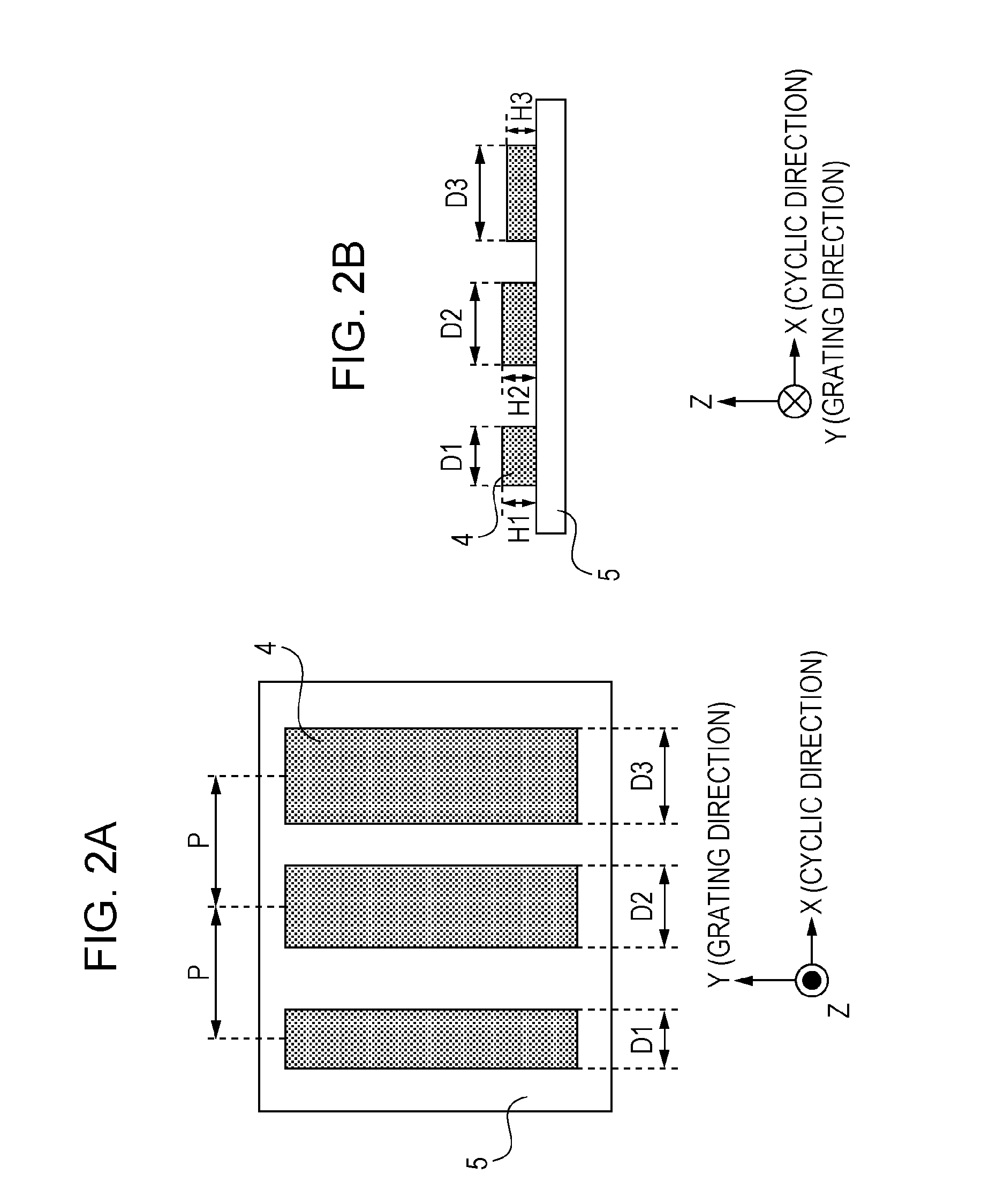

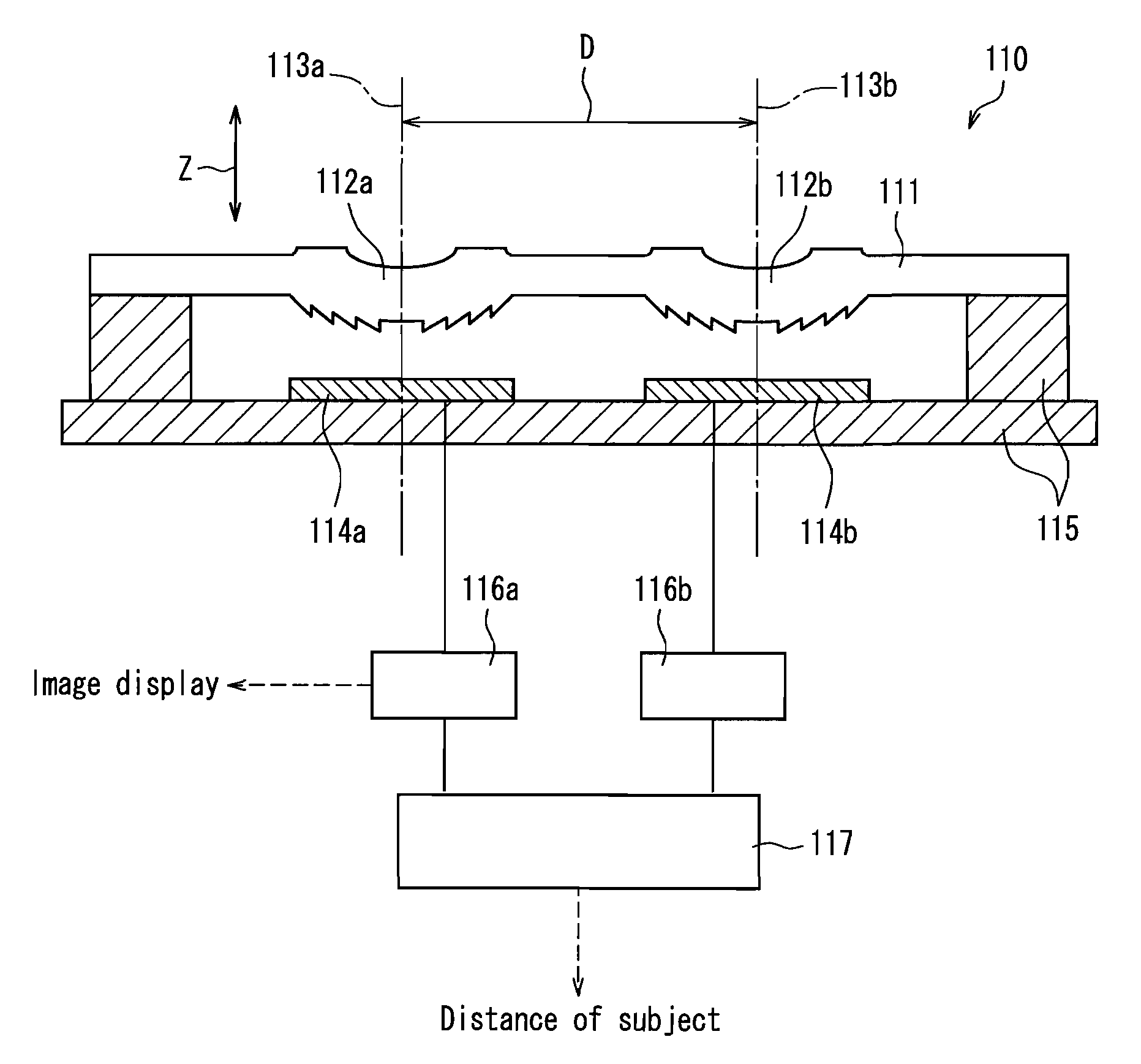

Displacement measurement device, exposure apparatus, and working device

ActiveUS20110141451A1InterferometersPhotomechanical apparatusMeasurement devicePhotovoltaic detectors

A device has a scale on which a grating pattern is formed, a light source to irradiate light on the scale, a wavelength plate to transform multiple diffracted lights from the light source into circular polarized light, respectively, an optical element to superposition and cause interference of the multiple diffracted lights, and a photodetector to receive the interfered light. Also, a generating unit to generate linearly polarized light by the light from the light source, so that the multiple diffracted lights input to the wavelength plate become linearly polarized light with a same mutual polarization direction.

Owner:CANON KK

Frequency tunable resonant scanner and method of making

InactiveUS20010034077A1Light provideBeam/ray focussing/reflecting arrangementsStatic indicating devicesEngineeringMechanical property

A MEMs scanning device has a variable resonant frequency. In one embodiment, the MEMs device includes a torsion arm that supports an oscillatory body. In one embodiment, an array of removable masses are placed on an exposed portion of the oscillatory body and selectively removed to establish the resonant frequency. The material can be removed by laser ablation, etching, or other processing approaches. In another approach, a migratory material is placed on the torsion arm and selectively stimulated to migrate into the torsion arm, thereby changing the mechanical properties of the torsion arm. The changed mechanical properties in turn changes the resonant frequency of the torsion arm. In another approach, symmetrically distributed masses are removed or added in response to a measured resonant frequency to tune the resonant frequency to a desired resonant frequency. A display apparatus includes the scanning device and the scanning device scans about two or more axes, typically in a raster pattern. Various approaches to controlling the frequency responses of the scanning device are described, including active control of MEMs scanners and passive frequency tuning.

Owner:MICROVISION

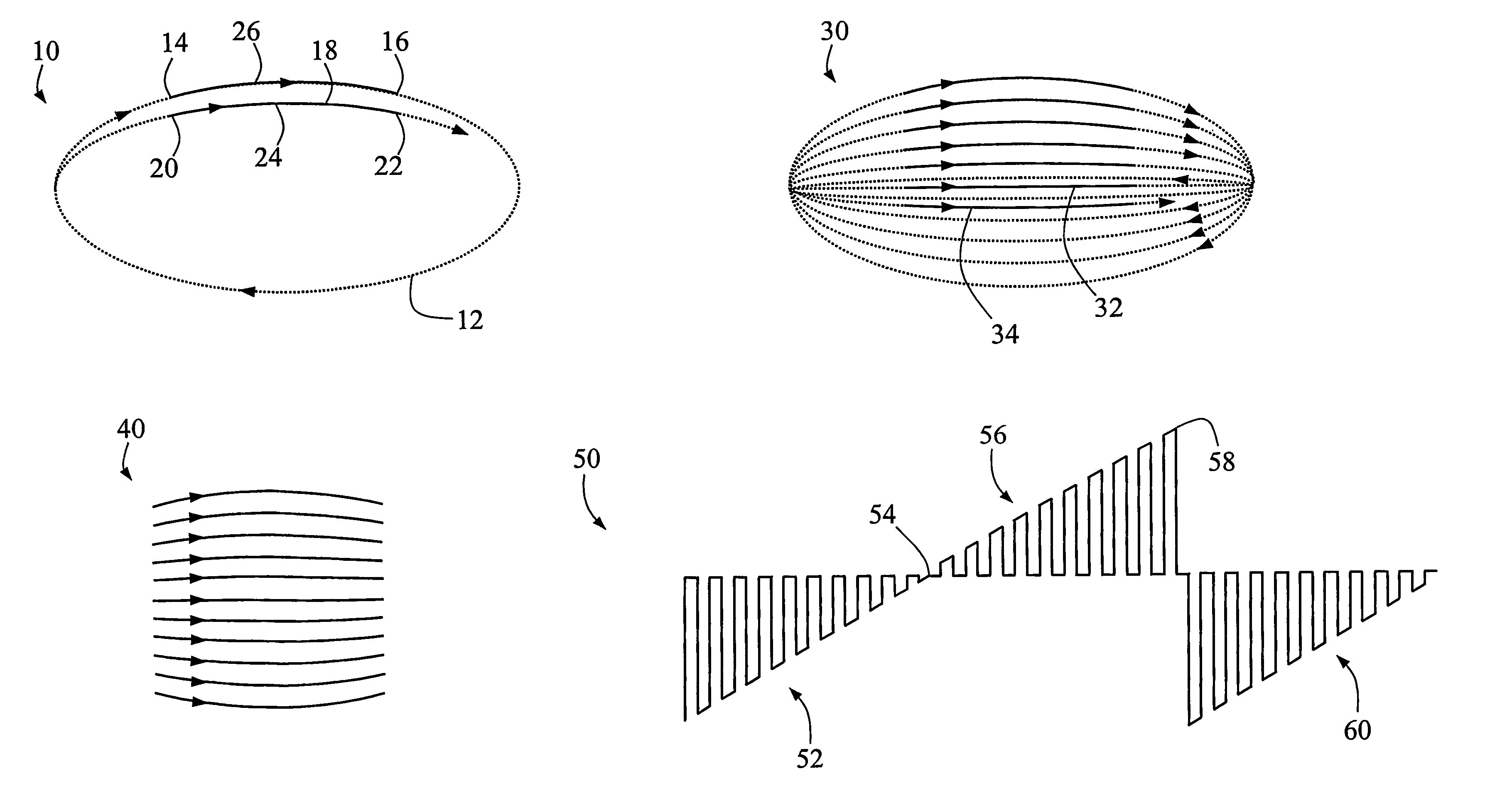

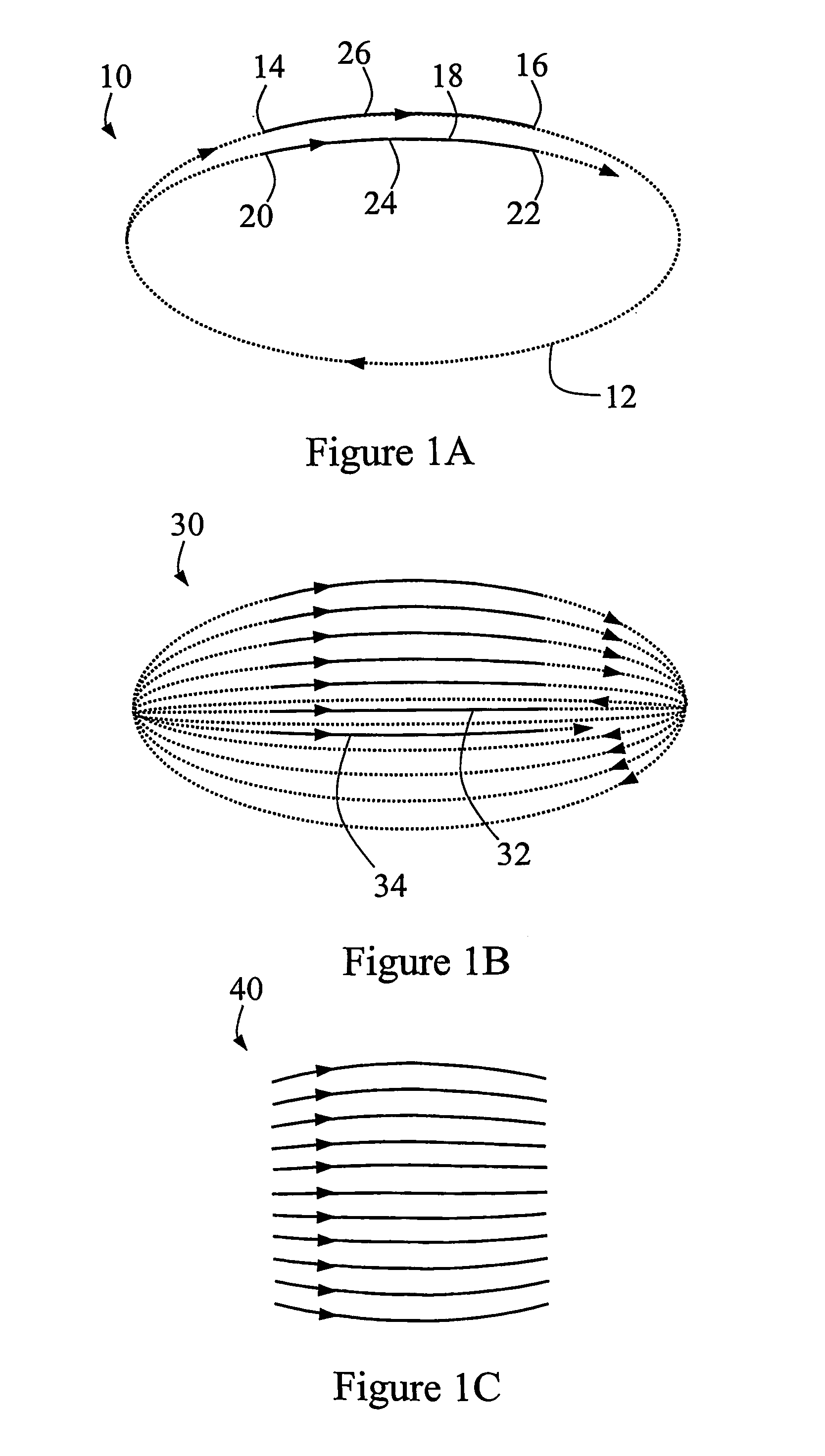

Scanning method and apparatus

A scanning apparatus and method, the apparatus comprising: a light transmission means (90) having an exit tip; first and second drive means (92,94) for resonantly driving the light transmission means (90) in orthogonal directions; wherein the first and second drive means (92,94) are operable to move the tip in an elliptical pattern while varying the eccentricity of the elliptical pattern, whereby a portion of the elliptical pattern having a centre on the minor axis of the elliptical pattern approximates—at least in appearance—a raster pattern.

Owner:OPTISCAN

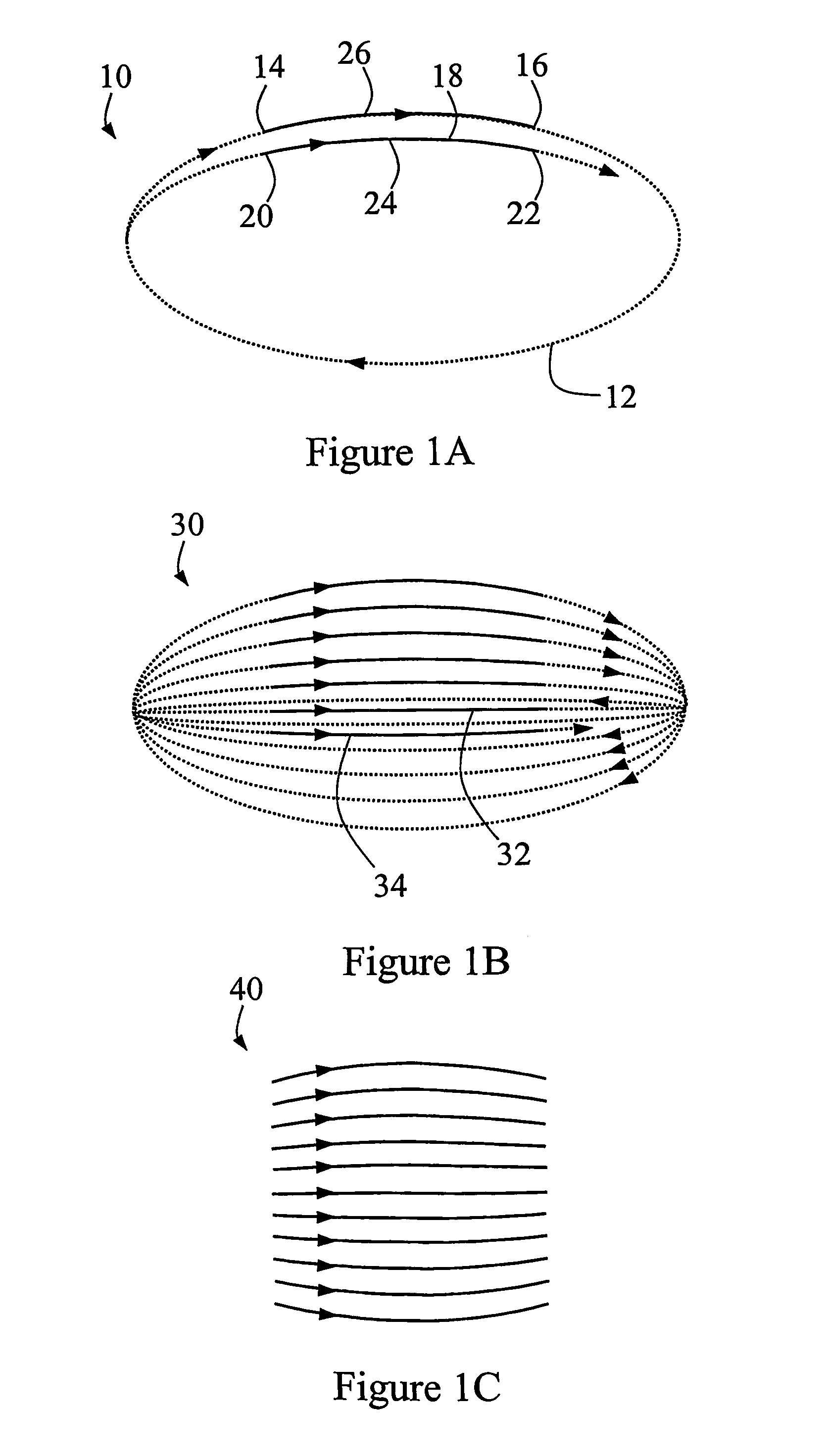

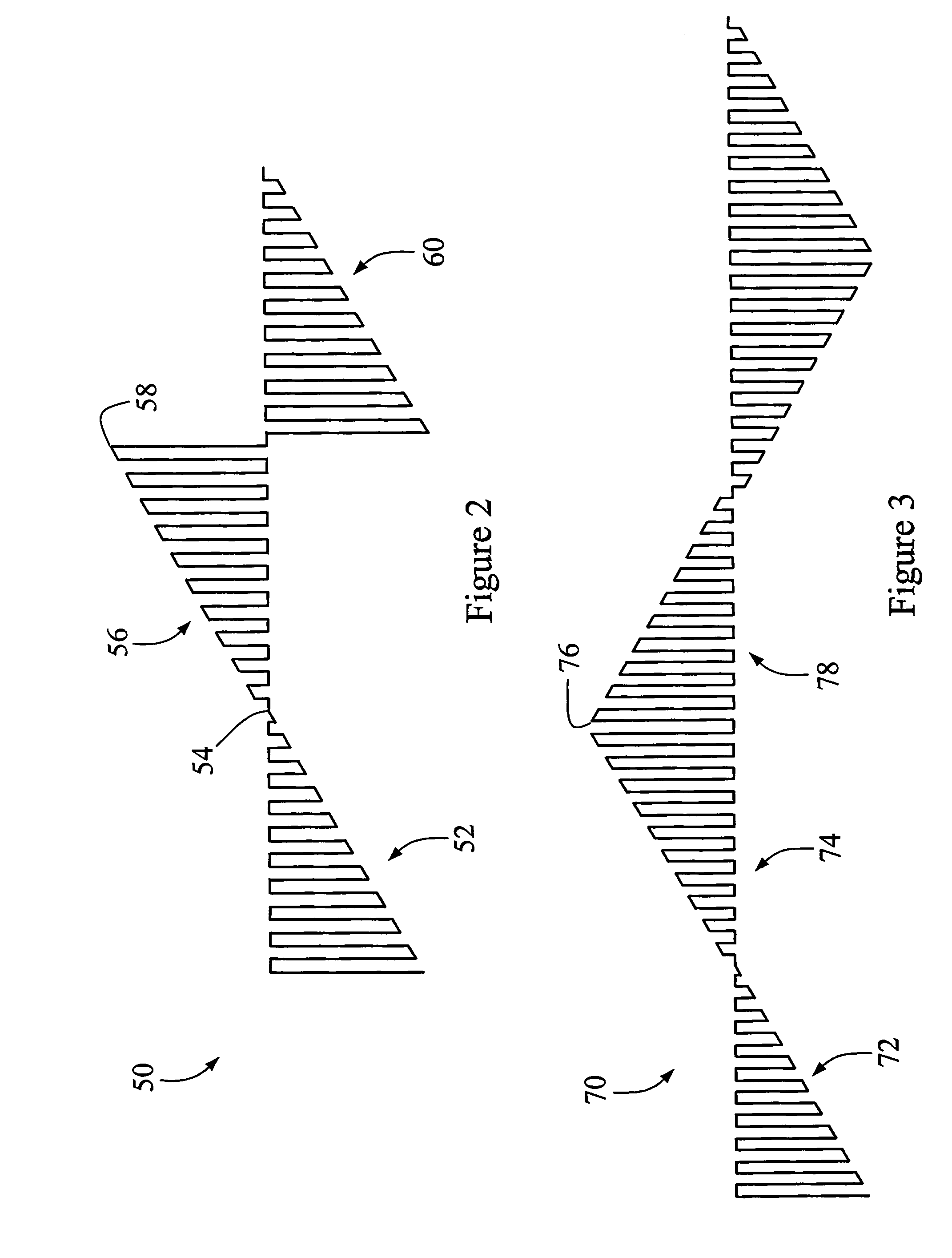

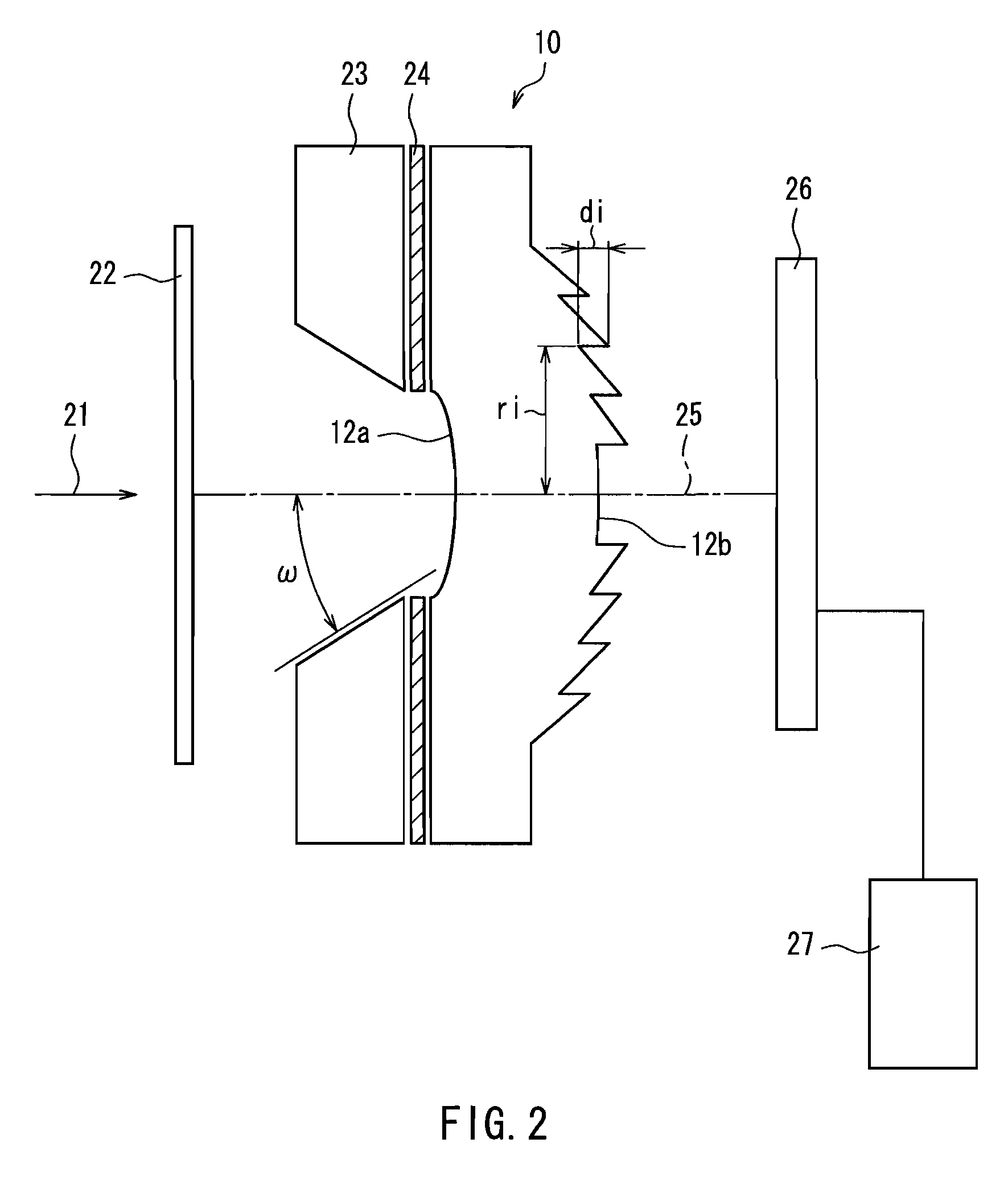

Diffractive imaging lens, diffractive imaging lens optical system, and imaging apparatus using the diffractive imaging lens optical system

ActiveUS20090225215A1Reduce decreaseReduce lightTelevision system detailsColor television detailsOptical axisImaging lens

A diffractive imaging lens 10 includes a surface on which a diffraction grating pattern is formed. The diffraction grating pattern is formed of a plurality of steps formed concentrically with an optical axis (25) at a center. The diffraction grating pattern is formed such that a first portion where amounts (di) of the steps are substantially the same in a radial direction of concentric circles and a second portion, outside of the first portion, where amounts (di) of the steps decrease with distance from the optical axis 25 are provided, or such that the amounts (di) of the steps decrease with distance from the optical axis 25 over the entire diffraction grating pattern.

Owner:PANASONIC CORP

Scanning method and apparatus

A scanning apparatus and method, the apparatus comprising: a light transmission means (90) having an exit tip; first and second drive means (92,94) for resonantly driving the light transmission means (90) in orthogonal directions; wherein the first and second drive means (92,94) are operable to move the tip in an elliptical pattern while varying the eccentricity of the elliptical pattern, whereby a portion of the elliptical pattern having a centre on the minor axis of the elliptical pattern approximates—at least in appearance—a raster pattern.

Owner:OPTISCAN

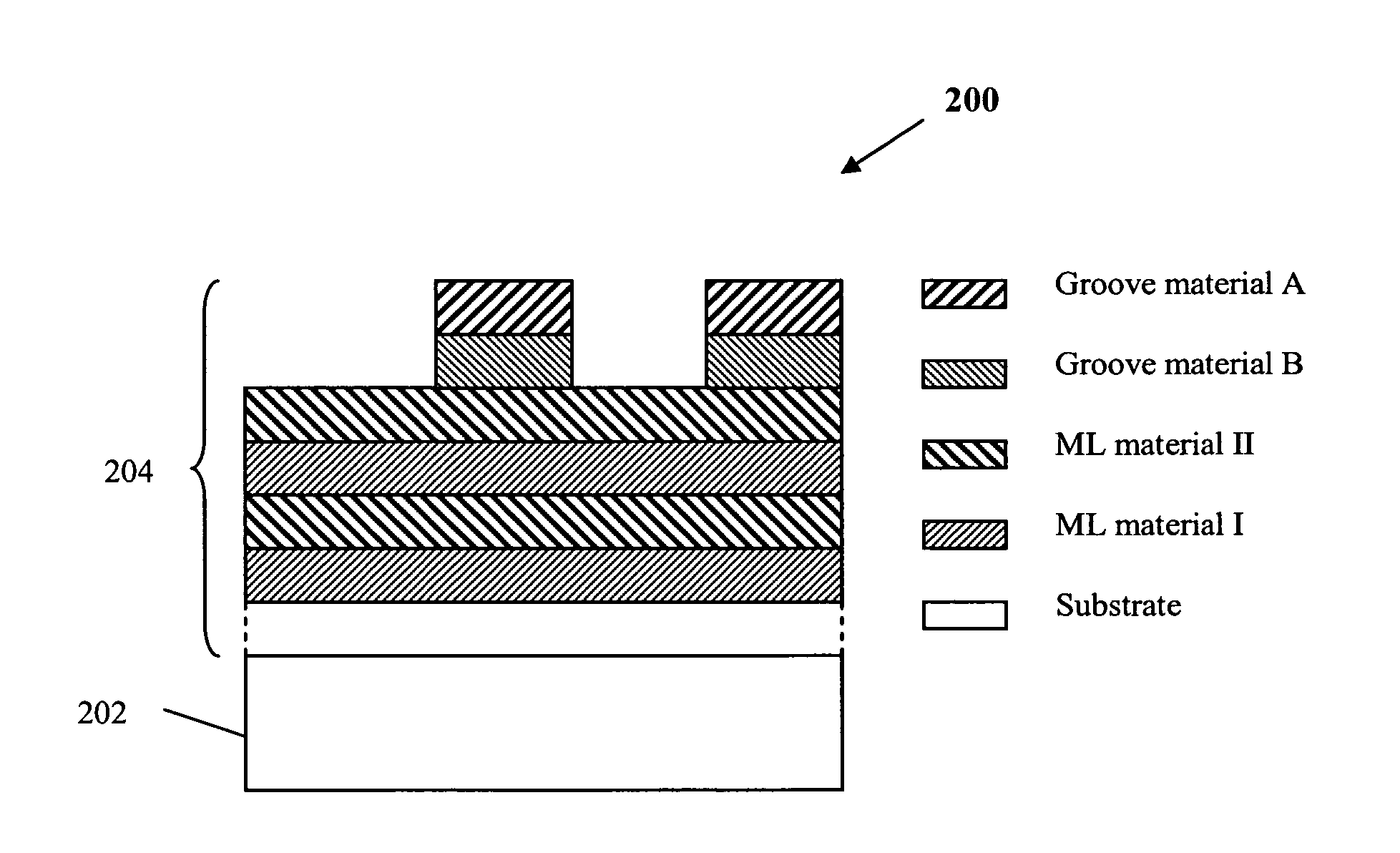

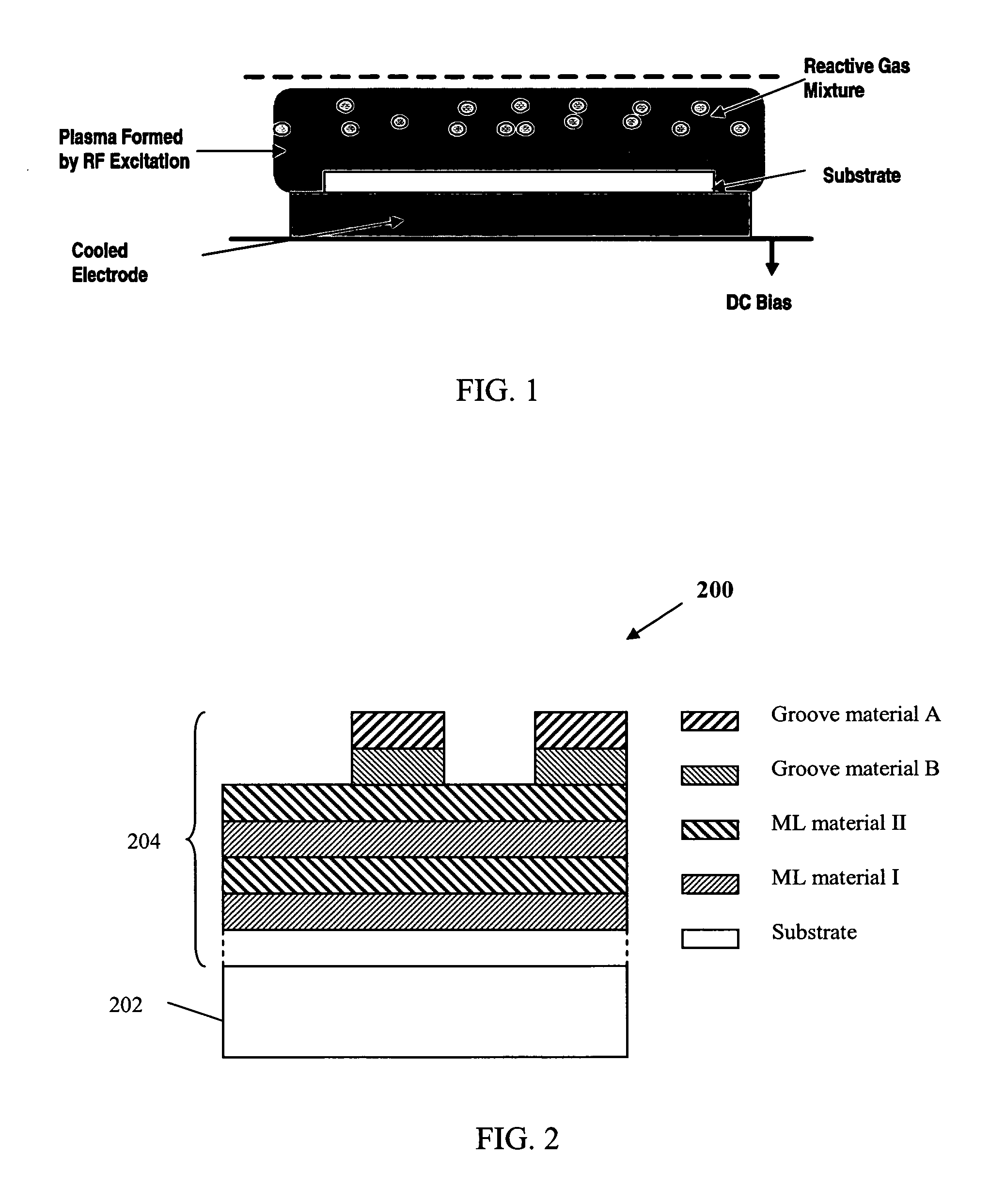

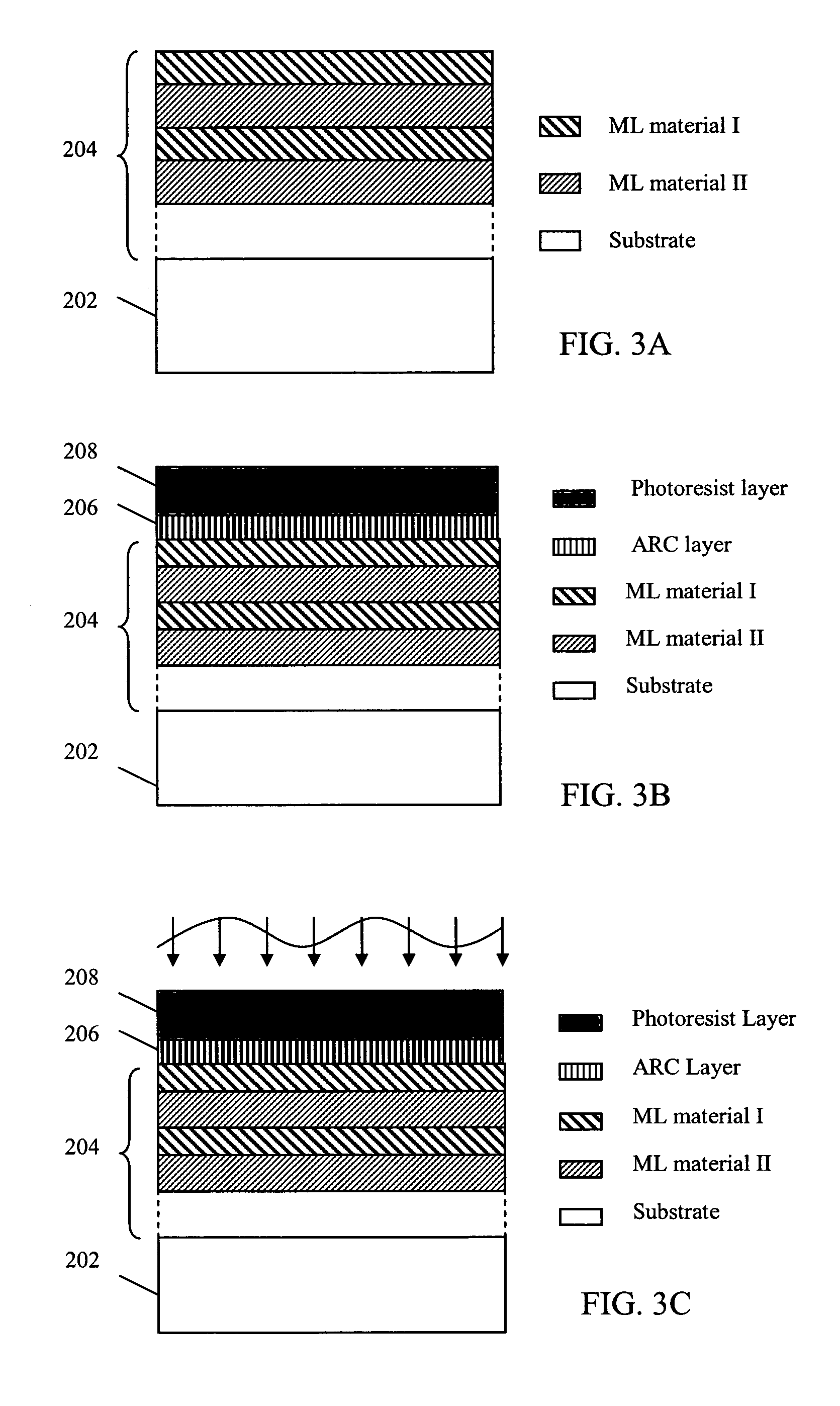

Method for making large scale multilayer dielectric diffraction gratings on thick substrates using reactive ion etching

ActiveUS7256938B2Optical resonator shape and constructionDiffraction gratingsDielectric structureLarge size

Methods of fabricating large size, high performance multilayer diffraction gratings having a thick substrate that take advantage of reactive ion etching during the fabrication process are provided herein. In one implementation, a method of making a multilayer diffraction grating comprises the steps of: providing a substrate having a thickness of at least 2.0 cm; applying a dielectric structure having a plurality of layers on the substrate; depositing a photoresist; exposing the photoresist to a grating pattern; developing the photoresist to produce the grating pattern in the photoresist; and reactive ion etching to transfer the grating pattern to the dielectric structure. In preferred form, the substrate material of the grating is selected to have low electrical resistivity and high thermal conductivity.

Owner:GENERAL ATOMICS

Imprint apparatus and method of manufacturing article

An imprint apparatus includes a detector and an adjusting device. A second mark formed on a substrate includes a grating pattern having grating pitches in first and second directions which are respectively parallel to first and second axes which are parallel to a pattern surface of a mold and orthogonal to each other. A first mark formed on the mold includes a grating pattern having a grating pitch in the first direction. The first and second marks have different grating pitches in the first direction. The detector includes an image sensor, and an optical system which forms a moire fringe on an image sensing surface of the image sensor. The adjusting device adjusts, in a plane including the second axis and a third axis that is perpendicular to the first and second axes, an angle between the optical axis of the detector and the third axis.

Owner:CANON KK

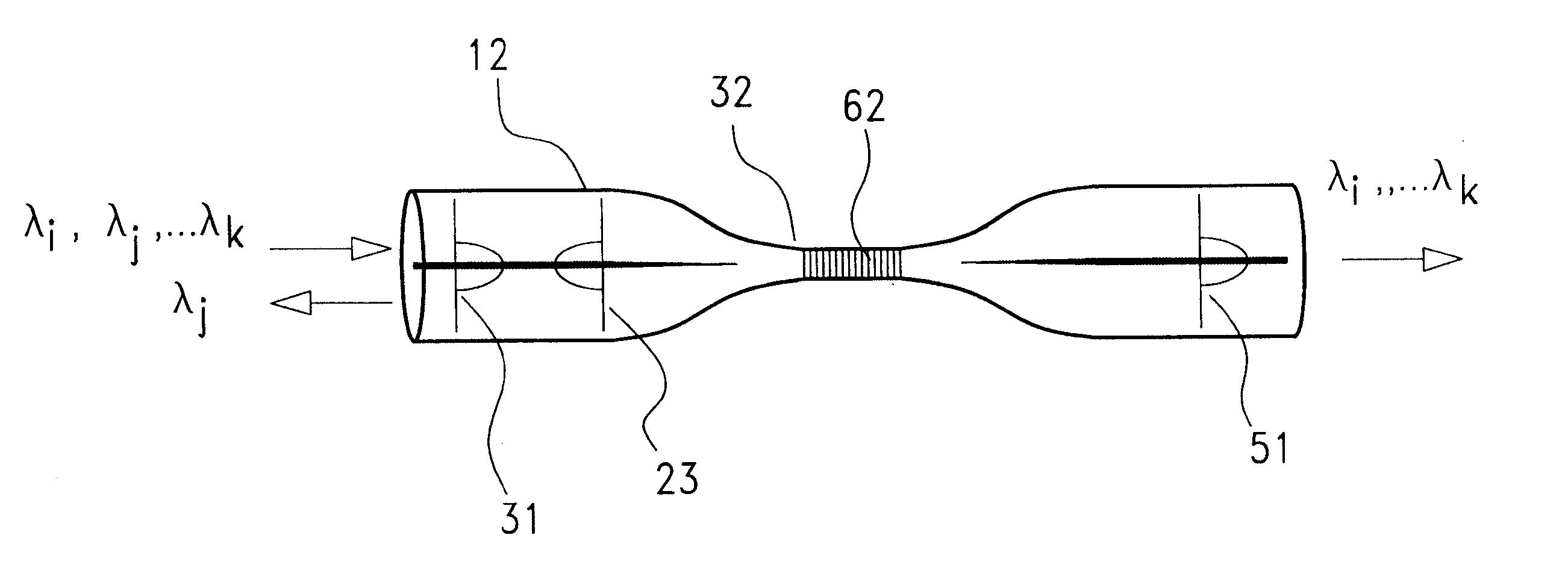

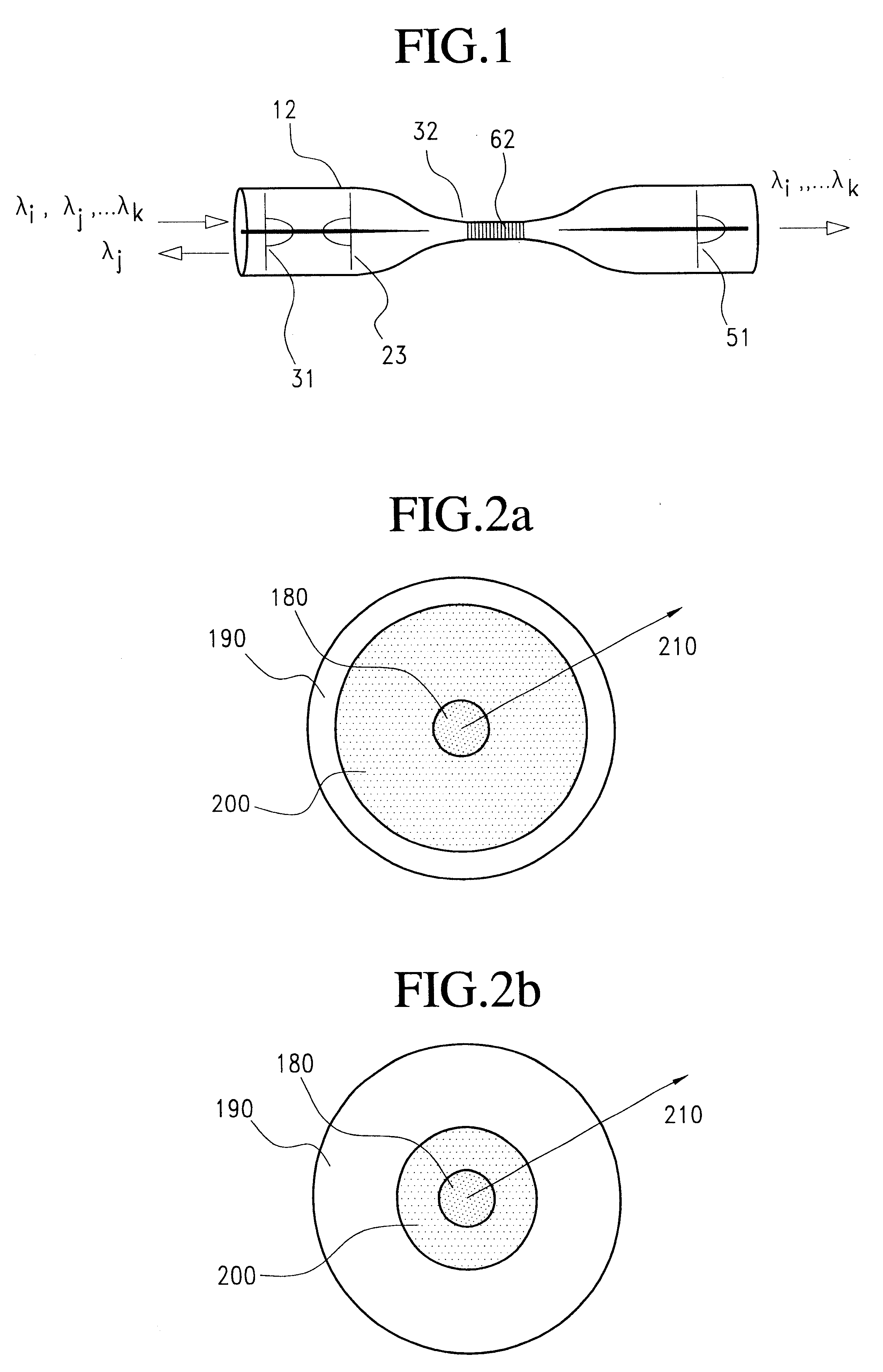

Tapered fiber gratings and applications

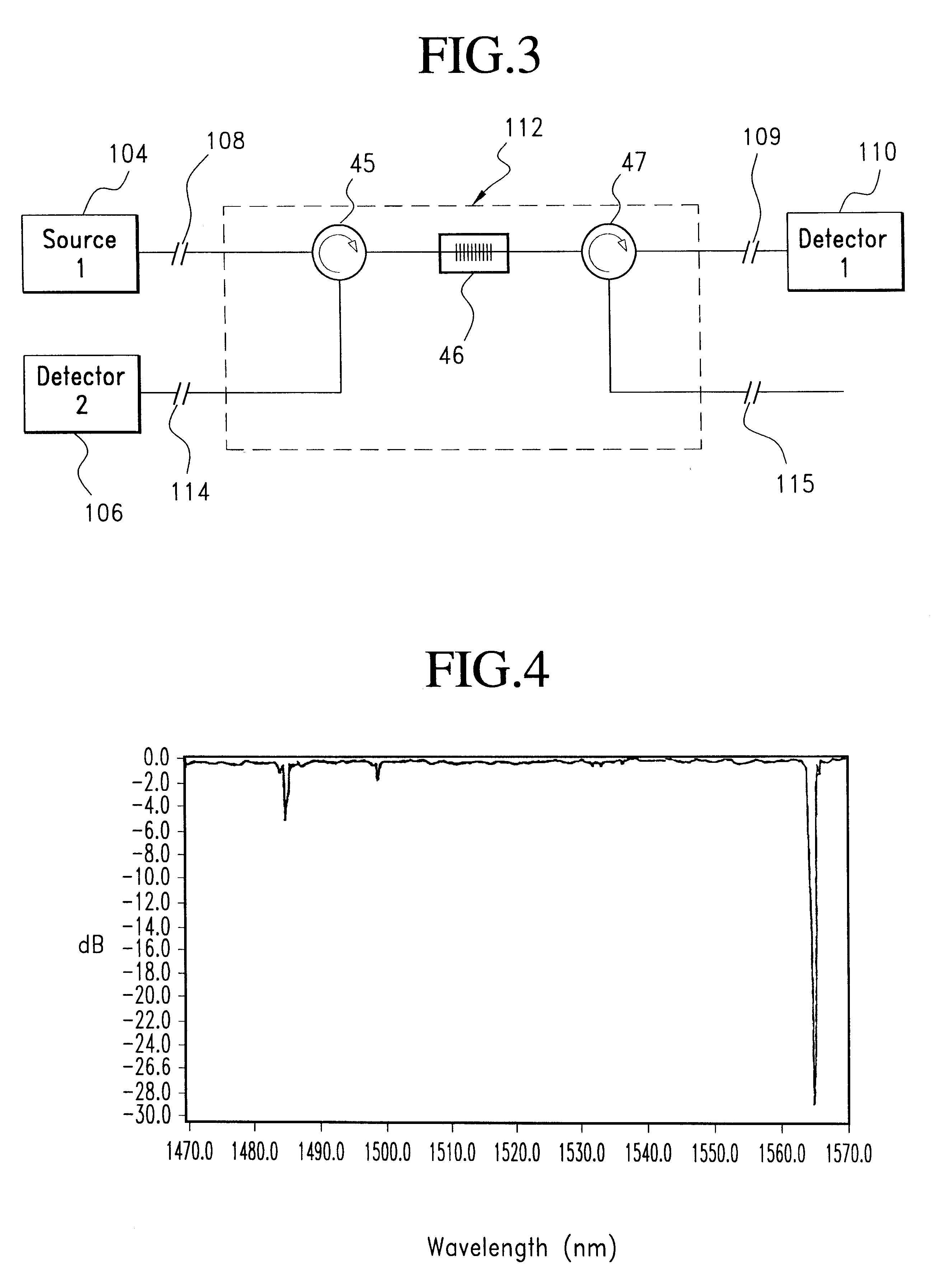

Optical filter devices in accordance with the invention are based on tapered optical fibers having transversely distributed refractive index variations in a small diameter waist region where waves are propagated in combined cladding / air-guided modes. The grating has a periodicity selected for reflection of a selected center wavelength and the waist diameter and grating pattern split the wavelengths of the lossy cladding modes from the backreflected signals by more than 10 nm. Such wavelength selective optical fiber devices have a variety of applications. In one application, a tapered fiber grating with optical circulators is used to add or drop optical signals for communication via a common transmission path. In another application, the tapered fiber grating is used with grating assisted mode couplers and circulators to form an add / drop multiplexer. In another application, these components are used with optical switches to produce programmable add / drop filters and crossconnects.

Owner:ARROYO OPTICS

Coating capable of repetitively copying and transferring molding grating pattern and template film including the same

InactiveCN101481574AImprove thermal deformationGood solvent resistanceDecorative surface effectsCoatingsMethacrylateAcrylic resin

The invention provides a coating which can repeatedly reproduce and transfer grating patterns obtained by mould pressing to the surface of a printing stock. The coating comprises the weight components: 30-40% of modified acrylic resin, 10-25% of firming agent, 0.15-0.5% of catalyzer and 40-55% of solvent; wherein, the modified acrylic resin comprises acrylic resin or DHMP, acylic acid hydroxy ester, epoxide resin, organic silicon resin containing hydroxide radical, evocating agent and solvent. The coating has suitable mould pressing strength, good surface compactness, difficult permeable solvent and low surface tension, still has clear grating pattern after mould pressing in the situation of repeated peeling. The invention also provides a template membrane which can repeatedly reproduce and transfer the grating patterns obtained by mould pressing; the template membrane comprises a base membrane and the coating fixedly overlaid on the base membrane. The coating forms the grating patterns by mould pressing. The template membrane can continuously reproduce the grating patterns to the printing stocks such as papers or plastic glass and the like by only a primary mould pressing by releasing layers or adhesive layers, thus saving working procedures and greatly reducing production costs.

Owner:汕头市龙湖昌丰化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com