Preparation method for solar wafer

A technology for solar wafers and wafers, which is applied in the manufacturing of final products, sustainable manufacturing/processing, electrical components, etc., can solve the problems of inability to precisely control the concentration of doping ions, complicated thermal diffusion process steps, and bending of silicon wafers. The effect of mixing uniformity, reducing compounding effect and reducing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

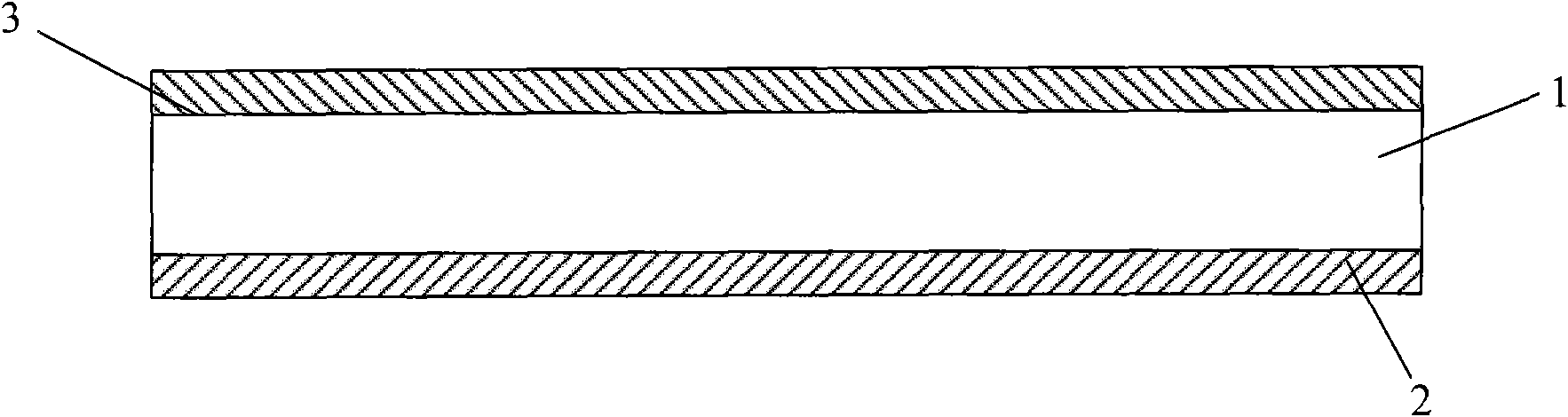

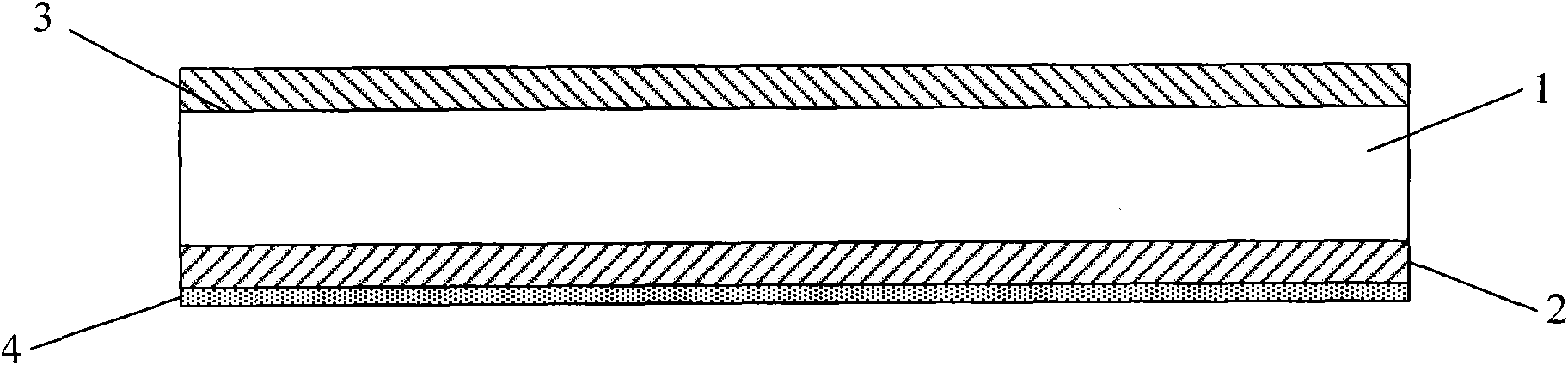

[0036] refer to Figure 1-Figure 6 , introduce in detail the preparation method of the solar wafer of the present invention, especially relate to the preparation method of the backside field of the solar cell, take the solar wafer of P-type substrate 1 as an example, introduce the preparation method of the solar wafer of the present invention, especially for the solar cell The fabrication method of the selective emitter comprises the following steps:

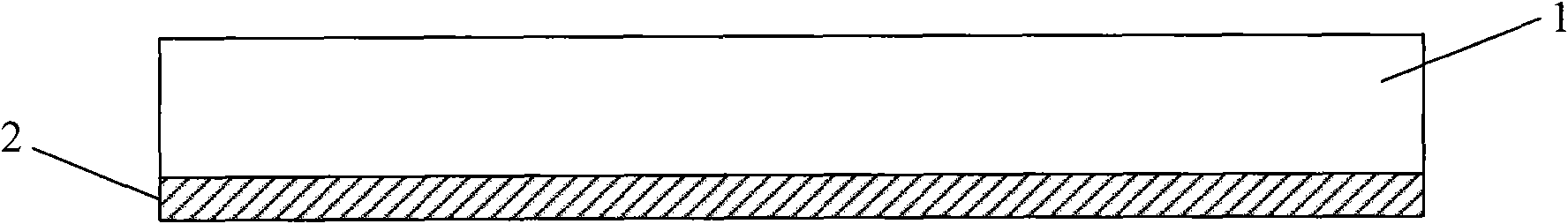

[0037] refer to figure 1 , step S 1 , implanting P-type ions such as boron ions by ion implantation on the back of the wafer based on P-type semiconductors to form a P+-type doped layer 2, the doped P-type ions are accelerated to 10-50keV, doped Concentration can be 2E15-7E15 / cm 3 Of course, those skilled in the art can also select ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com