Cu2O/C3N4/TiO2 heterojunction visible light catalyst and preparation method thereof

A C3N4, heterojunction technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems affecting the photoelectric catalytic performance of Cu2O, the low efficiency of photogenerated carrier collection, and carrier diffusion. The problem of unfavorable length ratio and other problems can achieve the effect of direct and fast electron transport channel, reducing electron-hole recombination rate and good photoelectric catalytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a Cu 2 O / C 3 N 4 / TiO 2 Preparation method of heterojunction visible light catalyst.

[0037] a Cu 2 O / C 3 N 4 / TiO 2 A method for preparing a heterojunction visible light catalyst, comprising the following steps:

[0038] Step 1: Cut the FTO glass as the substrate into 1x2cm, put it in acetone and ultrasonically clean it for 20 minutes, and then put it in an oven to dry for later use;

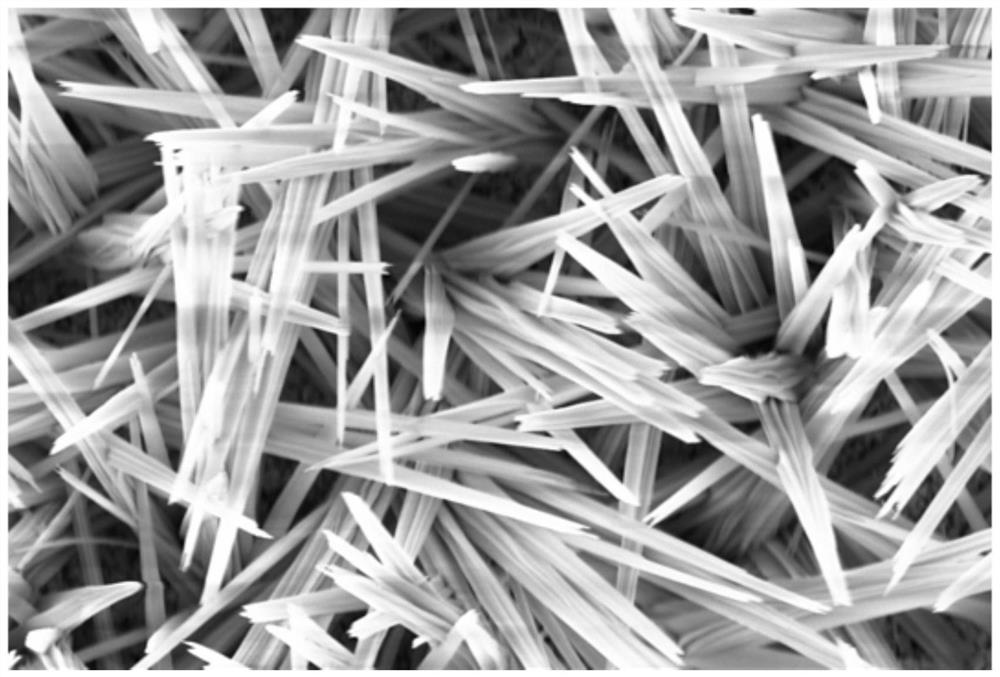

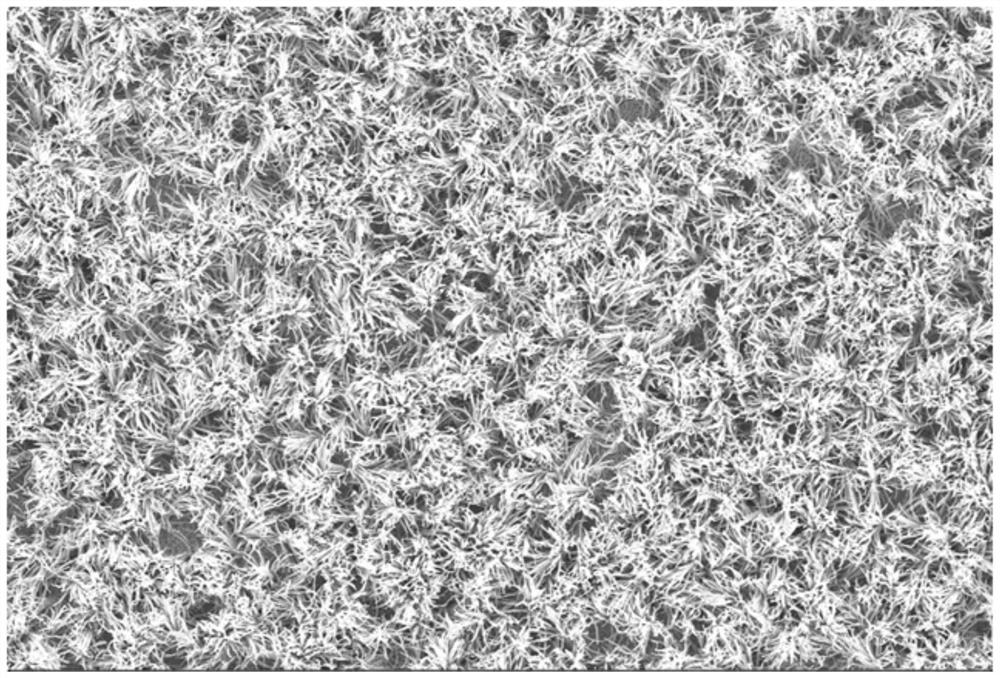

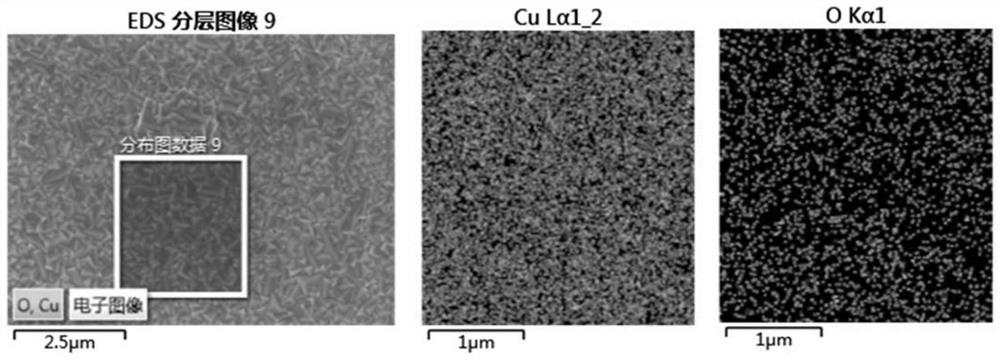

[0039] Step 2: Sputter 2um copper on the surface of FTO by sputtering, use electrochemical workstation, adopt constant current mode, use FTO / Cu as working electrode, mercury oxide as reference electrode, platinum sheet as counter electrode, 3mol NaOH For the electrolyte, electroplating is prepared as figure 1 Shown Cu(OH) 2 Nano-array, wherein, the electroplating current is 3mA-20mA, electroplating 2-30min;

[0040] Step 3: Put the prepared Cu(OH) 2 The nanoarrays were placed in a tube furnace for annealing treatment, the annealing treatment temperatur...

Embodiment 2

[0048] a Cu 2 O / C 3 N 4 / TiO 2 The heterojunction visible light catalyst is prepared by the above method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com