Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95results about How to "Precise Control of Uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

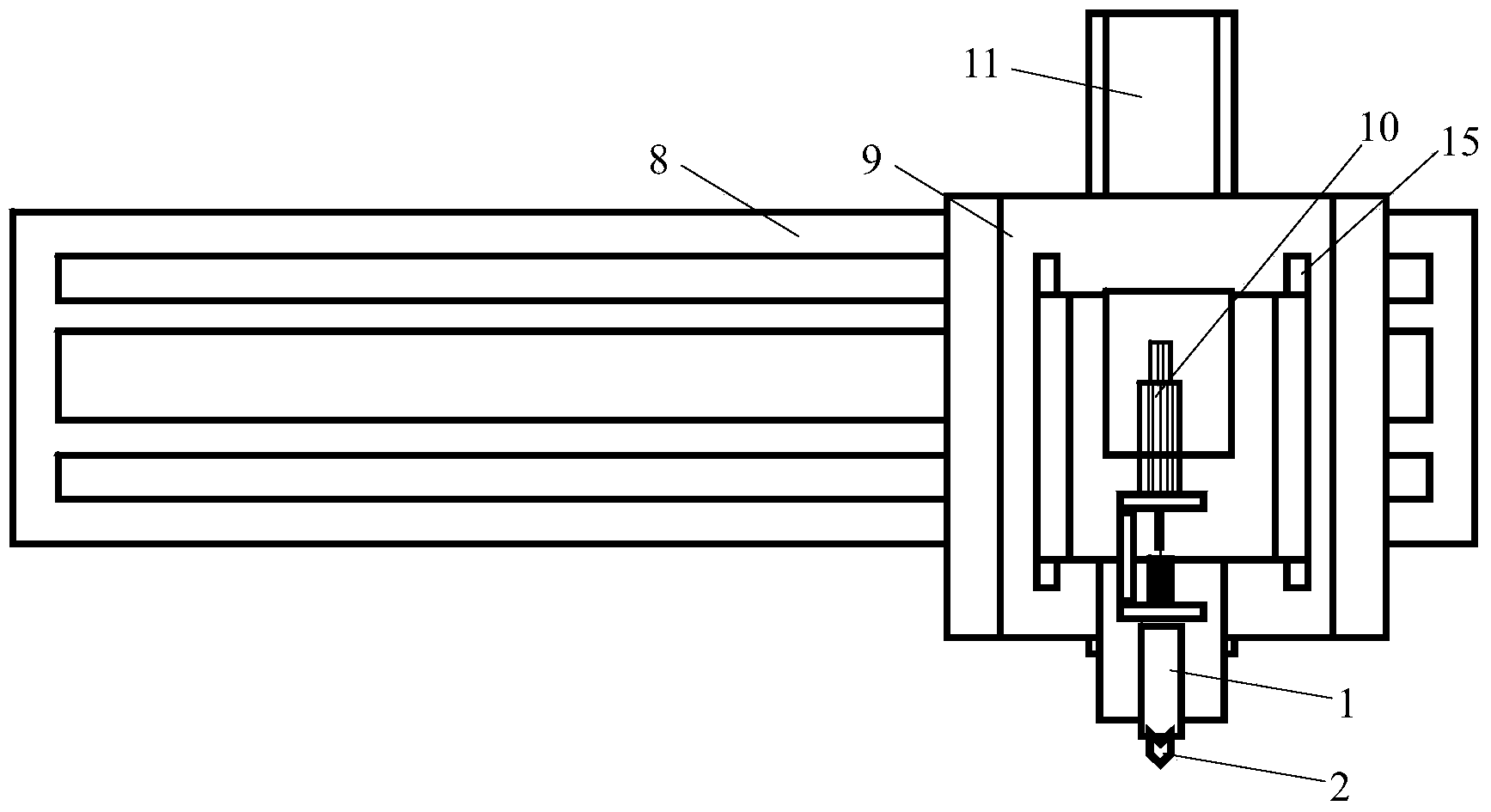

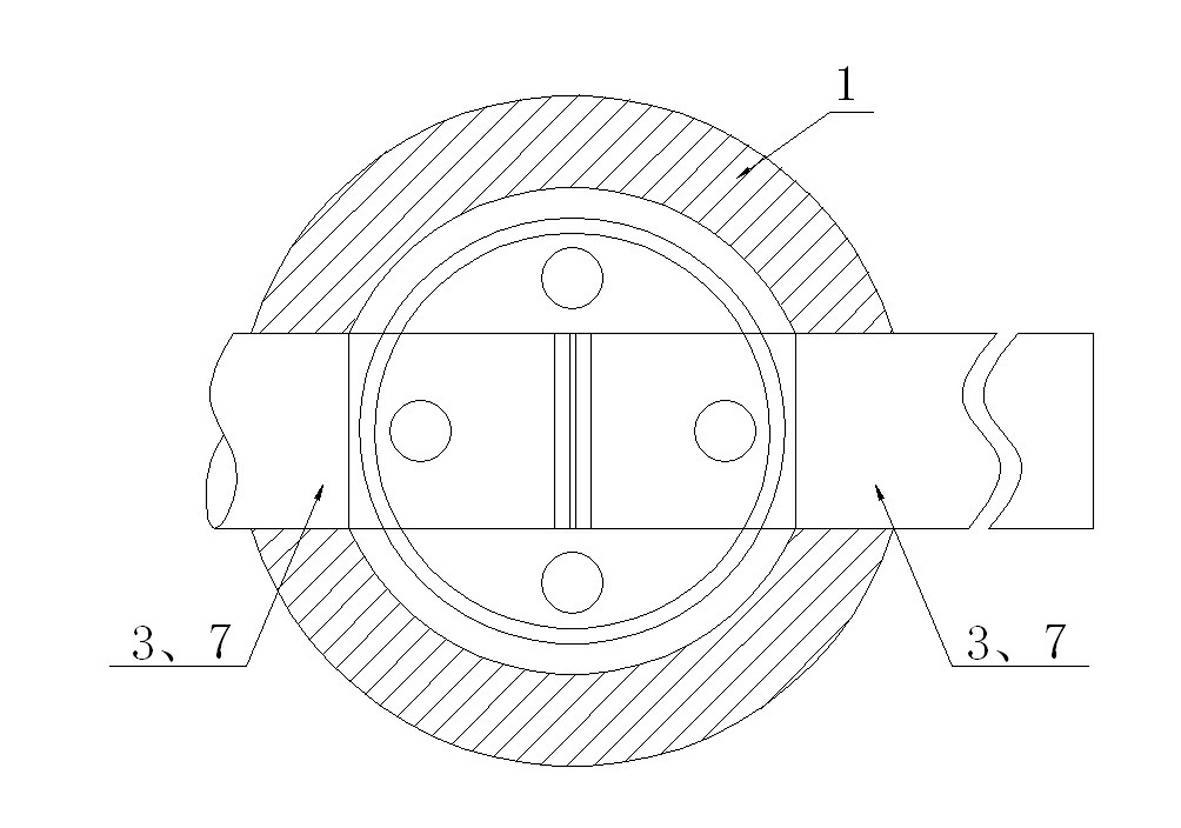

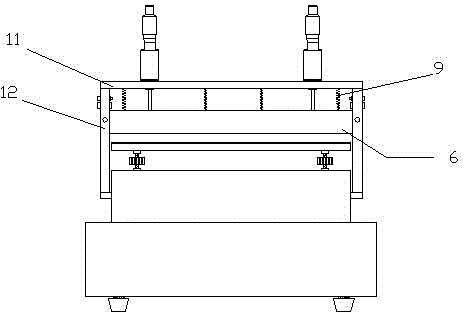

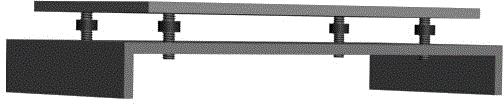

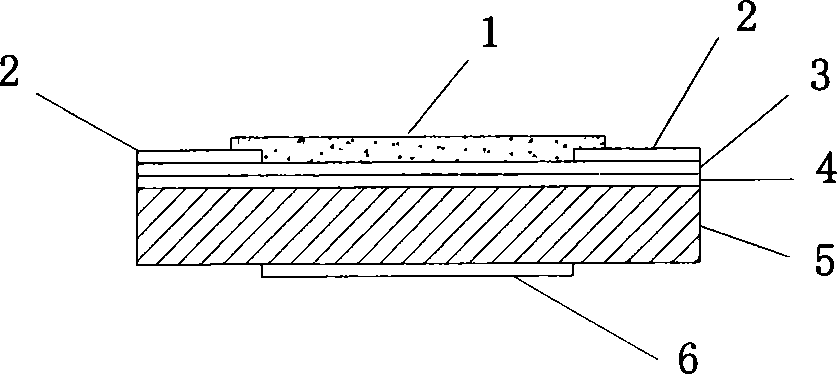

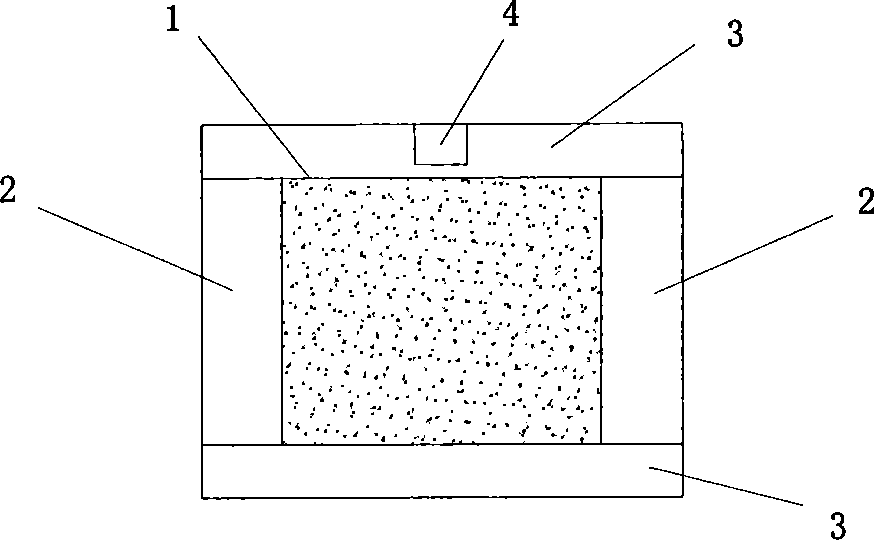

Net point punching device for die core

InactiveCN103878227APrecise Control of UniformitySmall toleranceMetal working apparatusPunchingMeasuring instrument

The invention relates to the technical field of displaying and discloses a net point punching device for a die core. The net point punching device comprises a punching mechanism, a laser distance measuring instrument, a displacement calculation controller and an upper computer. The punching mechanism and the laser distance measuring instrument are installed on an installation support, the installation base is installed on a first horizontal guide rail and can horizontally move along the first horizontal guide rail. A first driver is installed on the first horizontal guide rail and connected with the installation base through a first transmission mechanism. The displacement calculation controller is respectively and electrically connected with the laser distance measuring instrument and the upper computer. The upper computer is electrically connected with the punching mechanism and the first driver. The laser distance measuring instrument is adopted for accurately measuring the depth and bore diameter of net points, the flatness of the die core surface and the distance between the net points in real time. In the punching process, net point punching force and the moving position of the punching mechanism can be adjusted in real time, so that the bore diameter, the depth and evenness are accurately controlled, and then the depth and bore diameter tolerance of the net points is reduced.

Owner:BOE TECH GRP CO LTD +1

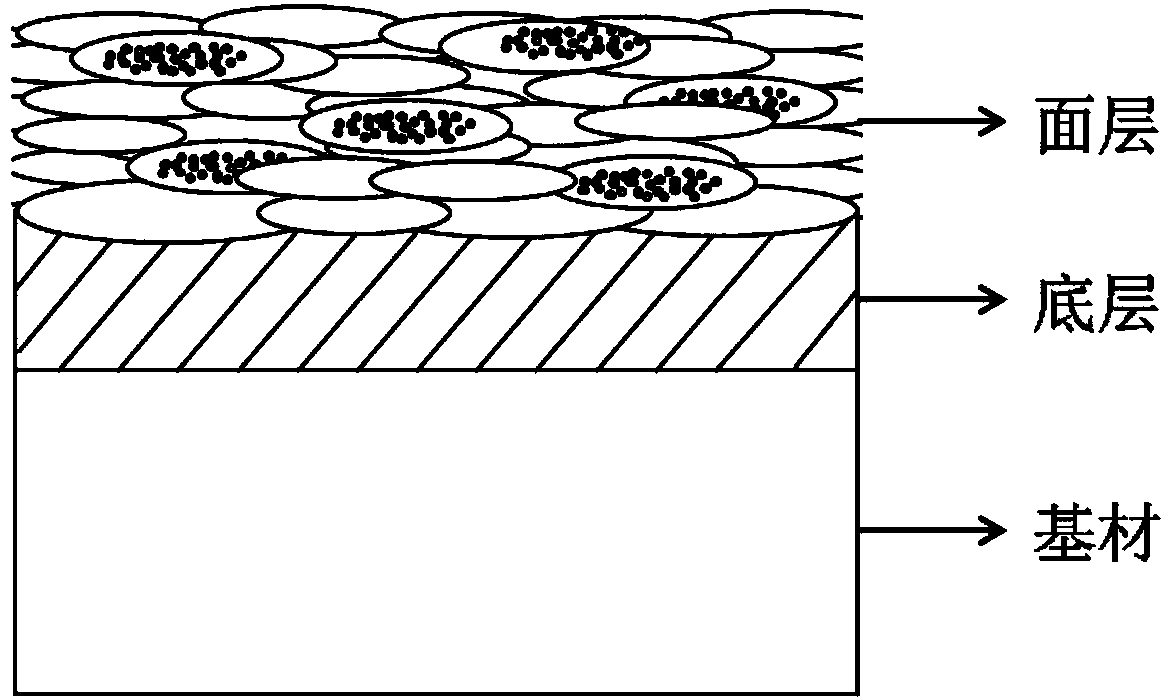

Carbon/carbon composite material laminated coating and preparation method thereof

The invention discloses a carbon / carbon composite material laminated coating and a preparation method thereof. The laminated coating is sequentially composed of a SiC under layer, a SiC transition layer and an alternative layer of SiC layer / ceramic layer on a base body of the carbon / carbon composite material. According to the preparation method of the carbon / carbon composite material laminated coating, a preparation method of the SiC under layer is realized by brush coating, spray coating or magnetron sputtering. A preparation method of the SiC transition layer and the alternative layer of SiC layer / ceramic layer sequentially comprises the following steps: ultrasonically cleaning the carbon / carbon composite material with the SiC under layer through acetone, and drying the material; cleaning the material through ion source sputtering; and preparing the SiC transition layer and the alternative layer of SiC layer / ceramic layer through magnetron sputtering. The prepared laminated coating disclosed by the invention has excellent oxidation resistance and thermal shock resistance at 1500 DEG C. The preparation method disclosed by the invention has a characteristic of being able to control thickness, and the prepared coating is good in thickness uniformity.

Owner:GUANGDONG INST OF NEW MATERIALS

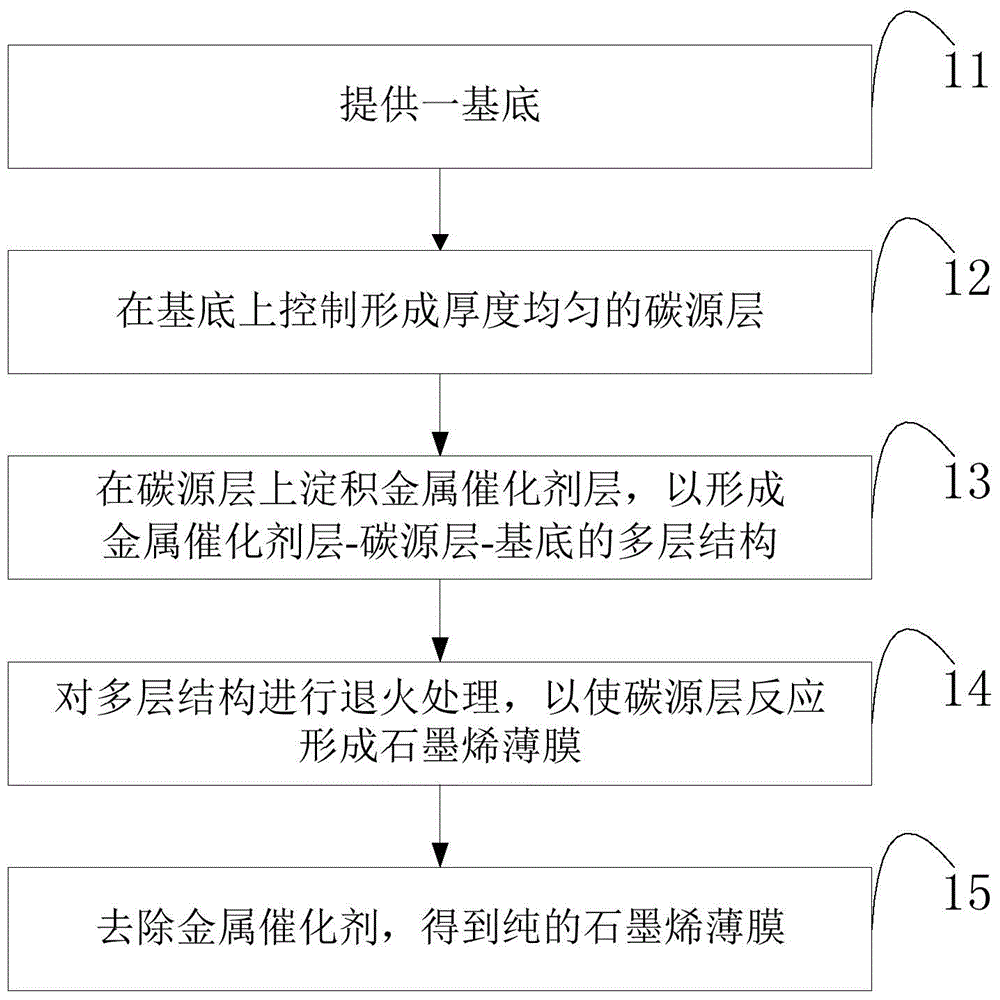

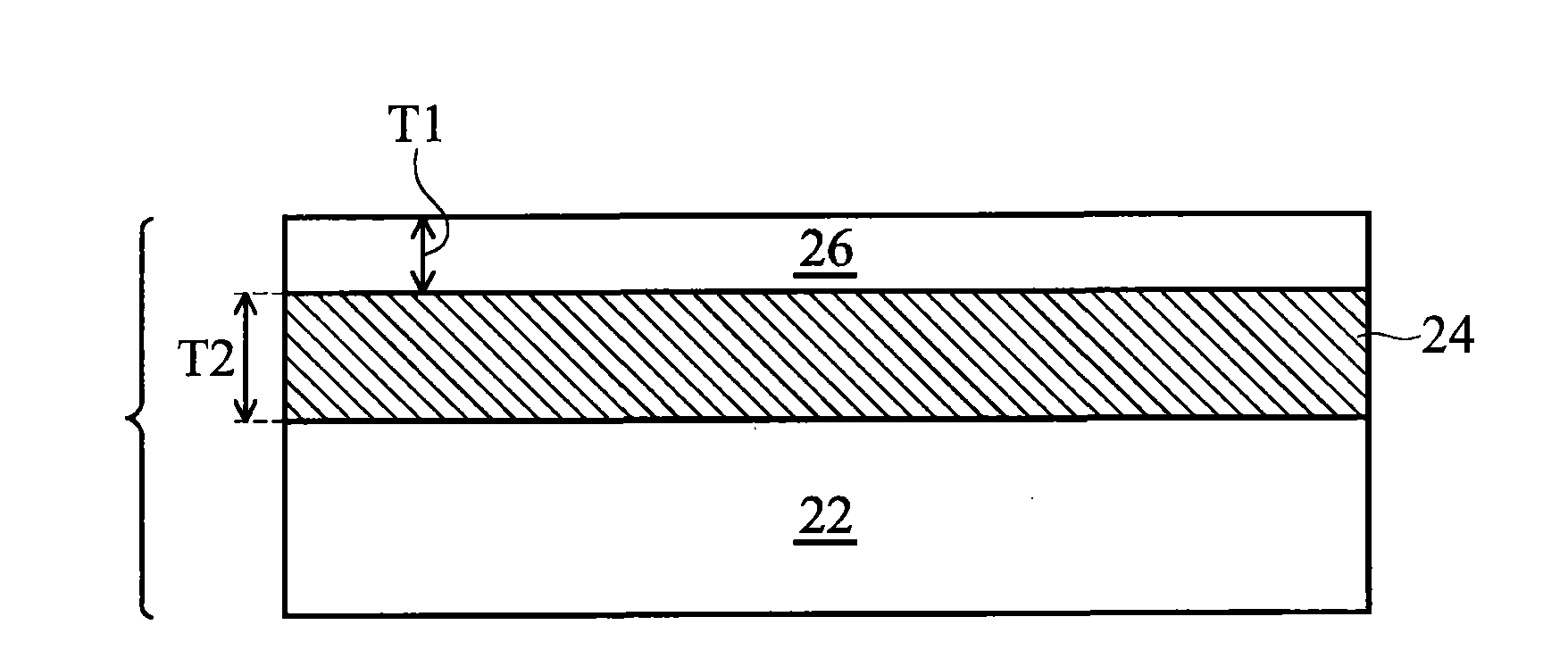

Preparation method of graphene film

The invention provides a preparation method of a graphene film. The method comprises steps as follows: providing a substrate; forming a carbon source layer with the uniform thickness on the substrate in a controlled manner; heating the carbon source layer to enable the carbon source layer to have a chemical reaction to be converted into a graphene film layer. Therefore, the uniformity and the thickness of the graphene film can be controlled accurately through accurate control on the uniformity and the thickness of the carbon source layer; meanwhile, the high-quality graphene film can be obtained with the preparation method of the graphene film, and the method can be compatible with the existing CMOS technology and is suitable for mass production.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

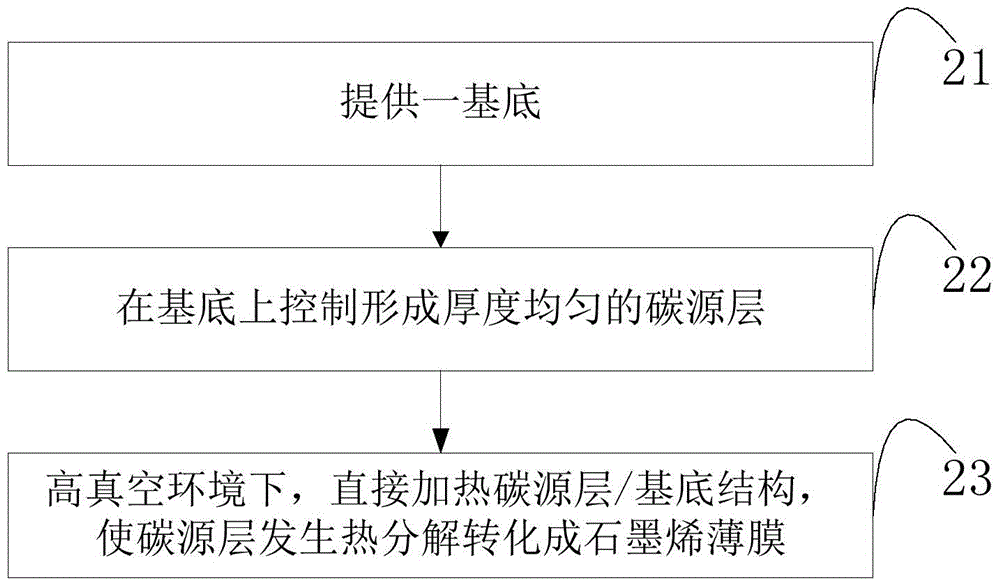

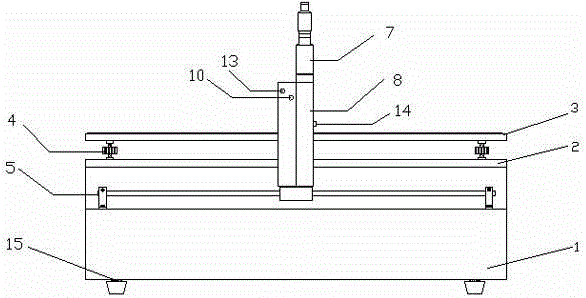

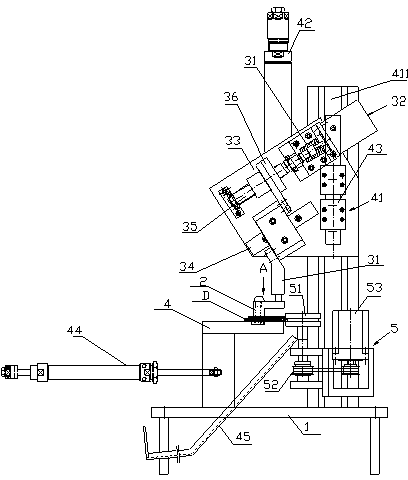

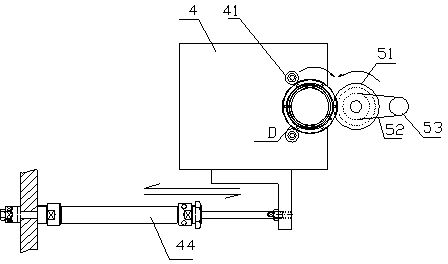

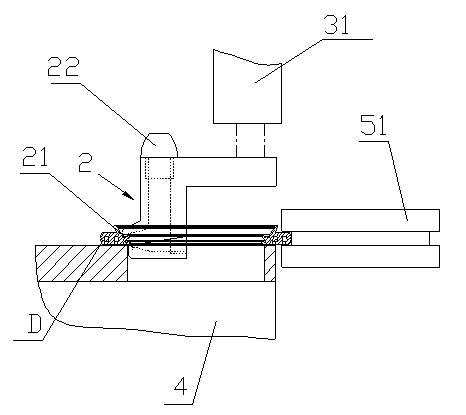

Electric self-propelled numerical-control plot drill seeder

ActiveCN104012222APrecise Control of UniformityEasy to operateSeed depositing seeder partsBroadcast seedersNumerical controlSeeder

The invention relates to an electric self-propelled numerical-control plot drill seeder aiming to solve the technical problems that plot seeders in the prior art are nonuniform in seeding and not precise enough in row length control. The electric self-propelled numerical-control plot drill seeder comprises a walking mechanism, an automatic control device, a seed separation mechanism, a furrowing and seeding mechanism and a lifting mechanism, and the seed separation mechanism, the furrowing and seeding mechanism and the lifting mechanism are correspondingly arranged on the walking mechanism; the seed separation mechanism comprises a seed separation unit and a seed storage unit, the seed separation unit is arranged above the furrowing and seeding mechanism, and the seed storage unit is arranged above the seed separation unit; the walking mechanism is an electric walking mechanism; the seed separation unit comprises a seed separation disc, a seed separation servo motor or a seed separation stepping motor, and the seed separation servo motor or the seed separation stepping motor is arranged below the seed separation disc, and drives the seed separation disc to rotate; the electric self-propelled numerical-control plot drill seeder has the advantages of uniform between-row and in-row seeding, high degree of automation, stepless row length setting (arbitrary row length setting), high row length control accuracy, simple operation, high sowing efficiency and the like.

Owner:李延民

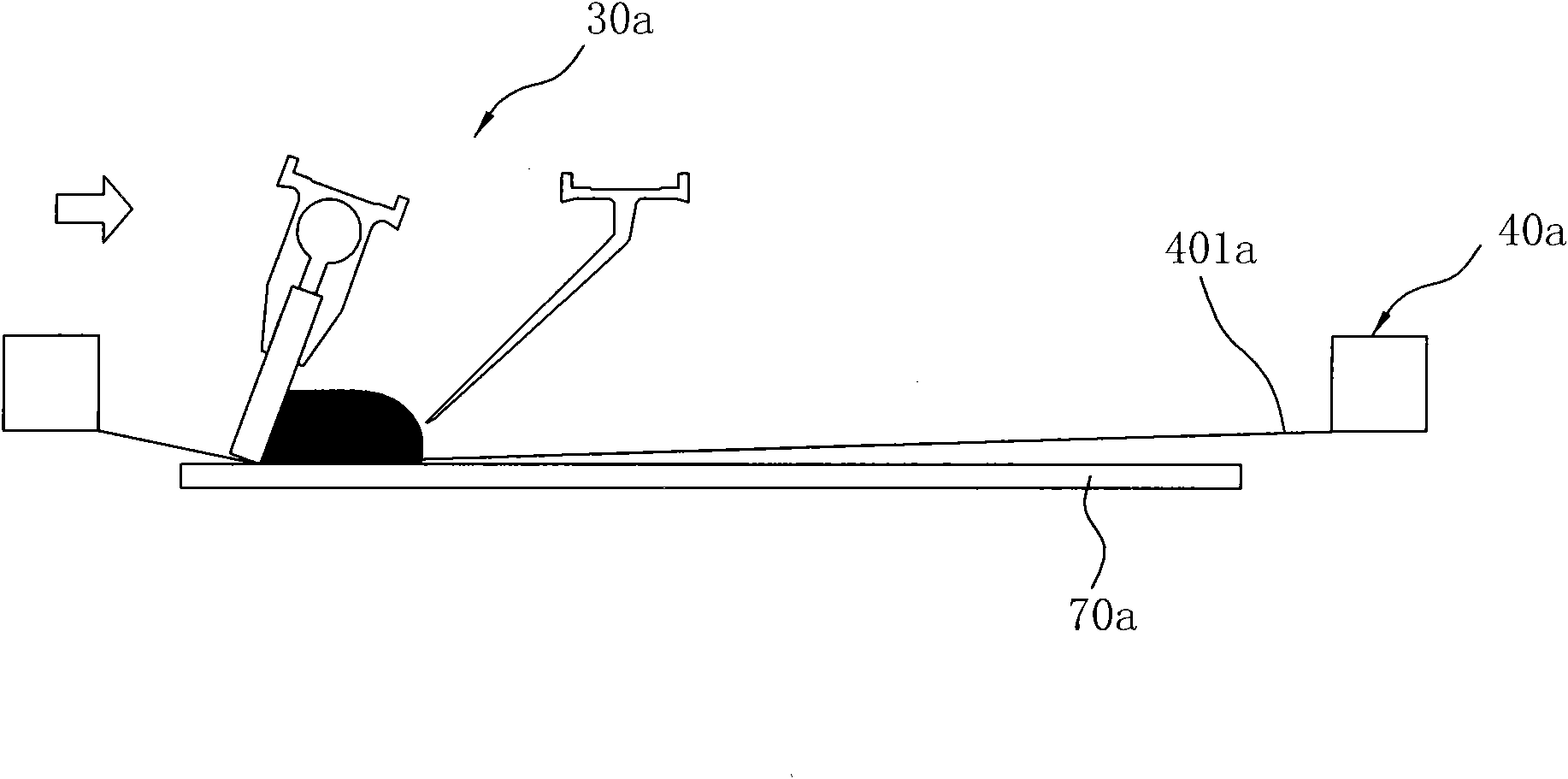

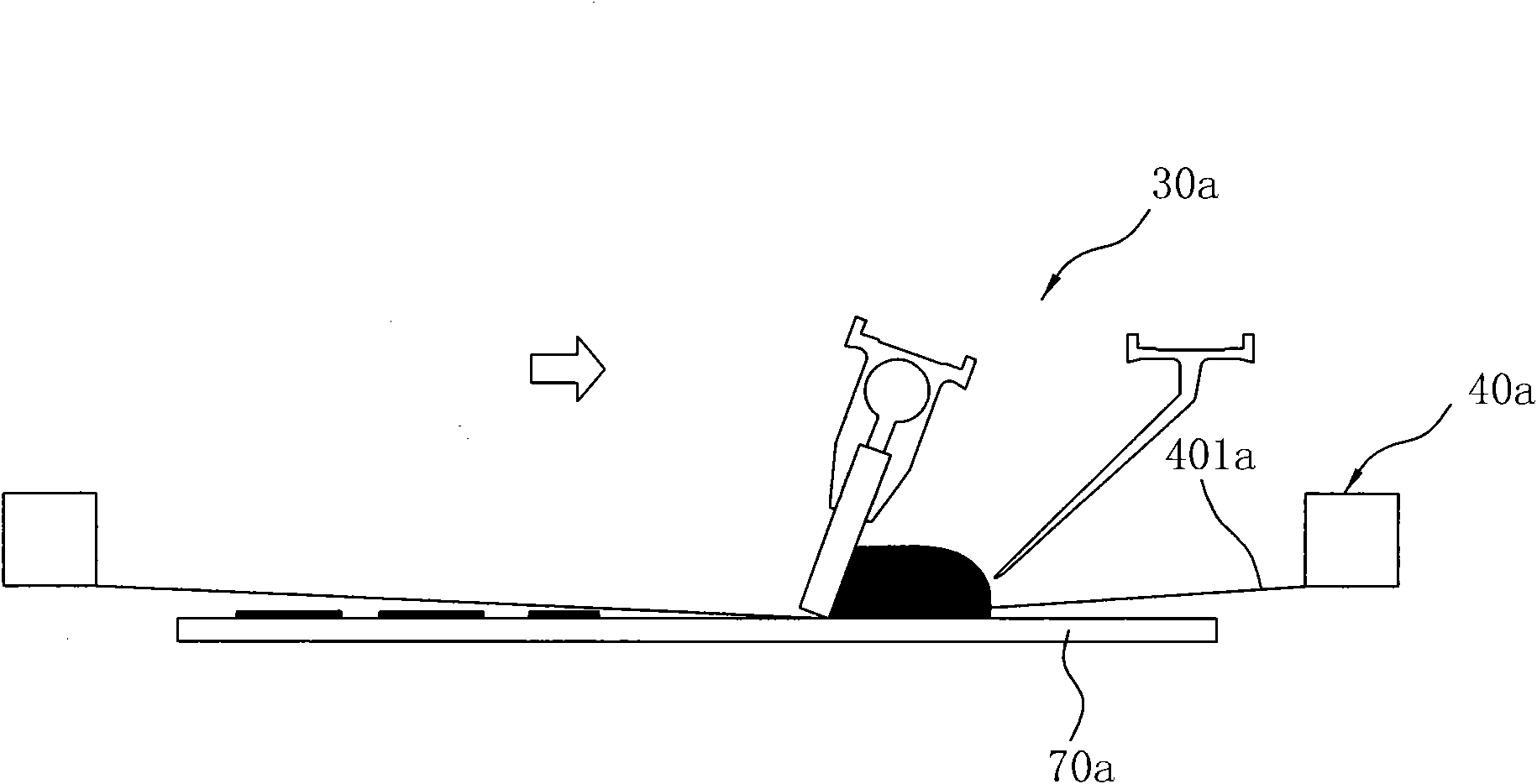

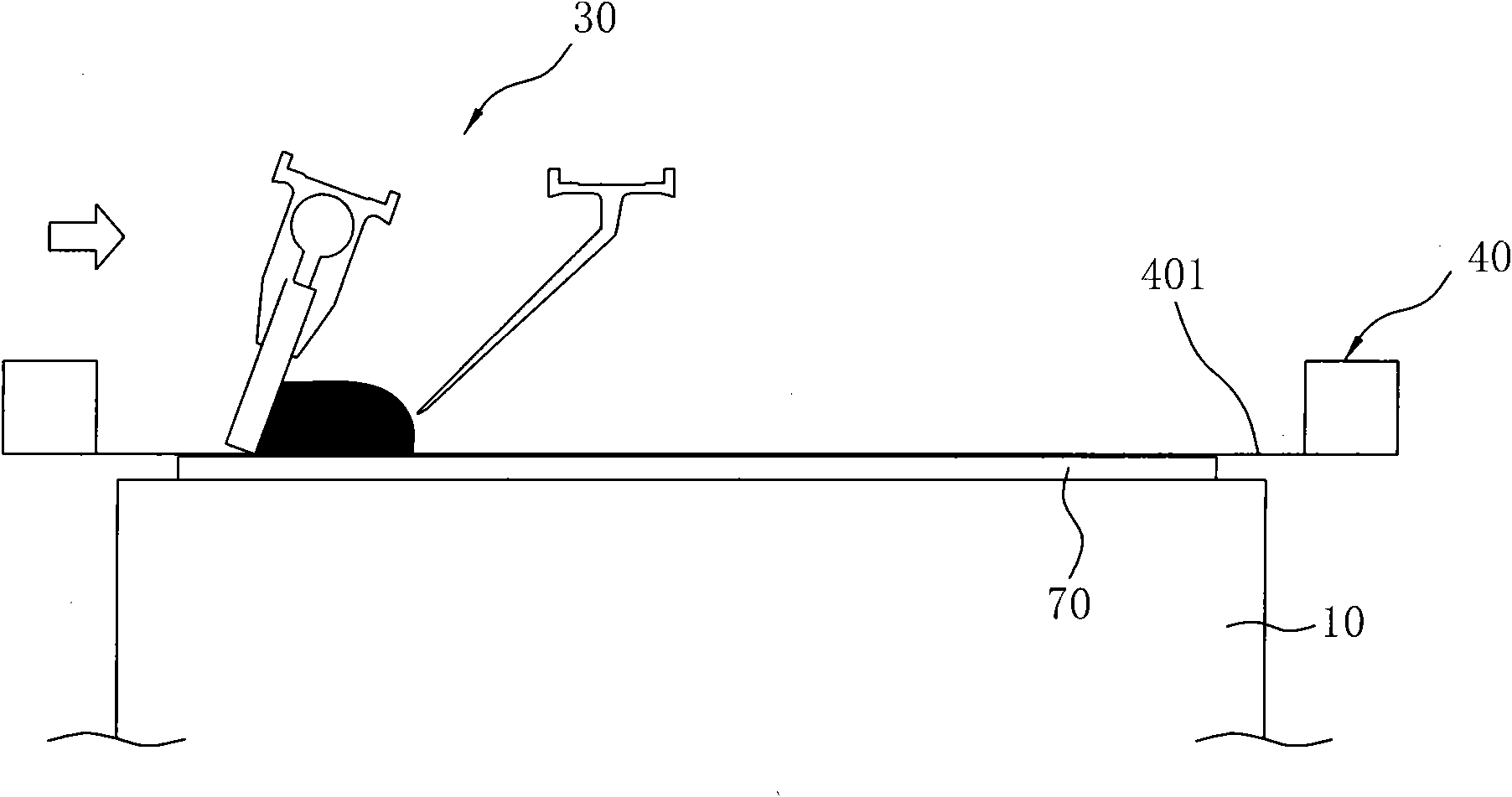

Non-contact screen printing method and non-contact screen printing equipment

InactiveCN101623950AAvoid breakingAccurately control the thicknessScreen printersPrinting press partsScreen printingPrinting ink

The invention discloses a non-contact screen printing method and non-contact screen printing equipment. The non-contact screen printing equipment comprises: a printing table of which the table top can be used for placing a printed object; a screen printing plate which is arranged between the printing table and a printing scraper and is used for printing ink on the printed object through the screen printing plate; and a printing head mechanism used for synchronously driving at least one printing scraper to move through the up and down movement of at least one driving device and pressing the printing scraper against the screen printing plate under the action of a constant pressure. The printing scraper prints at a constant pressure under the condition that the screen printing plate does not contact the printed object; and to a fragile, light and thin printed object such as a silicon chip, the method and the device can accurately control the thickness and uniformity of the printing ink so as to improve the printing stability and realize accurate printing.

Owner:ATMA CHAMP ENTERPRISE

Method for preparing rare earth doped optic fiber preform

ActiveCN102153276APrecise control of concentrationPrecise Control of UniformityGlass making apparatusMetal chlorideFiber

The method relates to the technical field of optic fiber production methods, in particular relating to a method for preparing a rare earth doped optic fiber preform. The method comprises the following steps: selecting a quarz base tube, introducing CCl2F2 and O2 into the quarz base tube, burning, polishing and depositing a barrier layer; preparing rare earth metal chloride, and dehydrating the rare earth metal chloride; selecting an intermediate AlCl3 and dehydrating the intermediate AlCl3; and heating, gasifying and mixing the dehydrated rare earth metal chloride and AlCl3; heating and gasifying glass generation compositions SiCl4, GeCl4 and POCl3; reelingly stirring and mixing the mixed metal chloride and the gasified glass generation compositions and depositing in the quarz base tube so as to form a rare earth doped core layer; and finally shrinking the generated product into a rod so as to form the optic fiber preform. The method has the advantages that the concentration and uniformity of various rare earth doped substances can be precisely controlled, so that the performance of the rare earth optic fiber can be further optimized.

Owner:上海傲世控制科技股份有限公司

Multi-component complex phase nano boride, corresponding ultra-high temperature oxidation-resistant coating and preparation method thereof

The invention discloses a multi-component complex phase nano boride, a corresponding ultra-high temperature oxidation-resistant coating and a preparation method, and belongs to the technical field ofultra-high temperature thermal protective coatings. The multi-component complex phase nano boride and the corresponding ultra-high temperature oxidation-resistant coating are composed of 3-20wt% of TiB2, 10-40wt% of SiC and the balance HfB2. A nano structure inside the nano HfB2-SiC-TiB2 coating can control the stress at the grain boundary so as to obtain a high-strength interface, inhibit dislocation movement in a fracture process, hinder crack growth and effectively improve the fracture toughness of the coating; a third phase of TiB2 is added for modification, and TiO2 with a low melting point generated in a service process of the coating can enhance the self-healing ability of an oxide film; and the coating can resist a temperature of more than 1800 DEG C and is more stable in performance, which can effectively solve the problems of poor fracture toughness and insufficient stability of the existing ultra-high temperature oxidation-resistant coating for an aircraft in a service environment.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Novel automatic flat-plate film-coating machine

InactiveCN104826769AEasy to cleanPrecise thickness controlLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a novel automatic flat-plate film-coating machine, which includes a pedestal, a film-coating bench, a film-coating plate, a film-coating plate adjustment device, a scraper unit and a driving unit. The scraper unit includes: a scraper, a scraper adjustment device and a scraper support, wherein the driving unit is connected to the scraper unit for controlling the operation of the scraper. The film-coating plate adjustment device is used for adjust the height and the level of the film-coating plate. The scraper adjustment device is used for adjust the height and the level of the scraper. The thickness and uniformity of a film are accurately controlled by means of cooperative effects of the film-coating plate adjustment device and the scraper adjustment device. By means of a rotary lifting device, the scraper rotates around a shaft, so that the scraper is convenient to clean after film coating. The novel automatic flat-plate film-coating machine can not only coat glass with a film but also coat a film on the base materials such as nonwoven cloths according to requirement. The machine is uniform in film thickness, is good in repeatability, is simple in processes and is convenient to use.

Owner:BEIJING FORESTRY UNIVERSITY

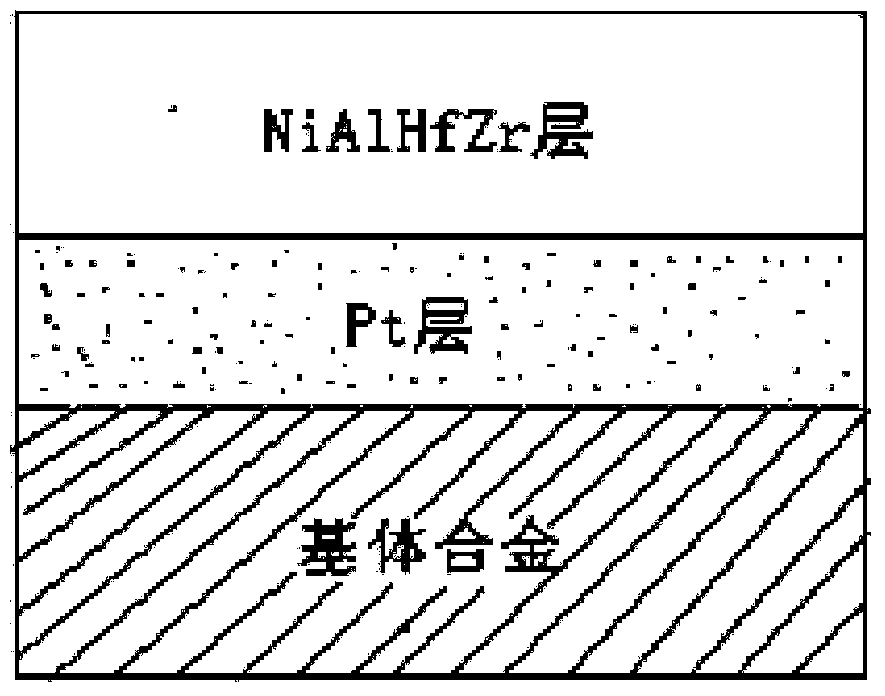

Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and preparation method thereof

ActiveCN103966615AImprove high temperature oxidation resistanceImprove adhesionVacuum evaporation coatingSputtering coatingOxidation resistantThermal barrier coating

The present invention discloses a Pt Ni Al bonding layer doped with binary trace active elements and capable of being completely oxidation resisting at 1200 DEG C and a preparation method thereof and belongs to the field of novel thermal barrier coatings and the preparation technologies. According to the invention, firstly, a Pt layer with the thickness of 5-10 microns is prepared on a nickel base monocrystal high temperature alloy matrix through the plating or the electron beam physical vapor deposition method, and then a NiAlHfZr coating with the thickness of 20-60 microns is deposited on the Pt layer through the electron beam physical vapor deposition method. The Pt layer reduces the interfacial holes and effectively improves the adhesion of an oxidation film; binary doping of Hf, Zr enables the NiAl coating surface to be smoother and denser and enables the oxidation film generated during the oxidation process on the coating surface to be straighter, especially with little oxidation increase, and greatly improves the oxidation resistance of the coating. The Pt Ni Al bonding layer is completely oxidation resisting at 1200 DEG C. The service life of the coating is prolonged to certain degree through doping of binary elements namely Hf and Zr and Pt modification.

Owner:BEIHANG UNIV

Preparation method of composite metal lithium negative electrode

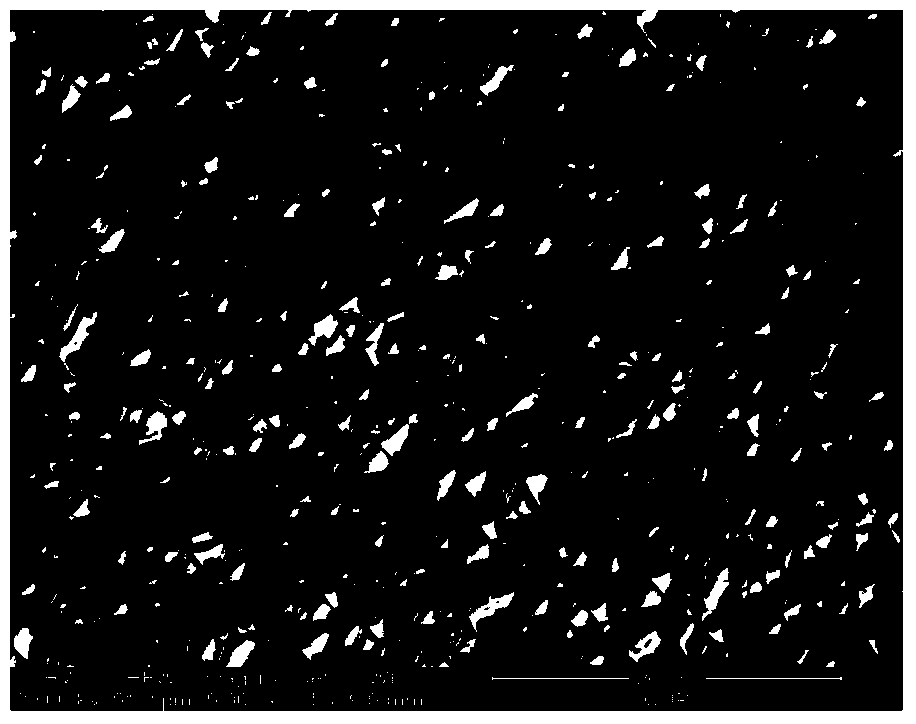

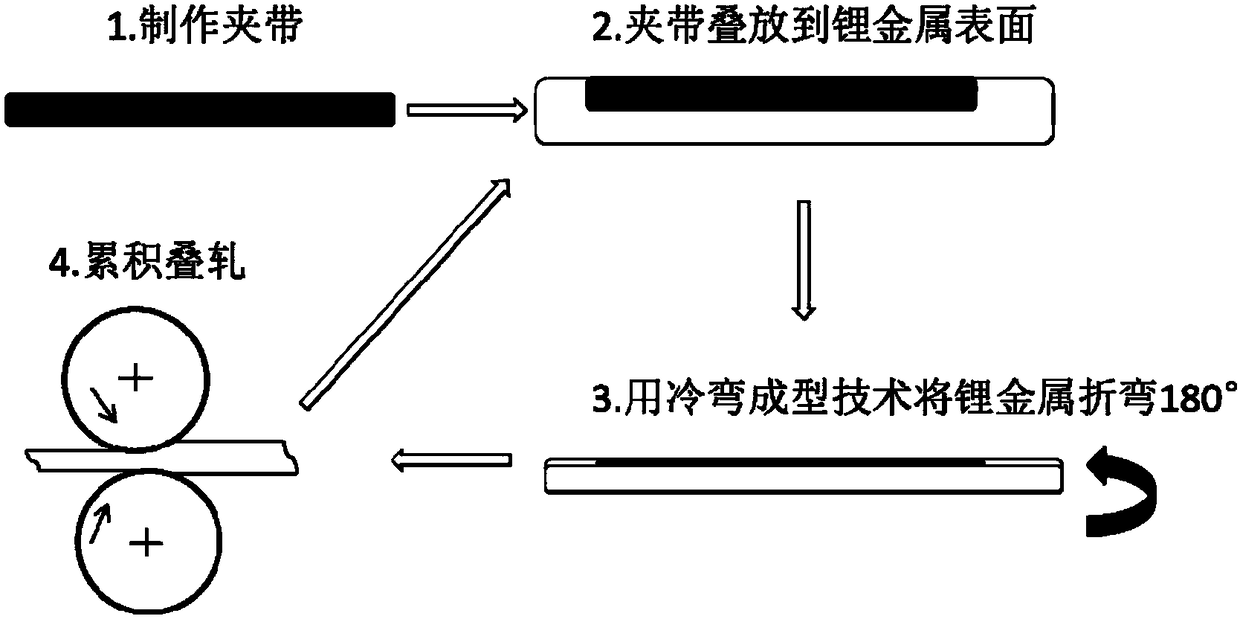

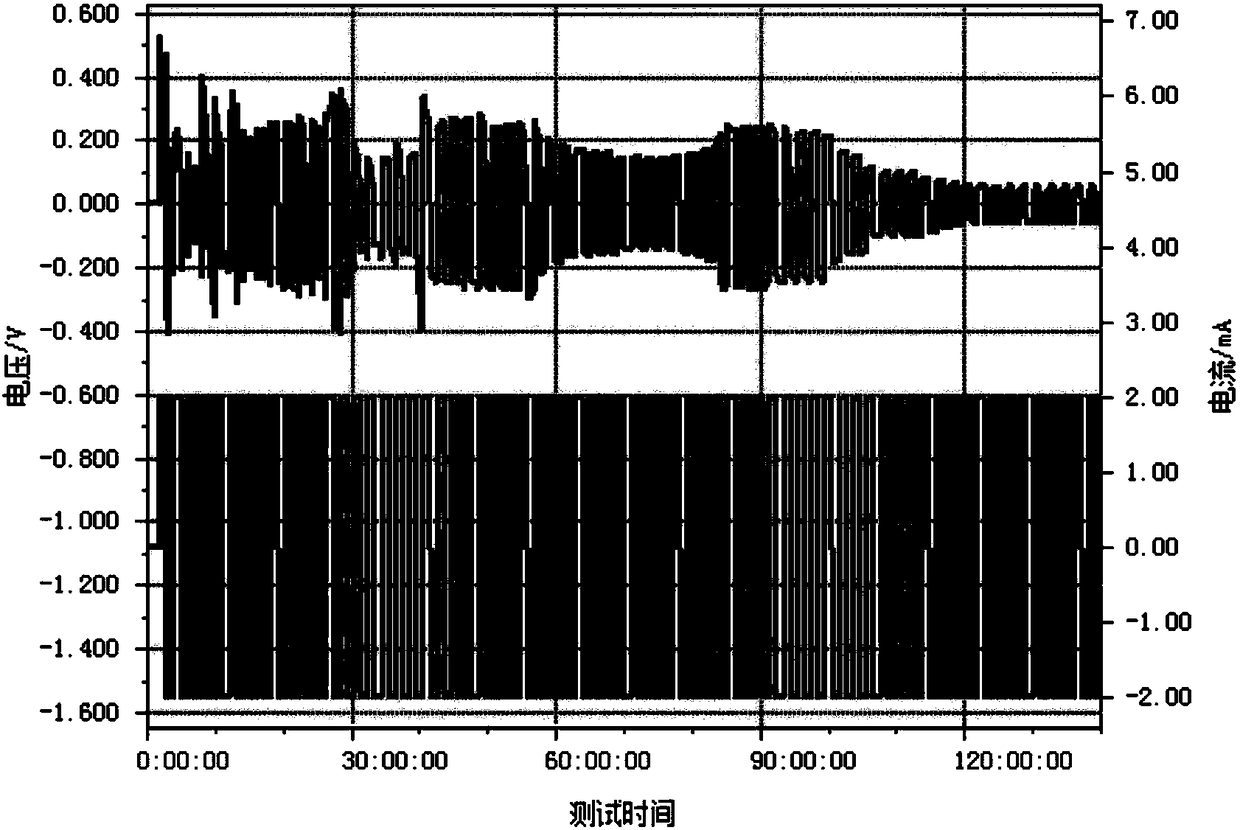

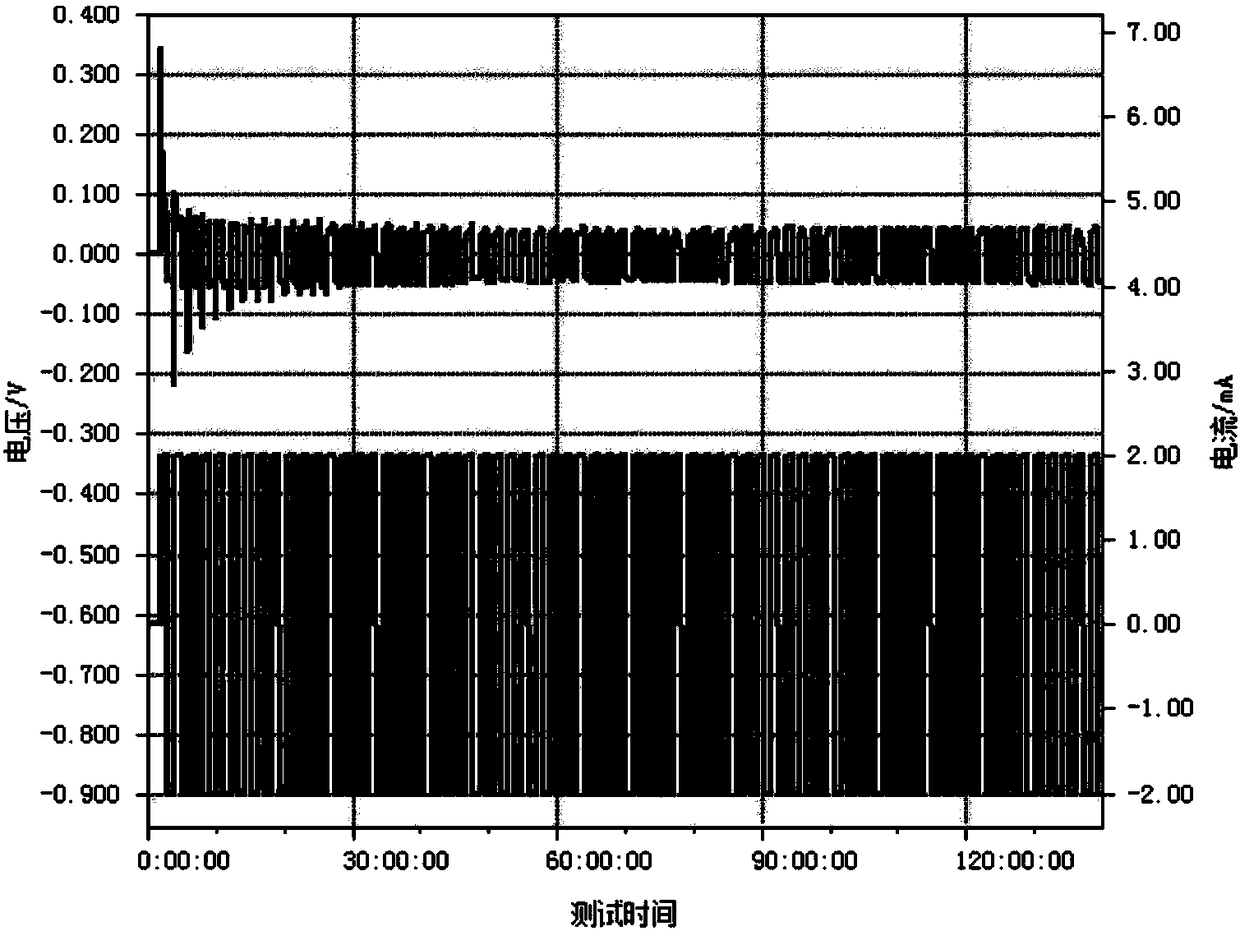

InactiveCN108598358AEvenly distributedEnsure consistencyElectrode rolling/calenderingSecondary cellsPolymer adhesiveInorganic materials

The invention provides a preparation method of a composite metal lithium negative electrode. The preparation method comprises the steps of pasting an inorganic material with a polymer adhesive to forma layered clamping tape; laying the clamping tape on a surface of lithium metal, bending the lithium metal for 180 degrees in a width direction by a cold roll formation technology to form a lithium / clamping tape / lithium composite structure; and performing rolling, pressing with deformation quantity by 20-50% to obtain a composite material rolled in one time, and repeating the step for 3-20 timesto obtain the composite metal lithium negative electrode material with a multi-layer structure. By the method, the lithium deposition morphology is improved, lithium dendrites growth is suppressed, sothat the cycle property and the safety of the battery are improved, and industrial and continuous production of the composite metal lithium negative electrode can be achieved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

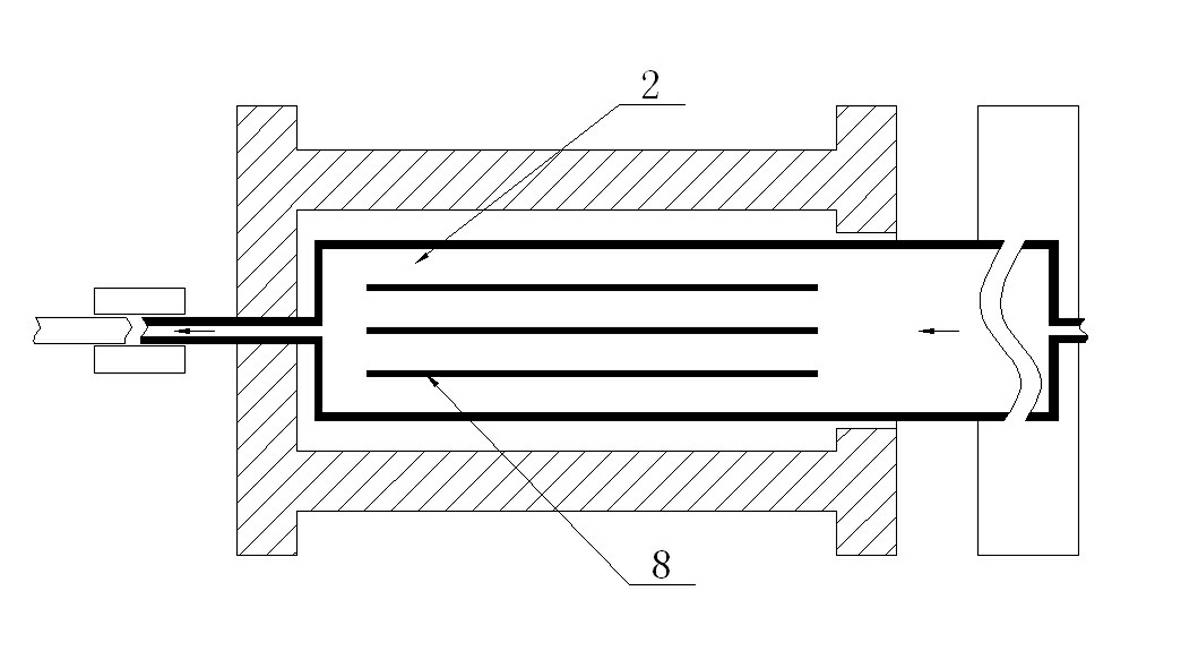

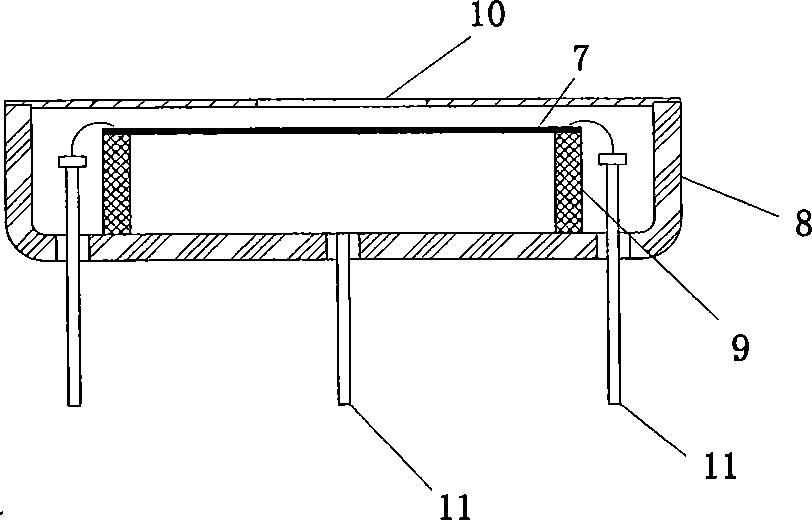

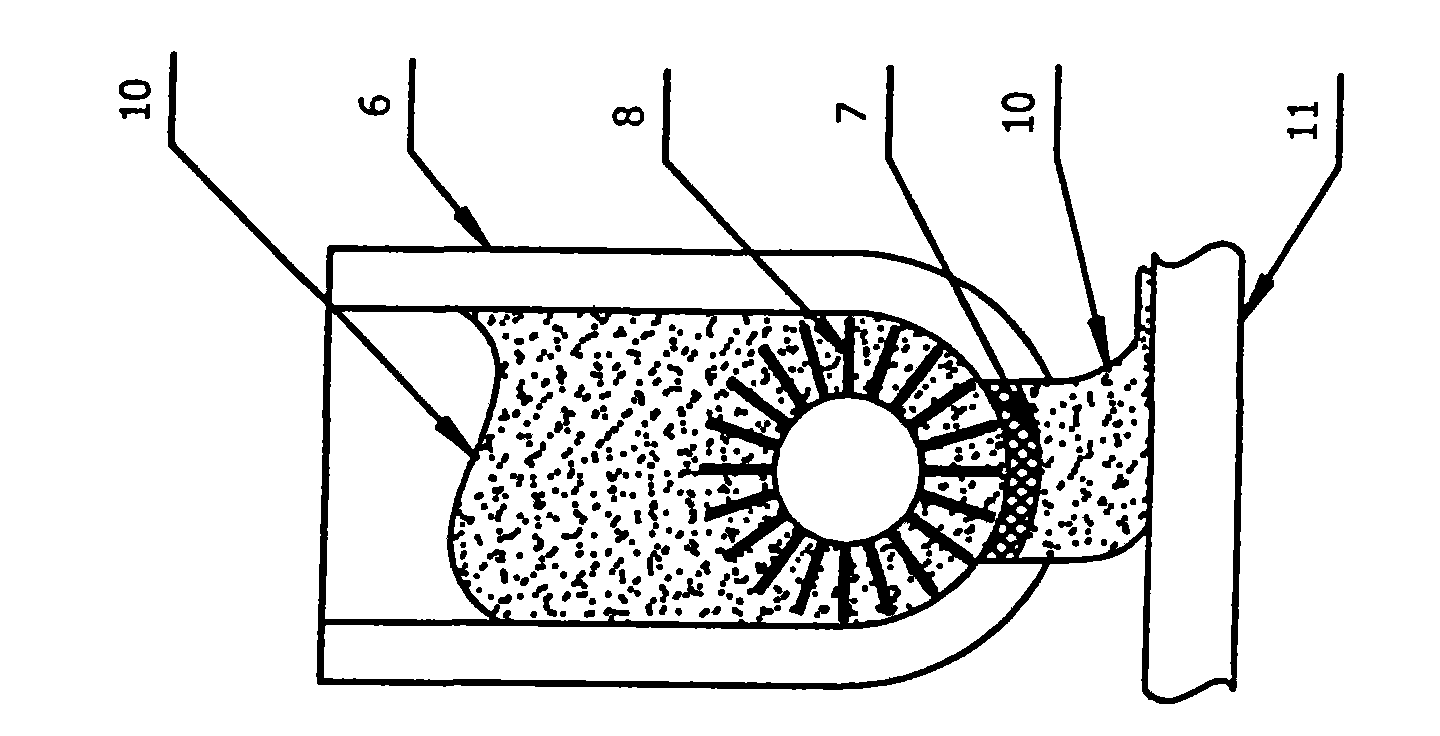

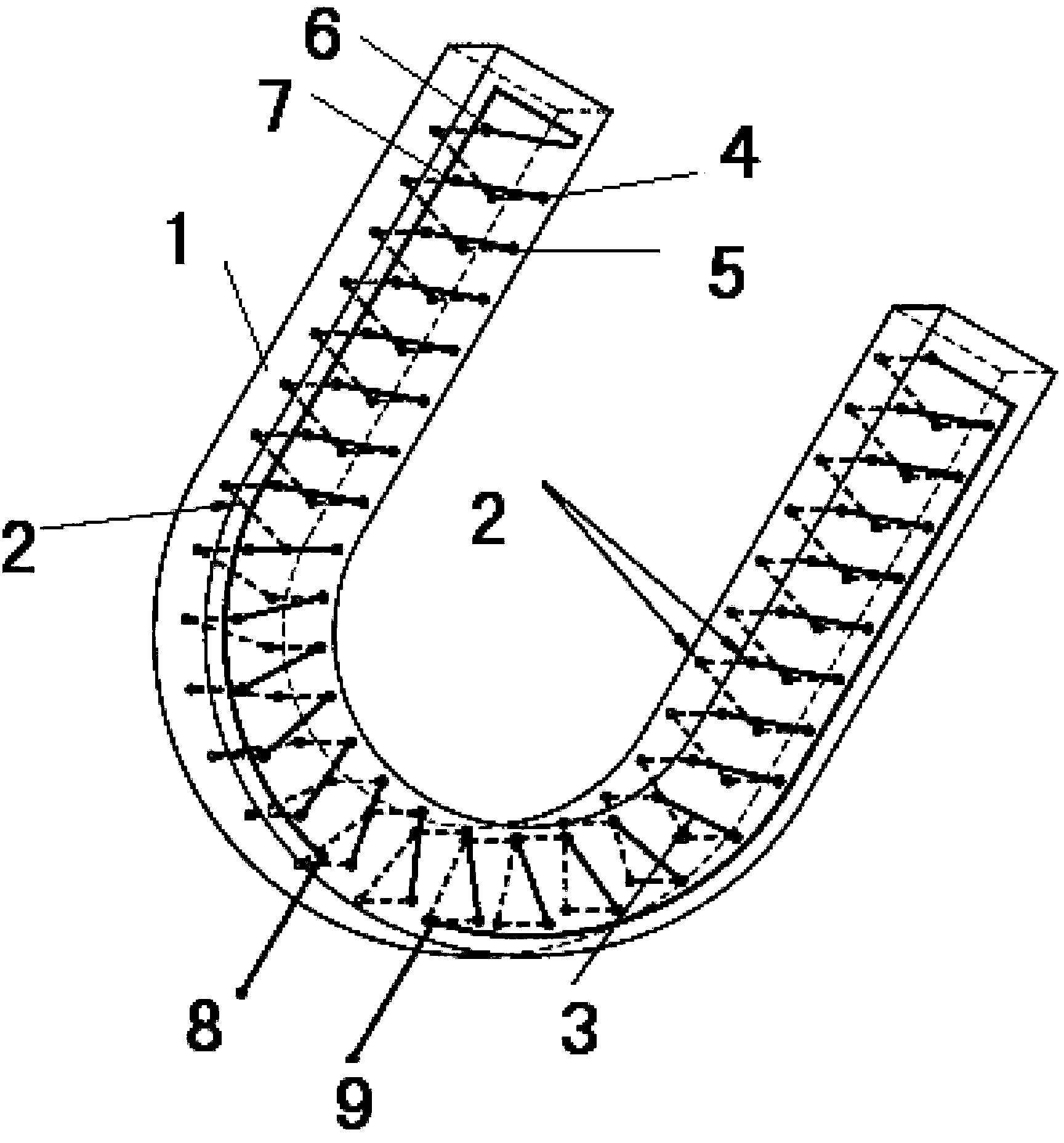

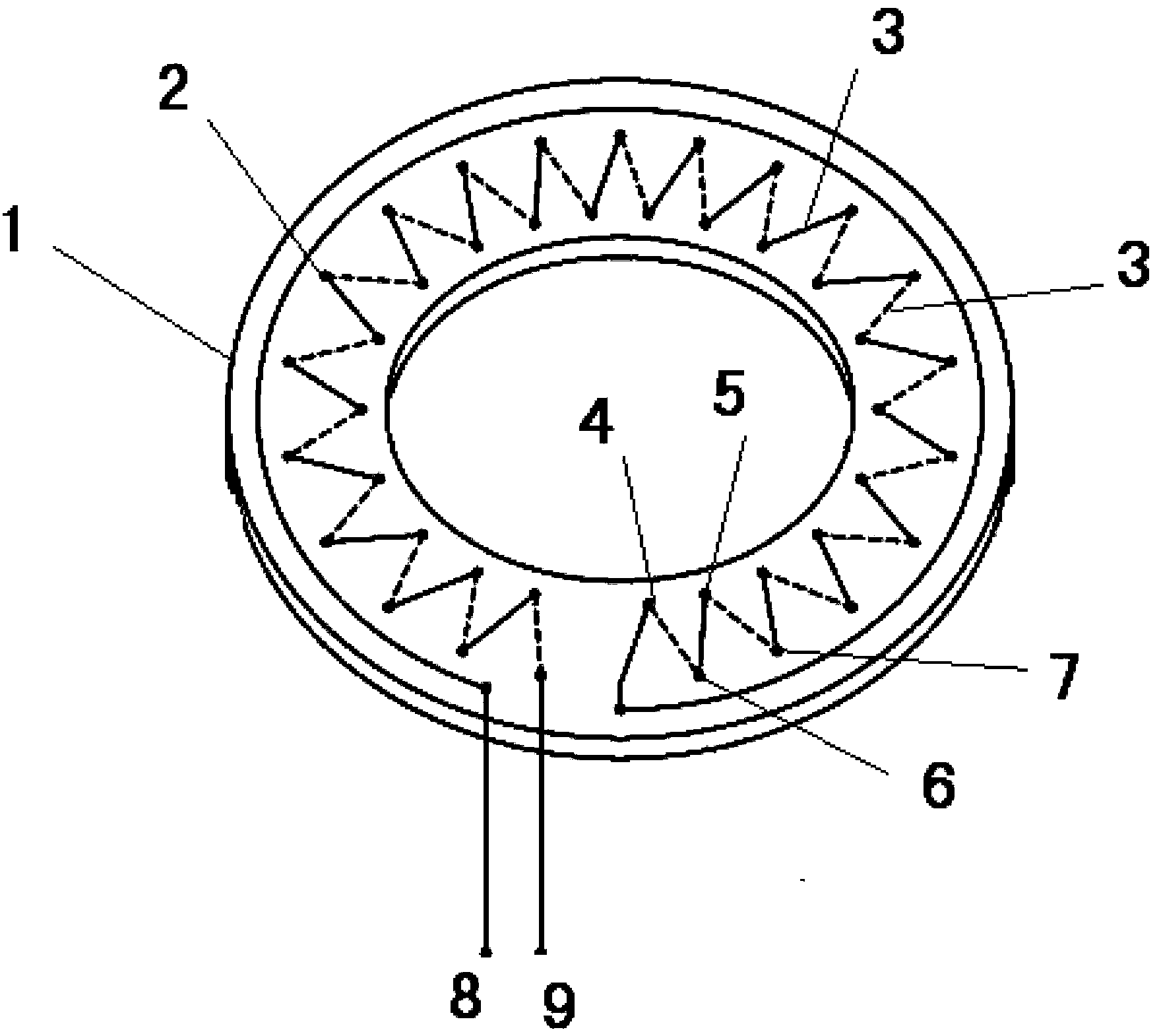

Double-sleeve extrusion die for extruding chalcogenide glass optical fiber preform rod and use method

ActiveCN104817263AUniformity controllablePrecise Control of UniformityGlass making apparatusChalcogenide glassEngineering

The invention discloses a double-sleeve extrusion die for extruding a chalcogenide glass optical fiber preform rod and a use method. The double-sleeve extrusion die comprises an outer sleeve, an inner sleeve, a splitter and a piston, wherein the inner sleeve is positioned in the outer sleeve, an outer sleeve nozzle and an inner sleeve nozzle are arranged at the bottoms of the outer sleeve and the inner sleeve respectively, the splitter is provided with a circular plate with a plurality of through holes, the through holes include a center hole and a plurality of peripheral holes formed in the periphery of the center hole, the splitter is arranged at the bottom of the outer sleeve, the inner sleeve nozzle is inserted into the center hole in the splitter, an annular groove matched with the inner sleeve is formed in the piston, so that the piston is right arranged in annular cavity between the outer sleeve and the inner sleeve and an inner cavity of the inner sleeve. The double-sleeve extrusion die can extrude chalcogenide glass optical fiber preform rods with the specific core package proportion and a shape of a specific core clad shape.

Owner:XUZHOU NORMAL UNIVERSITY

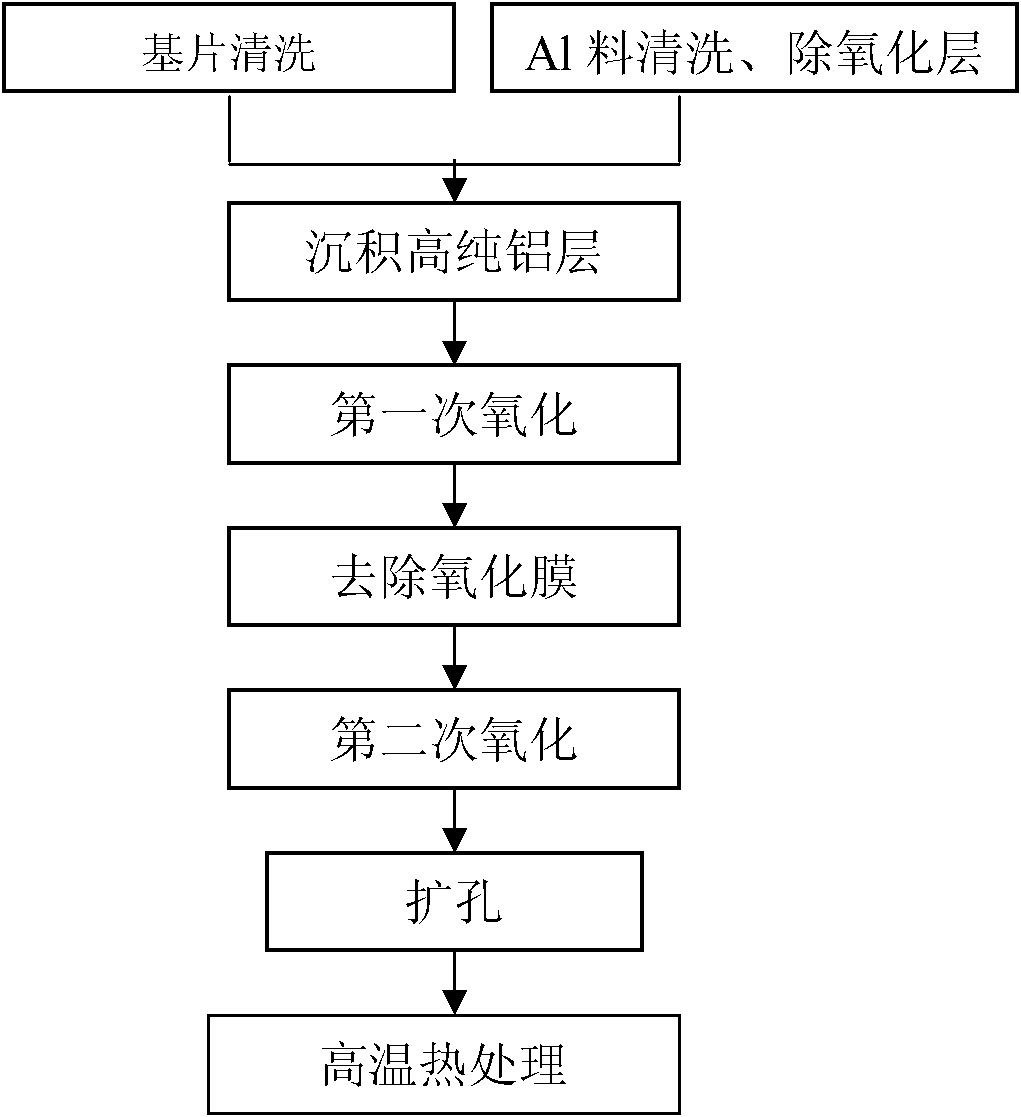

Preparation method of high transmission glass-based porous aluminum oxide substrate

InactiveCN101886247AHigh mechanical strengthEasy to get materialsAnodisationVacuum evaporation coatingAnode oxidationPore diameter

The invention provides a preparation method of a novel glass-based porous aluminum oxide substrate. The preparation method comprises the following steps of: firstly, preparing a high purity aluminum film by using glass as a substrate and adopting a vacuum thermal evaporation method; secondly, generating a porous aluminum oxide layer by using a primary anode oxidation method or a secondary anode oxidation method; thirdly, optimizing pore diameters of the porous aluminum oxide layer by using a pore expanding process; and fourthly, improving the transmission of the whole glass-based porous aluminum oxide substrate by using high temperature annealing treatment. The glass-based porous aluminum oxide substrate has favorable mechanical strength, ordered aluminum oxide pore heights and high transmission of visible light.

Owner:WUHAN UNIV OF TECH

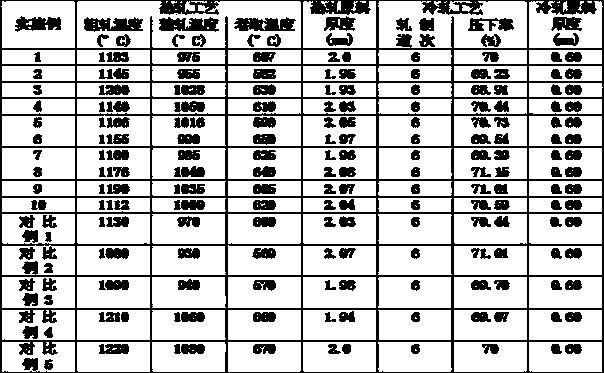

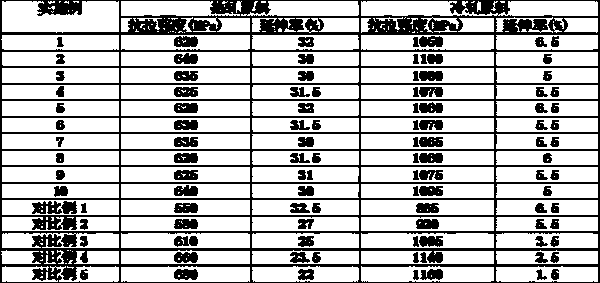

High-strength hot galvanized binding ribbon and production method thereof

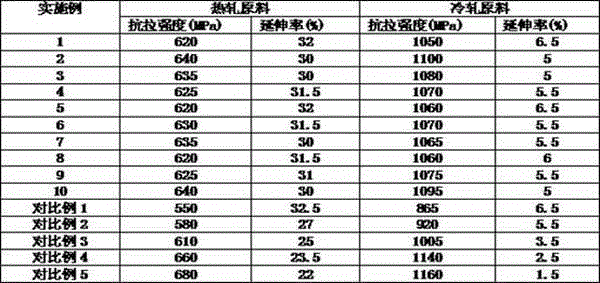

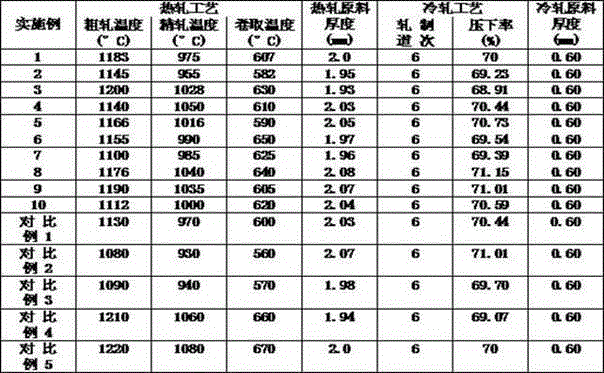

InactiveCN103805853APrecise thickness controlPrecise Control of UniformityHot-dipping/immersion processesFlexible elementsIngotZinc

The invention discloses a high-strength hot galvanized binding ribbon which consists of the following components in percentage by weight: 0.25-0.35% of C, 0.80-1.60% of Mn, not more than 0.010% of Si, less than or equal to 0.010% of P, less than or equal to 0.010% of S, 0.030-0.050% of Ti and 0.030-0.060% of Al. The high-strength hot galvanized binding ribbon is produced by the following steps: smelting, performing continuous casting to form ingots, and heating the ingots; roughing; finish-rolling; rolling; performing conventional electrolytic degreasing; performing cold rolling; and preparing the ribbon. The thickness of the high-strength hot galvanized binding ribbon is 0.60mm, the tensile strength is not less than 980MPa, the elongation is not less than 10%, the repeated bending frequency is not less than 10 (R=5mm), a layered brittle failure phenomenon is avoided, the thickness and uniformity of a zinc layer can be exactly controlled on the premise that the hot galvanized binding ribbon is not obviously rusted when placed in an indoor atmospheric environment for 180 days, and the mechanical property can be adjusted in the hot plating process. Subsequent procedures such as passivation and oil coating are eliminated, so that the process is shortened, and energy consumption is reduced.

Owner:武汉钢铁有限公司

Ultraviolet electricity scaling hot-dispelling electric detector

InactiveCN101251422AEffective absorptionImprove thermal conductivityPyrometry using electric radation detectorsElectricityPyroelectric detectors

The invention discloses an ultraviolet radiation electric calibration pyroelectric detector, which comprises a chip hanging up and encapsulated in a metallic tube case. The chip consists of a pyroelectric wafer; a metallic upper electrode layer, a polyimide insulation shielding layer, a multi-wall carbon nano-tube film capable of not only absorbing ultraviolet radiation but also being heated through conduction, which are deposited on the upper surface of the pyroelectric wafer in turn; and a signal electrode layer which is deposited on the lower surface of the pyroelectric wafer. The ultraviolet radiation electric calibration pyroelectric detector has the greatest advantage of adopting the multi-wall carbon nano-tube as an ultraviolet conduction and absorption film. Compared with the prior art adopting a black gold conduction and absorption film, the ultraviolet radiation electric calibration pyroelectric detector can absorb the ultraviolet radiation with higher efficiency and better heat conducting property, strengthen the photoelectric equivalence, and reduce calibration errors with stable performance of the multi-wall carbon nano-tube film. The ultraviolet radiation electric calibration pyroelectric detector adopts the insulation shielding layer made of polyimide, thereby bringing about compatibility with the micro-electronic technique, accurate control on the thickness and evenness of the film, and good heat stability.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

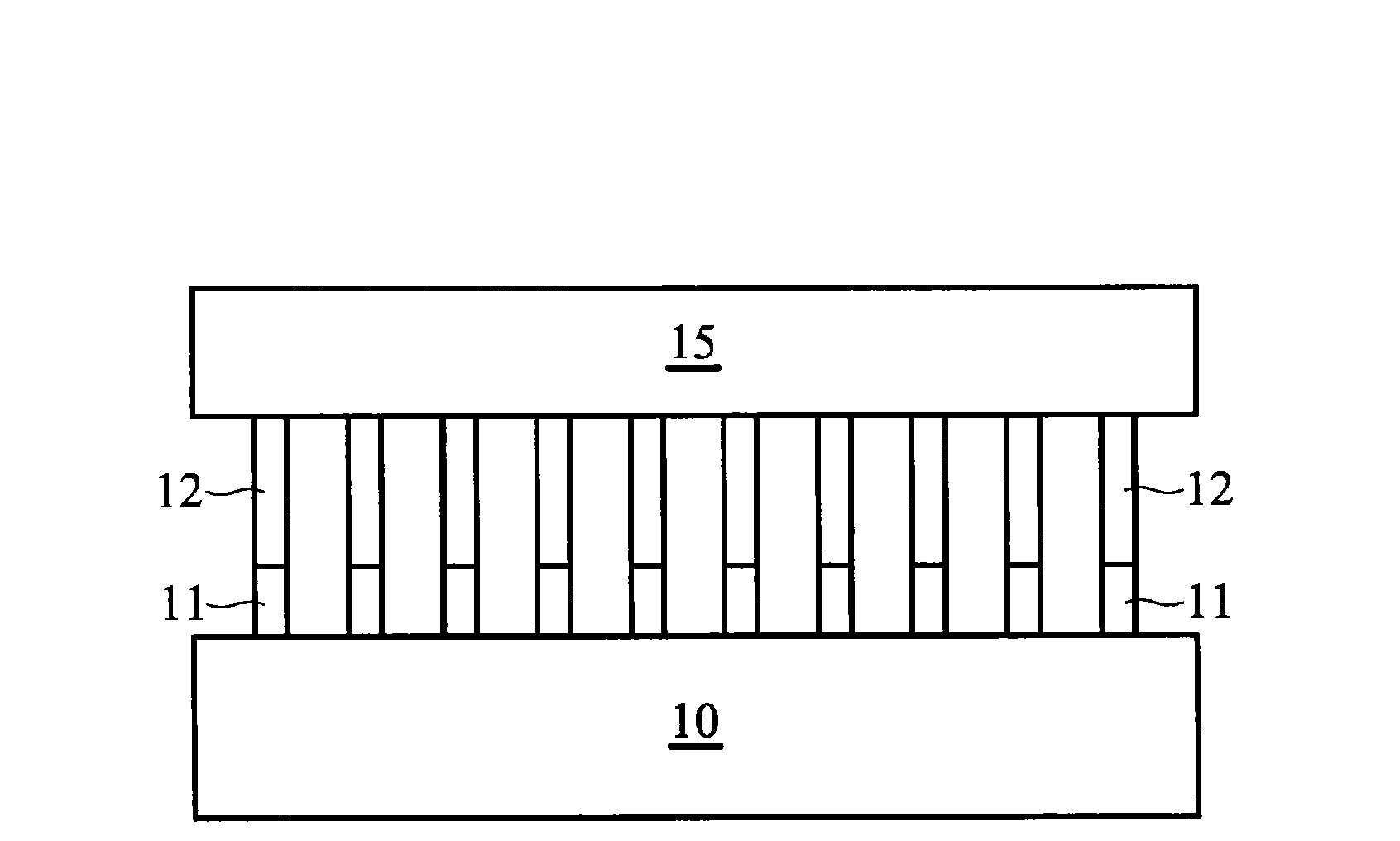

Manufacturing method for structure of extremely thin silicon on insulator and manufacturing method for semiconductor device

ActiveCN103367230APrecise thickness controlPrecise Control of UniformitySemiconductor/solid-state device manufacturingPower semiconductor deviceIon implantation

Disclosed are a manufacturing method for a structure of extremely thin silicon on an insulator (ETSOI) and a manufacturing method for a semiconductor device. The manufacturing method for the semiconductor device includes: providing silicon on insulator (SOI); forming a hard-mask layer on a top-silicon layer and carrying out a patterning processing on the hard-mask layer; and measuring real thicknesses of exposed areas of the top-silicon layer; injecting doping ions into the exposed areas of the top-silicon layer with an injection quantity related to corresponding real thicknesses of the injected areas; carrying out an etching processing, and removing part of the exposed areas of the top-silicon layer and forming trenches; forming side walls on flanks of the trenches and forming gate structures on areas defined by the flanks; carrying out a planarization processing so that upper surfaces of the gate structures are flush with an upper surface of the hard-mask layer; removing the hard-mask layer; and injecting ions into the exposed areas of the top-silicon layer and forming elevated source / drain areas. The manufacturing method for the structure of the extremely thin SOI and the manufacturing method for the semiconductor device enable the thicknesses and uniformity of the areas of the top-silicon layer on the extremely thin SOI structure to be controlled precisely so that damages on the top-silicon layer are prevented.

Owner:SEMICON MFG INT (SHANGHAI) CORP

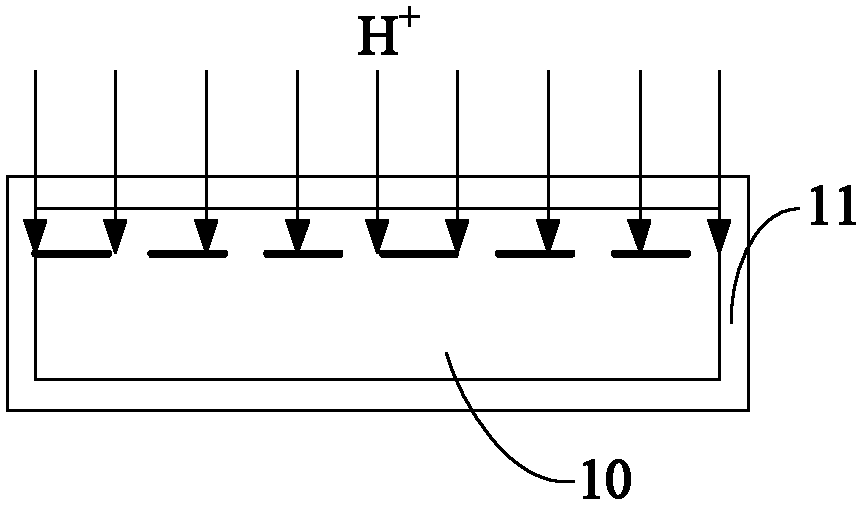

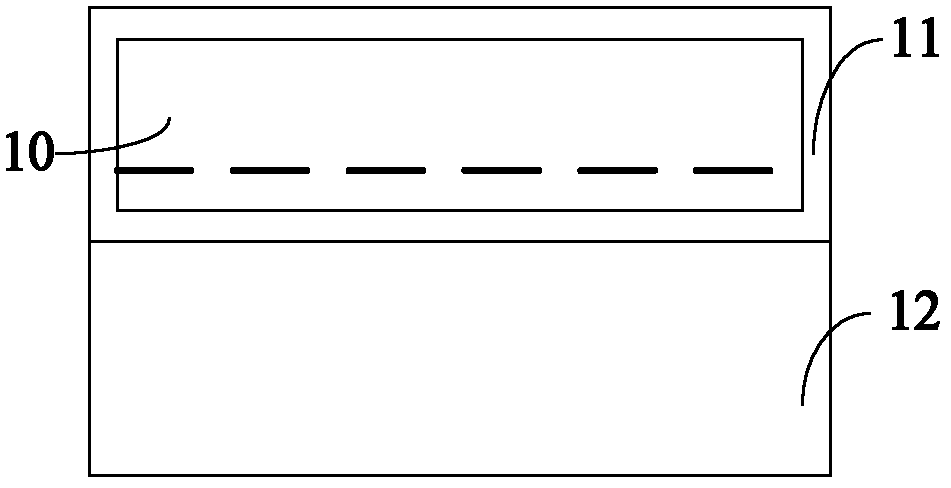

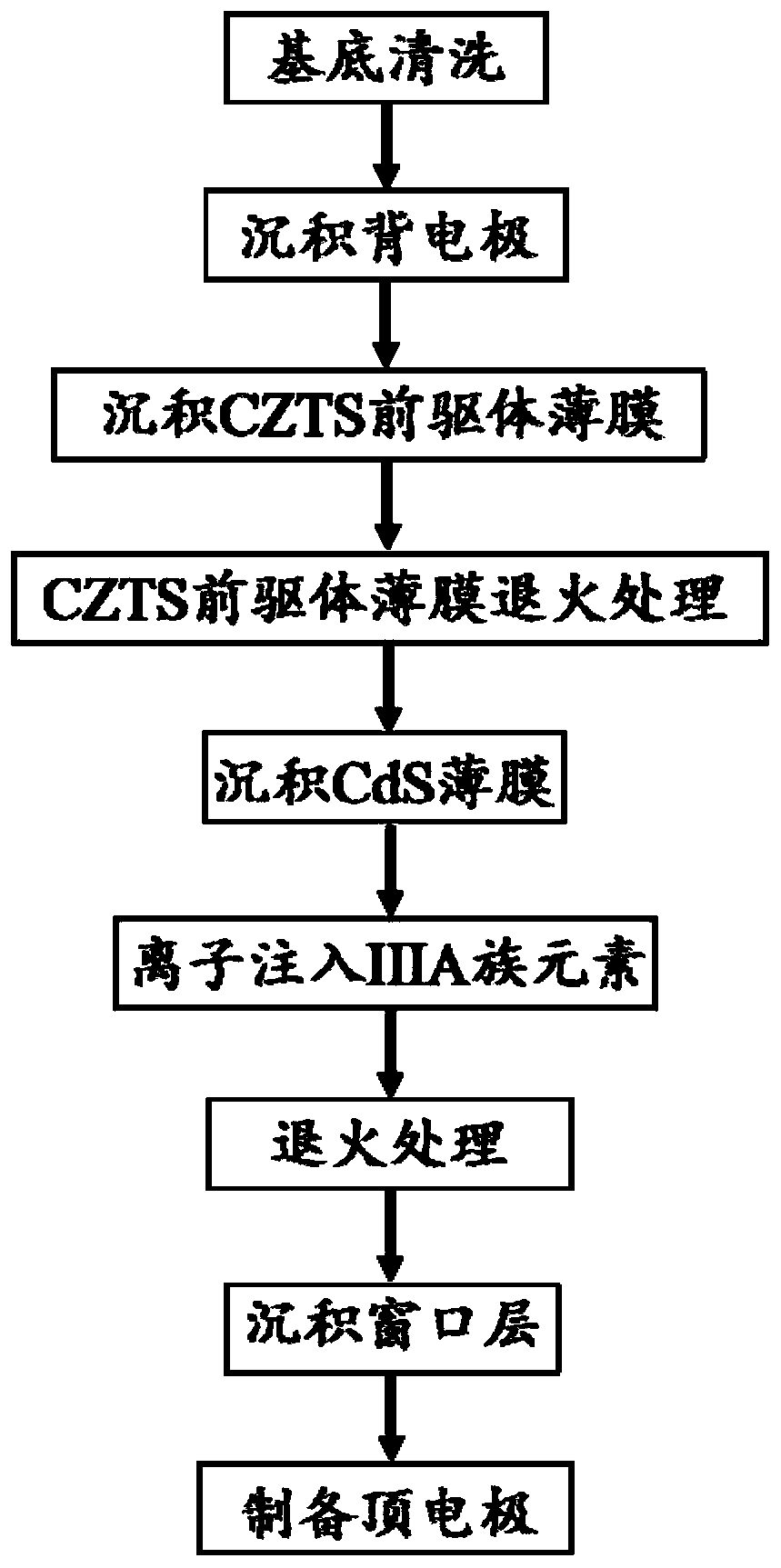

Method for preparing CZTS thin film solar cell using group IIIA element doped cadmium sulfide film

InactiveCN110112062APrecisely control the total dosePrecise control of depthFinal product manufactureSemiconductor/solid-state device manufacturingCZTSCadmium sulfide

The invention discloses a method for preparing a CZTS thin film solar cell using a group IIIA element doped cadmium sulfide film. The method comprises the steps of: cleaning a substrate; depositing metal molybdenum as a back electrode on the cleaned substrate; depositing a CZTS precursor film on the back electrode; annealing the CZTS precursor film to obtain a CZTS absorbing layer film; depositinga CdS film on the CZTS absorbing layer film, and doping the CdS film with a group IIIA element by ion implantation; and annealing the sample doped with CdS, then depositing a window layer on the doped CdS; preparing a top electrode on the window layer to obtain the CZTS thin film solar cell. Doping the Group IIIA element can improve the photoelectric performance of CdS, increase the width of a depletion region, and ensure high long-wave collection efficiency and photoelectric conversion efficiency. The ion implantation method can precisely control the concentration and depth distribution of the implanted ions, and the implanted layer does not peel off.

Owner:CENT SOUTH UNIV

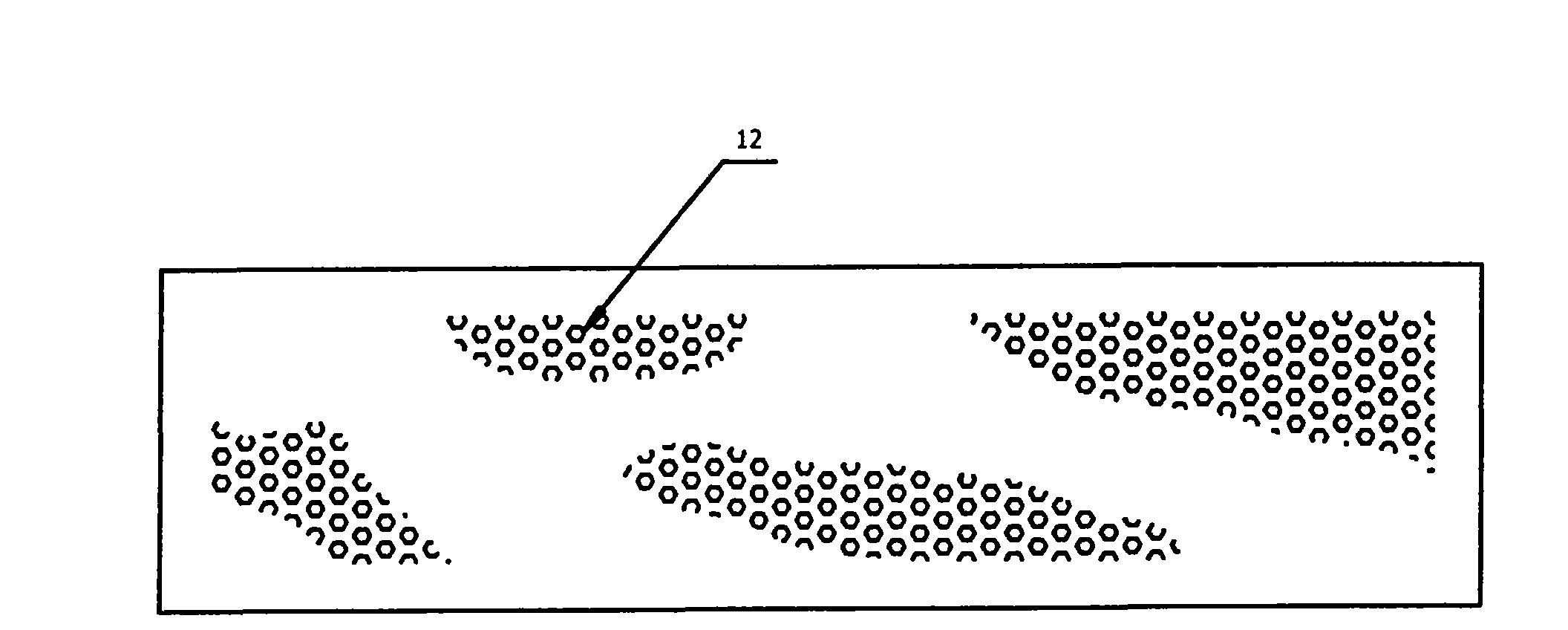

Ceramic powder feeding device and feeding method thereof

InactiveCN101579889APrecisely control the feeding amountPrecisely control the feeding speedFeeding arrangmentsFeeding patternsMaterials science

The invention in particular relates to a ceramic powder feeding device arranged on a ceramic wall ground tile production facility and a feeding method thereof. The ceramic powder feeding device comprises a storage hopper, a feeding screen plate, a rotary hair brush, a rotary device, ceramic powder, a load-bearing body and a middle screen plate open pore area, wherein the feeding screen plate is arranged in the storage hopper, feeding patterns are manufactured on the feeding screen plate, the middle screen plate open pore area of the feeding screen plate is a screen plate feeding area, the rotary hair brush is arranged in the storage hopper, the distance between the rotary hair brush and the feeding screen plate is adjustable, and the rotary device is arranged on the rotary hair brush. The ceramic powder feeding device can precisely control the feeding quantity, the feeding speed, the feeding evenness and the feeding patterns through the hair brush and related parts.

Owner:黎永健

Micro-filtration membrane and method for modifying same

ActiveCN109433017AIncrease release rateEnhanced Grading and Screening CapabilitiesUltrafiltrationFiltration membraneWater soluble

The invention relates to a micro-filtration membrane and a method for modifying the same, and belongs to the technical field of membrane modification. By the aid of the micro-filtration membrane and the method, the problem of difficulty in releasing enriched cells by micro-filtration membranes in the prior art can be solved. The micro-filtration membrane is modified by temperature-sensitive water-soluble polymer solution. The method for modifying the micro-filtration membrane includes (1), preparing the temperature-sensitive water-soluble polymer solution with the volume percent concentrationof 0.1%-6%; (2), coating the temperature-sensitive water-soluble polymer solution on the micro-filtration membrane to modify the micro-filtration membrane and drying the micro-filtration membrane coated with the temperature-sensitive water-soluble polymer solution to obtain a modified micro-filtration membrane. The micro-filtration membrane and the method have the advantages that membrane filtration technologies can be widely applied to the field of medical treatment, and accurate detection results can be obtained.

Owner:BEIJING MECHANICAL EQUIP INST

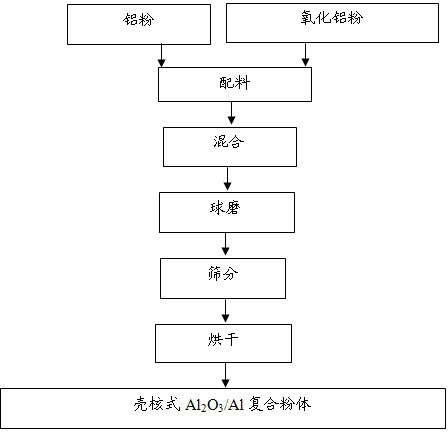

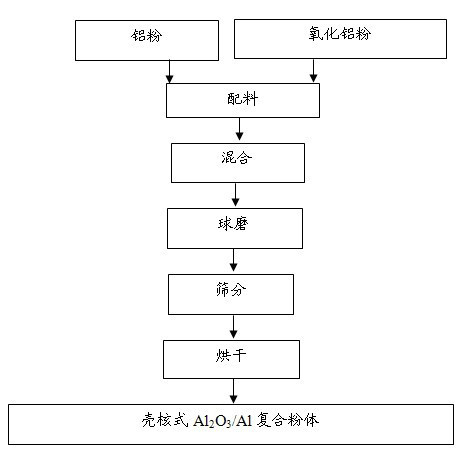

Core-shell Al2O3/Al composite powder preparation process

InactiveCN102423672APrecise control of putamen propertiesPrecise thickness controlMicroballoon preparationMicrocapsule preparationAl powderBall mill

The present invention relates to a core-shell Al2O3 / Al composite powder preparation process. According to the preparation process, 1-49% of Al2O3 powder is added to a planetary high-energy ball mill tank to carry out ball milling for 1-6 hours at a rotation speed of 100-500 r / min; then 51-99% of Al powder is added to the ball milled Al2O3 powder to carry out ball milling for 0.5-12 hours at a rotation speed of 100-500 r / min to prepare the core-shell Al2O3 / Al composite powder. The preparation process of the present invention has advantages of simple and convenient operation, easy control and less energy consumption. The core-shell characteristics of the prepared core-shell Al2O3 / Al composite powder raw material can be precisely controlled by adjusting the process conditions, wherein the core-shell characteristics of the prepared core-shell Al2O3 / Al composite powder comprise thickness, density, uniformity and the like.

Owner:JIUJIANG UNIVERSITY

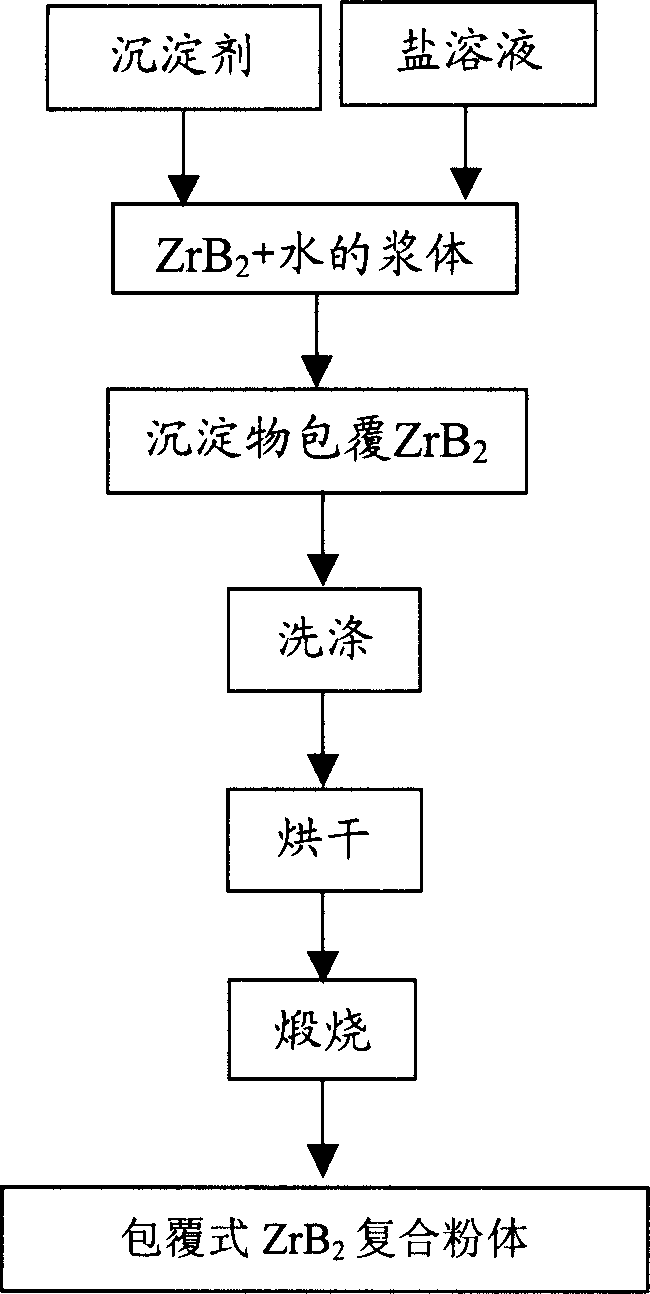

Process for preparing coated ZrB2 composite powder

InactiveCN1827554AImprove antioxidant capacityPrecise control of coating propertiesGramOxidation resistant

The invention relates to a method for preparation of inorganic powder with antioxidation susceptibility in the form of cladding. The method for preparation of composite powder of zirconium diboride in the form of cladding is characterized in that it contains the following steps: 1) mixing and stirring equably the mixture of the powder of zirconium diboride and the water with a proportion of 1 gram: 50-1000 milliliters to get the miscible liquid; 2) adding 1-100 kinds of saline solution in a same proportion as the former step, at the same time, adding precipitating reagents of PH value of 8-12 with the quantity added which can keep the PH value of the miscible liquid at 7-11.5 into the miscible liquid, obtaining composite powder of zirconium diboride in the form of cladding which is precursor of the cladding; and the said precipitating reagents is the materials generated by hydroxide ion of the water solution; 3) obtaining the products by washing, drying at 80-150 DEG C and calcining at 300-700 DEG C the composite powder. The invention is characterized in that it is of simple and convenient operation, easy control, low energy consumption, and good antioxidation susceptibility of the obtained composite powder of zirconium diboride in the form of cladding at the high temperature.

Owner:WUHAN UNIV OF TECH

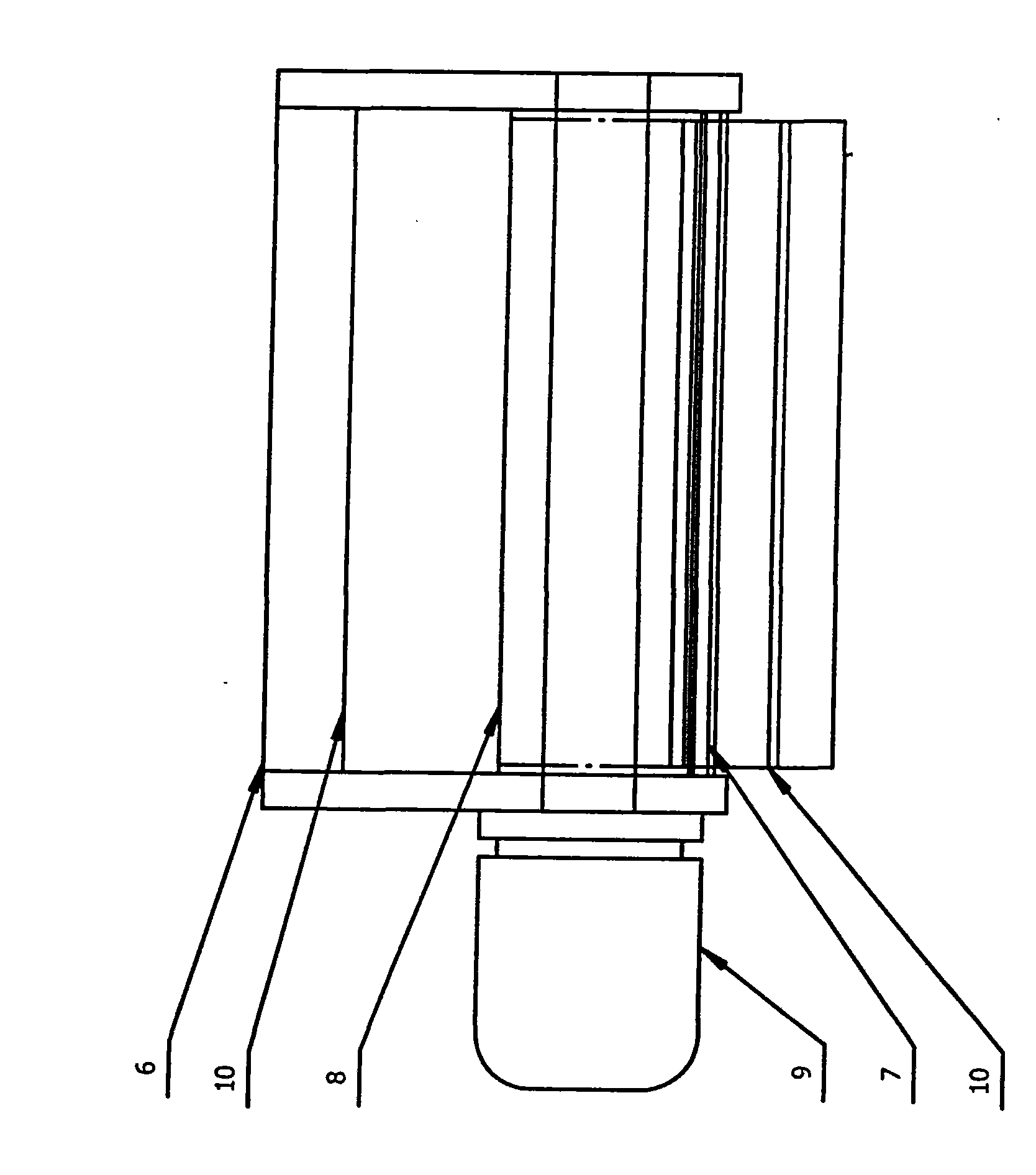

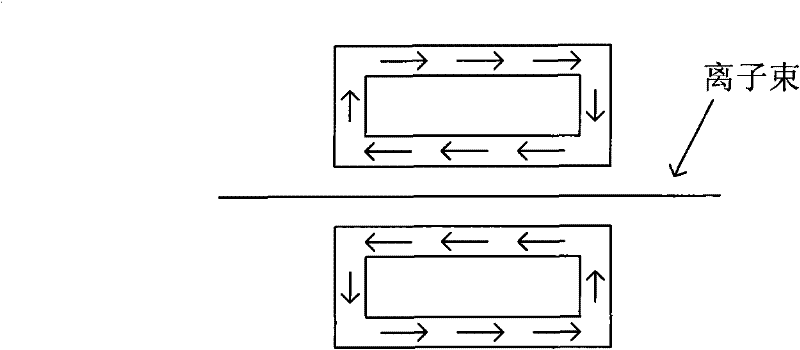

Ion implantation equipment and method thereof

ActiveCN102479654AImprove operational reliabilitySimple designElectric discharge tubesFinal product manufactureIon beamIon implantation

The invention discloses ion implantation equipment and a method thereof. In the ion implantation equipment, a beam path of an ion beam which is from an ion source system to a workpiece transmission apparatus is successively provided with: a deflection defocusing magnet, a deflection magnet, a deflection focusing magnet and an electrode system, wherein the deflection defocusing magnet is used to deflect the ion beam in a deflection plane and defocus the ion beam in a direction which is perpendicular to the deflection plane; the deflection magnet is used to deflect the ion beam in the deflection plane; the deflection focusing magnet is used to deflect the ion beam in the deflection plane and focus the ion beam in the direction which is perpendicular to the deflection plane; the electrode system is used to deflect the ion beam in the deflection plane. By using the equipment and the method of the invention, whole equipment cost can be greatly reduced and precise control of doping doses and doping uniformity can be realized.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

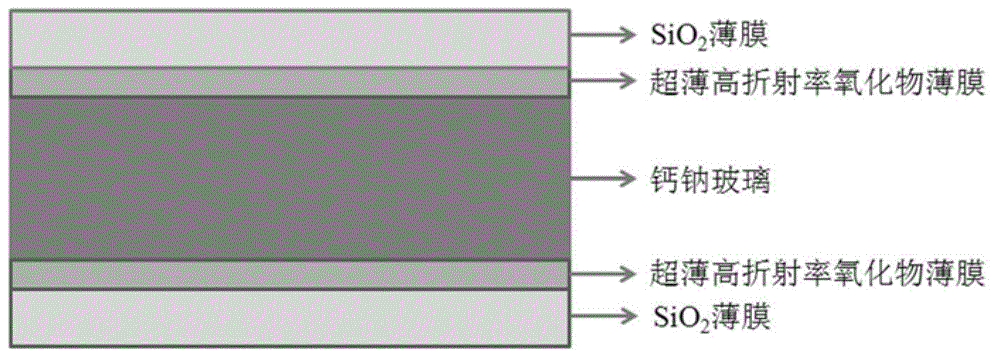

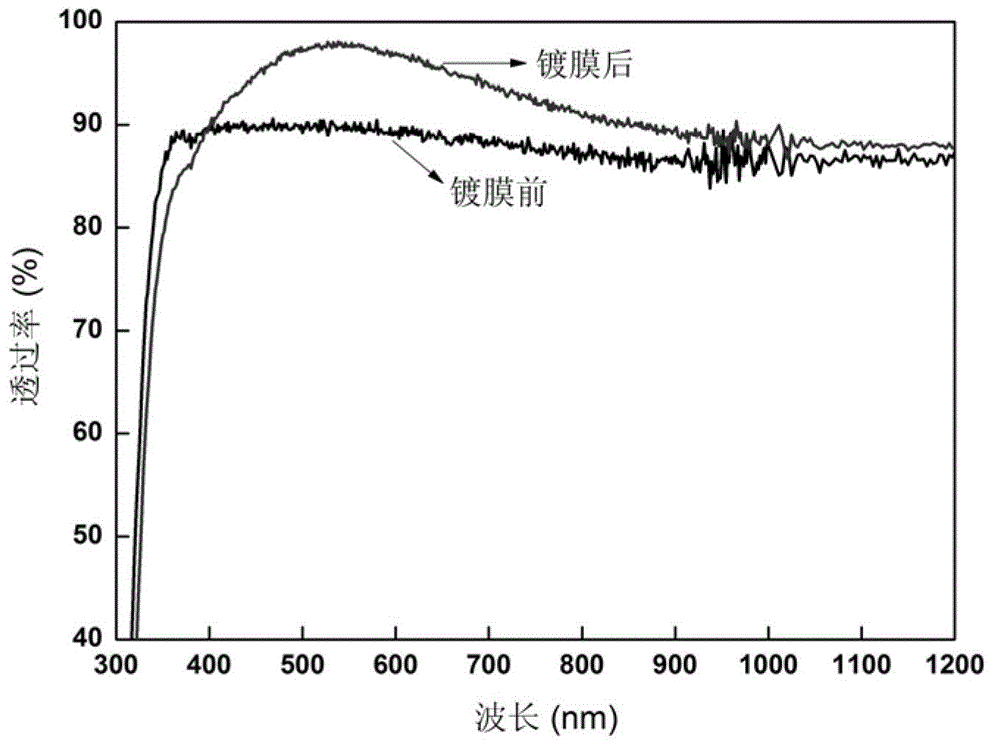

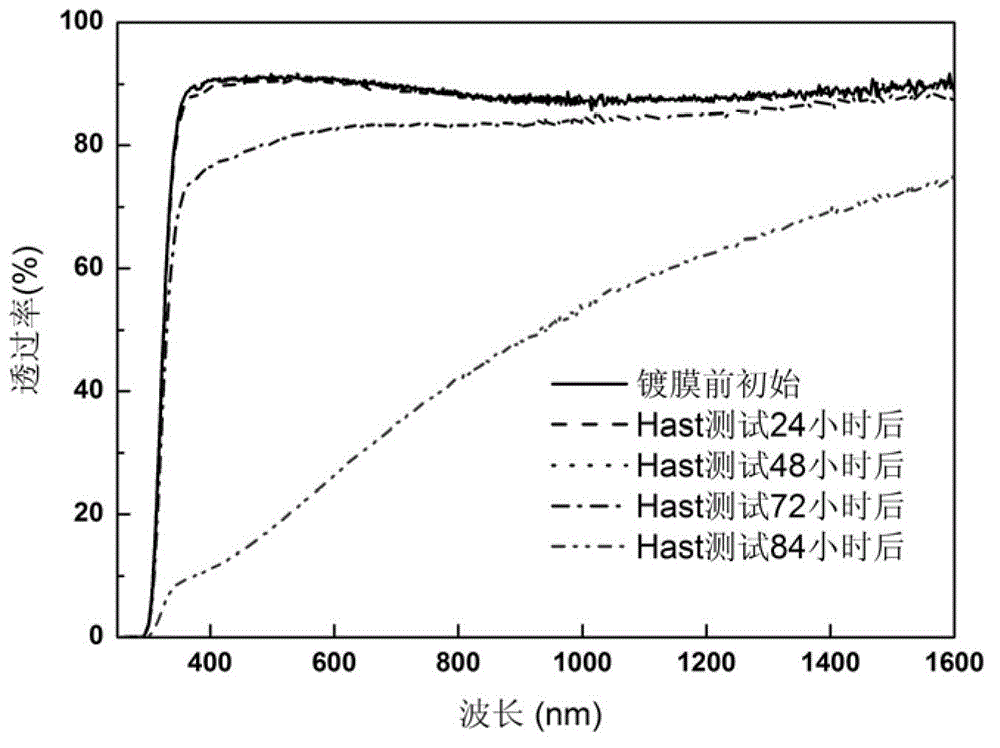

Method for forming durable dual-layer antireflection film on surface of soda-lime glass

InactiveCN102910835AEffective control of anti-reflection characteristicsIncreased durabilityWater vaporRefractive index

The invention discloses a method for forming a durable dual-layer antireflection film on the surface of soda-lime glass. The method comprises the following steps of: 1) adding a precursor of metal oxide and water steam into a reaction cavity for reaction to obtain a reaction product, and depositing the reaction product on the two surfaces of a base of the soda-lime glass by adopting an atomic layer deposition method to obtain a high refractive index oxide film; 2) taking a silicon source, a solvent and a catalyst as raw materials to prepare silica sol; 3) coating the silica sol prepared in the step 2) to the surfaces of the base of the soda-lime glass obtained in the step 1) by adopting a coating technology so as to form an SiO2 film on the high refractive index oxide film; and 4) solidifying the high refractive index oxide film and the SiO2 film on the surface of the soda-lime glass to obtain the soda-lime glass with the durable dual-layer antireflection film. The method is low in cost and is suitable for large-scale application. The dual-layer film formed on the surface of the soda-lime glass by adopting the method is excellent in antireflection effect and durability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

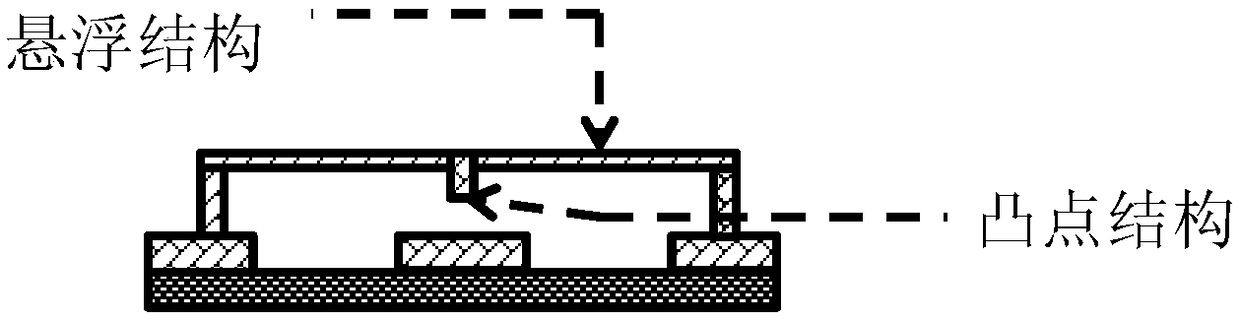

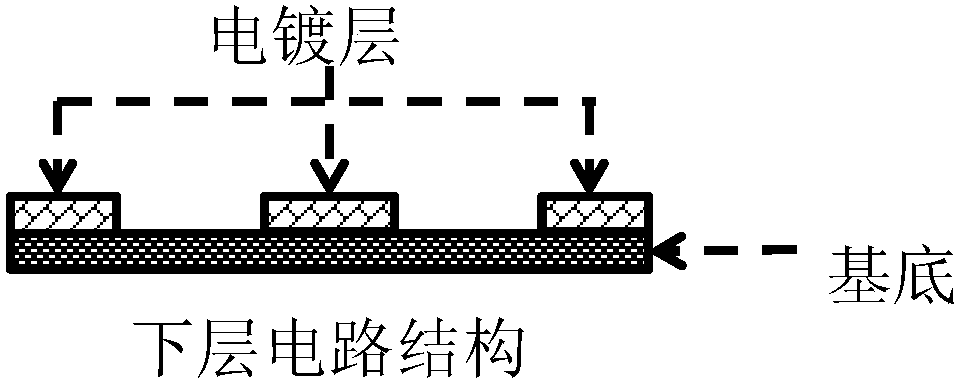

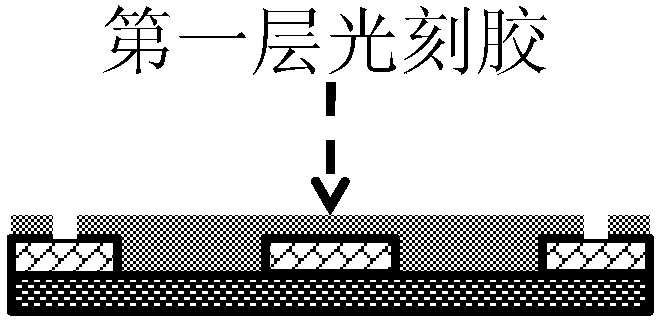

Preparation method of sandwich type photoresist sacrificial layer

ActiveCN108100990AEasy to makeLow heat treatment temperatureDecorative surface effectsChemical vapor deposition coatingDissolutionSandwich type

The invention discloses a preparation method of a sandwich type photoresist sacrificial layer in the field of manufacturing of RF MEMS devices. The preparation method mainly comprises the following five steps: preparation of lower layer photoresist, growth of a barrier layer, preparation of upper layer photoresist, etching of a Cu layer and heat treatment. According to the method, the problem of mutual dissolution between the two layers of photoresist is avoided by importing a Cu barrier layer, and the prepared sacrificial layer has the characteristics of simple release, accurate salient pointheight control, low device dependency, capability of manufacturing complex patterns, etc.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Method for preparing white-light LED package device with high color rendering index

ActiveCN106653980AHigh color rendering indexReduce outputSemiconductor devicesColor rendering indexHigh color

The invention provides a method for preparing a white-light LED package device with a high color rendering index. The white-light LED package device with the high color rendering index is prepared by atomizing and spraying fluorescent powders on a flip LED chip. By adopting the method provided by the invention, the color rendering index of the white-light LED package device can be effectively improved, and the color rendering index of the LED package device prepared from the same chip, silica gel and fluorescent powders can be improved to about 1 to 5; a problem that the white-light LED device has a relatively lower color rendering index is greatly solved, and the method is more suitable for the development tendency of the white-light LED device with the high color rendering index.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

Manufacturing method of printed circuit board (PCB) coil and PCB coil

InactiveCN103384456APrecisely control the number of turnsPrecise control of line lengthPrinted electric component incorporationMultilayer circuit manufactureCopper platingCopper wire

The invention discloses a manufacturing method of a printed circuit board (PCB) coil. The manufacturing method is characterized by comprising the following steps that (1) wiring design is conducted on the PCB coil by using electronic design automation (EDA) software; (2) a single-layer double-faced PCB is arranged; (3) a plurality of via holes are formed in the PCB of the step (2), and the inner sides and the outer sides of the via holes are distributed orderly in a double-row mode; (4) according to the wiring design of the step (1), etching wiring is conducted on the upper surface and the lower surface of the PCB of the step (2); (5) conductive materials are filled in the via holes of the step (3), the double-faced PCB is electrically connected through the via holes through electroless copper plating so that upper copper wires and lower copper wires are electrically connected; (6) protective layer rosin water is coated on the surfaces of wires arranged in the step (4), after the rosin water is condensed, the PCB coil is obtained. The invention further discloses the PCB coil prepared through the method.

Owner:UNI TREND TECH (CHINA) CO LTD

A method of forming a circuit structure

ActiveCN101651092APrecise size controlPrecise Control of UniformityNanostructure manufactureSemiconductor/solid-state device manufacturingSemiconductor materialsVolumetric Mass Density

A method of forming a circuit structure includes providing a substrate; etching the substrate to form a plurality of nano-structures; and growing a compound semiconductor material onto the nano-structures using epitaxial growth. Portions of the compound semiconductor material grown from neighboring ones of the nano-structures join each other to form a continuous compound semiconductor film. The present invention can accurately control the size of the nano column, the pattern density and the uniformity, thus causing the III-nitride film to have an improved quality formed thereon; causing obviously transverse growth to reduce the dislocation in the III-nitride film; causing the torque force required by the nano column breakage to be samll; and ensuring that the nano column portion is a portion having weak mechanical strength, which can be easily broken or etched.

Owner:TAIWAN SEMICON MFG CO LTD

Lubricant spraying system for gasket

ActiveCN103212503AImprove lubrication qualityPrecise dose controlSpraying apparatusRolling resistanceFriction force

The invention relates to a lubricant spraying system for a gasket. The lubricant spraying system for the gasket comprises a gasket platform used for placing the gasket to be sprayed, a spraying nozzle capable of obliquely moving to the inner side of the gasket, and a friction wheel capable of being arranged at one side of the gasket platform in a rotary mode, wherein at least two rotation rollers are symmetrically arranged on the gasket platform, and the gasket is in contacting connection with the rotation rollers and the friction wheel and rotates under the driving of rolling frictional force of the friction wheel. The lubricant spraying system for the gasket is capable of automatically spraying lubricant to the inner side of the gasket, accurately controls the dosage and uniformity of the lubricant on each gasket, and improves the lubricating quality of the gasket.

Owner:镇江泛沃新能汽车技术股份有限公司

A high-strength hot-dip galvanized strap and its production method

InactiveCN103805853BPrecise thickness controlPrecise Control of UniformityHot-dipping/immersion processesFlexible elementsIngotZinc

Owner:武汉钢铁有限公司

Cu2O/C3N4/TiO2 heterojunction visible light catalyst and preparation method thereof

PendingCN111841609APromote absorptionImprove separation efficiencyMaterial nanotechnologyCatalyst activation/preparationHeterojunctionPtru catalyst

The invention relates to a preparation method of a visible light catalyst Cu2O / C3N4 / TiO2 heterojunction visible light catalyst, comprising the following steps of: sputtering a layer of Cu on the surface of FTO glass, obtaining a Cu (OH) 2 nano array by an electroplating oxidation method, and carrying out annealing treatment to obtain a Cu2O nano array; compounding C3N4 and Cu2O nano arrays througha centrifugal compounding method; and finally, sputtering a layer of TiO2 to form a multi-stage heterojunction, so that separation and transmission of interlayer electron holes are promoted, and thecatalytic performance of the photocatalyst and the stability of an electrode material are further improved.

Owner:杭州紫芯光电有限公司

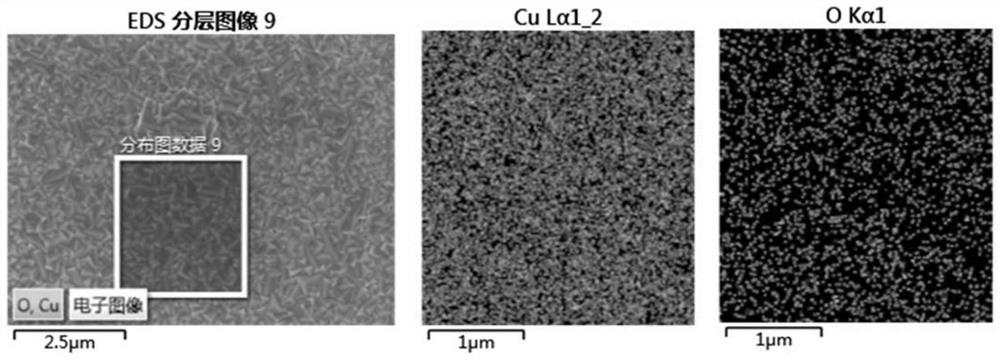

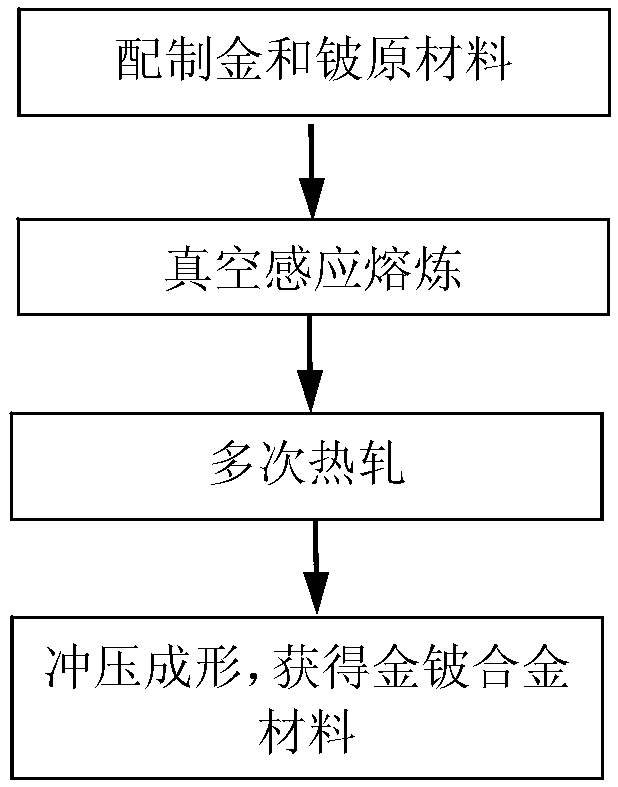

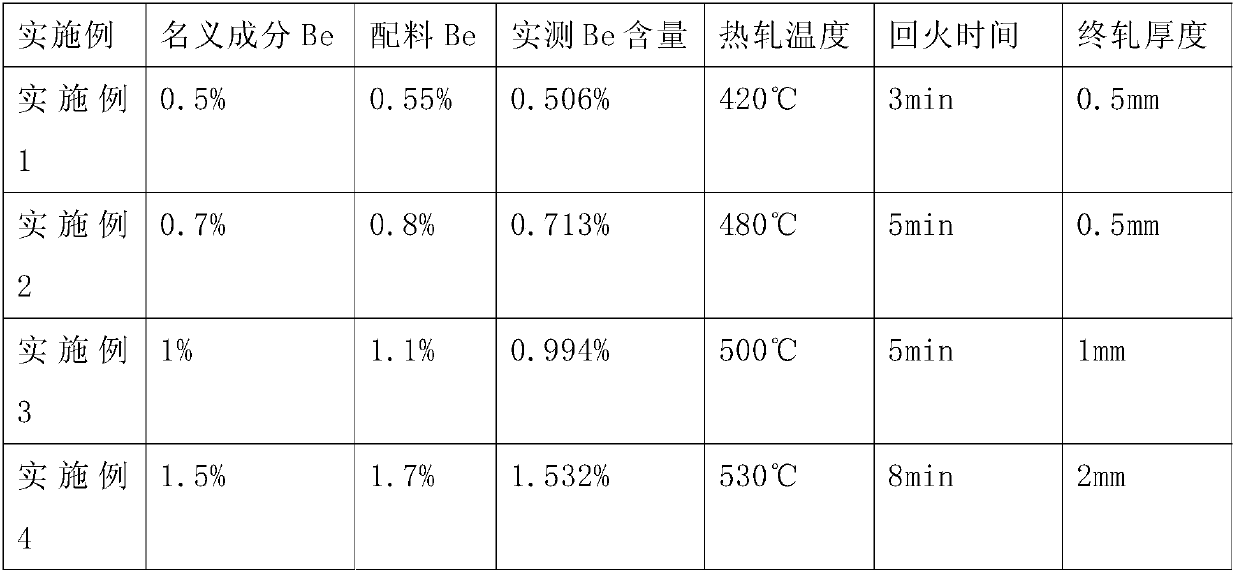

Semiconductor device gold beryllium alloy material and preparation method thereof

The invention discloses a semiconductor device gold beryllium alloy material and a preparation method thereof. The method comprises the following steps that 1) gold metal and beryllium metal are usedas raw materials, a vacuum induction smelting furnace is used, after the gold is completely melted, the beryllium metal is added, and smelting and casting are conducted to obtain a gold beryllium alloy cast ingot, wherein the alloy cast ingot comprises beryllium with the weight percentage equal to nominal 0.5%-2% plus a certain ratio, and the balance gold; 2) heat treatment is conducted on the alloy cast ingot obtained in the step 1 through a heating furnace; 3) thermoplastic processing is conducted on the cast ingot in the thickness direction by means of plastic processing equipment; 4) tempering heat treatment is conducted on a blank in the heating furnace every 1-2 procedures; 5) the step 3) and the step 4) are repeated until the required thickness of a plate is obtained; and 6) a stamping mold is adopted to machine the plate into the required gold beryllium alloy material. The gold beryllium alloy material obtained by the method is uniform in component, stable in alloy, ands regular in shape and can meet the performance requirements of ohmic contact electrodes of a semiconductor device.

Owner:GRIKIN ADVANCED MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com