Preparation method of composite metal lithium negative electrode

A composite metal and lithium negative electrode technology, which is applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the problems of difficult industrialization, high cost and safety hazards, and achieves simple preparation methods, constant area, and consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

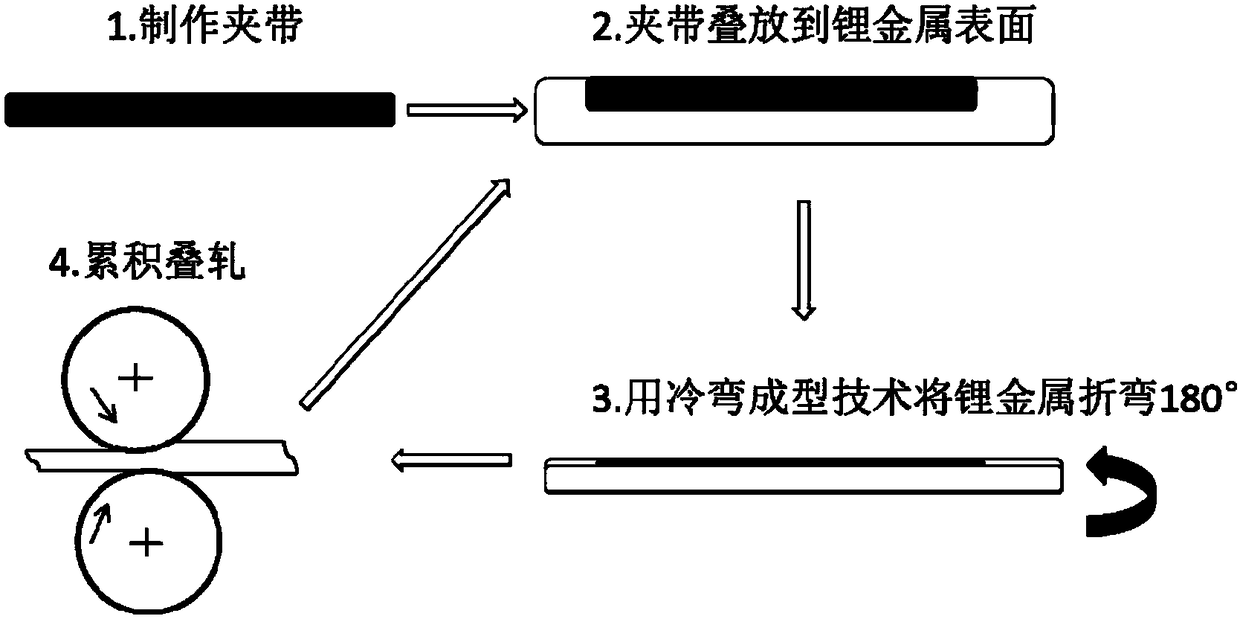

[0033] Such as figure 1 As shown, the entrainment with a thickness of 0.5 mm prepared by coating technology using graphite powder and PTFE as raw materials is spread on the surface of lithium metal, and the lithium metal is bent 180° in the width direction by cold bending forming technology. Form a composite structure of lithium / entrainment / lithium, and then roll, and the deformation of the down-press is 20% to 50%, to obtain a composite material that has been rolled once, and then spread the entrainment on the surface of the composite material that has been rolled for the first time Perform cold bending and rolling, and repeat this step 3 to 20 times, so as to obtain a composite lithium metal negative electrode material with a multi-layer structure, and perform automatic winding at the end of the rolling machine. The metal lithium layer of the material has a thickness of 20um, and the content of inorganic materials in the metal lithium layer is less than 5%; the thickness of ...

Embodiment 2

[0036]The entrainment with a thickness of 1mm prepared by using titanium carbide nanowires and PVDF as raw materials and screen printing technology is flattened on the surface of lithium metal, and the lithium metal is bent 180° in the width direction by cold bending forming technology to form lithium metal. The composite structure of / entrainment / lithium is then rolled, and the deformation amount is 20% to 50% to obtain a composite material that has been rolled once, and then the entrainment is flatly spread on the surface of the composite material rolled for the first time for cooling. Bending, rolling, and repeating this step 3 to 20 times, so as to obtain a composite lithium metal negative electrode material with a multi-layer structure, and perform automatic winding at the end of the rolling machine. The metal lithium layer of the material has a thickness of 1um, and the content of inorganic materials in the metal lithium layer is less than 5%; the thickness of the entrain...

Embodiment 3

[0038] Using silica fiber and PTFE as raw materials, entrainment with a thickness of 0.3mm prepared by tape casting technology is spread on the surface of lithium metal, and lithium metal is bent 180° in the width direction by cold bending forming technology to form lithium metal. The composite structure of / entrainment / lithium is then rolled, and the compression deformation is 20% to 50%, so as to obtain the composite material after one rolling. Then spread the entrainment on the surface of the composite material rolled for the first time for cold bending and rolling, and repeat this step 3 to 20 times to obtain a composite lithium metal negative electrode material with a multi-layer structure, and roll it at the end of the rolling machine Perform automatic rewinding. The metal lithium layer of the material has a thickness of 10um, and the content of inorganic materials in the metal lithium layer is less than 5%; the thickness of the entrainment layer is 10um, and the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com