Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

124results about How to "Easy for industrialized continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for purifying, reclaiming and condensing sugar in lignocellulose prehydrolysis liquid

ActiveCN101787398AEasy to operateEasy for industrialized continuous productionGlucose productionCelluloseFiltration membrane

The invention relates to a method for reclaiming and condensing sugar and removing toxicity inhibitors in lignocellulose prehydrolysis liquid by the applied nanofiltration technology. The method is realized by the following scheme: the pH value of the lignocellulose prehydrolysis liquid is firstly adjusted to 2.0-5.0, and the filtration pretreatment is carried out to remove suspended impurities; and then a filtration membrane is used for condensing sugar and remove inhibitors, the sugar of glucose, xylose and the like is trapped by the nanofiltration membrane, the weakly acidic inhibitors (formic acid, acetic acid, levulinic acid and the like) and the furfural inhibitors (furfural, 5-hydroxymethyl furfural and the like) continually penetrate through the nanofiltration membrane, the various inhibitors in the prehydrolysis liquid are removed, and the sugar in the prehydrolysis liquid is condensed to realize the purification, reclaiming and condensation of the sugar in the prehydrolysis liquid, so that the fermentability of the sugar is improved. The invention has the advantages of simple and safe operation, high efficiency and energy saving, and facilitates the continuous production; the nanofiltration has effects of purification, reclaiming and condensation; and the method can realize the industrial production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Processing method for instant sheet jelly and bean jelly

ActiveCN101341944AAvoid secondary pollutionReduce manual operationsFood preparationPotassiumChloride

The invention relates to a processing method of instant sheet jelly and bean jelly, which comprises: mixing and pulping, i.e. starch and water are mixed by the ratio of 1:2 to 9 to prepare starch sirup; and then citric acid with 0.01 weight percent to 0.9 weight percent of starch sirup and 0.01 percent to 1.2 percent of edible potassium chloride or 0.01 percent to 1.2 percent of edible calcium carbonate are added in to be evenly mixed, to obtain ground paste; the ground paste is measured, filled, sealed, cooked and cooled to obtain sheet jelly and bean jelly products. The processing method of the invention can prevent secondary pollution in production and other links and effectively reduce manual operation, the production process is simple, the product quality is good, the product guarantee period can be 3 to 9 months prolonged compared with the prior products on the market, and the product can be directly eaten after being unpackaged, or eaten by being mixed with accessorial seasoning, which is convenient to be eaten.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

Normal-pressure low-temperature plasma preprocessing technique of textile for digital inking printing

InactiveCN101100808AImprove clarityImprove color vibrancyUltrasonic/sonic fibre treatmentDyeing processEngineeringPre treatment

The invention relates to fabric plasma surface modification processing technology used in dye ink digital inking printing. The fabric is processed inking printing by dye ink in the digital inking printing machine after processing by impulse normal pressure air low temperature plasma, then baking to form the finished product. Compared with the traditional preprocessing technology, the invention has the advantages of fast, convenient, saving water and energy, low cost, no social effects of pollution, suiting for industrialization continuous production etc.

Owner:JIANGNAN UNIV

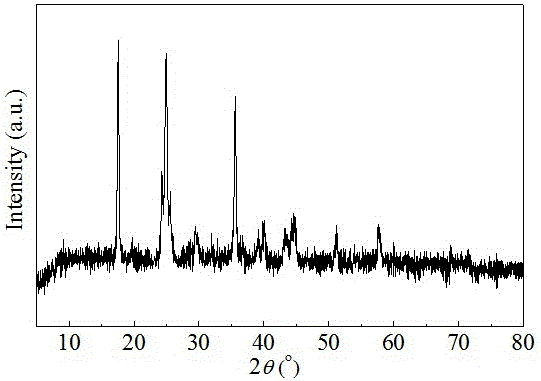

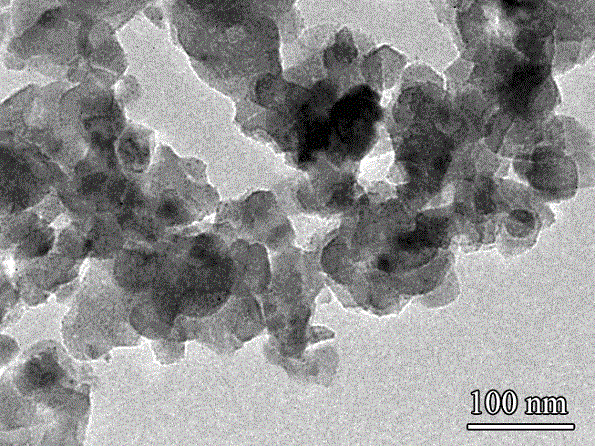

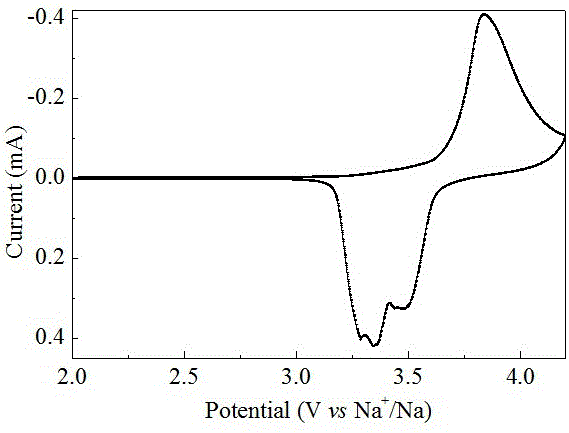

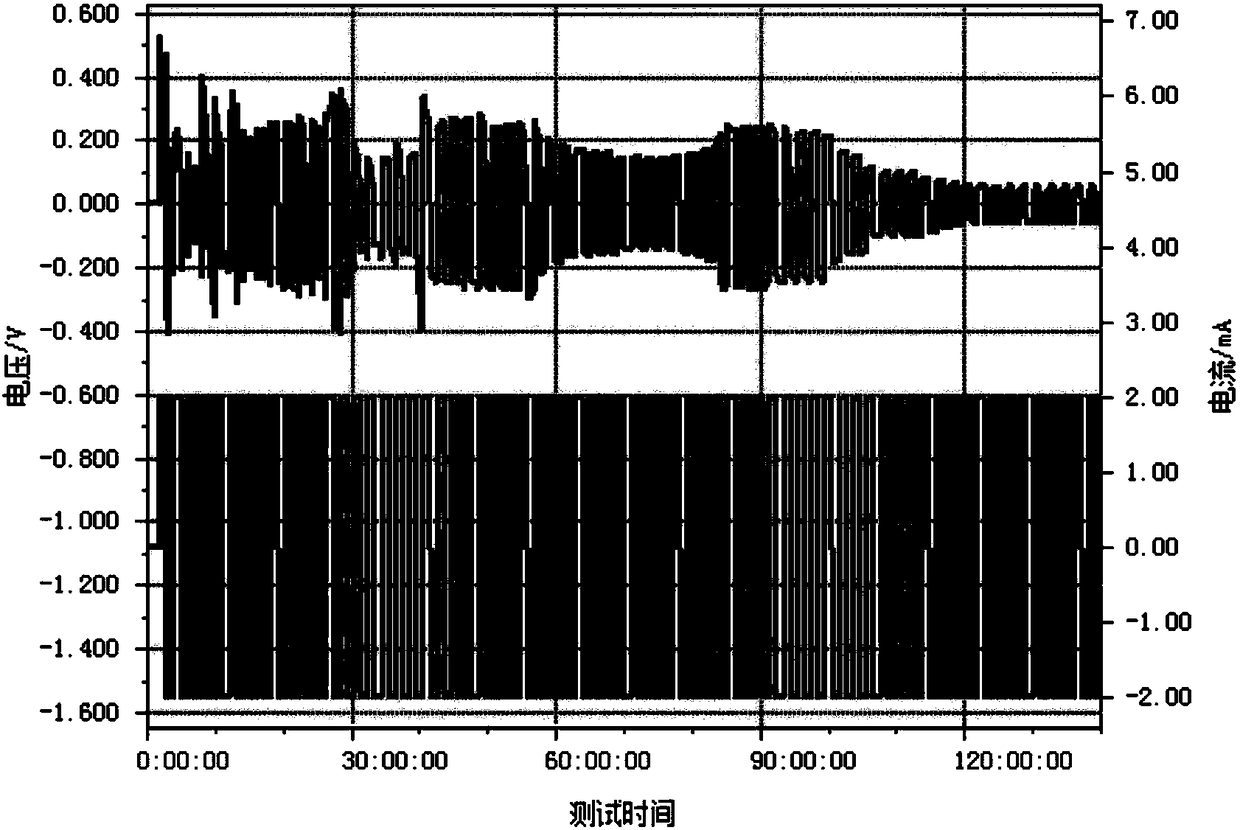

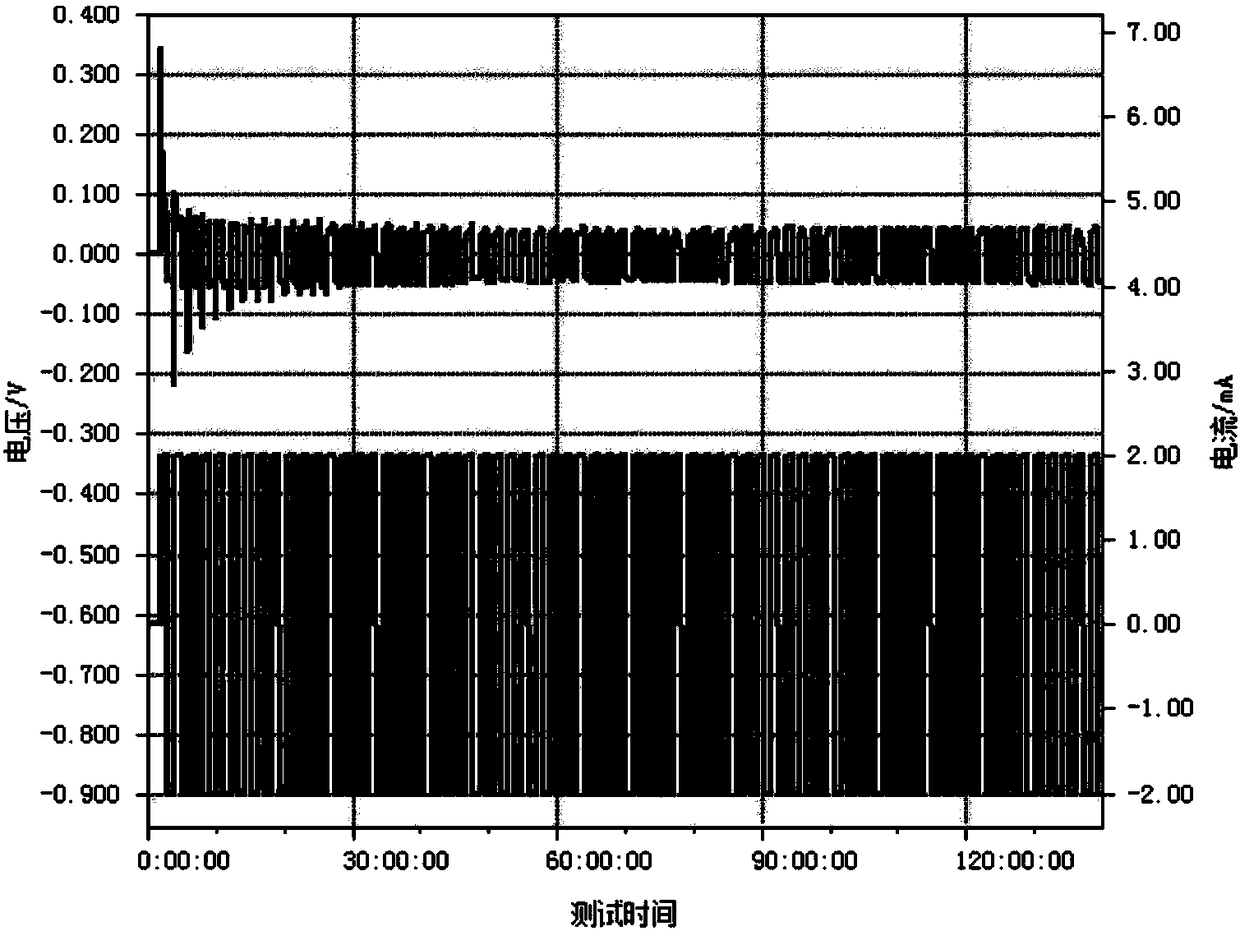

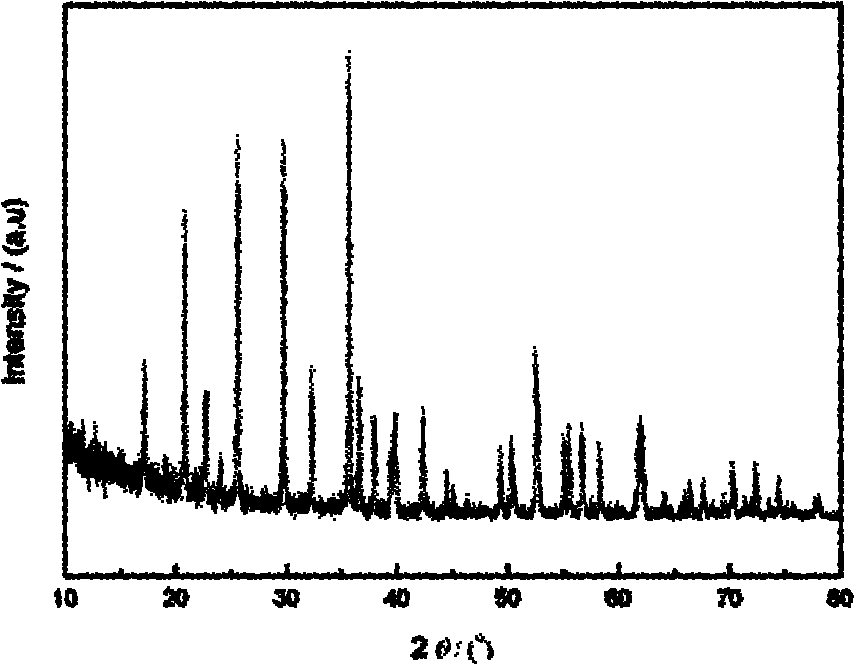

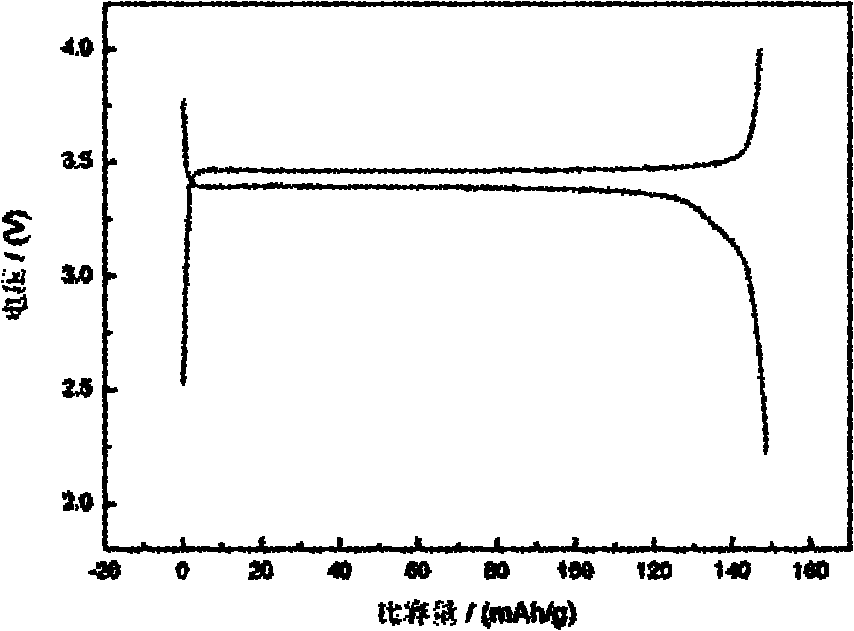

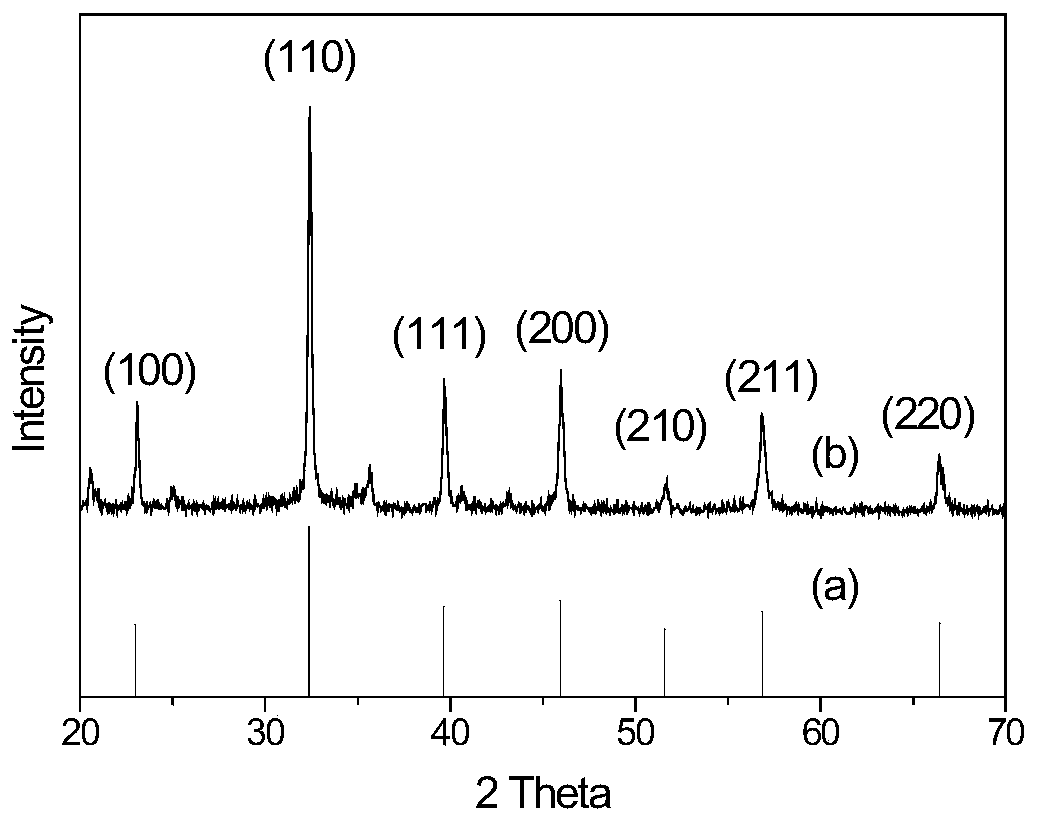

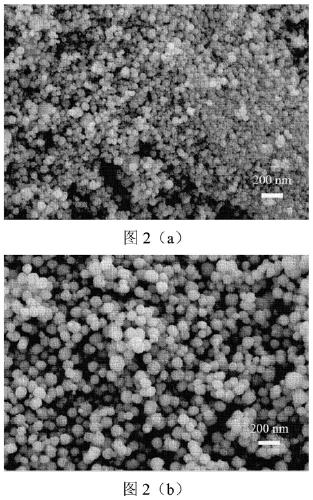

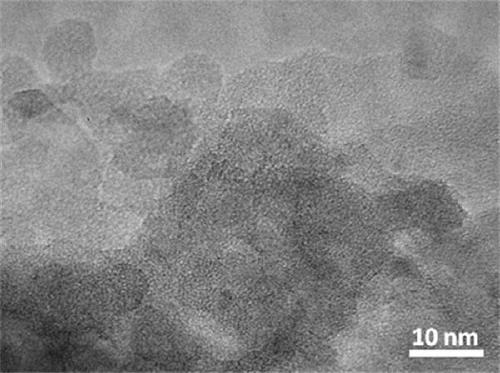

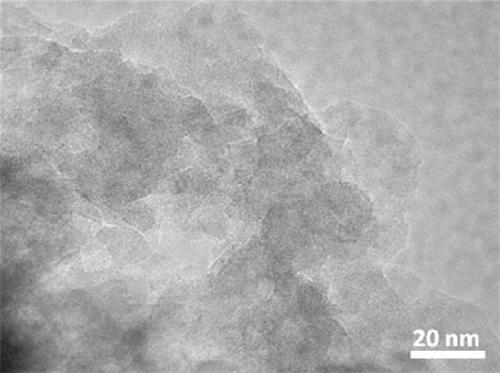

Potassium-sodium-manganese-iron-based Prussian-blue electrode material, and preparation method and application thereof

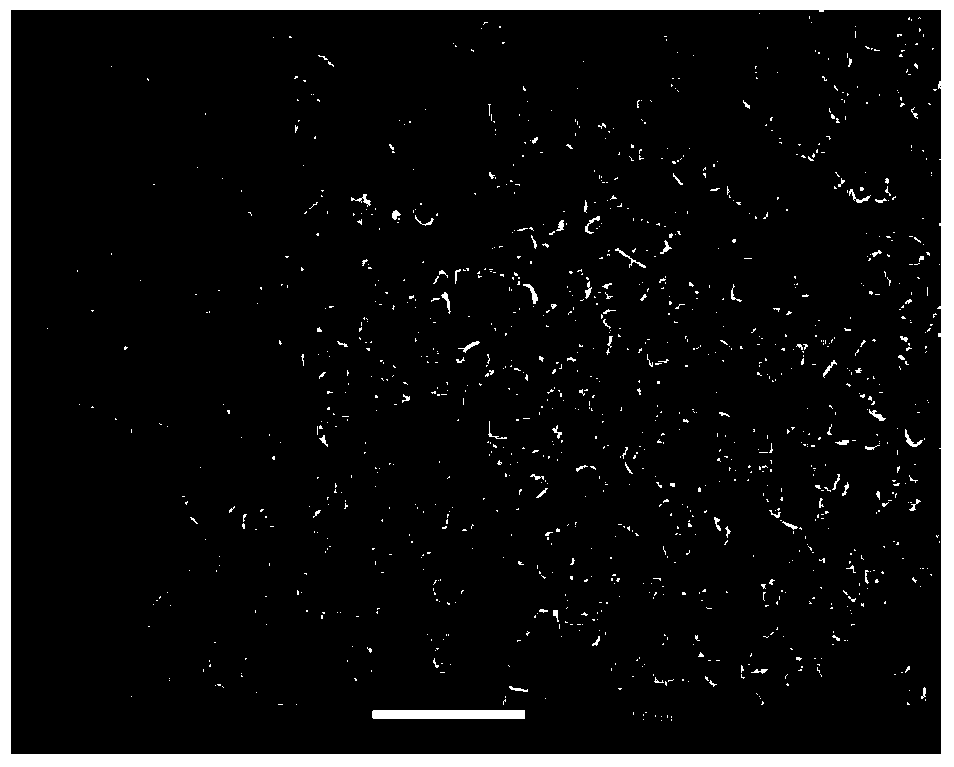

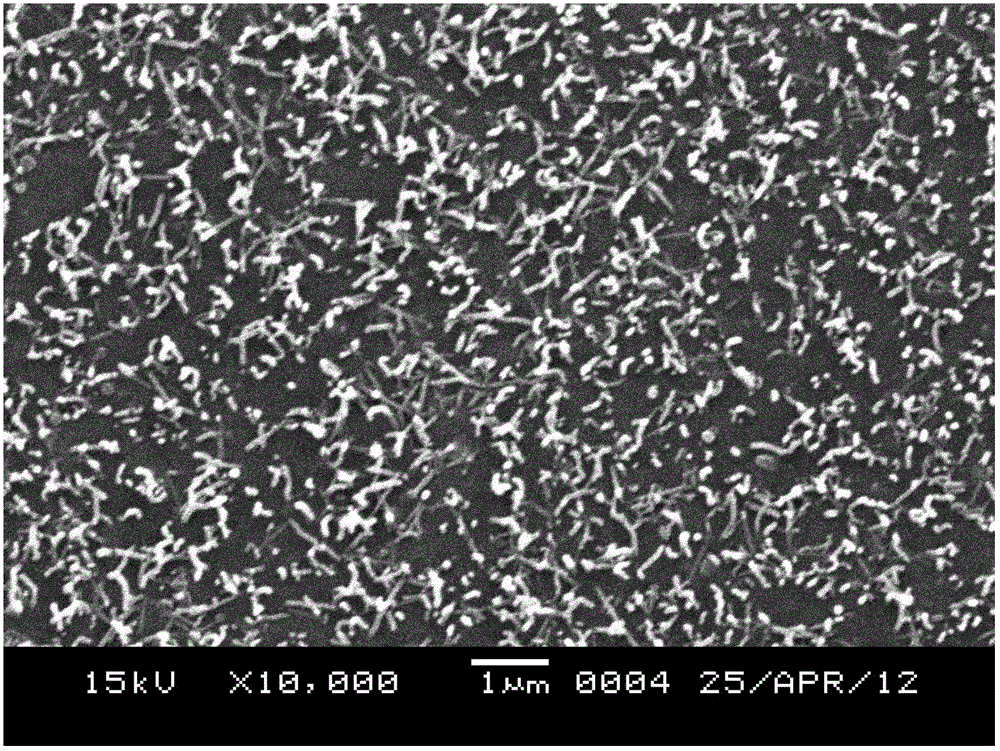

InactiveCN106549155AImproved magnification performanceImprove cycle stabilityMaterial nanotechnologyIron cyanidesNew energyManganese

The invention discloses a potassium-sodium-manganese-iron-based Prussian-blue electrode material, and a preparation method and application thereof, belonging to the technical field of synthesis of new-energy materials. According a technical scheme in the invention, the potassium-sodium-manganese-iron-based Prussian-blue electrode material has a general chemical formula of K<x>Na<y>MnFe(CN)<6>, wherein x and y are both more than 0 and less than 2; and the material has a cubic structure and a particle size of 10 to 200 nm. The invention also discloses the preparation method for the potassium-sodium-manganese-iron-based Prussian-blue electrode material and application of the material to the positive electrode of a sodium-ion battery. The potassium-sodium-manganese-iron-based Prussian-blue electrode material prepared in the invention has the cubic structure and a particle size of 10 to 200 nm; the nanometer three-dimensional structure of the material leads to increase in the specific surface area of the material and effective reduction in transfer distance of ions or electrons in the electrode material, so the rate performance and cycle stability of the electrode material are improved; and the electrode material has excellent electrochemical performance as a positive electrode material for the sodium-ion battery.

Owner:HENAN NORMAL UNIV

Honeycomb low temperature flue gas denitration catalyst and preparation method thereof

ActiveCN105964284AGood activity at low temperatureWide temperature windowPhysical/chemical process catalystsRare earthPollution

The invention relates to a honeycomb low temperature flue gas denitration catalyst and a preparation method thereof, and belongs to the field of atmosphere pollution control and environment catalysis materials. The catalyst adopts TiO2, V2O5, MoO3, WO3 and rare earth (La, Ce, Pr, Nd, Zr and Y) oxides as active components and P2O5 and SO3 as modification assistants, and is prepared through powder preparation, mixing and kneading steps. The catalyst has an excellent removal effect on NOx in low temperature flue gas, and the denitration efficiency at 170-180DEG C can reach 90% or above. The catalyst has high mechanical strength and anti-wear resistance, the vertical compressive strength is greater than 2.4MPa, and the hard end fly ash wear rate is smaller than 0.08% / Kg. The erosion, wearing and etching of fly ash to the catalyst are reduced, so the service life of the catalyst is prolonged. The catalyst has the advantages of simple and easily available production raw materials, simple and easily controllable preparation process, and easy realization of industrial production.

Owner:展宗城

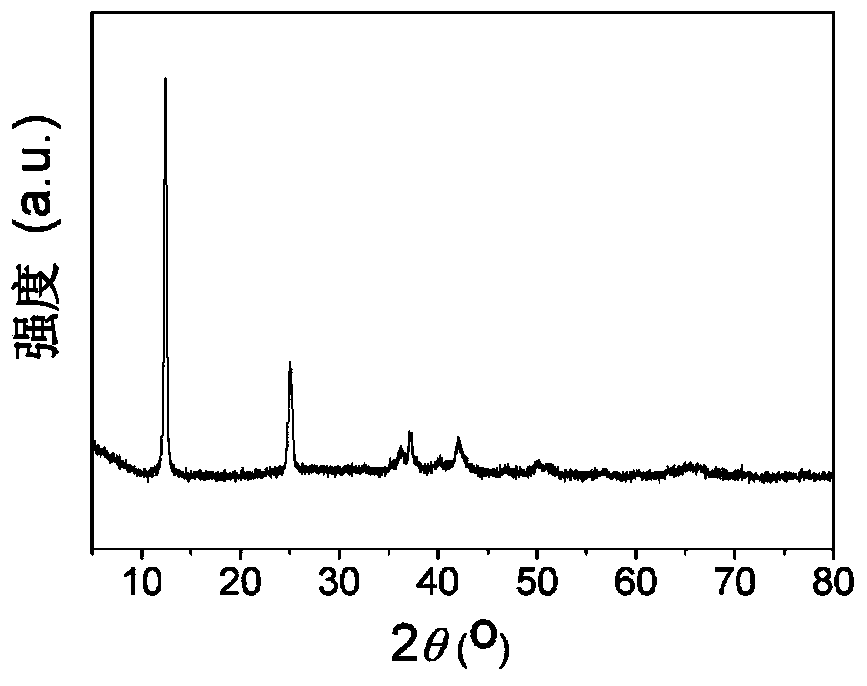

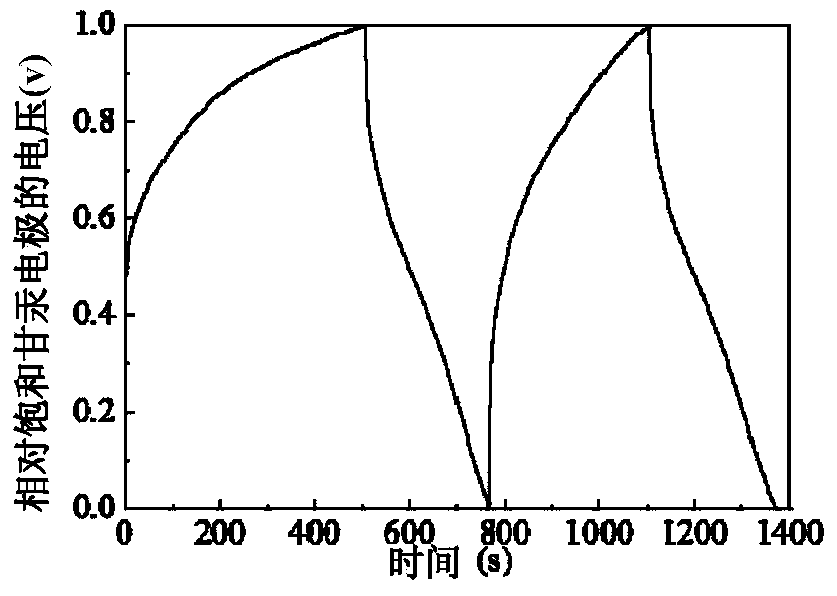

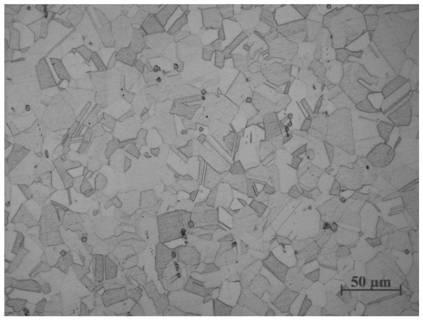

Anode material of high-magnification aqueous alkali metal electrochemical battery and preparation method of anode material

ActiveCN103441259APromote prolapseImprove electrochemical performanceAlkaline accumulatorsCell electrodesManganateCrystal structure

The invention relates to an anode material of a high-magnification aqueous alkali metal electrochemical battery and a preparation method of the anode material. The anode material is characterized is that the anode material is manganate with alkali metal of which the formula is AxMnO2, wherein A is one or two selected from Na and K; x is greater than 0 and less than 1; the crystal structure of the manganate with the alkali metal is of a layer-shaped structure. The anode material is of a nano-crystallized three-dimensional shape, the specific surface area of the material is increased, a conduction route for ions and electrons in an aqueous electrolyte is reduced, and the magnification property of an electrode material can be effectively improved.

Owner:ENPOWER ENERGY TECH ANHUI CO LTD +1

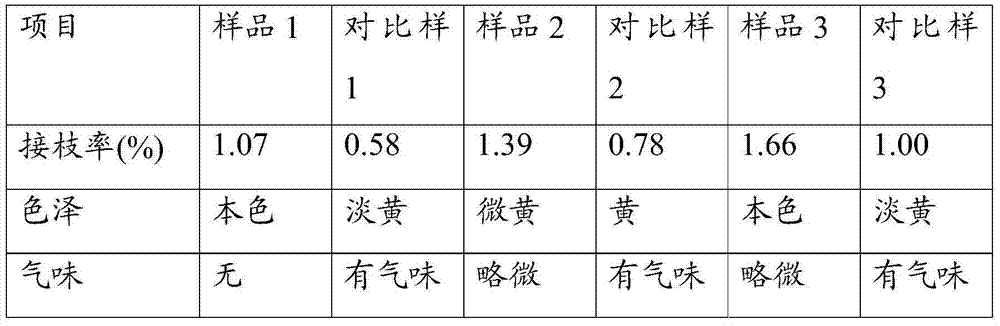

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Method for preparing ceramic with pore gradient

InactiveCN1830902AImprove performanceEasy to operateCeramicwareClaywaresTetramethylammonium hydroxidePorosity

A process for preparing the porosity-gradient ceramic includes such steps as adding deionized water to ceramic powder and disperser, ball grinding to obtain slurry A, adding deionized water to solidifying organic substance (starch or modified starch), ultrasonic dispersing or ball grinding to obtain slurry B, vacuum mixing, fast filling the mixture in mould, solidifying, drying and sintering. Said ceramic powder is chosen from alumina powder, SiC powder and Si3N4 powder. Said disperser is chosen from ammonium citrate and ammonium tetramethyl hydroxide.

Owner:TSINGHUA UNIV

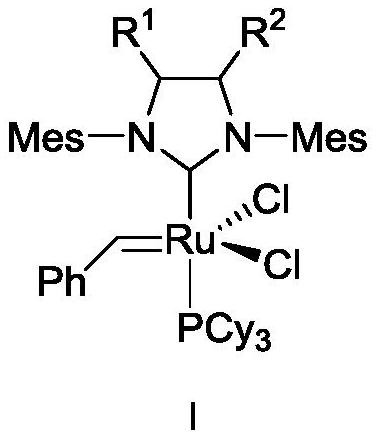

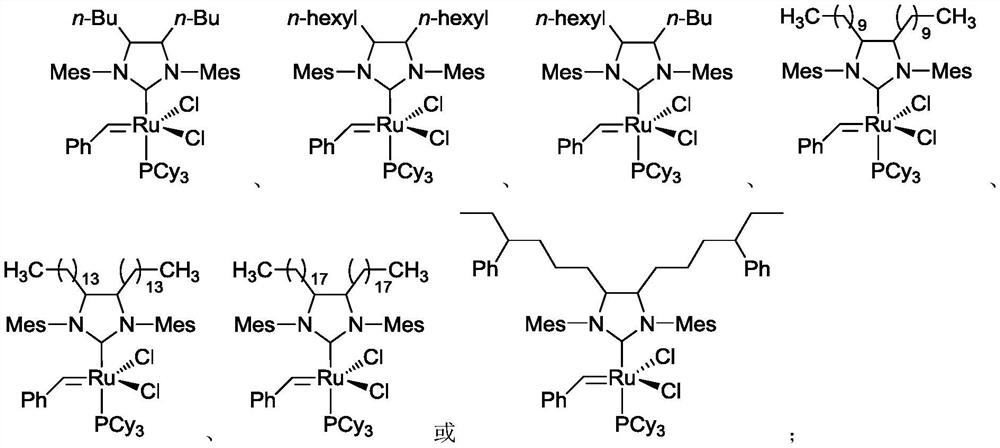

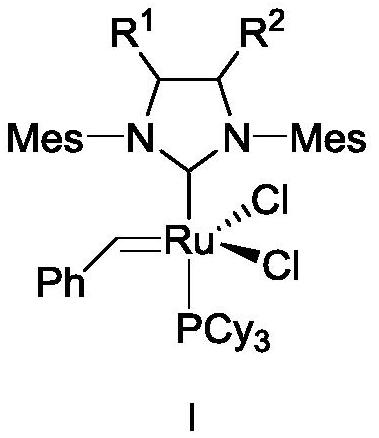

Resin composition, composite material and preparation method thereof

The invention discloses a resin composition, a composite material and a preparation method thereof. The invention particularly discloses a resin composition. The resin composition comprises a composition A and 100-500 parts of fiber reinforcements, wherein the composition A comprises 20-95 parts of dicyclopentadiene, 5-80 parts of epoxy resin, 30-70 parts of an epoxy resin curing agent, 0.1-3 parts of a curing accelerator and 0.1-4 parts of a catalyst composition; and the catalyst composition comprises a ruthenium carbene compound as shown in a formula I or a salt thereof, and chlorinated paraffin, wherein the chlorine content of the chlorinated paraffin is 5%-65%. The resin composition can be stored for a long time, the resin material prepared from the resin composition has good mechanical properties such as tensile strength, tensile modulus and elongation at break, and in addition, the preparation process of the resin material is suitable for industrial continuous production.

Owner:SHANGHAI ZHONGHUA TECH CO LTD

Photoelectrochemical cell

ActiveCN109187705AIncrease profitAchieve removalMaterial electrochemical variablesPhotocathodeEngineering

The invention provides a photoelectrochemical cell. The photoelectrochemical cell comprises a photocathode and a photoanode which are arranged in parallel on the space, and projections of the photocathode and the photoanode on a plane vertical direction located by the photocathode and the photoanode are free from overlapping; the photocathode and the photoanode of the photoelectrochemical cell provided by the invention can simultaneously and maximally receive the irradiation of the vertical sunlight; two poles of the photoelectrochemical cell designed through the structure can be prepared through a coating method, printing and like technology, the process is simple, each of two poles has a patterning function and is easy for industrial continuous production, and can simultaneously receivethe irradiation, is free from using a proton membrane and capable of being manufactured as a flexible device, and the utilization efficiency of the sunlight is relatively high. The photoelectrochemical cell provided by the invention can degrade organic pollutant at the photoanode and remove multiple heavy metal ions and perform hydrogen production reaction at the photocathode, the dual-aim of removing pollutant through the solar energy and removing the heavy metal ions and producing hydrogen through the solar energy can be realized, thereby solving the environment pollution and energy crisis problems.

Owner:THE UNIV OF NOTTINGHAM NINGBO CHINA

Zinc-boron-silicon system heat-resisting environmental-friendly emulsion opal glass and preparation method thereof

InactiveCN102910818ASmall expansion coefficientImprove heat resistanceGlass shaping apparatusGlass productionThermal dilatationAlkali metal oxide

The invention relates to zinc-boron-silicon heat-resisting environmental-friendly emulsion opal glass and a preparation method thereof. The glass is characterized by consisting of the following components in percentage by mass: 68-78% of SiO2, 0-4% of Al2O3, 10-15% of B2o3, 5-8% of ZnO, 0.5-3% of CaO, 0-2% of MgO, 2.5-4.5% of alkali metal oxide and 1-5% of P2O5. The preparation method comprises the steps of: preparing the components into a glass batch and melting; then moulding by casting; and annealing to obtain the emulsion opal glass. The method is environmental-friendly and free of pollution and the glass does not contain fluorine, has less erosion to the refractory matters and is molded in one step; and compared with the conventional emulsion opal glass, the prepared zinc-boron-silicon heat-resisting environmental-friendly emulsion opal glass is low in thermal expansion coefficient, stable in opacification, less in environment pollution, less in corrosivity of refractory matters, high in opacity, less in phosphorus volatilization and good in glossiness.

Owner:DONGHUA UNIV

Flexible electrochromism thin film preparation method

ActiveCN107167980ASimple preparation processReduce cost inputCoatingsNon-linear opticsSolid state electrolyteLithium compound

The invention provides a flexible electrochromism thin film preparation method. The flexible electrochromism thin film device includes at least two flexible transparent conductive layers, at least one electrochromism layer, and at least one high efficient solid electrolyte membrane; the solid electrolyte membrane is prepared from a PVB carrier, an inorganic lithium compound is dissolved in a polycarbonate solution as an electrolyte ion solution, an additive is added into the electrolyte ion solution according to a certain proportion, an organic solvent is used to dissolve the additive, an even sizing agent is formed through ball-milling, transparent even electrolyte layers are formed on surfaces of the transparent conductive layers through a silk-screen printing technology or a spraying method, a high efficient solid electrochromism device is acquired after vacuum seal, the adjustment voltage is 5-15 V under the action of a direct-current power supply, the high efficient solid electrochromism device changes from an achromatic color to a dark color, and the color changing efficiency is 5-30 seconds; and then a positive electrode and a negative electrode of the power supply are adjusted, the adjustment voltage is 5-10 V, and the high efficient solid electrochromism device becomes colorless again.

Owner:SHANGHAI DONGZHOU IND

Method for simultaneously extracting soybean oil and soybean milk powder by aqueous enzymatic method

InactiveCN105505556AWon't happenImprove qualityFatty-oils/fats refiningFatty-oils/fats productionAlkaline proteaseEnzymatic hydrolysis

The invention relates to a method for synchronously extracting soybean oil and soybean milk powder by an aqueous enzymatic method, which belongs to the technical field of plant grease processing. The method comprises the following steps: 1) dehulling soybeans and performing ultramicro grinding on the soybeans, extruding the soybeans and puffing the ground material to obtain a puffed product; 2) adding water into an enzymatic hydrolysis reaction vessel, heating steam and adding the puffed product to obtain mixed liquor, adjusting pH value of the mixed liquor, adding alkali protease for performing enzymatic hydrolysis, using a horizontal centrifuge after enzymatic hydrolysis is carried out for performing centrifugation to obtain emulsified oil, a hydrolysate and residues; and 3) using a disk centrifuge for performing centrifugation on the emulsified oil to obtain the soybean oil and a water phase, adding the water phase into the hydrolysate for concentration, and drying the material to obtain the soybean milk powder. The method has the advantages of simple process, short reaction time, less enzyme usage amount and low cost, and the prepared soybean oil has no solvent residues and has high quality. The soybean milk powder can be prepared when the soybean oil is prepared, the soybean milk powder can keep partial fat, and has advantages of rich bean fragrance, abundant nutrition, and good brewing property, and is suitable for continuous industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

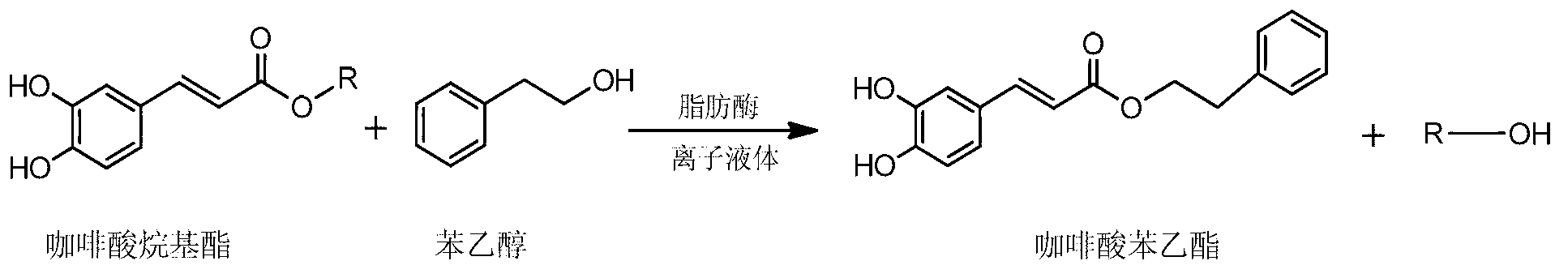

Biosynthesis method of caffeic acid phenethylester by means of transesterification

The invention discloses a biosynthesis method of caffeic acid phenethylester by means of transesterification. The caffeic acid phenethylester is prepared by reacting caffeic acid alkyl ester with phenylethyl alcohol in an ionic liquid by taking the ionic liquid as a reaction medium and lipase as a catalyst, the caffeic acid alkyl ester and the phenylethyl alcohol are added at a molar ratio of 1:(1-40), the lipase is added according to the molar ratio of the caffeic acid alkyl ester to the lipase of 1:(1-40), the ionic liquid is added according to the volume ratio of the phenylethyl alcohol to the ionic liquid of 1:(5-50), reaction temperature is 40-90 DEG C, oscillation rotation speed is 120-300 rpm (revolutions per minute), and reaction time is 10-72 hours. The transesterification method provided by the invention takes the ionic liquid as the reaction medium, is capable of increasing the solubility of a substrate with a product, improving the catalytic activity and reaction efficiency of an enzyme and shortening the reaction time, is simple in operation, mild in conditions, high in product yield, and environmentally-friendly, and has good application prospect.

Owner:JIANGSU UNIV OF SCI & TECH

Elastic and stretchable electrochromic device

The invention provides an elastic and stretchable electrochromic device. The device comprises at least two layers of elastic and transparent conductive film and at least one layer of elastic electrochromic film. The device is characterized that an all-solid-state and high-transparency elastic electrochromic film is formed by taking a high-molecular polymer as a carrier, and passing through a castfilm device under high temperature; an elastic and transparent conductive film is prepared on the surface of a release film by taking an acrylamide high-molecular polymer as a carrier and using a screen printing technology; and sequentially packaging a multilayer material by using a vacuum automatic laminator to obtain an elastic and stretchable electrochromic device; the color change efficiency is 5-15 seconds, the fading efficiency is 3-10 seconds, the transmittance is increased to 95%, the coloring efficiency reaches to 150cm2 / C, and the stretching deformation reaches to 400%. Flexible andstretchable electrochromic fibers are designed and producted, thereby solving the problem of elastic stretchable display and the key problem existing in the preparation of stretchable devices, the field of market application is greatly improved, and the elastic and transparent conductive film has a good application prospect in the fields of flexible batteries, energy storage, intelligent wearing,flexible display and the like.

Owner:SHANGHAI DONGZHOU IND

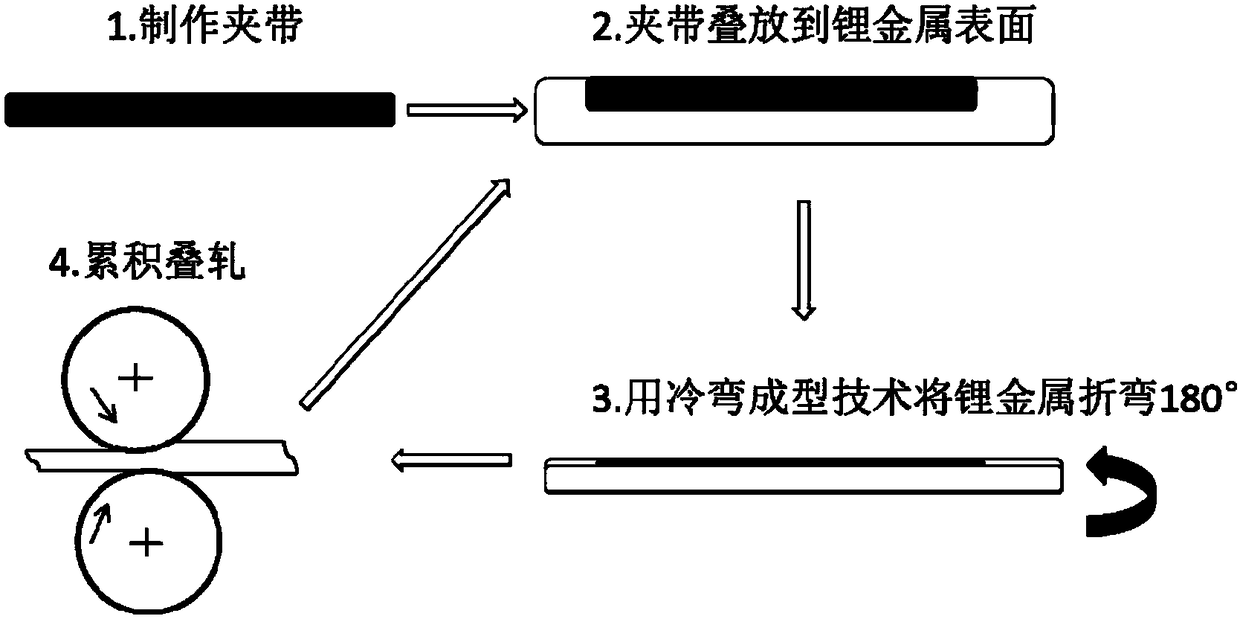

Preparation method of composite metal lithium negative electrode

InactiveCN108598358AEvenly distributedEnsure consistencyElectrode rolling/calenderingSecondary cellsPolymer adhesiveInorganic materials

The invention provides a preparation method of a composite metal lithium negative electrode. The preparation method comprises the steps of pasting an inorganic material with a polymer adhesive to forma layered clamping tape; laying the clamping tape on a surface of lithium metal, bending the lithium metal for 180 degrees in a width direction by a cold roll formation technology to form a lithium / clamping tape / lithium composite structure; and performing rolling, pressing with deformation quantity by 20-50% to obtain a composite material rolled in one time, and repeating the step for 3-20 timesto obtain the composite metal lithium negative electrode material with a multi-layer structure. By the method, the lithium deposition morphology is improved, lithium dendrites growth is suppressed, sothat the cycle property and the safety of the battery are improved, and industrial and continuous production of the composite metal lithium negative electrode can be achieved.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

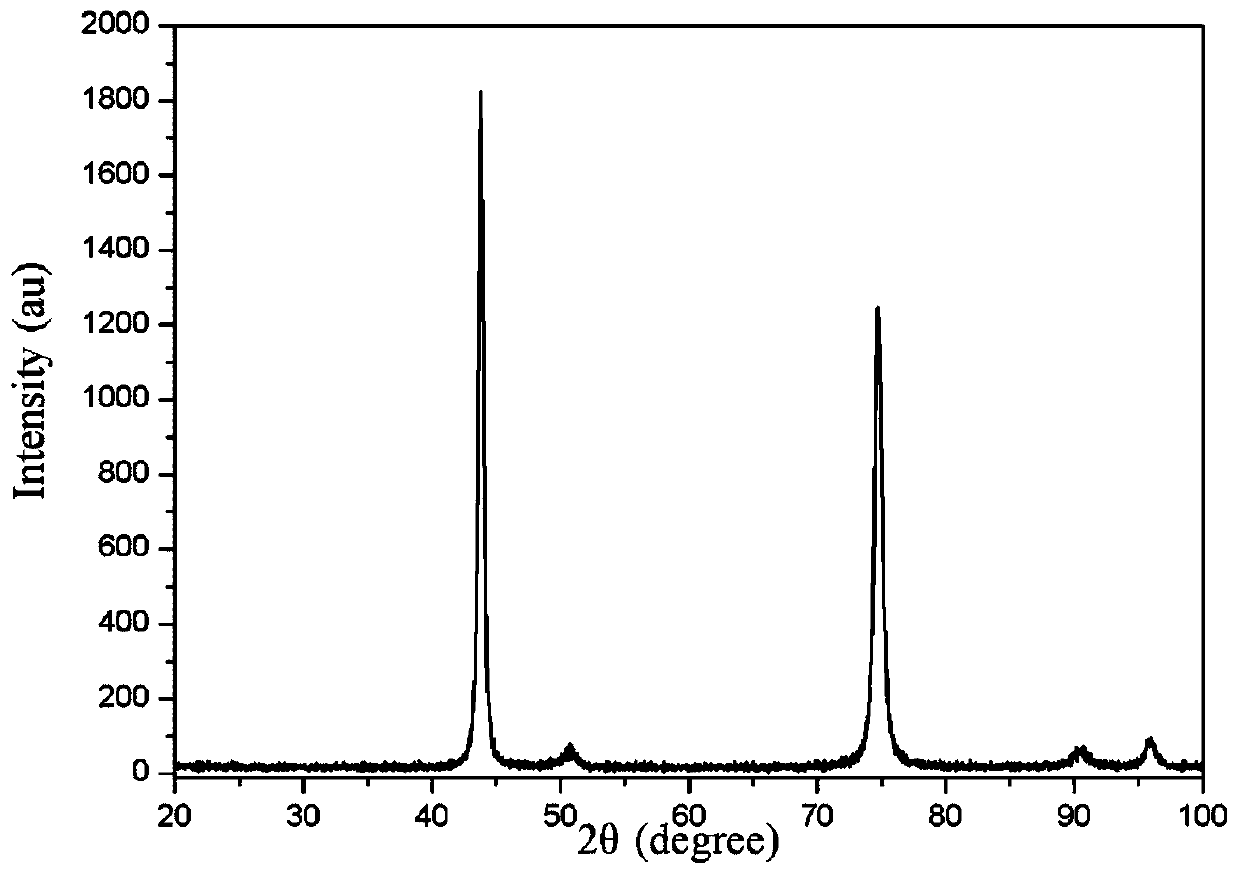

Nickel-based alloy ultra-thin plate

ActiveCN111411265AAchieve ultra-fine crystallizationImprove mechanical propertiesChemical compositionIndustrial equipment

The invention discloses a nickel-based alloy ultra-thin plate and a preparation method thereof. According to the percentage composition of the chemical components of alloy, the nickel-based alloy ultra-thin plate comprises 20%-30% of Fe, 20%-25% of Cr, 1.3%-1.9% of Al, 1.2%-1.6% of Ti, 0.5%-0.7% of Nb, 0.8%-1.0% of W, 0.5%-1.0% of V, 0.5%-0.7% of Mn, 0.2% of Mo, 0-0.02% of Zr, 0-0.15% of Si, 0-0.03% of C, 0.005%-0.04% of N, 0-0.004% of B, and the balance Ni and other inevitable impurities. The preparation method includes the steps of alloy smelting and casting, homogenization treatment, cogging, hot rolling, strong deformation cold rolling, finish rolling, recrystallization heat treatment and the like. By adoption of the mode of combining strong deformation rolling with heat treatment structure regulation and control, superfine crystallization and nano precipitated phase reinforcement of the alloy structure are realized, and the nickel-based alloy ultra-thin plate prepared through thepreparation mode has super strength and good ductility and toughness. Compared with the prior art, the nickel-based alloy ultra-thin plate prepared through the preparation method in the invention is simple in alloy composition, high in performance of ratio and long in service life, the preparation method and production technology are simple, industrialization scale production can be achieved withcommon industrial equipment, production efficiency is high and industrial application prospects are broad.

Owner:SHANGHAI JIAO TONG UNIV +1

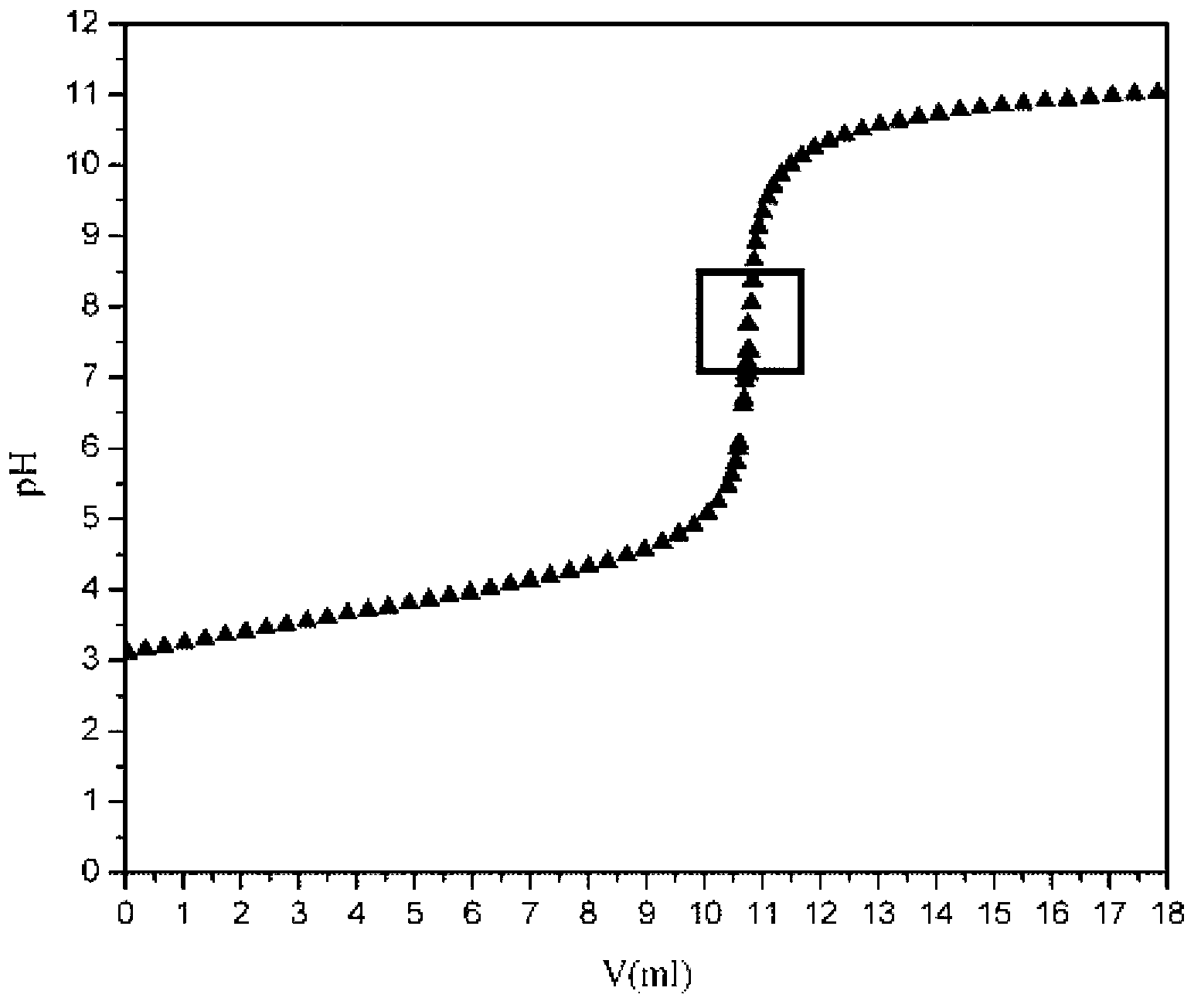

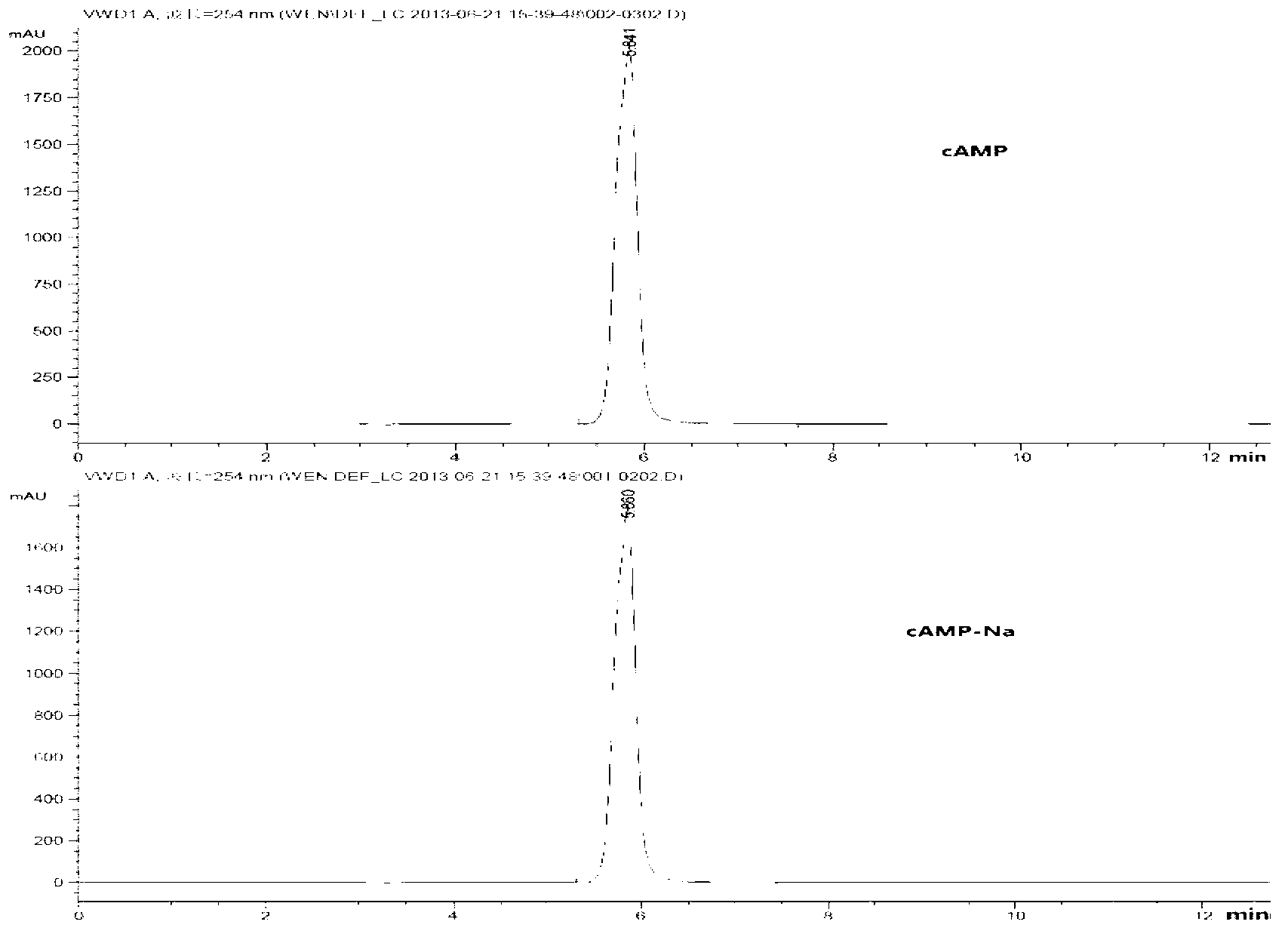

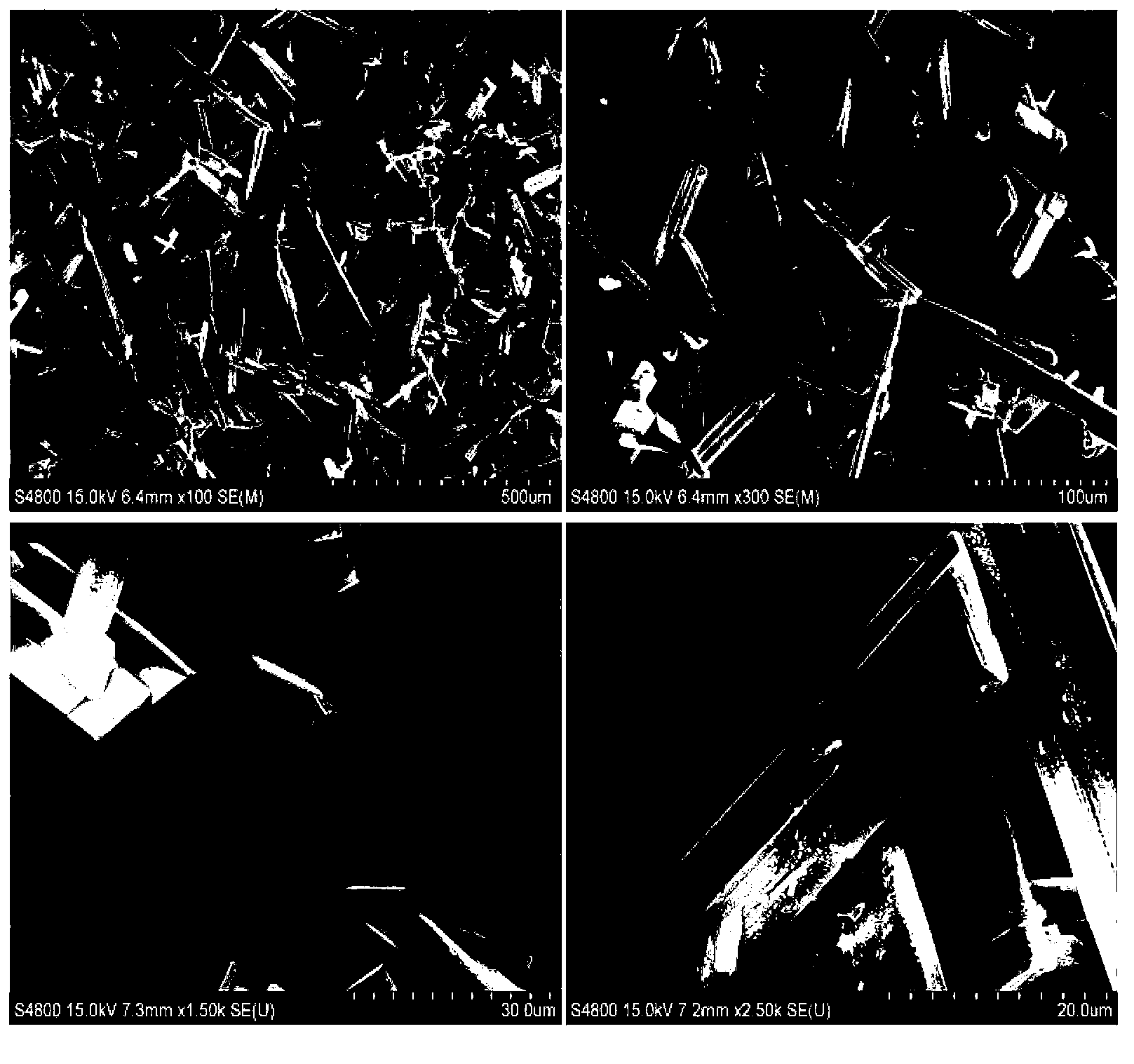

Crystallization method of cyclic adenosine monophosphate

InactiveCN103319557AHigh yieldUniform particle sizeSugar derivativesSugar derivatives preparationFiltrationSodium phosphates

The invention discloses a crystallization method of cyclic adenosine monophosphate. The crystallization method comprises the following steps: adding an organic solvent used as an anti-solvent into 10-400g / L of a cyclic adenosine sodium phosphate aqueous solution at pH of 7.0-9.0 under the condition of stirring, carrying out pumping filtration after crystallization is completely finished, washing crystals by the use of ethanol, and carrying out vacuum drying to obtain cyclic adenosine sodium phosphate crystals; dissolving the above cyclic adenosine sodium phosphate crystals in water to obtain a saturated solution of the cyclic adenosine sodium phosphate crystals, adjusting pH of the solution to 4.0-5.5 by the use of acid while stirring, carrying out crystal growing for 0.5-8h, adjusting pH to 1.0-2.5, carrying out pumping filtration after crystallization is completely finished, washing crystals by the use of ethanol, and carrying out vacuum drying to obtain cyclic adenosine monophosphate crystals. By the adoption of the method provided by the invention, quality of the final product is obviously improved, yield of the crystal product is stably raised, and granular size of the crystals can be controlled by changing crystallization stirring speed or temperature. The method provided by the invention is simple to operate, has good repeatability, and is suitable for industrial production of cyclic adenosine sodium phosphate.

Owner:NANJING UNIV OF TECH

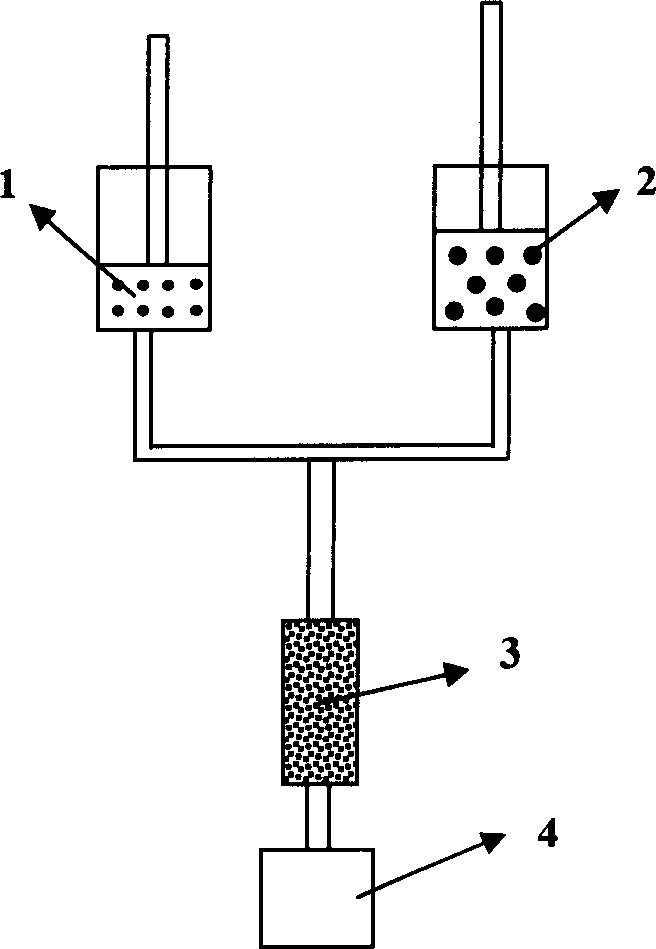

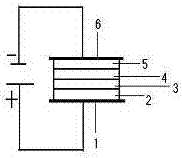

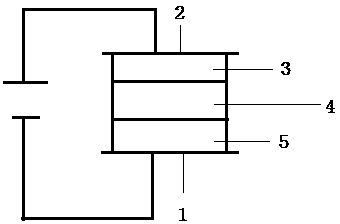

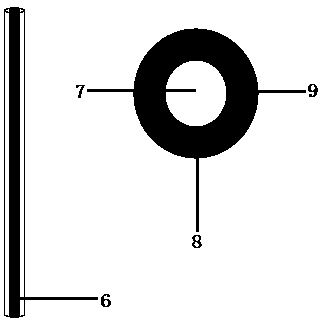

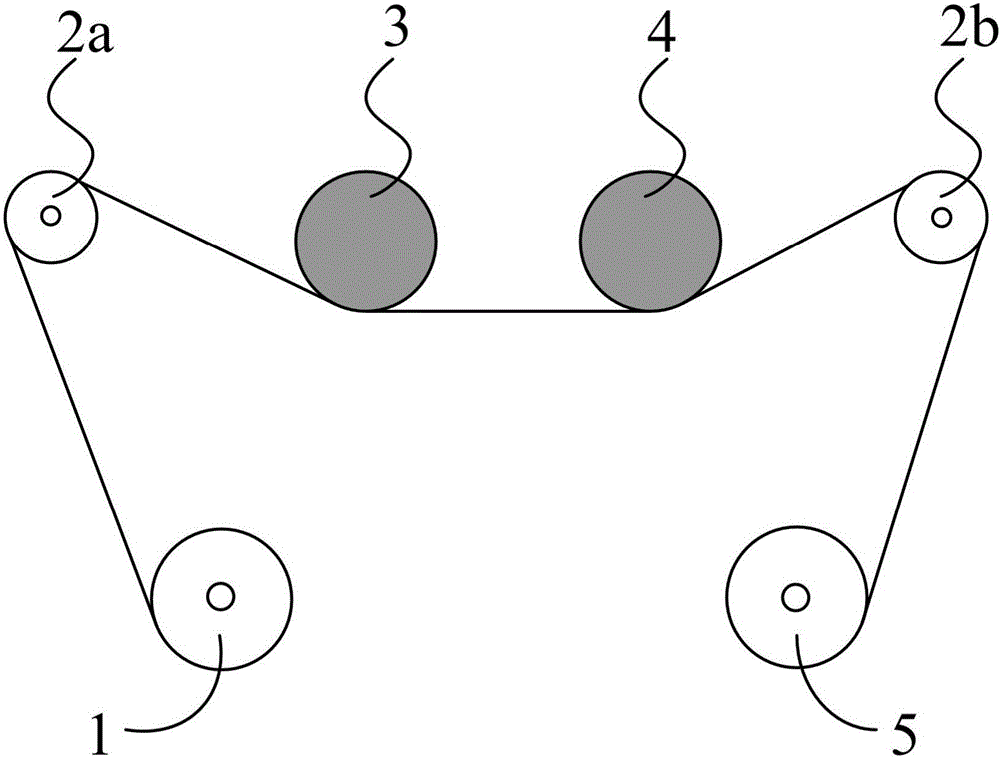

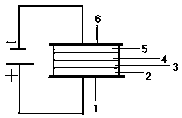

Device and method for continuously producing high-adhesive-force aluminized film

ActiveCN106521427ASimple processDoes not involve multiple stepsVacuum evaporation coatingSputtering coatingEngineeringSputter deposition

The invention discloses a device and method for continuously producing a high-adhesive-force aluminized film, and belongs to the technical field of flexible packaging base material films. The device is composed of an unwinding roller (1), a tension roller (2), a sputtering chamber (3), a film coating chamber (4), a winding roller (5), auxiliary water way, circuit and gas way systems and an auxiliary vacuum system. The method comprises the steps that uniform-speed film coating is carried out on a flexible base material under the drive of the unwinding roller (1) and the winding roller (5), the flexible base material is provided with a buffer layer in a sputtered and deposited mode when passing through the sputtering chamber (3), and the flexible base material with the buffer layer deposited is subjected to aluminum film deposition when passing through the film coating chamber (4). According to the device and the method, continuous operation can be achieved, the buffer layer sputtering process and the aluminizing process are completed in the same system, the flexible base material does not need to be taken out in the operation process, industrial continuous production is promoted, and the production efficiency can be greatly improved.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

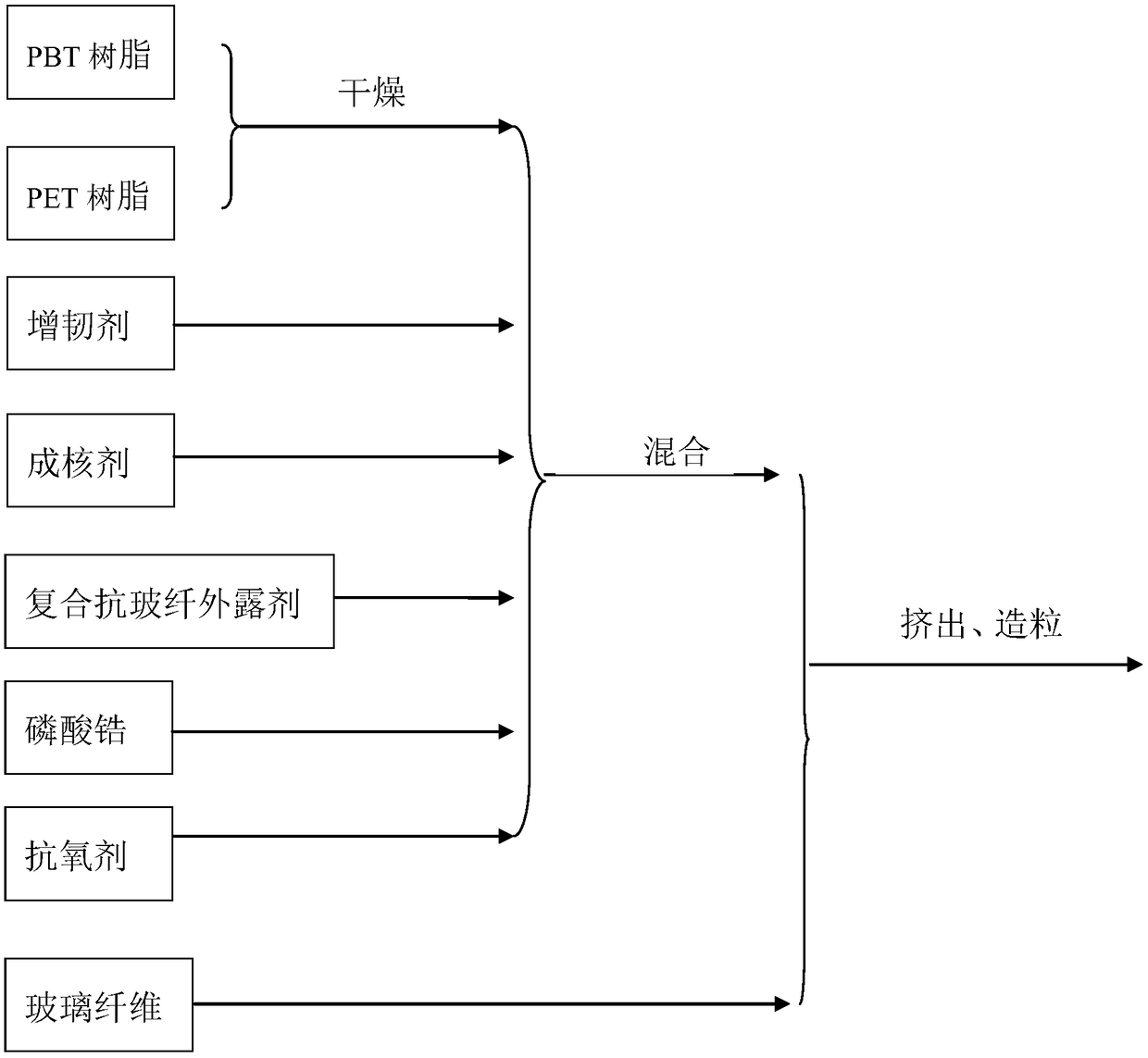

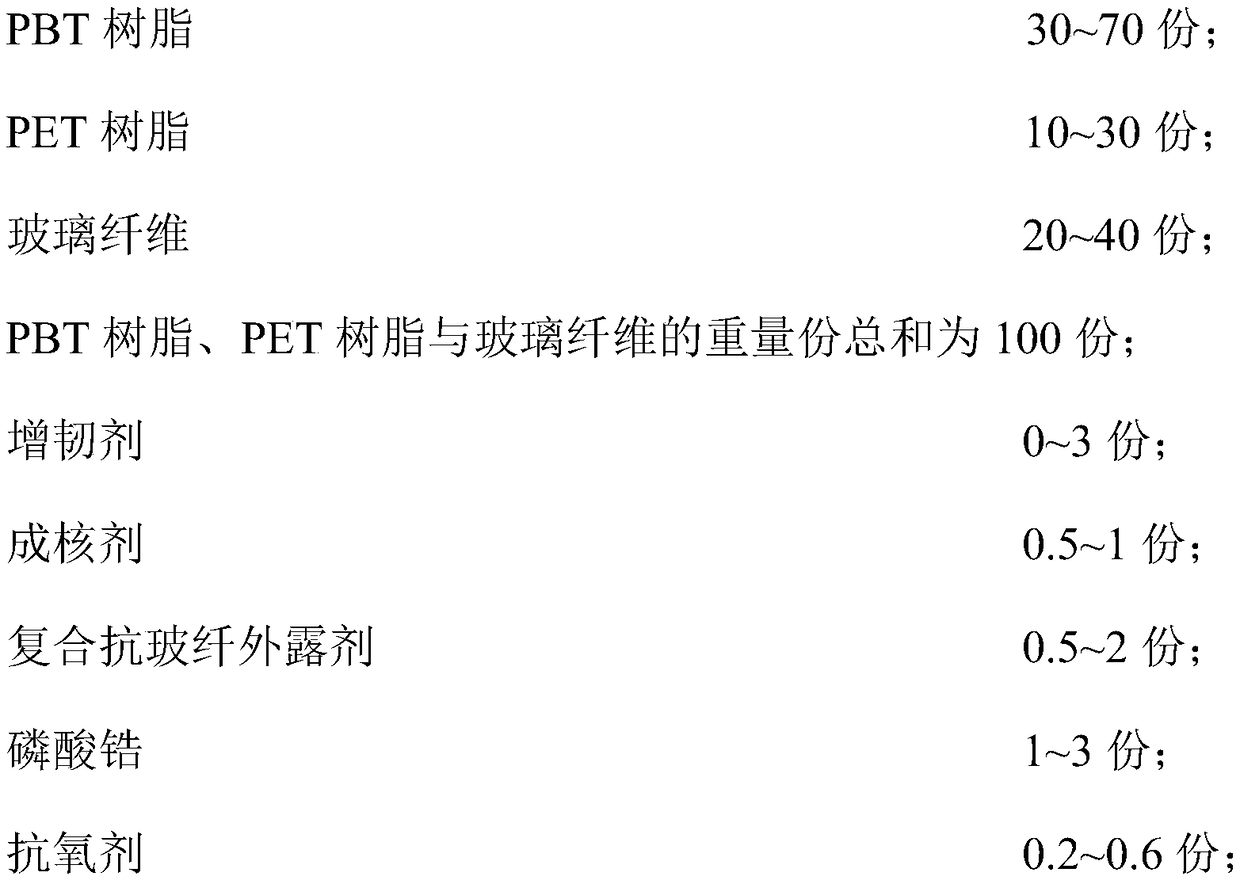

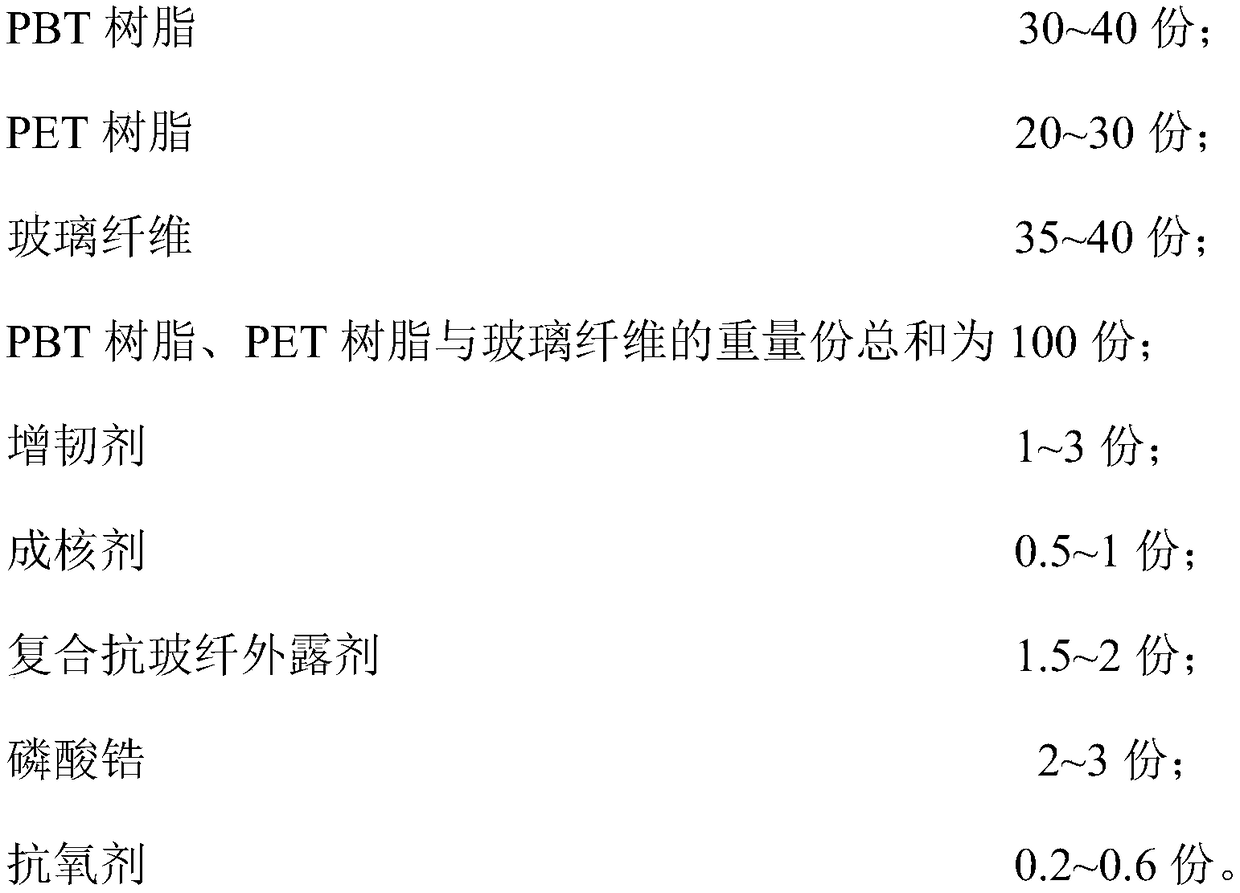

PBT/PET alloy material and preparation method thereof

The invention relates to a PBT / PET alloy material and a preparation method thereof. The PBT / PET alloy material is prepared from the following raw materials in parts by weight: 30-70 parts of PBT resin, 10-30 parts of PET resin, 20-40 parts of glass fibers, 1-3 parts of a flexibilizer, 0.5-1 part of a nucleating agent, 0.5-2 parts of a compound glass fiber exposure agent, 1-3 parts of zirconium phosphate and 0.2-0.6 part of an antioxidant, wherein the compound glass fiber exposure agent is prepared by mixing a fatty acid amide lubricant, an organosiloxane lubricant and an olefin wax lubricant in a mass ratio of (2-5): (2-5). The PBT resin is low viscosity resin, the characteristic viscosity of which is 0.65-0.85 dL / g. The PET resin is low viscosity resin, the characteristic viscosity of which is 0.50-0.80 dL / g. The alloy material is high in content of glass fibers and has excellent mechanical property, heat resistance and appearance.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Manufacturing of high-transmittance flexible electrochromic film

InactiveCN108931873ASimple preparation processReduce cost inputNon-linear opticsSolid state electrolyteSlurry

Provided is manufacturing of a high-transmittance flexible electrochromic film. A structure comprises at least a layer of flexible transparent conductive film, at least a layer of flexible electrochromic layer conducting film, at least a layer of flexible solid electrolyte film. The manufacturing is characterized in that the flexible solid electrolyte film uses a high-molecular polymer as a carrier, an inorganic lithium compound is dissolved in a polycarbonate solution and the solution is used as an electrolyte ionic solution, and an assistant is added in certain proportion, and the assistantis dissolved by an organic solvent, an evenly dissolved electrolyte slurry forms an all-solid-state high-transparent electrolyte film through a cast film machine in high temperature, then a vacuum automatic laminating machine is used to package multilayer materials in sequence, to obtain the high-transmittance electrochromic film. A problem of large-area display is solved, and a key problem of manufacturing of a flexible electrochromic device is also solved, and a problem of electrochromic glass is overcome, and industrialized production efficiency is greatly improved. In addition, the flexible electrolyte film has good application prospect in fields of flexible battery, energy storage, intelligent wearing, and flexible display.

Owner:SHANGHAI DONGZHOU IND

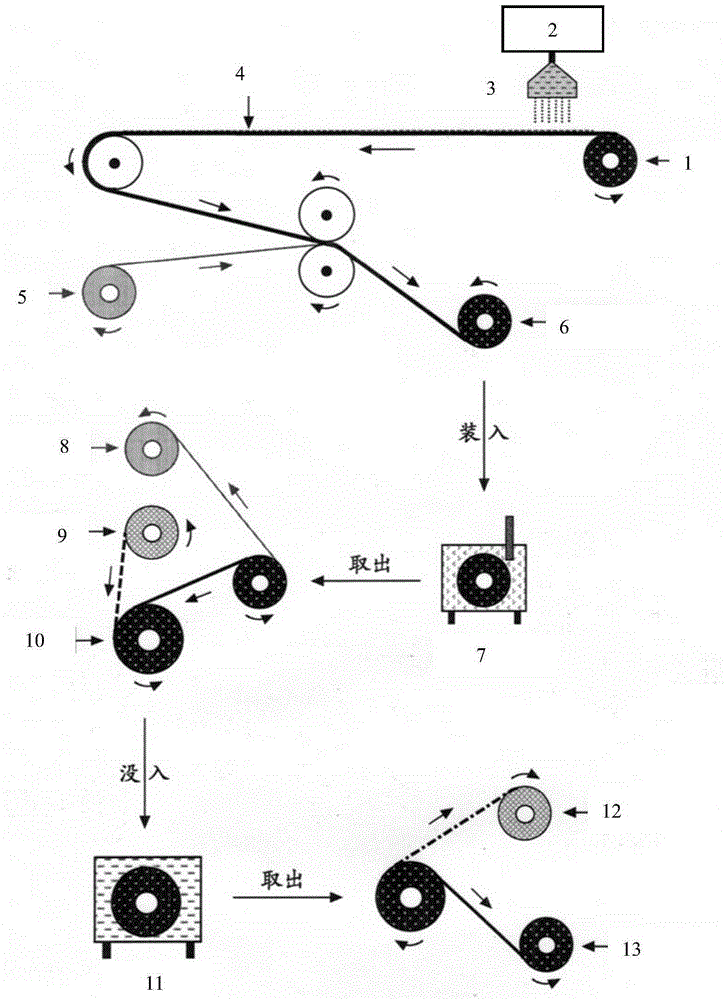

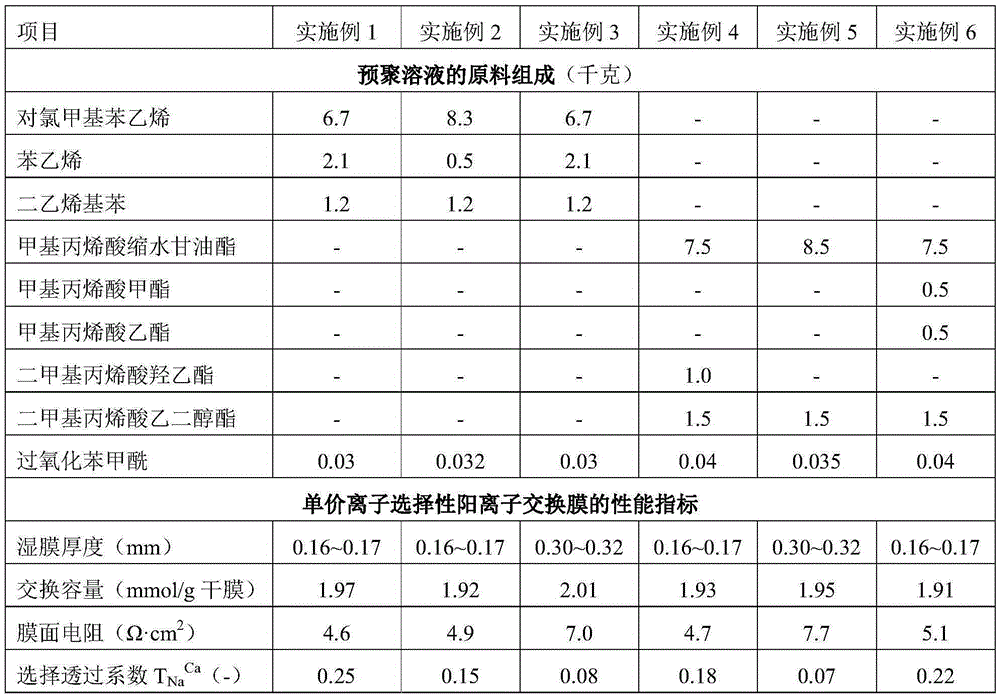

A method of manufacturing a monovalent ion selective cation exchange membrane

A method of manufacturing a monovalent ion selective cation exchange membrane is disclosed. The method includes a step 1) of unwinding a polystyrene-polyethylene series cation exchange membrane dry roll at a constant temperature, spraying one surface of the roll with a pre-polymerization liquid containing a functional monomer, a crosslinking agent and an initiator, laminating the roll with polyester protective membranes at intervals, tightly compressing, and then rolling to obtain a coated cation membrane roll one surface of which is coated with the pre-polymerization liquid; a step 2) of heating the coated cation membrane roll in the step 1) in a constant-temperature oven, initiating polymerization, taking the coated cation membrane roll out, peeling the polyester protective membranes off, and rolling with a polypropylene separating screen in a loose and interval manner to obtain a screen-separated cation membrane roll; and a step 3) of submerging the screen-separated cation membrane roll in the step 2) into an aqueous solution of trimethylamine to perform a quaternization reaction, washing a product, then peeling the polypropylene separating screen off, and separately rolling a wet membrane, and then the monovalent ion selective cation exchange membrane is obtained.

Owner:QUZHOU LANRAN NEW MATERIAL CO LTD

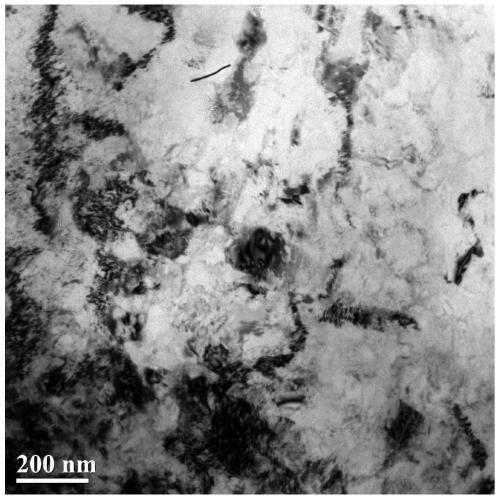

Method for preparing carbon clad lithium iron phosphate

InactiveCN102013478AImprove electrochemical performanceWell mixedCell electrodesUltrasonic radiationNew energy

The invention discloses a method for preparing carbon clad lithium iron phosphate, belongs to the technical field of new energy materials, and aims to provide a preparation method in which preliminary materials are mixed uniformly, precursor crystal particles are small, and carbon clad lithium iron phosphate with high electrochemical performance can easily obtained in the late stage of sintering. The technical key point is that the method comprises the following steps of: preparing a lithium source, ferrite, phosphate and a carbon source according to a stoichiometric ratio of 1:1:1-1.5:0.05-0.1, throwing into solution and mixing, and directly putting in ultrasonic radiation equipment for performing ultrasonic radiation treatment; and centrifugally washing and treating LiFePO4 precursors obtained by filtration, and roasting at the temperature between 300 and 1,000 DEG C for 6 to 24 hours at a nitrogen protective atmosphere so as to prepare the carbon clad lithium iron phosphate. The method has low cost, and a simple technical route and industrial continuous production can be easily realized.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

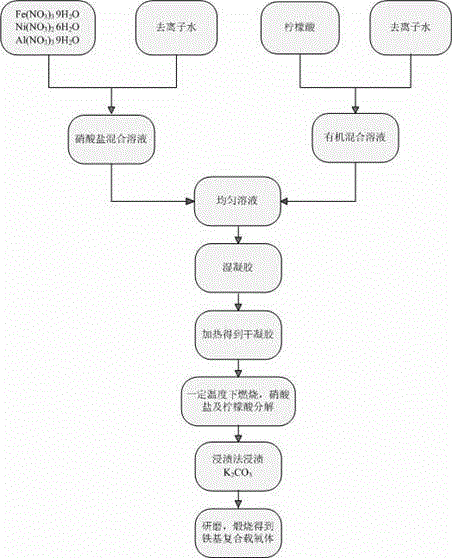

Iron-based compound oxygen carrier and preparation method thereof

InactiveCN104694206AHigh porosityHigh removal ratePhysical/chemical process catalystsFuel additivesDispersityPorosity

The invention provides an iron-based compound oxygen carrier applicable to biomass chemical looping hydrogen production and inhibition to tar generation, and a preparation method of the oxygen carrier. The iron-based compound oxygen carrier comprises the following chemical components in parts by mass: 60-70 parts of Fe2O3, 25-30 parts of Al2O3, 5-10 parts of NiO, 0-10 parts of K2CO3; the iron-based compound oxygen carrier is prepared by a collosol-gel method. The iron-based compound oxygen carrier prepared by the preparation method is good in porosity and dispersity, high in activity, and uniform in particle size; Ni and K in the oxygen carrier have better catalytic action on cracking of tar in the gasification process; and the oxygen carrier is applicable to a combined collaborative technology of the biomass chemical looping hydrogen production and the inhibition to the tar generation, and has the characteristics of high gasification efficiency, effectiveness in tar removal, and the like.

Owner:CHONGQING UNIV

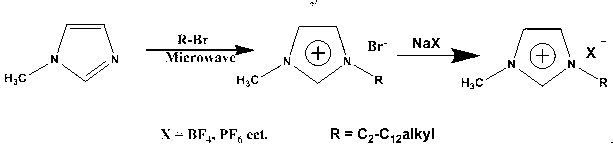

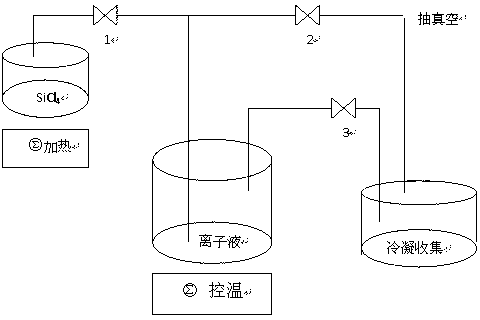

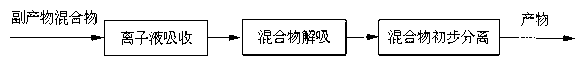

Method for recovering byproduct silicon tetrachloride produced in process of producing polycrystalline silicon

InactiveCN102807221AEliminate hazardsEasy and efficient recyclingEnergy inputHalogenated silanesPhysical chemistrySilicon tetrachloride

The invention provides a method for recovering a byproduct silicon tetrachloride produced in the process of producing polycrystalline silicon. Ionic liquid is recycled, so that SiCl4 is conveniently and efficiently recovered, the recovery rate is over 97 percent, hazards caused by the byproduct silicon tetrachloride produced in the process of producing the polycrystalline silicon are eliminated, and the silicon tetrachloride is recycled; a series of 1-alkyl-3-methylimidazole ionic liquid is synthesized under the condition of microwave radiation, and the imidazole ionic liquid with stable property is taken as an absorbent to absorb the SiCl4 by using the characteristic that the ionic liquid adsorbs gas; and after the ionic liquid is subjected to adsorption saturation, SiCl4 gas is released from the ionic liquid by heating and vacuumizing, so that the aim of recovering the SiCl4 is fulfilled.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Method for preparing catalyst-supported composite nano-fiber non-woven fabric

InactiveCN107815791AThe load is suitable forHigh load rateFilament/thread formingNon-woven fabricsNonwoven fabricUltrasonic dispersion

The invention relates to a method for preparing a catalyst-supported composite nano-fiber non-woven fabric. The method comprises the following steps: adding a solvent into a PMIA (Polyisophthaloyl Metaphenylene Diamine) solution for diluting, and removing bubbles to obtain a PMIA spinning solution; adding a micro / nano level denitration catalyst into a volatile solvent, and performing ultrasonic dispersion to obtain catalyst particle dispersion; injecting the PMIA spinning solution into a jet spinning device, injecting the catalyst particle dispersion into a spraying device, synchronously performing jet spinning on the PMIA spinning solution and spraying on the catalyst particle dispersion, and performing vacuum drying, thereby obtaining the product. The method disclosed by the invention issimple in process procedures and favorable for continuous industrial production. According to the method disclosed by the invention, catalyst particles are firmly sealed inside the nano-fiber non-woven fabric and can be used for a long time; and moreover, the composite nano-fiber non-woven fabric has high breathability, the utilization rate of the catalyst is greatly improved, and high precisionfiltration and synchronous denitration of coal-fired flue gas can be realized.

Owner:DONGHUA UNIV

Method for preparing nano-spherical barium titanate through micro-channel continuous process

InactiveCN110040770AShort reaction cycleImprove reaction efficiencyAlkaline earth titanatesNanotechnologyBarium titanateContinuous production

The invention relates to a method for preparing nanoscale spherical barium titanate by a micro-channel continuous method. The method comprises the following steps: (1) preparing a Ba solution, a Ti solution and alkali liquor; (2) pumping the mixed solution of the Ba solution and the Ti solution and alkali liquor into a T-shaped or Y-shaped mixer, and performing a reaction at a given temperature, wherein the mixer is provided with micro pipelines with the inner diameter of 0.5-1 mm. According to the method, the shape and the particle size of the spherical BaTiO3 powder can be improved for laying good foundation for industrial continuous production.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

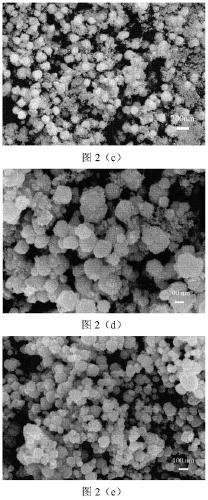

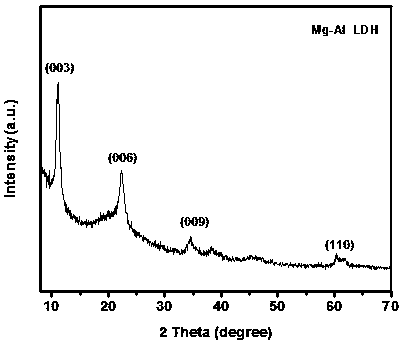

Method used for preparing layered double metal hydroxides through mechanical ball milling

InactiveCN109179338AGood stabilityHigh purityOxygen/ozone/oxide/hydroxideNanotechnologyDivalent metalAmmonium hydroxide

The invention discloses a method used for preparing layered double metal hydroxides through mechanical ball milling, and belongs to the technical field of nanometer functional material synthesis. Themethod comprises following steps: a divalent metal salt and a trivalent metal salt are introduced into a ball milling tank of a planetary ball mill, ammonium hydroxide liquid and grinding balls are introduced into the ball milling tank, ball milling is carried out for 2 to 3h at a rotating speed of 470r / min, a slurry obtained through ball milling is taken out from the ball milling tank, distilledwater is added for ultrasonic treatment and centrifugation, an obtained sample is subjected to vacuum drying at 120 DEG C until the weight is constant, and grinding is carried out so as to obtain a target product nanometer layered double metal hydroxide. The layered double metal hydroxide is high in stability, excellent in crystallinity, and low in cost; the method is simple, is benefit for largescale industrialized production, and is promising in application prospect.

Owner:HENAN NORMAL UNIV

Purpose of by-product ammonium thiosulfate generated in steel-making waste water treatment process as complexing agent for leaching silver and its application method

InactiveCN102560098AImprove leaching rateLow leaching rateProcess efficiency improvementSilver ionMaterials science

The invention discloses a purpose of a by-product ammonium thiosulfate generated in a steel-making waste water treatment process as a complexing agent for leaching silver and its application method. According to the invention, the by-product ammonium thiosulfate generated in the steel-making waste water treatment process as the complexing agent are reacted with the silver-containing solution for leaching silver; the by-product ammonium thiosulfate generated in the steel-making waste water treatment process is taken as the complexing agent for leaching silver, because thiosulfate radical ion and silver ion can form a stable complex, ammonia ion and silver ion can form stable silver-ammonia complex ion, therefore a better leaching effect is provided to silver chloride, silver oxide, silver sulfide and metal silver, and the ammonium thiosulfate solution possesses high leaching rate to silver under low concentration, the invention has the advantages of short leaching time, high leaching rate, good selectivity, low base metal leaching rate, small environment damage and small hidden trouble in safety production.

Owner:苏州久王环保科技股份有限公司

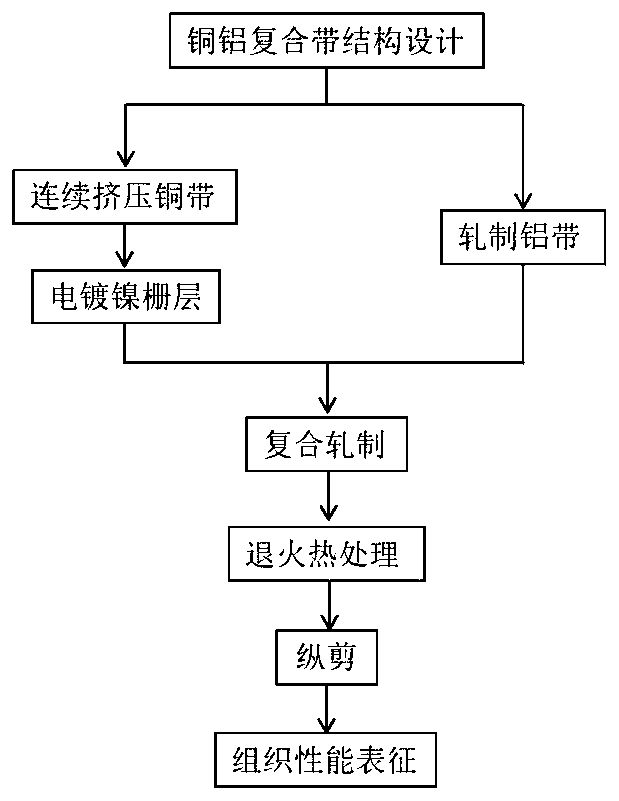

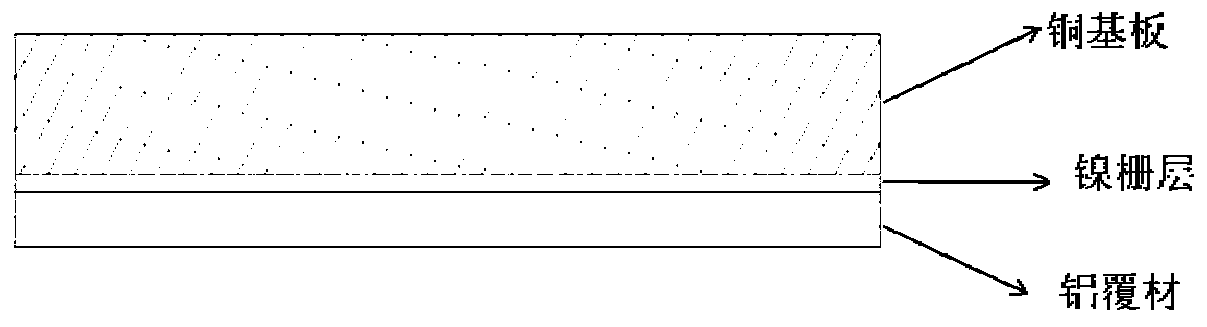

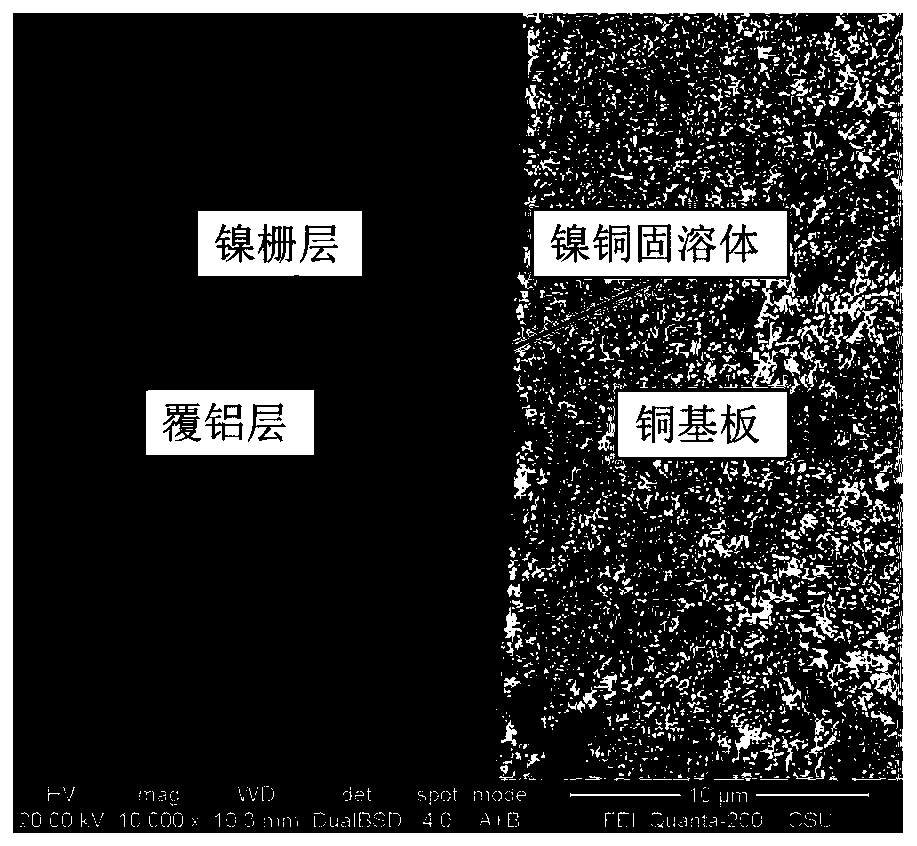

Copper-aluminum composite plate strip with added nickel grid layer and continuous production method thereof

ActiveCN110721999AHigh bonding strengthImprove mechanical propertiesMetal rolling arrangementsRoll speed control deviceComposite strengthComposite plate

The invention discloses a copper-aluminum composite plate strip with an added nickel grid layer and a continuous production method thereof. The copper-aluminum composite plate strip is characterized by comprising three layers of metal; the two outer layers are a copper substrate and an aluminum covering material correspondingly; and the middle layer is the nickel grid layer arranged on the surfaceof the copper substrate in an electroplated mode. The production method comprises the steps that the nickel grid layer of the corresponding thickness is electroplated on the surface of the copper substrate firstly; then the copper substrate with the nickel grid layer and the aluminum covering material are put into a composite rolling mill simultaneously, and compounding is completed through a single pass of large deformation; and then the composite plate strip is put into an online annealing furnace, heat treatment is conducted, and the copper-aluminum composite plate strip with high composite strength and good surface quality is obtained. The copper-aluminum composite plate strip has the outstanding advantages such as low cost, good mechanical properties and high bonding strength and iswidely applied to power electronics, automobiles, communication and other technical fields.

Owner:长沙博朗思达新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com