Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

620results about How to "Uniform film thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

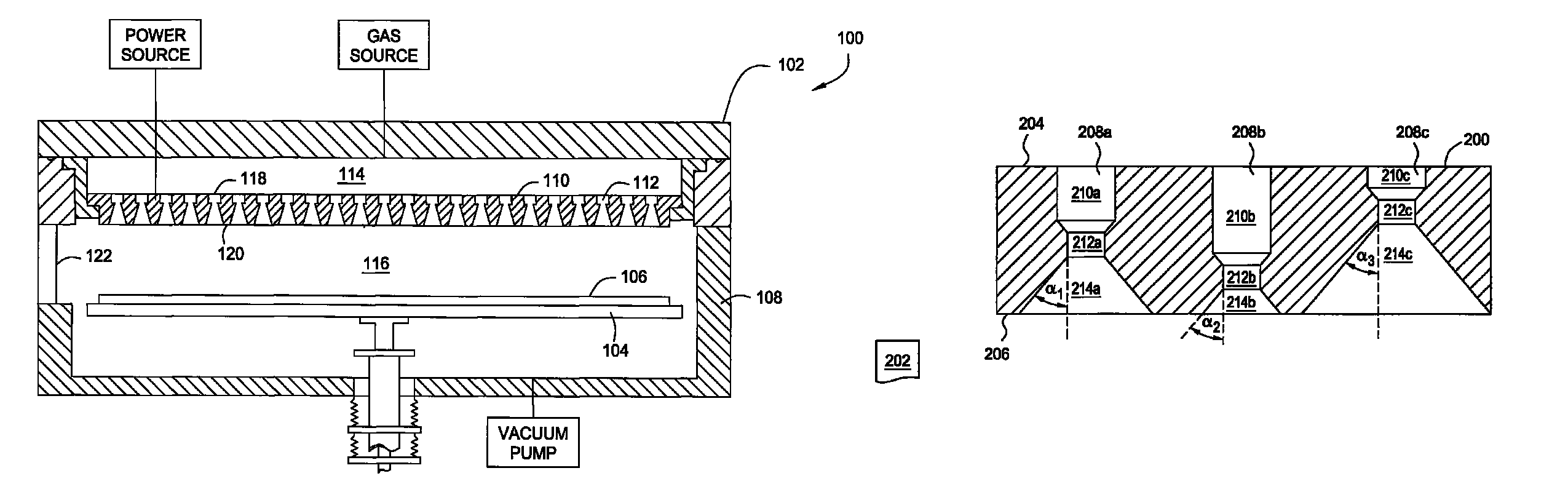

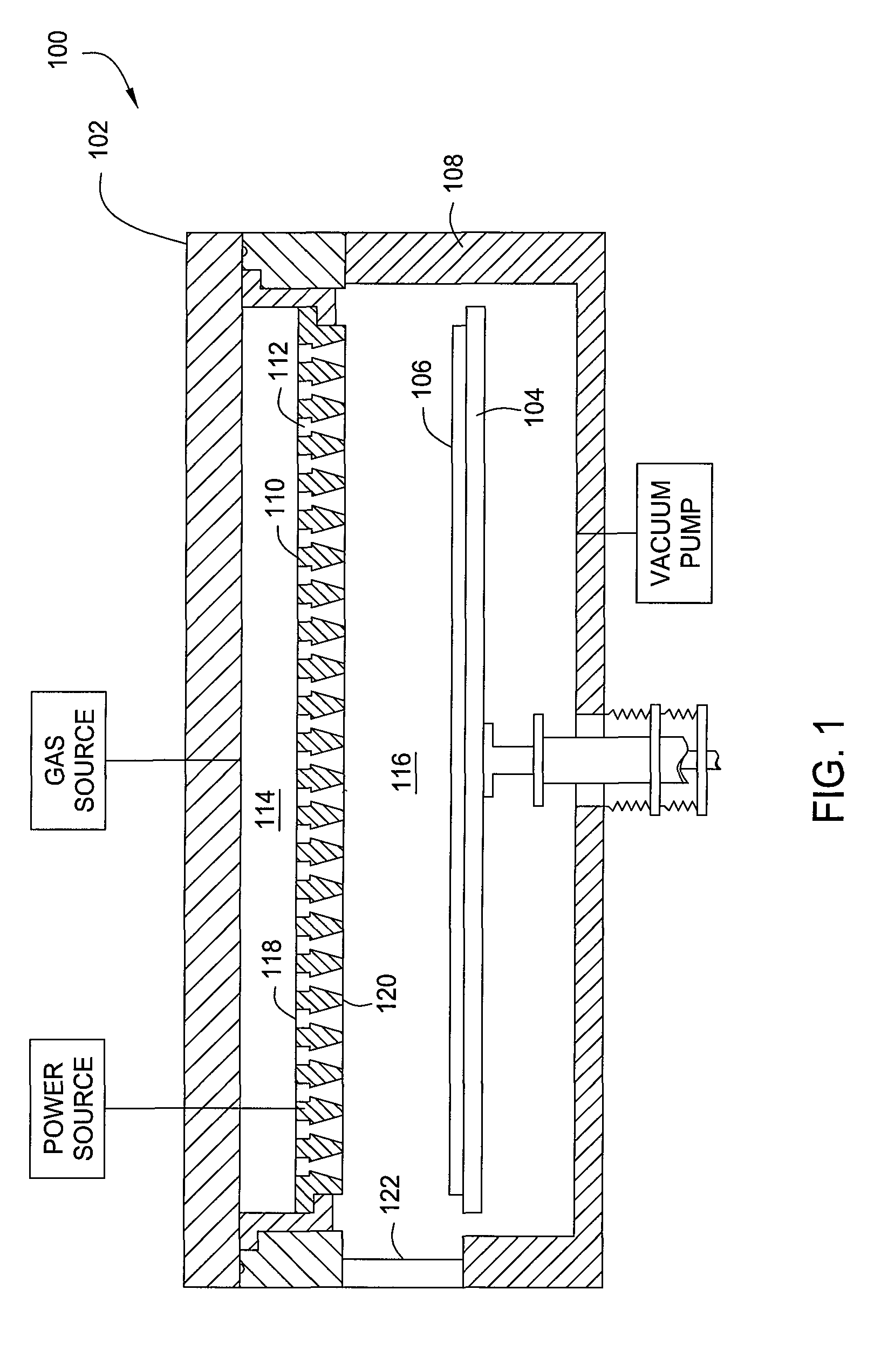

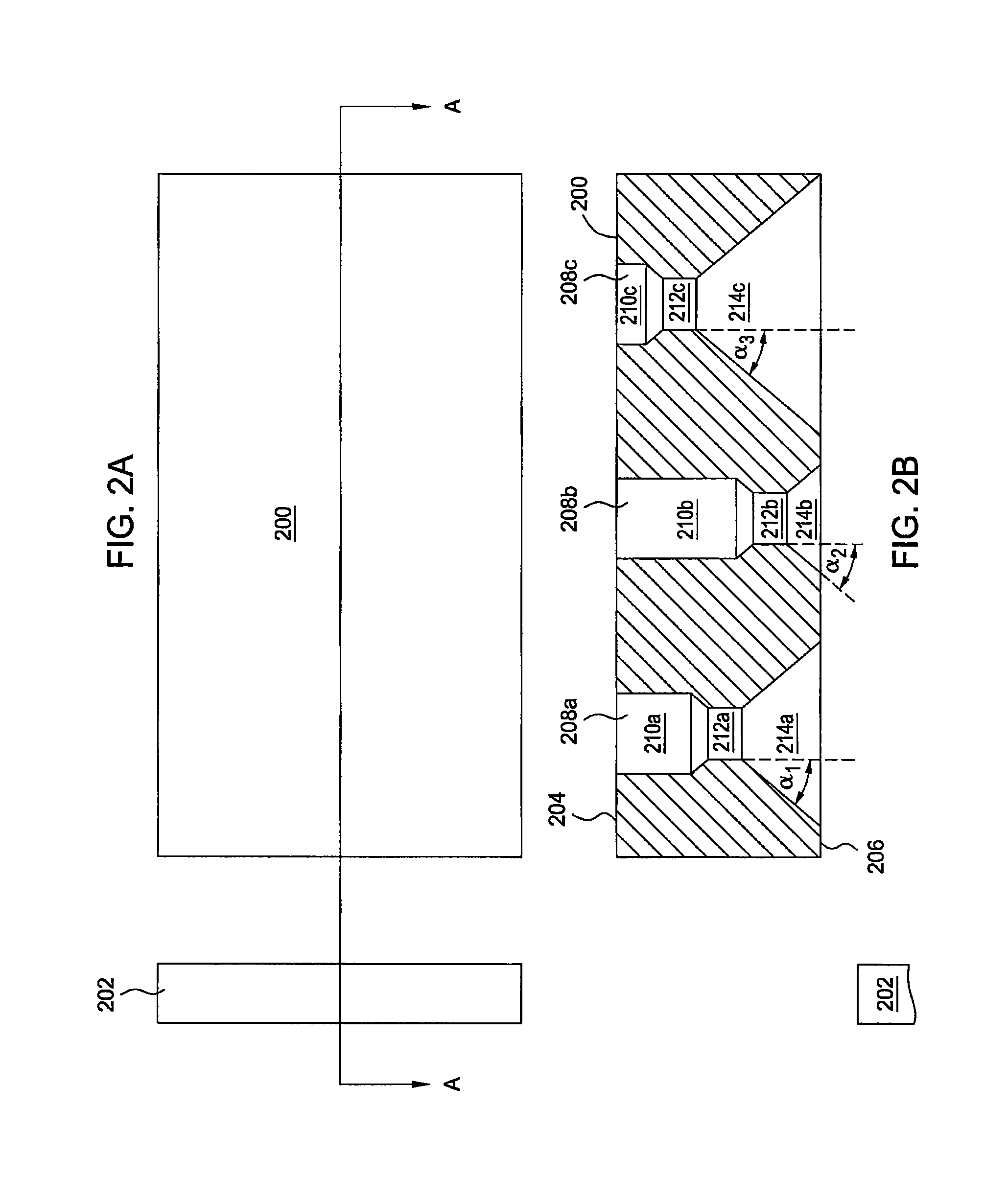

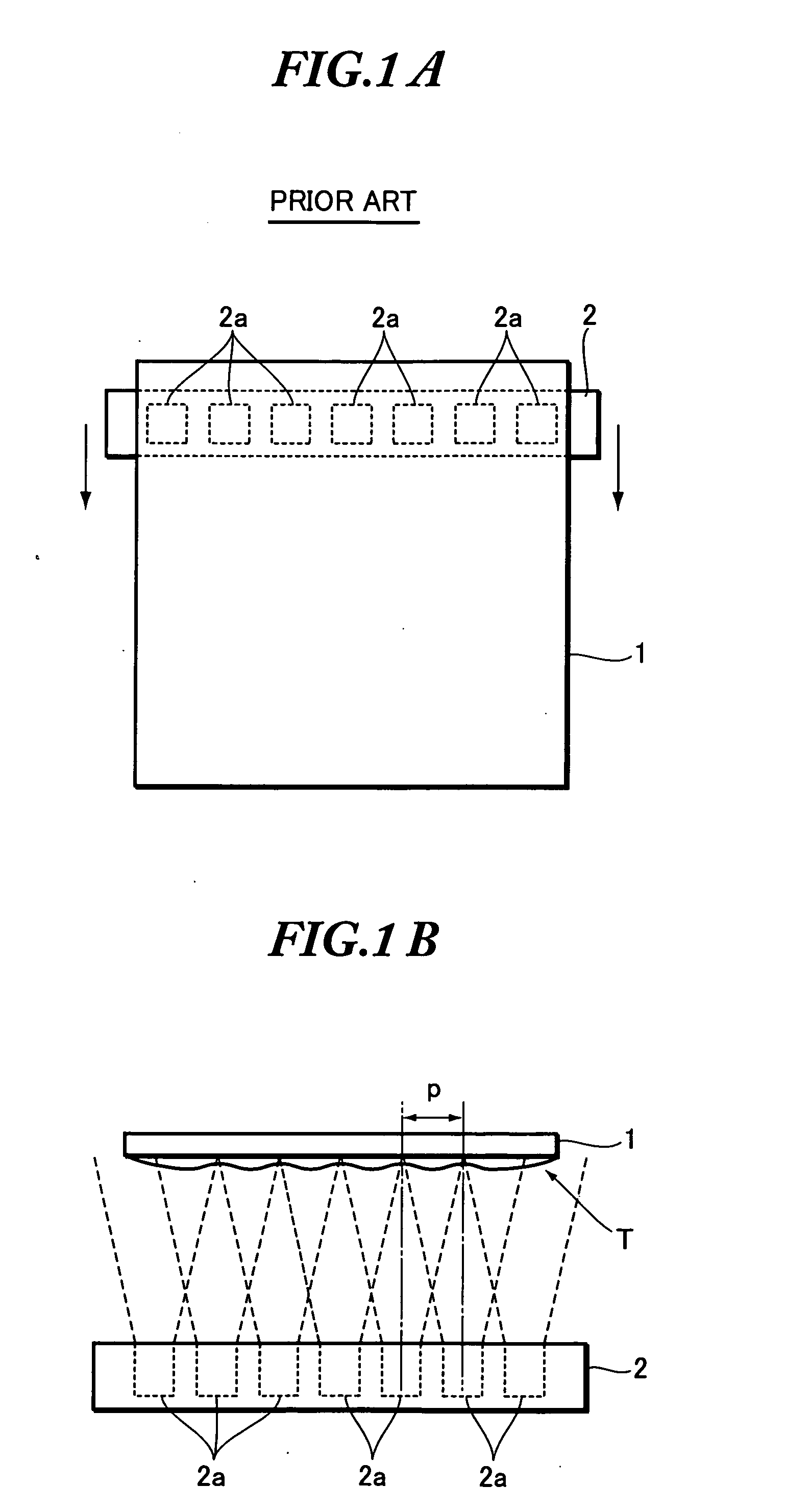

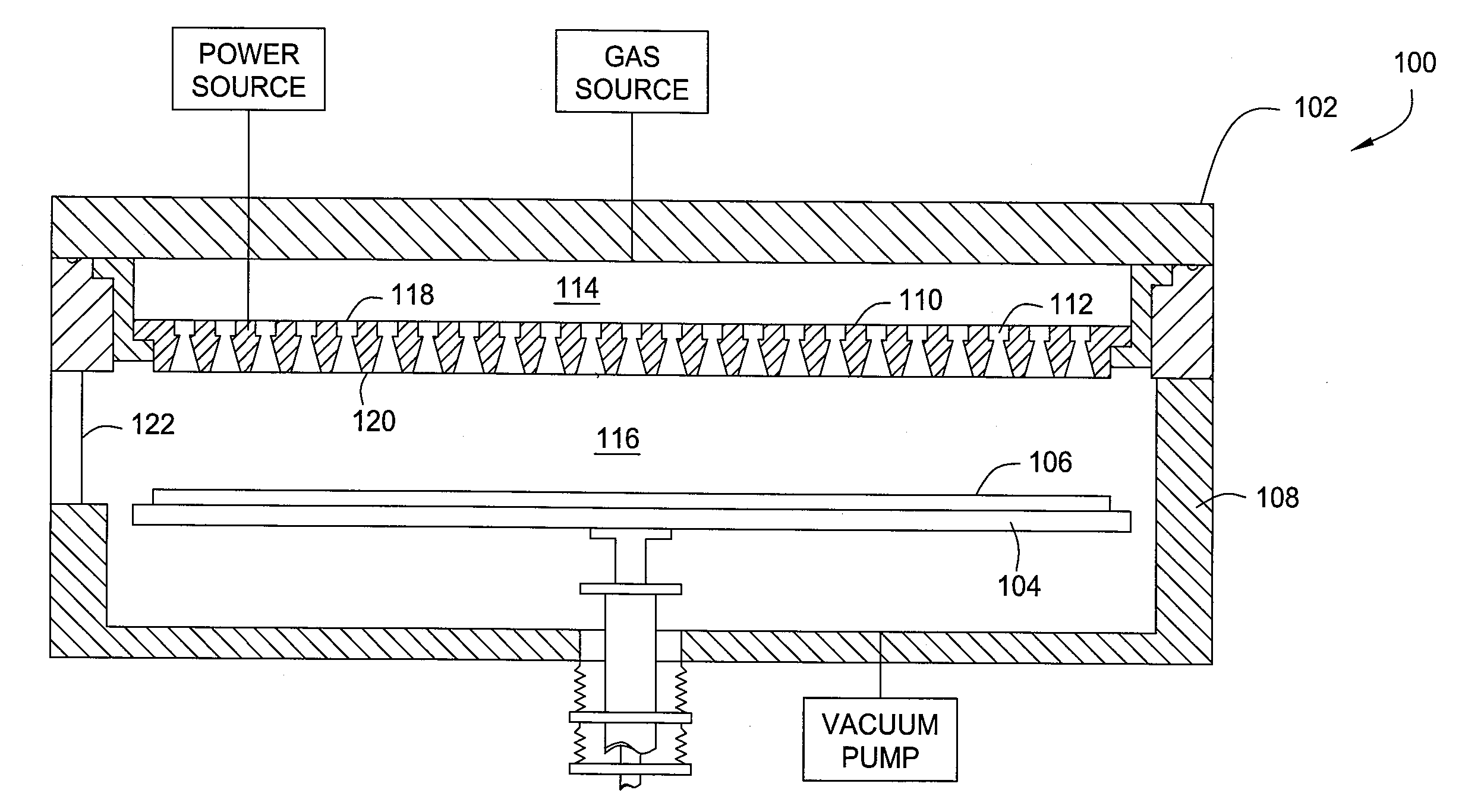

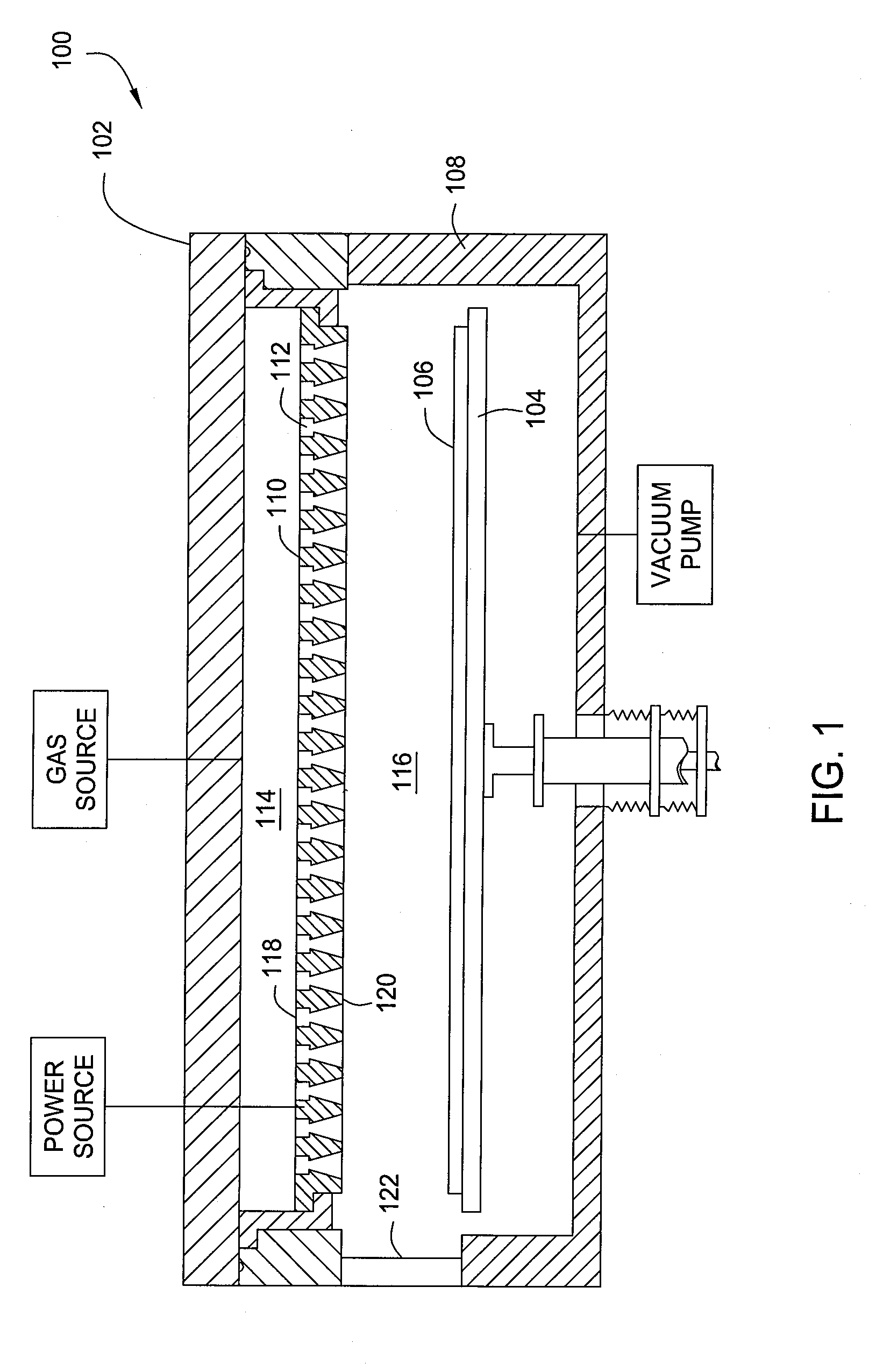

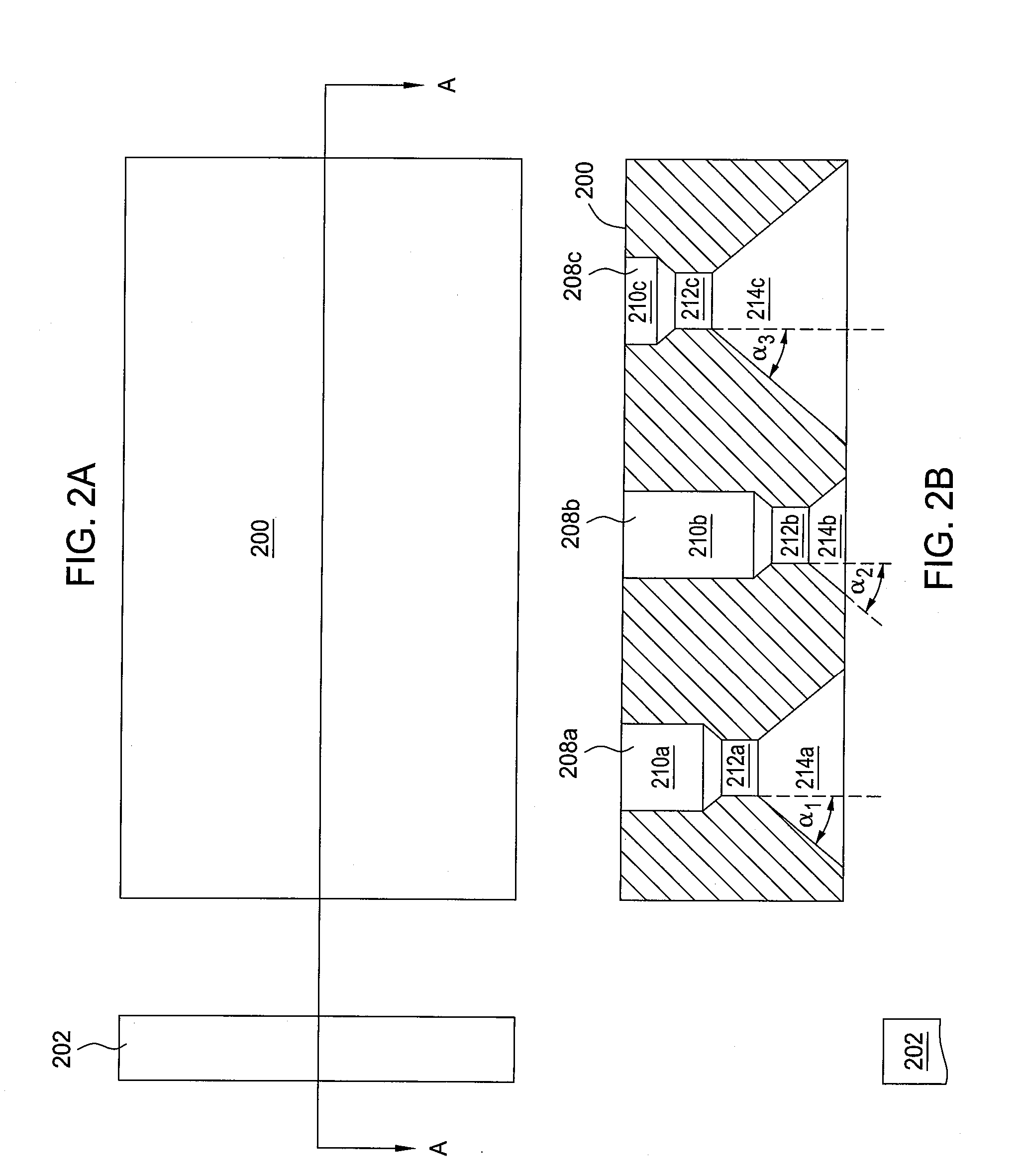

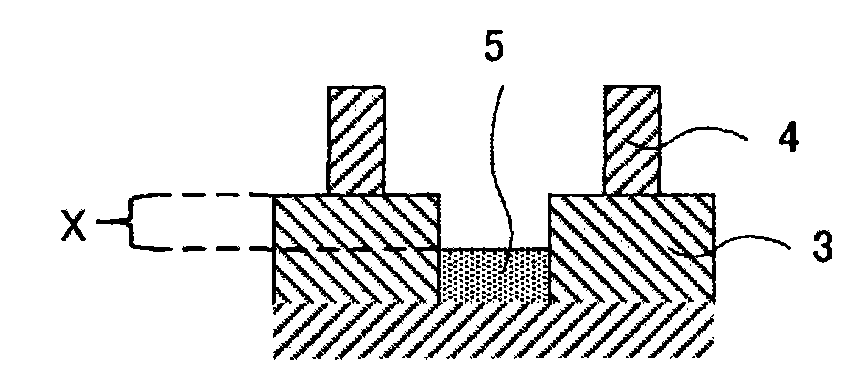

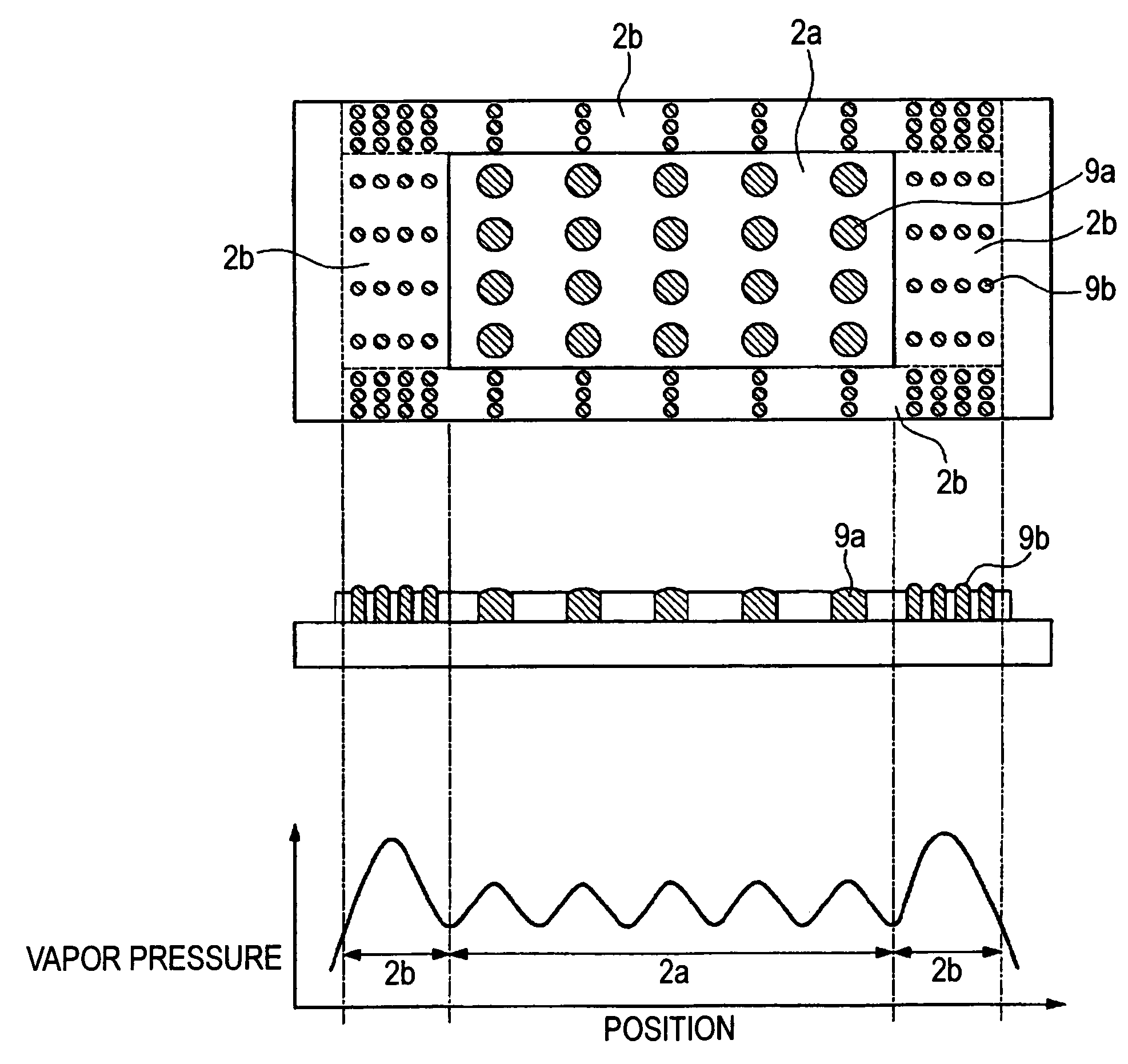

Diffuser plate with slit valve compensation

InactiveUS8328939B2Uniform plasma distributionUniform film thicknessLiquid surface applicatorsMolten spray coatingEngineeringMechanical engineering

The present invention generally comprises a diffuser plate for a PECVD chamber. The diffuser plate comprises a plurality of hollow cathode cavities. The edge of the diffuser plate that will reside closest to a slit valve within a processing chamber may have the shape and / or size of the hollow cathode cavities adjusted to compensate for the proximity to the slit valve. By adjusting the shape and / or size of the hollow cathode cavities closest to the slit valve, the diffuser plate may permit a uniform plasma distribution across the processing chamber and thus, a uniform film thickness upon a substrate during a PECVD process.

Owner:APPLIED MATERIALS INC

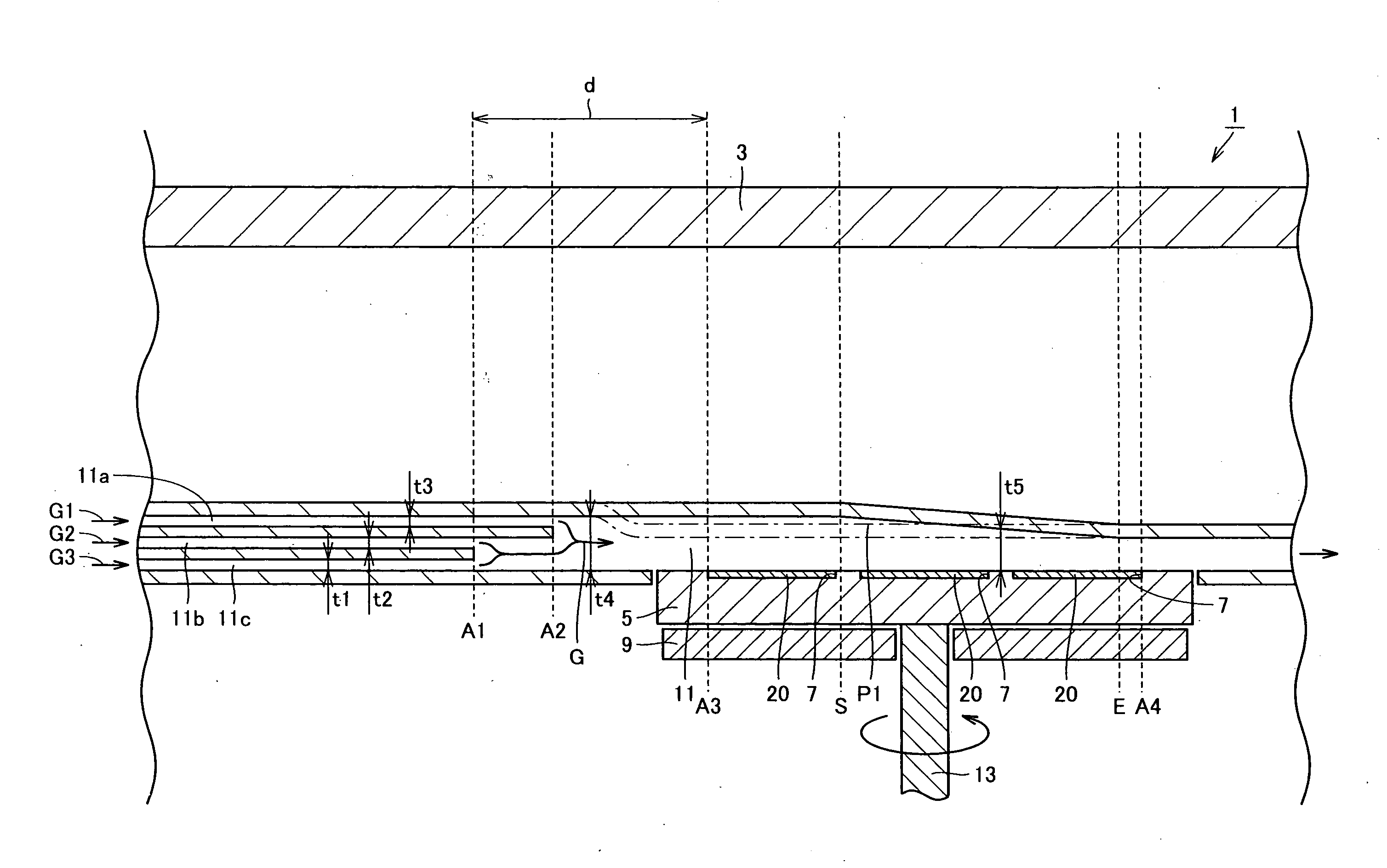

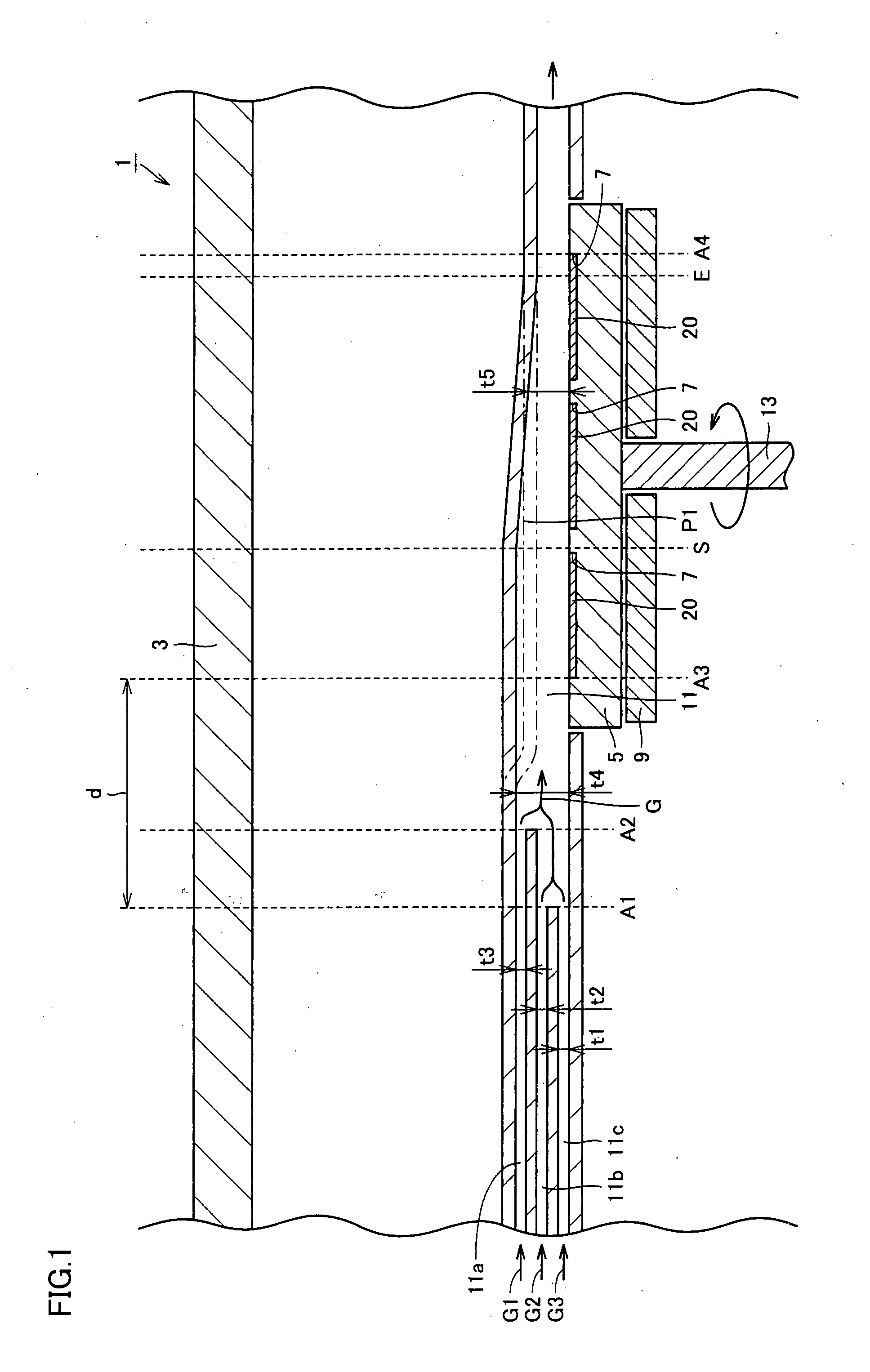

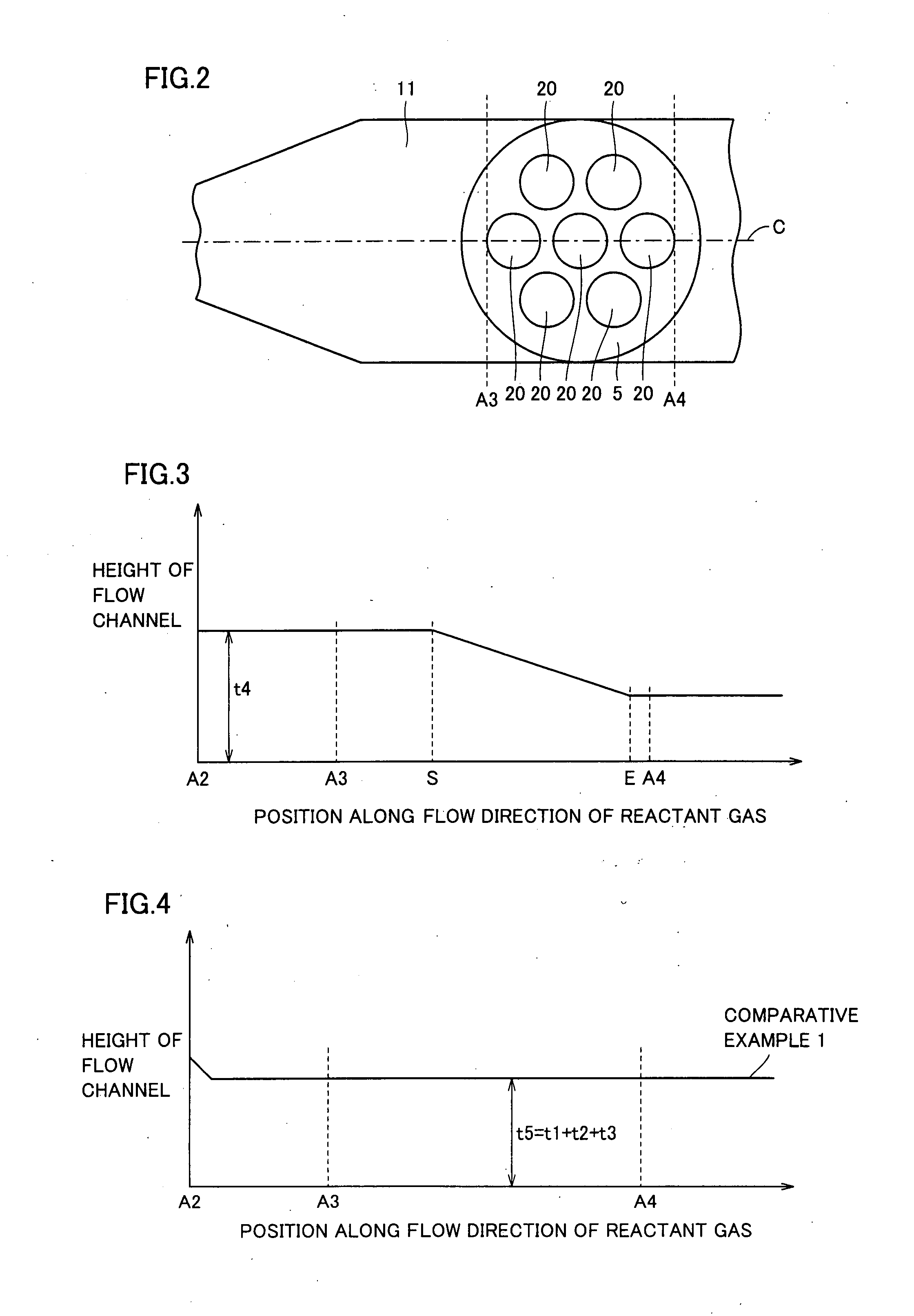

Metal organic chemical vapor deposition equipment

InactiveUS20080006208A1Uniform film thicknessImprove formation efficiencyAfter-treatment apparatusFrom chemically reactive gasesSusceptorProduct gas

Metal organic chemical vapor deposition equipment is metal organic chemical vapor deposition equipment for forming a film on a substrate by using a reactant gas, and includes a susceptor heating the substrate and having a holding surface for holding the substrate, and a flow channel for introducing the reactant gas to the substrate. The susceptor is rotatable with the holding surface kept facing an inner portion of the flow channel, and a height of the flow channel along a flow direction of the reactant gas is kept constant from a position to a position, and is monotonically decreased from the position to the downstream side. It is thereby possible to improve film formation efficiency while allowing the formed film to have a uniform thickness.

Owner:SUMITOMO ELECTRIC IND LTD

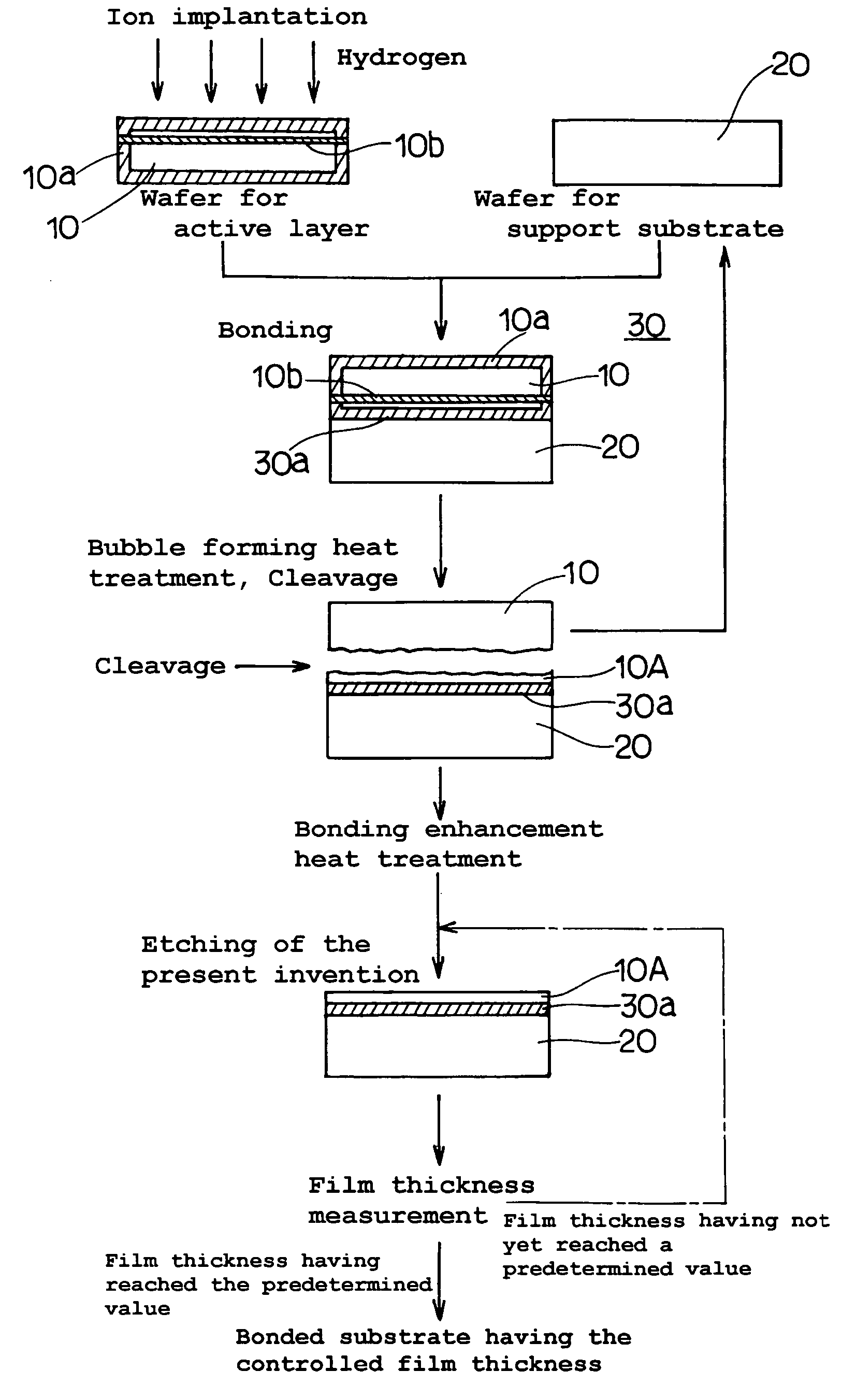

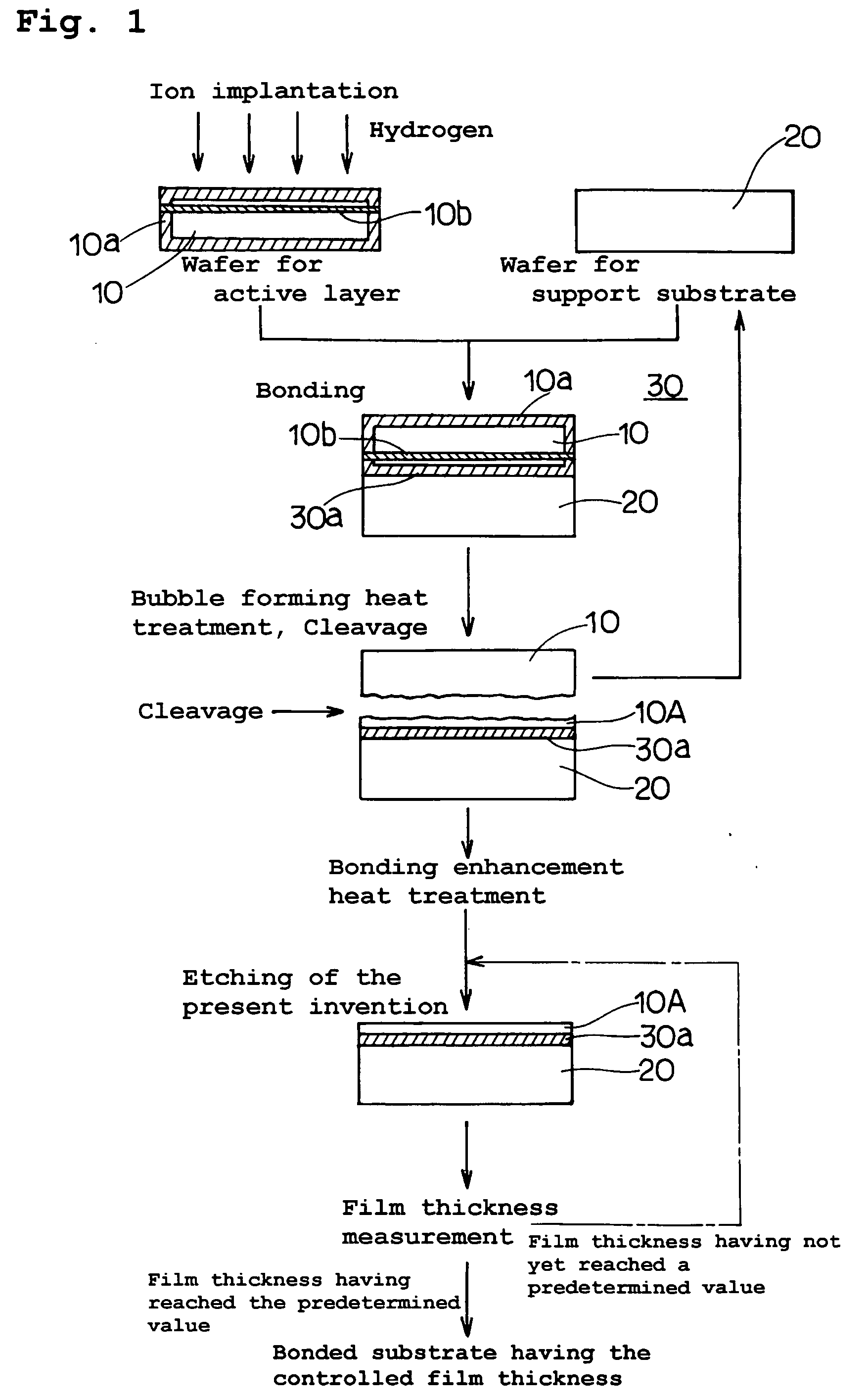

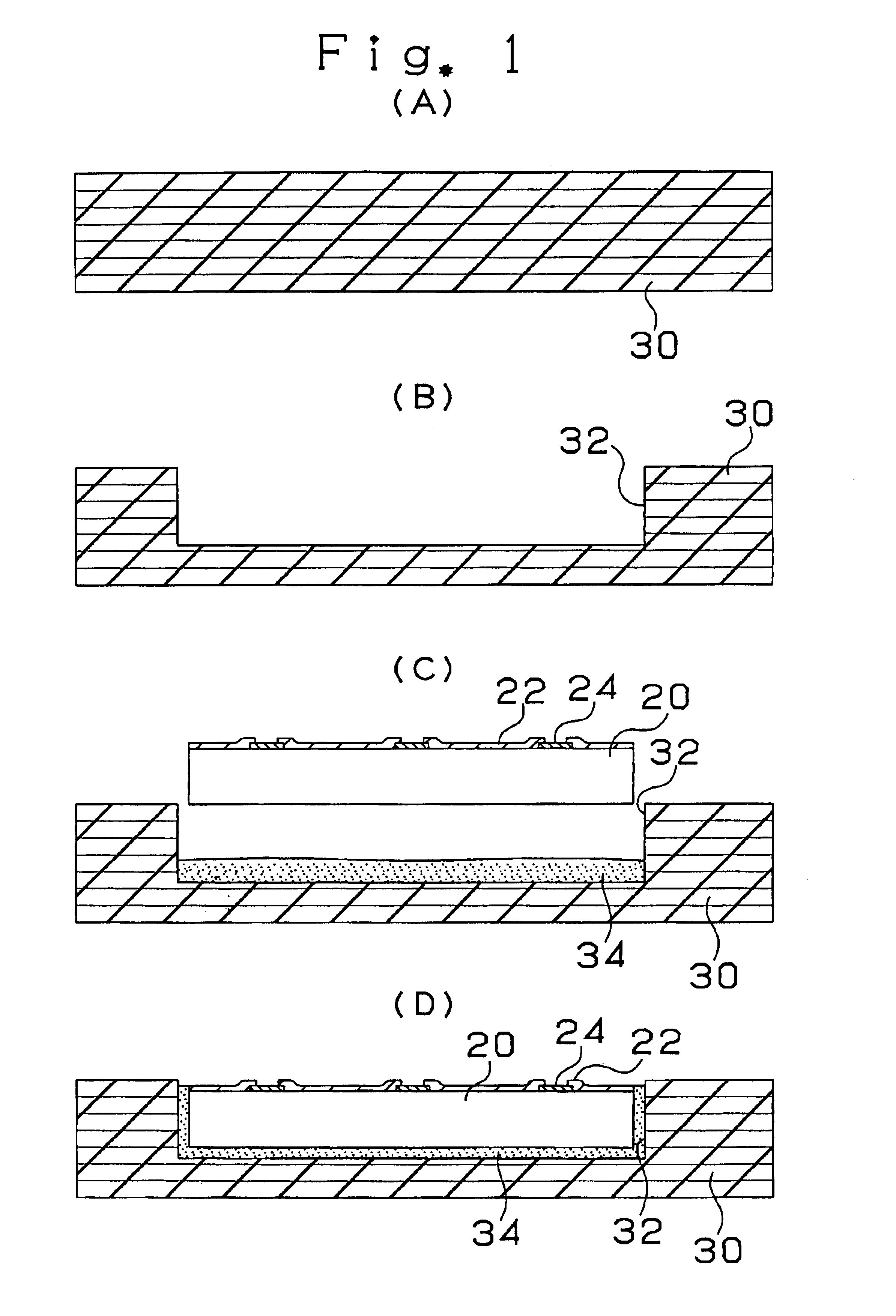

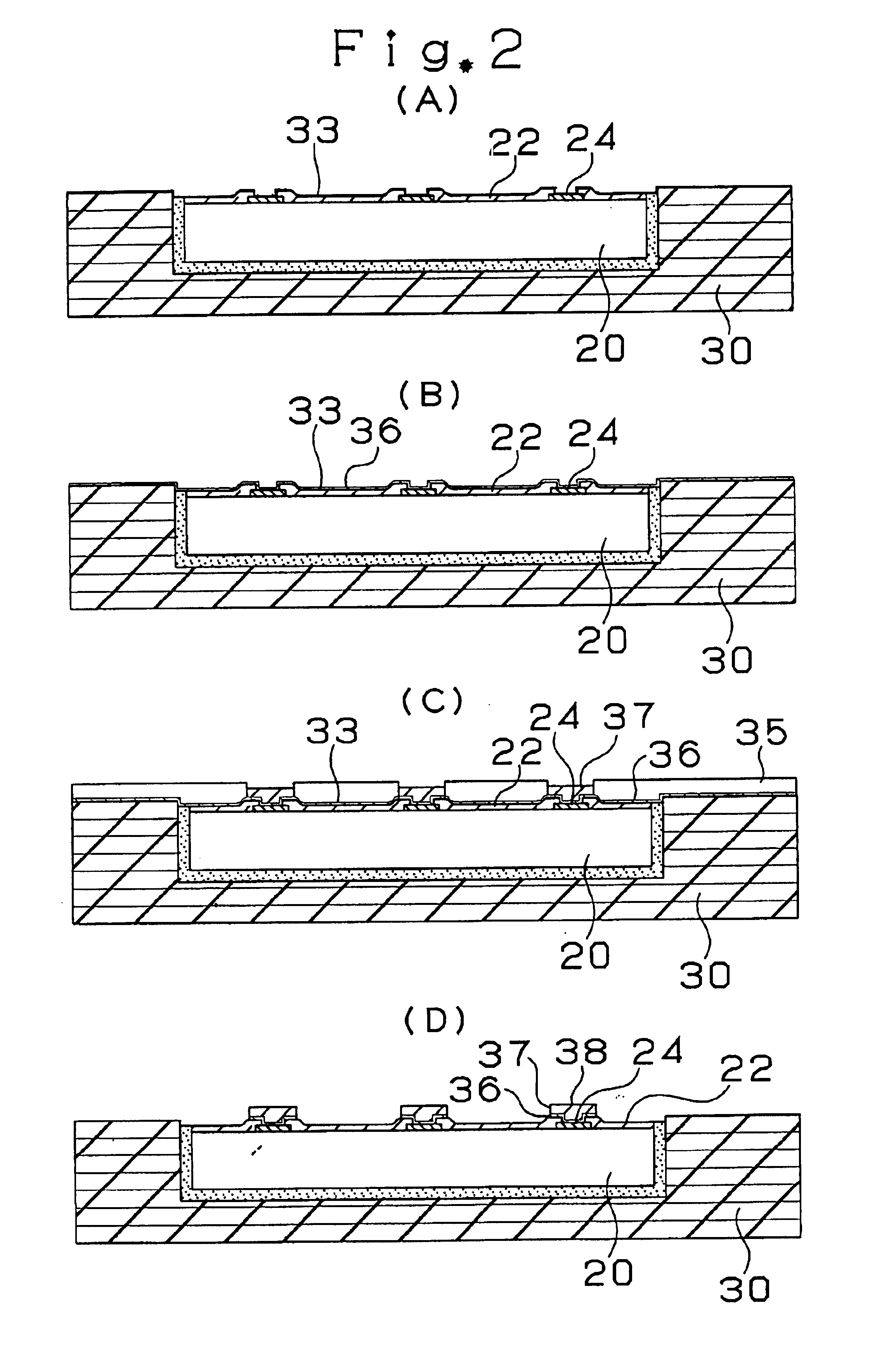

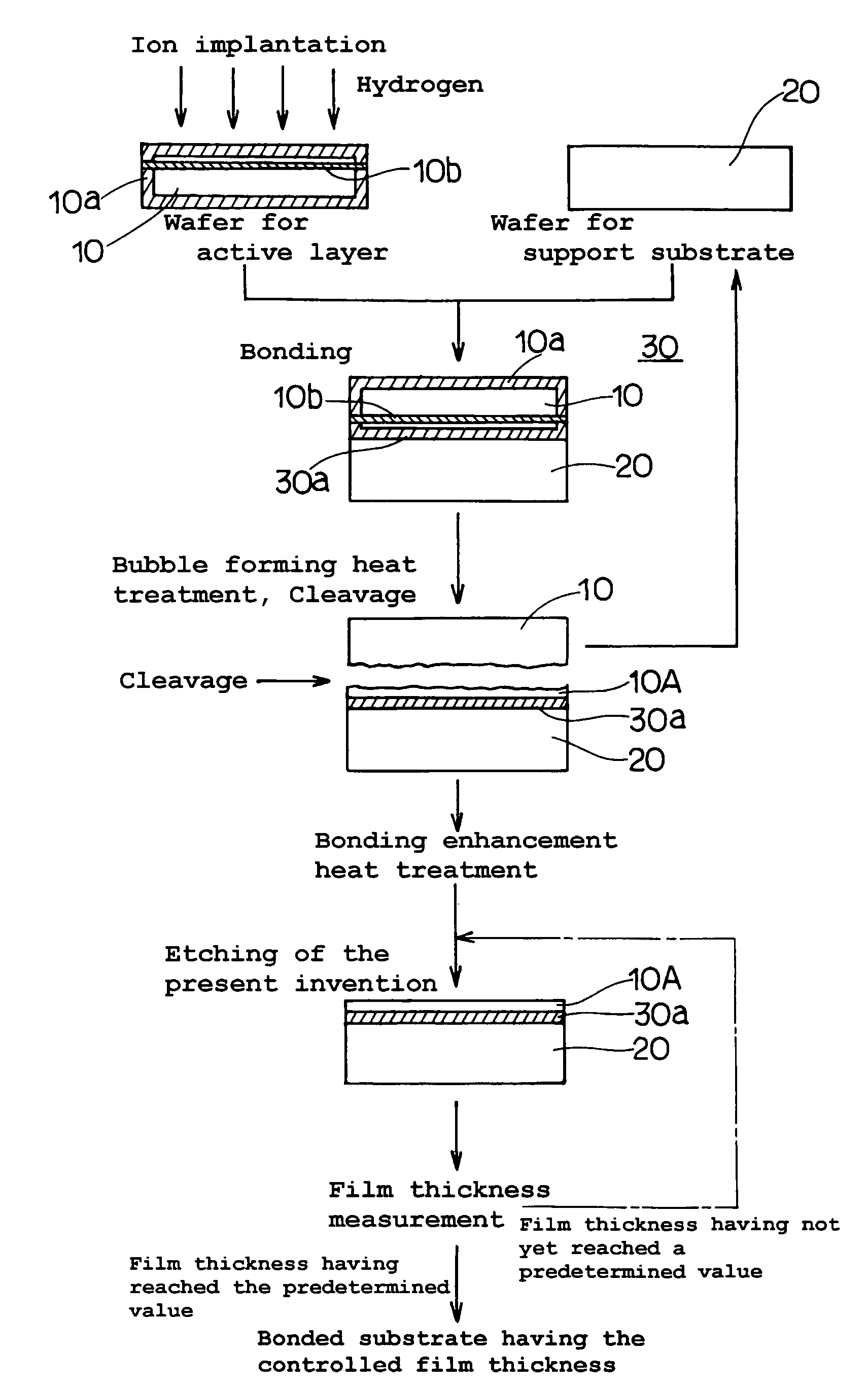

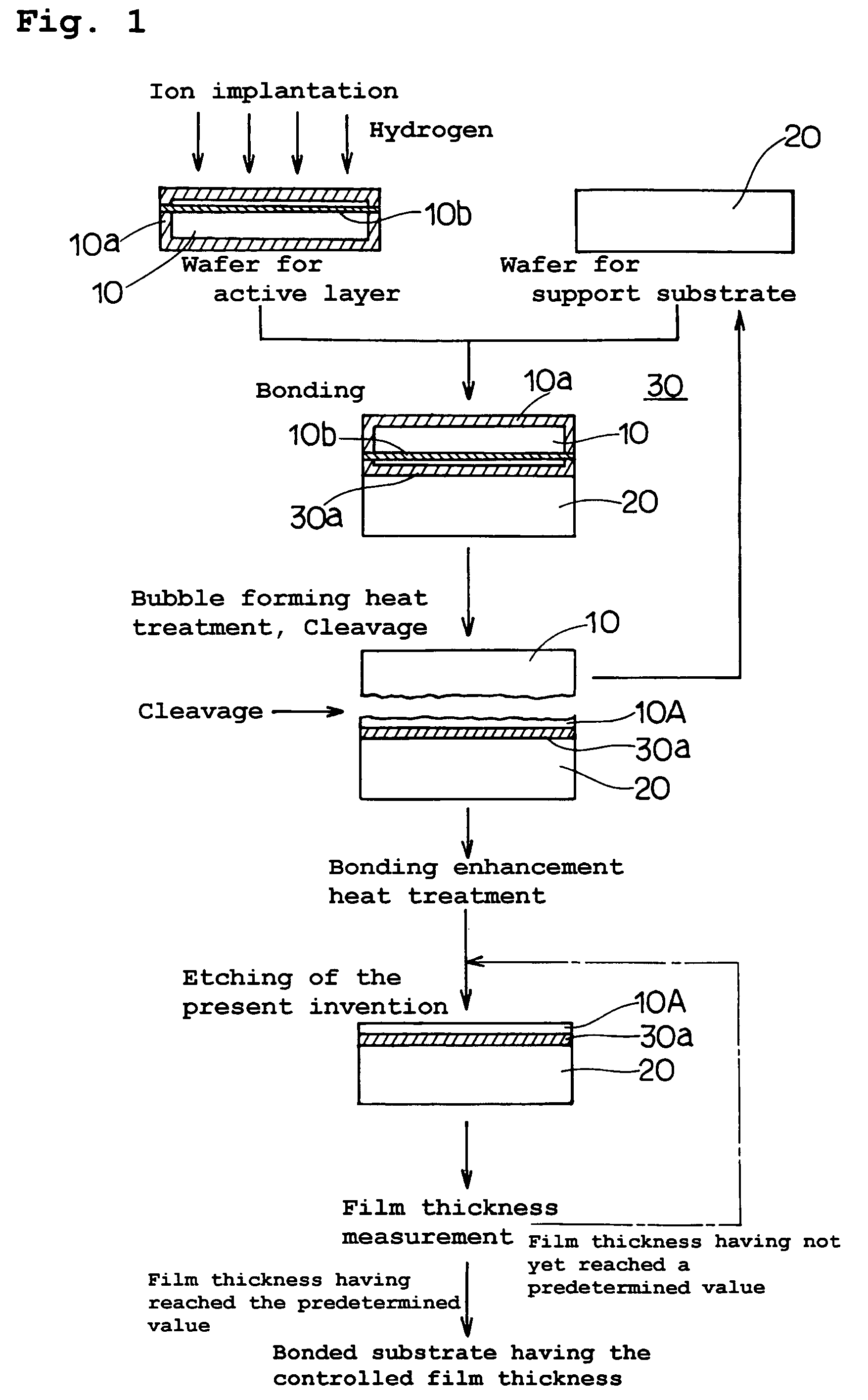

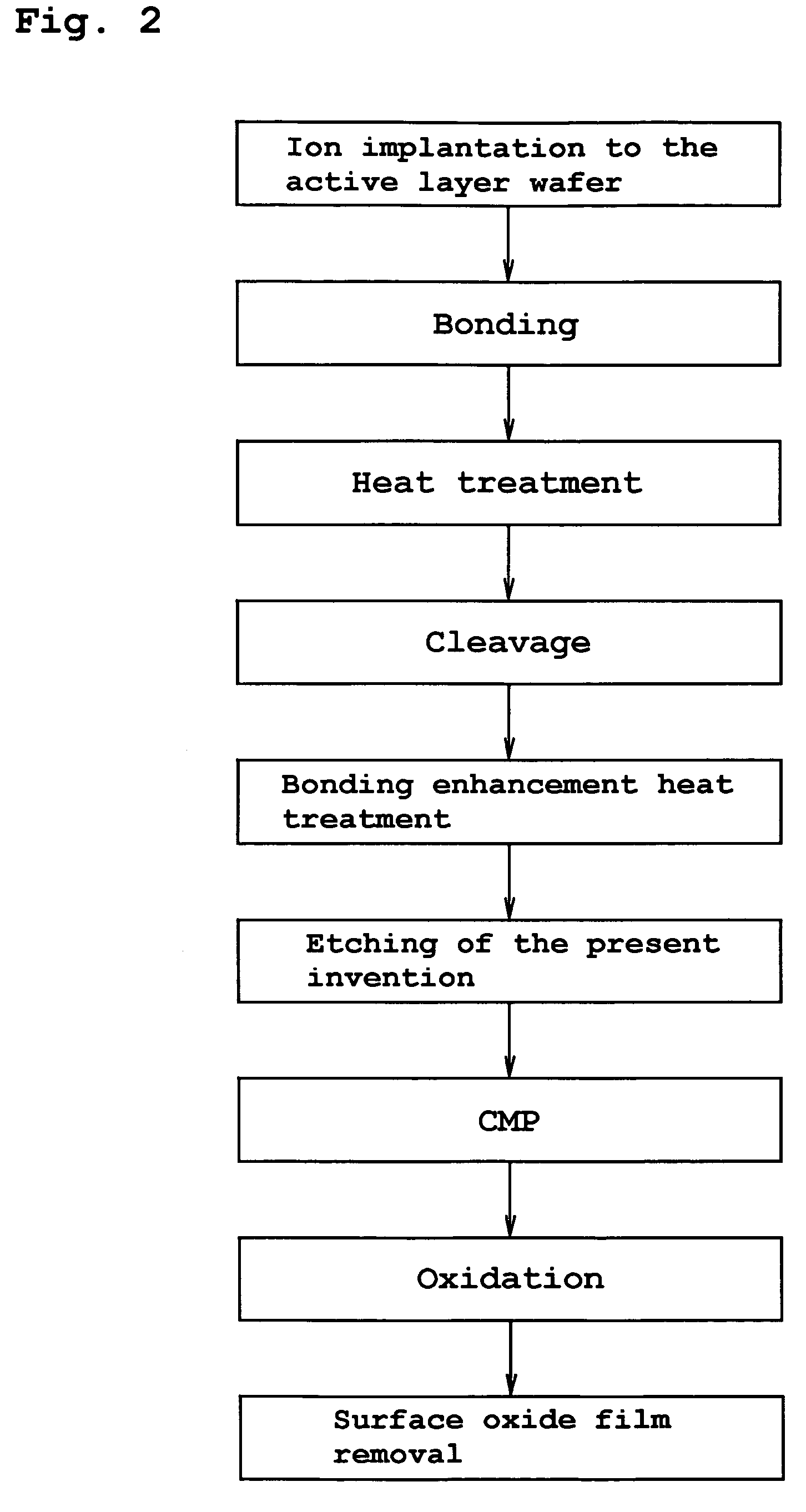

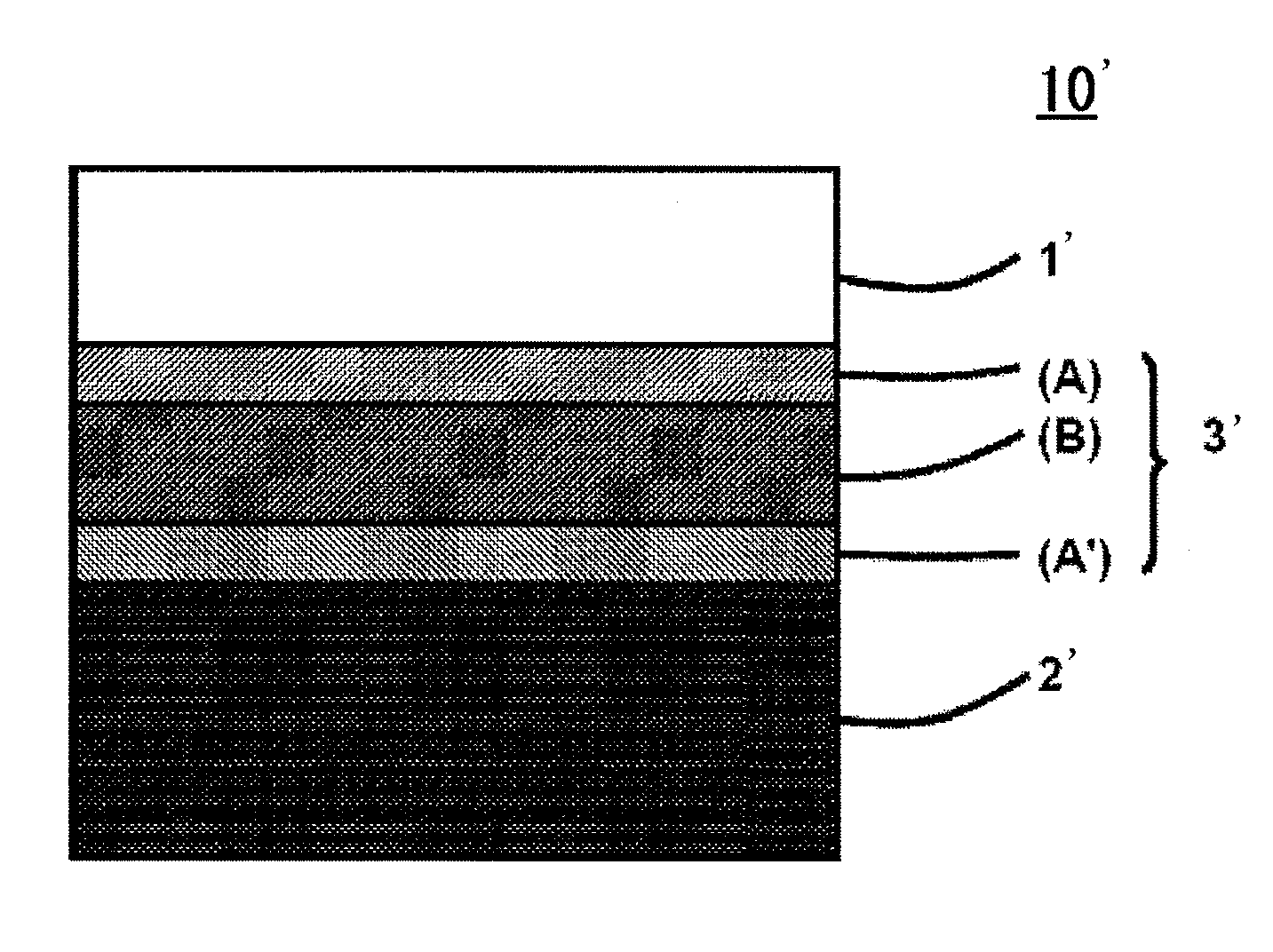

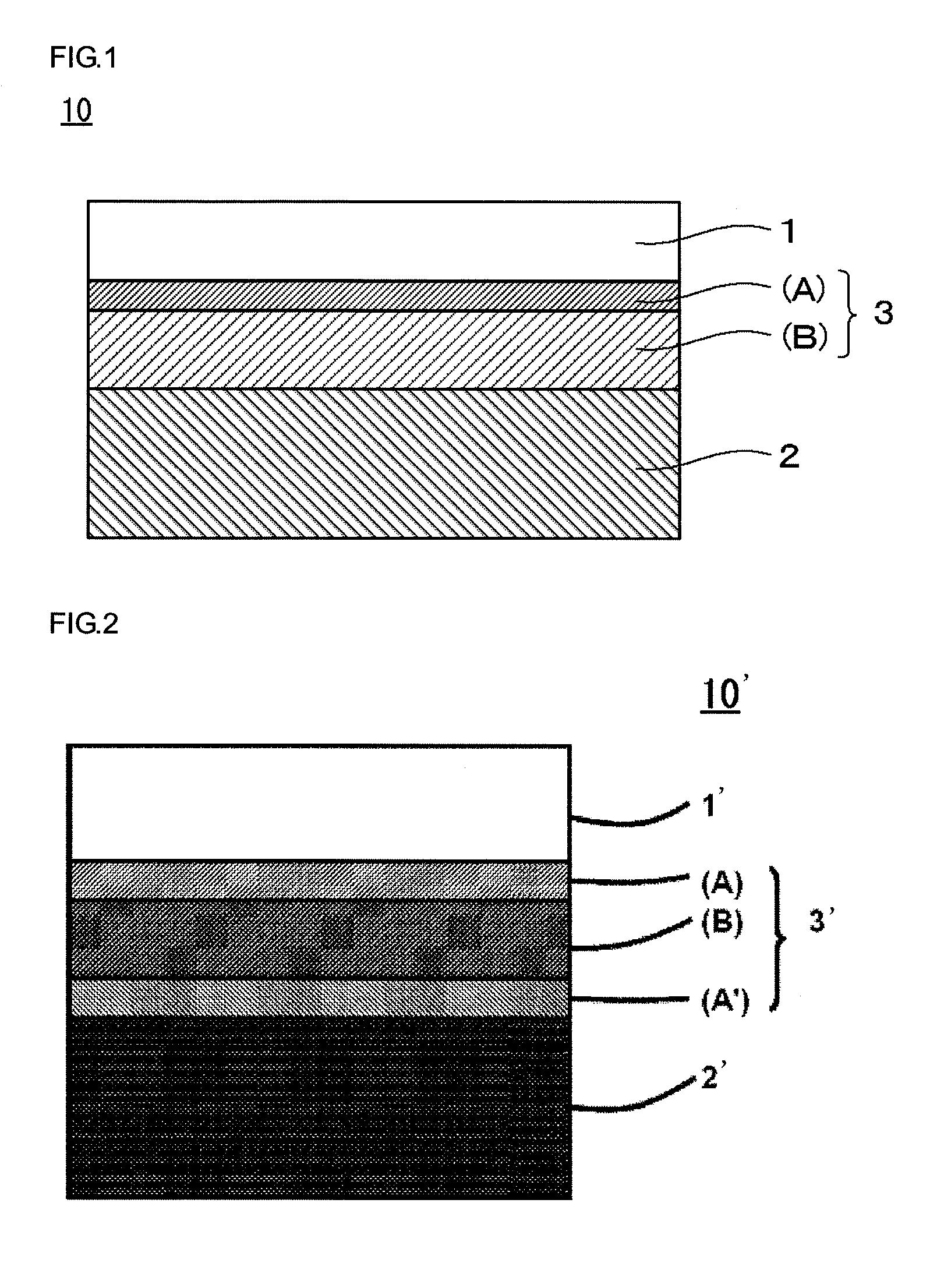

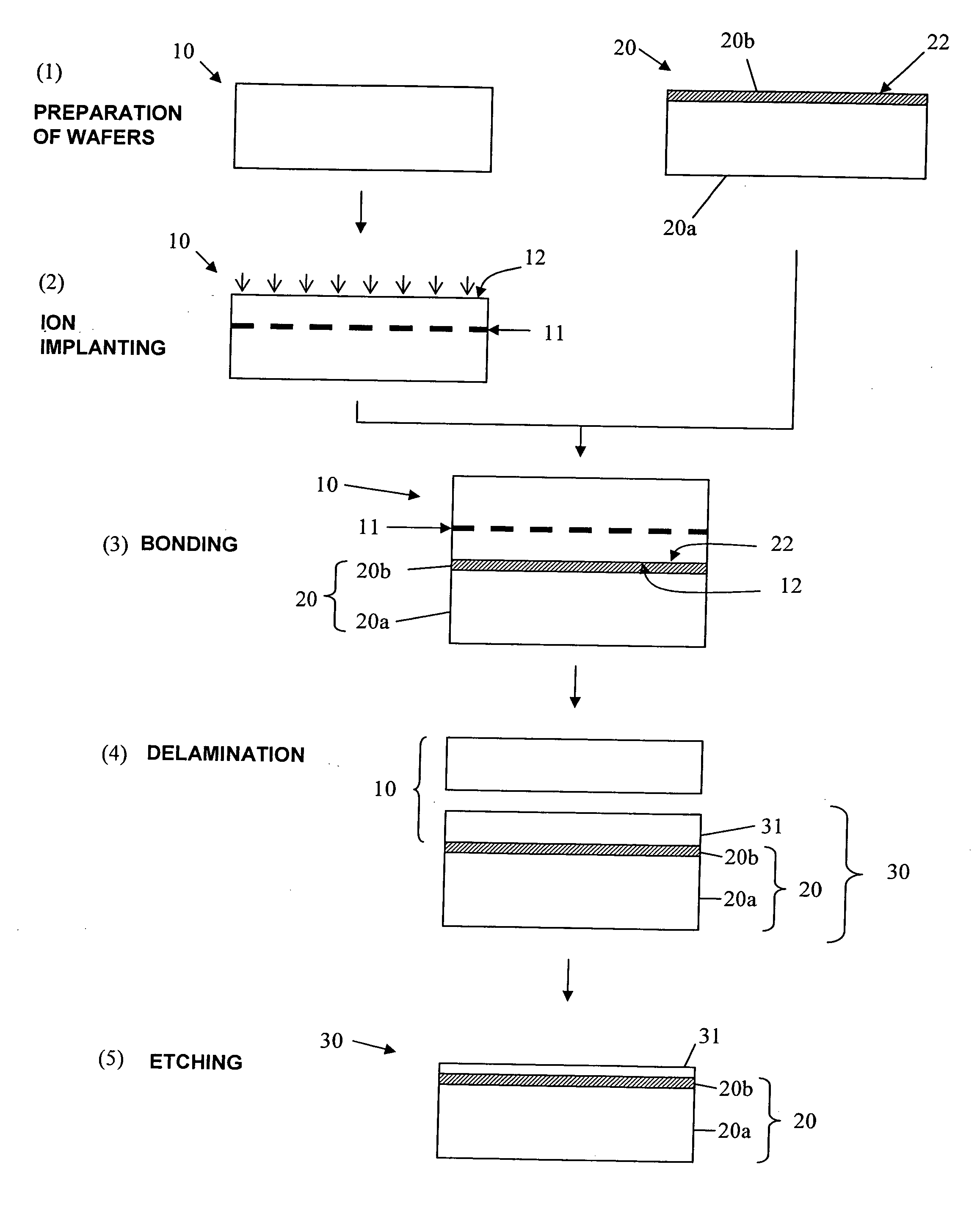

Laminated semiconductor substrate process for producing the same

InactiveUS20060118935A1Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

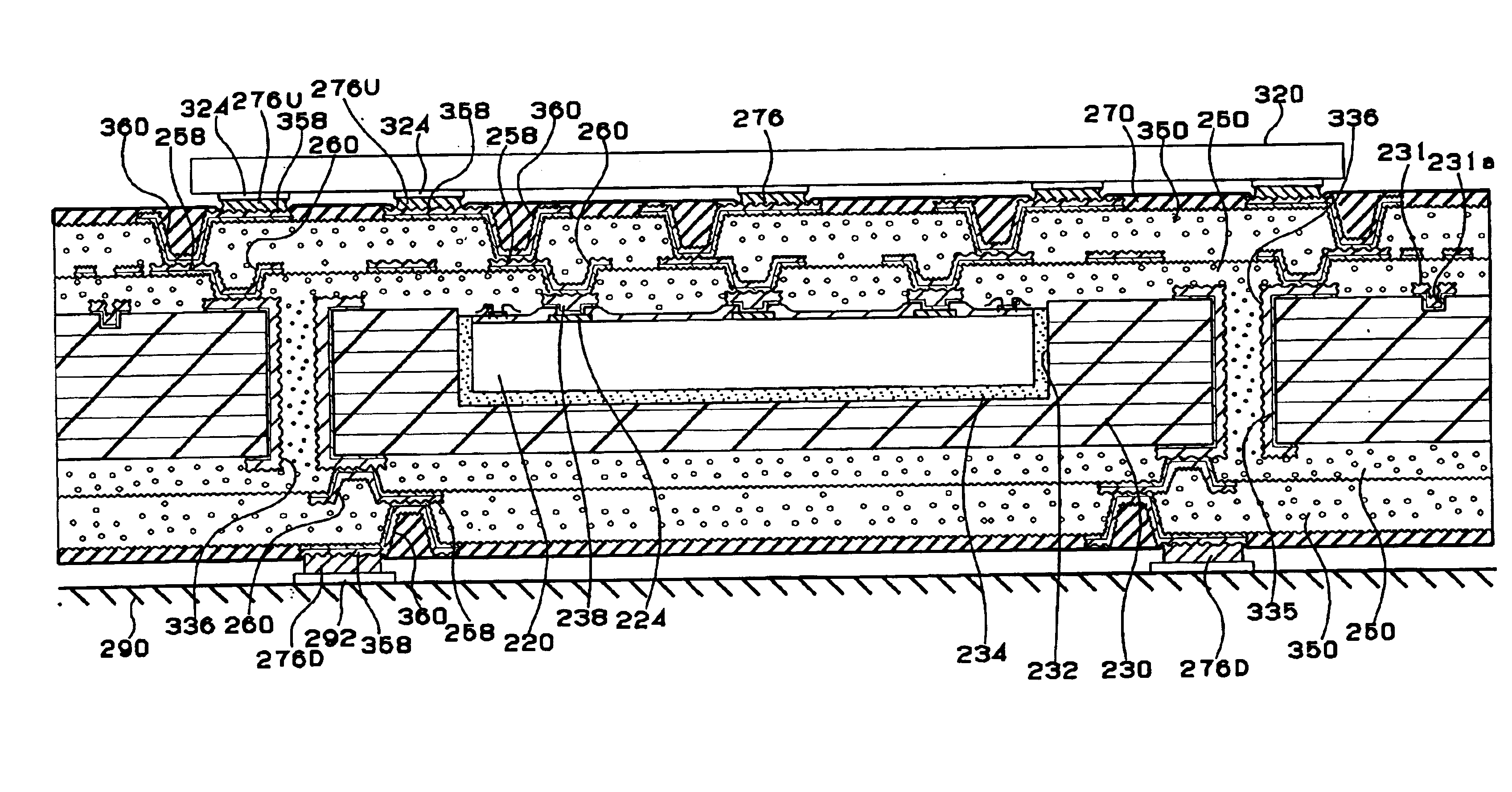

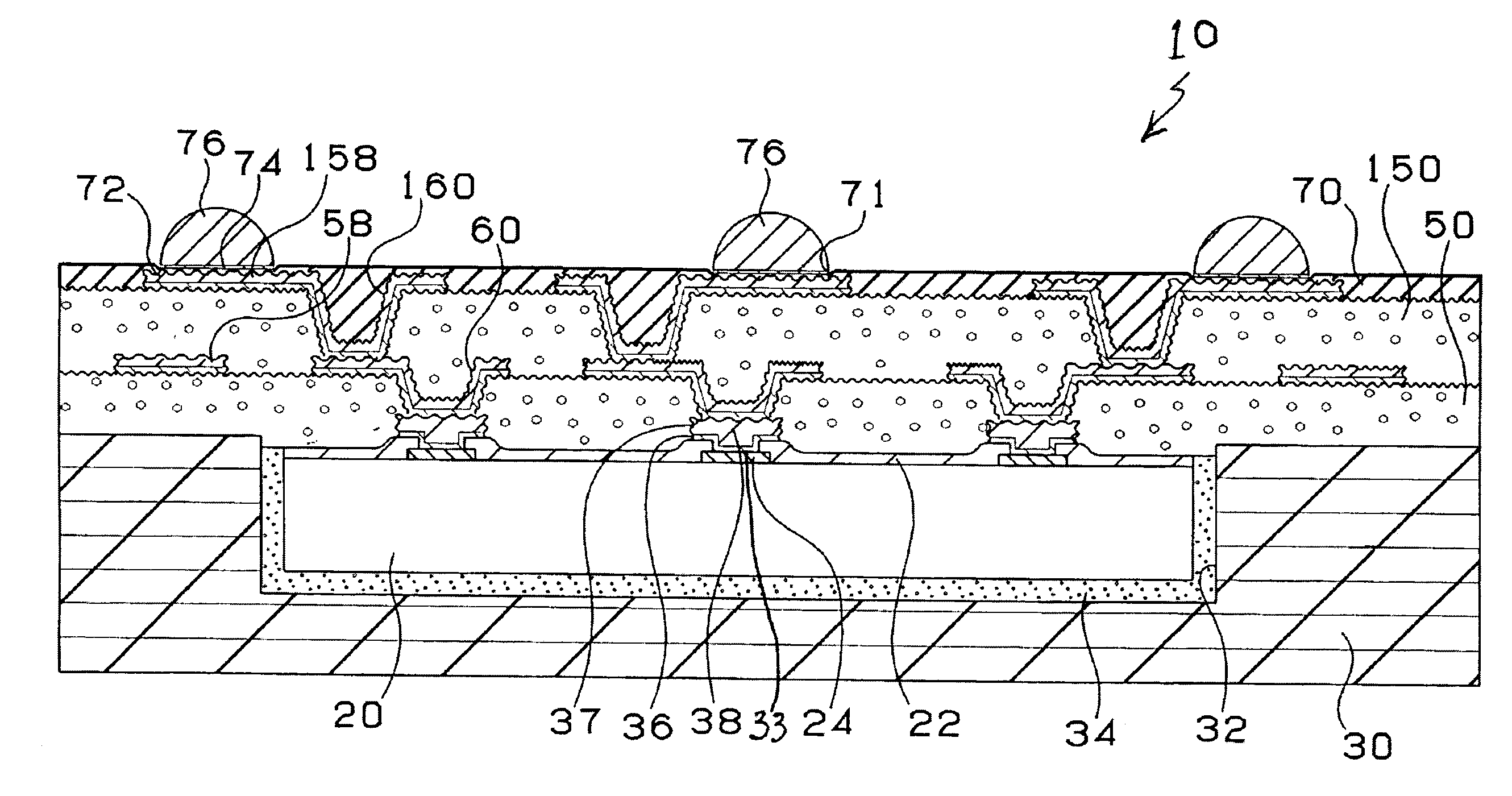

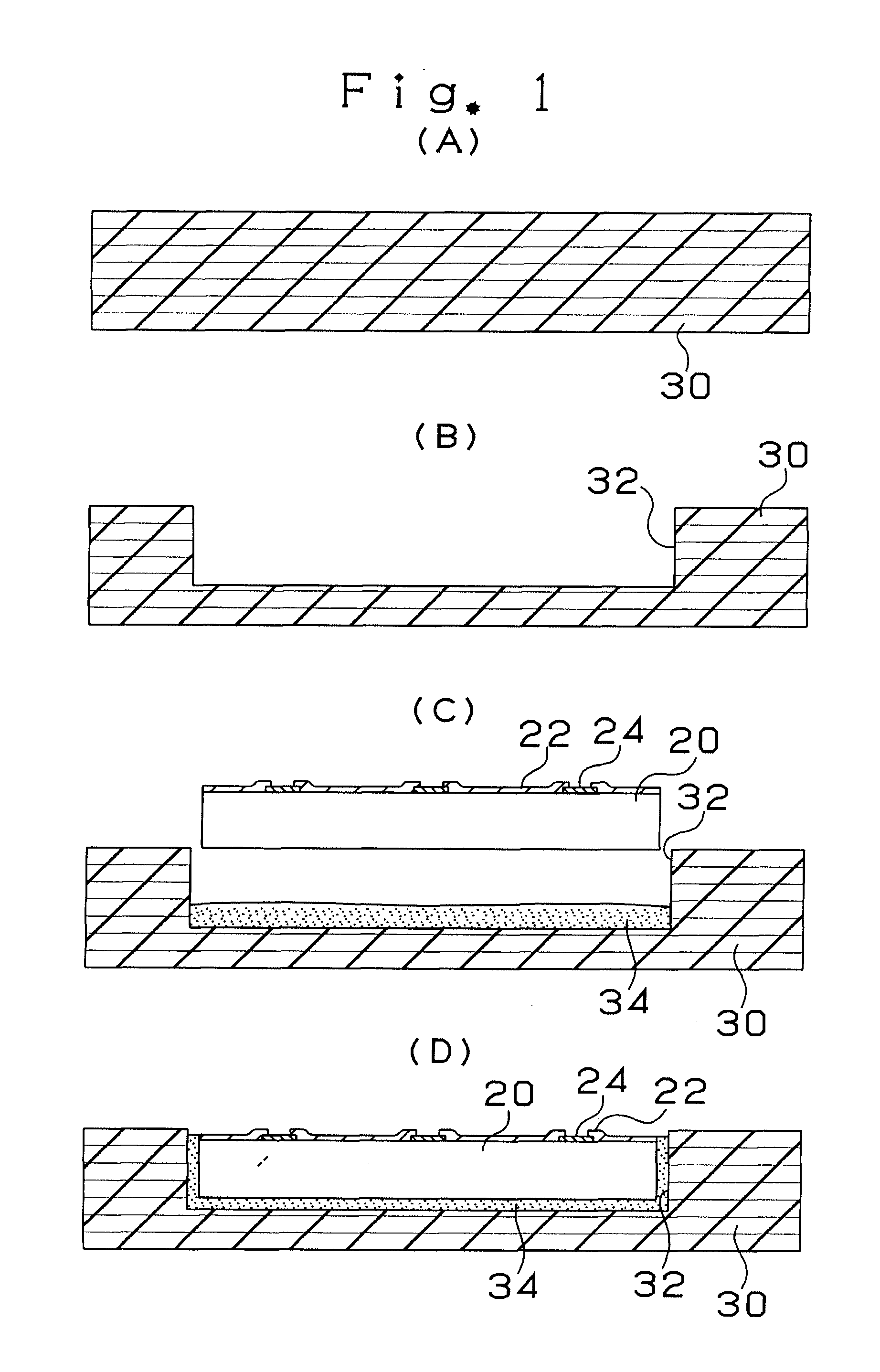

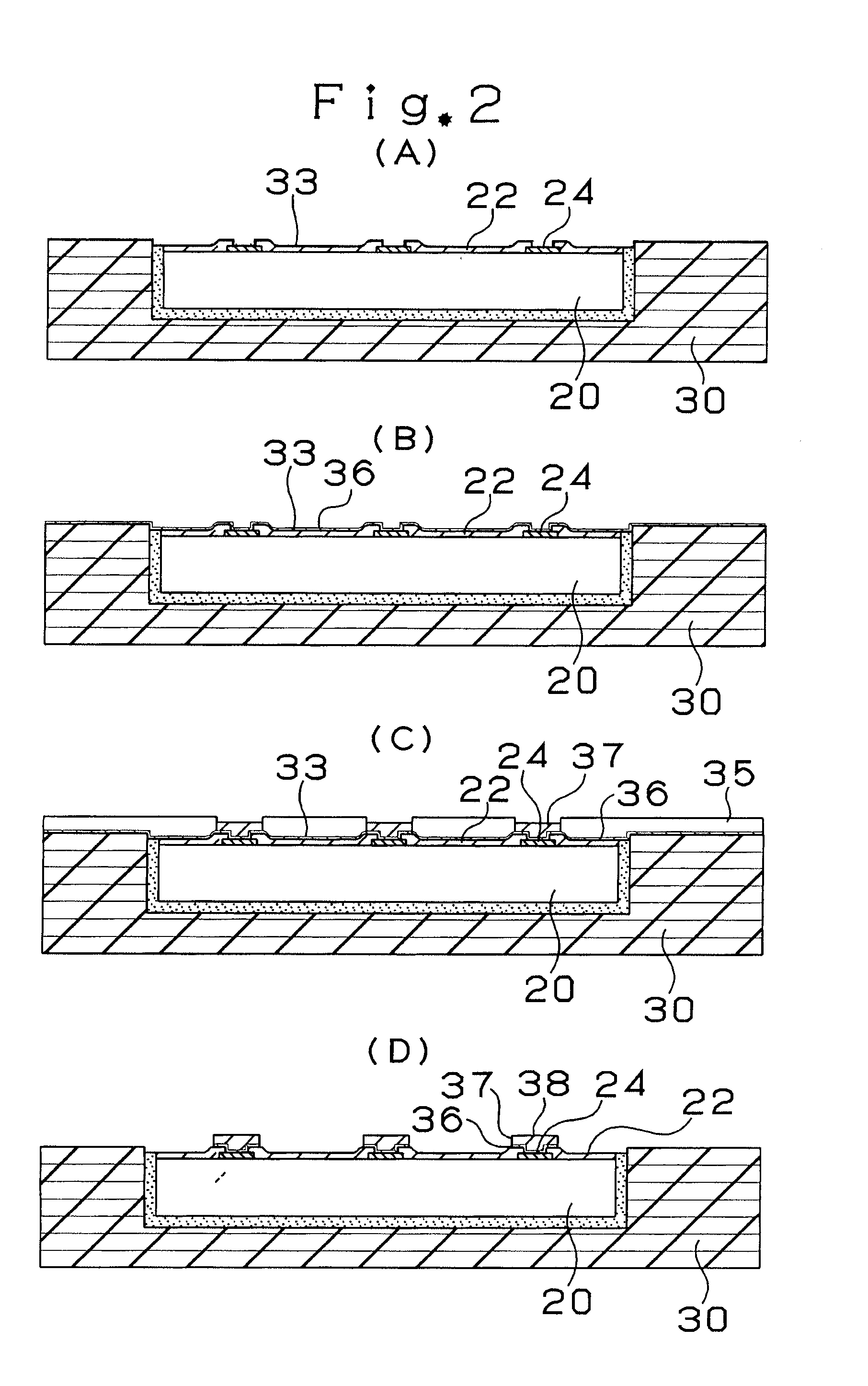

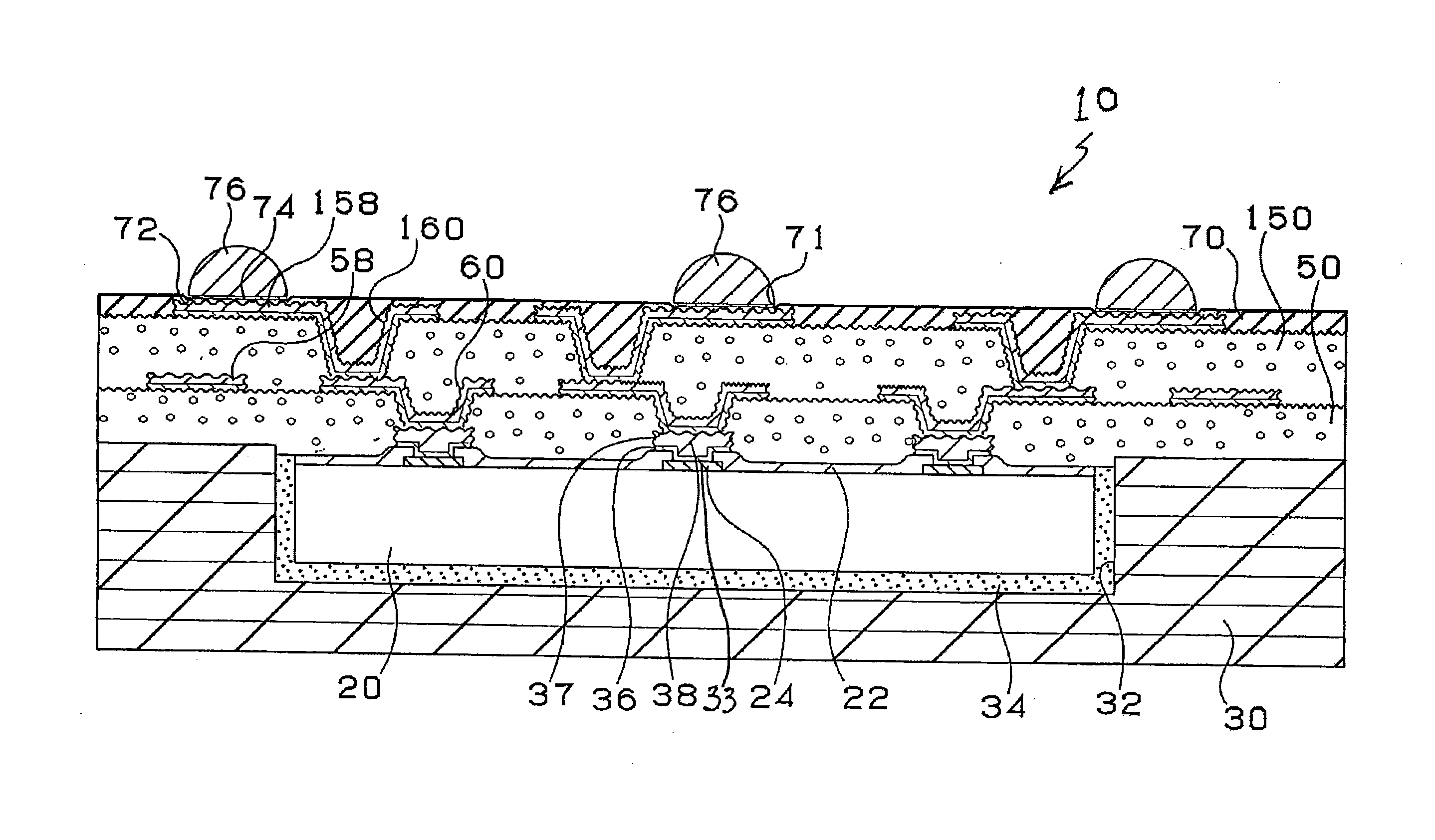

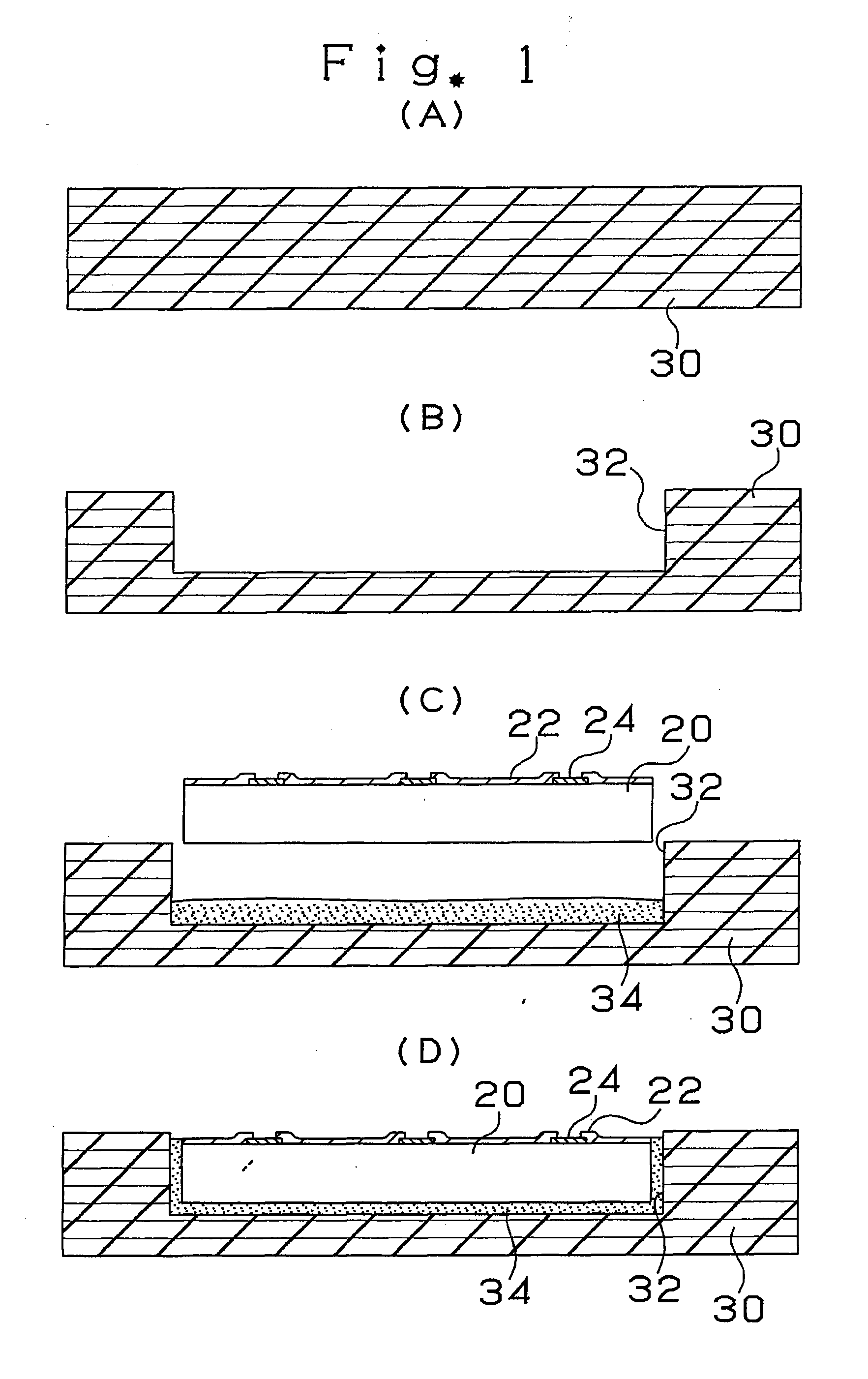

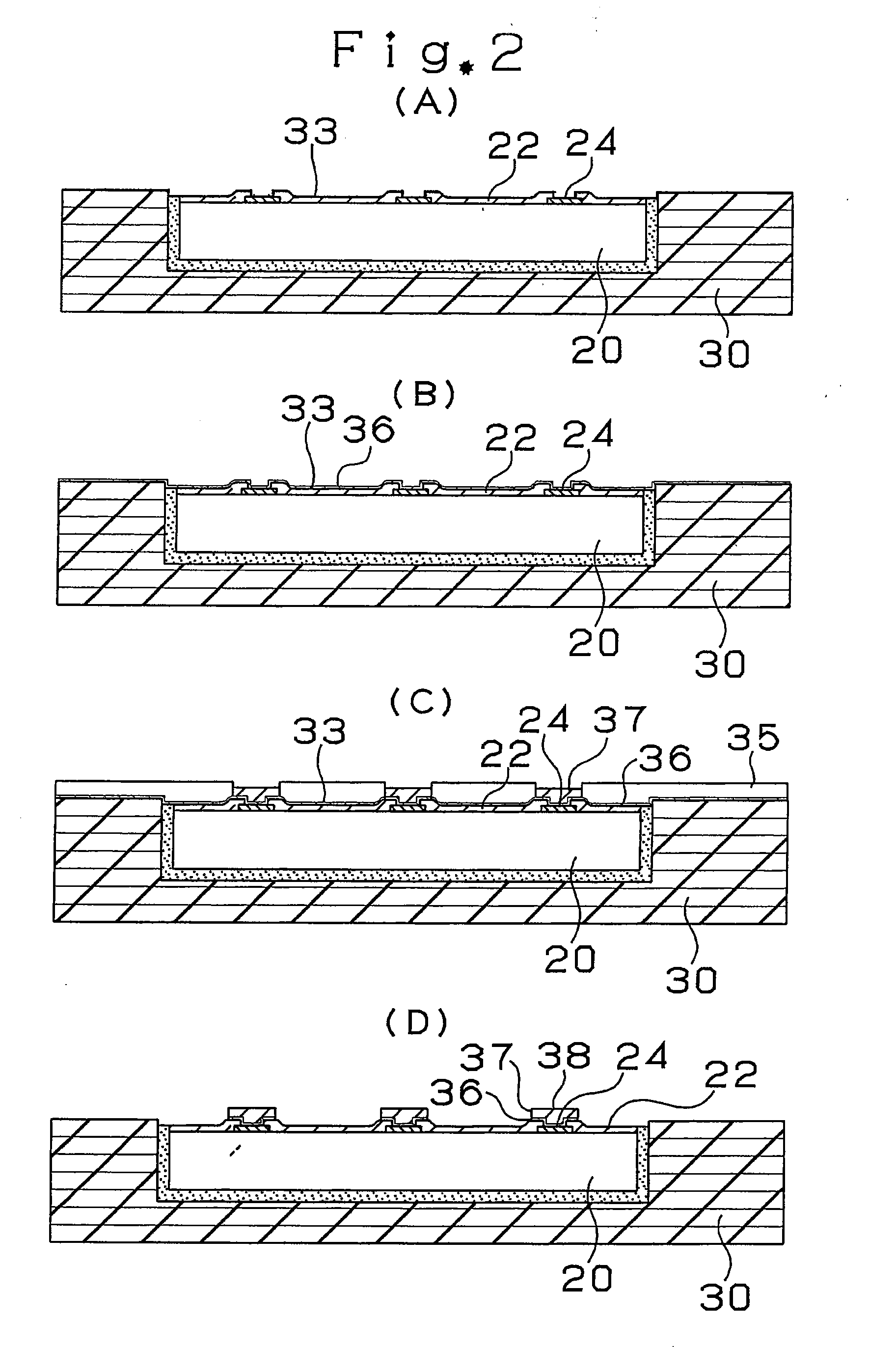

Multilayer printed wiring board and method for producing multilayer printed wiring board

InactiveUS6909054B2Low yieldWithout usingSemiconductor/solid-state device detailsPrinted electric component incorporationCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electrically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

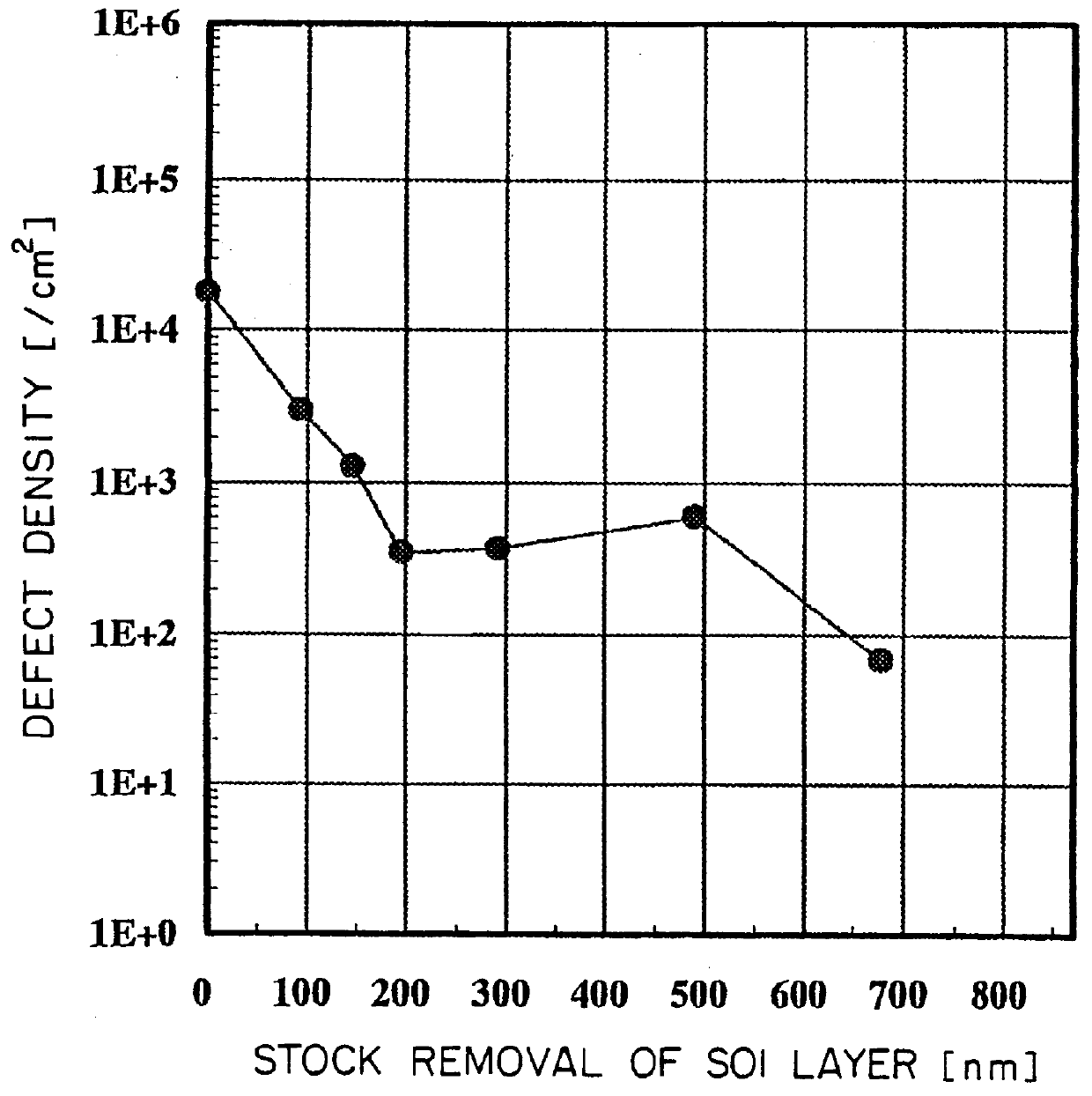

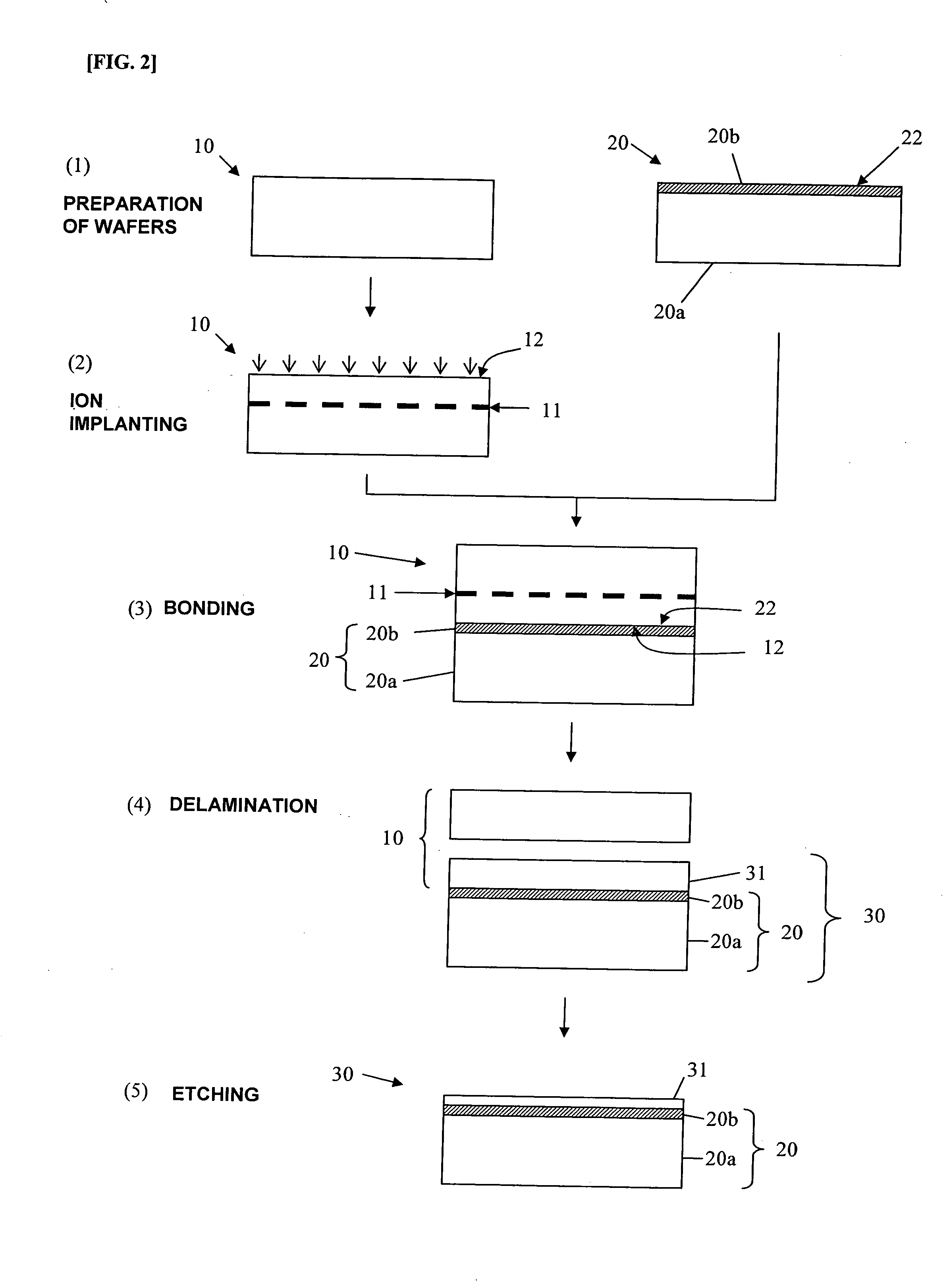

Method of fabricating an SOI wafer and SOI wafer fabricated thereby

InactiveUS6140210AReliably removedUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingNoble gasEtching

In a method of fabricating an SOI wafer, an oxide film is formed on the surface of at least one of two silicon wafers; hydrogen ions or rare gas ions are implanted into the upper surface of one of the two silicon wafers in order to form a fine bubble layer (enclosed layer) within the wafer; the ion-implanted silicon wafer is superposed on the other silicon wafer such that the ion-implanted surface comes into close contact with the surface of the other silicon wafer via the oxide film; heat treatment is performed in order to delaminate a portion of the ion-implanted wafer while the fine bubble layer is used as a delaminating plane, in order to form a thin film to thereby obtain an SOI wafer. In the method, a defect layer at the delaminated surface of the thus-obtained SOI wafer is removed to a depth of 200 nm or more through vapor-phase etching, and then mirror polishing is performed. Therefore, the obtained SOI wafer has an extremely low level of defects and a high thickness uniformity.

Owner:SHIN-ETSU HANDOTAI CO LTD

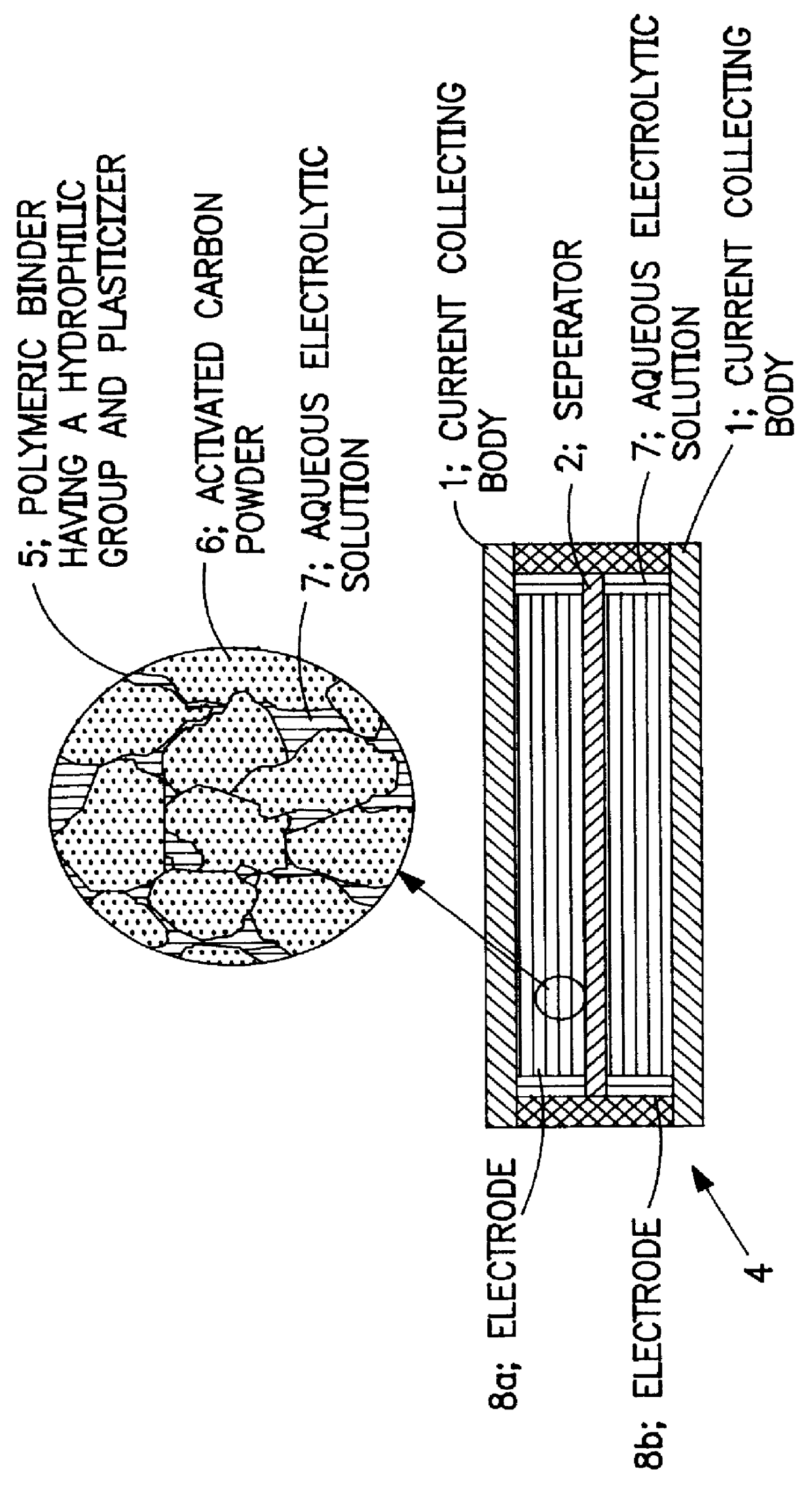

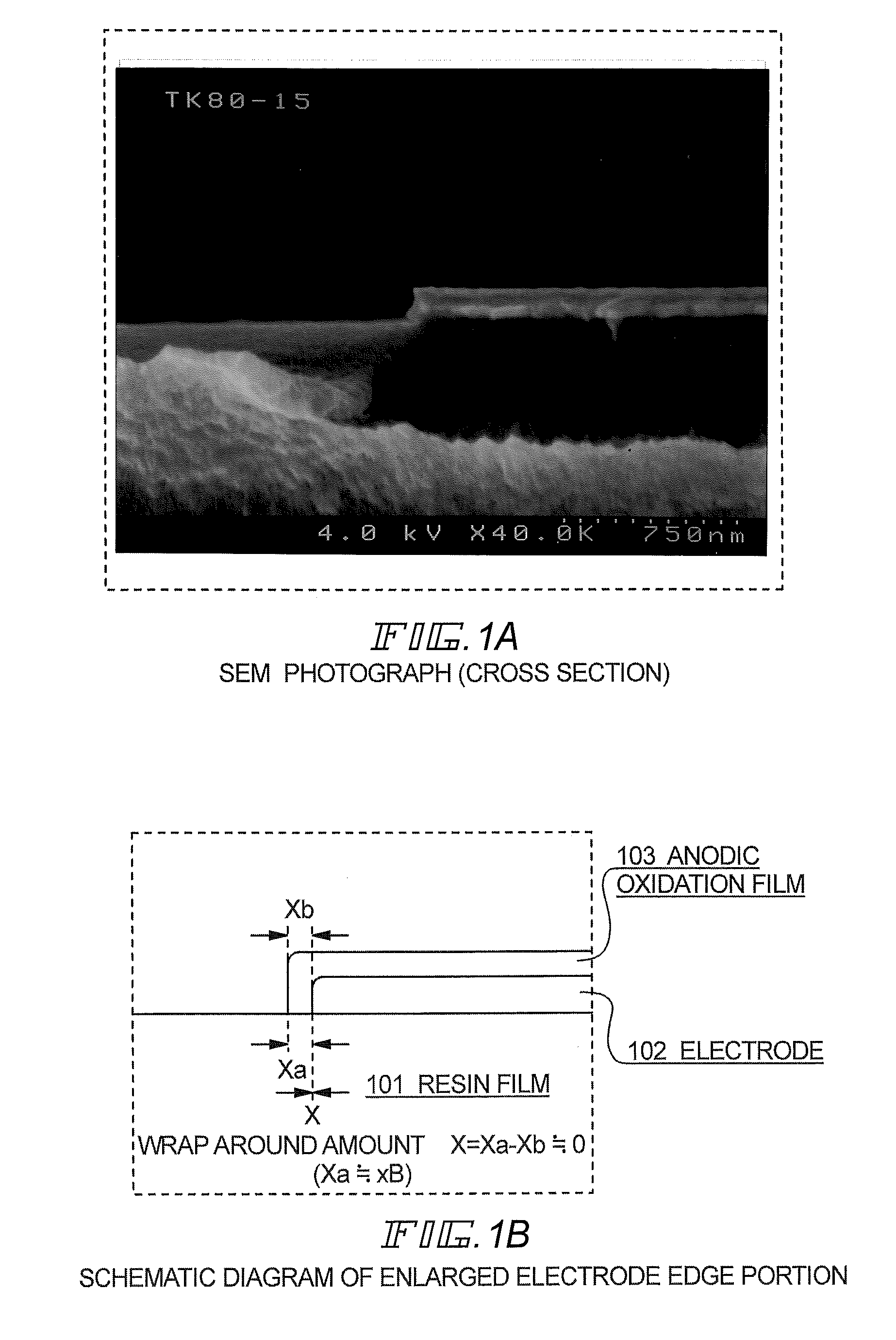

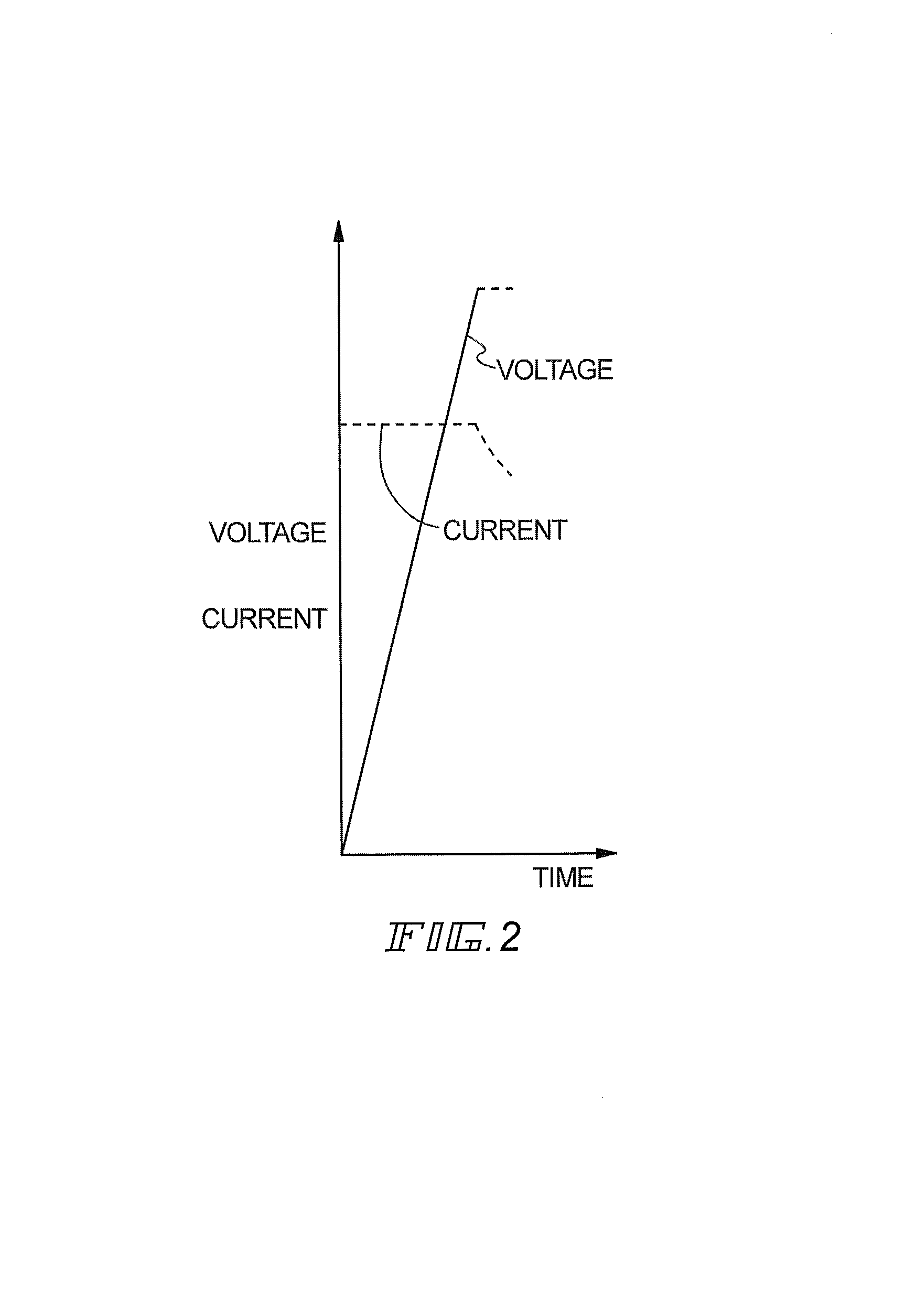

Electric double layer capacitor

InactiveUS6031712AImprove wettabilityLower internal resistanceHybrid capacitor electrolytesLiquid electrolytic capacitorsActivated carbonPlasticizer

An aqueous electric double layer capacitor having excellent wettability with aqueous electrolytic solution, low internal resistance, excellent easiness of forming uniform, thin and wide films and mechanical strength. Activated carbon powder, a polymeric binder having a hydrophilic group and a plasticizer are fully mixed to form a film which is then dried to form an electrode. By using a polymer having a hydrophilic group as a binder, wettability between an aqueous electrolytic solution and the electrode is improved and contact resistance between an electrolysis solution and the electrode can be reduced. In addition, by adding a plasticizer, the amount of polymer binder required to form a thin type electrode can be reduced, thus providing an aqueous solution electric double layer capacitor with low internal resistance.

Owner:TOKIN CORP

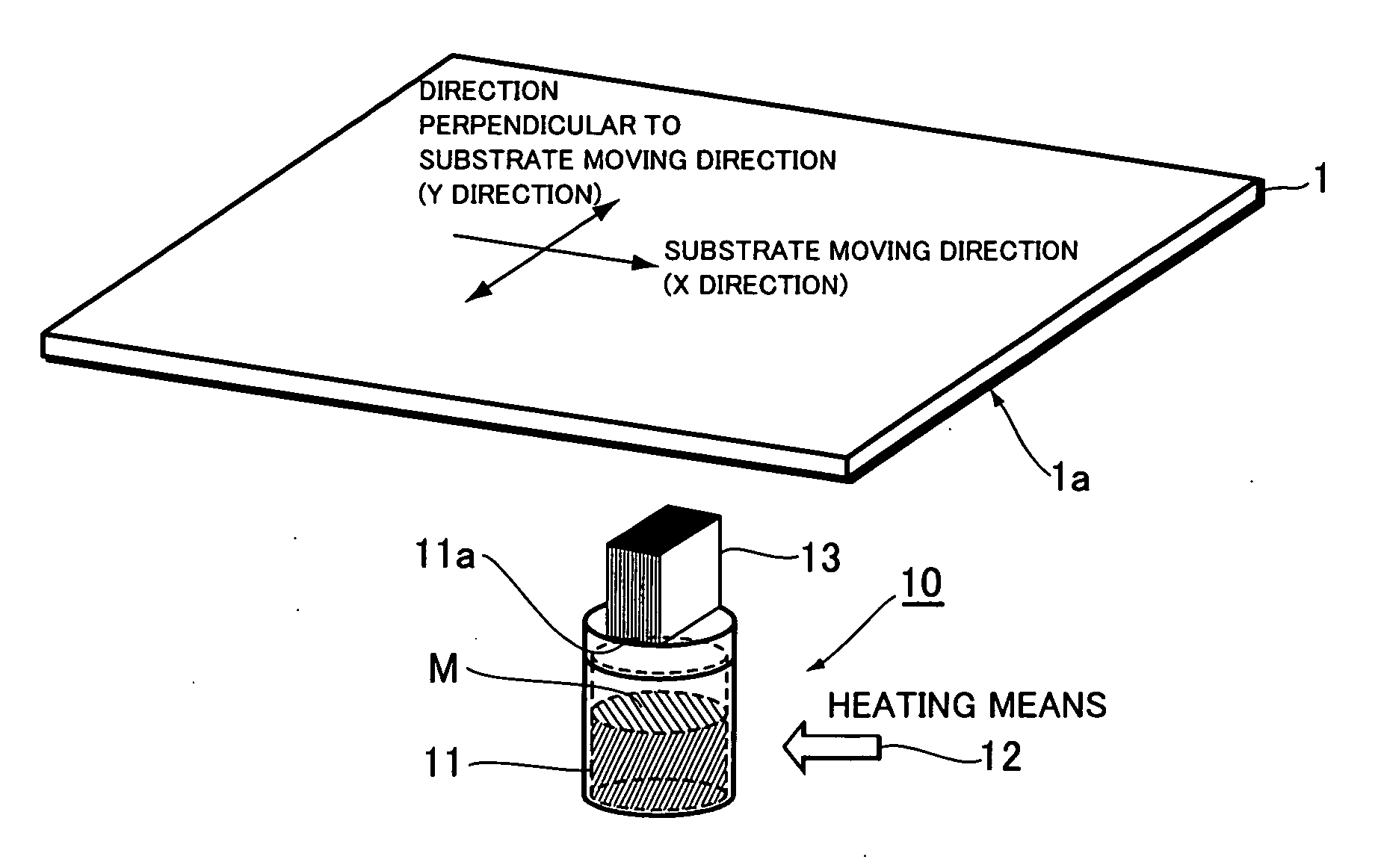

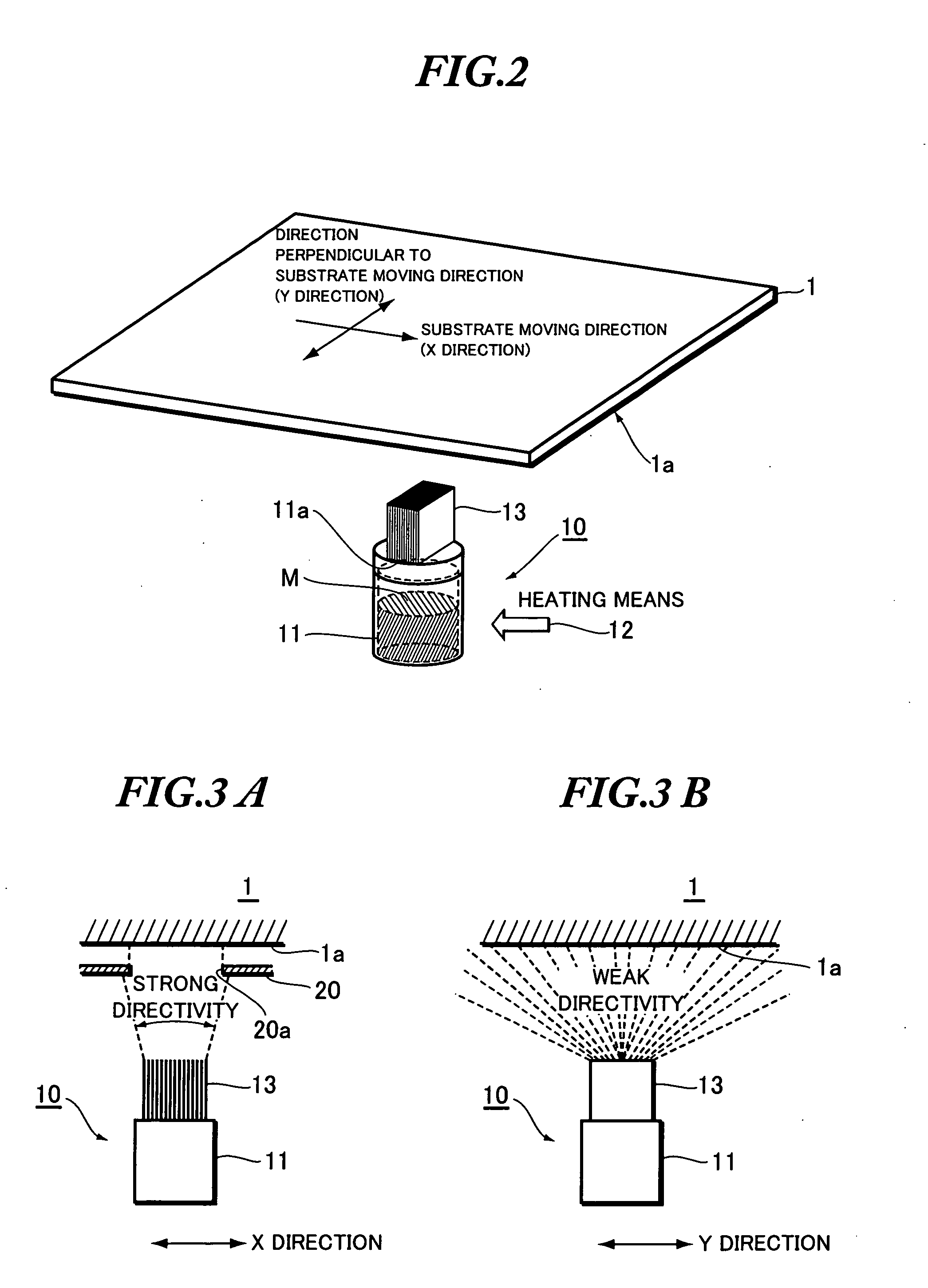

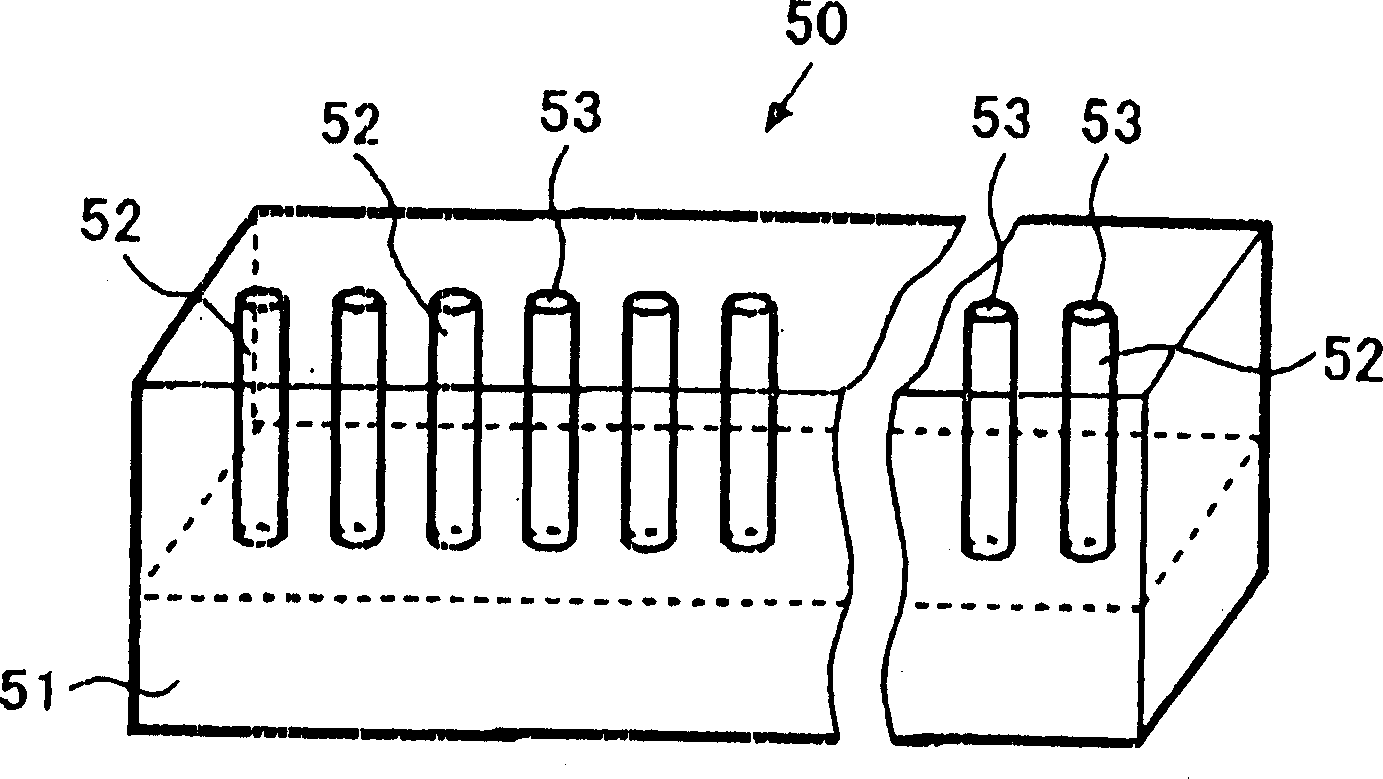

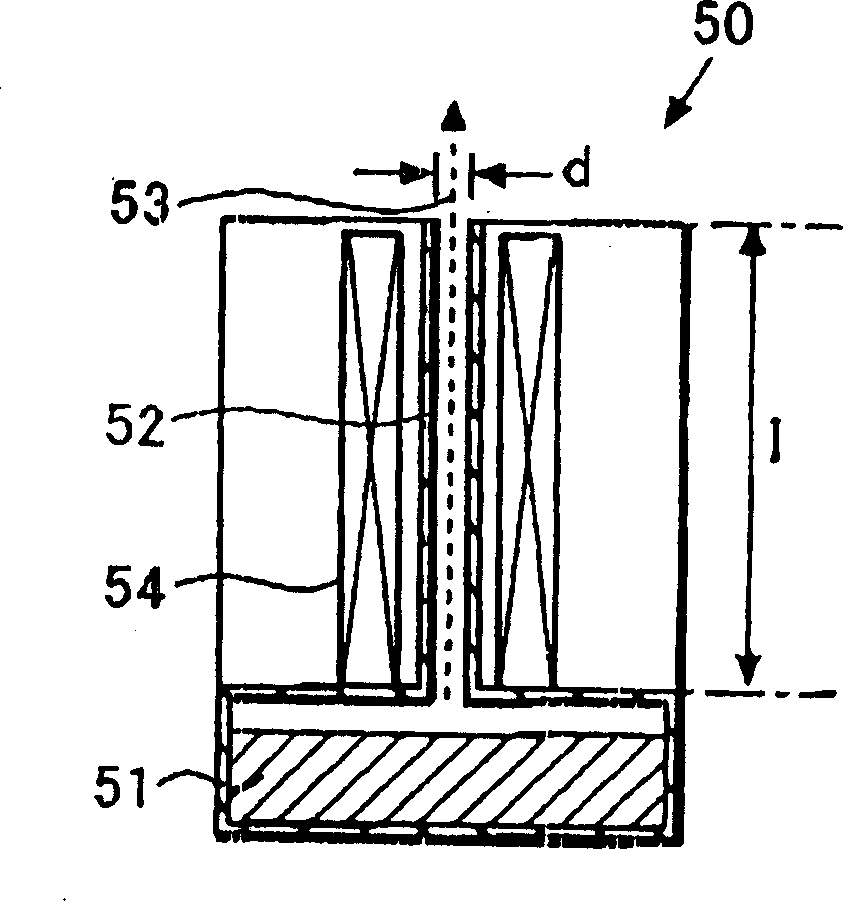

Film formation source, vacuum film formation apparatus, organic EL panel and method of manufacturing the same

InactiveUS20050263074A1Acceptable precisionImprove utilization efficiencyLiquid crystal compositionsElectroluminescent light sourcesEngineeringFree space

A film formation source of a vacuum film formation apparatus for forming thin film on the film formation surface of a substrate comprises: a material accommodating unit containing a film formation material; heating means for heating the film formation material contained within the material accommodating unit; a film formation flow control unit provided at an emission outlet of the material accommodating unit for controlling the direction of the film formation flow. The film formation flow control unit provides a strong directivity to the film formation flow with respect to the moving direction of the film formation surface relative to the film formation source.

Owner:TOHOKU PIONEER CORP

Multilayer printed circuit board and multilayer printed circuit board manufacturing method

InactiveUS20070227765A1Low yieldWithout usingPrinted electric component incorporationSemiconductor/solid-state device detailsCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a transition layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the transition layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

Diffuser plate with slit valve compensation

InactiveUS20080020146A1Uniform plasma distributionUniform film thicknessLiquid surface applicatorsMolten spray coatingVALVE PORTCathode

The present invention generally comprises a diffuser plate for a PECVD chamber. The diffuser plate comprises a plurality of hollow cathode cavities. The edge of the diffuser plate that will reside closest to a slit valve within a processing chamber may have the shape and / or size of the hollow cathode cavities adjusted to compensate for the proximity to the slit valve. By adjusting the shape and / or size of the hollow cathode cavities closest to the slit valve, the diffuser plate may permit a uniform plasma distribution across the processing chamber and thus, a uniform film thickness upon a substrate during a PECVD process.

Owner:APPLIED MATERIALS INC

Method for manufacturing organic electroluminescent display device

InactiveCN1489419AImprove directivityUniform film thicknessElectroluminescent light sourcesSolid-state devicesBeam directionEngineering

A vapor-depositing mask is disposed adjacent a surface of a substrate disposed in a vacuum chamber, vapor-depositing beams containing an organic EL material are generated by a vapor-depositing beam generator, the vapor-depositing beams pass through openings in the vapor-depositing mask, and the organic EL material is vapor-deposited in a predetermined region on the surface of the substrate. The vapor-depositing beams are guided through a plurality of vapor-depositing beam passing pipes provided in the vapor-depositing beam generator. Alternatively, the vapor-depositing beams generated by the vapor-depositing beam generator are guided through a vapor-depositing beam direction adjusting board having a plurality of vapor-depositing beam passing holes. This enhances directional uniformity of the vapor-depositing beams, thereby enabling making each film thickness of organic EL material layers uniform and thus enhancing precision of forming patterns of the layers.

Owner:SANYO ELECTRIC CO LTD

Resin composition for printing plate

InactiveUS20100093119A1Good solvent resistanceImprove the immunityPhotosensitive materialsLayered productsPolymer sciencePolycarbonate

Disclosed is a polymer having excellent solvent resistance which can be produced by using a polycarbonate diol having a repeating unit represented by the formula (1) and / or (2), having a hydroxyl group at both termini, and having a number average molecular weight of from 300 to 50,000:wherein R1 represents a linear or branched hydrocarbon group having 2 to 50 carbon atoms; and n represents an integer of 2 to 50,wherein R2 represents a linear or branched hydrocarbon group having 10 to 50 carbon atoms.

Owner:ASAHI KASEI E-MATERIALS CORPORATION

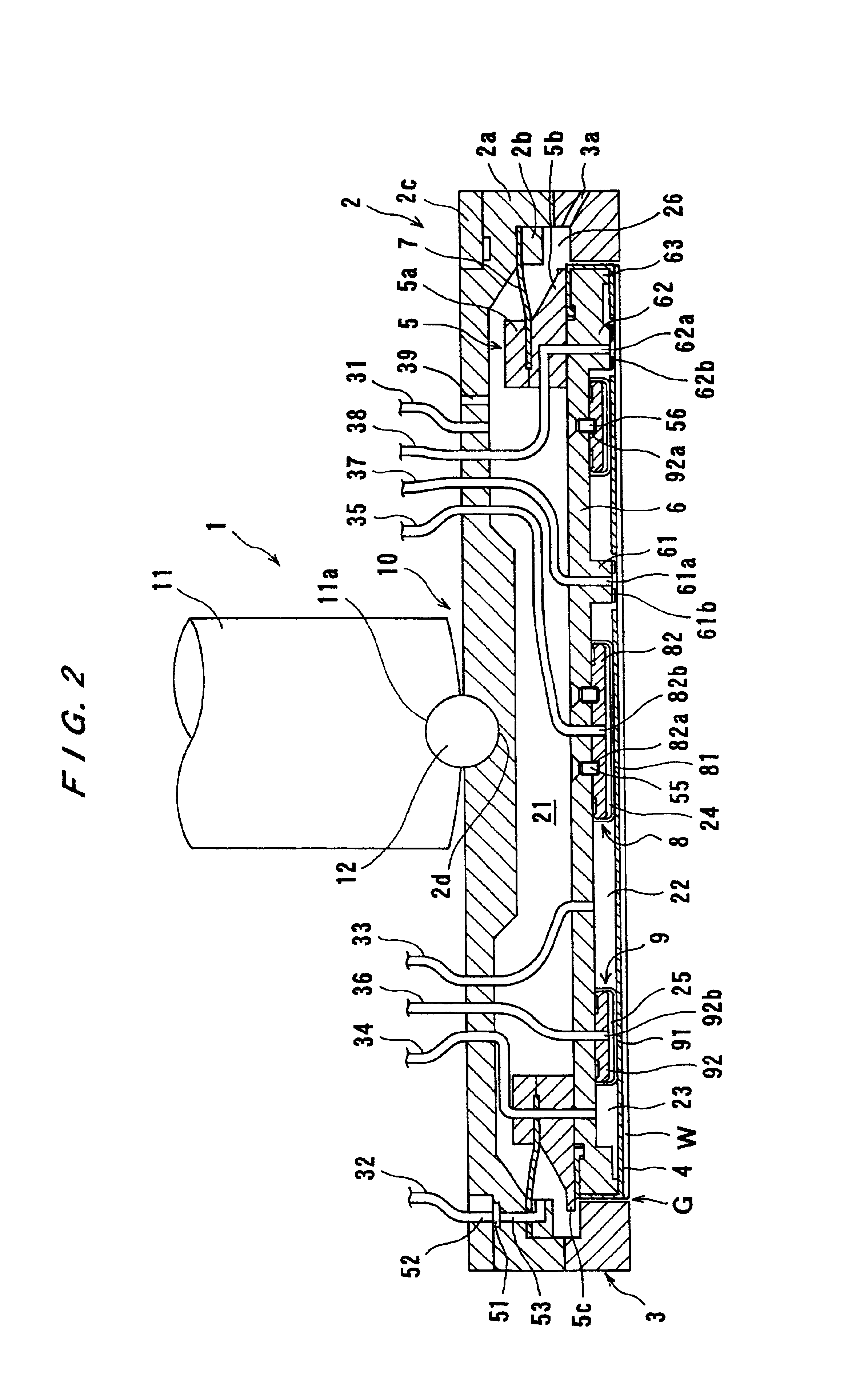

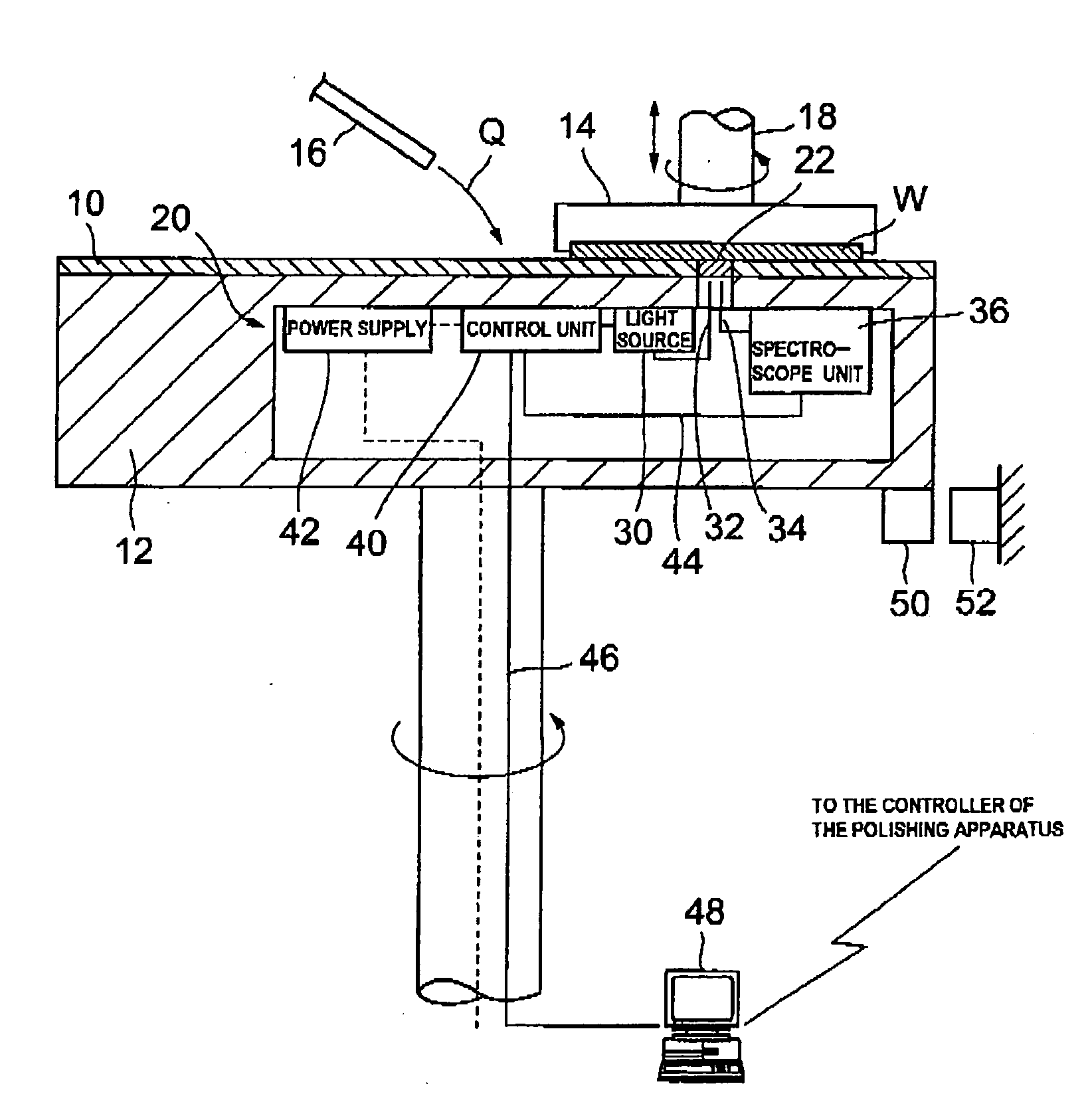

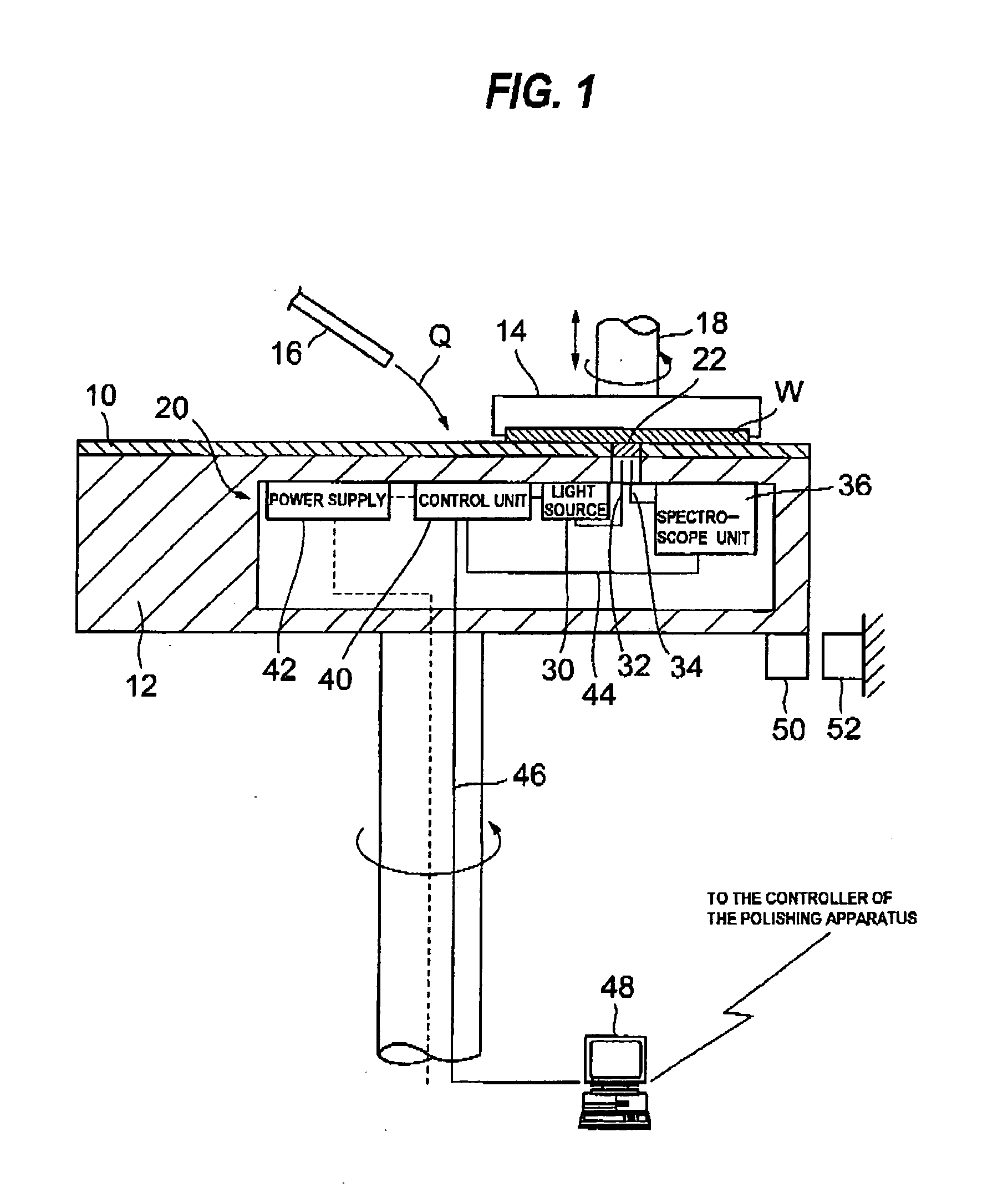

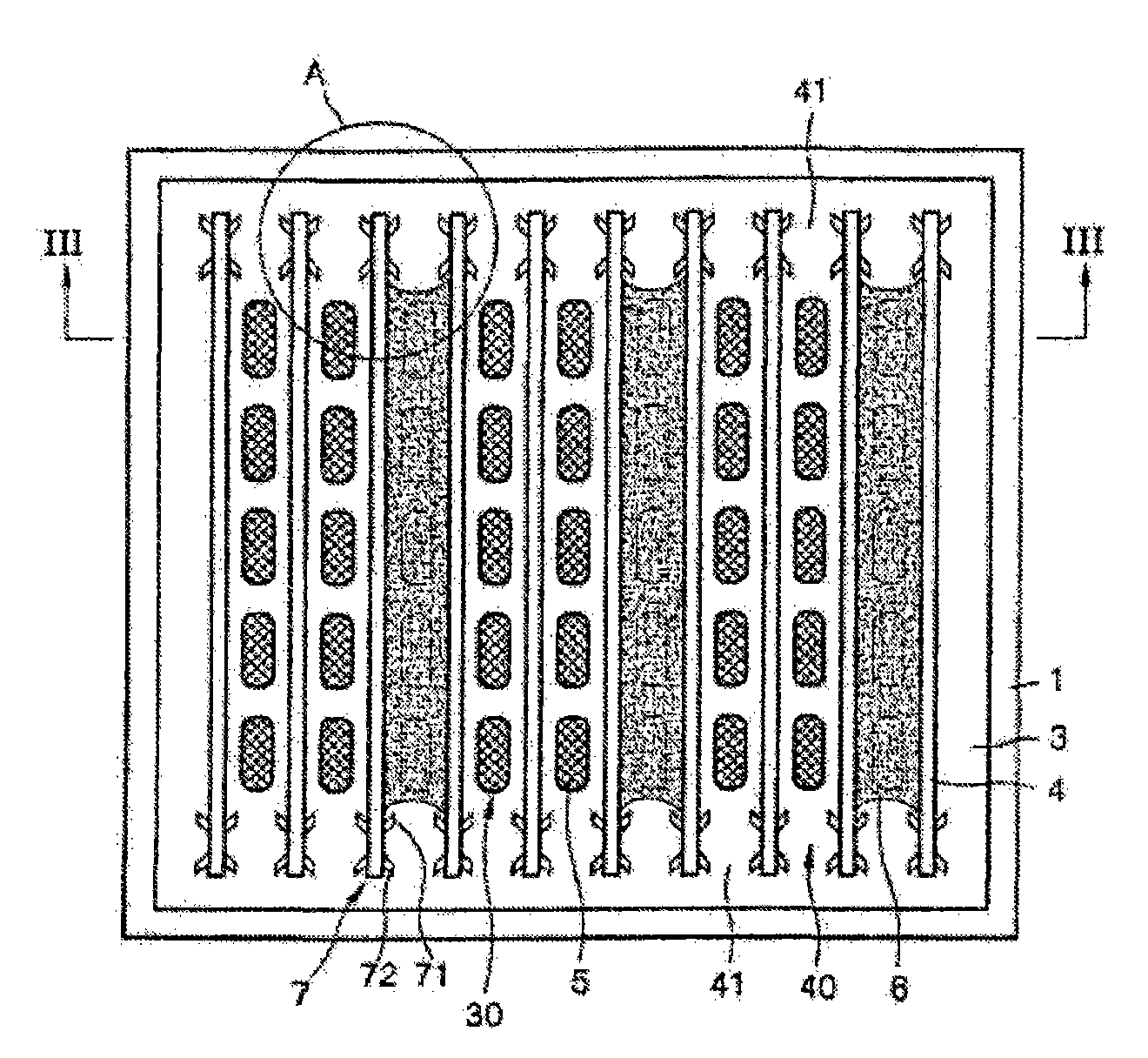

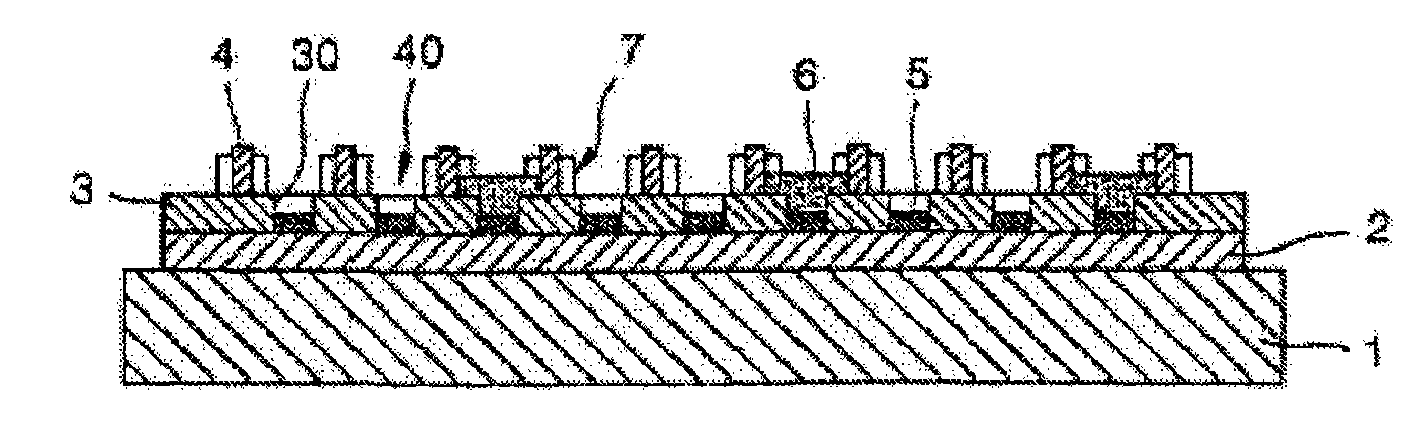

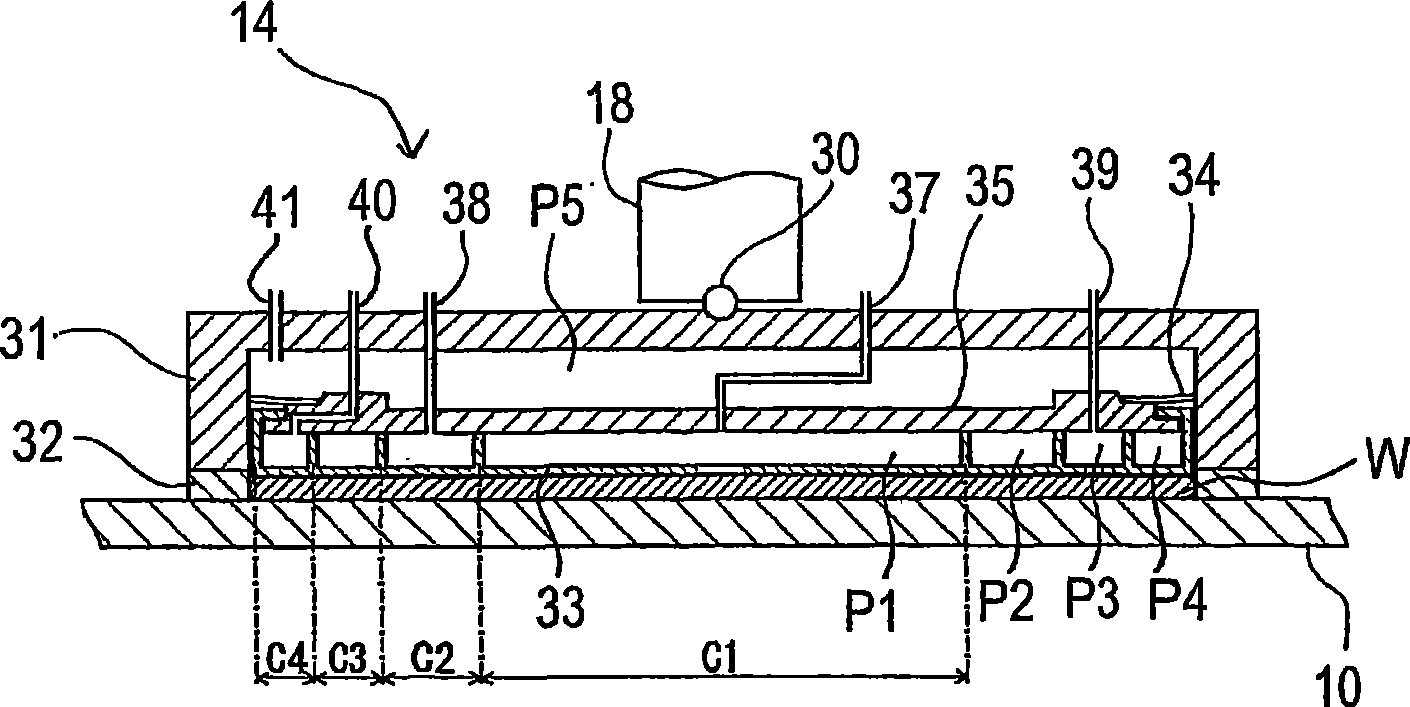

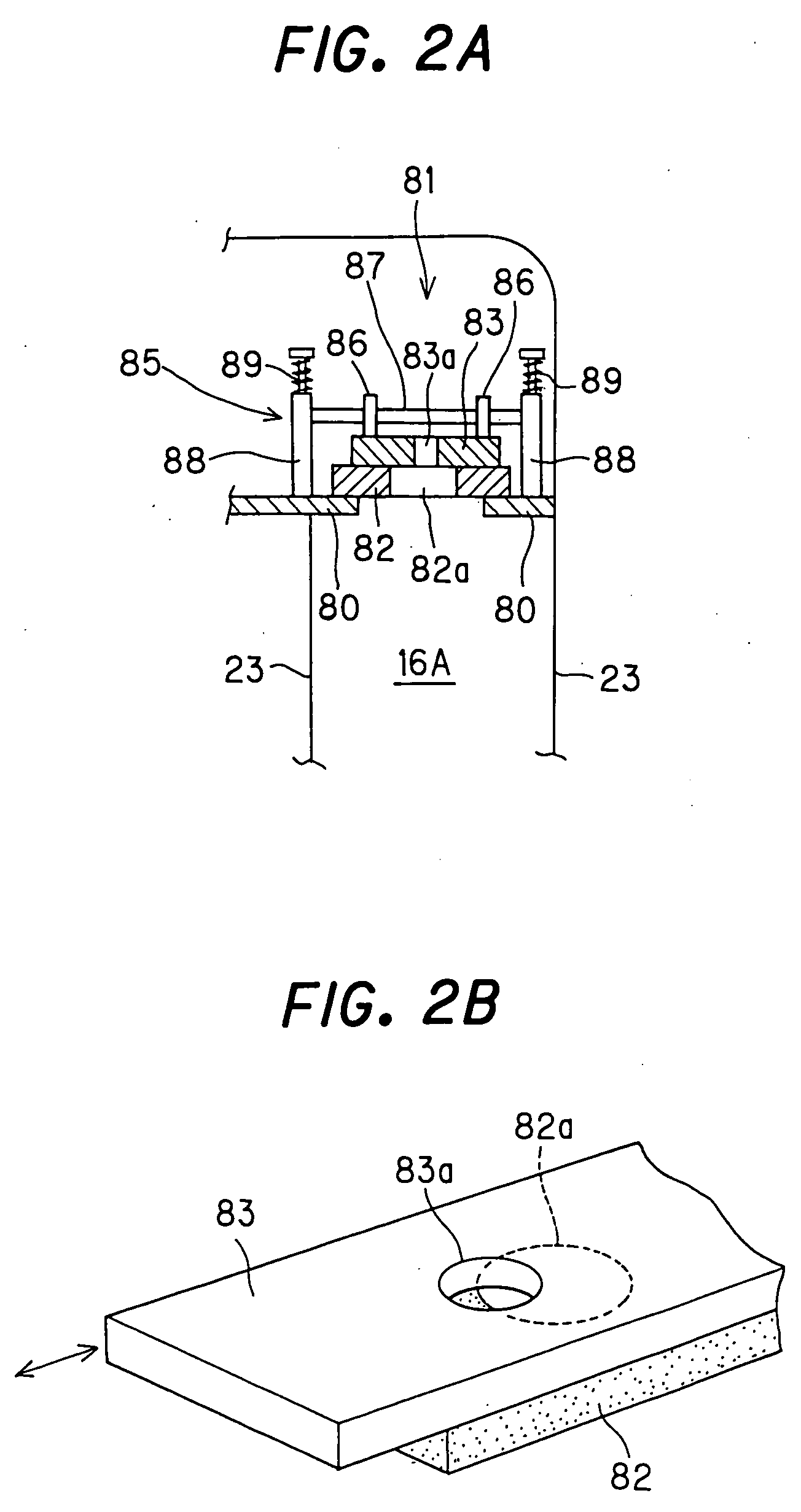

Substrate holding apparatus

InactiveUS6852019B2Uniform film thicknessSmooth movementPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention relates to a substrate holding apparatus for holding a substrate to be polished and pressing the substrate against a polishing surface. The substrate holding apparatus comprises a top ring body for holding a substrate, an elastic pad for being brought into contact with the substrate, and a support member for supporting the elastic pad. The substrate holding apparatus further comprises a contact member mounted on a lower surface of the support member and disposed in a space formed by the elastic pad and the support member. The contact member has an elastic membrane for being brought into contact with the elastic pad. A first pressure chamber is defined in the contact member, and a second pressure chamber is defined outside of the contact member. The substrate holding apparatus further comprises a fluid source for independently supplying a fluid into, or creating a vacuum in, the first pressure chamber and the second pressure chamber.

Owner:EBARA CORP

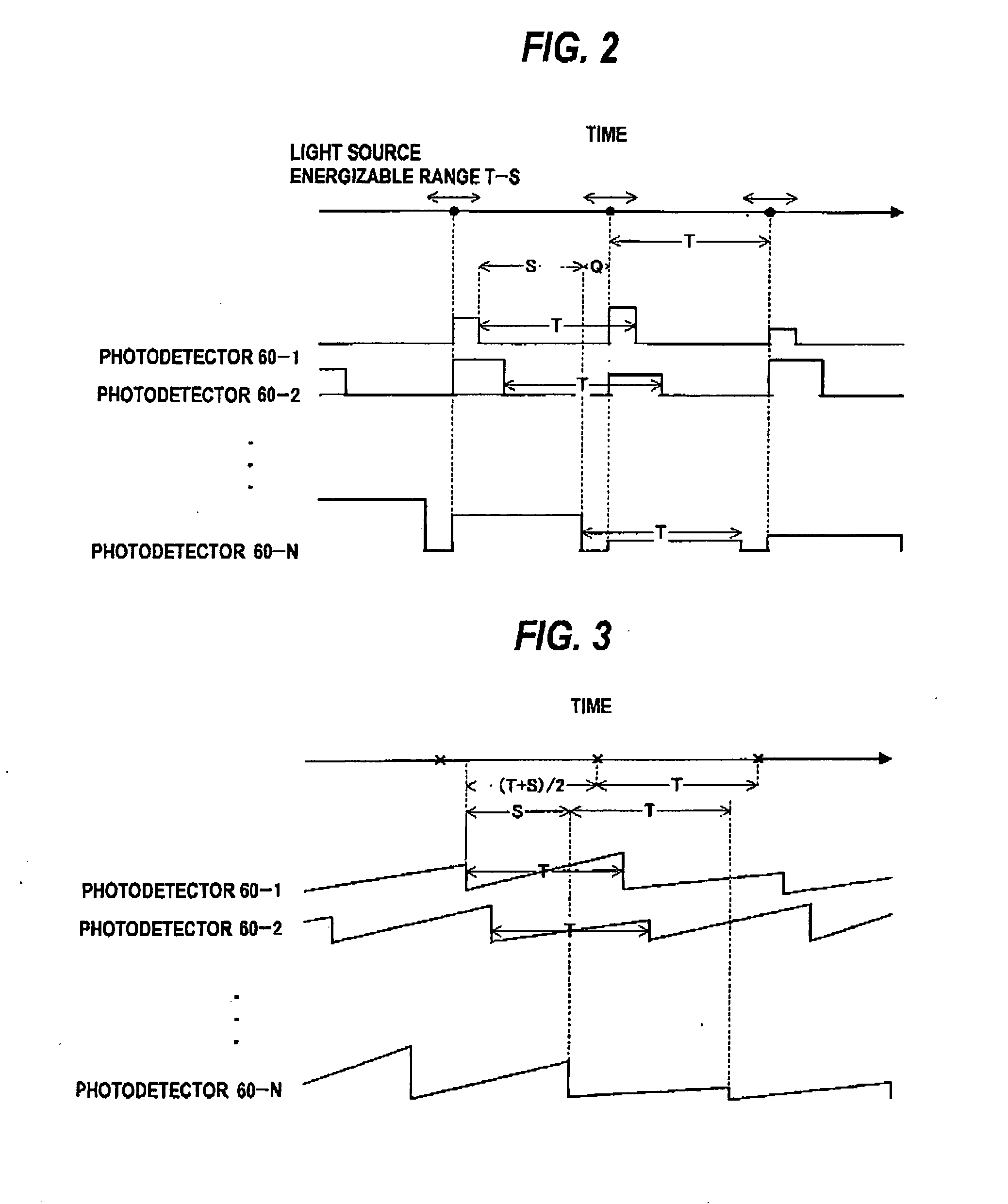

Processing end point detection method, polishing method,and polishing apparatus

ActiveUS20100015889A1Accurate polishing end point detectionUniform film thicknessSemiconductor/solid-state device testing/measurementSolid-state devicesLength waveArtificial intelligence

The present invention relates to a processing end point detection method for detecting a timing of a processing end point (e.g., polishing stop, changing of polishing conditions) by calculating a characteristic value of a surface of a workpiece (an object of polishing) such as a substrate. This method includes producing a spectral waveform indicating a relationship between reflection intensities and wavelengths at a processing end point, with use of a reference workpiece or simulation calculation, based on the spectral waveform, selecting wavelengths of a local maximum value and a local minimum value of the reflection intensities, calculating the characteristic value with respect to a surface, to be processed, from reflection intensities at the selected wavelengths, setting a distinctive point of time variation of the characteristic value at a processing end point of the workpiece as the processing end point, and detecting the processing end point of the workpiece by detecting the distinctive point during processing of the workpiece.

Owner:KIOXIA CORP +1

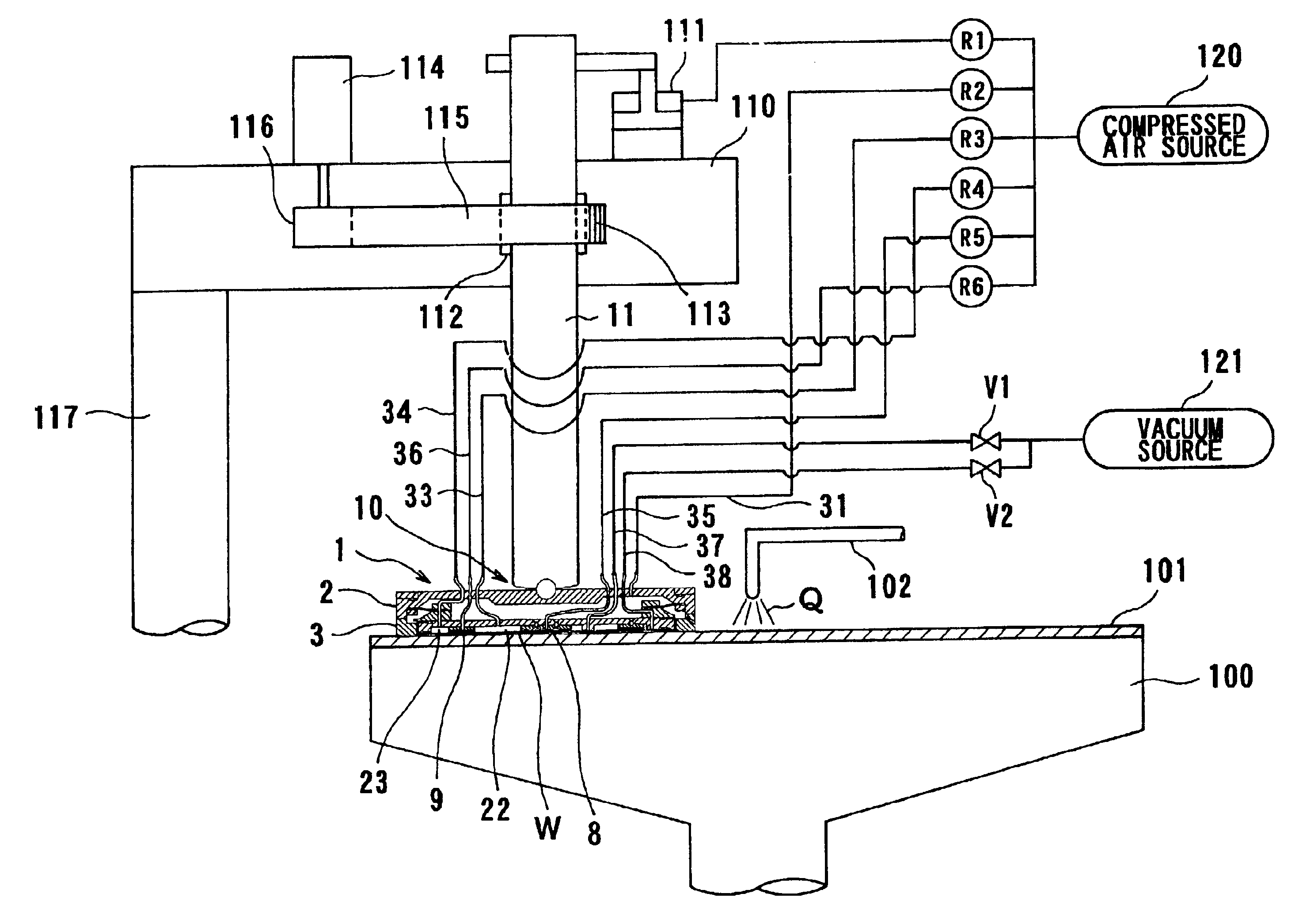

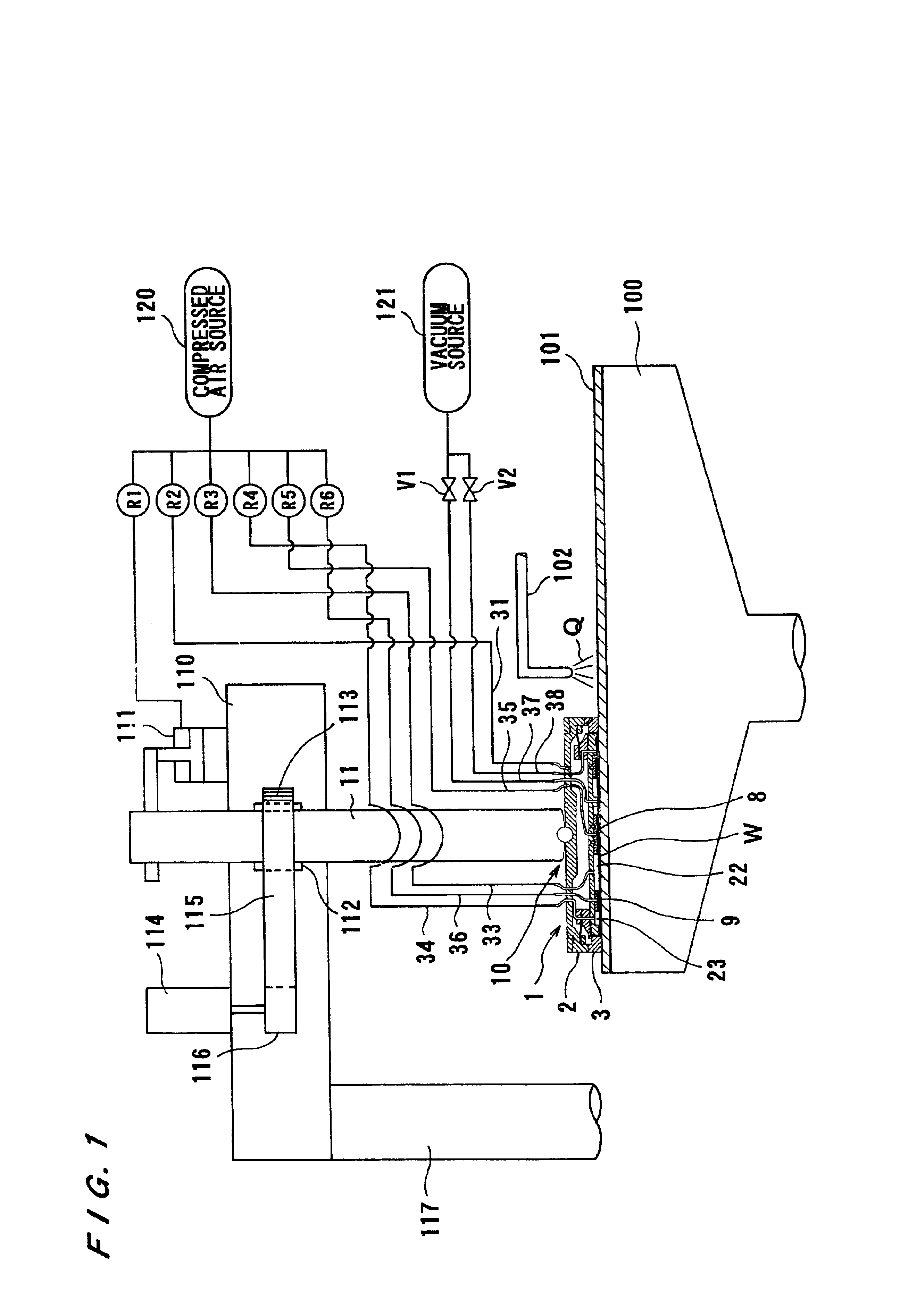

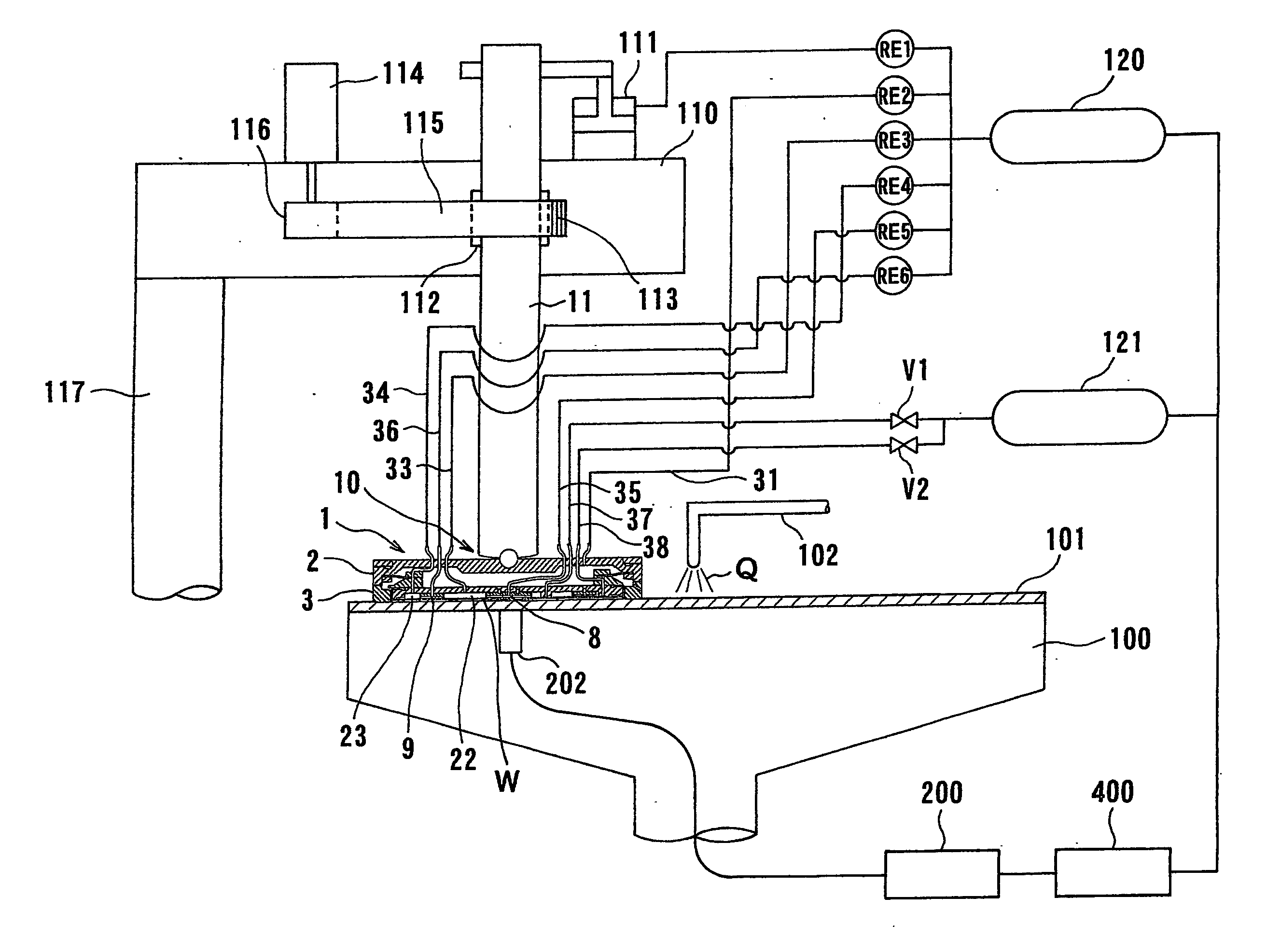

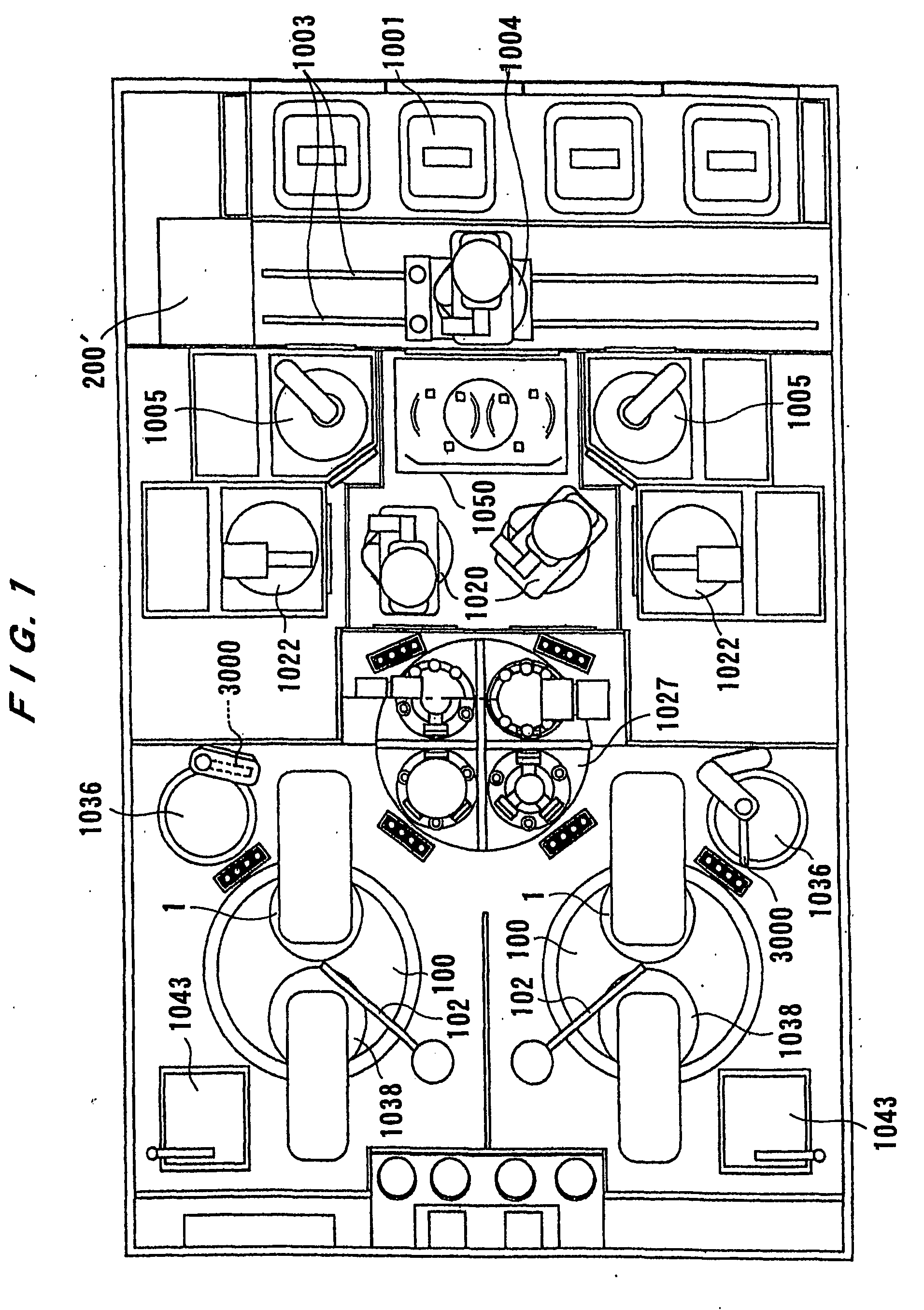

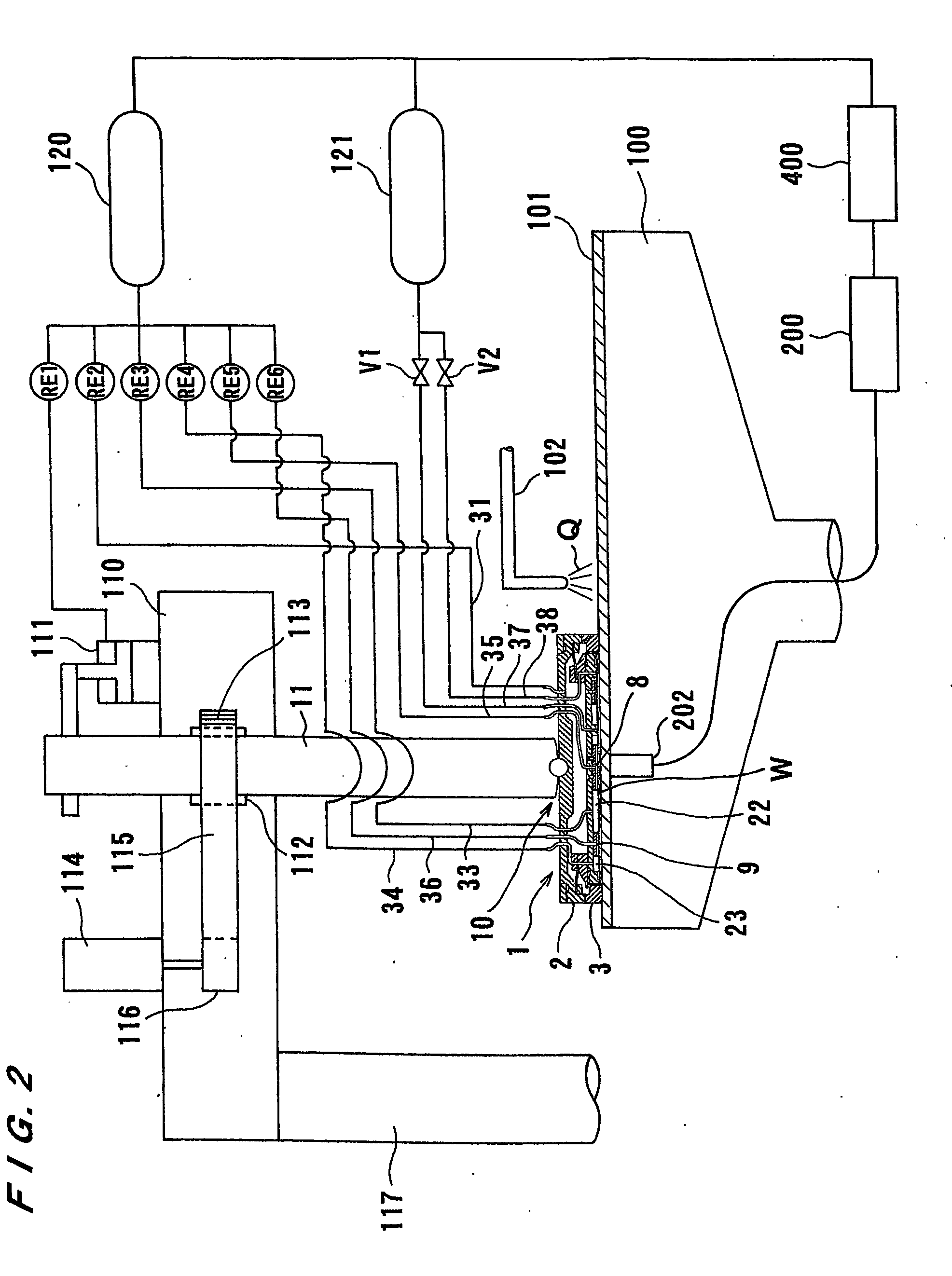

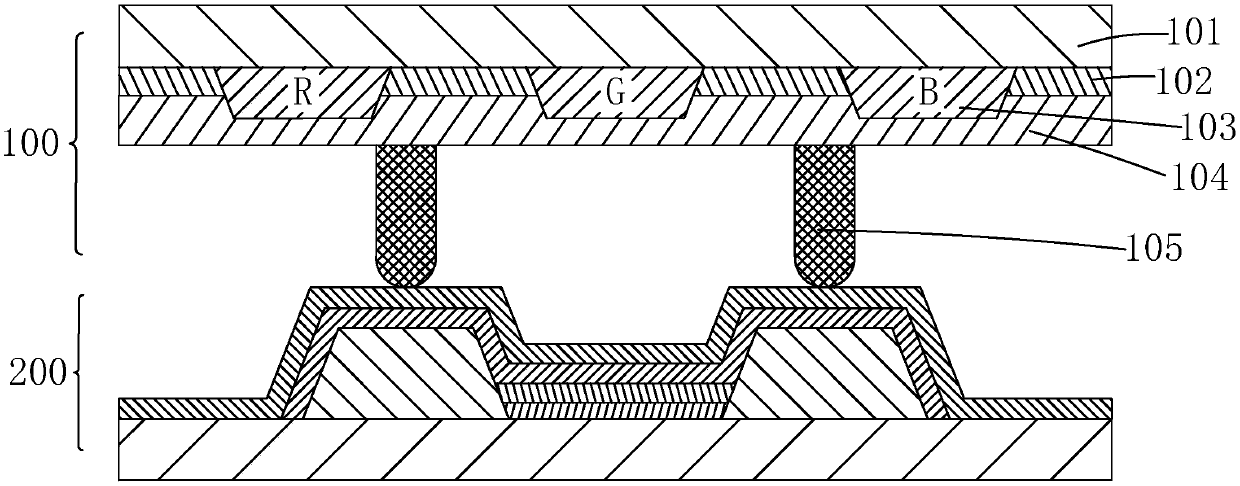

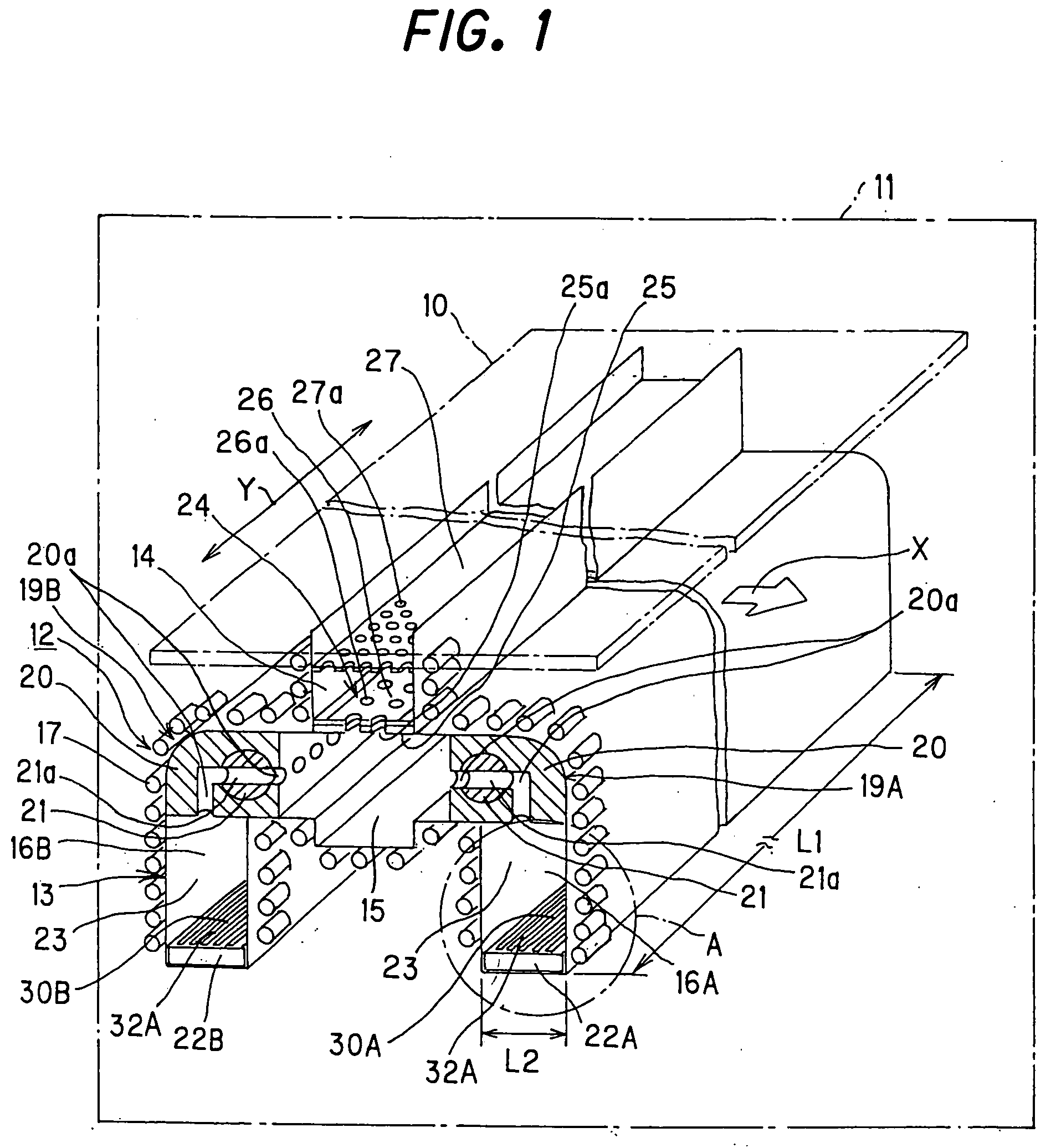

Substrate Polishing Apparatus And Substrate Polishing Method

ActiveUS20080139087A1Uniform film thicknessUniform and stable resultPolishing machinesRevolution surface grinding machinesEngineeringSemiconductor

The present invention relates to a substrate polishing apparatus and a substrate polishing method for polishing a substrate such as a semiconductor wafer to a flat finish. The substrate polishing apparatus includes a polishing table (100) having a polishing surface (101), a substrate holder (1) for holding and pressing a substrate (W) against the polishing surface (101) of the polishing table (100), and a film thickness measuring device (200) for measuring a thickness of a film on the substrate (W). The substrate holder (1) has a plurality of pressure adjustable chambers (22 to 25), and pressures in the respective chambers (22 to 25) are adjusted based on the film thickness measured by the film thickness measuring device (200).

Owner:EBARA CORP

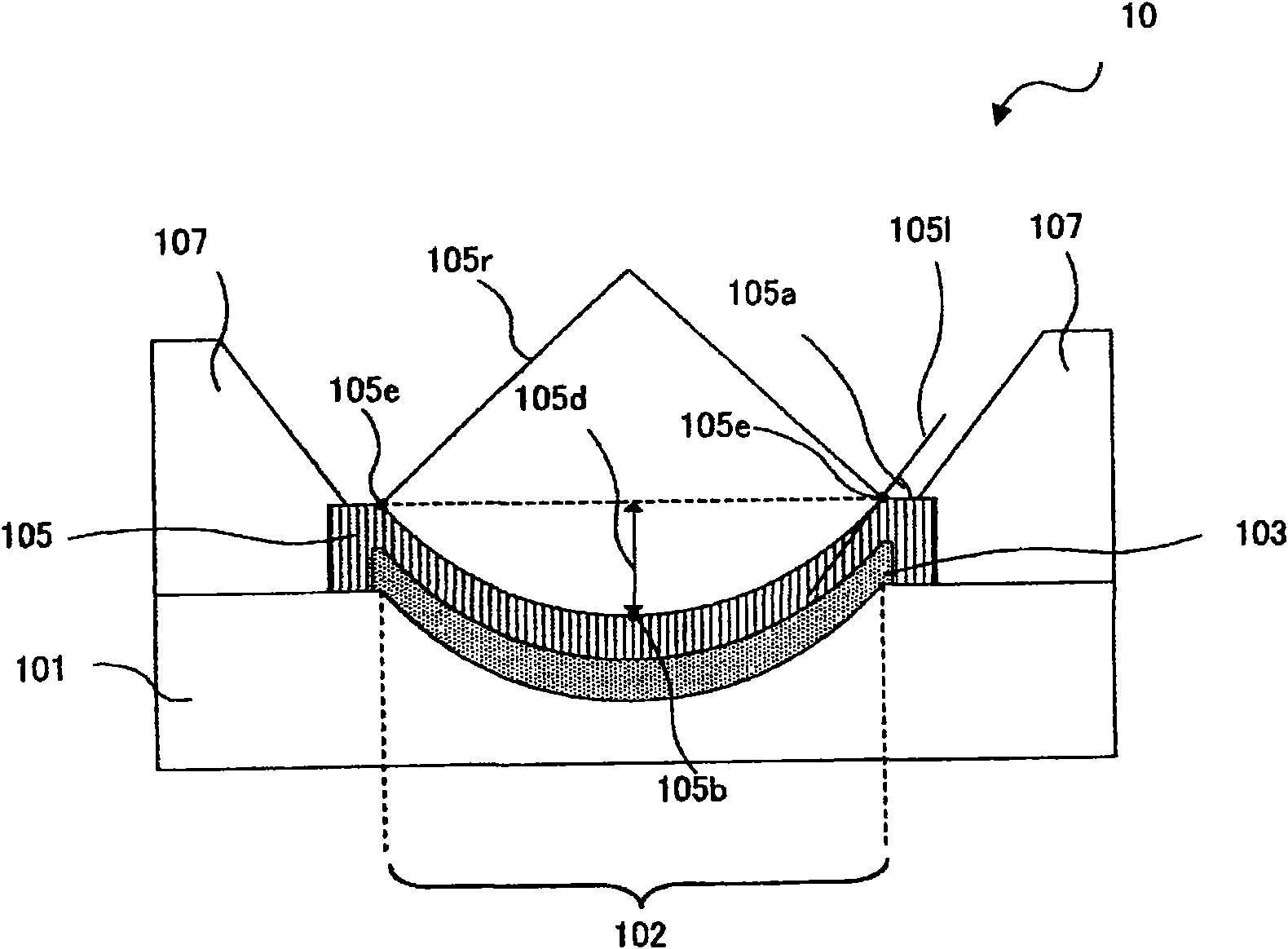

Organic el display panel and manufacturing method thereof

ActiveCN101689559AUniform film thicknessImprove wettabilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerEngineering

Disclosed is an organic EL display panel comprising a substrate, a rectilinear first bank arranged on said substrate and defining a rectilinear area, a second bank defining two or more pixel areas arranged in said rectilinear area, pixel electrodes provided in said pixel areas, a rectilinear organic layer that is arranged in said rectilinear area and that is formed by coating of said pixel areas and said second bank, and a counter electrode arranged on said organic layer. The first bank is higher than the second bank, and the material of the first and second banks is a resin. The anisole contact angle at the apex of said first bank is in the range of 30-60 DEG , and the anisole contact angle at the apex of said second bank is in the range of 5-30 DEG .

Owner:JAPAN DISPLAY DESIGN & DEV CONTRACT CO LTD

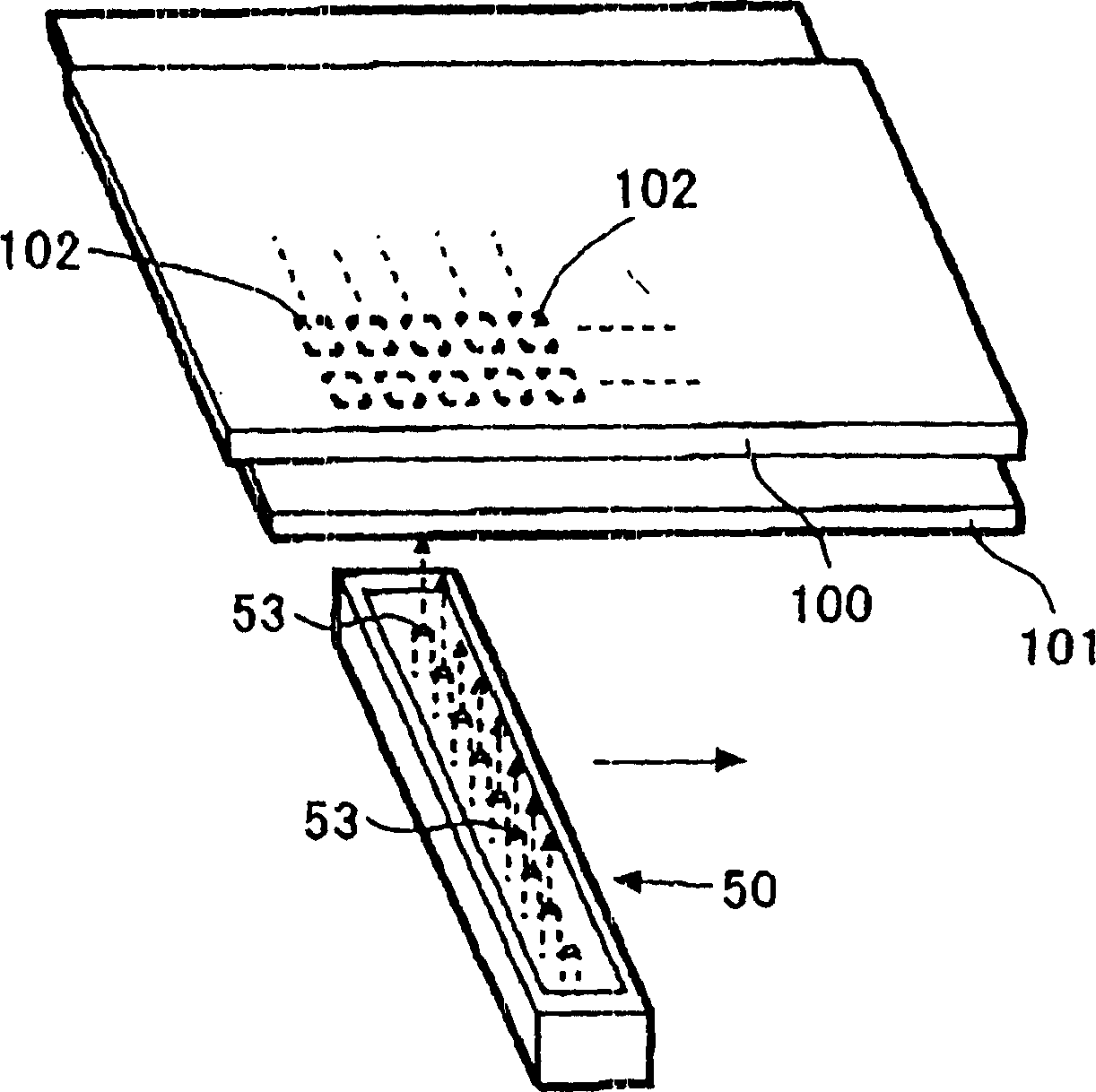

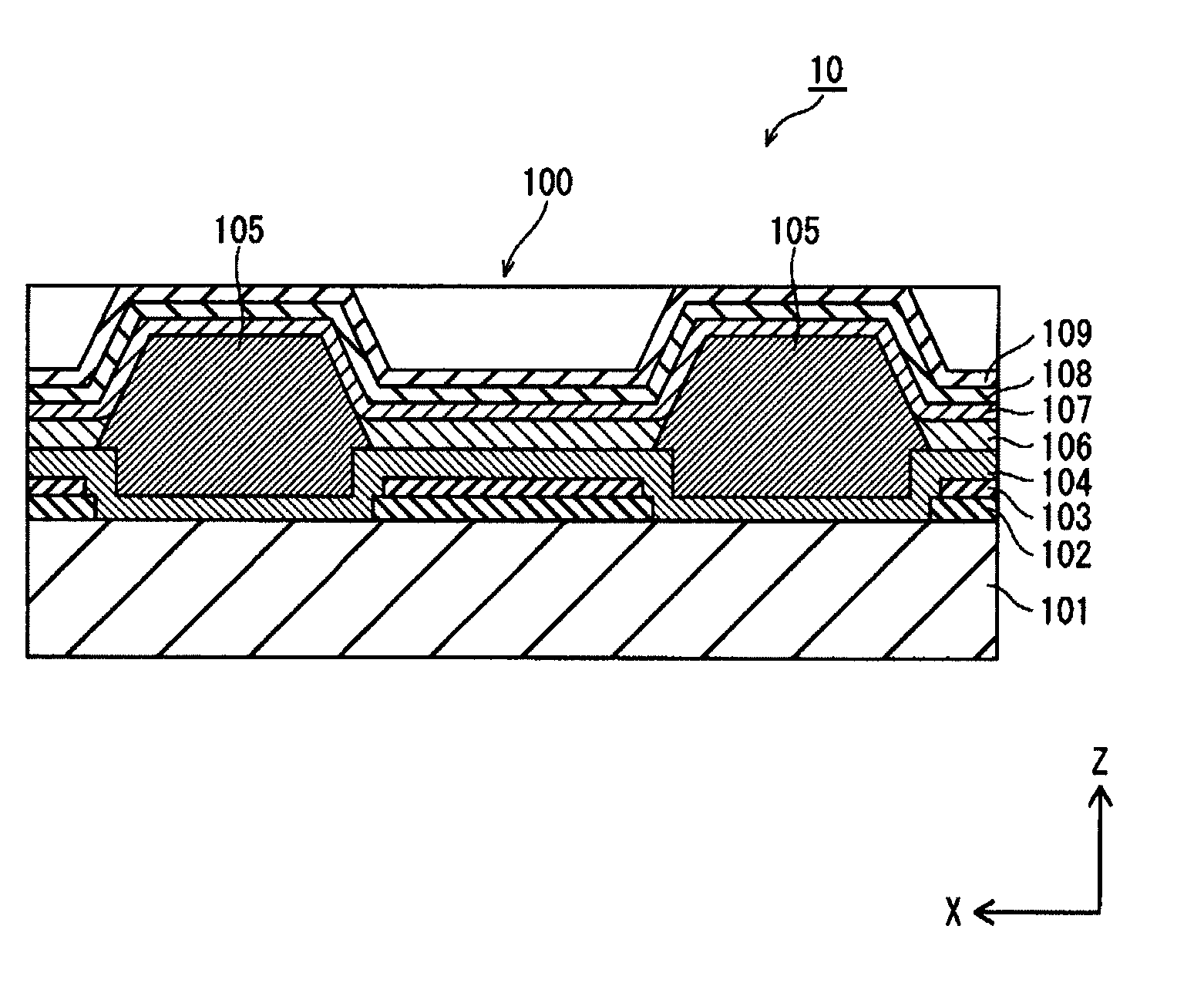

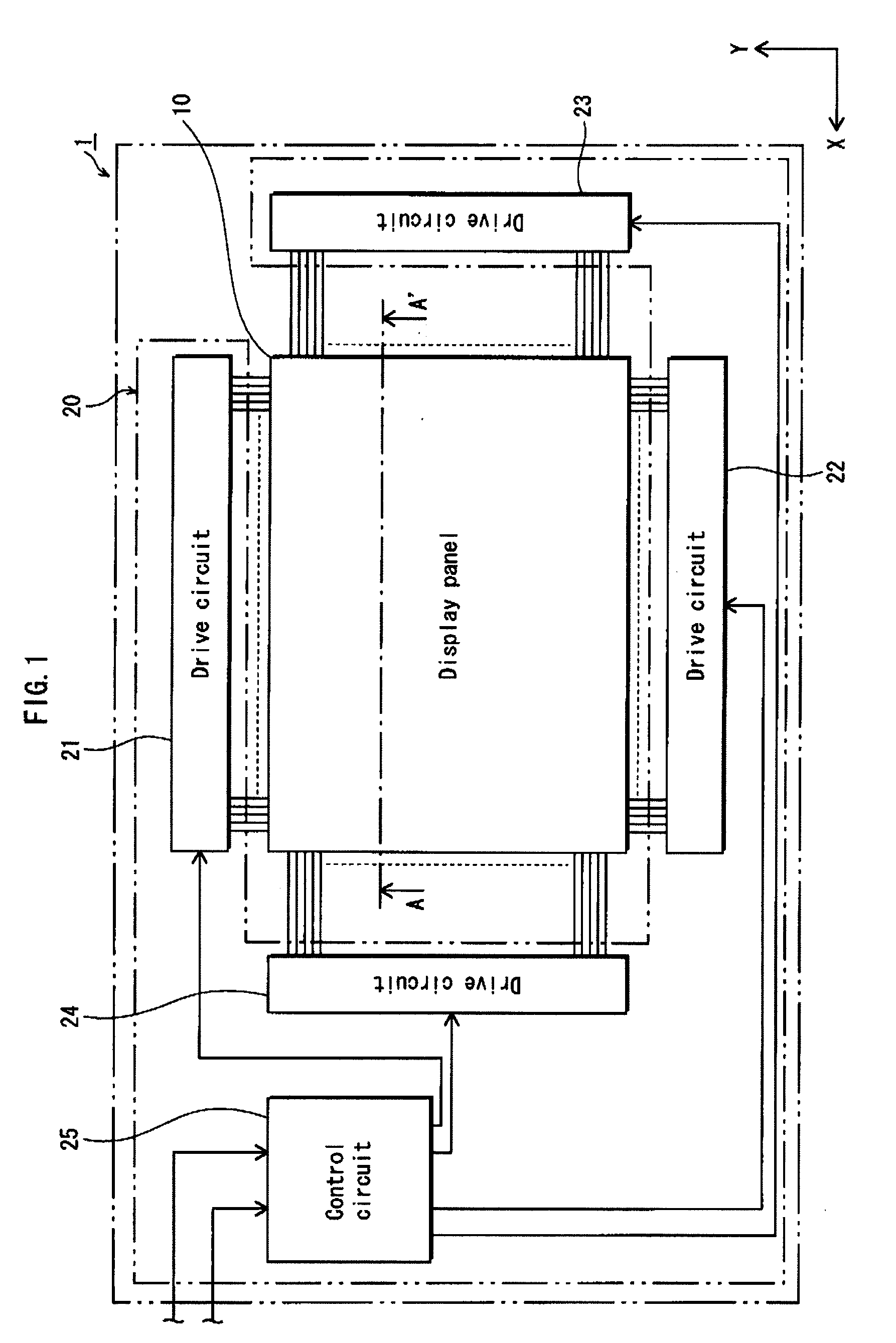

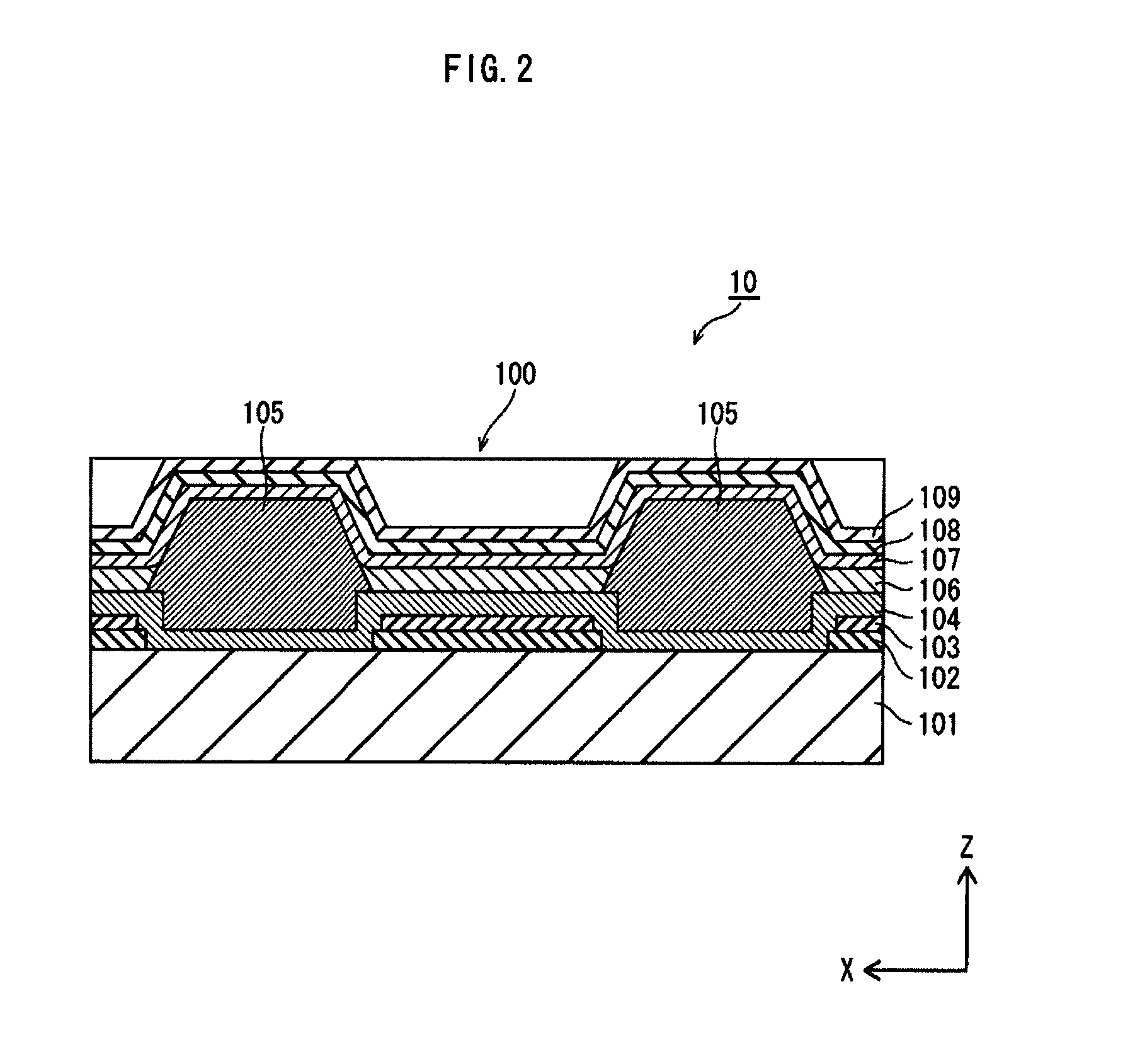

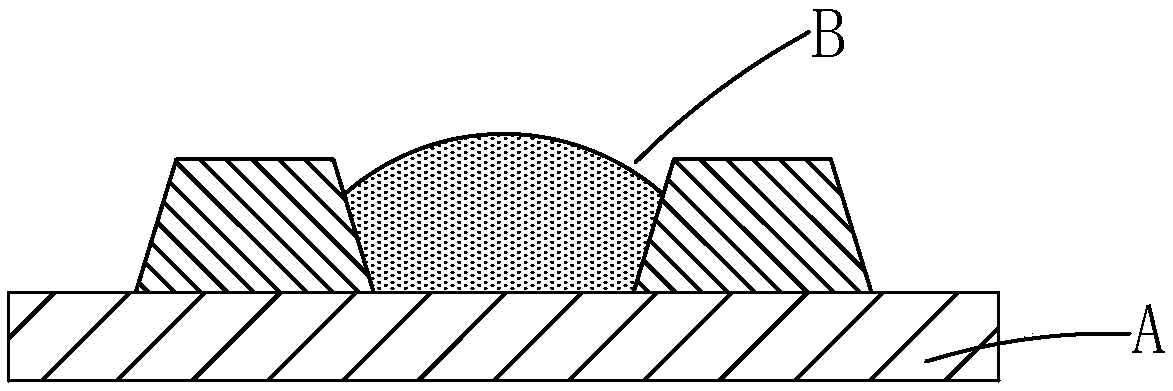

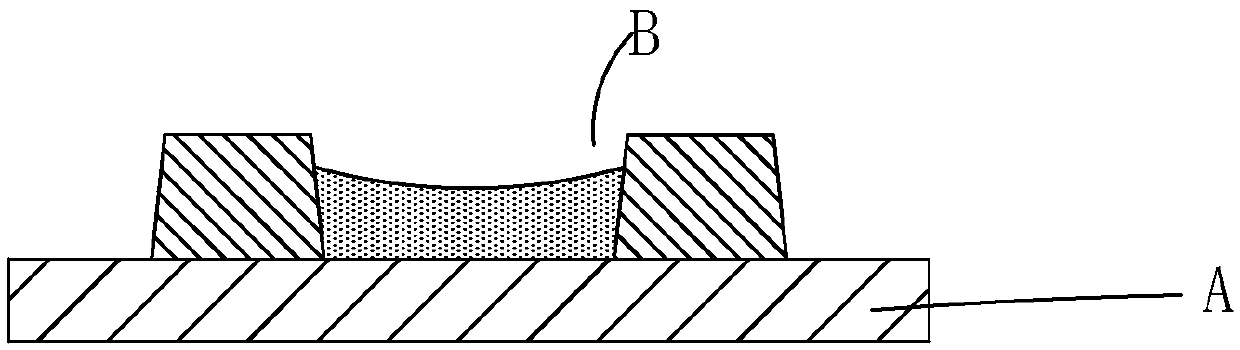

Display device and manufacturing method thereof

ActiveUS20110198623A1Uniform film thicknessNo luminance unevennessElectroluminescent light sourcesSolid-state devicesDisplay deviceOptoelectronics

A display device includes an array of light emitting cells. Banks define each of the light emitting cells. The light emitting cells include a first light emitting cell that is located in a central region of the array and a second light emitting cell that is located in a peripheral region of the array. First and third banks border the first light emitting cell with the first bank being closer to a periphery of the array than the second bank. Second and fourth banks border the second light emitting cell with the third bank being closer to the periphery of the array than the fourth bank. An inclination angle of an innermost sidewall of the third bank that is adjacent the second light emitting cell is different than an inclination angle of an innermost sidewall of the first bank that is adjacent the first light emitting cell.

Owner:JOLED INC

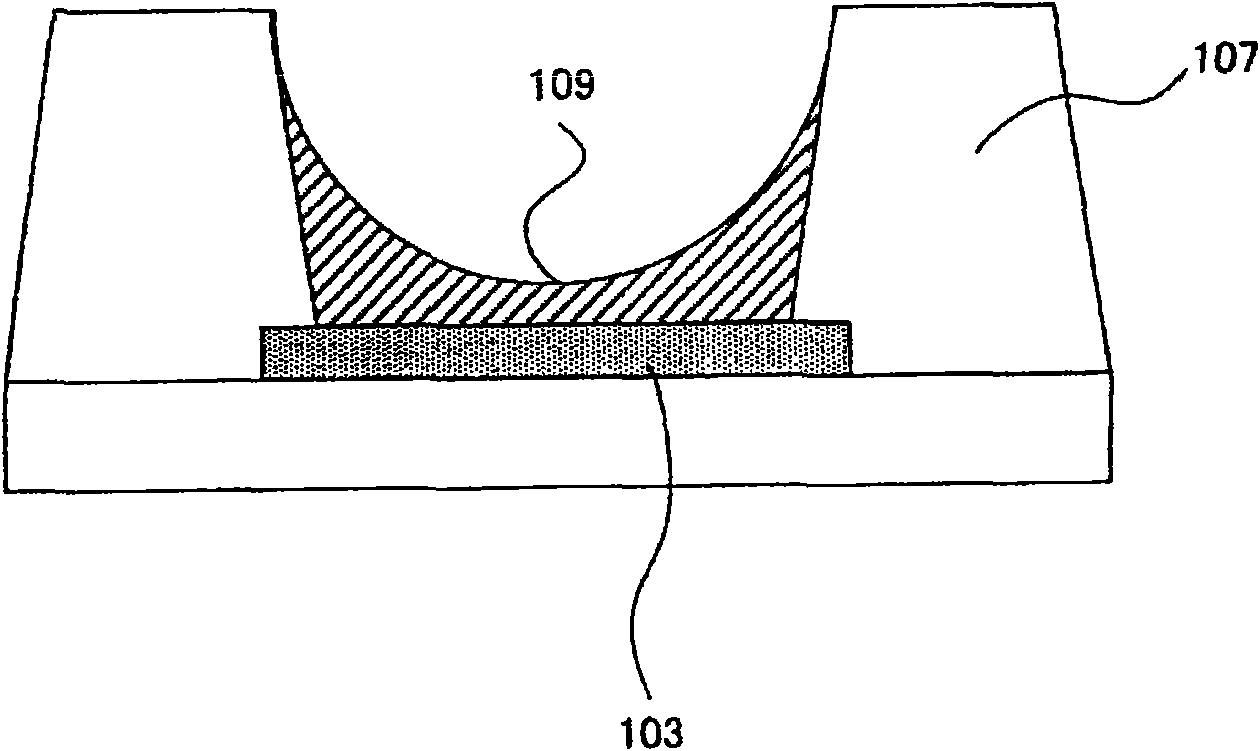

Organic el display panel

ActiveCN101681997AIncrease opening ratioSolution to short lifeElectroluminescent light sourcesSolid-state devicesHole injection layerOptoelectronics

Disclosed is an organic EL display panel with an organic light emitting layer of a uniform film thickness. The organic EL display panel comprises a substrate, a line-shaped bank that is arranged on the substrate and defines line-shaped regions on the substrate, and two or more organic EL elements arranged in a row in each of the line-shaped regions. Each of the organic EL elements includes an anode arranged on the substrate, a hole injection layer arranged on the anode and comprised of a metal oxide, an organic light emitting layer arranged on the hole injection layer, and a cathode arranged on the organic light emitting layer. The hole injection layer is formed in a concave or convex shape, a part of the hole injection layer is arranged below the bank, and the organic light emitting layeris formed by coating the line-shaped regions with an organic light emitting material.

Owner:JOLED INC

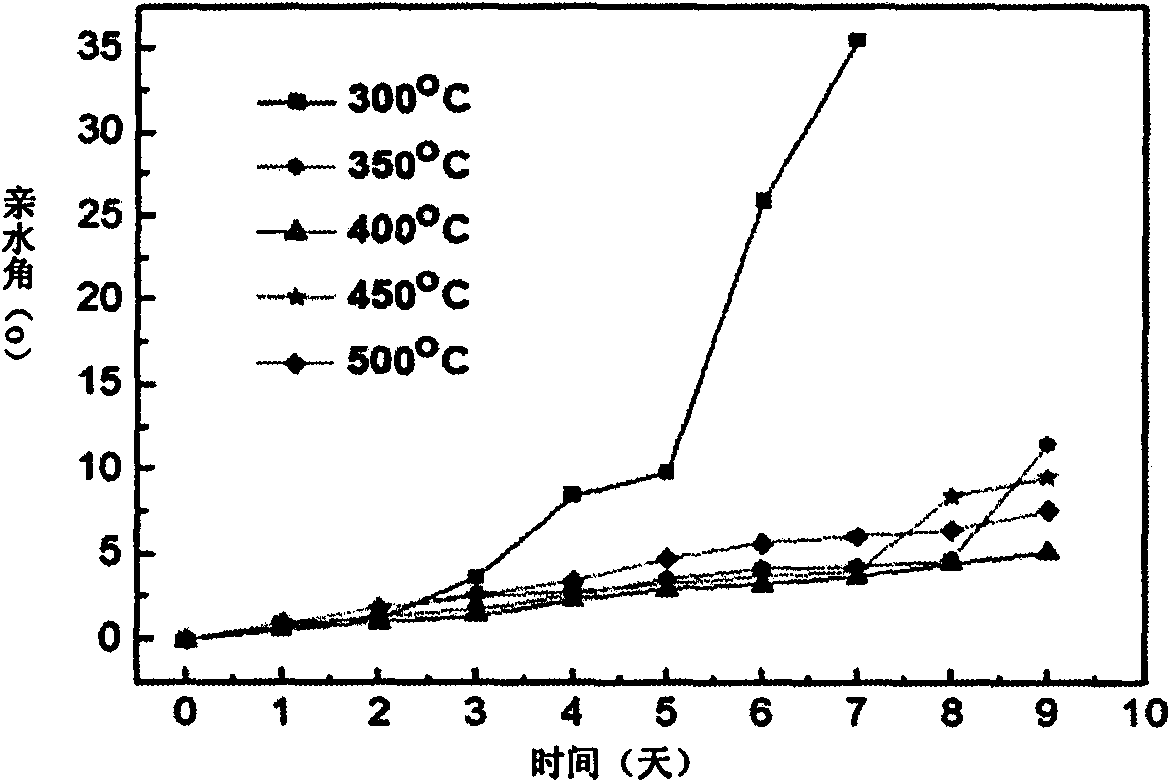

Self-cleaning super-hydrophilic thin film and preparation method thereof

InactiveCN101602933AOvercoming easy reunionOvercoming the weakness of not being easy to recycleOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsRare earthSolvent

The invention provides a self-cleaning super-hydrophilic thin film and a preparation method thereof. The preparation method comprises the steps of using tetra-n-butyl titanate as a precursor of TiO2, using anhydrous ethyl alcohol as solvent, adding glacial acetic acid, and magnetically agitating at room temperature to obtain solution A; synchronously, taking distilled water and anhydrous ethyl alcohol, adding doping salts, and magnetically agitating the mixture to obtain solution B; slowly adding the solution B to the solution A, adding hydrochloric acid to adjust pH value to 3-5, agitating to obtain TiO2 sol, and preparing a rare-earth-doped nanometer-sized TiO2 thin film by using a film drawing machine; immersing a substrate into the sol, drawing and plating a film after glass sheet and liquid surface are stable; drying after plating a layer of film and cooling at room temperature; repeating the steps to prepare the rare earth-doped nanometer-sized TiO2 thin film with different layers; thermally treating the base plated with the TiO2 thin film, and directly using the film-plated base. The thin film of the invention overcomes the weak points that nanometer-sized powder easily aggregates and is not easily recovered, the obtained crystal form is table, and the thin film has excellent self-cleaning and hydrophilic capacities.

Owner:CENT SOUTH UNIV

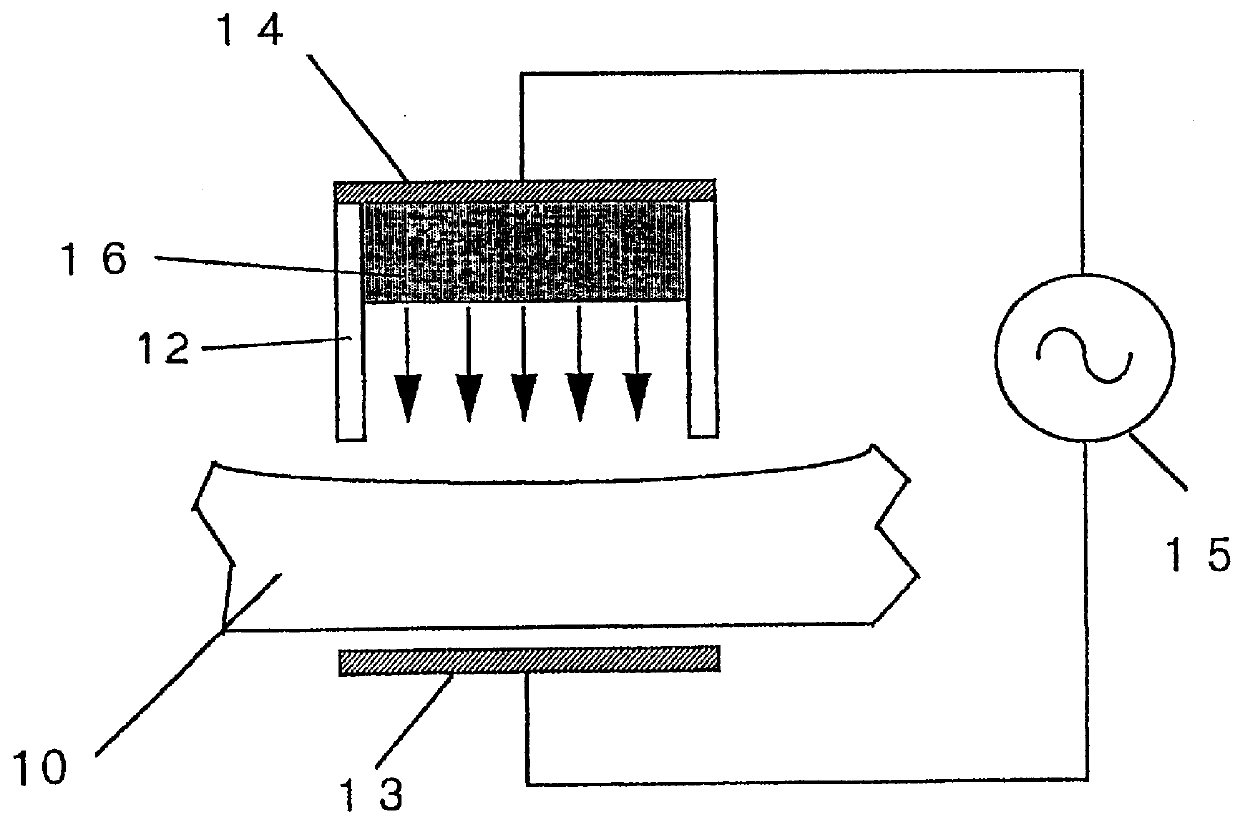

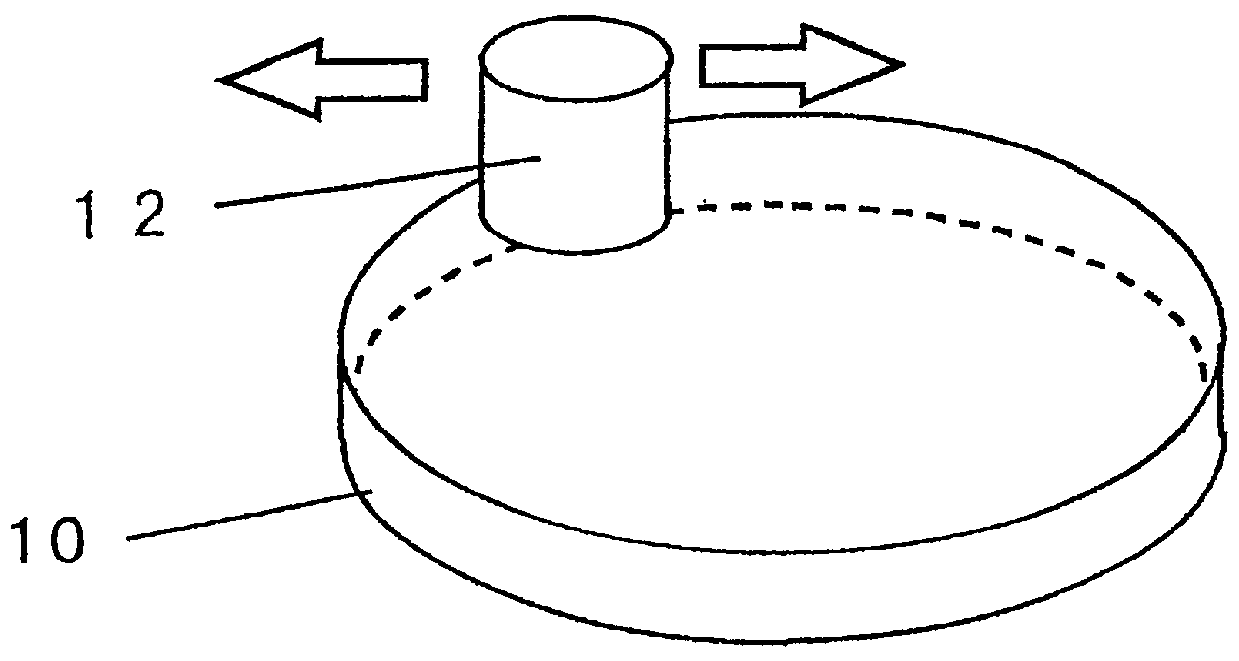

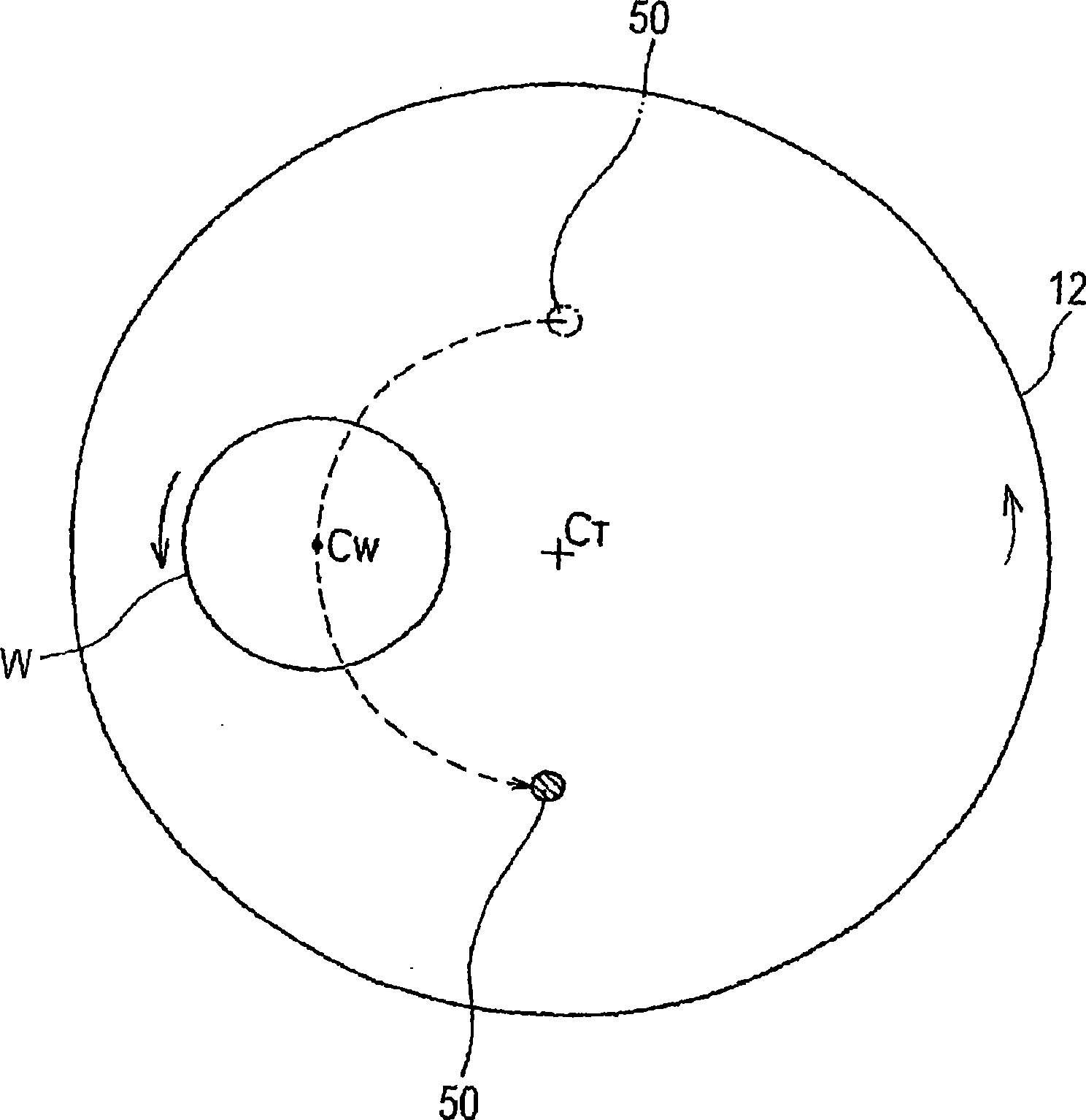

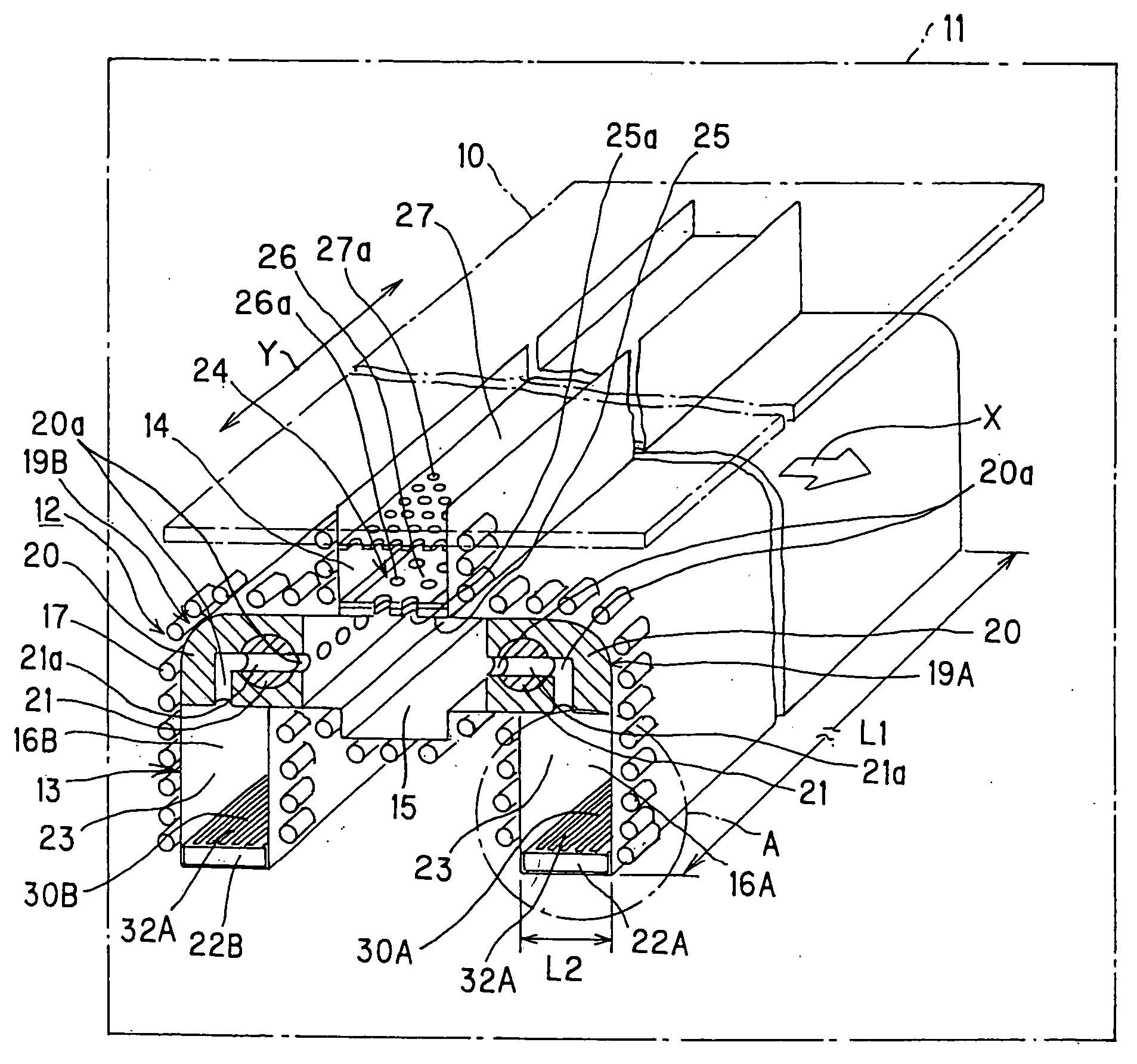

Polishing apparatus and polishing method

ActiveCN101511539AUniform film thicknessSemiconductor/solid-state device manufacturingLapping machinesSemiconductor

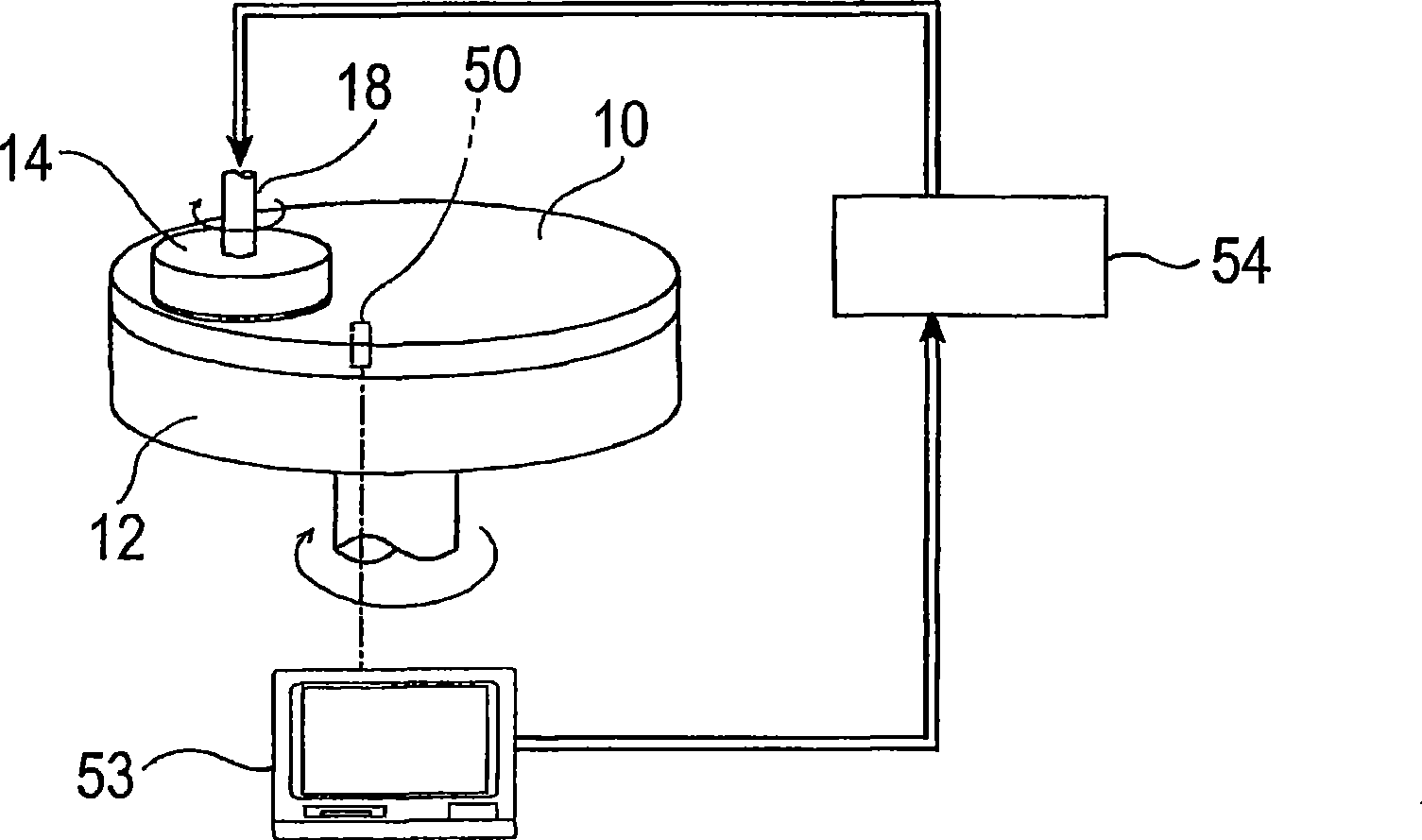

The present invention relates to a polishing apparatus and a polishing method for polishing a substrate, such as a semiconductor wafer, to planarize the substrate. The polishing apparatus according to the present invention includes a polishing table (10) having a polishing surface, a top ring (14) configured to press the substrate against the polishing table by applying pressing forces independently to first plural zones on the substrate, a sensor (50) configured to detect a state of the film at plural measuring points, a monitoring device (53) configured to produce monitoring signals with respect to second plural zones on the substrate, respectively, a storage device configured to store plural reference signals each indicating a relationship between reference values of each monitoring signal and polishing times, and a controller configured to operate the pressing forces against the first plural zones such that the monitoring signals, corresponding respectively to the second plural zones, converge on one of the plural reference signals.

Owner:EBARA CORP

Display device and manufacturing method thereof

ActiveUS20070263164A1Uniform film thicknessElectroluminescent light sourcesSolid-state devicesSimple Organic CompoundsInter layer

A bank for defining the regions in which pixels are formed has a stacked structure including: a base layer on the low level which also serves as an interlayer insulating film between the pixel forming regions; a middle bank layer on the middle level which serves to improve the fixation of an organic compound material (i.e., improve the uniformity of the film thickness of a positive hole transporting layer and an electron-transporting light emitting layer) in forming an organic EL layer; and a bank metal layer on the upper level which is made of a conductive material and serves also as a common voltage line (cathode line).

Owner:SOLAS OLED LTD

Multilayer printed circuit board and multilayer printed circuit board manufacturing method

InactiveUS20080151520A1Low yieldWithout usingPrinted electric component incorporationSemiconductor/solid-state device detailsCopperPrinted circuit board

A multilayer printed circuit board has an IC chip 20 included in a core substrate 30 in advance and a mediate layer 38 provided on a pad 24 of the IC chip 20. Due to this, it is possible to electronically connect the IC chip to the multilayer printed circuit board without using lead members and a sealing resin. Also, by providing the mediate layer 38 made of copper on the die pad 24, it is possible to prevent resin residues on the pad 24 and to improve connection characteristics between the pad 24 and a via hole 60 and reliability.

Owner:IBIDEN CO LTD

Color film substrate, manufacturing method thereof, and OLED display device

ActiveCN107731873AImprove flatnessImprove film thickness uniformitySolid-state devicesSemiconductor devicesResistColor film

The present invention provides a color film substrate, a manufacturing method thereof, and an OLED display device. The color film substrate is provided with a first black matrix (12) and a second black matrix (14) to block light together, and the risk of color mixing of display can be reduced. A first groove (121) of the first black matrix (12) and a second groove (131) of a dam layer (13) are setto contain and limit printing ink needed for the manufacture of a color-resist layer (15) together, the surface of the first groove (121) is hydrophilic, the surface of the second groove (131) is hydrophobic, the flatness and thickness uniformity of the color-resist layer 15 can be improved, the color film substrate is applied to the OLED display device, and the display quality can be improved. The dam layer (13) and the second black matrix (14) are set to substitute support posts in the prior art, and the process can be simplified.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Bonded semiconductor substrate manufacturing method thereof

InactiveUS7491342B2Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

Wafer process body, wafer processing member, wafer processing temporary adhesive material, and method for manufacturing thin wafer

ActiveUS20130220687A1Easy to disassembleImprove productivityPrinted circuit detailsSolid-state devicesProduction rateEngineering

Disclosed is a wafer process body, a temporary adhesive layer is formed on a supporting body, and a wafer having a circuit-formed front surface and a to-be-processed back surface is stacked on the temporary adhesive layer, wherein the temporary adhesive layer is provided with a first temporary adhesive layer including a non-aromatic saturated hydrocarbon group-containing organopolysiloxane layer (A) which is adhered to the front surface of the wafer so as to be detachable and a second temporary adhesive layer comprised of a thermosetting-modified siloxane polymer layer (B) which is stacked on the first temporary adhesive layer and adhered to the supporting body so as to be detachable. Thus, temporary adhesion of a wafer with a supporting body may become easy, process conformity with the TSV formation process and with the wafer-back surface-wiring process may become high, and removal may be done easily, with high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

Method of manufacturing color filter substrate, method of manufacturing electro-optical device, electro-optical device, and electronic apparatus

InactiveUS7459177B2Uniform film thicknessA large amountDomestic cooling apparatusLighting and heating apparatusEngineeringSolvent

The color filter substrate has a functional region which includes a plurality of colored layers and which functions as a color filter selectively transmitting predetermined color light components and a non-functional region other than the functional region. The method includes discharging, onto a substrate, a liquid material, in which coloring materials constituting the colored layers are dissolved or dispersed into a solvent, with a liquid droplet discharge method. In the discharging of the liquid material, the liquid material is discharged onto the functional region and the liquid material or the solvent is discharged onto the non-functional region. The amount of the solvent discharged onto the non-functional region per unit area is larger than the amount of the solvent discharged onto the functional region per unit area.

Owner:KATEEVA

Vacuum vapor deposition apparatus

InactiveUS20060162662A1Prevent unevenness in vaporizationEasy to handleBrushesVacuum evaporation coatingCrucibleEvaporation

A crucible is a monolithic structure extending over an entire area of a vaporizing chamber and has at least one slit groove provided in the upper surface thereof. The at least one slit groove has a length from one end of the upper surface of the crucible to other end thereof. The at least one slit groove is used as a portion for containing the evaporation material (dopant material or the like). Alternatively, a crucible is a monolithic structure extending over the entire area of the vaporizing chamber and has a plurality of holes provided in the upper surface thereof. The holes are used as portions for containing the evaporation material. Further, the crucible is divided into a plurality of regions, and individual electric heaters are provided under the lower surface of the crucible for the respective regions, whereby temperature can be individually controlled for the respective regions by the electric heaters.

Owner:MITSUBISHI HEAVY IND LTD

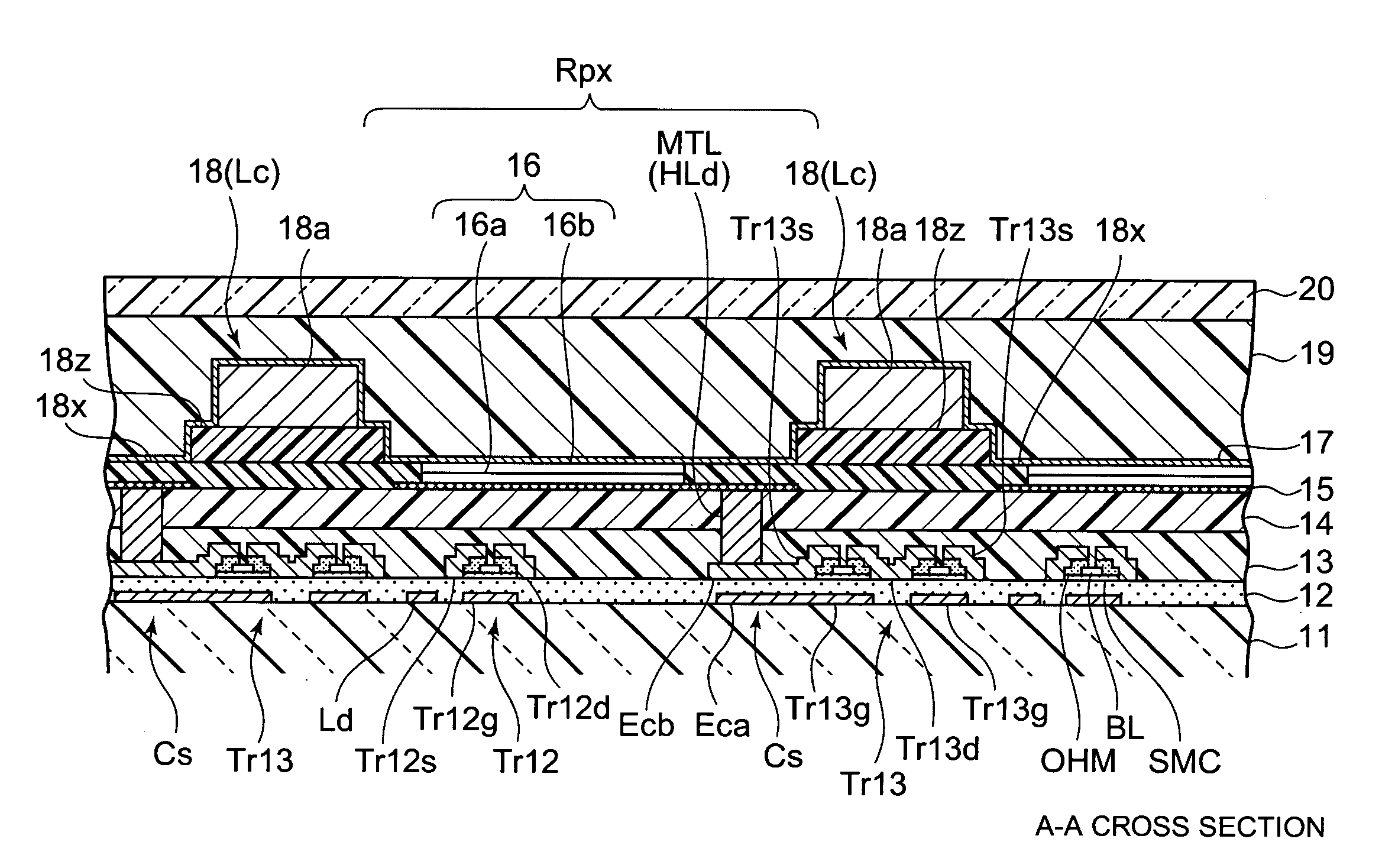

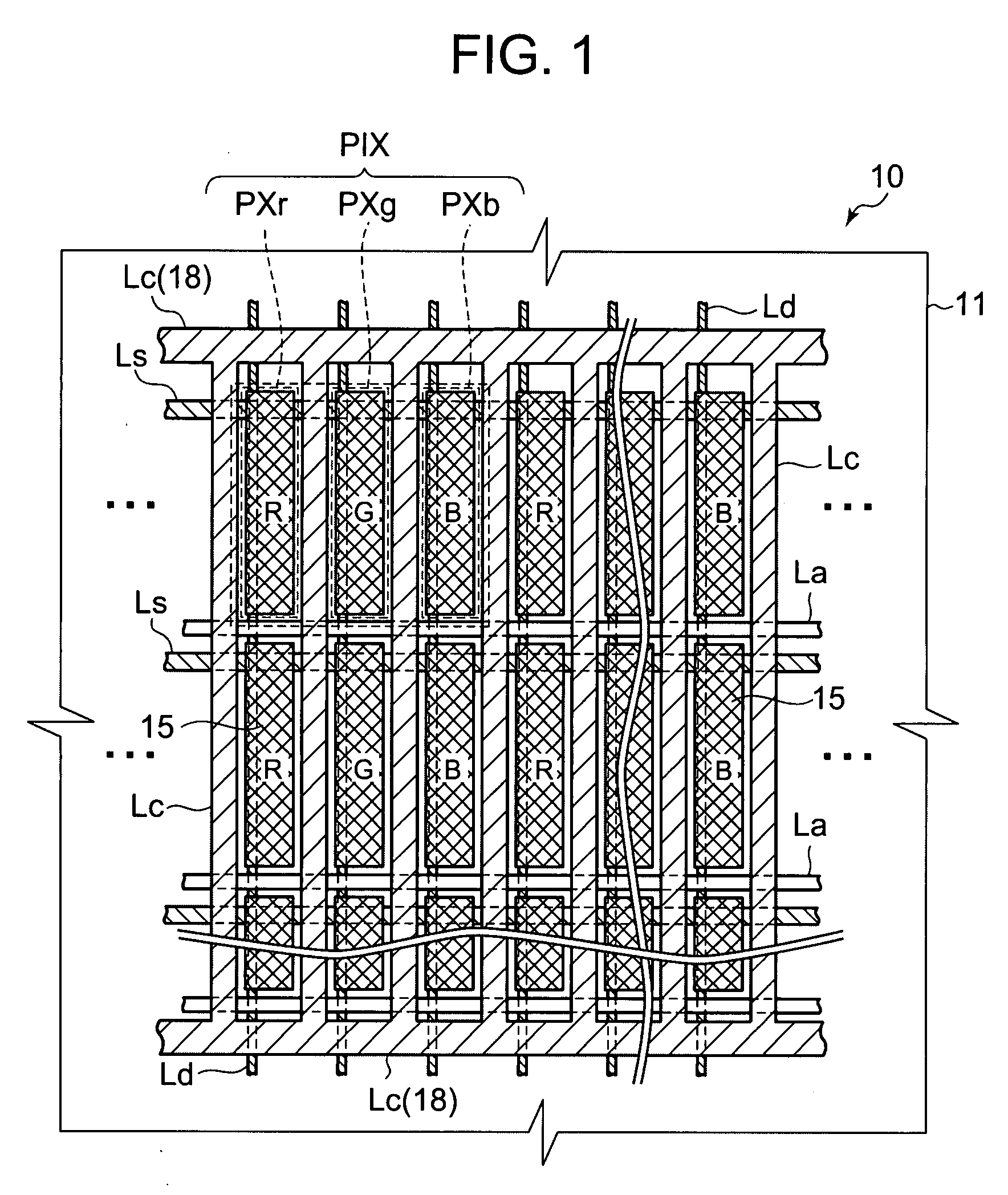

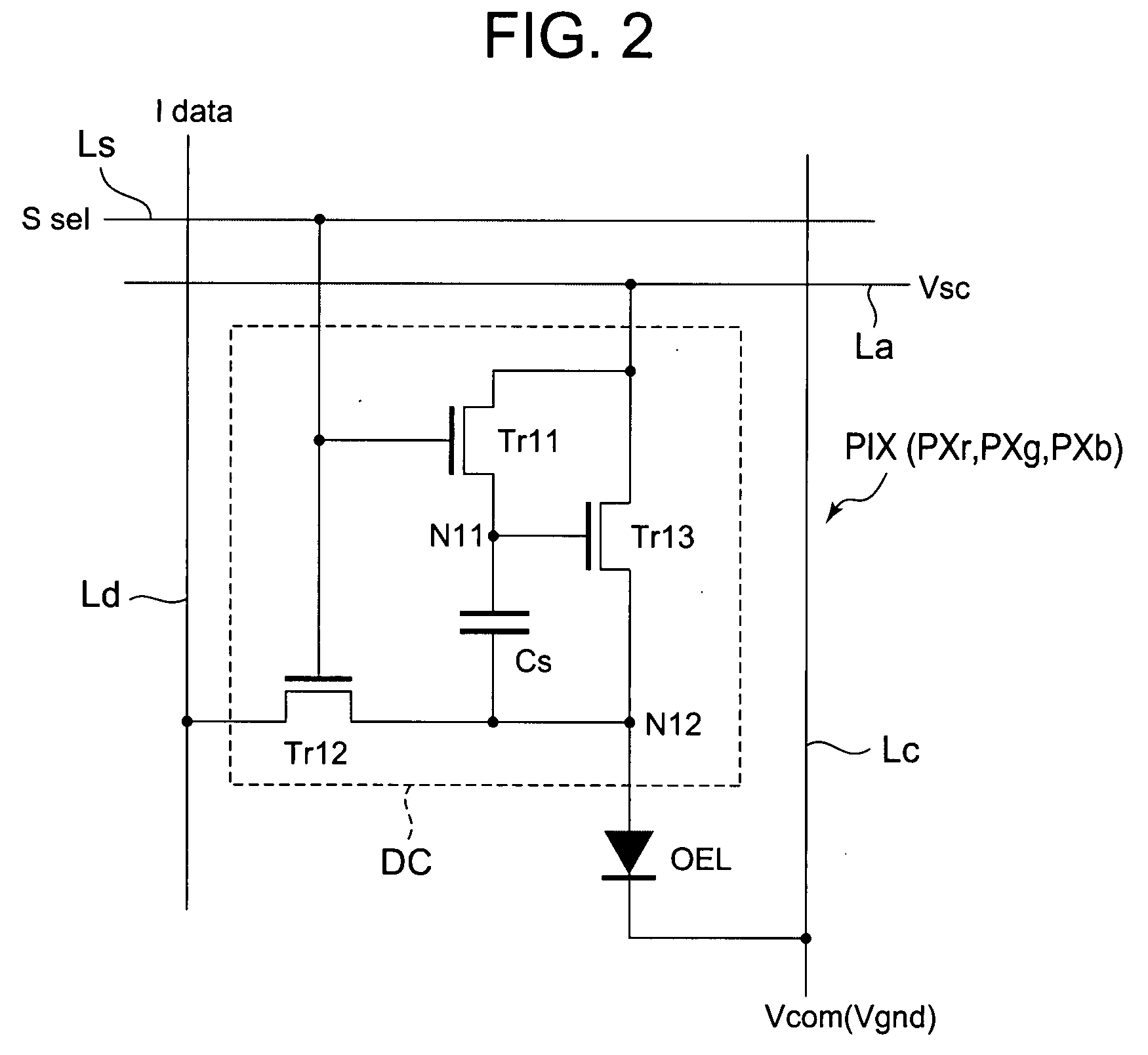

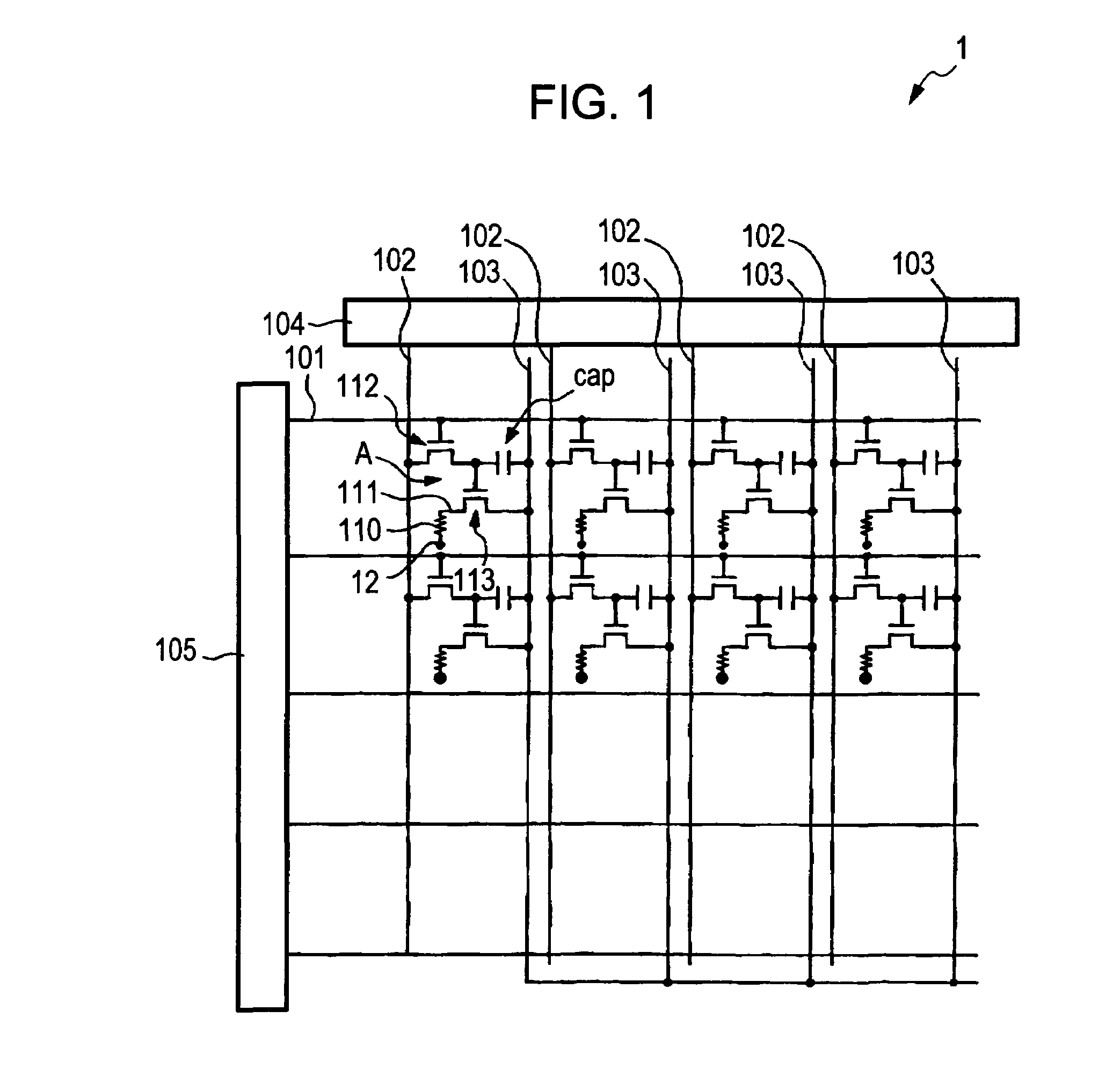

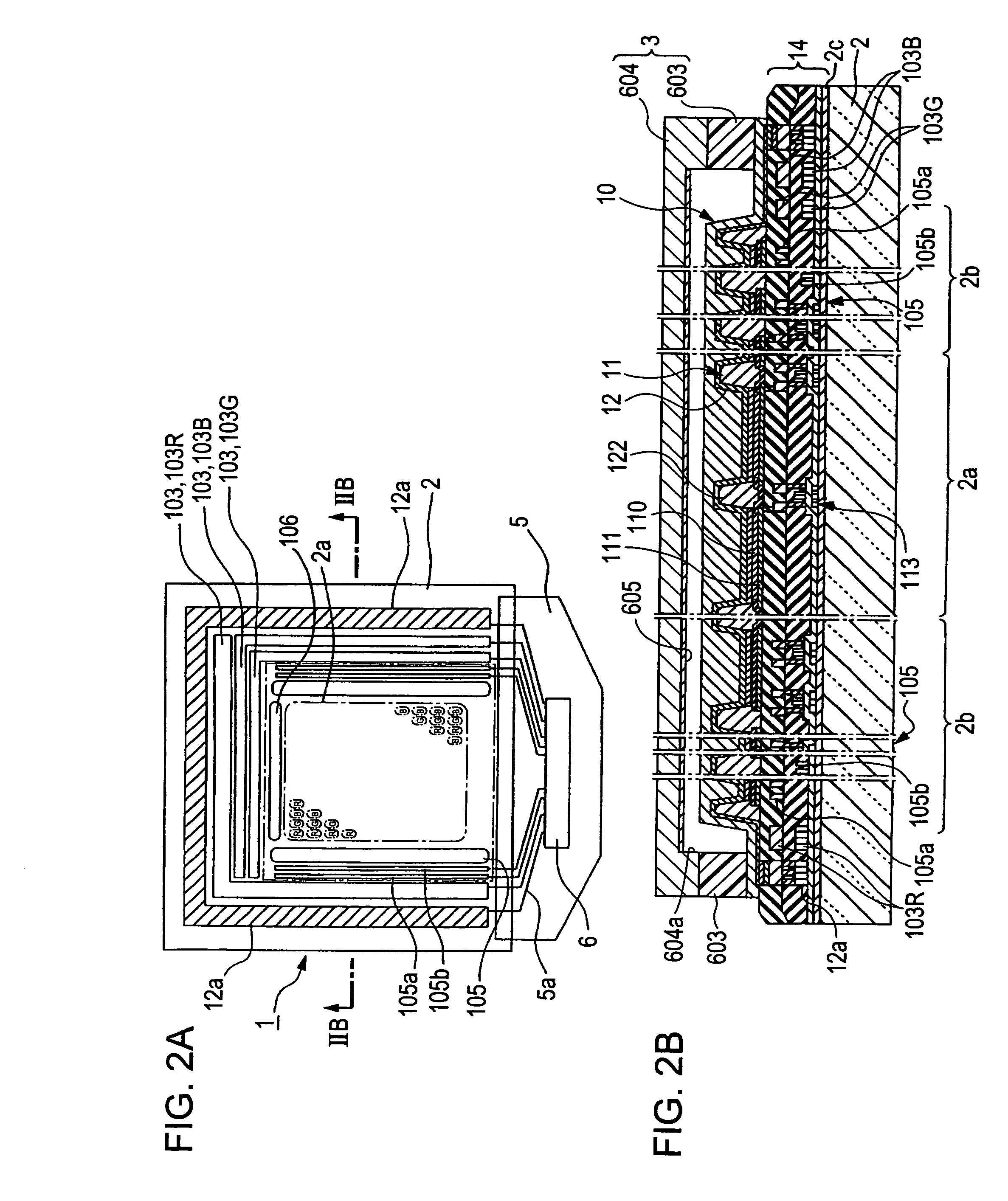

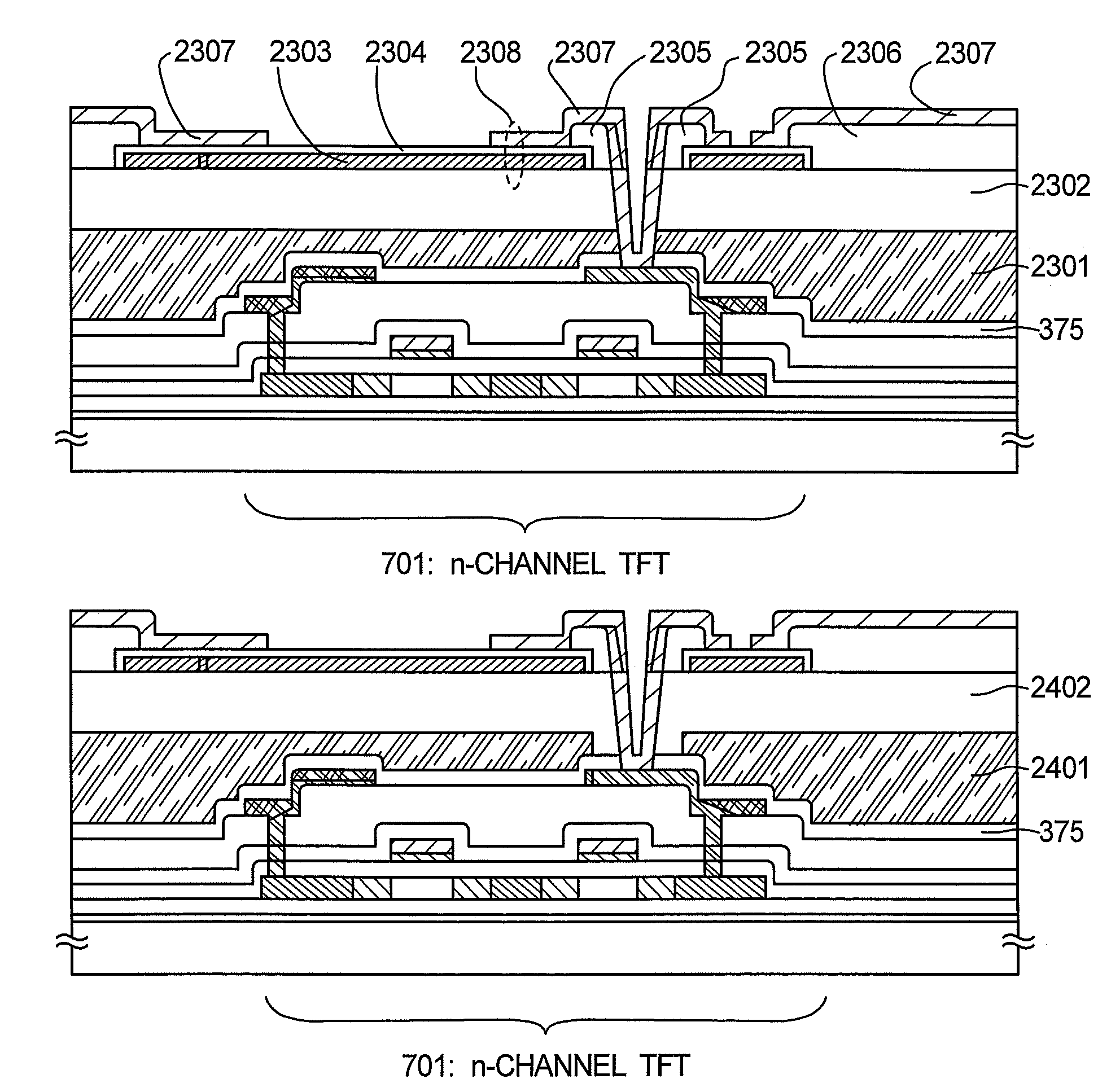

Semiconductor device comprising a thin film transistor comprising a semiconductor thin film and method of manufacturing the same

InactiveUS7821065B2Improve reliabilityUniform film thicknessTransistorElectroluminescent light sourcesSemiconductorCapacitor

Owner:SEMICON ENERGY LAB CO LTD

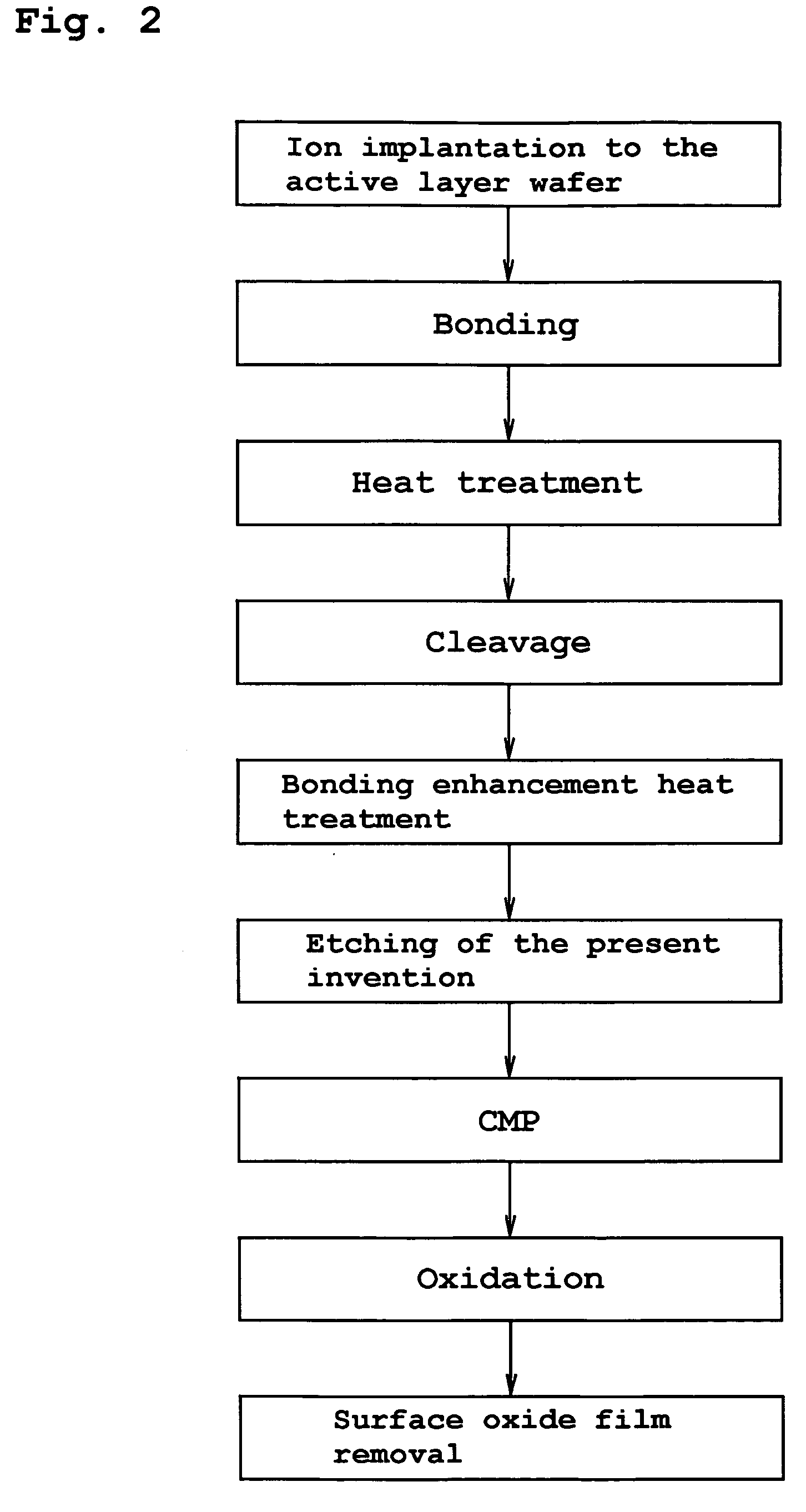

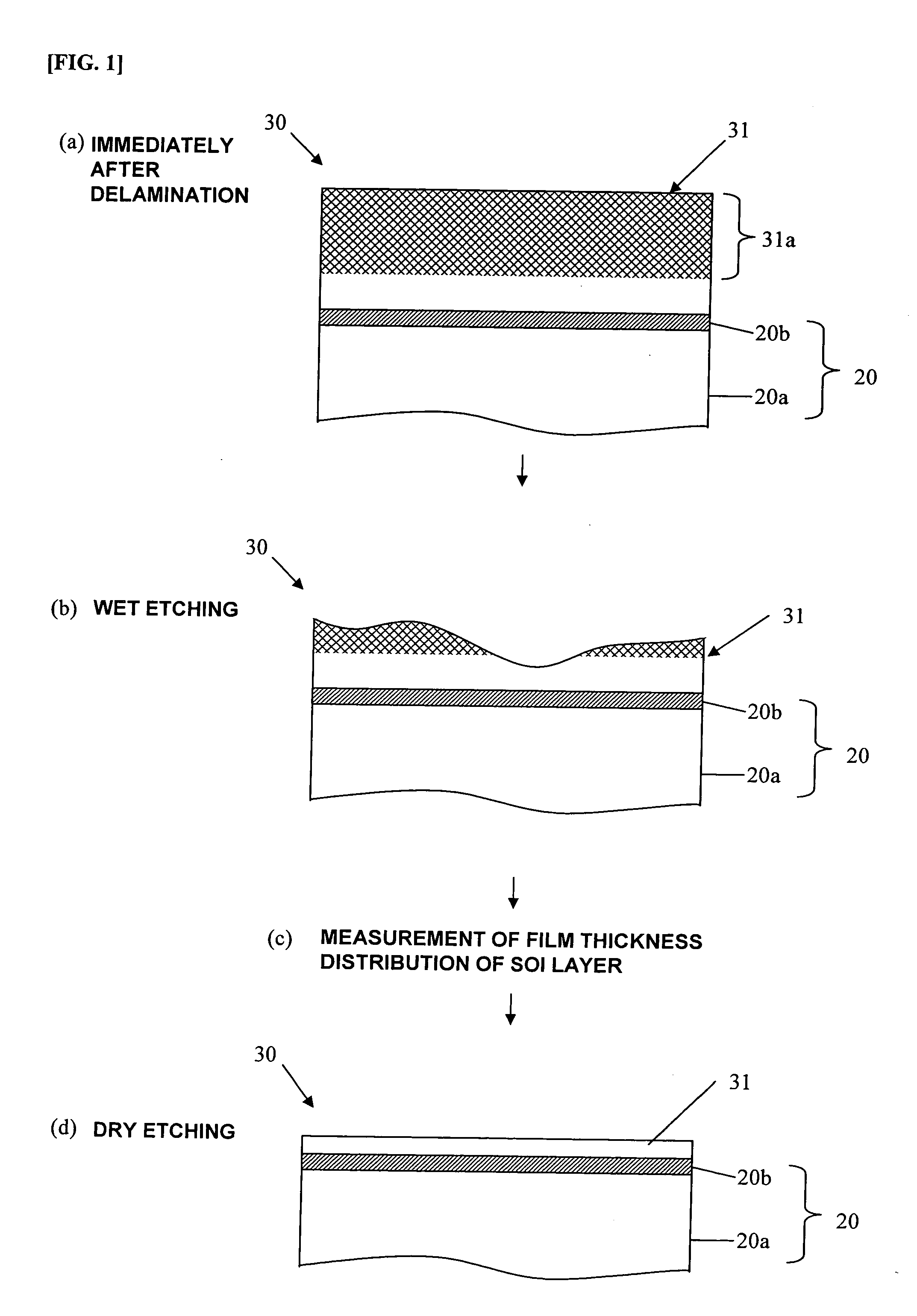

Method for manufacturing SOI wafer

ActiveUS20080299742A1Excellent productivityHigh etch rateSemiconductor/solid-state device testing/measurementSolid-state devicesChemistryProduction rate

There is disclosed a method for manufacturing an SOI wafer comprising: a step of implanting at least one of a hydrogen ion and a rare gas ion into a donor wafer to form an ion implanted layer; a step of bonding an ion implanted surface of the donor wafer to a handle wafer; a step of delaminating the donor wafer at the ion implanted layer to reduce a film thickness of the donor wafer, thereby providing an SOI layer; and a step of etching the SOI layer to reduce a thickness of the SOI layer, wherein the etching step includes: a stage of performing rough etching as wet etching; a stage of measuring a film thickness distribution of the SOI layer after the rough etching; and a stage of performing precise etching as dry etching based on the measured film thickness distribution of the SOI layer. There can be provided A method for manufacturing an SOI wafer having high film thickness uniformity of an SOI layer with excellent productivity.

Owner:SHIN ETSU CHEM CO LTD

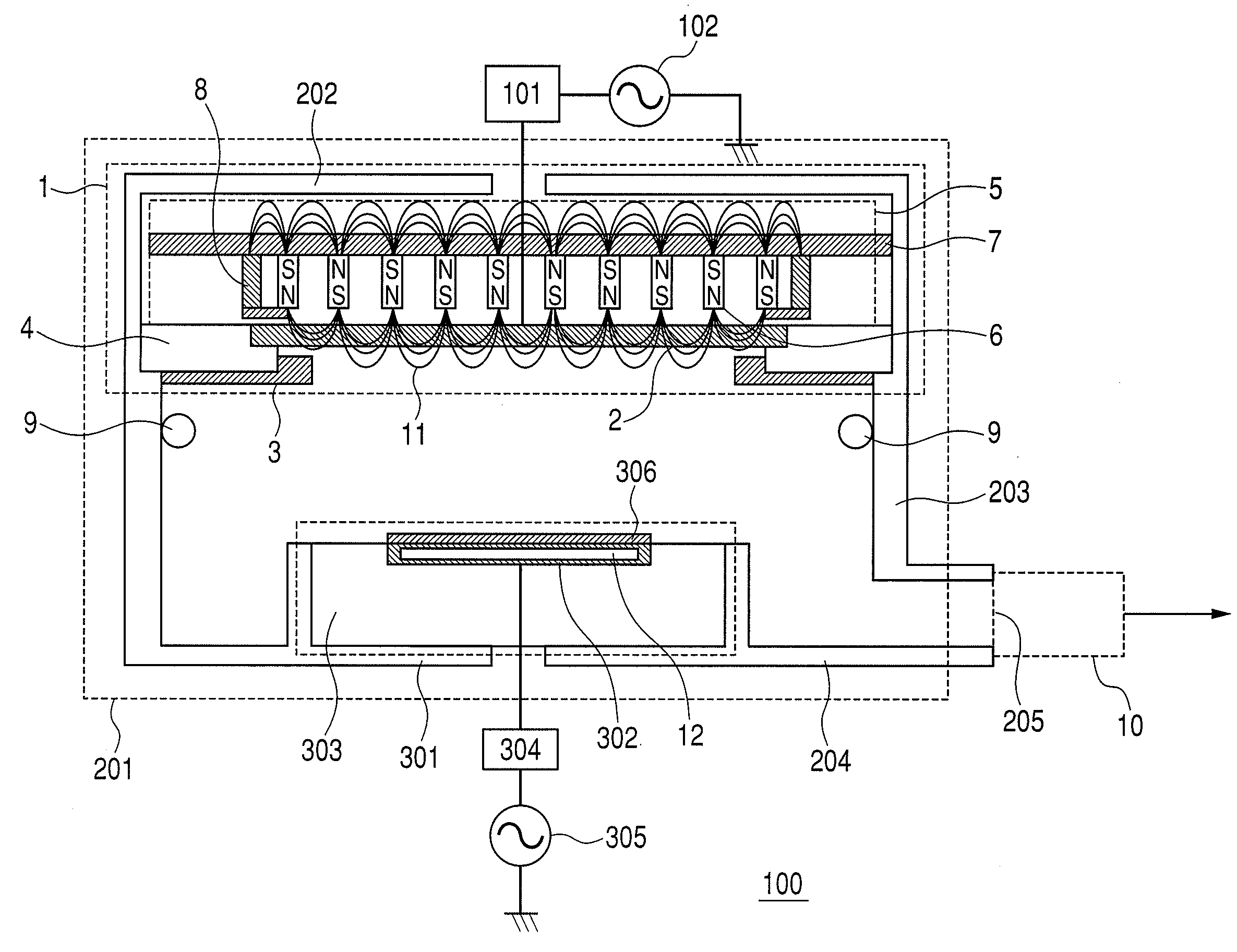

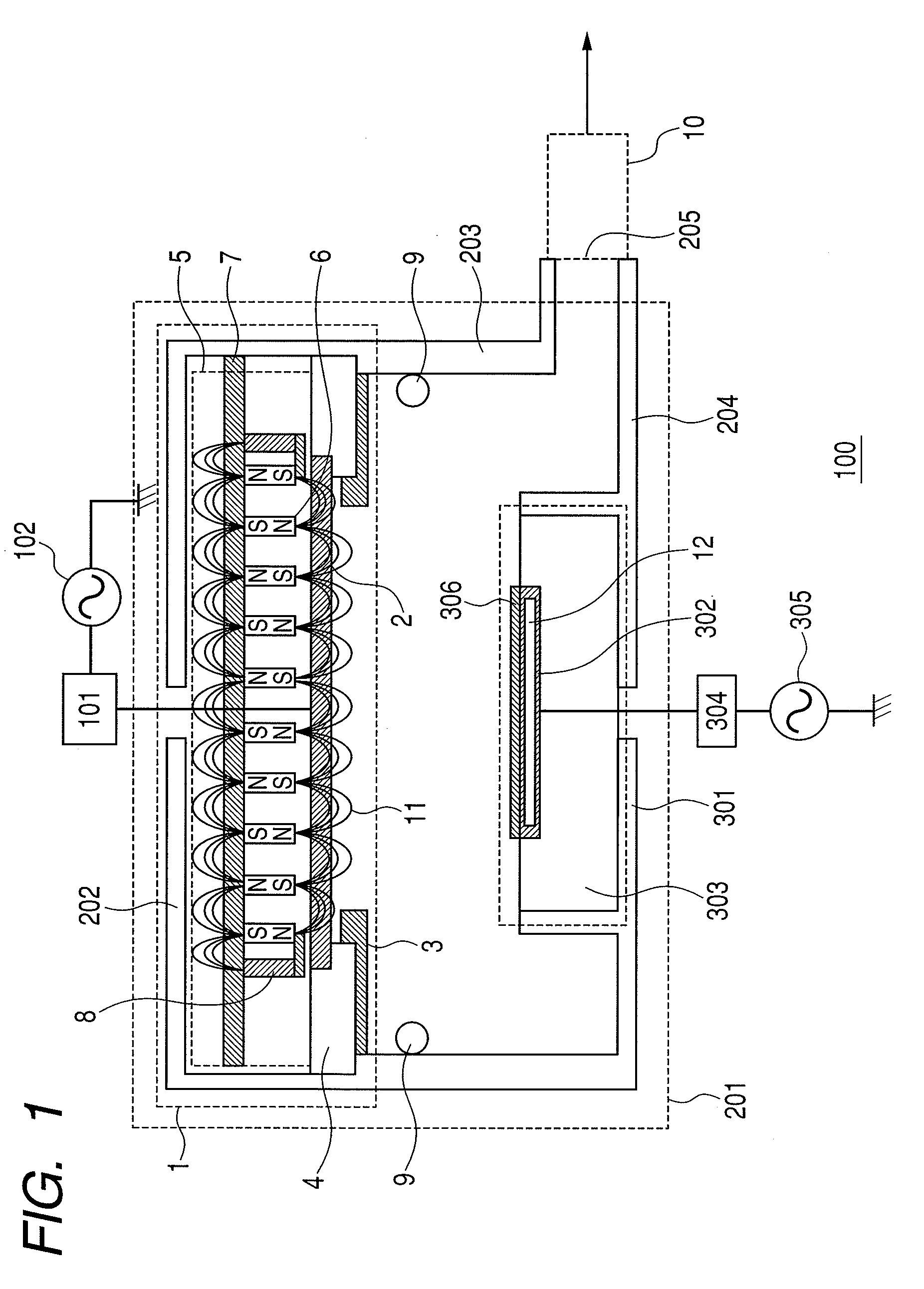

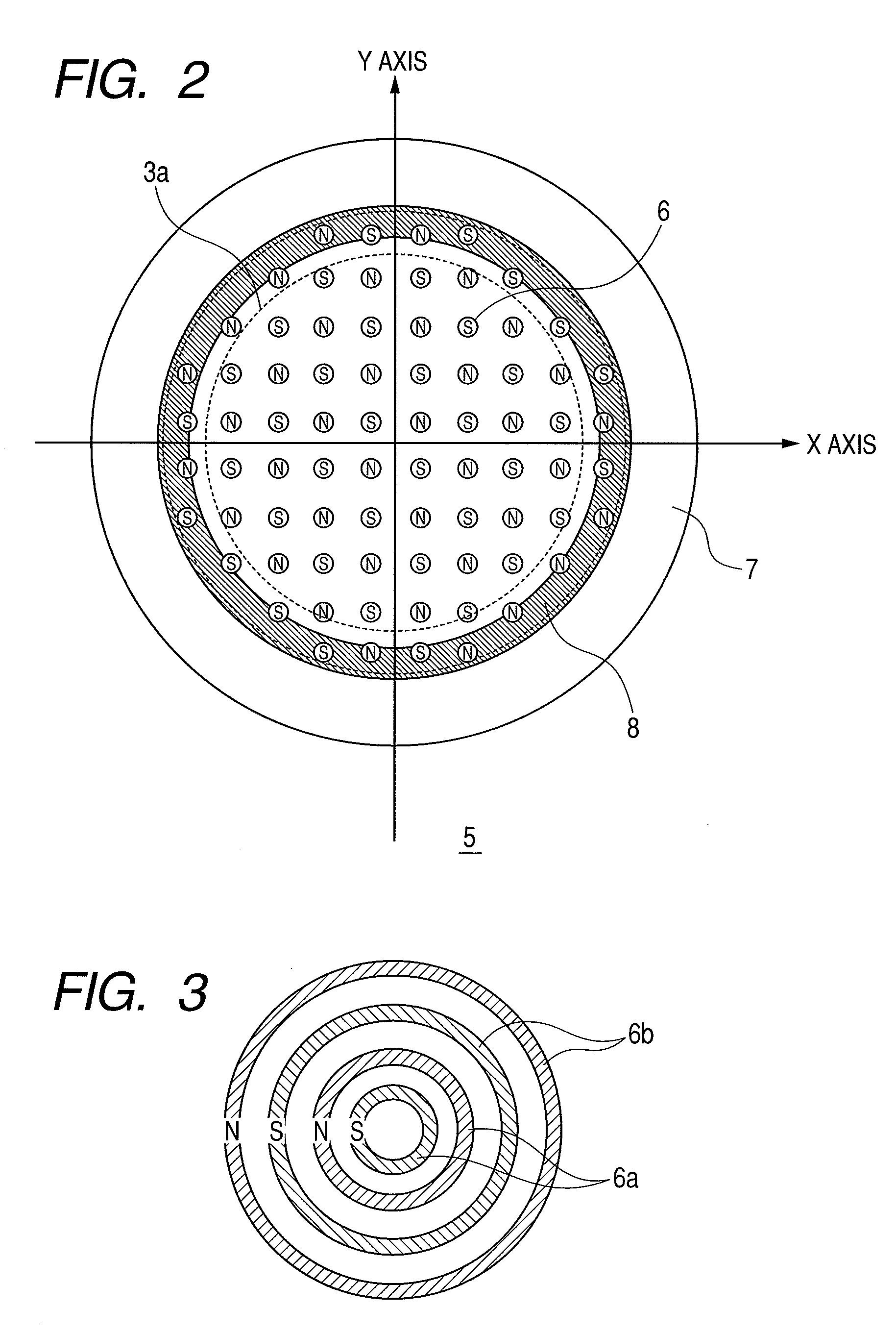

Plasma processing apparatus

ActiveUS20100294656A1Reduce instabilityUniform film thicknessCellsElectric discharge tubesMagnetic shieldPlasma processing

A plasma apparatus includes: a chamber which can be evacuated into vacuum; first electrode disposed within the chamber; a magnet mechanism having a magnet provided apart from and above the first electrode; a second electrode provided facing the first electrode; and a magnetic shield member provided in at least one of gaps between the first electrode and the magnet mechanism and between the first electrode and the second electrode.

Owner:CANON ANELVA CORP

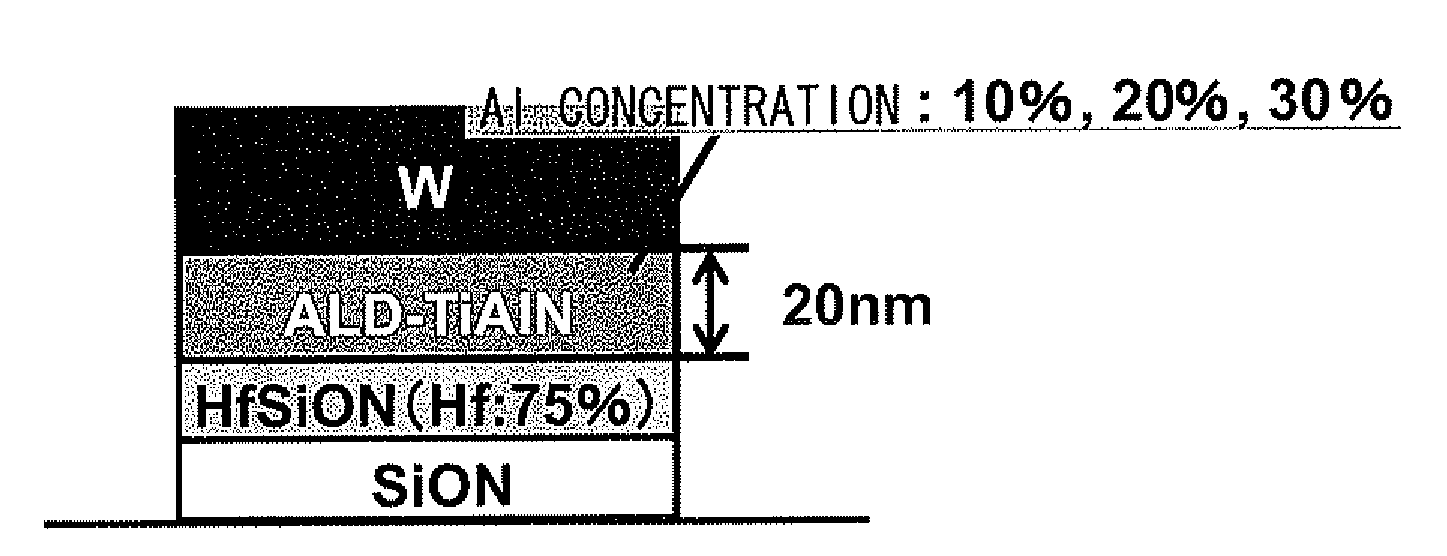

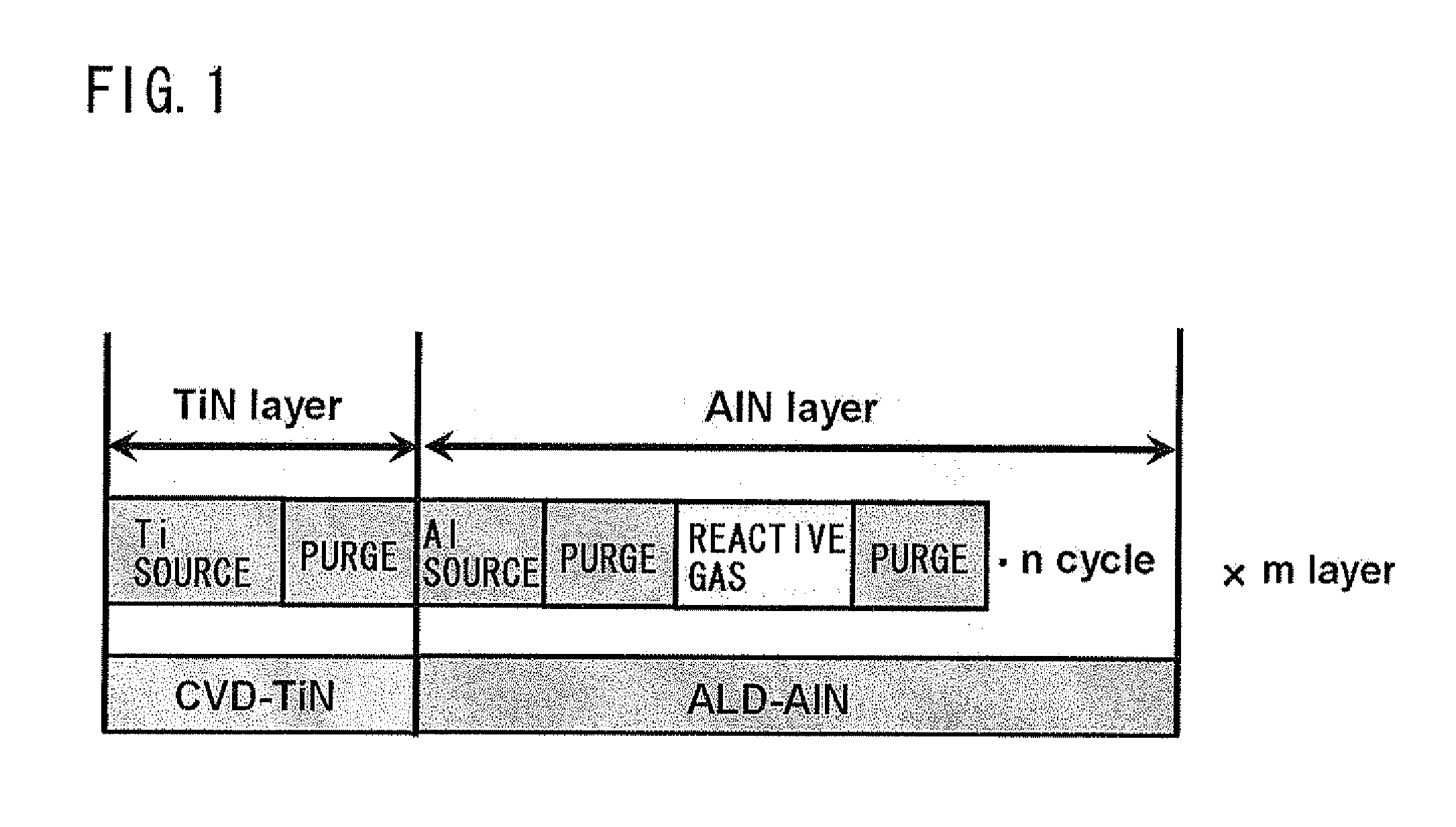

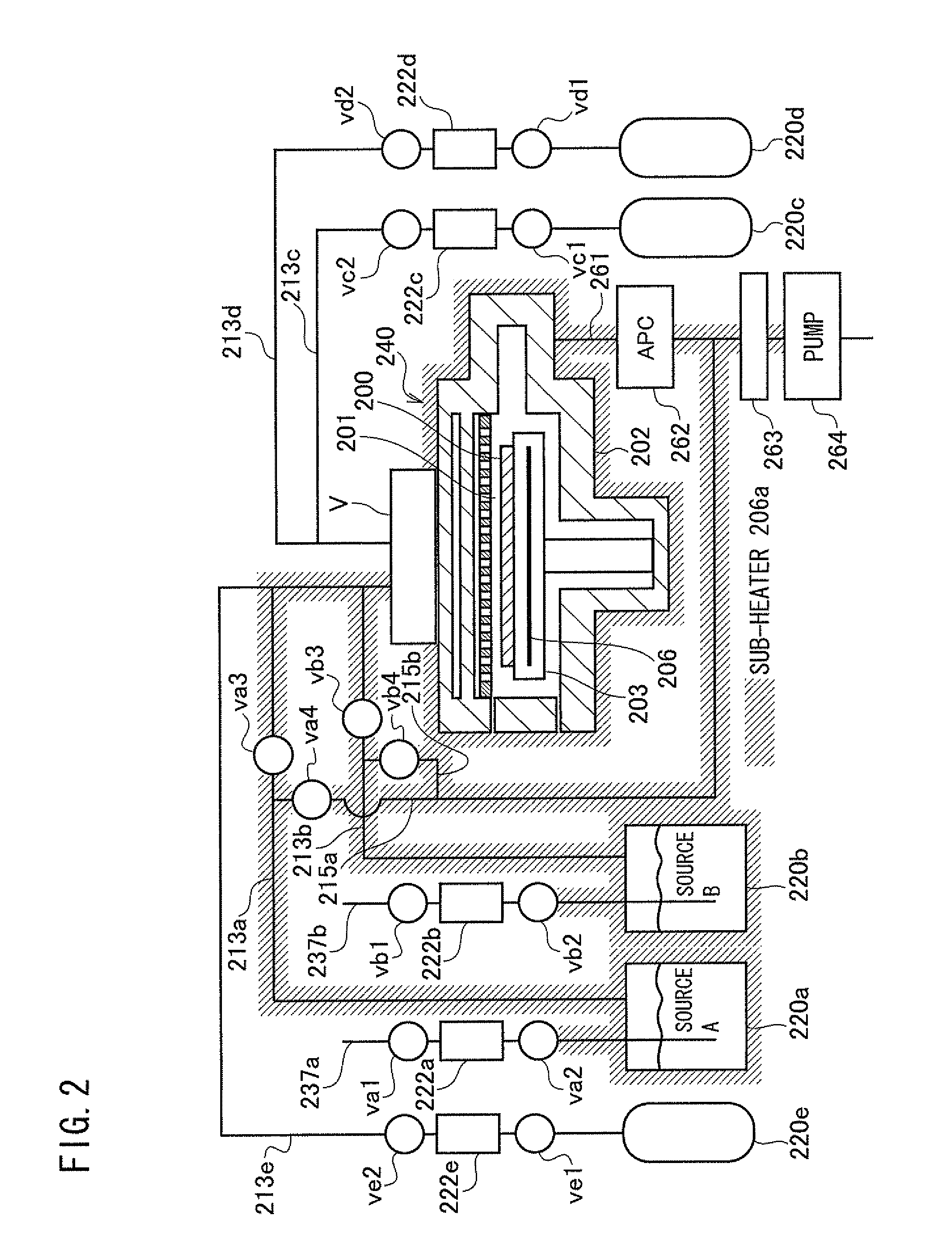

Method of manufacturing semiconductor device and substrate processing apparatus

ActiveUS20090325372A1Film formation rate of film can be moreImprove throughputLiquid surface applicatorsSemiconductor/solid-state device manufacturingTitanium aluminium nitrideSemiconductor

A manufacturing method of a semiconductor device of the present invention includes the step of forming an insulating film on a substrate, and the step of forming a high dielectric constant insulating film on the insulating film, and the step of forming a titanium aluminium nitride film on the high dielectric constant insulating film, wherein in the step of forming the titanium aluminum nitride film, formation of an aluminium nitride film and formation of a titanium nitride film are alternately repeated, and at that time, the aluminium nitride film is formed firstly and / or lastly.

Owner:KOKUSA ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com