Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1999results about How to "Reduce precipitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Laminated semiconductor substrate process for producing the same

InactiveUS20060118935A1Simple processReduce surface roughnessDecorative surface effectsSemiconductor/solid-state device detailsEtchingSurface roughness

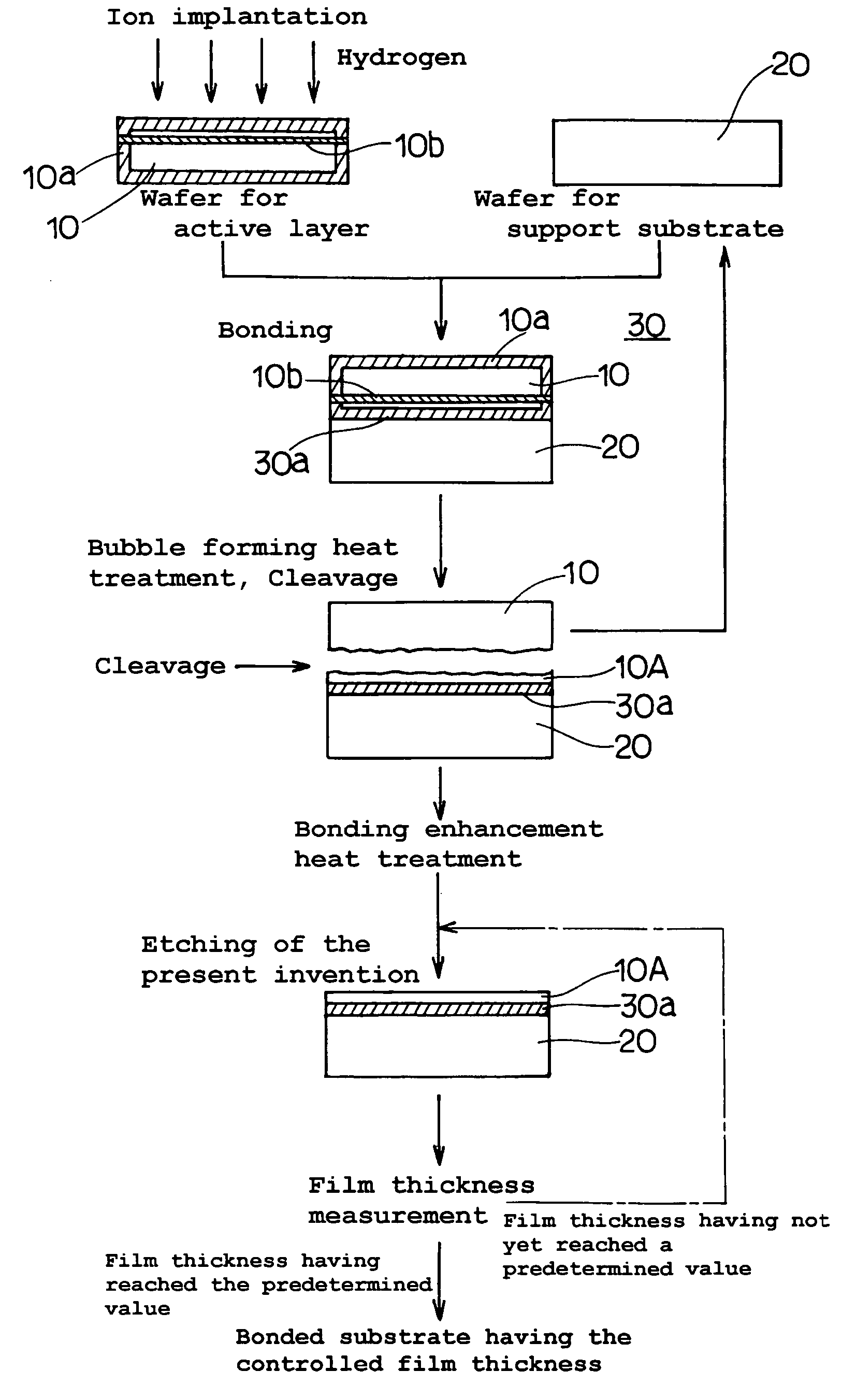

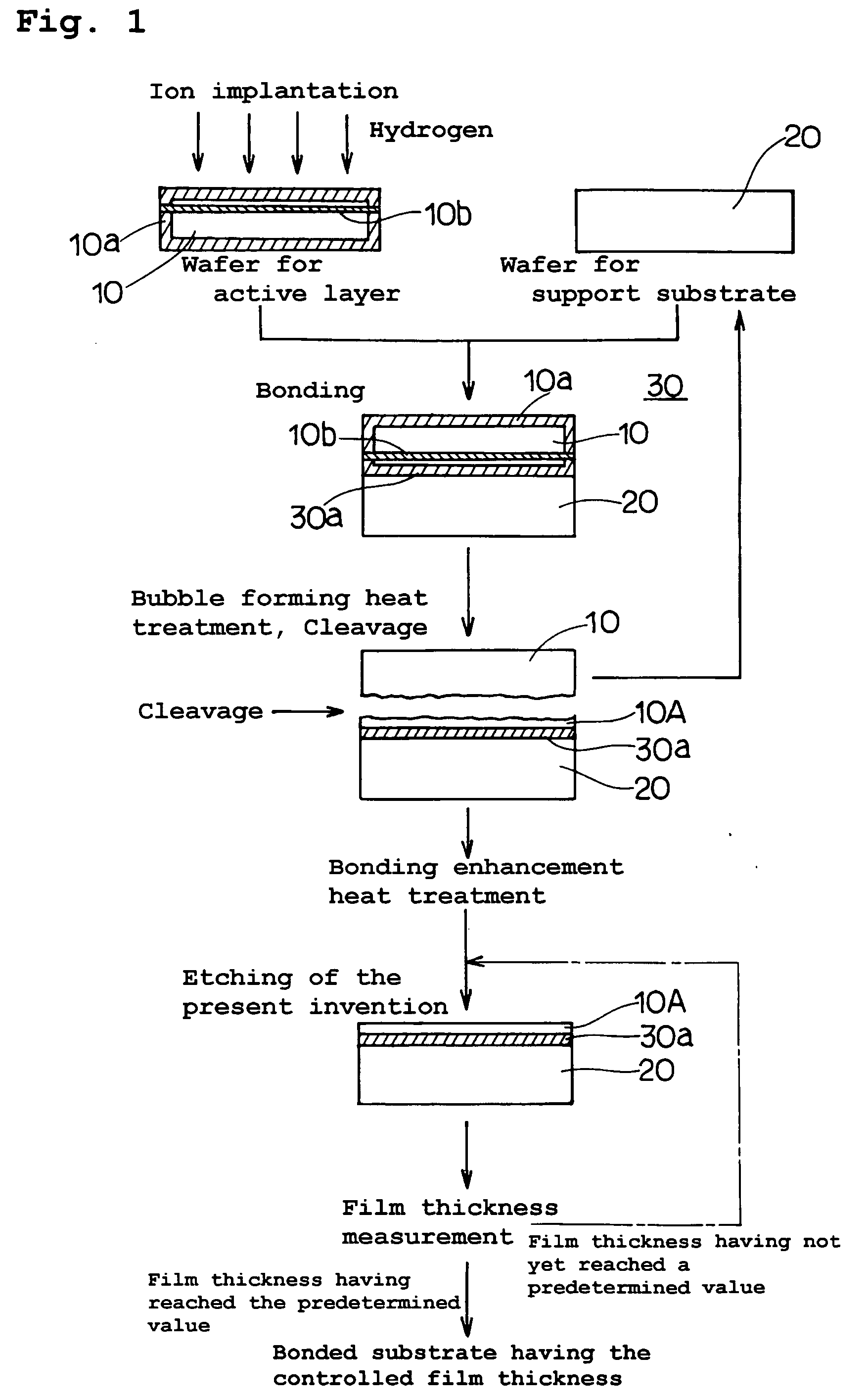

The present invention provides a bonded substrate fabricated to have its final active layer thickness of 200 nm or lower by performing the etching by only 1 nm to 1 μm with a solution having an etching effect on a surface of an active layer of a bonded substrate which has been prepared by bonding two substrates after one of them having been ion-implanted and then cleaving off a portion thereof by heat treatment. SC-1 solution is used for performing the etching. A polishing, a hydrogen annealing and a sacrificial oxidation may be respectively applied to the active layer before and / or after the etching. The film thickness of this active layer can be made uniform over the entire surface area and the surface roughness of the active layer can be reduced as well.

Owner:SUMCO CORP +1

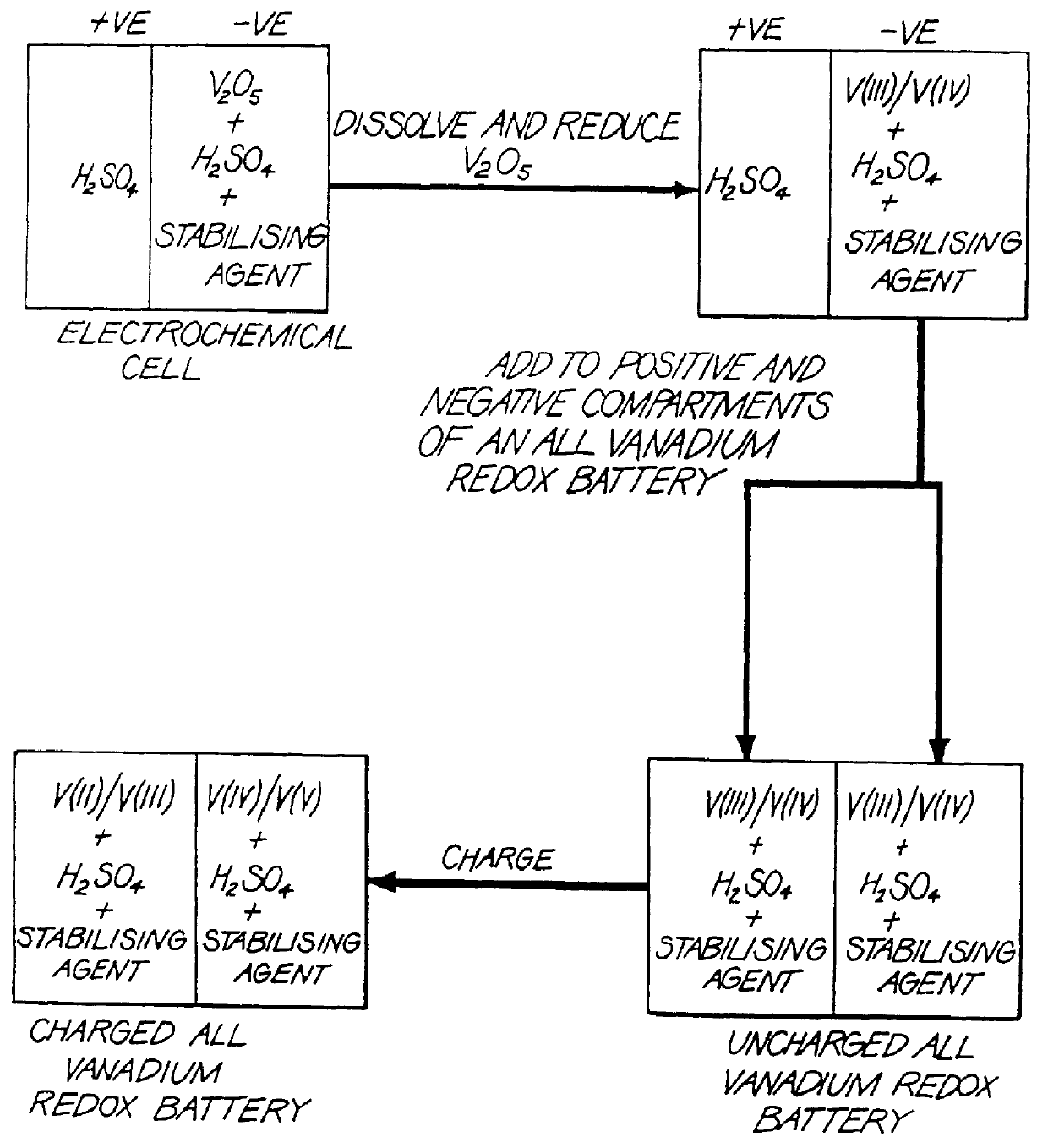

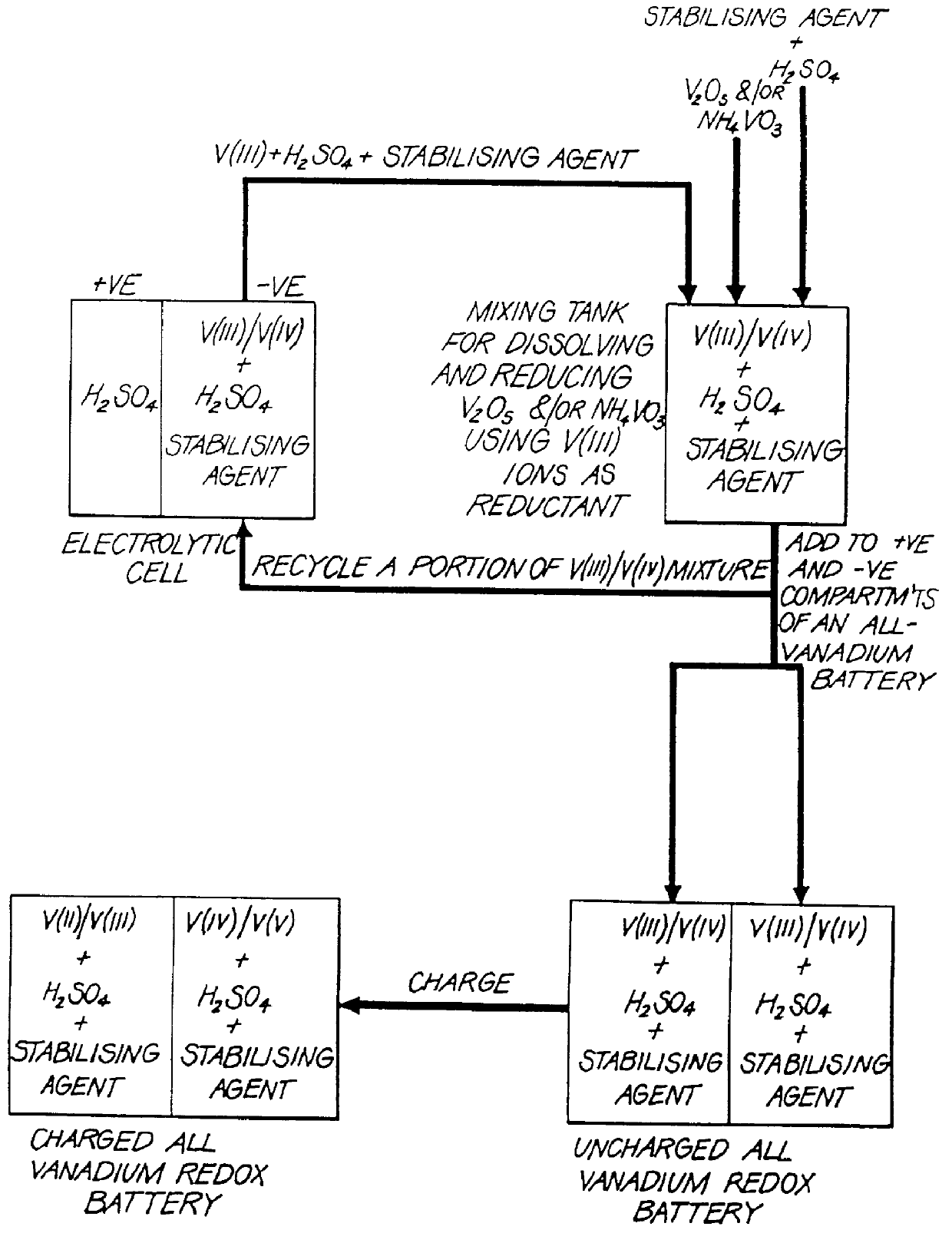

Stabilized electrolyte solutions, methods of preparation thereof and redox cells and batteries containing stabilized electrolyte solutions

InactiveUS6143443AReduce precipitationEffective amountLead-acid accumulatorsFinal product manufactureVanadium redox batteryFuel cells

Owner:VRB ENERGY INC

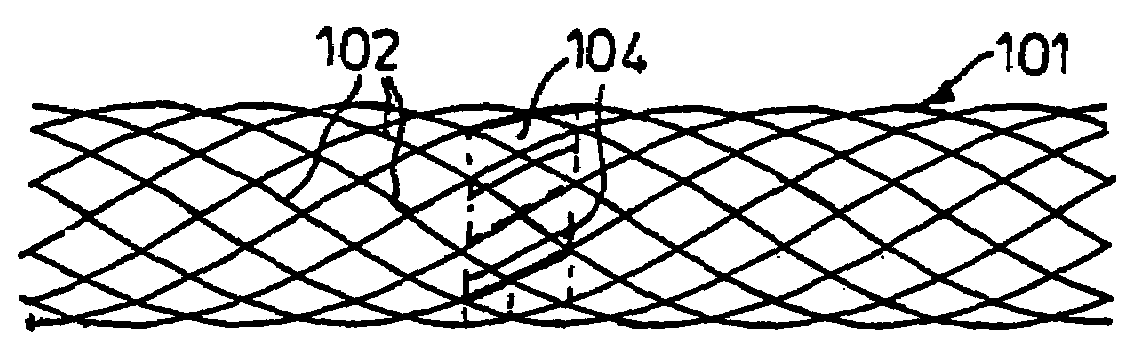

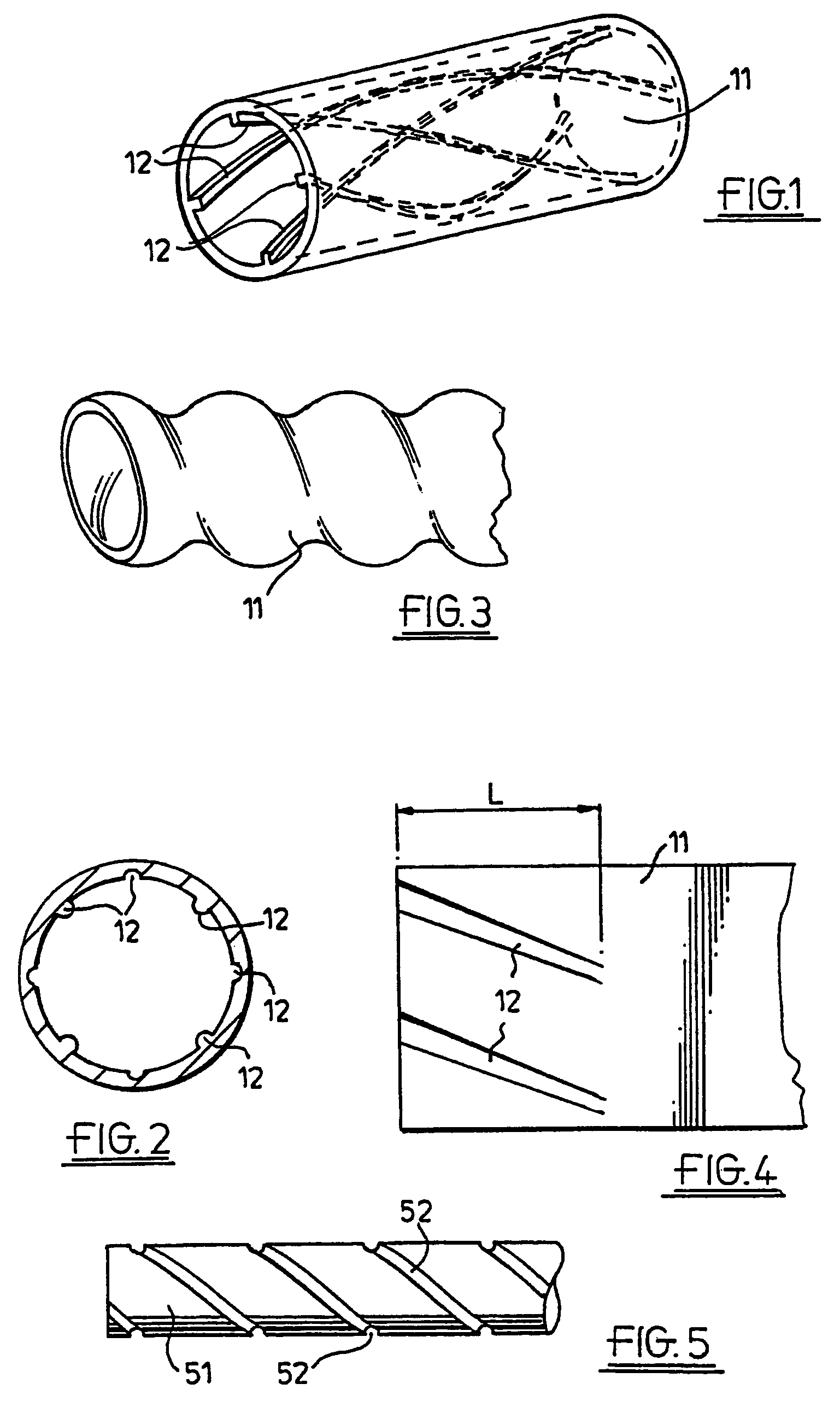

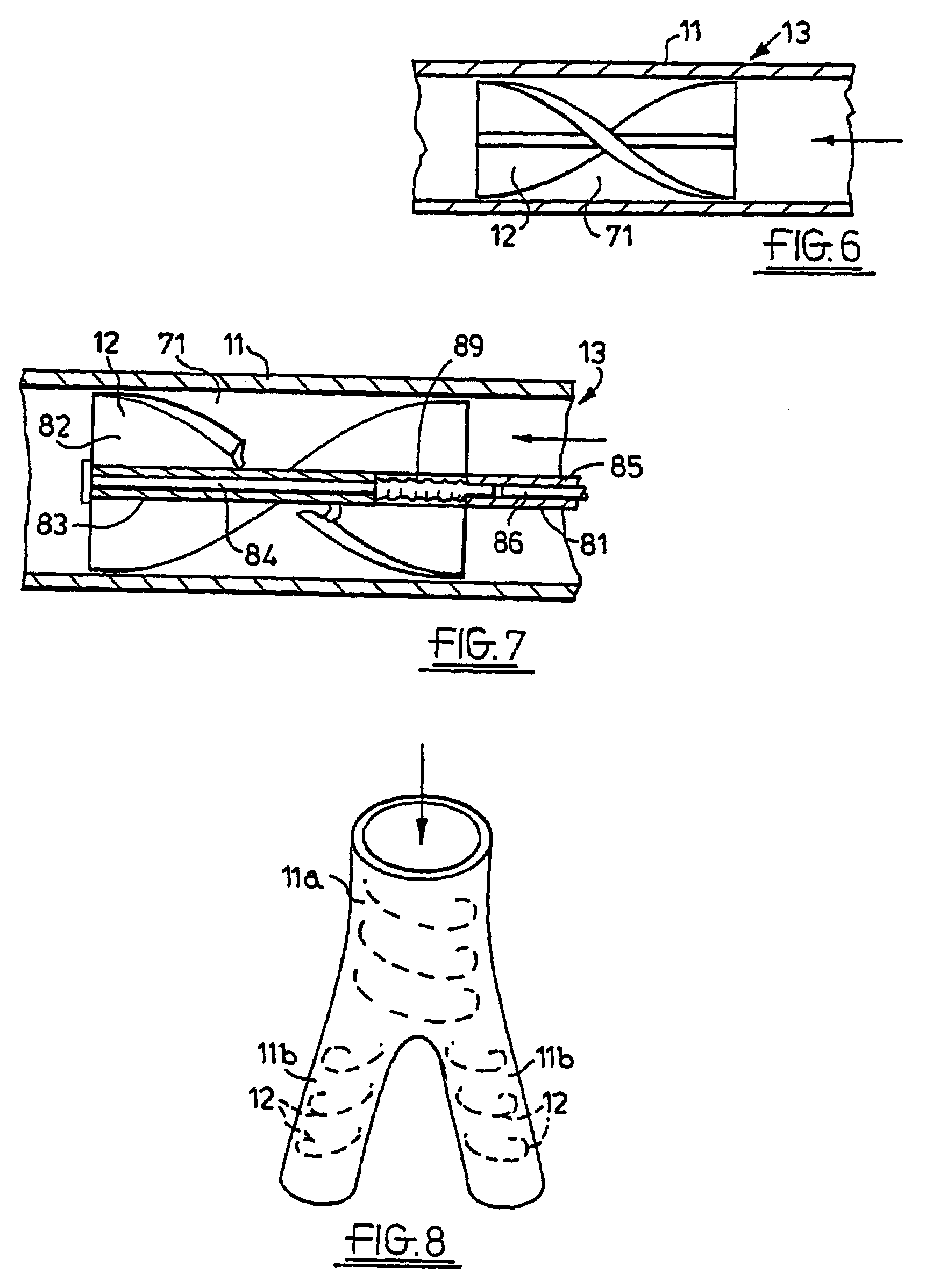

Blood-flow tubing

InactiveUS7682673B2Eliminate and reduce turbulenceReduce precipitationDialysis systemsCatheterInsertion stentTurbulent blood flow

Owner:VASCULAR FLOW TECH LTD

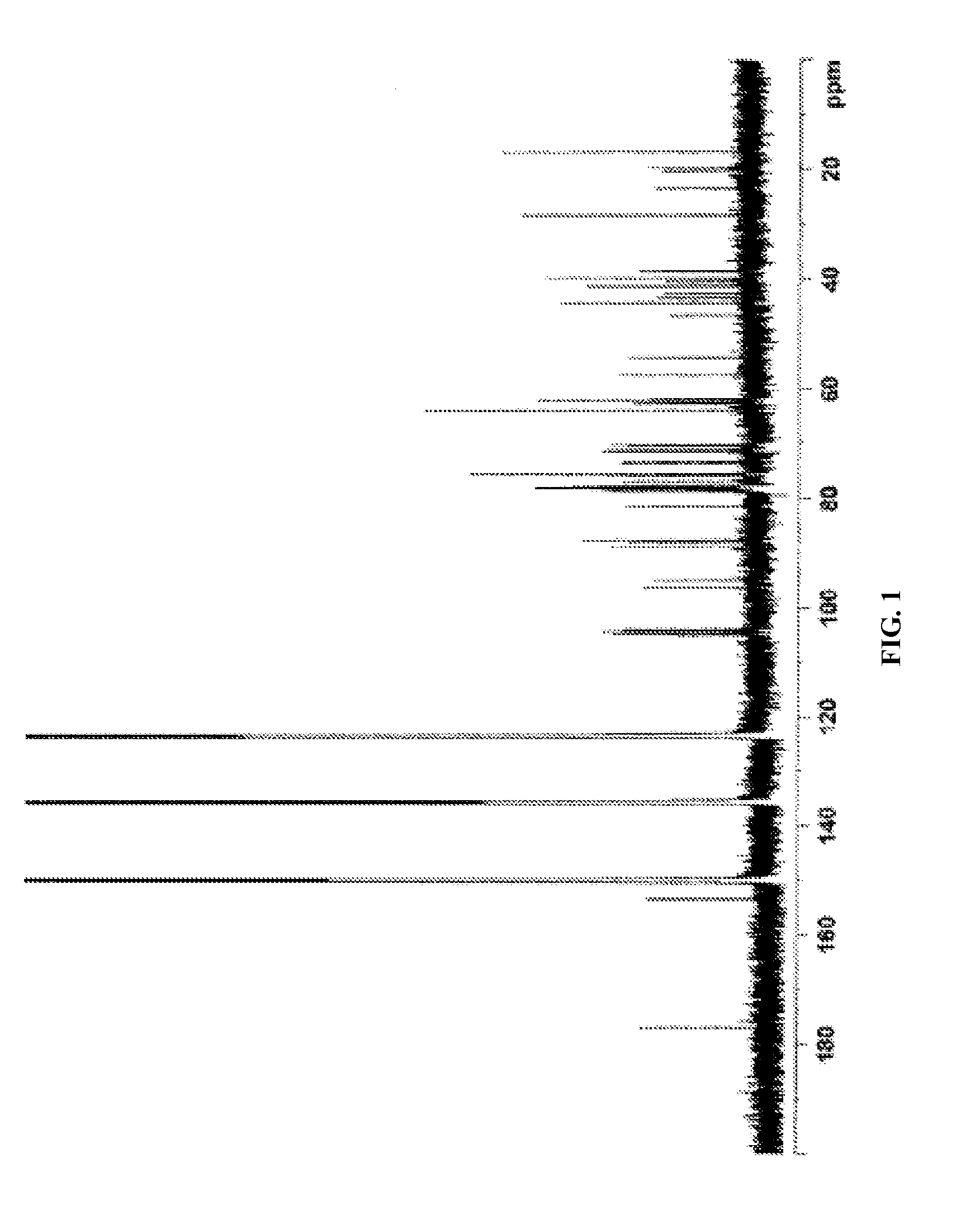

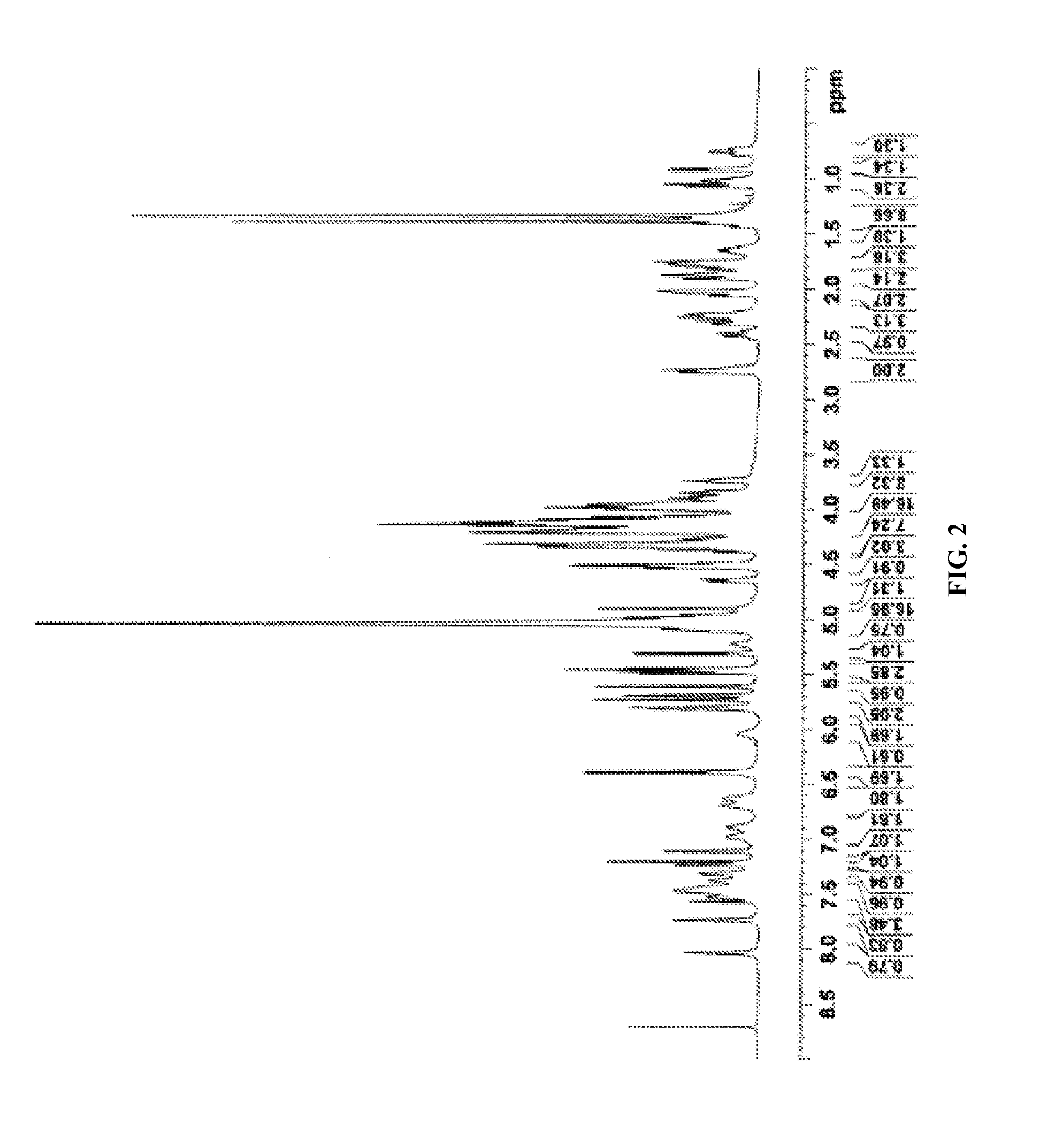

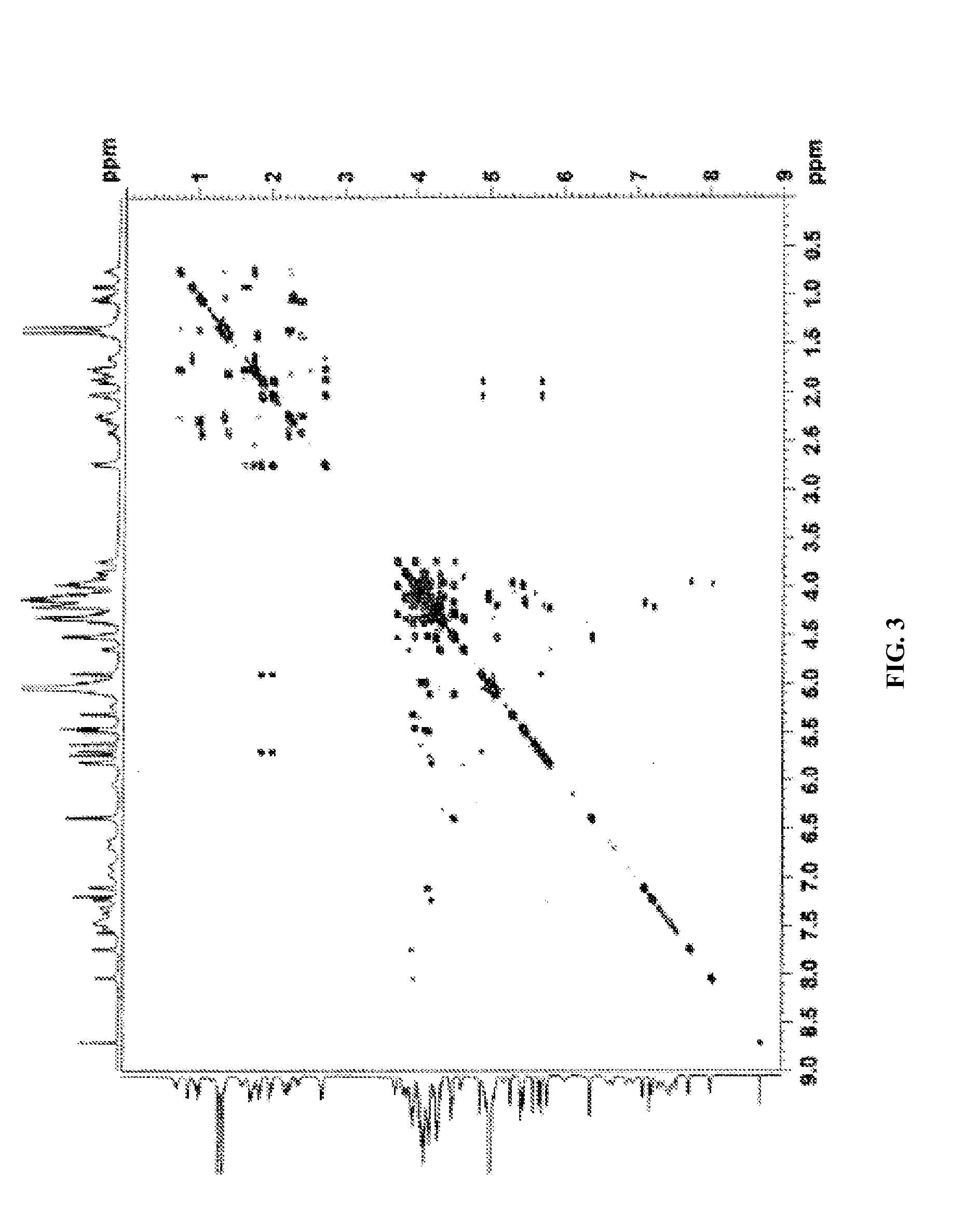

Compositions and Methods for Improving Rebaudioside M Solubility

ActiveUS20150017284A1Good water solubilityReduce precipitationMilk preparationDough treatmentSolubilityRebaudioside D

Rebaudioside M compositions with improved aqueous solubility and methods for preparing the same are provided herein. The rebaudioside M compositions include (i) disordered crystalline compositions comprising rebaudioside M and rebaudioside D, (ii) spray-dried compositions comprising rebaudioside M, rebaudioside D and steviol glycoside mixtures and / or rebaudioside B and / or NSF-02, (iii) spray-dried compositions comprising rebaudioside M, rebaudioside D and at least one surfactant, polymer, saponin, carbohydrate, polyol, preservative or a combination thereof. Sweetened compositions, such a beverages, containing the rebaudioside M compositions with improved water solubility are also provided herein.

Owner:THE COCA-COLA CO +1

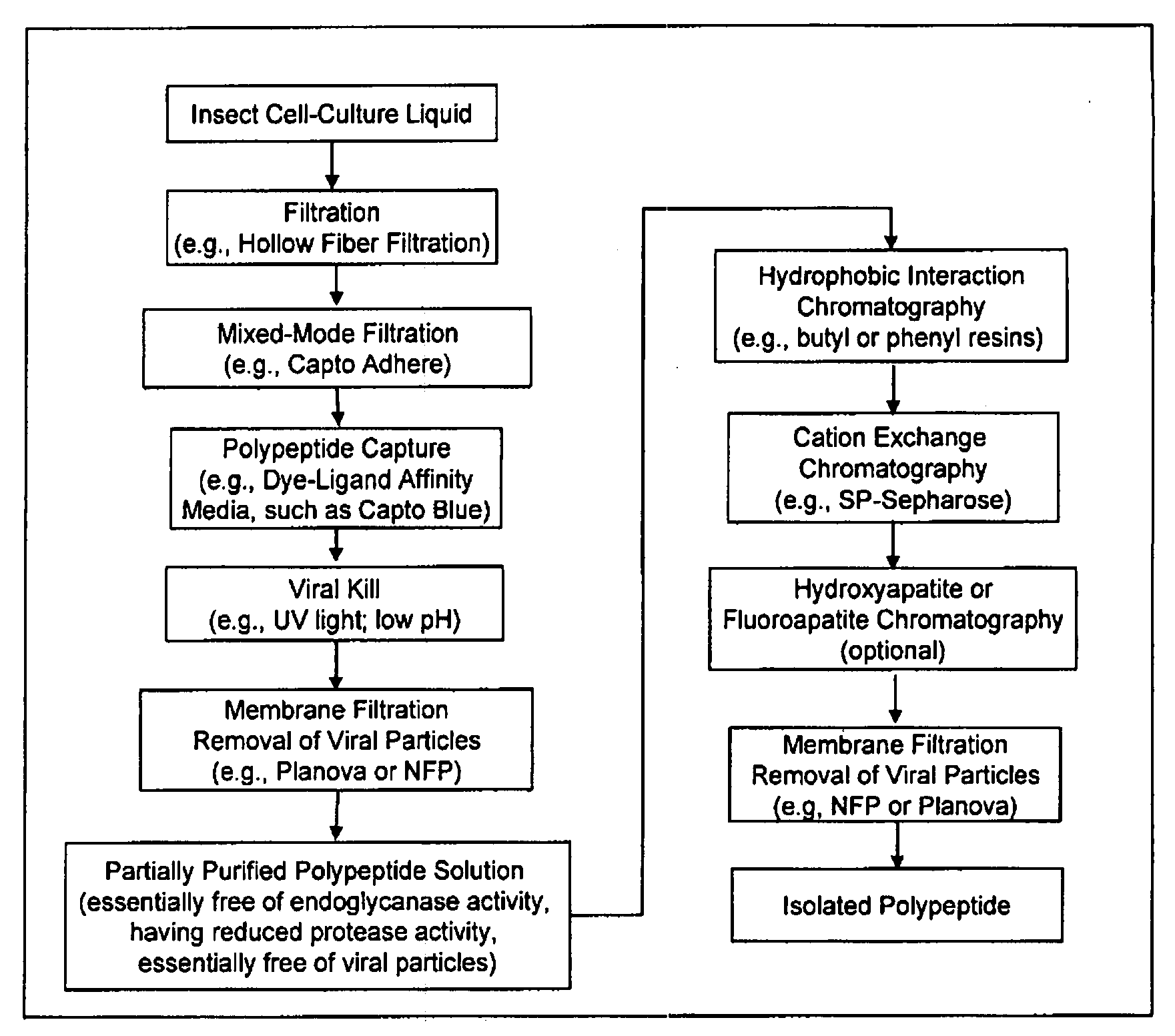

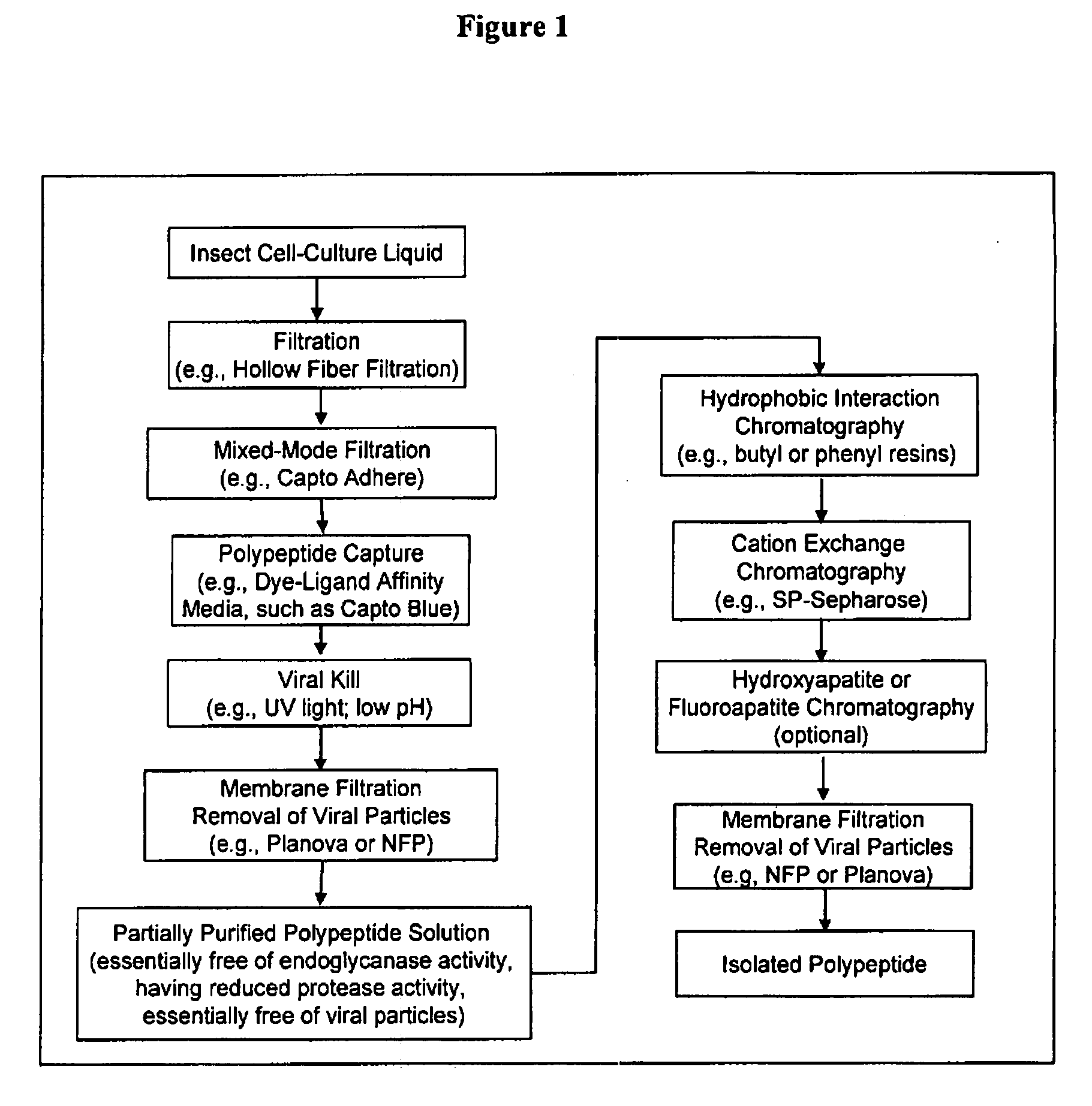

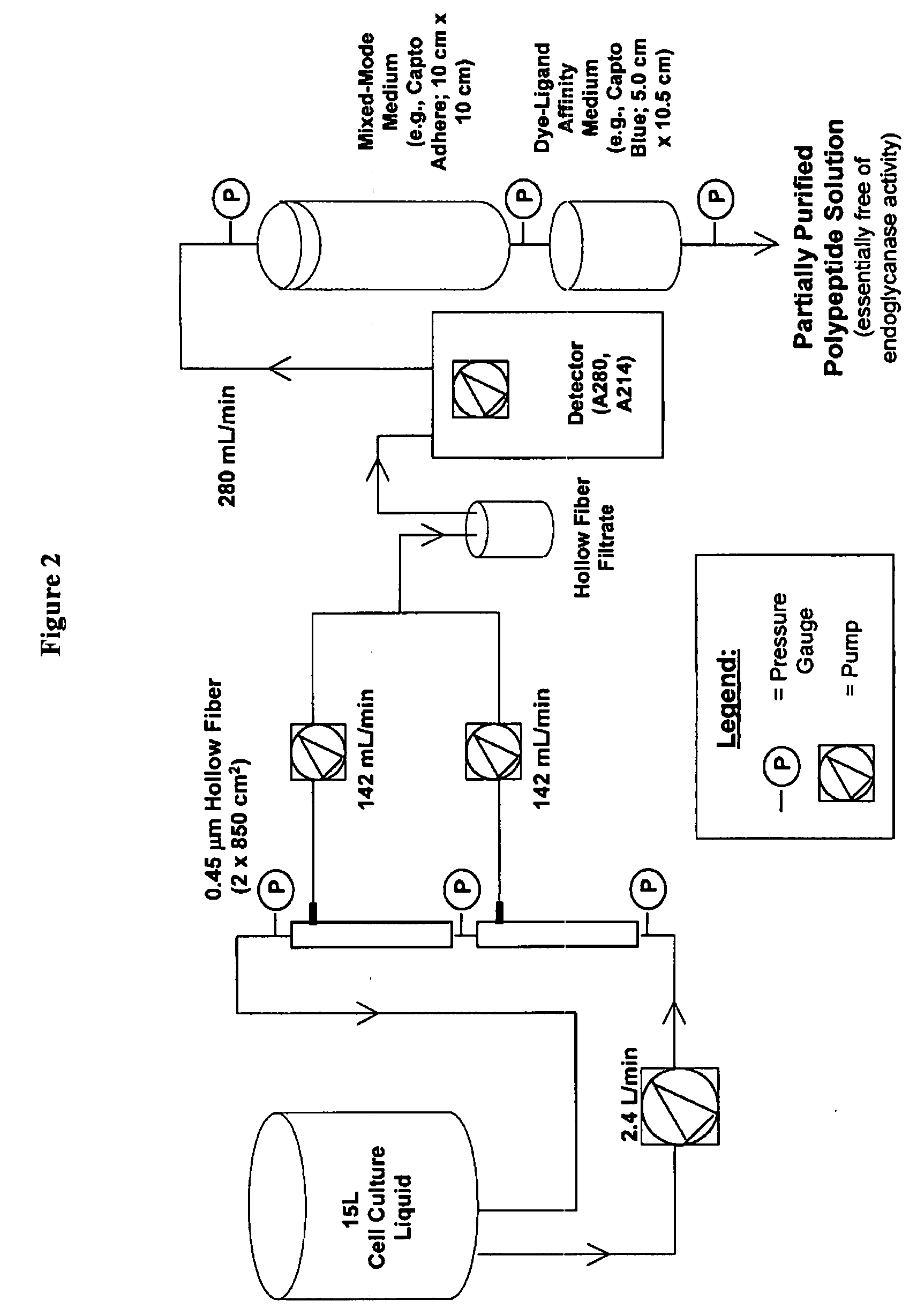

Manufacturing process for the production of polypeptides expressed in insect cell-lines

InactiveUS20080207487A1Promote recoveryReduce manufacturing costPeptide/protein ingredientsDepsipeptidesFiberCulture fluid

The present invention provides a manufacturing method for polypeptides that are produced in insect cells using a baculoviral expression system. In one example, the insect cell culture is supplemented with a lipid mixture immediately prior to infection (e.g., one hour prior to infection). The polypeptides are isolated from the insect cell culture using a method that employs anion exchange or mixed-mode chromatography early in the purification process. This process step is useful to remove insect-cell derived endoglycanases and proteases and thus reduces the loss of desired polypeptide due to enzymatic degradation. In another example, mixed-mode chromatography is combined with dye-ligand affinity chromatography in a continuous-flow manner to allow for rapid processing of the insect-cell culture liquid and capture of the polypeptide. In yet another example, a polypeptide is isolated from an insect cell culture liquid using a process that combines hollow fiber filtration, mixed-mode chromatography and dye-ligand affinity in a single unit operation producing a polypeptide solution that is essentially free of endoglycanase and proteolytic activities. In a further example, the isolated polypeptides are glycopeptides having an insect specific glycosylation pattern, which are optionally conjugated to a modifying group, such as a polymer (e.g., PEG) using a glycosyltransferase and a modified nucleotide sugar.

Owner:NOVO NORDISK AS

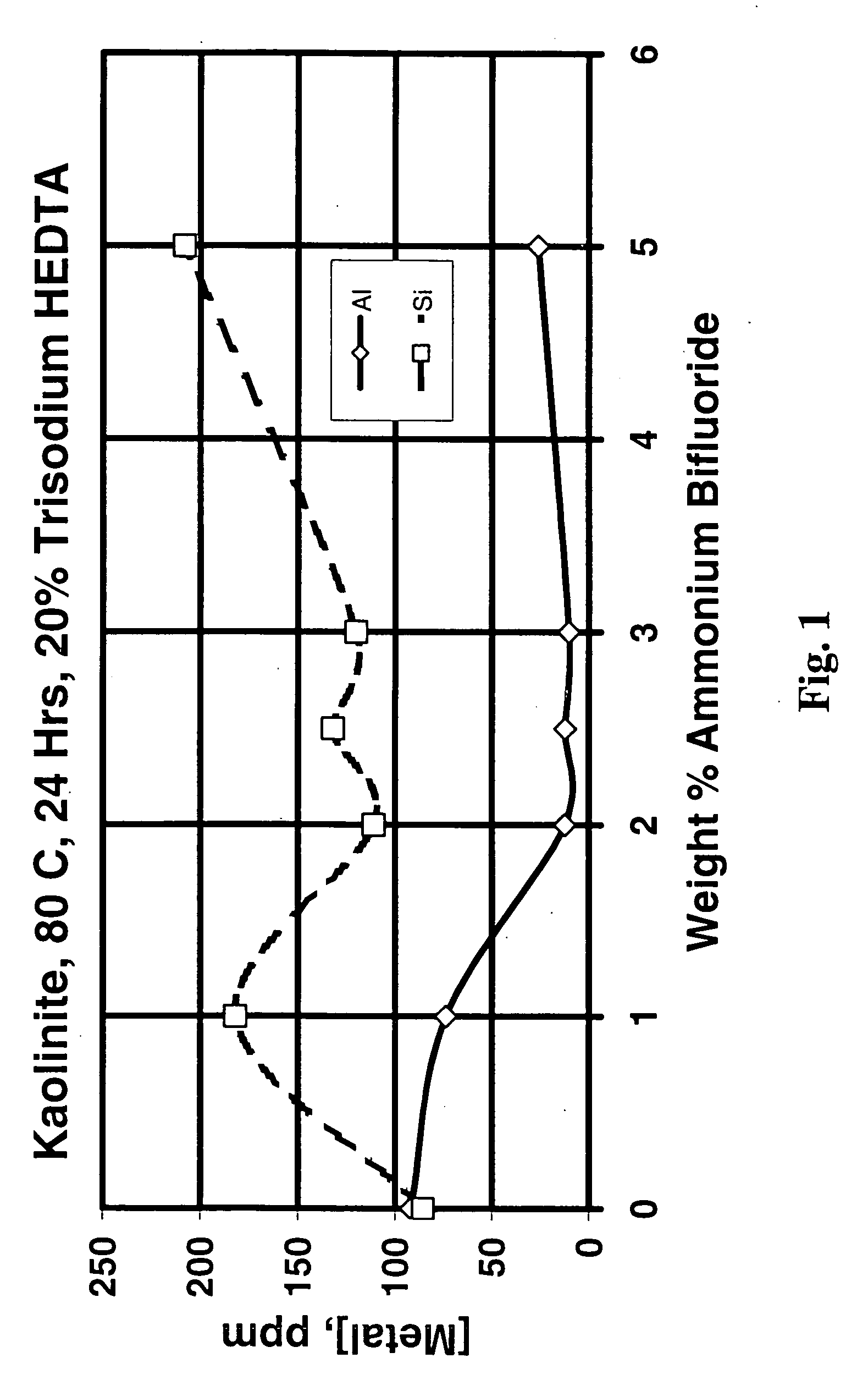

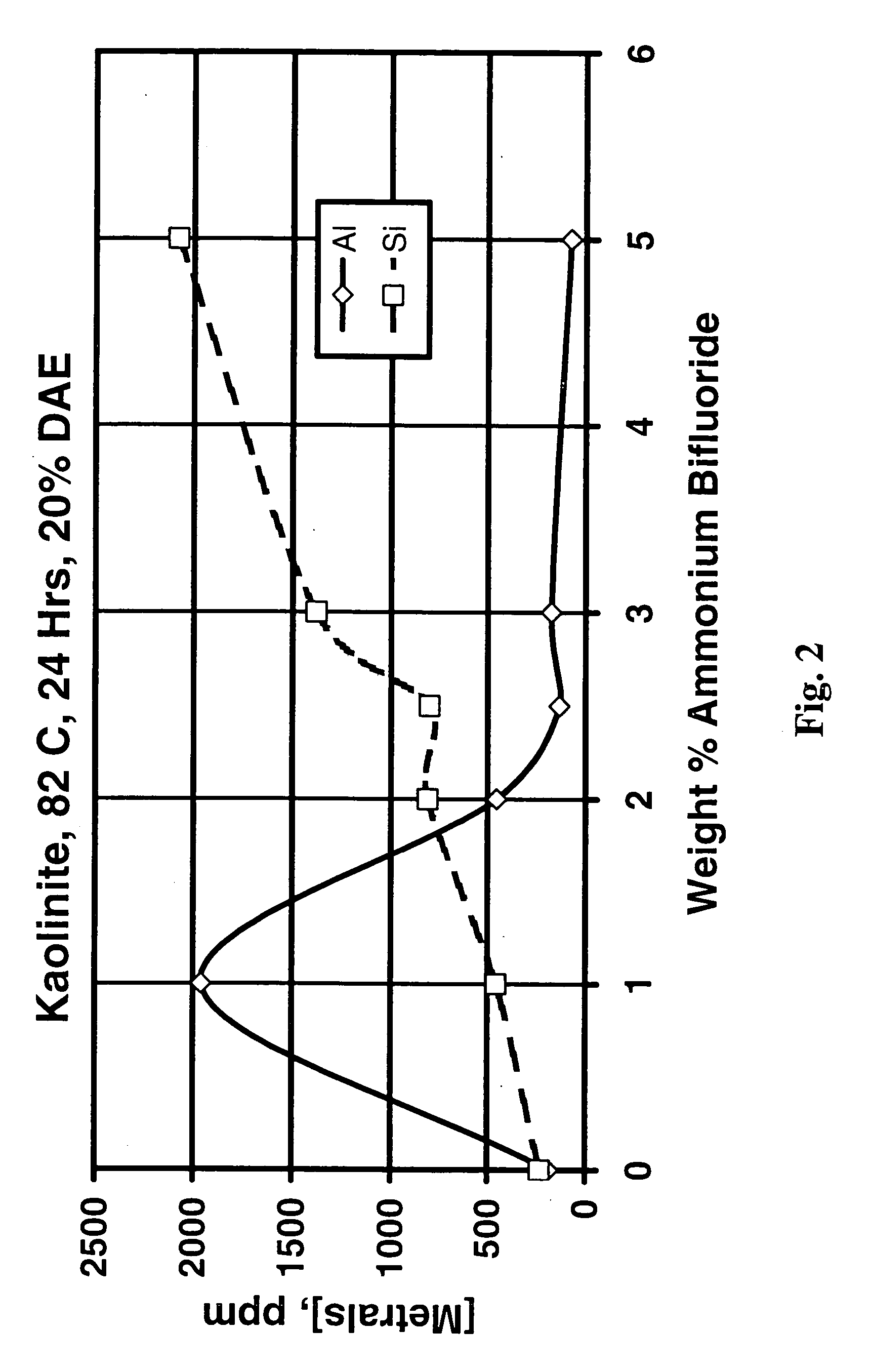

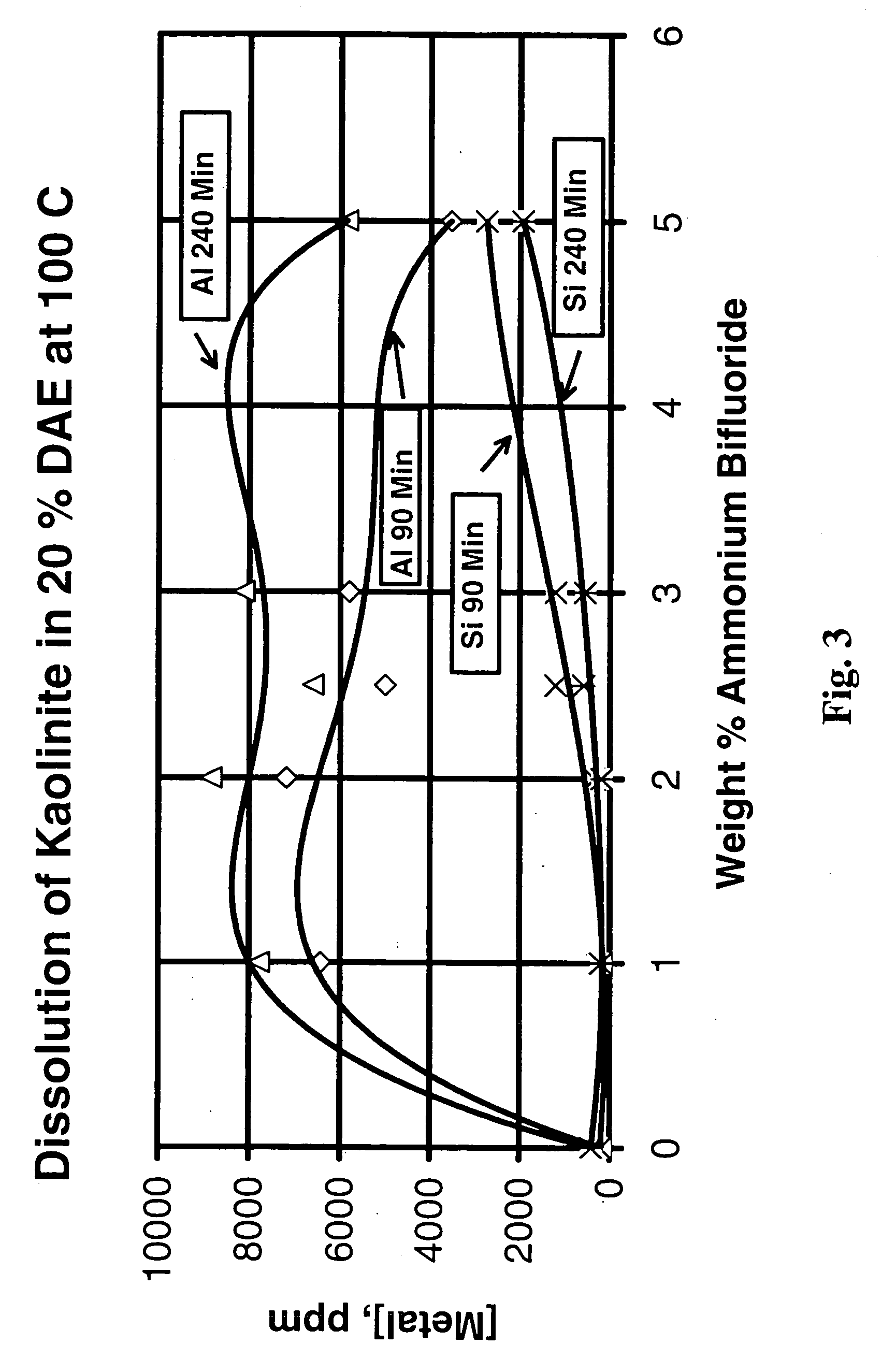

Composition and Method for Treating a Subterranean Formation

An aqueous oilfield treatment fluid containing a chelating agent and an HF source is described. This fluid is effective at dissolving siliceous materials such as clays and keeping the dissolved materials in solution. In particular it is effective at preventing re-precipitation of initially-dissolved silicon as silica and therefore reduces damage to sandstones with which it is contacted. Methods are given for using this fluid for sandstone matrix stimulation, removal of clay-containing drilling fluid components and filter cakes from wellbores, sandstone acid fracturing, and gravel pack and proppant pack cleaning.

Owner:SCHLUMBERGER TECH CORP

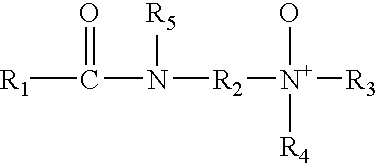

Acidizing stimulation method using viscoelastic gelling agent

InactiveUS20050137095A1Minimize the risk of damageReduce iron hydroxide precipitationFluid removalFlushingFluid viscositySURFACTANT BLEND

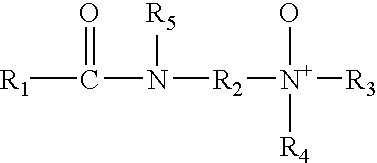

A method of acidizing a subterranean formation involves the use of a composition containing a solution of a viscoelastic amidoamine oxide surfactant and an HF-containing acidizing solution. The composition typically contains from about 0.1 to about 8 weight percent of surfactant solution and from about 92 to about 99.9 weight percent of HF-containing acidizing solution. The composition is pumped into the subterranean formation. As the acid reacts, the composition viscosifies and becomes a self-diverting agent created in-situ. When the acid is further spent, the fluid viscosity declines eventually returning to a low viscosity state, allowing for easy cleanup. The process allows for selective acidizing of less permeable zones of the formation and more uniform stimulation of the hydrocarbon bearing formulation.

Owner:BAKER HUGHES INC

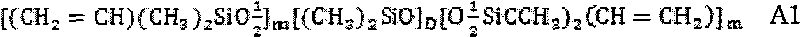

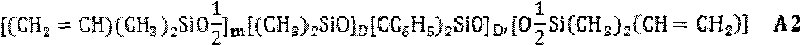

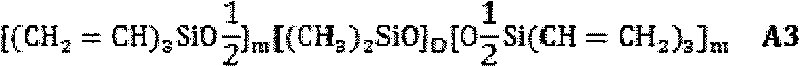

Organic silicon rubber encapsulating material for high-power LED

InactiveCN101747632AHigh light transmittance durabilityImprove temperature resistanceOther chemical processesSemiconductor devicesRefractive indexTackifier

The invention relates to an organic silicon encapsulating material for a high-power LED and a preparation method thereof. The organic silicon encapsulating material is prepared by mixing a component A containing vinyl polysiloxanes, a silicone resin component B, a component C containing hydrogen polysiloxane, a platinum catalyst component D, a component E of catalytic inhibitor of acetylene alcohols and a tackifier component F. The obtained encapsulating silicon rubber with different refractive indexes of level 1.4, level 1.5 and the like can be used for the encapsulation of various high-power LEDs and the encapsulation of other optical application. The organic silicon rubber encapsulating material for the high-power LED takes the silicone resin component B as a filling material, which not only enables that the silicone rubber has high transparency, high strength and high light transmittance, but also improves the temperature resistance, the yellowing resistance, and the durability of the high light transmittance of high-power LED products. The organic silicon rubber encapsulating material for the high-power LED can be prepared into two encapsulating forms of a single component and bi-component, which improves the adaptability and the encapsulating efficiency for encapsulating equipment and process procedures, and has the characteristics of reduced cost and convenient use.

Owner:陈俊光

Officinal health-care solid electronic aerosolization liquid and preparation method thereof

The invention provides an officinal health-care solid electronic aerosolization liquid, mainly comprising the following components by weight percent: 35-45% of propylene glycol, 30-35% of medicament, 10-15.0% of deionized water, 3-3.5% of tobacco leaf extract solution, 3-3.5% of tobacco flavour, 2-3.0% of excipient, 0.2-1.0% of calcium pectate and 0.3-0.8% of curing agent. The invention also provides a preparation method of the officinal health-care solid electronic aerosolizatioon liquid. The invention contains multiple officinal components having treating function on lungs, thus having treating function on symptoms such as dryness and itch of the throat and irritable cough which are caused by smoking, chronic pharyngitis and dryness of mouth and nose, thirst and dry cough, less sputum or distressed cough caused by the fact that sputum is glued; meanwhile the invention is solid, thus the stability of storing and use is improved, production and transportation are more convenient and flexible, and fragrance can be remained to be more complete.

Owner:FEELLIFE BIOSCI INT

Fine grained aluminium alloy and its preparing method

InactiveCN1936050AGive full play to the refinement effectLow costPhotography auxillary processesOxideTitanium oxide

The invention relates to a refined crystal grain aluminum alloy and the manufacturing method. It is made up from Si 0.2-7.5wt%, Mn 0.05-1.5wt%, Mg 0,05-6.0wt%, Zn 0.03-8.5wt%, Cu 0.05-7.0wt%, Ni 0.1-2.5wt%, Ti 0.01-0.15wt%, RE 0.01-0.3wt%, B 0.0001-0.10wt%, and the rest is Al. The technology feature is that it adds silicon titanium alumina, borax and or rare earth oxide or rare earth carbonate, or titanium oxide, borax and / or rare earth oxide or rare earth carbonate into aluminum cell. Add the manganese oxide, compound of copper or Ni would be also added. Comparing to traditional technology, the refiner is not added, and the refining effect is enhanced and the perdurability is prolonged. It could be used to produce wire, band, tube, panel, aluminum foil, etc.

Owner:DONGHUA UNIV

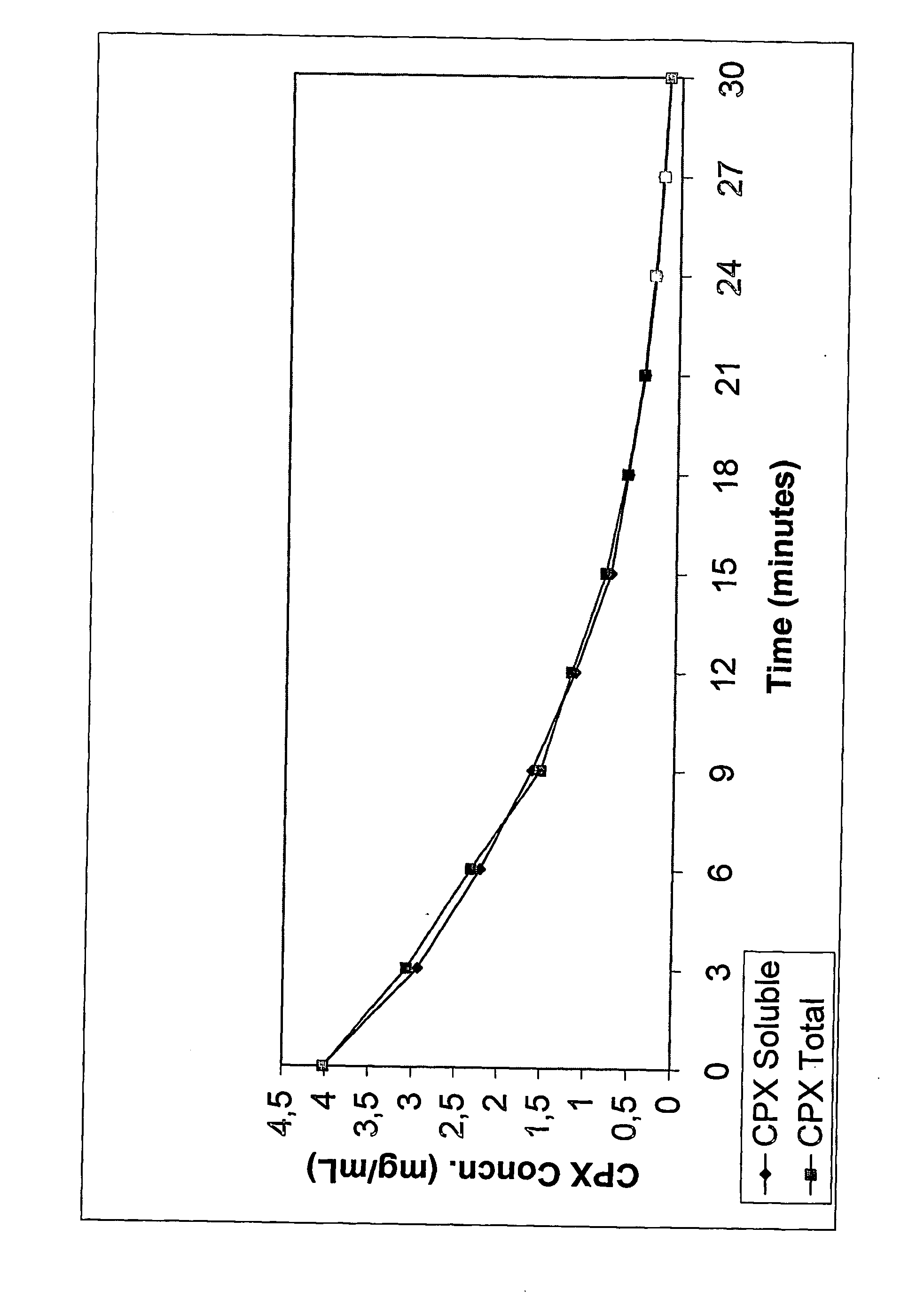

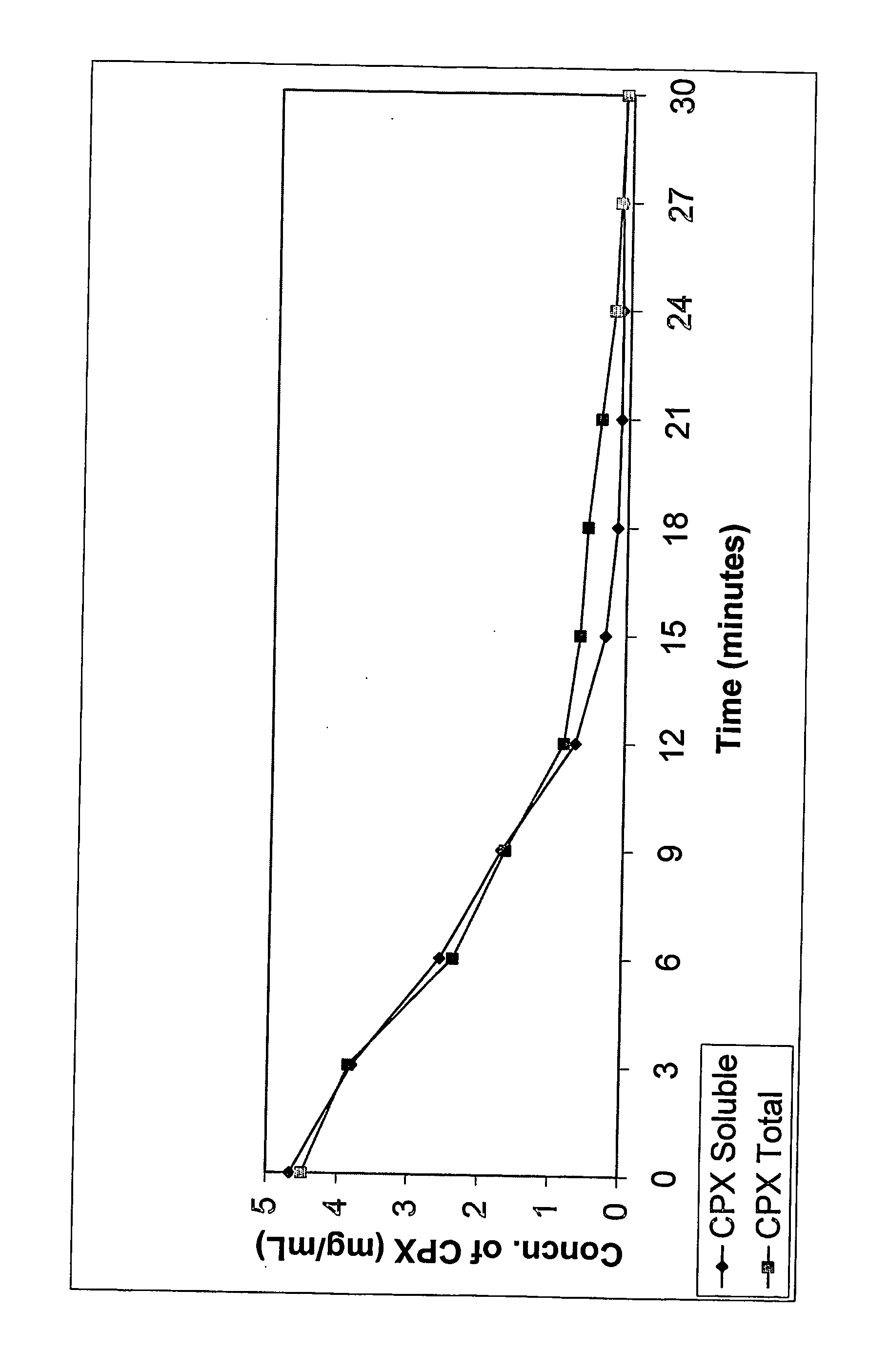

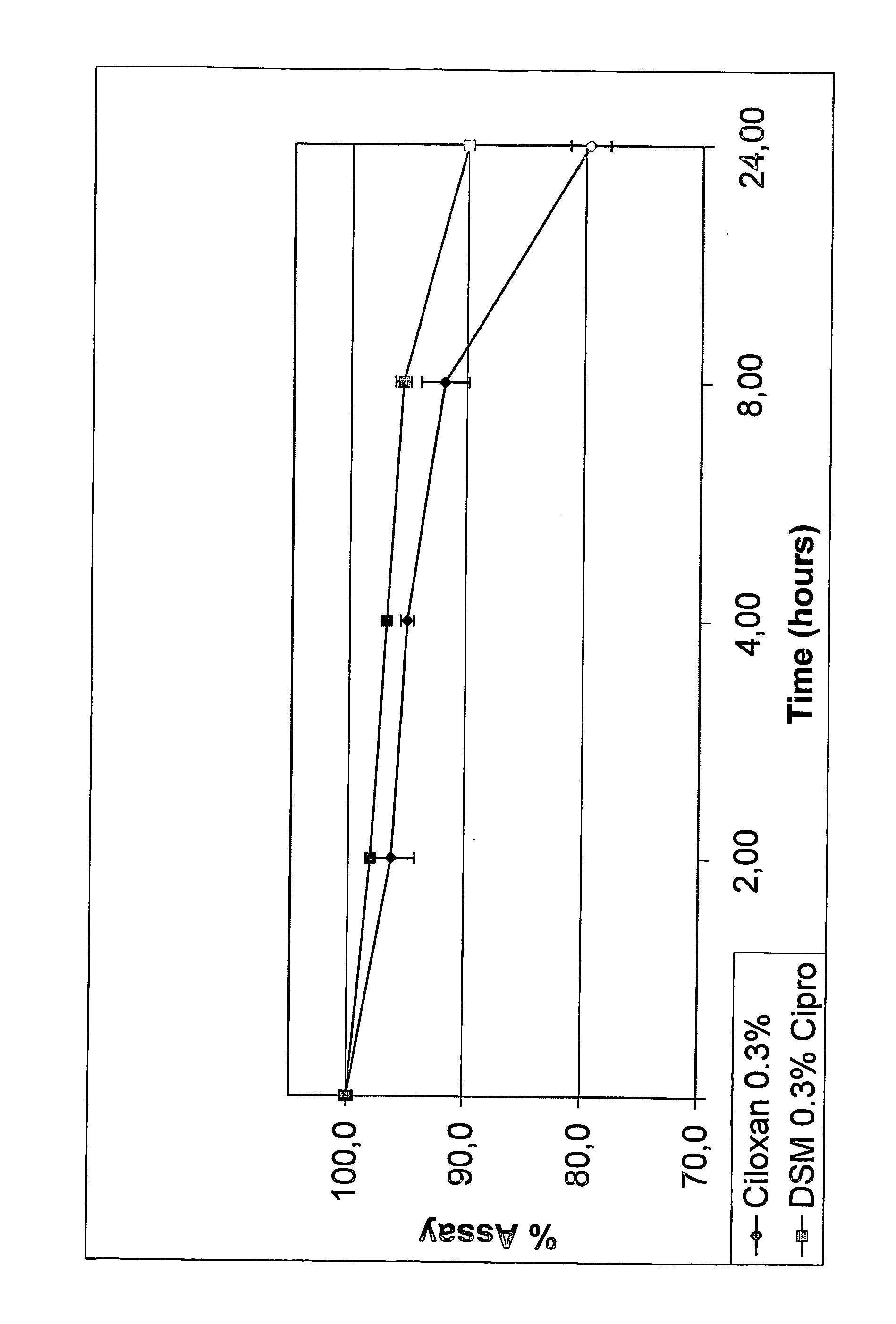

Fluoroquinolone formulations and methods of making and using the same

InactiveUS20070049552A1Reduce precipitationBiocidePharmaceutical delivery mechanismChemistryCyclodextrin

A pharmaceutical composition comprising a fluoroquinolone such as ciprofloxacin, cyclodextrin, and a hydroxy acid is described. The composition may be an aqueous composition, with such aqueous compositions preferably having a pH between 5 and 7. In some preferred embodiments, the composition further comprises a soluble polymer.

Owner:DSM IP ASSETS BV

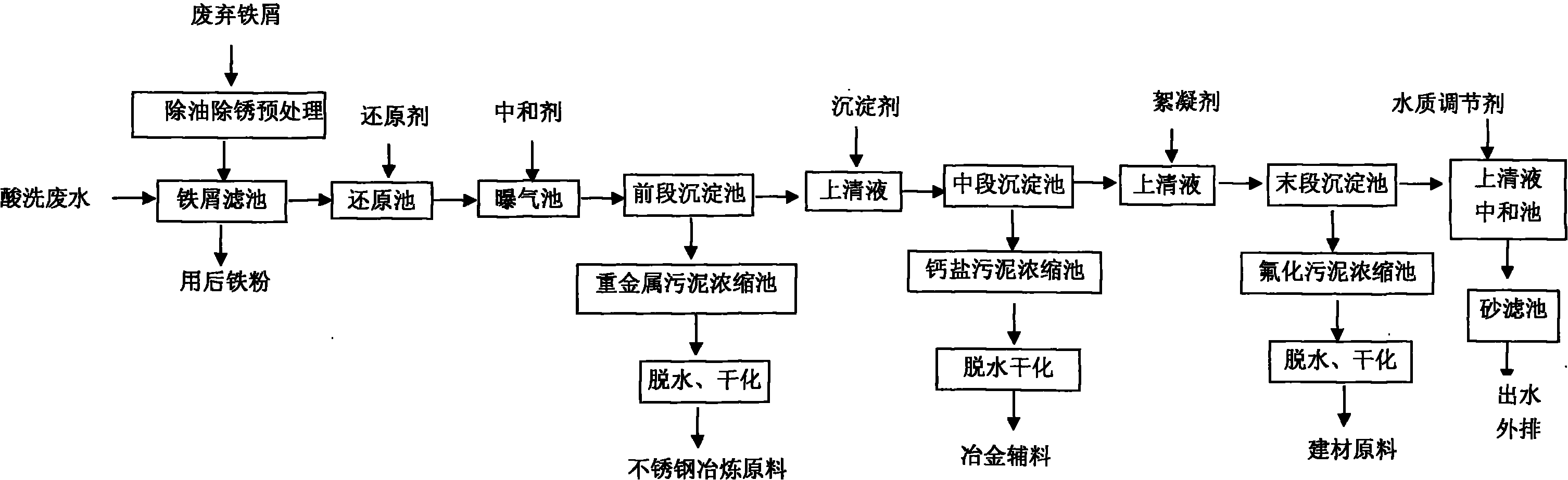

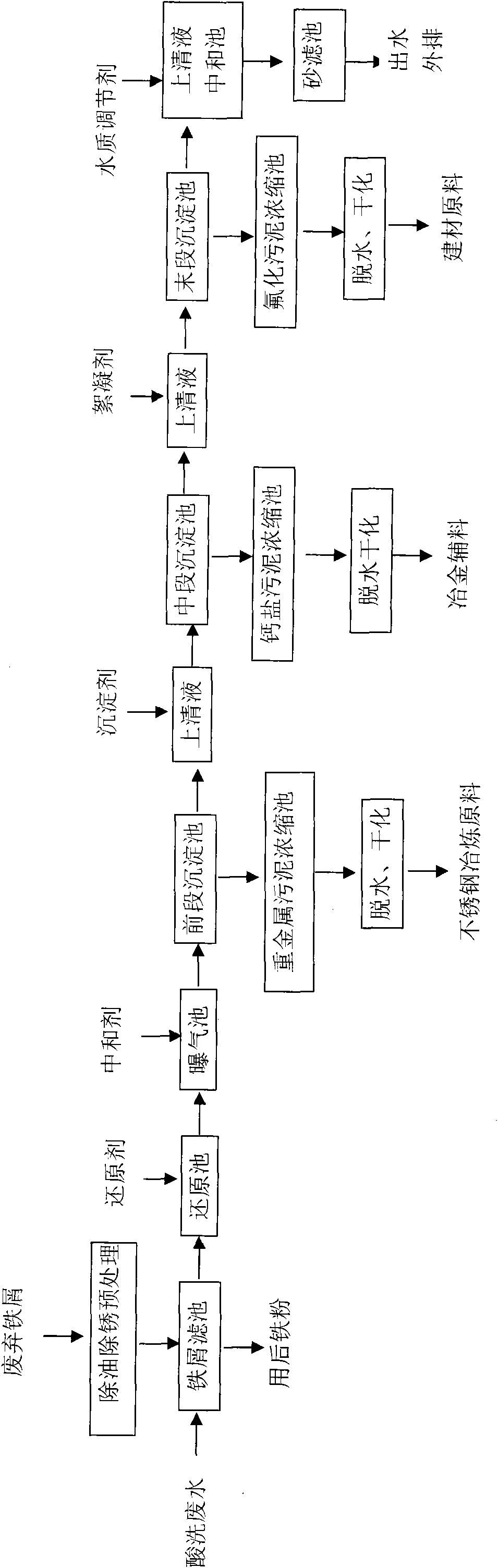

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

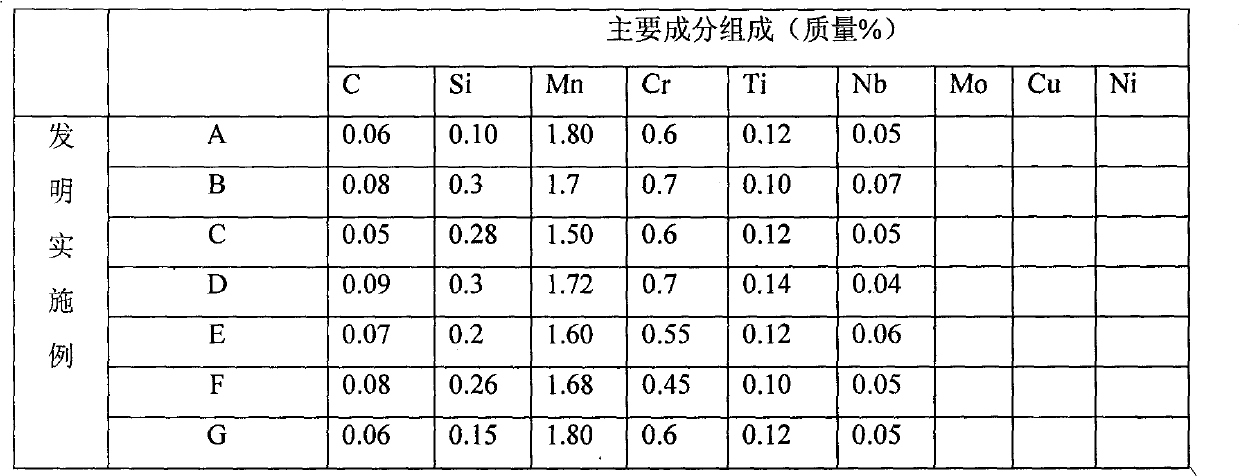

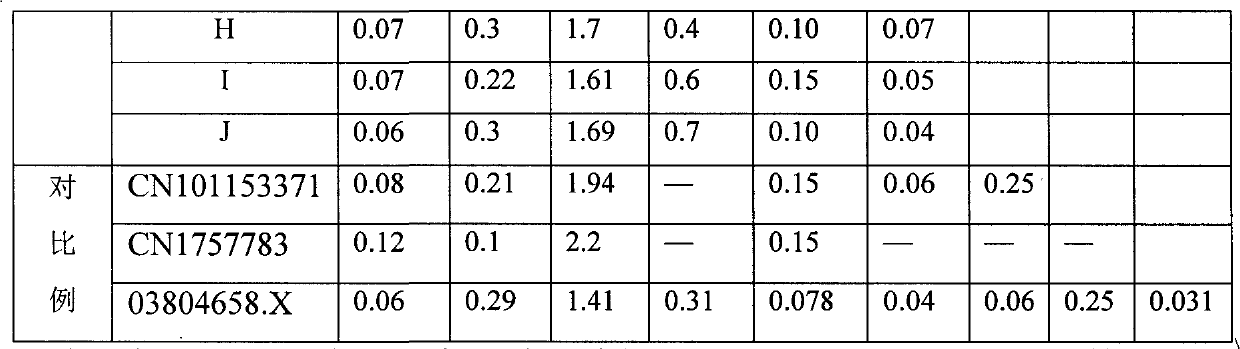

Low cost yield strength 700MPA level non-tempering processing high strength steel plate and manufacturing method thereof

ActiveCN101768698AImprove plasticityImprove toughnessTemperature control deviceManufacturing convertersSteel platesSheet steel

The invention discloses a low cost yield strength 700MPA level non-tempering processing high strength steel plate, which is characterized by, in terms of mass, comprising 0.05-0.10% of C, 0.1-0.4% of Si, 1.5-2.0% of Mn, less than 0.015% of P, less than 0.01% of S, 0.3-0.8% of Cr, 0.09-0.15% of Ti, 0.04-0.08% of Nb, less than 0.005% of N, less than 0.002% of O, and balance of Fe and unavoidable impurities. The manufacturing method of the steel plate comprises technological steps of smelting, rough rolling, fine rolling, reeling and cooling to obtain the steel plate with yield strength of 700-780MPa, tensile strength of 800-860MPa and elongation Delta larger than or equal to 18%. The yield strength 700MPA level non-tempering processing high strength steel plate simultaneously has abrasive resistance and better low temperature toughness, toughness and crispiness transition temperature is at around negative 40 DEG C, specific energy of shock at normal temperature can reach as high as 120J.

Owner:SHANDONG IRON & STEEL CO LTD

White inkjet ink improved for dispersion stability

ActiveUS20100039463A1Improve the problemReduce precipitationMeasurement apparatus componentsDuplicating/marking methodsDispersion stabilityRefractive index

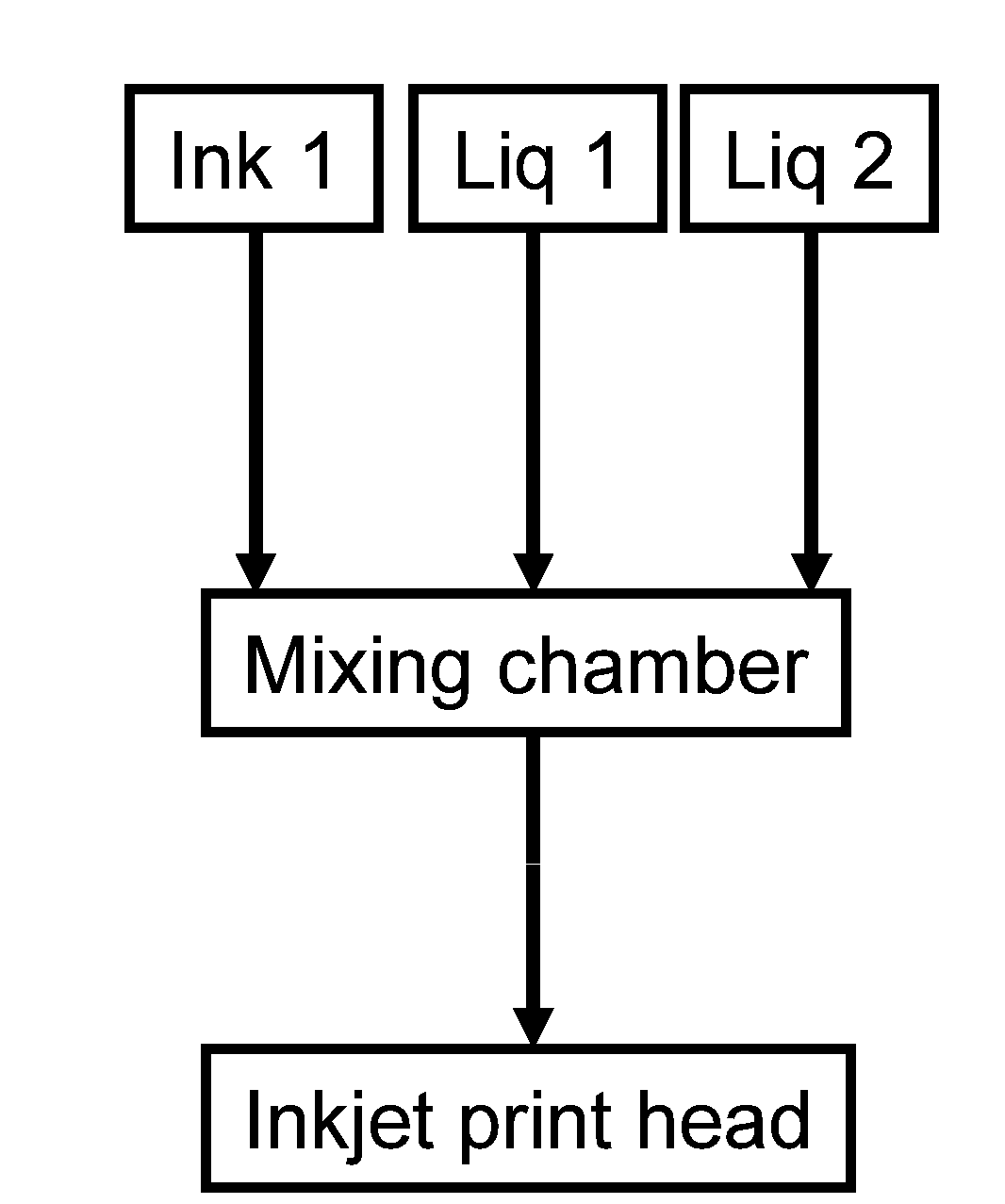

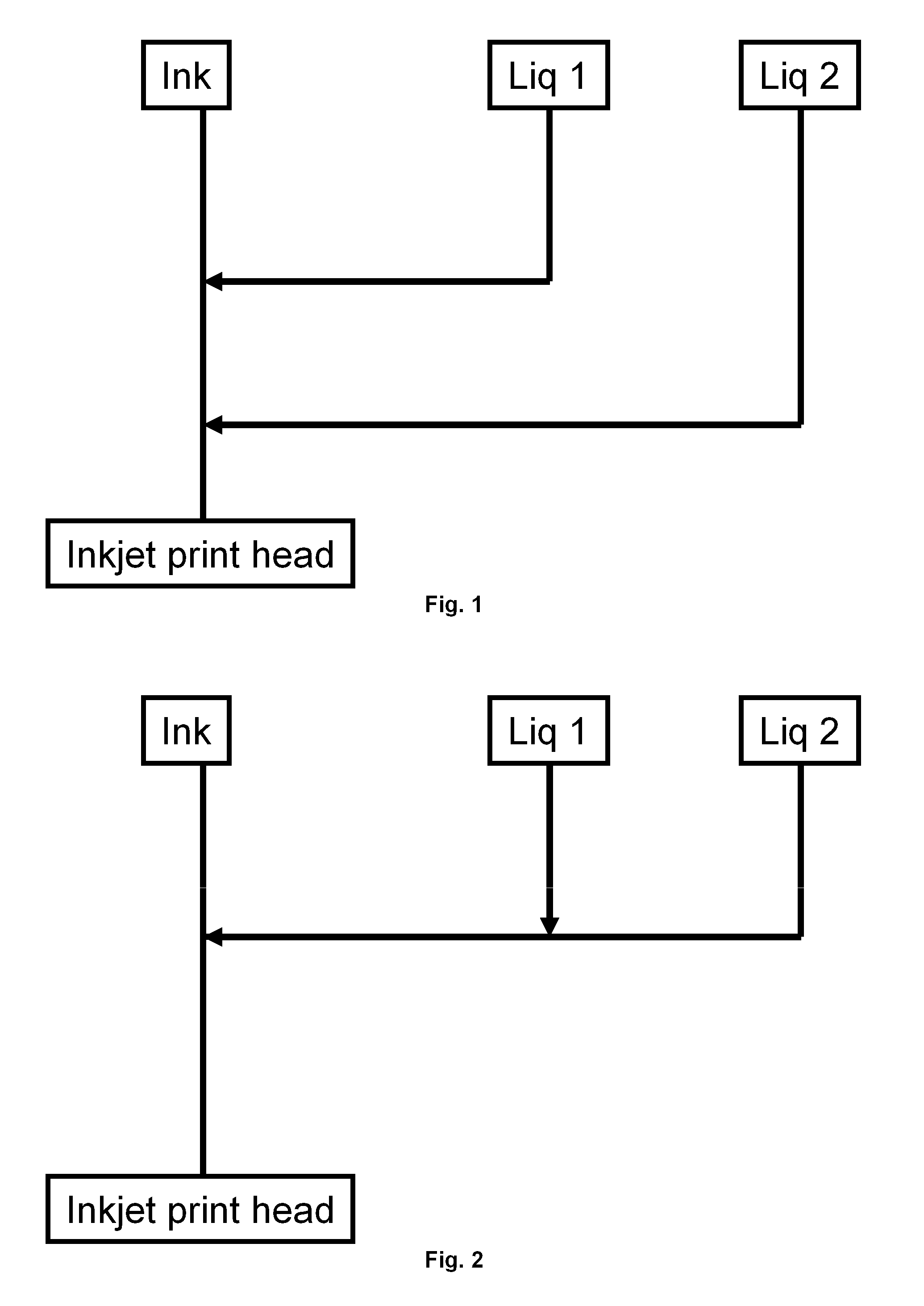

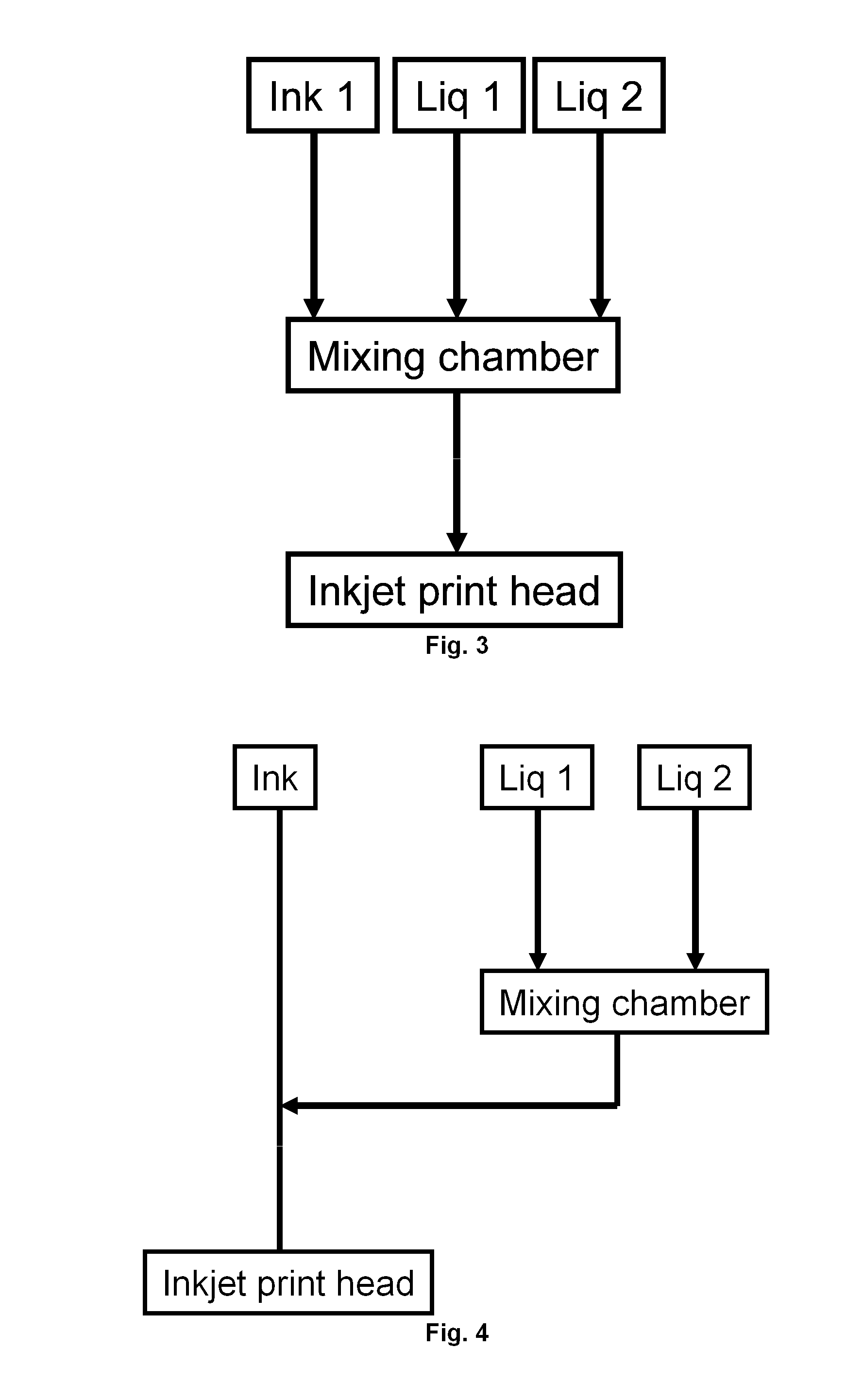

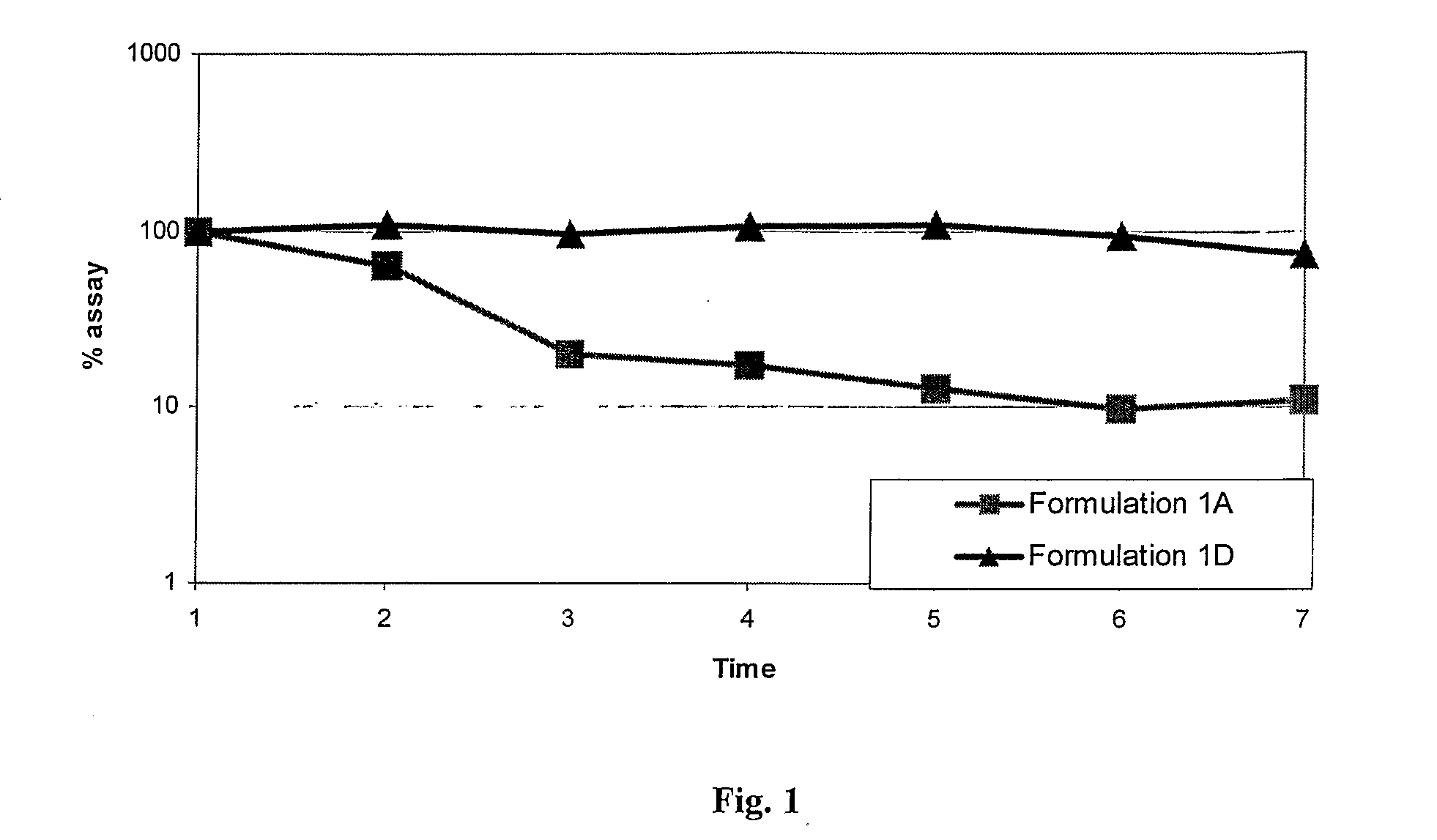

An inkjet printing method includes in order the steps of: a) providing to an inkjet printer one or more colorless liquids and a white ink including a pigment with a refractive index greater than 1.60; b) mixing the white ink in a controlled amount with the one or more colorless liquids to form a white ink-mixture wherein the viscosity is reduced by at least 5 mPa·s by reference to the white ink when measuring the viscosity at 40° C. with a Brookfield DV-II+Pro at 12 rotations per minute; and c) printing the white ink-mixture with the inkjet printer onto an ink-receiver. Additionally, a color inkjet ink set includes the one or more colorless liquids and the white ink, and an inkjet printer for use in the inkjet printing method.

Owner:AGFA NV

Novel Dispersible Tablet Composition

ActiveUS20080312168A1Reduce sedimentation rateDisintegrates quicklyBiocideCarbohydrate active ingredientsBULK ACTIVE INGREDIENTActive ingredient

The present invention relates to a novel dispersible tablet composition, which comprises of a pharmacologically active ingredient and at least one excipient, which reduces the sedimentation rate of active ingredient. This invention further relates to a process for the preparation of a dispersible tablet of a pharmacologically active ingredient.

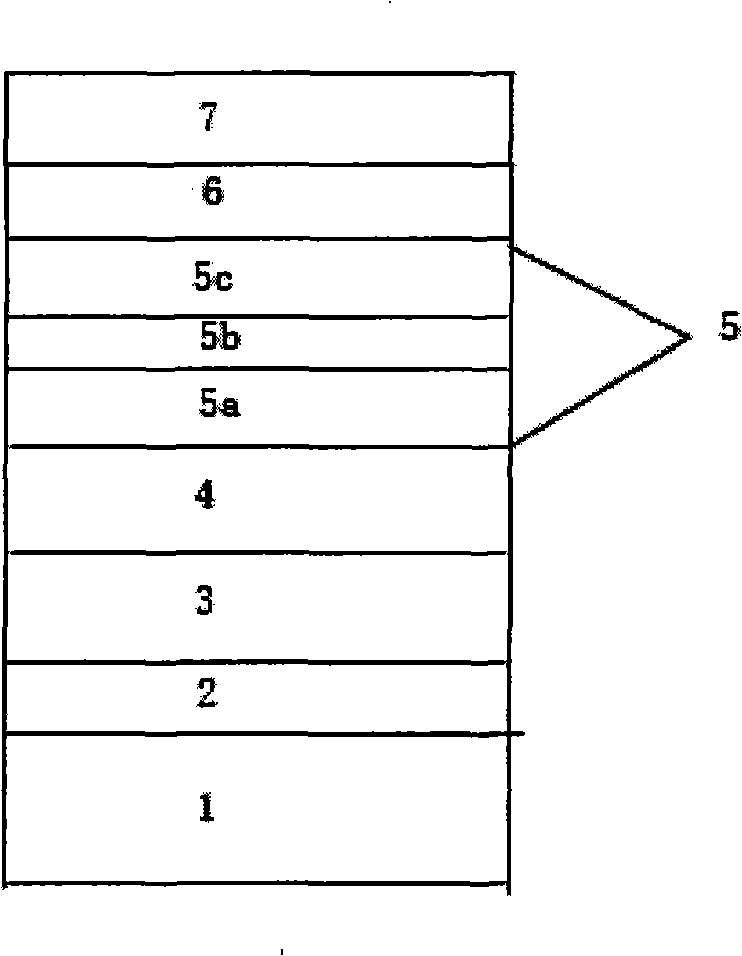

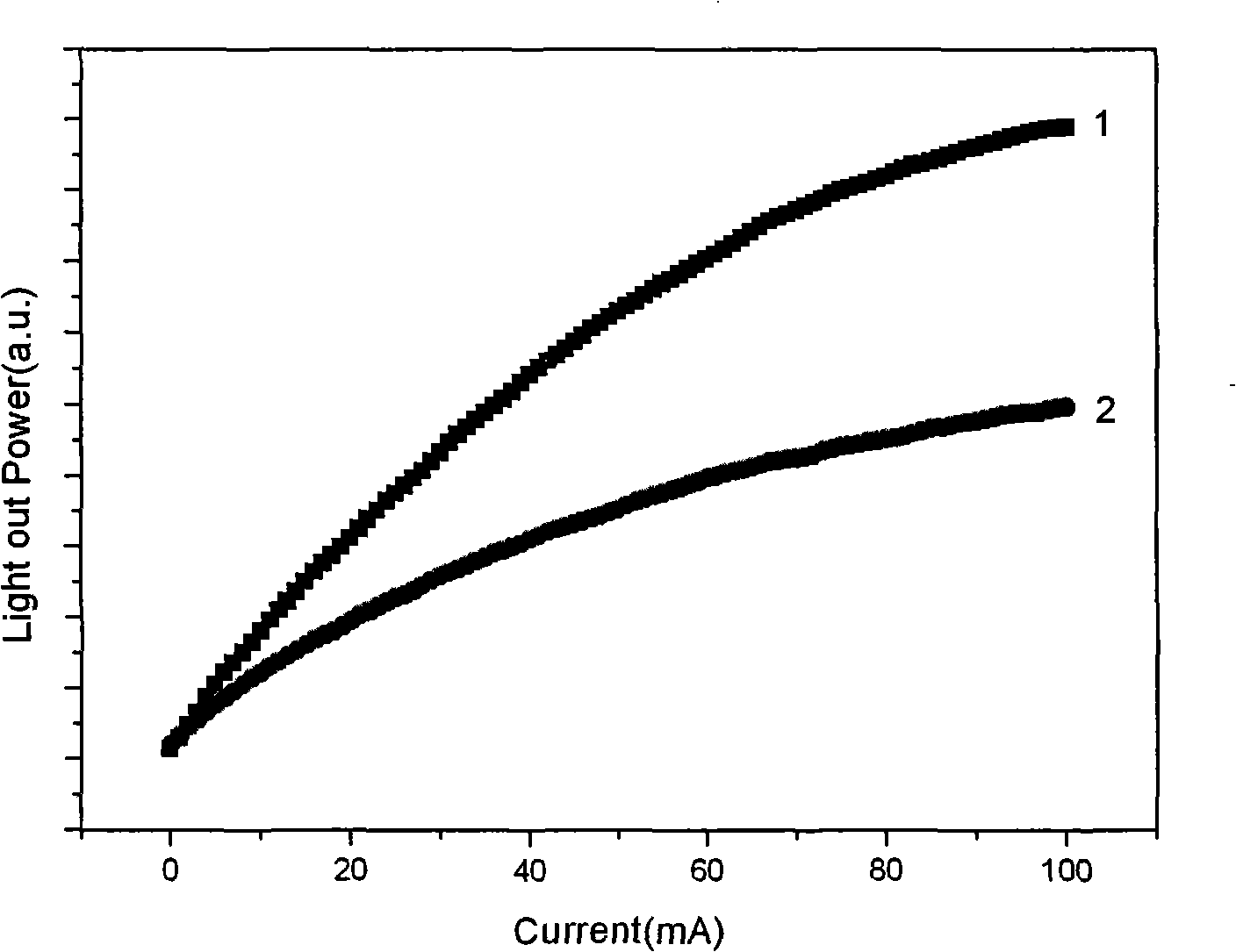

Manufacturing method of green light LED

ActiveCN101359710AReduce V-shaped defectsReduce precipitationSemiconductor devicesGreen-lightGreen led

The invention relates to a method for fabricating a green LED, which is mainly characterized in that through the introduction of an insert layer into an epitaxial growth InGaN / GaN quanta well, V type defects between the InGaN and the GaN is reduced and In precipitation is reduced; thus, the green LED with high brightness and strong antistatic ability can be obtained. With the introduction of the insert layer, the brightness of a 300micronx300micron green LED chip at 520nm under 20mA is improved from 100mcd to 250mcd and the antistatic ability of the chip is increased from HBM 500V (human-body model) to HBM 4000V.

Owner:EPILIGHT TECH +2

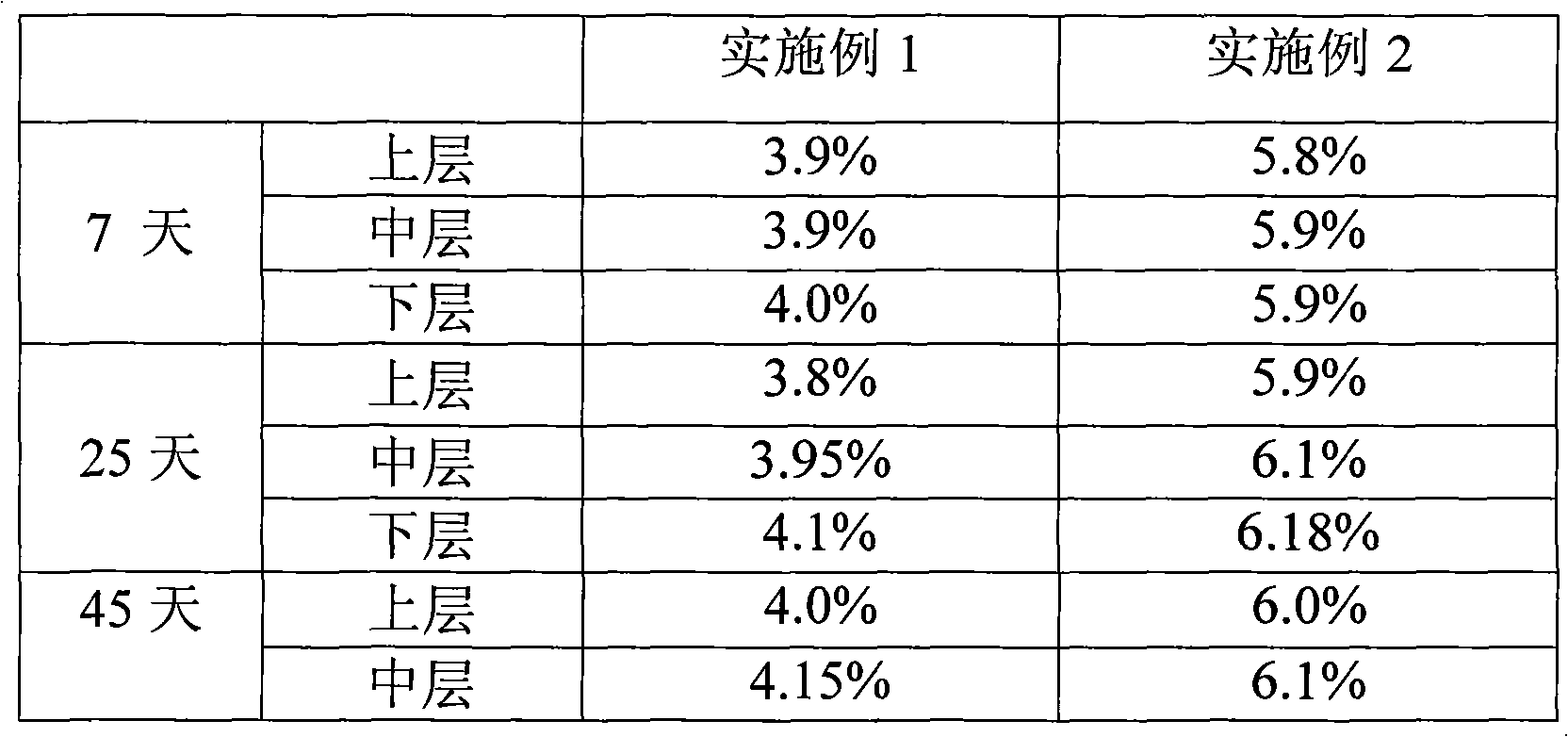

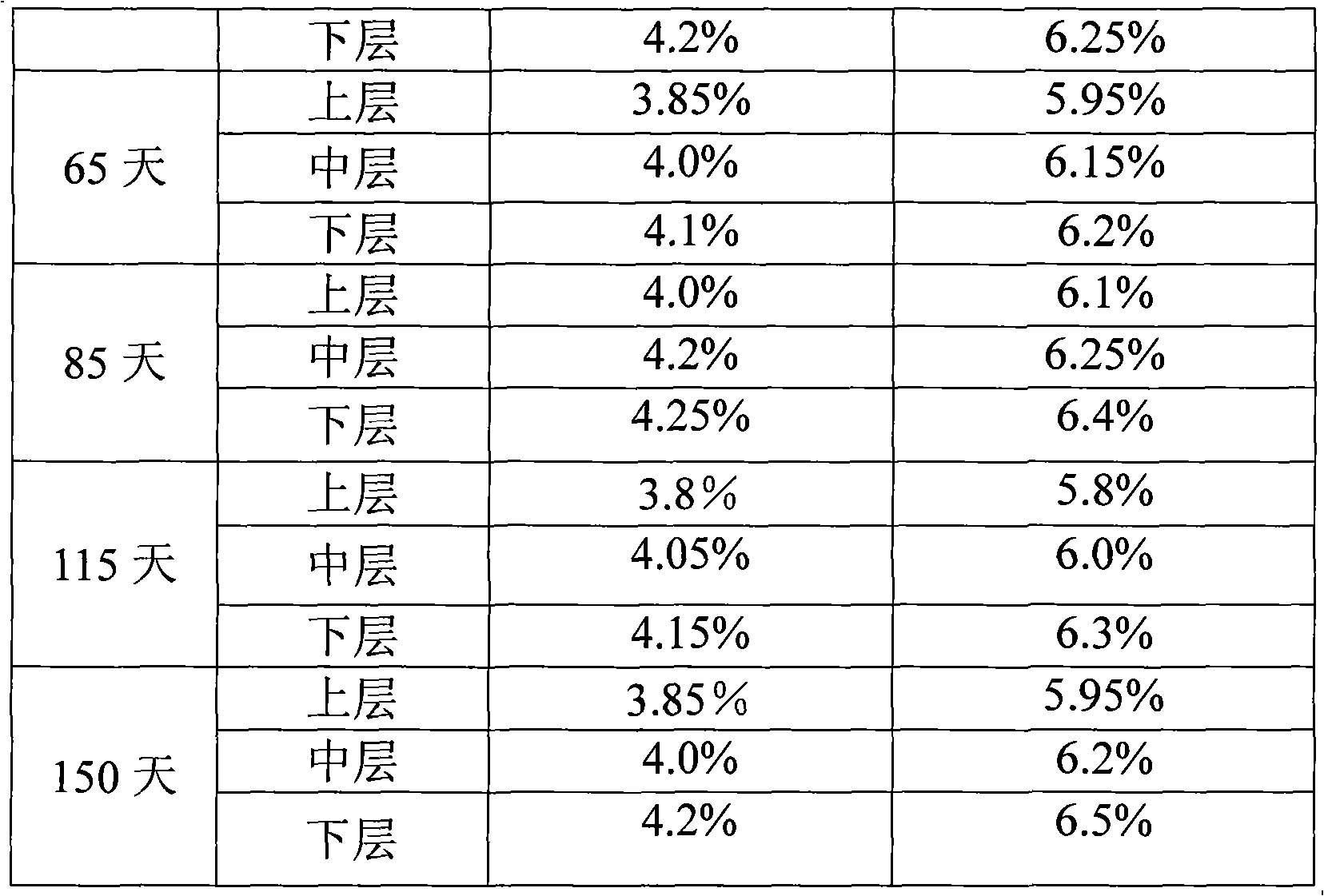

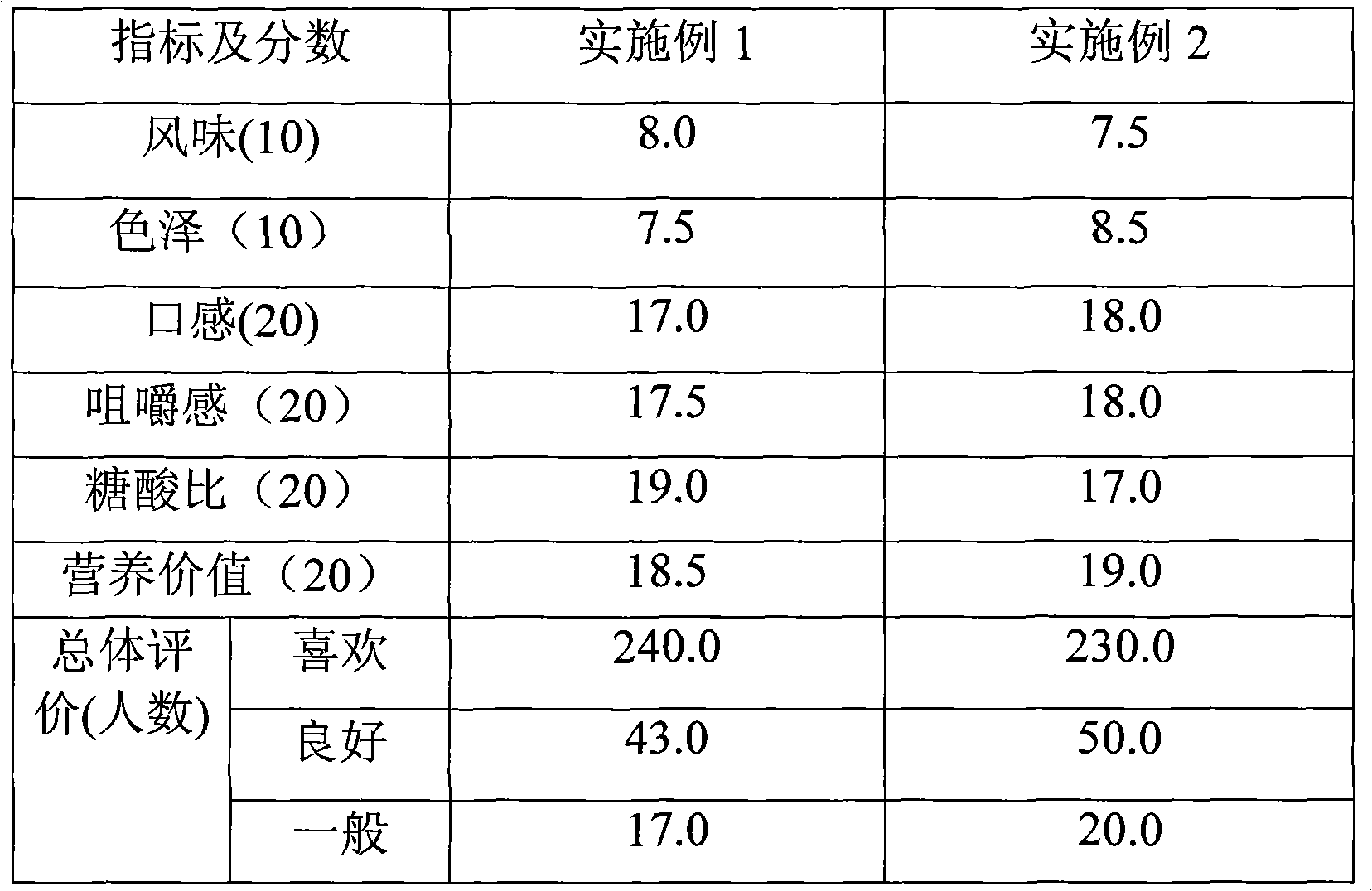

Milk and dairy food containing fruit granules and method for producing the same

The present invention relates to a diary product containing fruit granules. Every 100 weight parts of the diary product of the present invention contains 30 to 80 parts of milk and milk product, 1 to 15 parts of fruit granules, 0.2 to 1.0 part of stabilizer compound and 0.25 to 0.6 part of acidity regulator; wherein, the stabilizer compound contains modified bio-fermentation polysaccharide and thickener; the fruit granule contains coconut juice fermented polysaccharide granule and fruit vegetable granule. A production method of the diary product containing fruit granules is also related by the present invention.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and production technological method thereof

ActiveCN107287504AExcellent machinabilityReduce precipitationProcess efficiency improvementSulfurImpurity

The invention discloses medium carbon free-cutting non-quenched-and-tempered steel containing sulfur and tellurium and a production technological method thereof. The non-quenched-and-tempered steel mainly comprises 0.35%-0.50% of C, 0.10%-0.80% of Si, 0.75%-1.60% of Mn, 0-0.03% of P, 0.02%-0.08% of S, 0-0.08% of Mo, 0-0.025% of Nb, 0.02%-0.12% of V, 0.012%-0.016% of N, 0.02%-0.08% of Te, 0.001%-0.003% of Ca, and the balance Fe and inevitable impurities. The ratio of the tellurium to the sulfur is 0.25-2.5. According to the free-cutting non-quenched-and-tempered steel disclosed by the invention, occluded foreign substances in the steel can be subjected to modifying treatment by adding the tellurium, the cutting properties, fatigue resistance and the like of the non-quenched-and-tempered steel can be improved obviously, and pollution to the environment can be avoided.

Owner:SHANGHAI UNIV

Series flux cord welding rod used for pile-up welding reparing and remanufacturing large type medium high carbon steel parts

InactiveCN100999041AImprove crack resistanceHigh carbon contentArc welding apparatusWelding/cutting media/materialsHigh carbonRare earth

The present invention discloses a series flux-cored wire for reparation and refabrication of large-size medium-high carbon steel components and parts. Its chemical composition includes (wt%) 5-10 of fluorite, 25-45% of high-carbon ferrochrome, 2-10% of high-carbon manganese iron, 5-8% of tantiron, 10-15% of ferro-molybdenum, 8-14% of rare earth oxide, 5-15% of metal nickel, 2-5% of ferrovanadium, 0.5-2% of graphite, 2-4% of chloride and 1-2.5% of aluminium-magnesium alloy. Its external covering adopts low-carbon steel tape.

Owner:QINHUANGDAO WEIERDE SPECIAL WELDING IND

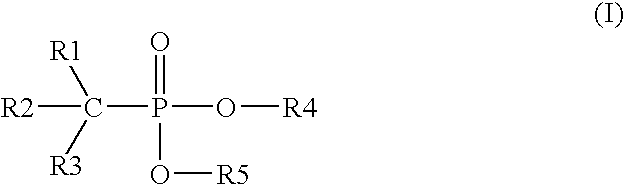

System stabilizers and performance enhancers for aqueous fluids gelled with viscoelastic surfactants

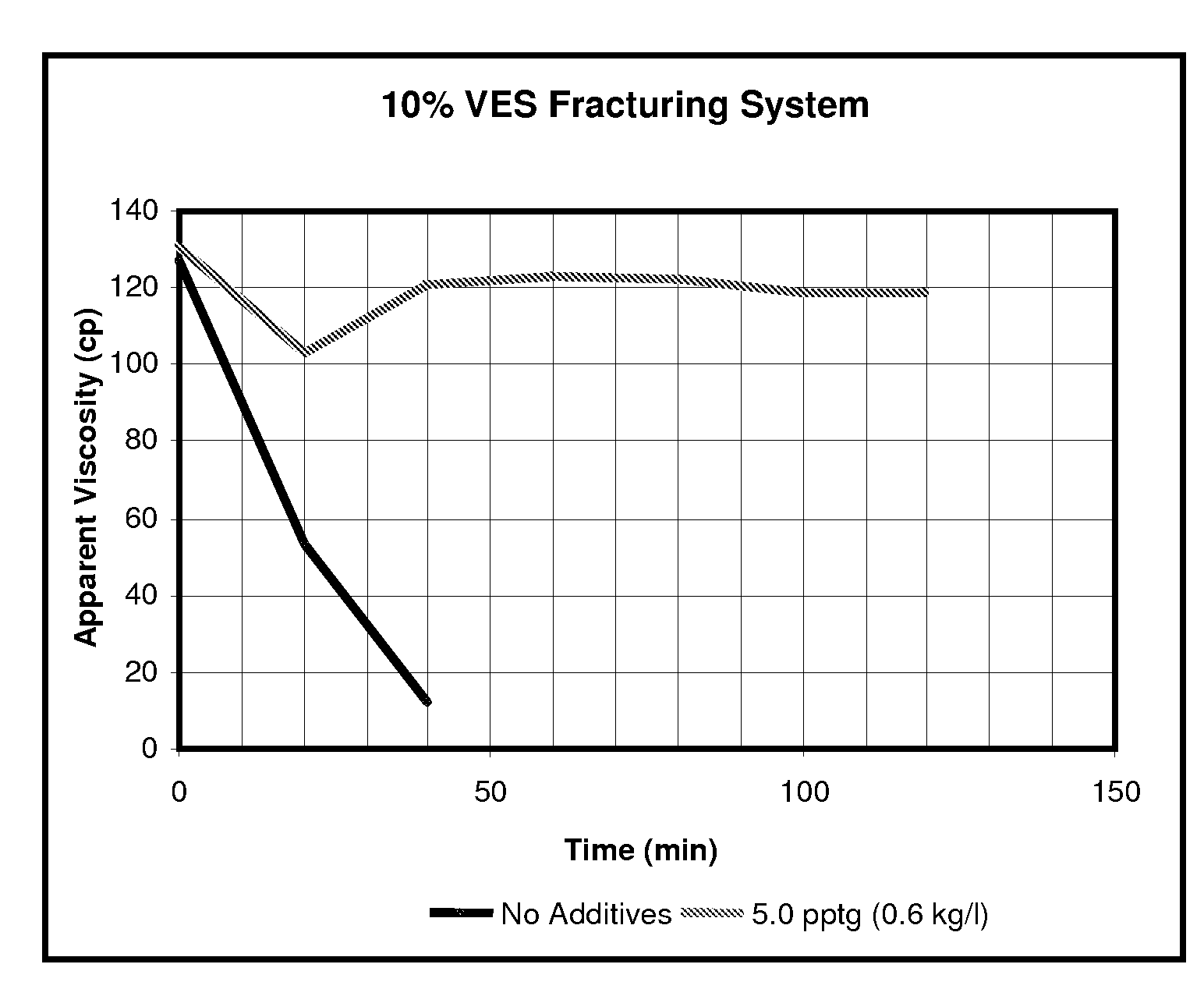

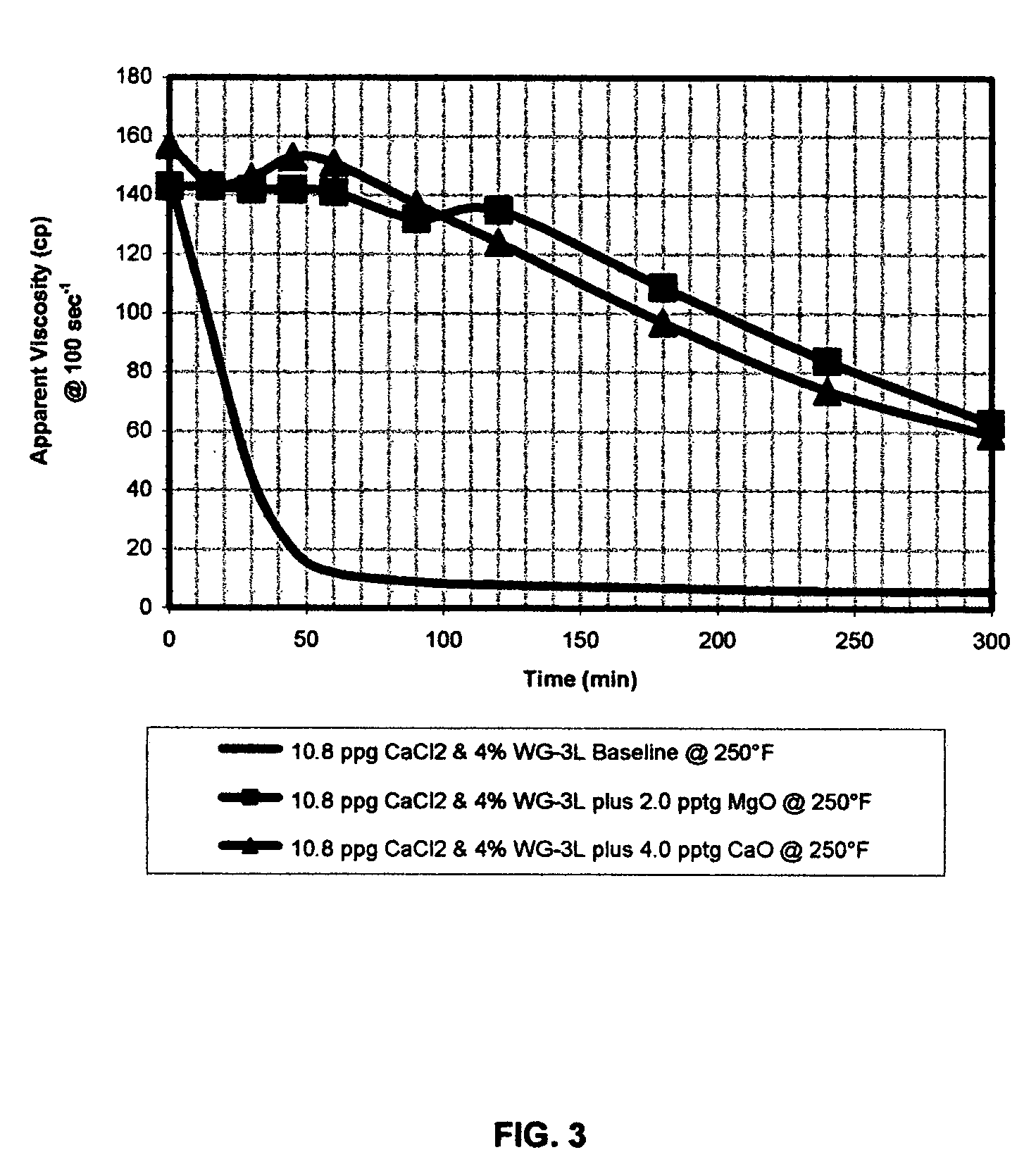

InactiveUS7343972B2Improve stabilityReduce precipitationFluid removalDrilling compositionFluid gelAlkaline earth oxides

An aqueous, viscoelastic fluid gelled with a viscoelastic surfactant (VES) is stabilized and improved with an effective amount of an alkali earth metal oxide and / or alkali earth metal hydroxide. These fluids are more stable and have reduced or no tendency to precipitate, particularly at elevated temperatures. The additives may also increase viscosity to the point where less VES is required to maintain a given viscosity. These stabilized, enhanced, aqueous viscoelastic fluids may be used as treatment fluids for subterranean hydrocarbon formations, such as in hydraulic fracturing.

Owner:BAKER HUGHES INC

A method for the treatment and reuse of ammonia-nitrogen-containing high-salt catalyst wastewater

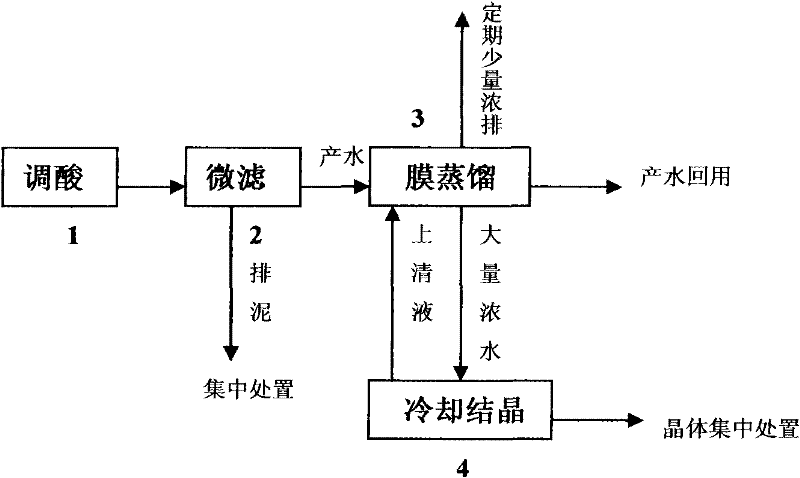

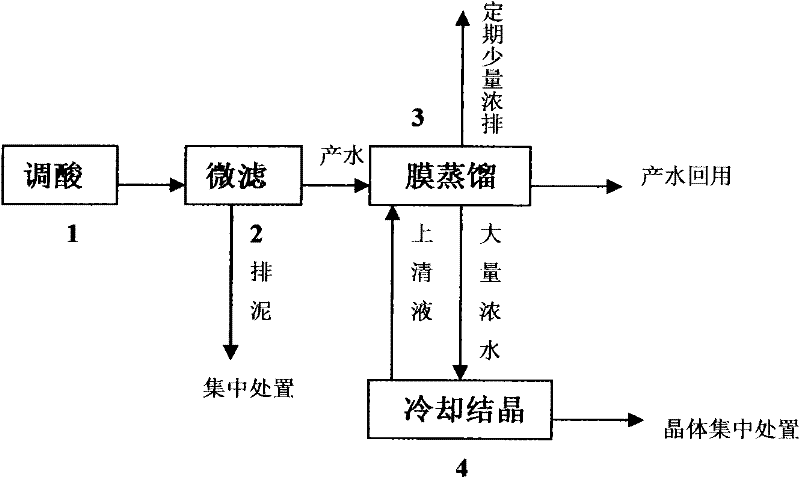

ActiveCN102295378ATake advantage of highly concentrated processingHigh salt contentWater contaminantsWater/sewage treatment bu osmosis/dialysisSocial benefitsSeparation technology

The invention relates to a recycling method for treating ammonia nitrogen containing high-salt catalyst wastewater by adopting a membrane separation technology. The process flow of 'acid regulation, micro-filtration, membrane distillation, cooling and crystallization' is adopted in the method. By adopting the process flow, salts, ammonia nitrogen and metal ions in the wastewater can be effectively removed, and deep treatment and recycle of the ammonia nitrogen containing high-salt catalyst wastewater are realized. The process flow makes full use of the technical advantages of membrane distillation, solves the problem that the discharge of high salts, ammonia nitrogen and metal ions of the ammonia nitrogen containing high-salt catalyst wastewater does not reach the standards, and realizes recycle of the produced water. After the ammonia nitrogen containing high-salt catalyst wastewater is treated by the process flow, the reclamation rate of the wastewater is more than 90 percent, and high recycle of the ammonia nitrogen containing high-salt catalyst wastewater is realized; and the method accords with the development strategies of energy conservation and emission reduction, and has remarkable social benefit and economic benefit.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-salt liquid state fermented soy sauce production process

The invention discloses a low-salt liquid state fermented soy sauce production process, comprising the following main processes: preparing koji in a koji-maker machine; mixing the wheat which is fried and smashed with koji, inoculating the mixture in soybean meal and bran which are cooked; preparing finished koji in a koji making disc machine; mixing the finished koji with brine, sending the mixture in a fermenting vat for fermentation; preparing the finished soy sauce through soaking, pouring oil, filtrating, mixing, sterilizing and filling to obtain the finished soy sauce. The soy sauce is characterized in that materials containing zygosaccharomyces Rouxii 2.180 accounting for 1.5-2.5% of the total weight of materials and torulopsis candida 2.202 accounting for 1.5-2.5% of the total weight of materials are added during the medium term of the fermentation process and the raw materials--soybean meal and bran are cooked by high temperature short-time continuous cooking process. Compared with the prior art, the raw material digestion rate can reach 88-90%, the protein utilization rate can reach 83%, the activity of neutral protease of the finished koji can reach 2000mu / g, the enzymesystem is complete, the defects such as long period of high-salt liquid state fermentation (180 days), burnt flavour and heavy bitter taste of low-salt solid state fermentation and the like are overcame and the produced soy sauce is characterized by strong soysauce-like aroma, alcohol-like aroma and ester-like aroma and the like.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Preparation method of micro/nano-structure ultrahigh-strength plastic stainless steel containing Nb

The invention belongs to the field of production of ultrahigh-strength plastic alloy steel, and relates to a preparation method of micro / nano-structure ultrahigh-strength plastic stainless steel containing Nb. The preparation method comprises the steps of: firstly preparing materials according to a composition proportion, adding 0.05-0.15% of Nb element on the basis of 316L austenitic stainless steel, then carrying out vacuum induction furnace smelting, casting blank forging, forged piece hot rolling and solution treatment, carrying out cold deformation on the steel plate which undergoes the solution treatment with deformations of 40%, 60%, 80% and 90% and with single reduction in pass controlled within 3-10% to prepare steel plate with different cold deformations, annealing the steel plate which undergoes the cold deformation with heating rate controlled at 50-200 DEG C / s, with heating temperature within 750-950 DEG C and with heat preservation time within 5-100s, and cooling to the room temperature at a cooling rate of 50-400 DEG C / s to obtain a superfine austenite structure with micro-nano scale. The obdurability of the material is synchronously improved. The yield strength of the final product can be up to 750-800MPa, the strength of extension is up to 1100-1200MPa and the percentage of elongation is 35-45%.

Owner:UNIV OF SCI & TECH BEIJING

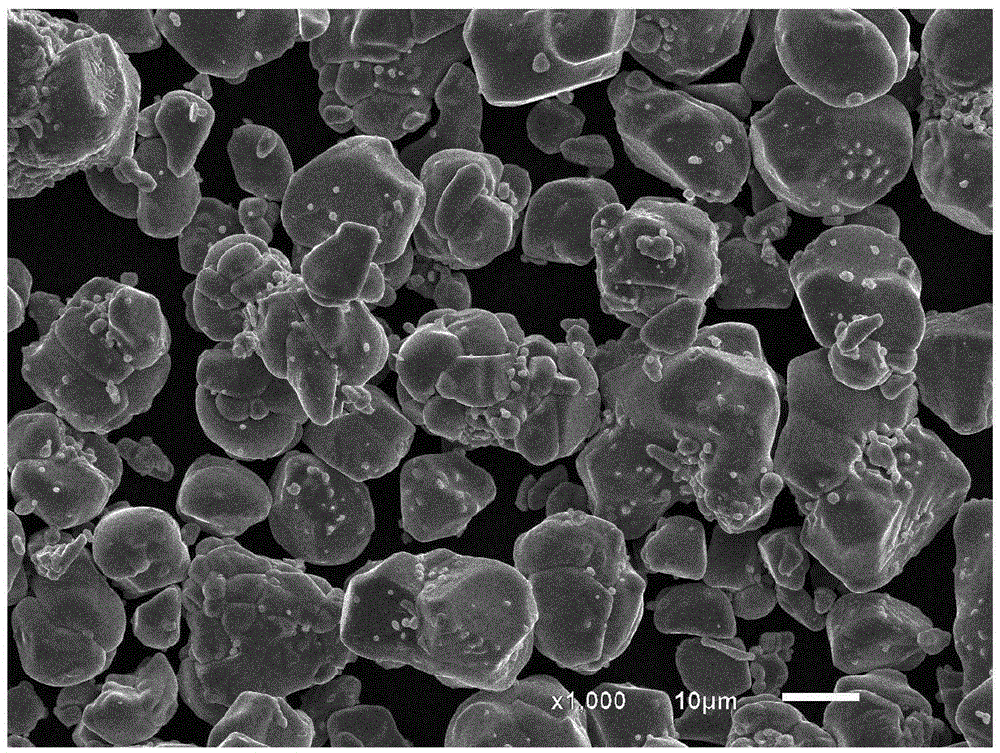

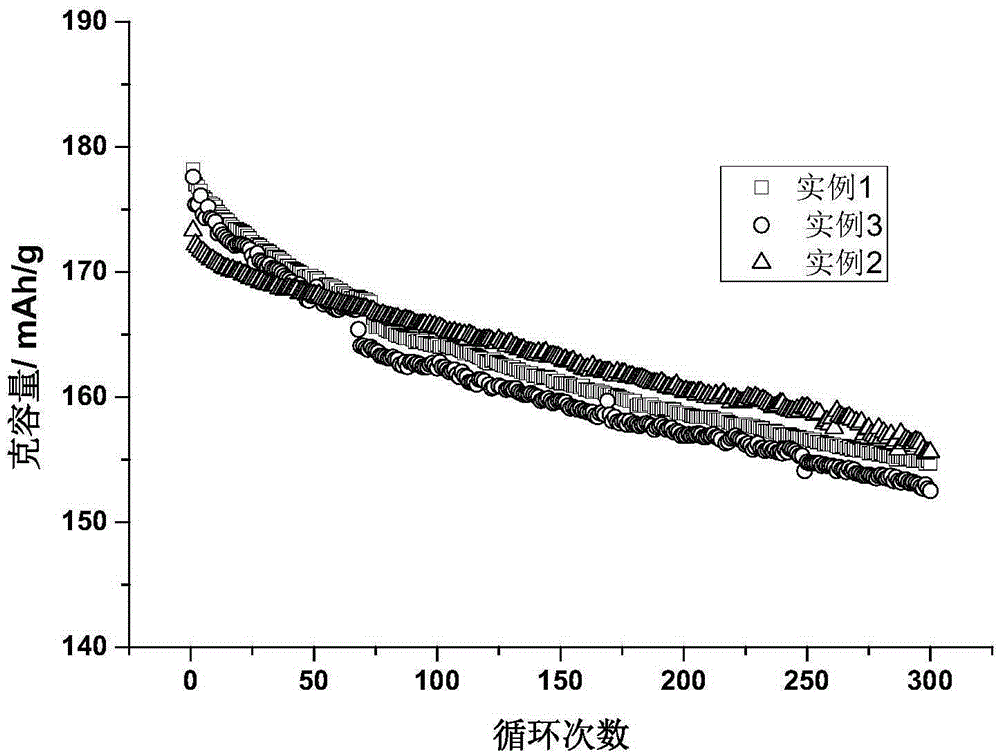

High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN105406036AIncrease volumetric energy densityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryHigh voltage

The invention discloses a high-voltage lithium cobalt oxide cathode material for a lithium-ion battery and a preparation method of the high-voltage lithium cobalt oxide cathode material. The high-voltage lithium cobalt oxide cathode material is prepared from a doped lithium cobalt oxide matrix and a coating on the surface of the doped lithium cobalt oxide matrix, wherein a general formula of the doped lithium cobalt oxide matrix is Li<x>Co<1-y>M<y>O<2-z>N<z>; the general formula of the coating is LiNi<x'>Co<y'>Al<z'>O<2>; and the preparation method comprises the following steps: firstly, obtaining the lithium cobalt oxide matrix Li<x>Co<1-y>M<y>O<2-z>N<z> through once sintering; secondly, preparing a lithium cobalt oxide cathode material precursor coated with Ni<x'>Co<y'>Al<z'>(OH)<2> on the surface by liquid-phase co-precipitation reaction; and finally obtaining the high-voltage lithium cobalt oxide cathode material through twice sintering. The high-voltage lithium cobalt oxide cathode material prepared by the method is good in processability and high in compaction density, has relatively high specific capacity and good cycle performance in a high-voltage state, and can be stably circulated at high voltage of 3.0V to 4.5V.

Owner:HUNAN CHANGYUAN LICO CO LTD +1

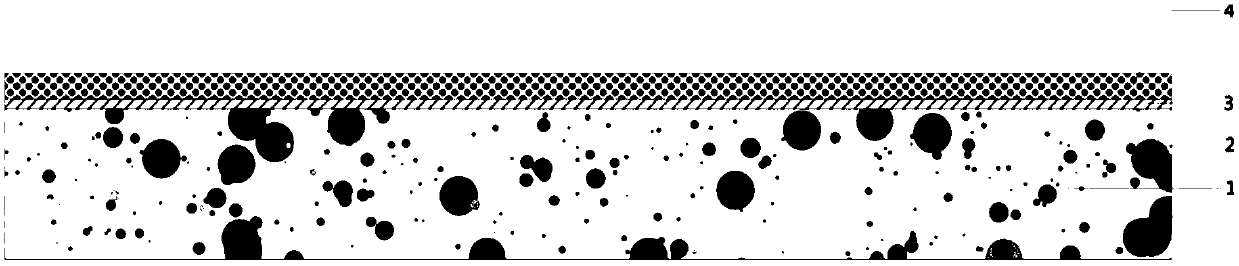

Full-body anti-slip ceramic brick and production method thereof

The invention relates to a full-body anti-slip ceramic brick and a production method thereof. According to the full-body anti-slip ceramic brick, a compound layer brick body is composed of a colored spot green body layer, large-particle colored spots mixed into the colored spot green body layer, a pattern decoration layer on the surface of the green body layer and a dry-particle glaze layer attached to the pattern decoration layer; the production method comprises the following steps: (1) pressing a green body, wherein green body powder is composed of conventional powder and large-particle powder; (2) drying under the conditions that the drying temperature is 80 to 100 DEG C and the drying time is 60 to 80 min; (3) decorating a pattern: before decorating the pattern, not applying any glazelayer or other protection layers on the surface of the blank body, so as to directly realize inkjet printing decoration on the surface of the blank body; (4) applying dry-particle glaze: spraying theglaze through a bell jar; (5) firing under the conditions that the temperature is 1150 to 1160 DEG C and the time is 50 to 60 min.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

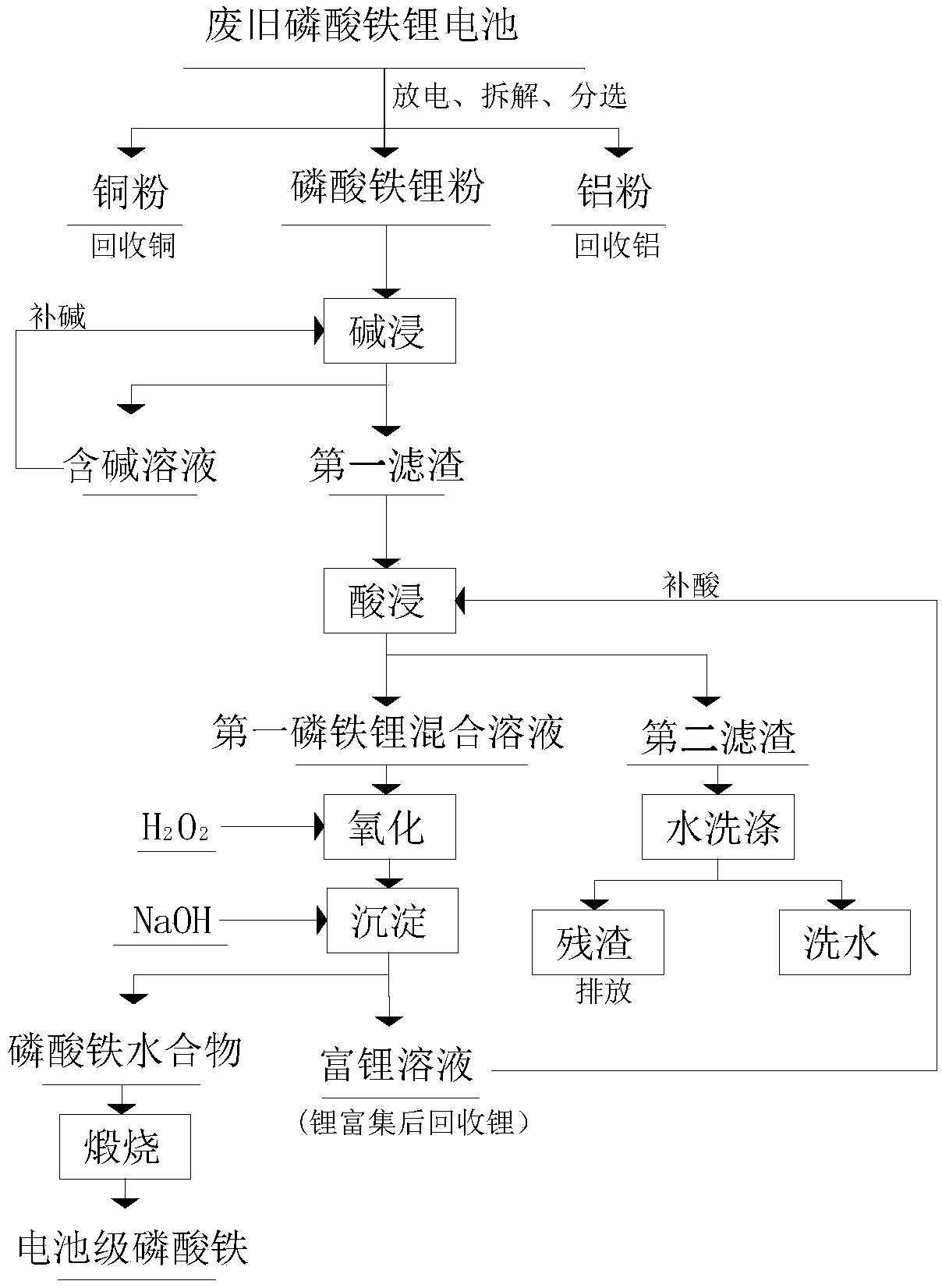

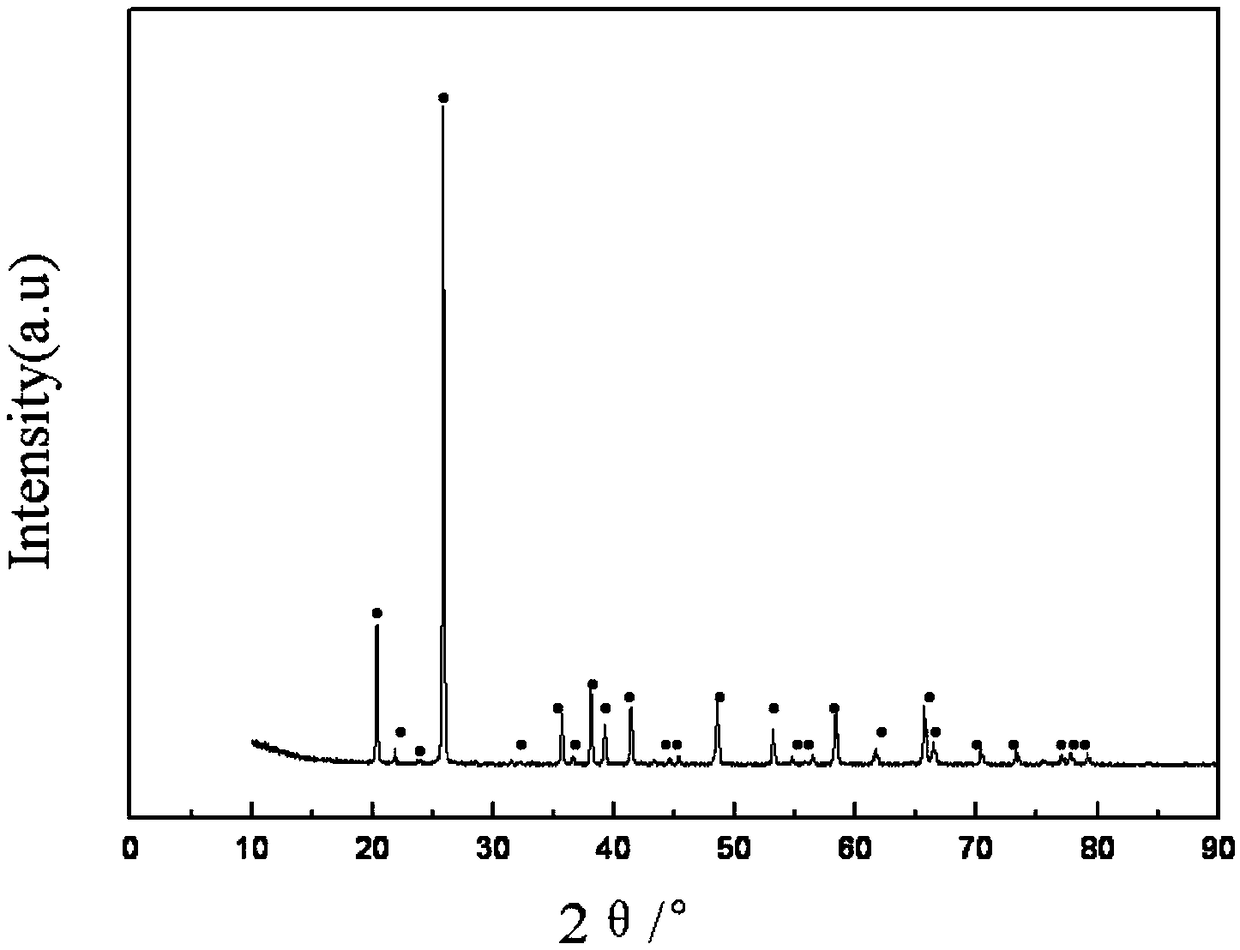

Method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries

ActiveCN109179358AEfficient removalHigh purityPhosphorus compoundsLithium iron phosphatePhosphoric acid

The invention discloses a method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries and relates to the technical field of battery recovery. The method can prepare anhydrous battery grade iron phosphate by battery disassembly and separation, alkali leaching, acid leaching, oxidation, precipitation and calcination. Through alkali leaching and then acid leaching and precipitation, impurities such as aluminum in lithium iron phosphate can be removed and the purity of iron phosphate can be improved. The alkali leaching solution and the lithium-rich solution can be reused so that a recovery cost is reduced. After repeated acid supply, the lithium-rich solution immerses novel filter wastes so that the concentration of lithium in the solution and the recovery rate of lithium can be increased and the recovery cost of lithium can be reduced. pH at the precipitation end point is low in a range of 1.0-2.5 so that the formation trend of iron hydroxide isreduced. The aging process after the precipitation reaction can improve the purity of iron phosphate and the produced iron phosphate meets the industry standards. The whole process is carried out at alow temperature so that the corrosion of the solution to the equipment is delayed and the energy consumption and recycling cost are reduced.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

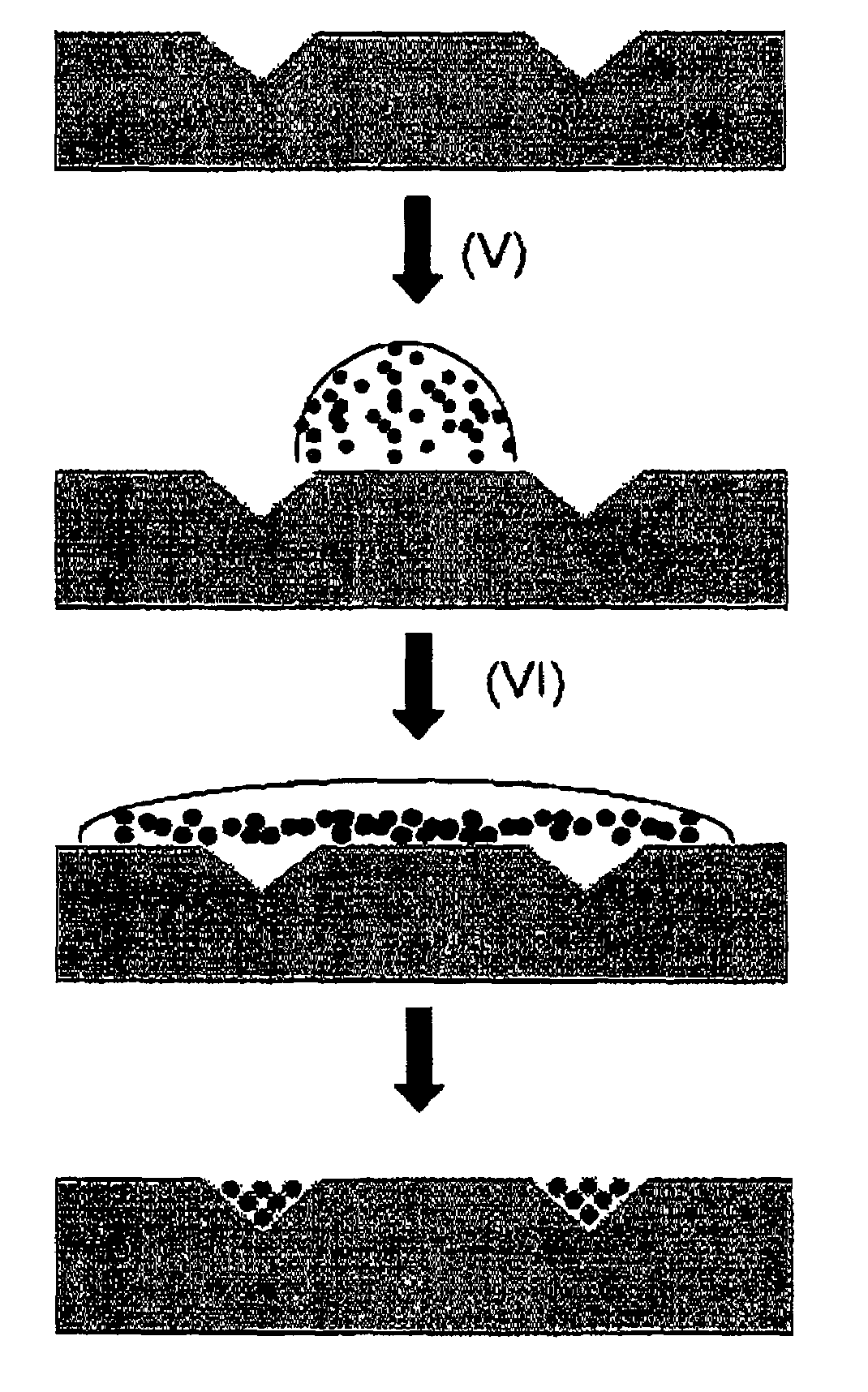

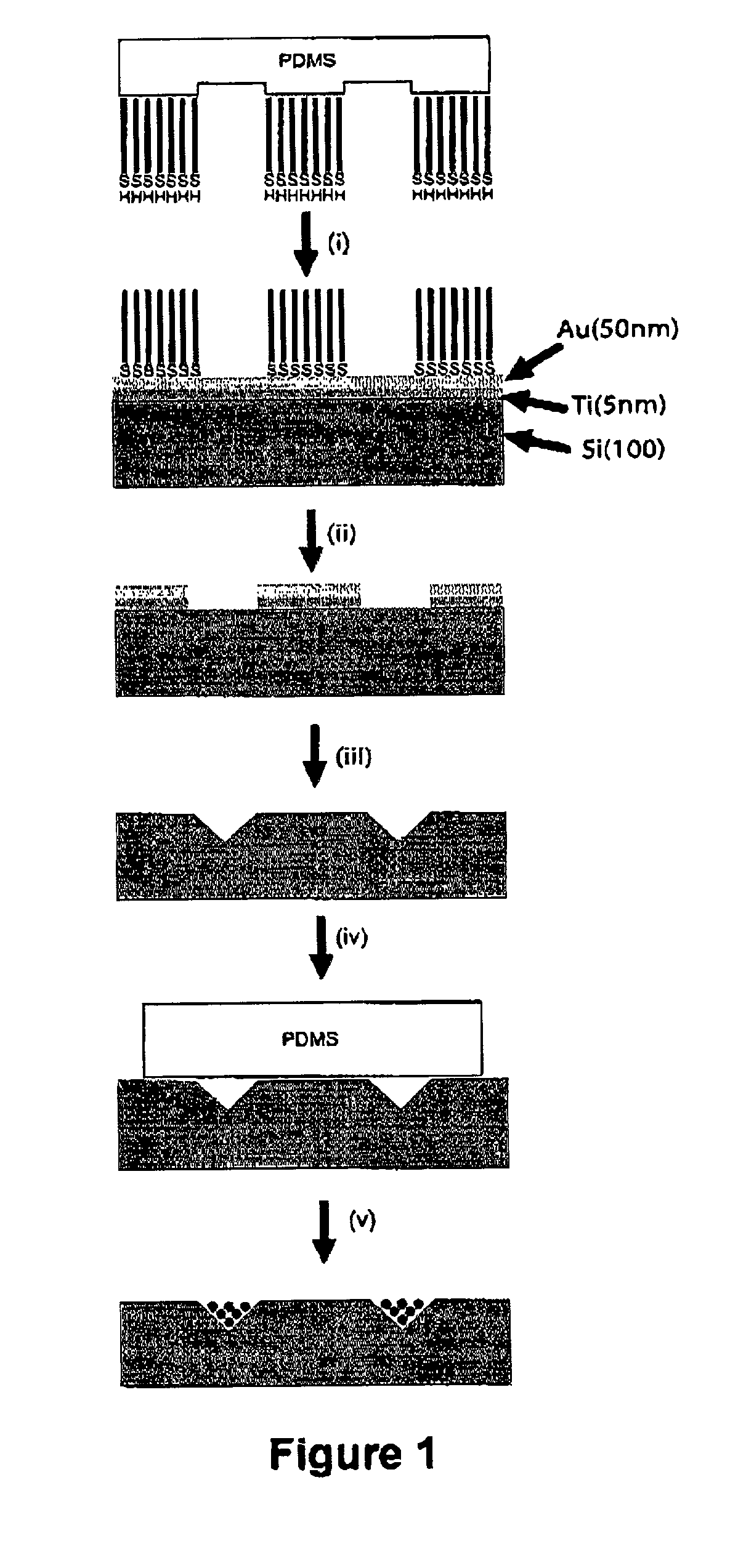

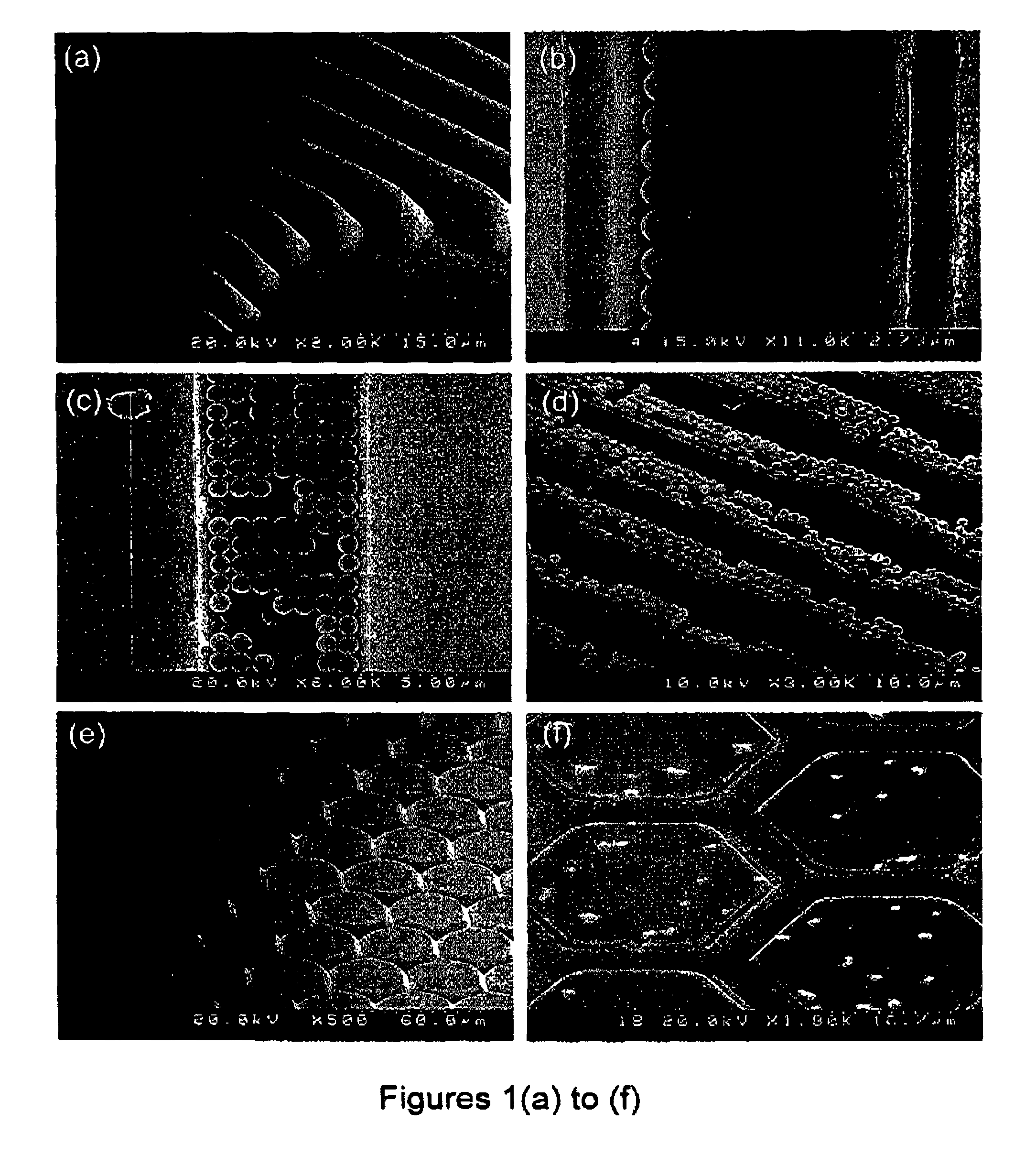

Composite materials having substrates with self-assembled colloidal crystalline patterns thereon

InactiveUS7045195B2Applicability in photonicsReduce precipitationMaterial nanotechnologyFrom normal temperature solutionsPhotonic ChipLab-on-a-chip

Composite materials having colloidal photonic crystals patterned in substrates for use in different technologies including lab-on-chip and photonic chip technologies. The colloidal crystals are patterned either on or within surface relief patterns in the substrates of the composite materials and each colloidal crystal exhibits Bragg diffraction.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

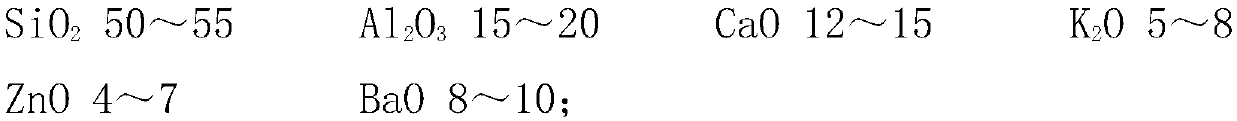

Glass composition for glass fiber, glass fiber, process for producing glass fiber and composite material

InactiveUS20100093510A1High affinityImprove adhesionGlass making apparatusGlass productionGlass fiberMaterials science

A glass composition for glass fiber comprises, by mass percentage in terms of oxide, 60 to 75% SiO2, 0 to 10% Al2O3, 0 to 20% B2O3, 5 to 15% Li2O+Na2O+K2O, 0 to 10% MgO+CaO+SrO+BaO+ZnO, 0 to 10% TiO2 and 0 to 10% Zr02. A glass fiber consists of the above glass composition for glass fiber. A process for producing a glass fiber comprises the steps of melting the above glass composition in a heat-resistant vessel and continuously drawing out the molten glass through a heat-resistant nozzle so as to form a glass fiber; coating the surface thereof with a chemical; and continuously reeling the coated glass fiber. A composite material is obtained by compositing the glass fiber with an organic resin.

Owner:NIPPON ELECTRIC GLASS CO LTD

Electroplating product and method for preparing same

InactiveCN101113527AImprove surface propertiesSurface properties such as good wear resistanceSuperimposed coating processElectrolytic organic material coatingAlloyElectroplating

A plating product comprises a matrix material and plated metal layers on the surface thereof; from the inner layer to the outer layer, the plated metal layers comprise a Cu layer, a Ni layer and a Cr layer in sequence, wherein the plated metal layers comprise a middle plating layer which is positioned between the Ni layer and the Cr layer and made from Pd, Ru or Rh, or an alloy of any two, three or four kinds of metals Pd, Rh, Ru and Ni. The invention also provides a preparation method of the plating product; according to the plating product of the invention, the middle plating layer is positioned between the Ni layer and the Cr layer, and the middle plating layer can inhibit metal Ni from precipitating to the surface of the plating product, so that the precipitation quantity of Ni can be greatly reduced, and the precipitation quantity of metal Ni can meet the specification of no more than 0.5 Mug per cm2.week; furthermore, compared with the existing ordinary plating products, the plating product of the invention also have good surface performances such as abrasion resistance, corrosion resistance and impact resistance.

Owner:精英塑胶(珠海)有限公司

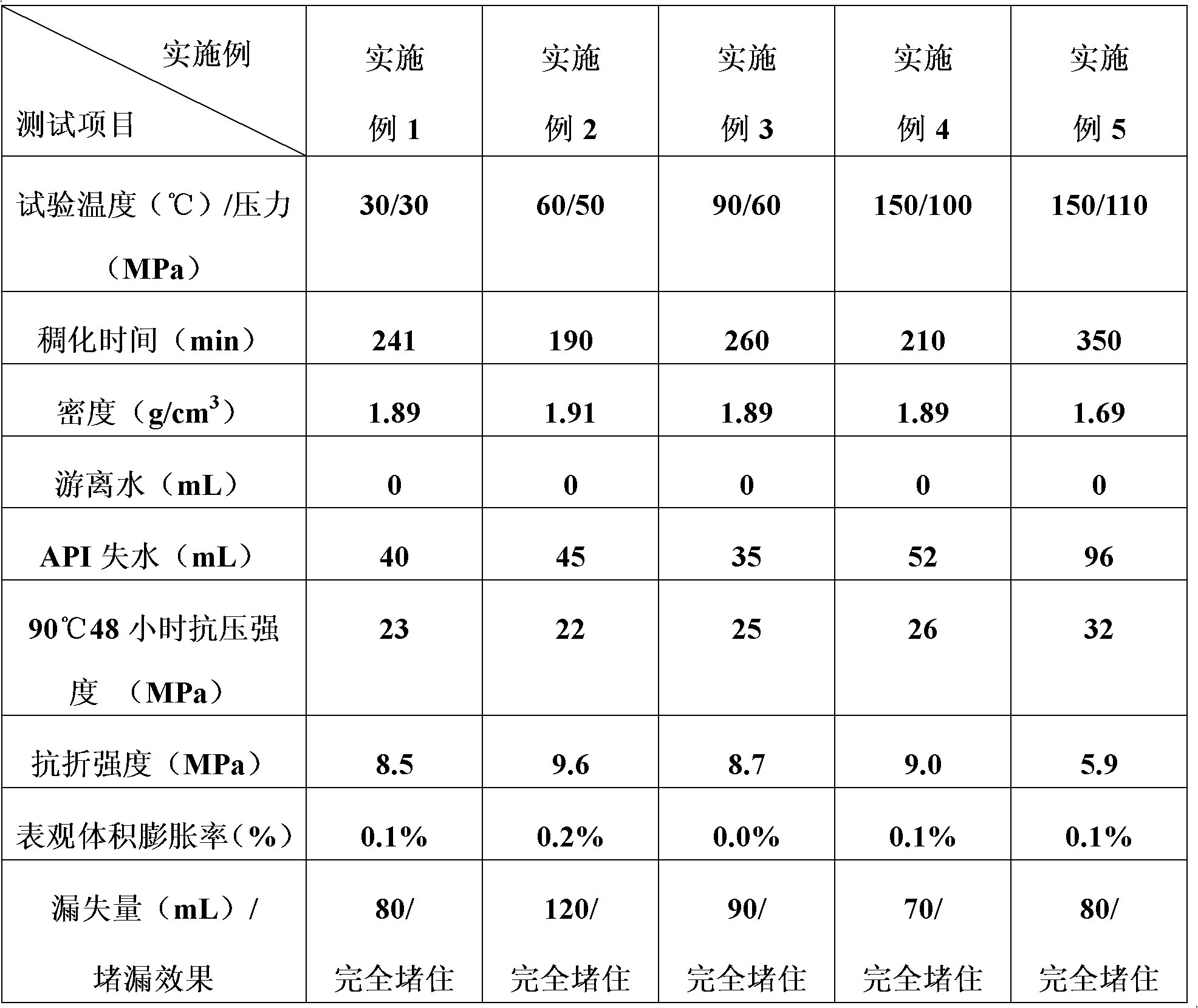

Leaking stoppage cement slurry for well cementation and preparation method thereof

InactiveCN101857800AGood high temperature application performanceEvenly dispersedDrilling compositionCementation processSodium sulfate

The invention relates to leaking stoppage cement slurry for well cementation and a preparation method thereof. The leaking stoppage cement slurry consists of the following components in parts by weight: 100 parts of oil-well cement, 50-150 parts of water, 0.01-8 parts of fibrilia, 1-20 parts of dispersing agent, 1-20 parts of filtrate reducer, 5-50 parts of alkali regulator, 1-10 parts of retarder and 0-1 part of defoaming agent, wherein the dispersing agent is lauryl sodium sulfate or sodium hexametaphosphate; the filtrate reducer is 2-acrylamide-2-methylpropanesulfonic acid or hydroxyethylcellulose; the alkali regulator is silicon powder; the retarder is sodium lignin sulfonate or citric acid; the defoaming agent is dimethyl silicon oil or tributyl phosphate; and the fibrilia is one or the mixture of two or more of jute, flax, hemp, ramie and sisal. The invention effectively solves the problem of leakage loss of cement slurry and inherent brittleness of set cement in the well cementation process on the premise of meeting various engineering performances required by the well cementation and provides the guarantee for subsequent operation of oil well gas.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com