Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

790results about "Electrolytic organic material coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

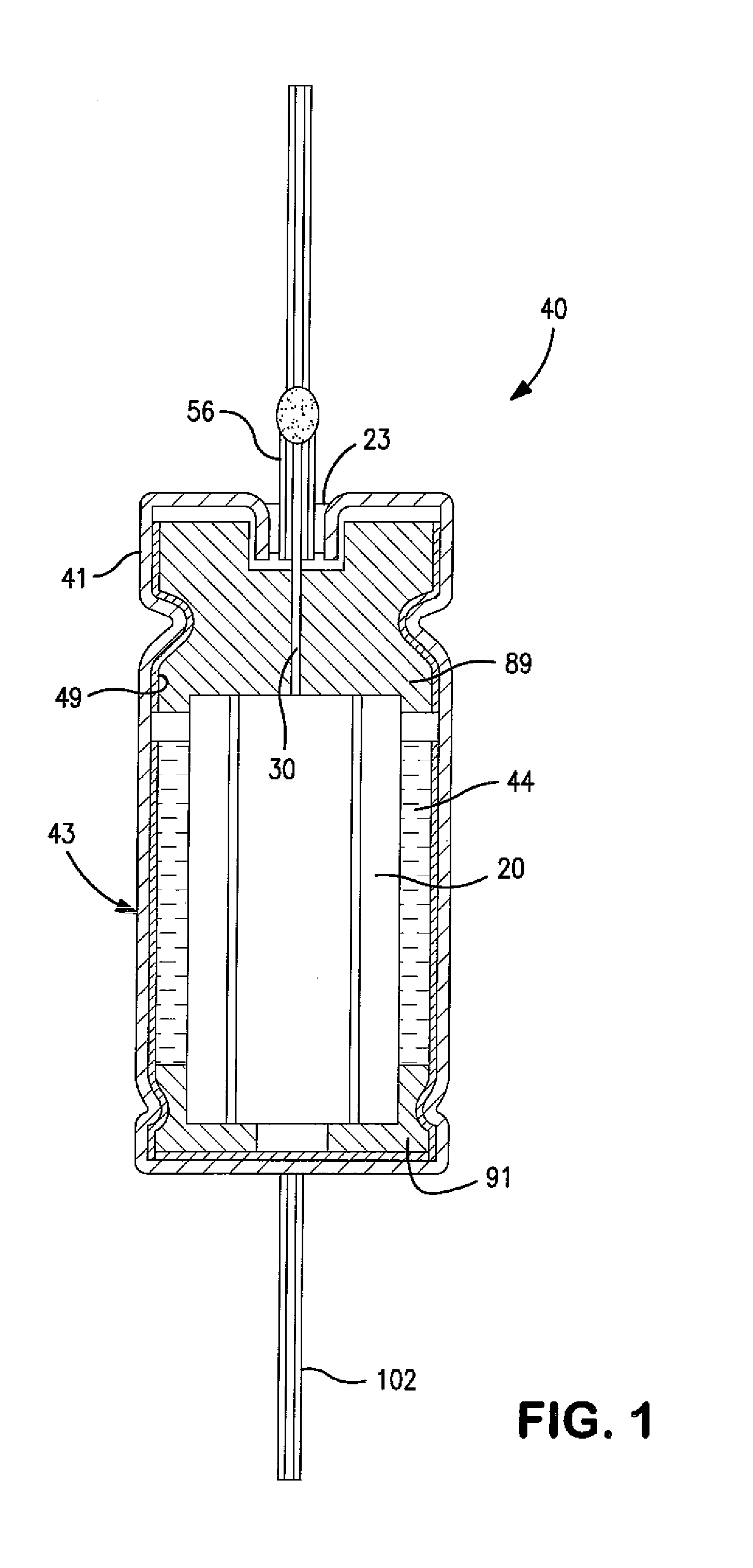

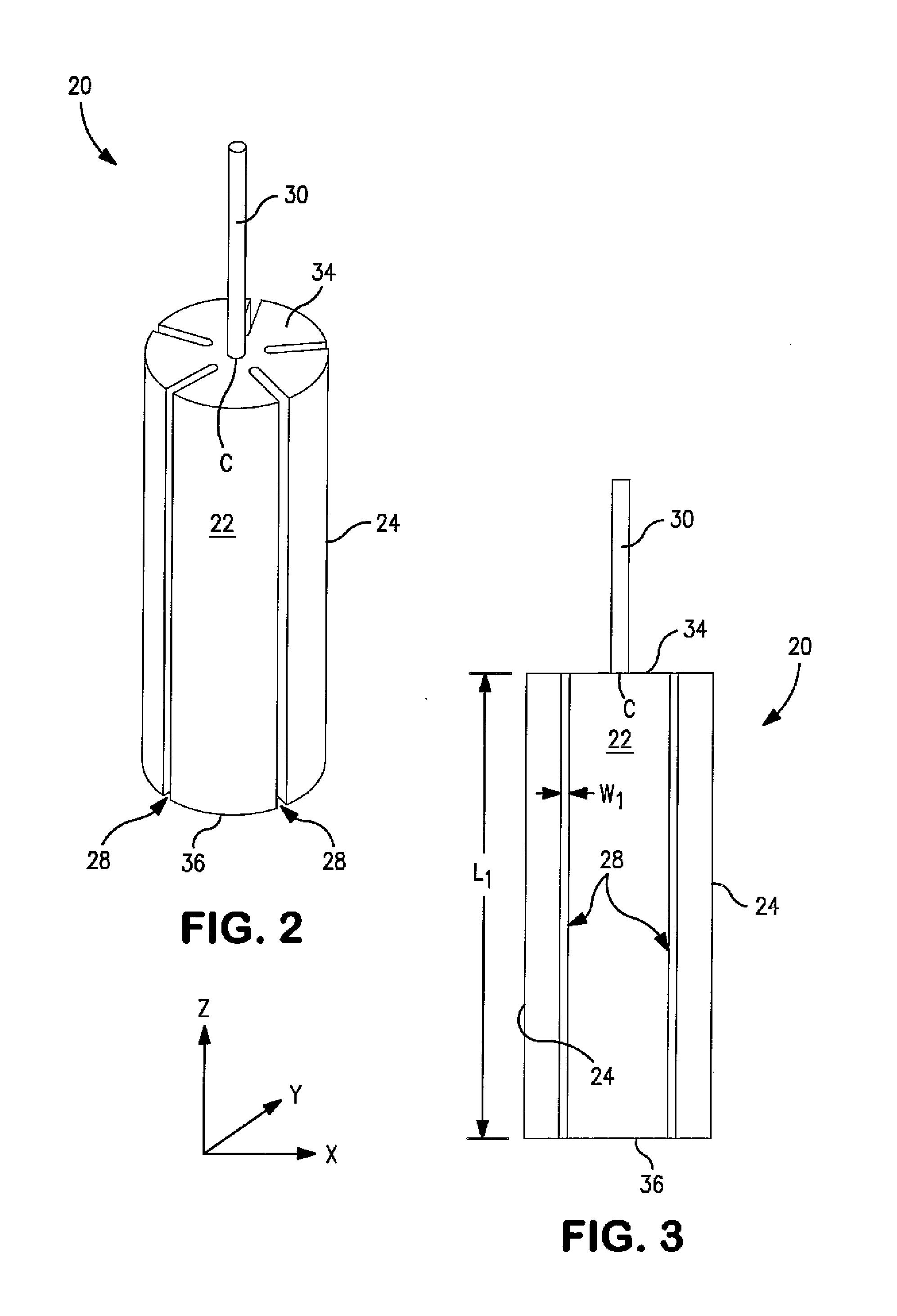

Devices and Methods for Target Molecule Characterization

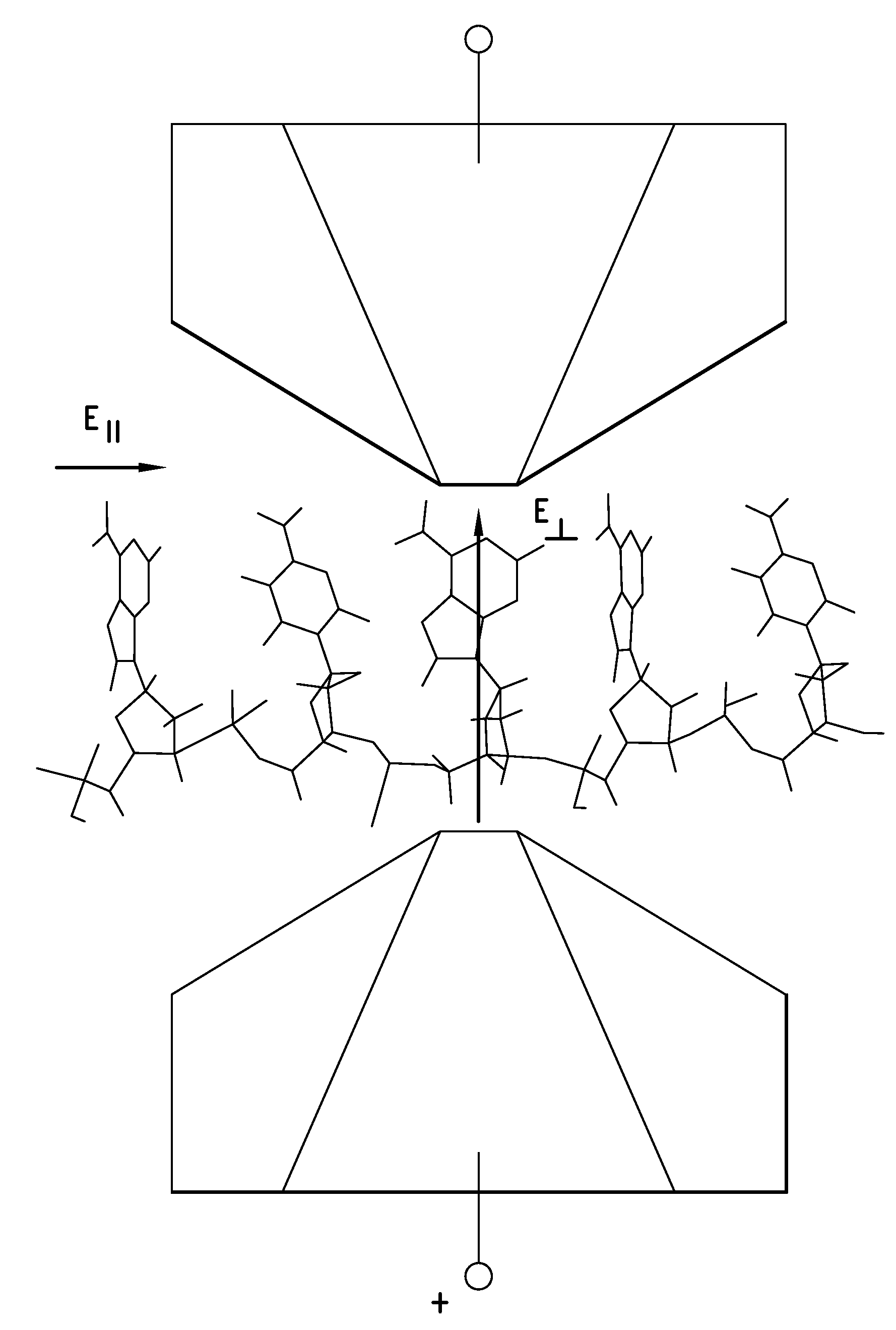

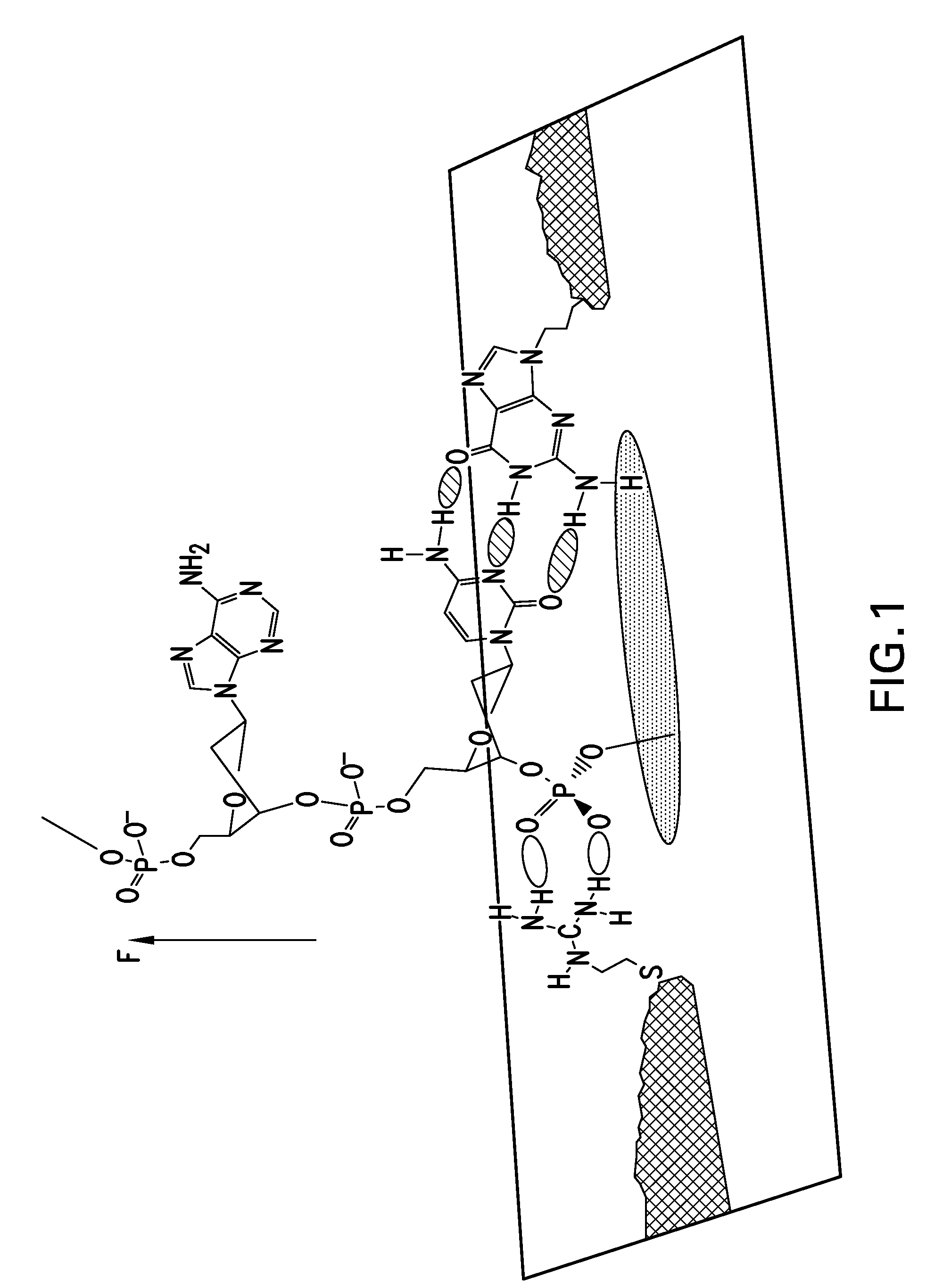

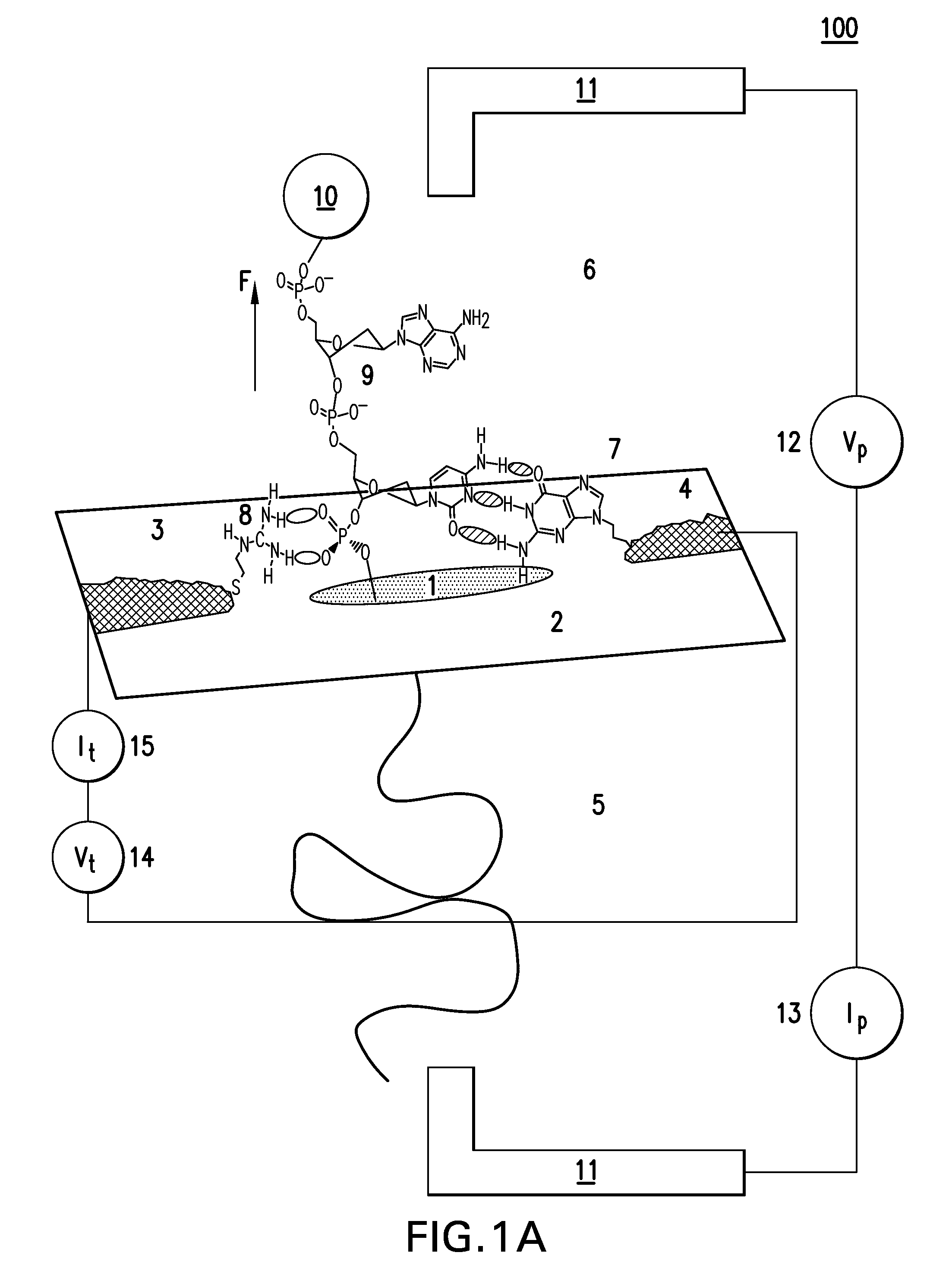

The present invention provides a device having at least one constriction that is sized to permit translocation of only a single copy of the molecule. The device has a pair of spaced apart sensing electrodes that border the constriction, which may be a nanopore. The first electrode is connected to a first affinity element and the second electrode is connected to a second affinity element. The first and second affinity elements are configured to temporarily form hydrogen bonds with first and second portions of the target molecule as the latter passes through the constriction.

Owner:ARIZONA STATE UNIVERSITY

Method of making a composite article comprising a ceramic coating

InactiveUS6919012B1Improve propertiesSuperior physical/mechanical and protective propertyAnodisationCellsSurface layerCeramic coating

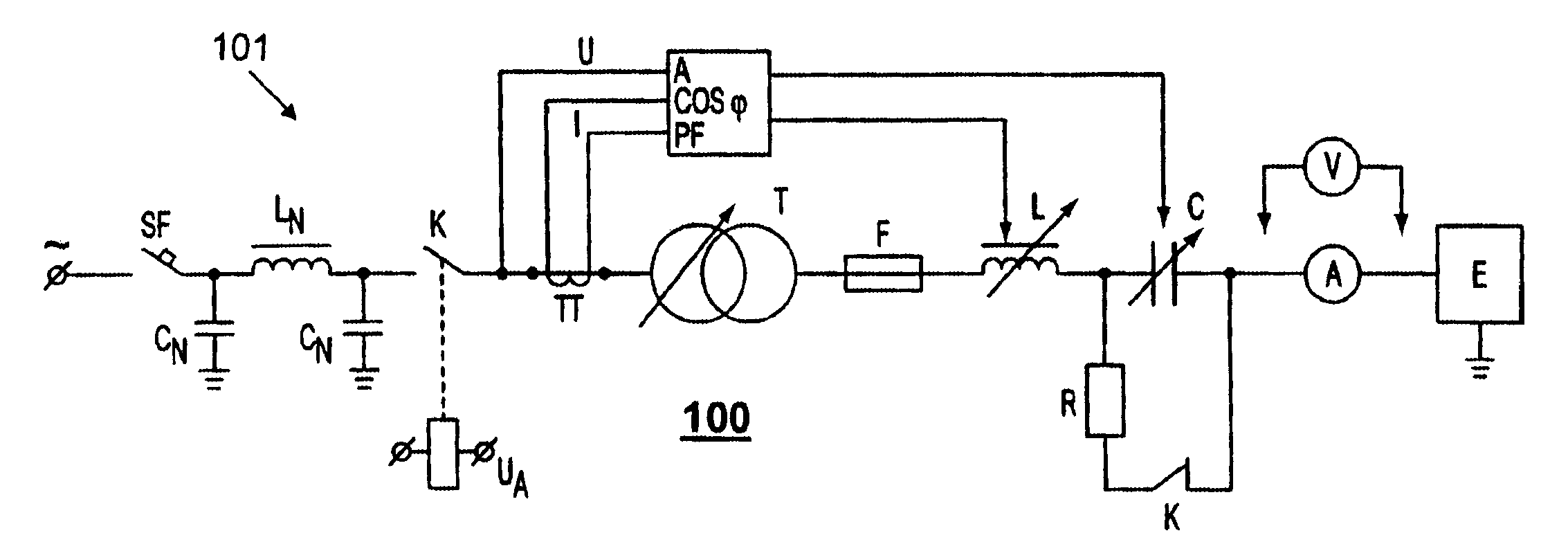

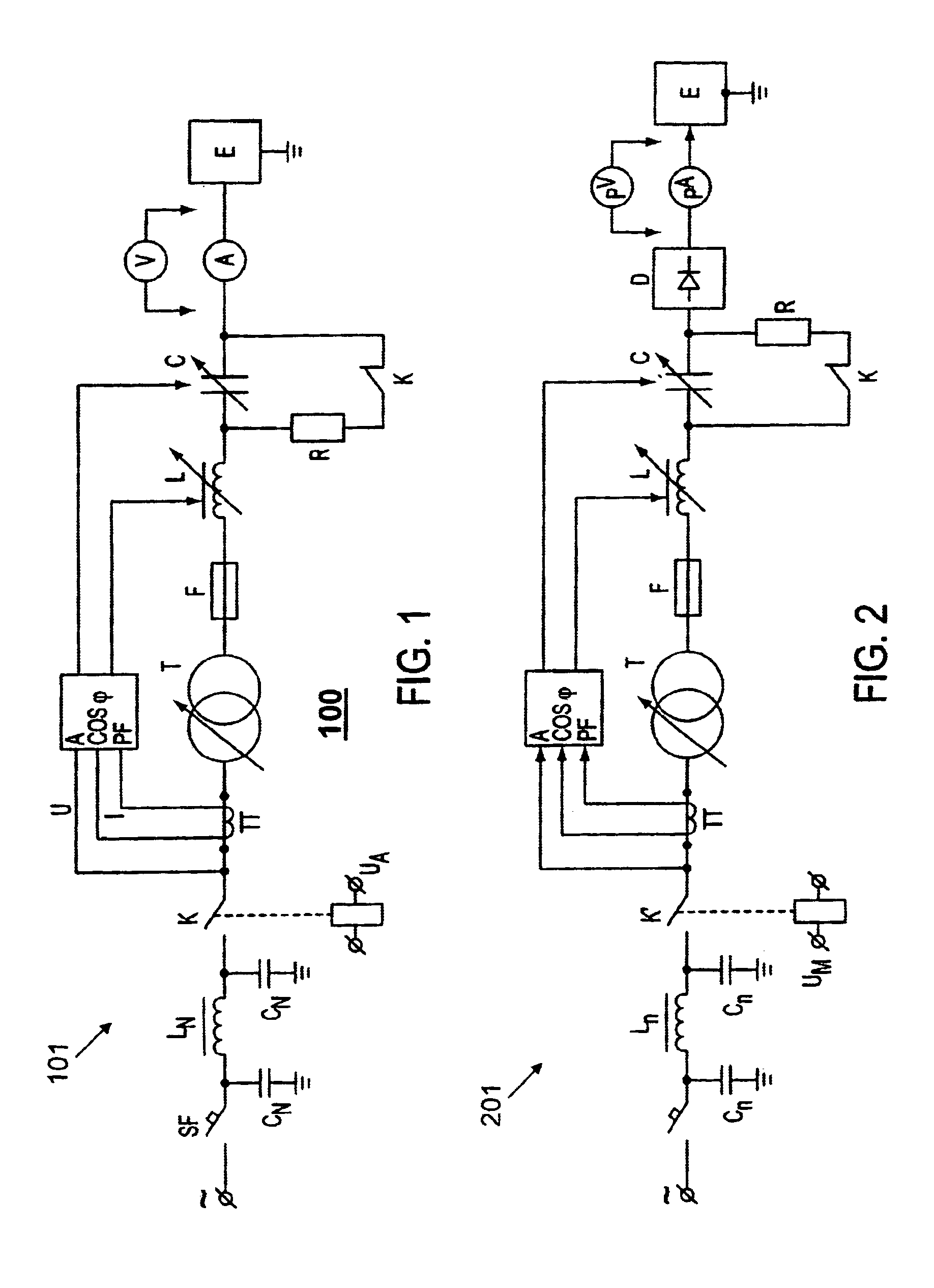

A ceramic coating is formed on a conductive article by immersing a first anodic electrode, including the conductive article, in an electrolyte comprising an aqueous solution of alkali metal hydroxide and an alkali metal silicate, providing a second cathodic electrode in contact with the electrolyte, and passing an alternating current from a resonant power source through the first electrode and to the second electrode while maintaining the angle φ between the current and the voltage at zero degree, while maintaining the voltage within a predetermined range. The resulting ceramic coated article comprises a coating which includes a metal, silicon, and oxygen, wherein the silicon concentration increases in the direction from the article surface toward an outer surface of the ceramic coating surface layer.

Owner:OLIMEX GROUP

Electroconductive polymer coating on electroconductive elements in a fuel cell

InactiveUS20060099481A1Reduce accumulationFuel cells groupingElectrode carriers/collectorsPolymer coatingsProton exchange membrane fuel cell

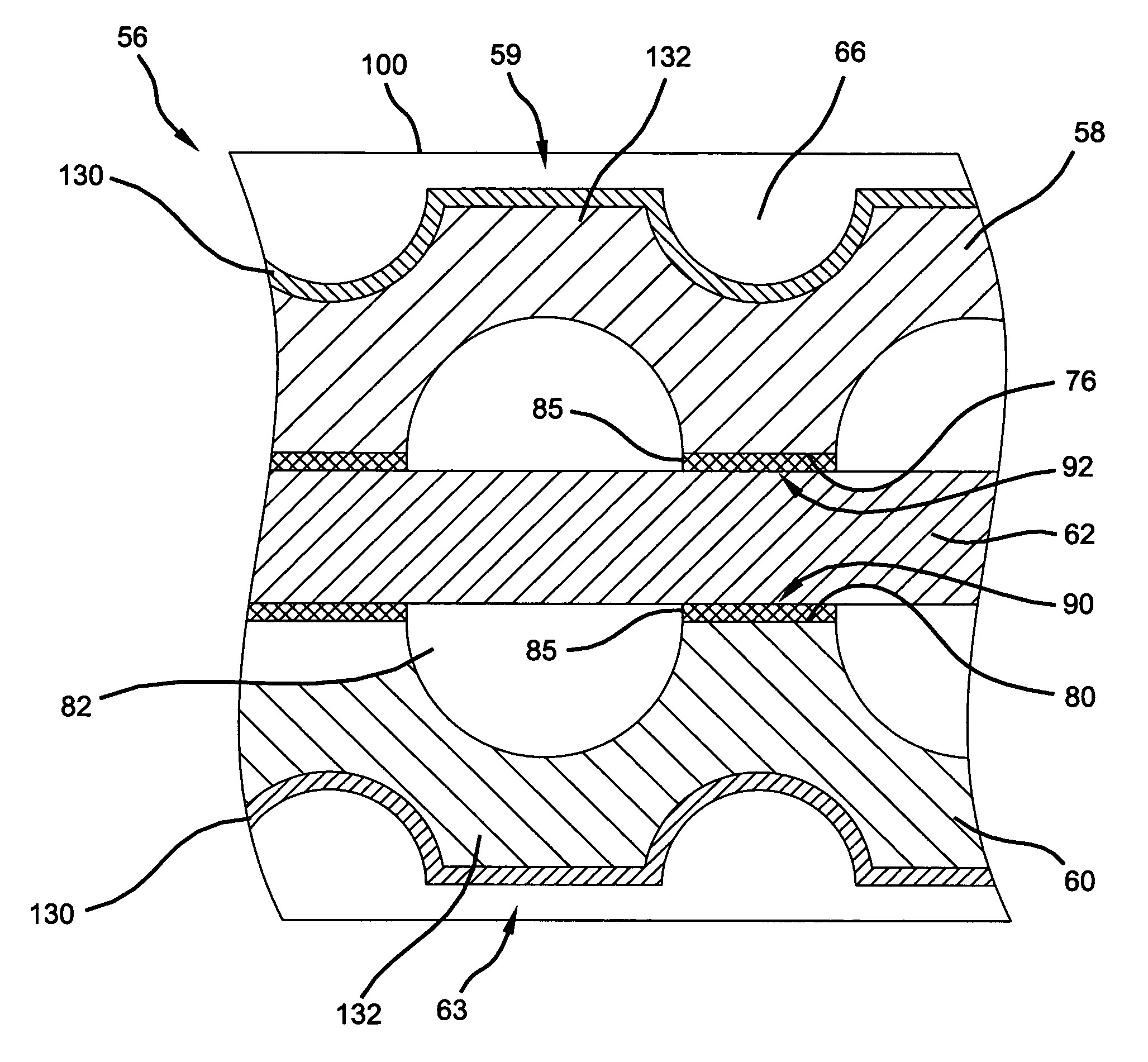

A bipolar plate for use in a proton exchange membrane fuel cell having an electrically conductive polymer coated on at least one region of a surface of the plate in contact with a flow field. The coated region is hydrophobic or hydrophilic as compared to an uncoated region of the surface to prevent liquid accumulation. Electroconductive polymer coatings are applied by electrochemical polymerization.

Owner:GM GLOBAL TECH OPERATIONS LLC

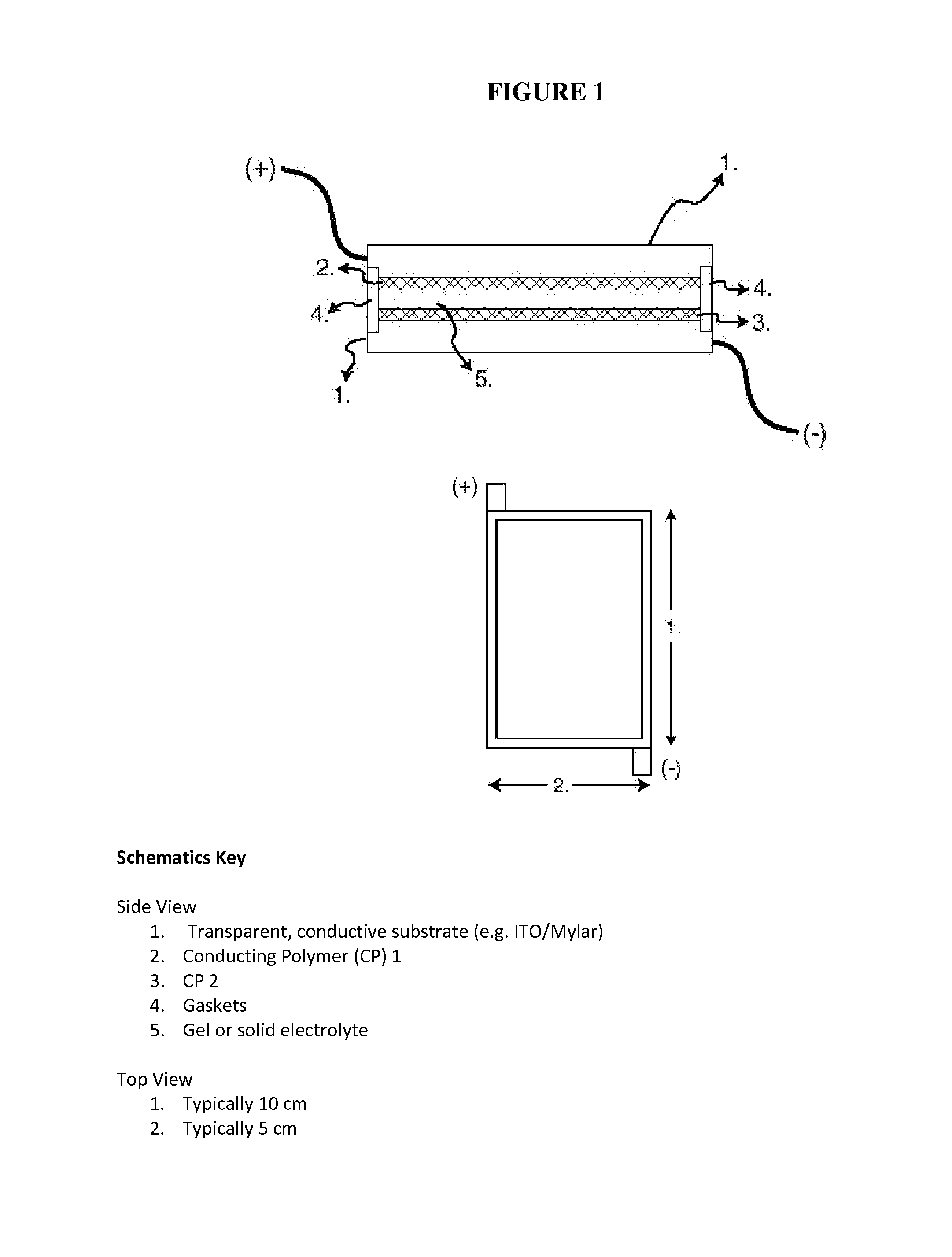

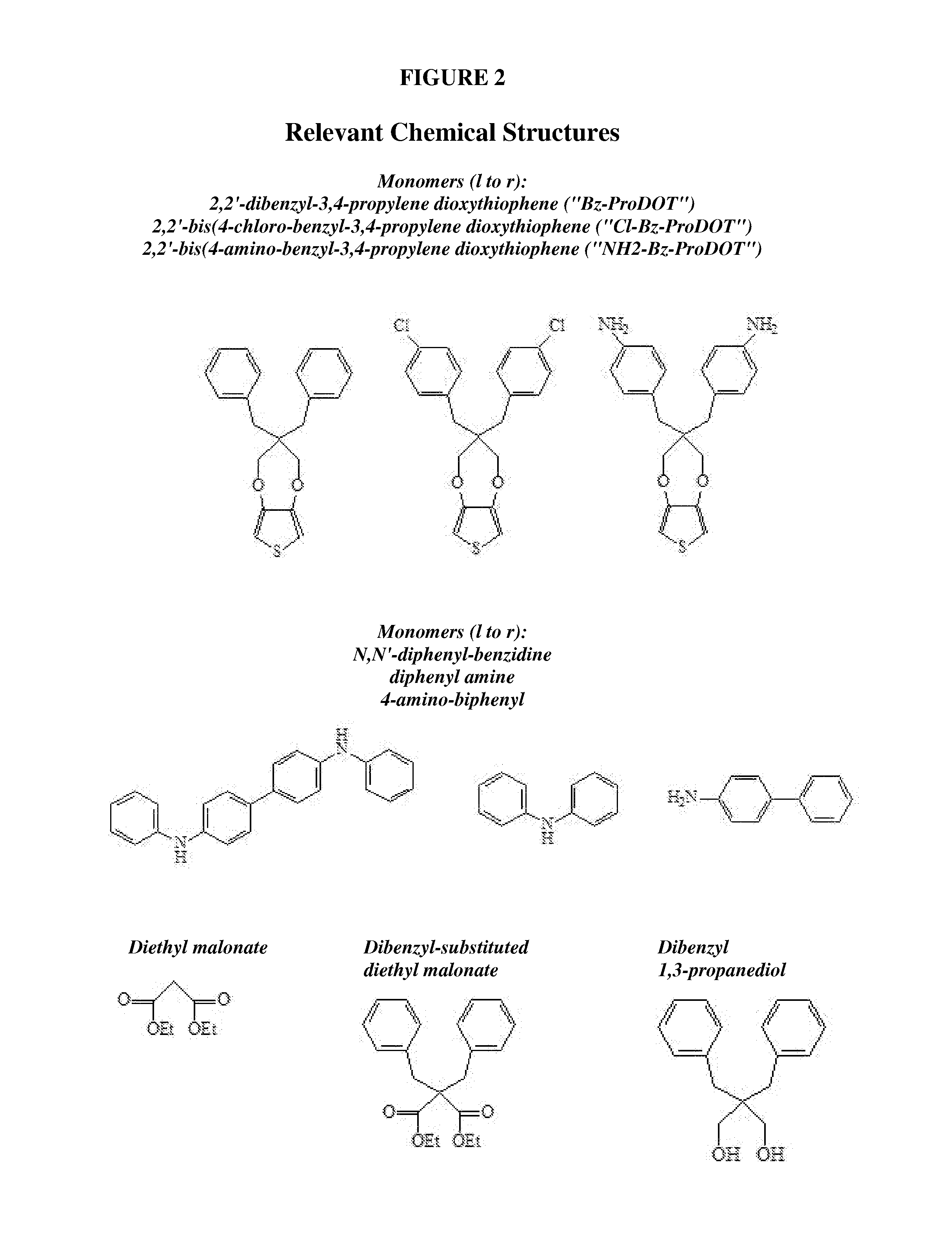

Complimentary polymer electrochromic device

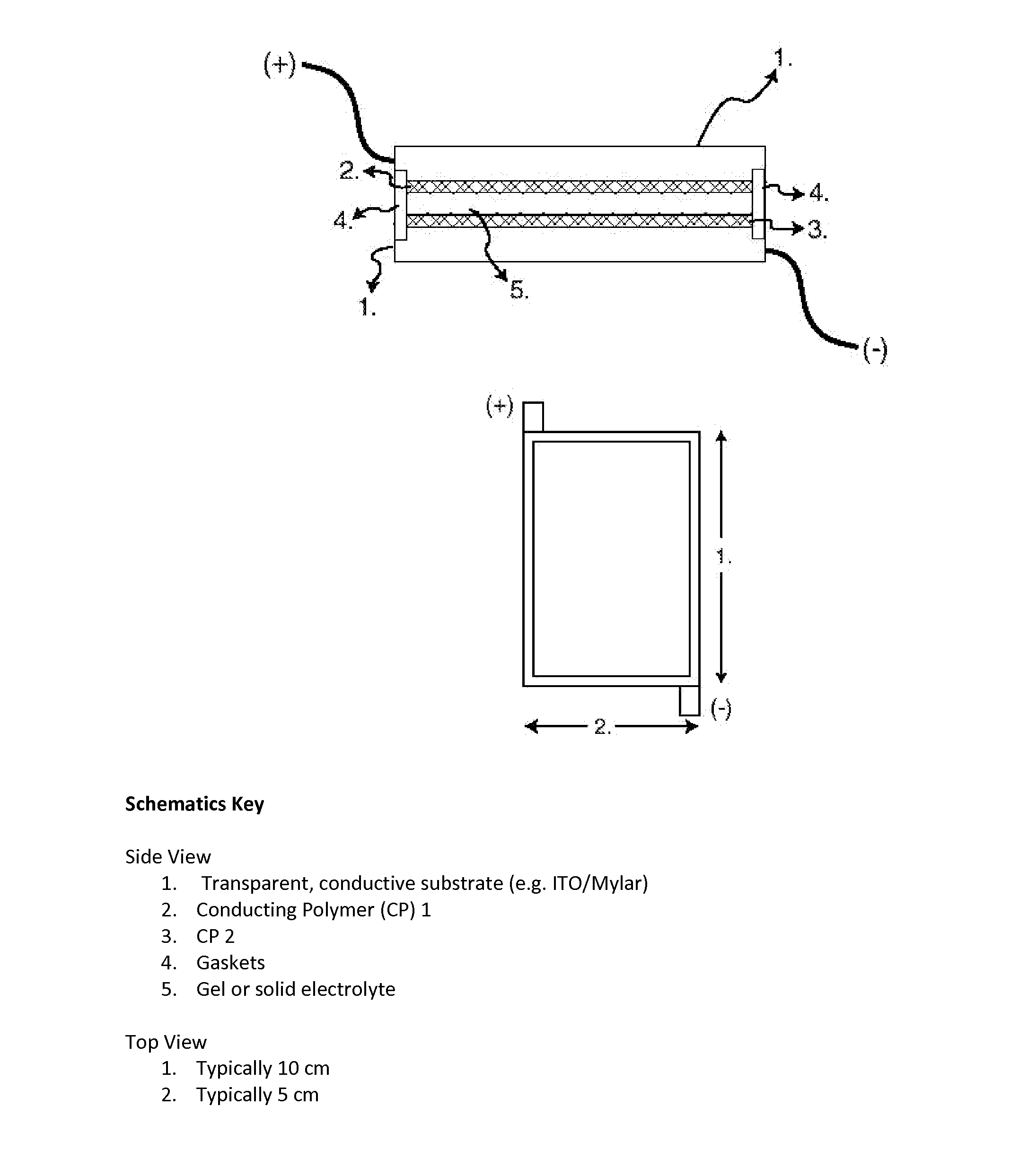

ActiveUS20130120821A1Overcomes drawbackImprove matchOrganic compound preparationDuplicating/marking methodsElectricityPolymer science

Owner:ASHWIN USHAS

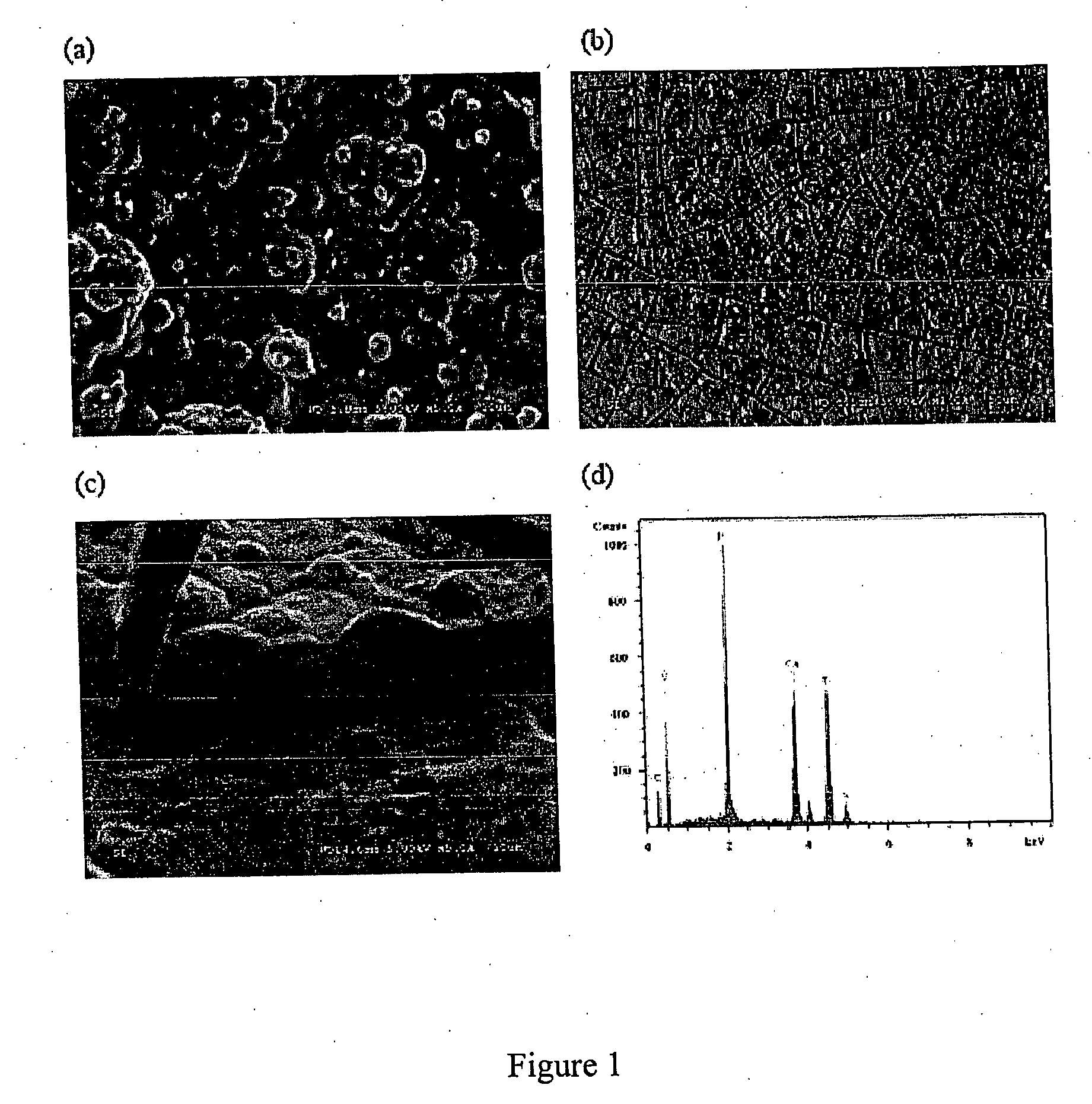

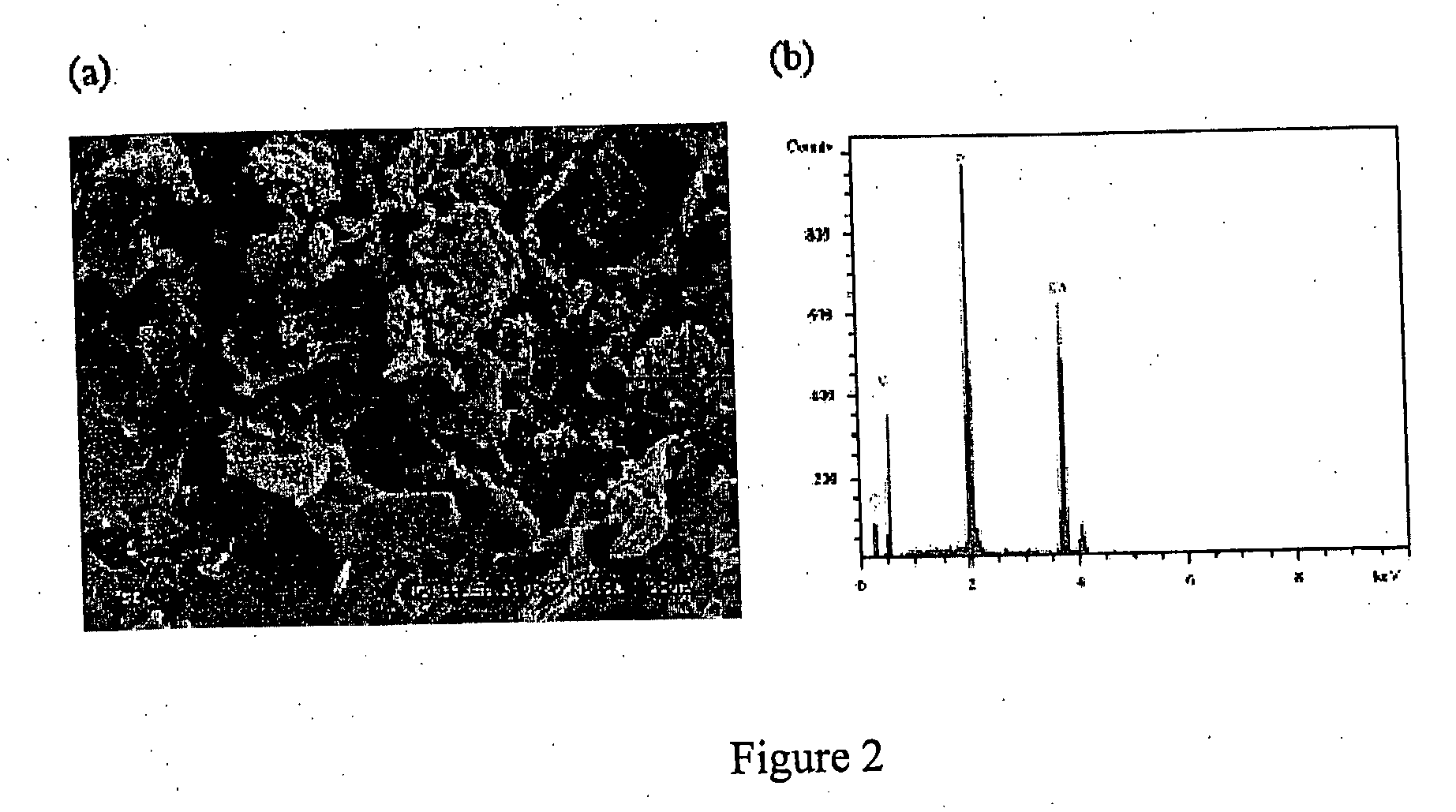

Preparation of super-hydrophobic surface for metal anti-corrosive and self-cleaning effects

InactiveCN101440510AGood environmental stabilityEasy to operateElectrolytic organic material coatingElectrochemical responseAlloy substrate

The invention relates to a method for preparing a super-hydrophobic surface with metal corrosion protection and self-cleaning functions, which comprises the following steps: 1) washing a metal or an alloy substrate clean by using acetone, deionized water and ethanol sequentially; 2) using the cleaned metal or the alloy substrate as an anode and a cathode respectively and putting the anode and the cathode into a fatty acid CH3(CH2)n-2COOH electrolyte solution with the concentration of between 0.001 and 0.5 mol per liter, wherein n is equal to between 10 and 14; and applying voltage of between 0.5 and 25 volts between the cathode and anode to perform an electrochemical reaction for 0.5 to 6 hours so as to deposit a layer of a fatty acid salt super-hydrophobic surface with the metal corrosion protection and self-cleaning functions on the surface of the metal or the alloy substrate serving as the cathode. The method has simple operation and low equipment requirement, is not limited by the shape of a substrate, is easy to achieve industrialization, and has comparatively wide practical value.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Method of electrolytically depositing a pharmaceutical coating onto a conductive osteal implant

InactiveUS20080011613A1Electrolytic inorganic material coatingPretreated surfacesCalcium biphosphateConductive materials

A method of electrolytically depositing a pharmaceutical coating onto a conductive osteal implant. The implant is submerged into an electrolytic cell containing an electrolysis solution of the pharmaceutical and acts as a cathode. When current is applied to the electrolytic cell, the pharmaceutical coating forms on the implant. The pharmaceutical can comprise bisphosphonates, including calcium salts. The implants can comprise any conductive material suitable for use as an osteal implant. The implants can also be electrolytically coated with calcium phosphate before coating with a pharmaceutical.

Owner:THE UNIV OF BRITISH COLUMBIA

Electroplating product and method for preparing same

InactiveCN101113527AImprove surface propertiesSurface properties such as good wear resistanceSuperimposed coating processElectrolytic organic material coatingAlloyElectroplating

A plating product comprises a matrix material and plated metal layers on the surface thereof; from the inner layer to the outer layer, the plated metal layers comprise a Cu layer, a Ni layer and a Cr layer in sequence, wherein the plated metal layers comprise a middle plating layer which is positioned between the Ni layer and the Cr layer and made from Pd, Ru or Rh, or an alloy of any two, three or four kinds of metals Pd, Rh, Ru and Ni. The invention also provides a preparation method of the plating product; according to the plating product of the invention, the middle plating layer is positioned between the Ni layer and the Cr layer, and the middle plating layer can inhibit metal Ni from precipitating to the surface of the plating product, so that the precipitation quantity of Ni can be greatly reduced, and the precipitation quantity of metal Ni can meet the specification of no more than 0.5 Mug per cm2.week; furthermore, compared with the existing ordinary plating products, the plating product of the invention also have good surface performances such as abrasion resistance, corrosion resistance and impact resistance.

Owner:精英塑胶(珠海)有限公司

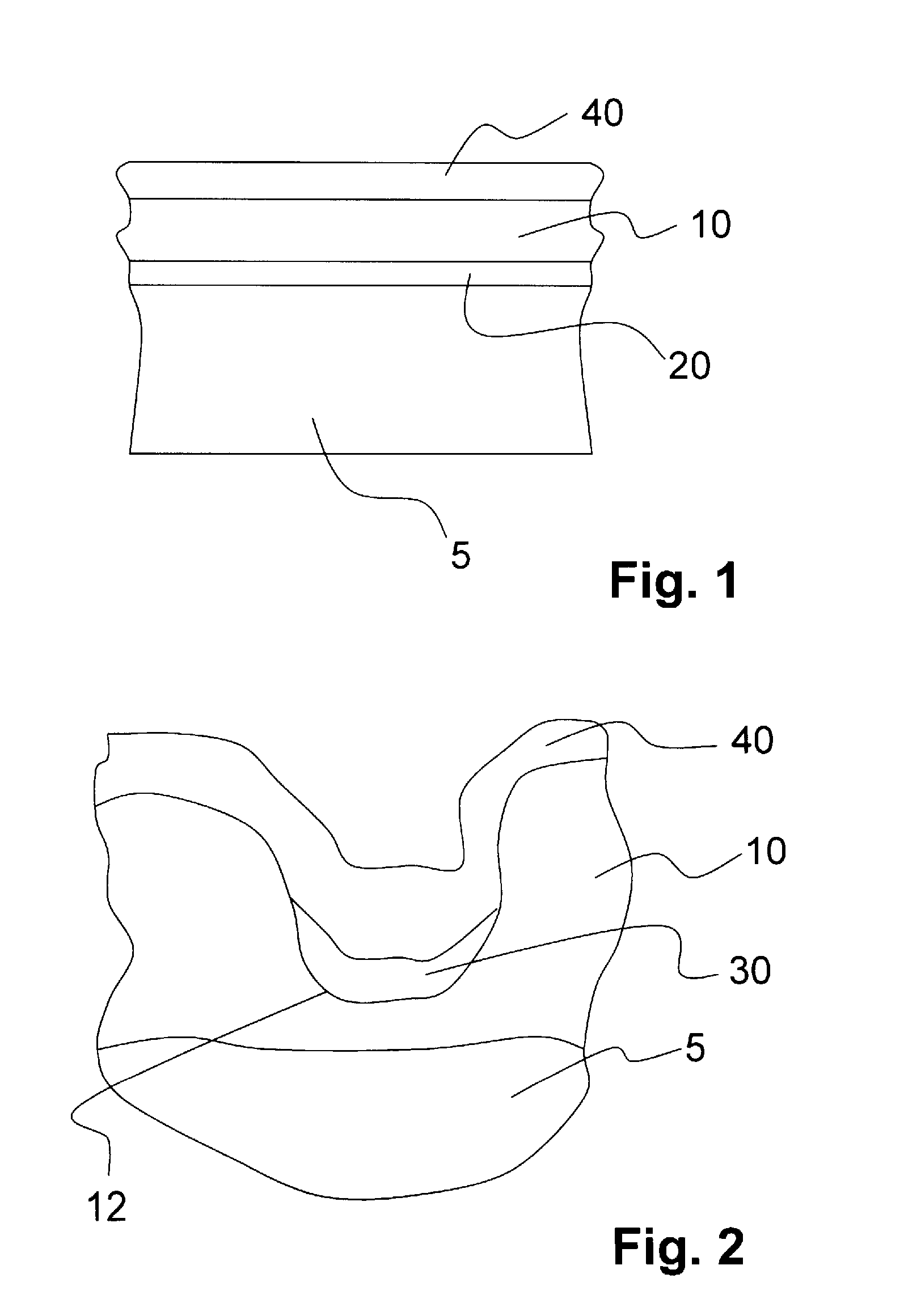

Implant and Method for Manufacturing Same

The present invention proposes a method for manufacturing an implant, in particular an intraluminal endoprosthesis, having a body such that the body has metallic material. To control the degradation in a desired time window, e.g., between four weeks and six months, the following production method is performed: a) preparing the body of the implant, and b) plasma-chemical treatment of at least a portion of the surface of the body in an aqueous solution by applying a plasma-generating electric alternating voltage to the body (5) of the implant, said voltage having a frequency of at least approximately 1 kHz, to create a first layer. The invention also relates to an implant obtainable by such a method.

Owner:BIOTRONIK AG

Article of manufacture and process for anodically coating aluminum and/or titanium with ceramic oxides

An article of manufacture and a process for making the article by generating corrosion-, heat- and abrasion-resistant ceramic coatings comprising titanium and / or zirconium dioxide using direct and alternating current on anodes comprising aluminum and / or titanium. Optionally, the article is coated with additional layers, such as paint, after deposition of the ceramic coating.

Owner:HENKEL KGAA

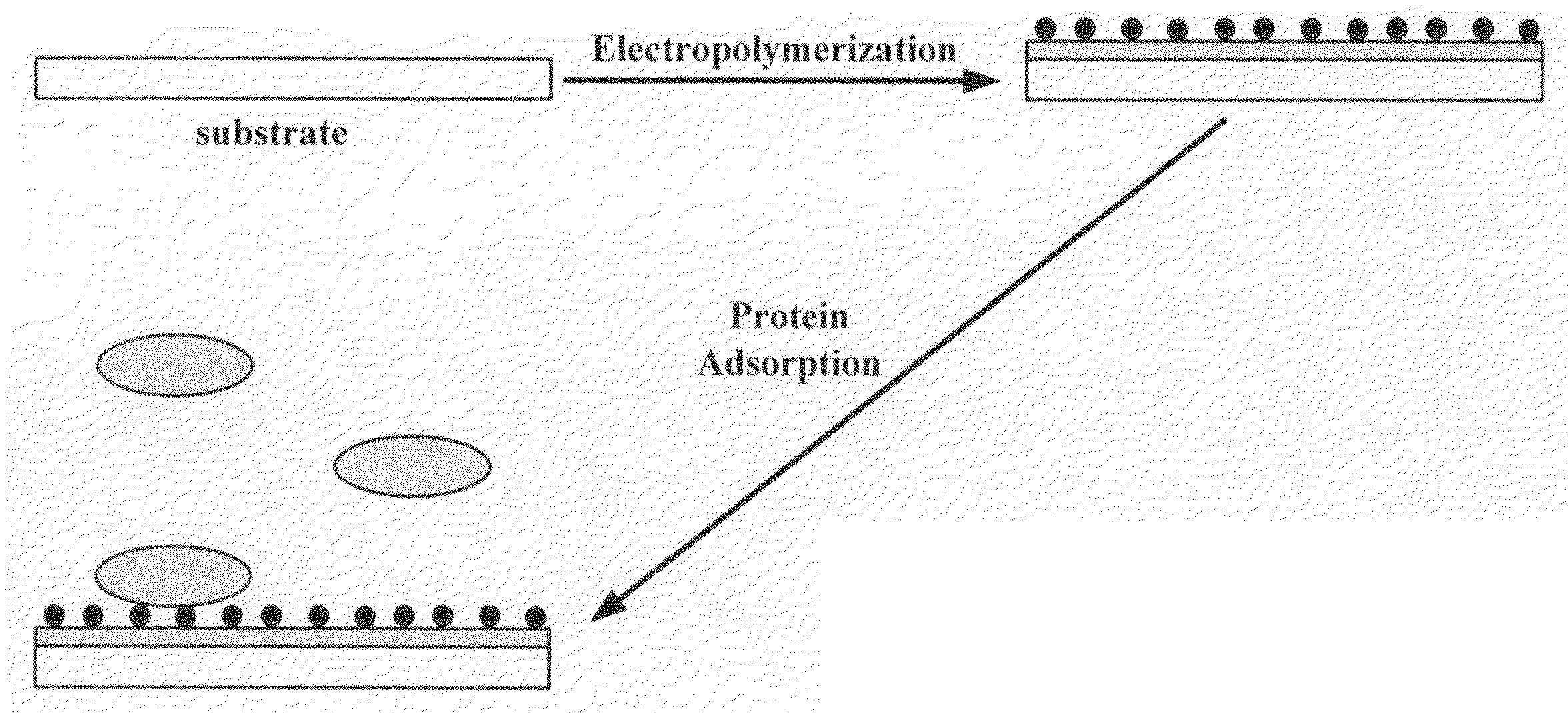

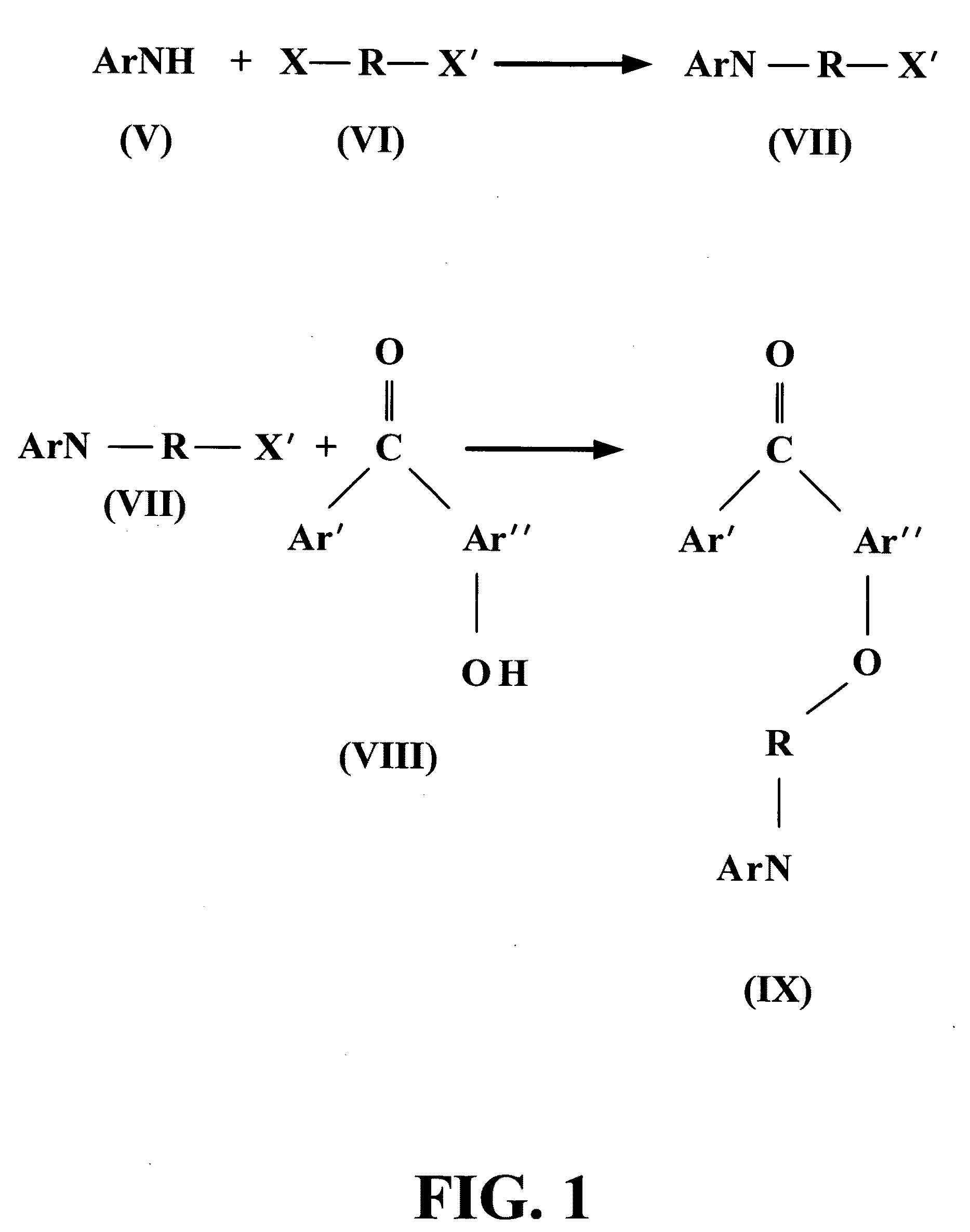

Methods for preparing polymer coatings by electrochemical grafting of polymer brushes, compositions prepared thereby and compositions for preparing the coatings

InactiveUS20090236229A1Surface reaction electrolytic coatingElectrolytic organic material coatingPolymer sciencePolymer coatings

New methods for the grafting of complex polymer coatings onto conducting surfaces, new grafting compositions and new substrates with grafted coating of the grafting compositions are disclosed. The method offers a new and convenient approach for the preparation of polymer coatings by electrochemically grafting and reactive crosslinking, and / or graft polymerizing.

Owner:ADVINCULA RIGOBERTO

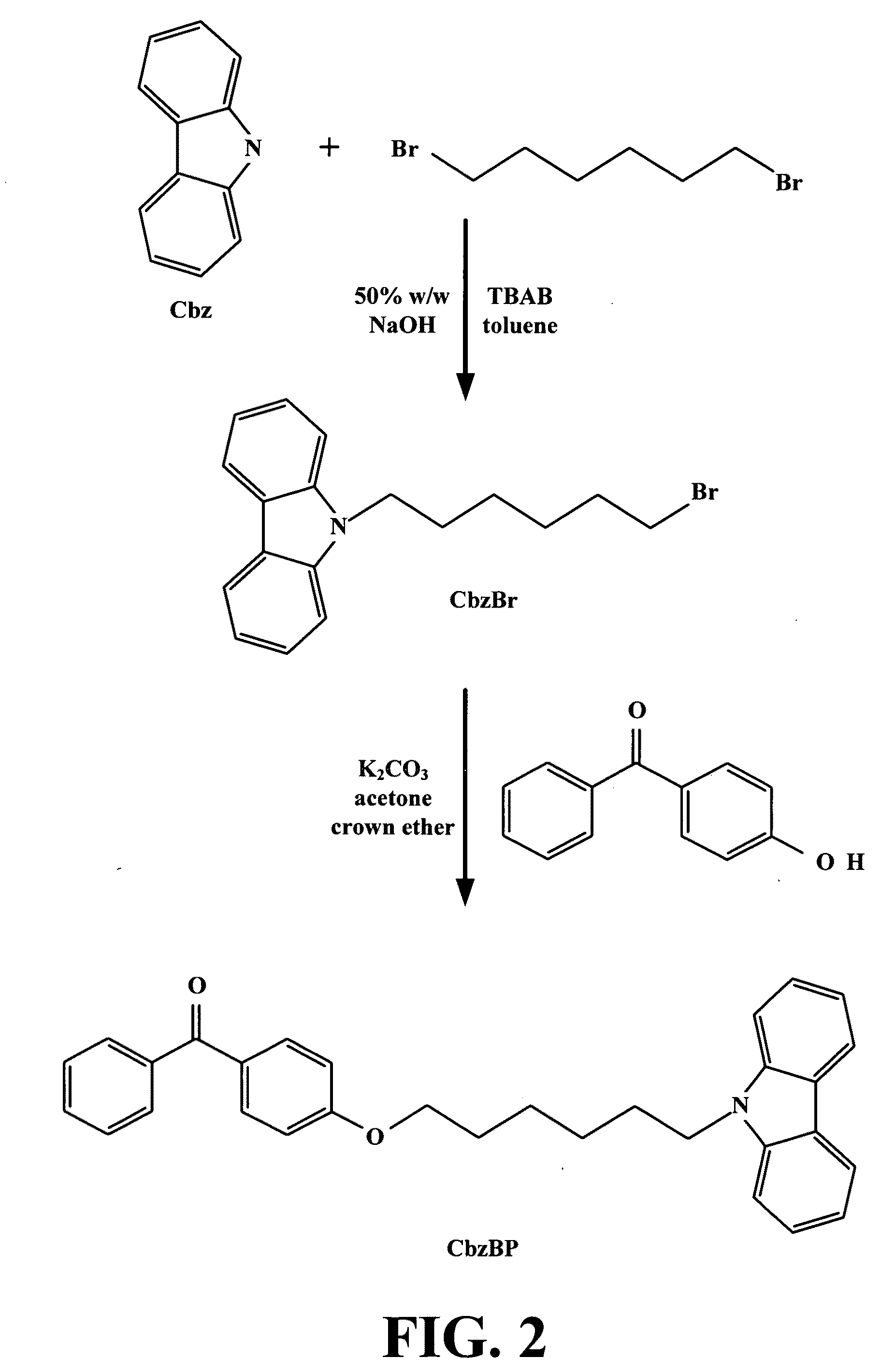

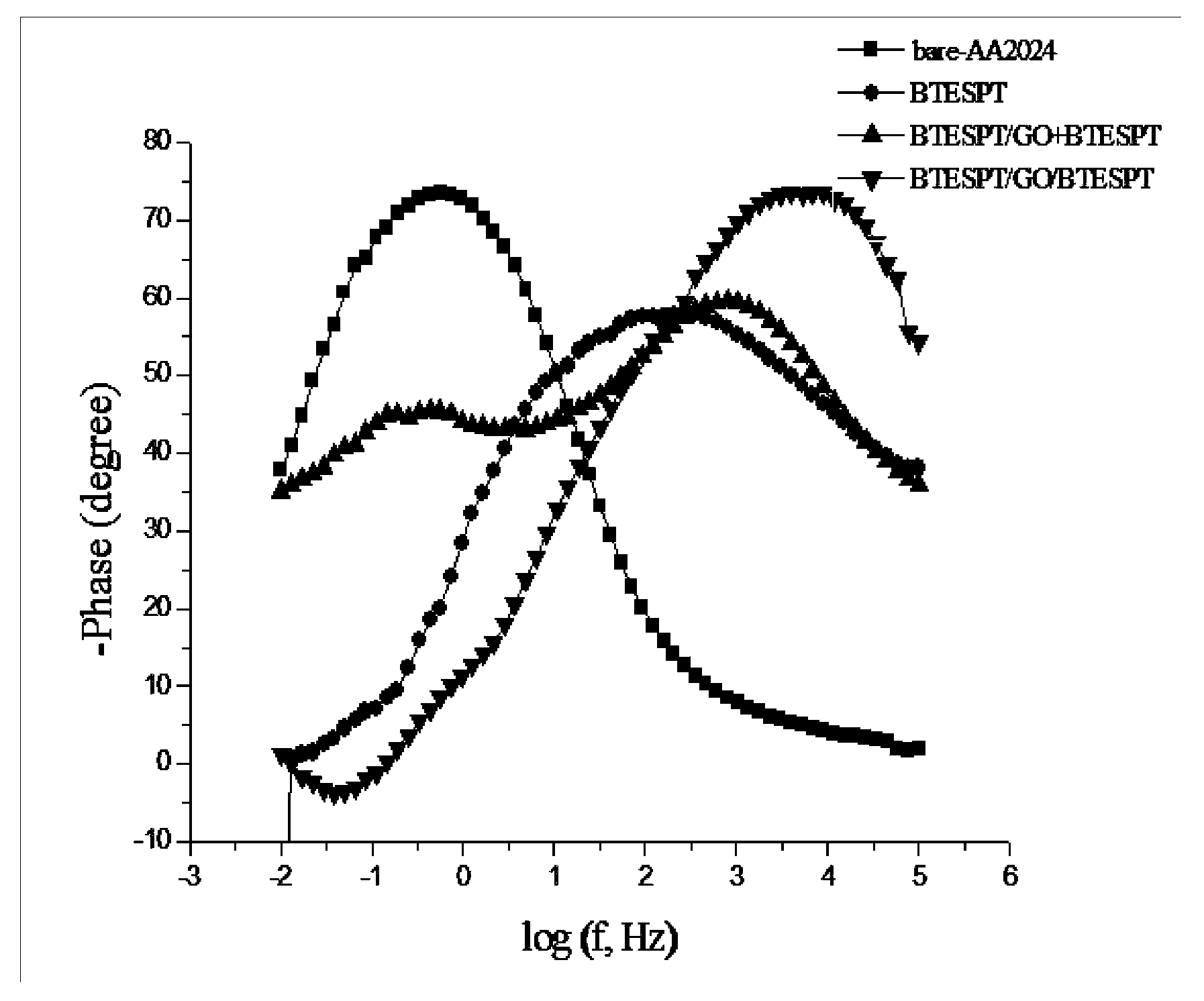

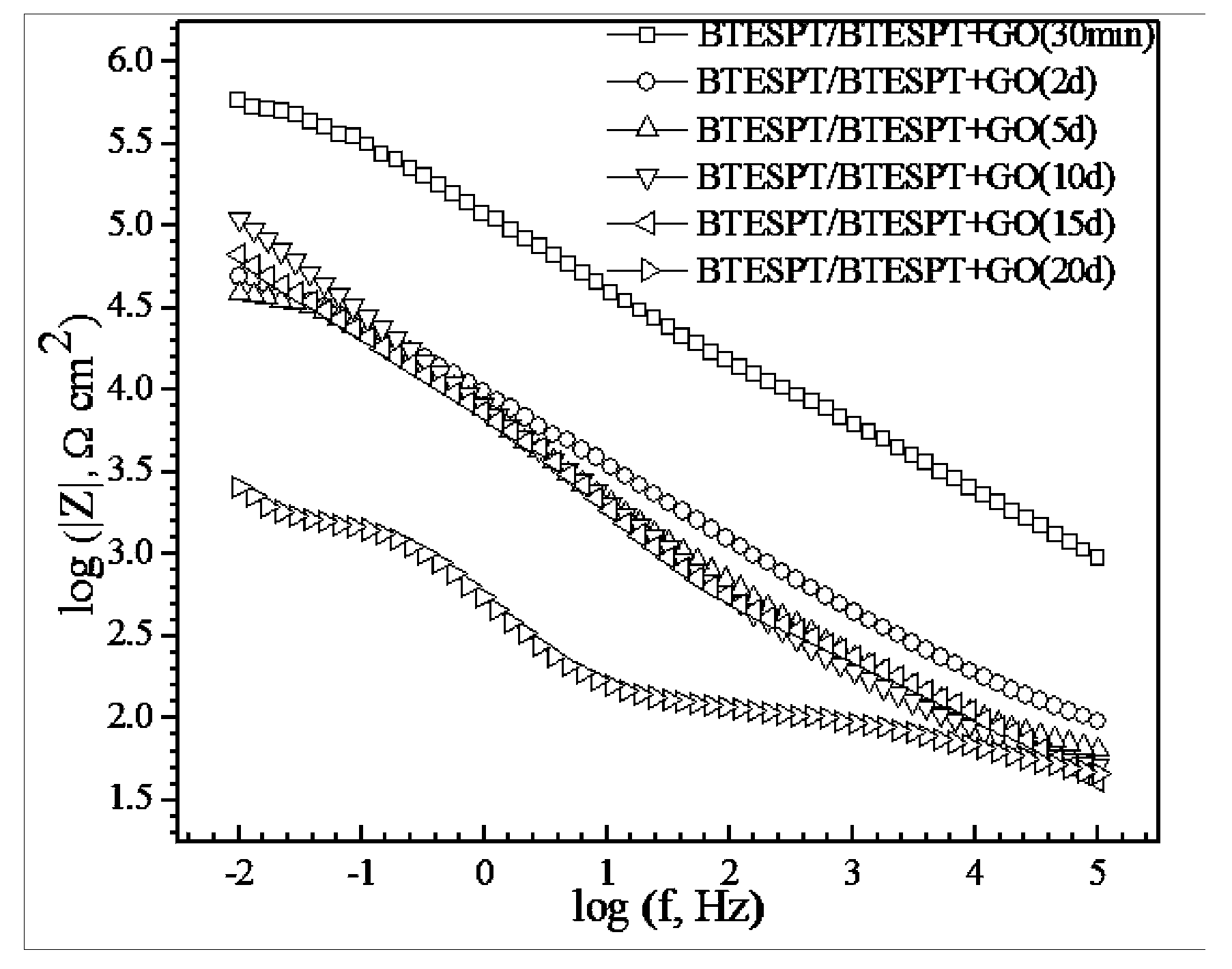

Preparation method of graphene composite anticorrosive coating

ActiveCN104231703ASimple manufacturing processFast film formationAnti-corrosive paintsElectrolytic organic material coatingPower flowDip-coating

The invention discloses a preparation method of a graphene composite anticorrosive coating. The preparation method comprises the following steps: (1) preparing an organic coating solution with a plurality of hydroxyls or amino groups; (2) preparing an oxidized graphene or modified graphene solution; (3) performing metal surface pretreatment; (4) performing electrodeposition to form an organic coating film; and (5) preparing the graphene composite anticorrosive coating. The method is simple and feasible in technology, the film forming speed is obviously improved, and the prepared coating is more compact and uniform; compared with a plain sample, the low-frequency impedance modulus value of the prepared composite coating is improved to 10<6.2> from 10<3.5> by performing electrochemical testing in 3.5wt% NaCl neutral electrolyte solution, the self-corrosion current is also remarkably reduced, and longer effective prevention effect on a matrix can be achieved. Compared with the conventional dip-coating method, the preparation method has lower requirement on the flatness of a metal surface, and controllable preparation can be effectively realized; the prepared coating is non-toxic and environment-friendly, controllable in thickness, and more compact and uniform, and more durable and stable protection effect on the metal matrix can be achieved.

Owner:OCEAN UNIV OF CHINA

Process for anodically coating aluminum and/or titanium with ceramic oxides

An article of manufacture and a process for making the article by generating corrosion-, heat- and abrasion-resistant ceramic coatings comprising titanium and / or zirconium dioxide using direct and alternating current on anodes comprising aluminum and / or titanium. Optionally, the article is coated with additional layers, such as paint, after deposition of the ceramic coating.

Owner:HENKEL KGAA

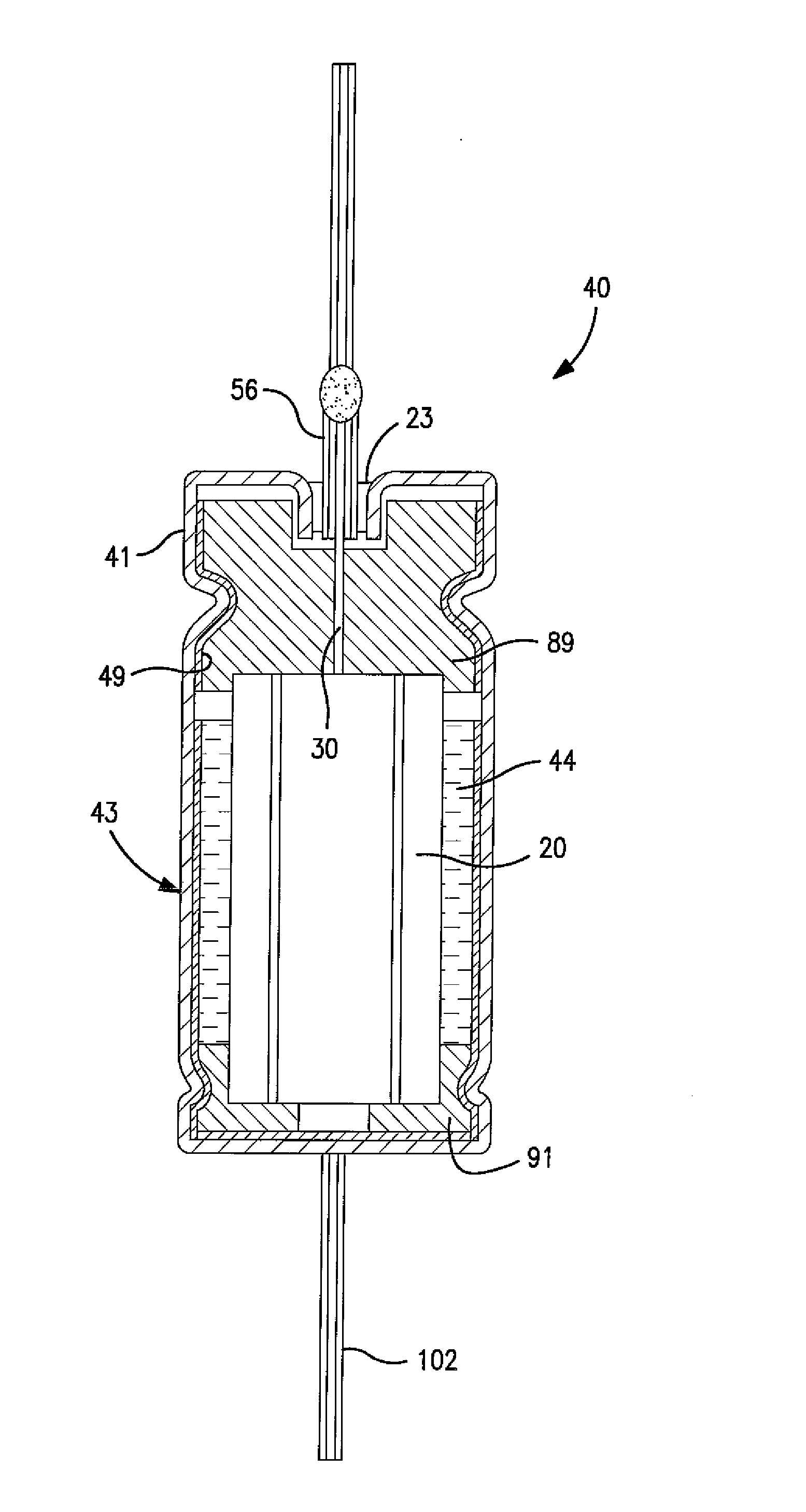

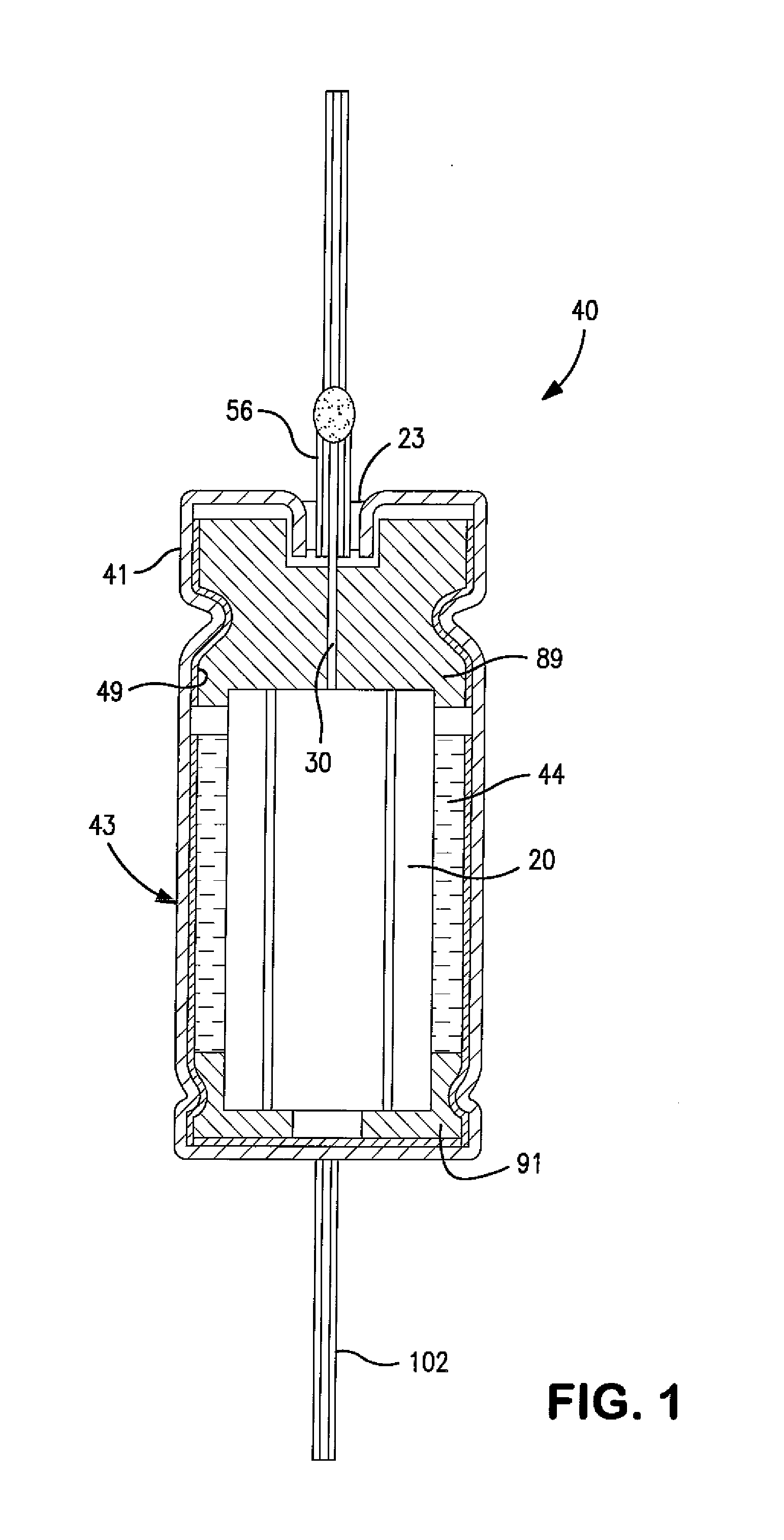

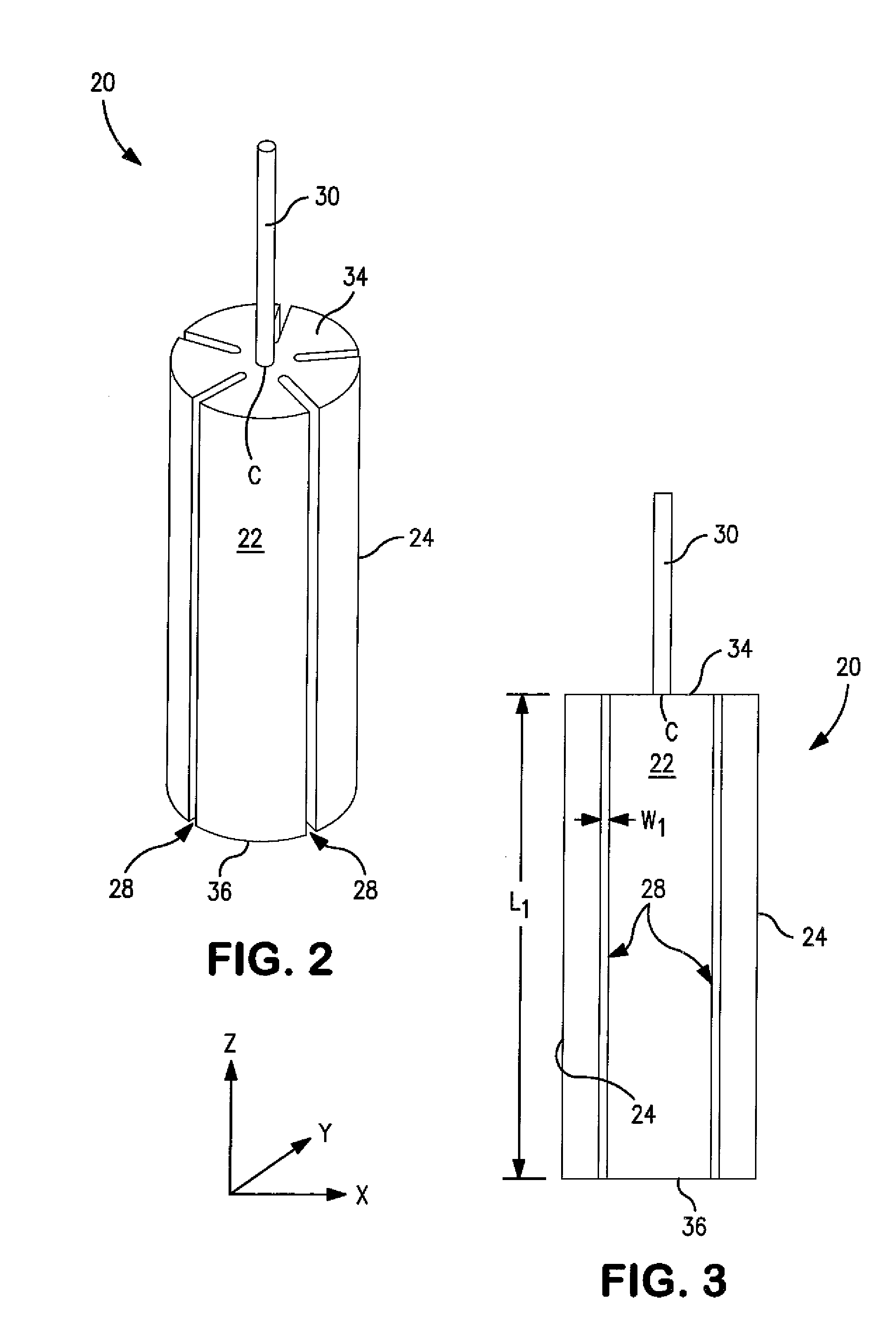

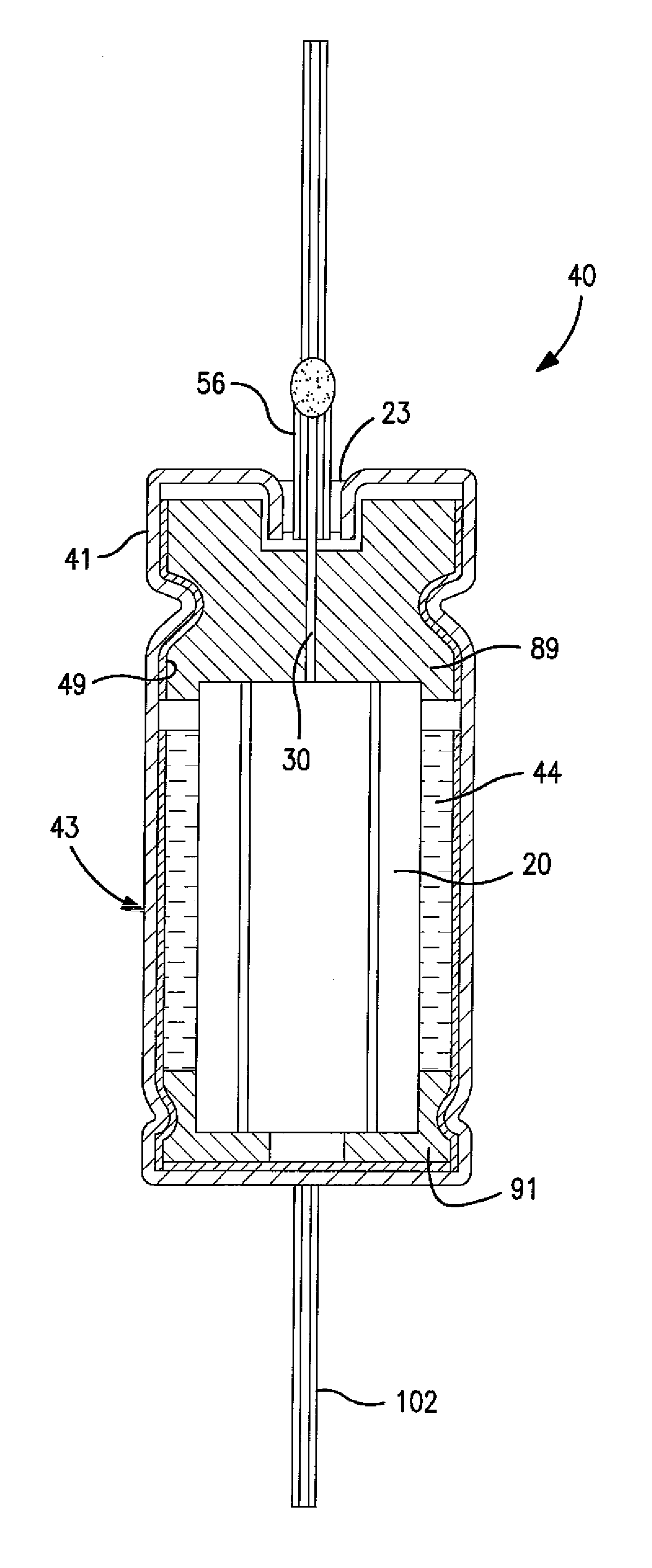

Wet Capacitor Cathode Containing a Conductive Copolymer

InactiveUS20130242464A1Liquid electrolytic capacitorsSurface reaction electrolytic coatingDielectricElectrolysis

A wet electrolytic capacitor that contains an anodically oxidized porous anode body, a cathode containing a metal substrate coated with a conductive coating, and a working electrolyte that wets the dielectric on the anode. The conductive coating contains a conductive copolymer having at least one thiophene repeating unit, as well as a pyrrole repeating unit and / or aniline repeating unit.

Owner:AVX CORP

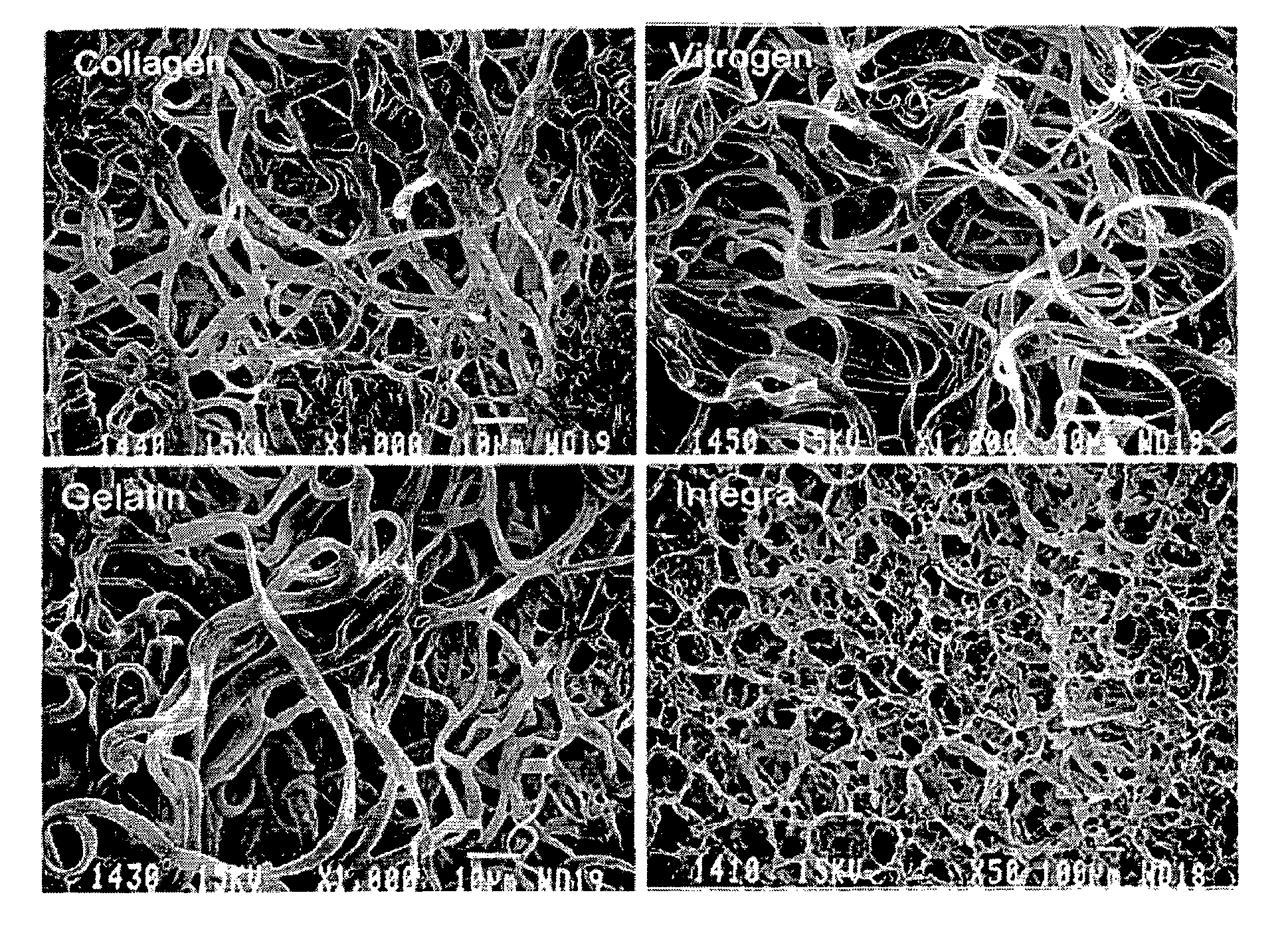

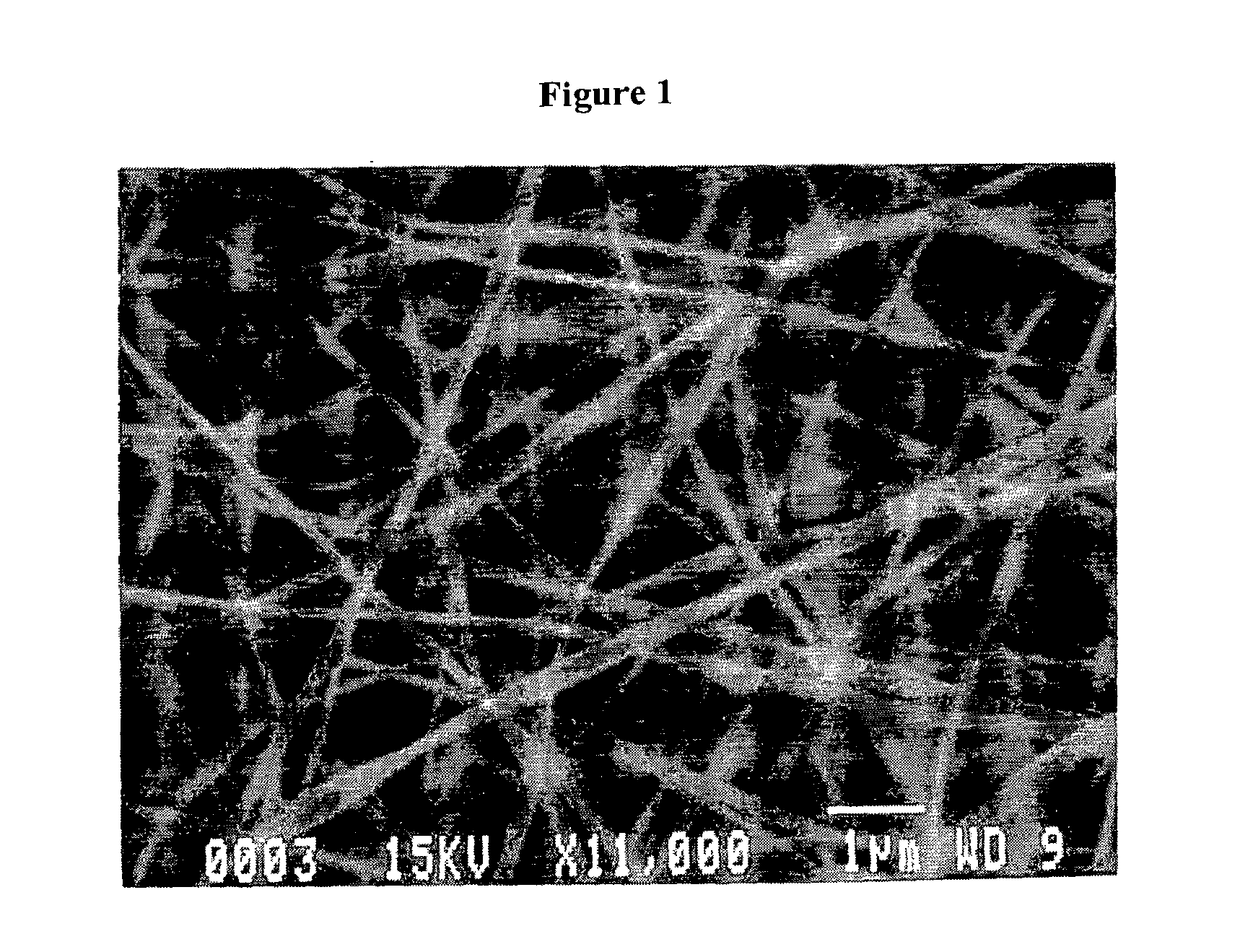

Sealants for Skin and Other Tissues

InactiveUS20100291058A1Prevent and reduce and eliminate flow of fluidFibrinogenSurgical adhesivesSealantBiomedical engineering

The present invention relates to sealants for skin and other tissues. The sealants include an electroprocessed material. The sealants may contain more than one electroprocessed materials and may contain additional substances. The invention further relates to methods of making and using such sealants.

Owner:ORGANOGENESIS

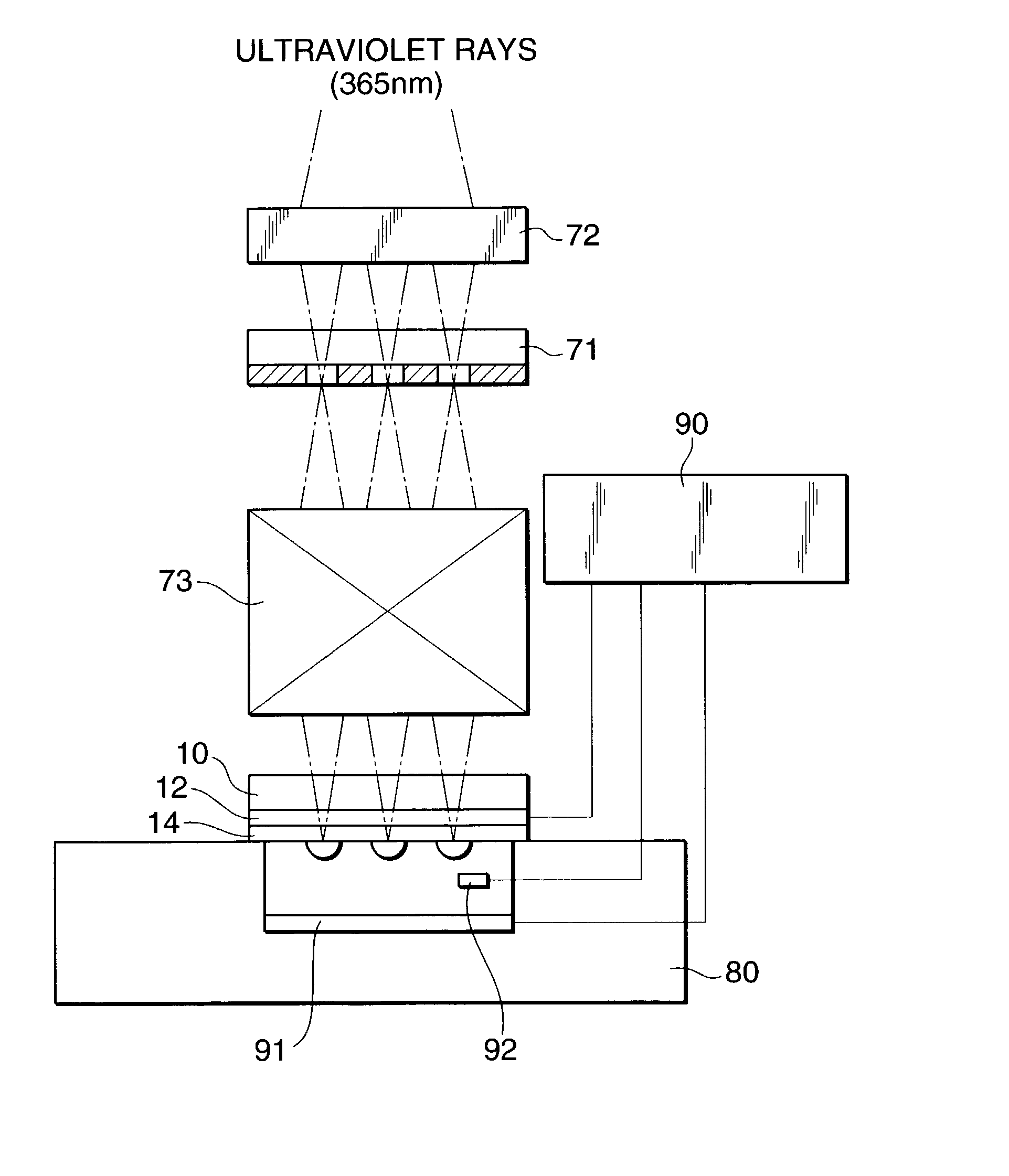

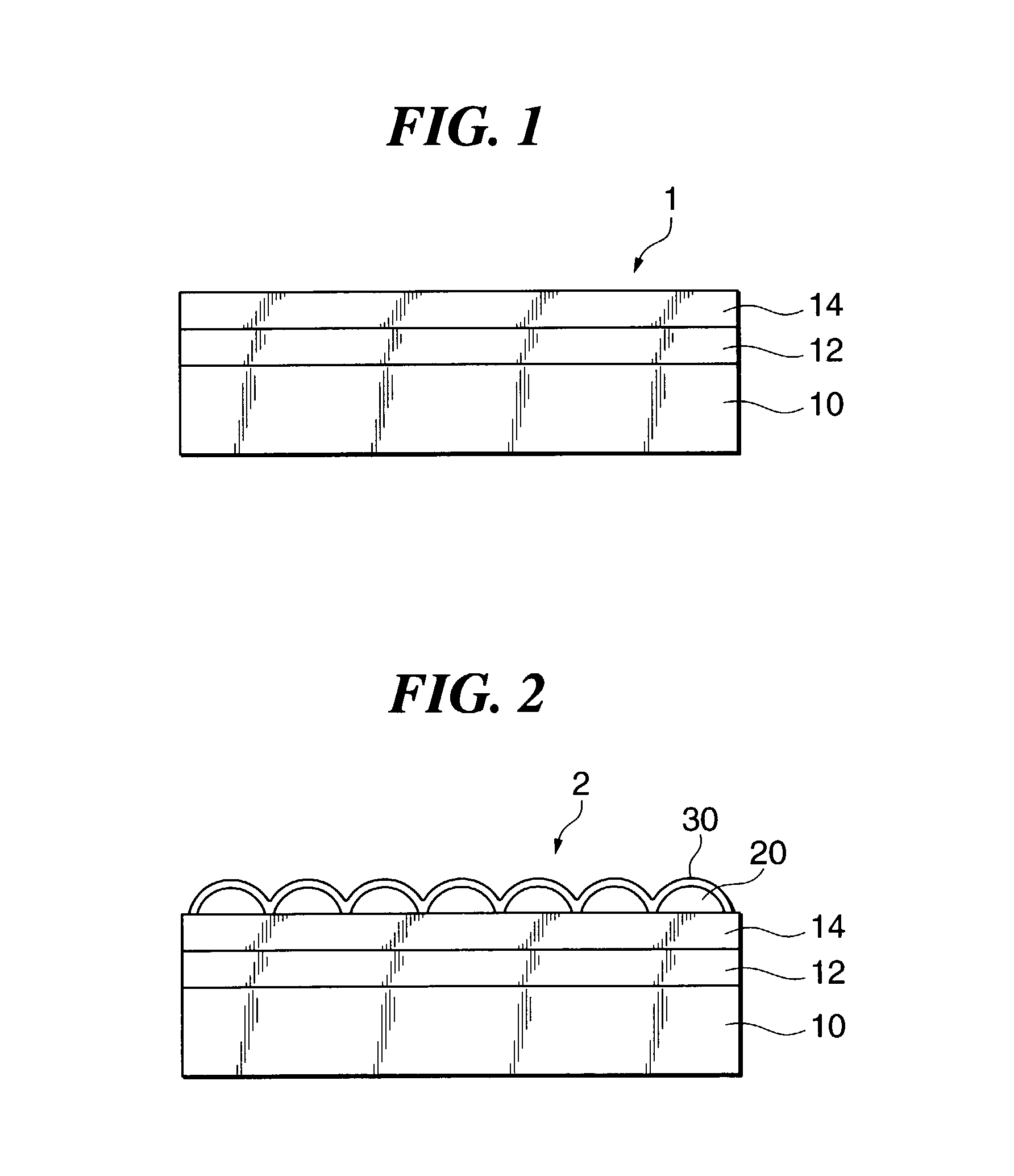

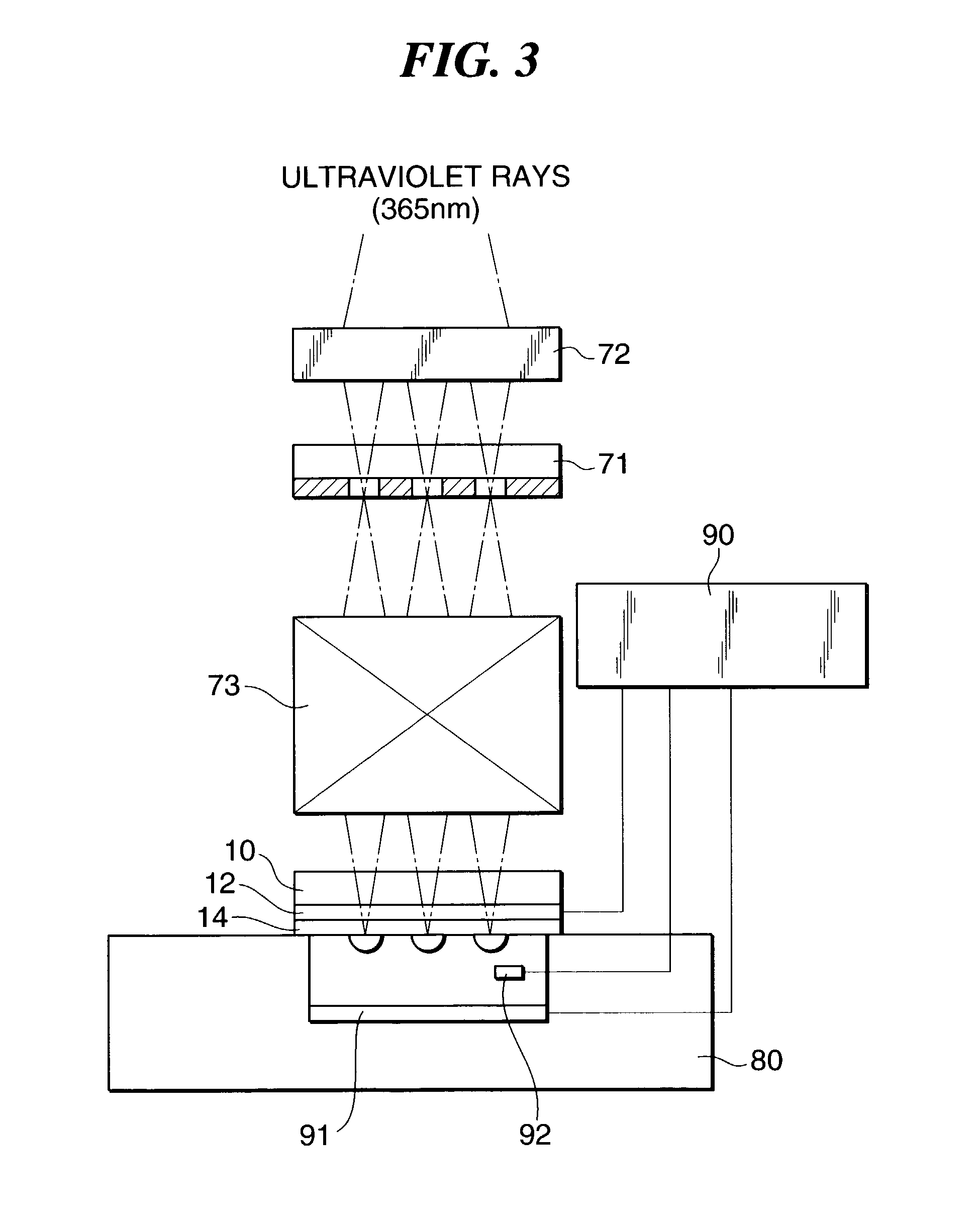

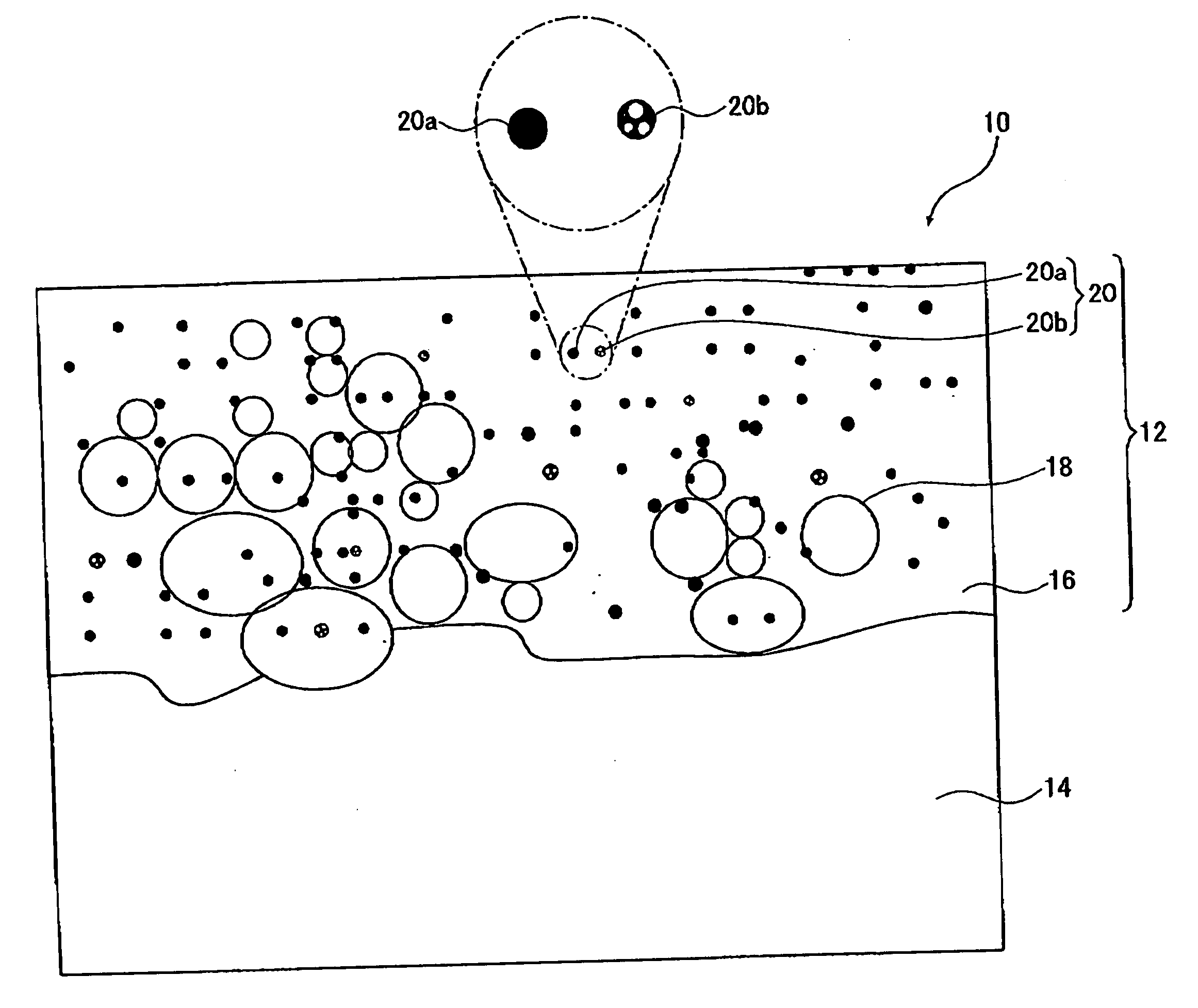

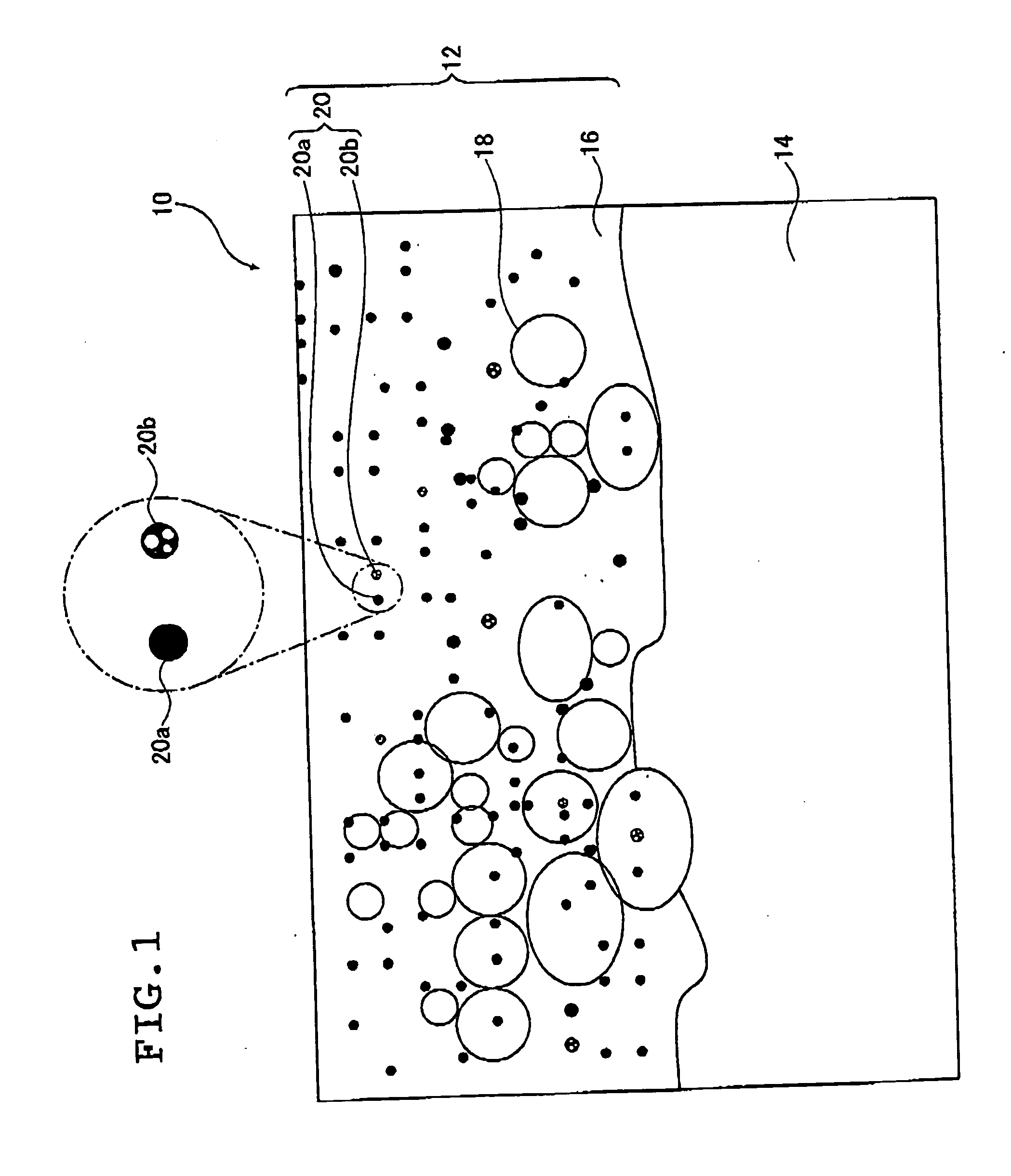

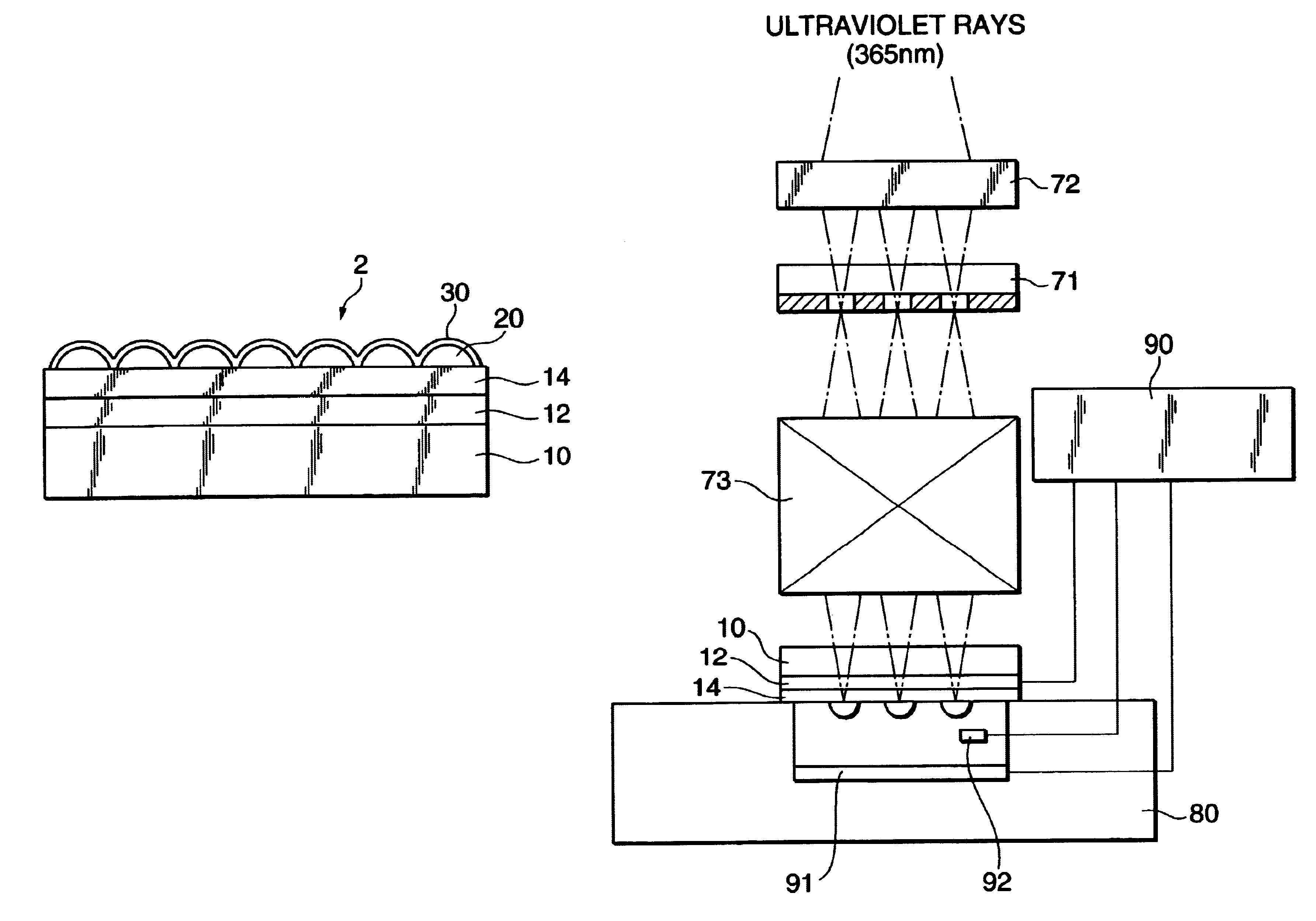

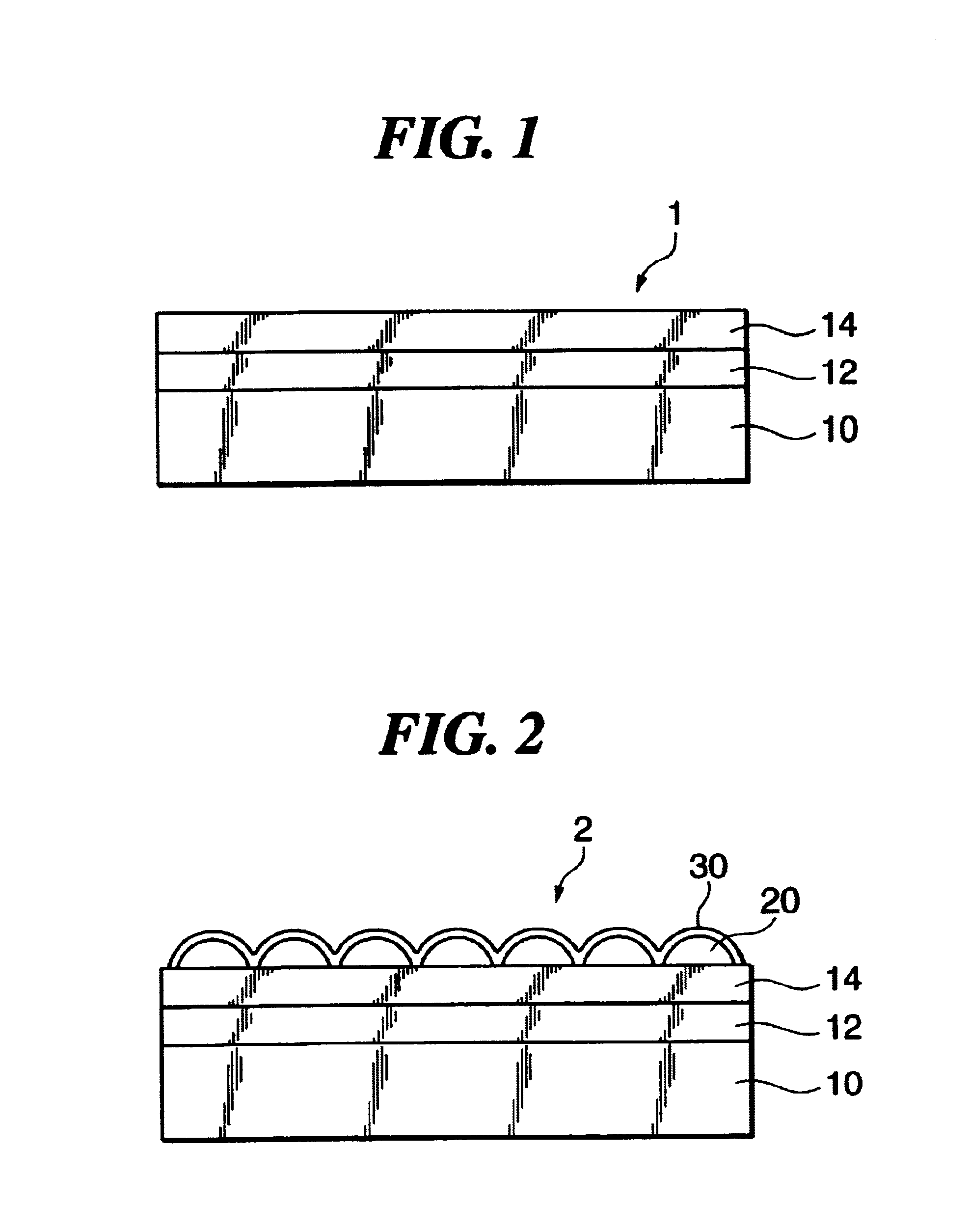

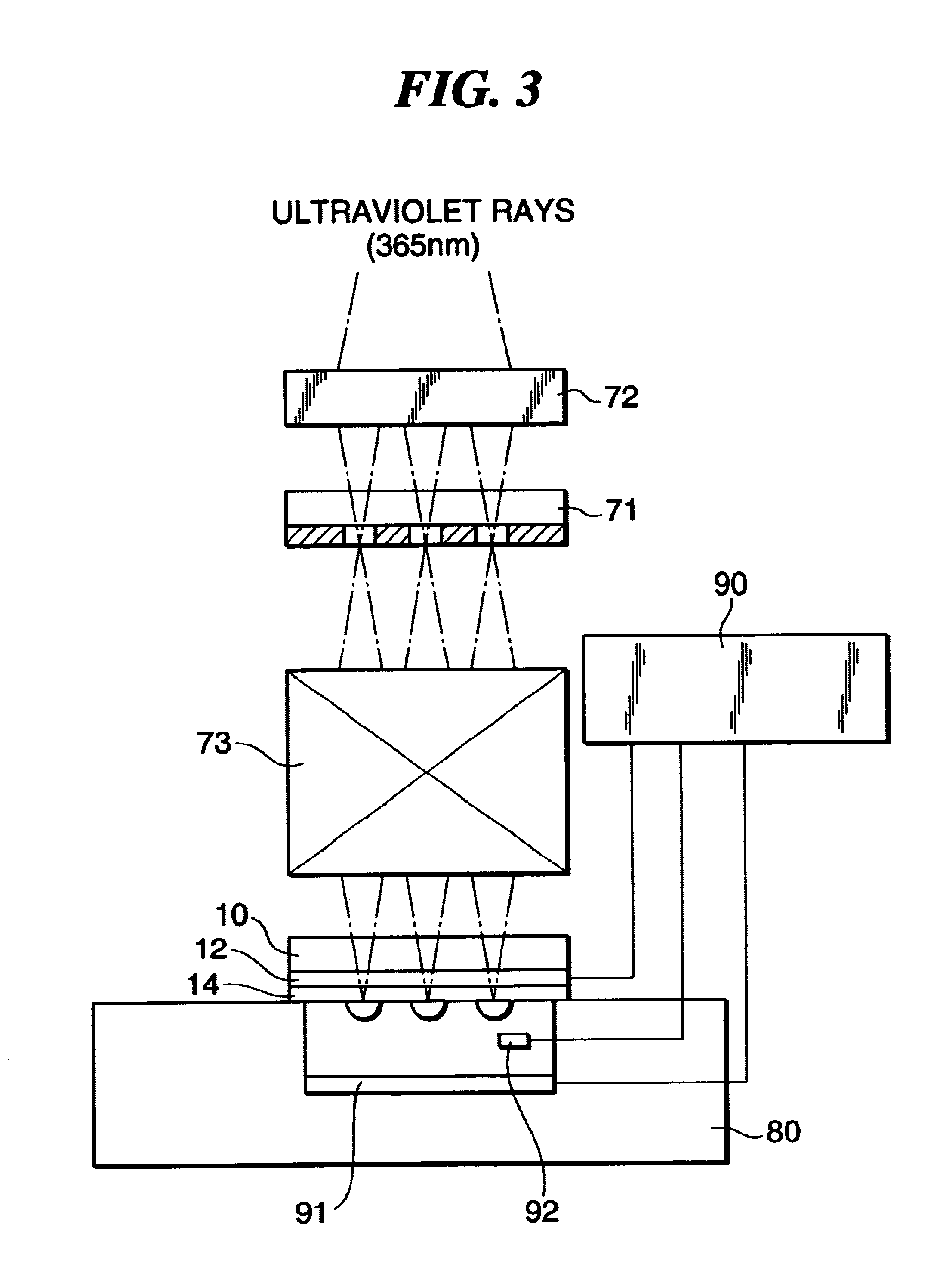

Method of manufacturing micro-lens array, electrolyte and manufacturing apparatus used therefor

A method includes the steps of disposing a substrate having a conductive thin film and a photo-semiconductor thin film in this order on an insulative base in an aqueous electrolyte material that solubility is lowered by a change of pH, irradiating with light a selected region of the photo-semiconductor thin film and precipitating the material to the selected region of the photo-semiconductor thin film to form a micro-lens array layer.

Owner:FUJIFILM BUSINESS INNOVATION CORP

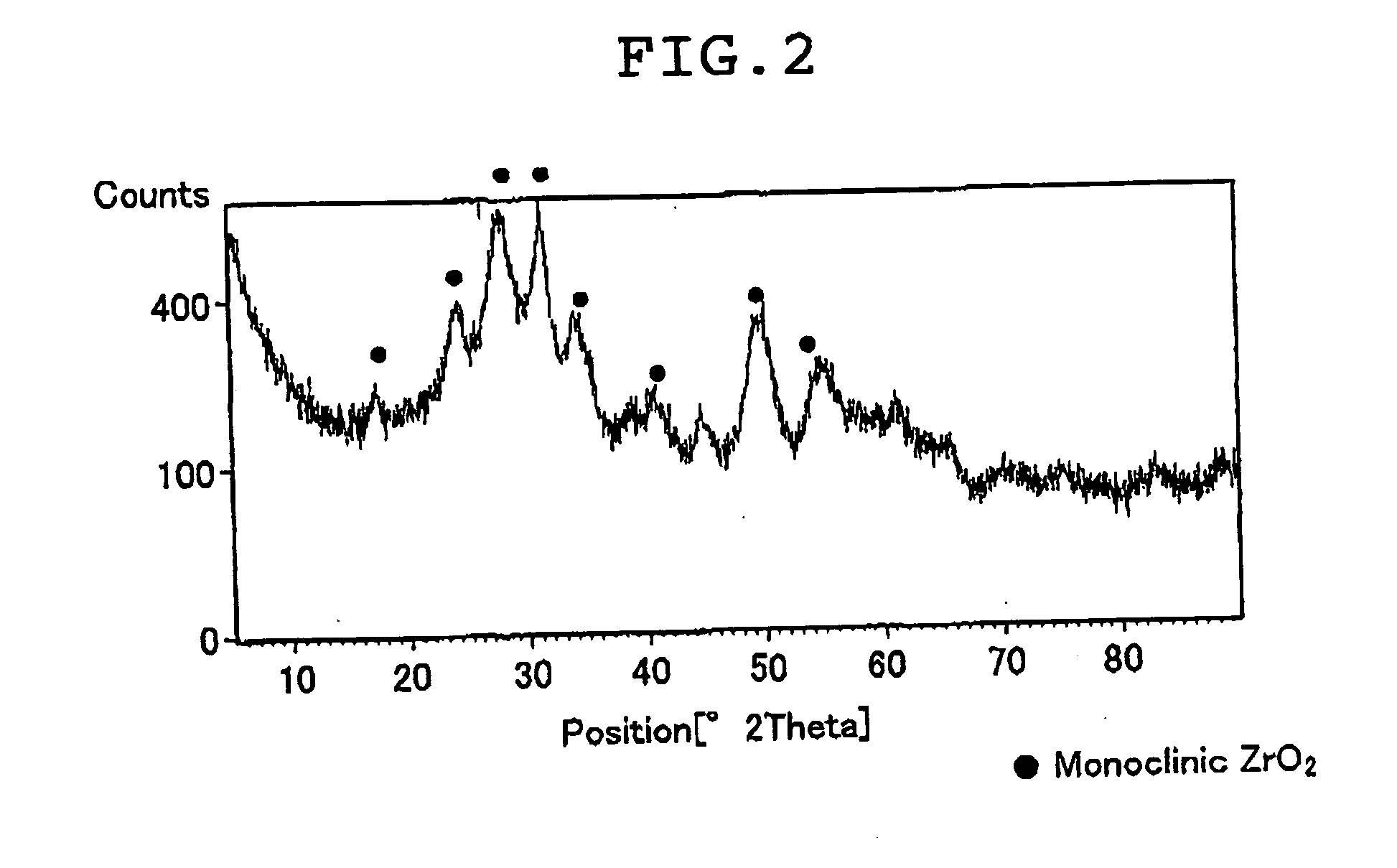

Method for coating a metal with a ceramic coating, electrolyte used therefor, ceramic coating, and metal material

InactiveUS20100025253A1Excellent abrasion resistanceReduce attackAnodisationElectrolytic inorganic material coatingElectrolysisCeramic coating

This invention provides a method for coating a ceramic film on a metal, which can form dense films on various bases of metals such as magnesium alloys. The formed ceramic film has excellent abrasion resistance, causes no significant attack against a counter material, and has excellent corrosion resistance. The method comprises electrolyzing a metallic base in an electrolysis solution using the metallic base as a working electrode while causing glow discharge and / or arc discharge on the surface of the metallic base to form a ceramic film on the surface of the metallic base. The electrolysis solution contains zirconium oxide particles having an average diameter of not more than 1 μm, satisfies the following formulae (1) to (3): 0.05 g / L≦X≦500 g / L (1), 0 g / L≦Y≦500 g / L (2), and 0≦Y / X≦10 (3); and has a pH value of not less than pH 7.0. In the formulae (1) to (3), X represents the content of zirconium oxide particles in the electrolysis solution; and Y represents the content of a compound of at least one element selected from the group consisting of Mg and the like, other than zirconium oxide.

Owner:NIHON PARKERIZING

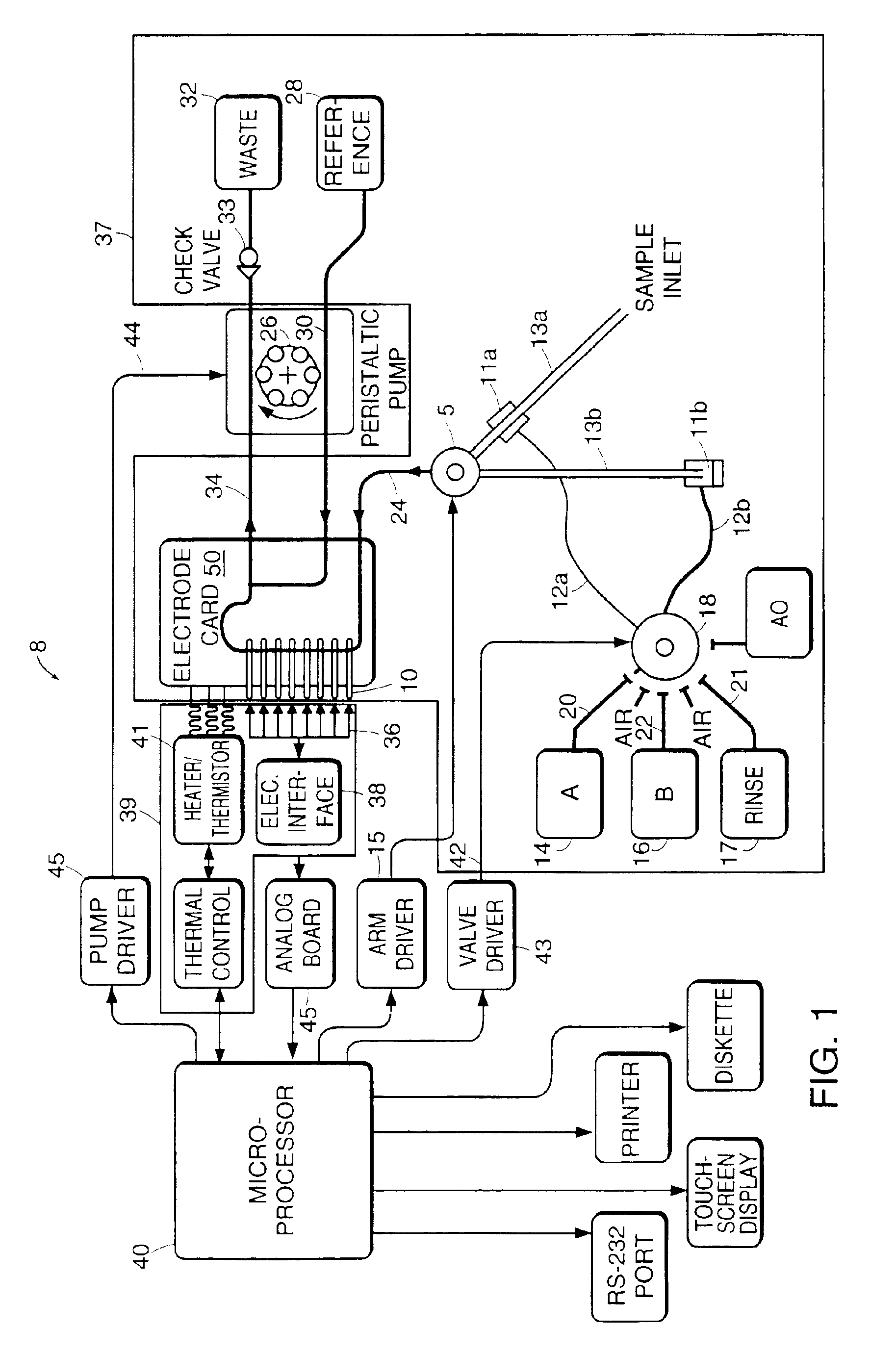

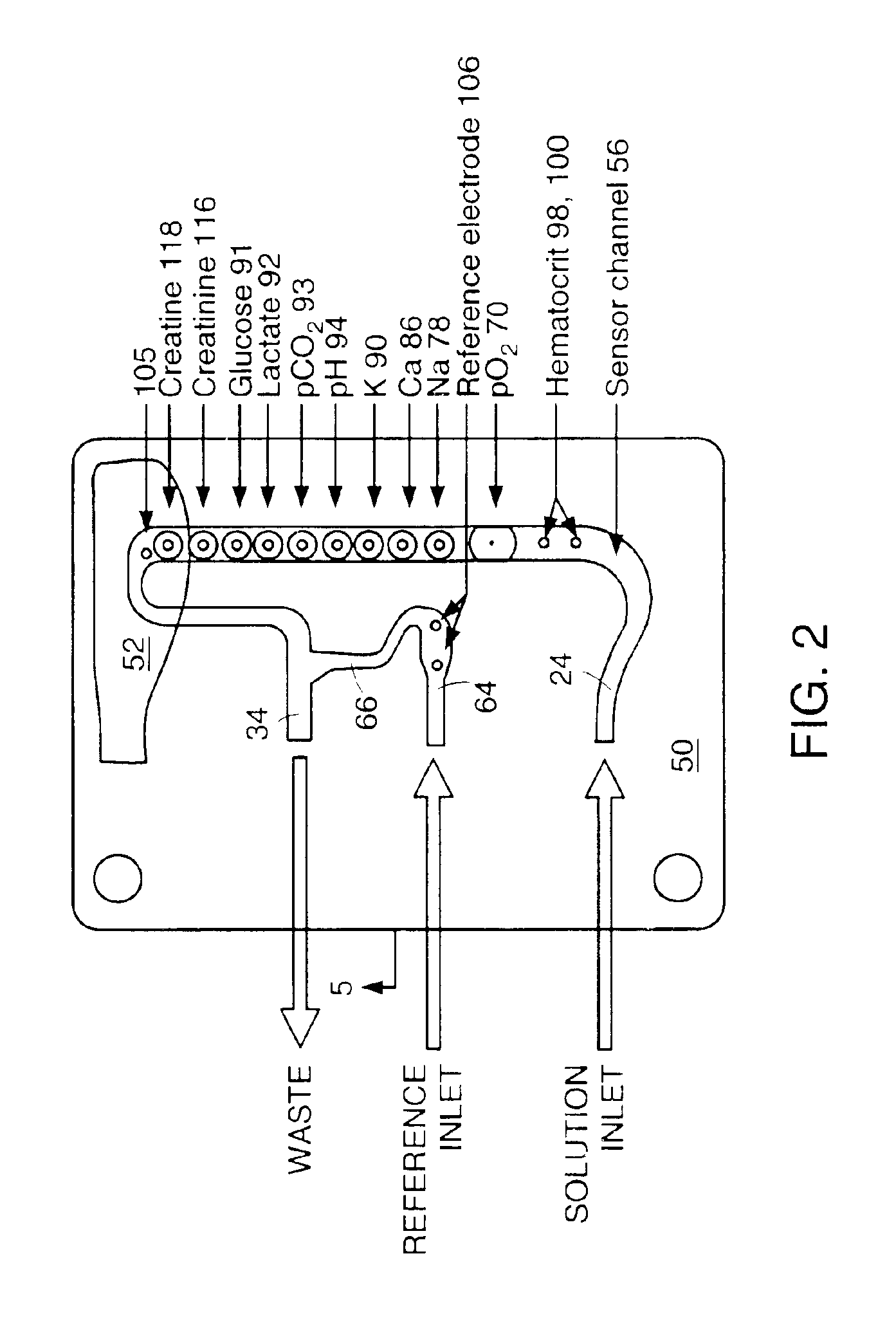

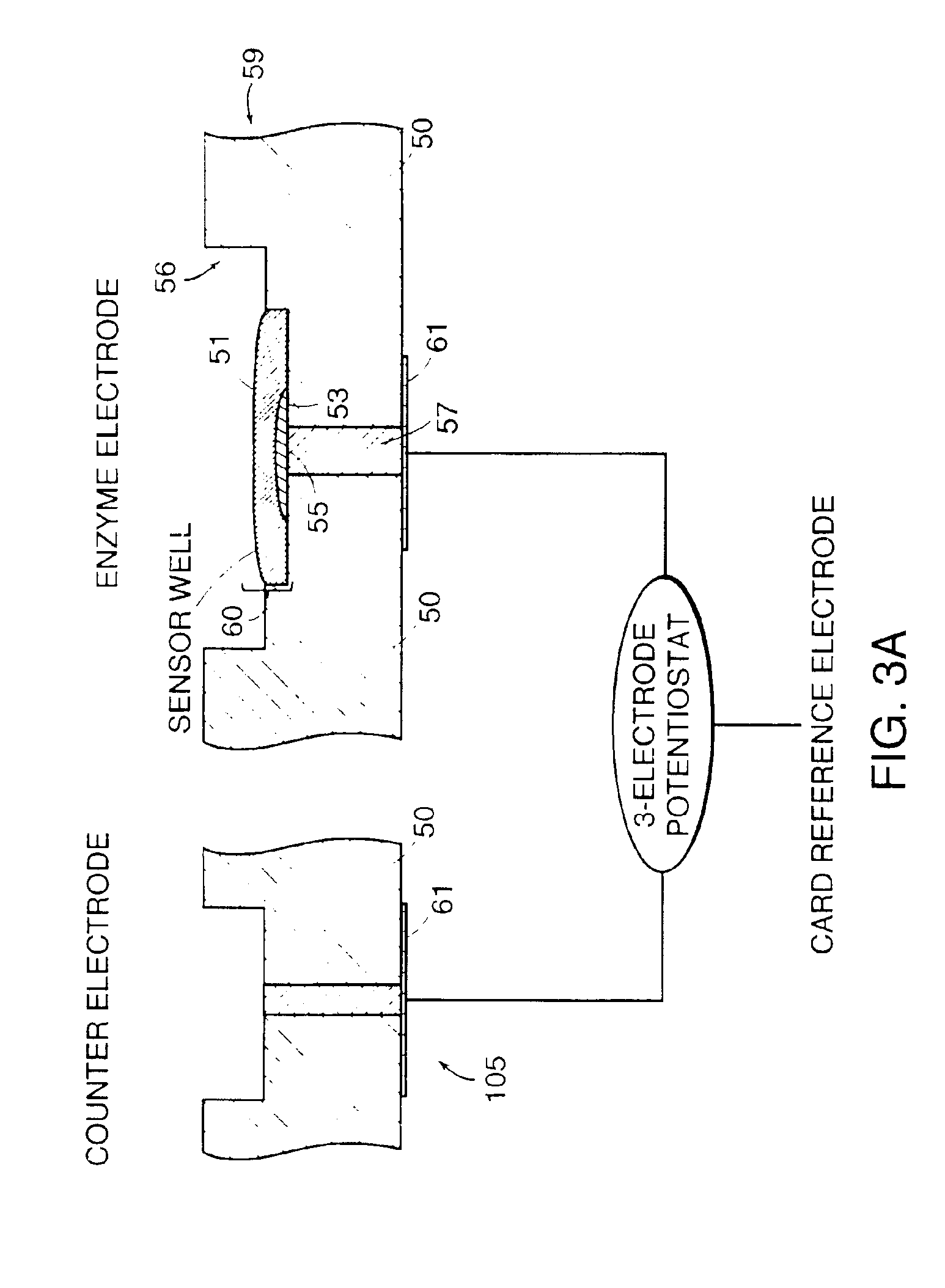

Composite membrane containing a cross-linked enzyme matrix for a biosensor

InactiveUS6960466B2Improve accuracyIncreasing lifetimeBioreactor/fermenter combinationsBiological substance pretreatmentsCross-linkElectrochemistry

An electrochemical sensor system and membrane and method thereof for increased accuracy and effective life of electrochemical and enzyme sensors.

Owner:INSTR LAB

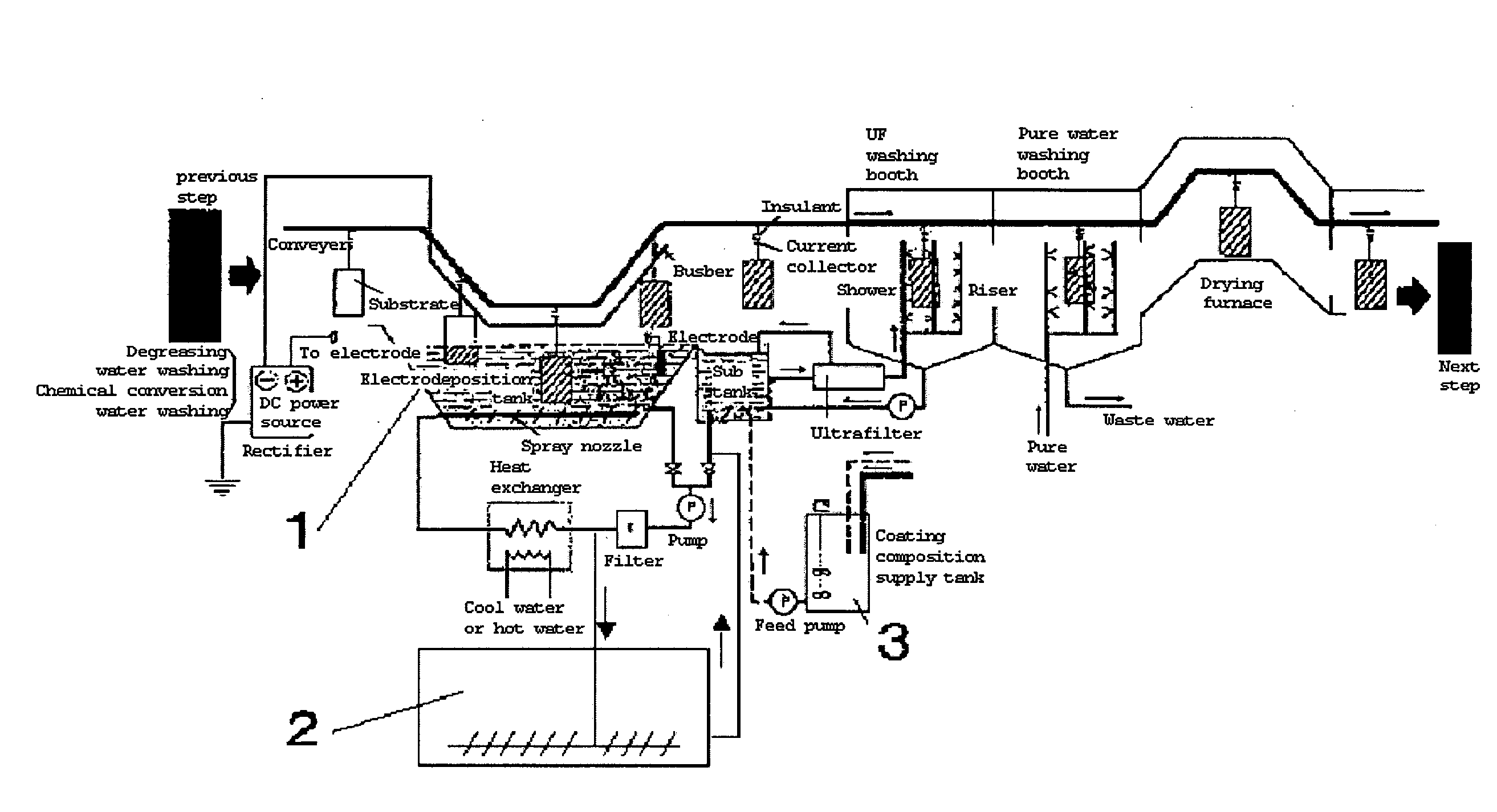

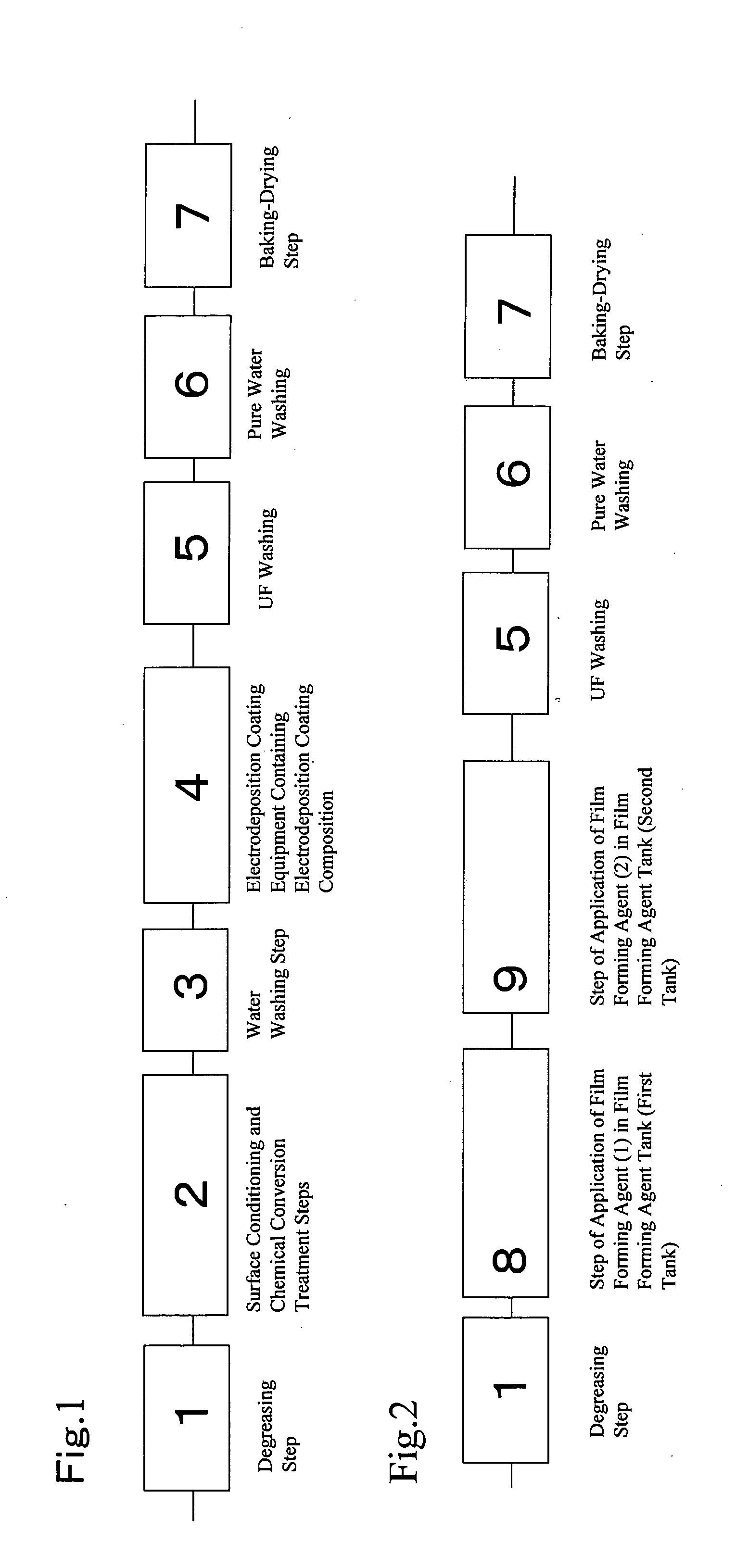

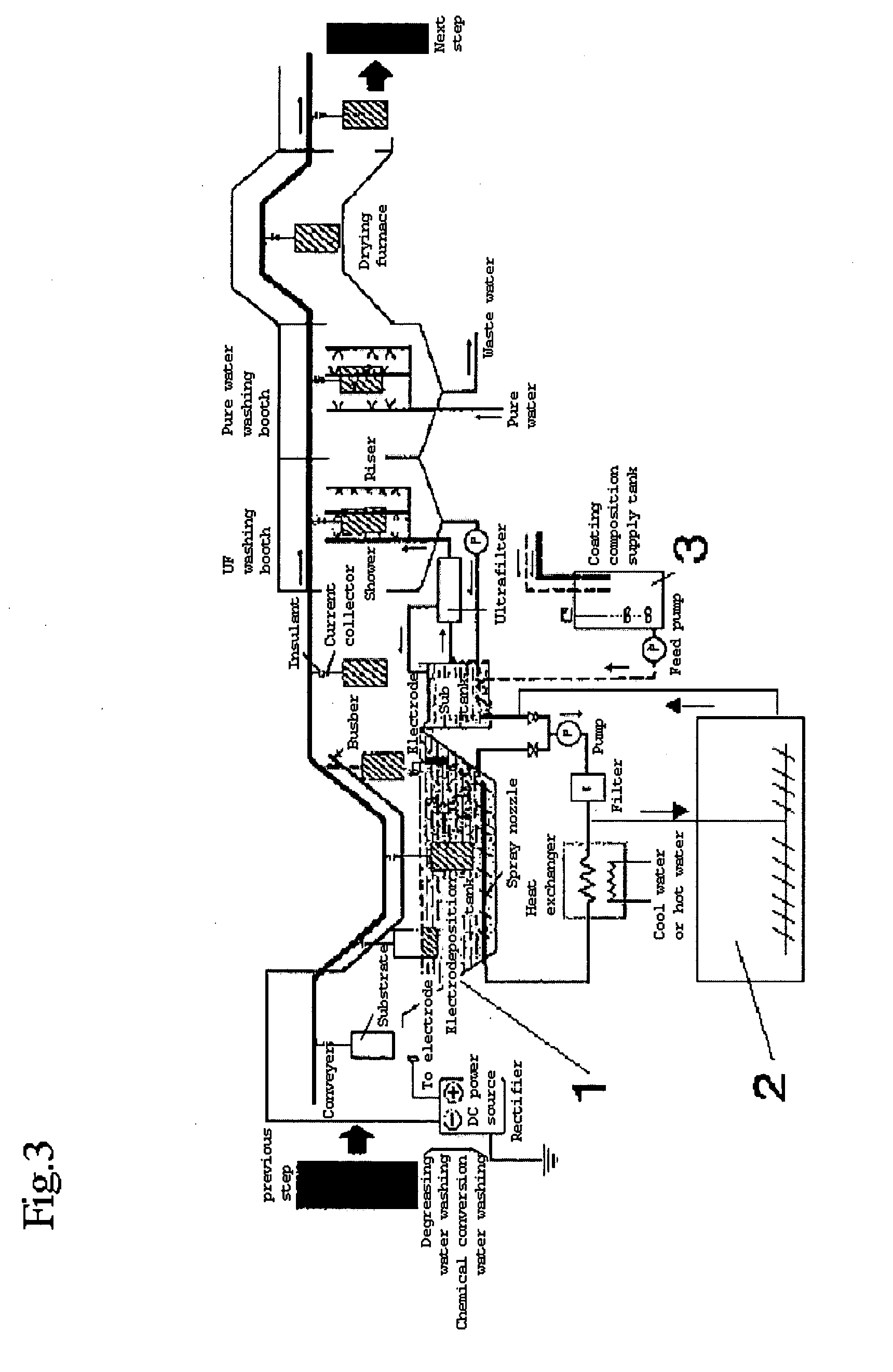

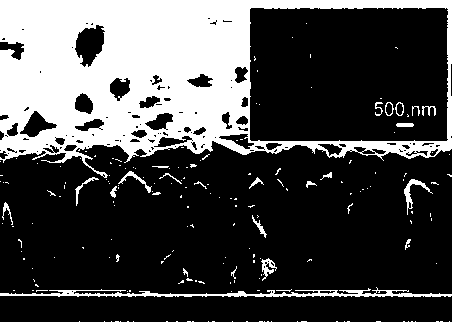

Method for forming multilayer coating film and coated article

ActiveUS20090101512A1Raise the gradeCorrosion resistanceSurface reaction electrolytic coatingElectrophoretic coatingsPhysical chemistryFilm-forming agent

An object of the present invention is to provide a coated article having excellent finish and corrosion resistance unaffected by a chemical conversion coating solution even if water washing after a pretreatment step is omitted and a pretreatment solution is carried as a contaminant into an electrodeposition coating composition.The present invention provides a method for forming a multilayer coating film comprising a chemical conversion coating film (F1) and an electrodeposition coating film (F2); the method comprising the following steps.Step 1: immersing a metal substrate in a coating film forming agent (1) as a chemical conversion coating solution to form a chemical conversion coating film (F1); andStep 2: without water washing, subjecting the metal substrate to electrodeposition coating using a coating film forming agent (2) as a cationic electrodeposition coating composition (I) to form an electrodeposition coating film (F2).

Owner:KANSAI PAINT CO LTD

Implant and Method for Manufacturing Same

The present invention relates to a method for manufacturing an implant, in particular an intraluminal endoprosthesis, with a body containing metallic material, preferably iron. To control the degradation of the implant, the method comprises the following steps: a) preparing the body of the implant, and b) incorporating hydrogen into at least a portion of the structure of the implant body near the surface. Furthermore, such an implant is described.

Owner:BIOTRONIK AG

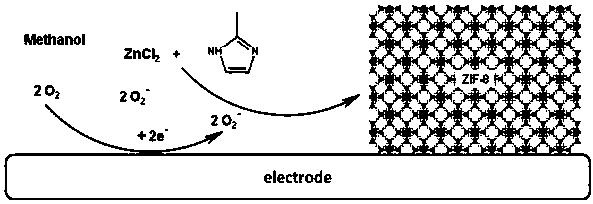

Method of depositing metal organic framework material by oxygen auxiliary cathode

InactiveCN108130574AAvoid depositionHigh selectivityElectrolytic organic material coatingSupporting electrolyteOrganic solvent

The invention provides a method of depositing a metal organic framework material by an oxygen auxiliary cathode. The method comprises the following steps: (1) preparing a reaction precursor solution which is composed of a 5-50mM metal source, a 10-250mM organic ligand and an organic solvent; and (2) carrying out electrochemical deposition on the surface of a conducting substrate of the cathode toobtain the material. The method provided by the invention does not corrode the deposited electrode, the selecting range of the conducting substrate is wide, the prepared MOF material is regulatable inshape, dimension and thickness in nanoscale, pure, free of adding a supporting electrolyte and low in cost, and can be synthesized in one step. The metal organic framework is simple in method and operation, and industrial production is conveniently achieved.

Owner:SUZHOU UNIV

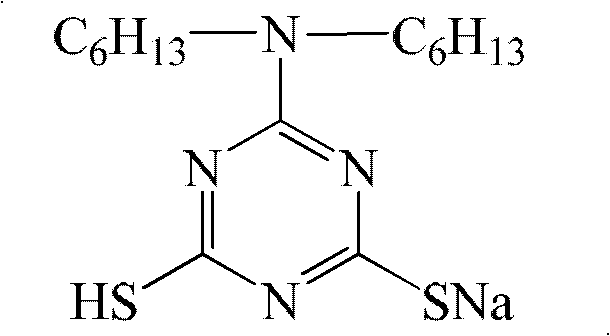

Method for preparing composite nano film on metal surface

InactiveCN101914797AReduce defectsImprove hydrophobicityElectrolytic organic material coatingElectrolysisMetallic materials

The invention discloses a method for preparing a composite nano film on a metal surface and realizes the preparation of the composite nano film by combining electrolysis polymerization with nano self-assembly technology. The method comprises the following steps of: electrolyzing and polymerizing a macromolecular initial-layer nano film bonded with the metal surface through a covalent bond on a cleaned metal surface by an electrolysis polymerization method; and then immersing the macromolecular initial-layer nano film into self-assembly solution and assembling and forming a polymeric macromolecular nano film bonded with an initial-layer macromolecular nano film through a covalent bond by nano self-assembling technology. Due the adoption of the method, the conversion of the metal surface from hydrophilcity to hydrophobicity is realized, the less defects, strong hydrophobicity, corrosion resistance and strong adhesiveness of a modified metal surface are achieved and effective long-term protection for metal materials is realized.

Owner:NORTHWEST A & F UNIV

Implantable electrode comprising a conductive polymeric coating

ActiveUS20140277318A1Internal electrodesSurface reaction electrolytic coatingImplantable ElectrodesConductive polymer

The present invention generally relates to coated electrodes comprising an electrically conductive substrate and a polymeric coating, and to methods for the preparation of the same.

Owner:HERAEUS MEDICAL COMPONENTS LLC

Preparation method of ion imprinted polymer film

ActiveCN103214689AEasy to operateMild preparation conditionsSemi-permeable membranesDispersed particle separationIn situ polymerizationRare earth ions

Belonging to the fields of electroactive functional polymer film material preparation and selective separation of ions, the invention relates to a preparation method of an ion imprinted polymer film. The invention is characterized by relating to a preparation method of an ion imprinted polymer film with an electronic control cation exchange function. The method includes: preparing a water solution of the monomer for polymer preparation, an electrolyte solution, a protonic acid solution, an imprinted ion solution and a doping ion solution, then mixing the five solutions, conducting in situ polymerization on a conductive substrate by a monopolar pulse electrodeposition method so as to synthesize imprinted ion removed ferricyanic group doped polymer film by one step. Being simple and fast to operate, the method provided in the invention needs no additional pickling step and can realize imprinted ion removal in situ. Also, the preparation conditions are mild and are easy to control. The ion imprinted polymer film prepared by the method has an electronic control cation exchange function, and can be used for selective removal of heavy metal ions in water or separation recycling of rare earth ions.

Owner:TAIYUAN UNIV OF TECH

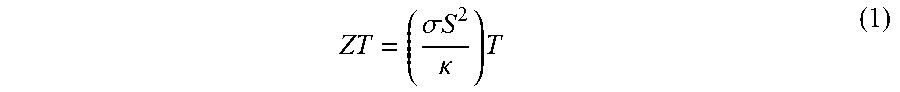

Thermoelectric Materials and Devices Comprising Graphene

ActiveUS20150380625A1Linear power generation responseWide temperature rangeElectric shock equipmentsThermoelectric device manufacture/treatmentThermoelectric materialsCvd graphene

Composite materials with thermoelectric properties and devices made from such materials are described. The thermoelectric composite material may comprise a metal oxide material and graphene or modified graphene. It has been found that the addition of graphene or modified graphene to thermoelectric metal oxide materials increases ZT. It has further been found that the ZT of the metal oxide becomes effective over a broader temperature range and at lower temperatures.

Owner:UNIV OF MANCHESTER

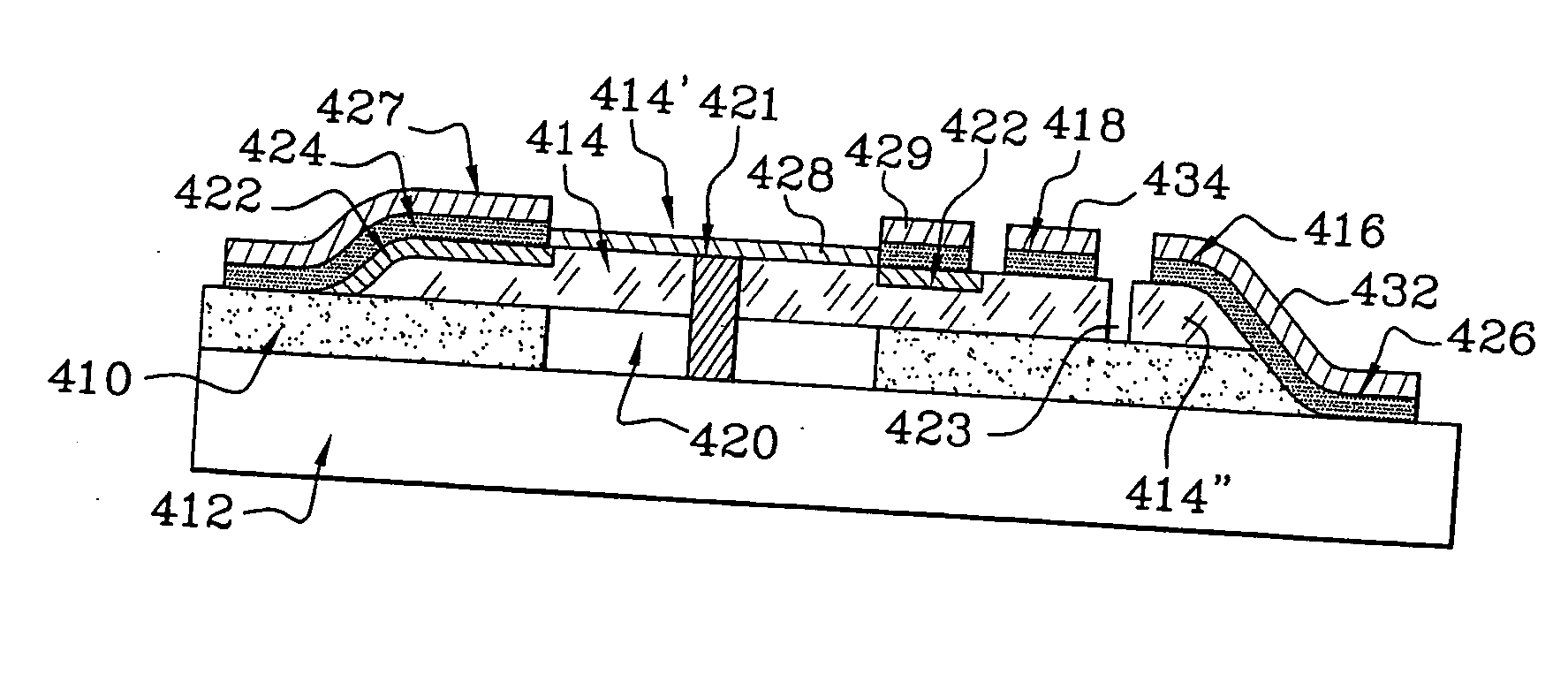

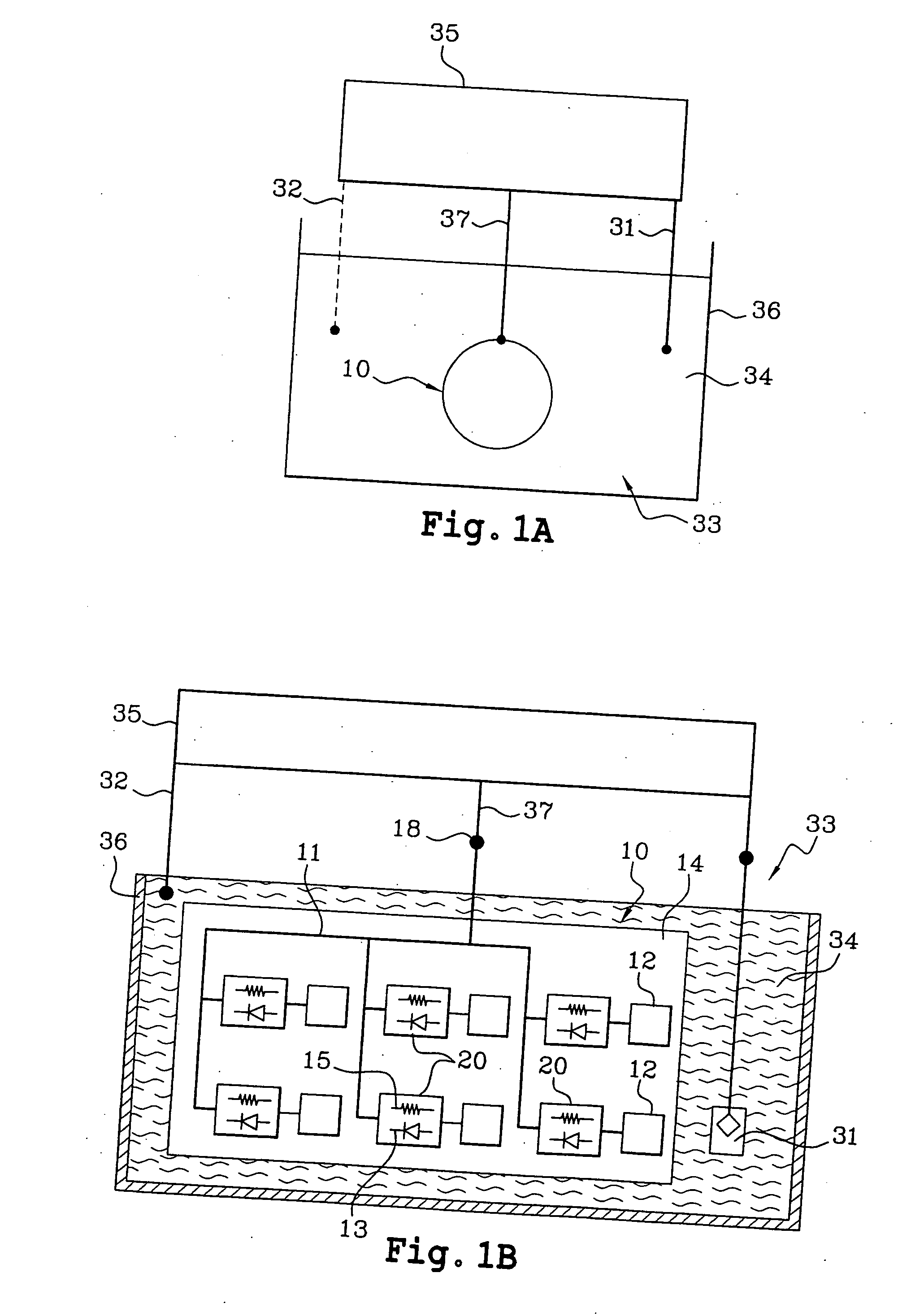

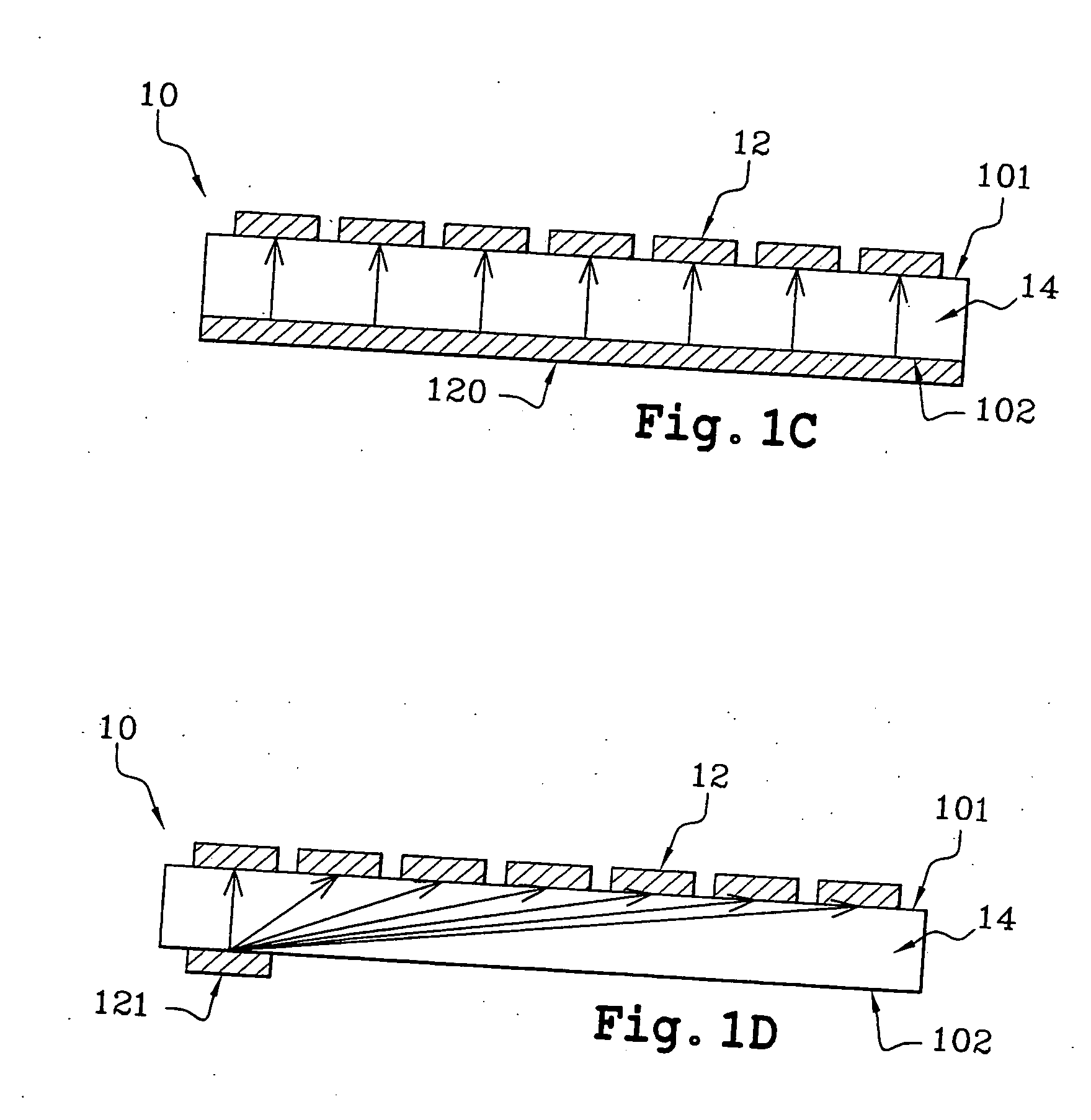

Coating support and method for the selective coating of conductive tracks on one such support

InactiveUS20060103018A1High voltageHigher lining thresholdSemiconductor/solid-state device detailsSolid-state devicesEngineeringVoltage

The present invention concerns a lining support comprising a plurality of conductive pads ( 12 ) associated with a shared addressing contact ( 18 ) and means of selecting at least one pad to be lined by electrochemical means among the plurality of pads. In accordance with the invention, the selection means comprise means ( 20 ) of shifting a polarisation voltage, connected between the shared addressing contact and at least one pad to be addressed. Application to the lining of conductive pads.

Owner:ALCHIMER SA

Wet Capacitor Cathode Containing an Alkyl-Substituted Poly(3,4-Ethylenedioxythiophene)

ActiveUS20130242467A1Liquid electrolytic capacitorsSurface reaction electrolytic coatingDielectricCapacitance

A wet electrolytic capacitor that contains an anodically oxidized porous anode body, a cathode containing a metal substrate coated with a conductive coating, and a working electrolyte that wets the dielectric on the anode. The conductive coating contains an alkyl-substituted poly(3,4-ethylenedioxythiophene) having a certain structure. Such polymers can result in a higher degree of capacitance than many conventional types of coating materials. Further, because the polymers are generally semi-crystalline or amorphous, they can dissipate and / or absorb the heat associated with the high voltage. The degree of surface contact between the conductive coating and the surface of the metal substrate may also be enhanced in the present invention by selectively controlling the manner in which the conductive coating is formed.

Owner:KYOCERA AVX COMPONENTS CORP

Preparation method of nanotube array positive electrode material of lithium sulphur battery

ActiveCN103840145AImprove conductivityIncrease loadElectrolytic inorganic material coatingCell electrodesLithium–sulfur batterySulfur

The invention relates to a preparation method of a nanotube array positive electrode material of a lithium sulphur battery, which belongs to a preparation method of positive electrode materials of lithium sulphur batteries and solves the problems, such as poor electrical conductivity and low specific capacity, of an existing positive electrode material of a lithium sulphur battery. The preparation method comprises the following steps: (1) preparing a titanium dioxide nanotube array, (2) depositing a conductive reinforcing material, and (3) depositing elemental sulphur, wherein the steps (2) and (3) can be repeated to form a multiple depositional cycle period, so that a positive electrode material with a multilayer coaxial heterostructure is obtained, and has different sulphur loading capacities. According to the preparation method, the titanium dioxide nanotube array is taken as a substrate material, and the conductive reinforcing material and the elemental sulphur are compounded and deposited and enter titanium dioxide nanotubes to form the positive electrode material with the coaxial heterostructure, so that the conductivity of the positive electrode material is improved, the sulphur loading capacity of the positive electrode material is improved, the cycling performance and specific capacity of a lithium sulphur battery are further improved, and the preparation method has certain impelling action for speeding up the further large scale application process of the sulphated lithium battery.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing micro-lens array, electrolyte and manufacturing apparatus used therefor

A method includes the steps of disposing a substrate having a conductive thin film and a photo-semiconductor thin film in this order on an insulative base in an aqueous electrolyte material that solubility is lowered by a change of pH, irradiating with light a selected region of the photo-semiconductor thin film and precipitating the material to the selected region of the photo-semiconductor thin film to form a micro-lens array layer.

Owner:FUJIFILM BUSINESS INNOVATION CORP

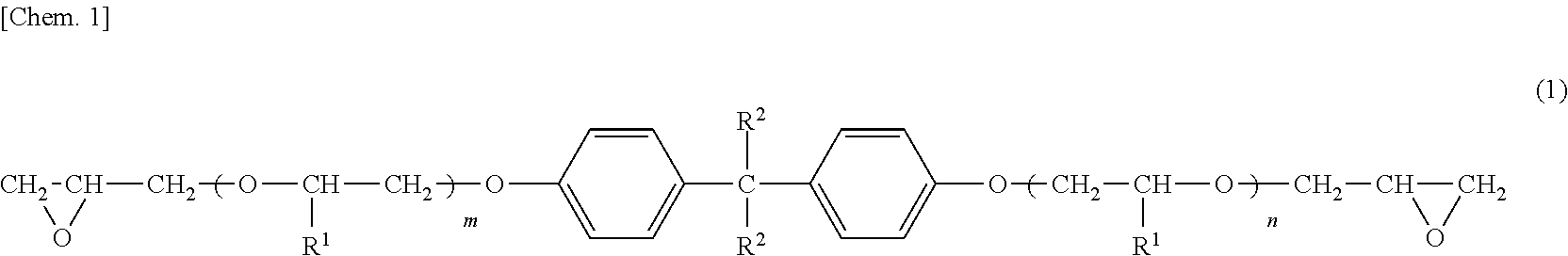

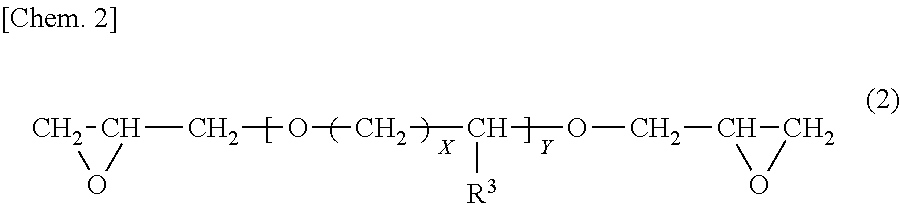

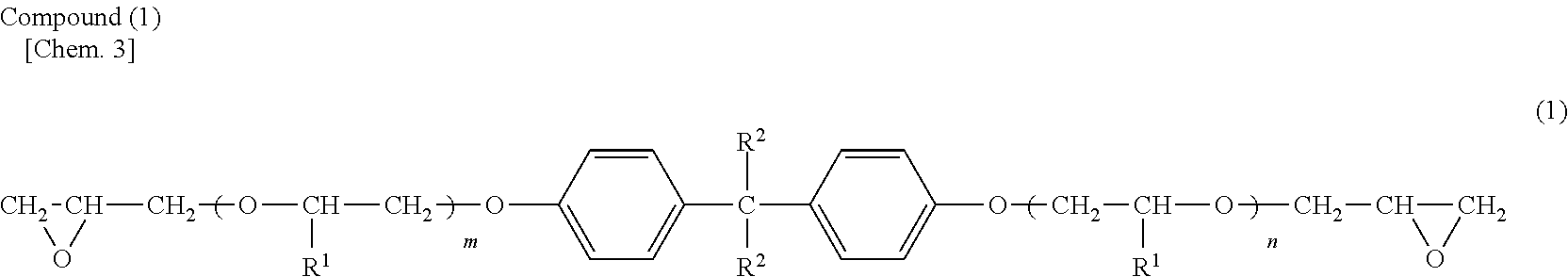

Cationic electrodeposition coating composition

ActiveUS20110062026A1Improve corrosion resistanceImprove the immunityDuplicating/marking methodsSurface reaction electrolytic coatingEpoxyNitrogen oxides

Object: To provide a coated article in which an electrodeposition coating film formed on an untreated steel sheet exhibits excellent corrosion resistance, in particular, excellent hot salt water immersion resistance at 55° C.; and a multilayer coating film formed by a 3-coat 1-bake coating method on the electrodeposition coating film, which is formed on the untreated steel sheet, exhibits excellent corrosion resistance in a combined corrosion cycle test.Means for Achieving the Object: The present invention provides a cationic electrodeposition coating composition including amino group-containing modified epoxy resin (A), blocked polyisocyanate curing agent (B), metal compound (C), and nitrogen oxide ion (E), wherein metal compound (C) is contained in an amount of 10 to 10,000 ppm calculated as metal, and nitrogen oxide ion (E) is contained in an amount of 50 to 10,000 ppm relative to the mass of the cationic electrodeposition coating composition.

Owner:KANSAI PAINT CO LTD

Acrylic aqueous dispersions for container coatings

Acrylic aqueous dispersions useful in coating compositions for coating food and beverage containers are disclosed. The aqueous dispersion is the reaction product of:(a) a hydrophobic vinyl addition polymer containing pendant or terminal ethylenically unsaturated groups,(b) a mixture of vinyl monomers including a vinyl monomer containing carboxylic acid groups;the reaction product containing active hydrogen groups and being at least partially neutralized with a base and dispersed in aqueous medium; the aqueous dispersion being substantially free of bisphenol A and derivatives thereof.

Owner:PPG IND OHIO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com