High-voltage lithium cobalt oxide cathode material for lithium-ion battery and preparation method of high-voltage lithium cobalt oxide cathode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery capacity and rate performance decline, large differences in crystal structure, poor crystal matching, etc., to achieve enhanced work Stability, reducing oxygen evolution, and avoiding the effect of rate performance decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

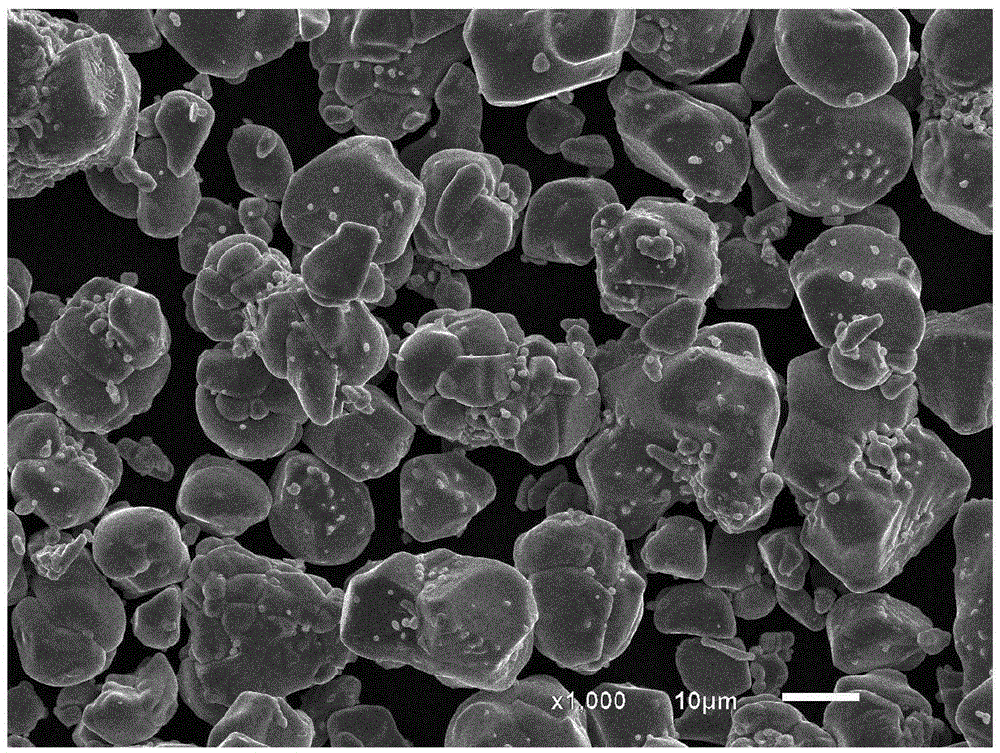

Image

Examples

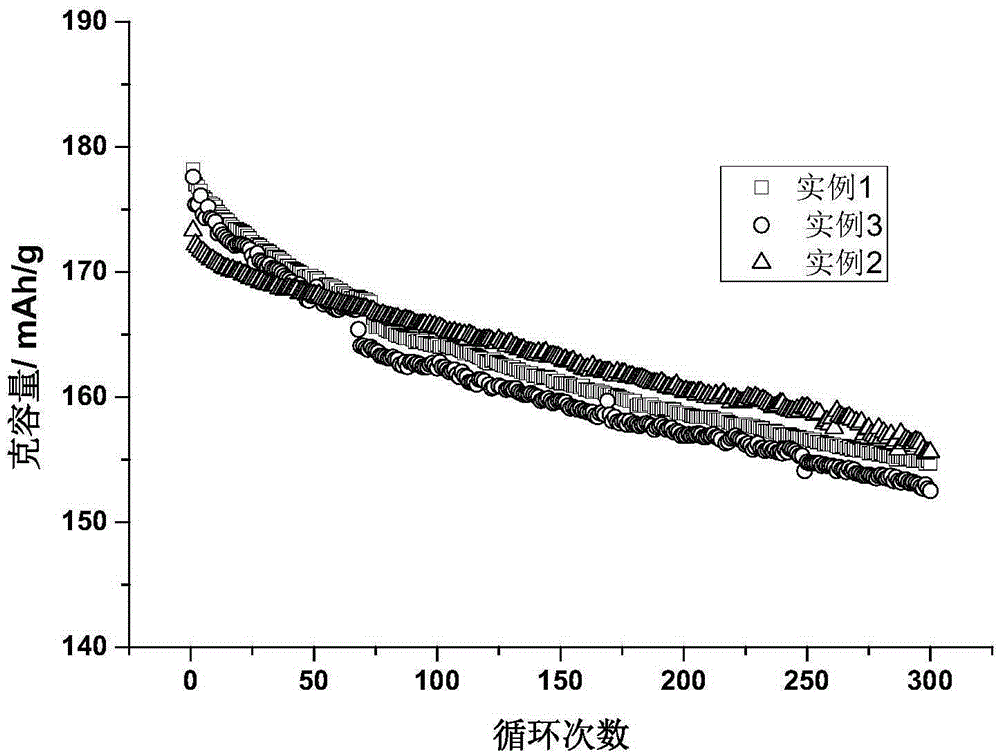

Embodiment 1

[0030] The high-voltage lithium cobaltate positive electrode material of the lithium ion battery of this embodiment is composed of a doped lithium cobaltate matrix and a coating on its surface, and the molecular formula of the doped lithium cobaltate matrix is Li 0.90 co 0.99 La 0.01 o 1.99 f 0.01 , the molecular formula of the coating is LiNi 0.85 co 0.10 Al 0.05 o 2 , the total weight of Ni, Co and Al in the coating is 0.1wt% of the weight of the doped lithium cobalt oxide matrix.

[0031] The preparation method of the lithium ion battery high-voltage lithium cobaltate positive electrode material of the present embodiment comprises the following steps:

[0032] (1) According to Li 0.90 co 0.99 La 0.01 o 1.99 f 0.01 The stoichiometric ratio, the tricobalt tetroxide, lithium carbonate, La (OH) 3 , LiF mixed evenly, and then sintered once at 700°C for 30 hours to obtain a doped lithium cobalt oxide matrix material;

[0033] (2) According to the Ni:Co:Al molar ra...

Embodiment 2

[0037] The lithium ion battery high-voltage lithium cobalt oxide cathode material of this embodiment is composed of a doped lithium cobalt oxide matrix and a coating on its surface. The molecular formula of the doped lithium cobalt oxide matrix is LiCo 0.90 SM 0.10 o 0.90 Cl 0.10 , the molecular formula of the coating is LiNi 0.70 co 0.15 Al 0.15 o 2 , the total weight of Ni, Co and Al in the coating is 0.3wt% of the weight of the doped lithium cobalt oxide matrix.

[0038] The preparation method of the lithium ion battery high-voltage lithium cobaltate positive electrode material of the present embodiment comprises the following steps:

[0039] (1) According to LiCo 0.90 SM 0.10 o 0.90 Cl 0.10 The stoichiometric ratio of cobalt carbonate, lithium hydroxide, Sm 2 o 3 , NH 4 Cl is mixed evenly, and then sintered once at 900°C for 16 hours to obtain a doped lithium cobalt oxide matrix material;

[0040] (2) According to the Ni:Co:Al molar ratio of 70:15:15, alumi...

Embodiment 3

[0044] The high-voltage lithium cobaltate positive electrode material of the lithium ion battery of this embodiment is composed of a doped lithium cobaltate matrix and a coating on its surface, and the molecular formula of the doped lithium cobaltate matrix is Li 1.10 co 0.95 Yb 0.05 o 0.95 f 0.05 , the molecular formula of the coating is LiNi 0.60 co 0.20 Al 0.20 o 2 , the total weight of Ni, Co and Al in the coating is 1.0wt% of the weight of the doped lithium cobalt oxide matrix.

[0045] The preparation method of the lithium ion battery high-voltage lithium cobaltate positive electrode material of the present embodiment comprises the following steps:

[0046] (1) According to Li 1.10 co 0.95 Yb 0.05 o 0.95 f 0.05 The stoichiometric ratio, the tricobalt tetroxide, lithium carbonate, Yb 2 (CO 3 ) 3 , LiF mixed evenly, and then sintered once at 1500 ° C for 4 hours to obtain a doped lithium cobalt oxide matrix material;

[0047] (2) According to the Ni:Co:Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com