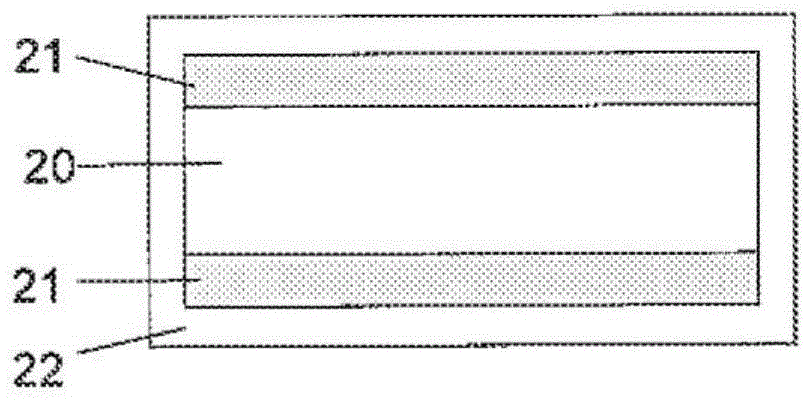

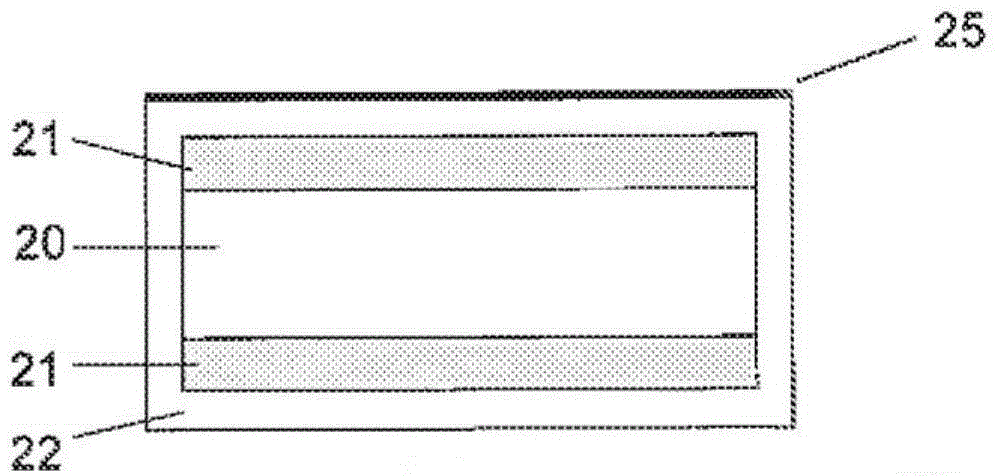

Method for manufacturing all-solid-state batteries in a multilayer structure

An all-solid-state battery, all-solid-state technology, applied to lithium-ion batteries, the manufacture of such batteries, and the field of all-solid-state lithium-ion batteries, which can solve the problems that cannot be assembled to make monolithic components, all-solid-state multi-layer battery units, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0236] a) Preparation of the substrate

[0237] Aluminium strips with a thickness of 15 μm are available. The tape was placed in an uncoiler and on a holding frame to create a rigid structure for holding without buckling the aluminum tape. The retaining frame has an outer insulating surface; however, its inner conducting surface is in electrical contact with the aluminum strip, to which an electrical potential can be applied.

[0238] b) Make Li 4 Ti 5 O 12 Colloidal suspension of nanoparticles / depositing anode layer / on anode layer Electrolyte layer deposited on top

[0239] For the fabrication of anodic electrodes on pre-prepared aluminum substrates, a colloidal suspension of nanoparticles with the following chemical composition: 2 g / l Li was produced in ethanol 4 Ti 5 O 12 , 0.02g / l carbon black powder, 0.3g / l Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3and a few ppm of citric acid. The size of the particles in the colloidal suspension is between 20 and 70 nm. By ...

example 2

[0249] a) Preparation of the substrate

[0250] A copper strip having a thickness of 5 μm, the smooth surface of which had been smoothed by electropolishing in advance, was coated with a 100 nm thin film of chromium (Cr) produced by metallization. The substrate is then placed in an uncoiler on a holding frame to create a rigid structure for holding without crimping the tape. The retaining frame has an outer insulating surface; however, its inner conducting surface is in electrical contact with the chromium-coated copper strip and enables the application of an electrical potential thereon.

[0251] b) Making Li 4 Ti 5 O 12 Nanoparticle colloidal suspension / depositing anode layer / on anode layer Electrolyte layer deposited on top

[0252] To make an anode electrode on a pre-prepared substrate, a colloidal suspension of nanoparticles was made in ethanol with the following chemical composition: 10 g / l Li 4 Ti 5 O 12 Nanopowder and a few ppm (<10 ppm) of citr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com