Preparation method of formicary-shaped porous silicon for lithium ion battery

一种锂离子电池、多孔硅的技术,应用在电池电极、二次电池、化学仪器和方法等方向,能够解决操作难度系数大、反应要求高、污染严重等问题,达到合成方法简单易行、原料廉价、产率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment comprises the following steps:

[0032] (1) Mix commercial silicon particles and magnesium powder in a mass ratio of 1:1.8 and put them into the container evenly;

[0033] (2) Put the container containing the reactant into a high-temperature furnace filled with inert gas and heat it to 400-700°C at a heating rate of 5°C / min. The holding time is 6h to obtain the product magnesium silicide, and the product is cooled to room temperature with the furnace after taking out;

[0034] (3) Put the product obtained in (2) into a ball mill tank protected by argon for ball milling, and then screen to obtain micron particles of magnesium silicide with different sizes, the particle size is 0.2-10 microns.

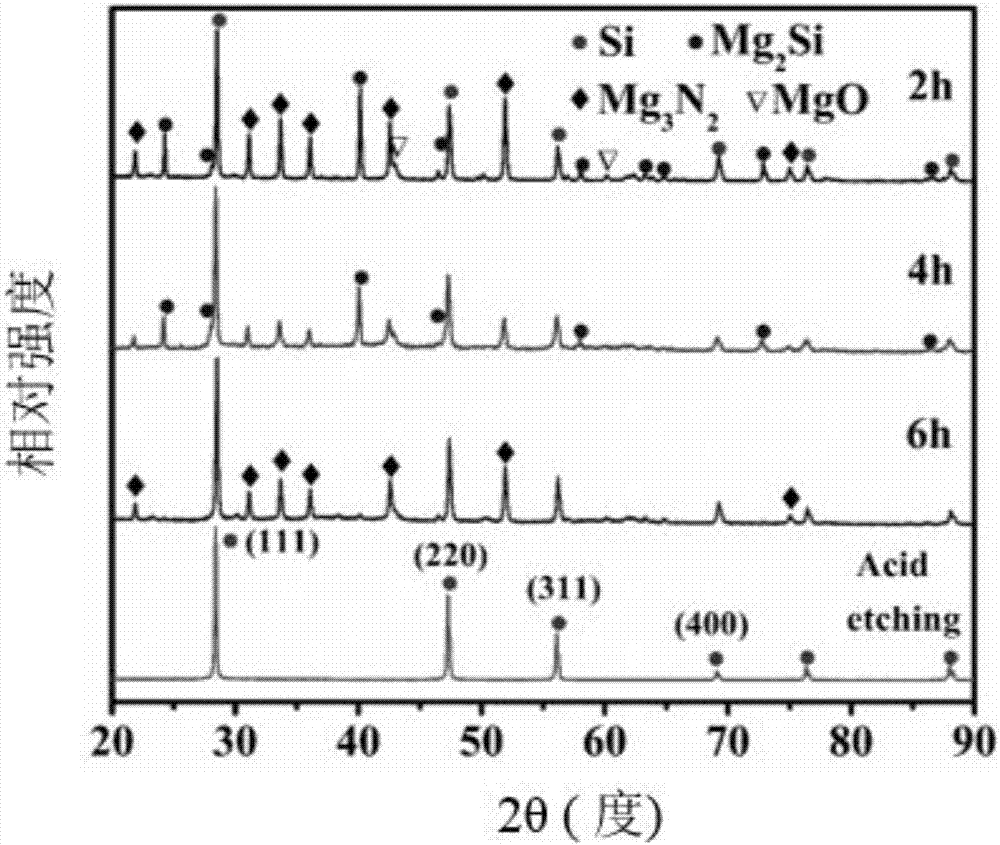

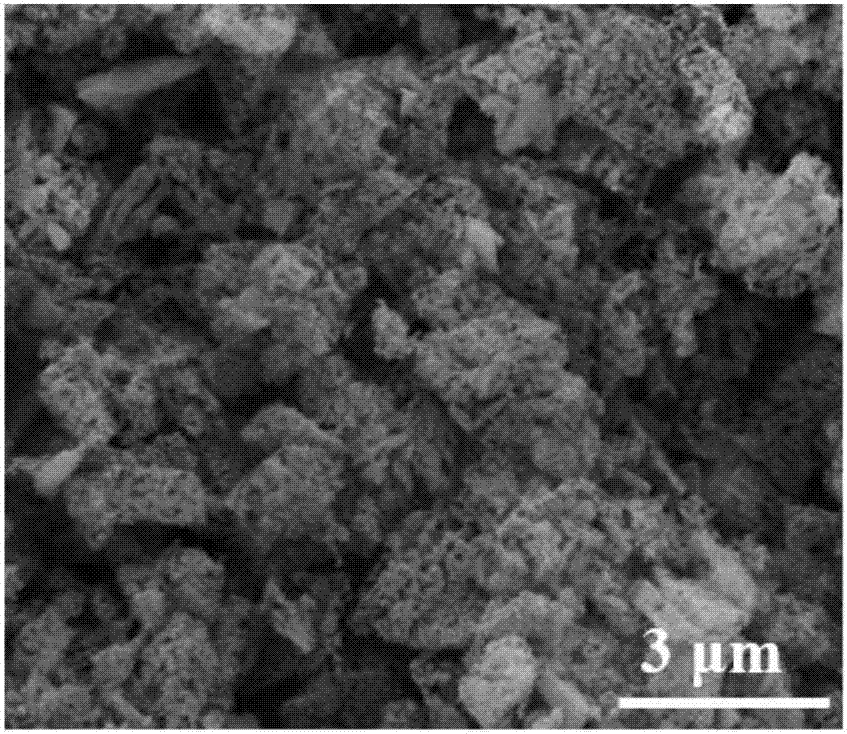

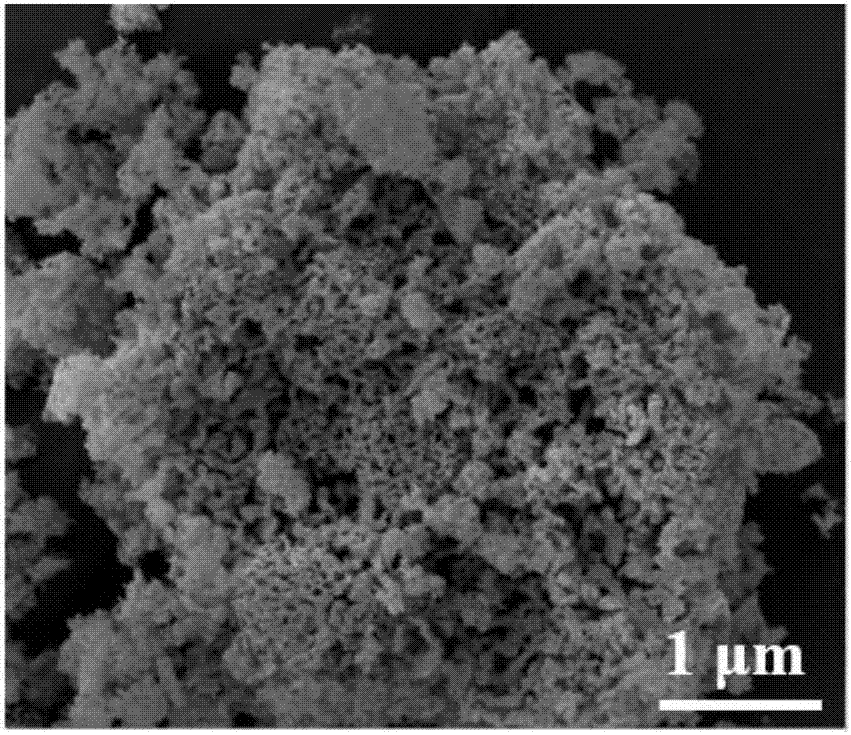

[0035] (4) Put the ball-milled magnesium silicide in (3) in a tubular furnace and heat it to a reaction temperature of 600-900° C. in an ammonia atmosphere, keep it warm for 2-24 hours, and take it out after the product is cooled to room temperature with the furna...

Embodiment 2

[0039] This embodiment comprises the following steps:

[0040] (1) Mix commercial silicon particles and magnesium powder in a mass ratio of 1:1.9 and put them into the container;

[0041] (2) Put the container containing the reactant into a high-temperature furnace filled with inert gas and heat it to 400°C at a heating rate of 3°C / min, and the holding time is 12h to obtain the product magnesium silicide. After the product is cooled to room temperature with the furnace, take it out ;

[0042] (3) Putting the product obtained in (2) into a ball mill jar protected by argon for ball milling, and then screening to obtain magnesium silicide micron particles of different sizes, the particle size being 1-8 microns.

[0043] (4) Put the ball-milled magnesium silicide in (3) in a tubular furnace and heat it to a reaction temperature of 650° C. in an ammonia atmosphere, keep it warm for 4 hours, and take it out after the product is cooled to room temperature with the furnace;

[0044]...

Embodiment 3

[0047] This embodiment comprises the following steps:

[0048] (1) Mix commercial silicon particles and magnesium powder in a mass ratio of 1:2 and put them into the container;

[0049] (2) Put the container containing the reactant into a high-temperature furnace filled with inert gas and heat it to 500°C at a heating rate of 10°C / min, and the holding time is 10h to obtain the product magnesium silicide. After the product is cooled to room temperature with the furnace, take it out ;

[0050] (3) Putting the product obtained in (2) into a ball mill tank protected by argon for ball milling, and then screening to obtain micron particles of magnesium silicide with different sizes, the particle size being 0.5-4 microns.

[0051] (4) Put the ball-milled magnesium silicide in (3) in a tubular furnace and heat it to a reaction temperature of 600° C. in an ammonia atmosphere, keep it warm for 6 hours, and take it out after the product is cooled to room temperature with the furnace;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| actual density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com