Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Turbulent blood flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

What you're hearing as a murmur is similar turbulent blood flow that results from the high-velocity regurgitation of blood backward across the valve, opposite of the direction the blood is supposed to flow.

Aortic prosthetic devices

ActiveUS7429269B2Reduced permanent pressure lossReasonable hemodynamic profileStentsHeart valvesSystoleProsthesis

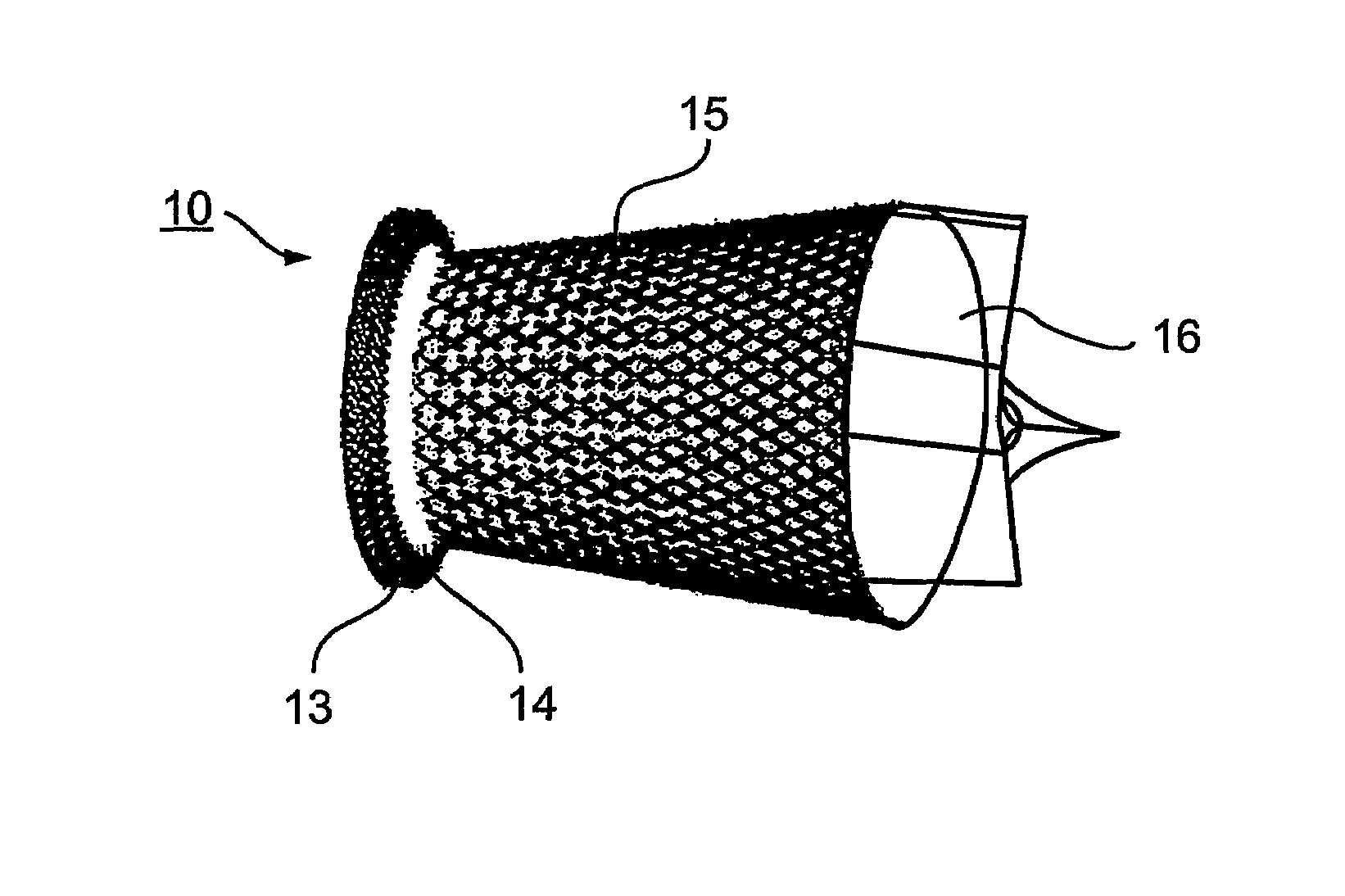

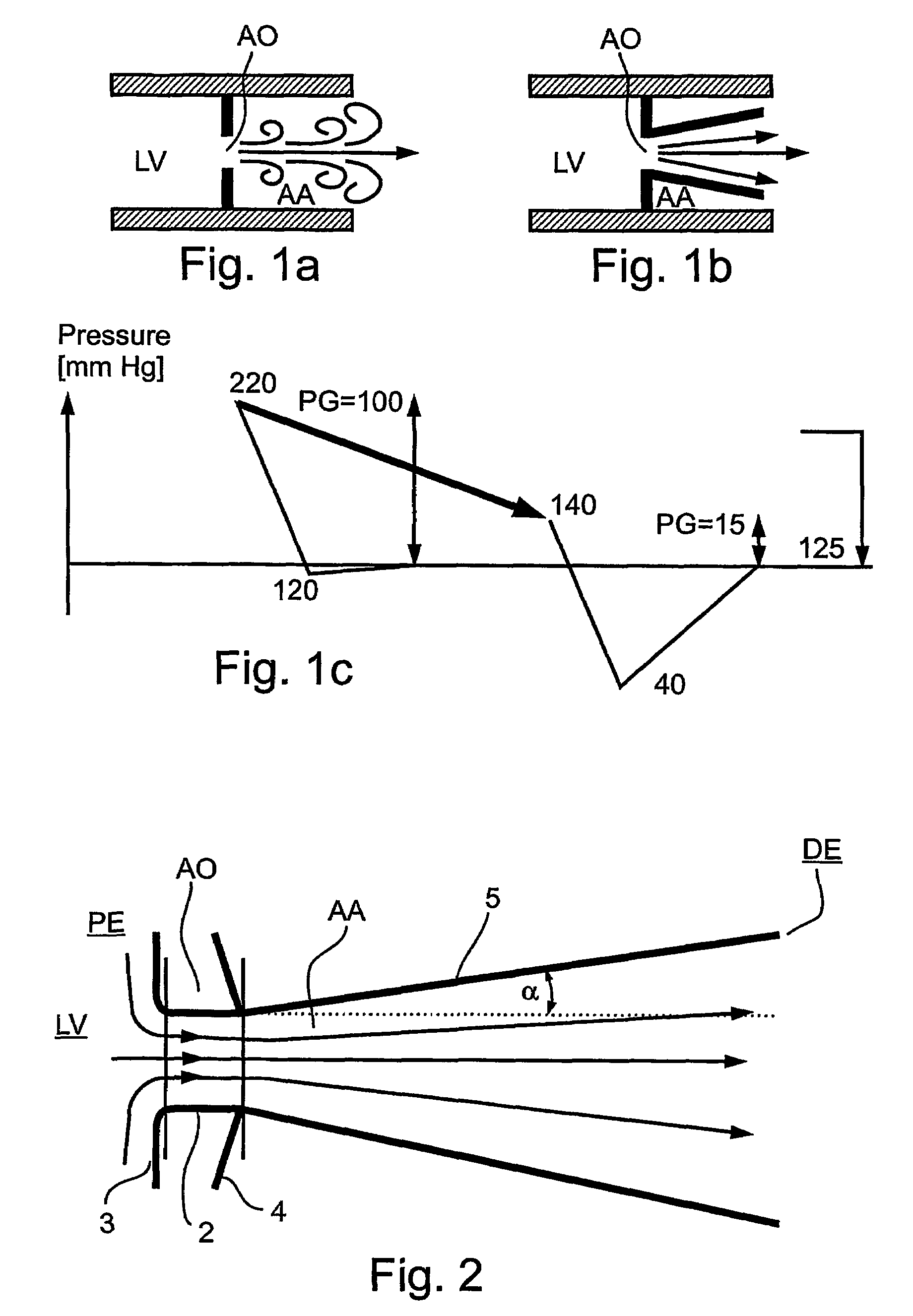

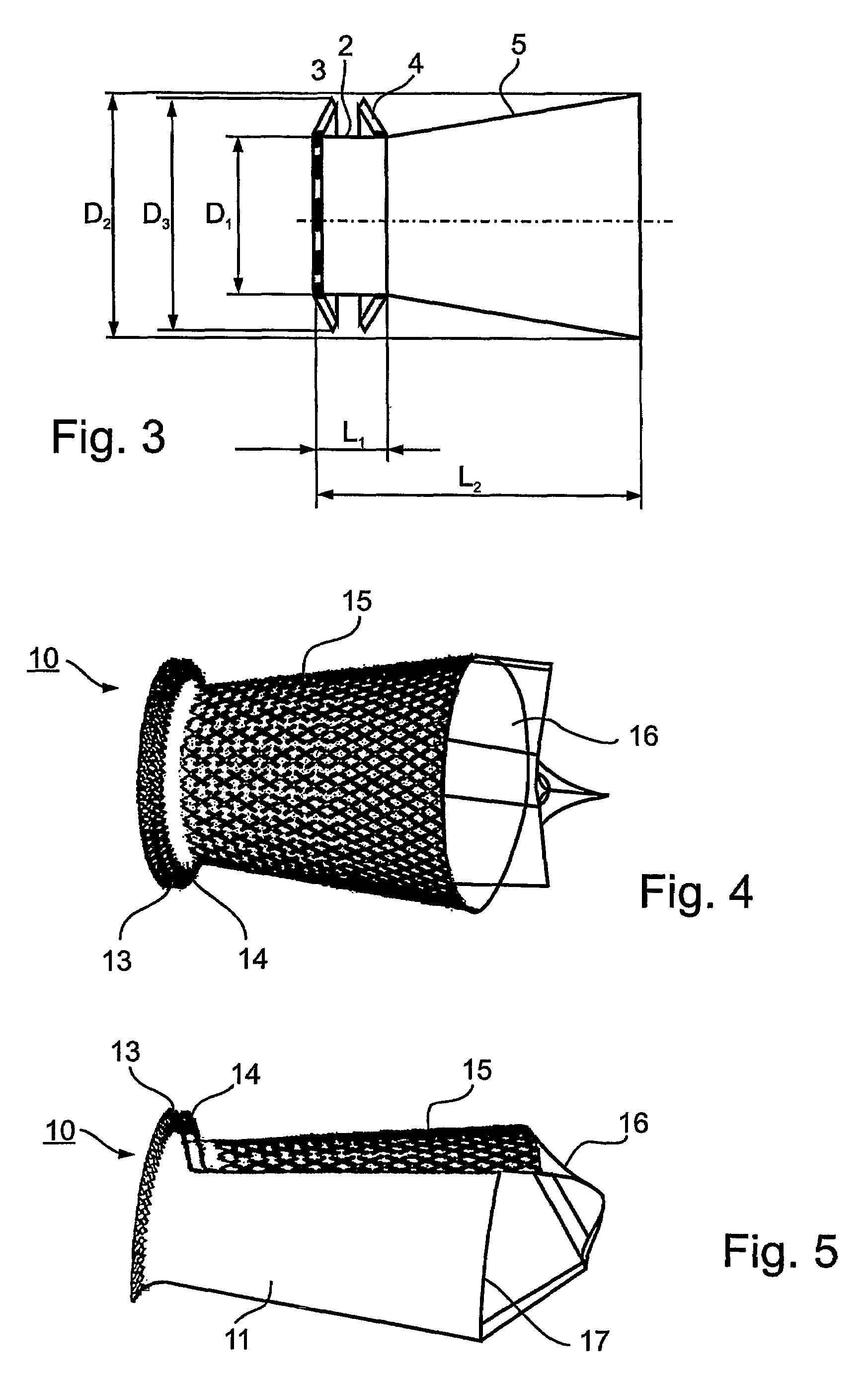

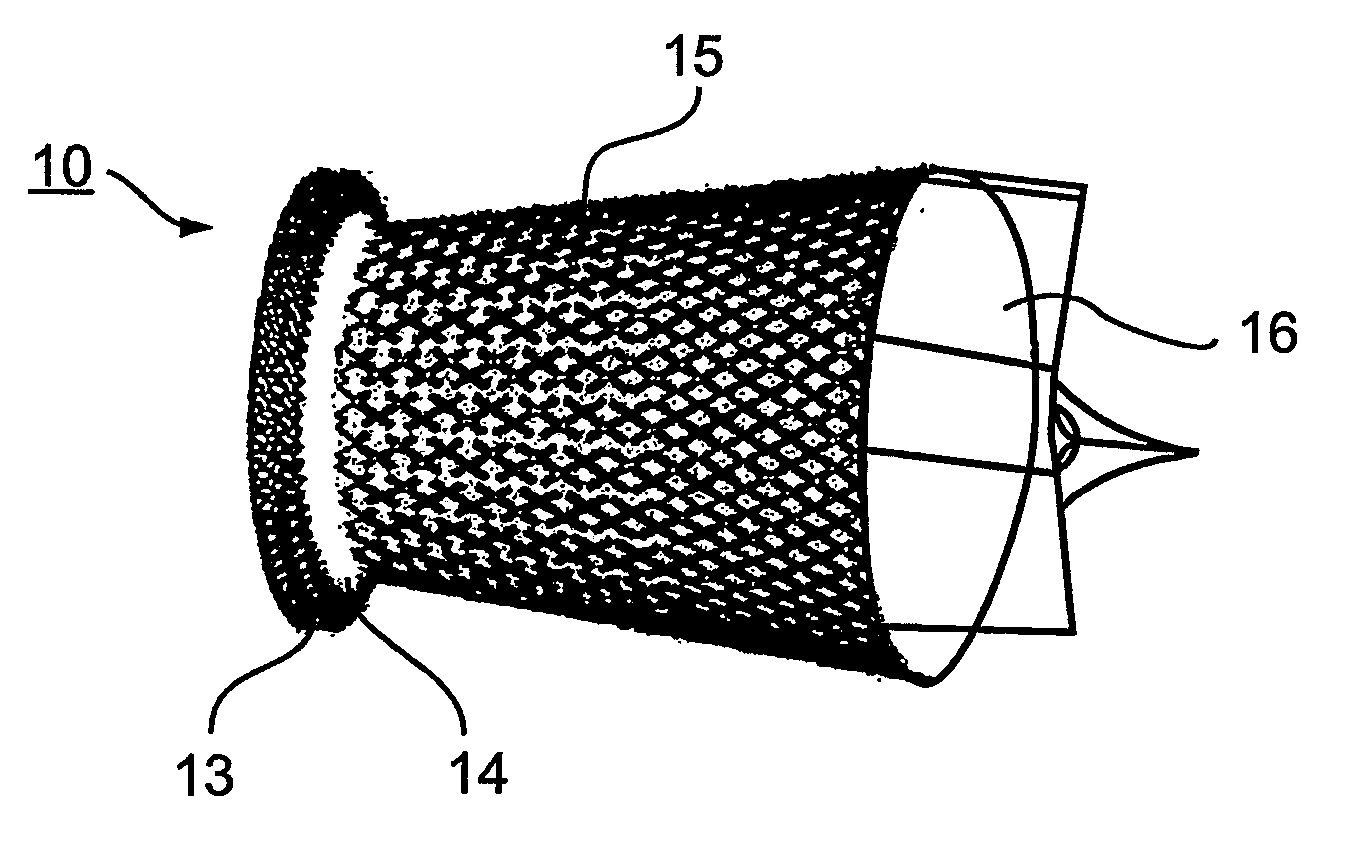

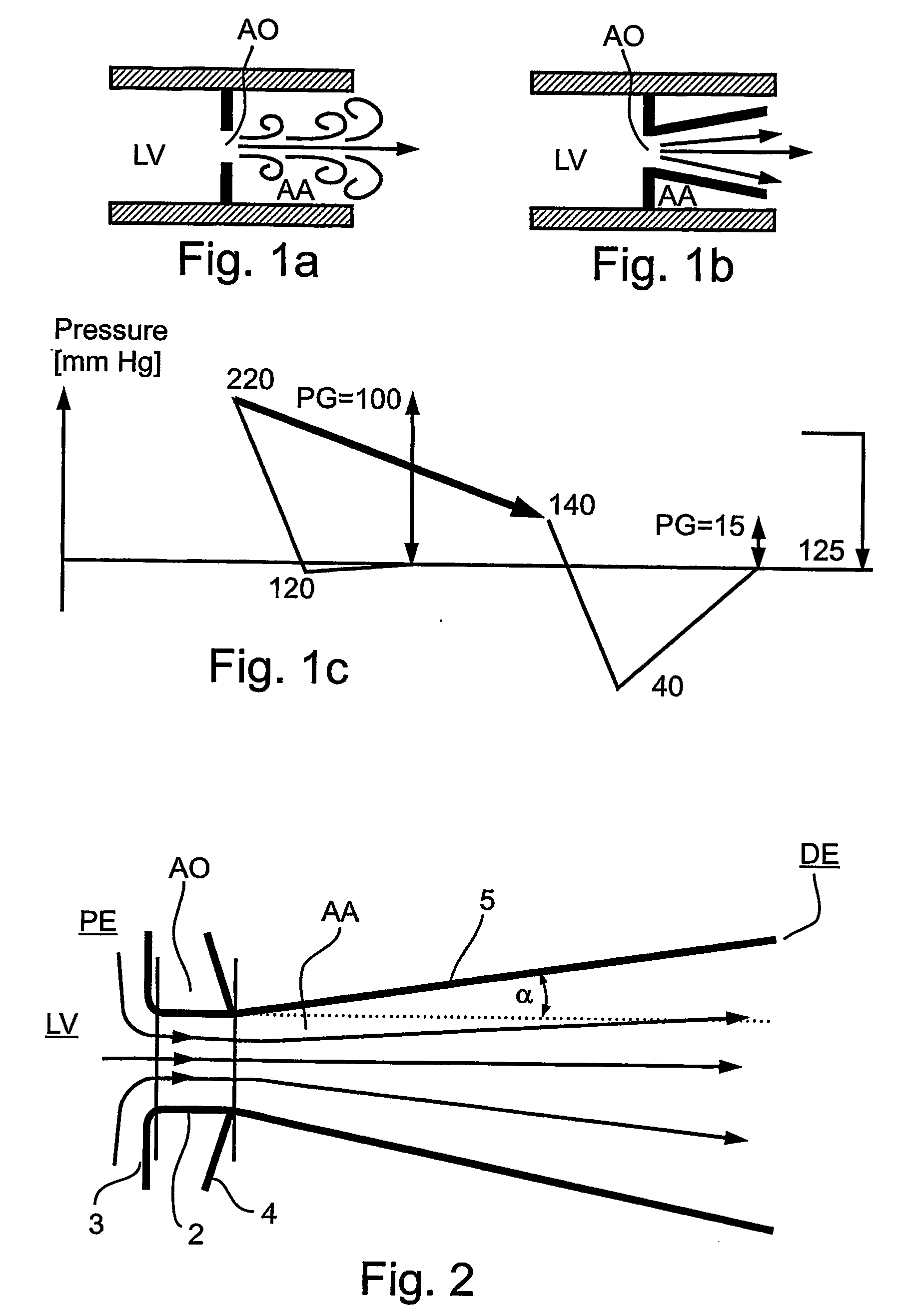

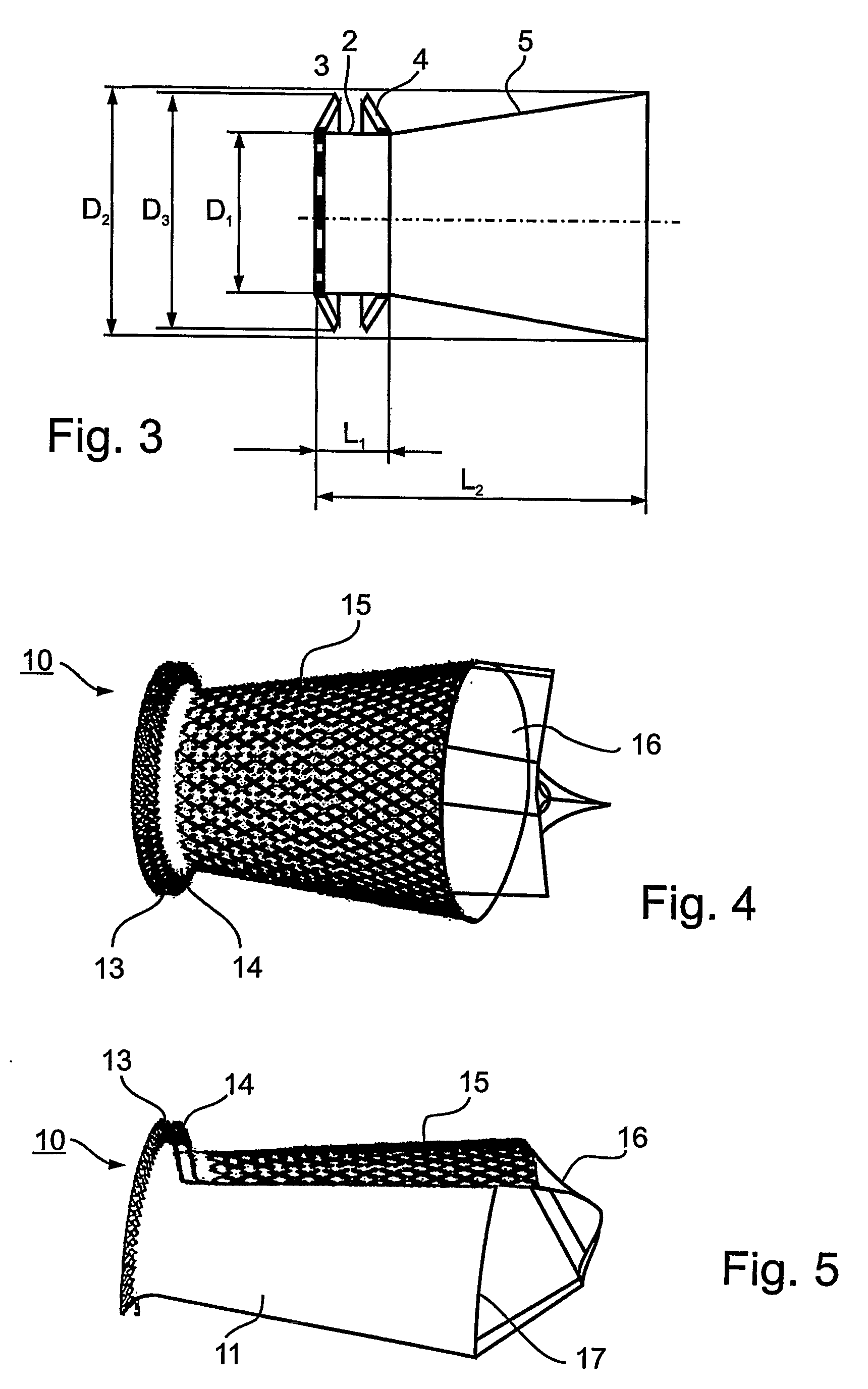

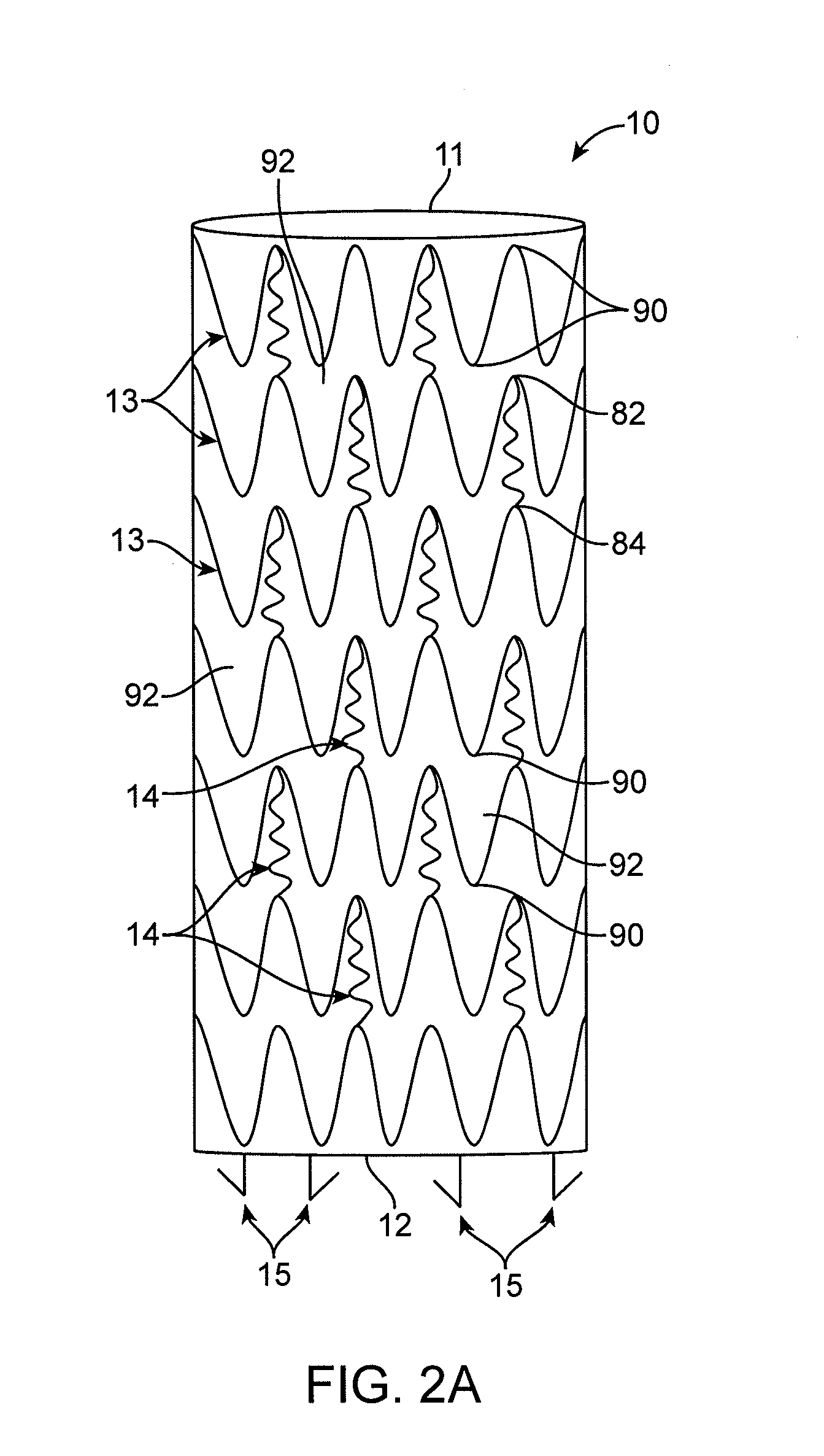

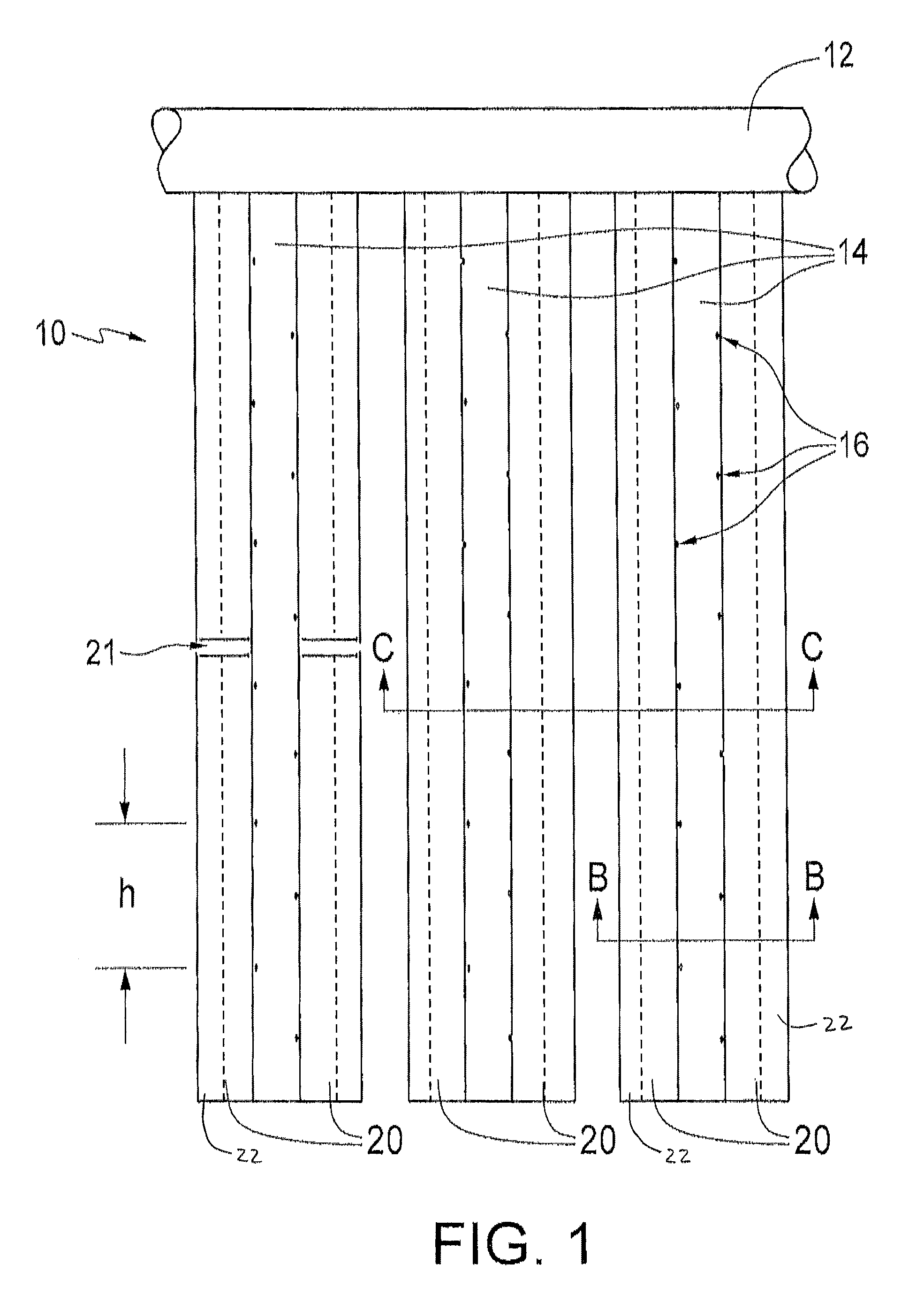

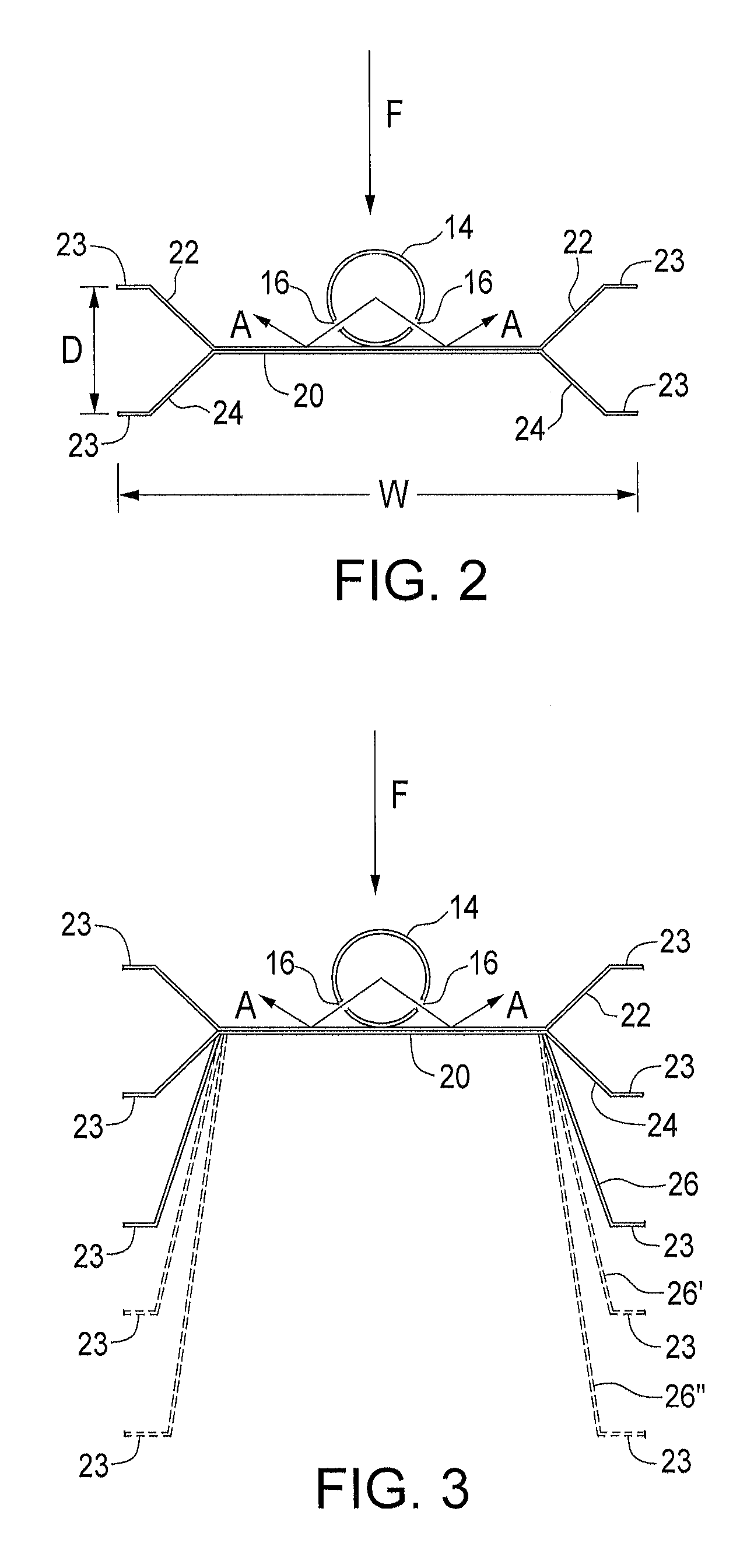

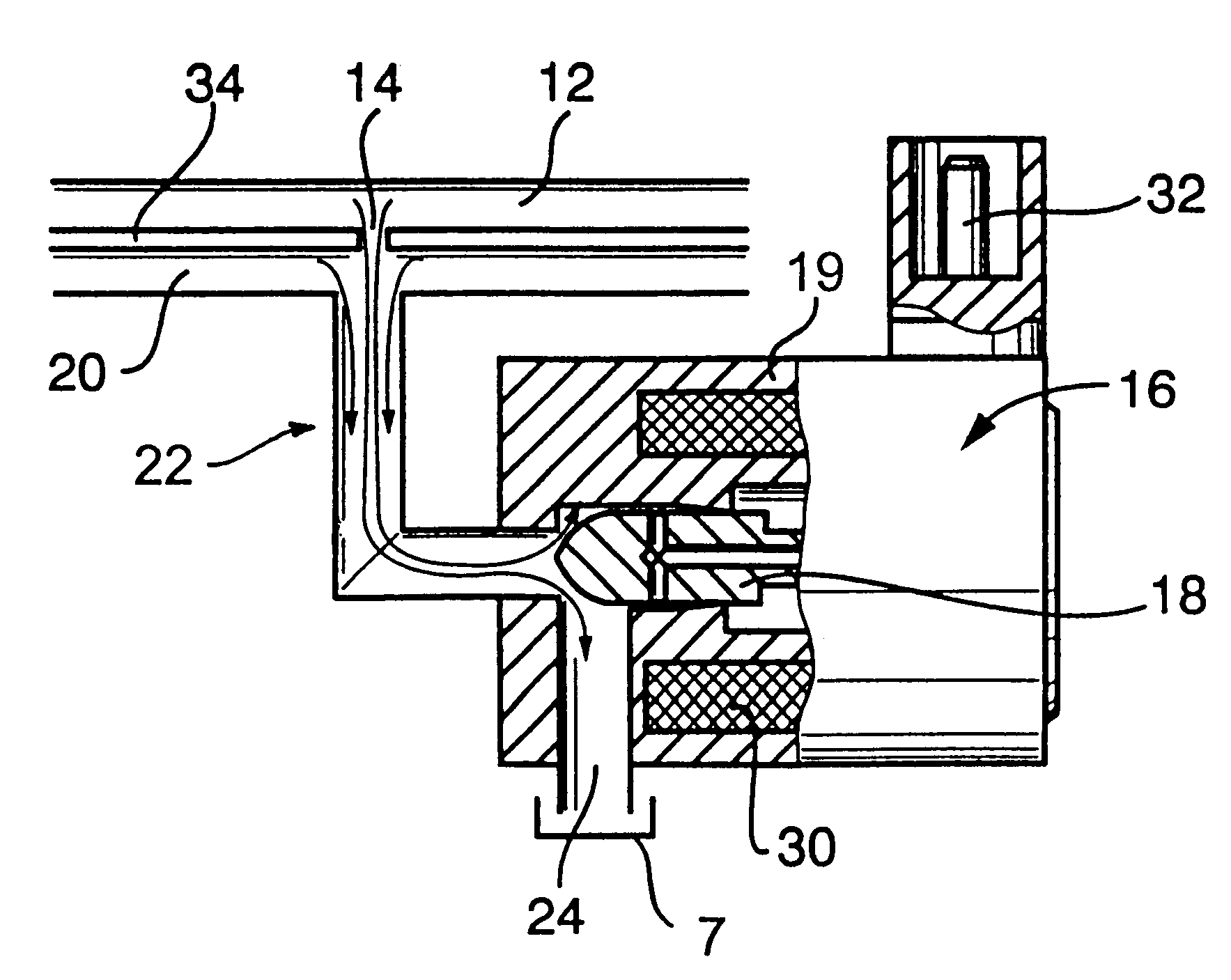

A prosthetic device is provided for treatment of an aortic valve, having a compressed state for transarterial delivery and being expandable to an expanded state for implantation. The device includes an expandable support implantable in the expanded state of the prosthetic device in an aortic annulus, and an inner envelope having an upstream portion that lines the inner surface of the support, and a downstream portion which, when the prosthetic device is in the expanded state, extends into an aorta and defines a diverging conical section having a diameter that gradually increases from an upstream end of the section to a downstream end of the section. The section is configured to produce, during systole, a non-turbulent blood flow into the aorta with pressure recovery at the downstream end of the section. Other embodiments are also described.

Owner:MEDTRONIC VENTOR TECH

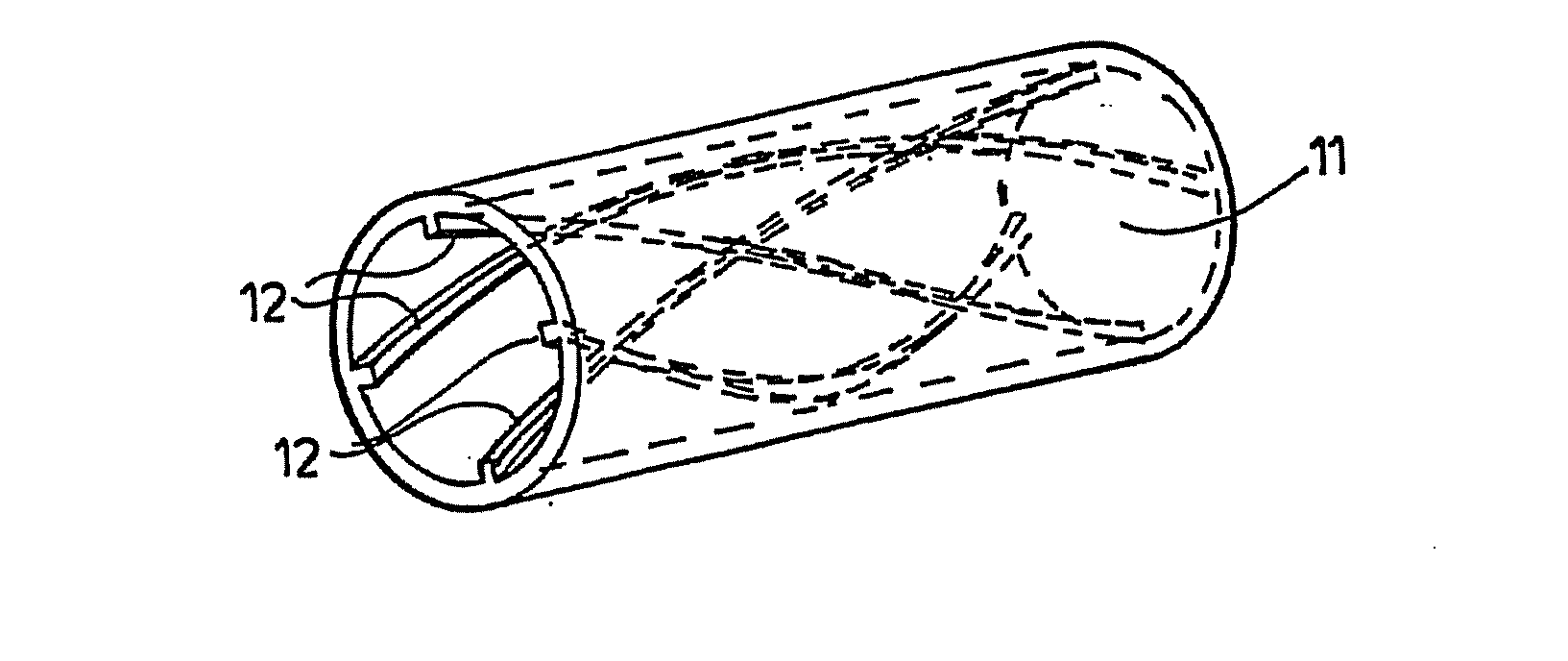

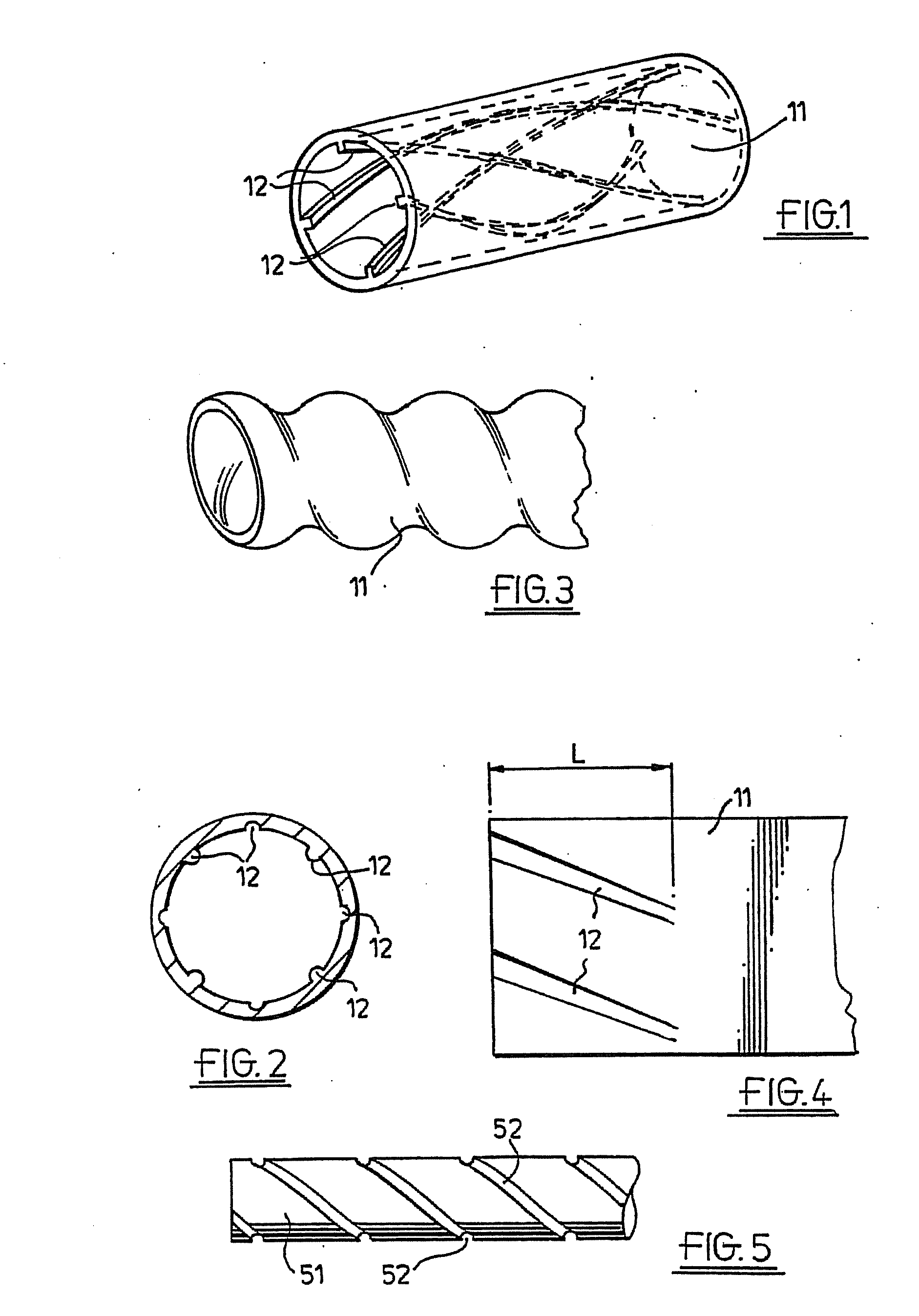

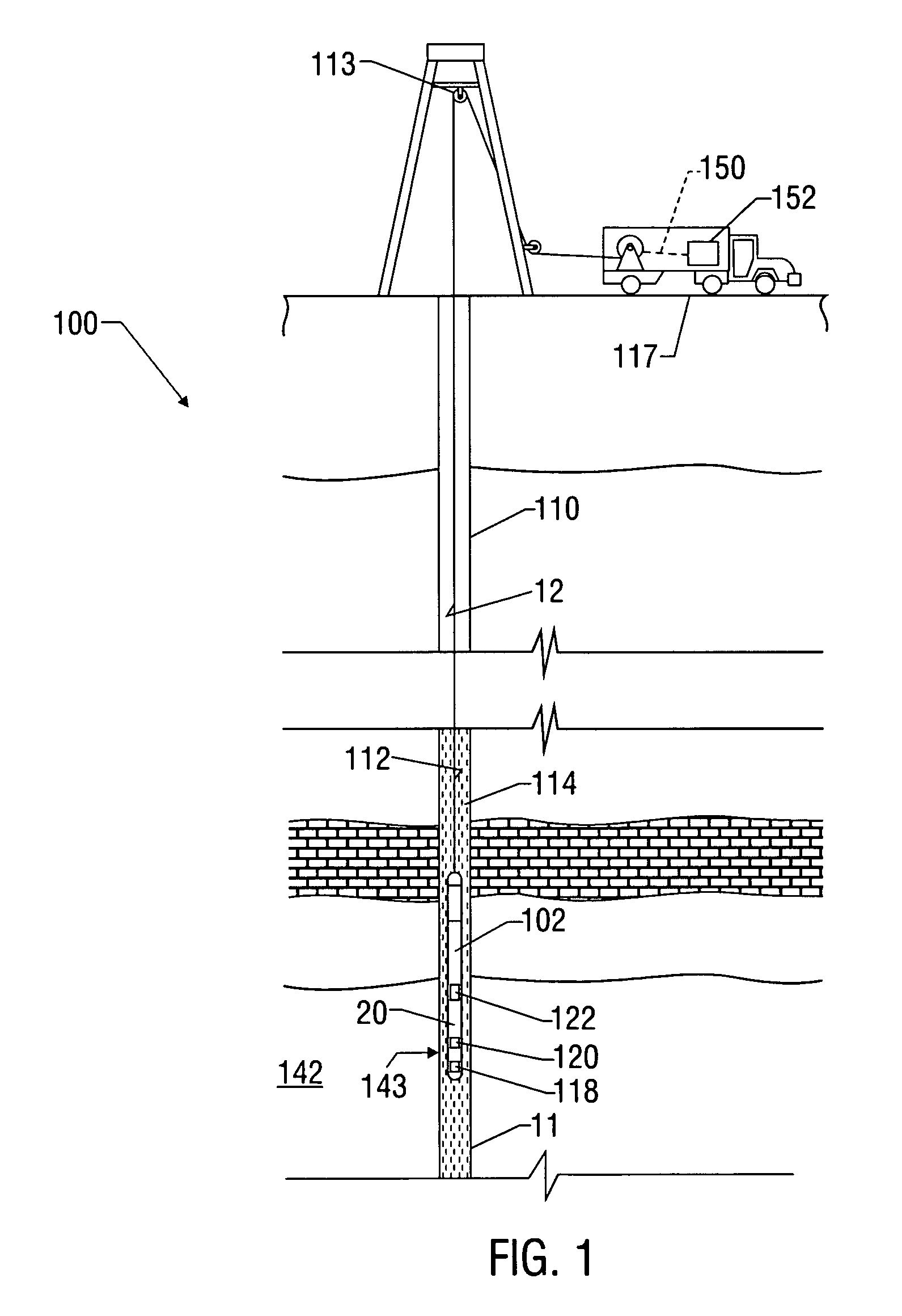

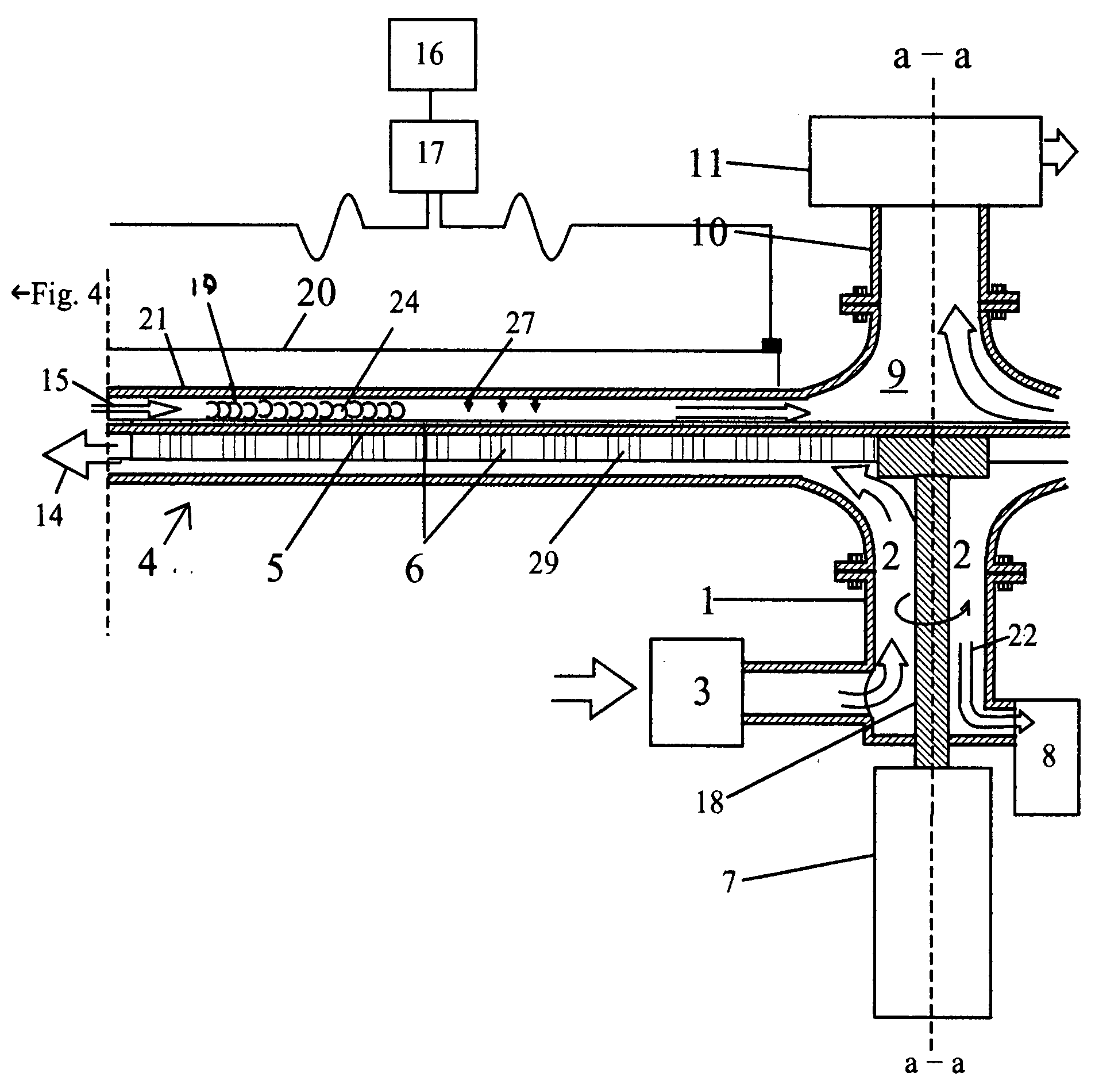

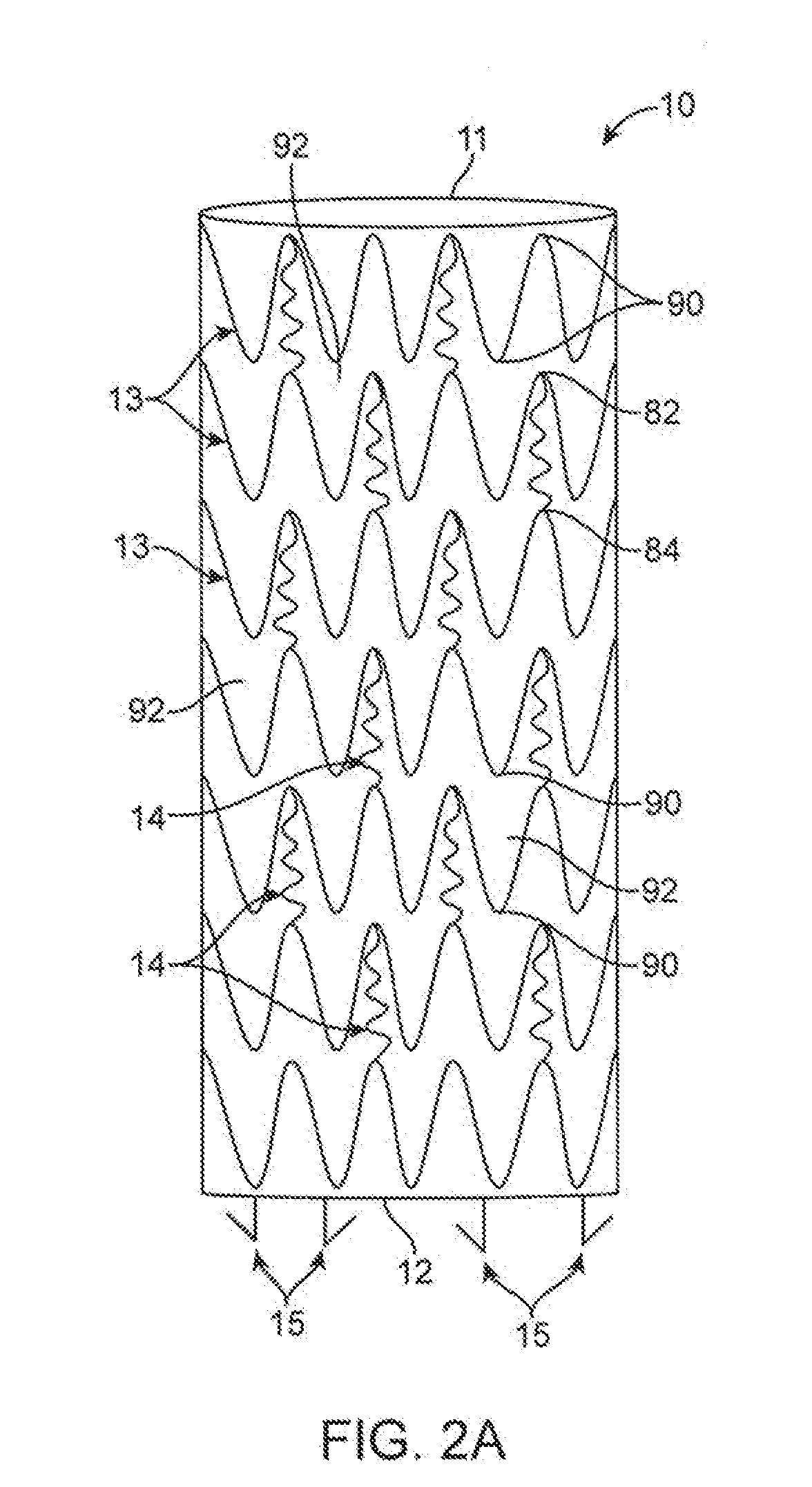

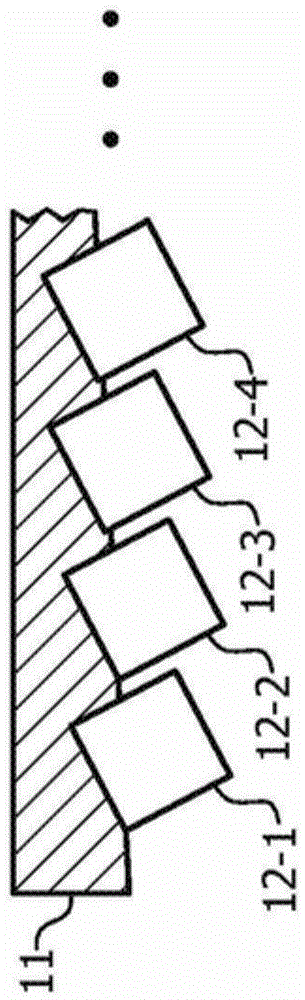

Implantable prosthetic devices particularly for transarterial delivery in the treatment of aortic stenosis, and methods of implanting such devices

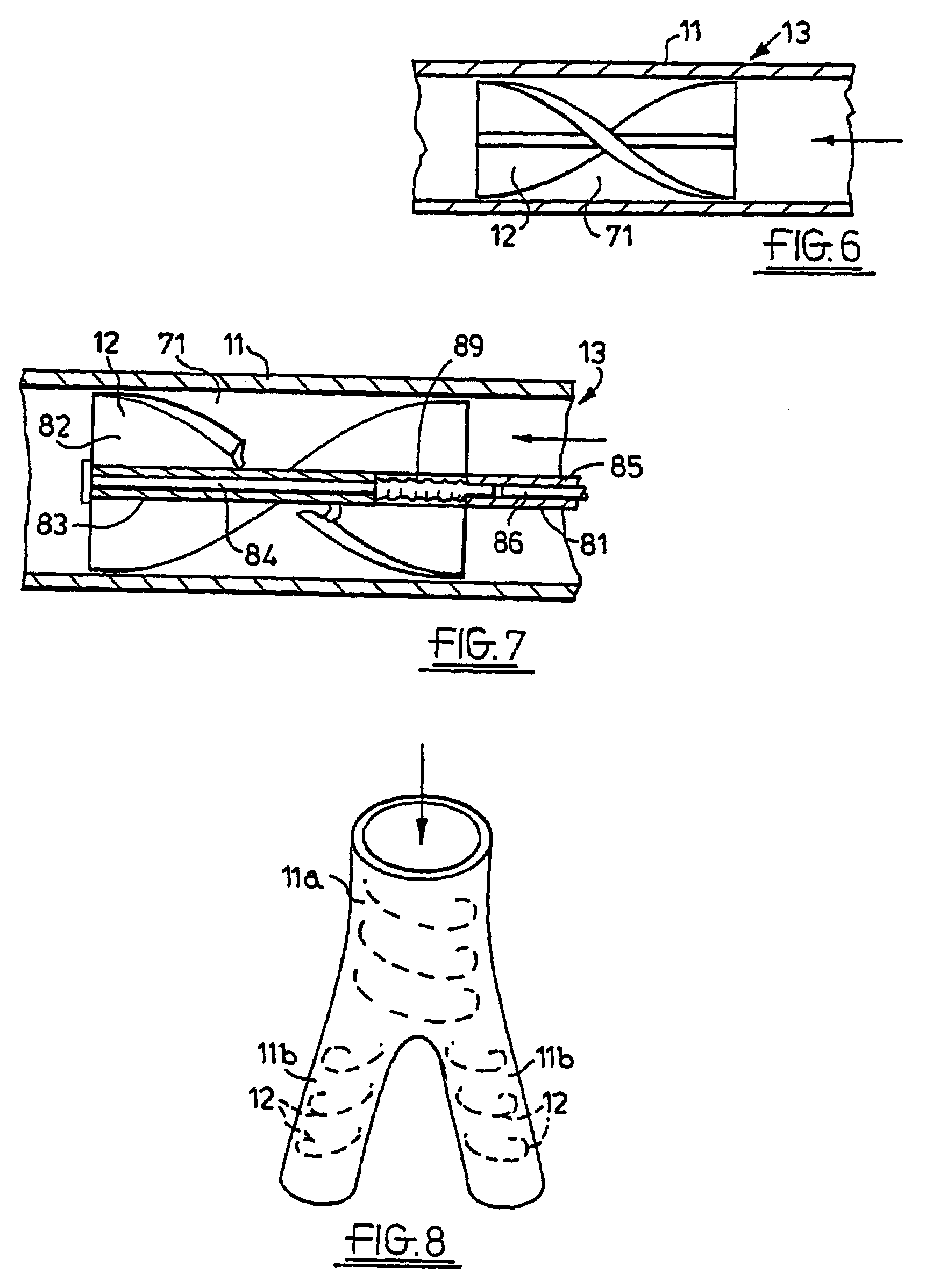

ActiveUS20060259134A1Reduce the possibilityReduced permanent pressure lossStentsHeart valvesSystoleProsthetic valve

Prosthetic devices as described for use in the treatment of aortic stenosis in the aortic valve of a patient's heart, the prosthetic device having a compressed state for transarterial delivery and being expandable to an expanded state for implantation. The prosthetic device includes an expandable metal base (10) constructed so as to be implantable in the expanded state of the prosthetic device in the aortic annulus of the aortic valve; and an inner envelope lining (11) tune inner surface of the metal base (10). The inner envelope, in the expanded state of the prosthetic device, extends into the aorta and is of a diverging conical configuration, in which its diameter gradually increases from its proximal end within the aortic annulus to its distal end extending into the aorta, such as to produce, during systole, a non-turbulent blood flow into the aorta with pressure recovery at the distal end of the inner envelope. Preferably, the distal end includes a prosthetic valve which is also concurrently implanted, but such a prosthetic valve may be implanted separately in the aorta Also described are preferred methods of implanting such prosthetic devices.

Owner:MEDTRONIC VENTOR TECH

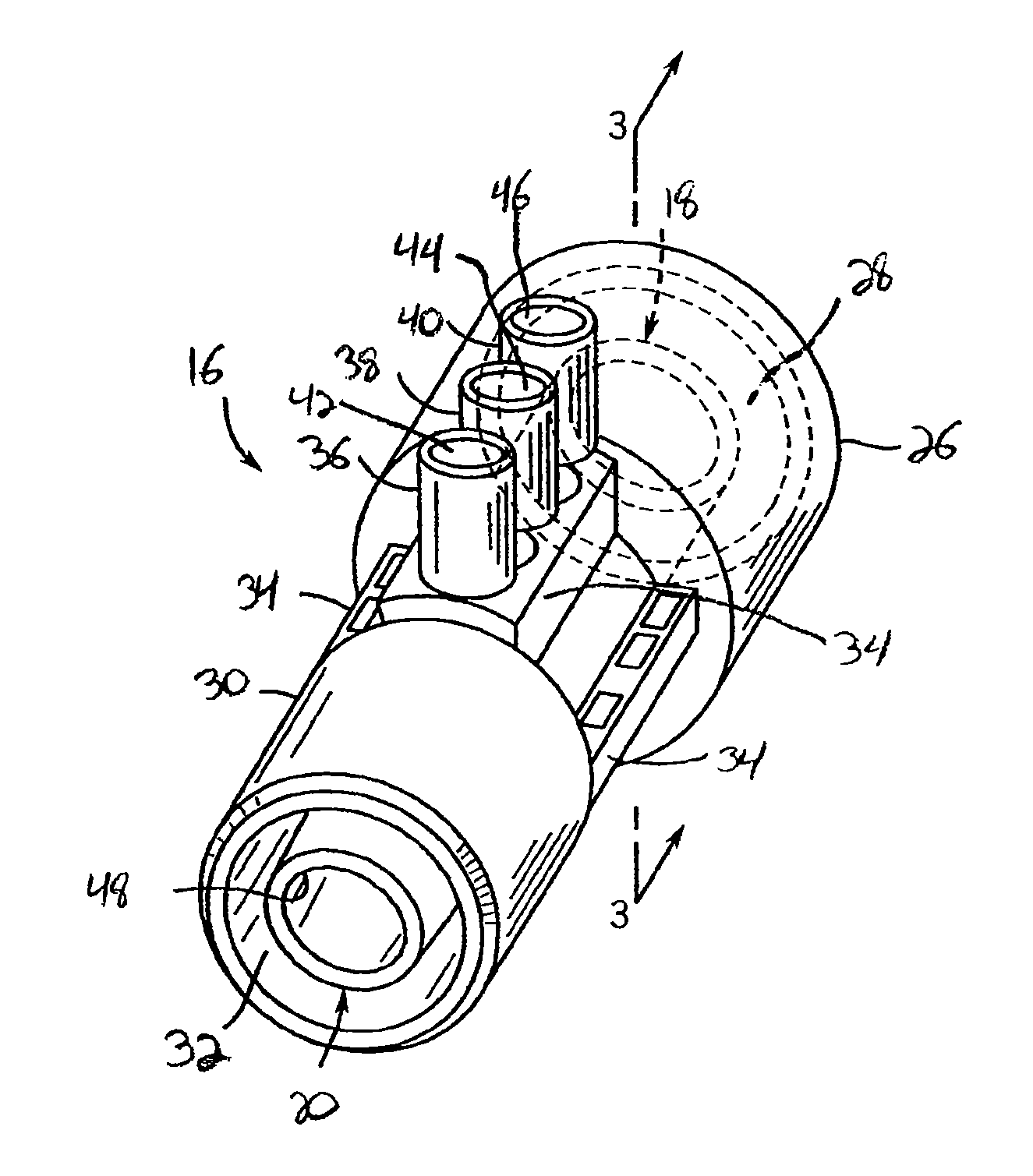

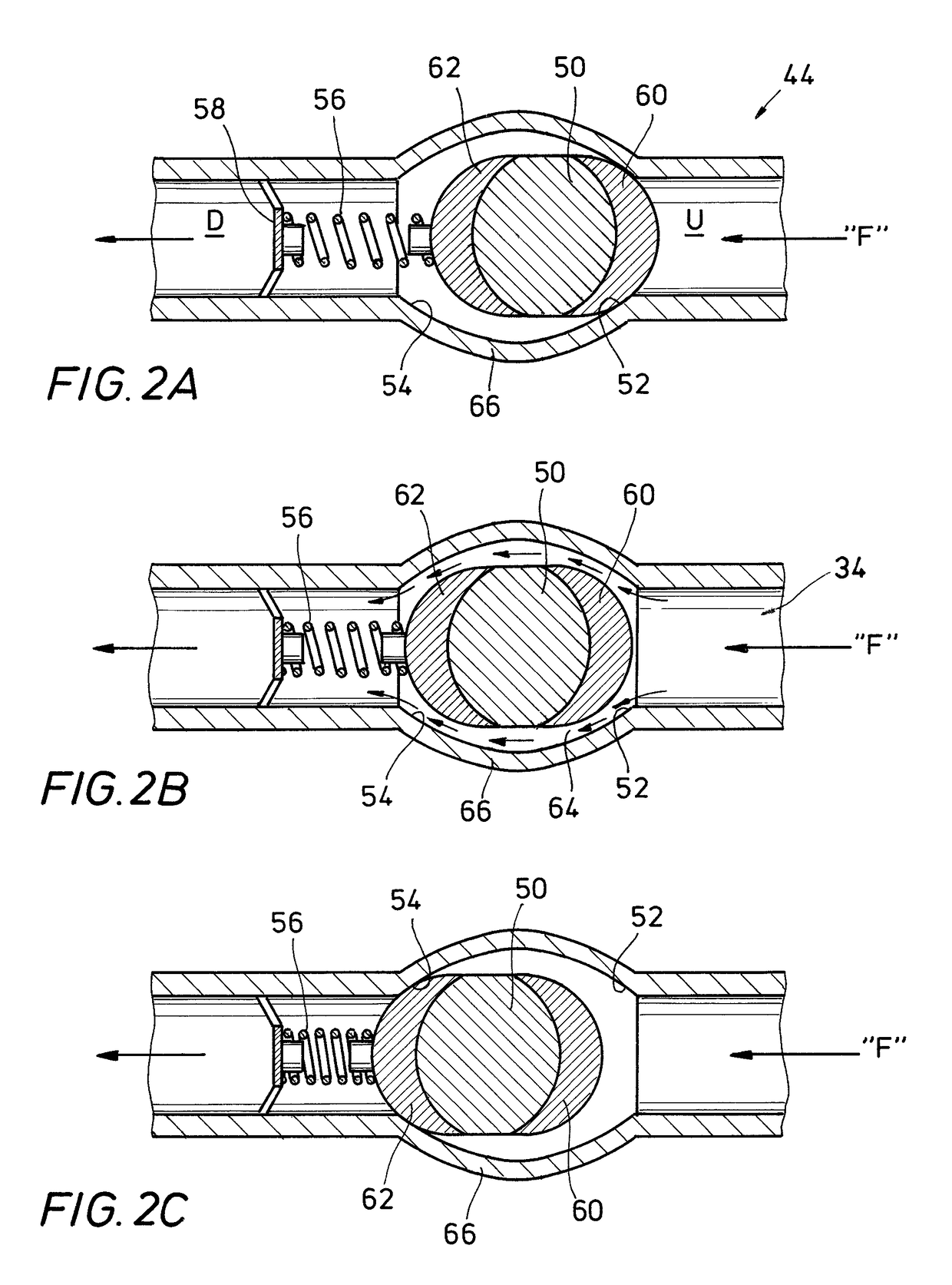

Blood-flow tubing

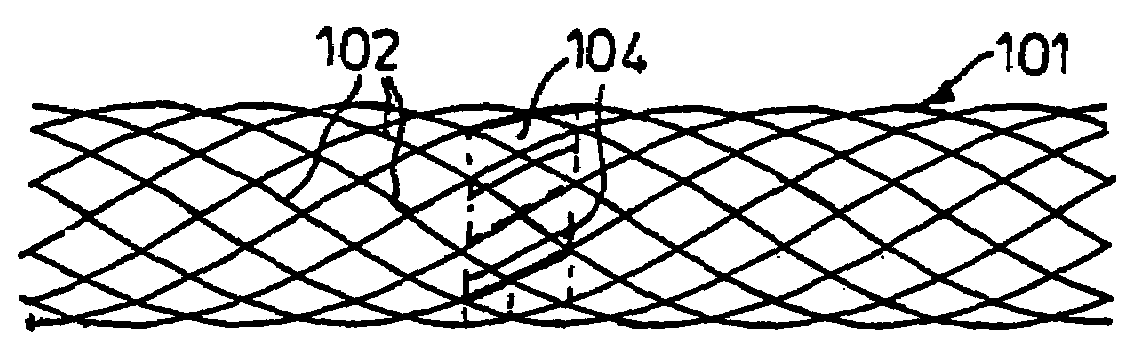

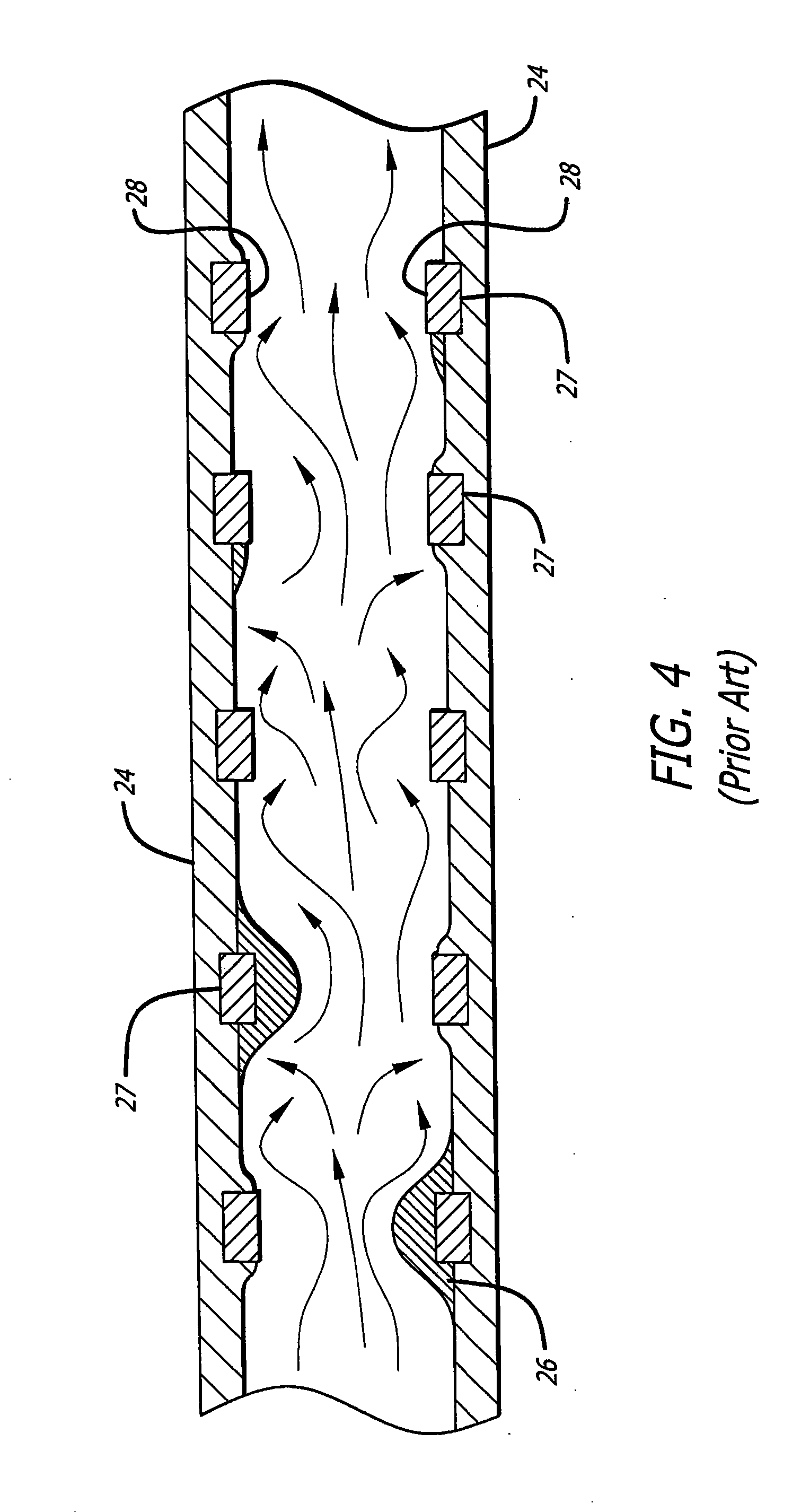

InactiveUS7682673B2Eliminate and reduce turbulenceReduce precipitationDialysis systemsCatheterInsertion stentTurbulent blood flow

Owner:VASCULAR FLOW TECH LTD

Liquid aeration plunger

ActiveUS7513301B2Effectively lift a heavy liquidHigh speedFlexible member pumpsFluid removalCarrying capacityEngineering

A plunger apparatus operates to propel one or more jets of gas through one or more internal orifices and / or nozzles out through an aperture and into a liquid load whereby a transfer of the gas into the liquid load causes turbulent aeration to the liquid load during a plunger rise. This action can boost the carrying capacity of a plunger lift system resulting in improved well production.

Owner:PCS FERGUSON

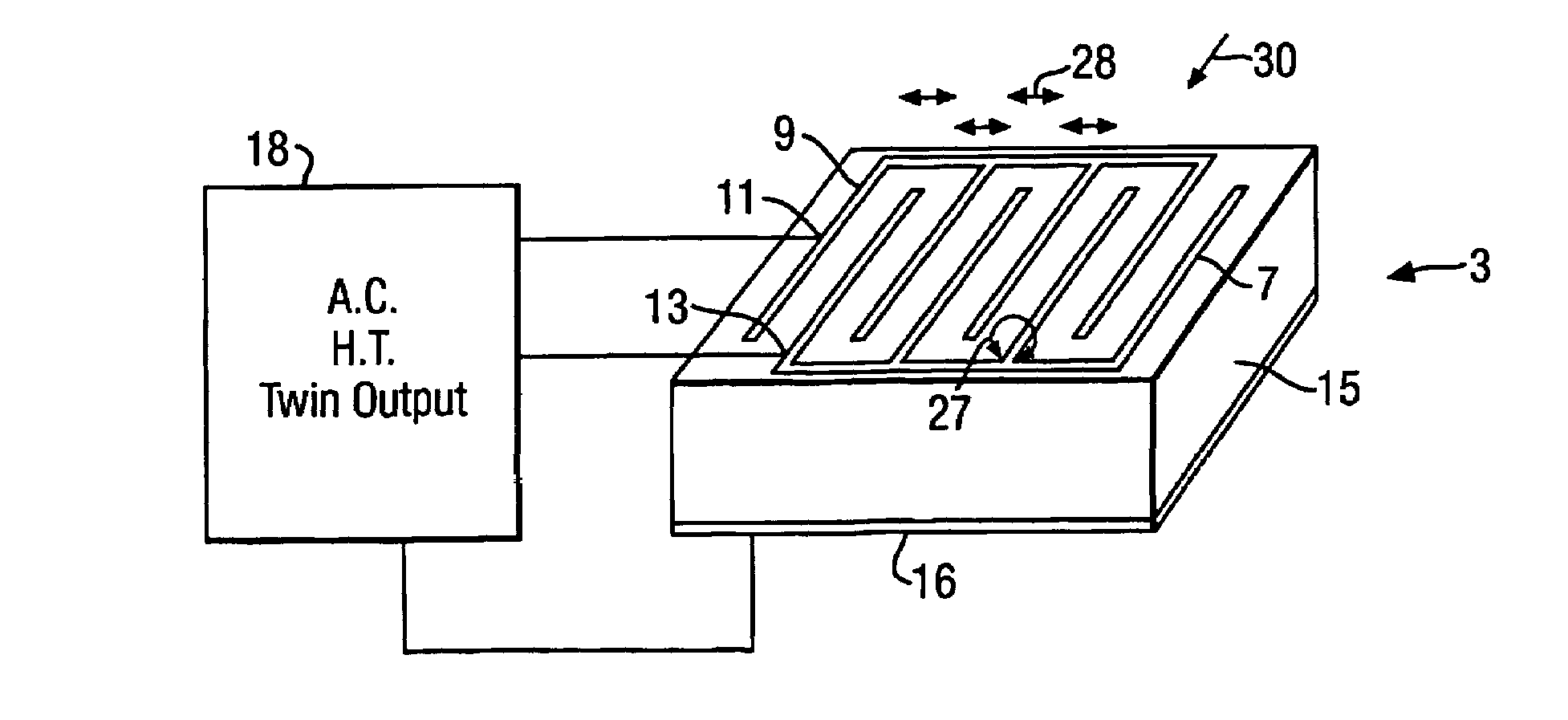

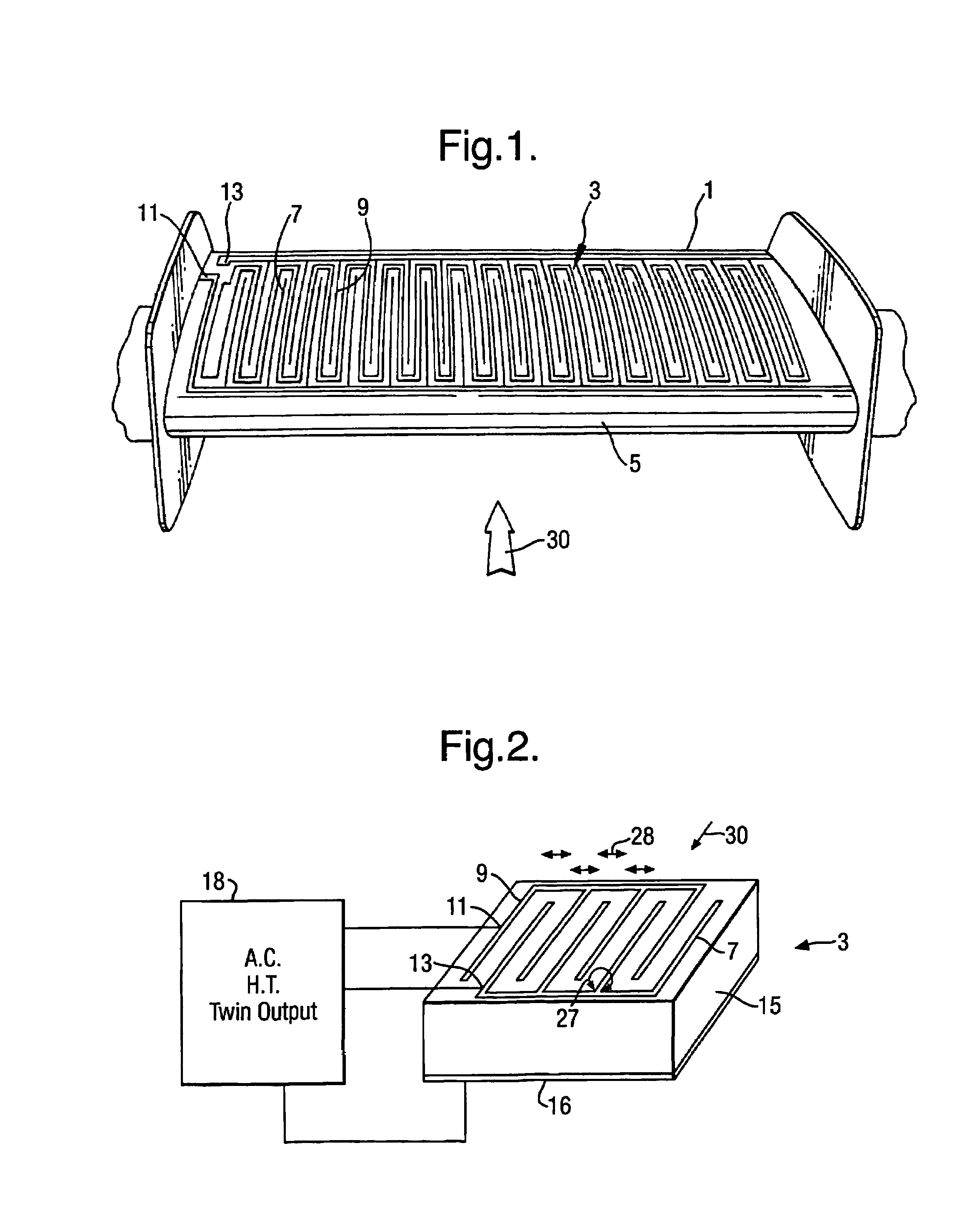

Turbulent flow drag reduction

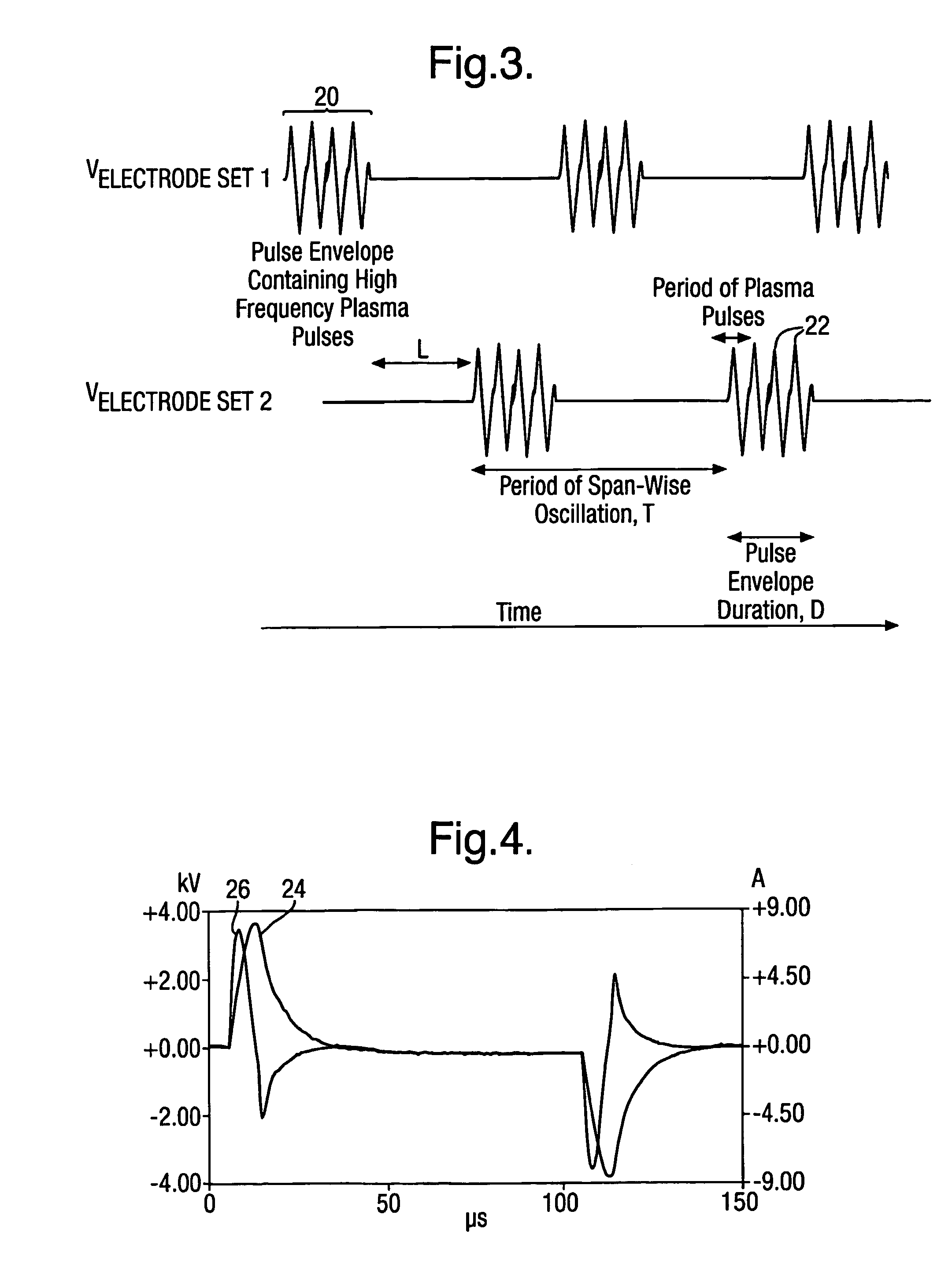

InactiveUS7017863B2Reduce resistanceObject's drag can be reducedBoundary layer controlsWingsPlasma generatorEngineering

The present invention relates to apparatus for influencing fluid flow over a surface, and more particularly, but not exclusively, to turbulent boundary layer flow drag reduction for an aircraft. The present invention provides such apparatus including a plasma generator comprising first and second spaced-apart independently controllable electrodes operable to cause a change in direction of the flow of the fluid over the surface.

Owner:AIRBUS OPERATIONS LTD

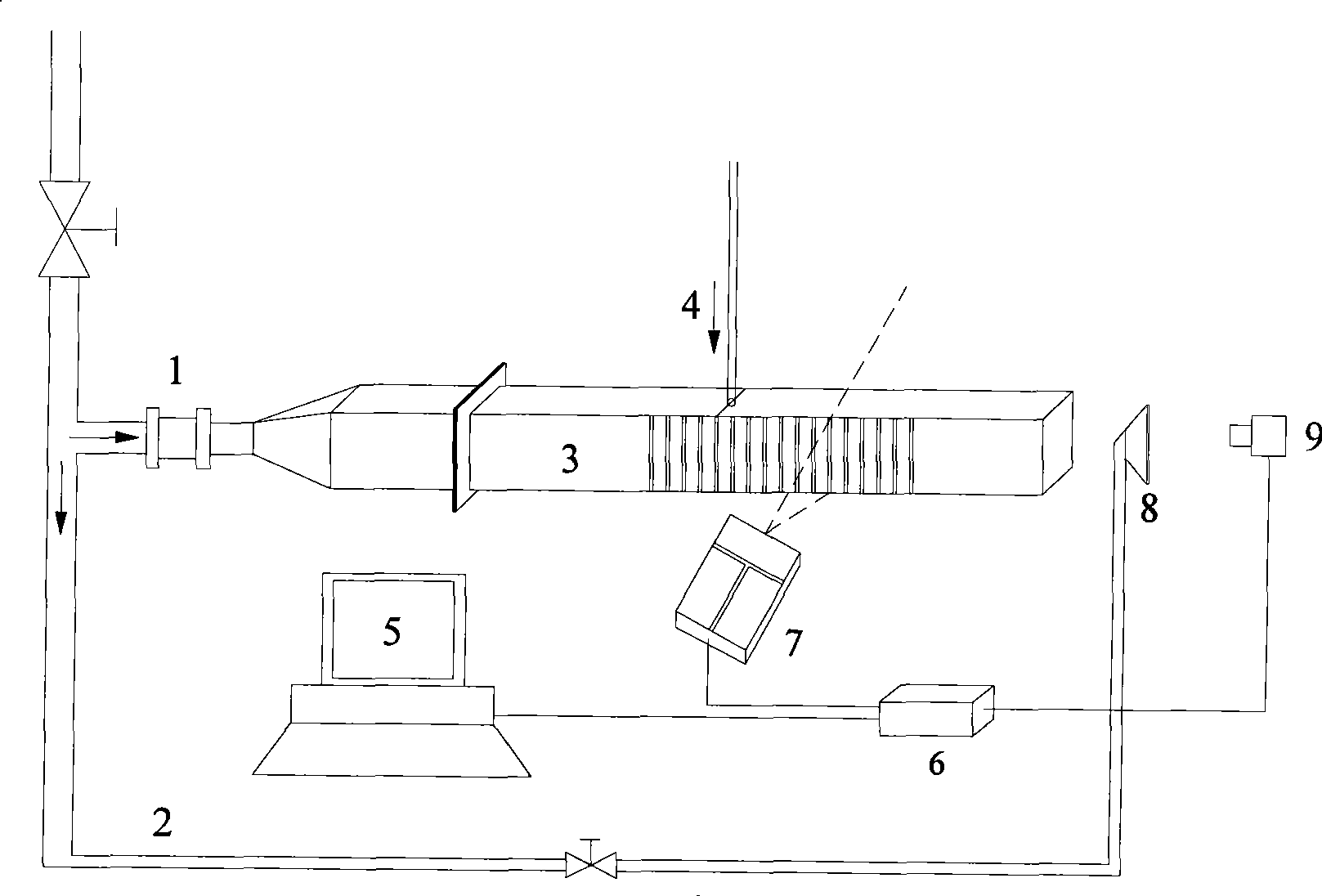

Test device for turbulent flow gas-liquid blending flow field in transverse flow

A device for testing a turbulent flow blending flow field in a crosscurrent comprises a blending test section communicated with a main airflow; an atomizing nozzle is arranged on the blending test section and communicated therewith; matt paint is uniformly applied onto the inner wall of the blending test section; a plurality of slits are formed on the lateral wall of the blending test section; a double pulse Nd:YAG laser is arranged on one side of the blending test section, and the slits are formed on the side; a CCD camera is arranged at the outlet of the blending test section; and the double pulse Nd:YAG laser and the CCD camera are connected with a computer through a PIV synchronous controller separately. The invention addresses the difficulties in filming the flow field of a rotating flow centrifugal nozzle in a limited passage during the process of atomizing blending in the cross flow, such as liquid accumulation on the inner wall, the influence of ambient light, the arrangement of the camera and frequent calibration due to the filming of different sections, and at last can obtain a clear blending particle picture, thereby obtaining the important information about the flow field, the velocity field, the distribution of vorticity and the like.

Owner:XI AN JIAOTONG UNIV

Blood-flow tubing

InactiveUS20070282417A1Eliminate and reduce turbulenceReduce precipitationBottlesDialysis systemsTurbulent blood flowBiomedical engineering

Owner:TAYSIDE FLOW TECH

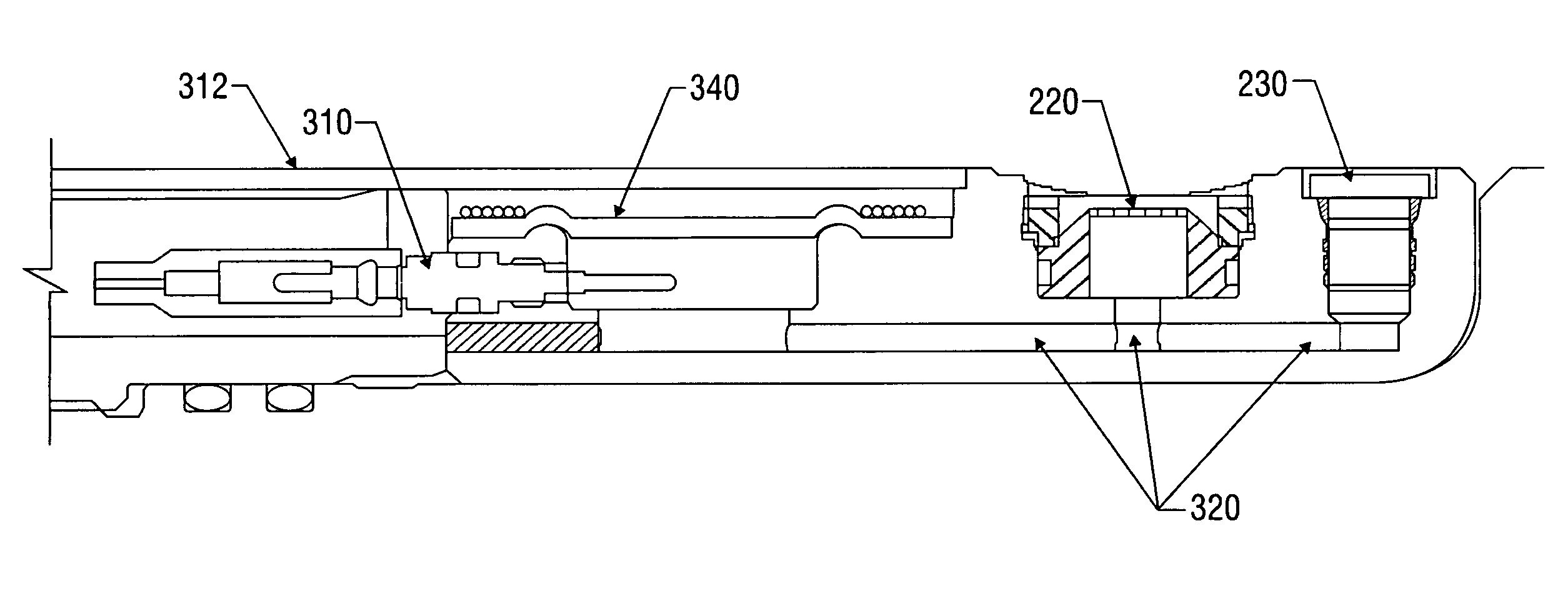

Apparatus and method for detecting fluid entering a wellbore

ActiveUS7464588B2Accurate locationAccurately presenceMaterial analysis using sonic/ultrasonic/infrasonic wavesSurveyUltrasonic sensorAcoustic energy

Owner:BAKER HUGHES HLDG LLC

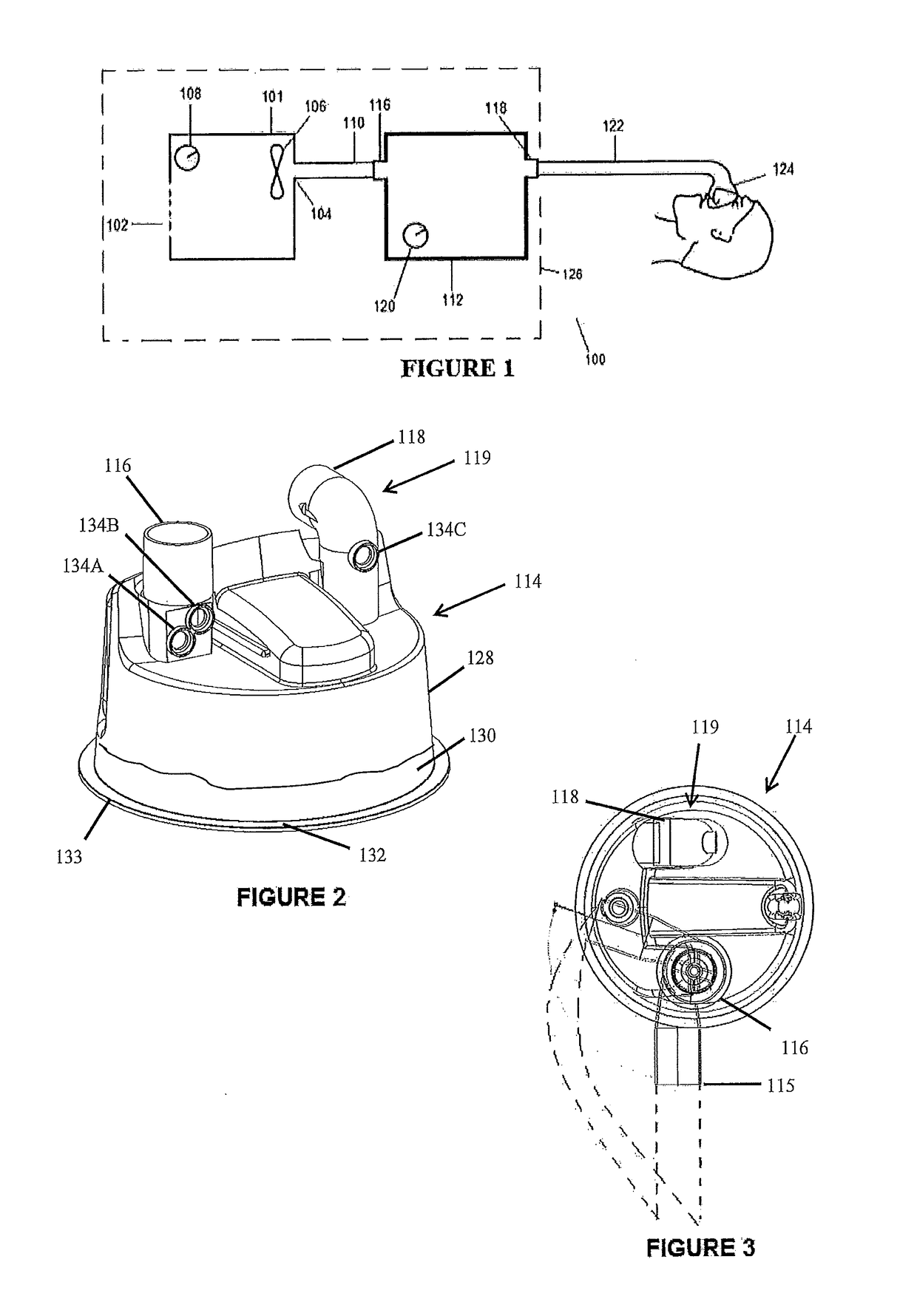

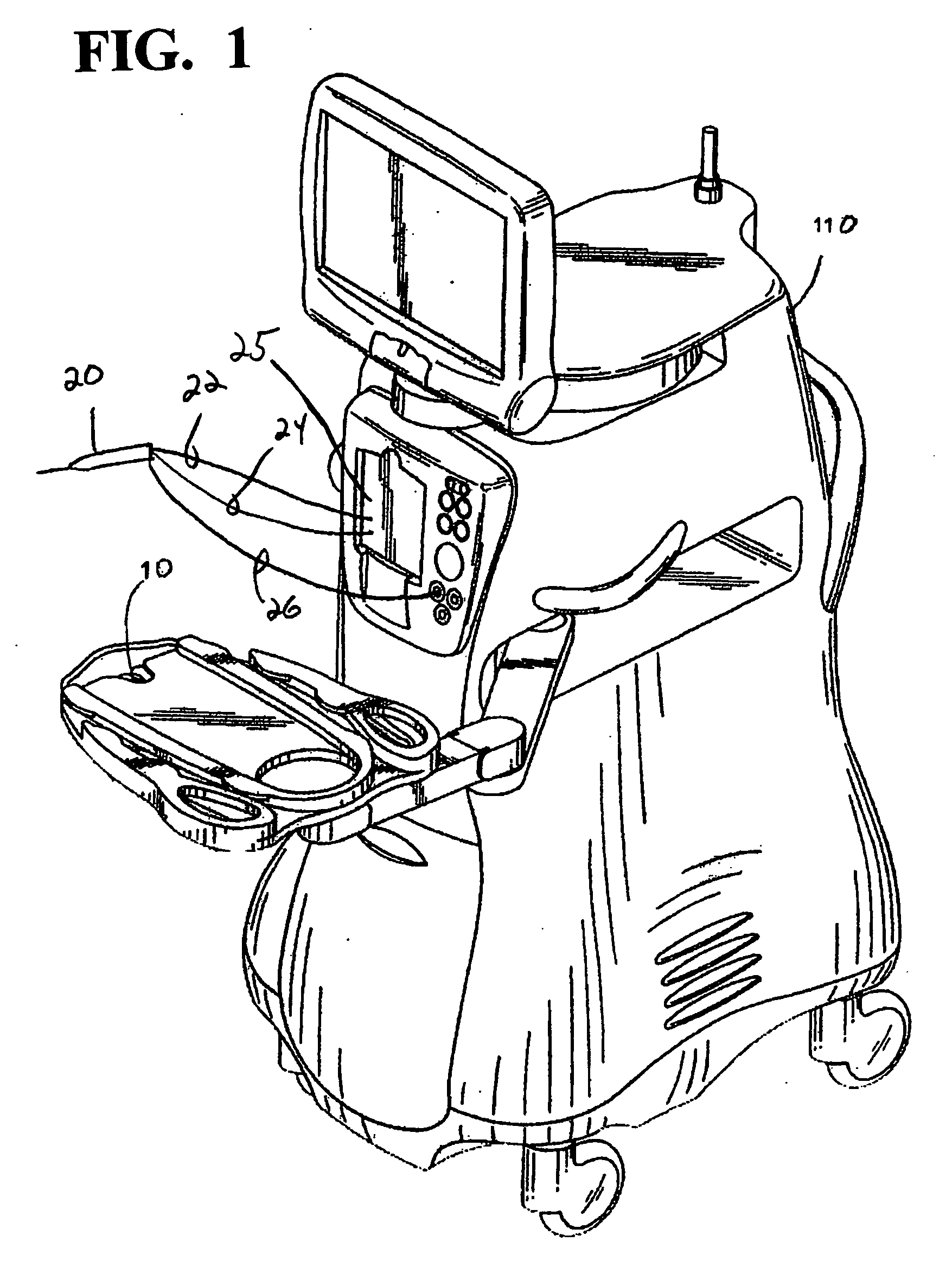

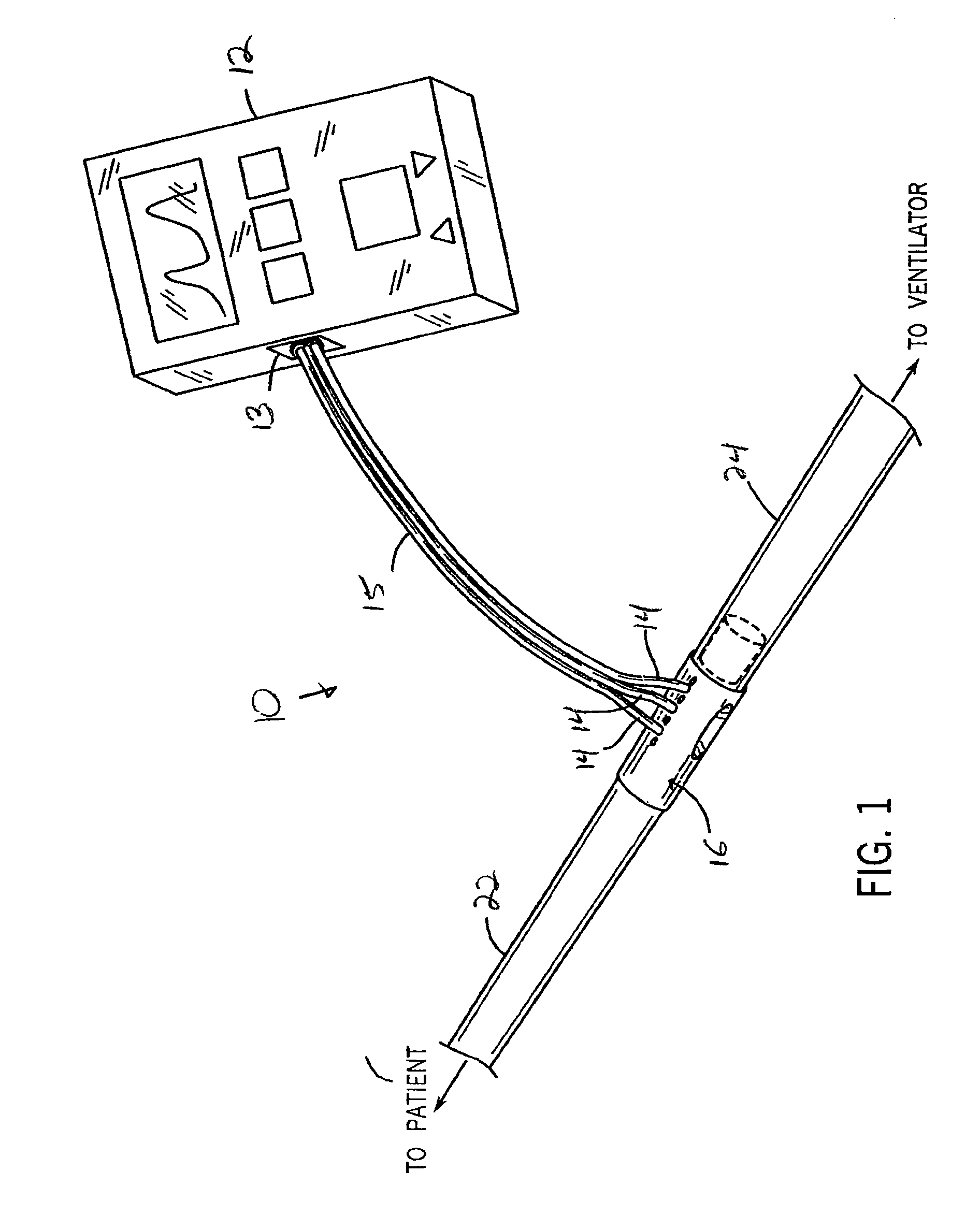

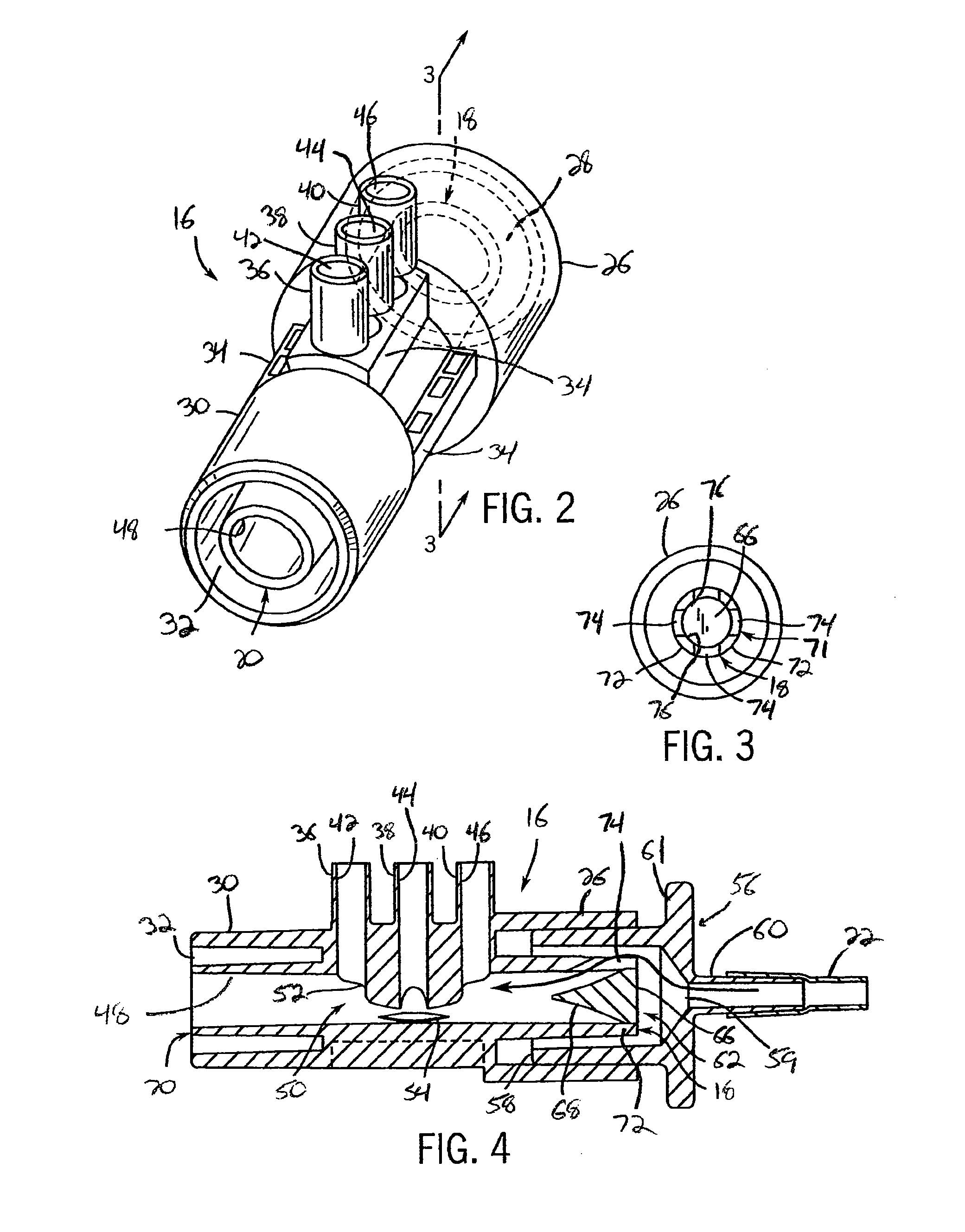

Flow mixers for respiratory therapy systems

ActiveUS20170197057A1Improve accuracyImprove flow uniformityRespiratorsElectrocardiographyEngineeringBreathing treatments

A flow of gases in a respiratory therapy system can be conditioned to achieve more consistent output from sensors configured to sense a characteristic of the flow. The flow can be mixed by imparting a tangential, rotary, helical, or swirling motion to the flow of gases. The mixing can occur upstream of the sensors. The flow can be segregated into smaller compartments to reduce turbulence in a region of the sensors.

Owner:FISHER & PAYKEL HEALTHCARE LTD

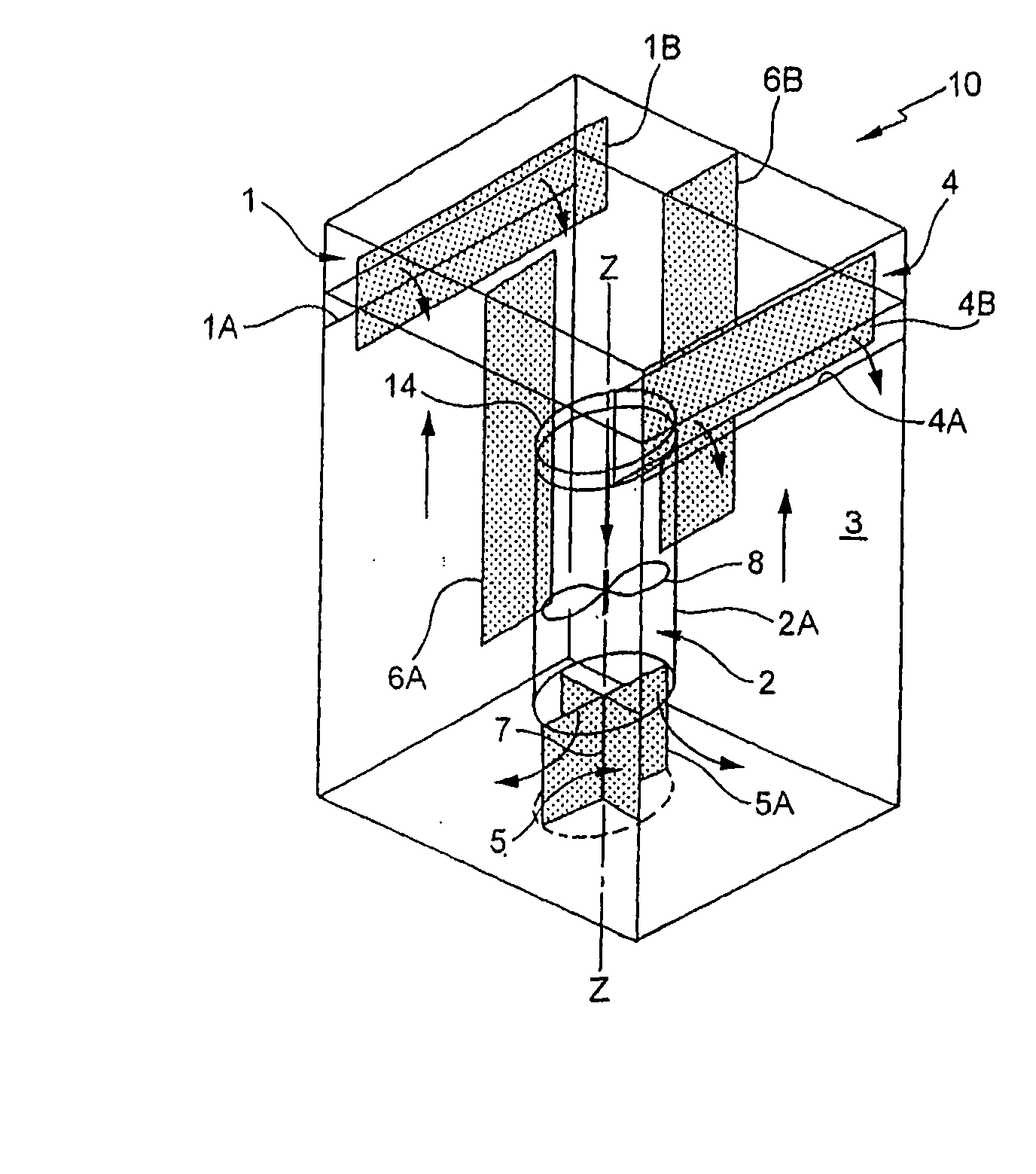

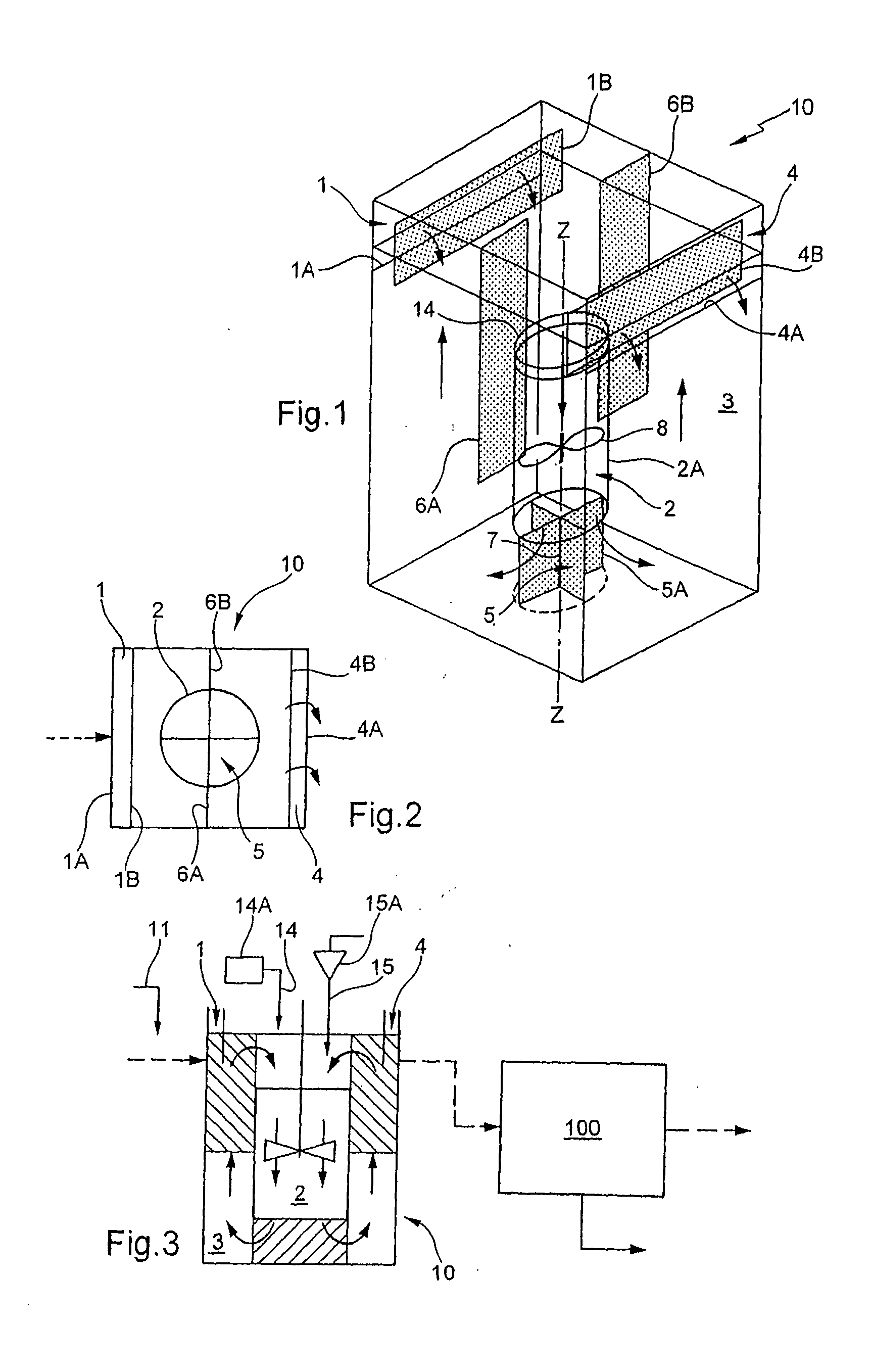

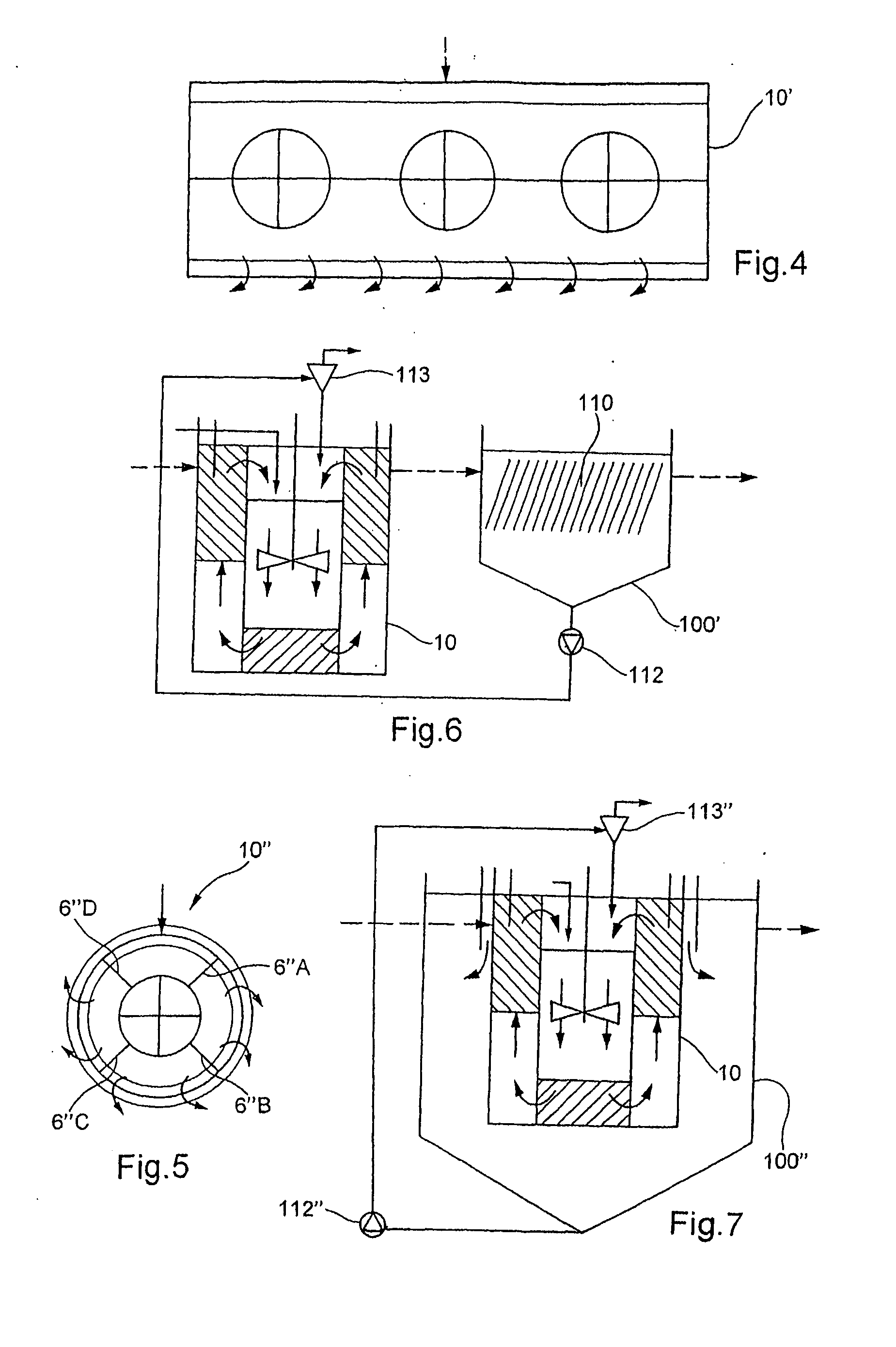

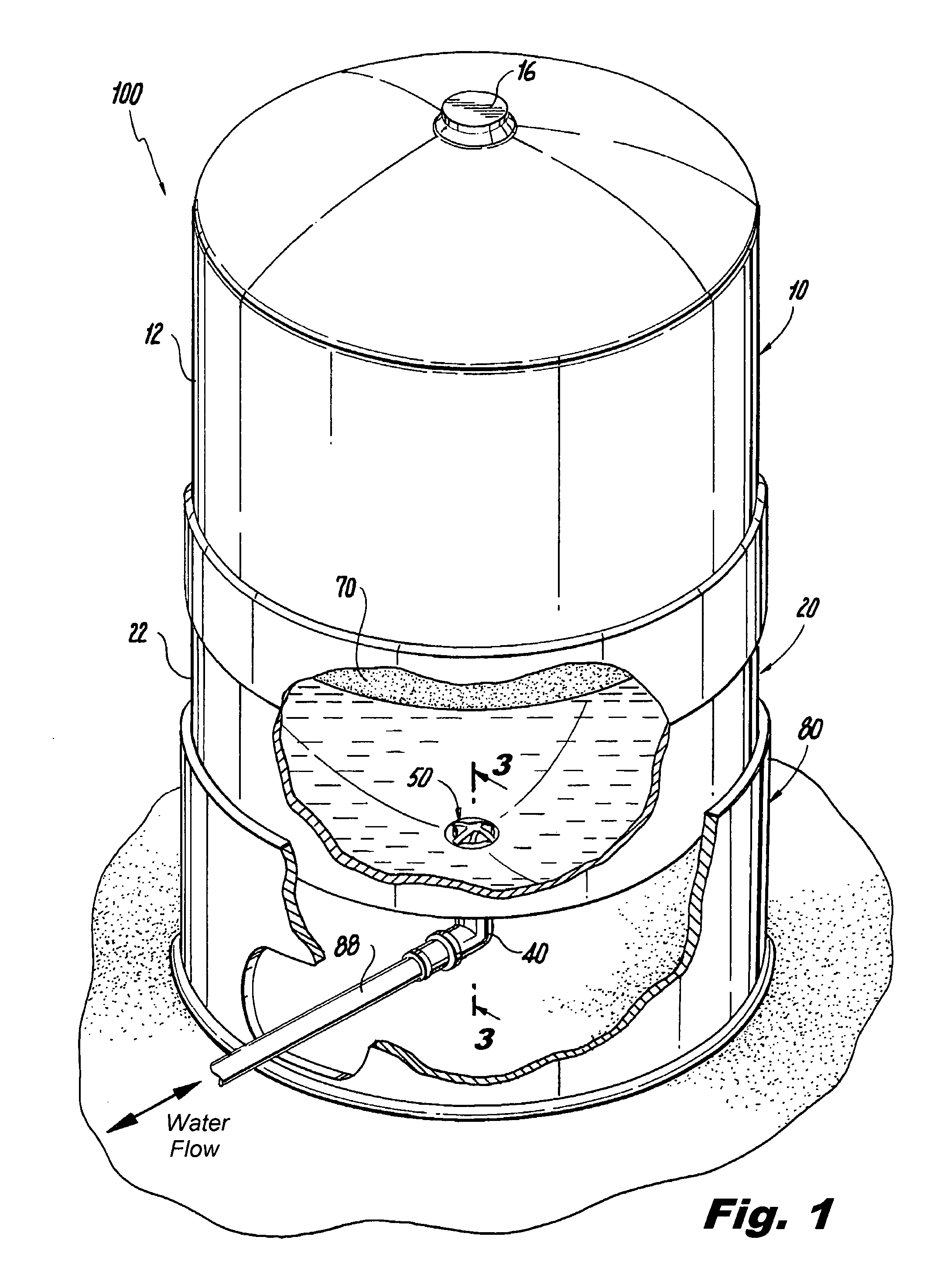

Method and apparatus for treating wastewater

ActiveUS20070114184A1Easy to combineImprove efficacyWater treatment compoundsDifferential sedimentationWastewaterTurbulent blood flow

A method and apparatus for treating wastewater. The apparatus comprises a reactor having a flow channel generally centrally located in a reactor and immersed in the water or wastewater in the reactor. An agitator is disposed within the flow channel and induces water or wastewater to enter the open upper end thereof and to move downwardly through the flow channel where the water or wastewater is discharged via a flow divider. A reagent is injected into the water or wastewater and the agitator within the flow channel serves to mix the reagent with the water or wastewater passing therethrough and in the process causes at least a slightly turbulent and downward axial flow through the flow channel.

Owner:VEOLIA WATER SOLUTIONS & TECH SUPPORT

Radial counterflow inductive desalination

ActiveUS20090045150A1Reduce salinityElectrostatic separatorsLiquid separation by electricityPorositySolvent

Simultaneous source-sink flow, or radial counterflow, is driven by a centrifugal pump disposed within a casing. Radially outward source flow of brine goes into a shrouding tank and concentrates while a radially inward sink flow of fresh water flows back over the pump to axial extraction. An axial pump drives sink flow and axial extraction.Convergent sink flow passes under an inductor to an axial exhaust port. Induced viscosity and inductive repulsion hinder the passage of brine in sink flow, so only fresh water can reach the axial exhaust port.Crystallization of scale-forming salts is aided by Joule heating from the inductor. Solvent and gases are continuously axially extracted in sink flow, favoring crystallization. Sodium chloride is cooled and crystallized in the shrouding tank. Brine comprising other salts flows out of the tank to treatment by suitable means. Thus brine is separated into fresh water, crystallized salt, and concentrated brine. Oil also is separated from brine.Metal recovery is another application, using the teacup effect, inductive repulsion, and grooved runners on the centrifugal pump to separate metals from light solids and water.Tiny centrifugal separation effects of innumerable turbulent eddy vortices are integrated by the forcing regime of the centrifugal pump and the axial pump. A coherent network of organized low pressure gradients along capillary and arterial vortices gives bulk porosity so that sink flow can go through source flow. In an embodiment comprising counter-rotating impellers in the centrifugal pump, radial vortices provide arterial conduits for sink flow of fresh water and gases to axial extraction.

Owner:VORSANA INC

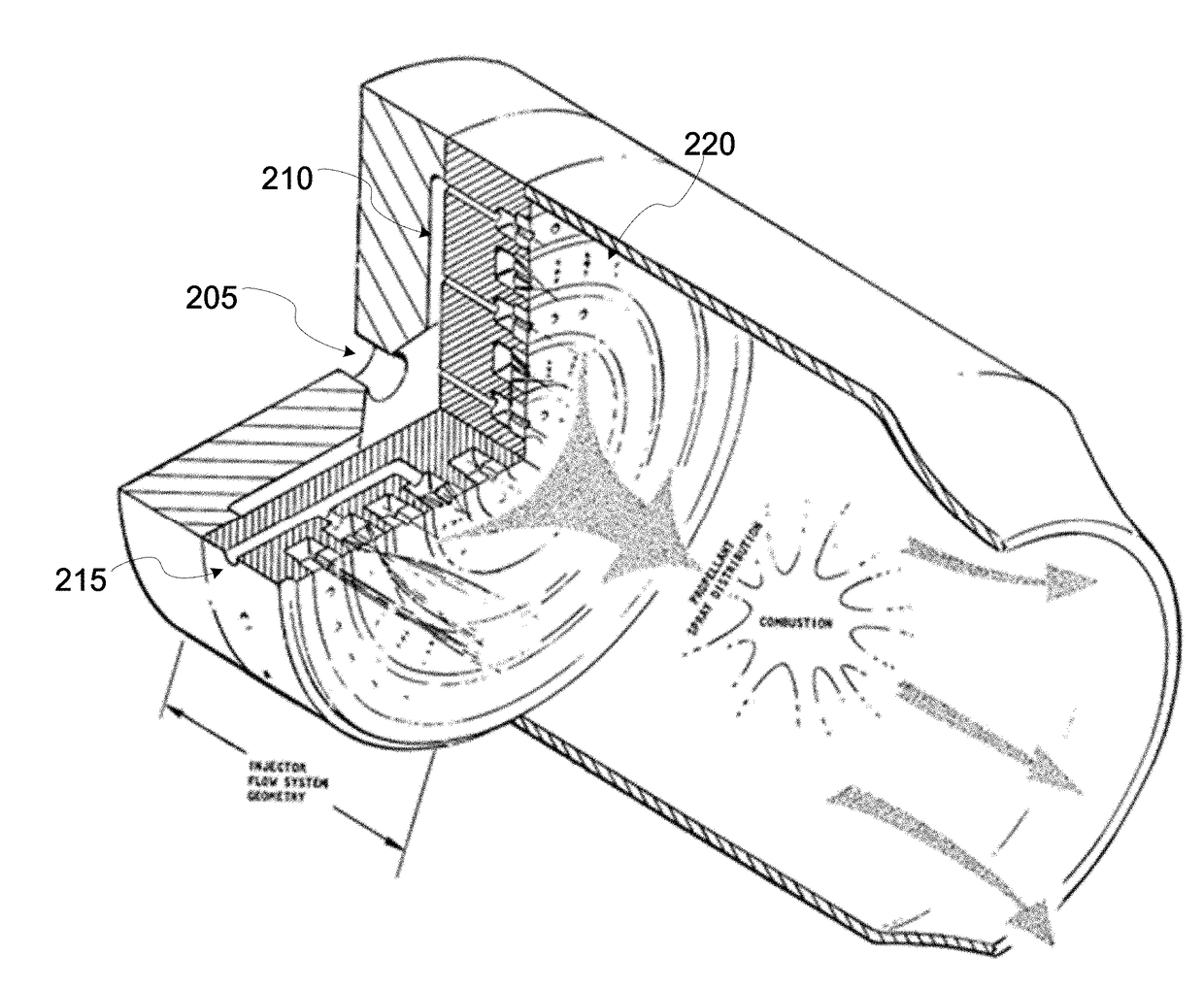

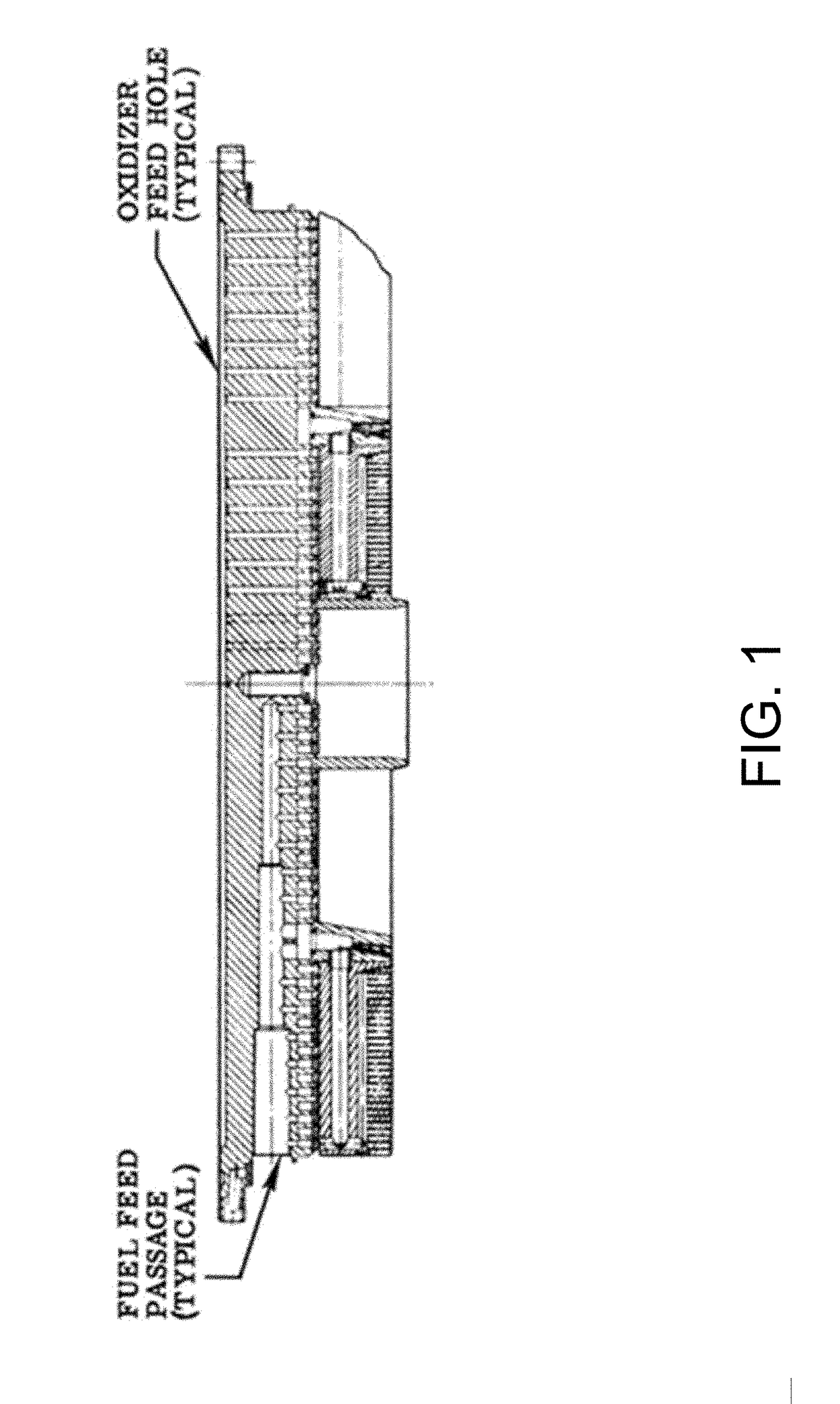

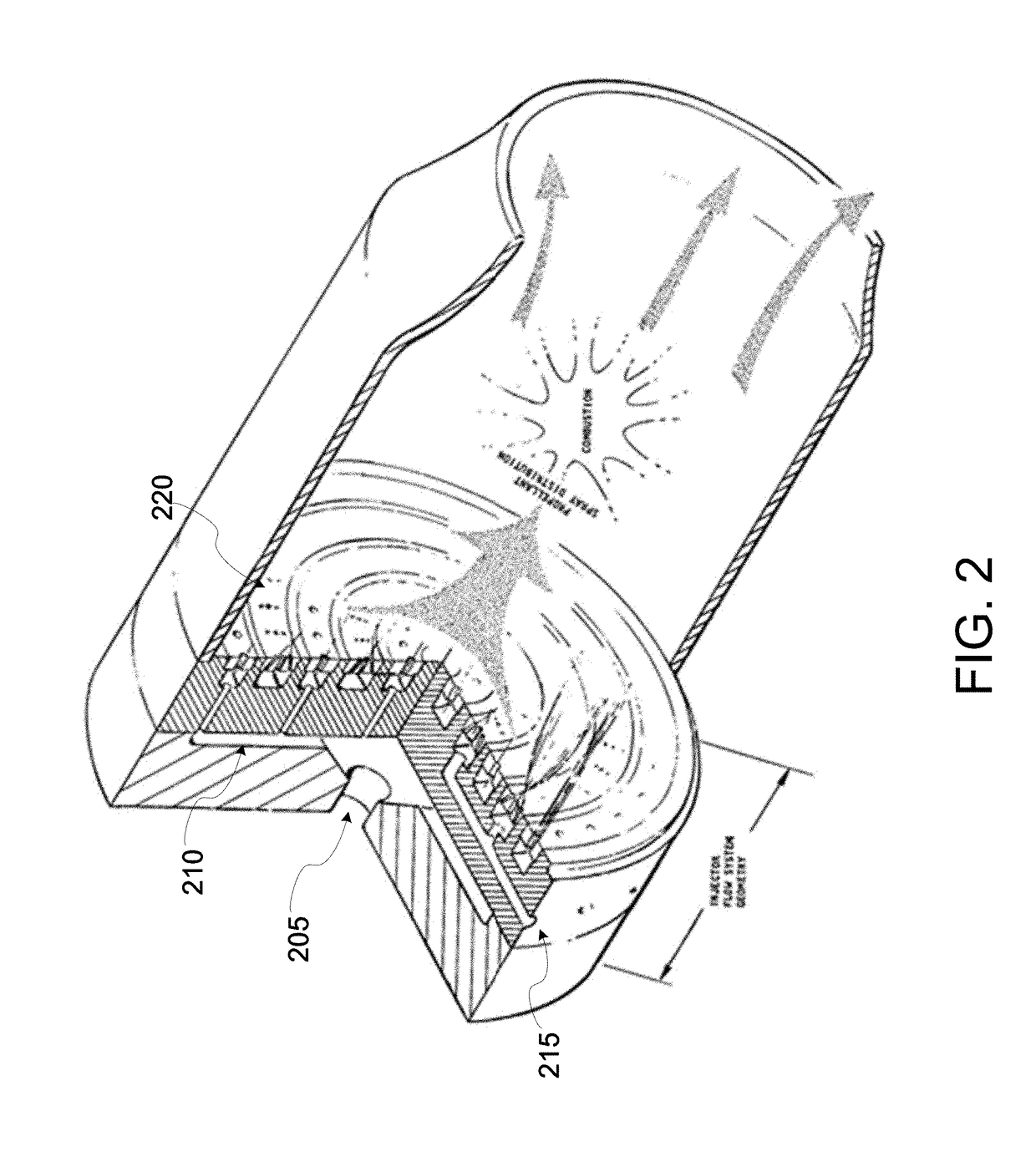

Fractal fluid passages apparatus

InactiveUS20180087701A1Reduce the cross-sectional areaComponent separation3D object support structuresCombustion chamberLiquid fuel

Aspects of the present disclosure include branching fluid passages in an apparatus that reduce turbulent flow and generate evenly distributed fluid pressure as the fluids branch off into the different passages. In some embodiments, the branching passages may be subdivided into two sets: the branching passages for the liquid fuel and the branching passages for the liquid oxidizer. In some embodiments, the two sets of passages are carefully designed in an elegant yet extremely intricate manner that is optimized for proper fluid flow and maximal burn efficiency. The ends of all of the passages meet at the injector interface, which dispense the liquids into the combustion chamber for ignition. Generally, these designs are achieved through additive manufacturing, and would be extremely difficult, if not impossible, to be manufactured using traditional techniques.

Owner:ADDITIVE ROCKET CORP

Fixed Swirl Inducing Blast Liner

Wear is reduced in abrasive slurry service at an outlet into an annular space defined by the wellbore and around the tool. In a gravel packing application with a crossover, the slurry exits a central passage and goes into an internal annulus in the tool. Turning vanes that make at least one full turn and that have a height at least partially the height of the annular space are there to impart a swirl movement to at least a portion of the slurry stream. The swirling motion has beneficial effects of reducing turbulence which allows a velocity reduction for a comparable output volume. As a result of the lower turbulence leading to the final exit from the tool into the surrounding annulus, the exit ports experience reduced erosion and longer service life.

Owner:BAKER HUGHES INC

Cross-flow filtration with turbulence and back-flushing action for use with online chemical monitors

ActiveUS20120132597A1Reduce buildWater/sewage treatmentLoose filtering material filtersInlet valveMonitoring system

A filtration and monitoring system includes an online monitoring device and a filter block having a chamber therein. An inlet pipe provides fluid to the filter block chamber and has an inlet valve located therein configured to shut off the flow of the fluid through the inlet pipe. An outlet pipe removes fluid from the filter block chamber. A filtered fluid conduit fluidically connects the filter block with the monitoring device. The outlet axis of the outlet pipe is offset from the inlet axis of the inlet pipe such that the fluid undergoes a change of direction while passing through the filter block chamber thereby causing turbulent flow within the filter block chamber. The turbulent flow within the filter block sweeps off particles that accumulate on the filter block chamber-side of the filter element to reduce the buildup of filter cake on the filter element. Closing the inlet valve causes a relatively sharp stop to the flow of fluid through the filter block, resulting in a back-flushing flow of fluid through the filter element from a pressure accumulator located in the filtered fluid conduit to the filter block chamber. The back-flushing flow of fluid dislodges filter cake accumulated on the filter block chamber-side of the filter element.

Owner:BL TECH INC

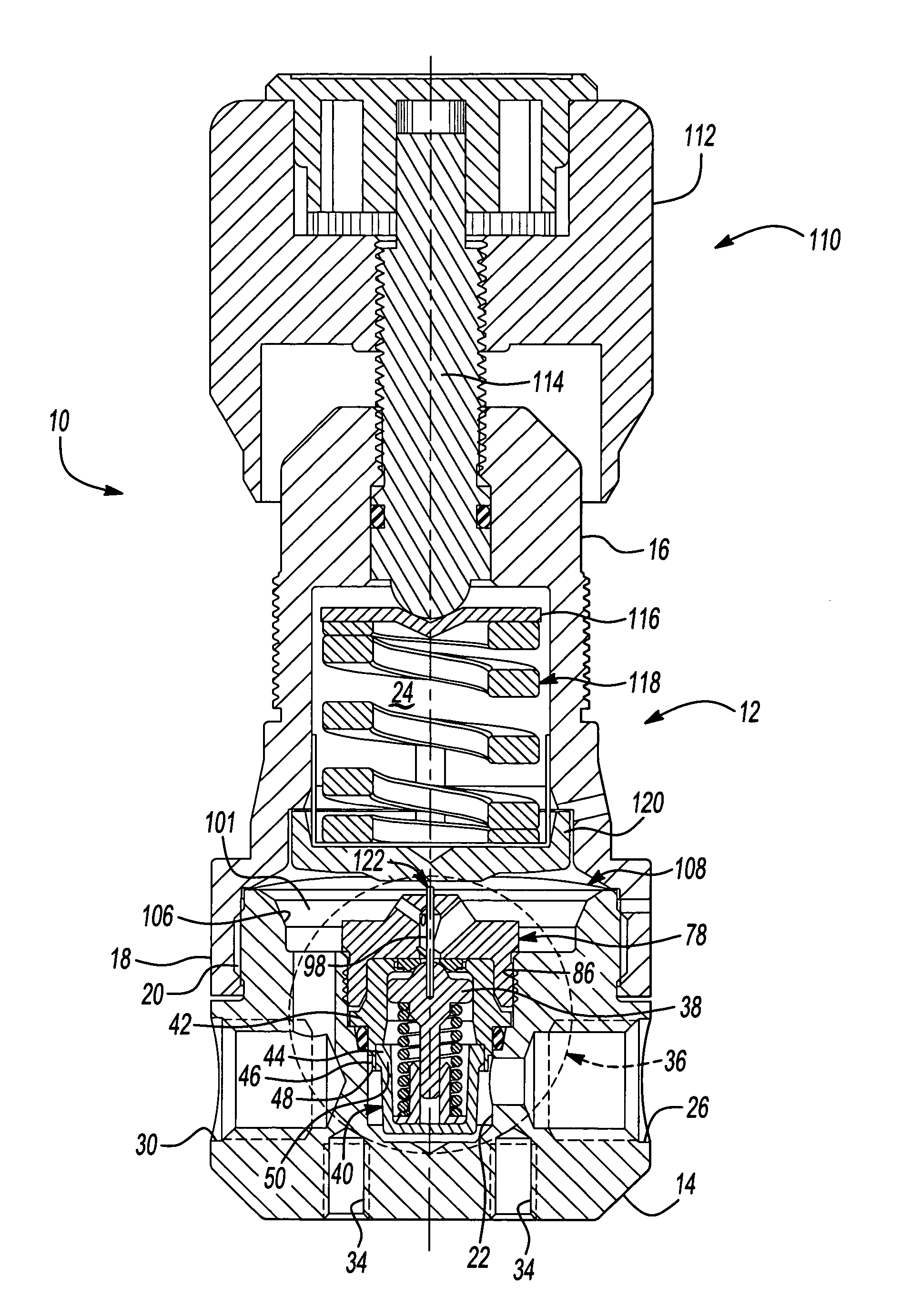

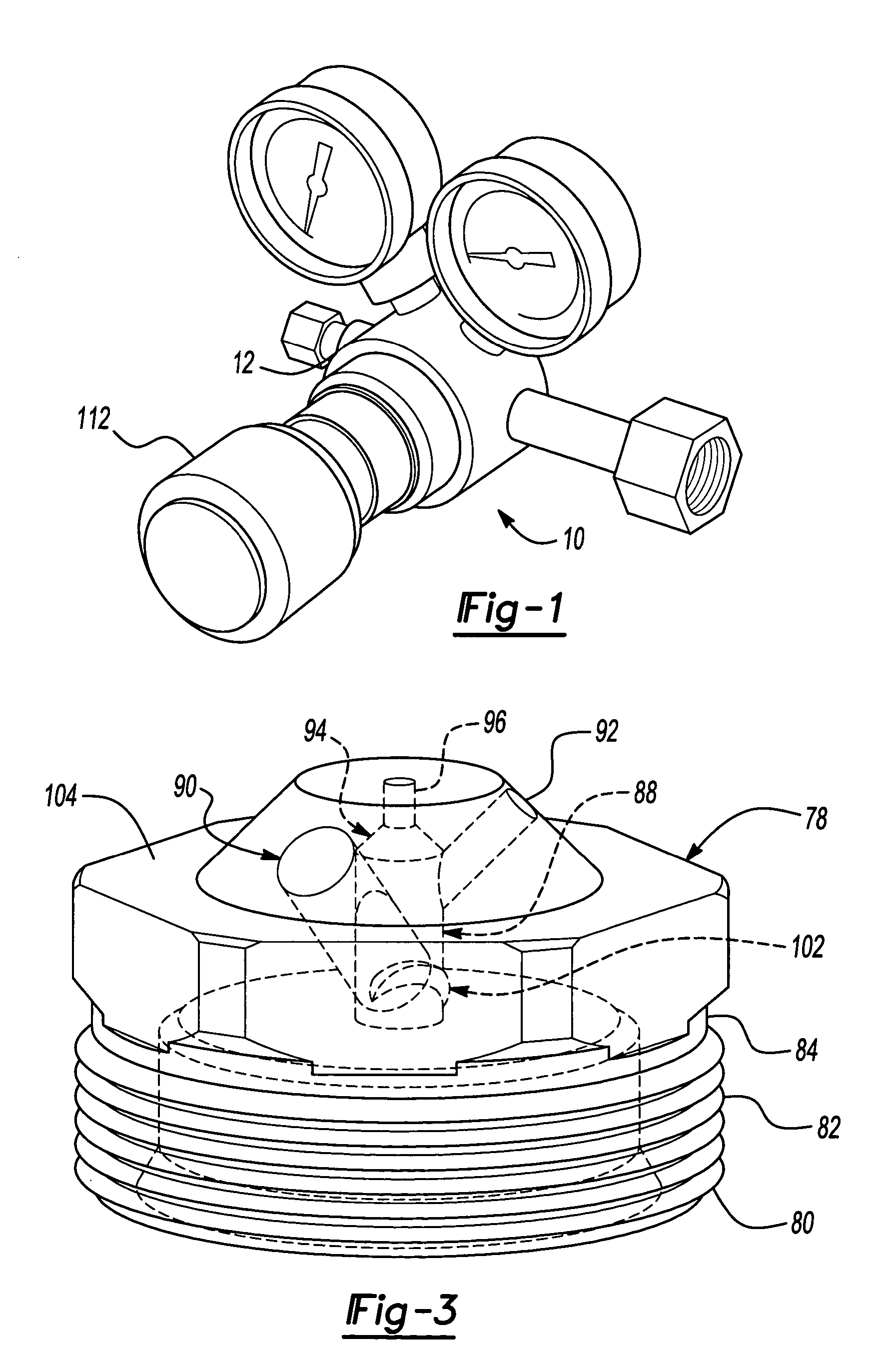

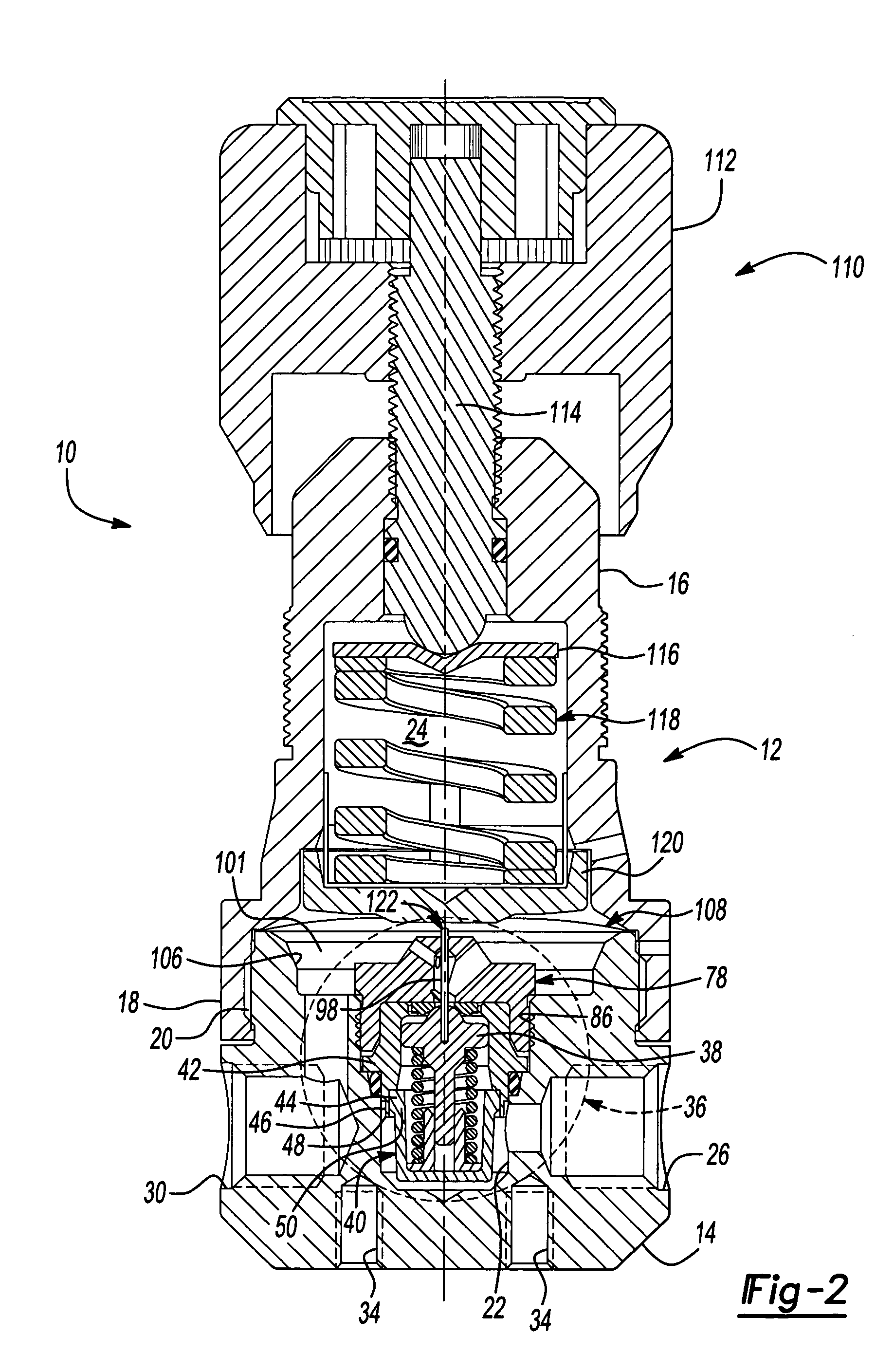

Gas pressure regulator

InactiveUS20050257836A1Vibration minimizationIncreased efficiency of fluid flowingOperating means/releasing devices for valvesFluid pressure control without auxillary powerStream flowEngineering

A gas pressure regulator capable of minimizing vibration and improving overall fluid flow efficiency. The gas pressure regulator achieves these benefits using varying techniques including providing a nozzle having a primary passage, a secondary passage, and a flow channel groove to smooth the fluid flow, reduce turbulence, and improve overall flowrate, without adversely effecting the necessary backpressure required for reliable operation. Additionally, the gas pressure regulator may use angled walls in the low-pressure cavity to enhance deflection and distribution. Still further, the gas pressure regulator may use additional flow channels to permit smooth fluid flow while eliminating fluid impact.

Owner:VICTOR EQUIP

Fluid pressure sensing chamber

InactiveUS20070098579A1Easy to primeFluid parameterFlexible member pumpsDifferential pressurePressure sense

A pressure sensing chamber having a canted tubing extension with a reduced diameter portion extending through the chamber. The tubing contains a plurality of ports so as to allow the purging of air from the chamber, but the ports are sized so that bubbles entering the tubing cannot easily flow into the chamber. The reduced diameter portion creates a pressure differential between the holes. This differential pressure creates flow through the chamber under high liquid flow and turbulent liquid flow events.

Owner:ALCON INC

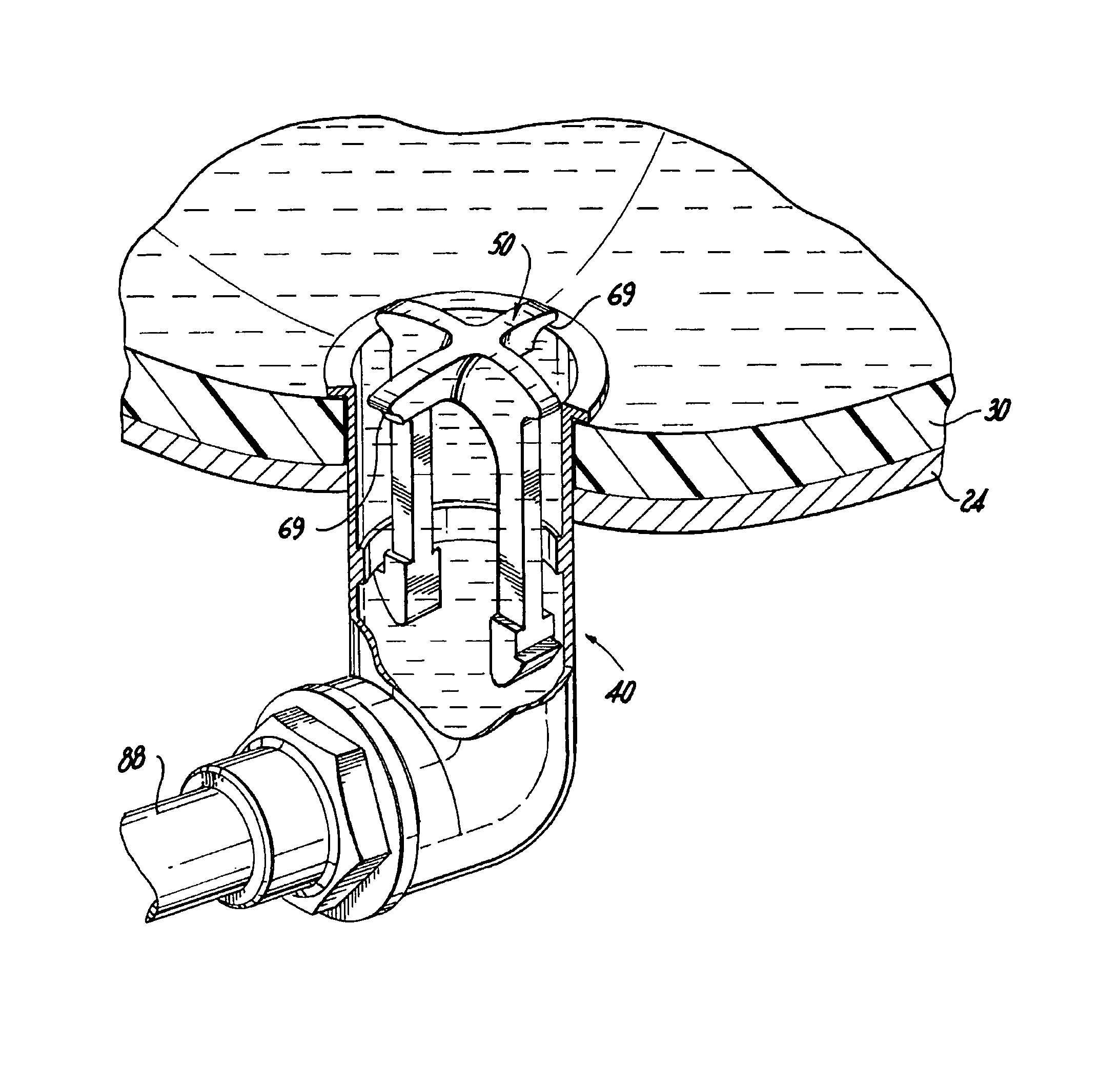

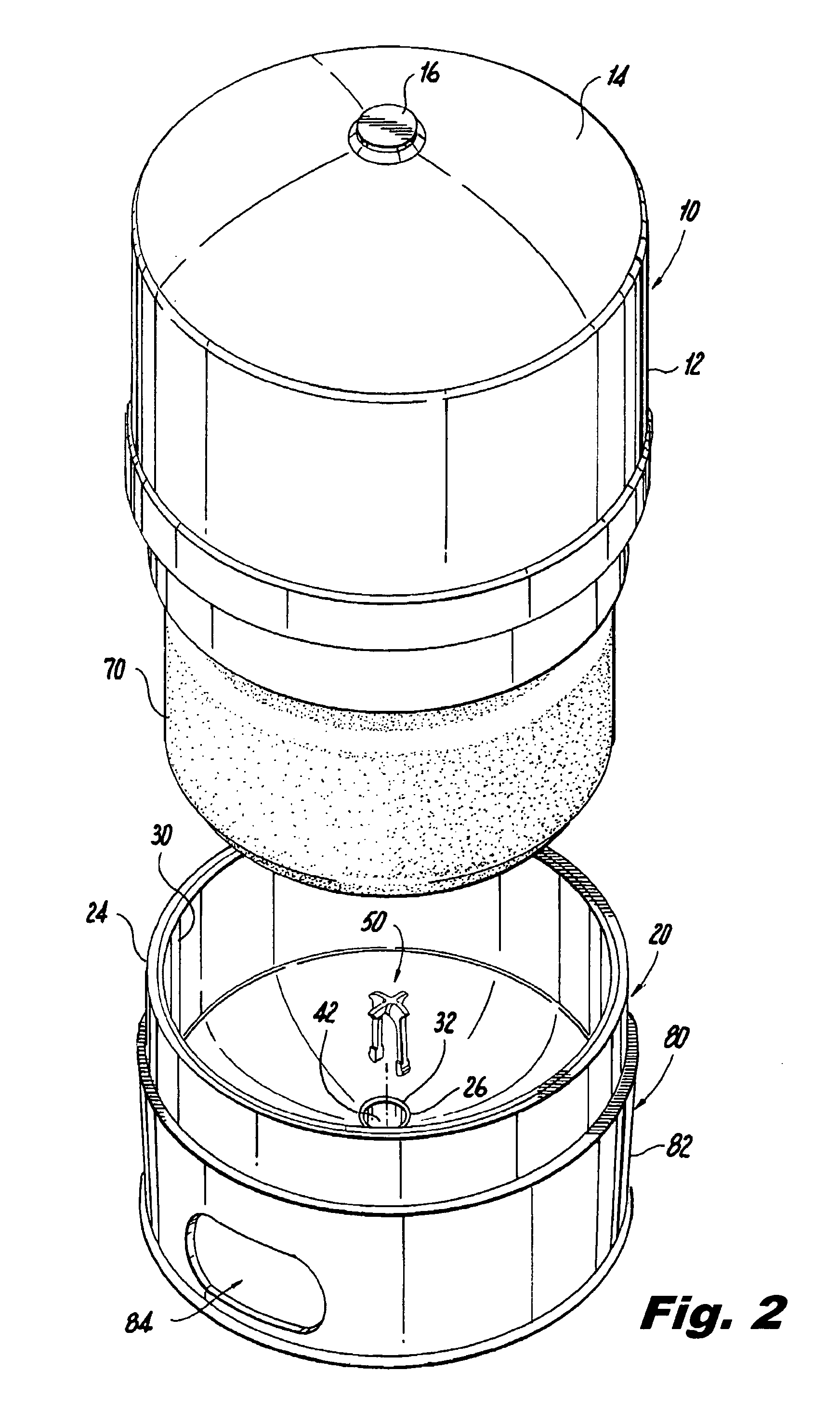

Device for causing turbulent flow in a tank assembly

Disclosed is a device for causing turbulent flow in a tank assembly that has an internal fluid cell and a fitting for allowing fluid to enter and exit the fluid cell from the exterior of the tank assembly. The device includes a main body portion and first and second retaining arms. The first and second retaining arms extend from the main body portion of the device and are adapted and configured for supporting the device substantially within the fitting of the tank assembly. A plurality of curved vane elements extend from the main body portion which cause turbulent flow in the fluid cell of the tank assembly by redirecting fluid entering the tank assembly axially through the fitting in a non-axial direction into the fluid cell.

Owner:AMTROL LICENSING INC

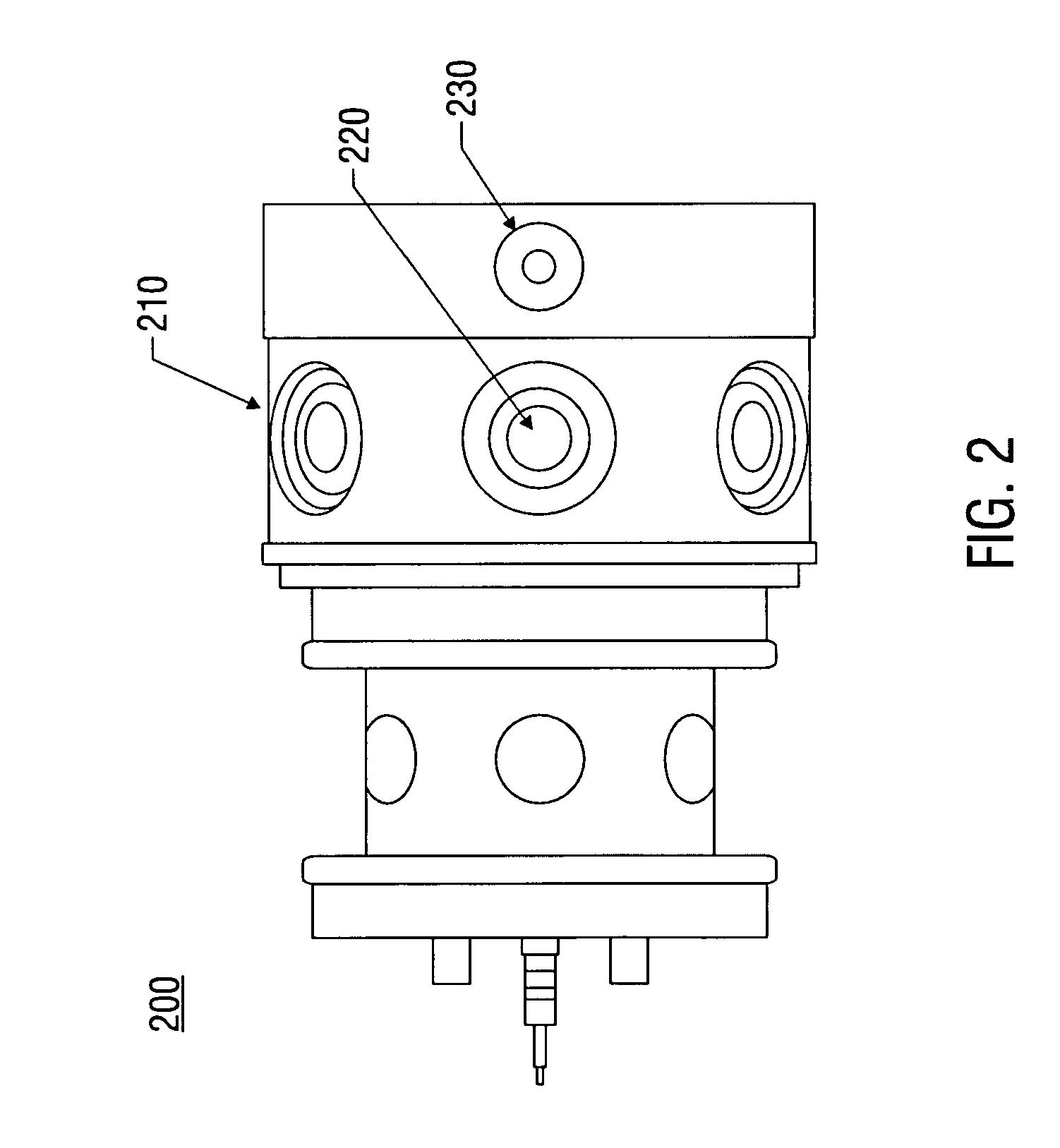

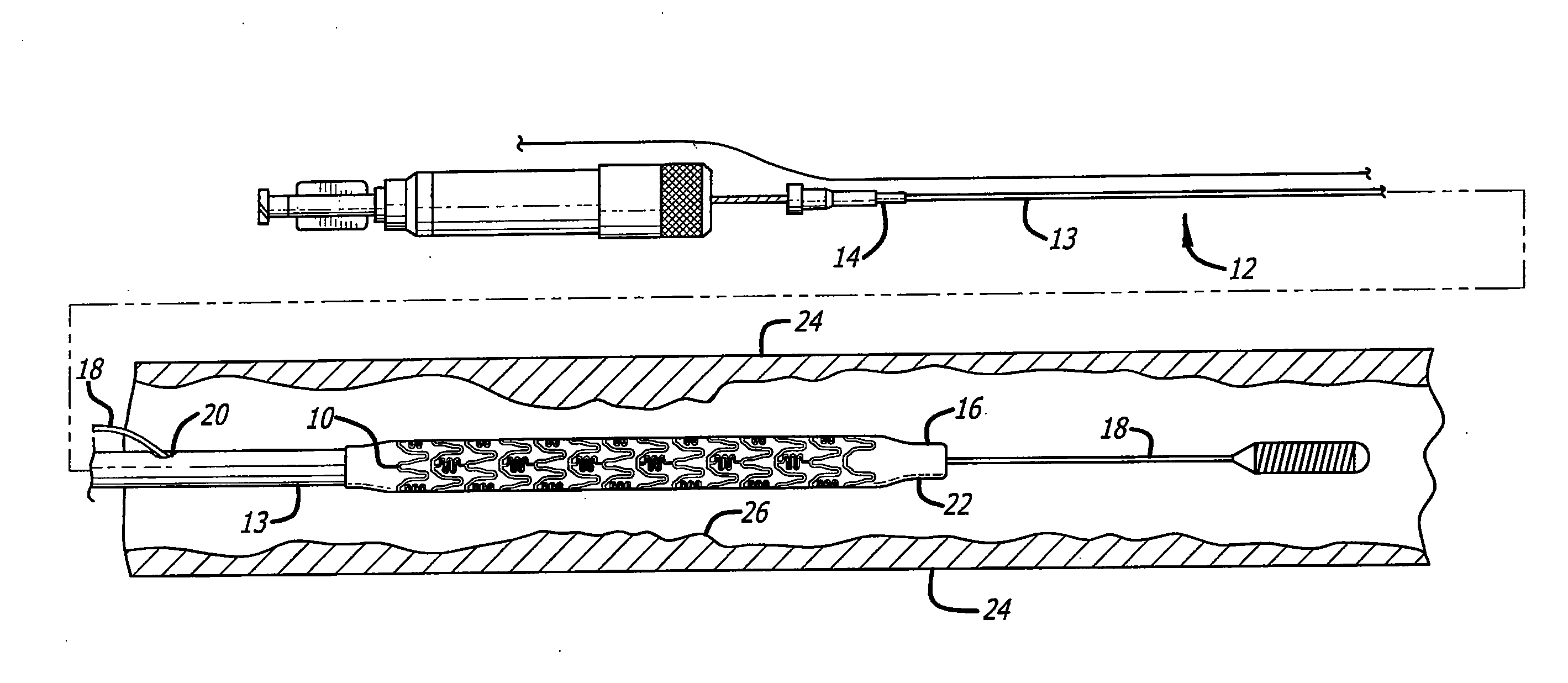

Electrochemical formation of foil-shaped stent struts

InactiveUS20120285836A1Improve clinical outcomesReduce turbulent blood flowCellsStentsInsertion stentIntravascular stent

An apparatus and method for electrochemically treating the struts of an intravascular stent is disclosed. An intravascular stent is mounted in a chamber and is electrochemically treated in order to remove a portion of the stent struts in order to form an airfoil shape. The airfoil-shaped stent struts will reduce turbulent blood flow in the vasculature in which the stent is implanted thereby improving clinical outcome.

Owner:ABBOTT CARDIOVASCULAR

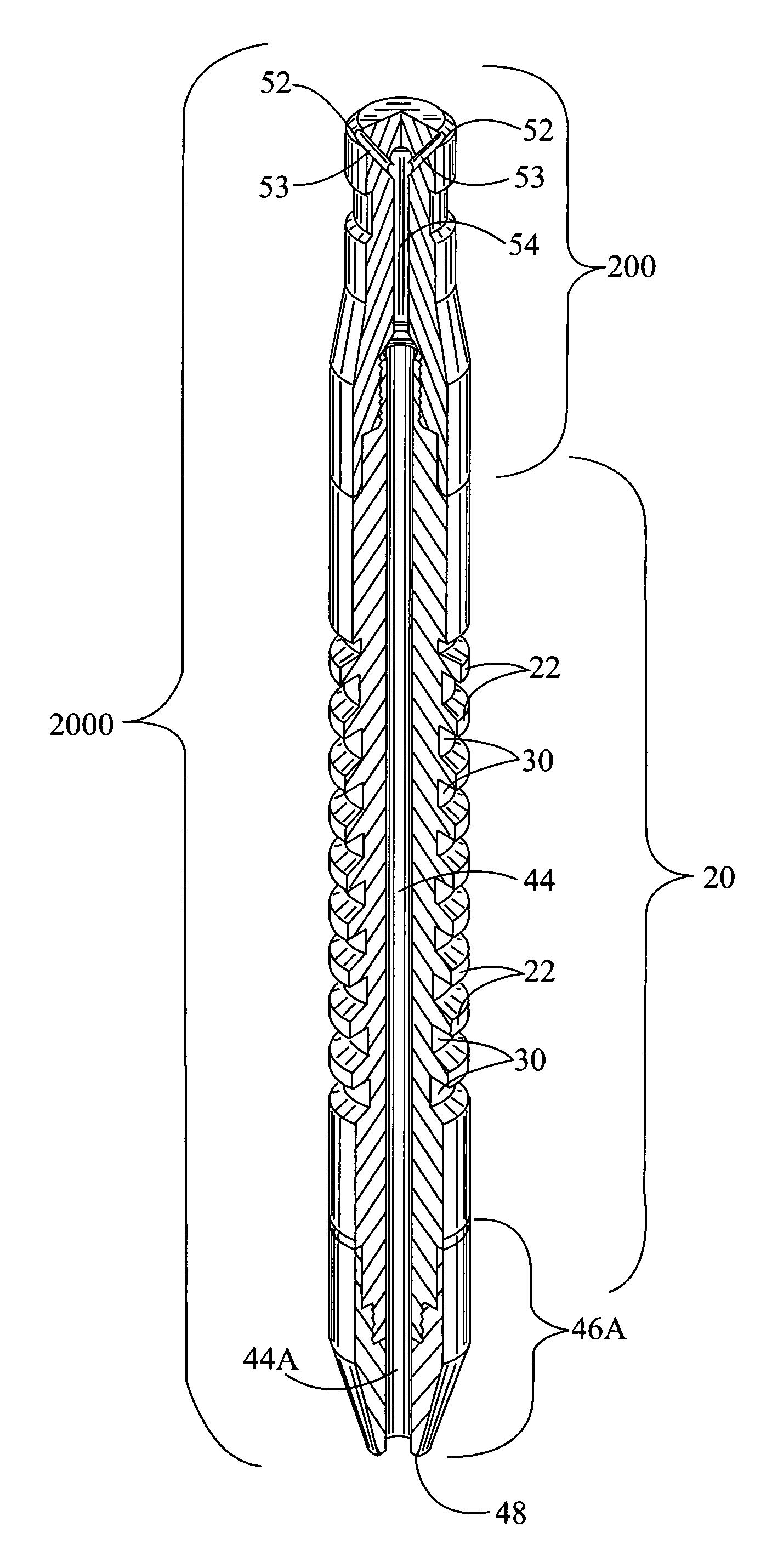

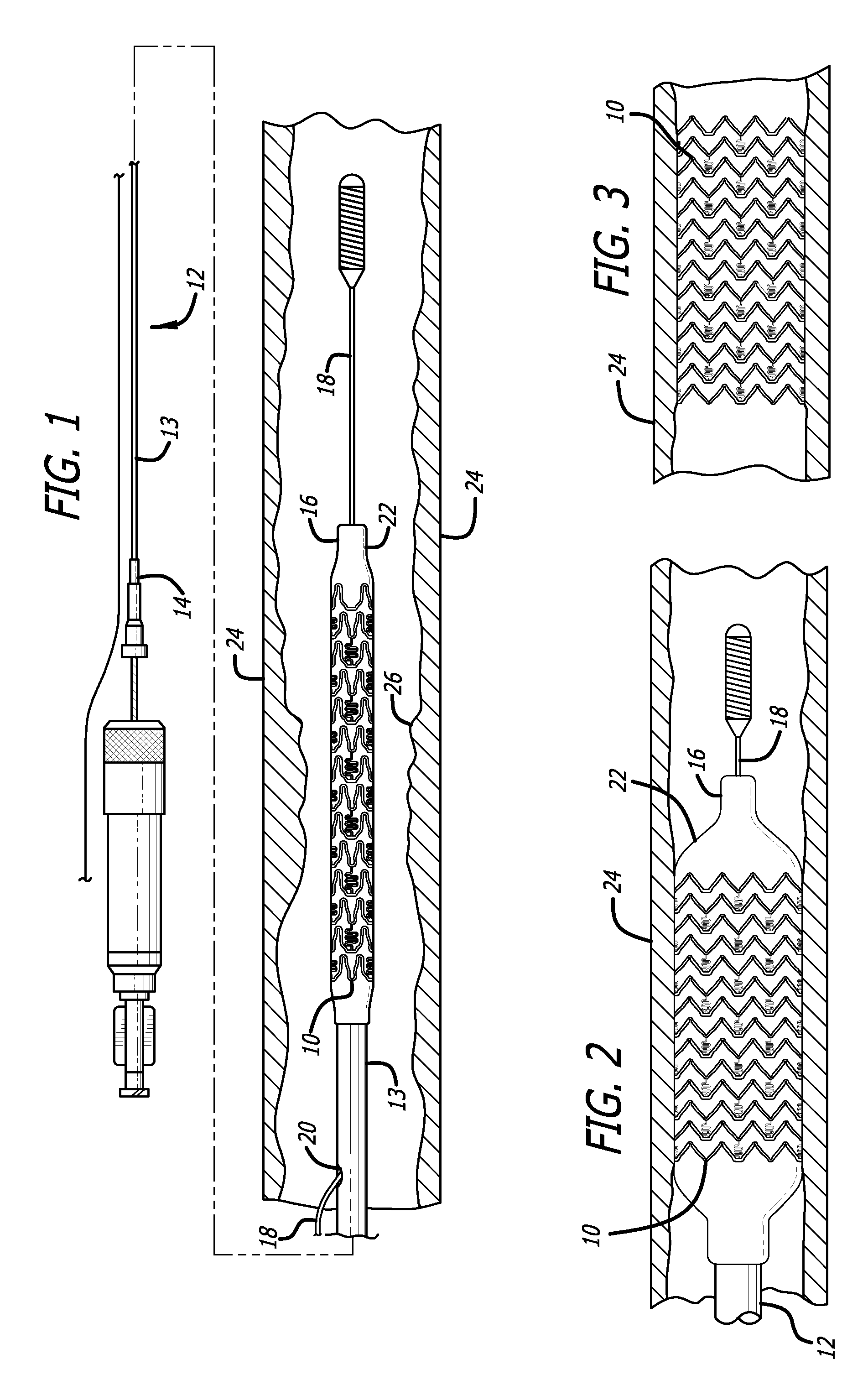

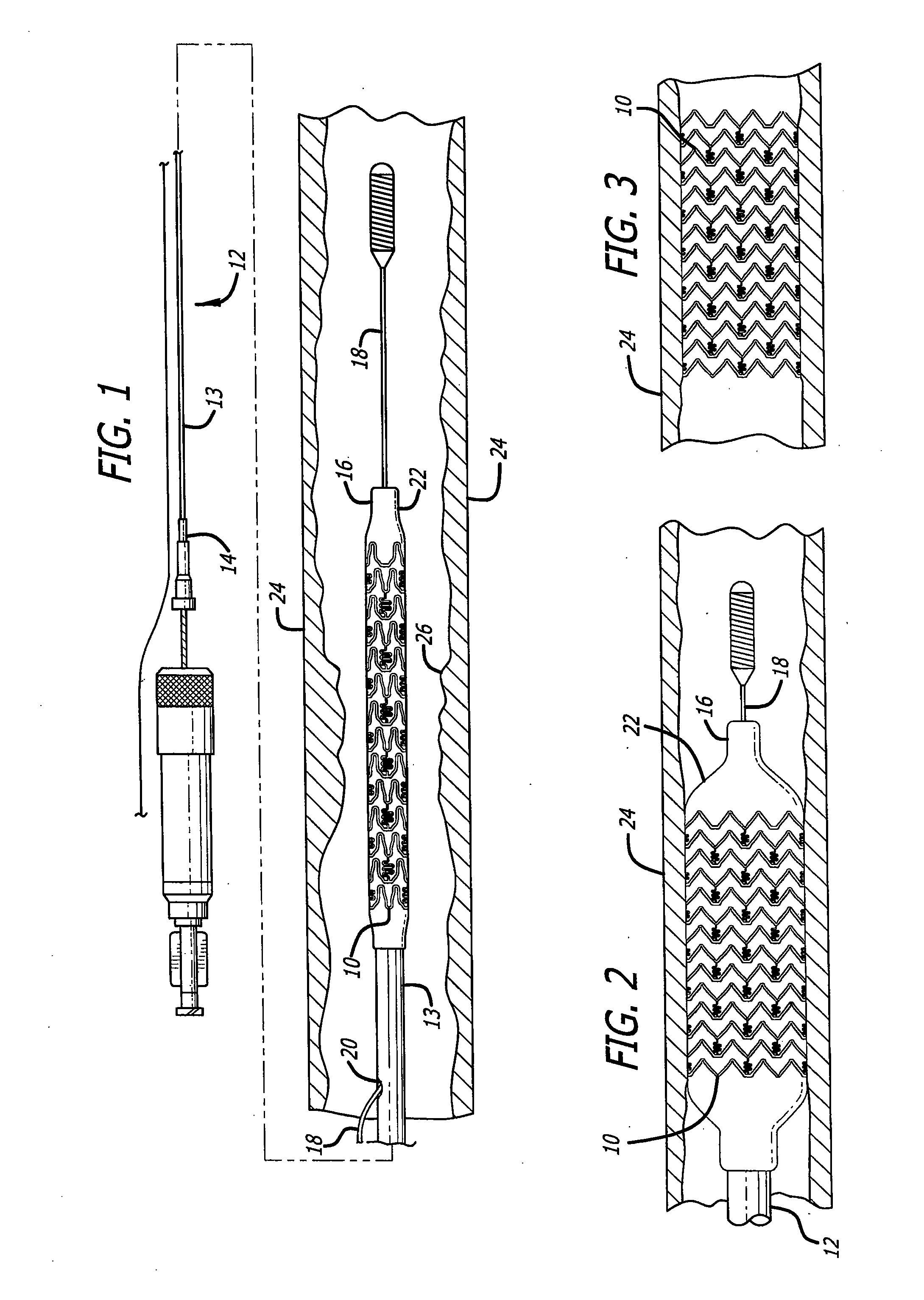

Apparatus and method for formation of foil-shaped stent struts

InactiveUS20130005218A1Improve clinical outcomesReduce turbulent blood flowStentsBlood vesselsCoronary arteriesInsertion stent

A device and method is disclosed for reducing turbulent blood flow over stent struts of an intravascular stent implanted in, for example, a coronary artery. An abrasive slurry is passed over the struts of an intravascular stent in order to remove a portion of the stent struts to form an airfoil shape. When the stent having airfoil-shaped struts is implanted in an artery, the flow of blood over the airfoil shape will reduce the likelihood of turbulent blood flow and thereby will reduce the likelihood of turbulent blood flow and thereby reduce the likelihood of a buildup in plaque or injury to the vessel wall.

Owner:ABBOTT CARDIOVASCULAR

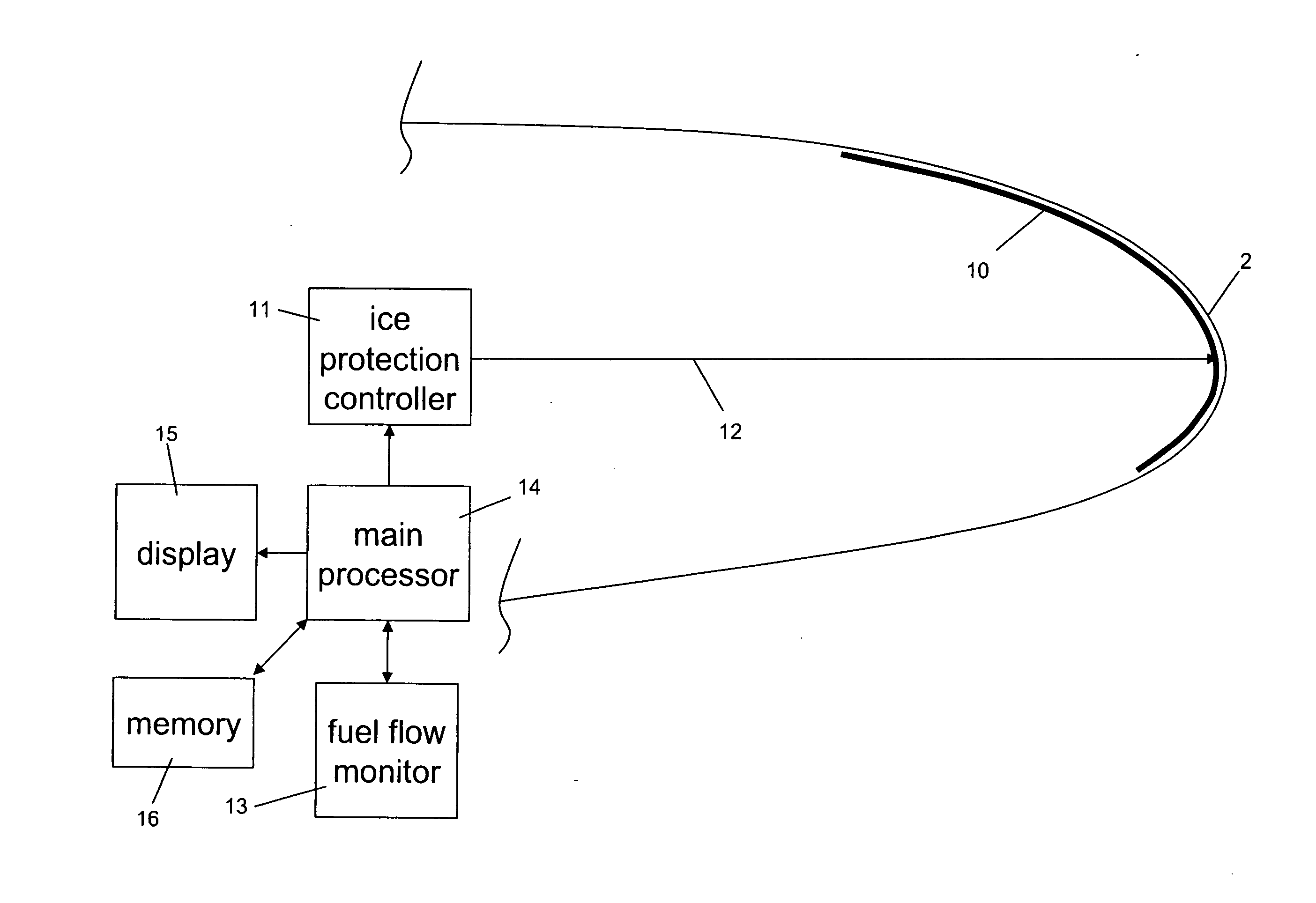

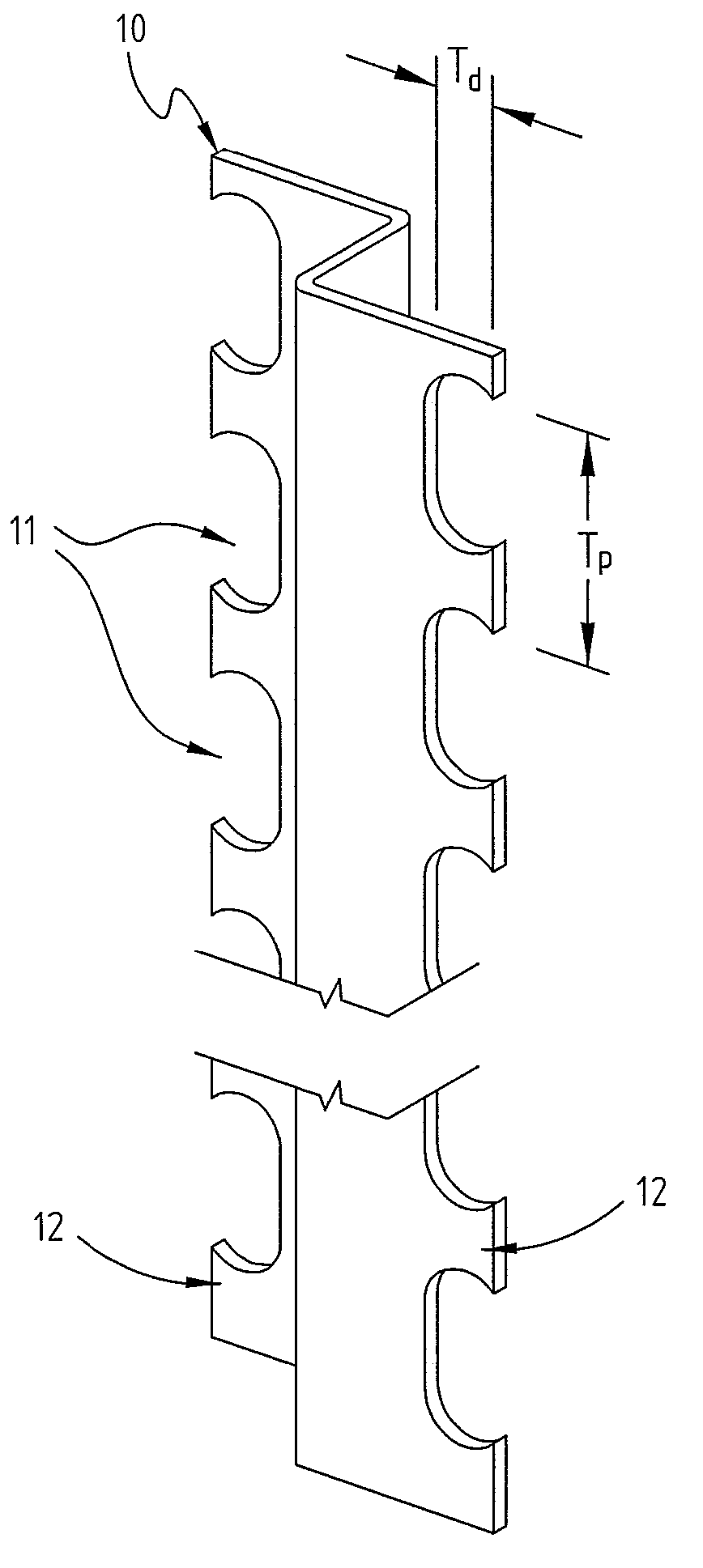

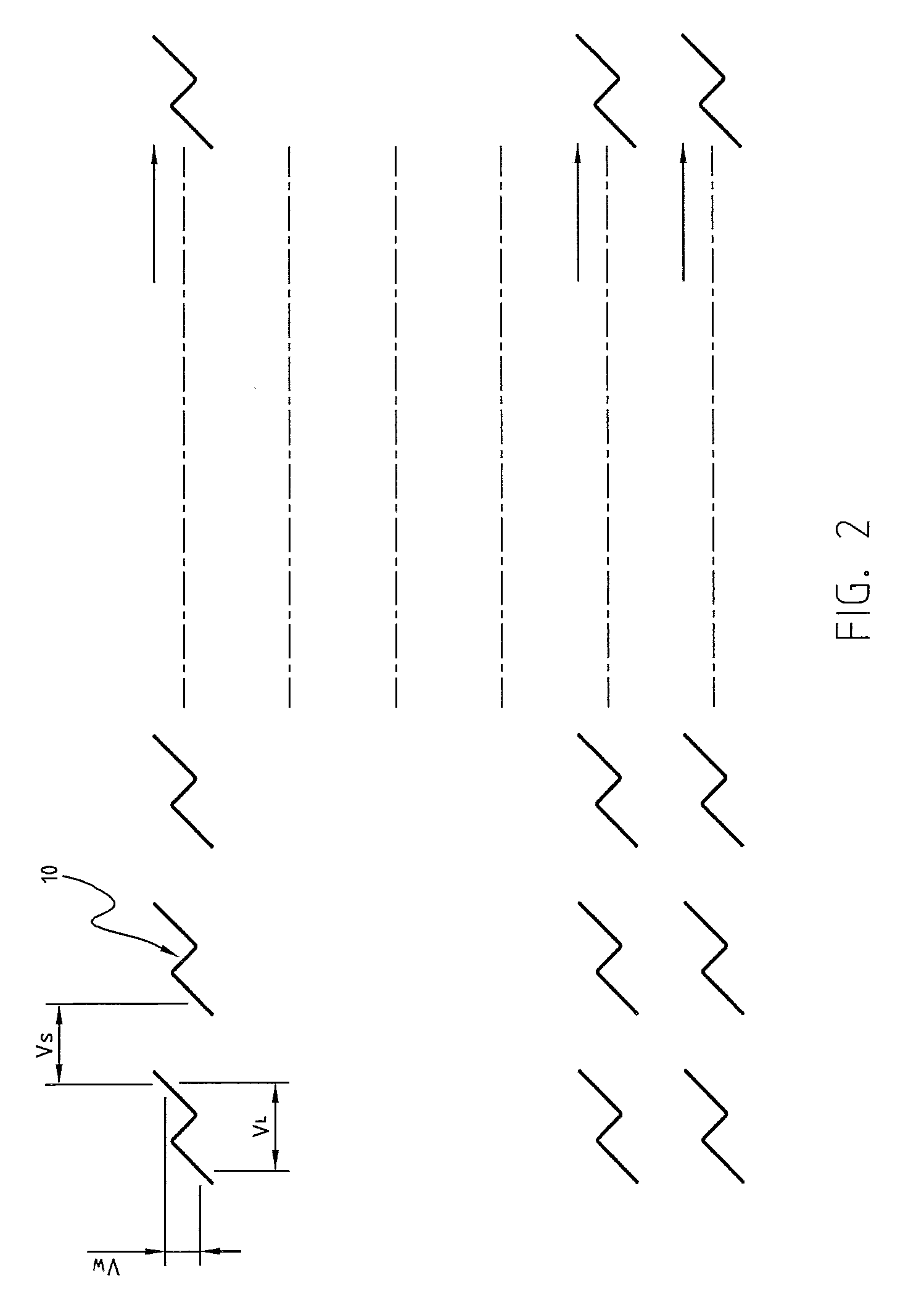

Laminar flow monitor

ActiveUS20120049002A1Airflow to be perturbed quickly and simultaneouslyLittle costAnalogue computers for trafficAerodynamic testingIce protection systemEngineering

A method of monitoring the performance of an aerodynamic surface of an aircraft. The aircraft is operated during a non-perturbed measurement period such that the flow of air over the surface is at least partially laminar. A parameter is measured which is indicative of the drag of the surface during the non-perturbed measurement period to provide non-perturbed drag data. Air flow is perturbed temporarily over the surface in a perturbed measurement period so that it undergoes a transition from laminar flow to turbulent flow. The parameter is also measured during the perturbed measurement period to provide perturbed drag data. The degree of laminar flow during the non-perturbed measurement period can then be estimated in accordance with the difference between the perturbed drag data and the non-perturbed drag data. An ice protection system can be used to perturb the air flow.

Owner:AIRBUS OPERATIONS LTD

Particle Interactions in a Fluid Flow

InactiveUS20100142314A1Likelihood of collision or interaction between the particles is increasedRaise the possibilityAuxillary pretreatmentFlow mixersParticle interactionParticle physics

Interaction between two different species of particles in a fluid stream is promoted by generating turbulent eddies in the fluid stream. The turbulent eddies are designed to be of such size and / or intensity that the two species of particles are entrained into the eddies to significantly different extents. Consequently, the different species of particles follow different trajectories, and the likelihood of collisions or interactions between the particles is increased. Optimum collision rates will occur for a system which maintains a Stokes Number (St) much less than 1 for one species, and or order 1 or greater for the other species. The invention has particular application in air pollution control, by promoting agglomeration of fine pollutant particles in air streams into larger particles to thereby facilitate their subsequent removal from the air streams.

Owner:HANSOM ENVIRONMENTAL PROD

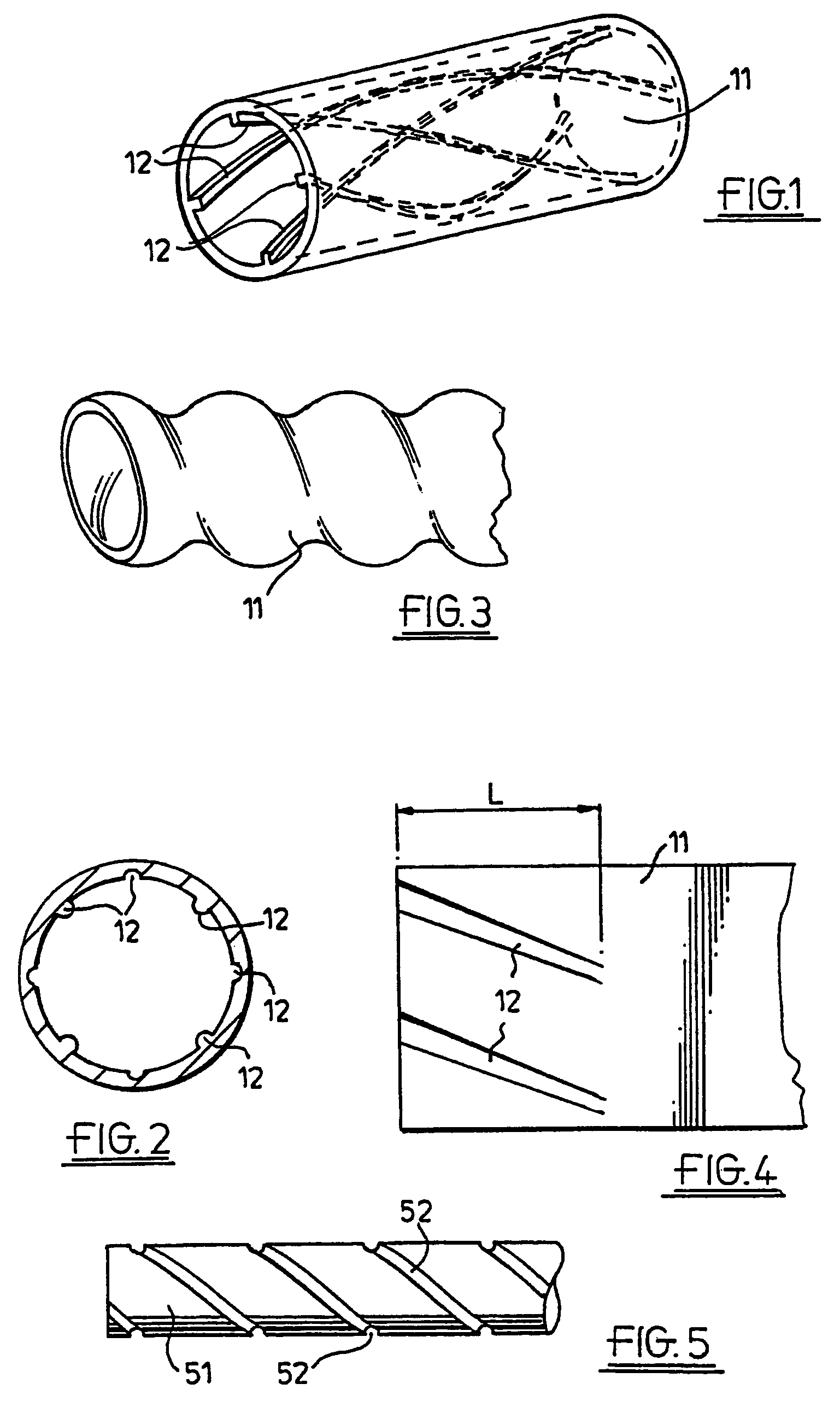

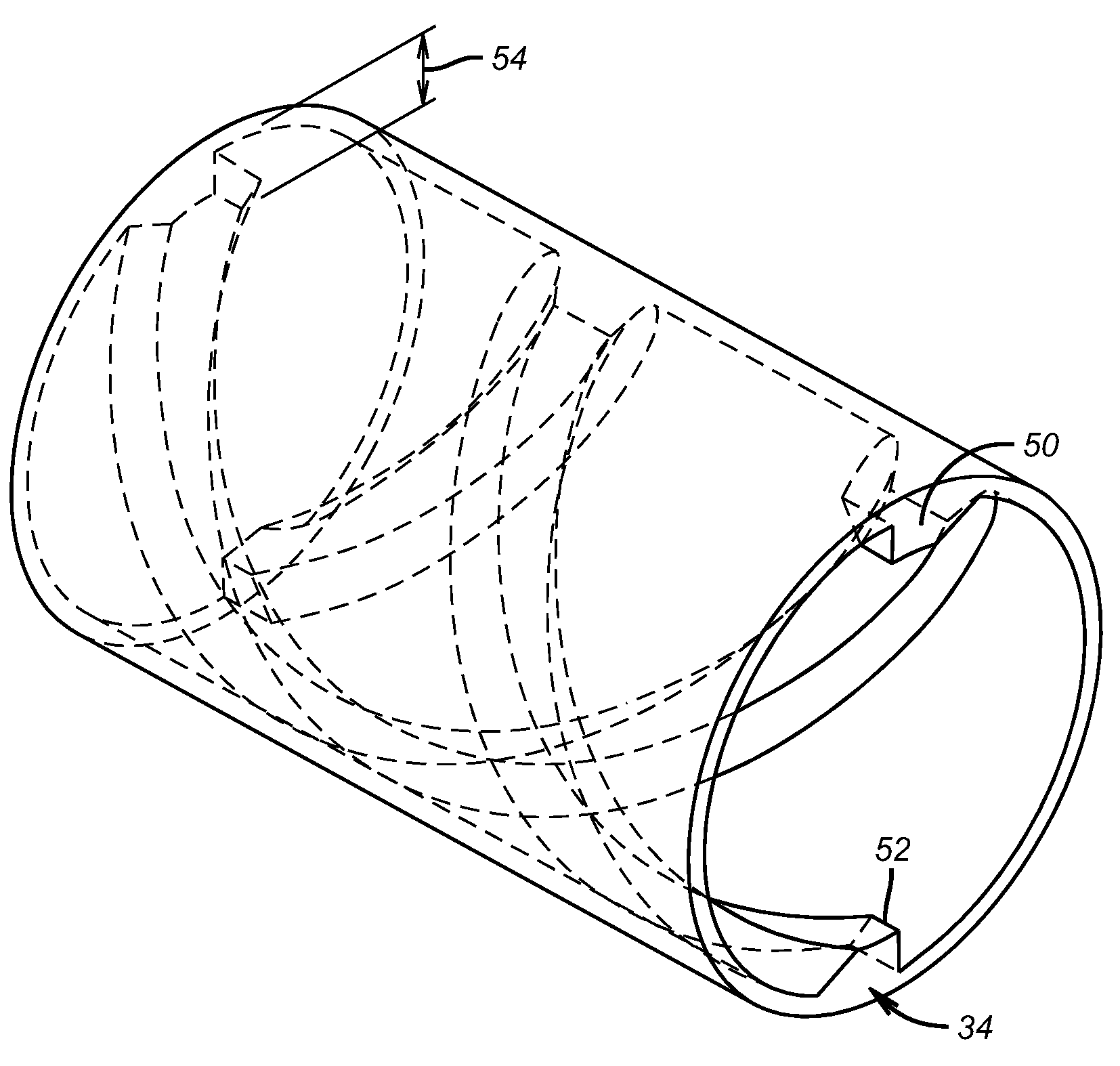

Stent to assist in arteriovenous fistula formation

There is described an arteriovenous fistula stent, having a tubular body comprising a series of sinusoidal shaped struts along the length of the tubular body. A plurality of curvilinear connectors extend between and are attached to adjacent struts wherein a first end of a connector is attached to a distal face of a proximal strut apex and a second end of a connector is attached to a proximal face of a distal strut apex. A pair of unconnected strut apexes are between pairs of connected apexes. When the tubular body is in a stowed configuration a proximal aperture and a distal aperture are circular and when the tubular body is in a deployed configuration the distal aperture is oblong or ovoid. There is also described a method for inserting a stent for use in creation of an arteriovenous fistula by identifying a candidate artery and a candidate vein and dissecting the candidate vein. Next, inserting a stent into the vein and creating a breach in the candidate artery at a desired angle and location. Next, introducing the stent and vein into the candidate artery and forming the stent into a curvature angle selected to minimize turbulent blood flow in an anastomosis formed by the vein and the artery. Optionally, there is a step of fastening a distal portion of the stent to the artery.

Owner:QUANTA COMPUTER INC +1

Fluid flow mixer

Owner:INNOVA GLOBAL LTD

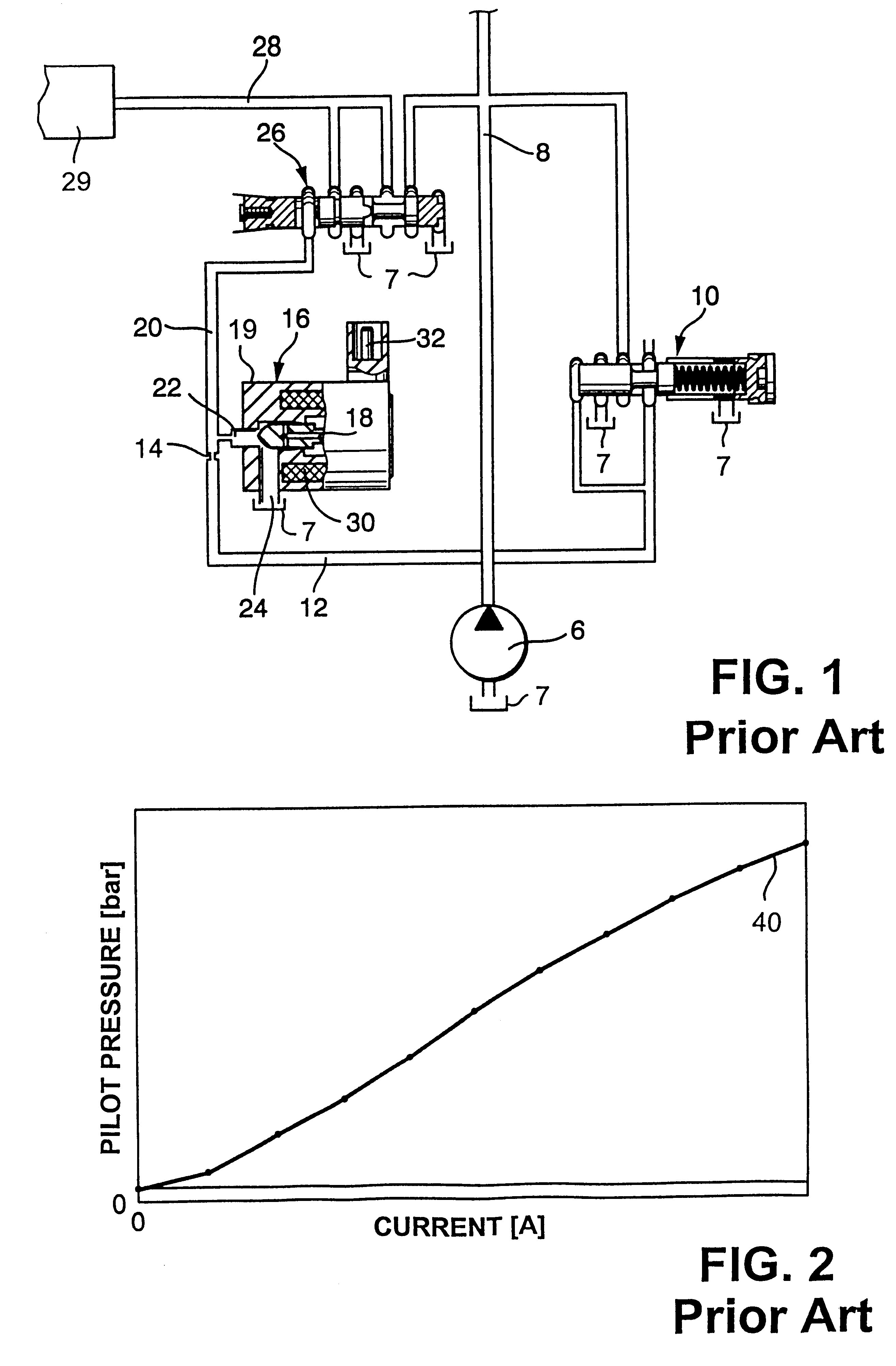

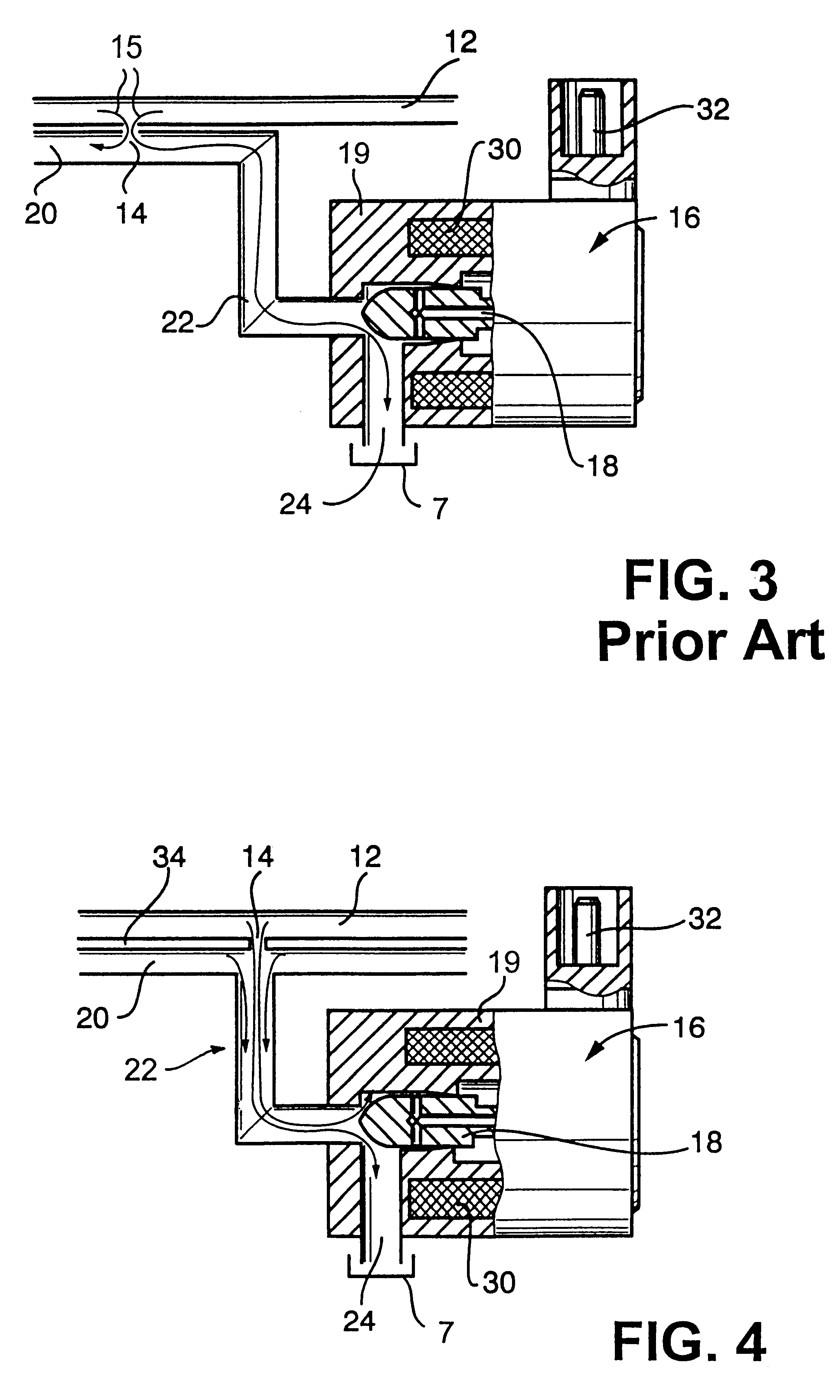

Pressure regulating method and apparatus

InactiveUS6196249B1Simple and compactDecrease in pilot pressureOperating means/releasing devices for valvesServomotor componentsStream flowEngineering

The pressure of hydraulic fluid which is supplied to the continuously variable transmission in the power train of a motor vehicle is regulated by an apparatus wherein an adjustable pilot valve can receive fluid from a pilot conduit leading to a pressure reducing valve. The pilot conduit normally receives fluid from a further conduit, wherein the pressure of fluid is at least substantially constant, by way of a flow restrictor. A branch conduit serves to evacuate fluid from the pilot conduit into the pilot valve when the latter is at least partially open. The fluid-discharging end of the flow restrictor confronts the inlet of the branch conduit, and such inlet is narrowed to reduce the likelihood of turbulence developing in the fluid stream flowing from the pilot conduit, across the further conduit and into the inlet of the pilot valve.

Owner:LUK GETRIEBE SYST

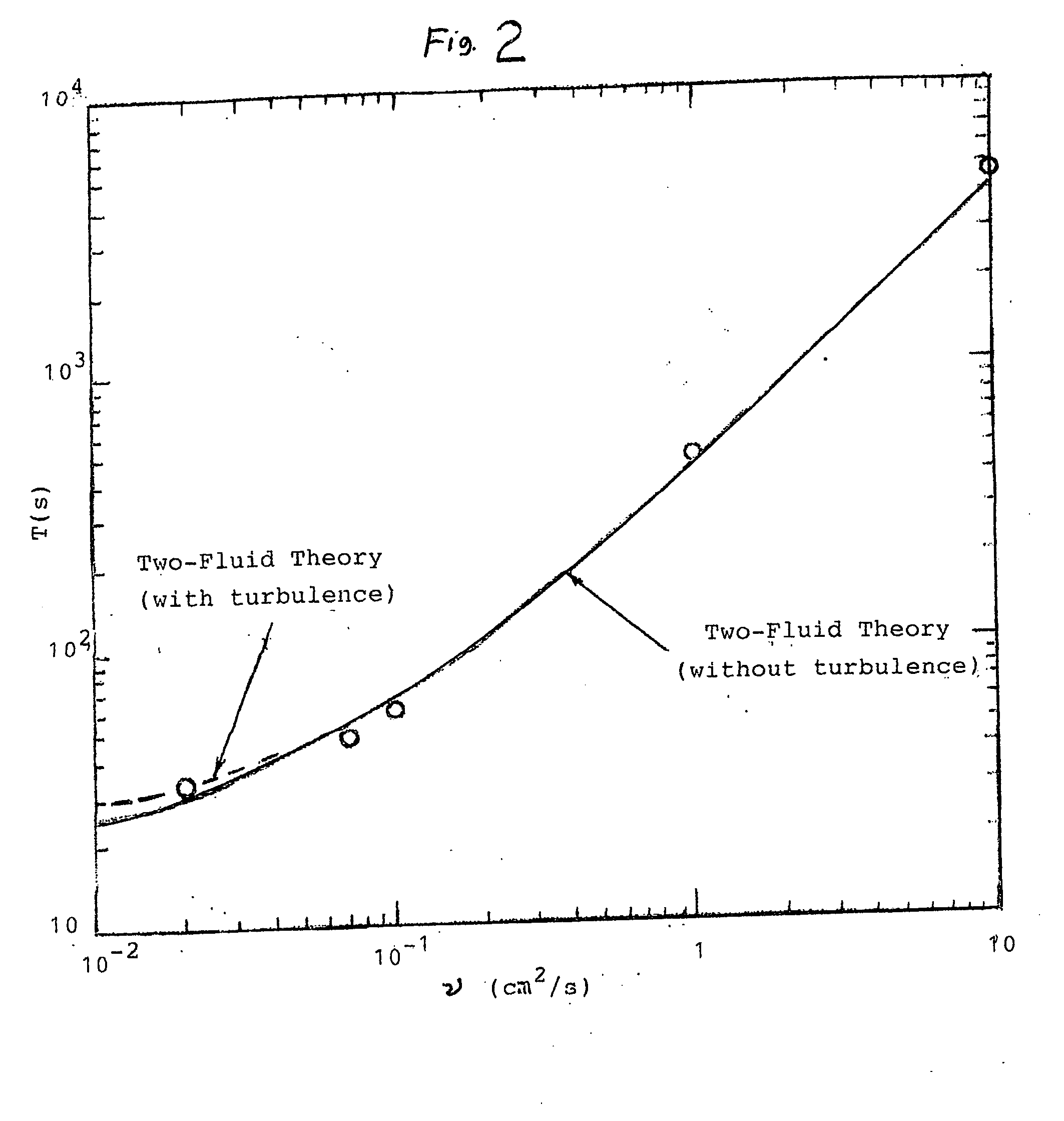

Pitot tube designs for compressible and incompressible fluid flow with viscosity and turbulence

InactiveUS20150122053A1High viscosityAffecting performance of deviceFluid speed measurementVolume/mass flow by differential pressureFully developedDie swell

This invention presents a Pitot tube design and methodology for determining the flow characteristics of fluids in subsonic and supersonic flow, including the effects of viscosity and turbulence. A new methodology, the Two-Fluid Theory, is developed which treats a real fluid as being composed of two ideal fluids: an inviscid fluid and a Poiseuille fluid. The resulting expression for flow velocity is applicable to a real fluid of any viscosity and to pipes of any L / D ratios, including entrance effects.Two designs, comprising annular, smooth-bore tubes, with devices for measuring total and static pressures, are presented: one for incompressible flow; one for compressible, supersonic flow. Allowance is made for the viscous component of the flow to become fully developed, in accordance with the Theory.

Owner:WILLARD JR HAROLD JAMES

Detection of turbulence in fluids

InactiveUS6992292B2Solid-state devicesMaterial analysis by optical meansTurbulent blood flowComputer science

A method of identifying the presence of turbulence in fluids, e.g. for distinguishing flames from other hot bodies, examines the correlation between adjacent pixels of an array viewing the fluid and particularly the proportion of negative correlation in the presence of strong positive correlation.

Owner:INFRARED INTEGRATED SYST

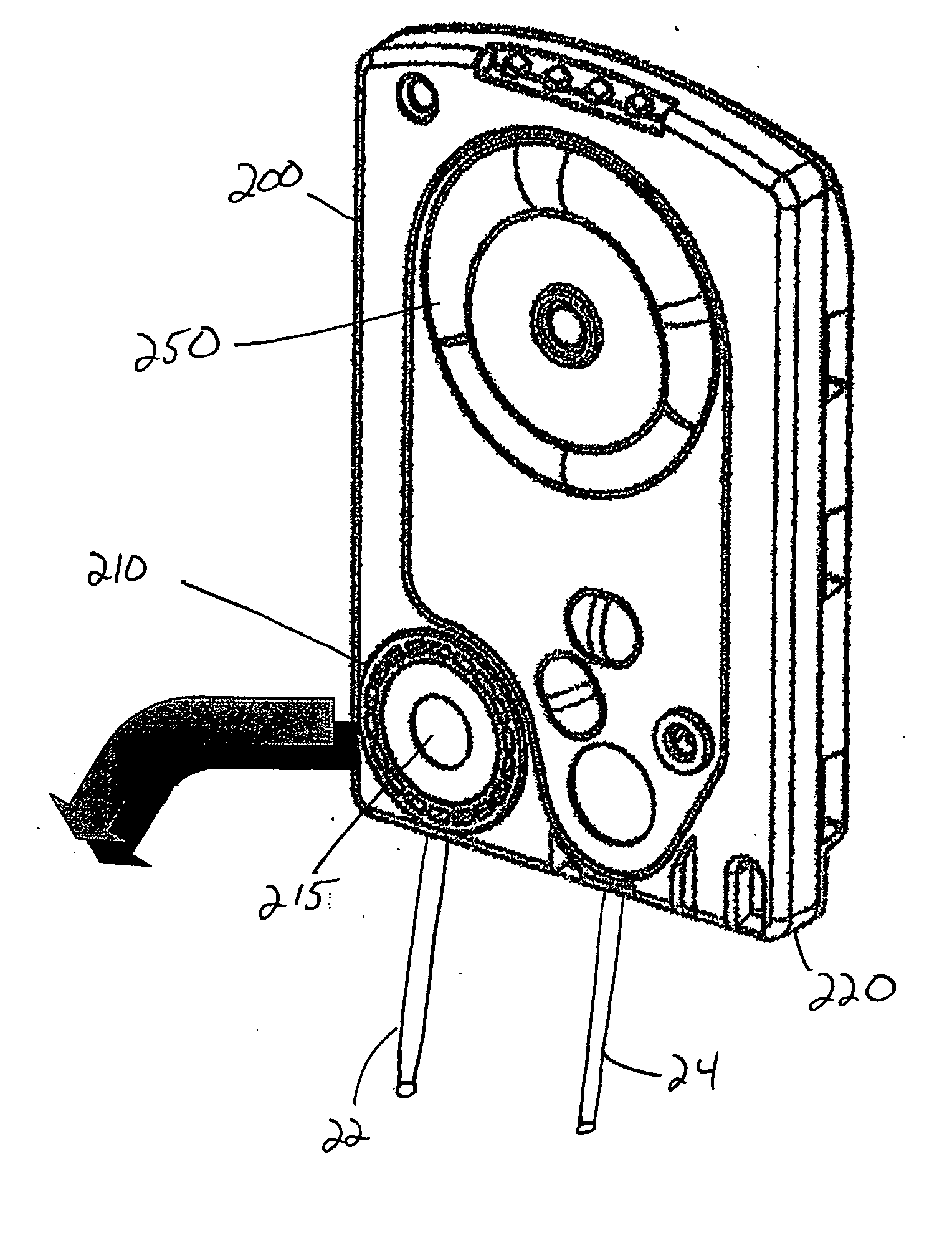

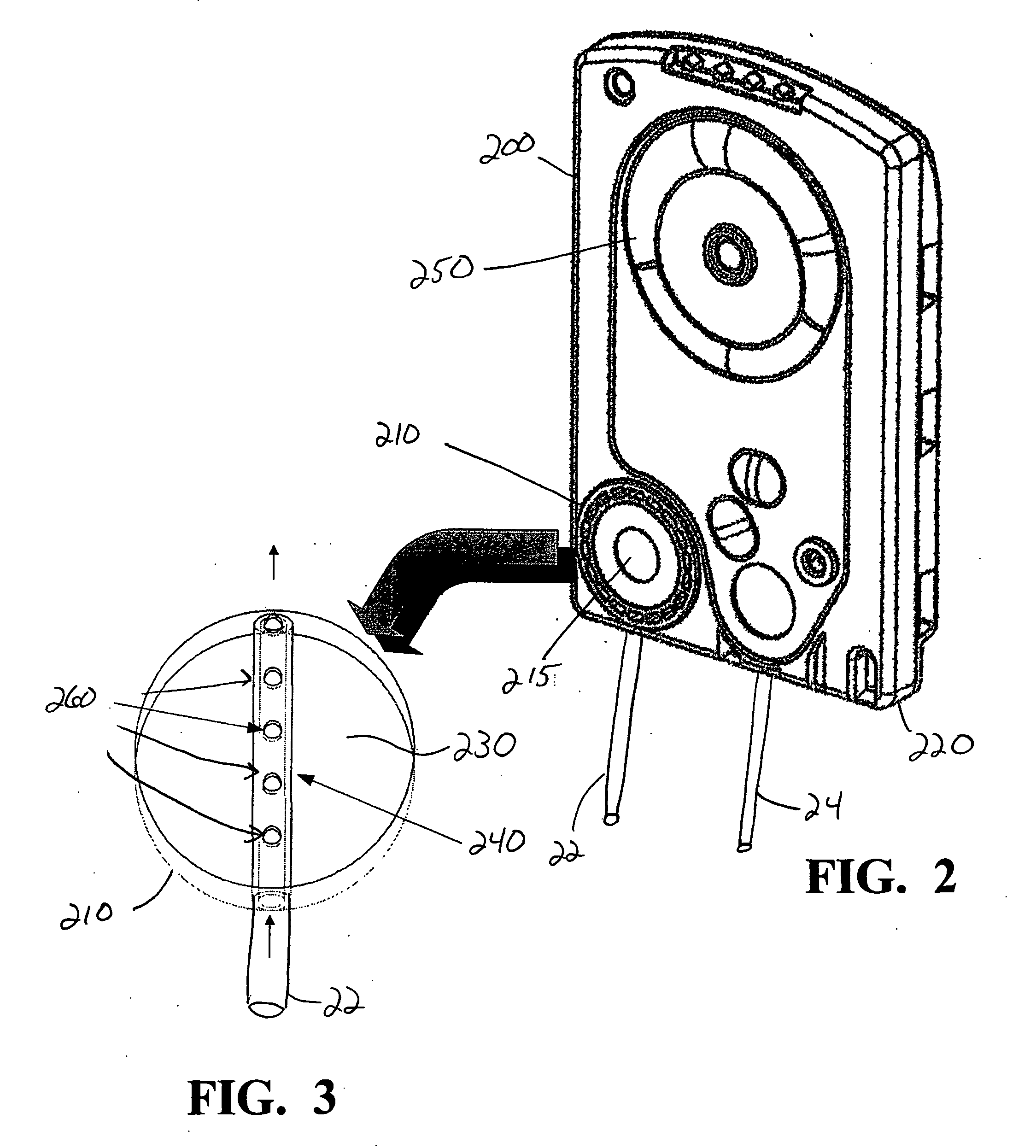

Gas Flow Diverter For Respiratory Monitoring Device

A gas flow diverter for increasing the turbulence of an incoming respiratory gas flow through a respiratory gas sensor is provided. The diverter is positioned at a patient or inlet end of a tube section of the sensor in order to divert the respiratory gas flow from the patient generally equally across the cross-sectional area of the tube section. The diverter can be formed integrally as a part of the sensor, or can be releasably attached to the sensor or to an adapter that is releasably connected to the inlet end of the sensor for use in situations in which the volume of the incoming respiratory gas flow from the patient is greatly reduced due to the size of the patient, i.e., when the patient is an infant.

Owner:TREYMED

Stent to assist in arteriovenous fistula formation

There is described an arteriovenous fistula stent, having a tubular body comprising a series of sinusoidal shaped struts along the length of the tubular body. A plurality of curvilinear connectors extend between and are attached to adjacent struts wherein a first end of a connector is attached to a distal face of a proximal strut apex and a second end of a connector is attached to a proximal face of a distal strut apex. A pair of unconnected strut apexes are between pairs of connected apexes. When the tubular body is in a stowed configuration a proximal aperture and a distal aperture are circular and when the tubular body is in a deployed configuration the distal aperture is oblong or ovoid. There is also described a method for inserting a stent for use in creation of an arteriovenous fistula by identifying a candidate artery and a candidate vein and dissecting the candidate vein. Next, inserting a stent into the vein and creating a breach in the candidate artery at a desired angle and location. Next, introducing the stent and vein into the candidate artery and forming the stent into a curvature angle selected to minimize turbulent blood flow in an anastomosis formed by the vein and the artery. Optionally, there is a step of fastening a distal portion of the stent to the artery.

Owner:BOARD OF RGT UNIV OF NEBRASKA

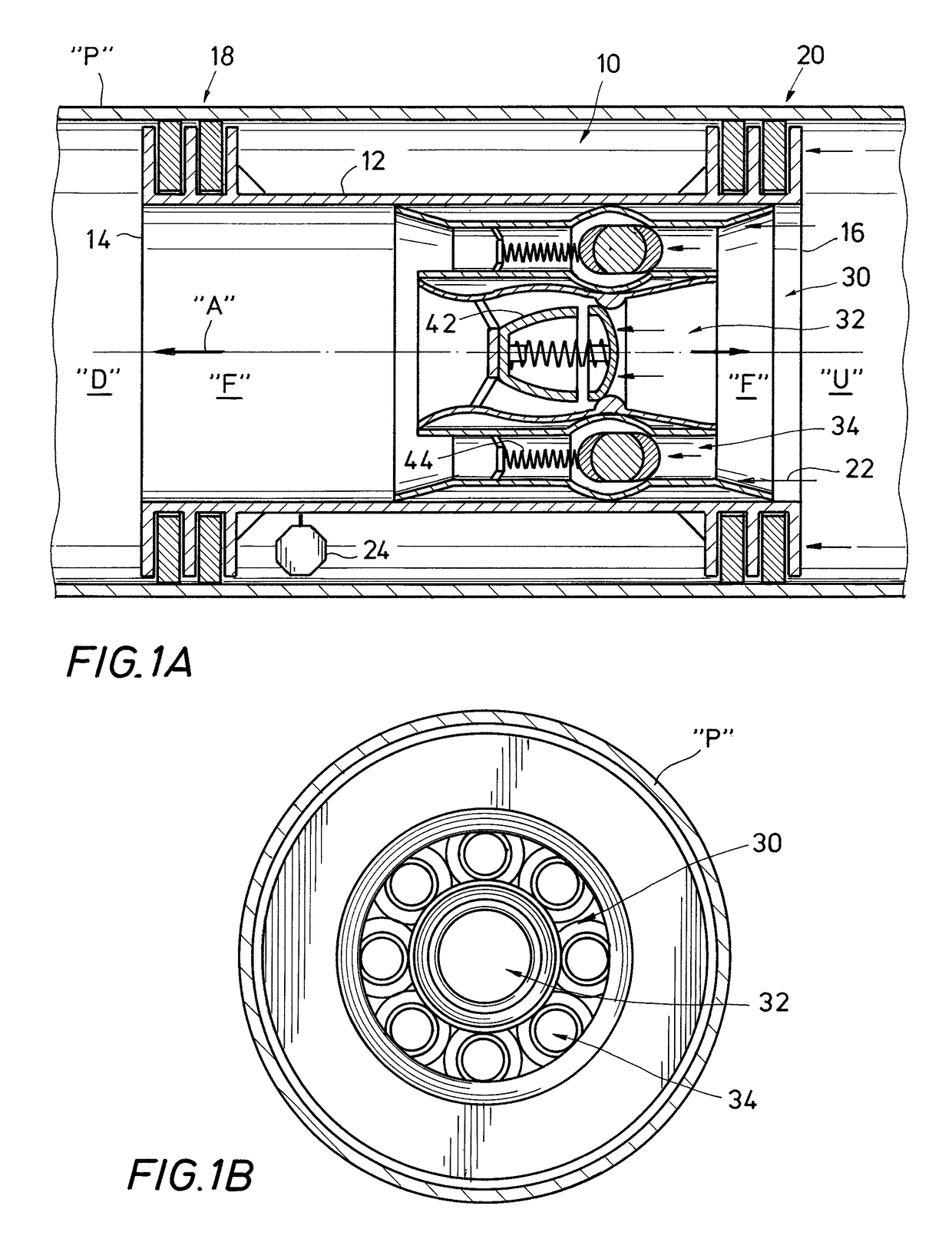

Variable speed pipeline pig with internal flow cavity

A pipeline pig includes a plurality of relief channels and a bypass channel extending therethrough. To regulate a speed of the pipeline pig, relief valves within the relief channels open when a differential pressure between upstream and downstream ends of the pipeline pig reaches a pre-selected minimum relief pressure. If the differential pressure reaches a pre-selected maximum relief pressure, such as when the pipeline pig encounters an obstruction, the relief valves close to allow the differential pressure to further increase to clear the obstruction. If the further increase in differential pressure is insufficient to clear the obstruction and the differential pressure reaches a pre-selected minimum bypass pressure, a bypass valve opens to permit fluid flow through the bypass channel while the relief valves are closed. Flow through the bypass channel operates to reduce turbulence and permit production through the pipeline if the pipeline pig becomes stuck and obstructs the pipeline.

Owner:SAUDI ARABIAN OIL CO

Non-imaging two dimensional array probe and system for classifying carotid stenosis

ActiveCN105491957ALow costBlood flow measurement devicesHealth-index calculationTurbulent blood flowImaging diagnostic

A non-imaging diagnostic ultrasound system for carotid artery diagnosis has a two dimensional array probe with a low element count and relatively large element size which can cover an area of the carotid artery at its bifurcation. The elements are operated independently with no phasing, and detect Doppler flow spatially beneath each element. The system produces maps of carotid blood flow in two or three dimensions and can assemble an extended view of the flow by matching segments of the carotid flow as the probe is moved over the vessel. Once the carotid artery has been localized, the degree of stenosis is assessed by automated measurements of peak systolic velocity and blood flow turbulence.

Owner:KONINKLJIJKE PHILIPS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com