Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2879 results about "Pilot valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pilot valve is a small valve that controls a limited-flow control feed to a separate piloted valve. Typically, this valve controls a high pressure or high flow feed. Pilot valves are useful because they allow a small and easily operated feed to control a much higher pressure or higher flow feed, which would otherwise require a much larger force to operate; indeed, this is even useful when a solenoid is used to operate the valve.

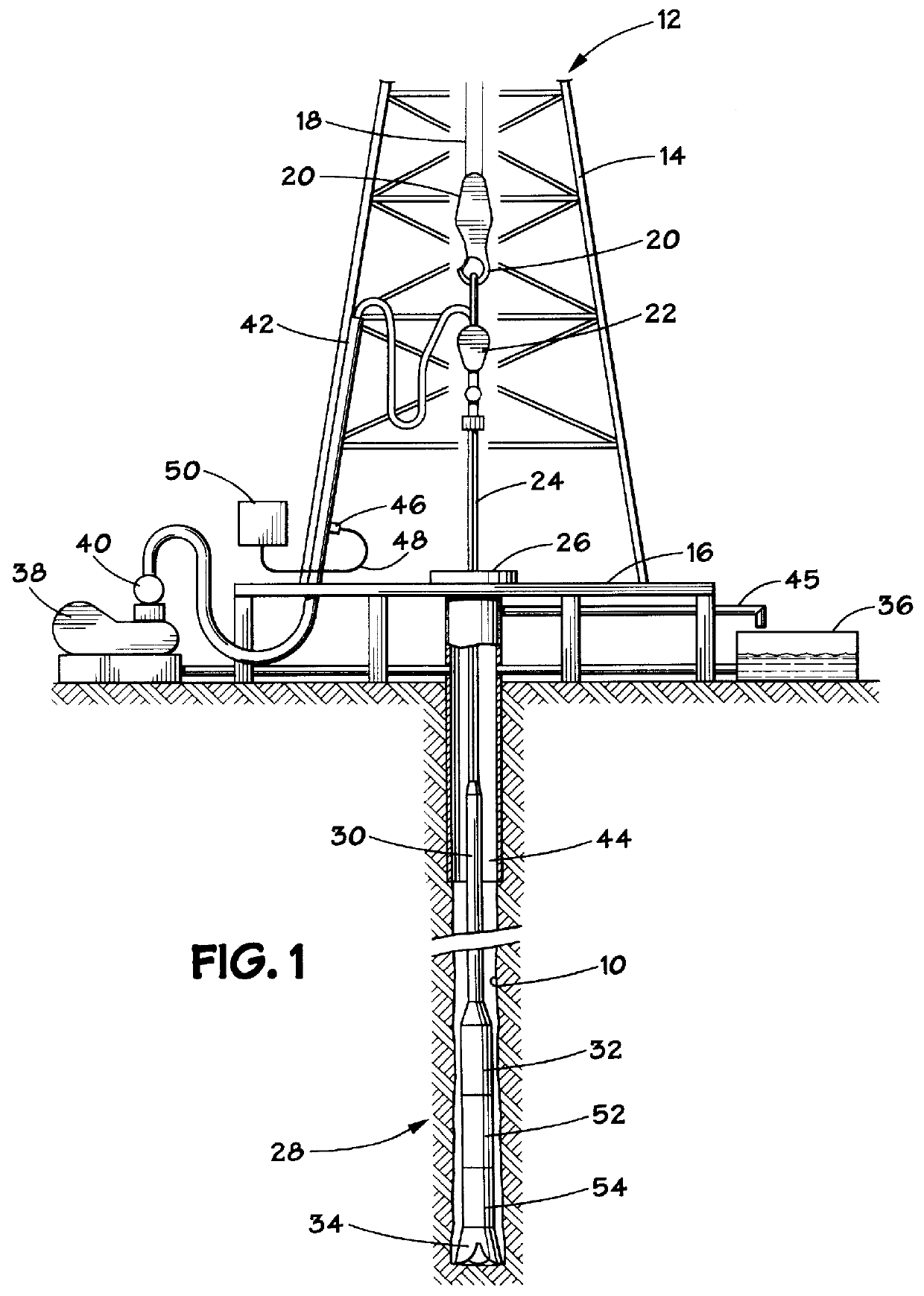

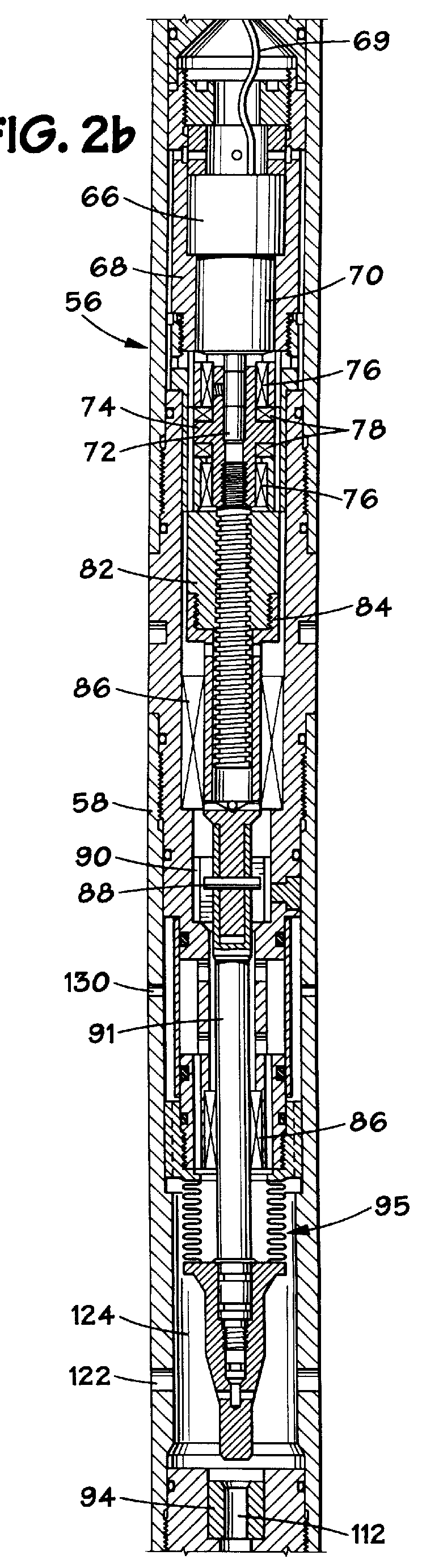

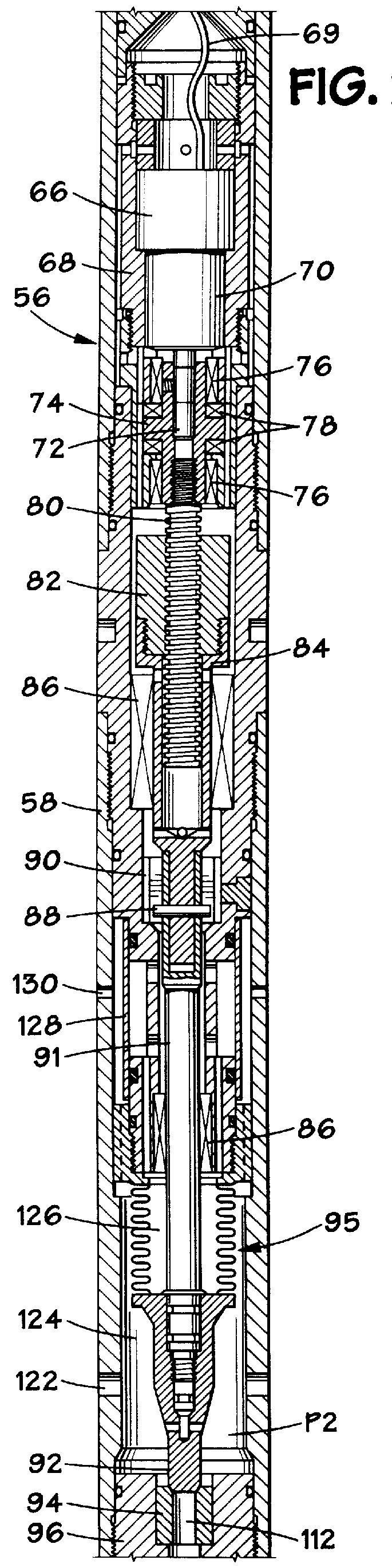

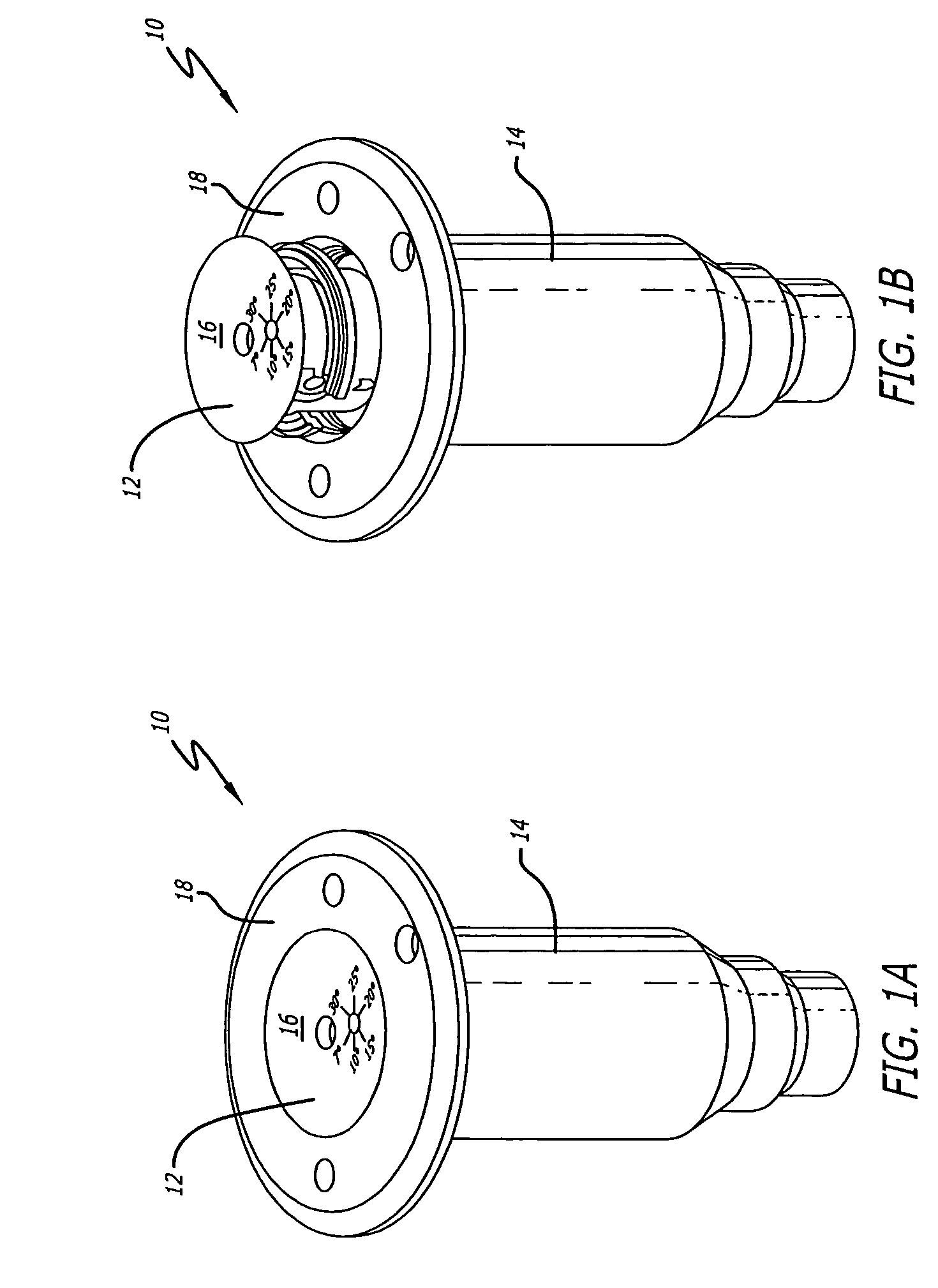

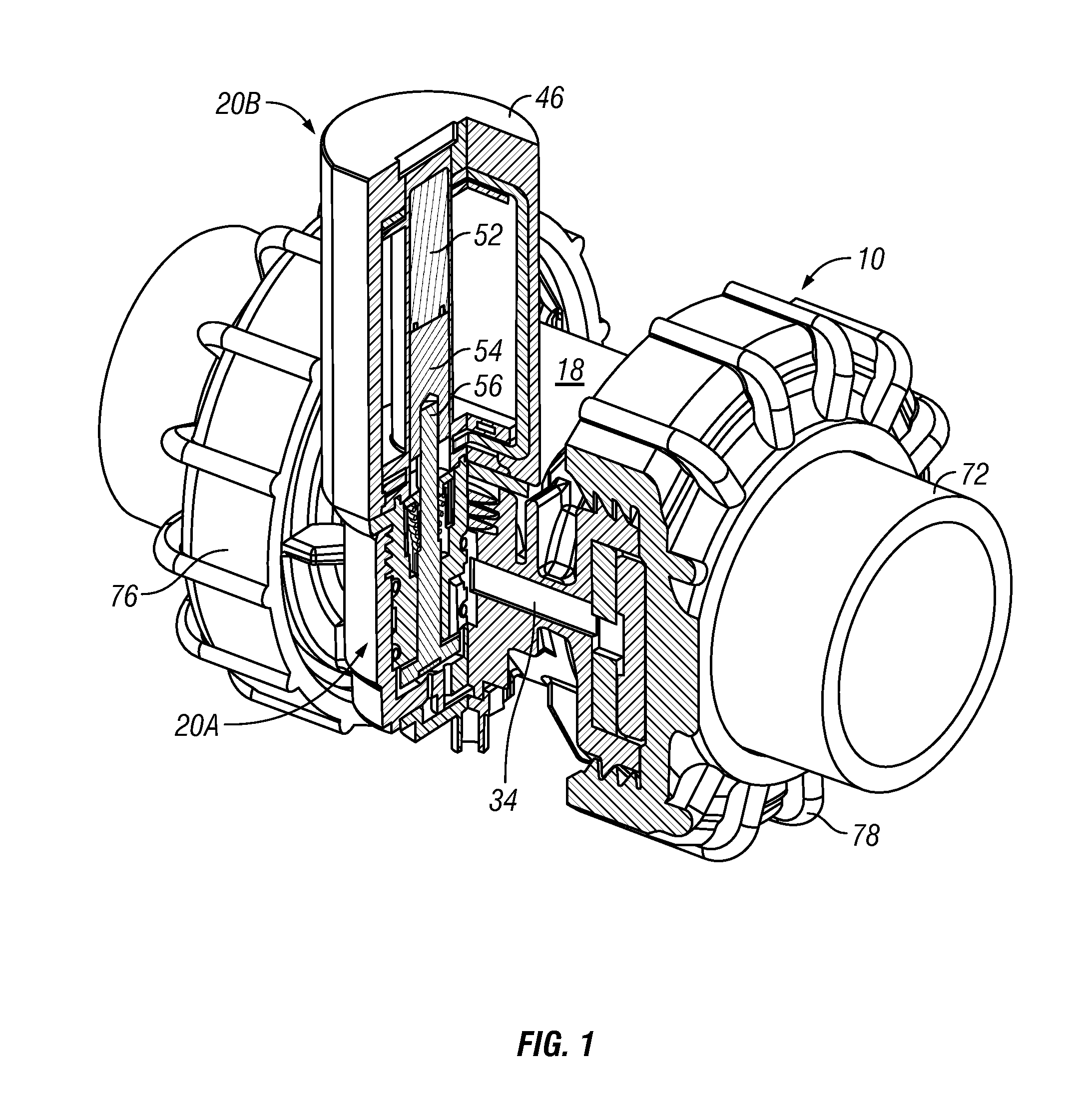

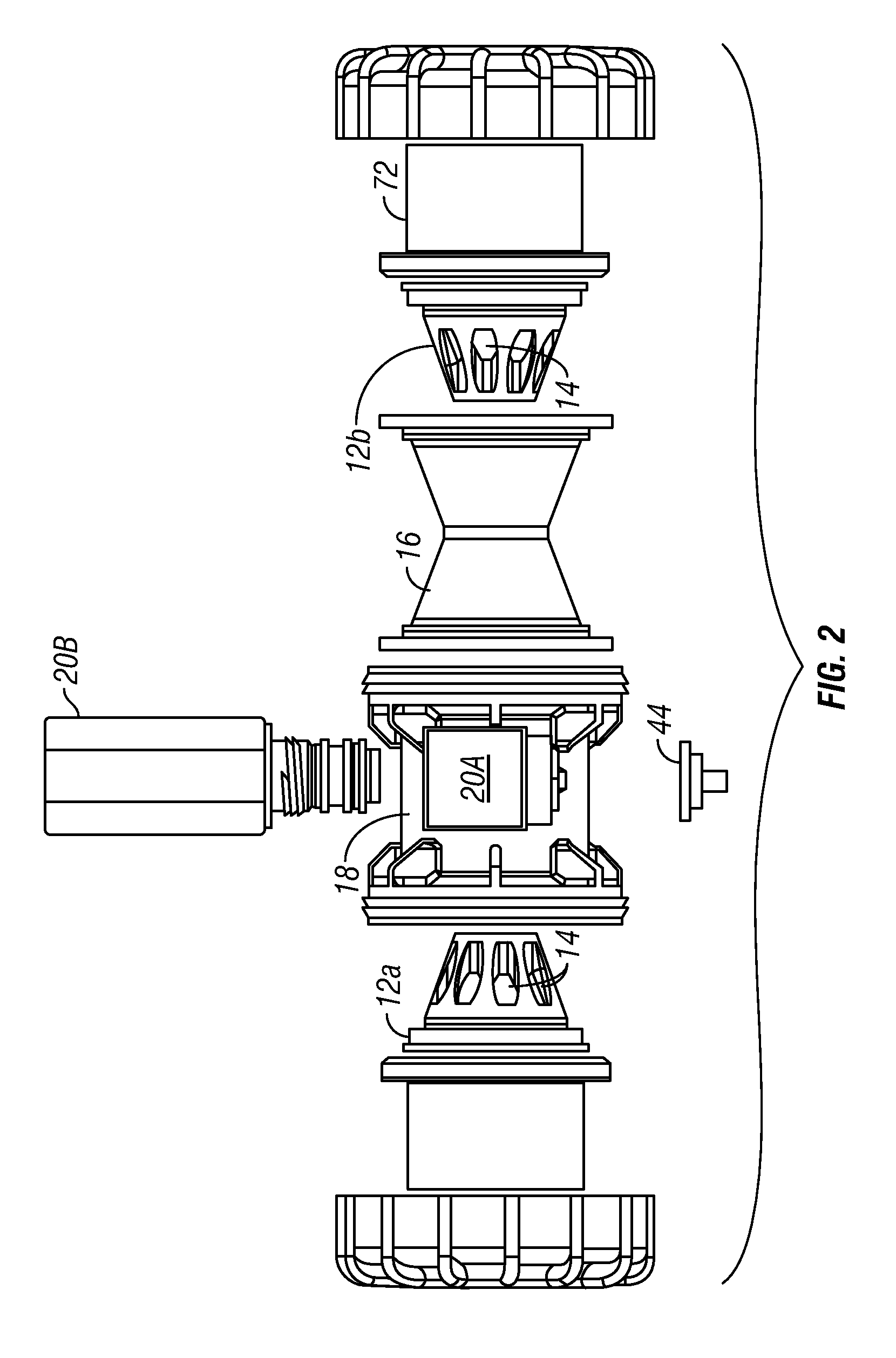

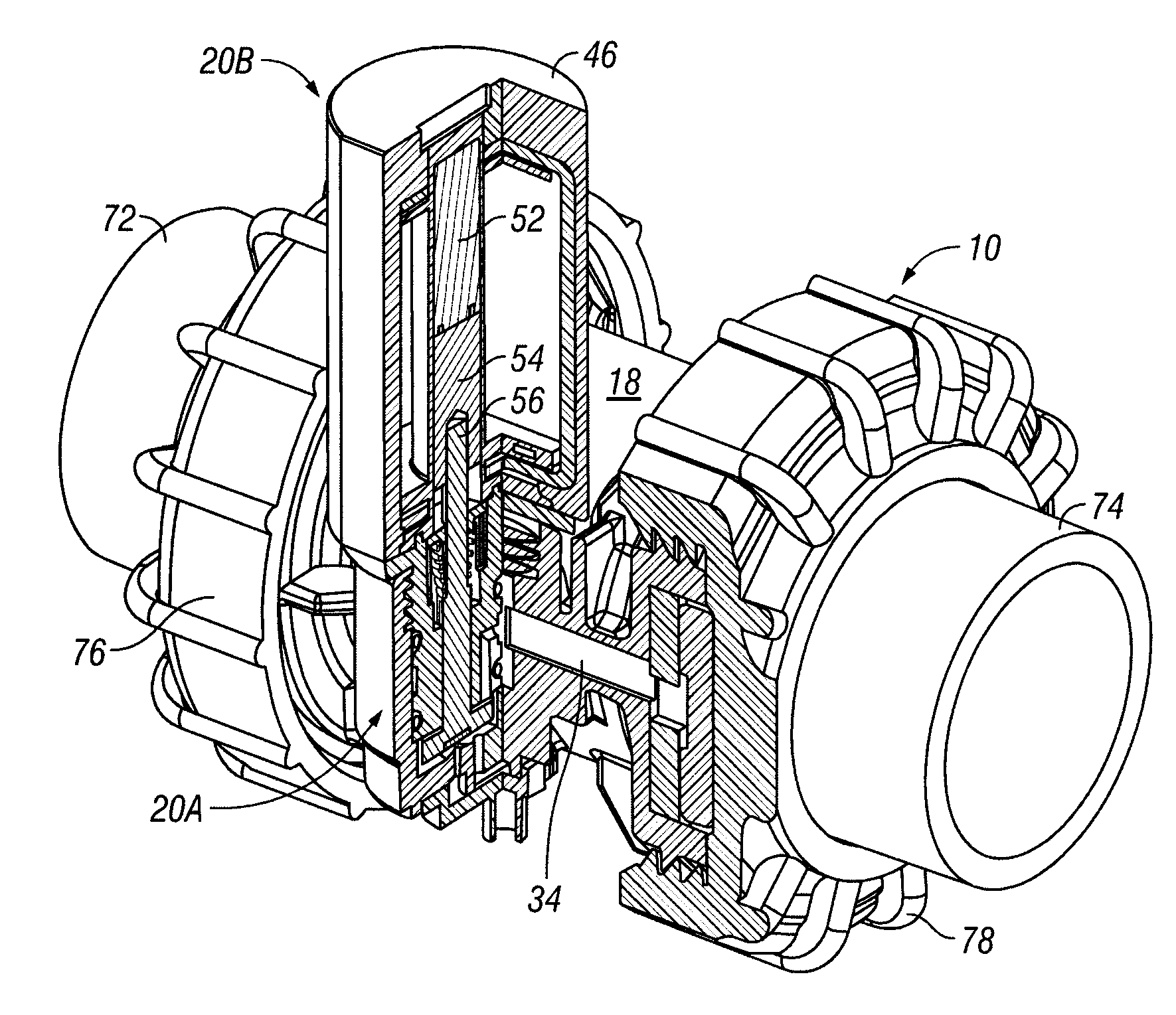

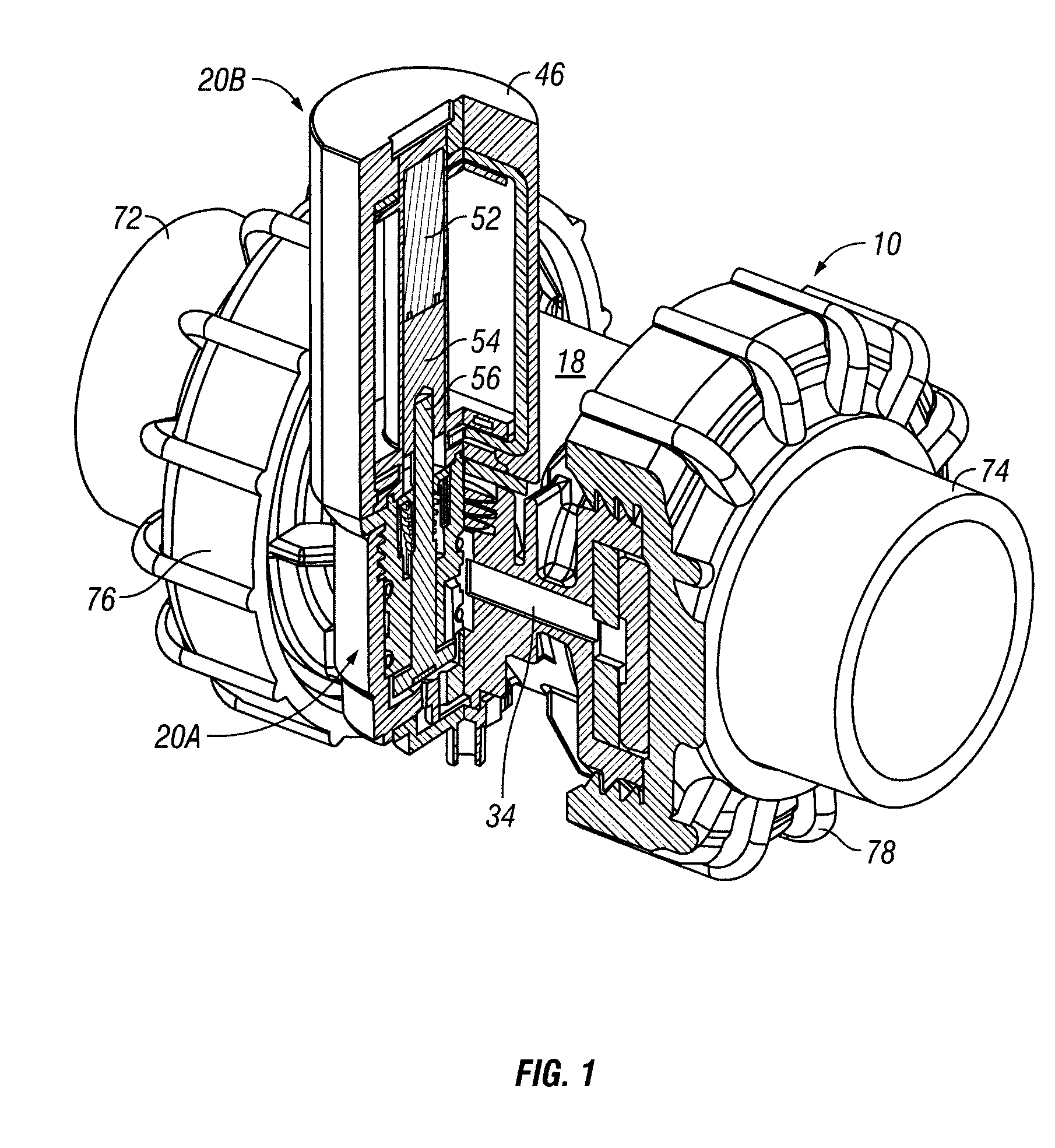

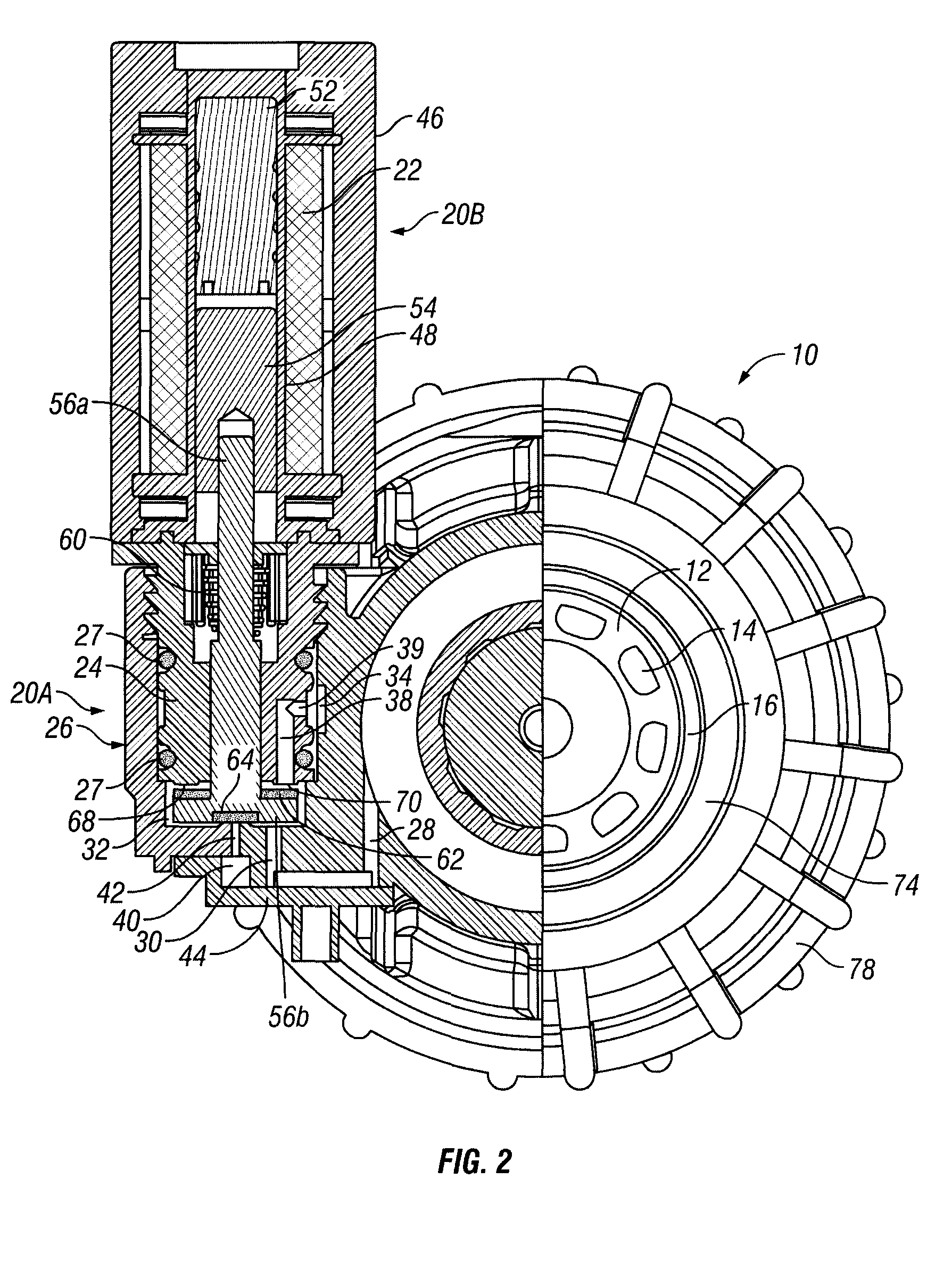

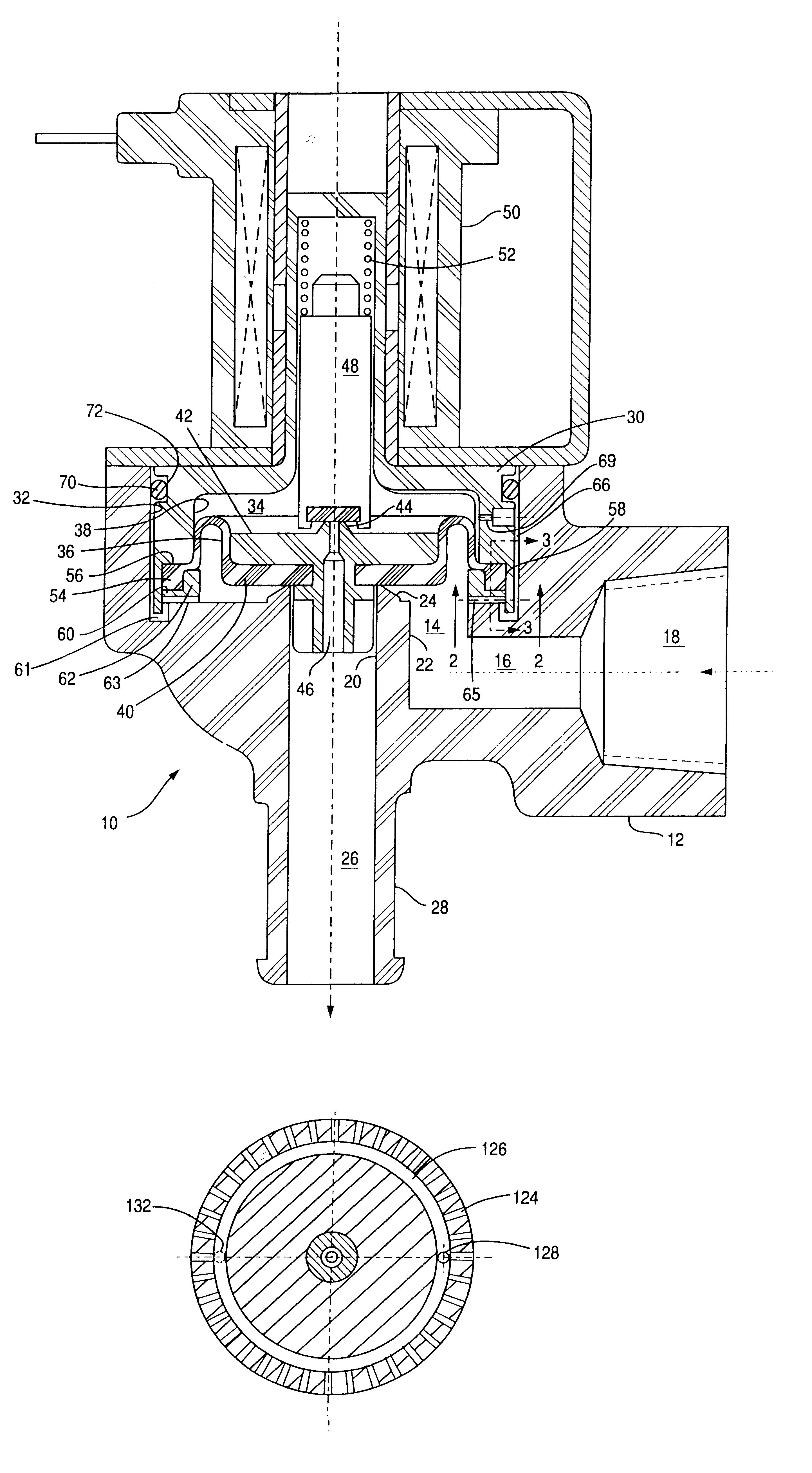

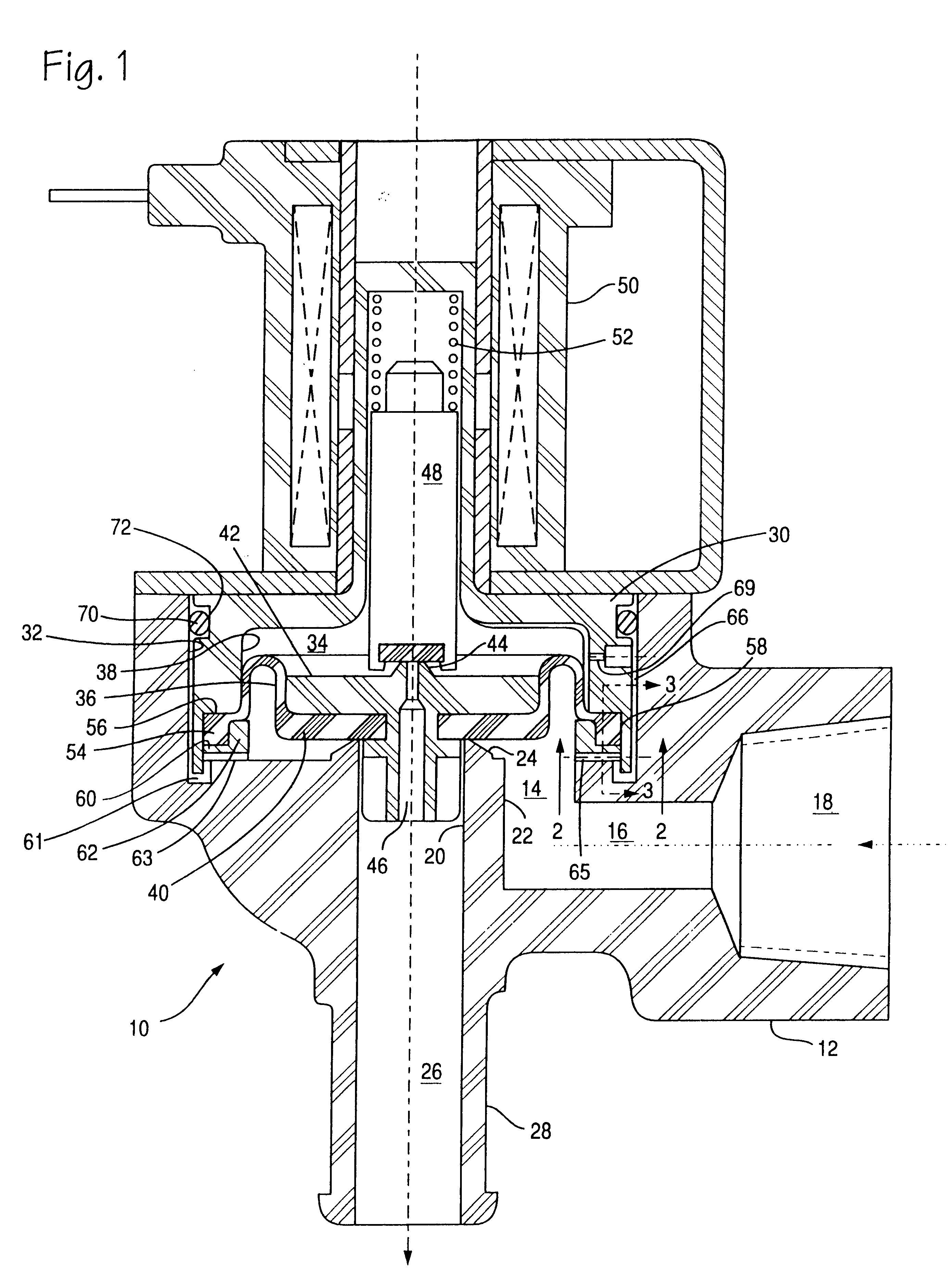

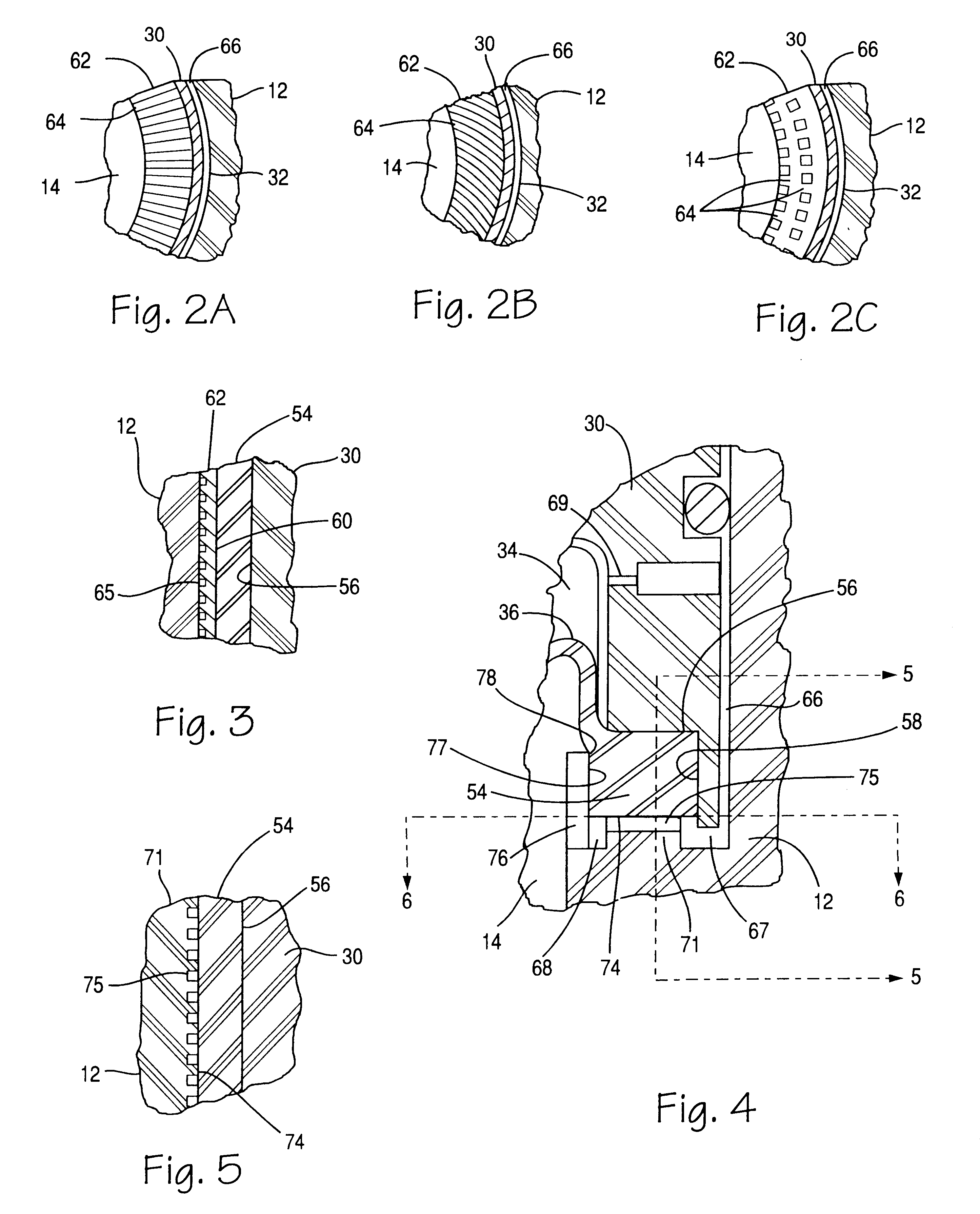

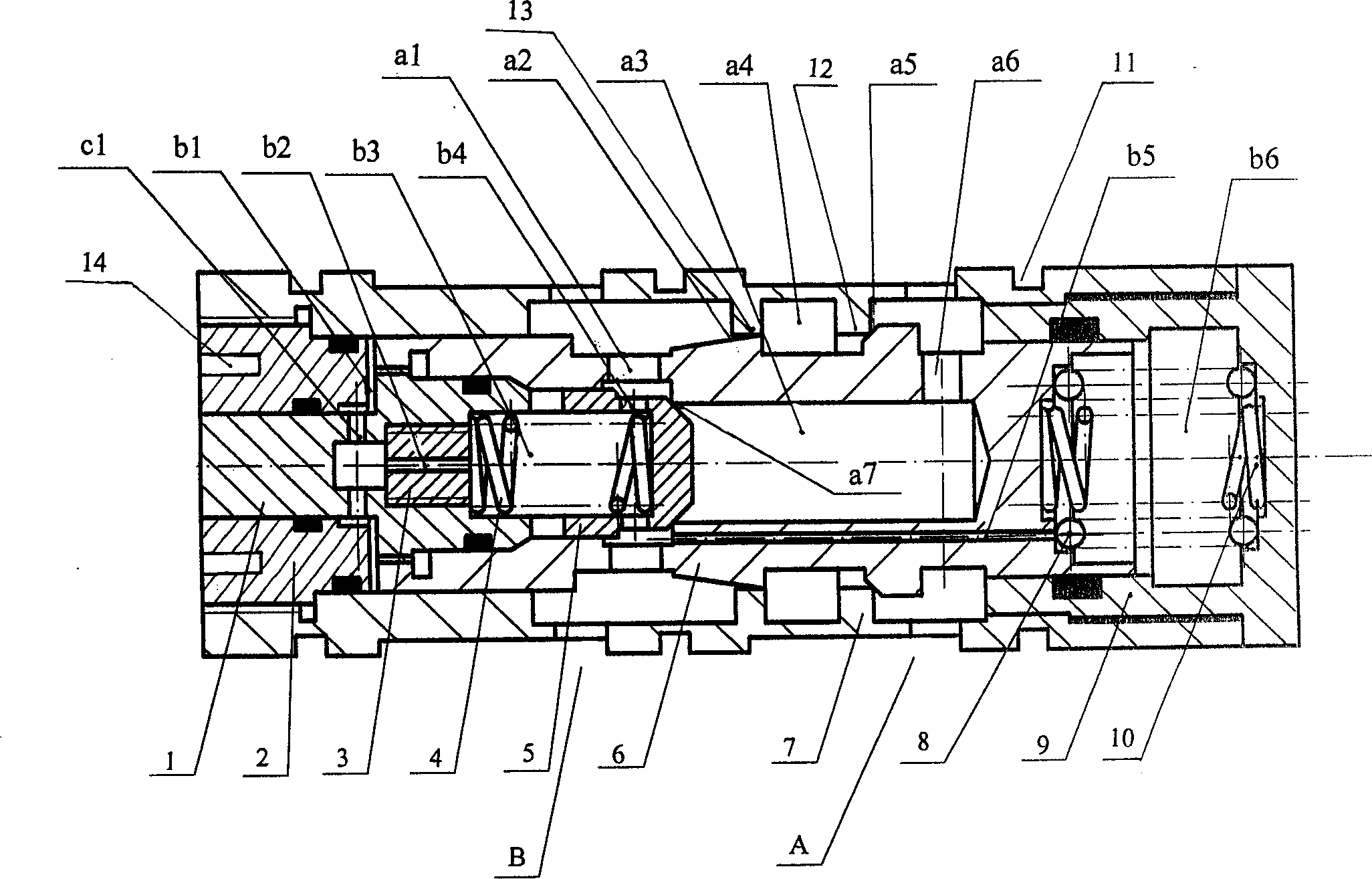

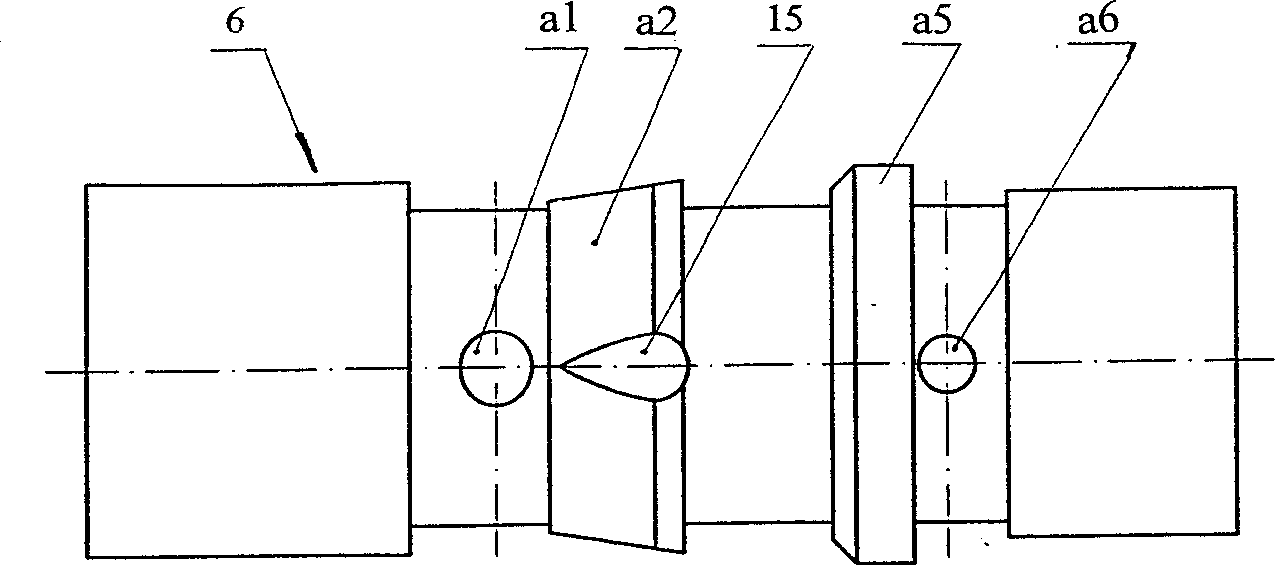

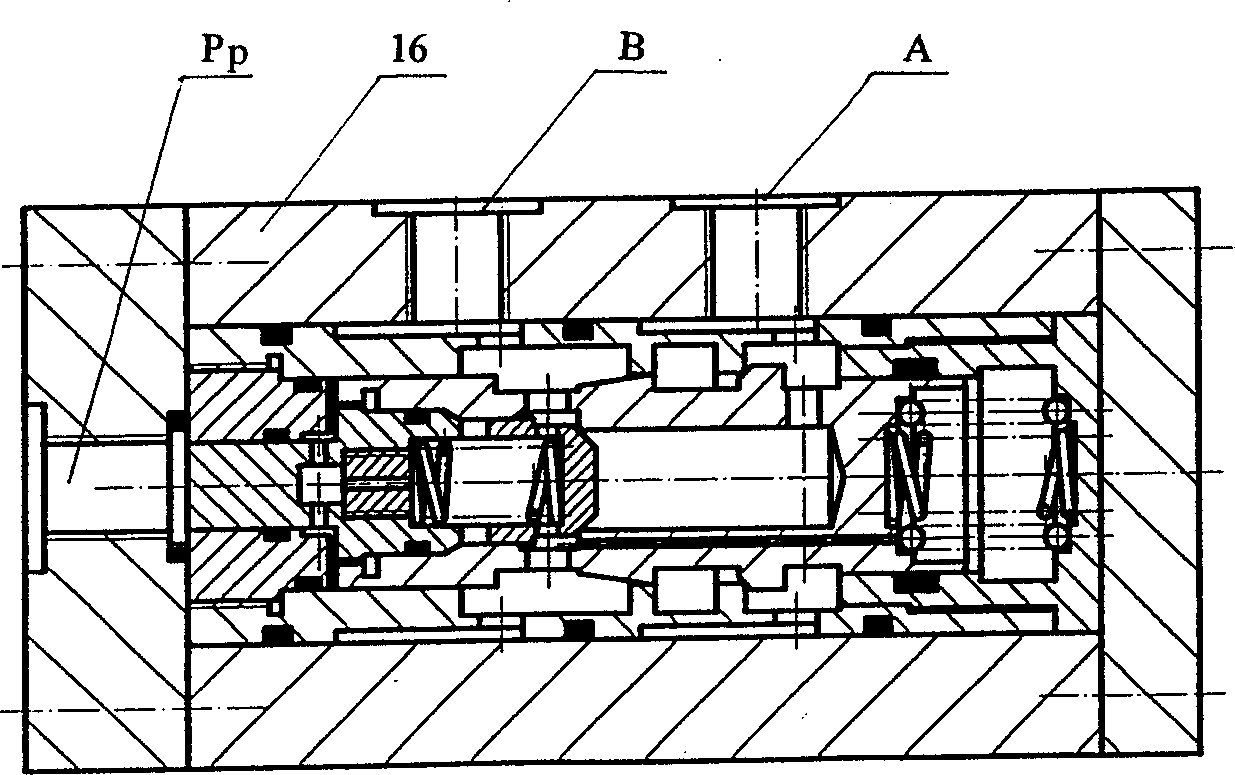

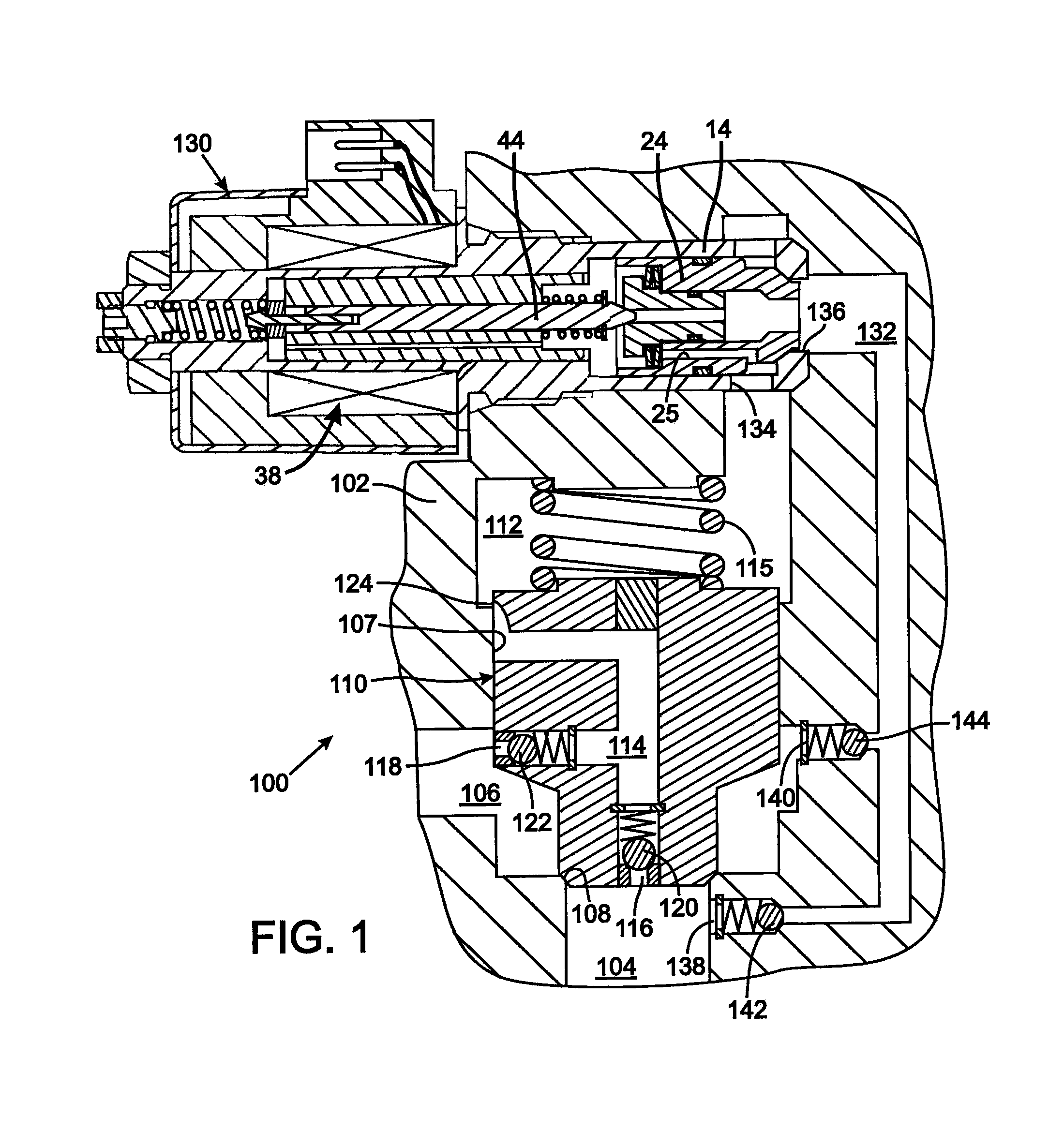

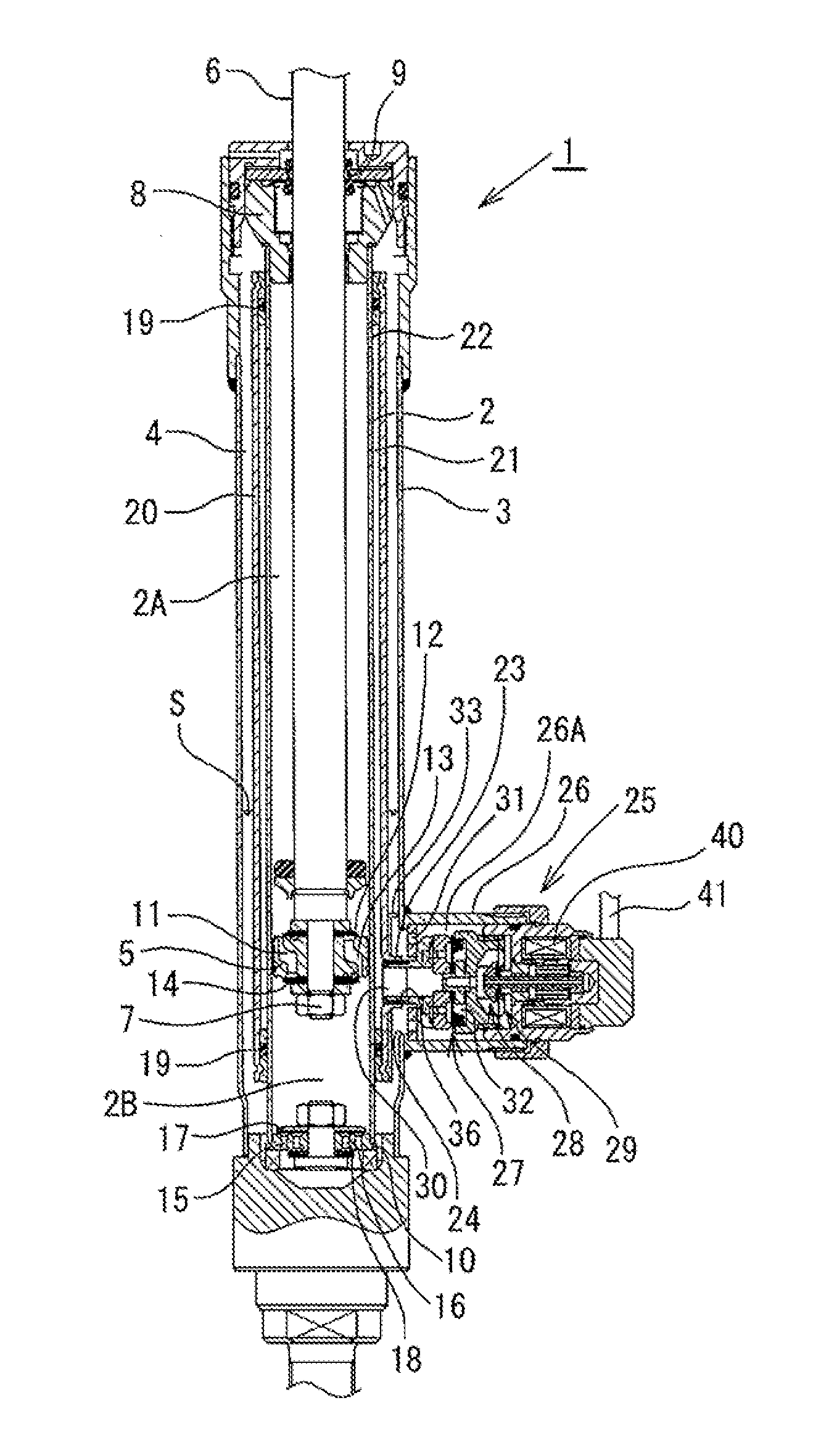

Servo-driven mud pulser

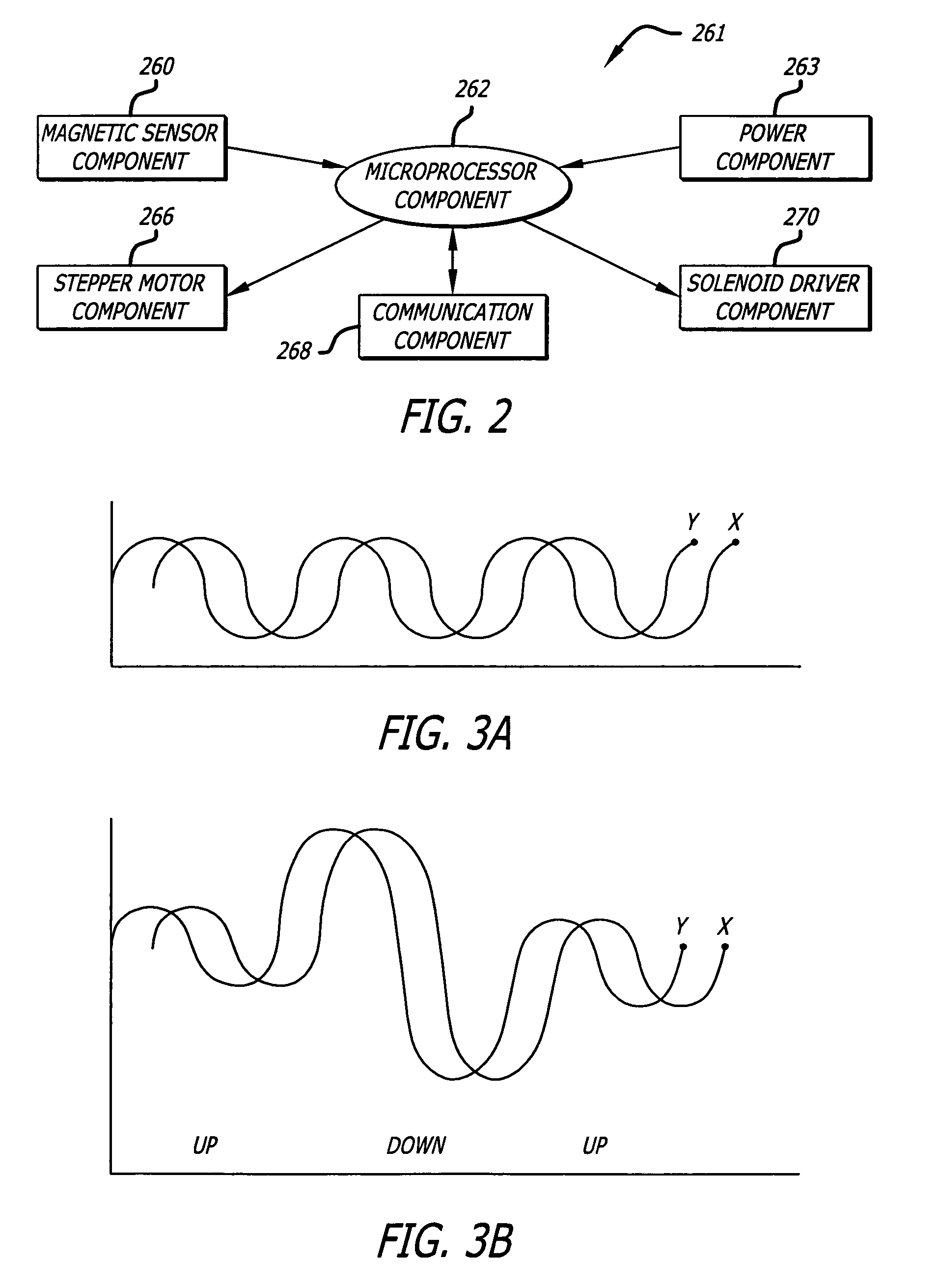

An improved servo-driven pulser is disclosed, for use in measurement while drilling applications. In the pulser, a battery powered on-board DC electric motor is used to operate a servo-valve, which in turn adjusts internal tool fluid pressures to cause operation of a main valve to substantially reduce mud flow to a drill bit, thereby creating a positive pressure pulse detectable at the surface. De-energizing the motor driving the pilot valve results in re-adjustment of internal fluid pressures, causing the main valve to reopen, thereby terminating the pressure pulse.

Owner:SMITH INT INC +1

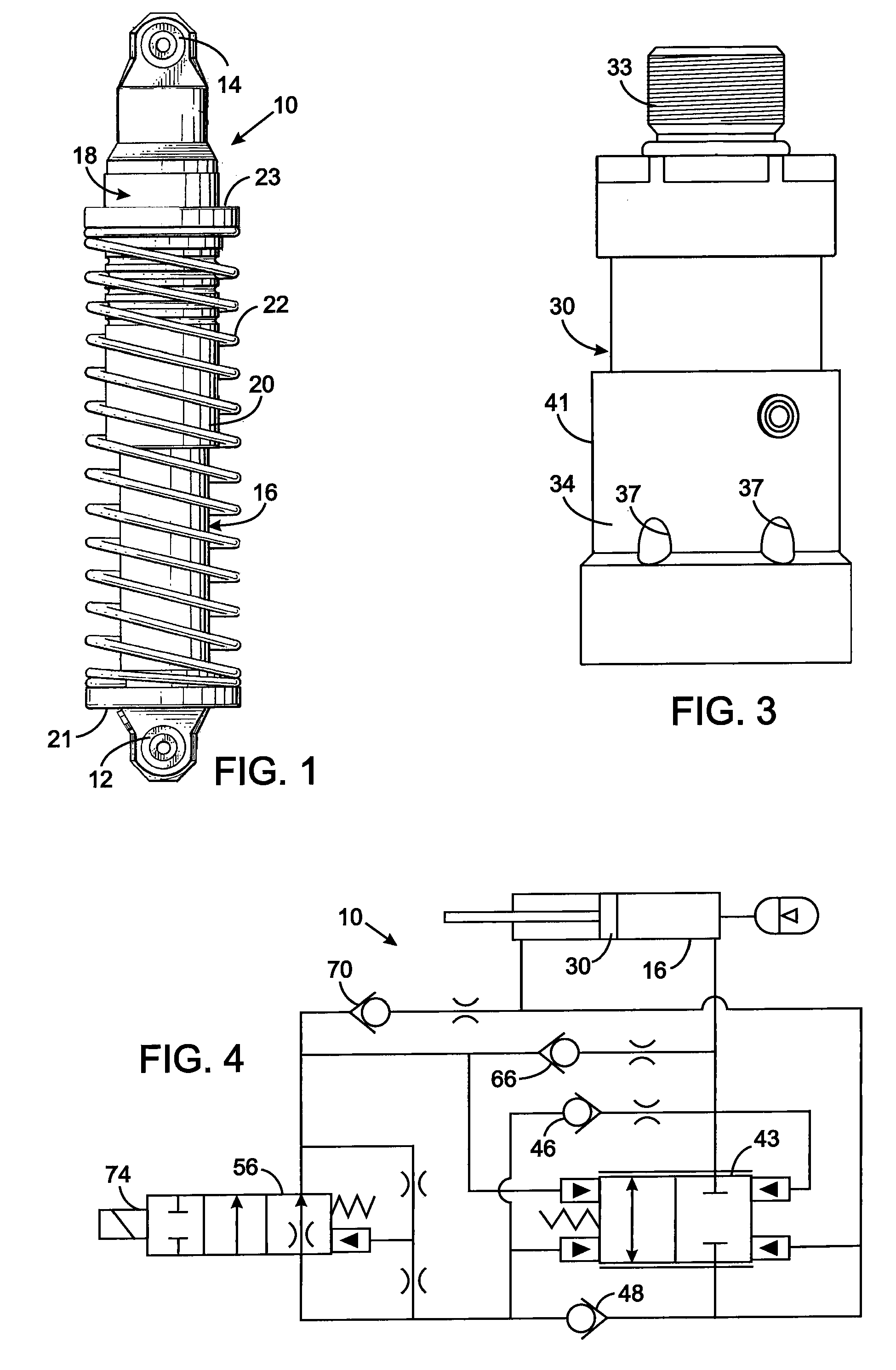

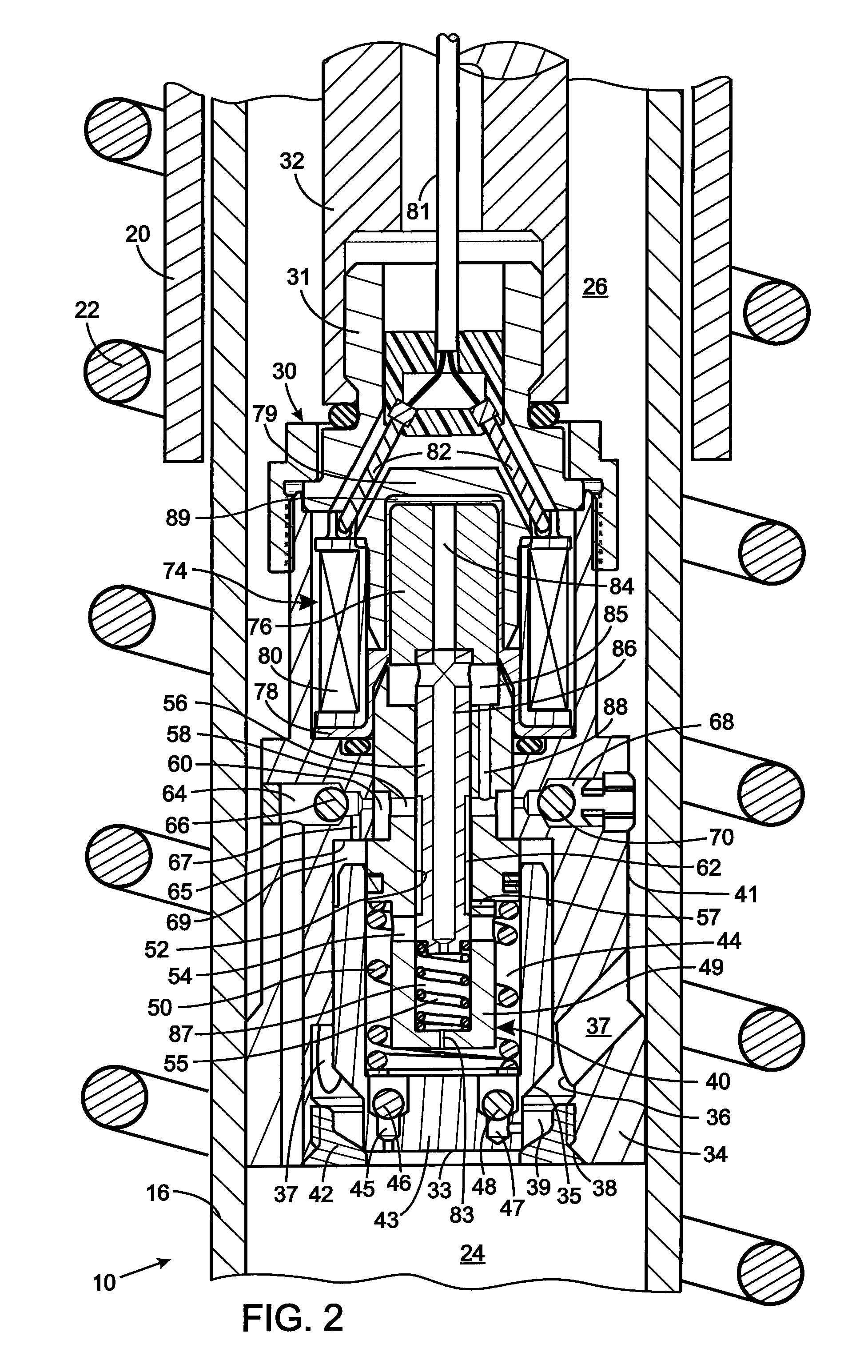

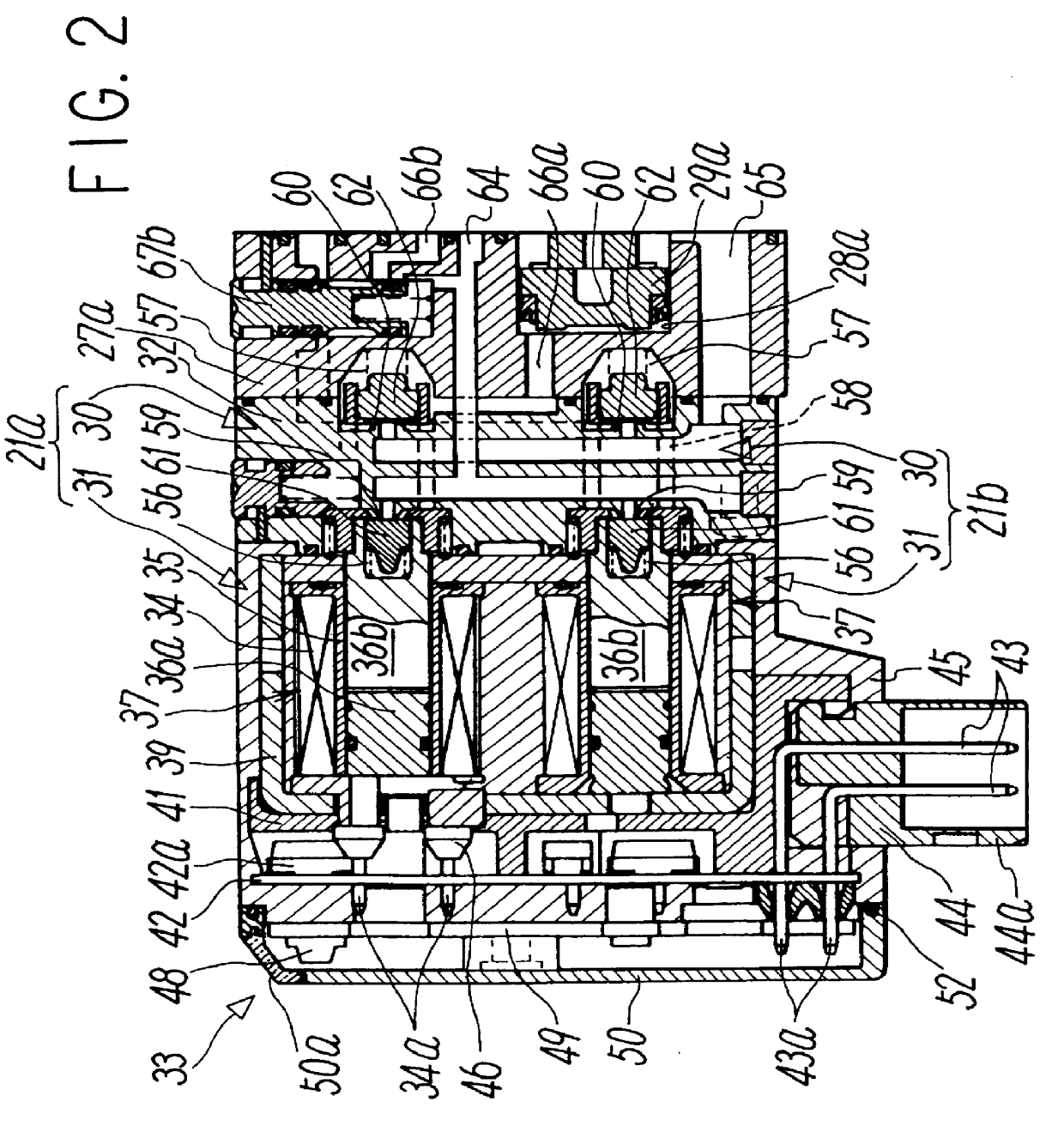

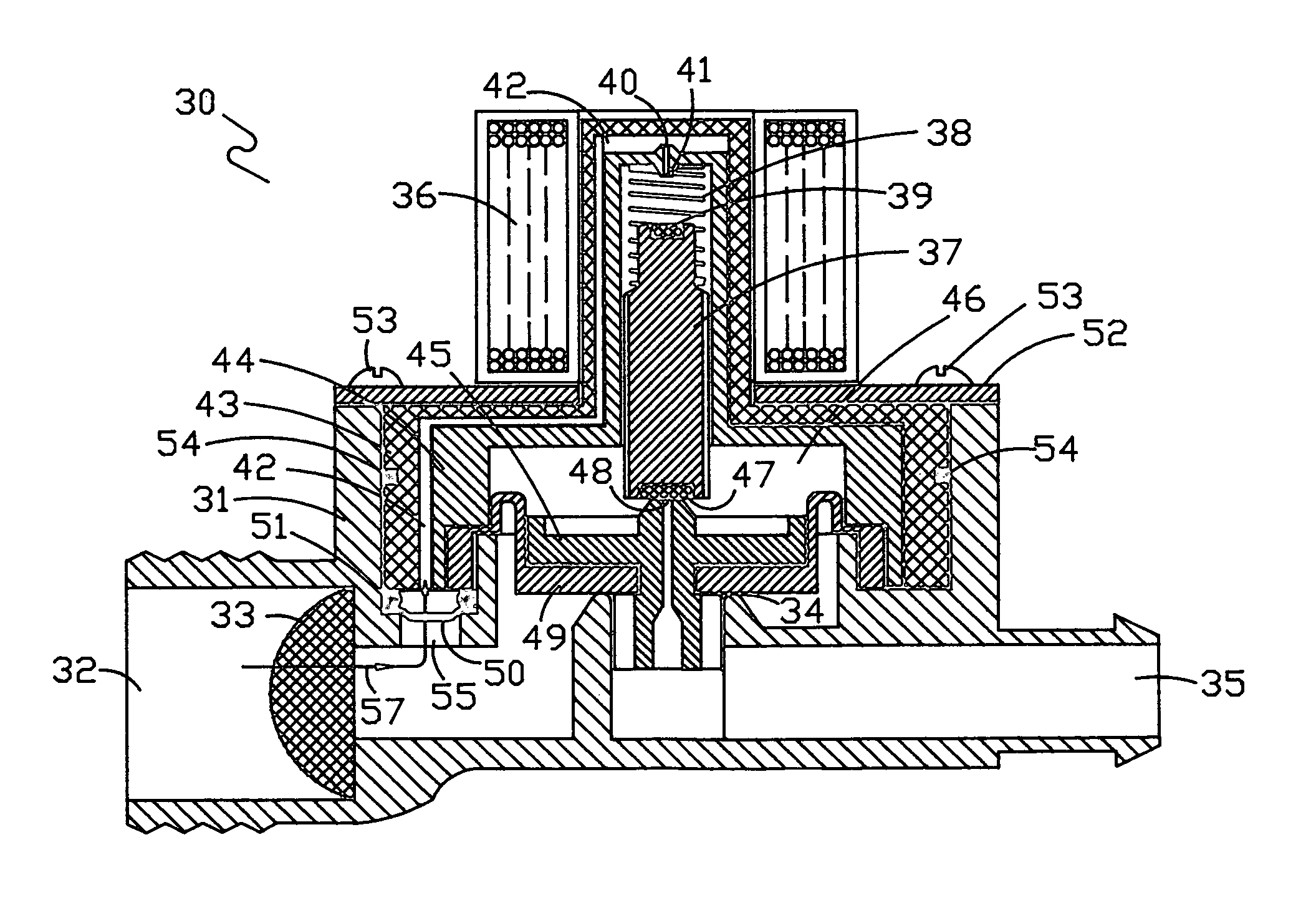

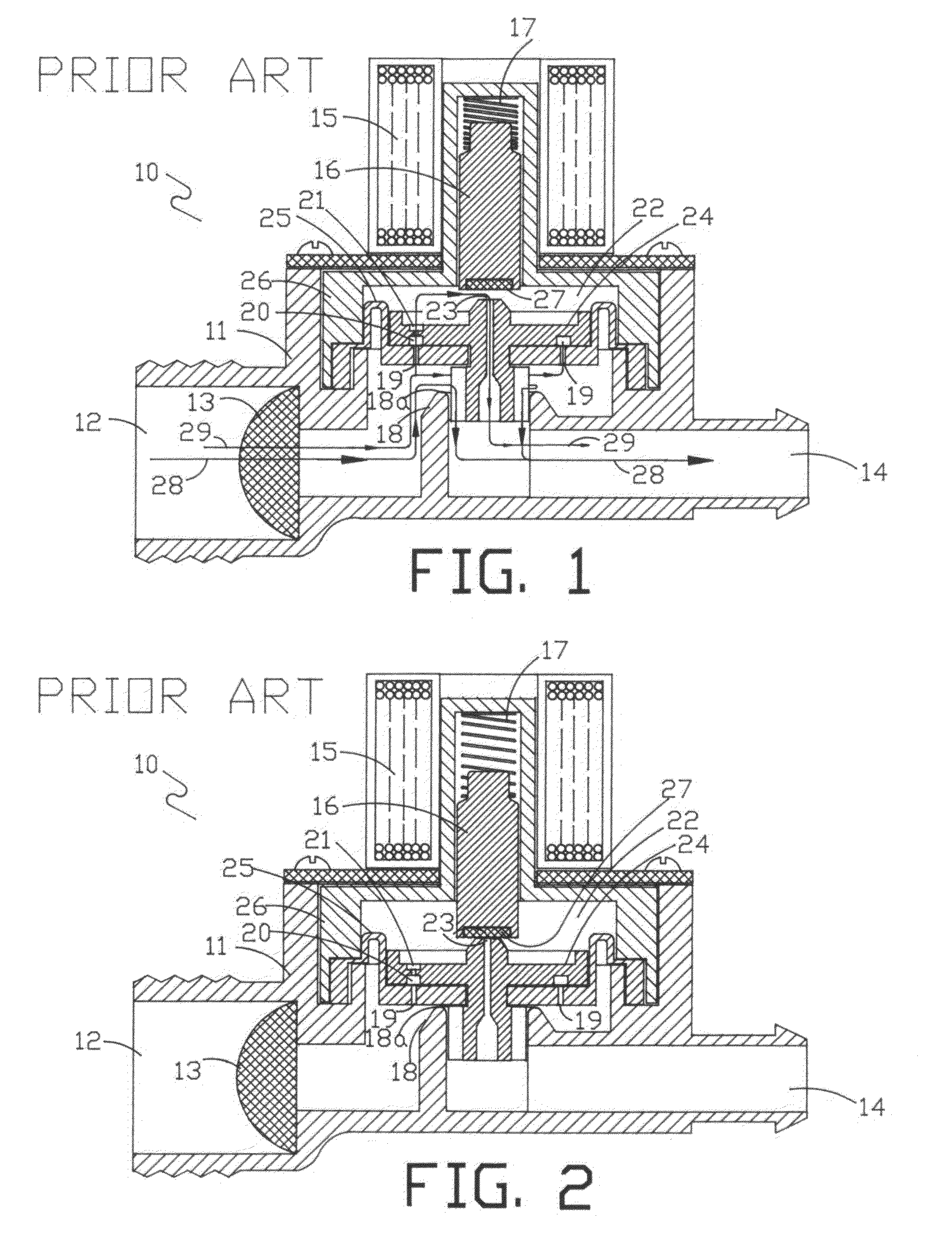

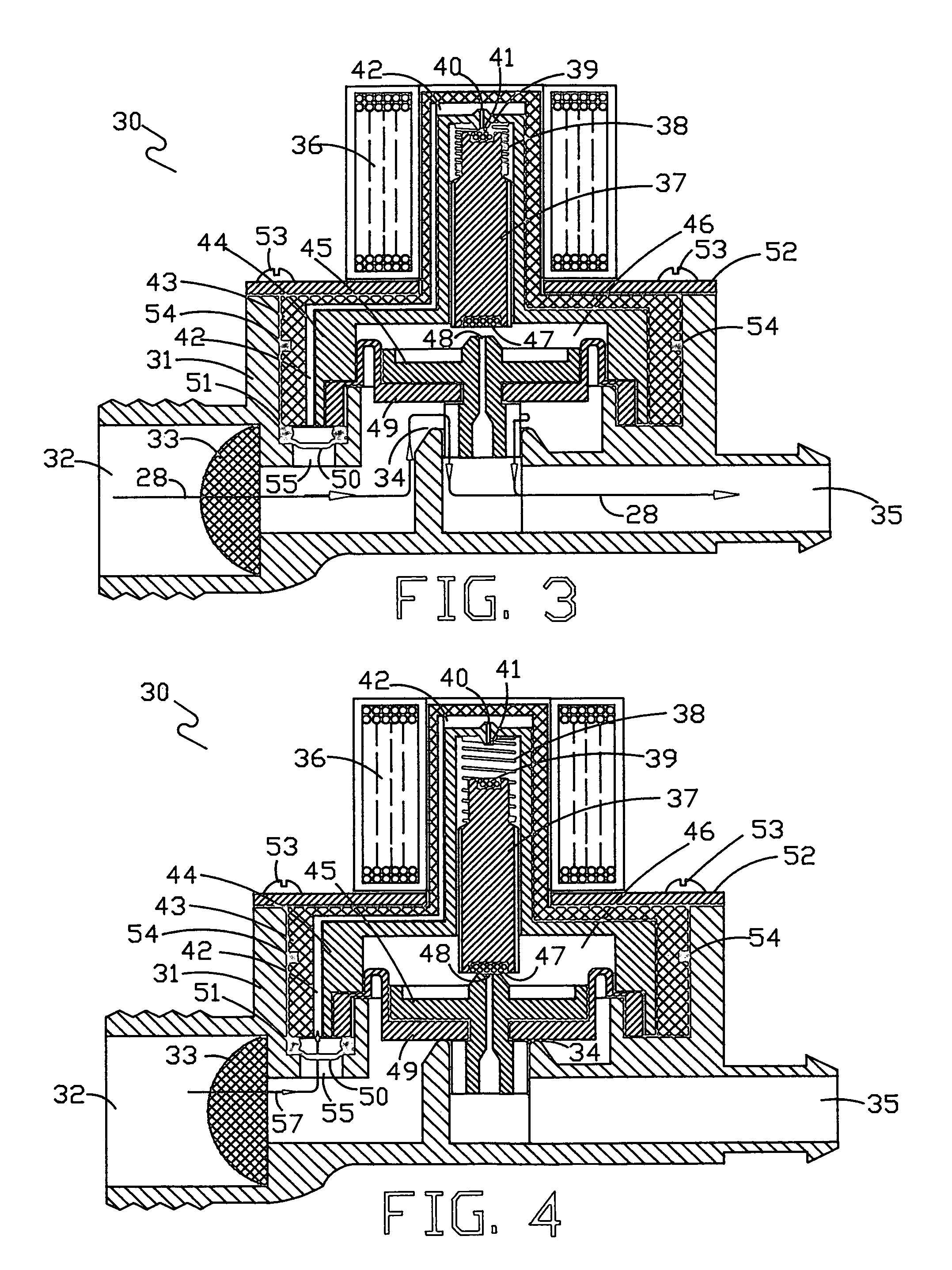

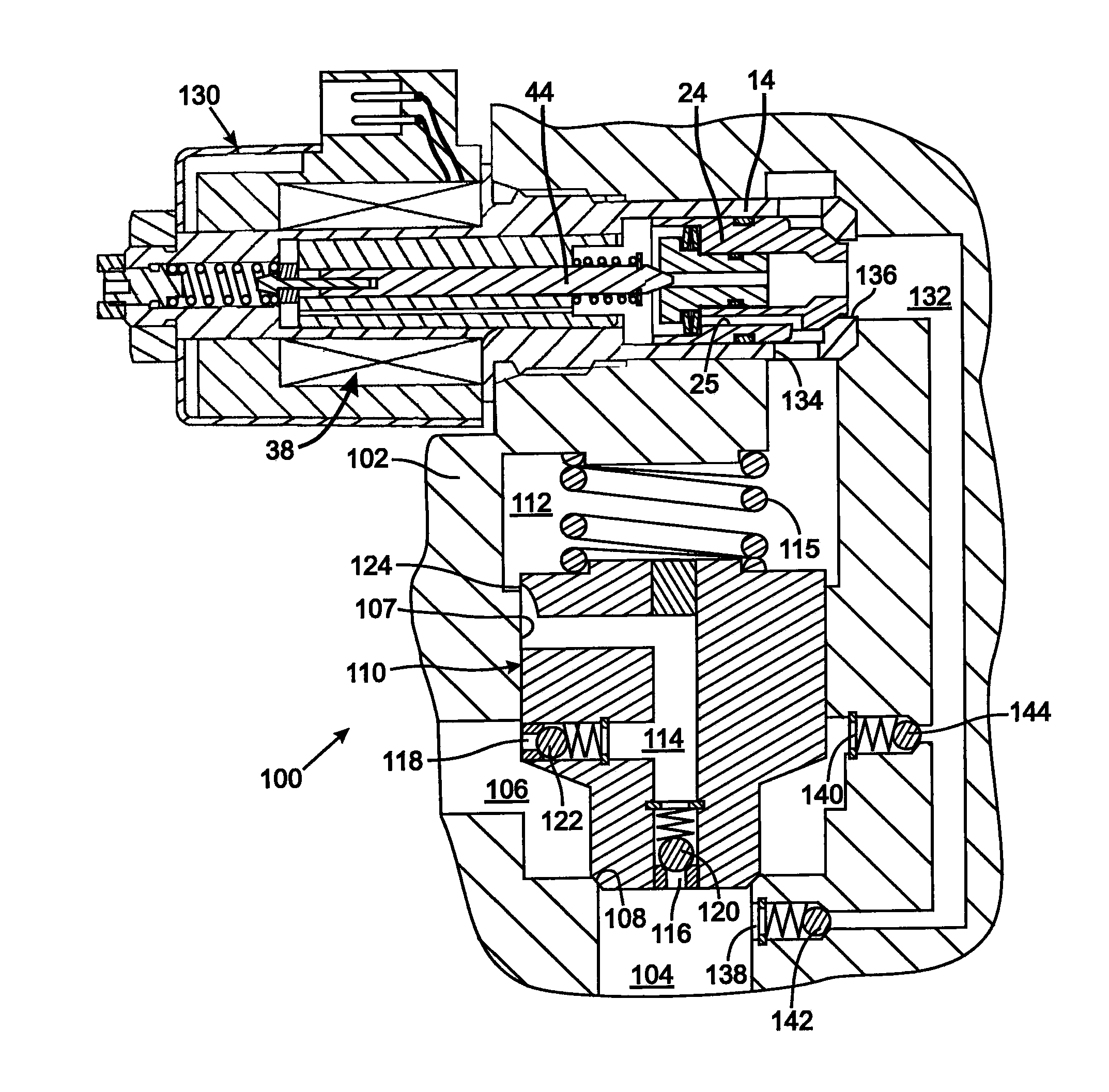

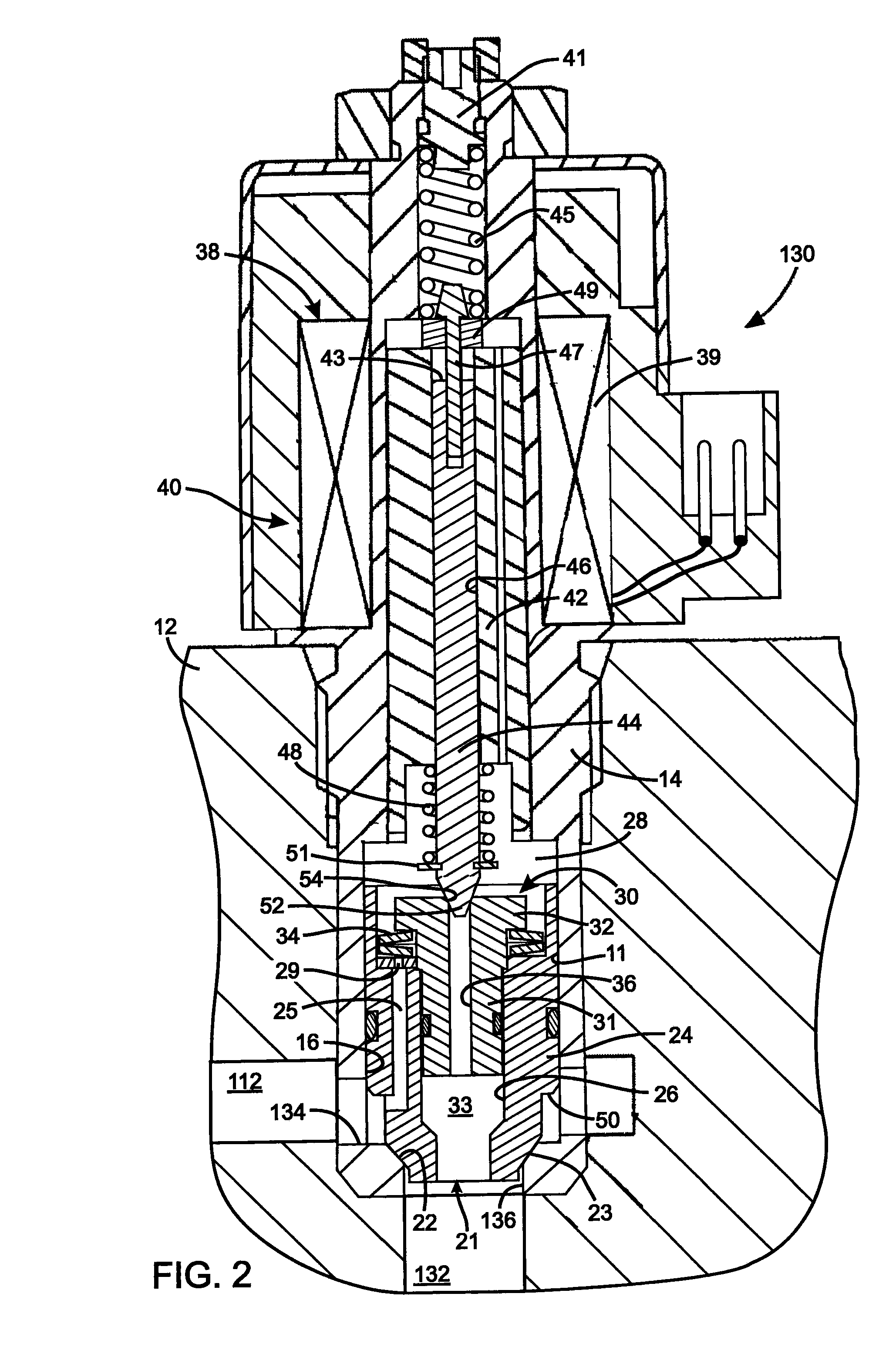

Piston With An Integral Electrically Operated Adjustment Valve For A Hydraulic Vibration Damper

A vibration damper includes a cylinder within which a piston is slidably received thereby defining compression and rebound chambers. The piston has a bore with a valve seat through which fluid flows between those chambers. A poppet selectively engages the valve seat and forms a pilot chamber an opposite side of the poppet from the valve seat. The greater pressure within the compression or rebound chambers is applied by a first logic arrangement to the pilot chamber and a pilot spool control a fluid flow between the pilot chamber and a pressure cavity in the piston body. A second logic arrangement connects the pressure cavity to either the compression and rebound chamber which has the lesser pressure. A solenoid that moves the pilot valve element to control pressure in the pilot chamber and thus the amount that the poppet moves to allow fluid flow through the piston.

Owner:HUSCO AUTOMOTIVE HLDG

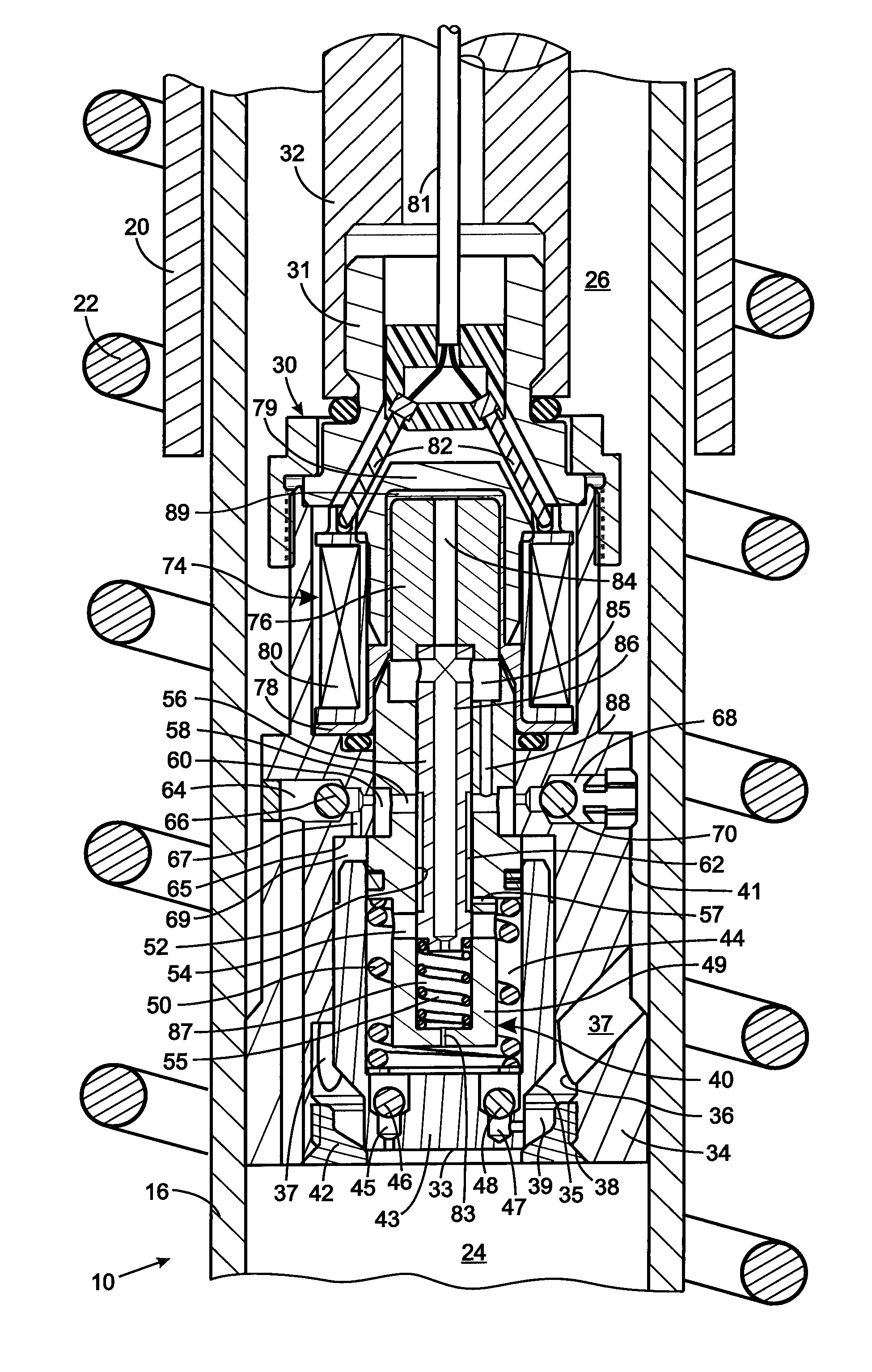

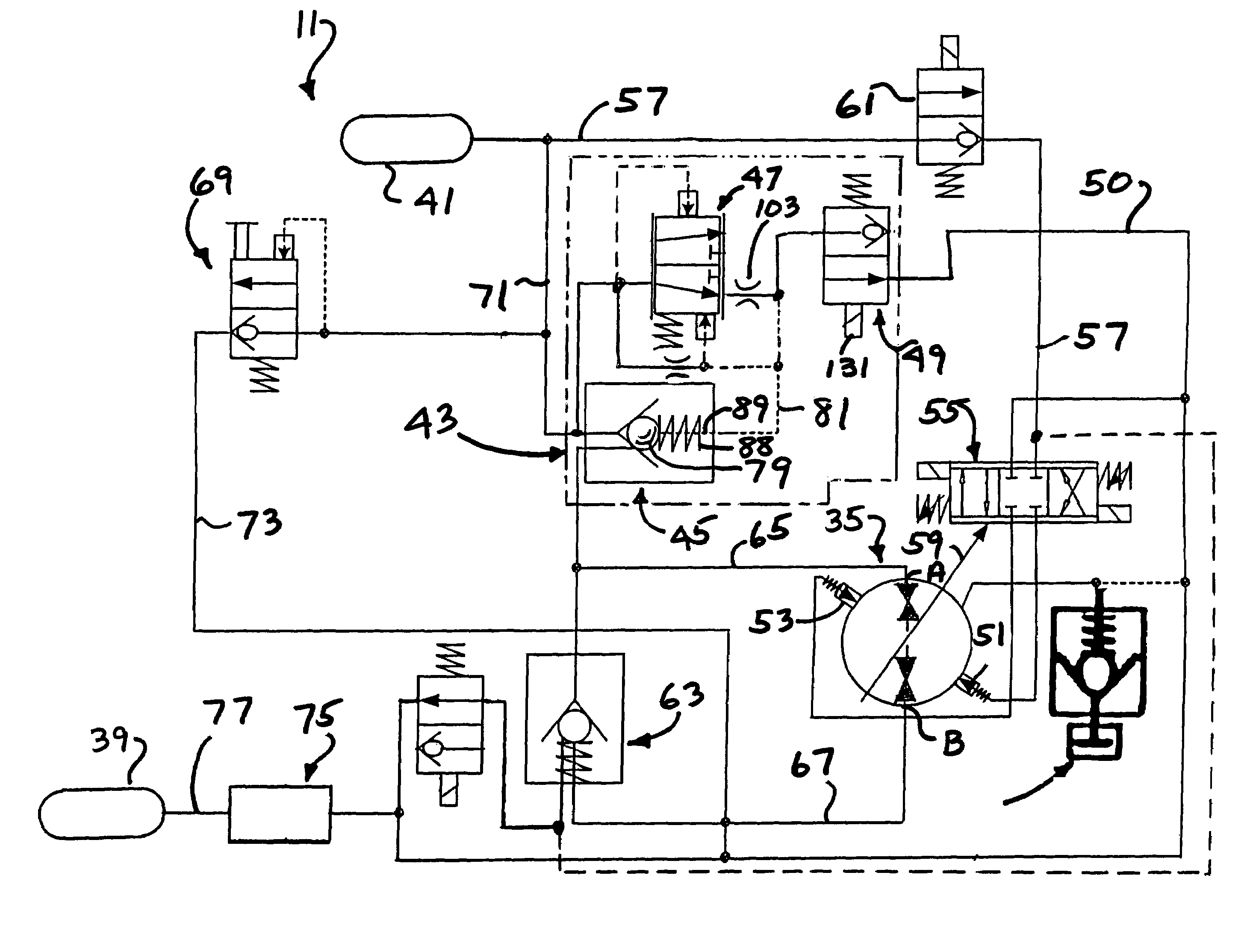

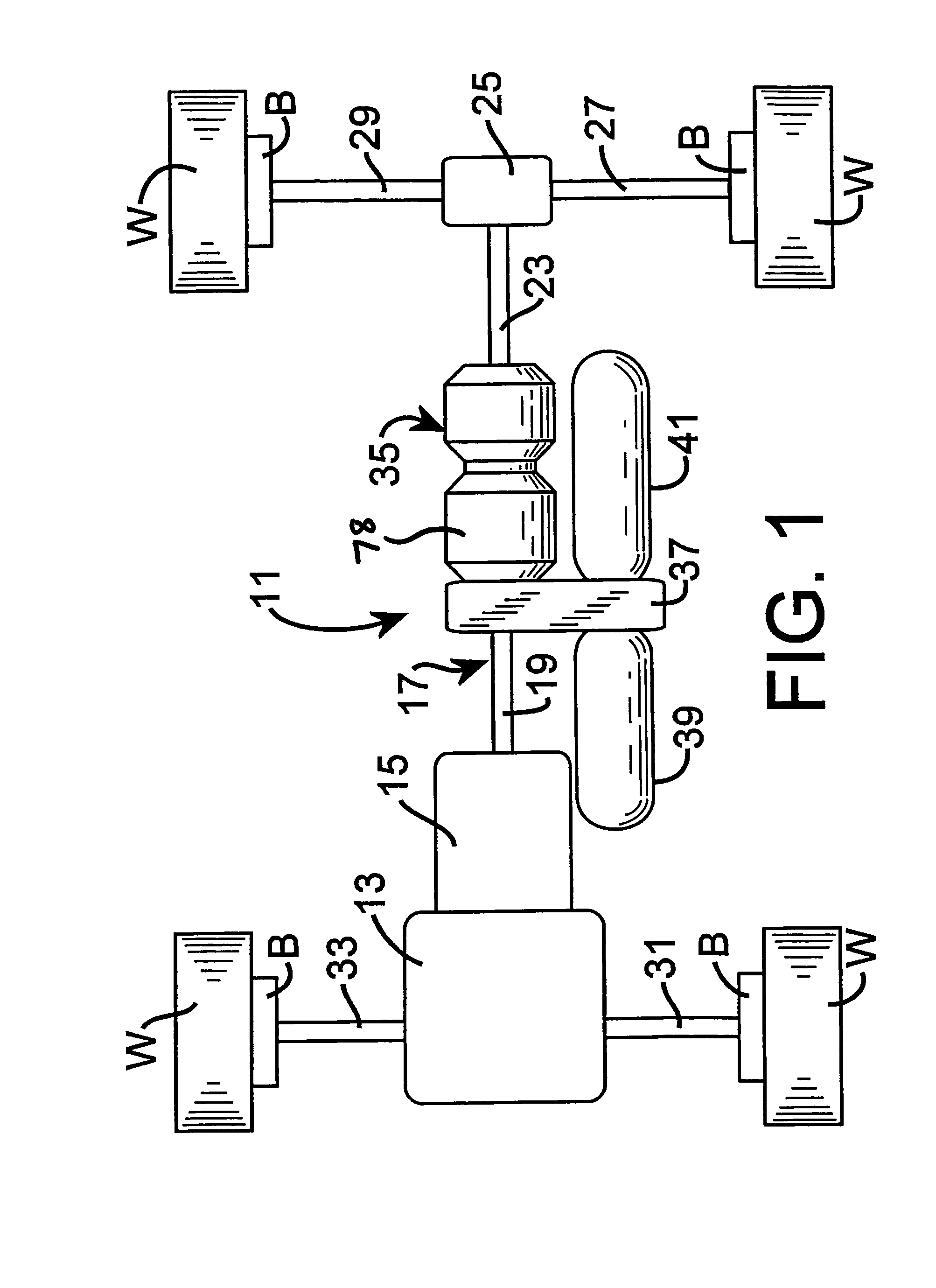

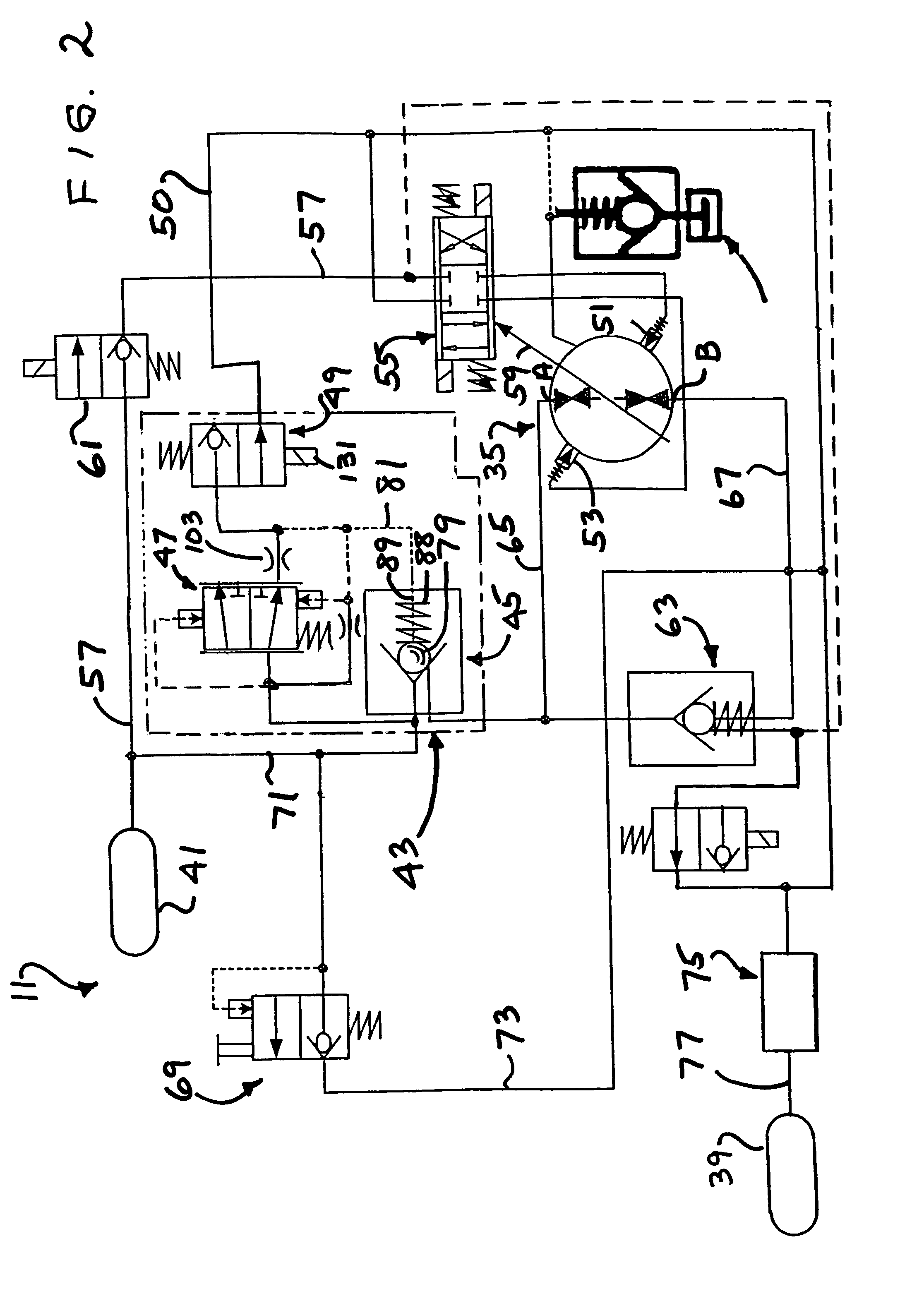

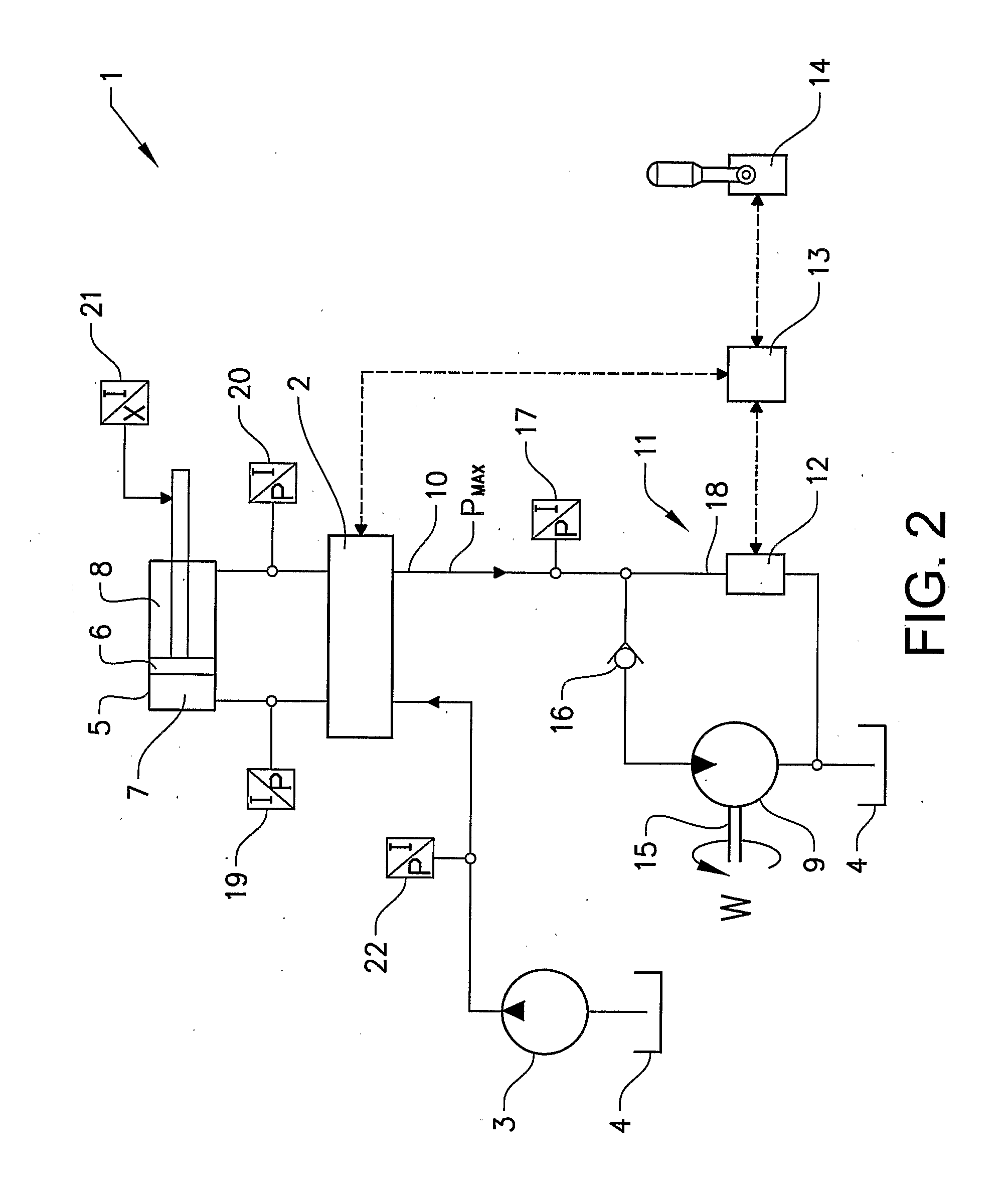

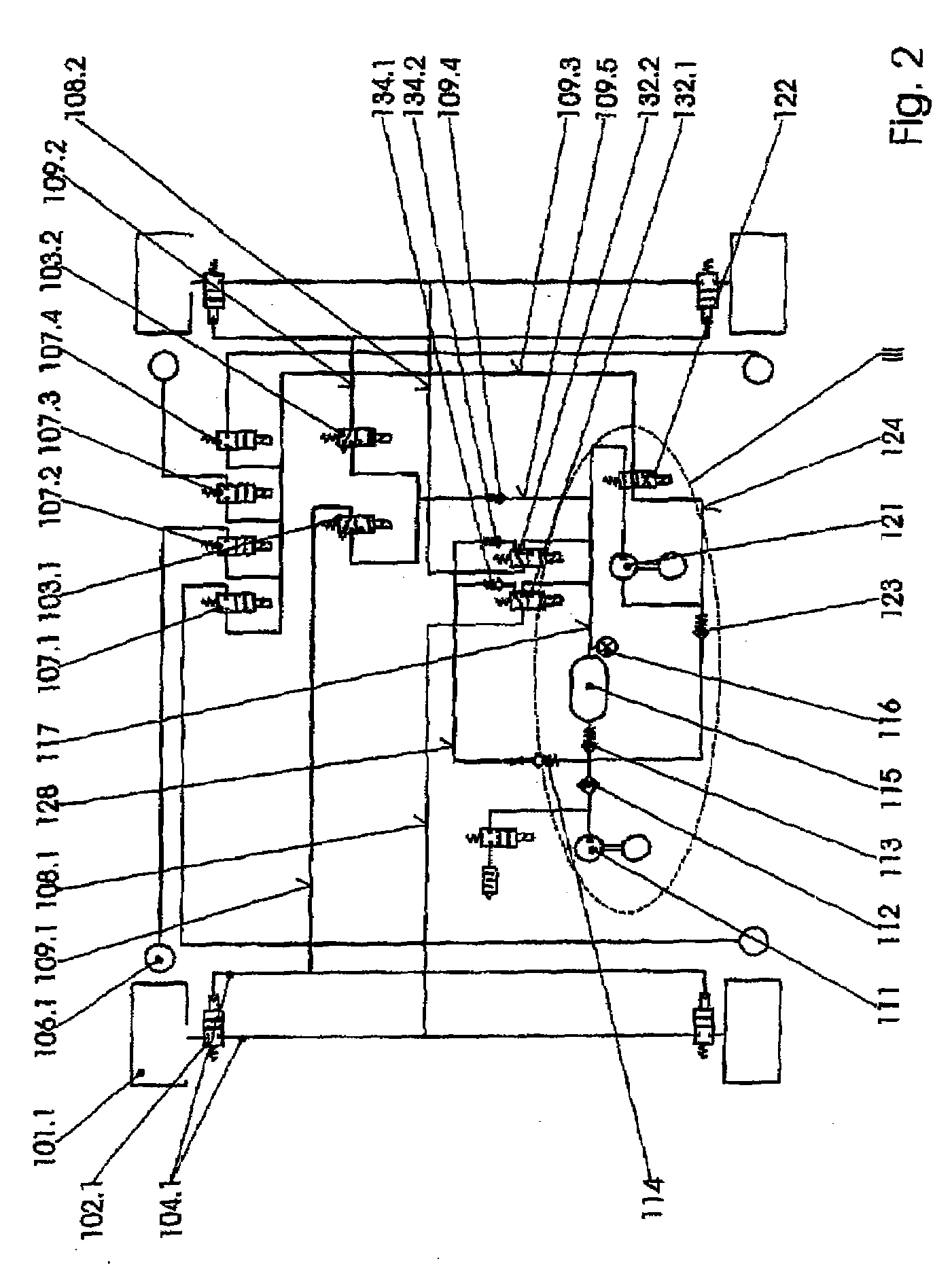

Hydraulic drive system and improved control valve assembly therefor

InactiveUS6971232B2Fast response timeSmall pressure dropBraking element arrangementsServomotor componentsEngineeringHigh pressure

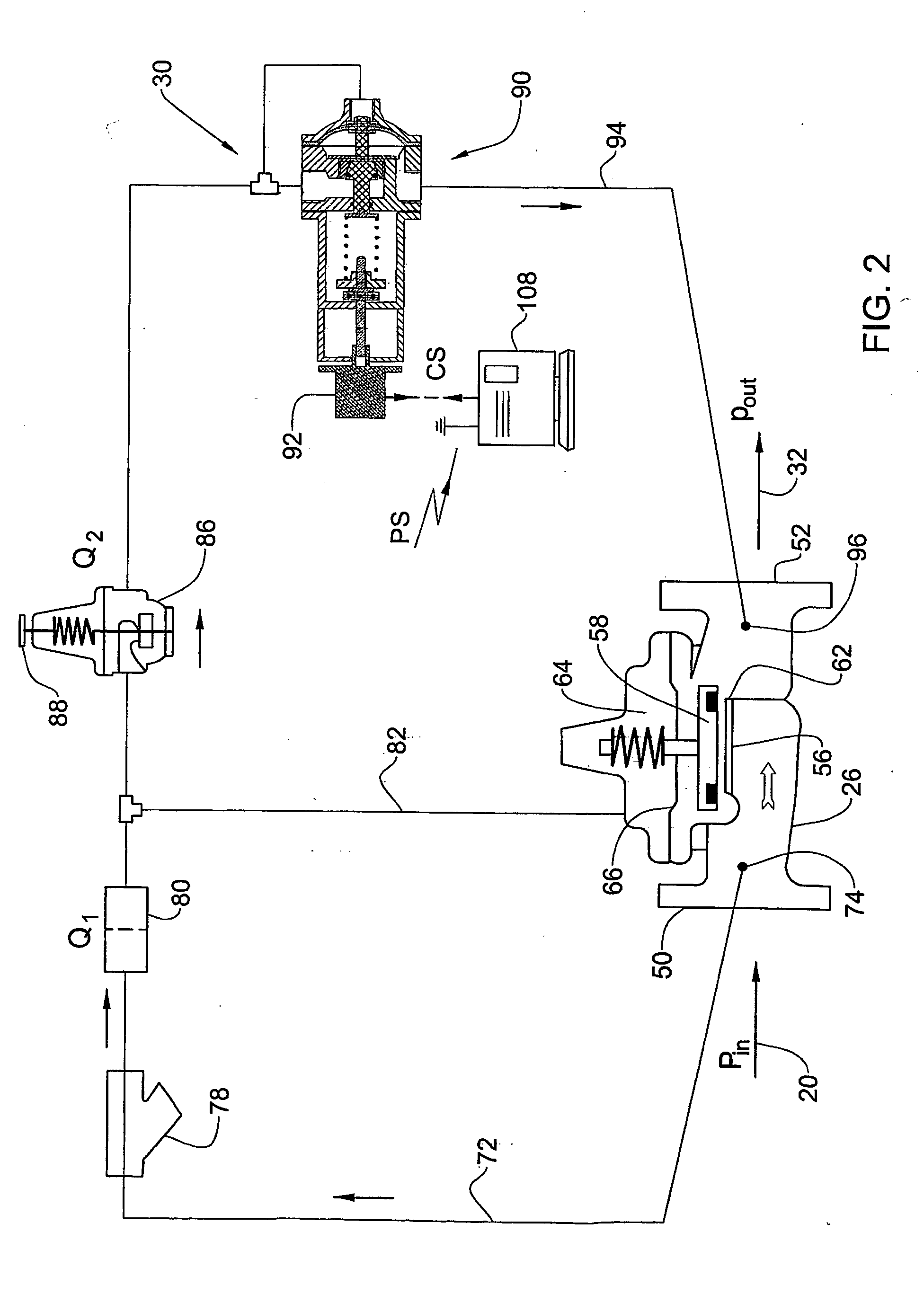

A control valve assembly (43) for use in a system in which a pump-motor unit (35) can either receive drive torque from a drive-line (17) or transmit torque thereto. The system includes a high pressure accumulator (41) and the control valve assembly is disposed between the pump-motor unit and the accumulator, and includes a mode valve (45) normally biased closed by pressure in a control cavity (89), the fluid pressure in which is controlled by a pilot valve assembly (49) in response to an electrical signal (133). A step-orifice valve (47) associated with the mode valve poppet member (79) provides a relatively larger orifice (115) into the control cavity (89) when pressure therein is high, and a relatively smaller orifice (119) into the control cavity when pressure therein is low, i.e., when the pilot valve assembly (49) is open. Thus, a large volume of flow can occur from the accumulator to the unit (35) in a motoring mode, with a relatively low pressure drop, while the poppet member is able to have softer, relatively longer opening time, but a relatively faster closing time.

Owner:EATON CORP

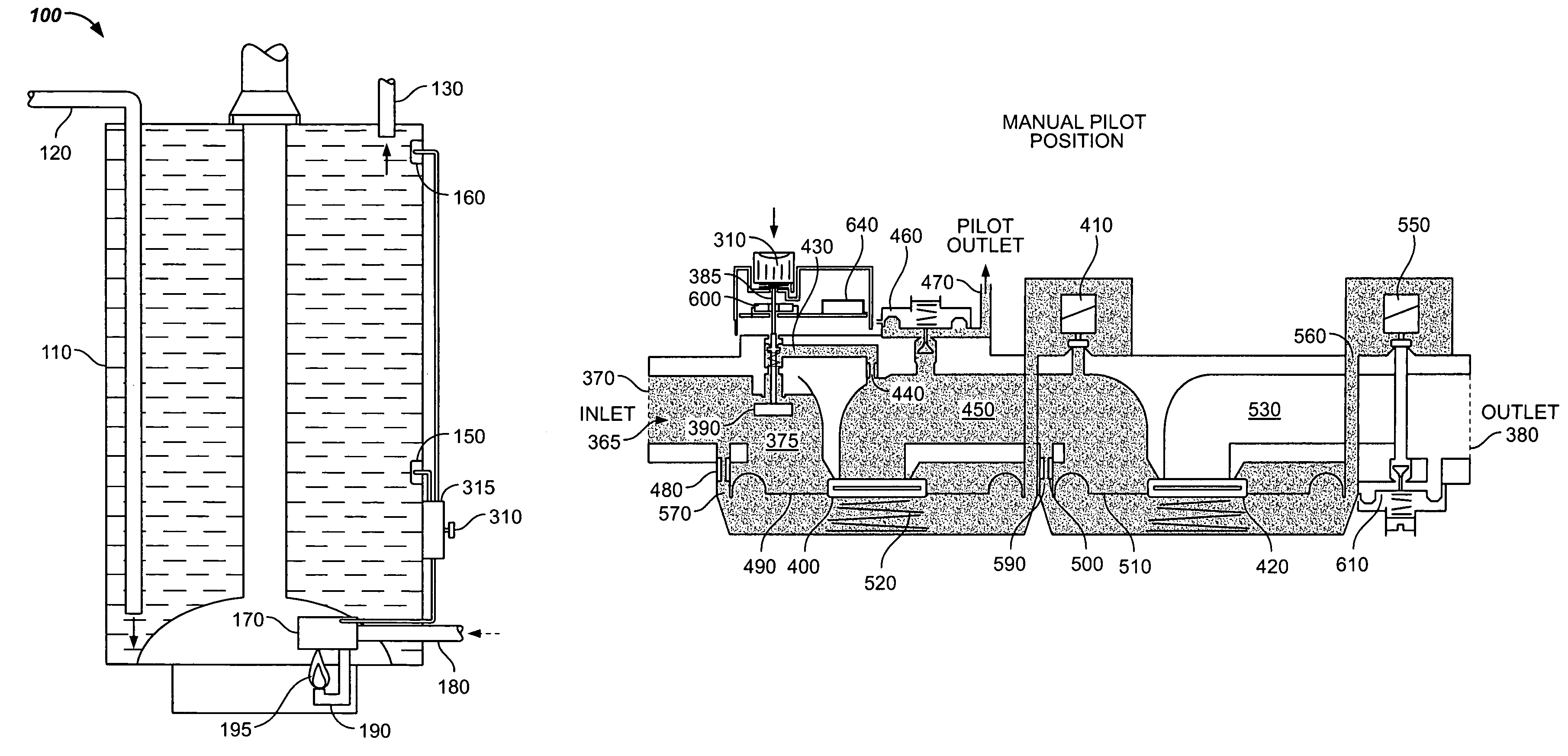

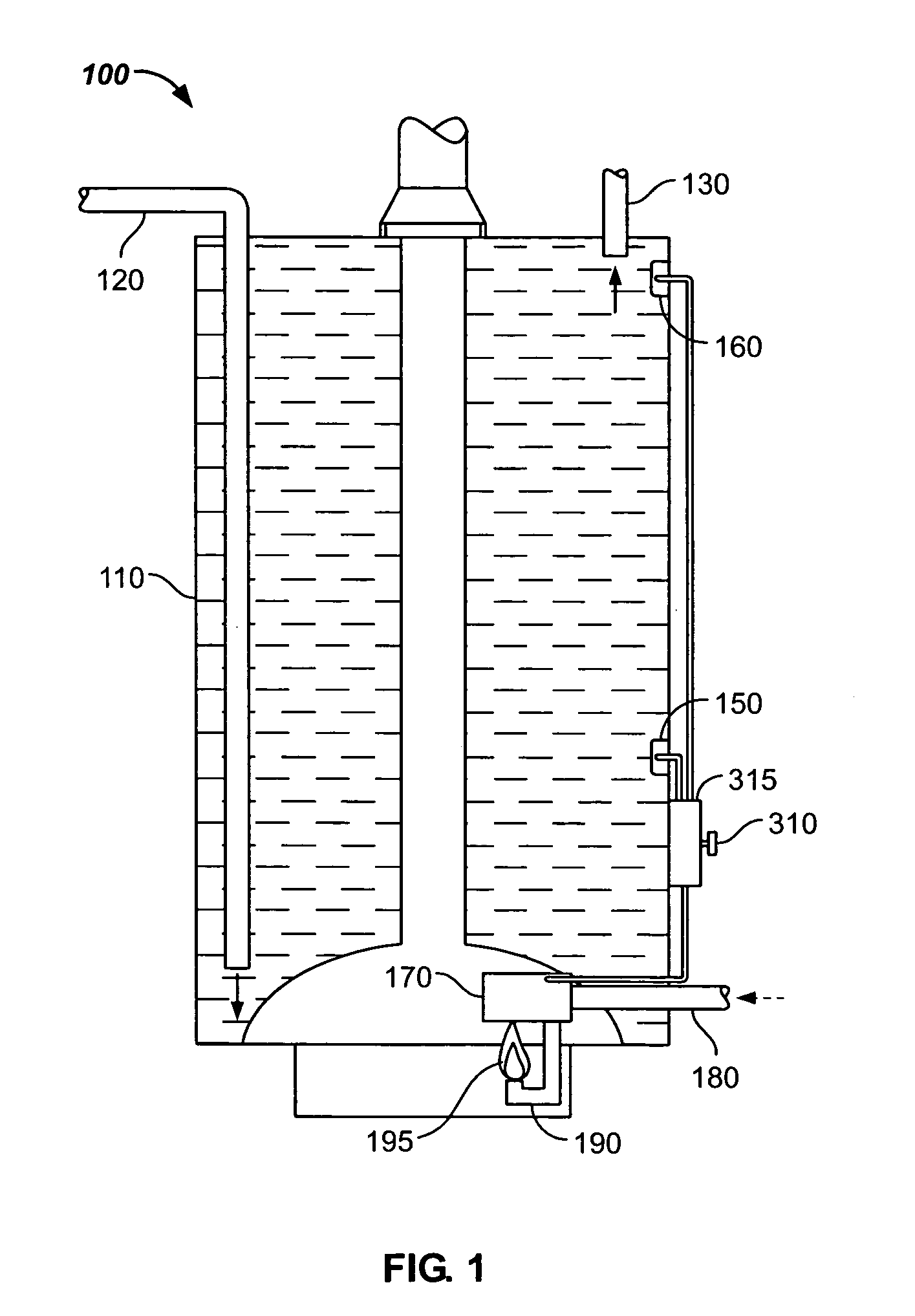

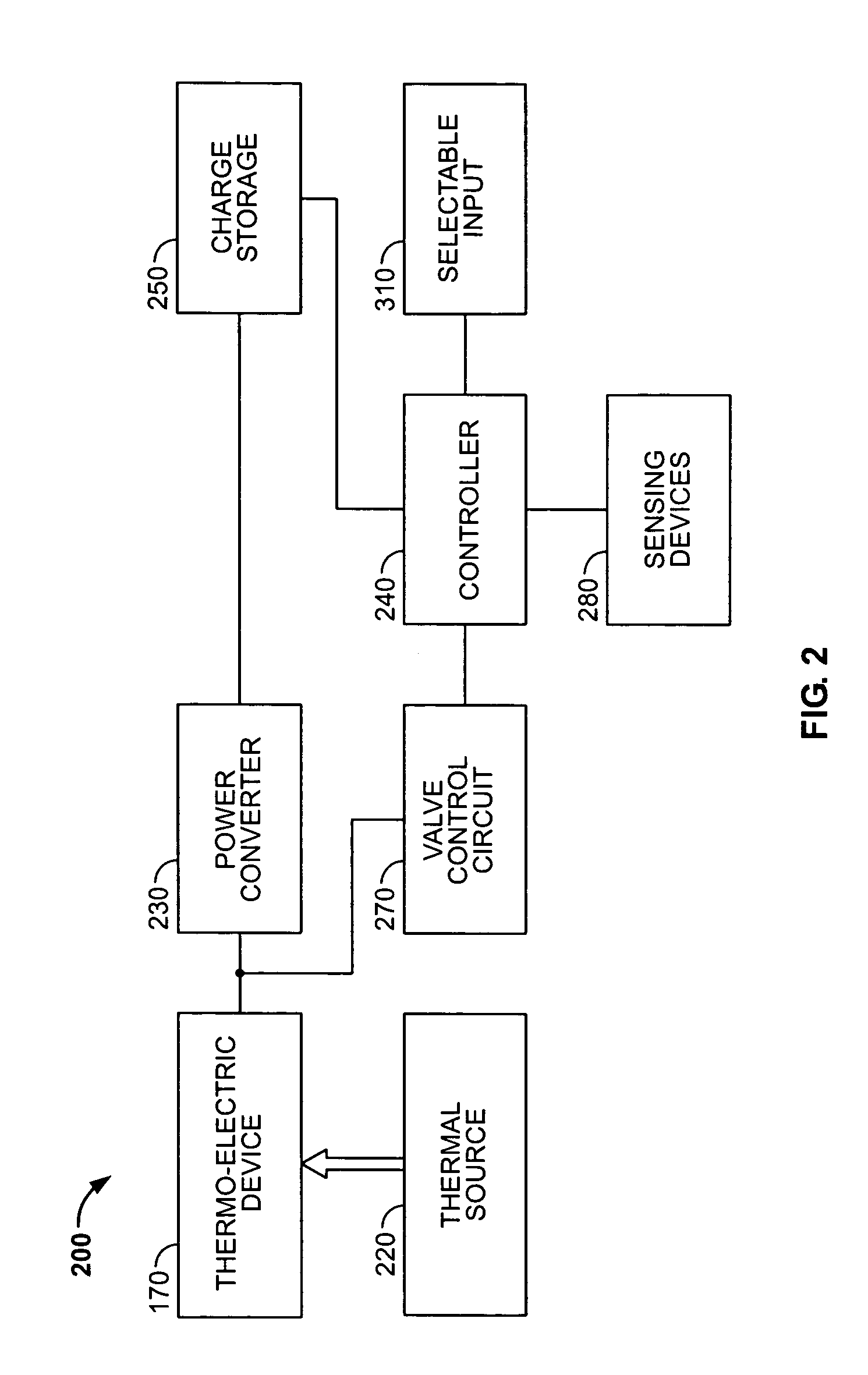

Method and system for combined standing pilot safety and temperature setting

ActiveUS7252502B2Temperature control without auxillary powerFuel supply regulationCombustorElectric potential

The method and apparatus provides a controller (which might comprise a microprocessor) that can control gas flow to a pilot burner in fluid communication with a manual pilot valve and an automatic pilot valve. The exemplary embodiments can comprise a selectable input device that can open the manual pilot valve to allow gas flow to the pilot burner. A pilot flame can then heat one or more thermal detection devices in thermal communication with the pilot burner, wherein the one or more thermal detection devices can output a variable voltage potential to the controller. The controller can then open the automatic pilot valve to maintain gas flow to the pilot burner after the manual pilot valve has been closed. In an exemplary embodiment, the only voltage potential used to power the controller is supplied by the one or more thermal detection devices.

Owner:ADEMCO INC

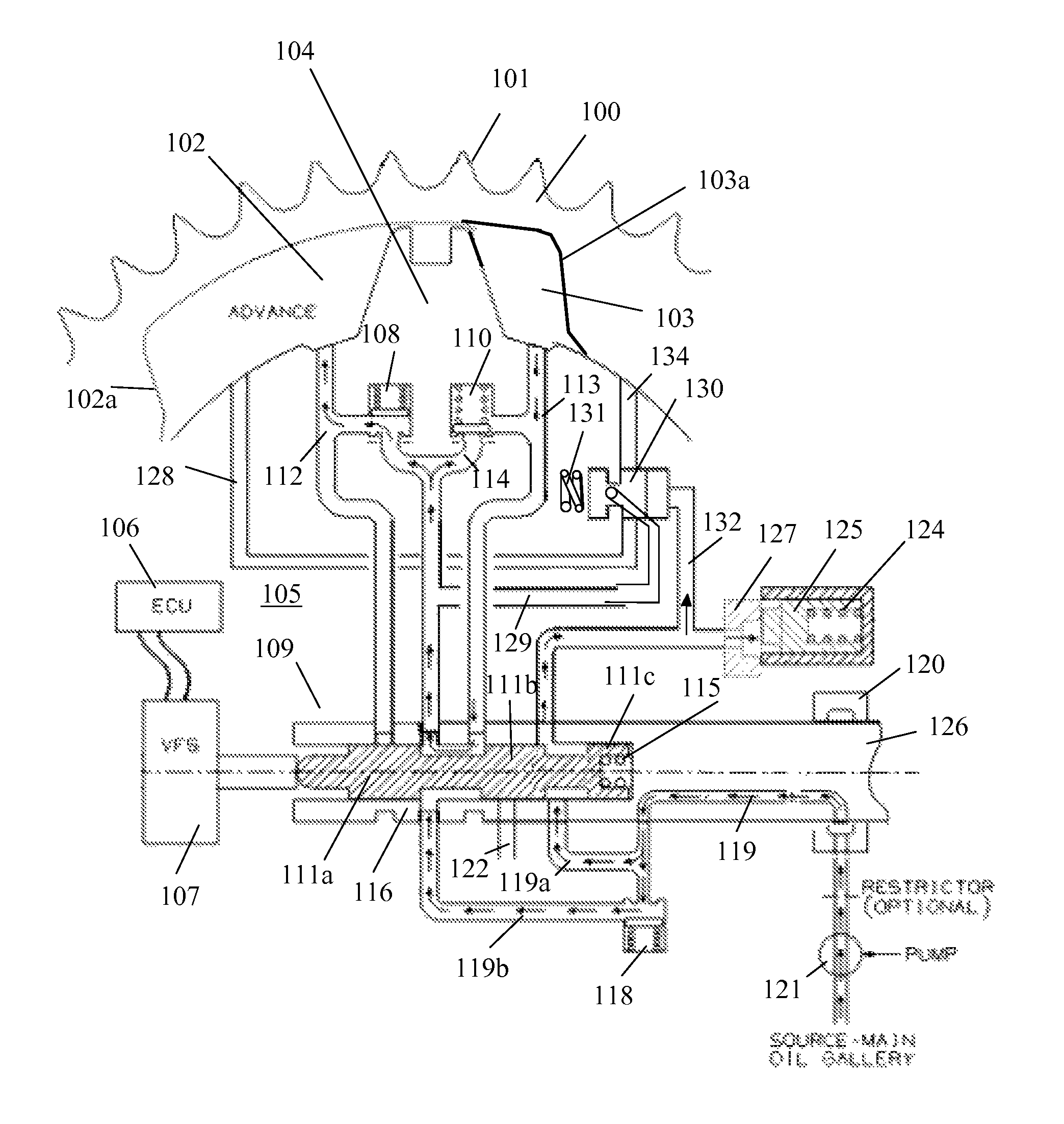

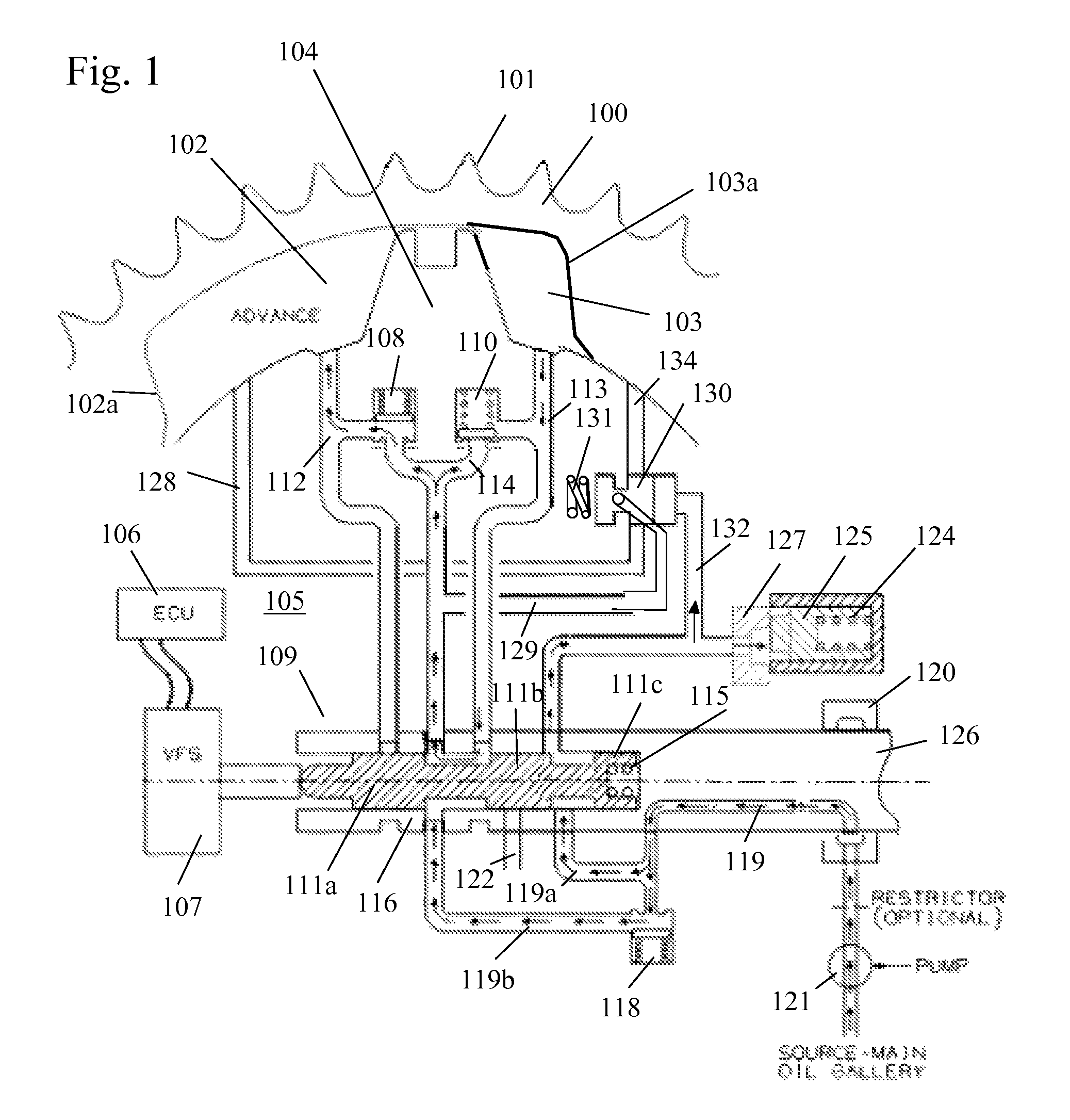

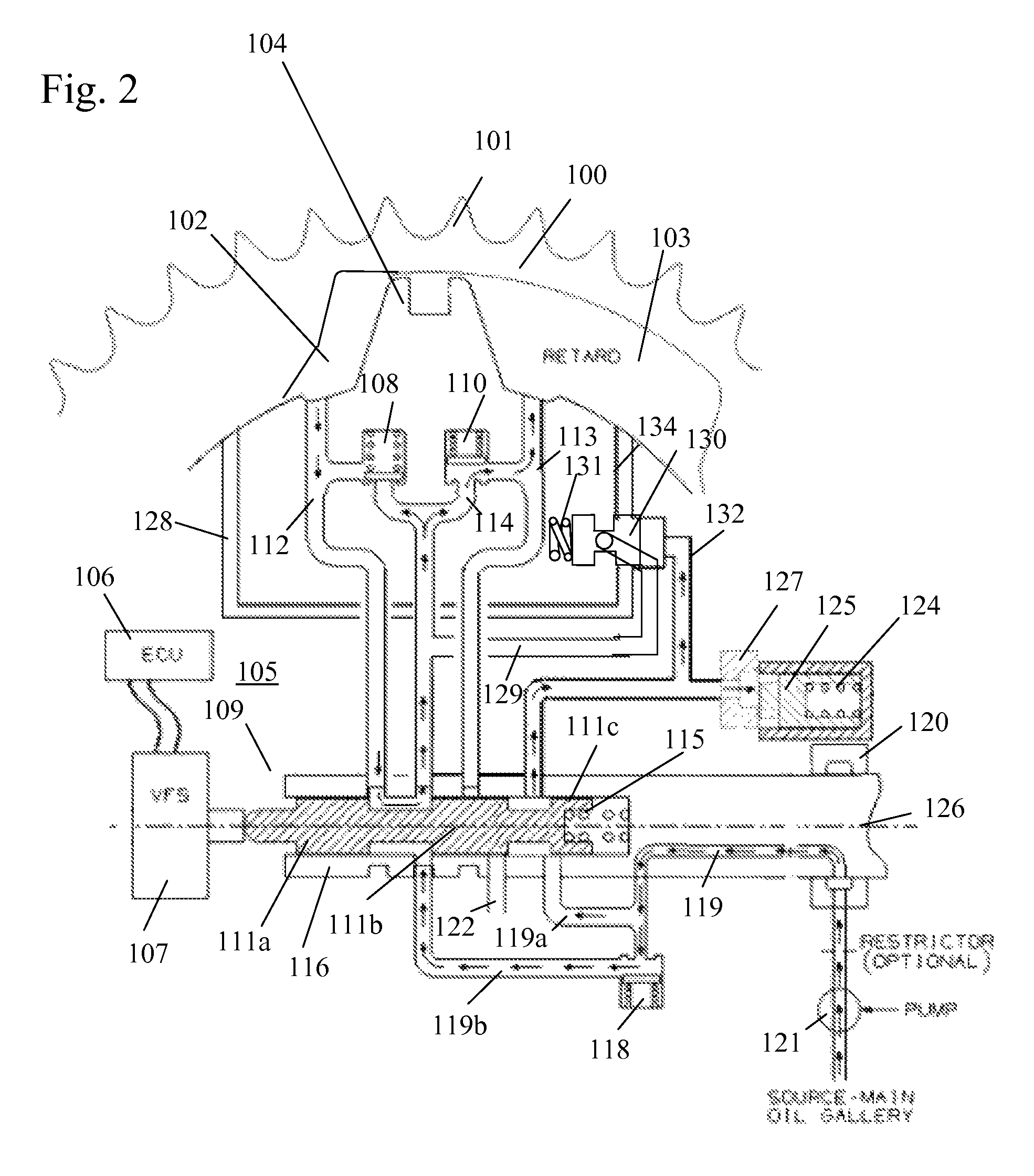

Variable camshaft timing device with hydraulic lock in an intermediate position

A variable cam timing phaser for an internal combustion engine including a piloted valve in the rotor assembly, movable from a first position to a second position, and detent lines communicating with the advance chamber or the retard chamber are restricted and or blocked when the rotor assembly is in or near an intermediate phase angle position. When the piloted valve is in the first position, fluid is blocked from flowing through the piloted valve. When the piloted valve is in a second position, fluid is allowed to flow between the detent line from the advance chamber and the detent line from the retard chamber through the piloted valve and a common line, such that the rotor assembly is moved to and held in the intermediate phase angle position relative to the housing assembly.

Owner:BORGWARNER INC

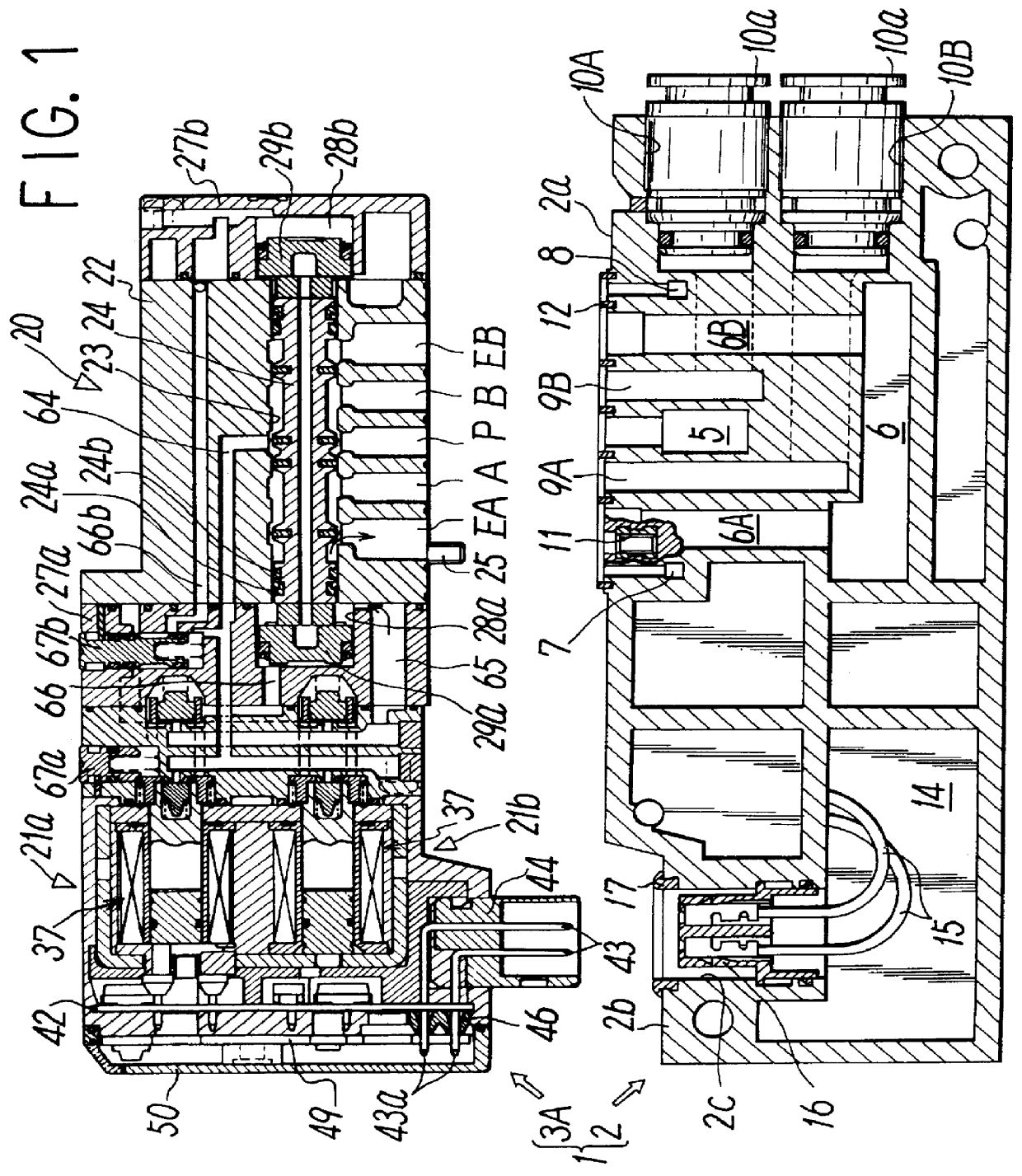

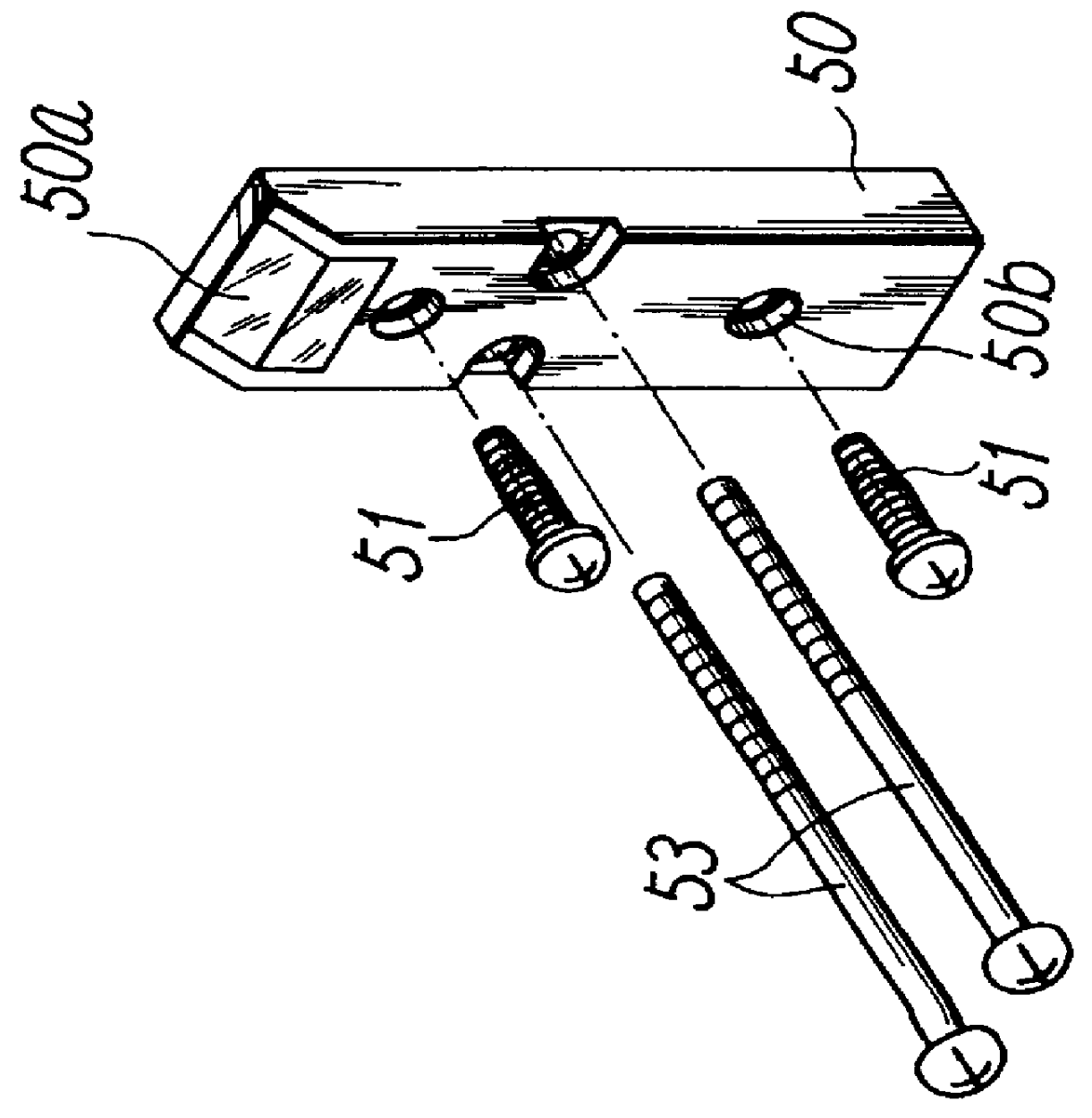

Sealed transfer valve assembly

InactiveUS6109298AImprove insulation performanceImprove sealingOperating means/releasing devices for valvesElectrical apparatusEngineeringSynthetic resin

A sealing article 17 is provided in the opening edge of a depression 2c provided in a manifold 2 to connect a supply connector 16 and a receiving connector 44 in an air-tight manner. A solenoid section 33, in which a solenoid 31 in each of pilot valve 21a and 21b and a receiving connector 44 that supplies power to connector 31 are sealed into a synthetic resin 45, is provided in a transfer valve 3A. Solenoid section 33 has a lamp circuit board 49 mounted on its outer surface to receive power from receiving connector 44, and includes power supply indicator lamps 48; and a cover 50, covering the whole of lamp circuit board 49, mounted to form an air-tight seal on its outer surface via a gasket 52.

Owner:SMC CORP

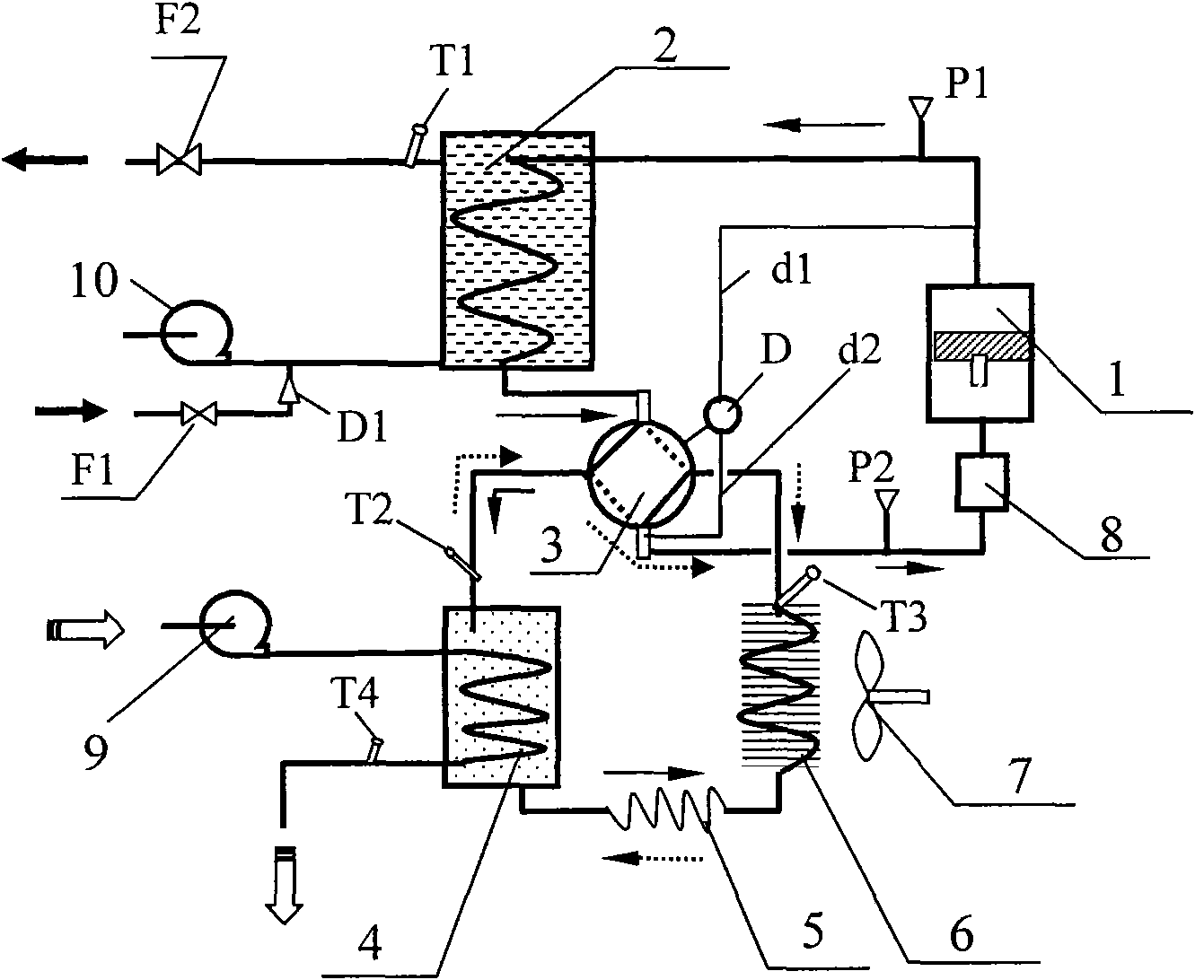

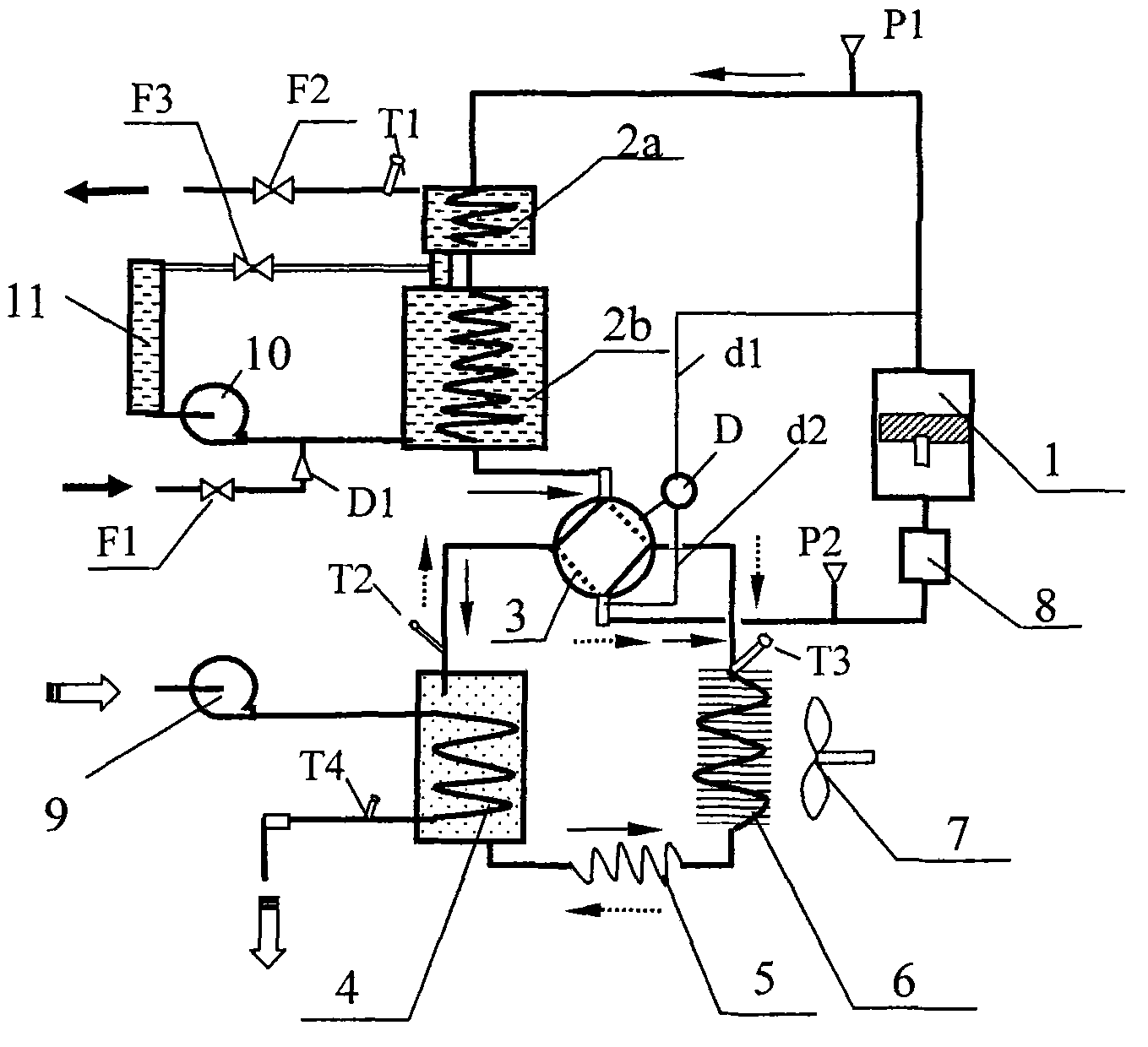

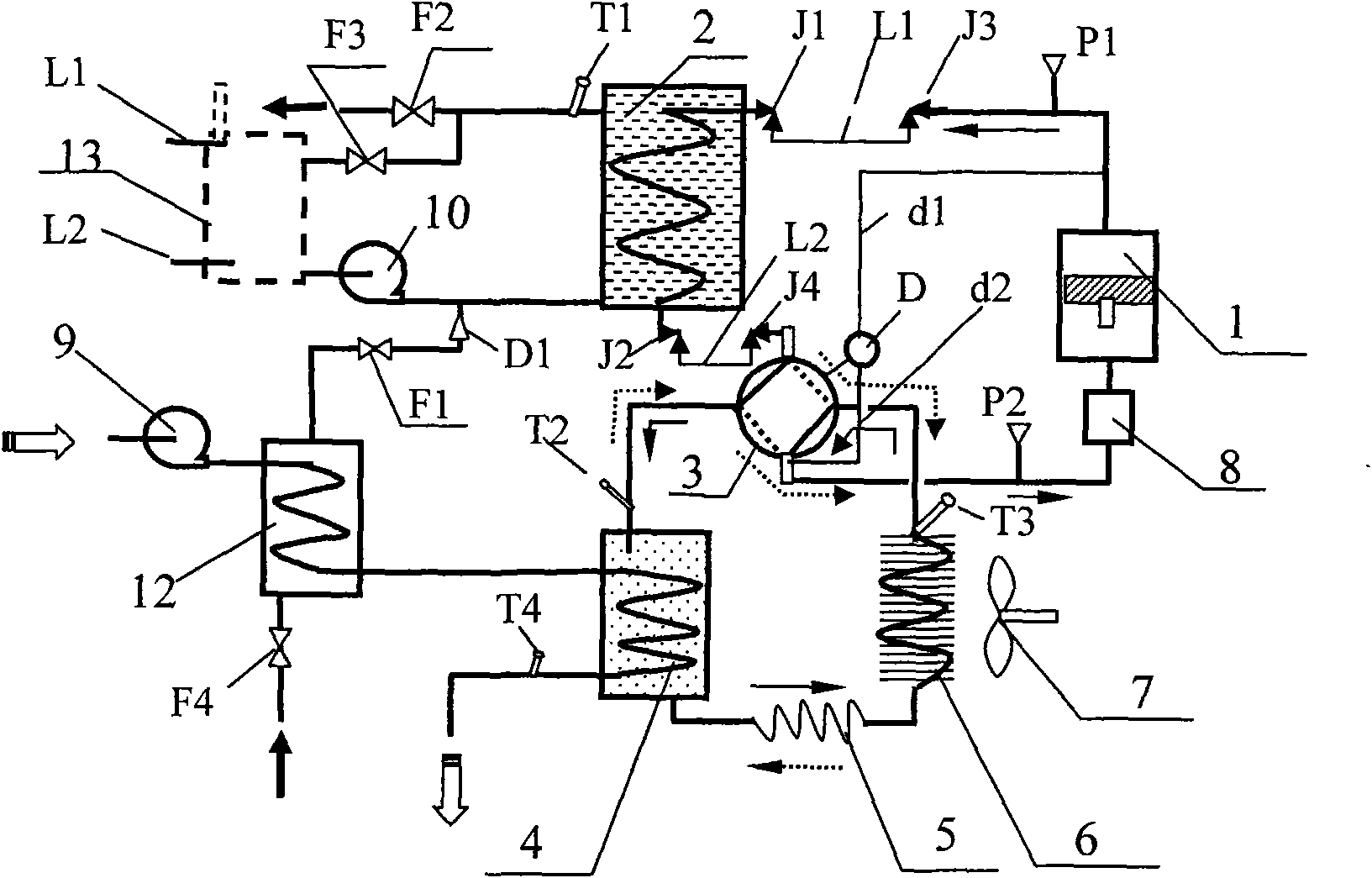

Dual heat-source heat-pump hot water device with extremely simple refrigerating loop

InactiveCN101943471AFix switching issuesSolve defrosting problemsFluid heatersHeat recovery systemsFour-way valveWater source

The invention discloses a dual heat-source heat-pump hot water device with an extremely simple refrigerating loop. The device is characterized by mainly comprising a compressor, a hot water condenser, a wind heat exchanger, a water heat exchanger, a four-way valve, a bidirectional throttle and the like, wherein a high pressure inlet of the four-way valve is connected with the outlet of the hot water condenser, and the other three ports thereof are connected with air inlets of the wind heat exchanger, the water heat exchanger and the compressor respectively; other ports of the wind heat exchanger and the water heat exchanger are connected with the bidirectional throttle; the exhaust port of the compressor is connected with the inlet of the hot water condenser, and is connected with high pressure air inlet of an electromagnetic pilot valve of the four-way valve; four functions of manufacturing hot water by utilizing water source or air energy and providing air-conditioning cool water by utilizing air-cooling or heating water can be realized by only switching the four-way valve, defrosting can be performed completely and quickly; and a water pre-heater is added to the device to reclaim the heat of waste hot water. The heat pump has the advantages of dual heat sources compensation and wide application range, has multiple functions, extremely simple structure, extremely convenient switching and over 5 of annual comprehensive energy efficiency ratio, and has great popularization value.

Owner:陈则韶

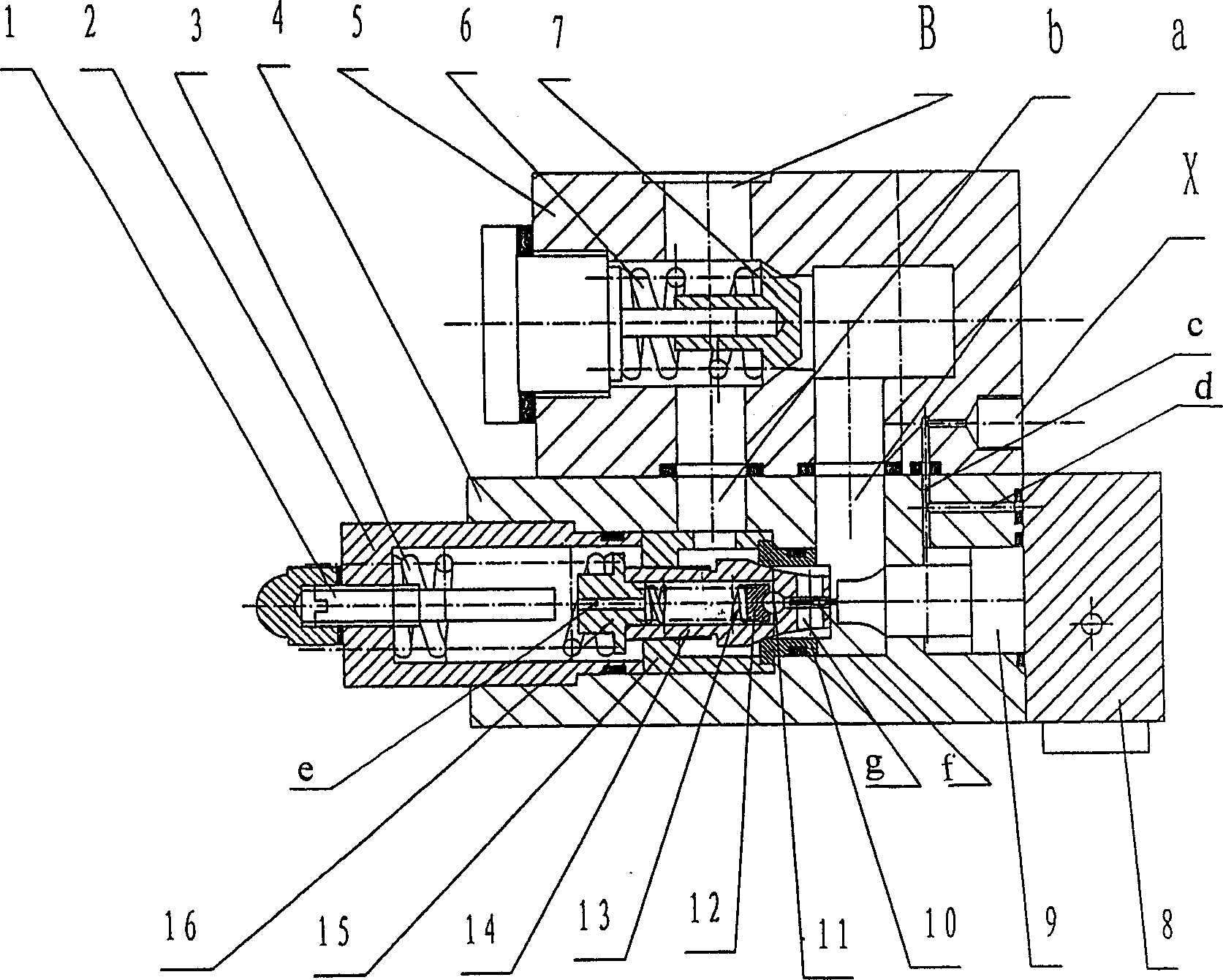

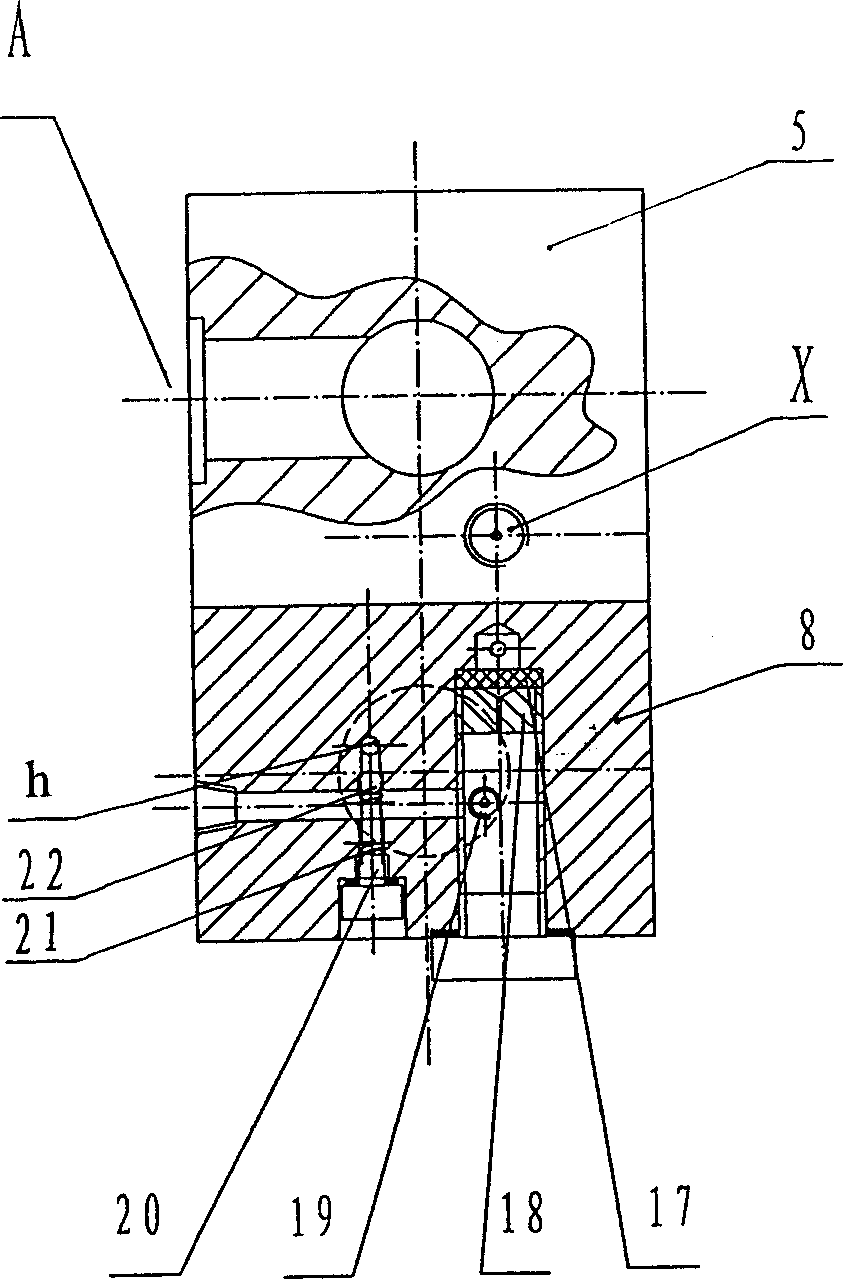

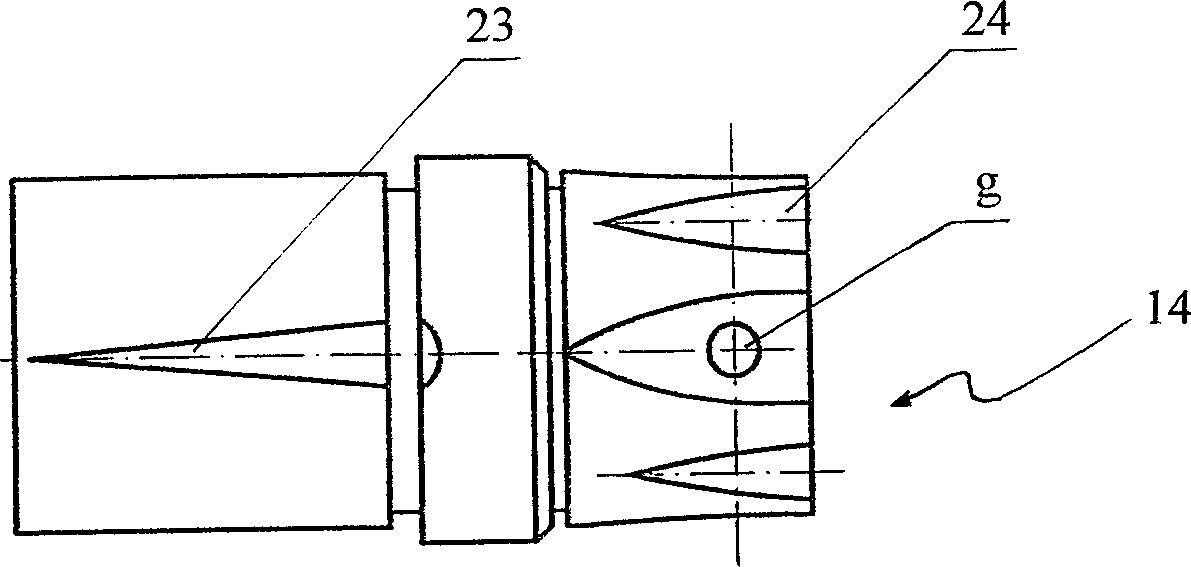

Hydraulic balancing valve

The hydraulic compensation valve comprises main valve, pilot valve and control valve, in which every valve comprises valve body, valve core and its front and rear two cavities, the valve core is connected with valve body by means of spring, pilot valve is placed in the main valve core, the control valve is connected with main valve, said control valve also includes two main oil holes A and B and control oil hole X which are positioned on its valve body, a piston is positioned in front cavity of the main valve, its cavity with rod and cavity without rod are respectively communicated with control oil hole X by means of oil channels of c and d positioned on valve body, the outside of rear end of the main valve core possesses several oblique grooves axially, these oblique grooves are communicated with oil hole B of main valve and rear cavity of main valve, and the rear end of main valve core is equipped with an oil hole e communicated with rear cavity of main valve and rear cavity of pilot valve.

Owner:卢永松

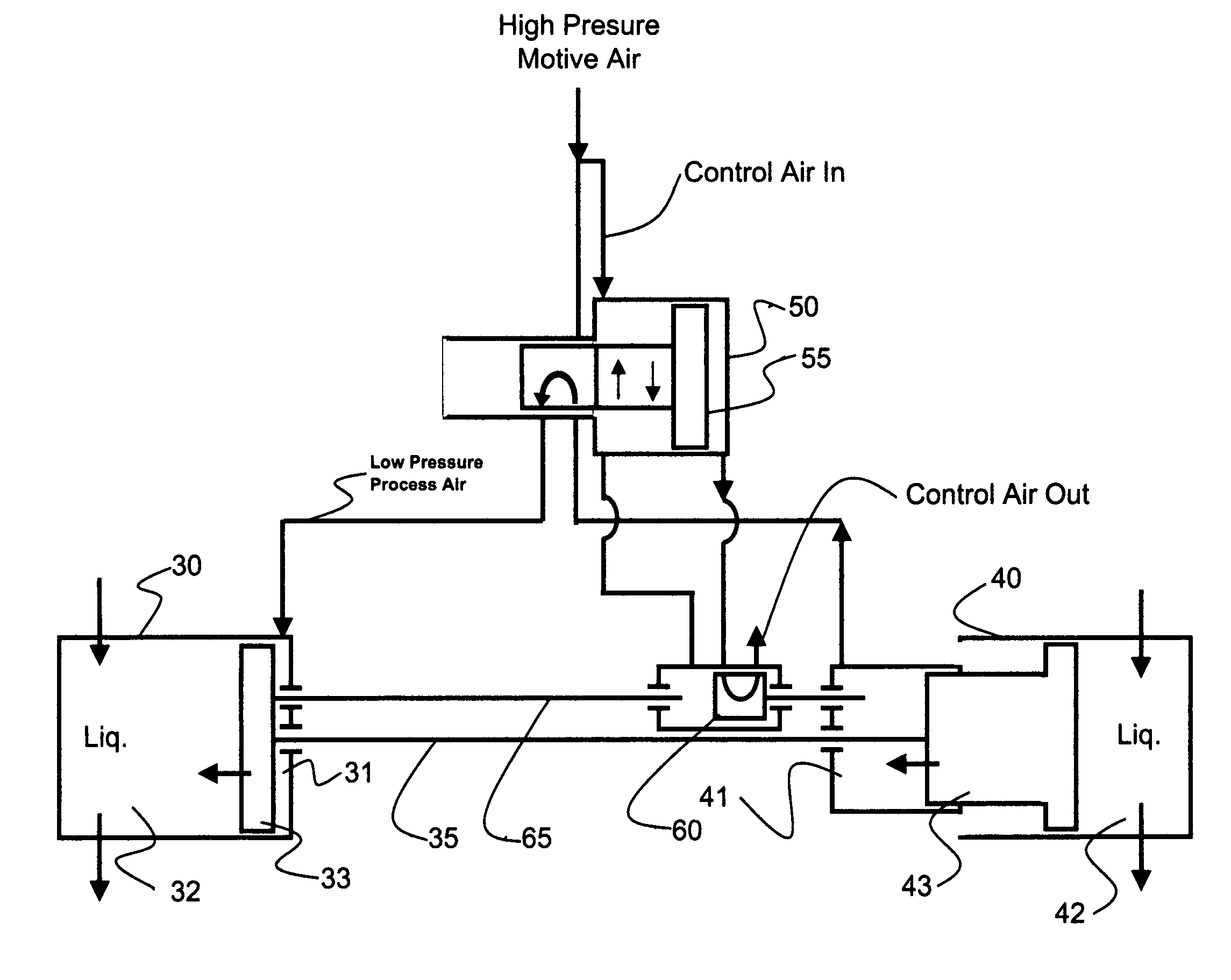

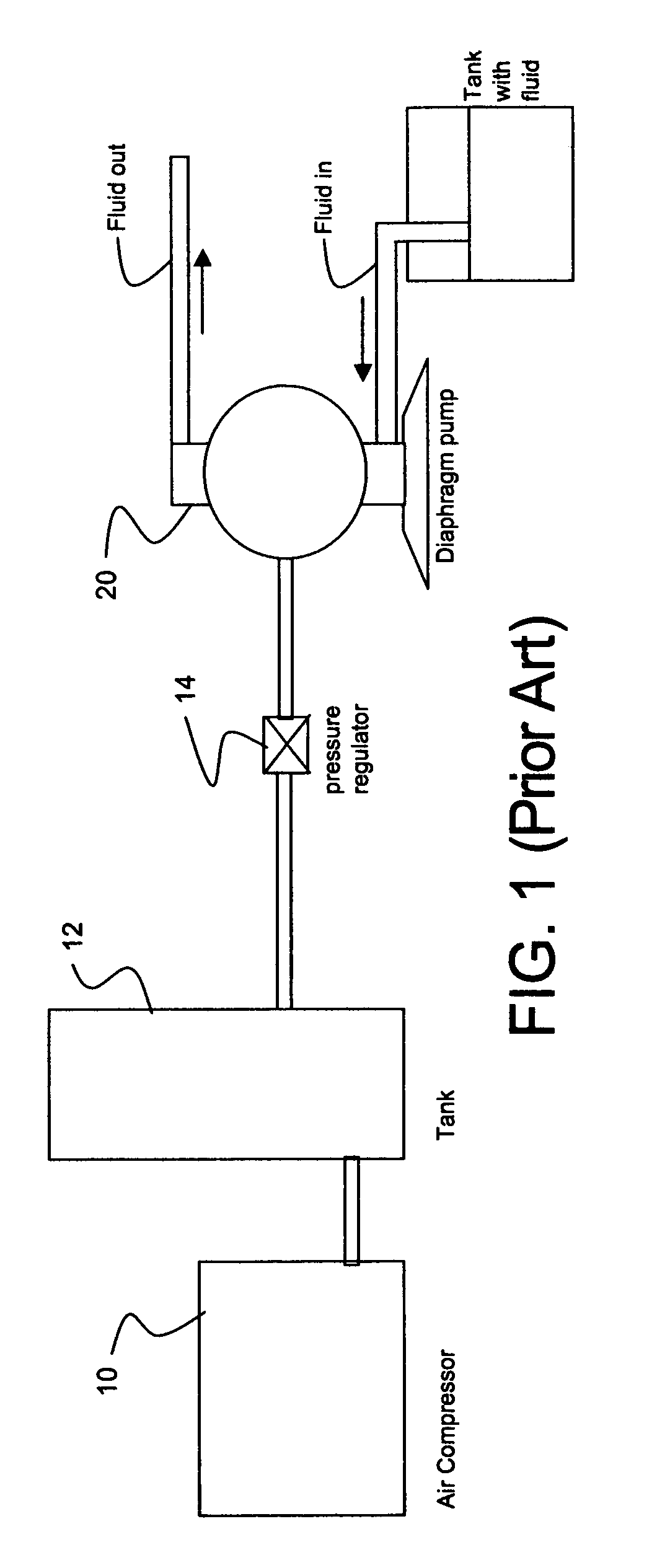

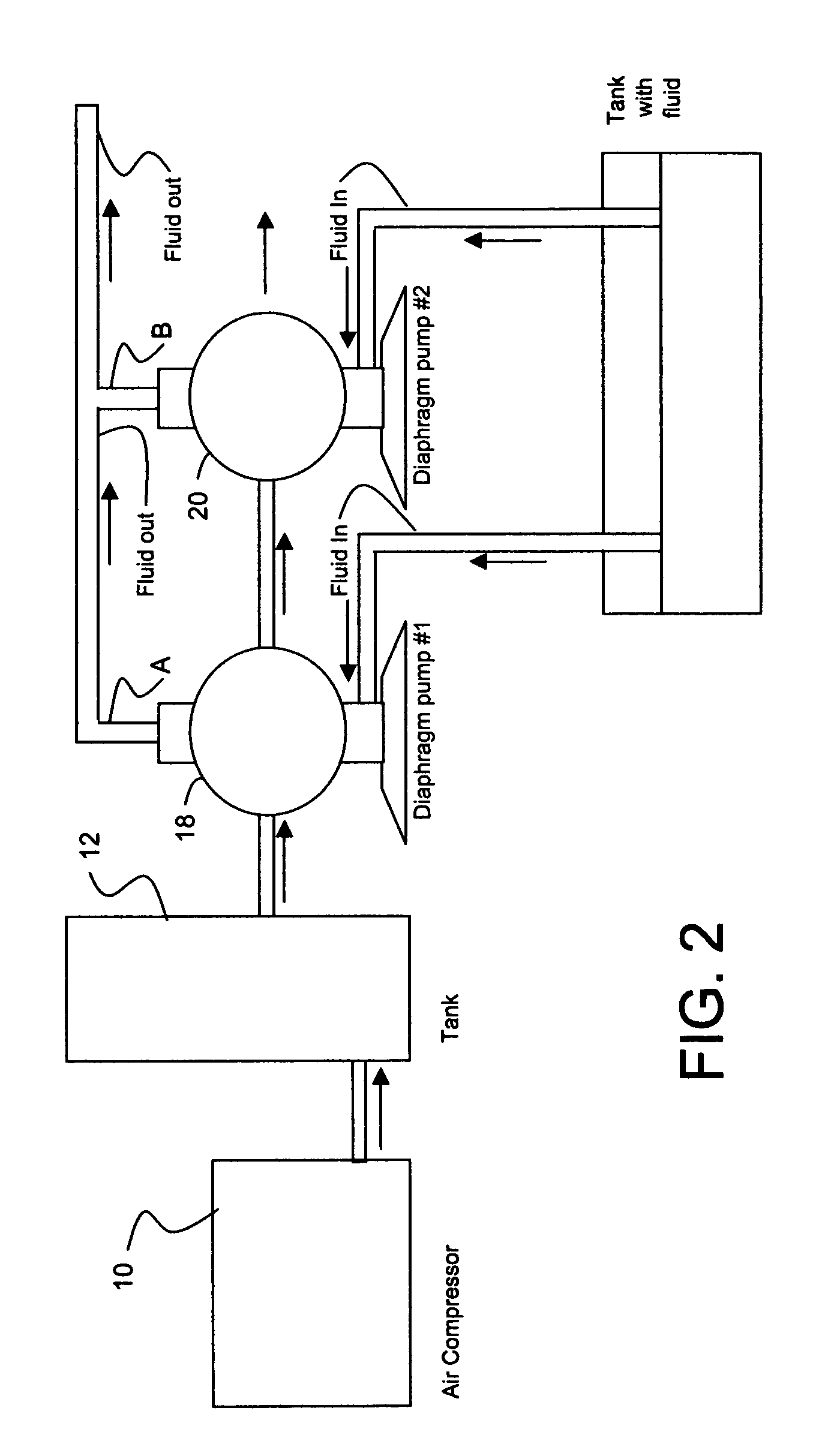

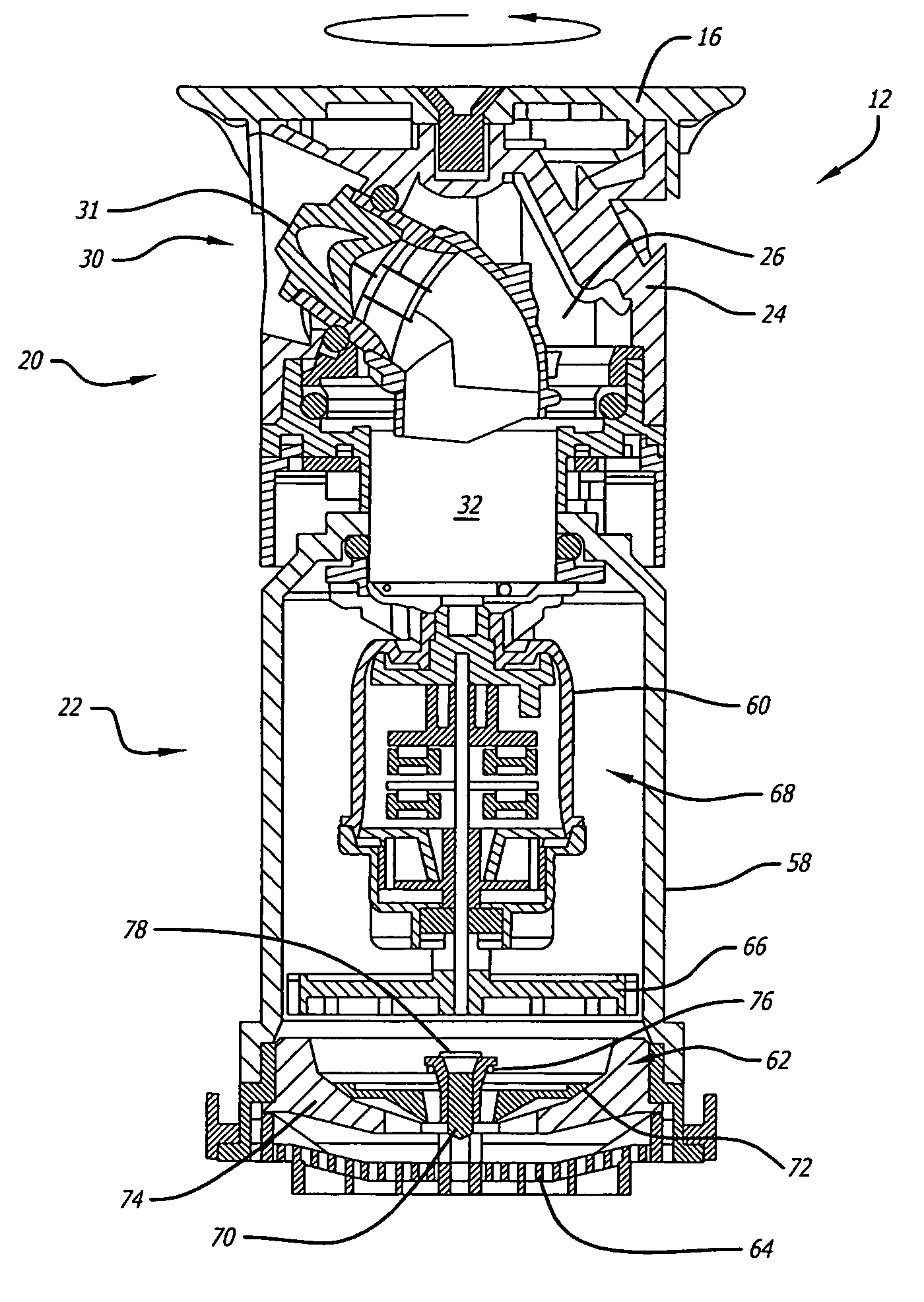

Expansible chamber pneumatic system

An expansible chamber pneumatic system, for example a fluid pump system, includes two or more double-acting diaphragm pumps, each with symmetrical left and right pump housings, each housing including an air chamber and a fluid chamber separated by a movable diaphragm. The diaphragms are connected for reciprocating movement in unison to pump fluid through their respective fluid chambers. Each pump includes an air valve actuated by Control air to direct Process air into one of the air chambers, simultaneously releasing used Process air from the other air chamber to thereby move the diaphragms, thereby to pump fluid. A pilot valve directs Control air to the air valve to position the air valve. The pilot valve is responsive to diaphragms reaching their travel limit in one direction to direct Control air to reverse the directions of Process air flow through the air valve to thereby reverse the movement of the pump diaphragms. Control air exhausts through the pilot valve to atmosphere. Process air exhausts through the air valve from one pump to become input or motive air for the next pump.

Owner:PSG CALIFORNIA LLC

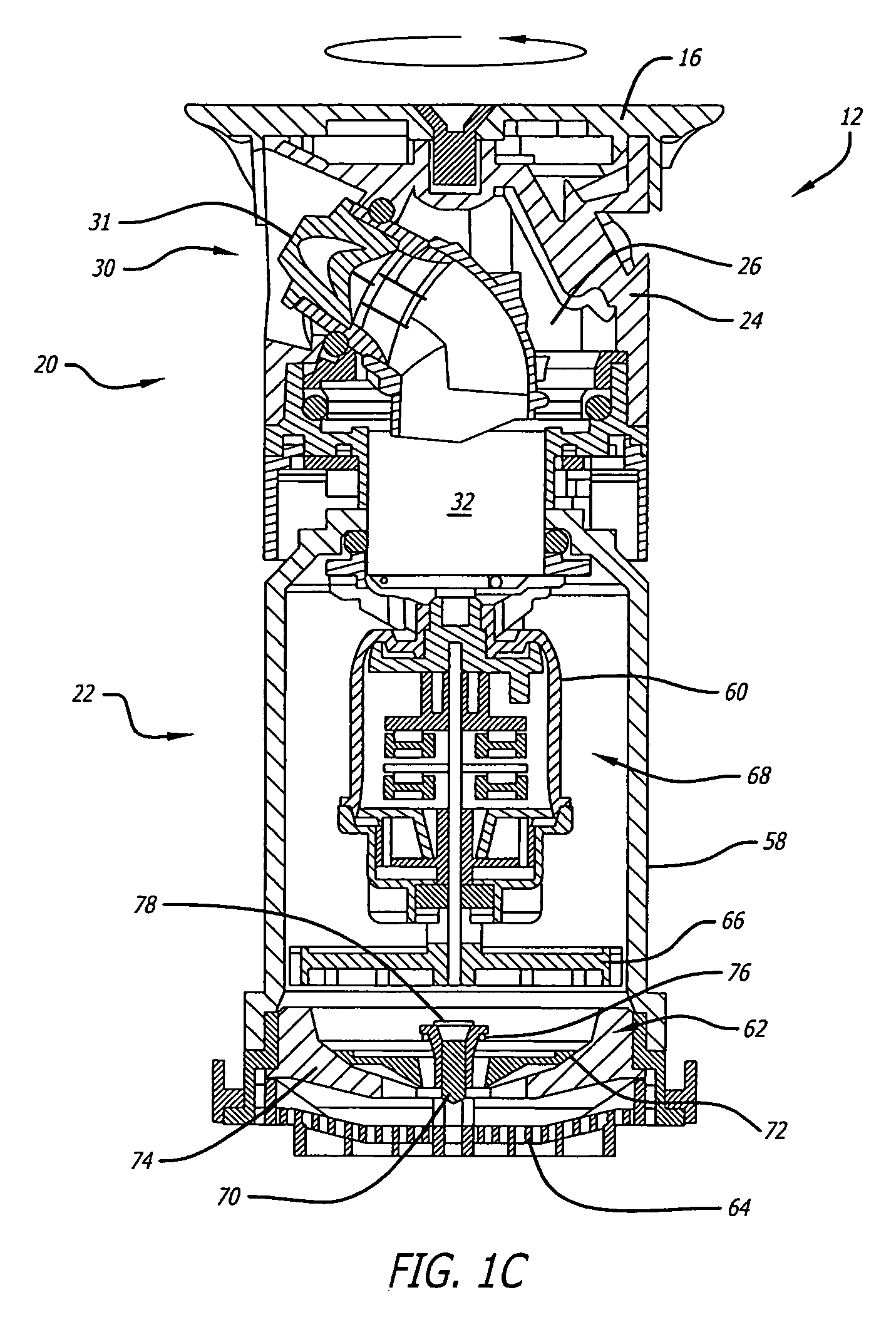

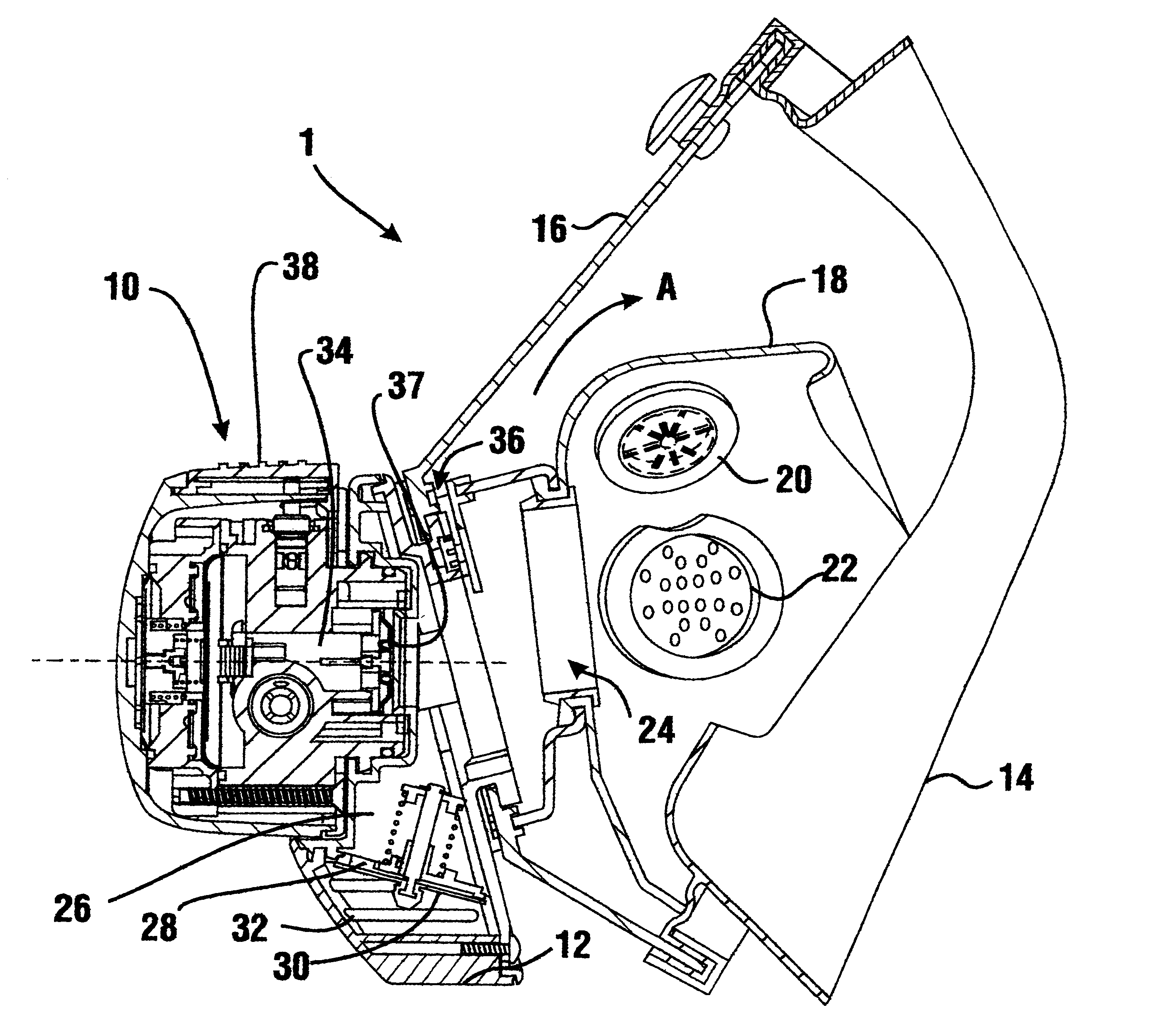

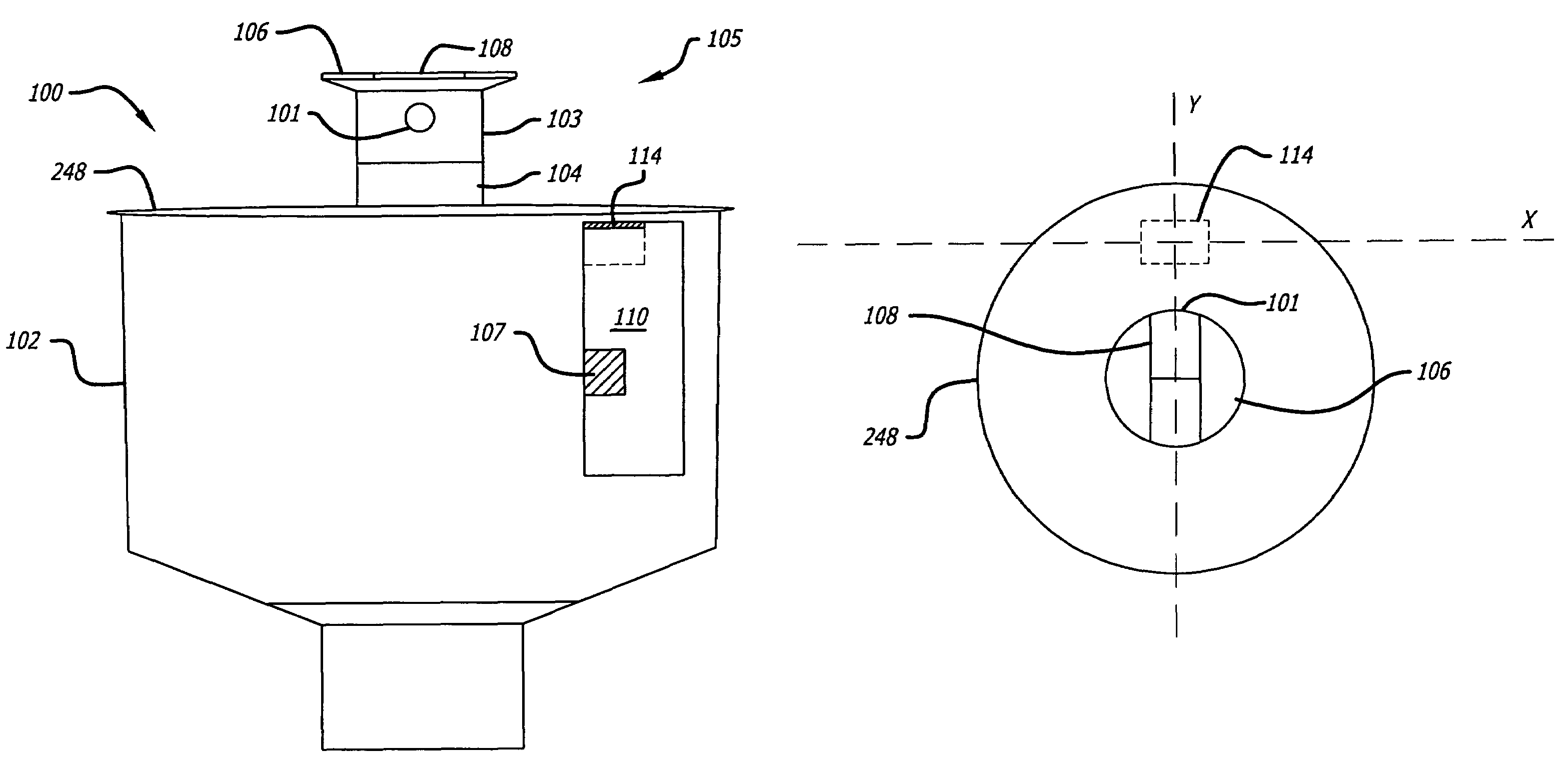

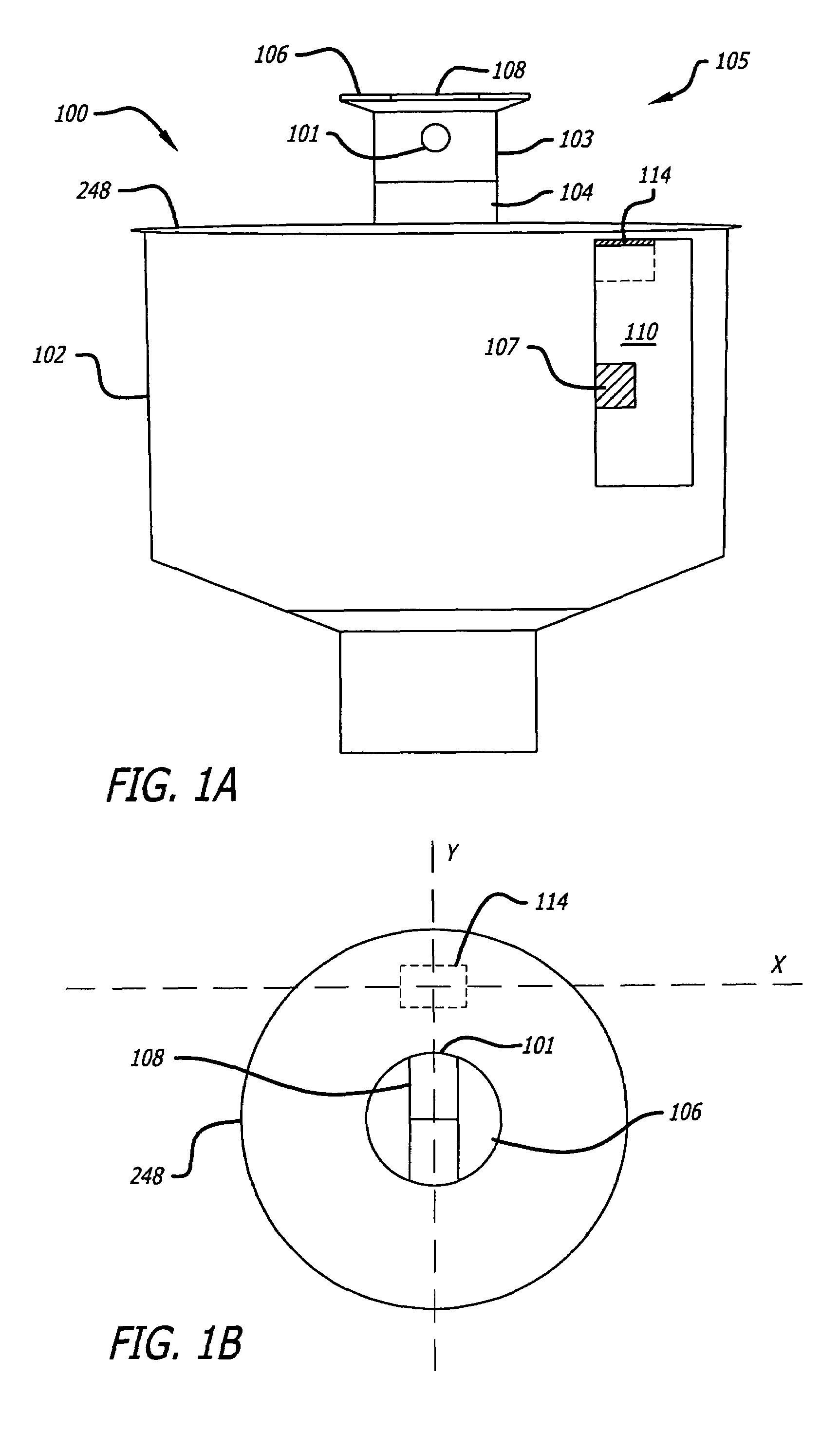

Sprinkler system

A rotary sprinkler having a rotatable nozzle assembly for watering an arc of ground traversed or swept by the nozzle assembly as the nozzle assembly rotates is disclosed. Oscillating rotation is achieved via a drive train that includes a trip spring that is drivable between first and second positions for reversing the direction of nozzle rotation. The sprinkler also includes: a variable trajectory nozzle; secondary opening adjacent the variable trajectory nozzle; an automatic break up screw configuration; a substantially constant speed turbine assembly; a bypass stator; a reversing cluster gear planetary drive with a uni-directional turbine; an overcenter reversing mechanism; a nozzle base clutch; an adjustable arc mechanism, solid arc limit stops, a snap ring installation method and an adjustable pilot valve which uses visual indicia.

Owner:TORO CO THE

Breathing apparatus

InactiveUS6394091B1Increase positive pressureReduce lossesChemical protectionBreathing filtersPositive pressureEngineering

A breathing apparatus includes a regulator which delivers air to a user wearing a mask. The regulator is connected to the mask through an adaptor. The adaptor includes an exhalation valve which enables the user's breath to pass out of the adaptor to atmosphere. The regulator includes a sensing diaphragm that is movable responsive to pressure in the mask. A main valve delivers air to the mask responsive to opening of a pilot valve. The pilot valve includes a pilot opening. A lever moves in response to the sensing diaphragm to open the pilot opening which causes flow through the main valve. Air from the main valve is also delivered to a positive pressure chamber. Pressure in the positive pressure chamber moves a positive pressure diaphragm which causes a positive pressure spring to biasingly engage the sensing diaphragm. The biasing of the sensing diaphragm causes the regulator to maintain a positive pressure in the mask. Positive pressure is discontinued by relieving pressure form the positive pressure chamber by manually actuating a vent valve.

Owner:SCOTT TECH INC

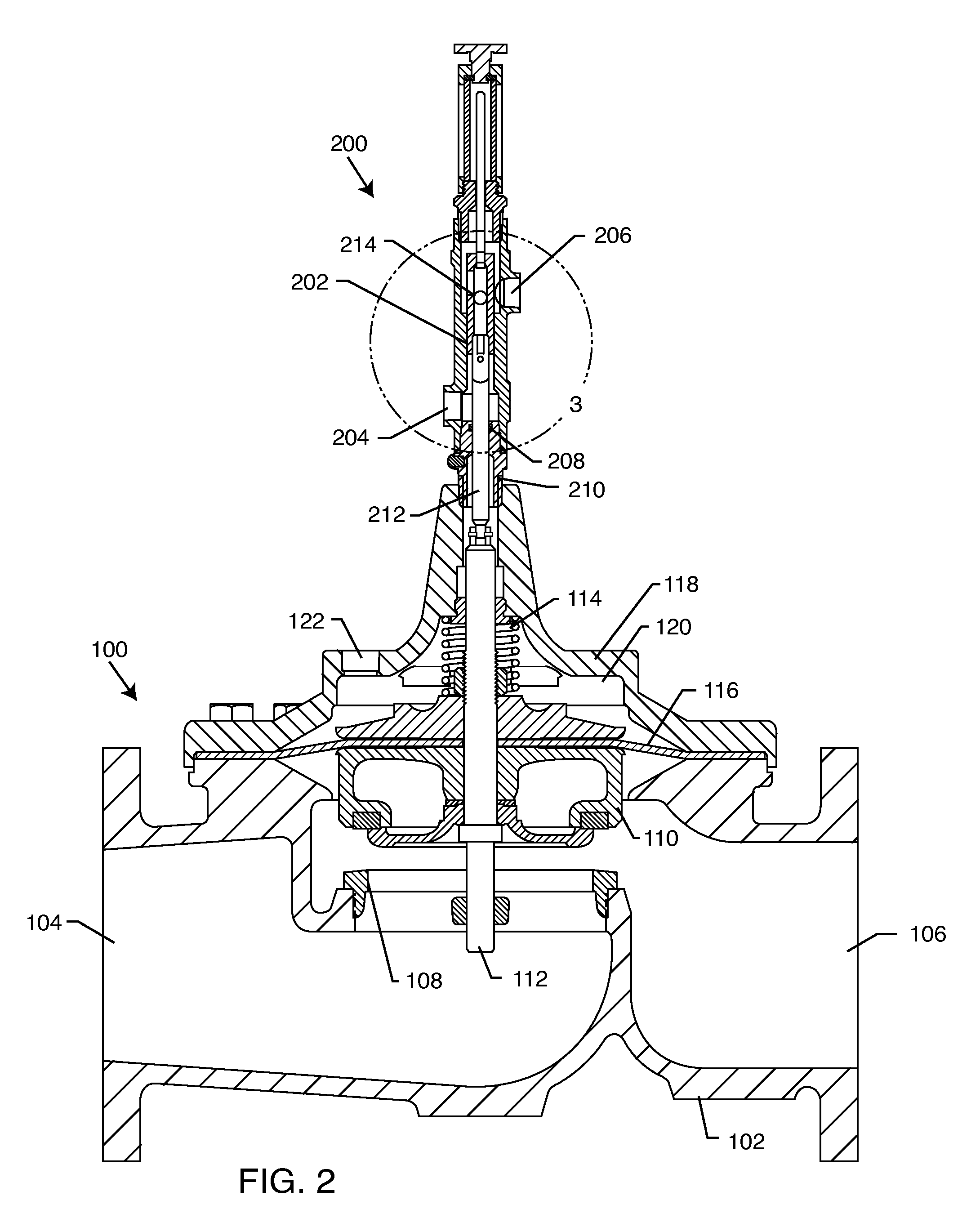

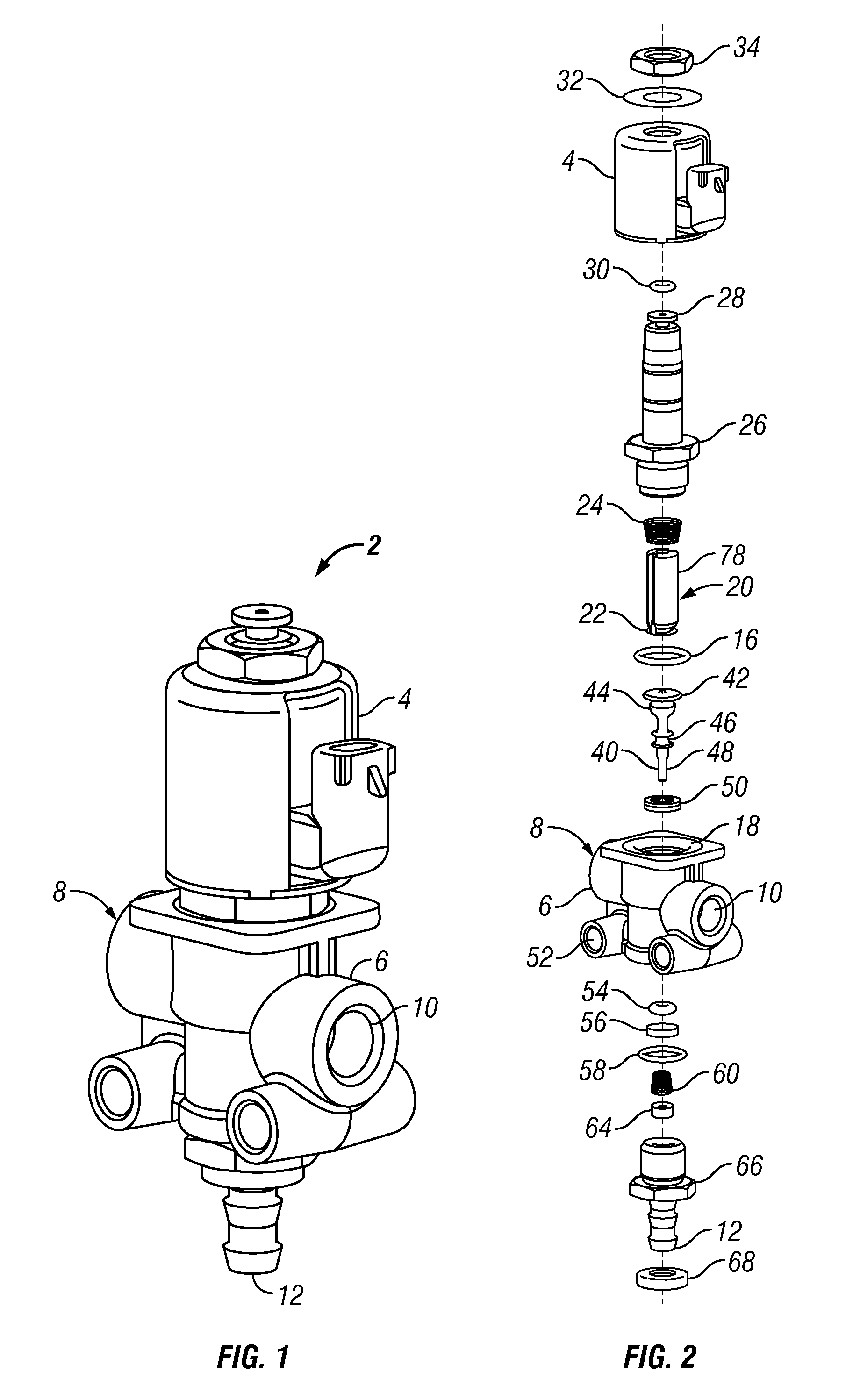

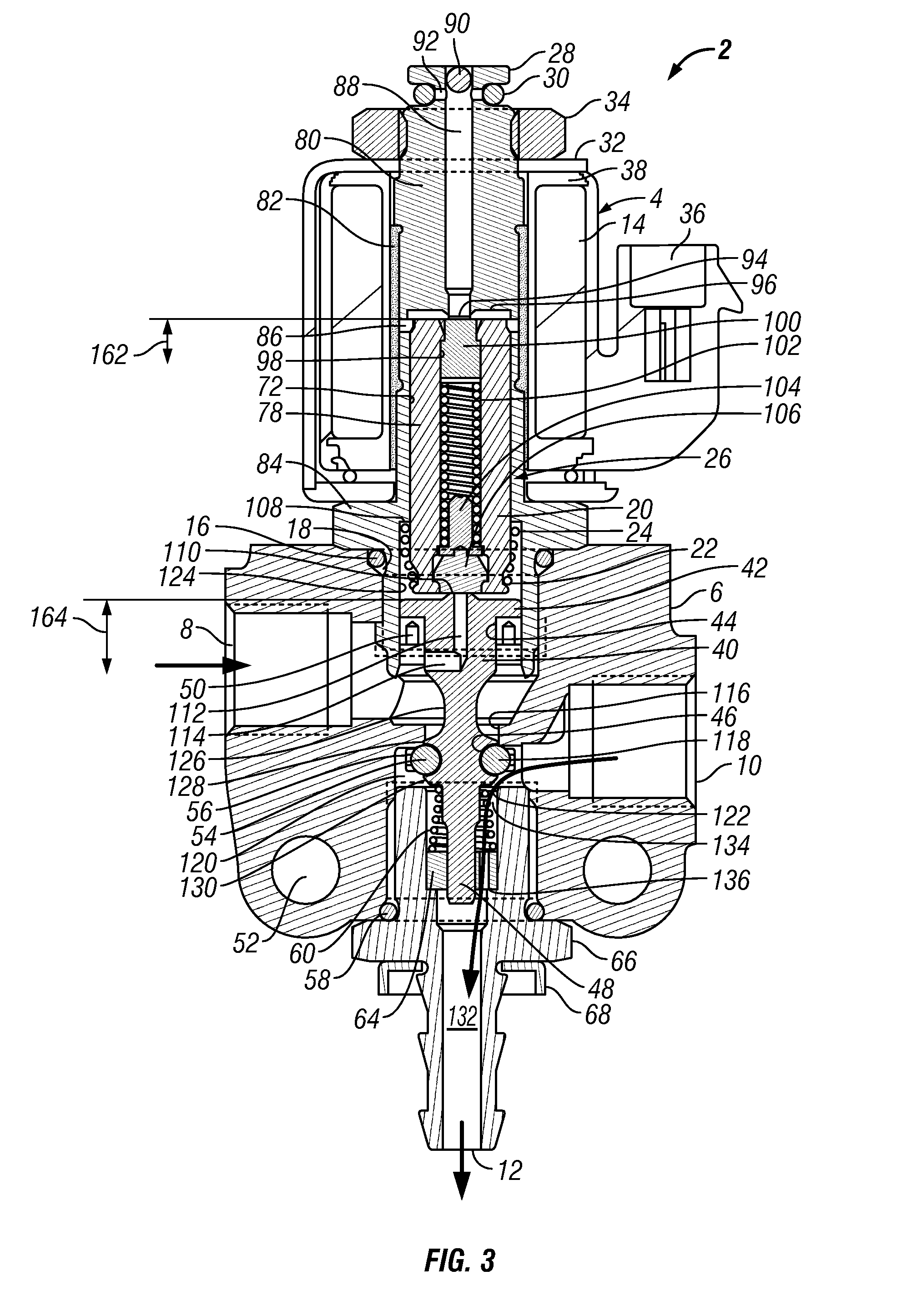

Pilot operated valve with fast closing poppet

InactiveUS20090212244A1Accurate modulationHigh trafficOperating means/releasing devices for valvesServomotor componentsControl roomEngineering

A pilot-operated valve has a main poppet controlling fluid flow between inlet and outlet ports in response to pressure in a control chamber. Fluid flow through a pilot passage, linking the control chamber and the outlet port, moves an exhaust spool between first and second positions to control fluid flow through passages in the main poppet. The first position blocks flow between the control chamber and the outlet port and provides a path between the control chamber and the inlet port. In the second position, flow between the control chamber and the outlet port is enabled, and a second path, that is more restricted than the first path, is provided between the control chamber and the inlet port. When the valve closes, flow through the first path allows movement of the main poppet at a faster rate than during opening when flow occurs through the more restricted second path.

Owner:HUSCO INT INC

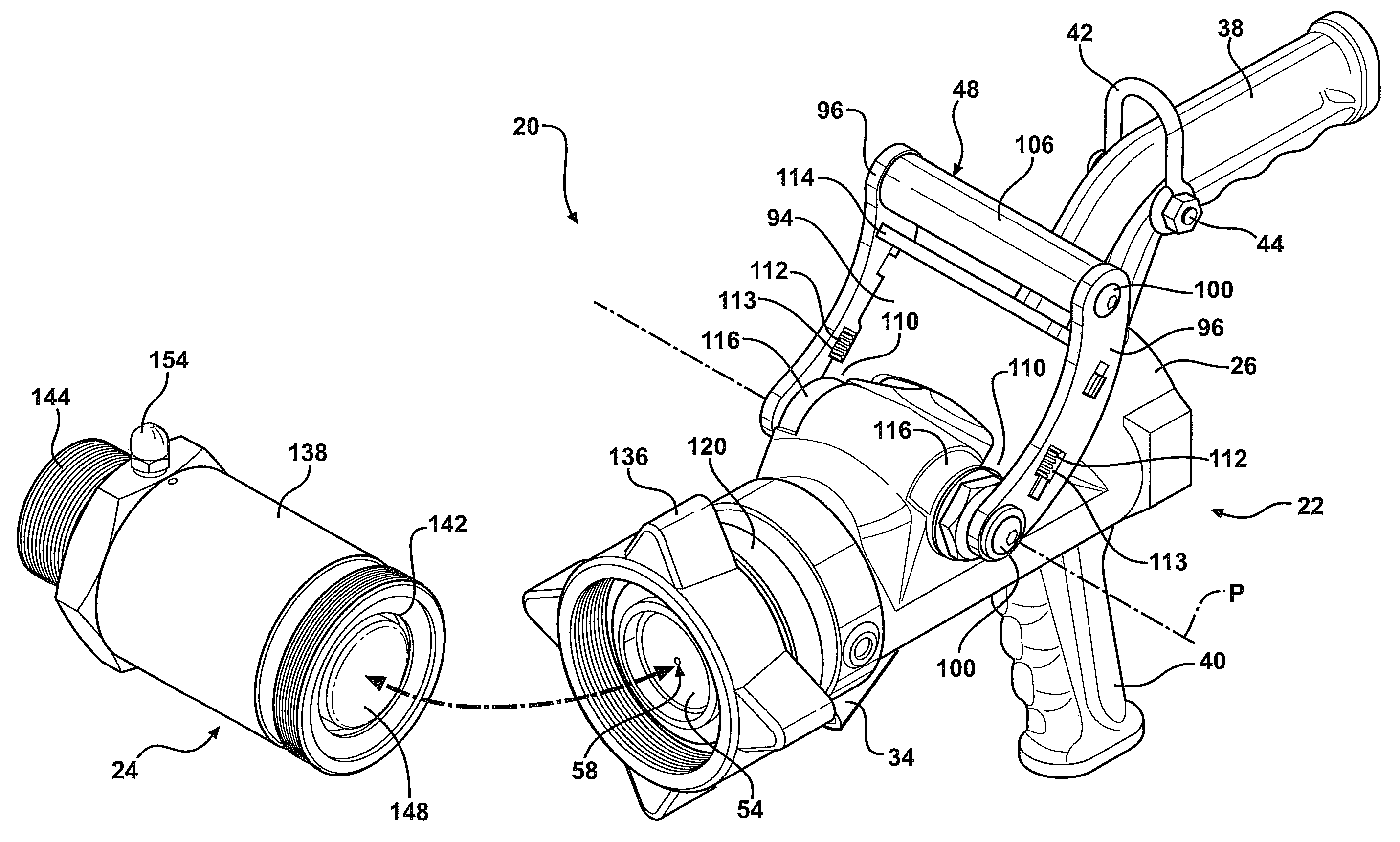

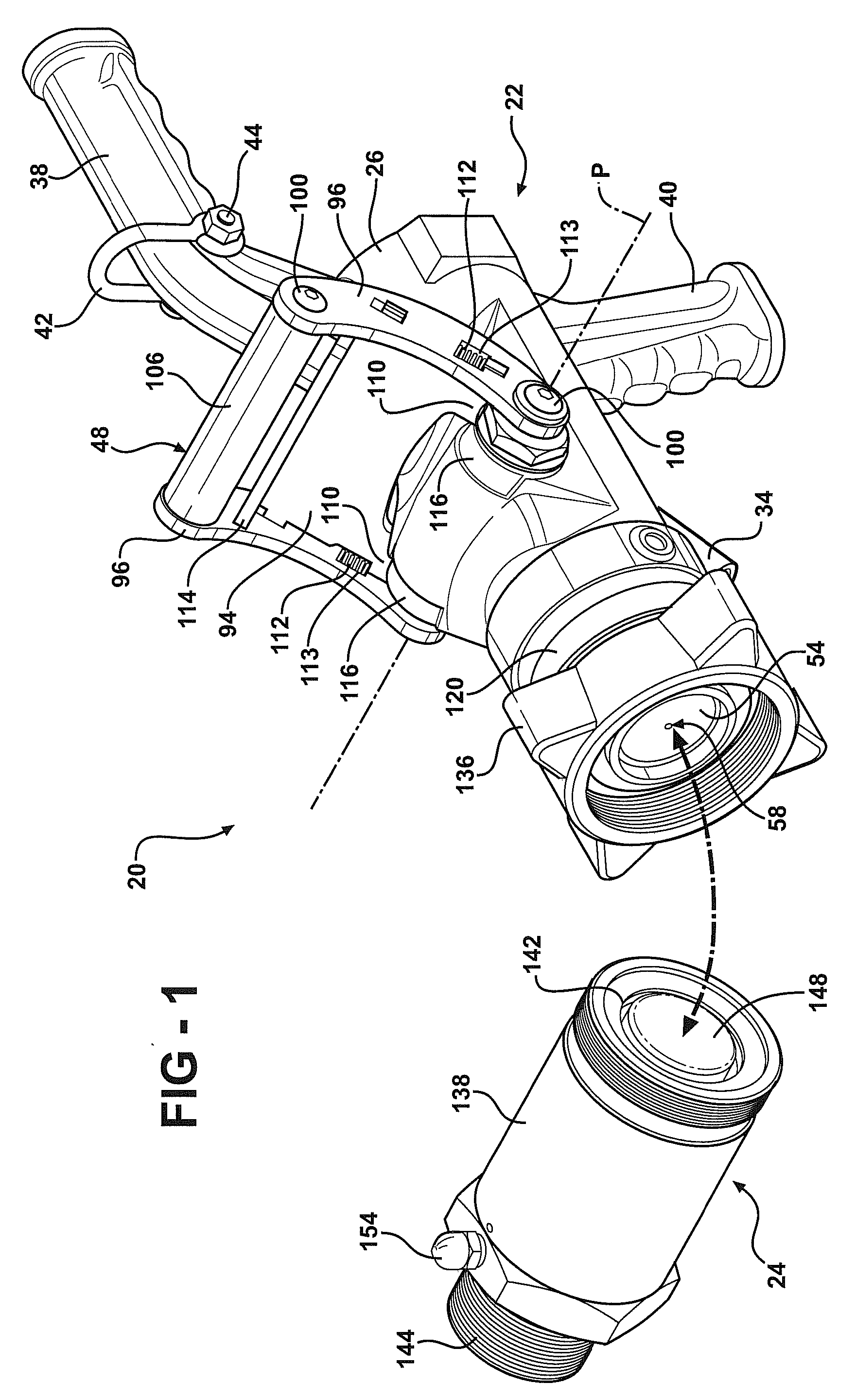

Low emission fluid transfer device

ActiveUS20100024904A1Easy to openEasy to moveServomotor componentsContainer filling methodsTransfer systemEngineering

A fluid transfer system includes a transfer device coupled to a dry break coupler. The transfer device includes a valve assembly moveable between an open and a closed position. The valve assembly includes a main valve and a pilot valve. An actuator controls both the main valve and the pilot valve. A cam plate interconnects the actuator and the valve assembly. The cam plate provides a quick acting shutoff to quickly move the valve assembly to the closed position. A pivotal and rotatable connector couples the transfer device to the dry break coupler. A lock is integrated with the actuator to lock the valve assembly in the closed position.

Owner:MARSHALL EXCELSIOR CO

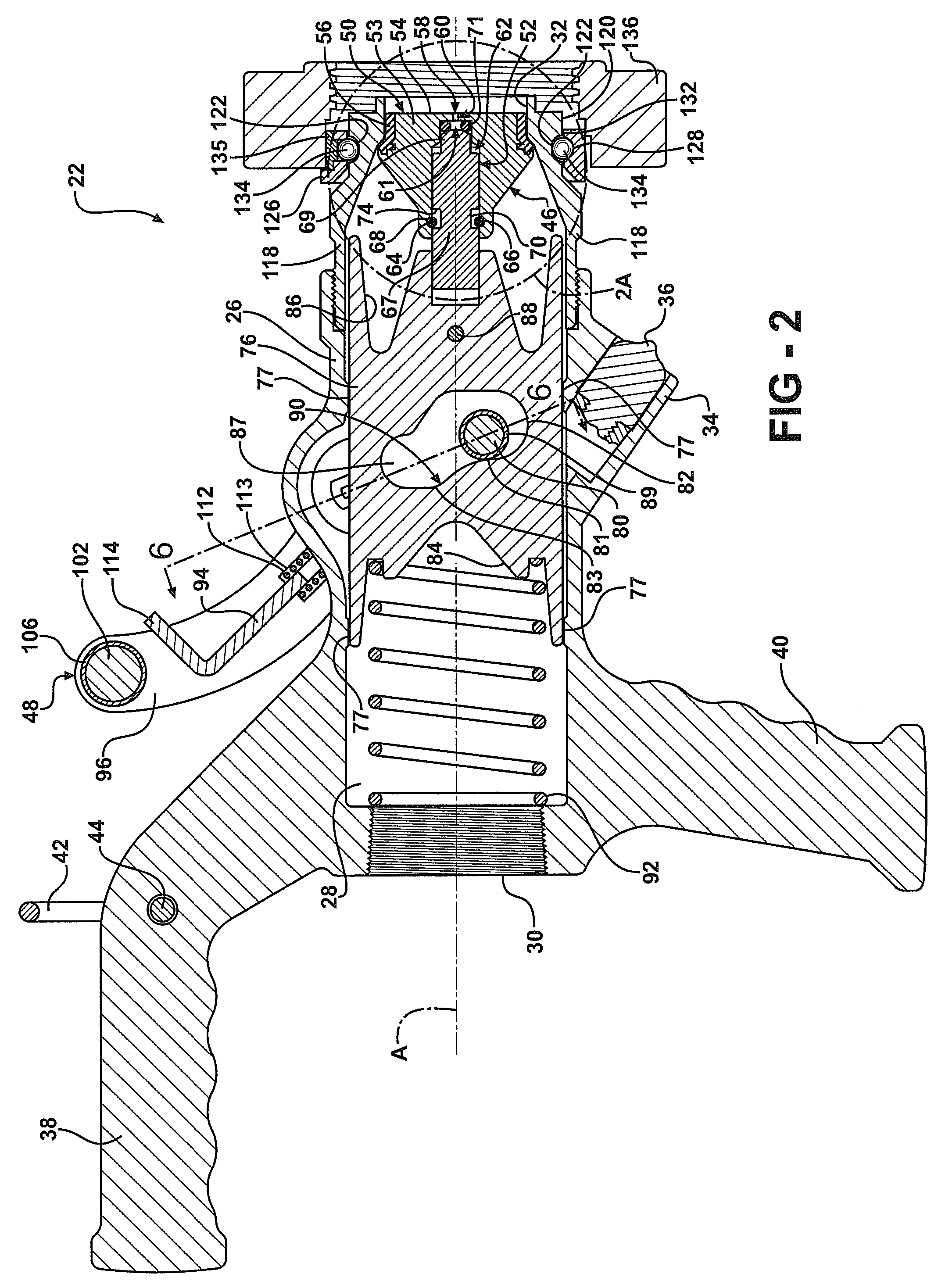

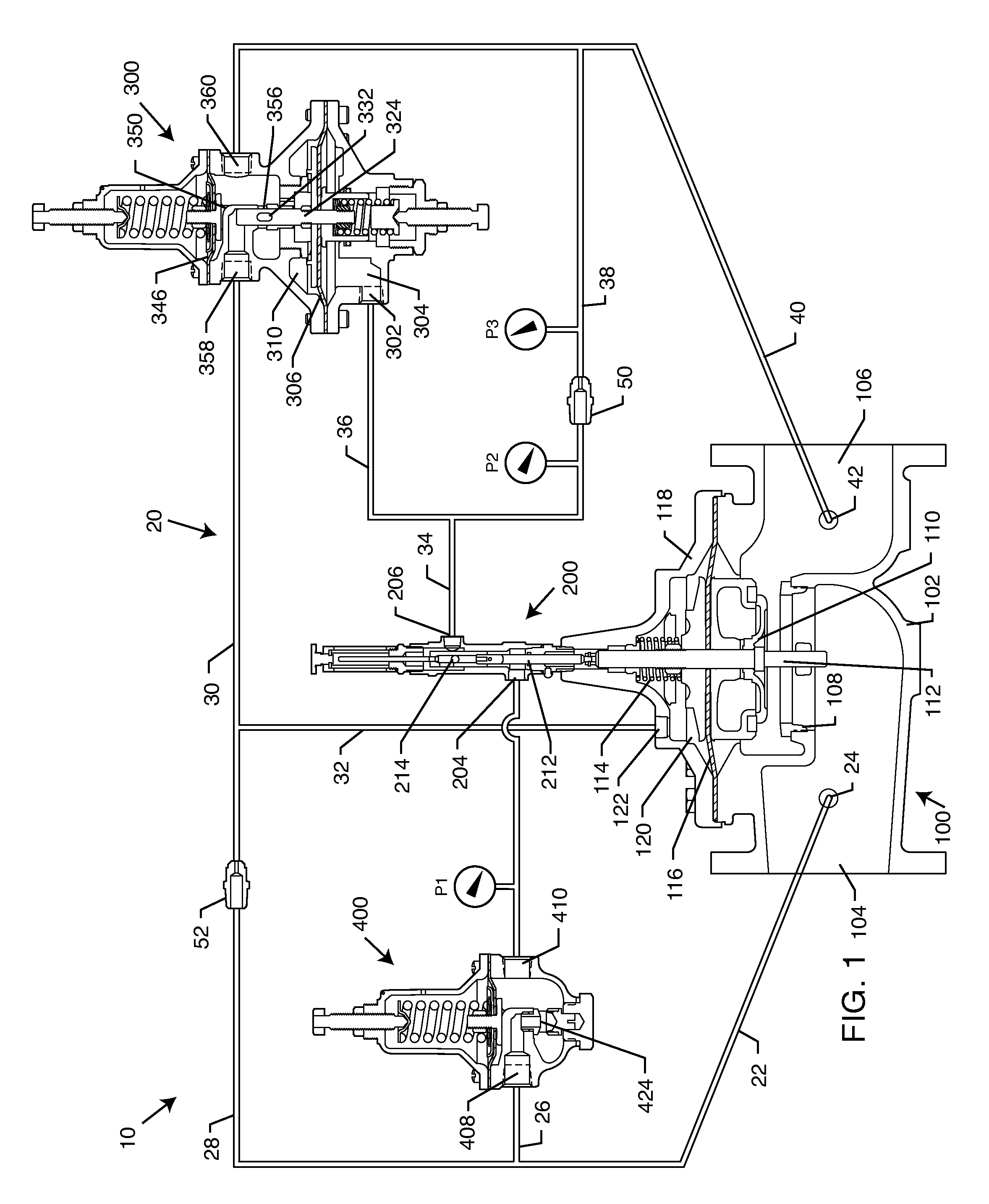

System and method for hydraulically managing fluid pressure downstream from a main valve between set points

ActiveUS20080251146A1Operating means/releasing devices for valvesCheck valvesControl systemEngineering

A system for hydraulically managing fluid pressure between selected set points includes a pilot control system operably coupled to a main valve. The pilot control system includes at least one fluid conduit, a variable orifice assembly, and a control pilot valve apparatus. Fluid is passed through a fixed orifice and into a first chamber of the control pilot valve apparatus. Fluid is passed through the variable orifice of the variable orifice assembly and into a second chamber of the control pilot valve apparatus. The main valve is hydraulically opened or closed in response to a pressure differential between the first and second chambers of the control pilot valve apparatus so as to manage fluid pressure downstream of the main valve between the selected upper and lower set points.

Owner:CLA VAL

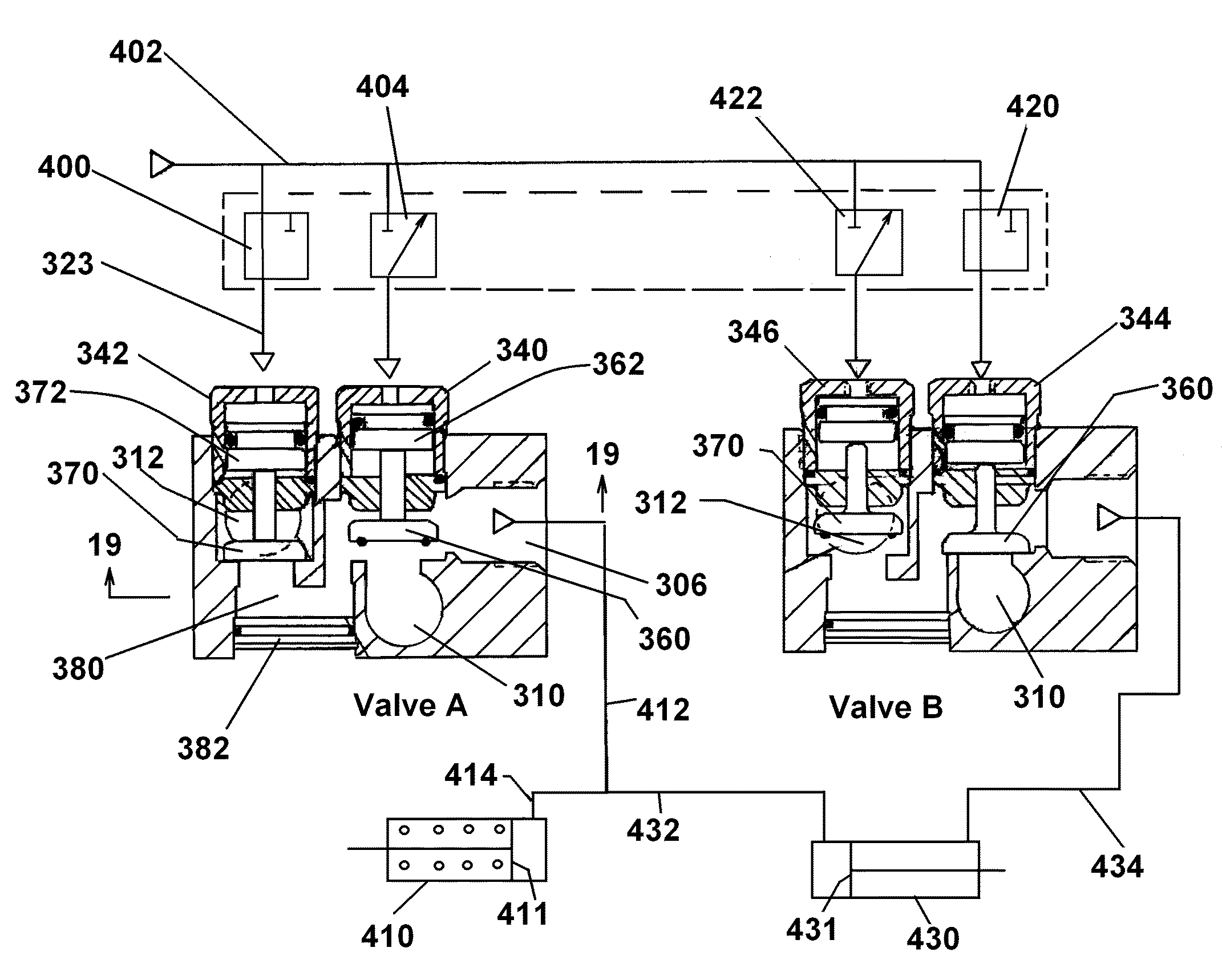

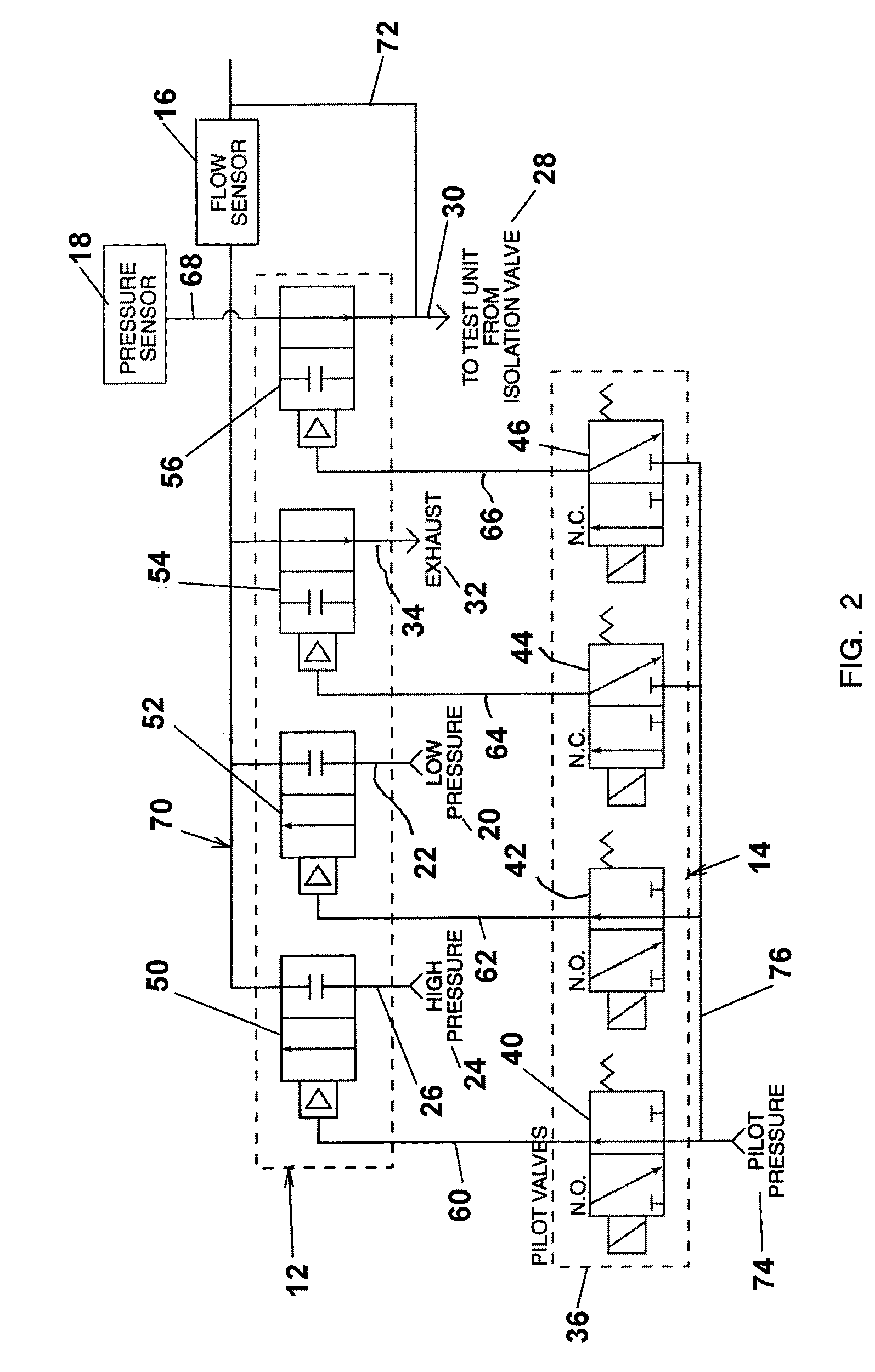

Pilot valve manifold

InactiveUS7490625B1Fluid-pressure actuator safetyDetection of fluid at leakage pointEngineeringVALVE PORT

A valve manifold includes a valve body carrying pairs of laterally spaced piston actuated valves controlled by control modules operative to selective pressurize and exhaust an outlet port connected to a fluidic device and configured in grouping permitting varying valve functionalities.

Owner:JOHNSON JOHN LESLIE +1

Three-way direct pilot valve

InactiveUS20070164243A1High strengthMore compactOperating means/releasing devices for valvesMultiple way valvesEngineeringPilot valve

The present disclosure provides a method, apparatus, and system of an inline direct acting solenoid pilot valve. The valve has a solenoid assembly with a longitudinally moveable core assembly that shifts alternatively between sealing engagement on a lower first end of the core assembly with a pilot port formed in a poppet and sealing engagement on an opposite upper end with a stationary pilot exhaust port in the solenoid assembly. The core assembly can move in the same or opposite direction than the poppet and thus is independently moveable from the poppet to effect the various modes of operation. Because the movement is independent, the core assembly can advantageously operate within the solenoid with a shorter stroke to produce a higher overall force per length relative to a conventional core assembly stroke that is longer than the poppet stroke. The overall design allows a more compact and simplified design.

Owner:ASCO CONTROLS LP

Sleeve valve for residential and commercial irrigation systems

ActiveUS7665713B1Diaphragm valvesOperating means/releasing devices for valvesSleeve valveEngineering

A sleeve valve includes a rigid mandrel with a plurality of openings and a generally cylindrical elastomeric sleeve that surrounds the mandrel. A generally cylindrical rigid sleeve valve housing surrounds the elastomeric sleeve and defines a control chamber between the elastomeric sleeve and the sleeve valve housing. A pilot valve is mounted to the sleeve valve housing for supplying pressurized liquid to, and venting pressurized liquid from, the control chamber through a first passage formed in the sleeve valve housing. A filter screens debris from pressurized liquid entering an inlet end of the sleeve valve housing before it enters a second passage that communicates with the pilot valve.

Owner:HUNTER INDUSTRIES

Clog resistant pilot valve

ActiveUS7703740B1Reduce probabilityReduce accumulationOperating means/releasing devices for valvesBiological activationPlunger

A clog resistant, pilot operated pilot valve having two fluid paths, one path for fluid flow from the valve input to the valve output, and the second path for fluid flow through input and output pilot apertures. The opening and closing of the pilot apertures controls the flow of fluid between the input and output of the pilot valve. A clog resistant pilot operated valve in which fluid flows through the pilot fluid path only during the time of transition from an valve open to a valve closed condition, or vice-versa, thereby reducing the probability of failure due to contaminants blacking the pilot activation path. A clog resistant pilot operated valve in which the plunger, used to open and close the pilot fluid paths, is ribbed in construction to reduce the probability that contaminants will cause seizure of the plunger movement.

Owner:FRLIN ROBERT C

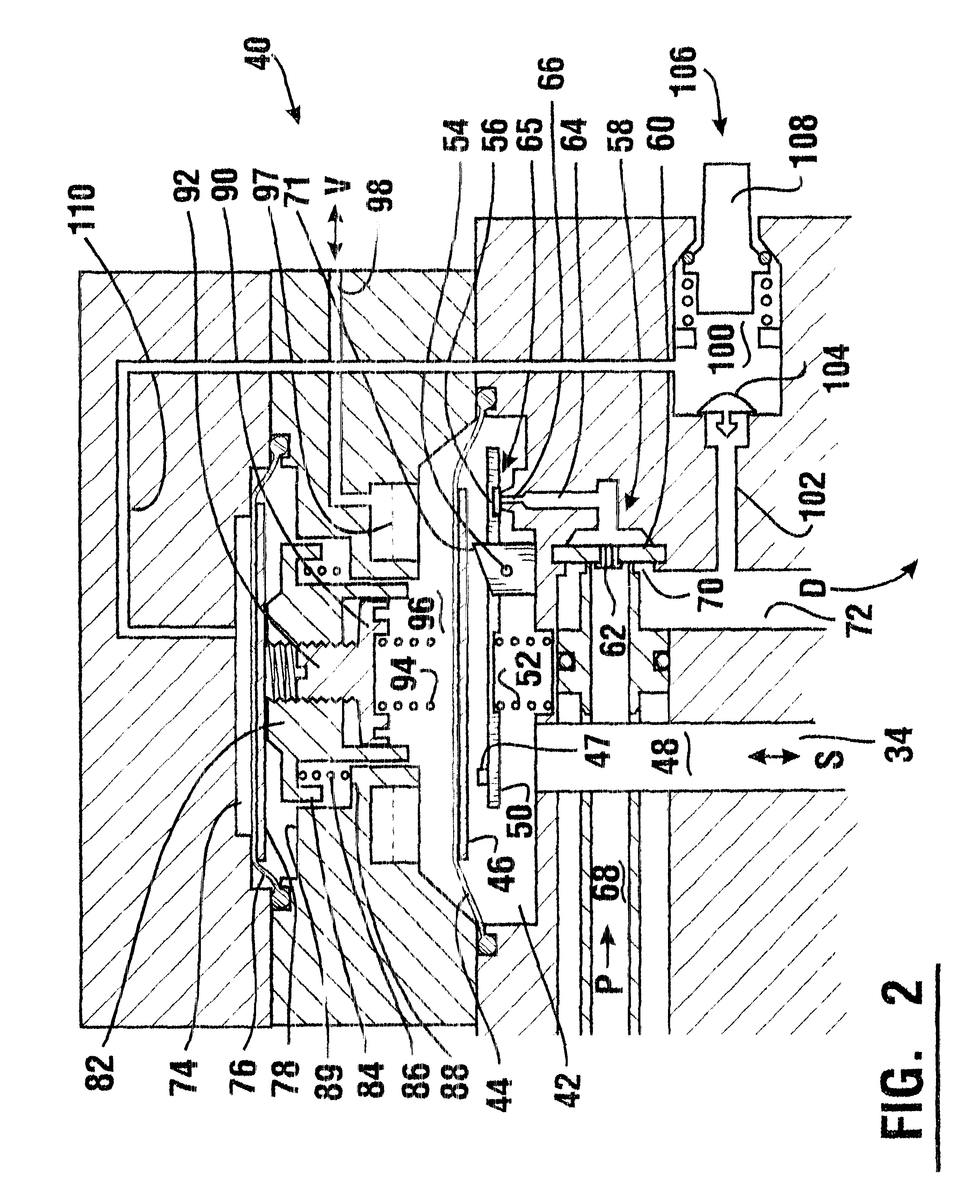

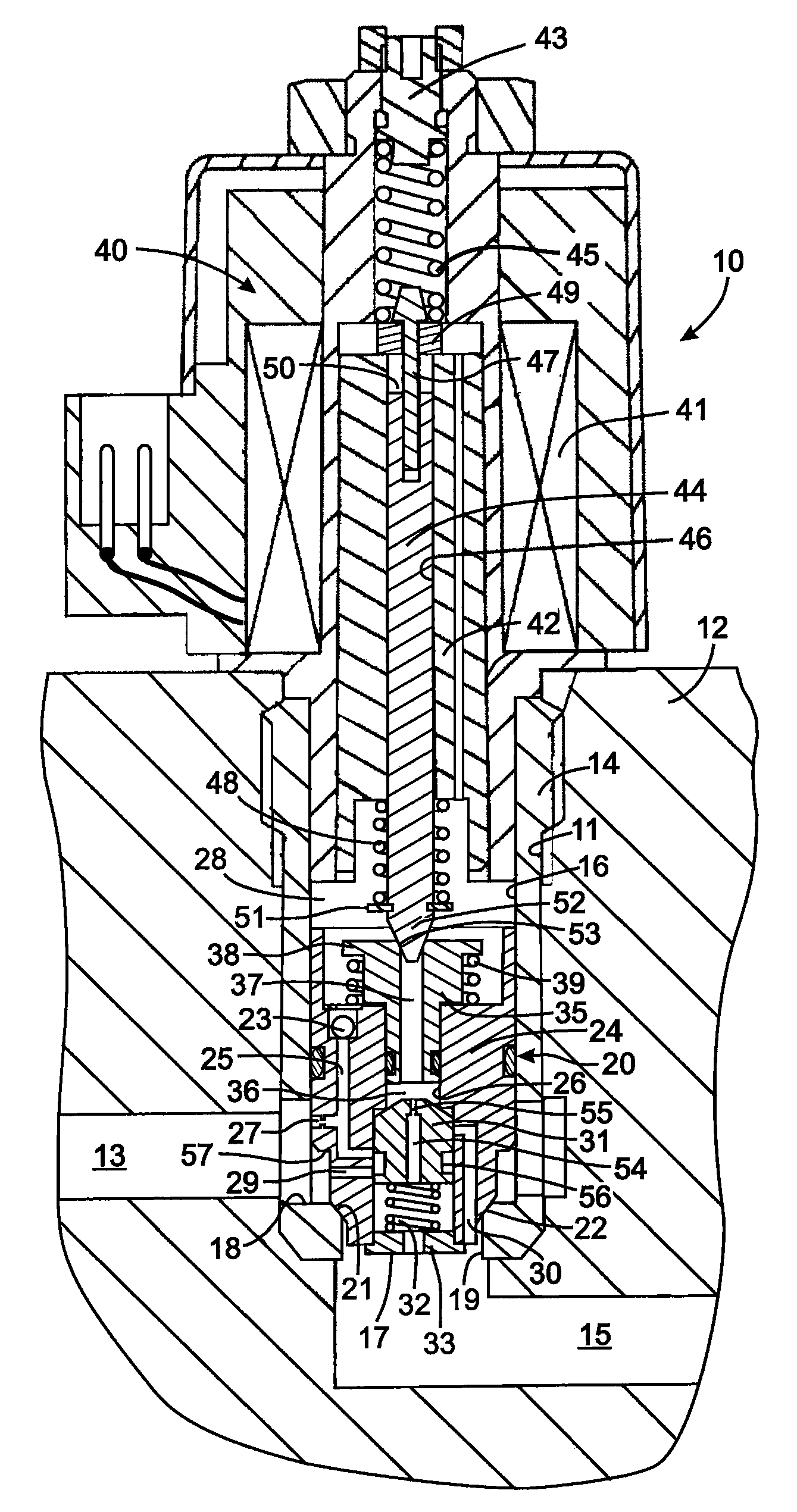

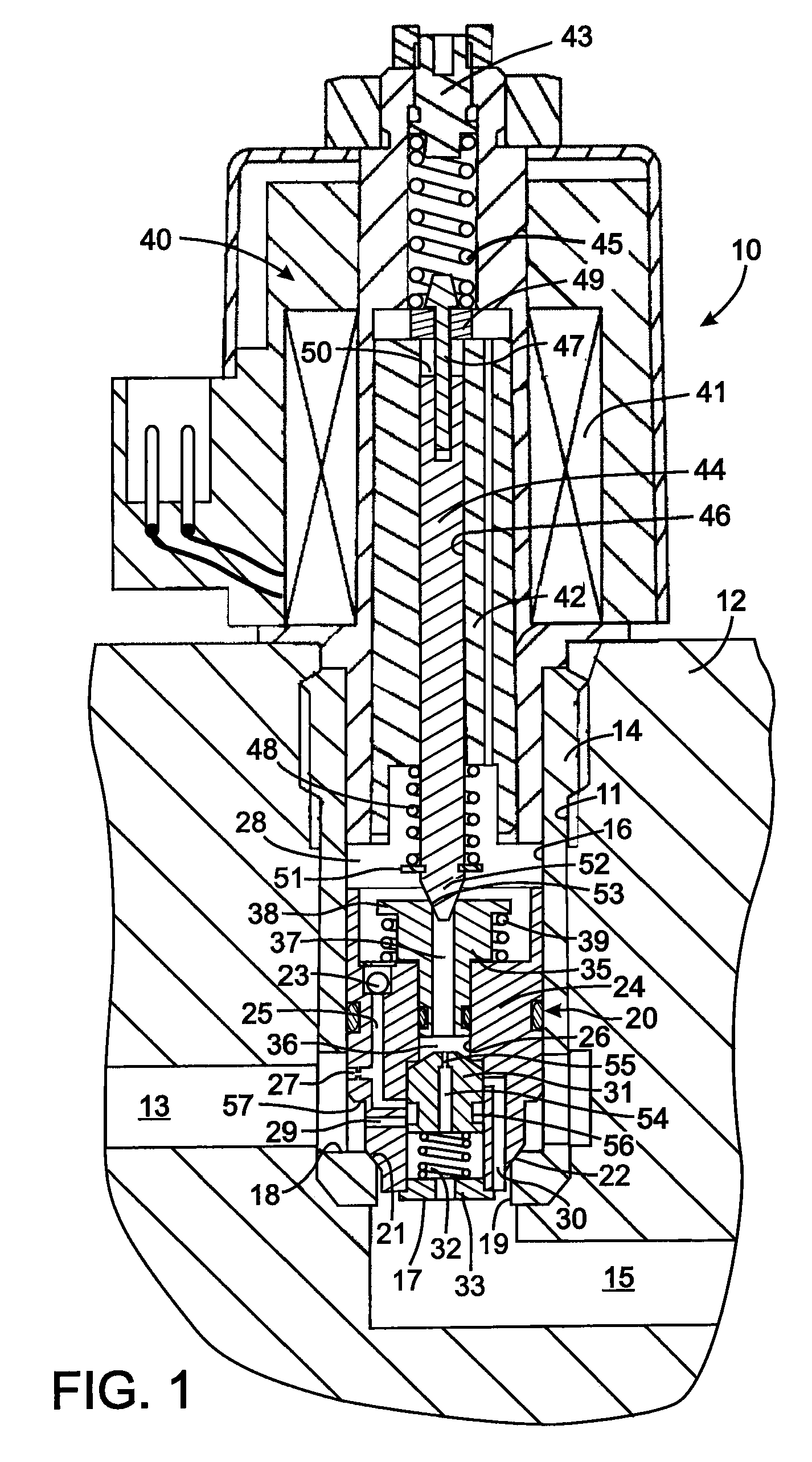

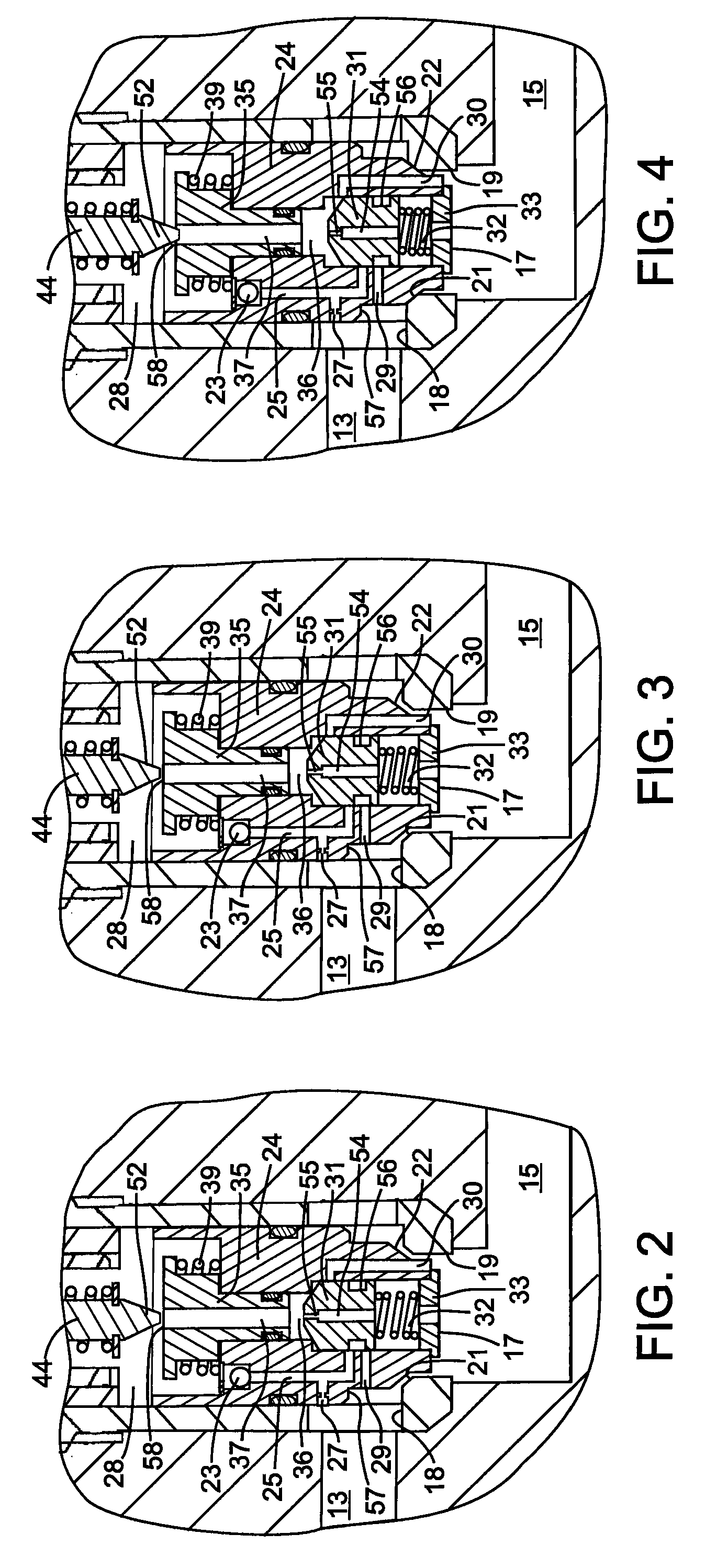

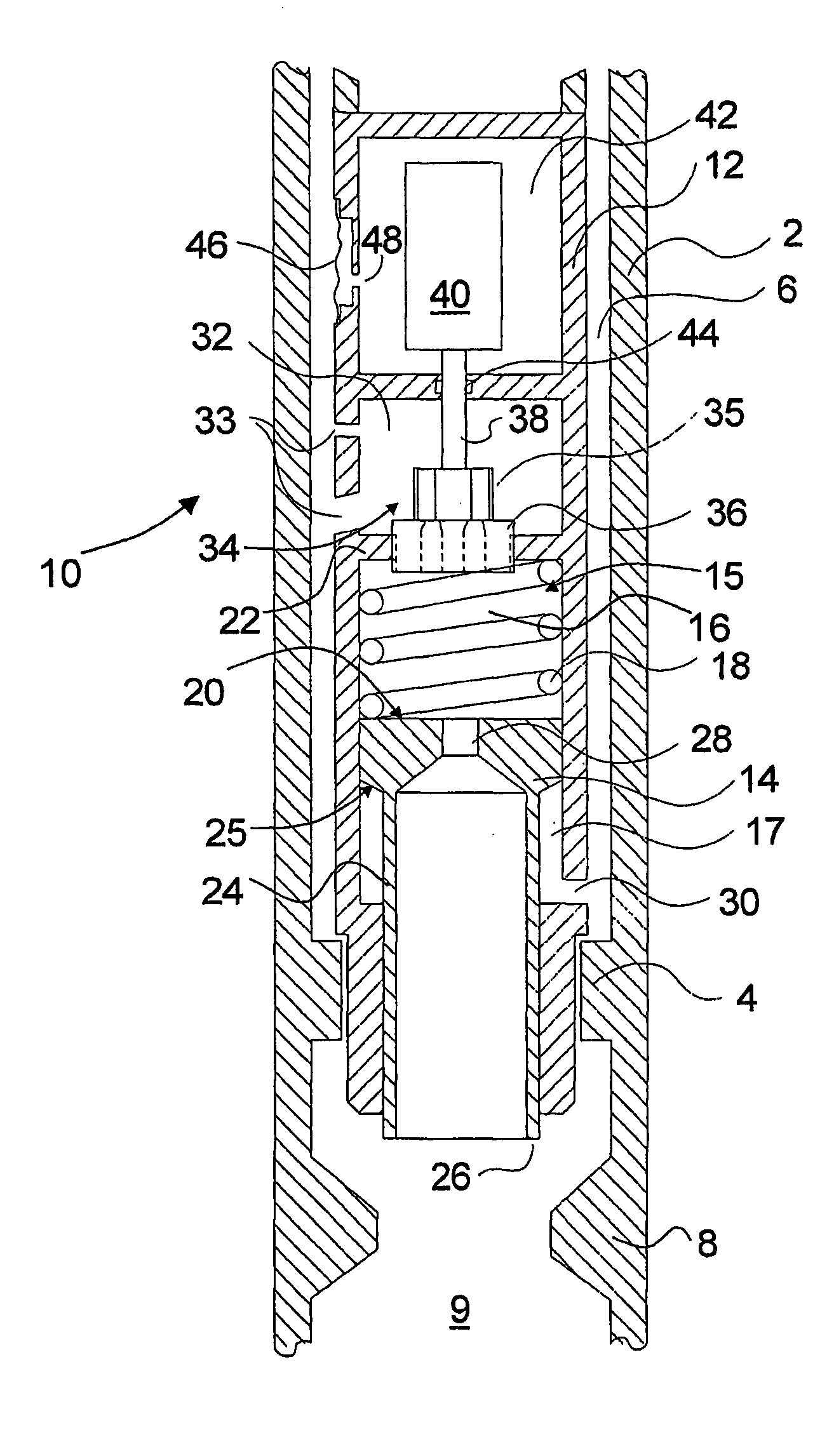

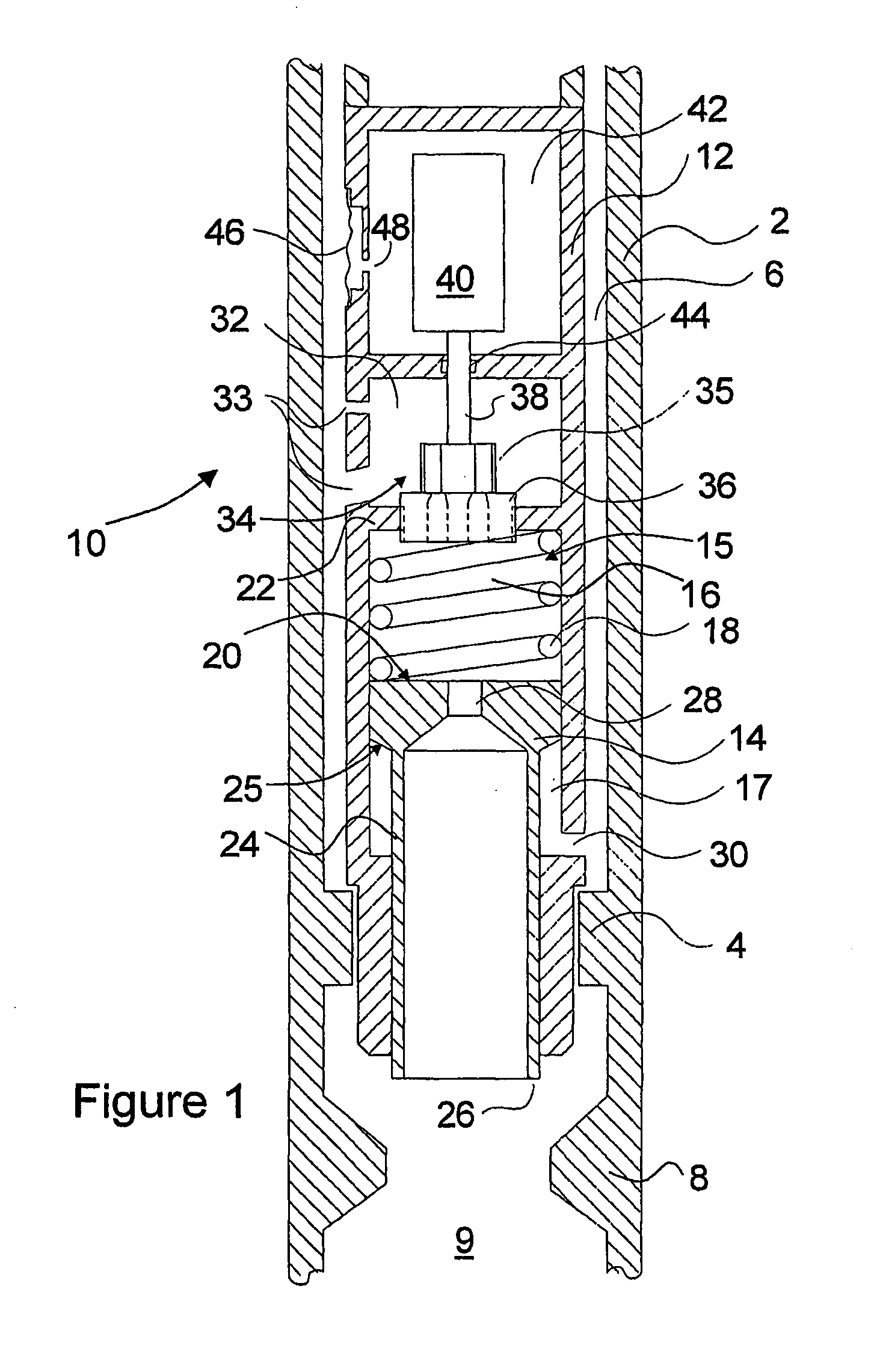

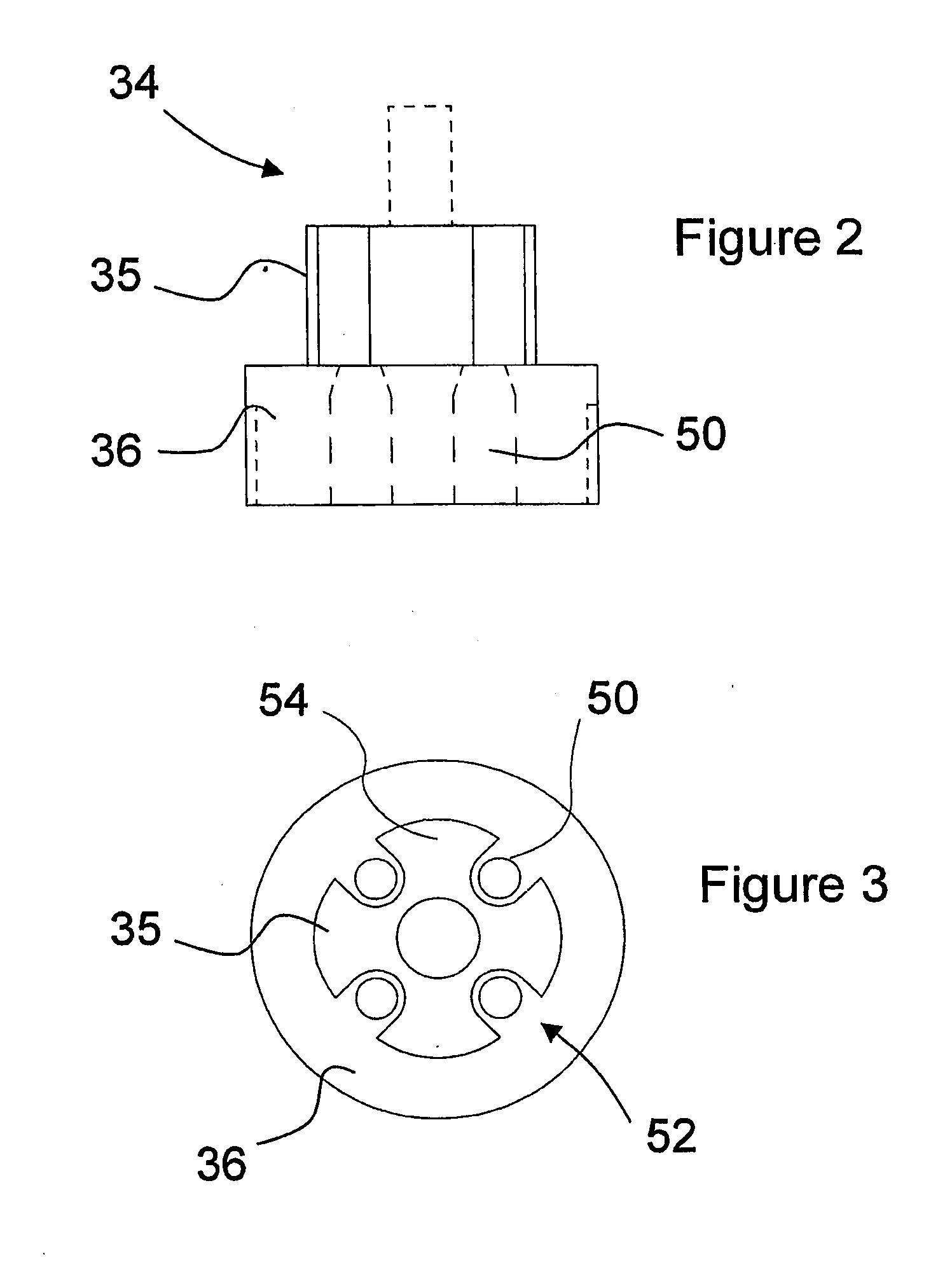

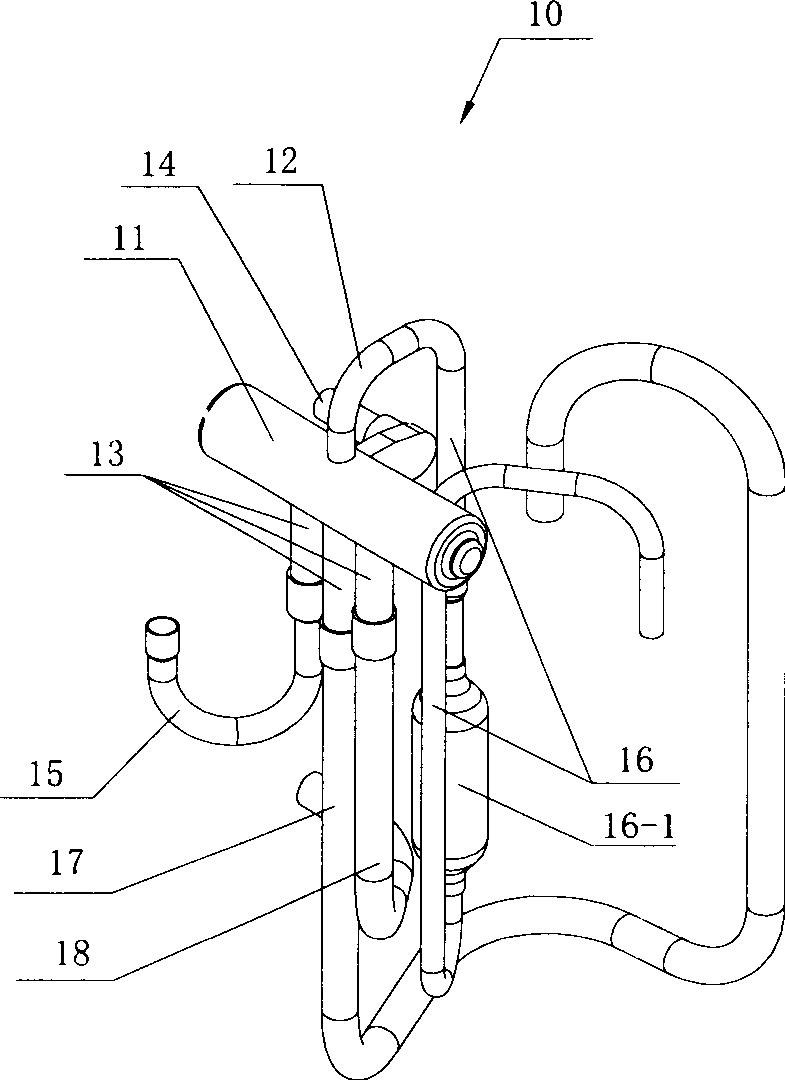

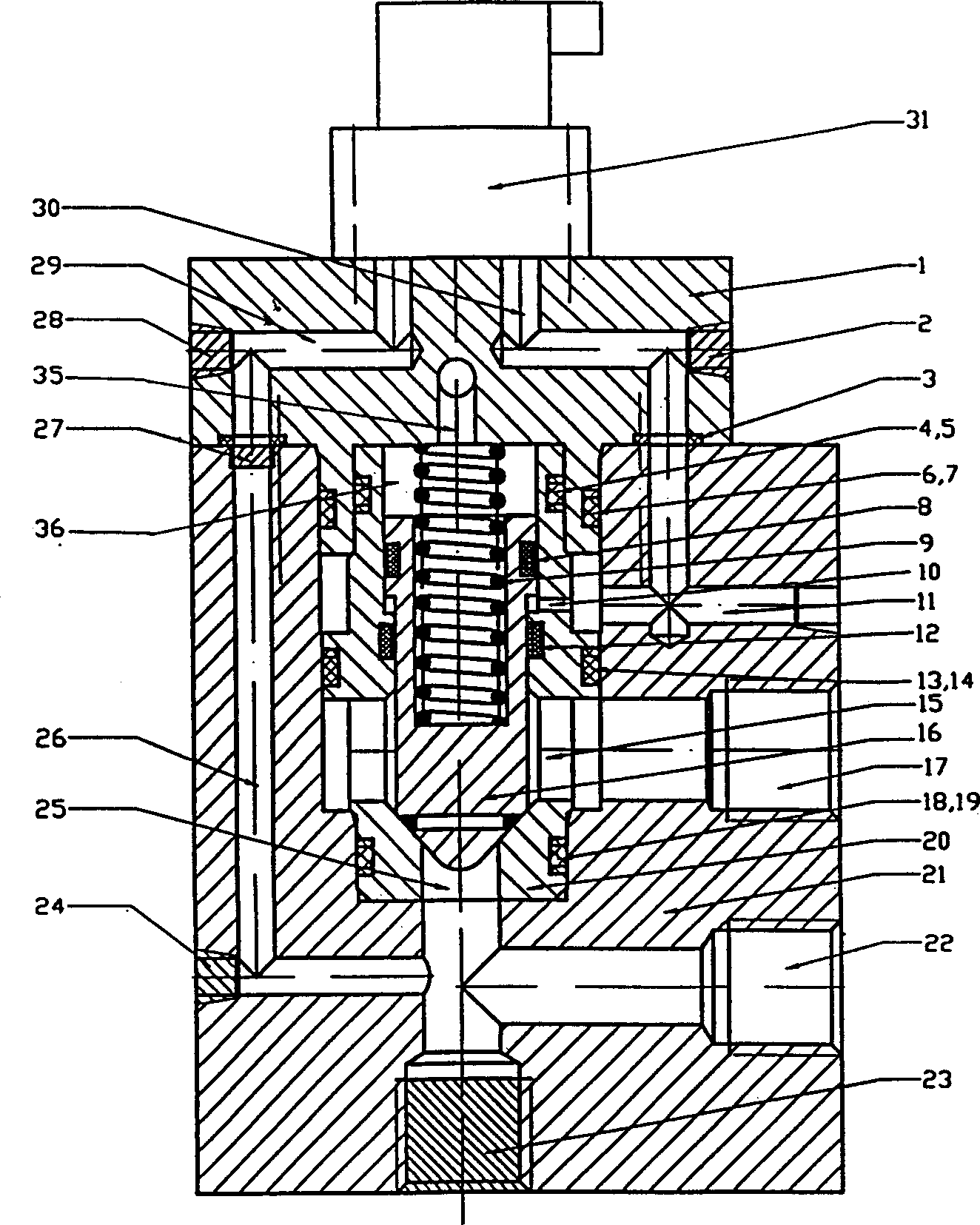

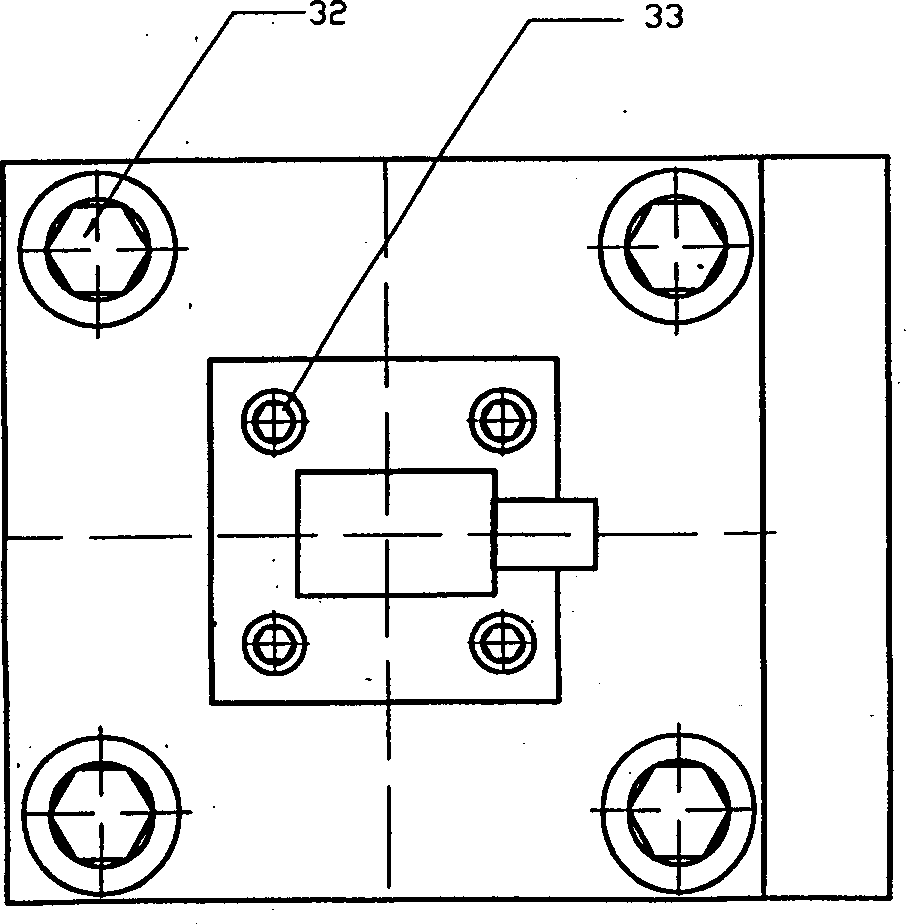

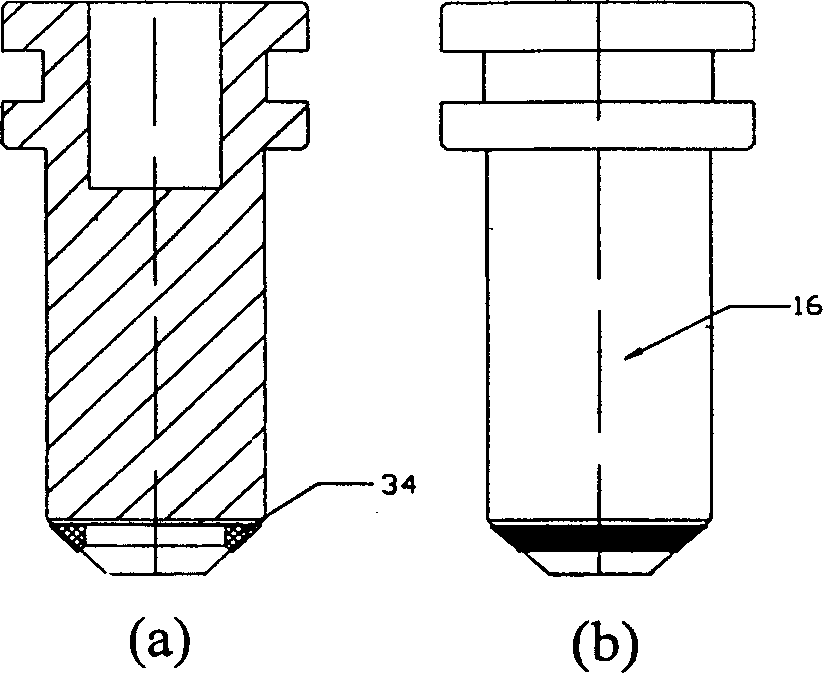

Apparatus for creating pressure pulses in the fluid of a bore hole

An apparatus for creating pressure pulses in the fluid of a bore hole is described. The preferred embodiment takes the form of a mud pulser apparatus (10) having a signalling valve controlled by a variable pilot valve (34). The forces on the signalling valve are balanced and controlled by the flow of mud through the variable orifice of the pilot valve. The arrangement is such as to act like a hydraulic amplifier, and results in the signalling valve being compensated for variable flow rates. In the preferred embodiment, the pilot valve has rotary vanes that allow it to be self-cleaning.

Owner:GEOLINK UK

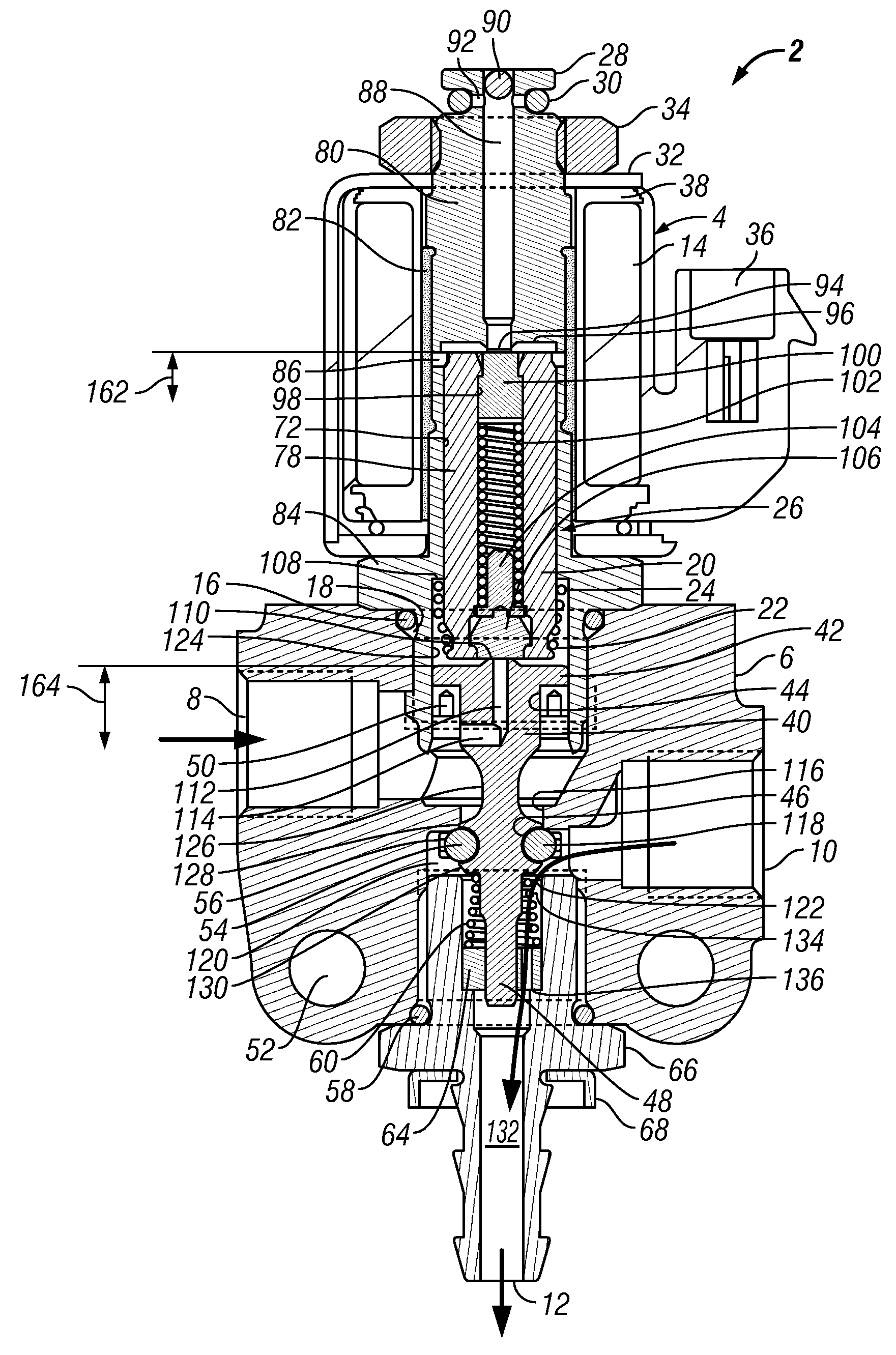

Solenoid Actuated Pilot Valve for Irrigation System Valve

ActiveUS20090120521A1Diaphragm valvesOperating means/releasing devices for valvesReciprocating motionSolenoid valve

A solenoid actuated pilot valve includes a pilot valve housing defining a pilot valve chamber and a solenoid. The solenoid includes and end cap connected to the pilot valve housing, a reciprocable plunger, and a piston having a shaft with a first end connected to and end of the plunger and a second end connected to a piston head. The end cap has a bore through which the shaft of the piston reciprocates and a first port separate from the bore. A first seal on a first side of the piston head is provided for sealing a first end of the first port. A second seal on a second side of the piston head is provided for sealing a first end of a second port in the pilot valve housing.

Owner:HUNTER INDUSTRIES

Foreign particle resistant valve

InactiveUS6457697B1Facilitate fabricationFacilitate serviceOperating means/releasing devices for valvesEngineeringSmall hole

An improved foreign particle resistant valve assembly having a pressure responsive diaphragm main valve member activated by a pilot valve which controls flow through small orifice passages whereby pressure forces are created across the diaphragm main valve member to permit and prevent flow through the main flow section of the valve. Several arrangements illustrate various configured foreign particle-screening passages that protect the pilot valve orifice passages from blockage. The screening may be an integral part of the valve body or may be a removable member to facilitate cleaning or manufacture, and may be adapted to metallic or plastic valves. Other embodiments provide the means to enlarge a pilot pressure drop orifice passage which would then be less susceptible to foreign particle blockage and could also be combined with the screening passage means of the first embodiment.

Owner:KOLZE

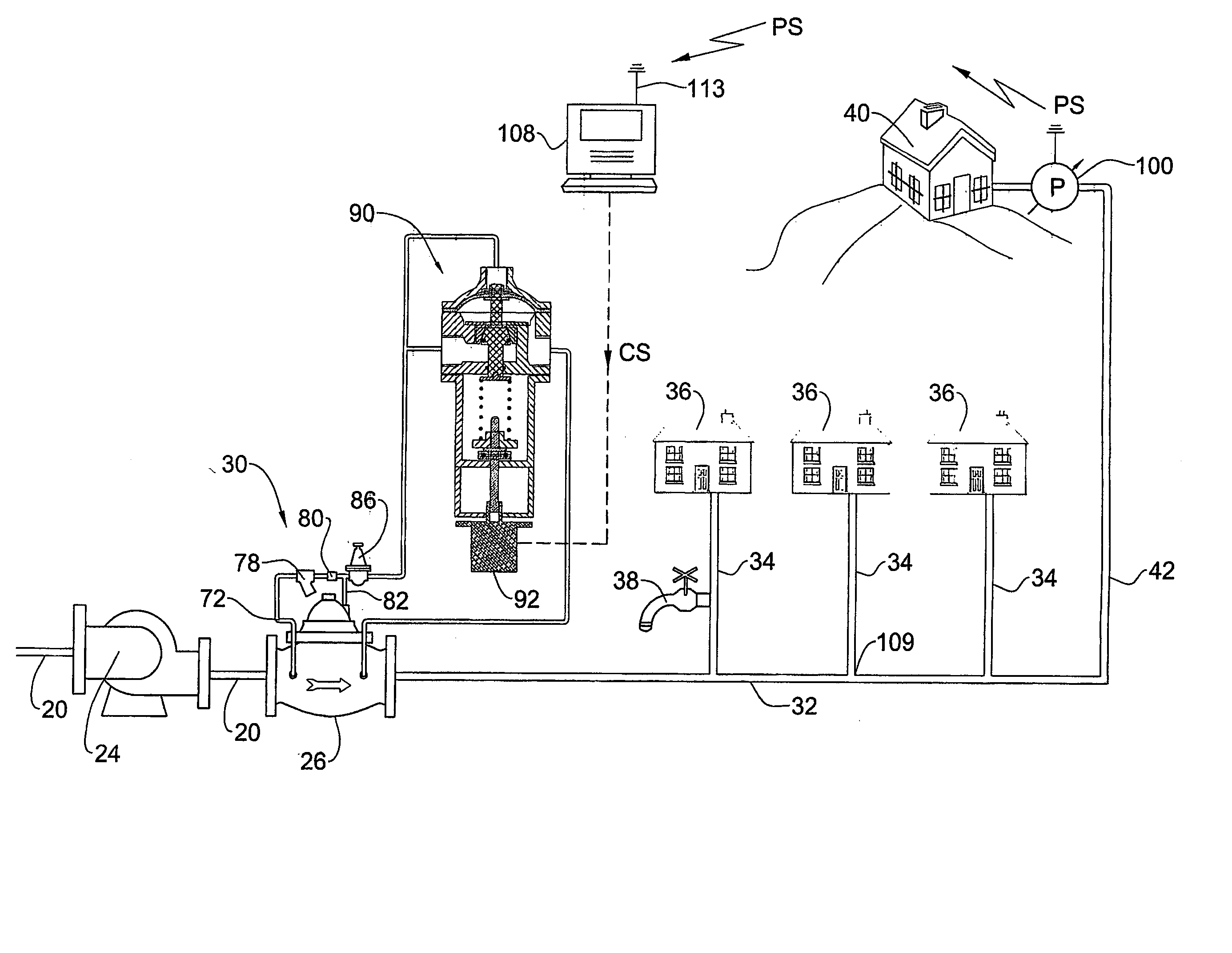

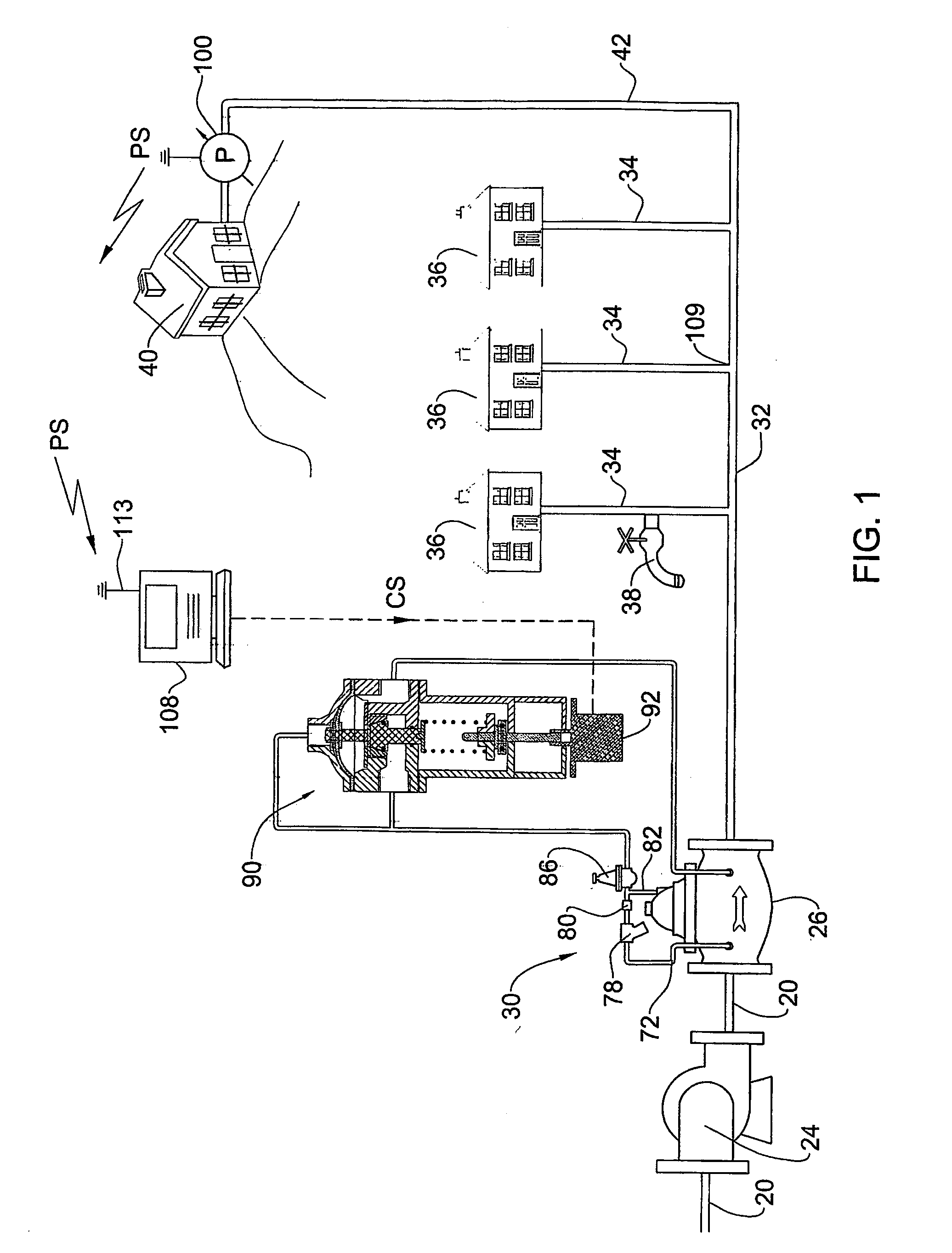

Water supply system

ActiveUS20050016593A1Operating means/releasing devices for valvesPipeline systemsControl signalControl system

A water supply system comprising a supply line and a network of consumers, one of which being a monitored consumer who receives the least amount of pressure, a pressure regulation system comprising a pressure reducing valve (PRV) associated with a pilot valve preset to a nominal output pressure and a pressure control system comprising a differential control valve (DCV). A pickup unit is provided for measuring a flow parameter indicative of the pressure at the monitored consumer and emitting a pressure signal to a controller generating in turn a control signal responsive to the pressure signal to activate an actuator of the DCV thereby governing the flow rate through the DCV, so as to obtain desired pressure at the monitored consumer, regardless of altering flow rate through the PRV.

Owner:STREAM CONTROL

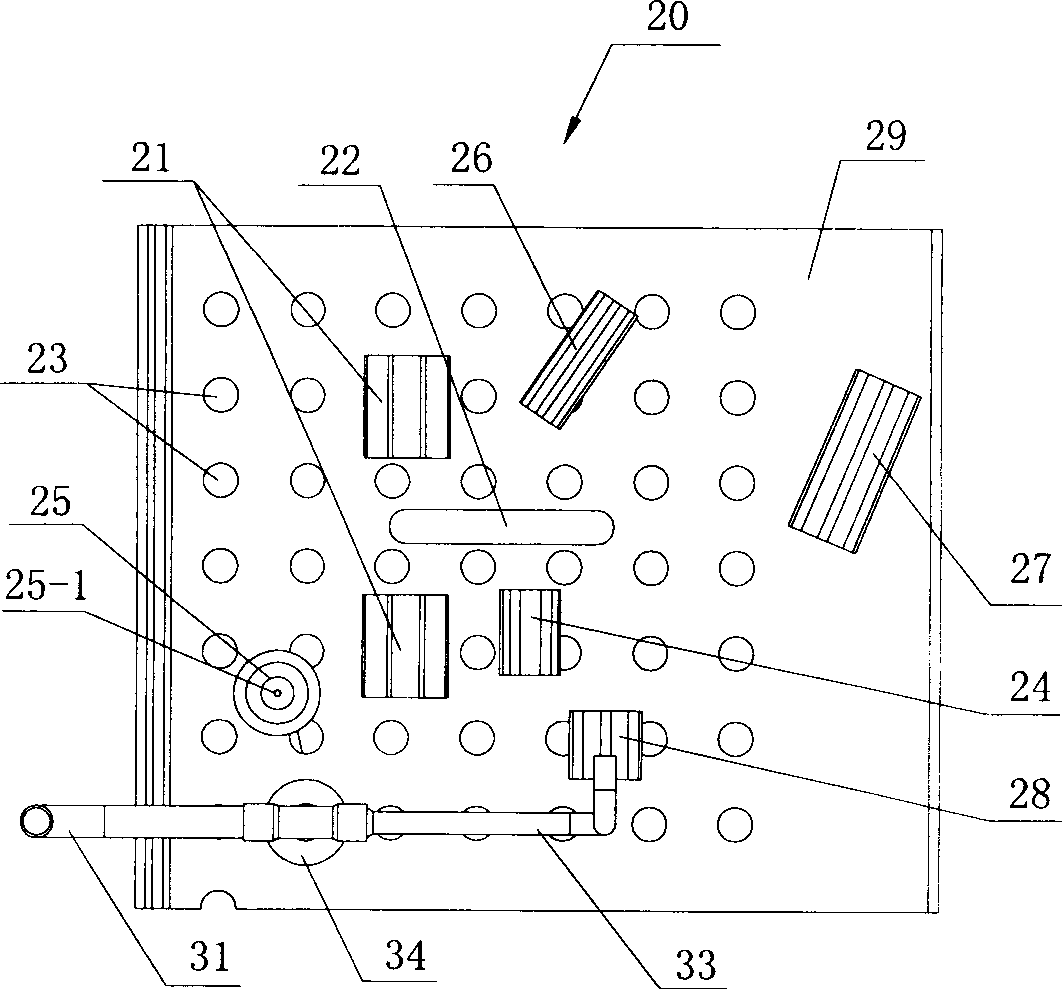

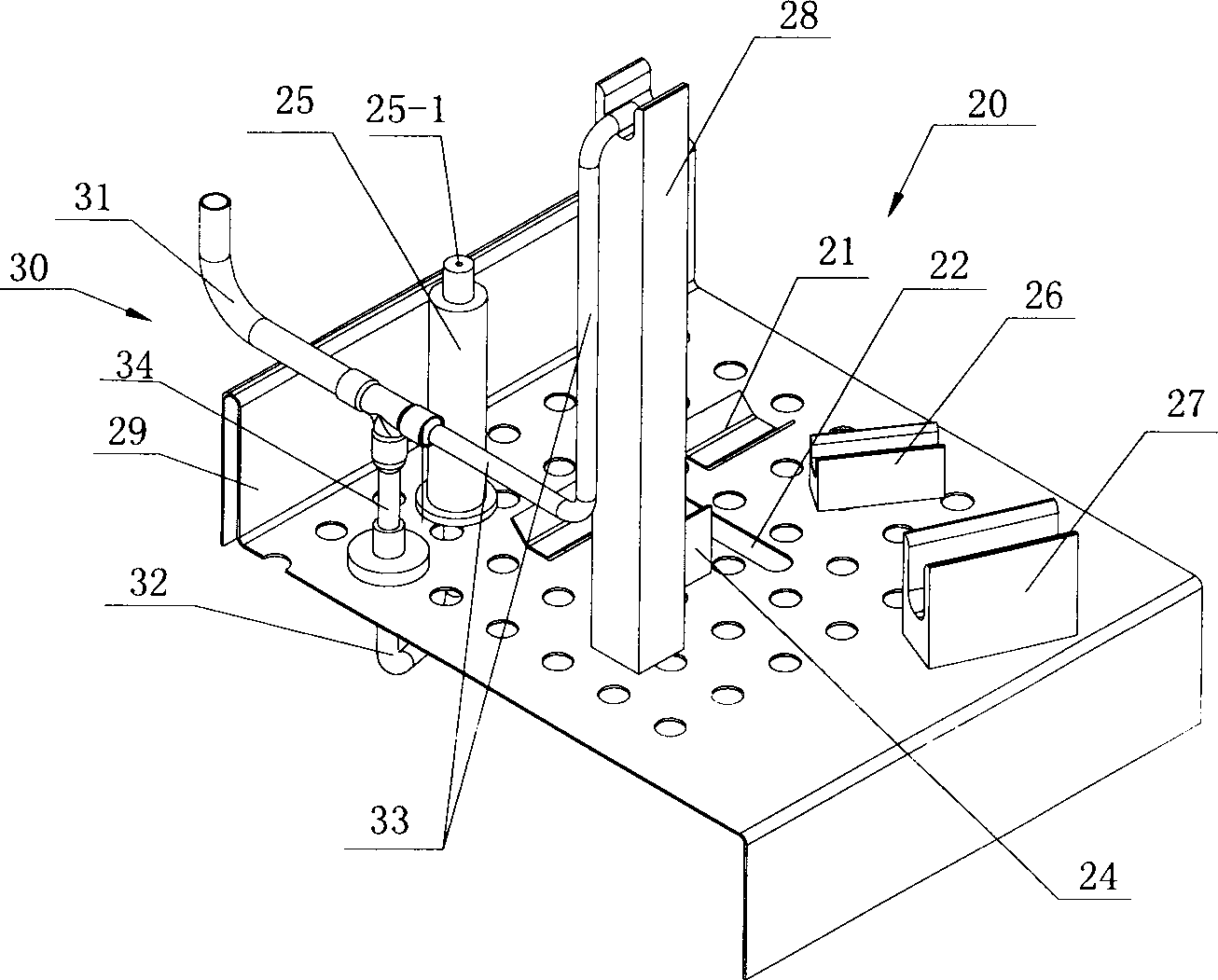

Air conditioner cross-valve welding frock

InactiveCN101362270APrecise positioningSolving big headachesWelding/cutting auxillary devicesAuxillary welding devicesFour-way valveManufacturing line

The invention provides a welding tool for a four-way valve of an air conditioner, and can solve the problems in the prior art that the four-way valve tube bank can not be positioned in the welding process and nitrogen filling protection can not be realized. The invention adopts the technical proposal that the four-way valve welding tool for the air conditioner comprises a water tank, a four-way valve welding device is arranged in the water tank, is used for positioning the four-way valve when being welded with the associated pipe, and comprises a fixing plate, V-shaped iron for positioning the four-way valve and a long groove for the tubule of the four-way valve to penetrate are arranged on the fixing plate, and a V-shaped groove A for positioning the pilot valve on the four-way valve is arranged on one side of the long groove. The four-way valve welding tool has the advantages that the four-way valve tube bank can be positioned accurately, nitrogen filling protection is always provided to the tube bank in the welding process, the welding efficiency and the welding quality of the air conditioner product line can be enhanced, and the performance of the entire air conditioner can be improved, so as to lead the product to be more competitive.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

Balancing valve

InactiveCN1356481AEasy to controlSensitive controlServomotor componentsSinistral and dextralEngineering

A balancing valve for the engineering machine with 8-50 tons of lifting weight is composed of main valve and pilot valve. The said main valve consists of cylindrical valve body and main valve core. The said pilot valve is positioned in the main valve core. The core of pilot valve is linked to main valve core via springs. The main valve core is linked to valve body via more springs with different spriral directions and rigidities. Its advantages include correct, sensitive and reliable control, and preventing the burble dropping down of load.

Owner:卢永松

Poppet valve operated by an electrohydraulic poppet pilot valve

ActiveUS20100155633A1Operating means/releasing devices for valvesServomotor componentsControl roomEngineering

A control valve includes a main poppet that moves in response to pressure in a primary control chamber and thereby controls the flow of fluid through a valve seat between first and second ports. A passageway extends between the second port and the primary control chamber and includes a variable flow restriction that decreases as the main poppet moves away from the valve seat. An electrohydraulic pilot valve has a pilot poppet which controls fluid flow from the primary control chamber to the first port in response to pressure in a pilot control chamber. A sub-pilot valve selectively releases pressure in the pilot control chamber to operate the pilot poppet to open and close a path between the inlet and the outlet. Using an electrohydraulic pilot valve enables the main poppet to operate quickly in controlling large fluid flow rates. Unidirectional and bidirectional versions of the control valve are described.

Owner:HUSCO INT INC

Sprinkler assembly

ActiveUS7631813B1Improved sprinkler body designEasy to disassembleValve arrangementsSelf-acting watering devicesSprinkler systemBody compartment

The present invention includes an improved sprinkler design having a magnetic sensing system for determining the position of the riser nozzle, a waterproofed motor housing and related cables, configurable sprinkler body compartments, and a pilot valve with a check valve assembly, both of which are located within the sprinkler body.

Owner:TORO CO THE

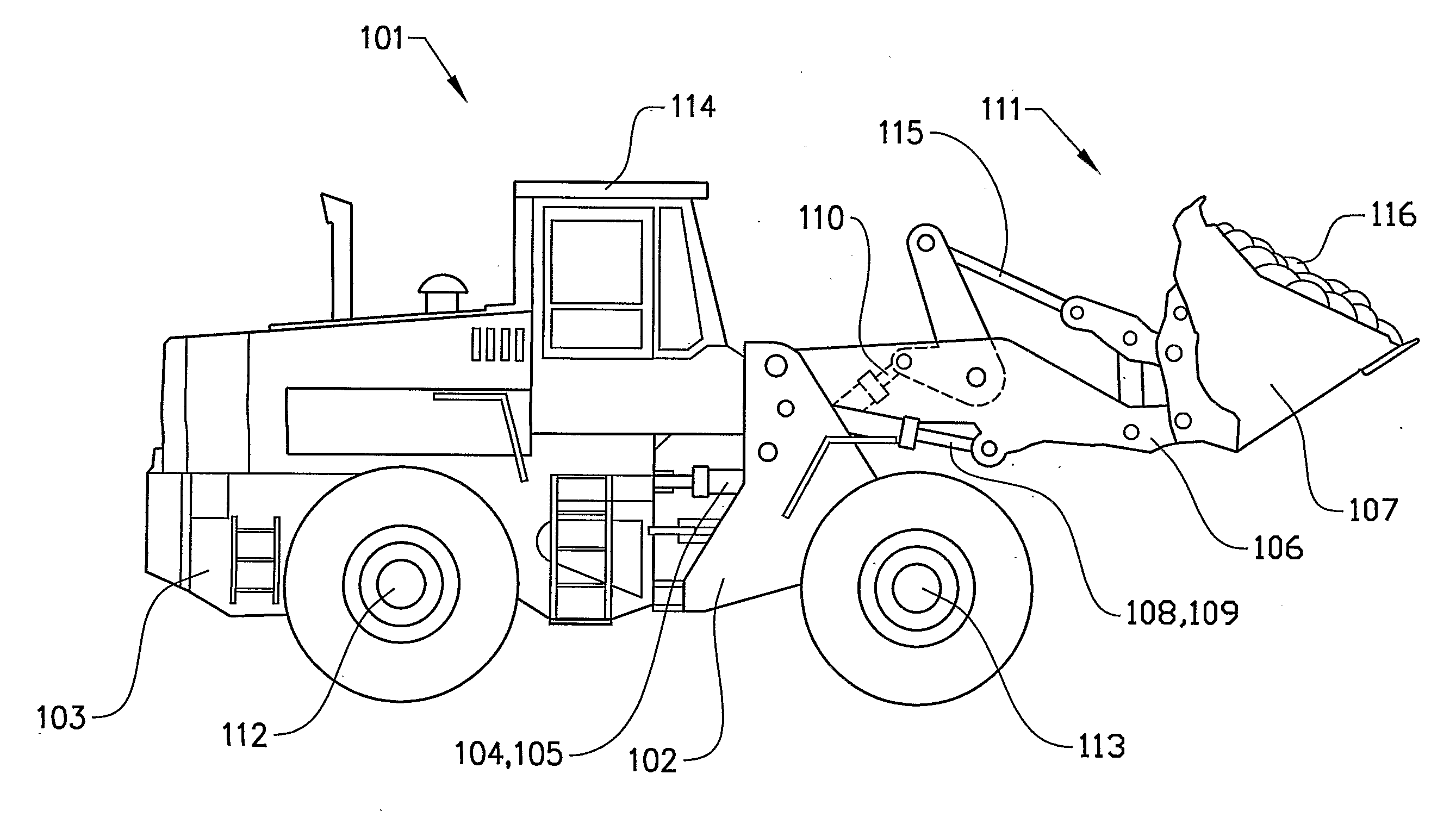

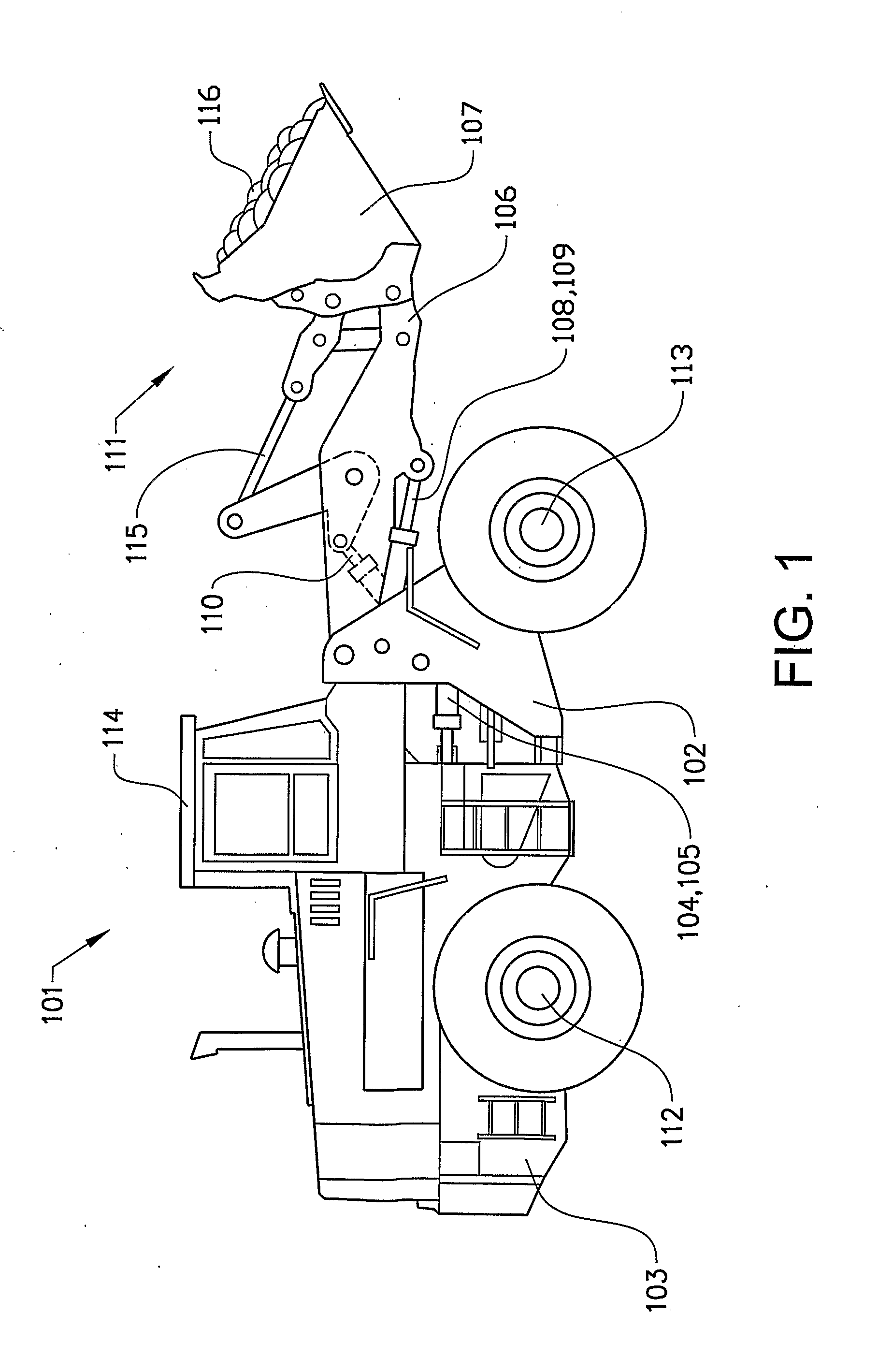

Hydraulic system and a working machine comprising such a hydraulic system

ActiveUS20120067432A1Facilitate energy recoveryReduce energy consumptionOperating means/releasing devices for valvesServomotor componentsWork functionEngineering

A hydraulic system for a working machine includes at least one work function and a control valve unit for controlling hydraulic fluid to and from the work function, and a recovery unit connected to a return port of the control valve unit for recovering energy from the work function. The system further includes an arrangement for limiting the pressure of the hydraulic fluid at the return port, which pressure limiting arrangement has a pilot-operated valve adapted to set a maximum allowable pressure at the return port of the control valve unit. The pressure is variable by controlling the pilot-operated valve by a control unit.

Owner:VOLVO CONSTR EQUIP

Control valve of high-pressure pneumatic switch

InactiveCN1386992ASimple structural designCompact designOperating means/releasing devices for valvesLift valveAutomatic controlPneumatic circuit

A control valve of high-pressure pneuamtic valve is composed of main valve and magnetic pilot valve which is an electromagnetic high-pressure ball valve. Said main valve consists of valve cover, conic valve core, valve bush and main body. The sealing surface of conic valve core is made of vulcanized rubber. The PTFE is used for the seal between conic valve and valve bush. Its advantages are simple and compact structure, reliable sealing, and high flow controlled by electronic signals.

Owner:ZHEJIANG UNIV

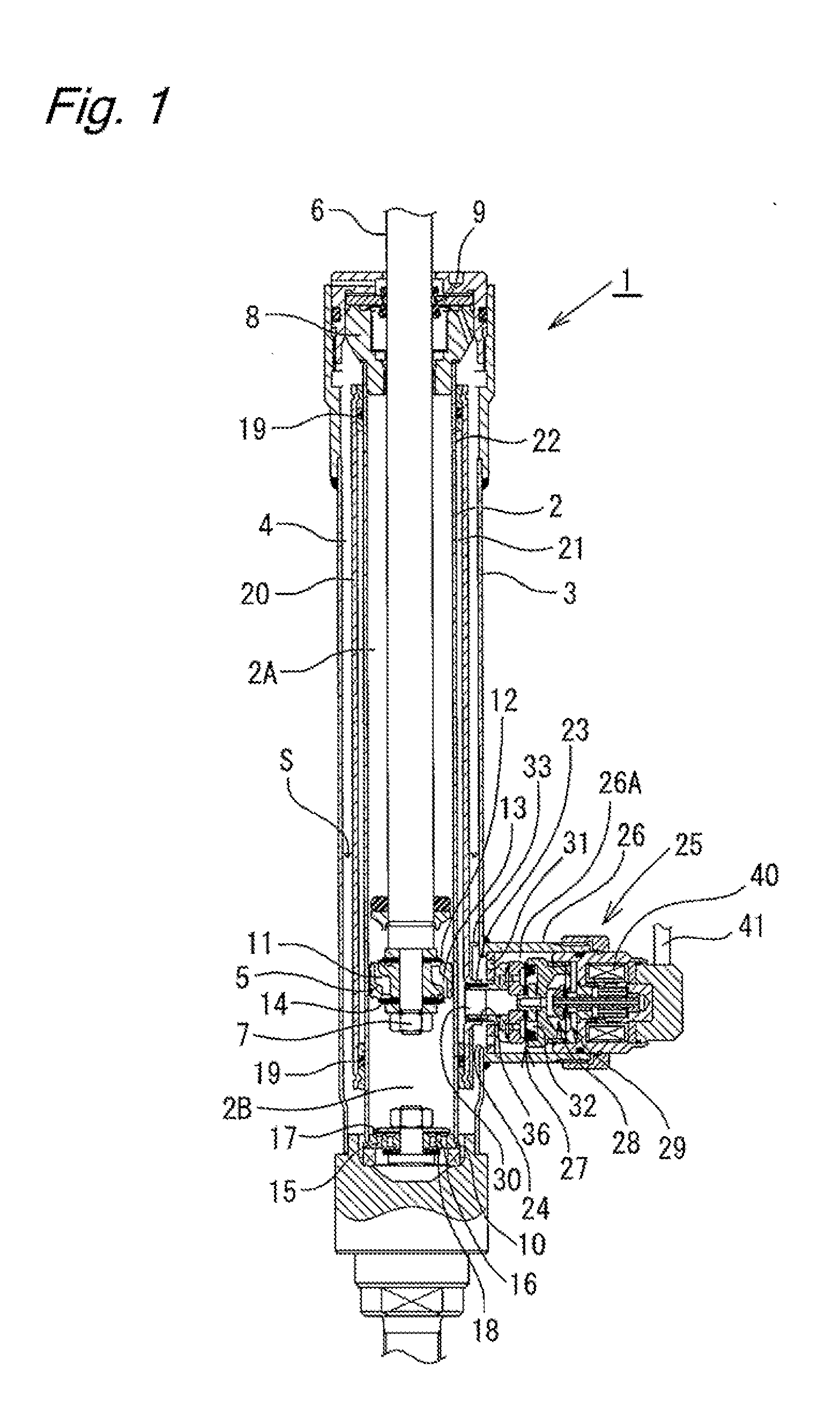

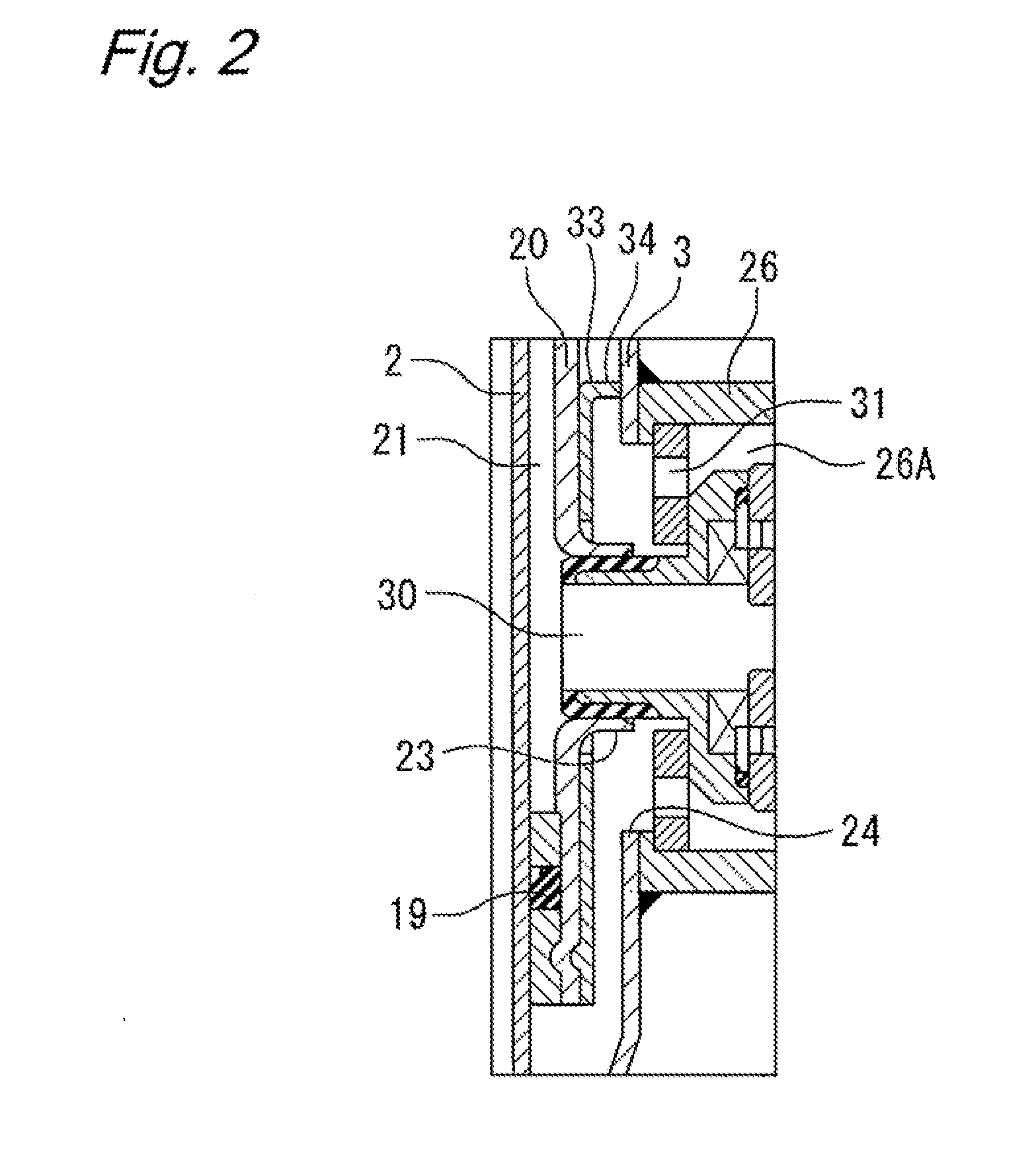

Shock absorber

A flow of hydraulic oil induced by sliding movement of a piston in a cylinder is controlled by a pilot-type main valve and a pilot valve, which is a pressure control valve, to generate a damping force. The pilot valve is adjusted in its valve-opening pressure with the thrust of a solenoid and adjusts the pressure in a back pressure chamber to control the valve-opening pressure of the main valve. A baffle plate is provided in a reservoir to isolate from each other the surface of hydraulic oil in the reservoir and an inlet port through which the hydraulic oil flows into the reservoir from a damping force generating mechanism, thereby suppressing the occurrence of aeration and cavitation. The baffle plate is secured by inserting a connecting port through a positioning opening and holding a separator tube with a pair of arm portions.

Owner:HITACHI ASTEMO LTD

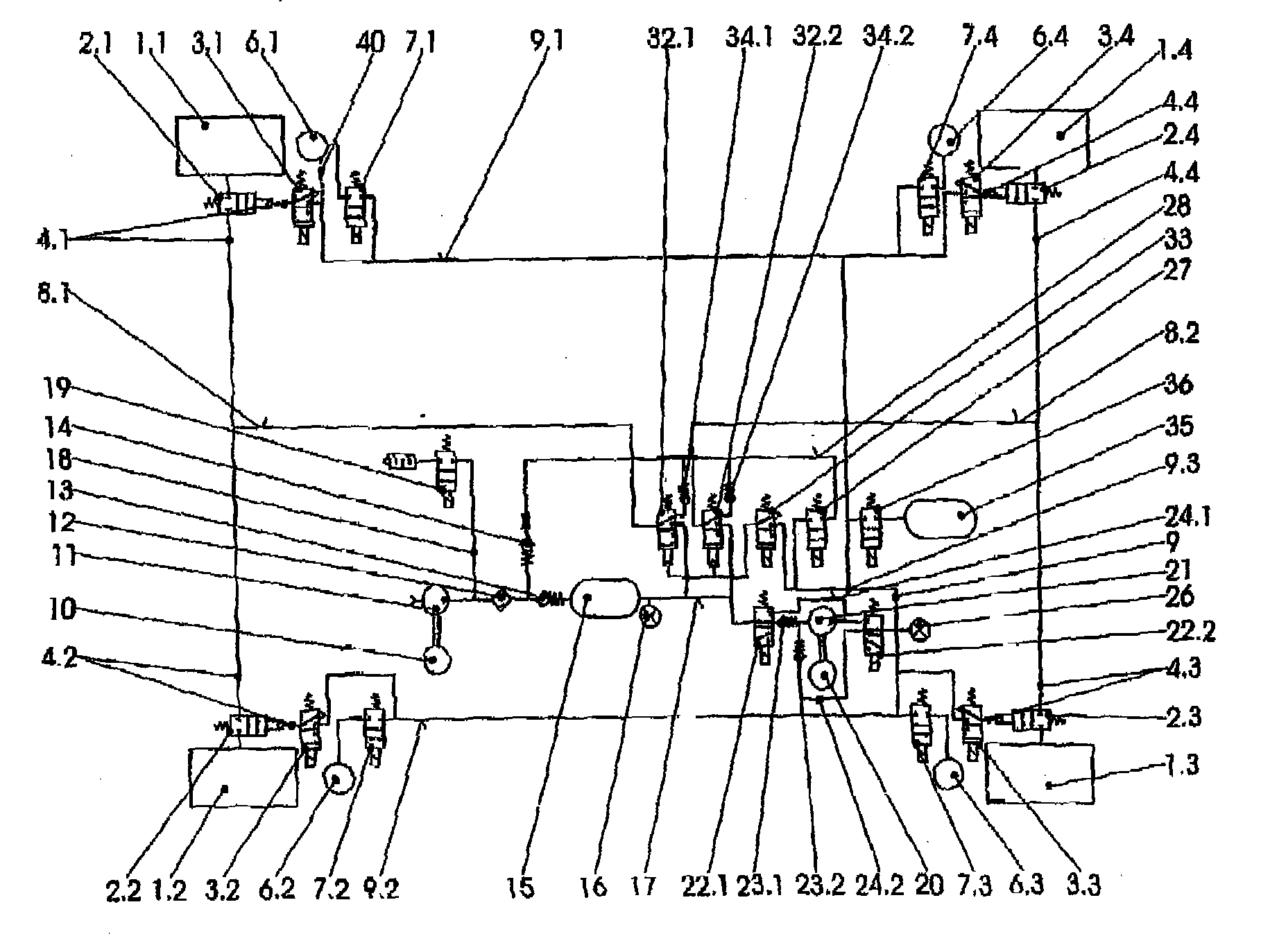

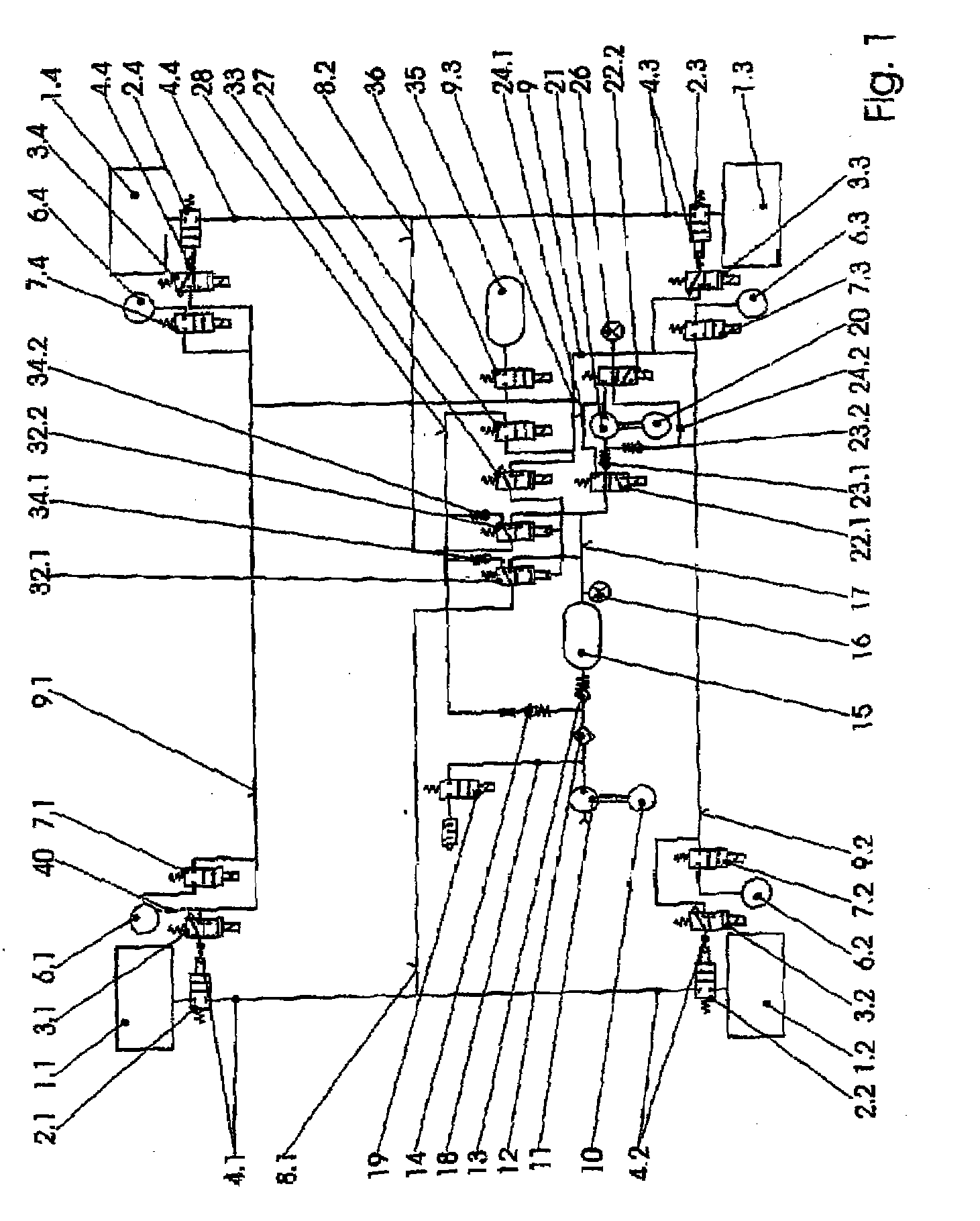

Tire inflation system

InactiveUS20090032158A1Minimal numberQuick and reliable operationTyre measurementsTyre-inflating valvesHigh pressureVehicle control

A tire inflation system comprising pneumatically controlled wheel valves that are situated in the wheels of a motor vehicle. An electrically actuated pilot valve that is fixed to the vehicle controls the respective wheel valves. To produce a small, low-cost, reliable tire inflation system, a first and a second compressor are provided. The first compressor supplies a first compressed air system with medium-pressure compressed air and the second compressor supplies a second compressed air system with high-pressure compressed air. The wheel valves are situated in the first compressed air system and the pilot valves are situated in the second compressed air system.

Owner:MAGNA STEYR FAHRZEUGTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com