Method for preparing battery grade iron phosphate from waste and old lithium iron phosphate batteries

A lithium iron phosphate battery, lithium iron phosphate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of reducing the economic value of products, affecting the purity of iron phosphate, increasing recovery costs, etc., and reducing lithium recovery. cost, corrosion mitigation, recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

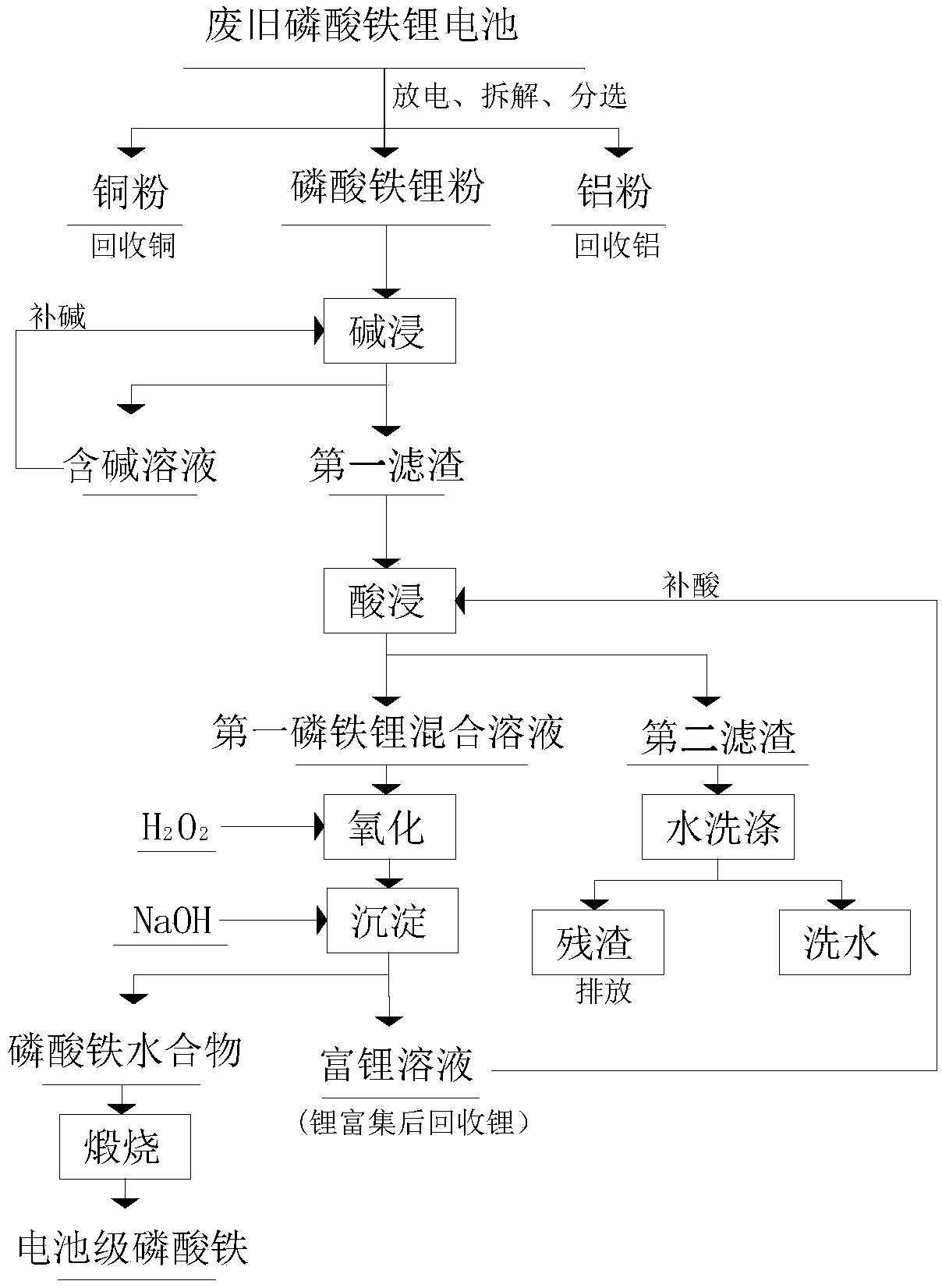

[0048] This embodiment provides a method for preparing battery-grade iron phosphate from waste lithium iron phosphate batteries, which mainly includes the following steps:

[0049] (1) Battery dismantling and separation: Discharge the waste lithium iron phosphate battery to below 2.0V, put it into a crusher for disassembly, and then separate it by vibrating screening and airflow screening to obtain the first lithium iron phosphate powder, Aluminum powder and copper powder;

[0050] (2) Alkaline leaching: put 300 g of the first lithium iron phosphate powder recovered from waste lithium iron phosphate batteries into 1.5 L of sodium hydroxide solution with a concentration of 3 mol / L and stir for 1 hour at a stirring speed of 500 r / min. room temperature (28°C), then filter and wash to obtain the first filter residue and alkali-containing filtrate, and the alkali-containing solution is supplemented with a second preset concentration of alkali and then continue to leach new second l...

Embodiment 2

[0056] This embodiment provides a method for preparing battery-grade iron phosphate from waste lithium iron phosphate batteries, which mainly includes the following steps:

[0057] (1) Battery dismantling and separation: Discharge the waste lithium iron phosphate battery to below 2.0V, put it into a crusher for disassembly, and then separate it by vibrating screening and airflow screening to obtain the first lithium iron phosphate powder, Aluminum powder and copper powder;

[0058] (2) Alkaline leaching: Put 300 g of the first lithium iron phosphate powder recovered from waste lithium iron phosphate batteries into 2.0 L of sodium hydroxide solution with a concentration of 1 mol / L and stir for 3 hours at a stirring speed of 600 r / min. room temperature (32° C.), then filter and wash to obtain the first filter residue and alkali-containing filtrate, and the alkali-containing solution is supplemented with a second preset concentration of alkali and then continue to leach new secon...

Embodiment 3

[0064] (1) Battery dismantling and separation: Discharge the waste lithium iron phosphate battery to below 2.0V, put it into a crusher for disassembly, and then separate it by vibrating screening and airflow screening to obtain the first lithium iron phosphate powder, Aluminum powder and copper powder;

[0065] (2) Alkaline leaching: put 300 g of the first lithium iron phosphate powder recovered from waste lithium iron phosphate batteries into 2.0 L of sodium hydroxide solution with a concentration of 4 mol / L and stir for 0.5 h at a stirring speed of 600 r / min. The temperature is room temperature (31°C), and then filtered and washed to obtain the first filter residue and alkali-containing filtrate. The alkali-containing solution is supplemented with a second preset concentration of alkali and continues to leach new second lithium iron phosphate powder. The first filter residue enters the next step ;

[0066] (3) Acid leaching: the first filter residue obtained in step (2) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com