Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Cementation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The cementation process is an obsolete technology for making steel by carburization of iron. Unlike modern steelmaking, it increased the amount of carbon in the iron. It was apparently developed before the 17th century. Derwentcote Steel Furnace, built in 1720, is the earliest surviving example of a cementation furnace. Another example in the UK is the cementation furnace in Doncaster Street, Sheffield.

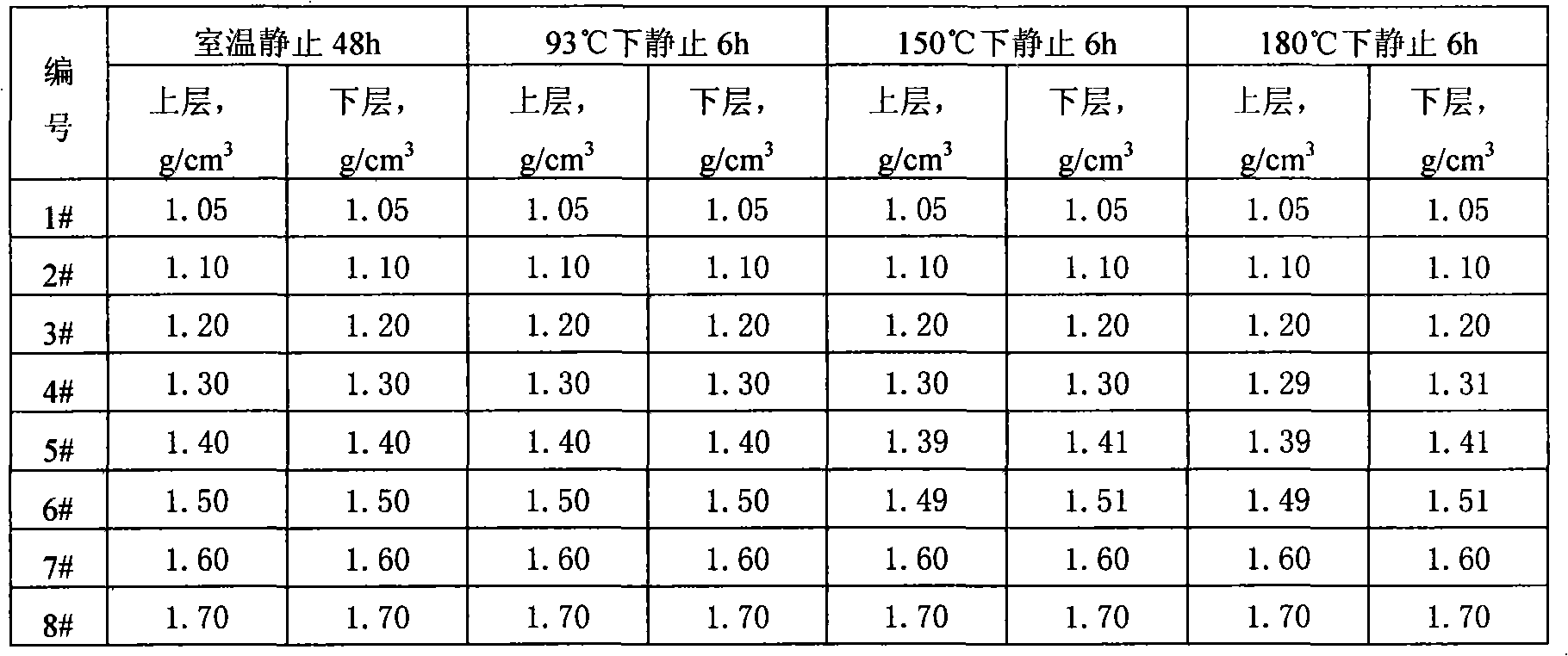

Leaking stoppage cement slurry for well cementation and preparation method thereof

InactiveCN101857800AGood high temperature application performanceEvenly dispersedDrilling compositionCementation processSodium sulfate

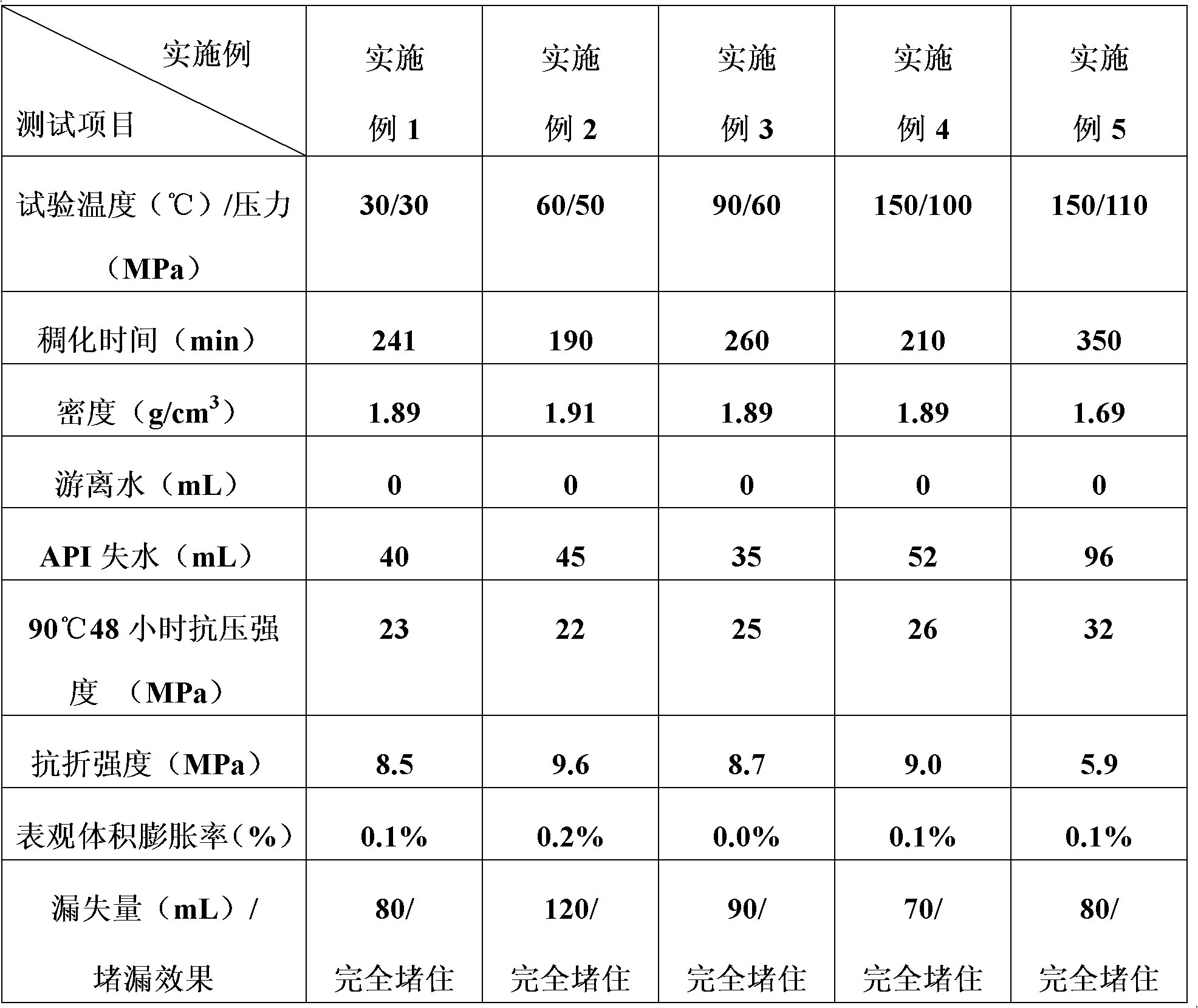

The invention relates to leaking stoppage cement slurry for well cementation and a preparation method thereof. The leaking stoppage cement slurry consists of the following components in parts by weight: 100 parts of oil-well cement, 50-150 parts of water, 0.01-8 parts of fibrilia, 1-20 parts of dispersing agent, 1-20 parts of filtrate reducer, 5-50 parts of alkali regulator, 1-10 parts of retarder and 0-1 part of defoaming agent, wherein the dispersing agent is lauryl sodium sulfate or sodium hexametaphosphate; the filtrate reducer is 2-acrylamide-2-methylpropanesulfonic acid or hydroxyethylcellulose; the alkali regulator is silicon powder; the retarder is sodium lignin sulfonate or citric acid; the defoaming agent is dimethyl silicon oil or tributyl phosphate; and the fibrilia is one or the mixture of two or more of jute, flax, hemp, ramie and sisal. The invention effectively solves the problem of leakage loss of cement slurry and inherent brittleness of set cement in the well cementation process on the premise of meeting various engineering performances required by the well cementation and provides the guarantee for subsequent operation of oil well gas.

Owner:SOUTHWEST PETROLEUM UNIV

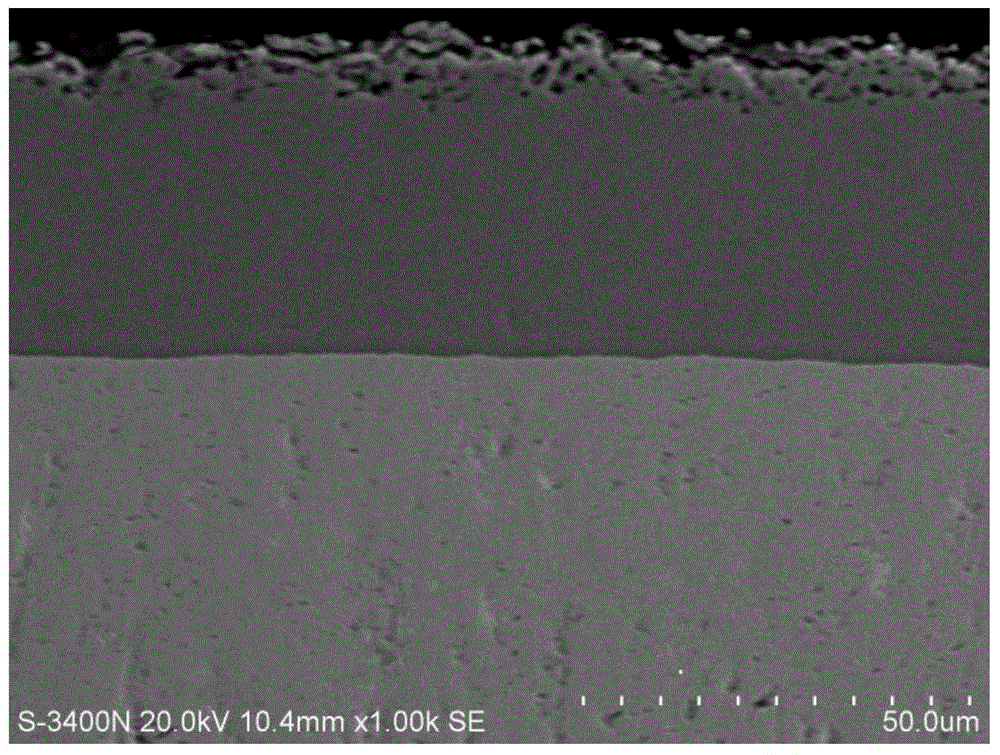

Niobic alloy high temperature antioxidation silicide coating and preparation method thereof

InactiveCN101200801AUniform compositionUniform thicknessSolid state diffusion coatingSuperimposed coating processCementation processVolumetric Mass Density

The invention discloses a niobium alloy high temperature antioxidation silicide coating and a preparation method thereof. Firstly, molybdenum layers, the particle size of most of which is 0.6-1.0 Mu m and the thickness of which is 50 Mu m-80 Mu m, are sintered through vacuum on a niobium alloy substrate surface layer. Under the protection of argon, a MoSi2 coating is made through the pack cementation silicification. The pack cementation silicification activator is NaF, the promoter is Al2O3, and the weight ratio of Si to Al2O3 to NaF is 35-45 to 50-65 to 3-5. The complex pack cementation process is suitable for preparing the silicide coating with high melting point and can coat the inside and the external surface of irregular structural components without the influences of the shape and the size of the components. The components and the thickness of the coating prepared through the method are uniform. The density is greatly improved compared with that of a material pulp reaction sintering method. With simple process and low requirement on equipment, the invention is a novel high temperature coating preparation technology.

Owner:CENT SOUTH UNIV

Process for preparing anti-bacteria stainless steel by double-layer glowing method

InactiveCN1793428AAvoid high copper contentAvoid the problem of easy cracking in the rolling processSolid state diffusion coatingHeat treatment process controlCementation processProduct gas

The invention relates to an antibiosis stainless steel manufacturing method used double layers glowing metallic cementation process. The stainless steel base material is put into double layers glowing metallic cementation furnace to cement antibiosis element. Its working conditions are as follows: gas pressure in the furnace is 1.33-133Pa; source-electrode voltage is 0.7-1.4KV; work piece voltage is 0.6-1.2KV; temperature is 800-1050 centigrade degree; interelectrode distance is 10-20mm; cementation time is 2-4h; antibiosis element is Cu or Ag; the time of vacuum aging treatment after Cu cementation is 1-10h; and temperature is 450-900 centigrade degree. The production technology is simple, and holds base material inherent corrosion resistance. The stainless steel surface has diffused layer containing copper or silver phase. Thus its surface has good germ resistance.

Owner:WUHAN UNIV OF SCI & TECH

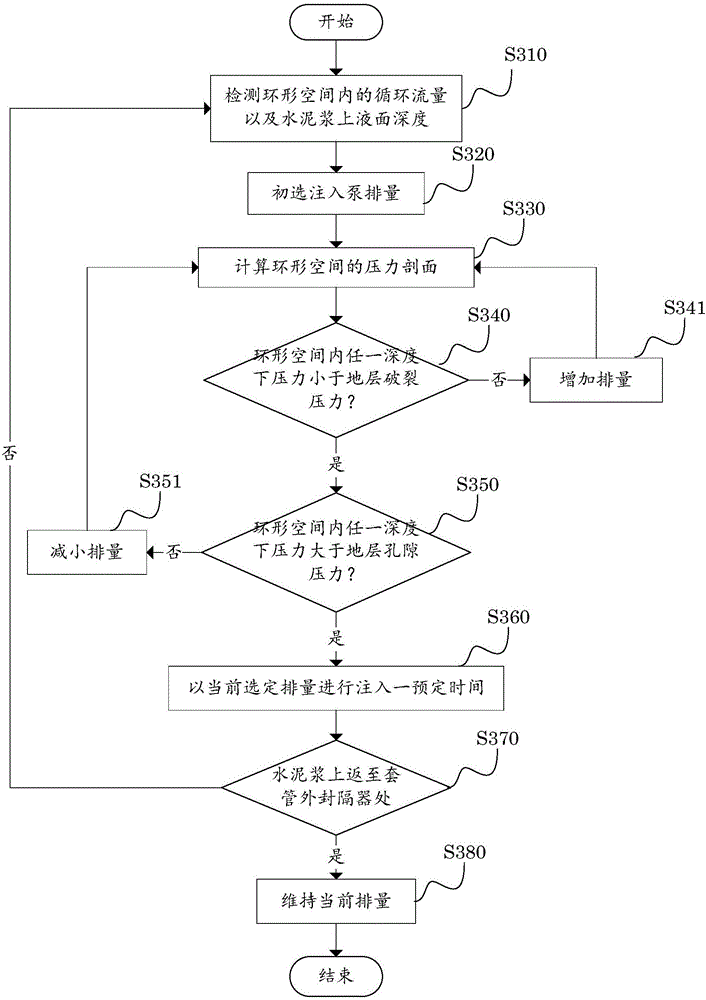

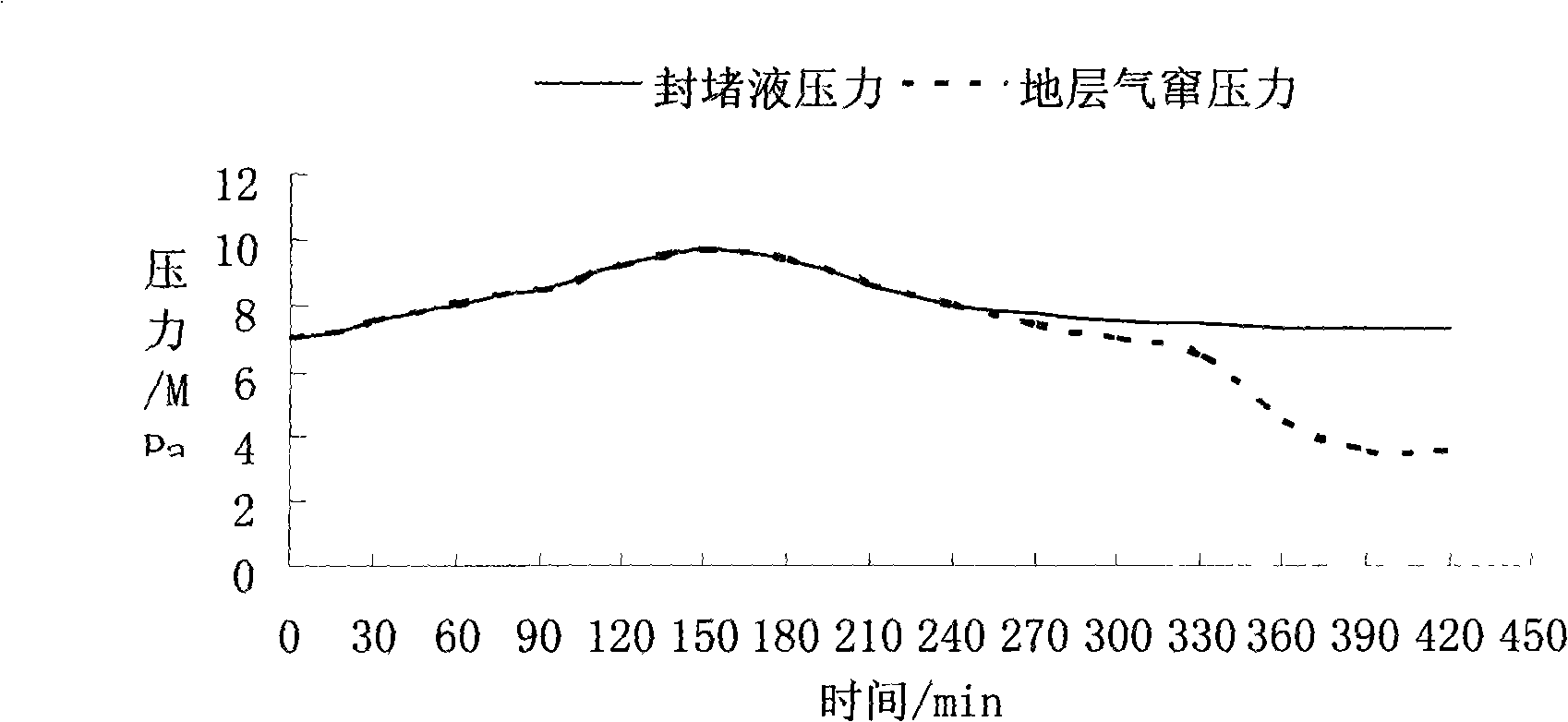

Method of balancing pressure for well cementation

InactiveCN102877812APrevent pressure leakageGuaranteed StrengthSealing/packingCement slurryCementation process

The invention discloses a method of balancing pressure for well cementation. The method comprises the following steps: a), adopting a cement slurry system of conventional density on a cementing isolation section; b), reducing pressure of a liquid pillar at the upper part of an annulus; and c), controlling wellhead back pressure of the annulus to ensure that the pressure in a weak layer is kept balanced. According to the well cementation process technology provided by the invention, a stratum can be effectively prevented from being pressed to leak, so as to soundly protect an oil-gas production layer; the strength of a cement sheath is guaranteed; the risk of environment pollution is low; the range of a stratum is wide; and the method is suitable for a reservoir stratum which is easy to leak and low in pressure.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

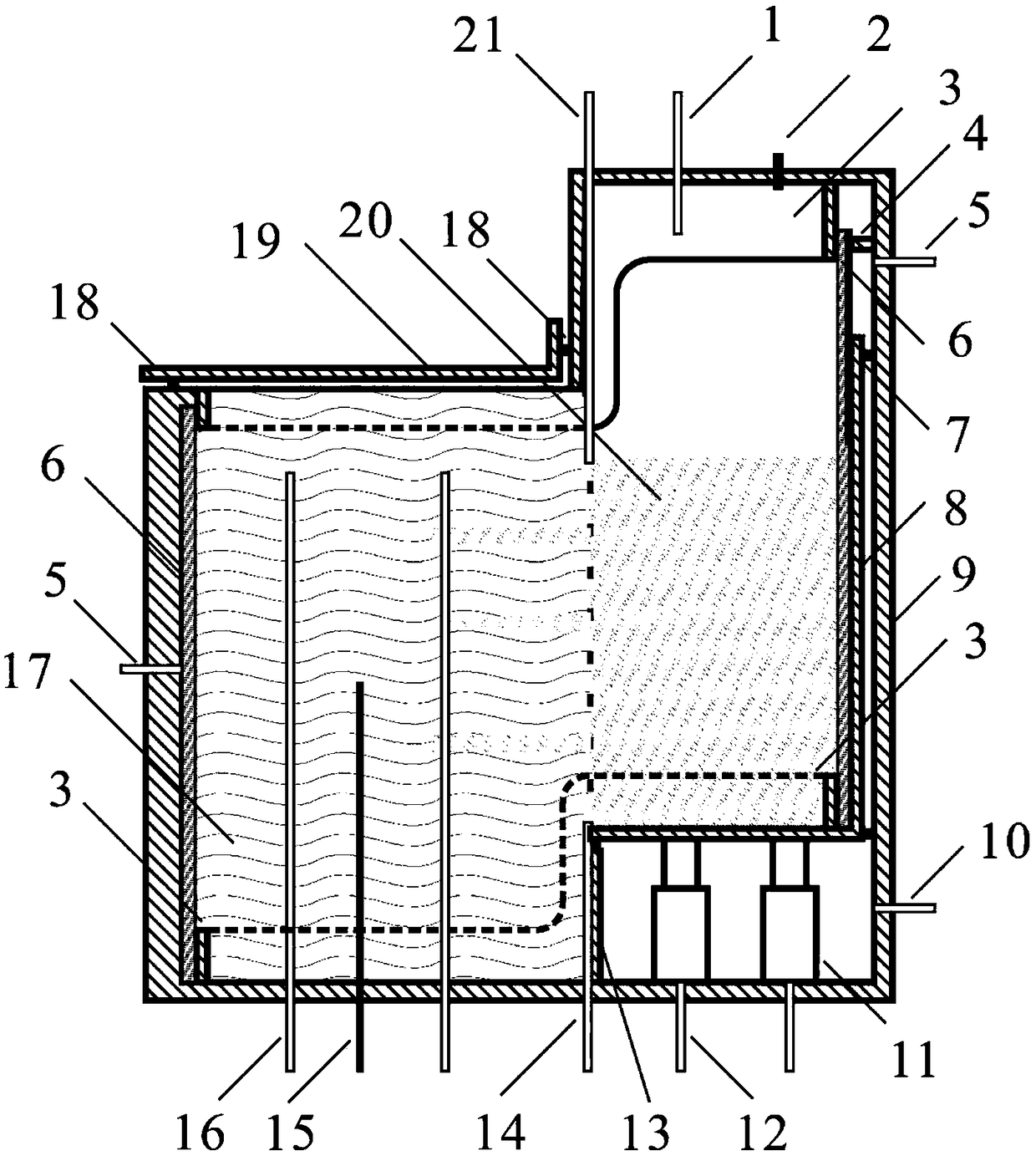

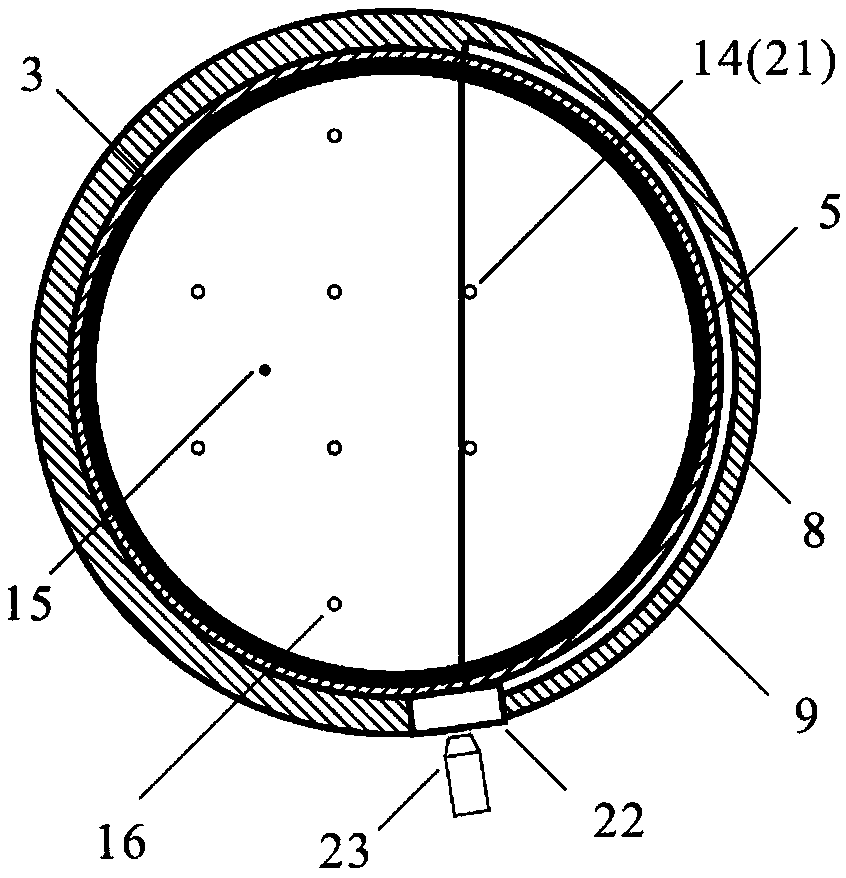

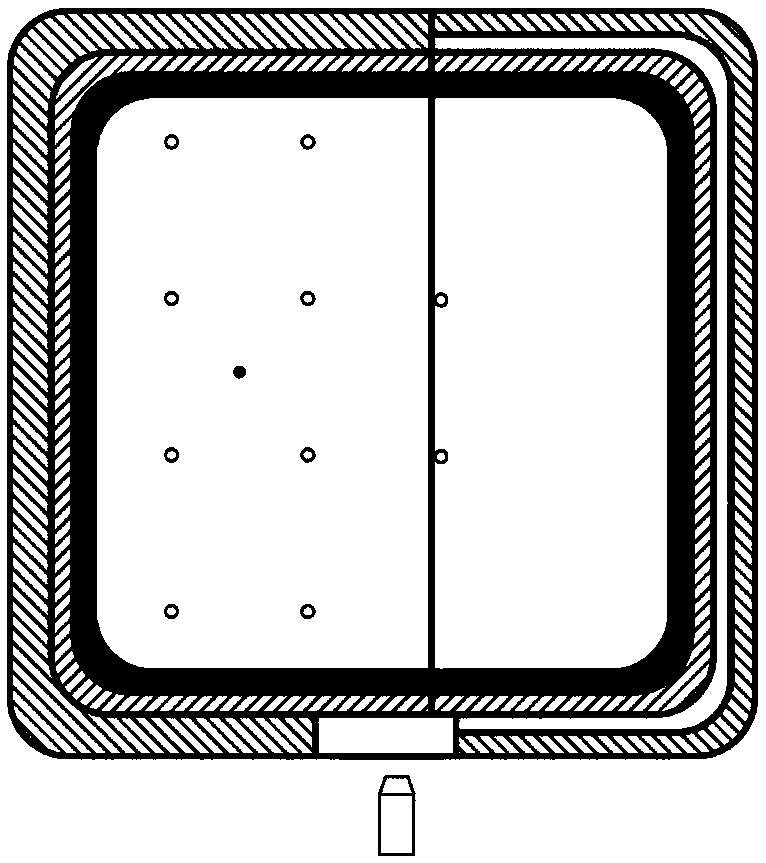

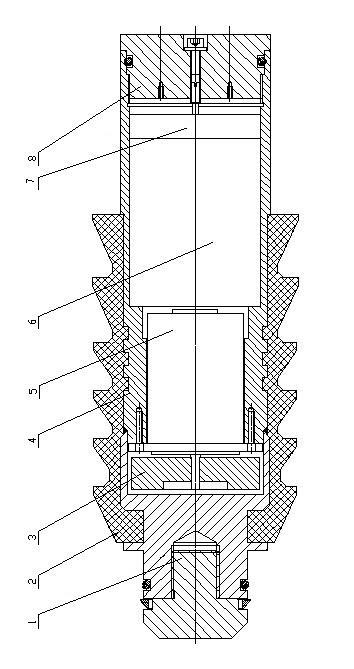

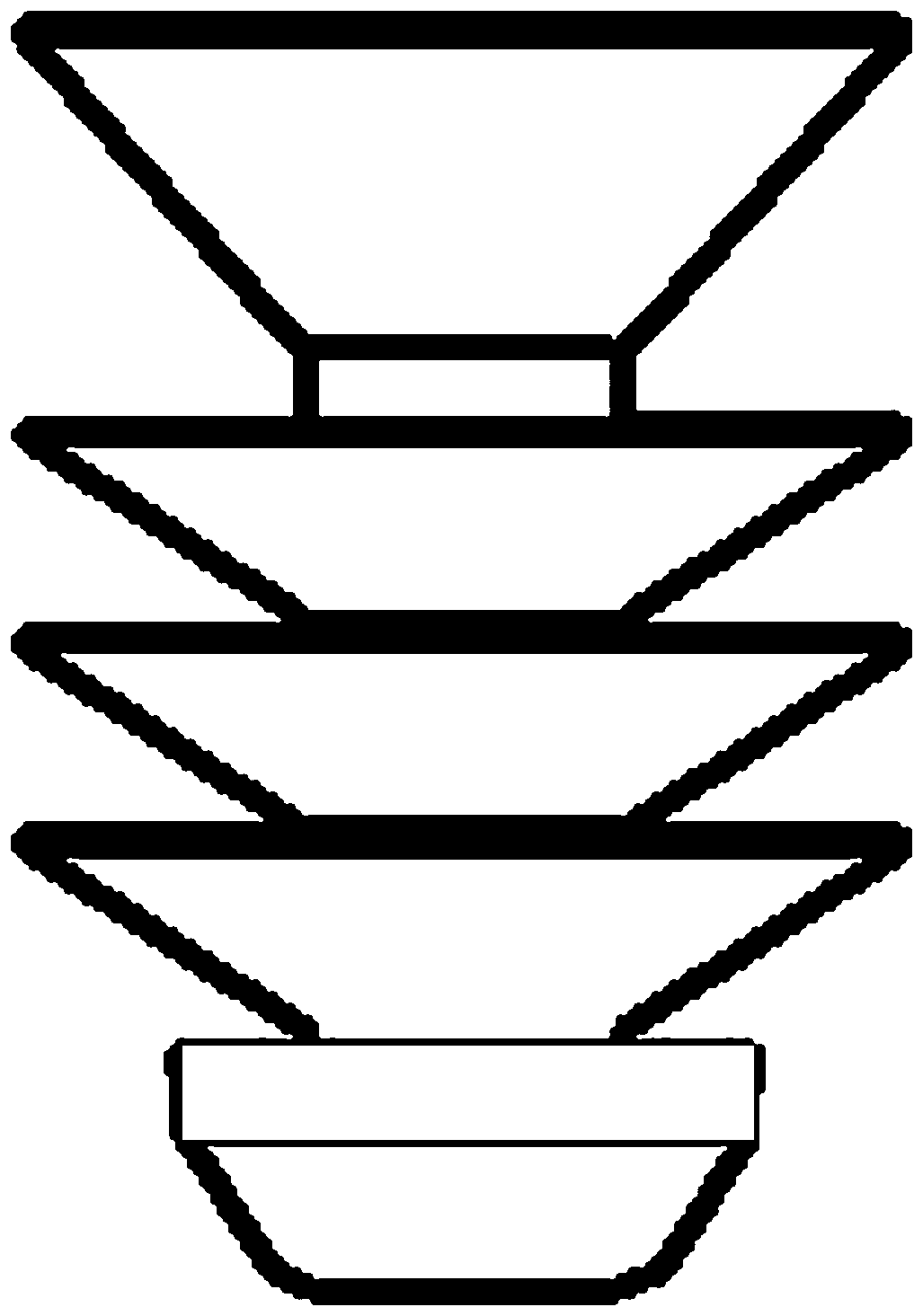

Visual system for testing cementation quality of specially-shaped well cementation interface II and intensity of specially-shaped body

ActiveCN109142192AThe test result is accurateReliable dataMaterial strength using steady shearing forcesPermeability/surface area analysisGeomorphologyWell cementing

The invention relates to the technical field of detection of the cementation quality of a well cementation interface II, in particular to a visual system for testing the cementation quality of a specially-shaped well cementation interface II and the intensity of a specially-shaped body. A simulated formation cavity and a well cementation cement / cement stone cavity are communicated to form an experimental cavity, and a perpendicular communicated surface is an interface II; circular sealing retainer rings are respectively arranged at the top and the bottom of the experimental cavity; a cement stone lifting die is arranged at the lower part of the well cementation cement / cement stone cavity; a thermocouple is arranged in the simulated formation cavity; multiple reaction gas injection pipes are arranged in the simulated formation cavity; visual windows are respectively formed in the sides of the simulated formation cavity and the well cementation cement / cement stone cavity; a sealing coveris arranged at the top of the simulated formation cavity; the top of the well cementation cement / cement stone cavity is sealed and is provided with a gas-liquid inlet / outlet. The device can be used for evaluating the cementation quality of the interface II and testing soil in a soft soil stratum and the quality of a cemented surface of cement in a well cementation process of a hydrate-containingstratum.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

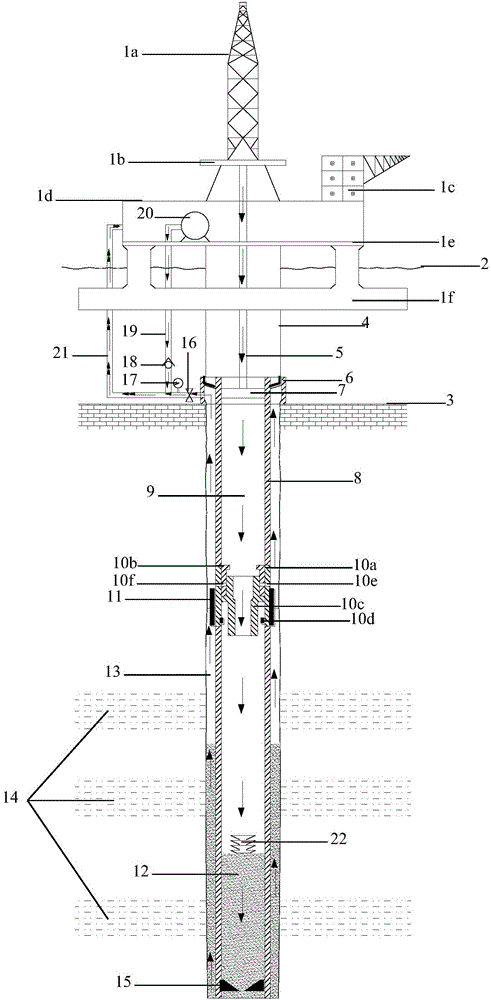

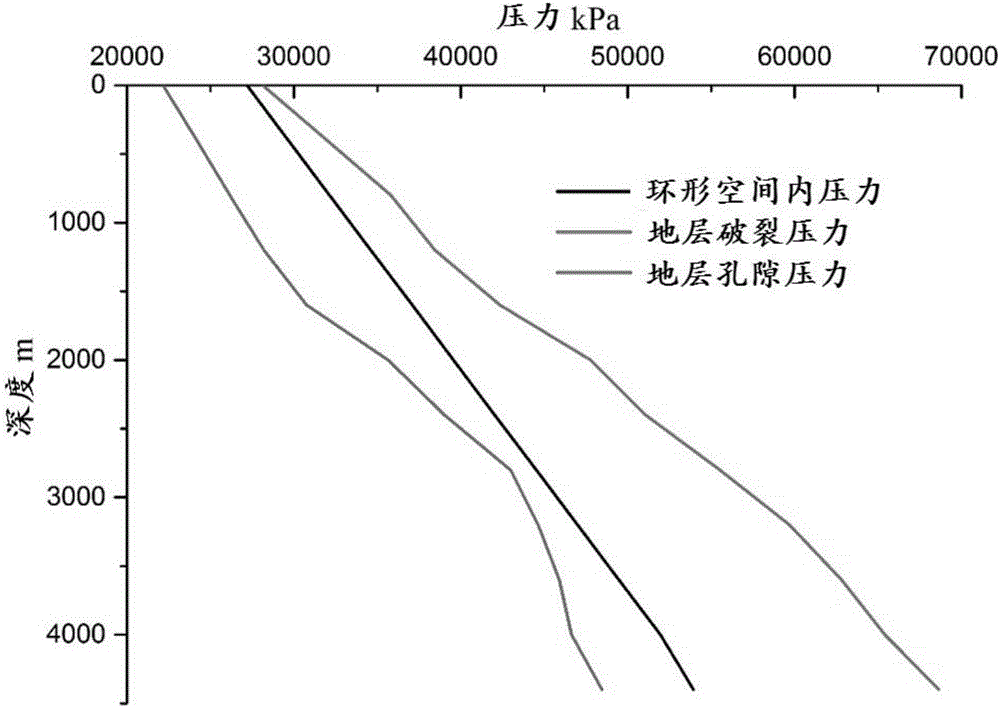

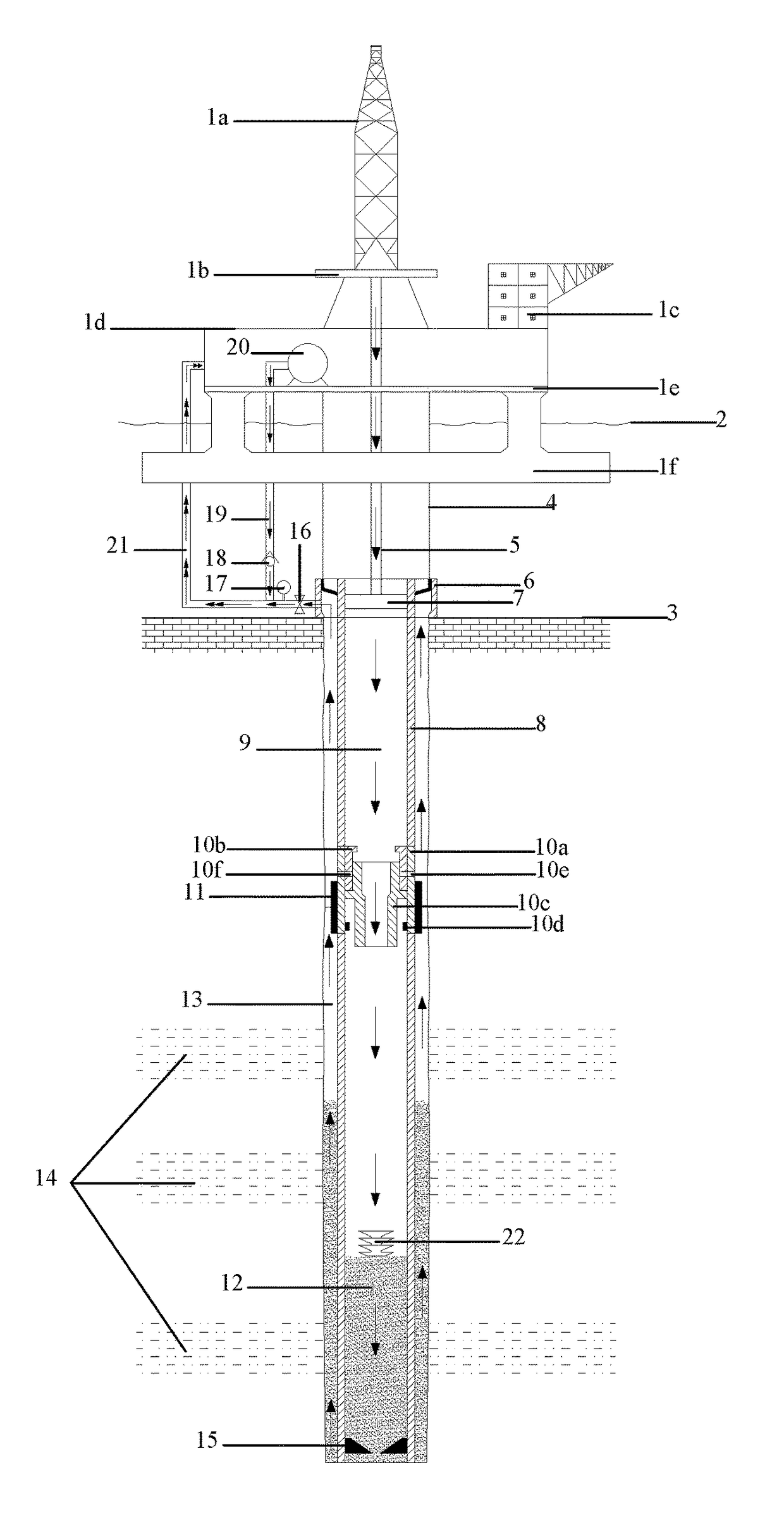

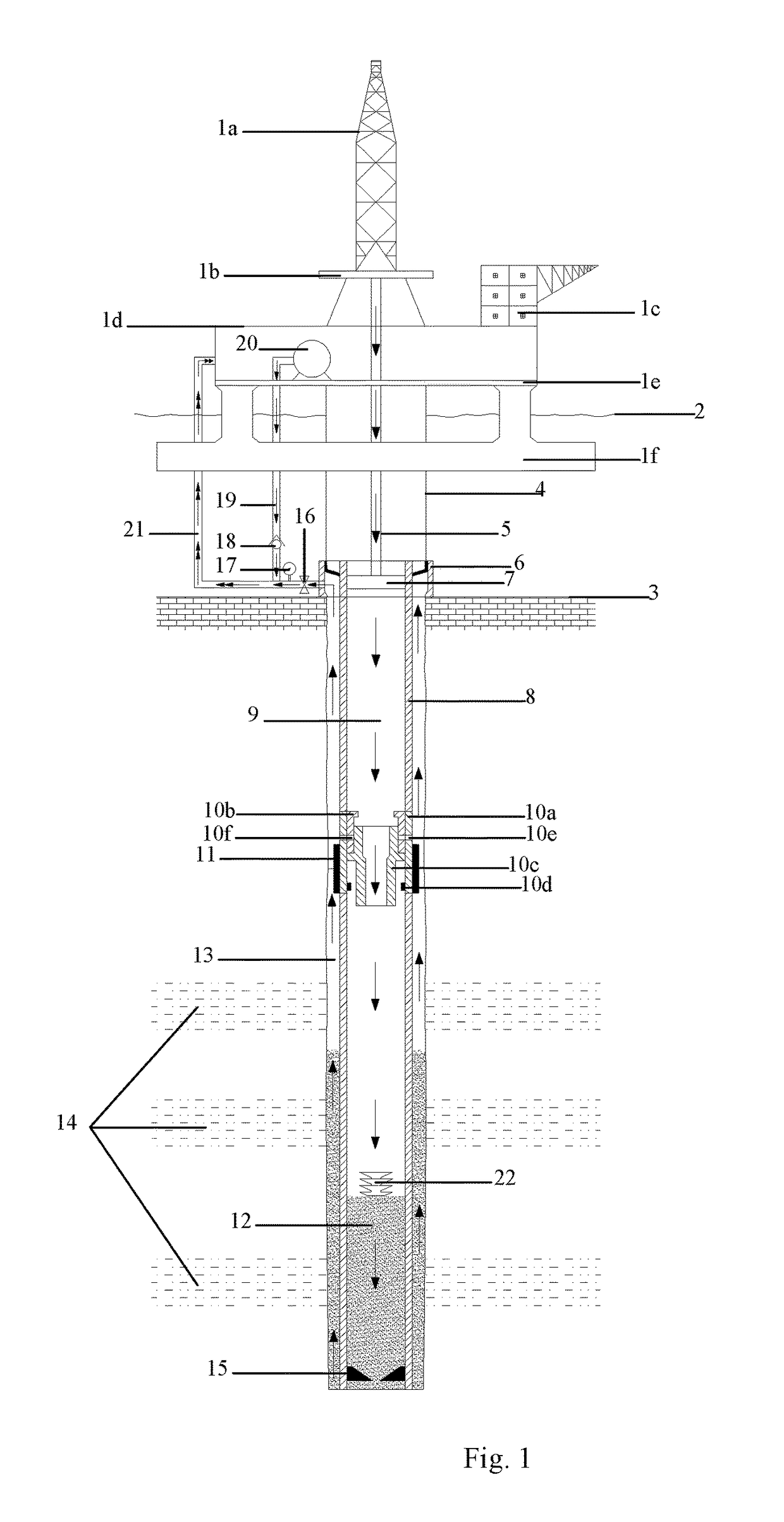

Well pressure control system and method used in well cementation stage

ActiveCN106285554ARelieve pressureAvoid safety accidents such as blowouts and blowoutsSurveySealing/packingHigh densityControl system

The embodiment of the invention provides a well pressure control system and method used in a well cementation stage and belongs to the field of ocean oil and gas development. The well pressure control system comprises an injection pump and a control device, wherein the control device is used for controlling the injection pump to inject fluid or gas into a backflow pipeline (communicated with an annular space of a well shaft) through an injection pipeline, reducing the pressure in the backflow pipeline and reducing the pressure in the annular space. The density of the fluid or gas is lower than the density of the drilling fluid in the annular space. According to the scheme provided by the invention, the accidents including well kick, blowout, and the like, triggered by the easy leaking ground layer cracked by the high-density cement paste in the well cementation process can be effectively avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

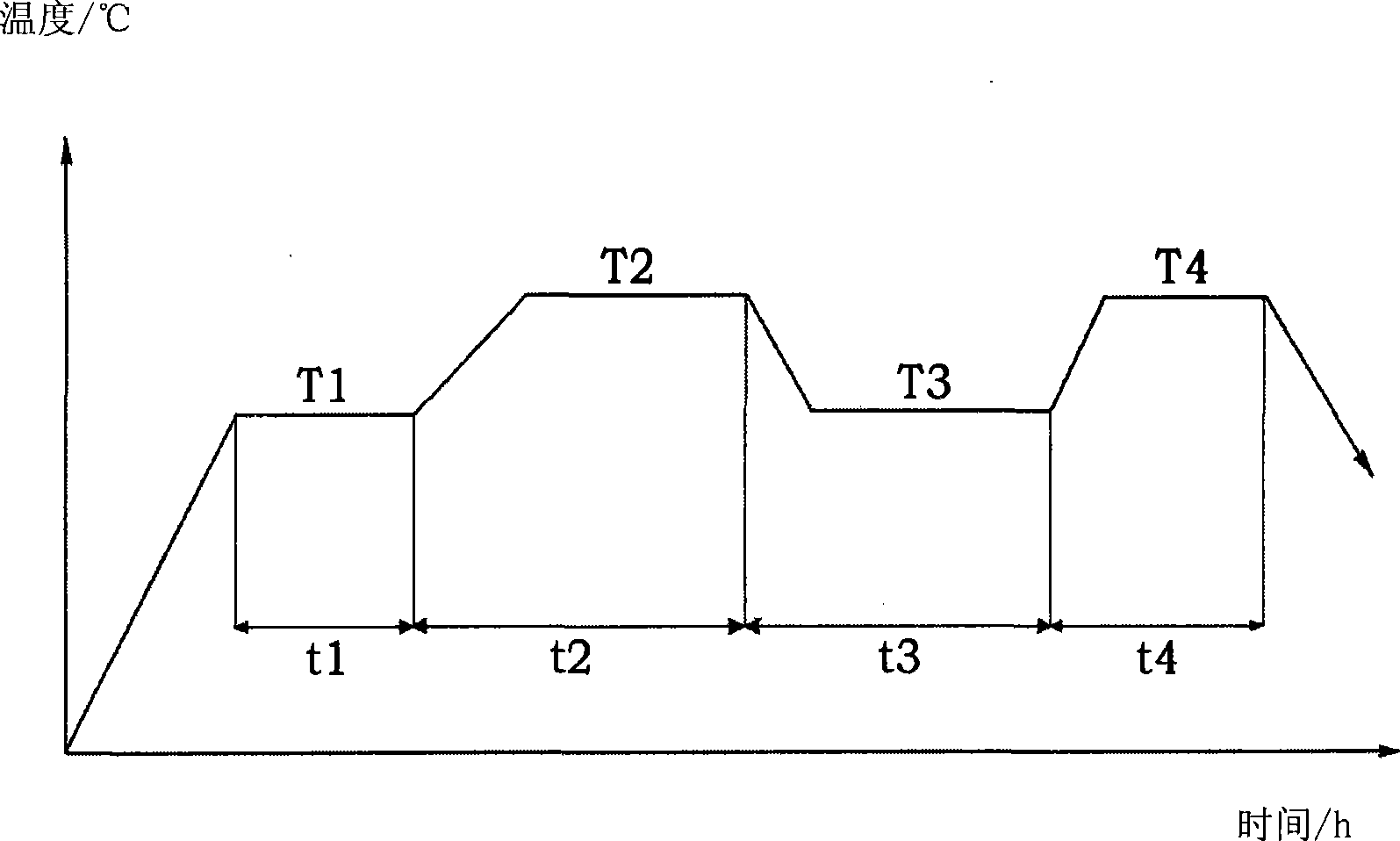

Cyclic heating rapid nitridation catalytic cementation process

InactiveCN101497980APromote absorptionIncrease penetration speedSolid state diffusion coatingFiberRare-earth element

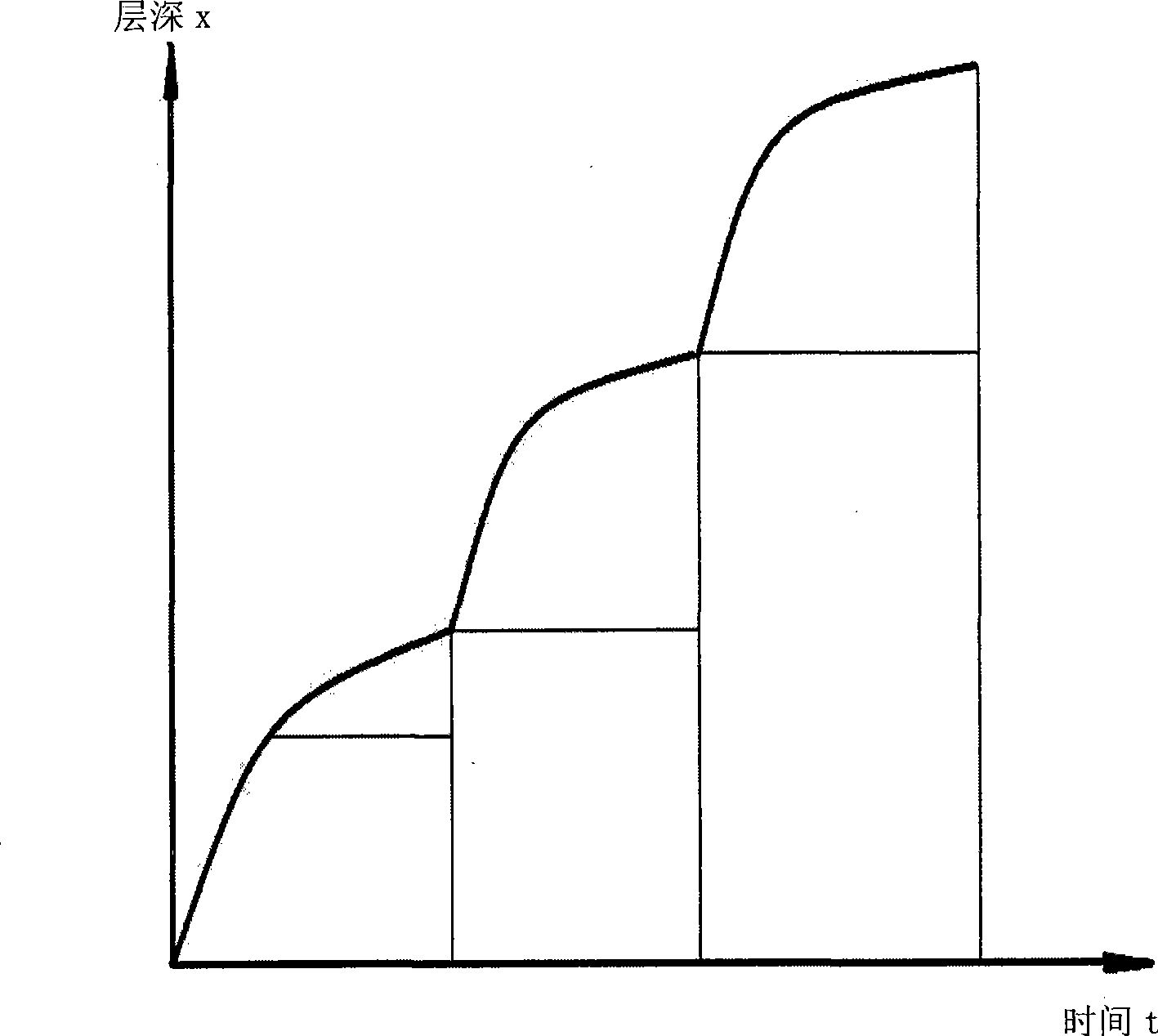

The invention relates to a circular-heating rapid nitriding catalysis process which comprises the following steps: ammonia gas is injected to discharge air after workpiece is put into a nitriding furnace; the nitriding furnace is heated from room temperature to T1 temperature and T2 temperature with two sections of heat insulation; and then another two section of heating and heat insulation are carried out at T1temeprature and T2 temperature; the ammonia gas resolution ratio is controlled within the range of 18-60 percent, and the nitriding is carried out; a thickening process is carried out by fully utilizing the strong-nitriding high-speed step, the depth of a nitriding layer and the nitriding time according to a plurality of parabolas with different P values; white powders of nitriding catalysis agent containing chlorinated rare-earth elements are put into a steel tube along with the workpiece from the nitriding charge, wherein the nitriding catalysis agent comprises the following components according to percentages by weight of 3-10 percent of chlorinated rear-earth, 5-35 percent of ammonium chloride, 20-50 percent of calcium chloride and 20-55 percent of sodium carbonate; two ends of the steel tube are tightly bound by aluminum silicate fiber or rock wool and are then put into the furnace, and the nitriding catalysis agent can play a nitriding effect during the whole nitriding process. The invention improves the absorption capacity of the surface of the workpiece to active nitrogen atoms, accelerates the nitriding speed of the nitrogen atoms, shortens the nitriding insulation time by more than 44.4 percent, saves the electrical energy by more than 32 percent and shortens the production period by more than 32.7 percent.

Owner:远立贤

Mo-Si-B coating on niobium-based alloy and preparation method of Mo-Si-B coating

InactiveCN104120426AImprove high temperature oxidation resistanceImprove antioxidant capacityMolten spray coatingSolid state diffusion coatingNiobiumCementation process

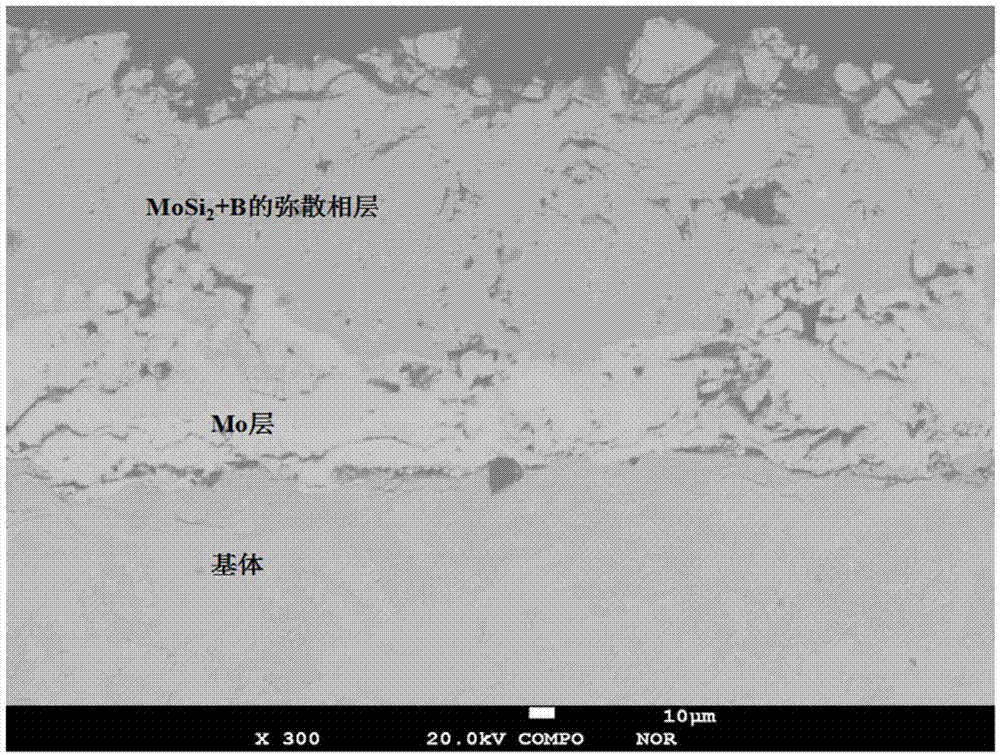

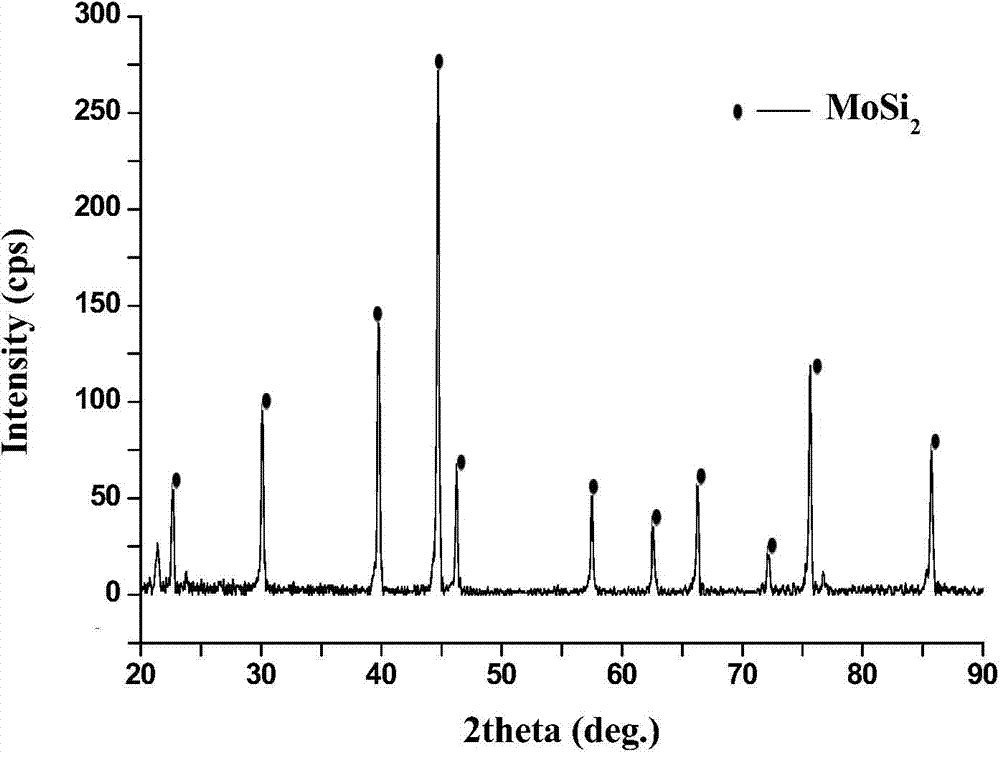

The invention discloses a Mo-Si-B coating on niobium-based alloy and a preparation method of the Mo-Si-B coating. The method comprises the steps of firstly, preparing a Mo layer on a Nb-based alloy by using an atmospheric plasma spraying process; then, enabling Si-B to be infiltrated to the Mo layer by using a pack cementation process to obtain a composite Mo-Si-B coating. Mo reacts with Si-B in the pack cementation process to generate MoSi2 and dispersed B. The Mo-Si-B coating disclosed by the invention is 100-140mu m thick and is structurally composed of the Mo layer in contact with a Nb-based alloy matrix and a MoSi2+B dispersed phase layer distributed outside the Mo layer. The coating can form a continuous, compact and good-cohesiveness borosilicate oxide layer when oxidizing at high temperature of 1250 DEG C, so that the high temperature oxidation resistance of the matrix is improved.

Owner:BEIHANG UNIV

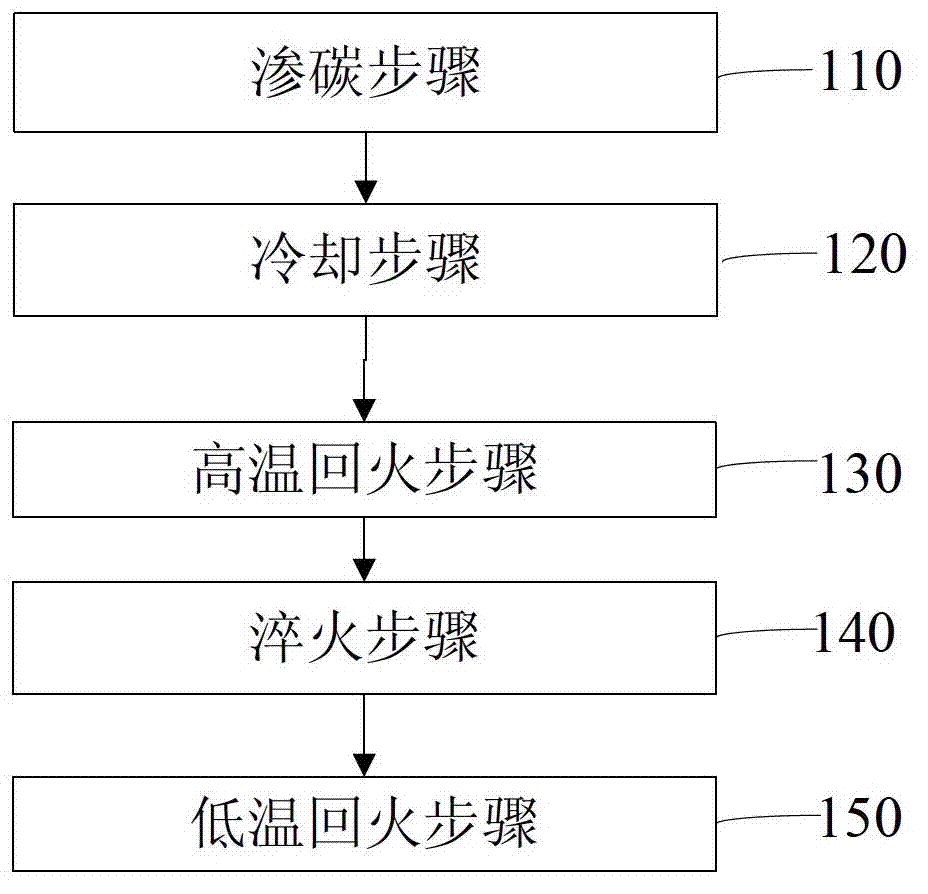

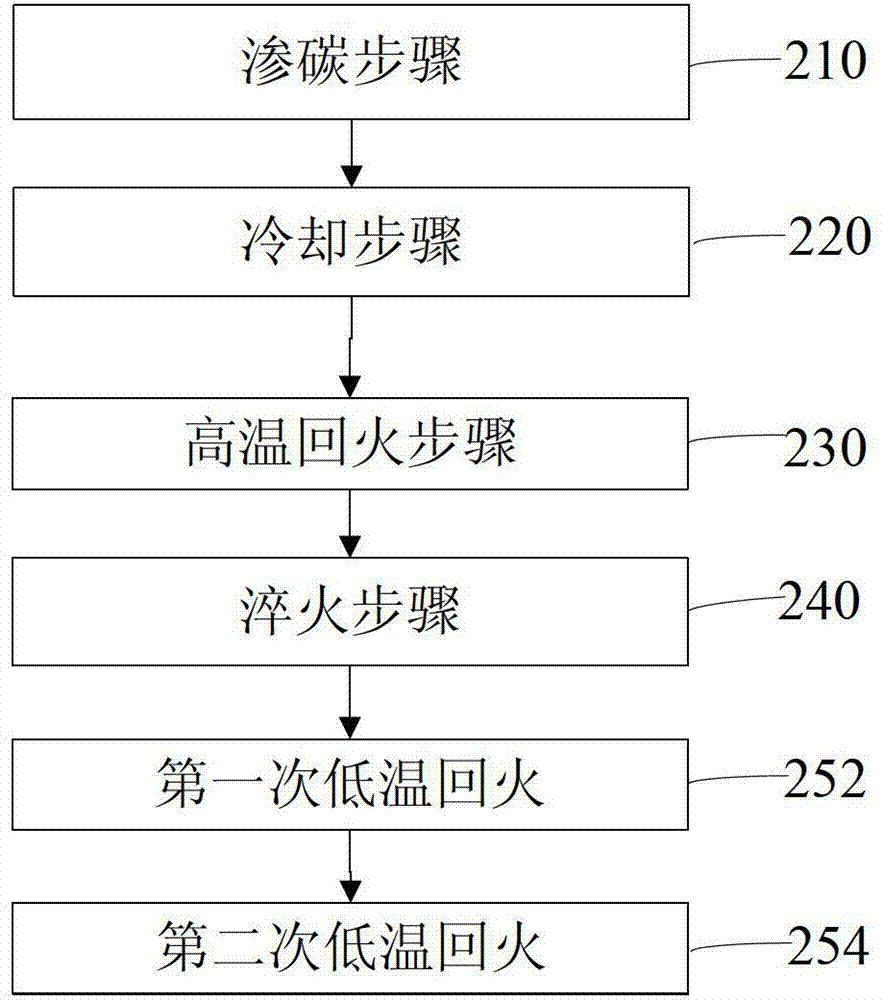

Carburization process for heavy machinery part

InactiveCN103397293AReduce martensitic transformationEliminate fragmentationSolid state diffusion coatingCementation processHot Temperature

The invention discloses a carburization process for a heavy machinery part. The process comprises the following steps of: firstly performing carburization on the part, wherein the carburization temperature is 910-950 DEG C; then cooling, namely cooling the part to 780-800 DEG C, and performing air cooling on the part outside a furnace; then performing high-temperature tempering, wherein the high-temperature tempering temperature is 650-680 DEG C; subsequently, quenching; and performing low-temperature tempering. The carburization process for the heavy machinery part can effectively prevent the generation of grinding cracks, so that the service life of the heavy machinery part can be prolonged.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

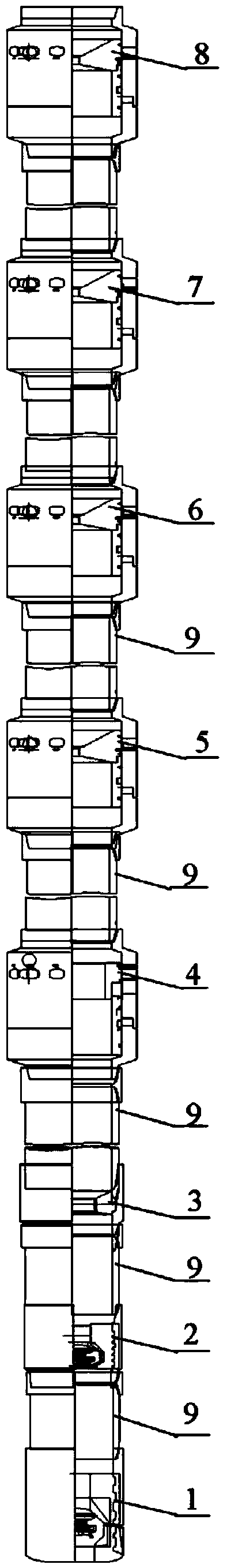

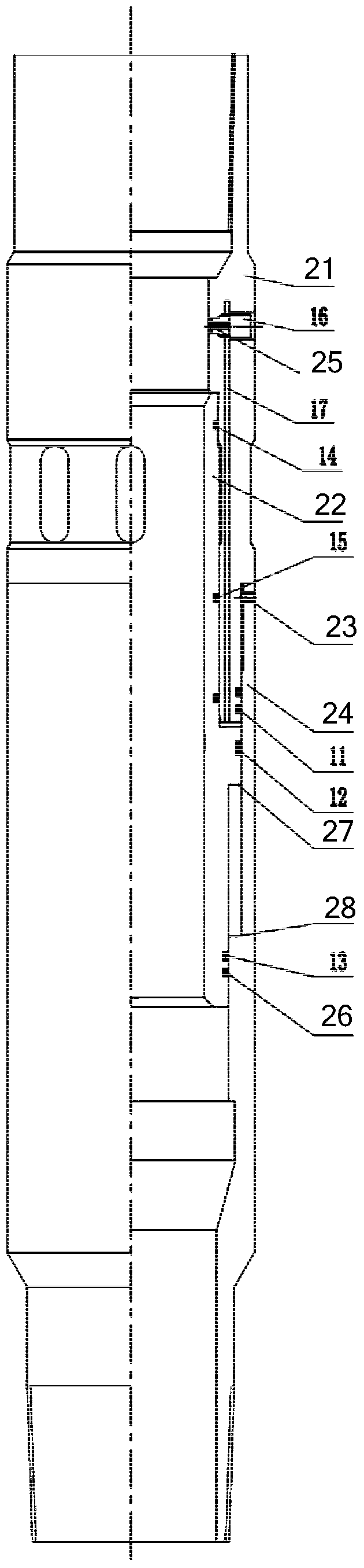

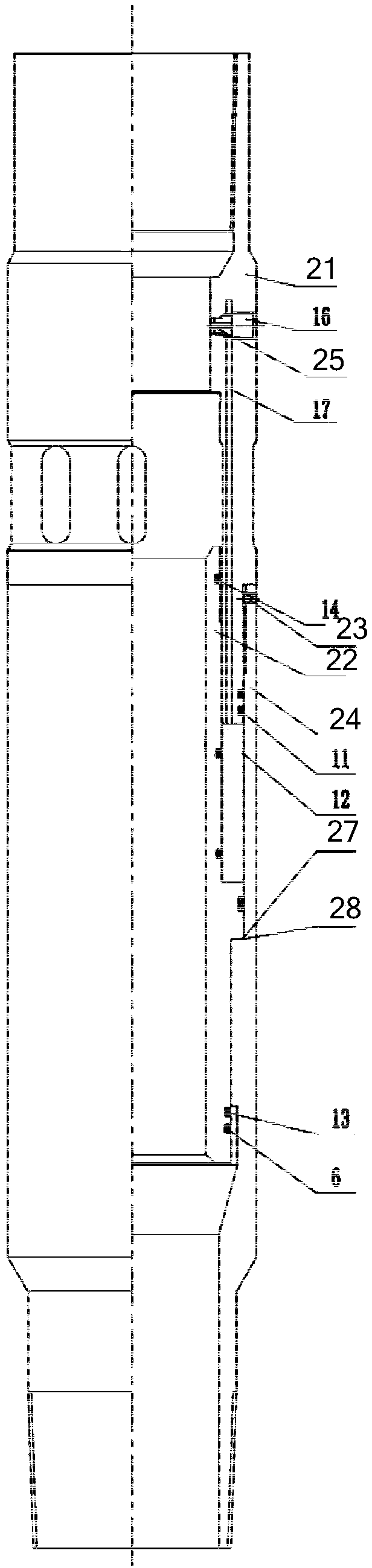

Cementation and fracture technique string and cementation and fracture technique process

The invention discloses a cementation and fracture technique string and a cementation and fracture technique process. The cementation and fracture technique string sequentially comprises a float shoe, a float collar, a collision base, a cementation pressure differential sliding sleeve and a cementation dropping sliding sleeve from bottom to top, wherein the float shoe, the float collar, the collision base, the cementation pressure differential sliding sleeve and the cementation dropping sliding sleeve are connected through a casing pipe, and the cementation pressure differential sliding sleeve is provided with a constant pressure valve. The cementation and fracture technique process comprises the steps of a well cementation process including tripping the cementation and fracture technique string into a wellhead, pouring cement paste into the cementation and fracture technique string, and waiting on cement setting after a rubber plug moves to the collision base, and a fracture process including pressurizing the cementation and fracture technique string from the ground to open the constant pressure valve arranged on the cementation pressured differential sliding sleeve and then performing fracture. The cementation and fracture technique string is low in rigidity, can be tripped into stratums very conveniently, and meanwhile can achieve good packing effects.

Owner:TIANJIN ANTON PETROLEUM MACHINERY MFG

Novel casing pipe restoration reinforcing agent, preparation method and construction method thereof

ActiveCN108546549AReduce viscosityImprove liquidityDrilling compositionBorehole/well accessoriesEpoxyFiber

The invention discloses a novel casing pipe restoration reinforcing agent, a preparation method and a construction method thereof. A formula comprises epoxy resin, curing agents, alloy powder, modified carbon fiber, coupling agents, dispersing agents and organic solvents. The formula provided by the invention can be used for oil gas field casing damage well casing pipe restoration and reinforcement; a grading hoop is used in the well cementation process; the casing pipe pressure-resistant grade cannot meet the oil gas well casing pipe restoration and reinforcement with high high-construction-pressure fracturing construction pressure resistant requirements. The casing pipe restoration reinforcing agent prepared by using the formula and the preparation method can realize the curing at the normal temperature and stratum temperature in a certain time; before curing, the viscosity is low; the flowability is high; the pumping injection is easy; after curing, the intensity and the material are similar to those of the casing pipe; the materials can be well fused with the metal casing pipe; after curing, the sealing effect is good after restoration on the sleeve damage position; the effective period is long; the anti-tension and pressure-resistant intensity is high; the bonding intensity with the metal sleeve is high; the acid and alkali resistance and anti-corrosion performance are realized; the damaged part of the restored casing pipe can be enabled to have the identical inner diameter with the original casing pipe; the diameter shrinkage and the diameter change cannot occur; thelater stage taking out tools and pipe columns are not influenced.

Owner:谢翠娥 +1

Followed vibration well cementation method

ActiveCN102108846AReach standbyOvercoming a single functionVibration devicesSealing/packingThermodynamicsWell cementing

The invention discloses a followed vibration well cementation method. In the method, in the well cementation process, a rubber plug moves in a sleeve downwards and simultaneously vibrates, and after the rubber plug moves downwards to the well bottom and touches and presses a float collar to make the float collar stop, the rubber plug continuously vibrates until cement slurry is about to be jelled. Through the method, the followed vibration in the whole well section from the well mouth to the well bottom can be implemented, the defect of single function of the rubber plug is overcome, and the aim of moving the sleeve of the whole well section is fulfilled, so that the sleeve and cement interface cementing quality is improved, the cement stone strength is improved and better application effect is achieved; and on the basis of not changing the conventional production and construction processes, the replacement function of the conventional rubber plug is still utilized, a sleeve resonanceprinciple is applied, and when the rubber plug moves in the sleeve, the followed vibration in the whole well section from the well mouth to the well bottom is implemented, so that the defect of single function of the rubber plug is overcome, vibration waves having the frequency same as the natural frequency of the sleeve of the oil well can be generated, and the well cementation quality is effectively and obviously improved.

Owner:XIAN MANYUAN ELECTROMECHANICAL EQUIP CO LTD +1

Steel plate multicomponent alloy co-cementation method

The invention relates to a heat treatment processing method for steel plate multicomponent alloy co-cementation, overcoming the shortcoming that anti-corrosion performance can not be achieved in the current heat treatment co-cementation process. The method comprises the following steps: 1, adding cementation promoter and floating balls into prepared powdery co-cementation alloy elements which comprise 1.5-2% of Zn powder, 0.2-0.7% of Al powder and 0.05-0.2% of rare earth powder by weight percent; 2, putting steel plates to be subject to heat treatment to a co-cementation furnace and then fixing, putting the co-cementation alloy elements into the co-cementation furnace, and then sealing the co-cementation furnace, wherein the steel plates are spaced and arranged in parallel; 3, vacummizing the co-cementation furnace and simultaneously starting to heat until 400-500 DEG C, insulating for 6-8 hours, and then cooling down slowly; and 4, taking the steel plates out of the furnace and carrying out anti-corrosion test comprising thickness test and rusty spot test. Through the co-cementation heat treatment, the alloy elements are cemented into the surfaces of the steel plates to form anti-corrosion layers, and the size of the steel plates is not changed, and the formed anti-corrosion layers have better effects.

Owner:浙锚科技股份有限公司

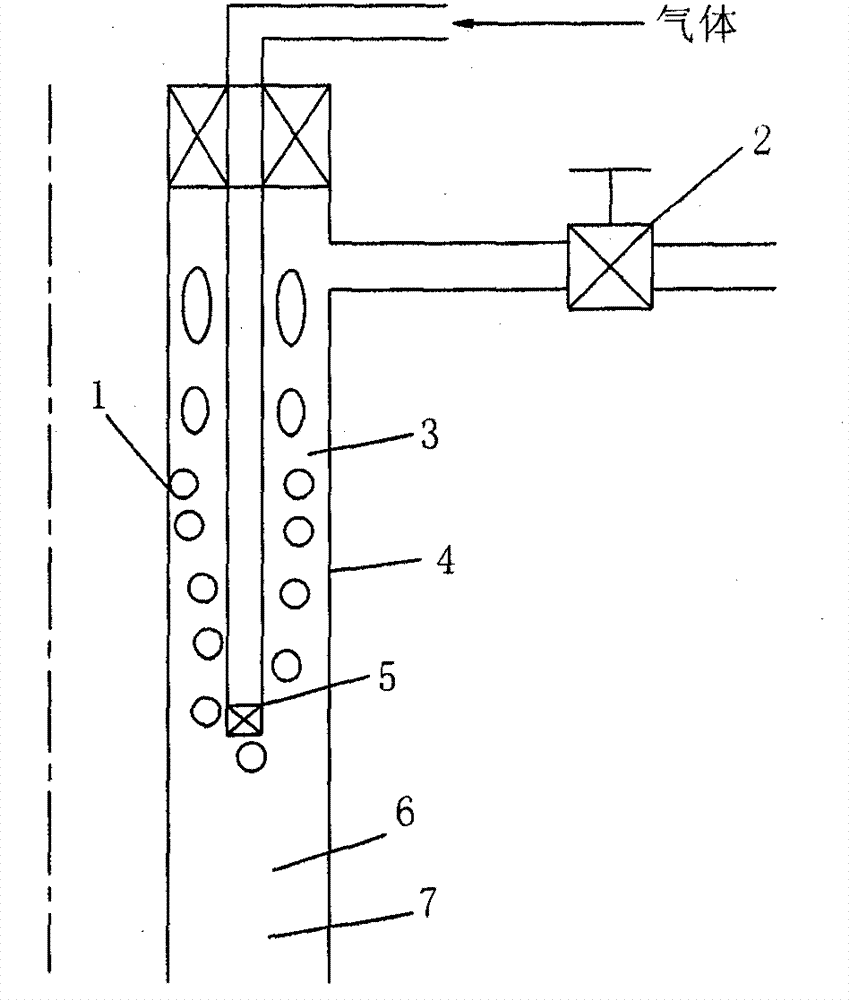

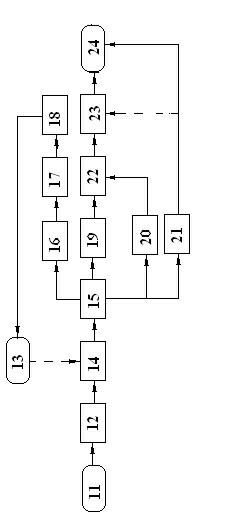

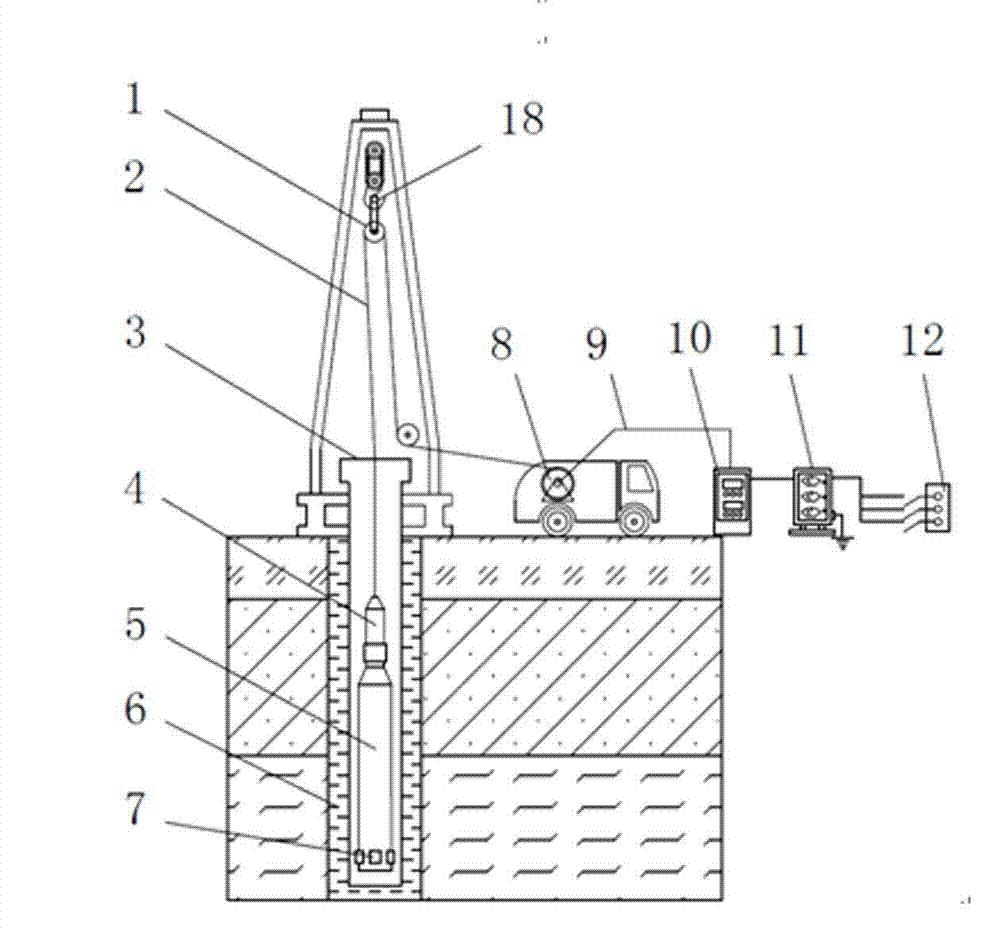

Vibration well cementation device and vibration well cementation method

The invention discloses a vibration well cementation device and a vibration well cementation method. The vibration well cementation device mainly comprises a cable, a transformer and a vibrator. The vibration well cementation method includes demounting a cement head after well cementation slurry is replaced and pressing is finished, and extending the vibrator and the cable into a casing; starting the transformer and the vibrator to vibrate in an appointed well depth; letting the vibrator to go up or down as vibrating; stopping vibration of the vibrator and lifting the vibrator out of a well mouth when initial solidification time of cement slurry of a vibrating layer is up. Under the condition of having no influence on conventional well cementation process, annulus cement slurry is vibrated within the full range of the casing by a manner of transmitting vibration wave and beating the casing during cementation, flowing deformation characteristics of the cement slurry are improved, and well cementation quality is improved.

Owner:CHINA PETROCHEMICAL CORP +1

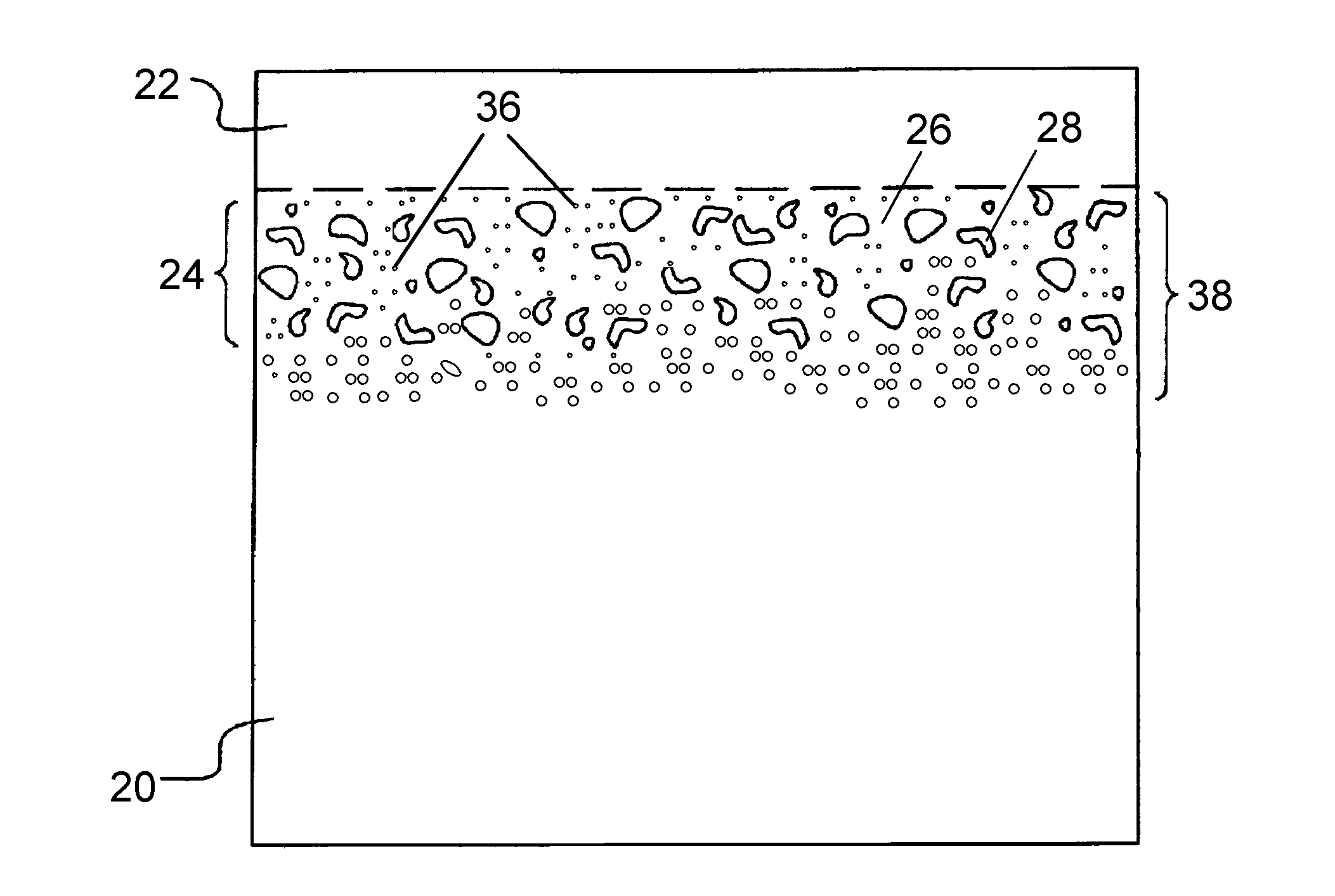

Carburization process for stabilizing nickel-based superalloys

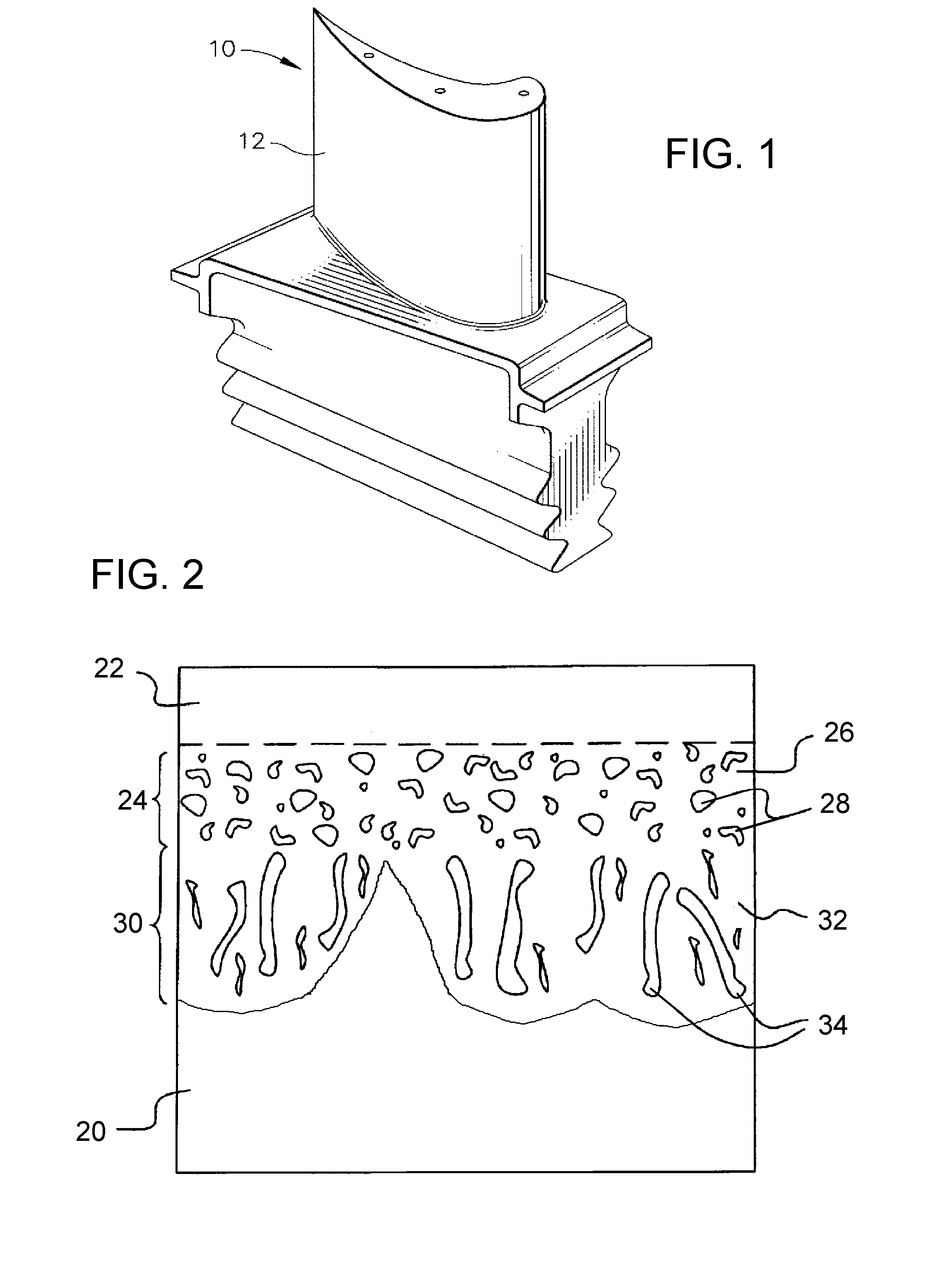

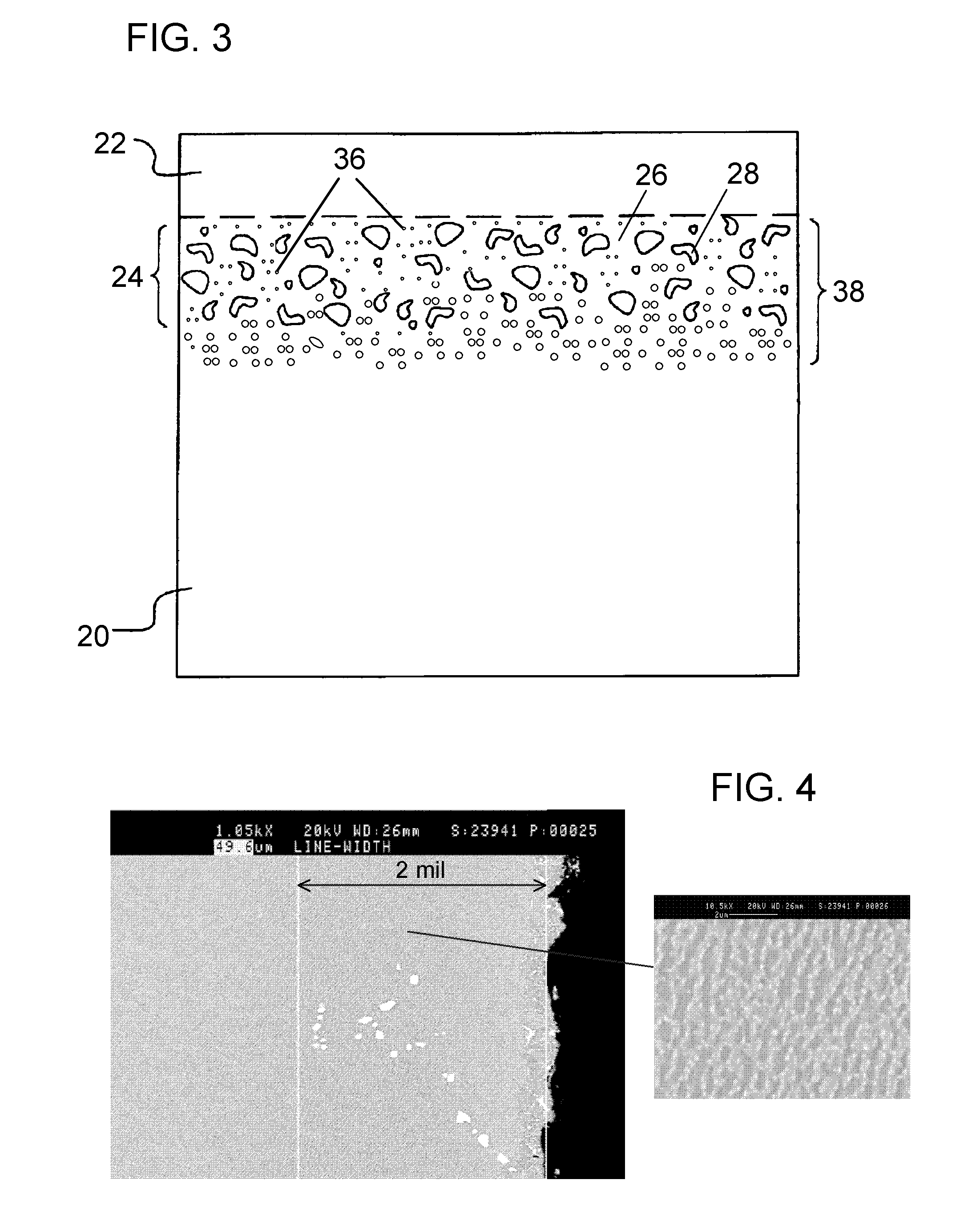

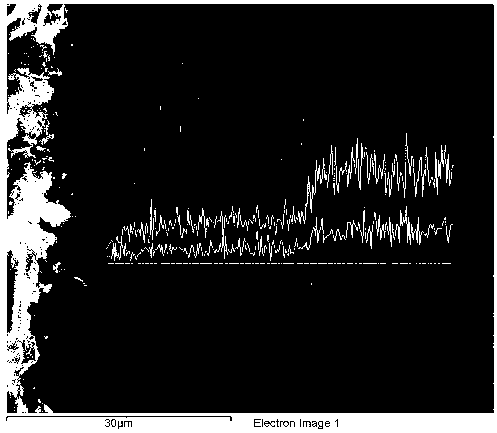

InactiveUS20100276036A1Solid state diffusion coatingSuperimposed coating processCementation processNickel based

A process by which a nickel-based superalloy substrate prone to deleterious reactions with an aluminum-rich coating can be stabilized by carburization. The process generally entails processing the surface of the substrate to be substantially free of oxides, heating the substrate in a non-oxidizing atmosphere to a carburization temperature, and then contacting the surface of the substrate with a carburization gas mixture comprising a diluted low activity hydrocarbon gas while maintaining the substrate at the carburization temperature. While at the carburization temperature and contacted by the carburization gas, carbon atoms in the carburization gas dissociate therefrom, transfer onto the surface of the substrate, diffuse into the substrate, and react with refractory metals within the substrate to form refractory metal carbides within a carburized region beneath the surface of the substrate. The substrate is then cooled in a non-oxidizing atmosphere to terminate carbide formation.

Owner:GENERAL ELECTRIC CO

Industrial waste coagulating agent and goaf filling material using same

The invention provides an industrial waste coagulating agent which comprises 3-20 wt% of sodium sulfate, 10-80 wt% of gypsum, 0-20 wt% of silica fume, 0-30 wt% of quick hardening cement, 5-75 wt% of alum and 2-10 parts of quick lime. Under the synergistic effect of all components and the condition that no or few cementitious materials are added, a cementation process of industrial waste can be completed by activating the activity of industrial waste and using effective components in industrial waste, a solidification body meeting the strength requirement of the goaf filling material is formed, the cost is low, and indirect discharge of waste cannot be caused. The goaf filling material comprises industrial waste and the industrial waste coagulating agent in a mass ratio of (3:1)-(15:1), the usage amount of the industrial waste coagulating agent is small, the cost is low, indirect discharge of waste cannot be caused, industrial waste can be effectively and reasonably used, and sustainable development of industrial production and economy is guaranteed.

Owner:南京坤元材料有限公司

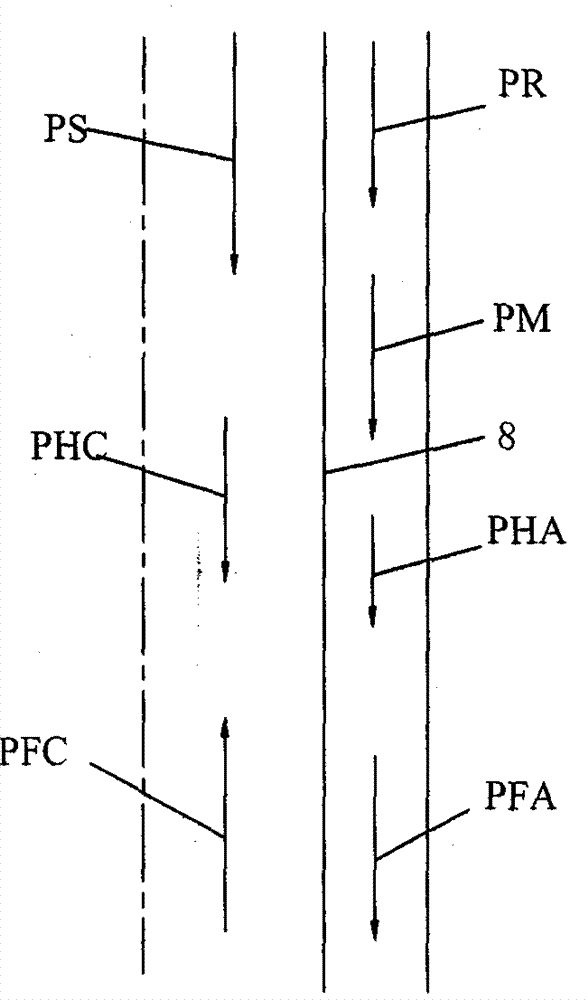

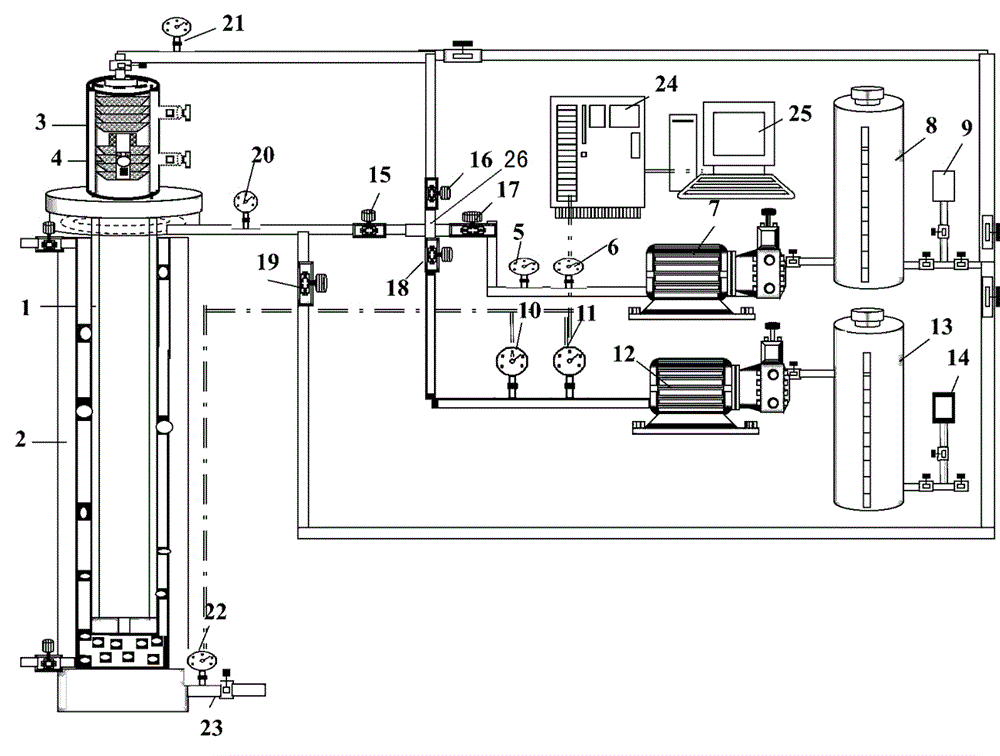

Experimental method of simulating cementing in well cementation process

InactiveCN104863541AIncrease motivationDeepen understandingConstructionsFlushingExperimental methodsCementation process

The invention relates to an experimental method for simulating cementing in a well cementation process. The experimental method comprises the following steps: firstly assembling experimental equipment, wherein the experimental equipment comprises a shaft simulating system, a drilling fluid circulating system, a cementing system and a computer data processing system, and the shaft simulating system comprises an inner organic glass tube for simulating a drill column, an outer organic glass tube for simulating a casing pipe, an internal rotating motor and a check valve; secondly, simulating drill fluid direct circulation, direct circulation of cementing in the well cementation process, drill fluid reverse circulation, and reverse circulation of cementing in the well cementation process. The experimental method has the benefits as follows: the method is simple and easy to operate, students can personally carry out simulation operations, so as to understand direct circulation of cementing in the well cementation process, reverse circulation of drill fluid and reverse circulation of cementing intuitively and visually, the enthusiasm of the students for learning can be kindled, and the understanding and mastering of students for direct circulation of cementing and reverse circulation of cementing in the well cementation process can be deepened.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Stainless steel low-temperature powder embedding iron-aluminum co-cementation agent and pack-cementation process method

InactiveCN103266298AImprove protectionImprove bindingSolid state diffusion coatingPtru catalystIron powder

The invention discloses a stainless steel low-temperature powder embedding iron-aluminum co-cementation agent and a pack-cementation process method. The stainless steel low-temperature powder embedding iron-aluminum co-cementation agent is characterized in that aluminum powder is taken as main an aluminum supplying agent, iron powder is a main iron supplying agent, iron-aluminum powder is taken as active filler to replace the conventional inactive ceramic powder filler, aluminum trichloride is taken as an activating agent, and a small amount of rare earth chloride can be added to be used as a catalyst; and a process comprises the following steps of: completely and uniformly mixing the cementation agent, then putting the cementation agent and a stainless steel sample to be subjected to iron-aluminum copermeation processing into a cementation tank, mixing sodium silicate with fire clay, carrying out sealing and drying, so as to obtain an iron-aluminum compound alloy layer with the certain thickness, wherein the alumetizing temperature is 380-600 DEG C, and the temperature is kept for 10 or more than 10 hours. The stainless steel low-temperature powder embedding iron-aluminum co-cementation agent has the advantages that the process method is simple, devices required for low-temperature embedding iron-aluminum co-cementation are simple, the cost is low, the aluminum content of the surface of the obtained iron-aluminum compound alloy layer is high, the iron-aluminum compound alloy layer has a very strong binding force with a matrix and good intermediate temperate oxidation resistance and corrosion resistance and can well protect the matrix.

Owner:NANCHANG HANGKONG UNIVERSITY

Sectioned well cementation technology for deep trona drilling and mining

InactiveCN108361001ASolve the problem of not being able to returnSolve the problem of not being able to return cementSealing/packingWell drillingWell cementing

Owner:HENAN ZHONGYUAN CHEM

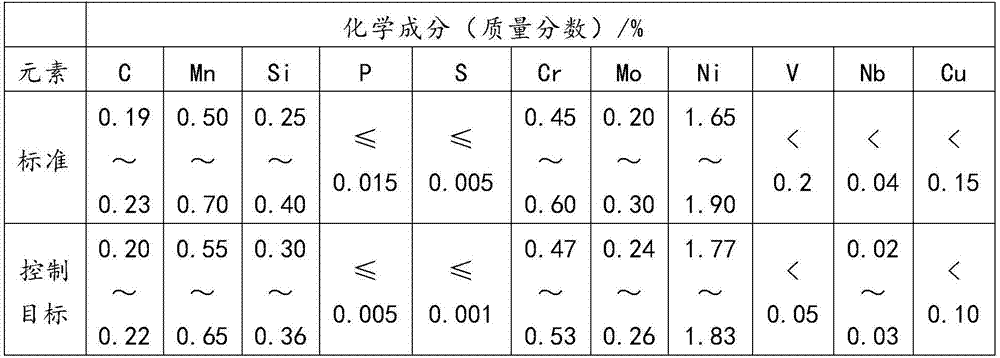

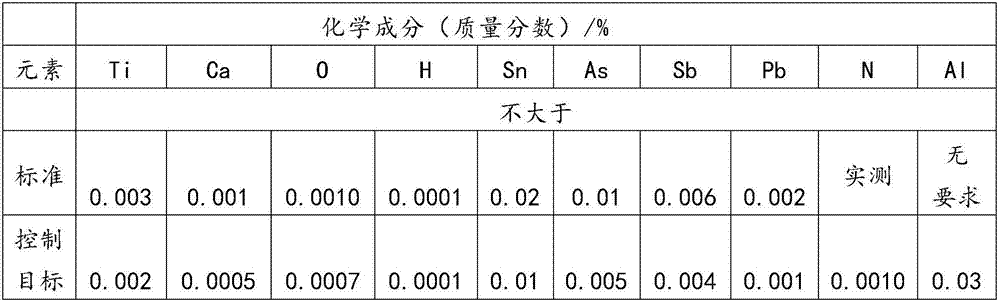

Method for manufacturing carburization bearing steel for high speed train

The invention discloses a method for manufacturing carburization bearing steel for a high speed train and aims to reduce contents of aluminum and titanium in steel to the minimum, reduce content of gas in steel and produce the ultrapure and ultra-fine grain carburization bearing steel with ultralow gas content through selecting specially-made high-purity ingot iron and pure metal charge and adopting vacuum induction + vacuum self-consuming smelting process. The method has the following advantages: the ultrapure carburization bearing steel with ultralow gas content is obtained, wherein content of hydrogen is not greater than 0.0001%, content of oxygen is not greater than 0.0006%, content of nitrogen is not greater than 0.0009%, content of fine series inclusions of A category, B category, C category and D category of nonmetallic inclusions is not greater than grade 1.0, content of Ds category is grade 0.5, and other types of inclusions are not contained; the grain size grade is grade 7.0 or above after the cementation process is adopted for treatment.

Owner:FUSHUN SPECIAL STEEL SHARES +2

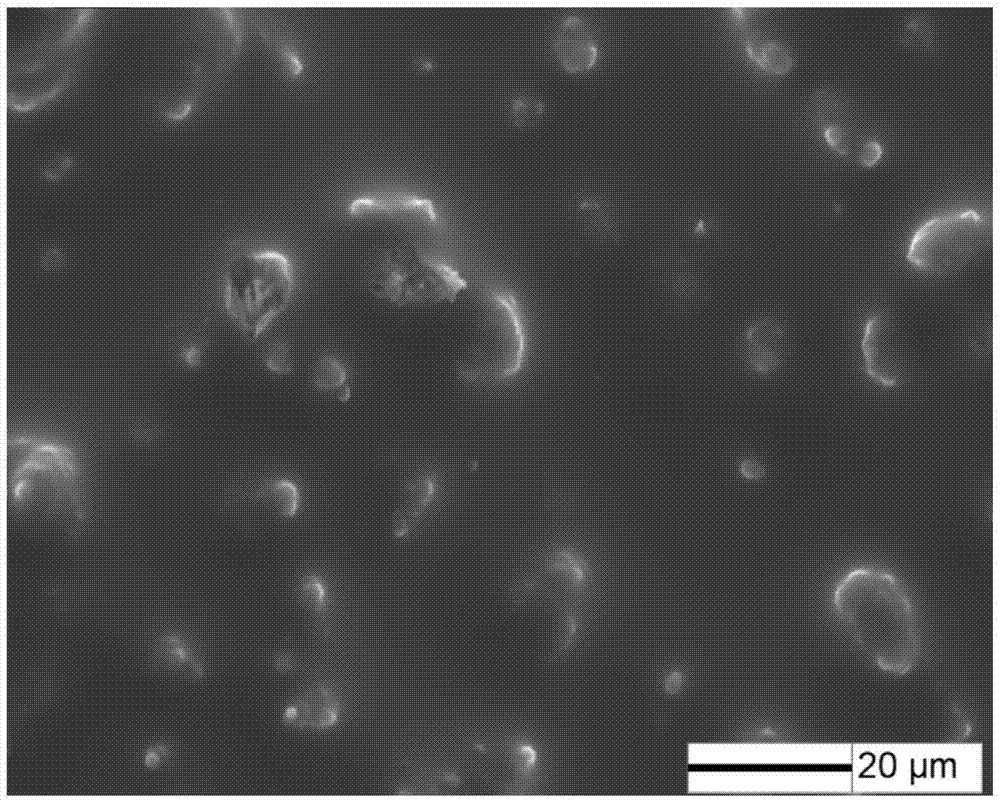

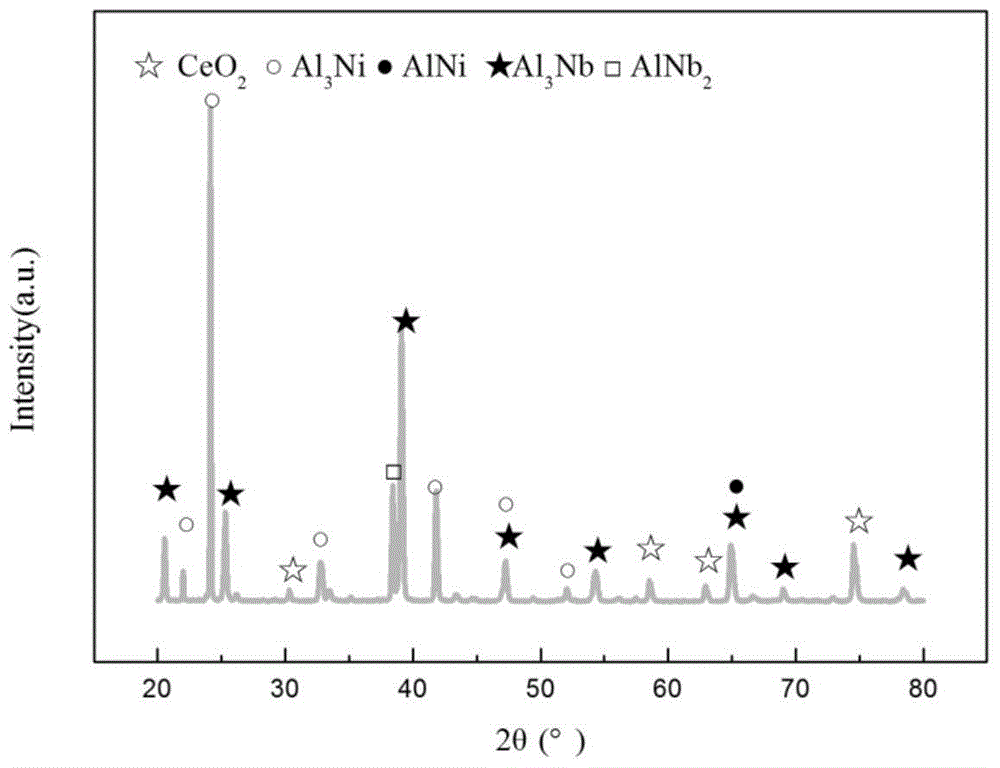

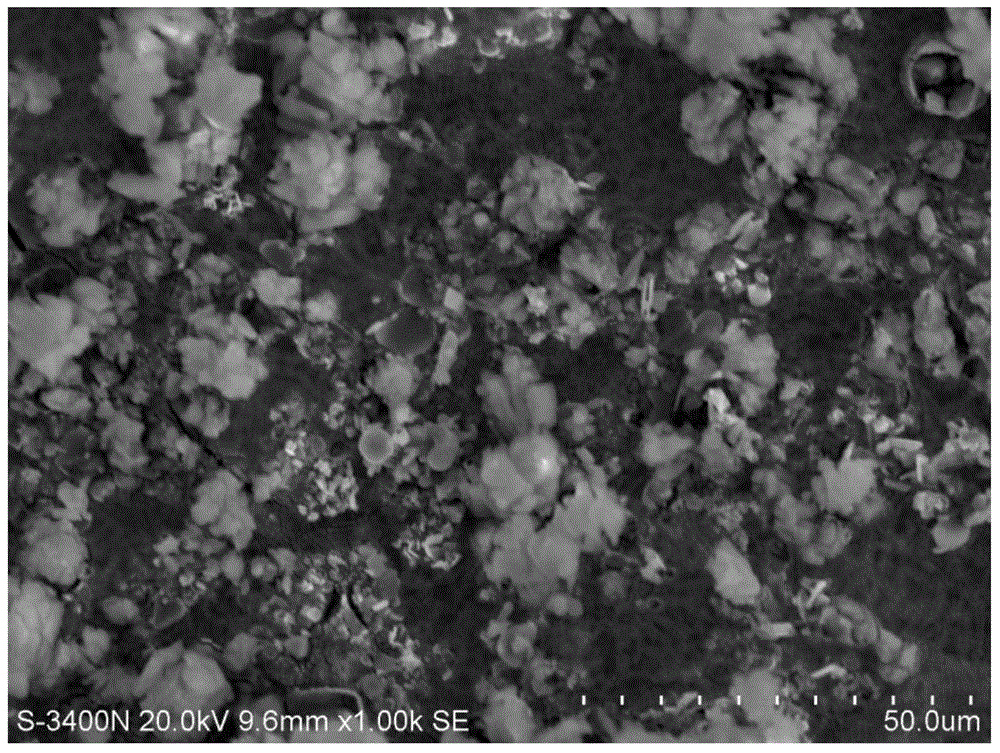

Method for preparing micrometer-particle-contained high-temperature-oxidation-resistant composite coating on surface of niobium alloy

InactiveCN105177536AImprove bindingExtended service lifeSolid state diffusion coatingLiquid/solution decomposition chemical coatingChemical platingMicrometer

The invention discloses a method for preparing a micrometer-particle-contained high-temperature-oxidation-resistant composite coating on the surface of niobium alloy. The method comprises the steps that firstly, a Ni-CeO2 plating is deposited on a substrate through a composite chemical plating process; and an Al-rich penetration layer is deposited on the plating through a pack cementation process, and the composite coating is formed. The composite coating prepared through the method can be well combined with the substrate, the coating is uniform and compact and good in high-temperature oxidation resistance and can bear oxidation at the temperature at 1200 DEG C, the service life of the coating is prolonged, and the process is simple.

Owner:GUANGXI UNIV +1

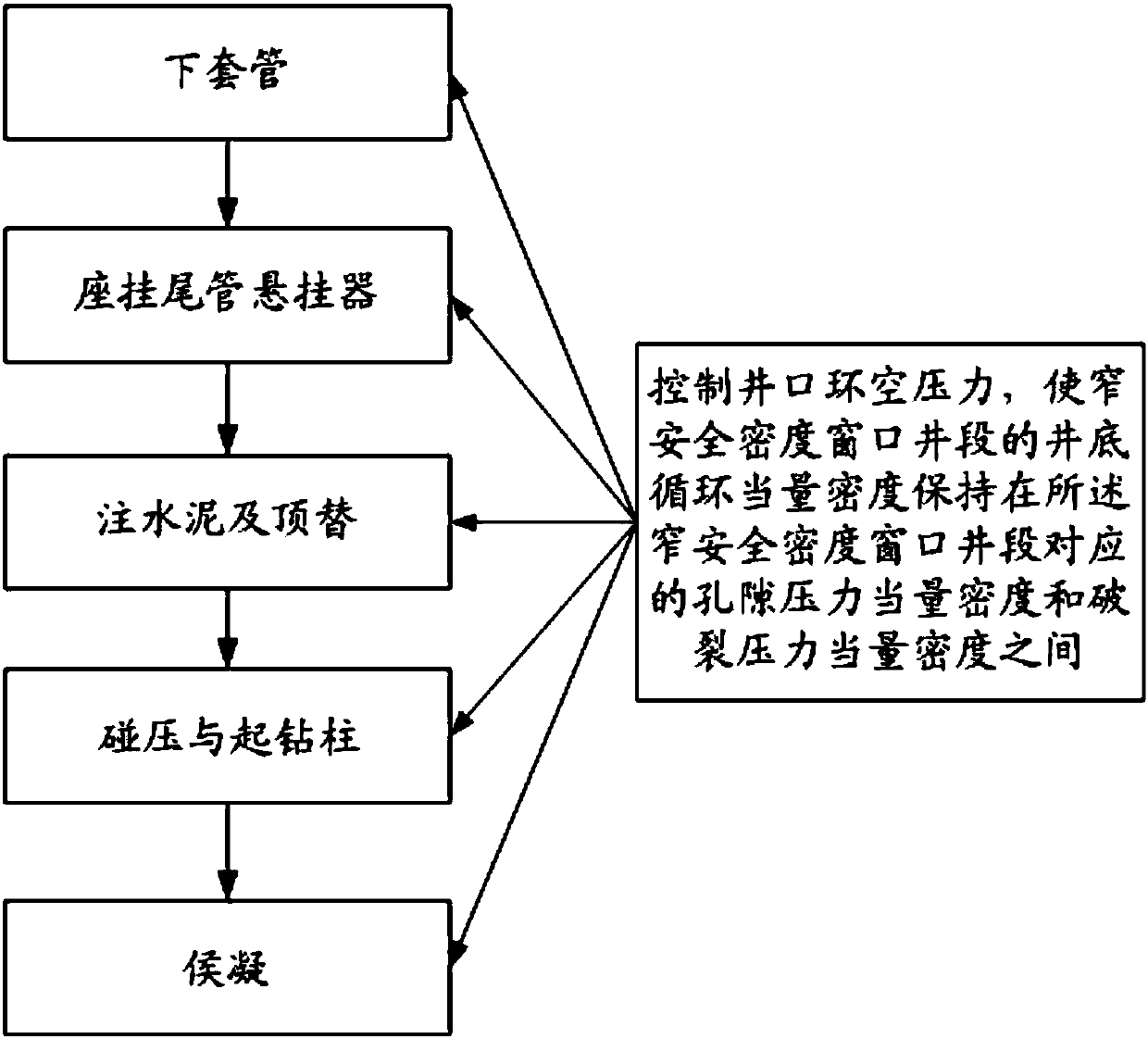

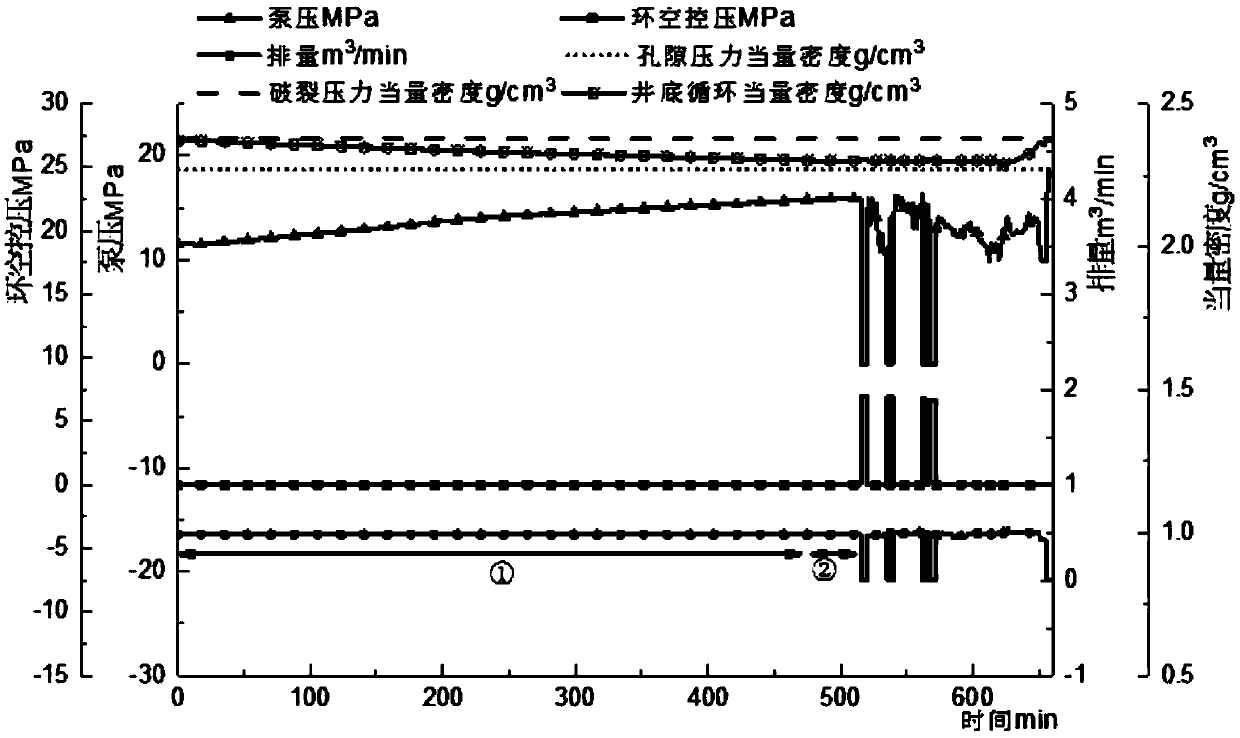

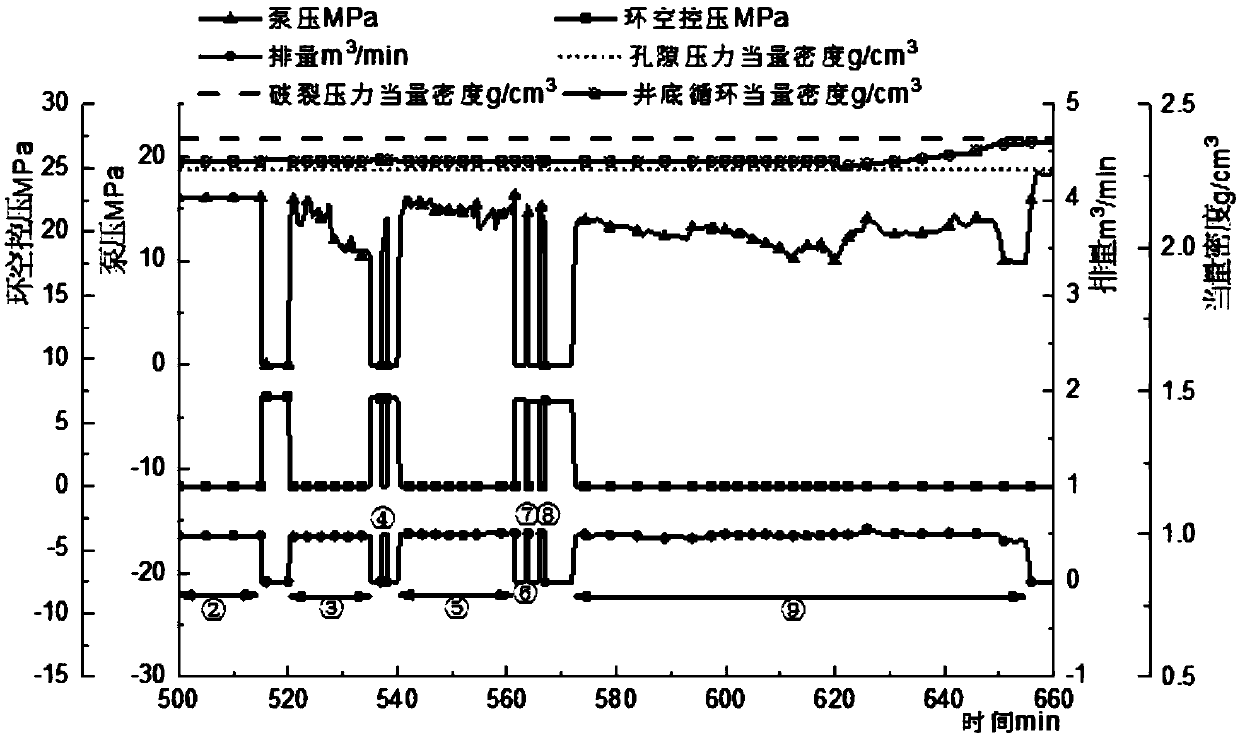

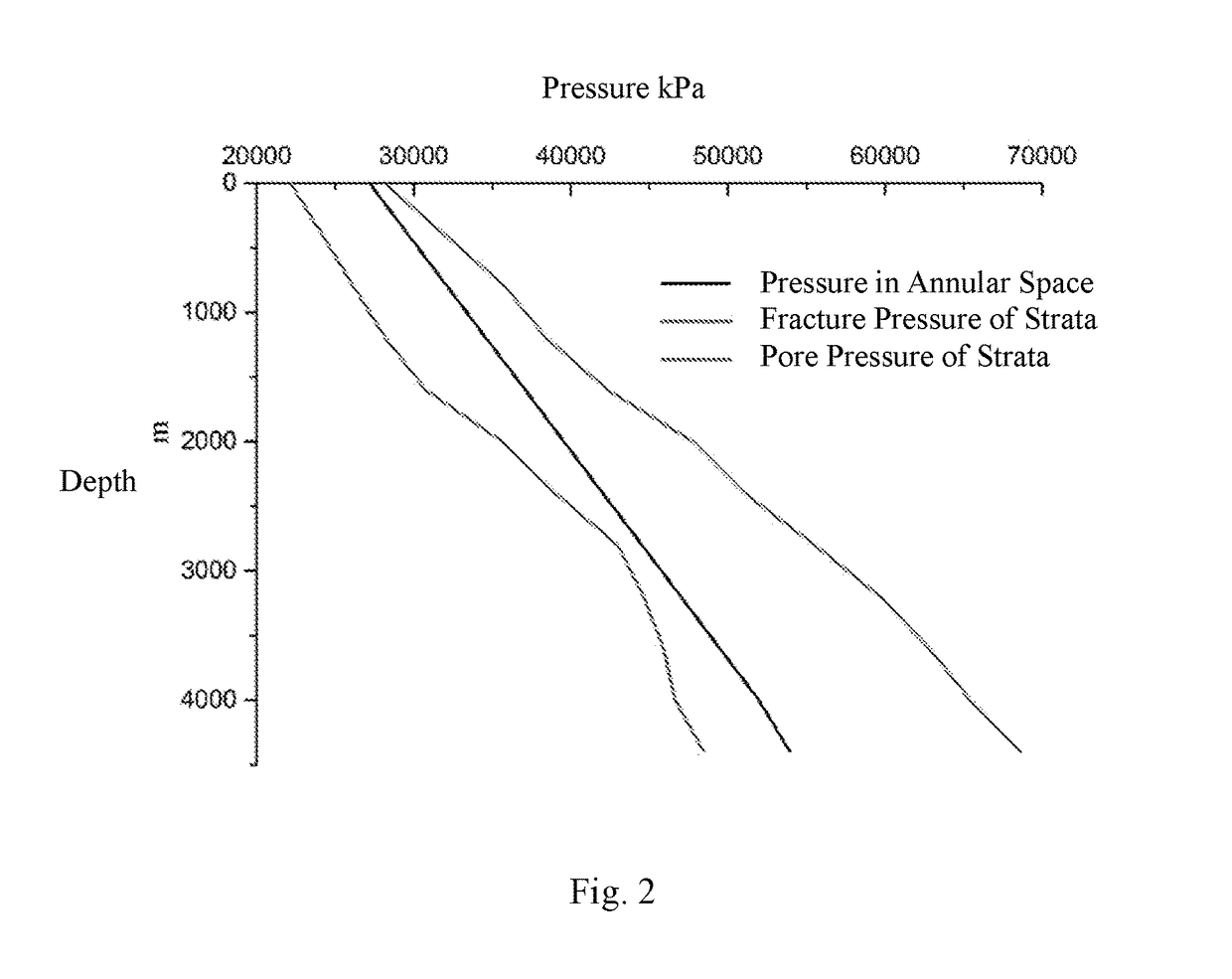

A drilling liner pressure control well cementation process

InactiveCN109723403AReduce the risk of cementing constructionReduce construction riskSealing/packingWell cementingCementation process

The invention discloses a drilling liner pressure control well cementation process, and belongs to the technical field of oil and gas development well cementation. The drilling liner pressure controlwell cementation process sequentially comprises a casing running stage, a drilling liner hanger seating and hanging stage, a cementing and replacing stage, a bump pressure and drill string pulling-outstage and a setting waiting stage. In the casing running stage, the drilling liner hanger seating and hanging stage, the cement injecting and replacing stage, the bump pressure and drill string pulling-out stage and the waiting stage, the well bottom circulation equivalent density of the narrow safety density window well section is kept between the pore pressure equivalent density and the rupturepressure equivalent density corresponding to the narrow safety density window well section by controlling the wellhead annulus pressure. According to the well cementation technology, through wellheadannulus pressure control, the well bottom circulation equivalent density corresponding to the narrow safety density window well section is made to be between the pore pressure equivalent density andthe rupture pressure equivalent density, it is guaranteed that a pressure-bearing weak stratum is not pressed to leak while the oil and gas display layer is pressed stably, the drilling liner well cementation construction risk is reduced, and the well cementation quality is improved.

Owner:PETROCHINA CO LTD

Well cementation process suitable for gas field

InactiveCN110984905AImprove pressure bearing capacityImprove cementing qualityProductsReagentsWell cementingCementation process

The invention discloses a well cementation process suitable for a gas field. The well cementation process comprises the following steps of injecting drilling fluid into a well to perform a pressure-bearing test, and performing leaking stoppage for a leaked stratum if leakage occurs in the well; driving a sleeve to the well bottom, and filling mud into a position between the well wall and the sleeve; sequentially injecting prepad fluid, first well cementation fluid and second well cementation fluid into the sleeve, then, starting to release a rubber plug, and utilizing the rubber plug to scrapeoff the first well cementation fluid and the second well cementation fluid on the inner wall of the sleeve; and injecting plug pressing fluid into the sleeve until touching and pressing happen, and ending well cementation. The pressure-bearing test is performed before the sleeve is driven in, and leakage prevention and stoppage are performed on the leaked stratum, so that pressure-bearing abilityof a well shaft can be improved.

Owner:SHAANXI YANCHANG PETROLEUM GRP

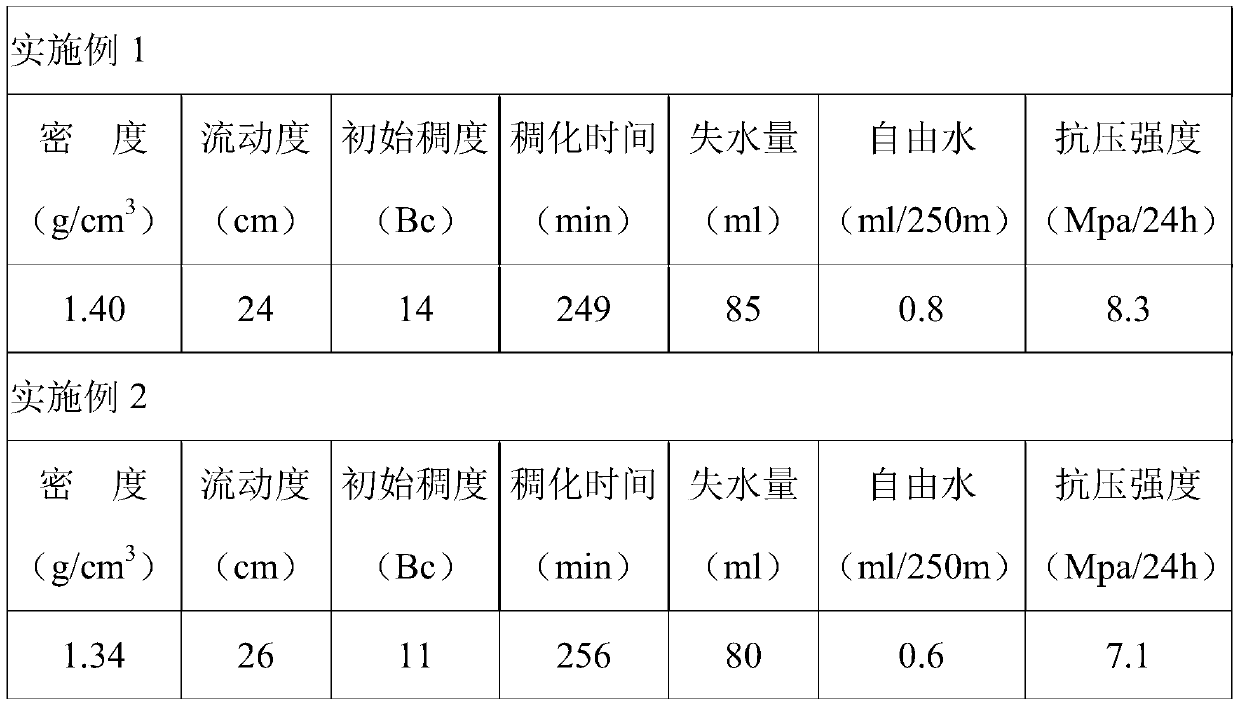

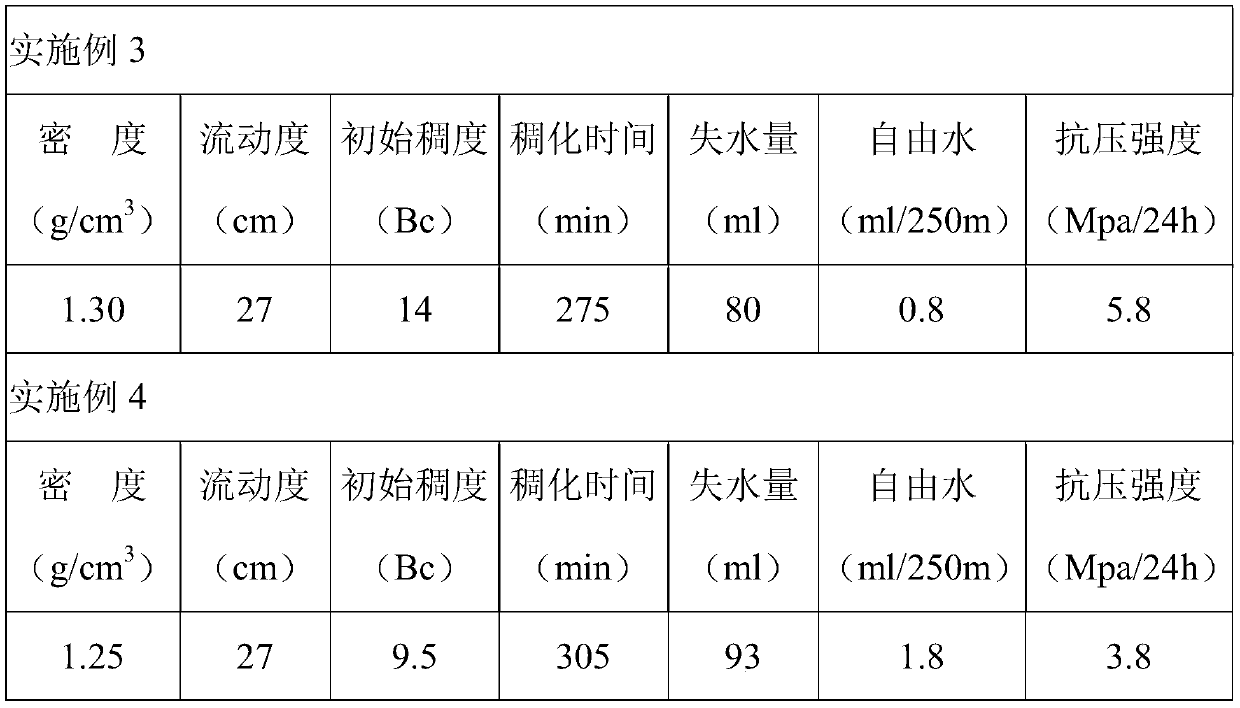

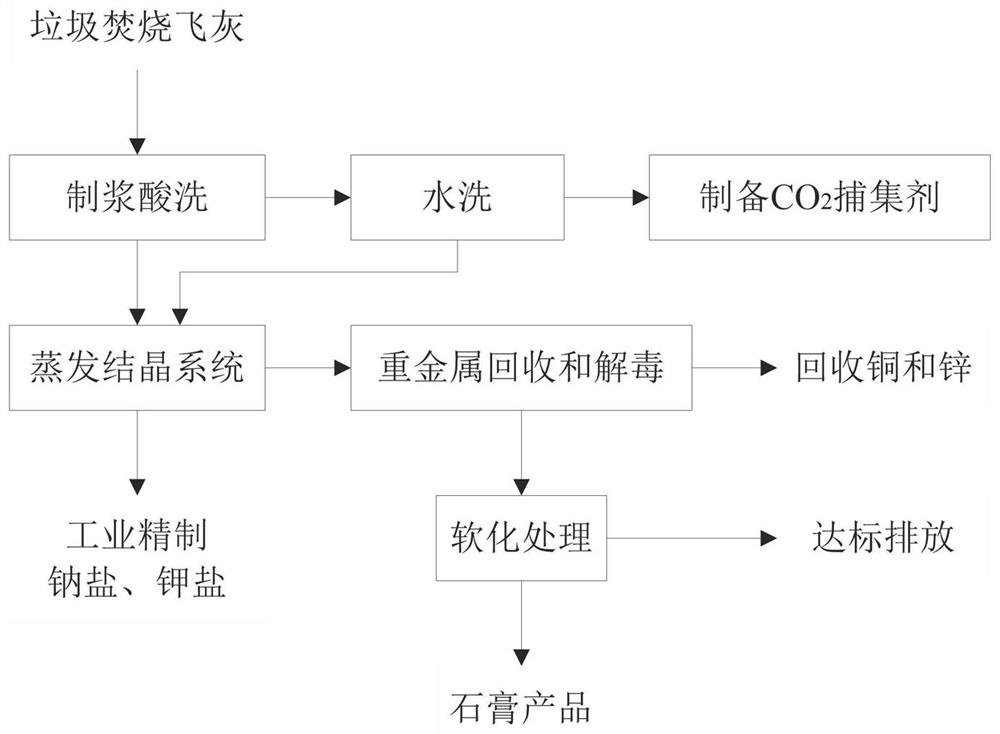

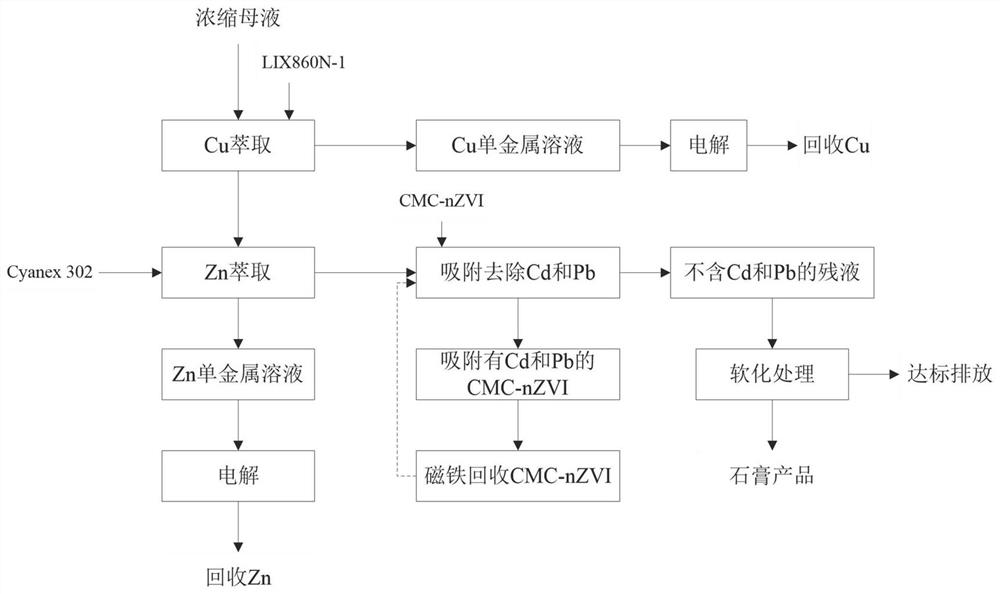

Household garbage incineration fly ash reduction recycling treatment method

InactiveCN112391534APrevent oxidationImprove leaching ratePhotography auxillary processesCalcium/strontium/barium sulfatesSlurryCementation process

The invention discloses a household garbage incineration fly ash reduction recycling treatment method. Garbage incineration fly ash serves as hazardous waste, but heavy metal in the garbage incineration fly ash has the huge potential and value of recycling. The method comprises the following steps that 1, fly ash, acid and an oxidizing agent are jointly added into a pickling tank to be stirred andmixed, and pickling slurry is generated; 2, the pickling slurry is subjected to solid-liquid separation, and pickling liquid and pickling waste residues are obtained; and 3, after the pickling wasteresidues are washed, ash residues capable of being recycled are obtained. According to the method, the acid leaching technology is optimized in the manner of adding the oxidizing agent; and the oxidizing agent is added, the oxidizing condition can be maintained in the whole leaching period, the oxidation-reduction potential is constantly kept in the state larger than 300mV, accordingly, the situation that metal components in the slurry are oxidized, and consequently PbCu0 alloy is formed in the reduction cementation process is prevented, and the leaching rate of Pb, Cu, Cd and Zn ions is obviously increased.

Owner:杭州灰弘环保科技有限公司 +1

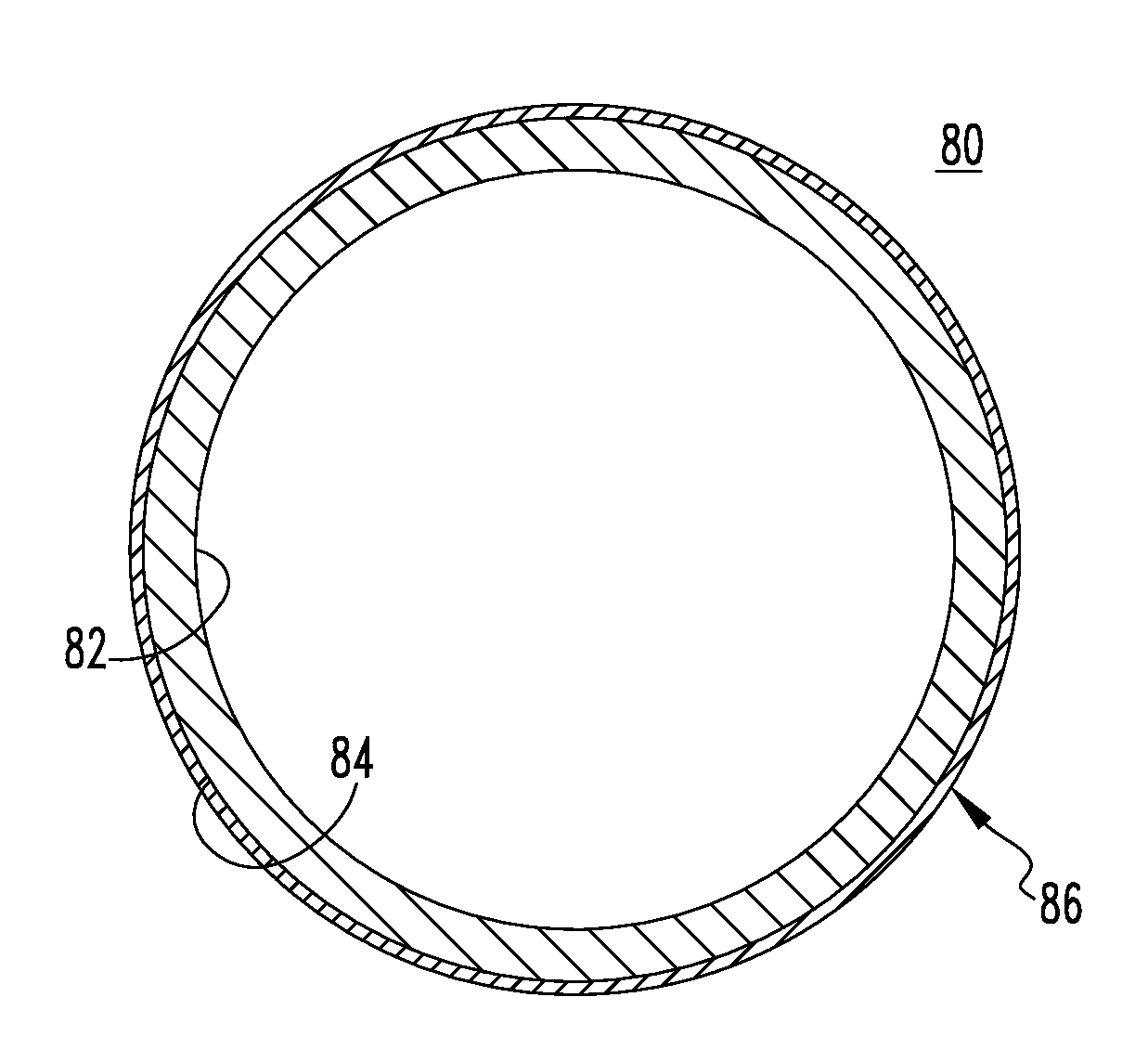

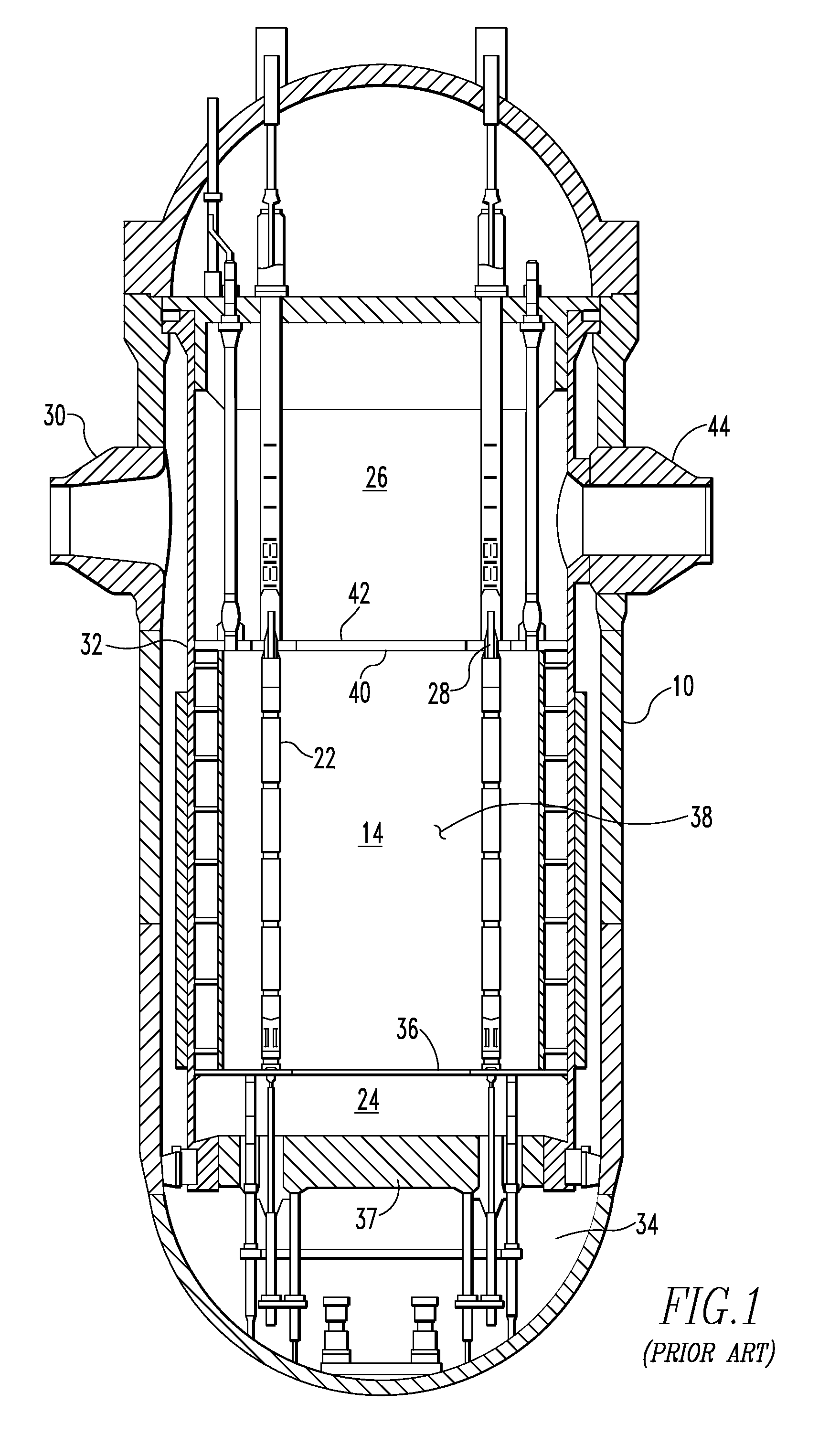

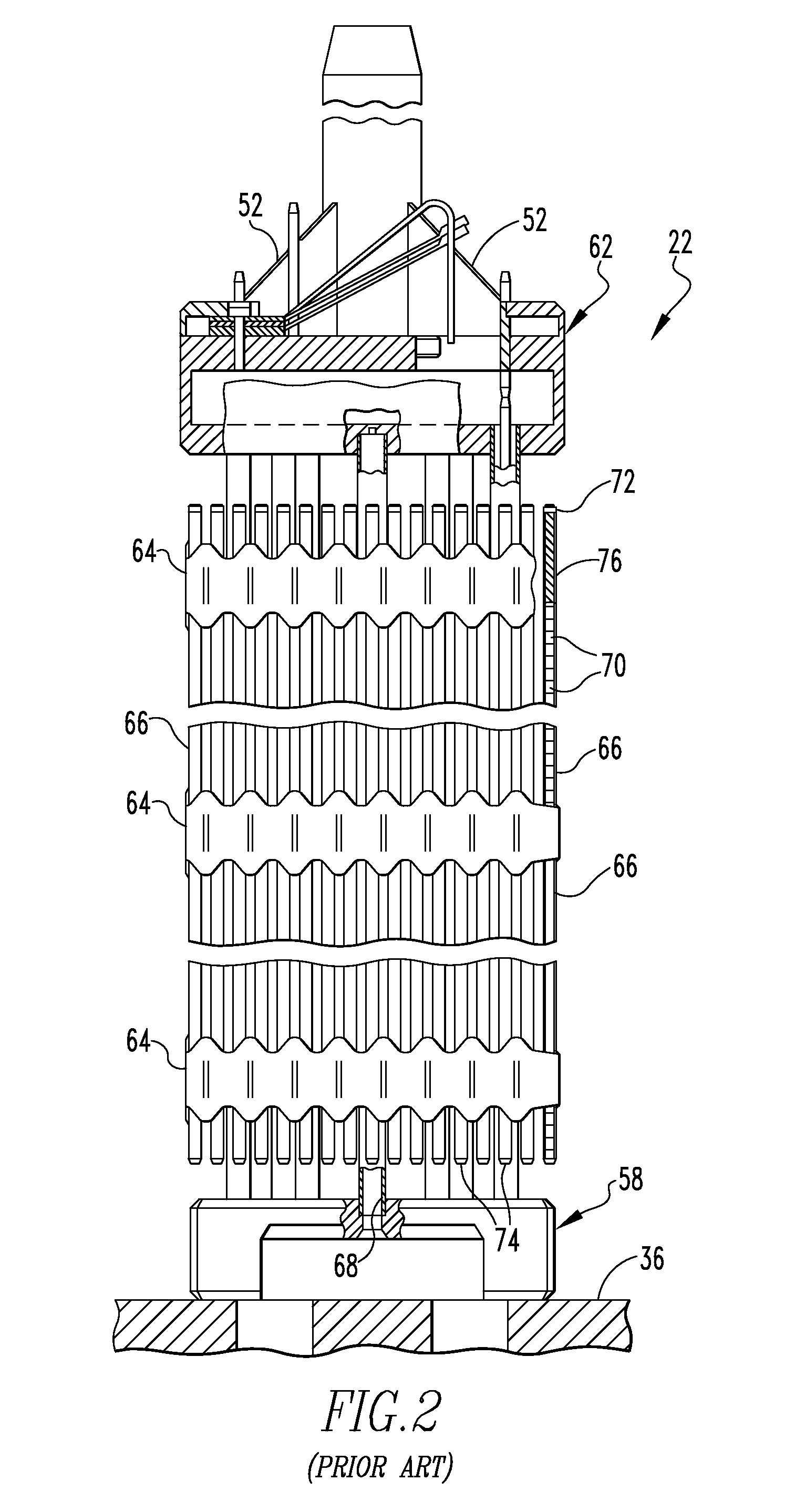

Corrosion and wear resistant coating on zirconium alloy cladding

The invention relates to compositions and methods for coating a zirconium alloy cladding of a fuel element for a nuclear water reactor. The composition includes a master alloy including one or more alloying elements selected from chromium, silicon and aluminum, a chemical activator and an inert filler. The alloying element(s) is deposited or are co-deposited on the cladding using a pack cementation process. When the coated zirconium alloy cladding is exposed to and contacted with water in a nuclear reactor, a protective oxide layer can form on the coated surface of the cladding.

Owner:WESTINGHOUSE ELECTRIC CORP

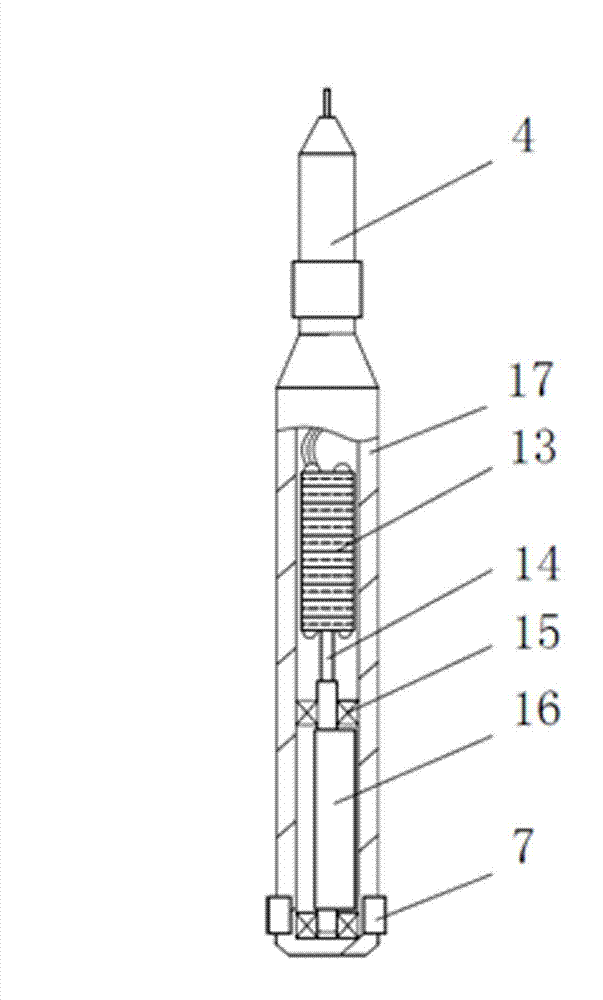

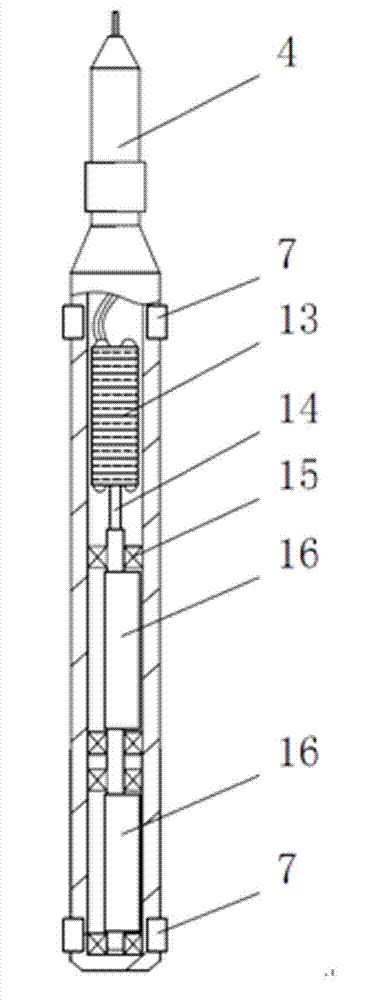

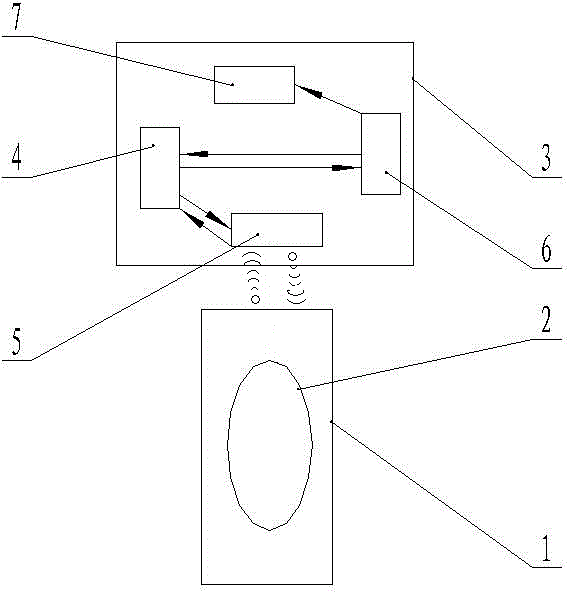

Device for tracking and positioning rubber plug through sonar

InactiveCN103913743AReduce complicationsImprove the success rate of cementingConstructionsAcoustic wave reradiationEngineeringCementation process

The invention relates to a complete unit used for tracking and positioning a rubber plug through a sonar system in the petroleum well cementation process, in particular to a device for tracking and positioning the rubber plug through sonar. The device comprises the rubber plug and a sonar generating and data processing system. The rubber plug is provided with a sonar array composed of a plurality of underwater acoustic transducers, wherein the sonar array is connected with the sonar generating and data processing system through sonar signals. Through the sonar positioning technology, the position of the rubber plug in a well, the distance between the rubber plug and a wellhead and the motion state of the rubber plug can be displayed by a data transmitting and processing system in real time, construction is facilitated, a technician is assisted in analyzing and solving problems and judging well conditions in time, the well cementation success rate can be greatly increased, and the number of down hole problems is reduced.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

Wellbore pressure control system and method for offshore well cementation stages

ActiveUS9631454B1Inhibition formationAvoid safety accidentsSurveyFluid removalHigh densityControl system

The present invention provides wellbore pressure control system and method for well cementation stages, and relates to the offshore oil and gas exploitation field. The wellbore pressure control system comprises: an injection pump; and a control device, configured to control the injection pump to inject a fluid or gas through an injection pipeline to a return pipeline that communicates with an annular space of the wellbore to decrease the pressure in the return pipeline and thereby decrease the pressure in the annular space, wherein, the density of the fluid or gas is lower than the density of a drilling fluid in the annular space. The technical scheme of the present invention can effectively prevent leaky zones from being fractured by high-density cement slurry in the well cementation process that may cause safety accidents such as well kick and well blowout, etc.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-temperature resistant water-based insulating liquid

InactiveCN101307224AImprove suspension performanceGood compatibilityDrilling compositionSulfonateWater based

The invention discloses a high temperature resistant sealing liquid which consists of the following compositions by weight portion: 100 portions of water, 5 portions of Attapulgite, 2.5 portions of a suspending agent, 1 portion of polypropylene sulfonate and 0 to 120 portions of baryta powder, wherein, the suspending agent is a multipolymer of vinylphenol, 2 acrylamido-2- methylpropanesulfonic acid, acrylic acid and acrylamide, and the portions of the compositions are weight portions The water-based sealing liquid has the functions of pressing, stabilizing, separating and replacing, etc. in the well cementation process of a deep well and an ultradeep well (a well bottom circulating temperature is up to 180 DEG C); moreover, the water-based sealing liquid can improve the interface cementation quality.

Owner:DAQING PETROLEUM ADMINISTRATION

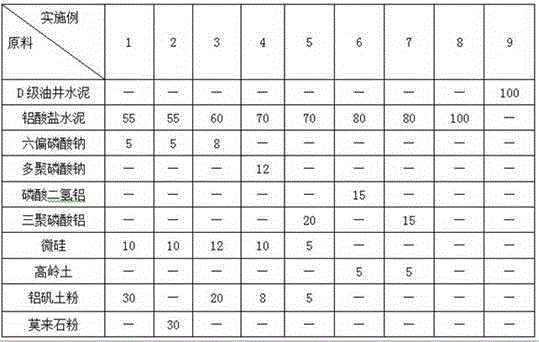

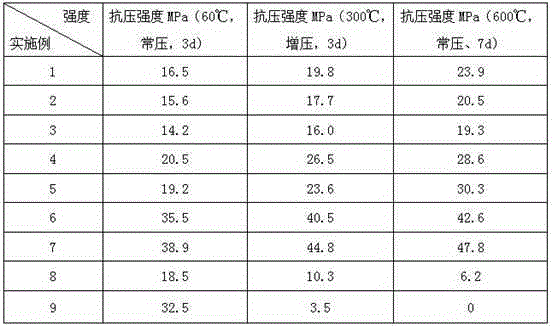

High temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and well cementation process method

InactiveCN102660241ALow elastic modulusDrilling compositionSealing/packingCementation processCement paste

The invention discloses high temperature-resistant oil well cement, underground high temperature-resistant oil well cement paste and a well cementation process method. The high temperature-resistant oil well cement comprises 65 to 95 weight parts of monocalcium aluminate and 5 to 35 weight parts of dicalcium silicate which are used as main components and citric acid. The underground high temperature-resistant oil well cement paste comprises 50 to 56 weight parts of 50 to 56 weight parts of high temperature-resistant oil well cement, 44 to 50 weight parts of clear water, and 0.5 to 1.5 weight parts of retarder citric acid. The thickening time of the underground high temperature-resistant oil well cement paste is controlled to be 2 to 9 hours by the retarder citric acid. When the underground high temperature-resistant oil well cement paste is used for well cementation, a well can resist 800 DEG C and more than 60 MPa, and elastic modulus is less than 10 GPa; and the underground high temperature-resistant oil well cement paste can be applied to thickened oil thermal wells, extradeep wells, very deep wells and geothermal wells.

Owner:WUXI WEISHI TECH

Cement for cementing fireflood thickened oil thermal production well

ActiveCN105271853AImprove high temperature resistanceImprove thermal shock resistanceAluminatePhysical chemistry

The invention discloses cement for cementing a fireflood thickened oil thermal production well and belongs to the technical field of oil production. The cement comprises raw materials in percentage by mass as follows: 55%-80% of aluminate cement, 5%-20% of phosphate, 5%-12% of an active admixture and 0-30% of a high-temperature-resistant admixture. The cement is mainly used in the fireflood thickened oil thermal production well cementation process and has the advantages of good high temperature resistance, long service life and low cost.

Owner:JIAHUA SPECIAL CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com