Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Increase penetration speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

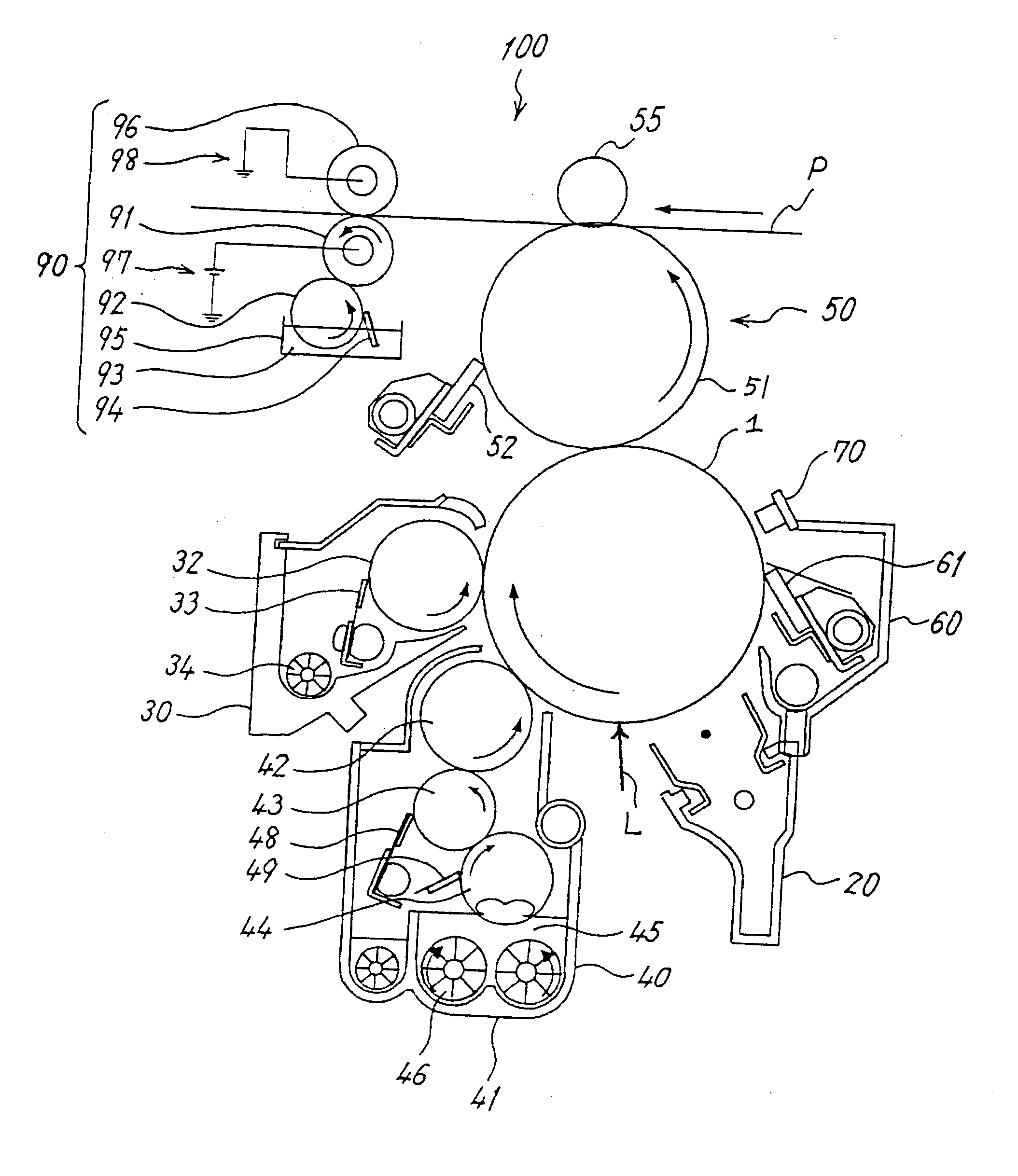

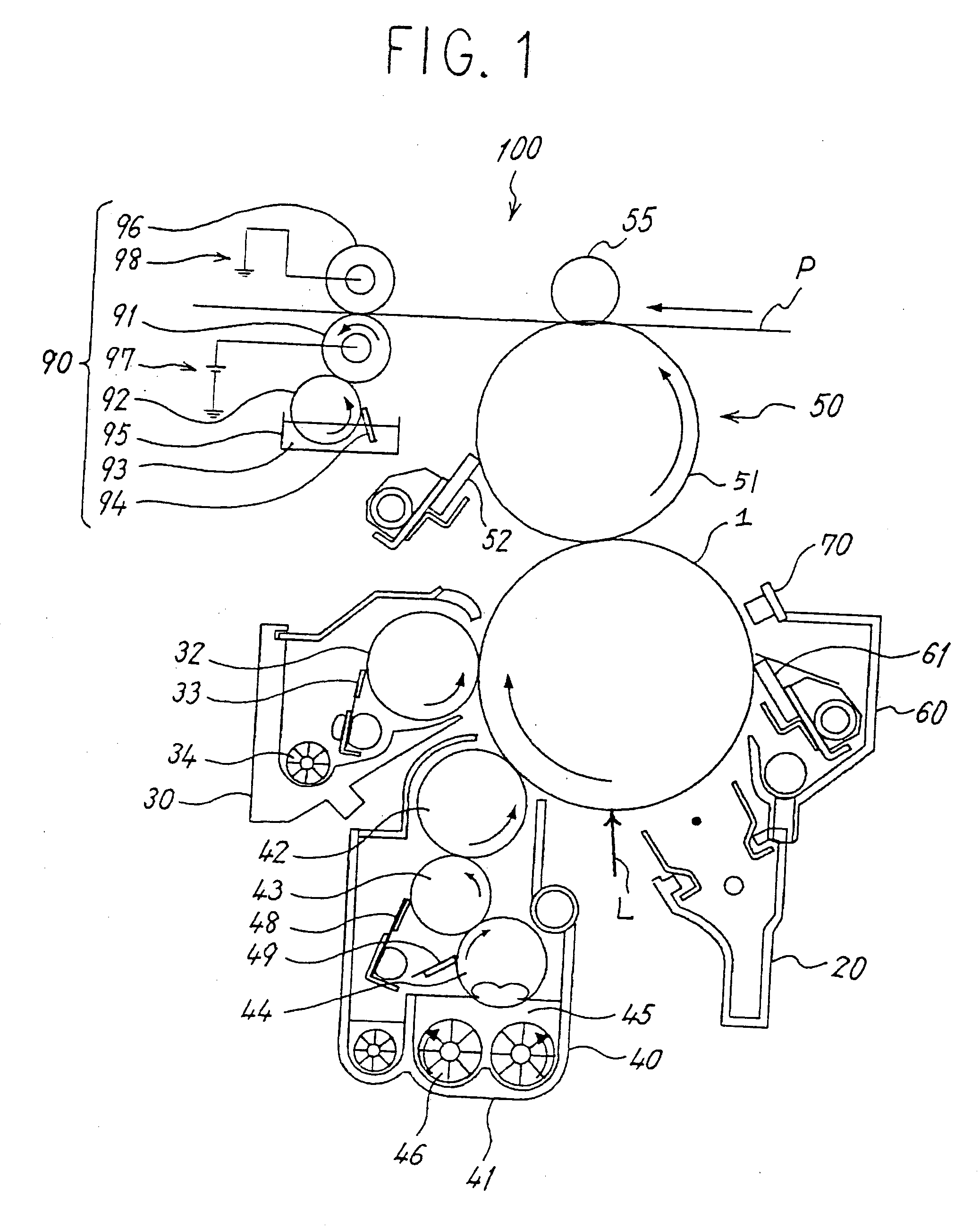

Fixing apparatus for nonheat fixing system, and image forming apparatus having fixing apparatus

InactiveUS20070098469A1Maintain qualityIncrease penetration speedElectrographic process apparatusFixing agentsImage formationEngineering

A fixing apparatus causes a softener to adhere to a toner image and then fixes the toner image onto a recording body. The toner image is formed using a liquid developer comprising a toner and carrier solution. The fixing apparatus comprises a fixing roller as a softener feeding device for feeding a fixer containing a softener to a transfer paper which is a recording body, and a pressurizing roller as a pressurizing device for pressurizing the transfer paper at a fixing nip which is a softener feeding position to which the fixer is fed. As the softener contained in the fixer, the one having an affinity for the carrier solution is used.

Owner:RICOH KK

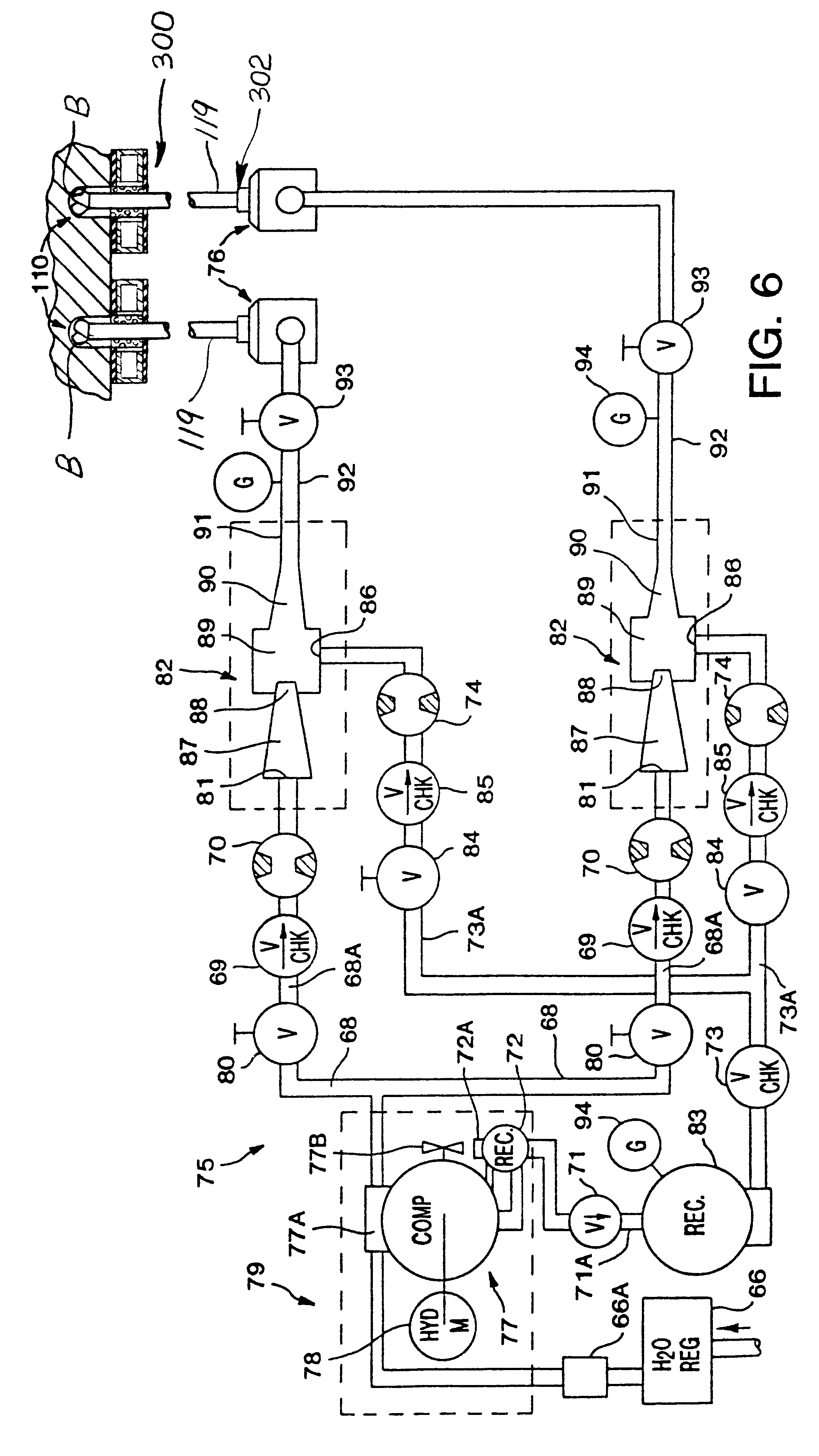

Noise suppression drilling system

InactiveUS6427782B2Lower Level RequirementsLoud noiseRotating vibration suppressionDrilling/boring measurement devicesNoise levelEngineering

The invention encompasses improvements in noise attenuation systems for reducing the audible noise level generated during earth boring operations using a hard surfaced rotary drill bit, and in dual bore-cutting elements for performing sequential first and second bore cutting to the design bore-gauge.

Owner:DOVER BMCS ACQUISITION CORP +1

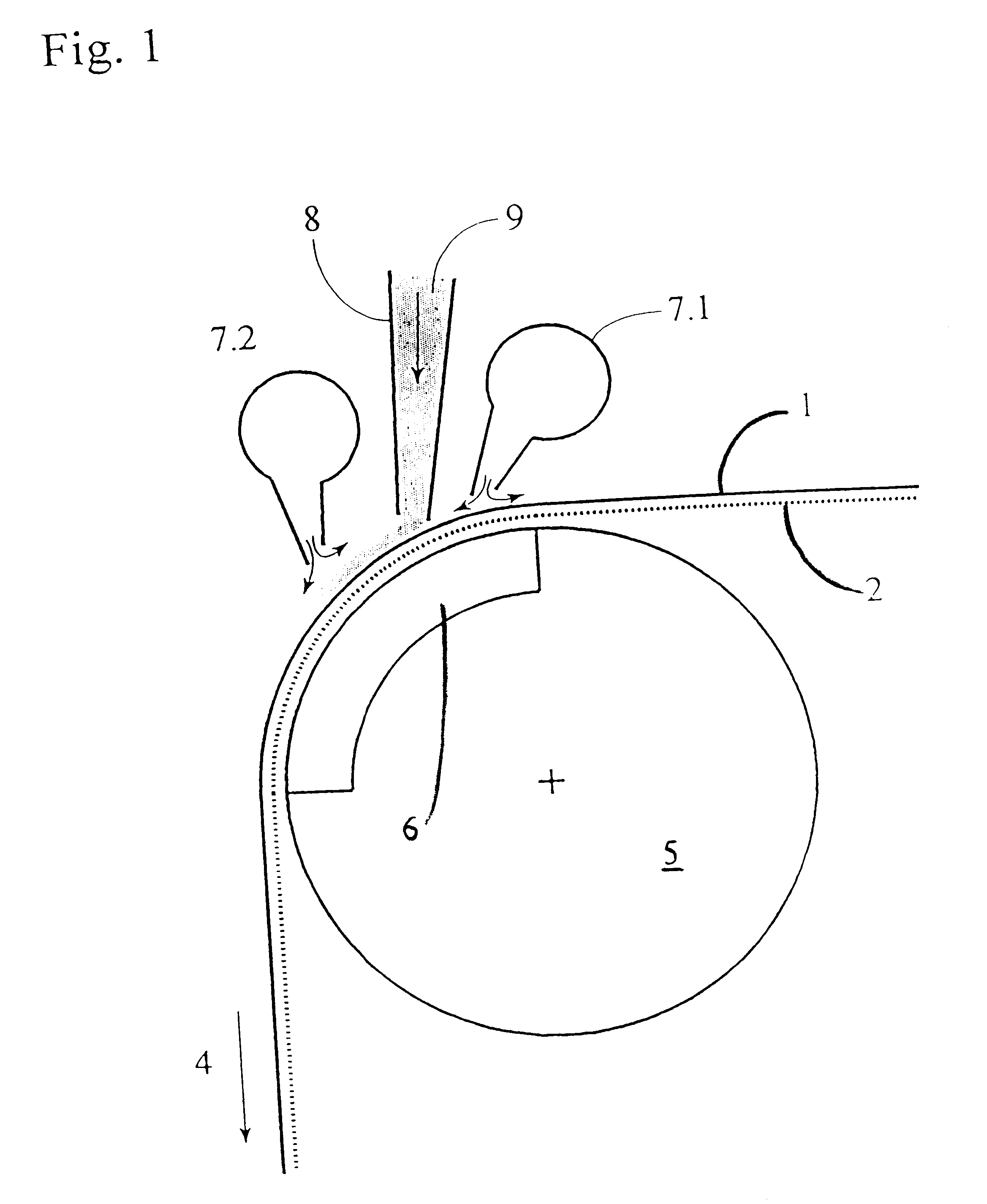

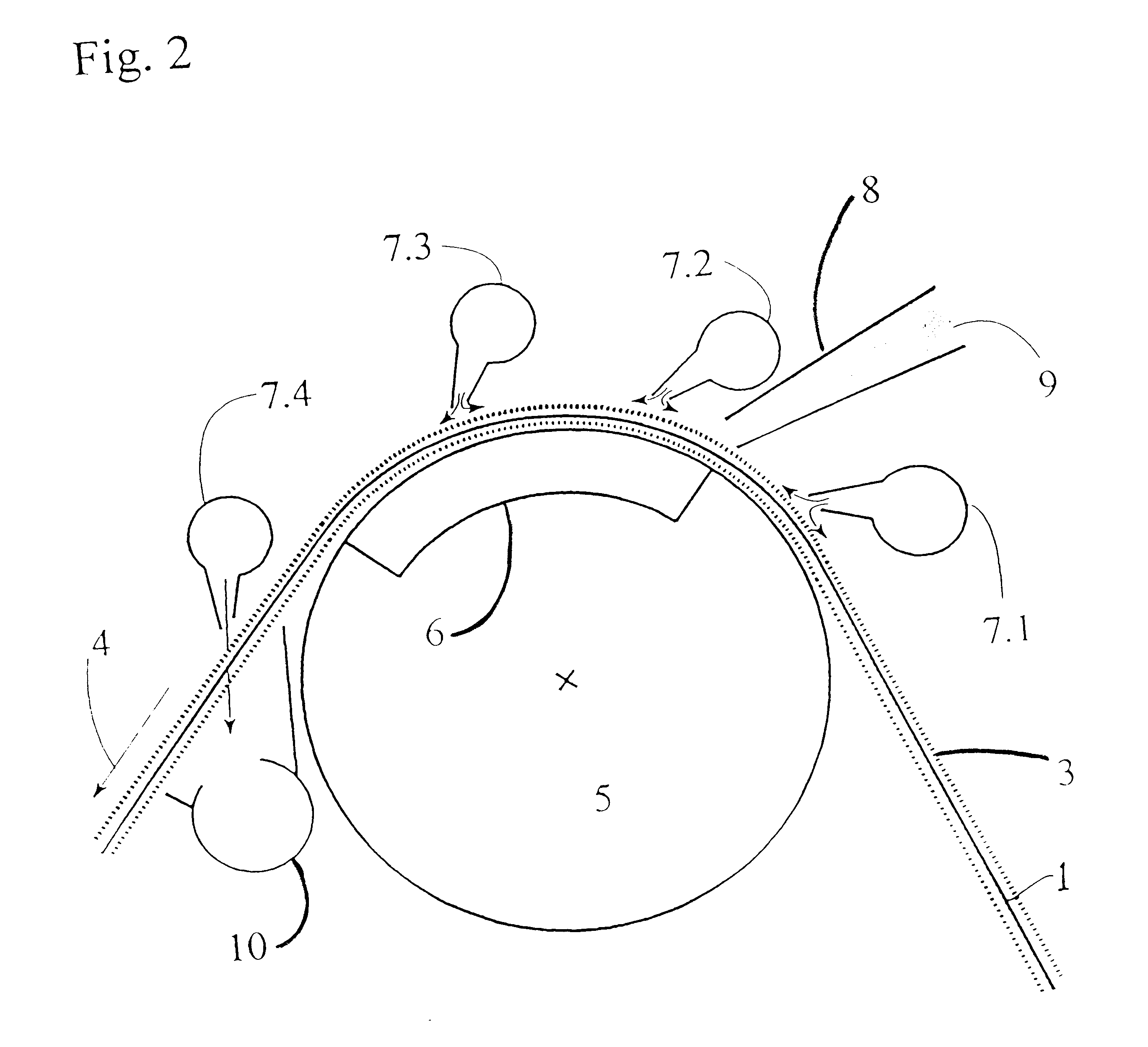

Process and device for acting on a paper or cardboard web with one of a fluid and pasty coating medium

InactiveUS6187142B1Reduction tendencyImprove breathabilityNon-fibrous pulp additionNatural cellulose pulp/paperCardboardEngineering

Process and device for acting on one of a still-wet and moist material web with one of a fluid and pasty coating medium in the manufacturing process. The process includes producing the material web in a wet section of a web producing machine, applying, in at least one coating point, a coating medium to at least one surface of the material web while the material web is in the wet section, and applying at least one of steam and water in the region of the at least one coating point. The device includes at least one endless, water-permeable belt, at least one coating device being adapted for one of direct and indirect application of a fluid or pasty coating medium onto at least one side of a still-wet material web, and at least one applicator device, positioned in a region in which the coating medium contacts at least one of the material web and at least one belt, being adapted to condition the at least one of the material web and the at least one belt with at least one of steam and water.

Owner:VOITH PATENT GMBH

Solid Rare Earth Nitriding Catalyst

InactiveCN102268632AFast nitridingIncrease the diffusion coefficientSolid state diffusion coatingWaxAmmonium chloride mixture

The invention is a solid rare earth nitriding infiltration accelerator, which is composed of the following ingredients uniformly mixed by weight percentage: 50-90% of rare earth chloride, 5-30% of ammonium chloride and 5-20% of urea. The rare earth permeation agent is a paste solid, packed in a wax-sealed carton with a plastic film, and then put into an iron can and put into a gas nitriding furnace together with the nitriding workpiece for use. The permeation accelerator of the invention has the advantages of simple preparation, convenient use, 30-60% increase in nitriding speed, energy saving, and increased workpiece surface hardness HV50-150.

Owner:哈尔滨意锋稀土材料开发有限公司

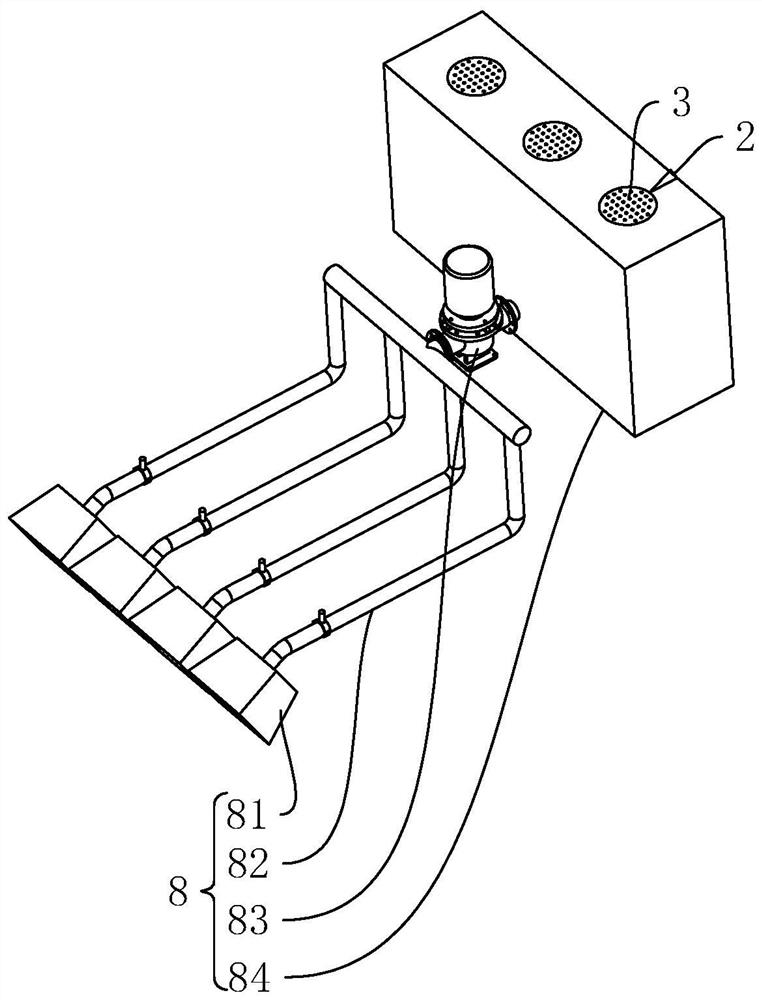

Ultra-high-pressure hydraulic auxiliary rock breaking TBM (Tunnel Boring Machine) cutterhead

InactiveCN106065776AIncrease penetration speedSimplified thrust structure arrangementTunnelsUltra high pressureSlag

The invention discloses an ultra-high-pressure hydraulic auxiliary rock breaking TBM (Tunnel Boring Machine) cutterhead. The ultra-high-pressure hydraulic auxiliary rock breaking TBM cutterhead comprises a TBM cutterhead body, wherein the TBM cutterhead body consists of a cutterhead, disc cutters arranged on the working face of the cutterhead, and four slag collection buckets uniformly distributed at the edge of the working face of the cutterhead; a plurality of nozzles are arranged on the working face of the cutterhead and are respectively close to running track coils; a water supply swivel joint, a power supply communication swivel joint used for being electrically connected with a TBM main control room, and a cutterhead fixing rack are arranged at the back of the cutterhead; a central control unit consisting of an ultra-high-pressure hydraulic filter, a preposed water supply pump, a booster pump, a pressure storage tank, a power motor and an electric control system is arranged on the cutterhead fixing rack; the power supply communication swivel joint is electrically connected with the power motor and the electric control system through a power supply circuit and a communication circuit. According to the ultra-high-pressure hydraulic auxiliary rock breaking TBM cutterhead, the injection speed of the disc cutters is improved, the injection thrust is reduced, the machine body thrust structural arrangement is simplified, and the running maintenance cost of TBM equipment and the project investment are reduced.

Owner:YELLOW RIVER ENG CONSULTING

Valve bush carbonitriding thermal treatment process for high-pressure common rail

InactiveCN105154894AReduce labor timeReduce critical cooling rateSolid state diffusion coatingFurnace typesThermal treatmentNitrogen

The invention provides a valve bush carbonitriding thermal treatment process for a high-pressure common rail. The process mainly solves the problems that an existing valve bush is poor in abrasion resistance, low in dimensional accuracy and short in service life. The process includes the steps of firstly, stress relief annealing, secondly, carbonitriding, thirdly, quenching treatment, fourthly, washing and drying, fifthly, freezing treatment and sixthly, tempering treatment. By the adoption of the valve bush carbonitriding thermal treatment process, the abrasion resistance of the valve bush is reinforced, the size accuracy of the valve bush is improved, and the service life of the valve bush is prolonged.

Owner:SHANDONG LIAOCHENG DERUN EMT DEVING

Structure-enhanced SMC (Sheet Moulding Compound) glass fibre impregnating agent and application thereof in production of twistless roving

Owner:JUSHI GRP CO

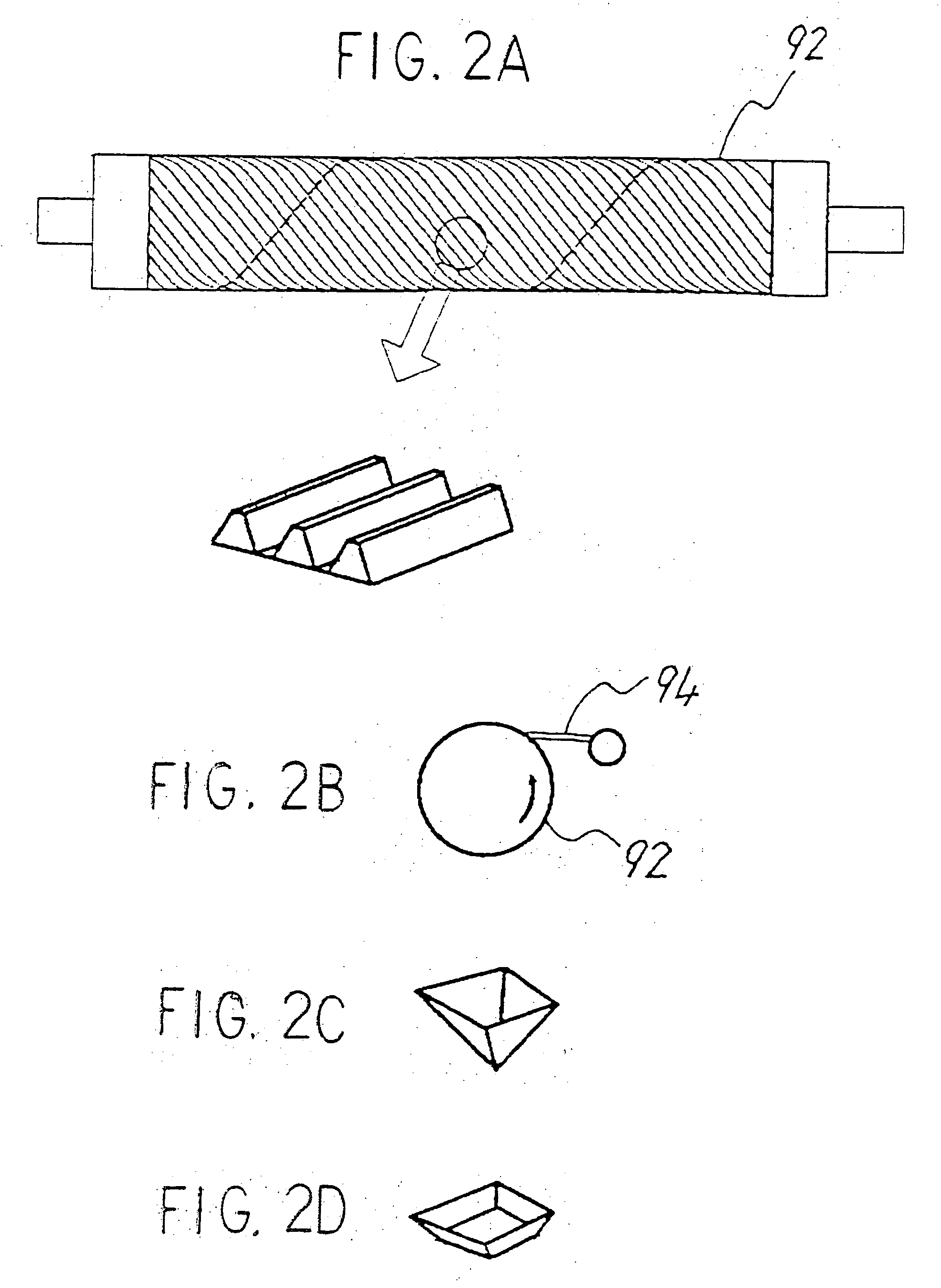

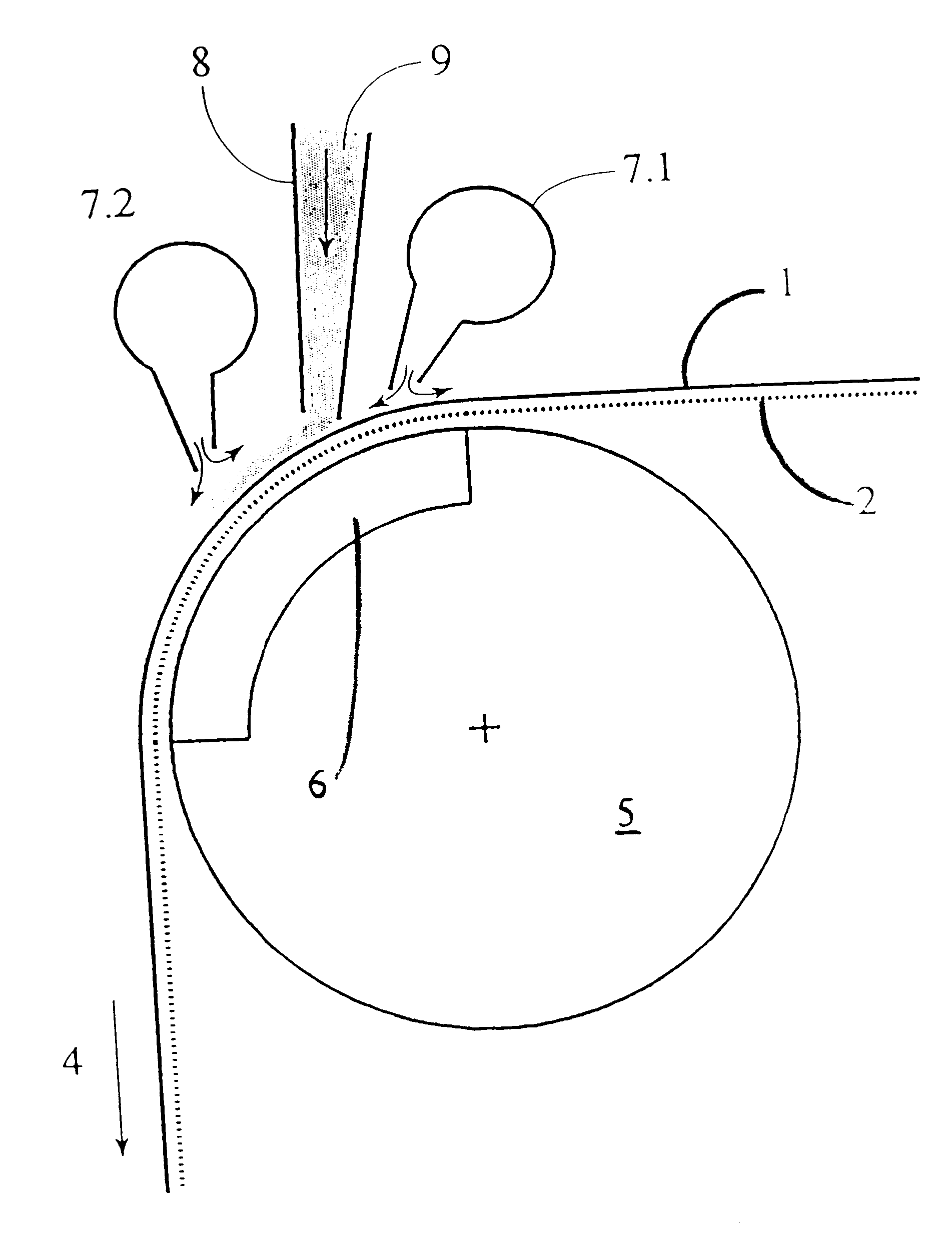

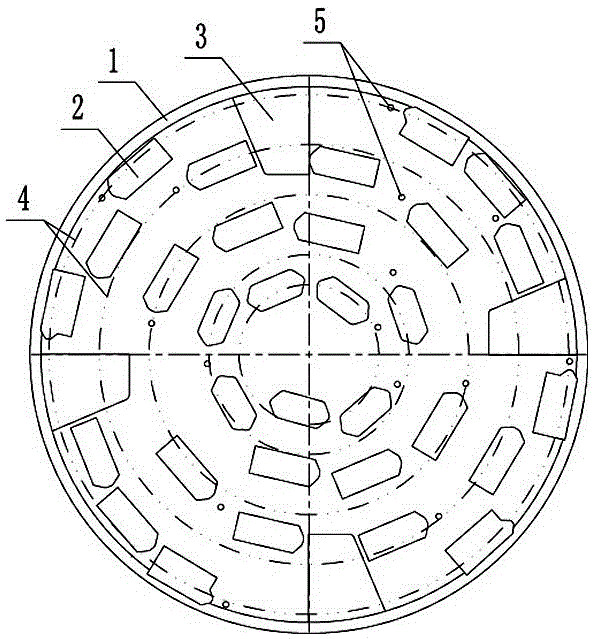

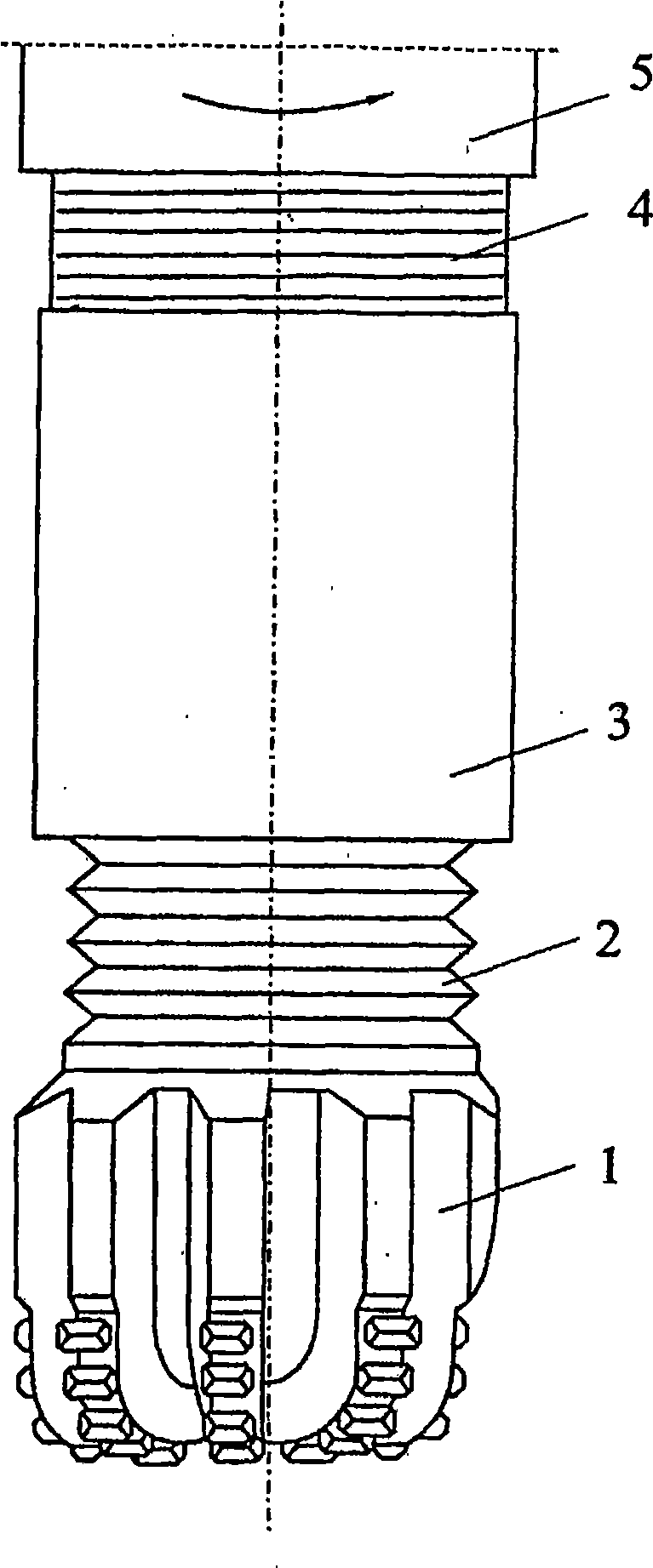

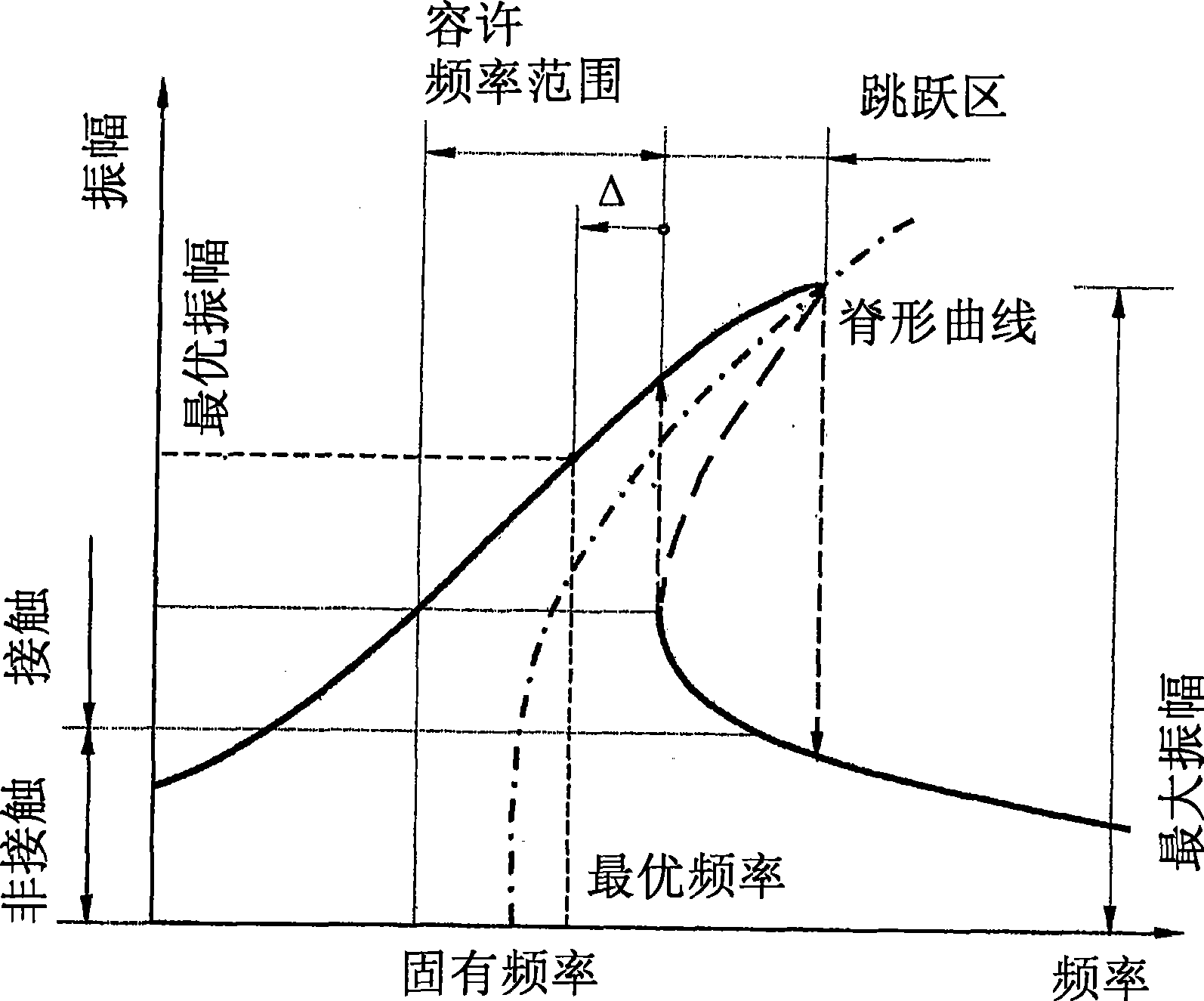

Resonance enhanced drilling method and apparatus

ActiveCN101490358AReduce energy inputIncrease penetration speedDrill bitsVibration drillingResonanceClosed loop

The present invention relates to drilling apparatus comprising a drill-bit (1) capable of rotary and high frequency oscillatory loading; and control means for controlling applied rotational and / or oscillatory loading of the drill-bit, the control means having adjustment means for varying the applied rotational and / or oscillatory loading, said adjustment means being responsive to conditions of the material through which the drill is passing. The control means is in use provided on the apparatus in a downhole location and includes sensors for taking downhole measurements of material characteristics, whereby the apparatus is operable downhole under closed loop real-time control. The apparatus can determine appropriate loading parameters for the drill-bit in order to achieve and maintain resonance between the drill-bit and the drilled material in contact therewith.

Owner:THE UNIV COURT OF THE UNIV OF ABERDEEN REGENT WALK

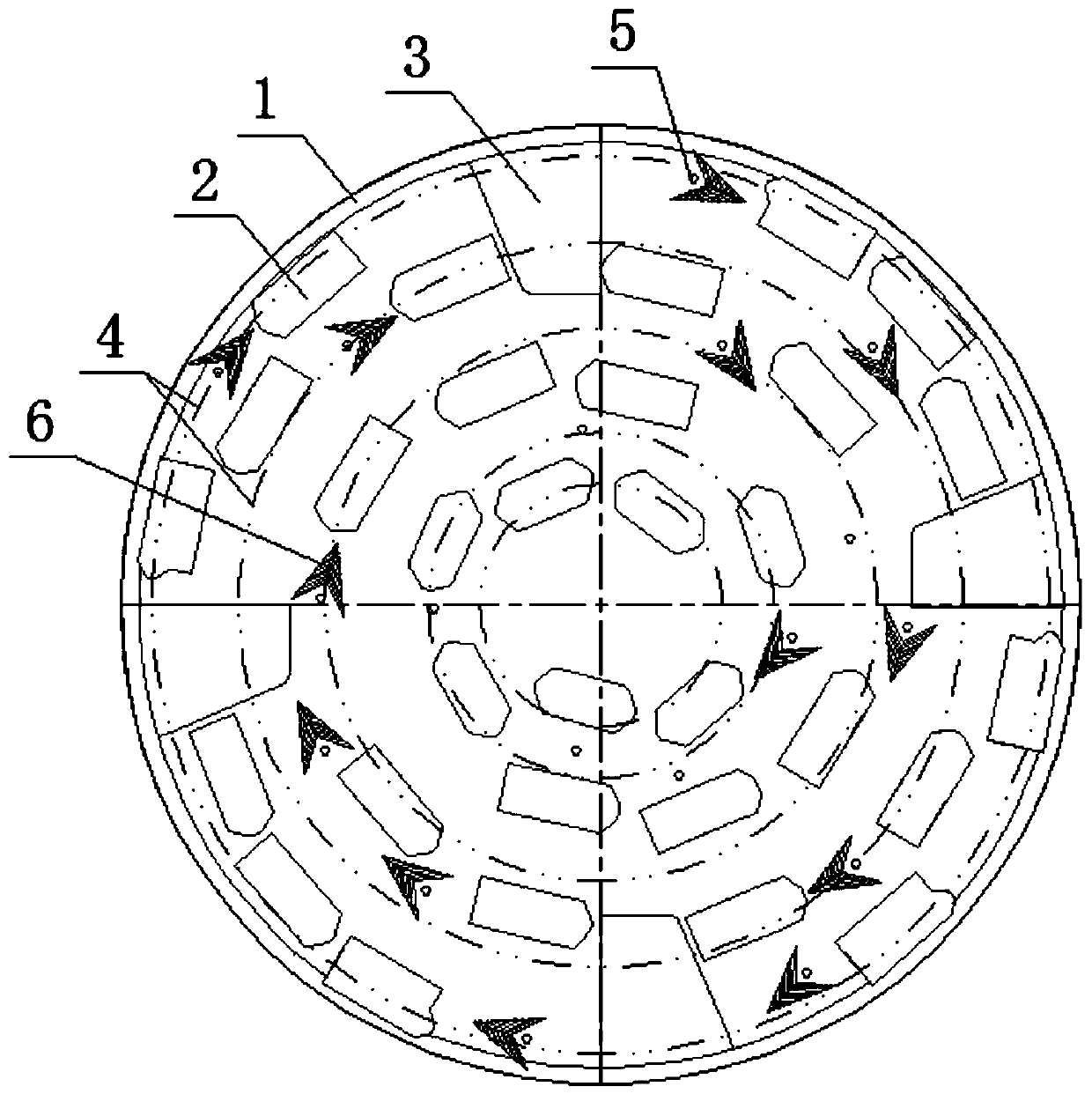

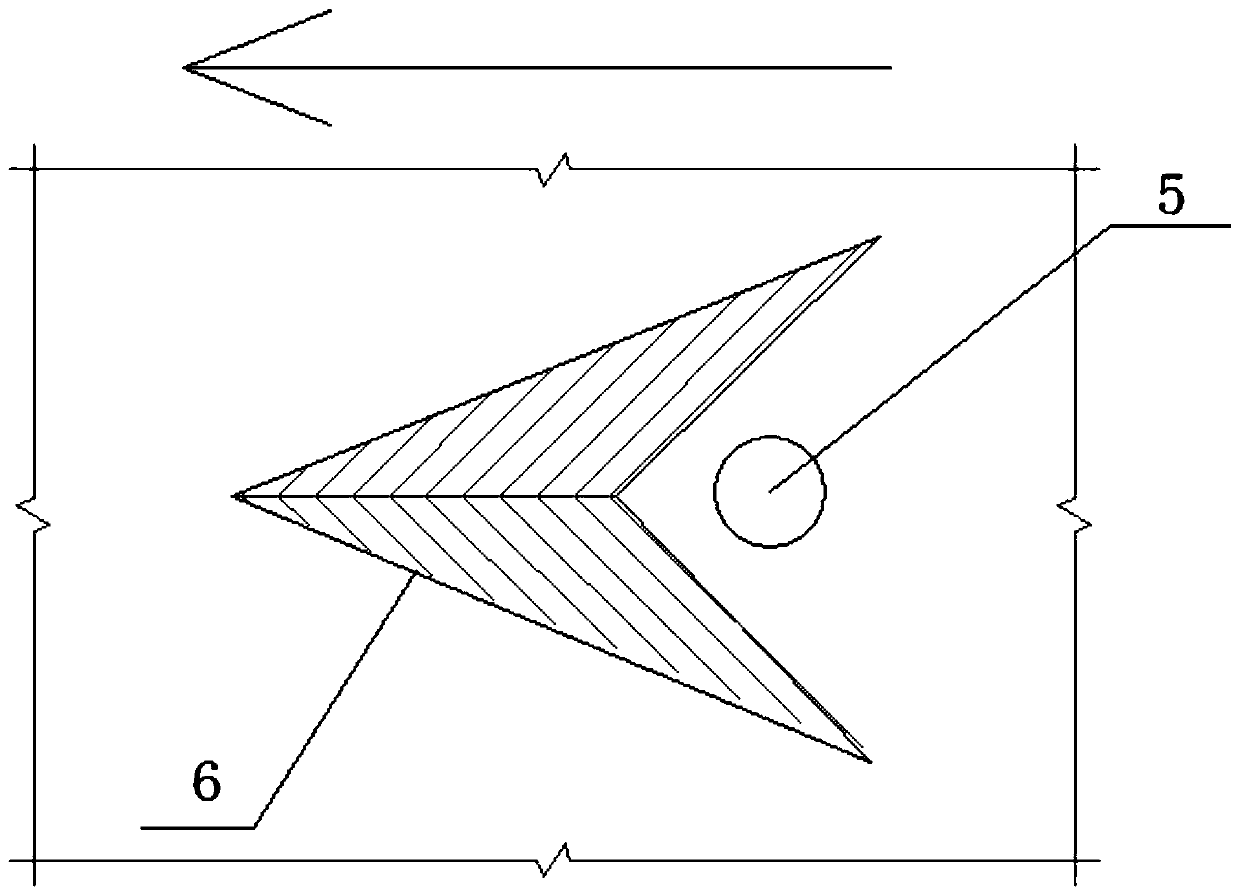

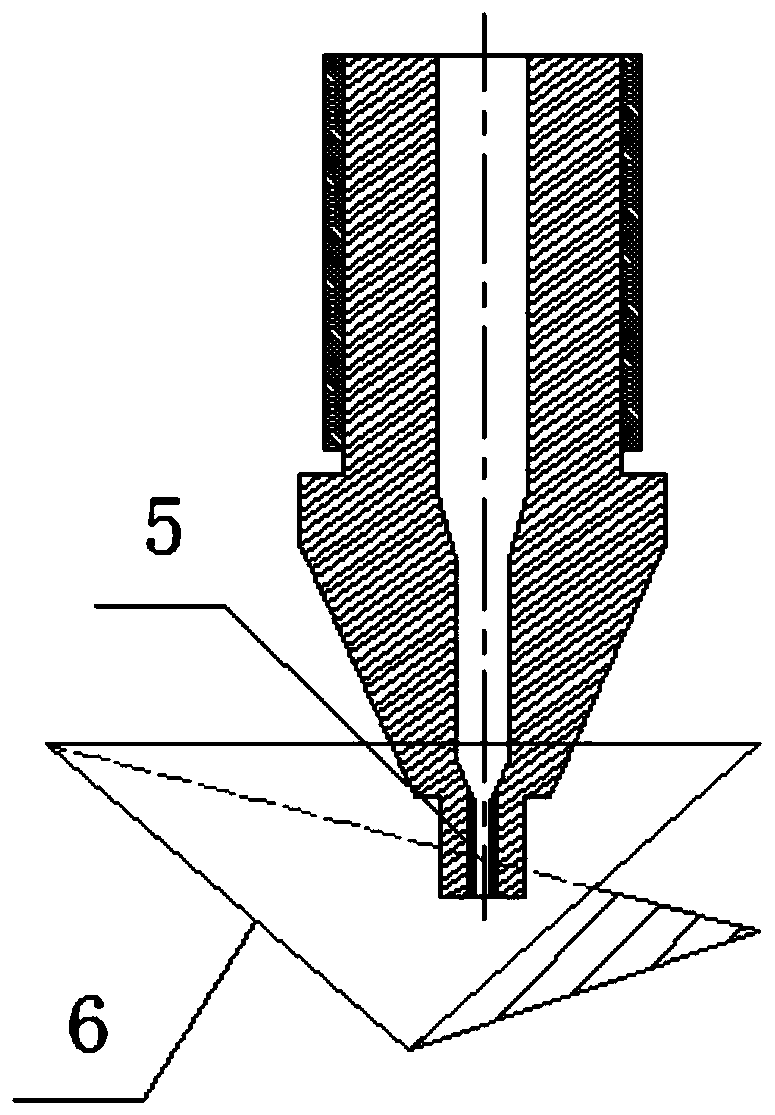

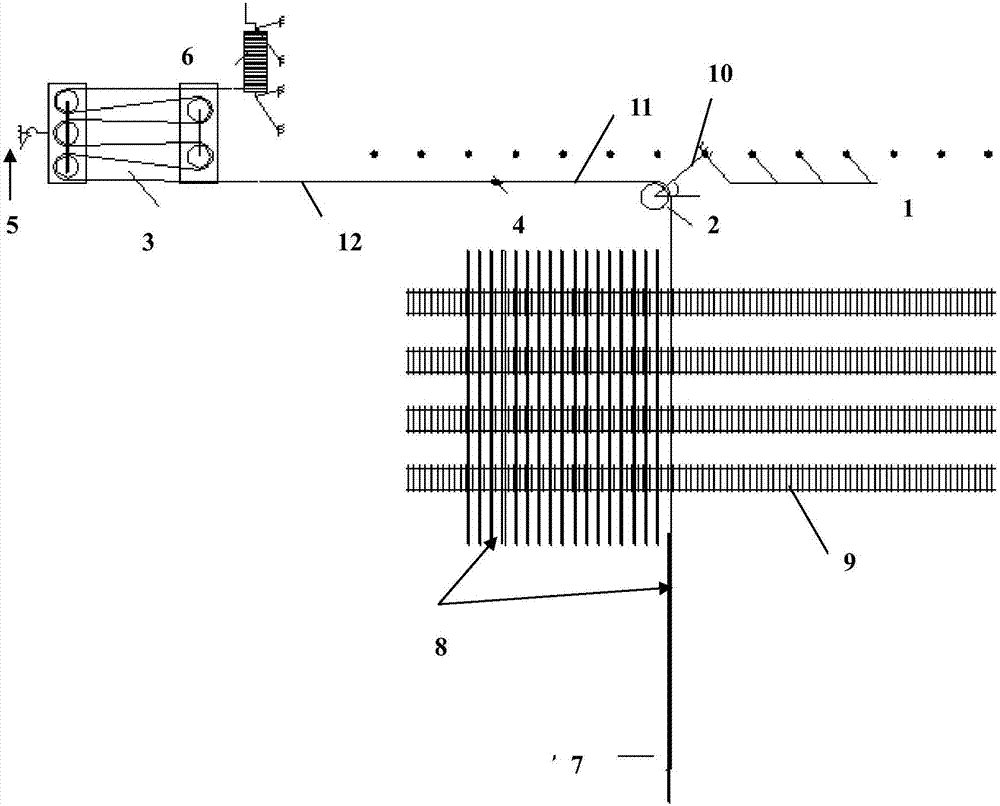

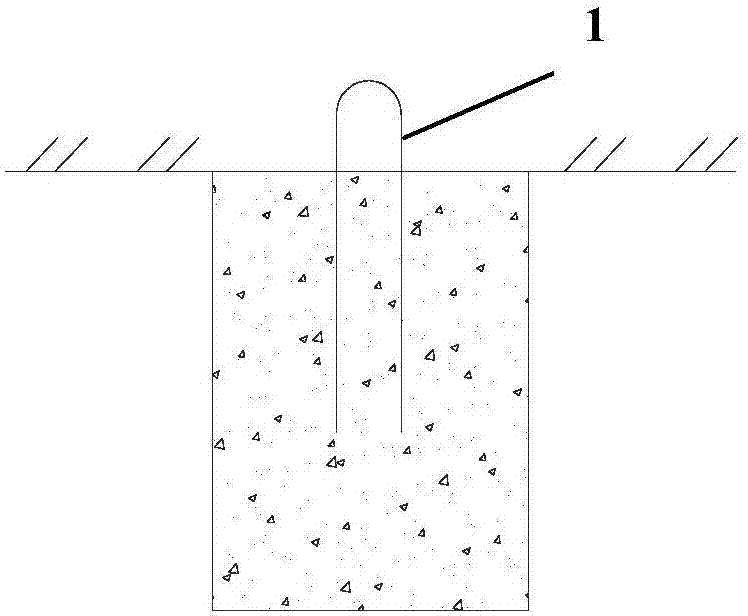

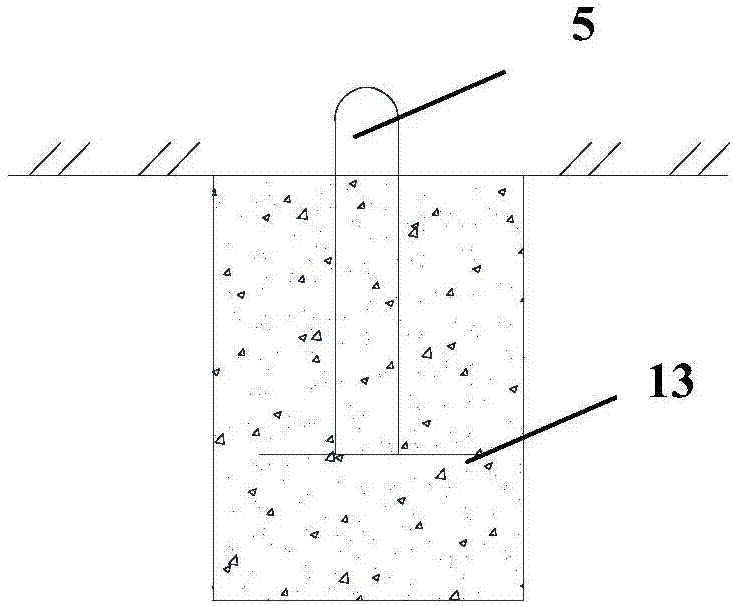

Tunneling machine for hard tunnel rock and cutterhead of tunneling machine

The invention discloses a tunneling machine for hard tunnel rock and a cutterhead of the tunneling machine. The cutterhead of the tunneling machine comprises a cutterhead (1), hobs (2) arranged on a working surface of the cutterhead (1), high-pressure water nozzles (5) arranged on the working surface of the cutterhead (1), and scrapers (6) arranged on the working surface of the cutterhead (1) andused for removing slag, wherein the scrapers (6) are arranged on the peripheries of the high-pressure water nozzles (5). According to the cutterhead of the tunneling machine, the scrapers used for removing slag are arranged on the working surface of the cutterhead and are located on the peripheries of the high-pressure water nozzles to remove earth and rock slag between the cutterhead and the tunneling face, so that it is guaranteed that water jet sprayed out of the high-pressure water nozzles can directly act on the tunneling face, rock is effectively cut, the rock breakage efficiency of high-pressure water is improved, and accordingly, the tunneling efficiency is improved; and the scrapers can prevent accumulated slag from moving towards the high-pressure water nozzles, so that hydraulicdevices (high-pressure water nozzles) are effectively prevented from being blocked, and the service life of the nozzles is prolonged.

Owner:YELLOW RIVER ENG CONSULTING

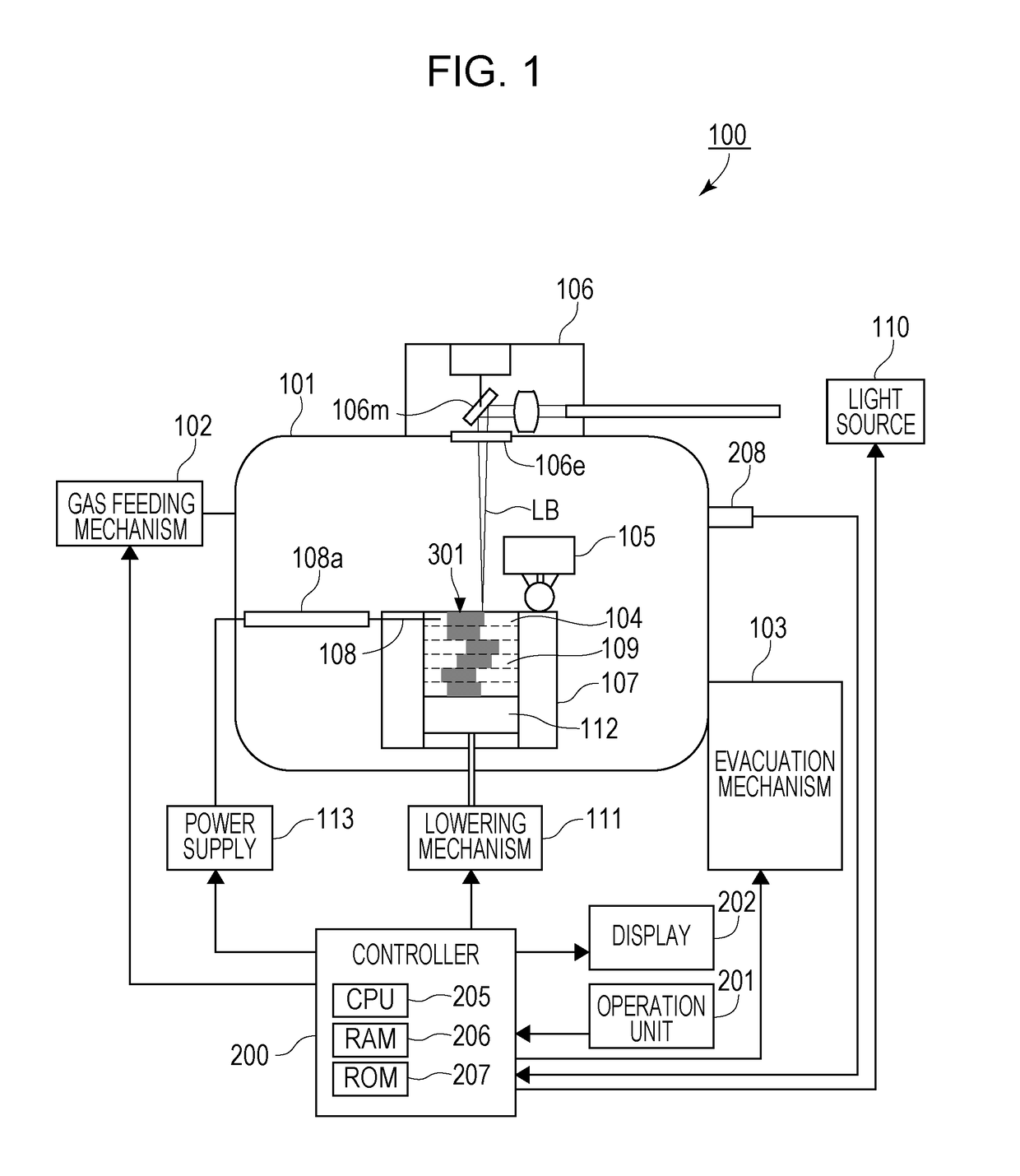

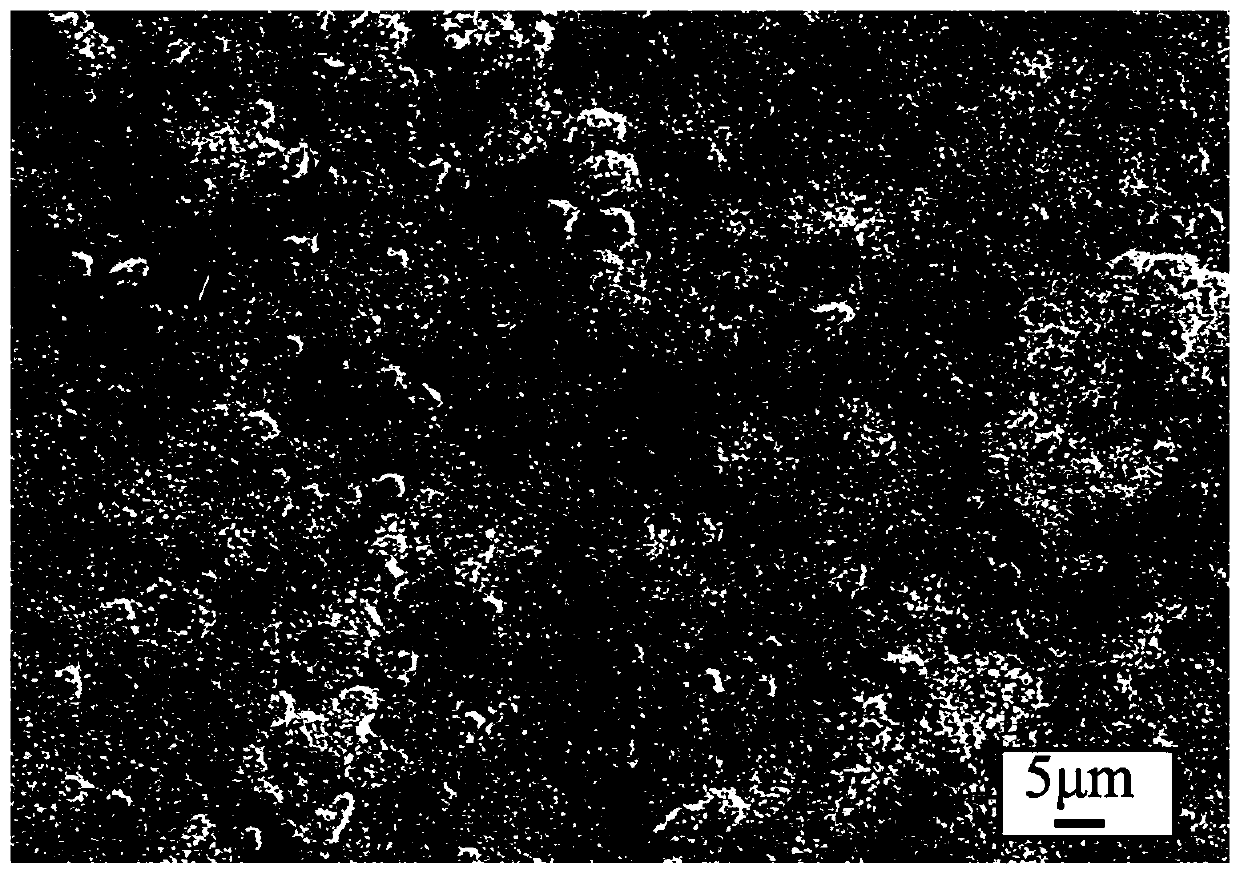

Method and apparatus for producing powder and method for manufacturing shaped object

InactiveUS20170165748A1Extension of timeEasy to controlAdditive manufacturing apparatusTransportation and packagingMetallurgyNitrogen

A method for producing a powder includes forming a layer of a raw material powder, and performing one of an operation of nitriding the raw material powder of the layer in an atmosphere containing nitrogen or an operation of carbonizing the raw material powder of the layer in an atmosphere containing carbon.

Owner:CANON KK

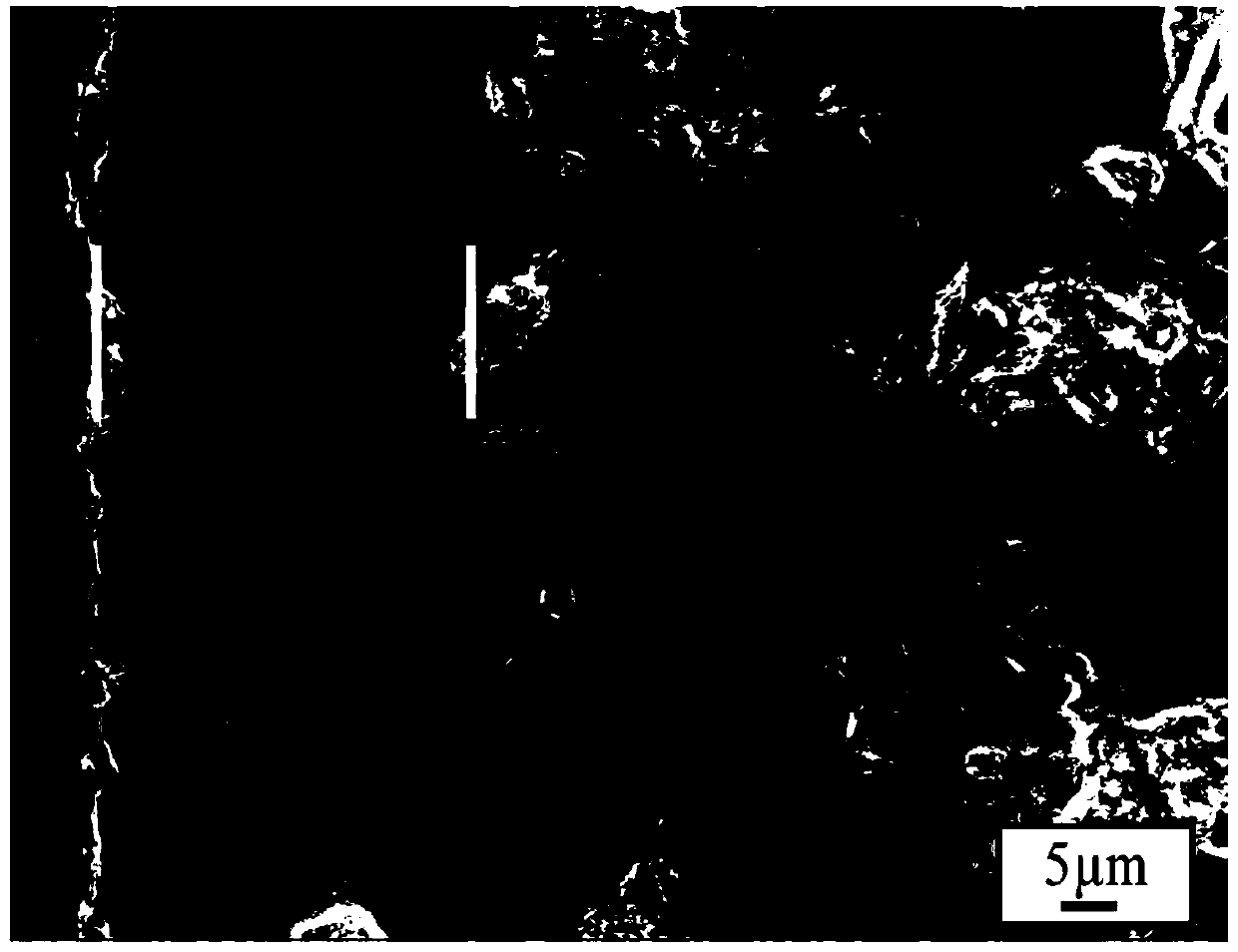

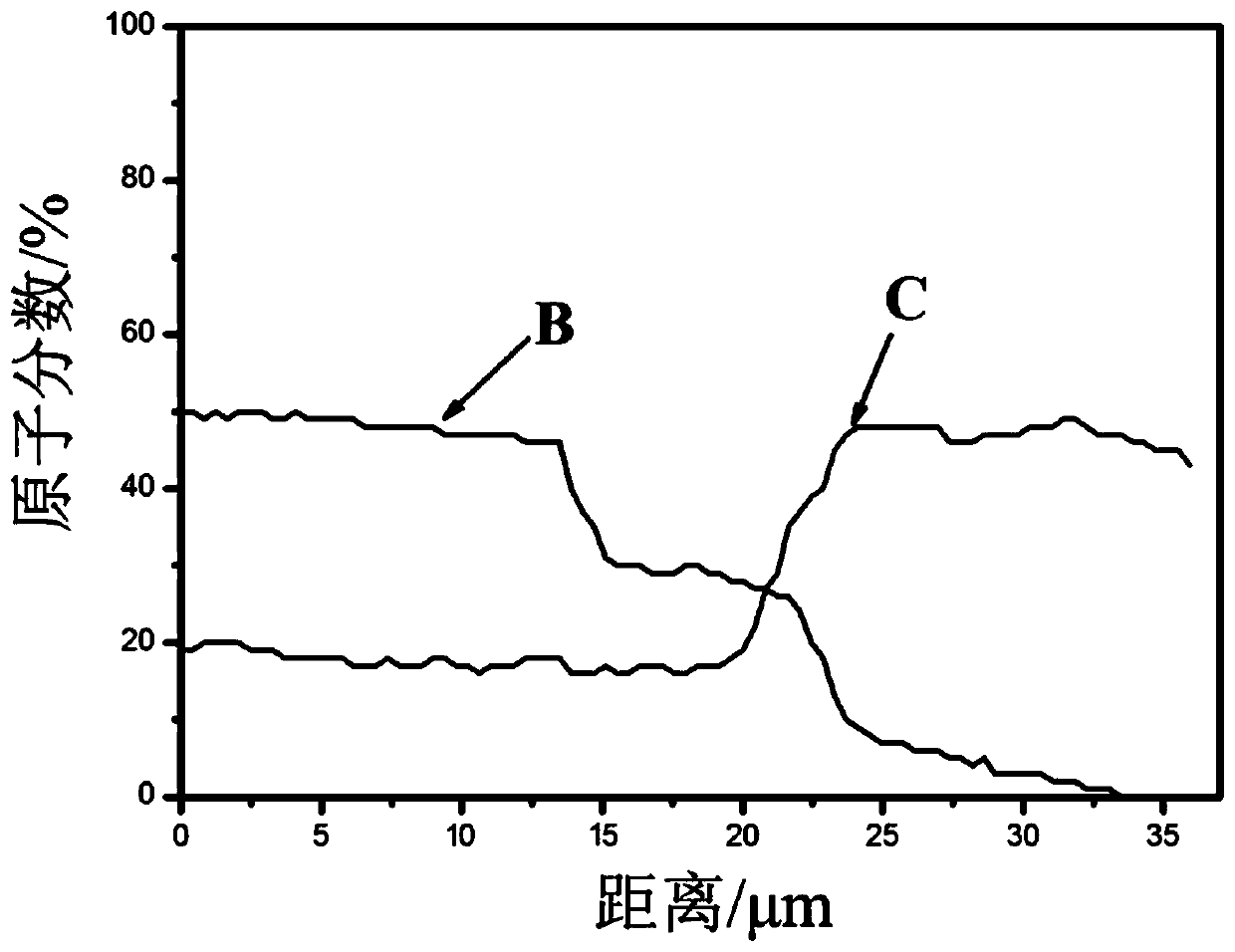

Method for preparing co-permeation layer on surface of TC4 titanium alloy through boro-carbonization method

InactiveCN110965017ALower hardness gradientPrevent falling offSolid state diffusion coatingCarburizingTitanium alloy

The invention discloses a method for preparing a co-permeation layer on the surface of a TC4 titanium alloy through a boro-carbonization method. The method comprises the steps that S1, preparing a carburized layer on the surface of the TC4 titanium alloy through the powder pack cementation technology, and forming a TiC deposition layer rich in carbon atoms on the surface of the TC4 titanium alloy;S2, preparing a boron-carbon co-permeation layer on the surface of the TC4 subjected to carburization pretreatment by adopting the powder pack cementation technology, wherein the thickness of the boron-carbon co-permeation layer is about 20-40 [mu]m, and the hardness of the boron-carbon co-permeation layer obtained through the carburization pretreatment can reach 2487.5 HV-2865.3 HV, which is 8-10 times of that of a TC4 titanium alloy matrix, and wear resistance and the service life of the boron-carbon co-permeation layer are greatly improved. The prepared boron-carbon co-permeation layer hasthe advantages of being thick in permeation layer, small in brittleness, high in hardness and resistant to wear; and the preparation method has the advantages of being high in permeation speed, low in cost, simple in process, small in workpiece deformation and the like and can be widely applied to the working condition environment with high wear resistance and service life requirements.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method of smelting high nitrogen steel using additional cathode glow discharging

InactiveCN1757760AIncrease penetration speedOvercoming brittlenessElectric furnaceAlloyLiquid surfaces

A technology for smelting high-nitrogen steel by additional cathode glow discharge includes such steps as arranging an anode above the liquid level of smelting bath in vacuum smelting apparatus, arranging a perforated additional cathode between said anode and liquid level, vacuum smelting while regulating the contents of alloying elements, filling N-contained gas, applying a voltage across the anode and cathode to ionize the N atoms into N ions, regulating voltage to form a stable glow region to deposit the N ions, active N atoms and mitride from cathode on the liquid surface, and diffusing and counterflowing to increase the content of N in steel.

Owner:SHANGHAI JIAO TONG UNIV

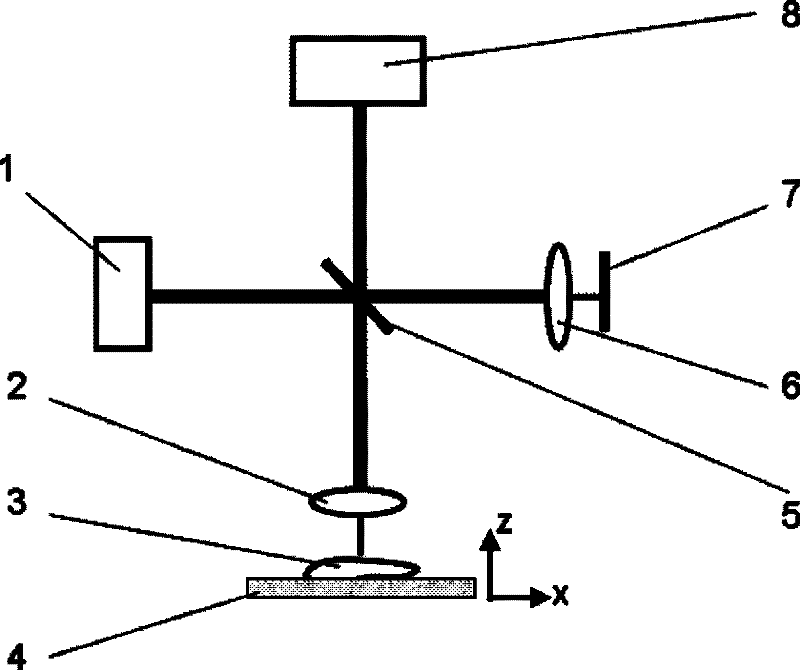

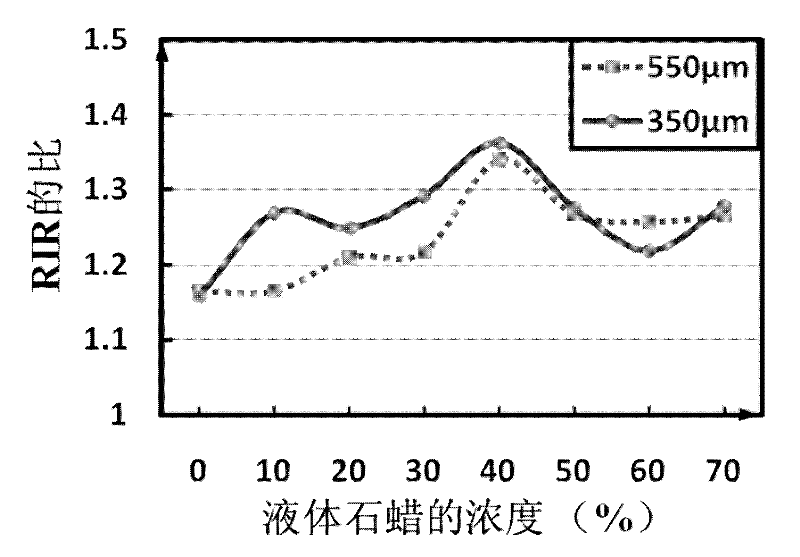

New application of liquid paraffin as light transparency enhancer

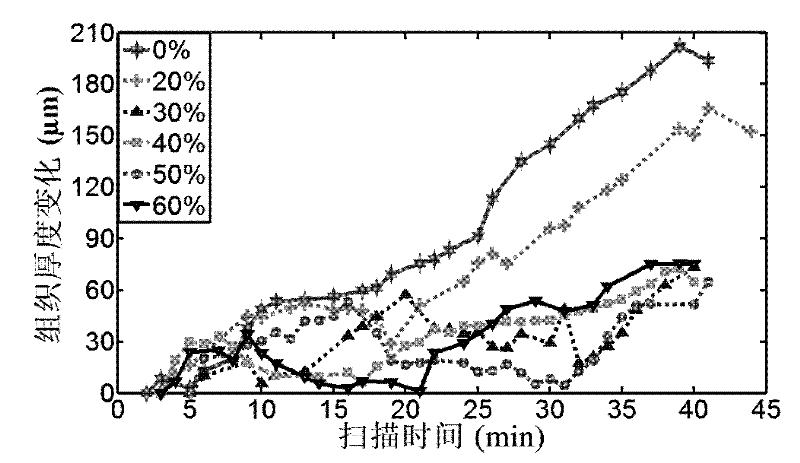

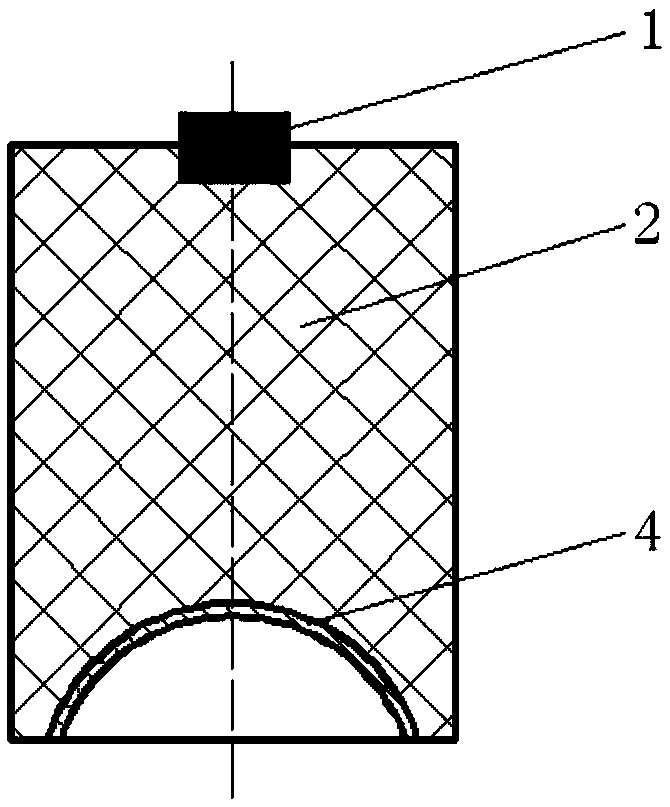

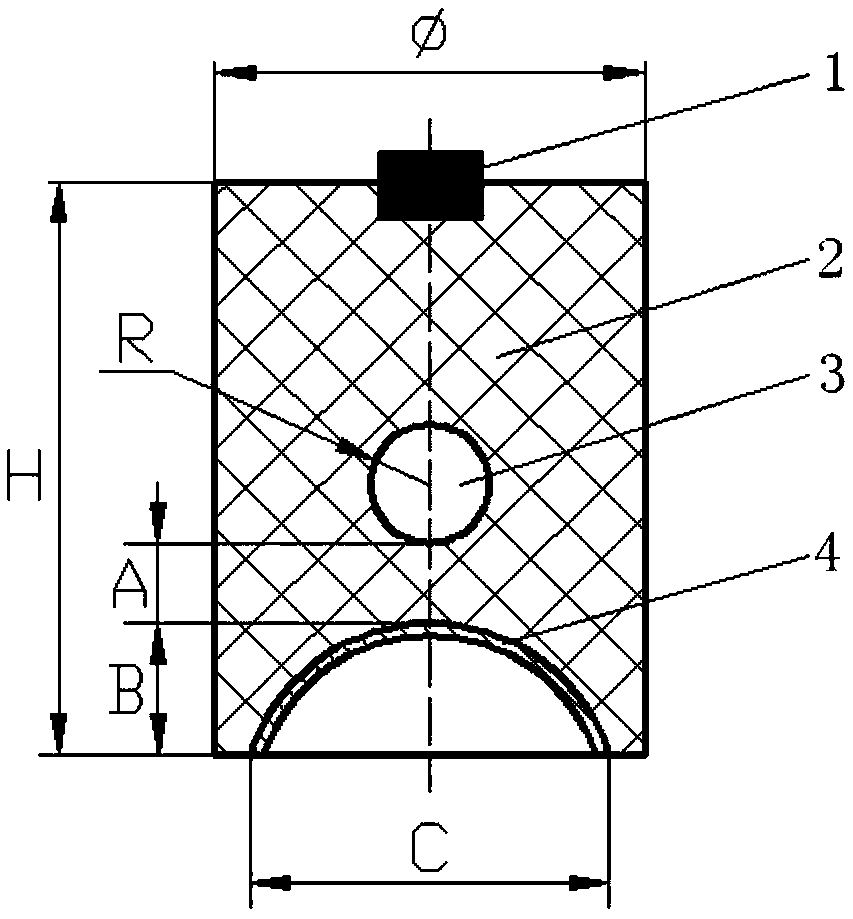

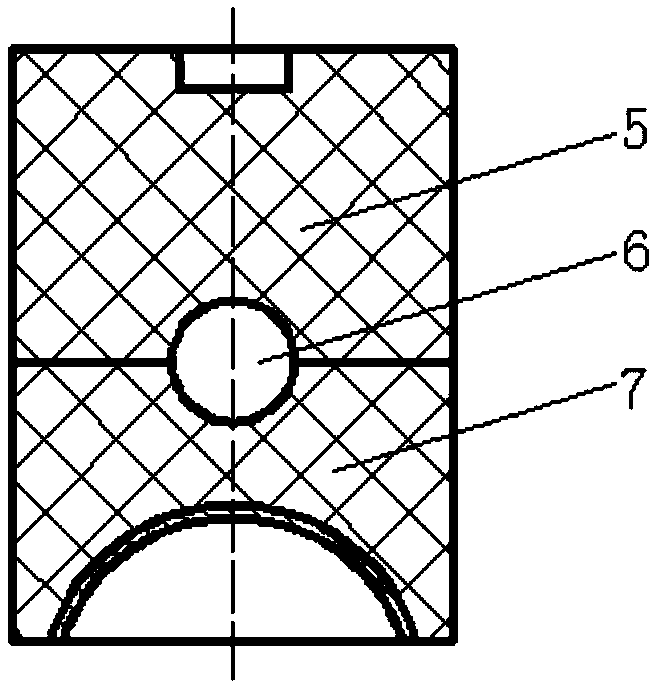

ActiveCN102284066AIncrease penetration speedReduce tissue deformationIn-vivo testing preparationsPhysicsBiological tissue

The invention discloses novel application of whiteruss as an optical transparency reinforcing agent. The whiteruss as the optical transparency reinforcing agent is mixed with a water-soluble optical transparent agent; then mixture is coated on the surface of a sample to be tested; by using the synergism between the moisture preservation and high osmosis and dehydration of the water-soluble optical transparent agent on biological tissues, the refractive index distribution inside the biological tissues can be smoothened, the deformation of a biological tissue structure is reduced, the scatter of the biological tissues on light is reduced, the detection depth in the biological tissues and the strength of internal transmission, scattering or reflecting of optical signals are improved by usingan optical detection method and more information from the inside of the tissues can be acquired. According to the invention, the application of the optical detection method to the field of biomedicine and clinical or non-clinical researches is promoted.

Owner:NANKAI UNIV

Charge structure for improving shaped charge penetration speed

The invention relates to a charge structure for improving the shaped charge penetration speed. The charge structure comprises a detonator, an explosive column and an explosive-shaped cover, one end ofthe explosive column is connected with the detonator, the other end of the explosive column is provided with the explosive-shaped cover, and the axes of the detonator, the explosive column and the explosive-shaped cover coincide with one another; and a hole ball is further arranged on the explosive column, the interior of the hole ball is air, and the sphere center is located on the central axisof the explosive column and is close to the top end of the explosive-shaped cover. According to the charge structure for improving the shaped charge penetration speed, the large penetration hole diameter is achieved, moreover, the penetration depth can also be improved, on the basis of existing large-penetration-hole-diameter shaped charge, the penetration speed can be improved by 15% or above under the condition that the penetration hole diameter is not reduced, the charge energy utilization rate is high, and the wide applicability is achieved.

Owner:中国船舶重工集团公司第七0五研究所

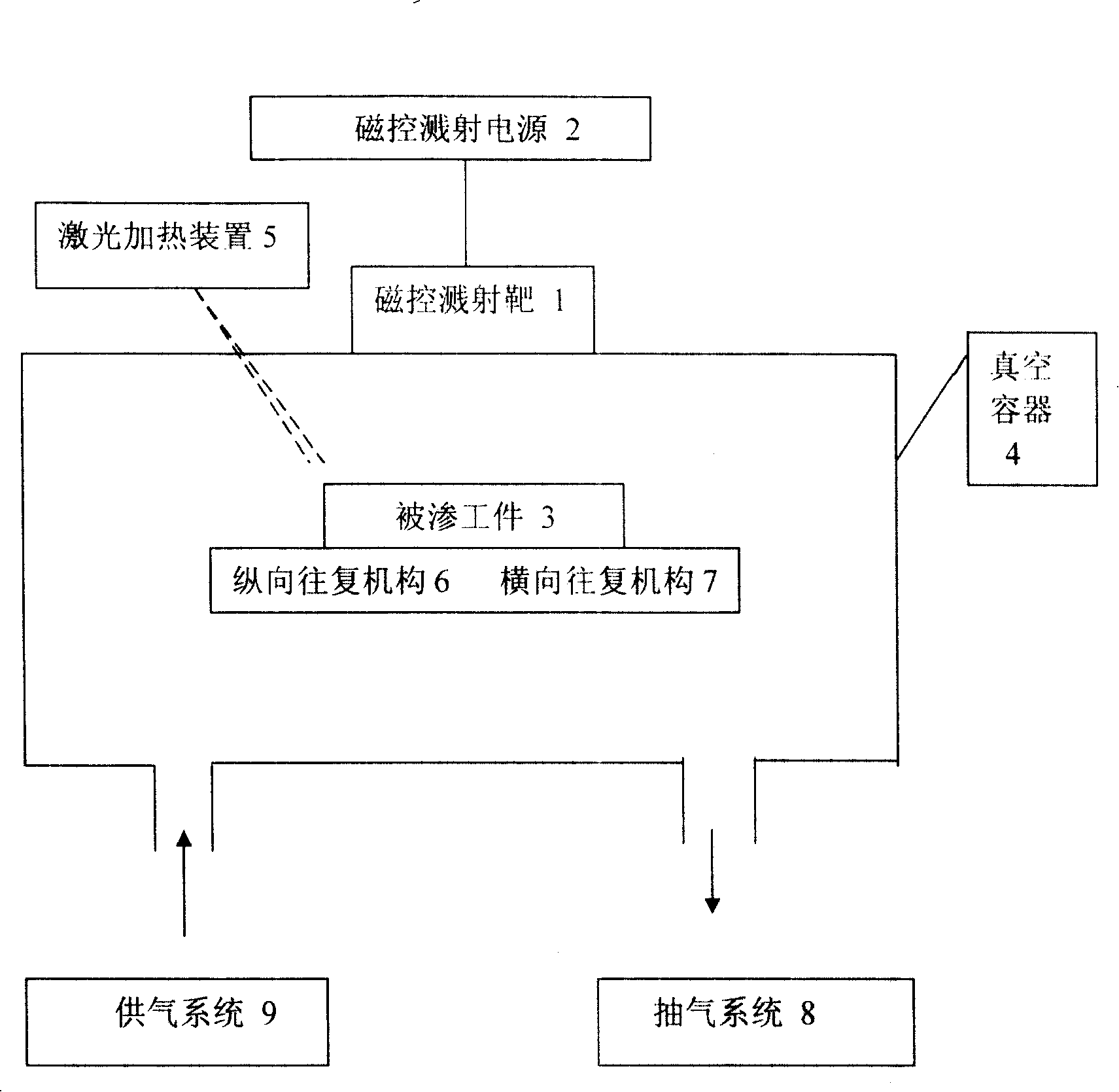

Composite plating process and equipment for magnetron sputtering-laser heating

InactiveCN101195905AMeet the surface depositionSatisfy the needs of infiltrationVacuum evaporation coatingSputtering coatingSputteringDiffusion

The invention discloses the magnetron sputtering-laser heating composite diffusion coating technology and the equipment, by utilizing the magnetron sputtering and a laser heating device, a single diffusion coating layer or a composite diffusion coating layer with a diffusion layer and a sedimentary layer or the diffusion layer plus the sedimentary layer which comprises metal element and nonmetal element is formed on the surface of a conducting workpiece. The invention has the advantages that by utility a magnetron sputtering target, sufficient pre-diffusing alloy element can be provided; by utilizing the laser heating, the diffused material can heated to high temperature in a short time and the diffusing speed is greatly increased; the DEG Cree of vacuum of the metal for diffusing is increased at least one order of magnitude compared with the common alloying method, and the surface quality of the diffused workpiece can be greatly improved; the diffusion coating can be performed continuously, and the production in large area and large scale can be realized.

Owner:GUILIN UNIV OF ELECTRONIC TECH

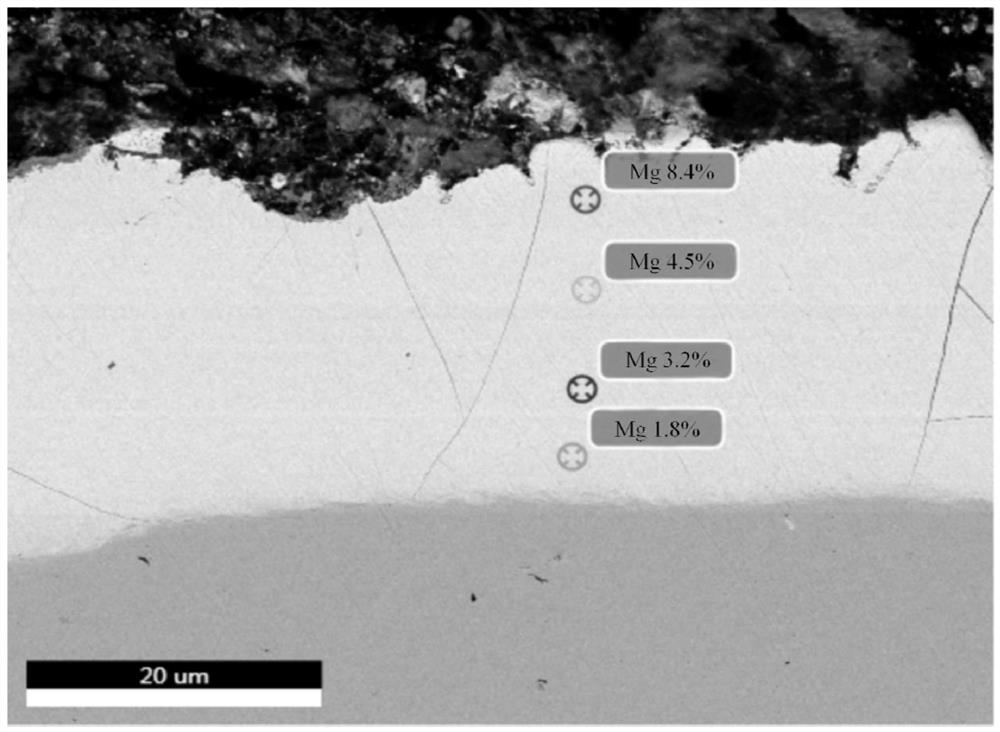

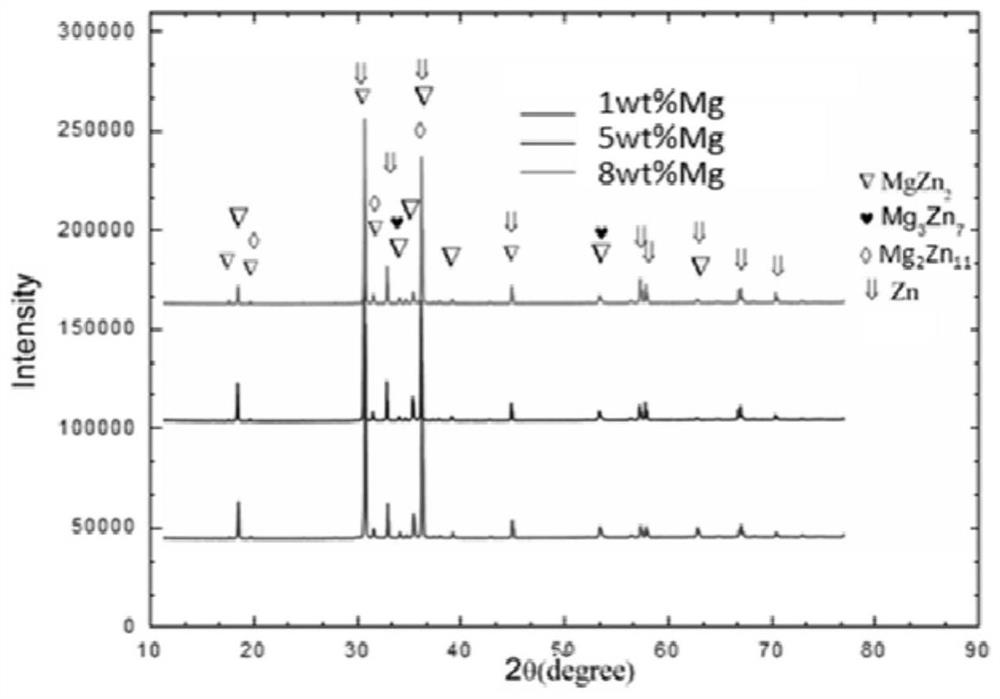

Sheradizing method and anti-corrosion metal part

ActiveCN111876723AHigh activityAvoid reaction of magnesium with airSolid state diffusion coatingProcess efficiency improvementHydrogen pressureMetal powder

The invention provides a sheradizing method and an anti-corrosion metal part. The sheradizing method comprises the steps that S1, oil and rust removal treatment is carried on a metal piece to be subjected to sheradizing, the treated metal piece and a sheradizing agent are jointly placed in a closed sheradizing tank, wherein the sheradizing agent comprises the following components of, in parts by mass, 20-100 parts of metal powder, 40-80 parts of a dispersing agent and 0.2-5 part of a decomposing agent, and the metal powder comprises 60-97 parts of zinc powder and 3-40 parts of magnesium powder; S2, air in the closed sheradizing tank is expelled, and a valve of the closed sheradizing tank is turned off; And S3, the closed sheradizing tank is heated to preset temperature, then hydrogen is introduced for pressurization until a preset hydrogen pressure condition is reached, heat preservation is carried out for 1-10 h, a sheradizing layer is formed on the surface of the metal piece, and sheradizing is completed. The sheradizing method is simple to operate, convenient to use, low in cost, high in economic benefit and wide in application range.

Owner:YANCHENG KEAO MECHAICAL

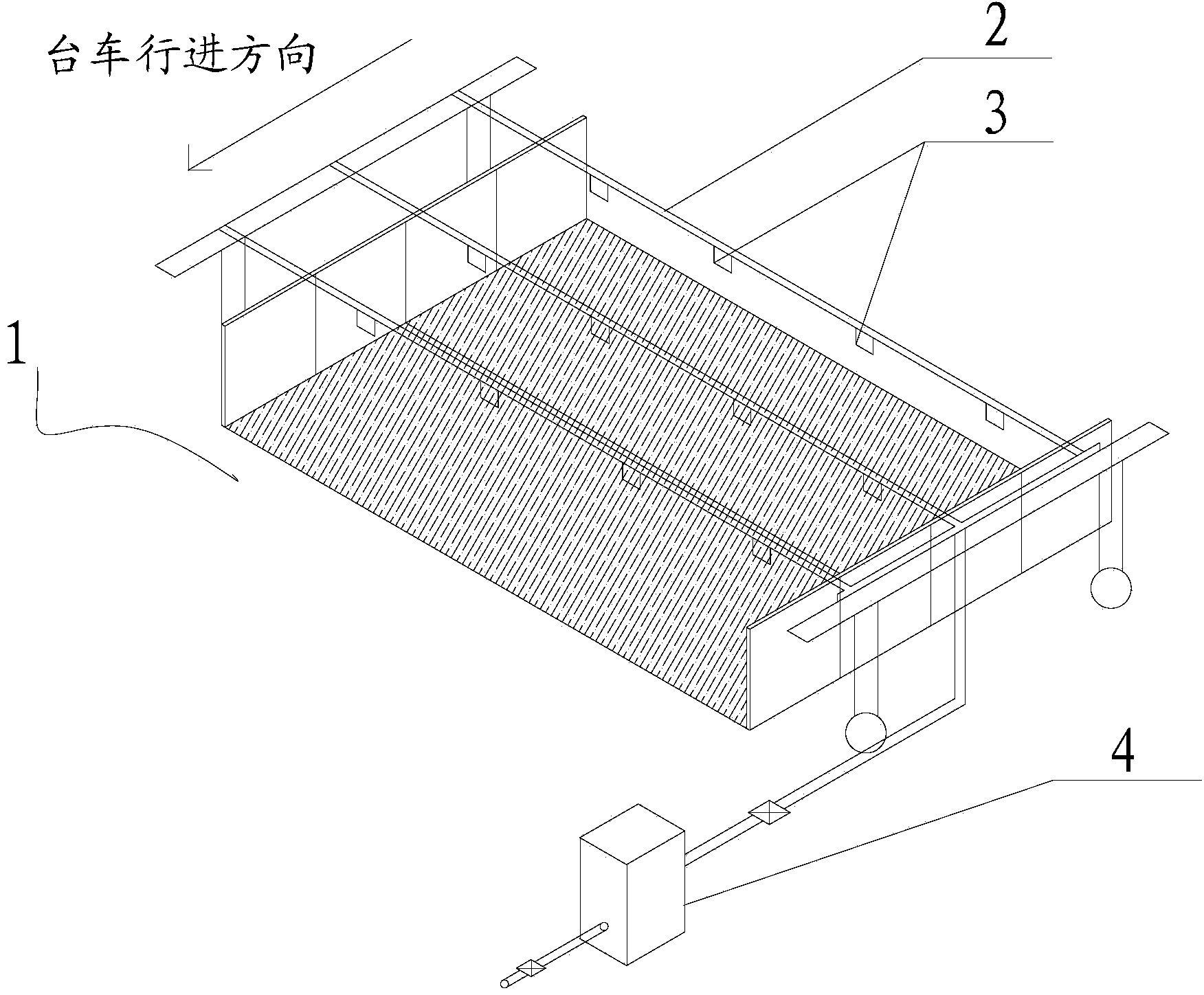

Sintering method and sintering device of metal compound powder

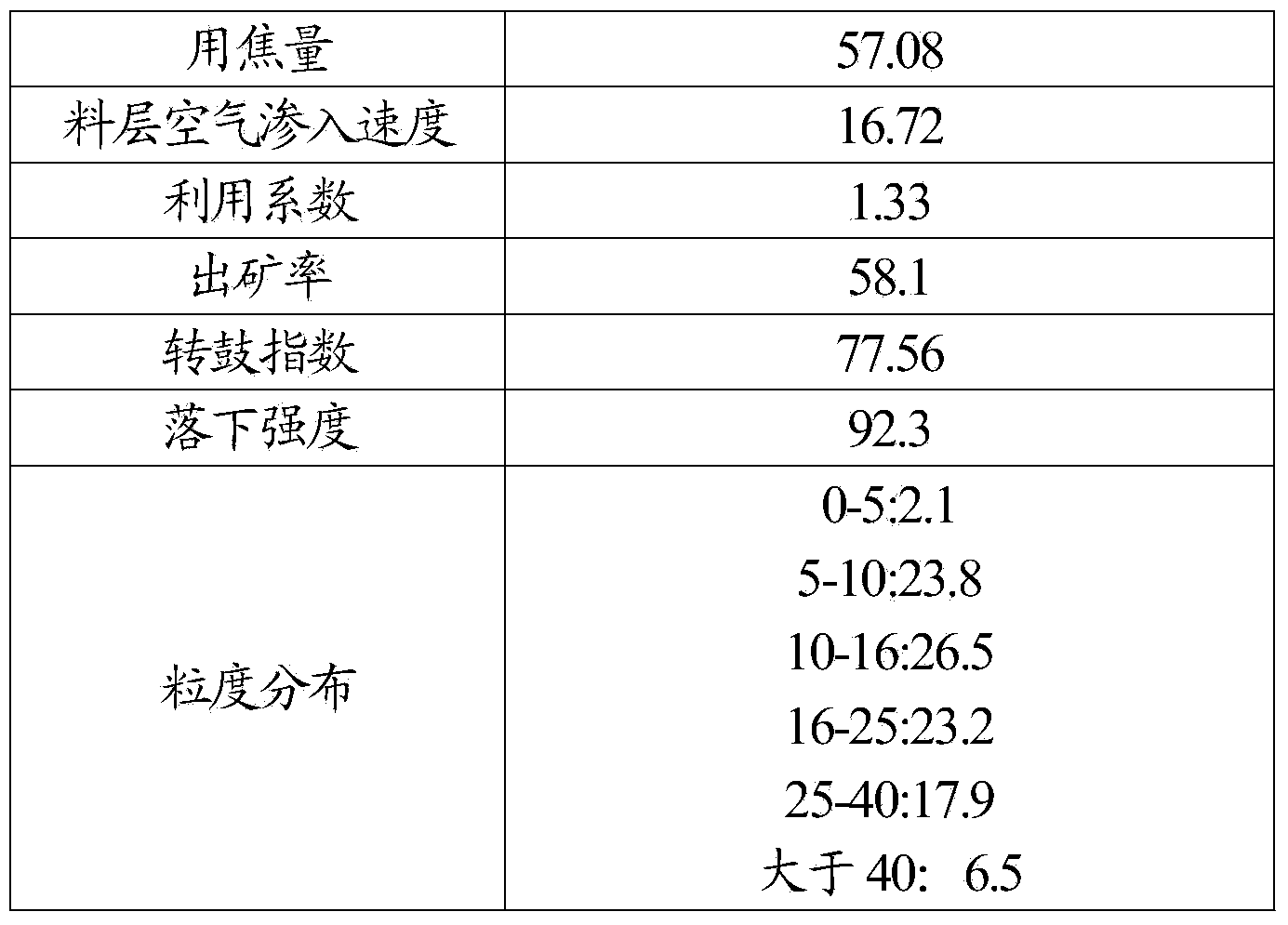

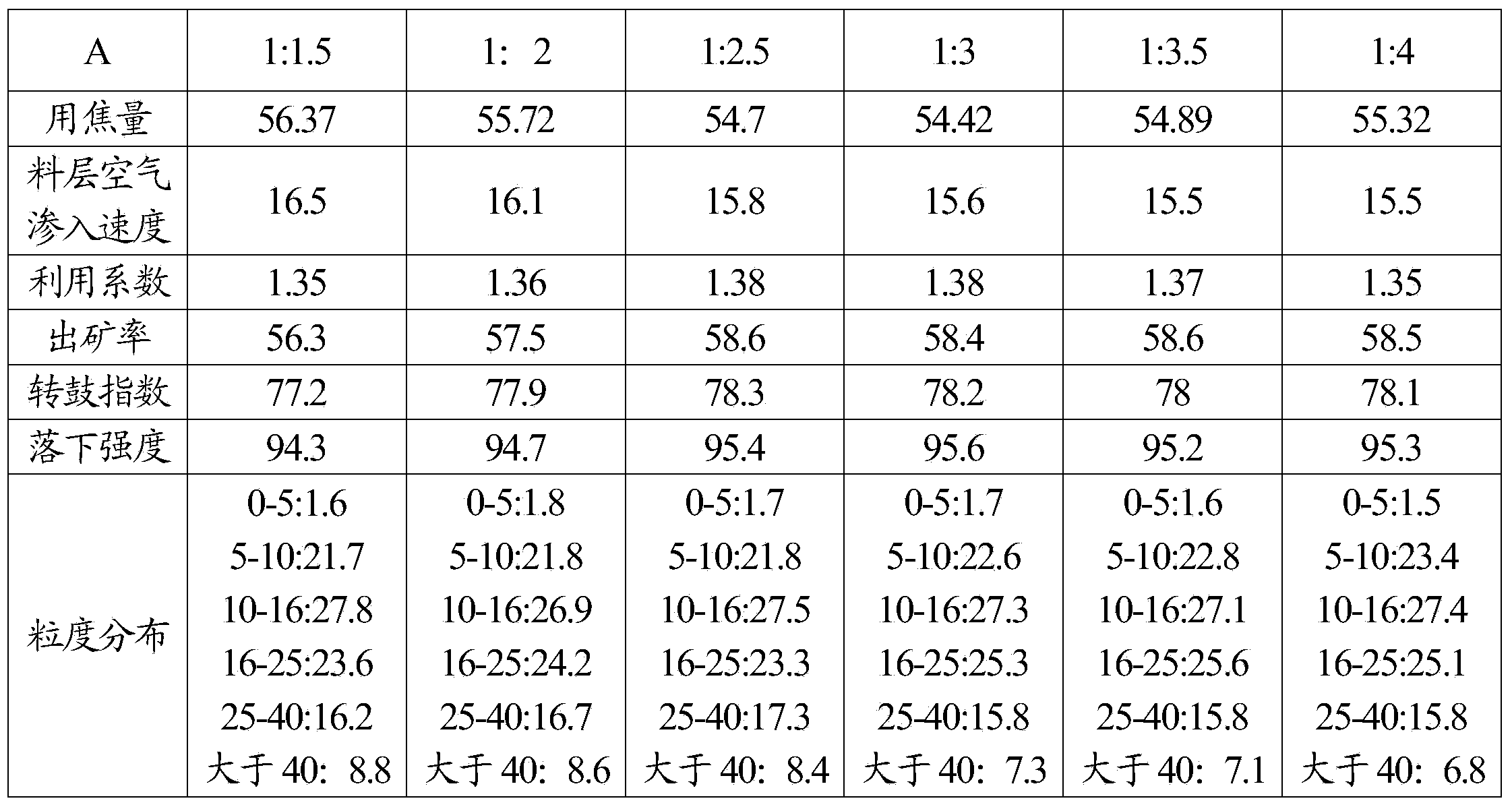

InactiveCN103924065AReduce the amount of coke used in sinteringIncrease penetration speedCombustion processMetal

The invention discloses a sintering method and a sintering device of metal compound powder, and particularly relates to a sintering method and a sintering device of metal compound powder. The method comprises the following steps: igniting a sintering feed containing the metal compound powder and simultaneously sucking air from the bottom of a material bed by an exhaust fan, and then jetting statured vapor from the periphery of the material bed within a certain period of time in the sintering feed combustion process, so that the statured vapor enters the sintering feed in combustion from the top of the material bed by the action of an exhaust fan. By adopting the method, the product quality of agglomerate can be effectively improved, for example, ore removal rate, agglomerate size component and the like can be effectively improved, and meanwhile, the coke amount also can be reduced in the sintering process.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

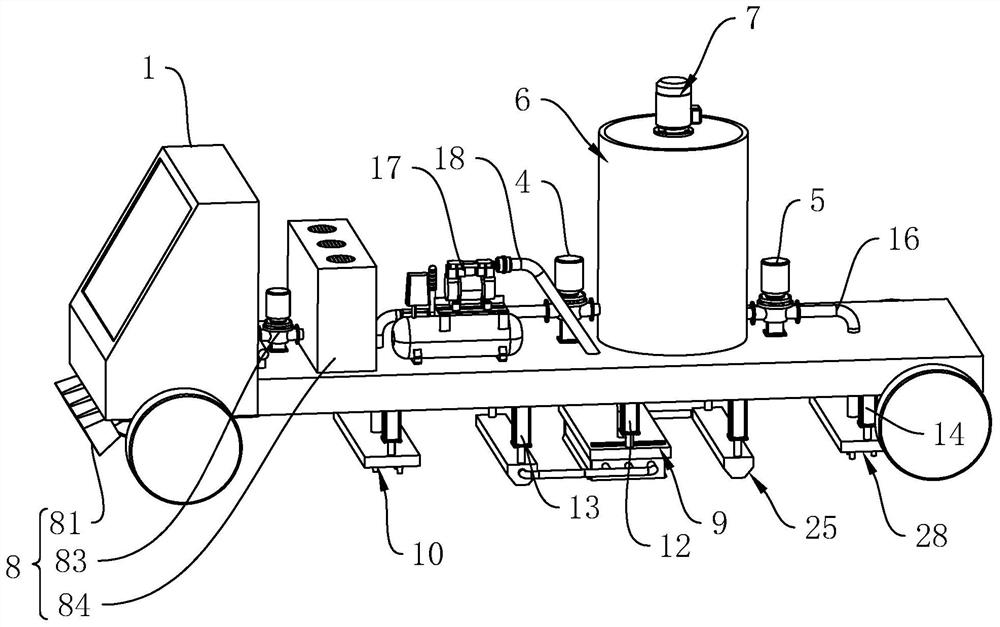

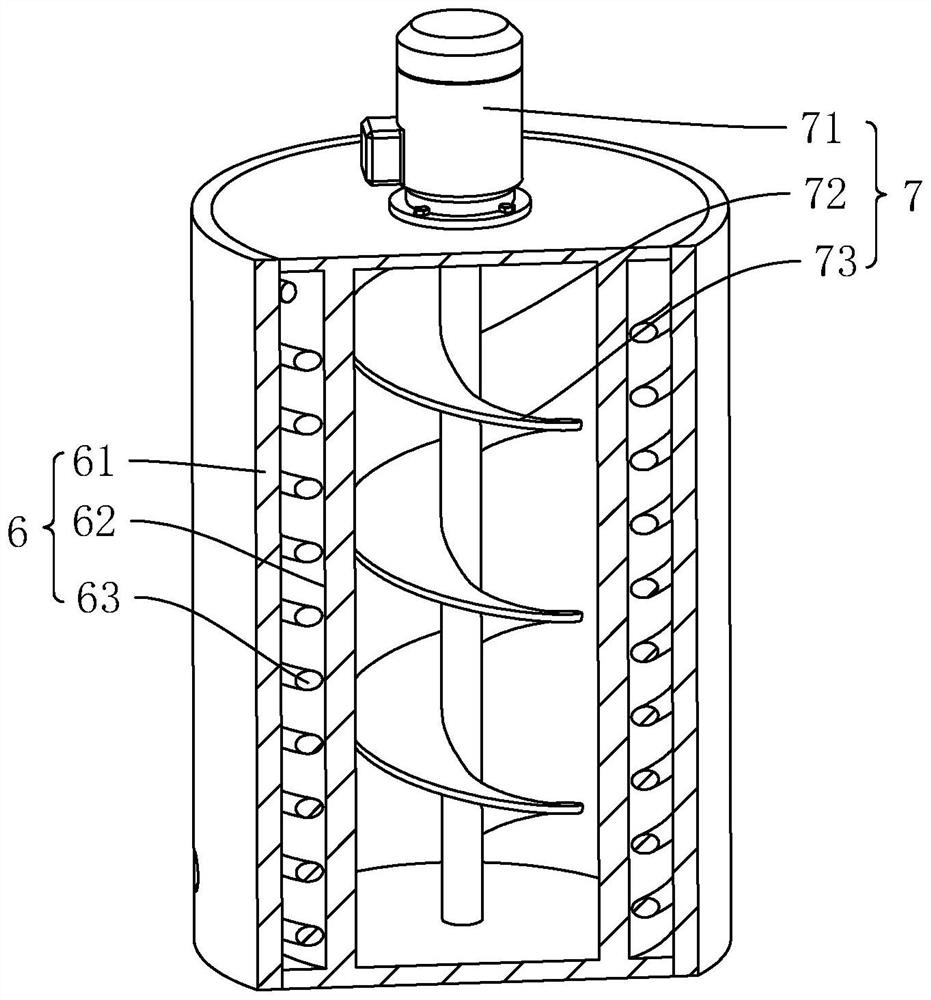

Pavement maintenance device and use method thereof

ActiveCN114032749AImprove maintenance effectGuarantee liquidityRoads maintainenceAutomotive engineeringPavement maintenance

The invention relates to a pavement maintenance device and a use method thereof. The pavement maintenance device comprises a vehicle body, a heating tank is installed at the top of the vehicle body, a stirring mechanism is installed on the heating tank, and a first spray head assembly, a jet head assembly and a second spray head assembly are sequentially arranged at the bottom of the vehicle body from the vehicle head to the vehicle tail. The heating tank is provided with a first high-pressure pump and a second high-pressure pump, a first feeding pipe is installed between the first high-pressure pump and the first spray head assembly, a second feeding pipe is installed between the second high-pressure pump and the second spray head assembly, an air compressor is fixedly installed at the top of the vehicle body and connected with an air feeding pipe, and the end, away from the air compressor, of the air supply pipe is connected with the jet head assembly. The pavement maintenance device has the effect of improving the curing effect of a curing agent.

Owner:HANGZHOU GUANGHUA ROAD & BRIDGE ENG

Method for carbonitriding on stainless steel surface

InactiveCN111500971AUniform steel structureFully release the stressSolid state diffusion coatingRare-earth elementTempering

The invention discloses a method for carbonitriding on a stainless steel surface. By quenching and tempering and ion implanting of rare earth elements on the stainless steel surface, the temperature,carbon potential and ammonia flow rate in a carbonitriding process can be fully controlled. A thickness and a microstructure of a carbonitriding layer on the stainless steel surface can be effectivelycontrolled, and stainless steel products with high strength, high hardness, good wear resistance and excellent fatigue resistance can be obtained. The method for carbonitriding on the stainless steelsurface has the good advantages of short production cycle, simple method and high production efficiency and can be applied to industrial production.

Owner:广州珈鹏科技有限公司

White tea suitable for drinking of people with dampness-heat constitution and manufacturing method thereof

InactiveCN105918521AGood medicineImprove drinking effectPre-extraction tea treatmentManufacturing technologyCucumber family

The invention discloses white tea suitable for drinking of people with dampness-heat constitution. The white tea is prepared from the following raw materials: tea fresh leaves, cucumbers, celeries, semen phaseoli, lotus root slices, radix puerariae, poria cocos, capillary wormwood herbs, Chinese wolfberry fruits, and mulberries. Each manufacturing technology of the white tea is subjected to a reasonable match and a strict control, the manufacturing cycle is greatly shortens, and the working efficiency is improved, so that the prepared white tea is excellent in color, fragrance, taste and shape, high in active ingredient extractum, and suitable for people with dampness-heat to drink.

Owner:ANHUI SHANGHANGSHAN TEA

Adipose tissue fixing solution as well as preparation method and application method thereof

InactiveCN110973116AFixed uniformEasy to preparePreparing sample for investigationDead animal preservationAcetic acidMedicine

The invention discloses an adipose tissue fixing solution as well as a preparation method and an application method thereof. The preparation method of the adipose tissue fixing solution comprises thefollowing steps: taking 32-36 parts of ethanol and 34-36 parts of salicylic acid and mixing well, adding 18-22 parts of formaldehyde and 3-5 parts of glacial acetic acid, and continuing to mix well toobtain a solution a; taking 10-14 parts of polyethylene glycol, 2-5 parts of calcium chloride, 6-10 parts of ammonium sulfate and 300-400 parts of water, ultrasonically mixing the materials well, andstoring the mixture in an environment of 4 DEG C for one night to obtain a solution b; and mixing the prepared solution a and the prepared solution b by using a magnetic stirrer, and obtaining the adipose tissue fixing solution after the solution a and the solution b are well mixed. The fixing method comprises the following steps: taking an adipose tissue sample, adding the adipose tissue fixingsolution, fixing the adipose tissue sample at room temperature for 3-24 hours, and carrying out dehydration treatment, transparency treatment and waxing treatment by adopting a full-automatic dehydrator. The adipose tissue fixing solution is simple in preparation method, low in toxicity and easy to operate, and has a good application prospect.

Owner:SUZHOU CANCERCELL BIOTECH

Method for penetrating I-steel transverse beam in reinforcing process of jacking bridge and culvert line

InactiveCN107178044AEnsure driving safetyIncrease penetration speedGround-workBlock and tackleEngineering

The invention discloses a method for penetrating an I-steel transverse beam in the reinforcing process of a jacking bridge and culvert line. The method comprises the following steps: setting a row of fixed pulley anchor columns, fixed pulleys, moving pulley set anchor columns, moving pulley sets and a windlass on the outer side of an existing line, winding a steel wire rope wound on the moving pulley sets and the fixed pulleys in a manual windlass rotating manner, enabling an I-steel transverse beam connected with the steel wire rope to penetrate into a transverse beam groove from a lower part, and the like. The method for penetrating the I-steel transverse beam in the reinforcing process of the jacking bridge and culvert line, which is disclosed by the invention, has the advantages that the power of the pulleys is taken, the mechanical principle is sufficiently utilized, construction convenience is achieved, the power and labor are saved, the penetration speed of the I-steel transverse beam is increased, the working efficiency is improved, running security of lines is ensured, and the like.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

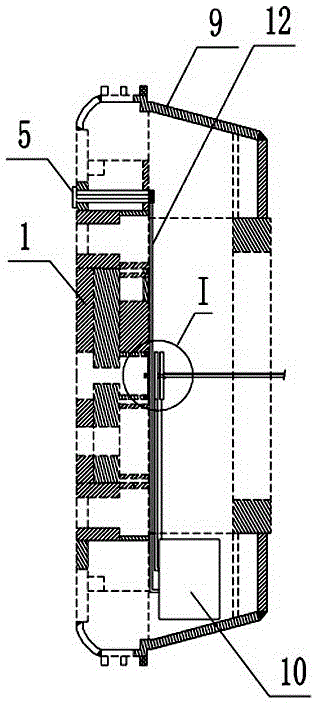

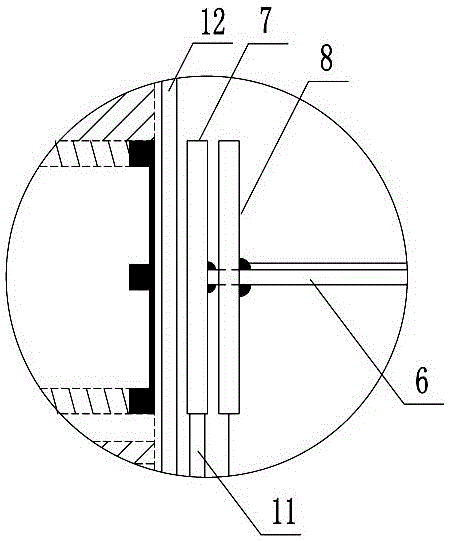

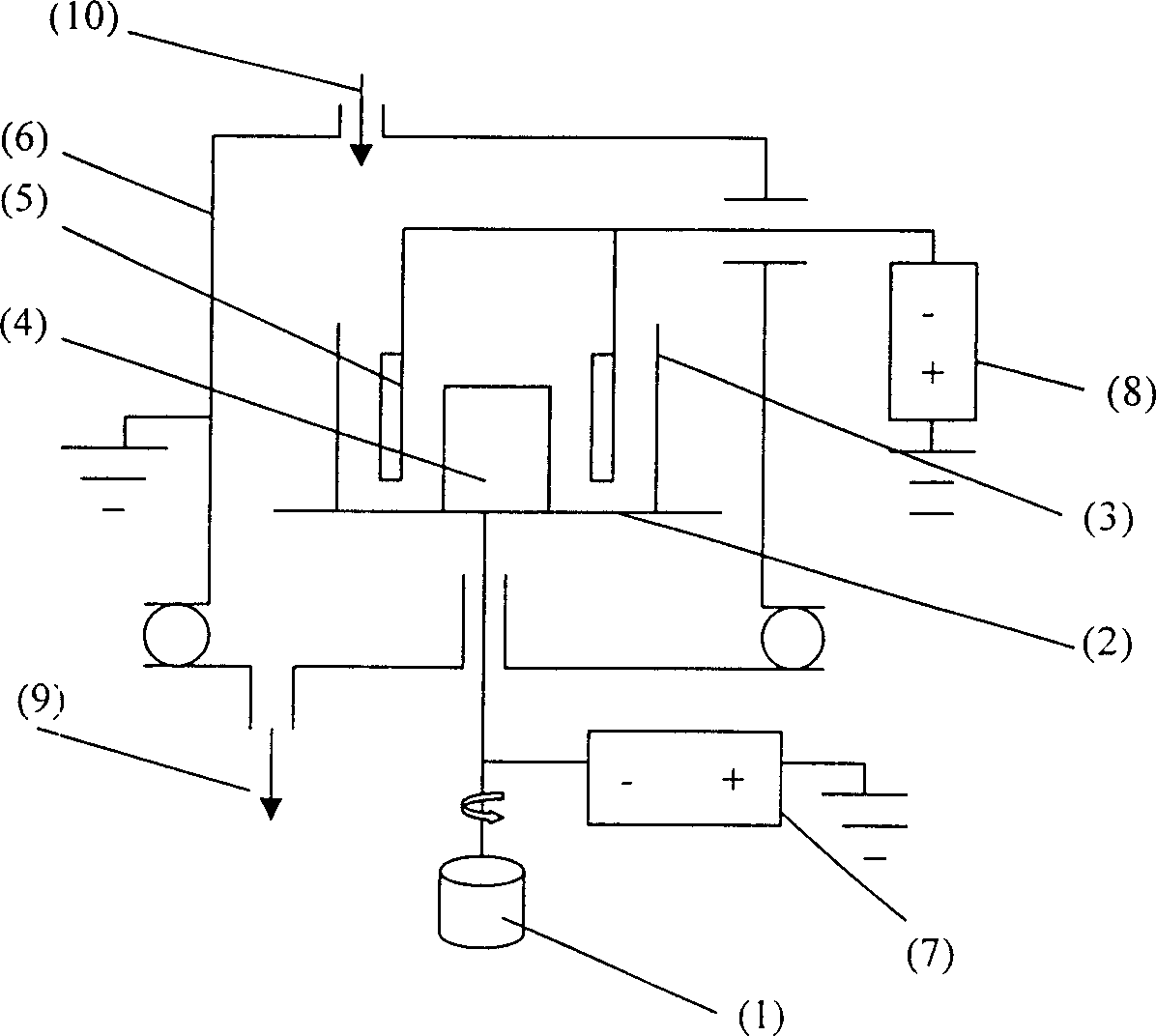

Dual-layer glow ion carbonizing apparatus and process

InactiveCN1174112CImprove adsorption capacityDiffusion fastVacuum evaporation coatingSputtering coatingMaterials scienceHeat treating

Owner:TAIYUAN UNIV OF TECH

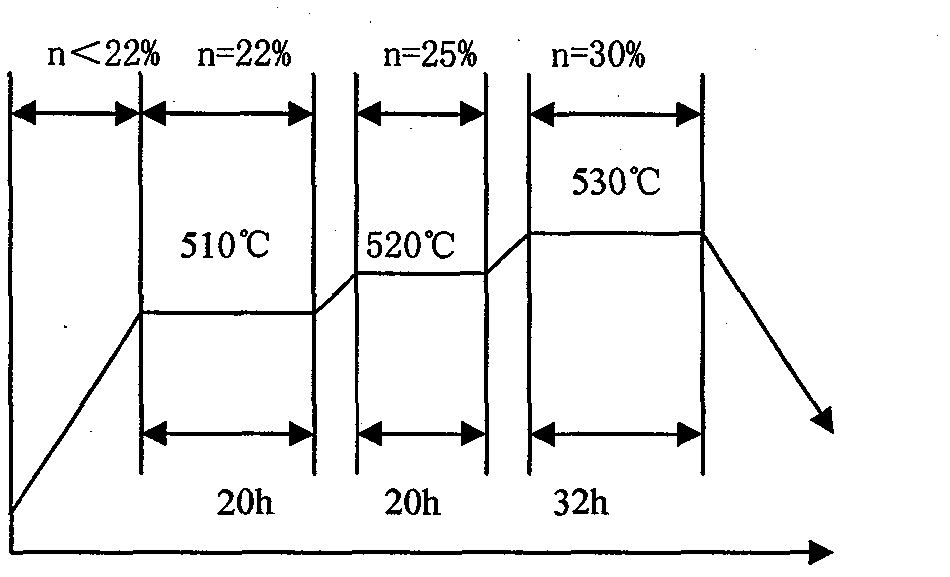

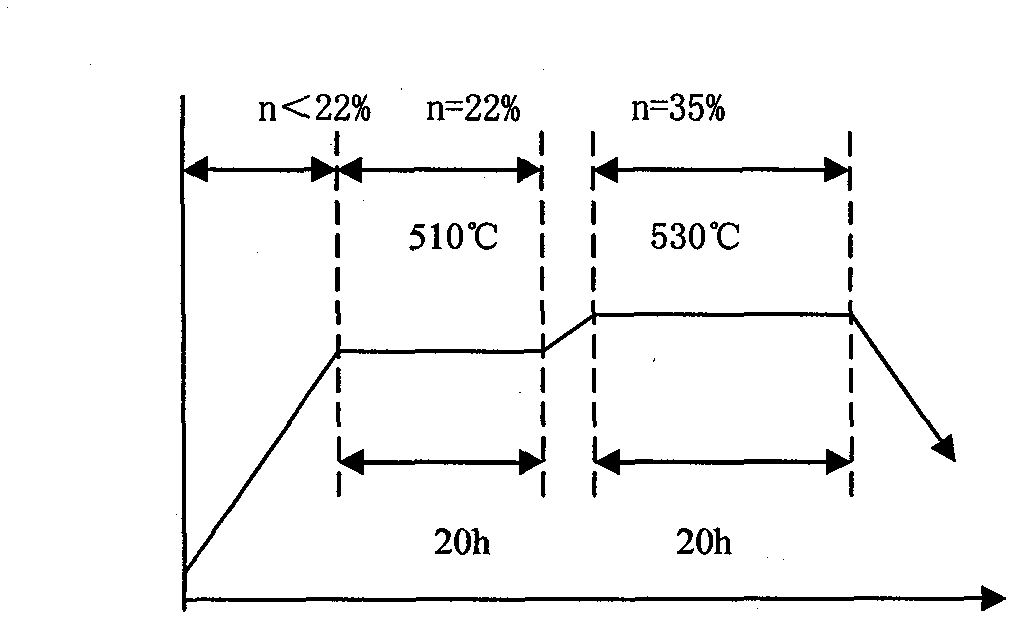

Method for shortening gas nitriding process time of structural alloy steel

ActiveCN104250720AEasy NitridingSpeed up spreadingSolid state diffusion coatingDecompositionFree cooling

The invention discloses a method for shortening the gas nitriding process time of structural alloy steel, relates to a method for shortening the gas nitriding process time of steel, and aims at solving the problems of long nitriding time and low production efficiency of an existing nitriding process of structural alloy steel. The method comprises the following steps: 1, putting an energizer / sand mixture into an iron bucket; 2, putting a structural alloy steel workpiece and the iron bucket with the energizer / sand mixture into a nitriding tank, sealing a furnace cover, introducing ammonia gas until the volume percent of the ammonia gas in a nitriding tank is 90%, uniformly heating until the temperature of the nitriding tank is 530-540 DEG C, preserving heat for 20 hours wherein the ammonia decomposition rate is 20%-35% and the temperature is 530-540 DEG C, naturally cooling to less than 150 DEG C along with a furnace, and discharging from the furnace to obtain a nitrided structural alloy steel workpiece with the nitriding layer depth of not less than 0.3 mm. The method of a nitriding process of the structural alloy steel can be obtained.

Owner:HARBIN TURBINE +1

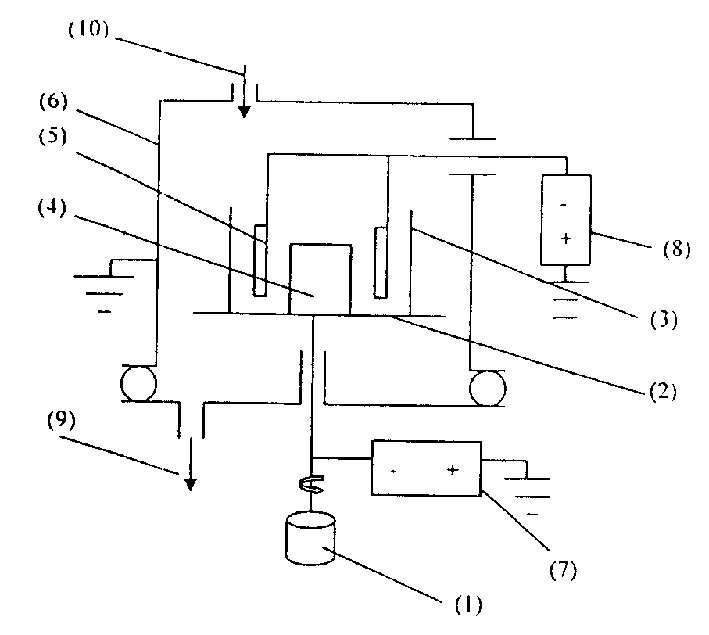

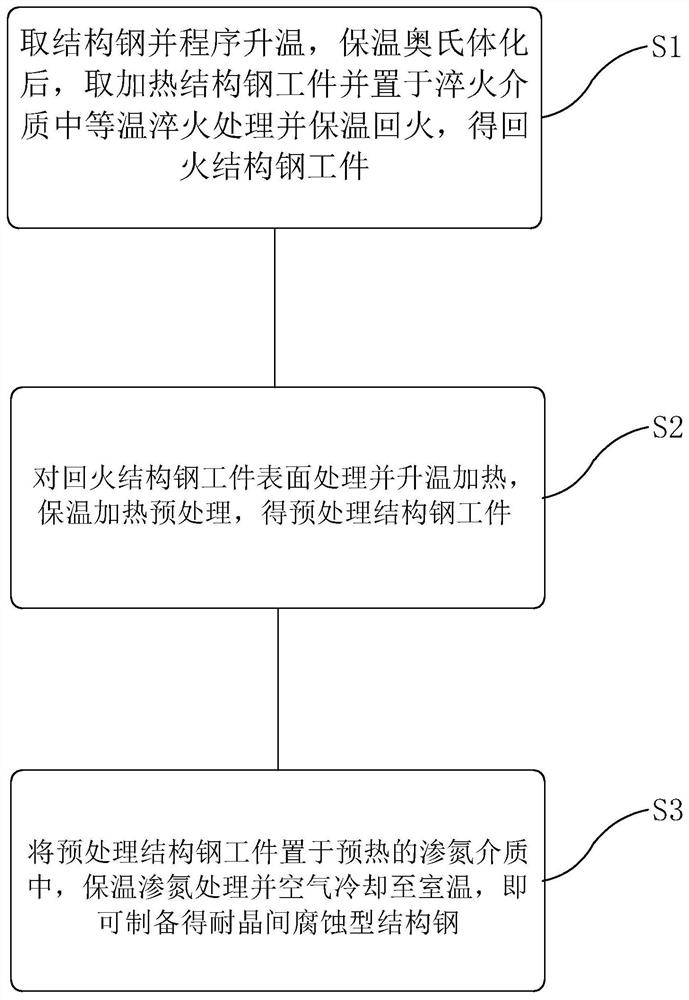

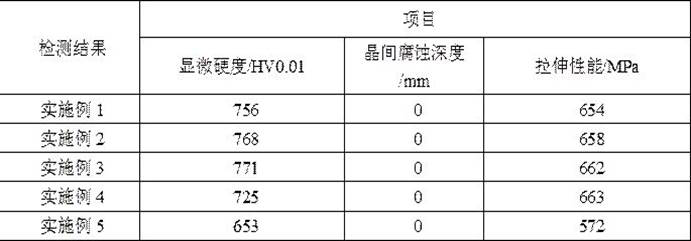

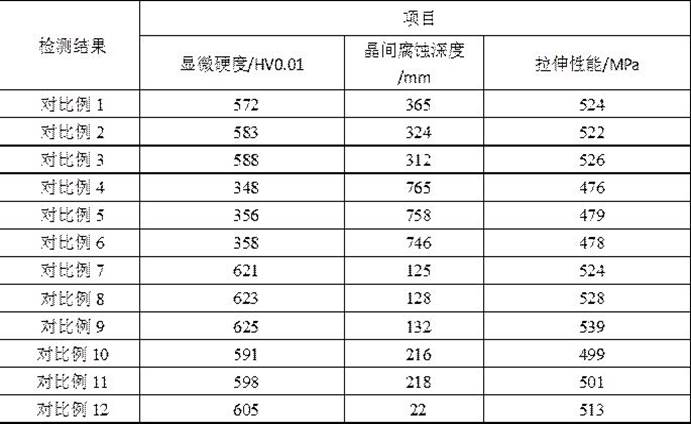

Quick-acting nitriding method for intergranular corrosion resistant structural steel

InactiveCN112176277ASimple internal structureImprove uniformitySolid state diffusion coatingAustemperingMetallurgy

The invention relates to the field of metal treatment, and particularly discloses a quick-acting nitriding method for intergranular corrosion resistant structural steel. The quick-acting nitriding method for the intergranular corrosion resistant structural steel comprises the following steps: S1, taking the structural steel, carrying out programmed temperature rise and heat preservation austenitizing, then taking a heated structural steel workpiece, putting the heated structural steel workpiece into a quenching medium, carrying out isothermal quenching treatment, and carrying out heat preservation tempering to obtain a tempered structural steel workpiece; S2, carrying out surface treatment on the tempered structural steel workpiece, performing temperature rising heating and heat preservation heating pretreatment, and obtaining a pretreated structural steel workpiece; and S3, placing the pretreated structural steel workpiece in a preheated nitriding medium, carrying out heat preservation nitriding treatment, conducting air cooling to the room temperature, and then preparing the intergranular corrosion resistant structural steel. The quick-acting nitriding method for the structural steel is quick and effective to operate, and the problems that in the nitriding process of the structural steel, short-time nitriding treatment can cause reduction of the thickness of a compound structural layer and poor uniformity and distribution can be effectively solved.

Owner:常州市汇丰天元热处理有限公司

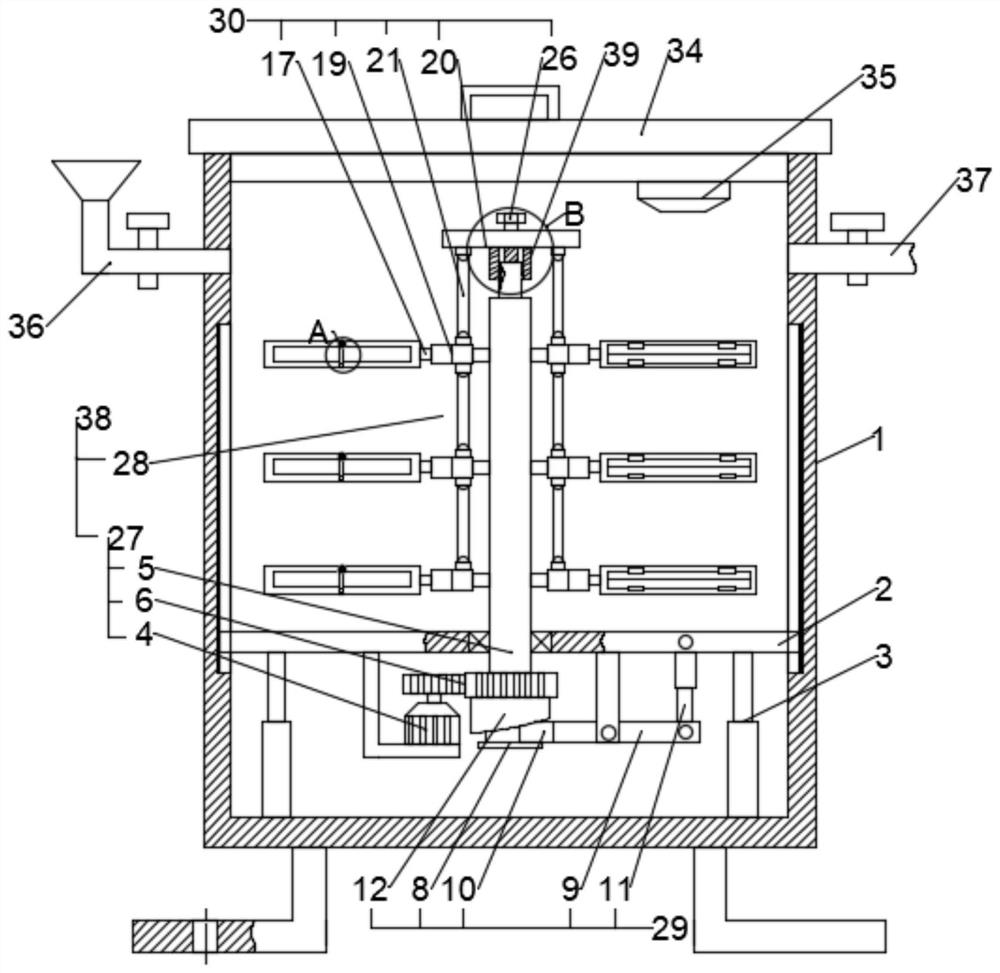

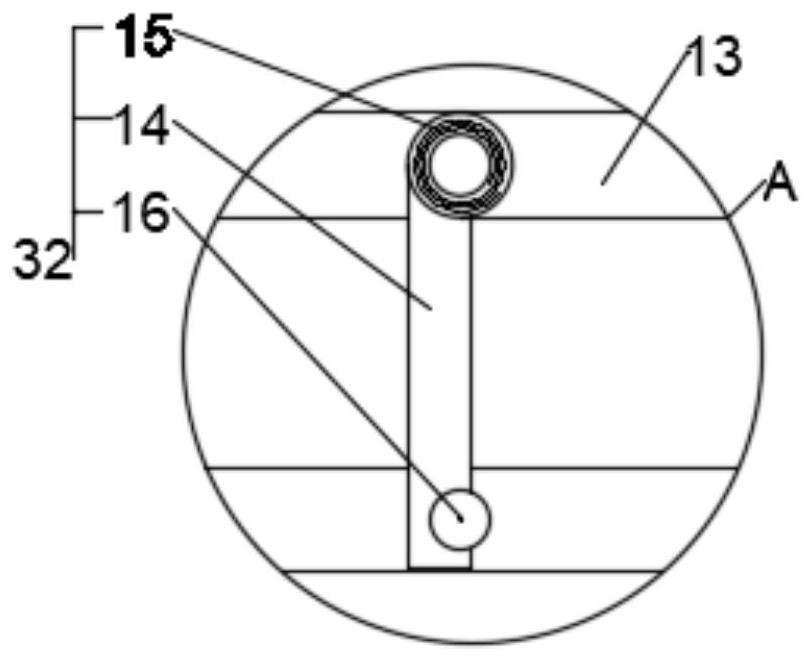

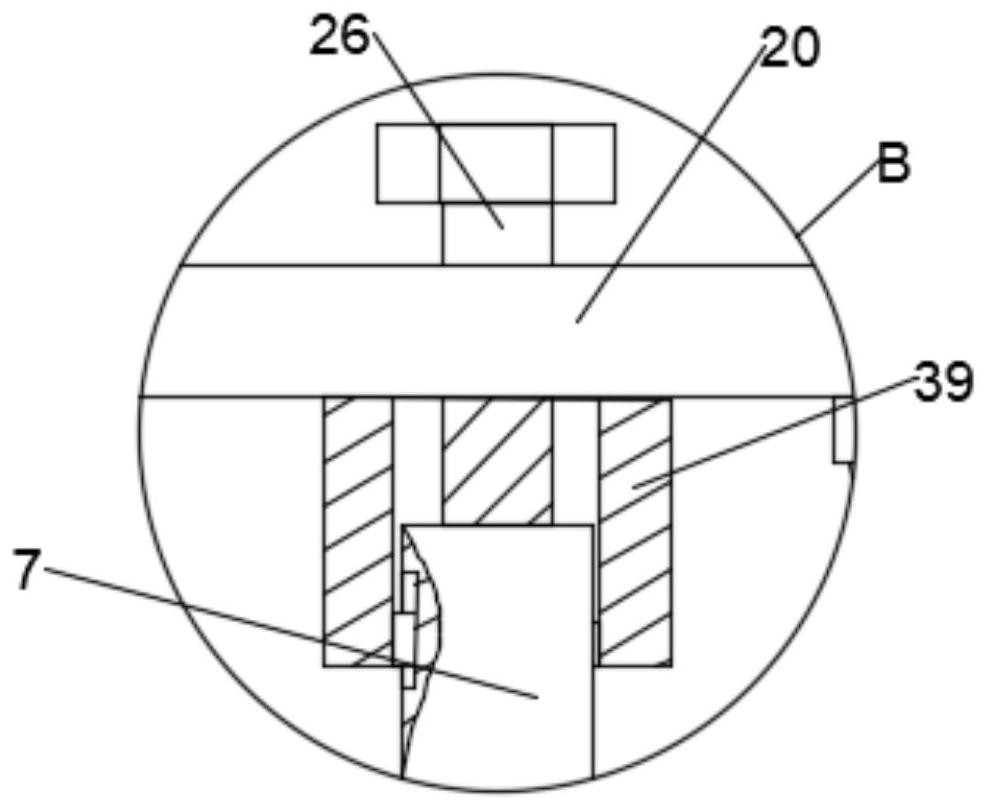

Glue residue removing device for circuit board processing

ActiveCN113766743AIncrease desmear efficiencyIncrease desmear effectPrinted circuit liquid treatmentEngineeringMechanical engineering

The invention is applicable to the field of circuit board processing devices, and provides a glue residue removing device for circuit board processing, which comprises a shell and a driving mechanism, and the driving mechanism comprises a power assembly for driving a circuit board to synchronously perform circular motion around a rotation center, a transmission assembly is used for driving the circuit board to swing back and forth in the process that the circuit board performs circular motion around the rotating center, and the transmission assembly is in transmission connection with the power assembly; a fixing mechanism is used for fixing the circuit board; a disintegrating slag collecting mechanism is connected with the fixing mechanism, and the disintegrating slag collecting mechanism is used for collecting insoluble substances generated in the slag removing process of the circuit board; according to the glue residue removing device for circuit board processing, the power assembly drives the circuit board to synchronously perform circular motion around the rotating center, so that the penetrating speed of a KMn04 solution from the side end face of the circuit board is increased, and the glue residue removing efficiency of the circuit board is effectively improved.

Owner:FOREWIN FPC SUZHOU

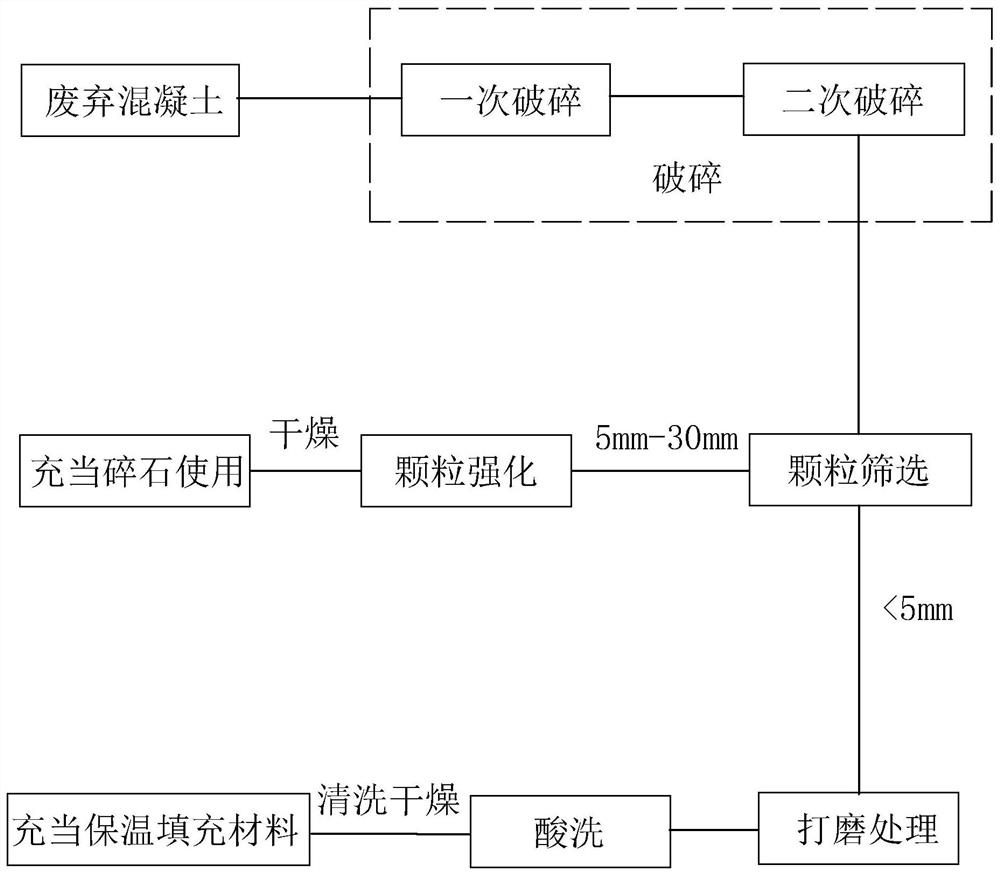

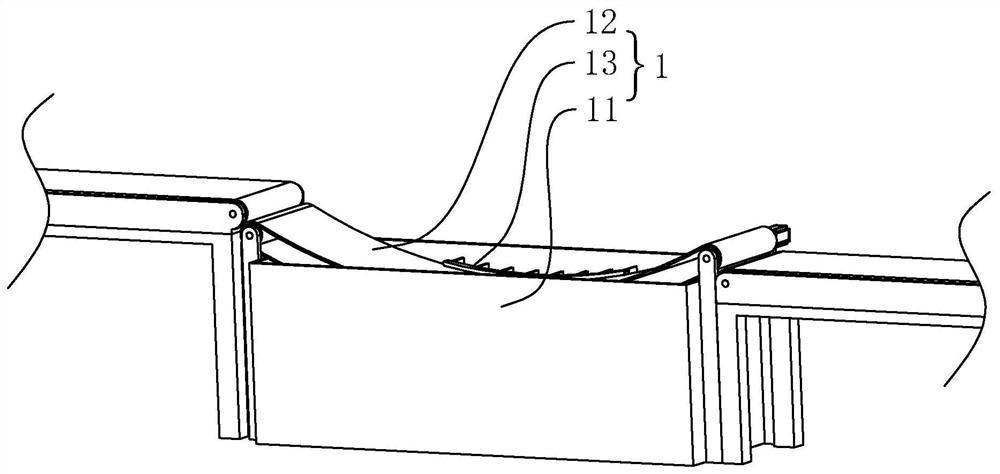

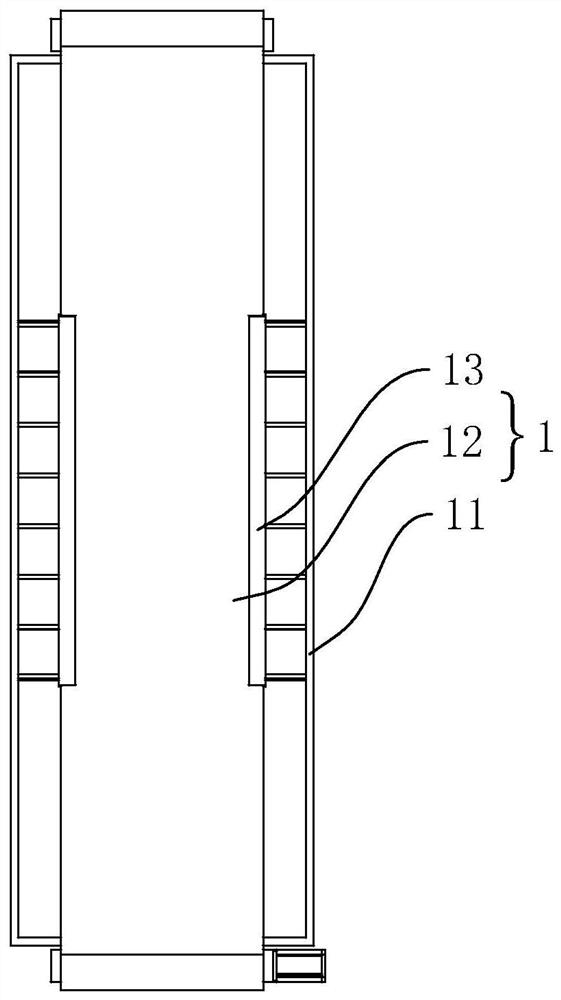

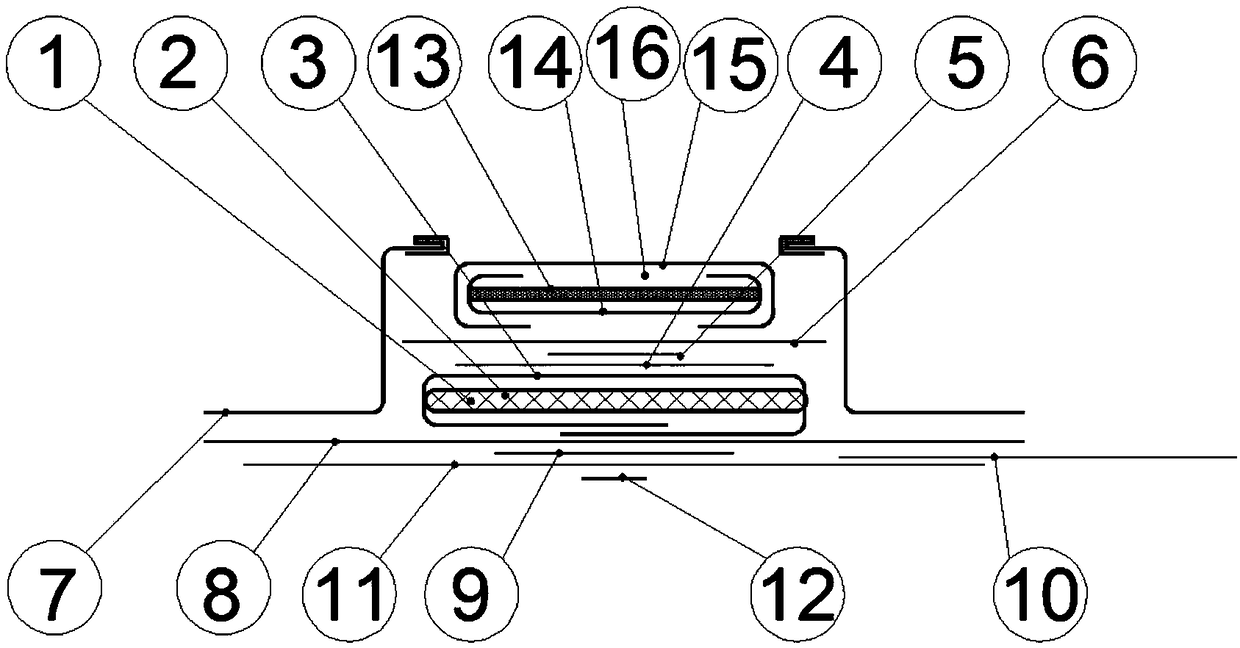

Concrete production technology with waste recycled

InactiveCN111977996AAchieve reuseSolve the problem that no suitable method can be foundSolid waste managementEnvironmental engineeringSODIUM SILICATE SOLN

The invention relates to a concrete production technology with waste recycled. The concrete production technology with the waste recycled comprises the following step: setting and hardening waste concrete, conducting secondary crushing after waste concrete blocks are subjected to primary crushing, screening crushed concrete granules, transporting the concrete granules to a reinforcing device for reinforcing, conducting over-drying after the concrete granules are reinforced, and supplying the over-dried concrete granules to fresh concrete for use as gravels and aggregates with the strength level lowered by two levels according to the original strength level of the waste concrete, wherein the reinforcing device comprises an immersion tank, a turning conveyor belt and turning devices, and anultrasonic oscillator is arranged on a bottom wall of the immersion tank. By means of the production technology, the waste concrete can be processed so that the waste concrete can serve as the fillingaggregates of the fresh concrete for reuse, and thus the production technology is environmentally friendly and economical; and by arranging the ultrasonic oscillator, the infiltration speed of a sodium silicate solution into the concrete granules can be improved, so that the processing efficiency is improved.

Owner:ZHEJIANG FANGYUAN BUILDING MATERIALS TECH

Processing technology of integrated shell of high-pressure flow environment-friendly integrated electric fuel pump

InactiveCN110665773AHigh hardnessImprove the strength of forcePretreated surfacesSolid state diffusion coatingSolution treatmentThermodynamics

The invention relates to a high-pressure flow environment-friendly integrated electric fuel pump, in particular to a processing technology of an integrated shell of the high-pressure flow environment-friendly integrated electric fuel pump. The technical scheme is as follows: the processing technology of the integrated shell of the high-pressure flow environment-friendly integrated electric fuel pump comprises the following steps: a, cold heading to obtain an integrated shell rough blank; b, carrying out solid solution treatment on the integrated shell rough blank in the step a; c, finishing the integrated shell rough blank; d, carrying out shot blasting treatment on the integrated shell rough blank; e, activating the integrated shell blank; f, performing non-metal element composite infiltration on the integrated shell blank; g, insulating the integrated shell blank; h, cooling the integrated shell blank; i, painting anti-corrosive primer to the surface of the integrated shell blank toform a primer film; and j, coating high-solid paint on the integrated shell blank to obtain a finished product. By adopting the scheme, the processing technology of the integrated shell of the high-pressure flow environment-friendly integrated electric fuel pump can improve the hardness and achieve good corrosion resistance.

Owner:RUIAN KEDA AUTO PARTS CO LTD

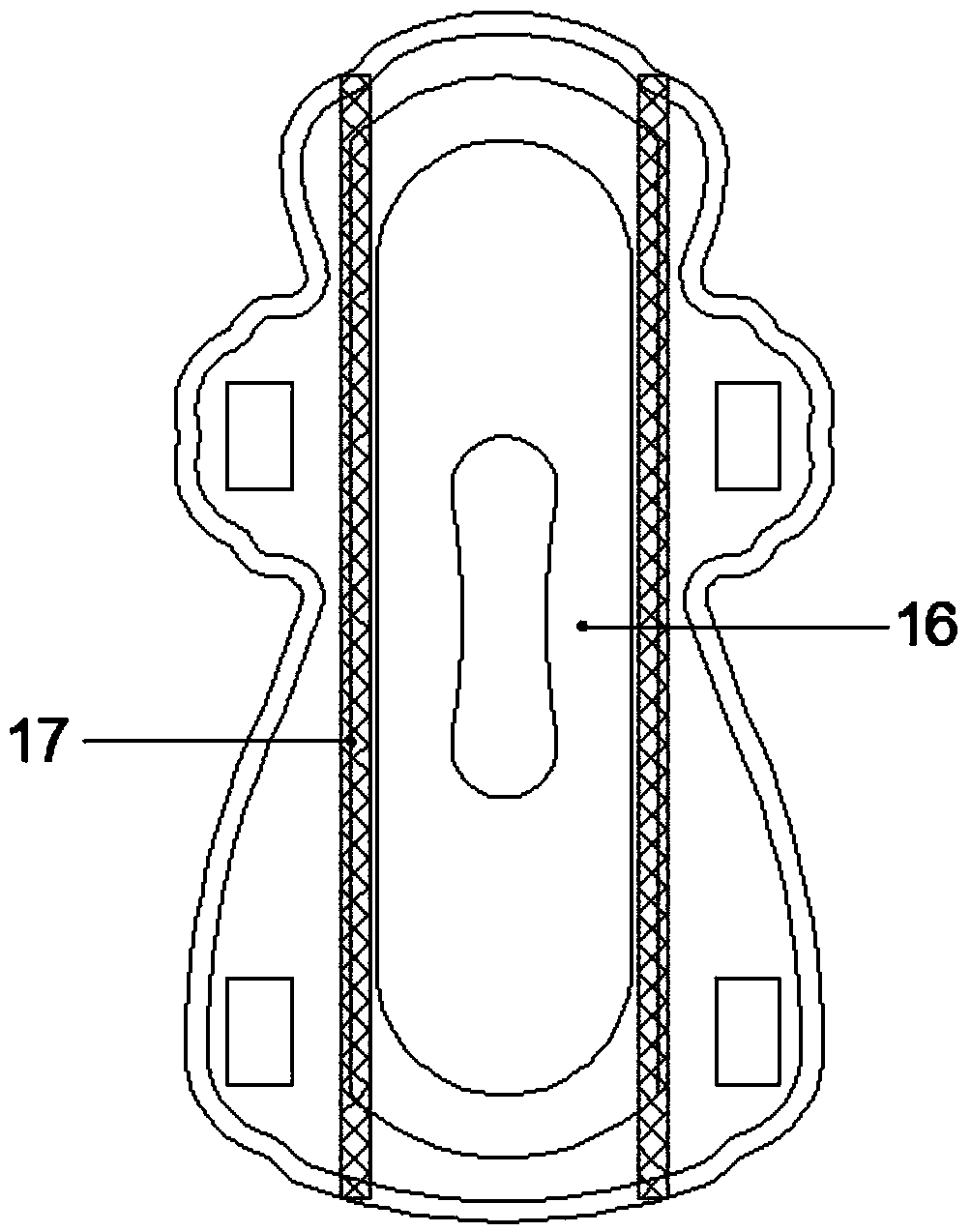

Separated multi-layer sanitary napkin

InactiveCN109009678AImprove hygieneImprove securityAbsorbent padsBandagesPulp and paper industryToilet paper

The present invention discloses a separated multi-layer sanitary napkin, belonging to the technical field of sanitation supplies. The separated multi-layer sanitary napkin comprises a cotton core, aninner cavity of the cotton core is filled with high polymer materials, toilet paper is arranged around the external portion of the cotton core, the bottom portion of the toilet paper is provided witha bottom film, the left and right sides of the top portion of the bottom film are provided with side non-woven fabrics, backlimb release paper is glued at the center of the bottom portion of the bottom film, the backlimb release paper is provided with shelter release paper, the top portion of the shelter release paper is glued with the bottom portion of the bottom film, and an envelope is glued with the bottom portion of the shelter release paper. The separated multi-layer sanitary napkin can separate layers and can directly strip and discard the layers after the layers are polluted to continuously use a bottom-layer standard sanitary napkin, can be used for many times, saves replacement time, is safe and rapid, and has high sanitation and safety in the usage process.

Owner:安徽珂力智能电气有限公司

A method for shortening the gas nitriding process time of alloy structural steel

The invention relates to a method for shortening the gas nitriding process time of alloy structural steel, which relates to a method for shortening the gas nitriding process time of steel. The purpose of the invention is to solve the problem of long nitriding time and low production efficiency in the existing nitriding process of alloy structural steel. Method: 1. Put the infiltrating agent / sand mixture into the iron drum; 2. Put the alloy structural steel workpiece and the iron drum containing the infiltrating agent / sand mixture in the nitriding tank, seal the furnace cover, and put it into Ammonia, until the volume fraction of ammonia in the nitriding tank is 90%, and then uniformly heated until the temperature of the nitriding tank is 530°C-540°C, and then the ammonia decomposition rate is 20%-35% and the temperature is 530°C-540 ℃ for 20 hours, and then naturally cooled with the furnace until the temperature is lower than 150 ℃, it can be taken out of the furnace, and a nitrided alloy structural steel workpiece with a nitrided layer depth of ≥0.3mm can be obtained. The invention can obtain a method for nitriding process of alloy structural steel.

Owner:HARBIN TURBINE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com