Quick-acting nitriding method for intergranular corrosion resistant structural steel

A kind of structural steel, corrosion-type technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of reduced thickness of compound structure layer, poor uniformity and distribution, etc., to inhibit growth and Precipitation and preparation steps are simple and convenient, and the effect of improving uniformity and uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

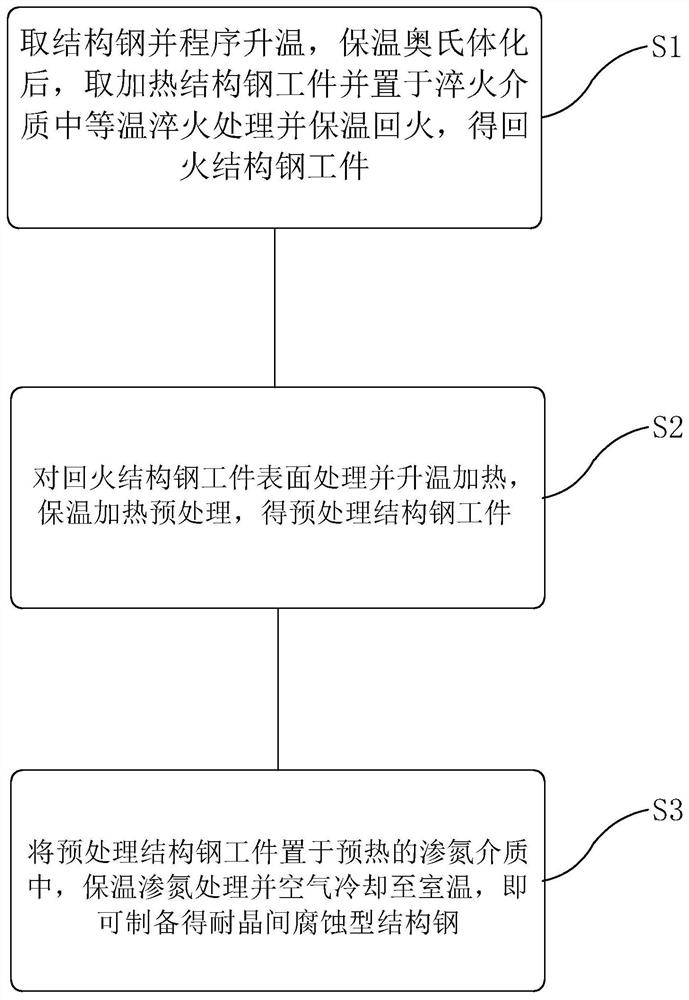

Method used

Image

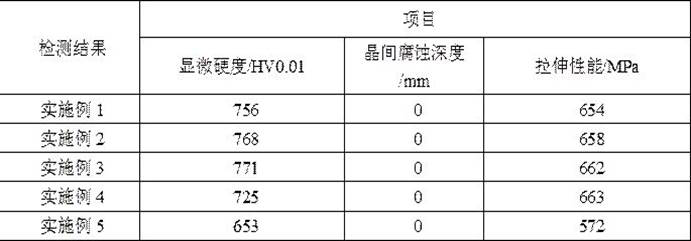

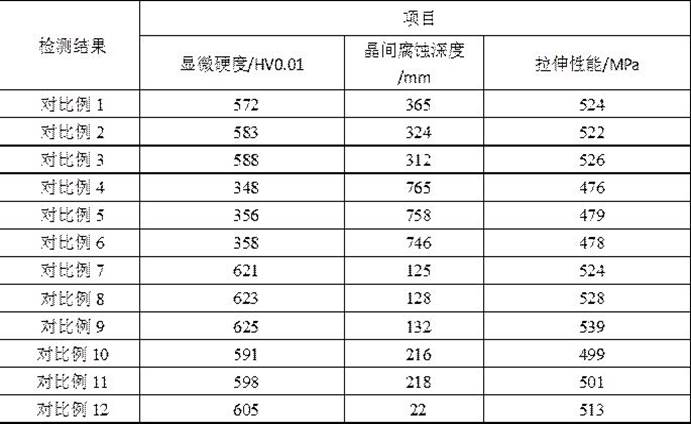

Examples

Embodiment 1

[0031] S1. Take the structural steel and place it in a box-type resistance furnace, heat it up at 5°C / min, and after austenitization treatment for 15 minutes, after the heat preservation treatment, take the heat preservation workpiece and place it in the quenching medium immediately, and control the quenching The temperature of the medium is 55°C. After isothermal treatment in the quenching medium for 30 minutes, the isothermal treatment is completed and the isothermally quenched workpiece is collected; the isothermally quenched workpiece is collected and placed in a box-type resistance furnace, and then the temperature is raised to 580°C at 10°C / min. After heat preservation and tempering for 75 minutes, after standing to cool to room temperature, the tempered structural steel workpiece was collected;

[0032] S2. Stir and mix cerium oxide and 0.5mol / L nitric acid at a molar ratio of 1:20 and place it under 200W for ultrasonic dispersion for 10 minutes, collect the dispersed sl...

Embodiment 2

[0035] S1. Take the structural steel and put it in a box-type resistance furnace, heat it up at 5°C / min, and after austenitization treatment for 17 minutes, after the heat preservation treatment, take the heat preservation workpiece and place it in the quenching medium immediately, and control the quenching The temperature of the medium is 60°C. After isothermal treatment in the quenching medium for 32 minutes, the isothermal treatment is completed and the isothermally quenched workpiece is collected; the isothermally quenched workpiece is collected and placed in a box-type resistance furnace, and then the temperature is raised to 590°C at 10°C / min. After heat preservation and tempering for 82 minutes, after standing to cool to room temperature, the tempered structural steel workpiece was collected;

[0036] S2. Stir and mix cerium oxide and 0.5mol / L nitric acid at a molar ratio of 1:20 and place it under 250W for ultrasonic dispersion for 12 minutes, collect the dispersed slur...

Embodiment 3

[0039] S1. Take the structural steel and put it in a box-type resistance furnace, heat it up at 5°C / min, and after austenitization treatment for 20 minutes, after the heat preservation treatment, take the heat preservation workpiece and place it in the quenching medium immediately, and control the quenching The temperature of the medium is 65°C. After isothermal treatment in the quenching medium for 35 minutes, the isothermal treatment is completed and the isothermally quenched workpiece is collected; the isothermally quenched workpiece is collected and placed in a box-type resistance furnace, and then the temperature is raised to 600°C at 10°C / min. After heat preservation and tempering for 100 minutes, after standing to cool to room temperature, the tempered structural steel workpiece was collected;

[0040] S2. Stir and mix cerium oxide and 0.5mol / L nitric acid at a molar ratio of 1:20 and place it under 300W for ultrasonic dispersion for 15 minutes, collect the dispersed slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com