Sintering method and sintering device of metal compound powder

A technology of metal compound and sintering method, which is applied in the field of sintering of metal compound powder and sintering device, can solve problems such as uneconomical restrictions, achieve the effects of reducing the amount of coke used for sintering, improving particle size, and increasing penetration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 - the sintering method of the sintered material with the existing vanadium-titanium ore weight content less than 20%

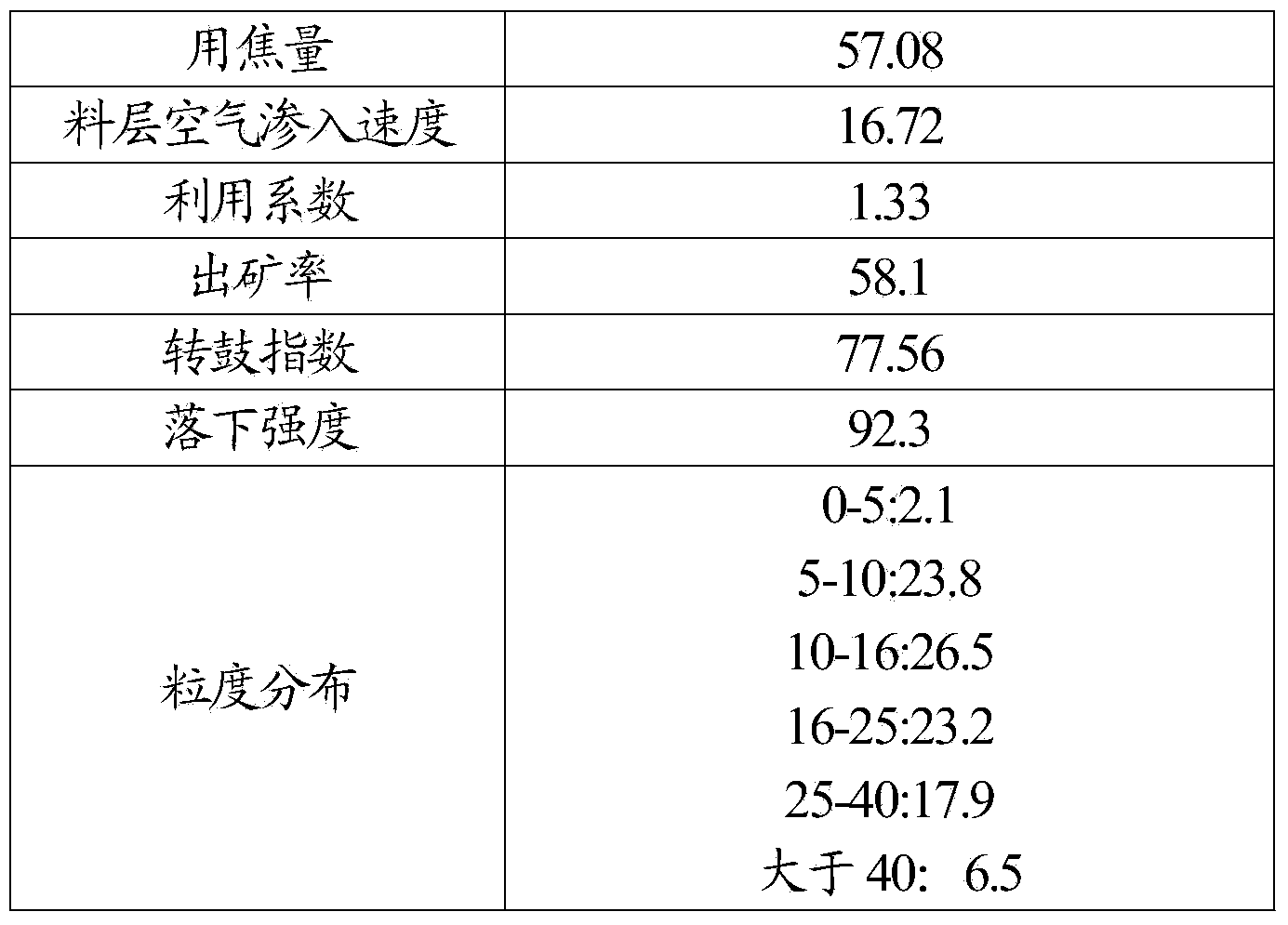

[0024] Adopt the common sintering method of the existing sintering material, do not spray saturated water vapor to the sintering material layer during the sintering process, and measure the physical and chemical indicators of the sintering material after the sintering material is sintered. The data obtained are shown in the table below.

[0025] Table 1: Existing sintering process

[0026]

[0027] In the above table, the amount of coke is used to represent the amount of fuel that needs to be added per ton of sintered ore during the sintering process. The data unit in the table is Kg;

[0028] The air infiltration speed of the material layer is represented by the suction negative pressure of the sintering exhaust fan. The data unit in the table is Kpa;

[0029] Utilization coefficient is an important index to measure the production c...

Embodiment 2

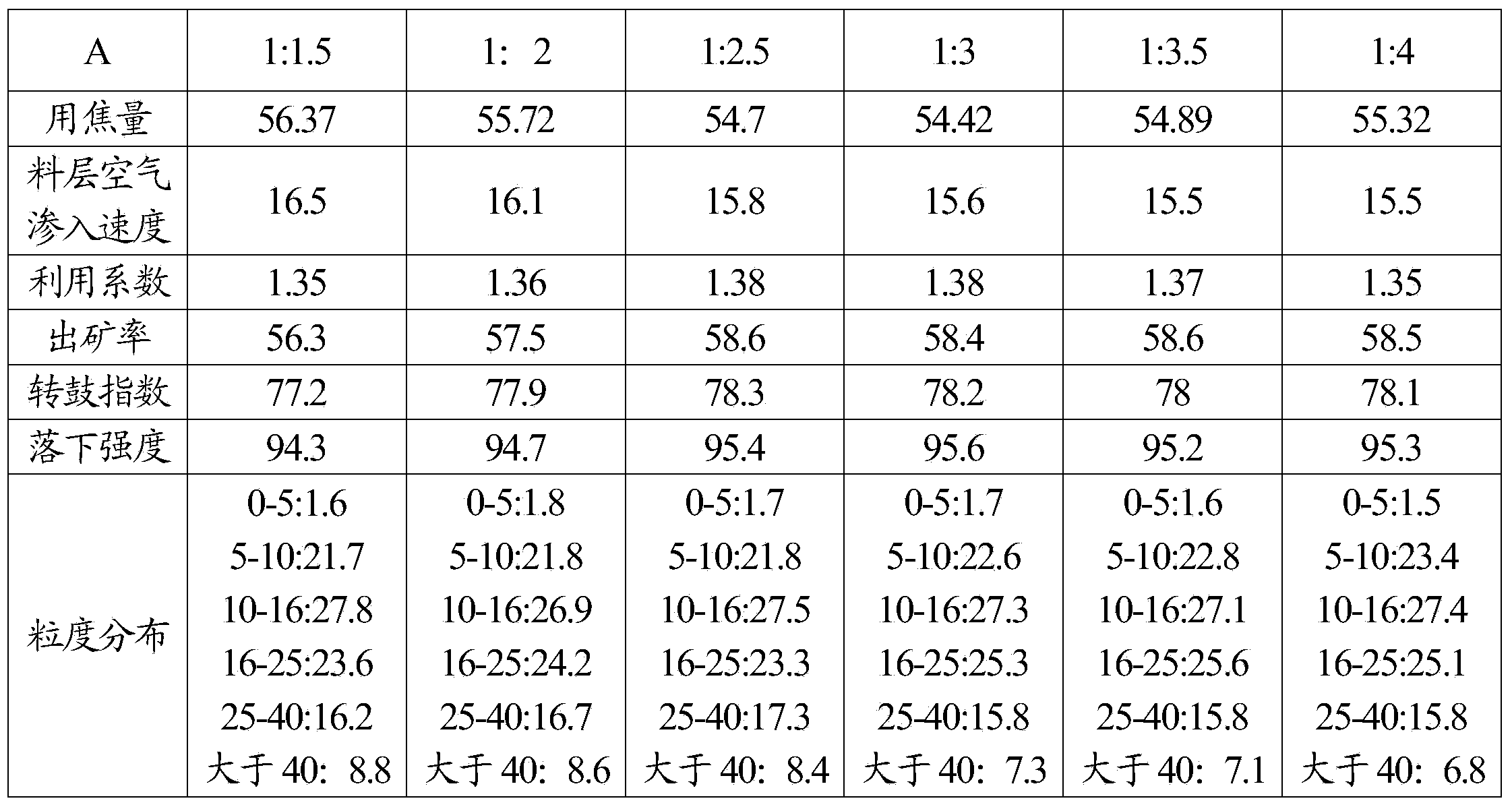

[0034] Embodiment 2 - the sintering of the sintered material with a vanadium-titanium ore weight content of less than 20% in this application

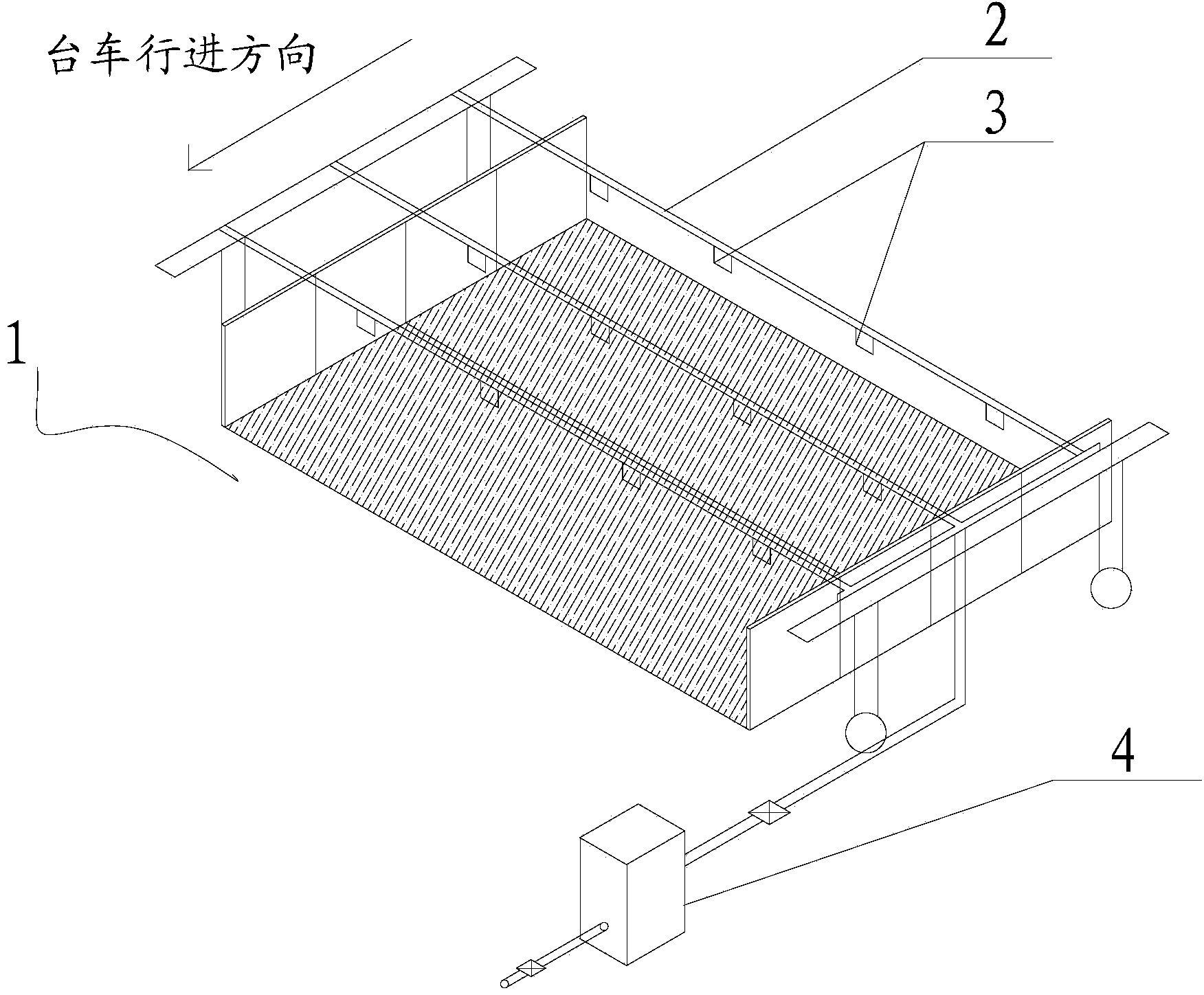

[0035] Using the same sintering device, the sintering device includes a sintering trolley, the lower part of the sintering trolley is provided with a draft device; the upper part of the sintering trolley is provided with a saturated water vapor pipeline, and the saturated water vapor pipeline is connected to the sintering table The horizontal plane of the traveling direction of the car is inclined; the saturated steam pipeline is connected with a nozzle on the pipe surface opposite to the sintering trolley; the saturated steam pipeline is vertically arranged with the horizontal plane of the sintering trolley; the saturated steam pipeline It is connected with the steam dehydration dryer so that the water vapor can be dried through the steam dehydration dryer before entering the saturated water vapor pipeline.

[0036] At the same time, ...

Embodiment 3

[0046] Embodiment three——the sintering of the sintering material whose weight content of vanadium-titanium ore accounts for 20%-40%

[0047] Using the same sintering device, the sintering device includes a sintering trolley, the lower part of the sintering trolley is provided with a draft device; the upper part of the sintering trolley is provided with a saturated water vapor pipeline, and the saturated water vapor pipeline is connected to the sintering table The horizontal plane of the traveling direction of the car is inclined; the saturated steam pipeline is connected with a nozzle on the pipe surface opposite to the sintering trolley; the saturated steam pipeline is vertically arranged with the horizontal plane of the sintering trolley; the saturated steam pipeline It is connected with the steam dehydration dryer so that the water vapor can be dried through the steam dehydration dryer before entering the saturated water vapor pipeline.

[0048] Simultaneously, a sintering me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com