Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Increase the drum index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

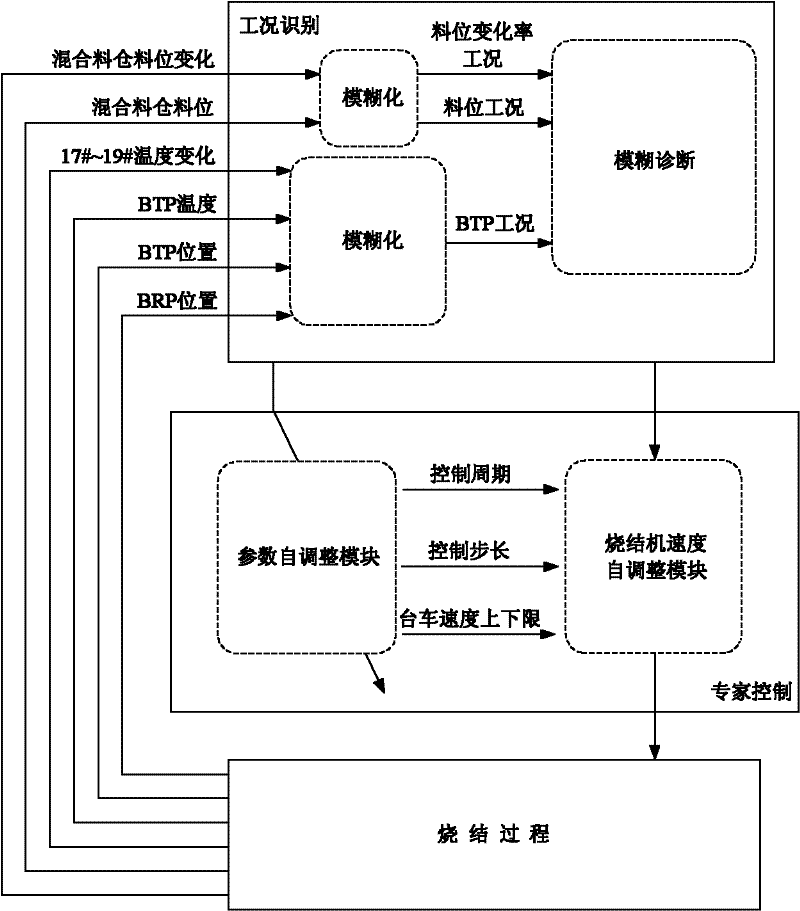

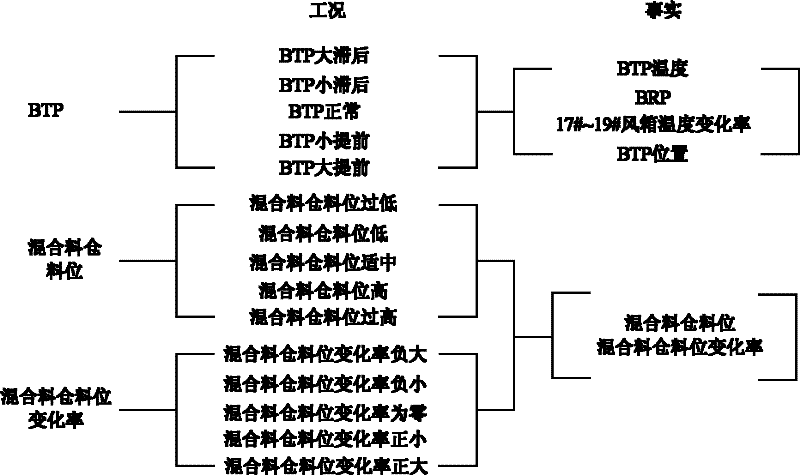

Self-tuning expert control method of burning trough point parameter based on working condition recognition

ActiveCN101907867AImprove anti-interferenceGuaranteed smooth operationAdaptive controlAutomatic controlControl period

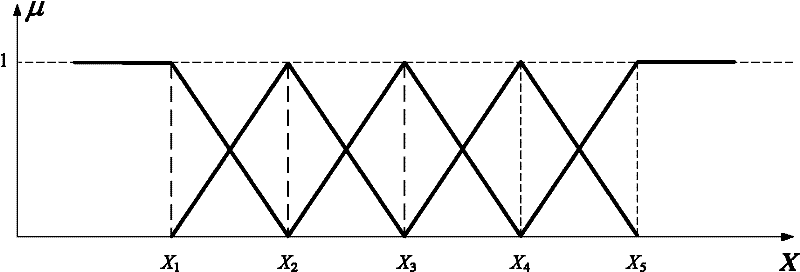

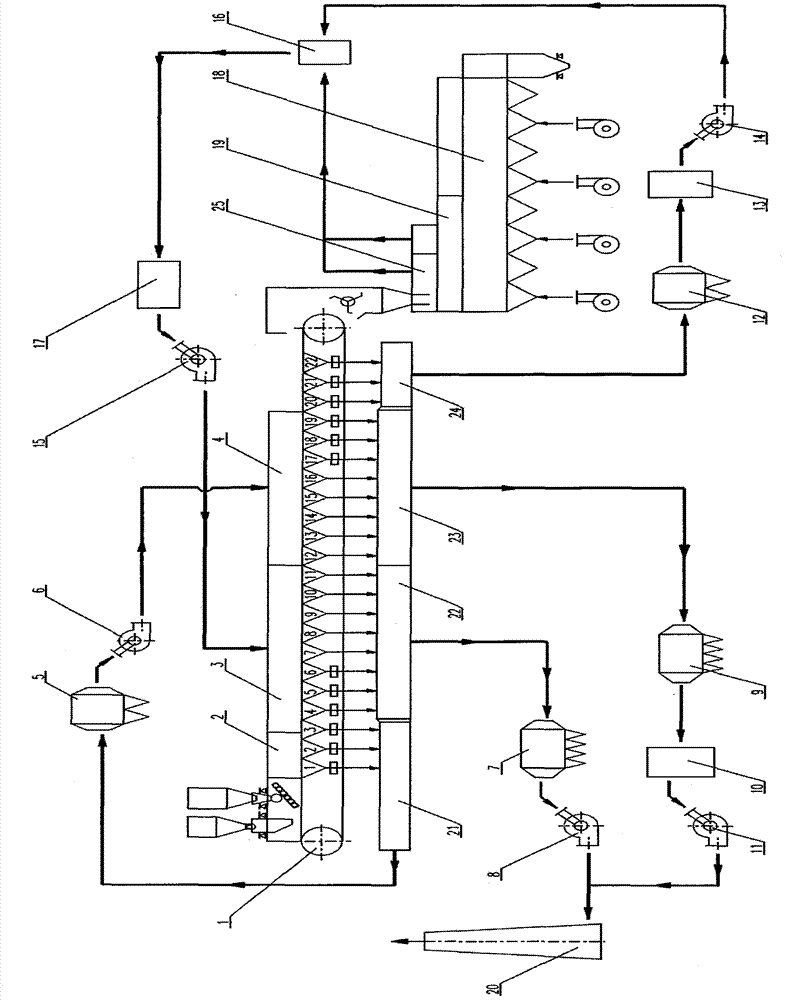

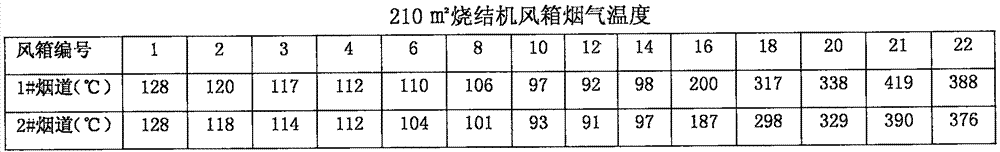

The invention provides a self-tuning expert control method of a burning trough point parameter based on working condition recognition, comprising the following steps of: firstly, data collection and fuzzification: collecting and calculating a mixture level, the change rate thereof, a deviation of a burning trough point position, burning trough point temperature, the change rate of a 17-19 air box temperature average value and 6 process variables of sintering waste gas temperature rising point position, and carrying out fuzzification treatment; secondly, fuzzy diagnosis: obtaining the working condition of a current sintering running state according to the 6 fuzzed process variables and based on a diagnosis rule; thirdly, online control: according to the working condition obtained in the fuzzy diagnosis step and based on an established expert rule, realizing automatic control of the burning trough point by online regulating a control period, a control step size as well as an upper limit value and a lower limit value of a sintering machine speed. The invention can efficiently inhibit the phenomenon of unsmooth sintering process caused by instable working condition and enhance the yield and the quality of sintered ores.

Owner:CENT SOUTH UNIV

Method for improving quality of high-chromium vanadium and titanium sinter

The invention provides a method for improving the quality of high-chromium vanadium and titanium sinter and belongs to the technical field of ferrous metallurgy. The method mainly comprises the steps that sintering return mines, high-chromium vanadium and titanium concentrate fines, ordinary iron ore concentrate powder, boron iron ore concentrate, metallurgical lime, magnesite, coke powder and other sintering raw materials are subjected to secondary atomization injection and blowing blending, wetting and pelletizing at a certain proportion; then distribution, ignition and sintering are conducted; and finally grain settlement and screening are conducted to obtain the high-chromium vanadium and titanium sinter good in metallurgical performance. The method has the characteristics of being simple in process, high in raw material adaptability, high in production efficiency, low in cost and the like. The quality of the high-chromium vanadium and titanium sinter and the sintering production efficiency can be improved remarkably; the method has important realistic significance for development and utilization of the high-chromium vanadium and titanium sinter and has wide application prospects.

Owner:NORTHEASTERN UNIV

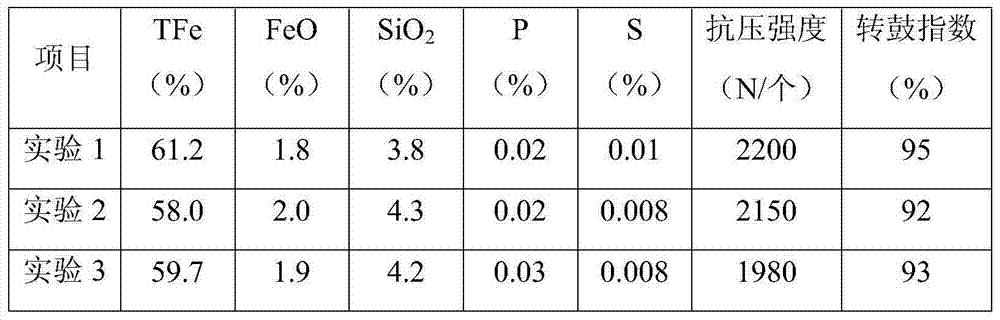

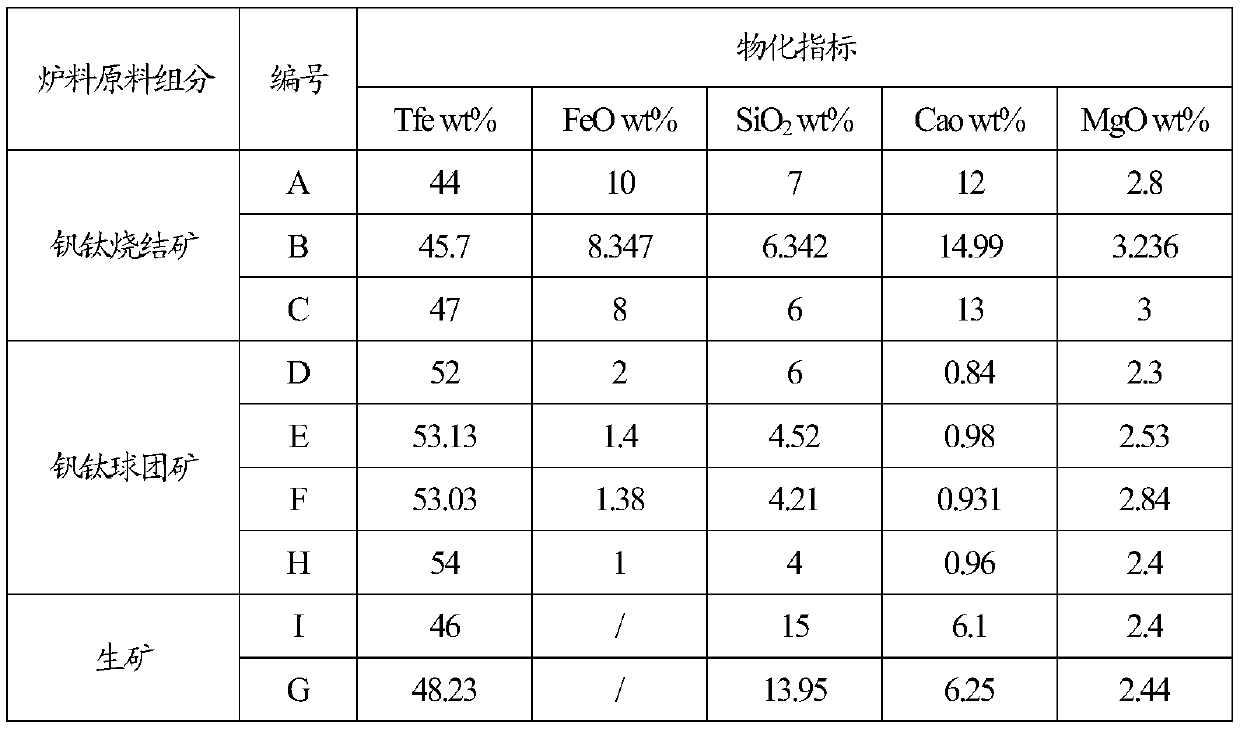

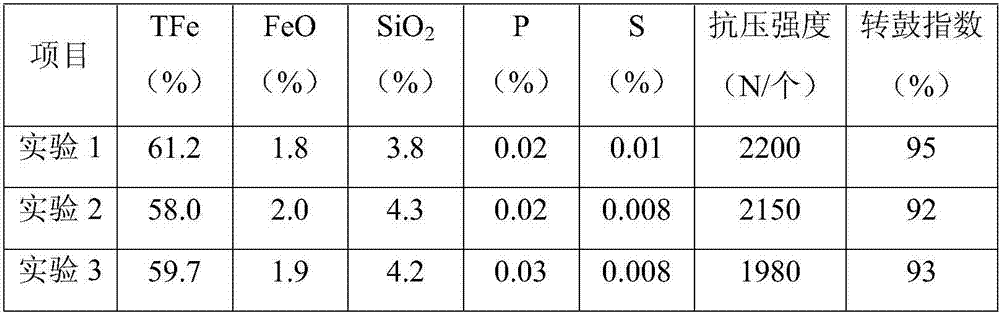

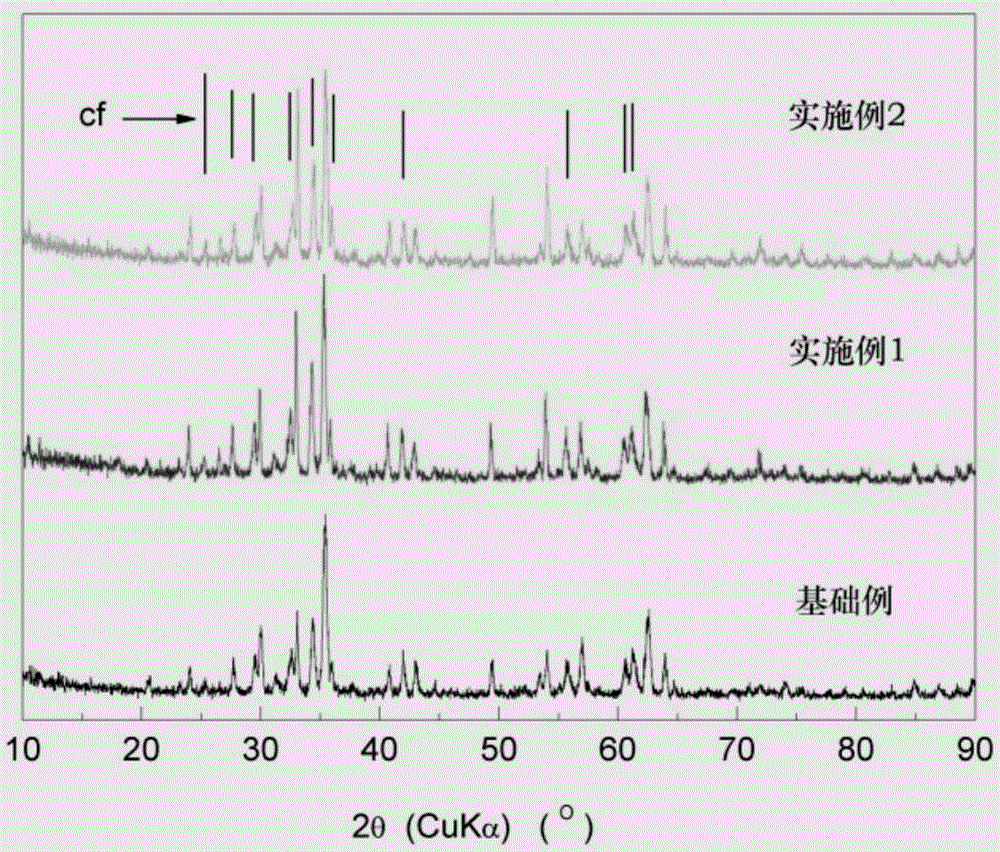

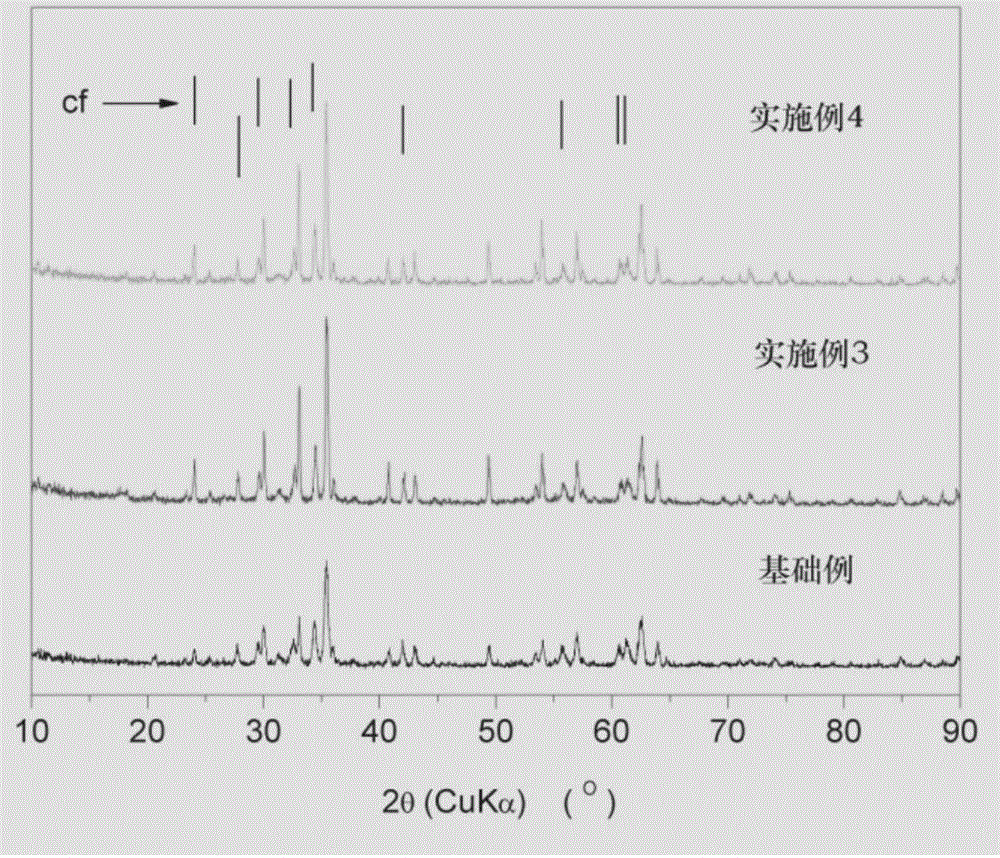

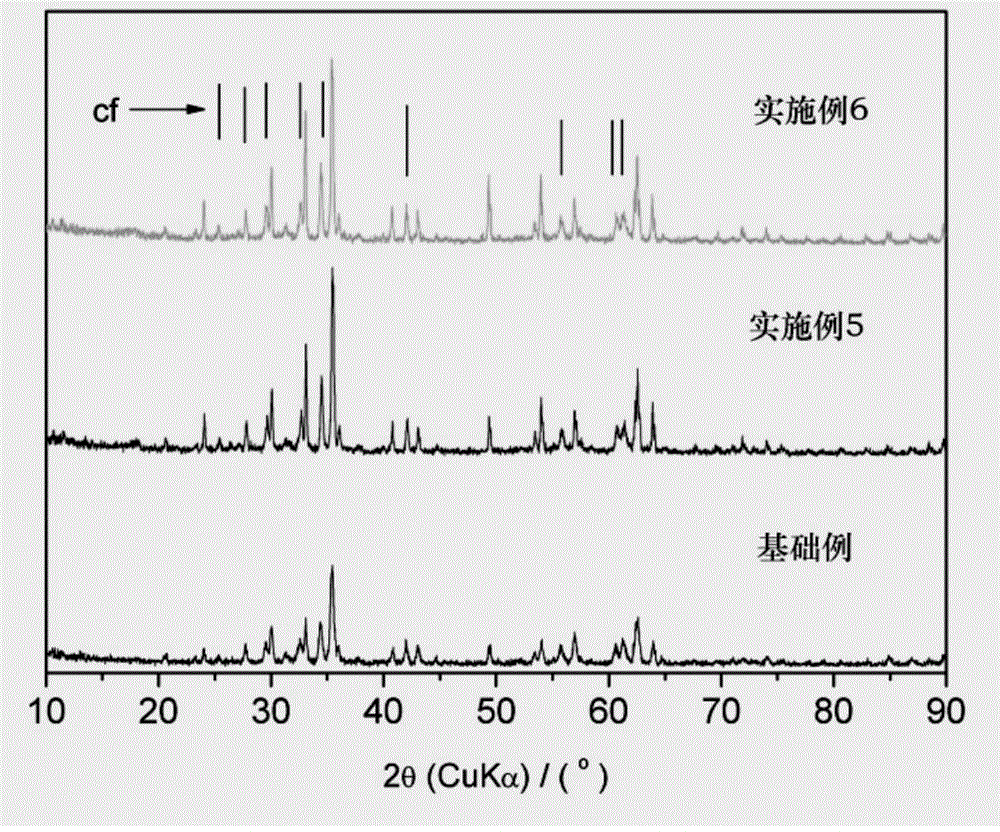

Preparation method of high-titanium type vanadium-titanium magnetite agglomerate added with limonite

The invention belongs to the technical field of preparation methods of an agglomerate, and in particular relates to a preparation method of a high-titanium type vanadium-titanium magnetite agglomerate added with limonite. The invention aims to solve the first technical problem of providing a preparation method of a high-titanium type vanadium-titanium magnetite agglomerate added with limonite, which has the advantages of large strength and high rate of finished products. The method comprises the following concrete steps: adding limonite into the agglomerate raw material, and then, preparing the agglomerate, wherein the weight ratio of the agglomerate raw material to the limonite is 88-92:8-12, and the limonite is crushed to the granules of which the granularity is less than 1mm, wherein the weight of the granules of which the granularity is less than 0.074mm accounts for 10%-50% of the total weight. The invention improves the adding proportion of the limonite powder in the high-titanium type vanadium-titanium magnetite and reduces the cost of the raw material for production.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

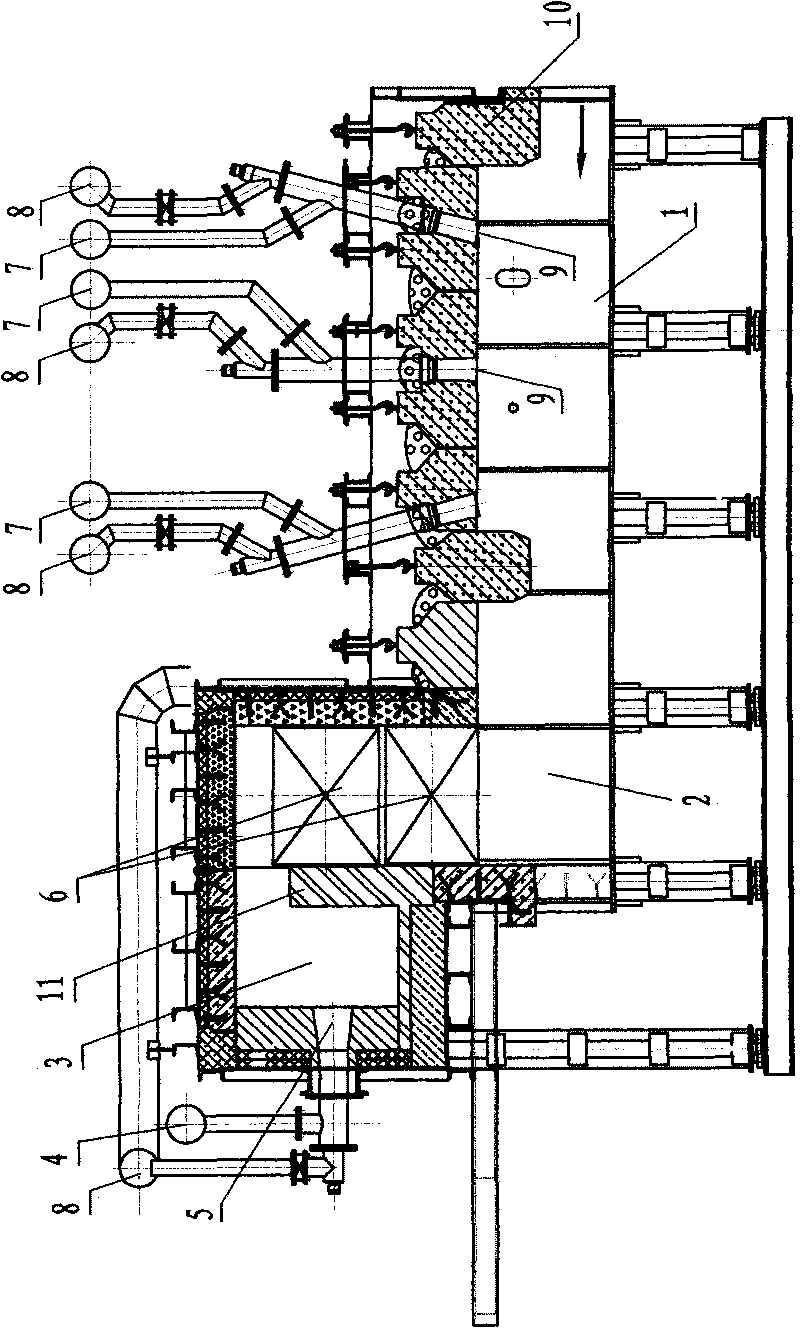

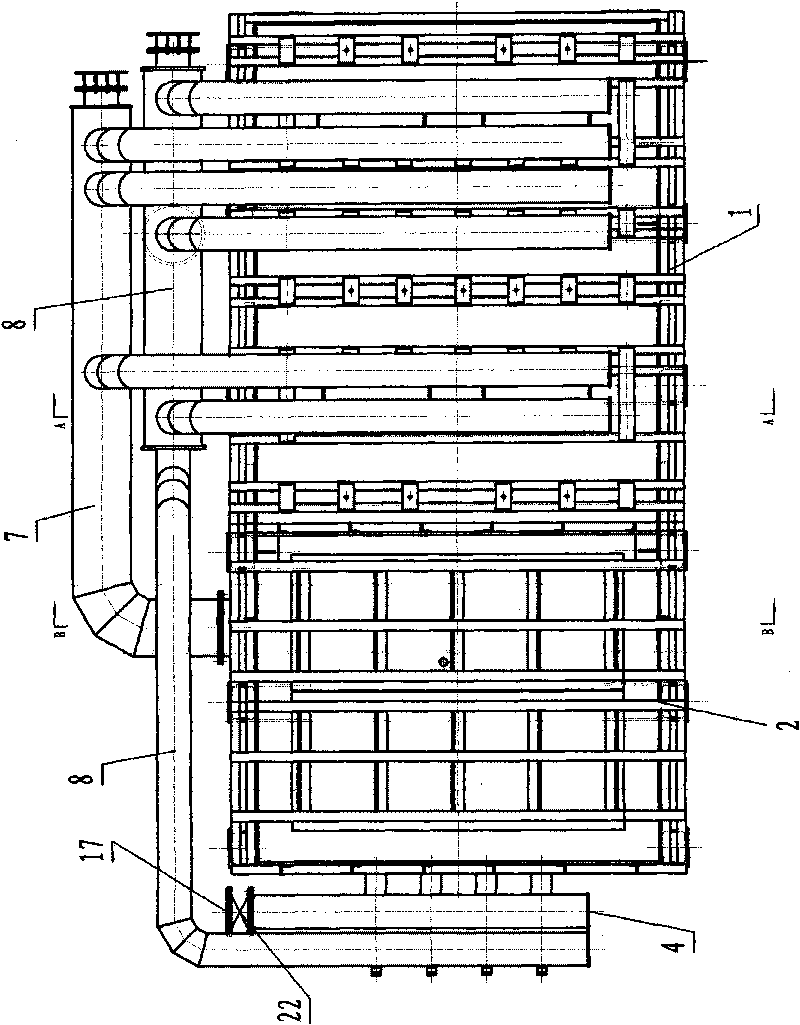

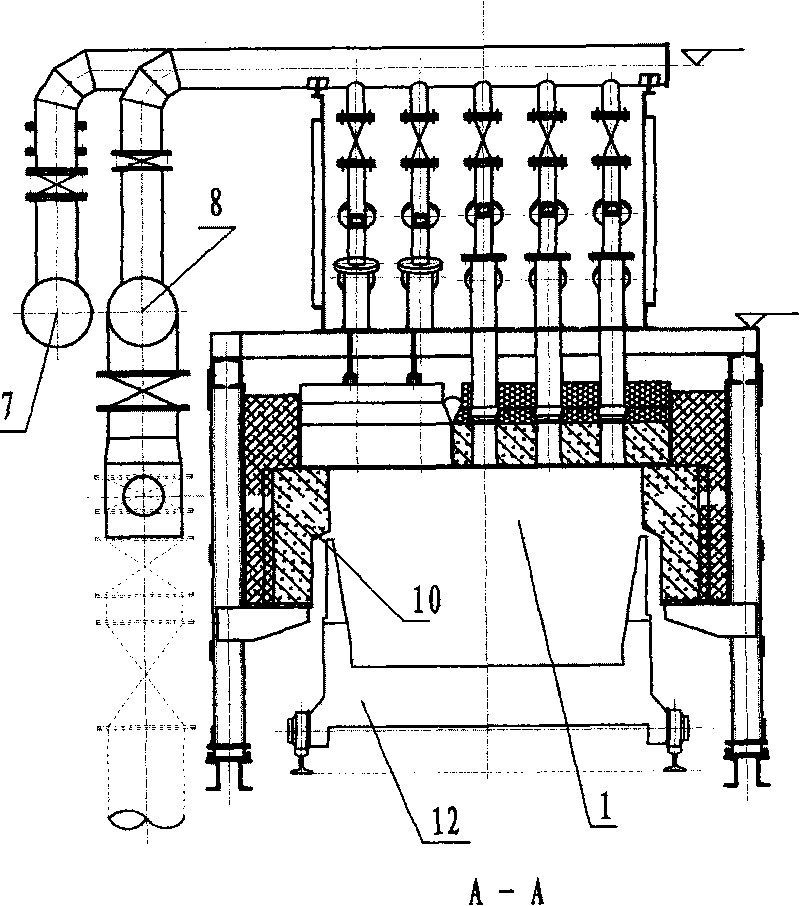

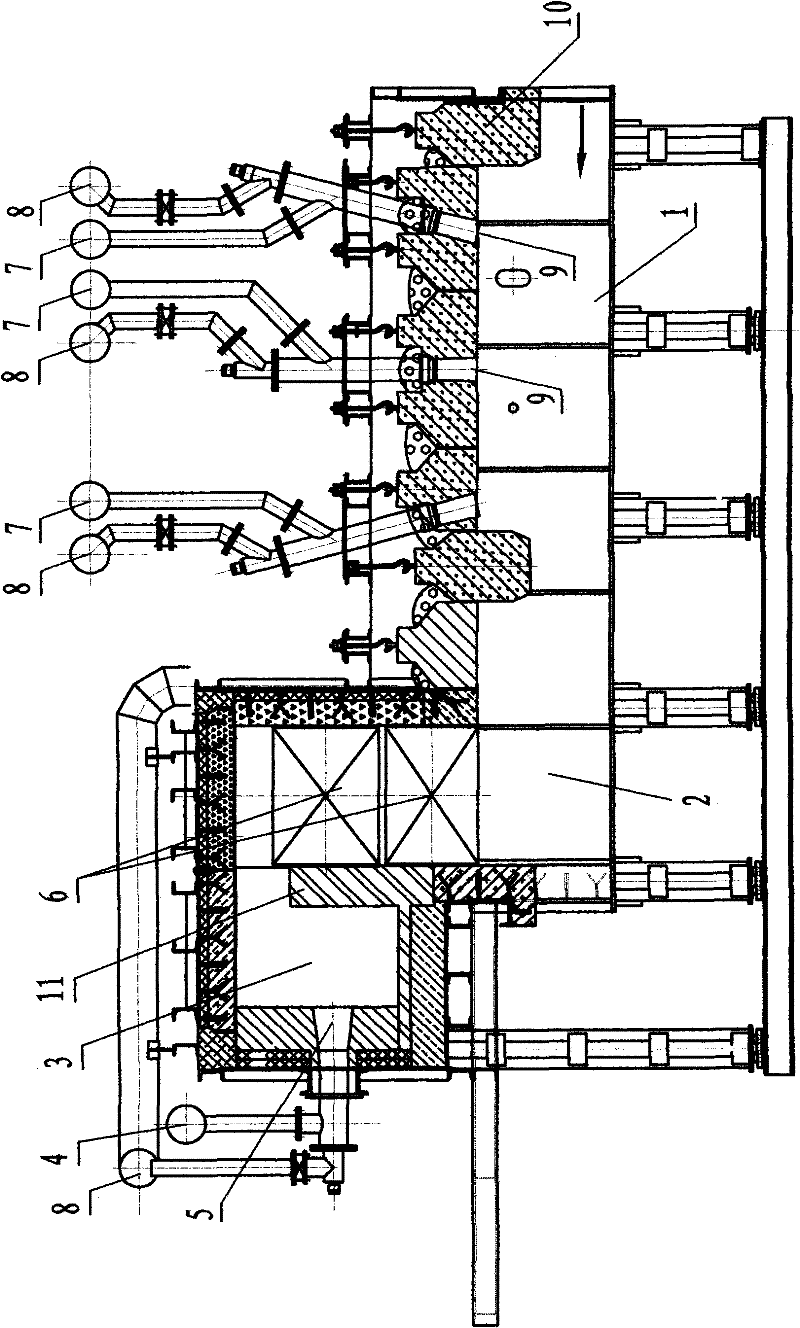

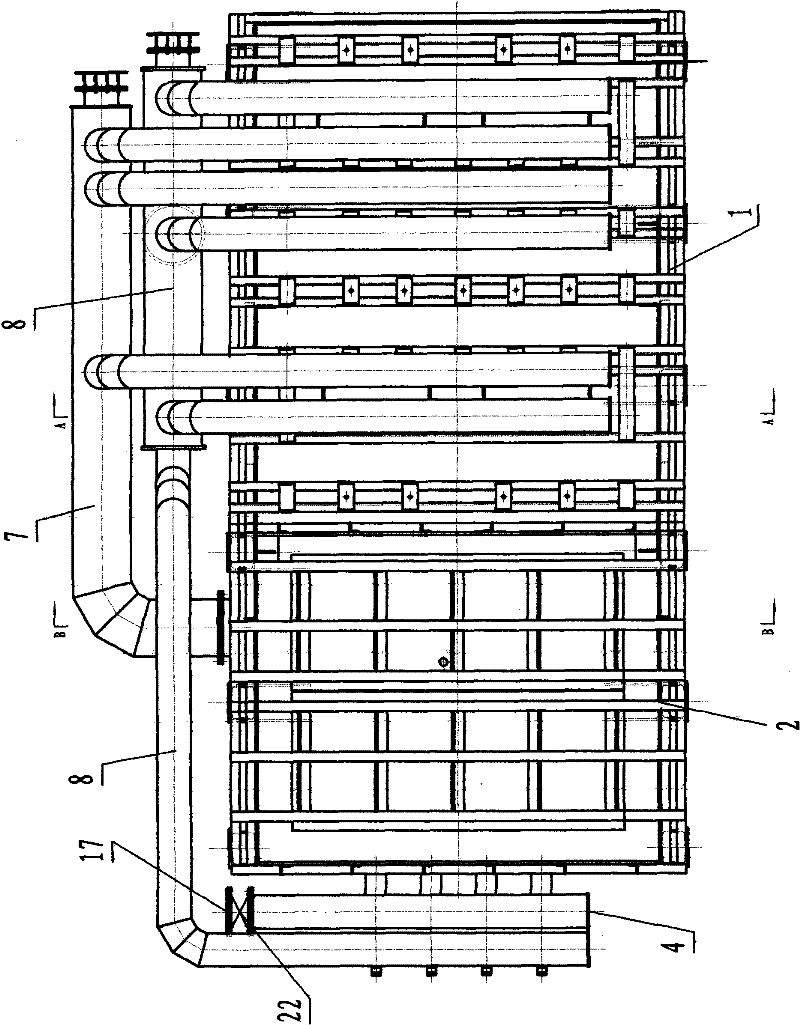

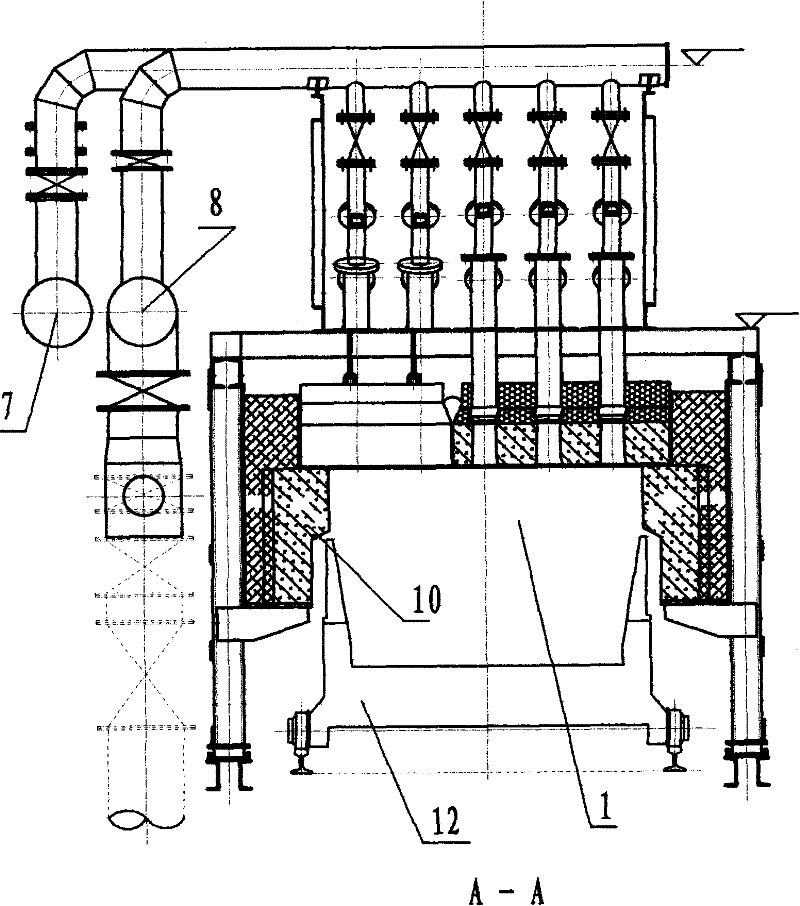

Single preheating, sintering, igniting and heat insulating furnace

The invention relates to a single preheating, sintering, igniting and heat insulating furnace with the advantages of simple structure, little pollution, obvious energy saving effect and high safety. The furnace comprises an igniting section and a heat insulating section, wherein the igniting section and the heat insulating section are connected into a whole and are arranged on a sintering machine table. The heat insulating section comprises an air preheating furnace, and an air heat exchanger is arranged in the air preheating furnace. The igniting section comprises a plurality of burning nozzles, and each burning nozzle is connected with a blast furnace gas pipe and a hot air pipe. A cold air inlet and a cold air input tube of the air heat exchanger are connected, and a fan is arranged on the cold air input tube. A hot air outlet of the air heat exchanger is connected with an inlet of the hot air tube. The air heat exchanger is arranged on a trolley. When the single preheating, sintering, igniting and heat insulating furnace is in working, the sintering compound of the waste gas trolley outputted by the air preheating furnace is insulated, and sucked into a large fume passage by the sintering compound surface of the trolley. The large fume passage is connected with the hot waste gas heat energy recovery system and the waste gas treating system to recover and utilize heat energy and remove harmful elements of sulphur and the like in the waste gas.

Owner:常州市黑山烧结点火炉制造有限公司

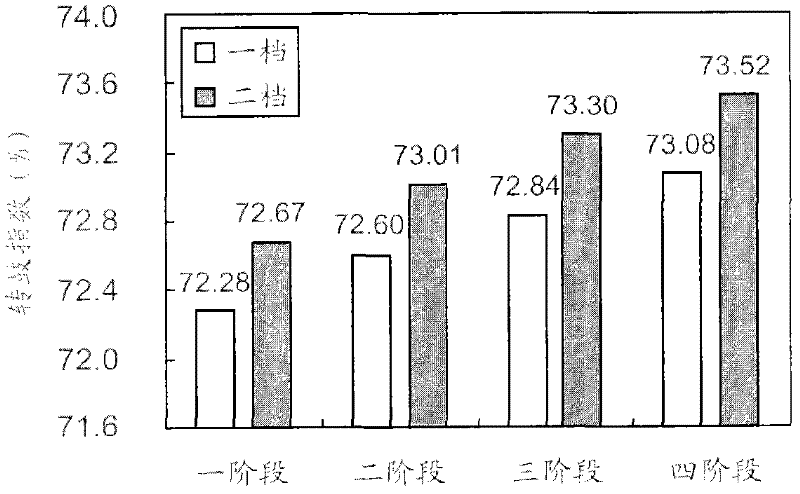

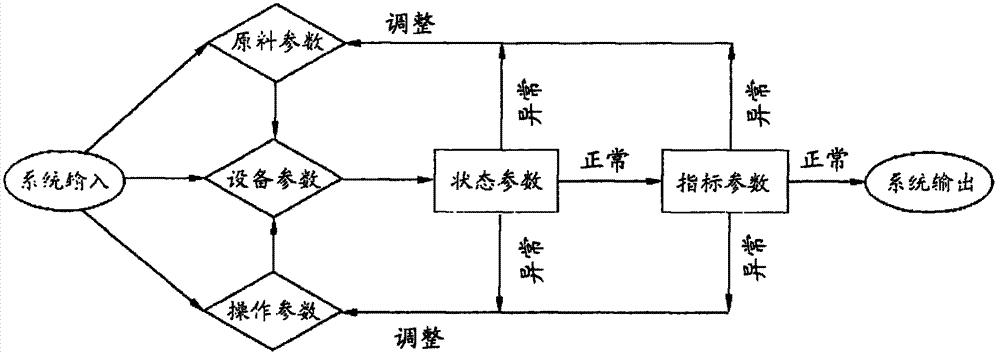

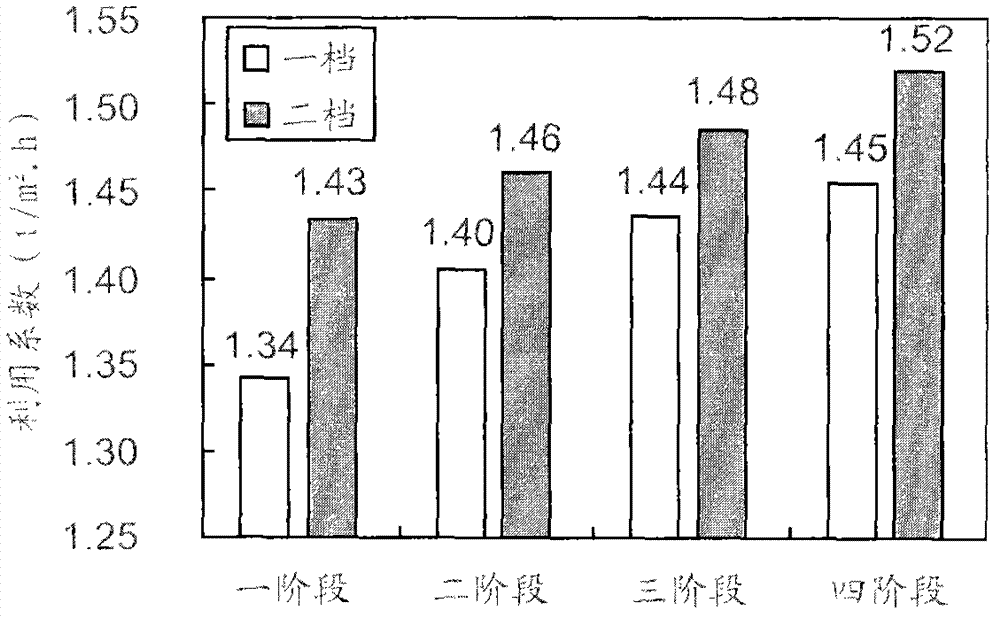

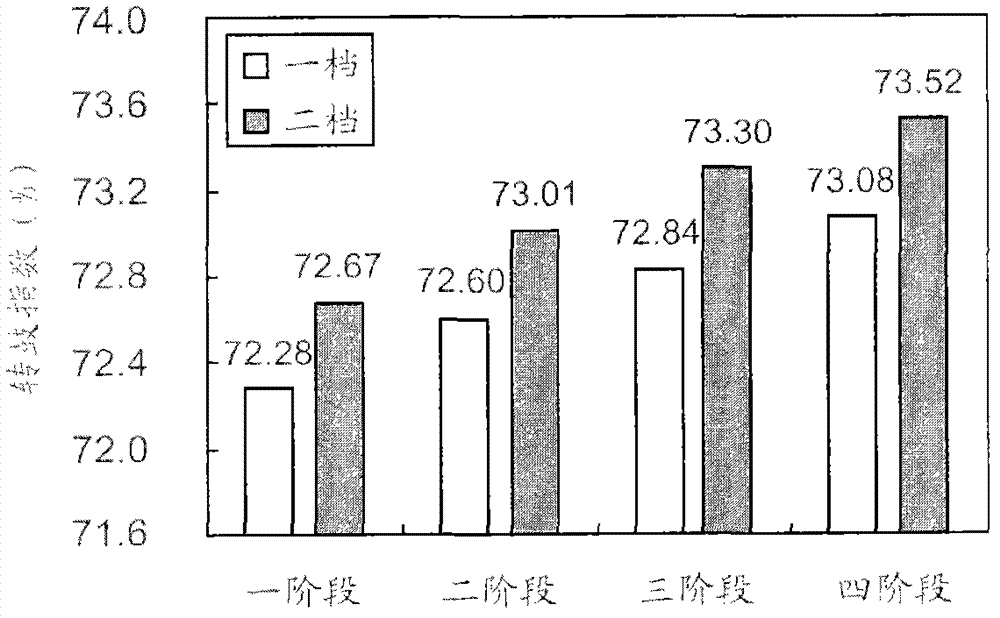

Process optimization method for sintering vanadium-titanium magnetite concentrate by large-scale sintering machine

ActiveCN102269993AGood technical and economic indicatorsImprove technical and economic indicatorsTotal factory controlProgramme total factory controlProcess optimizationSolid fuel

The invention provides a process optimization method for sintering a vanadium-titanium magnetite concentrate by a large-scale sintering machine. According to the invention, the method comprises the following steps that: a sintering process is constructed into a sintering system that includes input, an intermediate link and output; ore return quantity, feeding quantity, material layer thickness, machine speed, and material temperature and the like are selected and are taken as adjustable parameters; index parameters of a sintering system are improved by a plurality of phases that are connectedsequentially, wherein each phase among the plurality of phases comprises multi-group records that record adjustable parameters and the index parameters that are corresponding to the adjustable parameters during sintering production and a record in which index parameters satisfy a target range of the present phase is selected from the multi-group records; adjustable parameters at the next phase are controlled on the basis of a mean value of adjustable parameters of the last phase among the plurality phases, wherein the adjustable parameters of the last phase are in a record and satisfy a target range of the last phase and the target range of the next phase is not inferior to that of the last phase. According to the invention, index parameters including a utilization coefficient, a drum index and low solid fuel consumption and the like in the sintering process are improved.

Owner:PANZHIHUA IRON AND STEEL +1

Pellets prepared from blast furnace slag iron fine powder as well as preparation method and application of pellets

The invention belongs to the field of comprehensive utilization of solid waste resources and specifically relates to pellets prepared from blast furnace slag iron fine powder as well as a preparation method and application of the pellets. The invention aims at providing a method for preparing the pellets from the blast furnace slag iron fine powder, which is simple in process. The technical scheme adopted by the method provided by the invention comprises the following steps: a) performing crushing, screening, ball-milling and magnetic separation on blast furnace slag with the water content of not more than 10% to obtain iron fine powder, and controlling the particle size of the iron fine powder to be not more than 1.5mm, so that the iron fine powder with the particle size of less than 1mm accounts for above 20% of total weight of the iron fine powder and the iron content is not less than 60%; b) mixing the iron fine powder with a binding agent, adding water and uniformly mixing to obtain a mixture; and c) pressing the mixture for forming and air-drying to obtain the pellets. Compared with the conventional preparation of the pellets from steel slag, by adopting the method, the steps are saved, the production cost is reduced and the time is saved.

Owner:攀枝花环业冶金渣开发有限责任公司

Steel smelt additive and processing technology thereof

The invention relates to an additive in the process of smelting iron and steel, which comprises the following parts: 10%-15% sodium peroxide, 15%-25% sodium per chlorate, 5%-10% calcium chloride, 20%-28% borax, 5%-15% calcium nitrite, 5%-8% sodium methylol fibre, 5%-8% sodium perborate, 10%-20% polyacrylamide. The manufacturing technique comprises the following steps: (1) adding every part sequentially according to the weight and mixing mechanically; (2) mixing and heating; (3) filtering; drying and finishing the product. The invention improves the insufficient places of the original additive product, which develops a new additive; reduces the cost of smelting iron; adds the benefit.

Owner:刘钧

Composite sintering catalyst

ActiveCN102660349AImprove heat utilizationImprove breathabilitySolid fuelsCarboxymethyl starchSodium Bentonite

The invention relates to composite sintering catalyst which is made of, by weight percent, 3-12% of carboxymethyl starch, 20-60% of borax, 10-35% of dextrin, 5-10% of slaked lime, 10-30% of calcium bentonite and 5-15% of lignin. By the aid of the composite sintering catalyst, on the basis of not changing sintering components and sintering technology, the sintering process can be greatly improved,thermal utilization rate of fuels can be increased, consumption of the fuels is greatly reduced by 5-10%, reactivity of the fuels is enhanced, permeability of beds of material is improved, the speed of vertical sintering is increased, utilization coefficient of sintering is increased, the quality of sinters or refectories is improved, yield is increased by 3%-5%, and sintering cost is reduced.

Owner:通化耐博新材料股份有限公司

High-magnesium composite sinter and production method thereof

The invention relates to high-magnesium composite sinter and a production method thereof. A high-magnesium fluxing agent and other raw materials are prepared, optimized and then sintered in a sinter bed, so that the problems that in terms of existing high-magnesium sinter production, resource utilization and mineral generation are unreasonable, the yield is low, the strength is low, the return mine rate is high, and the solid fuel consumption is high are solved. The high-magnesium composite sinter is formed by crushing and mixing sinter of upper and lower layer structures. With composite calcium ferrite as the main binder phase, the upper layer of sinter is formed by sintering a material A, wherein MgO accounts for not greater than 1.8%, and Al2O3 accounts for not greater than 2.0%; and the lower layer of sinter is formed by sintering a material B, and the content of MgO of the lower layer of sinter is greater than that of the MgO of the upper layer of sinter. The material A comprises72-90% of iron-containing mineral powder raw materials, 7-20% of a low-magnesium fluxing agent and 3-8% of a solid fuel; and the material B comprises 0-90% of sinter, 0-70% of sintering return mine and 10-100% of a high-magnesium fluxing agent. The high-magnesium composite sinter is good in comprehensive metallurgical performance, the blast furnace burden structure can be optimized easily, and theslag mobility and desulfuration and dealkalization effects can be improved.

Owner:胡明意

Composite additive for sintering iron ore powder and method of manufacturing the same

The invention relates to a compound additive for sintering iron ore powder and a preparation method thereof, and provides the following technical scheme: the compound additive is prepared by evenly stirring the following raw materials: 30wt% to 50 wt% of combustion-supporting agent, 15wt% to 25wt% of oxygen-increasing agent, 3wt% to 10wt% of strengthener, 10wt% to 20wt% of catalytic agent, 5wt% to 10wt% of coarse rice hull, 5wt% to 10wt% of calcium fluoride, 2wt% to 5wt% of SHN pellet binder and 5wt% to 10wt% of boric anhydride. The invention has the characteristics of simple preparation process and low cost; and by applying the prepared compound additive in sintering the iron ore powder, the vertical sintering speed can be increased by more than 12%, the production yield can be increased by more than 4%, the tumbler index can be increased by more than 5%, the sintering iron grade can be improved by 1 to 1.5, the fuel consumption can be reduced by more than 10%, the emission of SO2 can further be reduced and the compound additive is free from materials causing damage on blast furnace production, such as K, Na and other elements, therefore, the invention can improve the air permeability of sintering beds, increasing the combustion speed and the reaction speed of the mineralizing process and improving the yield and the quality of the sintering ore.

Owner:WUHAN NEW ORIENTAL METALLURGICAL MATERIALS

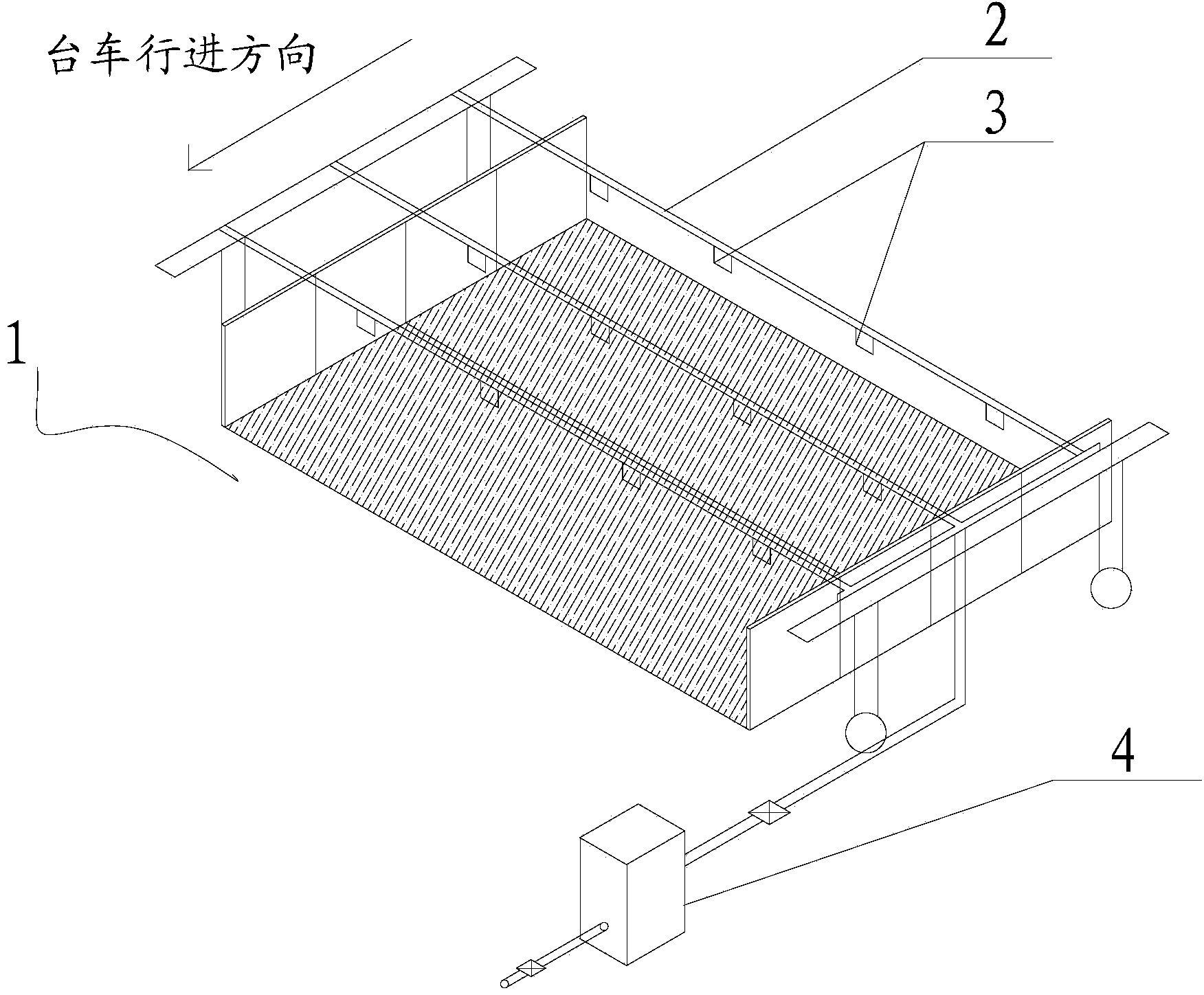

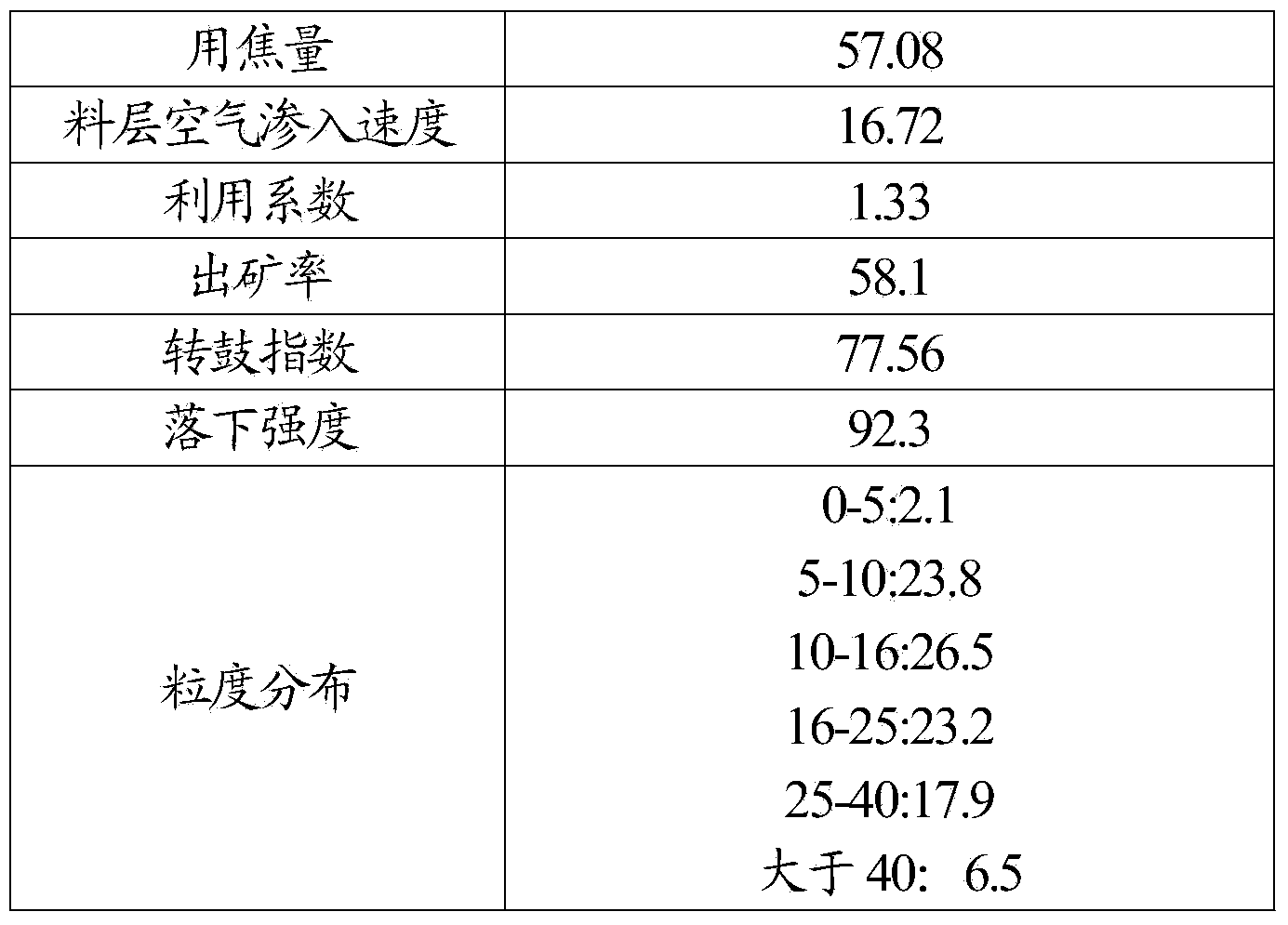

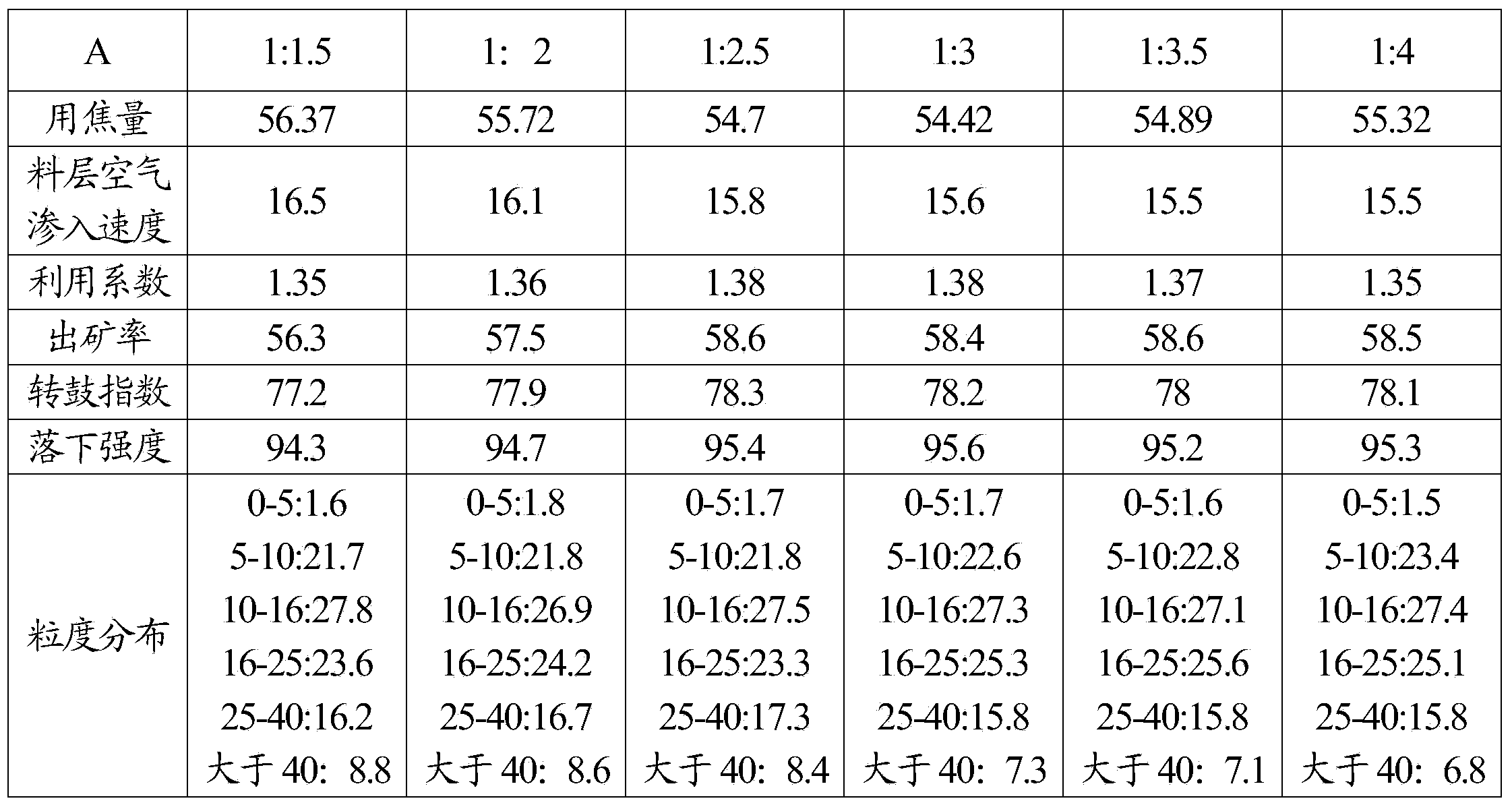

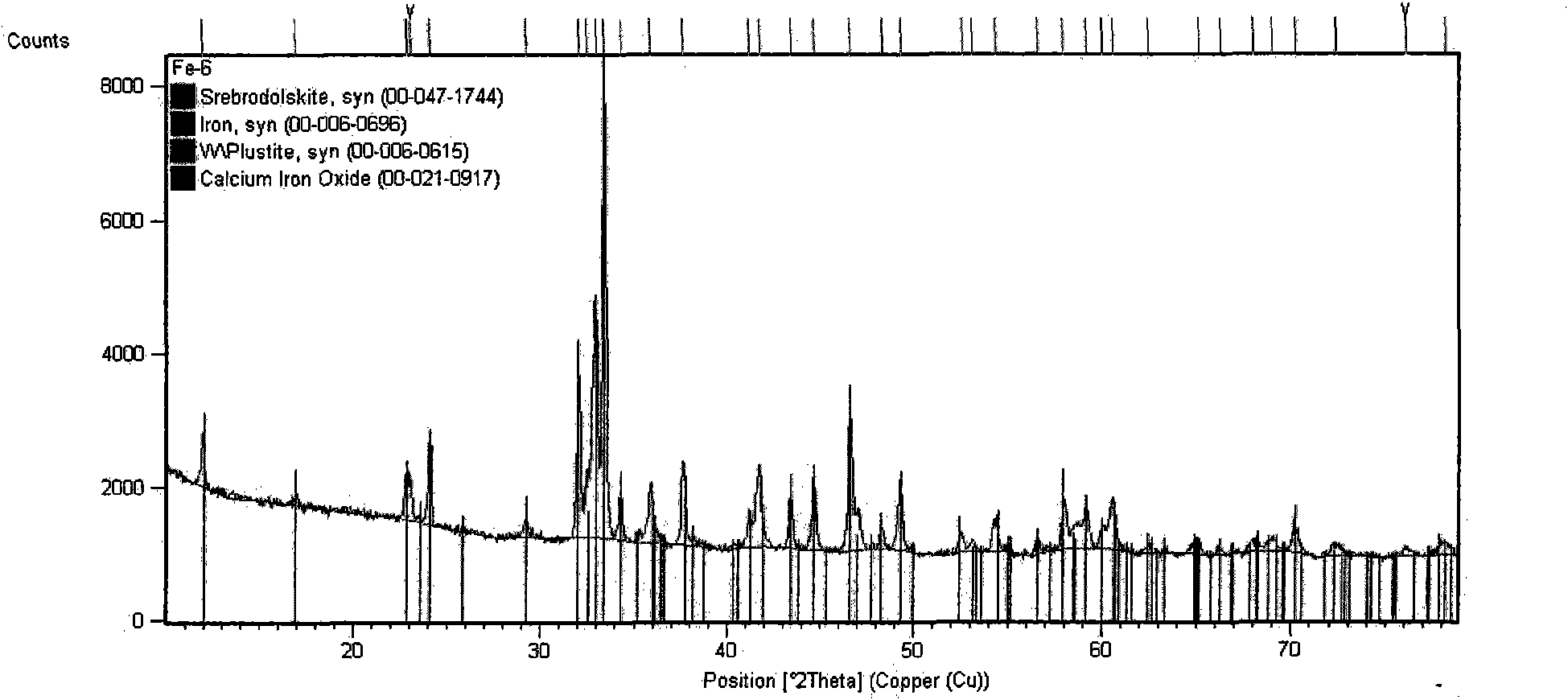

Sintering method and sintering device of metal compound powder

InactiveCN103924065AReduce the amount of coke used in sinteringIncrease penetration speedCombustion processMetal

The invention discloses a sintering method and a sintering device of metal compound powder, and particularly relates to a sintering method and a sintering device of metal compound powder. The method comprises the following steps: igniting a sintering feed containing the metal compound powder and simultaneously sucking air from the bottom of a material bed by an exhaust fan, and then jetting statured vapor from the periphery of the material bed within a certain period of time in the sintering feed combustion process, so that the statured vapor enters the sintering feed in combustion from the top of the material bed by the action of an exhaust fan. By adopting the method, the product quality of agglomerate can be effectively improved, for example, ore removal rate, agglomerate size component and the like can be effectively improved, and meanwhile, the coke amount also can be reduced in the sintering process.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

Novel metallurgical auxiliary material flux and preparation method thereof

The invention relates to a metallurgical auxiliary material flux and a preparation method thereof, which is characterized in that: the metallurgical auxiliary material flux is composed of the following components in percentage by weight: ferric oxide Fe2O3 60% to 75%, calcium oxide CaO 20% to 35% %, the sum of impurity content ≤5.0%. The components of the above-mentioned metallurgical auxiliary flux flux are crushed into particles of ≤20mm, mixed evenly, and then smelted at a high temperature of 1350°C to 1400°C, and the melting reaction produces a block material with a mineral phase structure of 2CaO·Fe2O3 as the main phase. After it is cooled, it is processed into a powder with a fineness of -200 mesh. The method of using the metallurgical auxiliary material flux is as follows: the added amount of the flux is 4-6% of the weight percentage of sintered ore or converter reduction pellets (at this time, the flux effect is the best). Mix well after adding. Compared with the prior art, the beneficial effects of the present invention are as follows: one is useful slagging material (CaO) and iron material (TFe) that can be reduced to iron; The auxiliary materials can be used for melting, and the effect of melting is stable; the third is that it does not pollute the environment.

Owner:LIAONING TIANHE TECH

Sintering method of high-grade vanadium-titanium-iron ore concentrates

The invention discloses a sintering method of high-grade vanadium-titanium-iron ore concentrates. The sintering method comprises the following steps that 1), sintering raw materials are mixed evenly and comprise the following components in parts by weight: 50-60 parts of high-grade vanadium-titanium-iron ore concentrate powder, 5-8 parts of iron ore concentrate powder, 10-20 parts of flux and 3-5parts of fuel A; 2), a potassium permanganate solution is sprayed onto the sintering raw materials, water is added to soak the sintering raw materials, and then pelletizing is conducted to obtain pellets B; and 3), the pellets B are distributed to obtain a material layer B, fuel C is distributed on the material layer B to obtain a material layer C, the thickness of the material layer B ranges from650 mm to 700 mm, the thickness of the material layer C ranges from 20 mm to 50 mm, and igniting and sintering in a nitrogen environment are conducted to obtain vanadium-titanium sinter. The sintering performance improvement effect is remarkable, and the sintering utilization coefficient, the yield and the drum index can be improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Self-tuning expert control method of burning trough point parameter based on working condition recognition

The invention provides a self-tuning expert control method of a burning trough point parameter based on working condition recognition, comprising the following steps of: firstly, data collection and fuzzification: collecting and calculating a mixture level, the change rate thereof, a deviation of a burning trough point position, burning trough point temperature, the change rate of a 17-19 air boxtemperature average value and 6 process variables of sintering waste gas temperature rising point position, and carrying out fuzzification treatment; secondly, fuzzy diagnosis: obtaining the working condition of a current sintering running state according to the 6 fuzzed process variables and based on a diagnosis rule; thirdly, online control: according to the working condition obtained in the fuzzy diagnosis step and based on an established expert rule, realizing automatic control of the burning trough point by online regulating a control period, a control step size as well as an upper limitvalue and a lower limit value of a sintering machine speed. The invention can efficiently inhibit the phenomenon of unsmooth sintering process caused by instable working condition and enhance the yield and the quality of sintered ores.

Owner:CENT SOUTH UNIV

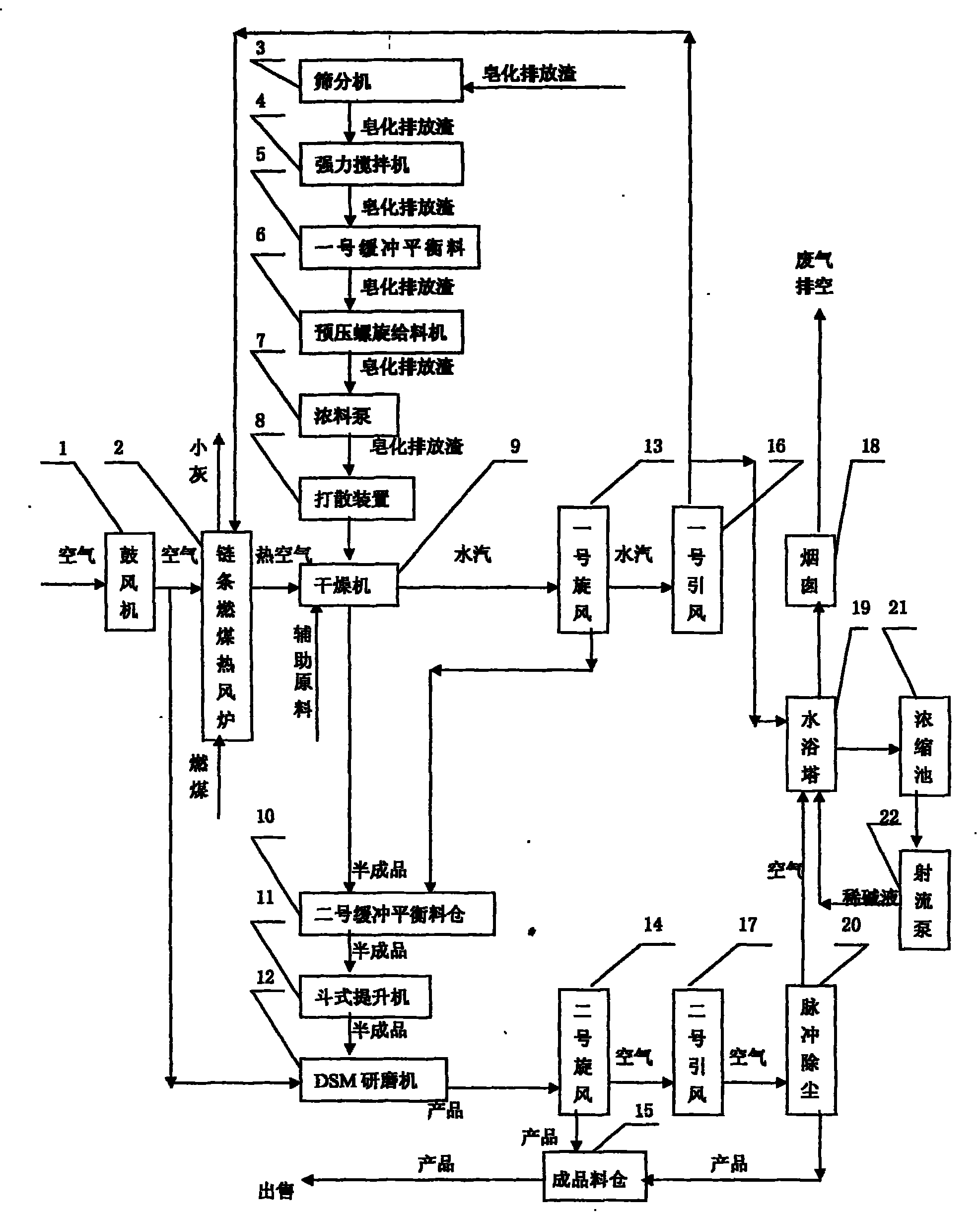

Novel method for producing iron ore sintering mine additive

InactiveCN101492769AUniform particle sizeImprove granulation effectProcess efficiency improvementIron ore sinteringUltimate tensile strength

The invention relates to a manufacturing method of a novel iron ore sinter additive. The invention is characterized in that the method comprises steps of adding basic oxider CaO, dolomite powder, stabilizer active MO in saponification discharge dregs of propylene oxide by chlorophydrin method, intensive mixing, reacting for 15min to 30min at 500 DEG C to 850 DEG C and constant pressure, removing harmful dissociated substances in the saponification discharge dregs, removing 20% to 67% of moisture content, milling the saponification discharge dregs to powder of 80 meshes to 300 meshes, thus obtaining the novel iron ore sinter additive. The invention uses saponification discharge dregs of propylene oxide by chlorophydrin method as main materials, thus the production cost is low. The chemical solid waste is recycled. The invention prepares grains from the sinter material in an improved manner, and drum index of sinter in the roasting process is improved, return fine rate being reduced, production of sinter being improved, and manufacturing efficiency of ironmaking being improved. Ore forming rate of the sinter and intensity are improved obviously, thus manufacturing cost of steel-making is reduced.

Owner:辽宁中生洁源实业有限公司

Preparation method of high-titanium type vanadium-titanium magnetite agglomerate added with limonite

The invention belongs to the technical field of preparation methods of an agglomerate, and in particular relates to a preparation method of a high-titanium type vanadium-titanium magnetite agglomerate added with limonite. The invention aims to solve the first technical problem of providing a preparation method of a high-titanium type vanadium-titanium magnetite agglomerate added with limonite, which has the advantages of large strength and high rate of finished products. The method comprises the following concrete steps: adding limonite into the agglomerate raw material, and then, preparing the agglomerate, wherein the weight ratio of the agglomerate raw material to the limonite is 88-92:8-12, and the limonite is crushed to the granules of which the granularity is less than 1mm, wherein the weight of the granules of which the granularity is less than 0.074mm accounts for 10%-50% of the total weight. The invention improves the adding proportion of the limonite powder in the high-titanium type vanadium-titanium magnetite and reduces the cost of the raw material for production.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Vanadium-titanium magnetite blast furnace burden structure and blast furnace smelting method

The invention discloses a vanadium-titanium magnetite blast furnace burden structure. The furnace burden structure comprises mineral aggregates and coke nuts, and the mineral aggregates are composed of, by mass, 45-50% of vanadium-titanium sintered ore, 8-12% of vanadium-titanium sintered ore nuts, 34-40% of vanadium-titanium pellets, and 5-10 % of raw ore. The use ratio of vanadium-titanium magnetite is increased by optimizing the furnace burden structure, the vanadium-titanium magnetite resources are sufficiently utilized, and cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

A selective sintering flue gas segmented comprehensive treatment process

The invention discloses a selective sintering flue gas sectional type comprehensive treatment technology, and belongs to the technical field of energy conservation and environmental protection. Flue gas circulation sintering is performed on ignition section flue gas with the high SO2 concentration and the low NOx concentration at a sintering head part; dust removal and desulfurization are performed on flue gas with the high SO2 concentration at a sintering middle part and then the flue gas is exhausted out; dust removal is performed on flue gas with the low SO2 concentration and the low NOx concentration at the sintering middle part and then the flue gas is exhausted out; dust removal and denitrification are performed on flue gas with the low SO2 concentration and the high NOx concentration at a sintering tail part, then the flue gas is mixed with flue gas at a high temperature section of a cooler, and waste heat recovery is performed; heated air circulation sintering is performed on the recycled hot flue gas; and steam generated after waste heat recycling can be used for waste heat power generation or steam-driving sintering of a main suction fan. According to the selective sintering flue gas sectional type comprehensive treatment technology, sintering flue gas section desulfurization and denitrification are achieved, and the flue gas discharge amount is decreased; and the flue gas waste heat recycling efficiency is improved, the construction investment and production running cost are lowered on the whole, and the selective sintering flue gas sectional type comprehensive treatment technology conforms to the energy-saving, environment-friendly, emission reduction, consumption reduction, efficiency increase and recycling economic running mode.

Owner:郑琨

A covering agent for thick material layer sintering

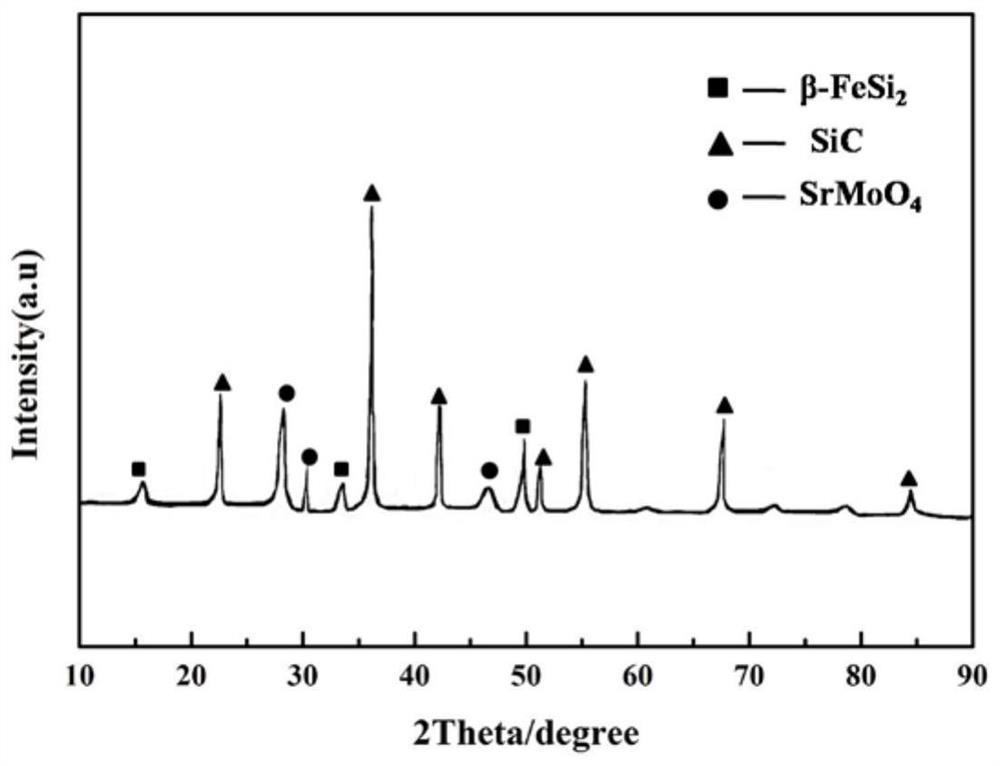

The invention discloses a covering agent for thick material layer sintering, which comprises (β-FeSi 2 +SiC) / SrMoO 4 Composite materials with expanded graphite; the above (β‑FeSi 2 +SiC) / SrMoO 4 The preparation method of the composite material is: the β‑FeSi 2 / SiC powder and SrMoO 4 Dispersed to get (β‑FeSi 2 +SiC)‑SrMoO 4 Composite powder; the SrMoO 4 melting, (β‑FeSi 2 +SiC)‑SrMoO 4 The composite powder is preheated, then the two are stirred and mixed, heat-treated to obtain a composite slurry, and the above composite slurry is poured into a preheated mold to obtain (β-FeSi 2 +SiC) / SrMoO 4 composite material. The covering agent has good heat storage and heat generation properties, can improve the quality, strength and output of sintered materials, and can reduce fuel consumption, thereby reducing sintering production costs and reducing environmental pollution.

Owner:河北永洋特钢集团有限公司

A kind of high-magnesium composite sinter and its production method

The invention relates to high-magnesium composite sinter and a production method thereof. A high-magnesium fluxing agent and other raw materials are prepared, optimized and then sintered in a sinter bed, so that the problems that in terms of existing high-magnesium sinter production, resource utilization and mineral generation are unreasonable, the yield is low, the strength is low, the return mine rate is high, and the solid fuel consumption is high are solved. The high-magnesium composite sinter is formed by crushing and mixing sinter of upper and lower layer structures. With composite calcium ferrite as the main binder phase, the upper layer of sinter is formed by sintering a material A, wherein MgO accounts for not greater than 1.8%, and Al2O3 accounts for not greater than 2.0%; and the lower layer of sinter is formed by sintering a material B, and the content of MgO of the lower layer of sinter is greater than that of the MgO of the upper layer of sinter. The material A comprises72-90% of iron-containing mineral powder raw materials, 7-20% of a low-magnesium fluxing agent and 3-8% of a solid fuel; and the material B comprises 0-90% of sinter, 0-70% of sintering return mine and 10-100% of a high-magnesium fluxing agent. The high-magnesium composite sinter is good in comprehensive metallurgical performance, the blast furnace burden structure can be optimized easily, and theslag mobility and desulfuration and dealkalization effects can be improved.

Owner:胡明意

A production method of super-thick material layer oxygen-enriched sintering

ActiveCN108330275BSolve the problem that it is not easy to enter the material layerReduce fuel consumptionDecompositionMixed materials

The invention relates to an ultra-thick material layer oxygen-enriched sintering production method. The method comprises the steps that two times of material distribution and two-time ignition is carried out, an upper-layer sintering mixture and a lower-layer sintering mixture are correspondingly provided with an oxygen generator, the sintering raw material and the fuel are subjected to primary uniform mixing and secondary mixing granulation to prepare a sintered mixture A, and an oxygen preparation agent solution is additionally added during the primary uniform mixing and the secondary mixinggranulation; the sintering raw material and the fuel are subjected to the primary uniform mixing and the secondary mixing granulation to prepare a sintered mixture B, and the oxygen preparation agentsolution is additionally added during the primary uniform mixing and the secondary mixing granulation; the sintering mixture A is added to a sintering trolley through a first distributor on the machine head of the sintering machine; the oxygen preparation agent solution in the sintering material in the lower direction of the first distributor is sprayed; and the sintering mixed material B is added to the surface of sintered ore, and an oxygen preparation agent solution is sprayed on the sintering material surface. The method has the advantages that oxygen is generated by high-temperature decomposition of the oxygen generator, and the oxygen is uniformly enriched at different parts of the sintered material layer; and the strength of the sintered ore is improved, and the fuel consumption ofthe sintered solid is reduced.

Owner:ANGANG STEEL CO LTD

A kind of vanadium-titanium magnetite blast furnace charge structure and blast furnace smelting method

The invention discloses a vanadium-titanium magnetite blast furnace burden structure. The furnace burden structure comprises mineral aggregates and coke nuts, and the mineral aggregates are composed of, by mass, 45-50% of vanadium-titanium sintered ore, 8-12% of vanadium-titanium sintered ore nuts, 34-40% of vanadium-titanium pellets, and 5-10 % of raw ore. The use ratio of vanadium-titanium magnetite is increased by optimizing the furnace burden structure, the vanadium-titanium magnetite resources are sufficiently utilized, and cost is reduced.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Pellets prepared from blast furnace slag iron concentrate powder and its preparation method and application

The invention belongs to the field of comprehensive utilization of solid waste resources and specifically relates to pellets prepared from blast furnace slag iron fine powder as well as a preparation method and application of the pellets. The invention aims at providing a method for preparing the pellets from the blast furnace slag iron fine powder, which is simple in process. The technical scheme adopted by the method provided by the invention comprises the following steps: a) performing crushing, screening, ball-milling and magnetic separation on blast furnace slag with the water content of not more than 10% to obtain iron fine powder, and controlling the particle size of the iron fine powder to be not more than 1.5mm, so that the iron fine powder with the particle size of less than 1mm accounts for above 20% of total weight of the iron fine powder and the iron content is not less than 60%; b) mixing the iron fine powder with a binding agent, adding water and uniformly mixing to obtain a mixture; and c) pressing the mixture for forming and air-drying to obtain the pellets. Compared with the conventional preparation of the pellets from steel slag, by adopting the method, the steps are saved, the production cost is reduced and the time is saved.

Owner:PANZHIHUA HUANYE METALLURGICAL SLAG DEV CO LTD

Production ingredients capable of improving quality of finished pellets and preparation process of production ingredients

InactiveCN113584303AImprove breathabilityGuarantee the quality of calcinationEconomic benefitsMagnetite

The invention discloses production ingredients capable of improving the quality of finished pellets. The production ingredients comprise the following components of 77%-80% of first magnetite, 2.5%-3.5% of second magnetite, 8%-12% of hematite, 6%-8% of fly ash and 1.5%-1.9% of bentonite. The invention further discloses a preparation process of the production ingredients capable of improving the quality of the finished pellets. The preparation method comprises the following steps of quantitative weighing, material mixing, pelletizing and matched burning. The preparation process has the beneficial effects that after the ingredients provided by the invention are adopted, the quality of green pellets is obviously improved, the air permeability in a furnace is good, the air pressure can be reduced by 1kpa, the coal gas is reduced by 3000m<3> / h, and the temperature of a calcining zone is increased by 20 DEG C (the calcining temperature is increased to 1150 plus or minus 20 DEG C from the original 1130 plus or minus 20 DEG C) because hematite and fly ash are added, so that the calcining quality of the pellets is ensured; by adopting an existing ingredient scheme, the problem of treatment of the fly ash is well solved, a virtuous cycle is established for utilization of the fly ash, and the method has high economic benefits and environmental protection effects.

Owner:舞钢中加钢铁有限公司

Composite sintering catalyst

ActiveCN102660349BImprove heat utilizationImprove breathabilitySolid fuelsCarboxymethyl starchRefractory

The invention relates to composite sintering catalyst which is made of, by weight percent, 3-12% of carboxymethyl starch, 20-60% of borax, 10-35% of dextrin, 5-10% of slaked lime, 10-30% of calcium bentonite and 5-15% of lignin. By the aid of the composite sintering catalyst, on the basis of not changing sintering components and sintering technology, the sintering process can be greatly improved, thermal utilization rate of fuels can be increased, consumption of the fuels is greatly reduced by 5-10%, reactivity of the fuels is enhanced, permeability of beds of material is improved, the speed of vertical sintering is increased, utilization coefficient of sintering is increased, the quality of sinters or refectories is improved, yield is increased by 3%-5%, and sintering cost is reduced.

Owner:通化耐博新材料股份有限公司

Compound flux of high-MgO sinter ore, and preparation method and application of the compound flux

The invention relates to a compound flux of high-MgO sinter ore, and a preparation method and application of the compound flux, belongs to the field of hematite sintering. The compound flux comprises a MgO source and a water-soluble additive, wherein the water-soluble additive is a combination of one or more than one of boric anhydride, calcium chloride, ferric oxalate, iron nitrate and ammonium ferrie oxalate. The preparation method comprises the following steps: first, dissolving the water-soluble additive in water; then, pouring the MgO source material to realize that the additive is uniformly adhered on the surfaces of the MgO source particles; putting into a drying oven below the temperature of 95 DEG C for drying, thereby obtaining the compound flux of the high-MgO sinter ore. During sintering, the compound flux, the hematite and the lime flux are mixed together to serve as the MgO flux, so that the MgO content in the sinter ore can be increased to 4 percent. Meanwhile, the additive has a low melting point, the sintering mineralization rate is improved, and as a result, reasonable mineral composition and phase structure can be obtained, the sinter ore strength and high-temperature metallurgical property can be improved, also, the finished product ratio and drum rotating index are obviously improved.

Owner:UNIV OF SCI & TECH BEIJING

Process optimization method for sintering vanadium-titanium magnetite concentrate by large-scale sintering machine

ActiveCN102269993BGood technical and economic indicatorsImprove technical and economic indicatorsTotal factory controlProgramme total factory controlProcess optimizationSolid fuel

The invention provides a process optimization method for sintering a vanadium-titanium magnetite concentrate by a large-scale sintering machine. According to the invention, the method comprises the following steps that: a sintering process is constructed into a sintering system that includes input, an intermediate link and output; ore return quantity, feeding quantity, material layer thickness, machine speed, and material temperature and the like are selected and are taken as adjustable parameters; index parameters of a sintering system are improved by a plurality of phases that are connectedsequentially, wherein each phase among the plurality of phases comprises multi-group records that record adjustable parameters and the index parameters that are corresponding to the adjustable parameters during sintering production and a record in which index parameters satisfy a target range of the present phase is selected from the multi-group records; adjustable parameters at the next phase are controlled on the basis of a mean value of adjustable parameters of the last phase among the plurality phases, wherein the adjustable parameters of the last phase are in a record and satisfy a target range of the last phase and the target range of the next phase is not inferior to that of the last phase. According to the invention, index parameters including a utilization coefficient, a drum index and low solid fuel consumption and the like in the sintering process are improved.

Owner:PANZHIHUA IRON AND STEEL +1

Single preheating, sintering, igniting and heat insulating furnace

ActiveCN101726187BShort conveying distanceLow costCombustion processFurnace typesCold airEngineering

The invention relates to a single preheating, sintering, igniting and heat insulating furnace with the advantages of simple structure, little pollution, obvious energy saving effect and high safety. The furnace comprises an igniting section and a heat insulating section, wherein the igniting section and the heat insulating section are connected into a whole and are arranged on a sintering machinetable. The heat insulating section comprises an air preheating furnace, and an air heat exchanger is arranged in the air preheating furnace. The igniting section comprises a plurality of burning nozzles, and each burning nozzle is connected with a blast furnace gas pipe and a hot air pipe. A cold air inlet and a cold air input tube of the air heat exchanger are connected, and a fan is arranged onthe cold air input tube. A hot air outlet of the air heat exchanger is connected with an inlet of the hot air tube. The air heat exchanger is arranged on a trolley. When the single preheating, sintering, igniting and heat insulating furnace is in working, the sintering compound of the waste gas trolley outputted by the air preheating furnace is insulated, and sucked into a large fume passage by the sintering compound surface of the trolley. The large fume passage is connected with the hot waste gas heat energy recovery system and the waste gas treating system to recover and utilize heat energy and remove harmful elements of sulphur and the like in the waste gas.

Owner:常州市黑山烧结点火炉制造有限公司

Novel method for producing iron ore sintering mine additive

InactiveCN101492769BUniform particle sizeImprove granulation effectProcess efficiency improvementIron ore sinteringUltimate tensile strength

The invention relates to a manufacturing method of a novel iron ore sinter additive. The invention is characterized in that the method comprises steps of adding basic oxider CaO, dolomite powder, stabilizer active MO in saponification discharge dregs of propylene oxide by chlorophydrin method, intensive mixing, reacting for 15min to 30min at 500 DEG C to 850 DEG C and constant pressure, removing harmful dissociated substances in the saponification discharge dregs, removing 20% to 67% of moisture content, milling the saponification discharge dregs to powder of 80 meshes to 300 meshes, thus obtaining the novel iron ore sinter additive. The invention uses saponification discharge dregs of propylene oxide by chlorophydrin method as main materials, thus the production cost is low. The chemicalsolid waste is recycled. The invention prepares grains from the sinter material in an improved manner, and drum index of sinter in the roasting process is improved, return fine rate being reduced, production of sinter being improved, and manufacturing efficiency of ironmaking being improved. Ore forming rate of the sinter and intensity are improved obviously, thus manufacturing cost of steel-making is reduced.

Owner:辽宁中生洁源实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com